Light-weight and high-strength shaft fork

A high-strength, lightweight technology, applied in the direction of shafts, shafts and bearings, mechanical equipment, etc., can solve the problems affecting processing quality, weight increase, and the length of the circumferential parting line, saving raw materials and energy, and improving the utilization rate of steel , the effect of overall weight reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

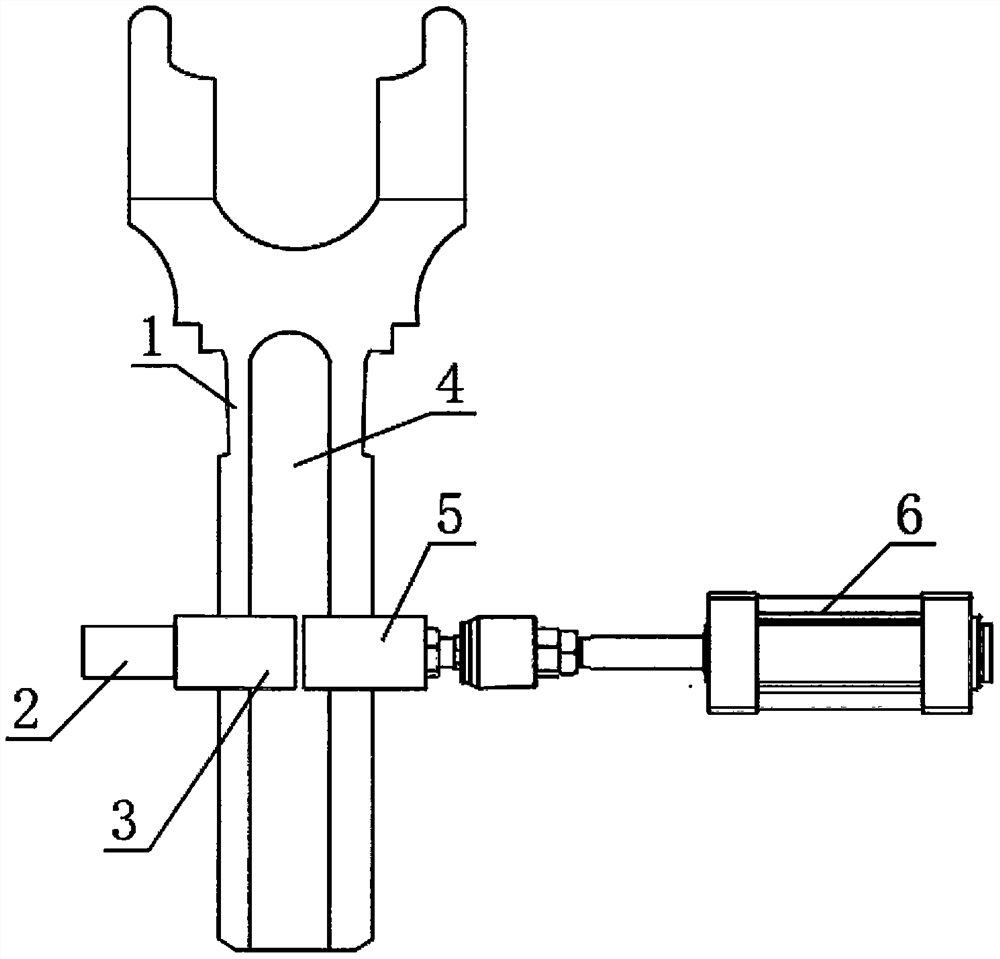

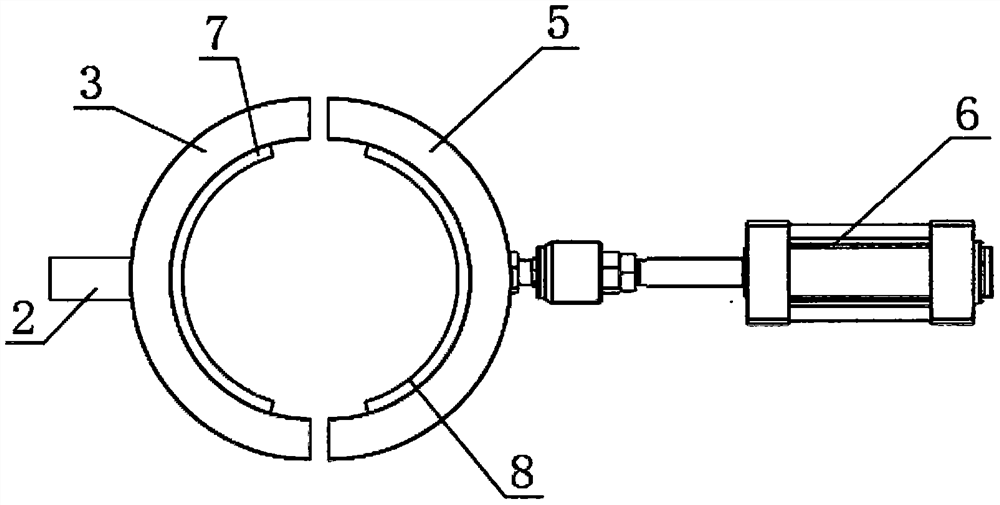

[0020]Seefigure 1 withfigure 2 The present invention provides a technical solution: a lightweight high intensity, including the first axis of the bodium 1, the bottom of the first axis body 1 has a hollow port 4, and a fastening mechanism; Including the fixing rod 2, the first fixing ring 3, the second fixing wheel 5, and the cylinder 6, the end of the fixing rod 2 fixes a first fixing ring 3, and the extended axis of the cylinder 6 is fixed to the first axis body 1. The solid second fixing wheel 5, the vertical first axis body 1 is close to the first fixing ring 3, the cylinder 6 work, the extended axis of the cylinder 6, and the second fixing wheel 5 is closely passed to the vertical first axis body 1 The vertical first axis body 1 is fixed to facilitate a better forging of the vertical first axis body 1.

[0021]In the present embodiment, it is preferable that the inner wall of the first fixing ring 3 is fixed to a first rubber pad 7, the first rubber pad 7 is a ring; the inner wall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com