Alkaline chemical polishing solution and alkaline chemical polishing method

A chemical polishing and alkaline technology, applied in the field of industrial polishing, can solve problems such as scratches and bumps on aluminum alloy parts, and achieve the effects of improving surface roughness, reducing production costs, and inhibiting pitting corrosion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

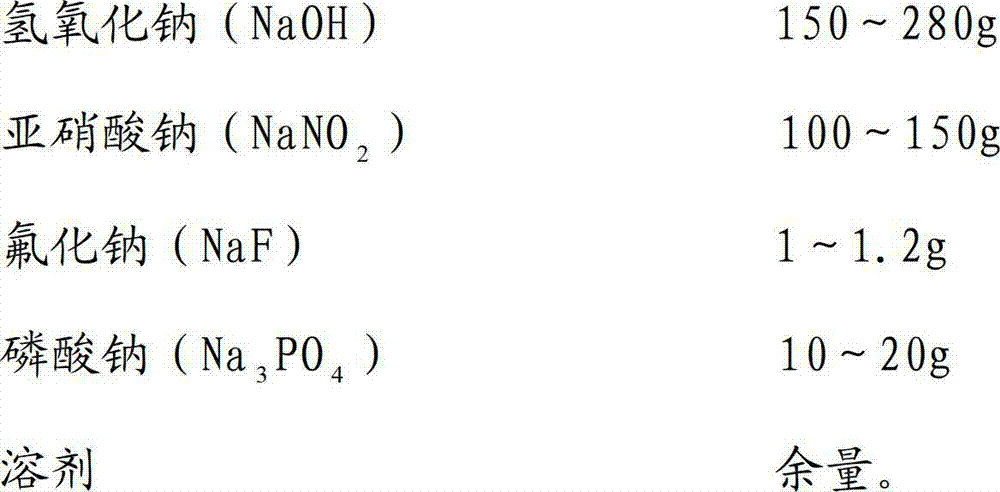

[0024] A kind of alkaline chemical polishing liquid, every 1L of alkaline chemical polishing liquid contains the following components:

[0025]

[0026]

[0027] Described solvent is industrial pure water.

[0028] A kind of alkaline chemical polishing method, mainly used in the polishing treatment of aluminum alloy, it comprises the following steps:

[0029] (1) For the parts to be treated, smooth the flaws and deep scratches on the surface of the aluminum alloy parts with sandpaper, and then perform mechanical sandblasting to remove the traces of sandpaper grinding;

[0030] (2) Heat the temperature of the above-mentioned alkaline chemical polishing solution to 90°C;

[0031] (3) Put the aluminum alloy into the above-mentioned alkaline chemical polishing solution for selective self-dissolution to level and polish the surface of the aluminum alloy. The time of putting it in is 15 seconds, and the polishing treatment of the aluminum alloy is completed.

Embodiment 2

[0033] A kind of alkaline chemical polishing liquid, every 1L of alkaline chemical polishing liquid contains the following components:

[0034]

[0035] Described solvent is industrial pure water.

[0036] A kind of alkaline chemical polishing method, mainly used in the polishing treatment of aluminum alloy, it comprises the following steps:

[0037] (1) For the parts to be treated, smooth the flaws and deep scratches on the surface of the aluminum alloy parts with sandpaper, and then perform mechanical sandblasting to remove the traces of sandpaper grinding;

[0038] (2) Heat the above-mentioned alkaline chemical polishing solution to 95°C;

[0039] (3) Putting the aluminum alloy into the above-mentioned alkaline chemical polishing solution for selective self-dissolution to level and polish the surface of the aluminum alloy. The putting time is 10s, and the polishing treatment of the aluminum alloy is completed.

Embodiment 3

[0041] A kind of alkaline chemical polishing liquid, every 1L of alkaline chemical polishing liquid contains the following components:

[0042]

[0043] Described solvent is industrial pure water.

[0044] A kind of alkaline chemical polishing method, mainly used in the polishing treatment of aluminum alloy, it comprises the following steps:

[0045] (1) For the parts to be treated, smooth the flaws and deep scratches on the surface of the aluminum alloy parts with sandpaper, and then perform mechanical sandblasting to remove the traces of sandpaper grinding;

[0046] (2) Heat the temperature of the above-mentioned alkaline chemical polishing solution to 100°C;

[0047] (3) Putting the aluminum alloy into the above-mentioned alkaline chemical polishing solution for selective self-dissolution to level and polish the surface of the aluminum alloy. The time of putting it in is 5 seconds, that is, the polishing treatment of the aluminum alloy is completed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com