Batch synthesis method of lithium niobate uniformly-doped polycrystal material

A technology of magnesium lithium niobate, chemical synthesis, applied in niobium compounds, chemical instruments and methods, inorganic chemistry and other directions, can solve the problems of soil environmental pollution, cumbersome preparation process, unsuitable for batch crystal production, etc. The effect of volatilization, low sintering temperature and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

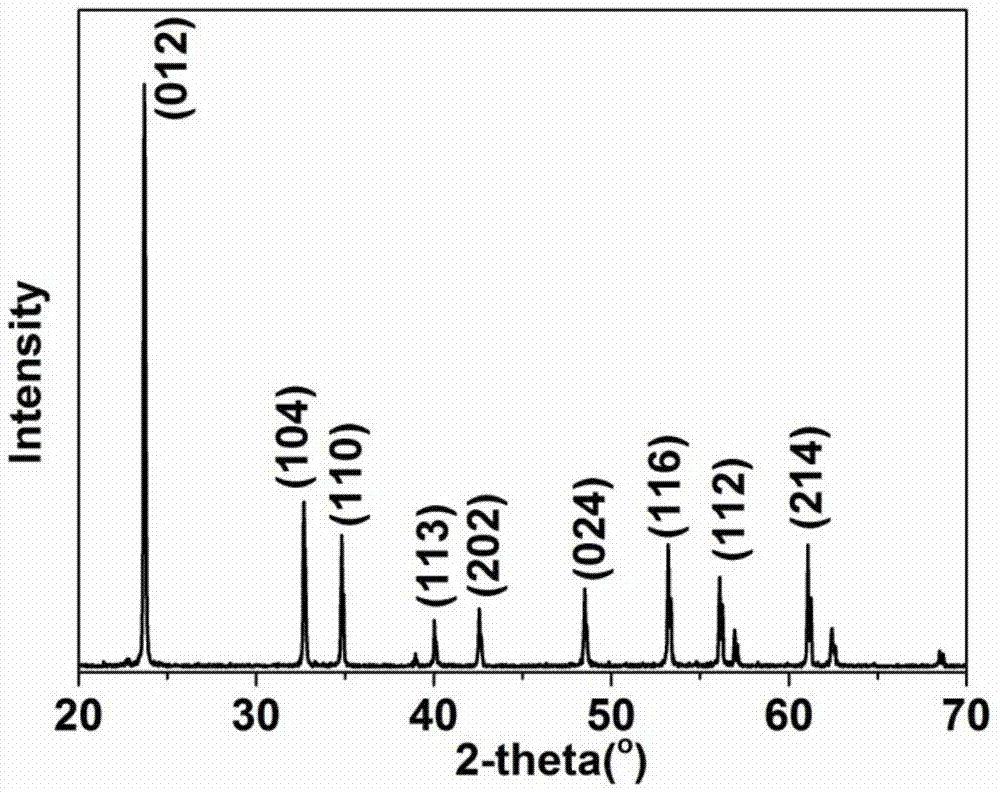

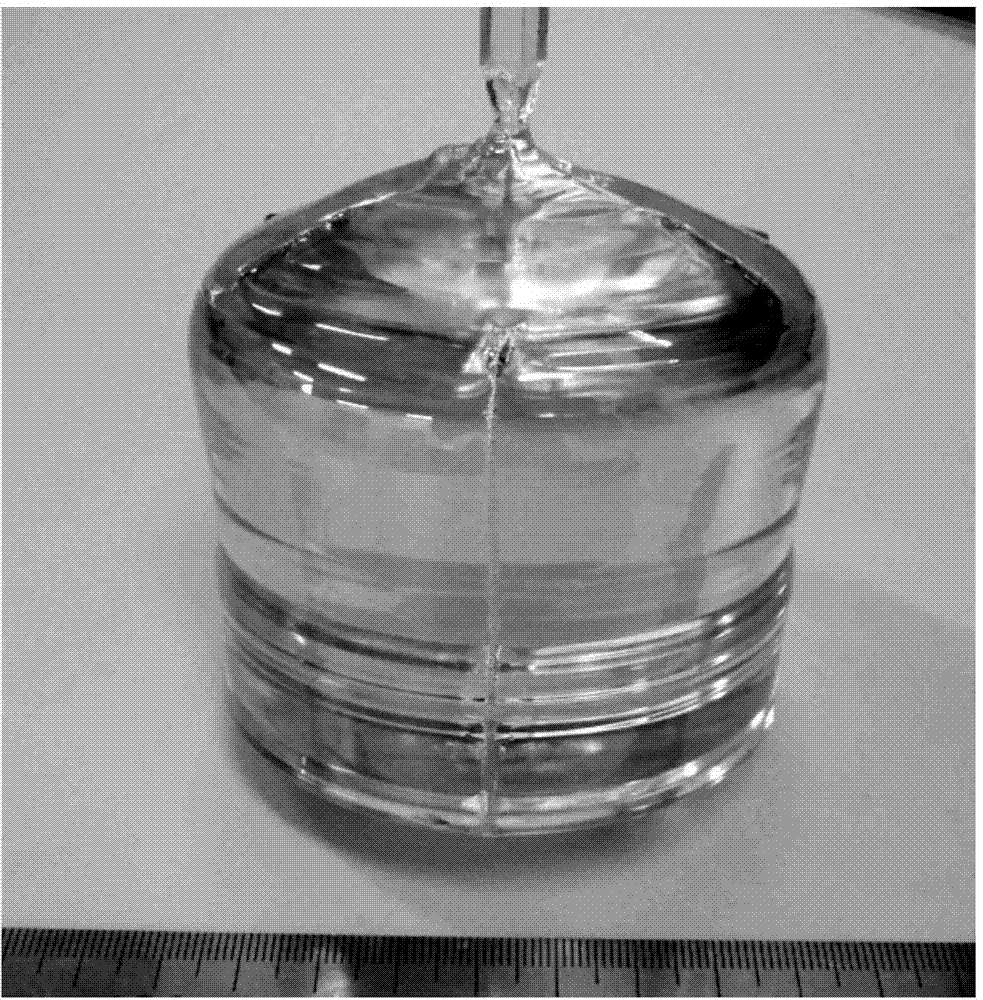

[0024] Synthesis of 1mol% Magnesium Doped Stoichiometric Lithium Niobate Polycrystalline Material

[0025] (1) Weigh 0.303g of MgO powder, add it to 30mL of 1mol / L citric acid solution, heat and stir until boiling, so that MgO is fully dissolved, and a stable transparent solution is obtained.

[0026] (2) Add deionized water to the solution obtained in step (1) until the total liquid volume is 200mL, add 1.5mL dispersant Tween 80 after cooling, and then adjust the pH value to 10 by adding ammonia water dropwise.

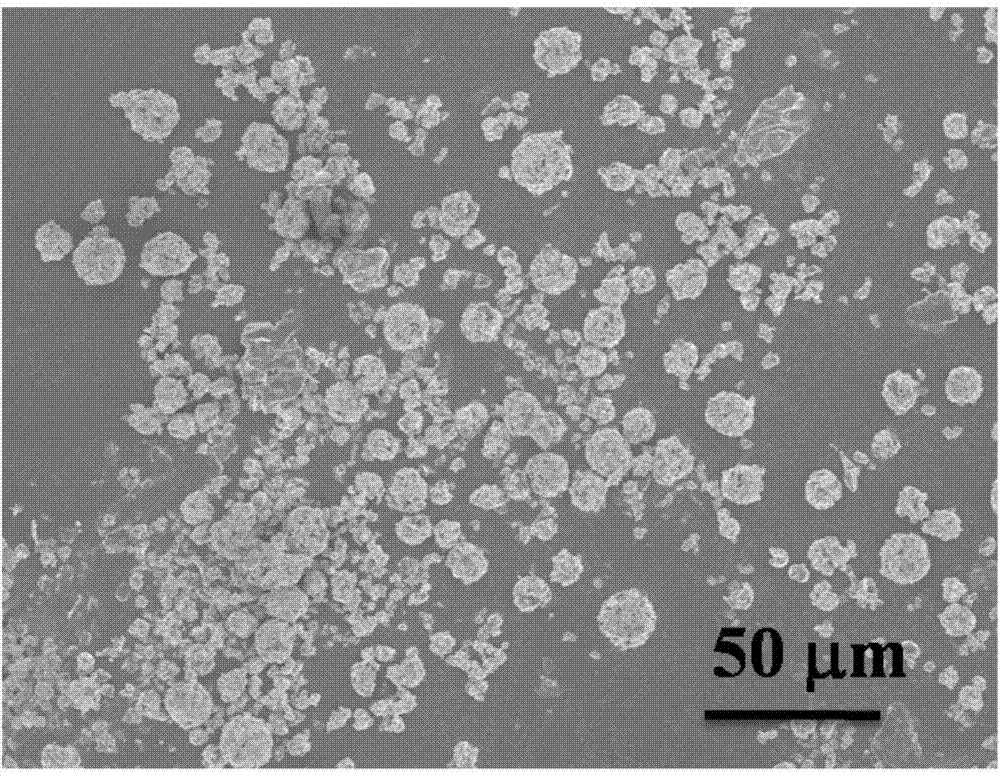

[0027] (3) Weigh 100g of niobium oxide and 38.388g of lithium carbonate, add them to the solution obtained in step (2), and ball mill the obtained suspension for 2 hours (the balls are selected as lithium niobate crystal balls) to achieve two solid phases Uniform and stable mixing of powder and magnesium ion solution. Using spray drying technology, the uniformly mixed solid phase and liquid phase substances are solidified (the temperature of the air inlet during spr...

Embodiment 2

[0030] Synthesis of 5mol% Mg-doped lithium niobate polycrystalline material with the same composition

[0031] (1) Weigh 1.516g of MgO powder, add it to 150mL of 1mol / L citric acid solution, heat and stir until boiling, so that MgO is fully dissolved, and a stable transparent solution is obtained.

[0032] (2) Add deionized water to the solution obtained in step (1) until the total liquid volume is 200mL, add 2mL dispersant Tween 80 after cooling, and then adjust the pH value to 10 by adding ammonia water dropwise.

[0033] (3) Weigh 100g of niobium oxide and 26.284g of lithium carbonate, add them to the solution obtained in step (2), and conduct ball milling on the obtained suspension for 5 hours (the balls are selected as lithium niobate crystal balls) to achieve two solid phases Uniform and stable mixing of powder and magnesium ion solution. Using spray drying technology, the uniformly mixed solid phase and liquid phase substances are solidified (the temperature of the air...

Embodiment 3

[0036] Synthesis of 6mol% Mg-doped lithium niobate polycrystalline material with the same composition

[0037](1) Weigh 1.819g of MgO powder, add it into 180mL of 1mol / L citric acid solution, heat and stir until boiling, so that MgO is fully dissolved, and a stable transparent solution is obtained.

[0038] (2) Add deionized water to the solution obtained in step (1) until the total liquid volume is 200mL, add 1.0mL dispersant Tween 80 after cooling, and adjust the pH value to 11 by adding ammonia water dropwise.

[0039] (3) Weigh 100g of niobium oxide and 26.284g of lithium carbonate, add them to the solution obtained in step (2), and ball mill the obtained suspension for 4 hours (the balls are selected as lithium niobate crystal balls) to achieve two solid phases Uniform and stable mixing of powder and magnesium ion solution. Using spray drying technology, the uniformly mixed solid phase and liquid phase substances are solidified (the temperature of the air inlet during sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com