Slip resistant gloves and method for producing the same

a technology of abrasion resistance and gloves, applied in the field of slip resistance gloves, can solve the problems of weak latex coating strength, insufficient slip resistance, and significantly inferior gloves in abrasion resistance, and achieve excellent slip resistance, improve abrasion resistance, and reduce the formation of metal parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0091]A seamless glove made of nylon knitted by a 13 gauge knitting machine was put on a metallic hand form, heated to 70° C., and then was dipped into a bath of a coagulant comprising 100 parts by weight of methanol and 1.0 part by weight of calcium nitrate, and thereafter the seamless glove was left standing at room temperature of 30 to 40° C. for 30 seconds to adjust the surface temperature of the hand form immediately before dipping in a rubber blended solution to 38° C.

[0092]On the other hand, alkylene oxide modified organopolysiloxane TPA-4380 (manufactured by GE Toshiba Silicones Co., Ltd., cloud point: 35° C.) as a film forming aid was added to the rubber blended solution shown in Table 1 in an amount of 0.05 part by weight based on 100 parts by weight of a rubber solid content to prepare a rubber blended solution. The seamless glove was dipped into a bath filled with this rubber blended solution and then pulled up. Subsequently, the raw glove was left standing at room tempe...

example 2

[0093]A glove was prepared in the same manner as in Example 1 except for changing the amount of alkylene oxide modified organopolysiloxane TPA-4380 to 0.10 part by weight.

example 3

[0094]A glove was prepared in the same manner as in Example 1 except for changing the amount of alkylene oxide modified organopolysiloxane TPA-4380 to 0.25 part by weight.

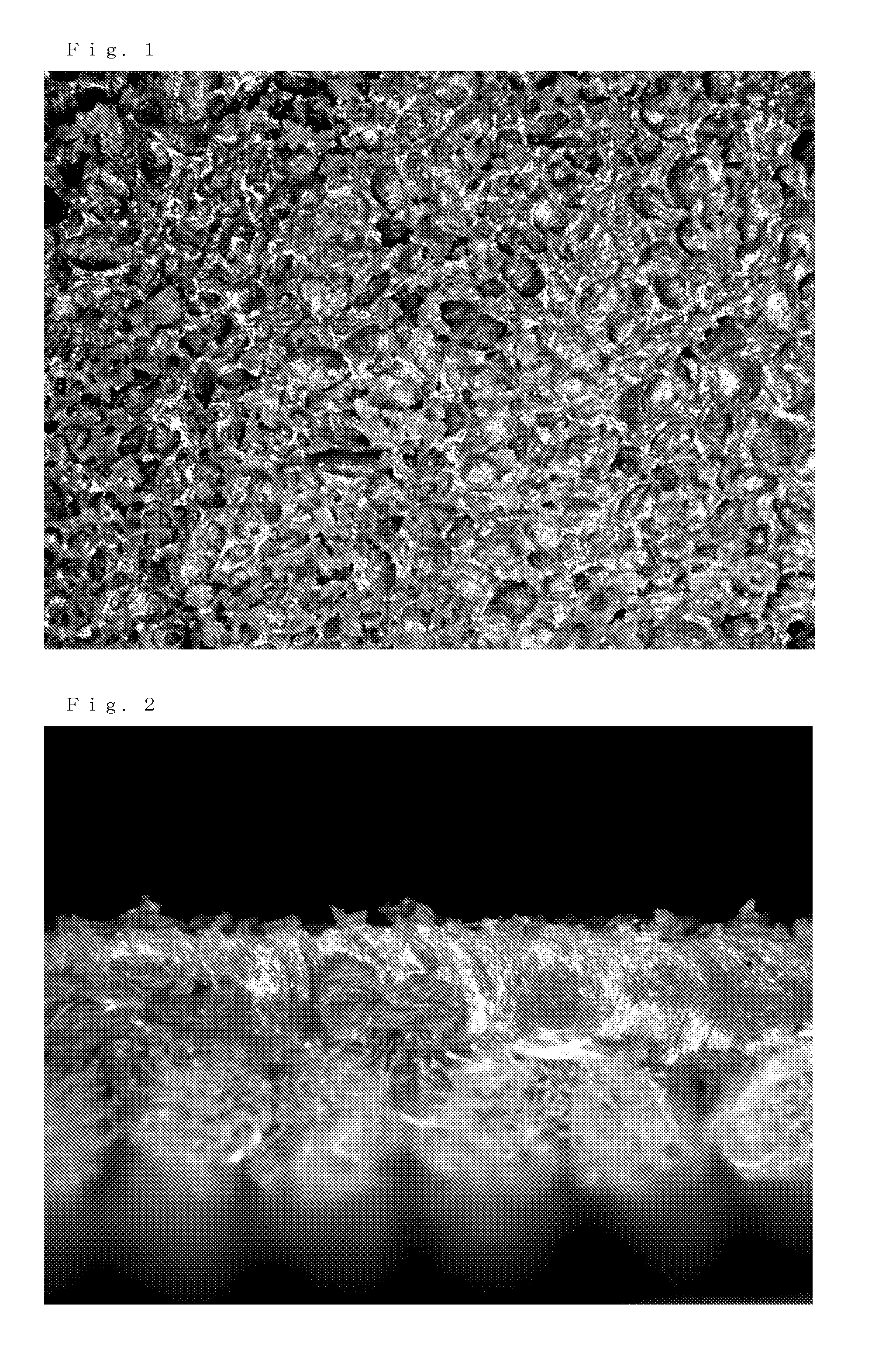

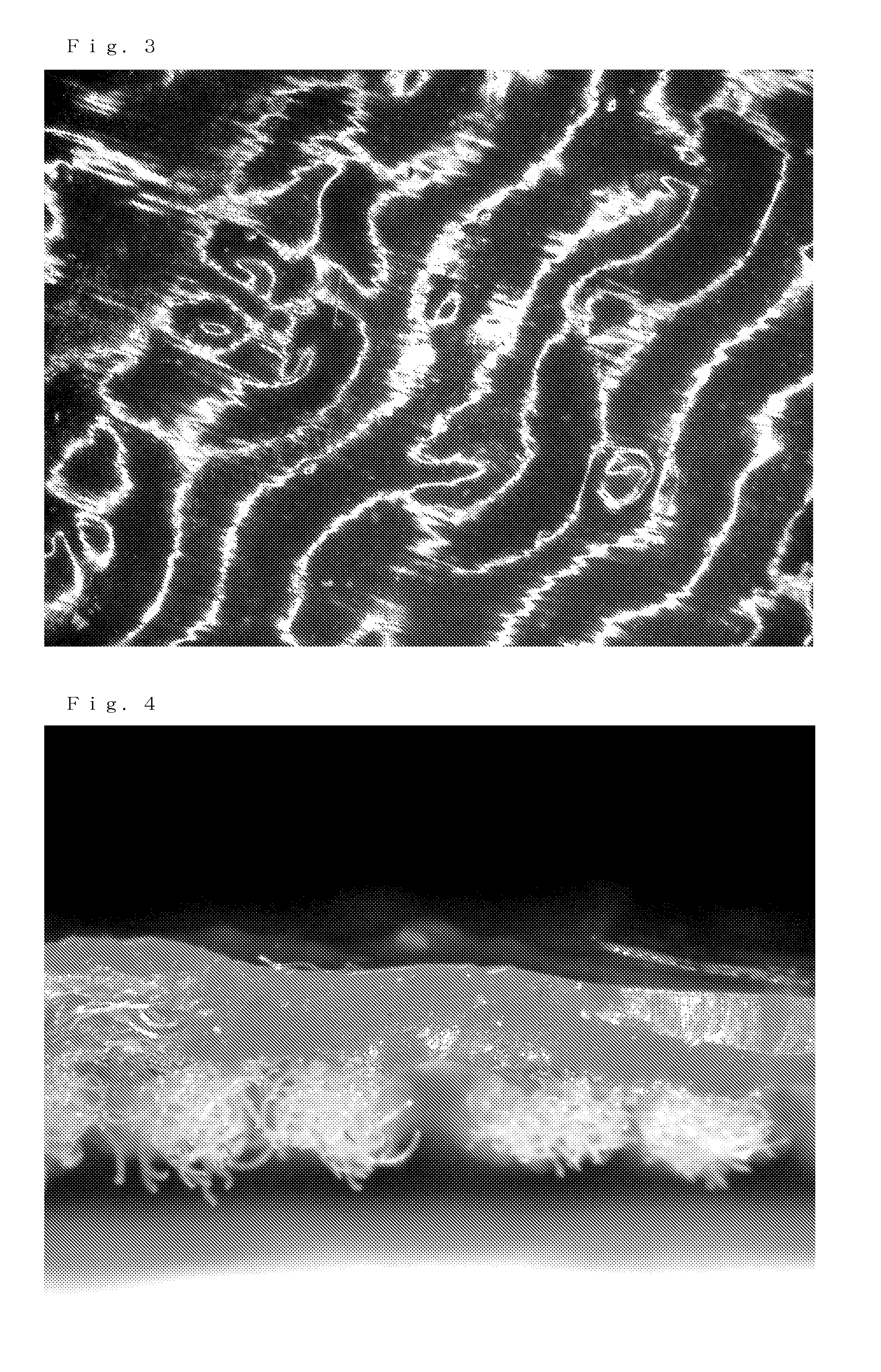

[0095]An enlarged micrograph (100 times magnification) of the surface of the palm of the obtained glove, which was taken from directly above using DIGITAL MICROSCOPE VHX-900 (manufactured by KEYENCE Corporation), is shown in FIG. 1, and an enlarged micrograph (100 times magnification) of a cross-section of a palm of the obtained glove, taken from directly above in the same manner, is shown in FIG. 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| cloud point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com