Patents

Literature

383 results about "Manganese(II) carbonate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Manganese carbonate is a compound with the chemical formula MnCO₃. Manganese carbonate occurs naturally as the mineral rhodochrosite but it is typically produced industrially. It is a pale pink, water-insoluble solid. Approximately 20,000 metric tonnes were produced in 2005.

Extinguishment combination with hot gas sol

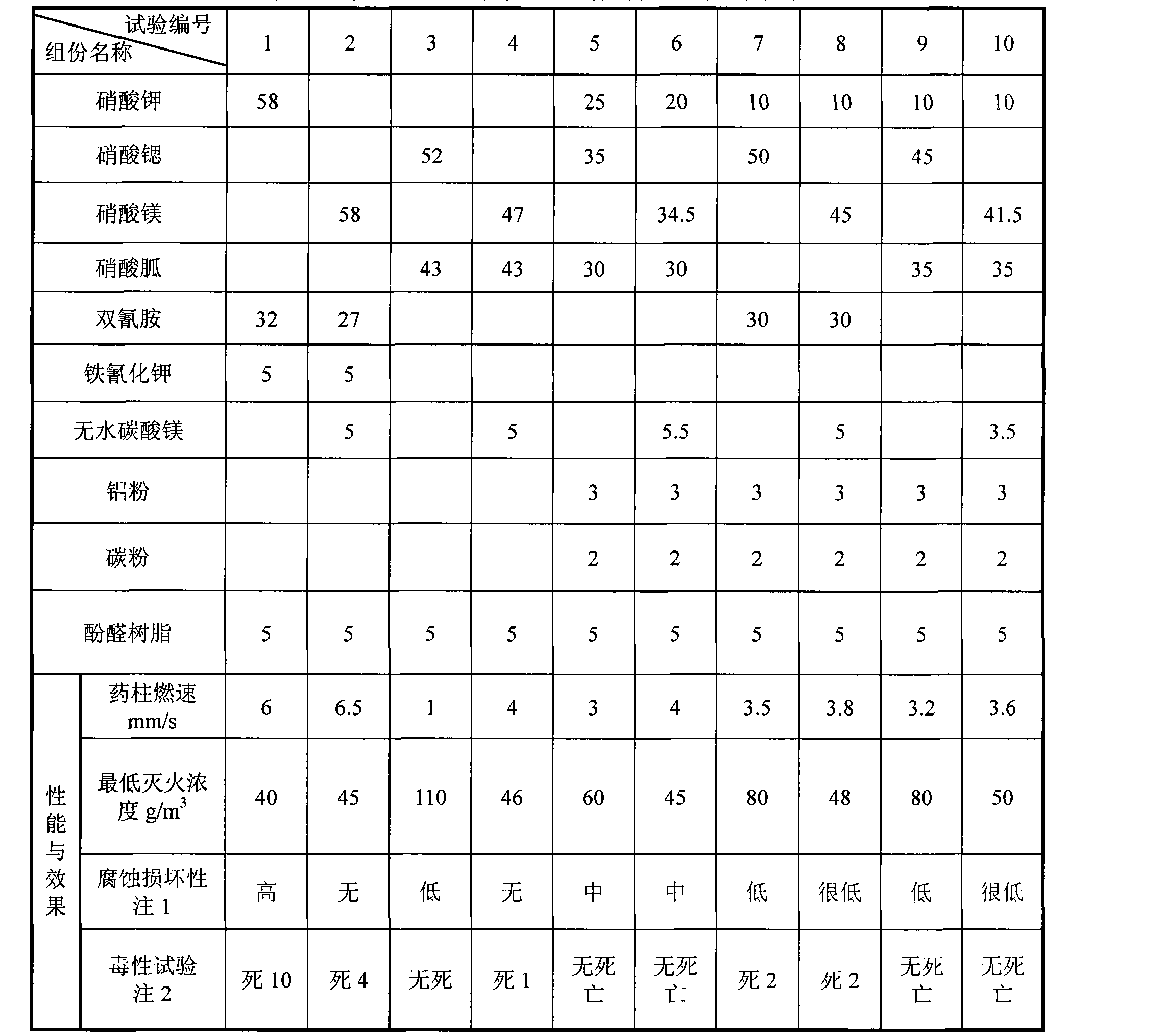

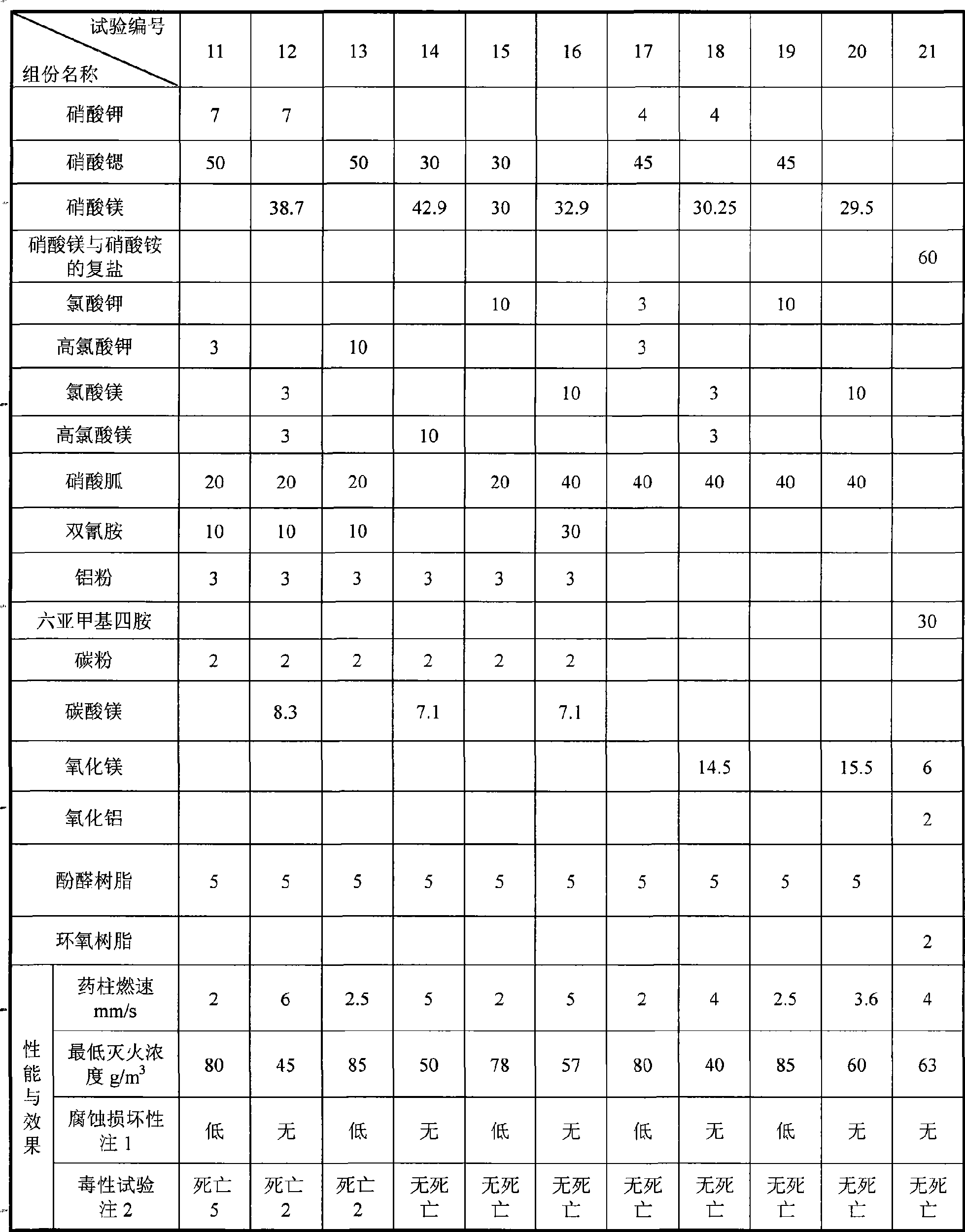

The invention provides ''a hot aerosol fire-extinguishing composition'' and relates to an oxidative magnesium salt hot aerosol fire-extinguishing composition represented by anhydrous magnesium nitrate. The composition is characterized in that the composition can be magnesium nitrate, magnesium carbonate, or other magnesium salt, and can also be a compound of magnesium nitrate, or other magnesium salt with potassium nitrate, strontium nitrate, or other potassium salt or strontium salt; a reducer can be one of or the combination of a plurality of ammonium carbamidine, dicyandiamide, red prussiate of potash, formamine, triazole, and tetrazole; a capability improver can be magnesium carbonate, manganous carbonate, aluminium powder, powdered carbon, magnesium hydrate, metal oxide, etc.; and the bond adopts phenolic resin, etc. The preparation of the magnesium salt comprises the continuous steps: medium temperature and low pressure dehydration, spray under the protection of nitrogen-oxygen flow or ultrafine grinding of grinded colloid, and microencapsulated hydrophobic treatment, etc. Compared with the prior art, the fire-extinguishing composition has the advantages of low price, extensive source, fire-extinguishing capability of K-type composition, and low causticity and toxicity of the ultimate product of combustion.

Owner:SHAANXI J&R FIRE FIGHTING CO LTD

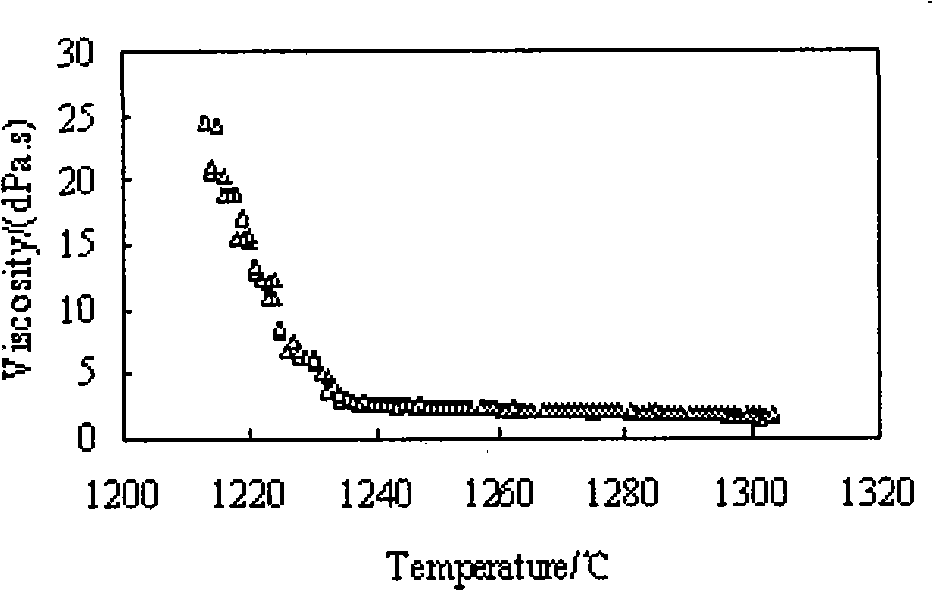

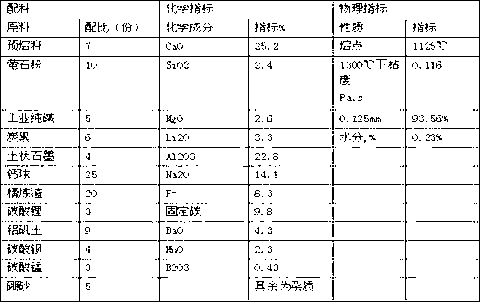

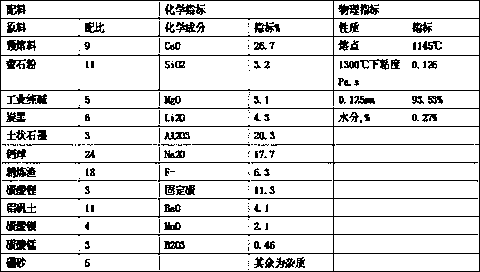

High-sodium low-fluorine continuous casting mould fluxes and preparation method thereof

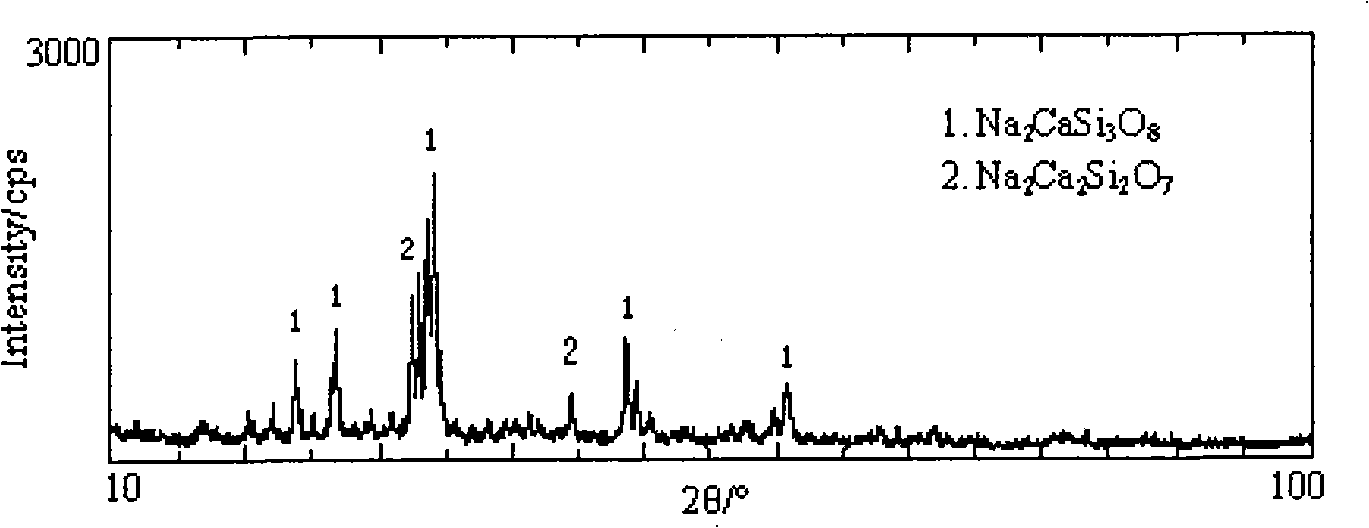

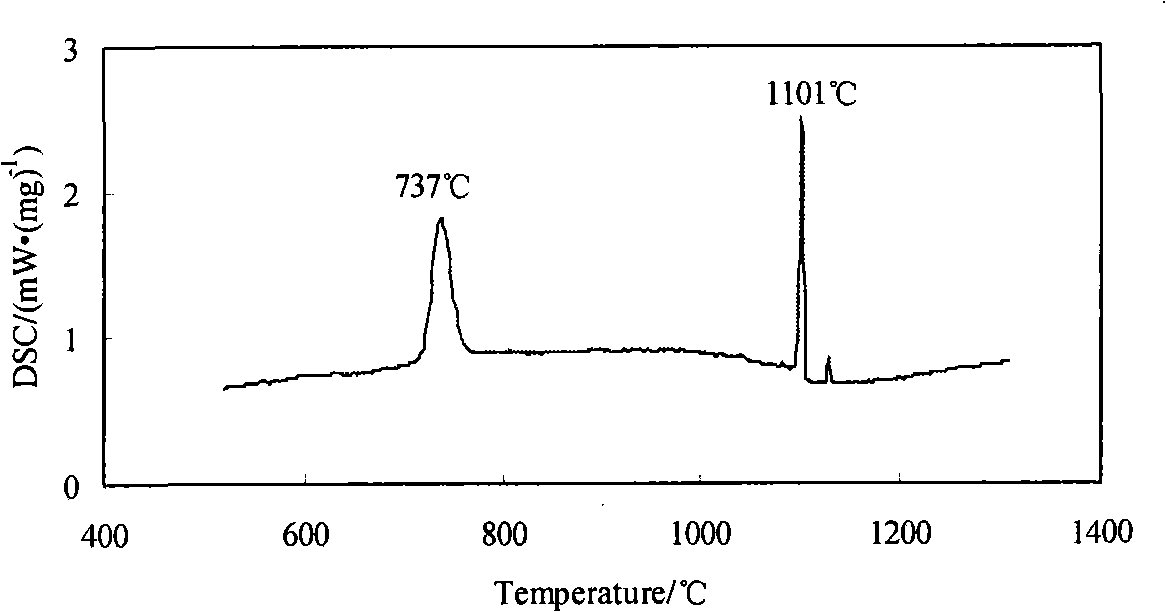

The invention relates to high-sodium low-fluorine covering slag, which is prepared from raw materials of wollastonite, limestone, quartz sand, fluorite, bauxite, manganese carbonate, magnesia, hydrous borax, industrial soda, lithium carbonate, and carbonaceous materials, and the chemical components of the covering slag meets the following weight percentage: more than 30 and less than 34 percent of CaO, more than 30 and less than 38 percent of SiO2, more than 12 and less than 25 percent of Na2O, less than 4 percent of MgO, less than 8 percent of MnO, less than 4 percent of B2O3, less than 1.5 percent of Li2O, less than 4 percent of Al2O3, less than 2 percent of F, more than 4 percent and less than 10 percent of C, and the balance being impurities. In the covering slag, the ratio of sigma CaO to the SiO2 is controlled to between 0.8 and 1.15 to ensure that the fused mass of the covering slag does not separate out crystals at high temperature and liquid slag in a slag film can lubricate a casting blank. Aiming at that the content of fluorine has adverse influence on environment and equipment, the invention adopts high-sodium low-fluorine continuous casting covering slag which not only can meet the requirement of coordinated control of heat transfer and lubrification of a continuous casting covering slag for crack sensitive steel to cast casting blank with good surface quality, but also can reduce the fluorine content in air and secondary cooling water, thus the air pollution is reduced and the corrosion of fluorine-contained water to equipment is reduced.

Owner:CHONGQING UNIV

Crystallizer protecting cinder for continuous casting of crack sensitive steel and its prepn process

InactiveCN1974062AReduce crystallization rateLower crystallization temperatureProcess efficiency improvementManganese(II) carbonateWollastonite

The present invention provides one kind of crystallizer protecting cinder for continuous casting of crack sensitive steel and its preparation process. The protecting cinder is compounded with wollastonite, limestone, quartz sand, fluorite, industrial soda, manganese carbonate and carbon material. Chemically, it consists of CaO 28-42 wt%, SiO2 26-40 wt%, CaF2 10-20 wt%, Na2O 4-10 wt%, MnO2 2-8 wt%, Al2O3 0-6 wt%, and C 2-10 wt%, and has the weight ratio between CaO and SiO 2in 1.0-1.2. The crystallizer protecting cinder can reduce the heat transfer, maintain the crystallization rate and the crystallization temperature of protecting cinder, reduce longitudinal cracks in the surface of cast billet, and raise continuous casting efficiency and quality.

Owner:CHONGQING UNIV

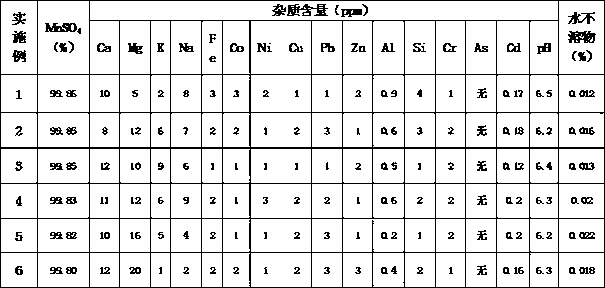

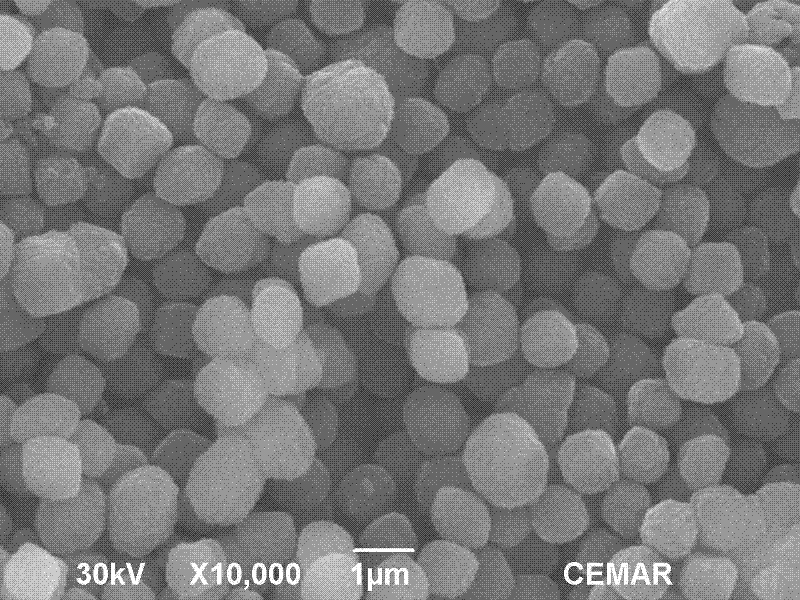

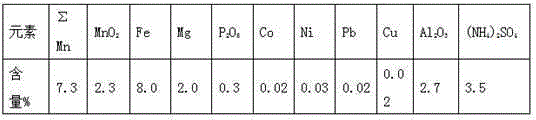

Method for production of high purity manganese sulfate by using pyrolusite as raw material

ActiveCN103011297AImprove controllabilityGood reproducibilityManganese sulfatesPyrolusiteAcid dissolution

The invention relates to a production method for high purity manganese sulfate. The production method is characterized in that pyrolusite is used as a raw material and is reduced by using a carbon fire method, then an acid is added for leaching, a vulcanizing agent is used to remove heavy metals consisting of cobalt and nickel, a fluoride is employed to remove calcium and magnesium, then filtering is carried out, ammonium bicarbonate or ammonium carbonate is added into a filtrate for deposition of manganese to realize separation of potassium and sodium, an obtained filtrate is used for recovery of the by-product ammonia sulfate for usage as an additive for metal manganese, the filter residue manganese carbonate is washed and then subjected to acid dissolution so as to obtain a manganese sulfate solution, and then crystallization is carried out to obtain a high purity manganese sulfate product, wherein mother liquor can be returned to a high purity system for reutilization. With the method provided by the invention, the high purity manganese sulfate product in which MnSO4 content is more than 99.8% and respective content of impurities consisting of Ca, Mg, K and Na is lower than 10 ppm is produced.

Owner:DAXIN MANGANESE MINE BRANCH OF CITIC DAMENG MINING IND

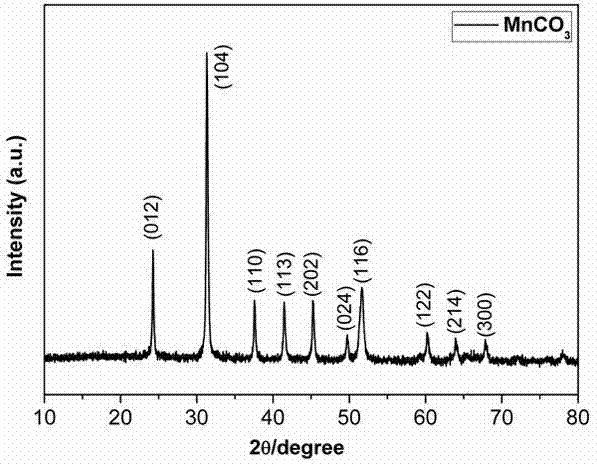

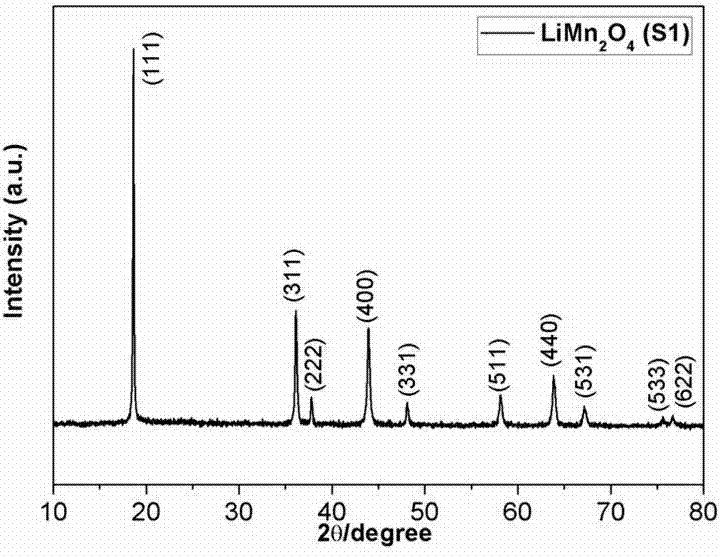

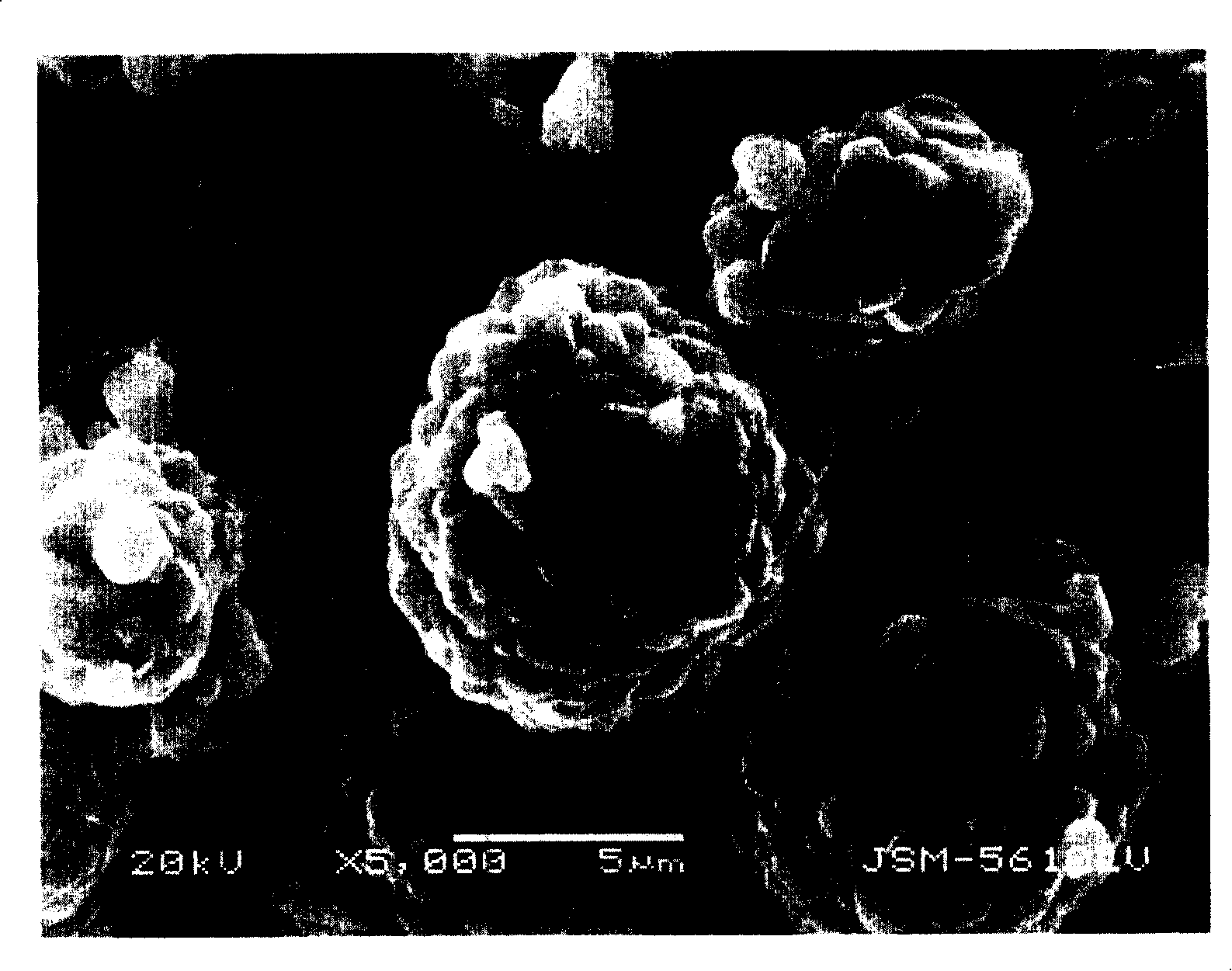

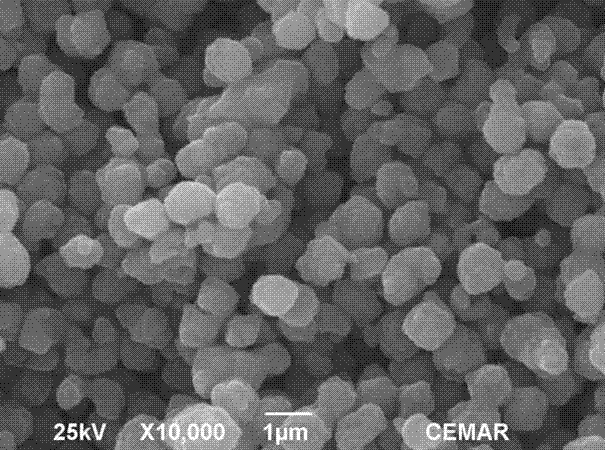

Novel preparation method of anode material LiMn2O4 of high-power-performance lithium ion battery

InactiveCN102655231ANo special requirementsSimple processCell electrodesManganates/permanganatesPower batteryManganese(II) carbonate

The invention discloses a novel preparation method of an anode material LiMn2O4 of a porous micrometer-level spherical power battery, and the anode material LiMn2O4 is high in specific capacity, high in rate capability and cycle performance, low in price, environmentally-friendly, and stable in structure, and belongs to the technical field of preparation of electrode materials of lithium ion batteries. The method is mainly characterized in that a novel synthetic route in which spherical manganese carbonate is taken as a template and low-eutectic salt is inserted into the spherical manganese carbonate is adopted, so that the LiMn2O4 material is prepared at a low temperature. The LiMn2O4 material prepared by the method is regular in shape, high in purity, large in tap density, high in specific capacity, good in cycle performance, and good in rate capability. Under the charging / discharging condition of the material such as 2, 10 and 20C, the specific capacity of the material is respectively to be 118, 106 and 98mAh / g. After the circulation is carried out by 500 times, the capacity retention rate is larger than 80%. Compared with the conventional solid phase method, the method successfully controls the shape of a product due to simple operation, so that the tap density, purity, specific capacity and rate capability of the product can be improved, therefore, the method is a novel development direction for preparing the high-performance anode material.

Owner:GUANGZHOU HKUST FOK YING TUNG RES INST

Method for manufacturing middle-temperature metal glaze and glaze material thereof

The invention relates to a middle temperature metal glaze manufacturing method and a glaze thereof, which adopts an SiO2-Li2O-PbO ternary system as glaze basic material, and the glaze basic material is made to be frits; the frits and part of metal oxides (such as V2O5, MnCO3, CuO and WO2, etc.) and other auxiliary glazes are mixed, and glaze slip is made by a way of adding water and ball milling; the glaze slip is applied on a white mud raw billet and is put in to a kiln after being dried, the metal oxides produce saturate state in the melting process through high temperature firing, and a metal glaze is formed on the glaze surface when in cooling. The glaze formula is as follows according to weight portion ratio: frits: 100 portions; manganese carbonate: 12 to 15 portions; copper oxide: 3 to 5 portions; vanadium pentoxide: 2 to 4 portions; kaolin: 5 to 7 portions; tungsten oxide: 0.5 to 1.5 portions; quartz: 20 to 30 portions; barium carbonate: 7 to 8 portions.

Owner:HUNAN LILING HONGGUANYAO CERAMICS

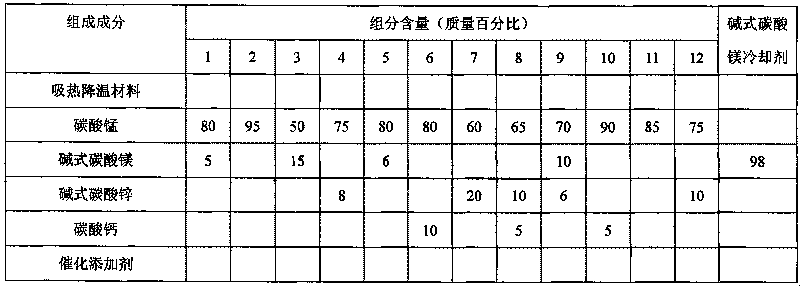

Catalytic chemical coolant for hot aerosol and preparation method thereof

InactiveCN101757760AImprove cooling efficiencyLow toxicityFire extinguisherHydroxyethyl celluloseFilm material

The invention relates to a catalytic coolant used in a hot aerosol fire extinguishing device and a processing technique of the catalytic coolant. As to the coolant, heat absorption cooling components mainly include manganese carbonate or manganese oxalate, manganese phosphate, potassium manganate, metal carbonate of a family I, a family II and a transition family, basic carbonate, oxalate and the like; a metal oxide or a hydroxide are adopted as a catalyst, an oxidant and a reinforcing filling; stearate, graphite and the like are adopted as a processing aid; composite solution of alkalis silicate and a water soluble polymer is adopted as an adhesive; and film materials such as hydroxymethyl or hydroxyethyl cellulose are adopted as a surface coating agent. The processing technique includes the steps of mould pressing, squeezing, pelletizing, coating and forming. Compared with the prior art, the catalytic coolant not only has high intensity and good cooling effect, but also can reduce secondary damage of an extinguishing agent and eliminate the content of poisonous gases in an extinguishing agent product so as to improve the environmental safety of the extinguishing agent.

Owner:SHAANXI J&R FIRE FIGHTING CO LTD

Flotation method of low ore grade manganous carbonate ore

The invention relates to a process that raw mine is ground into powder which is added with water to be prepared into pulp. Under certain pH value, inhibitor of carboxymethylcellulose nano solution, industrial water glass and tannin solution are added proportionally for absorbing calcium, magnesium and silicate. Then, sodium oleate is added as a collector for closed circuit circulation floating. Foam products after the floatation are flushed by water and then enter a sedimentation tank for the sedimentation or the pressure filtration. Thus, manganese concentrate fines above 20 percent are obtained. In the process, floatation is implemented on low grade poor manganese mine containing 10-14 percent of manganese, carbonaceous rock with the manganese content of 4-9 percent and electrolytic manganese leached slags with the manganese content of 1-3 percent to obtain manganese ore fines, the manganese content of which reaches above 20 percent. The recovery of manganese is more than 85 percent. And non-manganese emission for tailings can be realized. The manganese resources are lead to have extremely high utilization rate. Produced products can also lower acid consumption and ammonia consumption for electrolytic manganese production of downstream industry of manganese mines.

Owner:HUAYUAN QIANGHUA MINING

Method for producing manganese sulfate by high-temperature crystallization process

InactiveCN101224908AReduce manufacturing costImprove product qualityManganese sulfatesManganese sulphateManganese(II) carbonate

The invention provides a method for producing high-purity manganese sulfate by adopting a high temperature crystallization method, which includes that the ore pulp of manganese ore and sulfurous iron ore is heated, removed of iron, removed of heavy metal, neutralized, pressure-filtered to obtain a manganese sulfate solution with the content of 160-200g / L, which is pumped to a manganese sulfate solution for carrying out crystallization and purification; the crystallization and purification includes crystallization, solid-liquid separation, dissolution, pressure filtration and other technologies; the pressure-filtered manganese sulfate solution can be crystallized and purified repeatedly as required. The invention can adopt a large amount of low-grade manganese ore with the manganese content of 10-20 percent as the raw material to produce the high-purity manganese sulfate solution and further deep process various high-purity manganese products, such as: electrolytic manganese dioxide, high-purity manganese carbonate, electronic grade mangano-manganic oxide and manganese monoxide, chemical manganese dioxide, industrial grade manganese sulfate monohydrate, chemical grade manganese sulfate monohydrate, medicine grade manganese sulfate monohydrate, food grade manganese sulfate monohydrate, analytically pure manganese sulfate monohydrate and so on.

Owner:广西双德锰业有限公司

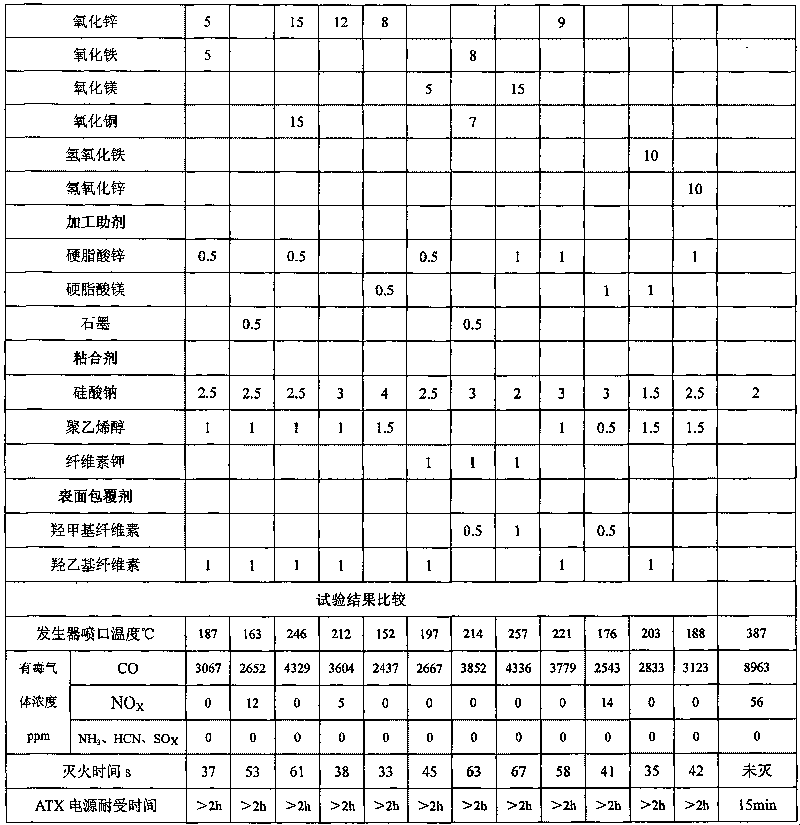

Method for separating copper, cobalt and manganese from cupric chloride manganese-cobalt-calcium-zinc impurity removal solution

ActiveCN105296754AShort processLow costRotary drum furnacesCrucible furnacesManganese(II) carbonateSulfate

The invention relates to a method for separating copper, cobalt and manganese from a cupric chloride manganese-cobalt-calcium-zinc impurity removal solution. The method comprises the steps that sodium sulfate is added to the cupric chloride manganese-cobalt-calcium-zinc solution, and calcium sulfate is removed by filtration; then sodium carbonate is added to a solution obtained in step one, a pH value is adjusted to 4.0-6.0 to allow copper ions in the solution to be precipitated, and copper precipitates are obtained by filtration separation; the copper precipitates are dissolved with sulfuric acid and are subjected to evaporation crystallization to form copper sulfate crystals; manganese powder is added to a solution after copper removal to allow cobalt ions to be reduced to cobalt powder to be precipitated, and cobalt powder is obtained after the filtration separation and is dissolved with acid to form a cobalt solution; and a solution after cobalt removal contains manganese and a little zinc and calcium, manganese is precipitated through the evaporation crystallization or by adding sodium carbonate, and manganese salts such as rough manganese carbonate are obtained. With the adoption of the method, three main valuable metals, namely copper, cobalt and manganese, can be separated and extracted economically and conveniently.

Owner:长沙百汇新材料科技有限公司

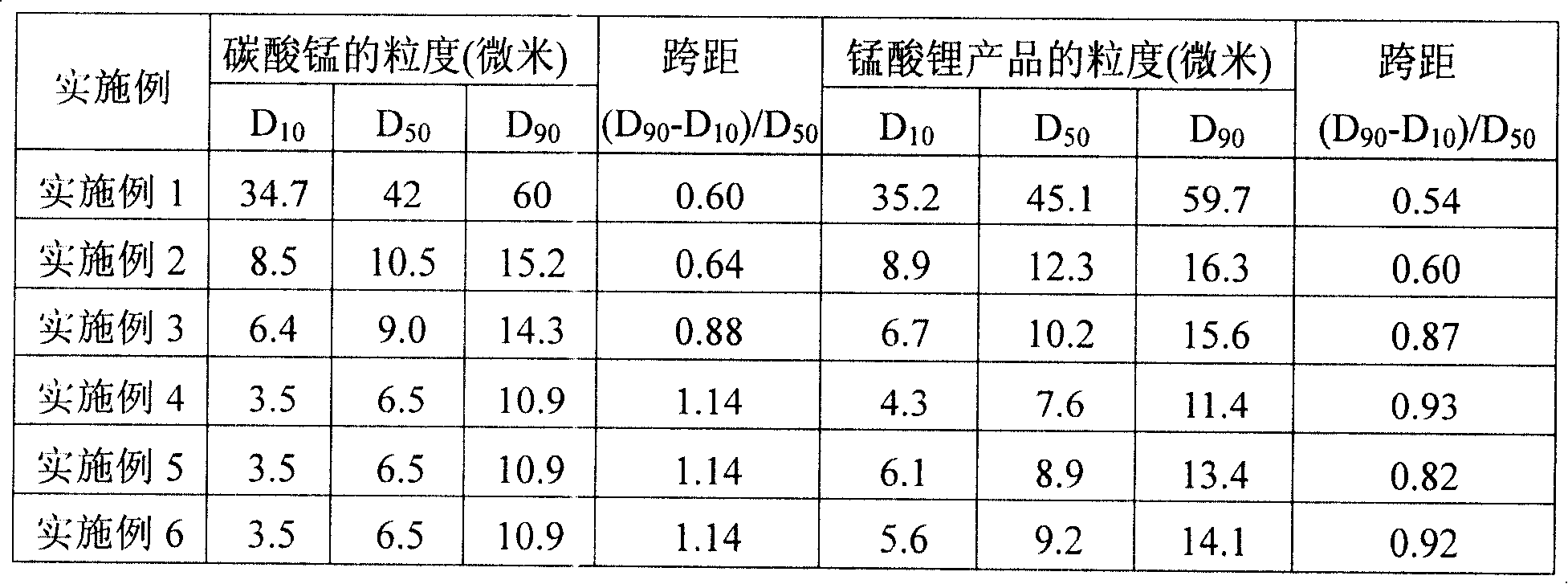

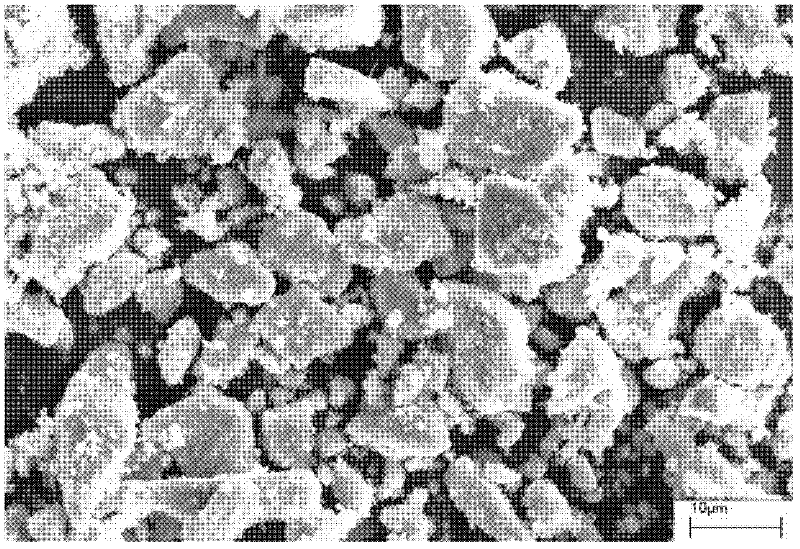

A method for preparing sphericity manganic acid lithium cell anode active material

InactiveCN101161592AImprove cycle performanceIncrease capacityCell electrodesManganates/permanganatesManganese(II) carbonateProduct gas

The invention relates to a making method of round-shape manganese acid lithium battery anode material, comprising that the round-shape carbonic acid manganese is baked under the existence of oxidbillity gas and from 300 centidegrees to 800 centidegrees for 2 hours to 5 hours, mixed evenly with lithium source and baked under the existence of oxidbillity gas so as to acquire the round-shape manganese acid lithium battery anode activity material. The invention can make the round-shape manganese acid lithium with controllable grain range from 5 microns to 50 microns. The art process is easy to be controlled; therefore, the invention is in particular applicable to continuous production in industry.

Owner:BYD CO LTD

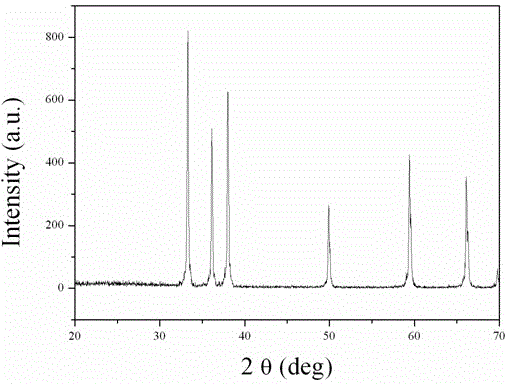

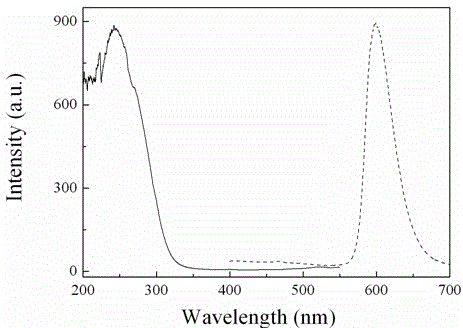

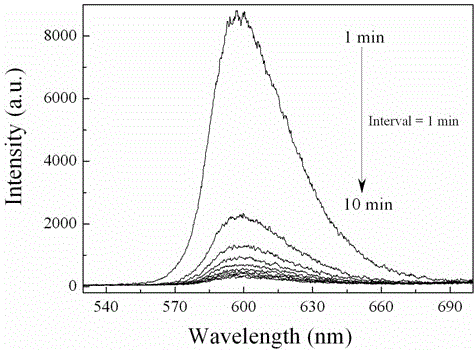

Manganese ion-activated red long-afterglow luminescent material and preparation method thereof

InactiveCN102719243AEasy to prepareGood long afterglow performanceLuminescent compositionsManganese(II) carbonateCrucible

The invention discloses a manganese ion-activated red long-afterglow luminescent material and a preparation method thereof, and belongs to the technical field of long-afterglow luminescent materials. The long-afterglow luminescent material comprises two components, namely AlN:Mn<2+>, wherein AlN is a matrix, and Mn<2+> is an activation ion. The preparation method of the material comprises the following steps of: based on aluminum nitride and manganese carbonate as raw materials, fully mixing the raw materials and placing into a boron nitride crucible; covering the boron nitride crucible; firing under the nitrogen atmosphere; and cooling to prepare the manganese ion-activated red long-afterglow luminescent material. The preparation method is simple to operate; and the prepared long-afterglow luminescent material is good in performance, and the afterglow time can continuously last for more than 2 hours in the dark environment. The long-afterglow luminescent material is low in production cost, stable in chemical property of the product, fluffy and easy to grind, and is free of radioactivity; and therefore, the harm to the environment can be avoided.

Owner:SOUTH CHINA AGRI UNIV

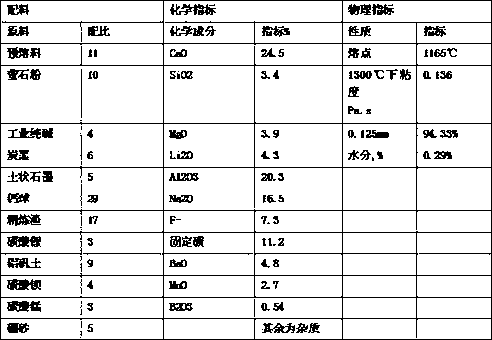

High aluminum steel special continuous casting crystallizer casting powder

The invention discloses high aluminum steel special continuous casting crystallizer casting powder, and the raw material formula proportion of parts by weight of the high aluminum steel special continuous casting crystallizer casting powder includes the premelting material 7 - 13 parts, fluorite powder 9 - 11 parts, industrial soda ash 4 - 6 parts, carbon black 6 parts, earthy graphite 3 - 6 parts, calcium balls 24 - 31 parts, refining slag 17 - 25 parts, lithium carbonate 3 parts, bauxite 9 - 15 parts, barium carbonate 4 parts, manganese carbonate 3 parts and borax 5 parts. The high aluminum continuous casting powder can effectively overcome the quality defects that more inclusions exist in a high aluminum steel continuous casting process and the melting point is high, and the quality of ordinary casting powder is extremely easy to deteriorate in the using process so that the process is not smooth, and cracks and concave pits are easy to appear on the surface of a casting blank and the production cost of iron and steel enterprises is increased. The high aluminum steel special continuous casting crystallizer casting powder achieves the use value maximally under the same resource conditions.

Owner:XIXIA LONGCHENG METALLURGICAL MATERIALS CO LTD

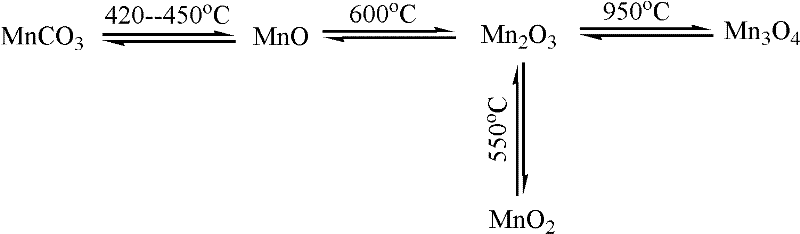

Method for preparing manganese sulfate by using sulfur-containing carbonaceous manganese carbonate ore

The invention provides a method for preparing manganese sulfate by using sulfur-containing carbonaceous manganese carbonate ore. The method comprises the following steps: 1, uniformly mixing manganese carbonate ore powder and pyrolusite powder in proportion and carrying out roasting; 2, immersing the roasted ore obtained in step 1 with anolyte, or industrial sulfuric acid or a composition thereof and carrying out filtering so as to obtain a filtrate which is a leachate containing manganese sulfate; and 3, adding ammonia water into the leachate, then adding a vulcanizing agent into the filtrate and carrying out filtering so as to obtain another filtrate which is a manganese sulfate solution meeting requirements for further processing indexes of a manganese salt. According to the invention, reduction roasting of the pyrolusite is carried out by using reductibility of the sulfur-containing carbonaceous manganese carbonate ore which looks like coal, has a low grade of manganese (with manganese content of about 10%) and can hardly be separated by using magnetism, the pyrolusite can be successfully reduced without usage of a reducing agent in the process of roasting, and the integral graded of manganese is improved; and economic benefit assessment results show that cost for reduction roasting of the manganese carbonate ore and the pyrolusite is lower than that for reduction roasting of the pyrolusite and reduction coal and a substantial effect is obtained through reduction roasting of the manganese carbonate ore and the pyrolusite.

Owner:DAXIN MANGANESE MINE BRANCH OF CITIC DAMENG MINING IND

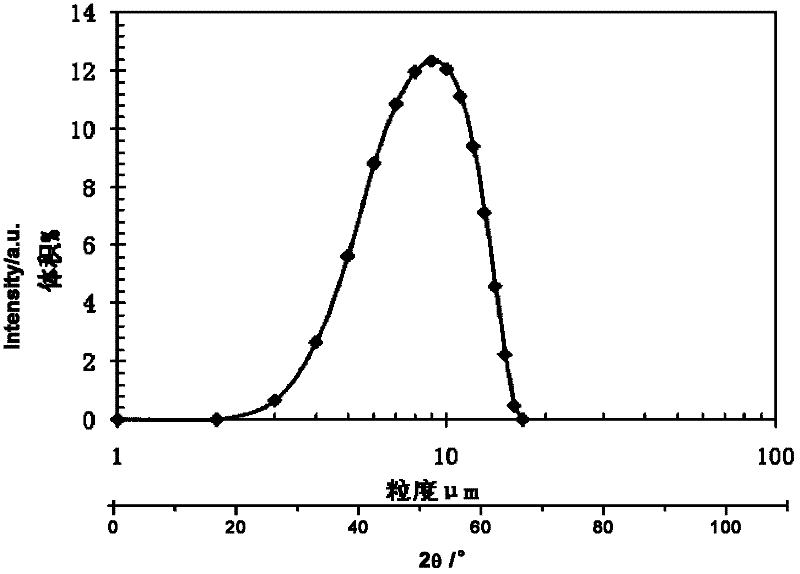

Preparation method of bulky-grain spinel lithium manganate material

InactiveCN102420326AEvenly dopedGood grain shapeCell electrodesManganese(II) carbonateManganous-manganic oxide

The invention discloses a preparation method of a bulky-grain spinel lithium manganate material, which belongs to the field of electrochemical materials. The bulky-grain spinel lithium manganate material is prepared through carrying out high-temperature sintering on a raw material such as manganese dioxide or manganese carbonate as with a doped element M to be converted into uniformly-doped bulky-grain mangano-manganic oxide, using the bulky-grain mangano-manganic oxide as the raw material of a Mn source, mixing the bulky-grain mangano-manganic oxide with an original material of Li, and sintering the obtained mixture. The mangano-manganic oxide prepared by the invention has a good crystalline grain shape; the grain size is in normal distribution; after the bulky-grain mangano-manganic oxide is used as the raw material of the Mn source and mixed with the original material of the Li, a bulky-grain lithium manganate product with a low surface area can be obtained without the obtained miture at a temperature which exceeds 900 DEG C; and the problem that oxygen loss is caused when the bulky-grain lithium manganate is prepared by high sintering exceeding 900 DEG C is solved. The lithium manganate prepared by the method has uniform granularity; the average grain size of the lithium manganate can be controlled in a range of 5-15 mum through the process; the specific surface area is between 0.2 m<2> / g and 0.6 m<2> / g; crystalline grains are complete; and the high-low temperature cycle service is excellent. The method provided by the invention has a simple process and low cost, and is applicable to industrial production.

Owner:UNIV OF SCI & TECH BEIJING

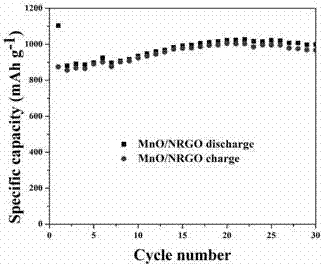

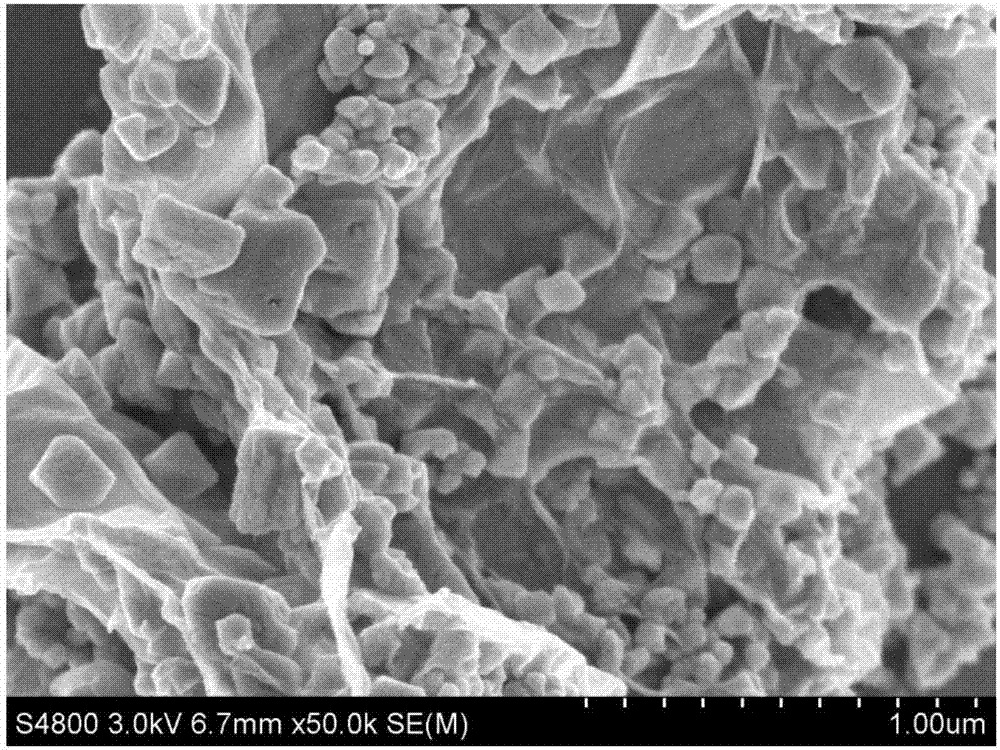

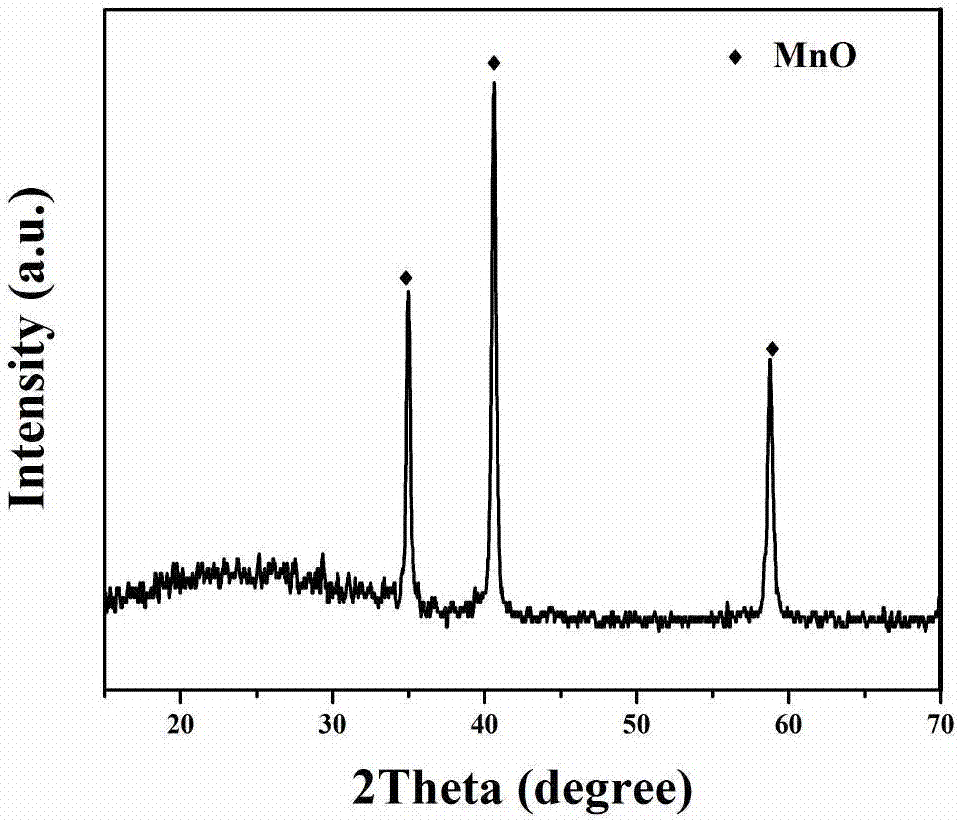

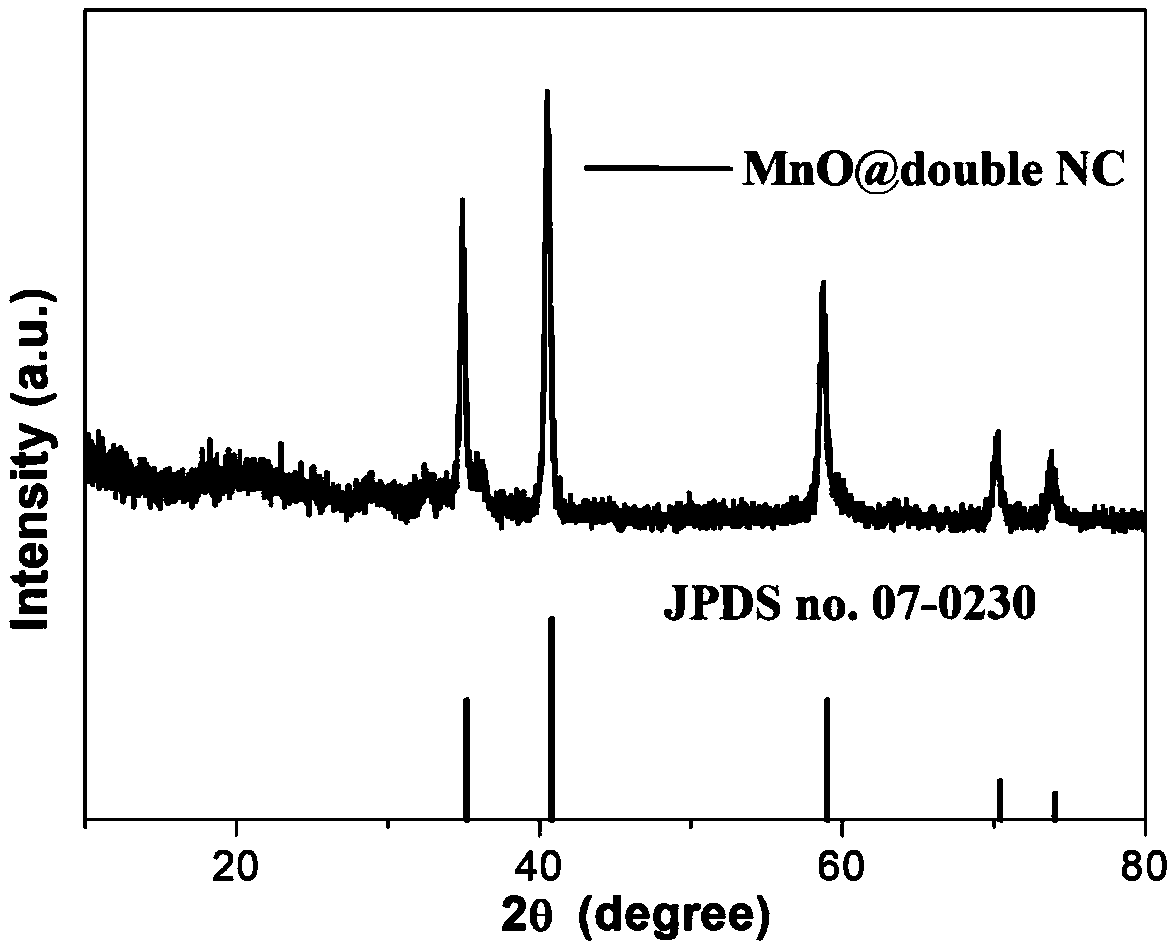

Preparation method of manganese monoxide/nitrogen-doped reduced graphene oxide composite electrode material

InactiveCN107195878AIncreased active sitesFavorable for adsorption growthCell electrodesSecondary cellsCvd grapheneUrea

The invention discloses a preparation method of a manganese monoxide / nitrogen-doped reduced graphene oxide composite electrode material. Manganese acetate, graphene and urea are regarded as main raw materials; and the preparation method comprises the steps of firstly preparing a compound of manganese carbonate and graphene by adopting a hydrothermal method; then carrying out heat treatment for the compound in a tubular atmosphere furnace to prepare granular MnO loaded on a thin graphene sheet; meanwhile, carrying out nitrogen doping for the graphene to enable the graphene to serve as an anode material for a lithium-ion battery. Due to addition of the urea in the synthetic method, for one thing, N atoms are introduced to dope the graphene, defects on the surface of the graphene are increased, the active sites are increased and the adsorptive growth of the Mn2+ is better facilitated; and for another, the urea which has a certain dispersion effect in the whole system enables the MnO particles to be uniformly diffused on the graphene sheet. As the MnO particles are loaded on the reduced graphene oxide sheet, the poor conductivity of the MnO is not only improved, but also gathering and powdering of the MnO particles in a continuous charging and discharging process is prevented; and accordingly, the electrochemical performance of the MnO particles is effectively improved.

Owner:SHAANXI UNIV OF SCI & TECH

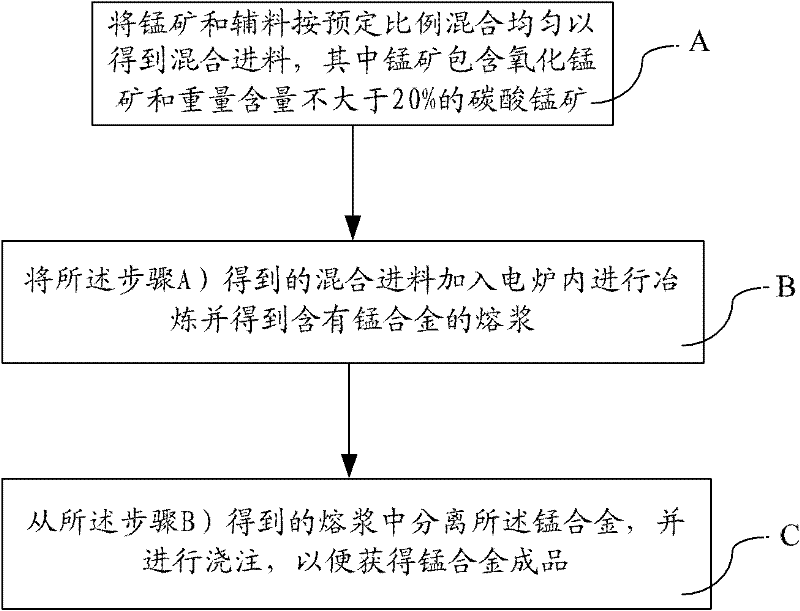

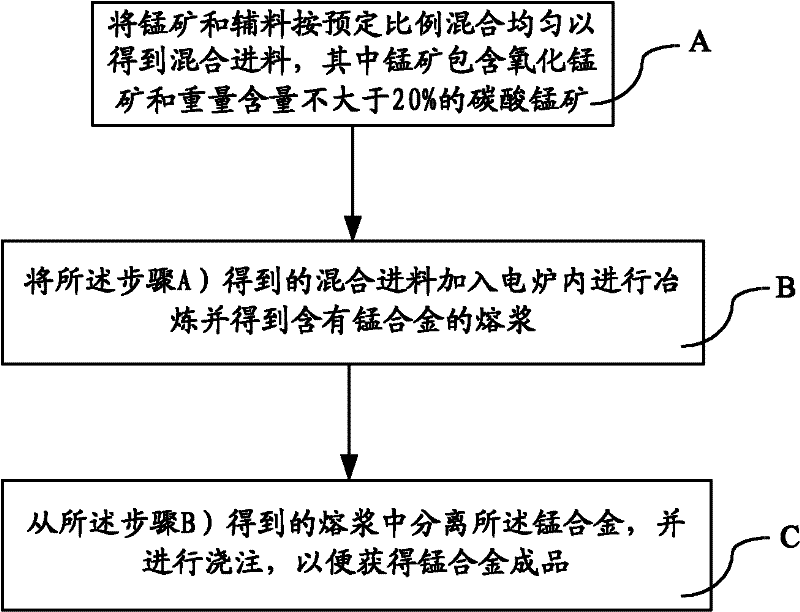

Smelting method of manganese alloy

The invention discloses a smelting method of a manganese alloy. The smelting method comprises the following steps of: A) mixing manganese ores and auxiliary materials evenly according to a preset ratio to obtain a mixed feeding material, wherein the manganese ores contain manganese oxide ores and manganese carbonate ores of which the weight content is no more than 20%; B) adding the mixed feedingmaterial obtained in the step A) in an electric furnace to smelt and obtain fused slurry containing the manganese alloy; and C) separating the fused slurry obtained in the step B) to obtain the manganese alloy, and pouring to obtain the manganese alloy finished product. According to the smelting method of the manganese alloy in the embodiment of the invention, the smelting cost of the manganese alloy can be greatly reduced and the pollution to the environment can be greatly lowered.

Owner:云南牧隆锰业有限公司

Fluoride-modified nickel-enriched ternary composite electrode material and preparation method thereof

ActiveCN108807950AAvoid corrosionImprove cycle stabilityCell electrodesSecondary cellsManganeseDissolution

The invention relates to a fluoride-modified nickel-enriched ternary composite electrode material. The fluoride-modified nickel-enriched ternary composite electrode material comprises a nickel-enriched ternary composite electrode material and a modifying layer, wherein the nickel-enriched ternary composite electrode material is prepared from the following raw materials: lithium carbonate, nickel carbonate, cobalt carbonate and manganese carbonate; the molar ratio of the lithium element, the nickel element, the cobalt element and the manganese element is (1.0-1.1):(0.6-0.8):(0.2-0.1):(0.2-0.1);the modifying layer is metal fluoride; the metal fluoride accounts for 1-5% of the mass percentage of the total electrode material. The invention further relates to a preparation method of the composite electrode material. After the nickel-enriched ternary electrode material is modified by the fluoride, dissolution of metal ions in an active material can be prevented, corrosion of the active material by an electrolyte can be resisted, the surface impedance can be reduced, the cycle stability of the material can be improved, and the problems of poor stability and fast capacity attenuation of the nickel-cobalt-manganese ternary electrode material can be solved.

Owner:ENERGY RESOURCES INST HEBEI ACADEMY OF SCI

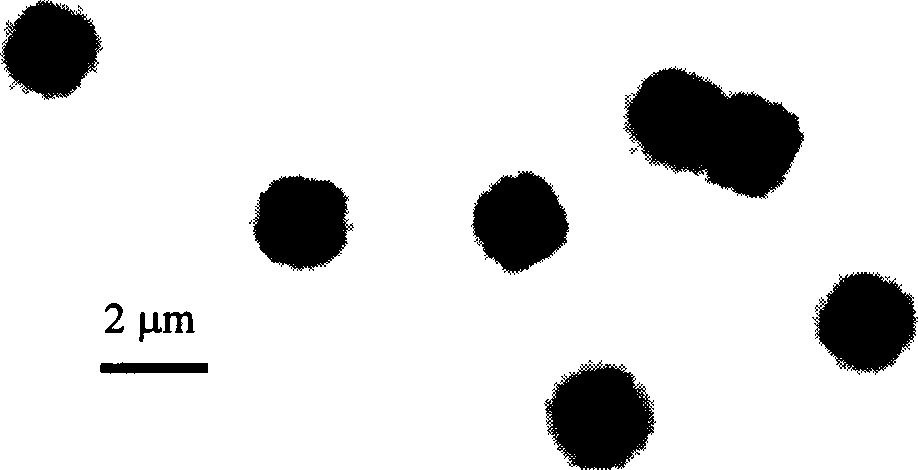

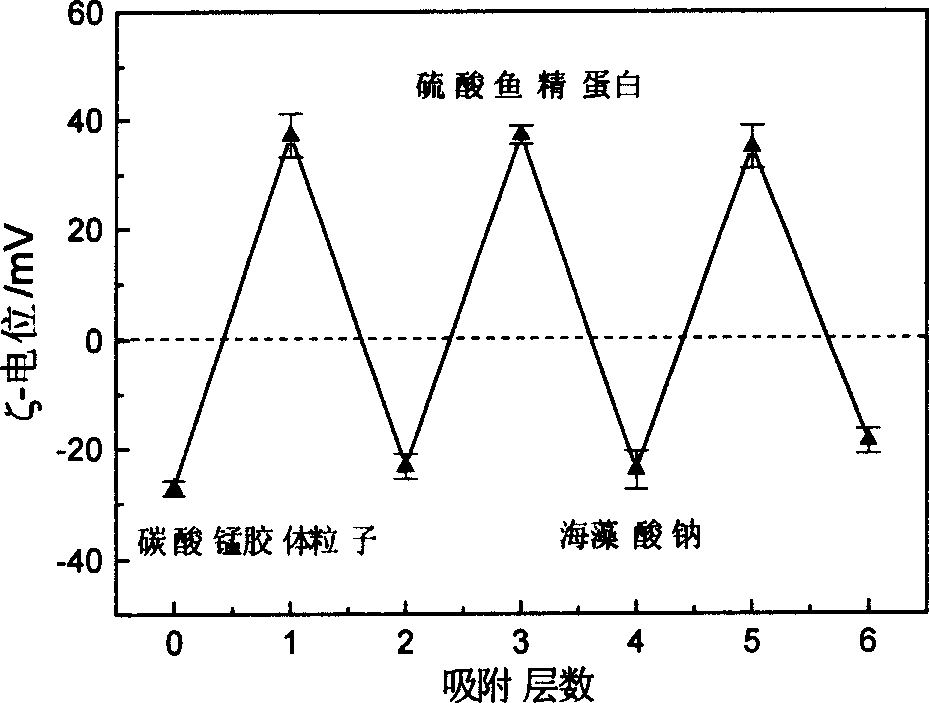

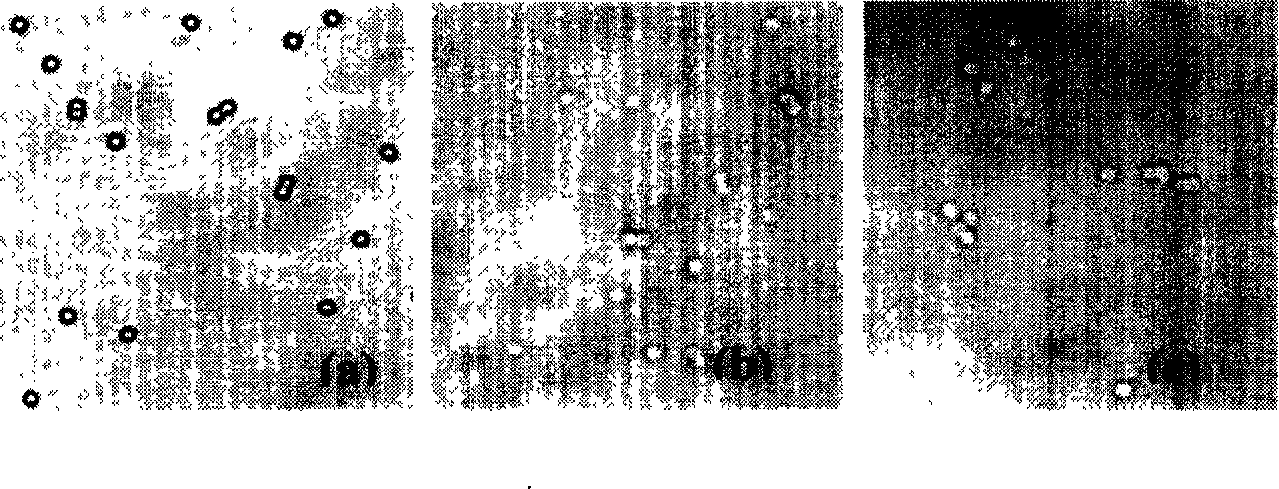

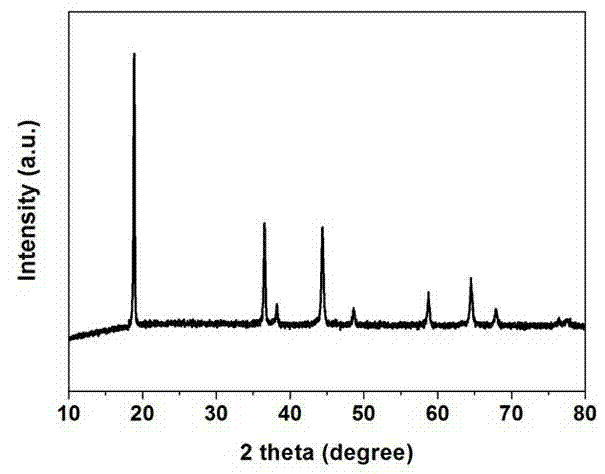

Nucleoprotamine and sodium alginate microcapsule and its preparation method

A protamine-sodium alginate microsoftgel with shell-core structure is prepared through reaction between manganese sulfate, ammonium dicarbonate, and polystyrene-sodium sulfonate solution to obtain the colloid particles of manganese carbonate, dispersing in liquid, adding it to the aqueous solution of protamine, stirring, removing excessive protamine, adding the aqueous solution of sodium alginate, stirring, removing excessive sodium alginate, altermative adsorption to obtain shell-core structure and removing manganese carbonate by acid solution.

Owner:SOUTH CHINA UNIV OF TECH

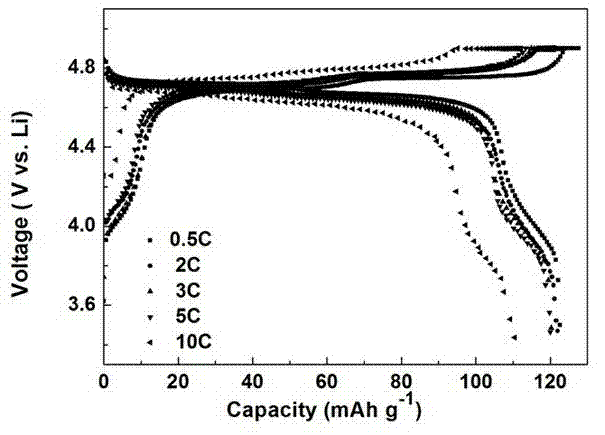

Preparation method of high-voltage cathode material Lil+xMn3/2-yNil/2-zMy+zO4 of lithium ion battery with long service life

InactiveCN102832381ASimple processEasy to operateCell electrodesManganese(II) carbonateElectrical battery

The invention discloses a novel preparation method of a high-voltage cathode material Lil+xMn3 / 2-yNil / 2-zMy+zO4 (M is one of Cr, Al, Fe and Co or a composite of Cr, Al, Fe and Co) of a submicron spherical lithium ion battery. The method comprises the steps of: preparing spherical manganese carbonate as a reaction material and a template agent in a solvent heating or deposition method, and then preparing the material Lil+xMn3 / 2-yNil / 2-zMy+zO4 by a novel route with a combination of insertion of low eutectic salts and medium-temperature calcination. The material Lil+xMn3 / 2-yNil / 2-zMy+zO4 prepared in the method has the advantages of regular morphology, high purity, large tapping density, high specific capacity, good rate capability and excellent circulating performance (the discharging specific capacity reaches 122mAh / g under 2C conditions, and the capacity retention rate is up to 76 percent after 1500-circle circulation; and the specific capacity are respectively 120.3mAh / g, 119.5mAh / g and 112.1mAh / g under 3C, 5C and 10C charging / discharging conditions, and the corresponding capacity retention rates are respectively 91 percent, 82 percent and 80 percent after 500-circle circulation). The synthetic process is simple and can be controlled easily. Moreover, doping elements can be easily introduced to further optimize physical properties and chemical properties of the material.

Owner:GUANGZHOU HKUST FOK YING TUNG RES INST

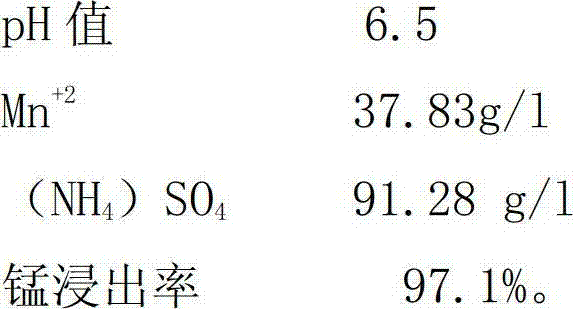

Method for preparing manganese sulfate solution from low-grade manganese oxide by reducing leaching at normal temperature and pressure

The invention relates to a method for preparing a manganese sulfate solution from low-grade manganese oxide by reducing leaching at normal temperature and pressure, which comprises the following steps: measuring contents of Mn<2+>, (NH4)SO4 and H2SO4 in an anolyte, and calculating addition amounts of manganese oxide ore, pyrite and sulfuric acid; adding the manganese oxide ore powder, sulfuric acid and pyrite as well as a small amount of scrap iron chips into the anolyte while stirring; adding an adsorbent to adsorb simple substance sulfur and other colloids, so that MnO2 and FeS2 ore particles can not be coated by the colloids, and MnO2 and FeS2 molecules are sufficiently subjected to redox at normal temperature and pressure; after leaching, adding a desulphurizer and an oxidizer to oxidize low-valence sulfur; and carrying out solid-liquid separation to obtain the manganese sulfate electrolyte. Under the condition of no external heating, the method provided by the invention utilizes the existing manganese carbonate technological equipment, and uses low-grade irrespective-impurity manganese oxide ore (the manganese grade is 10-18%) as the raw material; and the scrap iron chips, carbon-containing substance catalyst, capturing agent, adsorbent and heat generating agent are added, so that the manganese oxide ore and pyrite are subjected to reduction reaction, thereby leaching out the manganese sulfate solution.

Owner:广西天鸿鑫锰业科技有限公司 +3

Method for preparing electronic-grade manganese carbonate from manganese-copper-zinc-cobalt-calcium chloride solution

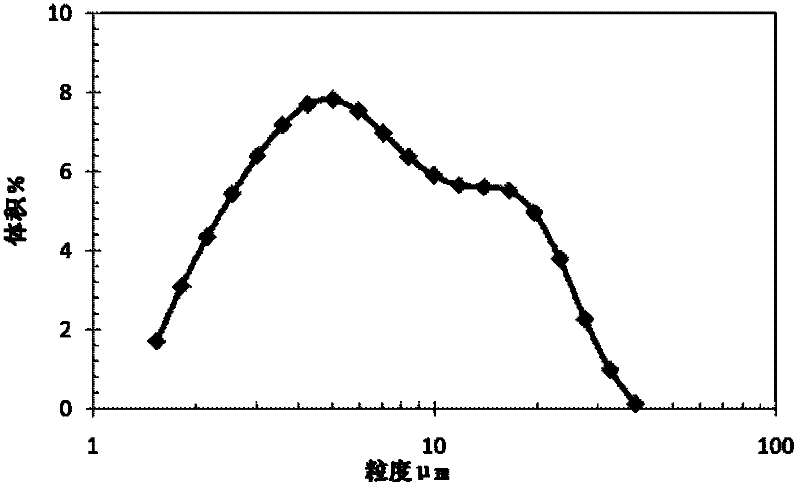

InactiveCN102887545AUniform particle size distributionOrthomorphicManganese compoundsManganese(II) carbonatePhysical chemistry

The invention discloses a method for preparing electronic-grade manganese carbonate from a manganese-copper-zinc-cobalt-calcium chloride solution. A P204 impurity removal solution generated by a cobalt production system, which is used as the raw material, is sequentially subjected to calcium removal, copper-zinc-cobalt enrichment and manganese carbonate precipitation to obtain the electronic-grade manganese carbonate. The method comprises the following steps: 1. removing calcium; 2. enriching copper, zinc and cobalt; and 3. precipitating manganese carbonate. The manganese carbonate obtained by the method disclosed by the invention has the advantages of uniform particle size distribution, regular appearance and high purity; and the dried incarnadine crystalline finished product satisfies the electronic-grade standard.

Owner:LANZHOU UNIVERSITY

High energy type zinc oxide piezoresistor material and preparation method thereof

InactiveCN102515740AReduce the residual pressure ratioReduce leakage currentVaristor coresOvervoltage protection resistorsTin dioxideHigh energy

The invention relates to a high energy type zinc oxide piezoresistor material and a preparation method thereof, which belong to the technical field of piezoresistor material preparation. The preparation method comprises (1) enabling manganese carbonate, barium carbonate and strontium carbonate to be mixed, ball-milled and calcined to obtain mixture A; (2) enabling titanium oxide, antimony pentoxide, bismuth trioxide, cobalt oxide, nickel oxide, silica and stannic oxide to be mixed in submicron-sized zinc oxide powder to obtain mixture B which is mixed and ball-milled with the mixture A to obtain mixture C; and (3) adding aluminum nitrate, silver nitrate, magnesium nitrate, a dispersing agent and an antifoaming agent in the mixture C, ball-milling and drying to obtain high energy type zinc oxide piezoresistor composite powders which are formed in a pressing mode and sintered to obtain a high energy type zinc oxide piezoresistor. The high energy type zinc oxide piezoresistor material is simple in preparation method, prepared zinc oxide piezoresistor has high energy density, low leakage current and residual voltage ratio, batch of products is stable, acceptability is high, and the high energy type zinc oxide piezoresistor material is applicable to scale production.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

A preparation method of a double-carbon layer coated manganese oxide composite material

ActiveCN109148859AImprove electrochemical performanceReduce lossesMaterial nanotechnologyCell electrodesCarbon layerCyclic process

The invention discloses a preparation method of a double-carbon layer coated manganese oxide composite material, belonging to the field of lithium ion battery negative electrode materials, comprisingthe following steps: adopting a coprecipitation method to synthesize spherical manganese carbonate, coating a layer of carbon source on the surface of the spherical manganese carbonate, and carrying out sintering treatment in an inert atmosphere to obtain a precursor; The precursor is put into hydrochloric acid solution, dispersed uniformly, and then the precursor is coated with a carbon source under vacuum, and then heat treated in an inert atmosphere to obtain a double carbon layer coated manganese oxide composite material. As that nanometer manganese oxide particles are prepared by heat treat manganese carbonate in a specific atmosphere and temperature, the nanometer material can alleviate the problems of poor conductivity and volume expansion of the manganese oxide negative electrode material and improve the electrochemical performance of the negative electrode material; The invention uses two layers of carbon as a protective layer to reduce the loss of the active material caused by the manganese oxide in the long-term circulation process, while alleviating the volume expansion in the lithium removal and intercalation process, and improving the electrochemical performance of the composite material.

Owner:CENT SOUTH UNIV

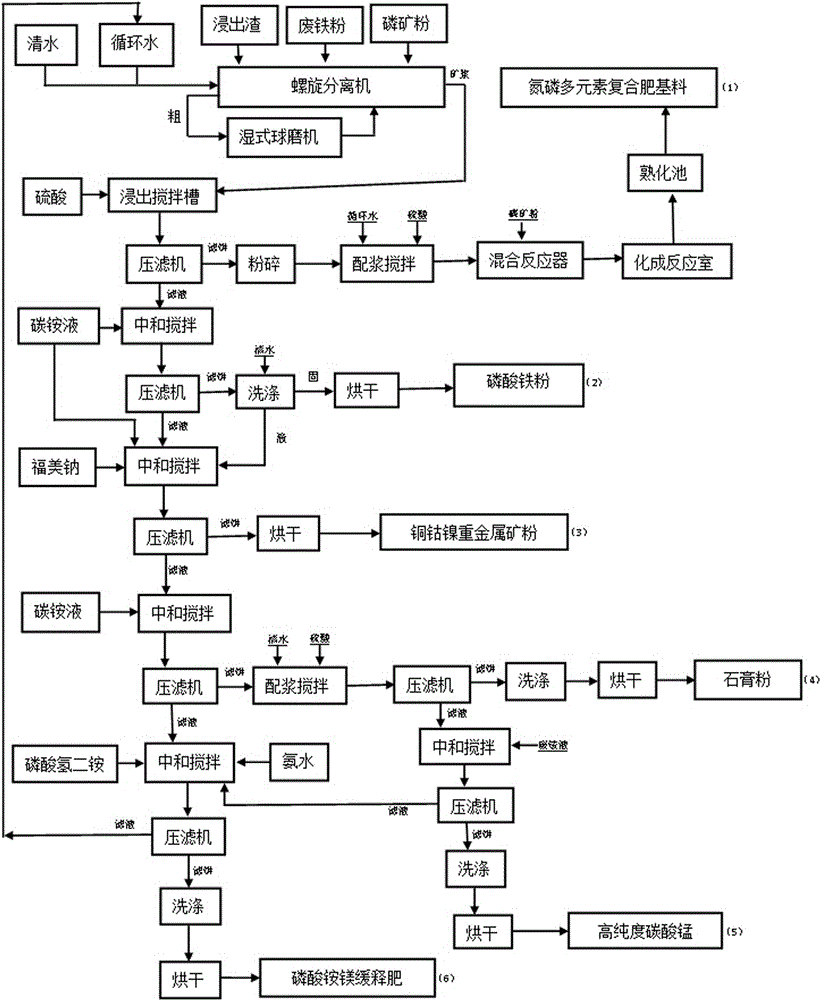

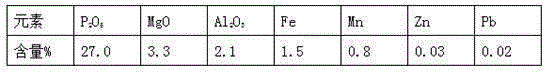

Comprehensive recycling method for leaching residues in electrolytic manganese metal production

InactiveCN105152153AThe preparation process steps are simpleEasy to operateCalcium/strontium/barium sulfatesProcess efficiency improvementFerric hydroxideMetals industry

A comprehensive recycling method for leaching residues in electrolytic manganese metal production concretely includes the steps that 1, a compound fertilizer substrate is prepared; 2, ferric phosphate powder is recycled; 3, copper-cobalt-nickel precious metal mineral powder is recycled; 4, gypsum powder is recycled; 5, high-purity manganese carbonate ore is prepared; 6, magnesium ammonium phosphate slow-release compound fertilizer is prepared. Iron, manganese and other resources in the leaching residues can be effectively recycled, and a certain amount of non-completely-dissolved manganese carbonate ore and manganese dioxide ore and precipitated ferric hydroxide and copper, cobalt and nickel precious metal sulfide ore contained in the leaching residues in electrolytic manganese metal production and Mn2+, NH4+ and other valuable substances can be recycled comprehensively and systematically, wherein the valuable substances are separated along with residue water; in this way, the effects of entire and comprehensive recycling and zero discharge are achieved, and the method has quite important meaning for energy conservation, emission reduction and environment pollution treatment in the electrolytic manganese metal industry.

Owner:赵阳臣

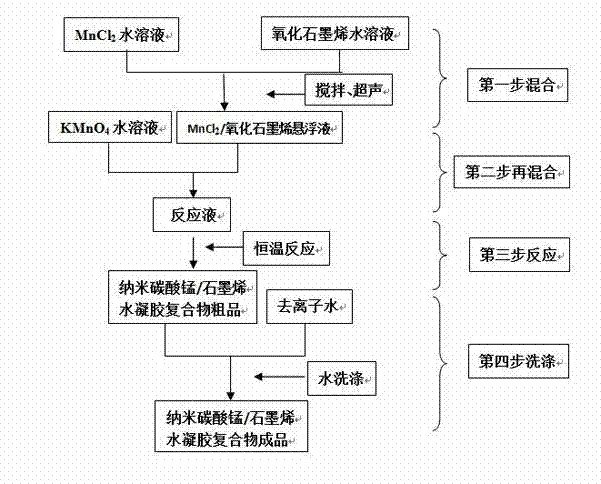

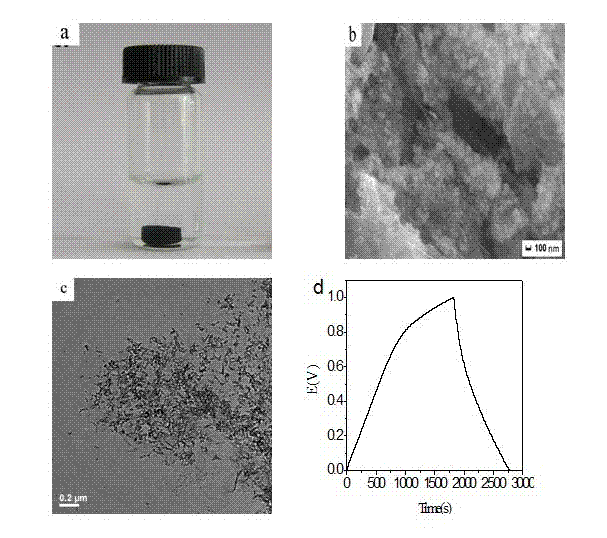

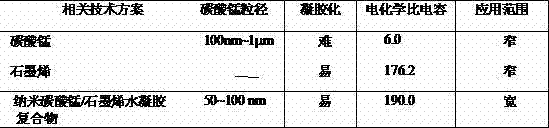

Nanometer manganese carbonate/graphene hydrogel complex and preparation method thereof

ActiveCN102757096AImprove electrochemical performanceThe preparation method is simple and reliableMaterial nanotechnologyGrapheneManganese(II) carbonatePhysical chemistry

The invention relates to a nanometer composite material, and in particular relates to a nanometer manganese carbonate / graphene hydrogel complex and preparation method thereof. The nanometer manganese carbonate / graphene hydrogel complex is prepared by the following steps: a first step of mixing: adding MnCl2 water solution into graphene oxide suspending liquid to obtain MnCl2 / graphene oxide suspending liquid under the conditions of stirring and sonic oscillation; a second step of mixing again: adding KMnO4 water solution into MnCl2 / graphene oxide suspending liquid to form reacting liquid; a third step of reacting: putting reacting liquid into an airtight reaction kettle to react at the constant temperature to obtain a nanometer manganese carbonate / graphene hydrogel complex crude product; and a fourth step of washing: washing the nanometer manganese carbonate / graphene hydrogel complex crude product with deionized water to obtain a nanometer manganese carbonate / graphene hydrogel complex finished product. The nanometer manganese carbonate / graphene hydrogel complex has good electrochemistry performance, and is widely suitable for fields of catalysis materials, electrode materials and the like. The preparation method is simple and reliable, and is suitable for industrial production.

Owner:NANJING UNIV OF SCI & TECH

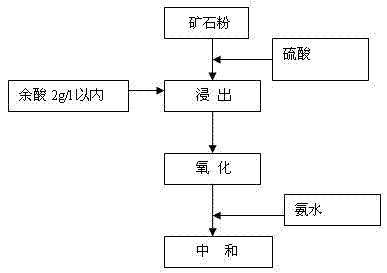

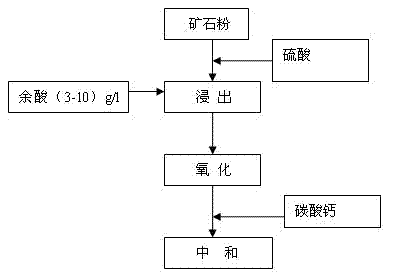

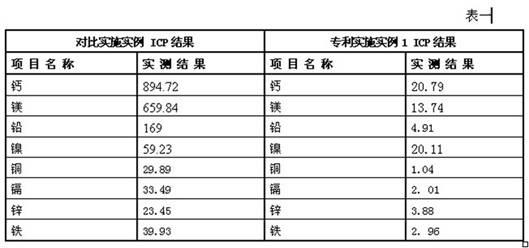

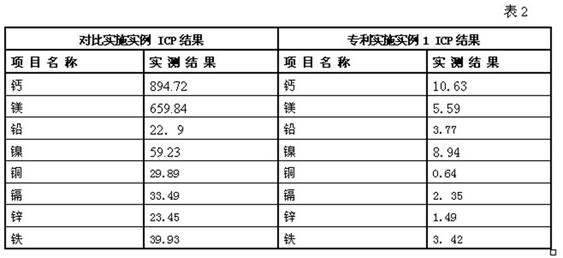

Technological method for leaching manganese ore with high spent acid

The invention discloses a technological method for leaching manganese ore with high spent acid, which comprise the steps: (1) according to the technological requirements, adding sulfuric acid into manganese ore powder, so as to obtain manganese sulfate leachate after reaction; in the leachate, keeping the concentration of the sulfuric acid be (3-10)g / l; (2) adding an oxidant into the leachate for oxidation treatment; and (3) adding calcium carbonate into the leachate to react with the sulfuric acid until the pH value is within a range of 6.4 plus or minus 0.2, so as to obtain manganese ore leachate. According to the method, the concentration of leached spend acid is increased so that the manganese carbonate ore and the acid react relatively thoroughly, the leaching rate is improved, the manganese content in slag is reduced, not only is the utilization rate of resources increased, but also the pollution to the environment is effectively reduced; calcium carbonate is used for substituting for all or part ammonia water for neutralizing the spent acid, so that the problem that ammonium sulfate which is produced by using the ammonia water and the excessive spent acid is supersaturated in a circulation system is effectively solved; and the neutralization cost is greatly lowered, and obvious economic benefits are obtained.

Owner:贵州武陵锰业有限公司

Method for removing calcium and magnesium ions in high-purity manganese sulfate production

ActiveCN111908511AAchieve removalGood removal effectManganese sulfatesManganese sulphateCalcium bicarbonate

The invention relates to the technical field of lithium battery positive electrode materials, and provides a method for removing calcium and magnesium ions in high-purity manganese sulfate production.The method provided by the invention comprises the following steps: firstly, adding soluble carbonate to convert a high-purity manganese sulfate precursor (crude manganese carbonate and / or crude manganese hydroxide) into manganese carbonate, simultaneously converting calcium and magnesium ions in the manganese carbonate into calcium carbonate and magnesium carbonate, and then introducing carbon dioxide to convert the calcium carbonate and the magnesium carbonate into calcium bicarbonate and magnesium bicarbonate; calcium bicarbonate and magnesium bicarbonate are easily dissolved in water andcan be separated from manganese carbonate through solid-liquid separation, so that calcium and magnesium ions are removed. The method provided by the invention is simple in steps, easy to operate, lowin cost and good in calcium and magnesium ion removal effect.

Owner:TSINGHUA UNIV

Manufacturing method of ultra-pure battery-grade manganese chloride for battery material

The invention relates to a manufacturing method of ultra-pure battery-grade manganese chloride for a battery material, which comprises the following steps that: manganese chloride solution which is prepared by leaching ordinary manganese carbonate or metal manganese with high impurity content through hydrochloric acid is added with hydrofluoric acid, fluoride, phosphoric acid, phosphate salt or polyphosphoric compound to remove calcium (Ca) and magnesium (Mg), sulfide, polysulfide or sulfuric organic sodium salt is used for removing heavy metal impurities, the pH value of the solution is maintained at 2.5 to 6.0, the solution is filtered after the reaction, filtered liquid enters an iron-removing reactor, the reaction temperature is controlled at 30 to 120 DEG C, the Baume degree is 30 to56 degrees Be, industrial peroxide or hydrogen peroxide is added under the pH value of 2.5 to 6.0 to remove the iron, organic matters can be removed by adding particle or powder active carbon under the temperature of 30 to 120 DEG C, filter liquid after the reaction and filter is pumped into a concentrator to be concentrated, crystallized and dripped at a normal pressure or a negative pressure, so an ultra-pure battery-grade manganese chloride product is obtained. For the manganese chloride product prepared through the method, the content of the manganese chloride product can reach more than 99 percent.

Owner:HUBEI HAOYUAN MATERIAL TECH

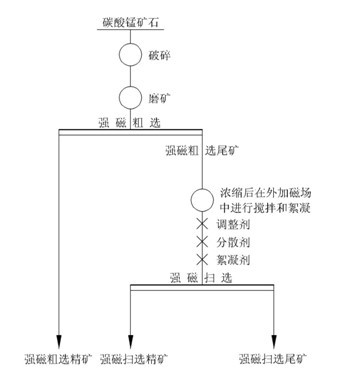

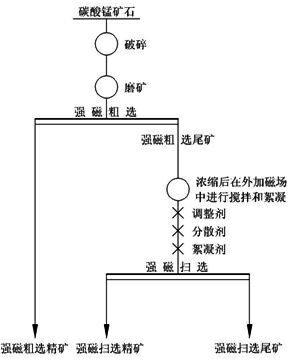

Flocculating-magnetic seperation method of low-grade carbonic acid manganese ore

InactiveCN102430471ATo achieve the purpose of comprehensive recyclingImprove recycling efficiencyMagnetic separationFlocculationManganese(II) carbonate

The invention relates to a flocculation-magnetic seperation method of low-grade carbonic acid manganese ore; the flocculating-magnetic seperation method comprises the following steps of: crushing the low-grade carbonic acid manganese ore, then grinding the ore till ore particles with the particle size less than 0.074mm accounts for more than 60wt%, adding water to the ore particles to condition pulp till the mass concentration is 15-30wt%, and carrying out strong magnetic rough concentration to respectively obtain strong magnetic rough concentration ore concentrate and tailings after strong magnetic rough concentration; then concentrating the tailings after strong magnetic rough concentration till the mass concentration is 15-30wt%, carrying out stirring flocculation in a container accompanied by an imposed magnetic field, adding a modifying agent in the stirring process to adjust the Ph value of ore pulp to be 8-10, and then sequentially adding a dispersing agent and a flocculating agent, wherein the addition amount of the dispersing agent is 1000-3000g per ton of dry ore, and the addition amount of the flocculating agent is 1000-2000g per ton of dry ore, and finally carrying strong magnetic scavenging on the ore pulp of the strong magnetic rough tailings subjected to flocculation processing to obtain the strong magnetic scavenging ore concentrate. Therefore, the flocculation-magnetic seperation method has the characteristics of high utilization ratio of resources, high comprehensive recovery rate and economic feasibility.

Owner:WUHAN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com