Patents

Literature

706results about How to "Cut evenly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

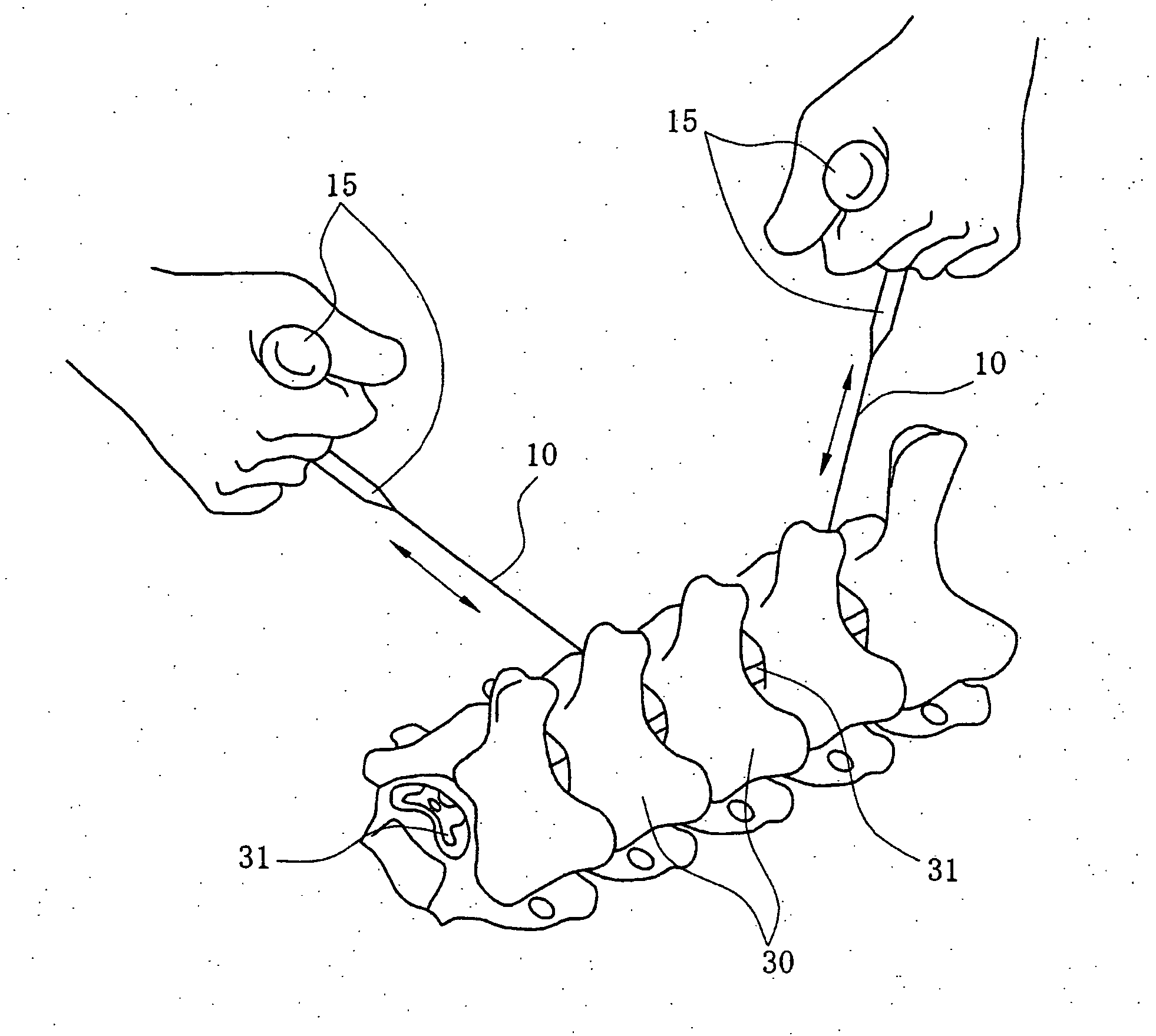

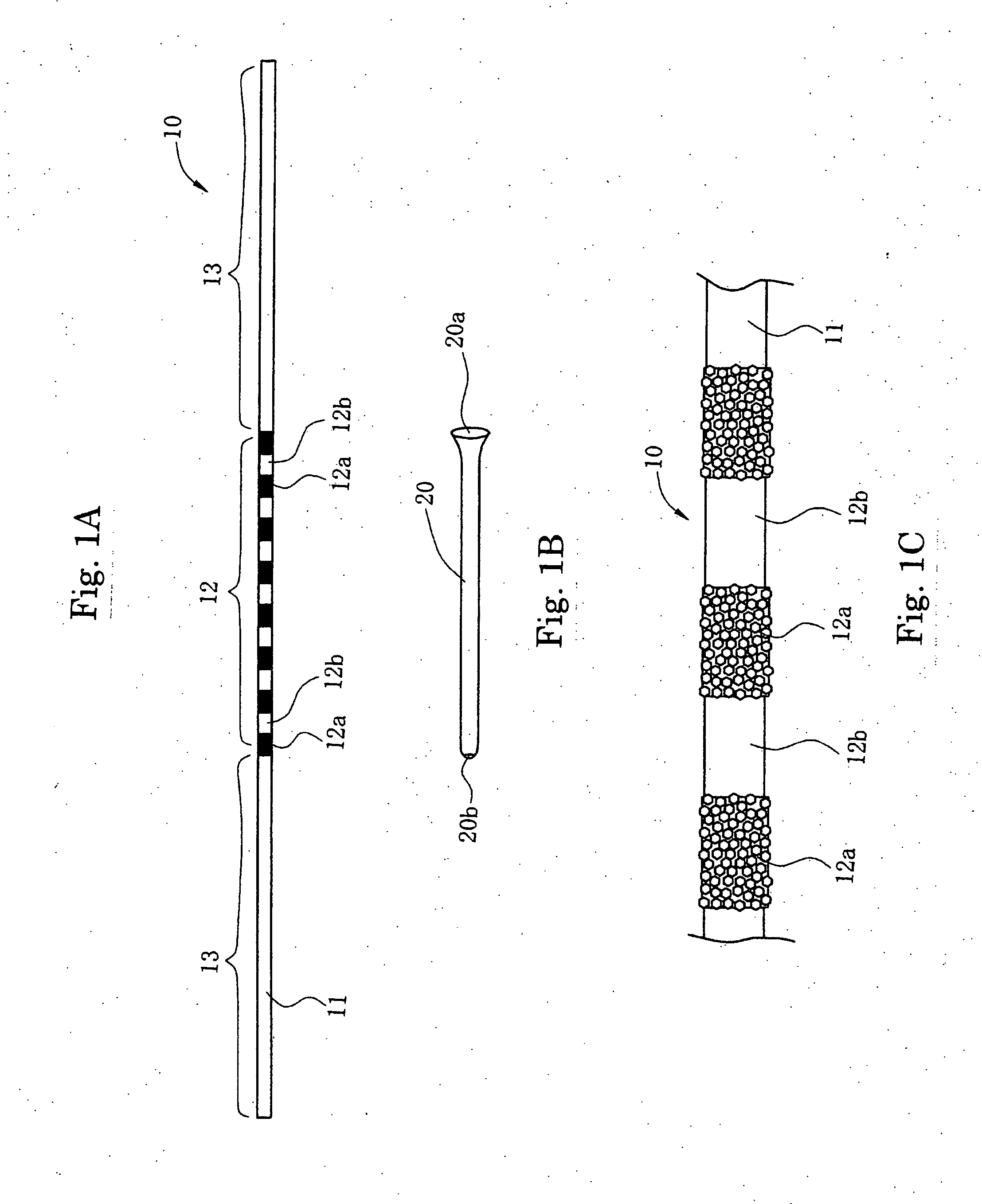

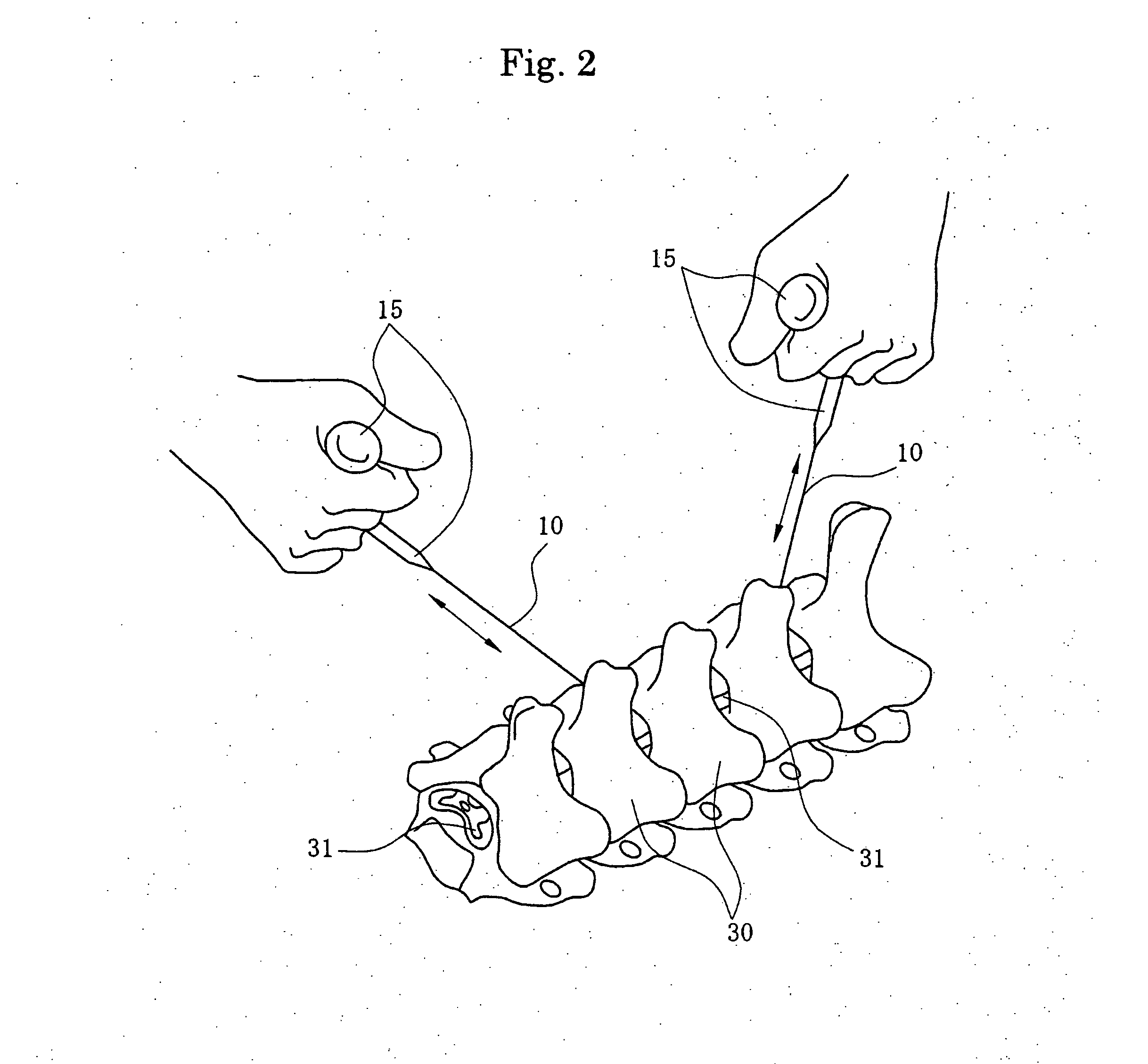

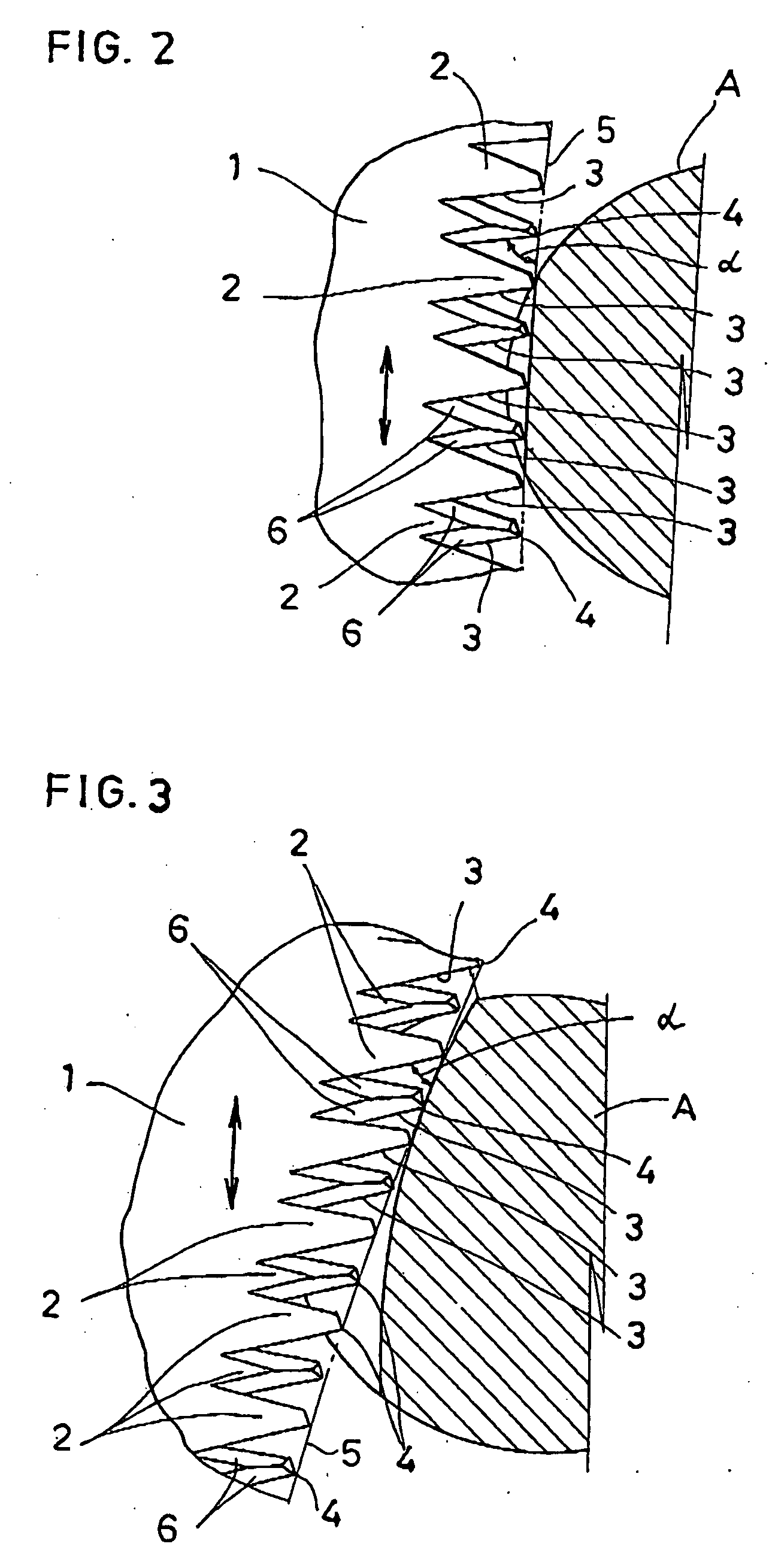

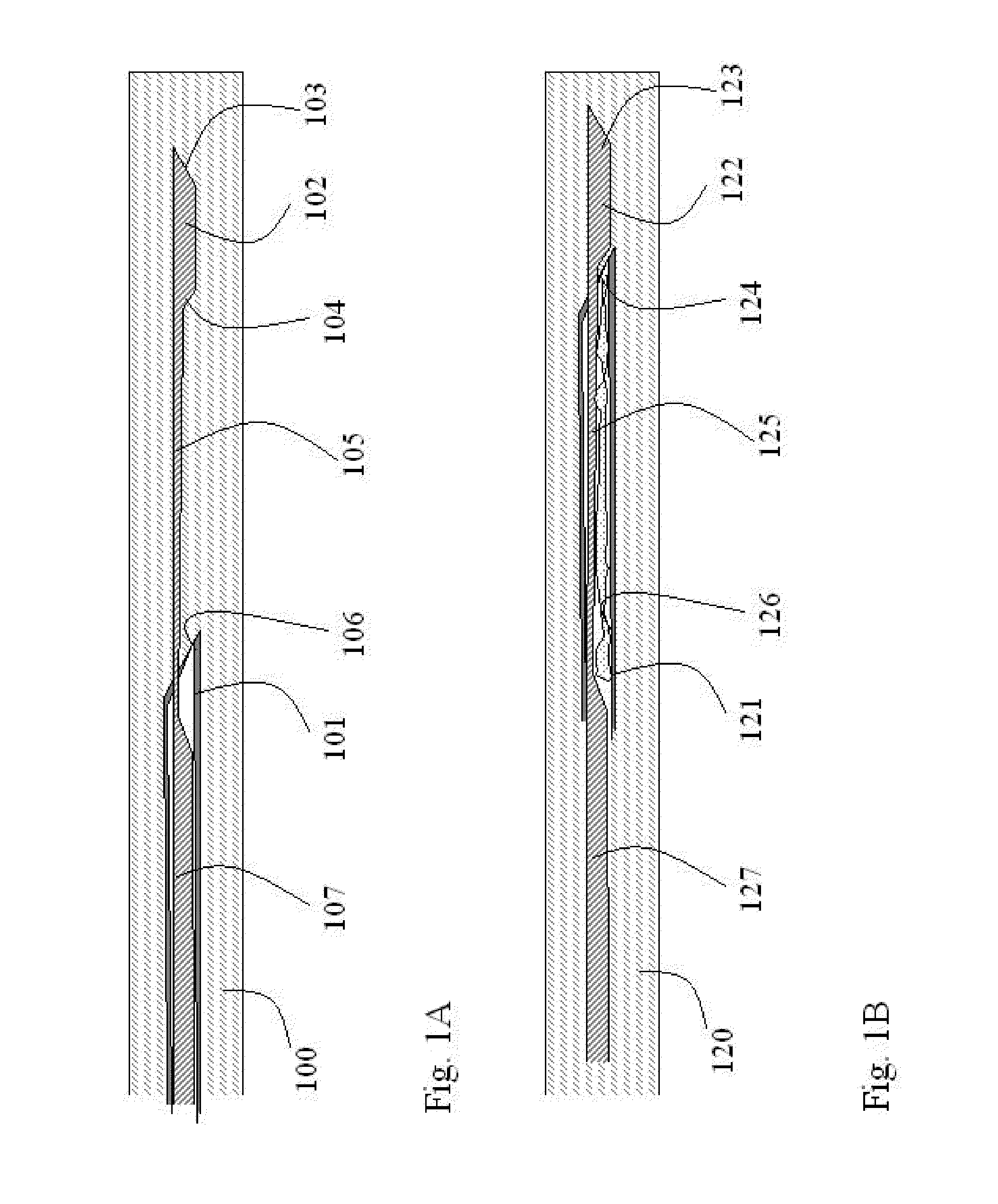

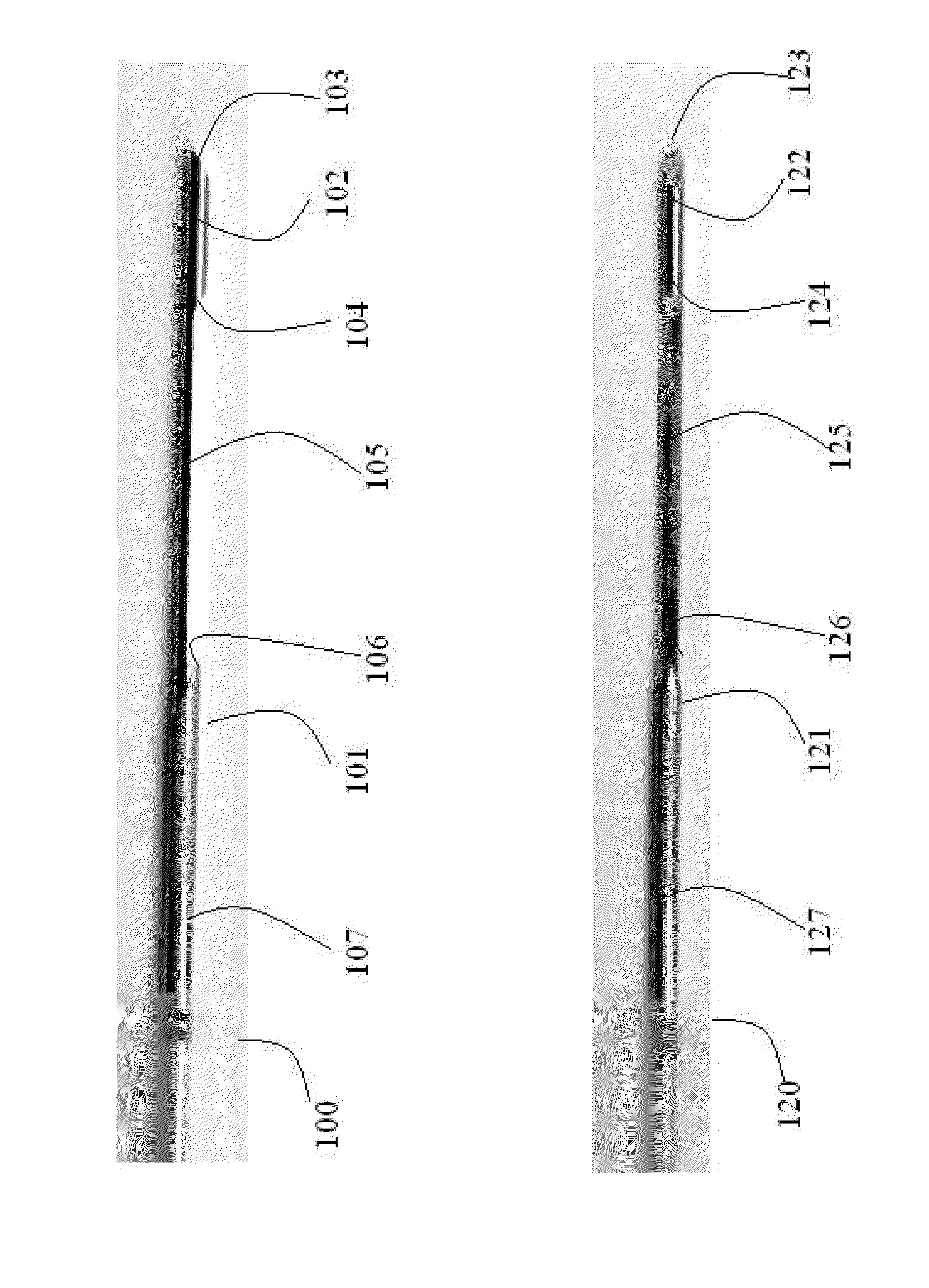

Surgical saw

A surgical saw for cutting bone that can be used with ease in tight places yet maintain sufficient cutting power. The surgical saw 10 has a flexible linear body made of twisted stainless steel wire and cutting parts formed on the flexible linear body. The cutting parts are made of abrasive material affixed to the flexible linear body 12a alternating with portions of the flexible linear body with no abrasive particles 12b. Auxiliary cutting parts 13 of lesser cutting power may be provided along both lateral sides of each of the cutting parts 12.

Owner:MANI INC

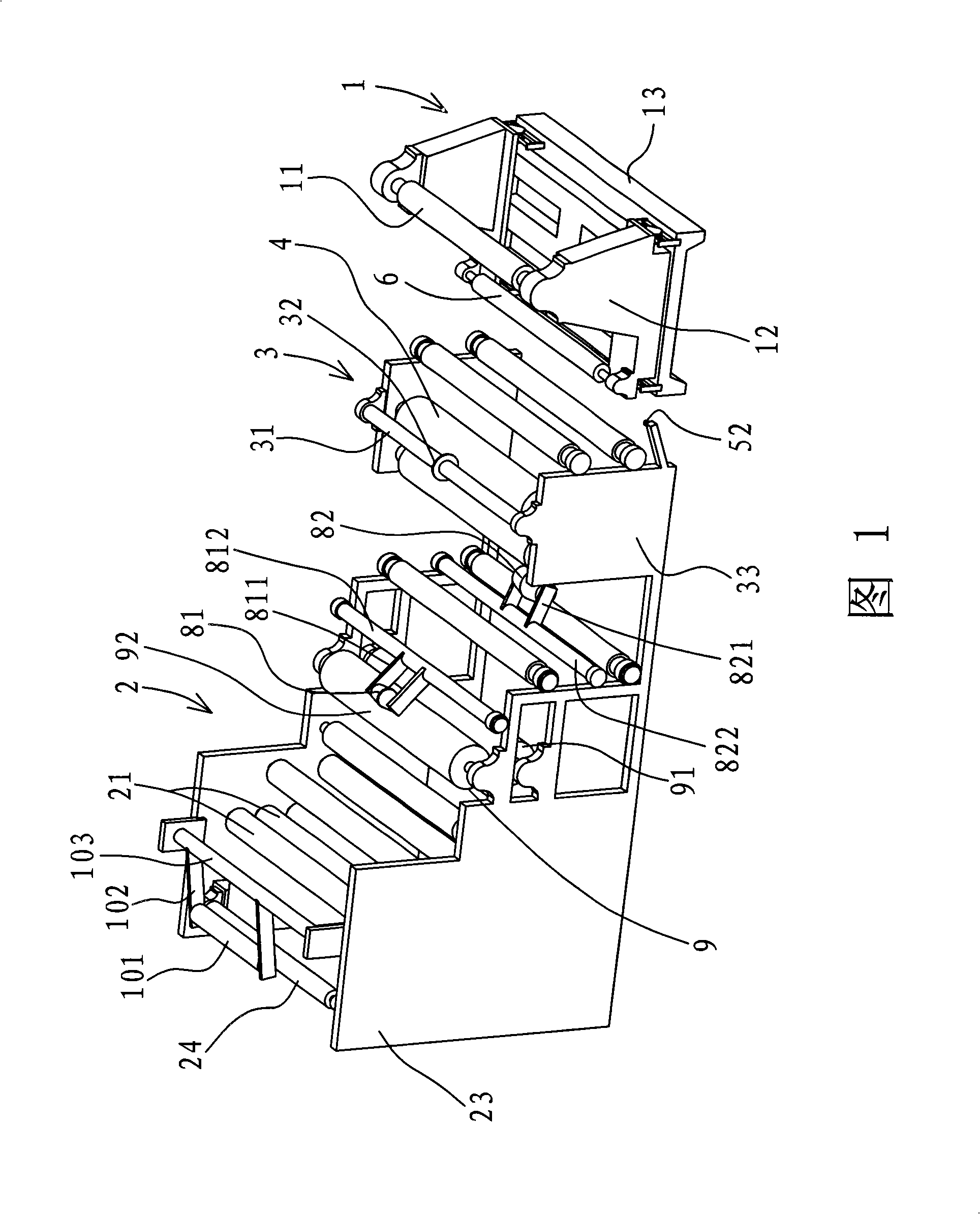

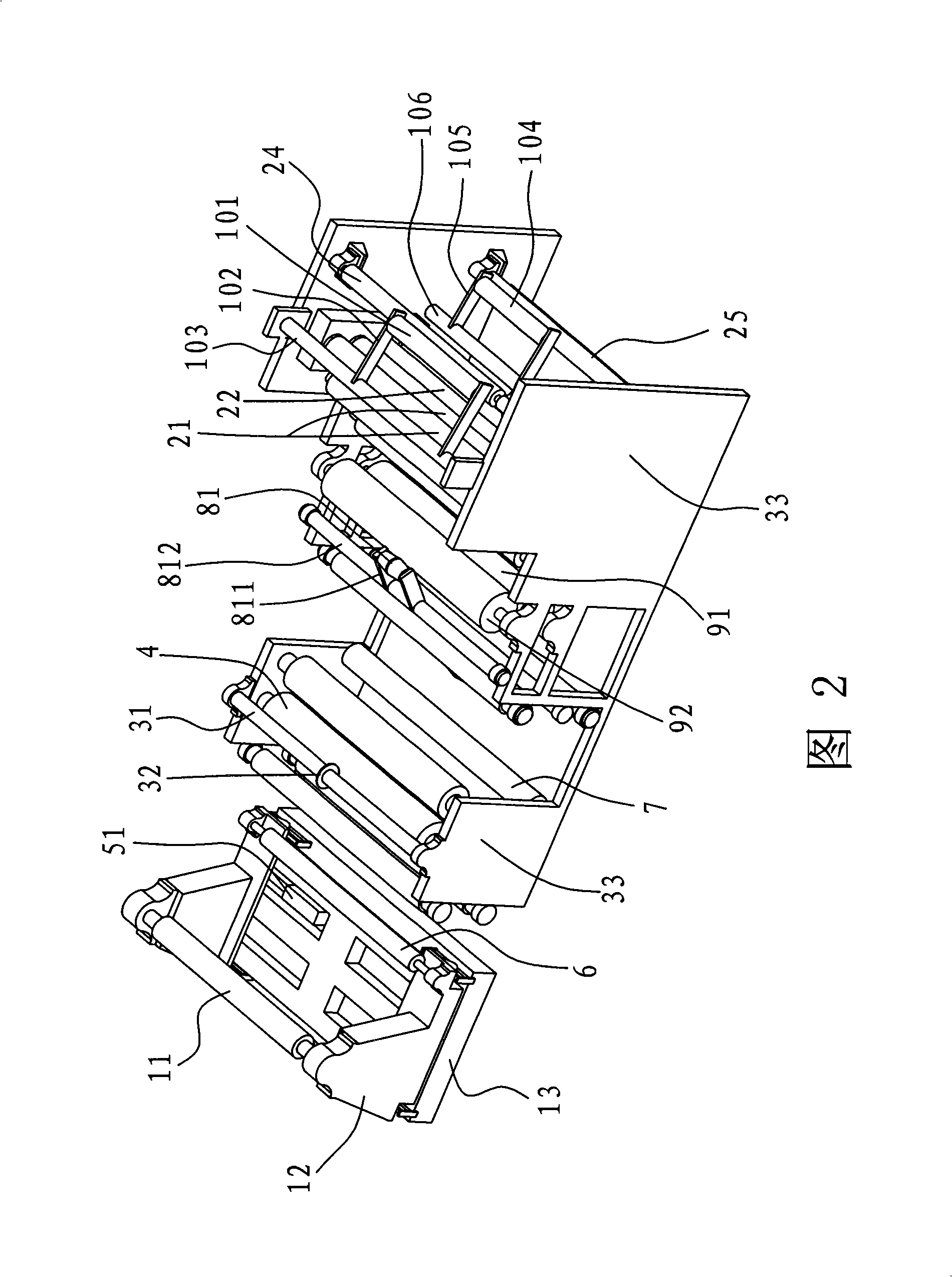

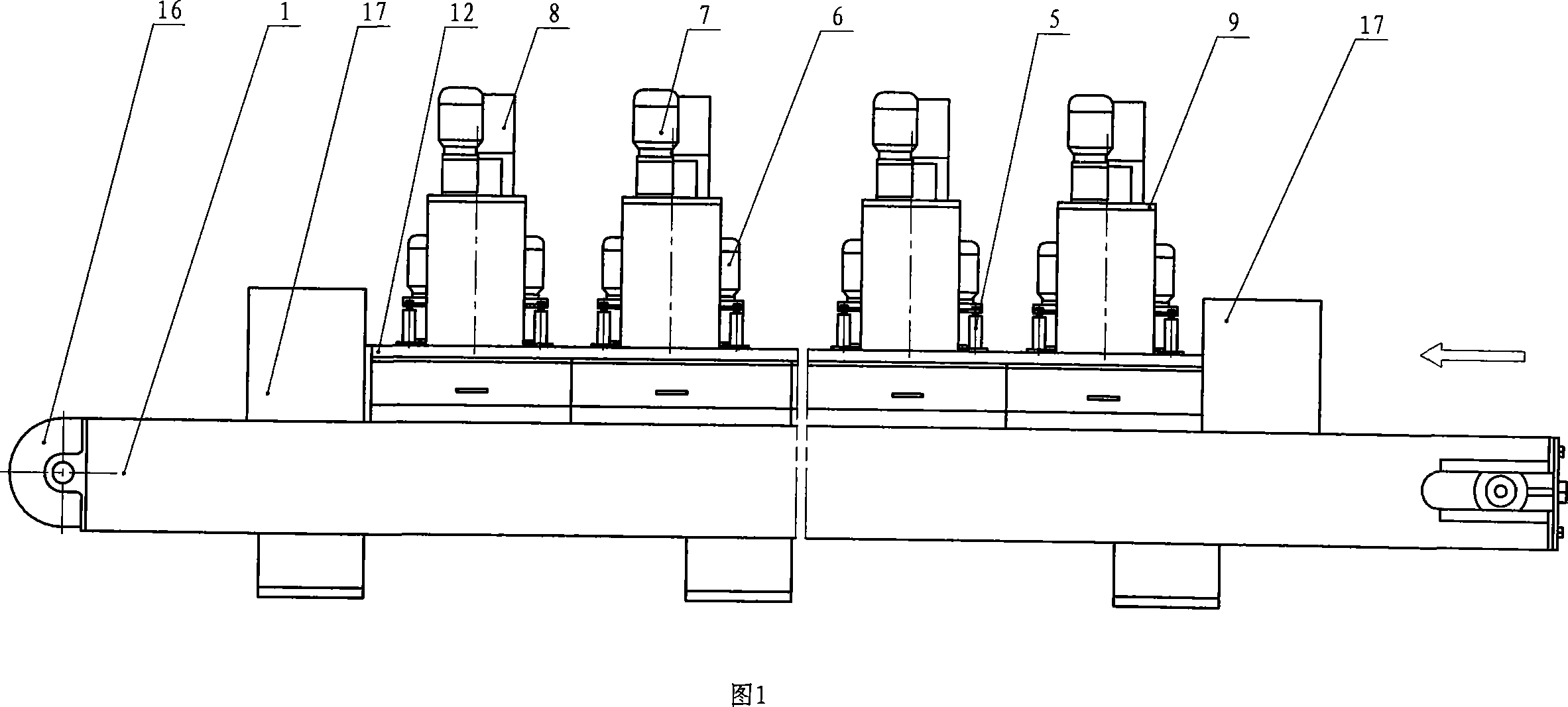

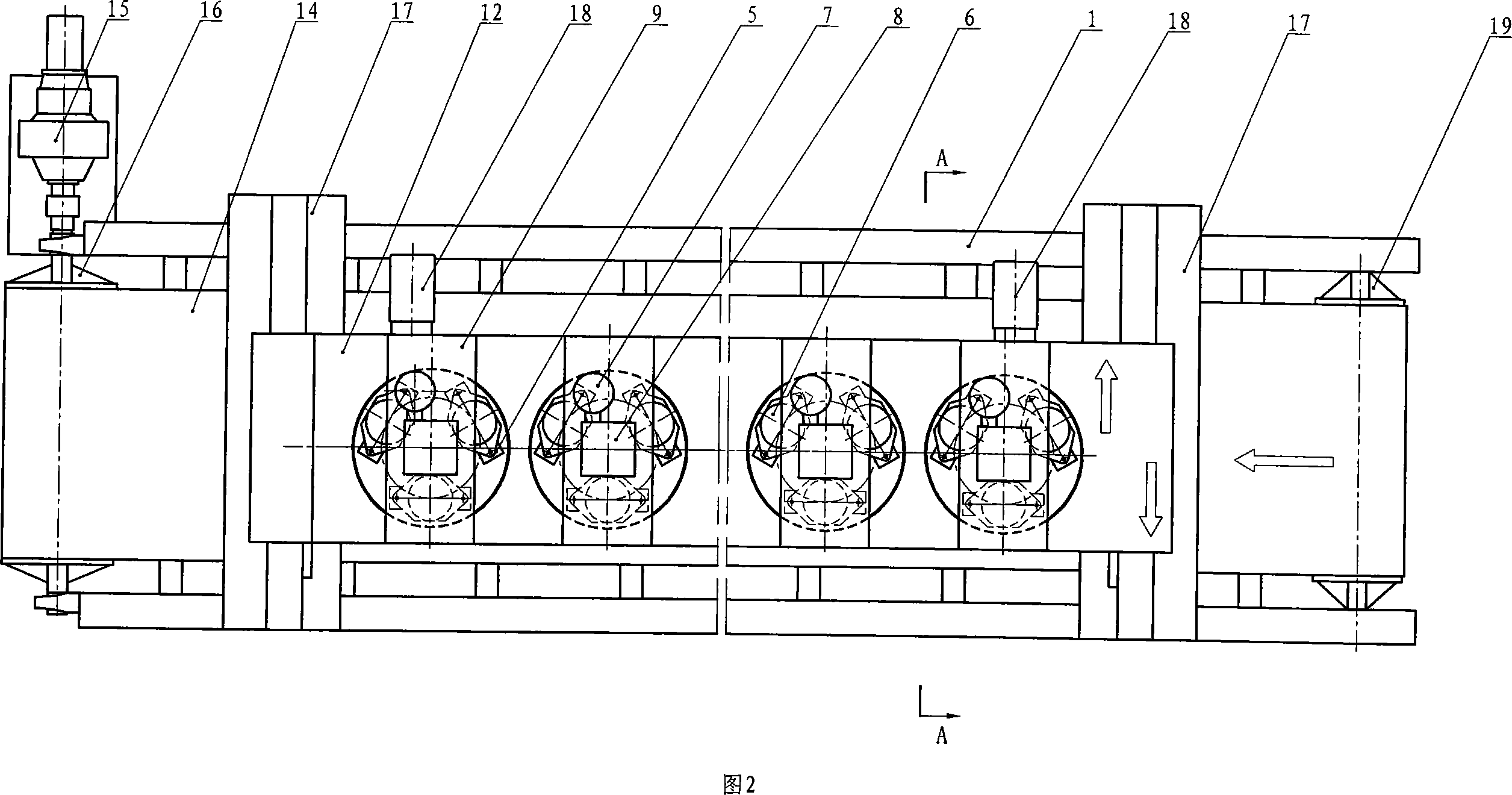

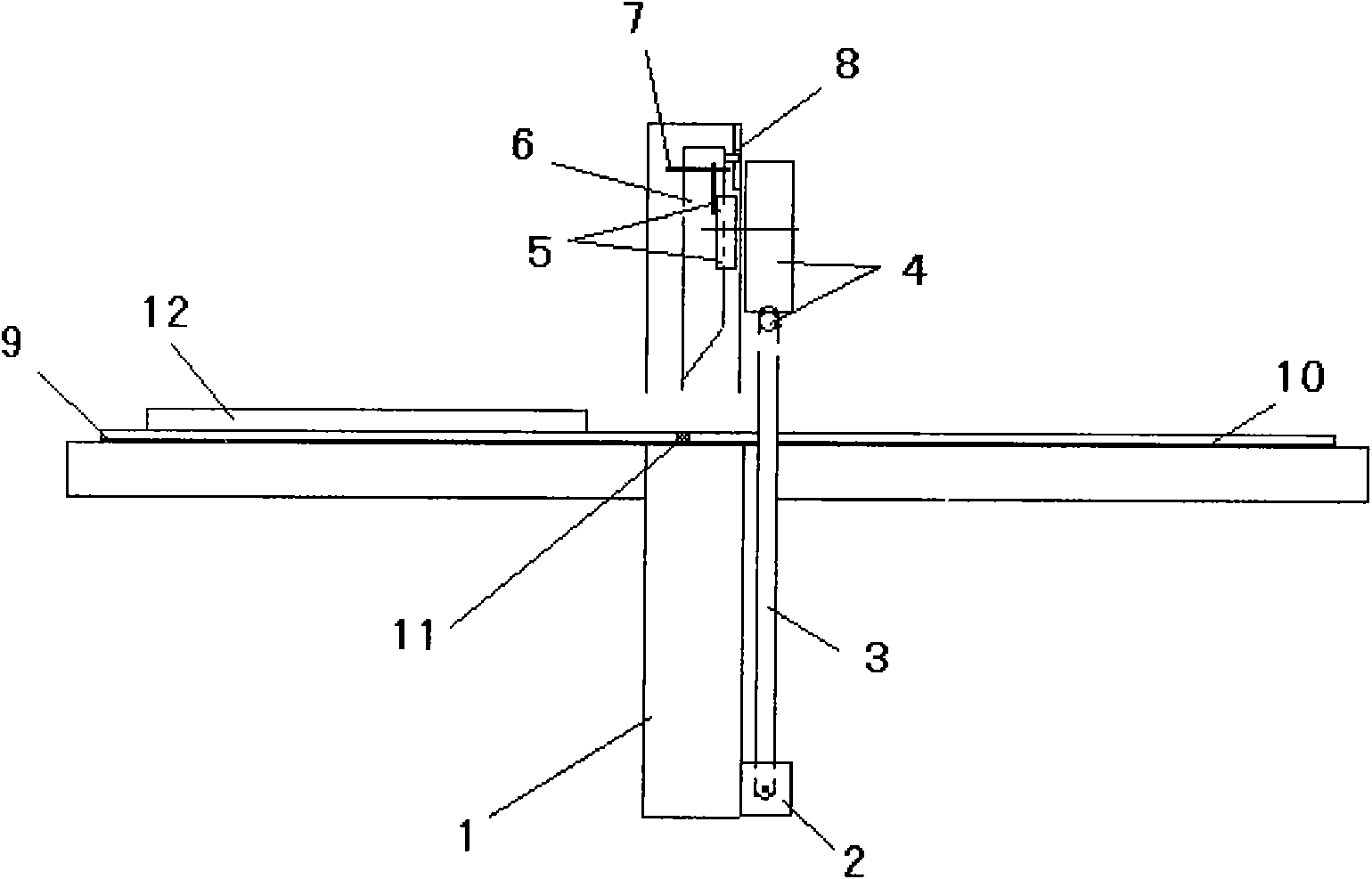

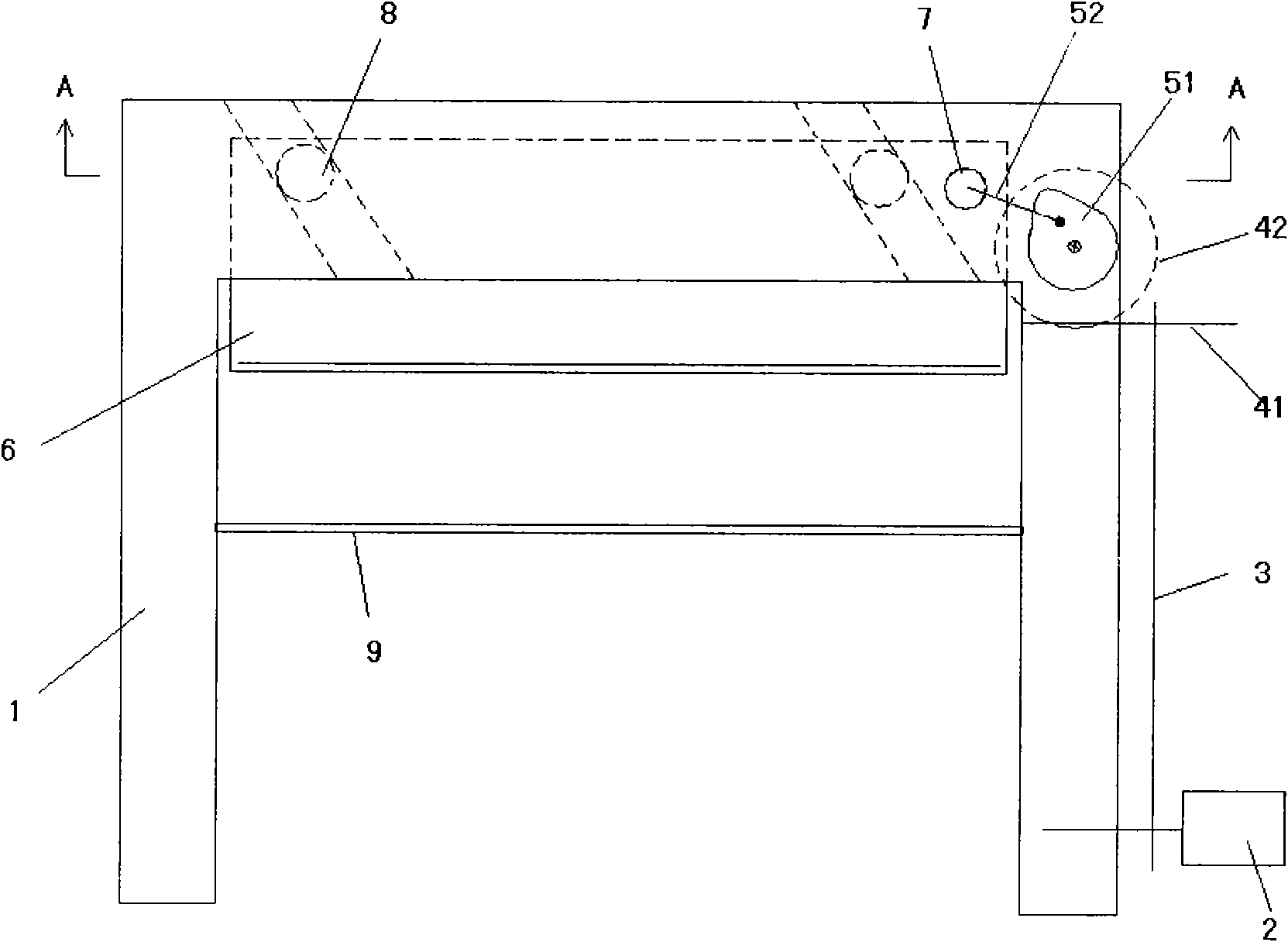

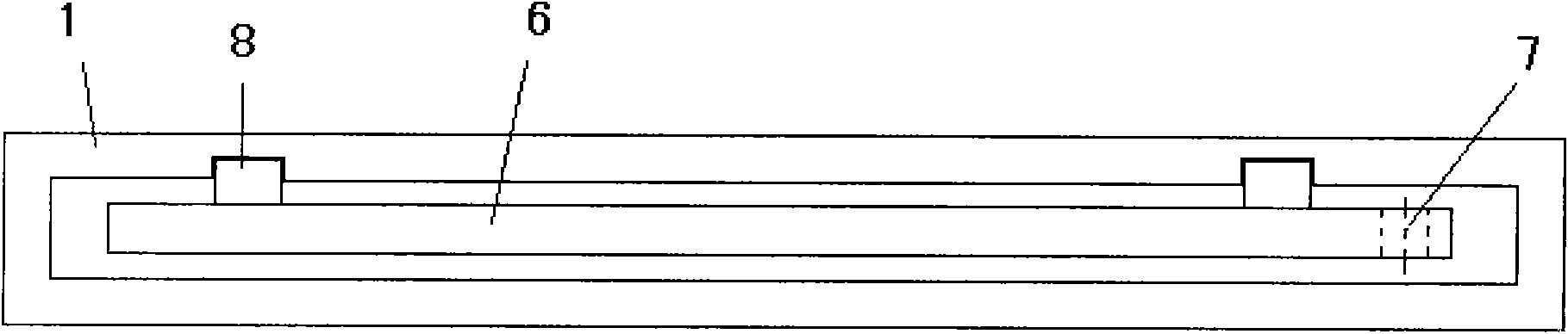

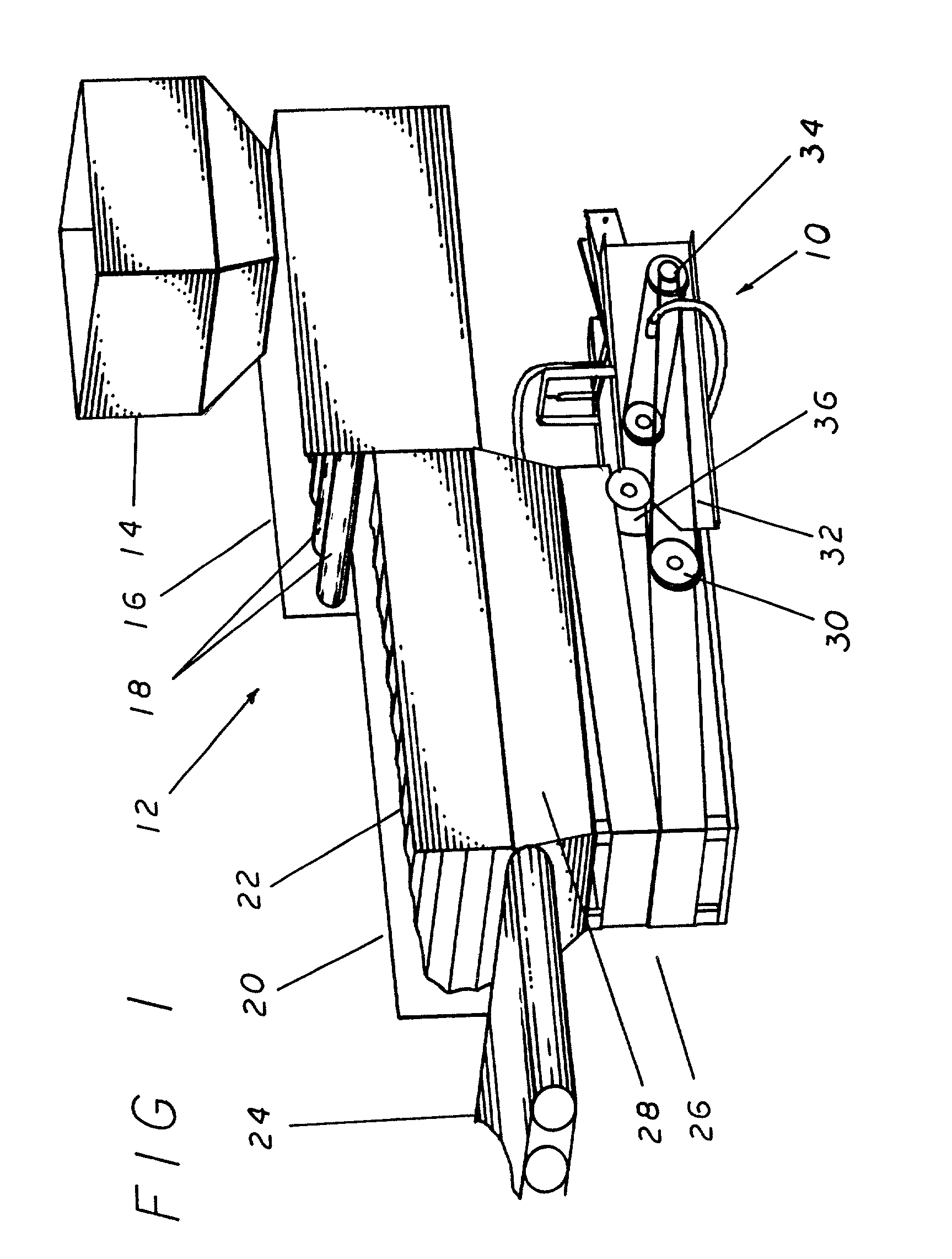

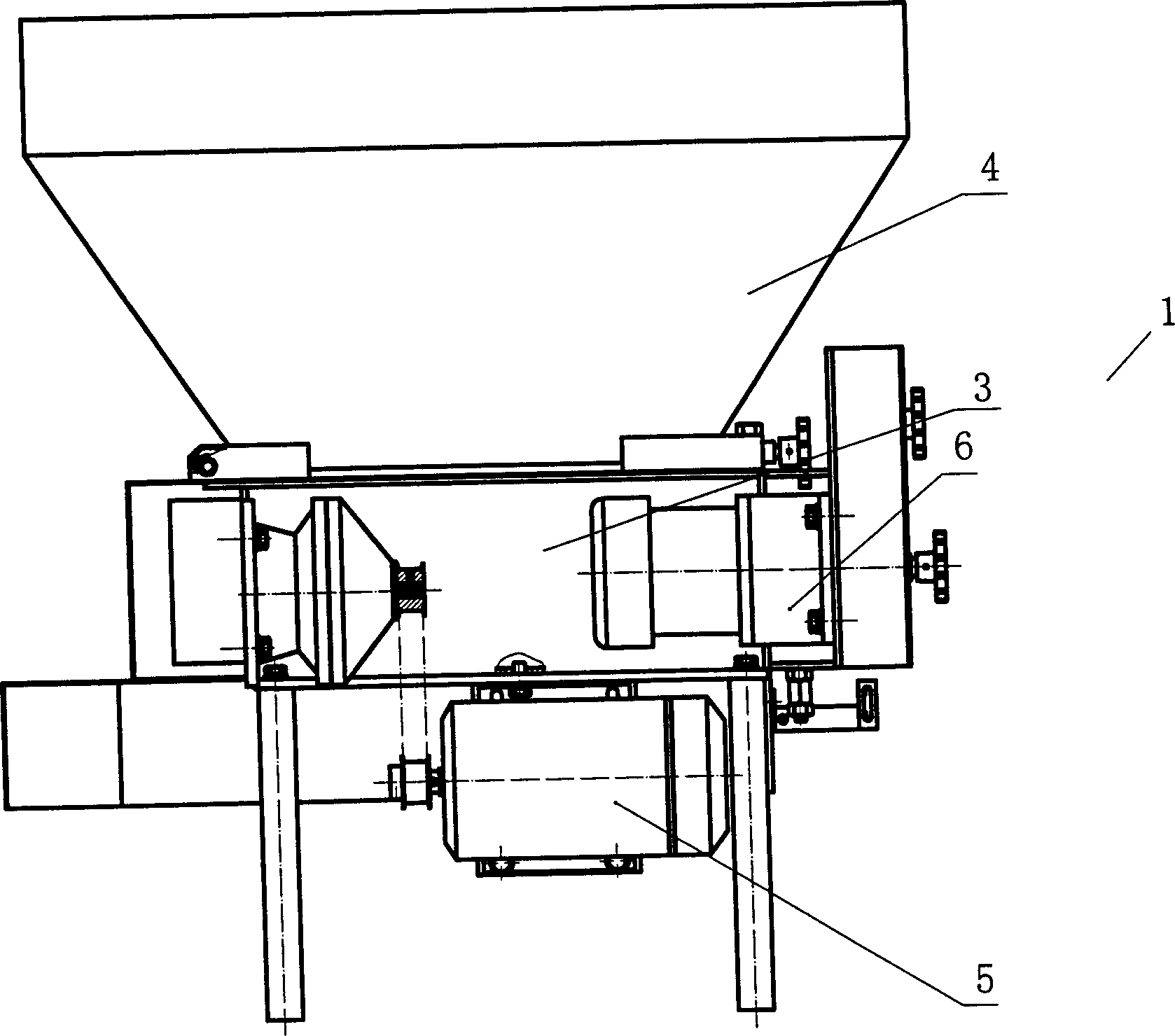

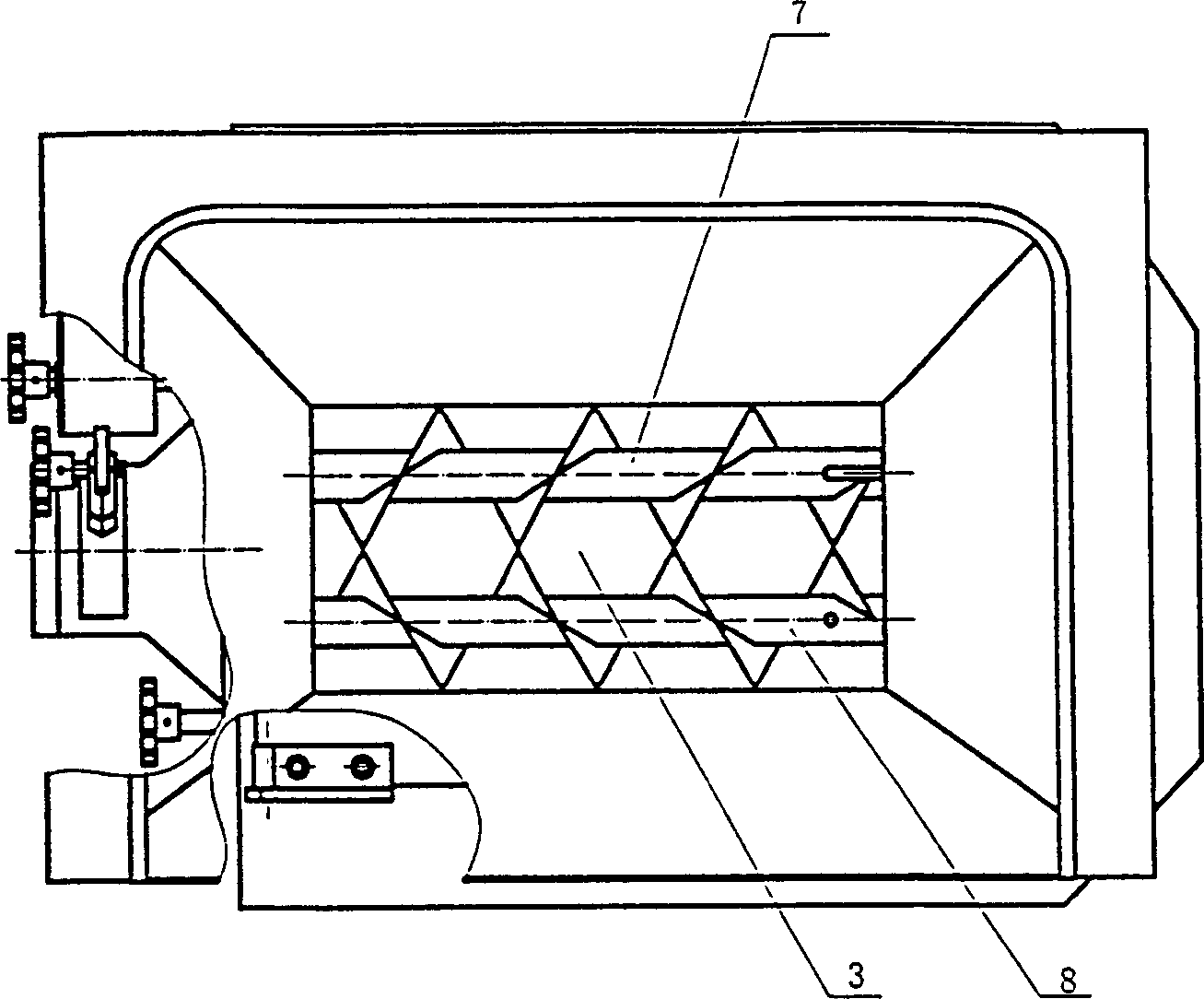

Splitting winding machine for base paper

ActiveCN101301969ACut evenlyOffset is automatically eliminatedMetal working apparatusArticle deliveryWinding machineEngineering

The invention relates to the decorative winding device technical field, in particular to a base paper cutting winding machine which comprises an unwinding device and a winding device. A cutting mechanism comprising a cutting roller and a cutting knife is arranged between the unwinding device and the winding device, the two ends of the cutting roller are movably arranged on a cutting bracket, and the cutting knife is coaxially arranged on the cutting roller. A driving roller is arranged right under the cutting roller, the two ends of the driving roller are movably arranged on the cutting bracket, and the cutting roller is respectively connected with the two ends of the driving roller by driving pairs. Two groups of guiding roller sets are arranged on the winding device, and the guiding roller sets are arranged on a winding frame. A first winding roller and a second winding roller are respectively arranged on the upper part and the lower part of the winding frame, and the first and the second winding rollers are respectively connected with a first driving mechanism and a second driving mechanism. By utilizing the cutting winding machine, cutting and winding works can be completed by one time, furthermore, the cutting is equal and the winding is neat, thus conserving manpower and cost.

Owner:东莞市华富立装饰建材有限公司

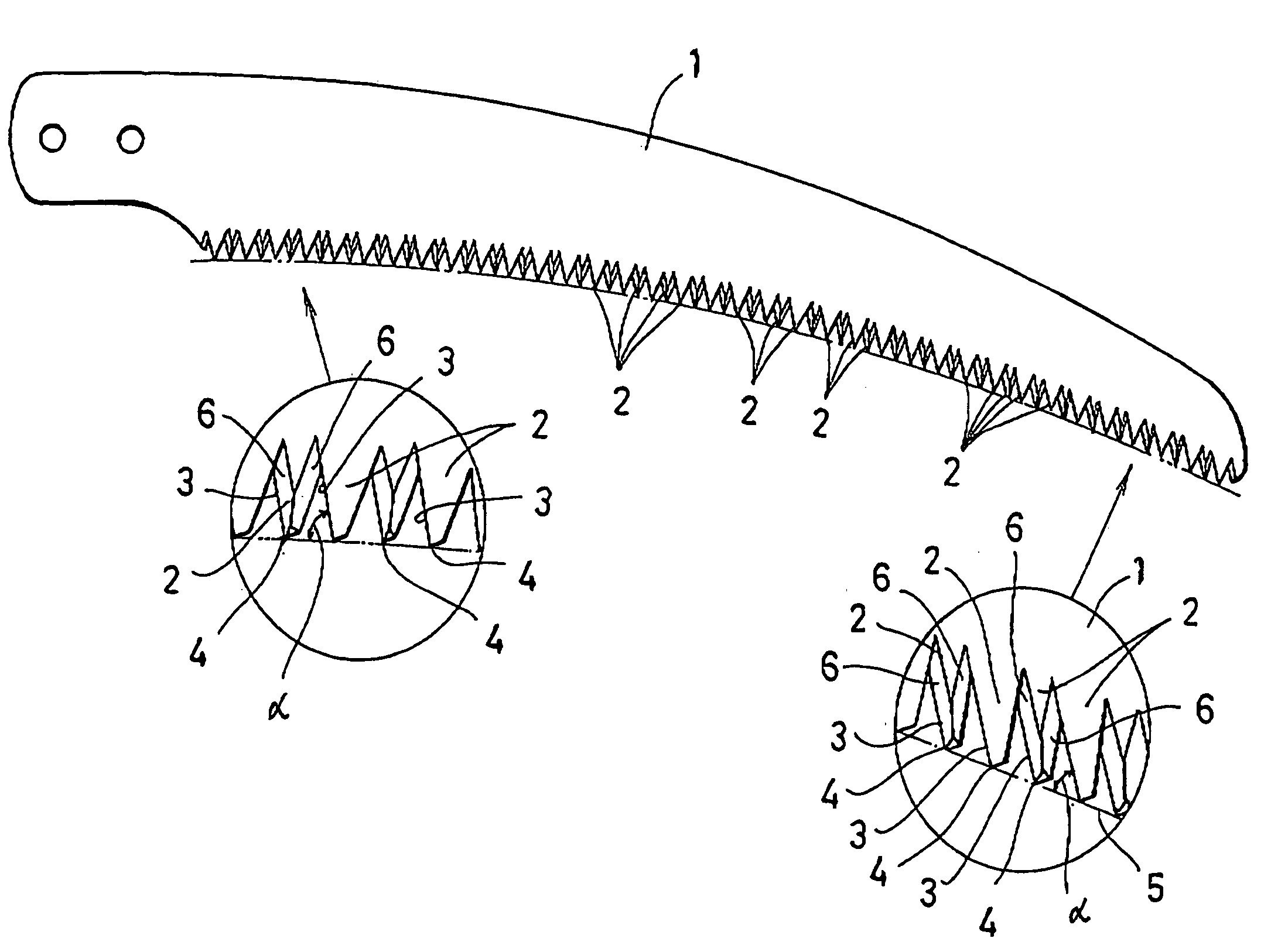

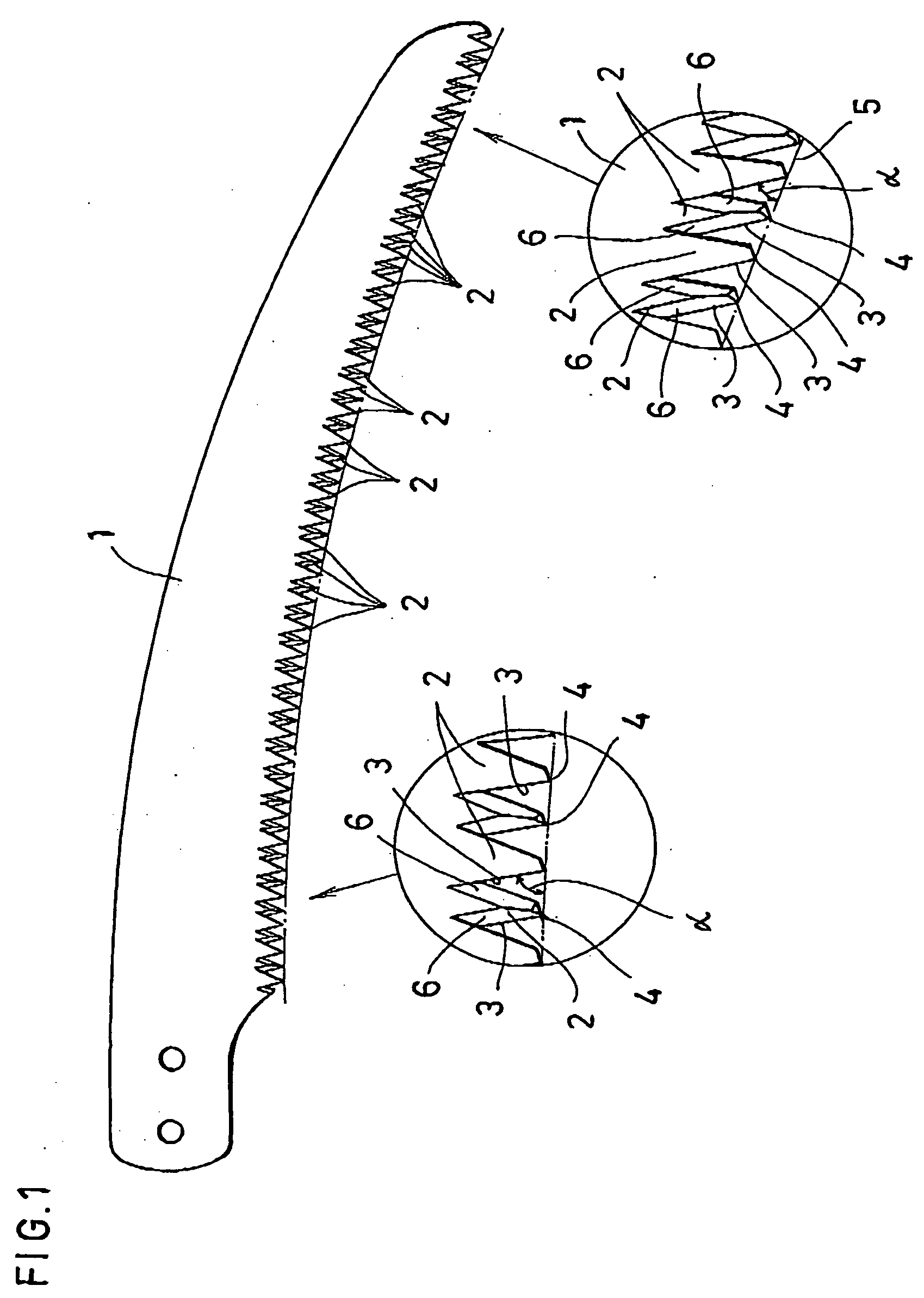

Curved saw

Owner:KANZAWA SEIKO

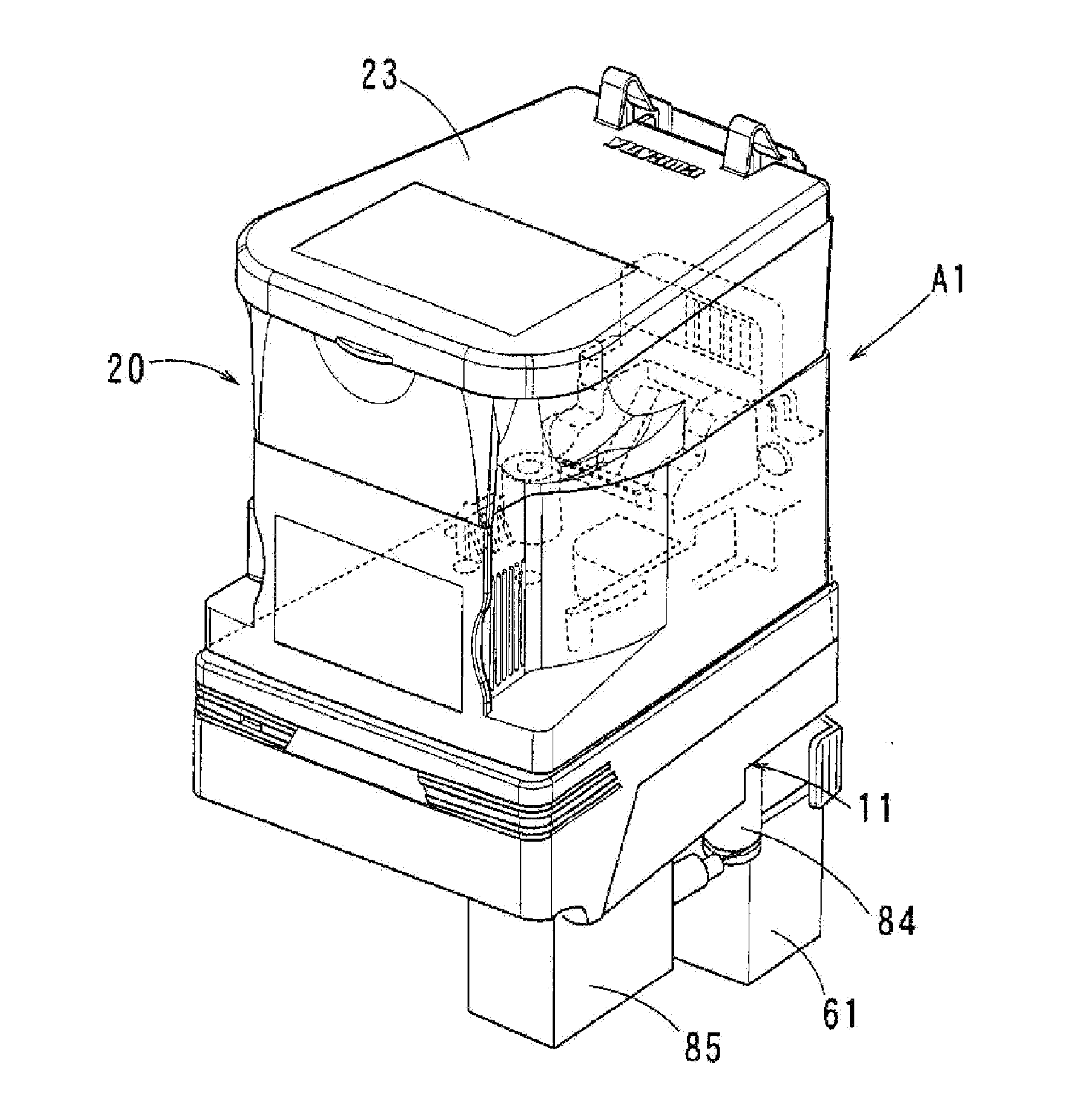

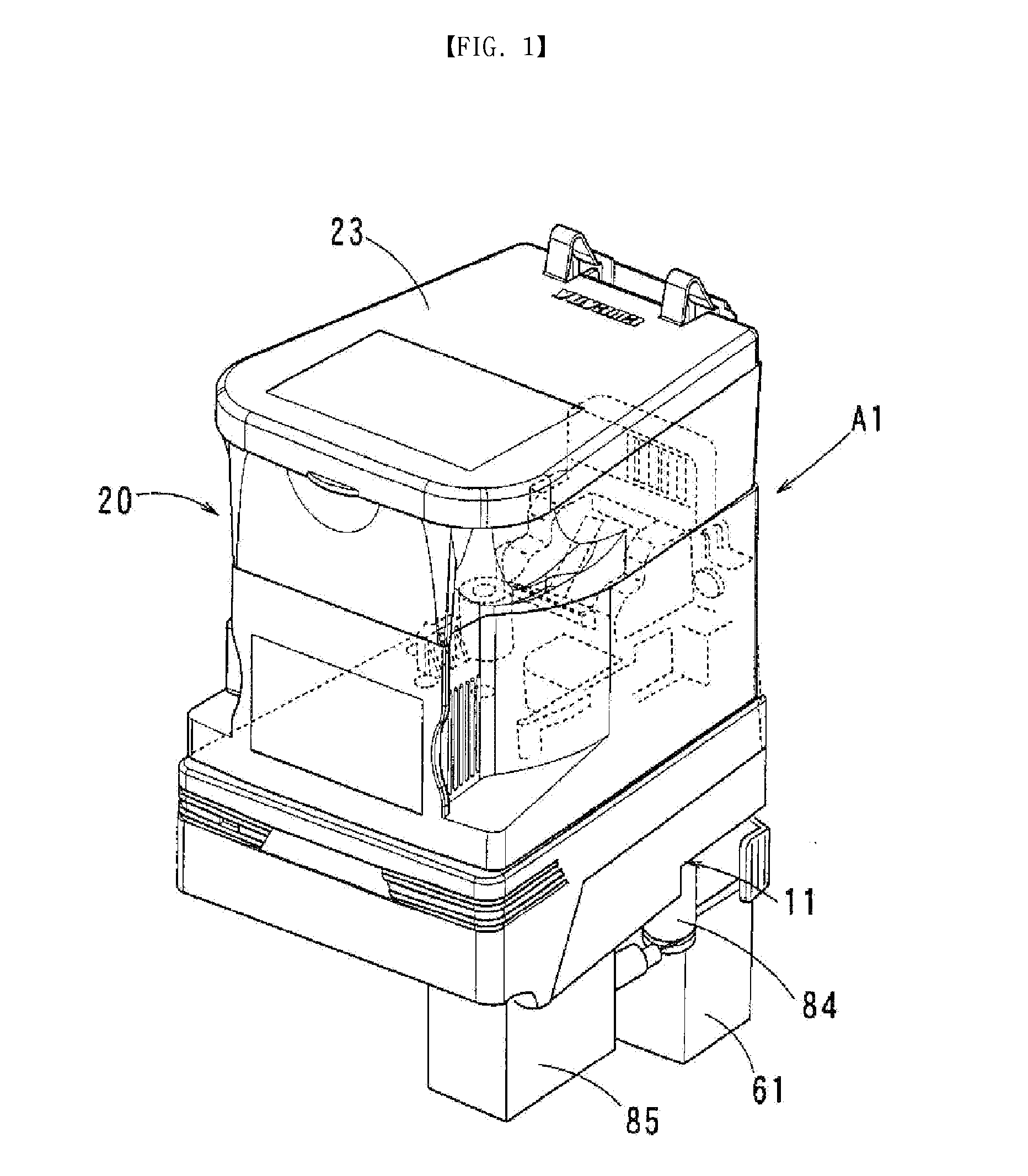

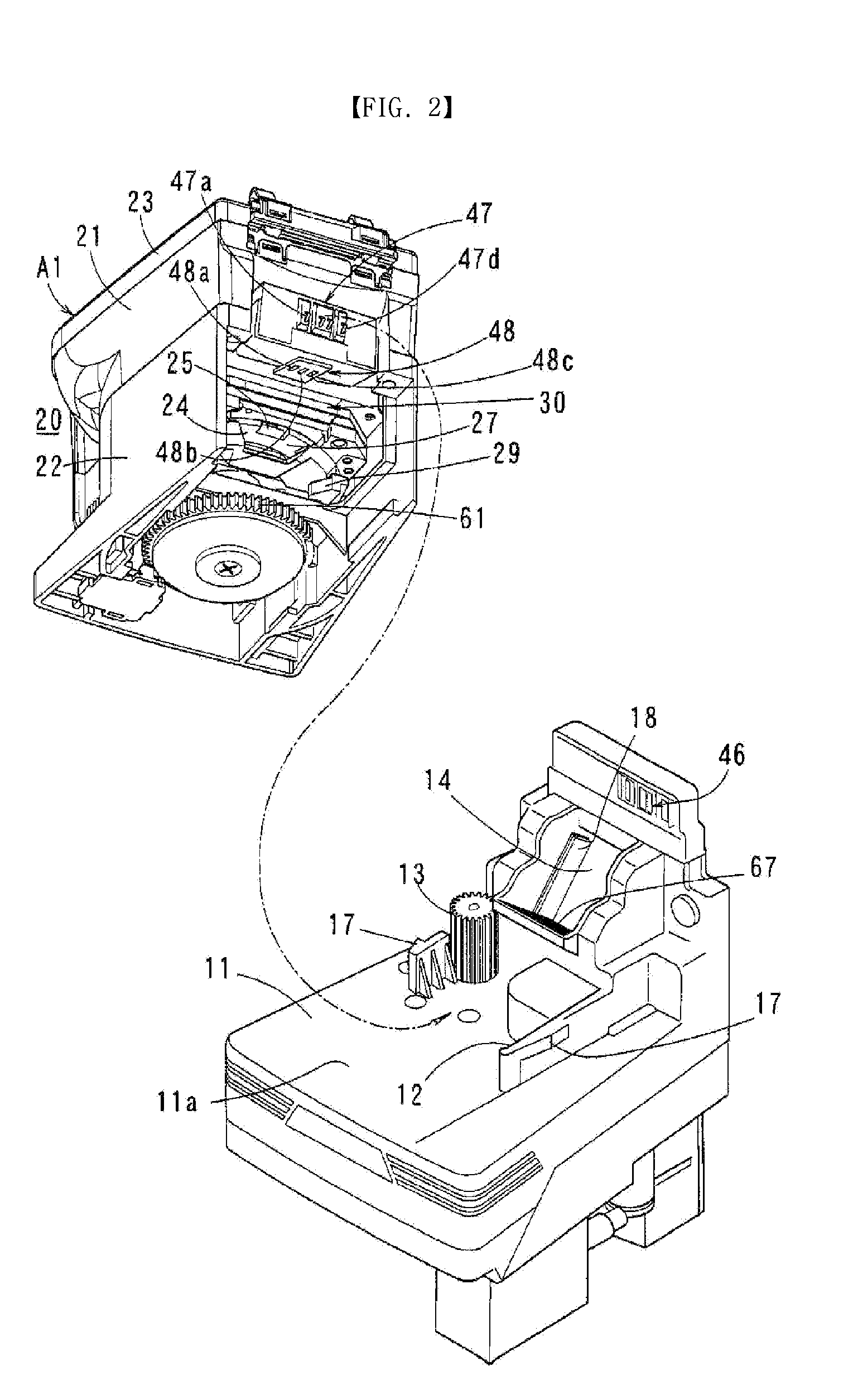

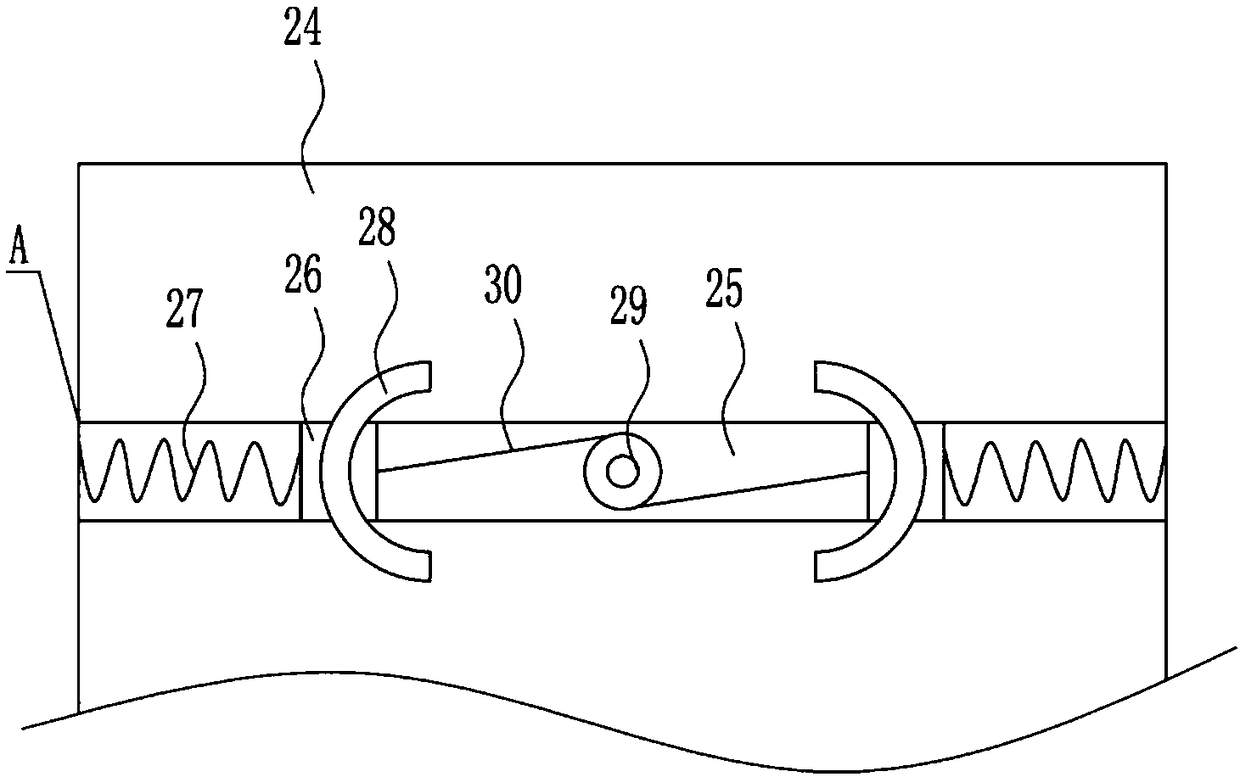

Powder removing device for tablet feeder

InactiveUS20110309101A1Cut evenlyAvoid connectionCoin-freed apparatus detailsOral administration deviceEngineeringPlunger

Powder (b) cut and attached to tablet pieces (T1, T2) can be removed smoothly. A tablet dividing feeder (A1) cuts and divides a tablet (T) in a receiving pocket into two halves with a fixed blade as a rotor rotates. Powder removing plates (64a, 64b, 66) are installed in a tablet supplying passage (14) of the feeder. The powder removing plate (64b) is vibrated by a vibration motor (71) to peel the powder (b) attached to the tablet on the powder removing plate and drop the powder (b) from a slit (a). The peeling operation is performed by temporarily leaving the tablet pieces (T1, T2) between the powder removing plates (64a, 64b). The powder removing plate (64b) is fluctuated by a plunger, and the tablet pieces may be left and dropped due to the fluctuation. The tablet piece drops along the powder removing plate (66), and the attached powder is peeled to be guided to a packaging process through a supply opening (90).

Owner:YUYAMA MFG CO LTD

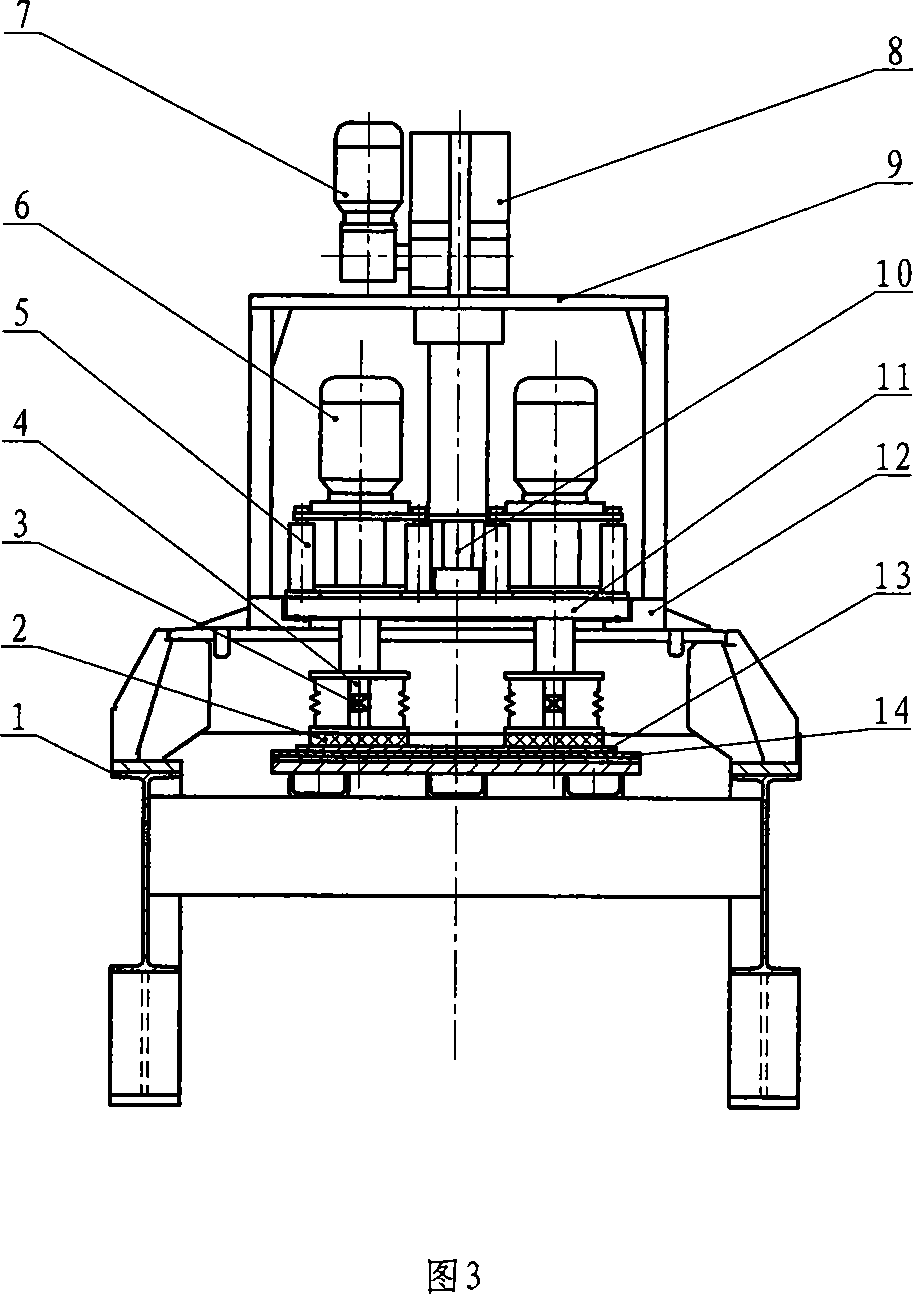

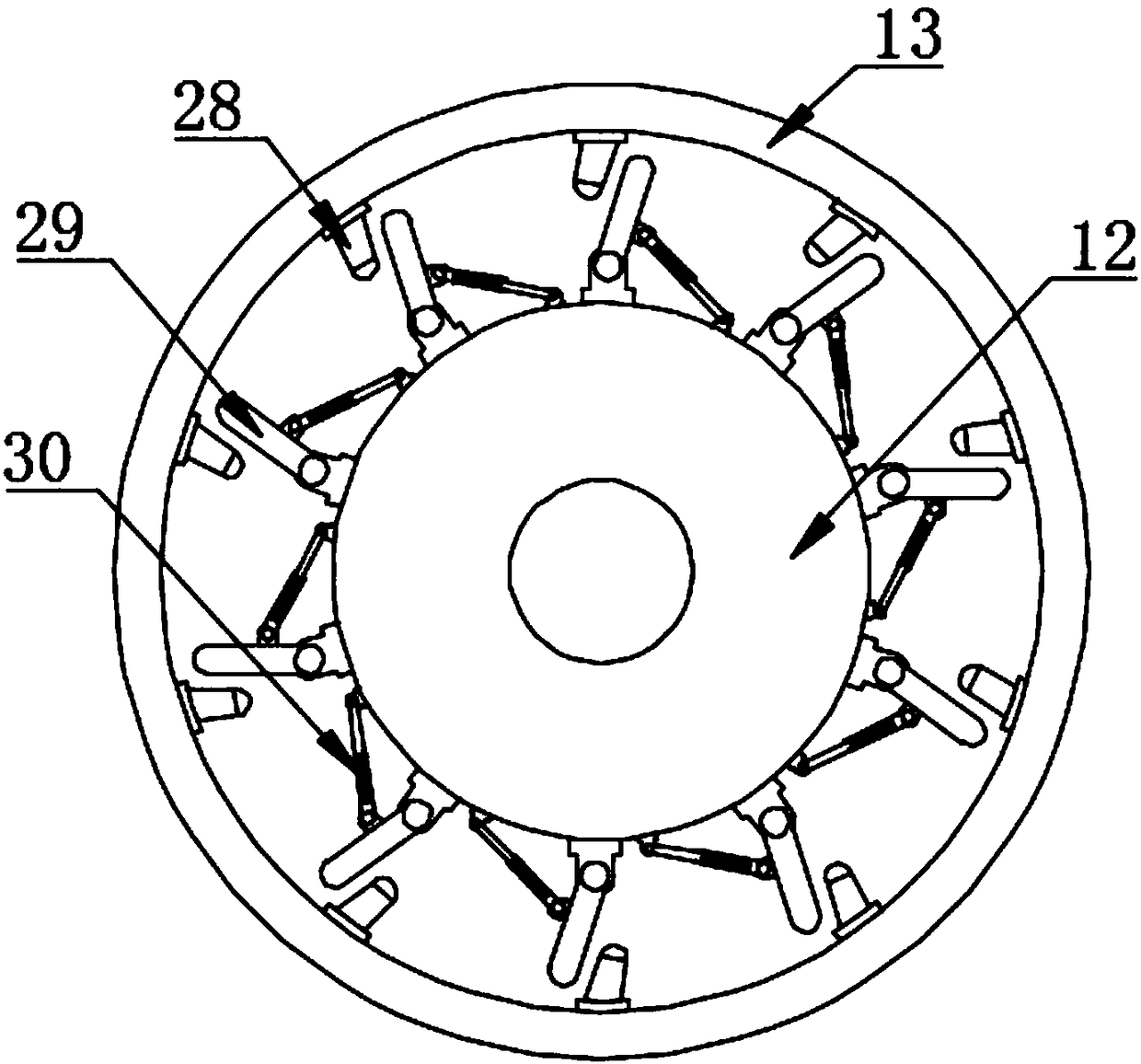

High-efficient glazer

InactiveCN101176982AGood rotational rigidityGood stabilityGrinding machine componentsPolishing machinesBuilding materialCeramic tiles

The invention discloses a high-efficiency polishing lathe with flexible self-adapting shape follow-up polishing and grinding performance, which comprises a horizontal conveyor, a reciprocating swing system, a lifting-type self-rotating mechanism and a fixing-type revolution mechanism; wherein, a second motor and a power supply device are arranged on a supporting bracket fixed on a swing beam; the second motor is connected with the center of a rotating table through one end of main shaft for the rotating table; the rotating table is arranged the swing beam; a first motor is arranged on the rotating table through a cylinder and the support; the output shaft of the first motor is connected with a drive shaft connected with a universal flexible coupler; an abrader is arranged at the lower end part of the universal flexible coupler; the first motor also moves upward and downward under the action of the cylinder when driving the abrader to rotate. The invention has an advantage of being widely applied in surface polishing grinding in plate building material such as polished ceramic tile and stone material.

Owner:佛山市科利得机械有限公司

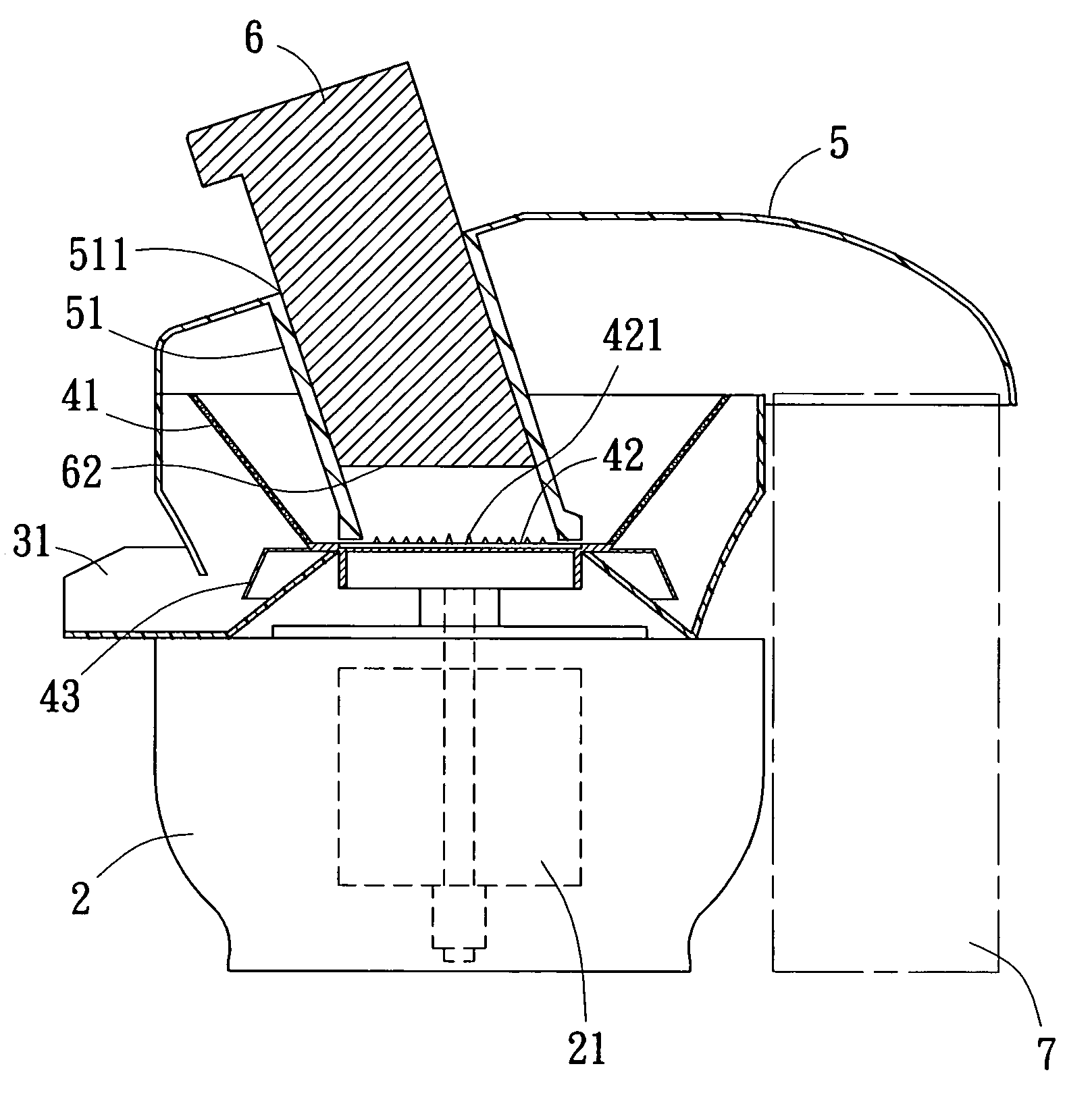

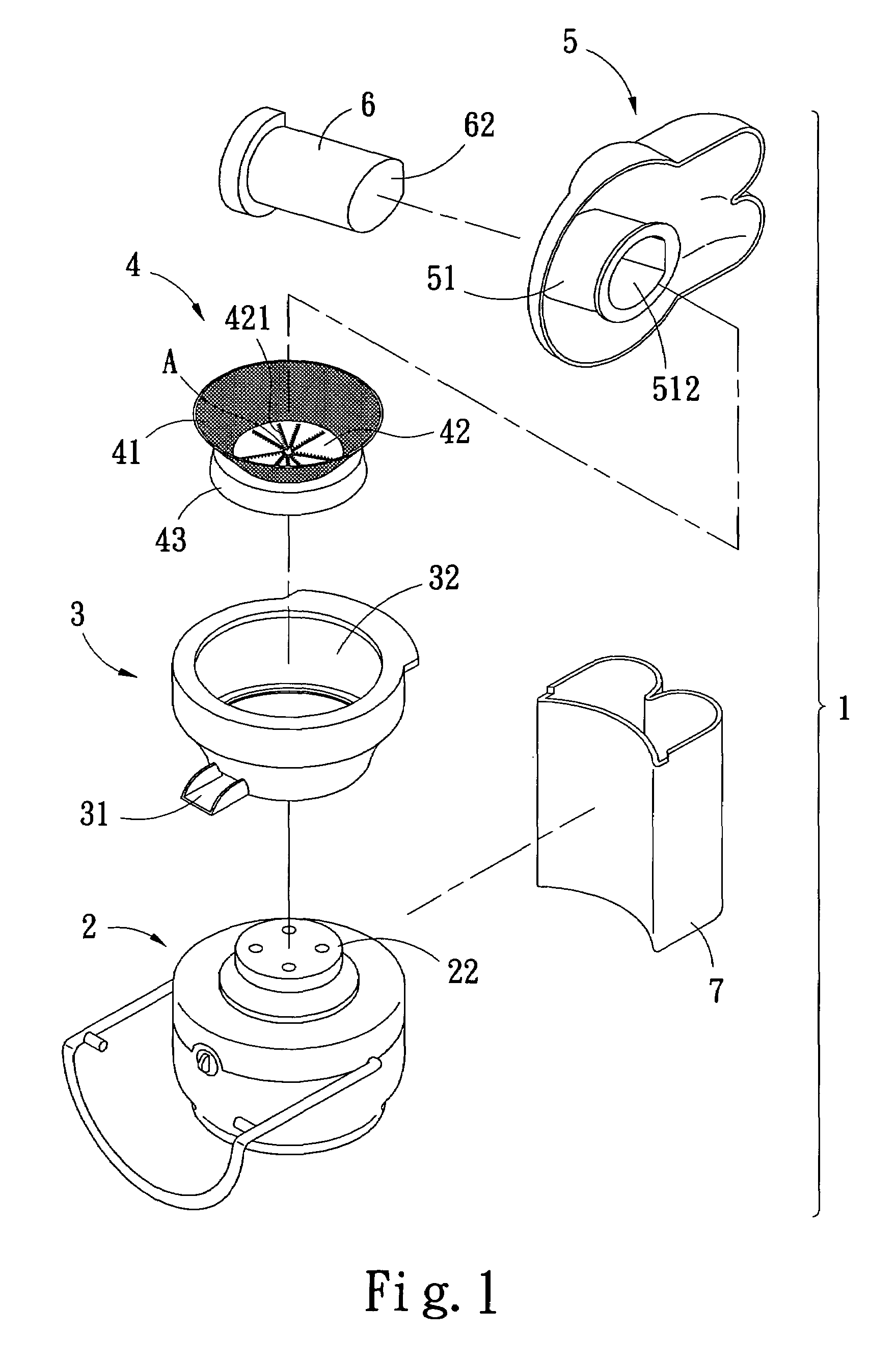

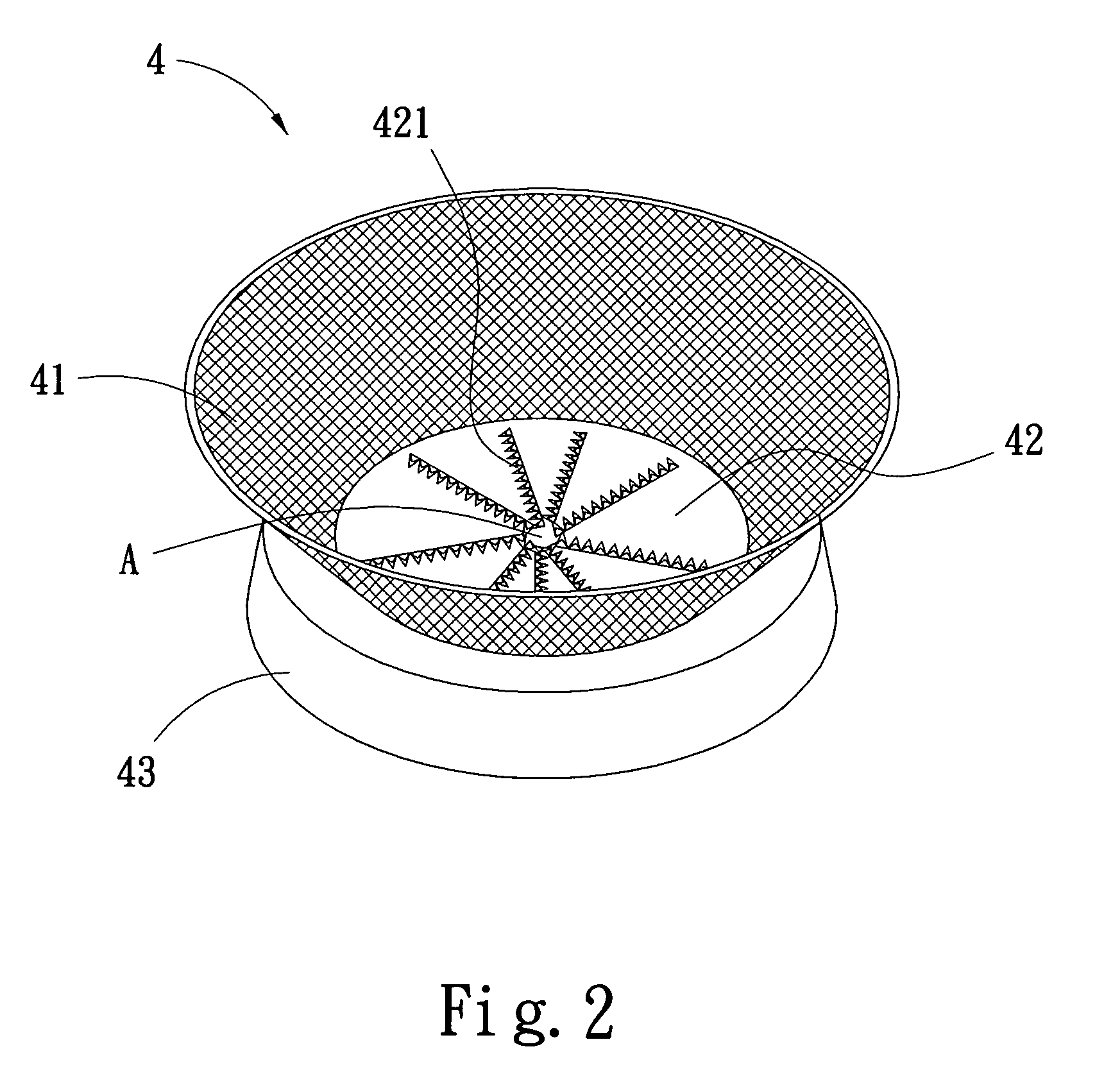

Food, vegetables and fruit processor

A food, vegetables and fruit processor comprises a base having therein an operating motor, a lower cover, a cutting seat and an upper cover. Wherein the upper cover is provided with an inclined feed-in pipe extending downwardly therefrom, one end of the feed-in pipe forms on the surface of the upper cover a material inlet, the other end of the feed-in pipe forms a material outlet. Food, vegetables and fruit can be cast into the feed-in pipe, and are pressed tight with a material pushing plunger to render the food, vegetables and fruit to be perfectly and smoothly cut or ground in an energy saving mode. The present invention is applicable to using as a food, vegetables and fruit processor having the functions of squeezing juice and grinding food.

Owner:LIN WEI CHIH

Cutting device of phloem fiber

The invention relates to a cutting device of phloem fiber, which is characterized in that the cutting device comprises a reverse U-shaped machine frame, one side of the machine frame is provided with a motor, the motor drives a group of worm and gear mechanisms through a transmission mechanism, worm wheels in the worm and gear mechanisms are coaxially connected with a crank disc of a crank connecting rod mechanism, a connecting rod is eccentricly connected on the crank disc, the other end of the connecting rod is connected with a cutter, the cutter spans between two vertical beams of the machine frame and is movably supported on the cross beam of the machine frame, the cutter is provided with a guide block and a guide groove in inclined movement correspondingly to the cross beams of the machine frame, both sides of the machine frame under the cutter are respectively provided with a material inlet support plate and a material outlet support plate, a cutter falling groove right aligned with the cutter is connected between the material inlet support plate and the material outlet support plate, and a hard pad block is arranged in the cutter falling groove. When the device provided by the invention is used for cutting the phloem fiber, the time and the labor can be saved, the cutting length required by the technology can be realized, the manual operation error can be reduced, and the production efficiency is high.

Owner:THE QUARTERMASTER RES INST OF THE GENERAL LOGISTICS DEPT OF THE CPLA +3

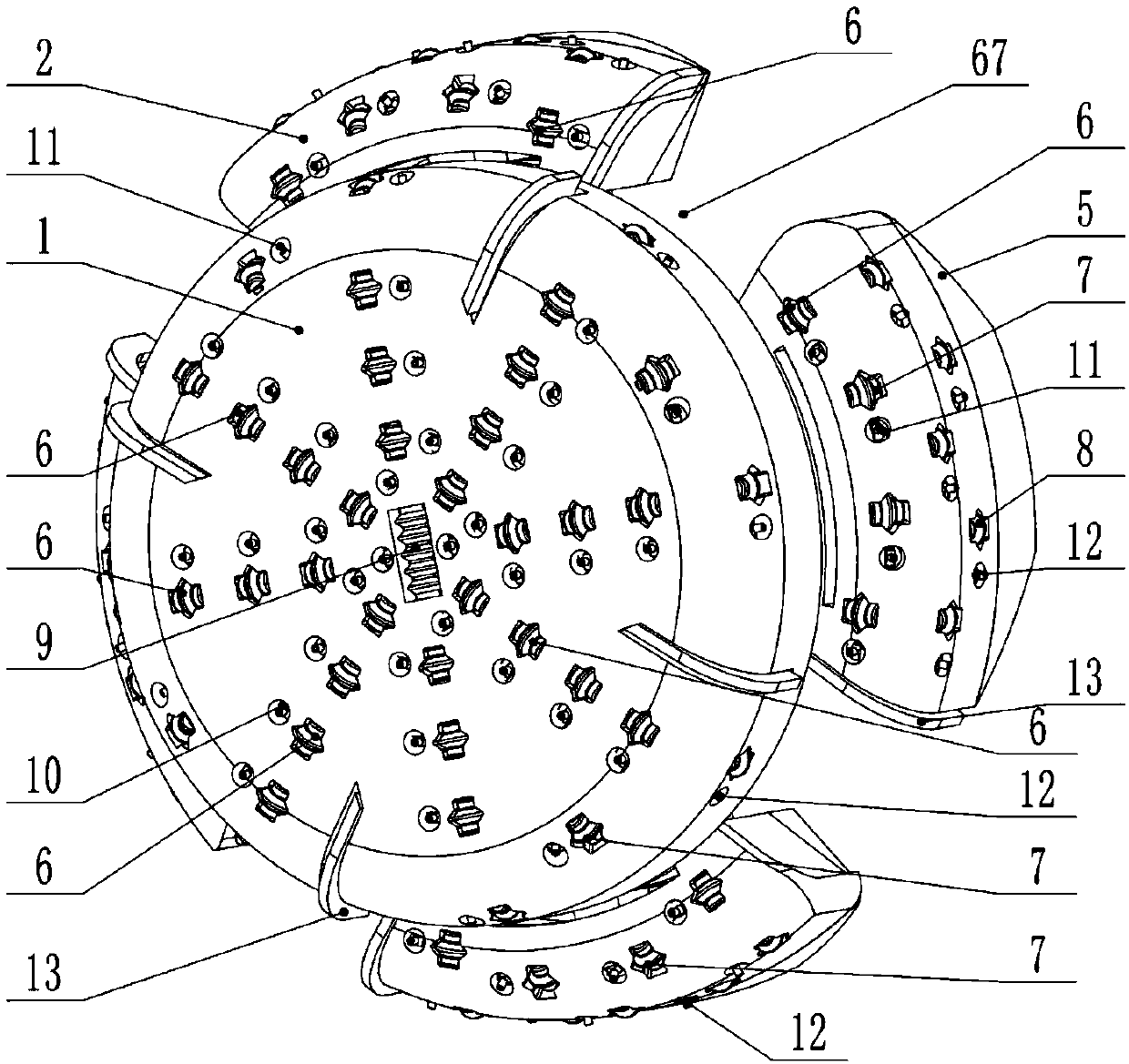

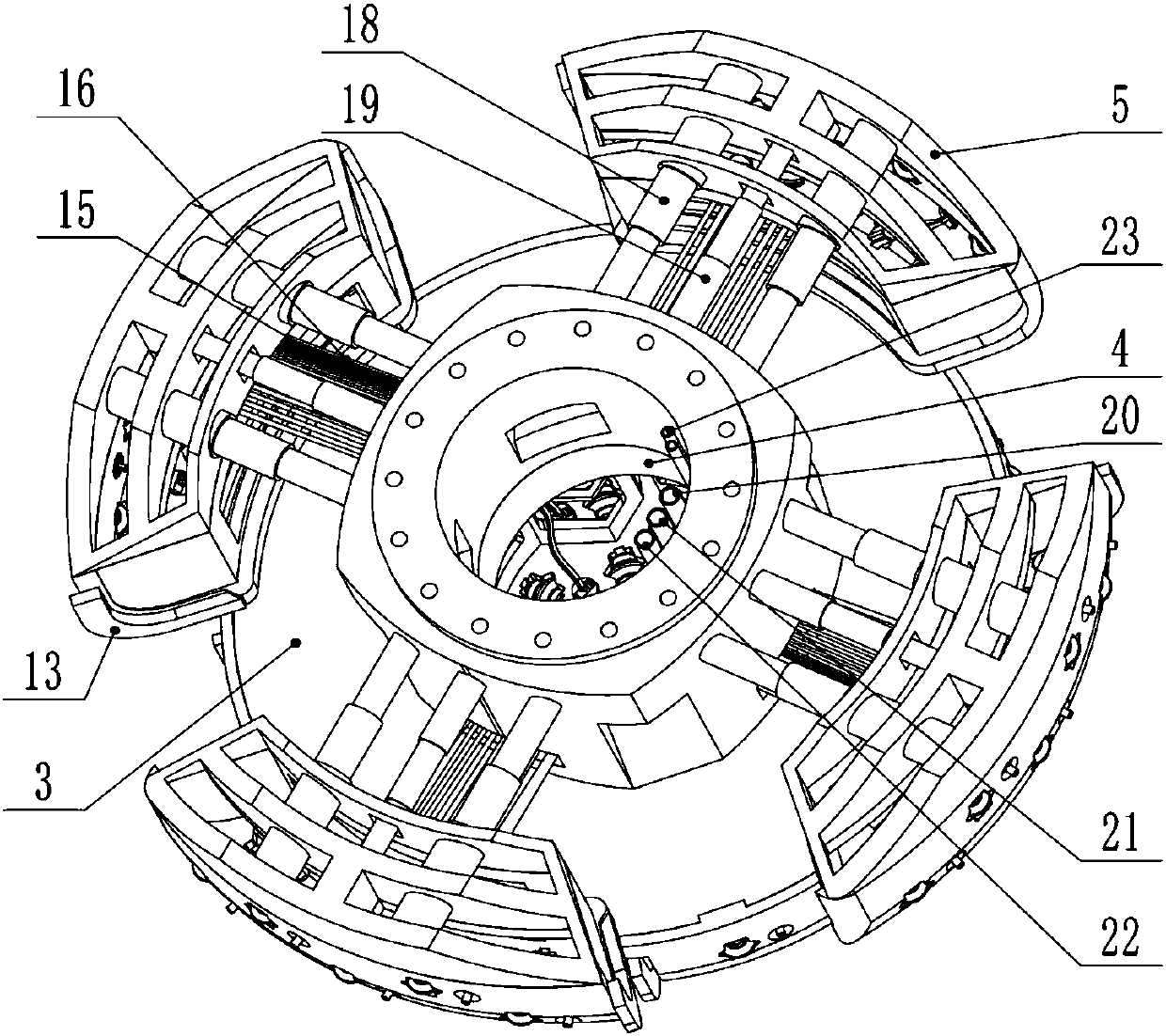

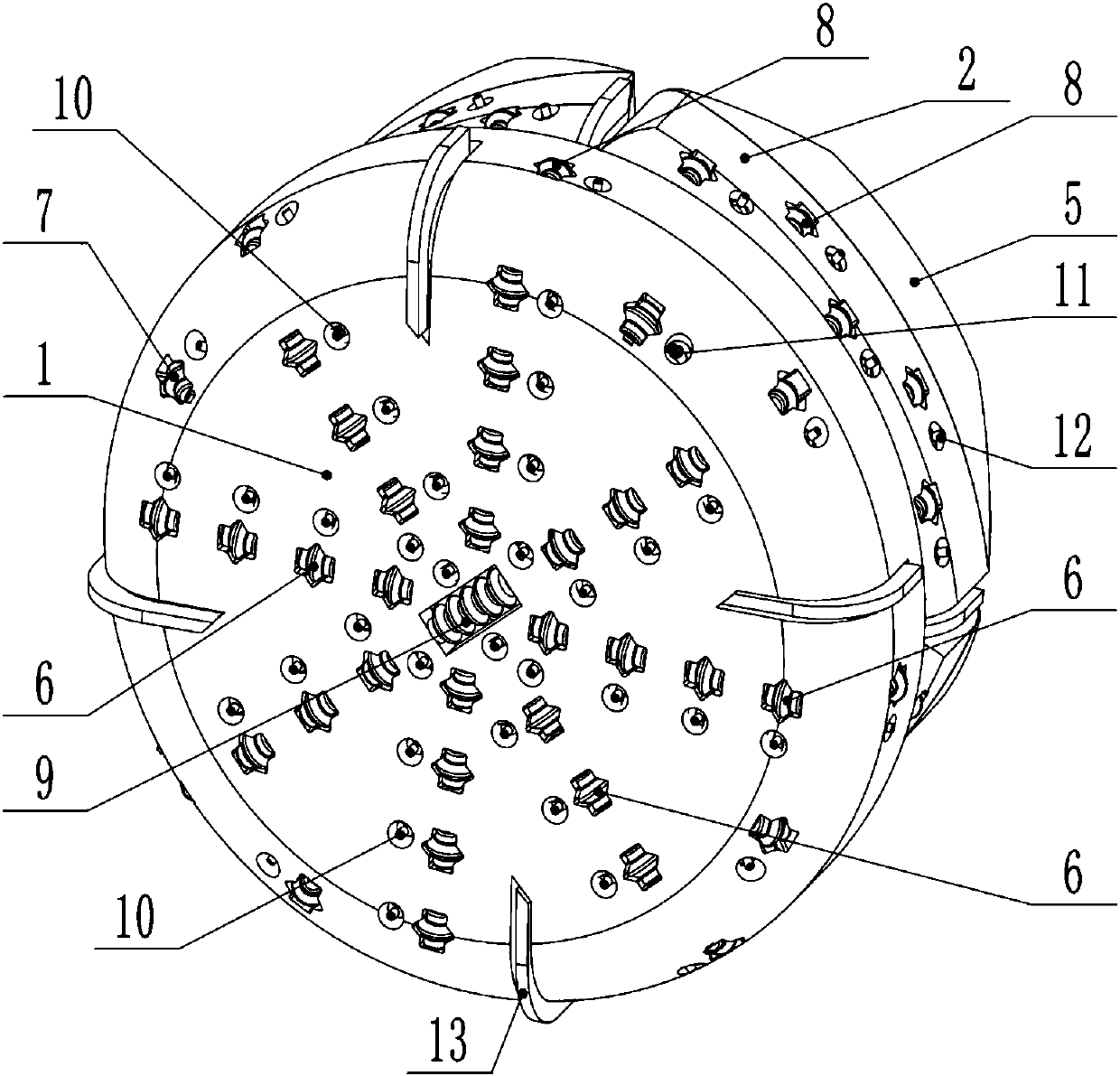

Full-fracture-surface hard-rock tunneling machine cutter disc and tunneling method

The invention belongs to the technical field of engineering machinery, and particularly discloses a full-fracture-surface hard-rock tunneling machine cutter disc and a tunneling method. The tunnelingmachine cutter disc comprises a main cutter disc mechanism, an expansion cutter disc mechanism and a connector; the connector is provided with connector mounting holes for connecting a cutter disc driving mechanism; the main cutter disc mechanism comprises a main cutter disc, a first slag removing cutter, a first hob assembly and a first water jet cutter assembly; the expansion cutter disc mechanism includes multiple auxiliary cutter disc mechanisms; each auxiliary cutter disc mechanism includes an auxiliary cutter disc, an auxiliary cutter disc mounting frame and a retractable mechanism; thecutting end of each auxiliary cutter disc is provided with a second hob assembly, a second water jet cutter assembly and a second slag removing cutter. The water jet cutter assembles of the cutter disc can carry out hydraulic incision on tunnel rock, the tunnel rock subjected to hydraulic incision is much looser, then the hob assemblies can roll and crush the much looser tunnel rock, the tunnelingstress is effectively reduced, and hobs are protected; the retractable mechanisms connected with the auxiliary cutter discs can change the cutting diameter of the auxiliary cutter discs, and the full-fracture-surface hard-rock tunneling machine cutter disc is capable of meeting demands of tunnels different in diameter.

Owner:陈南南

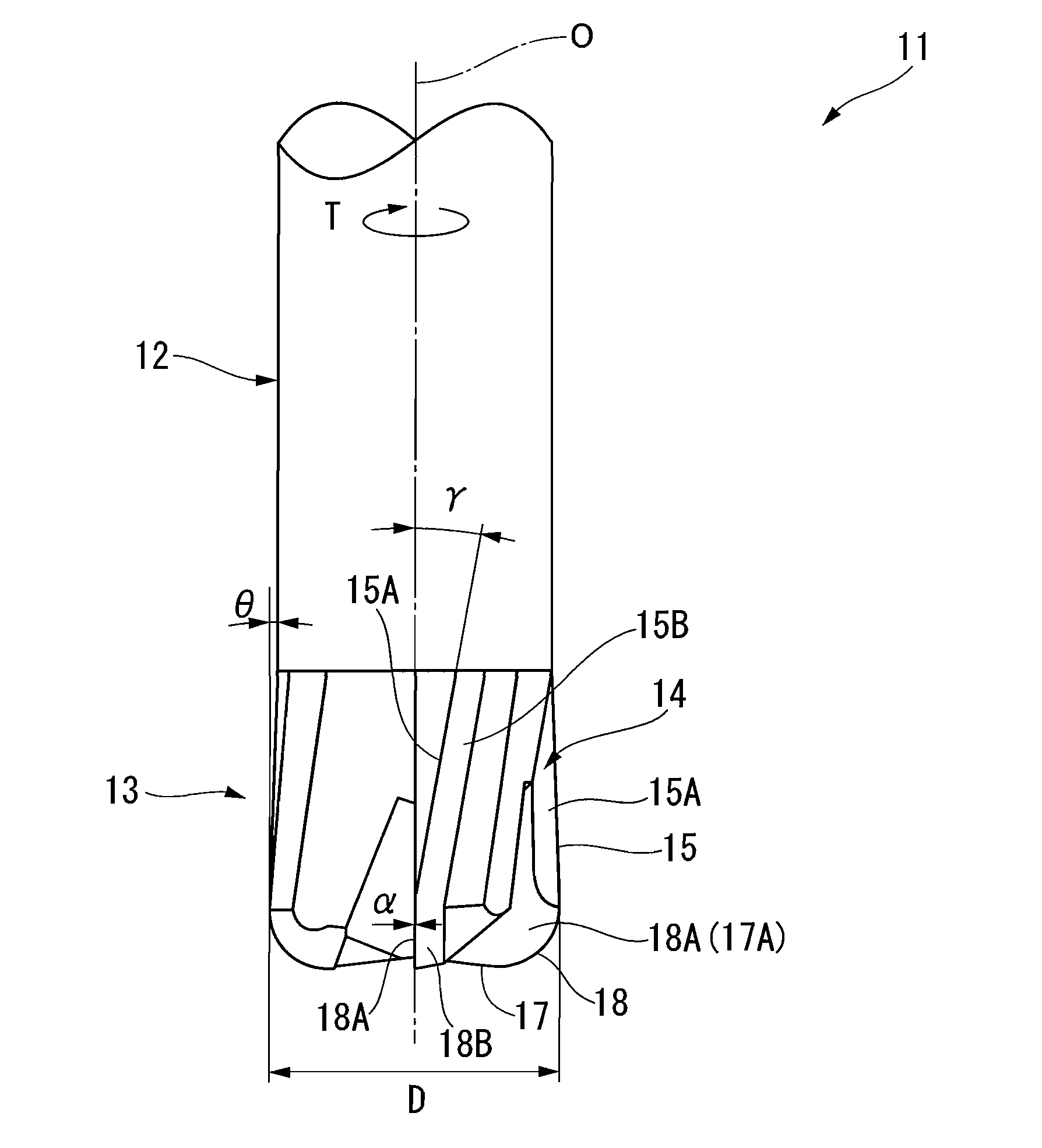

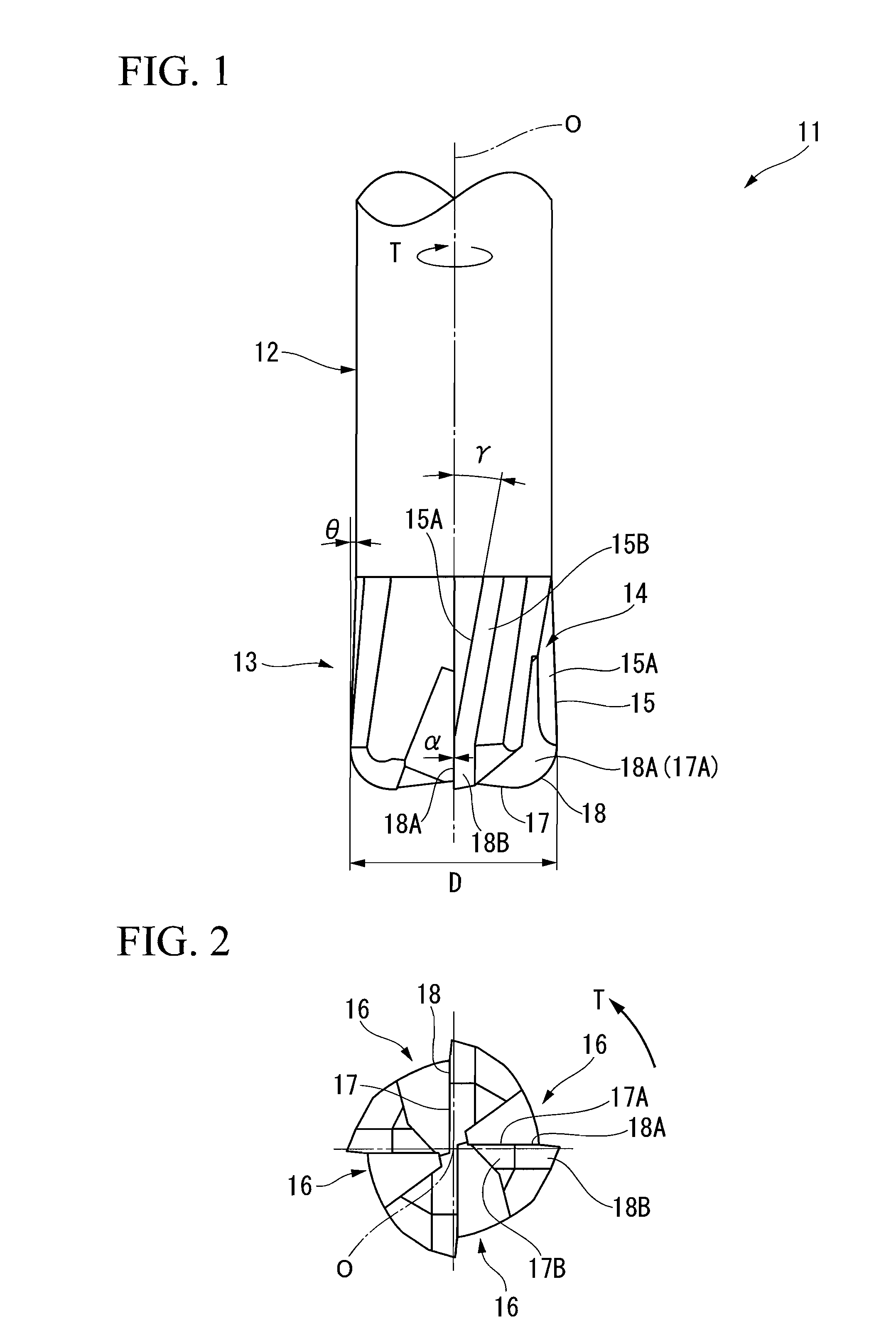

Radius end mill and cutting method

InactiveUS20100143052A1Reduce resistanceMade evenlyMilling cuttersShaping cuttersMilling cutterEngineering

An end mill body rotatable around an axis; peripheral cutting edges formed at a periphery of the end mill body located close to a distal end thereof; bottom cutting edges formed at a distal end of the end mill body; and corner cutting edges formed between the peripheral cutting edge and the bottom cutting edge. The corner cutting edges are formed to curve inwardly in a radial direction of the end mill body as they approach the distal end of the end mill body from the terminal end thereof and curve toward the terminal end of the end mill body after reaching the distal end of the end mill body. The bottom cutting edges are formed to communicate with the corner cutting edges and are close to the terminal end of the end mill body as the bottom cutting edge approaches inwardly in the radial direction. A value of a rake angle α of the corner cutting edge with respect to the axis −10°≦α≧10°. A rake surface of the corner cutting edge and a rake surface of the bottom cutting edge each are formed like a plane, and the rake surface of the corner cutting edge is formed to be flush with the rake surface of the bottom cutting edge. When an external diameter of the end mill body is D, a value of a curvature radius R of the corner cutting edge is greater than or equal to 0.1×D and is less than or equal to 0.3×D.

Owner:MITSUBISHI MATERIALS CORP

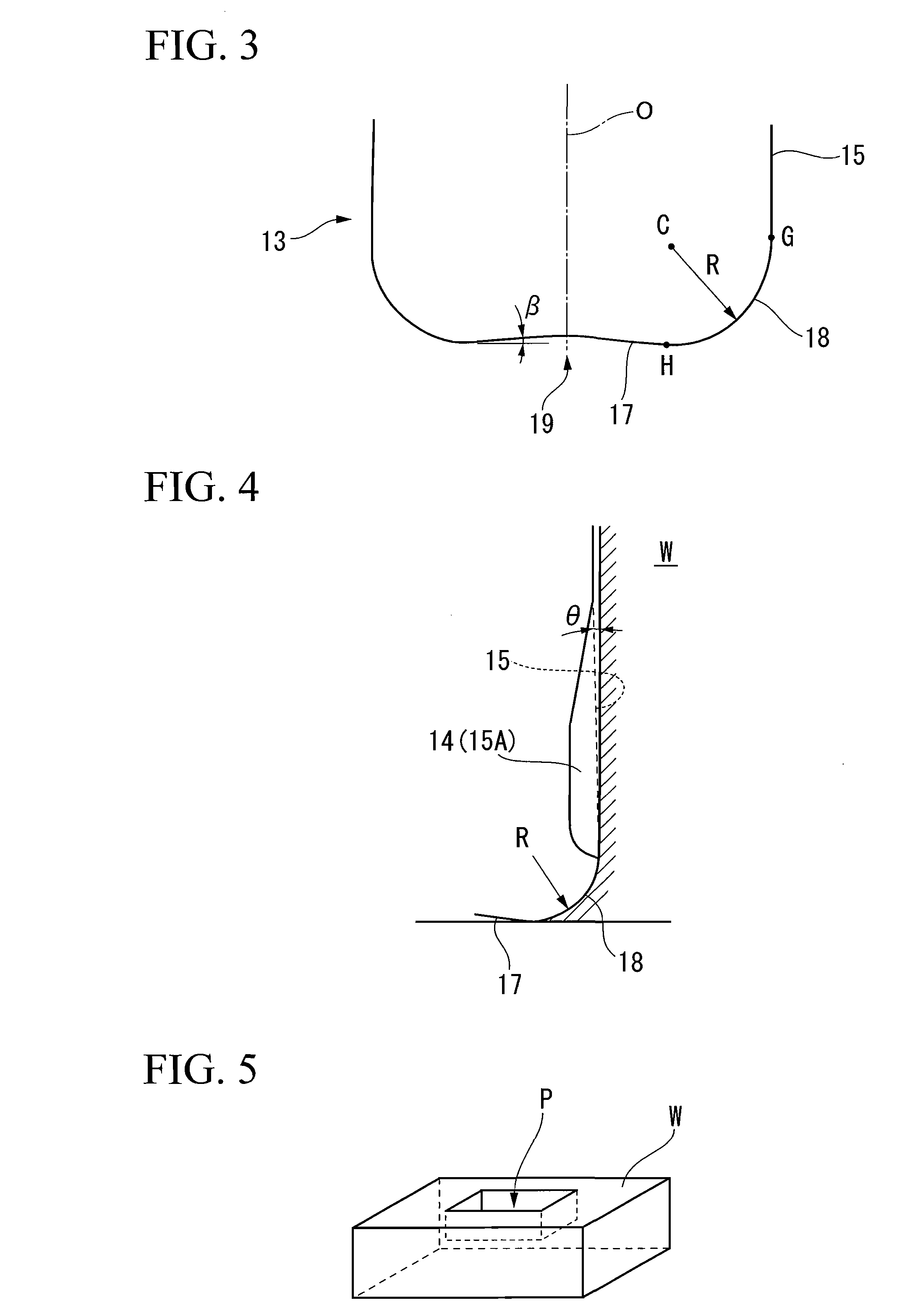

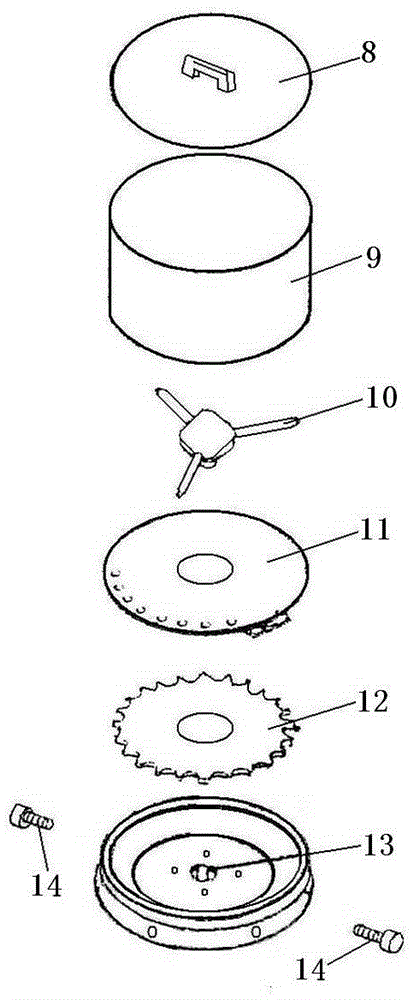

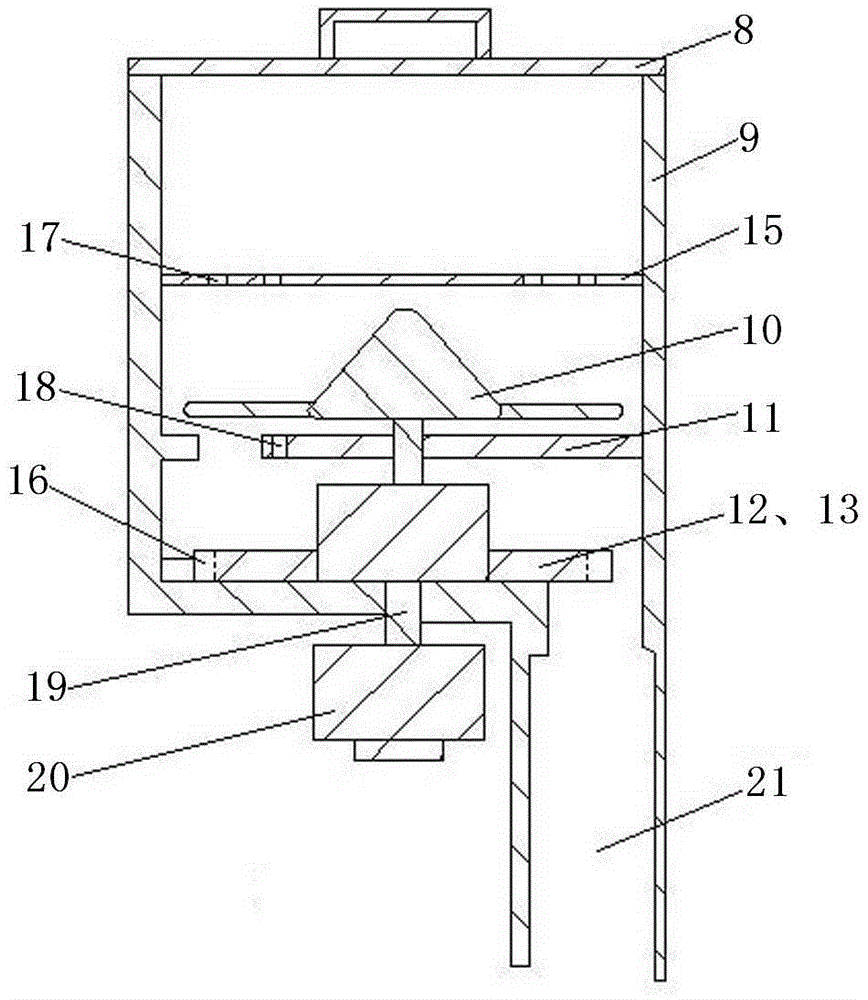

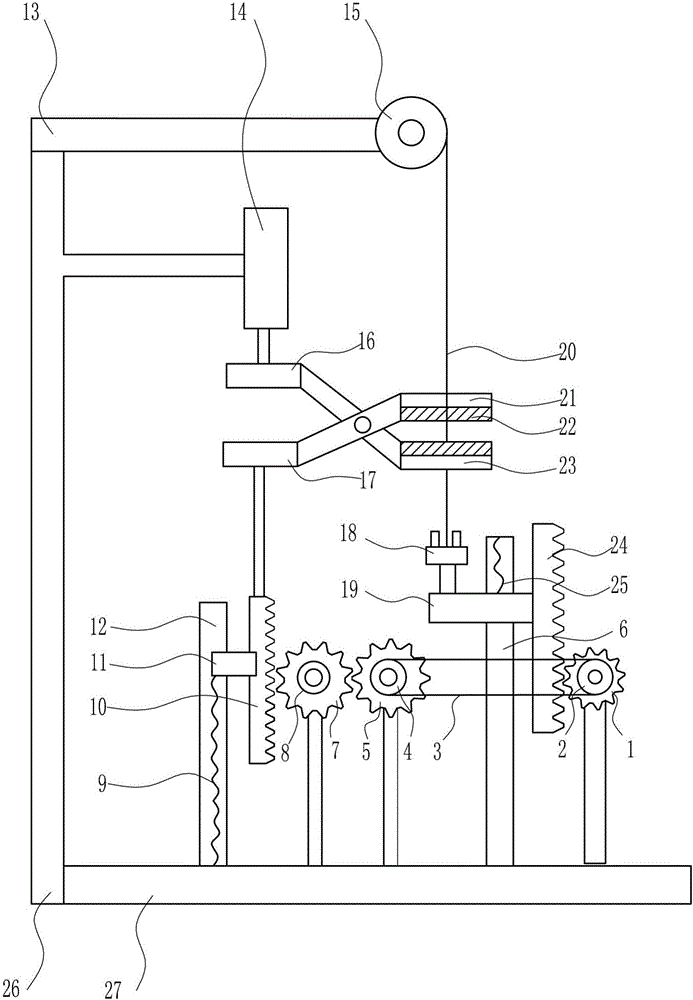

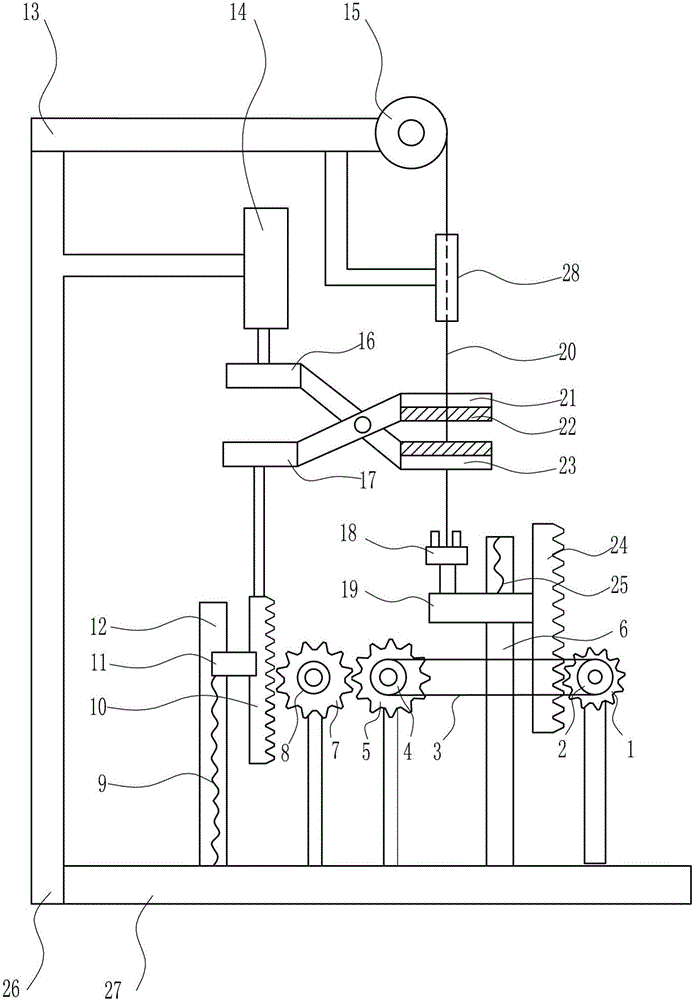

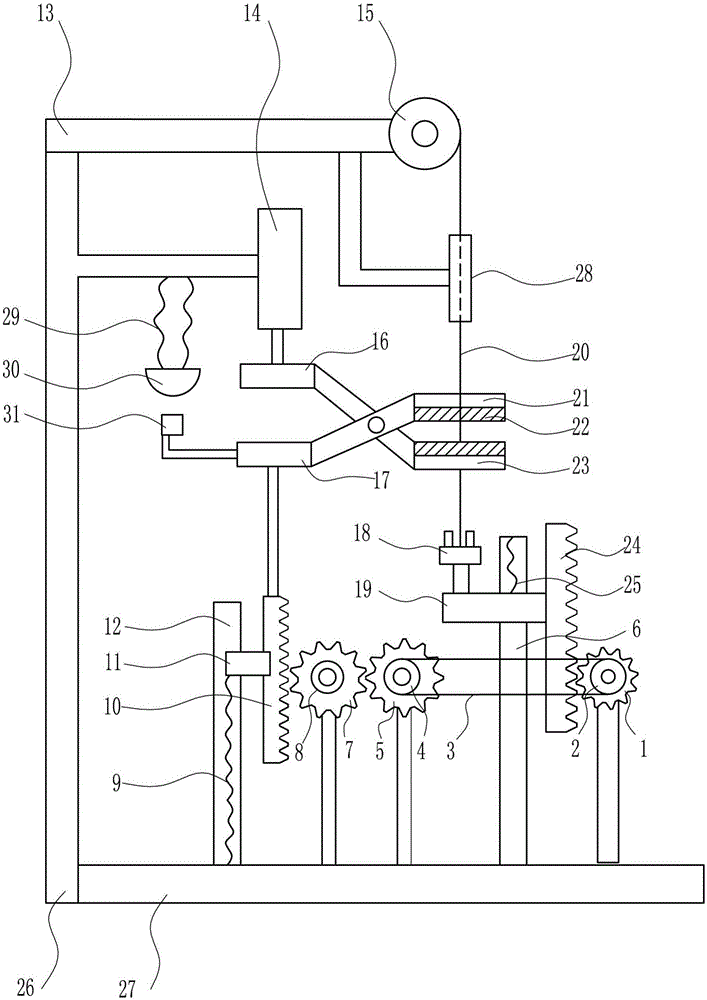

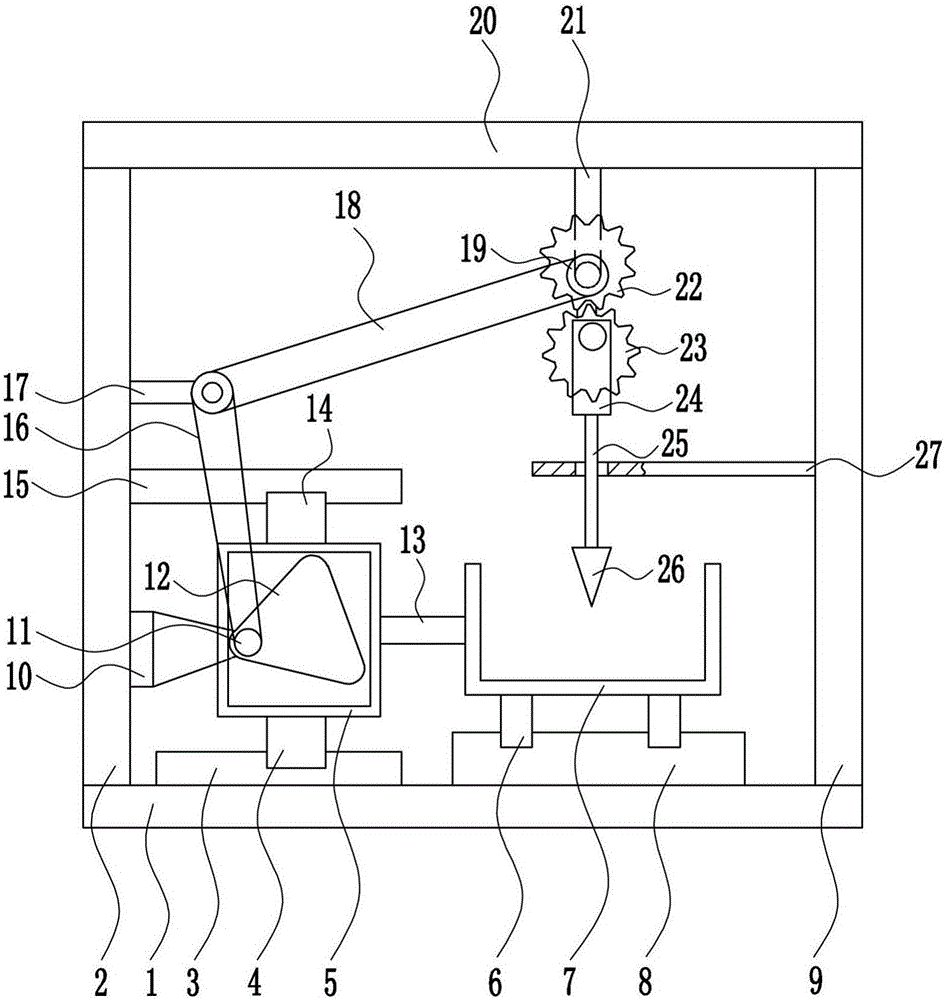

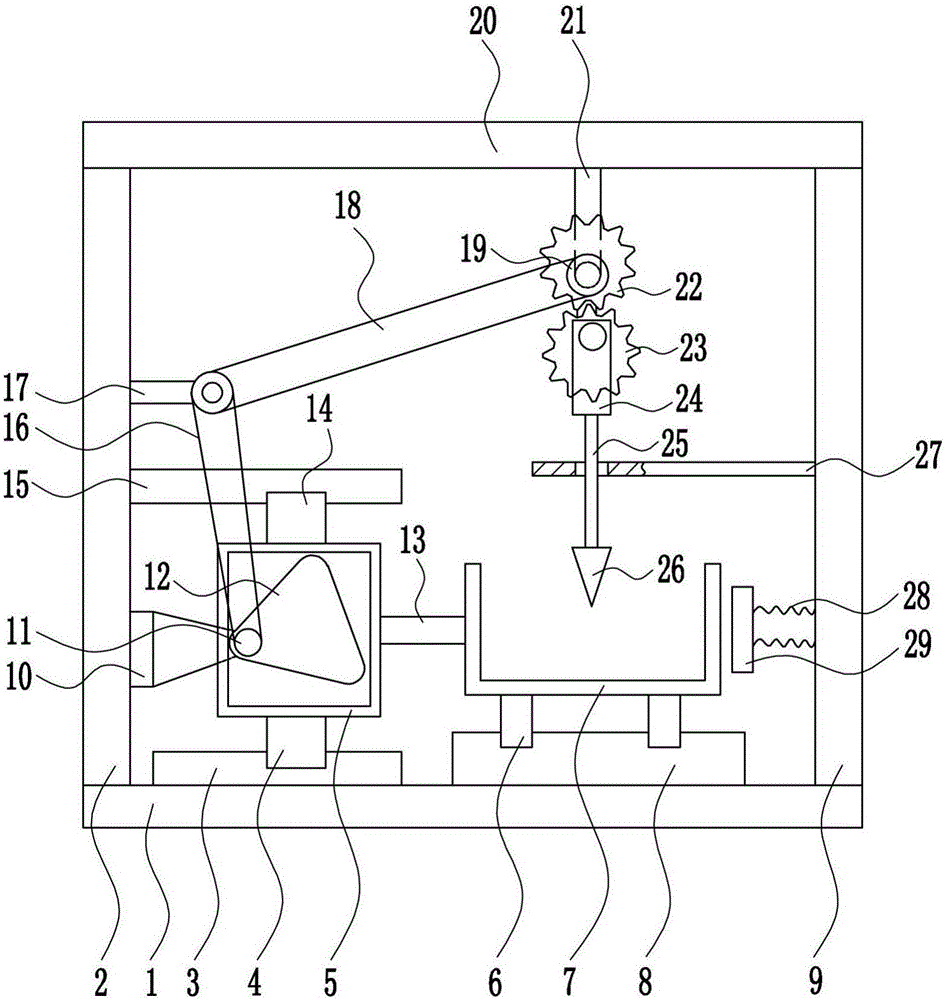

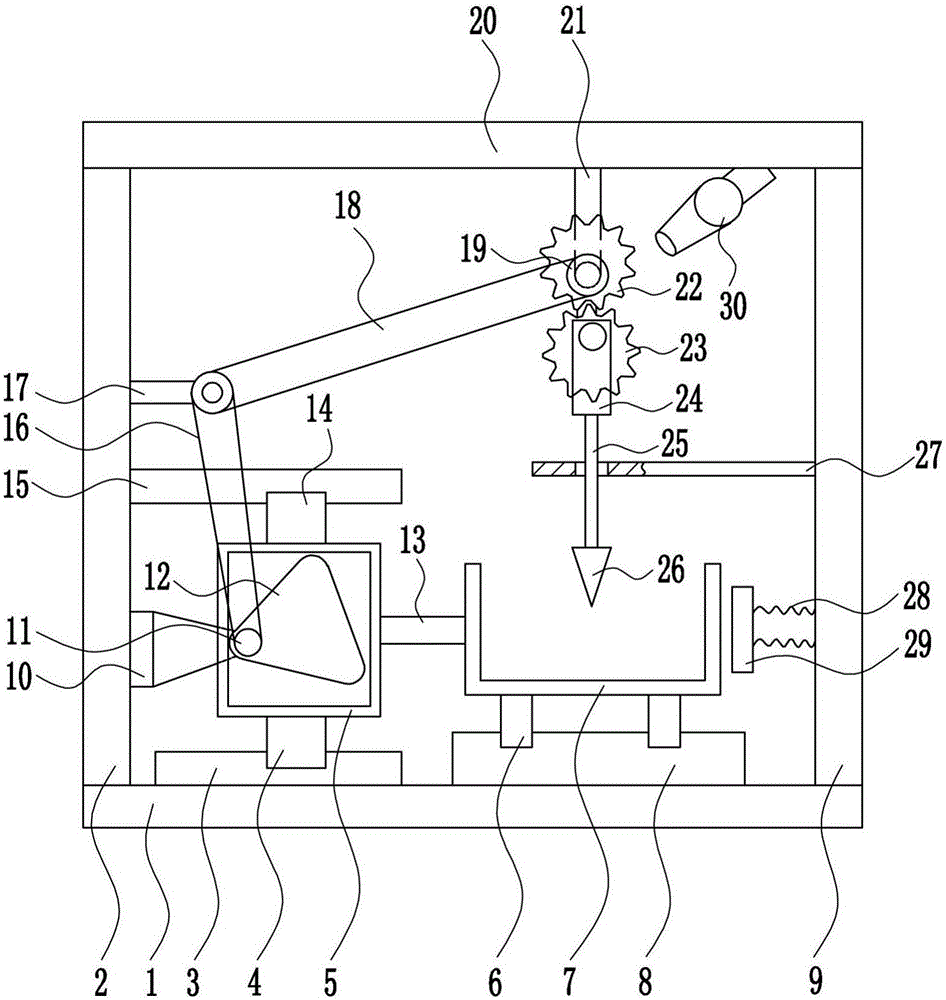

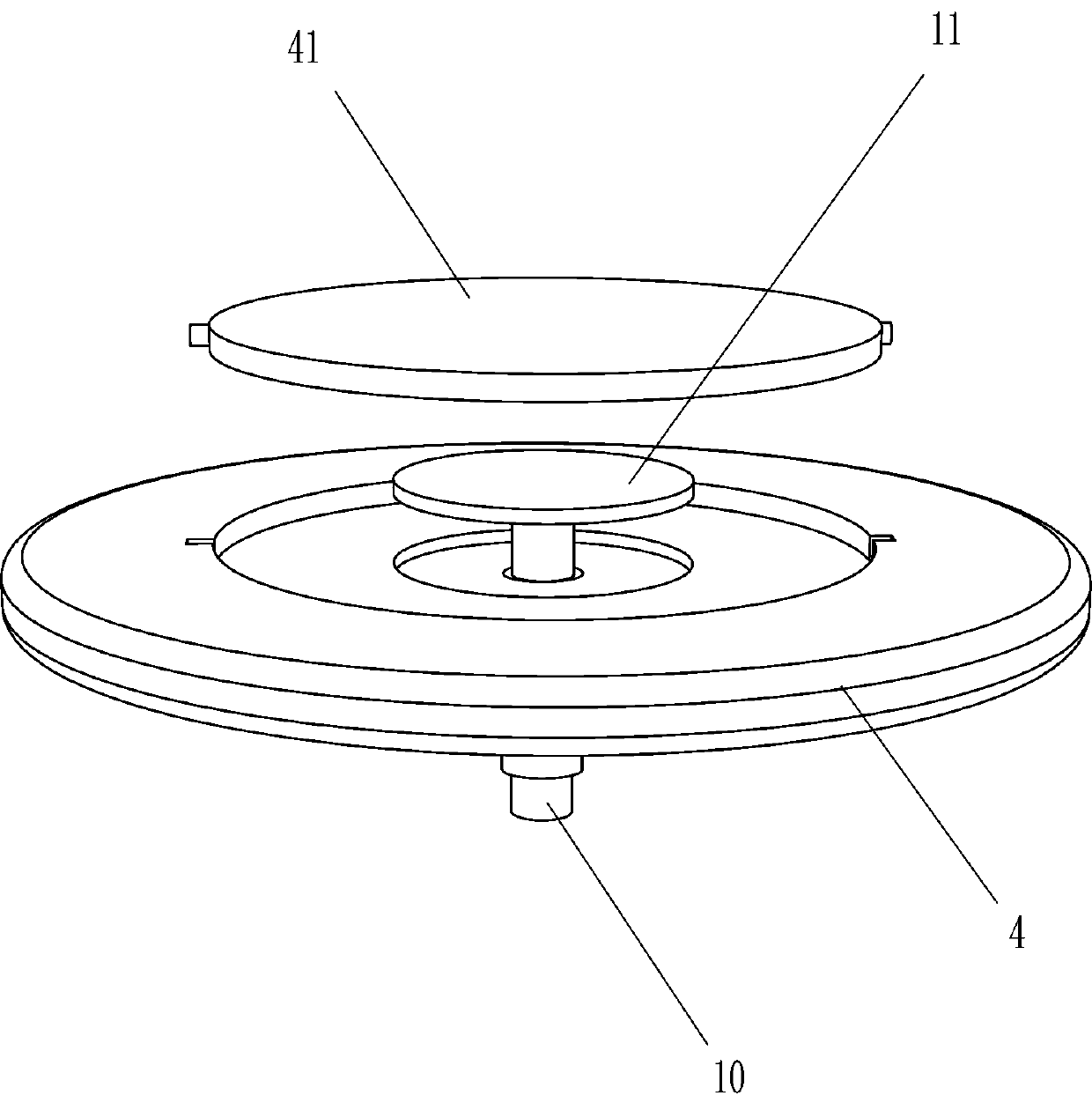

Swinging steel pipe equidistance cutting device

ActiveCN108581025AAchieve equidistant cutting effectAchieve intermittent feed functionTube shearing machinesShearing machine accessoriesPipe fittingDrive shaft

The invention discloses a swinging steel pipe equidistance cutting device. The left end of a driving shaft is fixedly connected with a first bevel gear; the first bevel gear is engaged with a second bevel gear; the second bevel gear is fixedly connected with the middle part of a driven shaft; the lower end of the driven shaft is fixedly connected with a semi-bevel gear; the semi-bevel gear is provided with teeth on one half and no tooth on the other half; third bevel gears are arranged on the two sides below the semi-bevel gear, and are fixedly connected with rotating shafts; the tooth part ofthe semi-bevel gear is engaged with the third bevel gears; the right ends of the rotating shafts are fixedly connected with small gears; the small gears are engaged with large gears; the right sidesof the large gears are fixedly connected with the upper ends of swing rods; and cutting blades are arranged at the middle parts of the lower ends of the swing rods. The device uses the small gears fordriving the swing rods to swing back and forth; when the swing rods swing, a first transmission belt drives the cutting blades to rotationally cut to realize swing cutting; and a fixed disc and a ratchet are used for realizing intermittent one-way rotation of a lead screw to achieve intermittent feeding function of pipes so as to finally achieve equidistance cutting effect of pipe fittings.

Owner:无锡市幸昌热能设备有限公司

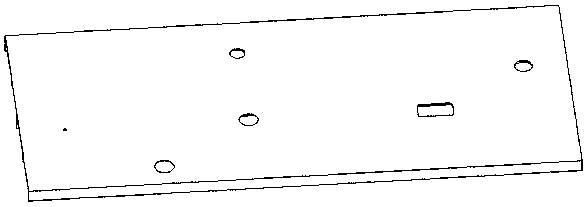

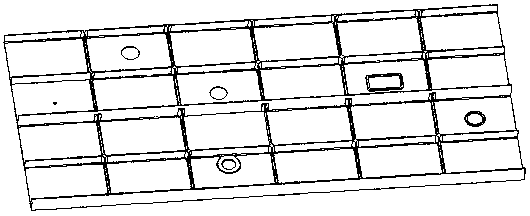

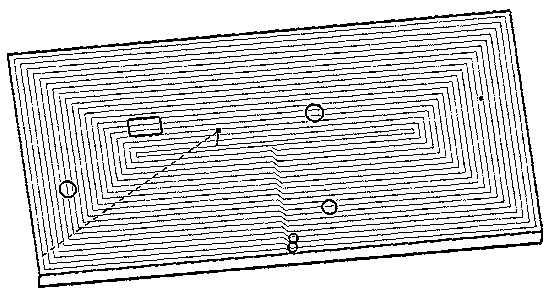

Milling method of high-precision suspended web

ActiveCN108746782ACut evenlyEven by forceWorkpiecesMilling equipment detailsWeb structureEngineering

The invention discloses a milling method of a high-precision suspended web. The milling method is used for efficient and stable milling of a large-size suspended web structure and comprises the stepsthat the glossy face of a part is subjected to rough milling, and the technical allowance is reserved; a frame face is subjected to rough milling, the technical allowance is reserved, and a pluralityof false bosses are reserved according to the structural characteristics, so that the structural rigidity of the part is improved; the frame face is pressed in an unstressed mode, a positioning datumface is corrected, and thus the situation that the machining error is caused by part deformation is prevented; a glossy face web is subjected to semi-fine milling, and the small allowance is reserved;and the glossy face web is subjected to finish machining in place in modes of a small-diameter tool in small cutting quantity and back-and-forth feed, and thus the situations that cutter back-off deformation is caused by the large cutting quantity, and the surface quality of a part becomes poor due to trajectory change and acceleration and deceleration of a machine tool are prevented. The millingstability of the large-size suspended web structure is effectively improved, the part machining efficiency and the surface quality integrity are improved, and reworking polishing of a bench worker isreduced.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

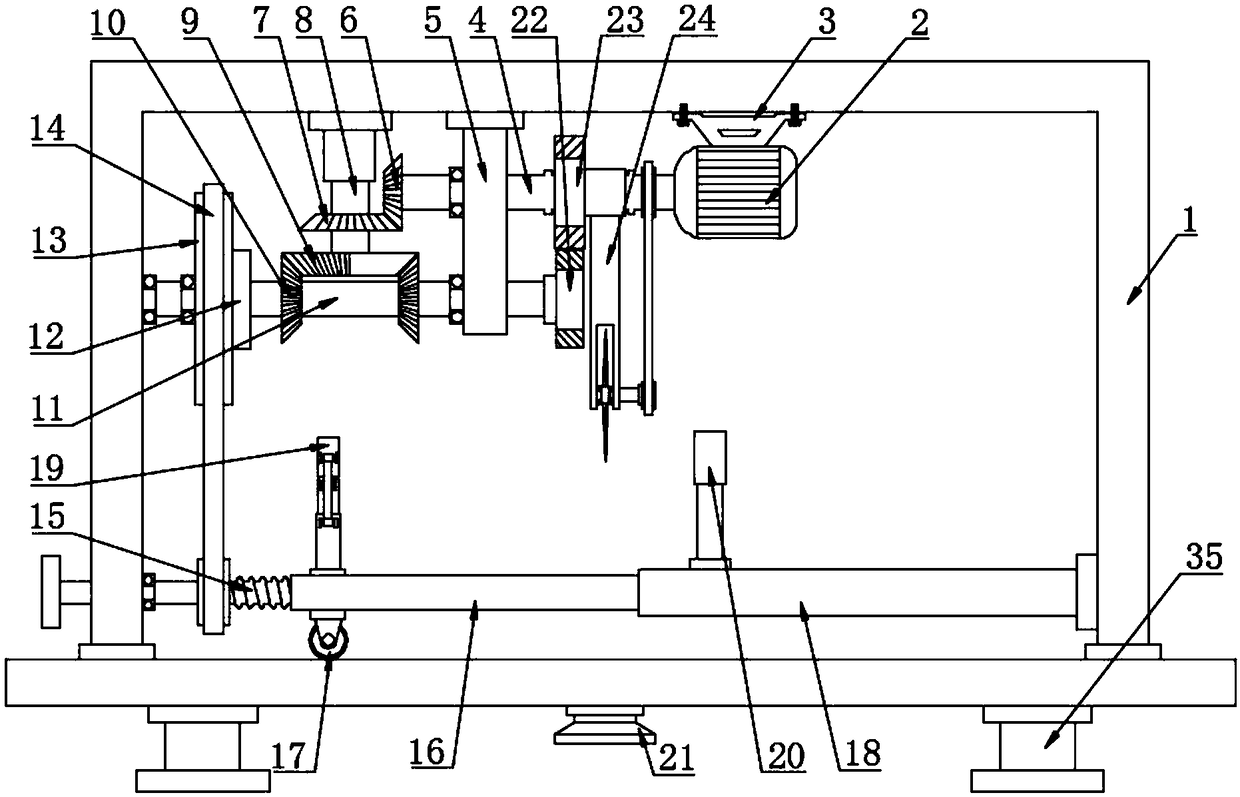

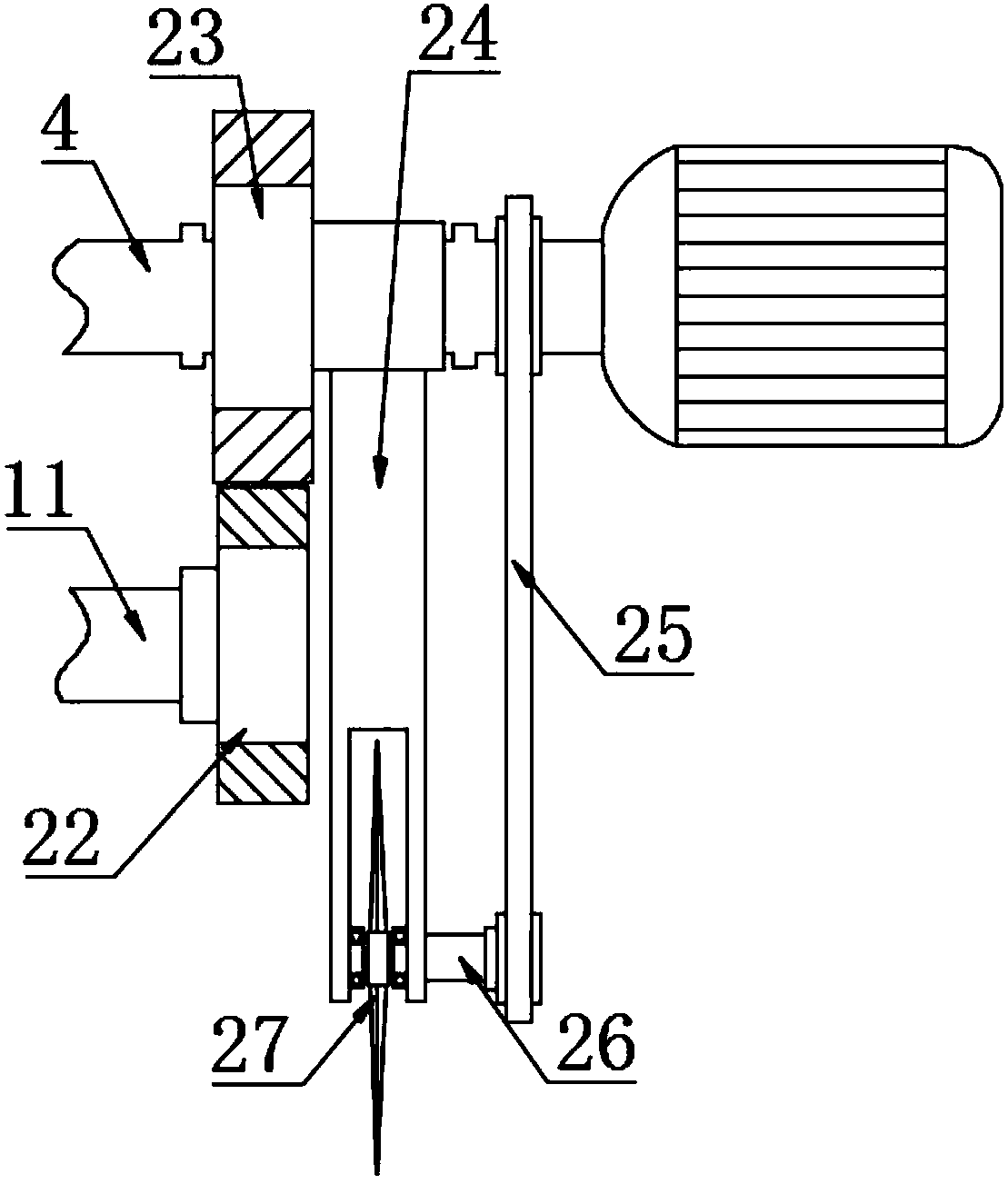

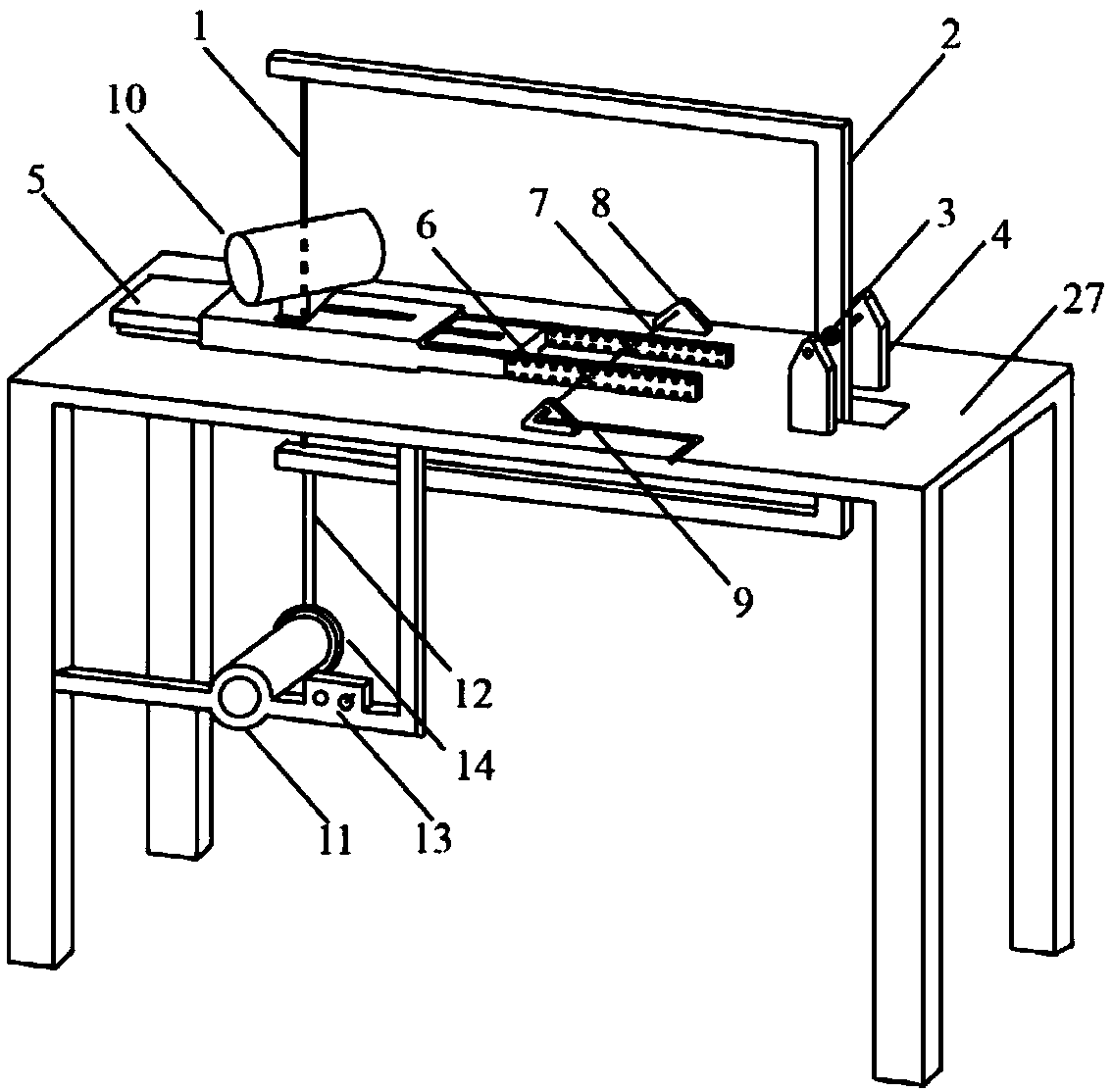

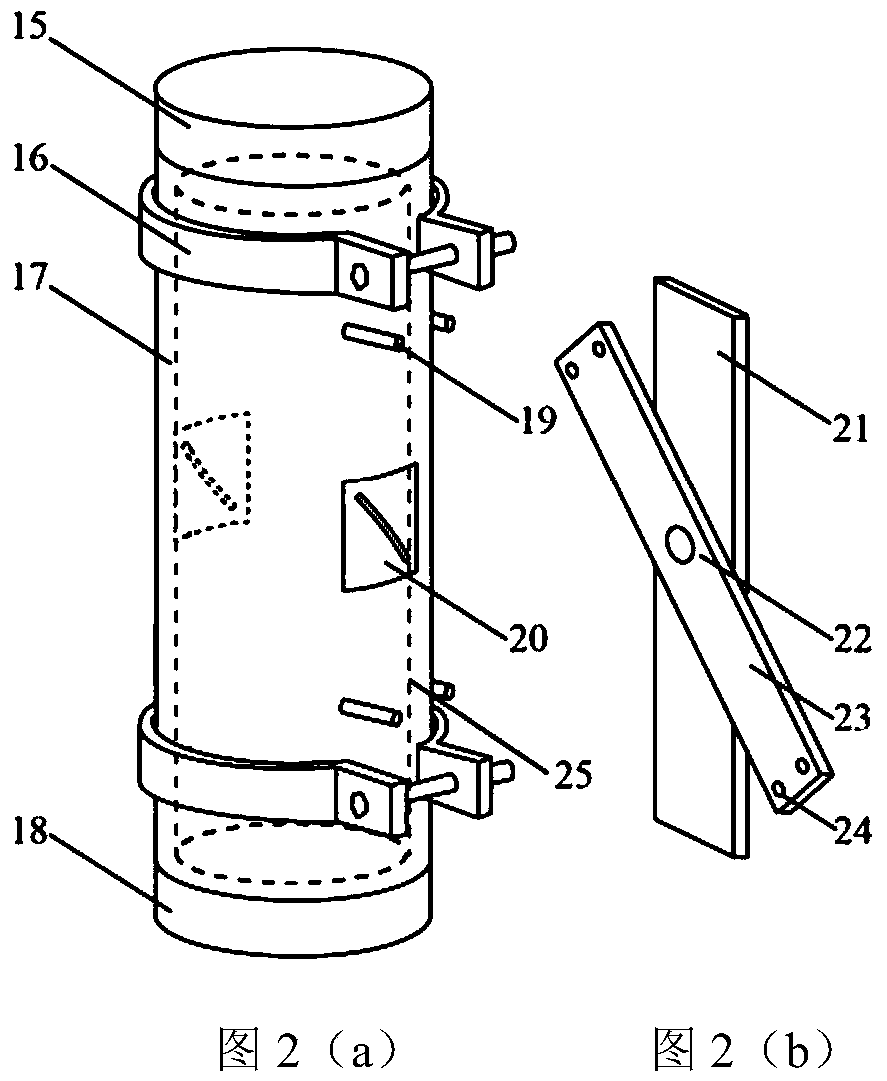

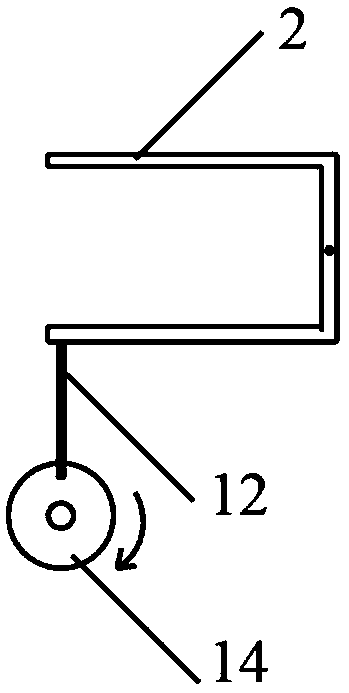

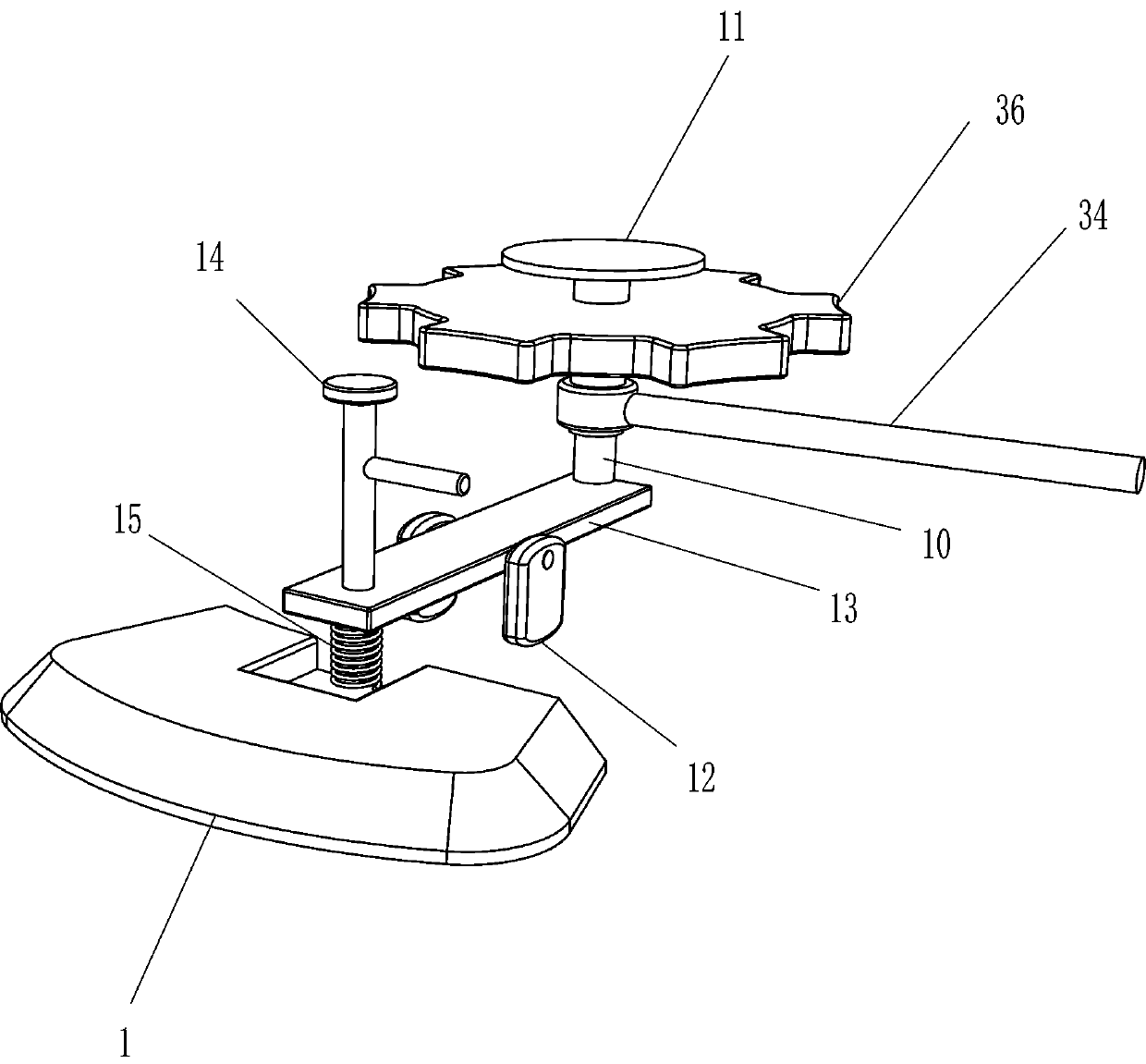

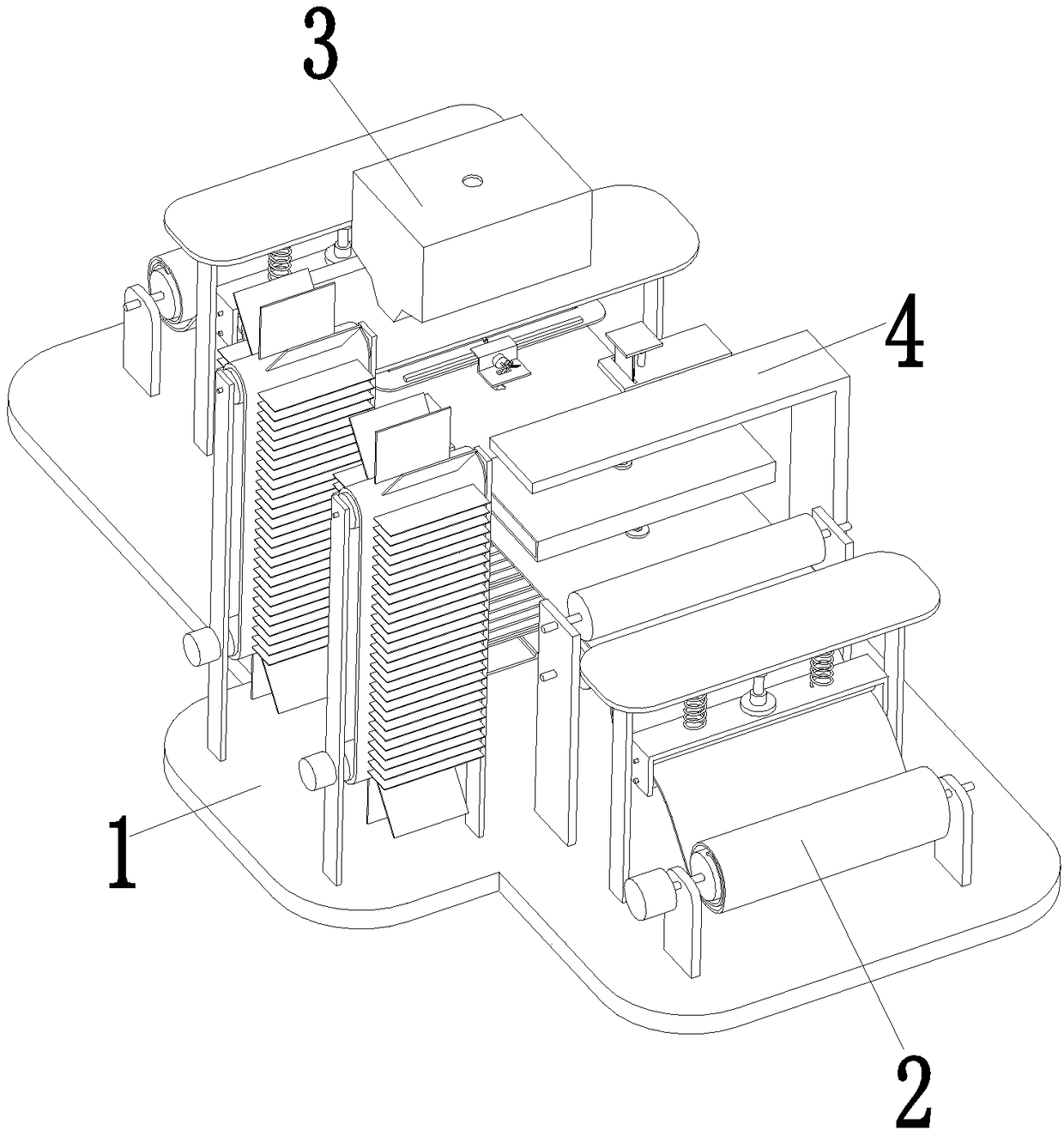

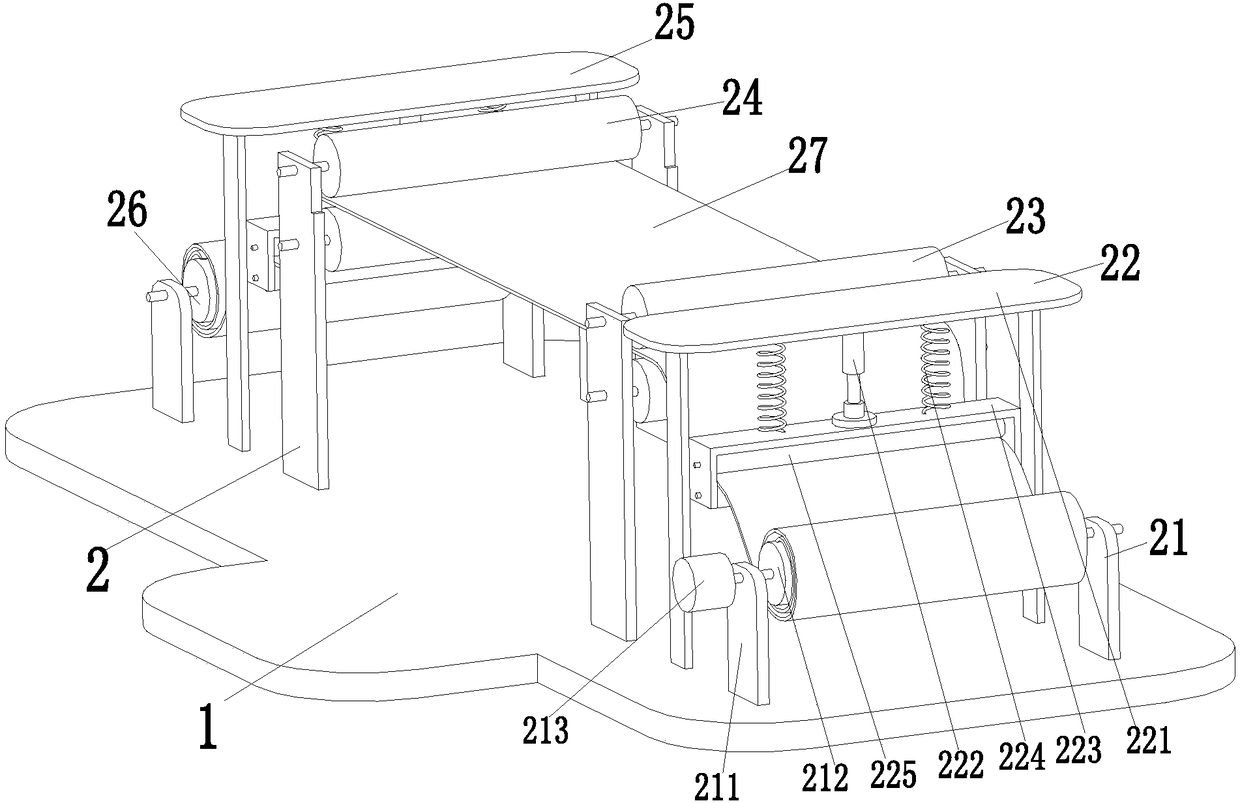

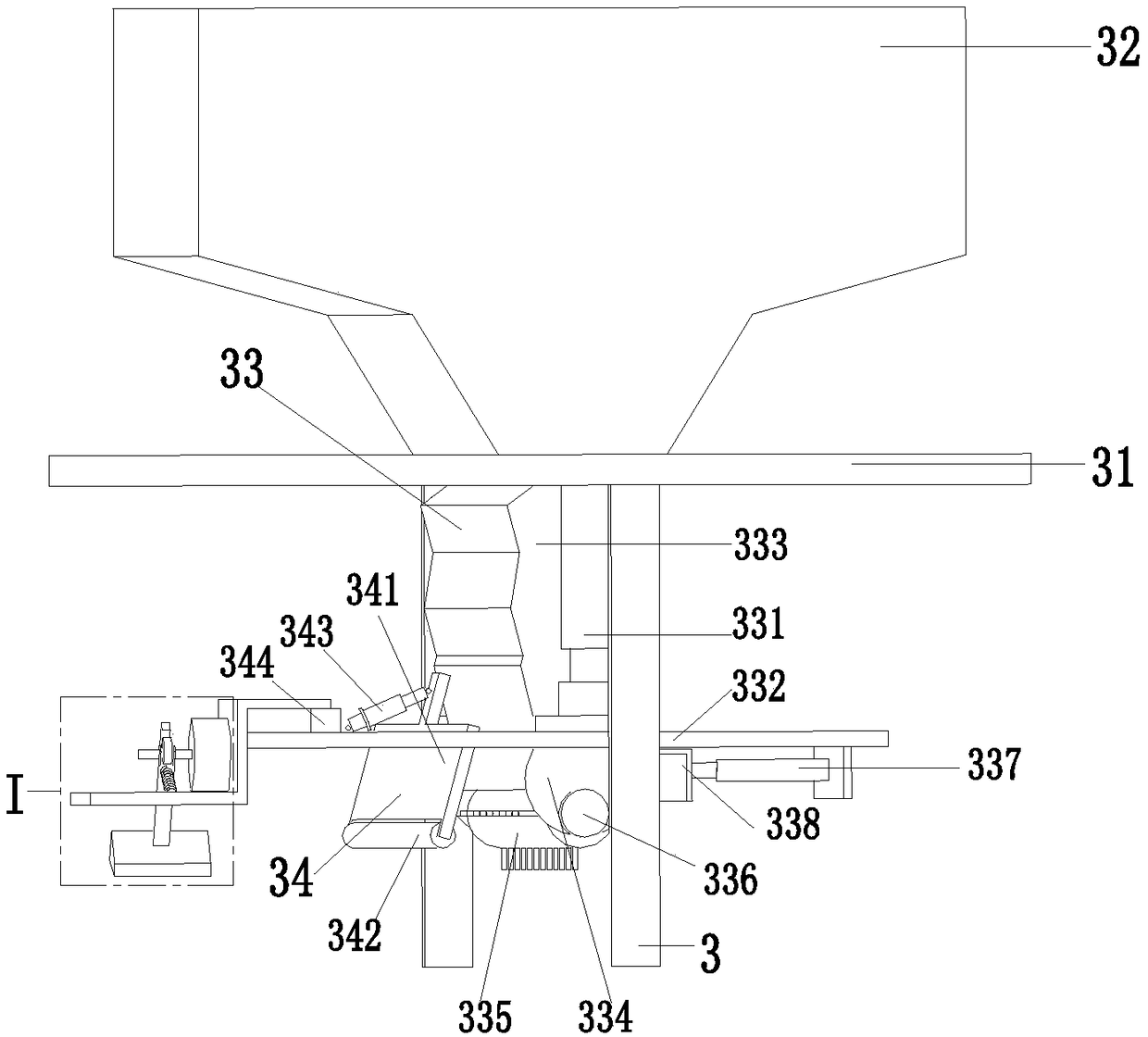

Prefabricated crack preparation device and method for standard rock test piece

The invention relates to a prefabricated crack preparation device and method for a standard rock test piece. The preparation device mainly comprises a cutting system, a driving system and a tabletop system. The standard rock test piece is arranged in the test piece cutter of the tabletop system and the test piece cutter comprises a crack positioning semi-open steel mold and a cutting angle adjuster. The cutting system is used for crack cutting of rock pieces. The driving system provides driving force for the cutting system. The cutting system and the driving system are arranged on the tabletopsystem. According to the prefabricated crack preparation device and method for standard rock test piece, the preparation of the inclined crack and the through crack of the standard rock test piece surface can be realized, the geometrical dimension and the cutting speed of the crack can be adjusted, the structure is simple, the manufacturing process is simple, the degree of mechanization is high,and the crack is prepared accurately, and can be widely applied to joint fracture rock mechanics tests in the field of hydroelectric, transportation, energy and mine engineering.

Owner:SHANDONG UNIV

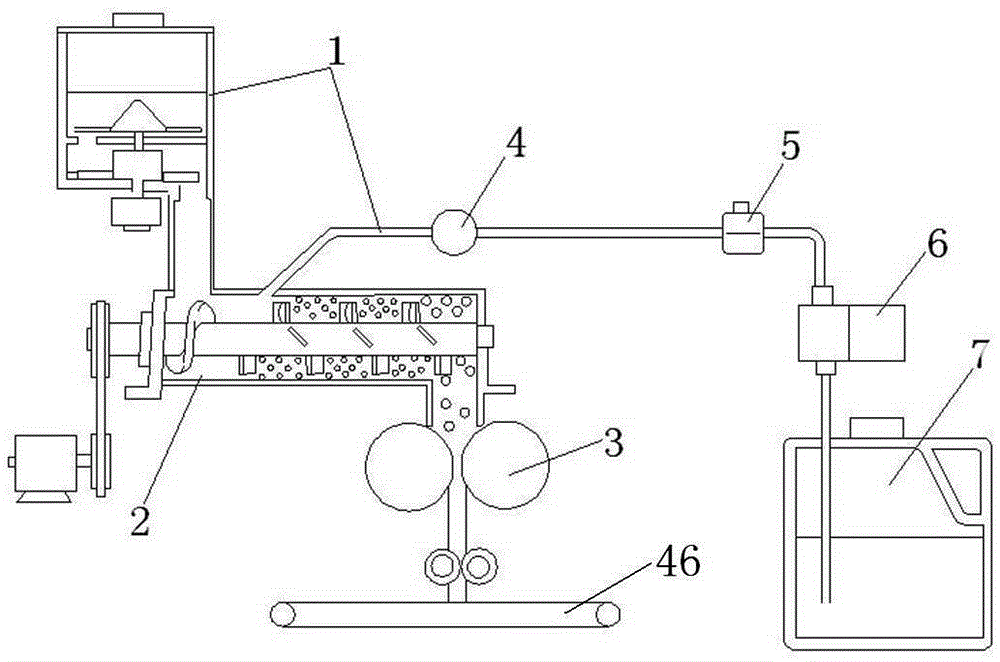

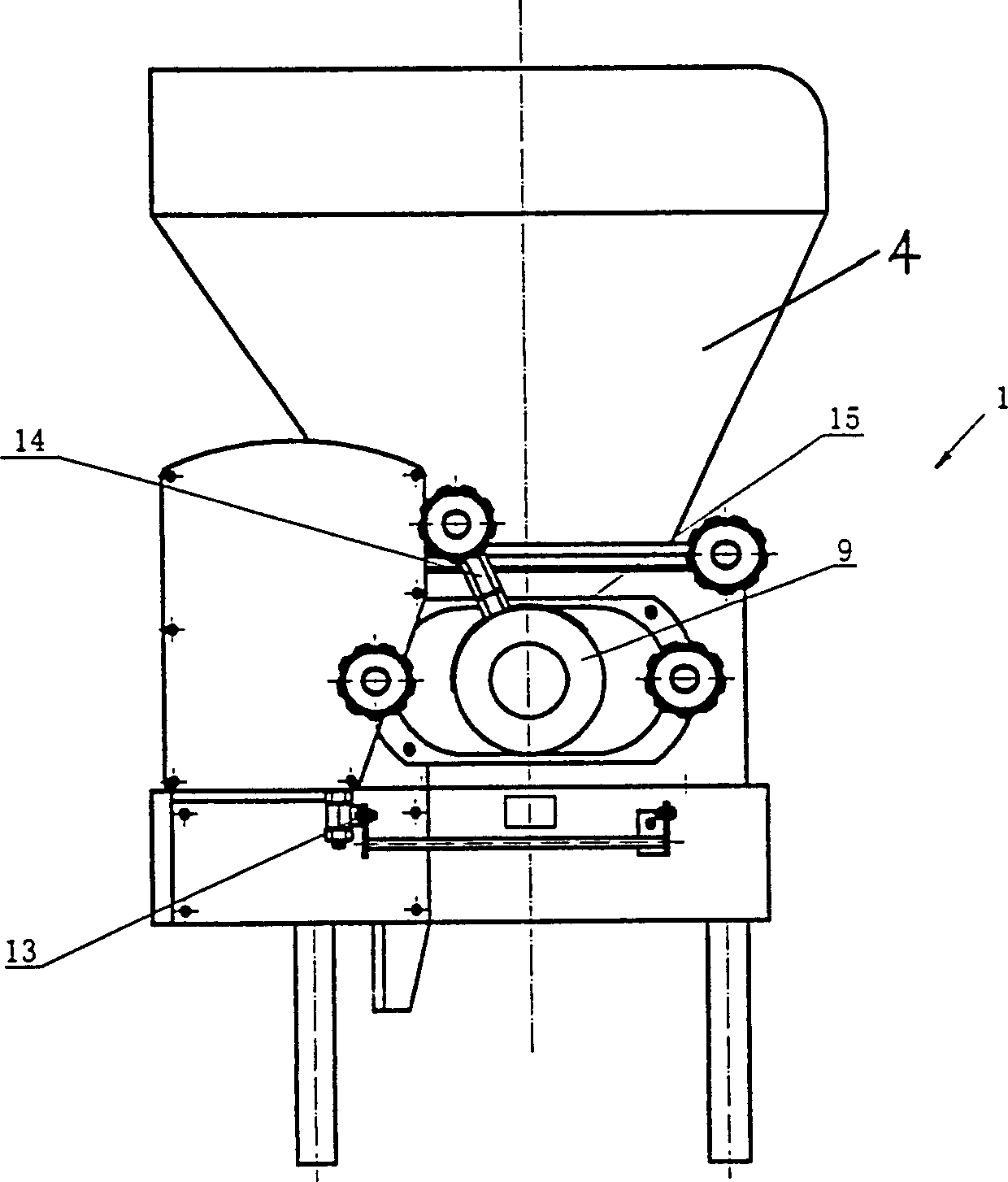

Fully automatic intelligent noodle processing and making method

ActiveCN105341018APromote hydrationWon't change colorMixing/kneading structural elementsDough-sheeters/rolling-machines/rolling-pinsEngineeringFully automatic

The invention relates to the field of food processing equipment, in particular to a fully automatic intelligent noodle processing and making method. The fully automatic intelligent noodle processing and making method is characterized by at least comprising the following steps: an extruding can is arranged, an extruding roller is arranged in the extruding can and can rotate in the extruding can, and a flour inlet is formed in the extruding can; a water inlet is formed in the flour inlet, flour is added from the flour inlet, water is added from the water inlet, the extruding roller is driven to rotate so as to mix the flour and the water, and the flour and the water are extruded to be formed into dough; a forming and cutting mechanism is arranged under the extruding can, and the forming mechanism comprises two dough pressing rollers and two dough cutting rollers, wherein two dough cutting rollers are arranged under the two dough pressing rollers to drive the two dough pressing rollers to rotate; the dough pressing rollers press the dough into wrappers and drive the two dough cutting rollers to rotate; the dough cutting rollers cut the wrappers into noodles. The fully automatic intelligent noodle processing and making method disclosed by the invention has the advantage that the fully automatic processing and making of noodles is realized.

Owner:上海老磨坊餐饮管理有限公司

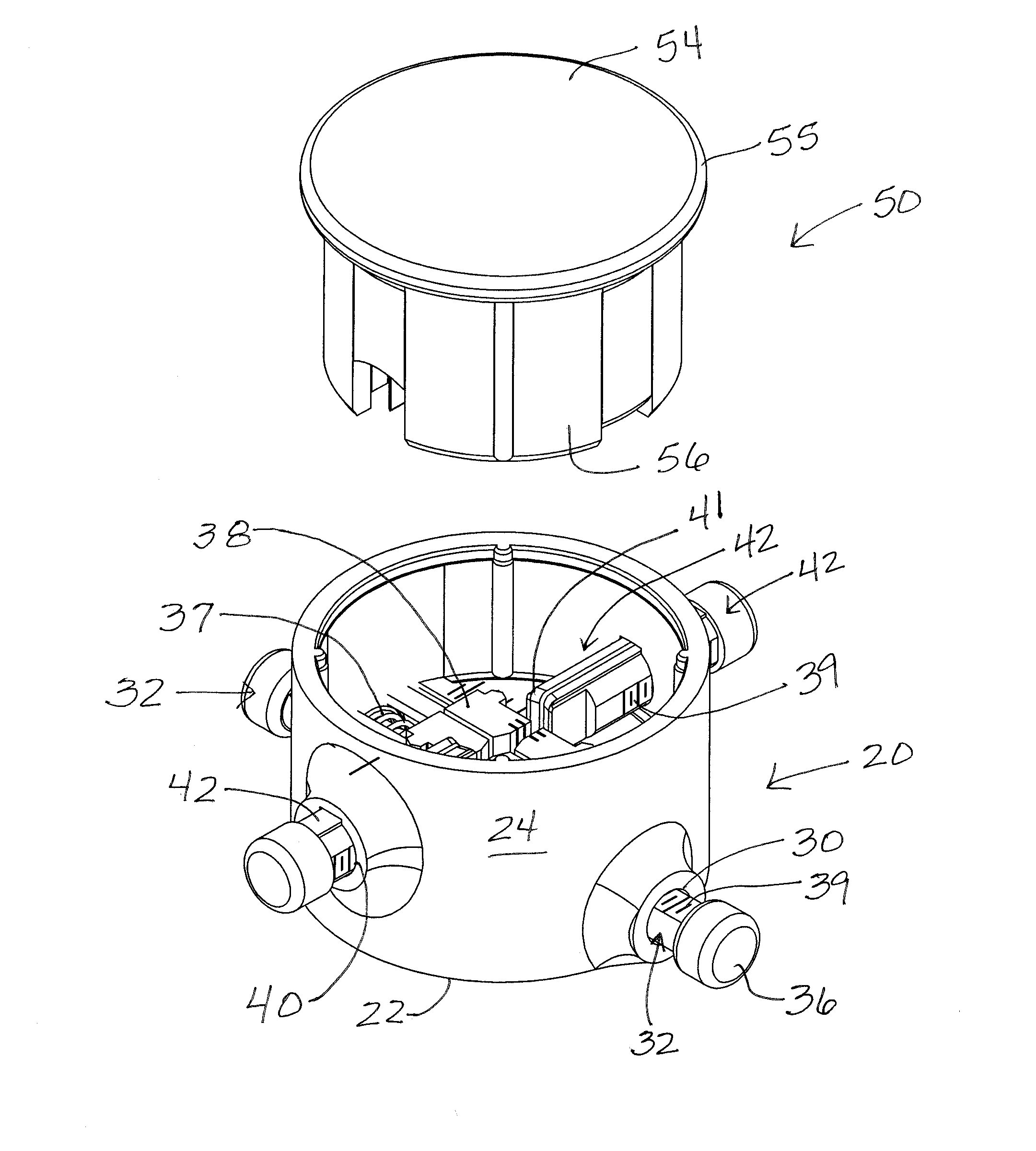

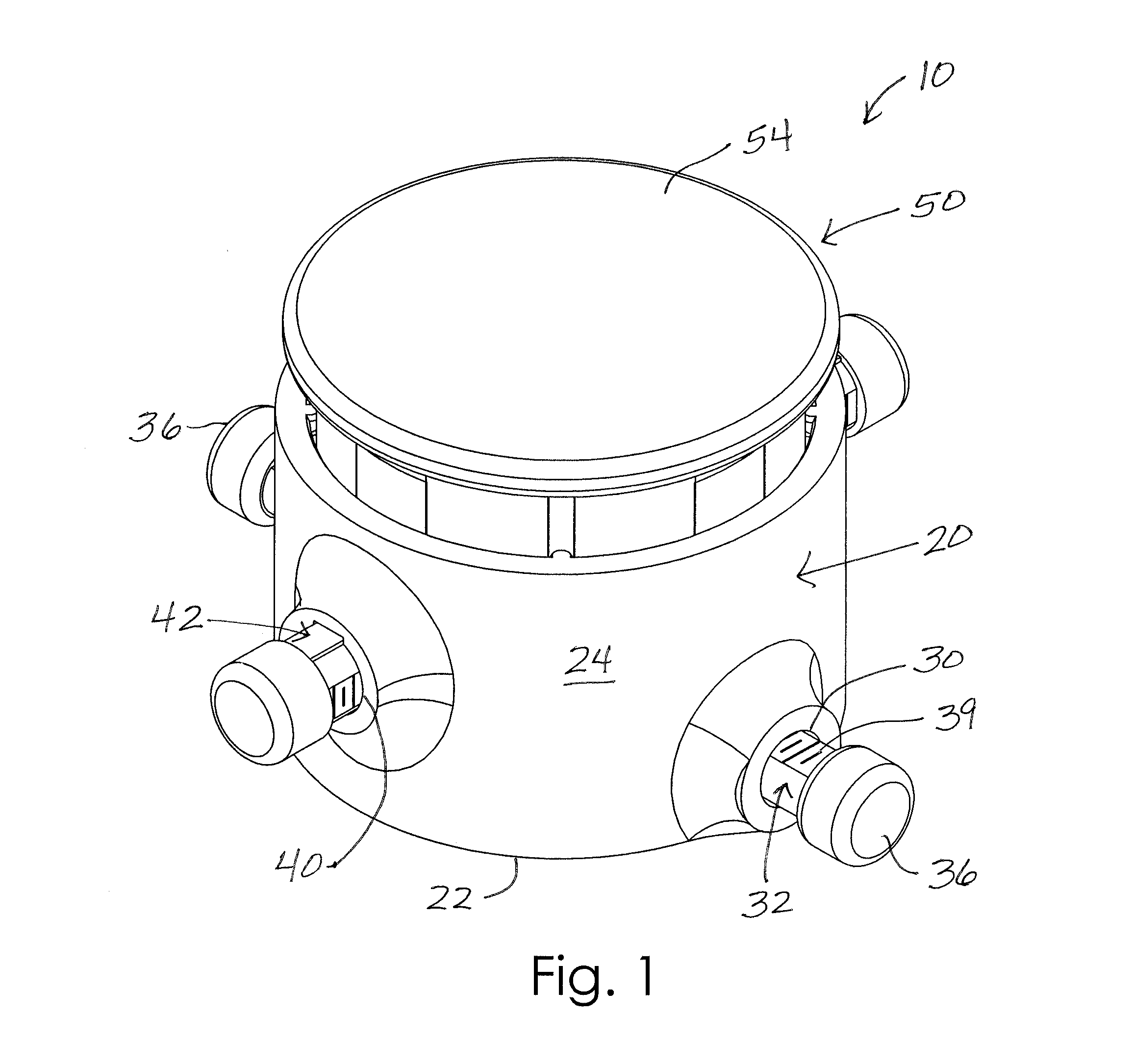

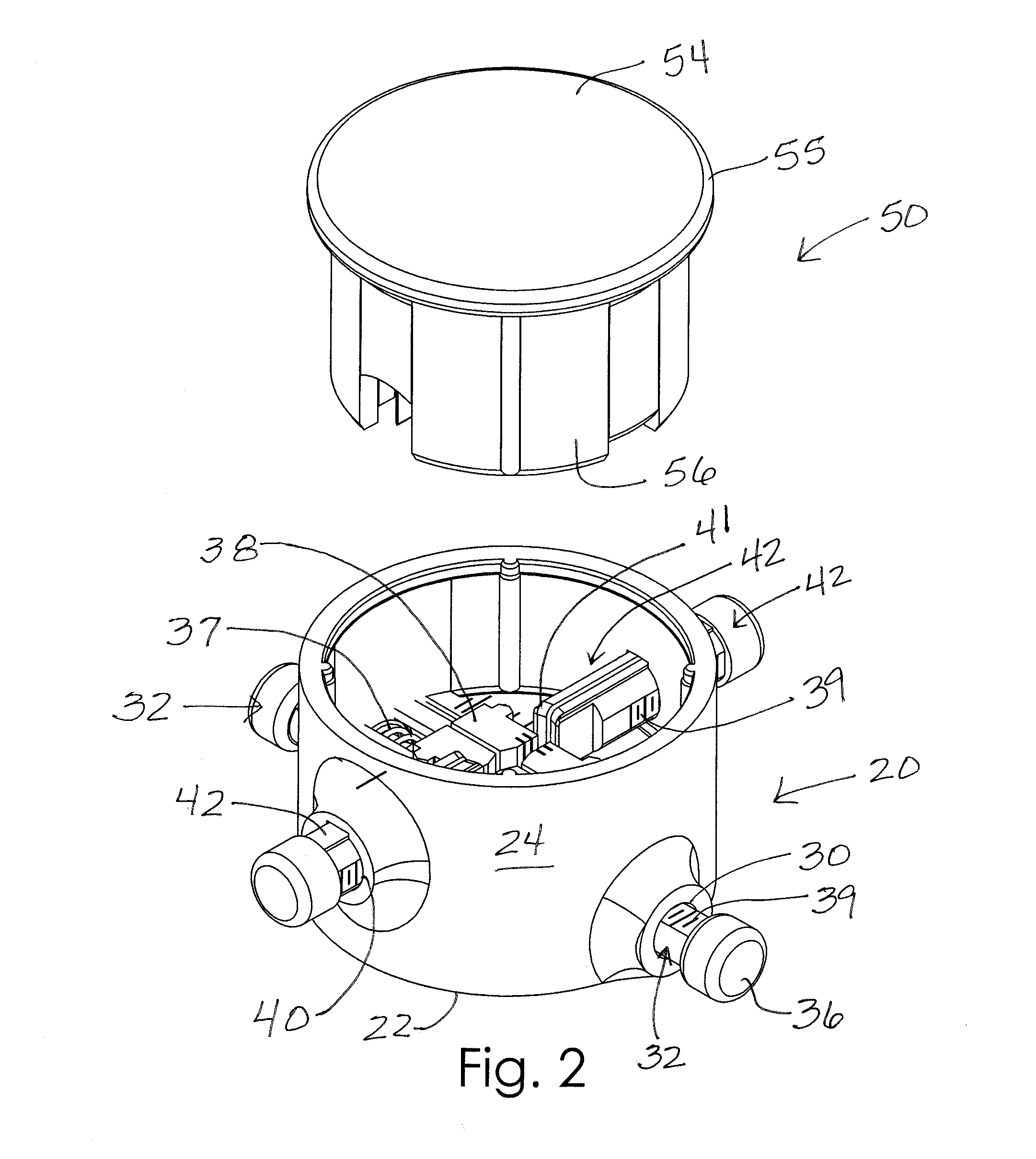

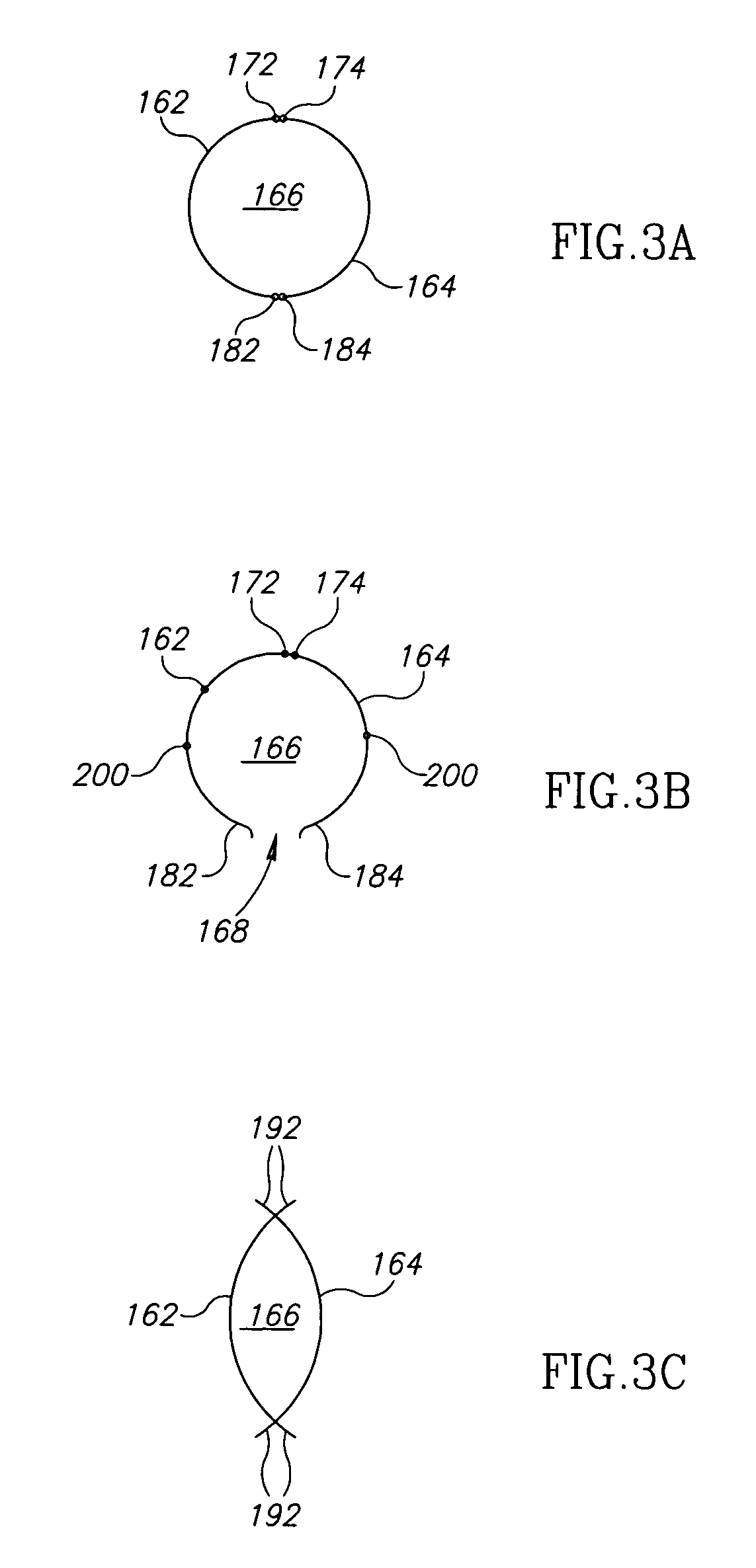

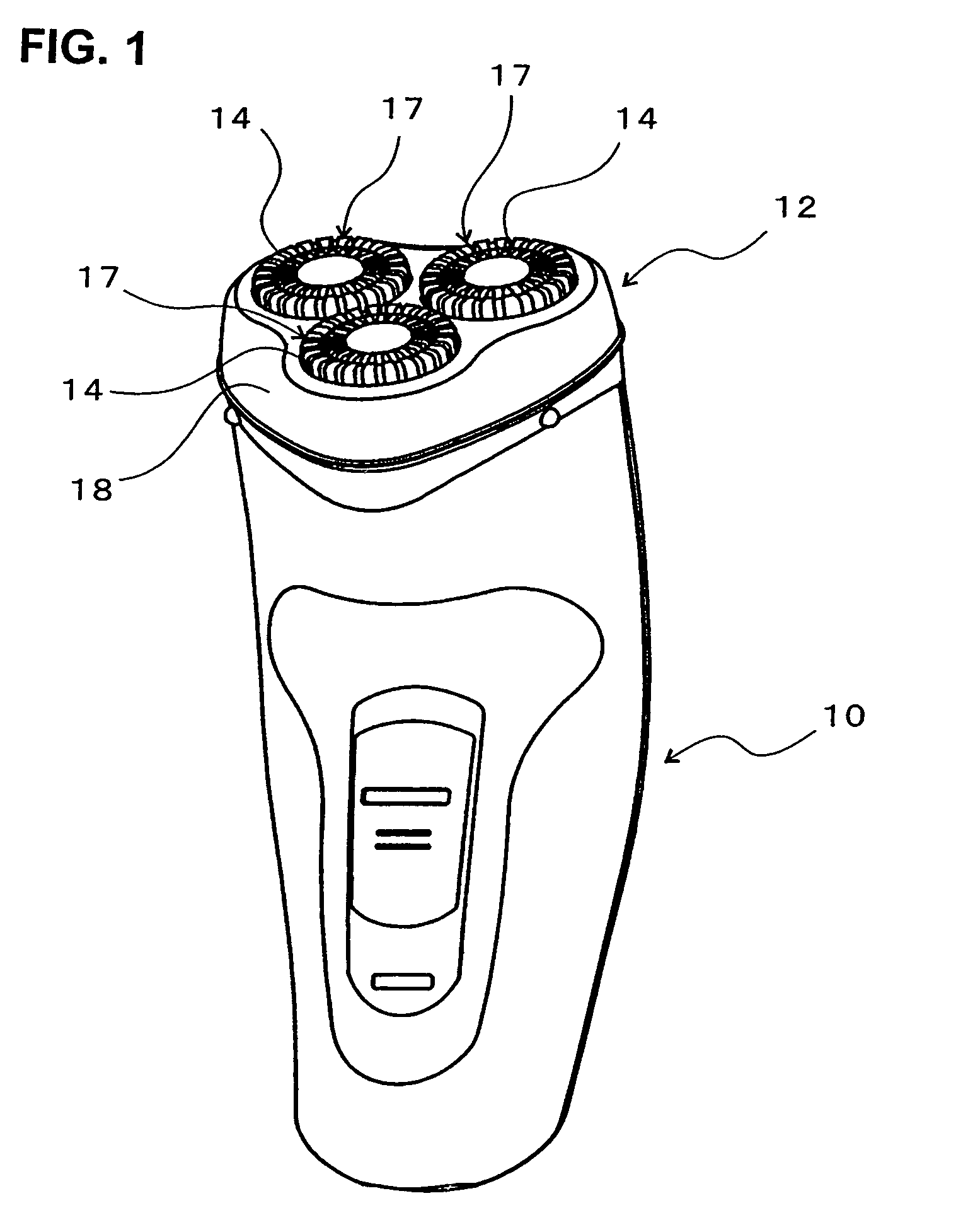

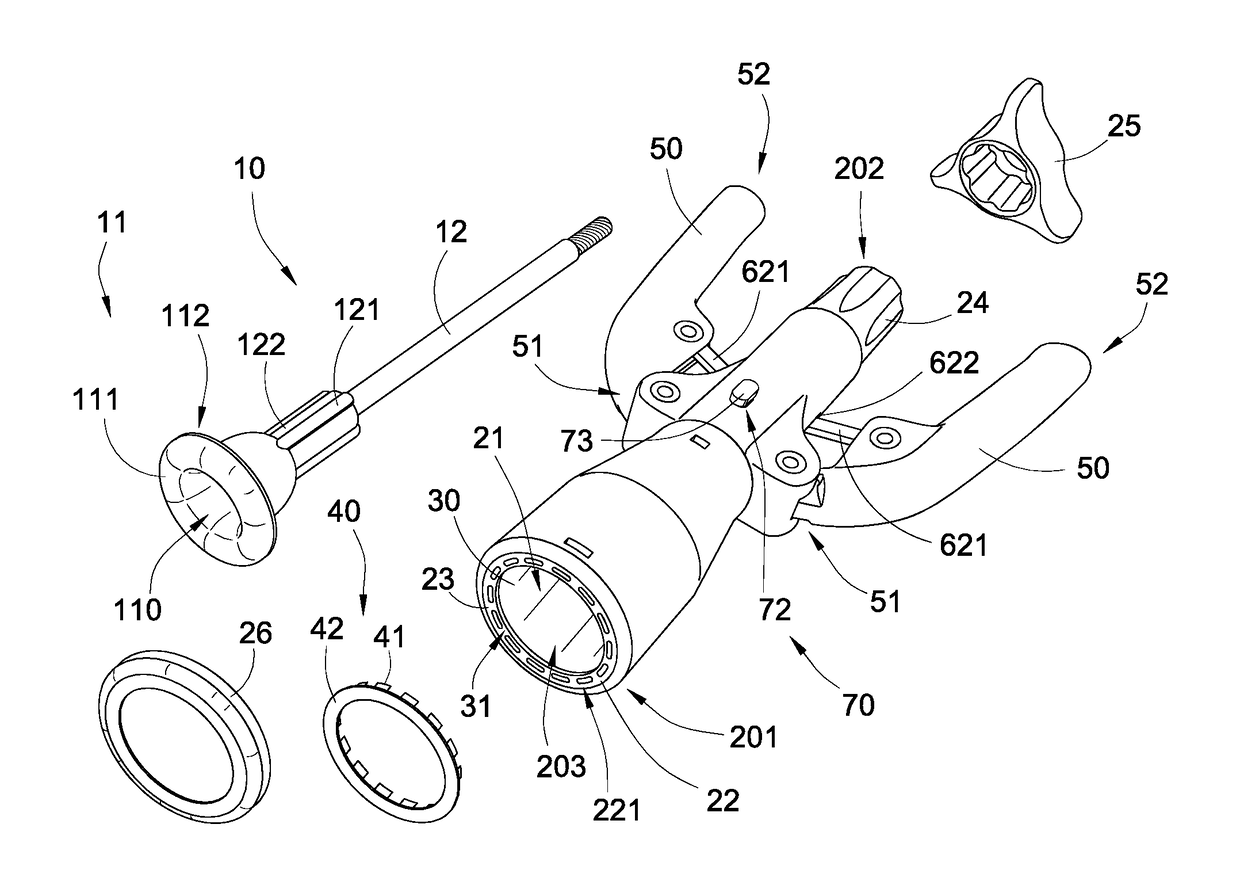

Pill Splitting Apparatus

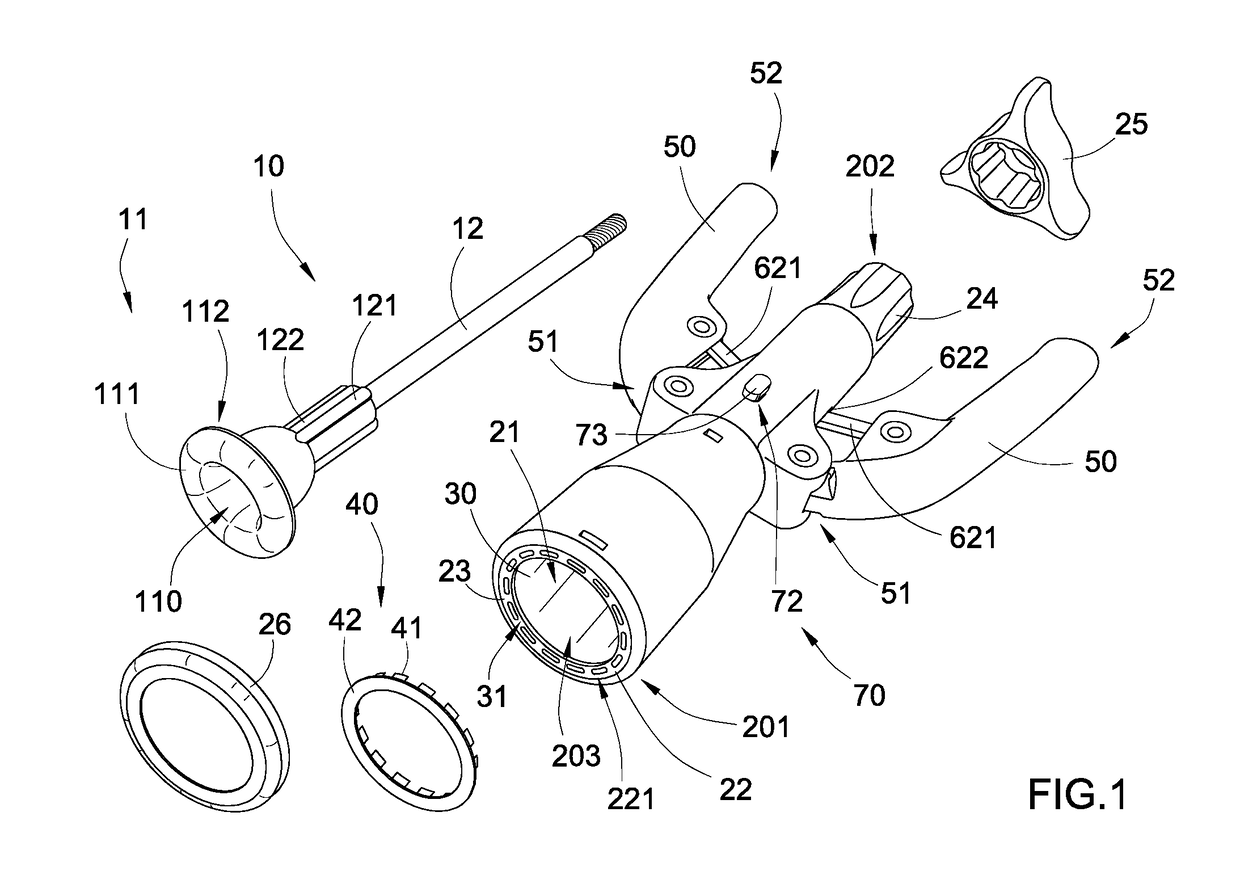

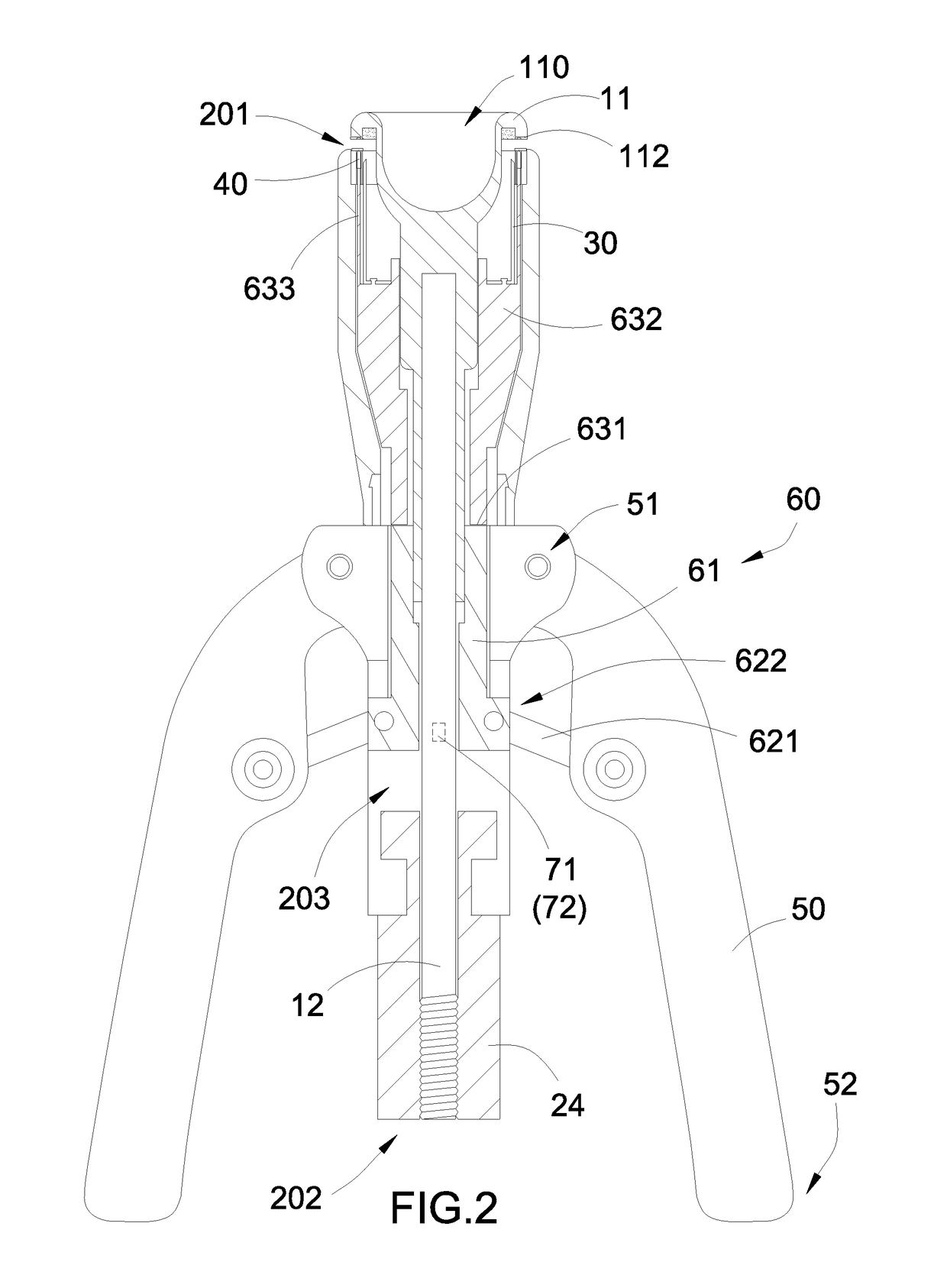

ActiveUS20160367441A1Easy to separateEasy to useOral administration deviceMetal working apparatusEngineeringPill splitting

A pill, or like object, splitting apparatus includes a base having a bottom and continuous side walls defining an interior area. The side wall defines primary apertures. A cutting platform is situated in the interior area in a first horizontal plane defined by apertures, the cutting platform defining a bore extending horizontally between the primary apertures. Primary clamp members extends through respective primary apertures into the bore of the cutting platform. The clamp members engage with the pill to position and hold the pill / tablet stable during the cutting process. A plunger assembly having a compression plate and a blade is operatively coupled to the compression plate, the plunger selectively positioned in communication with the interior area via the open top of the base such that the blade severs the pill upon a downward pressure on the compression plate. The cutting portion is interchangeable with different configurations of blade / blades.

Owner:MARTIN FRANCOIS

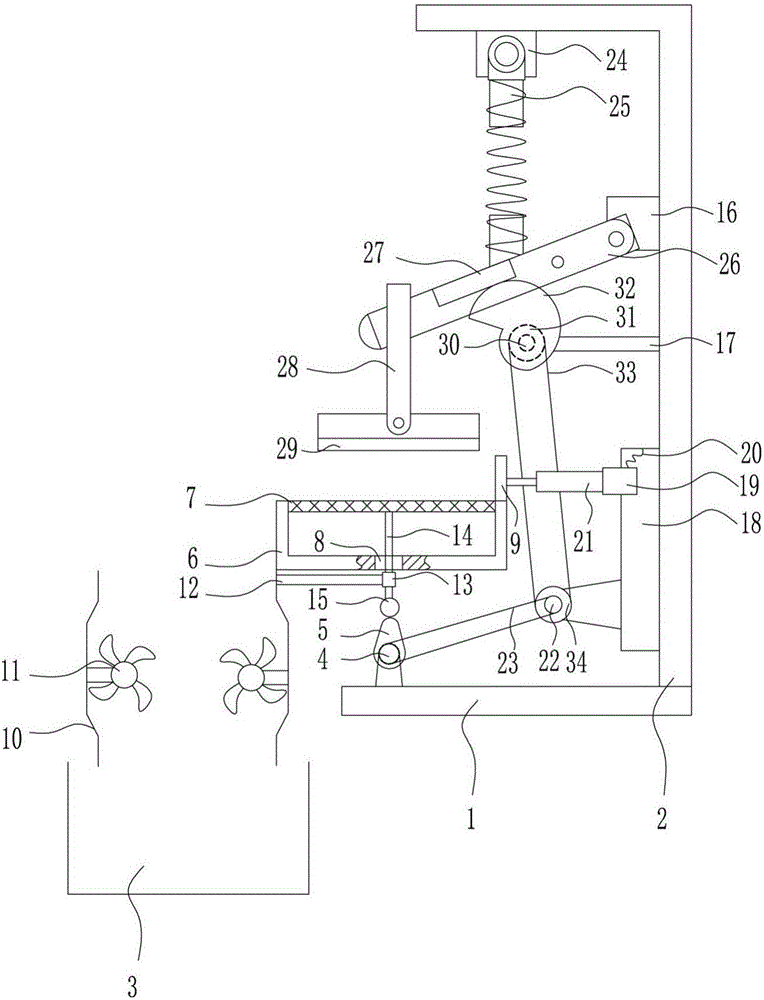

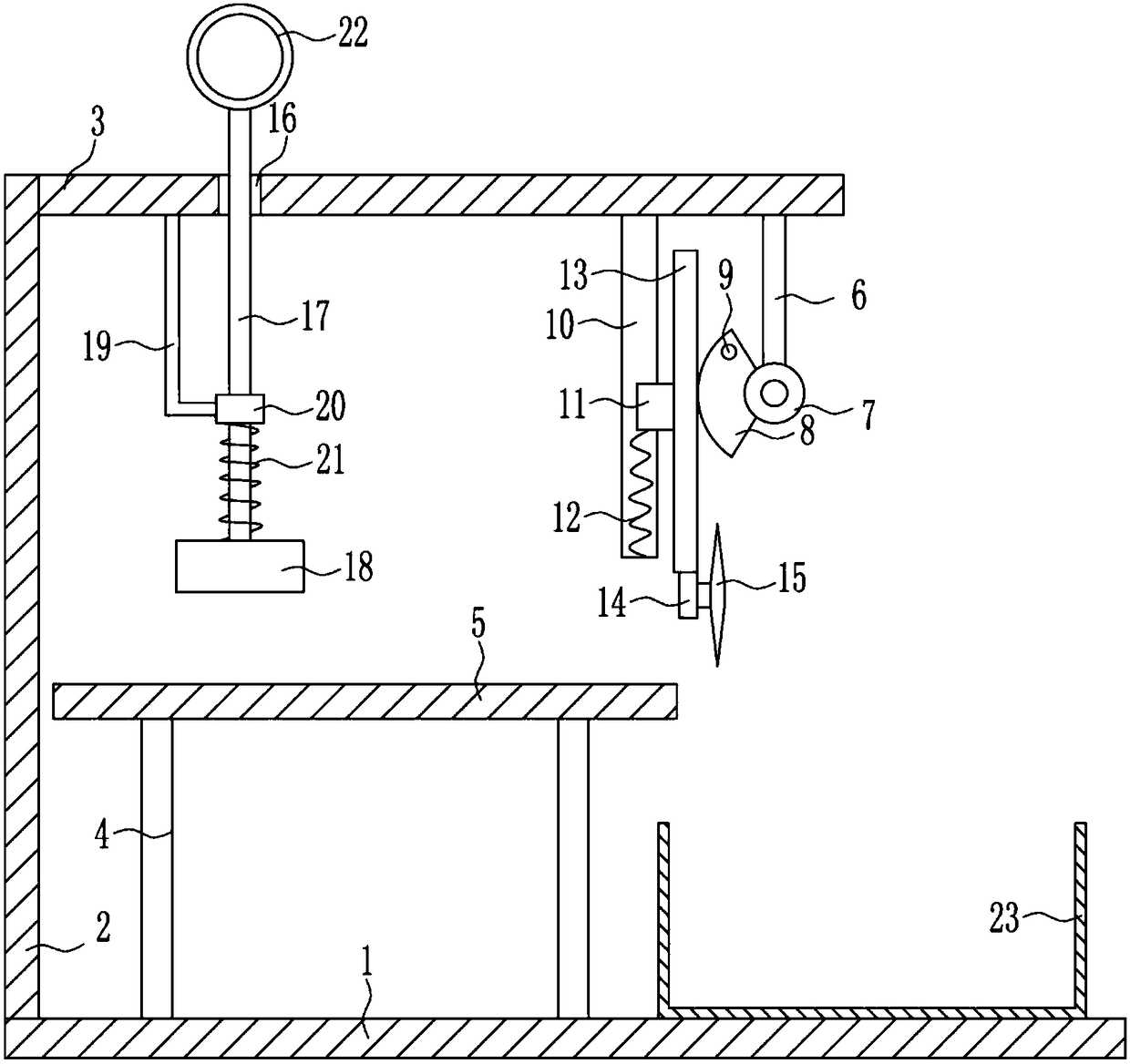

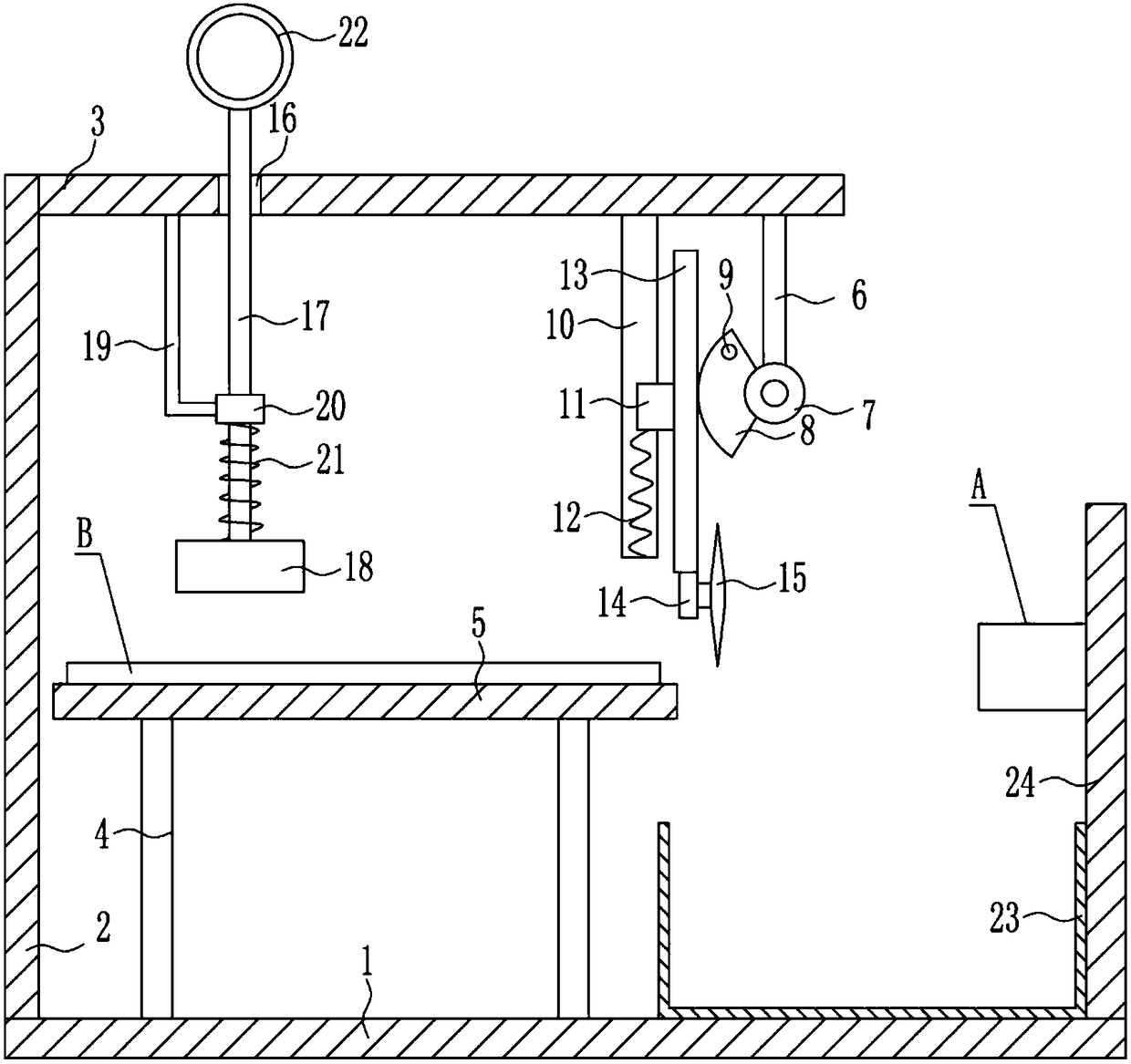

Grass cutting device used in animal husbandry

The invention relates to a grass cutting device, in particular to a grass cutting device used in animal husbandry. The technical problem to be solved by the invention is to provide the grass cutting device used in animal husbandry, which can perform air drying on cut grass in time, cuts grass uniformly and can separate grass cuttings with the grass. In order to solve the technical problem, the grass cutting device used in animal husbandry comprises a base plate, a 7-shaped rack, a collecting frame, a first belt pulley, a small cam, a cutting box, a screen, a push plate, a fan, a guide rod, a guide sleeve, a connecting rod, a sliding rail, a sliding block, a first spring, a cylinder, a fixed seat, an elastic piece, an oscillating rod, a first baffle block, a connection rod, a blade, a motor, a large flat belt, a fourth belt pulley and the like, wherein the first belt pulley and the 7-shaped rack are arranged on the base plate. According to the grass cutting device used in animal husbandry, by using the manner that the up-and-down motion of the blade works together with the up-and-down motion of the screen, the grass on the screen is uniformly cut, and the grass cuttings fall into the bottom inside the cutting box through the screen.

Owner:杨国锋

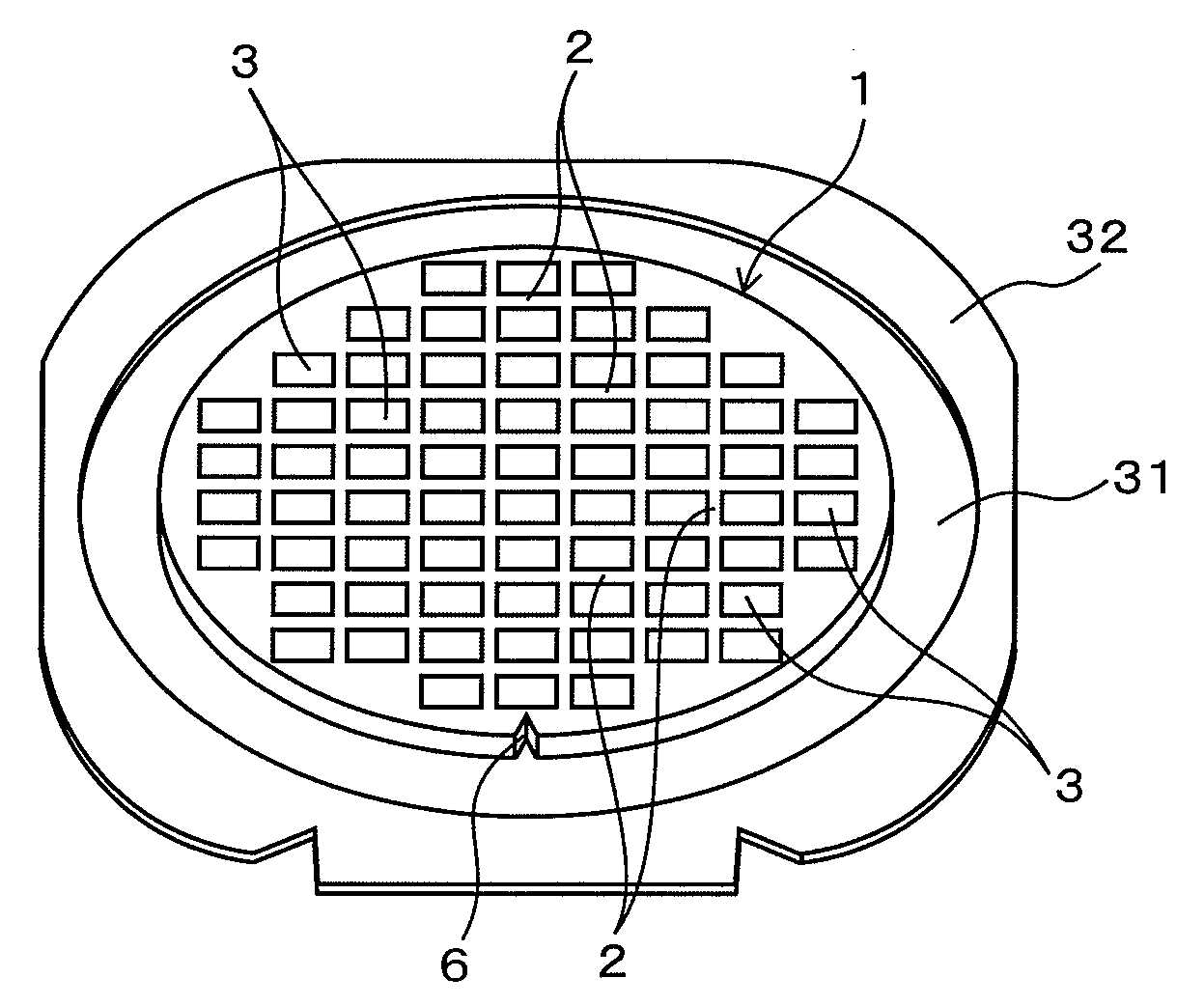

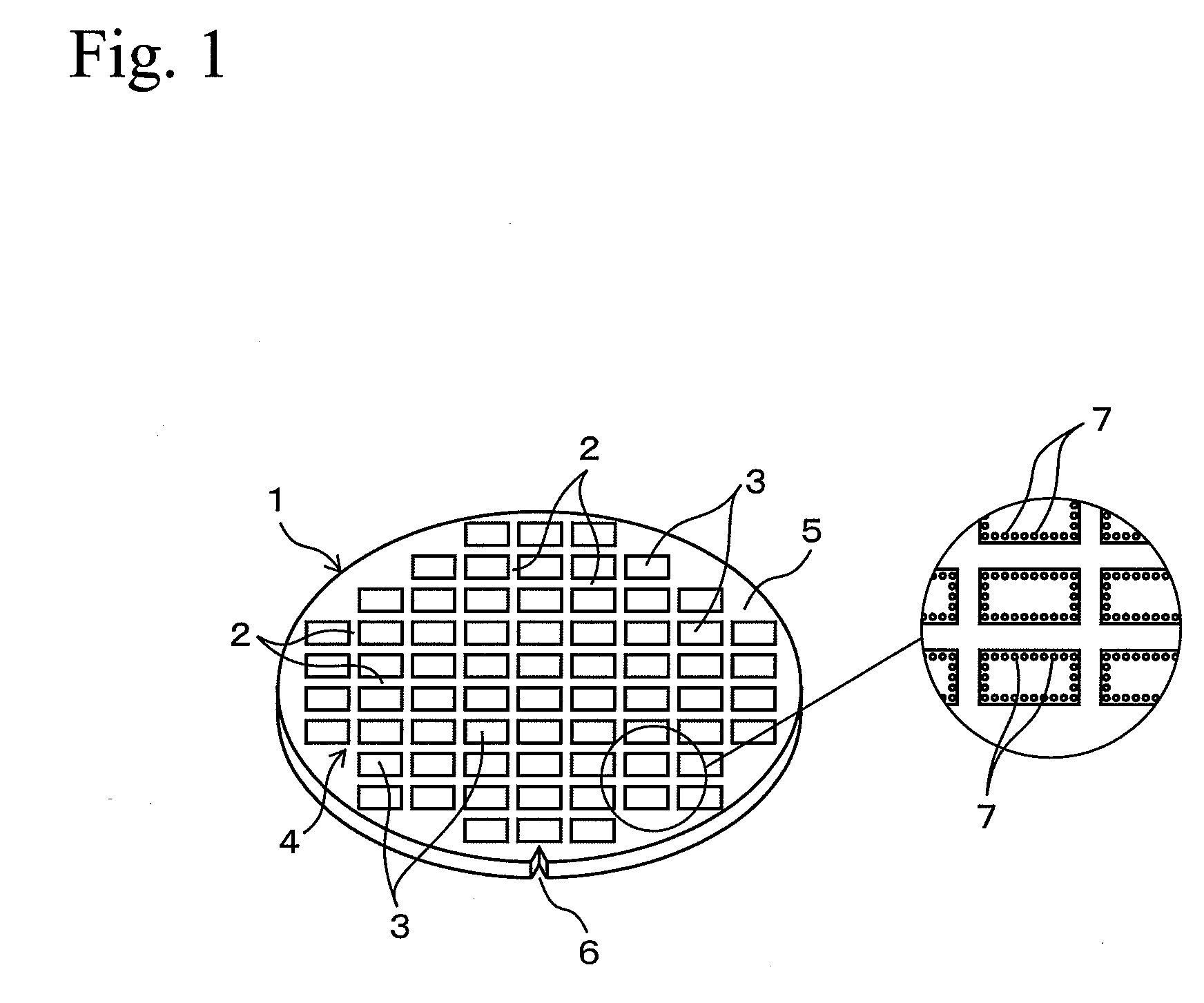

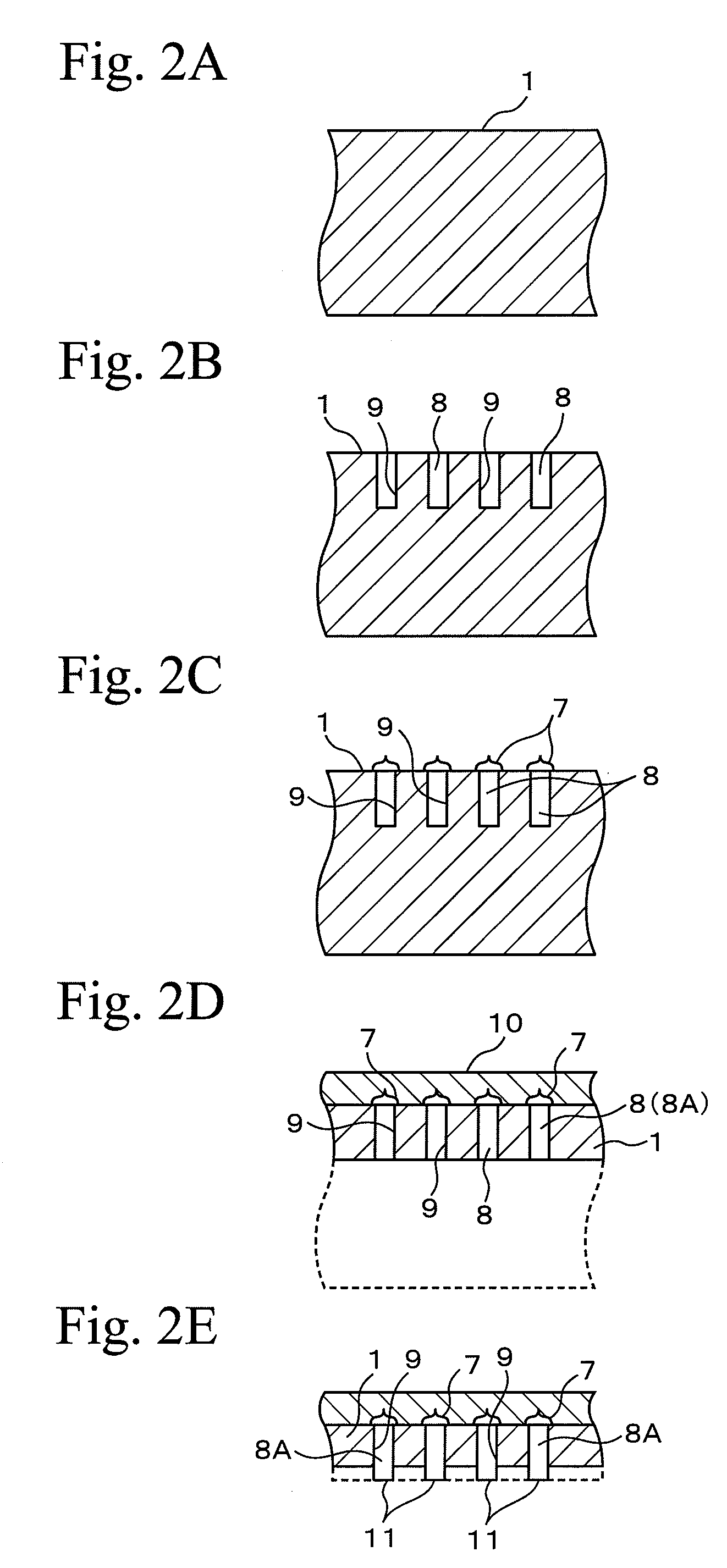

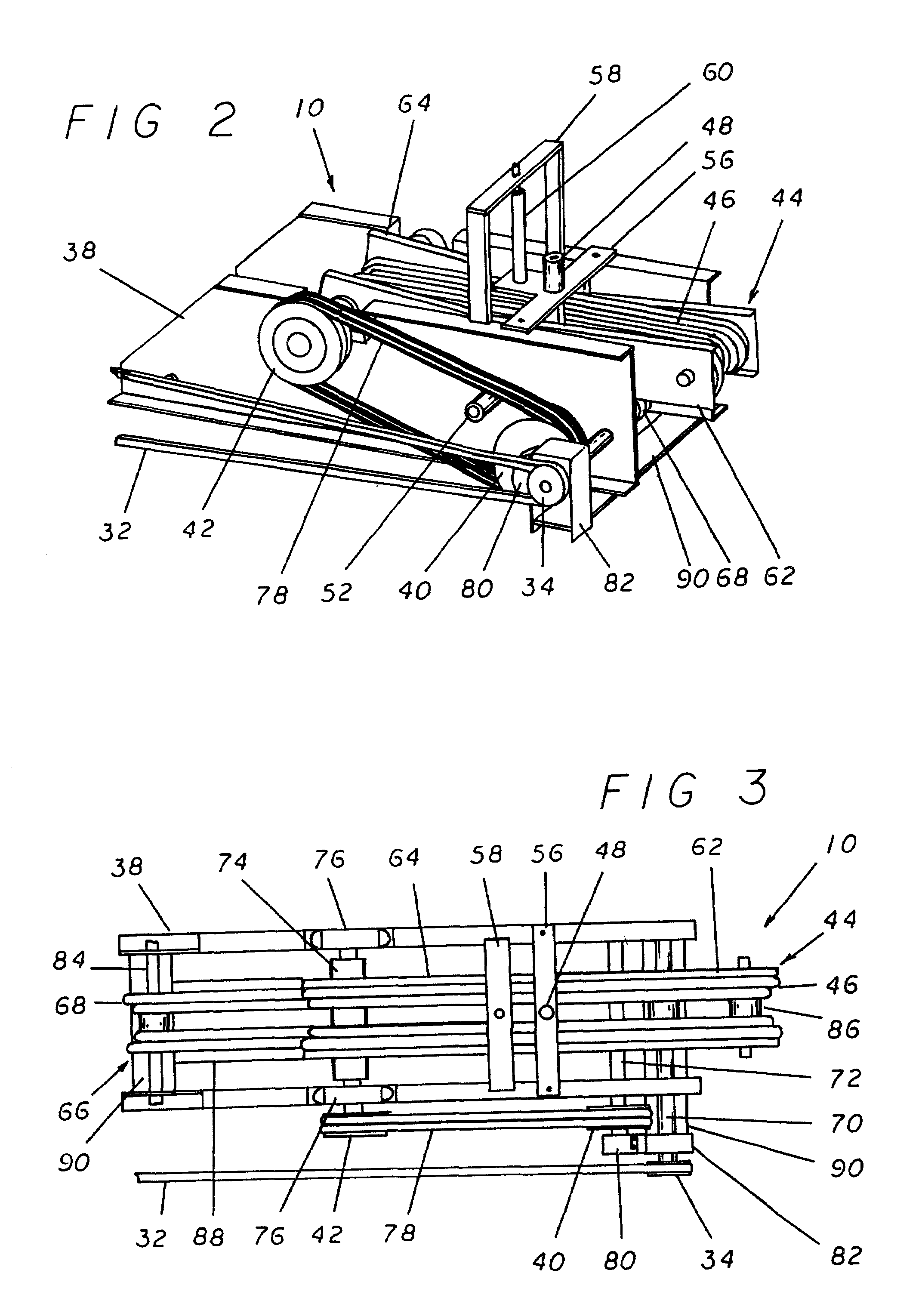

Production Method for Stacked Device

InactiveUS20080064187A1Easily and smoothlyIncrease productivitySemiconductor/solid-state device manufacturingWelding/soldering/cutting articlesDevice formEngineering

A production method for obtaining a stacked device from a wafer is provided. The wafer has: a device forming region formed on a surface having plural devices formed thereon, the devices having surfaces and thicknesses; a peripheral extra region surrounding the device forming region; and plural metal electrodes embedded in the surfaces of the devices and having thicknesses which are equal to or larger than the thicknesses of the devices. The method includes: a protective tape applying process for applying a protective tape to the surface of the wafer; a rear surface recess forming process for thinning only a region, which corresponds to the device forming region, on a rear surface by grinding, thereby forming a recess on the rear surface, forming a ring-shaped protrusion projecting from the rear surface on the peripheral extra region, and exposing the metal electrodes at the rear surface; an etching process for removing mechanical damage, which is provided to the recess by the grinding, by etching to the recess, and forming a rear surface side electrode portion by projecting the exposed metal electrodes from a bottom surface of the recess; and a dividing process for dividing the wafer into the devices.

Owner:DISCO CORP

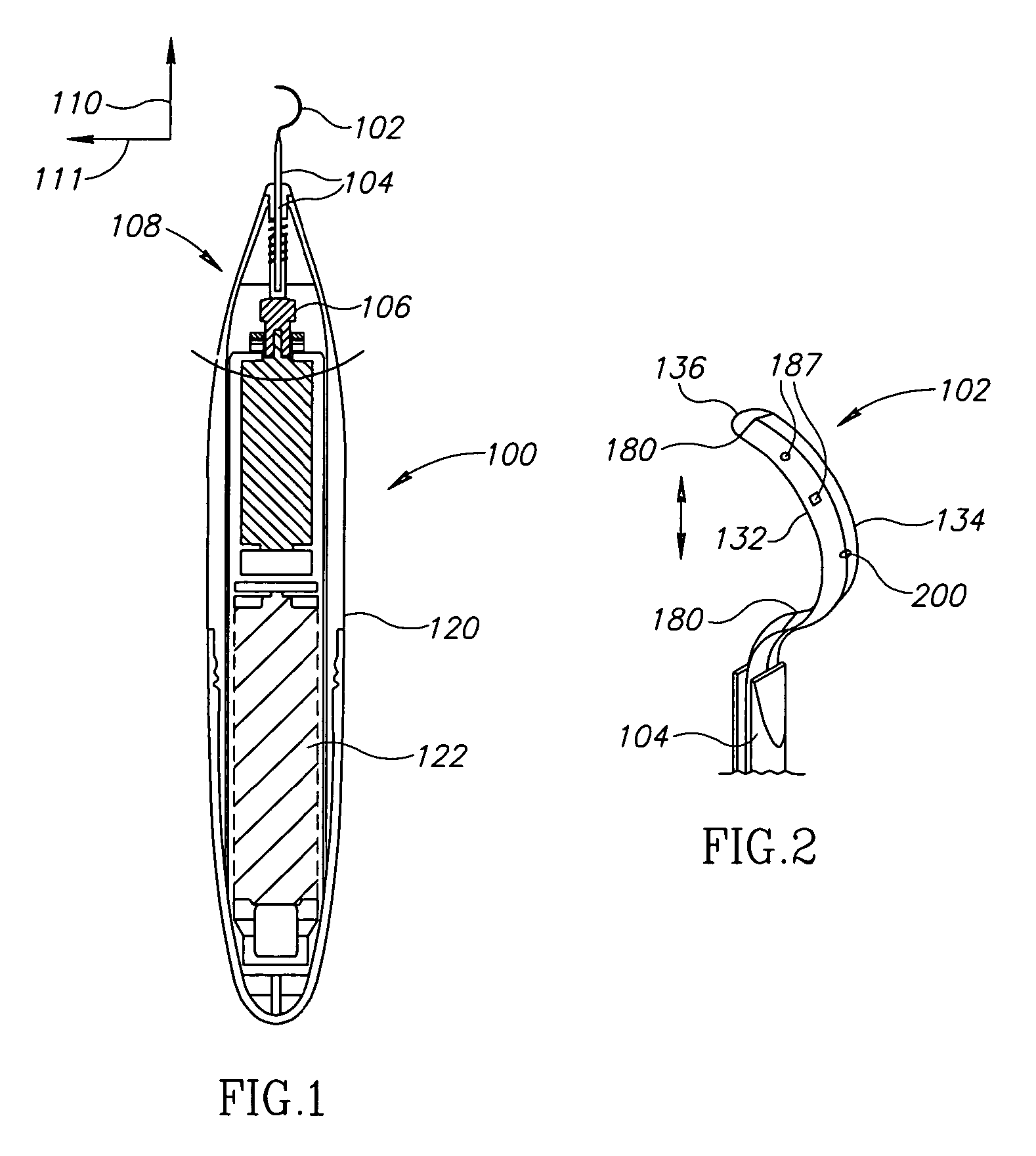

Biopsy method and gun set devices

InactiveUS20140228661A1Reduce transmissionCut evenlySurgical needlesDiagnostics using spectroscopyBiopsy methodsDensitometry

A novel set of biopsy-gun related tools are developed in order to make a better safer sampling and diagnosis, comprising a set of tools that takes the sample, releases a drug impregnated plug and additionally may inject drugs, measure pH and the molecular content of the penetrated tissues.A novel technology aiming to minimize the penetrated tissue damage, using a small diameter needle with capabilities for immediate spectroscopic analysis of the tissue, and followed by sampling and plugging of the tissue when needed.The invention describes a set of variable diameter thin tubes used to guide and insulate the penetrated organs, and a final operation of plugging the wounds with absorbable substances, impregnated with drugs.The supplementary low intensity radiation sources could increase the processes' accuracy and safety, offering the opportunity of gathering supplementary x-densitometry information.

Owner:VARIABLE GAUGE CATHETER INC

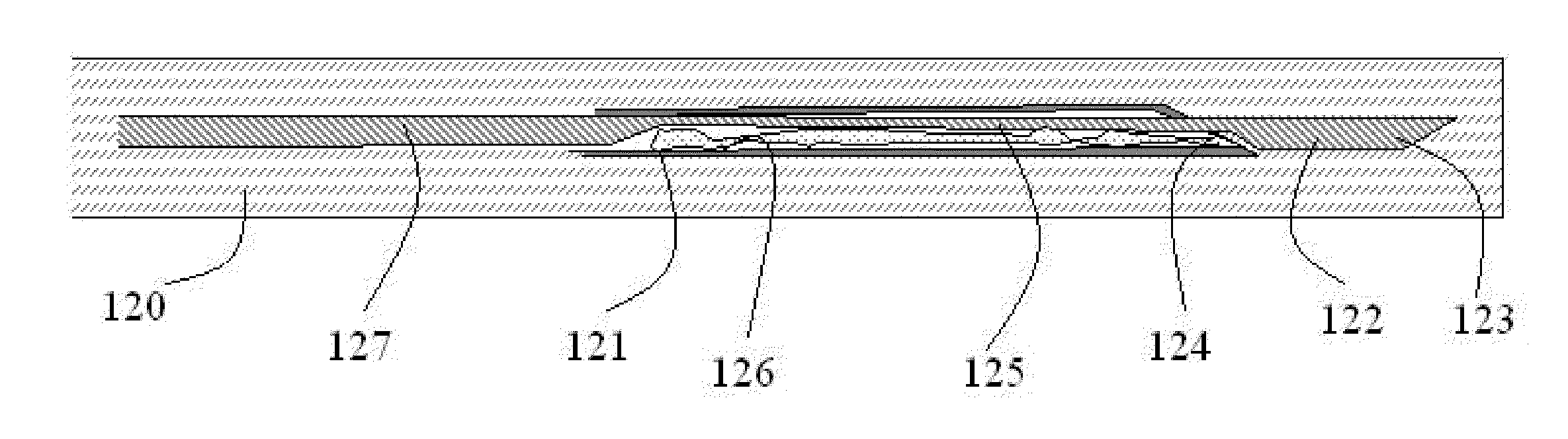

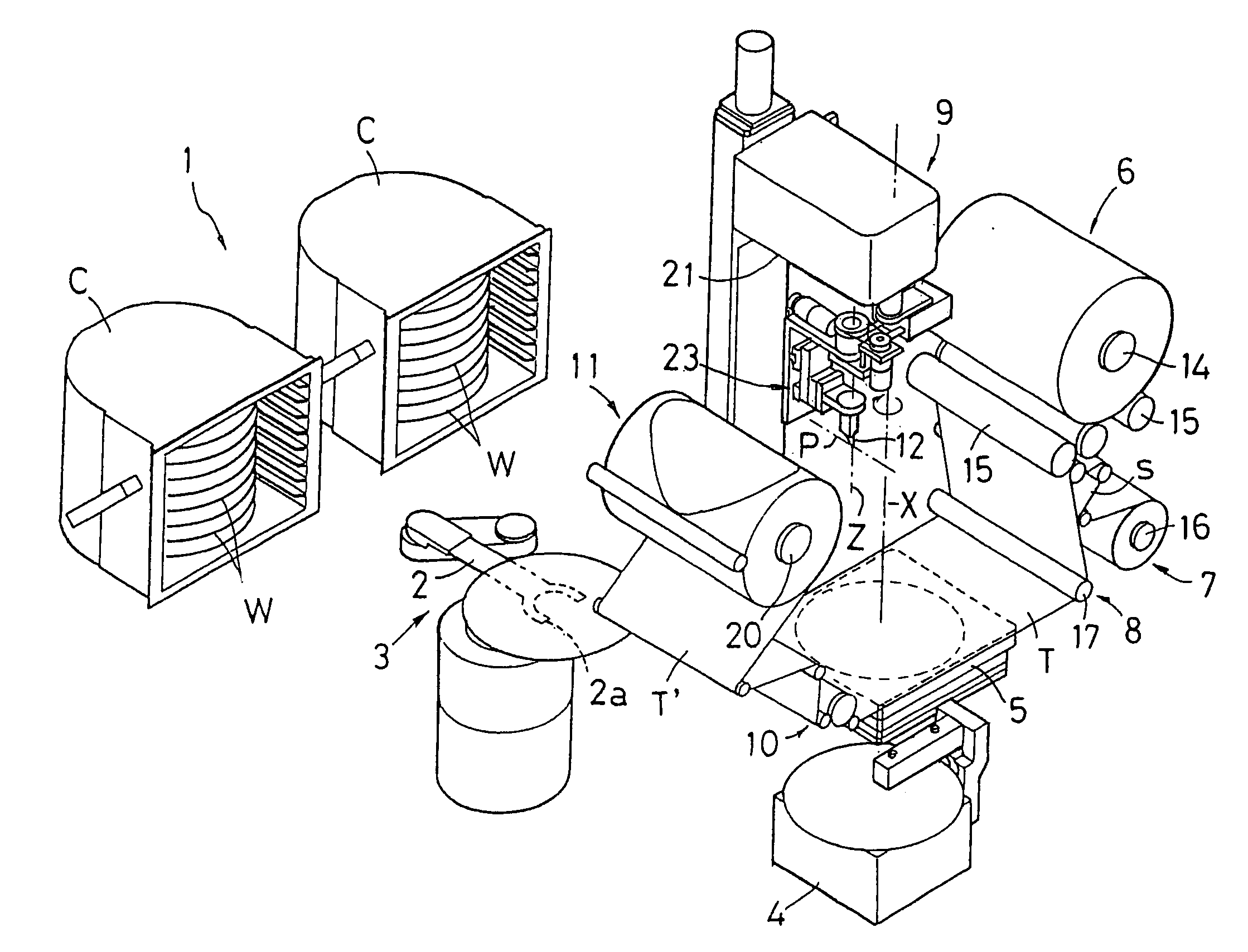

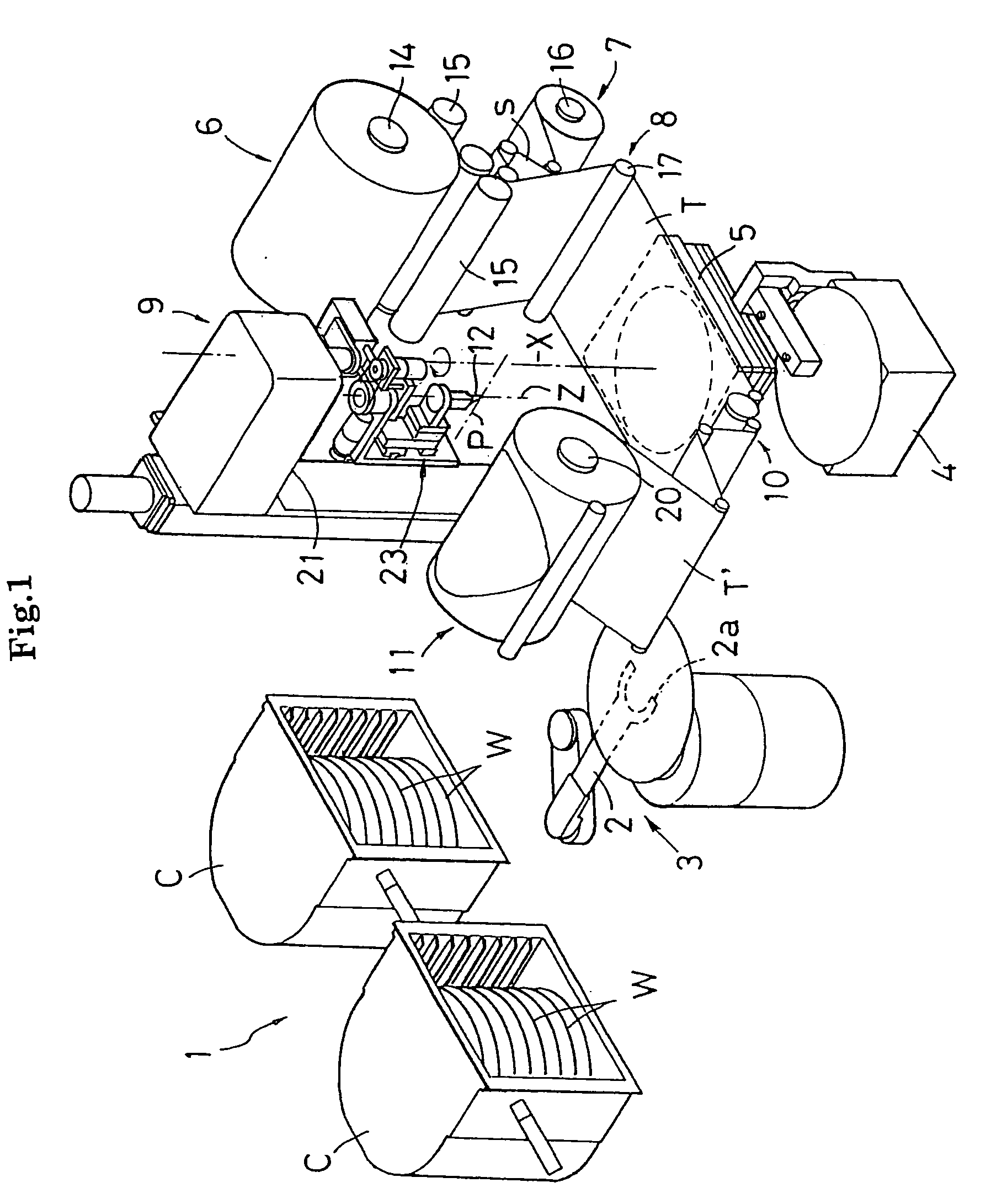

Method and apparatus for joining protective tape

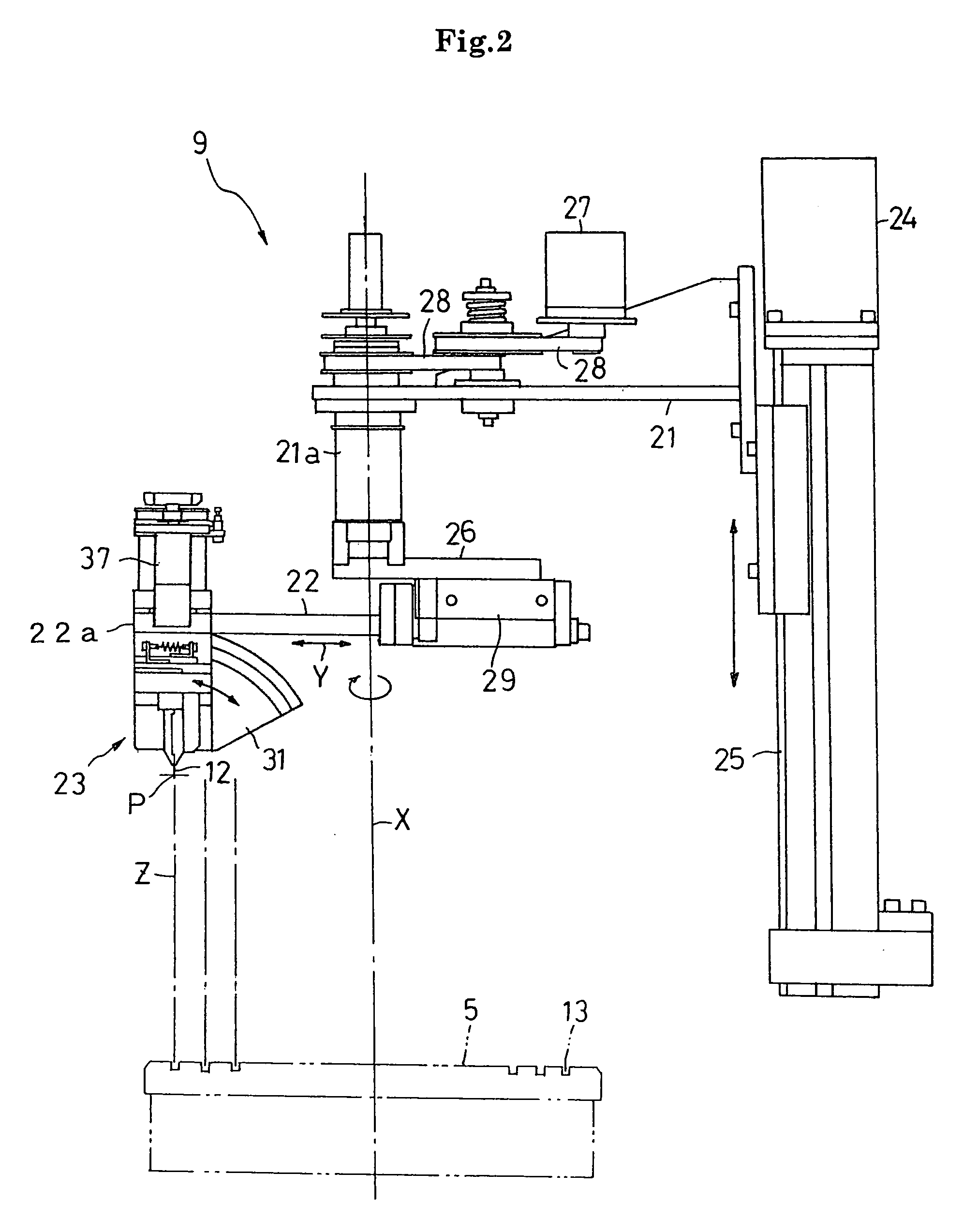

InactiveUS20060037694A1Smoothly and favorably cuttingCut evenlyLamination ancillary operationsControlling laminationSemiconductorEngineering

In a method for allowing a cutter blade to relatively travel along an outer periphery of a semiconductor wafer to cut a protective tape joined to a surface of the semiconductor wafer in conformity with an outer shape of the semiconductor wafer, the cutter blade is allowed to relatively travel along the outer periphery of the semiconductor wafer with a positioning notch provided on the outer periphery thereof. The cutter blade is rotationally turned at the fore half of the notch recessed on the outer periphery of the semiconductor wafer during the relative travel of the cutter blade in such a manner that its blade tip is directed toward the center of the wafer. In contrast, the cutter blade is rotationally turned at the rear half of the notch in such a manner that its blade tip is directed toward the outer periphery of the semiconductor wafer.

Owner:NITTO DENKO CORP

Capsulotomy instrument

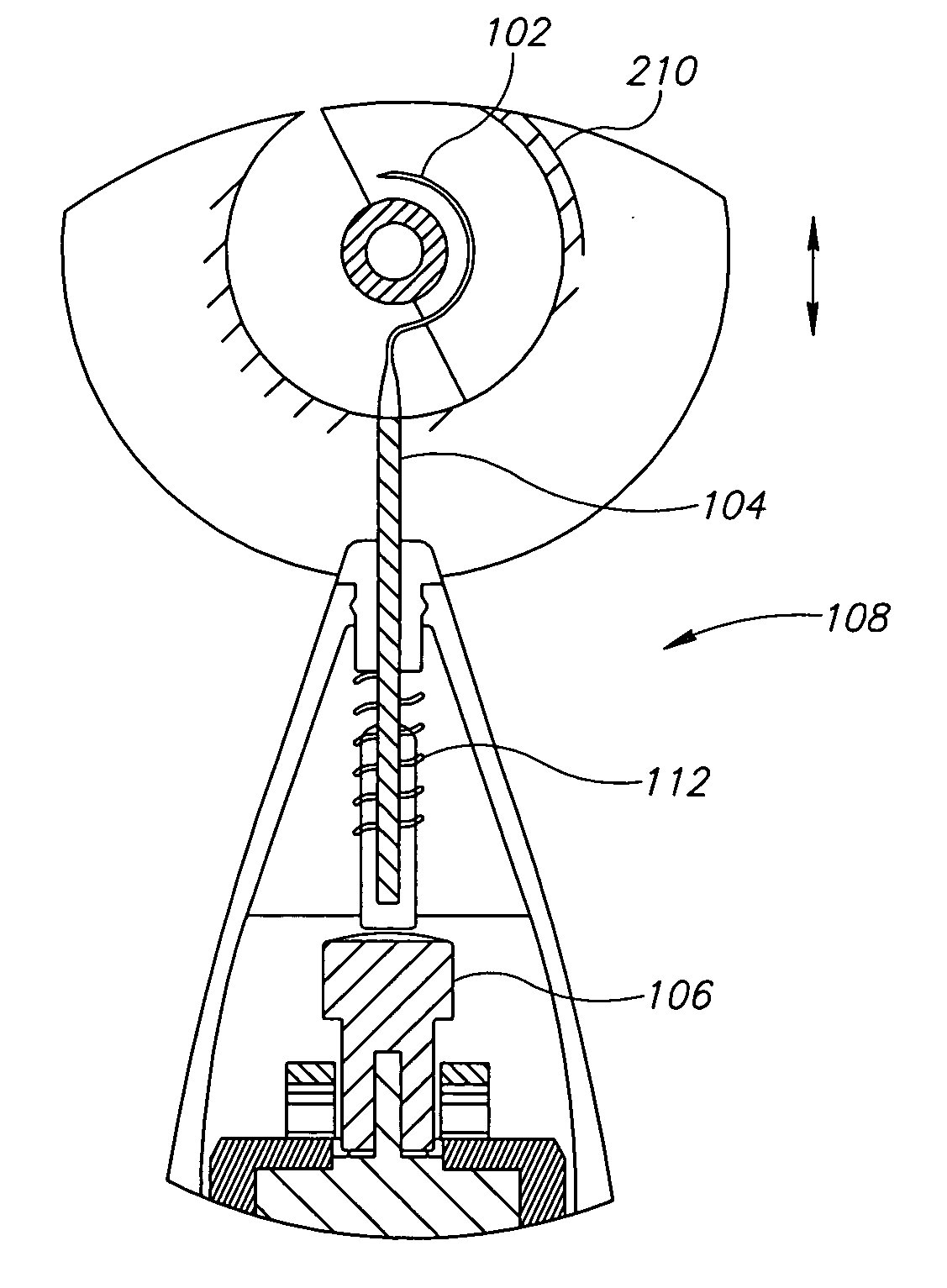

ActiveUS20060264990A1Cut evenlySafer and more predictable cutEye surgerySurgeryCapsulotomyEngineering

A capsulotomy cutting device, including a planar cutting head sized to fit into intraocular tissue, including at least one sharp edge and an oscillation mechanism adapted to oscillate the cutting head.

Owner:SAFE SURGERY TECH

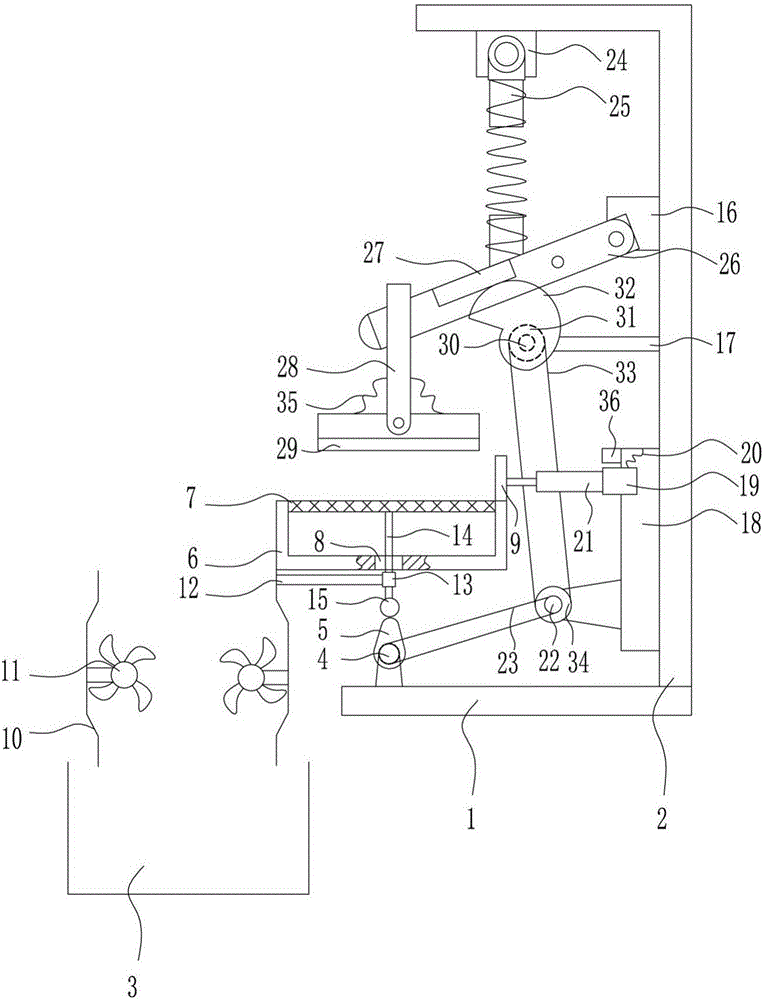

Hardware rebar equidistant efficient cutting device

The invention relates to a hardware rebar cutting device, in particular to a hardware rebar equidistant efficient cutting device which is simple to operate, uniform in cutting and high in cutting efficiency. The hardware rebar equidistant efficient cutting device comprises a first gear, a first belt wheel, a flat belt, a second belt wheel, a second gear, a first sliding rail, a third gear, a speed reducing motor, a first spring and a first rack, and a left frame, a second sliding rail, the speed reducing motor, the second gear, the first sliding rail and the first gear are sequentially arranged at the top of a base from left to right. The hardware rebar equidistant efficient cutting device has the advantages of simplicity in operation, uniformity in cutting and high cutting efficiency; by using the device, rebars can be cut quickly within short time, and sections of the rebars are cut uniformly in the process of cutting.

Owner:GUANGXI SHENGLONG METALLURGICAL CO LTD

Double-eccentric-gear type forage grass cutting device for animal husbandry

The invention relates to an animal husbandry forage grass cutting device, in particular to a double-eccentric-gear type forage grass cutting device for animal husbandry, and aims to solve the technical problem of providing a double-eccentric-gear type forage grass cutting device which is high in cutting efficiency, rapid in cutting speed and convenient to operate for animal husbandry. To solve the technical problem, the invention provides the double-eccentric-gear type forage grass cutting device for animal husbandry. The double-eccentric-gear type forage grass cutting device comprises a bottom plate, a left rack, a first sliding track, a first sliding block, a moving frame, a second sliding block, a cutting frame, a second sliding track, a right rack, a mounting base, a first belt pulley and the like, wherein the left rack, the first sliding track, the second sliding track and the right rack are sequentially arranged at the top of the bottom plate from left to right; the first sliding block is arranged on the first sliding track in a sliding manner. The double-eccentric-gear type forage grass cutting device has the effects of being high in cutting efficiency, rapid in cutting speed and convenient to operate, and is long in service life, high in production efficiency, excellent in cutting quality and favorably increased in overall levels such as overall properties.

Owner:邵鹏程

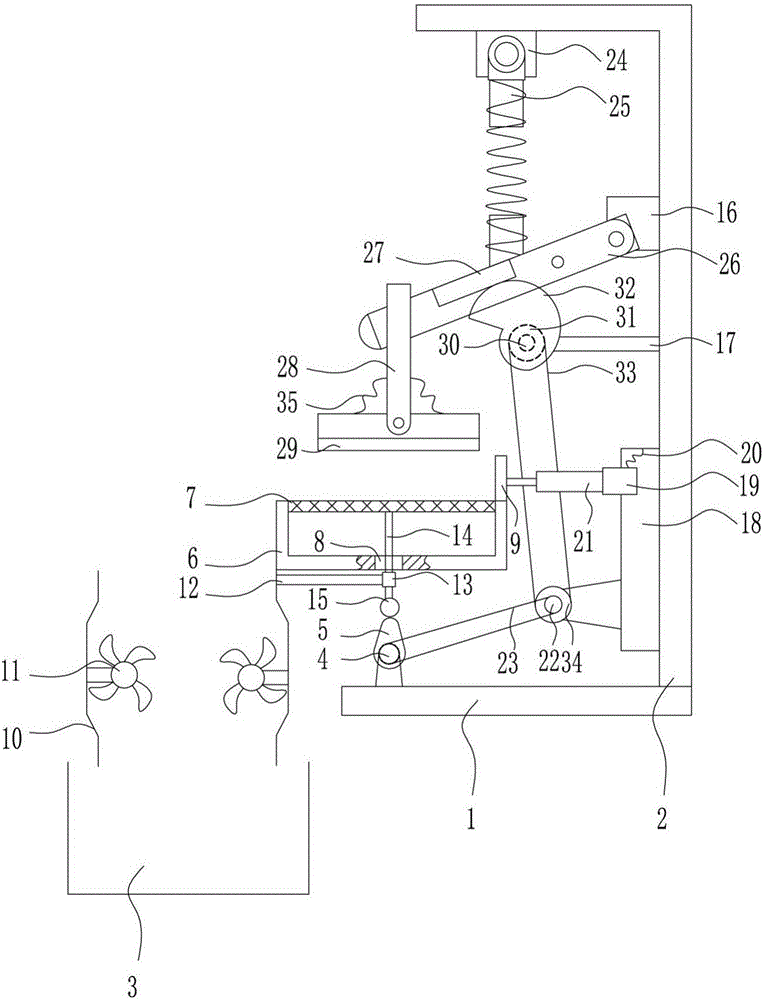

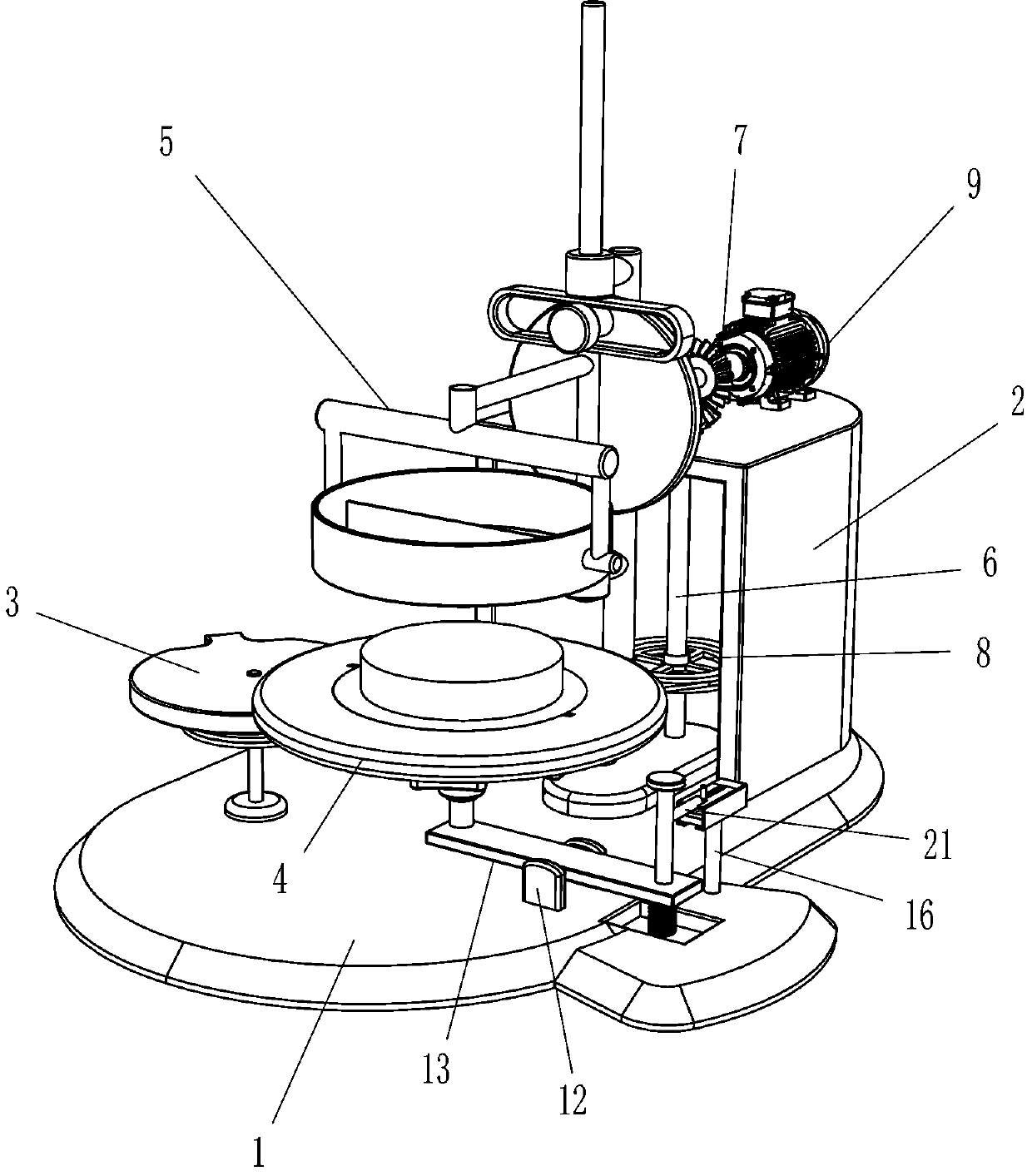

Automatic cake dicing equipment

ActiveCN111374162ACut evenlyEasy to take outBaked article cutting/slicingEngineeringMechanical engineering

The invention relates to cake processing equipment, specifically to automatic cake dicing equipment. The invention is to solve the technical problem of providing the automatic cake dicing equipment capable of uniformly cutting cakes and conveniently taking out the cake. The automatic cake dicing equipment comprises: a base, wherein the left side of the base partially protrudes frontwards; a mounting frame, which is arranged at one side of the upper part of the base; a steering mechanism, which is arranged at one side, far away from the mounting frame, of the base and used for rotating a cake;and a working disc, which is fixedly connected with and arranged at the upper part of the steering mechanism, wherein a circular groove is arranged at the top part of the working disc. The automatic cake dicing equipment provided by the invention reaches the effects of uniformly cutting the cake and conveniently taking out the cake; the cake is cut through up-down movement of the cutting mechanism; meanwhile, the cake intermittently rotates through the steering mechanism, so the cake can be uniformly cut.

Owner:长沙罗莎食品有限公司

Building reinforcing construction equipment

ActiveCN108487663AReduce labor intensityNo manual operationLiquid surface applicatorsSevering textilesFiberEngineering

The invention relates to building reinforcing construction equipment comprising a bottom plate. A tensioning conveying device is mounted on the bottom plate; a gluing device is mounted on the rear side of the bottom plate and located above the tensioning conveying device; a cutting collecting device is mounted on the front side of the bottom plate; the tensioning conveying device comprises a winding roller, a first adjusting roller, a first limiting roller, a second limiting roller, a second adjusting roller and a coiling roller which are sequentially mounted on the bottom plate from front toback; and a carbon fiber cloth body is wound around the coiling roller. The building reinforcing construction equipment can solve the problems that in the existing process of manual treatment of a carbon fiber cloth, the carbon fiber cloth needs to be manually cut according to the processing size, the carbon fiber cloth needs to be manually coated with glue, the glued carbon fiber cloth needs to be manually stacked, manual gluing is not uniform, the house reinforcing effect is affected, carbon fiber cloth manual stacking is complex in operation, the space required for stacking is large, and the space utilization rate is low.

Owner:浙江众安建设集团有限公司

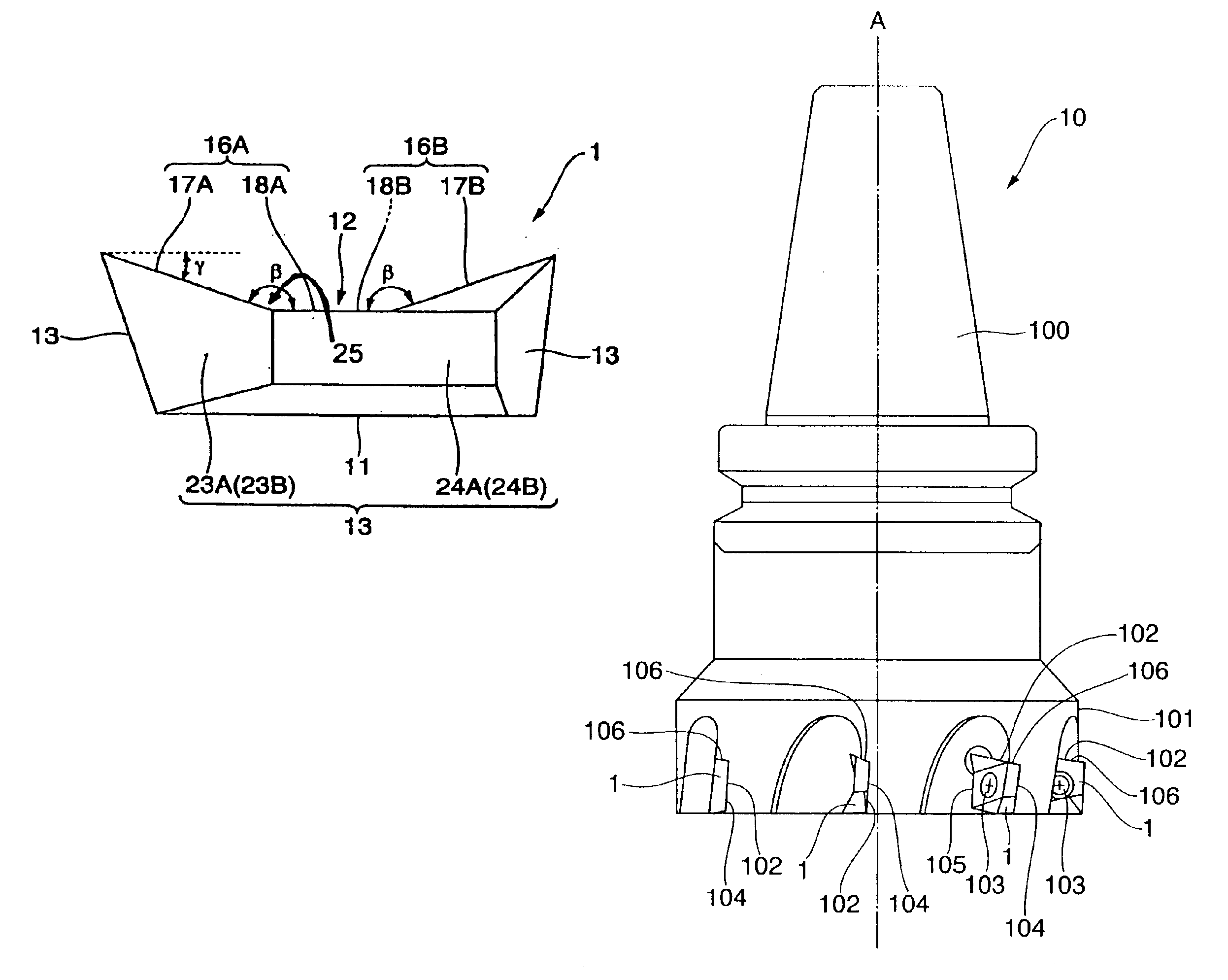

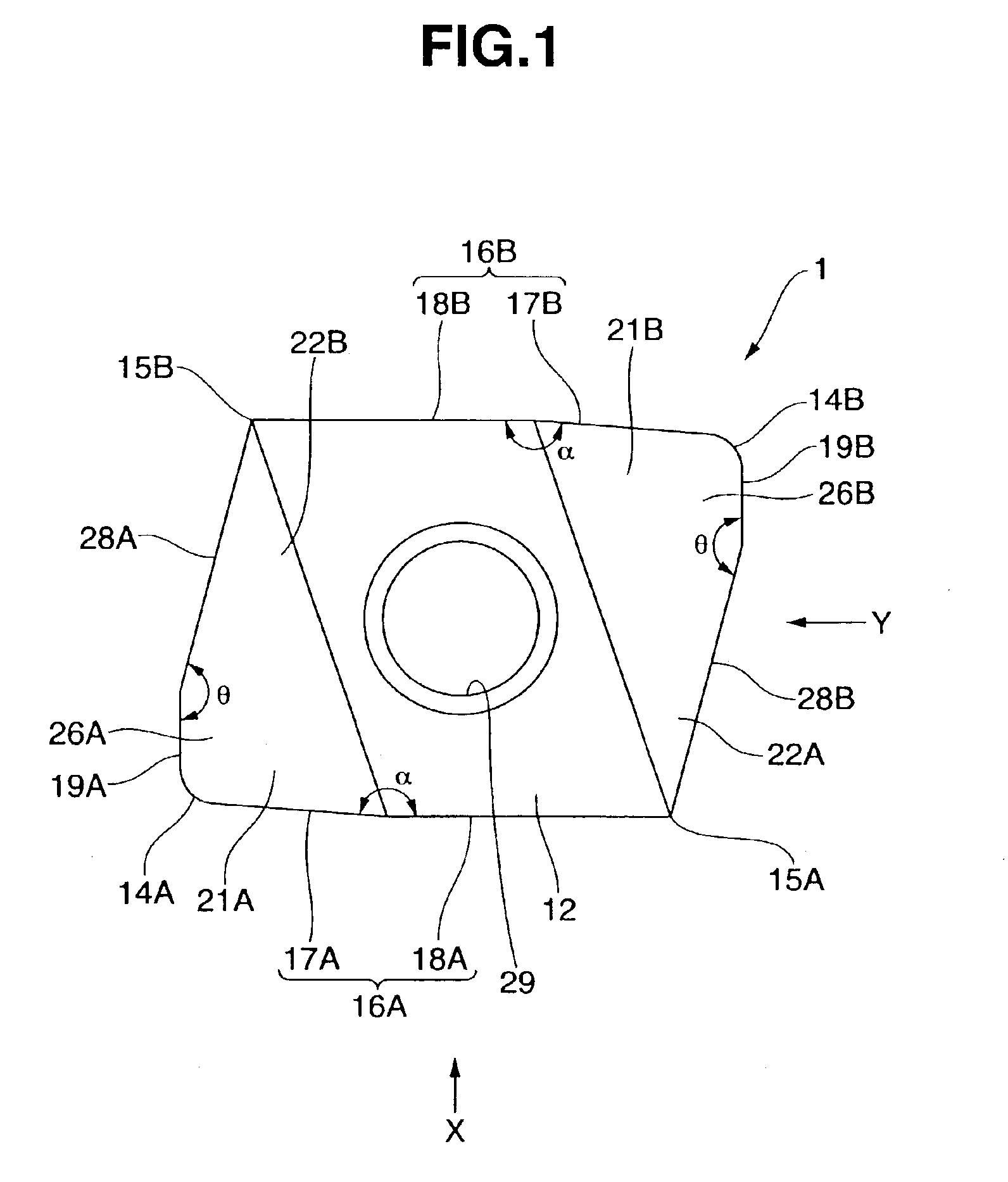

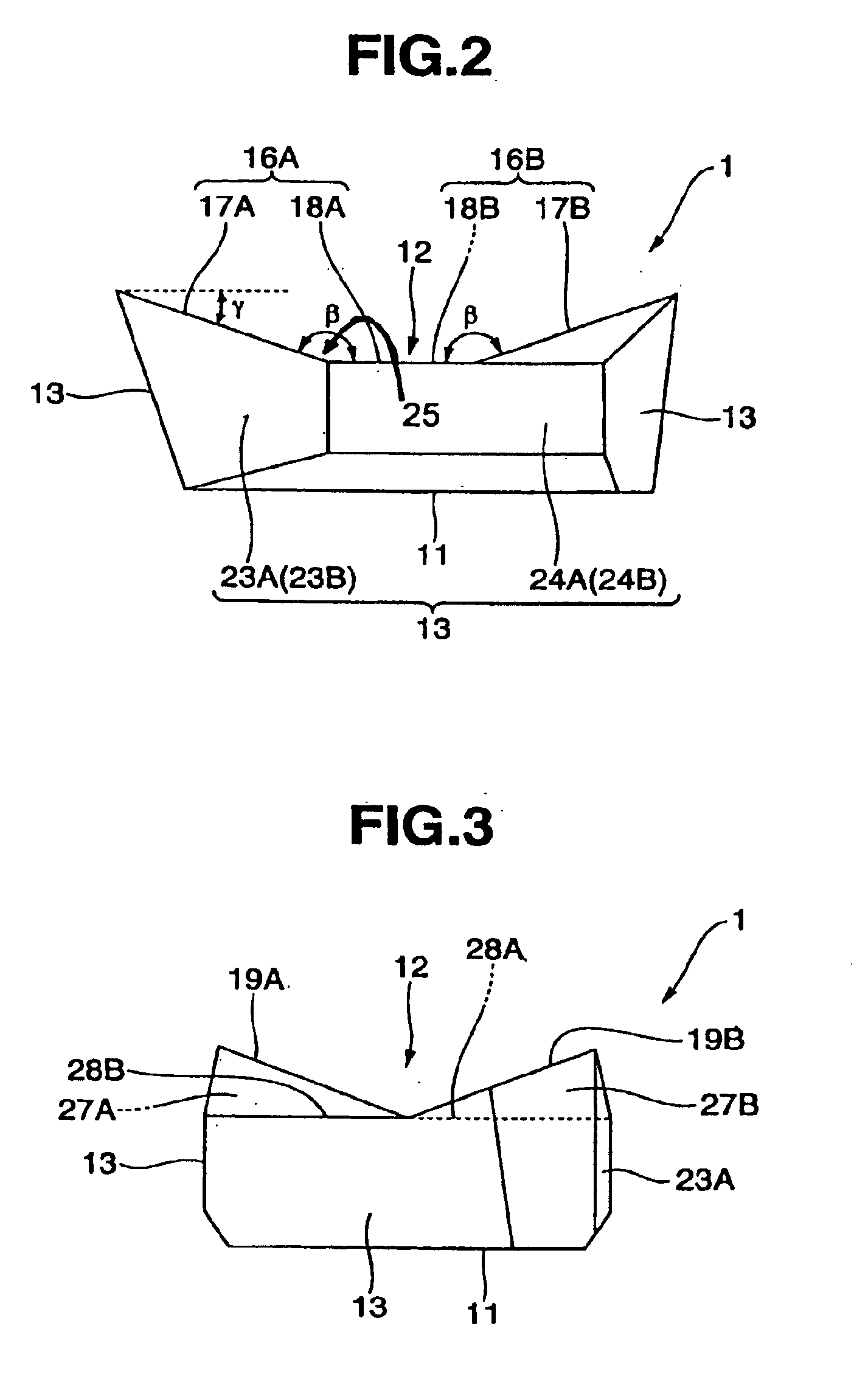

Cutting tool insert and cutting tool

ActiveUS6851897B2Large axial rake angleImprove performanceMilling cuttersTurning toolsEngineeringMechanical engineering

The cutting tool insert 1 is in a substantially plate form and of polygonal shape and is provided with a major cutting edge 16A (or 16B) extending from one corner 14A (or 14B) toward the other corner 15A (or 15B). The major cutting edge 16A (or 16B) comprises a first edge line and a second edge line that meet to form an obtuse angle, which causes the area where the first and second edge lines meet to protrude slightly outwards, as viewed from above. The first edge line slopes down towards the second edge line so that the distance with a seat face 11 decreases gradually as viewed from the side, and the first edge line forms an obtuse angle with the second edge line causing the top face area to dip down towards the seat face. The first edge line is shorter than the second edge line.

Owner:DAISHOWA SEIKI CO LTD

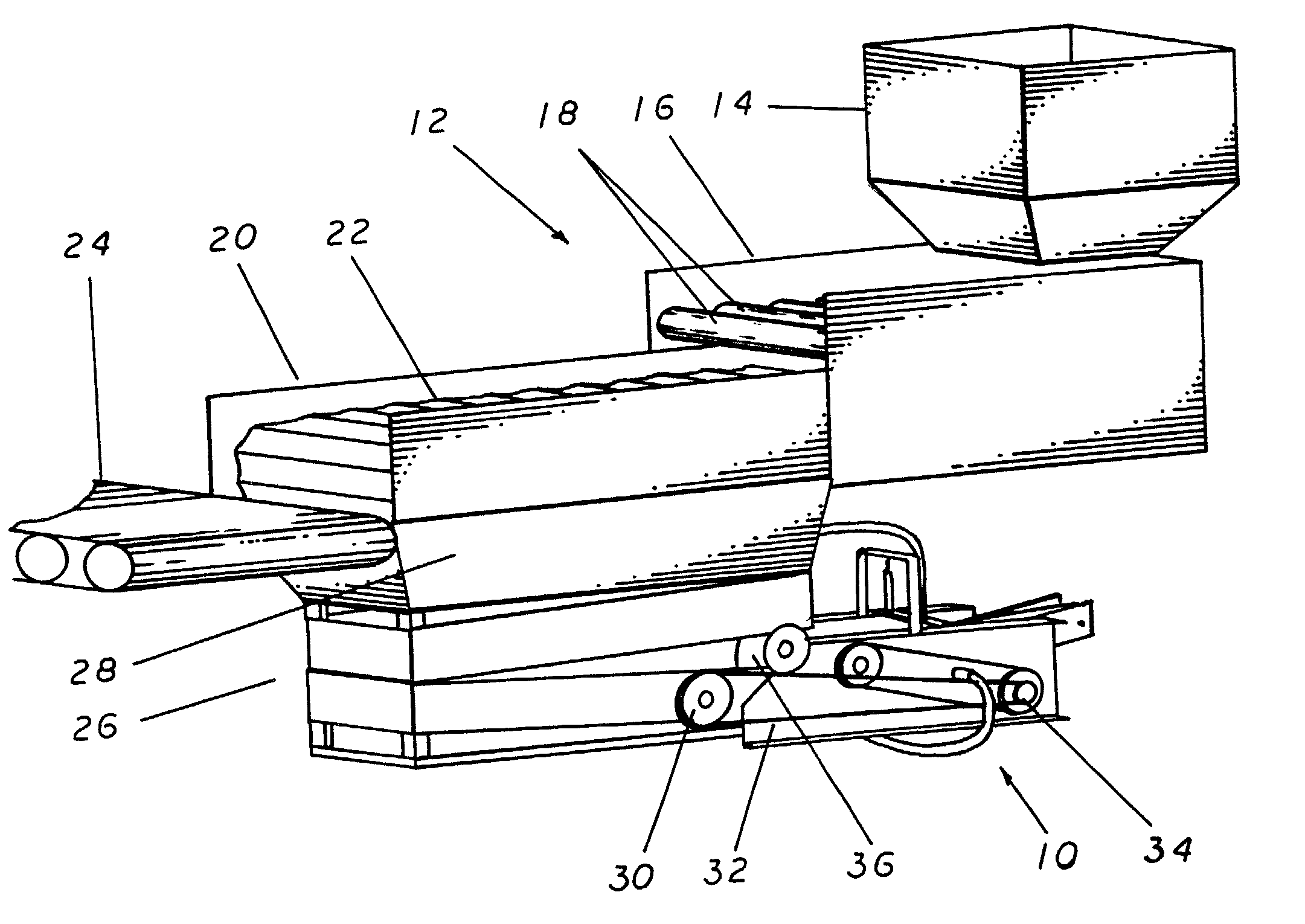

High pressure seed potato cutter

A method of cutting seed potatoes prior to their planting is provided in which a high pressure water jet is employed to slice the potatoes into the desired sized pieces. The present invention employs a single water jet, a plurality of water jets, or a cutting tube configuration containing either single or multiple water jet streams which are projected through the center of the cutting tubes or the cutting area and an equal amount of stream collector tube or tubes which contain the jet or jets and collects and directs the spent water to a proper location for its final collection or final discharge. Additionally, the use of this water jet system ensures that the seed potatoes that are cut will not contaminate one another through the cutting instrument as the water used in the cutting process only comes into contact with one potato and is then discharged from the system.

Owner:ZELINSKI JR WILLIAM JOHN +1

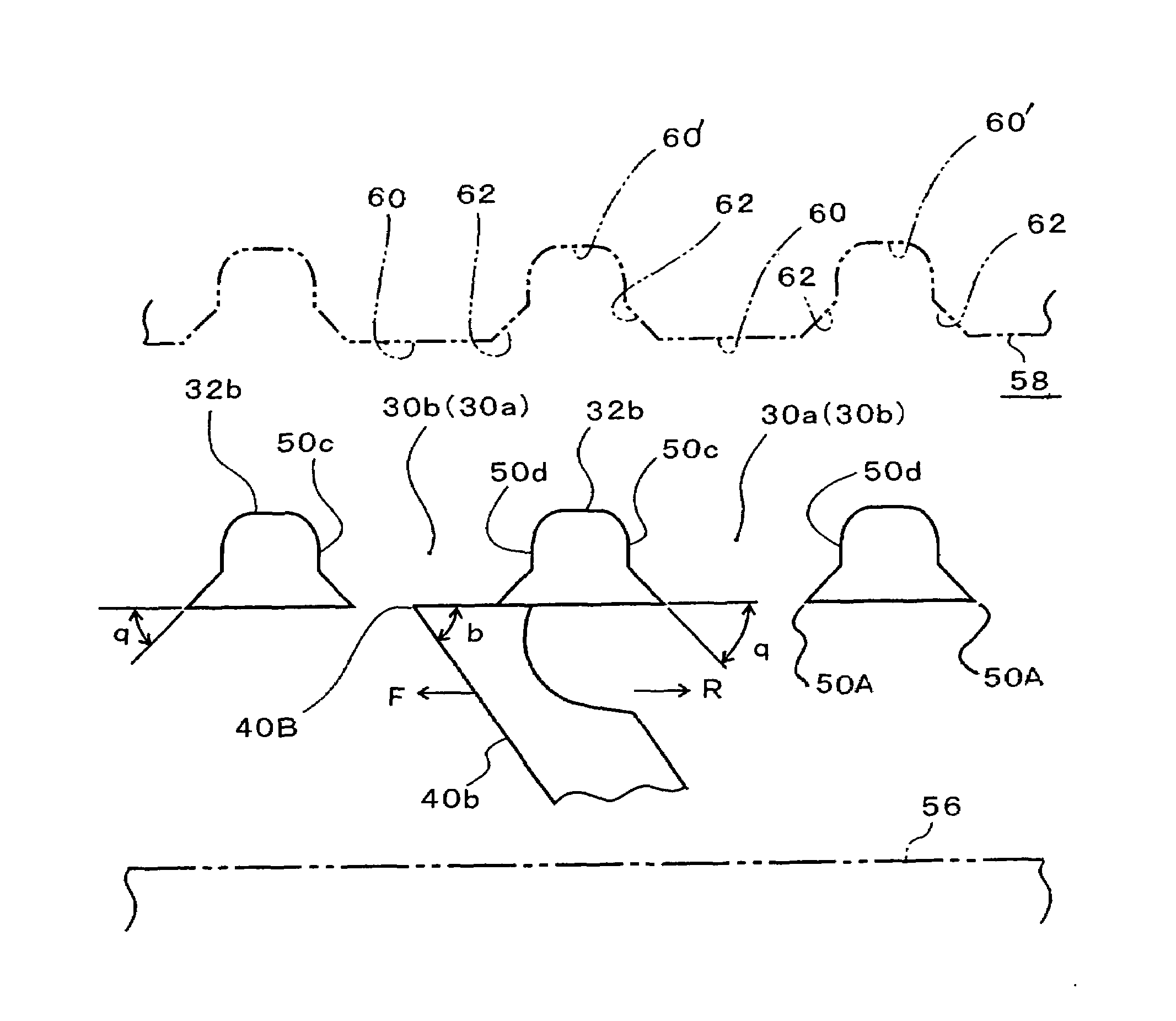

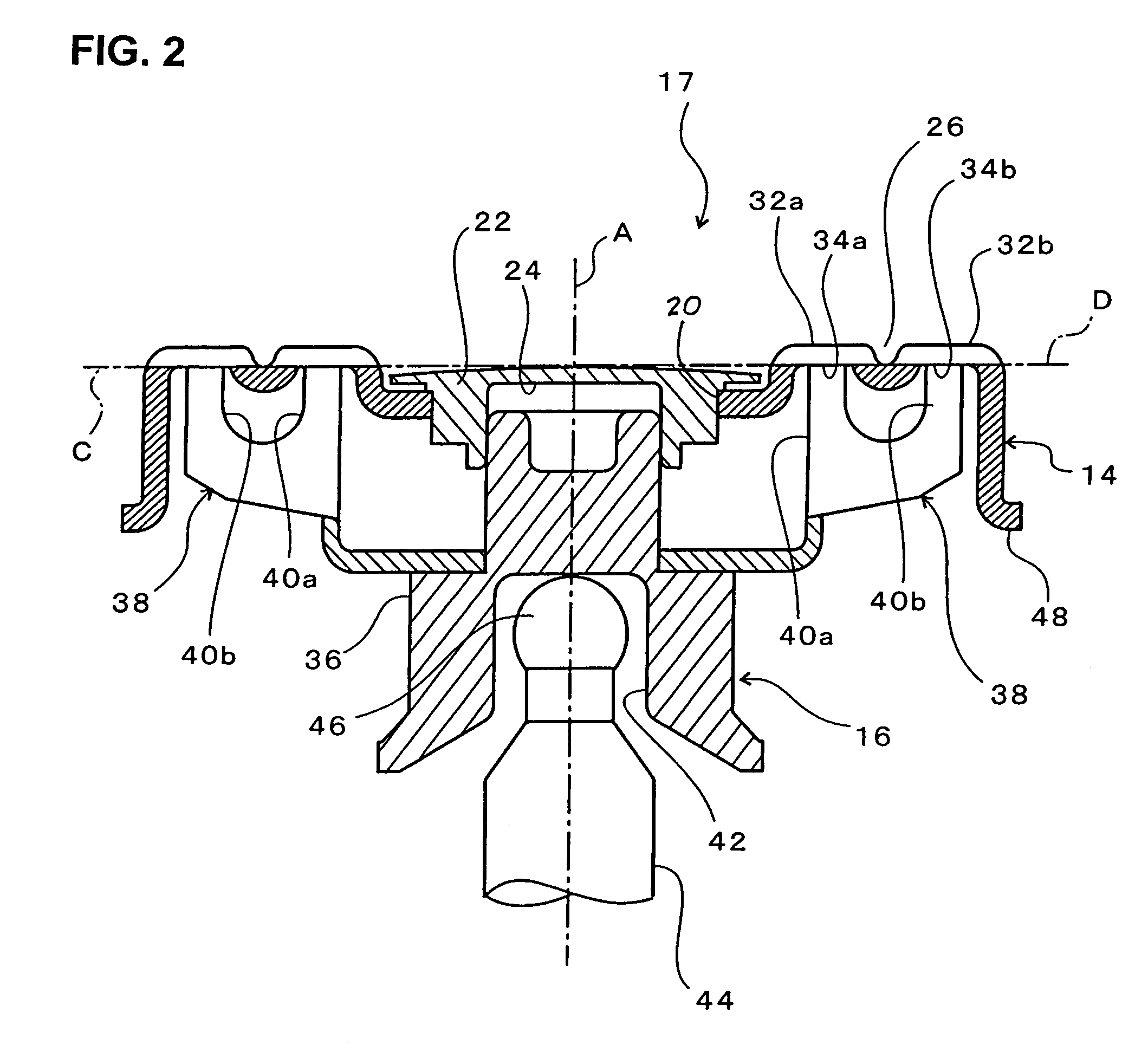

Rotary type electric shaver

InactiveUS7356929B2Sharp and clean shavingContributes to the shaver's sharp and clean shaving capabilitiesRod connectionsMetal working apparatusAcute angleThin layer

A rotary shaver including an outer cutter frame (18) provided on a shaver main body (10), an outer cutter (14) that is installed in this outer cutter frame (18) and has ring-shaped thin layer portions (28a, 28b) whose upper surfaces are the shaving surfaces, and an inner cutter (16) that has cutter bodies (38) that rotates and make sliding contact with the lower surface of the thin layer portions of the outer cutter to cut hair that entered hair introduction openings (30a, 30b) formed in the thin layer portions; wherein the hair introduction openings have a slit shape extending in substantially the radial direction of the thin layer portions, and the cutting edge angle (p, q) at the lower end(s) of the side wall surface(s) of the hair introduction openings (30a, 30b) defined by the ribs (32a, 32b) is an acute angle.

Owner:IZUMI PROD CO

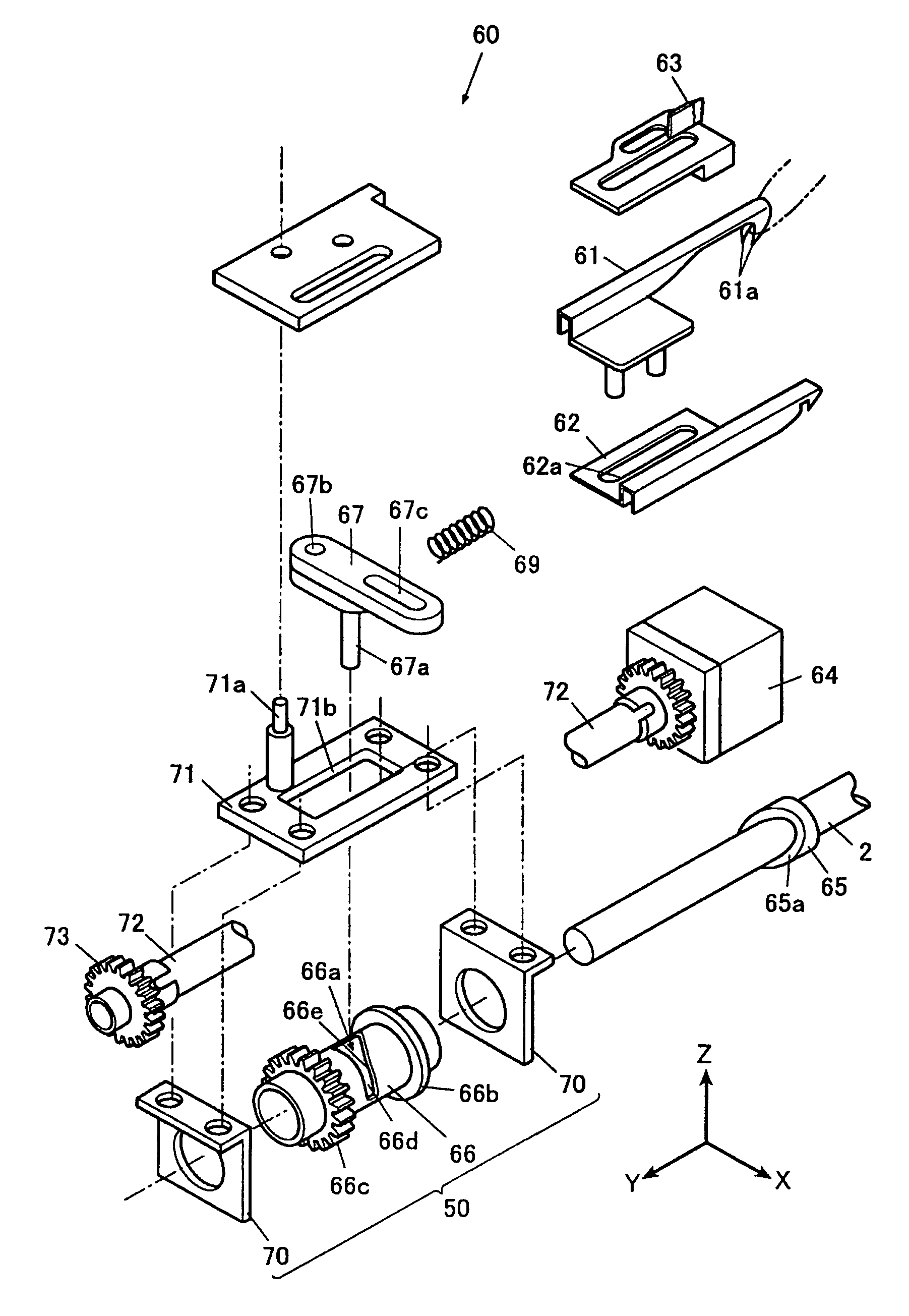

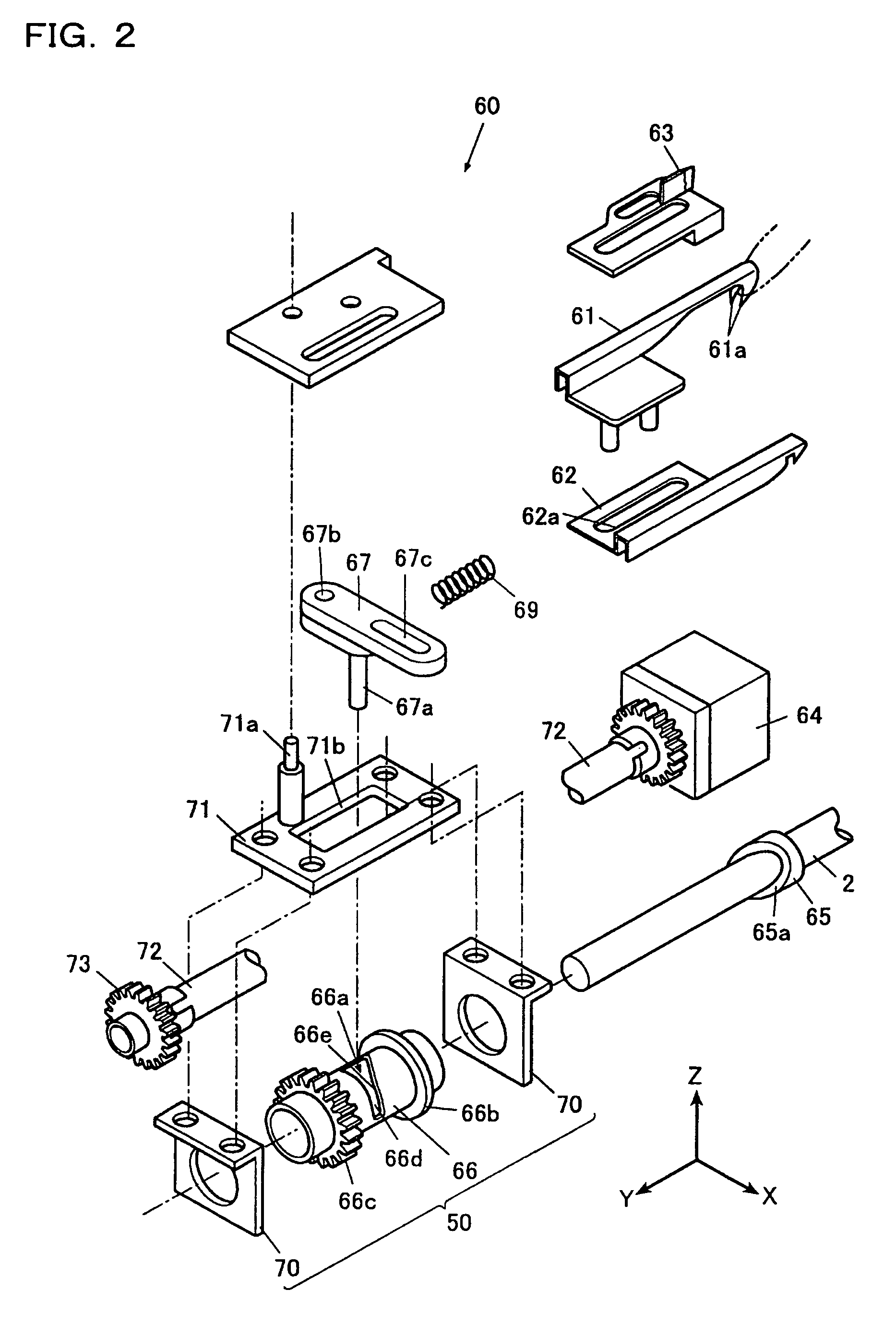

Thread cutting device of sewing machine

InactiveUS7603957B2Smoothly catchCut evenlyNeedle severing devicesSewing-machine control devicesBobbinEngineering

A thread cutting device includes a thread catching member having a catching portion, wherein the thread catching member moves back and forth across a path of a lower thread reeled out from a bobbin so as to catch the lower thread by the catching portion and cuts the lower thread by cooperating with a fixed knife, a first power transmitting portion which transmits a power to the thread catching member, a first cam member provided on a lower shaft rotated by a sewing machine motor and transmits a first moving force to the thread catching member through the first power transmitting portion, a second power transmitting portion which transmits a second moving force from a stepping motor to the thread catching member through the first power transmitting portion.

Owner:JUKI CORP

Bread cutting and forming apparatus

InactiveCN1771815AQuick squeezeQuick cutDough shaping and cutting apparatusReduction driveEngineering

The bread cutting and forming apparatus includes one frame, cutting machine, forming machine and control circuit. It features the cutting machine including auger compartment, detachable material bin, motor, reducer, two augers set inside the auger compartment and connected to the reducer and two layer cutting sleeve; and the forming machine including three-layer reciprocating horizontal conveyer belts, driving motor, reducer, reducing kneading channel of semi-circular cross section in the top of the upper layer conveyer belt, reducing vertical kneading channel in the middle layer conveyer belt, pressing channel comprising one pair of rolls to connect the middle layer conveyer belt and the low layer conveyer belt, and spring support damping plate in the top of the lower layer conveyer belt. The bread cutting and forming apparatus can produce unbaked bread in regular shape.

Owner:THE QUARTERMASTER EQUIPMENT RESEARCH INSTITUTE OF THE GENERAL LOGISITIC DEPARTME

Method and Device of Male Circumcision and Suture

ActiveUS20180055528A1Secure retentionCut evenlySuture equipmentsSurgical staplesAnnular cutterEngineering

A male circumcision and suture device includes a glans receiver socket including a glans socket for inserting into an excess foreskin of a patient and a socket shaft extended from the glans socket, an operation housing having a shaft channel extended from a front edge, an annular cutter coaxially coupled at the front edge of the operation housing, a plurality of staples spacedly disposed at the front edge of the operation housing, and two operation handles pivotally coupled at the operation housing to actuate the annular cutter and the staples at the same time. When the operation handles to are concurrently and pivotally actuated, the annular cutter is pushed out of the front edge of the operation housing for removing the excess foreskin of the patient and at the same time, the staples are pushed for applying stitches at a cut area of the excess foreskin of the patient.

Owner:WENG XIAOFENG +2

Fire extinguishing pipe cutting device for firefighting

The invention relates to a cutting device, in particular to a fire extinguishing pipe cutting device for firefighting. The fire extinguishing pipe cutting device for firefighting aims at achieving thetechnical effects that a fire extinguishing pipe does not need to be manually cut, time and labor are saved and length and pipe orifice cutting of the fire extinguishing pipe is uniform. According tothe technical scheme, the fire extinguishing pipe cutting device for firefighting comprises a bottom plate, a left support, a top plate, supporting rods, a placing table, a first supporting rod, a rotating shaft and the like; and the left support is fixedly connected to the left portion of the upper side of the bottom plate, the top plate is fixedly connected to the upper portion of the right side of the left support, the two supporting rods are fixedly connected to the left portion of the upper side of the bottom plate, the two supporting rods are arranged left and right, and the supportingrods are both located on the right of the left support. The effects that the fire extinguishing pipe does not need to be manually cut, time and labor are saved and length and pipe orifice cutting of the fire extinguishing pipe is uniform are achieved, the position of the fire extinguishing pipe can be better fixed through the arrangement of a third sliding rail, a third sliding block, a buffer plate and a fourth spring, and cutting of the fire extinguishing pipe is more uniform.

Owner:淮安市淮安区综合检验检测中心

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com