Preparation method of C.I. pigment yellow 151

A technology of pigment yellow and molar weight, applied in chemical instruments and methods, azo dyes, organic dyes, etc., can solve the problems of increasing product production cost, inconvenient production and use, and waste water, and achieves saving ice cost and reducing consumption. , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

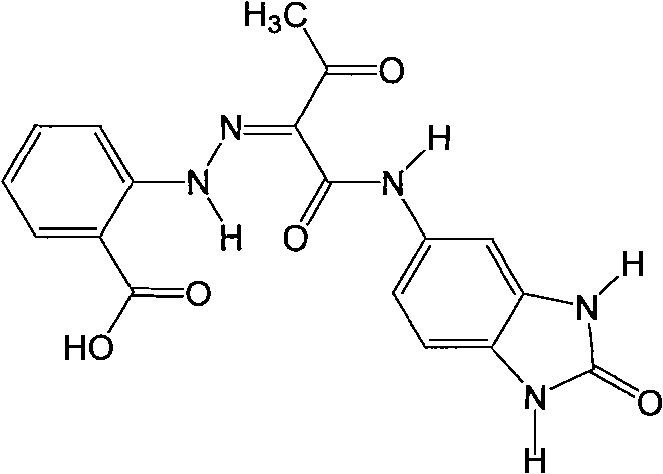

Image

Examples

preparation example Construction

[0021] The present invention provides a kind of preparation method of C.I. Pigment Yellow 151, the method comprises the following steps:

[0022] (1) 5-Acetoacetamidobenzimidazolone (AABI) is added to the anthranilic acid alkaline aqueous solution obtained by the co-current continuous synthesis preparation method, wherein the molar amount of anthranilic acid is equal to or slightly lower than The molar weight of 5-acetoacetamido benzimidazolone, stirring makes 5-acetoacetamido benzimidazolone dissolve completely, adds nitrite, in terms of nitrite, the molar weight of nitrite is the same as that of 5-acetoacetamido The molar weight of benzimidazolone is equal, stirring makes nitrite dissolve completely;

[0023] (2) At a temperature of 0-60°C, add the mixed solution obtained in step (1) dropwise into the buffer solution prepared with weak acid salt and acid, the pH of the buffer solution is 3-6.5, and dropwise add The dilute aqueous solution of the acid, so that the pH of the ...

Embodiment 1

[0040] (1) Continuous preparation of sodium anthranilate solution

[0041] A continuous pipeline reactor, the inner diameter of the pipeline is 2mm, the length is 1200mm, there is a mixing chamber at the front end, and there are two feed inlets, the front section of the feed inlet is 100mm, cooled by cold water through a casing, and the remaining pipelines are insulated from heat.

[0042] Preparation of reaction components: A component contains 10 grams of phthalimide and 9 grams of sodium hydroxide per 100 milliliters of aqueous solution; B component contains 30 grams of sodium hypochlorite solution per 100 milliliters of aqueous solution (reaching 10% containing available chlorine), 10 grams of sodium hydroxide.

[0043] Component A was injected into the tube reactor at a flow rate of 30 ml / min, while component B was injected at a flow rate of 30 ml / min. The front section of the reaction pipeline is cooled with 20°C water, and the temperature of the materials in the rest ...

Embodiment 2

[0051] (1) Synthesis of pigments

[0052] Add 8.2 grams of anthranilic acid, 14.26 grams of 5-acetoacetamidobenzimidazolone (AABI), 7.2 grams of sodium hydroxide and 200 milliliters of water into a 500 milliliter beaker, and stir until fully dissolved. Add 4.15 g of sodium nitrite, and stir until the mixture is clear. Add 2 g of sodium acetate and 20 ml of water into a 500 ml three-necked flask, add an appropriate amount of 10% hydrochloric acid solution under stirring, and adjust the pH value to 5.5. Raise the temperature to 40°C, add the prepared mixed solution dropwise, and at the same time add dropwise 10% hydrochloric acid solution, keep the pH value between 5.5 and 6.5, and add all dropwise in about 2 hours. After the dropwise addition, keep warm at 40°C until the reaction ends. The temperature was raised to 80° C. and maintained for 1 hour. Filter, wash with water, and dry at 80° C. to obtain 22.1 grams of coarse dry pigment powder with a yield of 98%.

[0053] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com