Patents

Literature

757 results about "Slip resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Slip resistance, n—the relative force that resists the tendency of the shoe or foot to slide along the walkway surface. Slip resistance is related to a combination of factors including the walkway surface, the footwear bottom, and the presence of foreign materials between them.

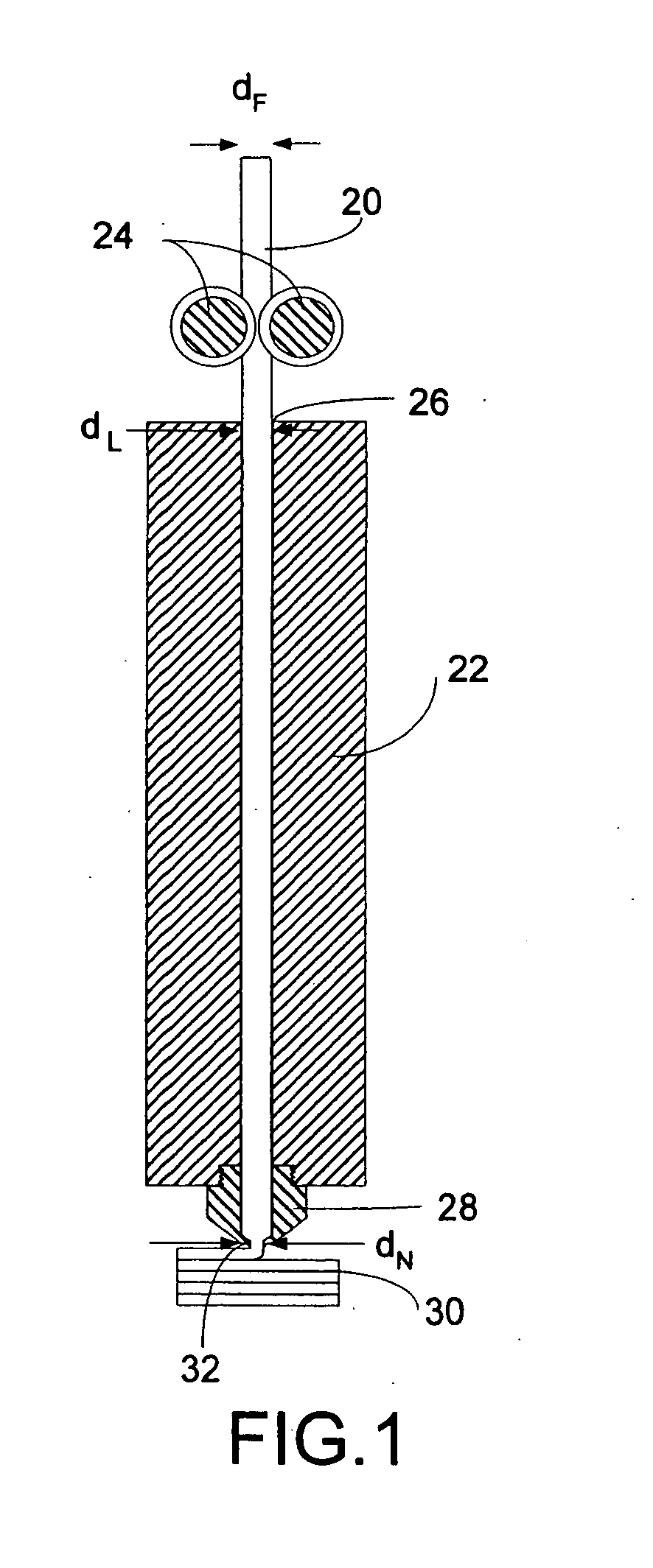

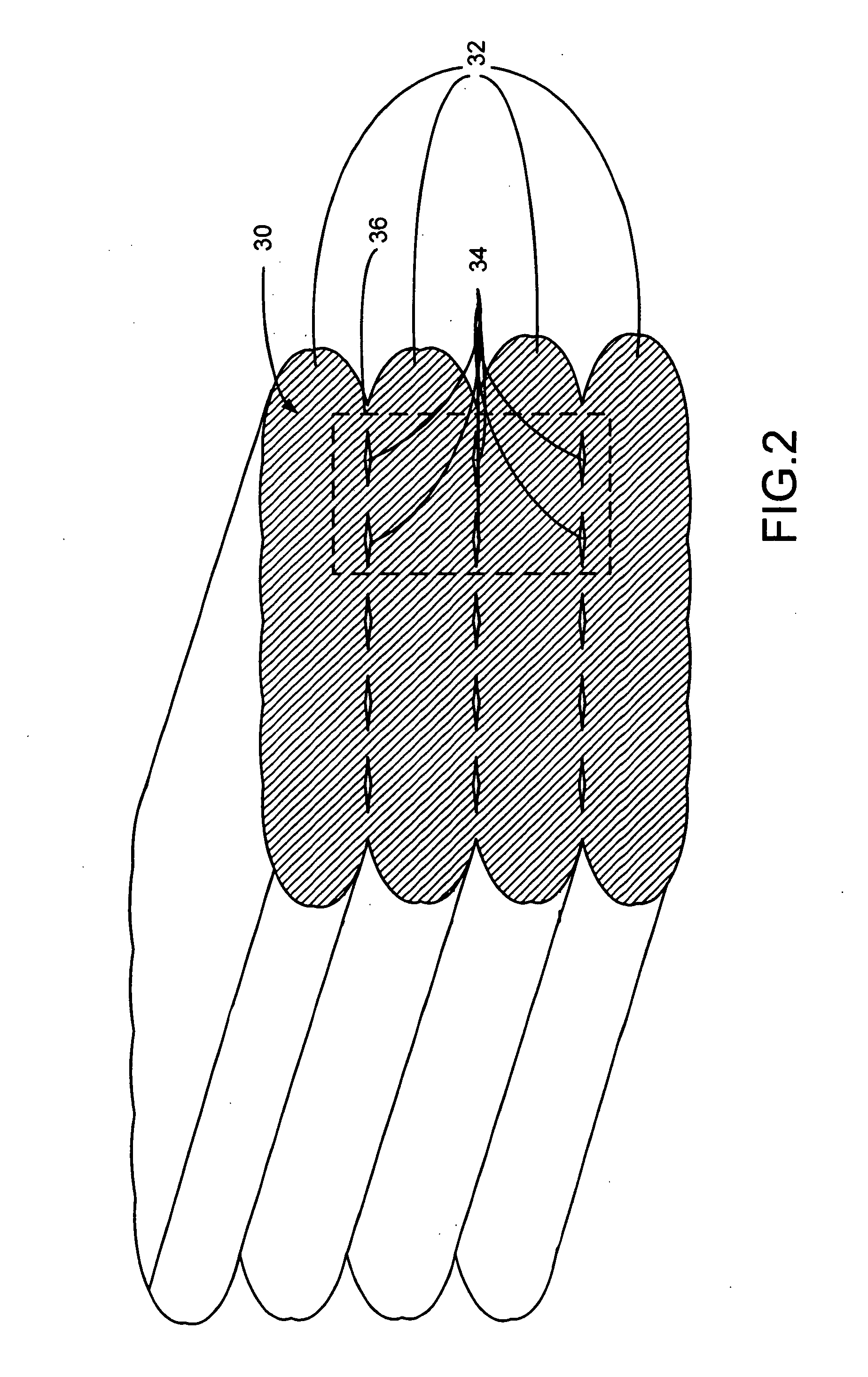

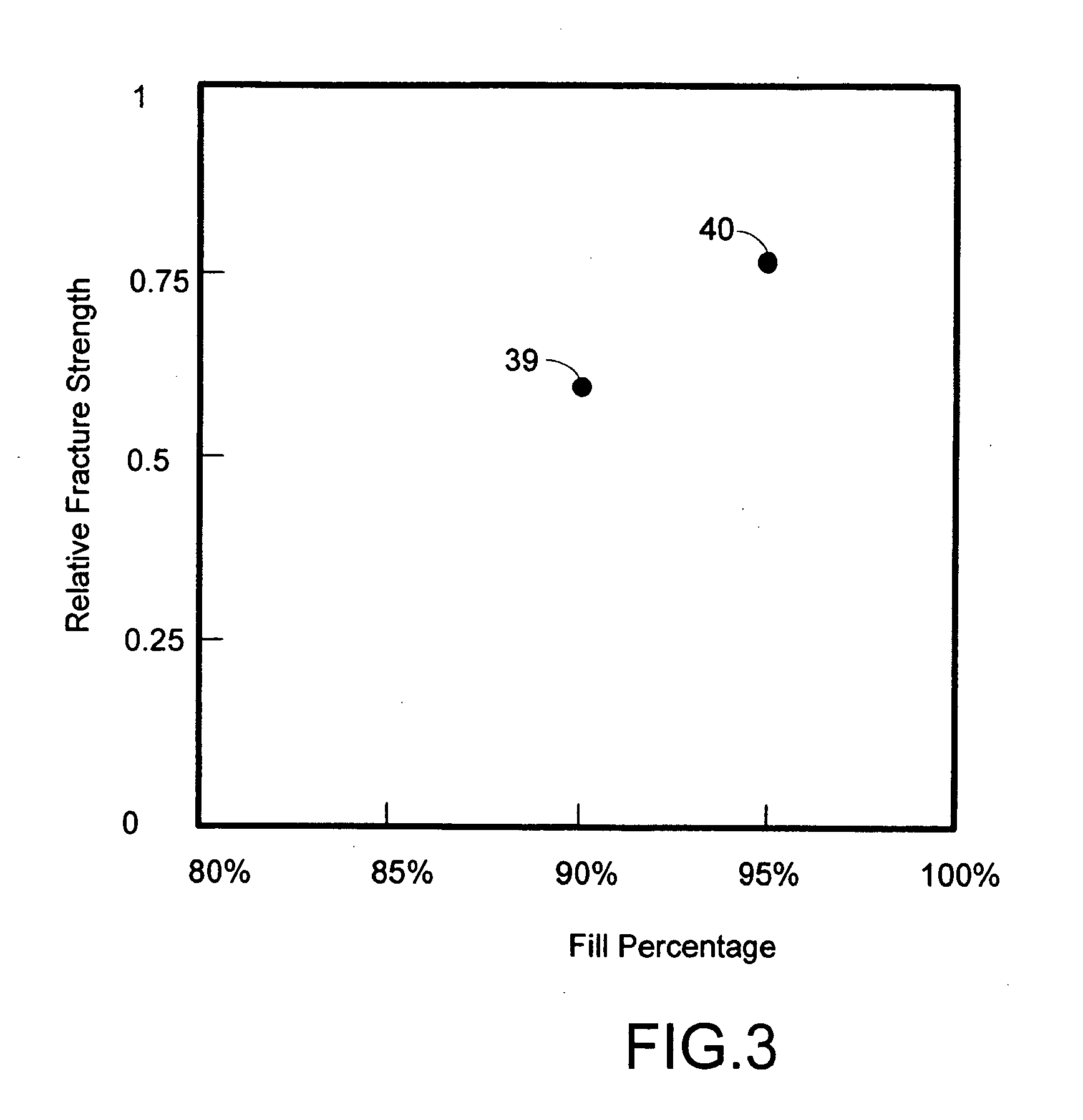

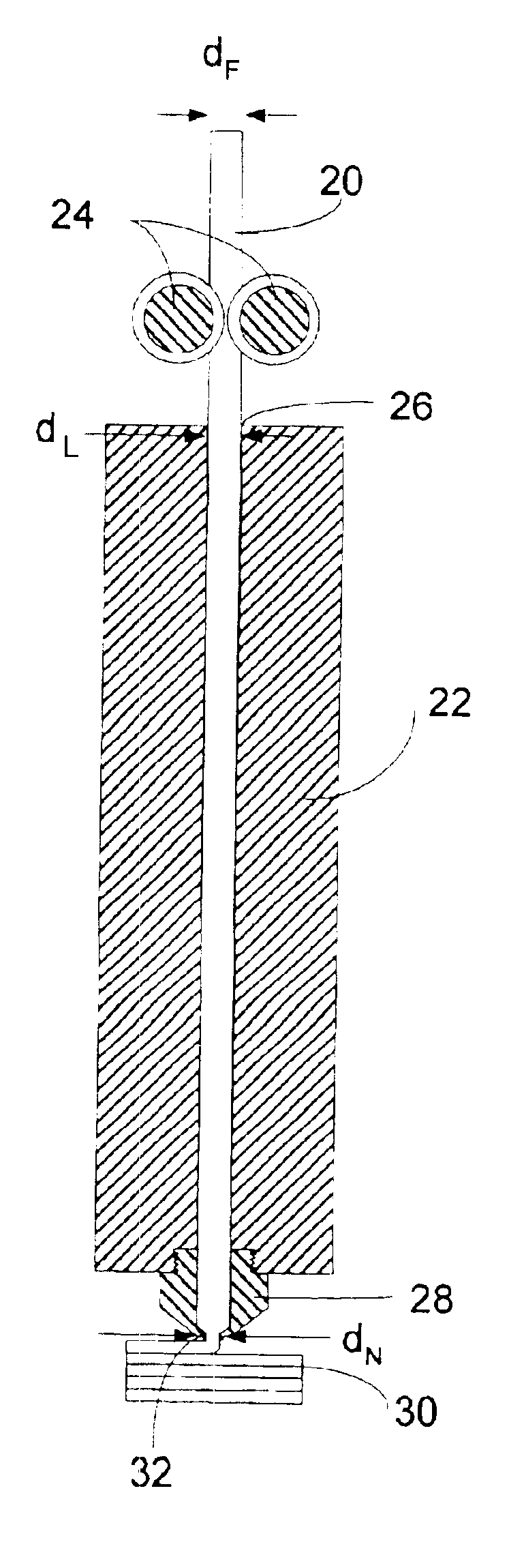

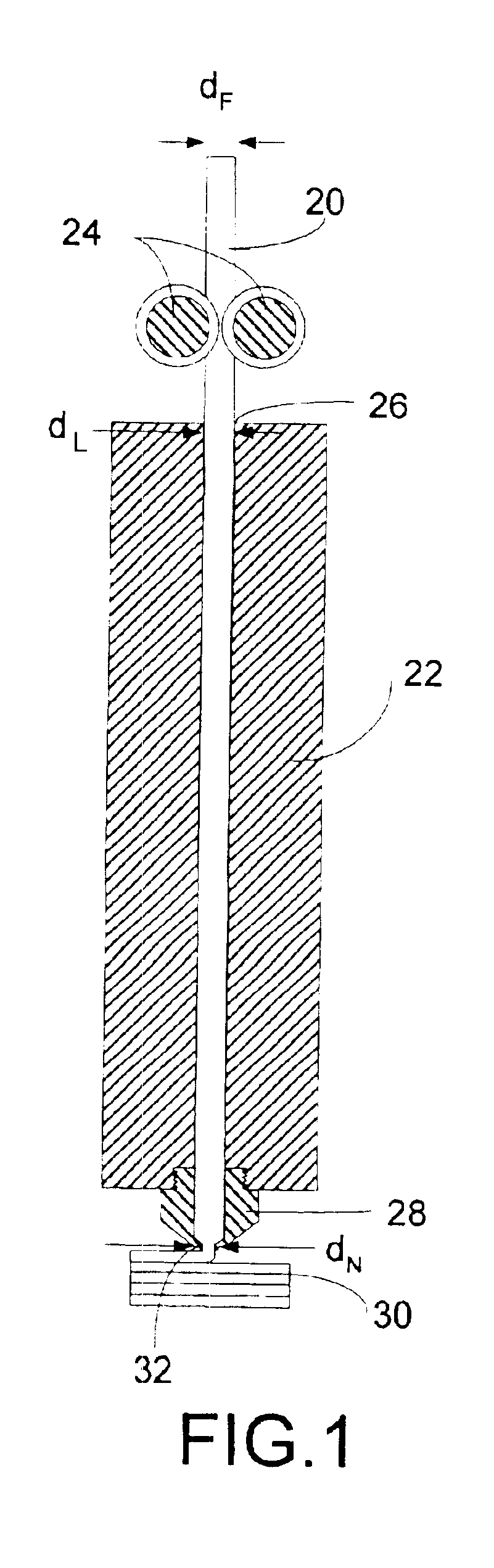

High-precision modeling filament

Disclosed is a modeling filament for use as feedstock in a fused deposition modeling liquifier, and a method for manufacturing the filament. The diameter and standard deviation of the filament are controlled to meet various tolerance requirements of jam resistance, slip resistance, model strength, liquifier overflow prevention and hysteresis-free transient response. Standard deviation of the filament diameter is matched to a filament target diameter. The resulting filament is used to form high-quality models.

Owner:STRATSYS INC

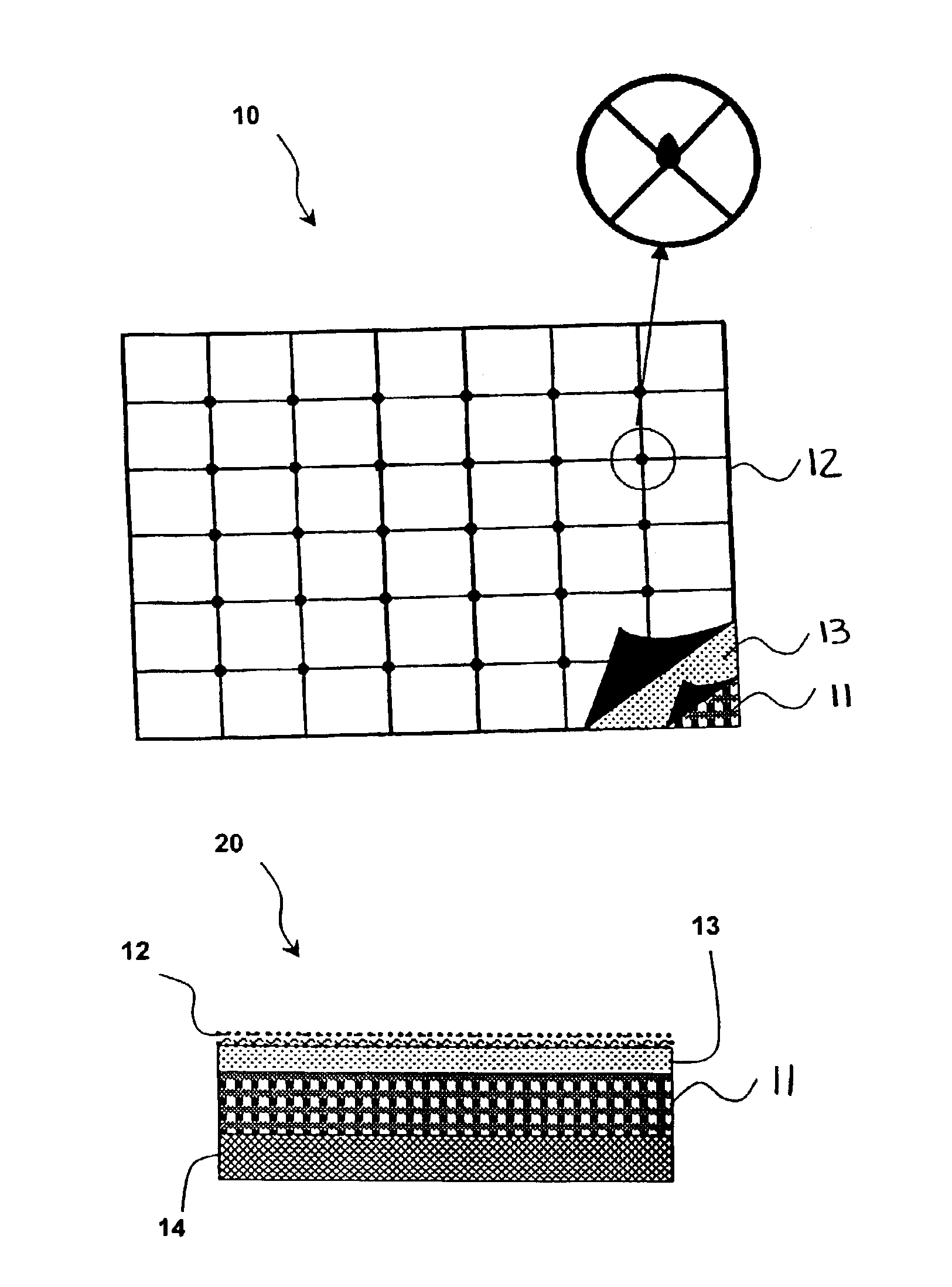

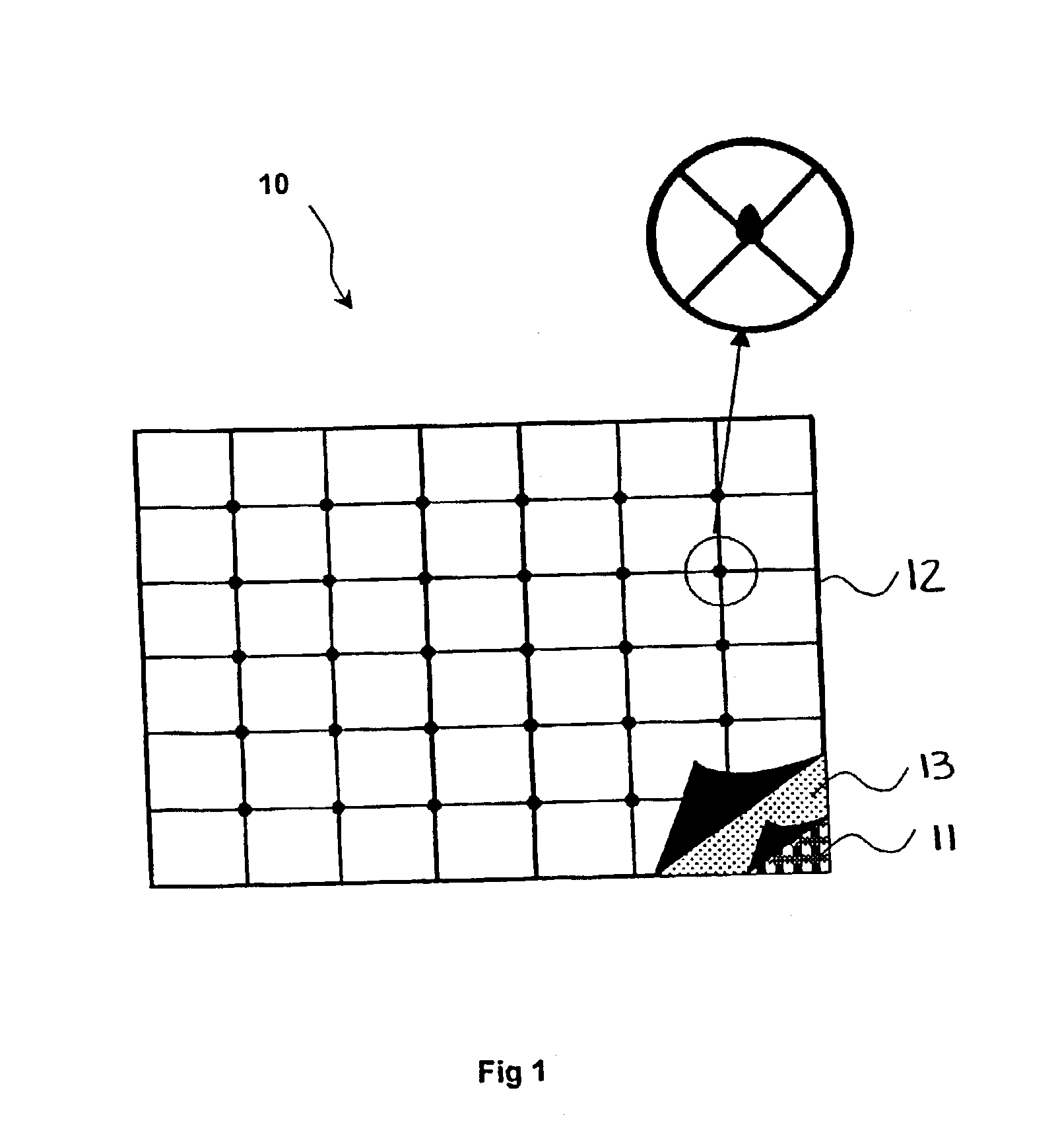

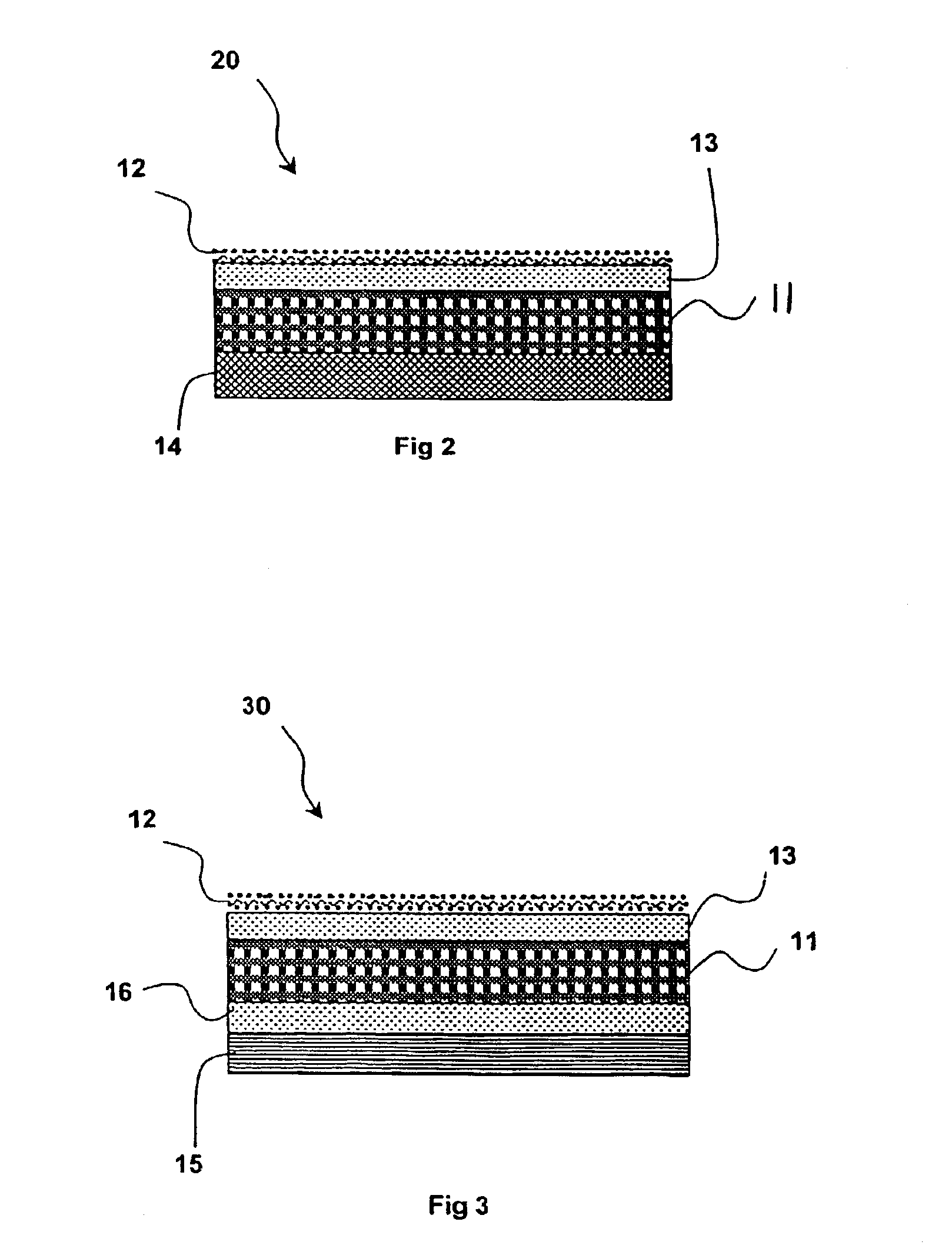

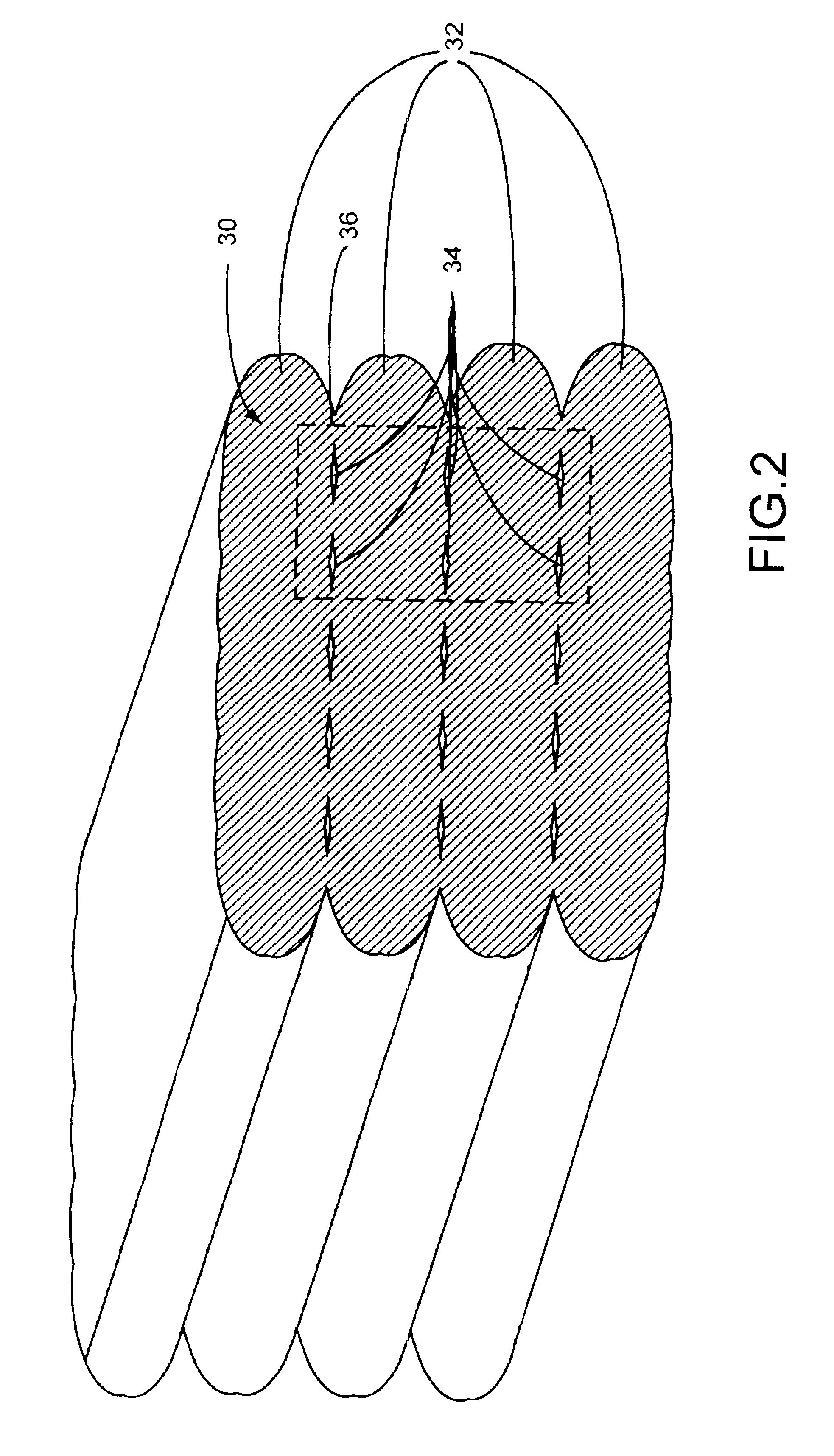

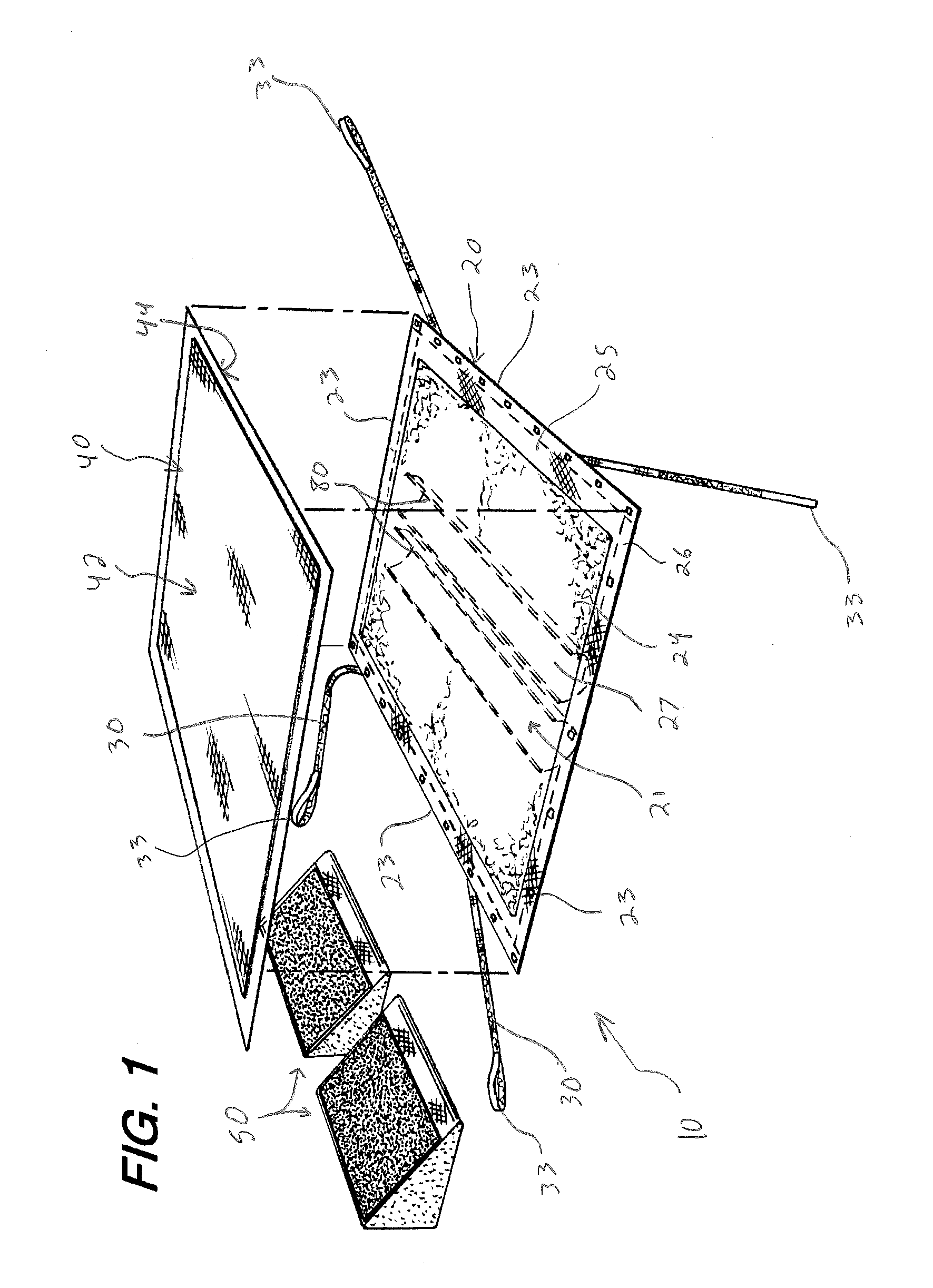

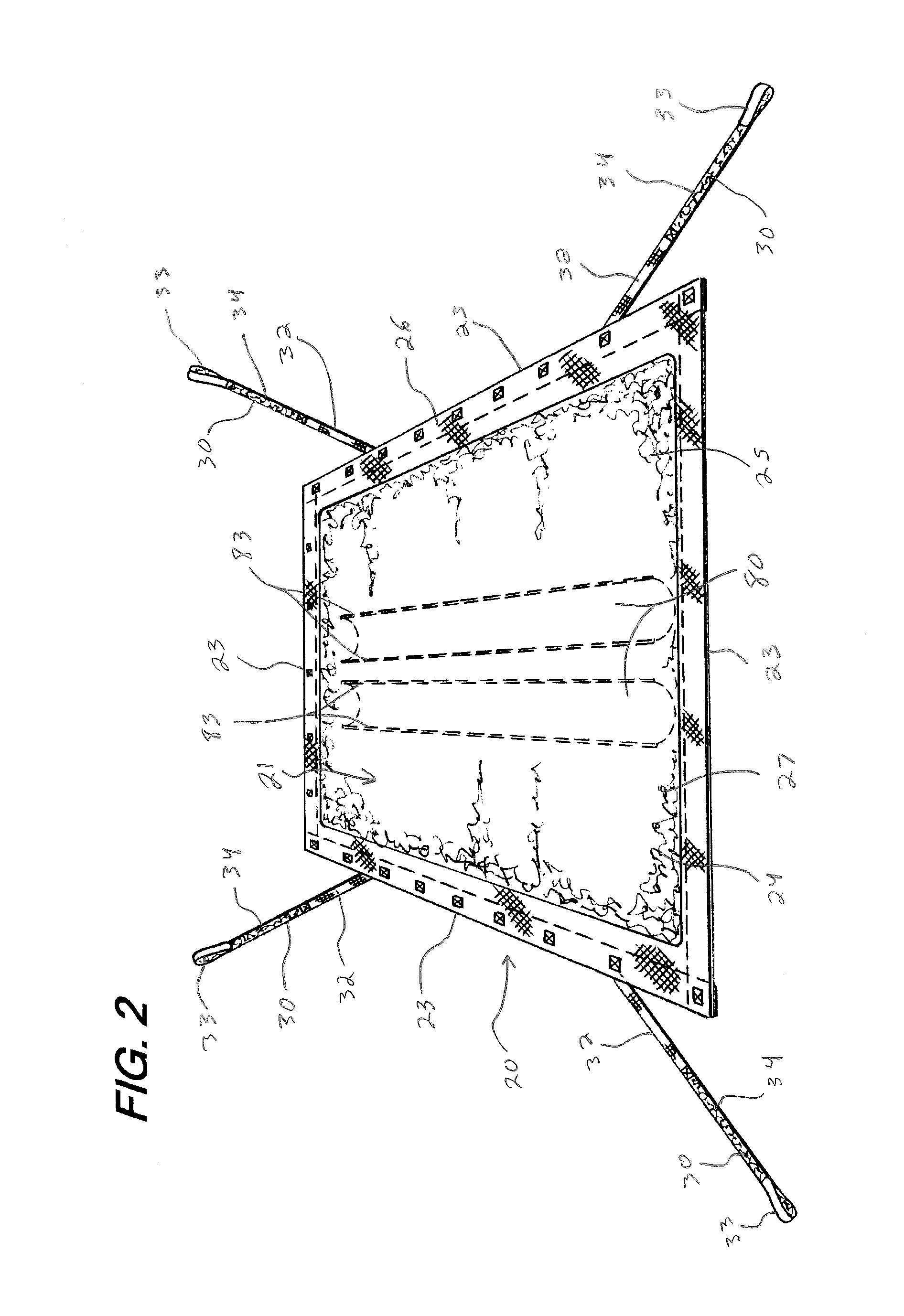

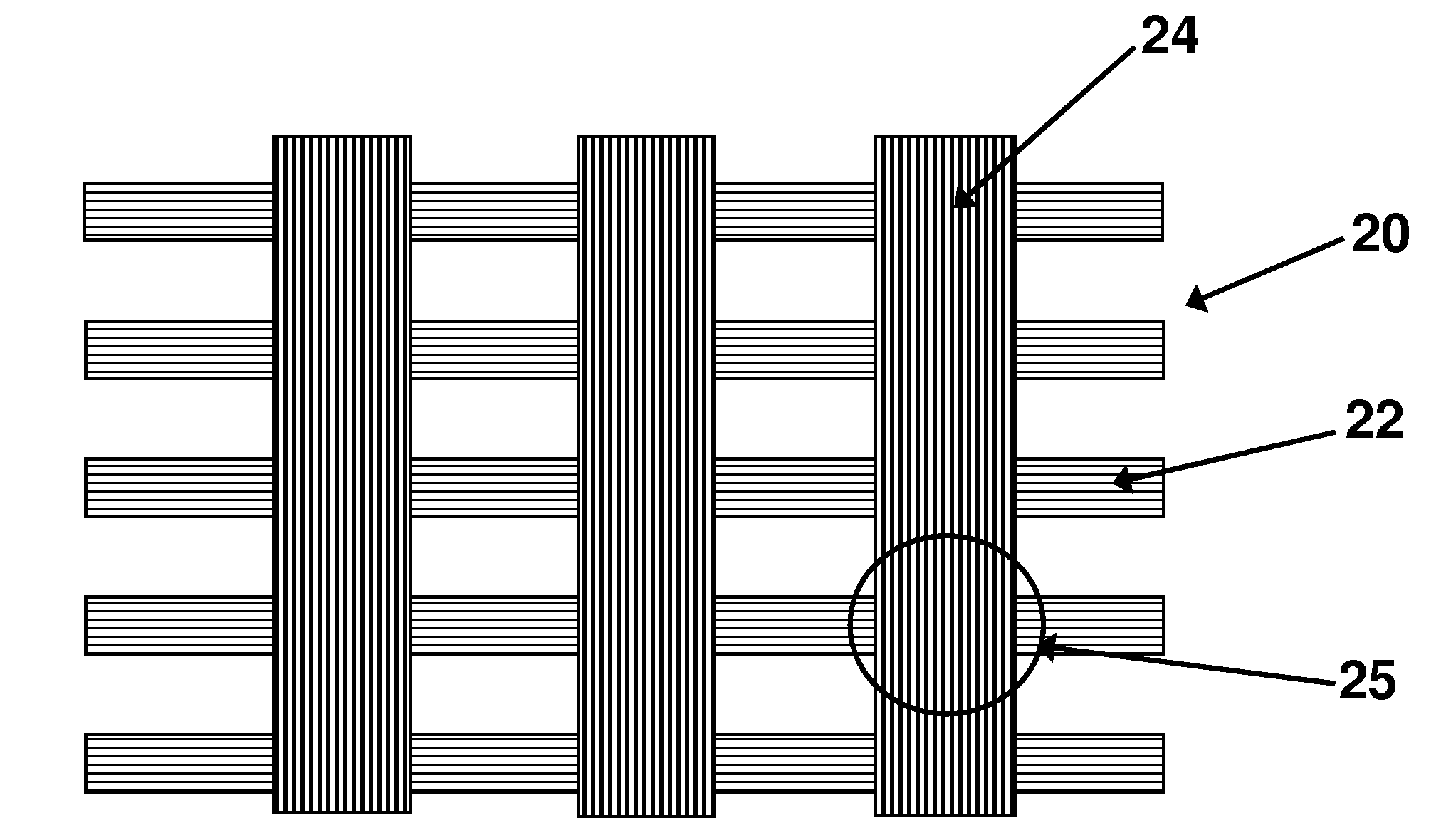

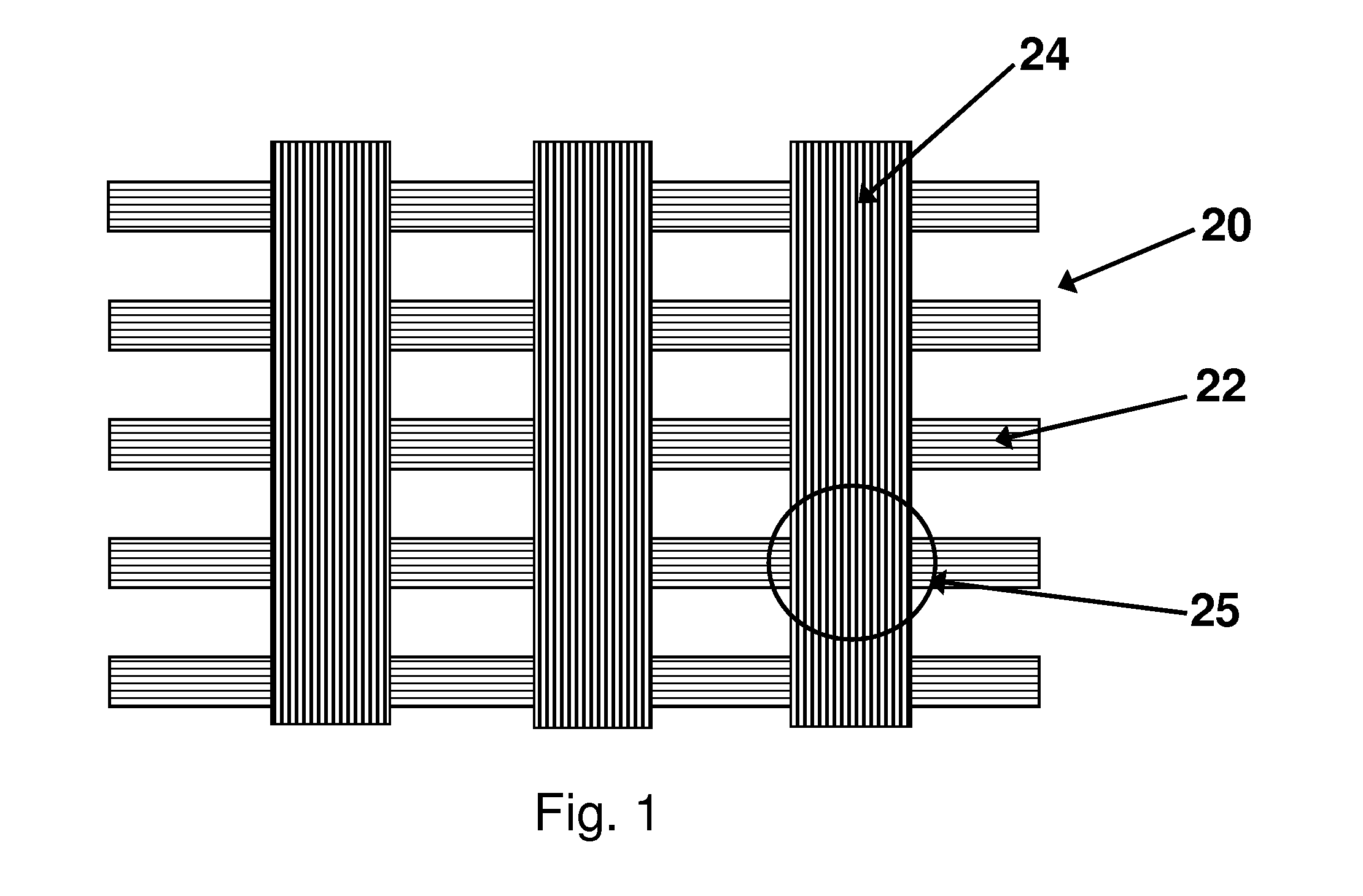

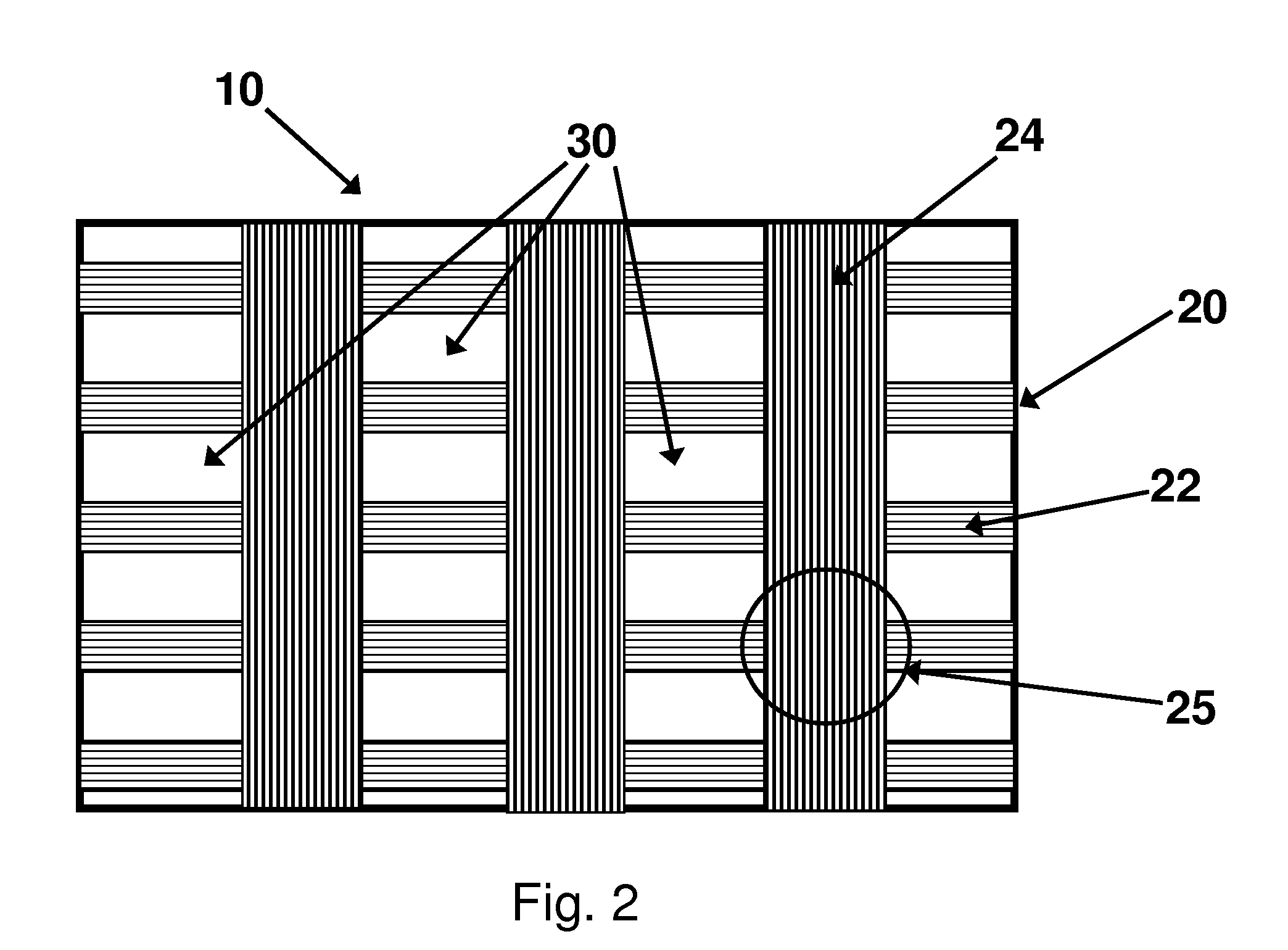

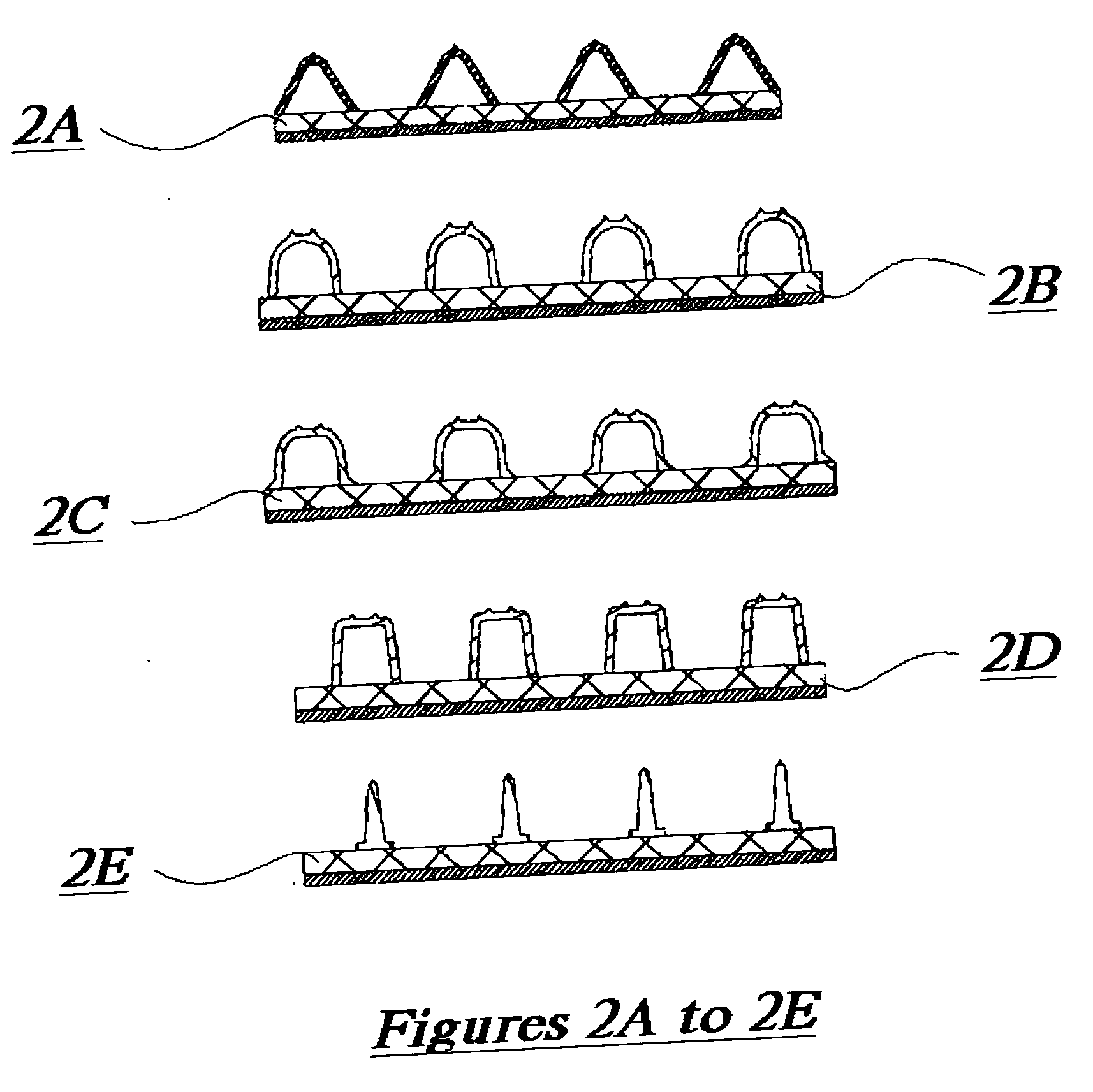

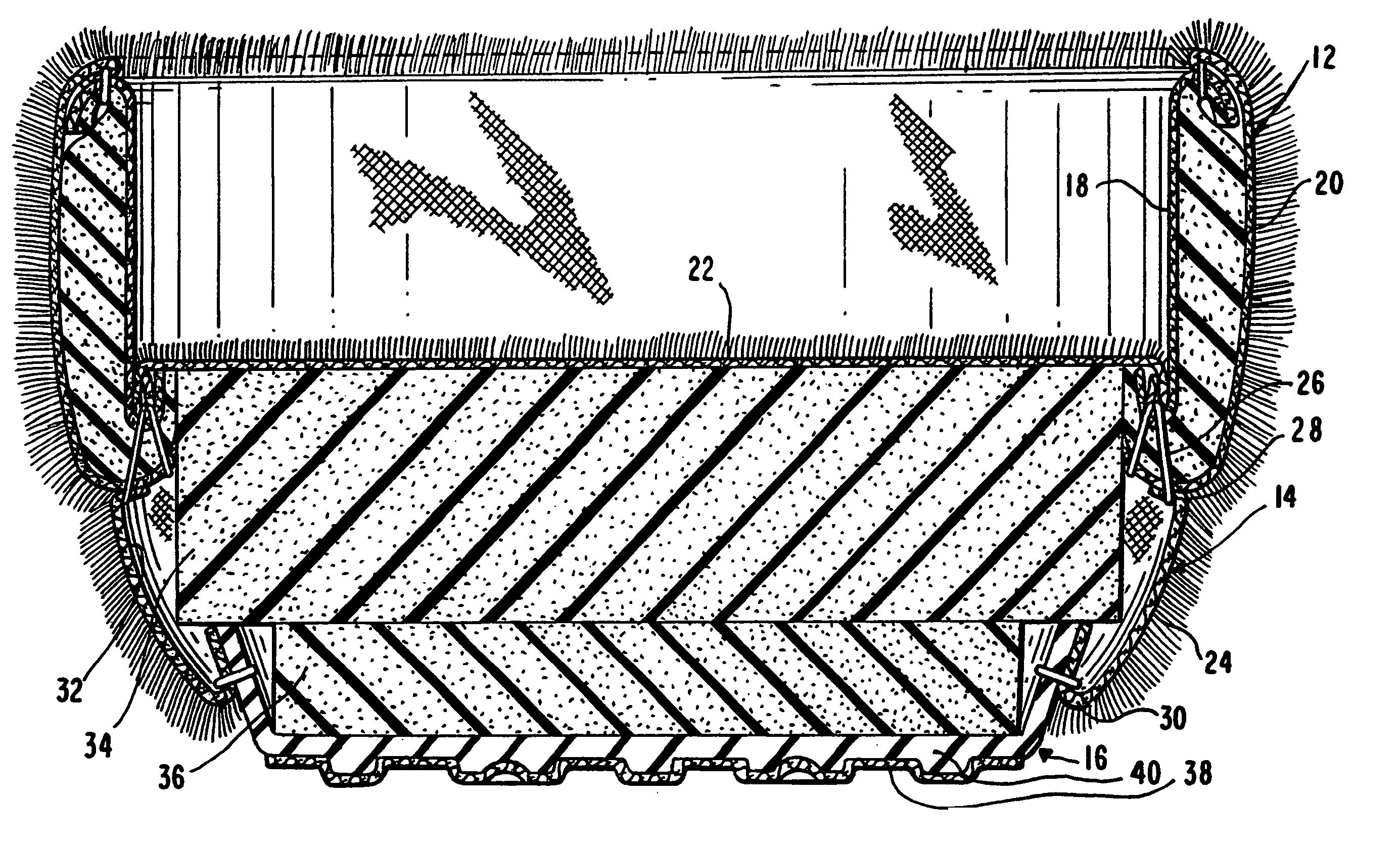

Multilayer slip resistant sheet material

InactiveUS6925766B2Increase coefficient of frictionGood walkabilityRoof covering using tiles/slatesTreadsEngineeringSlip resistance

There is provided a sheet material having a walking surface with high slip resistance. The sheet material has a flexible structural layer laminated to a mesh layer which has interconnected reinforced strands and protruding nodes to impart a high coefficient of friction. The high coefficient of friction of the sheet material provides a roofing underlayment which is safe to walk upon in dry, wet or dusty conditions, and on steeply sloped surfaces. The sheet material may also be used as an industrial wrapping material or a fabric.

Owner:OWENS CORNING INTELLECTUAL CAPITAL LLC

High-precision modeling filament

InactiveUS6866807B2Improve accuracyQuality improvementAdditive manufacturing apparatusMouldsHysteresisEngineering

Disclosed is a modeling filament for use as feedstock in a fused deposition modeling liquifier, and a method for manufacturing the filament. The diameter and standard deviation of the filament are controlled to meet various tolerance requirements of jam resistance, slip resistance, model strength, liquifier overflow prevention and hysteresis-free transient response. Standard deviation of the filament diameter is matched to a filament target diameter. The resulting filament is used to form high-quality models.

Owner:STRATSYS INC

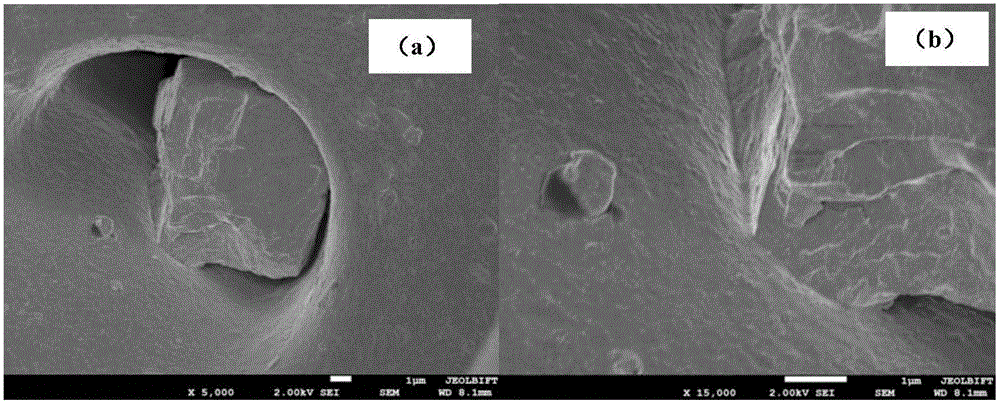

Sneaker sole material with high wear resistance and low hardness and preparation method thereof

The invention discloses a sneaker sole material with high wear resistance and low hardness and a preparation method thereof, particularly a method for preparing a sneaker sole material which is suitable for middle and high-grade sneaker soles with higher requirements on wear resistance and comfort. The sneaker sole material comprises the following components: butadiene rubber (BR), natural rubber (NR), styrene butadiene rubber (SBR), softening oil, a reinforcing agent, an activating agent, a coupling agent, a vulcanizer, a vulcanization accelerator, a tackifier and an anti-aging agent. A series of sole material with high wear resistance (DIN abrasion is less than or equal to 40mm<3>, and the length of grinding marks is 3.0 to 4.0mm) and low hardness (ShoreA 60-66) is prepared by screening the proportion of rubber composition, the coupling agent, the accelerator, and the activating agent and reasonably controlling a process on the basis of the rubber, the softening oil and the reinforcing agent. The material has the advantages that: (1) the total weight of a sneaker sole is expected to be reduced, namely the thickness of a rubber outer sole of a sneaker can be reduced under the condition that the material has the wearing life which is the same as that of the conventional sneaker sole, so that the total weight of the sole is reduced; (2) the humidity and slip resistance is improved, namely the hardness of the sole is lower and the sole is easy to distort under the condition of stress, so that the contact area of the sole and the ground is increased, and the aim of improving the humidity and slip resistance of the sole is fulfilled; and (3) the comfort is improved.

Owner:CHINA LEATHER & FOOTWEAR IND RES INST

Exterior wall composite insulation heat-proof plastering material

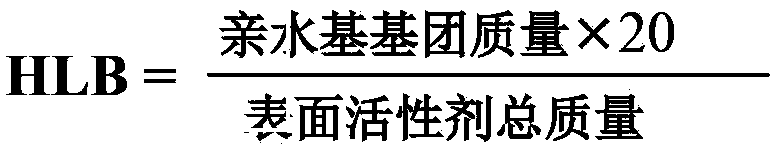

InactiveCN101229970ARealize resource utilizationImprove protectionSolid waste managementFiberResource utilization

The invention relates to compound thermal insulation plastering material for external wall, which consists of a compound cementing material and a lightweight aggregate. The compound cementing material consists of cement, active admixture, lime powder, promoter, surfactant, anti-crack and waterproof agent, water retaining agent, flame retardant, re-dispersible emulsion powder, alkali-resistance fiber and coal flying ash cenosphere; the lightweight aggregate consists of EPS grain and expanded perlite. The invention has the advantages of low density, thermal performance, high strength, good impact resistance, bond strength and low shrinkage. The compound cementing material adopts a plurality of polymeric cementing materials, allows the insulation material to have good bond performance and simultaneously ensures falling and slipping resistance performance. The invention has good water resistance and high softening coefficient. By using cement-based cementing material as main material and organic reinforced material and waterproof component as auxiliary materials, the invention has a hydrophobic rate more than 98 percent and a softening coefficient more than 0.7. The invention can save energy and protect environment. A great deal of industrial waste residue is used in the materials, which can save a great number of energy, realize resource utilization of the waste residue and is in favor of environmental protection.

Owner:SHANGHAI TONGBIAO INSULATION TECH

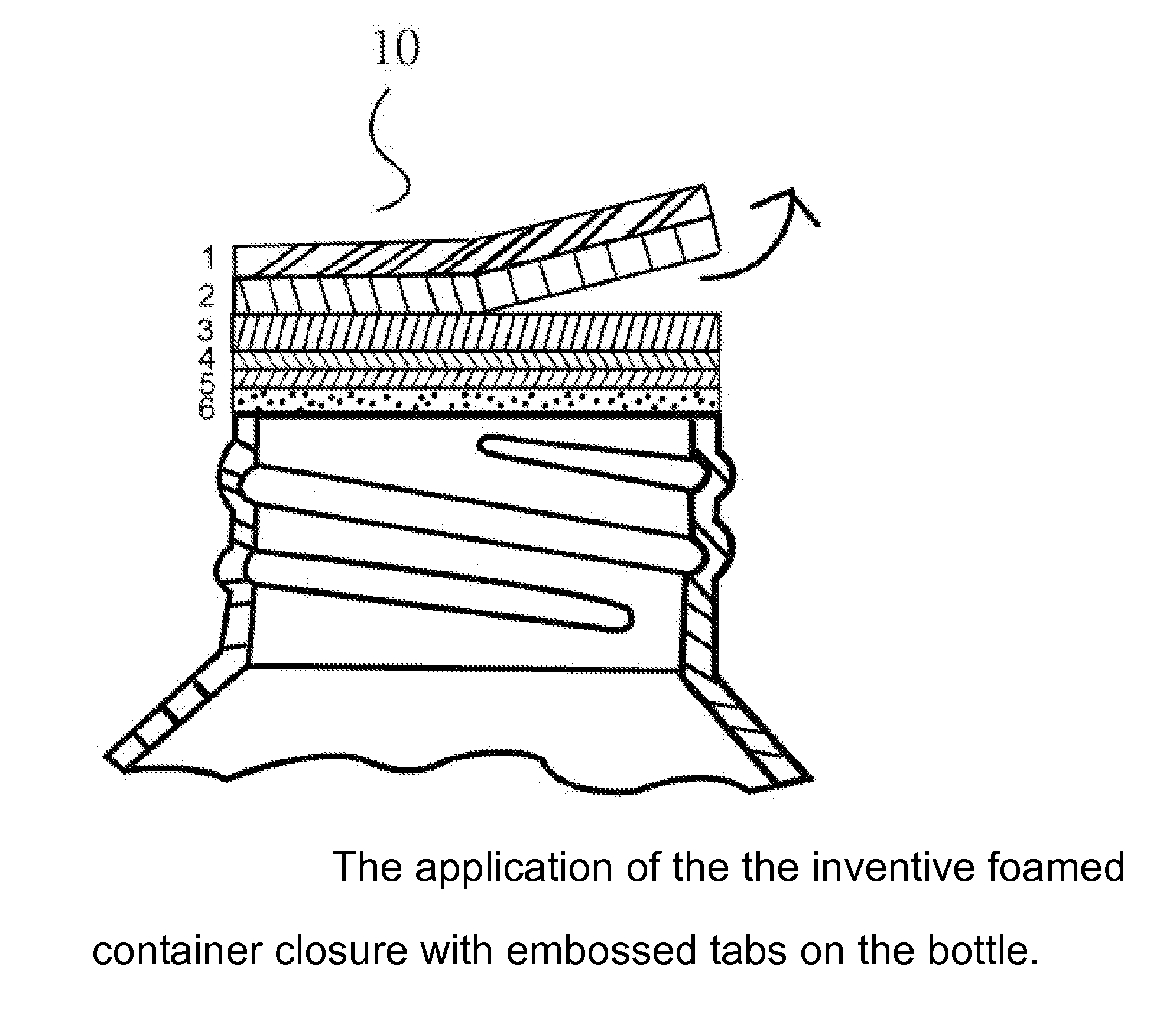

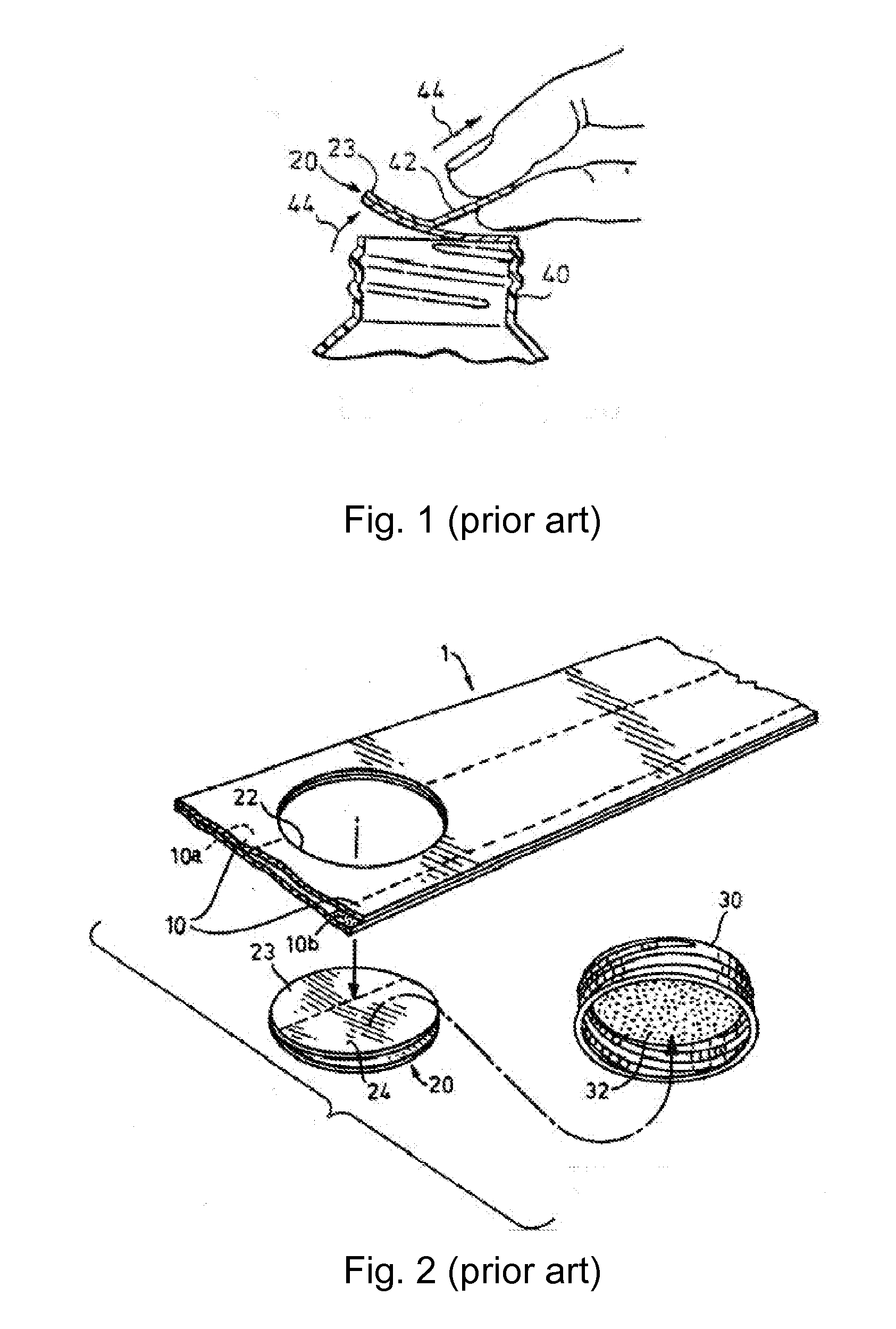

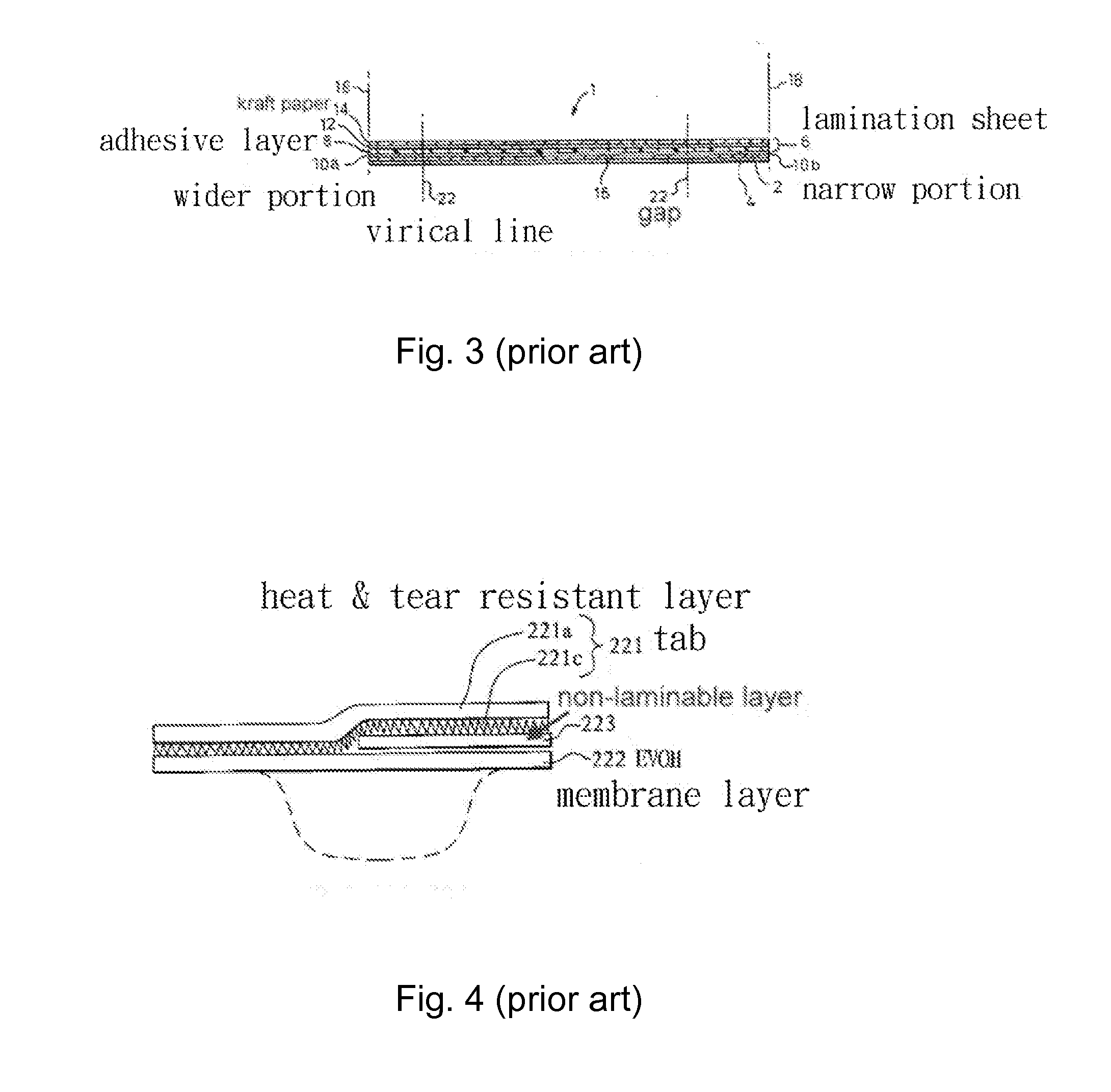

Environment-friendly foamed container closure laminate with embossed tabs

An environment-friendly foamed container closure laminate with embossed tabs is composed of, from top to bottom, a stiff polymer printing layer—the top surface of a half thereof is embossed, the bottom surface is printed; a stiff polymer reinforcement layer—its half bottom surface is embossed and the stiff polymer printing layer laminated with the stiff polymer reinforcement layer is used as a tab (if no printing is necessary, the stiff polymer printing layer and the stiff polymer reinforcement layer are combined to be a tab layer); a soft polymer foam layer—used as a sealing gasket; a high melting point polymer isolation layer—to insulate the heat transfer from the electromagnetic induction heated metal layer to the soft polymer foam layer; an electromagnetic induction heatable metal layer; and a peelable thermosensitive adhesive layer; the inventive environment-friendly foamed container closure laminate with embossed tabs exhibits a good touch feeling and non-slippery fallen away and it will not stick to the soft polymer foam layer, thereby the release layer is saved and the release agent is not necessary.

Owner:WELL PACK IND CO LTD

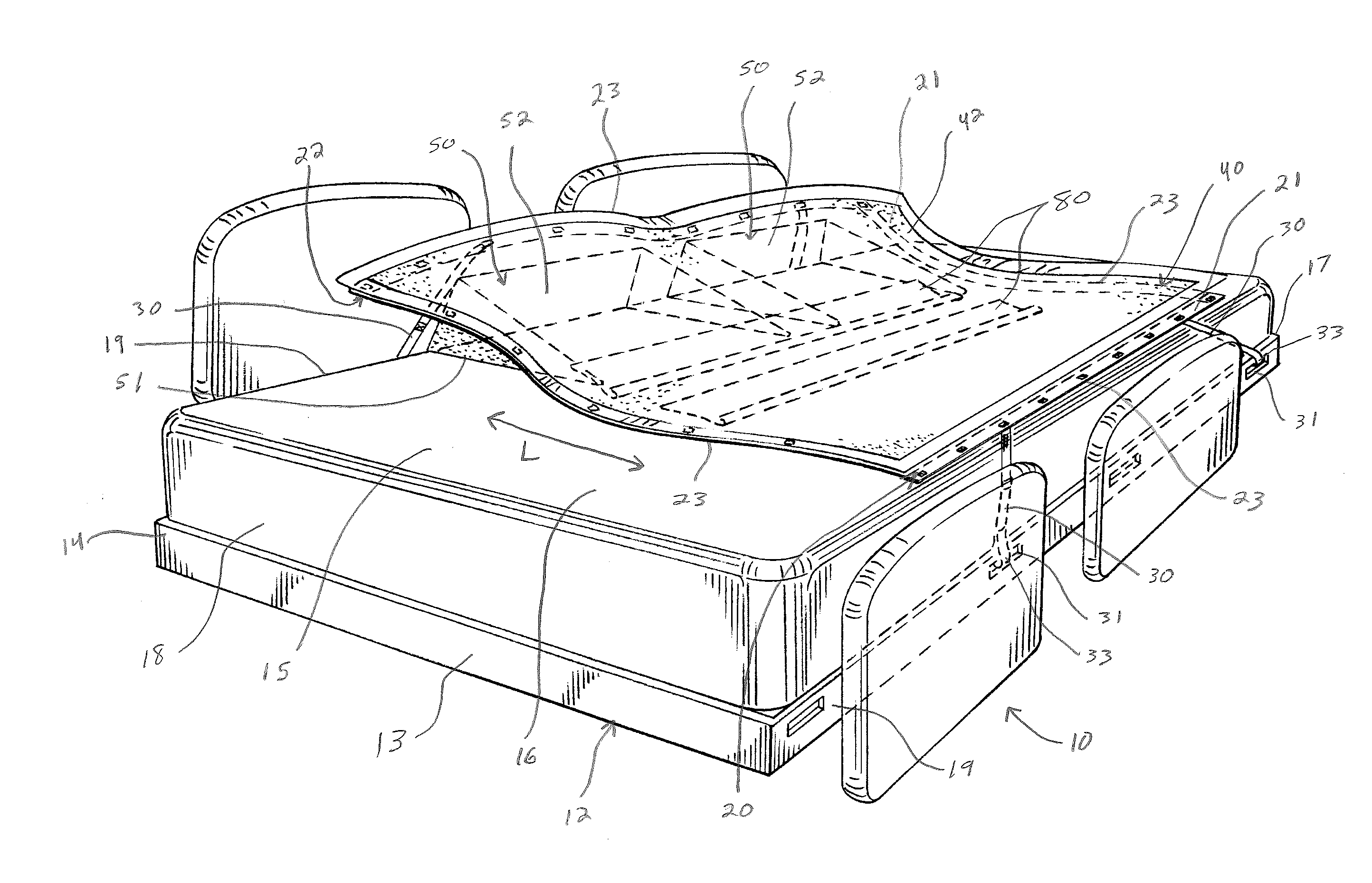

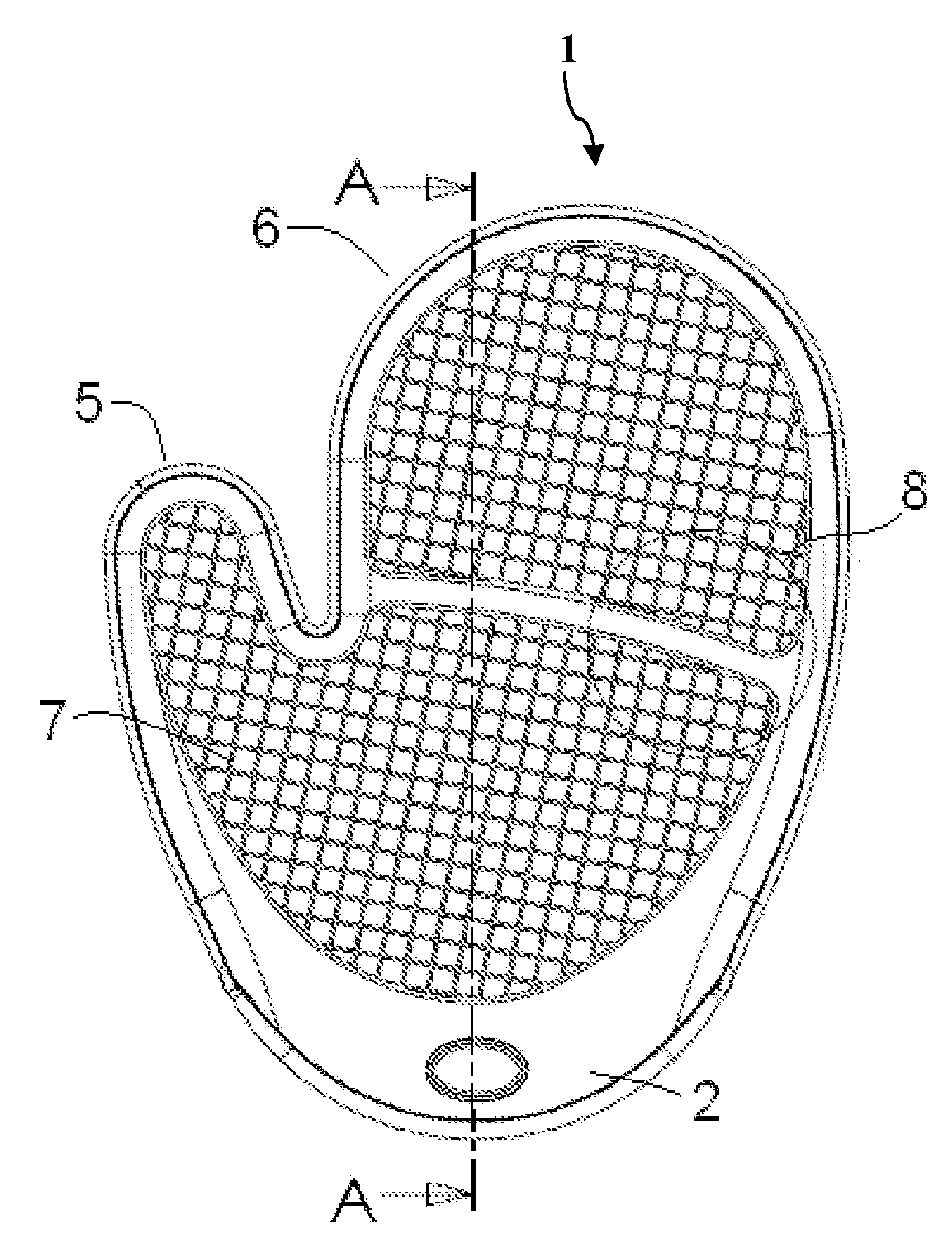

Apparatus and system for turning and positioning a patient

A system for use with a bed having a frame and a supporting surface includes a sheet having a bottom surface placed above the supporting surface of the bed, a top surface, and a plurality of tether straps connected to and extending from the sheet. Each tether strap is configured for connection to the bed. The bottom surface is at least partially formed of a low friction material, and the top surface is at least partially formed of a high friction material, such that the top surface provides greater slipping resistance than the bottom surface. The tether straps include at least two pairs of tether straps, with one pair connected proximate a top edge of the sheet and another pair connected proximate a bottom edge of the sheet. The sheet may further include a sliding member on the bottom surface to assist in lateral sliding of the sheet.

Owner:SAGE PRODS

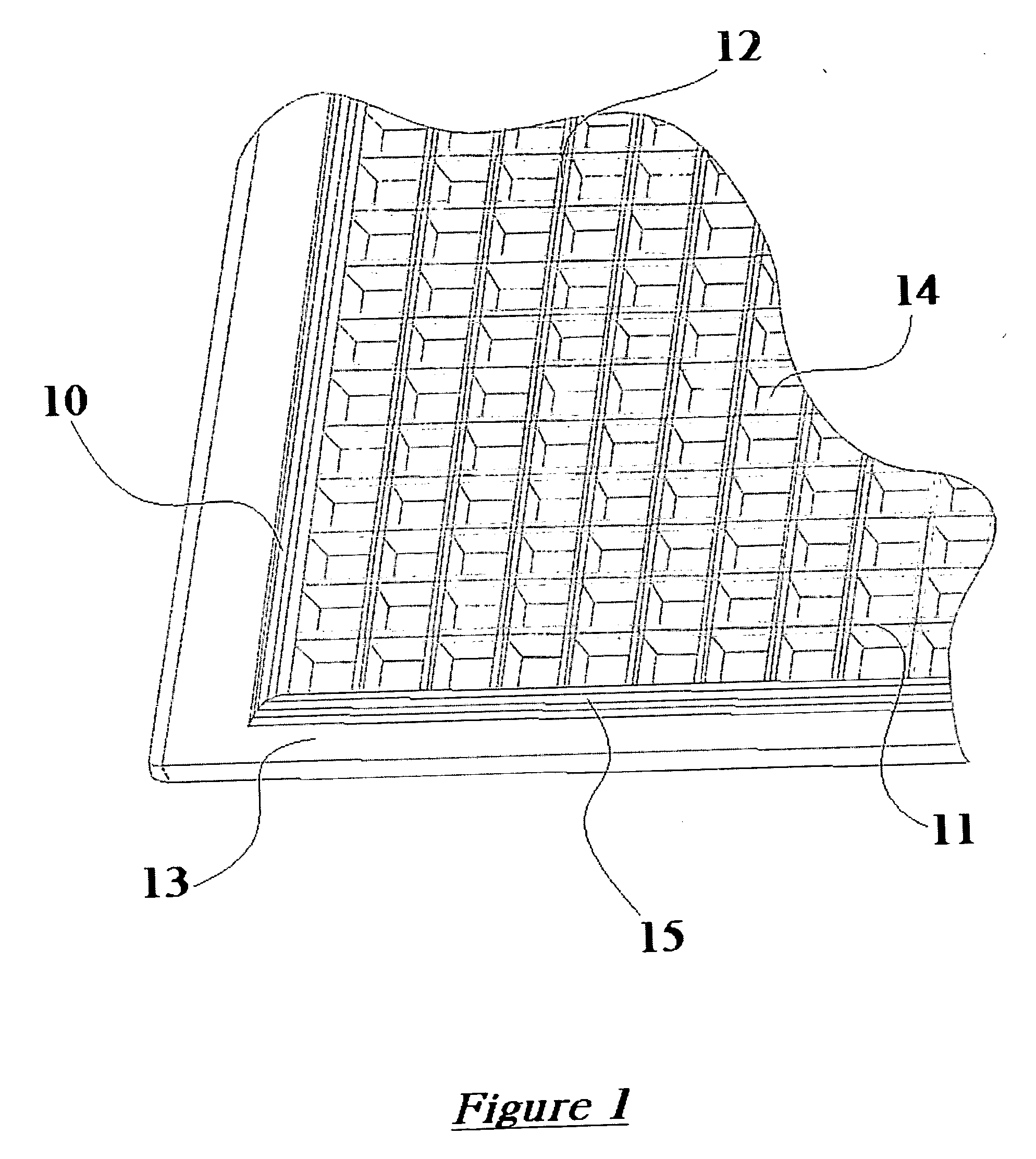

Sheet-Like Building and Construction Materials With High Wet Slip Resistance and High Water Penetration Resistance, and Methods of Making Same

Owner:BERRY FILM PROD CO INC

Surface protection system

An surface protection system of manufacture for protecting the surfaces, including restroom floors, from accidental liquid spills, including urine and water, with a top unit containing grid work of any geometric design containing a slip resistance top design that directs liquid down and into the absorbing core; an absorbing core attached to the top unit by any method, consisting of non woven material containing super absorbent polymer or super absorbent fiber, or similar material that has a high rate of absorbency and capacity to retain the liquid in the material; a moister barrier attached to the absorbing core and the top unit by any permanent means, including glue, heat welding, or other methods, and optionally, a backing unit containing slip resistant characteristics. All components being combined into one surface protection system that also provides for the user to stand on a portion of it, allowing a closer position to a urinal, toilet, beverage machine, drinking fountain, or other intended use of the surface protection system. An article of manufacture for protecting the counter surfaces from accidental liquid spills, including coffee, carbonated beverages, and water, with a top unit containing grip work grid work of any geometric design containing a slip resistance top design that directs liquid down and into the absorbing core; an absorbing core attached to the top unit by any method, consisting of non woven material containing super absorbent polymer or super absorbent fiber, or similar material that has a high rate of absorbency and capacity to retain the liquid in the material; a moister barrier attached to the absorbing core and the top unit by any permanent means, including glue, heat welding, or other methods, and optionally, a backing unit containing slip resistant characteristics. All components being combined into one surface protection system that also provides for the user to stand on a portion of it, allowing a closer position to a urinal, toilet, beverage machine, drinking fountain, or other intended use of the surface protection system.

Owner:WATERMAN WADE RICHARD +1

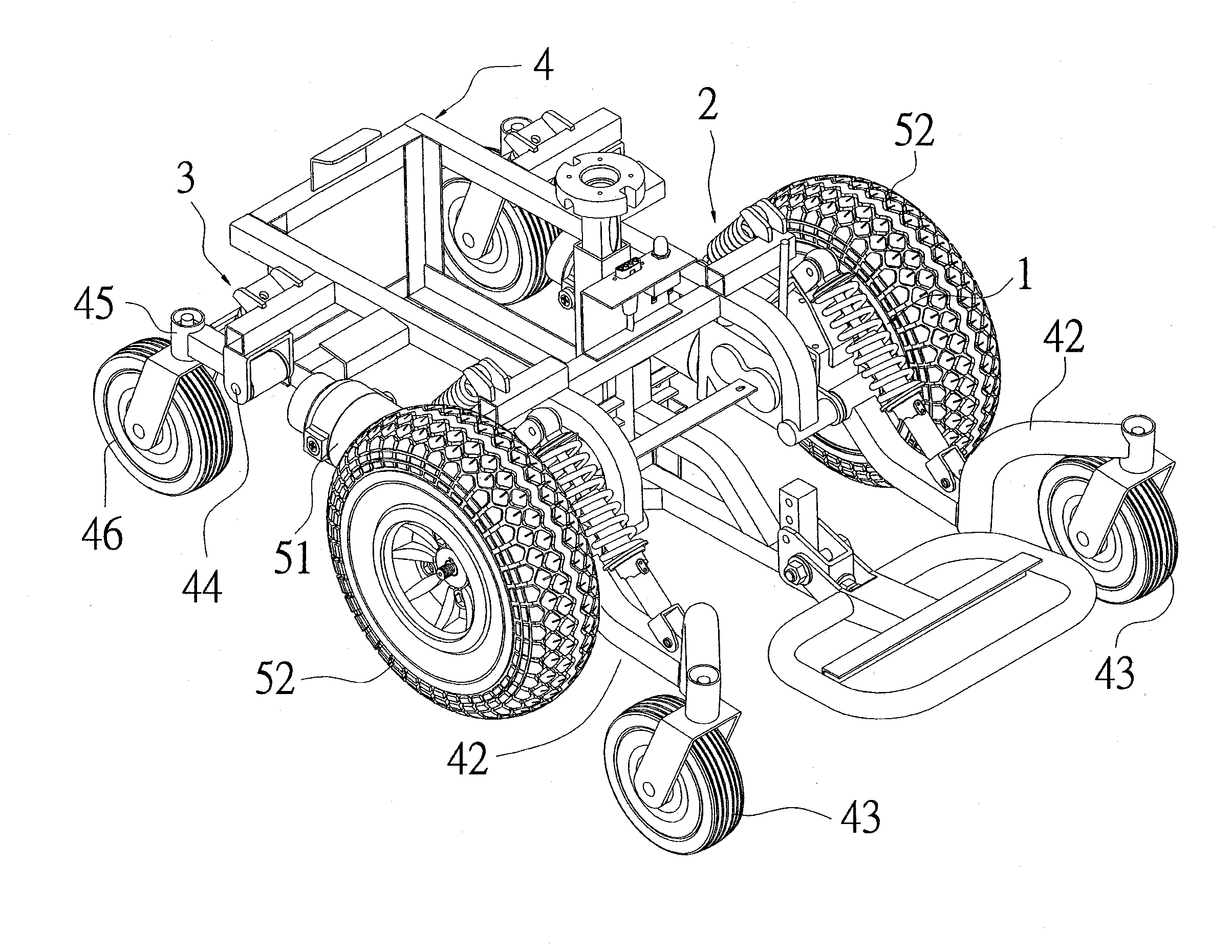

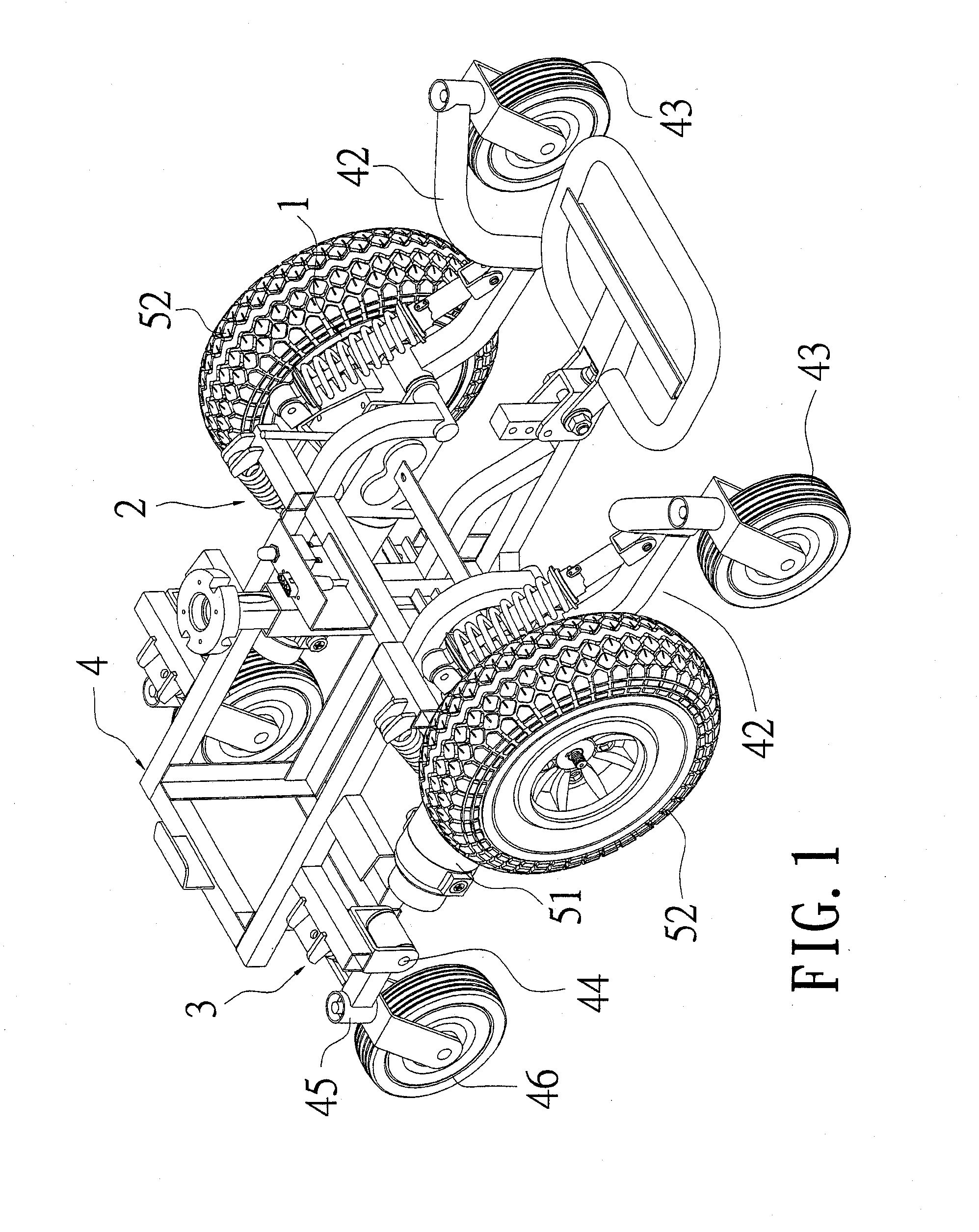

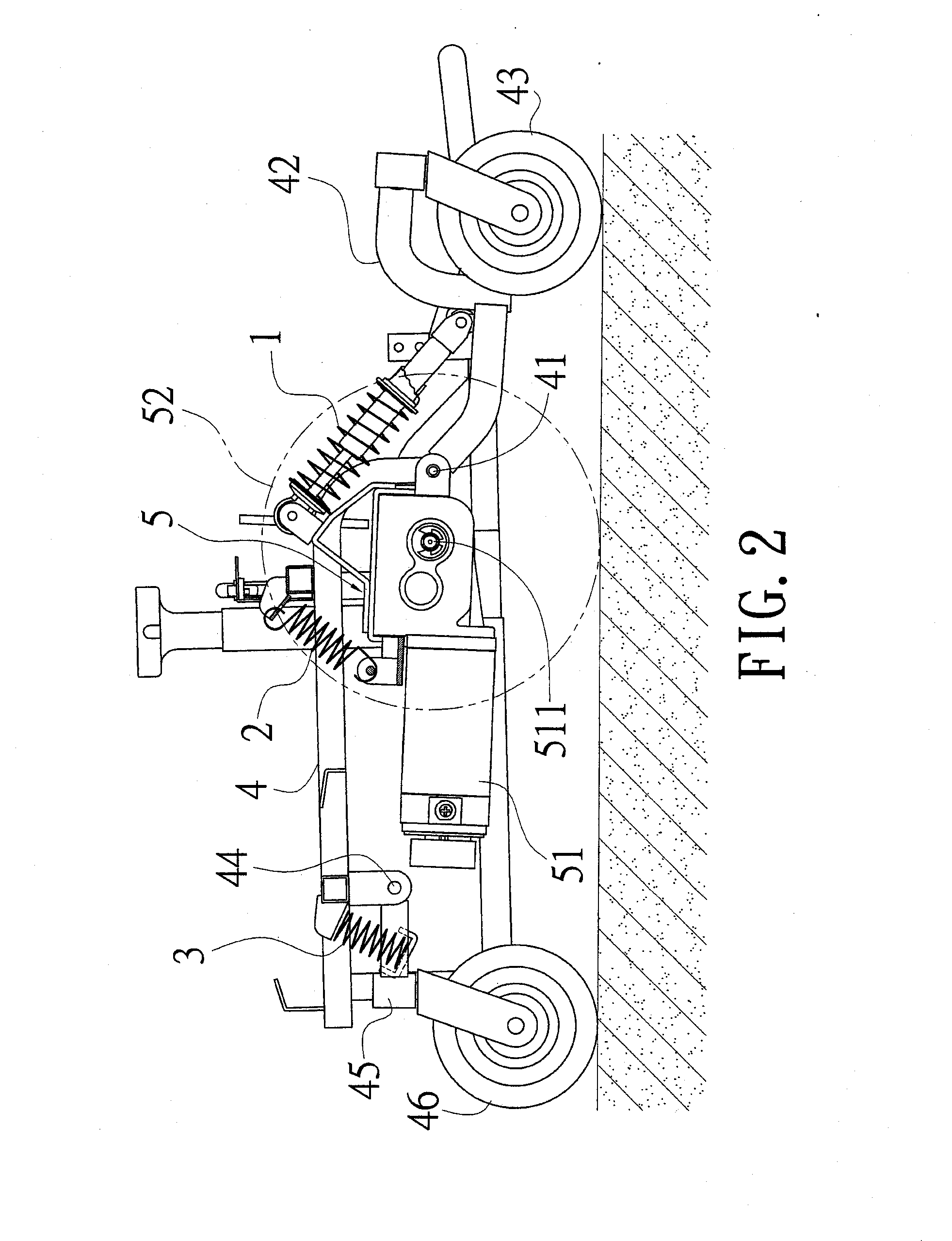

Suspension system for electric wheelchair

InactiveUS20110253464A1Easily slidSafety is assuredElectric propulsion mountingWheelchairs/patient conveyanceEngineeringSlip resistance

A suspension system for an electric wheelchair is revealed. A pivot on a front end of a wheelchair frame pivotally connects a front wheel frame and a drive set frame. A front suspension system is disposed between the front wheel frame and a drive set frame. The front wheel frame is assembled with front wheels, the drive set frame is disposed with a drive set and a drive wheel is arranged at a power output end of the drive set. Moreover, an auxiliary suspension device is arranged between the drive set frame and the frame while a rear end of the frame is disposed with rear wheels. Thereby the electric wheelchair has good stability and slip-resistance, not easily overturned or slid by interaction between the front and the auxiliary suspension devices while driving through concave surfaces or convex surfaces. Therefore the safety of users seated in wheelchairs is assured.

Owner:FREERIDER CORP

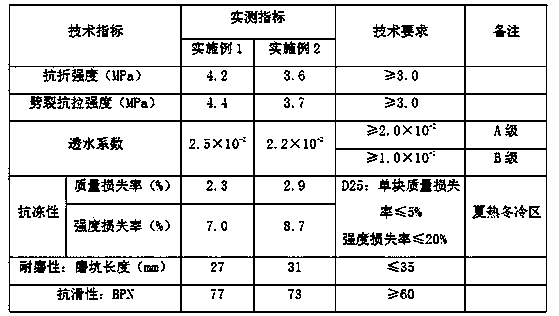

Ecological permeable pavement brick and preparation method thereof

The invention provides an ecological permeable pavement brick prepared from in a ratio of cement to coal ash, coarse aggregates of construction wastes to coarse aggregates of steel slag to sand to water to a water reducing agent of 1;(0.2-0.3):(1.6-1.8):(1.6-1.8):(0.7-0.9):(0.45-0.52):(0.03-0.04). The invention also provides a preparation method of the ecological permeable pavement brick according to the ratio. The ecological permeable pavement brick has the advantages of high breaking strength and splitting tensile strength, freezing resistance, wear resistance, slip resistance, good permeability and the like.

Owner:SHANDONG JIAOTONG UNIV

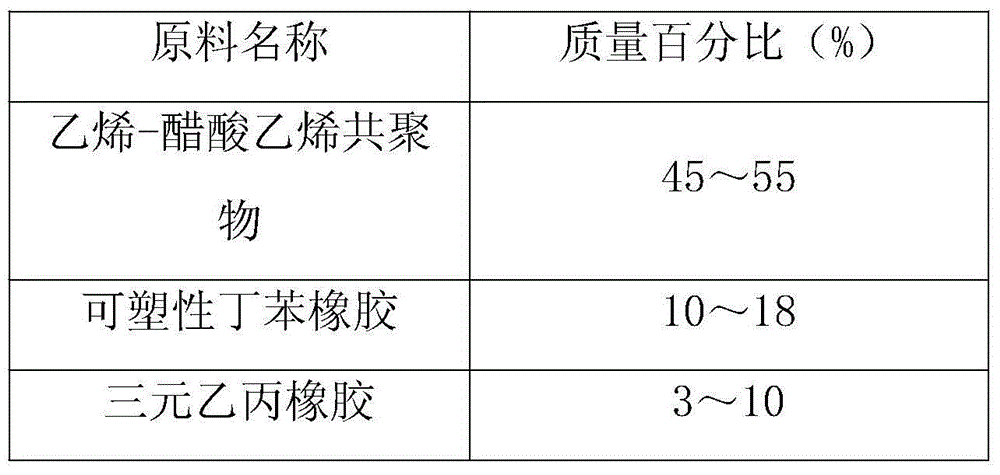

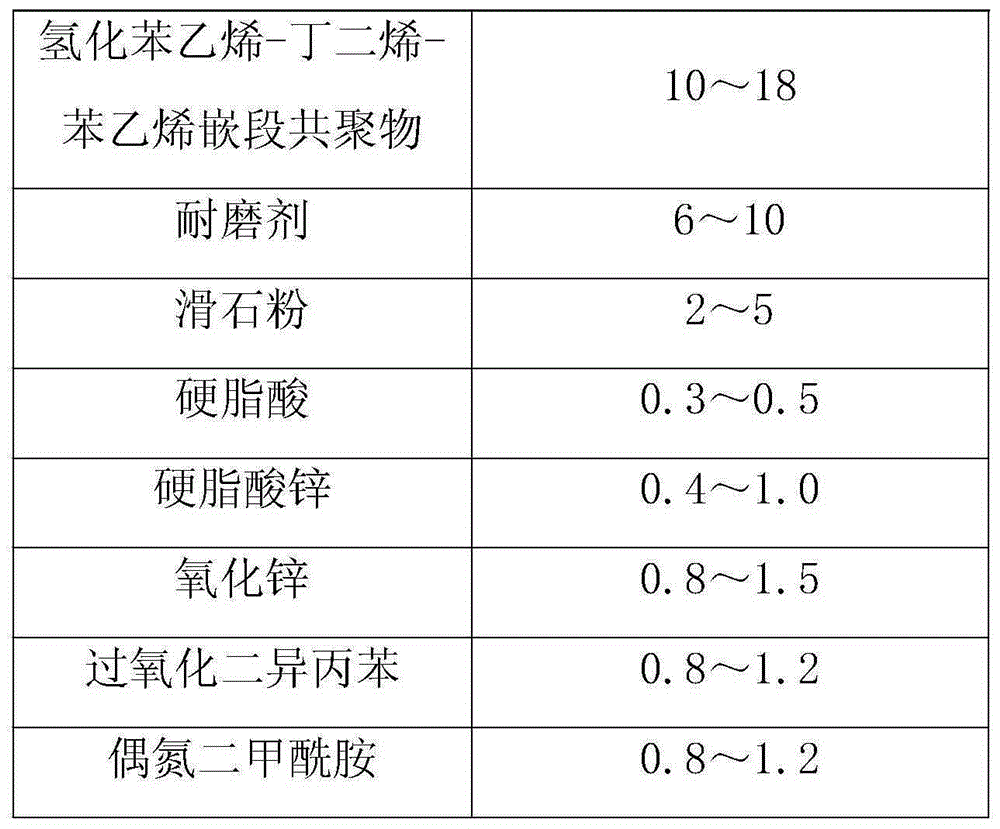

Super wear-resistant rubber foamed sport shoe material and preparation method thereof

InactiveCN104910507AImprove slip resistanceStrong slip resistanceSolesDomestic footwearPolymer scienceWear resistant

The invention discloses a super wear-resistant rubber foamed sport shoe material comprising the components of ethylene-vinyl acetate copolymer, plastic styrene-butadiene rubber (TVA), ethylene propylene diene monomer (EPDM), hydrogenated styrene-butadiene-styrene block copolymer (SEBS), a wear-resistant agent, talc powder, stearic acid, zinc stearate, zinc oxide, dicumyl peroxide (DCP) and azodicarbonamide. The invention also discloses a preparation method of the super wear-resistant rubber foamed sport shoe material. The super wear-resistant rubber foamed sport shoe material disclosed by the invention is good in slip resistance, the wear resistance of the sport shoe material is superior to that of common hard rubber, and the sport shoe material can be directly molded by ejecting. The invention also discloses a preparation method of the super wear-resistant rubber foamed sport shoe material, wherein physical parameters are strictly controlled during preparation to ensure that the prepared super wear-resistant rubber foamed sport shoe material has more excellent wear resistance and slip resistance.

Owner:厦门联合信诺新材料有限公司

Paving method of steel box girder bridge deck payment layer

ActiveCN101660293AReduce tensile stressReduce shear stressSolid waste managementBridge structural detailsBridge deckEngineering

The invention belongs to the field of building materials, in particular to a paying method of a steel box girder bridge deck payment layer. The paying method of the steel box girder bridge deck payment layer is characterized by comprising the following steps: (1) bridge deck pre-cleaning; (2) welding of shearing rivets; (3) binding of reinforcing mats; (4) payment of a high-toughness high-strengthlight aggregation concrete layer: paying high-toughness high-strength light aggregation concrete on steel plates of a steel box girder bridge deck and forming the high-toughness high-strength light aggregation concrete layer, wherein the high-toughness high-strength light aggregation concrete is higher than the shearing rivets by 1-2 cm and the thickness of the high-toughness high-strength lightaggregation concrete is 5-8 cm; (5) payment of a waterproof bonding stress absorbing layer, wherein the thickness of the waterproof bonding stress absorbing layer is 1-2 cm; and (6) payment of a payment layer for resisting slipping, reducing noise and draining: preparing the payment layer for resisting slipping, reducing noise and draining, wherein the thickness of the pavement layer is 3-5 cm. The payment layer has the characteristics of stress absorption, lightness and excellent slipping resistance.

Owner:WUHAN MUNICIPAL CONSTR GROUP

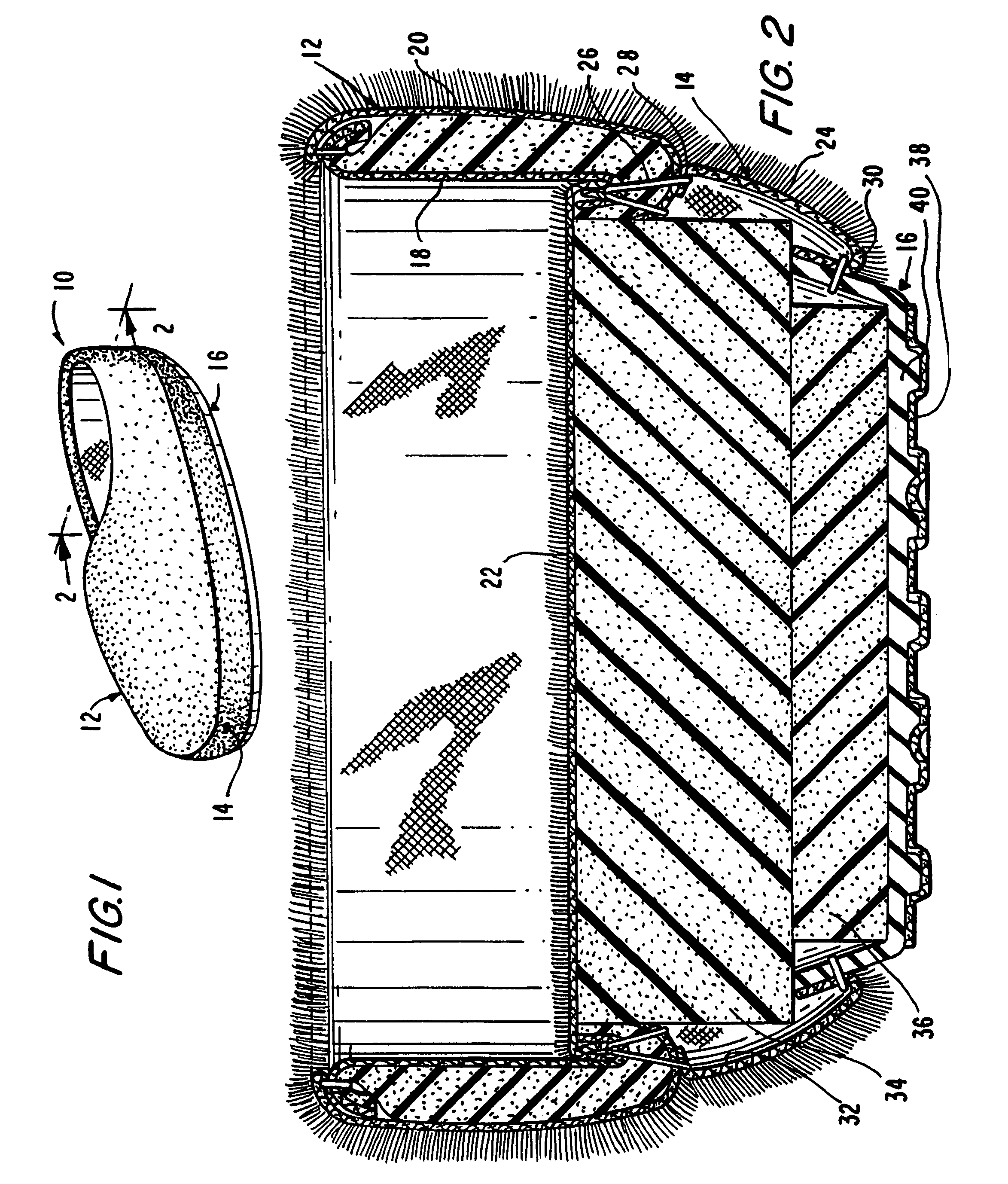

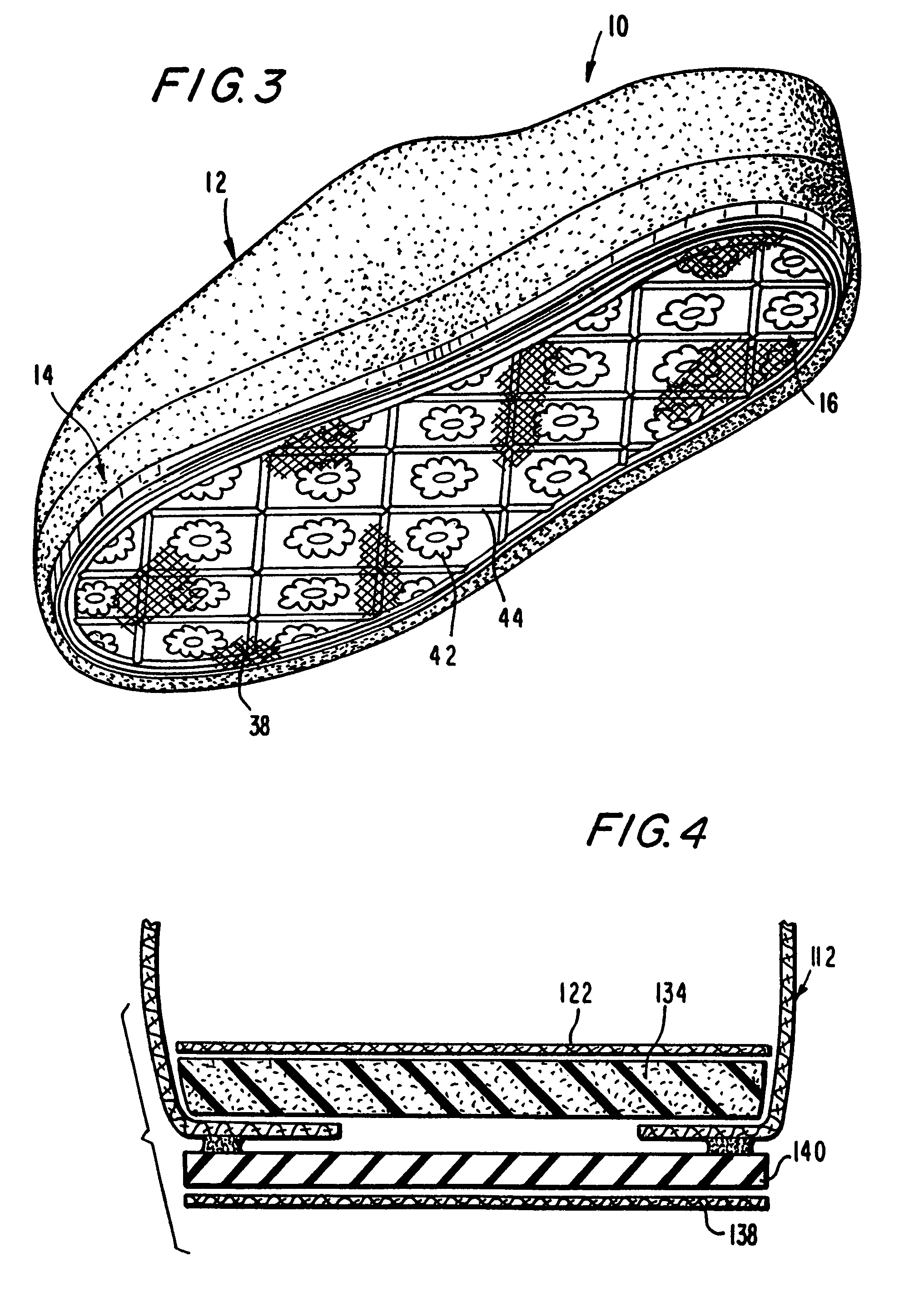

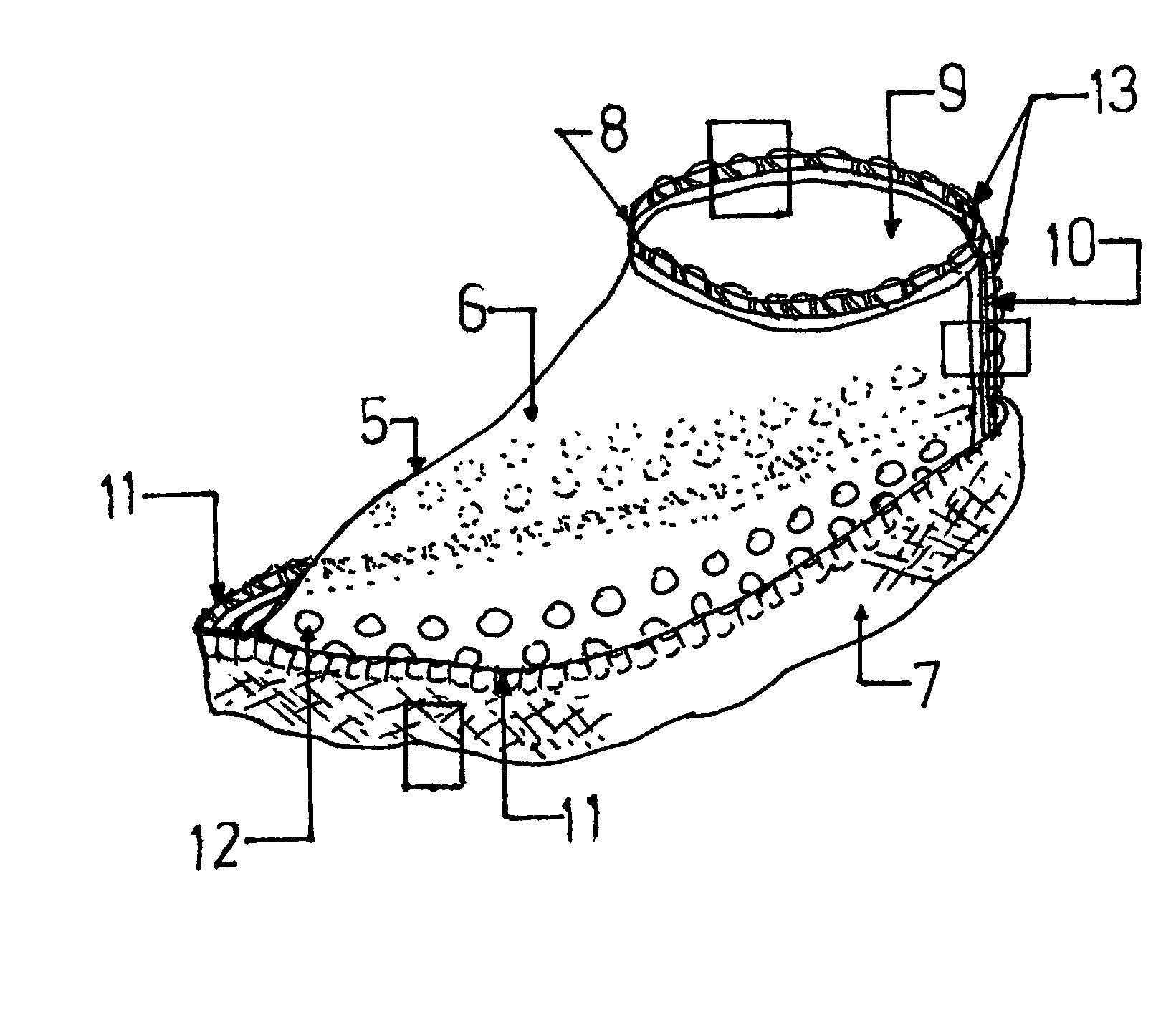

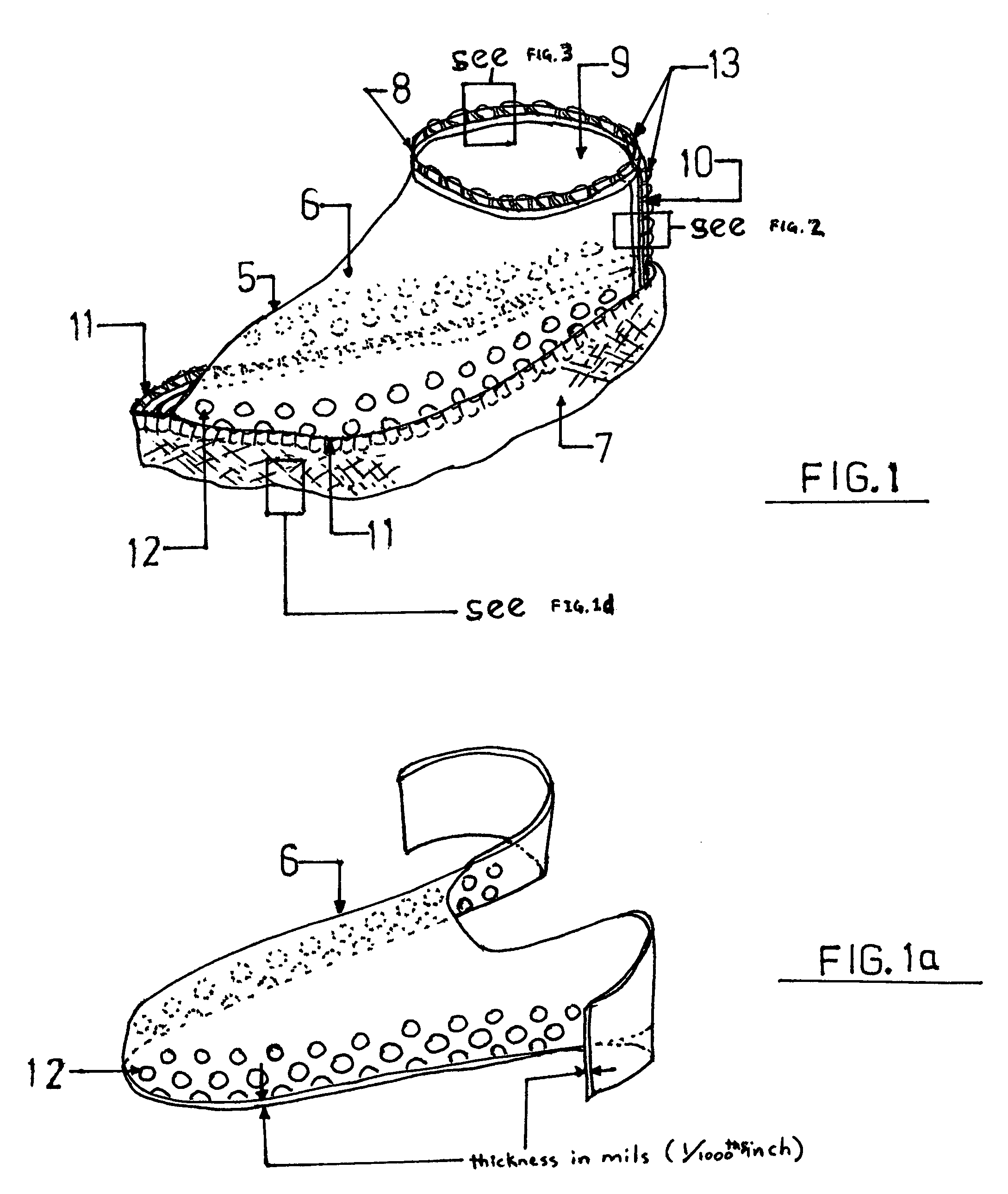

Shoe with slip-resistant, shape-retaining fabric outsole

InactiveUS7036246B2Improve skid resistanceUse quietSolesShoemaking devicesSlip resistanceCivil engineering

Owner:E S ORIGINALS

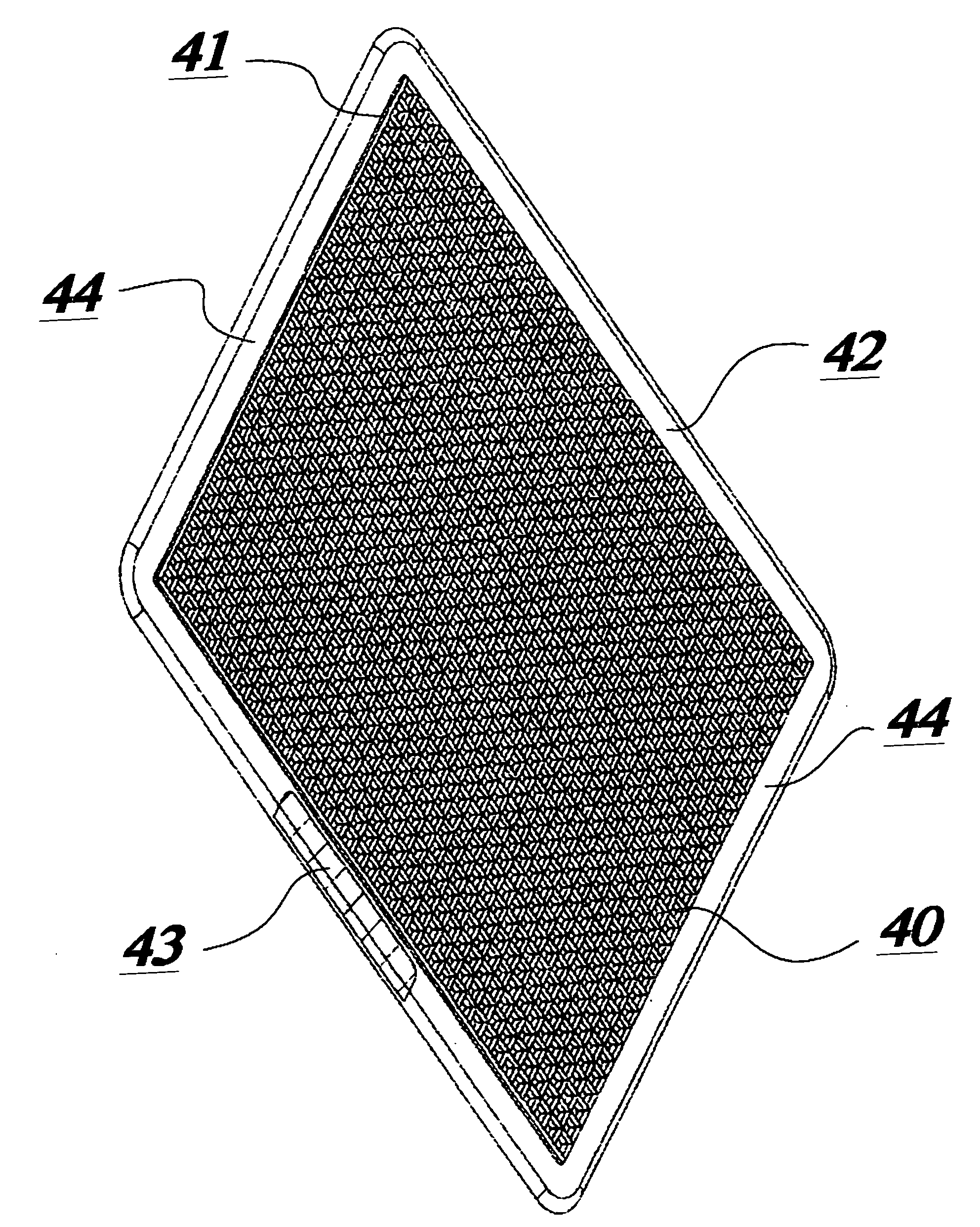

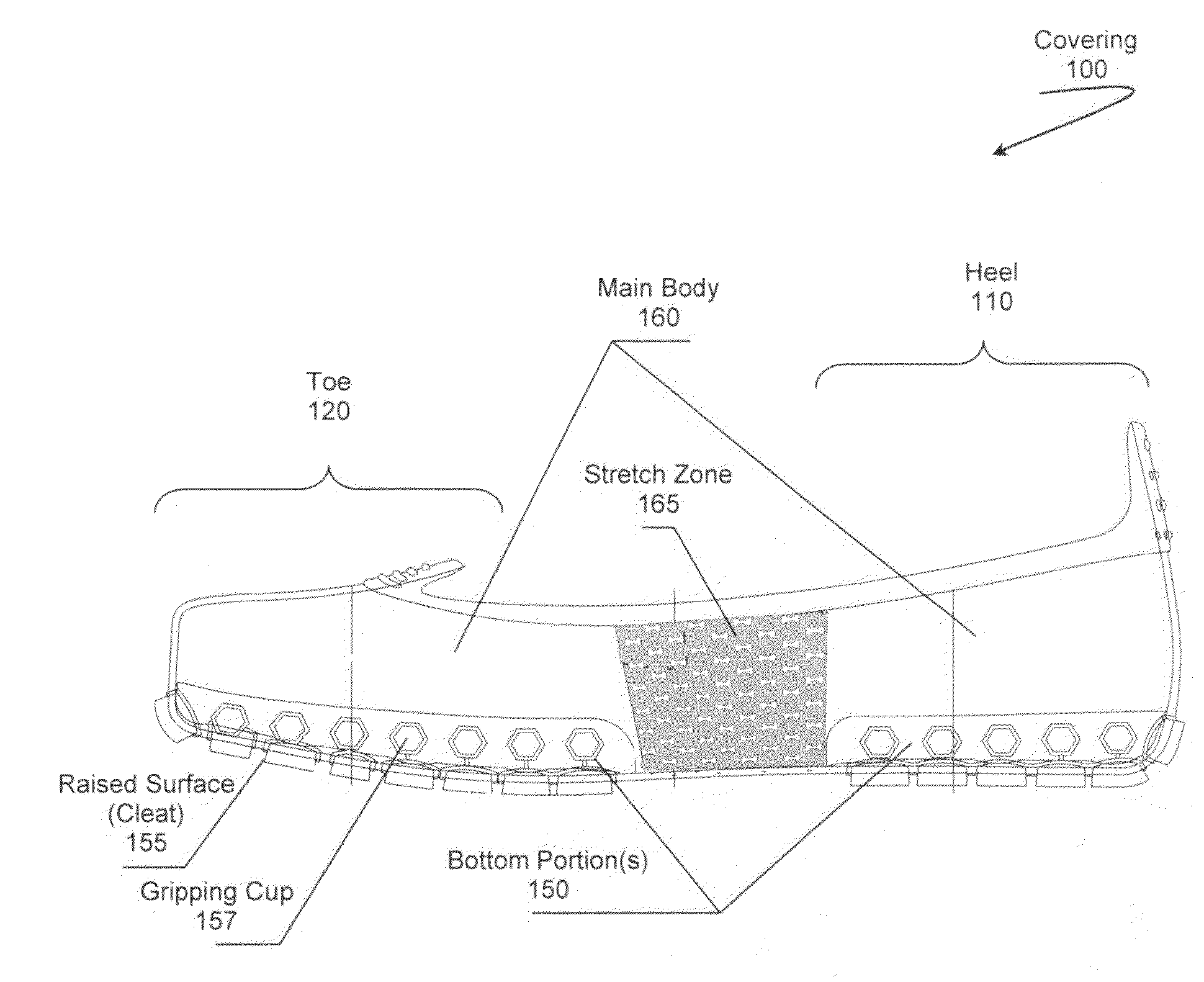

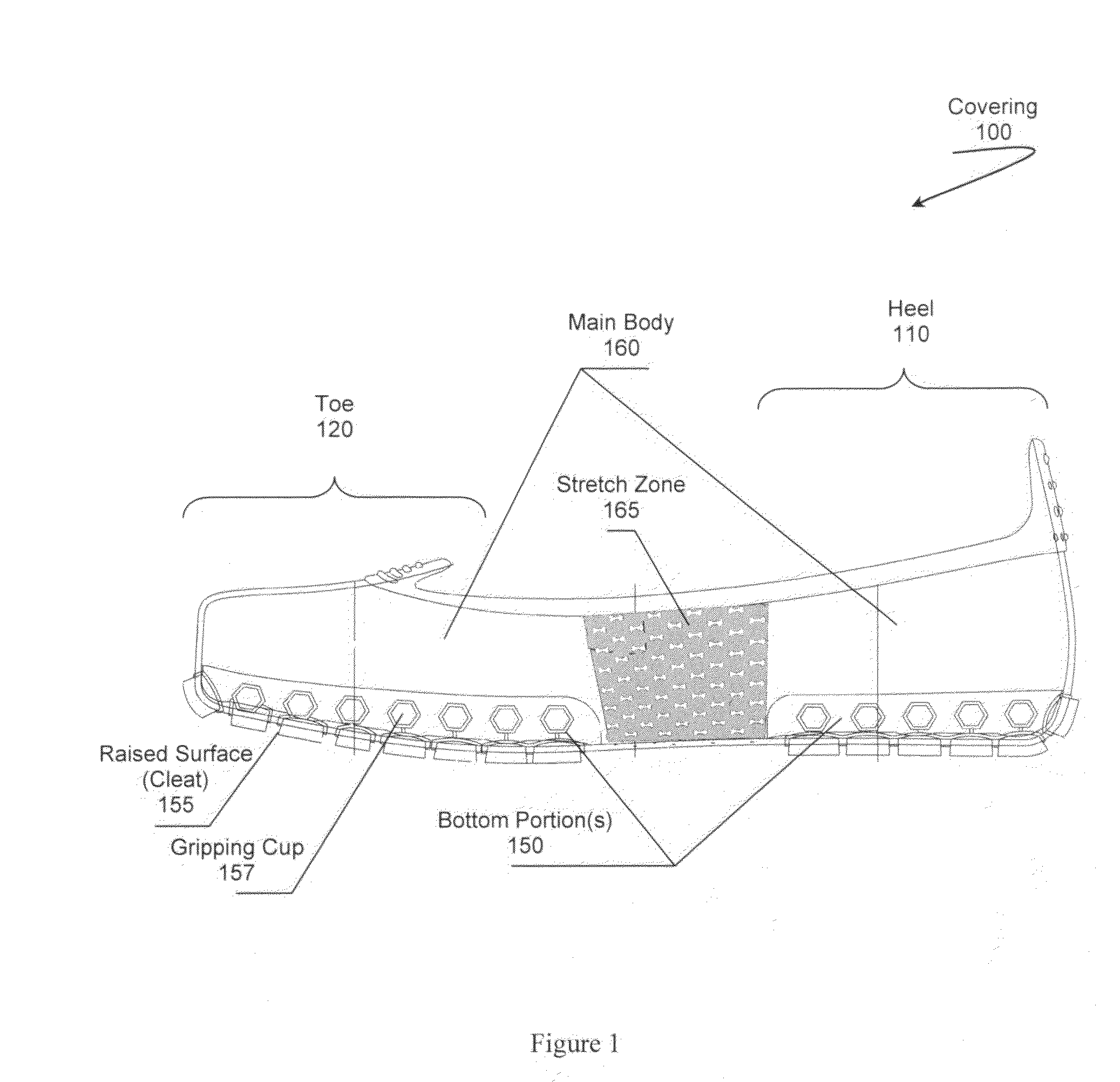

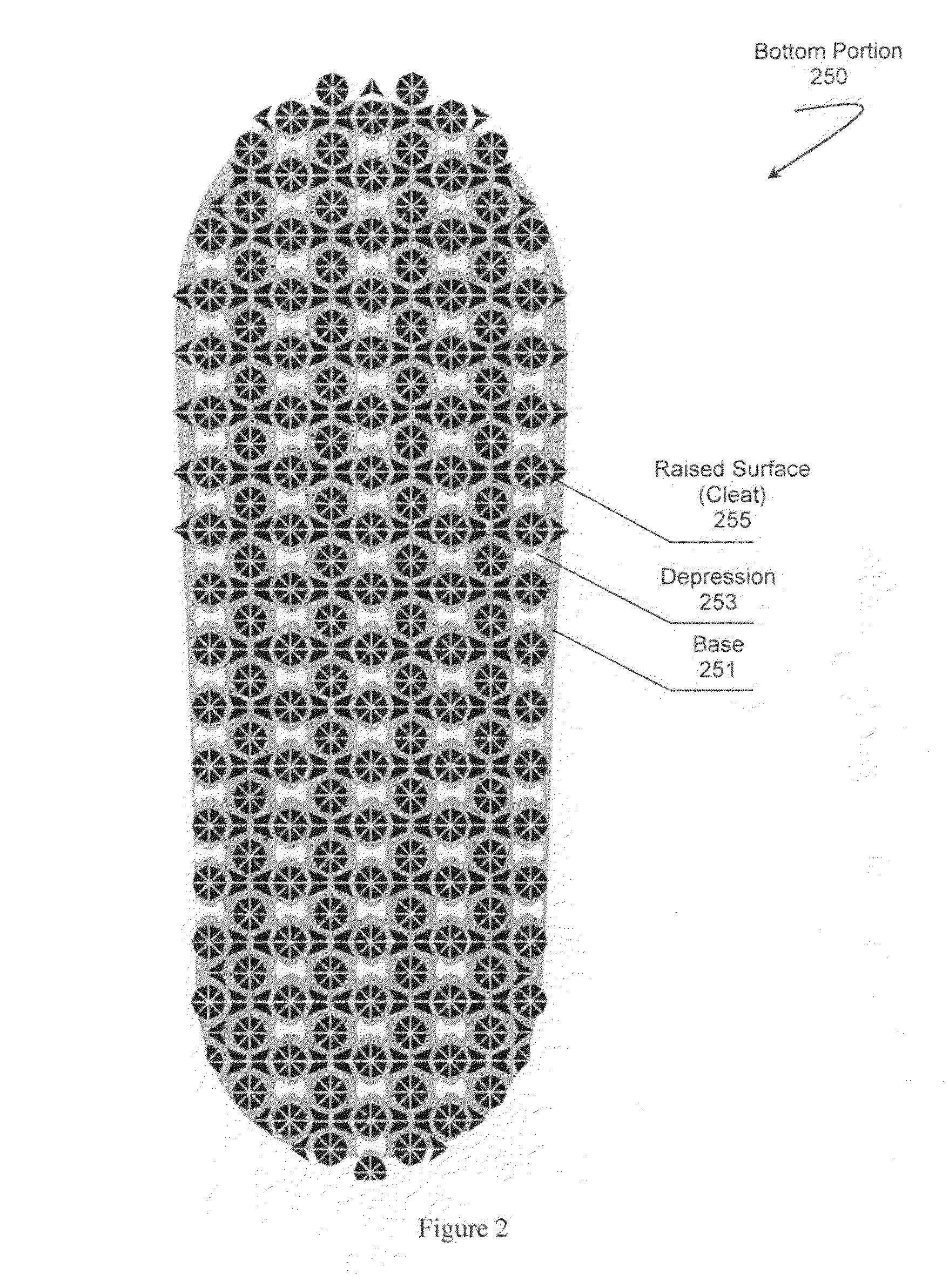

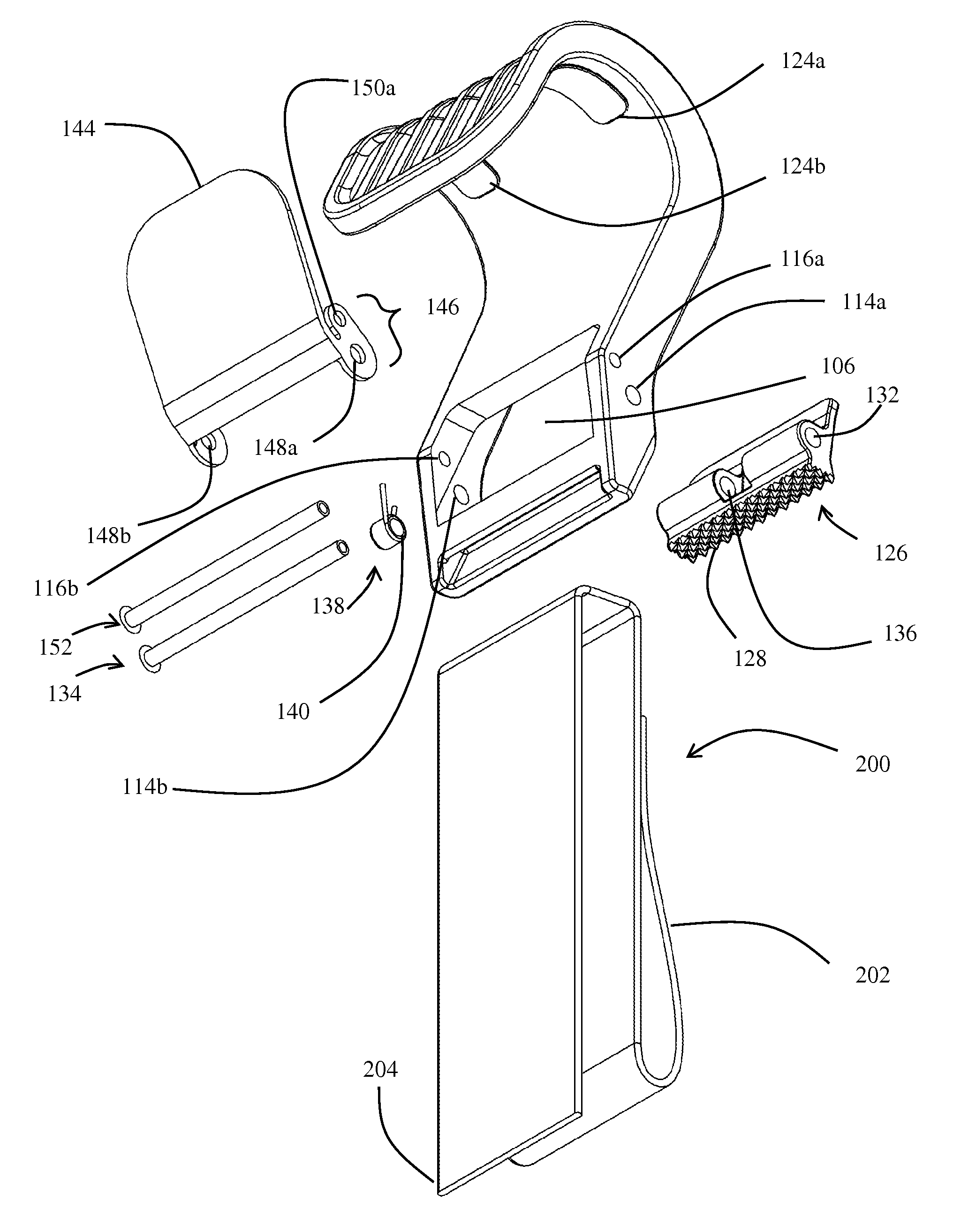

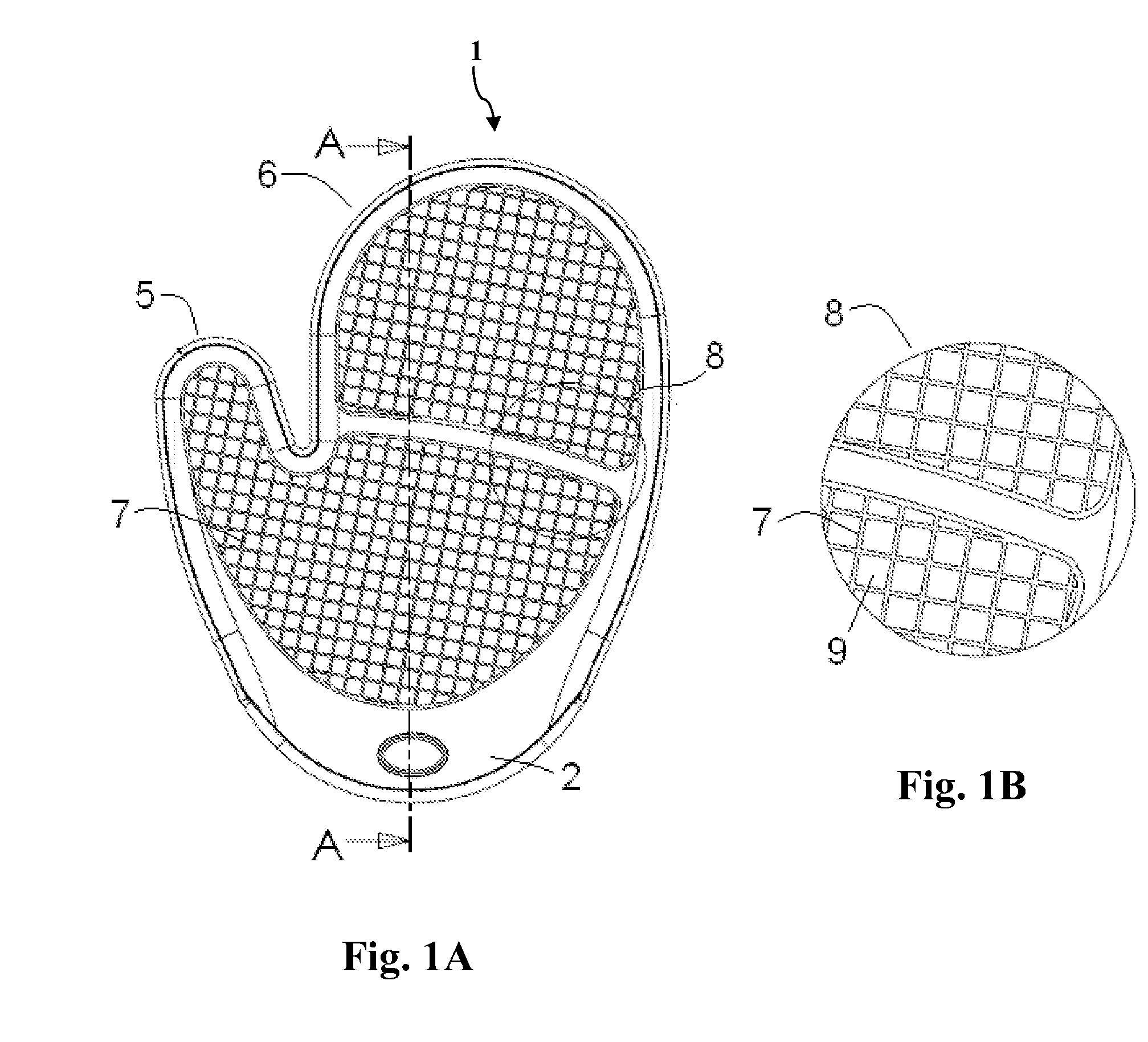

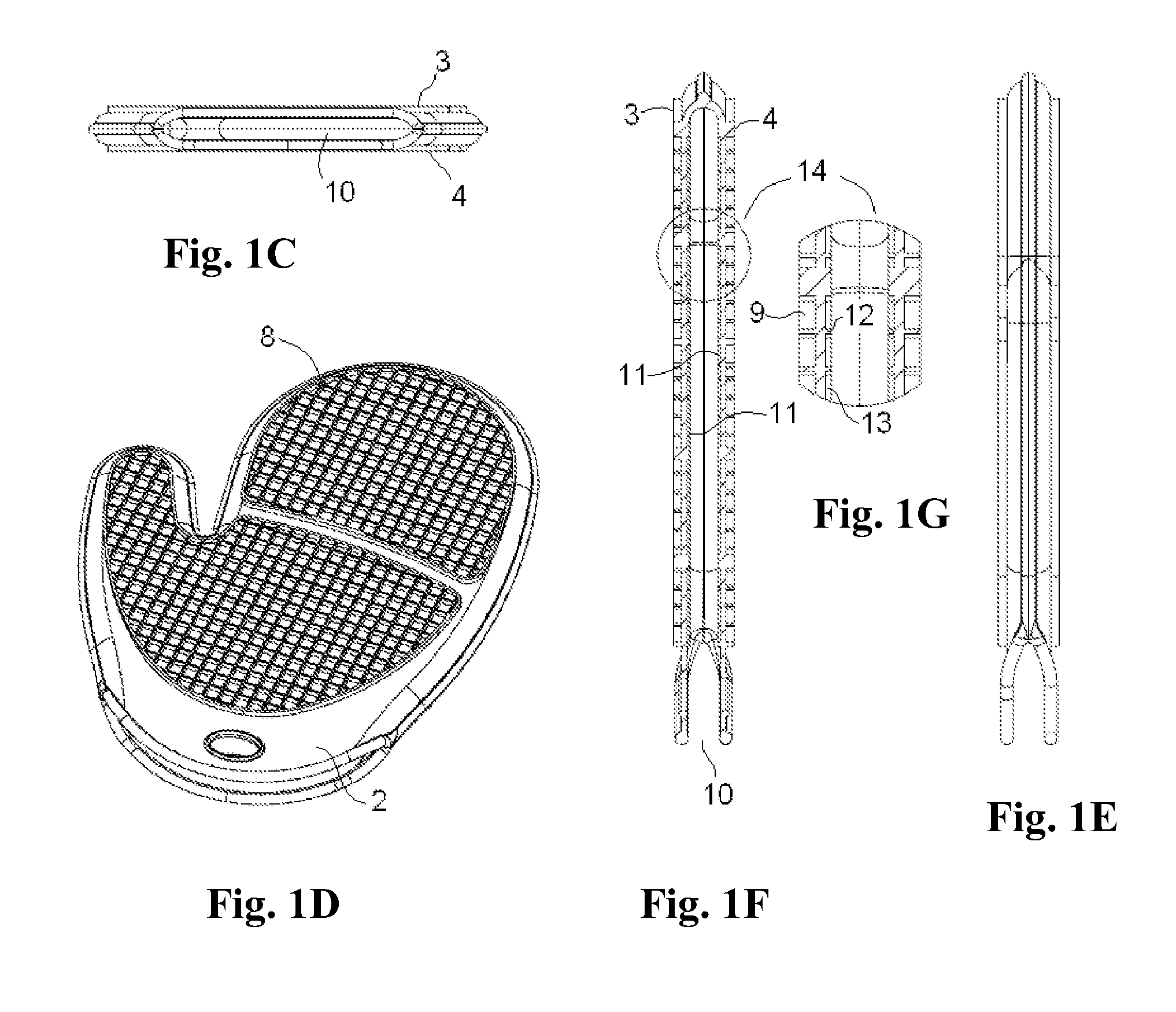

Latticed elastic shoe cover with cleats

Slip resistant covers are presented. An especially preferred slip-resistant cover includes an elastic shoe cover comprising a latticed surface that allows the shoe cover to stretch further than would ordinarily be possible if the shoe cover had a uniform thickness. Contemplated shoe covers can also comprise cleats on the bottom surface to provide slip resistance.

Owner:EARL J AND KIMBERLY VOTOLATO TRUSTEES OF THE VOTOLATO LIVING TRUST DATED JUNE 1 1994 AS WHOLLY AMENDED

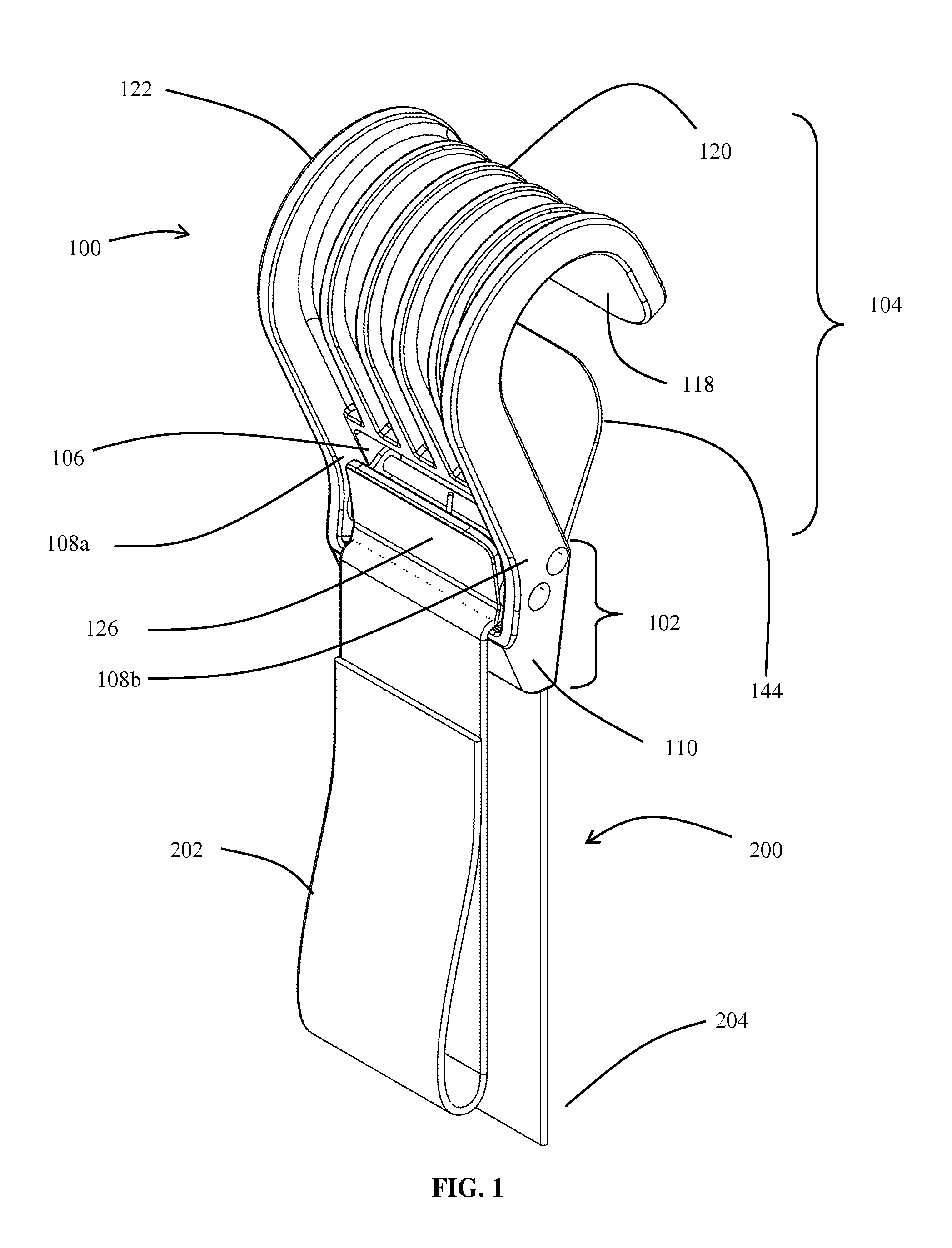

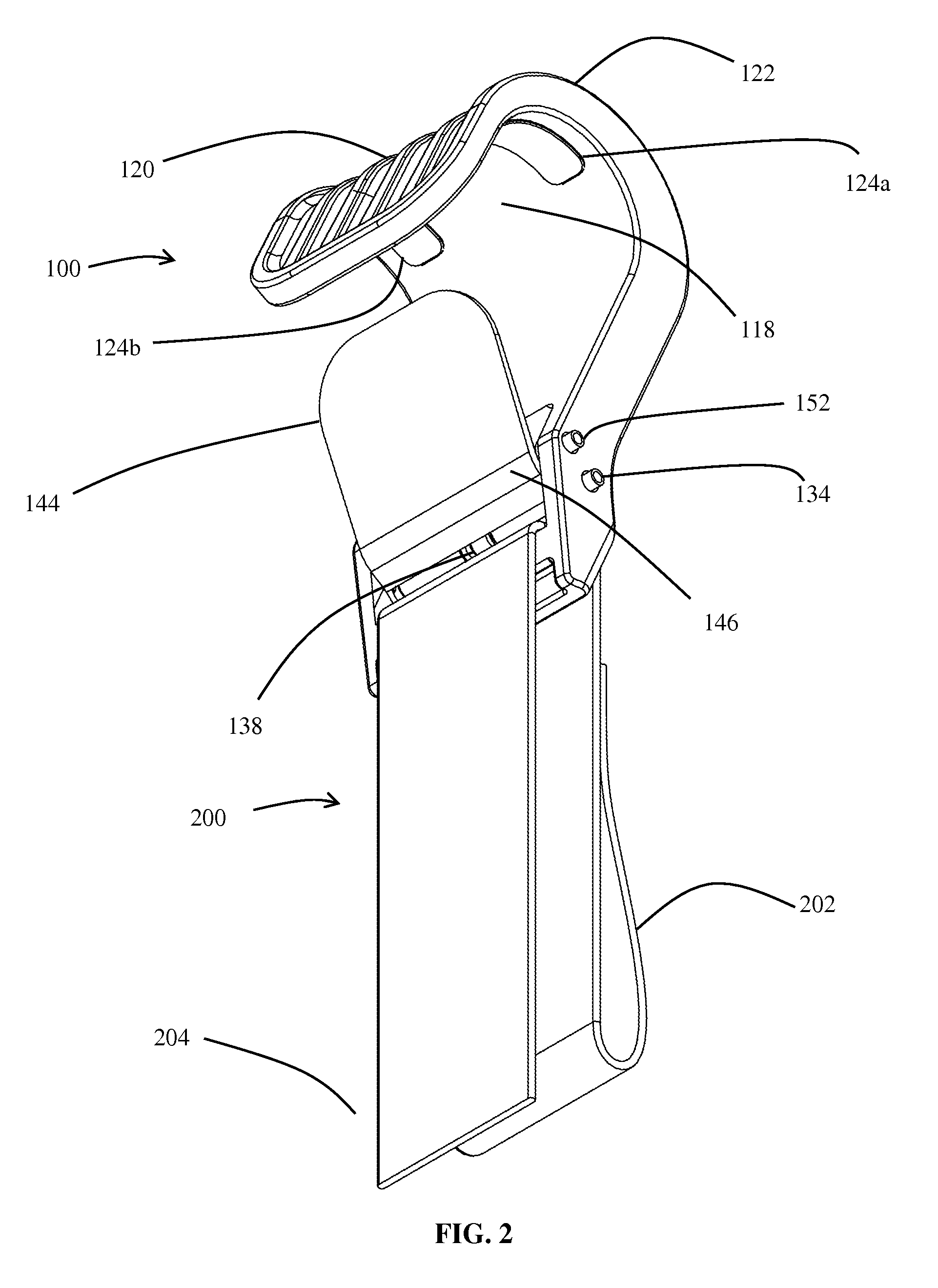

Strap attachment device

ActiveUS8387217B1Improve gripImprove securitySnap fastenersSafety beltsEngineeringMechanical engineering

A strap attachment device includes a main body with a lower body end that has an opening suited for a strap. Based on its position, a cam lever at the opening of the lower body end holds or releases the strap, permitting adjustment of the length of the strap that enters the opening. Extending upward from the lower body end is an upper body end that is curved into a hook or any other shape appropriate for connection to an object. A flexible or translatable gate may extend from the main body so as to prevent the upper body end from inadvertently becoming detached from the object. Slip-resistance on the upper body end resists slippage between the upper body end and the object during side-to-side movements. Ends of the strap may include a loop or handle or connect to other devices.

Owner:LIFELINE PROD LLC

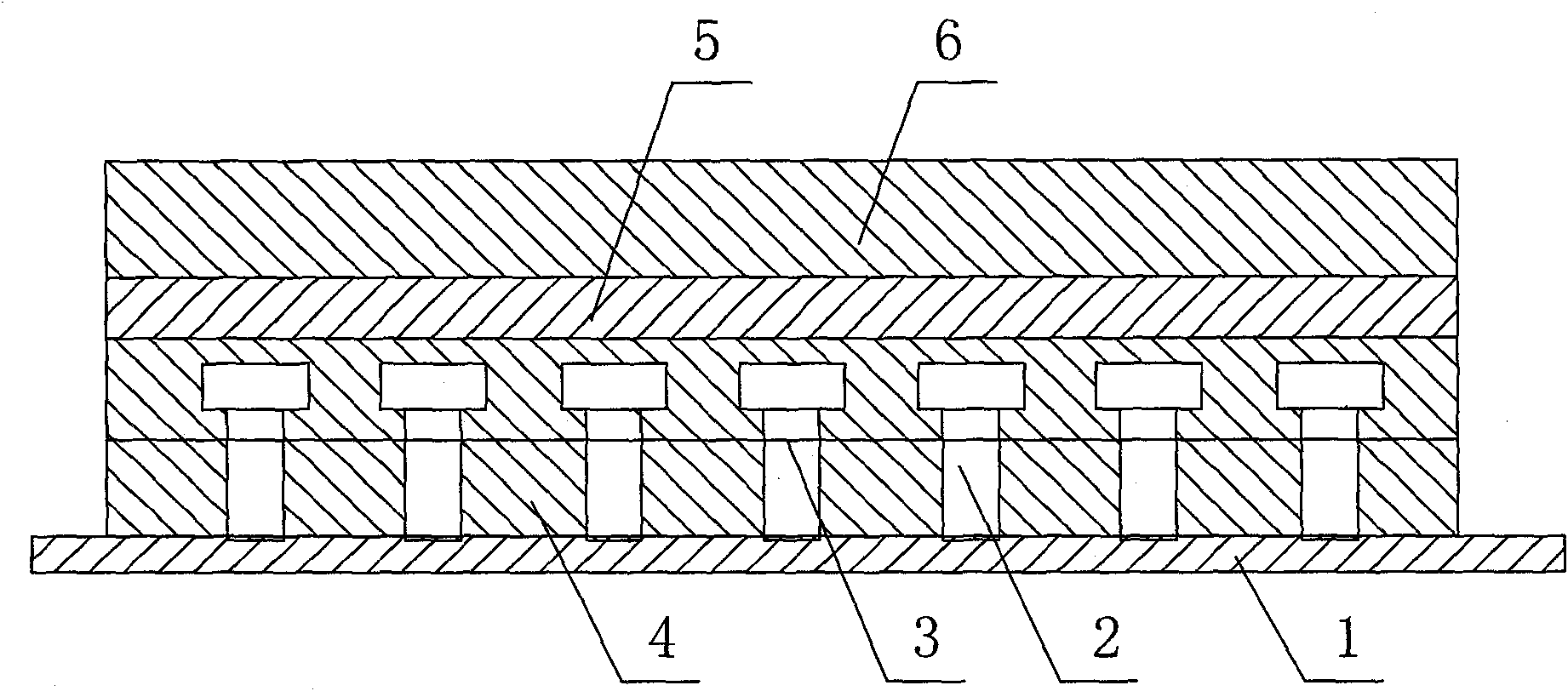

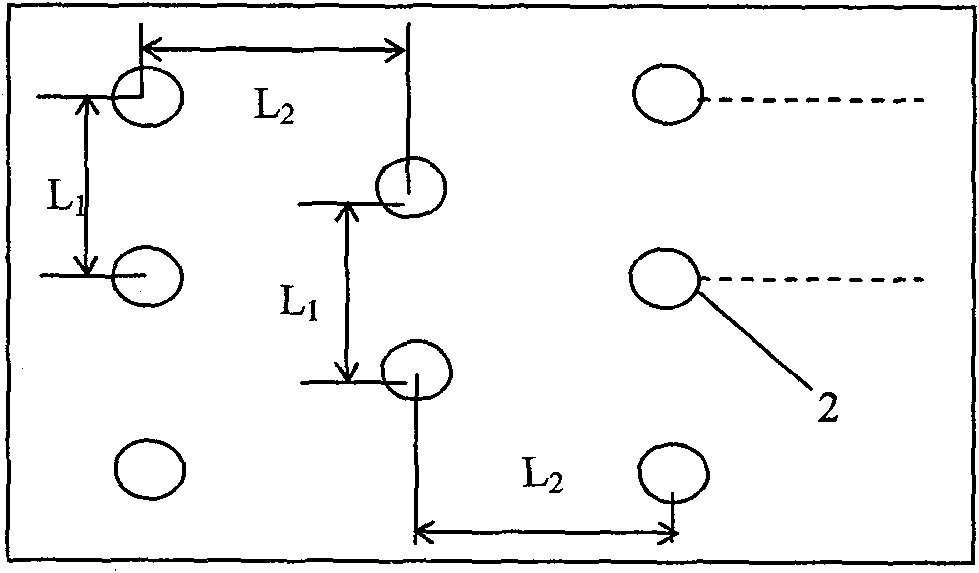

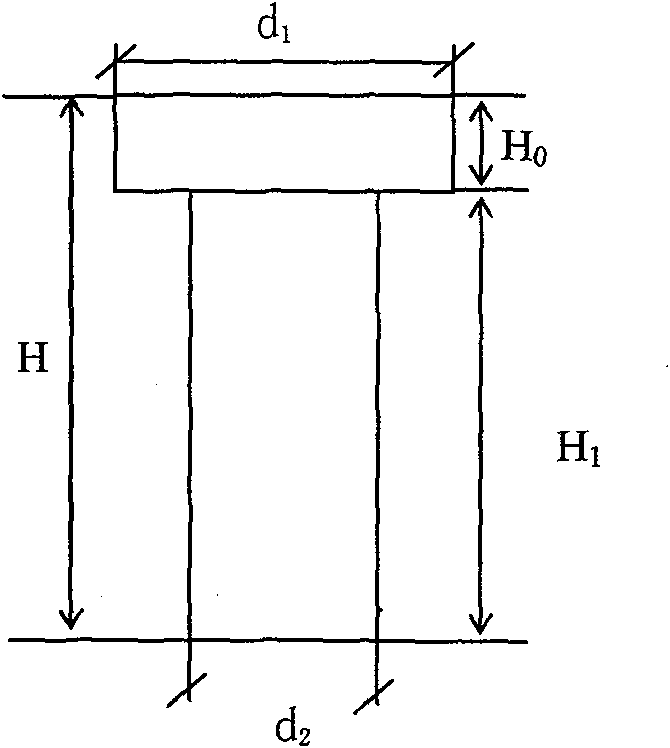

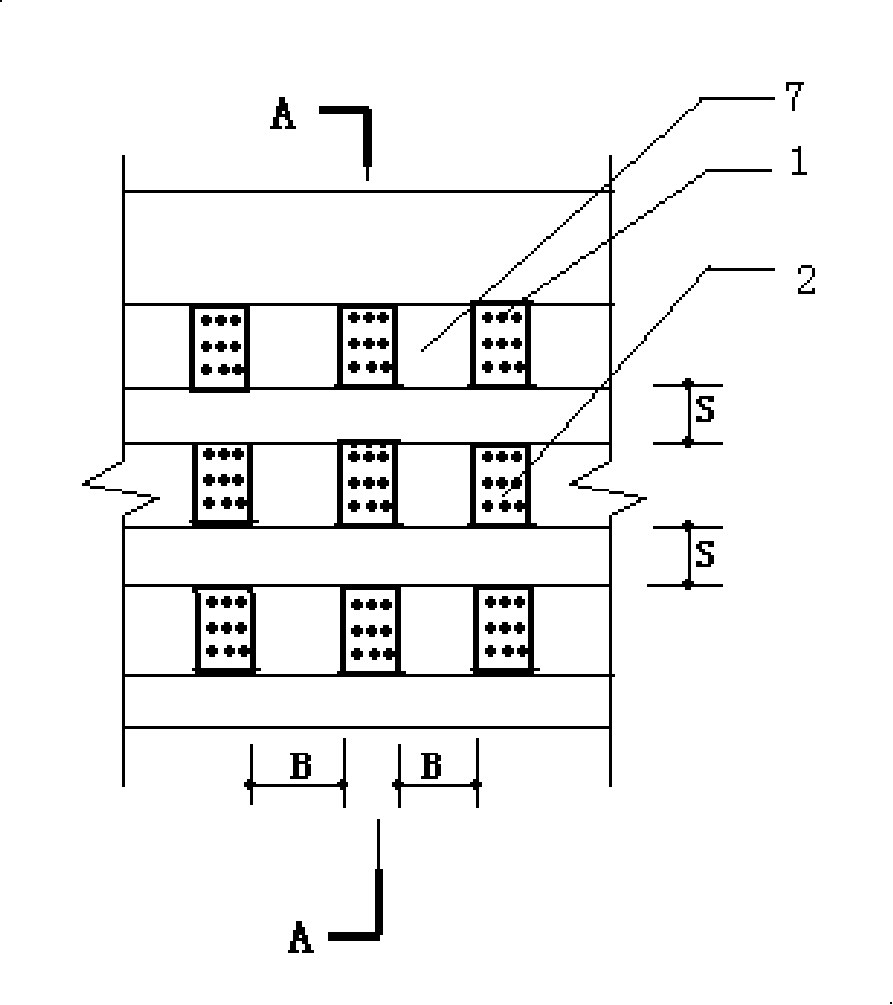

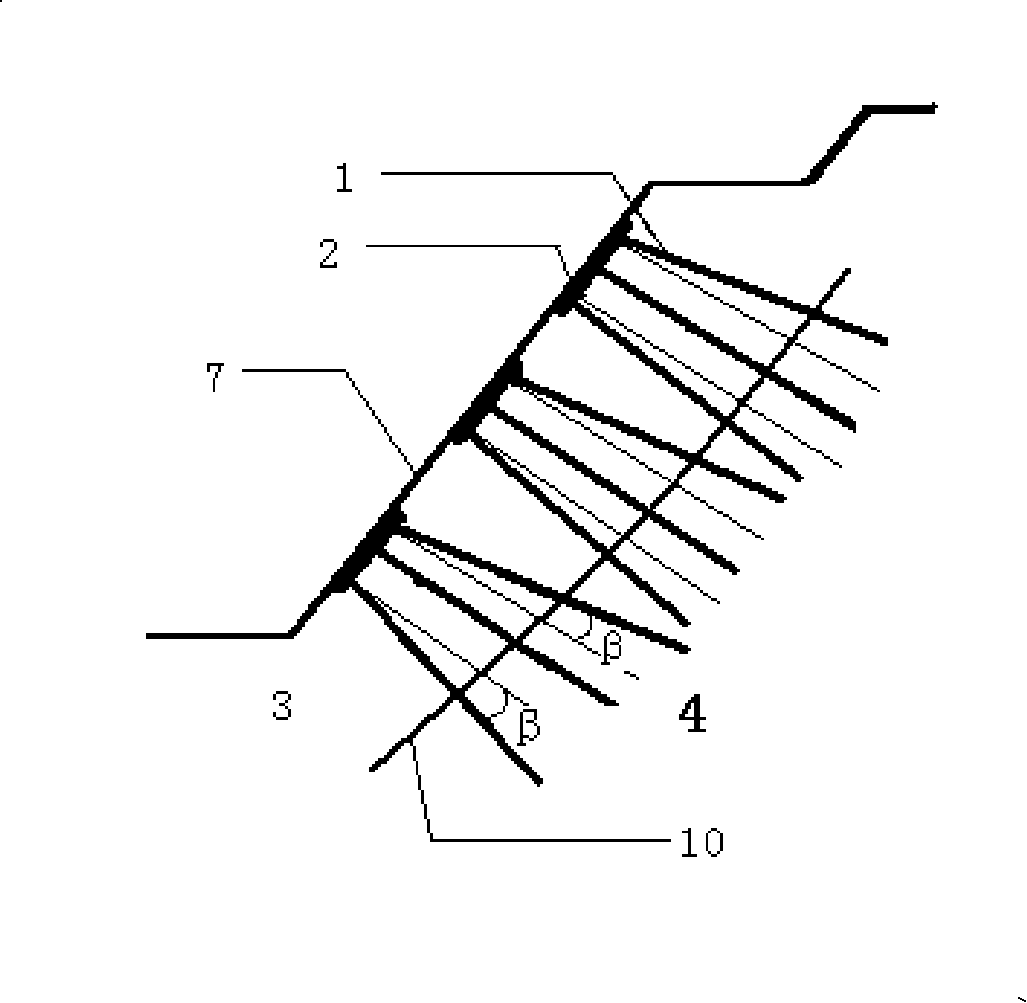

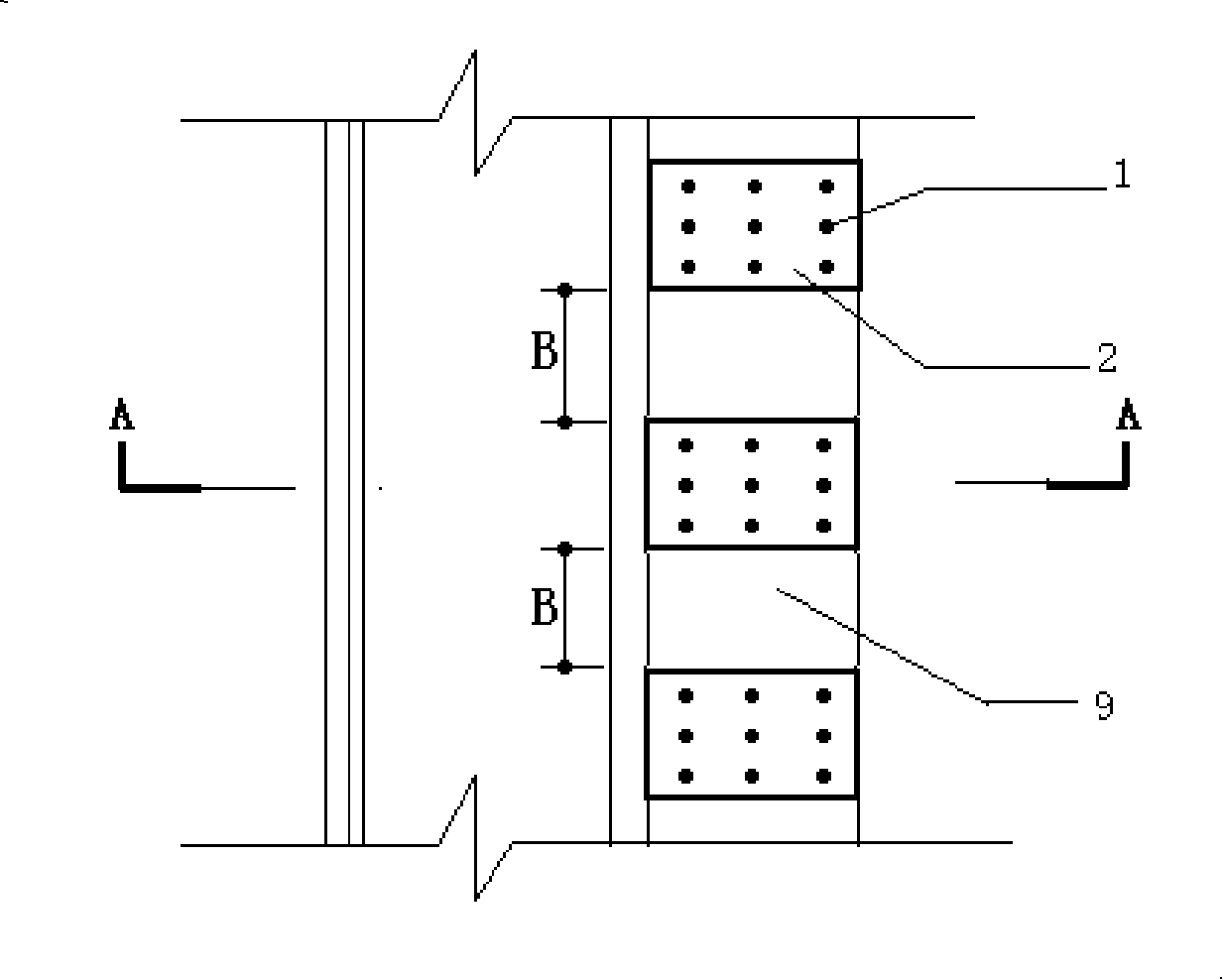

Skid resistant composite structure of miniature pile and method for reinforcing side slope

InactiveCN101220597AEffective reinforcementEasy constructionClimate change adaptationExcavationsReinforced concreteEngineering

The invention discloses a low-cost micro-pile anti-slide composite structure and a side slope reinforcement method in the supporting and retaining reinforcement field of deuterogene soil side slope. The micro-pile anti-slide composite structure is used for fixing the slip mass on a bedrock and comprises at least one group of micro-pile assembly which penetrates the slip mass and anchors on the bedrock; wherein, each micro-pile assembly comprises at least two micro-piles and a crest slab corresponding to the micro-pile; the crest slab is arranged on the slip mass and is fixedly connected with the micro-pile. The side slope reinforcement method includes a step of anchoring the micro-pile on the bedrock and a step of fixedly connecting the crest slab with the micro-pile; the micro-pile adopts a bored pile and the crest slab adopts a cast-in-place reinforced concrete member. The effect of pile group produced by micro-pile assembly arranged in rows and in column raises the slip resistance of rock and soil mass, which renders the unstable rock and soil mass to keep stable and prevents the rock and soil mass from sliding and damaging. The invention is mainly used for supporting and retaining reinforcement structure of unstable rock and soil side slope with medium altitude.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

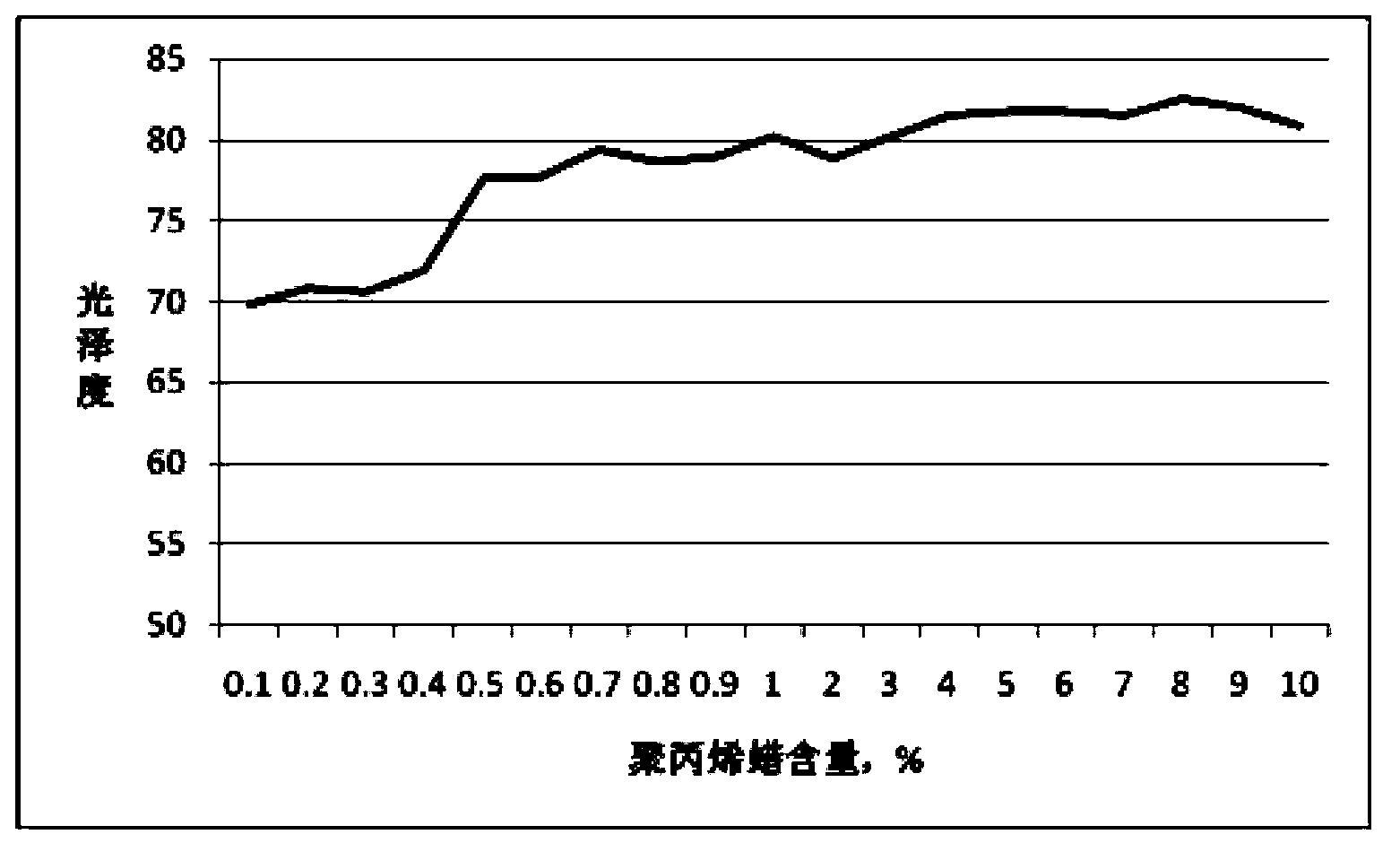

Stone crystal surface treatment composition and manufacturing method thereof

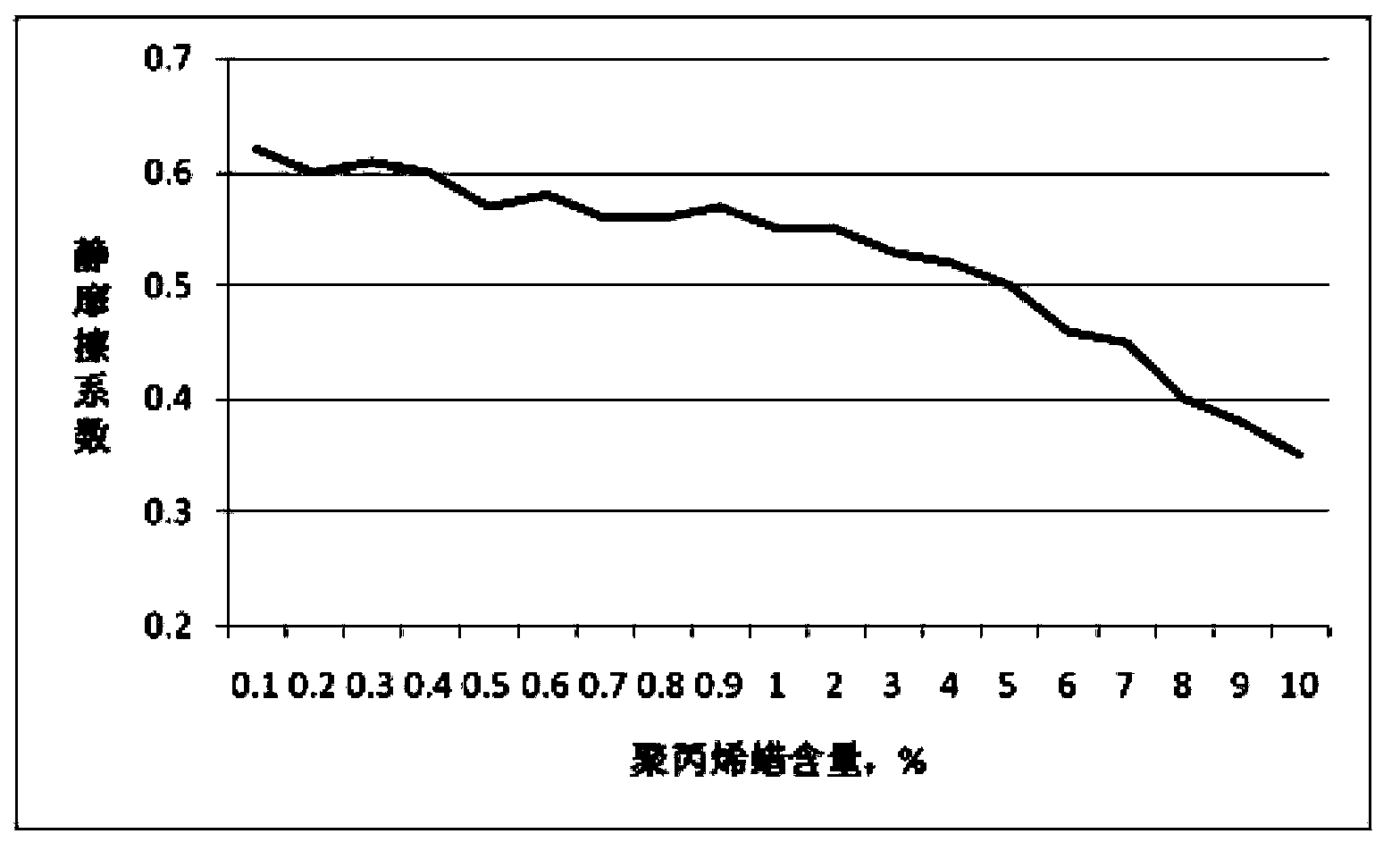

InactiveCN104119803AImprove mechanical propertiesNot easy to penetratePolishing compositionsHigh resistancePolyolefin

The invention discloses a stone surface treatment crystallizing agent comprising the following components in percentage by weight: 0.5-5% of polyolefin wax, 10-30% of fluorosilicic acid or fluorosilicate, 1-6% of acidity regulator, 0.5-5% of quick drying agent and the balance of water, wherein the polyolefin wax is added in an emulsion form, and the solid content of the polyolefin wax emulsion is kept within the range of 20-60%. The crystallizing agent disclosed by the invention can be used for crystallizing stones such as marble, waterstone or special granite and simultaneously hardening and brightening the surface of a stone floor so as to provide high glossiness and improved slip resistance for the crystal surface of the floor while protect the floor. Meanwhile, the treated stone surface has enhanced mechanical performance as well as higher wear resistance and chemical corrosion resistance, and water-soluble stains are not easy to permeate into the stone. The stone surface treated by using the crystallizing agent disclosed by the invention can be cleaned and treated by using water and is convenient and rapid in later-period maintenance and reduced in the maintaining cost as comparison with the stone surface treated by using a conventional waxing treatment method.

Owner:ECOLAB USA INC

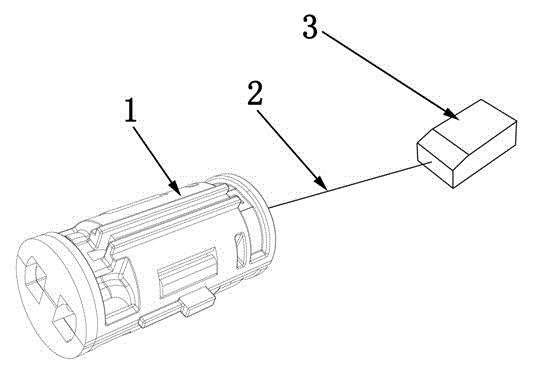

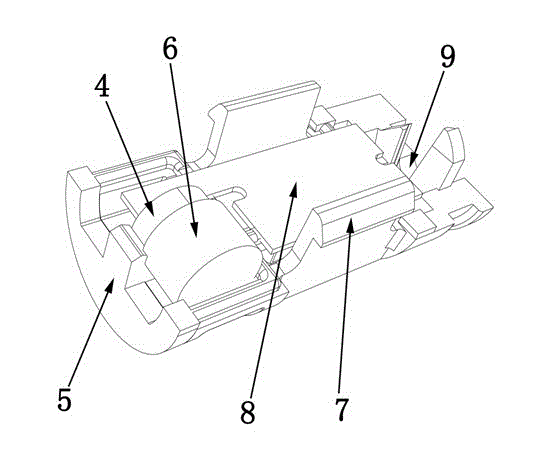

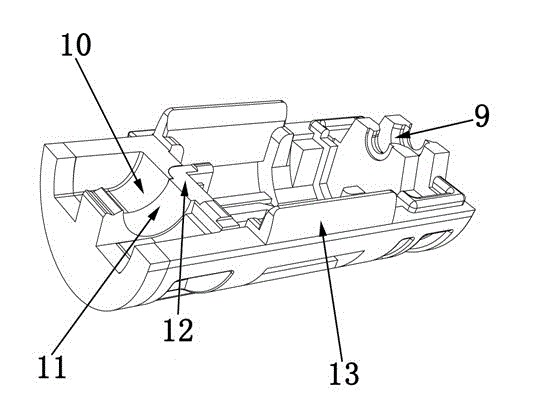

Vehicle-mounted microphone with casing adopting bi-color injection molding

ActiveCN102724612AGuaranteed acoustic performanceImprove production efficiencyElectrets selectrostatic transducerTransducer casings/cabinets/supportsWhole bodyEngineering

The invention discloses a vehicle-mounted microphone with a casing adopting bi-color injection molding. The vehicle-mounted microphone with the casing adopting the bi-color injection molding comprises a microphone casing, an electret microphone, a circuit board, a wiring harness and an inserting member. One end of the wiring harness butts against a positive and negative pad on the circuit board, the other end of the wiring harness is inserted in a corresponding groove of the inserting member through a terminal after crimping, and the electret microphone is in welding connection with the circuit board through positive and negative pins. The vehicle-mounted microphone further comprises a dustproof plug, the microphone casing comprises an upper casing and a lower casing, the upper casing and the lower casing comprise an upper casing base, a lower casing base, an upper casing cladding layer and a lower casing cladding layer respectively, the cladding layers and the casing bases are molded into a whole body through injection by means of a bi-color injection molding process, a microphone chamber formed between the upper casing and the lower casing is used for accommodating the electret microphone, and a dustproof chamber is used for accommodating the dustproof plug. The vehicle-mounted microphone with the casing adopting the bi-color injection molding can avoid vibration, protects the microphone, is high in manufacturing efficiency and good in slip resistance and cushion performance, saves cost, and can prevent dust. The casing and internal components are combined stably.

Owner:BEIJING SINCODE SCI & TECH

Preformed thermoplastic pavement marking and method utilizing large aggregate for improved long term skid resistance and reduced tire tracking

ActiveUS20110123770A1Labor savingShorten the timeTraffic signalsTextiles and paperThermoplasticEngineering

The present disclosure describes a preformed or in some cases a hot applied thermoplastic marking composition comprising a planar top surface portion and a planar bottom surface portion that are coplanar to each other, wherein said bottom surface portion is directly applied to a substrate via application of heat or pressure or both heat and pressure and wherein said top surface portion comprises an intermix that exits throughout said thermoplastic composition and includes large grit size aggregate in the range of about 8 to about 20 mesh or grit size, thereby reducing or eliminating tire tracking while also improving long-term skid resistance.

Owner:ENNIS FLINT INC

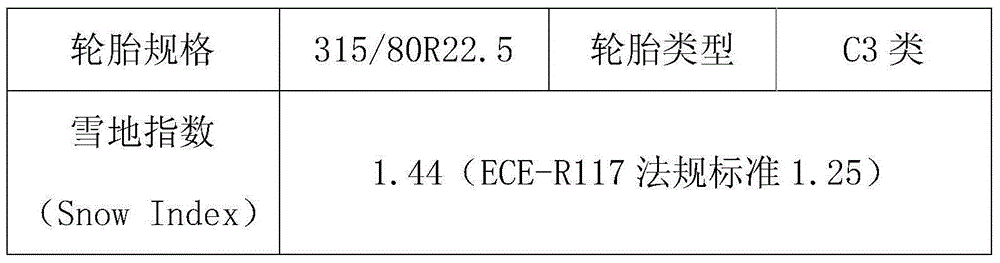

Tread rubber composition of all-steel truck snow tire

ActiveCN105037824AImprove driving performanceImprove driving safetySpecial tyresPolymer scienceMicrocrystalline wax

The invention discloses a tread rubber composition of an all-steel truck snow tire. The tread rubber composition is characterized by being composed of, by weight, 42-62 parts of natural rubber, 15-35 parts of oil-extended neodymium-based butadiene rubber, 25-34 parts of solution-polymerized styrene-butadiene rubber, 23-38 parts of high-dispersion white carbon black, 30-55 parts of carbon black N220, 2-4 parts of coupling agent liquid Si69, 1-10 parts of aromatic oil, 2-8 parts of zinc oxide, 0.5-3 parts of stearic acid, 2-4 parts of antiager 6PPD, 1.5-3 parts of antiager RD, 2-5 parts of microcrystalline wax, 1-3.5 parts of oil-extended sulfur, 1-2.5 parts of accelerator NS, 0.1-1 part of accelerator DPG and 0.1-0.5 part of scorch retarder CTP. By the adoption of the solution-polymerized styrene-butadiene rubber with the Tg appropriate to that of natural rubber, the neodymium-based rare-earth butadiene rubber with the lower Tg and white carbon black commonly used for semi-steel snow tires, at a specific proportion, the tire is moderate in tread hardness and good in elasticity, and has the advantages of excellent snow slip resistance, good snowfield road holding, high snowfield indexes and the like in a freezing snowfield.

Owner:HANGZHOU CHAOYANG RUBBER

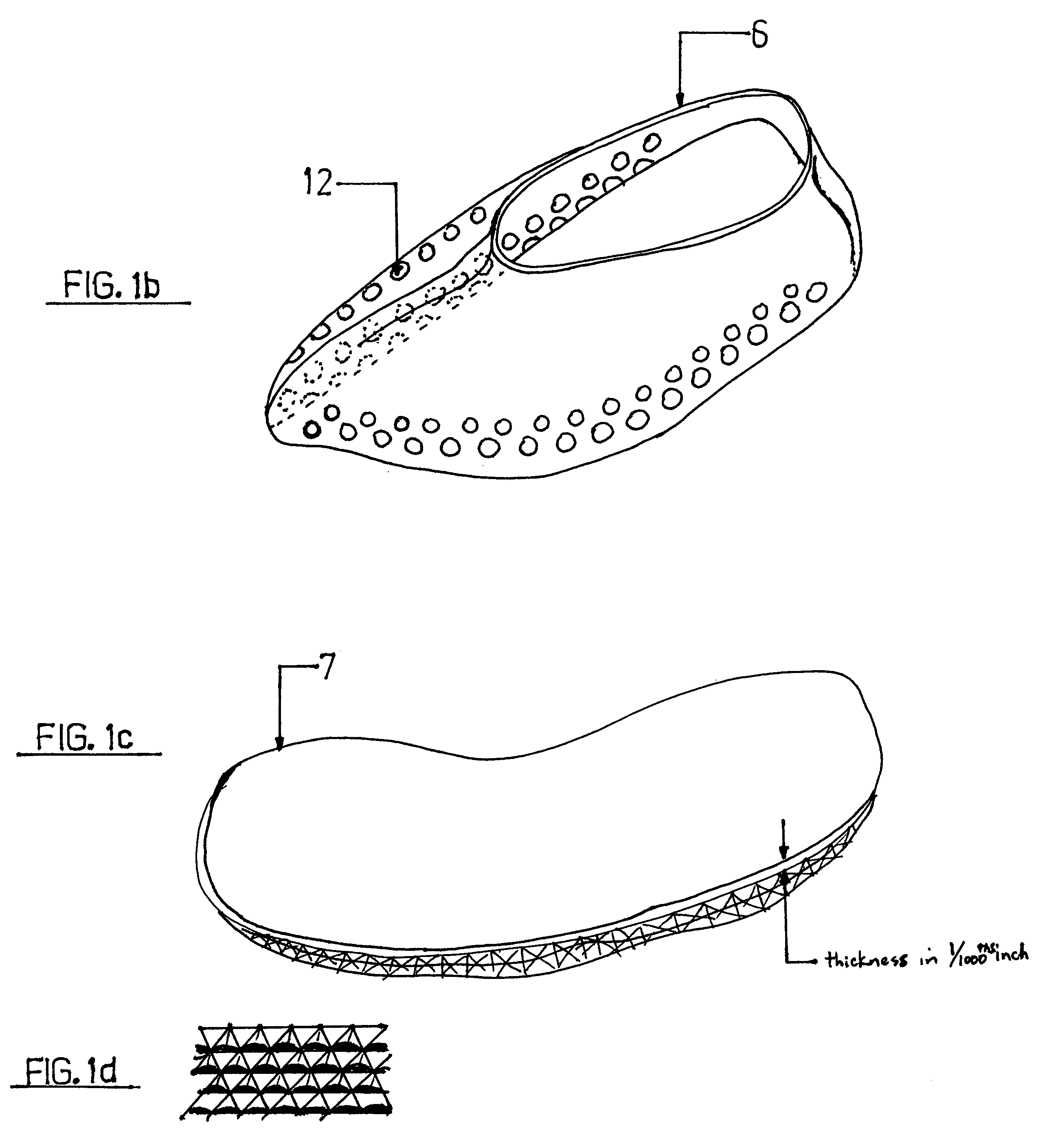

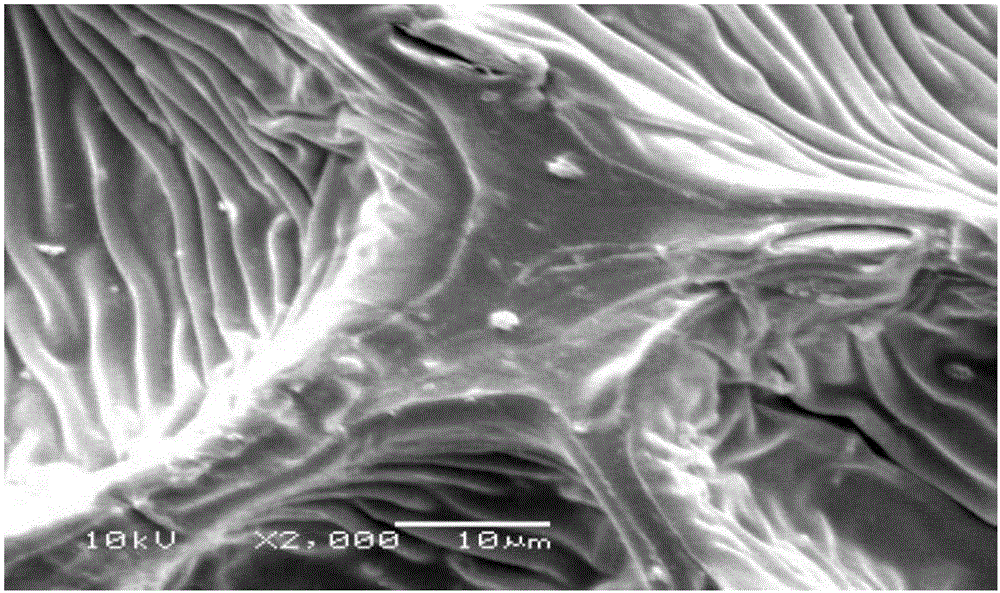

Slip resistant gloves and method for producing the same

InactiveUS20110265246A1Abrasion resistance is inferiorSlip resistant effect is improvedGlovesDomestic articlesFiberCoated surface

A slip resistant glove is disclosed which includes a fibrous glove and a rubber or a resin coating layer formed on the surface thereof, wherein recesses having a width of 0.1 to 425 μm, a depth of 0.1 to 200 μm and a number density of 1000 to 5000 per 1 square centimeter are provided at the surface of the coating layer. The glove of the present invention has well balanced slip resistance and abrasion resistance, and is excellent in slip resistance against oil, in particular, and has less amounts of anions and cations which cause rust.

Owner:SHOWA GLOVE

Silicone Gloves

The invention relates to silicone articles, specifically molded silicone gloves, and methods of making of the silicone gloves. The silicone gloves may optionally comprise a reinforced material. The silicone gloves may have heat resistance and slip resistance and can retain shape after deformation.

Owner:SAR HLDG INT

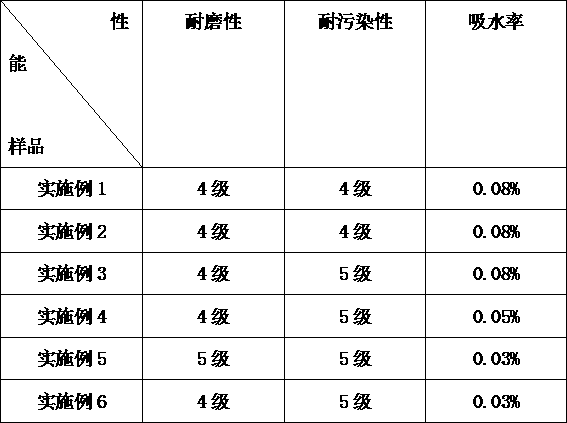

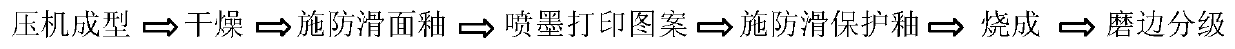

Dry-granular glazed ceramic tile and preparation method thereof

The invention discloses a dry-granular glazed ceramic tile and a preparation method thereof. The dry-granular glazed ceramic tile comprises a ceramic tile green body applied with cover glaze and dry-granular glaze, and is prepared by the steps of (1), spraying water to the dried ceramic tile green body until its surface water content reaches 5-10%, and applying the cover glaze; (2), applying the dry-granular glaze to the ceramic tile green body with the cover graze through a rubber roll engraved with granular patterns; (3), performing high-temperature calcination in a kiln at the temperature from 110 DEG C to 1190 DEG C for 1 hour to obtain the dry-granular glazed ceramic tile. Based on the new formula of the cover graze and the dry-granular glaze, under the productive technology which isdifferent from the prior art, the dry-granular glazed ceramic tile with excellent performance can be obtained; particularly, the dry-granular glazed ceramic tile has good slip resistance, its water absorption rate ranges from 0.03% to 0.08%, its wear resistance reaches 4th-5th level, and its stain resistance reaches 4th-5th level. The preparation method of the dry-granular glazed ceramic tile is simple, products prepared by the method have excellent performance, material and energy consumption is controllable, and environmental pollution is reduced effectively.

Owner:晋江恒发陶瓷有限公司

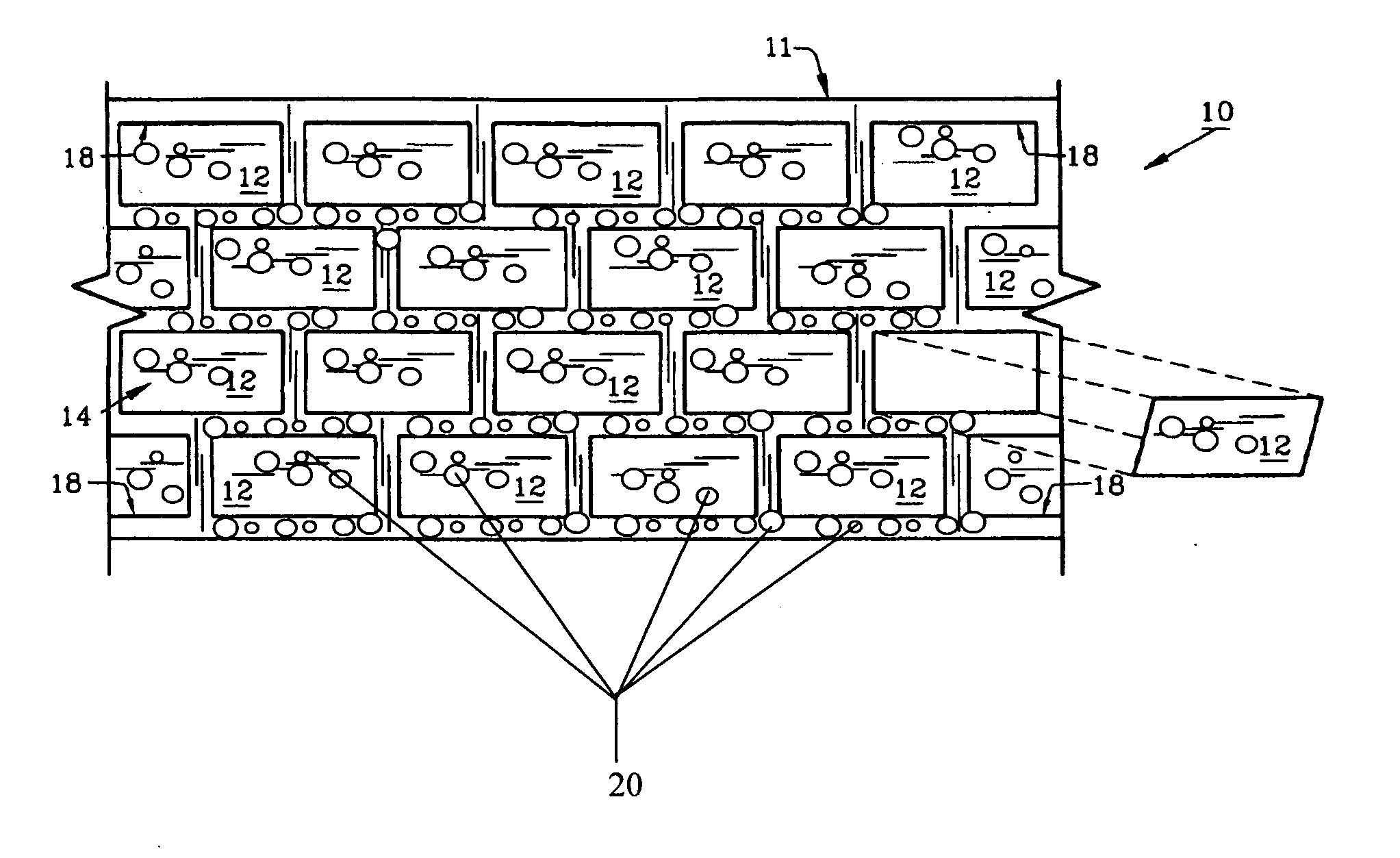

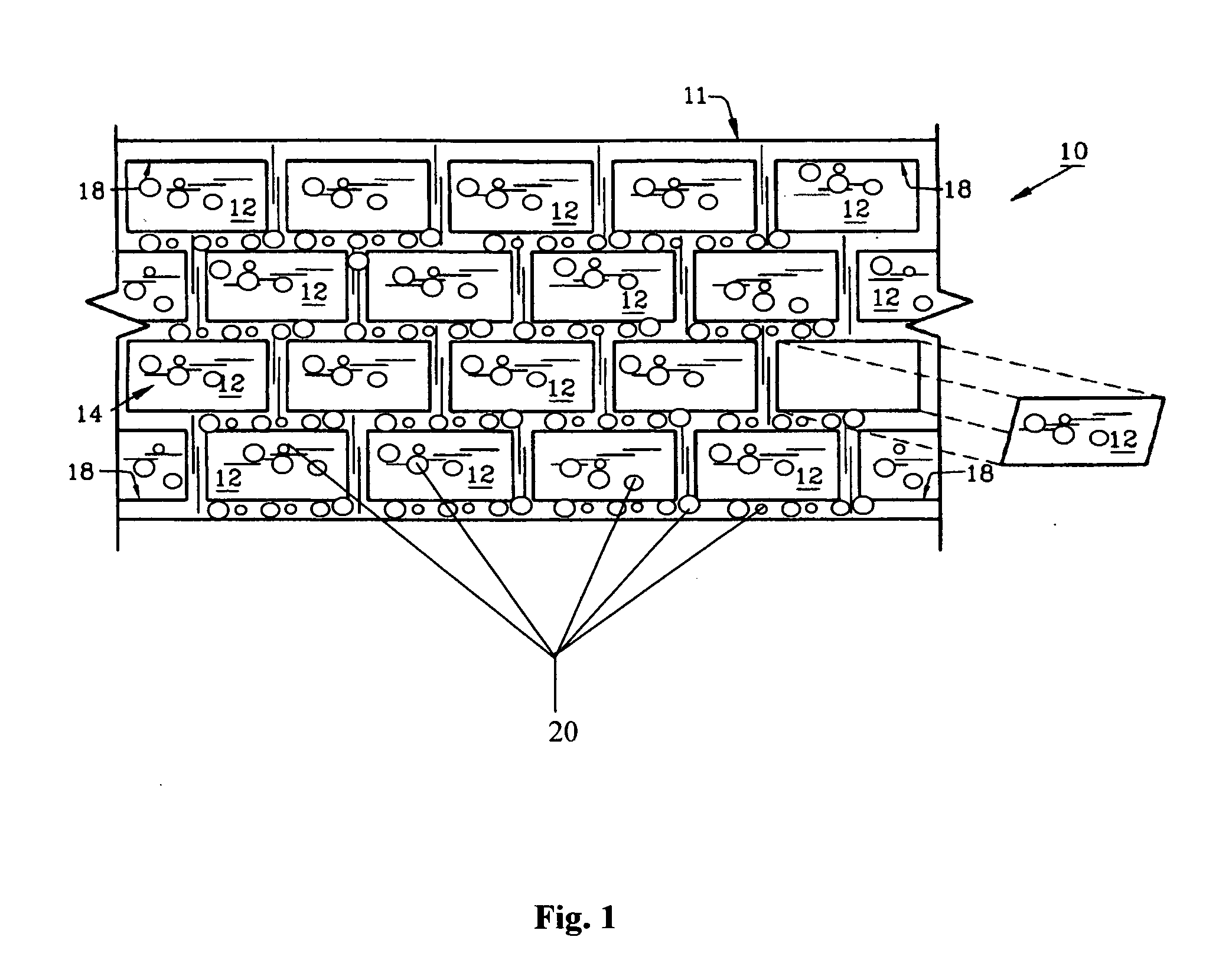

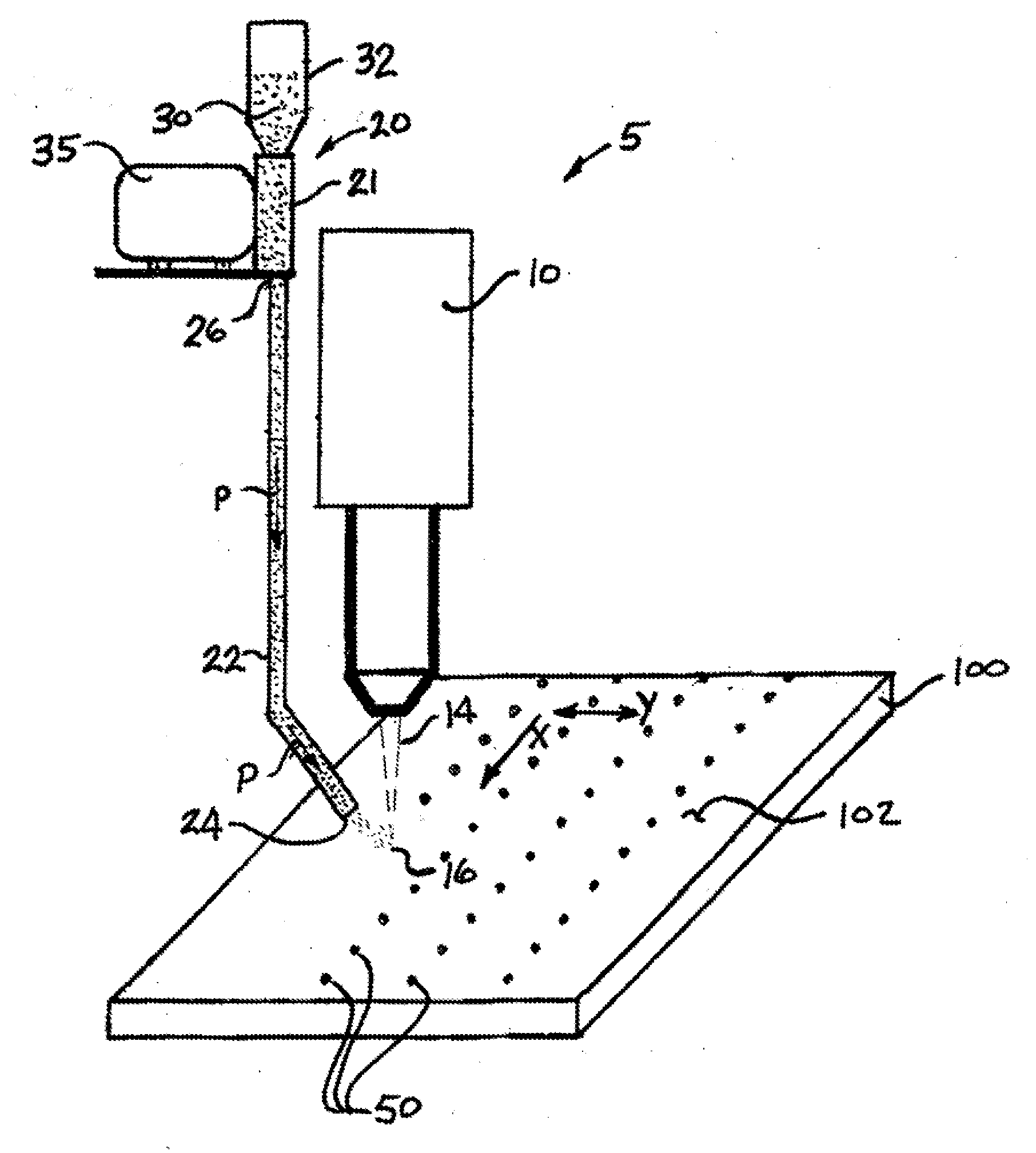

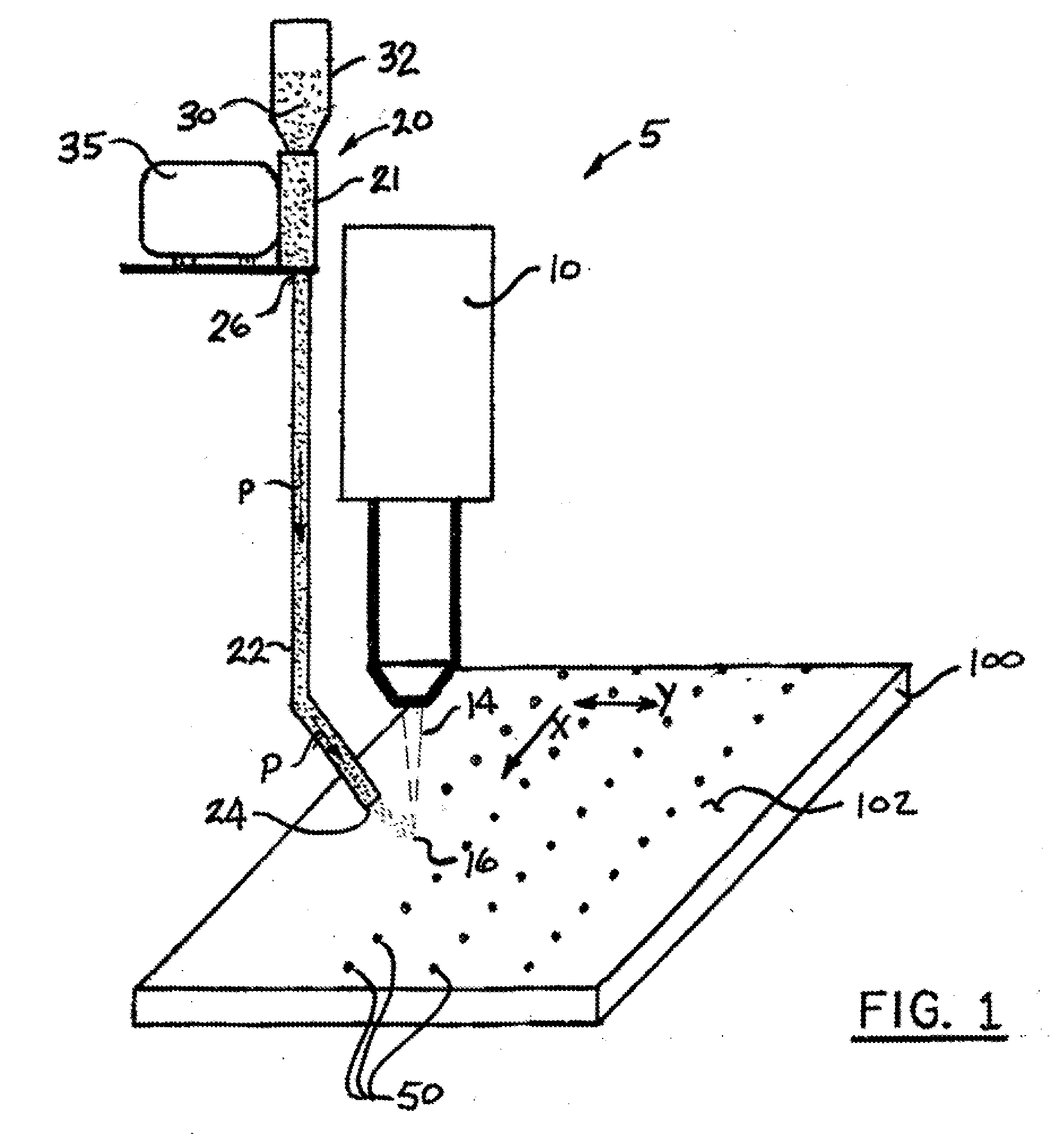

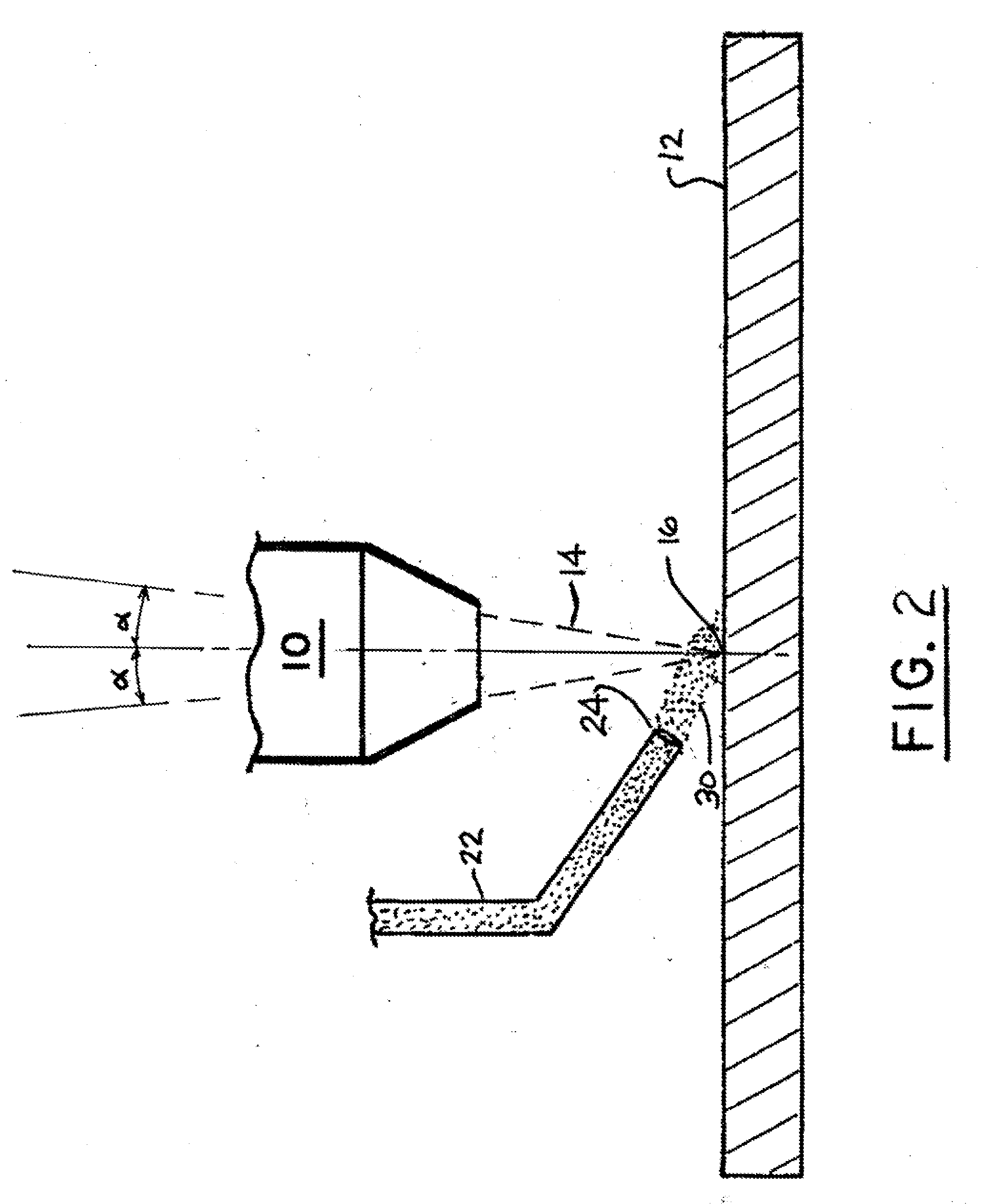

Method and apparatus for depositing raised features at select locations on a substrate to produce a slip-resistant surface

ActiveUS20090001058A1Welding/cutting media/materialsWelding/soldering/cutting articlesMetallic substrateSubstrate surface

An improved apparatus and method for applying a plurality of raised features at select locations on a metallic substrate using a high-powered radiant energy source, such as a laser, in combination with powder metallurgy such that the resultant substrate surface exhibits increased slip-resistance resulting from the presence of the raised features on the substrate.

Owner:OHIO GRATINGS

Wet water high-slipping resistance ink jet ceramic tile with delicate texture and making method thereof

The invention provides a wet water high-slipping resistance ink jet ceramic tile with delicate texture and a making method thereof. The making method includes the steps that slipping-resistance cover glaze, a decorative pattern and slipping-resistance protective glaze are sequentially applied to a blank, and then firing is conducted. The wet water static friction coefficient of the slipping resistance ceramic tile can reach 0.8 or above, and the difference value of dry and wet water static friction coefficients is 0.03 or above; through combination of the slipping-resistance cover glaze and the slipping-resistance protective glaze, the pattern has a bright developed color; the abrasion resistance of a glaze surface can reach the four level and 2,100 turns; the stain resistance reaches the fifth level. The ceramic tile can be used as a decorative material which is good in decorating effect and excellent in stain resistance and has the slipping resistance, and can be applied to the field of home decoration.

Owner:MONALISA GRP CO LTD

Hard coating film

ActiveUS20150197662A1High hardnessImprove impact resistanceAntifouling/underwater paintsFilm/foil adhesivesTransmittanceHardness

The present invention relates to a hard coating film, and, more particularly, to a hard coating film having hardness and excellent physical properties. According to the present invention, the hard coating film has high physical properties including hardness, fouling resistance, slip resistance, scratch resistance, transparency, durability, light resistance, and light transmittance.Thus, the hard coating film can find useful applications in various fields thanks to its excellent physical properties.

Owner:LG CHEM LTD

Novel composite shoe material and preparation method thereof

The invention provides a novel composite shoe material. The novel composite shoe material comprises the following components by weight percent: 20-50% of SBS, 20-50% of SEBS, 10-30% of PS, 10-30% of naphthenic oil, 5-20% of calcium carbonate, 1-20% of white carbon black, 1-10% of a compatilizer, 1-10% of a PE substrate, 1-5% of a wearing resistant modifier, 0.1-1% of stearic acid, 0.1-1% of an anti-aging agent, 0.05-1% of a foaming agent and 0.05-10% of a cross-linking agent, wherein the compatilizer comprises a maleic anhydride base compatilizer and an epoxy base compatilizer; the wearing resistant modifier comprises a compounded wearing resistant modifier; the anti-aging agent comprises a light stabilizer. The novel composite shoe material provided by the invention has excellent properties of small specific weight, light mass, high strength, high toughness, high resilience, high wearing resistance, high slip resistance, aging resistance, hydrolysis resistance and high size stability.

Owner:东莞市佳诗德塑胶科技有限公司

Disposable and non-disposable foot cap

Thin, lightweight footwear made of a polyethylene material that is composed of a top part and a sole part that are sewn together such that when fitted properly to the wearer's foot the footwear encompasses the foot and extends to the level of the ankle. The top part is porous allowing the ingress and egress of soap and water. The sole has slip resistance properties due to the material from which it is made and the texture of its outer surface. The finished product can be folded and compressed for storage, then later unfolded and worn without the folding adversely affecting its intended function of providing a barrier between the wearer's feet and the tub or shower floor on which the wearer stands while the wearer showers.

Owner:THOMAS JEFF C C

Composite sole and production method thereof

ActiveCN106117765AIncrease elasticityImprove skid resistanceSolesPolyureas/polyurethane adhesivesCelluloseFoaming agent

The present invention discloses a composite sole and a production method thereof. The composite sole is made by compositing an EVA (ethylene-vinyl acetate) injection molded midsole, a rubber outsole and an injection molded arch support sequentially; the EVA injection molded midsole is made with high-elasticity aging-resistant EVA foam material that is produced via the following steps of 1) modifying lignocellulose powder by using a silane coupling agent to obtain modified lignocellulose powder; 2) mixing partially hydrogenated styrene-butadiene polymer, ethylene-vinyl acetate copolymer and the modified lignocellulose powder for compounding; 3) adding a foaming agent, a bridging agent, an activating agent and zinc oxide into a mixing system for compounding; 4) granulating material that is compounded in steps 2) and 3), performing injection foaming, and cooling for molding. The composite sole has good elasticity, resilience, slip resistance and wear resistance, and meets the need for comfort to wear sports and leisure shoes and boots.

Owner:THE QUARTERMASTER EQUIPMENT RESEARCH INSTITUTE OF THE GENERAL LOGISITIC DEPARTME +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com