Milling method of high-precision suspended web

A high-precision, web technology, applied in milling machine equipment, milling machine equipment details, metal processing equipment, etc., can solve problems such as low efficiency, large deformation, poor surface quality, etc., achieve high efficiency, reduce cutting force, and reduce cutting residue volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

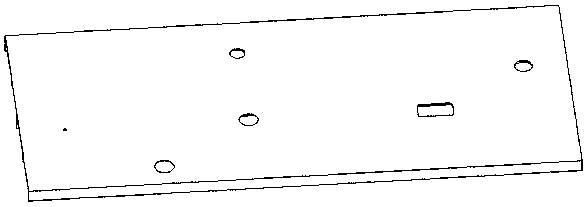

[0030] A milling method of a high-precision suspended web according to the present invention, the first step: rough milling the smooth surface of the part, leaving a process margin of 3~4mm, and using a milling cutter with a diameter of ≥30mm.

[0031] Step 2: Roughly mill the frame surface of the part, set the supporting process boss 2 in the center of the cavity 1 of the frame surface, the height of the supporting process boss 2 is the same as the height of the positioning rib edge, and leave a process margin of 3~ for the rest of the frame surface of the part 4mm.

[0032] Step 3: Repair the reference without stress, with the smooth surface of the part facing down, use gaskets to cover the gap caused by the deformation of the part, then press the part, mill the positioning rib and the top surface of the supporting process boss 2 to form a positioning reference noodle.

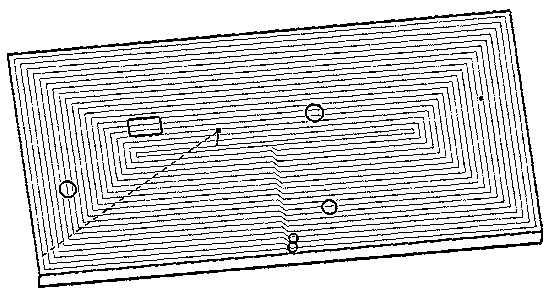

[0033] Step 4: Semi-finish milling smooth web, milling to remove the process allowance of the web part. ...

Embodiment 2

[0044]The present invention proposes a setting method for supporting process bosses 2 suitable for large-scale high-precision suspended web processing. The numerical control processing process is divided into rough milling smooth surface, rough milling frame surface, stress-free repair reference, and semi-finish milling smooth web , fine milling smooth web, rough milling frame surface process boss, fine milling frame surface and other stages, the specific implementation content and precautions are as follows:

[0045] 1) Rough milling smooth surface

[0046] There is a process allowance of 3~4mm, and the processing tool D≥32.

[0047] 2) Rough milling frame surface

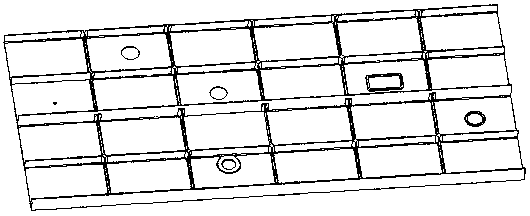

[0048] The support process boss 2 and the process allowance 3 are left. After the part is turned over, the support process boss 2 participates in the positioning, and the processing effect of the frame surface is as follows: Figure 4 shown. According to the large size and weak rigid structure characteristics o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com