Patents

Literature

4123 results about "Sodium nitrite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sodium nitrite is an inorganic compound with the chemical formula NaNO₂. It is a white to slightly yellowish crystalline powder that is very soluble in water and is hygroscopic. It is a useful precursor to a variety of organic compounds, such as pharmaceuticals, dyes, and pesticides, but it is probably best known as a food additive used in processed meats and (in some countries) in fish products.

Systems and methods for topical treatment with nitric oxide

InactiveUS7048951B1Reduce skin irritationBiocideInorganic active ingredientsSandwich likeTransdermal patch

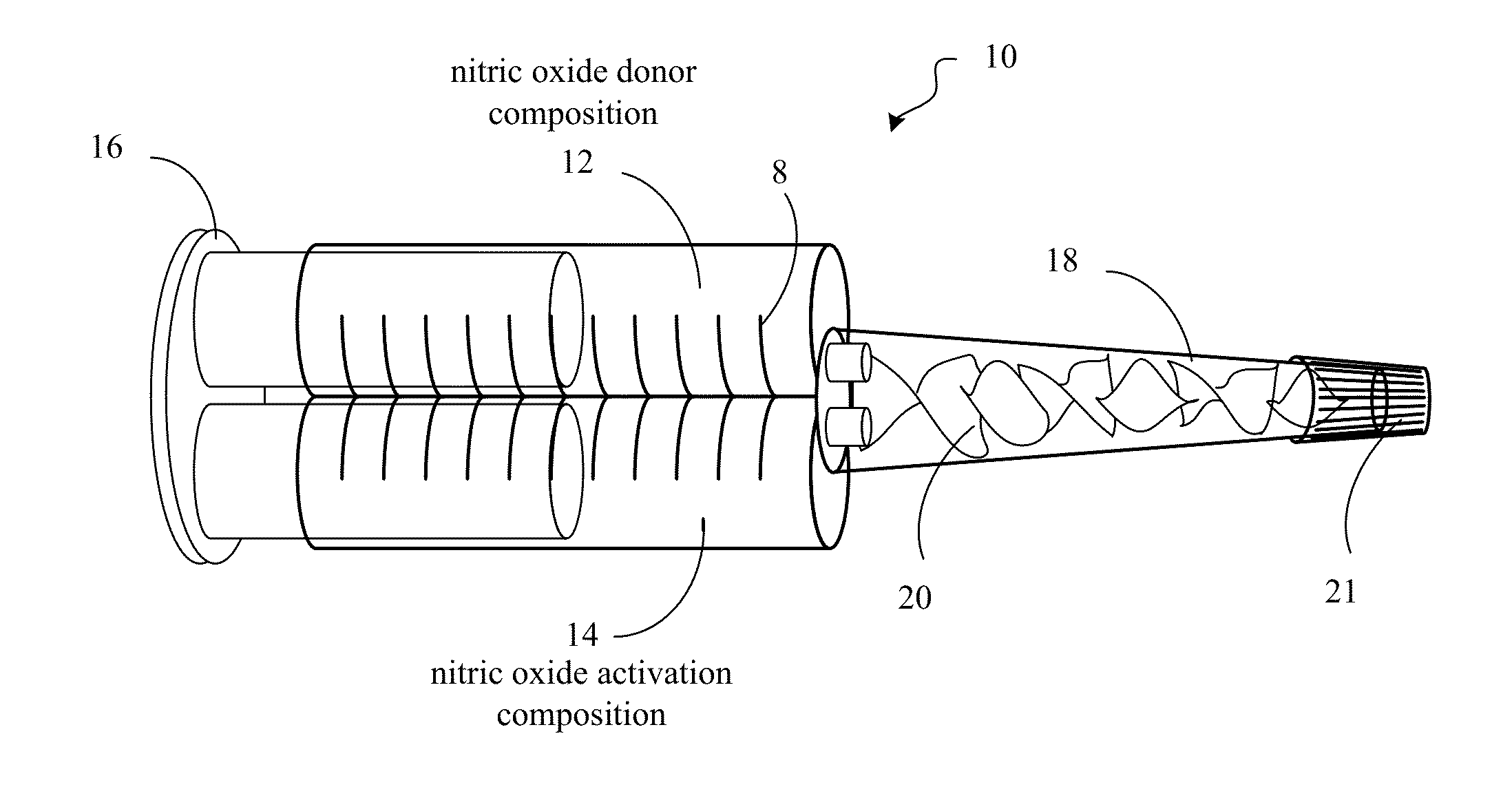

A simple, biocompatible system and procedure for generating nitric oxide (NO) is described. A mixture of powdered sodium nitrite, ascorbic acid, and maleic acid (or another organic acid of adequate strength) immediately generates nitric oxide (NO) on treatment with water. To slow down the NO generation, one may prepare an ointment from a nonaqueous medium (petrolatum, Vaseline™) and the three powdered ingredients, which on being applied topically on the skin will release NO as water permeates through this medium; alternatively, one may convert the aqueous sodium nitrite solution into a gel with hydroxyethylcellulose (or other gel-forming compound) and combine this gel with another gel obtained from aqueous ascorbic and maleic acids with hydroxyethylcellulose for topical application (on intact skin, burns intra-cavity, burns, intra-cavity, etc.). The two gels may be admixed immediately before use (possibly from a single container with separate chambers and dual nozzle, via pushing or squeezing the two gels through the nozzle), or may be applied in sandwich-like fashion (possibly as a transdermal patch) for further slowing down the delivery of NO.

Owner:NITRIC SOLUTIONS

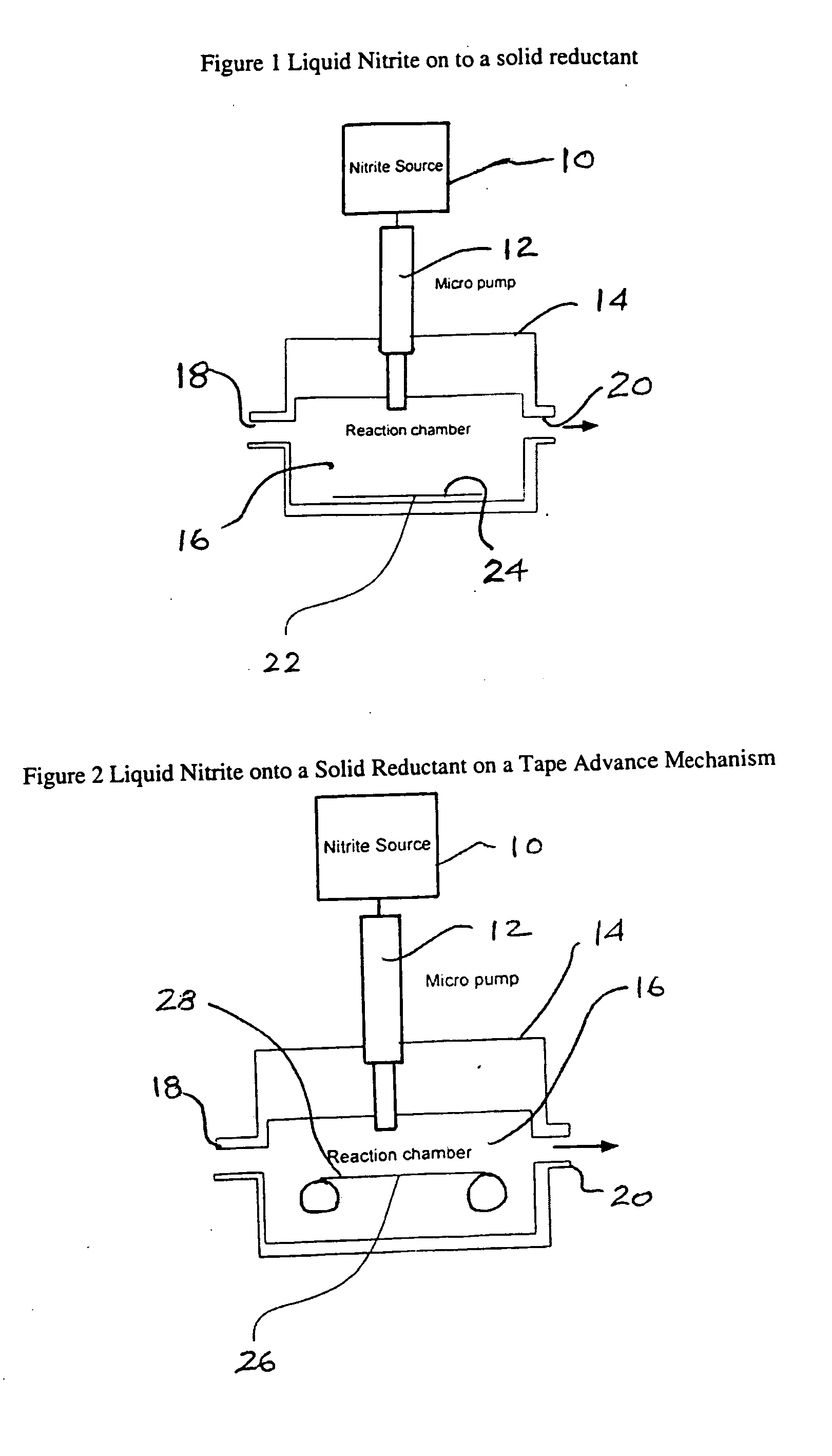

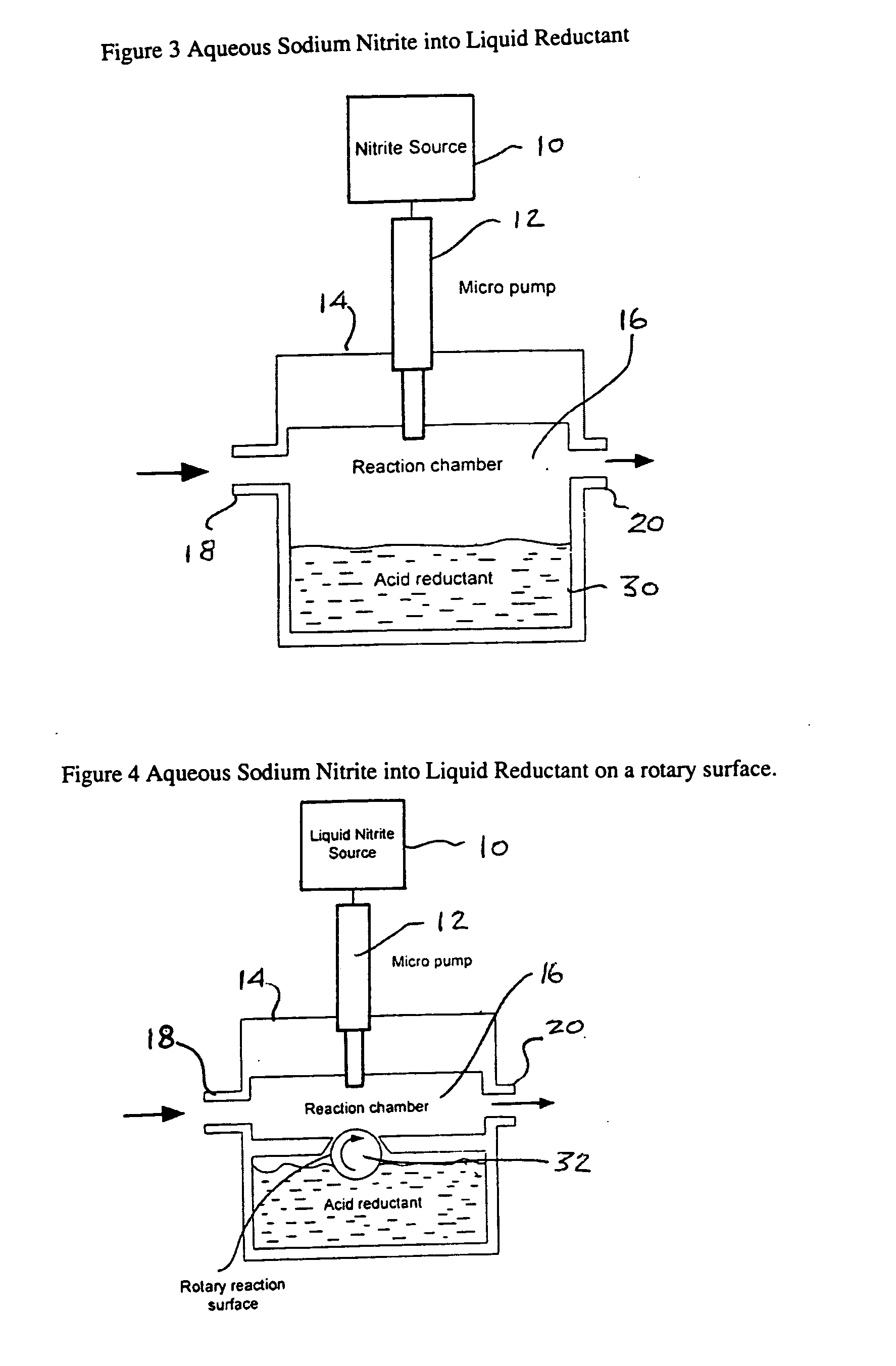

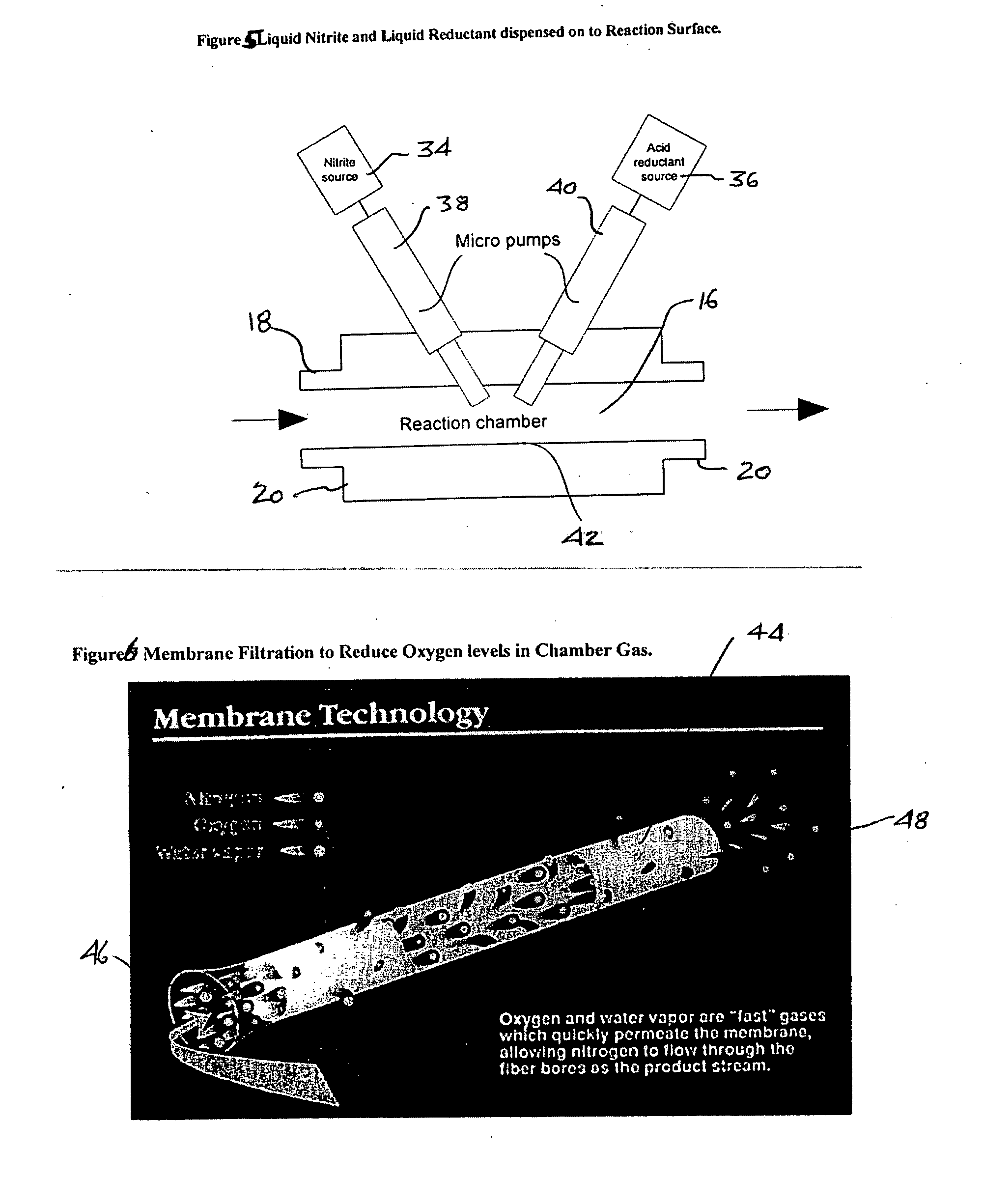

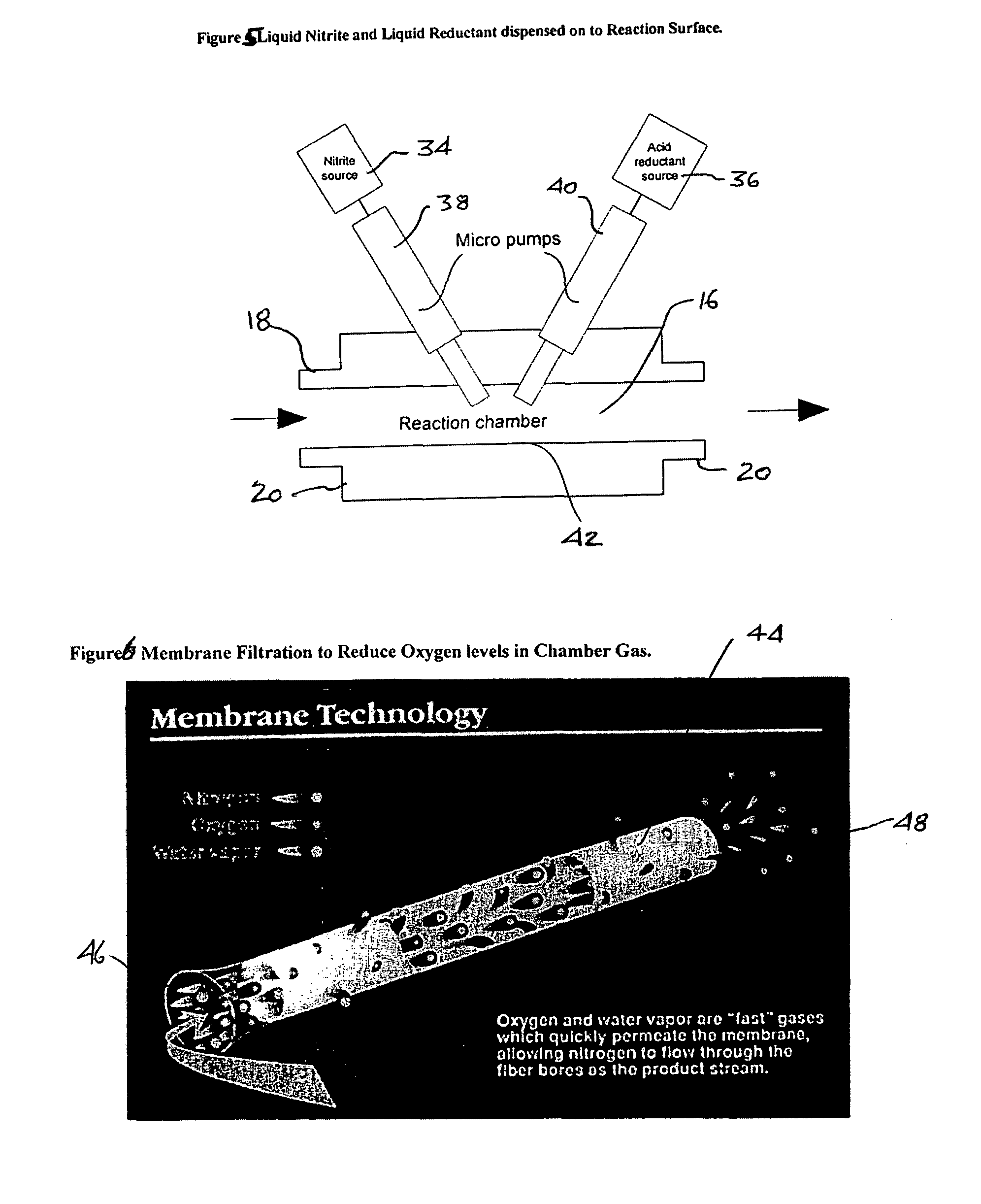

Method and apparatus for generating nitric oxide for medical use

ActiveUS20070190184A1Reduce weightReduce electric powerRespiratorsBiocideNitric oxide formationAcoric acid

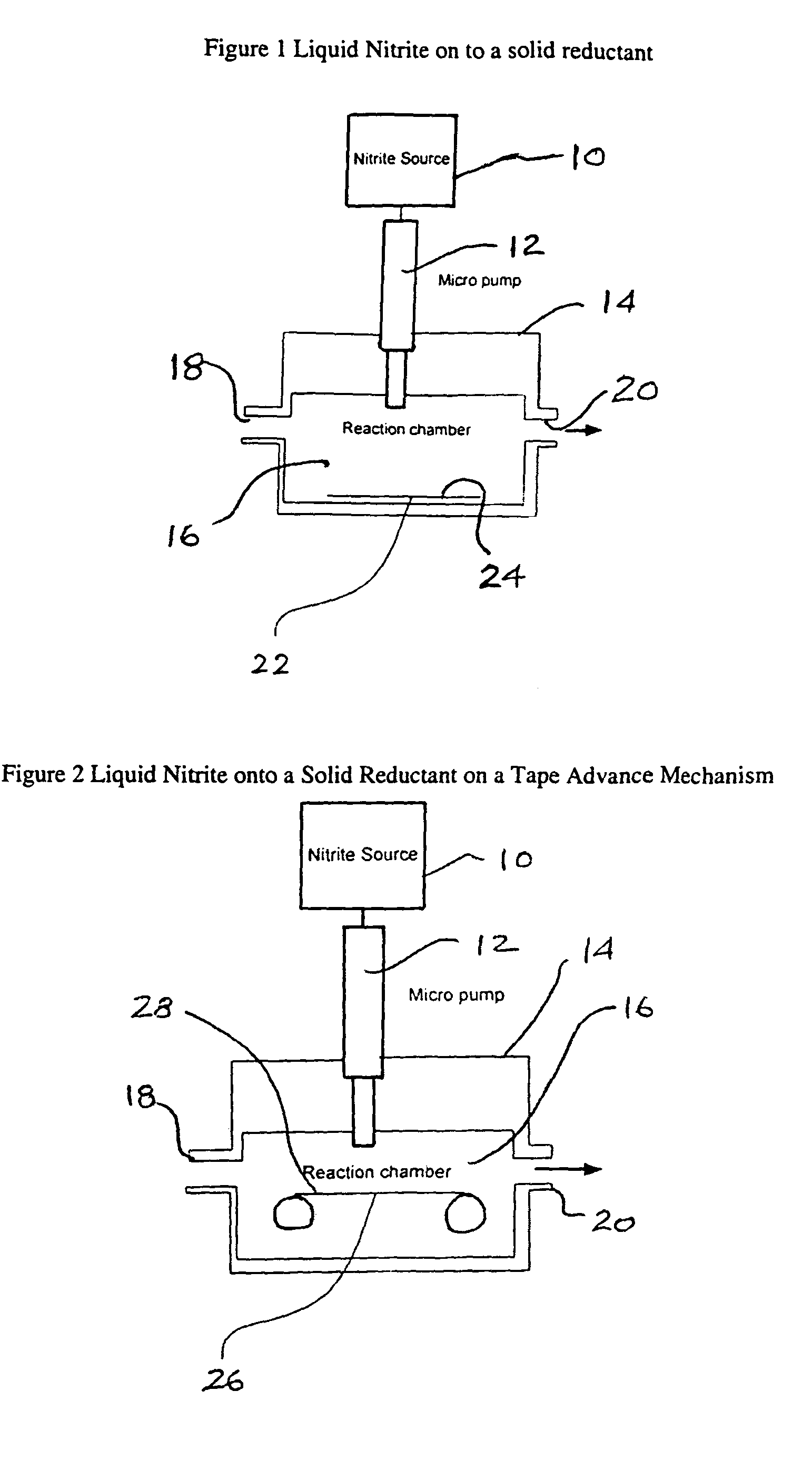

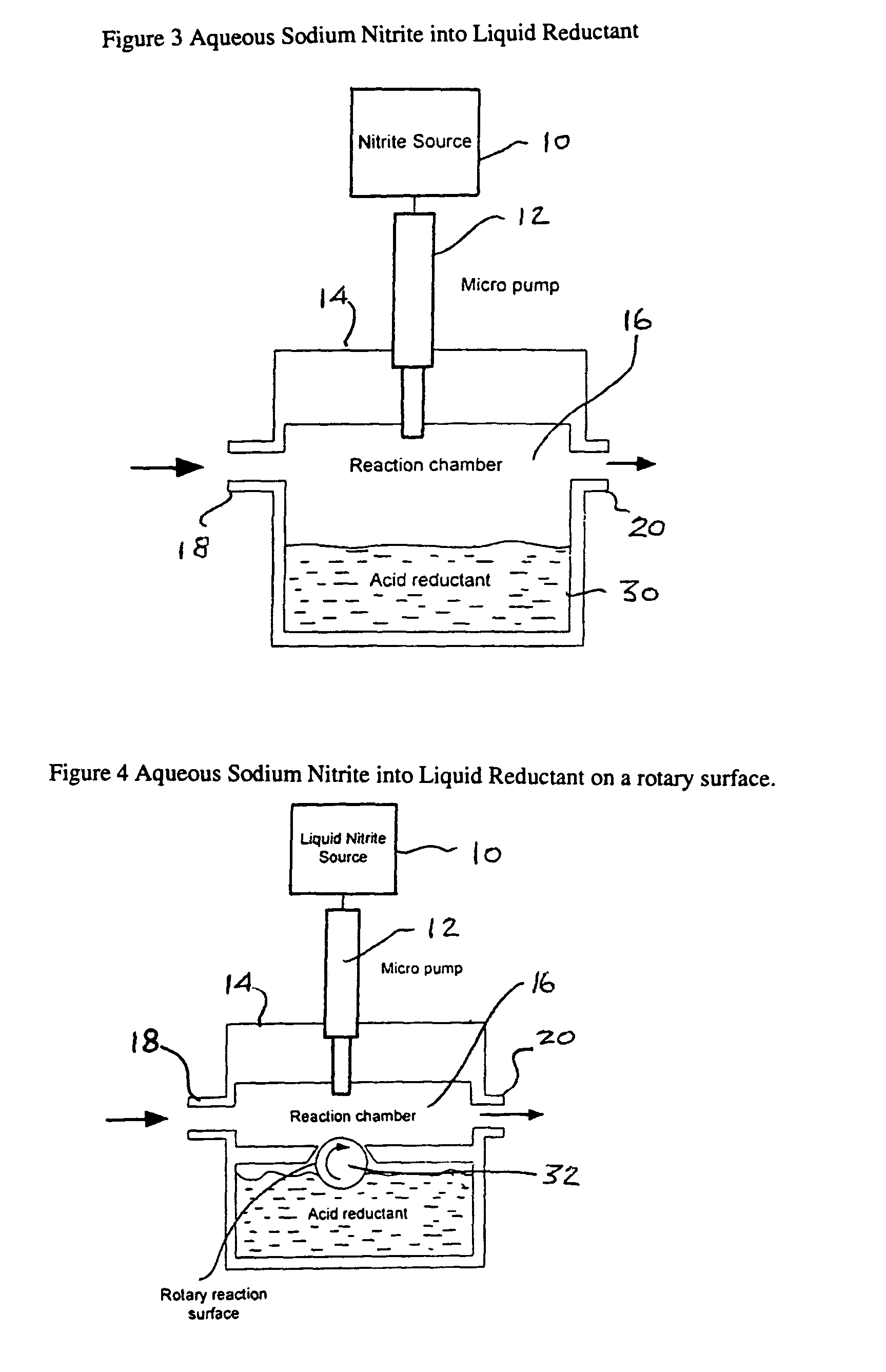

A method and system for generating and delivering nitric oxide directly to a patient. A reaction chamber is provided that is located at or in close proximity to the patient and reactants within the reaction chamber react together to produce a predetermined amount of nitric oxide. The reaction is controlled by metering at least one of the reactants into the reaction chamber to generate a predetermined quantity of nitric oxide as required by the patient. The reactants can include a nitrite salt, such as sodium nitrite, and a reductant such as ascorbic acid, maleic acid or a mixture thereof. By generating and delivering the nitric oxide directly to the patient in close proximity thereto, the formation of NO2 is minimized. One or both of the reactants may be in liquid form.

Owner:MALLINCKRODT HOSPITAL PRODUCTS IP LTD

Anti-emulsification water-soluble metal washing agent

The invention relates to an anti-emulsification water-soluble metal washing agent. Every 100 parts of the anti-emulsification water-soluble metal washing agent include the following components according to parts by weight: 3-7 non-ionic surfactant, 3-7 bi-ion active agent, 1-5 chelator, 1-5 rust preventive, 5-10 inorganic builder and the balance water, wherein the non-ionic surfactant is any one of fatty amine polyoxypropylene ether, alkylphenol ether and fatty amine polyoxyethylene alkyl ether ammonium sulfate, the bi-ion active agent is any one of alkyl dimethylin acetic acid betaine, lauramidopropyl betaine and cocamidopropyl betaine, the chelator is any one of sodium citrate, ethylenediaminetetraacetic acid tetrasodium salt and nitrilotriacetic acid sodium salt, the rust preventive is any one of sodium borate, sodium nitrite, sodium benzoate and long carbon chain carboxylic acid amine, and the inorganic builder is any one of trisodium phosphate, sodium metasillcate, sodium carbonate, sodium bicarbonate and sodium hydroxide. The anti-emulsification water-soluble metal washing agent has the advantage of higher cleaning capacity and reutilization capacity.

Owner:NANJING KERUN LUBRICANTS

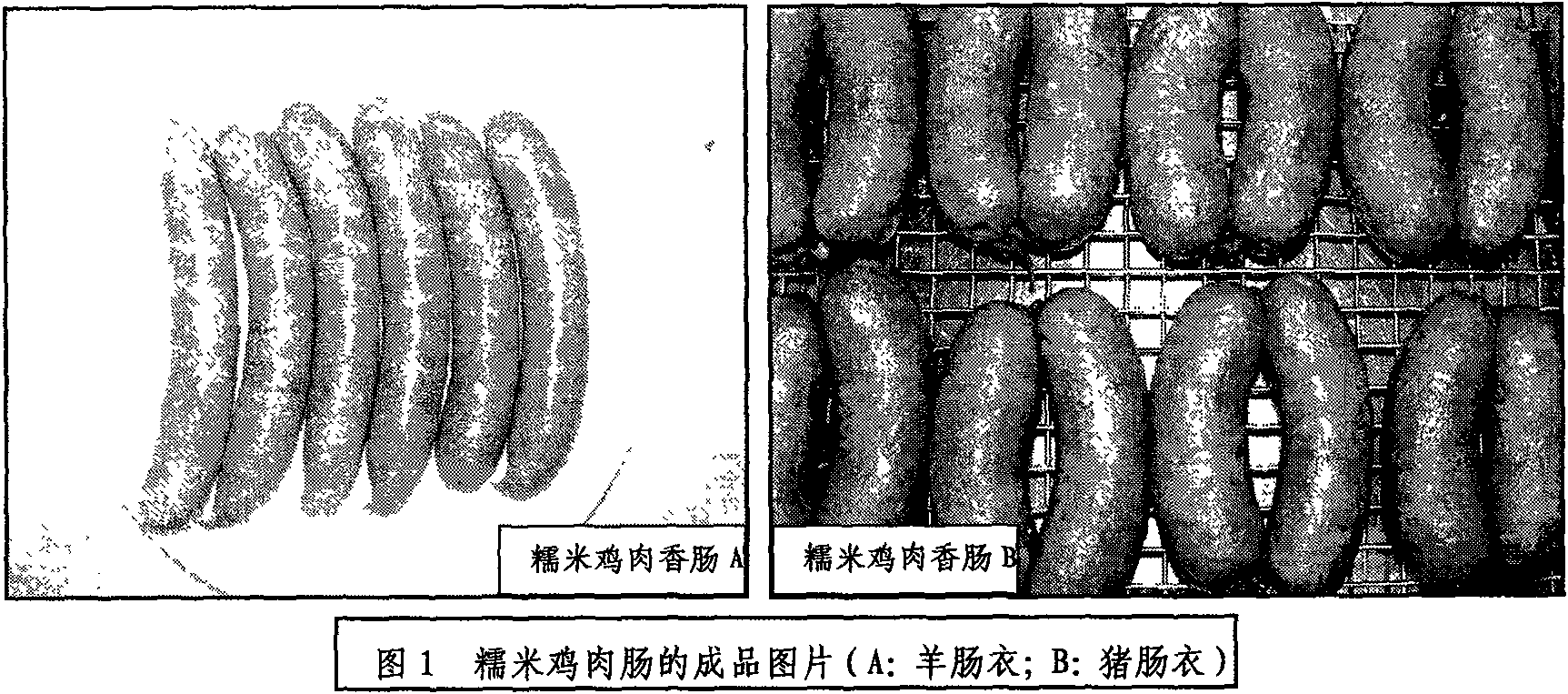

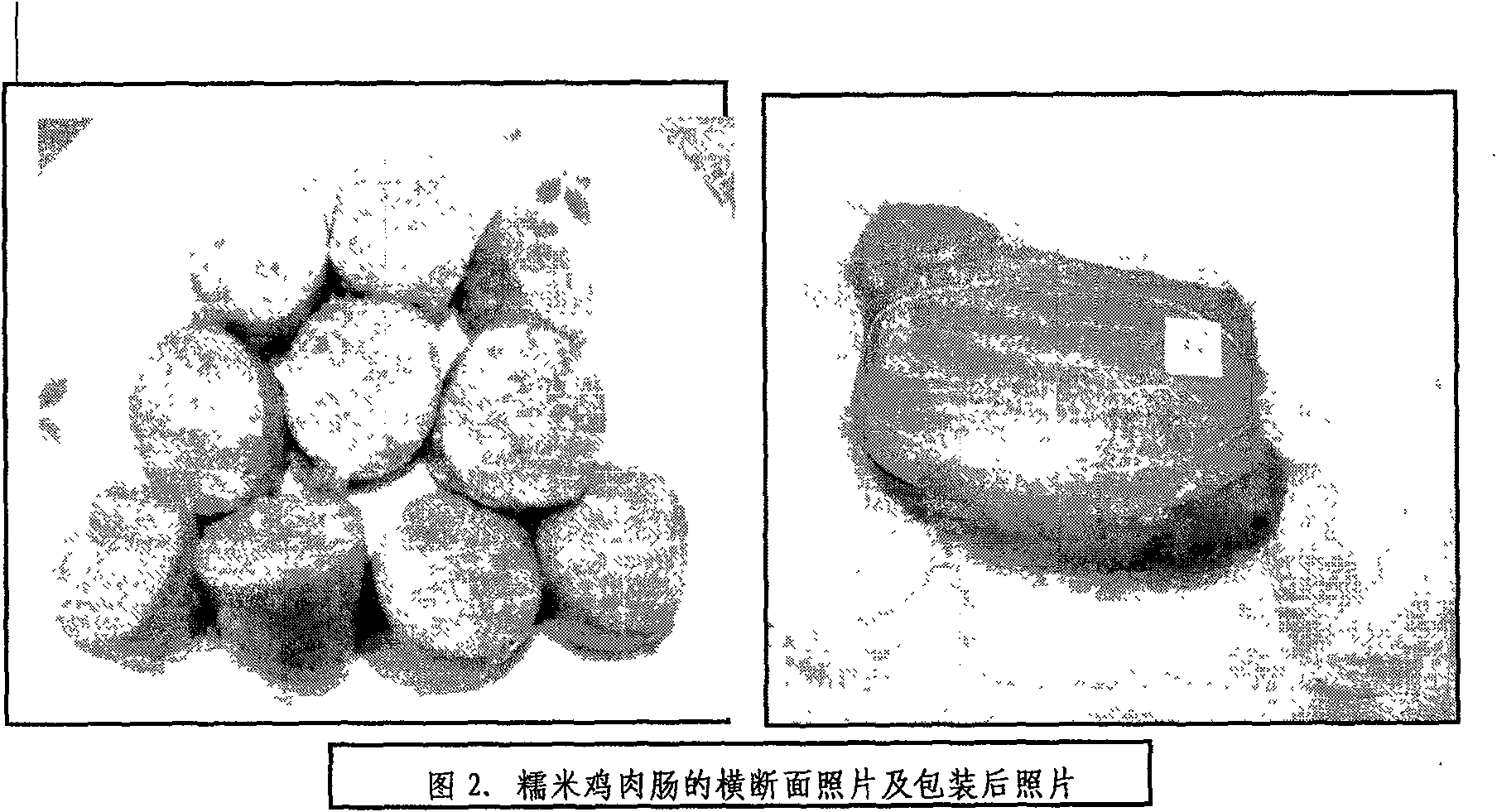

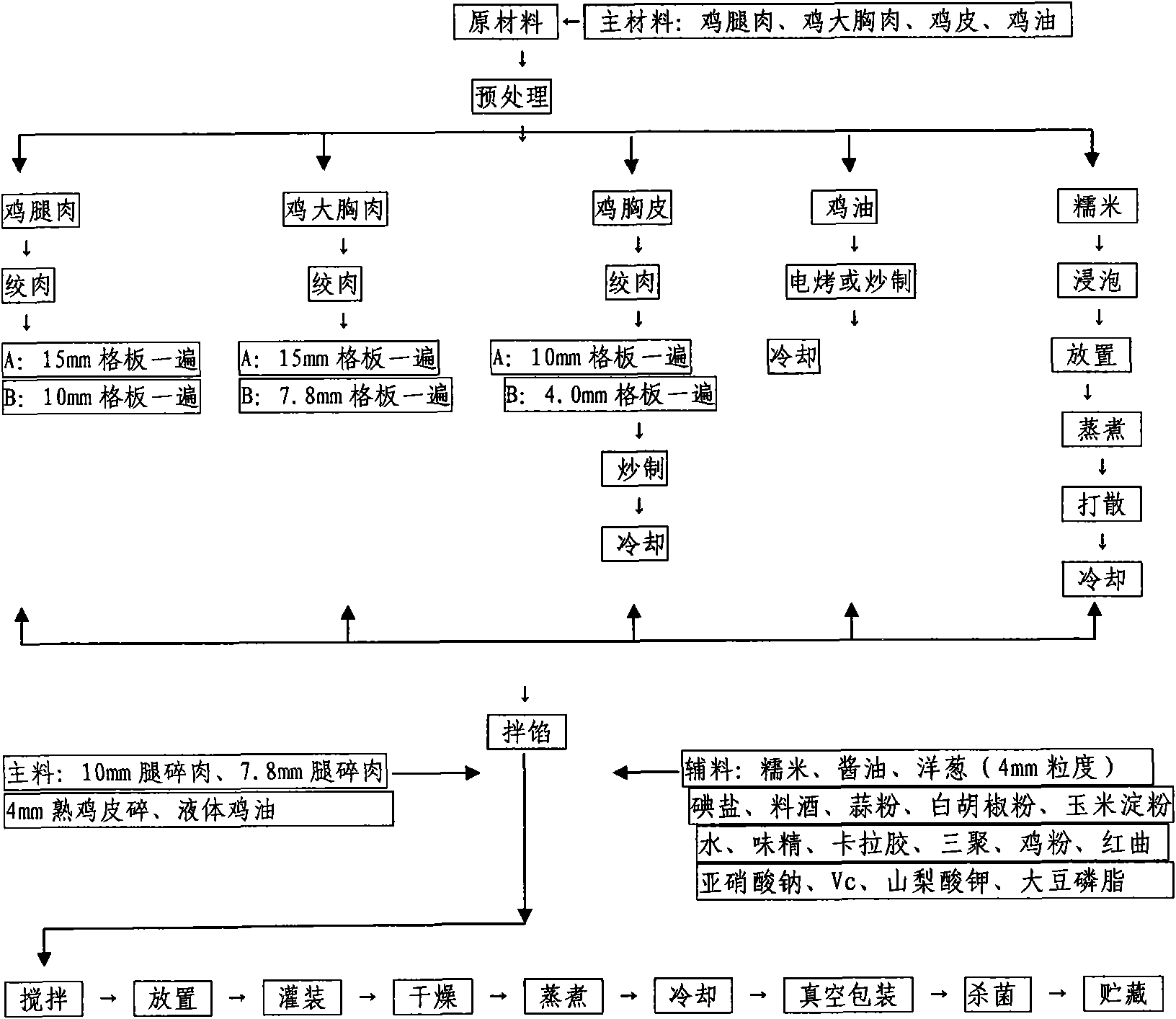

Cereal sausages and production method thereof

The invention provides sausages added with cereal (the cereal comprises sticky rice, rice, unpolished rice, black rice, purple rice, oat, buckwheat, barley, wholemeal, brown rice and millet; the sausages are pork sausage, beef sausage, mutton sausage, chicken sausage, duck sausage and fish sausage) and a production method thereof. 1. the product comprises the following materials by weight: 40-80% of animal meat, 5-20% of cereal and the products thereof, 10-20% of ice water mixture, 2-10% of animal (plant) fat, 0.1-0.3% of phosphate, 0.002-0.015% of sodium nitrite, 0.4-1.2% of salt, 0.5-5% of sugar, 0.1-0.5% of aginomoto, 0.5- 5% of soy sauce, 1- 8% of spice, 1-10% of starch, 0.1-0.5% of food gum, 0.5-2% of emulsifier, 0.2-2.0% of wine, 0.005-0.025% of edible pigment, 0.02-0.2% of sodium erythorbate, 0.01-0.8% of flavors and fragrances of meat (meat concentrate powder), 0.05-0.15% of preservative, and 0.001-0.005% of antioxidant; in a specific formulation, the sum of the weight percent of each component is 100%. 2. the processing method of the cereal sausages is as follows: choosing materials, preprocessing, mixing stuffing, placing, filling, drying, boiling, cooling, packaging, sterilizing, labeling, metal detecting, X-ray unit detecting, packing, and storing.

Owner:陈静 +2

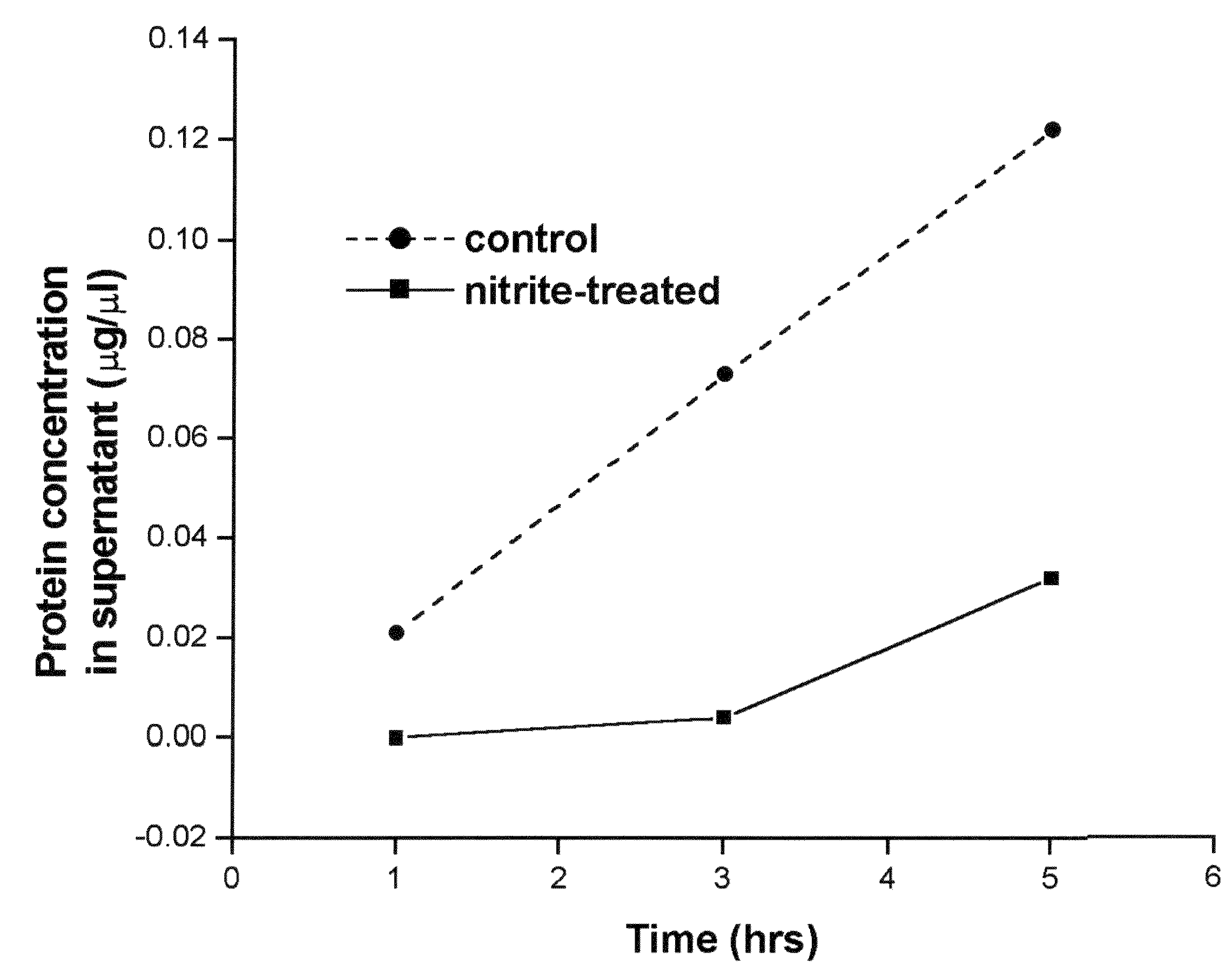

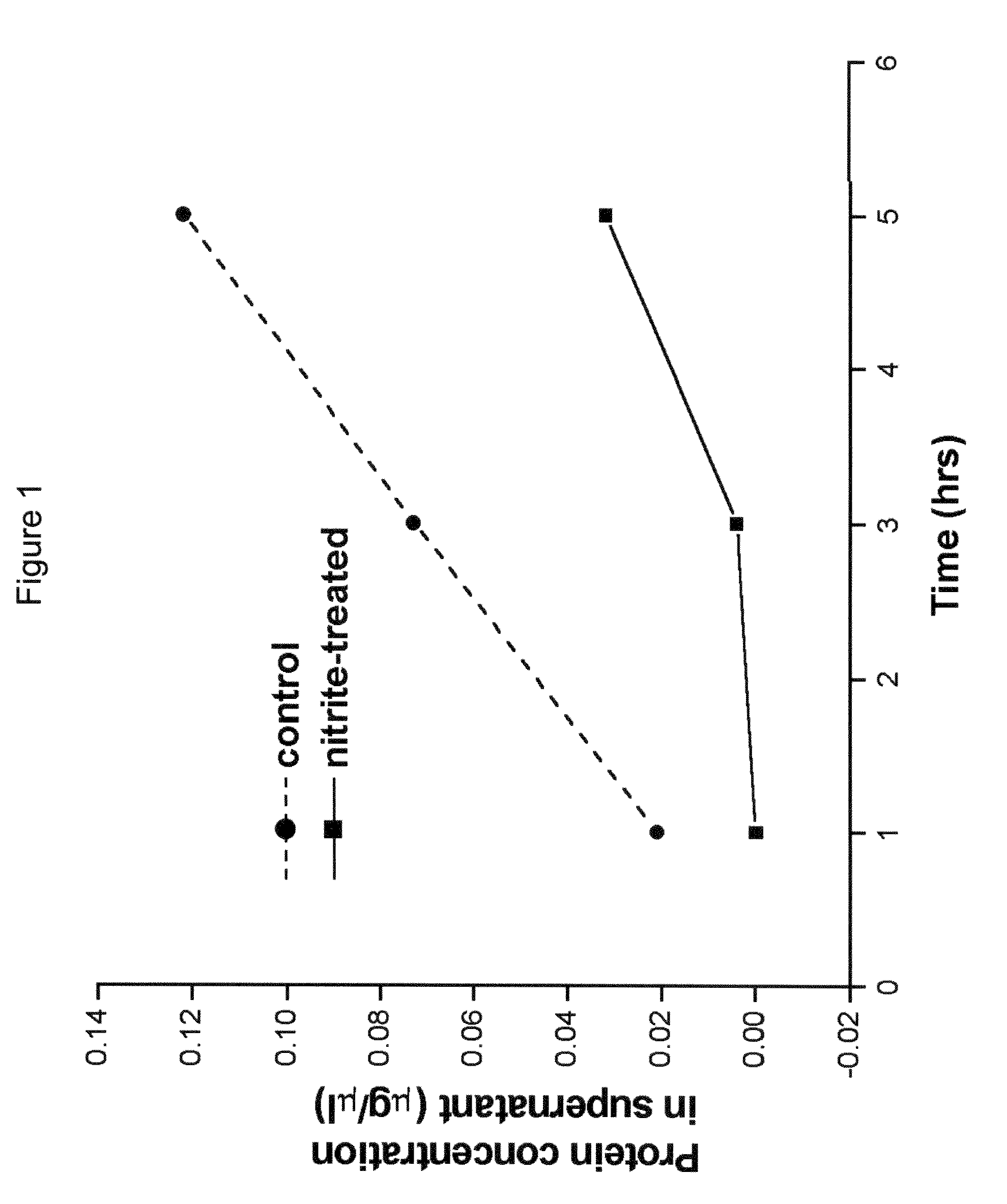

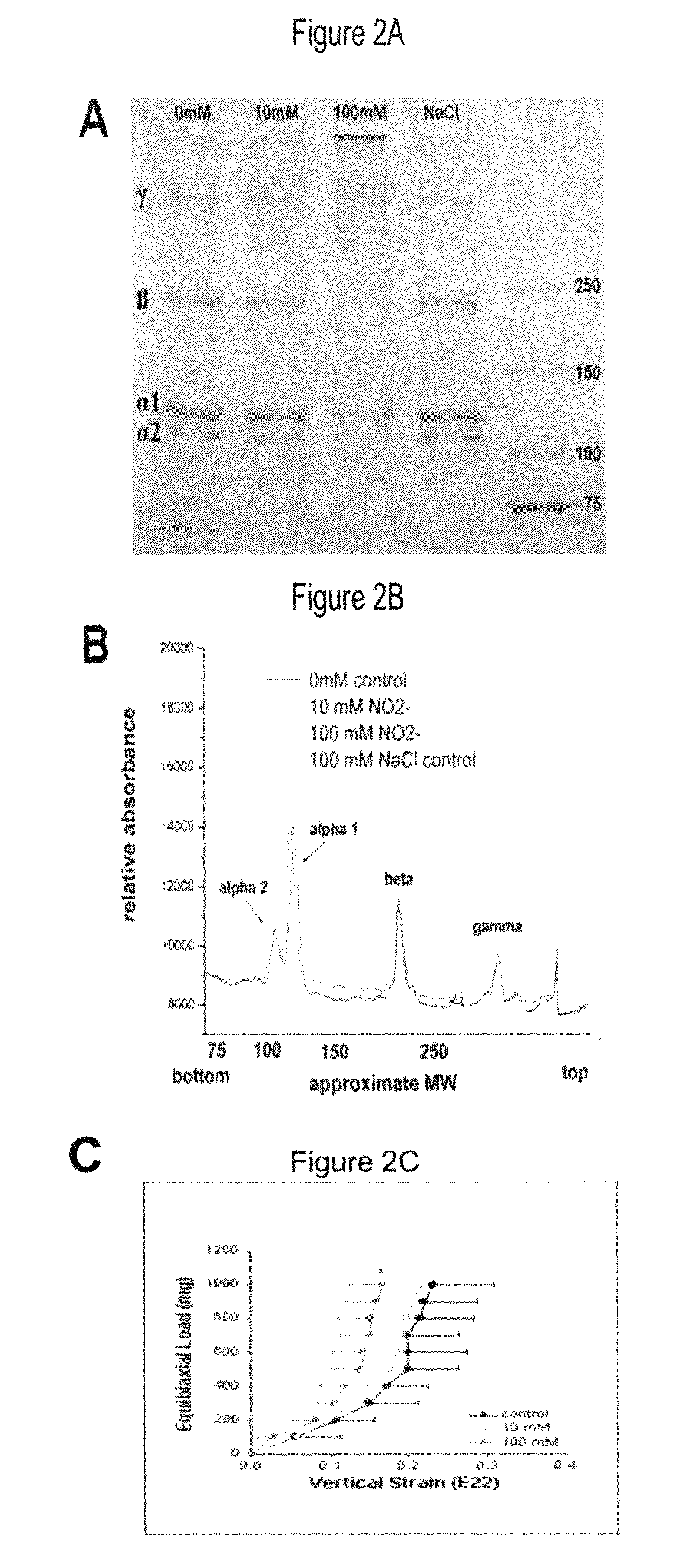

Method of stabilizing human eye tissue by reaction with nitrite and related agents such as nitro compounds

A method for stabilizing collagenous eye tissues by nitrite and nitroalcohol treatment. The topical stiffening agent contains sodium nitrite or a nitroalcohol in a buffered balanced salt solution and can be applied to the surface of the eye on a daily basis for a prolonged period. Application of the solution results in progressive stabilization of the corneal and scleral tissues through non-enzymatic cross-linking of collagen fibers. The compounds can penetrate into the corneal stroma without the need to remove the corneal epithelium. In addition, ultraviolet light is not needed to activate the cross-linking process. The resulting stabilization of corneal and scleral tissues can prevent future alterations in corneal curvature and has utility in diseases such as keratoconus, keratectasia, progressive myopia, and glaucoma.

Owner:THE TRUSTEES OF COLUMBIA UNIV IN THE CITY OF NEW YORK

Fusion tray of thermal transmission and storage medium, and preparation method

InactiveCN101050355AHigh Safe Operating Temperature Upper LimitSafe operating temperature upper limit expandedHeat-exchange elementsHigh energyWorking temperature

This invention discloses a method for preparing molten salt heat-transfer and heat-storage medium, which comprises potassium nitrate, sodium nitrate, sodium nitrite and additives. The additives are cesium nitrate and potassium chloride at a weight ratio of (0.1-0.8):1. The molten salt heat-transfer and heat-storage medium has such advantages as good heat transfer property, wide working temperature range, high heat stability, high upper limit of safe usage temperature, low melting point, high phase-change latent heat, low requirement for system size and energy, and high energy utility.

Owner:SUN YAT SEN UNIV +1

Low pervasion oilfield thermochemical cleanup additive and use thereof

InactiveCN101323780AComplete flowbackNo pollution in the processDrilling compositionPhosphoric acidNitrogen gas

The invention discloses a low permeability oil field thermochemical cleanup additive and applications thereof in acidification and fracturing technologies of low permeability oil field oil and water wells. The thermochemical cleanup additive consists of an agent A and an agent B. The agent A consists of certain parts by weight of phosphoric acid, sodium nitrite, dodecyl benzene sulphonic acid, emulsifier, surfactant and water; the agent B consists of certain parts by weight of urea, ammonium chloride and water. The agent A and the agent B thermally react under certain conditions to produce a large amount of nitrogen, carbon dioxide and high-temperature-hot-water and a large amount of heat simultaneously; in addition, the nitrogen and the carbon dioxide with certain pressure can form a large amount of bubbles under the function of a highly efficient active foaming agent for residues to be drained out of the oil and water wells. The thermochemical cleanup agent does not burn or explode easily and is mainly applied to the cleanup technology of the acidification and fracturing techniques of the low permeability oil and water wells for solving the problems such as inadequate drainage strength, reducing pollutions of remaining operating fluid to reservoir stratums and effectively enhancing the acidification and fracturing effects.

Owner:XI'AN PETROLEUM UNIVERSITY

Heavy-load metal machining total synthesis cutting fluid as well as preparation method and application thereof

ActiveCN104277902AImprove the lubrication effectImprove extreme pressure performanceAdditivesMachine partsSuperalloy

The invention belongs to the field of metal machining fluids, and discloses a heavy-load metal machining total synthesis cutting fluid as well as a preparation method and an application thereof. The total synthesis cutting fluid comprises the following components in percentage by weight: 20%-30% of mixed alcohol amine, 6%-9% of anti-rust agents, 4%-6% of special amine, 6%-10% of lubricating agents, 15%-25% of extreme pressure agents, 6%-10% of cosolvents, 1%-2% of water-softening agents, 1%-3% of corrosion inhibitors and the balance of water. The total synthesis cutting fluid disclosed by the invention has excellent lubricating extreme pressure property, can meet the requirement for heavy-load machining, namely reaming, drilling, tapping, threading, broaching, thread machining and the like, of difficult-to-machine materials, namely high-temperature alloy steel, a titanium alloy and the like; a product is green and environment-friendly without containing boron, sodium nitrite, secondary amine, chlorine, phenol, formaldehyde, heavy metals and the like; in addition, the total synthesis cutting fluid disclosed by the invention has excellent anti-rust property, biological stability and machining property, and can enhance the surface quality of a machined part, prolong the service life of a cutter and reduce the rejection rate, thus improving the production efficiency.

Owner:广州国机润滑科技有限公司

Compositions and methods for topical nitric oxide generation

InactiveUS20130330244A1Sufficiently viscousReduce probabilityNervous disorderAntipyreticMedicineHair growth

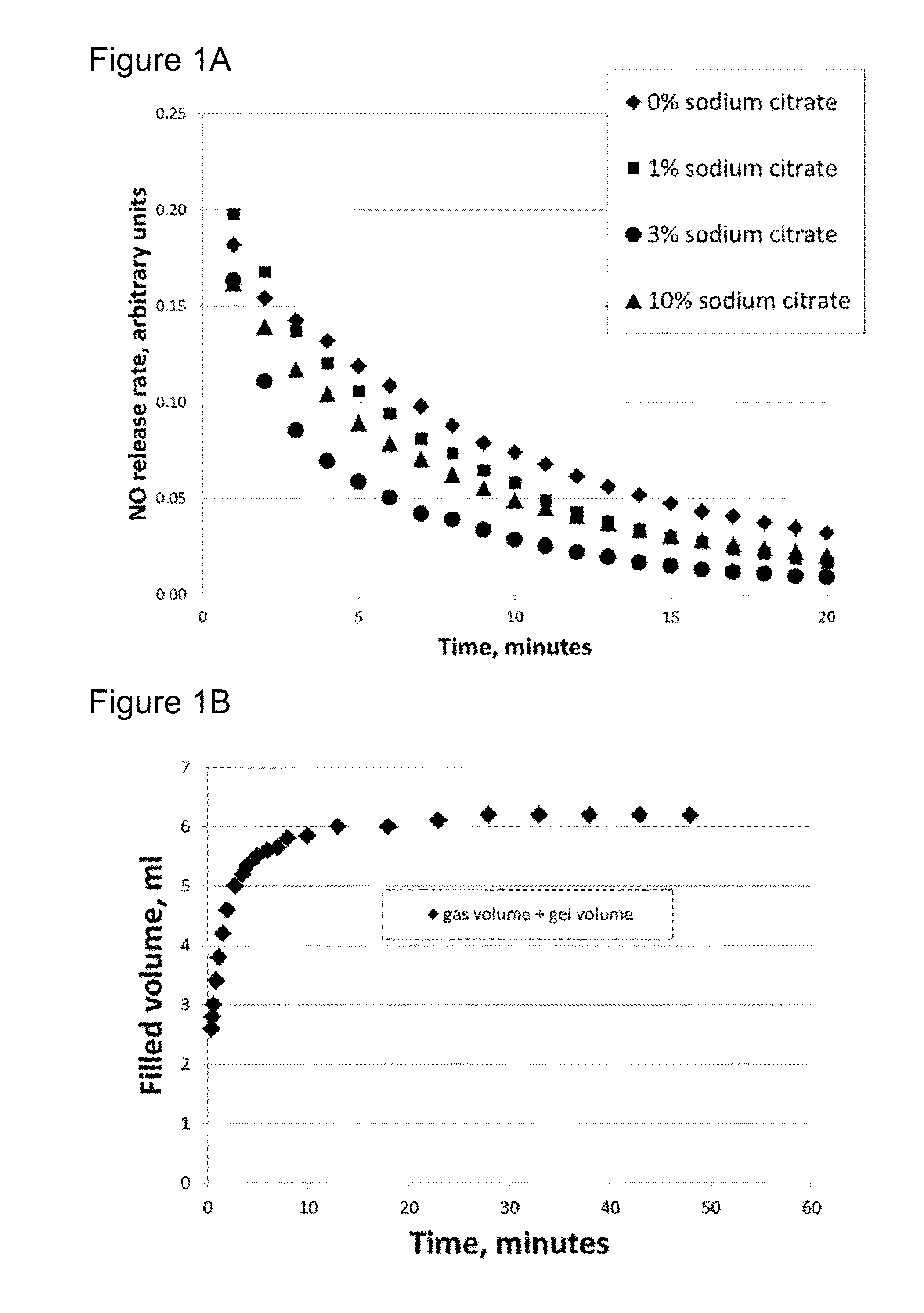

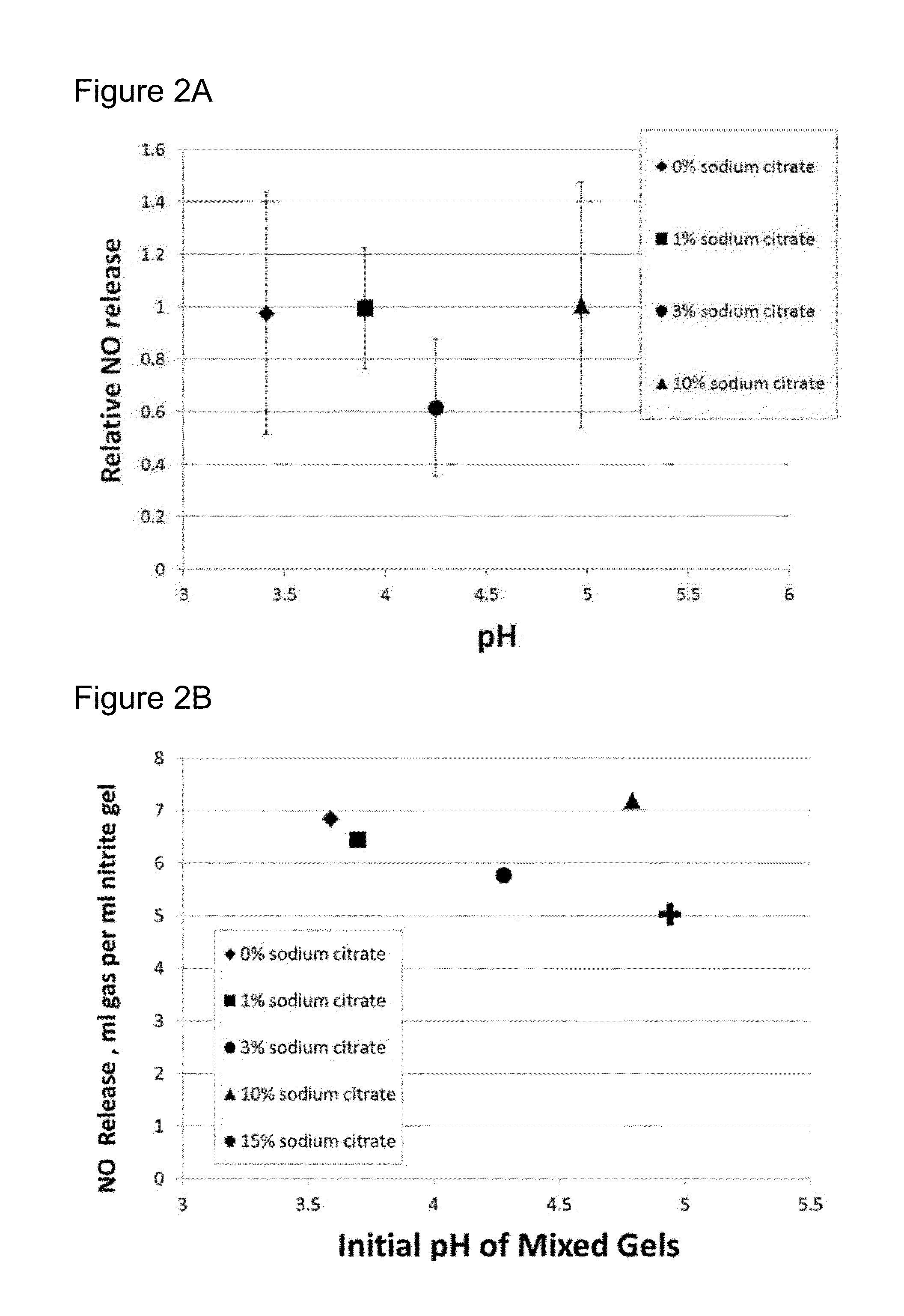

A simple, biocompatible two-component system and procedure for generating nitric oxide (NO) is described. One component comprises sodium nitrite or other nitrite source, and the other component comprises a reductant, an acid and a base although in certain embodiments the reductant and acid functions are provided by the same component. When these two components are mixed directly at a local site of administration or immediately prior to application and the mixture generates nitric oxide (NO) for topical application. The activated system is therapeutic for treatment of multiple conditions, including promotion of healing, disinfection, promotion of hair growth, and treatment of male and female sexual dysfunction.

Owner:NIOXX

Method for extracting platinum, rhodium and palladium from failed platinum alloy gauze

ActiveCN102586607AAdvanced and reasonable technologyAdvancedProcess efficiency improvementAlloySodium nitrite

The invention relates to a method for extracting platinum, rhodium and palladium from a failed platinum alloy gauze, which comprises the following steps of: separating to extract precious metals such as the platinum, the rhodium and the palladium from the failed platinum alloy gauze; dissolving through hydrochloric acid and nitric acid; removing nitro group, transforming sodium and leaching; obtaining platinum, rhodium and palladium complexing solution; adopting an ammonium chloride precipitation method to separate the platinum; adopting a sodium nitrite complexometry to separate the palladium and the rhodium; adopting a six nitroso rhodium acid ammonium method to purify the rhodium; adopting a dichlorodiamminopalladium method to purify the palladium; carrying out reduction to obtain spongy platinum, spongy palladium and rhodium powder through adding hydrazine hydrate; vacuum drying and roasting; and purifying again. The extracting method has advanced and reasonable process, and accurate and detailed parameters; the purity of the extracted spongy platinum, spongy palladium and rhodium powder is great than 99.9 percent, and the quality is stable; and the method is a very ideal method for extracting the precious metals such as the platinum, the rhodium and the palladium from the failed platinum alloy gauze.

Owner:太原瑞麟贵金属回收有限公司

Biomass curing-forming fuel and preparation method thereof

The invention discloses a biomass curing-forming fuel. The biomass curing-forming fuel consists of straws, saw dust, coal dust, a combustion improver, a sulfur-fixing agent and a dust-falling agent according to parts by weight, wherein the straw is one or combination of the straw of crops such as rice, wheat, soybean, corn, sorghum, cotton, rape and tobacco, a branch and a bark of trees and shrubs, rice hull, chaff and peanut coat; the combustion improver is one or more of table salt, sodium nitrate, potassium permanganate, potassium oxide, sodium nitrite and sodium hypochlorite and capable of realizing decomposition and combustion supporting at different temperatures; the sulfur-fixing agent is in a manner that sodium carbonate, calcium hydroxide and alkyl alcohol amine compounds are synergistically used and is capable of reducing discharging of sulfur dioxide; and the dust-falling agent is selected from iron sesquioxide and capable of lowering a melting point of ash and reducing dust volume. The biomass curing-forming fuel has the advantages that the combustion efficiency is high, the slag bonding and the soot formation are not generated, the black smoke is little, the fire power strong, the combustion is sufficient, the ash does not fly, the biomass curing-forming fuel is clean and sanitary and the like. The invention further discloses a preparation method of the biomass curing-forming fuel.

Owner:JINAN SANNONG ENERGY TECH

Mixed molten salt as heat transfer and storage medium low in melting point

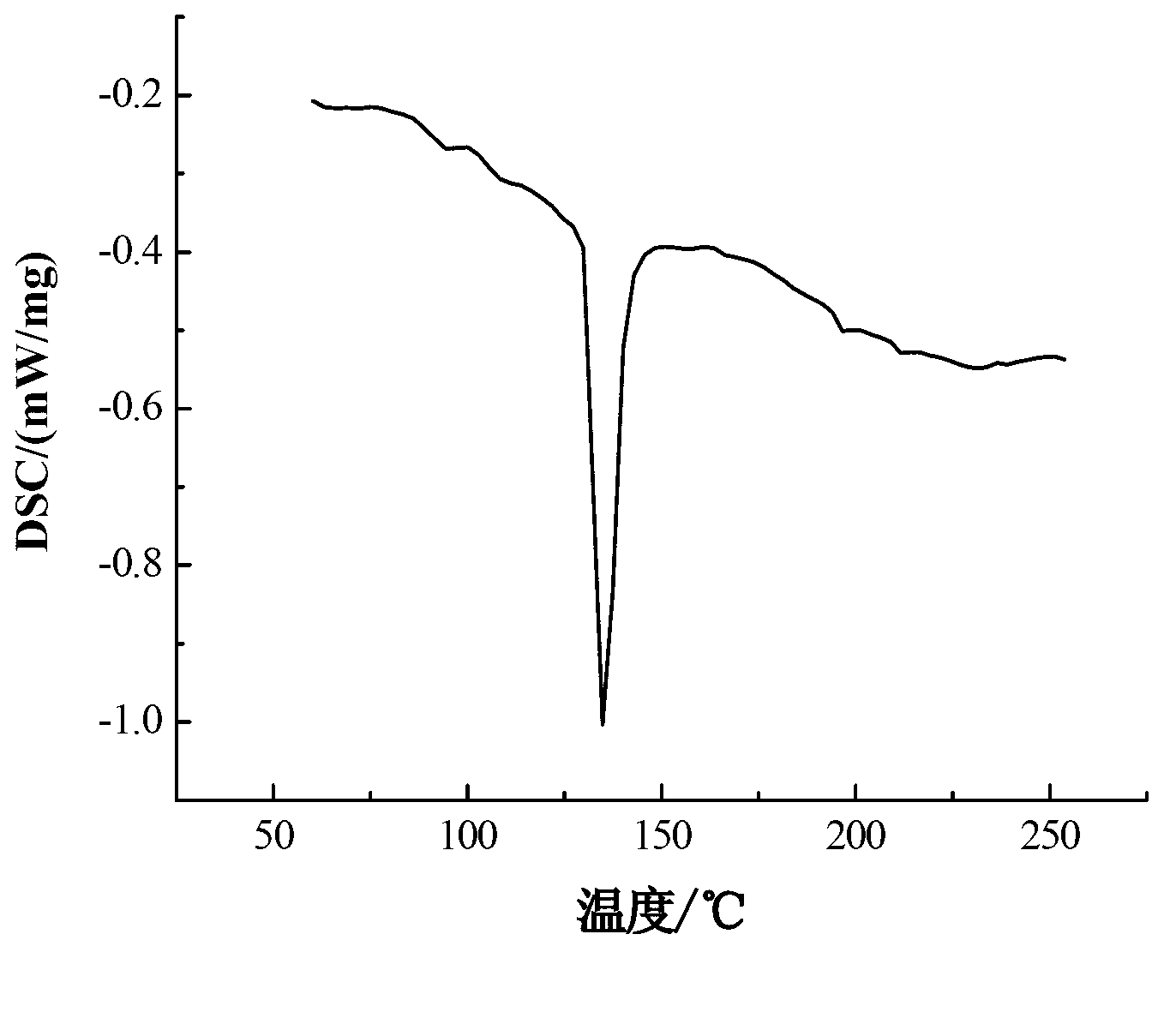

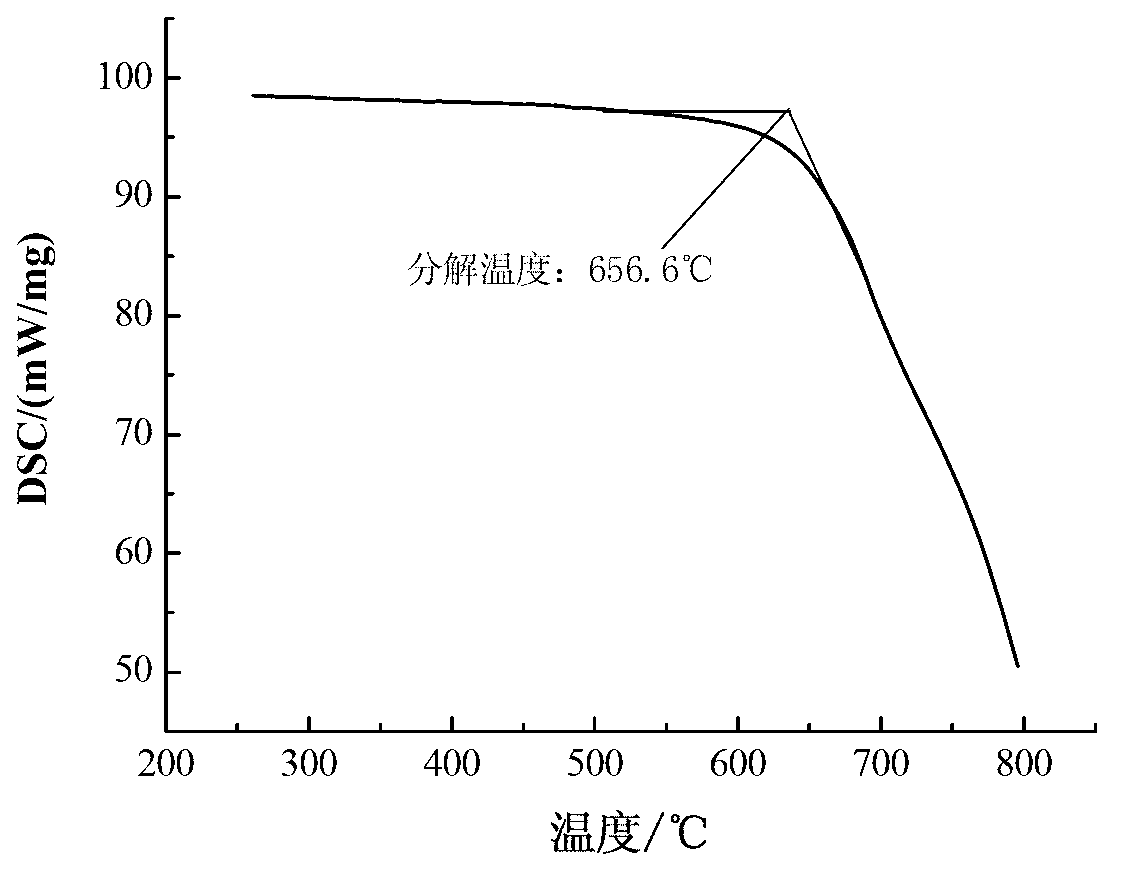

The invention relates to a formula of a mixed molten salt for medium-high temperature heat transfer and storage, and belongs to the physical heat transfer and energy storage technology in innovative and high technologies. The mixed molten salt comprises components in a ratio as follows: 10wt% of calcium nitrate, 60-70 wt% of potassium nitrate, 10-20 wt% sodium nitrate and 10wt% of sodium nitrite; the melting point of the mixed molten salt is about 130 DEG C, which is reduced by nearly 90 DEG C relative to solar salt and is reduced by about 15 DEG C relative to Hitec salt; and the thermal decomposition temperature thereof reaches above 650 DEG C. Sodium nitrate in the molten salt is changed into lithium nitrate, and the specific component ratio is as follows: 18-20wt% of calcium nitrate, 50-55 wt% of potassium nitrate, 9-10 wt% sodium nitrate and 18-20wt% of sodium lithium nitrate; after the component ratio is changed, the melting point of the mixed molten salt is about 90 DEG C, which is reduced by nearly 130 DEG C relative to the solar salt and is reduced by about 50 DEG C relative to the Hitec salt; and the thermal decomposition temperature thereof reaches above 600 DEG C. 10wt% of sodium carbonate is added continuously, then the melting point is raised to about 110 DEG C, while the decomposition temperature is raised by nearly 20 DEG C.

Owner:河北井矿新能源科技有限公司

Technique for producing ultra-low molecular heparin sodium (calcium)

InactiveCN101519459AImprove securityGood and long-lasting antithrombotic effectPulmonary artery embolismDisease

Aiming at the conditions that heparin has severe bleeding side effects in clinical practice and clinical application thereof is restricted, the invention discloses a technique for producing ultra-low molecular heparin sodium (calcium). The technique comprises the following steps of: taking heparin sodium solution, adding sodium nitrite solution for cracking; adjusting the lysis buffer by using alkaline; absorbing impurities by using an anion-exchange column; washing for obtaining ultra-low molecular heparin calcium; carrying out filtration by using an ultrafiltration membrane and obtaining a precipitate by using alcohol; and after desalting, dehydration, re-precipitation, cooling and drying, obtaining a finished product of ultra-low molecular heparin calcium. The product has better and safer antithrombotic effect under low level of anticoagulation, and can be widely used for preventing and treating diseases such as deep vein thrombosis, pulmonary embolism, disseminated intravascular coagulation, and the like.

Owner:SUZHOU FAST BIOLOGICAL PHARMACY TECH

Aqueous epoxy adhering dried fim lubricant

InactiveCN1450153AReduce pollutionSolution to short lifeLubricant compositionWear resistantCopper oxide

The present invention relates to a water epoxy adhesive dry film lubricant with low-volatile organic compound. Its formula is composed of (by weight portion) 100 portions of epoxy resin, 20-50 portions of solidifying agent, 30-80 portions of one of teflon, molybdenum disulfide and graphite or several kinds of them, 10-40 portions of one of chrome oxide, copper oxide or aluminium oxide, 2-10 portions of attapulgite, 0-30 portions of melamine urea complex, 2-5 portions of sodium dodecanesulfonate, 1-4 portions of sodium nitrate and 100-400 portions of diluting agent (water or water / ethyl alcohol). As compared with existent technology said lubricant can be solidified, and has the characteristics of low pollution and long life, etc. can be used as lubricant wear-resistant coating layer of various slide frictioning components

Owner:上海高分子材料研究开发中心

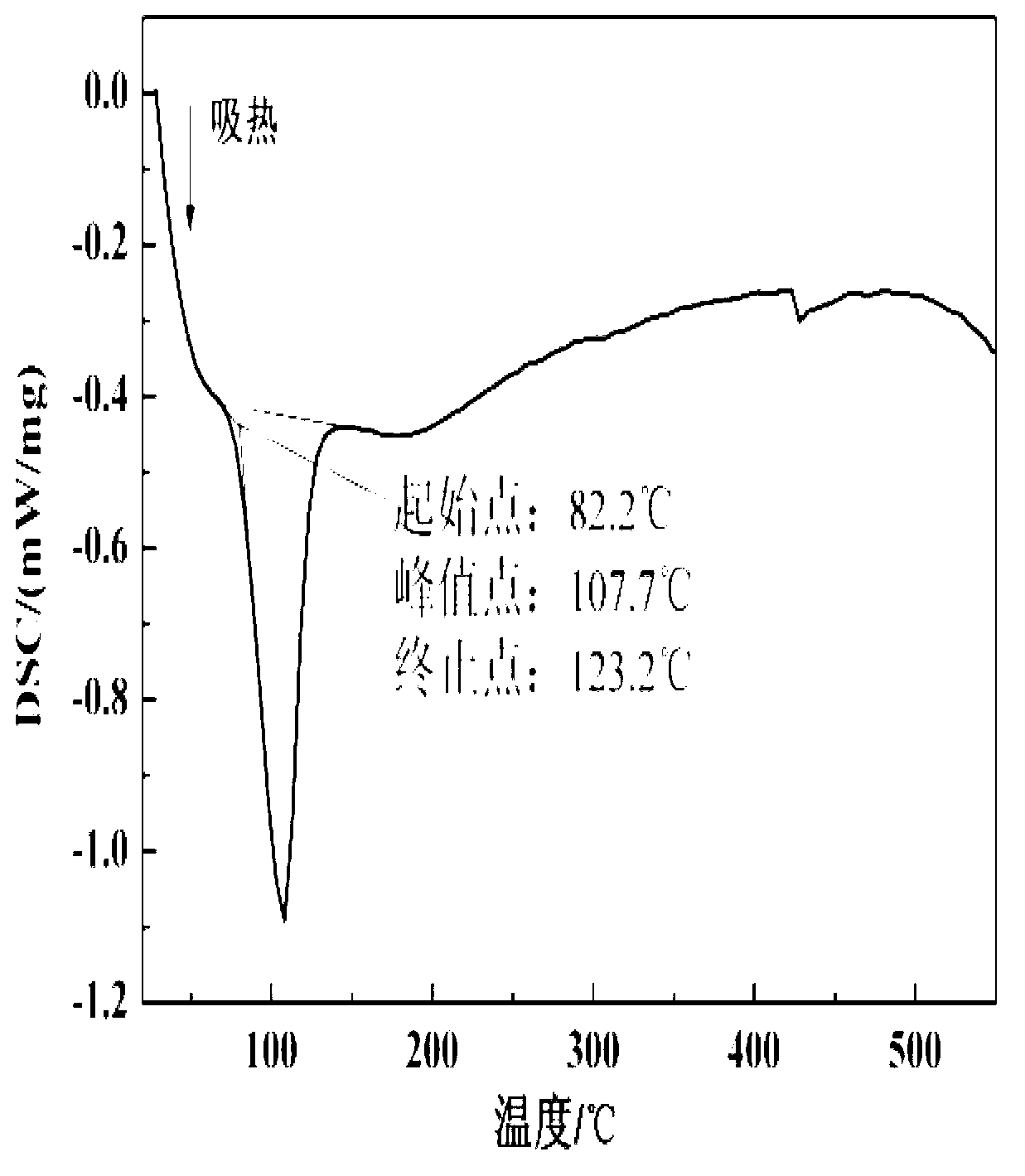

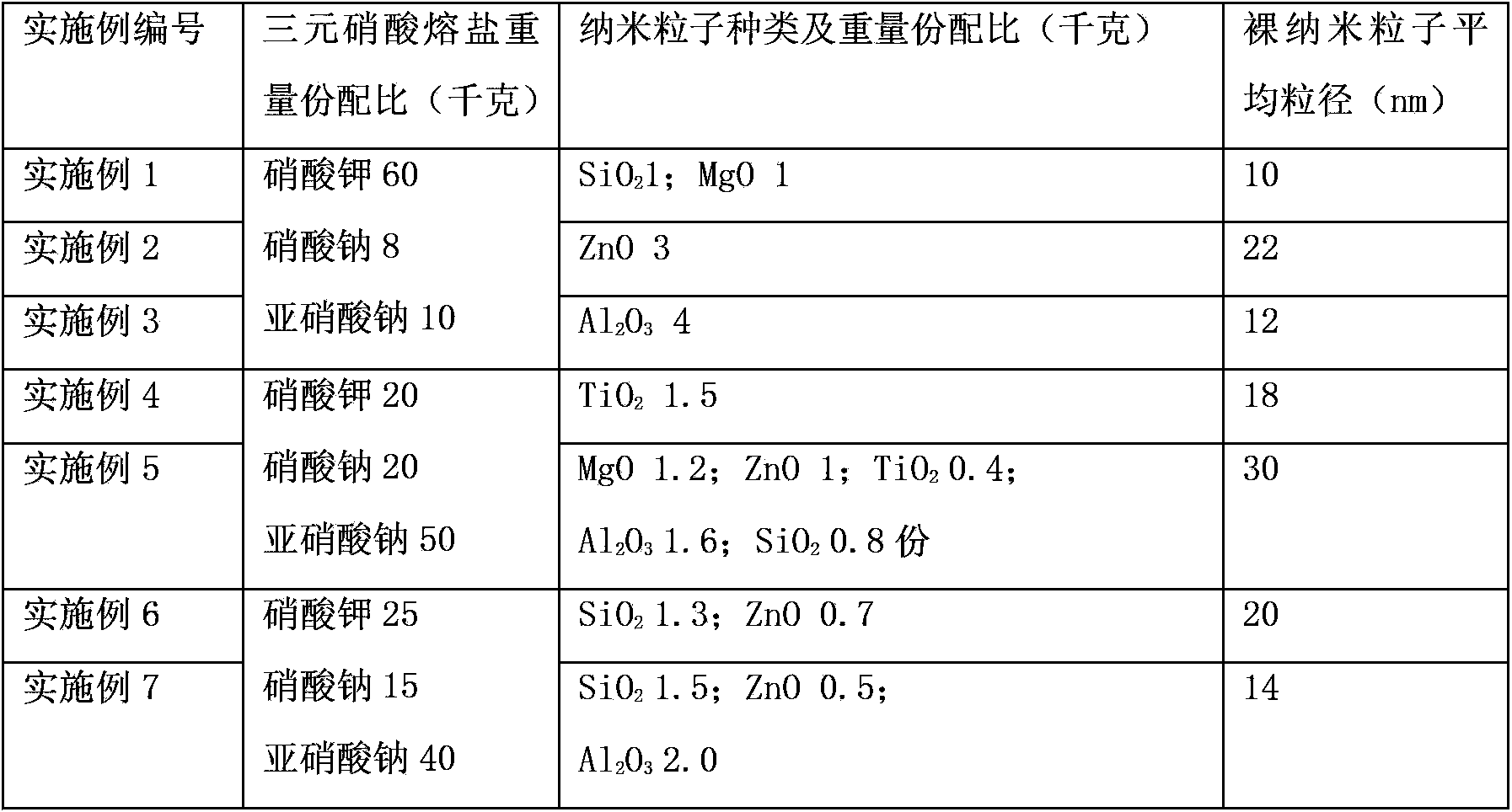

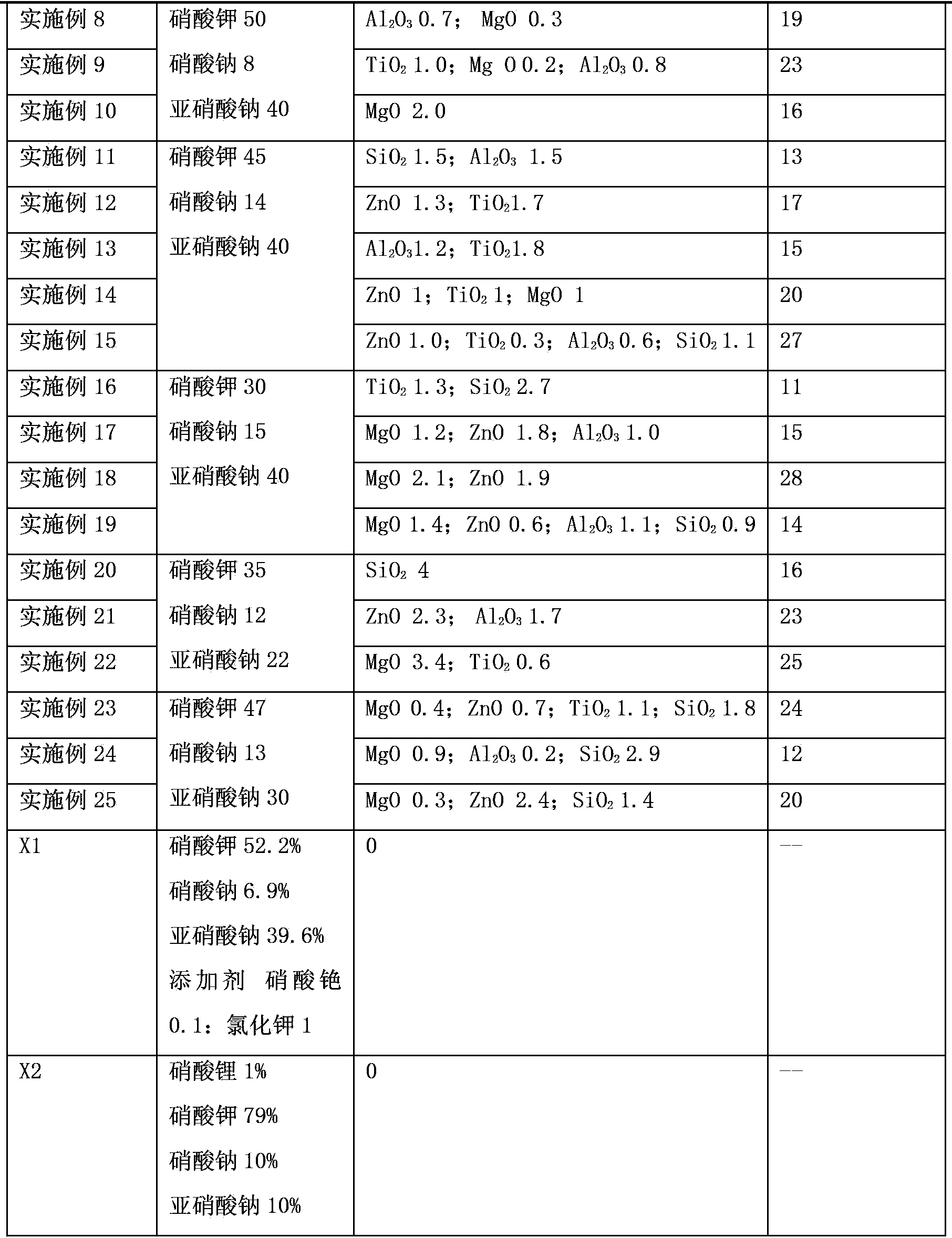

Ternary nitric acid nano-molten salt heat transfer and storage medium, preparation method and application thereof

InactiveCN103881662AOvercome solubilityOvercoming thermal conductivityHeat-exchange elementsMetal oxide nanoparticlesNanoparticles dispersion

Belonging to the technical field of heat storage and transfer, the invention provides a ternary nitric acid nano-molten salt heat transfer and storage medium, a preparation method and application thereof. The ternary nitric acid nano-molten salt heat transfer and storage medium contains a ternary nitric acid molten salt system formed by potassium nitrate, sodium nitrate and sodium nitrite. The ternary nitric acid nano-molten salt heat transfer and storage medium is characterized in that it also includes metal oxide nanoparticles and / or non-metal oxide nanoparticles. The nanoparticles are dispersed into the ternary nitric acid molten salt system to undergo compounding so as to form the ternary nitric acid nano-molten salt heat transfer and storage medium. The ternary nitric acid nano-molten salt involved in the invention has a low melting point, an upper limit use temperature up to 600DEG C, good thermal stability, and high heat conductivity, thus being very suitable for the heat storage and transfer system of industrial energy storage and solar-thermal power generation.

Owner:QINGHAI ENESOON NEW MATERIAL TECH & SCI CO LTD

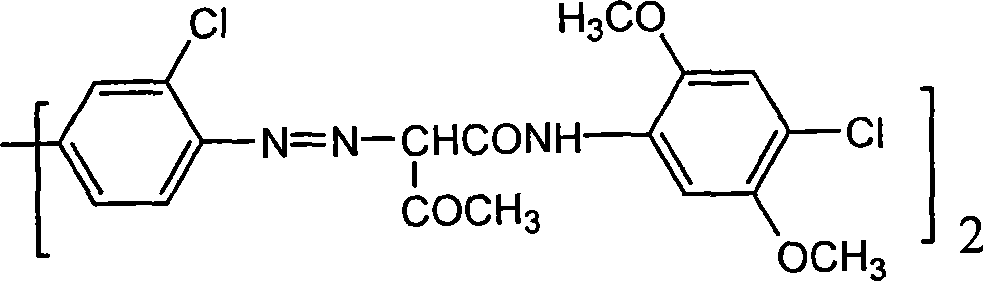

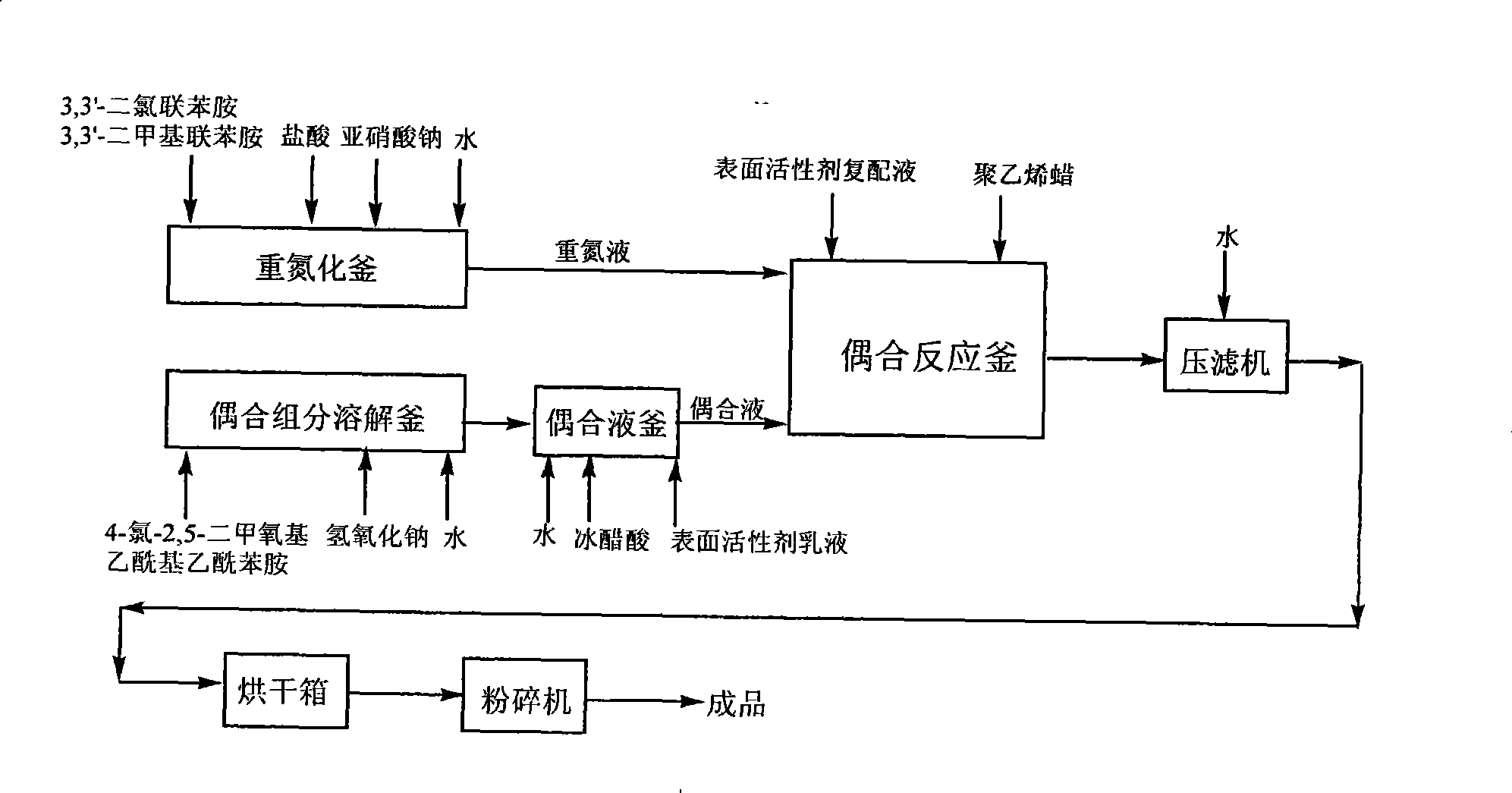

Method for preparing pigment yellow

The invention provides a method for preparing pigment yellow 83. The method comprises the following steps: 3, 3'-dichlorobenzidine, 3, 3'-dimethylbenzidine, hydrochloric acid and water are stirred, dissolved and added to sodium nitrite for diazotization, so as to obtain a diazonium solution; a sodium hydroxide solution containing 4-chlorine-2, 5-dimethoxy acetyl acetanilide is dripped into an acetic acid solution at the temperature between 20 and 40 DEG C, so as to prepare a coupling solution; the acetic acid solution contains an emulsion formed by well mixing anionic surfactant, nonionic surfactant, solvent and water; the diazonium solution is dripped into the coupling solution within 1 to 5 hours; the emulsion formed by compounding the anionic surfactant and non-polar hyper-dispersant is added to the coupling solution, reacts for 1 hour, and is heated to 90 to 100 DEG C; polyethylene wax is added in the mixture; and then the mixture, is insulated for 1 to 3 hours, pumped, filtered, washed, dried and ground, so as to obtain a finished product. The preparation method has the advantage of obtaining the pigment yellow 83 which is bright in color light, high in tinting strength, high in covering power and good in dispersibility.

Owner:宇虹颜料股份有限公司

Multifunctional preparation for controlling biological corrosion and blockage of oilfield production system

ActiveCN101875839AEliminate pollutionEliminate cloggingDrilling compositionDisinfectantSulfate-reducing bacteria

The invention relates to a multifunctional preparation for controlling biological corrosion and blockage of an oilfield production system. The contents of functional preparations in the treating water are as follows: 20 to 200 ppm of disinfectant: glutaraldehyde, acrolein, dodecyldimethylbenzyl ammonium chloride or dodecyldimethylbenzyl ammonium bromide, 10 to 100 ppm of inhibitor: sodium nitrateor sodium nitrite; and / or 10 to 20 ppm of sodium molybdate, sodium tungstate or lithium molybdate; 10 to 20 ppm of corrosion inhibitor: imidazoline quaternary ammonium; or / and 20 to 50 ppm of desulphurizing reagent: trihydroxymethyl nitromethane; or / and 10 to 20 ppm of penetrating agent: alkylpheol ethoxylates. The components undergo synergistic action so that the concentration of the single component is reduced obviously and reaches 25 to 90%, and the efficiency of killing the SRB (Sulfate Reducing Bacteria) reaches more than 90%.

Owner:PETROCHINA CO LTD

Bologna sausage and preparation method thereof

InactiveCN102038208AThe ratio of group allocation is reasonableBeautiful and fragrantFood preparationMonosodium glutamateFood additive

The invention relates to a bologna sausage. The bologna sausage comprises pork, chicken, emulsified skin, ice water, salt, sugar, monosodium glutamate, composite phosphate, modified starch, protein isolate, carrageenan, scallion powder, garlic powder, sodium erythorbate, potassium sorbate, a food additive, white wine, an edible pigment and sodium nitrite; and the raw materials are rolled, rubbed, salted, smoked, cooked and sterilized in turn after being mixed. The produced product has good color, aroma and taste, rich nutrition, low fat content and high protein content, and is convenient to eat and suitable for old people and children; and the preparation process is suitable for quick industrial production.

Owner:天津宝迪农业科技股份有限公司

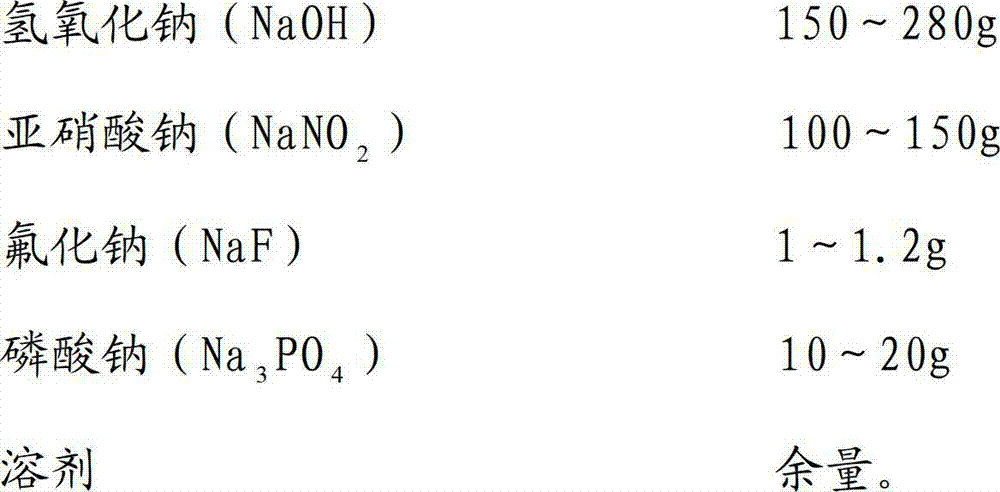

Alkaline chemical polishing solution and alkaline chemical polishing method

The invention discloses an alkaline chemical polishing solution and an alkaline chemical polishing method. Each 1 L of alkaline chemical polishing solution comprises components of 150-280 g of sodium hydroxide, 100-150 g of sodium nitrite, 1-.1.2 g of sodium fluoride, 10-20 g of sodium phosphate, and the balance of a solvent; and meanwhile, the alkaline chemical polishing solution is utilized for alkaline chemical polishing. The alkaline chemical polishing solution and the alkaline chemical polishing method, disclosed by the invention, have the beneficial effects of solving the problems of scratching and impacting of aluminum alloy parts, improving surface roughness of parts, lowering production cost and avoiding environment pollution as a selective self-dissolution function of aluminum and an aluminum alloy is utilized in an alkaline solution to flatten and polish the surface of the aluminum.

Owner:GUIZHOU AEROSPACE LINQUAN MOTOR CO LTD

Sodium nitrite-containing pharmaceutical compositions

ActiveUS8568793B2Prevent and reduce riskBiocideInorganic active ingredientsVolatile organic carbonSodium nitrite

Provided herein are pharmaceutically acceptable sodium nitrite and pharmaceutical compositions thereof. Also provided herein are methods for determining the total non-volatile organic carbon in a sodium nitrite-containing sample. Further provided herein are methods for producing pharmaceutically acceptable sodium nitrite. Still further provided herein are methods of treatment comprising the administration of pharmaceutically acceptable sodium nitrite.

Owner:HOPE MEDICAL ENTERPRISES HOPE PHARMA

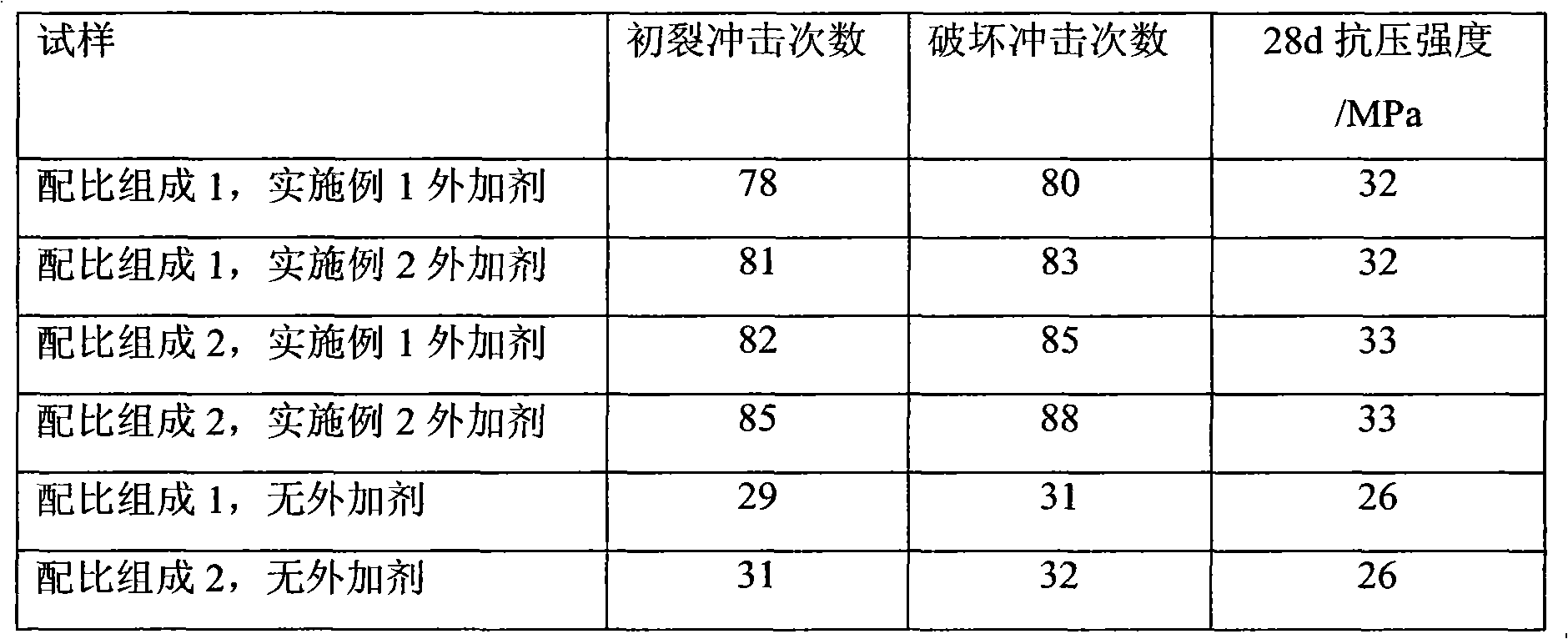

Concrete complex additive

The invention provides a concrete complex additive which comprises the following components by weight percent: 17.5-58.0% of efficient water reducing agent, 0.5-5.5% of organosilicon waterproofing agent, 0.2-2.5% of organosilicon reinforcing agent, 3.5-25% of polyacrylamide, 1.2-2.8% of triethanolamine, 3.2-6.3% of sodium nitrite, 0.3-1.2% of glycol, 0.6-1.3% of glycerol, 2.8-5.5% of sodium gluconate and the balance of water. The impact resistance, crocking resistance, impermeability and waterproofness of the concrete material can be obviously improved by using the complex additive provided by the application in the preparation process of the concrete, thus the concrete complex additives is especially suitable for the requirement on high-performance concrete for construction of airfield runways or highway bridges.

Owner:JIANGSU FENGTAI TOOLS

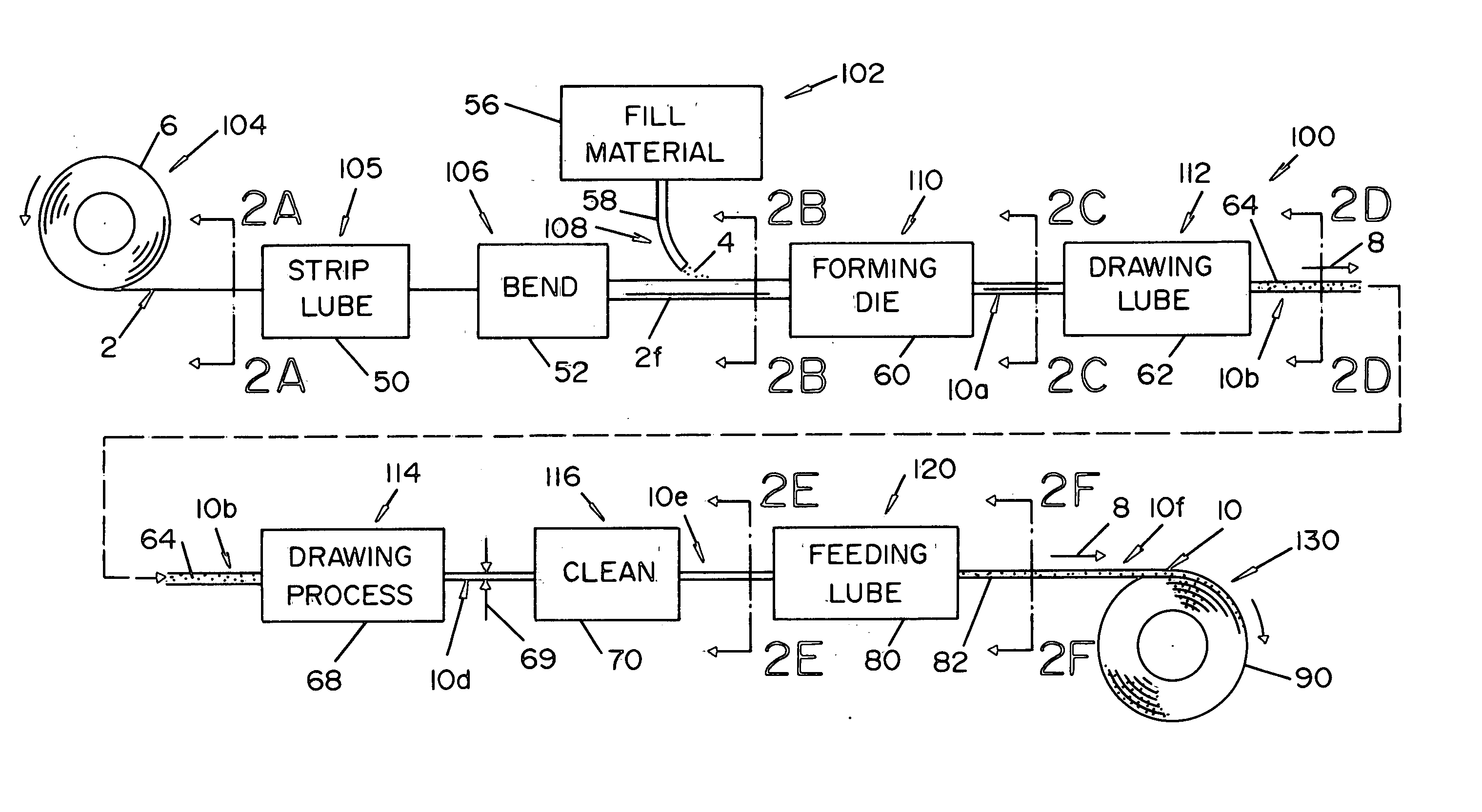

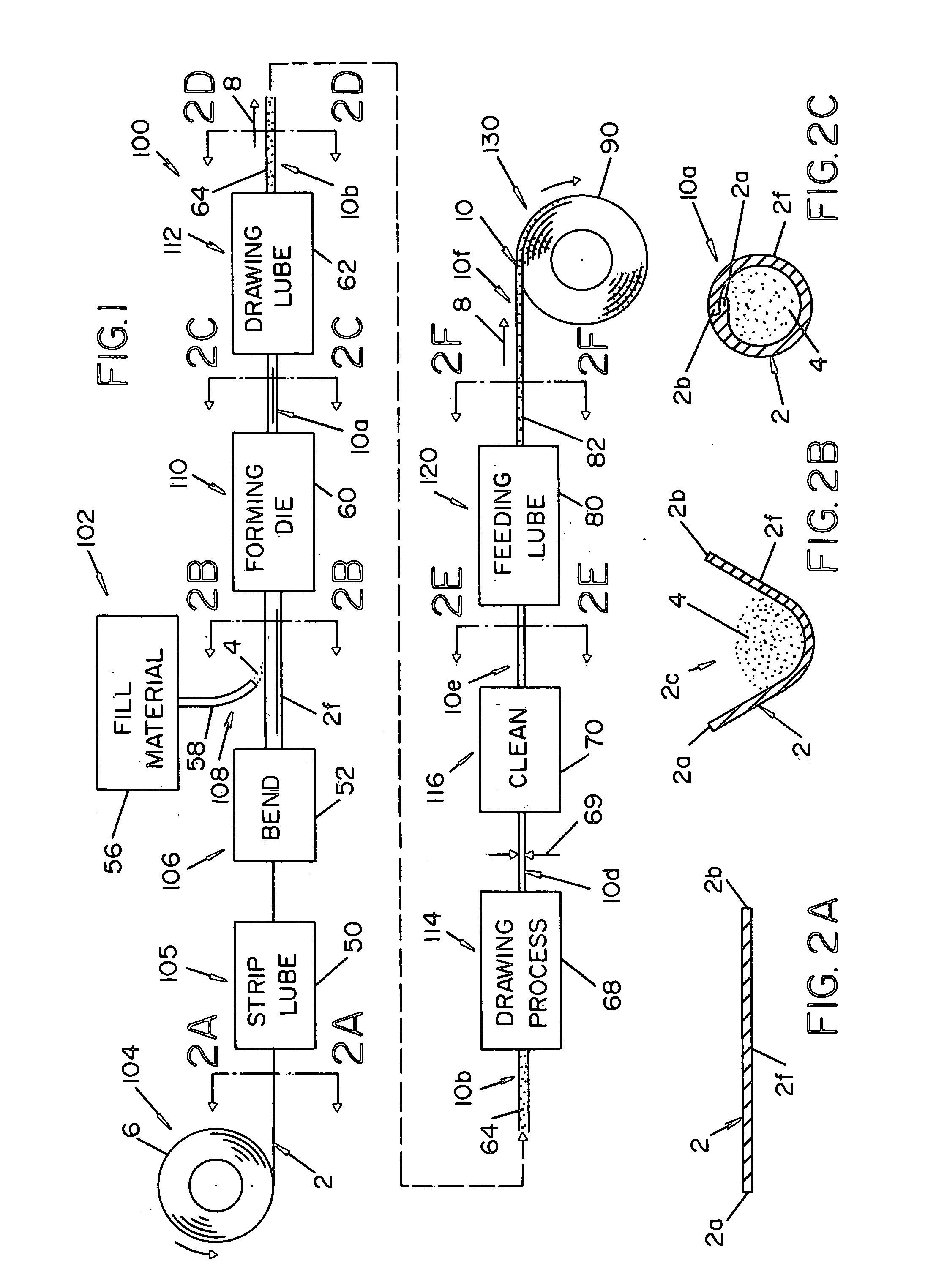

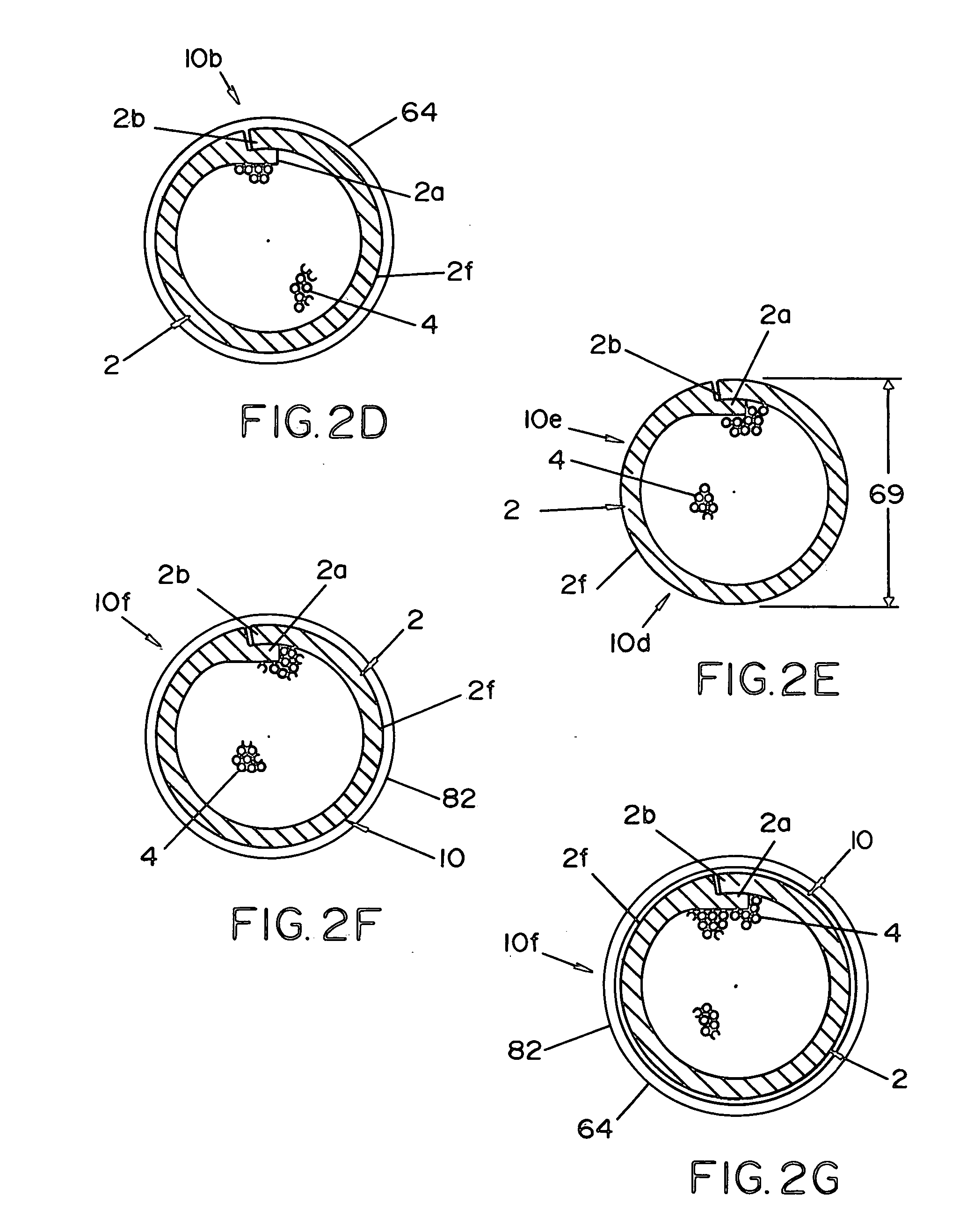

Cored welding electrode and methods for manufacturing the same

InactiveUS20060261054A1Improved welding arc stabilityImproved arc stabilityWelding/cutting media/materialsSoldering mediaFilling materialsSodium sulfate

A manufacturing method is presented for manufacturing cored welding electrode, including provision of a cored electrode structure with core fill material substantially enclosed within a sheath material, and application of a sodium based feeding lubricant to the cored electrode structure. A cored welding electrode is provided, including a tubular sheath material with a center core area, a core fill material within the core area, and a sodium based lubricant coating on the sheath material, wherein the lubricant comprises sodium sulfate, sodium carbonate, and / or sodium nitrite.

Owner:LINCOLN GLOBAL INC

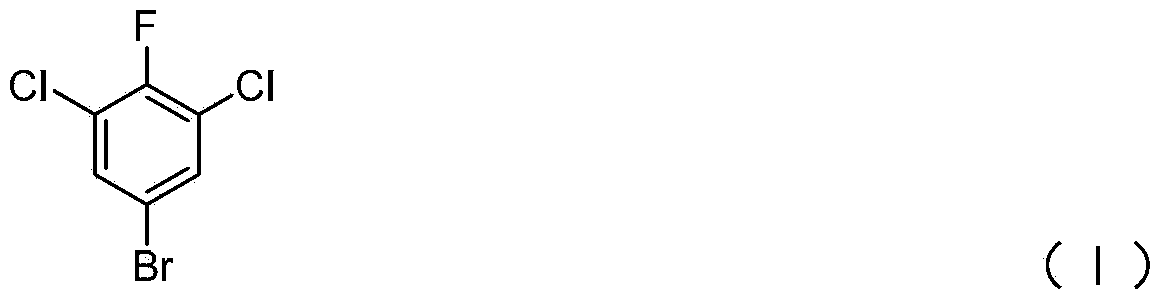

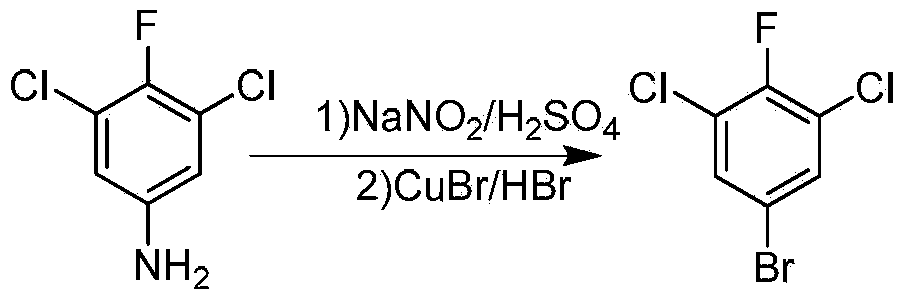

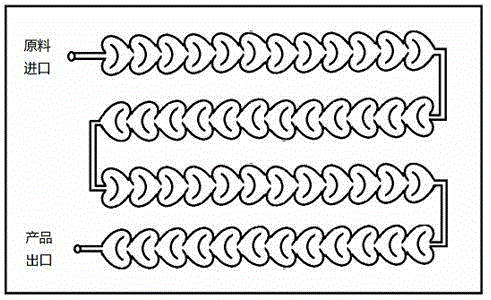

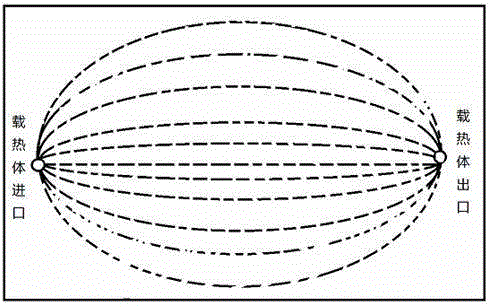

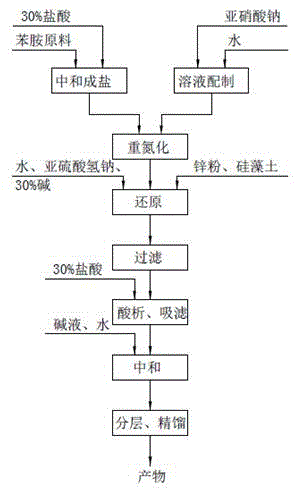

Preparation method of 5-bromo-1,3-dichloro-2-fluorobenzene

ActiveCN103664511AEasy to operateHigh purityHalogenated hydrocarbon preparationDecompositionSide reaction

The invention discloses a preparation method of 5-bromo-1,3-dichloro-2-fluorobenzene, which comprises the following steps: (1) simultaneously feeding ammonium salt and a sodium nitrite aqueous solution into a tubular reactor for tubular diazotization reaction so as to obtain a diazonium salt intermediate, wherein the ammonium salt is prepared through dissolving 3,5-dichloro-4-fluoroaniline in sulfuric acid; (2) dissolving cuprous bromide in hydrobromic acid, heating to 100-130 DEG C, dropwise adding the diazonium salt intermediate prepared in the step (1) for reaction, and after the complete reaction, performing after-treatment to obtain the 5-bromo-1,3-dichloro-2-fluorobenzene. According to the preparation method, the tubular diazotization reaction technology is adopted to prepare diazonium salt, so that the side reaction including diazonium salt coupling and decomposition and the like can be reduced, the diazotization reaction is enabled to be more stable, and the final yield is improved; in addition, the tubular diazotization reaction technology has a series of advantages of continuity in production, safety, short reaction time, energy saving and the like, and is relatively suitable for industrial production in the future.

Owner:ZHEJIANG LINJIANG CHEM

Method for preparing hydrazinobenzene in continuous micro-channel reactor

InactiveCN106316879AHigh mixing mass transfer effectImprove thermal conductivityHydrazine preparationToxic gasContinuous flow

The invention relates to a method for preparing highly pure hydrazinobenzene by using continuous flow micro-channel reactor. The method concretely comprises the following steps: preparing aniline hydrochloride from hydrochloric acid and aniline, respectively pumping the aniline hydrochloride and a sodium nitrite solution into the micro-channel reactor by two metering pumps to obtain a diazo salt solution, reducing the obtained reaction solution, carrying out acid separation on the reduced solution, filtering the obtained solution, neutralizing the filtered solution, and distilling the neutralized solution to obtain the highly pure hydrazinobenzene. The diazotization process is a strong exothermic reaction, and the generated diazo salt easily decomposes after standing at a high temperature for a long time, and generates toxic gases which pollute environment and even blast. The mixing effect of the heart-shaped micro-channel reactor is far better than the mass transfer effect generated by stirring, so the aniline conversion rate can reach 99%, the mixing mass transfer effect is good, and heat conduction is fast to avoid local overheating phenomenon; and the reaction can be carried out at constant temperature conditions, so the temperature runaway blast danger of general reactors is eliminated, and the safety is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preserved meat fillet, and its preparing method

A preserved meat (beef or pork) is prepared from edible meat, soy, ginger juice, yellow wine, flavouring wine or liquor, gourmet powder, edible salt, sugar, VC, spices powder, sodium nitrite, potassium sorbate, milk powder, bone powder and cane sugar through slicing meat, mixing it with others, spreading on screen, baking, roasting and packing.

Owner:SHANDONG NORMAL UNIV

Method and test strip of detecting oxidizing adulterant in urine

A single reagent system and a method to detect and measure oxidizing adulterants in bodily fluid being screened for drugs of abuse are disclosed. The system comprising a strip containing 0.05 to 0.2 micromole / 25 sq. mm. of a benzidine derivative and is used to detect sodium hypochlorite (bleach), chlorine, hydrogen peroxide, sodium bromide, sodium iodide, sodium nitrite, and pyridinium chlorochromate adulterants in urine, sweat, saliva, blood or other bodily fluids during screening for drugs of abuse.

Owner:BRANAN MEDICAL

Method and apparatus for generating nitric oxide for medical use

Owner:MALLINCKRODT HOSPITAL PRODUCTS IP LTD

Laser-absorbing nano oxide paint

The laser-absorbing nano oxide paint consists of nano oxide powder as main material, adhesive PVA, cladding agent polyglycol, antirust sodium nitrite, emulsifier OP-10, dispersant and deionized water. The paint of the present invention has a laser absorbing rate as high as 94-95%, excellent technological properties, including no agglomeration, no deposit, easy to brush and spray, no pollution, no irritative smell, no spraying and burning after in the laser treatment, etc.

Owner:SHANGHAI UNIV OF ENG SCI

Gas self-production system used for plug removal and energy increase of oil-water well and application method thereof

ActiveCN103333670ALess equipment required for preparationSimple processDrilling compositionHexamethylenetetraminePotassium nitrite

The invention relates to a gas self-production system used for plug removal and energy increase of an oil-water well and an application method thereof. The gas self-production system comprises, by weight, 3-10% of urea, 5-25% of a nitrite, 5-25% of an activator and 40-85% of water. The nitrite is one of sodium nitrite, ammonium nitrite and potassium nitrite. The activator is one of methyl formate, ammonium amidosulfonate, ammonium-monochloracetat, hexamethylenetetramine and formaldehyde. When the gas self-production system is used, the above materials are mixed at ambient temperature under ambient pressure, and injected into oil-bearing strata having a temperature higher than 50 DEG C, so as to remove plug, increase energy and increase enhance rate. The gas self-production system can be applied for plug removal and energy increasing of low-pressure low-energy wells in an oil field scattered reserve unit.

Owner:CHINA PETROCHEM & CHEM JIANGSU OILFIELD BRANCH +2

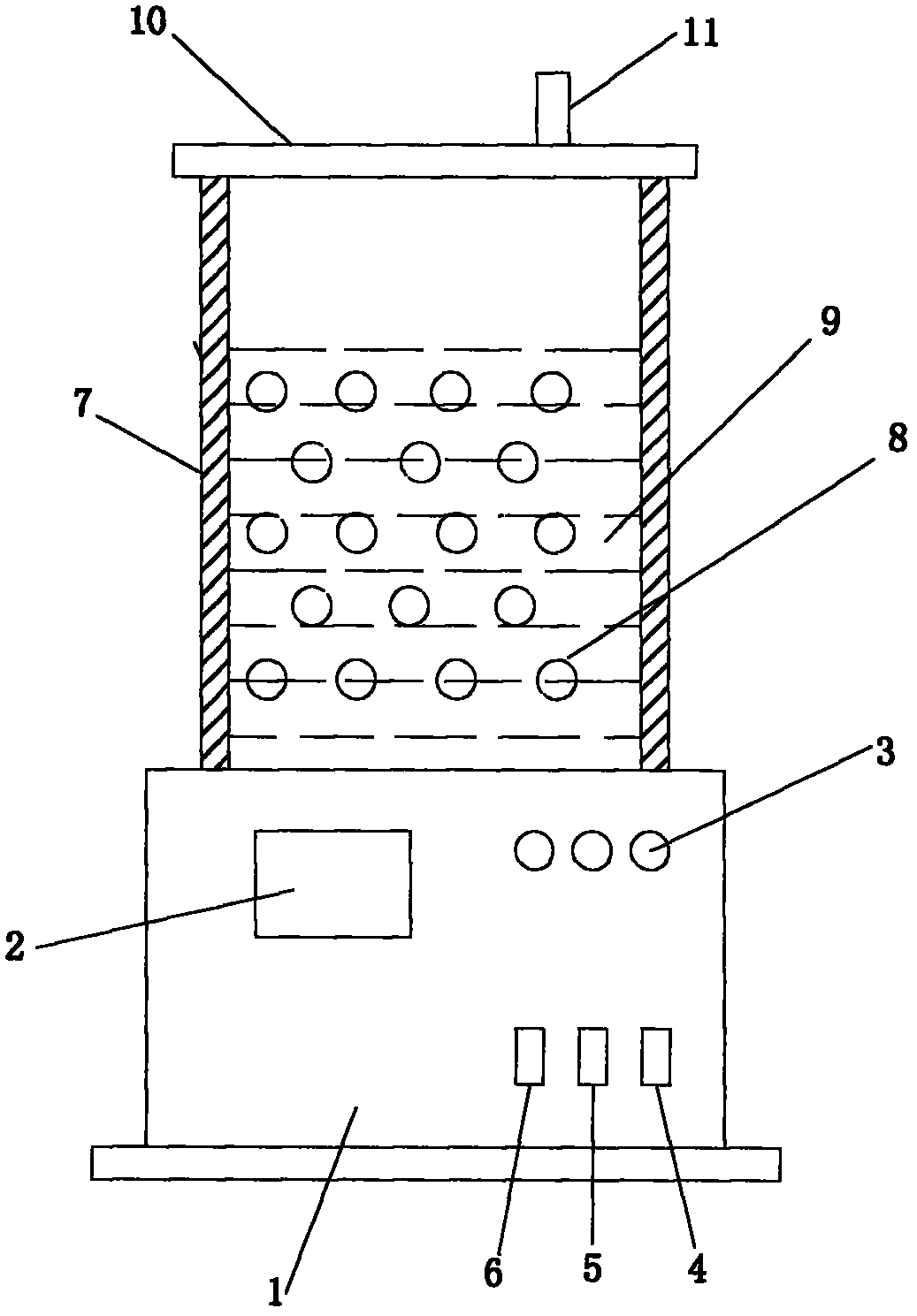

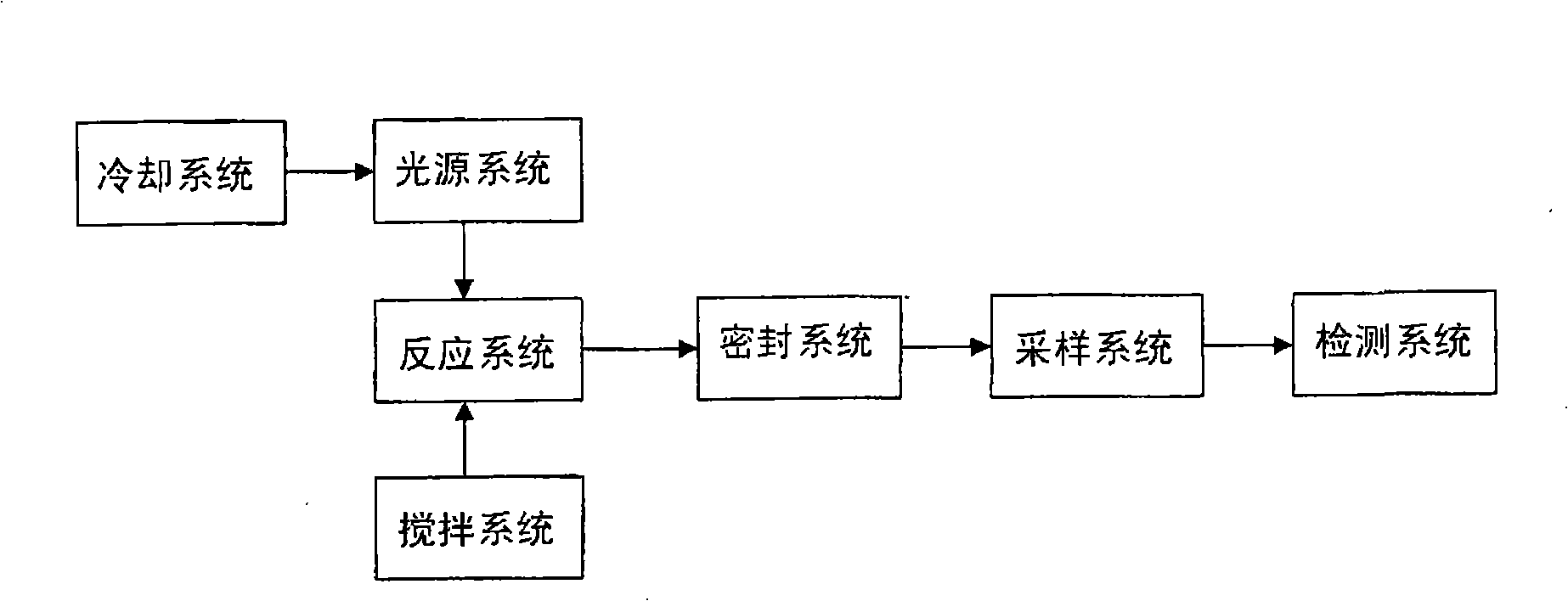

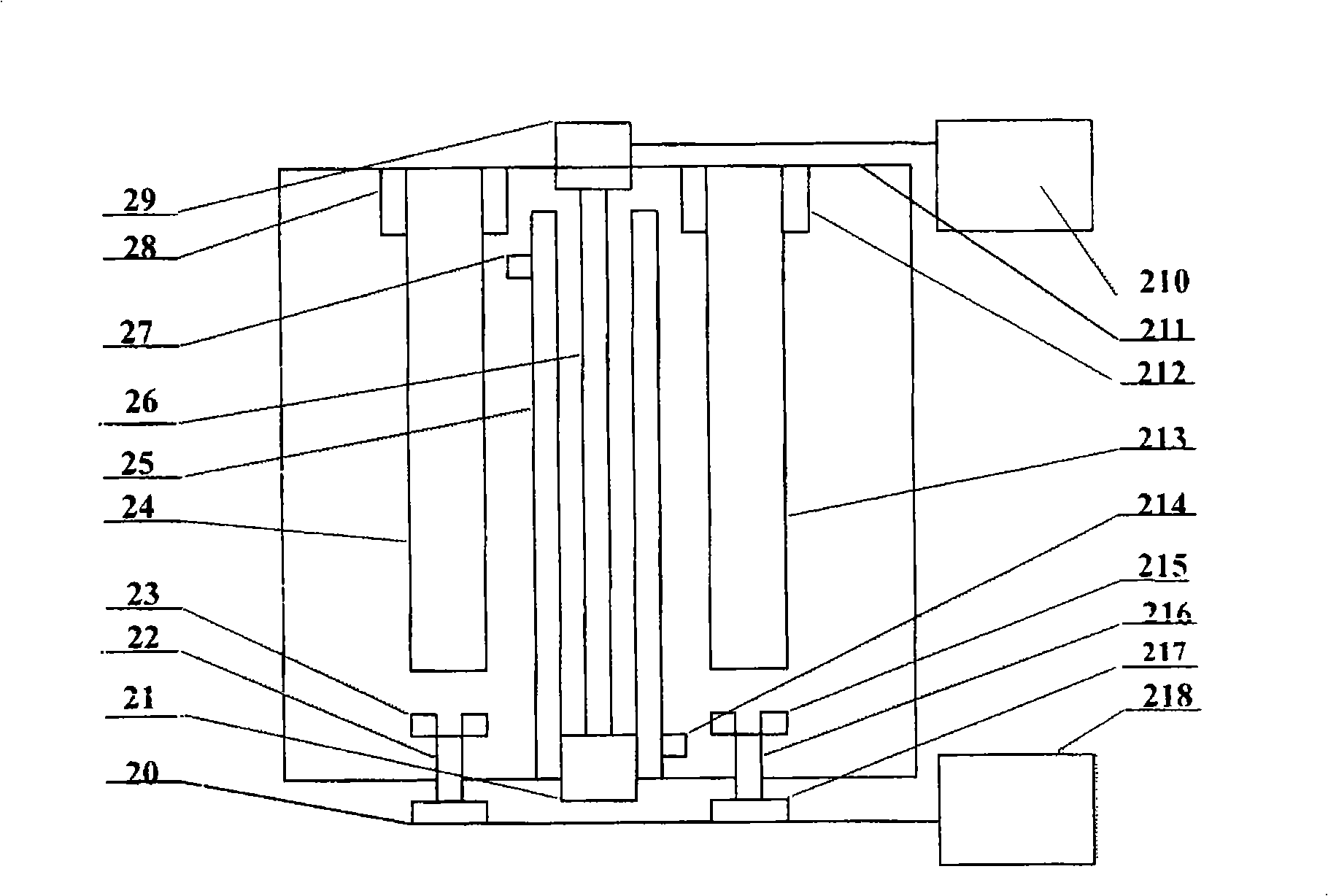

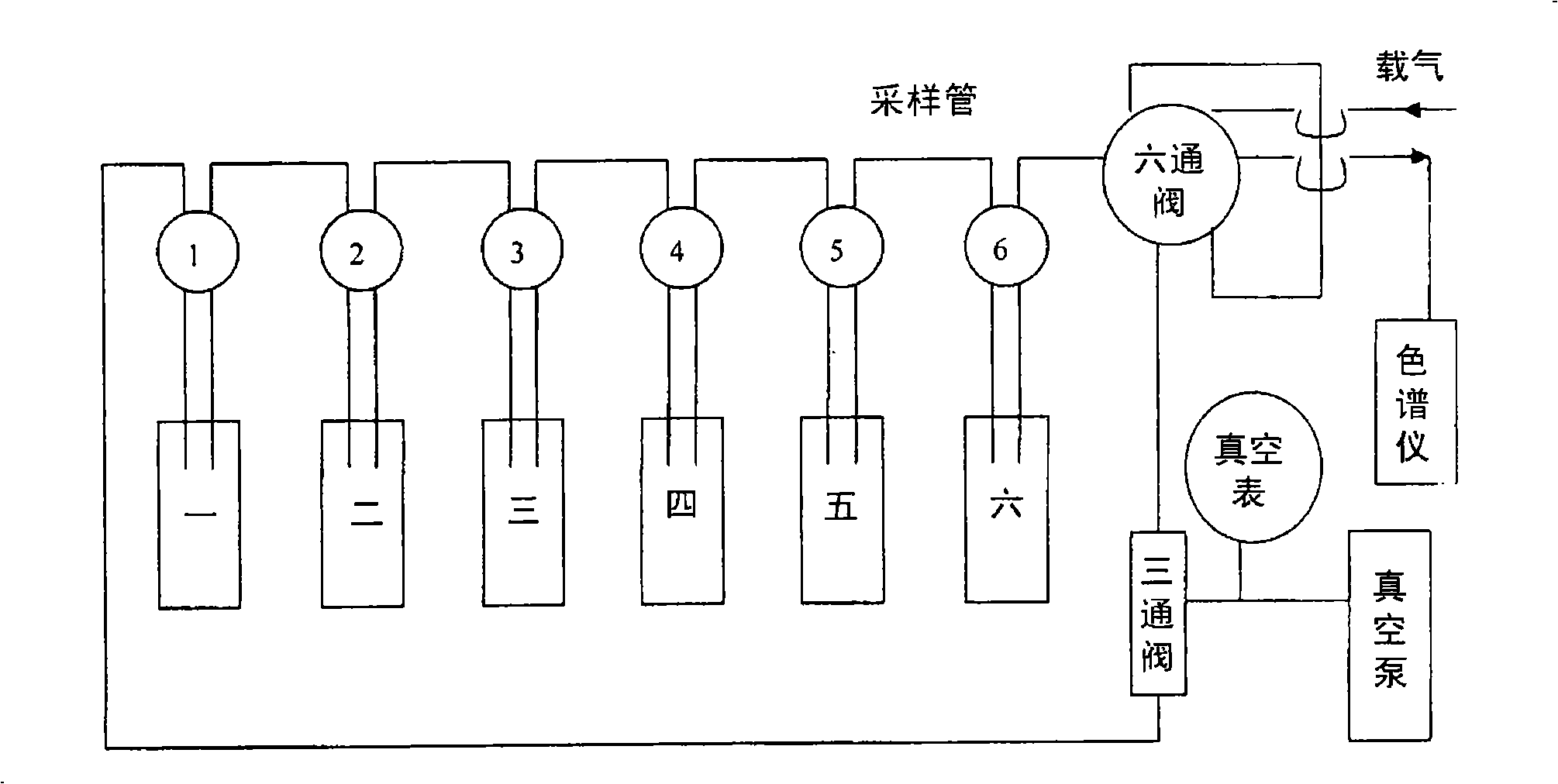

Multi-channel reaction device for fast appraisement of hydrogen manufacturing performance of photocatalyst

InactiveCN101315357AImprove evaluation efficiencyImprove efficiencyChemical methods analysisGas phaseEngineering

A multi-way reaction device for rapid appraisement of photo-catalysis hydrogen production activity is composed of a light source system, a reaction system, a stirring system, a sealing system, a cooling system, a sampling system and a detection system. The multi-way reaction device includes a light reactor, a tubular light source which is driven by a decelerating motor to rotate at an uniform speed is arranged in the center of the light reactor, the light source is arranged in a quartz jacket, and cooling water or a sodium nitrite solution is introduced into the quartz jacket for cooling the light source; a plurality of quartz reaction tubes are uniformly distributed around the light source, the opening part of each quartz reaction tube is in closed connection with the light reactor, a magnetic stirrer is arranged at the lower part for driving rotary at the uniform speed, all volumes of the quartz reaction tubes are the same, and the quartz reaction tubes are connected with a gas chromatography through arranging vacuum pumps and sampling pipelines. The multi-way reaction device can carry out a plurality of groups of photo-catalysis hydrogen production reactions at the same time, and rapidly screen different photolysis hydrogen production catalysts; in addition, when different detectors are selected, the multi-way reaction device can perform rapid multi-way appraisement of various photo-catalytic reactions.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com