Manufacturing method of ultra-pure battery-grade manganese chloride for battery material

A battery material and manufacturing method technology, applied in the direction of manganese halide, etc., can solve the problems that manganese lithium batteries cannot be used, the purity of manganese chloride products is not high, and the product quality cannot meet the requirements of battery-grade products, and achieve high purity and appearance. The effect of bright colors and high cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

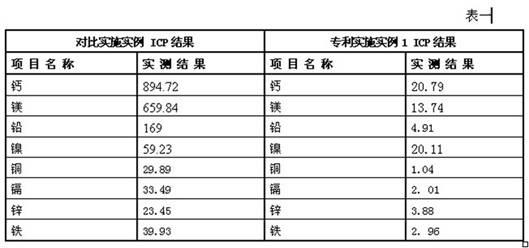

[0023] 500gMnCO 3 Add 800~1000ml of 30% hydrochloric acid to dissolve, heat and stir to raise the temperature to 80°C, add 20g of hydrofluoric acid or fluoride or phosphoric acid or phosphate or polyphosphoric compounds to remove Ca and Mg, keep the pH value of the solution at 2.0~5.0, and keep warm under stirring React for 1 hour, then add sulfide or polysulfide to remove Co, Ni, Pb, Cd, Cr heavy metal impurities, keep the pH value at 4.5~5.5, stir and keep warm for 0.5 hour, filter. Return the filtrate to the iron removal reactor, control the Baume degree at 30~53 °Be', control the temperature at 30~120°C, add peroxide or hydrogen peroxide and 10 g of activated carbon, control the pH at 2.5~5.5, and react 1 hour, filtered, and the filtrate was concentrated, crystallized, and dehydrated to obtain 560g of a high-purity manganese chloride product. According to ICP detection, calcium in the obtained manganese chloride is 20.79 ppm, magnesium is 13.74 ppm, nickel is less than 20...

Embodiment 2

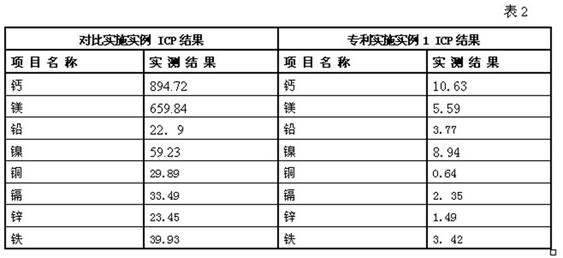

[0030] Add 1500~2000ml of 30% hydrochloric acid to 500g of manganese metal, heat and stir to raise the temperature to 80°C, add 20g of hydrofluoric acid or fluoride or phosphoric acid or phosphate or polyphosphorus compound to remove Ca and Mg, keep the pH value of the solution at 2.0~5.0, stir Under heat preservation reaction for 1 hour, then add sulfide or polysulfide to remove Co, Ni, Pb, Cd, Cr heavy metal impurities, keep the pH value at 4.5~5.5, stir and heat preservation reaction for 0.5 hour, and filter. Return the filtrate to the iron removal reactor, control the Baume degree at 30-53 °Be', control the temperature at 30-120 °C, add activated carbon and peroxide or hydrogen peroxide, control the pH at 2.5-5.5, and react for 1 hour , filtered, and the filtrate was concentrated, crystallized, and dehydrated to obtain 1560 g of a high-purity manganese chloride product. According to ICP detection, calcium in the obtained manganese chloride is 10.63 ppm, magnesium is 5.59 p...

Embodiment 3

[0036]Add 3000~4000ml of 30% hydrochloric acid to 1000g manganese metal, heat and stir to raise the temperature to 80°C, add 40g of hydrofluoric acid or fluoride or phosphoric acid or phosphate or polyphosphorus compound to remove Ca and Mg, keep the pH value of the solution at 2.0~5.0, stir Under heat preservation reaction for 1 hour, then add sulfide or polysulfide to remove Co, Ni, Pb, Cd, Cr heavy metal impurities, keep the pH value at 4.5~5.5, stir and heat preservation reaction for 0.5 hour, and filter. Return the filtrate to the iron removal reactor, control the Baume degree at 30-53 °Be', control the temperature at 30-120 °C, add activated carbon and peroxide or hydrogen peroxide, control the pH at 2.5-5.5, and react for 1 hour , filtered, and the filtrate was concentrated, crystallized, and dehydrated to obtain 3047g of a high-purity manganese chloride product. According to ICP detection, calcium in the obtained manganese chloride is 10.63 ppm, magnesium is 5.59 ppm, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com