Preparation method of perovskite type nanocrystalline

A perovskite type and nanocrystal technology, applied in nanotechnology, nano optics, nanotechnology, etc., can solve the problems of poor performance of perovskite quantum dots and insufficient halogen ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

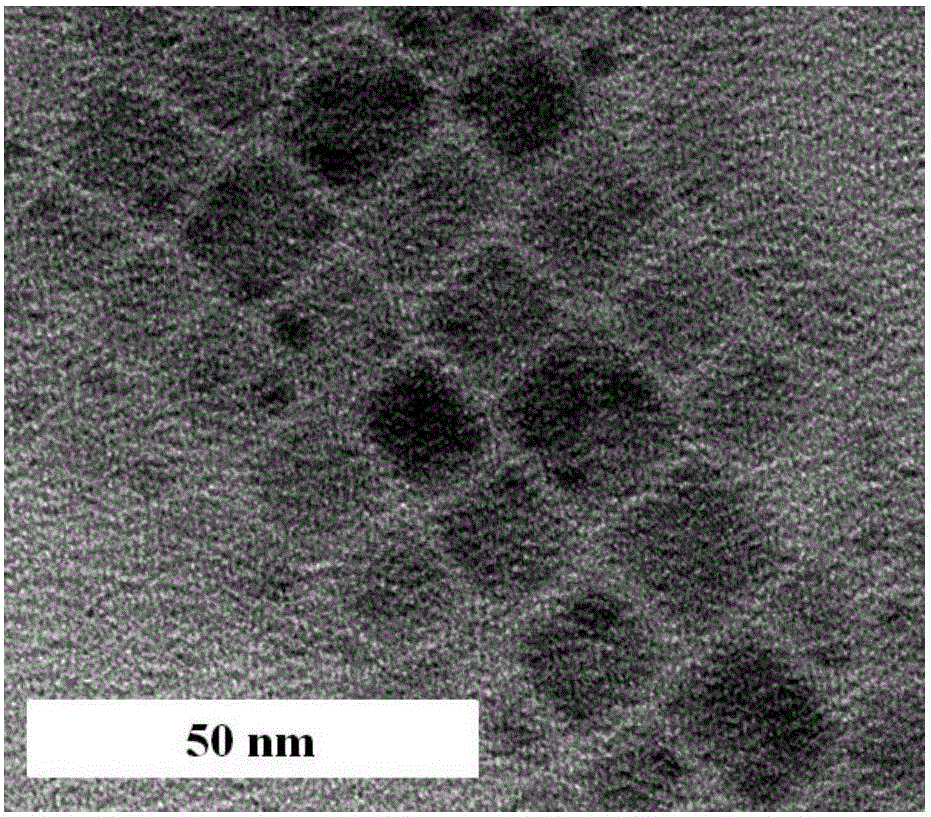

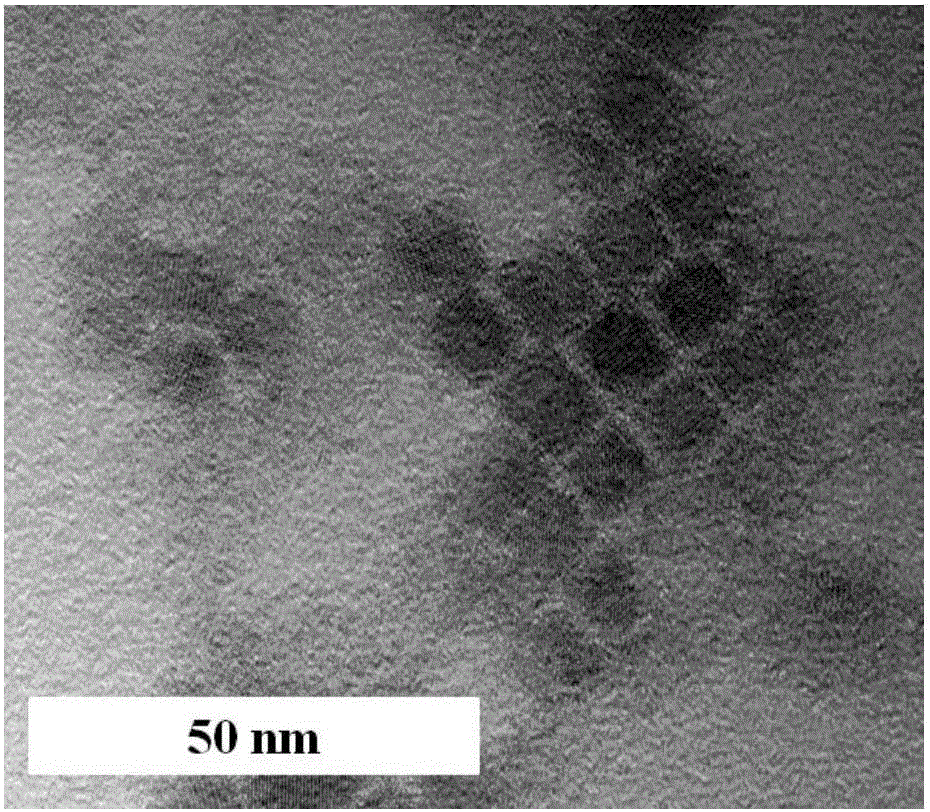

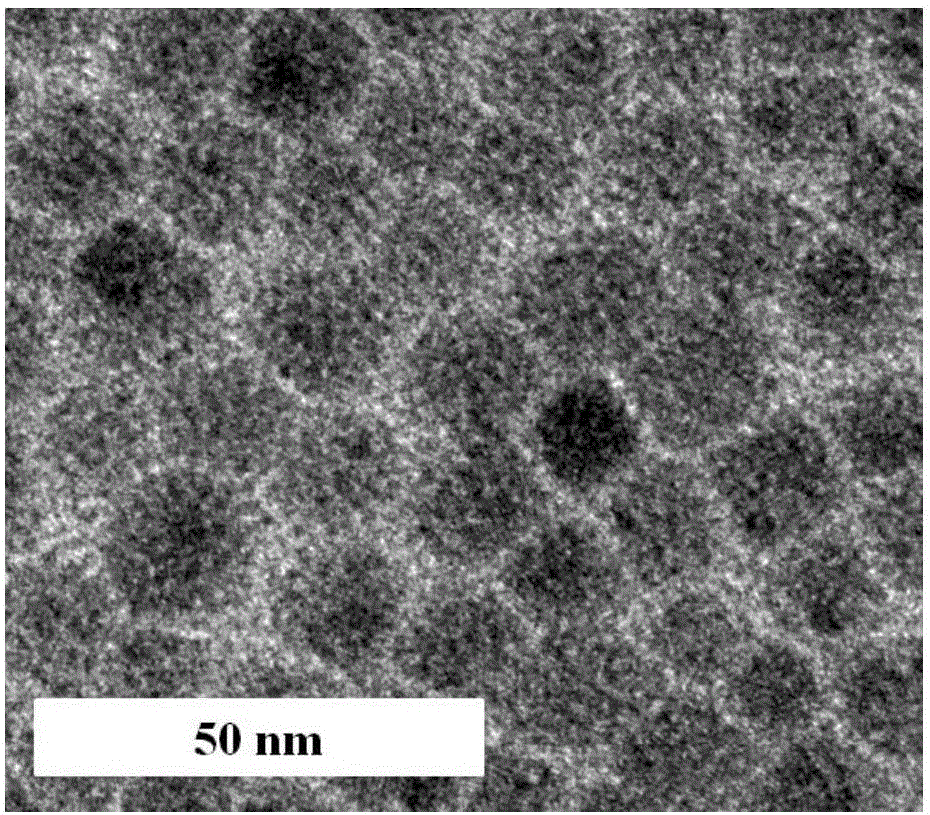

Image

Examples

Embodiment 1

[0082] A preparation method of perovskite nanocrystals, said method comprising the following steps:

[0083] (1) Dry oleic acid at 100°C for 120min, mix 1 part of CsCl, 35 parts of eicosene and 2 parts of oleic acid, vacuum degas, dry at 100°C for 120min, and heat to 120°C under the protection of argon. ℃ for 0.5h to obtain cesium oleate solution;

[0084] (2) Dry oleylamine and oleic acid at 100°C for 120 min, add 4 parts of PbO, 20 parts of NH 4 Cl and 600 parts of eicosene were mixed, vacuum degassed, dried at 100°C for 60 minutes, then injected with 50 parts of oleylamine and 50 parts of oleic acid, vacuum degassed, dried at 100°C for 120 minutes, heated to 120°C, Inject the cesium oleate solution that step (1) obtains under gas protection, react quickly for 15s, and cool in an ice bath;

[0085] (3) Add an equal volume of acetone to the reaction in step (2) and the cooled stock solution, centrifuge at 8000rpm for 5min, and get the precipitate; disperse the precipitate i...

Embodiment 2

[0088] A preparation method of perovskite nanocrystals, said method comprising the following steps:

[0089] (1) Dry oleic acid at 150°C for 10min, mix 1 part of CsBr, 75 parts of octadecene and 5 parts of oleic acid, vacuum degas, dry at 150°C for 10min, and heat to 180°C under nitrogen protection Reaction 3h, obtains cesium oleate solution;

[0090] (2) Dry oleylamine and oleic acid at 150°C for 10 minutes, mix 12 parts of PbO, 40 parts of NH 4 Br and 1000 parts of octadecene were mixed, vacuum degassed, dried at 150°C for 10 minutes, then injected with 80 parts of oleylamine and 80 parts of oleic acid, vacuum degassed, dried at 150°C for 10 minutes, heated to 250°C, Inject the cesium oleate solution obtained in step (1) under protection, react quickly for 1 s, and cool in an ice bath;

[0091] (3) Add an equal volume of acetone to the reaction in step (2) and the cooled stock solution, centrifuge at 12000rpm for 1min, and get the precipitate; disperse the precipitate in t...

Embodiment 3

[0094] A preparation method of perovskite nanocrystals, said method comprising the following steps:

[0095] (1) Dry the oleic acid at 120°C for 60min, add 1 part of Cs 2 1. 50 parts of hexadecene and 3.2 parts of oleic acid were mixed, vacuum degassed, dried at 120° C. for 60 minutes, and heated to 150° C. for 1 hour under argon protection to obtain cesium oleate solution;

[0096] (2) Dry oleylamine and oleic acid at 120°C for 60 minutes, mix 8 parts of PbO, 32 parts of NH 4 I and 800 parts of hexadecene were mixed, vacuum degassed, dried at 120°C for 0.5min, then injected with 66 parts of oleylamine and 67 parts of oleic acid, vacuum degassed, dried at 120°C for 60min, heated to 180°C, Inject the cesium oleate solution obtained in step (1) under nitrogen protection, react quickly for 5s, and cool in an ice bath;

[0097] (3) Add an equal volume of acetone to the reaction in step (2) and the cooled stock solution, centrifuge at 10000rpm for 3min, and get the precipitate; d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com