Patents

Literature

321results about How to "Achieve composite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

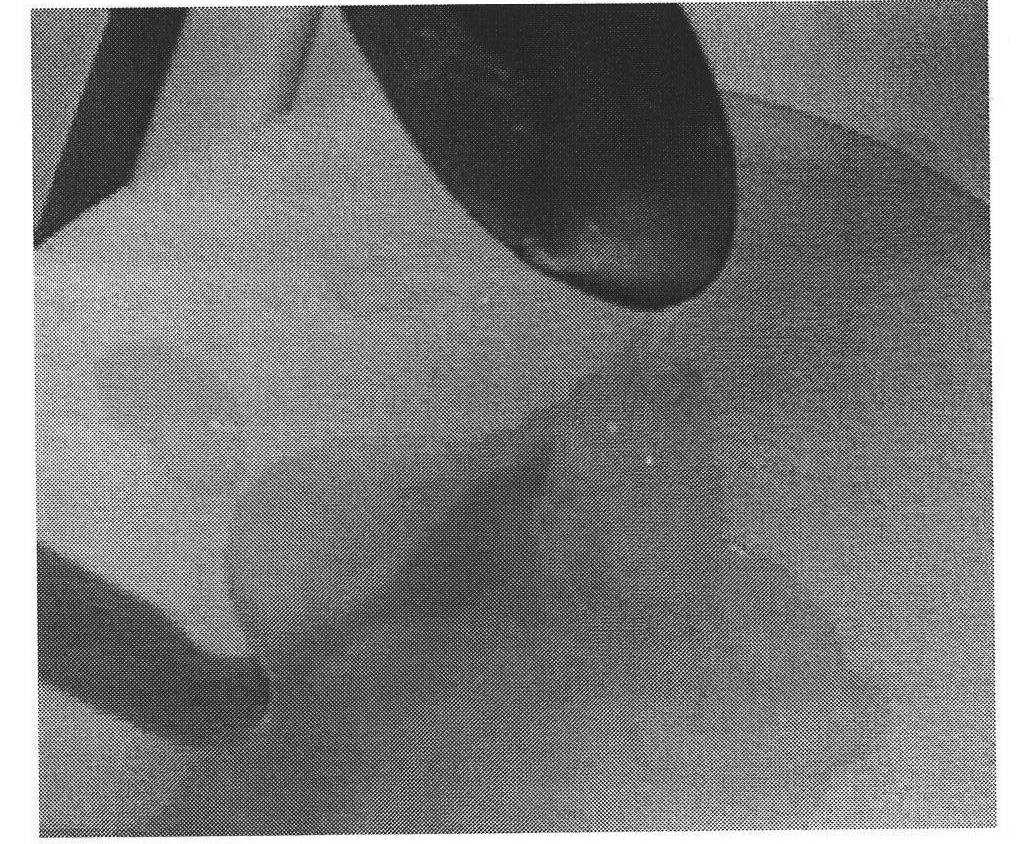

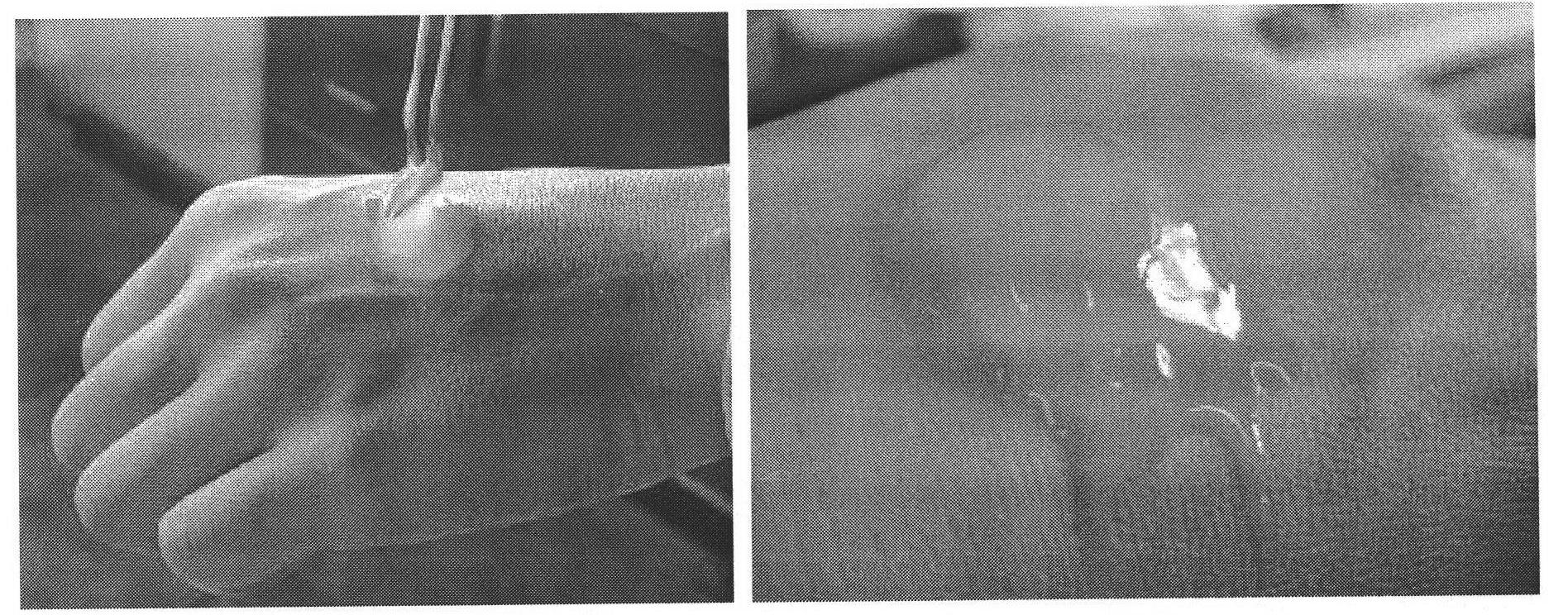

Human-body absorbable trauma dressing containing Yunnan white drug powder or Yunnan white drug powder extractive

InactiveCN101804218AIncrease usageImprove usabilityAbsorbent padsBandagesDressing changeCurative effect

The invention discloses a human-body absorbable trauma dressing containing Yunnan white drug powder or Yunnan white drug powder extractive, which is a novel medicine-carried dressing or a novel formulation of Yunnan white drug powder. The invention has the following remarkable characteristics: (1) the dressing can be absorbed by human bodies to lessen the pain added by dressing change and reduce the treatment cost; (2) the dressing can be made into a film solid dressing or an aquagel dressing so as to expand the use modes, the scope of applications and the drug effect of the Yunnan white drug powder; and (3) the curative effect of the dressing is enhanced by selecting a carrier material, auxiliary medicaments and functional accessories and adjusting the microstructure structure. The novel absorbable Yunnan white drug powder dressing overcomes the defects of the traditional Yunnan white drug powder in use and has economic and social values.

Owner:王艳

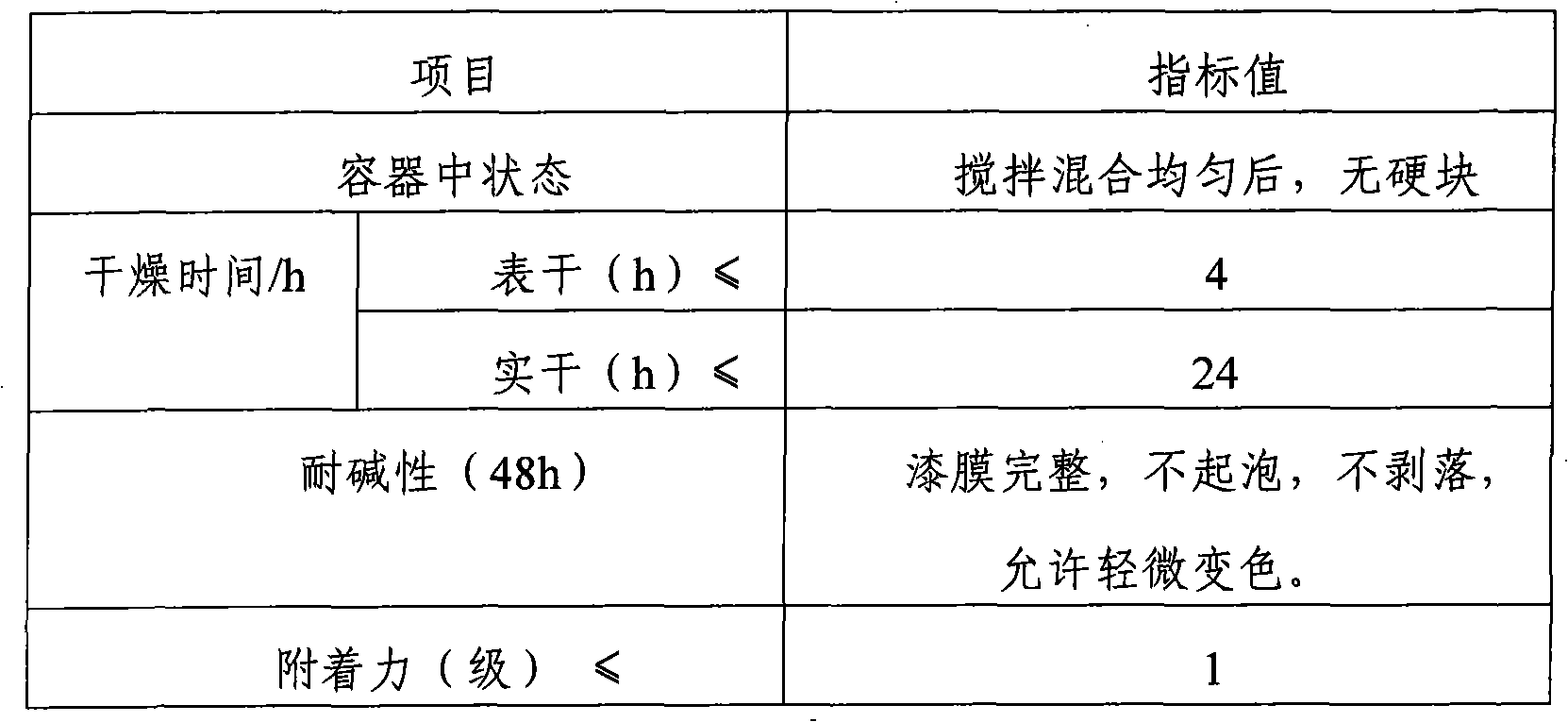

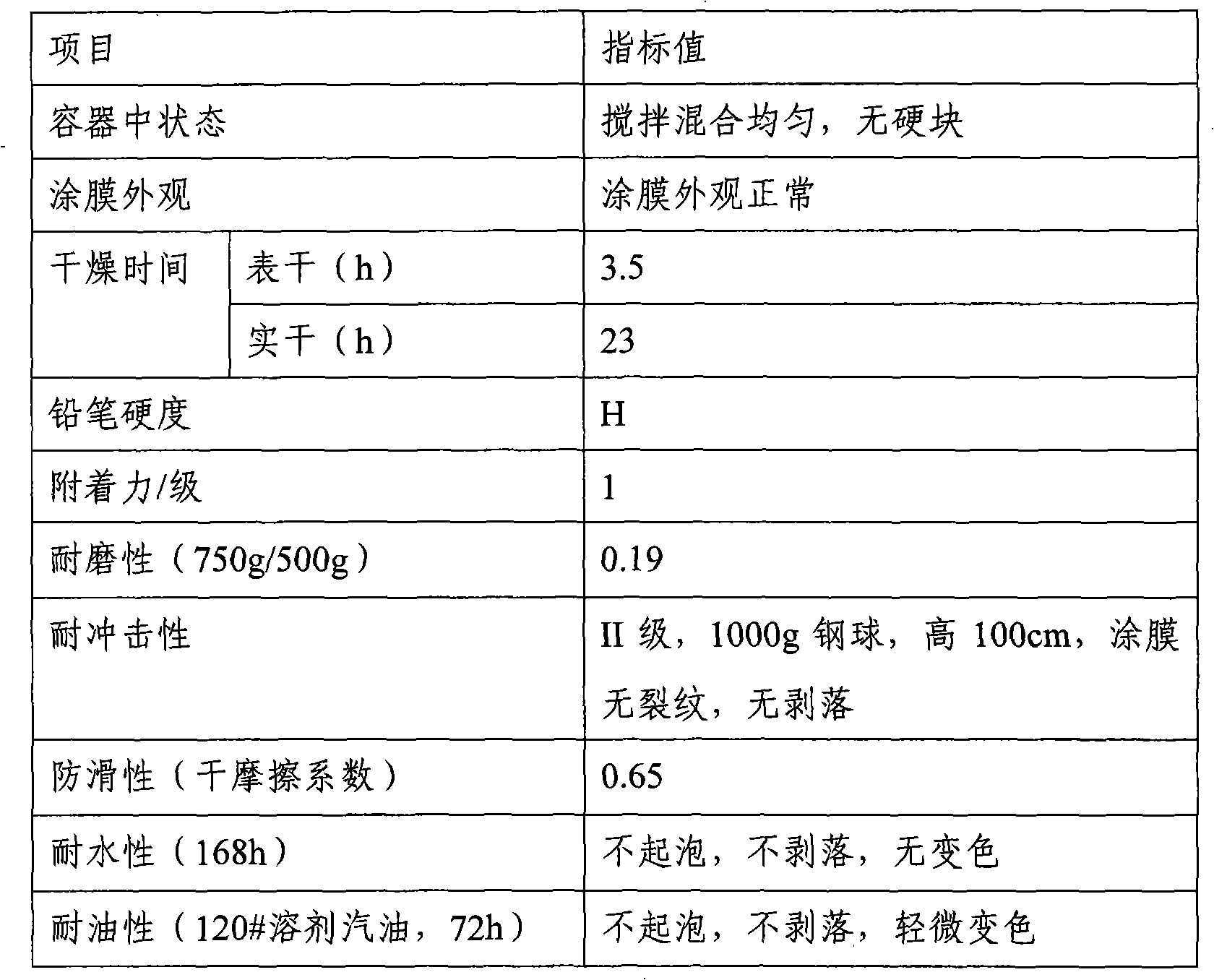

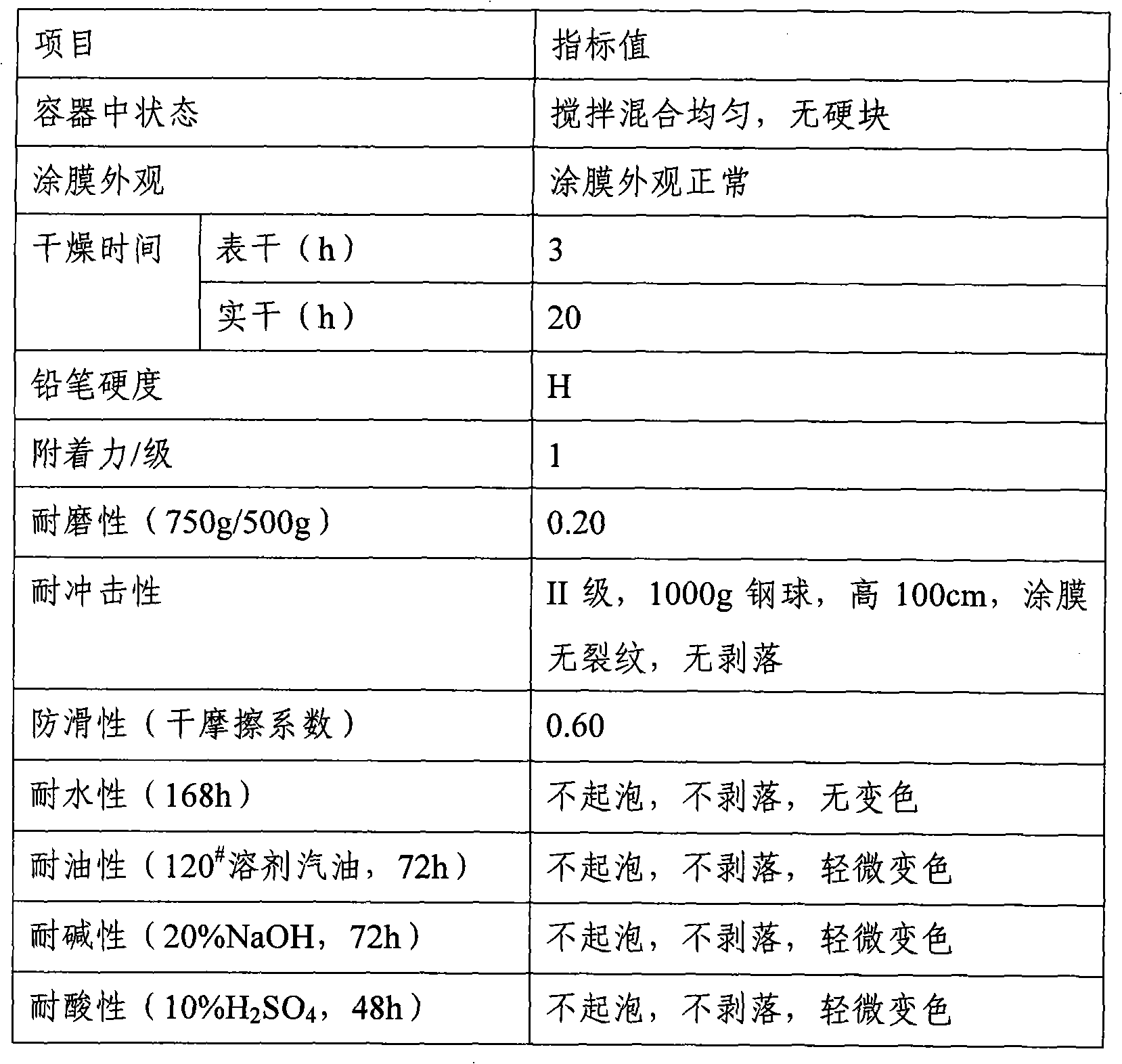

Compound epoxy flooring coating and preparation method thereof

InactiveCN101654583AHigh mechanical strengthImprove corrosion resistanceRosin coatingsEpoxy resin coatingsSolvent freeFirming agent

The invention relates to compound epoxy flooring coating adopting the mixture of epoxide resin and modified resin as a base material and further comprising organic solvent, dispersant, wetting agent, antifoaming agent, flatting agent, scratch resistance agent, pigment and stuffing as well as reactive diluent selected according to requirements. When in use, the coating is mixed and solidified withthe components of firming agent, accelerant, etc. By regulating the content of the components, the compound epoxy flooring coating of the invention can be used for manufacturing a solvent or solvent-free autolevelling epoxy floor. The compound epoxy flooring coating of the invention has favorable over-all properties, and not only has the characteristics of high mechanical strength, favorable anti-corrosion property, high adhesive force and good wear resistance property of the epoxide resin but also has the characteristics of good weather resistance, high decorative property and hardness and shock resistance of the modified resin; and the preparation method thereof is simple and practicable, is low-cost, and is suitable for mass preparation.

Owner:北京红狮科技发展有限公司

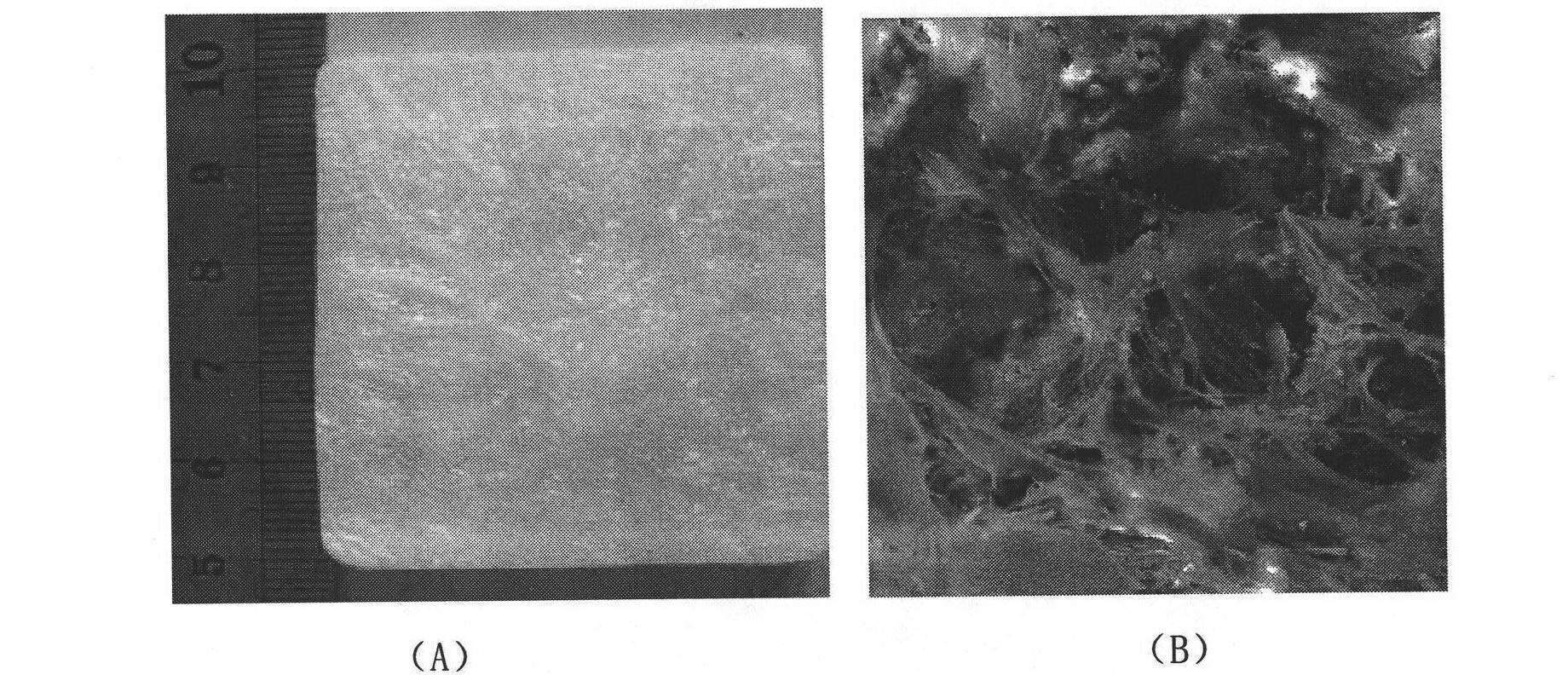

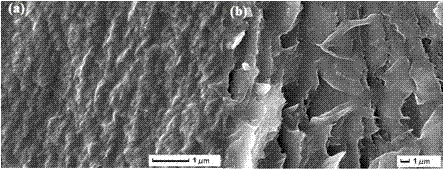

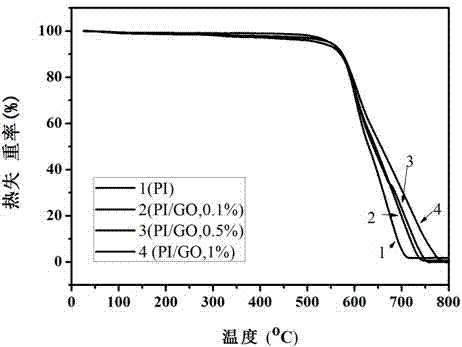

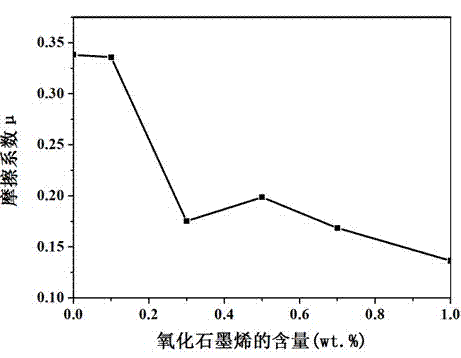

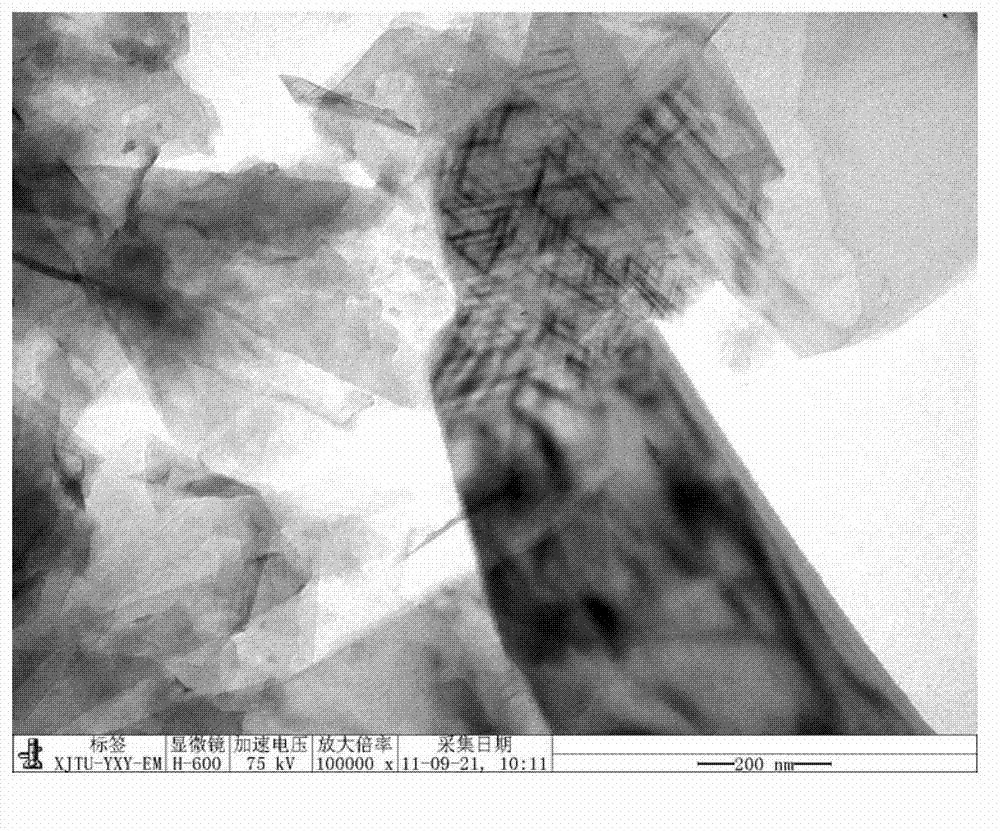

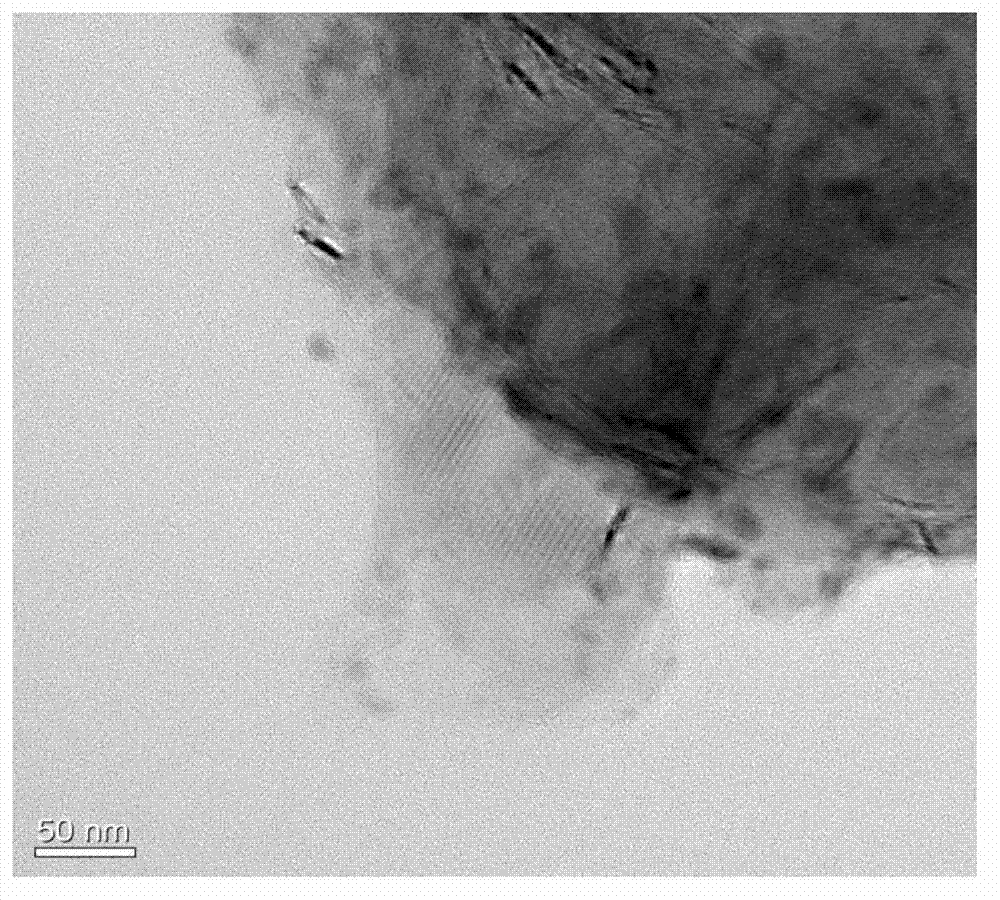

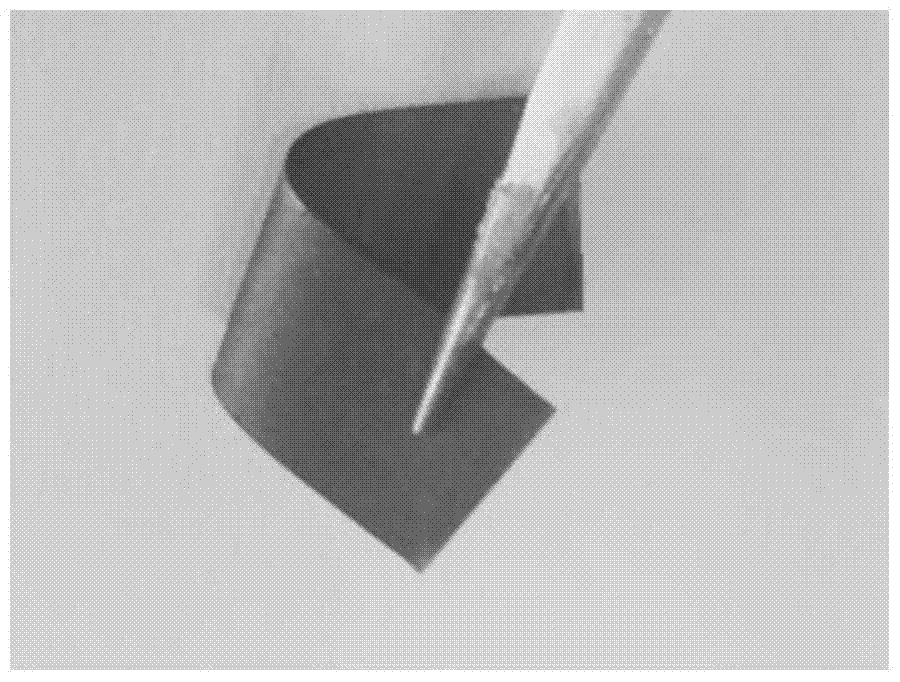

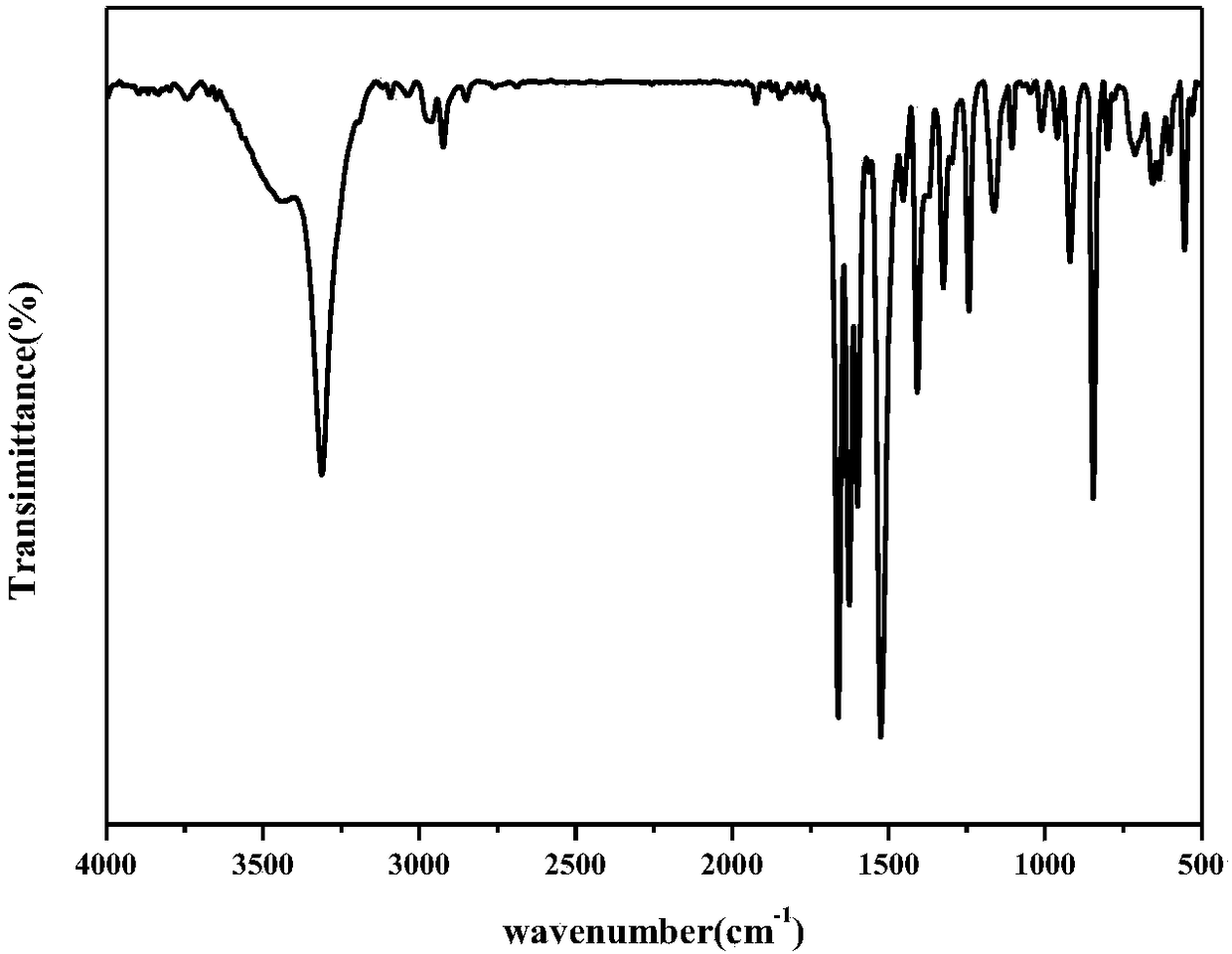

Preparation method for polyimide/oxidized graphene nanocomposite film

InactiveCN103589152ASolve the shortcomings of poor wear resistanceSolving Dispersion ProblemsPolyamideDissolution

The invention relates to a preparation method for a polyimide / oxidized graphene nanocomposite film, and belongs to the technical field of preparation of functional polymer materials. The preparation method comprises the following steps: performing ultrasonic even dispersion on the oxidized graphene in an organic solvent to obtain an oxidized graphene sheet suspension, wherein per ml of the oxidized graphene sheet suspension contains 1.3*10<-5>-1.3*10<-4>g oxidized graphene sheets; introducing nitrogen for carrying out deoxidization protection, adding diamine monomers into the suspension, mechanically stirring until full dissolution is achieved, adding dianhydride monomers, the moles of which are equal to that of the diamine monomers, in batches, and mixing for one to six hours under the ice bath conditions, so as to obtain polyamide acid / oxidized graphene composite solution; pouring the polyamide acid / oxidized graphene composite solution onto a die, removing the organic solvent, performing gradient temperature rise within 100-300DEG C, and carrying out thermal imidization to obtain the polyimide / oxidized graphene nanocomposite film.

Owner:JIANGSU UNIV

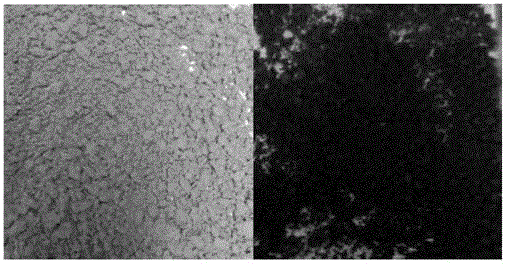

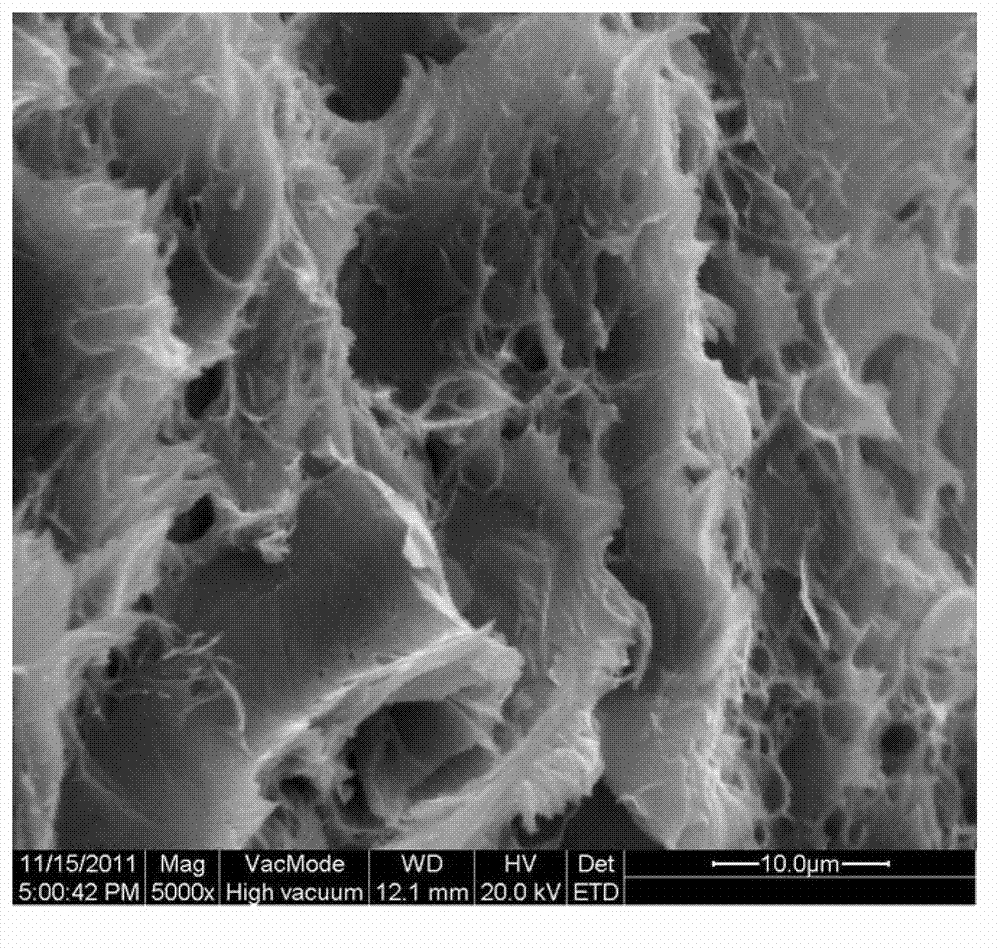

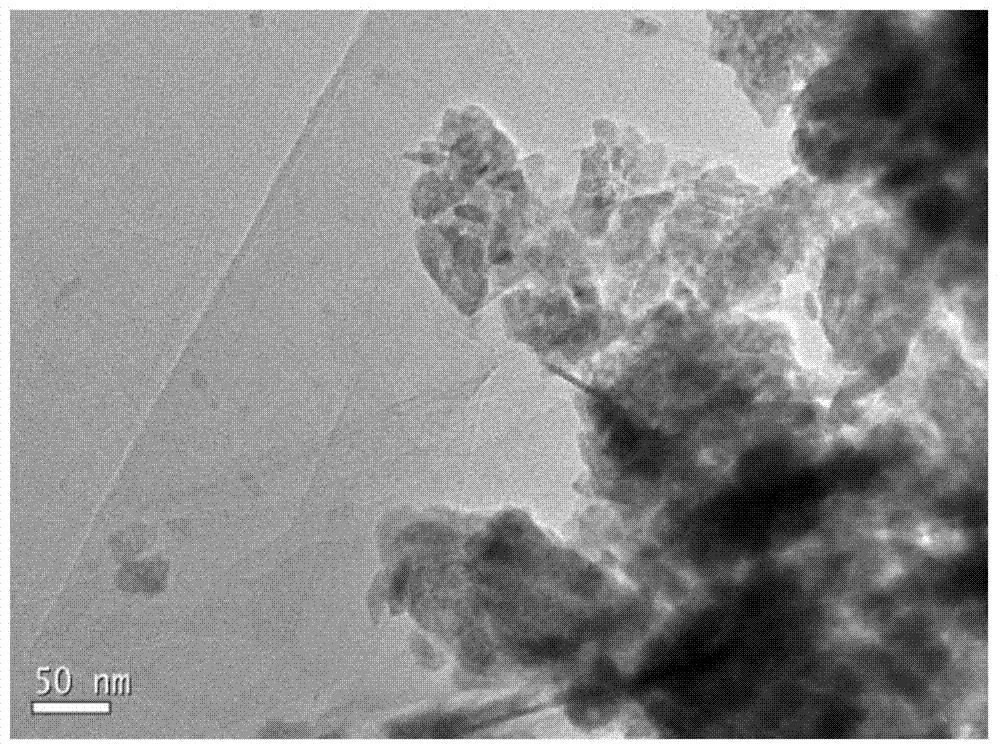

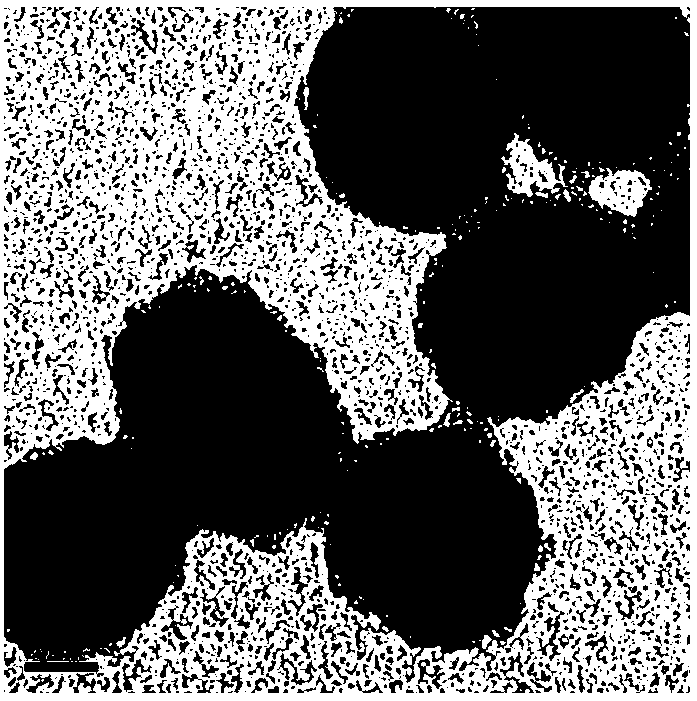

Preparation method of high-performance graphene oxide/solution polymerized styrene-butadiene rubber composite material

The invention relates to a preparation method of a high-performance graphene oxide / solution polymerized styrene-butadiene rubber composite material, belonging to the field of rubber composite materials. The preparation method comprises the following steps: preparing a solution polymerized styrene-butadiene rubber emulsion, compounding graphene oxide with the solution polymerized styrene-butadiene rubber emulsion, co-flocculating the composite emulsion, and mechanically blending. The solution polymerized styrene-butadiene rubber emulsion has the advantages of simple preparation technique and low cost. By using the emulsion compounding, the graphene oxide has high peeling property and high dispersity. The graphene oxide / solution polymerized styrene-butadiene rubber master batch can be directly machined or combined with solution polymerized styrene-butadiene rubber solid, and can also be doped with other fillers to prepare the high-performance solution polymerized styrene-butadiene rubber nano composite material. The solution polymerized styrene-butadiene rubber composite material prepared by the method can maximally display the function of the graphene oxide; and the method can enhance the mechanical strength, wearability and slip resistance of the solution polymerized styrene-butadiene rubber composite material, and lower the heat generation and the like. The method is simple and easy to implement, and has wide application prospects.

Owner:BEIJING UNIV OF CHEM TECH

High amino content ordered mesoporous silicon dioxide film and its preparation method and application

InactiveCN101214966AHigh transparencyImprove thermal stabilitySilicaTenebresent compositionsPolymer scienceSilanes

The invention relates to a preparing process and application sequential mesoporous silicon dioxide film with high amino content. The preparing process of the invention takes various surface active agent as template, takes tetraethyl ortho-silicate and 3-3-aminopropyl triethoxysilane as the silicon source, utilizing sol-gel manner, leading the amino silane to take the molar percentage of the whole silane of 30-60 by introducing amino silane directly part of silica sol, after forming homogeneous solution, relying on the synergy of the silane and organic templates, forming films by dip-coating on the clear substrate, finally forming functional sequential silicon dioxide film with different meso-structure and high amino content. The silicon dioxide mesoporous film of the invention has perfect assembly and fixing property to organic molecules, inorganic anions, protein, enzyme molecule and the like object materials.

Owner:NAT UNIV OF DEFENSE TECH

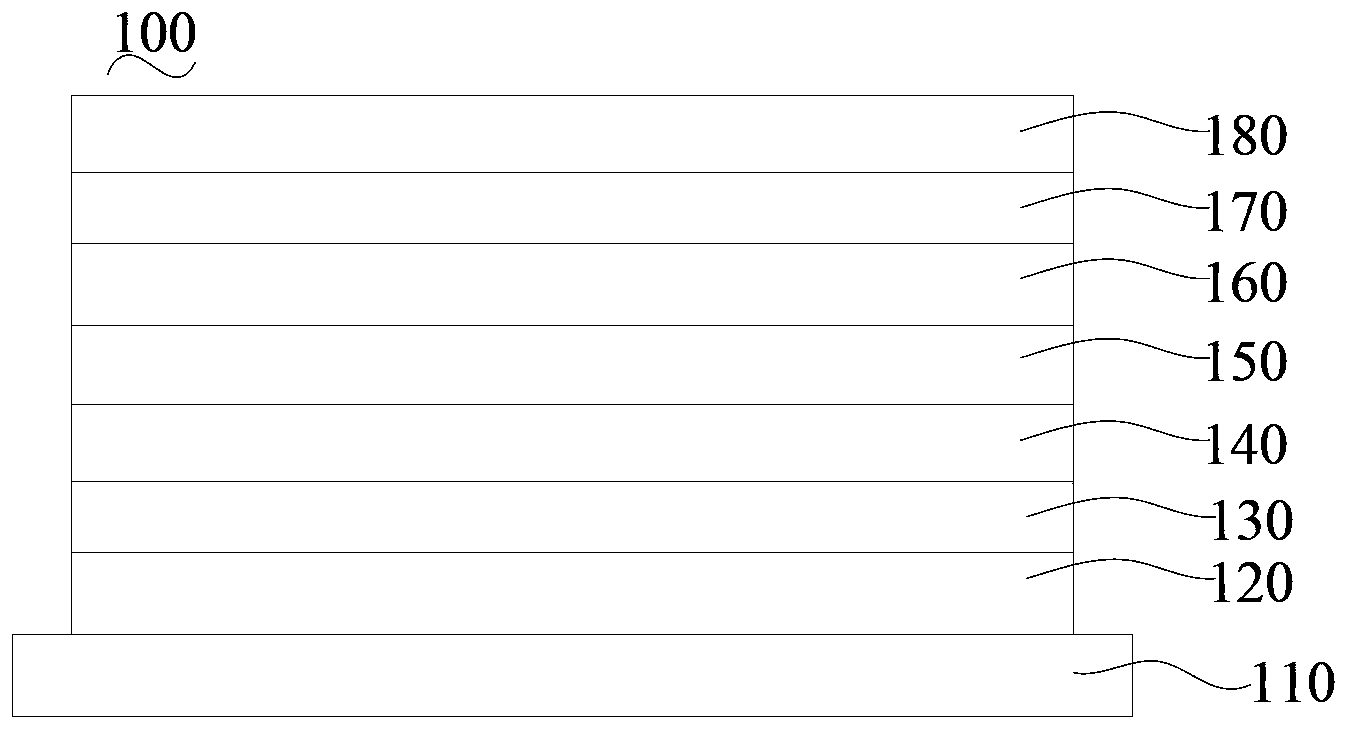

Top emission organic light-emitting device and manufacturing method thereof

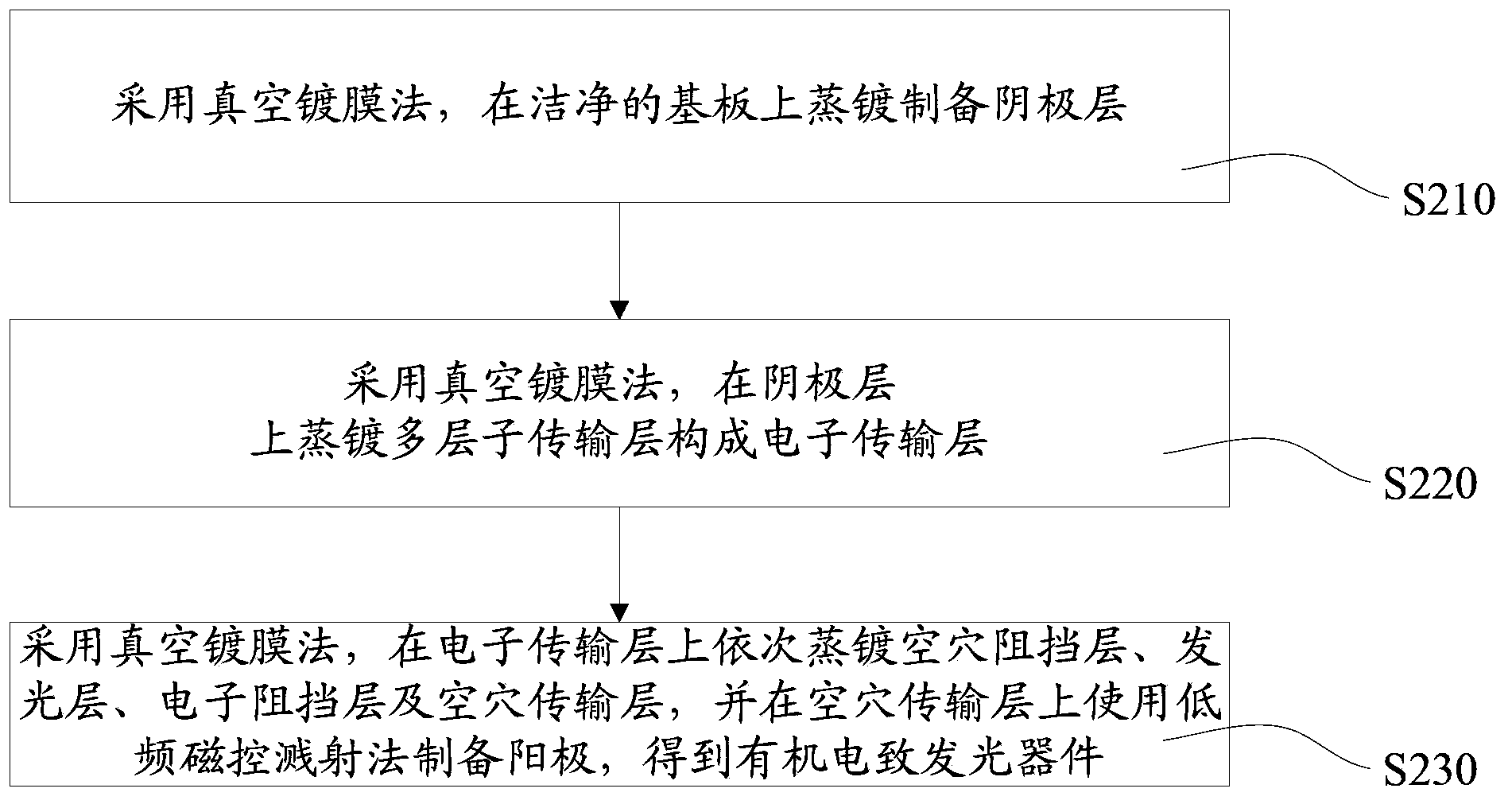

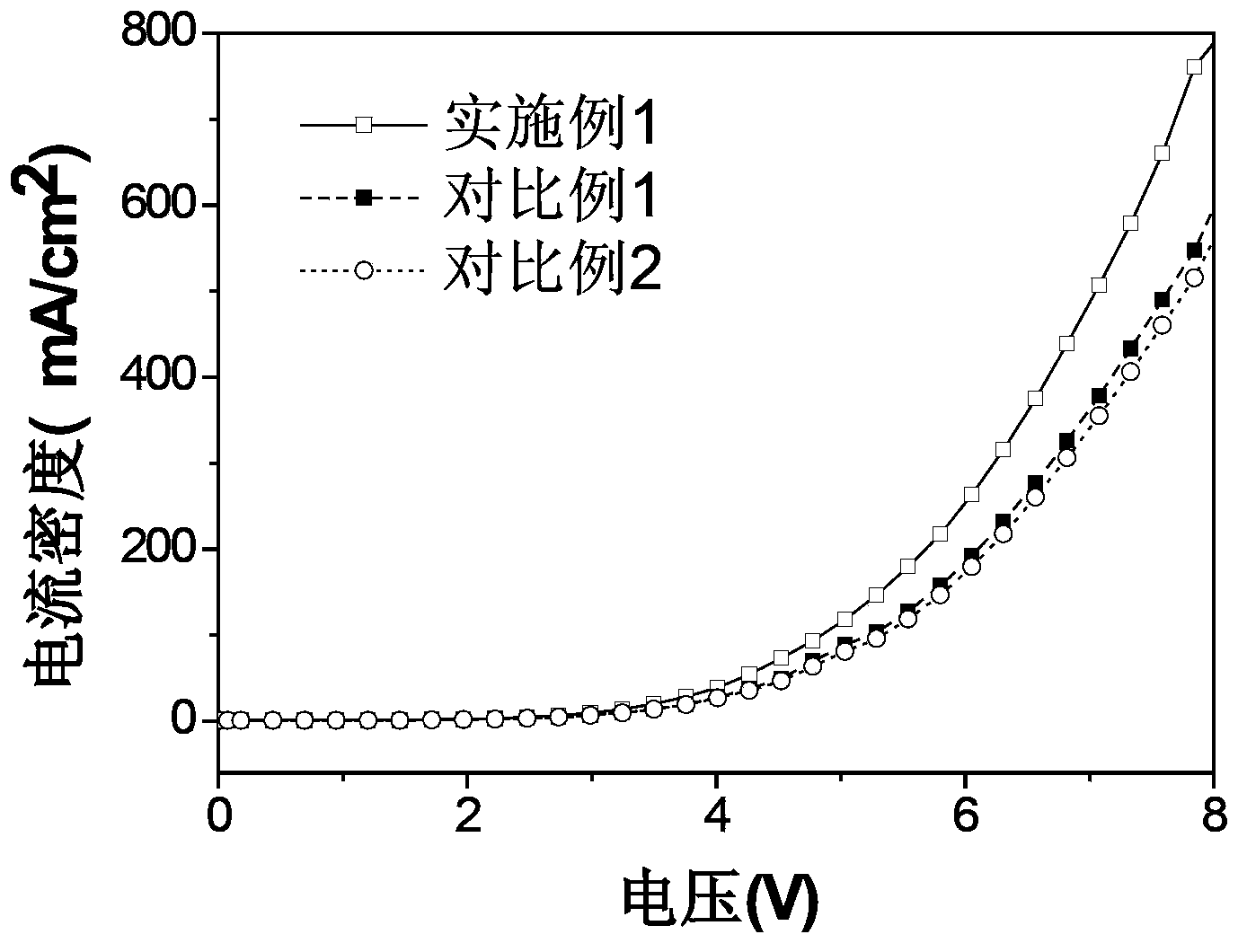

InactiveCN103730589ASolve the problem of low light extraction efficiencyImprove injection efficiencySolid-state devicesSemiconductor/solid-state device manufacturingElectronic transmissionElectron hole

The invention relates to a top emission organic light-emitting device. The top emission organic light-emitting device comprises a substrate, a cathode electrode layer, an electronic transmission layer, an electron hole barrier layer, a luminous layer, an electronic barrier layer, an electron hole transmission layer and an anode electrode all of which are arranged in a stack-up mode. The electronic transmission layer comprises a plurality of sub-transmission layers which are arranged in a stack-up mode. Each sub-transmission layer is mainly made of main materials and doping materials mingled with the main materials. The light of the top emission organic light-emitting device is emitted from the anode electrode on the top, and therefore the problem that the luminous efficiency of a traditional top emission electrode is low is solved. The gradient doping method is adopted in the electronic transmission layer of the top emission organic light-emitting device, ohm contact is formed between the electronic transmission layer and the cathode electrode layer, and therefore the carrier injection efficiency is improved, the doping concentration is reduced gradually along with the increasing of the thickness of the electronic transmission layer, electrons are injected and transmitted in a gradient mode, carrier injection is controlled, excition recombination can be controlled, and the high light-effect is achieved. The invention further relates to a manufacturing method for the top emission organic light-emitting device.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

PVC (Polyvinyl Chloride)/graphite alkene antistatic composite material and preparation method thereof

The invention discloses a PVC (Polyvinyl Chloride) / graphite alkene antistatic composite material. The PVC graphite alkene antistatic composite material is prepared by the following ingredients in percentage by weight: 2-20% of a shock resistance modifying agent, 0.5-10% of an electric conductive filler, 2-20% of a processing agent and the balance of matrix resin. In addition, the invention also provides a preparation method of the PVC / graphite alkene antistatic composite material. Due to the adoption of the preparation method, the PVC has the antistatic property, and the enhancing and toughening are realized at the same time; and the surface resistivity of the prepared PVC / graphite alkene antistatic composite material is 104-108 omega, the volume resistivity is not more than 108 omega / cm, the tensile strength is not less than 50MPa, the impact strength is not less than 5kJ / m<2>, the elongation at break is not less than 75%, and the antistatic requirements on GB / T20105-2006 and MT164-2007 and MT165-2007 in the colliery industry are met.

Owner:XIAN UNIV OF SCI & TECH

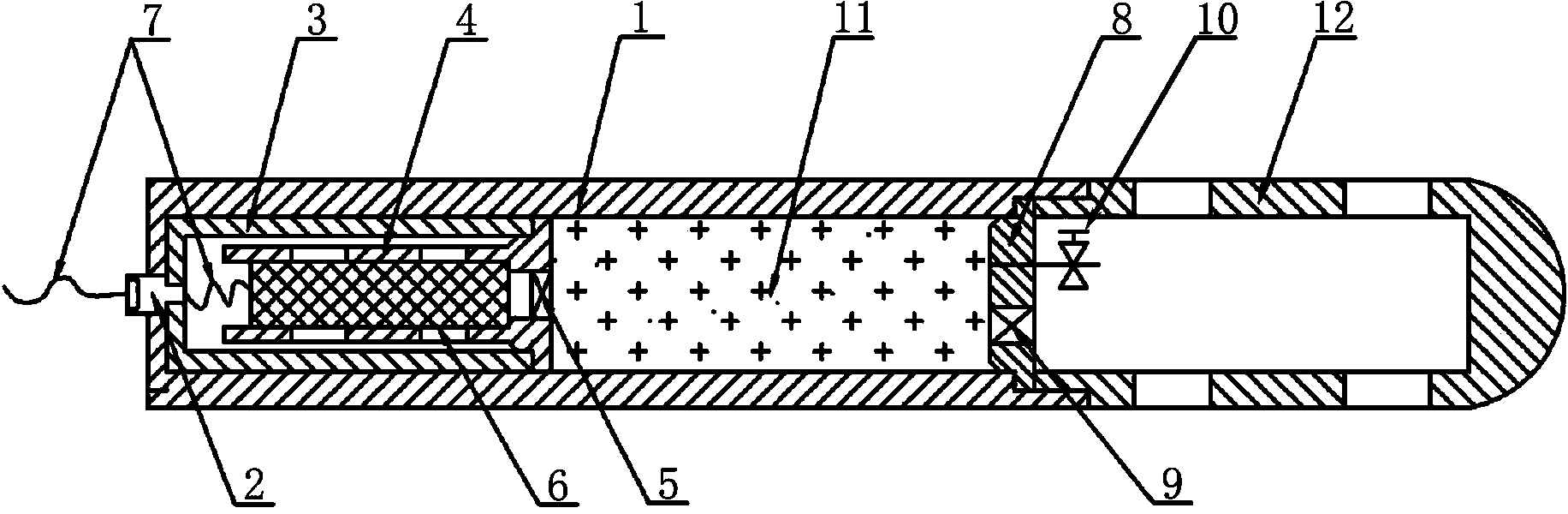

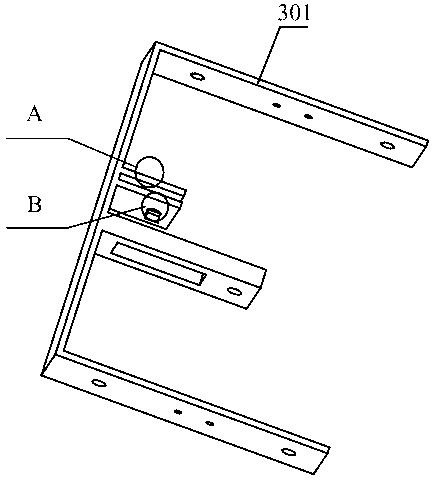

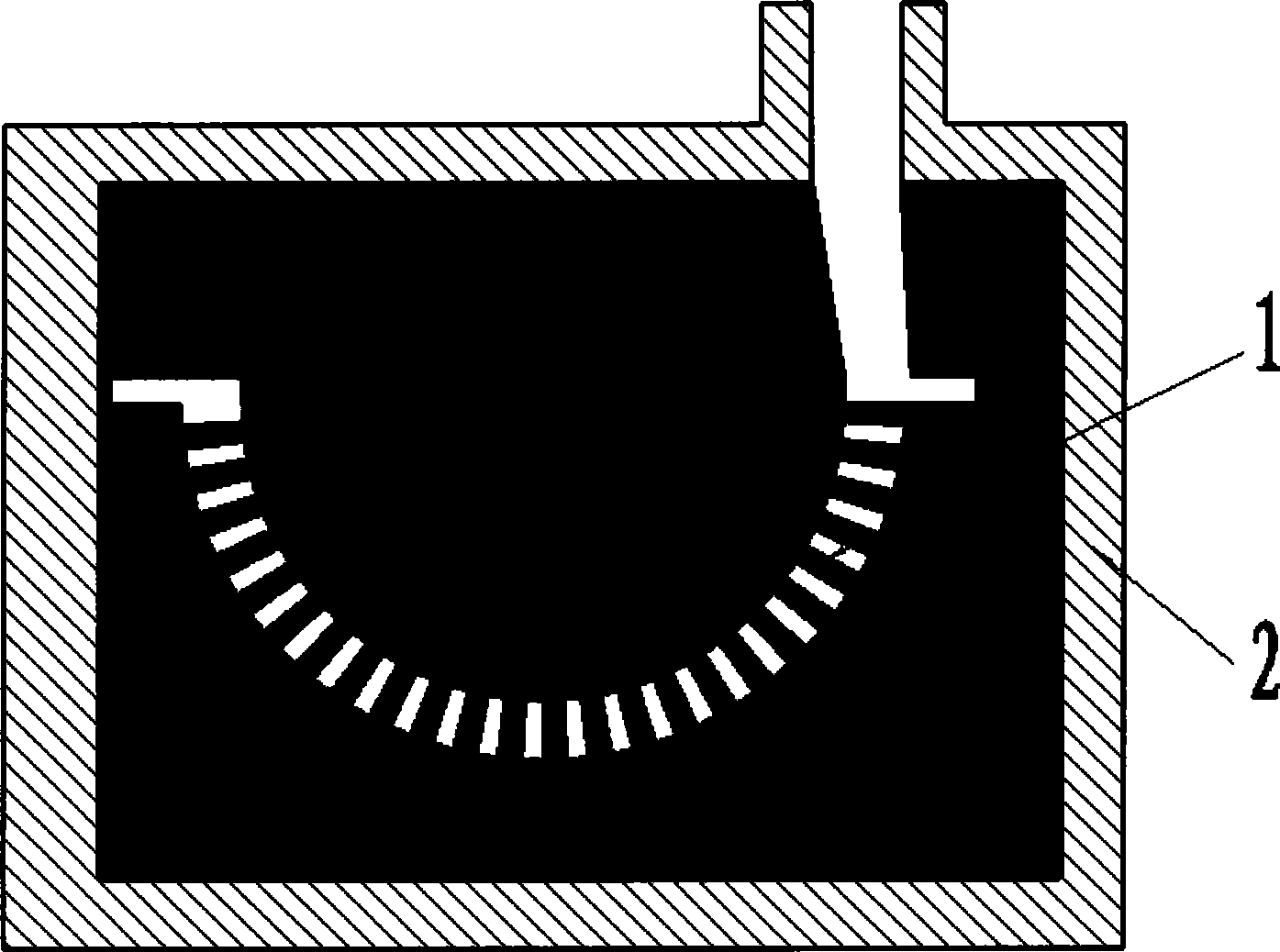

Chemical and physical combined explosion fracturing device and manufacturing method thereof

ActiveCN103352684ASolve the limited effect of fracturingSolution rangeFluid removalInterference fitHigh pressure

The invention relates to the fracturing technology, in particular to a chemical and physical combined explosion fracturing device and a manufacturing method of the chemical and physical combined explosion fracturing device. The chemical and physical combined explosion fracturing device and the manufacturing method of the chemical and physical combined explosion fracturing device resolve the problems at the existing fracturing technology is limited in fracturing effect, narrow in application range and poor in use safety. The chemical and physical combined explosion fracturing device comprises a fracturing device outer shell, wherein the front portion of an inner cavity of the fracturing device outer shell is in interference fit with a powder chamber outer barrel, an inner cavity of the powder chamber outer barrel is provided with a powder screening pipe in a sleeved mode, a first explosion film is arranged on an opening in the rear end of the powder screening pipe in a sealing mode, an inner cavity of the powder screening pipe is filled with a powder pillar which is connected with an ignition line, a pressing nut is arranged on an opening in the rear end of the fracturing device outer shell in a sealing mode, a through hole penetrating through the front portion and the rear portion is formed between the front end surface and the rear end surface of the pressing nut, a second fracturing film is arranged on the through hole in a sealing mode, and the rear portion of the inner cavity of the fracturing device outer shell is filled with high-pressure CO2 in a sealing mode. The chemical and physical combined explosion fracturing device and the manufacturing method of the chemical and physical combined explosion fracturing device are suitable for the development of petroleum, natural gas, coal bed gas, shale gas and the like, and suitable for a pre-fracturing and permeability-increasing process of extraction of coal bed gas under a coal mine shaft.

Owner:ZHONGBEI UNIV

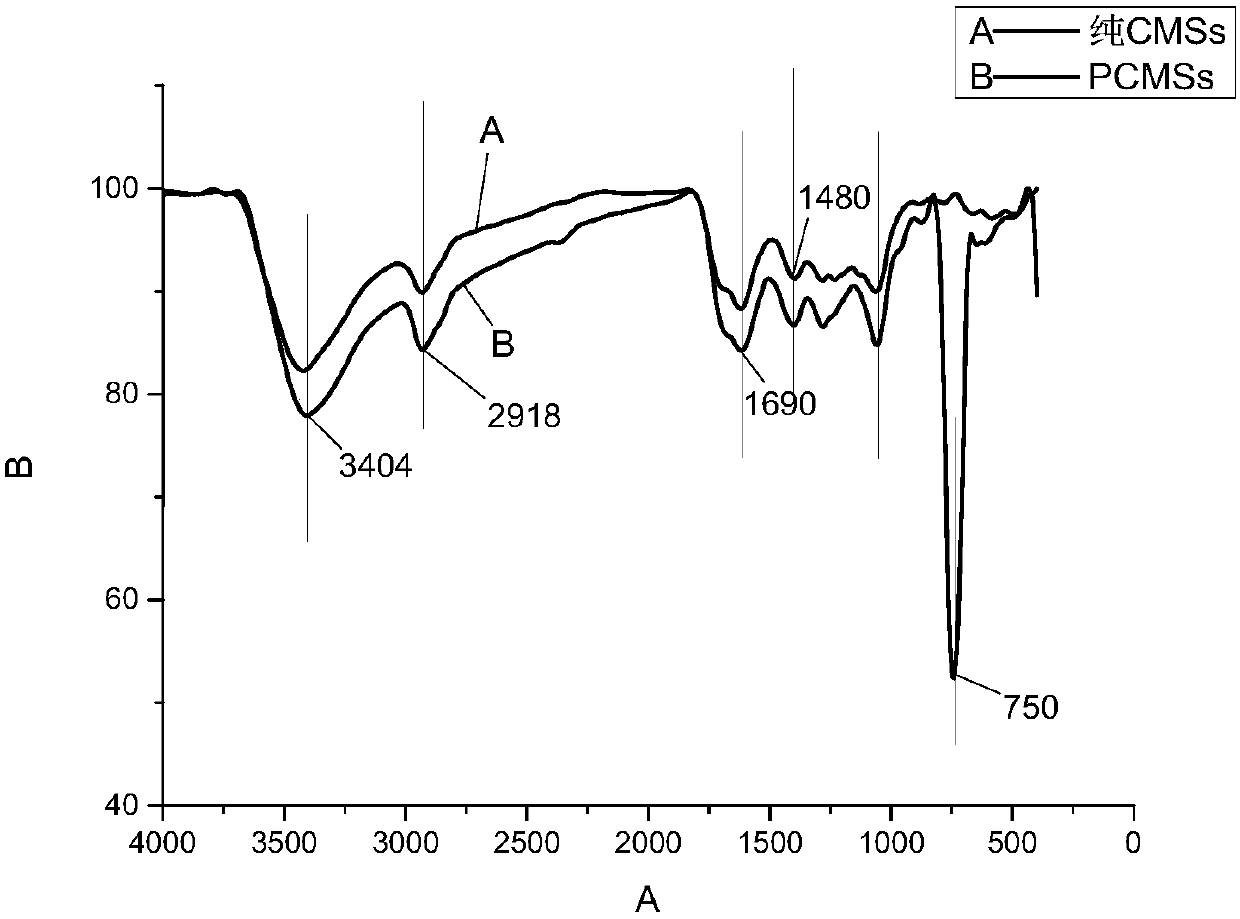

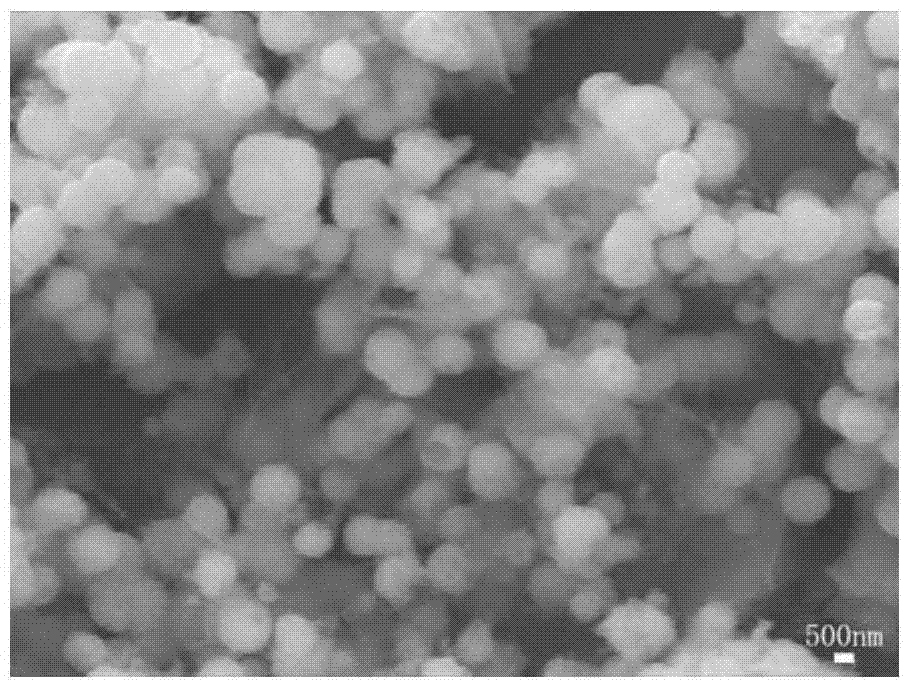

Flame-retardant PET (polyethylene terephthalate)/nanocarbon microsphere composite material and preparation method thereof

The invention relates to the field of flame-retardant polymer composite materials and preparation thereof, and in particular to a functionalized nanocarbon microsphere blending modified polyethylene terephthalate (PET) and a preparation method thereof. Nanocarbon microsphere flame retardant is first treated by low-temperature plasma, so that hydroxyl groups and carboxyl groups are generated on thesurface, phosphor-nitrogen flame retardant is grafted onto the surfaces of the nanocarbon microspheres, and the surface is then wrapped by a layer of PET by in-situ polymerization, so that a nanocarbon microsphere flame retardant which is highly compatible with the base material PET is prepared. PET and the prepared nanocarbon microsphere flame retardant are melted to be blended and molded by injection, and thereby the PET / functionalized nanocarbon microsphere composite material is prepared. The flame-retardant property of the PET / functionalized nanocarbon microsphere composite material prepared according to the invention is excellent, the heat resistance is increased, moreover, the tensile strength is also improved to a certain degree, and the defects of phosphor-nitrogen intumescent flame retardants, i.e. poor durability and poor compatibility between carbon microspheres and base material PET, are overcome.

Owner:JIANGSU YUXING FILM TECH +1

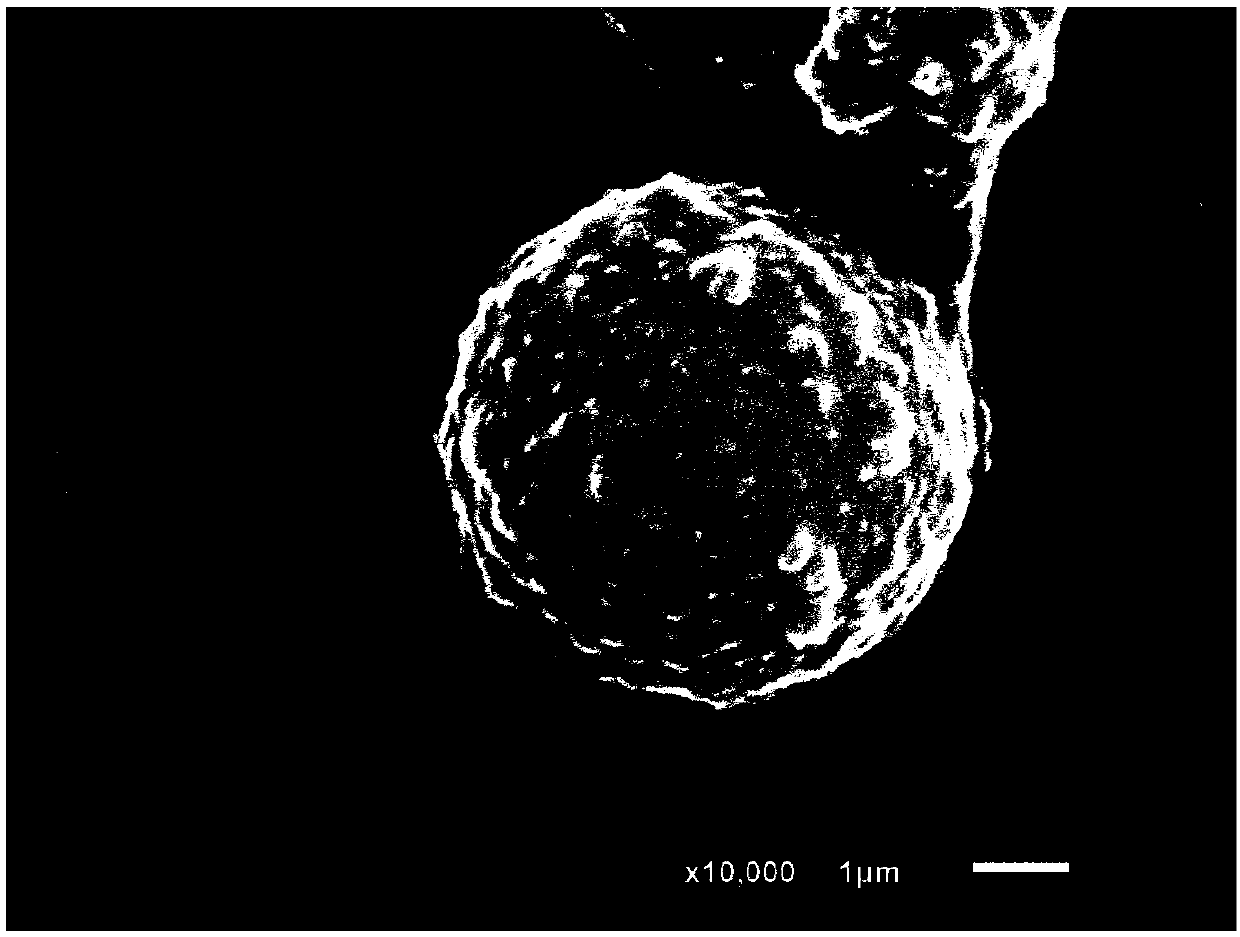

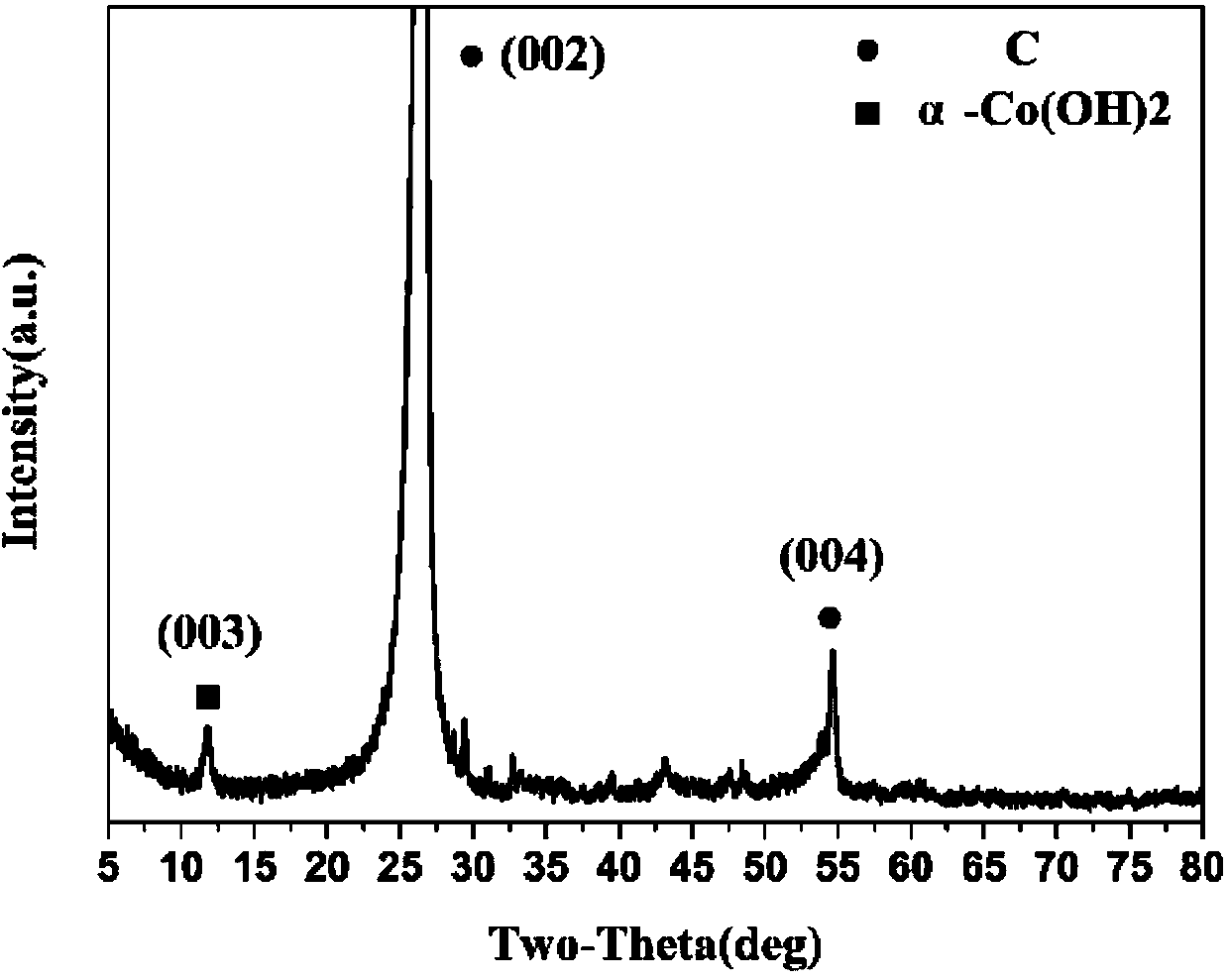

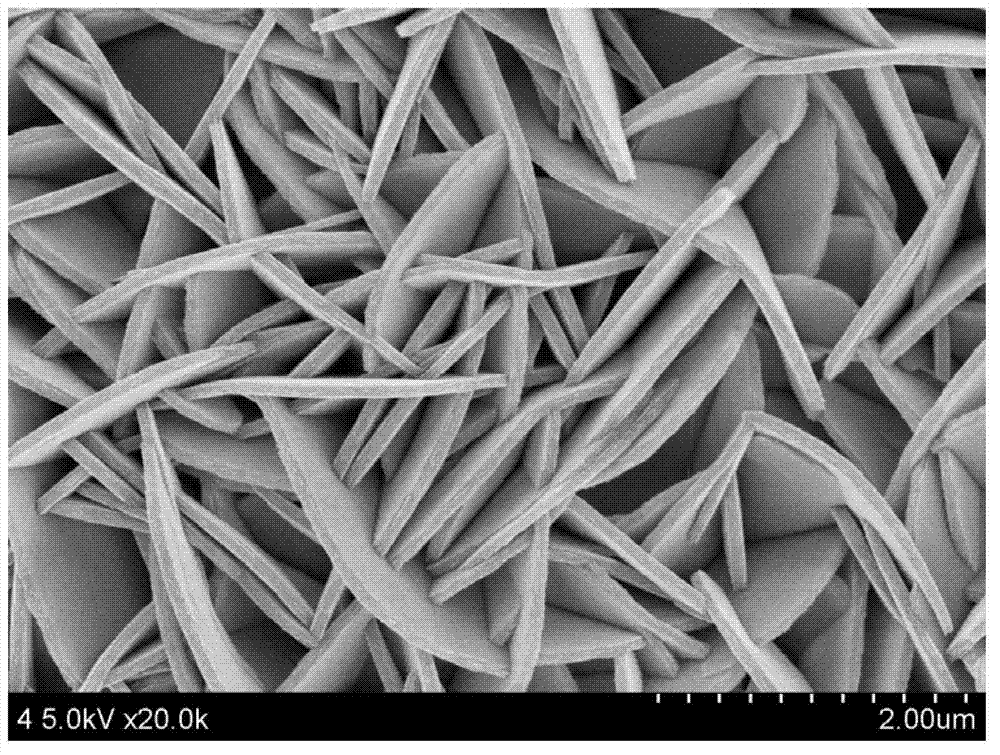

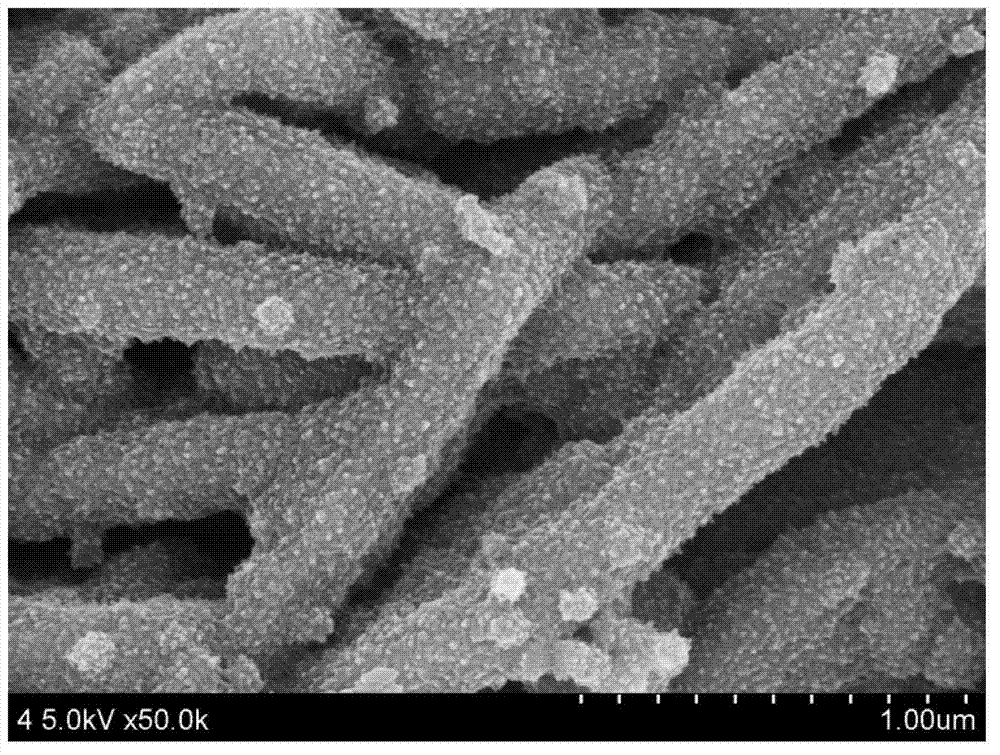

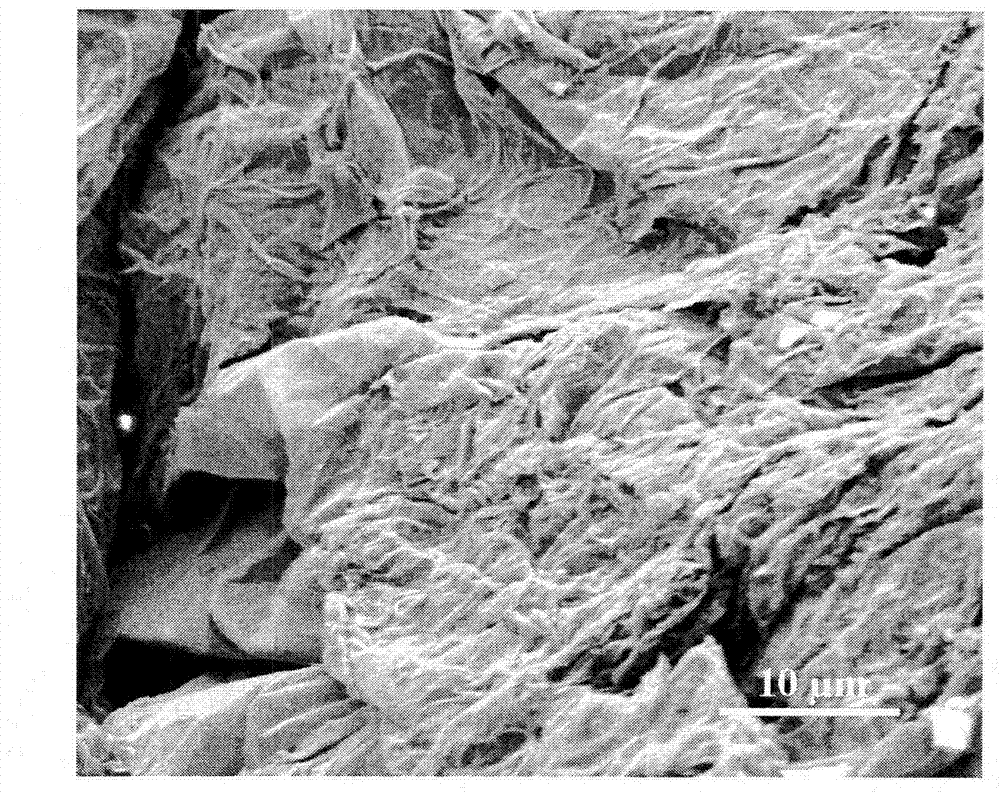

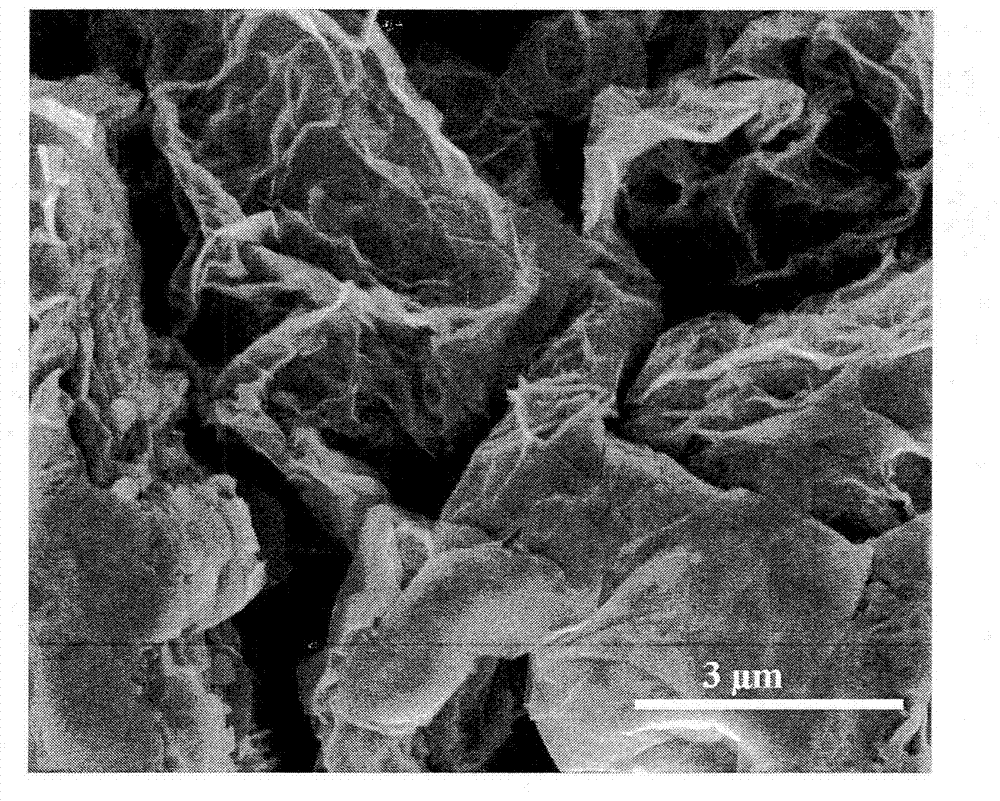

Preparation method for different carbon fibers / cobalt hydroxide electrode and solid-liquid composite electrode system

InactiveCN103426649ALower internal resistanceImprove cycle stabilityHybrid capacitor electrodesHybrid/EDL manufactureCapacitanceFiber

The invention relates to a preparation method for different carbon fibers / a cobalt hydroxide electrode and a solid-liquid composite electrode system. By means of pretreatment and modification of different carbon fibers, the carbon fibers serve as a substrate, composite of metal oxide or hydroxide and the carbon fibers are realized by the electrochemical deposition, and a solid electrode is obtained and has high specific capacitance in the alkaline aqueous solution. Redox substances are added into the alkaline aqueous solution, a composite electrode system that the solid electrode and liquid-phase electrolyte supply the pseudocapacitance jointly is obtained. The composite electrode system has ultra-high specific capacitance, is applied in supercapacitors, and has the advantages of ultra-high energy density, high power density and long service life. The specific capacitance of the composite electrode system can be adjusted by changing the concentration and volume of the redox substances, and the energy density and power density of the supercapacitors can be further changed to meet different using requirements.

Owner:JILIN UNIV

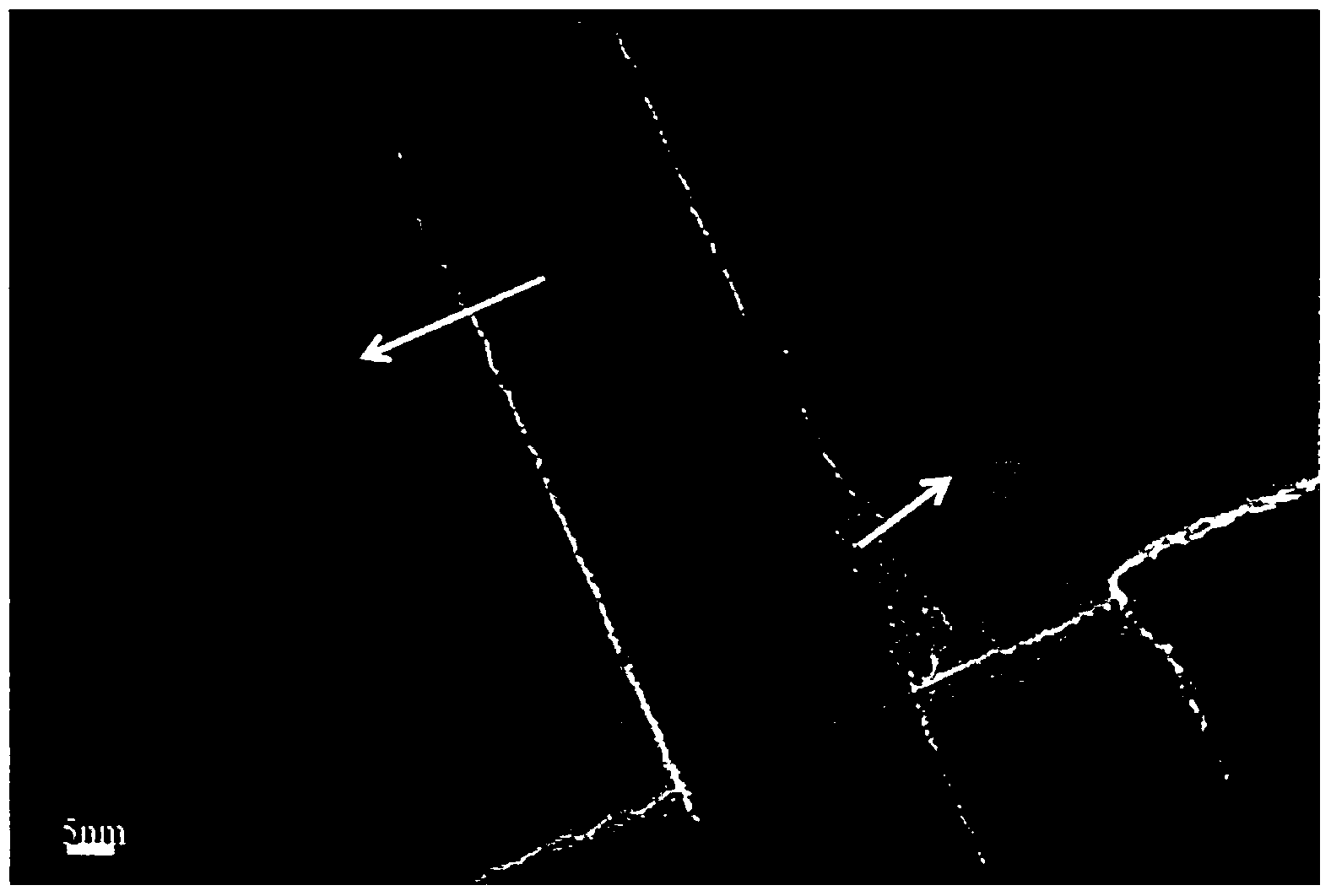

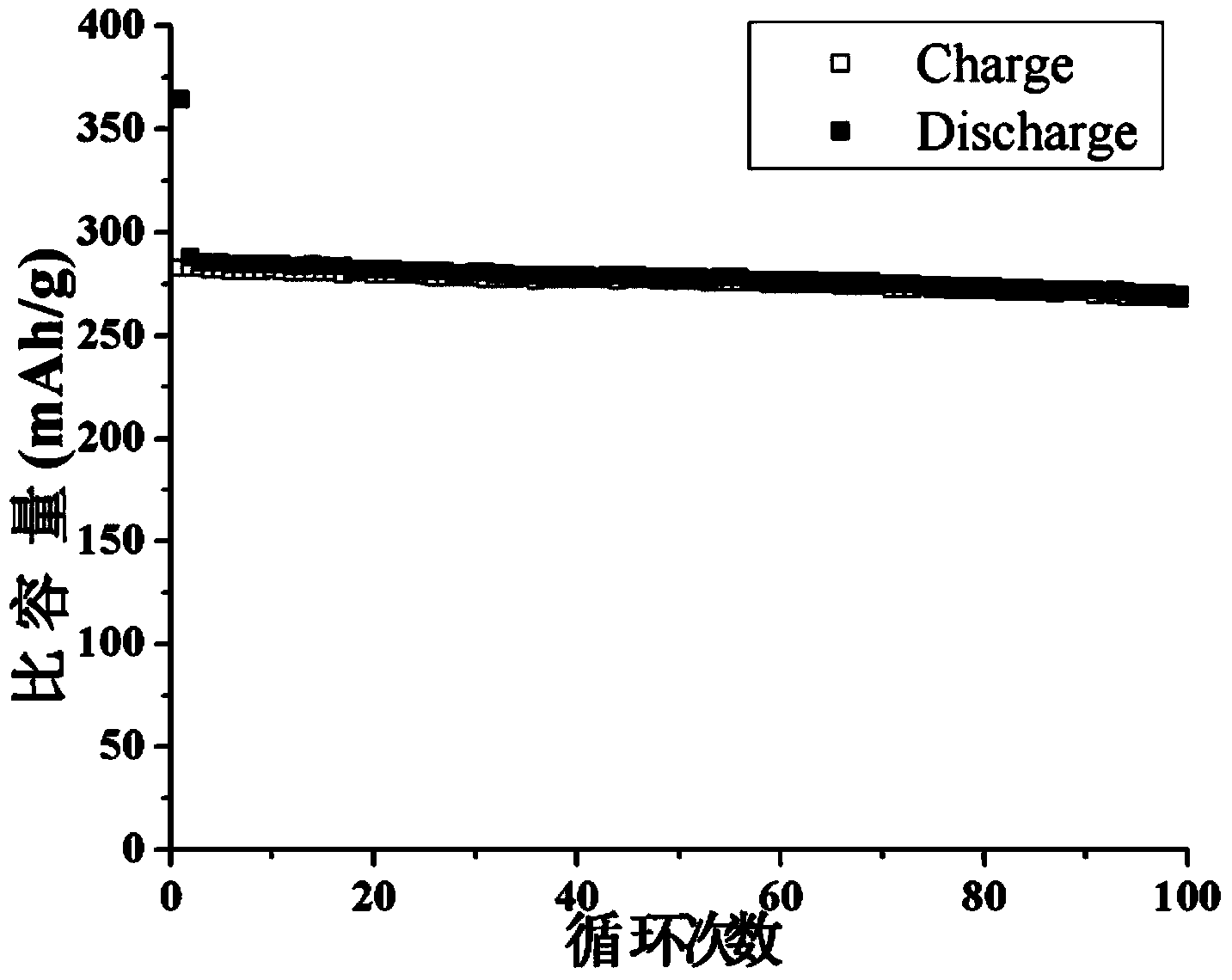

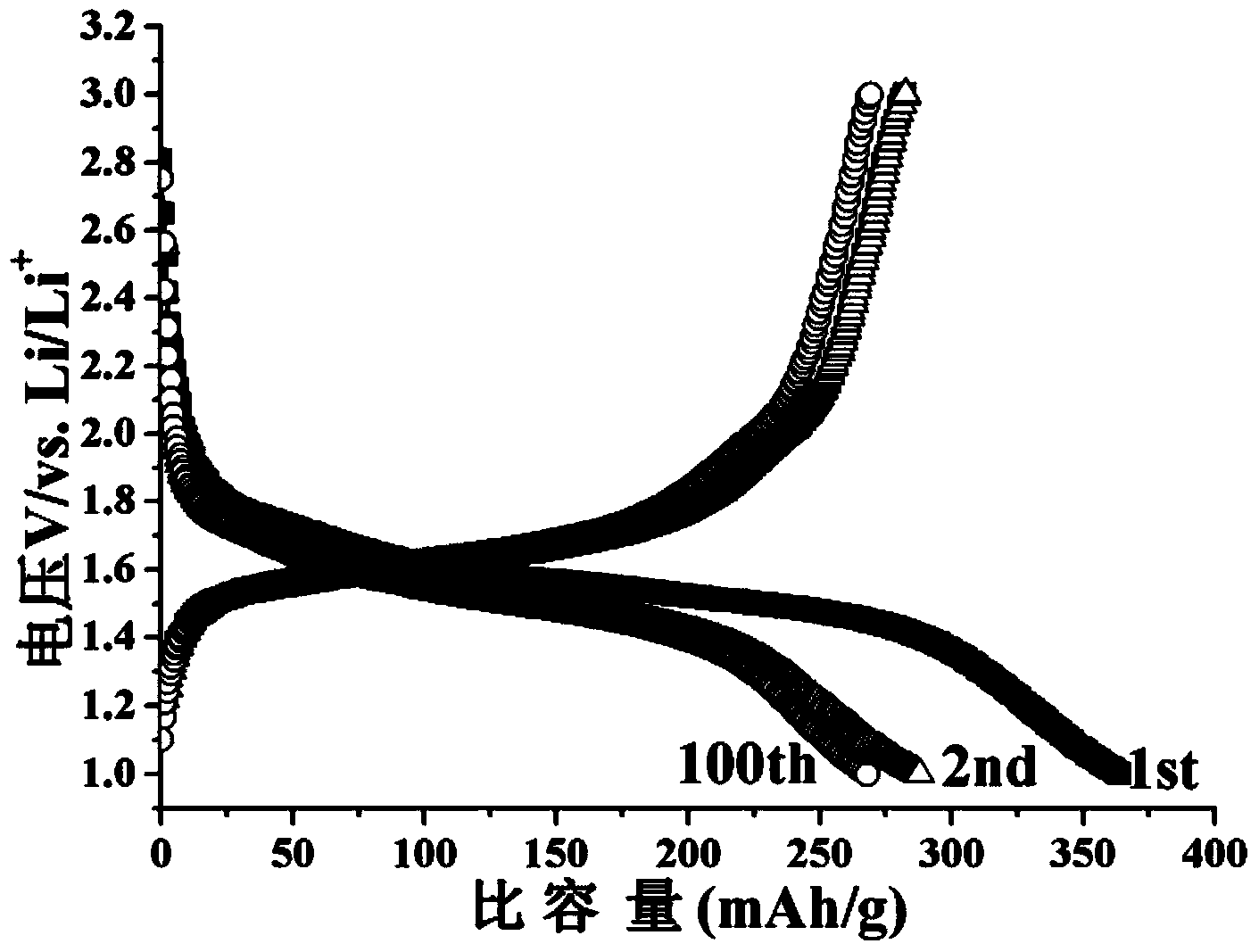

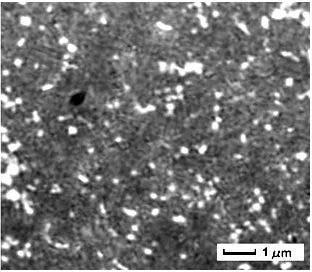

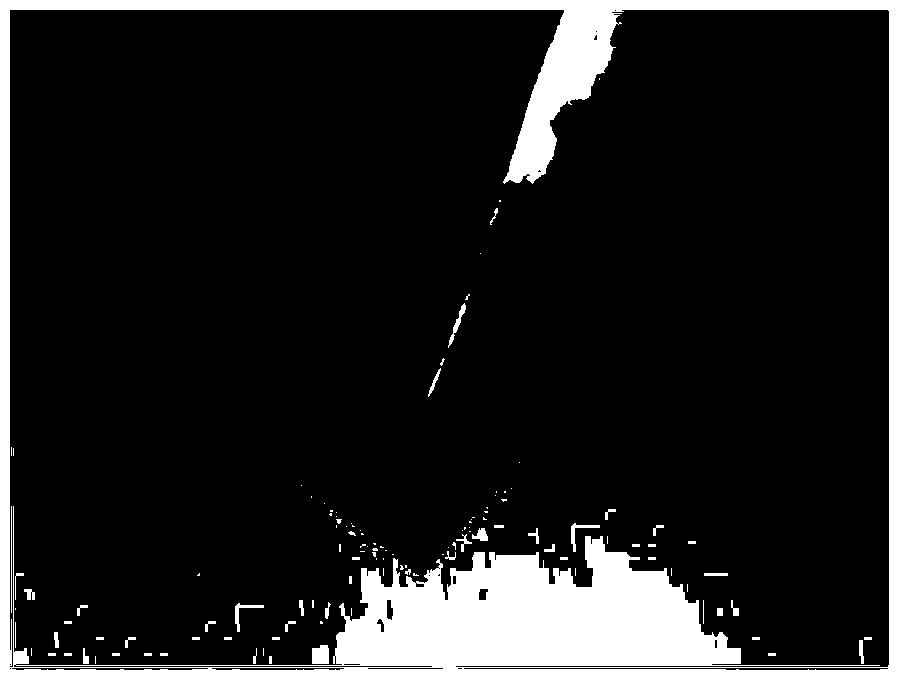

Preparation method and application of nano TiO2(B)/carbon composite fibers for lithium ion battery cathode

InactiveCN103456934AComponent structure controllableSimple processMaterial nanotechnologyCell electrodesCarbon compositesFiber

The invention relates to a preparation method and application of nano TiO2(B) / carbon composite fibers for a lithium ion battery cathode. The preparation method comprises the following steps: firstly, synthesizing tetrabutyl titanate / polyvinylpyrrolidone precursor fibers through electrostatic spinning; then, drying the precursor fibers, and carbonizing the precursor fibers at the temperature of 300-500 DEG C under the protection of nitrogen or argon; finally, carrying out hydro-thermal treatment on the carbonized product to obtain the nano TiO2(B) / carbon composite fibers. The preparation method disclosed by the invention is simple and convenient, the composition of titanium dioxide and carbon source is realized in one step, and the introduction of carbon source is not required in subsequent experiment, thus the purity of a product is ensured, the raw material is saved, and the production cost is low. The obtained nano TiO2(B) / carbon composite fibers for the lithium ion battery cathode material have good cycle performance, and can keep high capacity especially at quick charging and discharging rates, thus the cycle efficiency is high, the capacity is reduced slowly, the conductivity is improved because of the introduction of carbon, and the resistance is reduced.

Owner:EAST CHINA UNIV OF SCI & TECH

Iron-based composite material reinforced by in-situ titanium carbide grains and preparing method thereof

The invention discloses an iron-based composite material reinforced by in-situ titanium carbide grains and a preparing method thereof. The preparing method is characterized in that: high-strength high-toughness spheroidal graphite cast iron is used as a matrix, in-situ grown submicron titanium carbide grains are used as reinforcing grains, and the titanium carbide grains are uniformly distributedon the spheroidal graphite cast iron matrix to obtain a high-strength high-toughness iron-based composite material; and iron powder, titanium powder and carbon powder are fully mixed by utilizing a mechanical alloying method to form composite powder, spheroidal graphite cast iron is molten and treated by a conventional method, the composite powder is added to molten iron during secondary inoculation in proportion, constant temperature is kept for 5-10min and casting is carried out to obtain a cast-state composite material, and the cast-state composite material is subjected to isothermal quenching heat treatment to obtain the iron-based composite material. According to the iron-based composite material prepared by the method disclosed by the invention, the in-situ titanium carbide grains are small in size and uniformly distributed on the matrix so as to ensure the characteristics of high strength and high toughness of the iron-based composite material.

Owner:JIANGSU TANGCHEN AUTOMOBILE PARTS

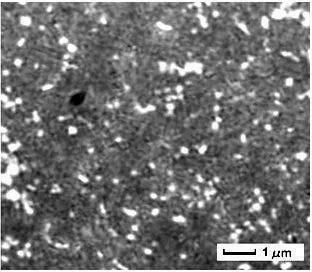

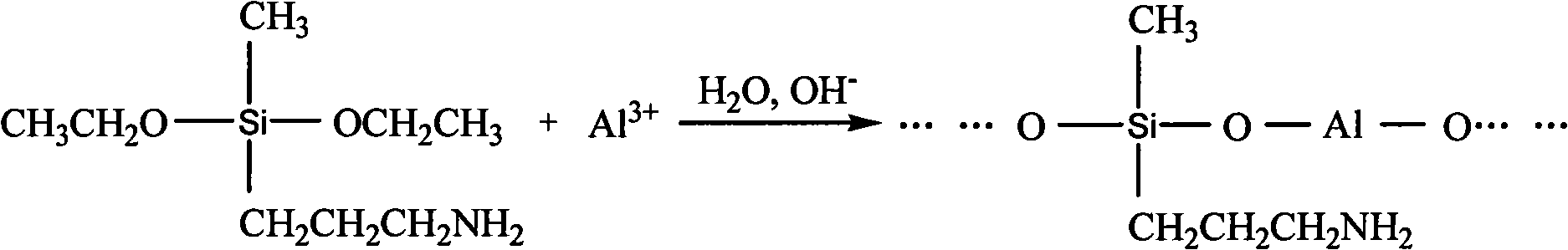

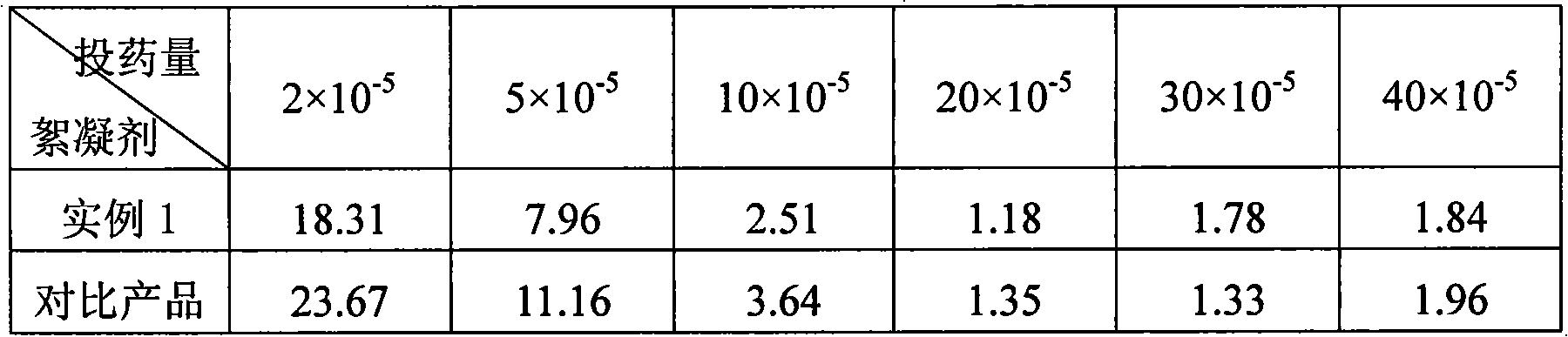

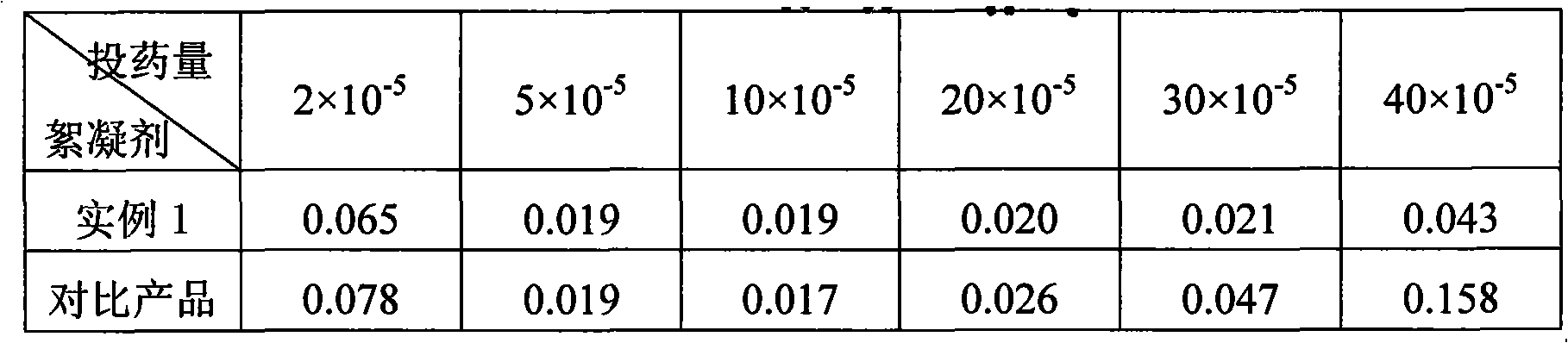

Covalent bond type inorganic organic composite flocculant, preparation process and use thereof

ActiveCN101298347AAchieve compositeGood decolorization effectWater/sewage treatment by flocculation/precipitationSimple Organic CompoundsAluminium chloride

The invention relates to a covalent bond type inorganic / organic compound flocculant, a production technique and an application thereof. The invention adopts Gamma-APDES (gamma-Aminopropylmethyldiethoxysilane) and aluminum chloride solution as the raw materials to produce the covalent bond type inorganic / organic compound flocculant by gradually dripping alkaline. The a covalent bond type inorganic / organic compound flocculant, the production technique and the application thereof have the advantages that the inorganic constituent and the organic constituent in the flocculant are bonded by covalent bond, which has good stability, good turbidity removal and decoloration effect and wider optimal dosing range. The covalent bond type inorganic / organic compound flocculant can be used for the water purification and the turbidity removal, decoloration, deoiling and solid-liquid separation during the wastewater treatment.

Owner:PEKING UNIV

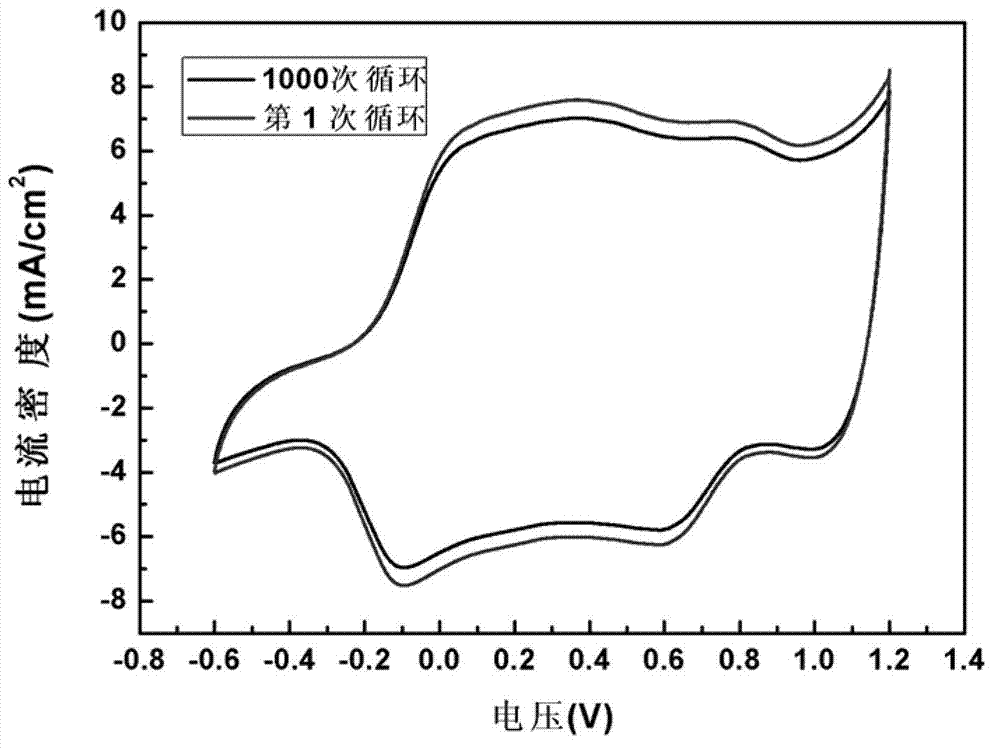

Preparation method of nickel oxide/polyaniline composite electrochromic film

The invention relates to a preparation method of a nickel oxide / polyaniline composite electrochromic film. The preparation method comprises the following steps of: soaking FTO (Fluorine-doped Tin Oxide) conductive glass into a mixed solution, keeping the temperature of 160-180 DEG C for 6-12hours, naturally cooling to the room temperature, cleaning and calcining to obtain FTO conductive glass with a NiO layer, wherein the mixed solution is prepared from nickel acetate tetrahydrate, potassium persulfate, ammonia water and water; and dissolving an aniline monomer into a sulfuric acid solution to obtain a deposition liquid, then, soaking the FTO conductive glass with the NiO layer into the deposition liquid to be used as a working electrode, and carrying out electrolytic deposition on the electrode by using a platinum sheet to obtain the nickel oxide / polyaniline composite electrochromic film. By the preparation method, organic and inorganic electrochromic materials are compounded on the micro-nano level; and the prepared film has favorable electrochromic performance and a wide application prospect in the fields such as intelligent windows and large screen display.

Owner:DONGHUA UNIV

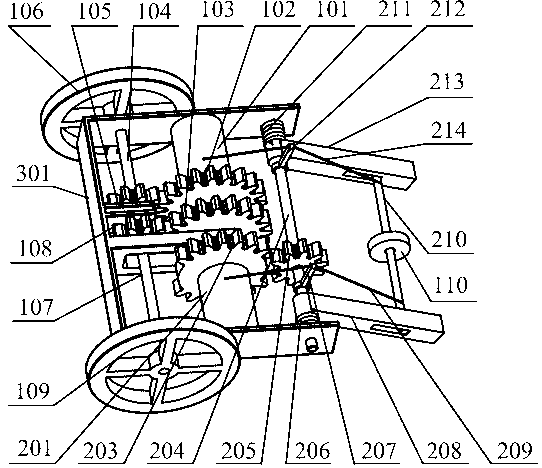

Hopping robot with wheel movement function

The invention discloses a hopping robot with a wheel movement function. The hopping robot with the wheel movement function comprises a robot body which is horizontally arranged, a wheel movement mechanism and a hopping mechanism, wherein the wheel movement mechanism is mounted in the robot body, and the hopping mechanism is mounted at an opening end of the robot body. A design of a front-back symmetric structure is used, and thus the fact that after the robot is landed, no matter the front face or the back face touches the ground, the robot can hop again is benefited, and the influence of landing turning to secondary hop is reduced; through the arc-shaped through hole structure design of protrusions with arc-shaped supporting holes arranged on the horizontal edges of the robot body, synchronous movement and asynchronous movement of two rolling wheels under the drive of a single electric motor are achieved; and by using wheel-type movement and the hopping function, the robot has multiple kinds of movement modes, by using the structure that a teeth-missing gear is meshed with a gear, instant unconstrained release of an energy storage component is achieved, and thus improvement of the hopping performance of the energy storage component is benefited. The hopping robot with the wheel movement function is taken as a moving carrier of an airborne instrument, after an airborne sensor is added to the hopping robot with the wheel movement function, the hopping robot with the wheel movement function can be used in the fields of environmental monitoring, urban counterterrorism, military reconnaissance, earthquake relief, science adventure and the like.

Owner:ZHEJIANG UNIV

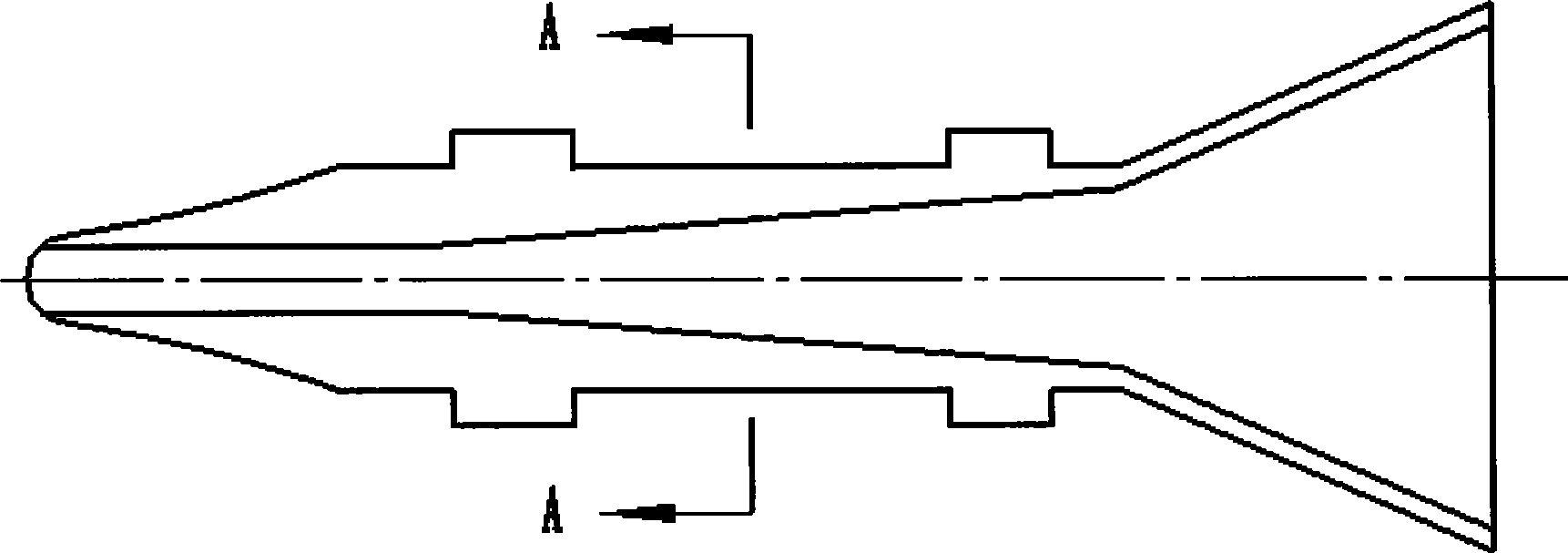

Method for preparing composite wear-resistant foreplate

InactiveCN101412095AInhibited DiffusionReduce the temperatureGuiding/positioning/aligning arrangementsWear resistantHardness

The invention discloses a method for preparing a composite antiwear guide plate, which comprises the following steps: alloy dust core bars are bound into bundles and arranged in a guide plate casting mould cavity, and the volume of the alloy dust core bars accounts for 20 to 60 percent of the total volume of the guide plate; molten matrix metal is cast into the guide plate casting mould cavity, the alloy dust core bars are melted and dissolved under the heat effect of the matrix metal, a great number of alloy elements and the molten matrix metal generate metallurgical combination reaction so as to generate a highly dispersed alloy structure on the original position; and finally the alloy structure is cooled and solidified, and the bar-shaped hard phase is metallurgically and transitionally combined into a whole with the matrix metal, thereby preparing the composite guide plate which takes the high-strength and high-ductility metal as the matrix and contains a certain number of metallurgically combined bar-shaped hard points. The composite anti-wear guide plate has high strength and high ductility of the matrix metal and high hardness and high wear resistance of the hard phase, can simultaneously bear high pressure and strong wear, and has the characteristics of long service life, low price, simple preparation and so on.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

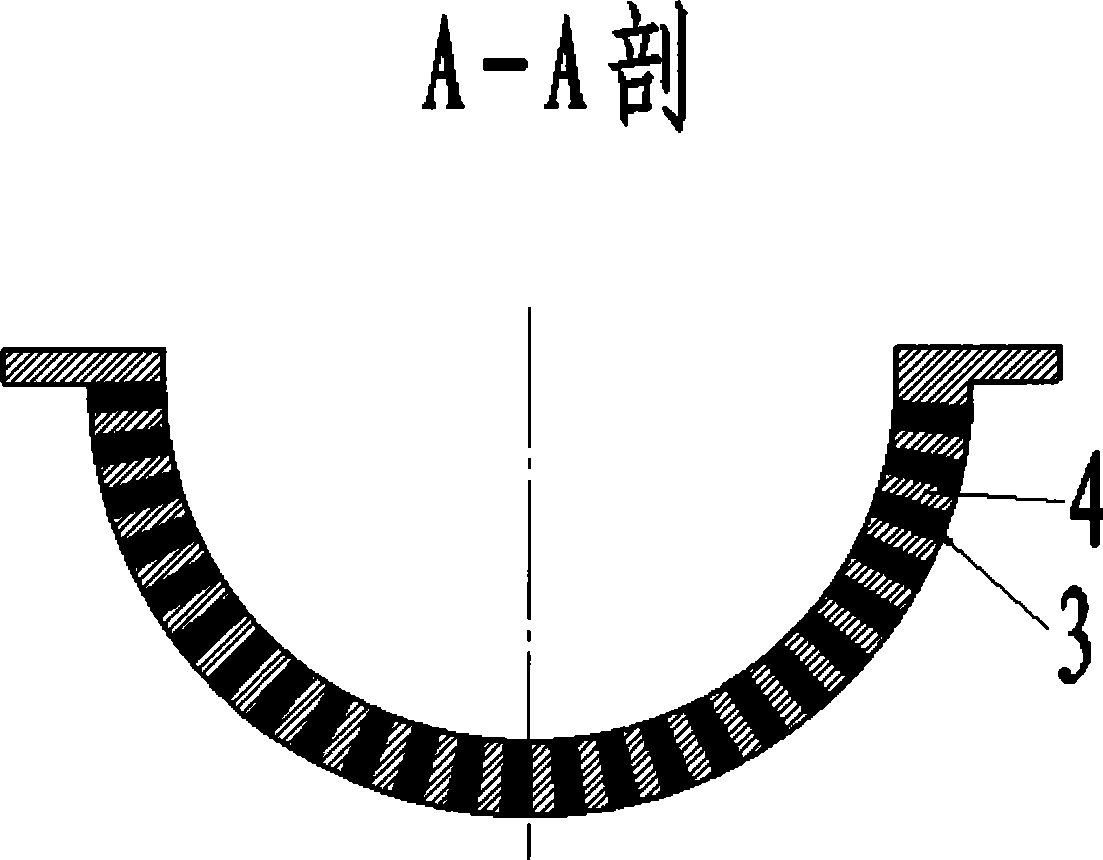

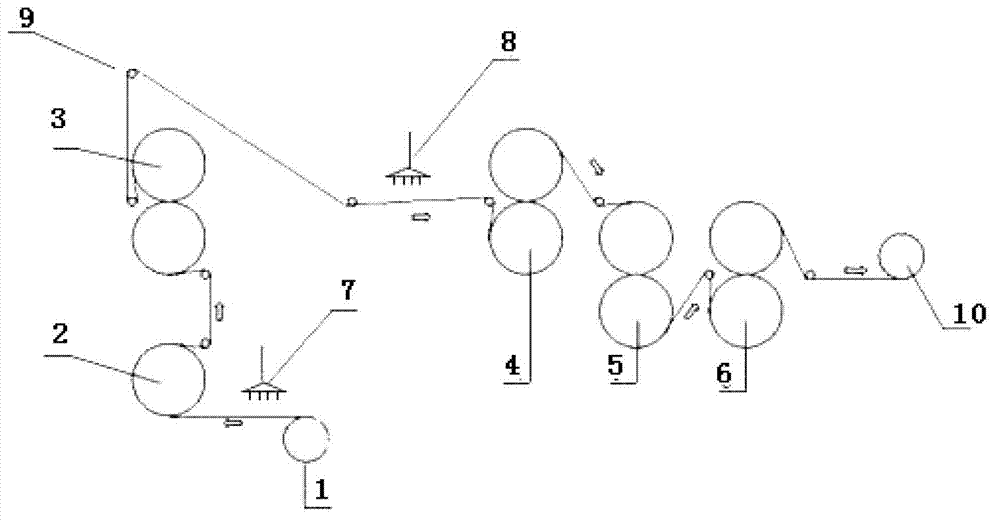

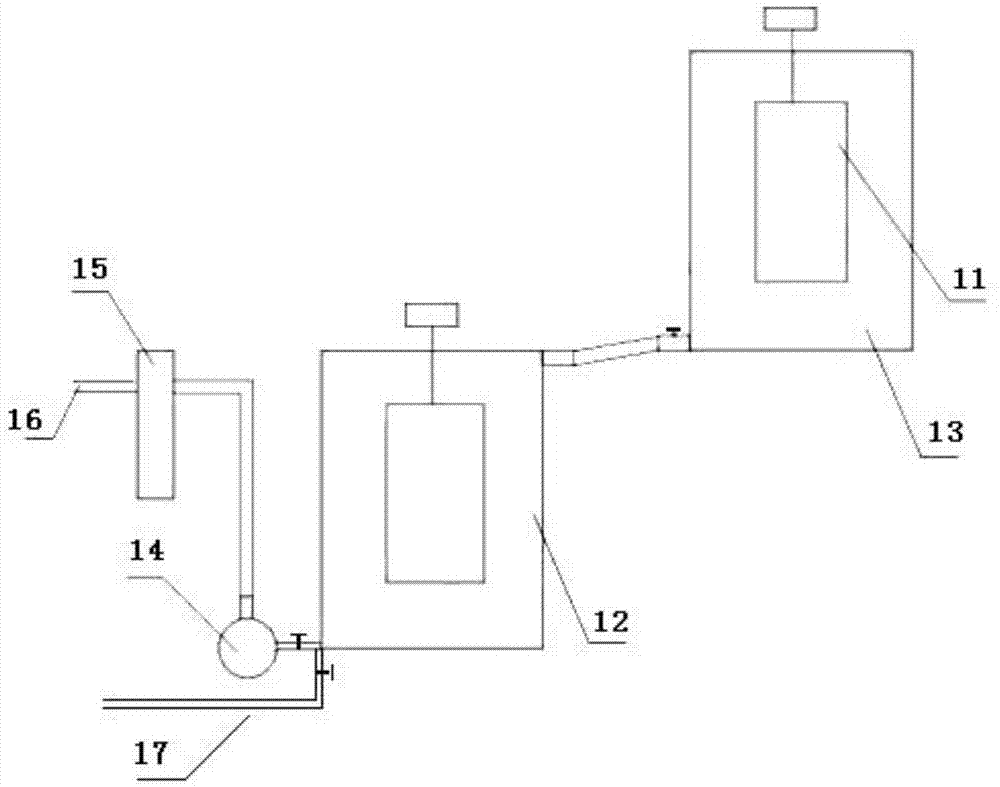

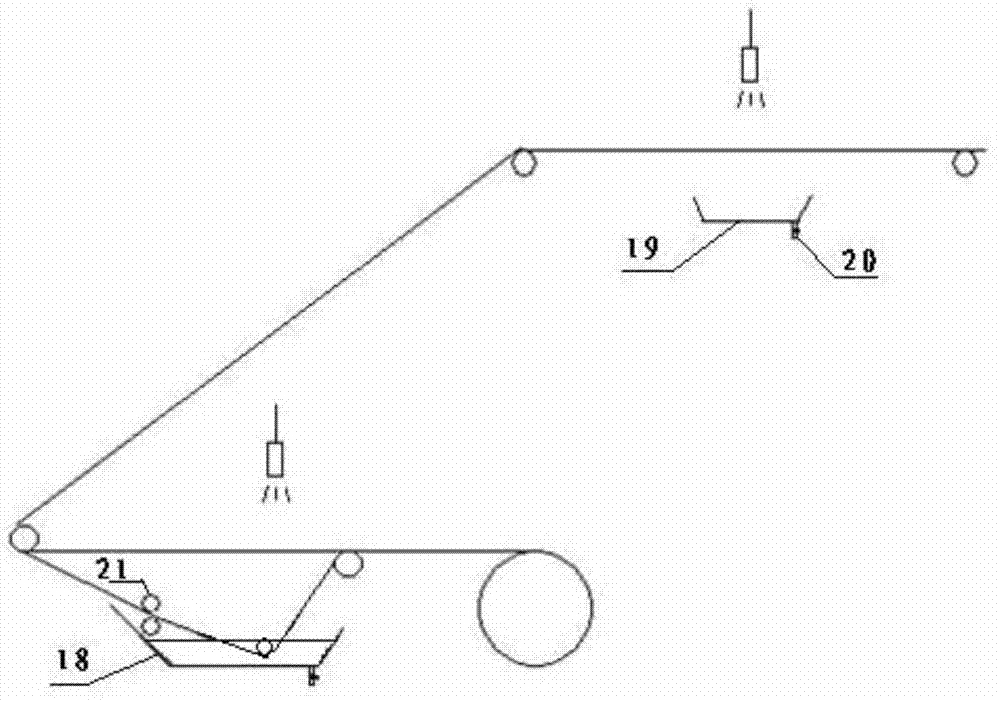

In-situ polymerization composite surface sizing system and surface sizing craft for needle punching non-woven fabrics

ActiveCN103111404AMeet quality requirementsReduce viscosityFibre treatmentPretreated surfacesIn situ polymerizationSynthetic Polymeric Macromolecules

The invention discloses an in-situ polymerization composite surface sizing system and a surface sizing craft for needle punching non-woven fabrics, namely a chemical process that organic monomers are polymerized to form high polymer materials and a flame planting composite process that non-woven fabrics are soaked by the organic monomers are combined in the same production line in a situ mode. The surface sizing system comprises a glue producing device, a glue seeping / flame planting sizing device and a drying device. The surface sizing craft achieved through the surface sizing system comprises the steps of (1) adding an emulsifying agent, a buffer agent and some water inside a burdening pot, stirring, evenly mixing the emulsifying agent, the buffer agent and the water, adding butyl mehtacrylate and methyl metacrylate, stirring, adding an initiating agent, stirring for an hour in a temperature range of 60 to 70 DEG C to form prepolymer, adding remaining water, stirring, evenly mixing the remaining water and the prepolymer, obtaining water miscible liquid, cooling the water miscible liquid to room temperature, introducing the water miscible liquid to a mixing pot, adding a polysaccharide compound into the mixing pot, mixing the polysaccharide compound with the water miscible liquid in a continuously stirred mode, forming suspension liquid; (2) treating the needle punching non-woven fabrics in a sizing mode through the glue seeping / flame planting sizing device; and (3) drying the needle punching non-woven fabrics and finalizing the design.

Owner:SHANDONG UNIV

Preparation method of thin layer graphene polymer composite material

ActiveCN102779649ASimple processLow costElectrolytic capacitorsCell electrodesBatch productionLithium electrode

The invention discloses a preparation method of a thin layer graphene polymer composite material. The method includes enabling a graphite intercalation compound and / or thin layer graphene with a catalyst adsorbed on the surface and at least one polymer monomer to form a mixed reaction system and conducting catalytic polymerization reaction under the set condition to obtain the thin layer graphene polymer composite material. An intercalation agent in the graphite intercalation compound and the catalyst are at least selected from any one of inorganic acid, organic acid, halogen, metal salt and metal oxide. The preparation method is simple in process, easy to implement, safe, environment-friendly, low in cost and suitable for industrial batch production. Further, the obtained composite material can be applied to lithium ion battery electrode materials or super capacitor electrode materials.

Owner:苏州格瑞丰纳米科技有限公司

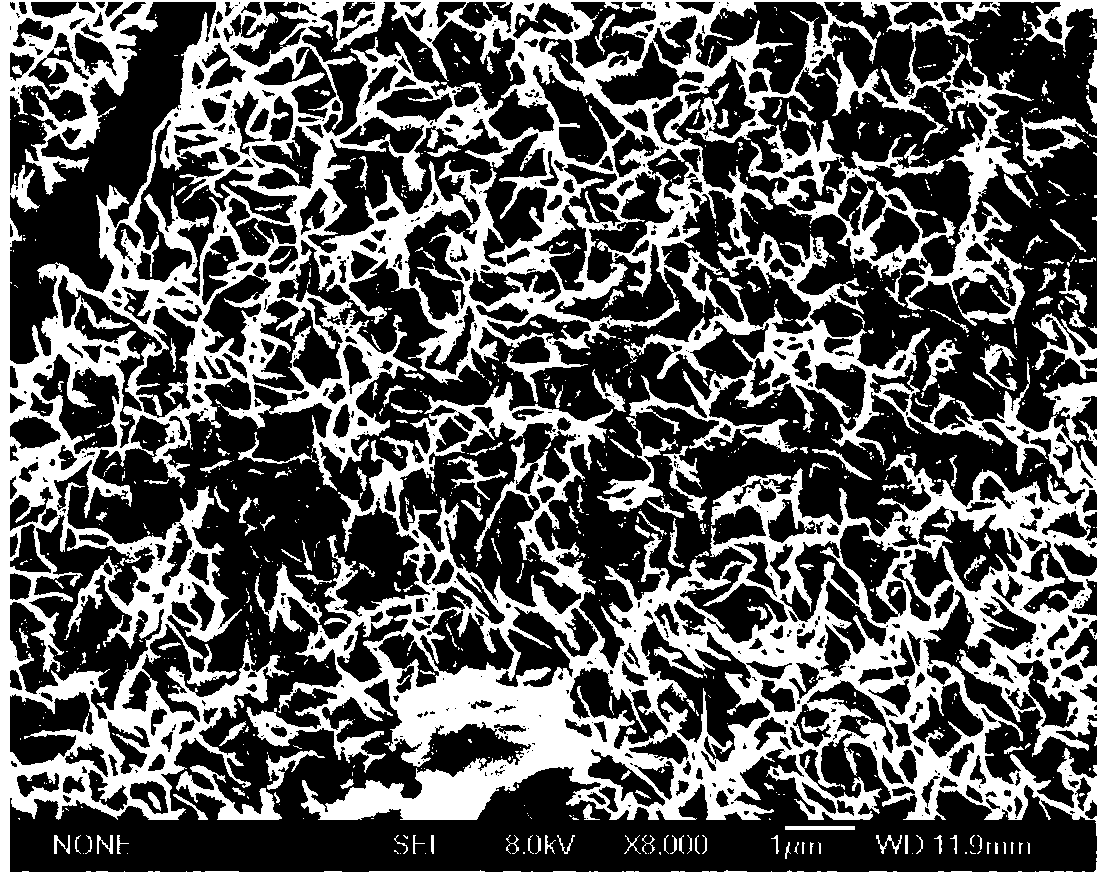

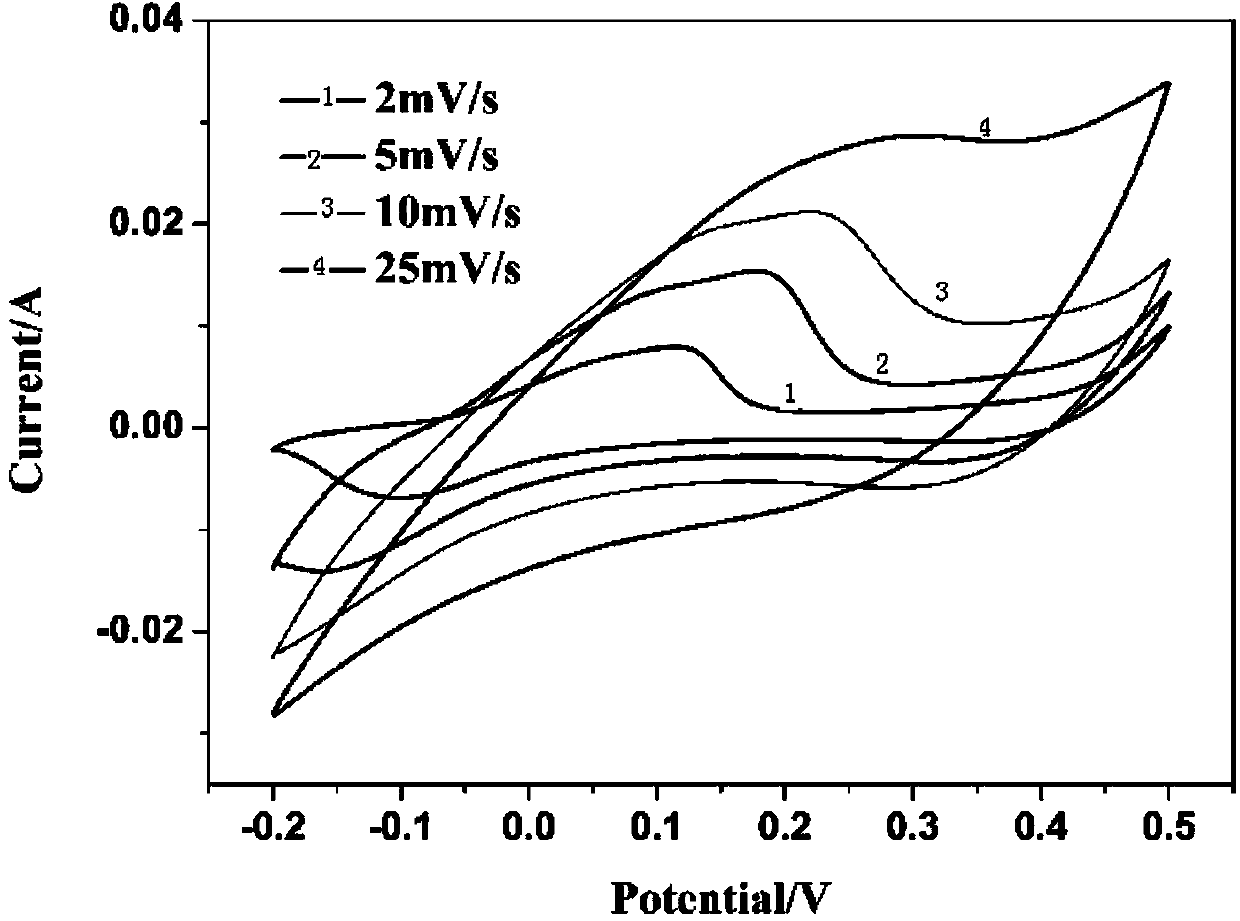

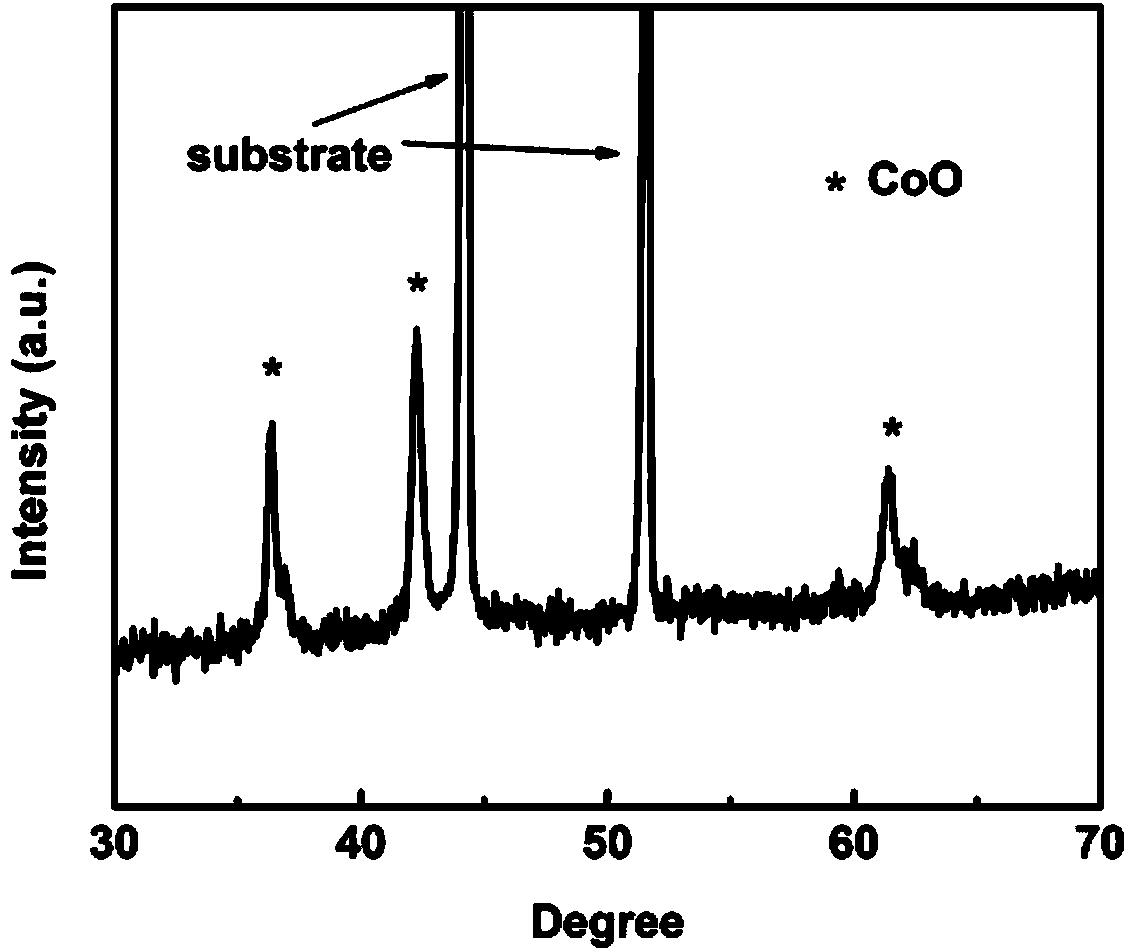

Production method and application of cobaltous oxide/carbon nanostructure array

InactiveCN103632856AEasy to makeLow costMaterial nanotechnologyHybrid capacitor electrodesCapacitanceCarbon layer

The invention belongs to the technical field of production of composite capacitive materials of super capacitors, and particularly discloses a production method and application of a cobaltous oxide / carbon nanostructure array. The production method includes taking a nickel net as a substrate on the hydrothermal condition of 95 DEG C to obtain a precursor of a cobaltous oxide nano linear array; when obtaining the cobaltous oxide array through annealing, generating a graphite carbon layer with good crystallinity on the surface of cobaltous oxide by the chemical vapor deposition technology; ensuring the corresponding flow rate of the carbon source gas and nitrogen in reaction to be 6 : 80 and controlling corresponding ventilation time to obtain cobaltous oxide / carbon array materials most applicable to the supper capacitors. Carbon obtained by the method is good in crystallinity and high in electricity conductivity; after the carbon is composited with the cobaltous oxide, obtained electrode materials are good in power density and energy density performance, the specific capacity of the electrode materials can reach 3282.2F / g, 96.9% of the specific capacity is still kept after 10000-times circulation, so that the production method has good application prospect.

Owner:HUAZHONG NORMAL UNIV +1

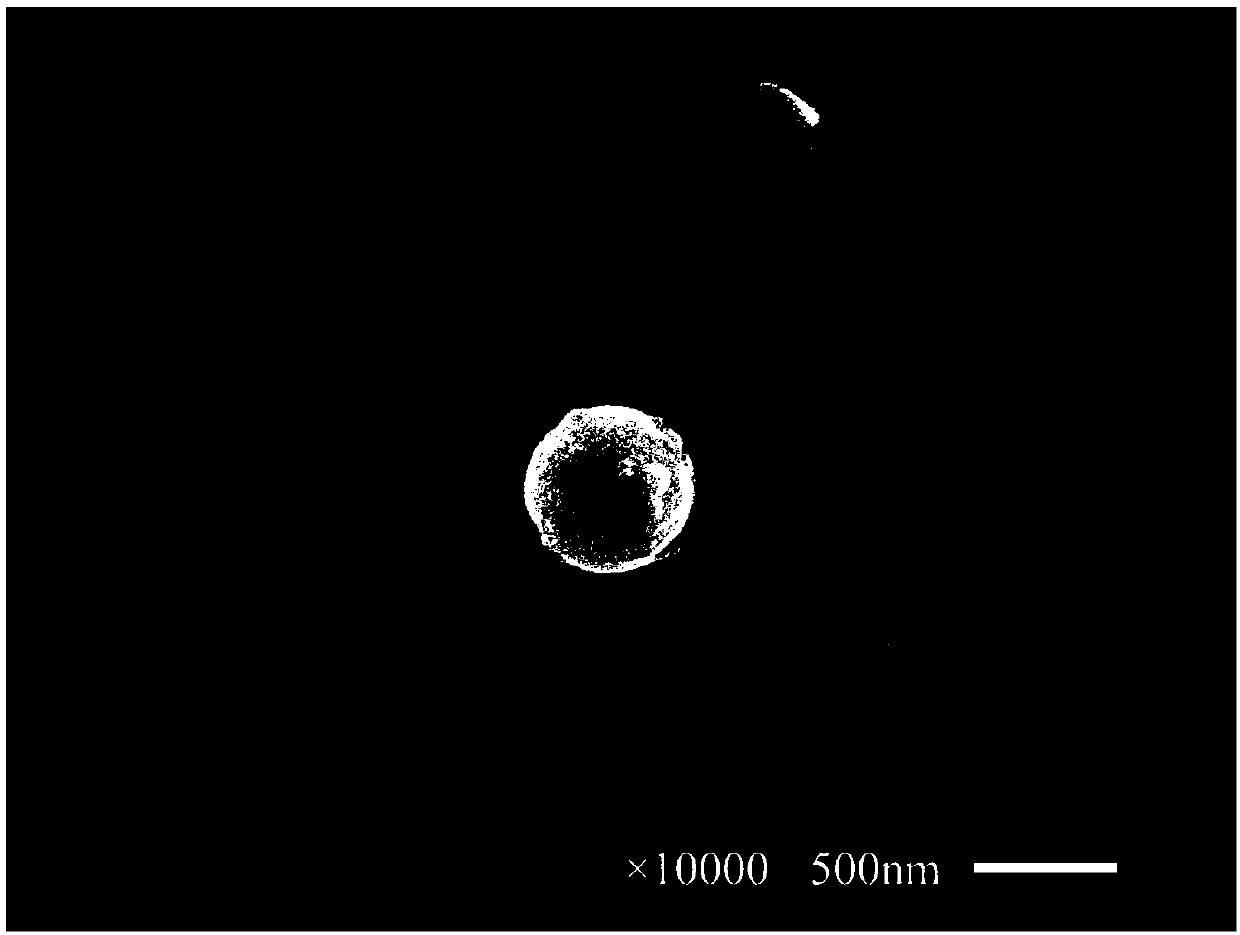

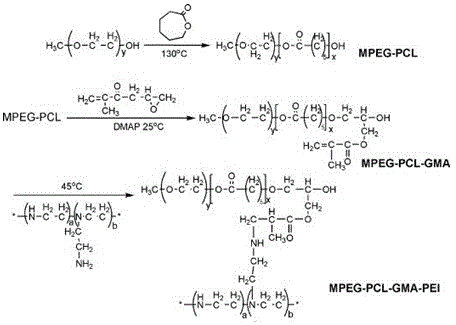

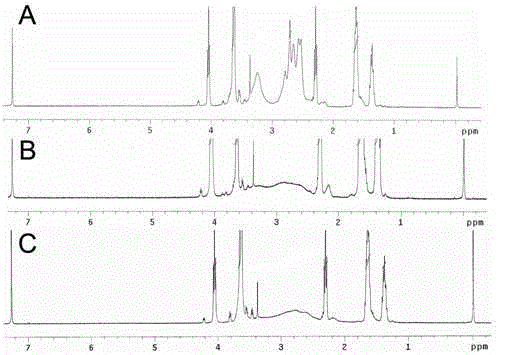

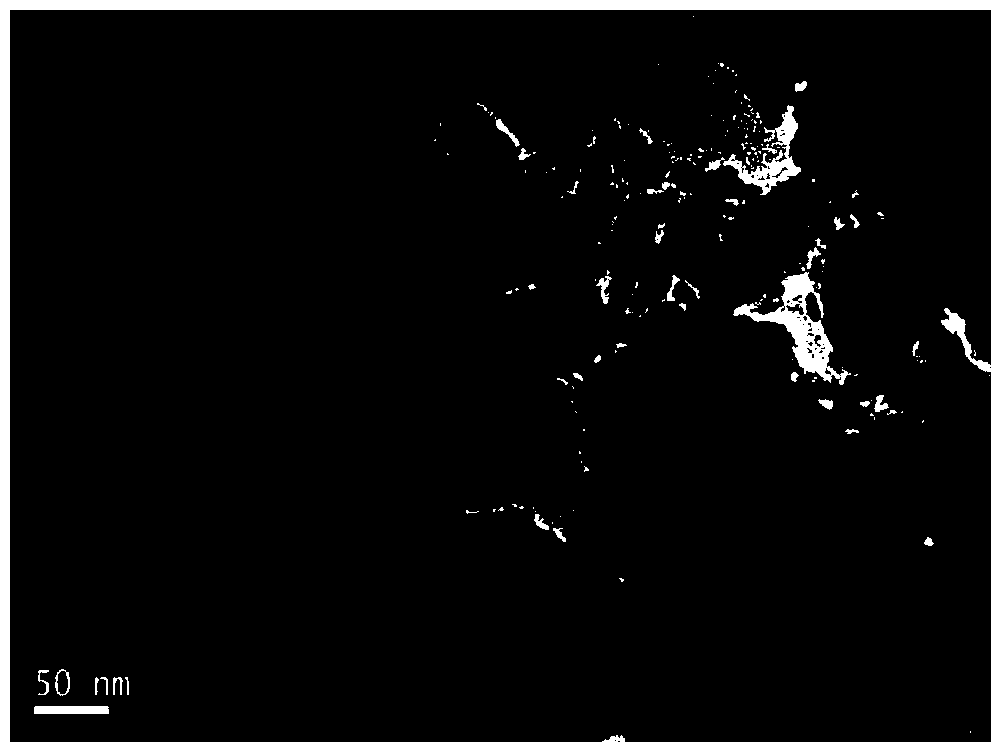

Cationic polymer-loaded paclitaxel/indocyanine green co-delivery micelle and preparation method thereof

InactiveCN105194670AAchieve compositeOrganic active ingredientsEnergy modified materialsCationic polymerizationSurface charges

The invention provides a cationic polymer-loaded paclitaxel / indocyanine green (ICG) co-delivery micelle and a preparation method thereof. To simultaneously load the chemotherapeutic paclitaxel and the photosensitizer ICG, an amphiphilic degradable cationic nano-micelle MPEG-PCL-PEI is used as a loading medium for the chemotherapeutic paclitaxel; a cationic polymer block is introduced into a polymer MPEG-PCL which forms the nano-micelle, so surface charges of the micelle can be changed; negatively-charged ICG molecules are adsorbed through interaction between positive and negative charges, and sustained release of paclitaxel and ICG is realized; so a novel method is provided for integrated diagnosis and treatment of tumors. According to the invention, the triblock cationic polymer synthesized from an amphiphilic polymer-grafted cationic fragment can simultaneously load the chemotherapeutic paclitaxel and the photosensitizer ICG approved by FDA, so compounding of the chemotherapeutic and fluorescence molecules is realized, and fluorescent imaging of a tumor site as well as target drug delivery for a tumor is complished.

Owner:WENZHOU MEDICAL UNIV

Flexible heat-preserving tapestry brick and preparation method thereof

ActiveCN103113057AAchieve compositeImprove mechanical propertiesSolid waste managementFiberCross-link

The invention discloses a flexible heat-preserving tapestry brick and a preparation method of the flexible heat-preserving tapestry brick. The raw material of the brick is sizing agent or dry power formed by evenly mixing mud powder, a hollow filler, crylic acid monomers, a cross-linking agent, reinforced fibers, a solvent, an initiator and a fire retardant according to a certain proportion. The preparation method comprises the following steps of: forming in a mould in a heating way, drawing, drying, trimming and the like to obtain the flexible tapestry brick with the functions of heat preservation and flame retardance. The flexible heat-preserving tapestry brick has the characteristics of being flexible, heat-preserving, water-resistant, fire-resistant, anti-stain, anti-aging, scrubbing-resistant, low in specific gravity, simple in production process, low in cost and the like, thereby being widely applicable to the decoration indoors and outdoors.

Owner:南通南京大学材料工程技术研究院

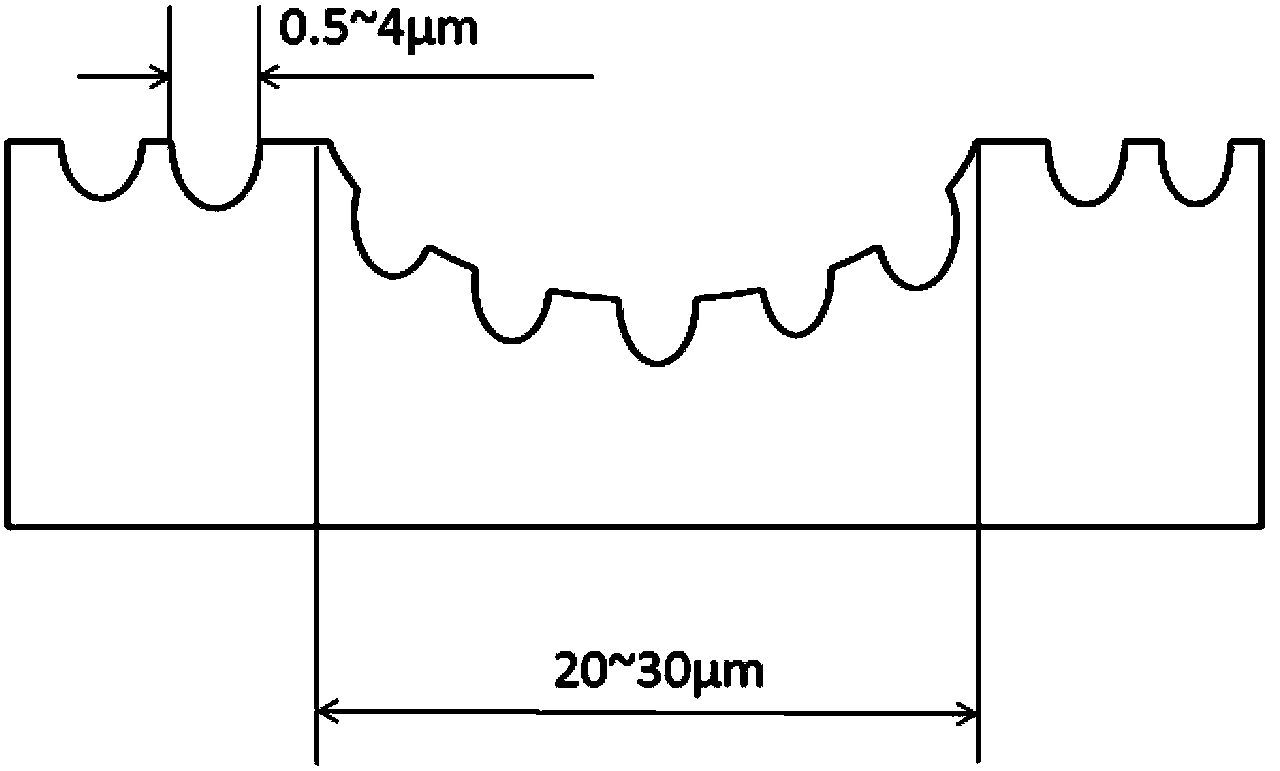

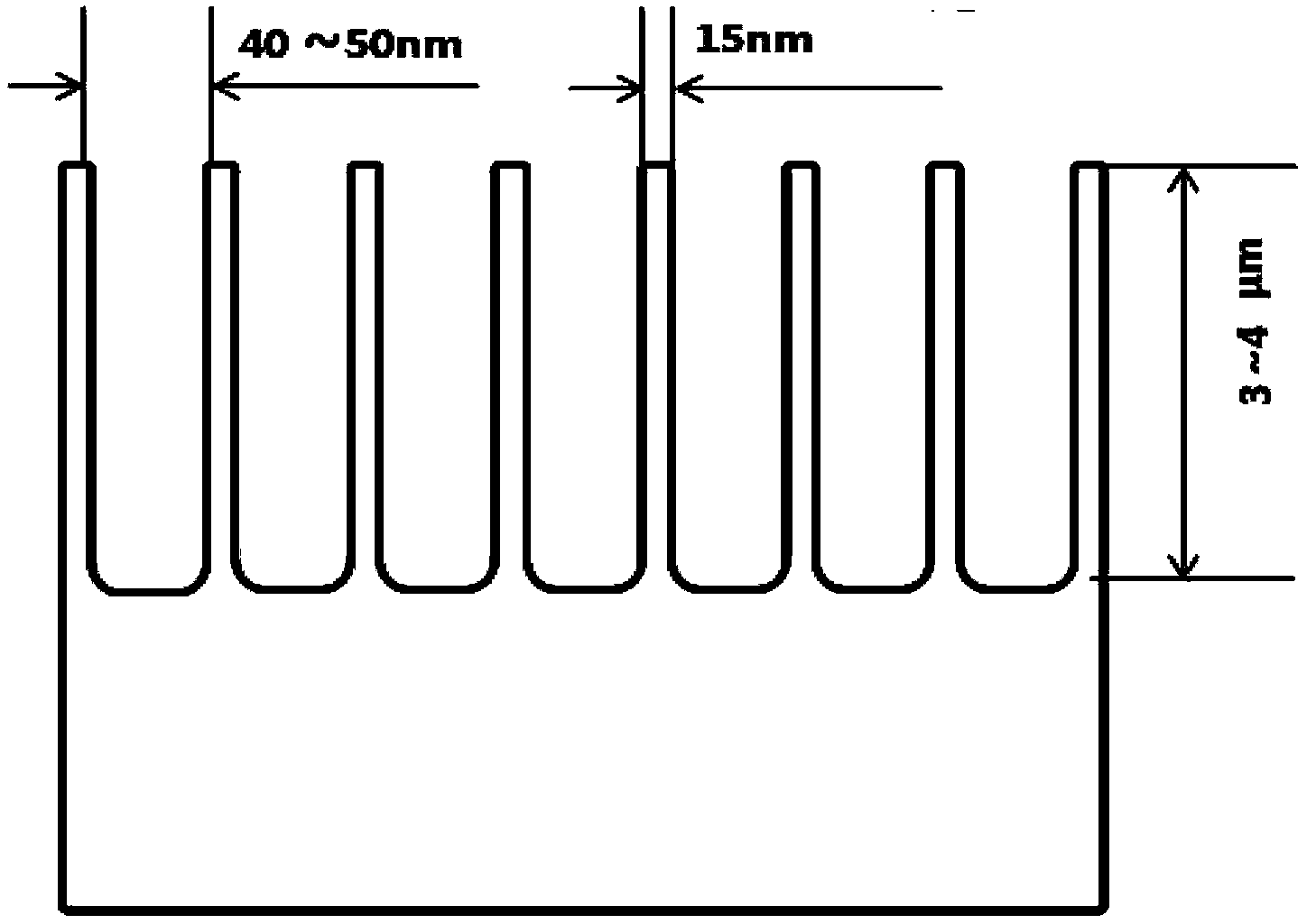

Preparation method of titanium surface multilevel porous structure

InactiveCN103361703AIncrease roughnessHigh adsorption rateSurface reaction electrolytic coatingTitanium alloyMedical treatment

In order to solve the problems that existing titanium and titanium alloys have low bioactivity and low bonding strength with bone tissues, the invention relates to a preparation method of a titanium surface multilevel porous structure. The method comprises: 1. polishing a titanium material by 240-mesh, 600-mesh and 1000-mesh metallographical sandpaper hierarchically, then performing ultrasonic cleaning with acetone and alcohol in order at room temperature, and conducting drying so as to obtain a treated titanium material; 2. carrying out sand blasting treatment with aluminum oxide particles; 3. soaking the titanium material subjected to the sand blasting treatment in a sulfuric acid solution; 4. taking the acid-etched titanium material as the anode, and taking platinum as the cathode, placing them in an NH4F aqueous solution, and conducting anodic oxidation treatment, thus obtaining the anode oxidized titanium material; and 5. cleaning the anode oxidized titanium material with an NaOH solution, deionized water and anhydrous ethanol, and performing drying, thus obtaining the titanium surface multilevel porous structure with high bioactivity and high bonding strength with bone tissues. The method provided in the invention is applied in the biomedical field.

Owner:HARBIN INST OF TECH

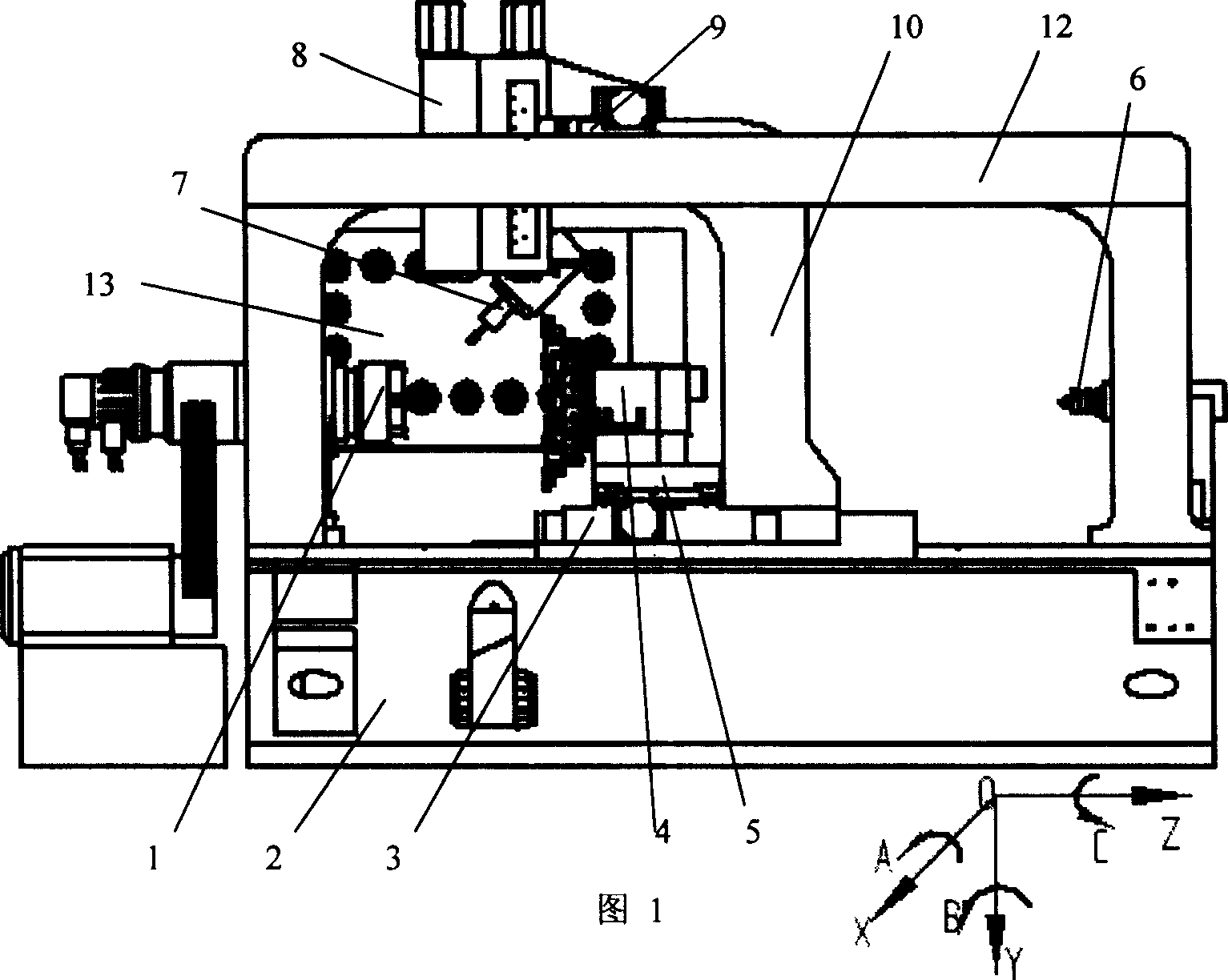

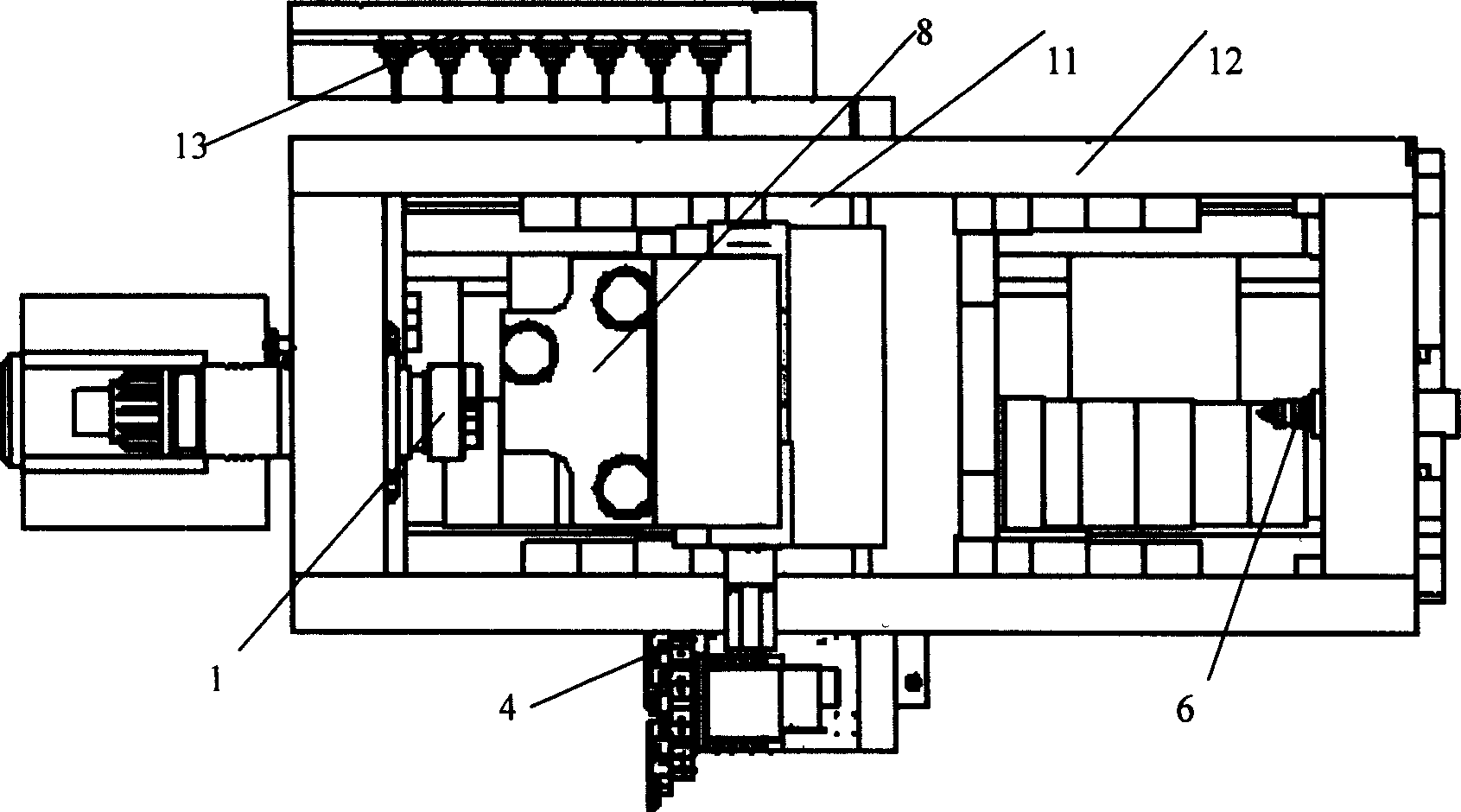

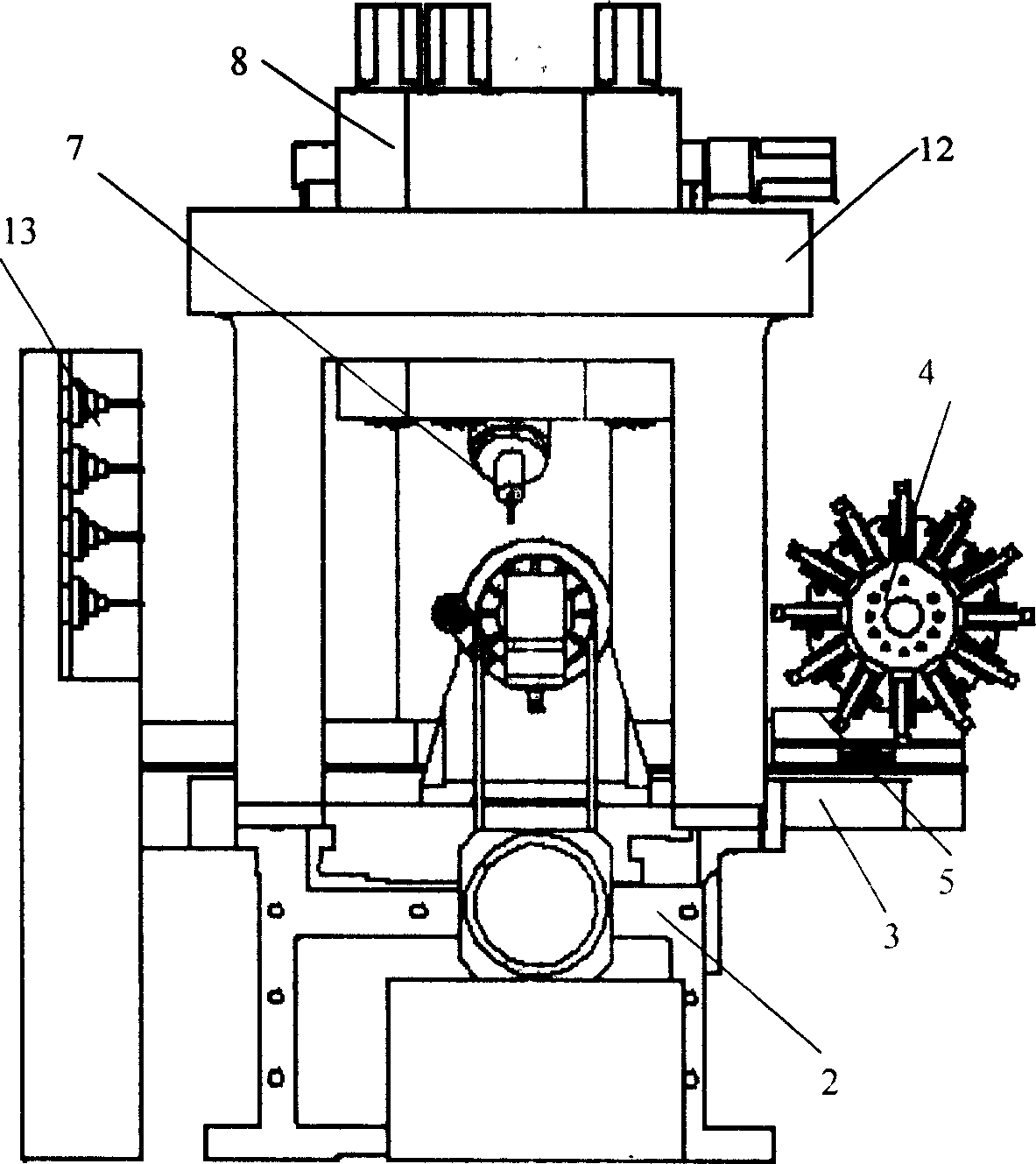

Double gantry horizontal series parallel schematic milling composite digital controlled machine tool

InactiveCN1555963AAchieve compositeIncrease stiffnessOther manufacturing equipments/toolsSlide plateDigital control

A dual-gantry combined horizontal numerally controlled machine-tool able to perform turning, milling, drilling, reaming, boring, etc is composed of two mainshafts for turning and milling, two tool carriages for turning and milling, small and big gantries, main body, saddle, two longitudinal slide plates and tailstock. Its advantages are high machining precision, and high rigidity.

Owner:XIAN UNIV OF TECH

A kind of preparation method of flexible electrode material

InactiveCN104362326BLarge specific surface areaImprove discharge performanceElectrode carriers/collectorsManganeseMechanical property

The invention discloses a preparation method of a flexible electrode material. In this method, graphene is used as an electrode material, an aqueous solution of graphene and manganese salt is used as an electrolyte, sulfuric acid is used to adjust the acidity of the electrolyte, and electrochemical deposition is used to load a composite material of manganese dioxide and graphene on the surface of the graphene film. By adjusting the electrolyte concentration, current, temperature and time during the electrodeposition process, the particle size, distribution density and specific surface area of manganese dioxide graphene composites can be precisely controlled, and bendable manganese dioxide with good mechanical properties can be prepared. Manganese / graphene composite electrode materials. This manganese dioxide / graphene composite electrode material not only has good electrochemical performance after high-temperature calcination, but also has good flexibility and can be bent, suitable for making batteries with flexible structures, and does not require binders and conductive additives And the current collector can be directly made into the electrode, which saves the complicated coating process and the process is simple.

Owner:SOUTH CHINA NORMAL UNIVERSITY

Preparation method for polyazobenzene multifunctional nanoparticles based on rare earth up-conversion material

InactiveCN108192590AExcellent UV ResponsivenessDrug release behaviorInorganic non-active ingredientsIn-vivo testing preparationsYolkCross-link

The invention discloses a preparation method for polyazobenzene multifunctional nanoparticles based on a rare earth up-conversion material. The preparation method comprises the following steps: 1) synthesizing NaYF4: Tm<3+>, Yb<3+>, Tm<3+> / NaYF4 core / shell up-conversion nanoparticles; 2) coating a silica shell layer onto the surface of hydrophobic UCNPs through a reversed-phase microemulsion method, carrying out functional modification with an MPS silane coupling agent, and allowing particle surface to obtain carbon-carbon double bonds so as to make a preparation for subsequent polymerizationreaction; 3) preparing a double response shell with photoresponse azobenzene as a cross-linking agent and methacrylic acid as a monomer; and 4) etching a silicon layer so as to prepare multifunctionalnanoparticles with rare earth nanoparticles as a core and a double response shell-yolk structure as a shell. According to the invention, by utilization of the up-conversion effect of the rare earth nanoparticles to near-infrared laser, ultraviolet light and visible light are generated, so a microsphere shell azobenzene element can control drug release under the action of a light switch, and a novel idea and a route are provided for solving the problem that stimuli responsiveness of a carrier is limited in an ultraviolet area.

Owner:HUBEI UNIV OF TECH

Preparation method of flexible electrode material

InactiveCN104362326ALarge specific surface areaImprove discharge performanceElectrode carriers/collectorsElectrolytic agentElectrical battery

The invention discloses a preparation method of a flexible electrode material. According to the method, graphene is taken as an electrode material, an aqueous solution of graphene and manganese salt is taken as an electrolytic solution, the acidity of the electrolytic solution is adjusted by sulfuric acid, a manganese dioxide / graphene composite material is loaded onto the surface of a graphene film by an electrochemical deposition process, and the particle size, distribution density and specific surface area of the manganese dioxide / graphene composite material are accurately controlled by adjusting the concentration of the electrolytic solution, current, temperature and time in the electrochemical deposition process, so that the bendable manganese dioxide / graphene composite electrode material with good mechanical property is prepared; the manganese dioxide / graphene composite electrode material subjected to high-temperature calcination is good in electrochemical performance and flexibility, bendable and suitable for manufacturing flexible batteries; electrodes can be directly manufactured without an adhesion agent, a conductive additive and a current collector, so that a complicated coating process is removed and the process is simple.

Owner:SOUTH CHINA NORMAL UNIVERSITY

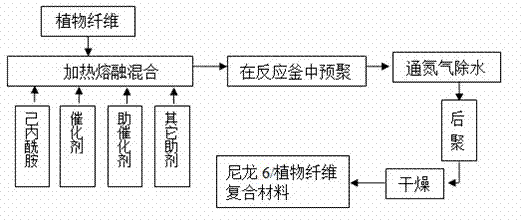

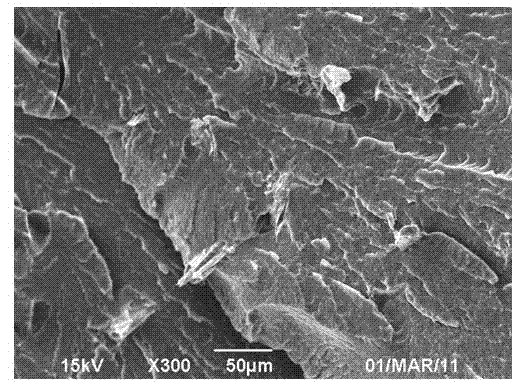

Nylon 6/plant fiber composite material and preparation method thereof

InactiveCN103044911APreparation Recipe ImprovementsImproved Polymerization ProcessFiberIn situ polymerization

The invention discloses a nylon 6 / plant fiber composite material and a preparation method thereof. The composite material is prepared and obtained by in-situ polymerization of the following components in part by weight: 100 parts of Epsilon-caprolactam, 0.2-1.5 parts of plant fibers, 0.3-0.8 part of catalyst, 0.3-1 part of cocatalyst, 0.5-3 parts of activators and 2-10 parts of water. The preparation method of the nylon 6 / plant fiber composite material comprises the following steps: melting the monomer Epsilon-caprolactam, uniformly agitating and mixing with the plant fiber, the catalysts, the cocatalyst, the activator and the water and singly dispersing the plant fibers in the molten Epsilon-caprolactam, adding into a reaction vessel for reaction and preparing the nylon 6 / plant fiber composite material with excellent performance through the processes of prepolymeriazation, nitrogen introduction, water removal and post polymerization.

Owner:HUBEI UNIV OF TECH

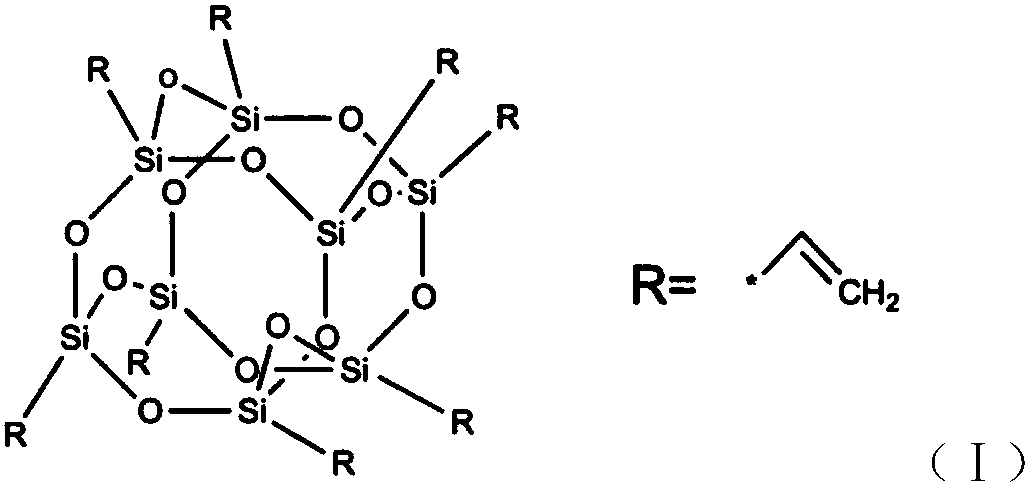

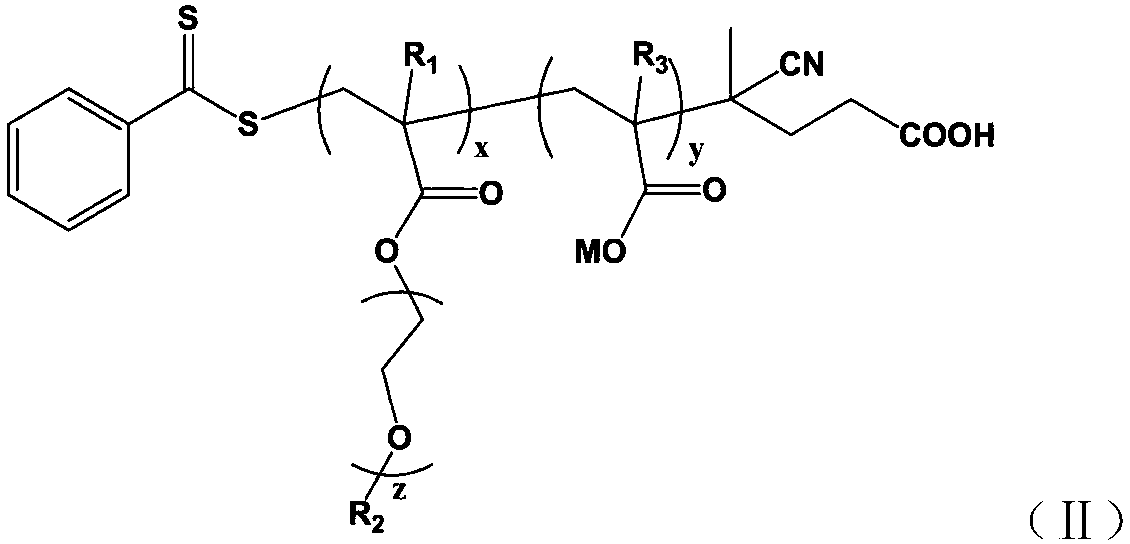

Preparation method and applications of composite super-early strength admixture

The invention discloses a composite super-early strength admixture preparation method, which comprises: dissolving octavinyl POSS and a block polycarboxylic acid A containing a thiol group in a tetrahydrofuran solvent, carrying out a thiol-alkenyl click chemistry reaction under the action of a catalyst, and carrying out rotary evaporation to remove the tetrahydrofuran solvent after completing thereaction so as to obtain a POSS-based star block polycarboxylic acid water-reducing agent; and at a temperature of 20-40 DEG C, simultaneously adding a soluble calcium salt B aqueous solution and a soluble silicate C aqueous solution into the POSS-based star block polycarboxylic acid water-reducing agent in a dropwise manner at a uniform speed, and carrying out thermal insulation for 2-5 h after completing the adding so as to obtain the composite super-early strength admixture. According to the present invention, the POSS core inorganic nanometer structure material in the composite super-earlystrength admixture can achieve the compounding of the polycarboxylic acid water-reducing agent and the nanometer material, such that the dispersion efficiency of the inorganic nanometer structure material is high, the inorganic particles are stable and do not easily settle, the early strength is easily increased, and the transportation cost can be reduced.

Owner:JIANGSU SOBUTE NEW MATERIALS +3

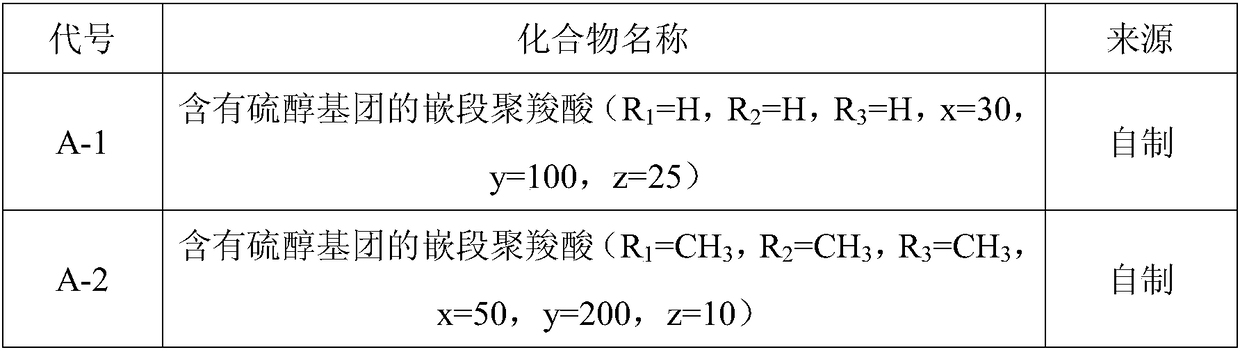

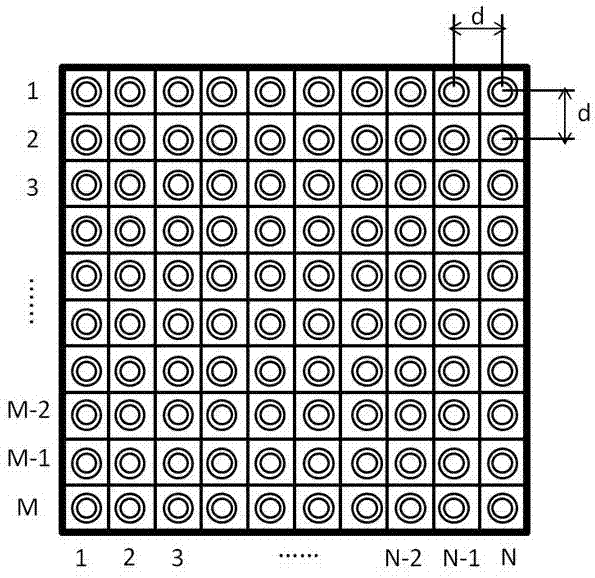

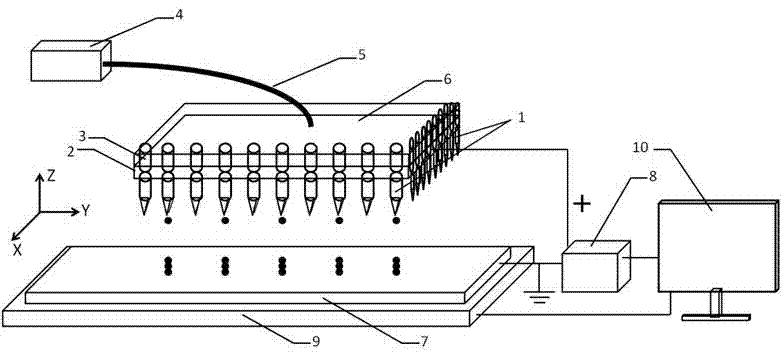

Large-scale ink-jet printing method for three-dimensional metamaterial array

The invention discloses a large-scale ink-jet printing method for a three-dimensional metamaterial array. Through design of a universal sprayer of an M x N nozzle array and a special sprayer of a specific topological structure, pattern information is directly and rapidly printed to a substrate through the nozzle array, and then a large-scale nano structure array can be rapidly and conveniently obtained. Through accurate control over the movement of a displacement table, the size and appearance features of the nano structure can be controlled, and three dimension, inclination, bending, spiral, a heterostructure and the like are included. By utilization of the ink-jet printing method, various complex topological structure arrays can be prepared. The large-scale ink-jet printing method is applicable to various materials and substrates and is widely applied to the demand field of different devices.

Owner:SOUTHEAST UNIV

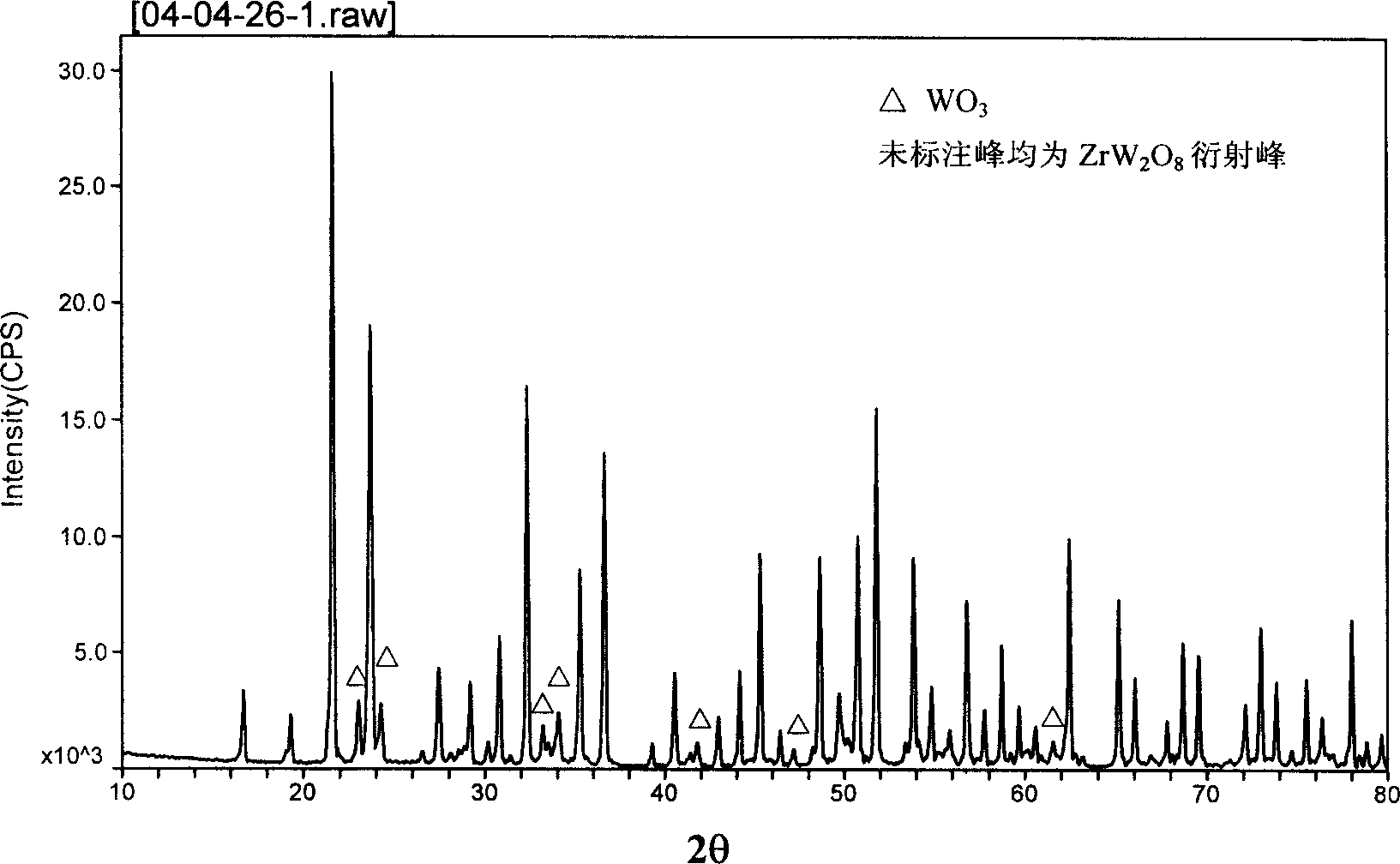

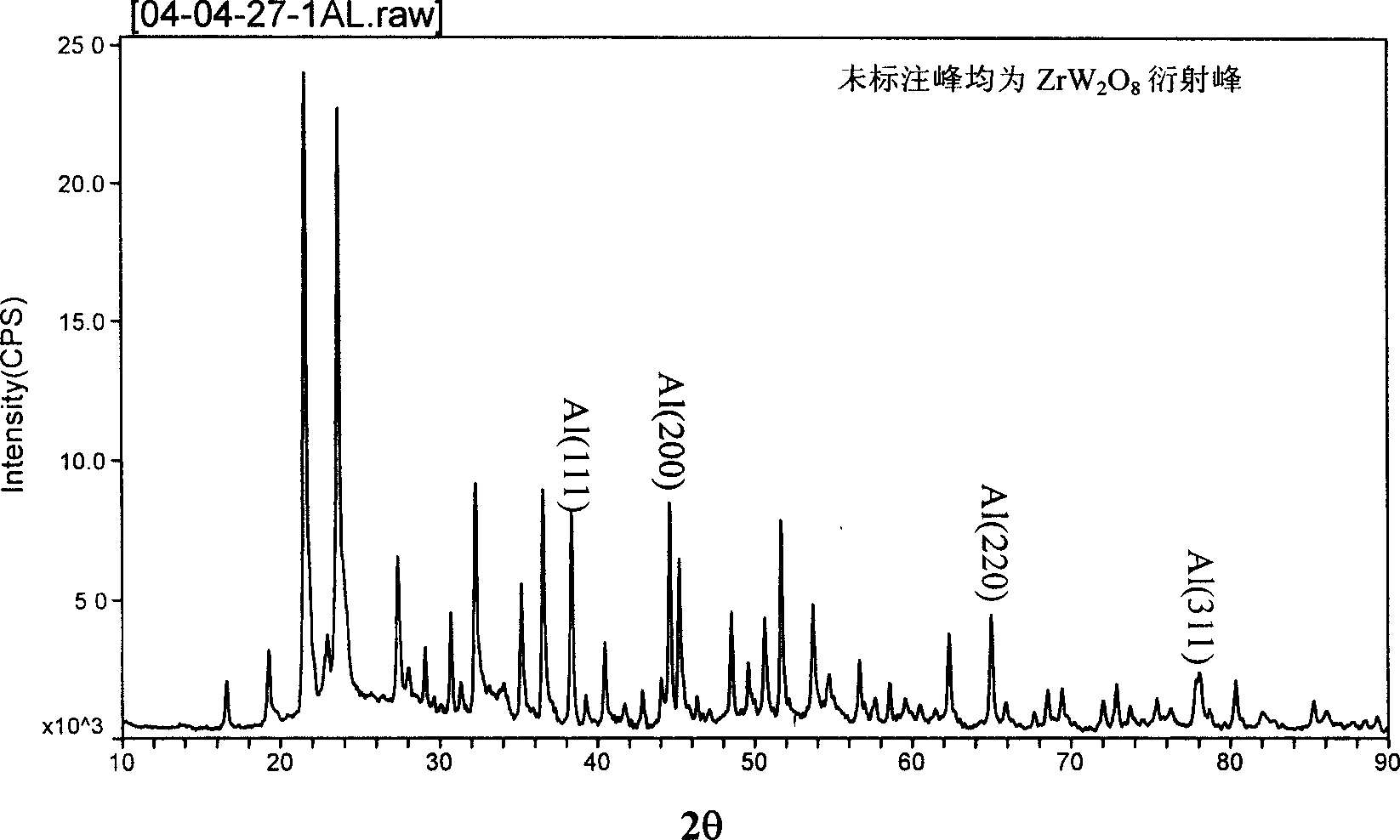

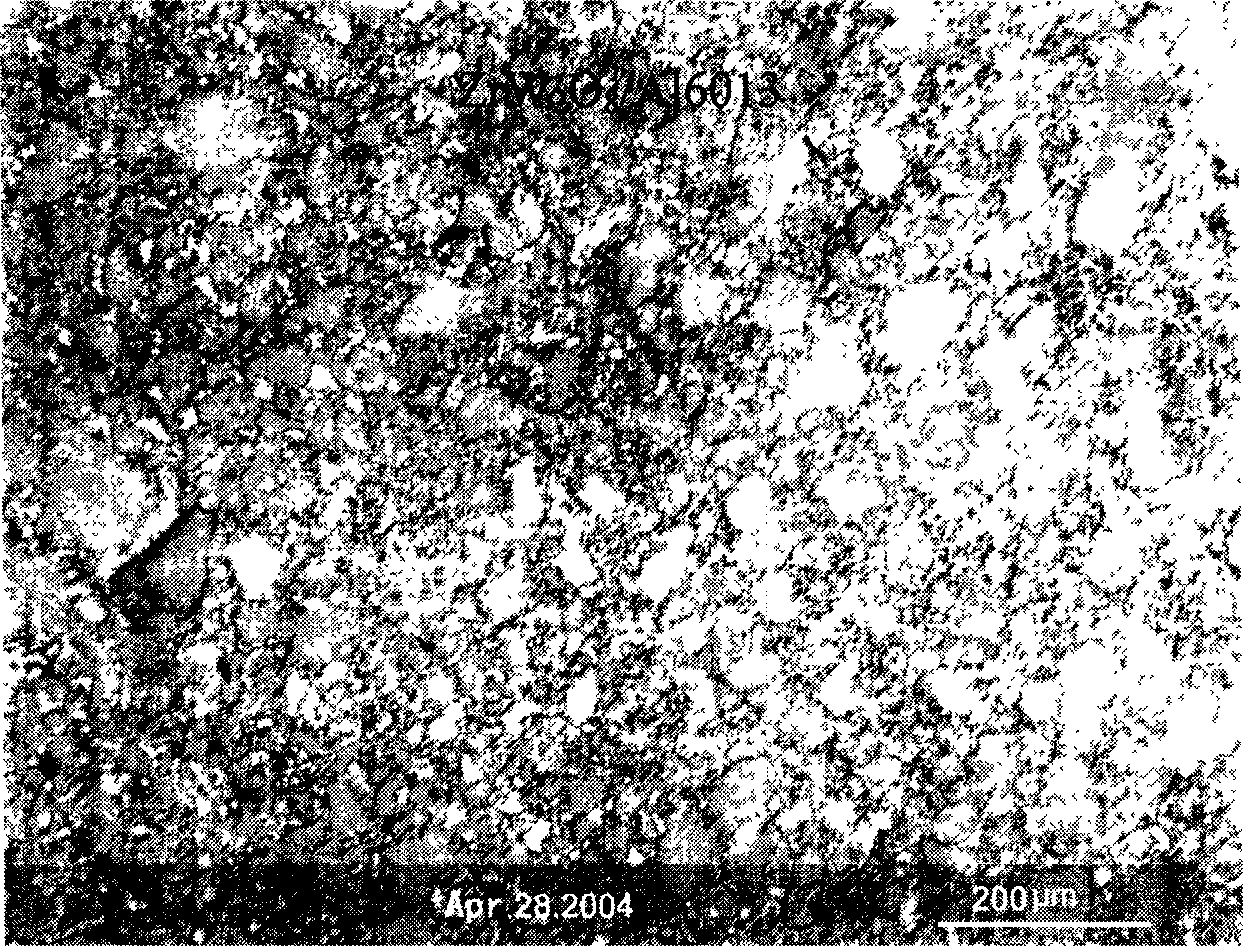

Preparation method of aluminium base zirconium tungstate particle composite material

InactiveCN1718815AHigh bonding strengthAchieve compositeParticle compositionUltimate tensile strength

A process for preparing Al-based ZrW2O8 (or SiCp=ZrW2O8) particle composition with high compactness and strength and near zero expansibility includes such steps as prefabricating the blank of ZrW2O8 (or SiCp=ZrW2O8) particles, preheating it, penetrating the molten Al in the gaps between said particles, and quick solidifying.

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com