Patents

Literature

323results about How to "Avoid pitting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

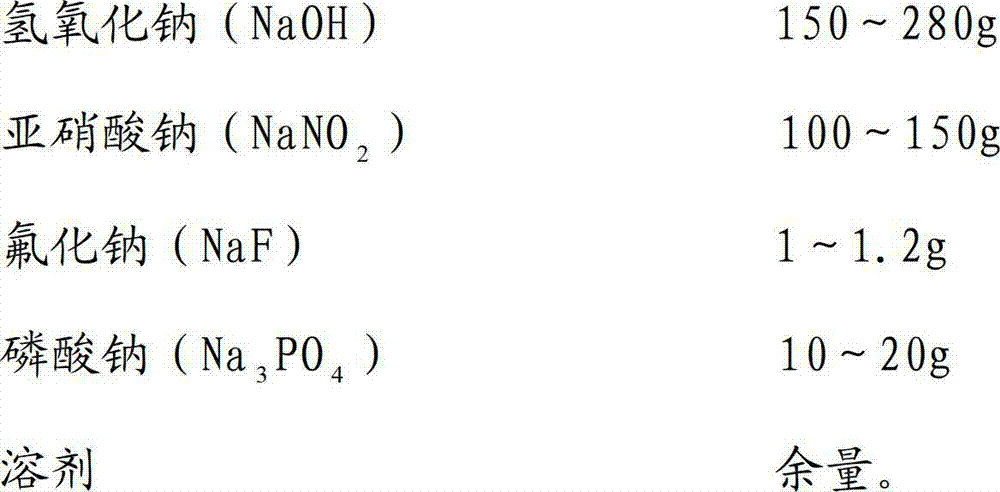

Alkaline chemical polishing solution and alkaline chemical polishing method

The invention discloses an alkaline chemical polishing solution and an alkaline chemical polishing method. Each 1 L of alkaline chemical polishing solution comprises components of 150-280 g of sodium hydroxide, 100-150 g of sodium nitrite, 1-.1.2 g of sodium fluoride, 10-20 g of sodium phosphate, and the balance of a solvent; and meanwhile, the alkaline chemical polishing solution is utilized for alkaline chemical polishing. The alkaline chemical polishing solution and the alkaline chemical polishing method, disclosed by the invention, have the beneficial effects of solving the problems of scratching and impacting of aluminum alloy parts, improving surface roughness of parts, lowering production cost and avoiding environment pollution as a selective self-dissolution function of aluminum and an aluminum alloy is utilized in an alkaline solution to flatten and polish the surface of the aluminum.

Owner:GUIZHOU AEROSPACE LINQUAN MOTOR CO LTD

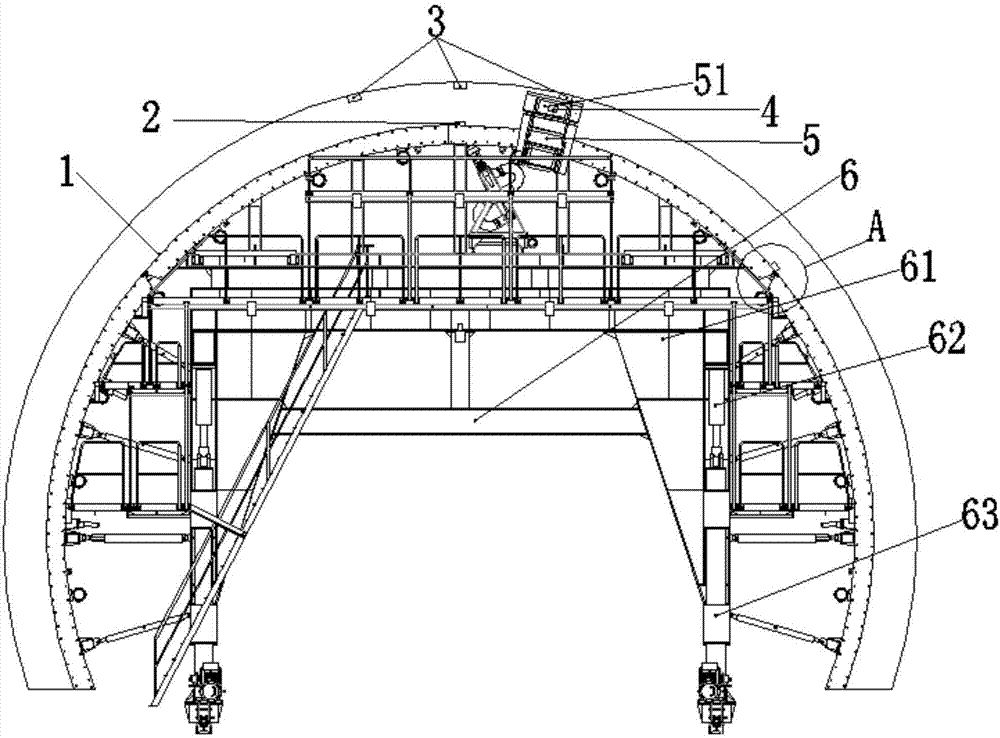

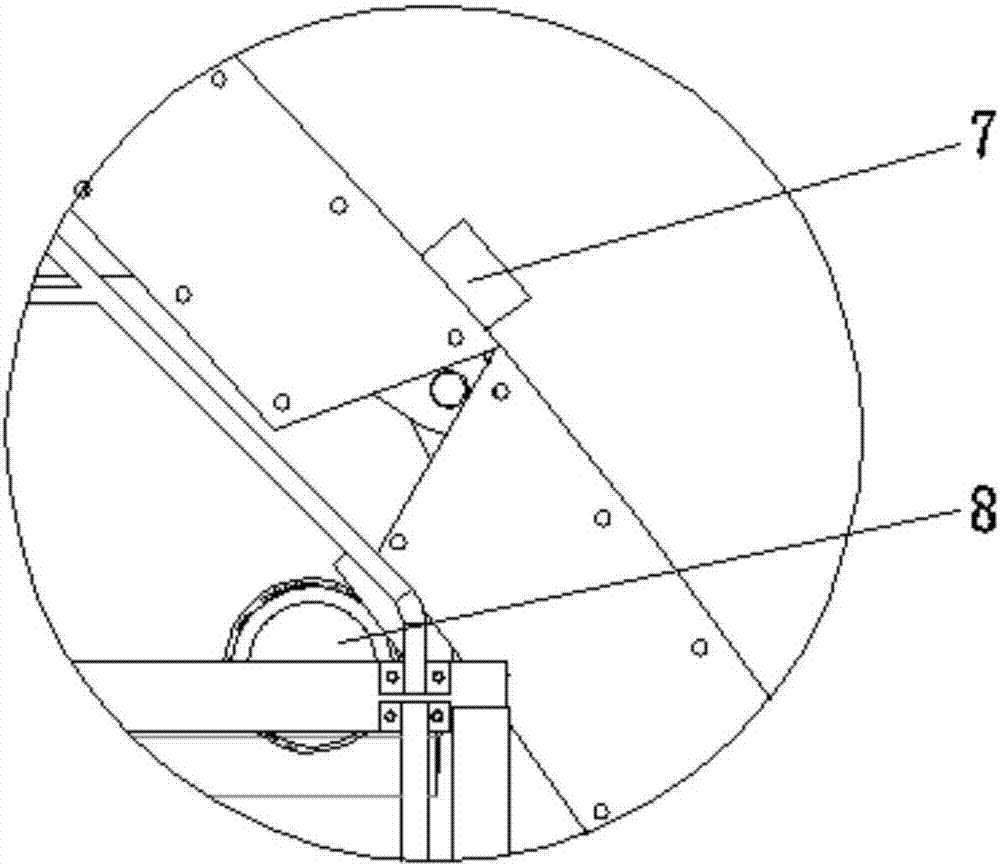

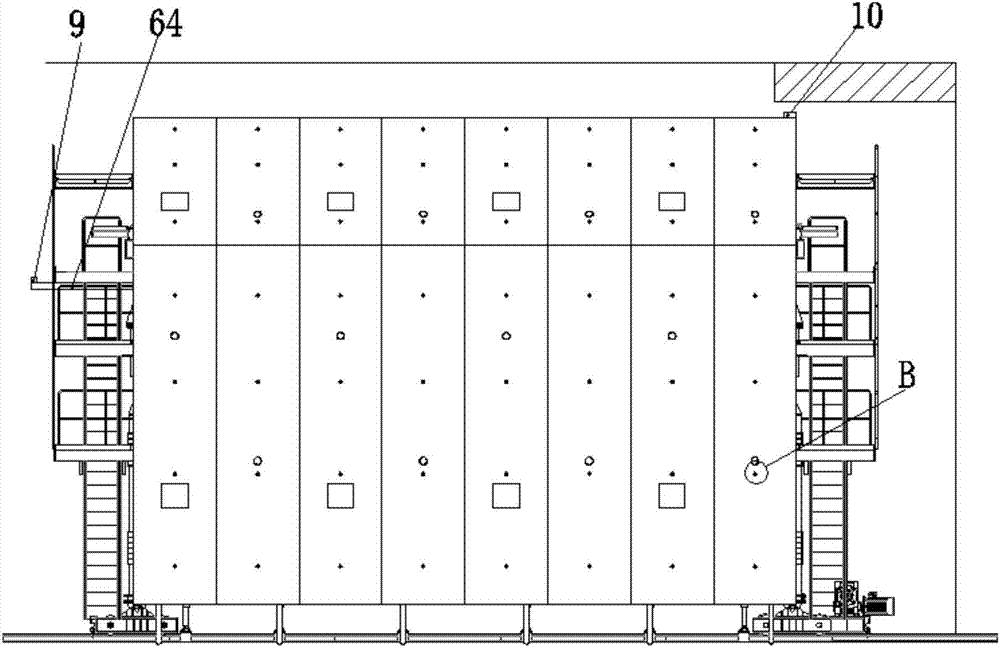

Intelligent tunnel lining trolley

PendingCN107956490AEasy loading and unloadingPlace stableUnderground chambersTunnel liningMonitoring systemSteel frame

Provided is an intelligent tunnel lining trolley, characterized by comprising a door-shaped main steel frame, a concrete pouring informationized monitoring system, an end template, a template cleaningand surface lubricating system, an automatic running gear, and a layered window-by-window pouring and cleaning system. The tunnel lining trolley is simple in structure and reasonable in design, and real-time monitoring of each parameter in a concrete pouring process is realized, automation degree of equipment is improved, cleaning and template surface lubrication operation flow are simplified. The intelligent tunnel lining trolley provides convenience for on-site management and construction, and has certain environmental protection property and very high security.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +1

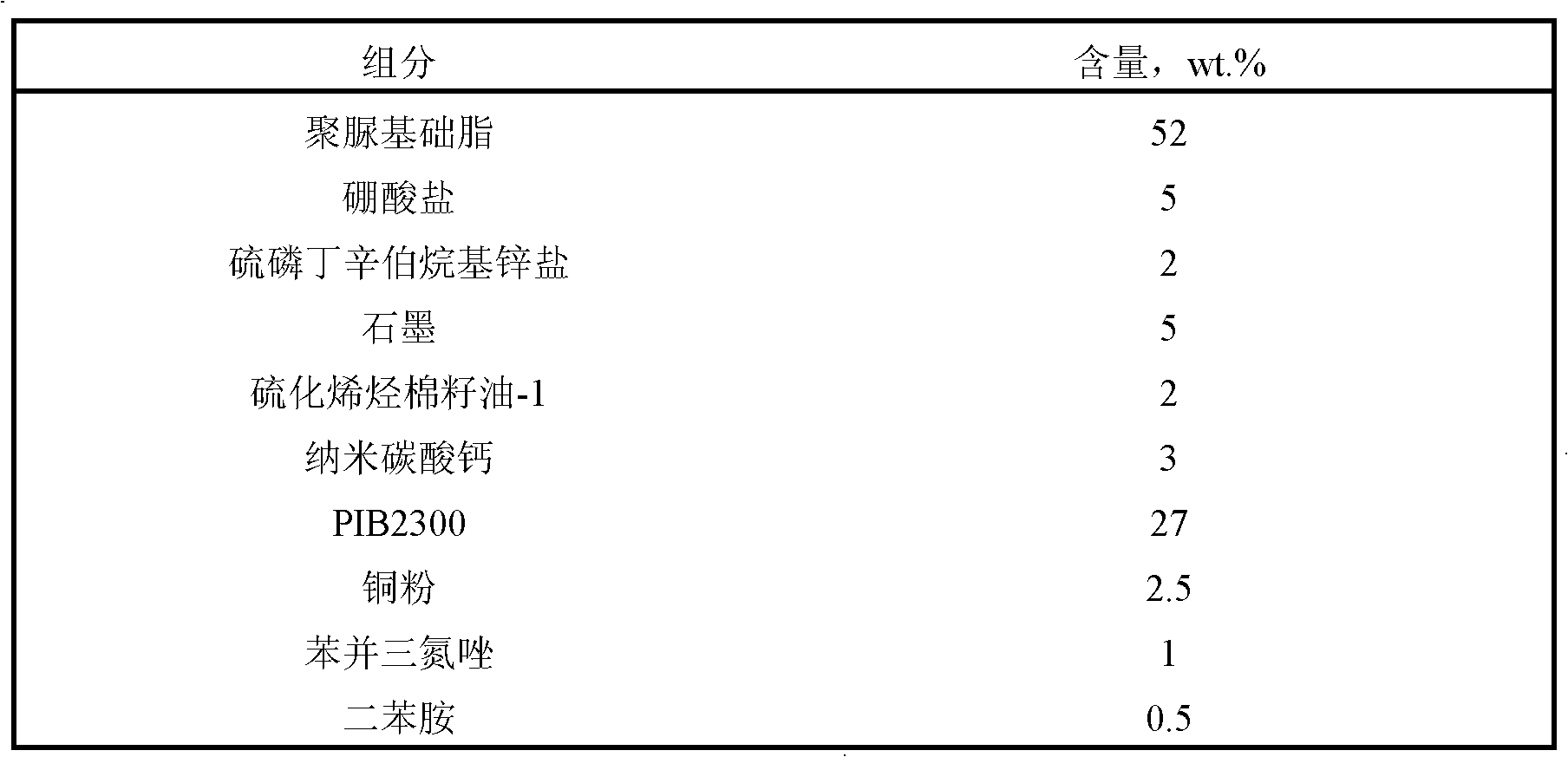

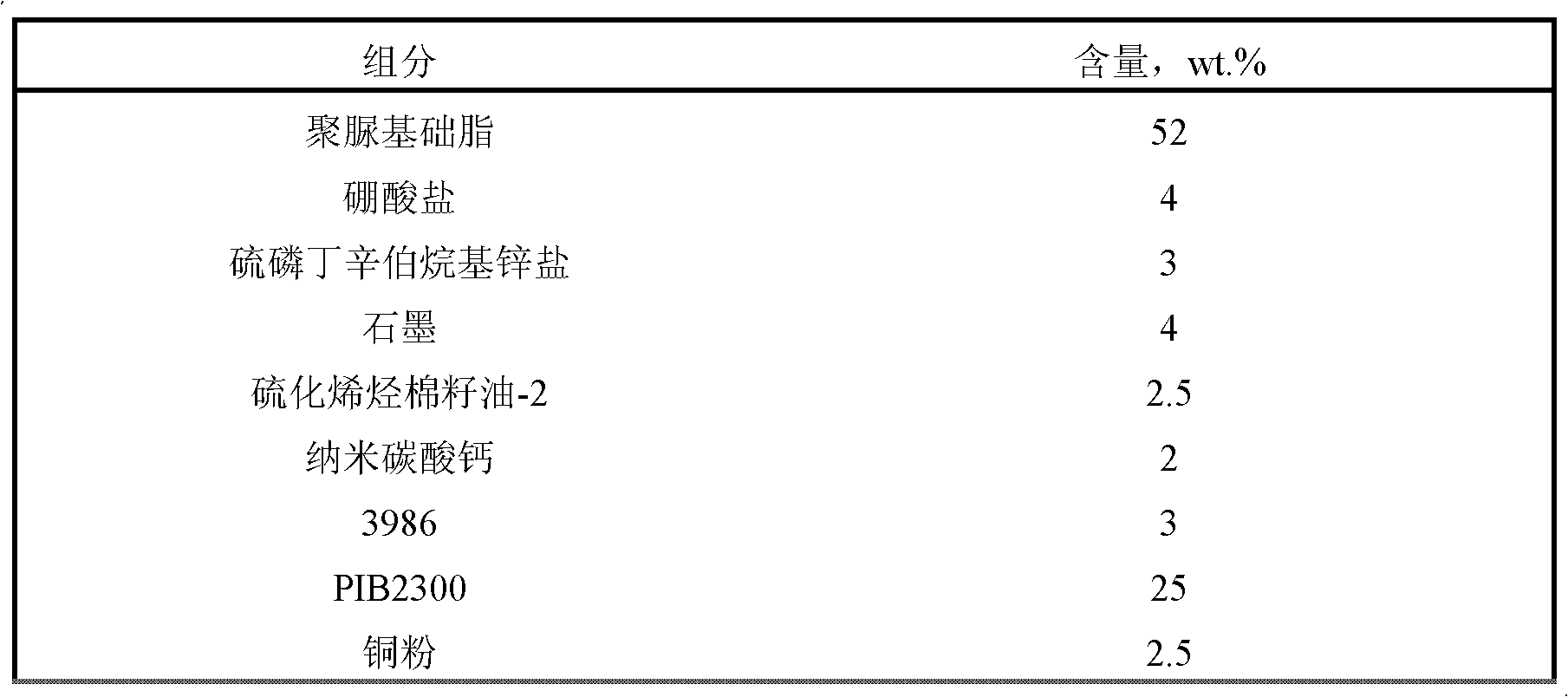

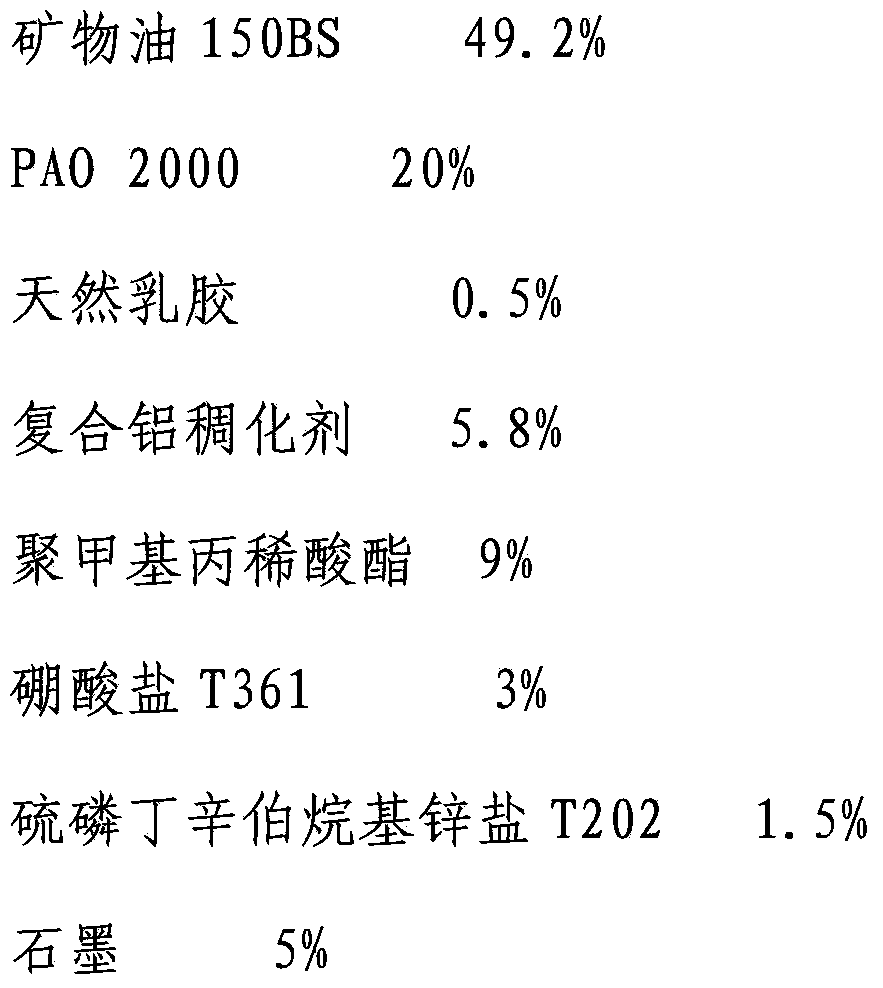

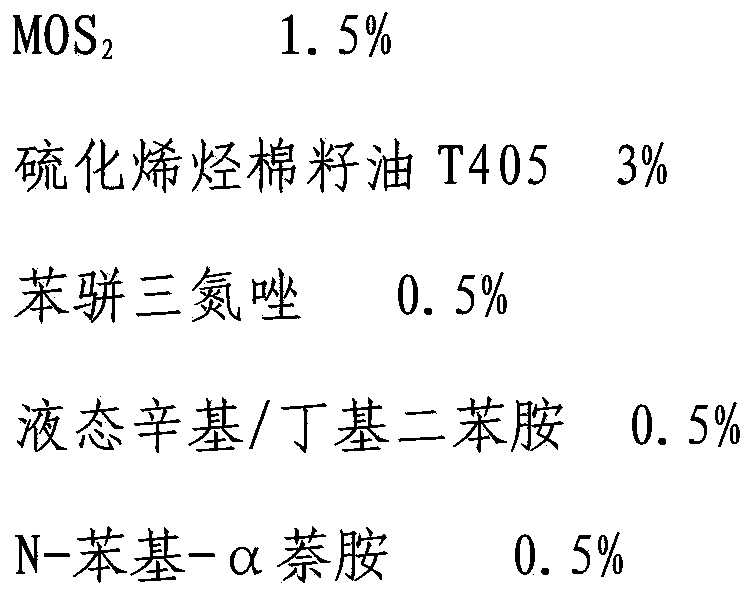

Heavy-duty self-repairing open gear grease

The invention discloses a clean-type heavy-duty open gear grease with self-repairing function. The product is composed of a lubricating grease base grease prepared from an organic compound thickening mineral oil containing carbamido in molecules or synthetic oil, and additives. A base grease thickener is composed of an MDI and organic amine in a molar ratio of 1:1-3; and the base oil is mineral oil or poly alpha olefin synthetic oil. The heavy-duty open gear grease comprises the following components, calculated by the weight of the base grease: 50-60wt% of base grease, 4-8wt% of a extreme pressure antiwear agent, 1-4wt% of an oily agent, 6-8wt% of a solid additive, 0.5-1.5wt% of an antirust agent, 25-35wt% of a tackifier, 2-4wt% of a self-repairing additive, and 0.3-1.0wt% of an antioxidant. The invention adopts borate as the extreme pressure antiwear agent added with an extreme pressure agent containing a small amount of sulfur phosphorus, so as to improve the extreme pressure anti-wear performance of the lubricating grease, as well as realize low toxicity, tastelessness and environment-friendliness of the grease. Besides, soft metal Cu nanoparticles employed by the invention endow good self-repairing performance on the grease. Compared with a traditional open gear lubricant product, the heavy-duty open gear grease provided by the invention has characteristics of excellent lubrication performance, self repairing, tastelessness and environment-friendliness, and can be widely used for lubricating of open gears.

Owner:PETROCHINA CO LTD

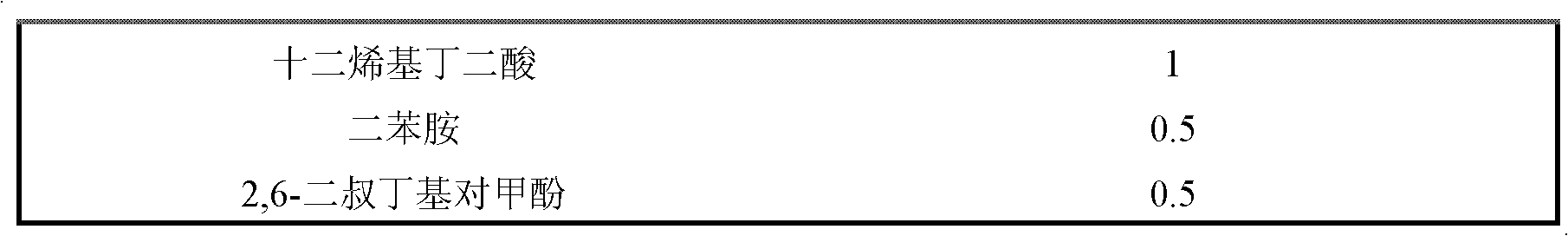

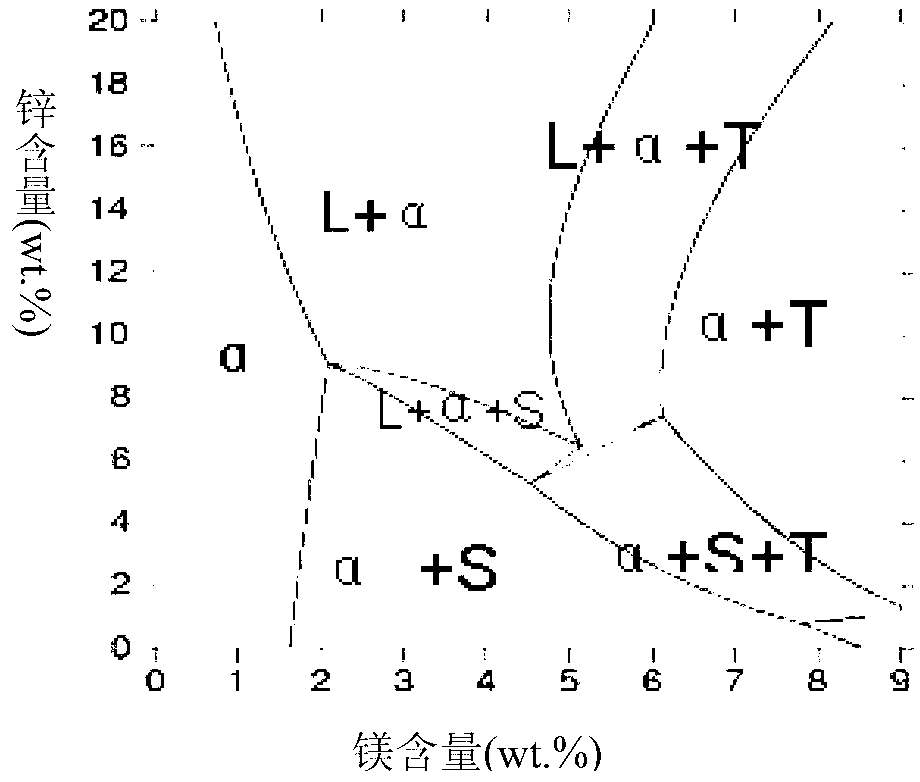

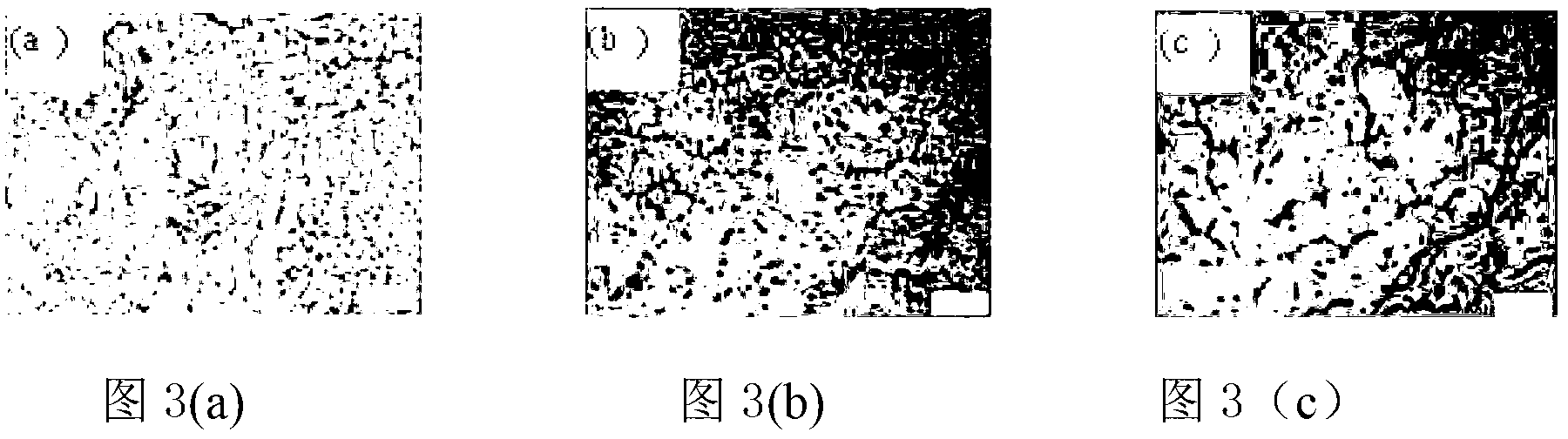

High-Zn, high-Mg and low-Cu ultrahigh-strength corrosion-resisting aluminum alloy and heat treatment method

The invention discloses a high-Zn, high-Mg and low-Cu ultrahigh-strength corrosion-resisting aluminum alloy and a heat treatment method. The alloy comprises the following components by mass percentage: 6.5-8.3% of Zn, 2.3-3.0% of Mg, 0.8-1.2% of Cu, 0.1-0.2% of Zr, less than 0.15% of Fe, less than 0.1% of Si, and the balance of Al. A preparation method of the alloy comprises the steps of blending, smelting, semi-continuous casting, homogenizing, thermoplastic deformation, short time solid solution, and ageing heat treatment. For the high-Zn, high-Mg and low-Cu ultrahigh-strength corrosion-resisting aluminum alloy prepared with the method, the hardness (HV) is 185-209, the tensile strength sigma b is greater than or equal to 650Mpa, the percentage elongation delta is greater than or equal to 7%, the pitting resistance is high, the cast ingot yield is high, and the stress corrosion resistance is further improved while the mechanical property is kept after multiple regression reageing treatment. The alloy and the heat treatment method solve the problems that the cast ingot yield in the existing high-copper Al-Zn-Mg-Cu ultrahigh-strength aluminium alloy is low, and the strength, toughness and corrosion resistance cannot be compromised. The heat treatment method is simple to operate, and the industrial production is facilitated.

Owner:CENT SOUTH UNIV

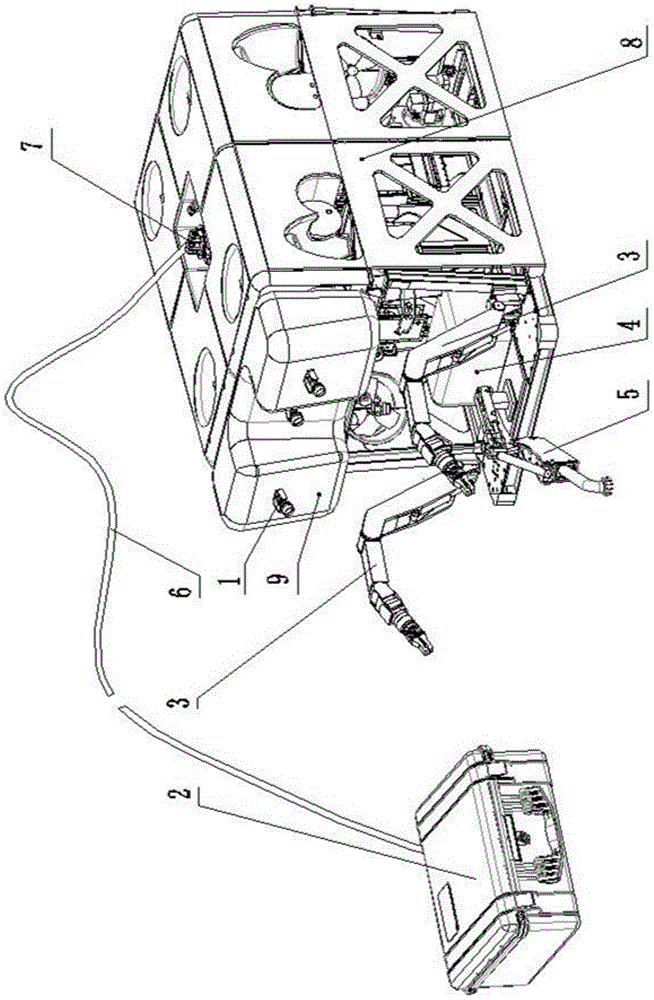

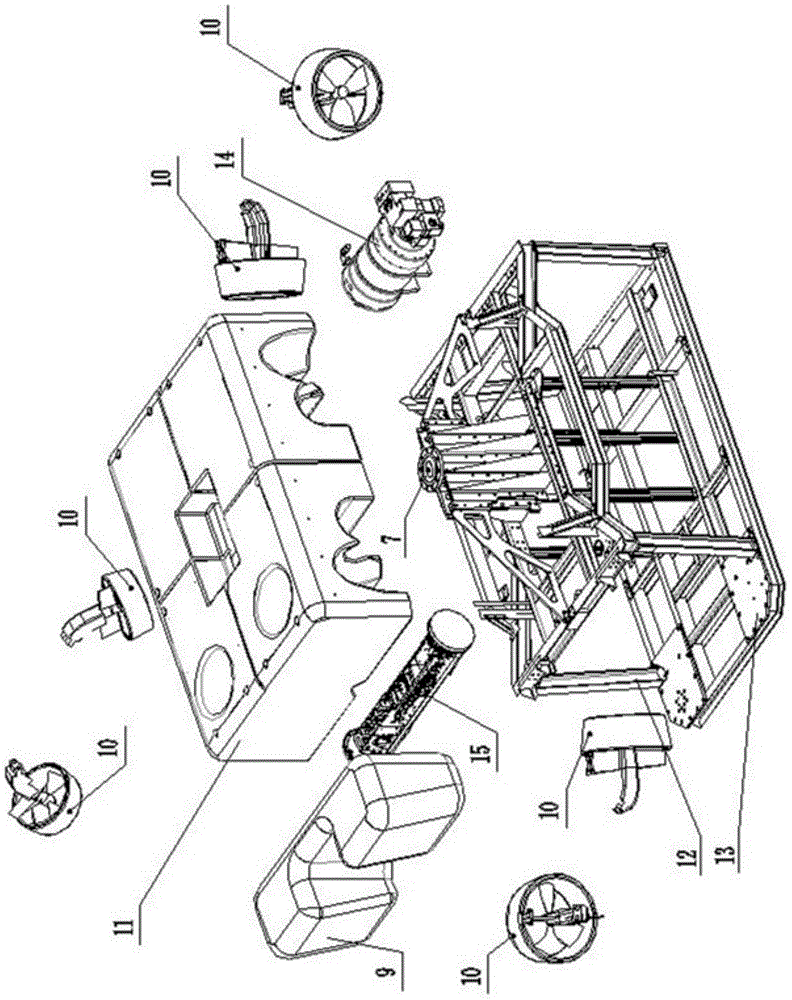

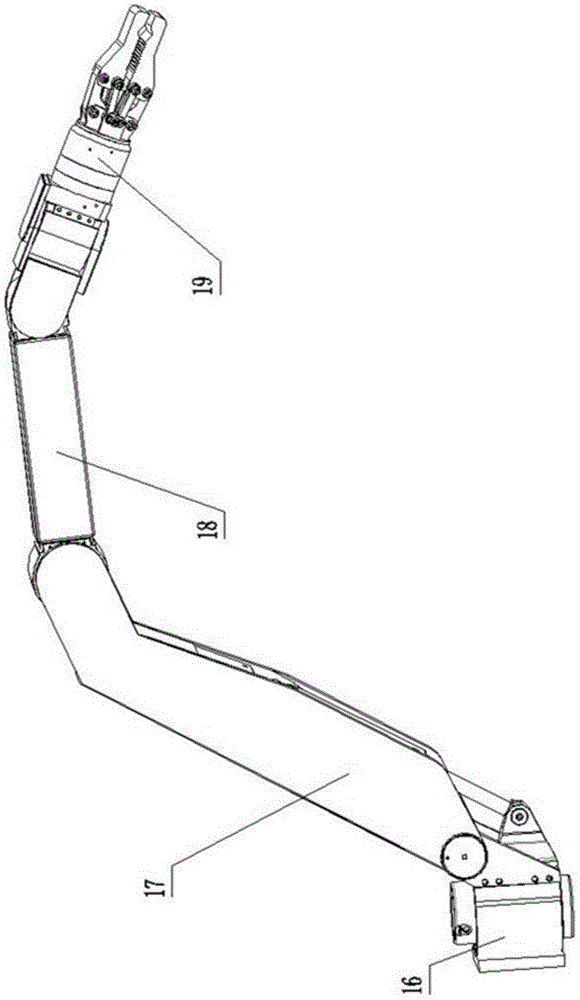

Underwater unmanned operation aquaculture robot

InactiveCN104813975AStrong ability to workAccelerated corrosionProgramme-controlled manipulatorClimate change adaptationCommunication interfaceRobotic arm

The invention discloses an underwater unmanned operation aquaculture robot. An unmanned underwater vehicle is connected with a remote control station through a communication cable; a base plate is provided with a frame and a hydraulic system; the frame is provided with a communication interface, a plurality of propellers and a control system; the communication interface is connected with the communication cable; a rear buoyancy unit is connected with the frame through a frame side plate; the rear buoyancy unit is connected with a front buoyancy unit; the front buoyancy unit is provided with a plurality of cameras; the frame is provided with two mechanical arms; the base plate is provided with a bait storage tank and a feeding and capture execution device which are connected with each other. According to the underwater unmanned operation aquaculture robot, the working capability is high, the corrosion resistance to the seawater is high, carried operation tools are more, the manipulation is simple, the object grabbing technology is accurate, the combination is rapid and convenient, the function configuration is flexible and diverse, the efficiency is high, and the cost is low.

Owner:DALIAN HEHAI TECH CO LTD

Aluminium alloy foil and its producing method

InactiveCN1473949ARaise the recrystallization temperatureImprove welding strengthMetal rolling arrangementsManganeseCopper

The present invention discloses a kind of aluminum alloy foil for heat exchanger of air conditioner, cooler, heater unit, radiator, etc. in automobile and its production process. The aluminum alloy foil is produced with Al, Fe, Si, Mn, Zn, Cu, Mg, Zr and Ti, and through smelting, casting, homogenizing, cutting, milling, heating, rolling, annealing, finish rolling and other steps. The aluminum alloy foil thus produced has no deformation, subsidence and collapse.

Owner:沈健生

Defectivity and process control of electroless deposition in microelectronics applications

ActiveUS7410899B2Reduce decompositionGrowth inhibitionSludge treatmentSemiconductor/solid-state device detailsElectroless depositionAlloy

Methods and compositions for electrolessly depositing Co, Ni, or alloys thereof onto a substrate in manufacture of microelectronic devices. Grain refiners, levelers, oxygen scavengers, and stabilizers for electroless Co and Ni deposition solutions.

Owner:MACDERMID ENTHONE INC

Heavy-load open-type gear lubricating grease and preparation method thereof

ActiveCN104164277AGood adhesionGood extreme pressure and anti-wear propertiesLubricant compositionAntioxidantHeavy load

The invention discloses a heavy-load open-type gear lubricating grease and a preparation method thereof. The lubricating grease comprises the following components in percentage by weight: 57 to 80% of basic oil, 3 to 6% of composite aluminum thickening agent, 3 to 7% of extreme pressure anti-wear additive, 2 to 5% of oiliness agent, 5 to 10% of solid additive, 0.5 to 1% of antirust agent, 6 to 13% of tackifier, and 0.5 to 1.0% of antioxidant. The provided lubricating grease is developed on the basis of the conventional open gear lubricating grease, is capable of solving the problems that the production of conventional lubricating grease consume too much energy and the conventional lubricating grease contains substances that can pollute the environment, has the advantages of good adhesive performance and extreme pressure anti-wear performance, and can fully meet the requirements on restricted substances RoHS 2.0 in Europe Union. The friction resistance and the energy consumption are prominently reduced by the provided lubricating grease, so that the lubricating grease can satisfy the requirements of modern industrial development.

Owner:深圳市超润达科技有限公司

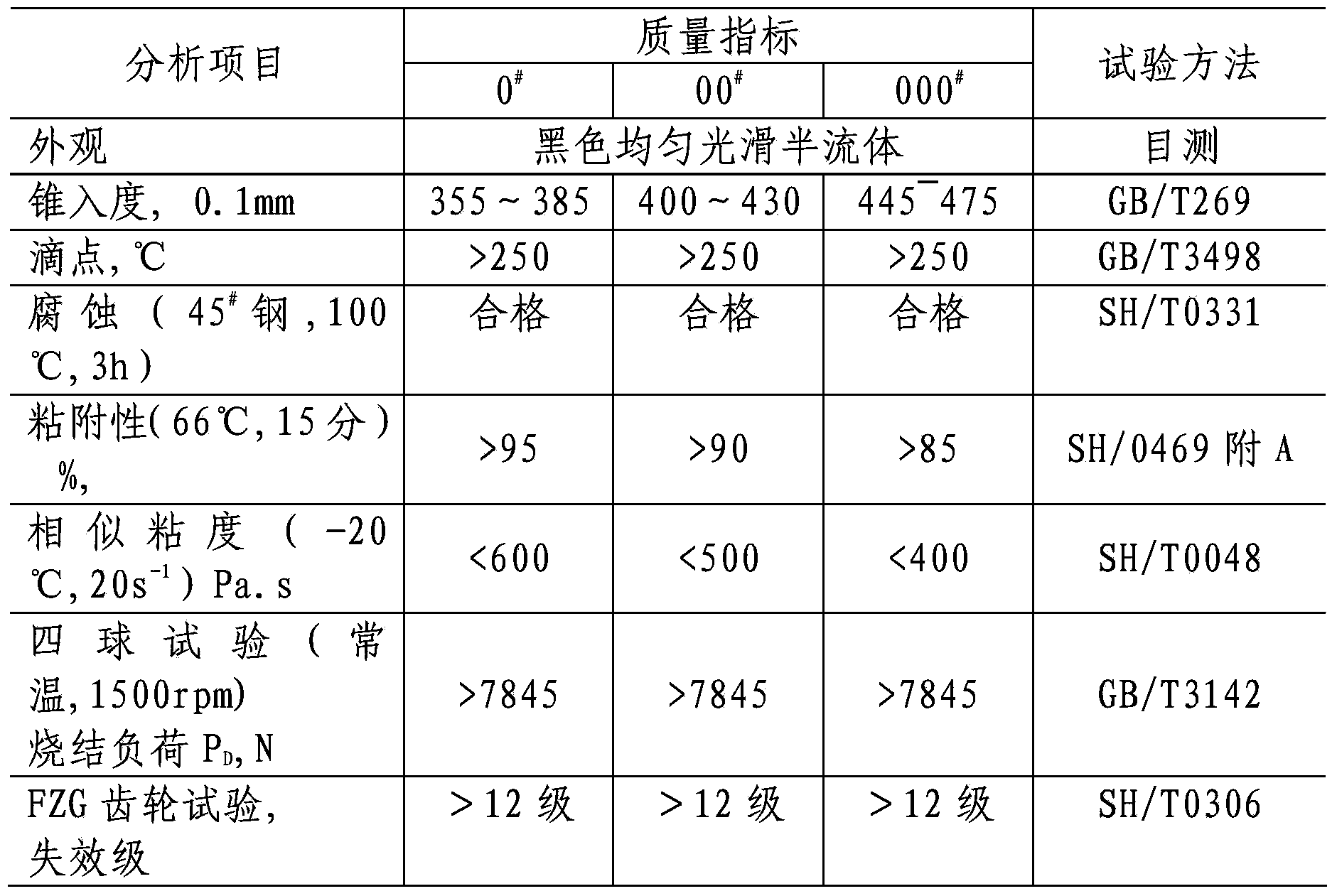

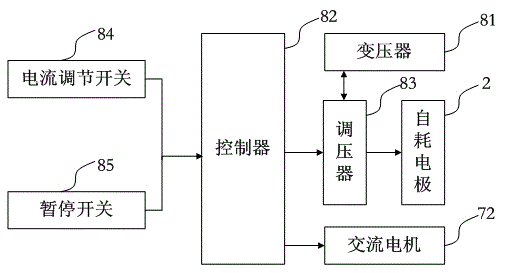

Electro-slag remelting method of self-consumable electrode and electro-slag furnace

An electro-slag remelting method of a self-consumable electrode comprises the following steps: 1) welding a plurality of smelted castings in series into a whole, to form the self-consumable electrode; 2) slowly descending the self-consumable electrode and inserting into furnace slag of an electro-slag furnace, after energizing and arc striking, adjusting the remelting voltage and the remelting current; 3) slowly melting one end of the self-consumable electrode, gathering molten metal into metal molten droplets, falling off from the end of the self-consumable electrode, passing through a slag pool into a metal molten pool, and forming an ingot casting through forced cooling by a water-cooling crystallizer; 4) when melting the falling-off metal molten droplets, descending after pausing the non-molten self-consumable electrode for 10-20 s, and accelerating the descending speed by 10%-20%; and 5) after completion of electro-slag remelting, carrying out annealing treatment of the obtained ingot casting, and then carrying out mechanical processing to obtain the finished product. The invention also provides the electro-slag furnace for electro-slag remelting of the self-consumable electrode. Energy and raw materials are saved, the production efficiency is improved, the production time is shortened, and the high-purity ingot casting is obtained.

Owner:HUNAN LIFANG ROLLER +1

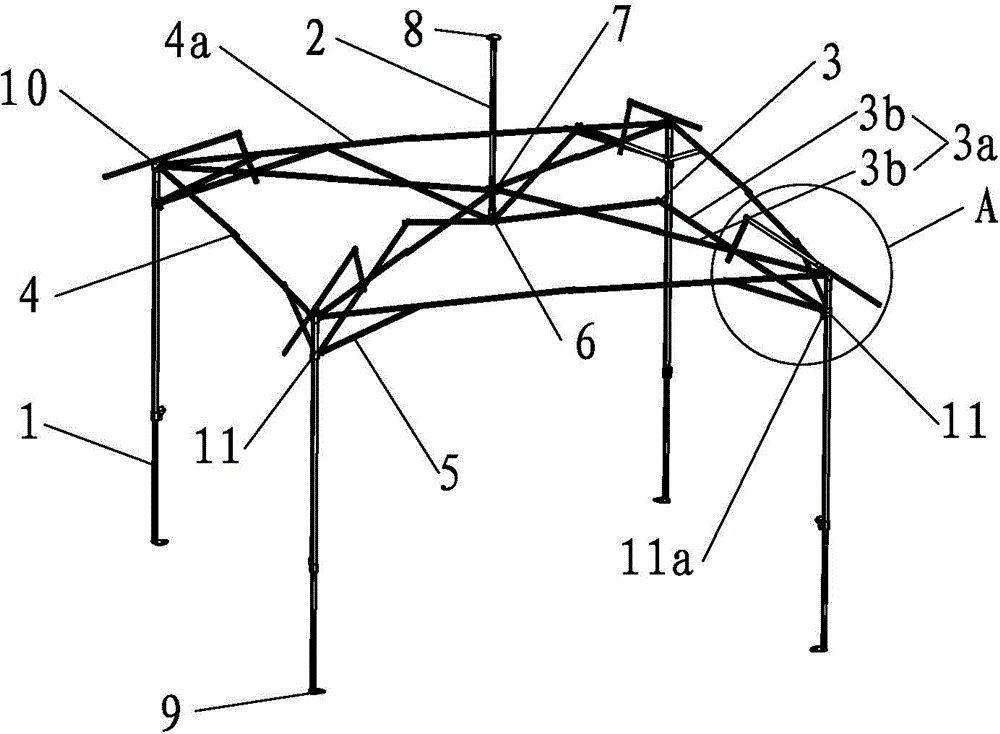

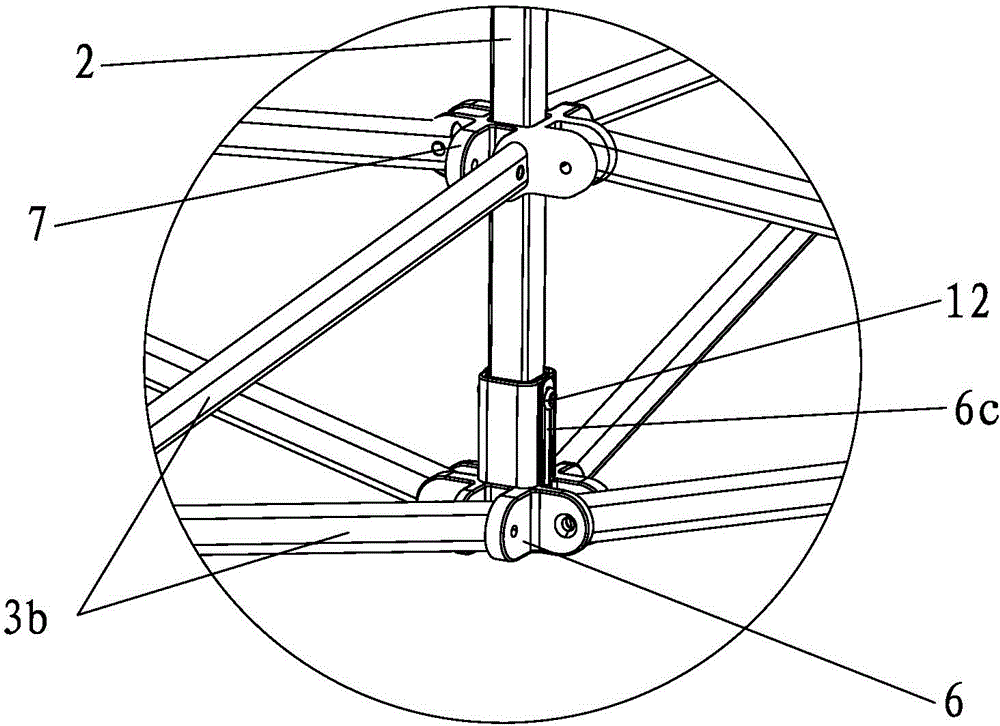

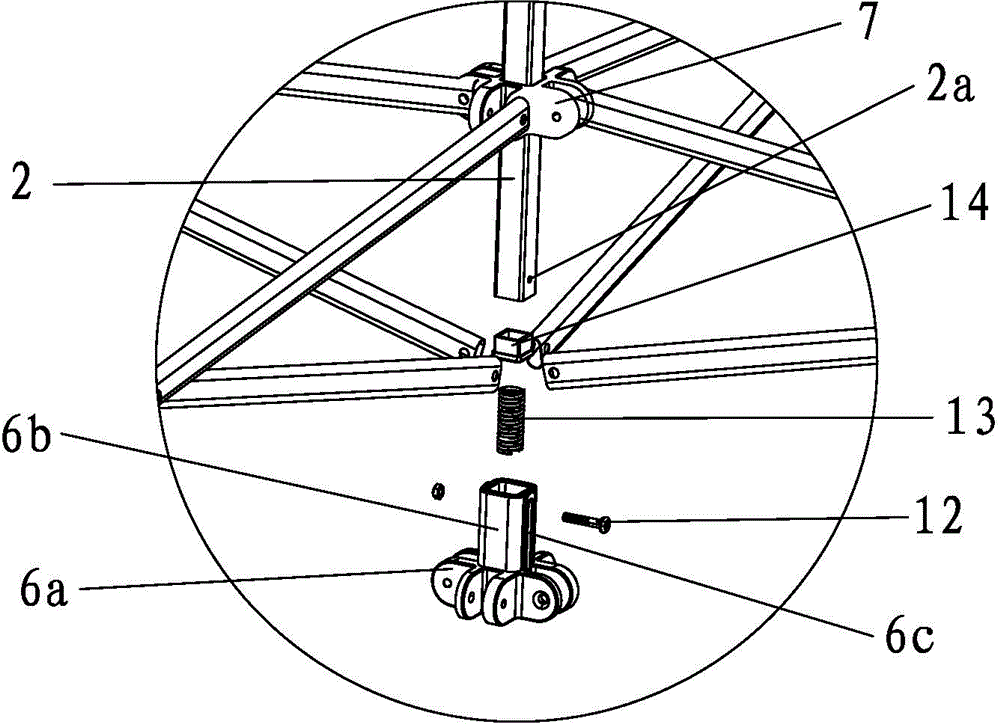

Water accumulation preventing high-top tent

The invention provides a water accumulation preventing high-top tent. The water accumulation preventing high-top tent comprises vertical rods, a center rod and supporting top rod groups, wherein a center fixing and connecting seat is installed at the bottom end of the center rod, a connecting pin and a spring is arranged between the center rod and the center fixing and connecting seat, an elongated slot or a pin hole is further formed in the bottom end of the center rod, the center fixing and connecting seat is provided with a blind hole, the blind hole is provided with a pin hole or an elongated slot, the connecting pin penetrates through the elongated slot and the pin hole to connect the center rod with the center fixing and connecting seat, the spring is placed in the blind hole, and one end of the spring presses against the bottom end of the center rod; a water accumulation preventing rod group is additionally connected onto each supporting top rod group. Since the center rod or the side wall of the blind hole is provided with the elongated slot, and the spring is arranged between the center rod and the center fixing and connecting seat, the spring is in a compressed state after the tent is unfolded and an upward force can be applied to the center rod, and thus pits or water accumulation are not easily caused at unsupported positions of tent fabric.

Owner:CAMPVALLEY XIAMEN LEISURE PRODS

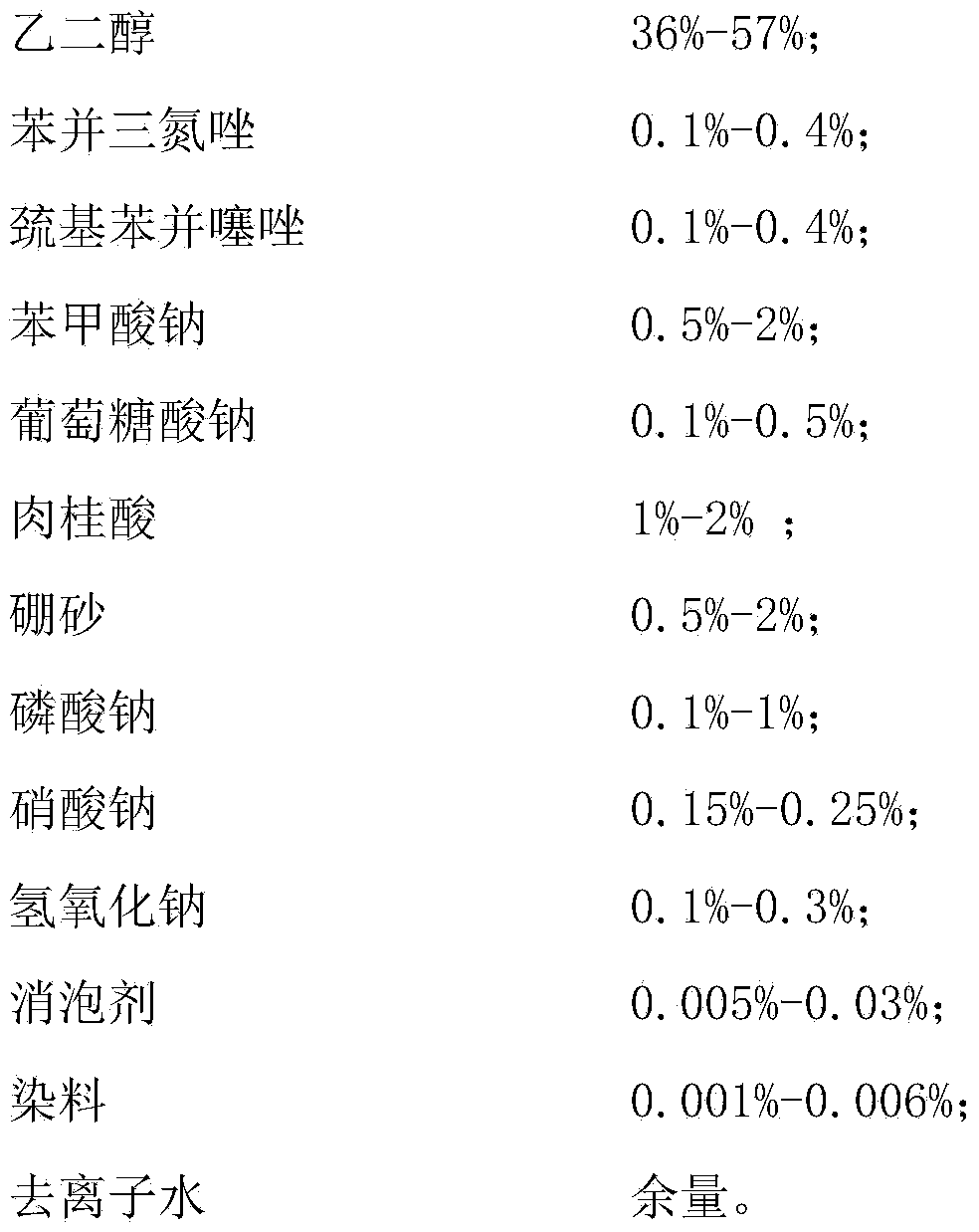

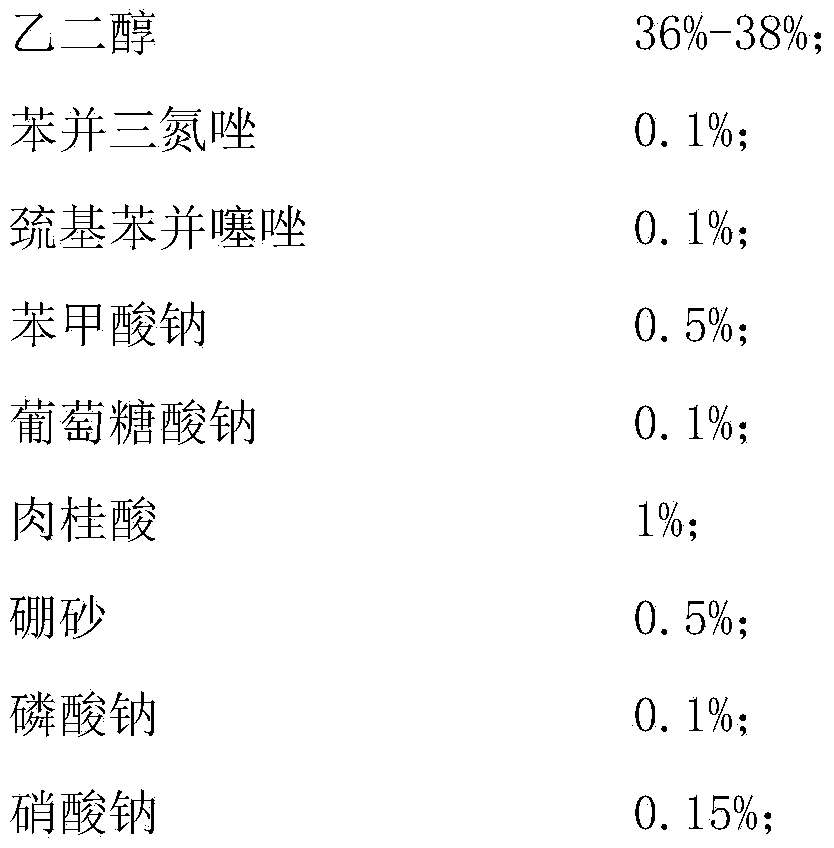

Anti-freezing fluid for solar water heater and preparation method thereof

The invention discloses an anti-freezing fluid for a solar water heater. The anti-freezing fluid is composed of the following components by weight percent: 36-57 percent of glycol, 0.1-0.4 percent of 1H-Benzotriazole, 01.-0.4 percent of mercaptobenzothiazole, 0.5-2 percent of sodium benzoate, 0.1-0.5 percent of sodium gluconate, 1-2 percent of cinnamic acid, 0.5-2 percent of borax, 0.1-1 percent of sodium phosphate, 0.15-0.25 percent of sodium nitrate, 0.1-0.3 percent of sodium hydroxide, 0.005-0.03 percent of an antifoamer, 0.001-0.006 percent of dye and deionized water in balancing amount. The anti-freezing fluid is good in stability, has the PH rangeability smaller than that of a common anti-freezing fluid at high temperature for a long time, does not separate out particles and flocculent precipitates to block a pipeline, and has good rust inhibition effect on metal material for manufacturing the solar heater. Moreover, the invention further provides a preparation method for the anti-freezing fluid, which is simple and easy to operate.

Owner:RICHU DONGFANG SOLAR ENERGY

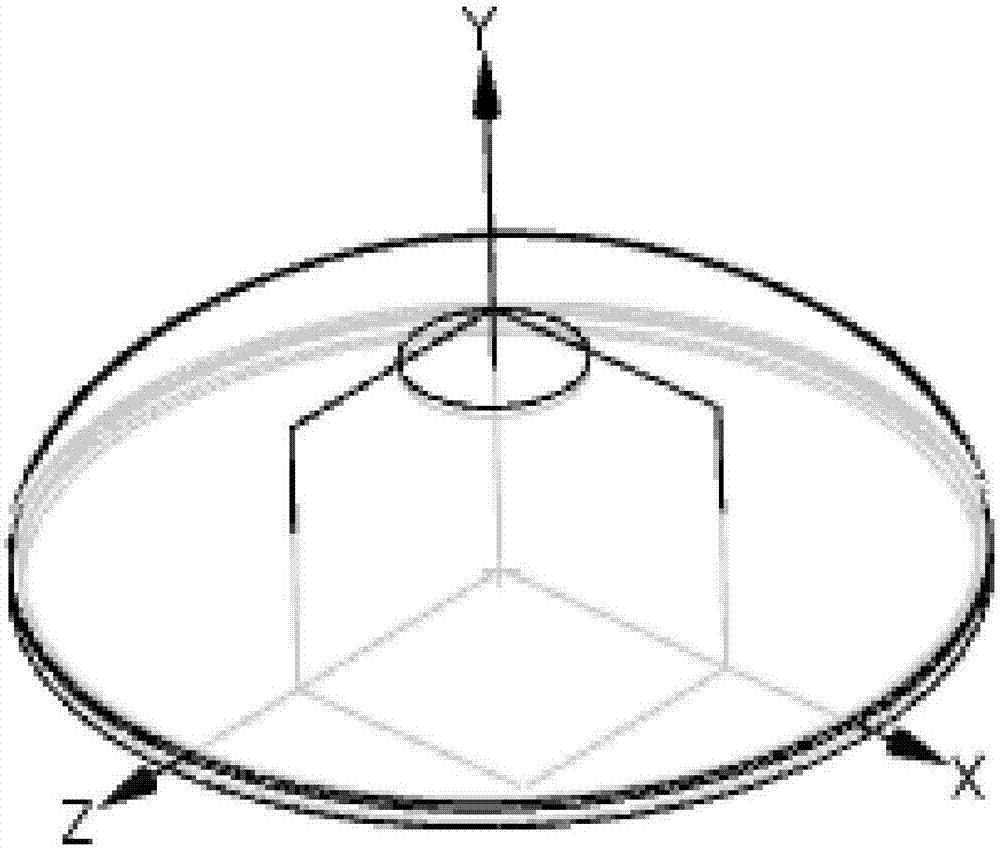

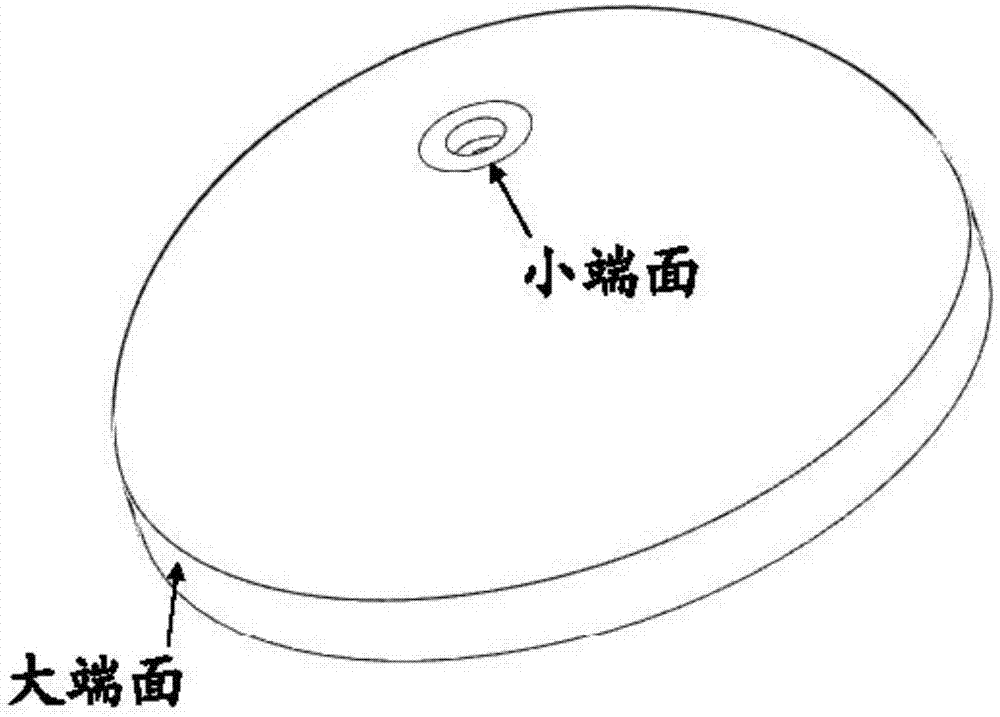

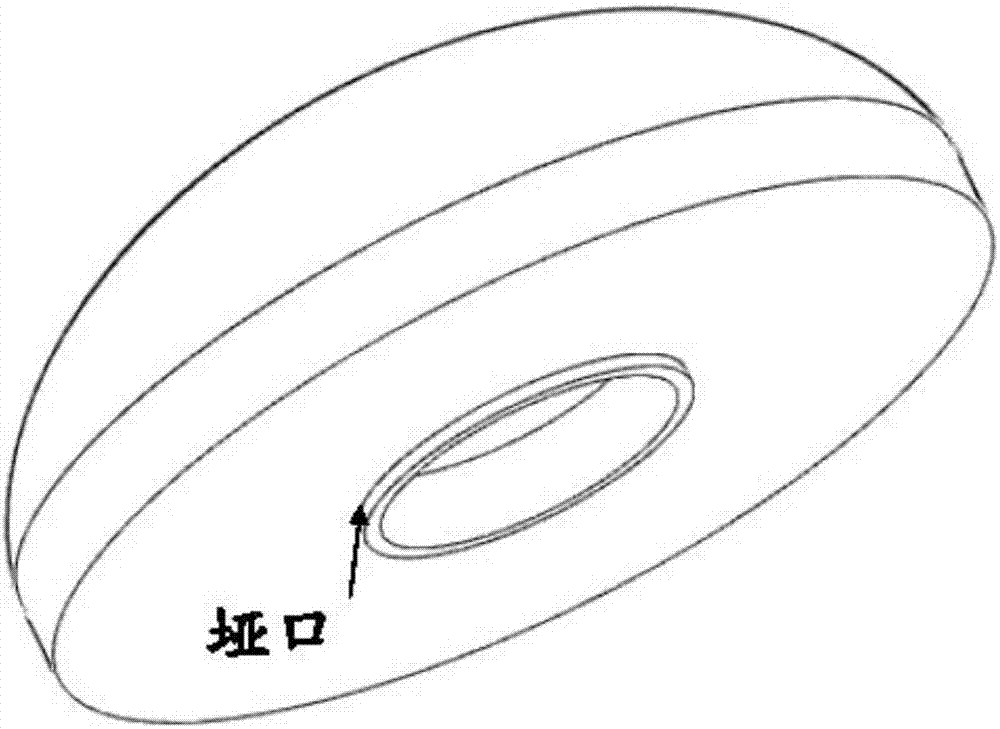

Heat treatment deformation control method for large-diameter and large-modulus elliptical molded surface container semispherical shell

ActiveCN107513677APrevent collapseSmall quenching deformationFurnace typesHeat treatment process controlQuenchingAqueous solution

The invention relates to a heat treatment deformation control method for a large-diameter and large-modulus elliptical molded surface container semispherical shell and belongs to the technical field of container manufacturing. By means of the heat treatment deformation method, due to the fact that an integrated quenching and aging heat treatment tool is designed, the elliptical molded surface container semispherical shell and the heat treatment tool can be tightly matched, the quenching transfer time is shortened, the phenomenon that the top of the shell collapses and pits happen in the circumferential direction of the shell during quenching is avoided, quenching and time aging deformation is reduced, and therefore the heat treatment performance of the elliptical molded surface container semispherical shell can be ensured; and meanwhile, the subsequent machining precision of the shell is also ensured. In addition, a UCON water solution with the concentration ranging from 6% to 10% is adopted in the method to serve as a quenching medium, dynamic flowing of the water solution is maintained, the cooling speed and uniformity of the shell are ensured, meanwhile, quenching deformation is also controlled, and therefore the product precision is ensured.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

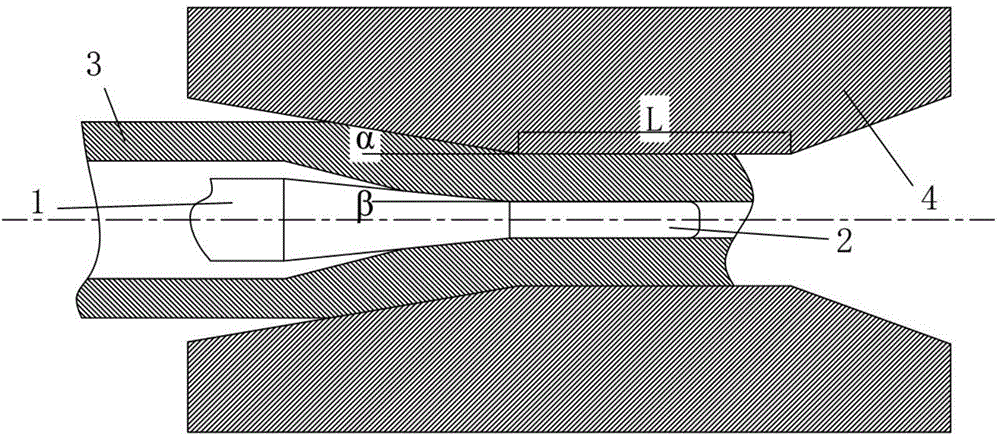

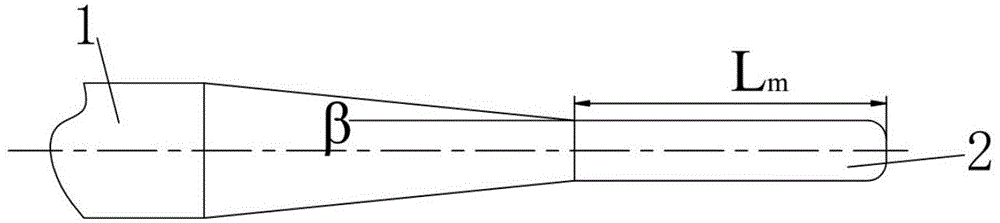

Technology for preparing small-bore and thick-wall metal tubes by rotary swaging technique

ActiveCN104475479AAvoid prone inner wall cracksAvoid pittingMetal-working apparatusEngineeringSwaging

The invention provides a technology for preparing small-bore and thick-wall metal tubes by a rotary swaging technique and belongs to the technical field of metal working. The technology comprises the following processes: (1) an appropriate tube blank is selected, the tube blank undergoes descaling, and cut-to-length is carried out; (2) the tube blank is installed onto a feeding mechanism, and it is ensured that a mandrel unit passes through an inner bore of the tube blank; (3) the mandrel unit is fed to a fixed position, and a mandrel head part is positioned inside a die sizing area; (4) the feeding mechanism sends the tube blank into a rotary swaging case for rotary swaging; and (5) the processes from (2) to (4) are repeated, and the forming process is finished after 1-3 passes. The technology is simple and easy to do. Size precision of the product is high (+ / -0.02 to + / -0.08mm). Defects such as inner-wall crack, pit, folding and the like which are easy to happen to small-bore and thick-wall metal tubes prepared by the present drawing technology are avoided. The technology provided by the invention can be used for molding of various small-bore and thick-wall metal tubes.

Owner:UNIV OF SCI & TECH BEIJING +1

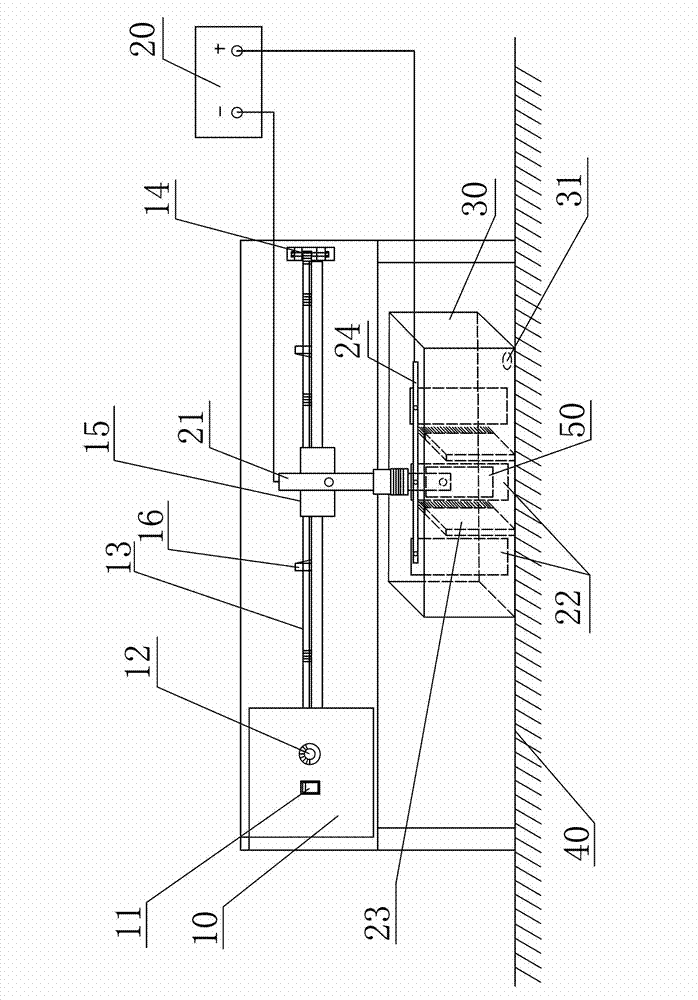

Electric brush plating device of flat plate type metal component

The invention discloses an electric brush plating device of a flat plate type metal component. The electric brush plating device comprises a movement control device, a brush, an anode plate and an electric brush plating groove, wherein the brush and the anode plate are fixedly mounted in the electric brush plating groove; a plating component is mounted on the movement control device and is positioned in the electric brush plating groove; the plated surface of the plating component is opposite to the anode plate; the plating component and the anode plate are respectively connected with the cathode and the anode of a direct-current power supply; the bristles of the brush face the plated surface of the plating component; the movement control device controls the plating component to do horizontal reciprocating rectilinear movement in the electric brush plating groove; when the plating component moves in front of the brush, the plated surface of the plating component do friction movement relative to the bristles of the brush. According to the electric brush plating device, the brush and the plating component do relative flexible friction movement in partial time during the whole electric brush plating process, so that the electric deposition speed is accelerated effectively; and a plating layer is prevented from generating pinholes, pocking marks, nodules and the like. Therefore, the quality of the plating layer is improved.

Owner:ACADEMY OF ARMORED FORCES ENG PLA +1

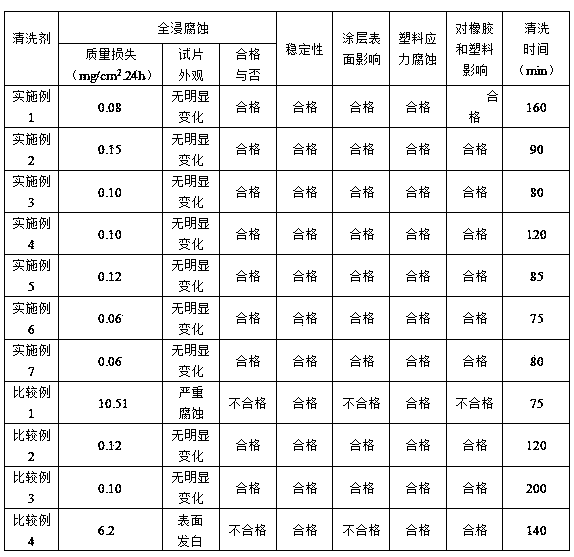

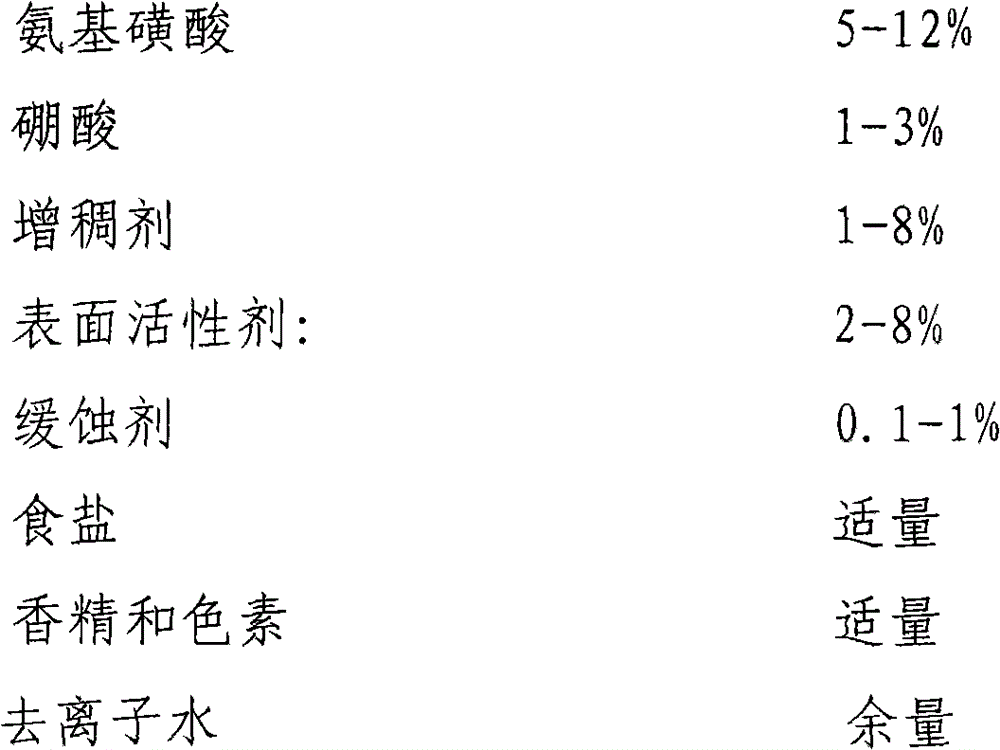

Cleaning agent for aircraft pipelines and preparation method thereof

ActiveCN103642612AGood synergyKeep efficientSurface-active non-soap compounds and soap mixture detergentsOrganic acidChemistry

The invention relates to the field of aviation and specifically relates to a cleaning agent for aircraft pipelines and a preparation method thereof. The cleaning agent comprises an organic acid, a corrosion inhibitor, a surfactant, auxiliaries and deionized water, wherein the organic acid is a complex organic acid, the complex organic acid comprises an aminosulfonic acid and an organic acid with a low pH buffer value, and the complex organic acid accounts for 8-20% by weight of the total cleaning agent; in order to further improve the pH buffer capacity of the cleaning agent and improve the proportion of the organic acid with the buffer function in the complex organic acid to keep the high efficiency in descaling of the cleaning agent, the proportion of the complex organic acid to the aminosulfonic acid in parts by weight is (25-50): (75-50). By adding the high-efficient corrosion inhibitor in the formula, the corrosion to metal materials caused by the acid is greatly reduced, so that the safety of aircraft materials is ensured.

Owner:成都民航六维航化有限责任公司

Aluminum alloy clad material

InactiveUS20110027610A1Small thicknessReduce weightWelding/cutting media/materialsCoatingsFilling materialsImpurity

Disclosed is an aluminum alloy clad material which includes a core material; a sacrificial anode material on one surface of the core material; and a filler material on the other surface of the core material and composed of an Al—Si alloy, in which the core material contains 0.3 to 2.0 percent by mass of Mn, 0.15 to 1.6 percent by mass of Si, 0.1 to 1.0 percent by mass of Cu, and 0.1 to 1.0 percent by mass of Mg, with the remainder including Al and inevitable impurities, the sacrificial anode material contains 7.0 to 12.0 percent by mass of Zn, 0.3 to 1.8 percent by mass of Mn, and 0.3 to 1.2 percent by mass of Si, with the remainder including Al and inevitable impurities, and has a thickness of 10 to 30 μm. The sacrificial anode material shows resistance to both local corrosion and general corrosion.

Owner:KOBE STEEL LTD

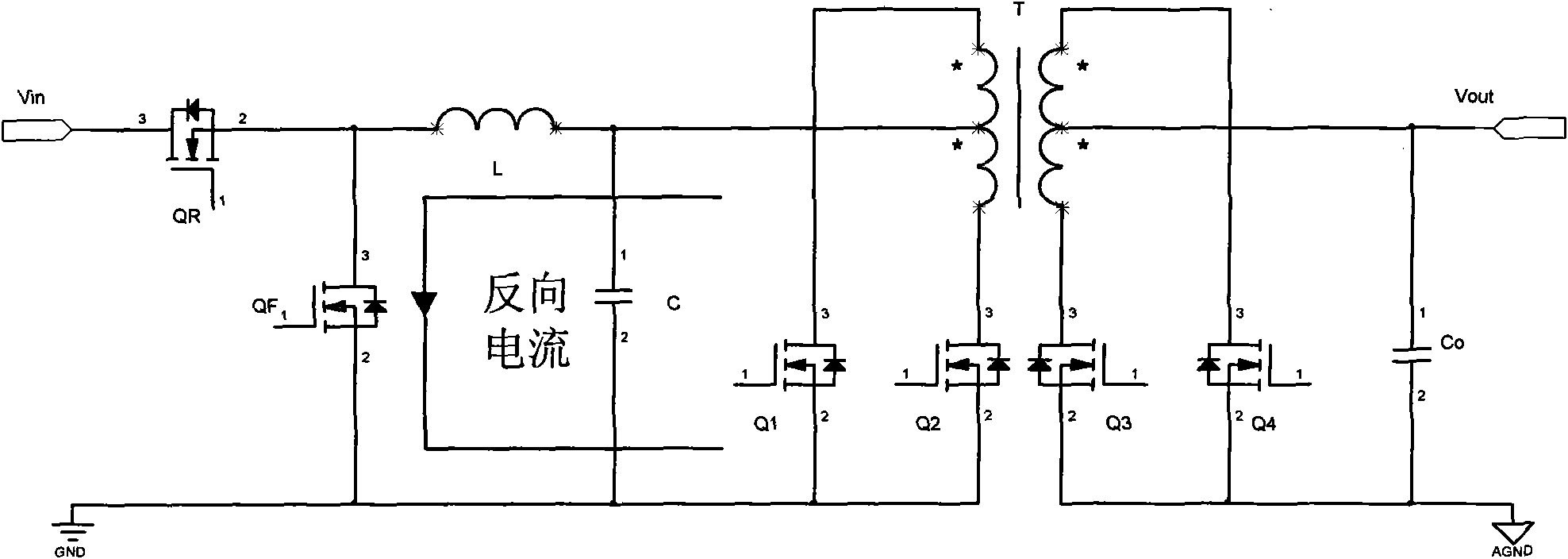

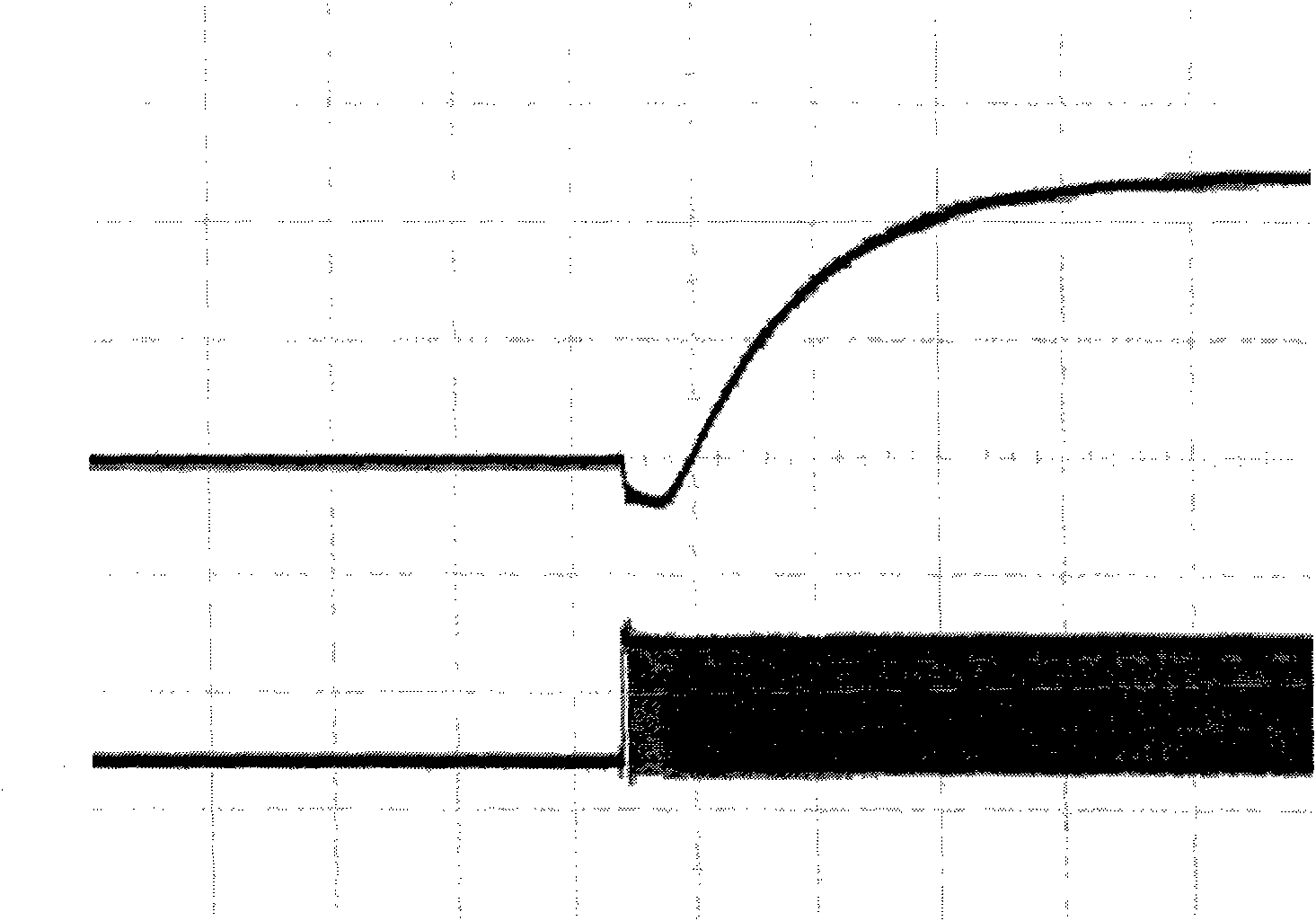

DC/DC converter and pre-bias switching circuit thereof

ActiveCN101630911AEliminate reverse currentStress reliefDc-dc conversionElectric variable regulationLinear regionControl signal

The invention discloses a DC / DC converter and a pre-bias switching circuit thereof. The pre-bias switching circuit comprises a P-type switching tube, a switching tube driving signal providing module and a current-reflowing tube driver driving signal generating module, wherein the first input end of the switching tube driving signal providing module is connected with a switching control signal; the switching tube driving signal providing module is driven by the switching control signal to provide a driving signal for the P-type switching tube so that the P-type switching tube working in a linear region gradually enters a saturation region; the output end of the P-type switching tube is connected with the first input end of the current-reflowing tube driver driving signal generating module; the second input end of the current-reflowing tube driver driving signal generating module is also connected with a current-reflowing tube control signal output by a pulse width modulation (PWM) controller of the DC / DC converter; and the output end of the current-reflowing tube driver driving signal generating module outputs a triangular signal with a continuously increasing peak voltage to a current-reflowing tube driver of the DC / DC converter. The invention can monotonically start the circuit.

Owner:ASTEC POWER SUPPLY (SHENZHEN) CO LTD

Chemical and mechanical polishing liquid and its use

ActiveCN1900206AAvoid pittingAvoid corrosionOther chemical processesSemiconductor/solid-state device manufacturingHigh surfaceMetal

The chemical and mechanical polishing fluid includes at least one kind of grinding particle and one kind of carrier, as well as at least one kind of metal corrosion inhibitor. The present invention also discloses the use of this chemical and mechanical polishing fluid in polishing metal parts. The chemical and mechanical polishing fluid of the present invention has less faults in the polished metal surface, lowered metal eliminating rate and high surface quality of polished metal parts.

Owner:ANJI MICROELECTRONICS (SHANGHAI) CO LTD

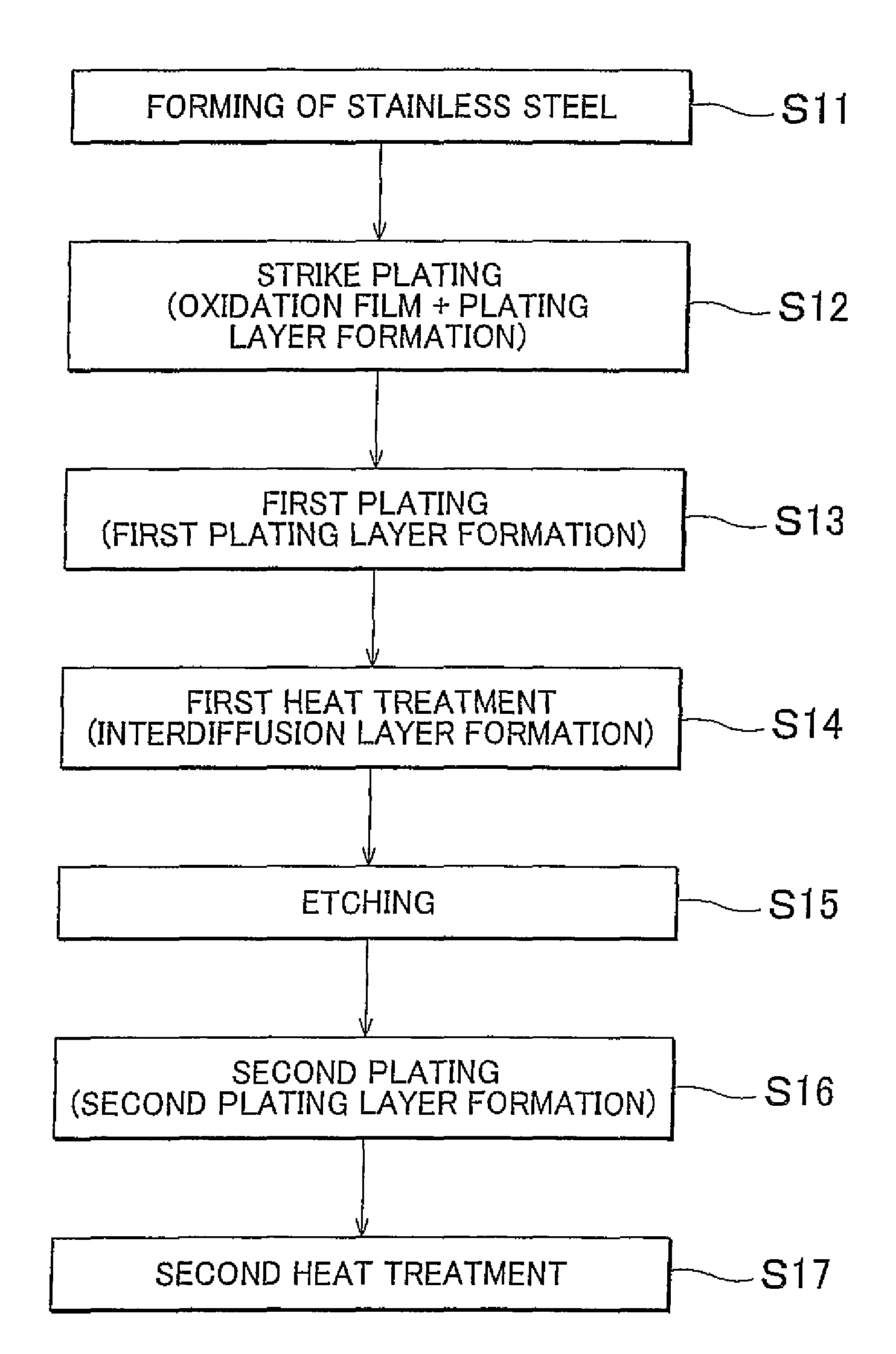

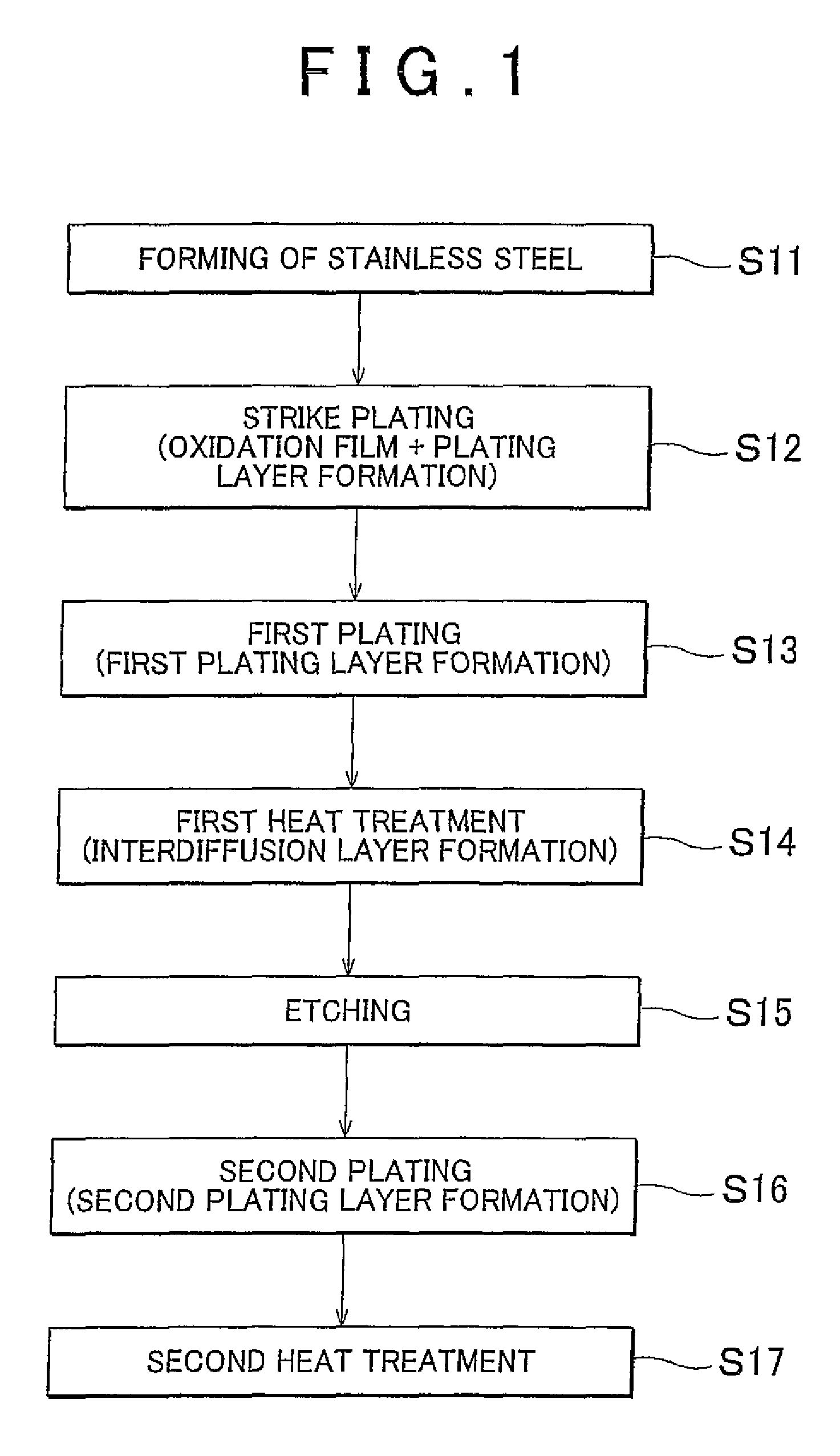

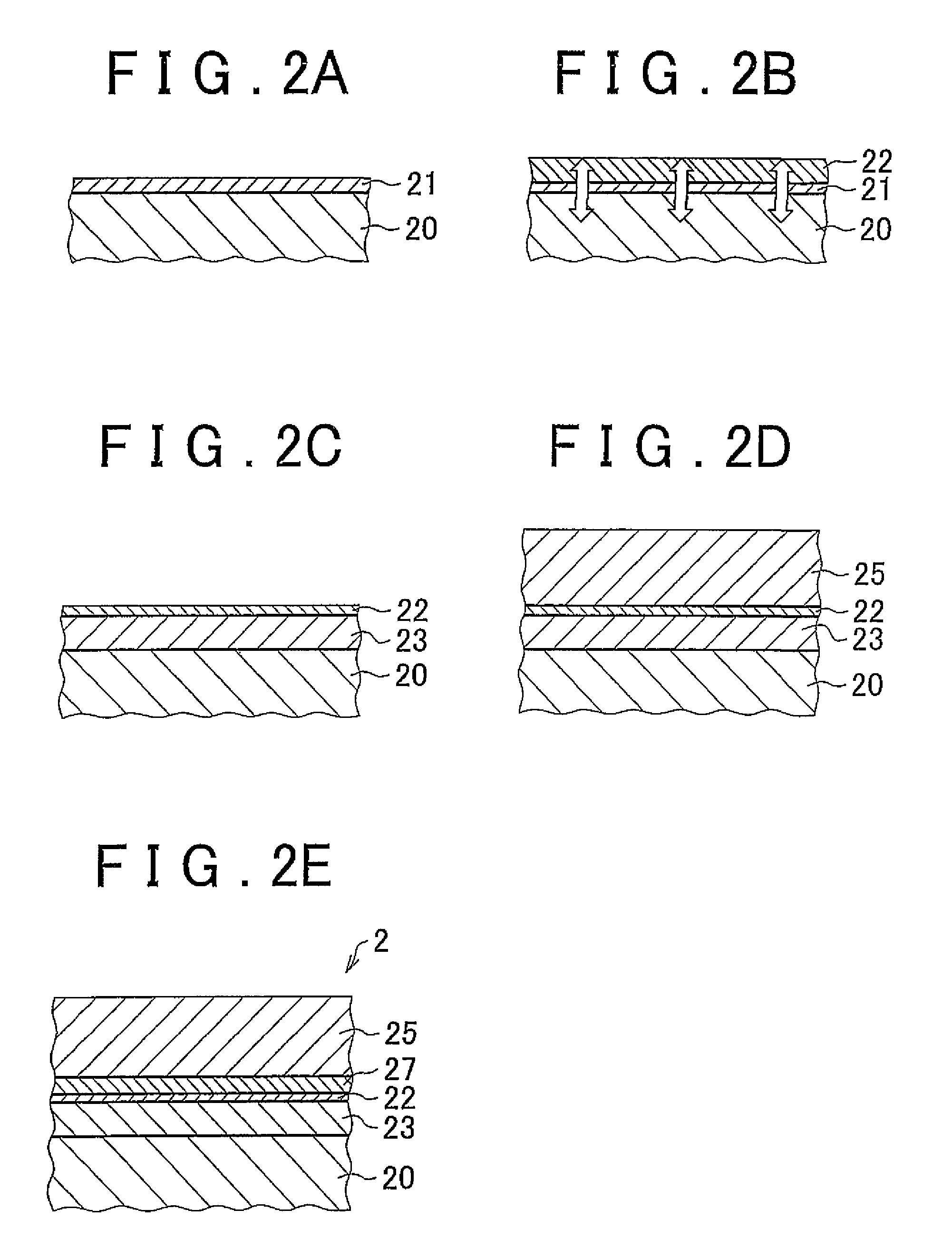

Method of plating stainless steel and plated material

The method of plating a stainless steel substrate including depositing a first plating metal layer over the stainless steel substrate), forming an interdiffusion layer in which elements of the stainless steel substrate and elements of the first plating metal layer interdiffuse, by applying a heat treatment to the stainless steel substrate coated by the first plating metal layer, and coating a second plating metal layer over the surface of the stainless steel substrate over which the interdiffusion layer is coated.

Owner:TOYOTA JIDOSHA KK

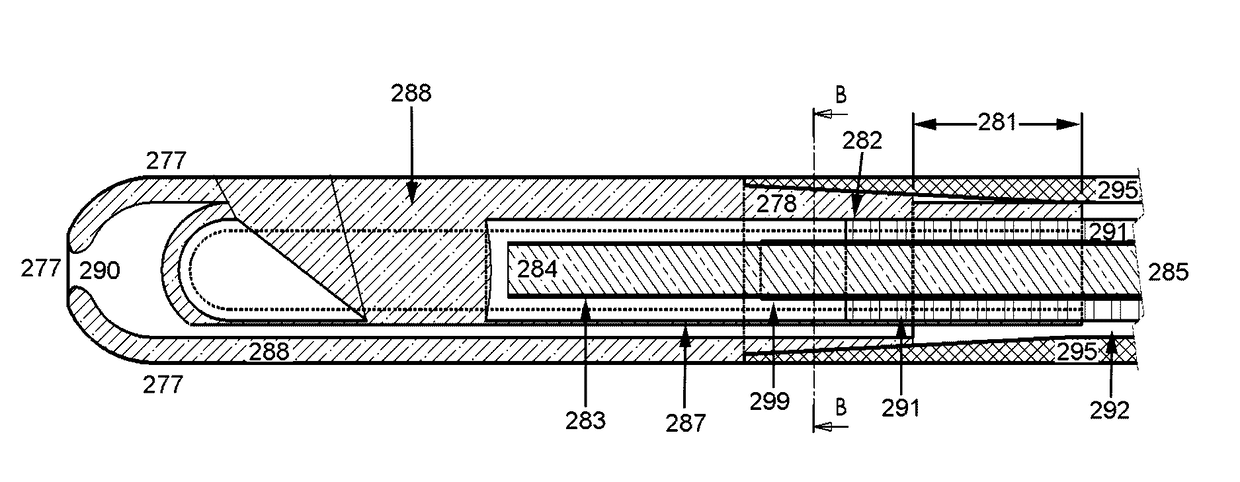

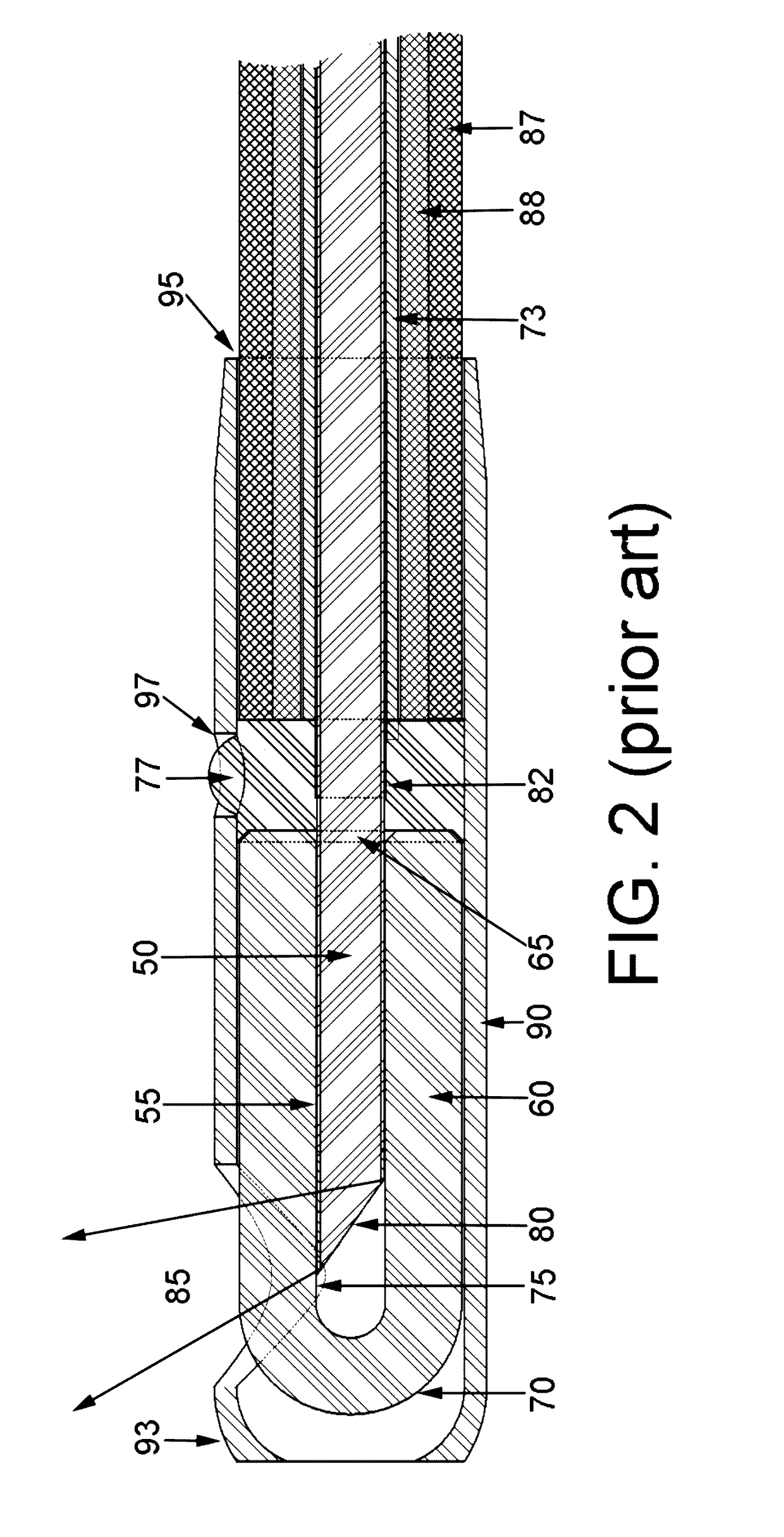

Lateral delivery device with active cooling

ActiveUS9662173B1Avoid pittingImprove output qualitySurgical instrument detailsCatheterTotal internal reflectionActive cooling

Herein is disclosed an optical device for directing electromagnetic radiation and a means for manufacturing the same. The optical device can include a total-internal-reflection (TIR) element which includes a TIR surface; a TIR protective cap fused about the TIR element, thereby providing a liquid-free volume between the TIR surface and an internal surface of the TIR protective cap; a sleeve element fused to a portion of the TIR protective cap, thereby providing at least one fluidic pathway between the sleeve element and the TIR protective cap, the at least one fluidic pathway adapted to carry a stream of a cooling fluid through the optical device during use; and an optical pathway from the TIR surface to an external surface of the sleeve element; where any of the at least one fluidic pathway does not cross the optical pathway.

Owner:CYCLONE BIOSCI LLC

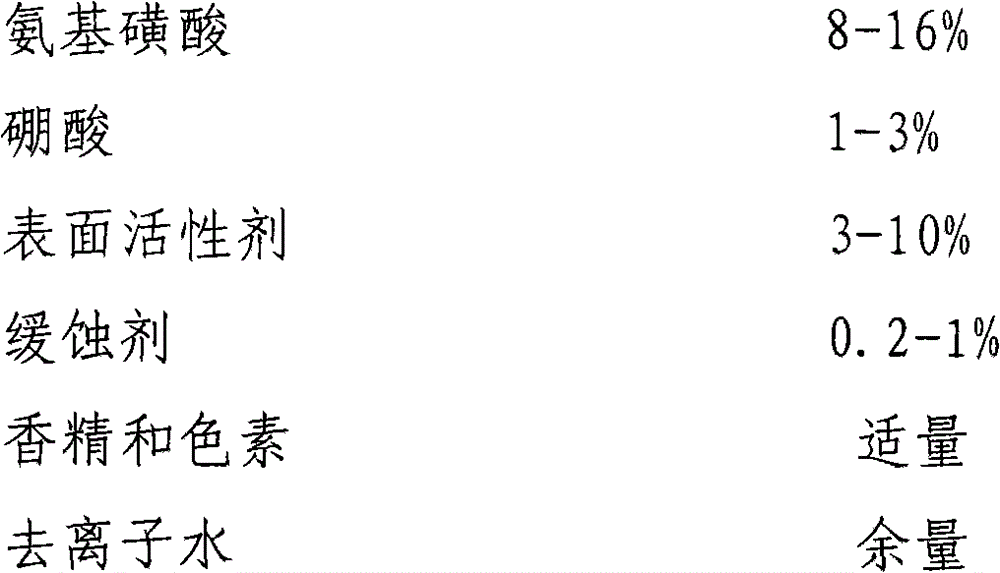

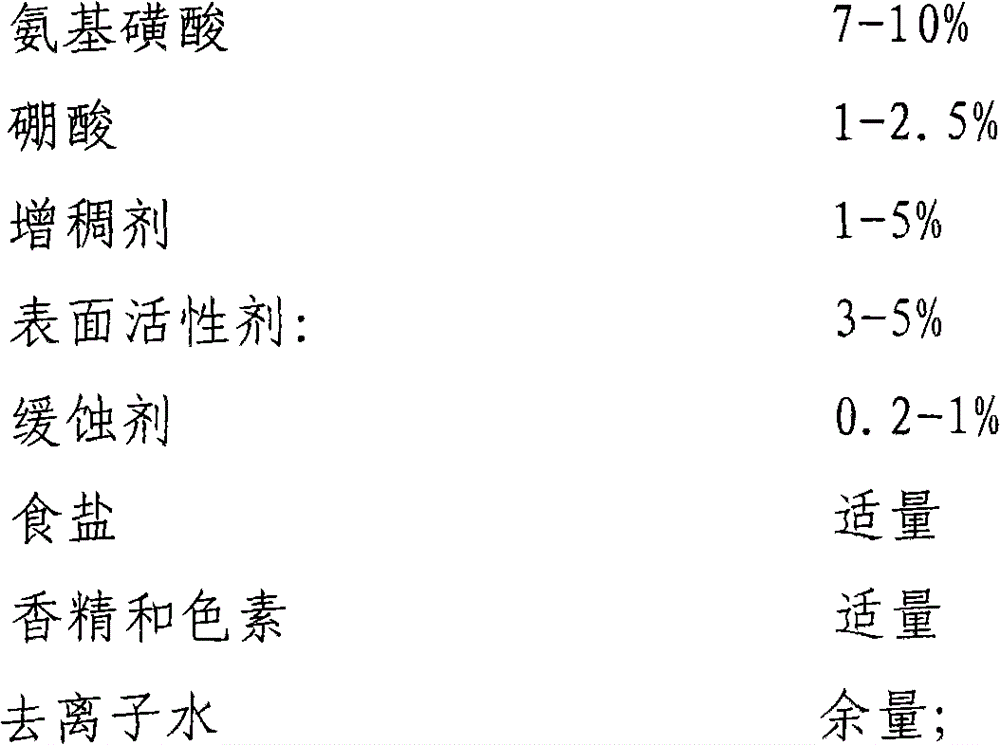

Matched cleaning agent for vacuum drainage pipelines of airplane toilets and preparation method and cleaning process of matched cleaning agent

ActiveCN102746958AHigh viscosityGood wall hangingHollow article cleaningSurface-active non-soap compounds and soap mixture detergentsJet aeroplaneVertical plane

The invention relates to the field of aerospace, in particular to a matched cleaning agent for vacuum drainage pipelines of airplane toilets. The cleaning agent comprises a cleaning agent I and a cleaning agent II which are matched and synergistic for graded cleaning. The cleaning agent I which is an acidic thixotropic cleaning agent and good in wall cling performance is used for cleaning firstly, is capable of effectively removing scale on inclined planes or vertical planes of a pipeline system and can be used for pipe leakage detection; and then the cleaning agent II which is low in viscosity, good in liquidity and high in scaling capability is used for cleaning. The invention further discloses a preparation method of the matched cleaning agent and a cleaning process using the matched cleaning agent. The matched cleaning agent is capable of effectively removing iron rust, water scale, urine scale and other dirt of the vacuum and circulating toilets and plays a protecting role in metal pipelines without corroding the pipelines.

Owner:北京雅迪力特航空新材料股份公司

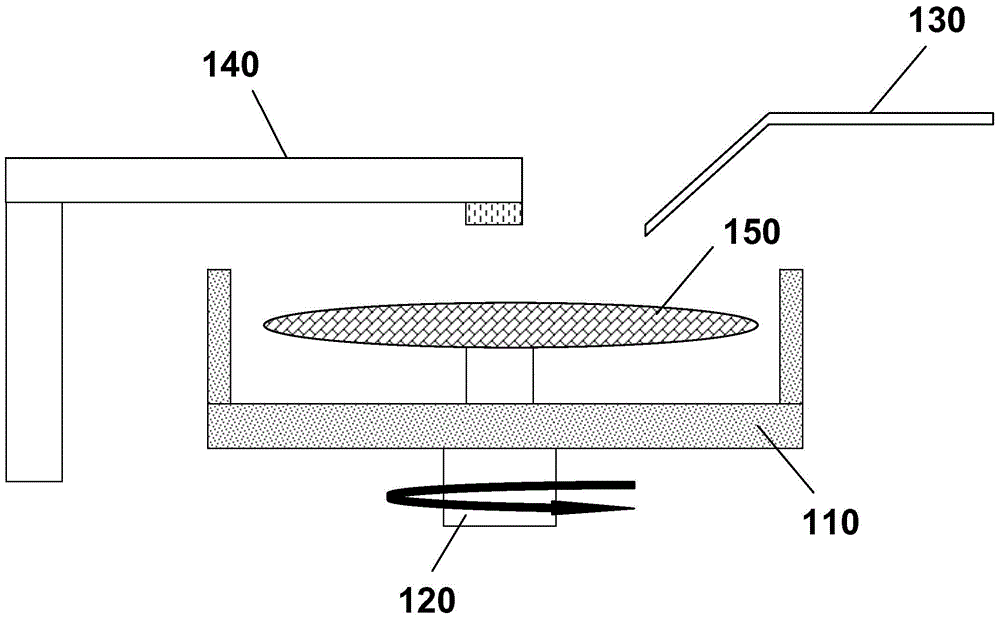

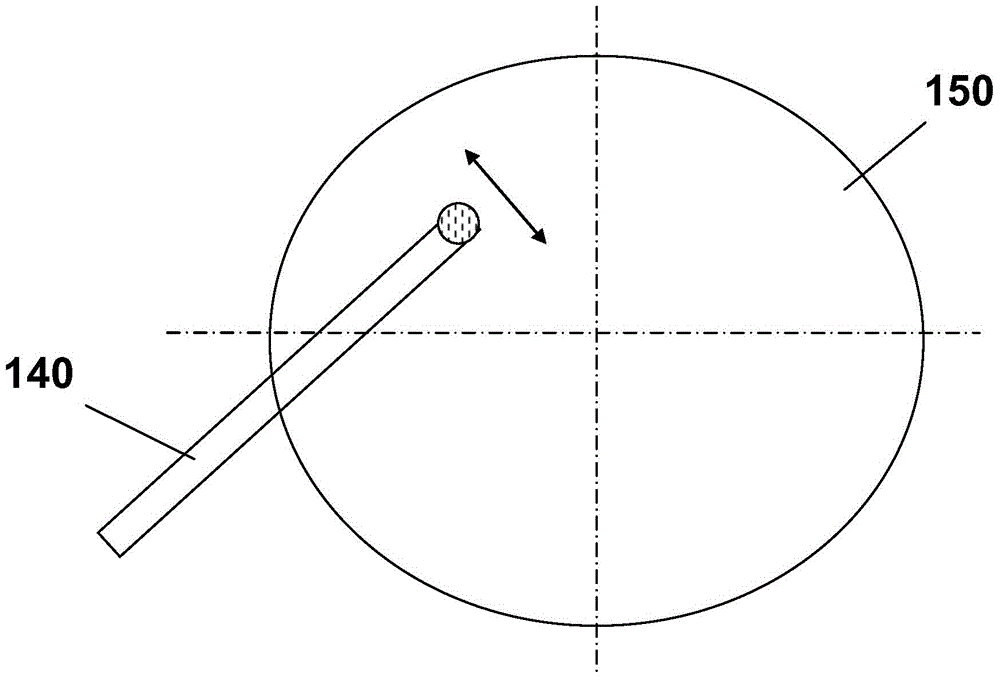

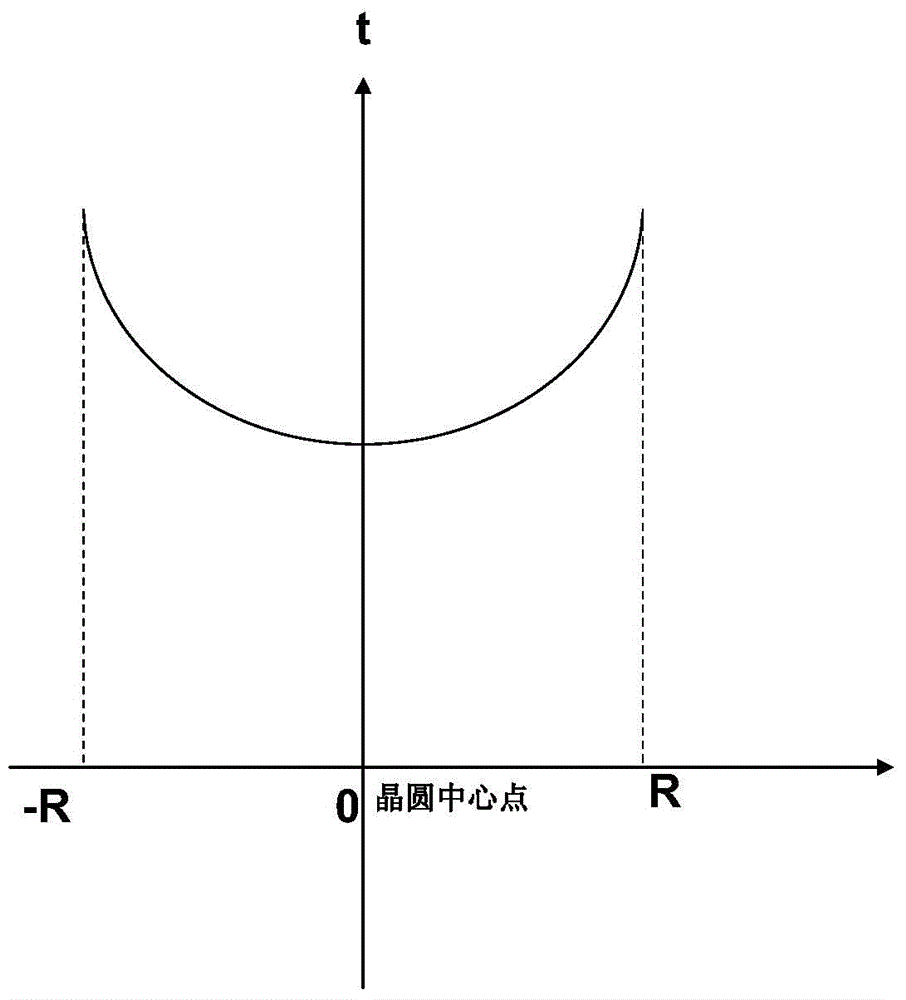

Wafer cleaning method

InactiveCN104900480AAvoid damageAvoid pittingSemiconductor/solid-state device manufacturingCleaning using liquidsEngineeringEnergy density

The invention discloses a wafer cleaning method. A mega-sonic generator is utilized to clean the surface of a wafer. The method comprises the steps that the wafer is rotated and the mega-sonic generator is enabled to move between the edge of the wafer and the center of the wafer in a reciprocating way, and energy density distribution of the mega-sonic generator on the surface of the wafer is changed in the movement process of the mega-sonic generator. The energy density distribution of the mega-sonic generator on the surface of the wafer is changed so that mega-sonic energy affected by the center point of the wafer is enabled to be consistent with mega-sonic energy affected by other positions of the wafer, and thus damage to the structural layer of the center point of the wafer in the cleaning process or generation of pits at the center of the wafer can be avoided.

Owner:ACM RES SHANGHAI

Method for making hydrophobic and oleophobic easy-to-clean glass

InactiveCN107117825AReduce usageEnvironmentally friendlyAntifouling/underwater paintsPaints with biocidesOrganic solventSilica gel

The invention belongs to the technical field of coated glass making, and in particular relates to a method for making hydrophobic and oleophobic easy-to-clean glass. The method comprises the following steps: mixing organosiloxane with absolute ethyl alcohol, adjusting the pH value of a solution, adding deionized water to promote hydrolysis, further adding fluorosilicone modified silicon dioxide, stirring to implement hydrolysis so as to form modified silica gel, leaving to stand, aging, and pouring the silica gel into deionized water which is violently stirred, thereby obtaining an aqueous hydrophobic and oleophobic easy-to-clean coating. The aqueous hydrophobic and oleophobic easy-to-clean coating prepared with the method is environmental-friendly since the amount of an organic solvent is reduced; when the surface of glass is coated by the prepared aqueous hydrophobic and oleophobic easy-to-clean coating, the solvent is slow in volatilization speed, so that the coating surface thickness uniformity is improved, and a phenomenon that a hydrophobic coating surface has spots as the solvent is volatilized too rapidly is avoided.

Owner:浙江鼎昇新材料科技股份有限公司

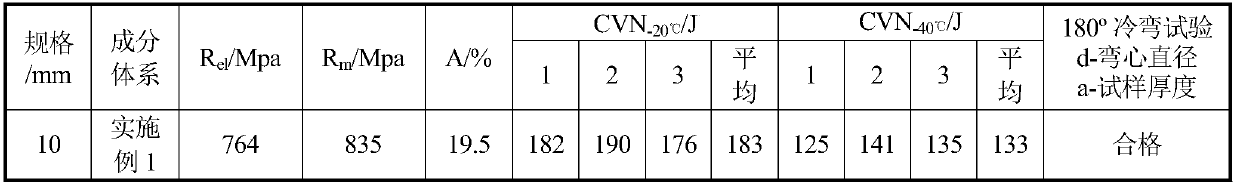

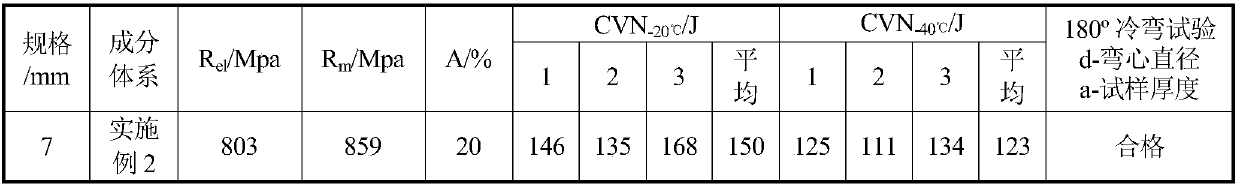

Economical high-toughness 800MPa-level automobile beam steel and production method thereof

The invention provides economical high-toughness 800MPa-level automobile beam steel. The economical high-toughness 800MPa-level automobile beam steel is prepared from the following components in percentage by weight: 0.07-0.11% of C, 1.55-1.80% of Mn, 0.05-0.20% of Si, less than or equal to 0.015% of P, less than or equal to 0.008% of S, 0.020-0.040% of Nb, 0.10-0.20% of Mo, 0.03-0.06% of Al, 0.09-0.13% of Ti, less than or equal to 0.005% of N, and the balance of Fe and inevitable impurities. The invention further provides a production method for the economical high-toughness 800MPa-level automobile beam steel, and the production method comprises the following steps: a top and bottom re-blowing converter process, LF refining, slag continuous casting, 1780mm mill rolling, and front-sectioncooling. The automobile beam steel has high strength, high toughness and low production cost. While used as an automobile structure part, the automobile beam steel can avoid occurrence of a cracking phenomenon in use in processes such as shearing, stamping, bending and welding.

Owner:ANYANG IRON & STEEL

High temperature-resistant bearing grease and preparation method thereof

InactiveCN109337737AGood high and low temperature resistanceGood lubricityLubricant compositionChemistryParaffin oils

The invention relates to the field of lubricating grease, in particular to high temperature-resistant bearing grease and a preparation method thereof. The high temperature-resistant bearing grease comprises the following components in percentage by weight: 70-80% of base oil, 12-18% of a thickening agent and 8-15% of additives, wherein the base oil comprises paraffin oil, polyol ester, di-n-octyladipate and poly-alpha olefin; the thickening agent comprises bentonite and calcium sulfonate complex ester; and the additives comprises an antioxidant, a rust inhibitor, an extreme pressure wear-resistant agent and other additives. The invention furthermore discloses the preparation method of the high temperature-resistant bearing grease. The produced bearing grease produced has excellent high and low temperature properties, lubricating performance, water resistance and extreme pressure wear resistance, low noise and long service life. At the same time, the preparation method is simple and strong in operability.

Owner:安徽中天石化股份有限公司

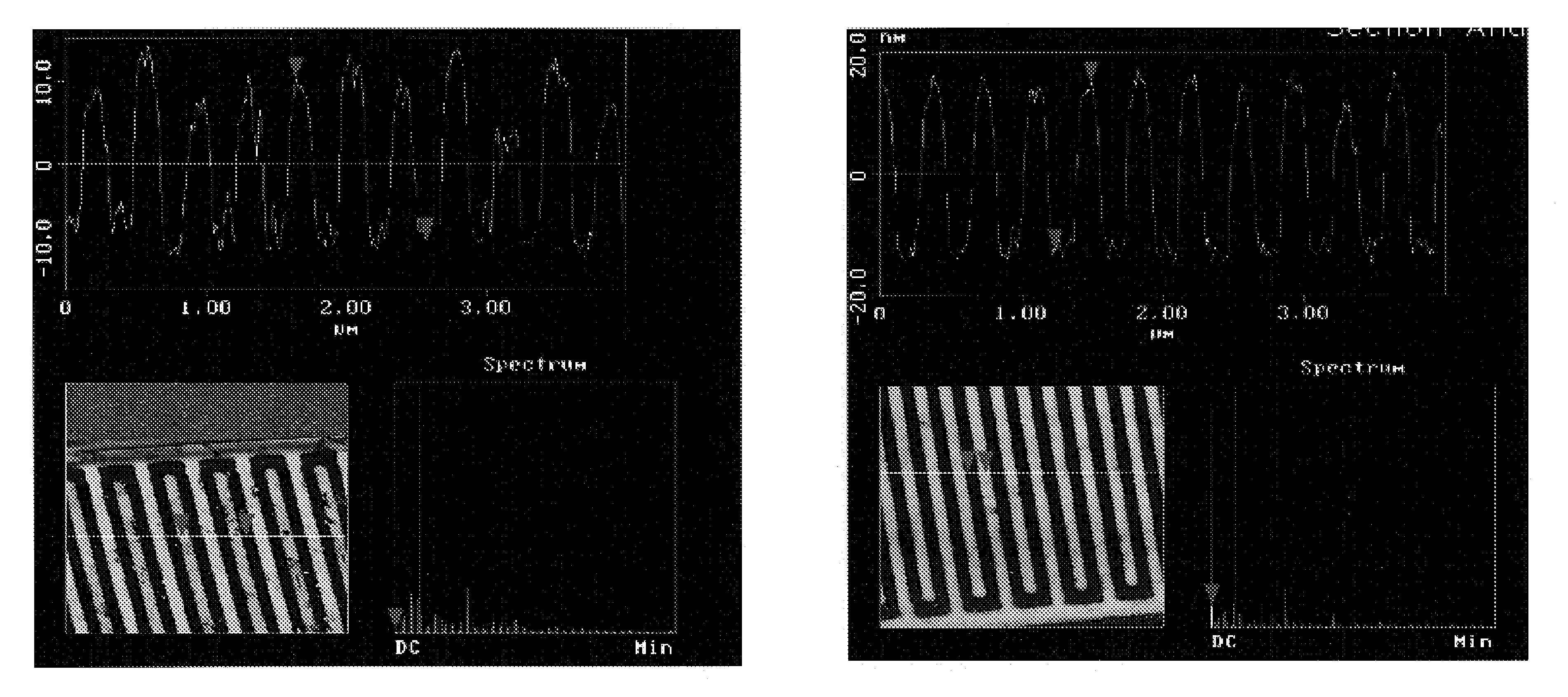

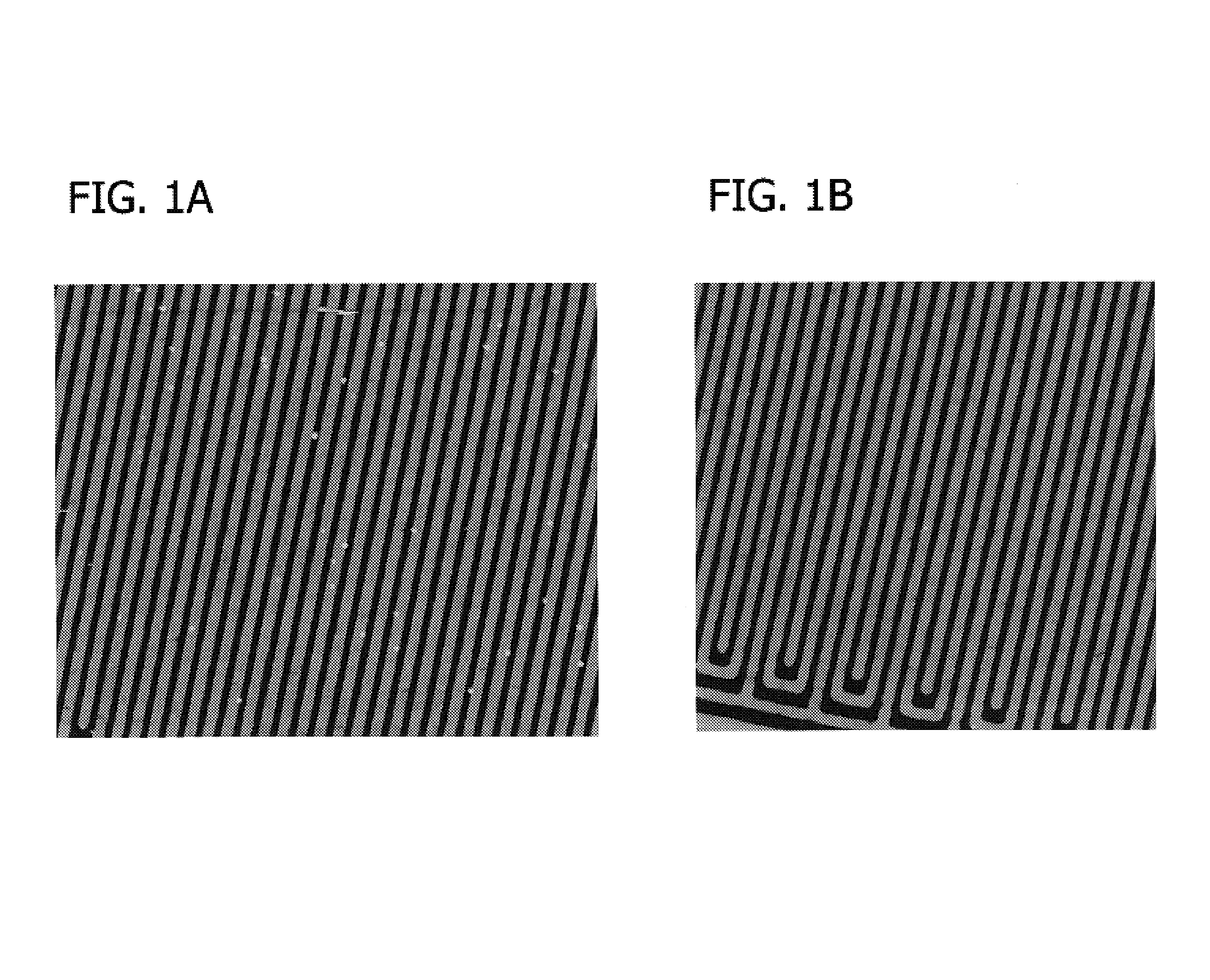

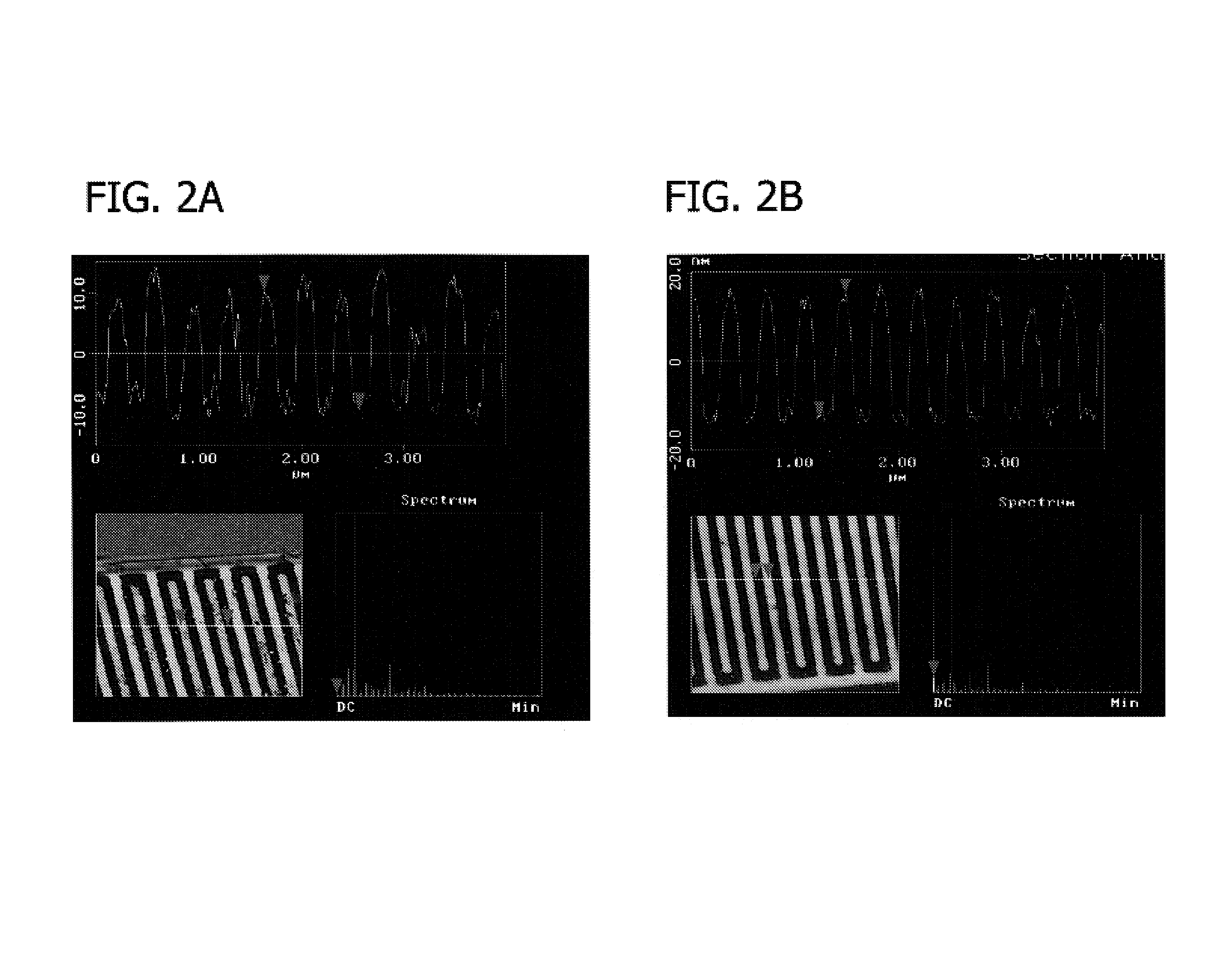

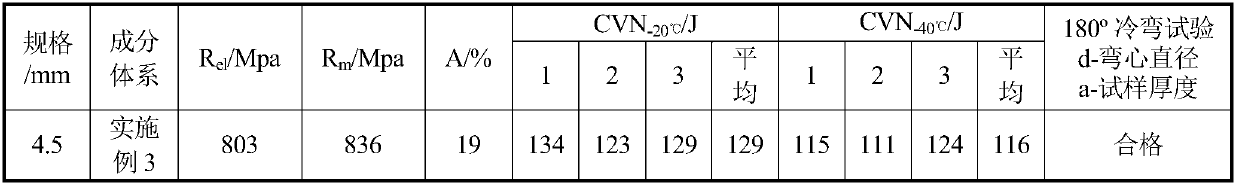

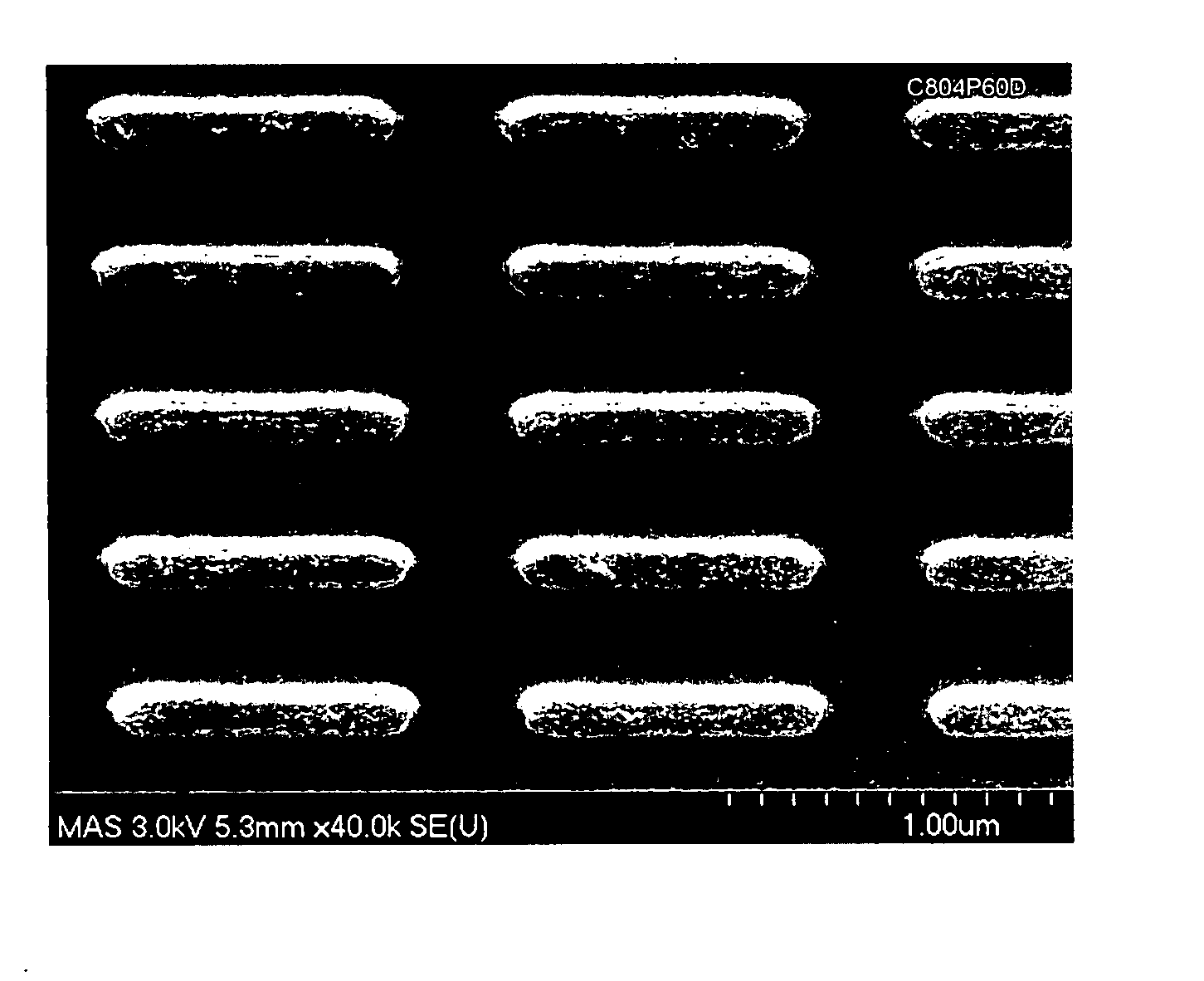

Defectivity and process control of electroless deposition in microelectronics applications

ActiveUS20070066059A1Reduce decompositionAvoid pittingNon-metal conductorsSemiconductor/solid-state device detailsAlloyElectroless deposition

Methods and compositions for electrolessly depositing Co, Ni, or alloys thereof onto a substrate in manufacture of microelectronic devices. Grain refiners, levelers, oxygen scavengers, and stabilizers for electroless Co and Ni deposition solutions.

Owner:MACDERMID ENTHONE INC

Defectivity and process control of electroless deposition in microelectronics applications

ActiveUS20070062408A1Reduce decompositionGrowth inhibitionSludge treatmentSemiconductor/solid-state device detailsAlloyElectroless deposition

Methods and compositions for electrolessly depositing Co, Ni, or alloys thereof onto a substrate in manufacture of microelectronic devices. Grain refiners, levelers, oxygen scavengers, and stabilizers for electroless Co and Ni deposition solutions.

Owner:MACDERMID ENTHONE INC

Painting method

The invention relates to a painting method. The painting method comprises the following steps of: (1) painting a primer; (2) painting a first layer of finish paint and then painting a second layer of finish paint after the first layer of finish paint is dried; and (3) painting celluloid paint, namely painting at least one layer of celluloid paint on the surface of the second layer of finish paint. The painting method is characterized in that: the first layer of finish paint is dried in a baking mode and the drying temperature is between 140 and 160 DEG C, so that the volatilization of a solvent in the first layer of finish paint is accelerated and a pockmark phenomenon can be avoided; and at the same time, the second layer of finish paint is more susceptible to adhesion by the temperatureof a dried workpiece, so that whitening and paint-flowing phenomena can be avoided. In the painting method, the first layer of finish paint is dried by a drying method, so the volatilization of the solvent is accelerated and the pockmark, whitening and paint-flowing defects are overcome successfully.

Owner:苏州雅泛迪铝业有限公司

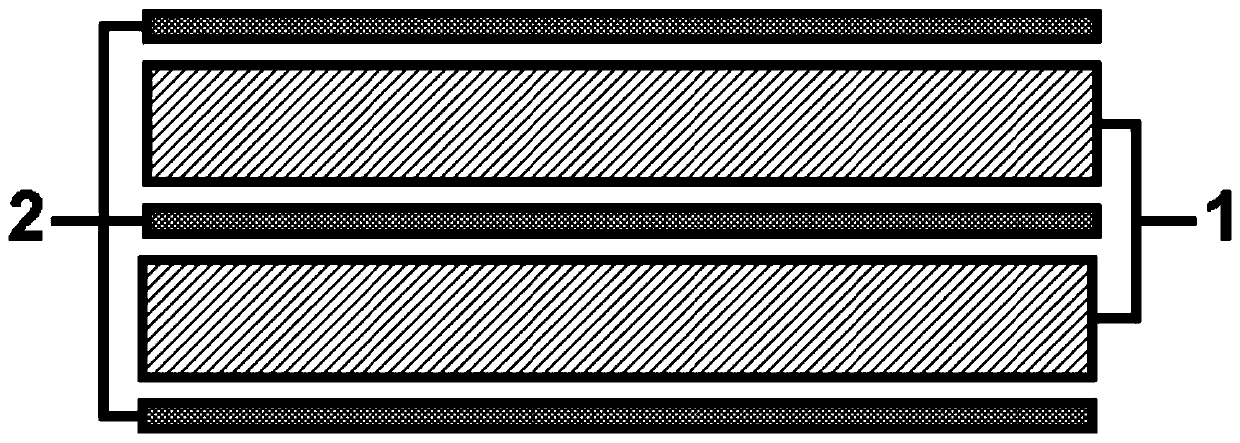

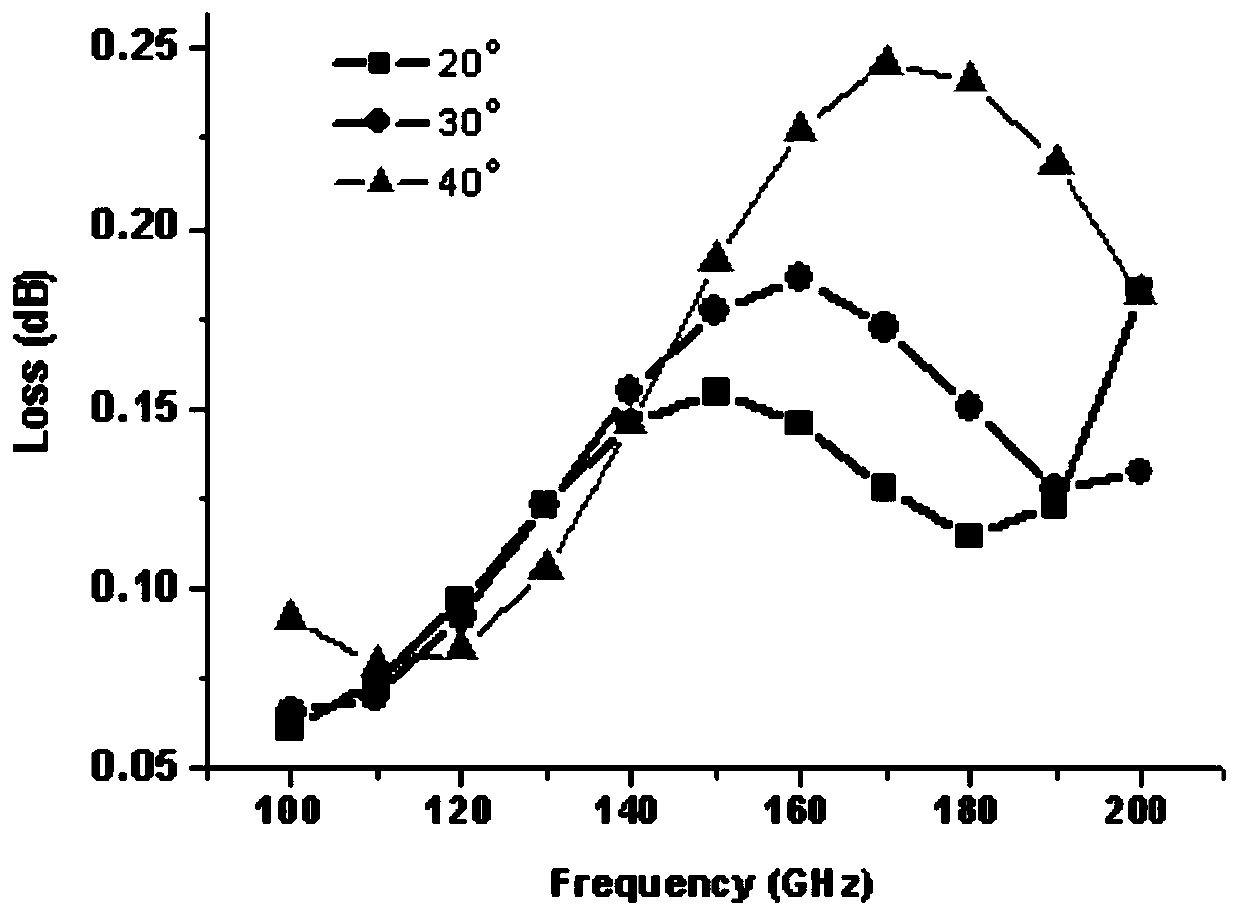

6G radome suitable for terahertz antenna and preparation method thereof

ActiveCN110350317AImprove temperature resistanceLightweightRadiating element housingsMaxillary gingivaBisphenol

The invention relates to a 6G radome suitable for a terahertz antenna and a preparation method thereof. The radome comprises an outer skin, a foam core layer, a middle skin, a foam core layer and an inner skin. The 6G radome is characterized in that the prepreg formed by combination of fiber reinforcement and resin is used as the skin material. As for the prpreg, the resin is polyphenylene ether modified bisphenol M cyanate ester resin and has the following dielectric properties: dielectric constant is less than or equal to 2. 6 and the loss factor is less than or equal to 0. 004. The fiber reinforcement is quartz fiber braid. The prepreg gum content is 30wt%-44wt%. The hot-pressing pot forming technology is used. The radome has high wave transmittance within the range of 100-200GHz and can meet the transmission performance requirements of the 6G antenna network within the terahertz band.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

Method for overcoming defect of pocks on surface of ultra-low carbon steel

ActiveCN104588418AReduce thicknessGuaranteed surface qualityProfile control deviceWork rollInsertion depth

The invention belongs to the technical field of steel rolling and discloses a method for overcoming defect of pocks on the surface of ultra-low carbon steel. The method comprises the following steps that the tapping temperature of an ultra-low carbon steel blank is controlled, and the tapping temperature is controlled within the range of 1200 DEG C-1240 DEG C; the finish rolling steel throwing speed is increased and is controlled to range from 12 m / s to 15 m / s; the cooling water opening amounts of front three racks of finishing rolling work rolls are controlled to be 50%, 50% and 80% respectively; finish rolling second pass and third pass roll gap water is opened; the insertion depth of bending rolls and straightening rolls of a withdrawal and straightening machine is controlled, and the bending rolls and the straightening rolls are at the high-depth section. Due to the technological operation that the ultra-low carbon steel in the hot rolling and cold rolling technological sections is combined and adjusted, the ferric oxide skin layers are greatly prevented from being generated, and thus the defect of the pocks is overcome.

Owner:SHOUGANG CORPORATION +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com