Double-roller rotary forging forming method for constructing large-diameter thin-wall composite metal disc

A composite metal and large-diameter technology, which is applied to web-type wheels, vehicle parts, transportation and packaging, etc., can solve problems such as limited reduction rate, damage to the flow direction of metal fibers, and insufficient compactness of the composite layer, so as to achieve tissue bonding and compactness. Effect of densification and defect repair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

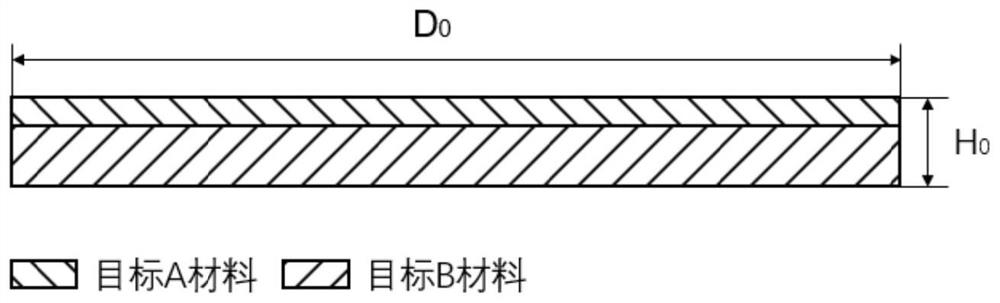

[0035] A double-roller pendulum forming method for constructing a large-diameter thin-walled composite metal disc, comprising the following steps:

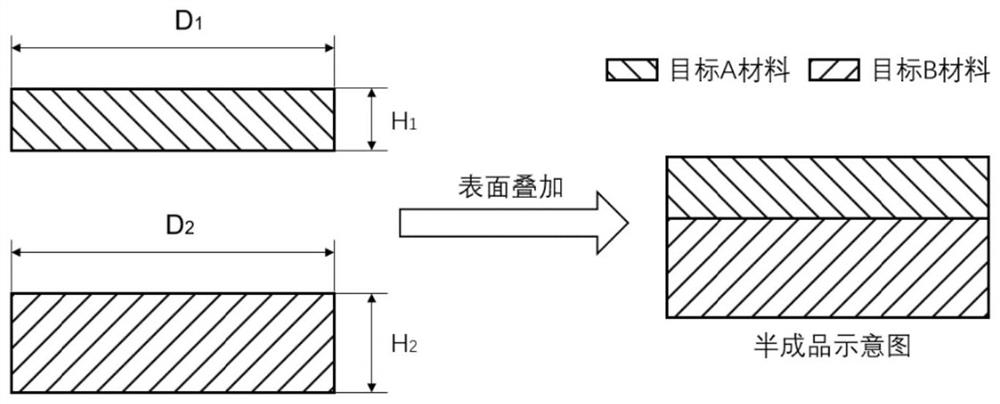

[0036] S1. Preparation of semi-finished products 2: Process and polish the surfaces of the composite discs A and B to expose fresh metal. After accurately stacking A and B together, perform electron beam sealing and welding in a vacuum chamber, such as figure 2 shown.

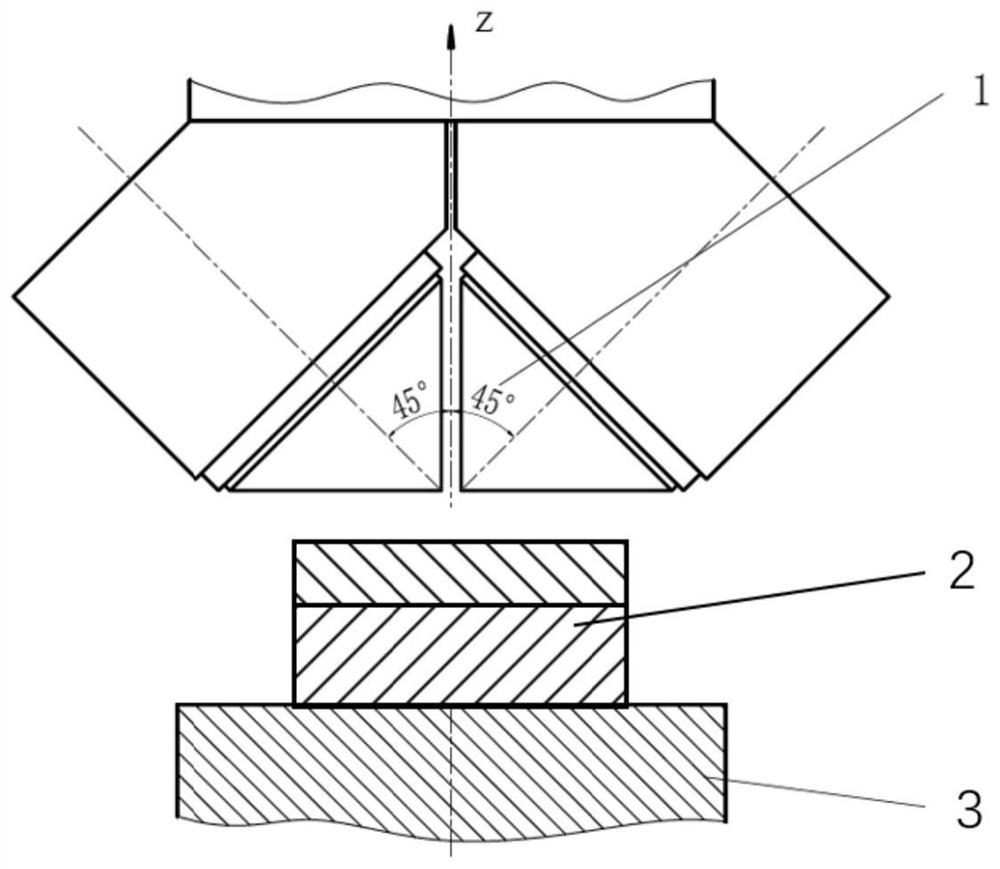

[0037] S2. Positioning of semi-finished products: The semi-finished products after electron beam sealing and welding are placed in a heating furnace and heated to a suitable forging temperature range, and kept for a period of time to ensure a firm bond between the composite interfaces, and then quickly transferred to the center of the lower mold of the forming equipment. ,like image 3 shown.

[0038] S3. The semi-finished product 2 is formed under the pendulum rolling of the double-cone roller 1: the double-cone roller 1 revolves around the central axis of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com