Patents

Literature

45results about How to "High rate discharge" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Composite lithium ion battery ceramic diaphragm and preparation method thereof

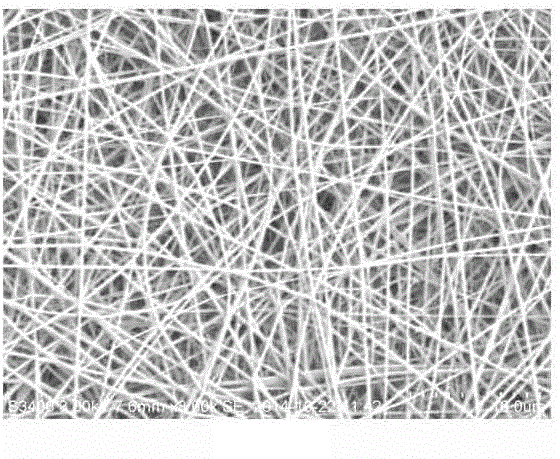

InactiveCN104681764AIncrease contactReduce interface impedanceCell seperators/membranes/diaphragms/spacersPolyolefinElectrospinning

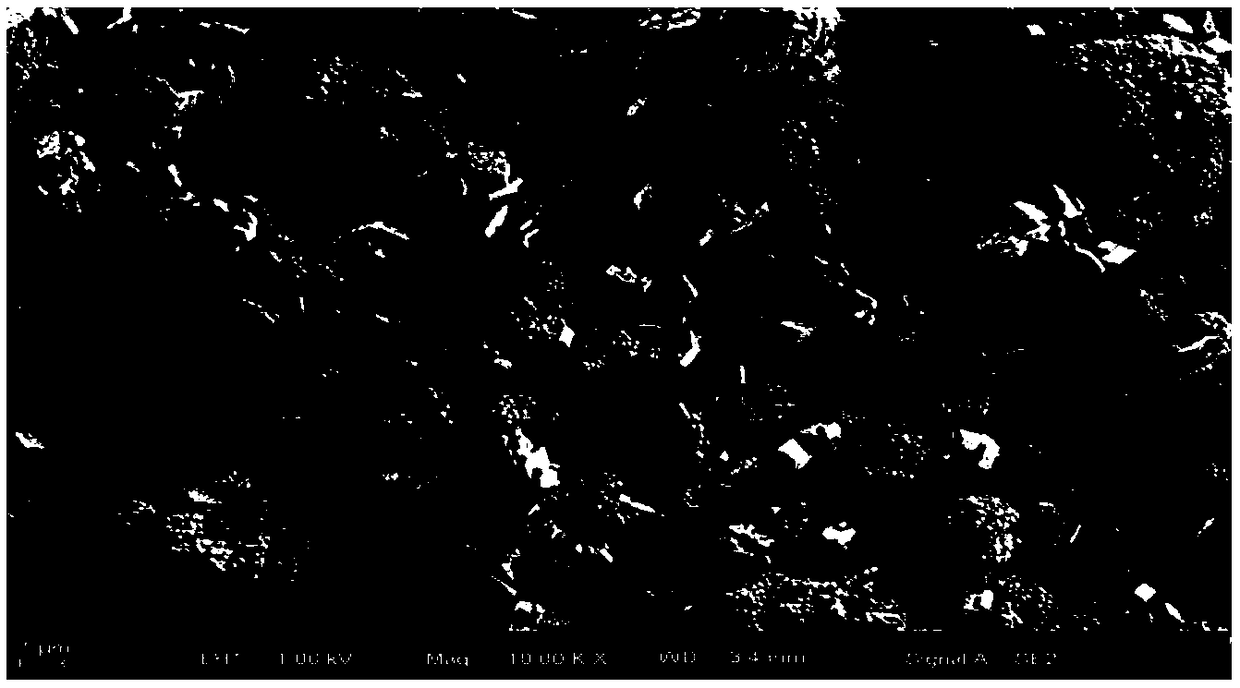

The invention discloses a composite lithium ion battery ceramic diaphragm, wherein single-face or double-face electrostatic spinning is carried out on a ceramic coating diaphragm. The preparation method comprises the following steps: step 1, preparing an electrostatic spinning solution; step 2, carrying out electrostatic spinning; and step 3, treating the composite diaphragm obtained by spinning. The electrostatic spinning is carried out on the surfaces of the existing polyolefin ceramic coating diaphragm and non-woven fabric ceramic coating diaphragm, the electrostatic spinning can be used for fastening and constraining ceramic granules to prevent the ceramic granules from dropping, and moreover, the electrostatic spinning is used as a soft buffering layer to perfect the contact of the diaphragm with the surface of an electrode, so as to reduce the interface impedance of the diaphragm and a battery pole piece and help to improve such properties of the battery as rate discharge and cycle life, etc.

Owner:LONGYAN ZIJIN INNOVATION RES INST

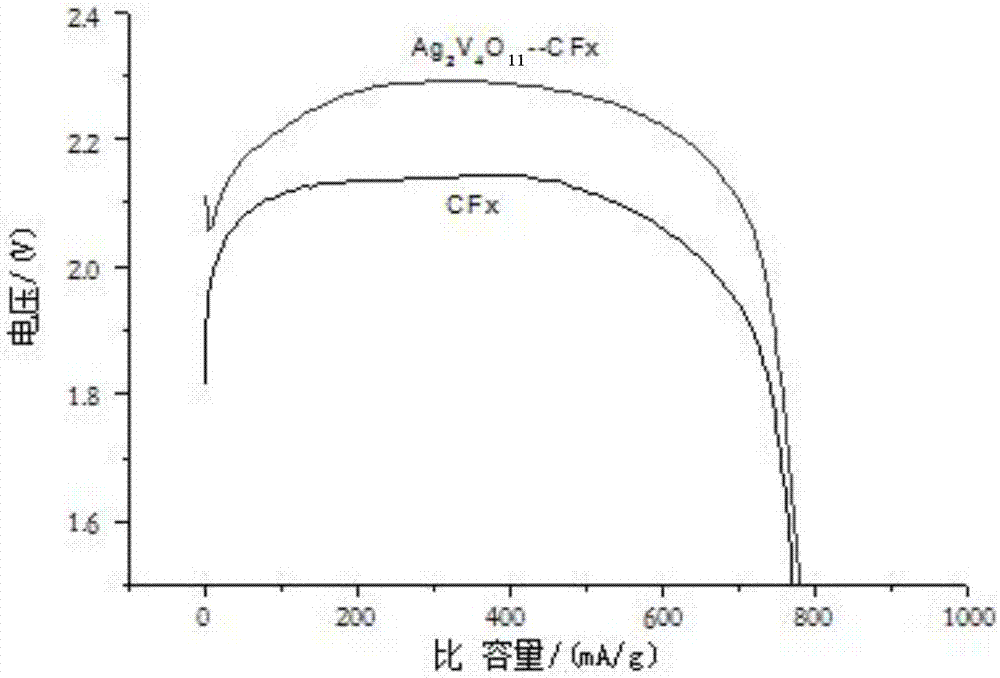

Surface finish method of carbon fluoride material

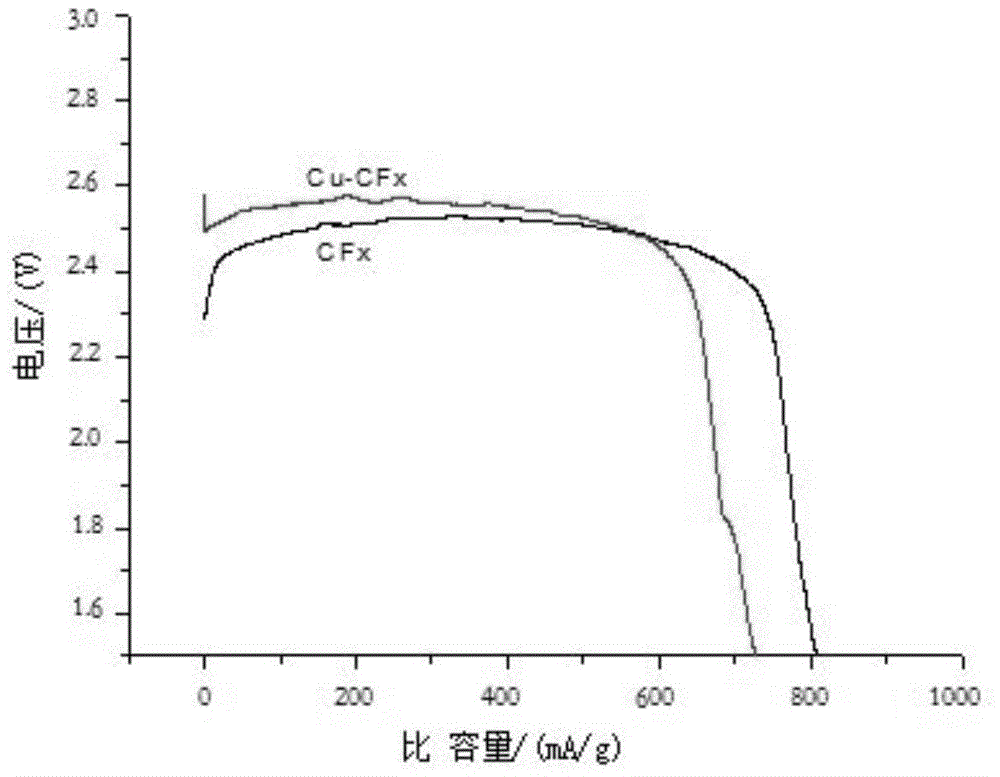

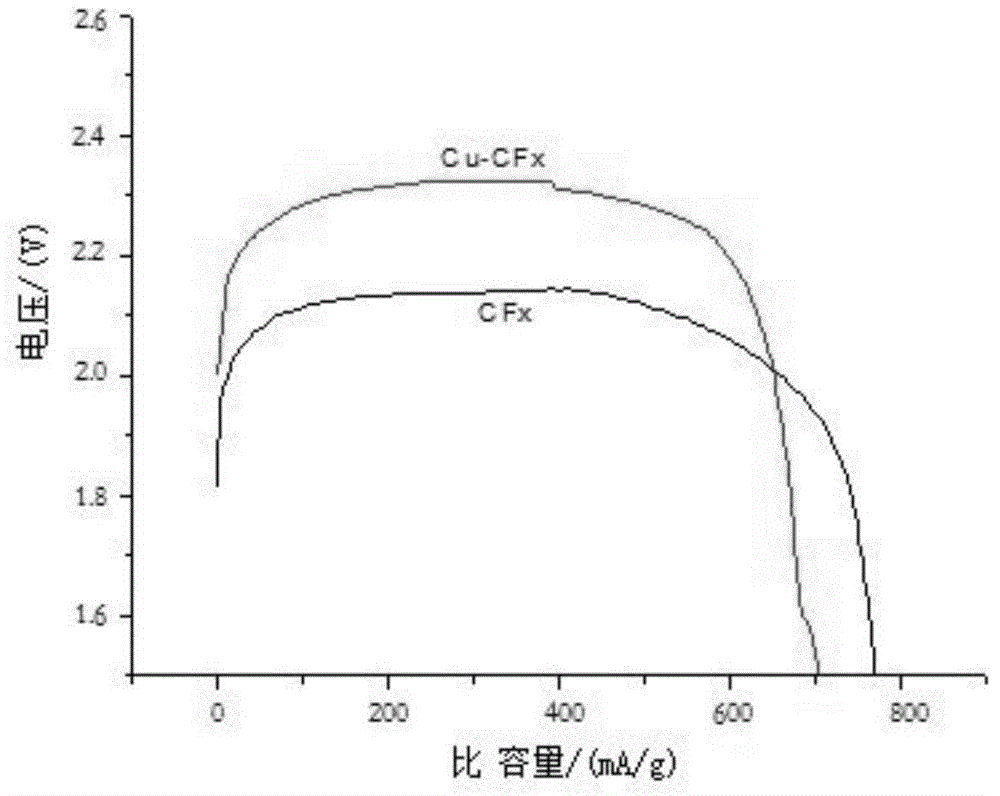

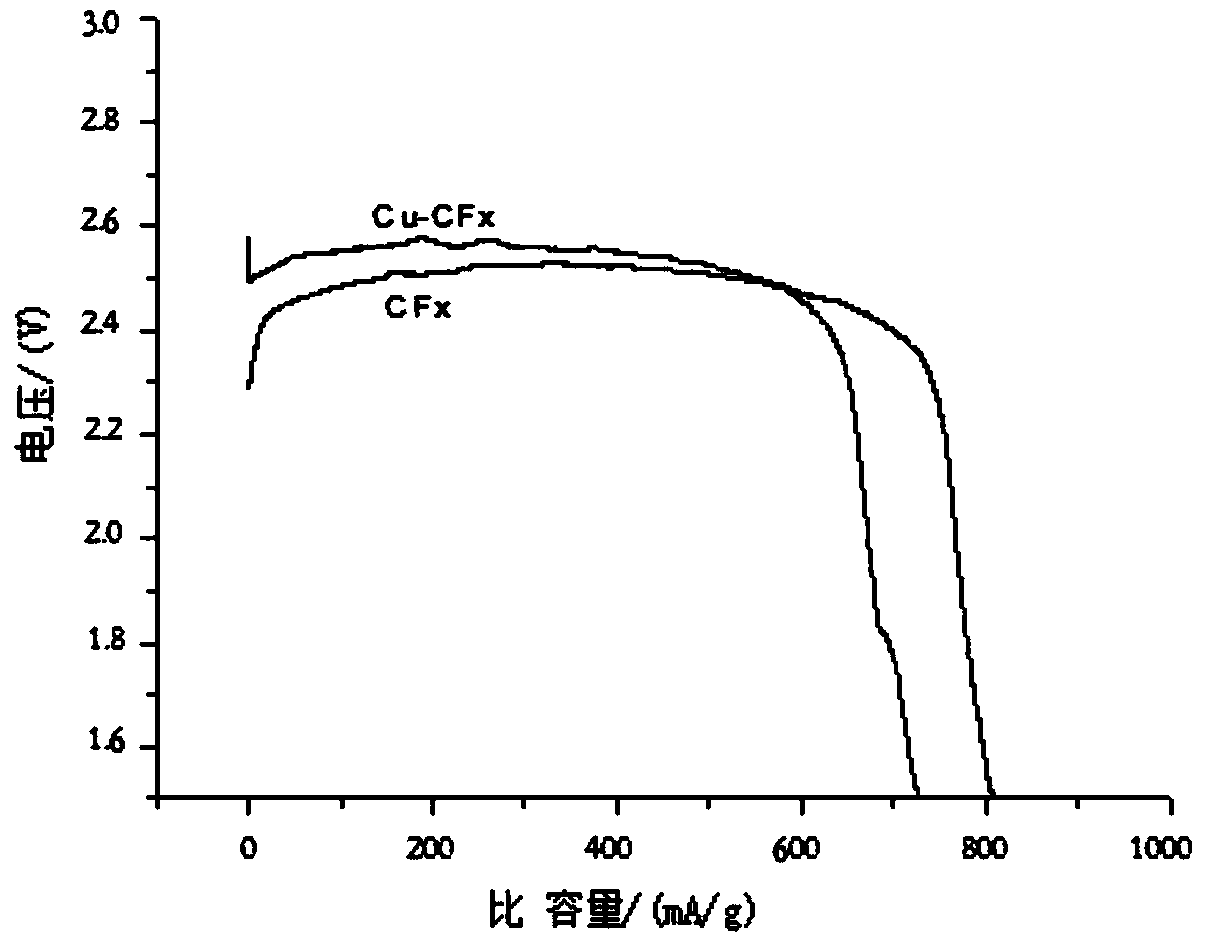

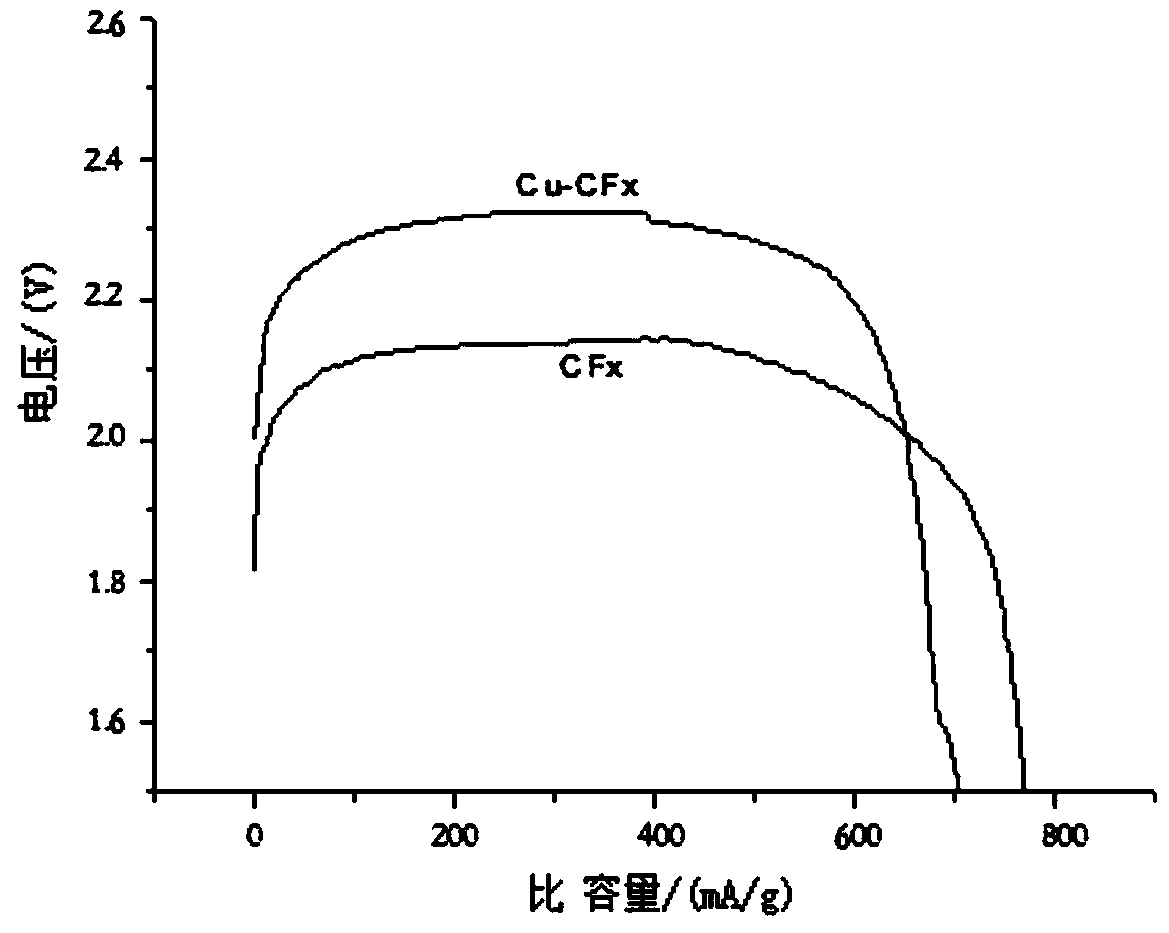

ActiveCN104577107AImprove voltage hysteresisHigh rate discharge and low temperature performance improvementNanotechnologyPrimary cell electrodesSolventPowder mixture

The invention relates to a surface finish method of a carbon fluoride material. The method comprises the following steps: (1) mixing nanometer copper and carbon fluoride, then adding a solvent for ball milling so as to form a combined pulp; (2) drying the mixed pulp so as to form a mixture; (3) screening the mixture so as to obtain the powder mixture; (4) putting the powder mixture into an atmosphere oven so as to be calcined; (5) taking out the calcined powder mixture, lowering the temperature of the calcined powder mixture to the room temperature, and then screening the calcined powder mixture of which the temperature is lowered so as to form the carbon fluoride material modifies by the nanometer copper. According to the invention, the carbon fluoride and the nanometer copper with good conductivity are mixed, and after the mixture is calcined at a high temperature in an inert atmosphere, the nanometer copper reacts on the surface of the carbon fluoride, so that the phenomenon that the voltage of carbon fluoride is delayed is obviously improved, and high-ratio discharge and low temperature performance are greatly improved. The carbon fluoride with a finished surface, prepared by the method, is used as a positive material to be made into a lithium-carbon fluoride battery system, wherein the lithium-carbon fluoride battery system has the properties of high-ratio discharge and low temperature high-current discharge, so that the application range of the lithium-carbon fluoride battery system is extended.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 18 RES INST

Composite positive electrode material and preparation method and application thereof

ActiveCN108172794AImprove cycle lifeHigh rate dischargeMaterial nanotechnologyCell electrodesHigh rateButton battery

The invention discloses a composite positive electrode material and a preparation method and an application thereof, and belongs to the technical field of preparation of an electrochemical power supply material. The composite positive electrode material provided by the invention adopts a core-shell structure, wherein the inner core is metal oxide-doped and composite carbon material-coated lithiummanganese iron phosphate, and the shell is metal oxide-doped and composite carbon material-coated lithium vanadium iron phosphate. The composite positive electrode material provided by the invention has excellent cycle life, high-rate discharging and low-temperature performance and safety performance, as well as relatively high energy density. When the composite positive electrode material is at 0.5C rate, the initial discharging specific capacity of a button cell is greater than 155mAh / g, and after 100 cycles, the capacity retention ratio is greater than 95%.

Owner:LANGFANG GREEN IND TECH CENT +1

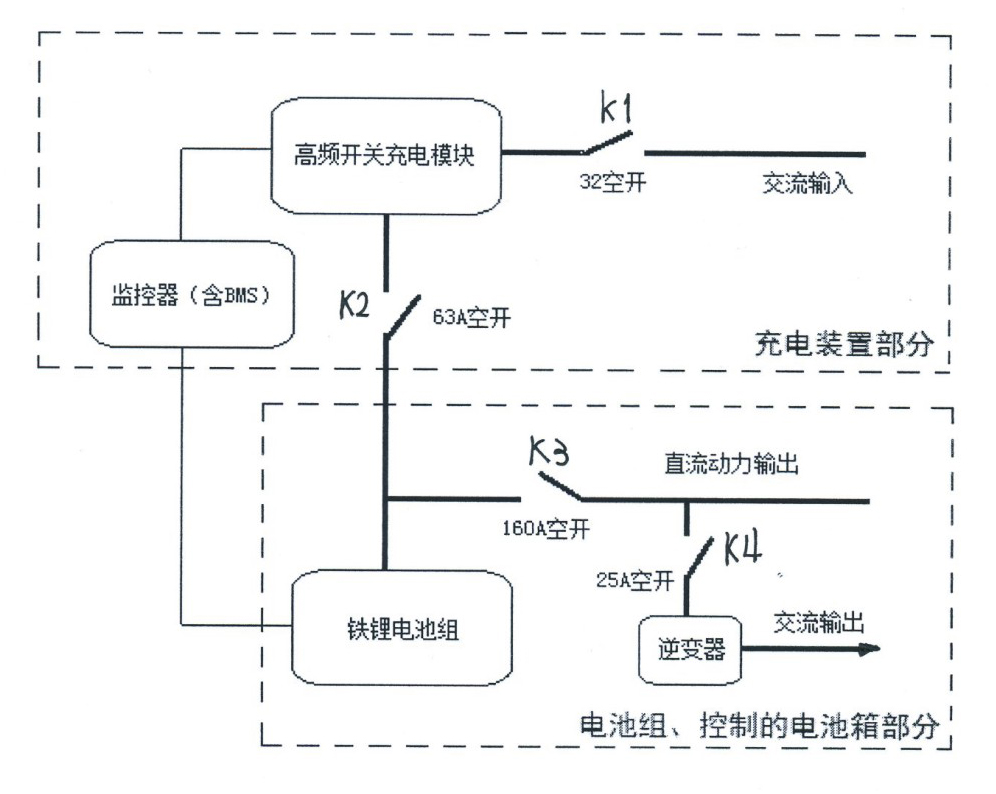

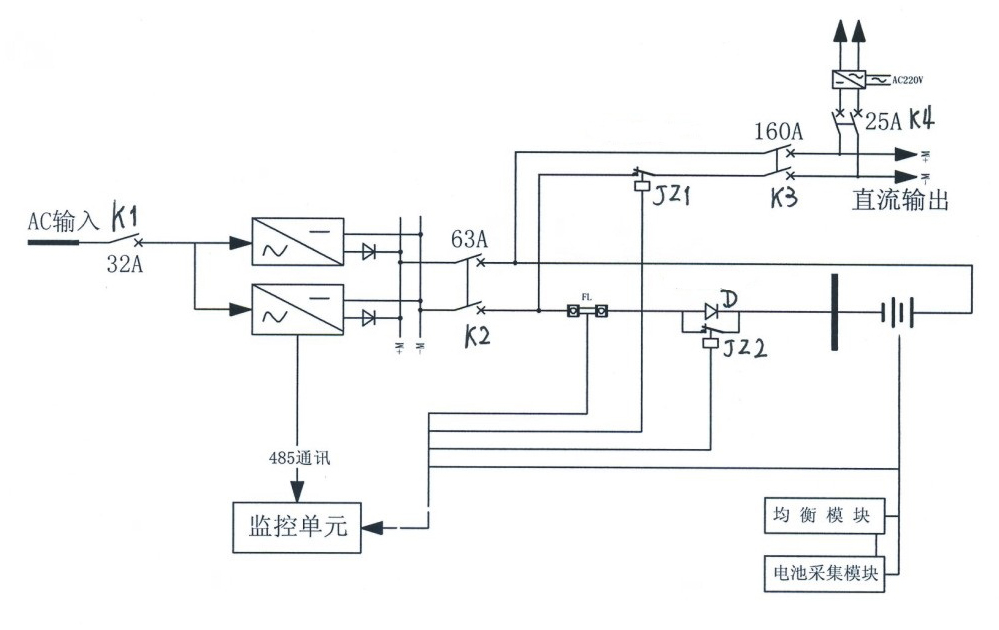

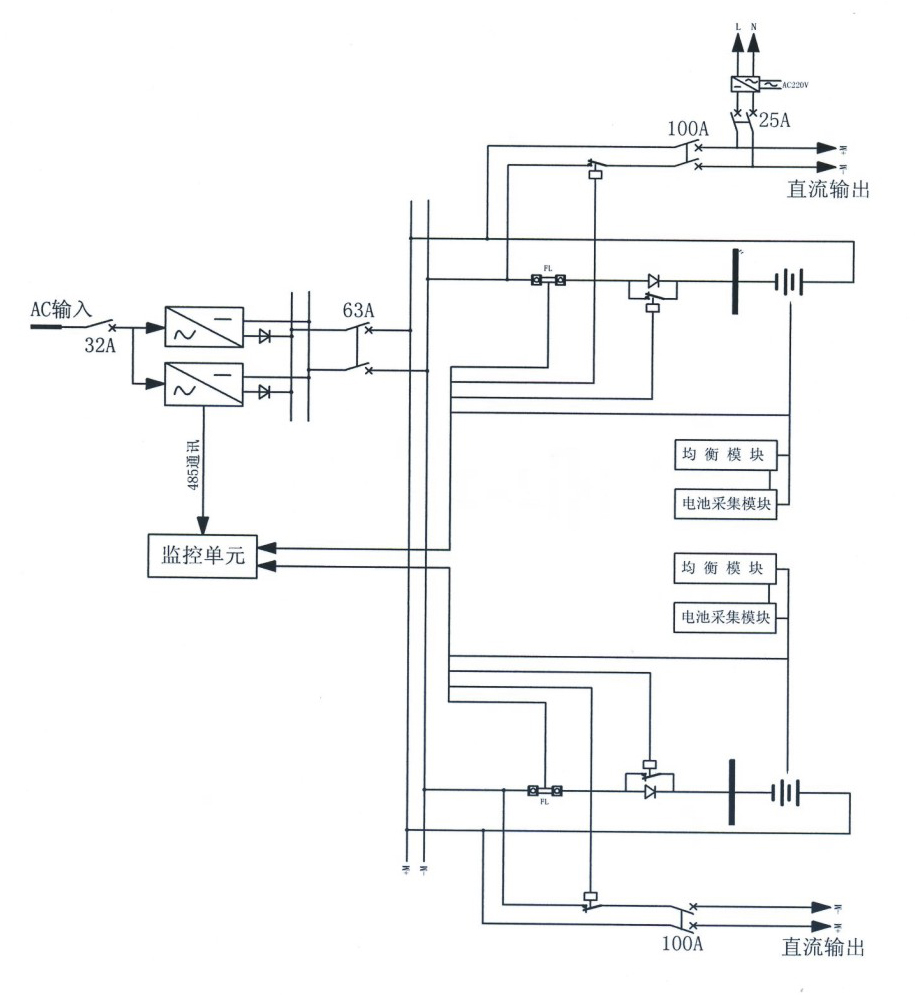

Direct current power supply emergency system of transformer substation based on lithium iron battery

ActiveCN102035249ASolution to short lifeImprove intelligencePower network operation systems integrationInformation technology support systemDistribution controlTransformer

The invention discloses a direct current power supply emergency system of a transformer substation based on a lithium iron battery. The direct current power supply emergency system consists of portable split structure units which are connected in a fast-connection plugging mode. The portable split structure units comprise a lithium iron battery pack unit, a power distribution control switch unit,an inverter unit and a charging control unit, wherein the power distribution control switch unit comprises two air switches, the inverter unit comprises an inverter, and the charging control unit comprises an alternating current air switch, an air switch, a rectifier and a monitor device unit. The direct current power supply emergency system has small size of unit structures, is convenient for transformation and assembly in situ, greatly meets the emergency requirement of accident rescue of a power system and can be simultaneously used as a standby power supply for the field maintenance of the direct current power supply of the transformer substation.

Owner:STATE GRID SICHUAN ELECTRIC POWER CORP ELECTRIC POWER RES INST +1

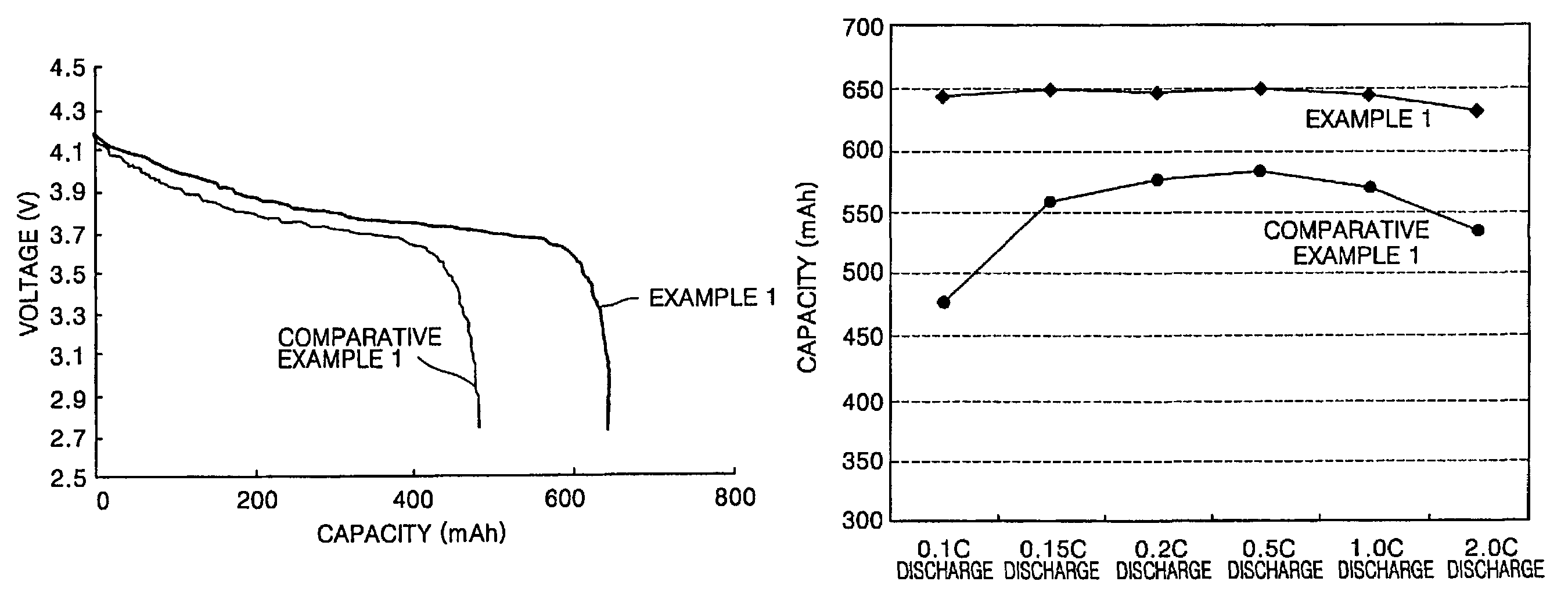

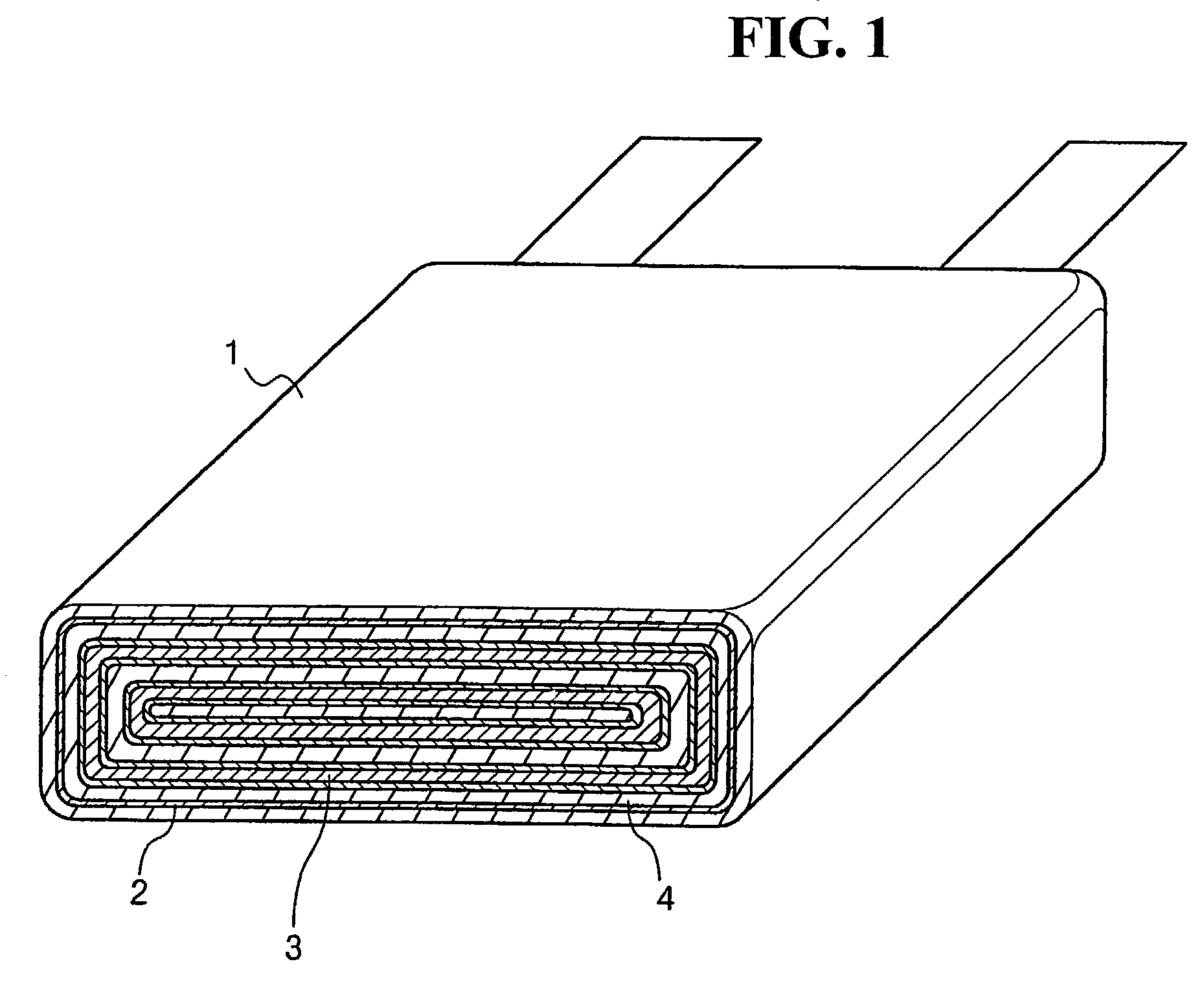

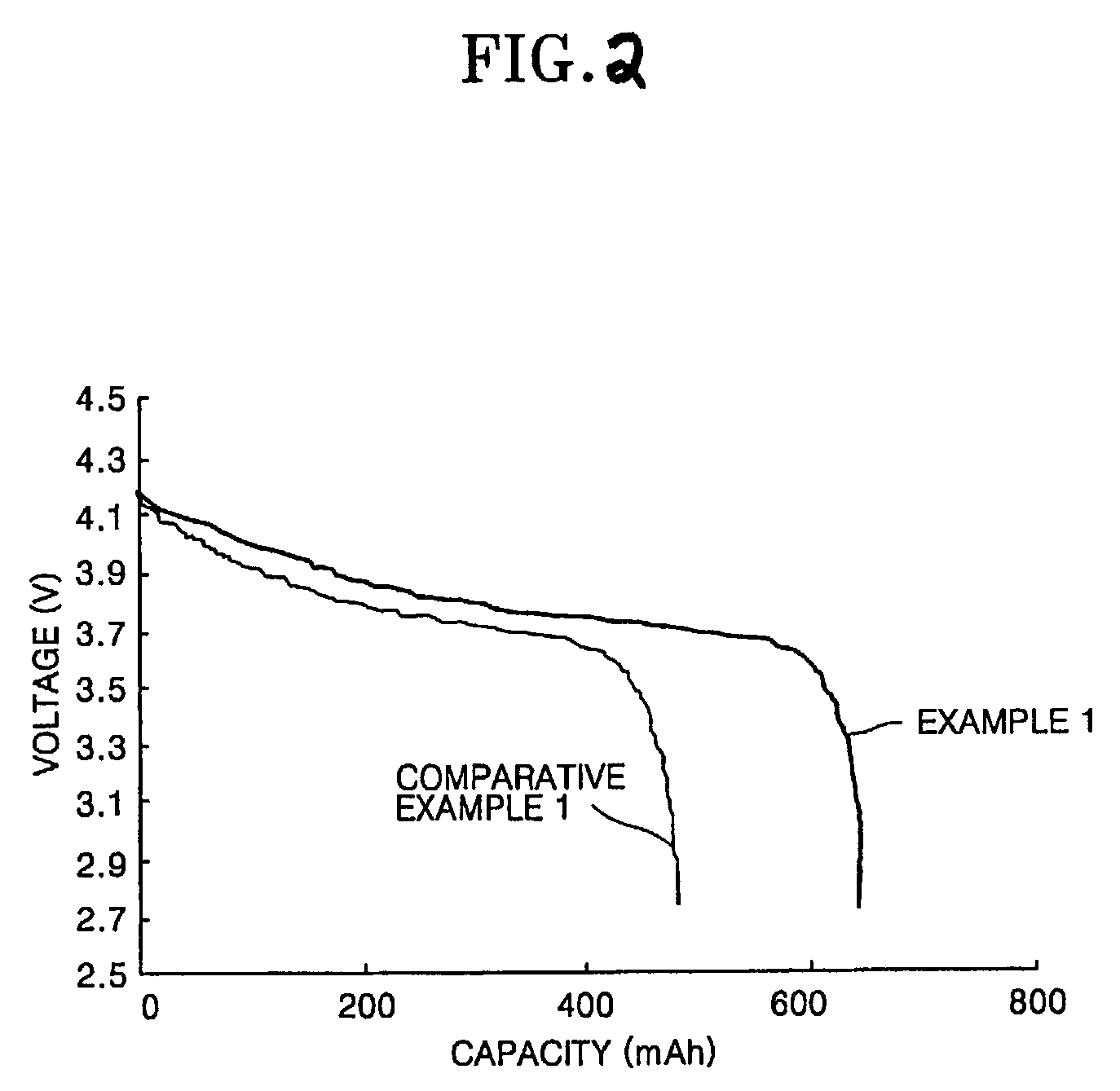

Polymer electrolyte and lithium battery employing the same

ActiveUS7223501B2Improve conductivityImprove electrochemical stabilityNon-metal conductorsSolid electrolytesPolyesterPolymer electrolytes

A solid polymer electrolyte, a lithium battery employing the same, and methods of forming the electrolyte and the lithium battery. The polymer electrolyte includes polyester (meth)acrylate having a polyester polyol moiety having three or more hydroxide (—OH) groups, at least one hydroxde group being substituted by a (meth)acrylic ester group and at least one hydroxide group being substituted by a radical non-reactive group, or its polymer, a peroxide having 6 to 40 carbon atoms, and an electrolytic solution including a lithium salt and an organic solvent.

Owner:SAMSUNG SDI CO LTD

Preparation method of mixed cathode material for lithium battery

ActiveCN104577124BImprove high rate discharge performanceEasy dischargeCell electrodesSecondary cellsHigh rateSlurry

Owner:CHINA ELECTRONIC TECH GRP CORP NO 18 RES INST

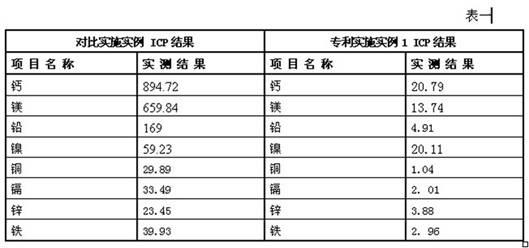

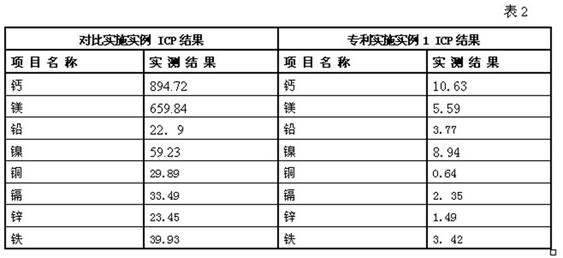

Manufacturing method of ultra-pure battery-grade manganese chloride for battery material

The invention relates to a manufacturing method of ultra-pure battery-grade manganese chloride for a battery material, which comprises the following steps that: manganese chloride solution which is prepared by leaching ordinary manganese carbonate or metal manganese with high impurity content through hydrochloric acid is added with hydrofluoric acid, fluoride, phosphoric acid, phosphate salt or polyphosphoric compound to remove calcium (Ca) and magnesium (Mg), sulfide, polysulfide or sulfuric organic sodium salt is used for removing heavy metal impurities, the pH value of the solution is maintained at 2.5 to 6.0, the solution is filtered after the reaction, filtered liquid enters an iron-removing reactor, the reaction temperature is controlled at 30 to 120 DEG C, the Baume degree is 30 to56 degrees Be, industrial peroxide or hydrogen peroxide is added under the pH value of 2.5 to 6.0 to remove the iron, organic matters can be removed by adding particle or powder active carbon under the temperature of 30 to 120 DEG C, filter liquid after the reaction and filter is pumped into a concentrator to be concentrated, crystallized and dripped at a normal pressure or a negative pressure, so an ultra-pure battery-grade manganese chloride product is obtained. For the manganese chloride product prepared through the method, the content of the manganese chloride product can reach more than 99 percent.

Owner:HUBEI HAOYUAN MATERIAL TECH

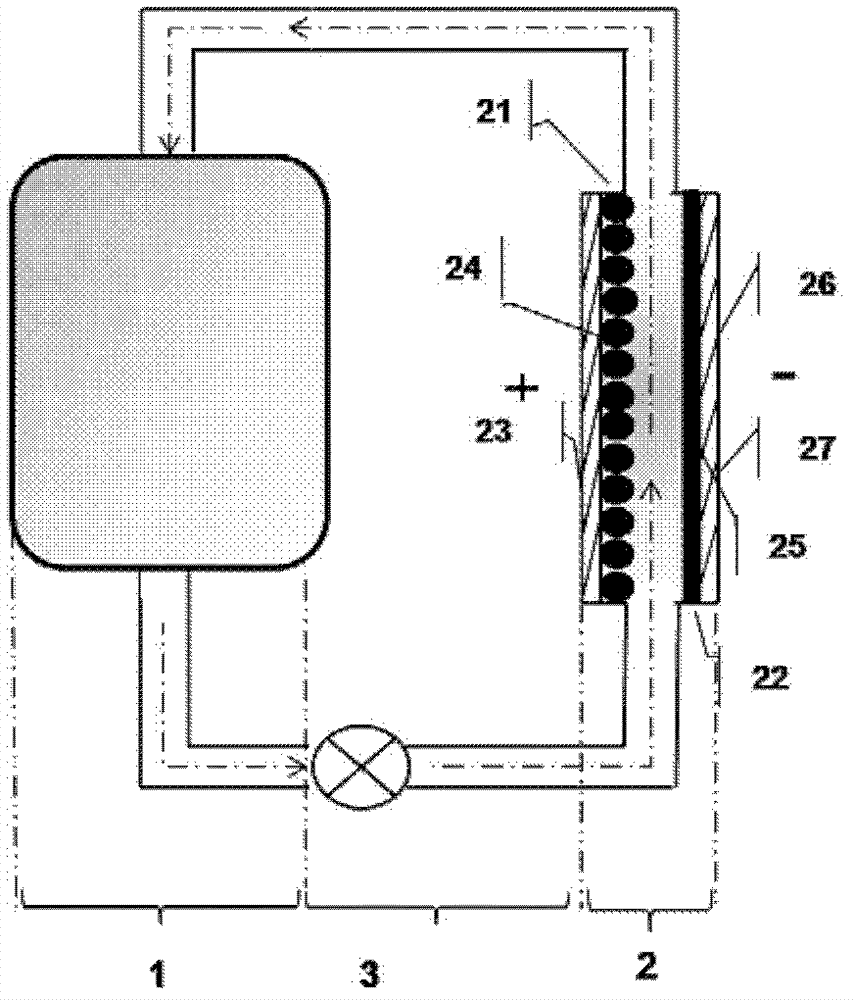

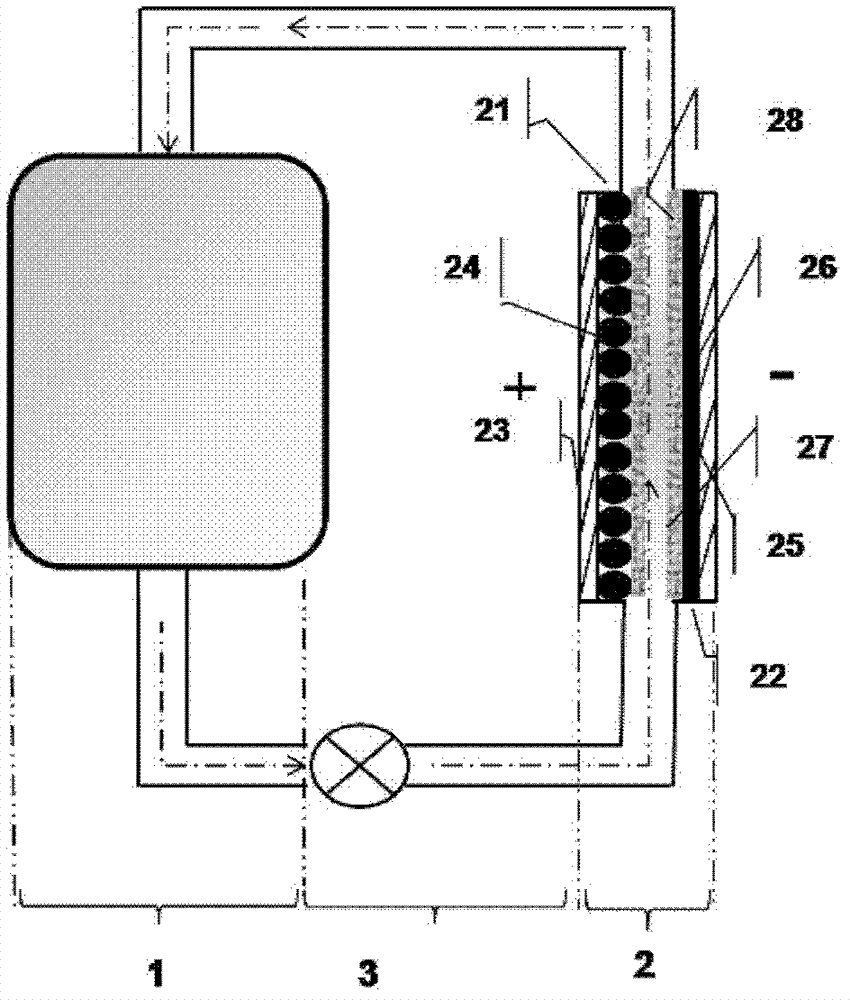

Novel large-volume primary lithium liquid flow storage battery

InactiveCN102956912AImprove cooling effectIncrease the reaction areaRegenerative fuel cellsActive material electrodesElectrochemical responseCurrent collector

The invention relates to a novel large-volume primary lithium liquid flow storage battery. The novel large-volume primary lithium liquid flow storage battery comprises a liquid storage part, a reaction part, and a fluid driving part, wherein the liquid storage part contains a mixed solution, and the mixed solution has liquidity and is constituted by positive active materials and an electrolyte; the reaction part comprises a positive pole and a negative pole, the positive pole is a complex carbon material cathode carrier formed on a current collector, the negative pole is alkali metal or alloy of the alkali metal, and a channel through which fluid can flow is formed between the positive pole and the negative pole; the fluid driving part drives the mixed solution to flow through the channel of the reaction part and generate electrochemical reaction with the positive pole and the negative pole in the channel. The novel large-volume primary lithium liquid flow storage battery is good in high-rate output performance, can be adaptable to large-current-density charging, and is wider in use temperature range. Besides, due to the uninterrupted circulation of the liquid, the radiation effect of the battery is greatly improved, so that the safety performance is guaranteed.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

Binding agent coating surface of diaphragm as well as preparation method and application of binding agent

ActiveCN106189946AShorten the transmission pathImprove high temperature storage performanceNitrile polymer adhesivesElectrolytic agentLithium

The invention discloses a binding agent coateing the surface of a diaphragm as well as a preparation method and application of the binding agent. The binding agent is prepared from acrylonitrile, methyl methacrylate, an unsaturated carboxylic acid monomer, acrylamide, water and an initiator; the mol ratio of the acrylonitrile to the methyl methacrylate to the unsaturated carboxylic acid monomer to the acrylamide to the water is (1.5 to 2.5) : 1 : 1 : (0.5 to 1) : (6.67 to 55); the initiator accounts for 0.5 percent to 0.8 percent of the total mass of reaction materials. By coating between the diaphragm and positive and negative pole pieces with the binding agent, the binding is firm and a boundary has no gap; a transmission way of lithium ions is shortened and a high-temperature energy storage property of batteries can be improved; the safety of the batteries under a working condition is improved; furthermore, the diaphragm of the binding agent is utilized, so that the liquid preserving amount of electrolyte can also be increased, and rate discharge and circulating properties are improved.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

Battery diaphragm and preparation method thereof

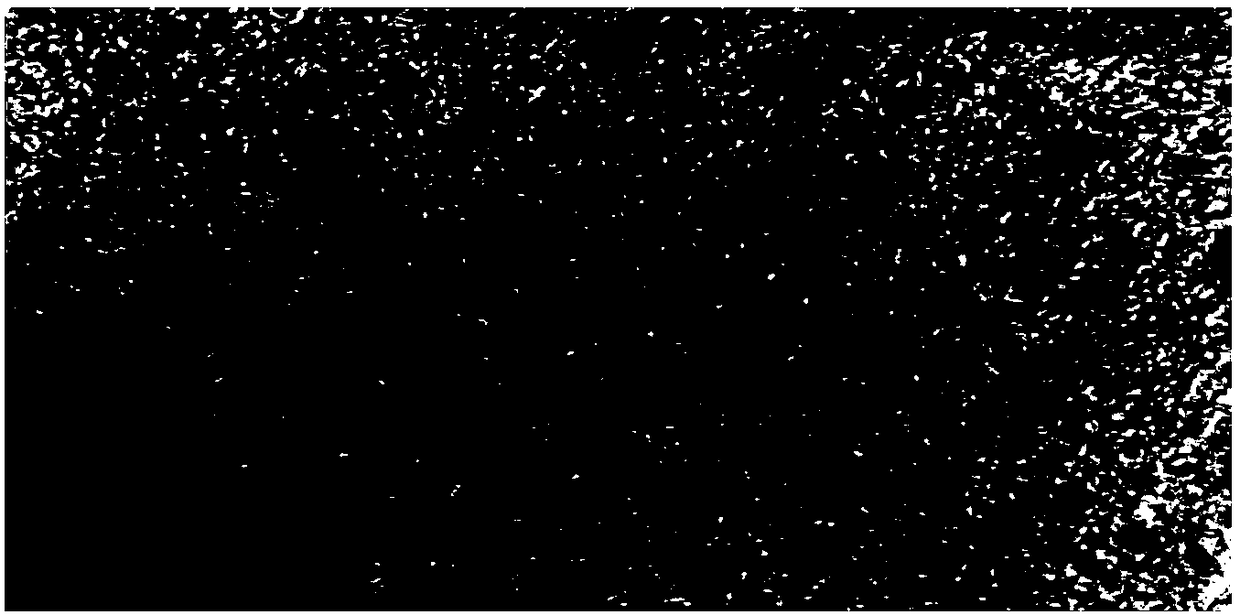

ActiveCN108807804AHigh rate dischargeImprove cycle performanceCell component detailsAgricultural engineeringSlurry

The invention belongs to the technical field of batteries, and particularly relates to a battery diaphragm and a preparation method thereof. The battery diaphragm provided by the invention comprises abase film and a PVDF / PMMA composite coating arranged on at least one side face of the base film in a coating manner; and preferably, the battery diaphragm comprises a base film and PVDF / PMMA composite coatings arranged on both sides of the base film in a coating manner. According to the battery diaphragm provided by the invention, a PVDF / PMMA composite coating is obtained by spraying a mixed slurry of PVDF and PMMA on at least one side face of the base film in a spraying manner, and the prepared battery diaphragm has low air permeability value added, has excellent bonding performance, needlepunching strength, tensile strength and heat shrinkage performance, and can improve the rate discharge and cycle performance of the battery.

Owner:HEBEI GELLEC NEW ENERGY MATERIAL SCI&TECHNOLOY CO LTD

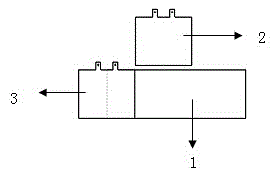

Lithium ion battery electrode, lithium ion battery and lithium ion battery preparation method

InactiveCN108878765ALower internal resistanceHigh rate dischargeElectrode manufacturing processesFinal product manufactureElectrical batteryCurrent collector

The invention discloses a lithium ion battery electrode, a lithium ion battery and a lithium ion battery preparation method. The lithium ion battery electrode comprises an anode and a cathode, the cathode comprises a cathode piece and a cathode lug, the cathode lug is arranged at a middle position of the cathode piece, the cathode piece comprises a current collector and a cathode substance coatedon the current collector; the anode comprises an anode piece and an anode lug, the anode lug is arranged at a middle position of the anode piece, the anode piece comprises a current collector and an anode substance coated on the current collector, isolated layers are arranged positions, corresponding to the cathode lug, on the front and the back of the anode piece, and deintercalation of lithium ions in the anode substance is blocked. The lithium ion battery electrode disclosed by the invention has the advantages that the cathode lug is arranged at the middle position, and the isolated layersare arranged at corresponding positions of the anode piece, thereby guaranteeing that no anode substance exists at a corresponding position of the cathode plug and reducing internal resistance while safety of a lithium battery is guaranteed, and high-rate discharge can be realized more easily.

Owner:SHANDONG PENGXIANG PHOTOELECTRIC TECH

Phosphate composite cathode material and preparation method and application thereof

ActiveCN109638262ARepair defects caused by broken lattice boundariesImprove cycle lifeCell electrodesSecondary cellsPhosphatePhosphoric acid

The invention relates to a phosphate composite cathode material and a preparation method and application thereof. The composite cathode material has a core-shell structure, wherein the core is a phosphate-based lithium ion battery cathode material doped with metal oxide, and the shell is a cladding layer composed of an N-doped titanium oxide, a composite carbon material, and a transition metal oxide lithium cathode material. The invention can design the cladding layer composed of the N-doped titanium oxide, the composite carbon material and the transition metal oxide lithium cathode material,so that the transition metal on the surface of the phosphate-based cathode material and the carbon can be coordinated by X-C bonds, and the carbon is stably coated on the surface of the cathode material, and the structure can repair the lattice interface, prolong the cycle life and improve the cycle stability of the cathode material, and improve the electrochemical performance of the material. Thefirst discharge specific capacity of the phosphate composite cathode material is greater than 152mAh / g at 8C rate, and the capacity retention rate is greater than 95% after 1500 cycles. The phosphatecomposite cathode material has good application prospect.

Owner:LANGFANG GREEN IND TECH CENT +1

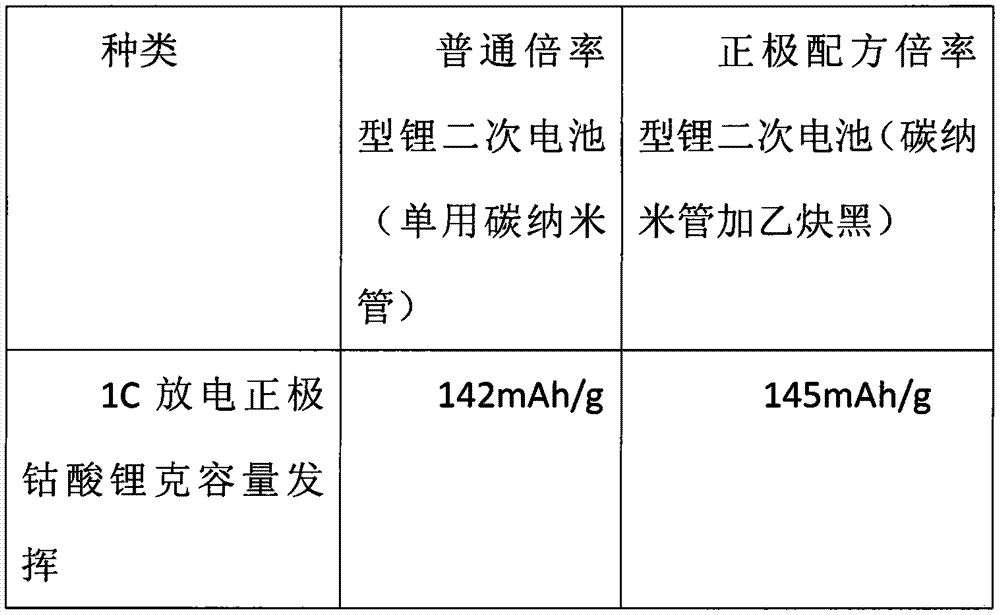

Lithium ion secondary battery positive pole piece and production method thereof

InactiveCN104766945AHigh rate dischargeIncrease ratingsCell electrodesSecondary cellsAluminium-ion batteryAdhesive

The invention relates to the technical field of a lithium ion battery, and particularly relates to a lithium ion secondary battery positive pole piece and a production method thereof. The lithium ion secondary battery positive pole piece comprises active material lithium cobalt oxide or a mixture of lithium cobalt oxide and lithium manganate, a carbon nano-tube, acetylene black, a polyvinylidene fluoride adhesive and an NMP solvent, wherein the mass ratio of the active material lithium cobalt oxide or the mixture of the lithium cobalt oxide to the lithium manganate to the carbon nano-tube to the acetylene black to the polyvinylidene fluoride adhesive to the NMP solvent is 94.5: 1.5: 2: 2: 65. According to a positive pole formula, two conducting agents (carbon nano-tube and acetylene black) are added, and the extraction and insertion speed of lithium ions in a positive pole material can be increased by utilizing the synergistic effect of the tubular structure of the carbon nano-tube and the spotted conducting structure of the acetylene black, so that the gram volume of a battery main material and the rate discharge of the battery can be improved.

Owner:SHENZHEN SHENG ENERGY TECH CO LTD

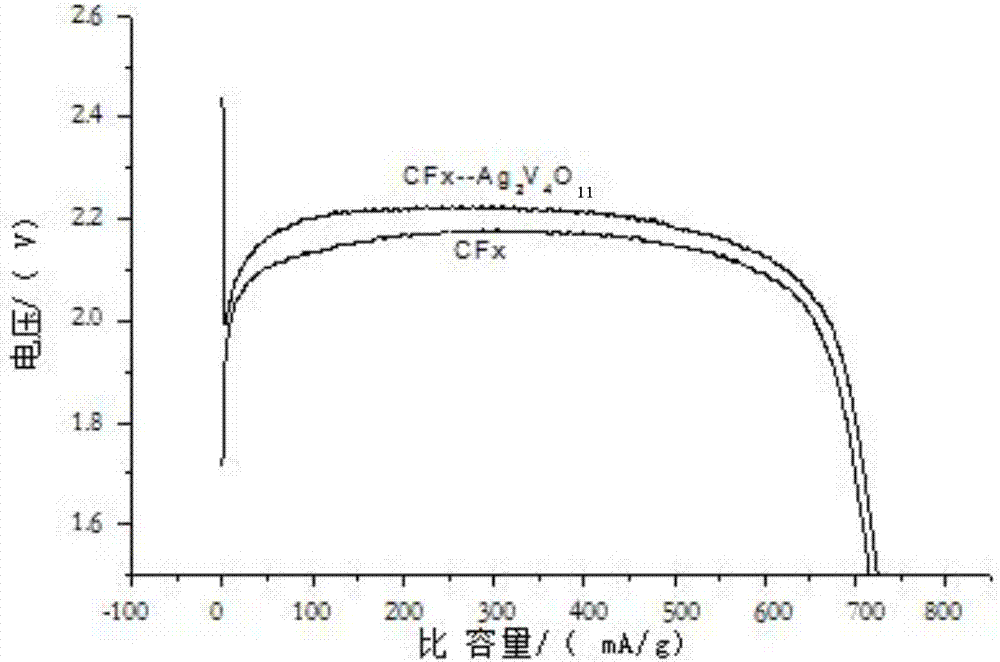

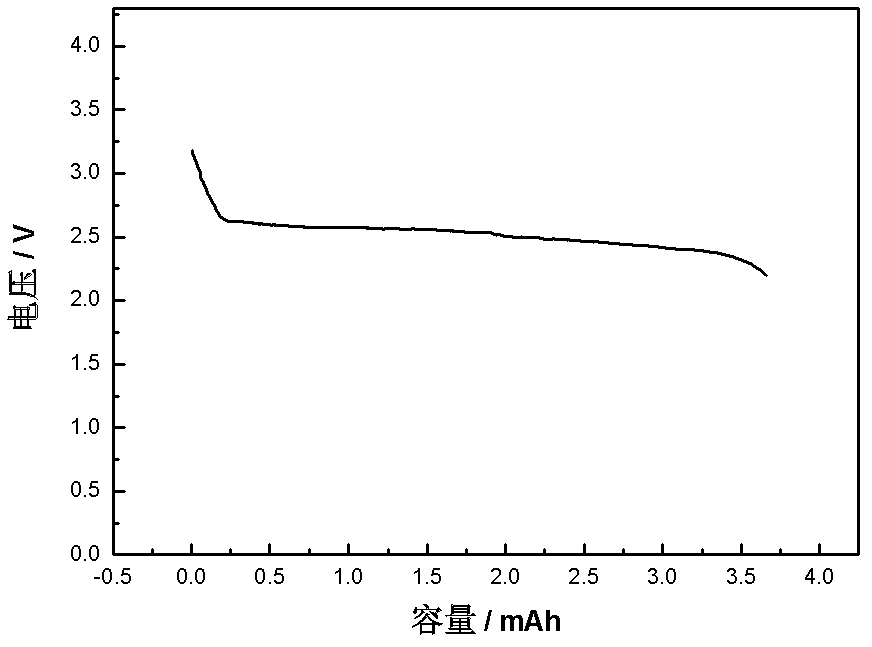

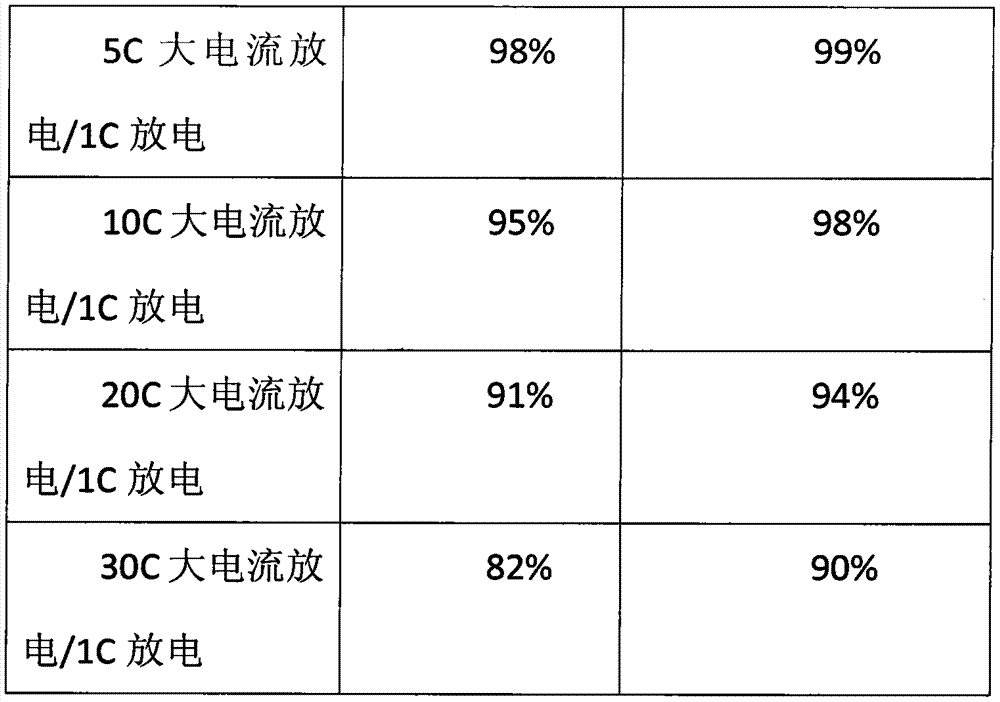

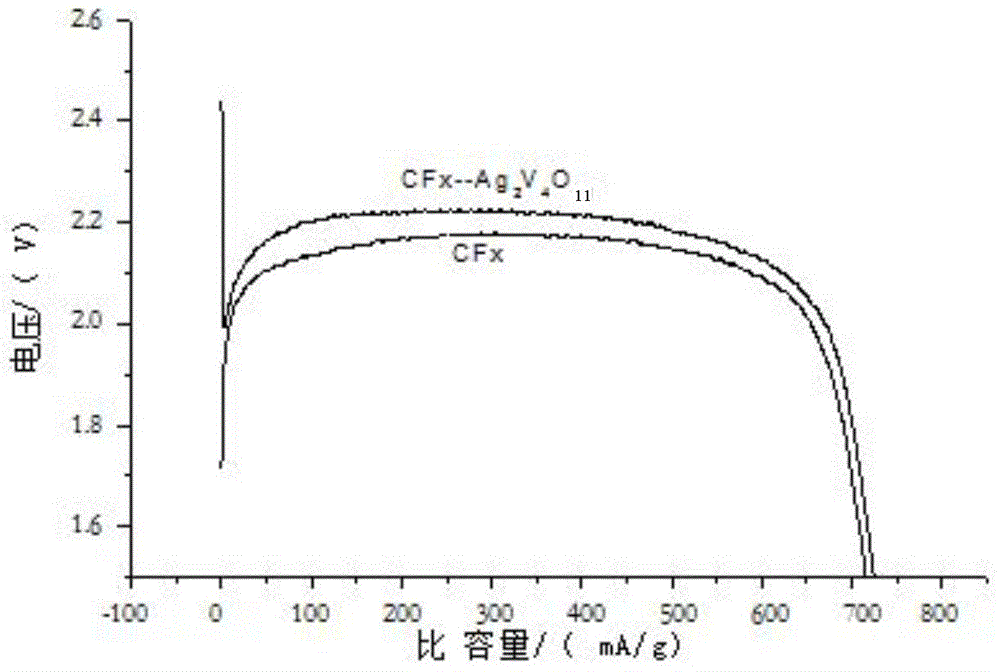

Preparation method of mixed anode material for lithium battery

ActiveCN104577124AImprove high rate discharge performanceEasy dischargeCell electrodesSecondary cellsHigh rateSlurry

The invention relates to a preparation method of a mixed anode material for a lithium battery. The preparation method is characterized by comprising the following steps: doping an Ag2V4O11 material into a carbon fluoride material, wherein the doping process comprises the step of placing carbon fluoride, Ag2V4O11 and a solvent into a ball mill to be milled to form mixed slurry; drying the mixed slurry, and cooling the dried slurry to obtain a dried mixture; screening the dried mixture to obtain the mixed anode material for the lithium battery. According to the preparation method disclosed by the invention, the Ag2V4O11 material is mixed with the carbon fluoride material, the two substances are mixed through an additive, and the Ag2V4O11 material is good in high-rate discharge performance, so that the initial voltage lagging problem of carbon fluoride can be solved, the discharge performance of carbon fluoride can be effectively improved, the high rate discharge of a lithium-carbon fluoride battery system can be greatly improved, the low-temperature heavy current discharge of the lithium-carbon fluoride battery can be improved, and the application range of the lithium-carbon fluoride battery system can be expanded.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 18 RES INST

Diaphragm for battery and preparation method and battery thereof

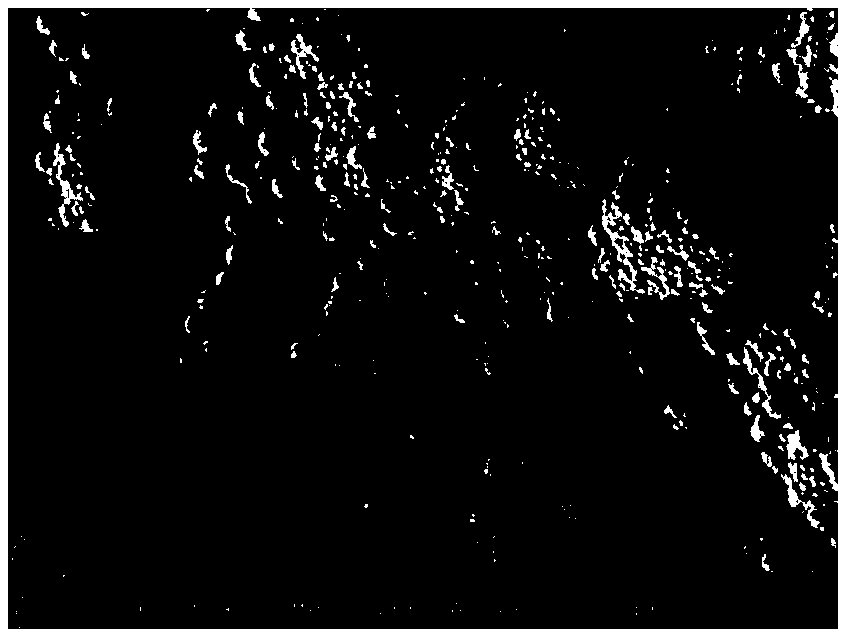

ActiveCN108987650AHigh rate dischargeImprove cycle performanceCell component detailsEngineeringIon migration

The invention belongs to the technical field of batteries, in particular to a separator for batteries, a preparation method thereof and batteries. The battery diaphragm comprises a composite coating diaphragm and a PMMA coating coated on at least one surface of the composite coating diaphragm. Preferably, the PMMA coating is provided on both surfaces on the outside of the composite coating diaphragm. The diaphragm used in the battery has low permeability increase value, meets the requirements of ion migration of the battery, improves the adhesion performance with the electrode plate, reduces the interface resistance, and thus improves the rate discharge and cycle performance of the battery.

Owner:HEBEI GELLEC NEW ENERGY MATERIAL SCI&TECHNOLOY CO LTD

Diaphragm for battery and preparation method thereof

ActiveCN108963168AGuaranteed air permeabilityImprove adhesionCell component detailsHardnessEngineering

The invention belongs to the technical field of batteries, in particular to a separator for batteries and a preparation method thereof. The separator for battery comprises a base film, an aramid coating and a composite coating of PVDF and PMMA. On the premise of guaranteeing the permeability of the separator, the adhesive force is improved, the adhesion between the separator and the battery electrode sheet is good, the interface resistance is reduced, and the cell hardness is improved. A method for prepare a separator for a battery. The composite coating of PVDF and PMMA was obtained by spraying the mixture of PVDF and PMMA on the aramid coatings. The prepared separator has low permeability and value-added, good adhesion to the battery electrode, and can improve the rate discharge and cycle performance of the battery.

Owner:HEBEI GELLEC NEW ENERGY MATERIAL SCI&TECHNOLOY CO LTD

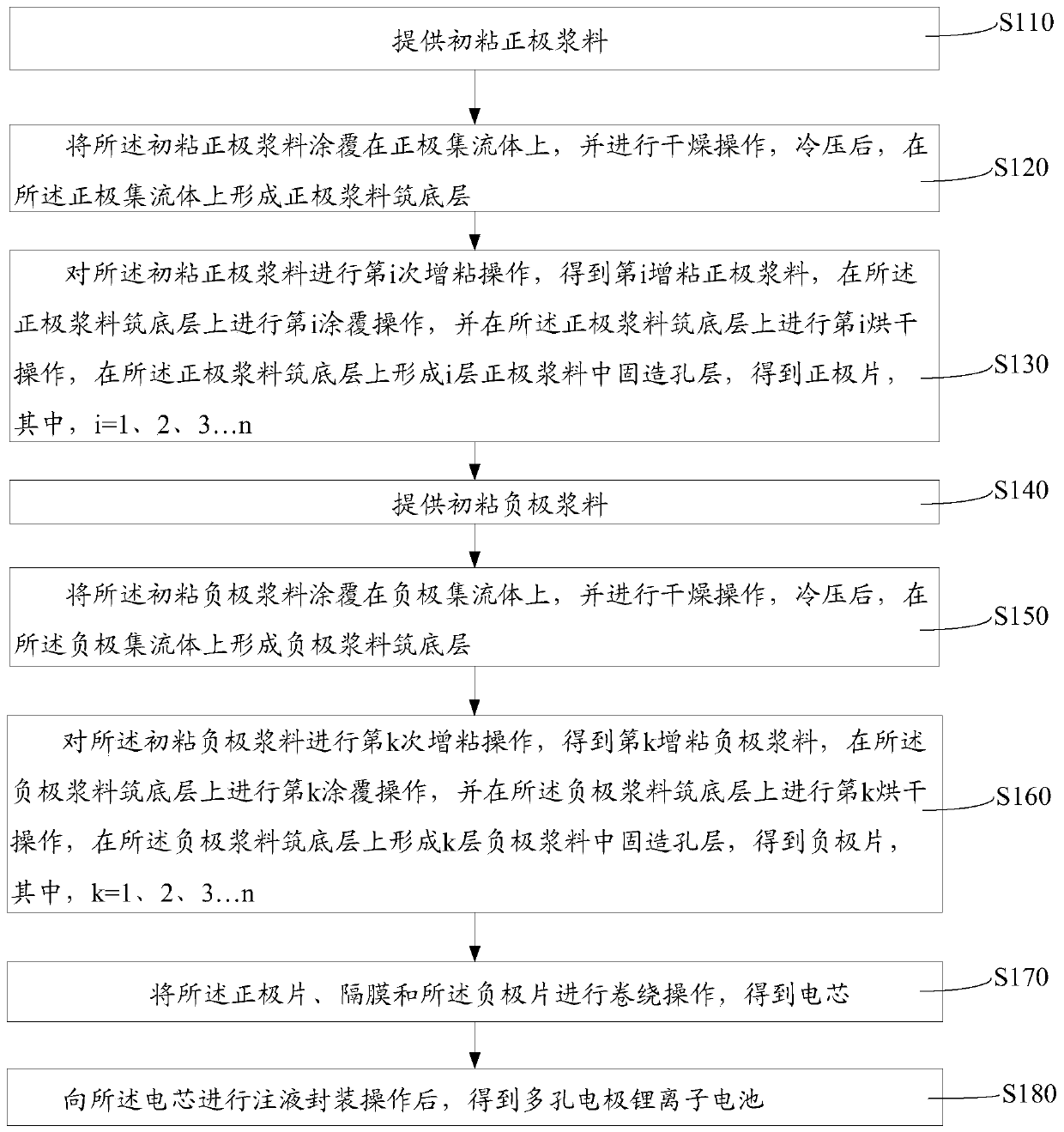

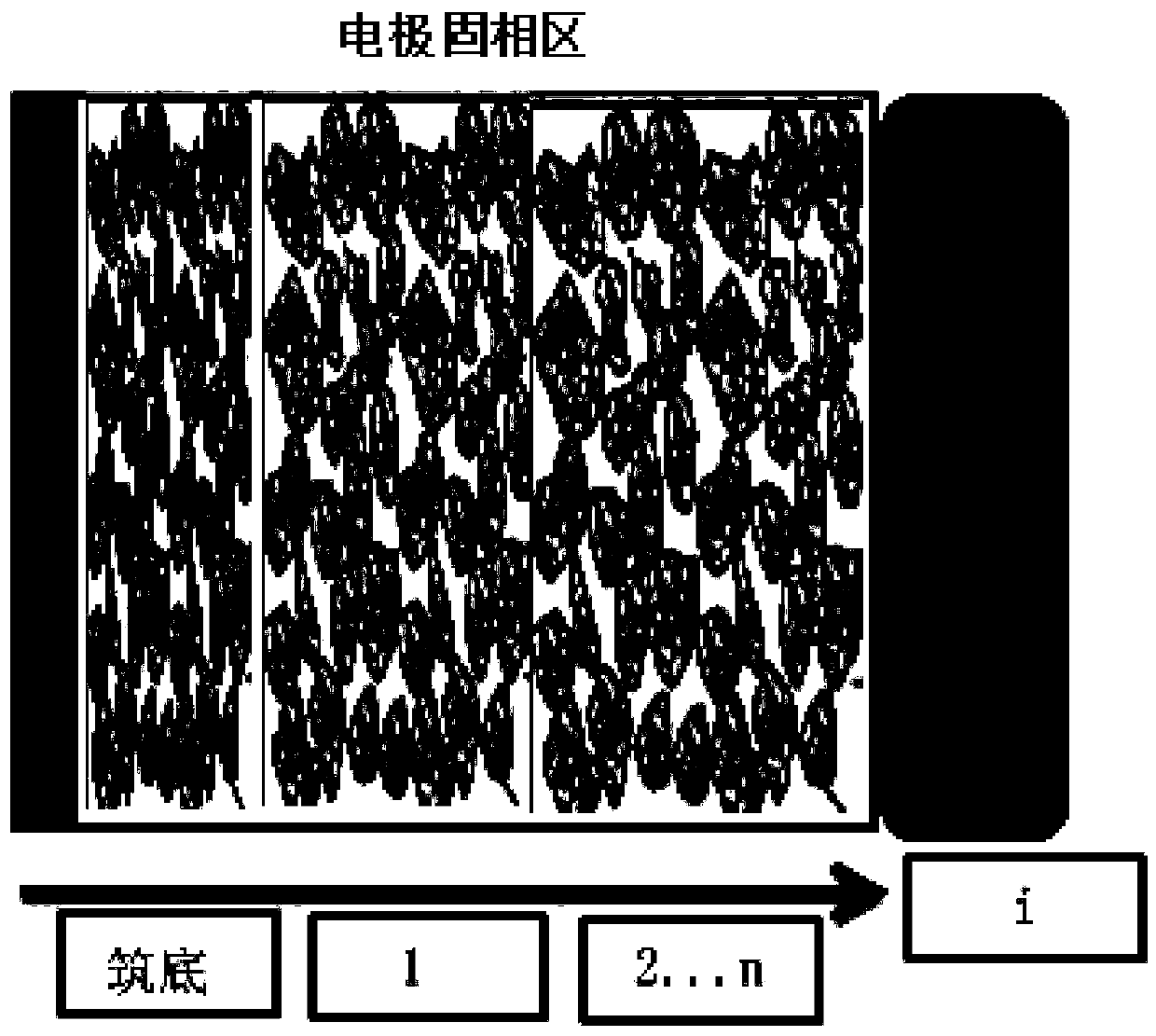

Porous electrode lithium-ion battery and preparation method thereof

ActiveCN109786654AHigh viscosityIncrease coating volumeElectrode manufacturing processesFinal product manufactureHigh rateHigh energy

The invention discloses a preparation method of a porous electrode lithium-ion battery. According to the method, a positive current collector is coated with initial-viscosity positive paste, a positive paste bottom building layer is formed after drying and cold-pressing, then the i(th) viscosity increasing operation is performed on the initial-viscosity positive paste to obtain the i(th) viscosity-increased positive paste, the i(th) positive paste middle-solidified pore-forming layer is formed after coating and drying, and a positive plate is obtained; a negative current collector is coated with initial-viscosity negative paste to form a negative paste bottom building layer, the k(th) viscosity increasing operation is performed on the initial-viscosity negative paste to obtain the k(th) viscosity-increased positive paste, the k(th) negative paste middle-solidified pore-forming layer is formed after coating and drying, and a negative plate is obtained; and the positive plate, a membraneand the negative plate are wound to obtain a cell, and the porous electrode lithium-ion battery is obtained after liquid injection and packaging. According to the prepared electrode plates, on the basis of guaranteeing a high coating amount and a high thickness of the electrode plates, the electrode plates have a porous structure, and therefore the lithium-ion battery can perform rapid charging under the condition of high energy density and meanwhile has high-rate discharge and low-temperature discharge performance.

Owner:EVE ENERGY CO LTD

Self-healing solid polymer electrolyte for lithium battery and preparation method of solid polymer electrolyte

ActiveCN110224173AImprove solubilityAvoid bringing inSolid electrolytesSecondary cellsSelf-healingSolid state electrolyte

The invention discloses a self-healing solid electrolyte for a lithium battery and a preparation method of the solid electrolyte, and belongs to the technical field of lithium ion batteries. The electrolyte comprises the following components of silyl-terminated polyether, bis (fluorosulfonyl) lithium imide, organic auxiliaries, additives, a first solvent and a second solvent, wherein the first solvent is used for dissolving silyl-terminated polyether and bis (fluorosulfonyl) lithium imide, and the second solvent is used for dissolving the organic auxiliaries; based on 100 parts of total mass of the first solvent and the second solvent, the usage of the silyl-terminated polyether is 25-50 parts; the molar ratio of the mole number of bis (fluorosulfonyl) lithium imide to the mole number of silyl-terminated polyether is 1 to 10-30; the usage of the organic auxiliaries is 1-10 parts; and the usage of the additives is 0-15 parts. By virtue of the novel self-healing solid electrolyte material provided by the invention, the performance of the energy density, the cycle life, the rate discharge and the like of the battery are not lower than those of the existing liquid organic electrolyte.

Owner:TIANNENG SAFT ENERGY JOINT CO

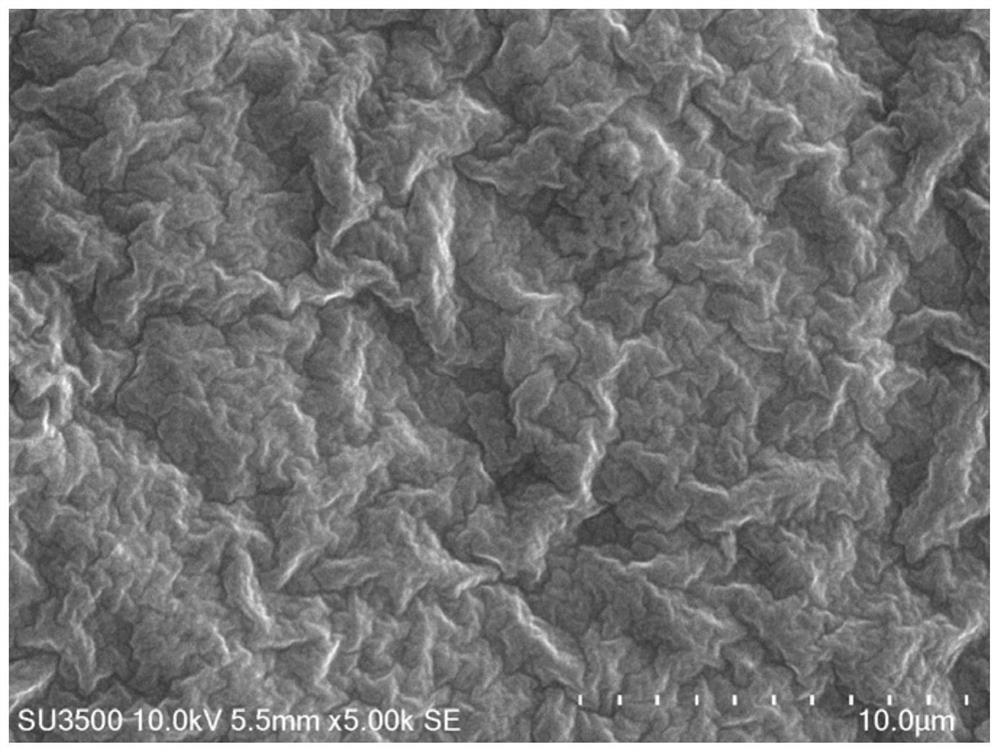

Lithium ion battery electrode containing micro-nano graphene coated single crystal positive electrode material

ActiveCN111969203AImprove performanceLower impedanceMaterial nanotechnologyCell electrodesMicro nanoSingle crystal

The invention relates to the technical field related to lithium ion batteries, and particularly provides a lithium ion battery electrode containing a micro-nano graphene coated single crystal positiveelectrode material. Raw materials comprise the micro-nano graphene coated single crystal positive electrode material, a conductive agent, a binder and a current collector, wherein the preparation rawmaterials of the micro-nano graphene coated single crystal positive electrode material include graphene and a single-crystal positive electrode material, and the single-crystal positive electrode material is a layered single-crystal structure. The invention provides the lithium ion battery electrode containing the micro-nano graphene coated single crystal positive electrode material. Crystal forms and particle size distribution of the single crystal positive electrode material before and after coating are basically consistent, and when the micro-nano graphene coated positive electrode material meeting the conditions is used as the preparation raw material of the battery electrode, comprehensive performance of the battery is favorably optimized.

Owner:宁夏汉尧富锂科技有限责任公司 +1

Preparation method of glass fiber nonwoven fabric aramid coating diaphragm

InactiveCN109546057AHigh mechanical strengthCompensation for defects of low mechanical strengthCell component detailsGlass fiberSlurry

A preparation method of a glass fiber nonwoven fabric aramid coating diaphragm belongs to the technical field of lithium ion battery diaphragms. The preparation method includes the following steps: A,preparation of aramid slurry: taking PMIA, alumina, dispersant and oil solvent at a certain ratio, heating and stirring the materials, dissolving the materials at 70-90 DEG C, and mixing the materials evenly to obtain a mixture; and B, preparation of a diaphragm: coating a piece of glass fiber nonwoven fabric with the mixture by means of oil coating, and obtaining an aramid coating diaphragm through an extraction process. The glass fiber nonwoven fabric aramid coating diaphragm prepared by the invention has better air permeability, higher mechanical strength and higher ionic conductivity, andcan improve the rate discharge and cycle performance of lithium ion batteries.

Owner:HEBEI GELLEC NEW ENERGY MATERIAL SCI&TECHNOLOY CO LTD

A kind of composite cathode material and its preparation method and application

ActiveCN108172794BImprove cycle lifeHigh rate dischargeMaterial nanotechnologyCell electrodesComposite cathodeElectrical battery

The invention discloses a composite positive electrode material and a preparation method and an application thereof, and belongs to the technical field of preparation of an electrochemical power supply material. The composite positive electrode material provided by the invention adopts a core-shell structure, wherein the inner core is metal oxide-doped and composite carbon material-coated lithiummanganese iron phosphate, and the shell is metal oxide-doped and composite carbon material-coated lithium vanadium iron phosphate. The composite positive electrode material provided by the invention has excellent cycle life, high-rate discharging and low-temperature performance and safety performance, as well as relatively high energy density. When the composite positive electrode material is at 0.5C rate, the initial discharging specific capacity of a button cell is greater than 155mAh / g, and after 100 cycles, the capacity retention ratio is greater than 95%.

Owner:LANGFANG GREEN IND TECH CENT +1

A kind of surface modification method of carbon fluoride material

ActiveCN104577107BImprove voltage hysteresisHigh rate dischargeNanotechnologyPrimary cell electrodesPowder mixtureSolvent

The invention relates to a surface finish method of a carbon fluoride material. The method comprises the following steps: (1) mixing nanometer copper and carbon fluoride, then adding a solvent for ball milling so as to form a combined pulp; (2) drying the mixed pulp so as to form a mixture; (3) screening the mixture so as to obtain the powder mixture; (4) putting the powder mixture into an atmosphere oven so as to be calcined; (5) taking out the calcined powder mixture, lowering the temperature of the calcined powder mixture to the room temperature, and then screening the calcined powder mixture of which the temperature is lowered so as to form the carbon fluoride material modifies by the nanometer copper. According to the invention, the carbon fluoride and the nanometer copper with good conductivity are mixed, and after the mixture is calcined at a high temperature in an inert atmosphere, the nanometer copper reacts on the surface of the carbon fluoride, so that the phenomenon that the voltage of carbon fluoride is delayed is obviously improved, and high-ratio discharge and low temperature performance are greatly improved. The carbon fluoride with a finished surface, prepared by the method, is used as a positive material to be made into a lithium-carbon fluoride battery system, wherein the lithium-carbon fluoride battery system has the properties of high-ratio discharge and low temperature high-current discharge, so that the application range of the lithium-carbon fluoride battery system is extended.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 18 RES INST

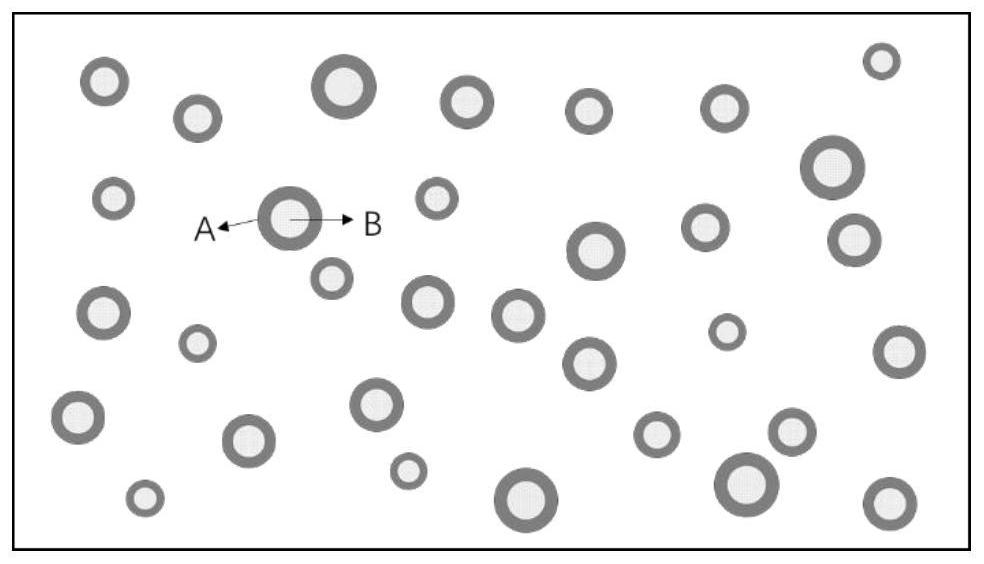

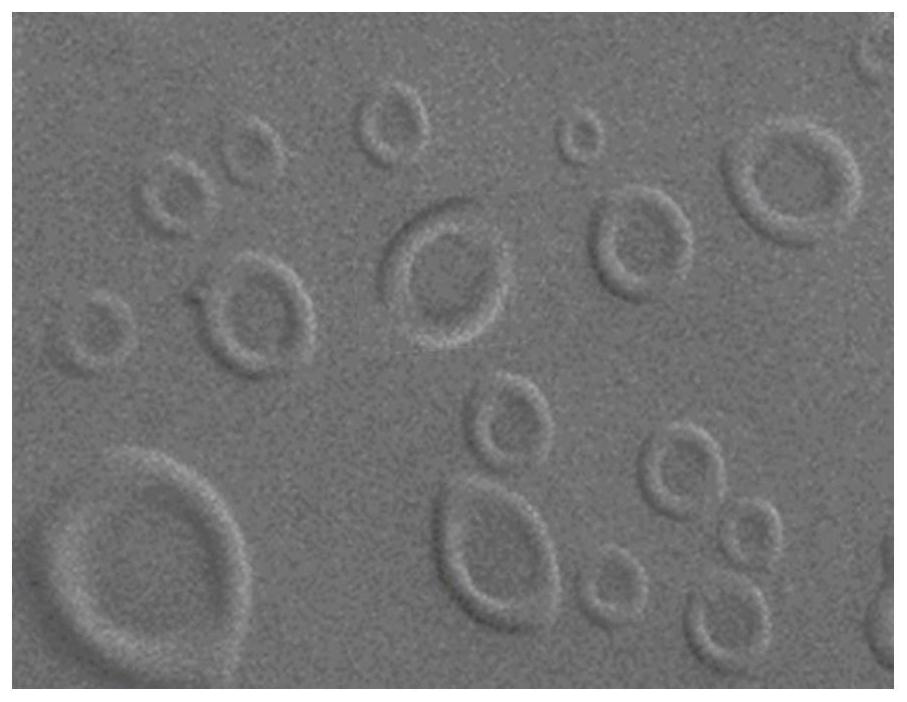

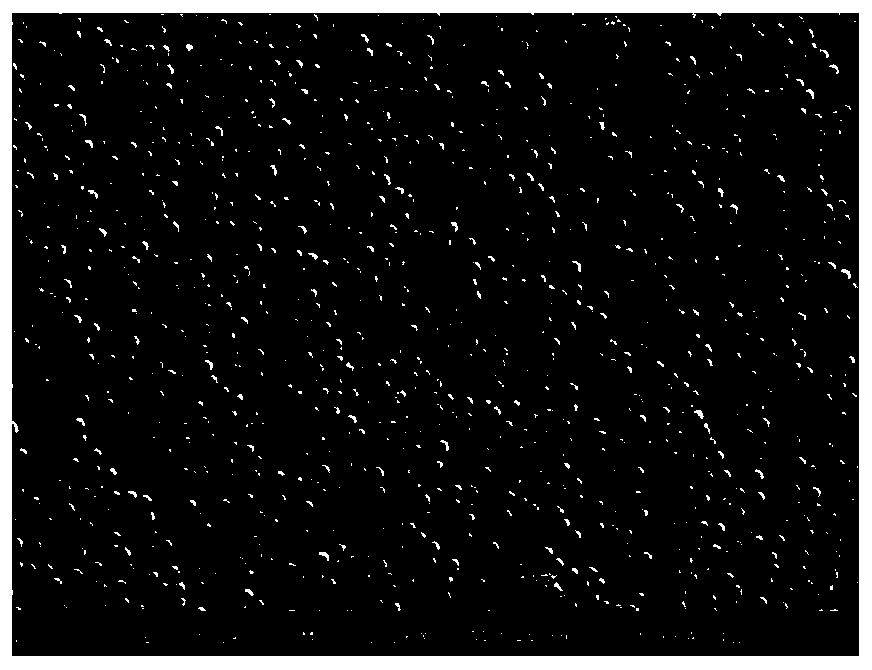

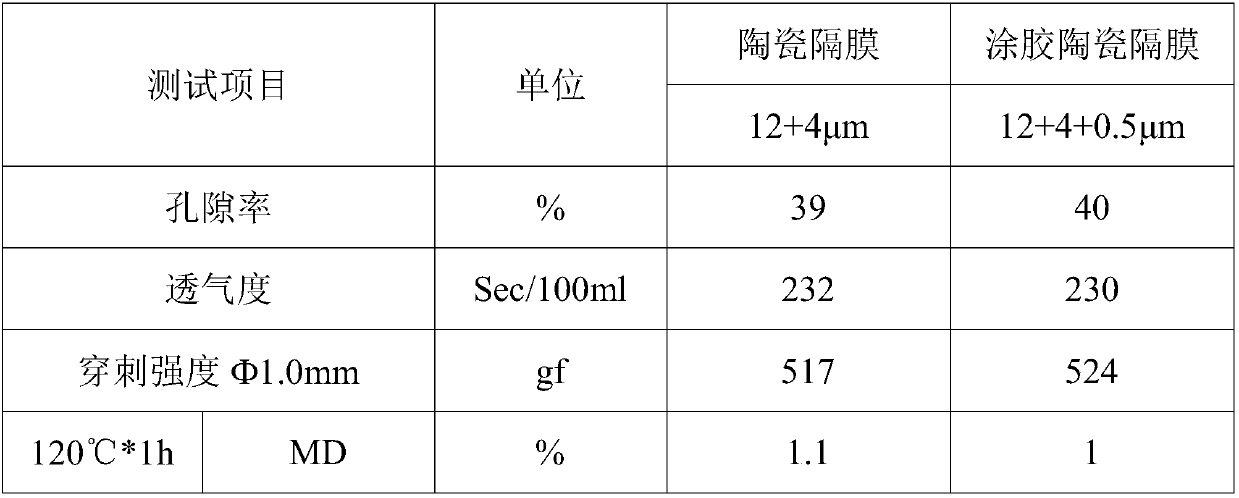

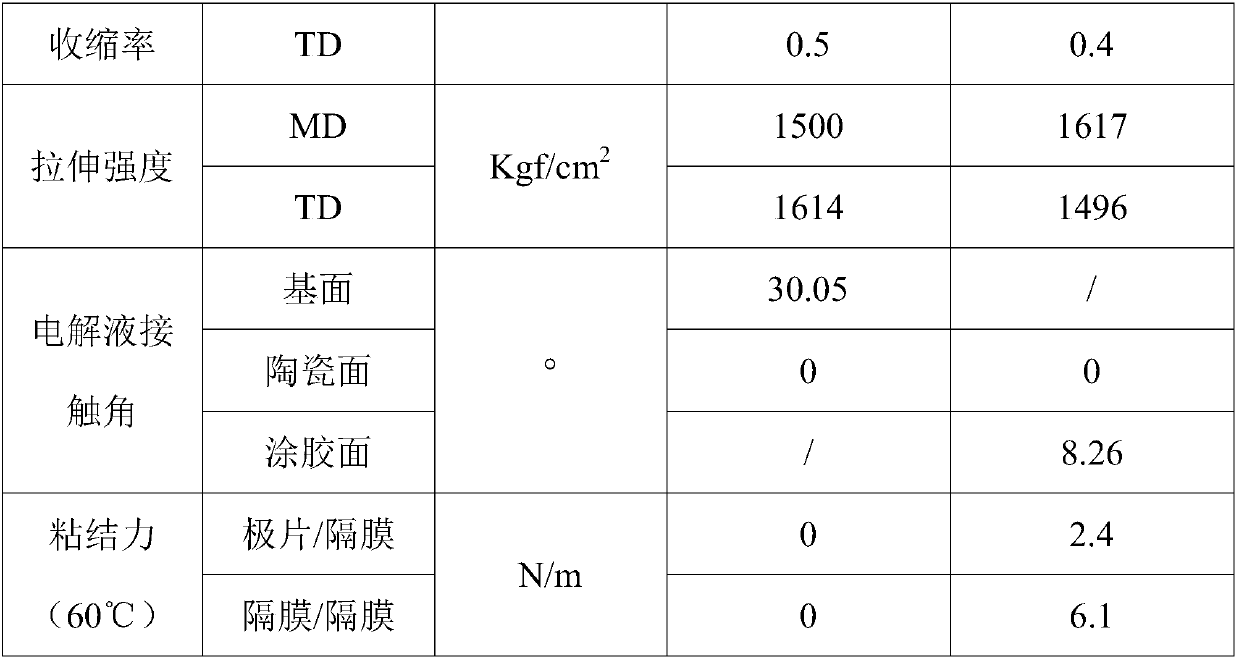

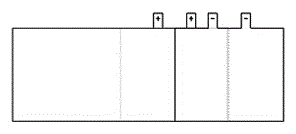

Battery diaphragm, preparation method thereof and battery

PendingCN114665218AHigh rate dischargeImprove cycle lifeCell seperators/membranes/diaphragms/spacersStructural engineeringBattery cell

The invention discloses a battery diaphragm and a preparation method thereof and a battery, the battery diaphragm comprises a diaphragm base material and a PVDF coating coated on at least one side surface of the diaphragm base material, and the PVDF coating comprises ring-like coating points with the distribution density of 30 / cm < 2 >-800 / cm < 2 >. Compared with an existing multi-layer coating diaphragm, the battery diaphragm provided by the invention has the advantages that the coverage rate of the PVDF coating is relatively low, the air permeability of the battery diaphragm is good, good bonding force between the battery diaphragm and a battery pole piece can be ensured, and meanwhile, the performance of rate discharge, cycle life and the like of a battery can be improved.

Owner:SINOMA LITHIUM BATTERY SEPARATOR CO LTD

A kind of negative electrode material of lithium ion battery and preparation method thereof

ActiveCN108963221BSmall volume changeImprove stabilityCell electrodesSecondary cellsInternal resistanceManganese oxide

The present invention relates to the technical field of lithium batteries, in particular to a lithium ion battery negative electrode material and a preparation method thereof. The preparation method comprises: (1) mixing a manganese source and a zinc source in an organic solvent evenly, and then adding terephthalate Formic acid, mixed evenly, sealed and reacted at 120-180°C for 3-8 hours to obtain precursor A; (2) heat-treating precursor A at 180-250°C in a water vapor atmosphere to obtain the lithium-ion battery negative electrode material; In the present invention, the manganese source and the zinc source are simultaneously reacted with the terephthalic acid ligand to generate zinc-doped Mn(PTA) n , the precursor A is heat-treated in water vapor to obtain Mn x Zn 1‑x O‑PTA material, which is a metal oxide organic framework with manganese dioxide and zinc dioxide as active centers, this structure can reduce the volume change of manganese dioxide during charging and discharging, thereby improving material stability and reducing The internal resistance of the material can extend the cycle life of the manganese dioxide electrode material and improve the performance of rate discharge.

Owner:唐山东日新能源材料有限公司

Separator for battery and preparation method thereof

ActiveCN108807804BHigh rate dischargeImprove cycle performanceCell component detailsElectrical batteryPhysical chemistry

Owner:HEBEI GELLEC NEW ENERGY MATERIAL SCI&TECHNOLOY CO LTD

A kind of binder coated on the surface of diaphragm, its preparation method and application

ActiveCN106189946BShorten the transmission pathImprove high temperature storage performanceNitrile polymer adhesivesLithiumAcrylonitrile

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

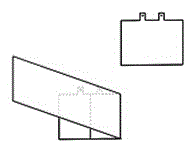

Method for improving rate discharge of soft-package ion battery

ActiveCN105140462AHigh rate dischargeReduce resistanceNon-aqueous electrolyte accumulator electrodesEngineeringPole piece

The invention discloses a method for improving the rate discharge of a soft-package ion battery, belonging to the technology of an ion battery. The technical scheme of the method comprises a binity pole piece group, a trinity pole piece group and a diaphragm paper, wherein pole piece monomers in positive and negative pole piece groups are overlapped according a certain method and separated by diaphragm paper to form a lamination body overlapped by the binity pole piece group or a lamination body overlapped by the trinity pole piece group, and the lamination bodies can be overlapped for many times according to demands. The invention provides the method for improving the rate discharge of the soft-package ion battery.

Owner:JUHEYUAN SCI & TECH CO LTD

A highly stable lithium-ion battery

ActiveCN108987701BSmall volume changeImprove stabilityCell electrodesFinal product manufactureElectrolytic agentInternal resistance

The invention belongs to the technical field of lithium ion batteries, and in particular relates to a lithium ion battery with high stability, comprising a positive electrode, a negative electrode, a diaphragm and an electrolyte, and the negative electrode comprises a negative electrode active material, a conductive agent and a binder, and is characterized in that: The negative electrode active material is Mn x Zn 1‑x O‑PTA, where 0.1≤x≤0.5; in the present invention, the manganese source and the zinc source are simultaneously reacted with terephthalic acid ligands to generate zinc-doped Mn(PTA) n , heat treatment of precursor A in water vapor to obtain Mn x Zn 1‑x O‑PTA material is a metal oxide organic framework with manganese dioxide and zinc dioxide as active centers. This structure can reduce the volume change of manganese dioxide during charging and discharging, thereby improving material stability and reducing The internal resistance of the material can prolong the cycle life of the manganese dioxide electrode material and improve the performance of the rate discharge.

Owner:广州明美新能源股份有限公司

A self-healing solid polymer electrolyte for lithium battery and preparation method thereof

ActiveCN110224173BWell mixedUniform pore size distributionSolid electrolytesSecondary cellsSolid state electrolyteElectrolytic agent

The invention discloses a self-healing solid electrolyte for a lithium battery and a preparation method of the solid electrolyte, and belongs to the technical field of lithium ion batteries. The electrolyte comprises the following components of silyl-terminated polyether, bis (fluorosulfonyl) lithium imide, organic auxiliaries, additives, a first solvent and a second solvent, wherein the first solvent is used for dissolving silyl-terminated polyether and bis (fluorosulfonyl) lithium imide, and the second solvent is used for dissolving the organic auxiliaries; based on 100 parts of total mass of the first solvent and the second solvent, the usage of the silyl-terminated polyether is 25-50 parts; the molar ratio of the mole number of bis (fluorosulfonyl) lithium imide to the mole number of silyl-terminated polyether is 1 to 10-30; the usage of the organic auxiliaries is 1-10 parts; and the usage of the additives is 0-15 parts. By virtue of the novel self-healing solid electrolyte material provided by the invention, the performance of the energy density, the cycle life, the rate discharge and the like of the battery are not lower than those of the existing liquid organic electrolyte.

Owner:TIANNENG SAFT ENERGY JOINT CO

A kind of lithium ion battery negative electrode material and preparation method thereof

ActiveCN112018375BOffset volume changesImprove stabilityNegative electrodesSecondary cells servicing/maintenanceElectrical batteryInternal resistance

The invention belongs to the technical field of lithium batteries, and specifically relates to a lithium-ion battery negative electrode material and a preparation method thereof. The method includes separately preparing Mo5SiB2-ZrB2 composite and lithium-doped zirconium vanadate material, and then dispersing the two into Appropriate amount of distilled water, stir and mix, then transfer to a hydrothermal automatic reaction kettle for activation reaction, then transfer to a reaction bottle, place in an ultrasonic disperser, heat to 70-85°C, ultrasonicate for 2 hours, cool the solution and centrifuge Remove the distilled water and dry the solid product to obtain the lithium ion battery negative electrode material; in the present invention, lithium is doped into the zirconium vanadate material. The zirconium vanadate material has good thermal shrinkage and cold expansion capabilities and can offset the lithium The volume change of the ion battery anode material during the charge and discharge process, or when the temperature rises, thereby improving the stability of the lithium ion battery anode material, reducing the internal resistance of the material, extending the cycle life of the lithium ion battery anode material and increasing the discharge rate. performance.

Owner:安徽天时新能源科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com