Diaphragm for battery and preparation method and battery thereof

A separator and battery technology, applied in the field of battery separator and its preparation, can solve the problems of poor adhesion between the coating and the pole piece, unable to meet customer needs, etc., and achieve lower interface resistance, excellent rate discharge and cycle performance, tensile strength Excellent effect of tensile strength and heat shrinkage properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0108] According to another aspect of the present invention, the preparation method of the separator for batteries as described above comprises the following steps:

[0109] (a) preparing a composite coating separator;

[0110](b) Coating a PMMA coating on at least one surface outside the composite coating separator obtained in step (a), drying to obtain a separator for a battery.

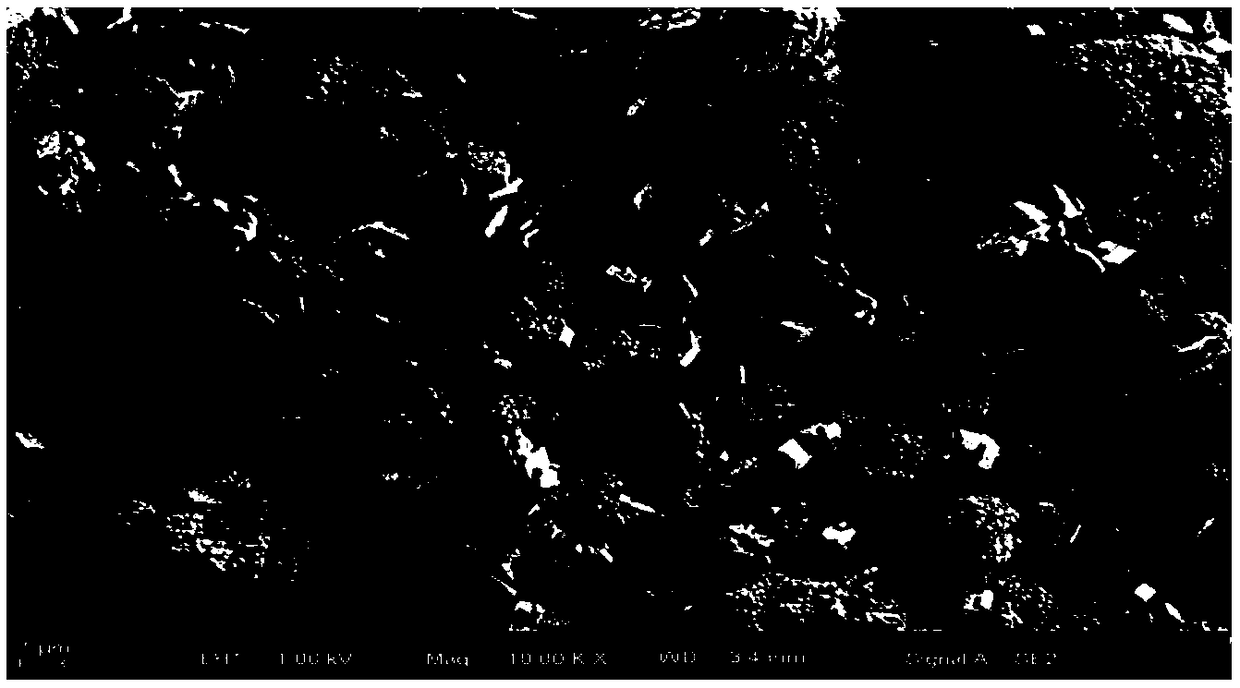

[0111] The preparation method of the battery separator in the present invention has simple process, strong operability and low production cost. By adopting the mode of spraying, the PMMA coating is covered in dots without increasing the thickness and reducing the coating area coverage, thereby ensuring the separator It has excellent air permeability and meets the requirements of lithium ion migration.

[0112] Preferably, the drying temperature of the PMMA coating in the step (b) is 30-60°C, the drying time is 1-4min, and the coating method is spraying;

[0113] Typical but non-limiting examples ...

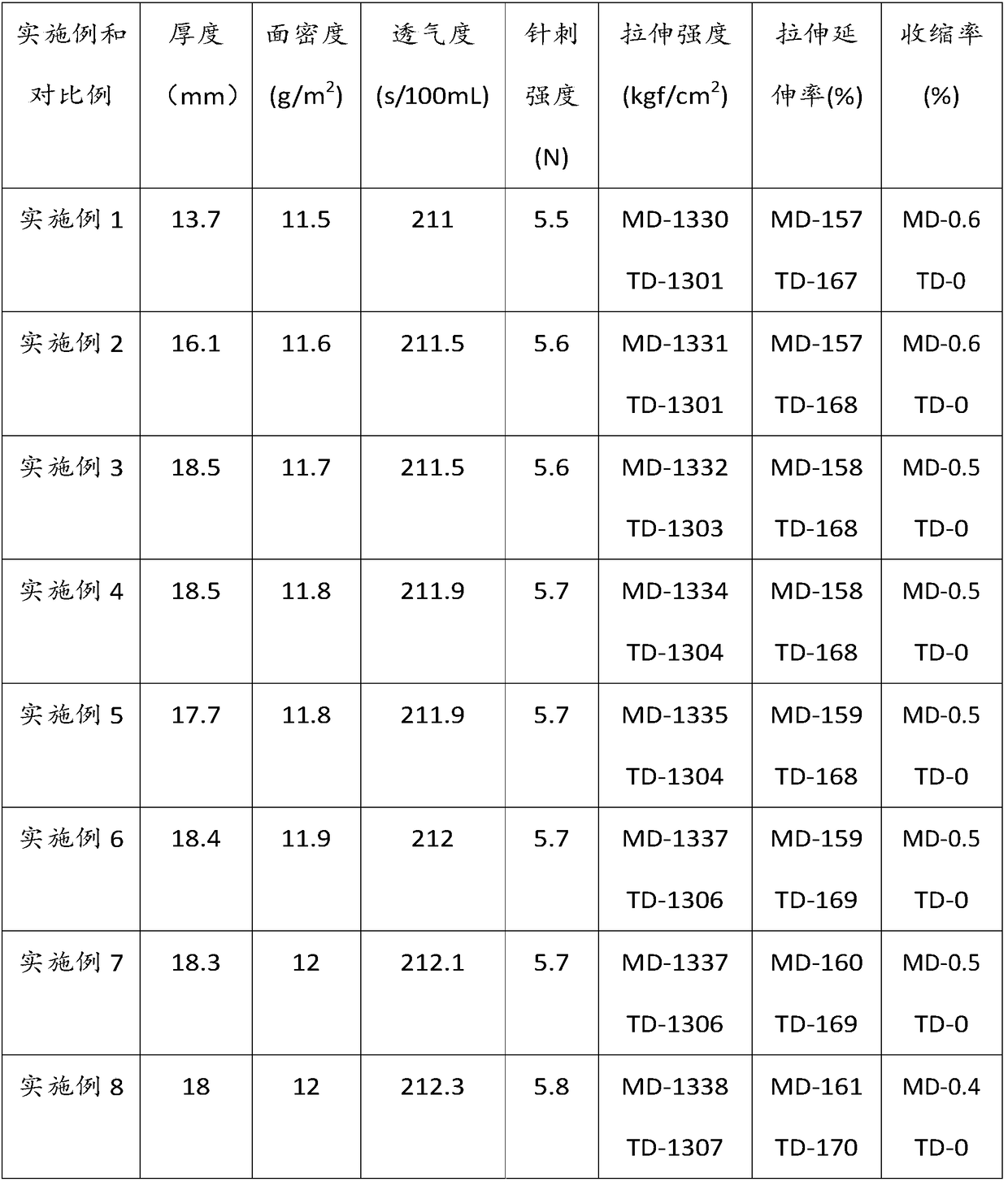

Embodiment 1

[0139] A separator for batteries, comprising a composite coating separator composed of a polyethylene base film and a boehmite coating, and a PMMA coating coated on one side of the composite coating separator.

[0140] The preparation method of the separator for the battery comprises the following steps:

[0141] (a) Add 95 parts of boehmite powder and 1.5 parts of vinyl bis stearamide to 75 parts of water, mix and stir for 50 minutes to disperse evenly, then add 25 parts of polyvinyl alcohol, 8 defoamers and 15 parts of polyvinyl acrylate Stir the ester evenly to obtain a boehmite slurry; apply the boehmite slurry on both sides of a polyethylene-based film with a thickness of 11.5um by micro-gravure roll coating to form a boehmite with a thickness of 2.2um on one side The coating is then dried in an oven at a drying temperature of 30°C and a drying time of 5 minutes;

[0142] (b) Add 20PMMA, 20 parts of thickener and 0.0015 parts of sodium lauryl sulfate to 95 parts of water...

Embodiment 2

[0144] A separator for a battery, comprising a composite coating separator composed of a polyethylene base film and a PVDF coating, and PMMA coatings coated on both sides of the composite coating separator.

[0145] The preparation method of the separator for the battery comprises the following steps:

[0146] (a) Add 110 parts of boehmite powder and 0.8 parts of polyethylene wax to 90 parts of water, mix and stir for 70 minutes to disperse evenly, then add 18 parts of polyethylene glycol, 15 parts of octanol and 7 parts of polybutylacrylate and stir well , to obtain the boehmite slurry; the boehmite slurry is coated on both sides of a polyethylene-based film with a thickness of 12.5um by using a micro-gravure roller coating method to form a boehmite coating with a thickness of 1.8um on one side. Then use an oven to dry, the drying temperature is 80 ° C, and the drying time is 1 min;

[0147] (b) Add 30 parts of PMMA, 10 parts of povidone and 0.0005 part of sodium dodecylbenz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com