Patents

Literature

93 results about "Roller Coating Method" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polishing film and method for making same

ActiveCN101225281AUniform performanceReduce manufacturing costOther chemical processesPolishing compositionsOrganic solventRoller Coating Method

The invention discloses a polishing film and the preparation method, which adopts the ultrafine micro mist as the grinding material and prepares in flow-casting coating method, namely the powdered or granular resin is dissolved into the organic solvent and then added in functional additive to make the resin adhesive, then the abrasive of surface-modified ultrafine micro mist is added into the resin adhesive and the spread coating liquid can be obtained after fully mixing, finally the paint is painted on the surface of soft base in flow-casting coating method and the polishing film can be obtained after drying and curing. The preparation method of the polishing film has the advantages of small equipment investment, simple operation, high productivity and automation level, steady craft, even film performance and low manufacturing cost. The polishing film can adjust the craft parameters of the flow-casting craft conveniently according to the different quality requirement and standards of the products, and can achieve production in multi-specification and small lot production and overcomes the problems that the rapid transformation of the product specification is difficult due to the limit of the equipment structure in roller coating method.

Owner:HENAN UNION ABRASIVES

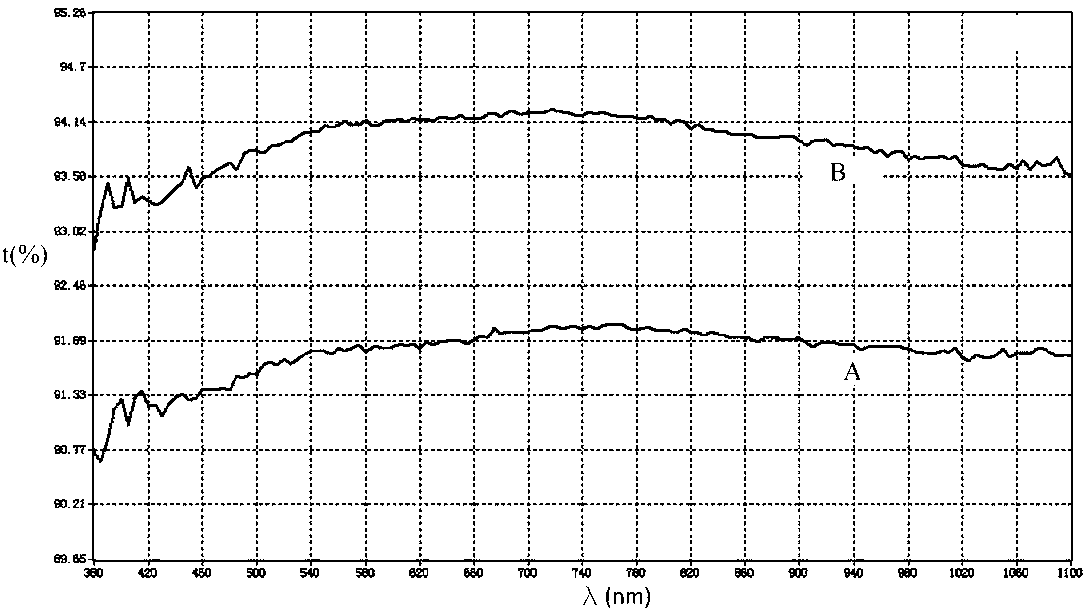

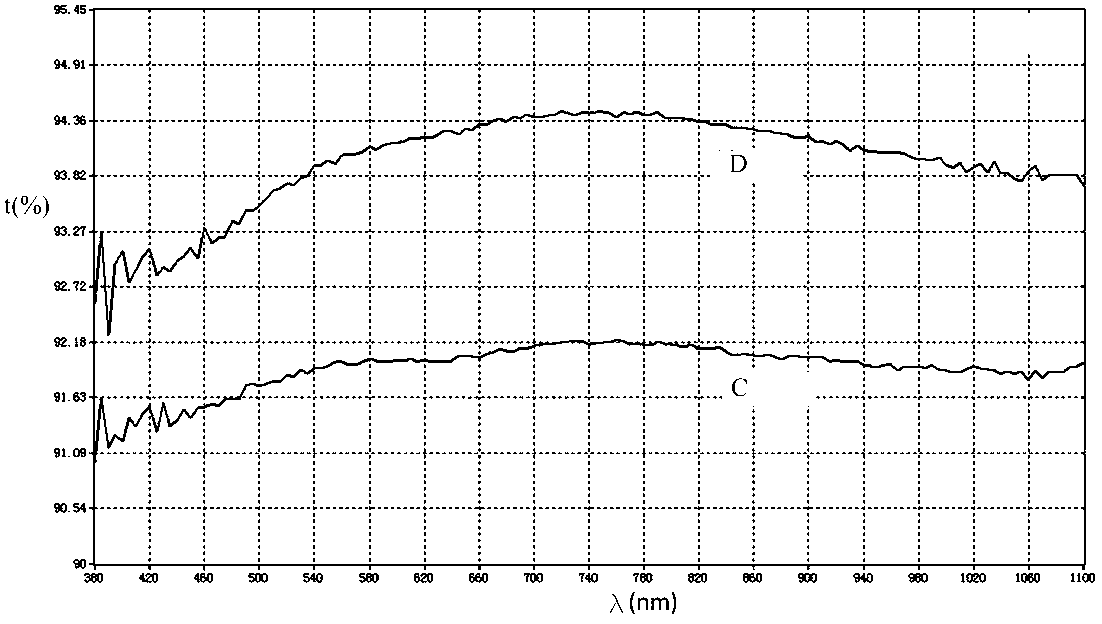

Glass anti-reflection coating liquid and application method of glass anti-reflection coating liquid in anti-reflection glass preparation

The invention provides a glass anti-reflection coating liquid. A water-based nanometer silicon sol anti-reflection coating liquid is obtained by taking water a solvent, mixing two or more than two nanometer silicon sols with different properties, and then adding an organic addition agent, and the refractive index parameter of a thin film is 1.10-1.45. An application method of the glass anti-reflection coating liquid in anti-reflection glass preparation is characterized in that the glass anti-reflection coating liquid is coated on the surface of glass by adopting a roller coating method, a dip-coating method or a spray finishing method, and curing treatment is carried out at the temperature of more than 100 DEG C. Compared with the prior art, the glass anti-reflection coating liquid has the advantages that water is used as the solvent, and the content of organic ingredients, especially the content of volatile organics is low, and therefore, the glass anti-reflection coating liquid is environment-friendly and economic, and no lots of exhaust gases are generated in the production process of the anti-reflection glass; and the glass anti-reflection coating liquid is suitable for being coated by a roller coating technology, and an obtained coating has good adhesion property and hardness of more than 4H. The glass anti-reflection coating liquid is particularly suitable for production of the anti-reflection solar glass.

Owner:ZHOUSHAN PUTUO XIAHE MATERIAL TECHN CO LTD

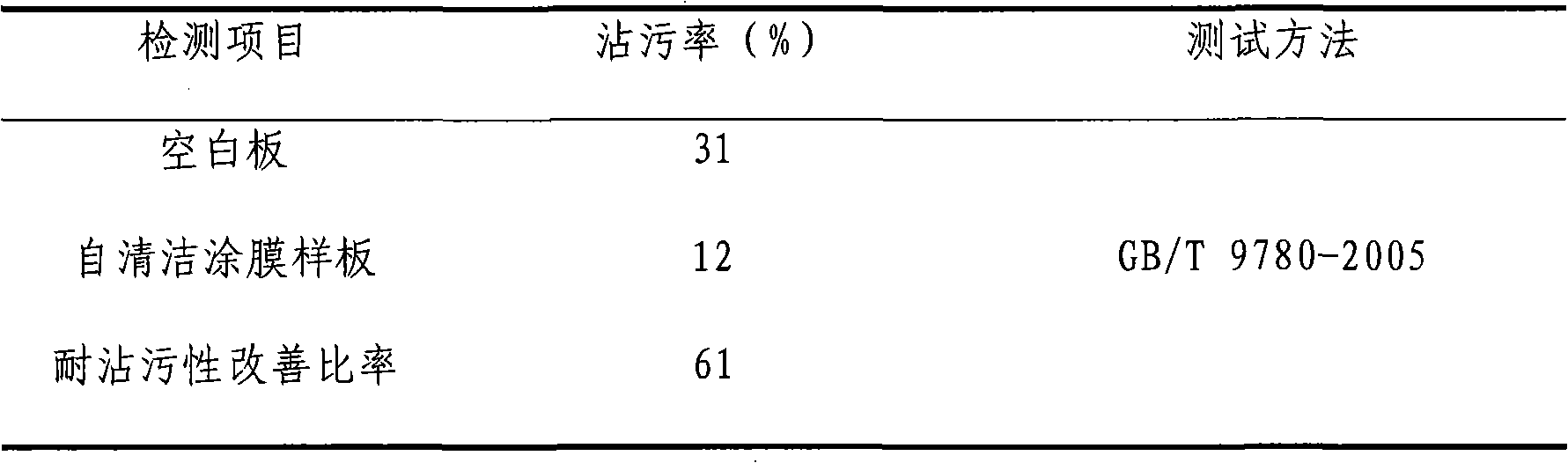

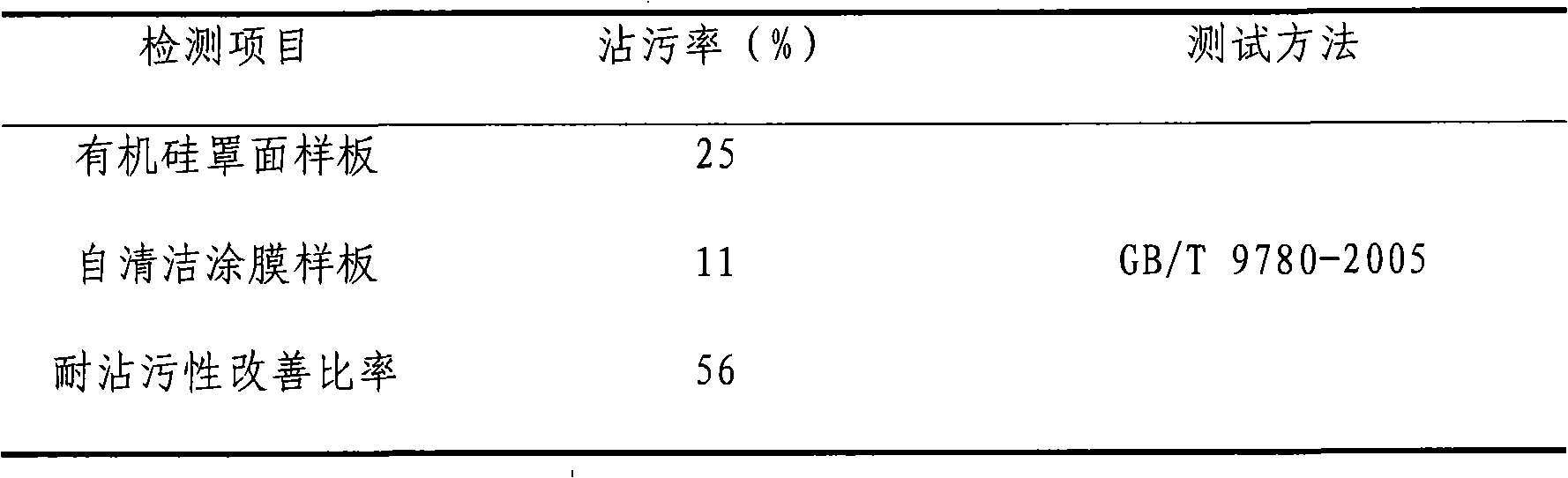

Self-cleaning coating agent for construction exterior wall paint, preparation and use method

InactiveCN101328336ANature impactImprove protectionSpecial surfacesPolyester coatingsAir cleaningUltraviolet

The invention provides a self-cleaning film agent for exterior wall paint, a preparation method and an application method thereof. The preparation method for the self-cleaning film agent is mainly characterized in that: the preparation method comprises the following steps of: taking nanometer titanium oxide composite collosol as a reference; dispersing the collosol in an alkaline aqueous solution after adding an anionic surfactant or a non-ionic surfactant with a mass percent of between 0.1 and 10 to form a transparent and stable dispersion system; and finally adding a certain number of film forming substances into the system to obtain the self-cleaning film agent for the exterior wall paint. The self-cleaning film agent is applied to the surface of the exterior wall paint for secondary coating through a spray coating method or a roller coating method or a brush coating method, and a film is formed at a normal temperature, thereby forming a multifunctional coating with stain and ultraviolet irradiation resistance and air cleaning performance on the external surface of the paint. As the method has the obvious advantages of good performance, simple process, convenient construction, durable effect, environmental friendliness, etc., the method can be applied to various exterior wall paints in a large scale.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

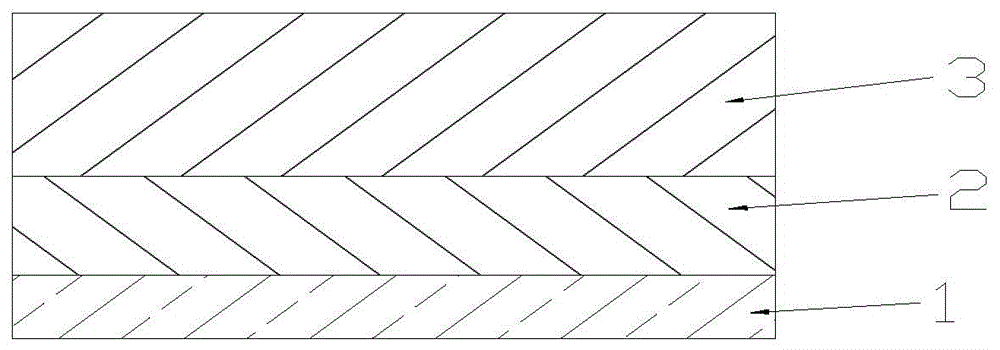

Preparation method of UEA116 ultraprecise ground belt

The invention relates to a preparation method of UEA116 ultraprecise ground belt. The method includes the following steps: (1) bi-orientated polyethylene terephthalate film is taken as a matrix; (2) mixed solution A and B are prepared by binding agent, cross linking agent and solvent; (3) the mixed solution A is coated on the matrix by adopting a roller coating method, grains are implanted into matrix resin bed by adopting a static sand planting method, the resin bed is dried by predrying treatment at 75-85 DEG C, then the mixed solution B is coated on the dried glue sand bed surface by adopting the roller coating method, the resin bed is hardened by precuring treatment at 75-85 DEG C, and finally polyester film abrasive belt is crossly linked at normal temperature, thus obtaining the ultraprecise ground belt. The invention adopts micro powder or nano grinding micro powder as grinding material, utilizes novel polyurethane resin material as the binding agent and hexamethylene diisocyanate as the cross linking agent, uses polyester film with extreme high evenness and strength as the matrix and adopts fine-processing method and novel coated abrasive, thus ensuring ultraprecise grinding and polishing.

Owner:HUBEI YULI ABRASIVE BELTS GRP +2

Preparation method and application method of solvent-free moisture-curable resin for synthetic leather

The invention provides a preparation method and an application method of a solvent-free moisture-curable resin for synthetic leather. The preparation method is as below: adding polytetrahydrofuran glycol, isophorone diisocyanate and bismuth octoate to the reactor, heating to 75-80 DEG C, polymerizing for 1-1.5 h to obtain the solvent-free moisture-curable resin for synthetic leather. The application method is as below: mixing and stirring the solvent-free moisture-curable resin for synthetic leather and bis-N,N'-(methyl-butyl methylene)-diethylenetriamine, coating the mixed material on the synthetic leather surface by a roller coating method, curing at the temperature of 85-95 DEG C, then drying at 120-135 DEG C, and finally cooling and rolling. The solvent-free moisture-curable resin for synthetic leather obtained by the invention is used for surface moisture solidification process for synthetic leather, so as to obtain brightening surface with high brightness, water resistance and wear resistance. The application process does not produce contamination, and can solve the solvent pollution problem in synthetic leather moisture curing process.

Owner:SHAANXI UNIV OF SCI & TECH

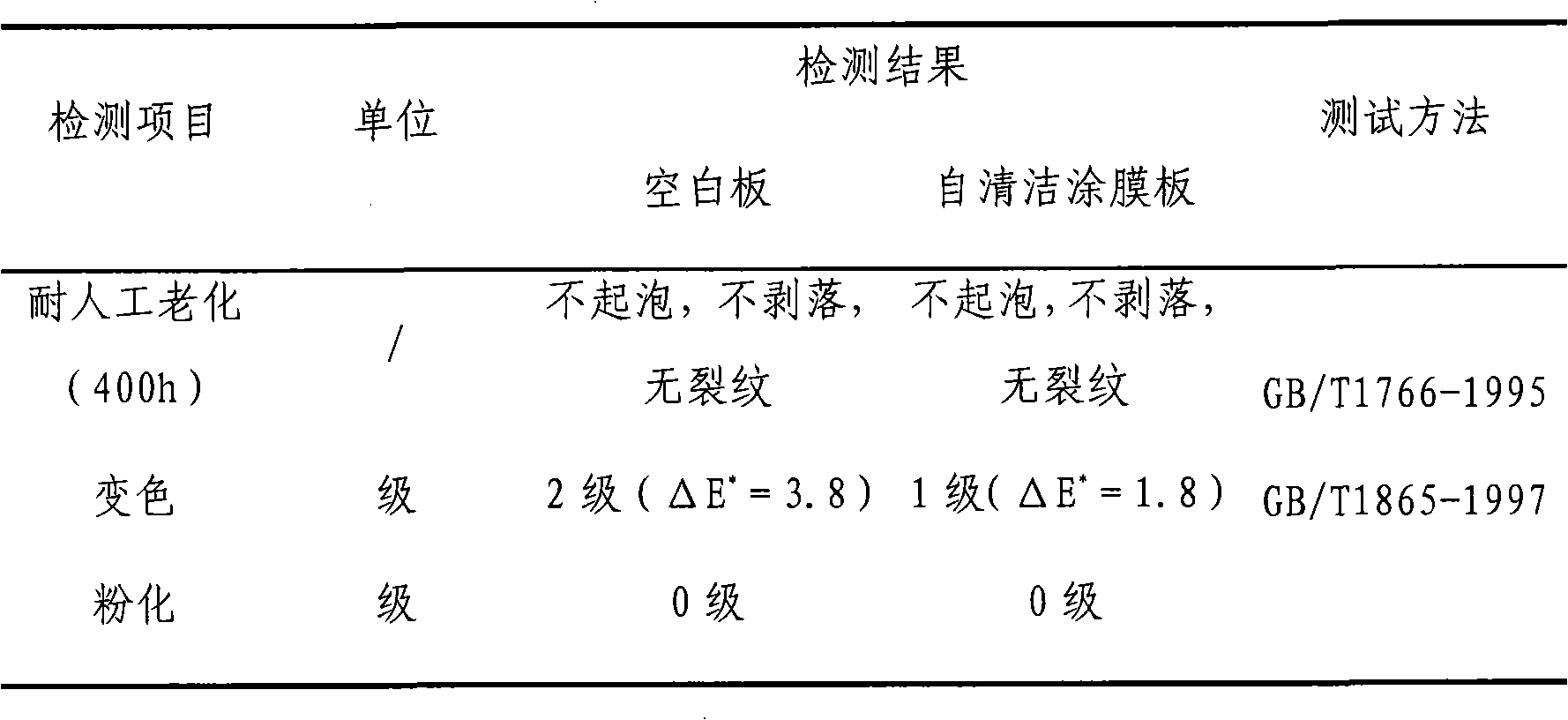

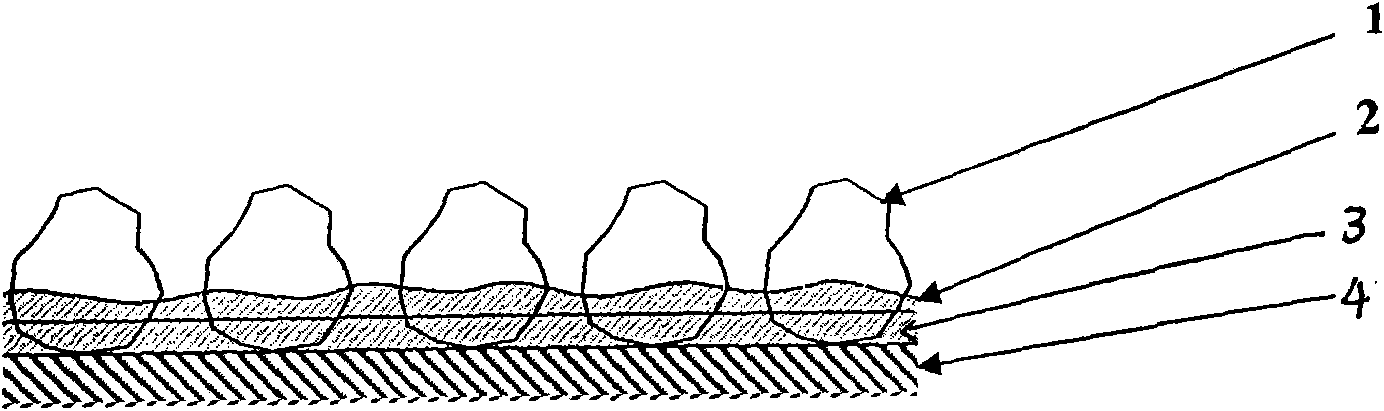

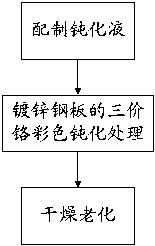

Color passivated galvanized steel plate and manufacturing method thereof

ActiveCN103572273AImprove corrosion resistanceColorfulMetallic material coating processesSheet steelRoller Coating Method

The invention discloses a manufacturing method of a color passivated galvanized steel plate. The manufacturing method comprises the following steps: plating a well prepared trivalent chromium passivation solution on the surface of a galvanized steel plate at normal temperature by adopting a roller coating method; passivating and then forming a layer of thin and dense thin film, wherein the layer of oxide film existing independently can separate metal from outside and enable the metal to be in a passivated state. The passivated films with different colors can be obtained according to different speed ratios of a coating roller of a roller coating machine to a steel strip. The color of the passivated film is bright and less prone to changing, the formed film is uniform and less prone to falling off, the corrosion resistance performance can achieve and even be better than that achieved by a traditional hexavalent chromium passivation process, and the time of enabling neutral salt mist to resist white rust is more than 120h.

Owner:CHANGSHU HUAYE STEEL STRIP

Glass with antibacterial, anti-fingerprint and transmission increasing triple efficacy and preparation method thereof

The invention discloses a glass with antibacterial, anti-fingerprint and transmission increasing triple efficacy and a preparation method thereof. The glass includes a glass substrate and a monolayer film formed on at least one surface of the glass substrate. The monolayer film is a porous network structure SiO2-TiO2-Ag2O-fluoroalkyl silane composite membrane formed by SiO2, TiO2, Ag2O and fluoroalkyl silane. The preparation method of the glass provided by the invention comprises: letting an SiO2-TiO2-Ag2O-fluoroalkyl silane sol-gel solution form on the glass substrate by Czochralski method, spraying method, roller coating method, spin-coating method or spray coating method, and conducting drying to obtain the glass with antibacterial, anti-fingerprint and transmission increasing triple efficacy. The existence of SiO2 and TiO2 endows the glass with the transmission increasing function, the existence of Ag2O endows the glass with the antibacterial function, and the existence of fluoroalkyl silane endows the glass with the anti-fingerprint function. Therefore, the glass provided by the invention has antibacterial, anti-fingerprint and transmission increasing triple efficacy.

Owner:XINYI ENERGY SAVING GLASS SICHUAN CO LTD

Method for protecting silk fabrics

InactiveCN101818453AExtended shelf lifeExtended service lifeAnimal fibresRoller Coating MethodPolymer chemistry

The invention discloses a method for protecting silk fabrics, which comprises the following steps of: coating a polymer emulsion film-forming agent containing a certain amount of antimicrobial on the two sides of a fabric; and then carrying out heat-curing or room temperature air-drying to form a soft and transparent continuous closing film on the surface of the fabric, wherein the thickness of the film is 0.1 to 0.5mm, the viscosity of the selected film-forming agent is 50 to 20,000cp, the solid content of the film-forming agent is 20 to 55 percent, and the antimicrobial content in the film-forming agent emulsion is 1 to 5 weight percent. The coating method is a manual coating method by a rubber scraper blade or a manual roller coating method by a rubber roll; and the surface continuous film has certain closing function of isolating air and functions of resisting mould and damp, and can prolong the service life and hold time of a textile. The method is applicable to various silk-containing textiles and silk decorative fabrics.

Owner:SUZHOU VOCATIONAL UNIV

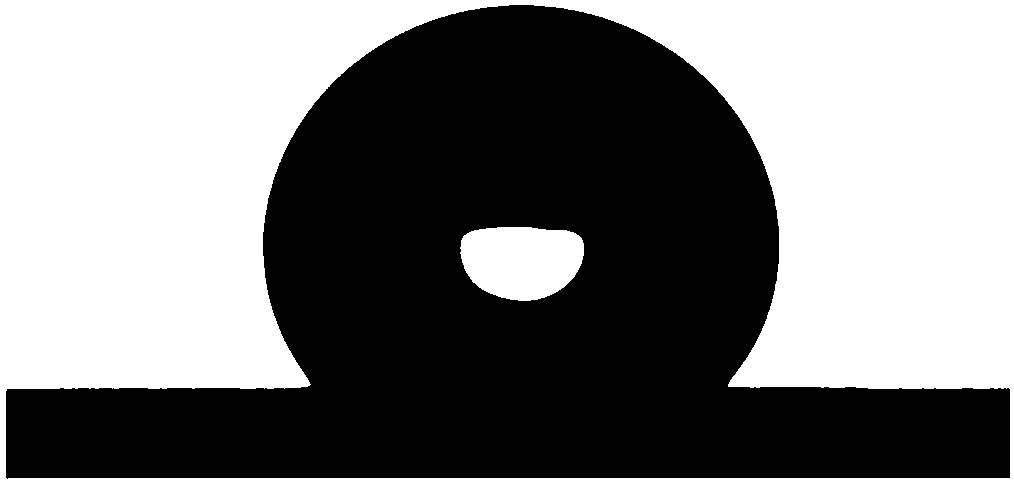

Water-based super-amphiphobic paint as well as preparation method and application thereof

InactiveCN108299880AMeet environmental protection requirementsReduce manufacturing costCoatingsWater basedFiber

The invention relates to water-based super-amphiphobic paint as well as a preparation method and application thereof. The water content in the paint is 60 to 99 percent; a film can be formed by a spray coating, soaking pulling, brush coating and roller coating method; after the high-temperature curing for 5 min to 2h, a super-amphiphobic coating with the water drop contact angle being greater than165 degrees, water drop rolling angle being smaller than 5 degrees, oil drop contact angle being 155 degrees and the oil drop rolling angle being smaller than 10 degrees can be obtained on the surface of a substrate. The preparation method has the advantages that the process is simple; green and environment-friendly effects are achieved; no harm is caused on the human body and the environment. The paint has the wide application in the fields of fiber treatment, self cleaning, moisture condensation resistance and the like.

Owner:SOUTHEAST UNIV

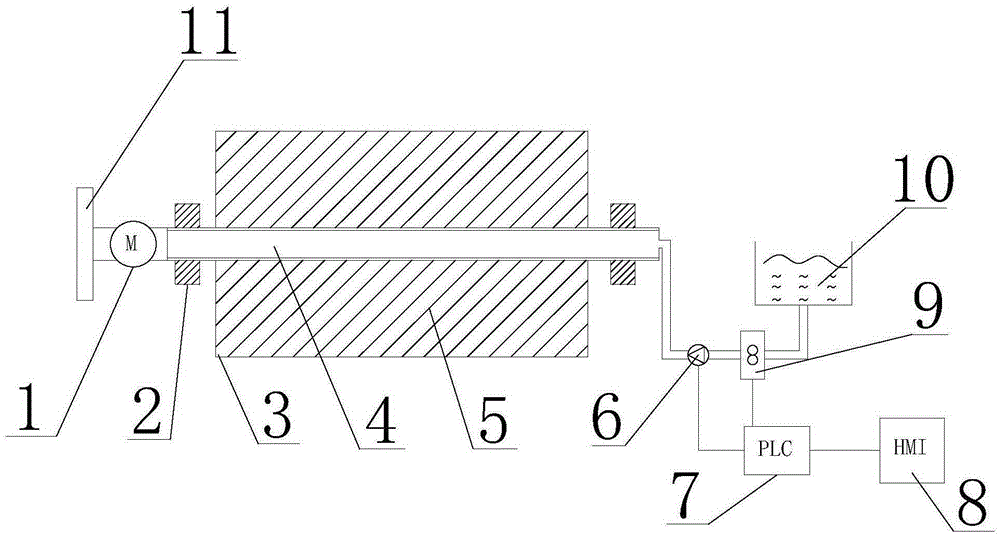

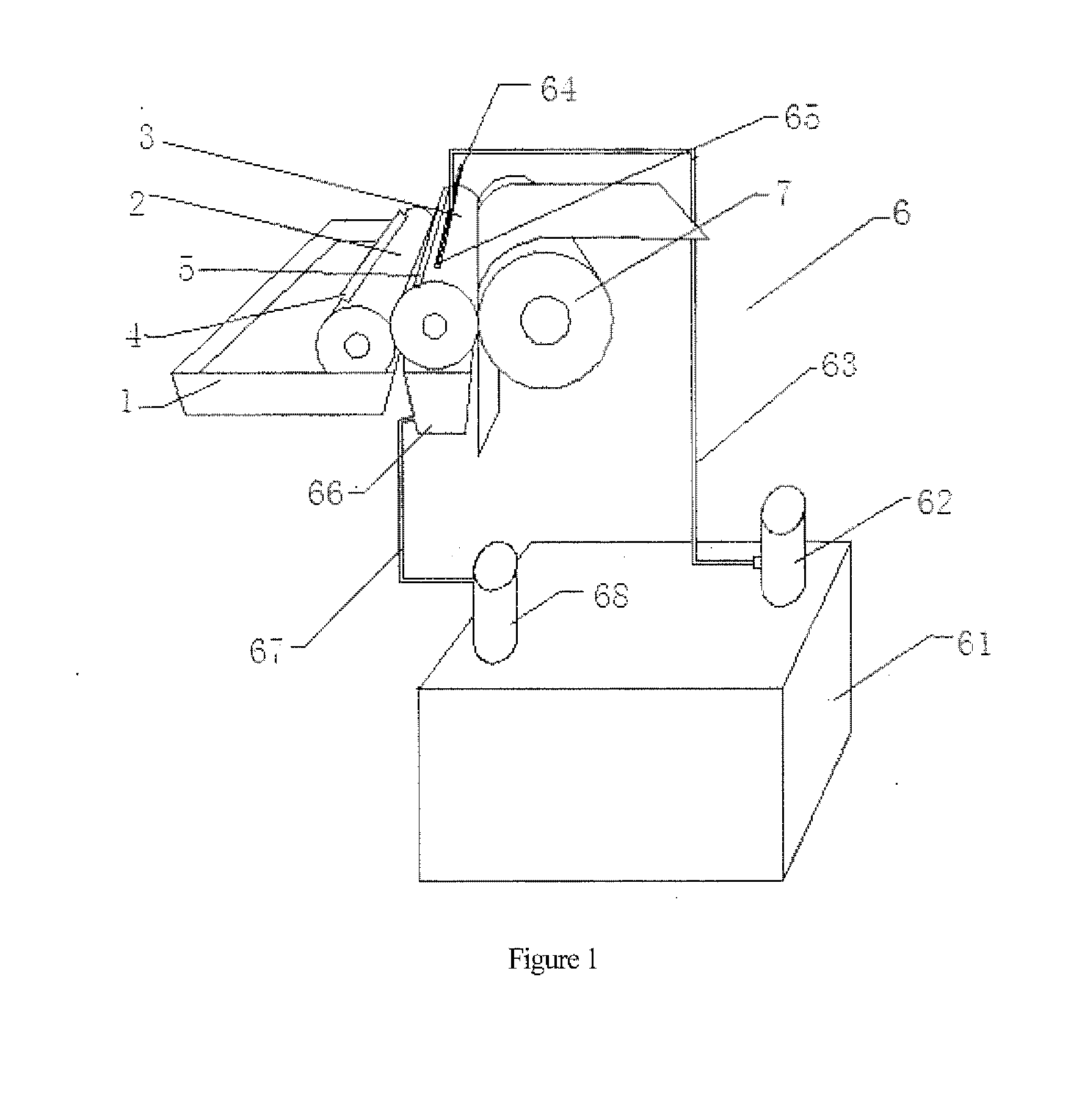

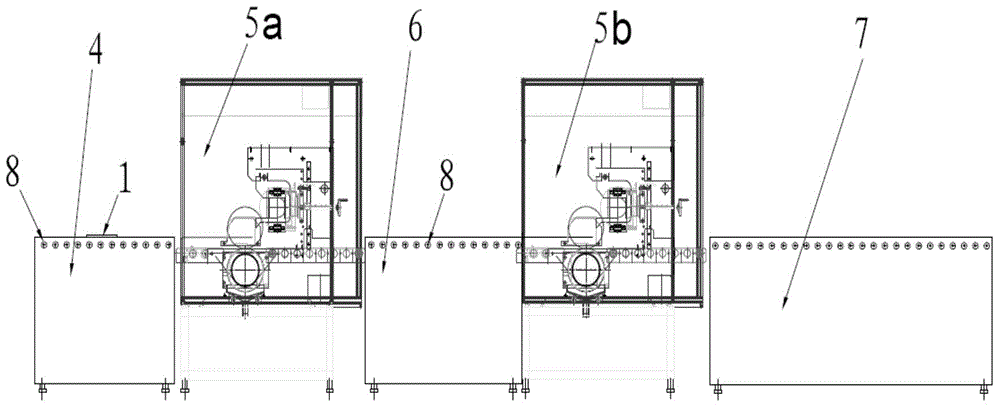

Painting method where roller coating is performed though roller and roller coating device

ActiveCN105268605AImprove working environmentRoller evenlyLiquid surface applicatorsCoatingsRoller Coating MethodEngineering

Owner:GLOBE ENVIRONMENTAL SHANGHAI

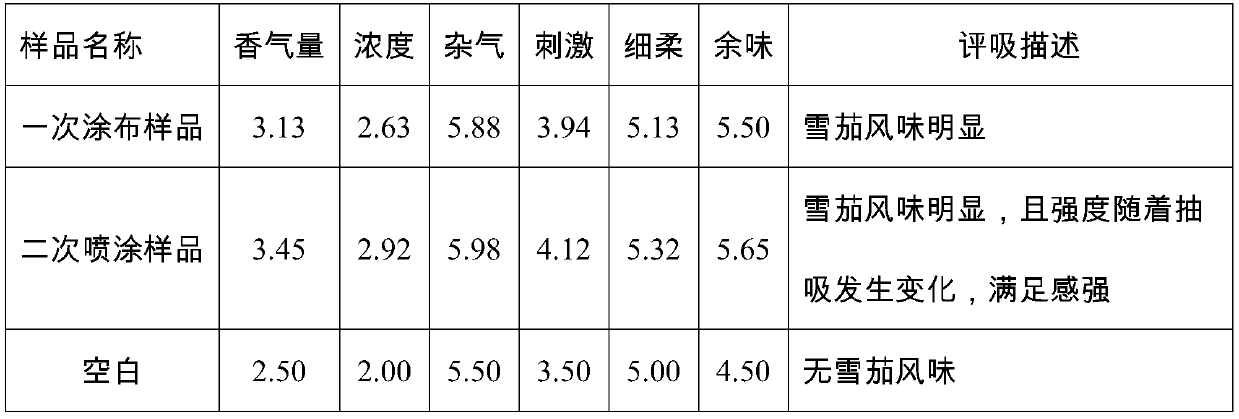

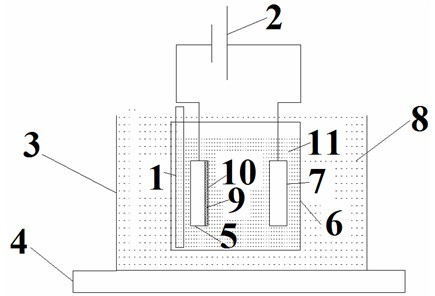

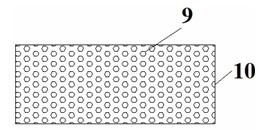

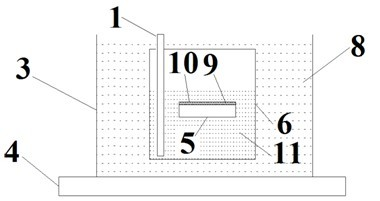

Coating preparation method of cigar-flavored cigarette paper

ActiveCN111418874AEnhance sensory experienceIncrease concentrationTobacco preparationTobacco treatmentBiotechnologySpray coating

The invention discloses a coating preparation method of cigar-flavored cigarette paper. The coating preparation method comprises the following steps: preparing a tobacco concentrate; carrying out molecular distillation treatment on the tobacco concentrate, and collecting light components to obtain a first tobacco extract; adding a mixture of amino acid and sugar into a tobacco leaf extract, and performing filtration, dilution, membrane separation and vacuum concentration after the reaction is finished so as to obtain a second tobacco extract; preparing a tobacco recombinant; preparing spice for cigar-flavored tobacco; preparing a cigar-flavored coating liquid; coating the cigarette paper for the first time by adopting a roller coating method; and coating the cigarette paper for the secondtime by adopting a spraying coating method to obtain the cigar-flavored cigarette paper. According to the coating preparation method of the cigar-flavored cigarette paper, the cigar flavor of cigarettes can be effectively enhanced, the concentration and thickness of smoke can be increased, the prepared cigar-flavored cigarette paper shows a dyeing effect without additionally adding pigments, and the sensory experience of the cigar-flavored cigarettes can be optimized.

Owner:CHINA TOBACCO HENAN IND +1

Method for preparing functionally gradient composite coating in osmosis plating

InactiveCN102383115AImprove bindingImprove mechanical propertiesElectrolytic coatingsLiquid/solution decomposition chemical coatingChemical platingSalt spray test

The invention discloses a method for preparing a functionally gradient composite coating by using an osmosis membrane in electroplating or chemical plating. The method is applicable to the surface strengthening, decorating and repairing of various electroplating or chemical plating parts and comprises the following steps: (1) sand blasting or polishing, oil removing, etching and weak etching treatment for the surface of a base material; (2) increasing the distribution density of the strengthening phase particles by 0-90% on the surface of the osmosis membrane by adopting a flame plating or roller coating method and then placing the osmosis membrane on the surface of the base material; (3) osmosis plating in a coating bath with prepared coating solution; and (4) repeating the steps (2) and(3) until the coating reaches the required thickness, otherwise, the work stops. The method has the advantages that: (1) the bond strength of the composite coating and the base material is high, the composite coating is not easy to strip off, the strengthening phase particles are in gradient distribution along the thickness direction of the coating, and the content of the outermost layer can reach 90vol.%; (2) the surface hardness of the composite coating can reach 55-80HRC, the salt spray resistance test can reach 30-12000 hours, and the composite coating can work continuously for 4000 hoursat the high temperature of 1100 DEG C; (3) the surface is smooth and bright, and reprocessing and polishing treatment is not required; and (4) the size and shape of the workpiece are not limited, thedeformation is avoided in the osmosis plating process, the worn workpiece with processing error can be repaired, and a deep blind hole and an inner cavity with a complicated shape can be processed ifthe osmosis chemical plating is adopted.

Owner:NANCHANG HANGKONG UNIVERSITY

Method for preparing self-adhesion rubber asphalt waterproof roll tearing-free film

The invention discloses a method for preparing a self-adhesion rubber asphalt waterproof roll tearing-free film, and relates to a method for preparing a building thin film. The method comprises the following steps of: adding 100 parts of anacardol (98 percent), 70-95 parts of formalin (37 percent) and 2,775-4,000 parts of polyvinyl alcohol aqueous solution (5 percent) into a reactor; then adding the residual 95-120 parts of formalin (37 percent) for a continuous reaction to obtain film stoste; and neutralizing the film stoste until the pH is 7.0, diluting the film stoste until the concentration of the film stoste is 5 percent, coating the film stoste on the surface of the just formed self-adhesion rubber asphalt waterproof roll by a roller coating method, and under the common action of the temperature of the roll and sweeping of a fan, quickly drying the film stoste on the surface of the roll to form a film. The film in the invention is self-dissolved and decomposed into alkaline slurry of concrete, and the bonding strength between the solidified concrete and the roll cannot be influenced.

Owner:CHONGQING XINLUJIE TECH

Method for producing synthetic leather for clothes by chemical foaming pore forming coating technology

InactiveCN102505517AImprove water vapor permeabilityImprove breathabilityDry-cleaning apparatus for textilesPolymer scienceFoaming agent

A method for producing synthetic leather for clothes by chemical foaming pore forming coating technology adopts a nonwoven fabric for synthetic leather as a base material, employs multilayer chemical foaming hole forming coating technology, solves problems in production process of synthetic leather for clothes, and produces synthetic leather for clothes with high performance. A bottom foamed coating is manufactured on a surface of a nonwoven fabric for synthetic leather through a roller coating method by using mixed slurry containing solvent-type polyurethane, a chemical foaming agent, a low temperature foaming modifier and a pore forming agent; original solvent-type polyurethane wet-method solidification coating technology is substituted; and the solvent pollution problem and the solventresidue problem of DMF are solved; a film is formed on a release paper surface through a scrape coating method by mixed slurry containing solvent-type polyurethane and the pore forming agent; an adhesive is coated on the film by scrape coating; then the film is adhered to the nonwoven fabric for synthetic leather with the bottom foamed coating; a solvent-type polyurethane dry-method transfer-filmcoating is formed on the bottom foamed coating; and finally water washing is performed to obtain the synthetic leather for clothes.

Owner:福建可利得皮革纤维有限公司

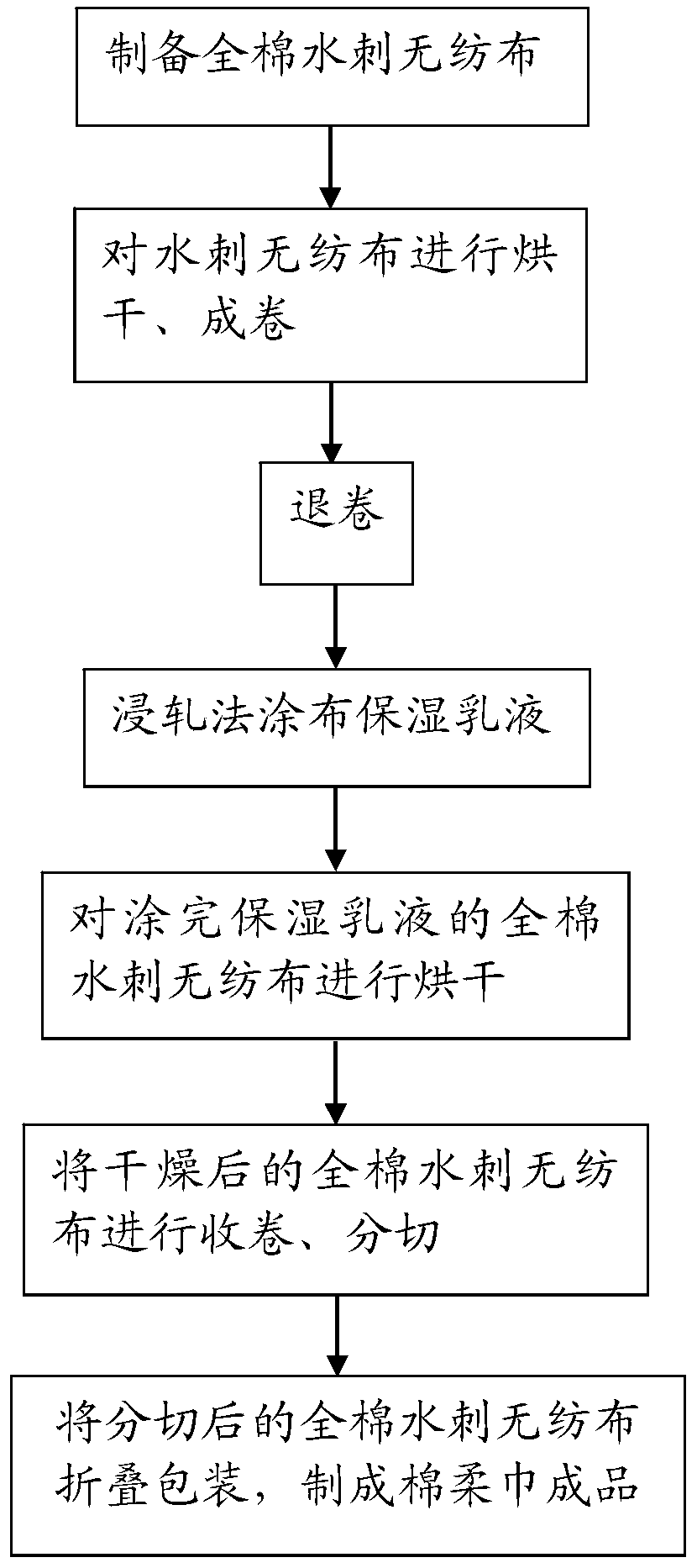

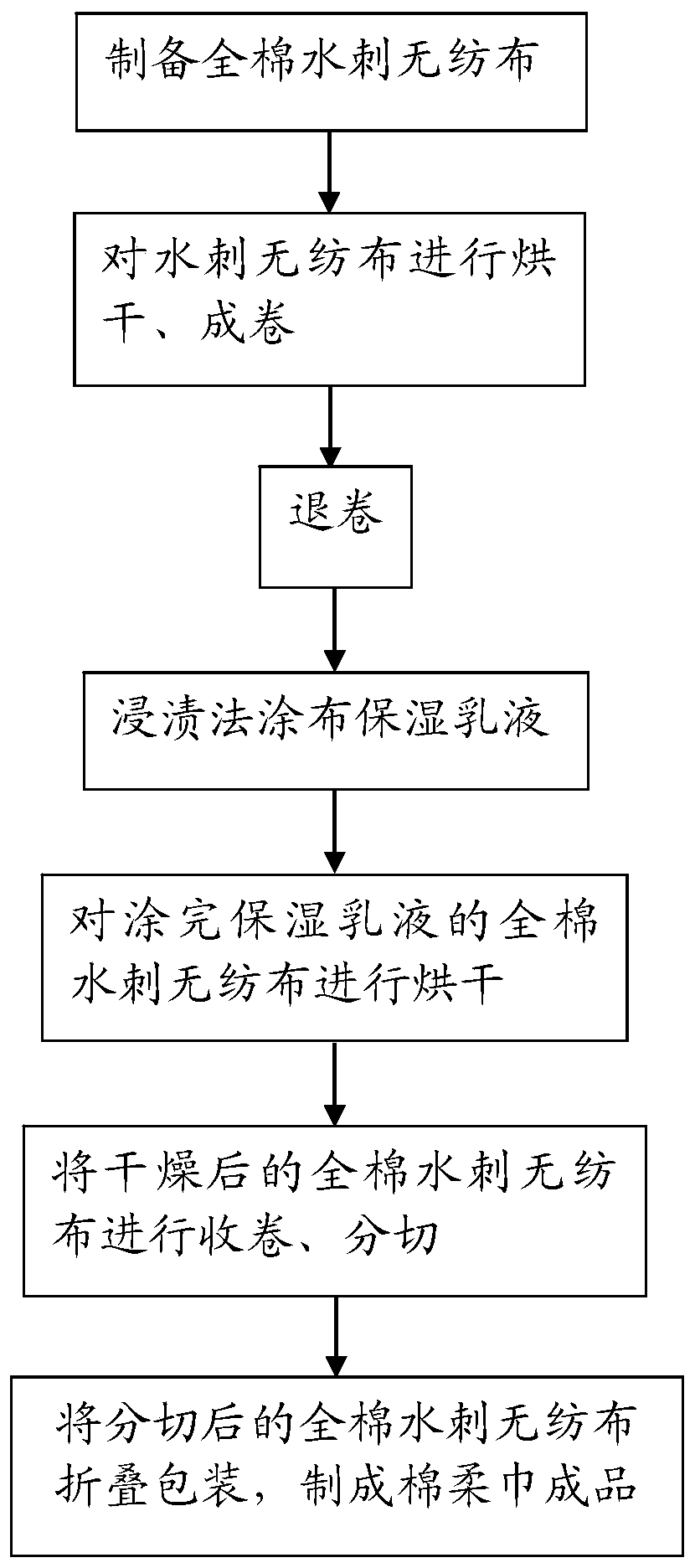

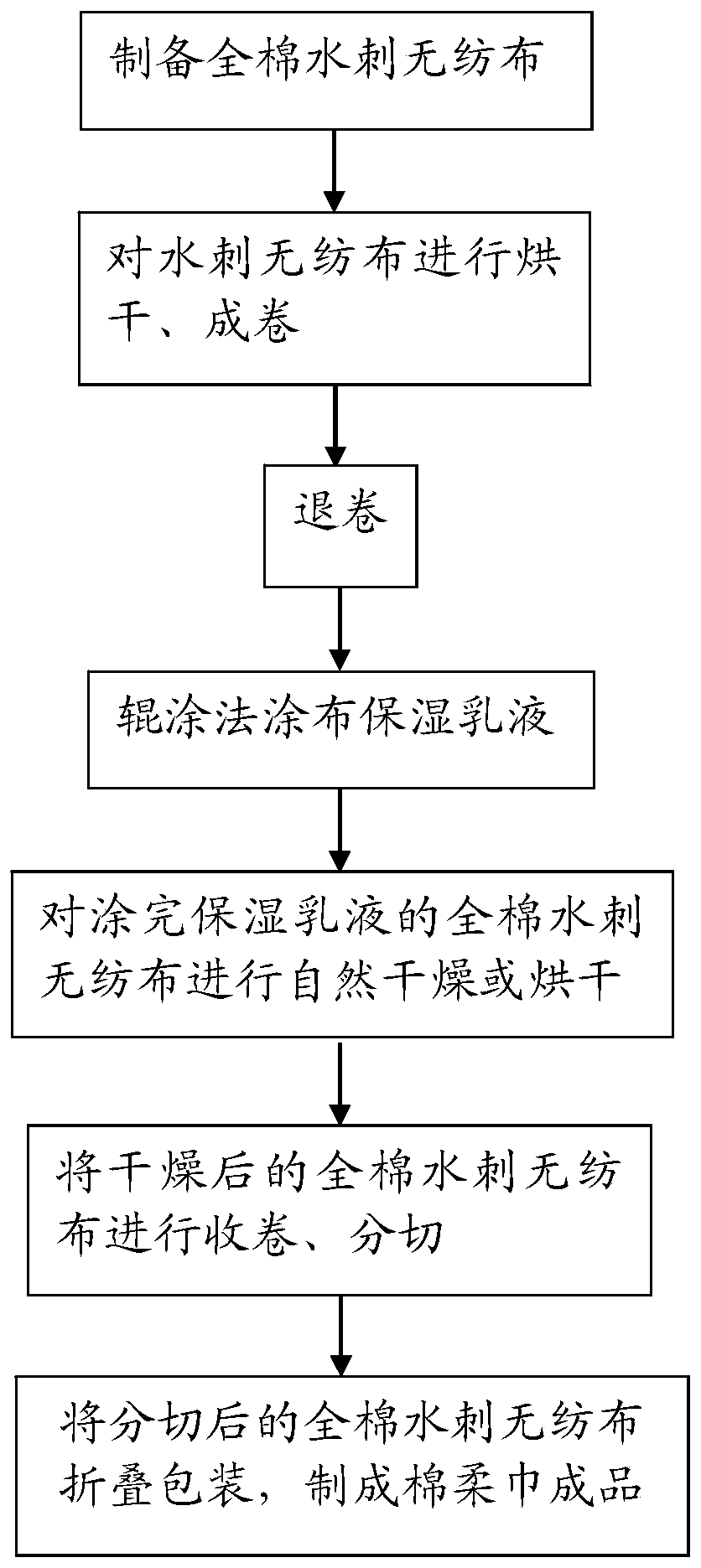

Preparation method of super-soft moisturizing cotton towel and super-soft moisturizing cotton towel

InactiveCN111270412AGuaranteed ratioMaintain soft propertiesTextile treatment by spraying/projectingNon-woven fabricsTextile printerPolymer science

The invention discloses a preparation method of a soft moisturizing cotton towel and the soft moisturizing cotton towel. The method comprises the steps of preparing an all-cotton spunlaced nonwoven fabric; performing unwinding; applying a moisturizing emulsion; drying the all-cotton spunlaced nonwoven fabric coated with the moisturizing emulsion; and performing processes of winding, slitting, finishing and the like on the dried all-cotton spunlaced nonwoven fabric. Main components of the moisturizing emulsion are a humectant, lipids and pure water. A method for adding a moisturizing solution incudes a padding method, an impregnation method, a roll coating method, a printing method, a stamping method, a dry cloth spraying method and a wet cloth spraying method, and the addition amounts ought to be designed in the seven methods respectively ensure the proportion of the moisturizing solution on the soft cotton towel, so that the moisturizing emulsion can completely permeate an inner layerof the fabric, fibers are fully moistened, and the overall softness characteristic of the interior and exterior of the soft cotton towel can be ensured after drying.

Owner:WINNER MEDICAL (HUANGGANG) CO LTD +1

Method for preparing waterproof thin film abrasive paper

InactiveCN103862398AImprove anti-blocking performanceExtended service lifeAbrasion apparatusAdhesiveRoller Coating Method

The invention discloses a method for preparing waterproof thin film abrasive paper. The method includes the following steps of firstly, selecting a PET film or a PVC film as base cloth; secondly, coating the base cloth with a layer of primer through a roller, wherein the primer comprises adhesives, fillers, coupling agents and diluents, and the mass ratio of the adhesives to the fillers to the coupling agents to the diluents is 100:10-40:2:10-40; thirdly, enabling abrasive materials to adhere to the primer through a gravity abrasive plantation method, and then conducting drying, wherein the drying temperature ranges from 80 DEG C to 100 DEG C; fourthly, coating the layer of abrasive materials with a layer of laminating adhesive through a roller coating method, and then placing the product into a curing oven at the temperature of 100 DEG C to 120 DEG C to be cured for 24 hours to 48 hours, wherein the laminating adhesive comprises adhesives, fillers, pigments and diluents, and the mass ratio of the adhesives to the fillers to the pigments to the diluents is 100:10-40:5:10-40. Adhesive paper prepared through the method has an excellent anti-blocking effect, and is long in service life and high in strength.

Owner:JIANGSU FENGMANG COMPOUND MATERIAL SCI&TECH GRP CO LTD

Preparation method of cathode protection coating on aluminum alloy surface

The invention discloses a preparation method of an aluminum-magnesium-rich alloy coating for protecting an aluminum alloy cathode. The method disclosed by the invention comprises the following steps of mixing epoxy resin, aluminum-magnesium metal micropowder, a curing agent, a solvent, an auxiliary, a coupling agent and a defoaming agent according to a certain ratio; placing the mixture into a ball mill for sufficiently grinding to ensure that all components in the mixture are uniformly distributed so as to prepare a corrosion-resistant coating; then, covering the coating on the aluminum alloy surface washed in advance and subjected to ultrasonic treatment by using a spray coating or brush coating or roller coating method; finally, curing at room temperature, and drying for 5-7d to form a cathode protective coating with high corrosion resistance on the aluminum alloy surface. The coating prepared by using the method disclosed by the invention has favorable corrosion resistance 10 times of that of a magnesium-rich coating under salt-spray and seawater environments and still can protect an aluminum alloy matrix even if the coating on the aluminum alloy surface is damaged; the method is relatively simple, good in repeatability and suitable for industrial production.

Owner:GUANGDONG OCEAN UNIVERSITY

Energy-saving and environment-friendly solid wood door UV roller coating method

PendingCN111013981AImprove environmental performanceImprove product qualityPretreated surfacesCoatingsSolid woodEngineering

The invention discloses an energy-saving and environment-friendly solid wood door UV roller coating method. The method comprises the following steps that A, a plain plank is sanded; B, waterborne coloring is performed, specifically, waterborne colorant roller coating is performed on the door plank by adopting a double-roller coloring roller coating machine; C, waterborne base coat drying is performed; D, UV putty roller coating is performed, specifically, putty roller coating is performed for the first time, semi-curing is performed by adopting LED lamps, then putty roller coating is performedfor the second time, and full curing is performed by adopting the LED lamps; E, UV undercoat roller coating is performed, specifically, undercoat roller coating is performed for the first time, curing is performed by adopting the LED lamps, undercoat roller coating is performed for the second time, and curing is performed by adopting the LED lamps; and F, UV finishing coat roller coating is performed, specifically, finishing coat roller coating is performed for the first time for embellishing, then finishing coat roller coating is performed for the second time, curing is performed by adoptingthe LED lamps, finally, finishing coat roller coating is performed for the third time, and curing is performed by adopting the LED lamps. According to the energy-saving and environment-friendly solidwood door UV roller coating method, by optimizing a UV roller coating process and adopting a waterborne colorant, the environment-friendly property of products can be greatly improved; and by performing curing treatment by adopting the LED lamps and the like, the product production energy consumption can be reduced easily.

Owner:重庆市豪迈家具有限公司

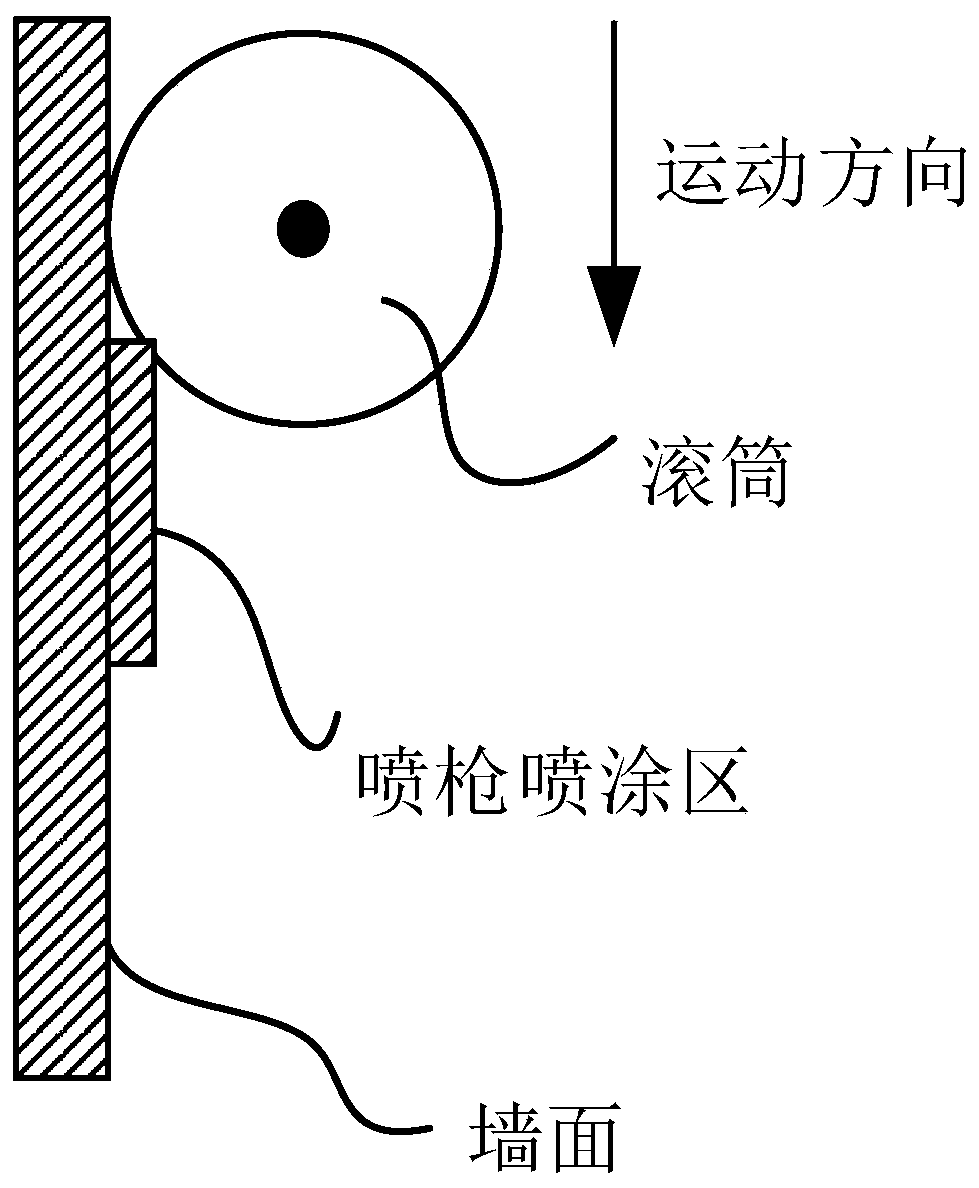

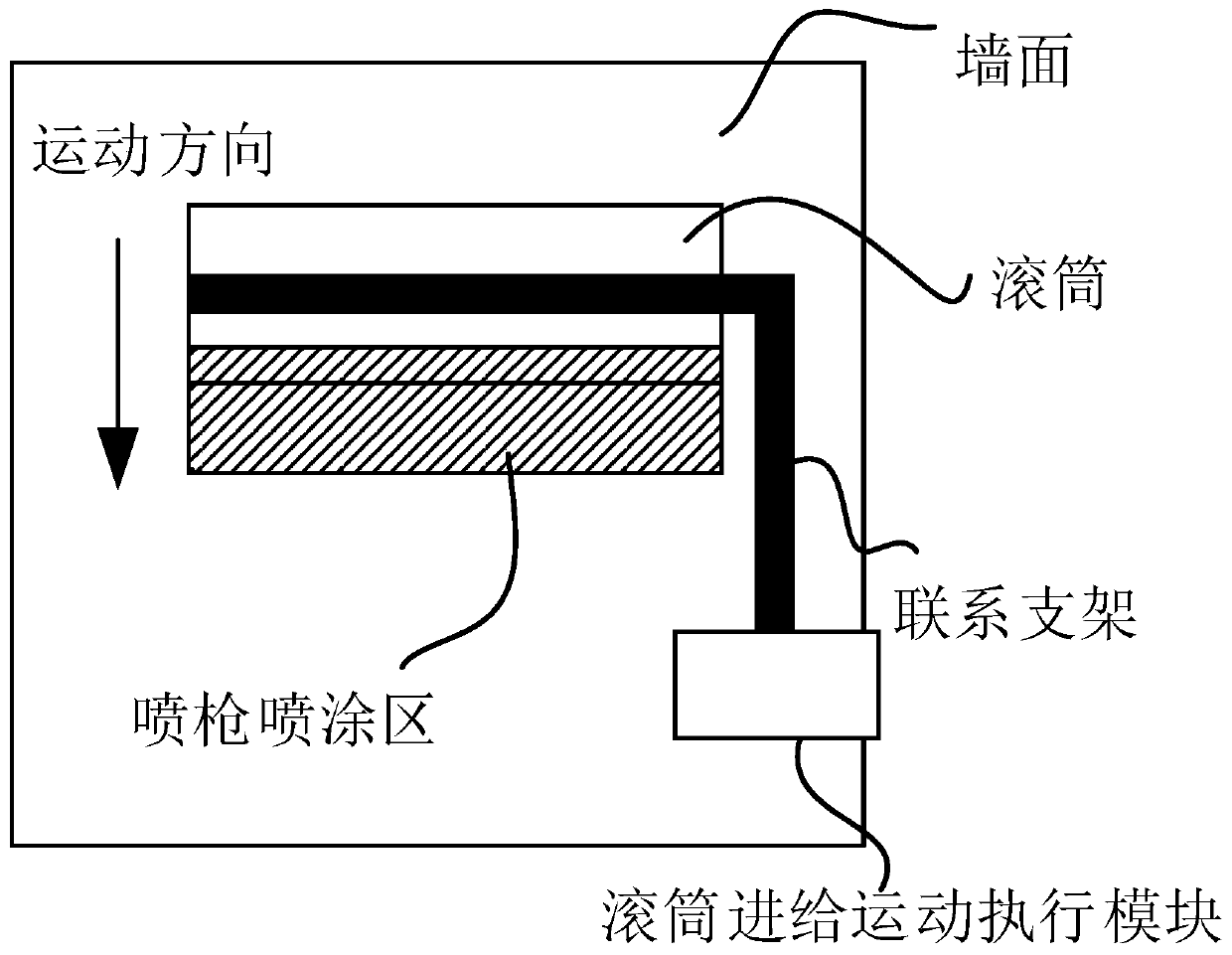

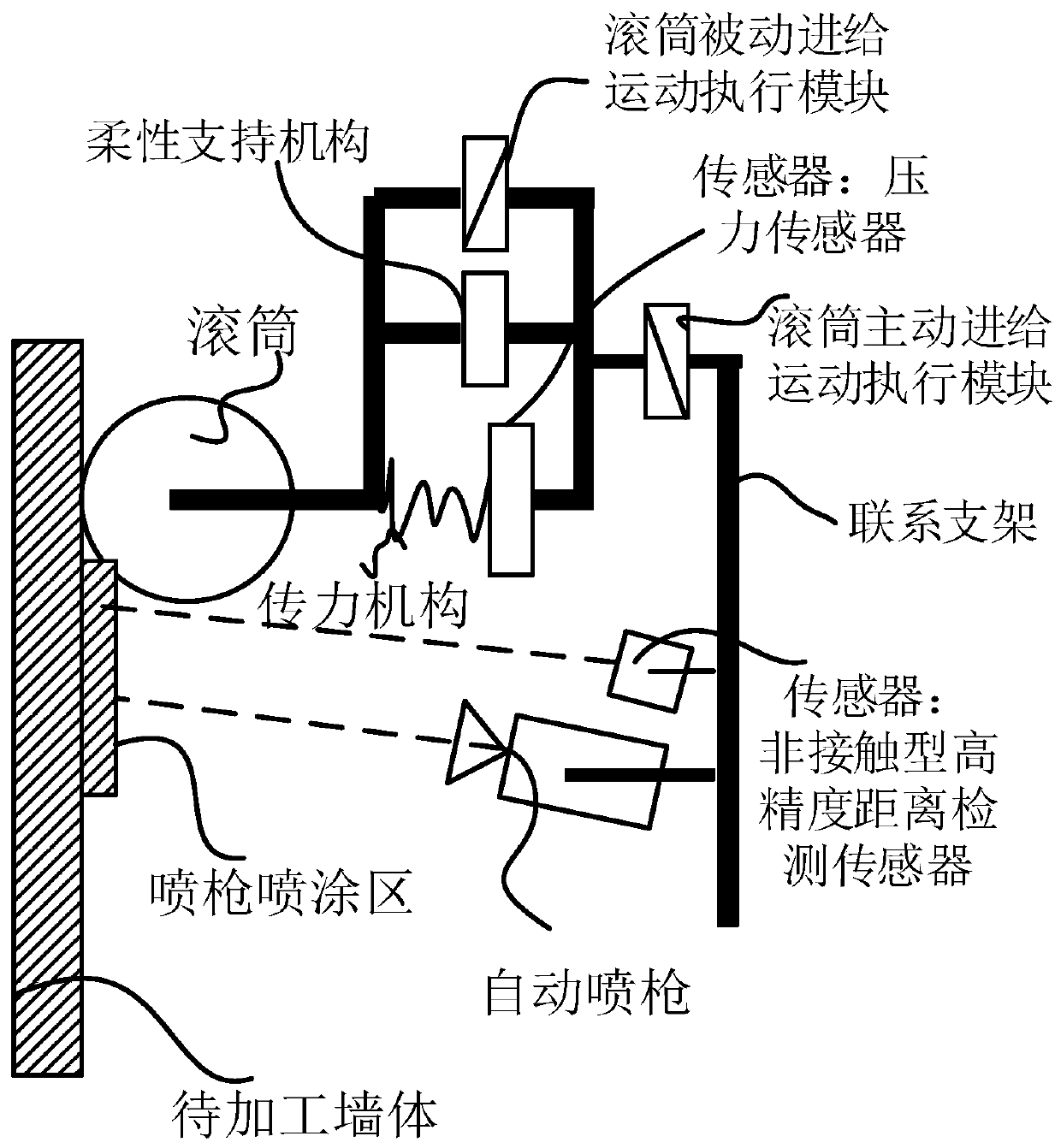

Roller coating method for finishing operation by combining automatic spray gun and roller of robot

InactiveCN111255199AWaste less splashImprove thickness uniformityBuilding constructionsControl systemControl engineering

The invention discloses a roller coating method for finishing operation by combining an automatic spray gun and a roller of a robot. The roller coating method comprises the following steps of providing a sensor, a controller, the roller, the automatic spray gun, a roller feeding motion execution module and a connecting support; the roller is arranged in front of the connecting support so as to facilitate the roller coating work; the automatic spray gun is connected with the connecting support to align to a wall; the sensor is connected with the controller, the sensor feeds back parameters of the wall surface condition to the controller, and the controller drives the roller to be in dynamic contact with the wall surface, so that the thickness of the roll-coated paint film is uniform; the roller feeding motion execution module and the pressure sensor are located between the roller and the connecting support to work in a matched mode; the roller feeding motion execution module provides flexible support and feeding motion execution force in a small range for the roller; the controller is connected with the sensor and a robot control system for driving the contact support through data lines; and after the automatic spray gun sprays the wall, the roller moves in the direction of the spraying area so that the roller is roll-coated on the surface of the wall.

Owner:珠海心怡科技有限公司

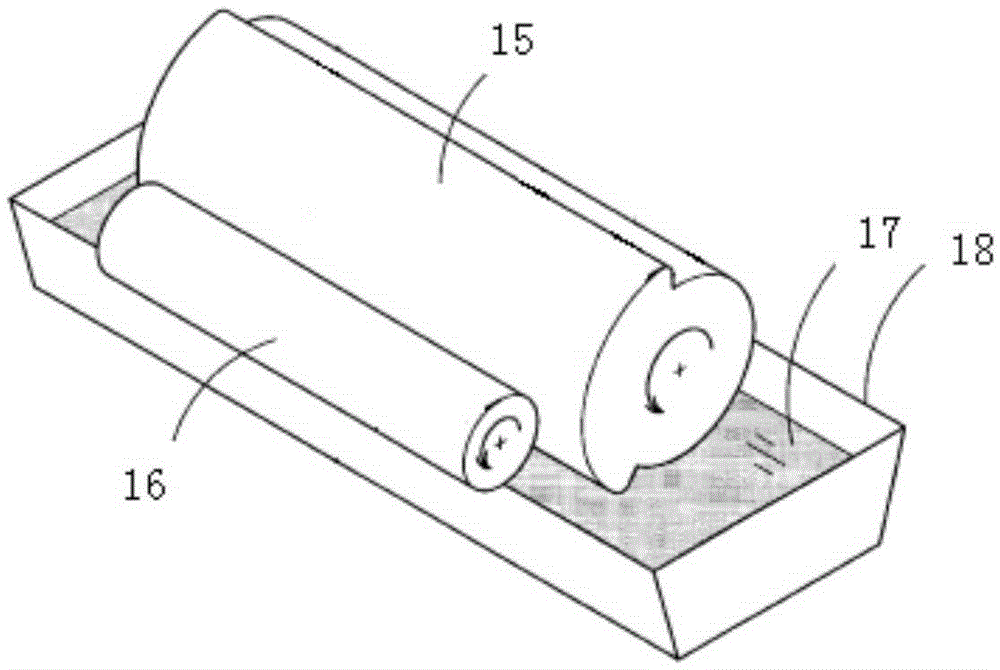

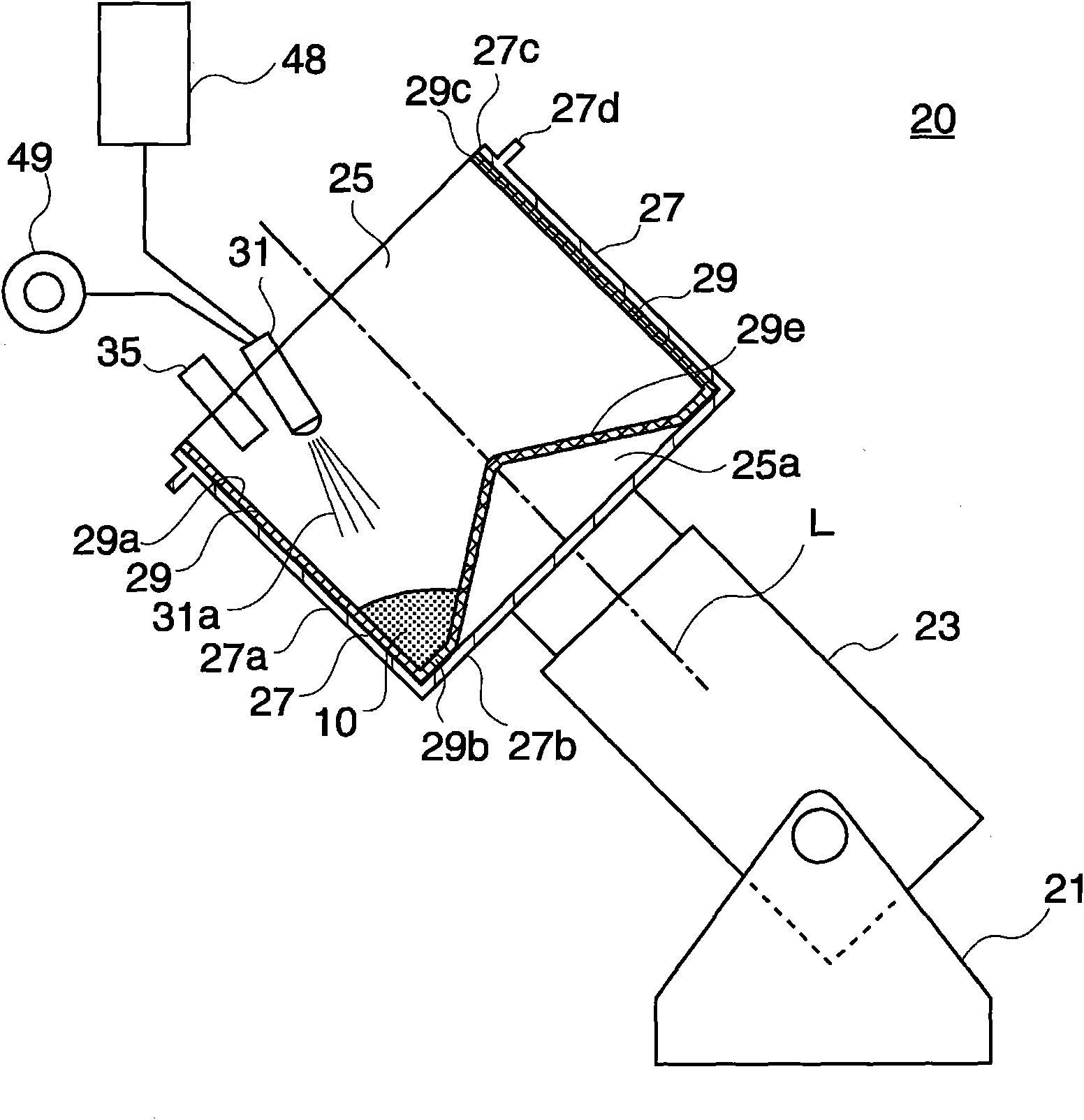

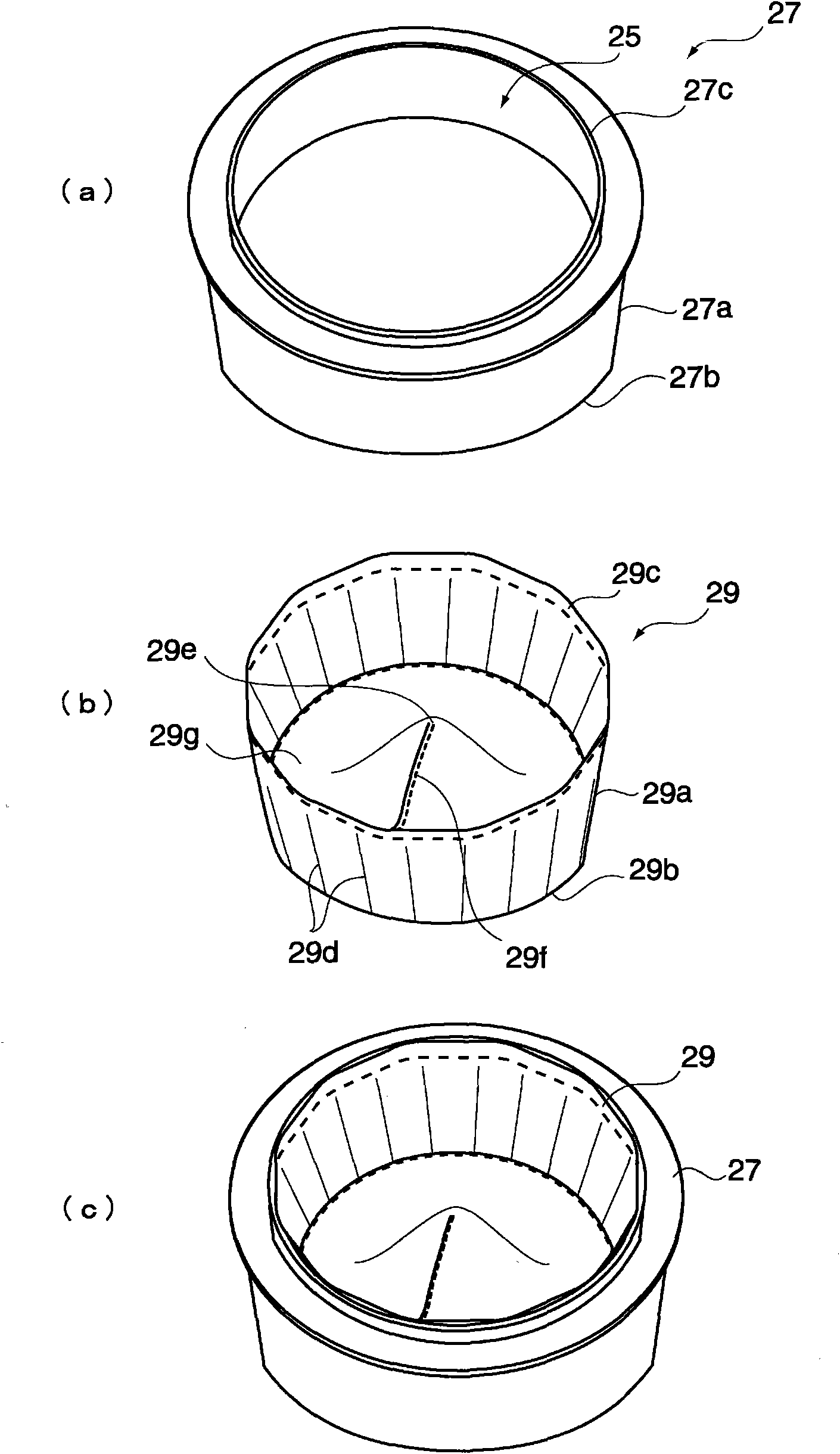

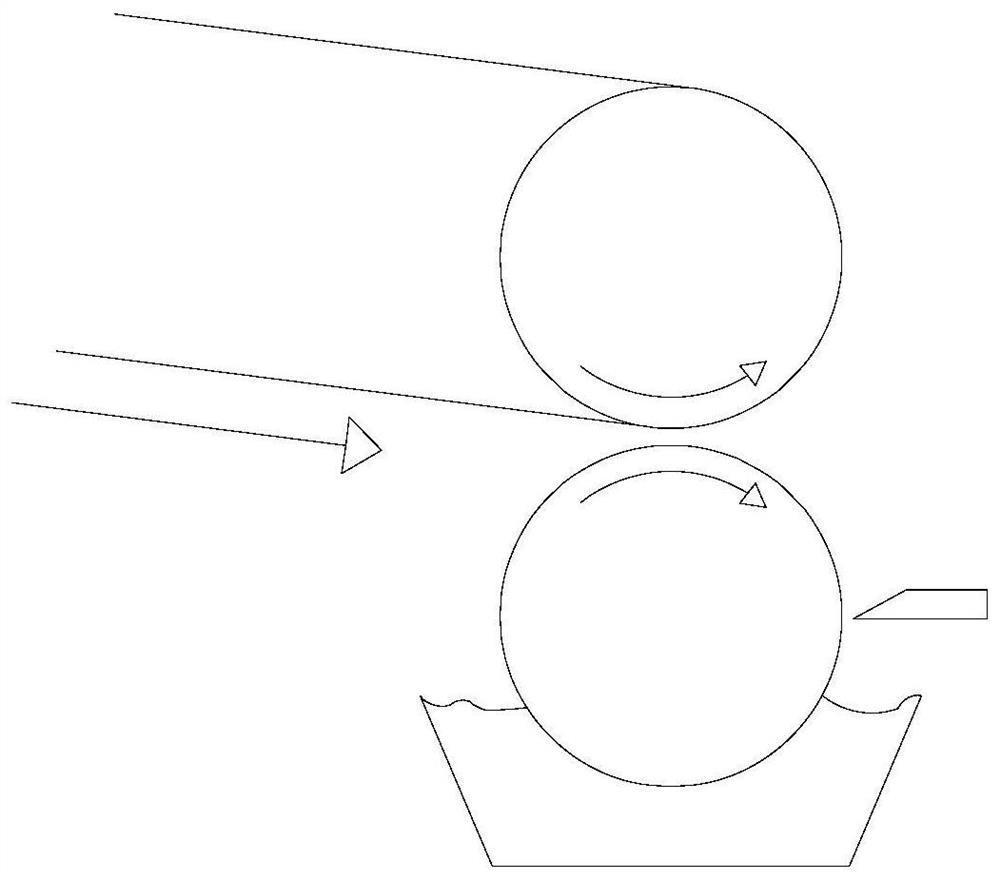

Roller coating device and roller coating method

InactiveCN101940996AEfficient and smooth stirringAvoid sticking to each otherPretreated surfacesCoatingsRotational axisRoller Coating Method

The invention provides a roller coating device and a roller coating method capable of preventing processed objects from mutually adhering and thinly and evenly coating coated components. The roller coating device is provided with a rotary unit which is provided with a containing space and rotates surrounding a rotary shaft inclining in a specified angle relative to a level direction; a containingunit which is formed by meshed material and is provided with a cylinder part and a bottom part, and is mounted in the containing space by means that the center of the bottom is coherent with the rotary shaft, and rotates with the rotary unit under the condition of containing a plurality of processed objects; a spraying unit for spraying treatment fluid to the plurality of processed objects flowing in the containing unit; and a heating unit for curing the coated components adhered on the surface of the plurality of processed objects by heating the plurality of processed objects flowing in the containing unit, wherein the bottom part of the containing unit is provided with a protrusion part which protrudes to the upper side of the rotary shaft and causes the plurality of processed objects to flow between the protrusion part and the cylinder.

Owner:NAKATA COATING CO LTD

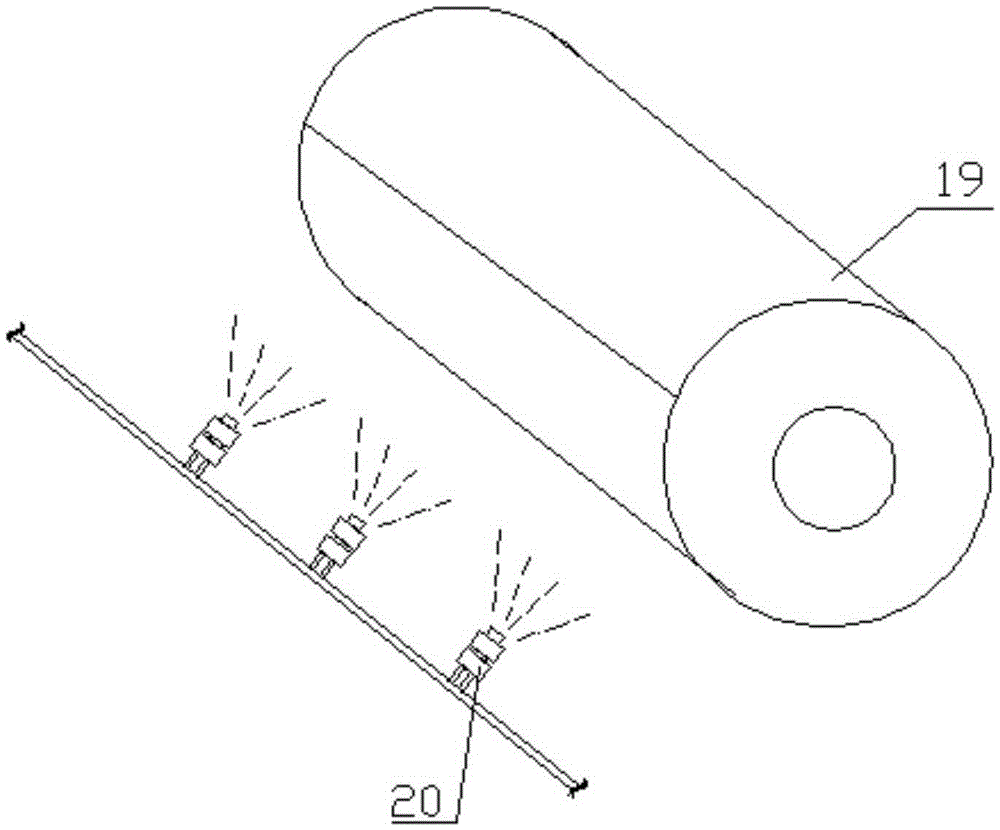

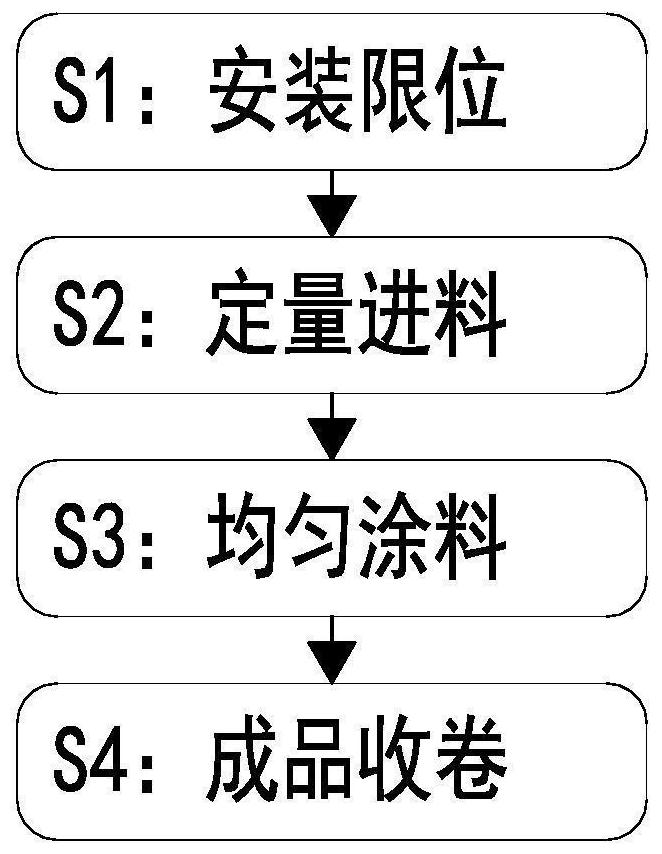

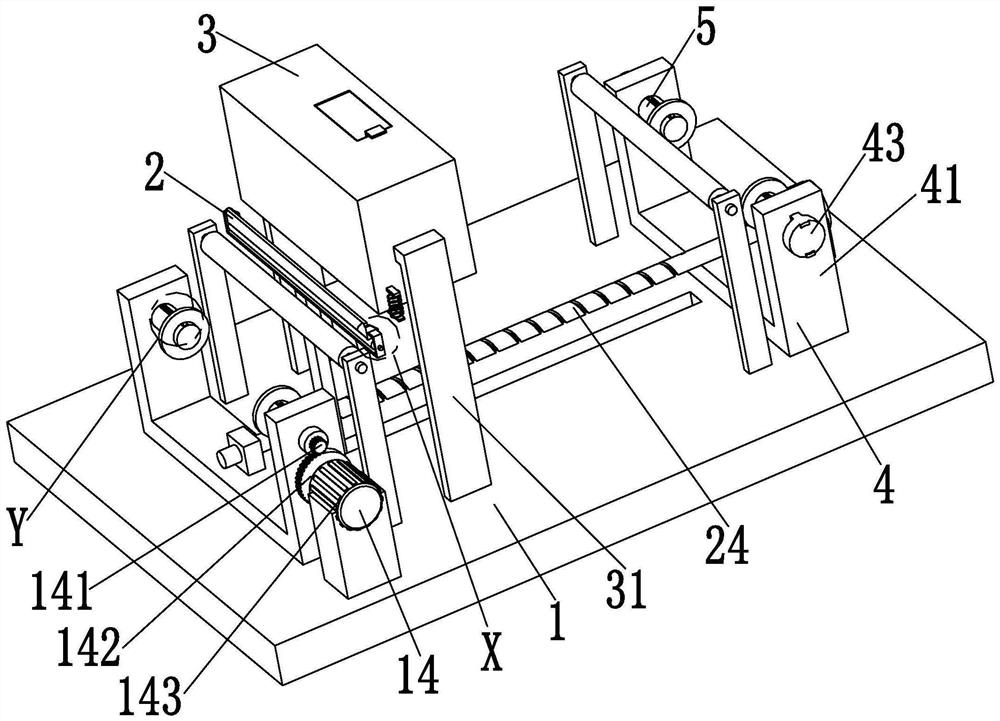

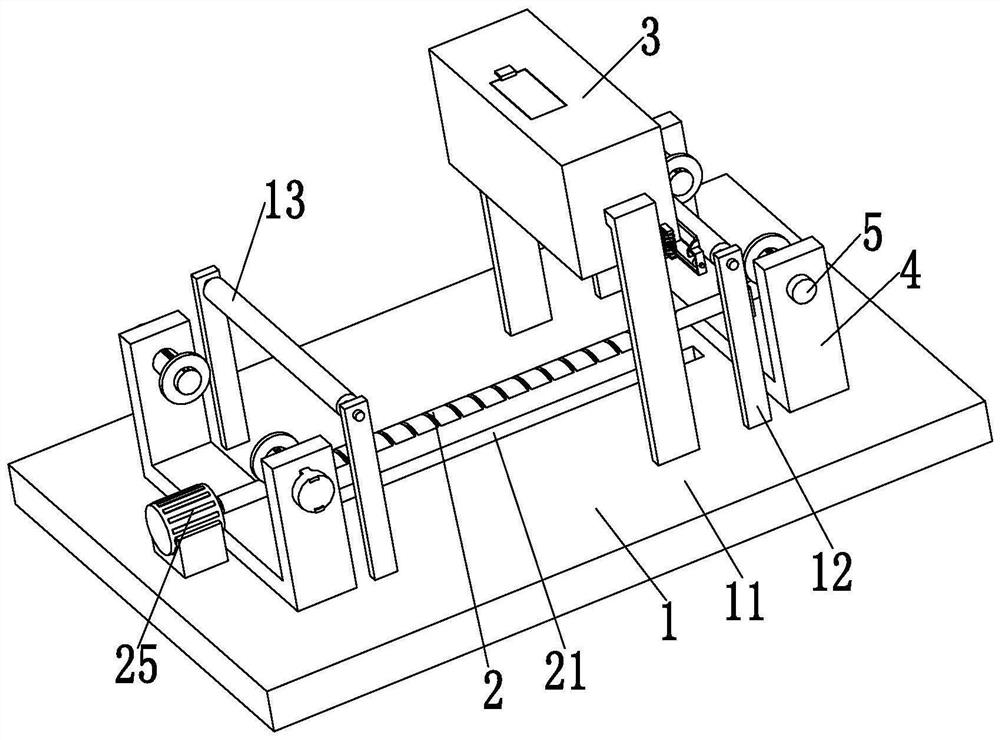

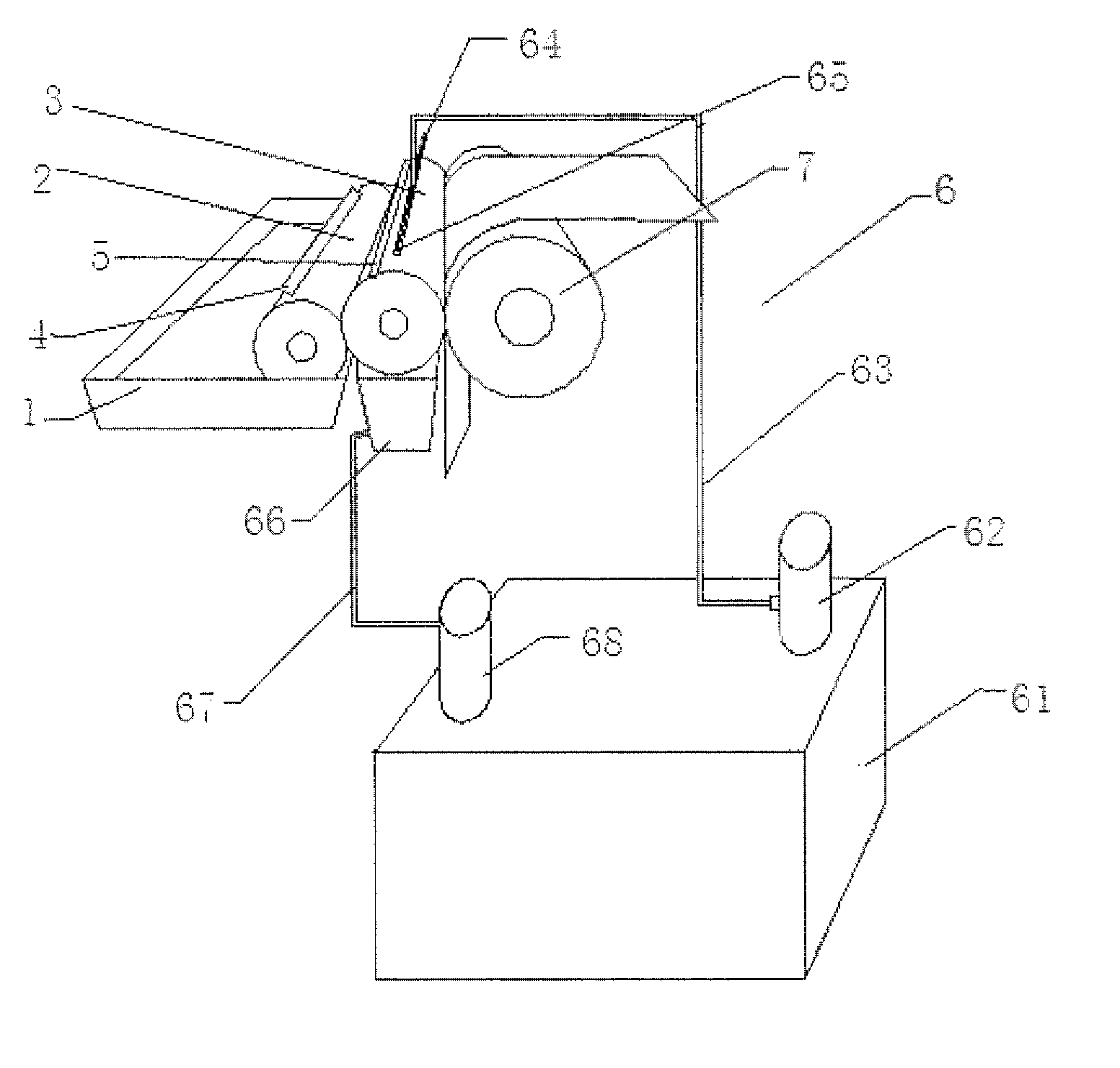

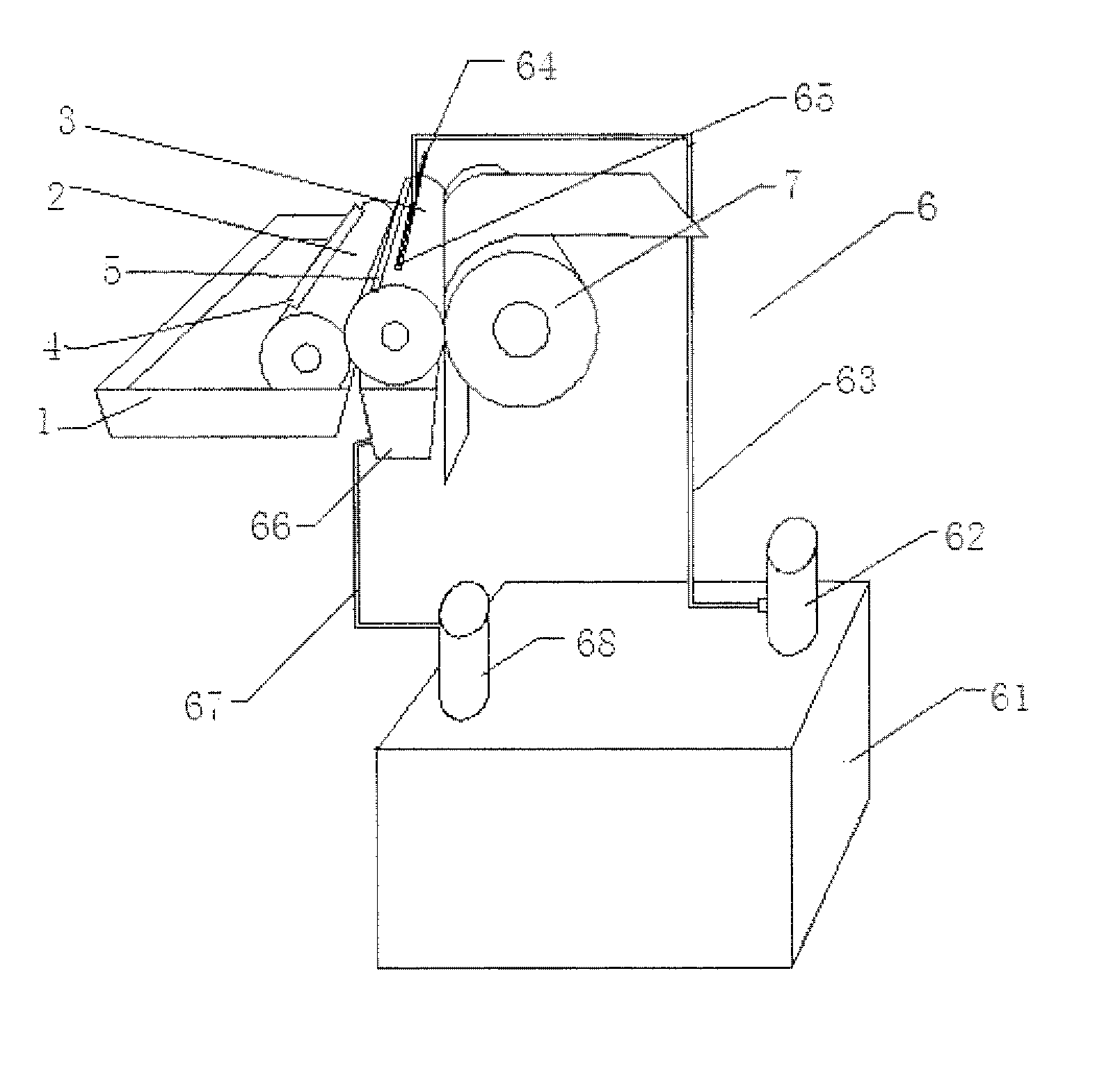

Preparation method of self-adhesive polymer modified asphalt waterproof coiled material

ActiveCN113019815AGuarantee the quality of workReduce wasteLiquid surface applicatorsCoatingsPolymer sciencePolymer modified

The invention relates to a preparation method of a self-adhesive polymer modified asphalt waterproof coiled material. The method uses a preparation machine of the self-adhesive polymer modified asphalt waterproof coiled material. The machine comprises a base, a coating device, a quantitative feeding device, U-shaped plates and rotating columns, wherein the coating device is arranged in the middle of the upper end of the base; the quantitative feeding device is installed on the left side of the upper end of the base; the U-shaped plates are symmetrically fixed to the left and right sides of the upper end face of the base; and the rotating columns are symmetrically and rotationally arranged on the front and rear sides of the upper ends of the U-shaped plates. The preparation method of the self-adhesive polymer modified asphalt waterproof coiled material provided by the invention can solve the problems that according to a traditional preparation method of a self-adhesive waterproof coiled material gluing layer, when the surface of a waterproof coiled material is coated with glue, the waterproof coiled material cannot be quantitatively coated with the glue, so that a large amount of the glue is often wasted; and the surface of the waterproof coiled material is usually coated with the paint through a roller coating method, and partial areas of the glue coating layer may be non-uniformly distributed, so that the adhesion of the self-adhesive waterproof coiled material is reduced, and the working quality of the self-adhesive waterproof coiled material is influenced.

Owner:滨州环亚新材料科技有限公司

Hot sealing coating for calorifier aluminum foil, and its preparation method and coating method

ActiveCN1800279AImprove adhesionImprove temperature resistanceOther chemical processesHot plates heating arrangementsHeat resistanceEther

The invention discloses an electric heater aluminum plate used heat sealed paint and it's preparing and coating method. The paint is formed by ternary trichloroacetic resin with carboxyl, n-butyl methacrylate, dioctyl phthalate, butanone and acetic ether; the preparing method is that first preparing for the ternary trichloroacetic resin with carboxyl, adding the raw material into the high speed dispersion machine to stir and dissolve them until the resin dissolves to obtain the hest sealed paint. The coating art is that it uses acetic ether to dilute the heat sealed paint and adds blue paint into it to stir them; it adopts net roller coating method to coat it and solid it.

Owner:JIANGSU ALCHA ALUMINUM CO LTD

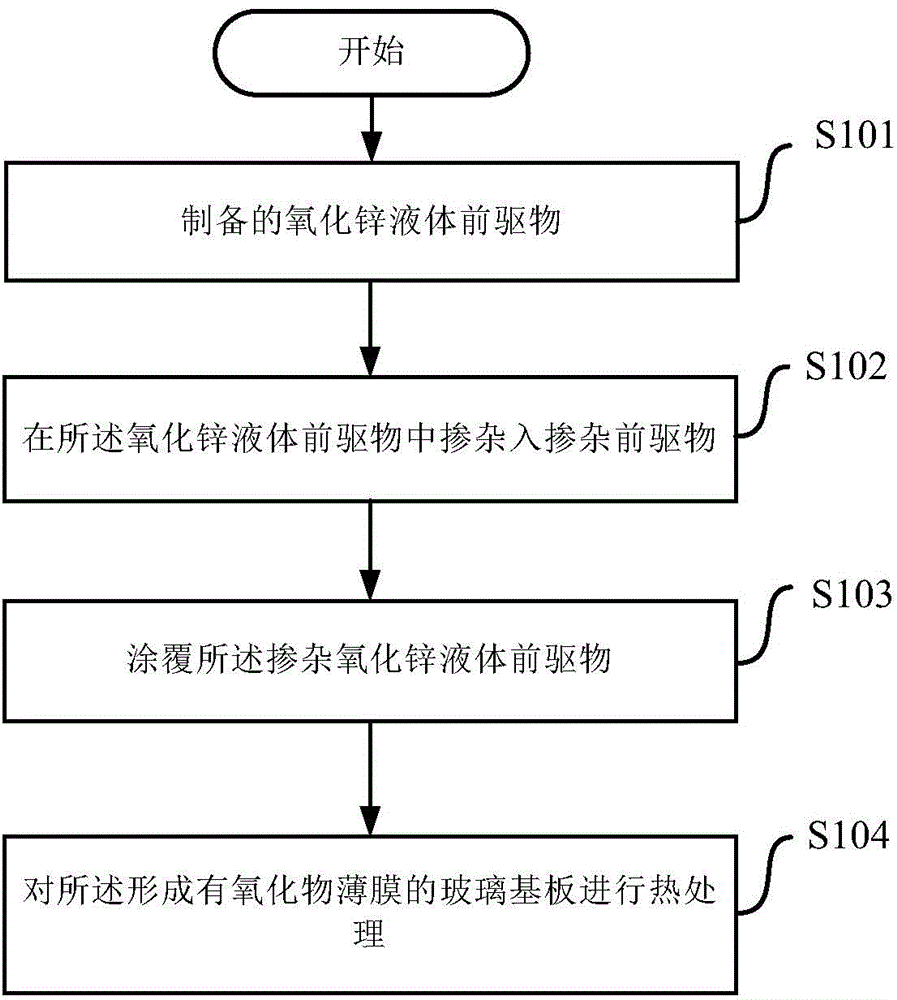

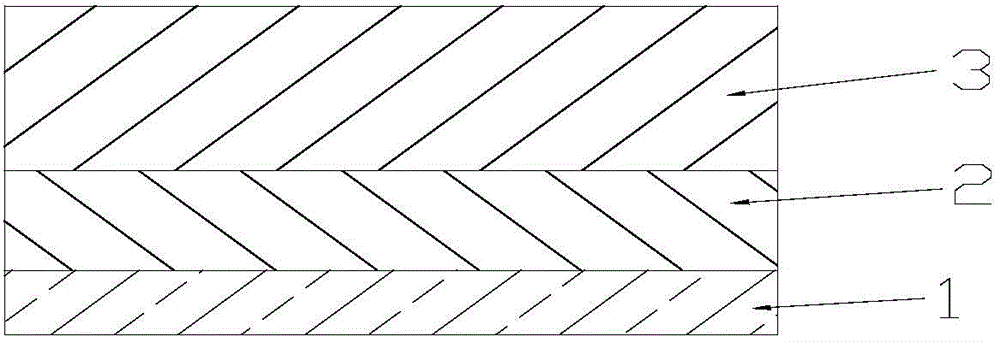

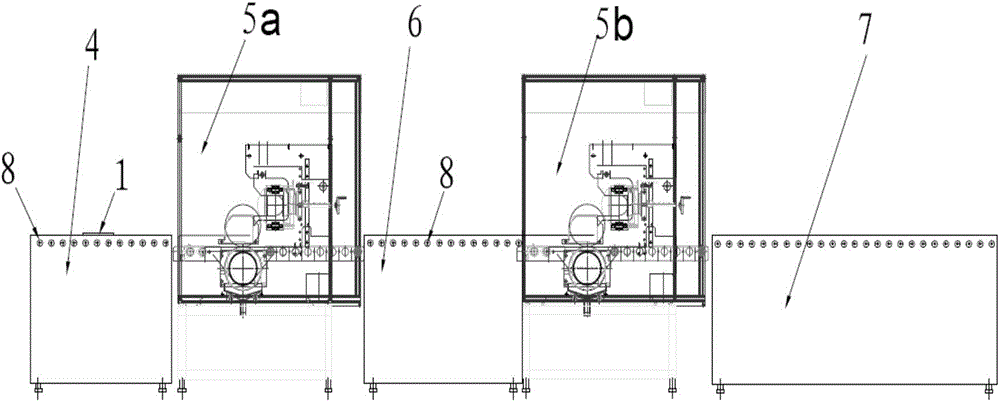

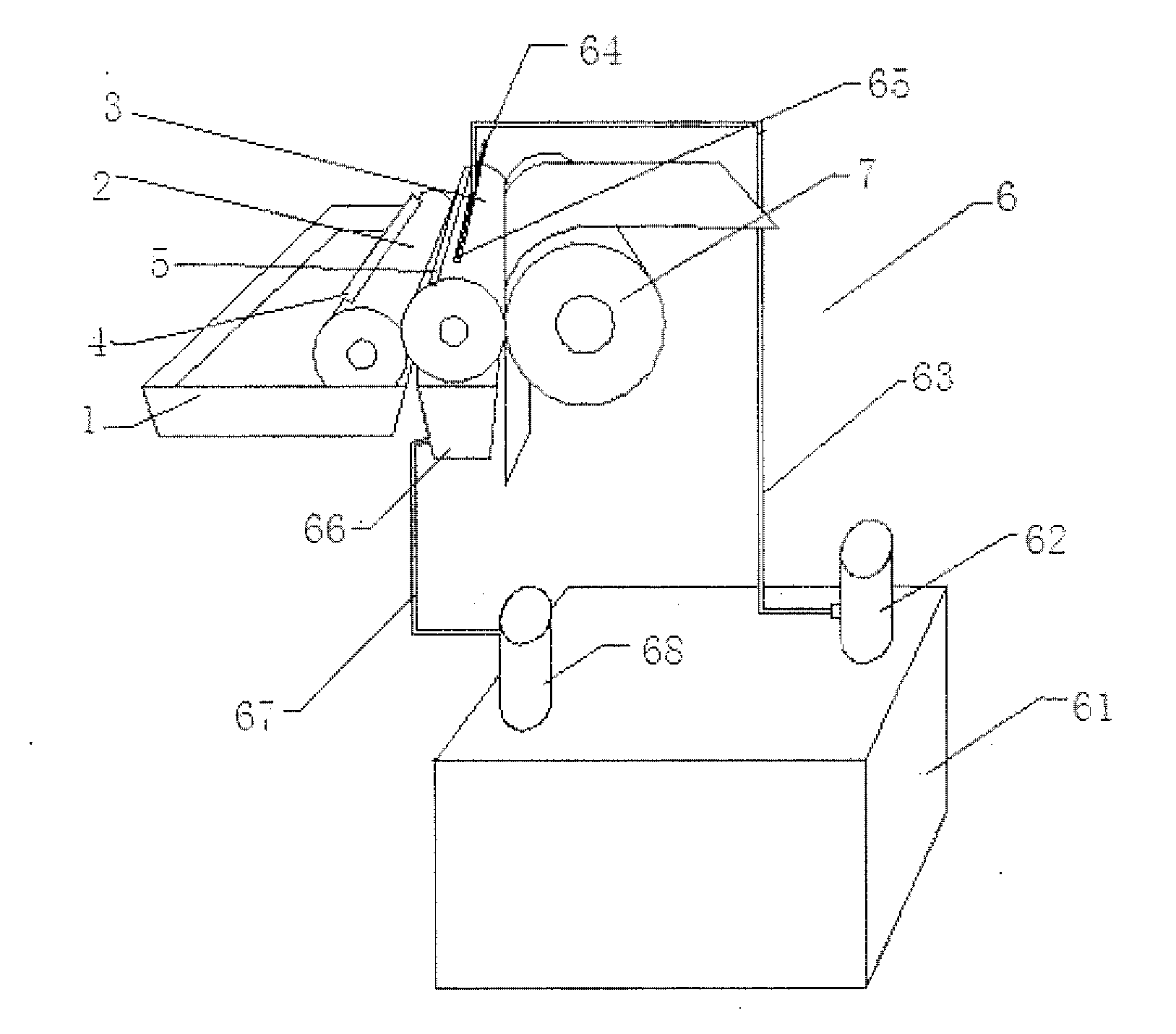

Preparation method of zinc oxide-based transparent conducting film glass

The invention provides a preparation method of zinc oxide-based transparent conducting film glass. The preparation method of the zinc oxide-based transparent conducting film glass comprises the following steps: (a) preparing a zinc oxide liquid precursor; (b) doping a doping precursor in the zinc oxide liquid precursor to form a doped zinc oxide liquid precursor; (c) coating the doped zinc oxide liquid precursor on a glass substrate by utilizing a liquid phase roller coating method; and (d) carrying out heat treatment on the glass substrate coated with an oxide film, so as to form the zinc oxide-based transparent conducting film glass. By changing a formula of a precursor mixed liquor, quality of a film layer can be controlled, and functions of the film layer can be improved. The preparation method of the zinc oxide-based transparent conducting film glass has the advantages that a technology is simple, equipment cost and raw material cost are low, operation is easy, and industrial mass production can be facilitated; a zinc oxide-based doped transparent conducting oxide film is plated on a moving glass surface by adopting the appropriate liquid precursor, and the obtained transparent conducting film has the characteristics of high transmittance and high conductivity and can be widely applied to thin-film solar cells.

Owner:CHINA TRIUMPH INT ENG +2

Roller coating method for production of patterned insulation board used for building exterior wall

InactiveUS20150174606A1Increase productivityRotary intaglio printing pressDecorative surface effectsProduction lineInsulation layer

The present invention provides a roller coating method for production of patterned insulation board used for building exterior wall. In this method, a metal veneer and a substrate are produced firstly, and a pattern is printed on the metal veneer, and then an insulation layer is added between the metal veneer and the substrate to produce the patterned insulation board which is finally arranged onto the wall body. In this way, the defect that an decorative layer has to be arranged after installation of an insulation board is avoided (it is inconvenient to directly print a pattern on the insulation board arranged on the wall body by making use of the roller coating production line, so the existing insulation board is generally less decorative and unaesthetic), and the integration of decoration and insulation is realized.

Owner:LIAONING CHAOSHUO TOMA TECH STEEL PLATE PRINTING

Preparation method of large-area transparent conducting film glass

The invention provides a preparation method of large-area transparent conducting film glass. The preparation method of the large-area transparent conducting film glass comprises the following steps: (a) coating a coating liquid precursor on a glass substrate, so as to form a tin oxide doped transparent conducting oxide film on the glass substrate; and (b) carrying out heat treatment on the glass substrate coated with the oxide film so as to form transparent conducting film glass; and coating the liquid precursor on the glass substrate by utilizing a liquid phase roller coating method. By changing a formula of precursor mixed liquor, quality of a film layer can be controlled, and functions of the film layer can be improved. The preparation method of the large-area transparent conducting film glass has the advantages that a technology is simple, equipment cost and raw material costs are low, operation is easy, and industrial mass production can be facilitated; a tin oxide doped transparent conducting oxide film is plated on a moving glass surface by adopting an appropriate liquid precursor, and the obtained transparent conducting film has the characteristics of high transmittance, high conductivity and a suede structure and can be widely applied to thin-film solar cells and low-radiation energy-saving glass.

Owner:CHINA TRIUMPH INT ENG +2

A kind of polishing film and preparation method thereof

ActiveCN101225281BUniform performanceReduce manufacturing costOther chemical processesPolishing compositionsOrganic solventAbrasive agent

The invention discloses a polishing film and a preparation method thereof. The ultrafine powder is used as an abrasive material and prepared by a casting coating method, that is, powdery or granular resin is dissolved in an organic solvent and functional additives are added. Then add the surface-modified ultrafine powder abrasive into the resin glue, mix thoroughly to make a coating solution, and then apply the coating evenly on the surface of the flexible substrate material by casting coating method, Drying, solidification, that is. The equipment of the present invention has the advantages of small investment, simple operation, high production efficiency and automation level, stable process, uniform film performance, low manufacturing cost, and can conveniently adjust the casting process according to the different quality requirements and standards of each user for the product. The parameters are adjusted to achieve multi-specification and small-batch production, which overcomes the difficulty of rapid change of product specifications caused by the limitation of equipment structure in the roller coating method.

Owner:HENAN UNION ABRASIVES

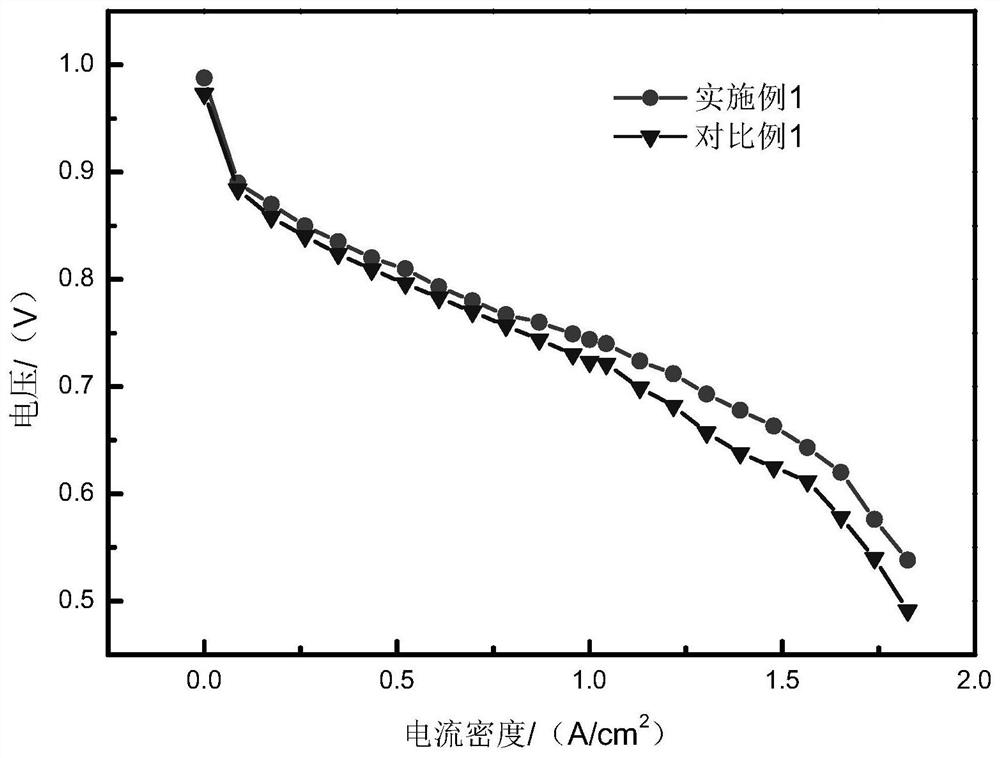

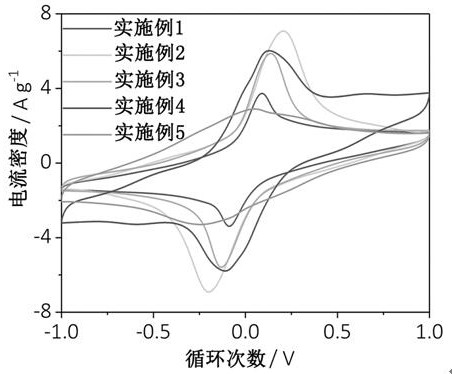

Proton exchange membrane fuel cell gas diffusion layer microporous layer and preparation method thereof

PendingCN113991129AUniform structureImprove conductivityCell electrodesSolid electrolyte fuel cellsActive agentRoller Coating Method

The invention belongs to the technical field of fuel cells, and particularly relates to a gas diffusion layer microporous layer of a proton exchange membrane fuel cell and a preparation method thereof. The preparation method comprises the following steps: dipping a base material in a water repellent for 0.5-5 minutes, then putting the base material in a drying oven at 50-120 DEG C, carrying out drying for 5-30 minutes, then carrying out weighing, repeating the operation for multiple times until the content of the water repellent in the base material is 5-10%, then carrying out roasting in a muffle furnace at 200-300 DEG C for 10-120 minutes, taking a conductive agent, a water repellent, a surfactant and a solvent as raw materials, and performing mechanical stirring and ultrasonic dispersion until uniform microporous layer slurry is formed; coating a substrate subjected to hydrophobic treatment with the microporous layer slurry by adopting a roller coating method, and then carrying out drying and roasting to form the gas diffusion layer. The roller type coating method is adopted, so the problems that microporous layer slurry permeates into the base material, large holes of the base material are blocked, and a transmission channel and a drainage channel of reaction gas are blocked are solved, the gas transmission capacity and the drainage capacity are enhanced, and the battery performance is improved.

Owner:WUXI WEIFU HIGH TECH CO LTD

Roller coating method for production of patterned insulation board used for building exterior wall

InactiveUS9364851B2Increase productivityLiquid surface applicatorsRotary intaglio printing pressProduction lineInsulation layer

The present invention provides a roller coating method for production of patterned insulation board used for building exterior wall. In this method, a metal veneer and a substrate are produced firstly, and a pattern is printed on the metal veneer, and then an insulation layer is added between the metal veneer and the substrate to produce the patterned insulation board which is finally arranged onto the wall body. In this way, the defect that an decorative layer has to be arranged after installation of an insulation board is avoided (it is inconvenient to directly print a pattern on the insulation board arranged on the wall body by making use of the roller coating production line, so the existing insulation board is generally less decorative and unaesthetic), and the integration of decoration and insulation is realized.

Owner:LIAONING CHAOSHUO TOMA TECH STEEL PLATE PRINTING

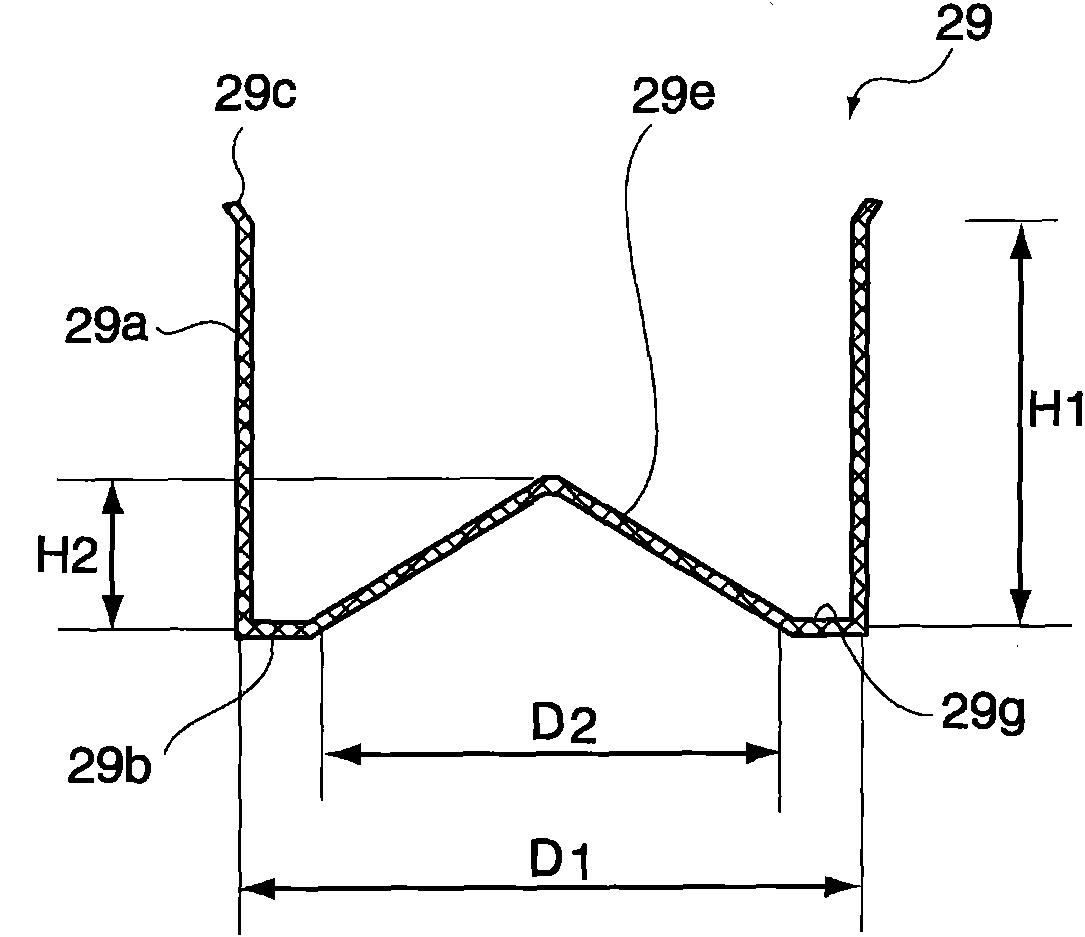

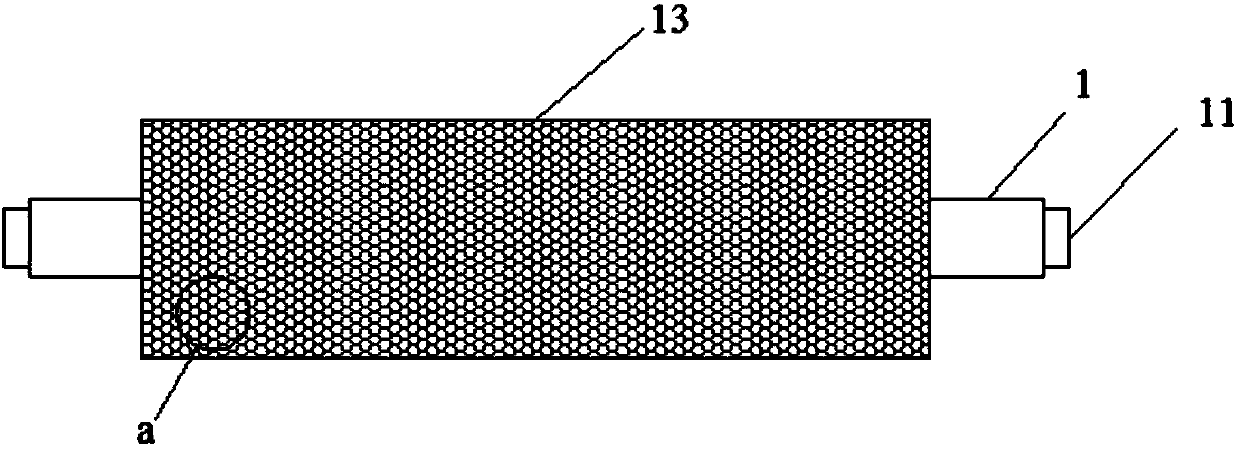

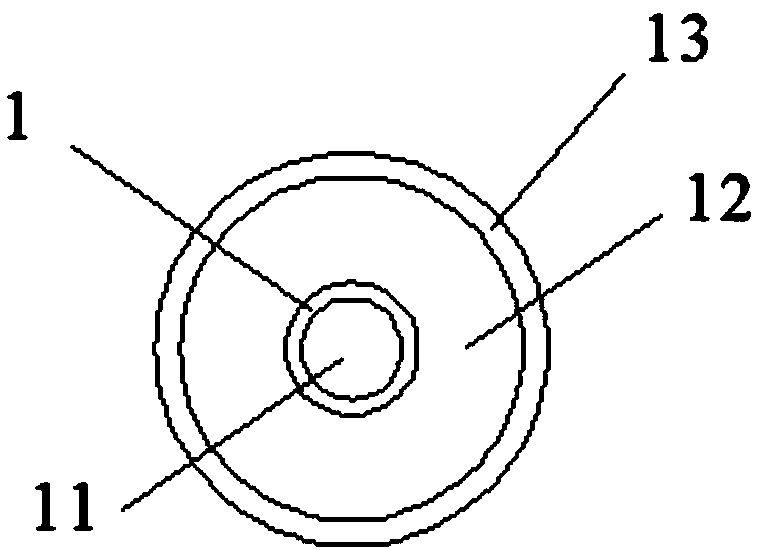

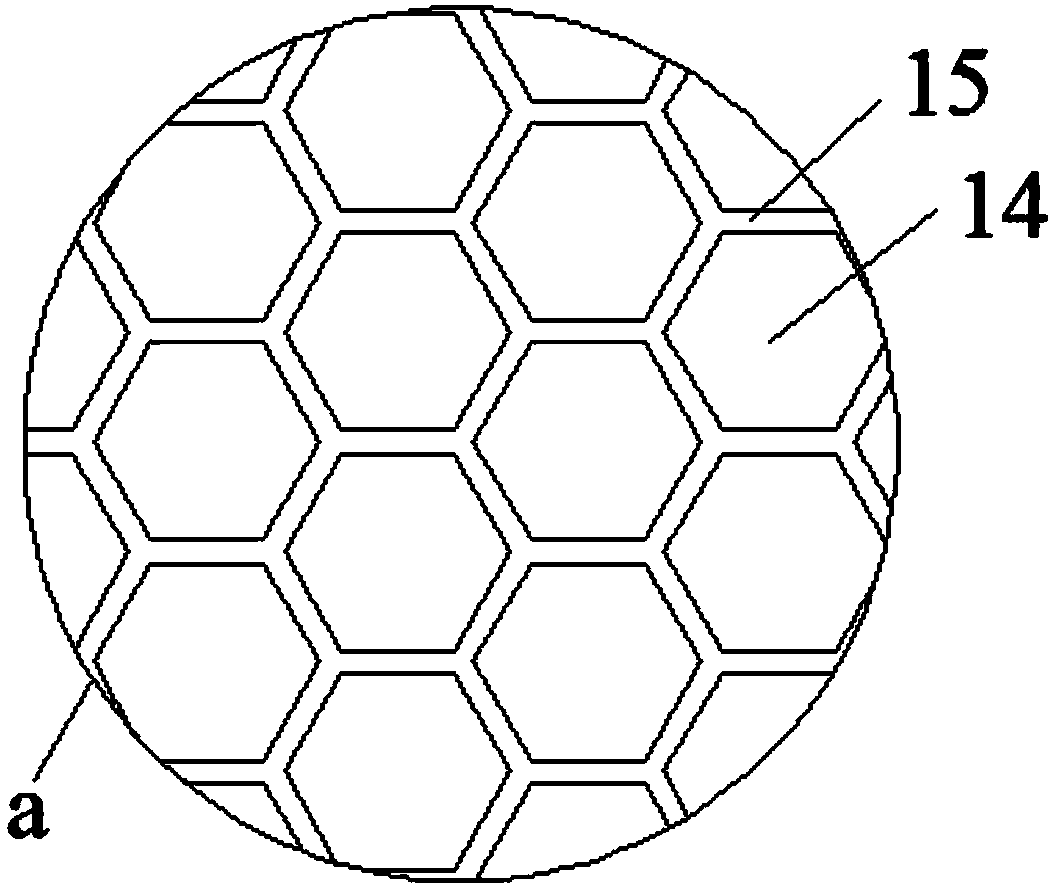

Micro concave roller and micro concave roller coating method

InactiveCN108043653AShorten the lengthSmall diameterLiquid surface applicatorsPaper/cardboardRoller Coating MethodOperating speed

The invention discloses a micro concave roller and a micro concave roller coating method. the micro concave roller comprises a spindle, wherein bearing shafts are arranged at two ends of the spindle;a steel sleeve is arranged on the spindle in a sleeving manner; a hard ceramic tube is arranged on the outer surface of the steel sleeve in the axial direction in a sleeving manner; a plurality of hexagonal net holes are formed in the surface of the hard ceramic tube; the opening angle of each of the net holes is 60 degrees; the opening length is 133 microns; the depth of each of the net holes is33 microns; the net wall width of the micro concave roller is 8 microns; the line number of the micro concave roller is 180; and the diameter of the micro concave roller is 200-250 mm. The coating method comprises the following steps: adjusting the operating direction of paper and the micro concave roller, wherein the operating direction of the paper is opposite to that of the micro concave roller; and adjusting the operating speed of the paper and the micro concave roller, wherein the operating speed of the paper is less than that of the micro concave roller. According to the invention, the operating direction of the roller is changed; and the diameter of the microstructure of the micro concave roller are improved to enable the diameter of the micro concave roller is small and the material taking quantity of the micro concave roller to be large; and the moving direction of the micro concave roller is opposite to that of the paper, so that the relative speed of the paper and the microconcave roller is increased and the coating effect is improved.

Owner:CHANGDE JINDE NEW MATERIAL TECH CO LTD

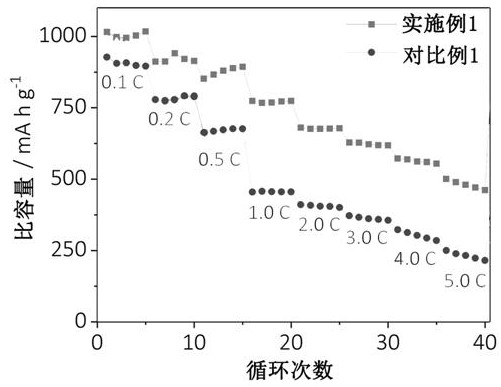

Preparation method of tungsten oxide/clay mineral nanomaterial modified diaphragm for lithium-sulfur battery

ActiveCN113381121AImprove adsorption capacityAccelerate catalytic conversion reactionLi-accumulatorsCell component detailsElectrical batteryLithium sulfur

The invention discloses a preparation method of a tungsten oxide / clay mineral nanomaterial modified diaphragm for a lithium-sulfur battery. The preparation method comprises the following steps of: mixing a tungsten oxide / clay mineral nanomaterial, a conductive agent and a binder, performing ball-milling the mixture, adding a solvent to adjust the viscosity of slurry to 700-1300 mPas, and performing uniform stirring to obtain slurry; applying the slurry on one side of a commercial diaphragm by adopting a roller coating method, and carrying out thermocuring to obtain the modified diaphragm. The tungsten oxide / clay mineral nano material has strong electrocatalytic activity and high adsorption performance, and can effectively accelerate the catalytic conversion reaction of polysulfide; the carbon material with high electron conductivity is beneficial to rapid transmission of electrons in the catalytic conversion process; the prepared modified diaphragm can effectively restrain the problems of low battery capacity, low active substance utilization, slow dynamics, relatively poor rate capability and cycle stability caused by shuttling of polysulfide in a lithium-sulfur battery, so that the electrochemical performance of the battery is remarkably improved.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com