Patents

Literature

219results about How to "Guaranteed ratio" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

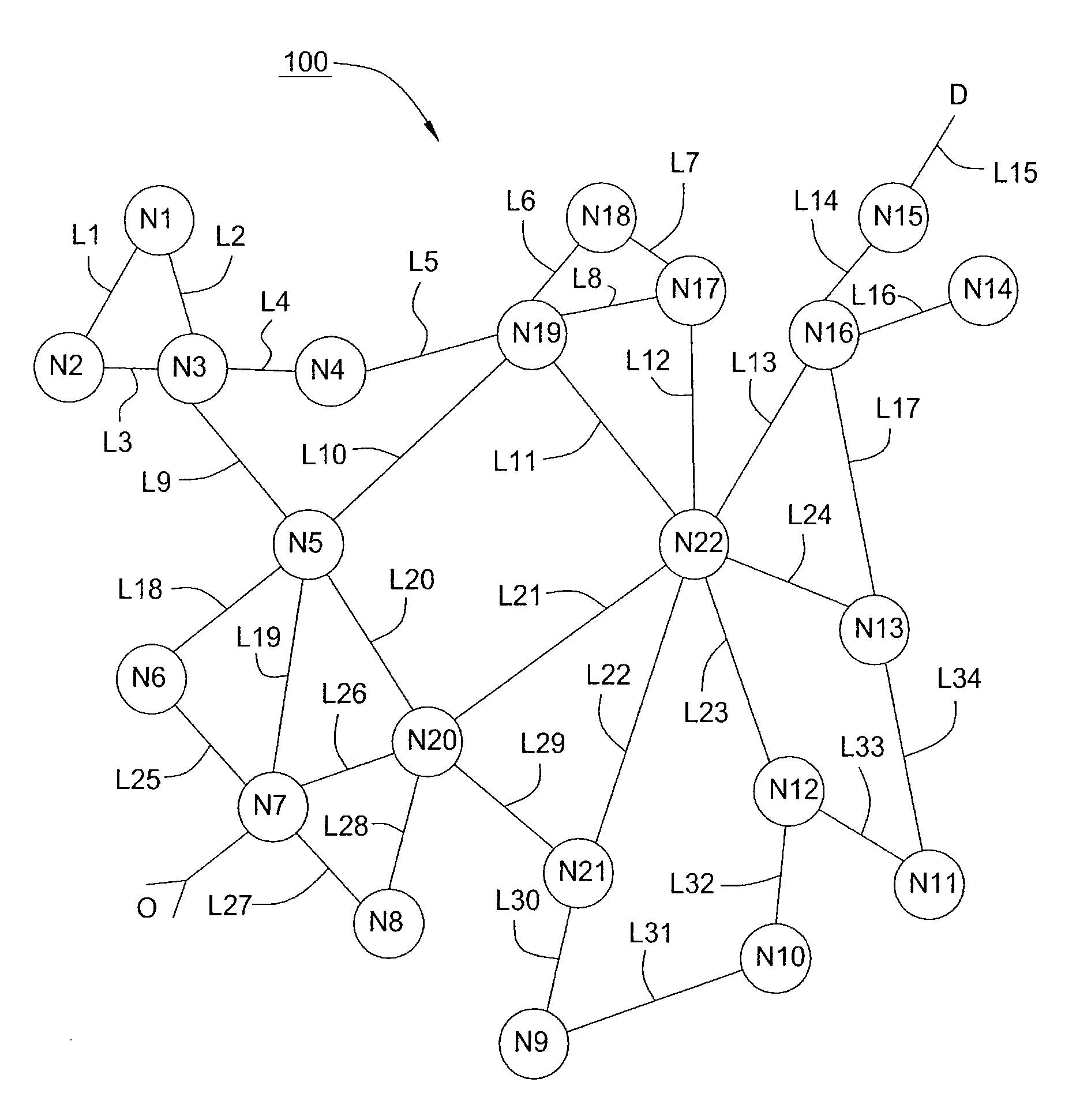

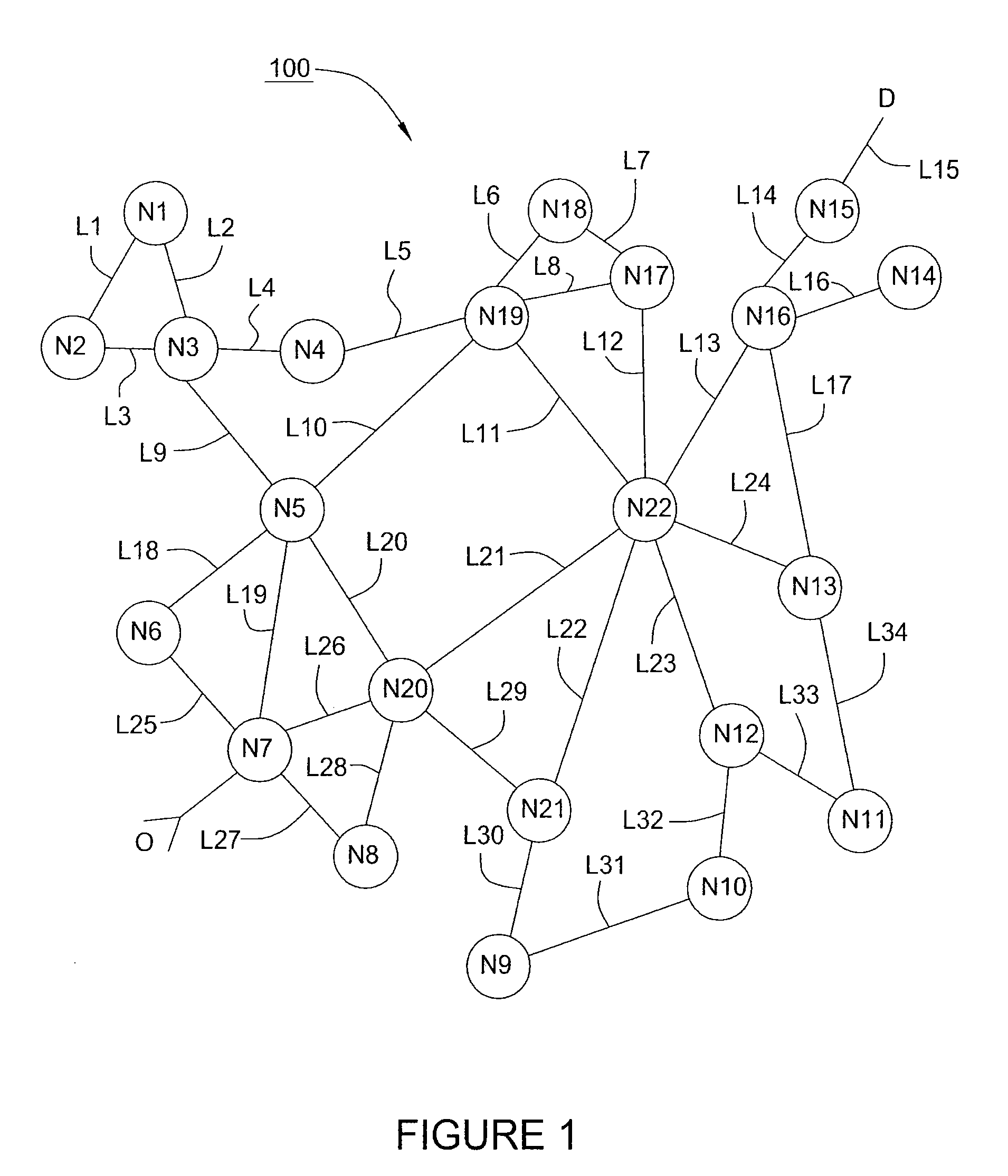

Method and apparatus for efficient routing of variable traffic

InactiveUS20080239991A1Effective trafficMinimize biasData switching by path configurationTraffic networkTraffic load

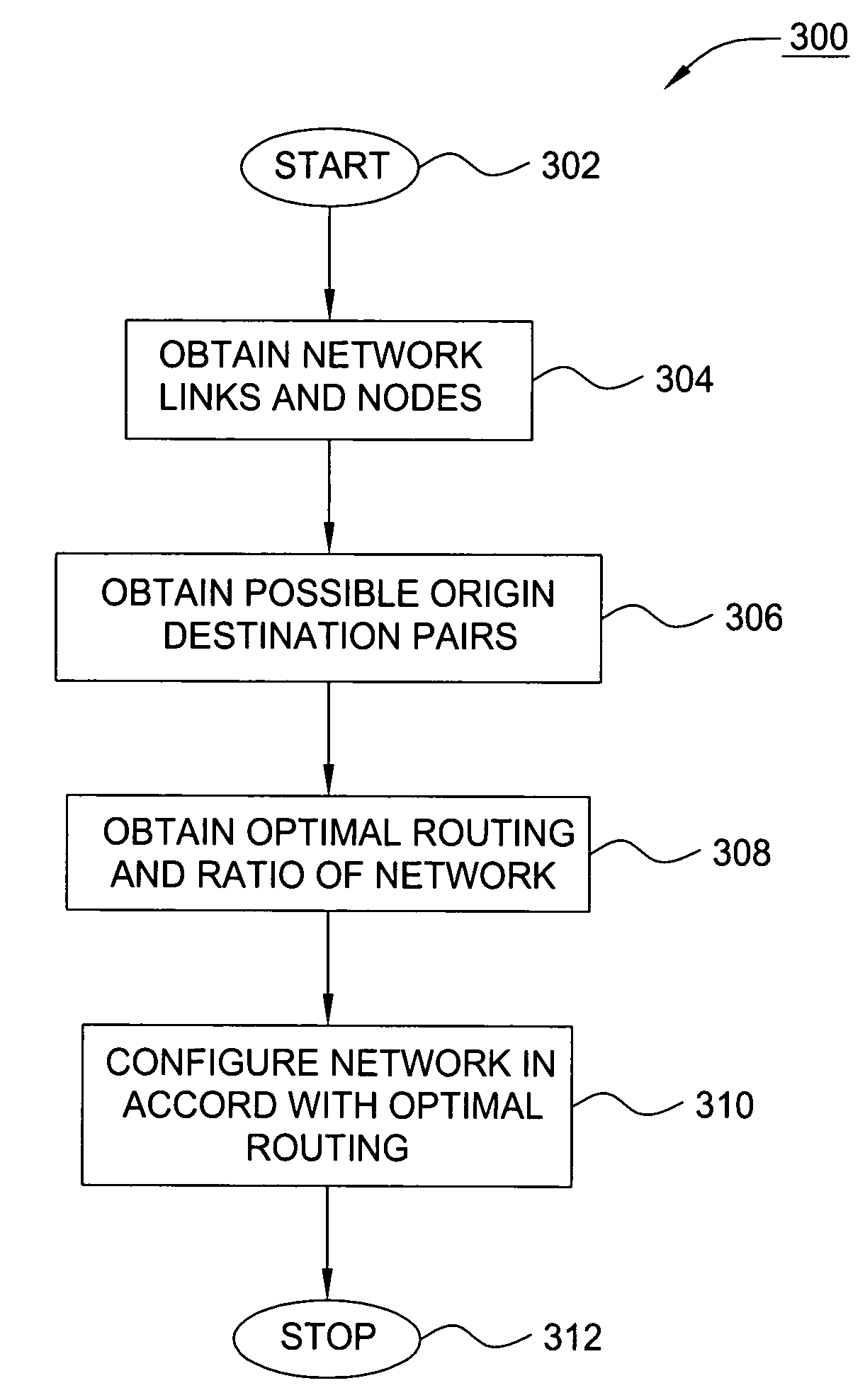

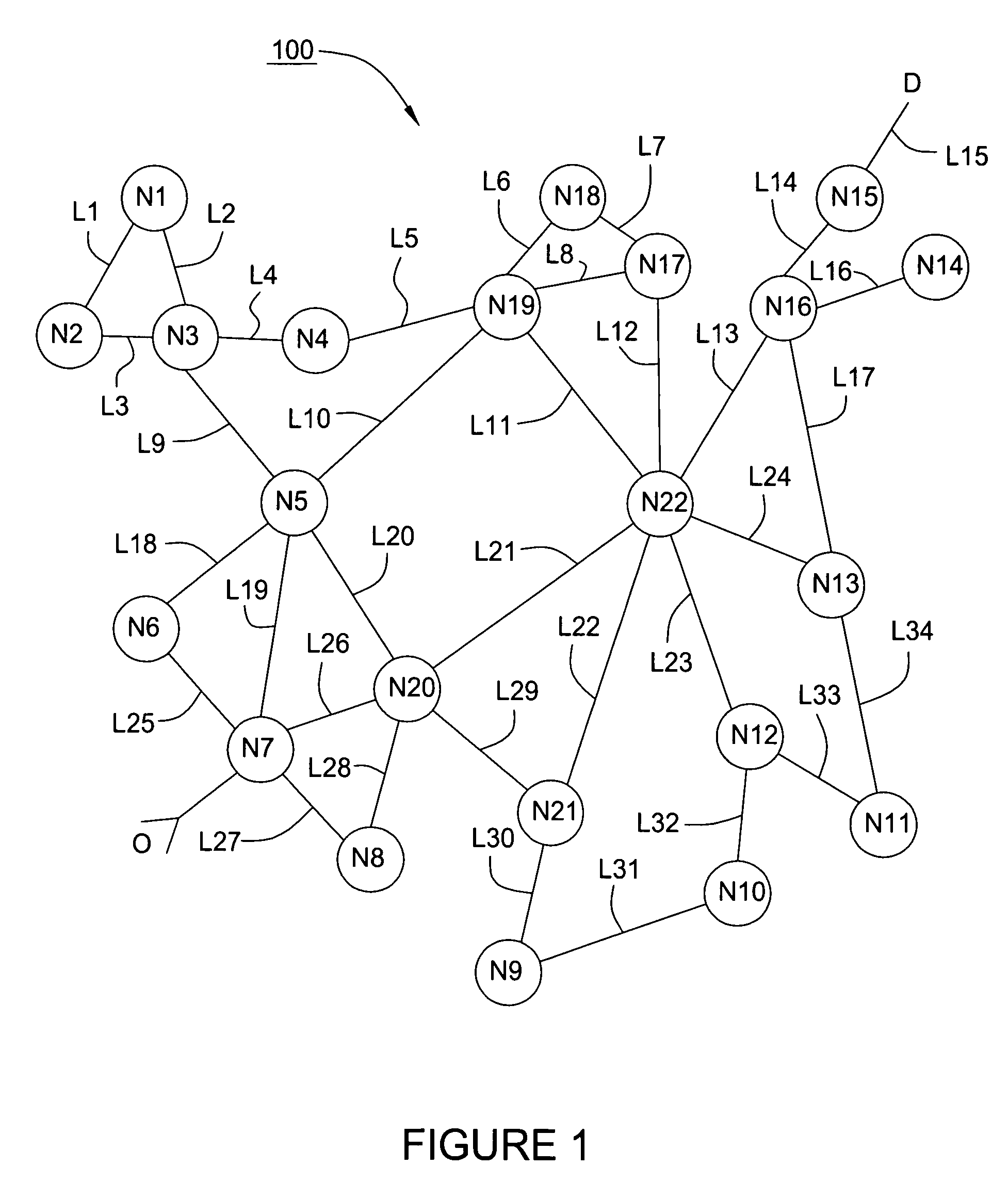

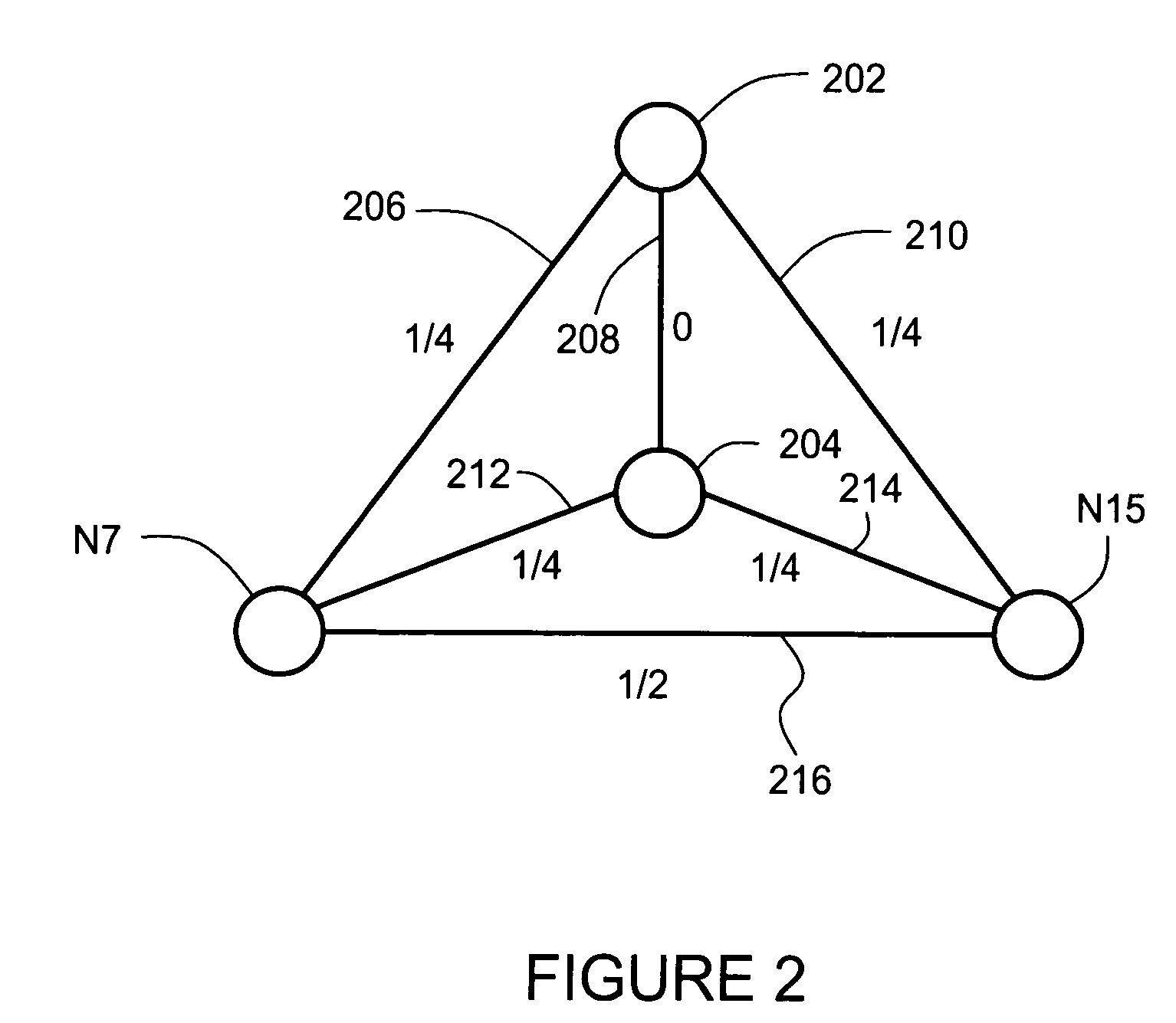

A method and apparatus for provide highly efficient traffic routing for a wide range of possible traffic matrices (TM) in an intra-domain network. That routing optimally balances the traffic loads over a range of traffic matrices so as to minimize the deviation for any particular traffic matrix from the optimal routing. Such a routing provides a guaranteed performance ratio against the best possible network routing. The invention utilizes a method of optimally configuring a traffic network based on solving a linear program to obtain the optimal routing, and then configuring the routing on the network accordingly.

Owner:AT & T INTPROP II LP

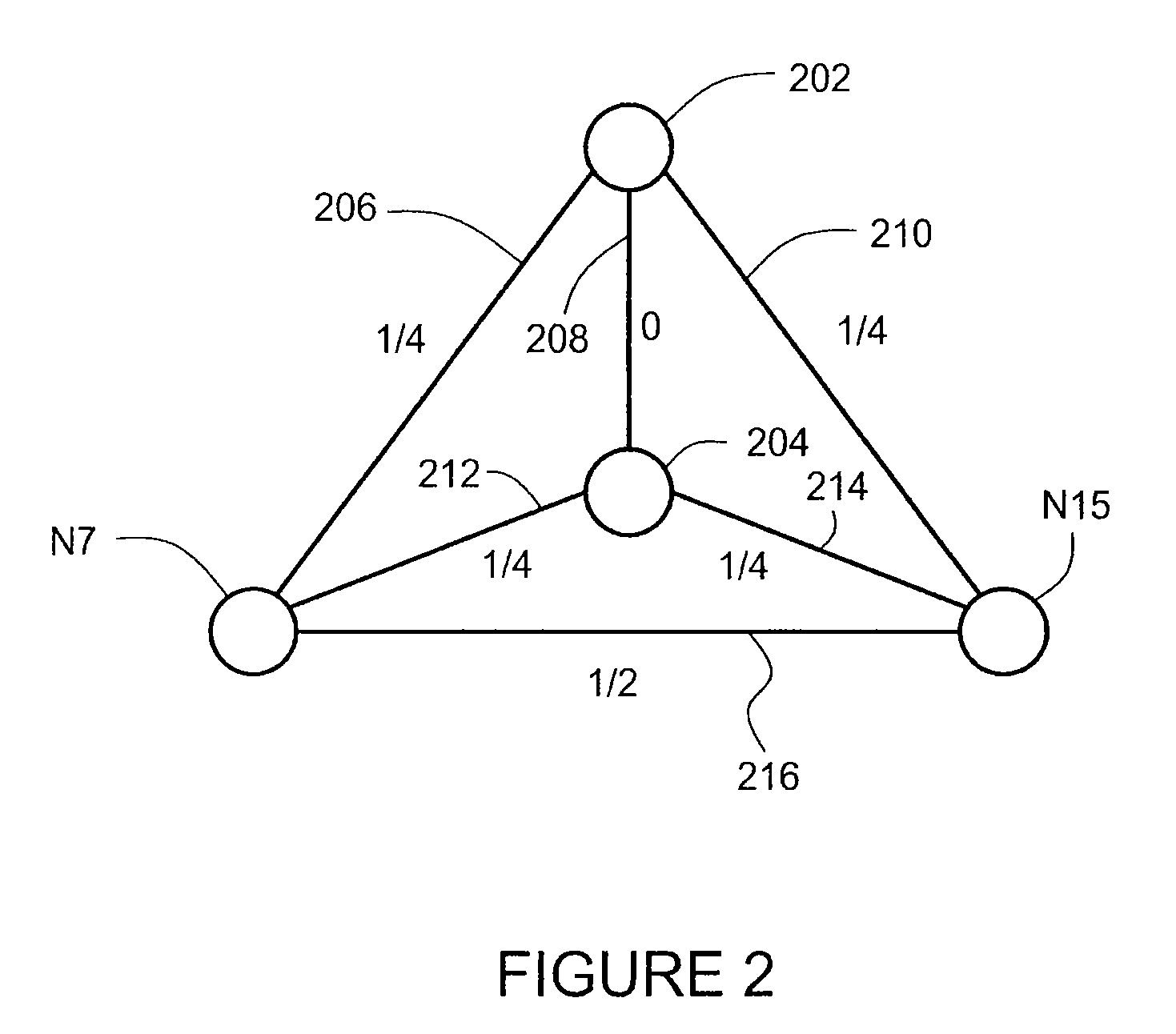

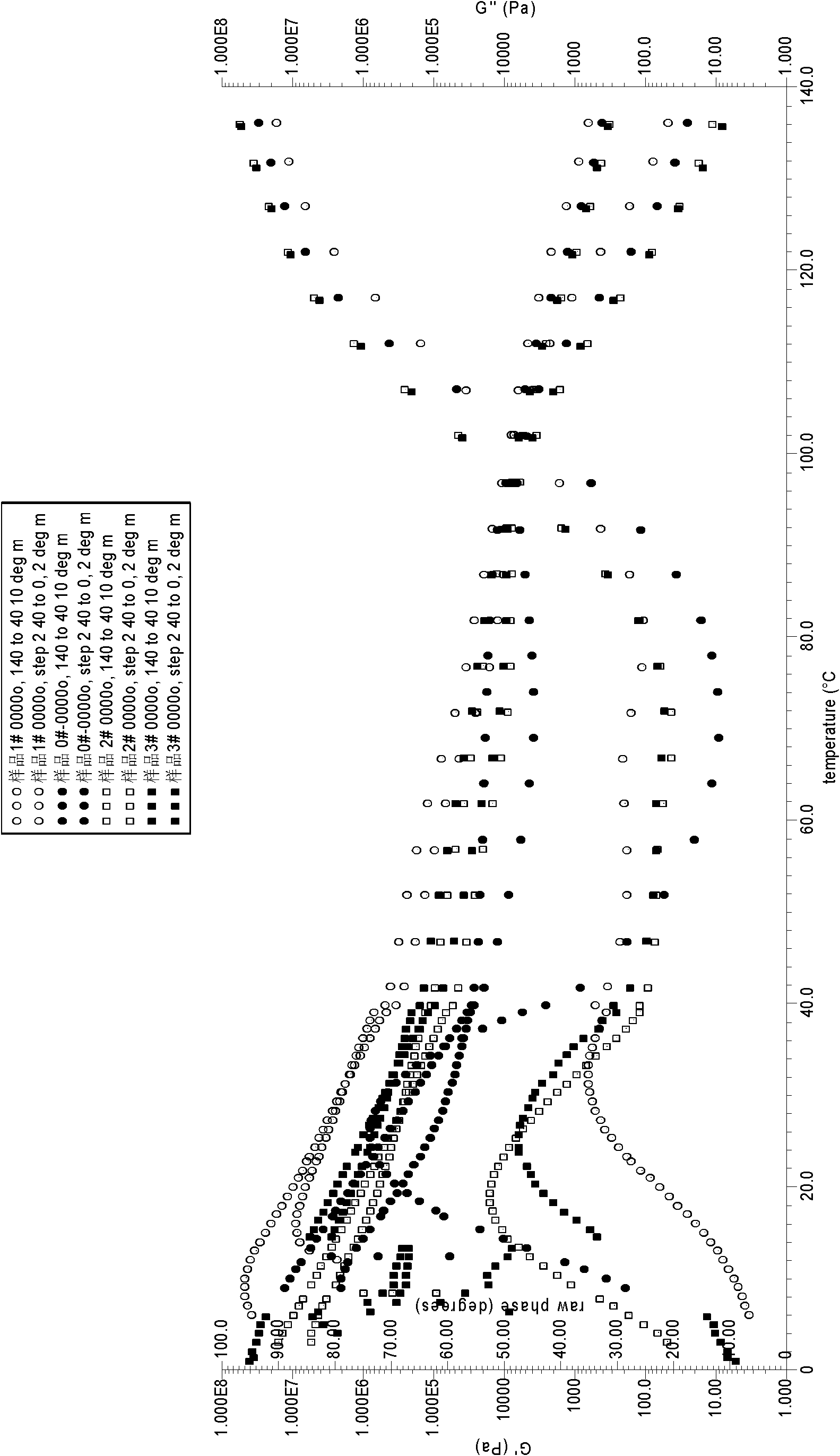

Waxy Hot Melt Adhesives and Disposable Absorbent Articles

ActiveCN102277112AGood adhesionPrevent over-migrationMineral oil hydrocarbon copolymer adhesivesSynthetic resin layered productsWaxHot-melt adhesive

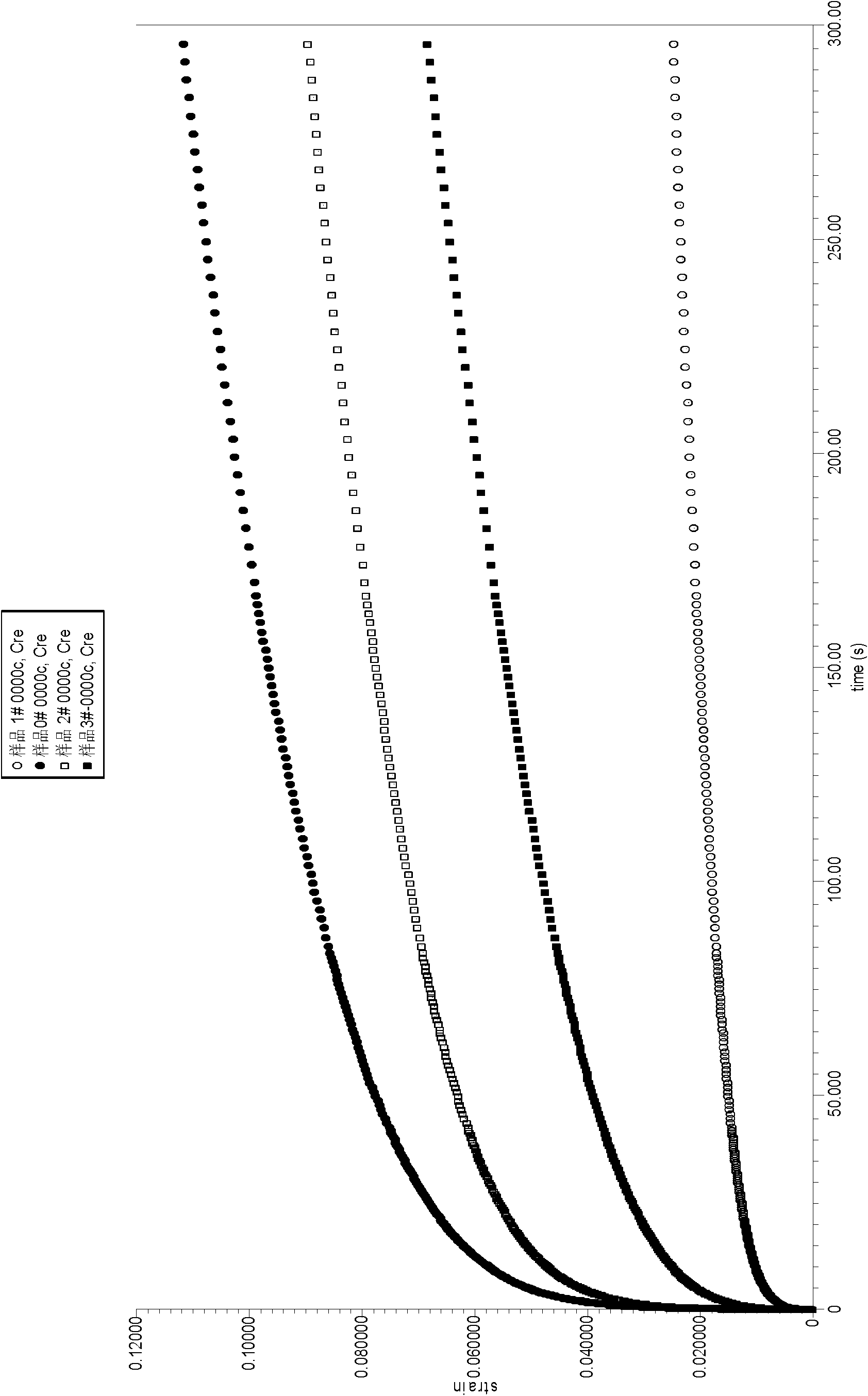

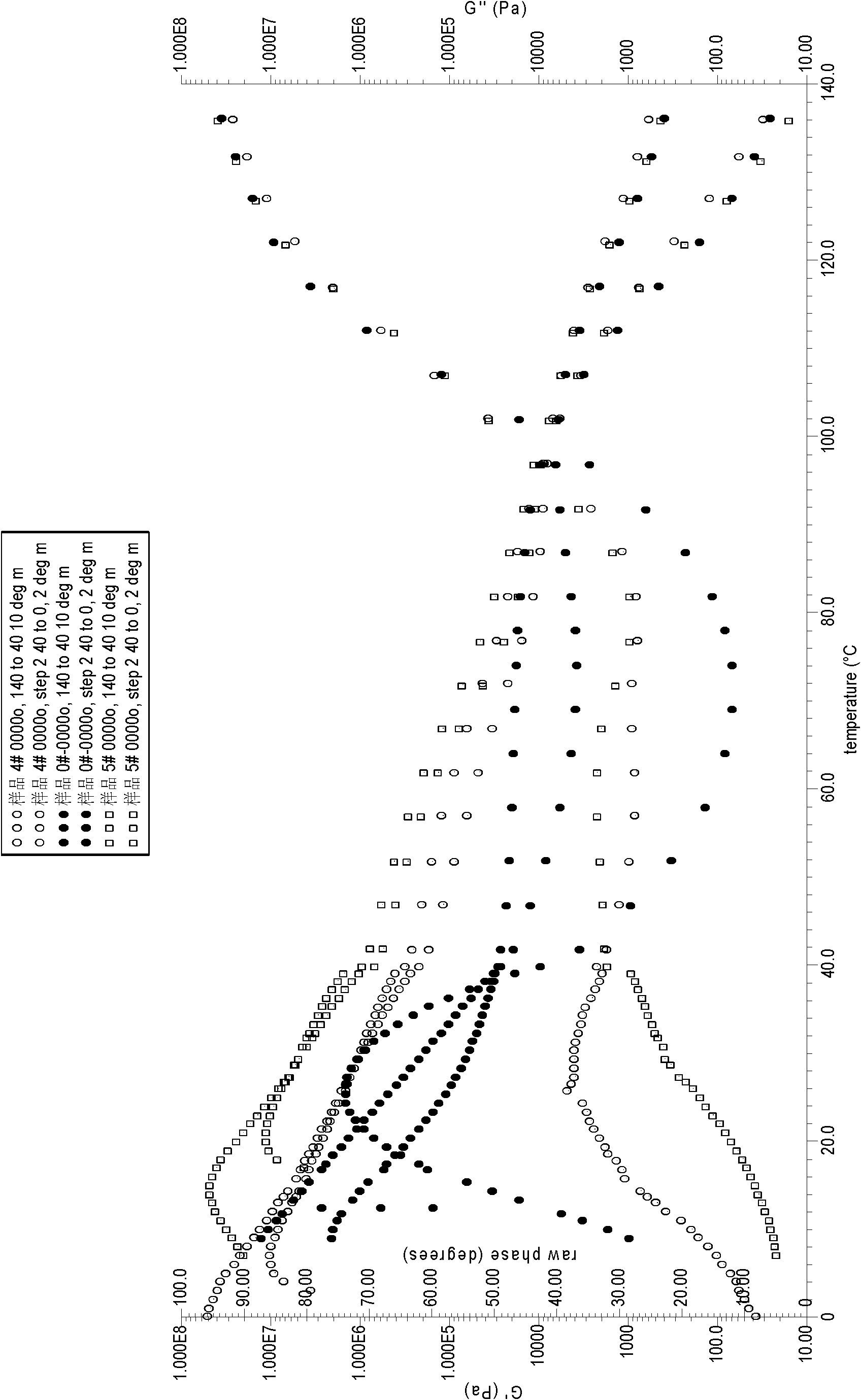

1) Wax-containing hot melt adhesive comprising 1 to 40 % of a styrenic block copolymer (a), 3 to 15 % of a modified thermoplastic elastomer (b) comprising -COO- groups, and 5 to 25 % of a wax (c). 2) Disposable absorbent article employing said hot melt adhesive. The article bonded by the hot melt adhesive of the present invention has excellent creep resistance and aging resistance.

Owner:BOSTIK FENDELI CHINA ADHESIVE CO LTD

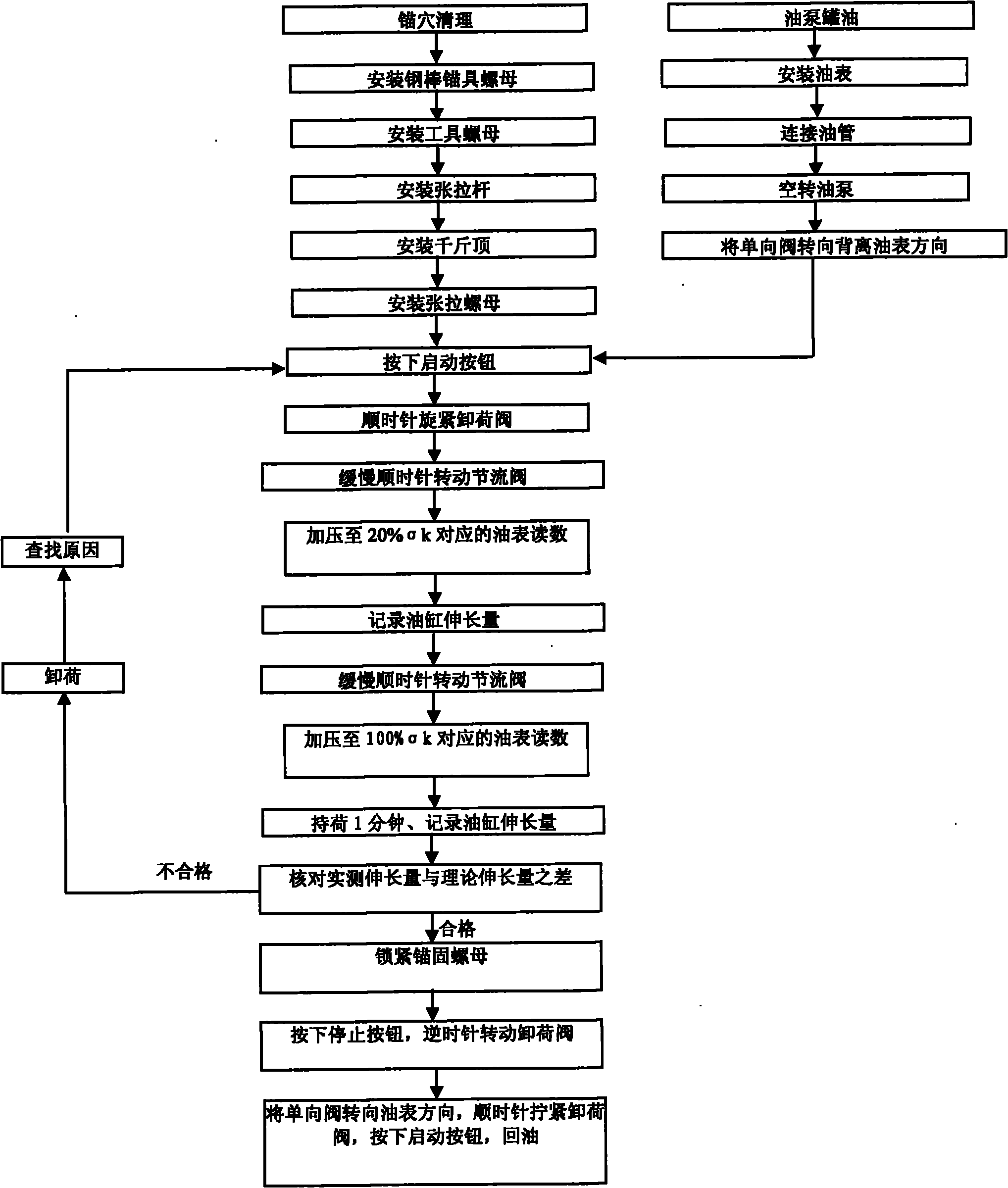

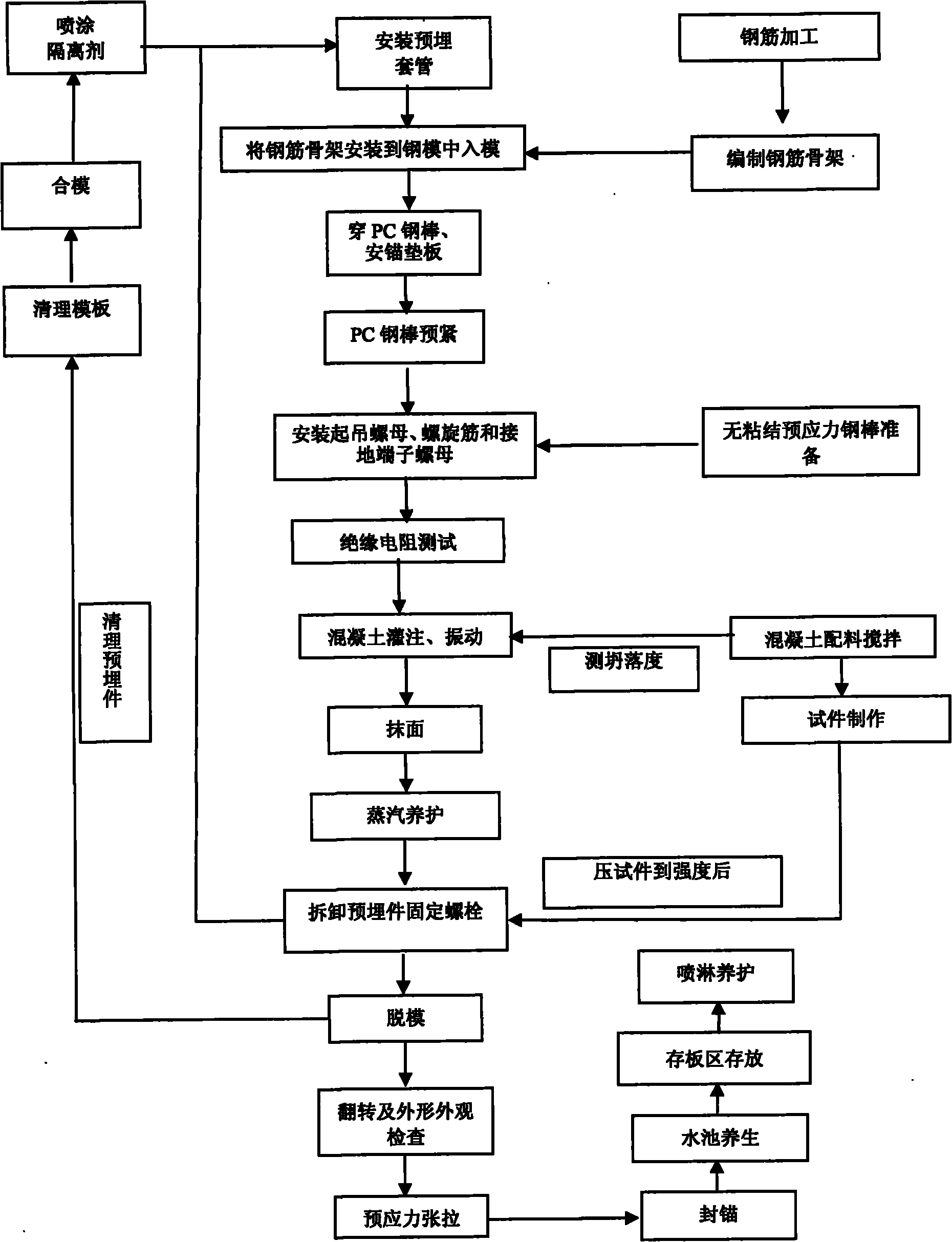

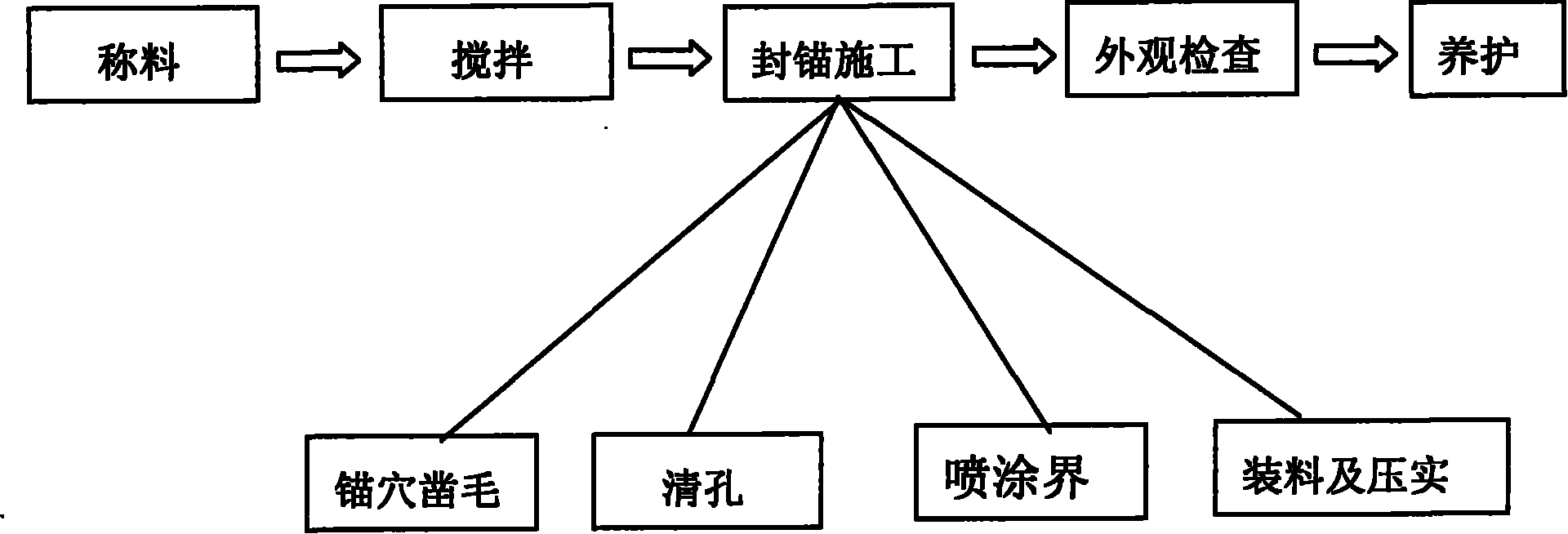

Concrete track slab prefabricating construction method of CRTS I type slab ballastless track

InactiveCN101830036AImprove cutting efficiencyUniform clothCeramic shaping apparatusRebarInsulation resistance

The invention relates to a concrete track slab prefabricating construction method of a CRTS I type slab ballastless track. The method comprises the following steps of: (1) weaving a steel reinforcement framework; (2) mounting the steel reinforcement framework in a steel mould, wherein the steel mould is internally sprayed with a separant and provided with a pre-embedded sleeve; (3) penetrating a PC (Prestressed Concrete) steel rod and mounting an anchor backing slab; (4) pre-tightening the PC steel rod; (5) mounting a hoisting nut, a spiral bar and a grounding terminal nut; (6) testing an insulation resistor; (7) pouring concrete and vibrating; (8) plastering the surface; (9) maintaining by using steam; (10) dismounting fixing bolts of a pre-embedded piece; (11) demoulding: cleaning the pre-embedded piece and a template, closing the mould, spraying the separant in the steel mould and mounting the pre-embedded sleeve for later use; (12) overturning and examining shape: turning over the CRTS I type slab ballastless track contrete track slab obtained in the step (11) and examining the shape and the appearance; (13) stretching by prestress; (14) sealing the anchor; (15) maintaining in a water pool; and (16) storing in a slab storage area.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION +1

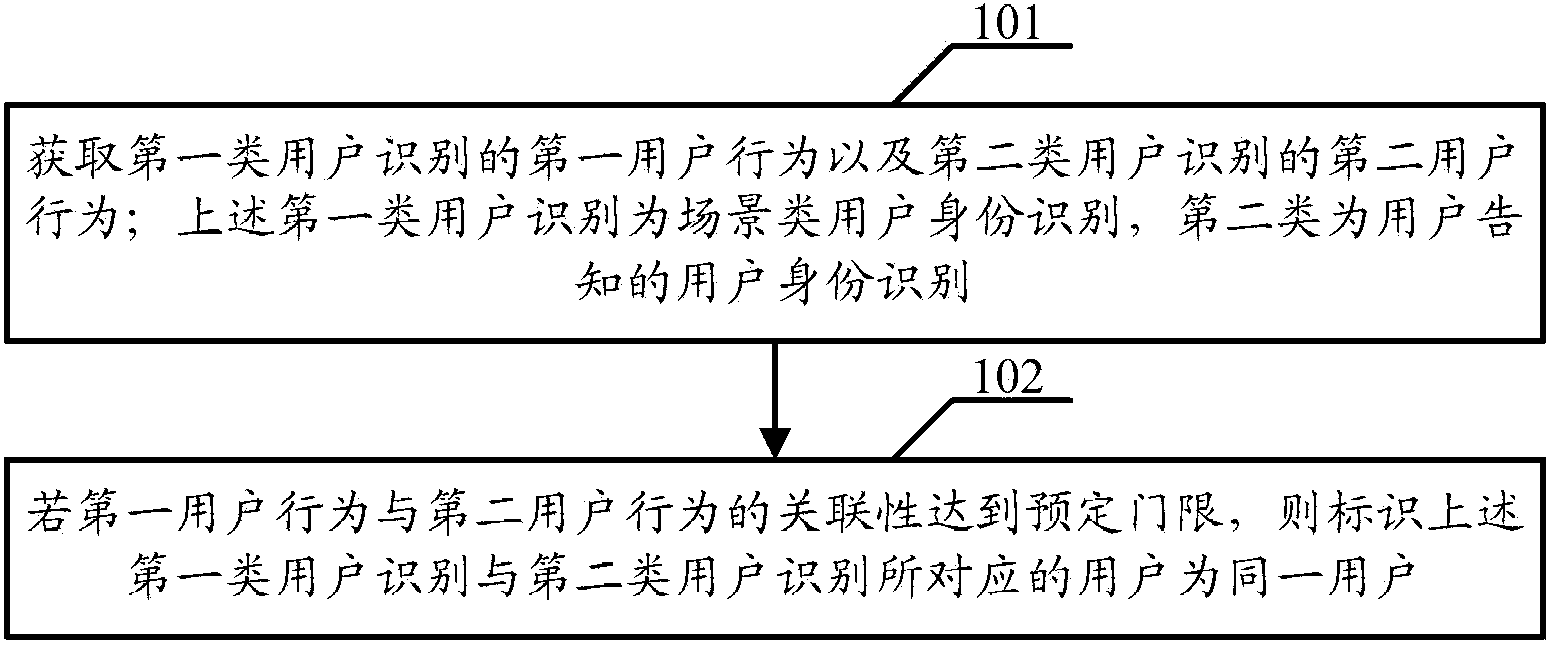

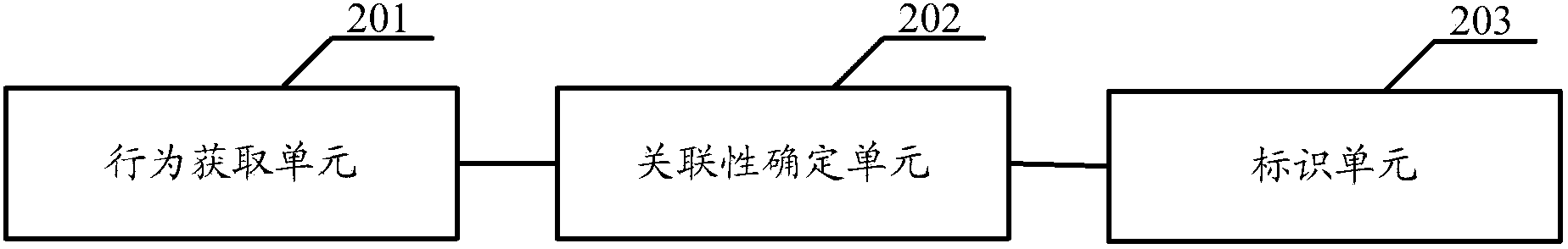

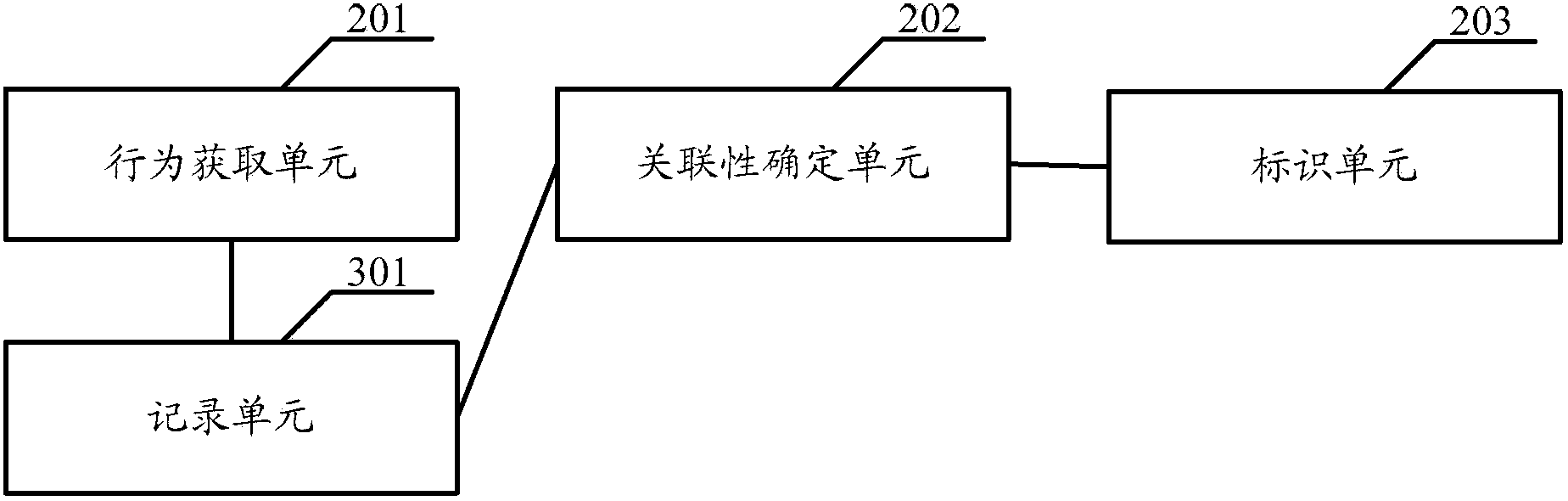

Method for identifying internet users and device thereof

The embodiment of the invention discloses a method for identifying Internet users and a device thereof. the method comprises the following steps: a first user behavior of a first-class user identification and a second user behavior of a second-class user identification are obtained; the above first-class user identification is a scene user identity identification, and the second-class user identification is a user identity identification notified by users; and if relevance between the first user behavior and the second user behavior reaches a predetermined threshold, users corresponding to the above first-class user identification and the second-class user identification are identified as the same user. Based on the above scheme, the above first-class user identification can guarantee the percentage of user identification, and the second-class user identification can guarantee validity and stability of user identification. Through relevance between the user behaviors, whether the users are the same user is determined. If the same user determined, identifications can be unified, and success rate and validity of user identity identification are prompted on the precondition of guaranteeing the coverage.

Owner:TENCENT TECH (SHENZHEN) CO LTD

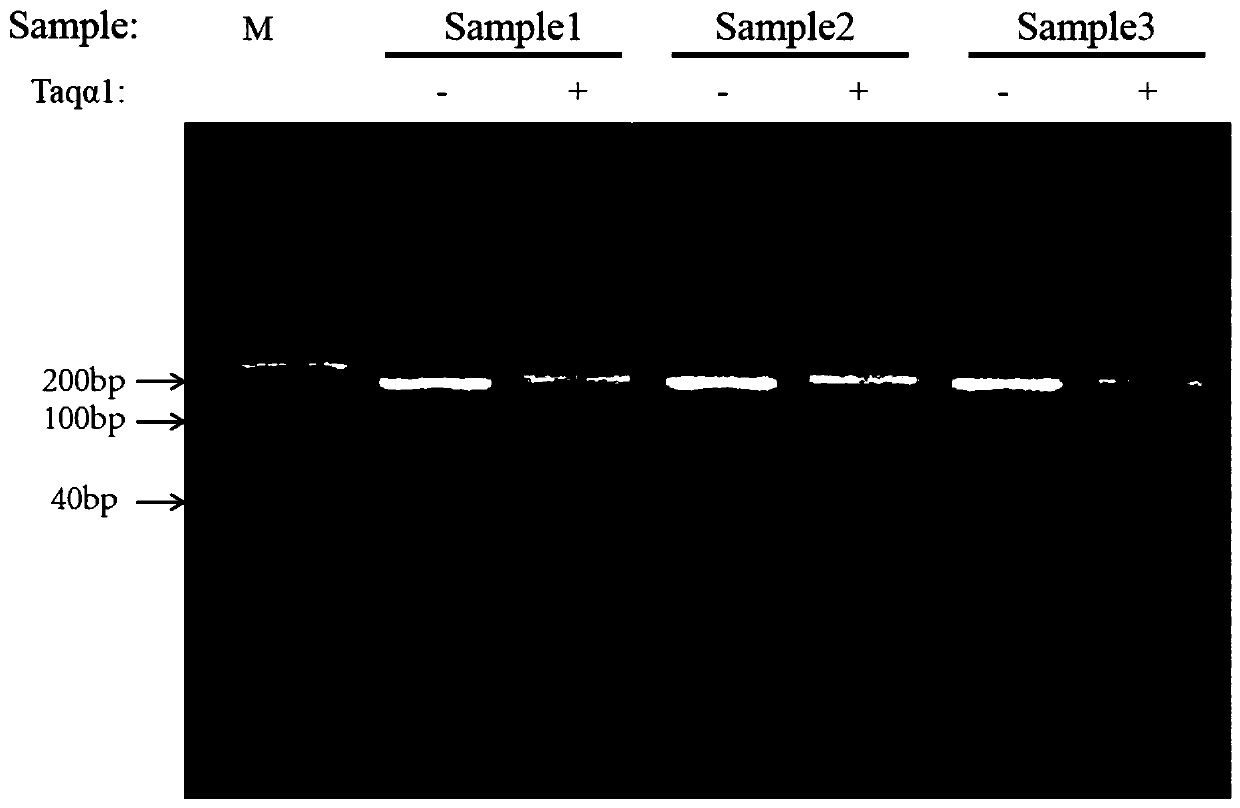

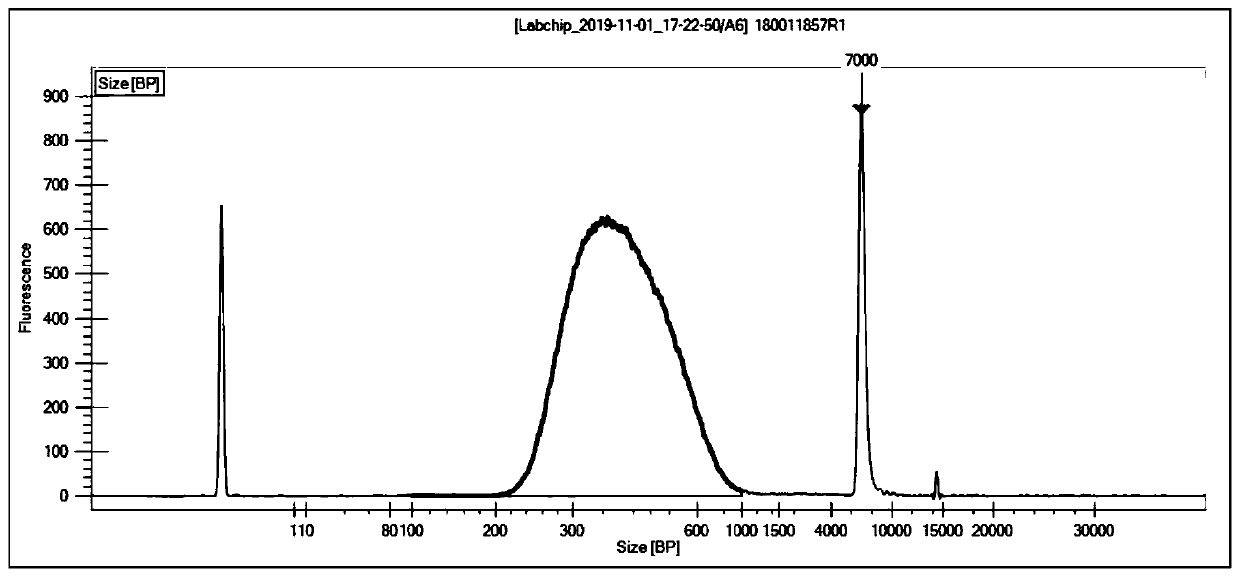

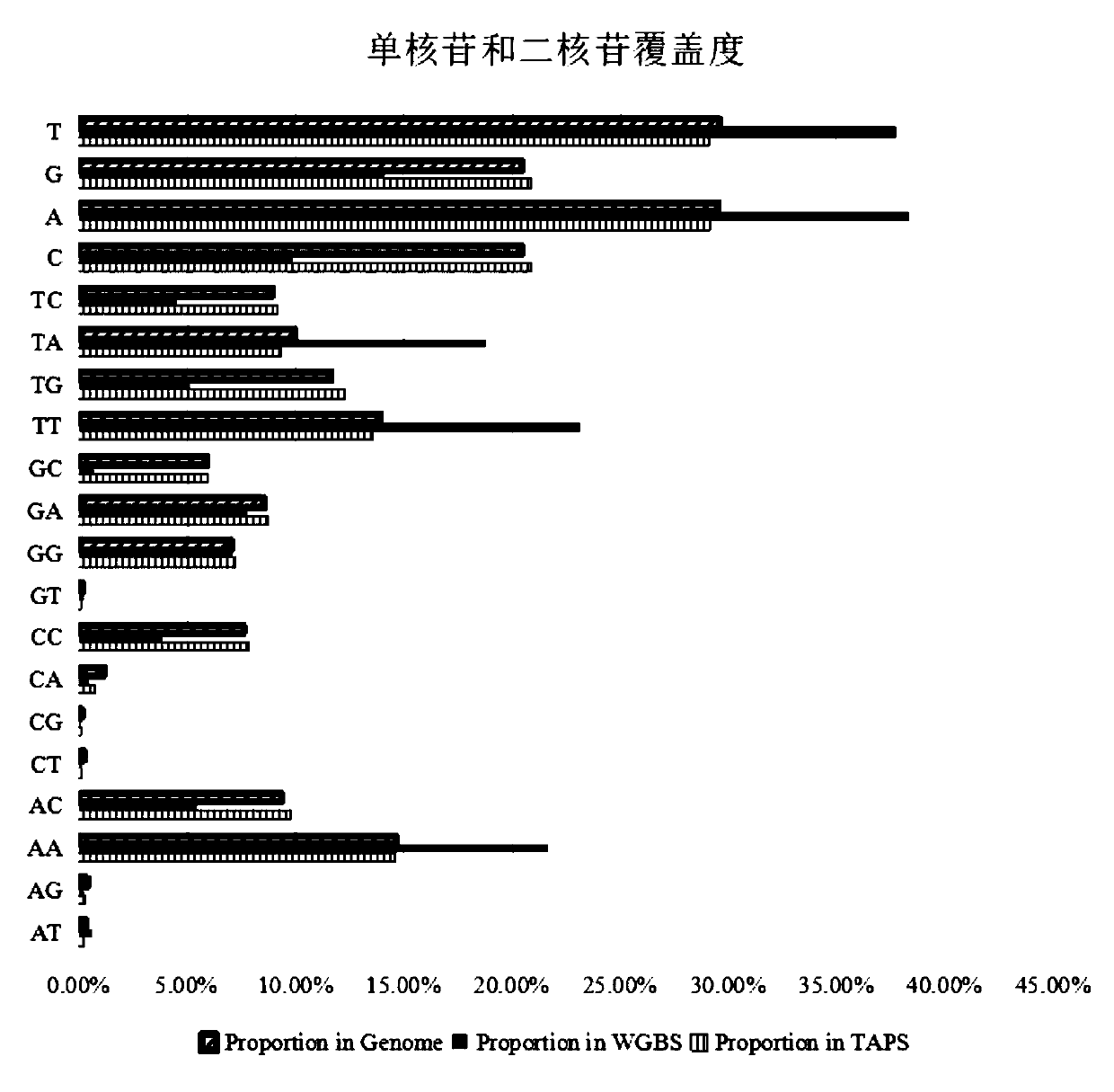

Whole-genome methylation non-bisulfite sequencing library, construction and applications thereof

InactiveCN110820050ASolve the defect of low usage rateReduce usageNucleotide librariesMicrobiological testing/measurementDihydrouracilPhosphoric acid

The invention relates to the technical field of bioinformatics, particularly to a whole-genome methylation non-bisulfite sequencing library, a construction and applications thereof, wherein the sequencing library comprises a TET enzyme reaction solution, the TET enzyme reaction solution comprises the following independently packaged components: a TET enzyme oxidation buffer solution, and the TET enzyme oxidation buffer solution comprises, by micromole, (20-167)*10<3> parts of HEPES or Tris-Cl, (100-333)*10<3> parts of NaCl, 3.3*10<3> parts of alpha-KG or 2-oxoglutarate, 6.67*10<3> parts of ascorbic acid and 4*10<3> parts of adenosine triphosphate. According to the invention, by combining the kit, Fe(NH4)2(SO4)2 and TET enzyme, 5mc can be oxidized into 5cac, the 5cac is reduced into dihydrouracil under the action of a reducing agent, and T is identified through PCR sequencing, so that the the DNA methylation C-to-T conversion under the non-bisulfite condition is achieved, the defects ofbase imbalance and low sequencing data use rate of the existing methylation sequencing library constructed based on the bisulfite conversion are solved; and the formula further has effects of simplecomponents, extremely low TET enzyme use amount and significant cost reducing.

Owner:BEIJING GENEPLUS TECH +1

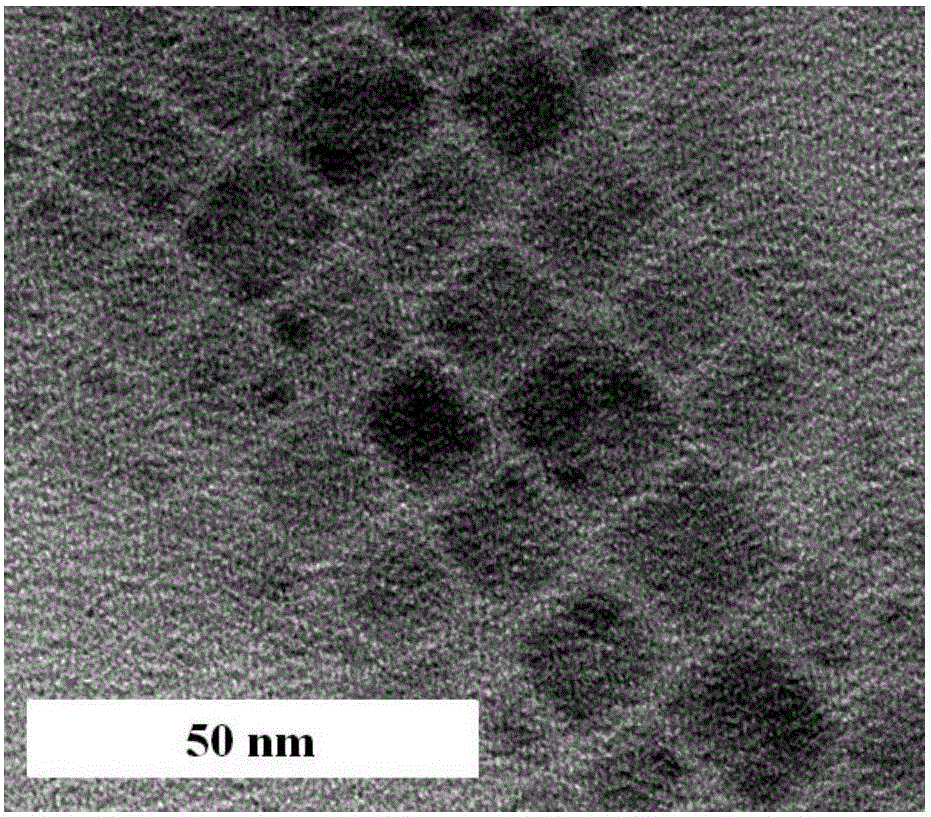

Preparation method of perovskite type nanocrystalline

ActiveCN106753356AImprove performanceSynthetically selectiveMaterial nanotechnologyNanoopticsHalogenPhotoelectric conversion

The invention relates to a preparation method of perovskite type nanocrystalline. The perovskite type nanocrystalline is CsPbXY, wherein X is selected from any one of Cl, Br or I; Y is selected from any one of Cl, Br or I; X is different from Y; a is greater than or equal to 0, b is greater than or equal to 0, and a+b=3. The method comprises the steps that cesium salt, long-chain olefin and oleic acid are mixed; under the inert gas protection, heating reaction is performed to obtain an oleic acid cesium solution; PbO, ammonium halide and long-chain olefin are mixed; then, oleylamine and oleic acid are injected; heating is performed; the oleic acid cesium solution is injected under the inert gas protection; reaction and cooling are performed to obtain the CsPbXY perovskite type nanocrystalline. When the method is used for synthesizing the perovskite type nanocrystalline, the types and the proportion of halogen can be regulated and controlled; the performance of the perovskite type nanocrystalline is controlled; the method is simple; the photoelectric conversion performance of the synthesized perovskite type nanocrystalline is good; meanwhile, the synthetic raw materials use low-toxicity PbO; green and environment-friendly effects are achieved.

Owner:SOUTH UNIVERSITY OF SCIENCE AND TECHNOLOGY OF CHINA +1

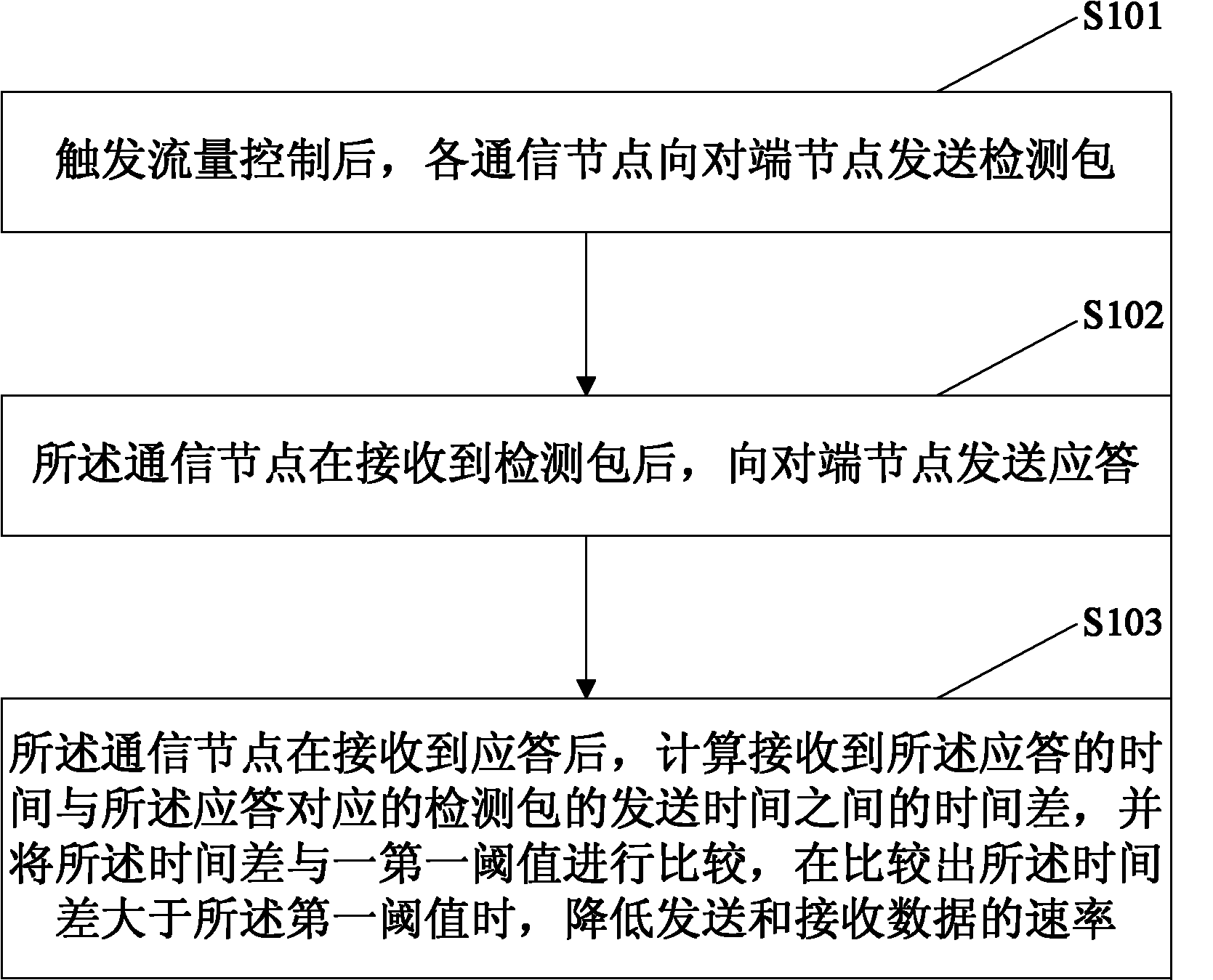

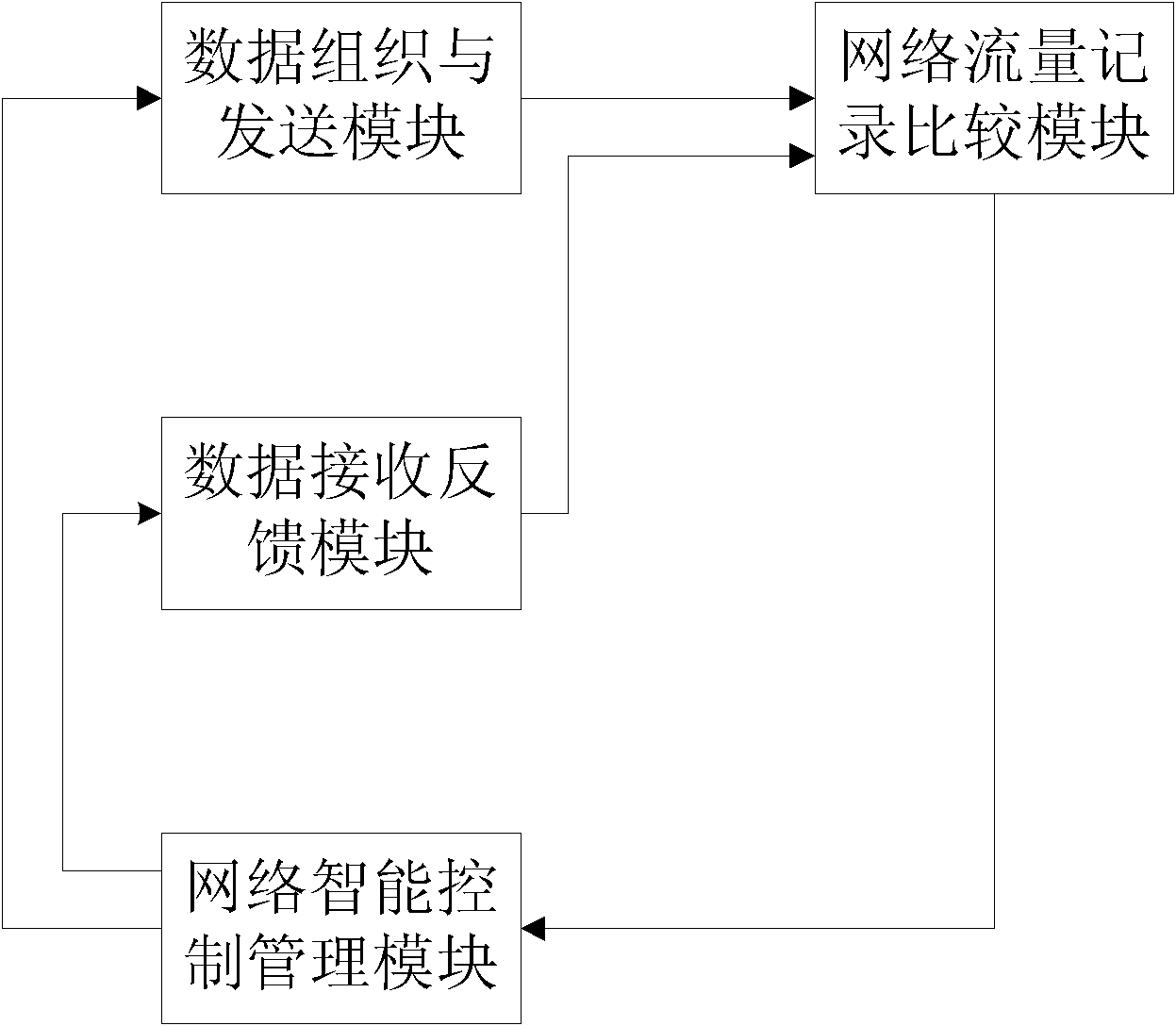

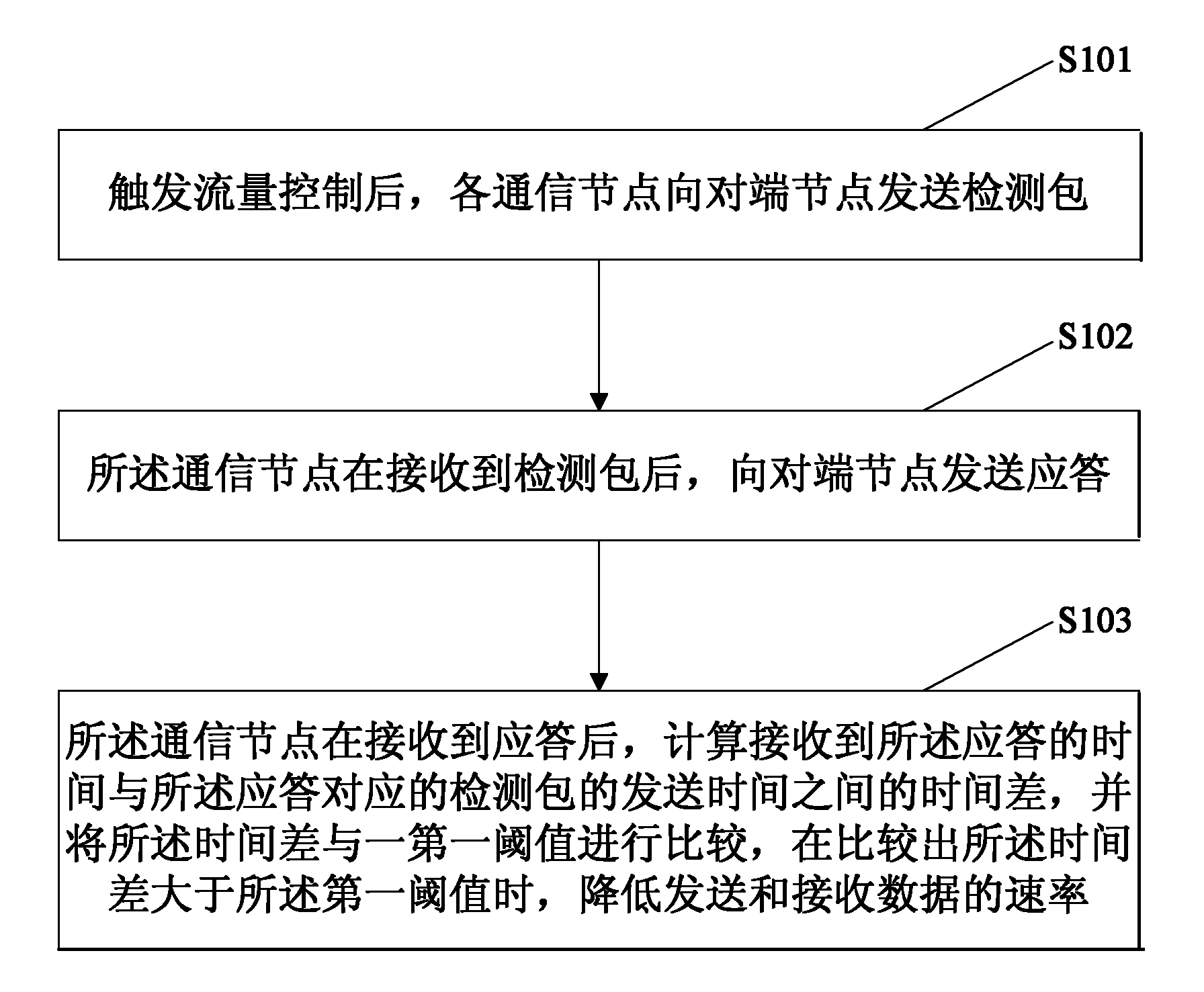

Method and device for controlling flow of network working under full duplex model

The invention provides a method and a device for controlling the flow of a network working under a full duplex model. The method comprises the following steps that: each communication node transmits a detection packet to an opposite end node after the flow control is triggered; the communication node transmits response to the opposite end node after receiving the detection packet; the communication node calculates the time difference between the time of receiving the response and the time of transmitting the detection packet relative to the response after receiving the response, and compares the time difference with a first threshold; and the communication node reduces the speed of transmitting and receiving data when the time difference is larger than the first threshold. The method can intelligently regulate the speed of transmitting and receiving data according to the network state and effectively solve the influence on client machines when a great number of data is transmitted, is more flexible compared with the method of purely limiting the transmission speed, and can also ensure the proportion reserved for the client machines to use the network bandwidth.

Owner:INSPUR BEIJING ELECTRONICS INFORMATION IND

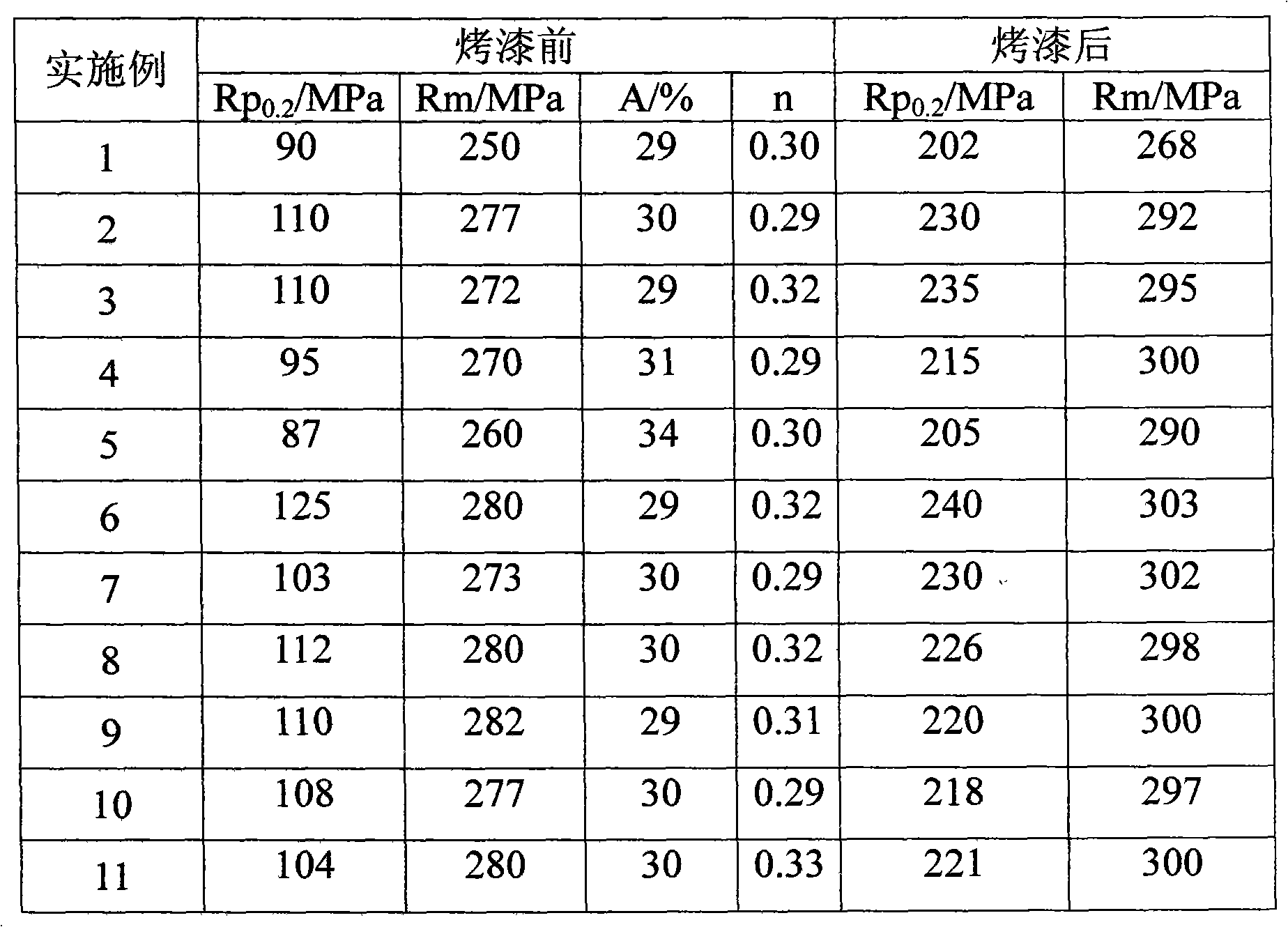

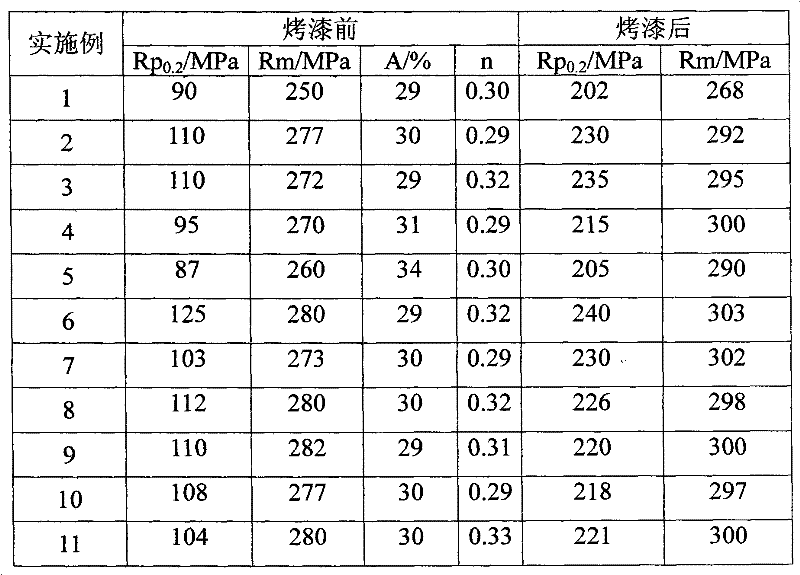

Aluminium alloy with high forming property for automobile body plate

The invention discloses an aluminium alloy with high forming property for an automobile body plate, comprising the following chemical constituents in percentage by weight: 0.50-1.20wt% of Si, 0.35-0.70wt% of Mg, 0.01-0.20wt% of Cu, 0.05-0.20wt% of Mn, less than or equal to 0.10wt% of Cr, 0.01-0.25wt% of Zn, less than or equal to 0.15wt% of Ti, 0.05-0.15wt% of Fe and the balance of Al. The aluminium alloy material of the invention has lower yield strength before baking finish, which is favourable for stamping shaping; and after baking finish, the yield strength is improved. The material has higher forming property and simultaneously satisfies the requirements of the impact resistance of the automobile body plate.

Owner:CHINA NON-FERROUS METALS PROCESSING TECH CO LTD

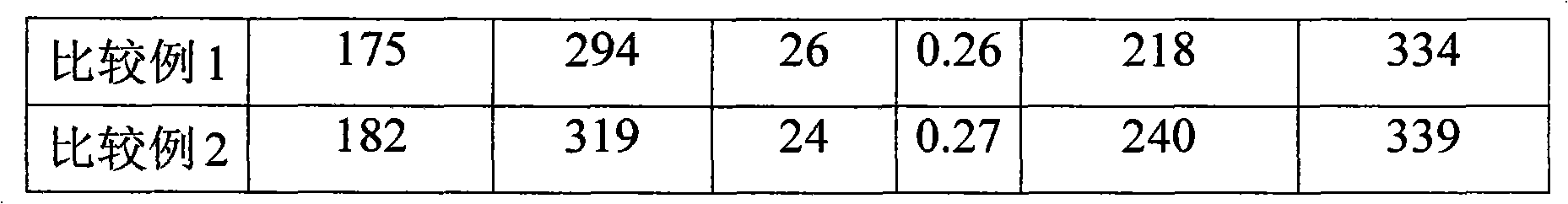

Method for reducing metal and alloy hydroxide gel by hydrogen separated from electrochemistry cathode

InactiveCN101144176APrecise control of ingredientsGuaranteed ingredientsElectrolytic coatingsAlkaline accumulator electrodesPotassiumAlloy

The present invention discloses a method for reducing metal hydroxide gel and metal hydroxide-carbon gel and alloy gel and alloy hydroxide-carbon gel through electrochemical cathodic hydrogen evolution in potassium chloride aqueous solution, and directly further forming and preparing electrode materials of metal and metal-carbon and alloy and alloy-carbon. The electrode prepared by the method can obtain composition of metal: carbon or alloy: carbon with definite proportion, thereby the electrode composition is stable. The tin-carbon gel and tin-cobalt-carbon gel of the present invention is prepared by a definite proportion chemical precipitation method, and overcomes the disadvantage that the coating element content can not be accurately controlled if an electrochemical deposition method is adulterated. The experimental battery consisting of the tin-carbon anode and the lithium sheet cathode prepared with the process has 20 times circulation time and specific capacity of up to 327.4 mAh / g under 0.2 C charging and discharging current; the prepared experimental battery consisting of the tin-cobalt-carbon anode and the lithium sheet cathode has 50 times circulation time specific capacity of up to 278.5 mAh / g under 0.3 C charging and discharging current.

Owner:BEIHANG UNIV

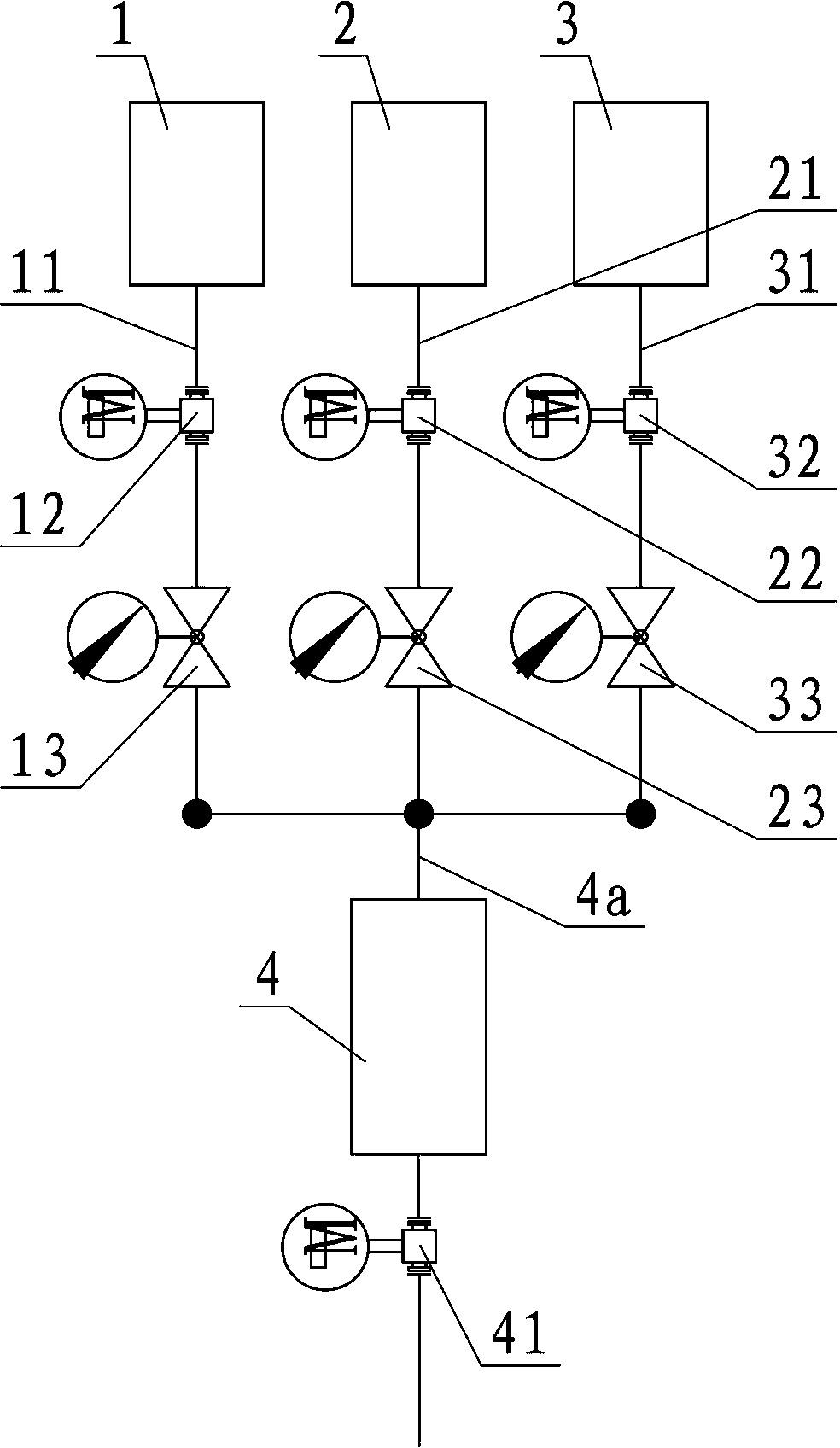

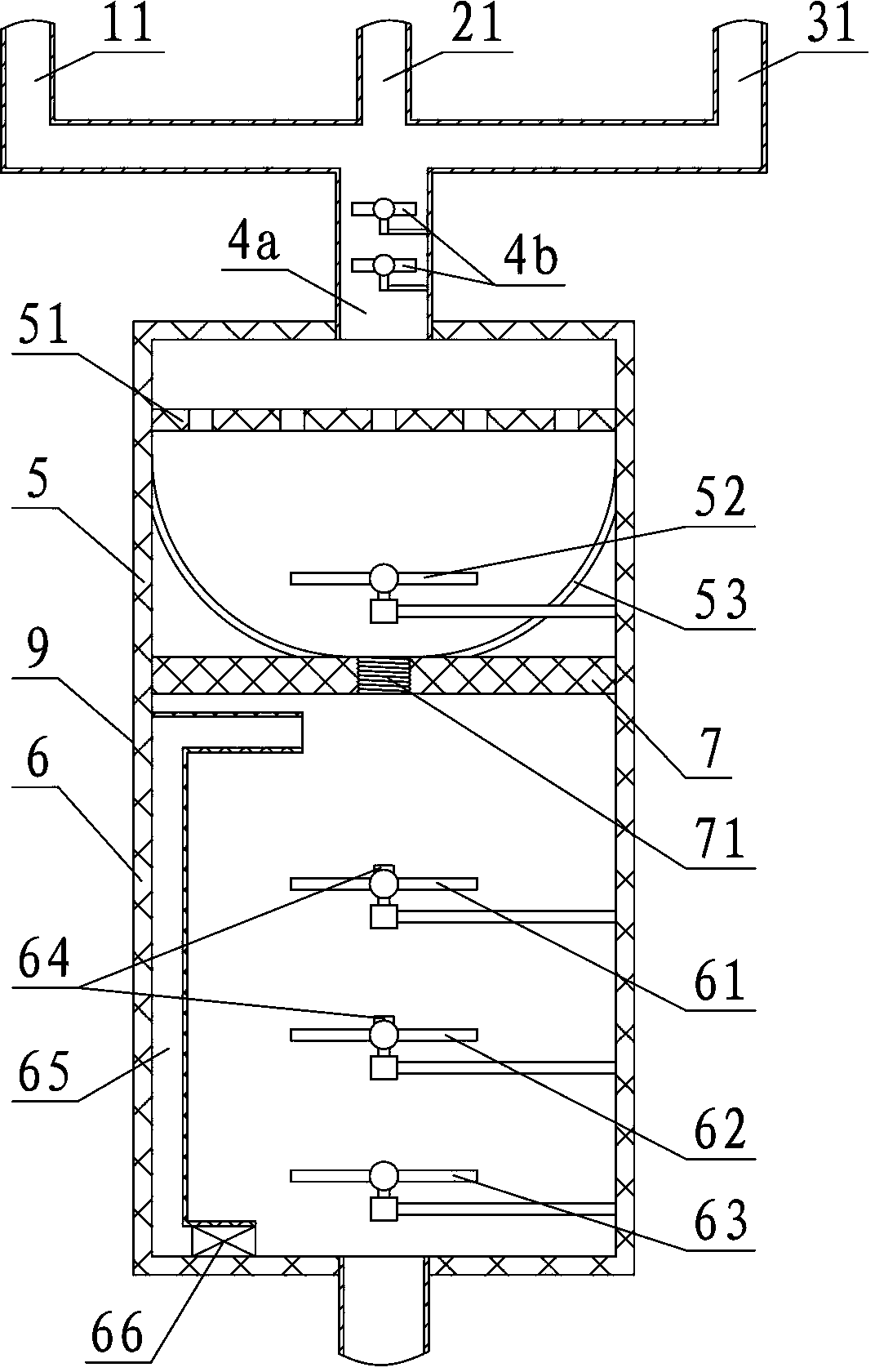

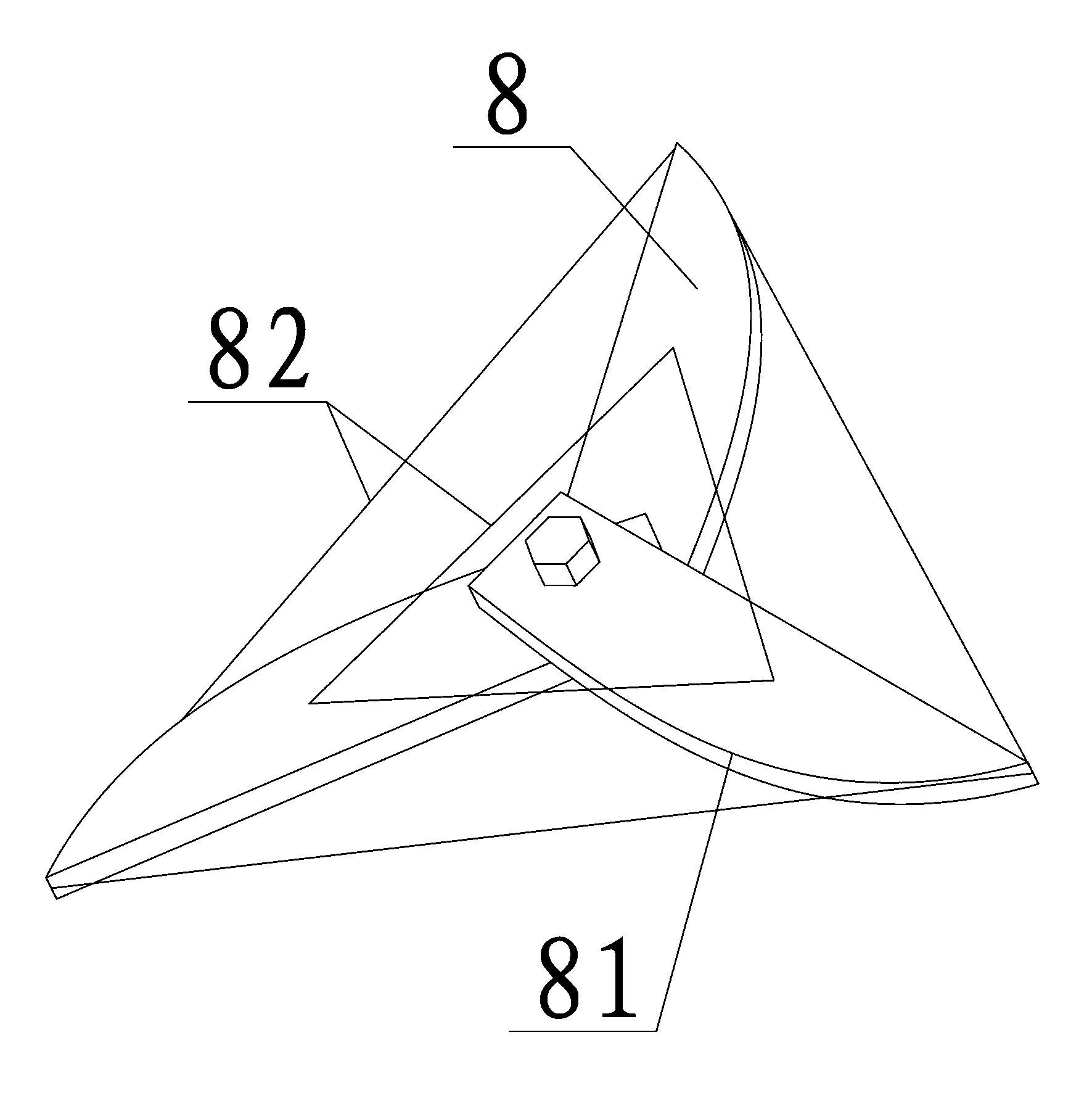

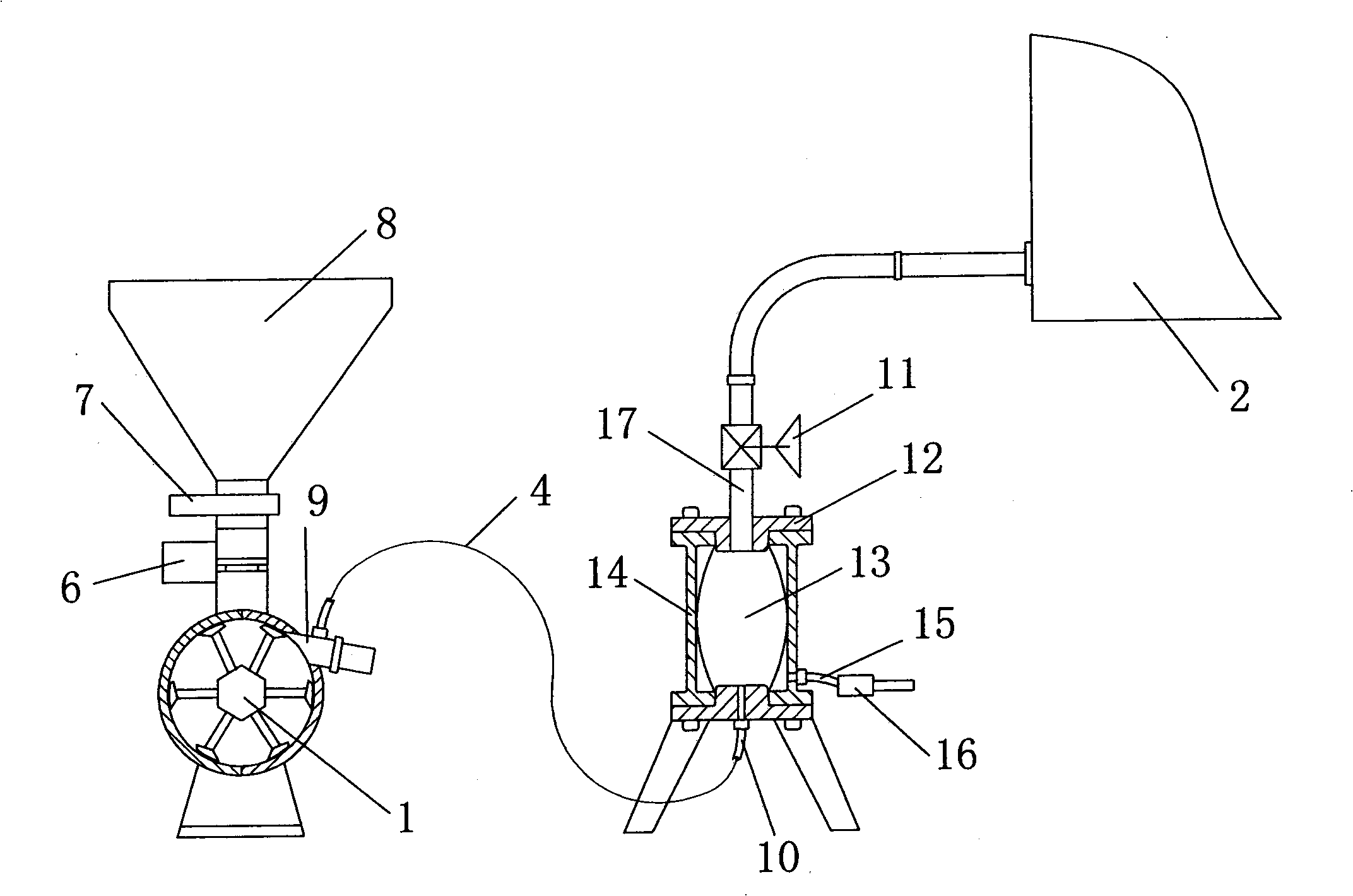

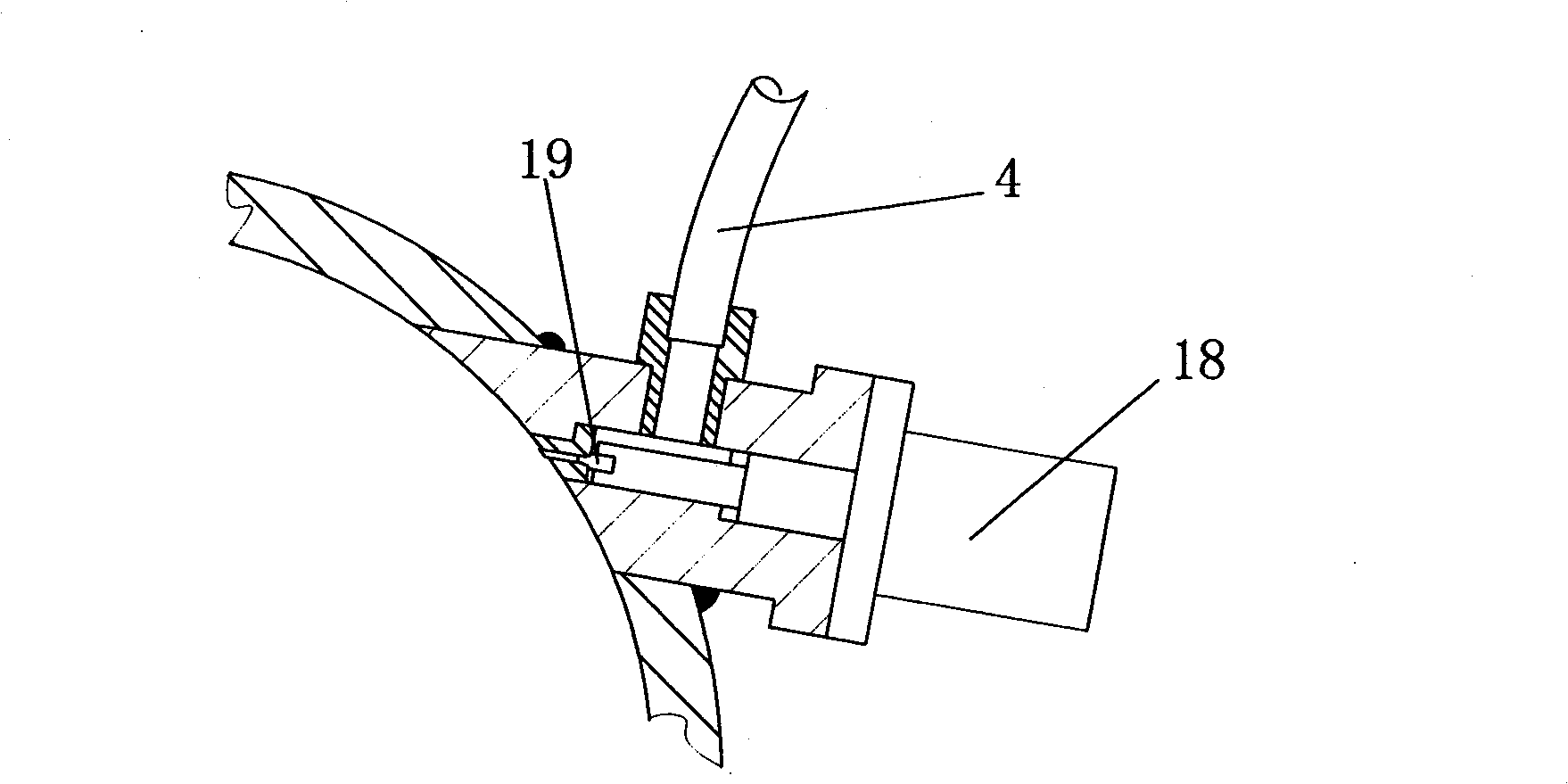

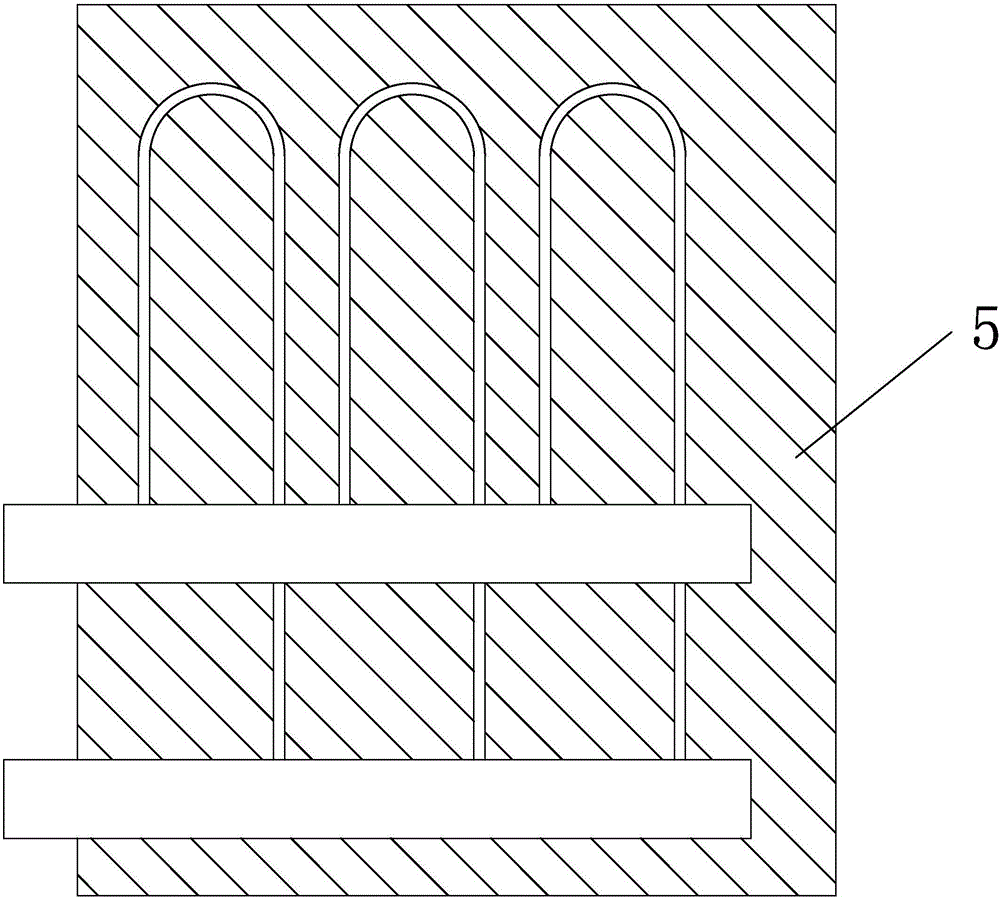

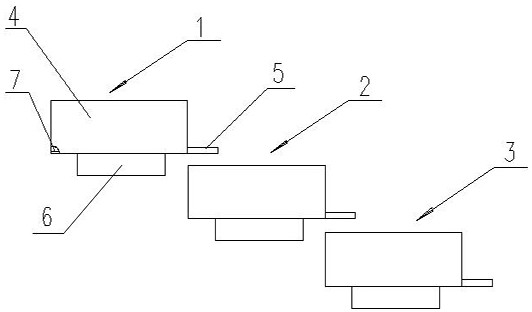

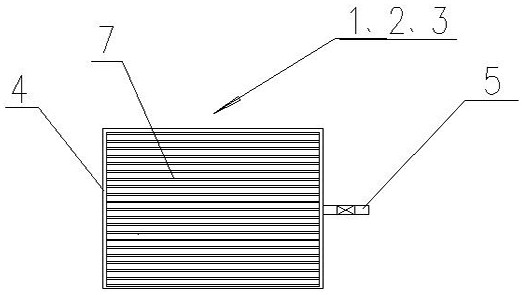

Concentration preparation device for mixed solution

InactiveCN104258780AGuaranteed ratioGuaranteed flow rateMixing methodsMixer accessoriesProcess engineeringProduction quality

The invention discloses a concentration preparation device for a mixed solution. The device comprises three solution storage devices and a solution mixing device, wherein the three solution storage devices are communicated with an input opening of the solution mixing device through respective pipelines; a flow meter and a proportion regulating valve are arranged on each pipeline; a flow meter is arranged on an output opening pipeline of the solution mixing device; the openness of the three proportion regulating valves is changed, so that the proportion of different solutions, entering the solution mixing device, in the three pipelines is further regulated. According to the invention, the proportioning is stable, and the mixed solution can be used for a long time after the proportion of the mixed solution is regulated; the production efficiency can be improved to the greatest extent, and meanwhile, the production quality is guaranteed; the production automation is realized, and the labor intensity of workers is alleviated; the device is convenient to operate and reliable to run.

Owner:HANGZHOU FANTENG TECH

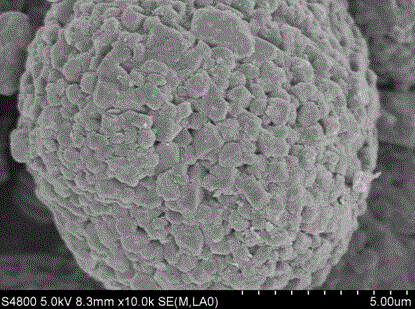

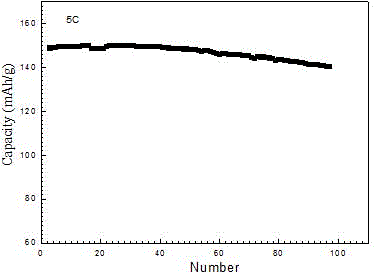

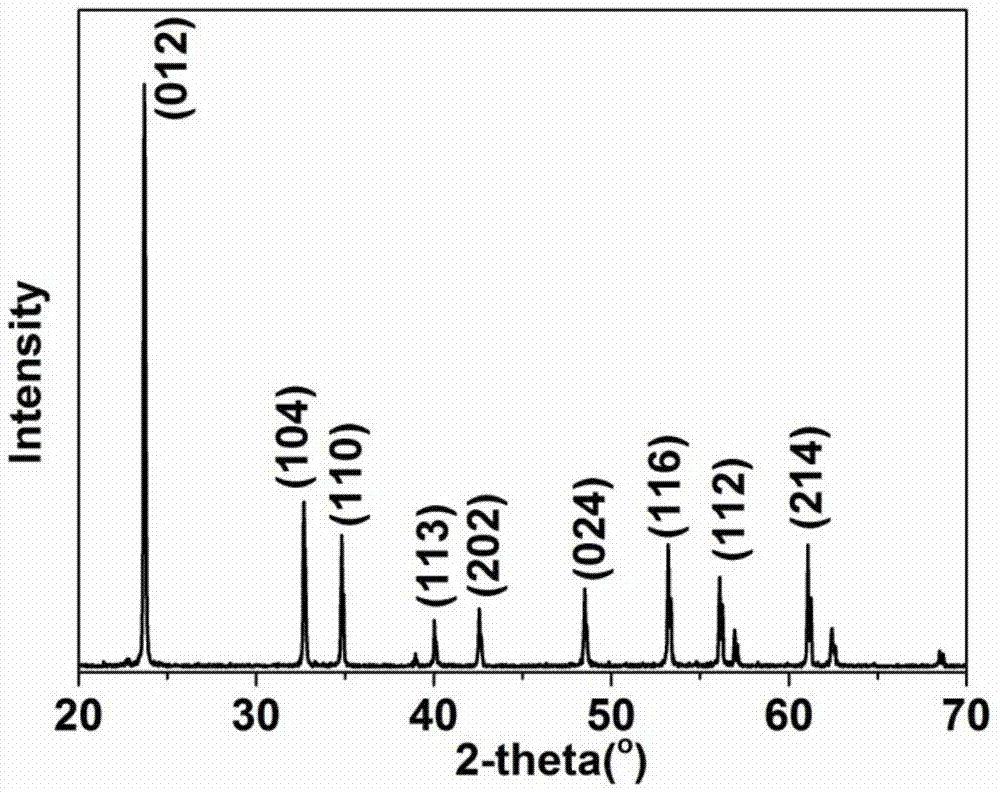

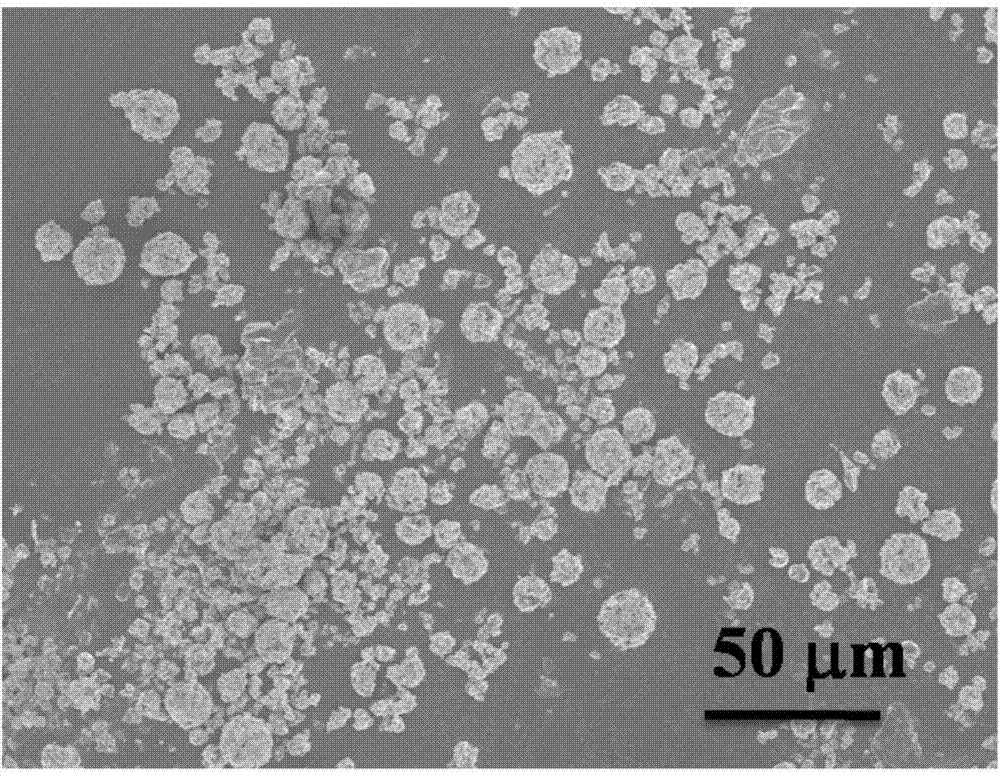

Nickel cobalt lithium manganate composite anode material of lithium ion battery and preparation method of nickel cobalt lithium manganate composite anode material

ActiveCN104835955AImproved magnification performanceImprove cycle performanceCell electrodesManganateConductive materials

The invention relates to a nickel cobalt lithium manganate composite anode material of a lithium ion battery and a preparation method of the nickel cobalt lithium manganate composite anode material, and belongs to the technical field of anode materials of lithium ion batteries. The composite anode material comprises nickel cobalt lithium manganate and lithium lanthanum titanate wrapping the surface of the nickel cobalt lithium manganate. The chemical formula of the composite anode material is LiNixCoyMn(1-x-y) O2 / LizLa (2-z) / 3TiO3, x is greater than 1 and smaller than 1, y is greater than 0 and smaller than 1, (x+y) is greater than 1 and smaller than 1, z is greater than or equal to 0.5 and smaller than or equal to 1.5, and the mass percent of the lithium lanthanum titanate is 0.5-1.5%wt. A layer of stable conductive materials which are the lithium lanthanum titanate wraps the surface of the nickel cobalt lithium manganate composite anode material. On one hand, the structure of the nickel cobalt lithium manganate composite anode material is quite stable; and on the other hand, the ionic conductivity of the nickel cobalt lithium manganate material is quite high, so that dissolution of the nickel cobalt lithium manganate material is restrained, the conductivity is improved, and the rate capability and the recycling performance of the material are greatly improved.

Owner:中国东方电气集团有限公司

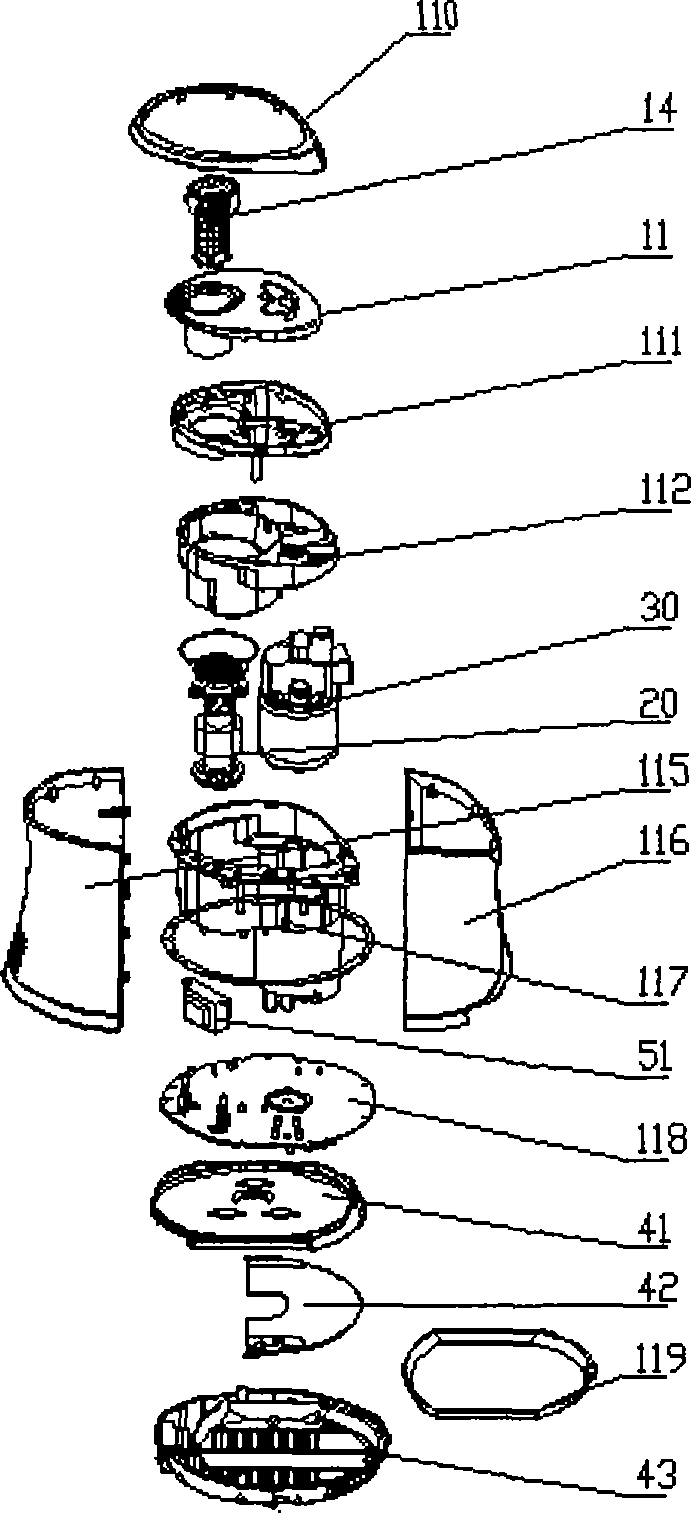

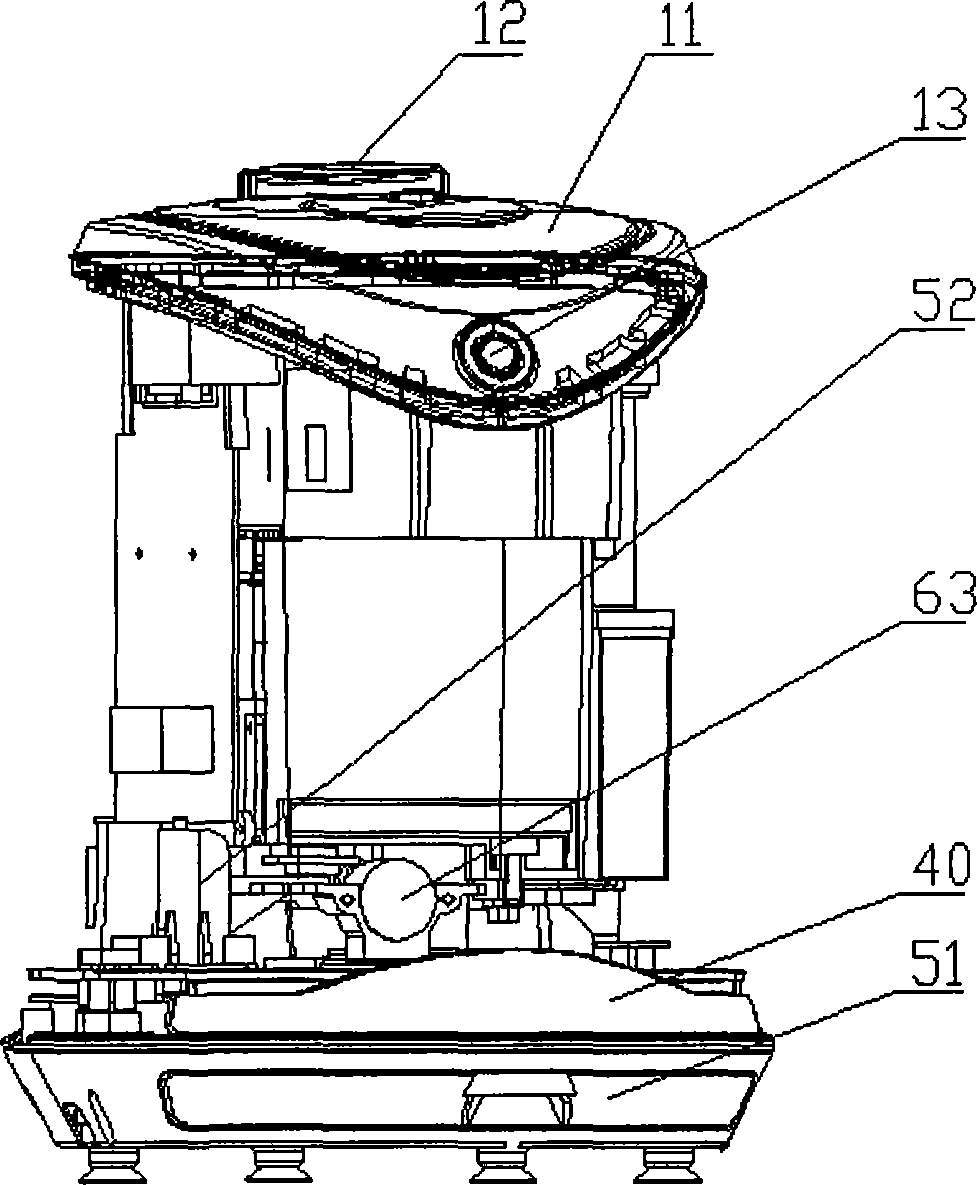

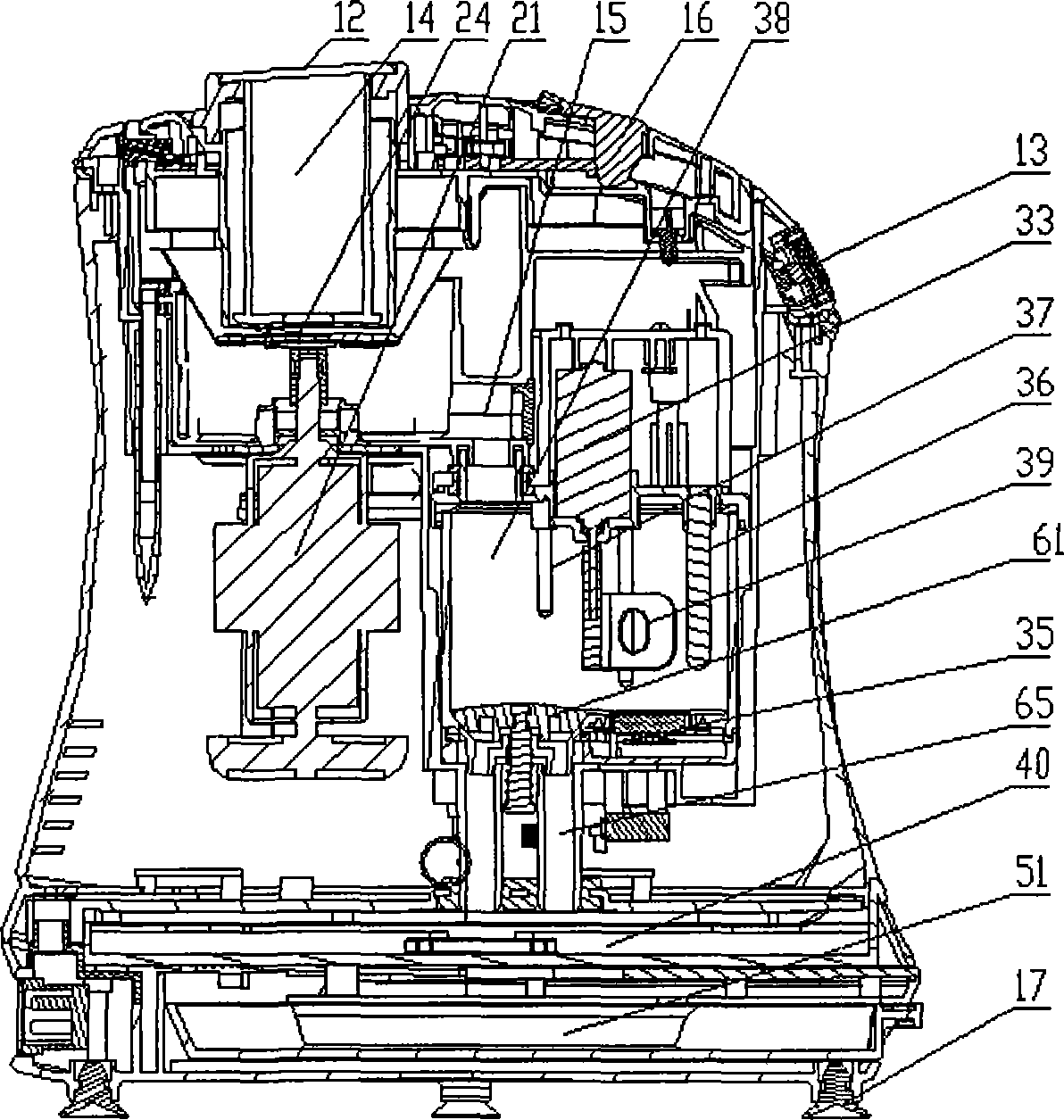

Mask machine

ActiveCN104382745AEasy to transportGuaranteed ratioCosmetic preparationsToilet preparationsEngineeringMechanical engineering

A mask machine comprises the following parts: a control module, a shell part, a juicing mechanism, a stirring mechanism, a mask forming mechanism, a cleaning mechanism and a liquid discharge mechanism. The mask machine possesses automatic cleaning function and realizes the dismounting-free cleaning purpose. Further, by arranging a screw conveying device, the problem that a mask juice cannot be smoothly conveyed is solved. Further, by arranging a quantitative metering device, the proportions of raw materials are strictly guaranteed, and the mask quality is guaranteed.

Owner:北京美源创世科技发展有限公司

Method and apparatus for efficient routing of variable traffic

InactiveUS7388842B1Minimize biasGuaranteed performance ratioError preventionTransmission systemsTraffic networkLinearity

A method and apparatus for provide highly efficient traffic routing for a wide range of possible traffic matrices (TM) in an intra-domain network. That routing optimally balances the traffic loads over a range of traffic matrices so as to minimize the deviation for any particular traffic matrix from the optimal routing. Such a routing provides a guaranteed performance ratio against the best possible network routing. The invention utilizes a method of optimally configuring a traffic network based on solving a linear program to obtain the optimal routing, and then configuring the routing on the network accordingly.

Owner:AMERICAN TELEPHONE & TELEGRAPH CO

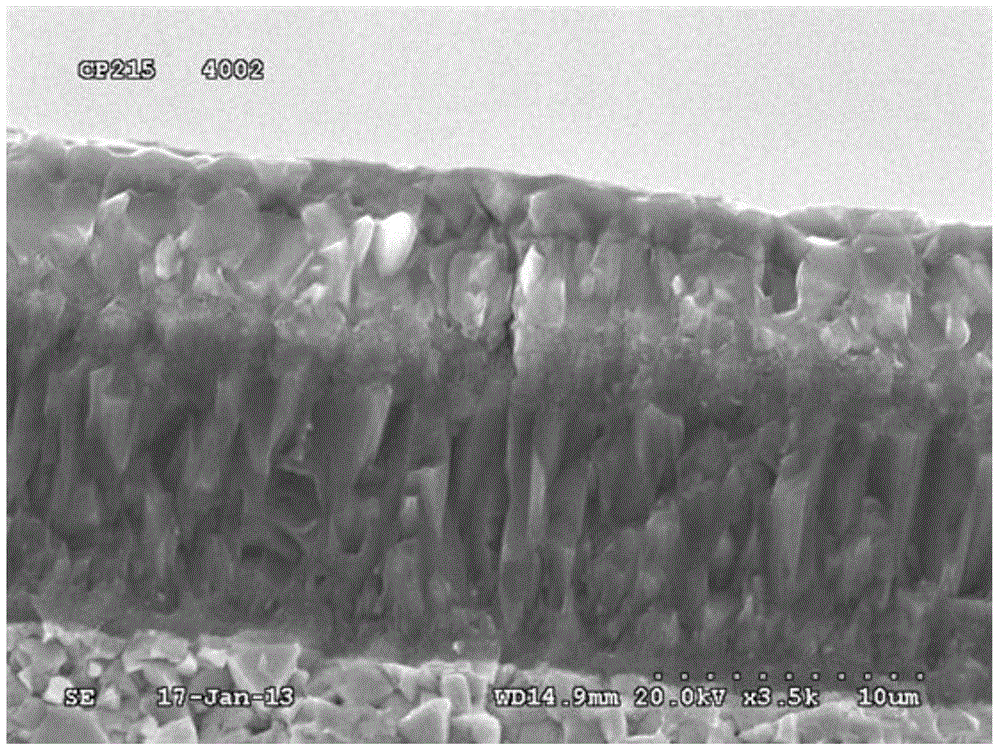

Magnesia carbon brick and preparation method thereof

The invention relates to a magnesia carbon brick and a preparation method thereof. The magnesia carbon brick is prepared from, by weight, 60%-75% of fused magnesite particles, 10%-30% of fused magnesite fine powder, 5%-10% of carbon, 1%-5% of an antioxidant, 1%-3% of a binding agent and 0.4%-1% of furfural waste liquid. In the preparation process, the fused magnesite particles are placed in a mixing mill to be dry-mixed for 2-15 min, then phenolic resin and the furfural waste liquid are added to continue to be mixed for 5-15 min, then carbon is added to the mixture, mixing is carried out for 5-15 min, finally the fused magnesite fine powder and the antioxidant are added to continue to be mixed for 8-15 min, pug is formed, the rotating speed of the mixing mill is set to range from 950 r / min to 1,000 r / min, mixing time ranges from 10 min to 60 min, and the magnesia carbon brick is prepared after compression moulding and drying solidification. The preparation method is simple, the steps are easy to operate, the uniformity of mixed materials of the magnesia carbon brick is improved, the quality of the mixed materials of the magnesia carbon brick is improved, the labor intensity of workers is lowered, the use amount of phenolic resin is reduced, and due to the addition of the furfural waste liquid, the material mixing process is more even, and phenolic resin is prevented from being caked.

Owner:江苏苏嘉集团新材料有限公司

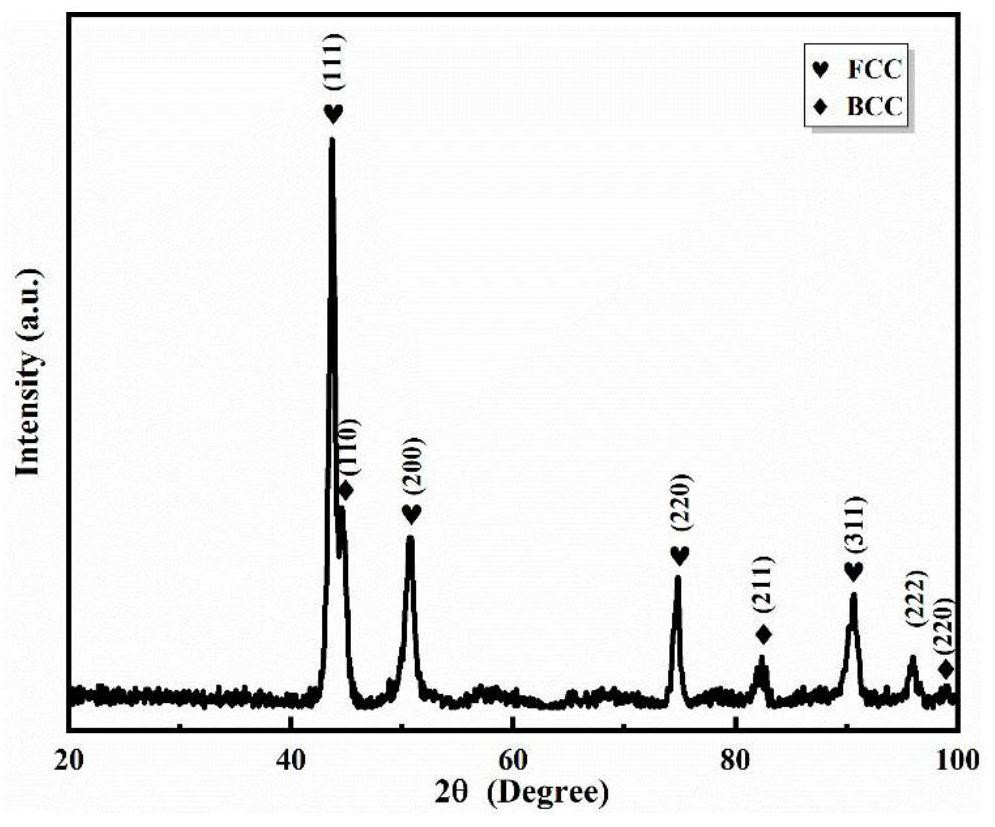

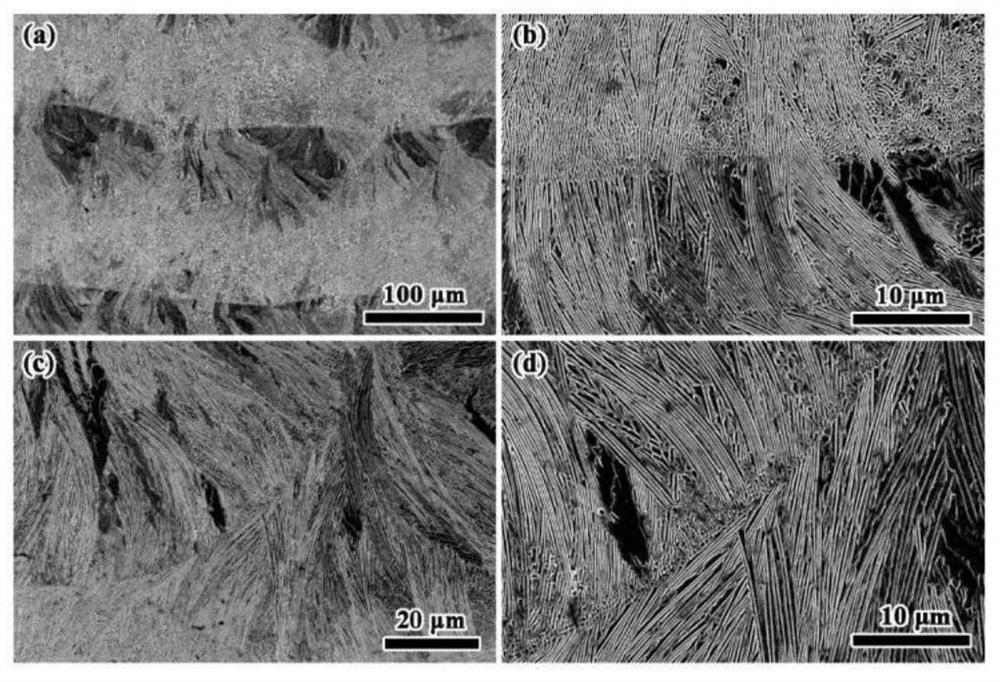

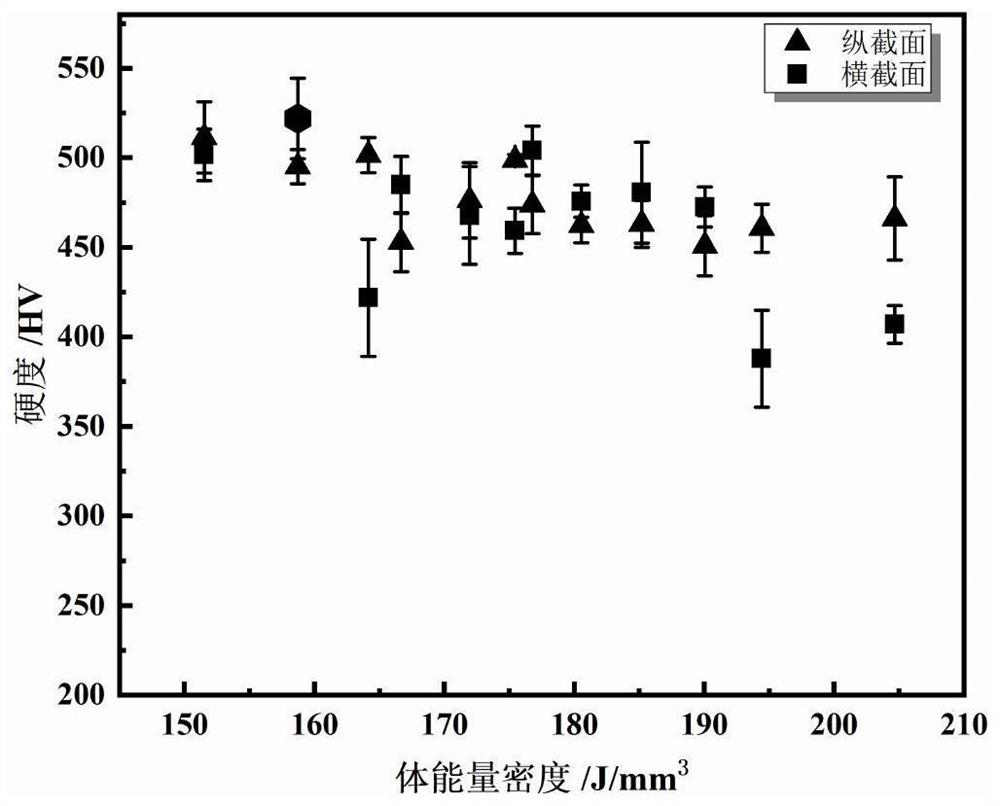

Method for preparing high-toughness eutectic high-entropy alloy based on selective laser melting technology

ActiveCN112935252AImprove compactnessImprove densification performanceAdditive manufacturing apparatusIncreasing energy efficiencySelective laser meltingHigh entropy alloys

The invention provides a method for preparing a high-toughness eutectic high-entropy alloy based on a selective laser melting technology, and belongs to the technical field of metal material laser additive manufacturing. The molar ratio of the AlCoCrFeNi pre-alloy powder to the Ni powder is controlled, the proportion of all elements in the eutectic high-entropy alloy is guaranteed, and a complete eutectic structure is obtained in the alloy; by optimizing the technological parameters of selective laser melting forming, the compactness of the eutectic high-entropy alloy is improved, meanwhile, the residual stress in the eutectic high-entropy alloy is reduced, cracks are prevented from being formed in the alloy, the obtained eutectic high-entropy alloy can achieve high compactness without subsequent treatment, the mechanical property of the eutectic high-entropy alloy is improved, and integrated precision forming of the high-strength and high-toughness eutectic high-entropy alloy complex structural part is achieved. The result of the embodiment shows that the density of the eutectic high-entropy alloy prepared through the preparation method is larger than 98%, the yield strength is larger than 970 MPa, and the tensile strength is larger than or equal to 1270 MPa.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

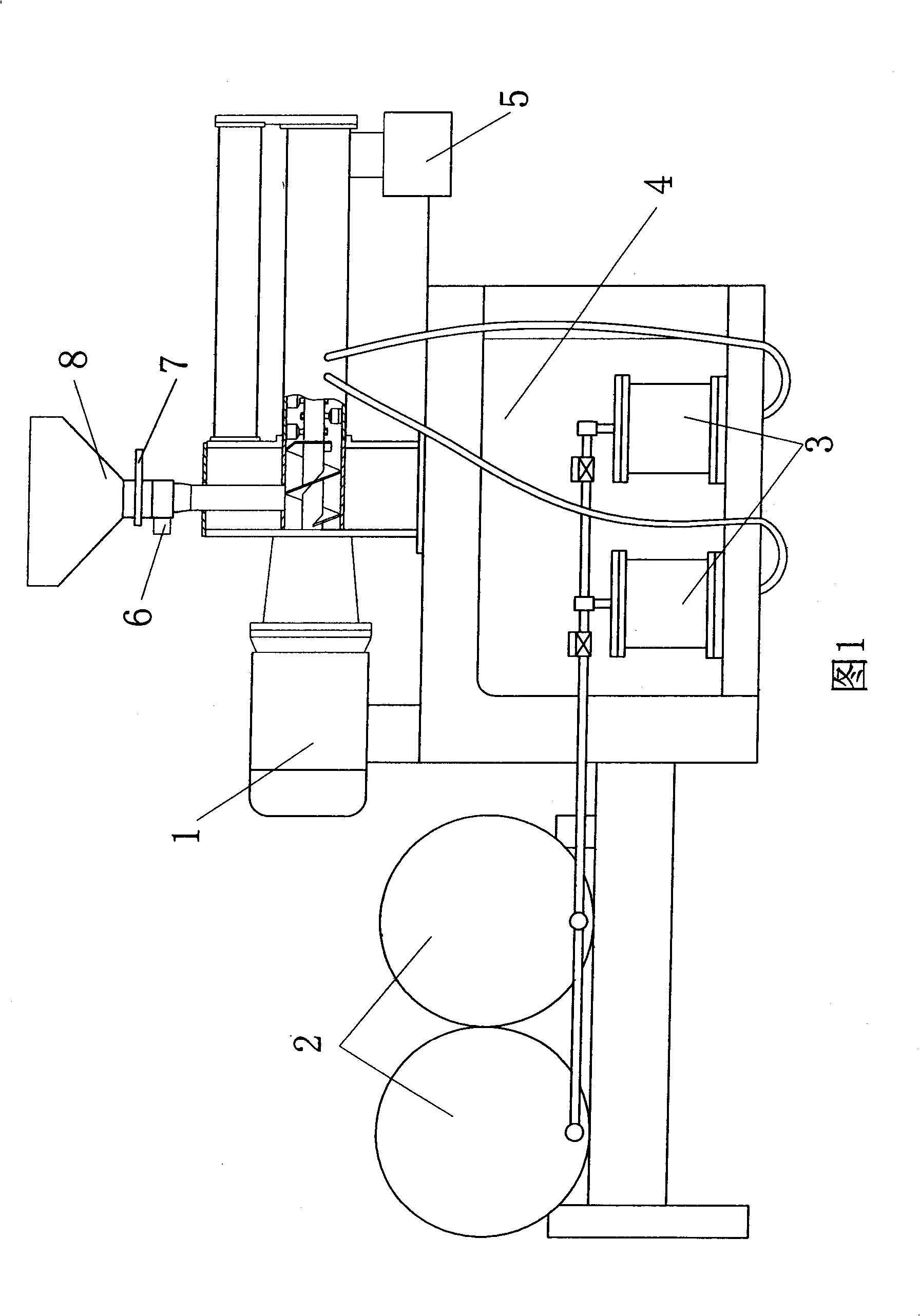

Continuous automatic pug mixer

InactiveCN101347818AHigh viscosityThe amount added is stableMould handling/dressing devicesProportional controlDry sand

The invention provides a continuous automatic sand mixing machine, comprising a sand mixing packing auger, a dry sand bin and an enclosed resin quantitative device; the material inlet of the sand mixing packing auger is connected with the lower mouth of the dry sand bin; the lower mouth of the dry sand bin is provided with a proportion control valve and a sand adding valve; the material outlet of the sand mixing packing auger is provided with a funnel; the shell of the sand mixing packing anger is provided with a resin feeding valve; the enclosed resin quantitative device is connected with the resin feeding valve on the sand mixing packing auger by a delivery pipe; the sand adding valve and the resin feeding valve are connected with the same electromagnetic control valve. The sand adding valve and the resin feeding valve are controlled by the same electromagnetic control valve, thus ensuring the synchronous adding of the dry sand and the resin and ensuring the normal proportion and the strength of sand core. The adopted enclosed resin quantitative device has an anti-oxidation function and can ensure that the resin flux is stable, the quantification is exact and the material inlet of the resin is not blocked.

Owner:济南林青铸造技术有限公司

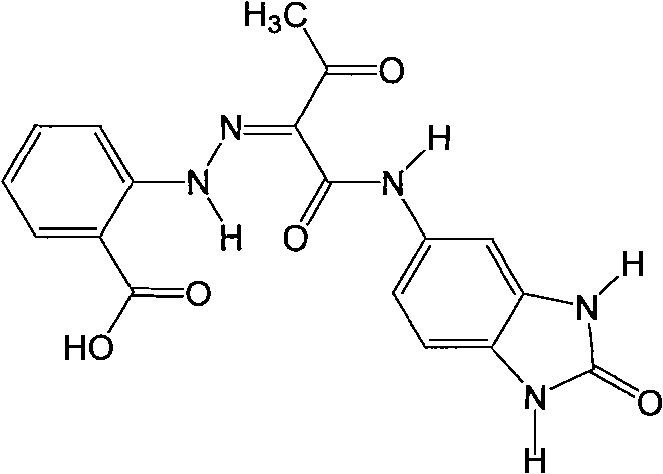

Preparation method of C.I. pigment yellow 151

The invention relates to a preparation method of C.I. pigment yellow 151, which comprises the steps of: taking phthalimide and NaOX as starting materials to prepare strong-basicity solution of o-aminobenzoic acid; dissolving a coupling component 5-acetyl acetamido benzimidazolone (AABI) in the strong-basicity solution without acid precipitation; diazotizing and coupling under a proper pH condition; synthesizing the pigment for once; and optionally pigmenting and surfacing to obtain the C.I. pigment yellow 151. The technology is simplified, the ice use cost is saved, the use level of acid and alkali is greatly reduced, the production waste water is greatly reduced, the good economic benefit is obtained, and the environmental harmfulness is greatly reduced.

Owner:ANSHAN HIFICHEM CO LTD

Method for producing feed of high-yield dairy cow by using corn straws fermented by Rhodotorula glutinis

InactiveCN102178037AStrong reproductive abilityFull of nutritionFood processingAnimal feeding stuffChemistryMilk yield

The invention discloses a method for producing a feed of high-yield dairy cows by using corn straws fermented by Rhodotorula glutinis. The method comprises the following steps of: activating a yeast strain to obtain a corn straw material fermented by the Rhodotorula glutinis by adding aqueous solution, uniformly mixing 40 to 60 weight percent of corn material, 5 to 10 weight percent of cottonseedmeal, 5 to 12 weight percent of distillers dried grains with soluble, 10 to 20 weight percent of concentrated feed and 20 to 30 weight percent of corn straw material fermented by the Rhodotorula glutinis to obtain a mixture, feeding the mixture into a solid fermentation chamber and fermenting, drying a fermented solid feed, crushing, adding a silage into the solid feed, and mixing and stirring uniformly and packaging to obtain the feed of the high-yield dairy cows. In the method, the corn straws are fermented by a biological strain and then are taken as a feed raw material, so that the cost is reduced, the nutrition is rich and easy to absorb, and the method is favorable for improving the milk yield of dairy cows.

Owner:河南宏翔生物科技有限公司

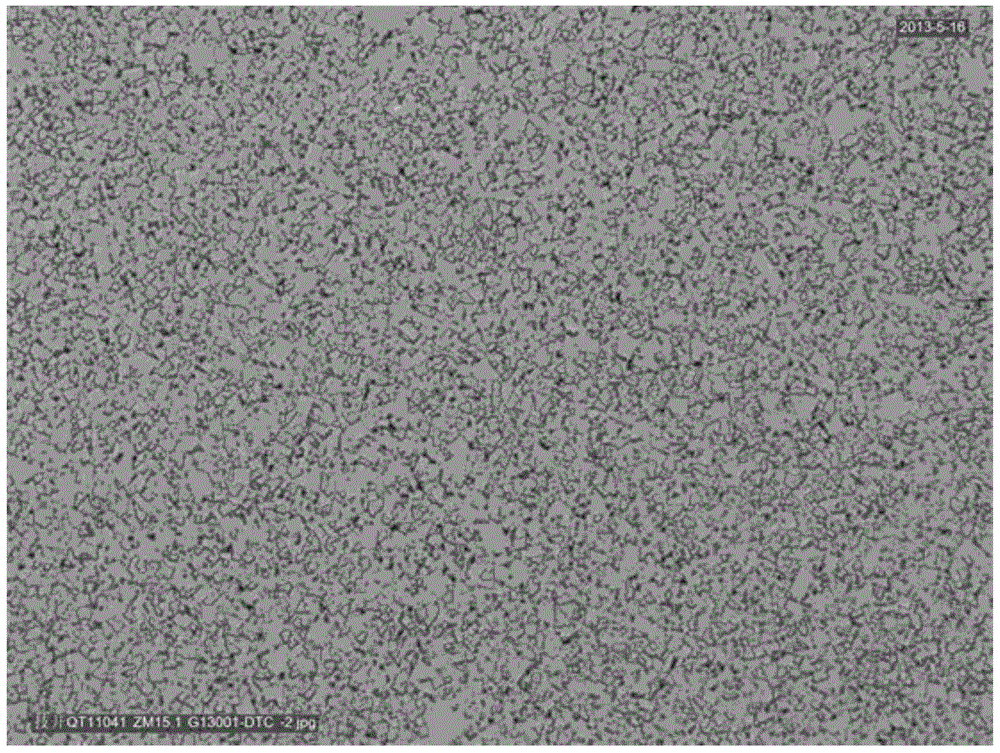

Production method of twin-structure hard alloy matrix

The invention discloses a production method of a twin-structure hard alloy matrix, which comprises the following steps: proportioning, ball milling, granulating, pressure molding, sintering and the like. The WC adopted in the proportioning step is composed of 17 wt% of coarse-grain WC and 3 wt% of fine-grain WC. The tungsten carbide crystal grains in the twin-structure hard alloy prepared by the method have two grain sizes, and the coarse-grain tungsten carbide is uniformly distributed in the fine-grain tungsten carbide. The coarse-grain tungsten carbide has the advantages of complete crystal, fewer defects and fewer borders. The higher-proportion coarse-grain tungsten carbide provides favorable tipping resistance for the matrix material; and the fine-grain tungsten carbide provides favorable wearability for the matrix. Therefore, by adopting the coarse / fine tungsten carbide proportion, the matrix material has favorable comprehensive properties, and can be used in the field of steel turning coated tips.

Owner:ZIGONG CEMENTED CARBIDE CORP

Hot rolling pickle sheet with high yield ratio

InactiveCN102312155AGuarantee the shape qualityReduce residual stressEngineeringMechanical engineering

The invention provides a hot rolling pickle sheet with high yield ratio. The hot rolling pickle sheet with high yield ratio is characterized by comprising the following chemical ingredients of 0.04-0.06wt% of C, 0.007-0.010wt% of S, 0.015-0.020wt% of P, 0.15-0.35 wt% of Mn, 0.02-0.03 wt% of Si, 0.030-0.060 wt% of Als. The invention solves a problem of vehicle body weight losing, increases structural strength and processing performance, reduces production costs, and enhances vehicle body strength and security.

Owner:CHINA FIRST AUTOMOBILE

Aluminium alloy with high forming property for automobile body plate

The invention discloses an aluminium alloy with high forming property for an automobile body plate, comprising the following chemical constituents in percentage by weight: 0.50-1.20wt% of Si, 0.35-0.70wt% of Mg, 0.01-0.20wt% of Cu, 0.05-0.20wt% of Mn, less than or equal to 0.10wt% of Cr, 0.01-0.25wt% of Zn, less than or equal to 0.15wt% of Ti, 0.05-0.15wt% of Fe and the balance of Al. The aluminium alloy material of the invention has lower yield strength before baking finish, which is favourable for stamping shaping; and after baking finish, the yield strength is improved. The material has higher forming property and simultaneously satisfies the requirements of the impact resistance of the automobile body plate.

Owner:CHINA NON-FERROUS METALS PROCESSING TECH CO LTD

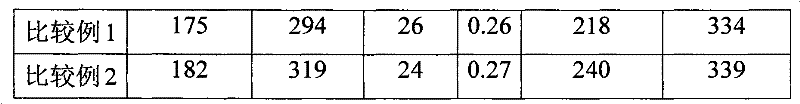

High-power LED lamp cooling device

InactiveCN106195661ASpeed up the cycleIncrease air velocityElectric circuit arrangementsLighting heating/cooling arrangementsAutomatic controlTurbine blade

The invention discloses a high-power LED lamp cooling device which comprises a mounting substrate. Mounting seats are arranged on the surface of the mounting substrate. A light source chip is mounted inside each mounting seat in a matched mode, and graphite plates are arranged on the light source chips and fixedly connected with a capillary pipe heat absorbing plate. The mounting substrate is fixedly connected with a bottom surface support inside a lampshade, and a motor is additionally mounted at the top end of the interior of the lampshade. Turbine blades are additionally mounted at the shaft end of the motor. Cooling grid plates are evenly mounted at the upper end of the side edge of the lampshade, cooling grids are arranged on the positions, below the cooling grid plates, of the surface of the lampshade, and the cooling grid plates and the capillary pipe heat absorbing plate are connected with a cooling liquid circulating device through guiding pipes. The cooling liquid circulating device and the motor are connected with a controller through wires. The novel high-power LED lamp cooling device has the multi-gear cooling capacity, an automatic control mode is adopted, and equipment energy consumption is greatly lowered on the premise of guaranteeing the cooling capacity.

Owner:中山市风华稀柠照明设计有限公司

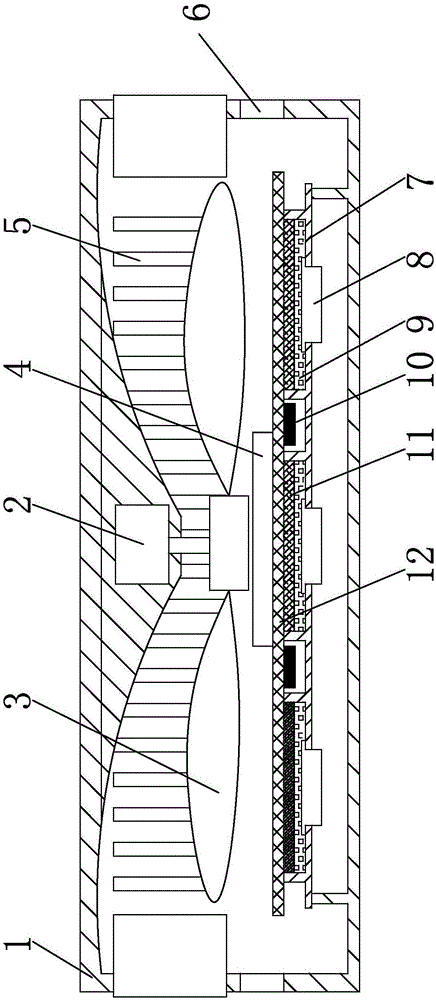

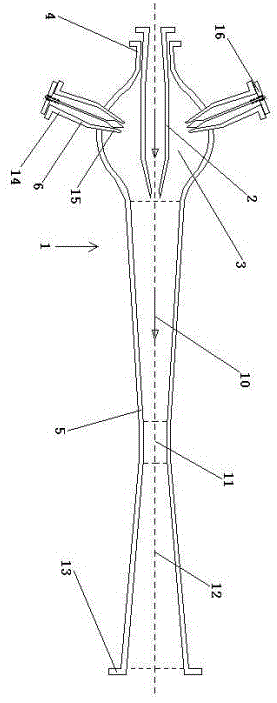

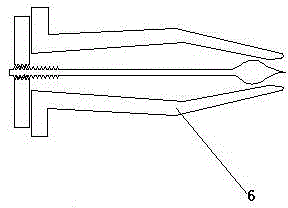

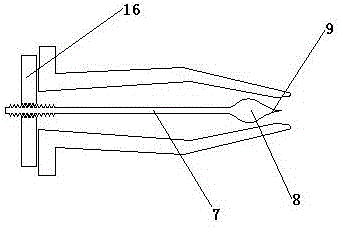

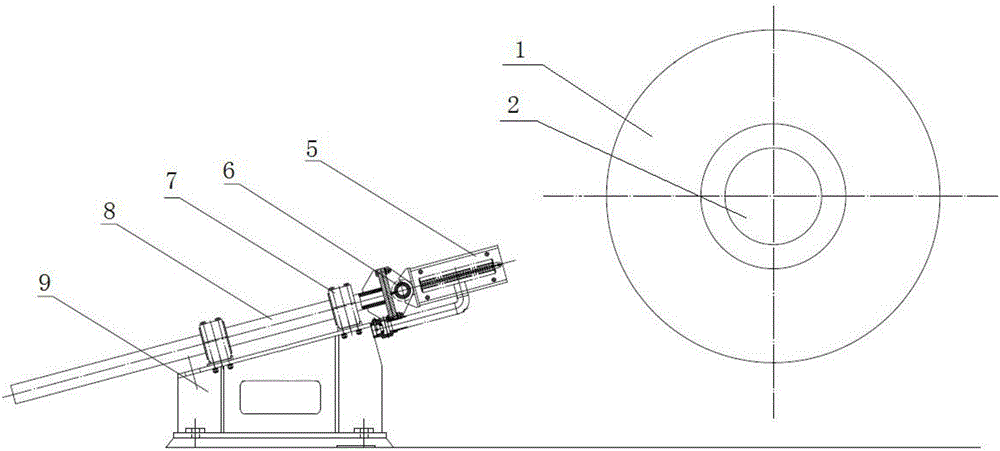

Pulverization matching-type multi-inlet medium ejector

The invention relates to a pulverization matching-type multi-inlet medium ejector which comprises a pipe body, a nozzle and at least two pulverization branch pipes, wherein the nozzle and the pulverization branch pipes are respectively and hermetically communicated with the pipe body; the pipe body is provided with a vacuum chamber as well as a nozzle hole and a venturi which are respectively and hermetically communicated with the vacuum chamber; the nozzle is arranged in the nozzle hole, and an atomizing nozzle is aslant communicated with the side periphery of the vacuum chamber; the free ends, which are located outside and inside the vacuum chamber, of the atomizing nozzle are respectively an outer port and an inner port; the interior axes of the pulverization branch pipes are provided with pulverization sticks; the free ends, which are located at the inner port, of the pulverization stick are provided with pulverization heads. The pulverization branch pipes are transformed into a pulverization device provided with the pulverization sticks, so that the flow velocity and pulverization degree of different steam or fluids which flow through the two pulverization branch pipes are adjusted by virtue of adjusting the positions of the pulverization heads in the inner port, and the different adjusting schemes of the pulverization sticks in the two pulverization branch pipes can be used for ensuring the matching of the fluids which enter into the ejector.

Owner:SUZHOU JINXIANG TITANIUM EQUIP

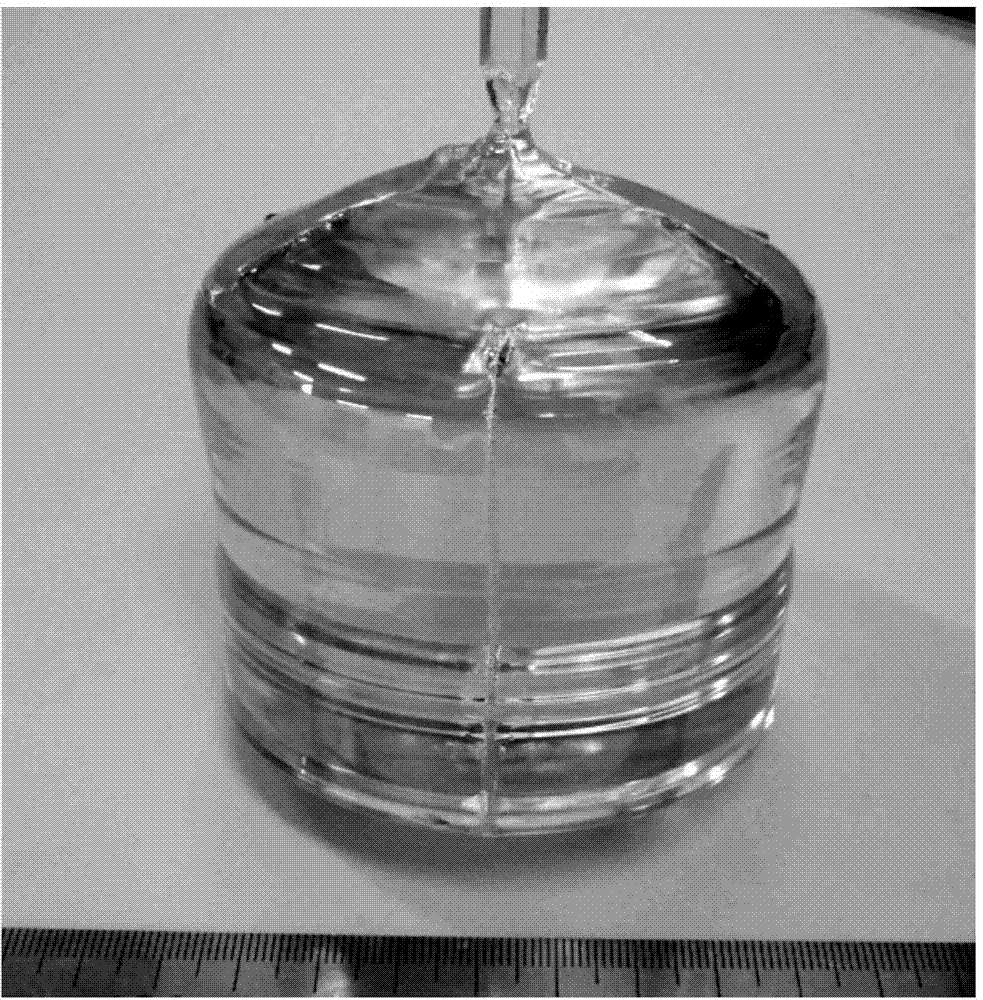

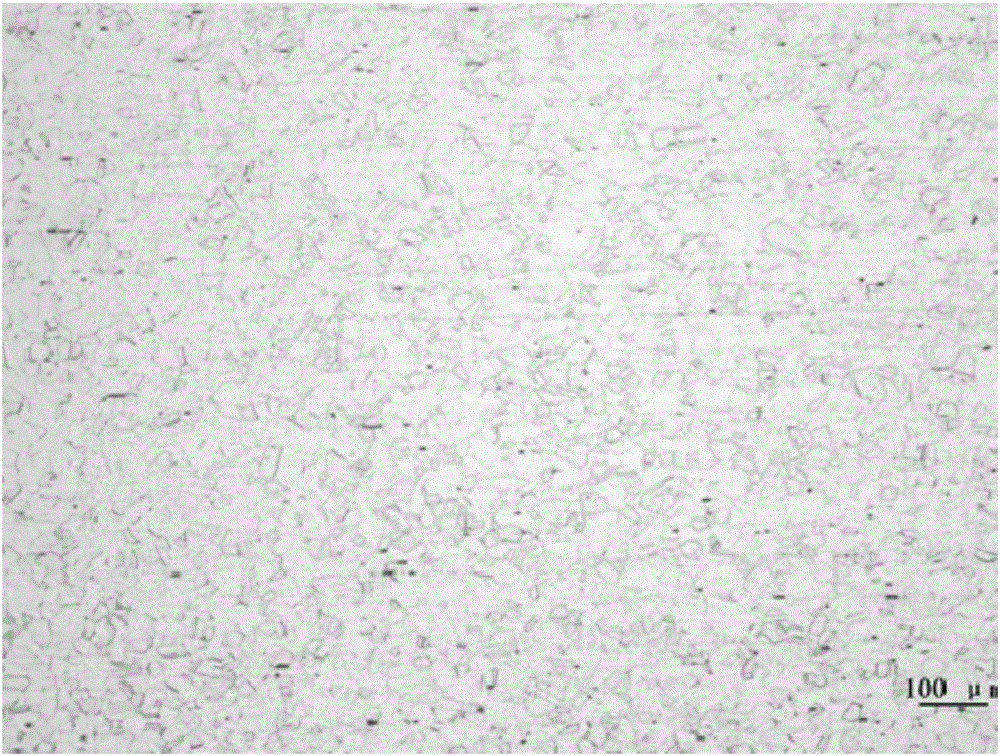

Batch synthesis method of lithium niobate uniformly-doped polycrystal material

The invention relates to a batch synthesis method of a lithium niobate uniformly-doped polycrystal material, belonging to the field of inorganic material preparation. The method comprises the following steps of dissolving magnesium oxide into organic acid to sufficiently react with organic acid to form colorless and transparent solution; then adding a certain proportion (stoichiometric or identical component) of niobium oxide and lithium carbonate nano particles, uniformly mixing by using a ball-milling technology to form a suspension; carrying out spray drying on the suspension to obtain doped lithium niobate polycrystal precursor, wherein the precursor particle is a nano particle formed by uniformly doping magnesium ions into niobium oxide and lithium carbonate; and finally, carrying out low-temperature sintering on the precursor to obtain granular lithium niobate uniformly-doped polycrystal material with uniform components. According to the invention, used raw materials are conventional materials, and niobium oxide and lithium carbonate are more uniformly mixed in the solution. The method is suitable for synthesis of other doped raw materials and has universality.

Owner:SHANDONG UNIV

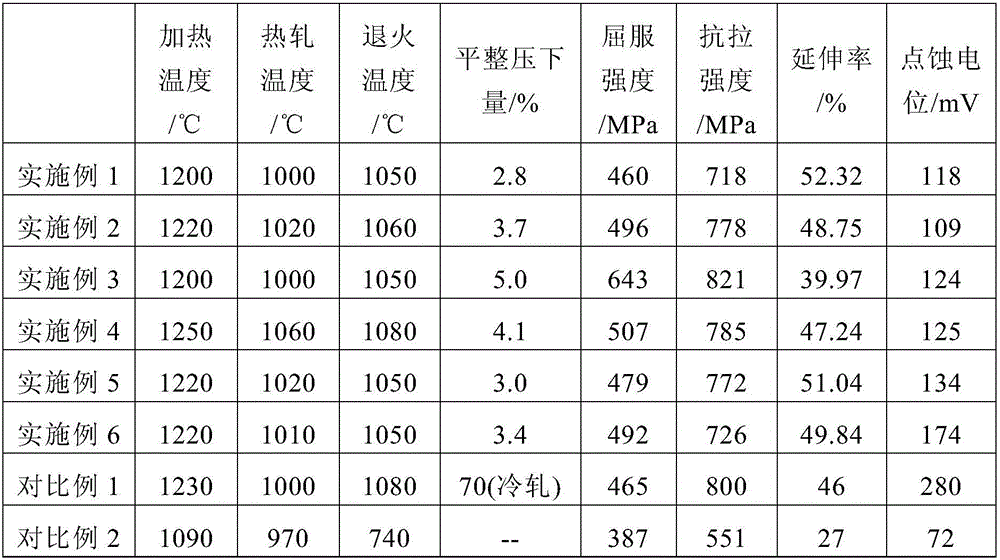

High-strength austenitic stainless steel for economical railway vehicle and manufacturing method thereof

The invention discloses high-strength austenitic stainless steel for an economical railway vehicle and a manufacturing method thereof. The high-strength austenitic stainless steel comprises the following chemical components in percentage by mass: 0.03-0.12% of C, 0.4-0.8% of Si, 8.5-14.5% of Mn, 14.0-15.5% of Cr, 1.2-1.8% of Ni, 0.15-0.25% of N, V not more than 0.15%, Ti not more than 0.10%, V+Ti not less than 0.05%, Cu not more than 0.60%, P not more than 0.03%, S not more than 0.01%, and the balance of Fe and inevitable impurities; the room-temperature yield strength is not less than 400 MPa; the tensile strength is not less than 700 MPa; and the ductility is not less than 35%. The stainless steel is applied to the railway vehicle, and can reduce the manufacturing cost under the precondition of satisfying the safety requirement; and the stainless steel is applied to a railway truck, can improve the strength when guaranteeing the economy and the service life, and improves the vehicle lightness level.

Owner:BAOSTEEL DESHENG STAINLESS STEEL

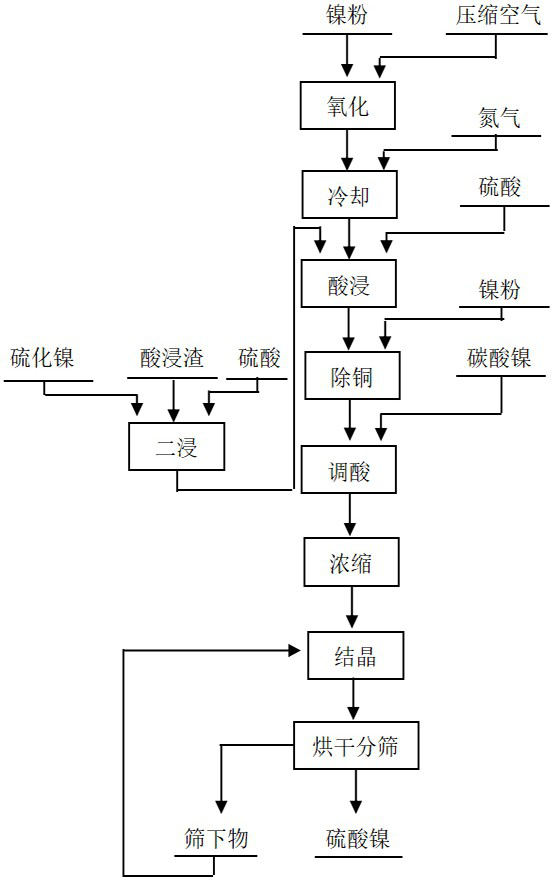

Method for preparing electronic-grade nickel sulfate from nickel powder, crystallization device and control method of crystallization device

PendingCN113321248AIncrease the concentration of nickel ionsCrystalline Free Acid ControlSolution crystallizationNickel sulfatesAcid dissolutionHydrometallurgy

The invention discloses a method for preparing electronic-grade nickel sulfate from nickel powder, a crystallization device and a control method of the crystallization device, and relates to the technical field of non-ferrous metal hydrometallurgy. The method comprises the steps of oxidation, cooling, acid leaching, copper removal, acid adjustment, concentration, cooling crystallization, drying and screening, and secondary leaching, and is characterized in that in the oxidation step, the temperature of nickel powder in a calcining furnace is controlled to be 400-700 DEG C, the use amount of compressed air for each kilogram of nickel powder is 1-5 m3, and the reaction is carried out for 1.0-2.5 hours; the acid leaching comprises the following steps: putting the cooled nickel oxide in a reactor, controlling the temperature to be 45-70 DEG C, adding dilute sulfuric acid to control the pH value to be 0.5-1.5, and reacting for 1-3 hours. The invention also provides a crystallization device and a control method of the crystallization device. According to the method, metal nickel can be oxidized into divalent nickel oxide, hydrogen cannot be released when acid is added for dissolution, a large number of oxidizing agents do not need to be additionally added, new impurity ions are not added in the process, the nickel ion concentration is relatively improved, and nickel sulfate crystal particles are uniform.

Owner:HUNAN JINYUAN NEW MATERIALS CO LTD

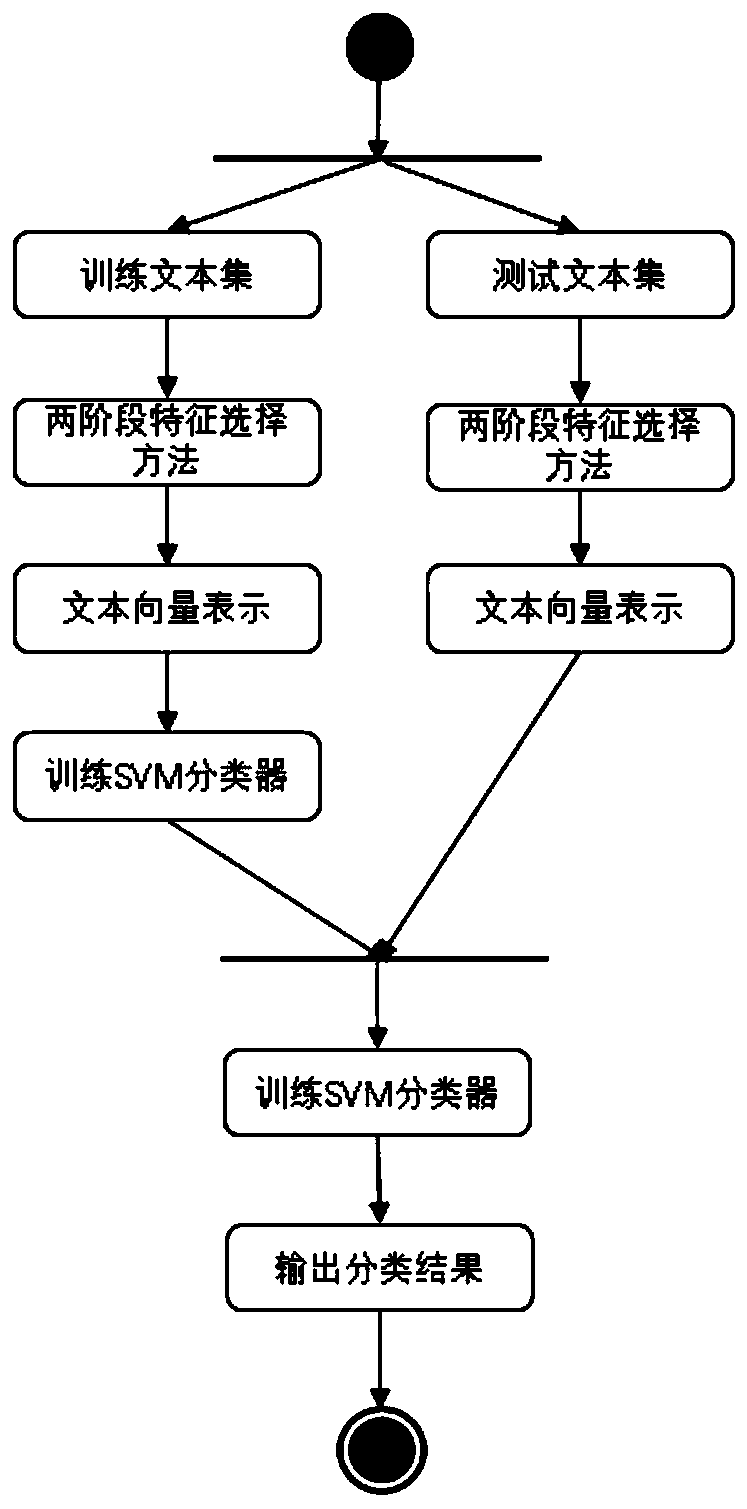

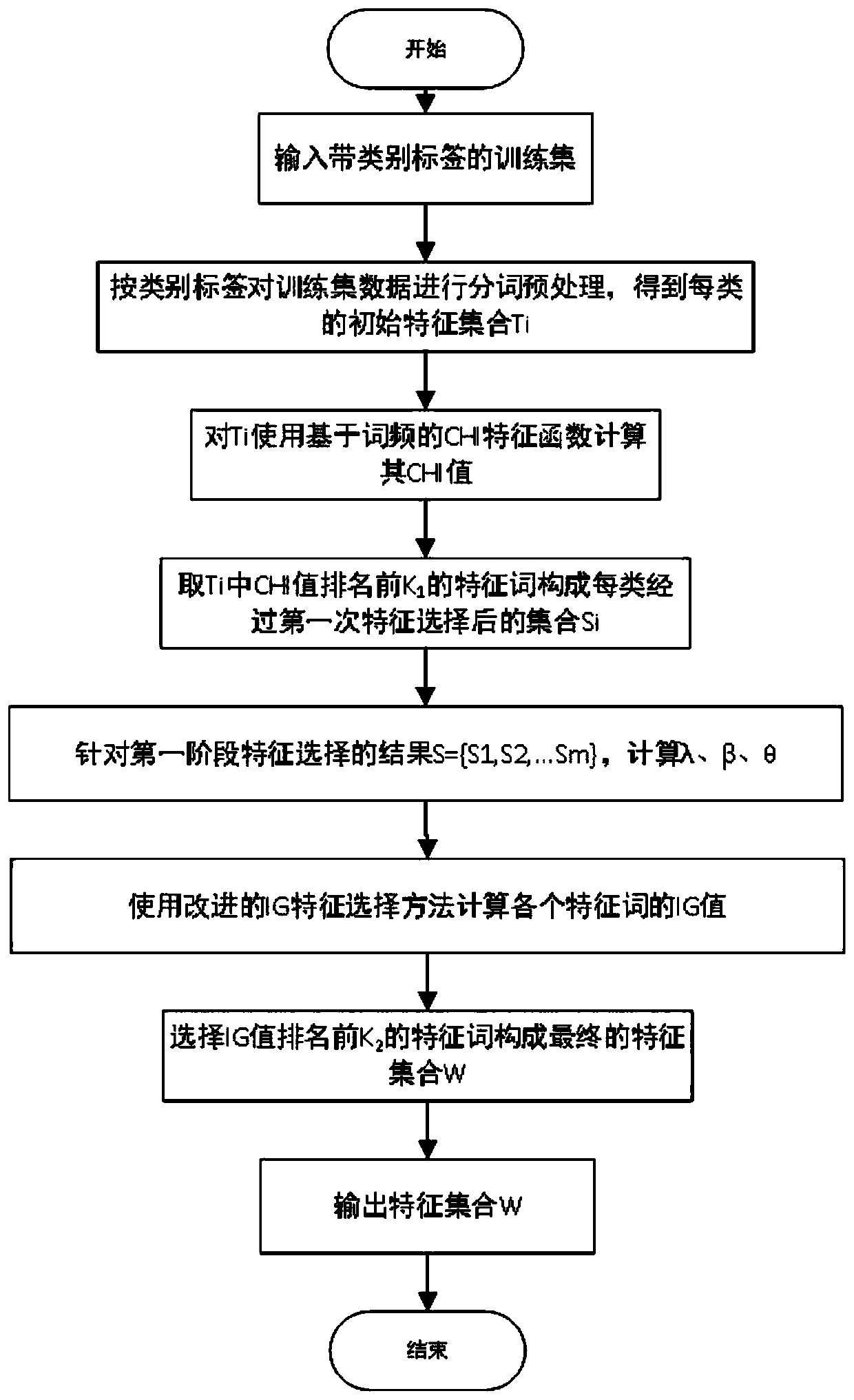

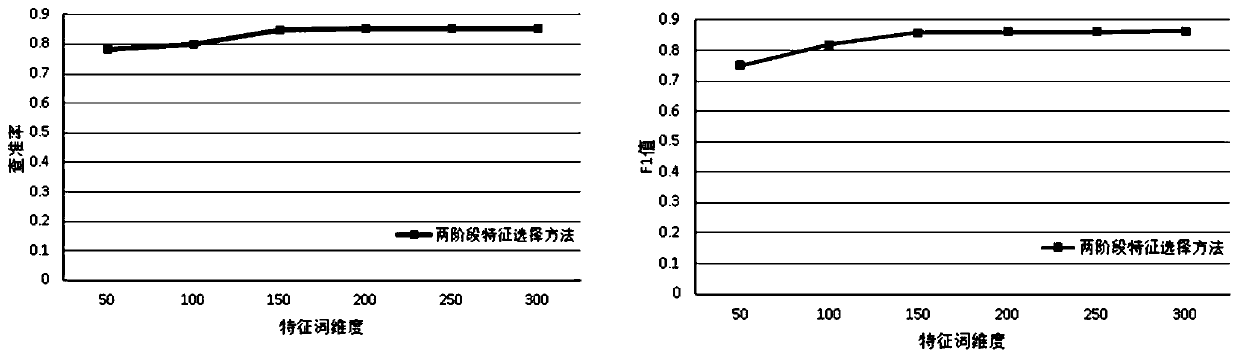

Two-stage text feature selection method under unbalanced data set

ActiveCN111144106AReasonable designGood effectCharacter and pattern recognitionNatural language data processingData setFeature set

The invention discloses a two-stage text feature selection method under an unbalanced data set, and belongs to the field of text feature selection in natural language processing. According to the invention, word segmentation preprocessing is carried out on training set data according to category labels; an initial feature set Ti is formed for each category, a CHI method based on word frequency isused for carrying out first-stage local feature selection on Ti, and then an improved IG method is used for carrying out second-stage global feature selection on a result obtained after first-stage feature selection. The invention relates to a feature selection method considering global and local features. The proportion of the features in the small class samples in the final feature set is ensured; a comparison experiment is performed on the method and three related feature selection methods on a news corpus with a label provided by a Sogou laboratory, a result shows that the method is superior to the compared methods in precision ratio, recall ratio and F1 value, and the classification accuracy of the unbalanced data set is improved.

Owner:SHANDONG UNIV OF SCI & TECH

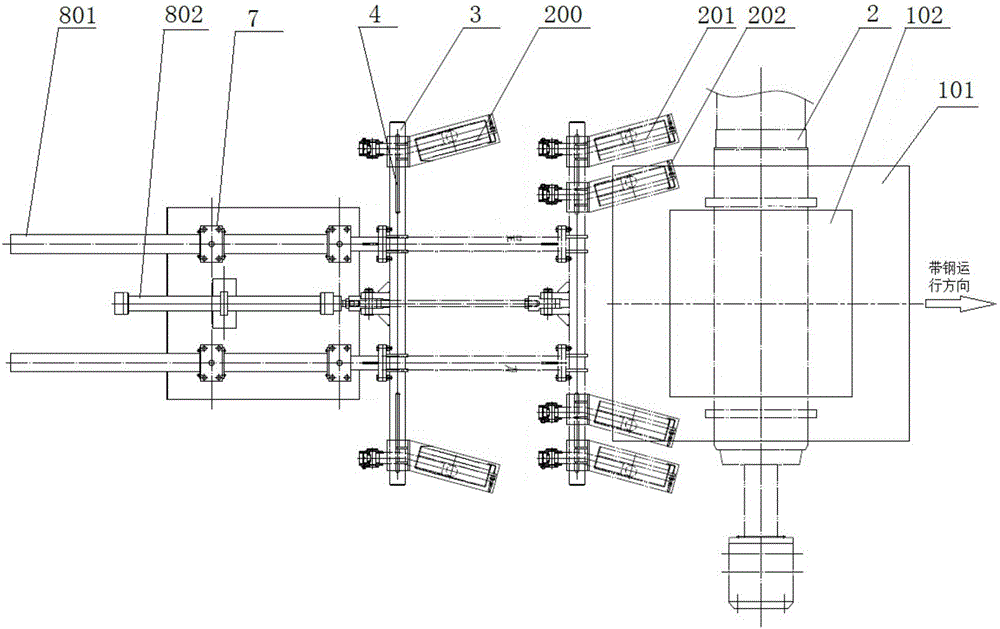

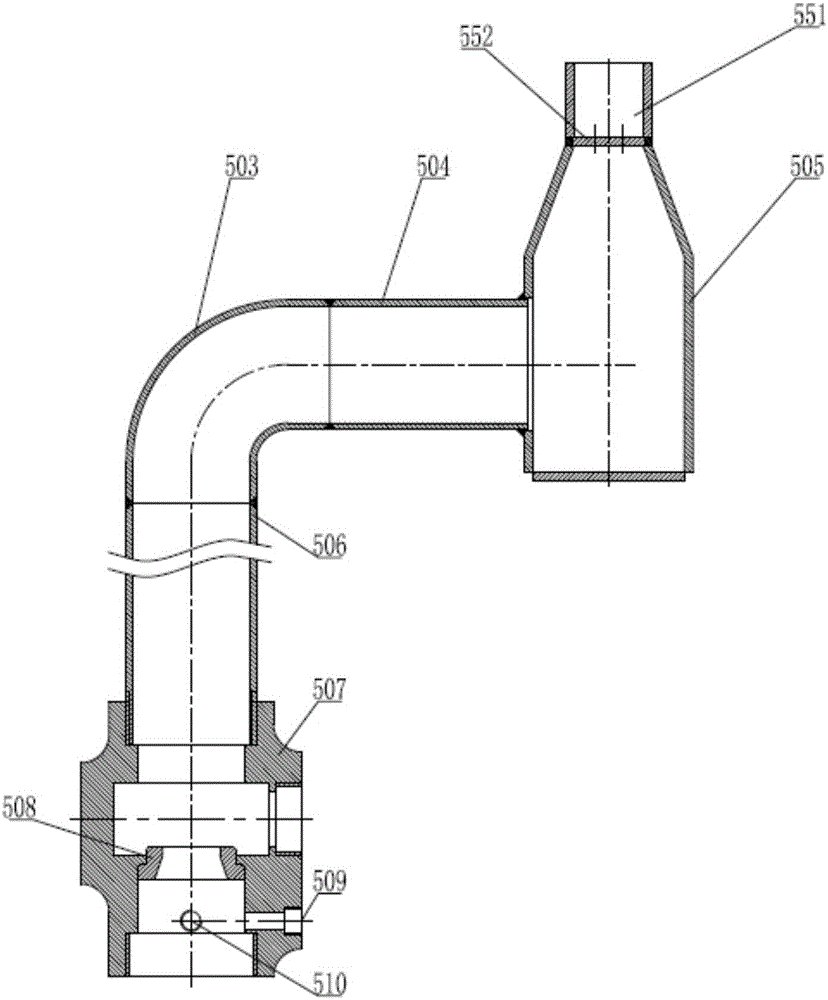

Edge heating apparatus for preventing cracking of edges of band steel, and method thereof

ActiveCN104985021AImprove the heating effectImprove uniformityTemperature control deviceCombustion chamberEngineering

The invention discloses an edge heating apparatus for preventing cracking of edges of band steel, and a method thereof. The apparatus comprises a base support, a moving mechanism, a heating mechanism and a PLC; the base support is arranged at one side of an uncoiler; the moving mechanism is arranged on the upper end surface of the base support, and the moving mechanism comprises a vertical bracket, vertical drivers, transverse brackets, transverse guide rails and a transverse driver; the heating mechanism is fixedly arranged on the transverse guide rails, and the heating mechanism comprises an igniting electrode, a combustion chamber, a nozzle plate, a nozzle, an air and gas mixing tube and an air and gas mixer; and the PLC is respectively connected with the vertical drivers, the transverse driver and the igniting electrode. The edges of the band steel can be heated to an assigned temperature through the method by using the apparatus to eliminate a temperature difference of the strip steel in the width direction in order to effectively eliminate cracking of the edges in the uncoiling process of steel coils.

Owner:WISDRI WUHAN WIS IND FURNACE

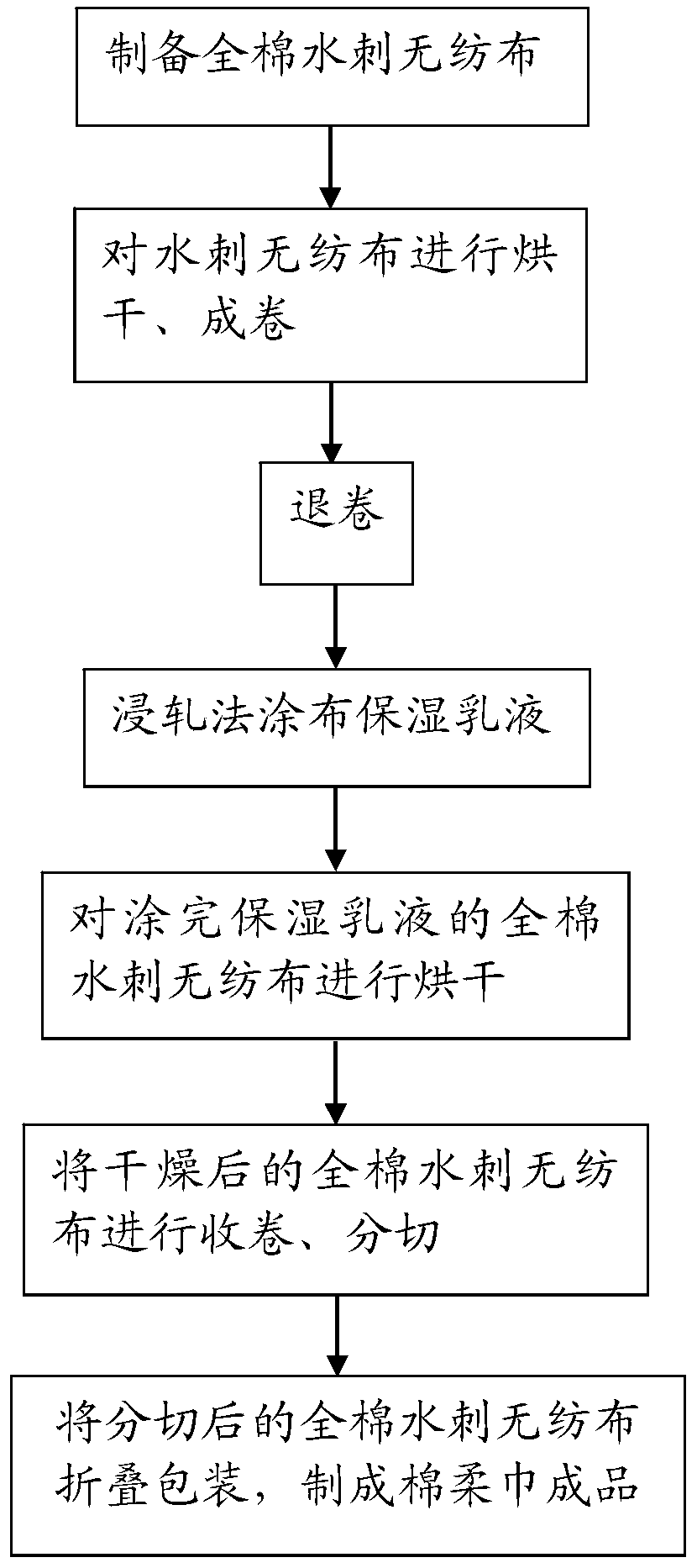

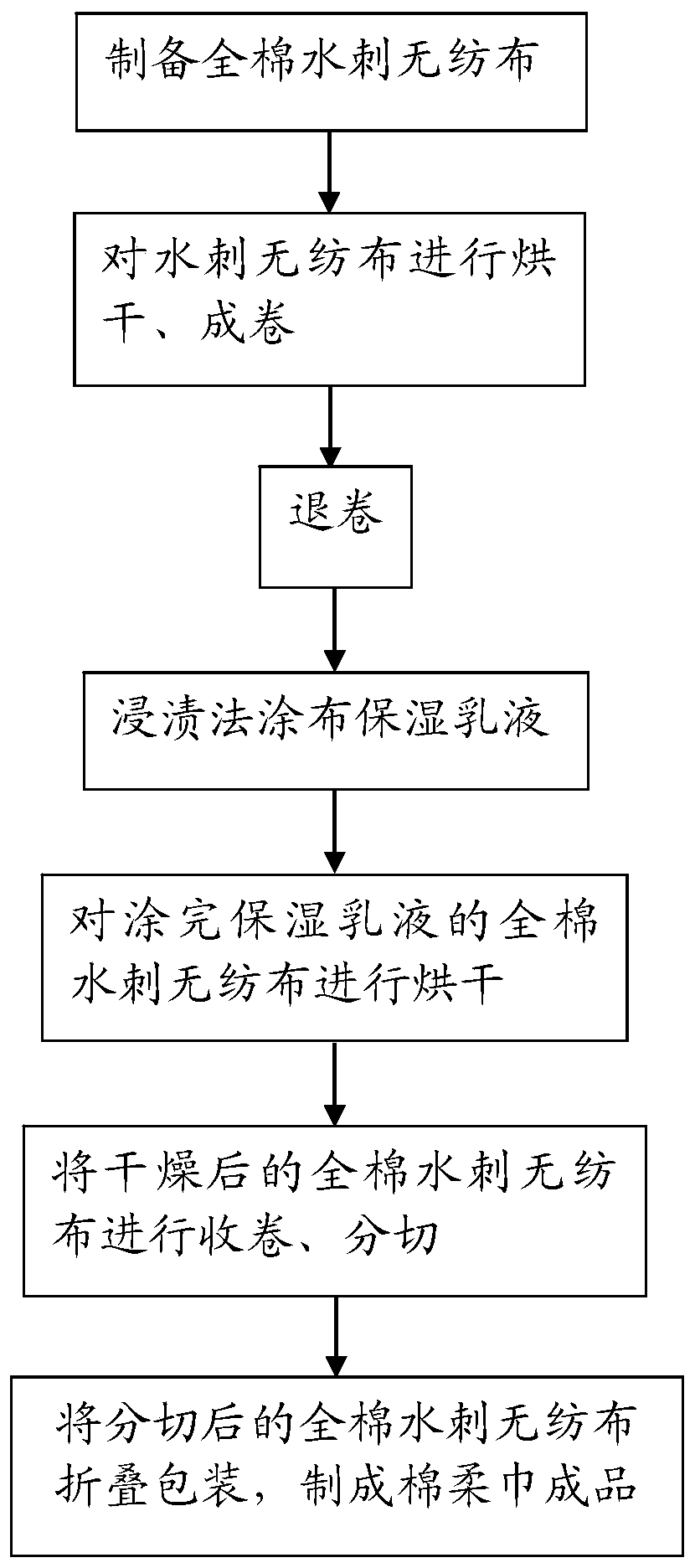

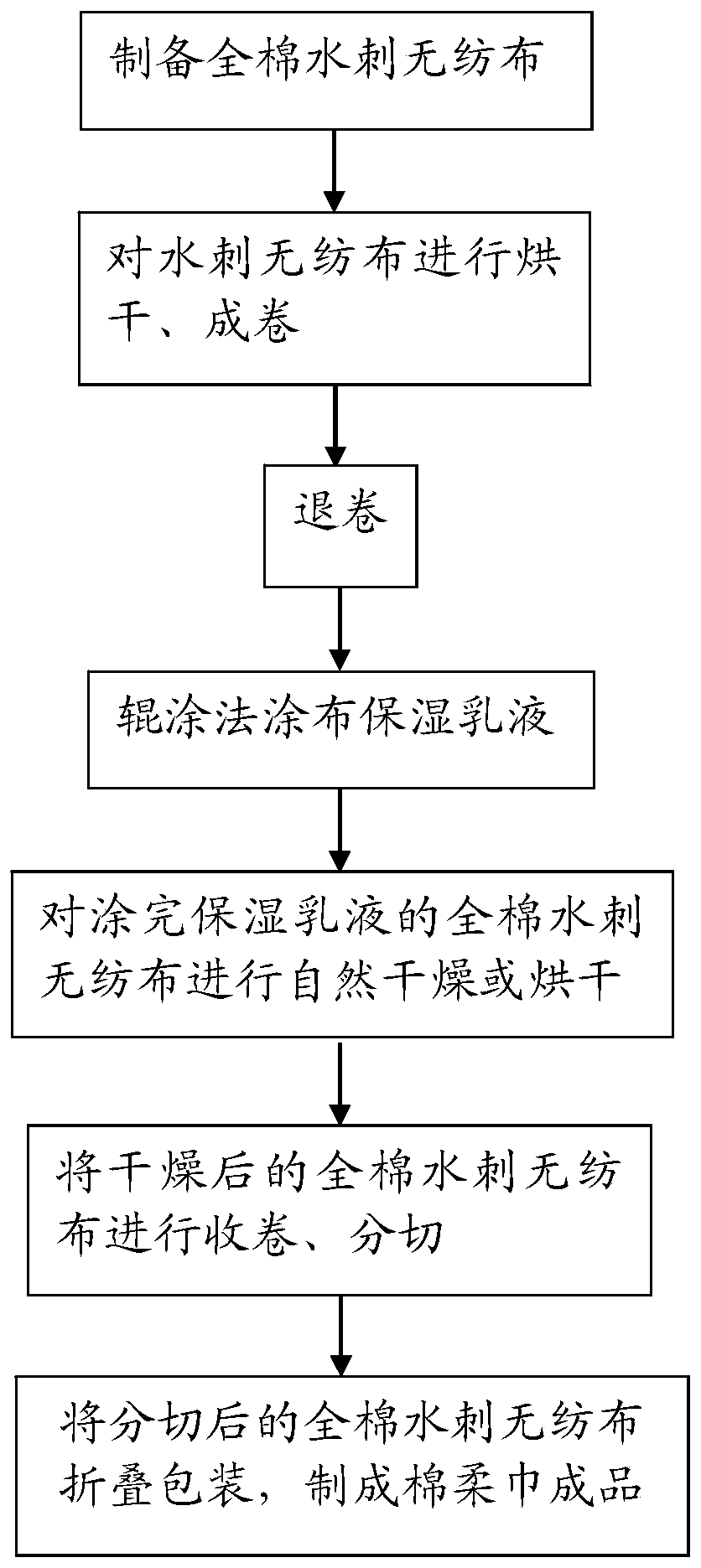

Preparation method of super-soft moisturizing cotton towel and super-soft moisturizing cotton towel

InactiveCN111270412AGuaranteed ratioMaintain soft propertiesTextile treatment by spraying/projectingNon-woven fabricsTextile printerPolymer science

The invention discloses a preparation method of a soft moisturizing cotton towel and the soft moisturizing cotton towel. The method comprises the steps of preparing an all-cotton spunlaced nonwoven fabric; performing unwinding; applying a moisturizing emulsion; drying the all-cotton spunlaced nonwoven fabric coated with the moisturizing emulsion; and performing processes of winding, slitting, finishing and the like on the dried all-cotton spunlaced nonwoven fabric. Main components of the moisturizing emulsion are a humectant, lipids and pure water. A method for adding a moisturizing solution incudes a padding method, an impregnation method, a roll coating method, a printing method, a stamping method, a dry cloth spraying method and a wet cloth spraying method, and the addition amounts ought to be designed in the seven methods respectively ensure the proportion of the moisturizing solution on the soft cotton towel, so that the moisturizing emulsion can completely permeate an inner layerof the fabric, fibers are fully moistened, and the overall softness characteristic of the interior and exterior of the soft cotton towel can be ensured after drying.

Owner:WINNER MEDICAL (HUANGGANG) CO LTD +1

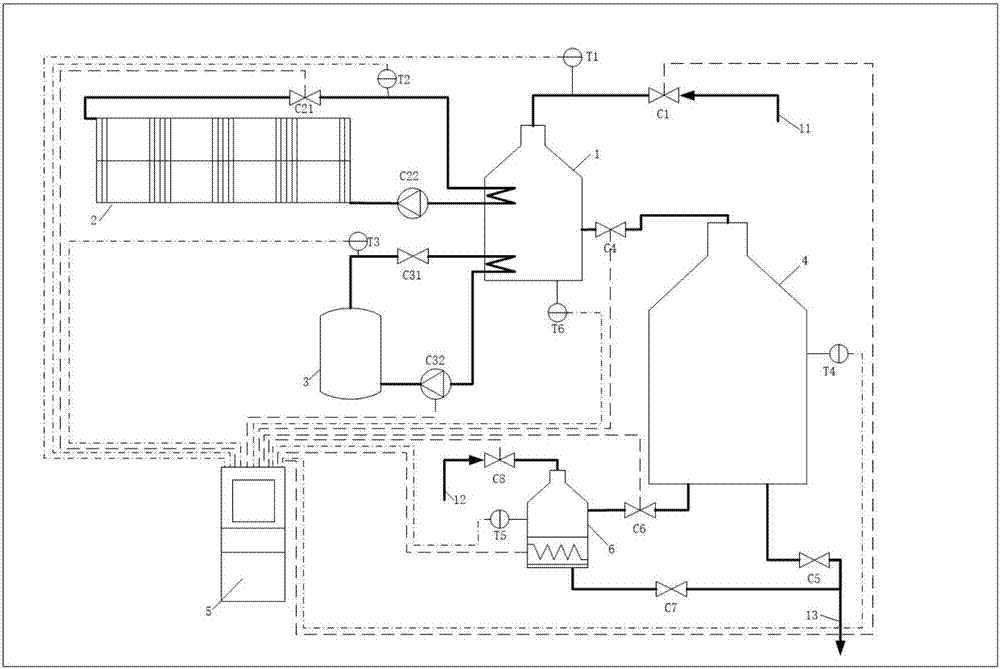

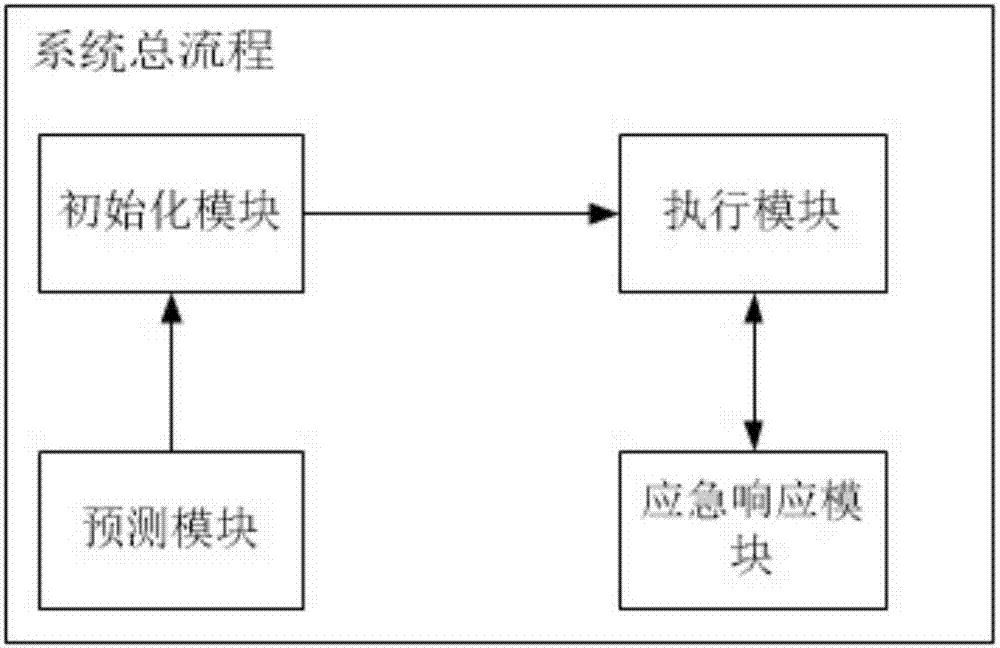

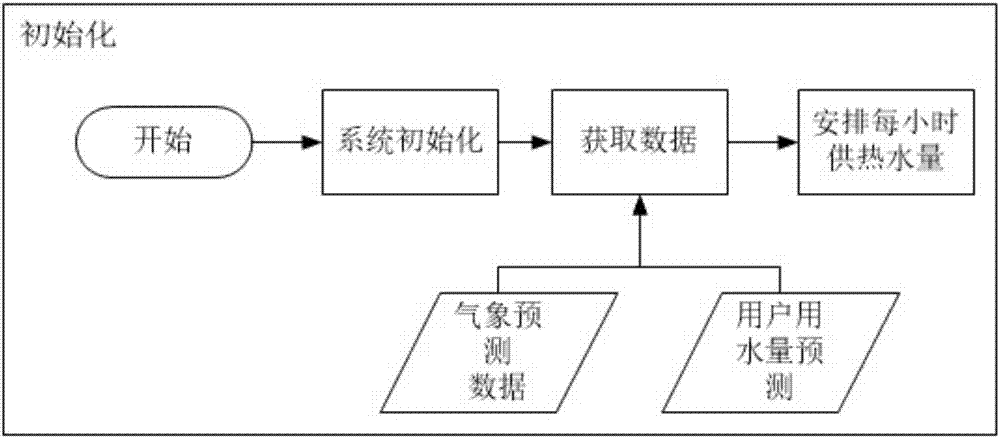

Solar composite heat source hot water system and control method thereof

InactiveCN107131552ANo need to change water habitsReduce output costLighting and heating apparatusClimate change adaptationWater useWater storage tank

The invention discloses a solar composite heat source hot water system, and relates to the field of hot water supply systems. The system comprises a solar heat collector, an auxiliary heat source, a heat supply water tank, a heat storage water tank and a control device; the solar heat collector and the auxiliary heat source are connected with the heat supply water tank through a pipeline, the heat supply water tank is connected with a heat exchanger in the heat storage water tank, the control device is connected with valves and control pumps on pipelines, and through meteorological forecasting data and water using amount forecasting data, opening and closing instructions are sent to the valves and / or control valves; on the basis of not additionally arranging or modifying equipment configuration, and not changing the user hot water using habits, hot water is provided for a user ceaselessly for 24 hours; the system and the control method can ensure the proportion of solar energy in the whole system to the maximum extent, the system efficiency is improved, the hot water output cost is reduced, the redundant hot water amount in the water storage tank can be reduced to the great extent, and energy losses caused by hot water cooling is avoided.

Owner:SHANGHAI JIAO TONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com