Preparation method of high-performance graphene oxide/solution polymerized styrene-butadiene rubber composite material

A technology of solution-polymerized styrene-butadiene rubber and composite materials, which is applied in the field of preparation of high-performance graphene oxide/solution-polymerized styrene-butadiene rubber composite materials, can solve problems such as high cost, environmental pollution, graphene oxide peeling and uniform dispersion, etc. Achieve the effect of low heat generation and anti-wet skid comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

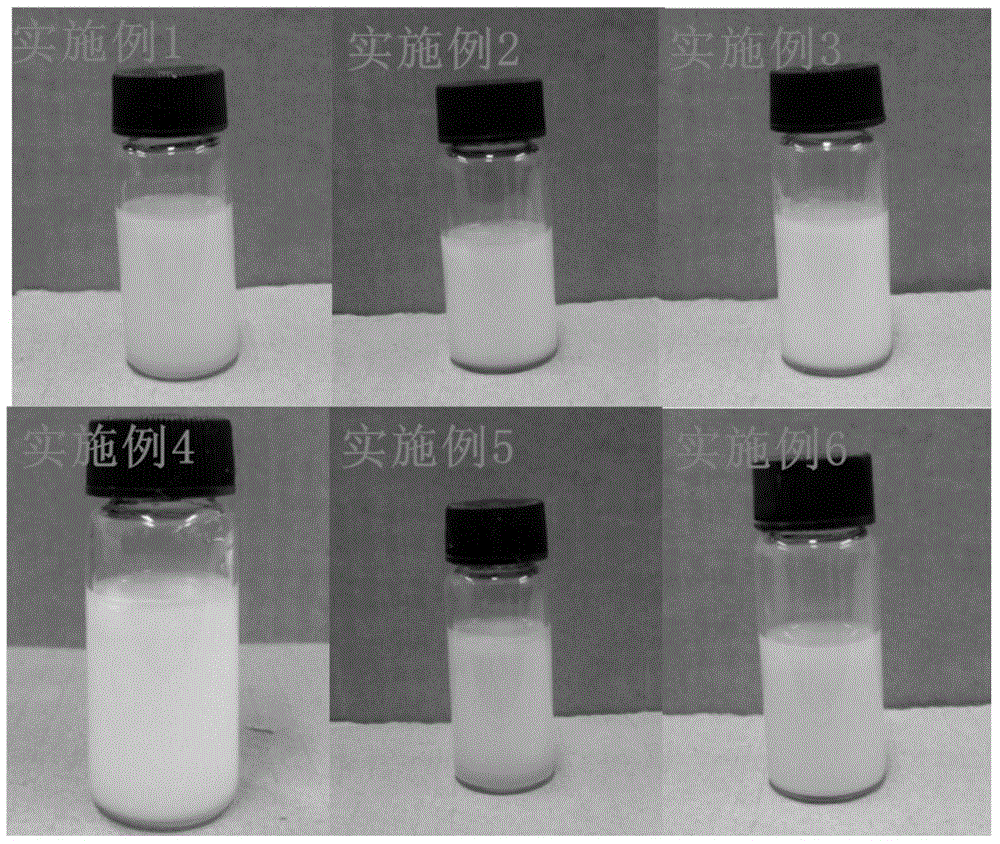

Embodiment 1

[0047] A. a preparation method of solution polystyrene butadiene rubber emulsion, is characterized in that following preparation steps:

[0048] (1) Solution polystyrene butadiene rubber dissolved

[0049] Weigh 20g of solution-polymerized styrene-butadiene rubber, add it to a 500ml three-necked flask equipped with a thermometer, a stirring paddle, and a condensing reflux device, add 300ml cyclohexane to the three-necked flask, control the dissolution temperature to 50°C, and the stirring paddle speed to 400rpm, The dissolution time is 8h.

[0050] (2) Preparation of composite emulsifier

[0051] Weigh 0.1g sodium laurate, 0.1g sodium dodecylsulfonate, 5g sodium dodecyl sulfate, 5g alkylphenol polyoxyethylene ether, 0.1g glycerol polyoxypropylene ether, 2g polyoxyethylene polyoxyethylene ether, Oxypropylene pentaerythritol ether was added into a three-necked flask with a capacity of 2000ml equipped with a thermometer, mechanical stirring, and condensing reflux, and 1257.7g o...

Embodiment 2

[0074] A. a preparation method of solution polystyrene butadiene rubber emulsion, is characterized in that following preparation steps:

[0075] (1) Solution polystyrene butadiene rubber dissolved

[0076] Weigh 20g of solution-polymerized styrene-butadiene rubber, add it into a 500ml three-necked flask equipped with a thermometer, stirring paddle, and condensing reflux device, add 300ml of hexane into the three-necked flask, control the dissolution temperature to 30°C, and the stirring paddle speed to 600rpm, dissolve The time is 10h.

[0077] (2) Preparation of composite emulsifier

[0078] Weigh 5g of sodium oleate, 0.1 part of sodium octadecyl sulfate, 3g of alkylphenol polyoxyethylene ether, 0.1g of fatty alcohol polyoxyethylene ether, and 2g of polyoxypropylene polyoxyethylene regular glycol ether. In a 2000ml three-necked flask equipped with a thermometer, mechanical stirring, and condensing reflux, add 1097.8g of deionized water into the three-necked flask, control t...

Embodiment 3

[0101] A. a preparation method of solution polystyrene butadiene rubber emulsion, is characterized in that following preparation steps:

[0102] (1) Solution polystyrene butadiene rubber dissolved

[0103]Weigh 20g of solution-polymerized styrene-butadiene rubber, add it to a 500ml three-necked flask equipped with a thermometer, a stirring paddle, and a condensing reflux device, add 300ml cyclohexane to the three-necked flask, control the dissolution temperature to 60°C, and the stirring paddle speed to 100rpm, Dissolving time is 5h.

[0104] (2) Preparation of composite emulsifier

[0105] Weigh 3g sodium laurate, 0.1g sodium octadecylsulfonate, 2g sodium octadecyl sulfate, 5g alkylphenol polyoxyethylene ether, 0.5g glycerol type polyoxypropylene ether, 2g polyoxypropylene polyoxyethylene Ethylene triol ether was added into a three-necked flask with a capacity of 2000ml equipped with a thermometer, mechanical stirring, and condensing reflux, and 1257.4g of deionized water w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com