Color passivated galvanized steel plate and manufacturing method thereof

A technology of galvanized steel sheet and production method, which is applied in the coating process of metal materials, etc., can solve the problems of carcinogenicity, hexavalent chromium is highly toxic, and teratogenicity-induced genes, etc., and achieves improved corrosion resistance, environmentally friendly technology, and good decoration sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

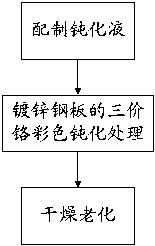

Image

Examples

Embodiment approach 1

[0037] The oxidizing agent, Cr 3+ Add salt, complexing agent, film-forming accelerator, and salt-spray resistant additives into pure water in sequence according to the formula ratio, and dissolve them completely under stirring. The specific content is: Cr 3+ Salt: 15-30g / L, complexing agent: 15-25 g / L, oxidizing agent: 20-30 g / L, salt spray resistance additive: 5-15 g / L, film-forming accelerator: 3-10 g / L L. Then adjust the pH to 2.0-3.5 with acid. The prepared trivalent chromium passivation solution is plated on the surface of galvanized steel sheet at room temperature by roller coating method, and the speed ratio of the coating roller of the roller coater and the steel strip is adjusted to 0.6-0.9, and the obtained passivation film is light blue With rainbow colors. The galvanized steel sheet after passivation cleaning enters the drying tunnel at 65-70°C for drying and aging.

Embodiment approach 2

[0039] The oxidizing agent, Cr 3+ Add salt, complexing agent, film-forming accelerator, and salt-spray resistant additives into pure water in sequence according to the formula ratio, and dissolve them completely under stirring. The specific content is: Cr 3+ Salt: 15-30g / L, complexing agent: 15-25 g / L, oxidizing agent: 20-30 g / L, salt spray resistance additive: 5-15 g / L, film-forming accelerator: 3-10 g / L L. Then adjust the pH to 2.0-3.5 with acid. The prepared trivalent chromium passivation solution is plated on the surface of galvanized steel sheet at room temperature by roller coating method, and the speed ratio of the coating roller of the roller coater and the steel strip is adjusted to 1.0-1.2, and the obtained passivation film is light green With rainbow colors. The galvanized steel sheet after passivation cleaning enters the drying tunnel at 70-75°C for drying and aging.

Embodiment approach 3

[0041] The oxidizing agent, Cr 3+ Add salt, complexing agent, film-forming accelerator, and salt-spray resistant additives into pure water in sequence according to the formula ratio, and dissolve them completely under stirring. The specific content is: Cr 3+ Salt: 15-30g / L, complexing agent: 15-25 g / L, oxidizing agent: 20-30 g / L, salt spray resistance additive: 5-15 g / L, film-forming accelerator: 3-10 g / L L. Then adjust the pH to 2.0-3.5 with acid. The prepared trivalent chromium passivation solution is plated on the surface of galvanized steel sheet at room temperature by roller coating method, and the speed ratio of the coating roller of the roller coater and the steel strip is adjusted to 1.5, and the obtained passivation film is light yellow with iridescence . The galvanized steel sheet after passivation cleaning enters the drying tunnel at 70-75°C for drying and aging.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com