Electro-slag remelting method of self-consumable electrode and electro-slag furnace

A consumable electrode, electroslag remelting technology, applied in the field of electroslag metallurgy, can solve the problems of low purity and density of magnesium alloy ingots, increase production time, reduce ingot purity and density, and save energy and raw materials. , solve the problem of current loss, improve the effect of purity and density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

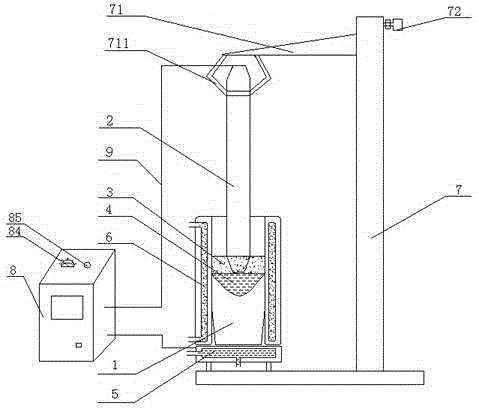

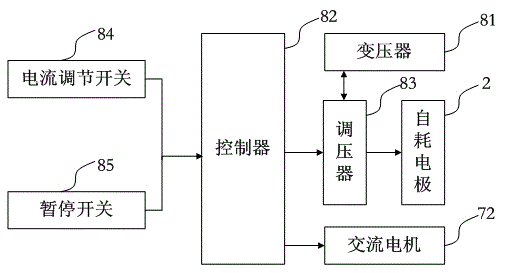

[0027] refer to figure 1 with figure 2 , an electroslag furnace used for electroslag remelting of consumable electrodes, including a furnace body 1, a consumable electrode 2 is arranged on the central upper side of the furnace body 1, and a slag pool 3, a metal melting pool 4 and bottom water tank 5; the side wall of the furnace body 1 is provided with a water-cooled crystallizer 6; the outside of the furnace body 1 is provided with an electrode lifting mechanism 7 connected to the consumable electrode 2 through a lifting arm 71, and the lower end of the lifting arm 71 is provided with The clamping mechanism 711 is a pair of clamping claws; the outer side of the furnace body 1 is provided with a main control cabinet 8, which includes a transformer 81, a controller 82 and a voltage regulator 83, and on the main control cabinet 8 There is a current regulation switch 84 and a pause switch 85, the current regulation switch 84 is used to adjust the size of the remelting current, ...

Embodiment 2

[0032] Electroslag furnace is as embodiment 1.

[0033] The electroslag remelting method of steel casting comprises the following steps:

[0034] 1) Three steel castings smelted in an electric arc furnace are welded in series to form a consumable electrode 2. The size of each steel casting is Φ200mm×280mm and the weight is 650 kg. After welding to form a consumable electrode 2, The head diameter and the tail diameter of the consumable electrode 2 are 140 mm, and the diameter of the middle part is 200 mm.

[0035] 2) Slowly lower the consumable electrode 2 and insert it into the slag of the electroslag furnace for secondary electroslag. After the arc is energized, adjust the remelting voltage to 57-61V and the remelting current to 6000-6500A, of which the slag The composition weight percentage is 70%CaF 2 +30%Al 2 o 3 ;

[0036] 3) The end of the consumable electrode 2 melts slowly, and the molten metal gathers into metal droplets, which fall off from the end of the consu...

Embodiment 3

[0042] Electroslag furnace is as embodiment 1.

[0043] The electroslag remelting method of iron casting comprises the following steps:

[0044] 1) Four iron castings smelted in an electric arc furnace are welded in series to form a consumable electrode 2. The size of each iron casting is Φ120mm×180mm and the weight is 300 kg. After welding to form a consumable electrode 2, The head diameter and the tail diameter of the consumable electrode 2 are 70 mm, and the diameter of the middle part is 120 mm.

[0045] 2) Slowly lower the consumable electrode 2 and insert it into the slag of the electroslag furnace for secondary electroslag. After the arc is energized, adjust the remelting voltage to 55-59V and the remelting current to 4000-4500A, of which the slag The composition weight percentage is 40%CaF 2 + 35%Al 2 o 3 + 25%CaO;

[0046] 3) The end of the consumable electrode 2 melts slowly, and the molten metal gathers into metal droplets, which fall off from the end of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com