Preparation method of flexible electrode material

A flexible electrode and constant current technology, applied in battery electrodes, electrode carriers/current collectors, circuits, etc., can solve problems such as manganese dioxide composite and composite material flexibility, etc., and achieve good reproducibility , good discharge performance and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] A method of preparing a flexible electrode material, including the following steps:

[0029] 1) Taking graphene film as an electrode material, the aqueous solution of graphene and manganese salt as an electrolyte, regulating electrolytic acidity with sulfuric acid, and sedimentation of constant current method electrochemistry.Composite materials.

[0030] 2) The materials after electrochemical deposition are burned for 1 to 24h under the conditions of 300 ~ 380 ℃, and flexible electrode materials can be obtained after burning.

[0031] Preferably, the concentration of graphene in the above electrolyte is 0.1 to 100 mg / ml, the concentration of sulfuric acid is 0.2 to 1.0 mol / L, and the concentration of manganese salt is 0.15 ~ 1.5 mol / L.

[0032] More preferably, the concentration of graphene in the above electrolyte is 1 to 10 mg / ml, the concentration of sulfuric acid is 0.2 ~ 0.5 mol / L, and the concentration of manganese salt is 0.6 ~ 1.0 mol / L.

[0033] Preferably, the ab...

Embodiment 1

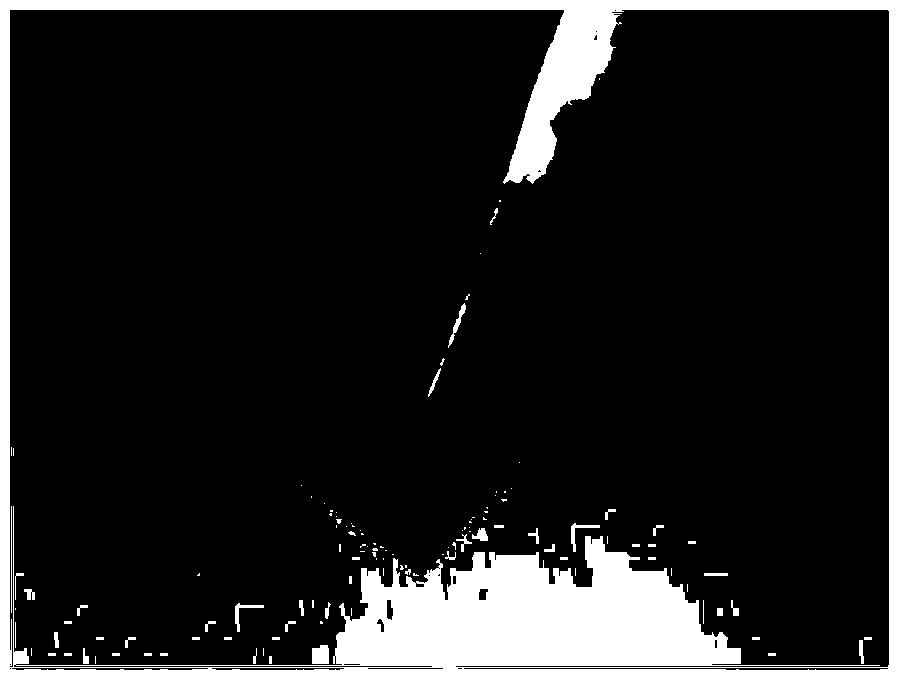

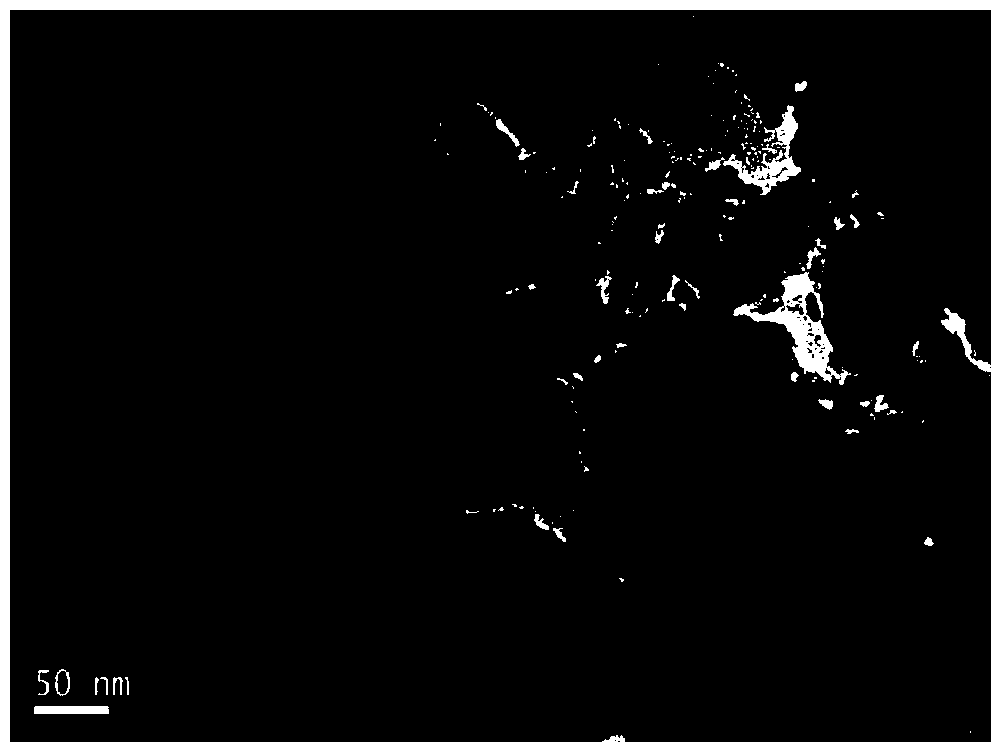

[0042] Take graphene and 100ml of exfoliating water into 250ml to burn the cup, stir with ultrasonic and mechanical stirring for 4h, the dispersing power is 500W, and then add sulfuric acid and manganese sulfate, with 1mg / ml graphene, 0.3m manganese sulfate solutionAs an electrolyte, the electrode material is based on the graphene film, and the electrochemical deposition is used to use the constant current method at a high temperature of 95 ° C. The sedimentary current is 2mA / CM 2 , The deposition time is 2880s; the electrical deposition material is placed in the Marve furnace, burned for 24h under 380 ° C, and the pupae are protected during the burning process, and the wind is used to form a convection.After burning, you can get manganese dioxide / graphene composite flexible electrode material.The thickness of the prepared flexible electrode materials is 0.1mm to 0.5mm, and the mass of manganese dioxide is 60%to 80%.

[0043] Manganese dioxide / graphene compound flexible electrode ...

Embodiment 2

[0049] Take graphene and 100ml of exfoliating water into 250ml to burn the cup, stir with ultrasonic and mechanical stirring for 4h, the dispersing power is 500W, and then add sulfuric acid and manganese sulfate, with 1mg / ml graphene, 0.3m manganese sulfate solutionAs an electrolyte, the electrode material is based on the graphene film, and the electrochemical deposition is used to use the constant current method at a high temperature of 95 ° C. The deposition current is 2mA / CM 2 , The deposition time is 2880s; the electrical deposition material is placed in the Marve furnace, burned for 24h under 300 ° C, and the pimeline is protected during the burning process, and the wind is used to form a convection.After burning, you can get manganese dioxide / graphene composite flexible electrode material. Figure 6 Essence

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com