Bread cutting and forming apparatus

A molding device and bread technology, which is applied to dough molding and cutting equipment and other directions, can solve the problems of unsuitable continuous production operations, irregular shape of bread blanks, and large equipment occupied space, etc., and achieves wide application range, uniform weight, and reduced The effect of weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to clearly illustrate the structure and achieved effects of the present invention, the embodiments of the present invention will be described in detail with reference to the accompanying drawings.

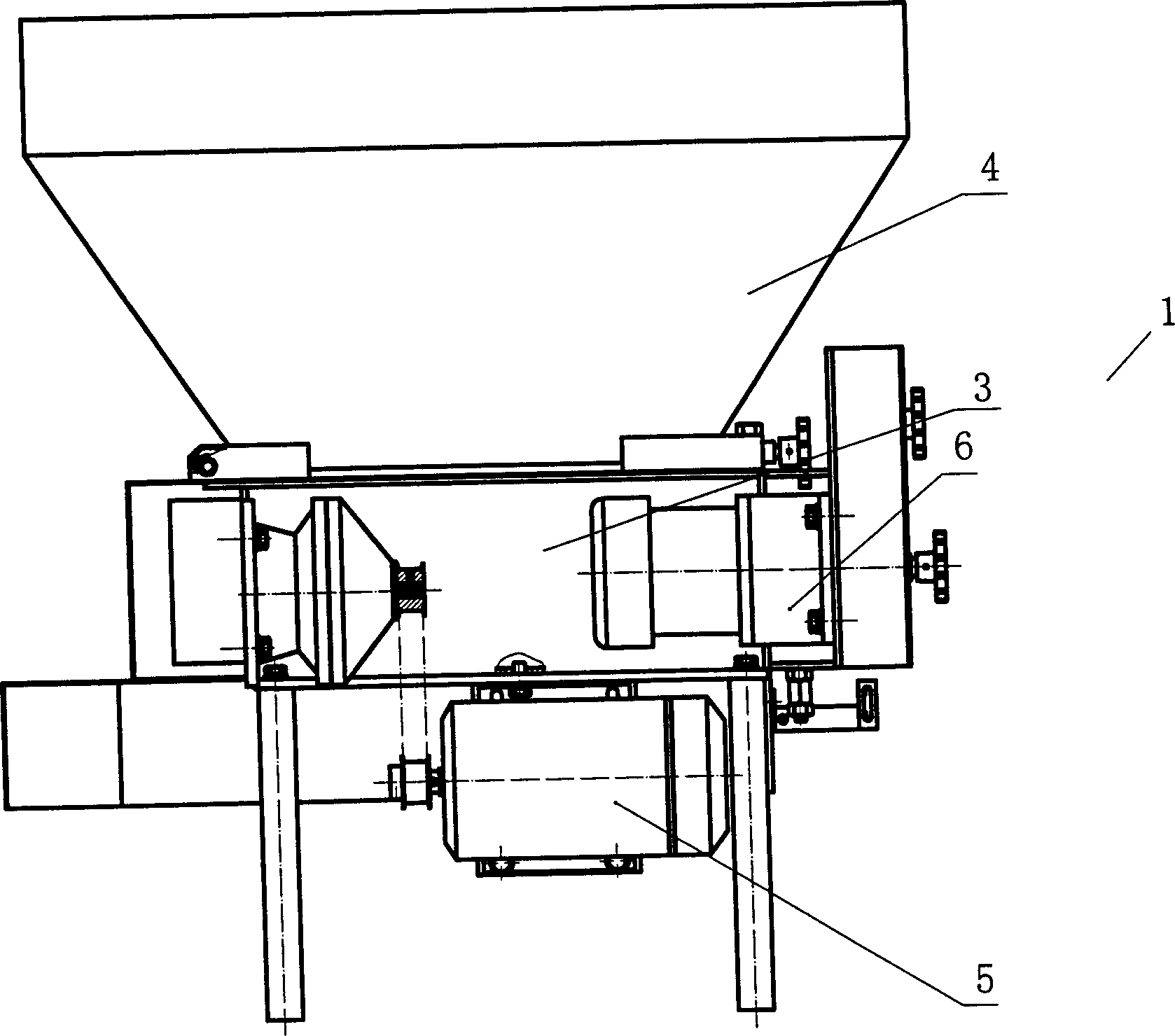

[0018] Such as figure 1 , Figure 5 As shown, the present invention includes a cutting machine 1, a forming machine 2 and a control circuit arranged on a frame.

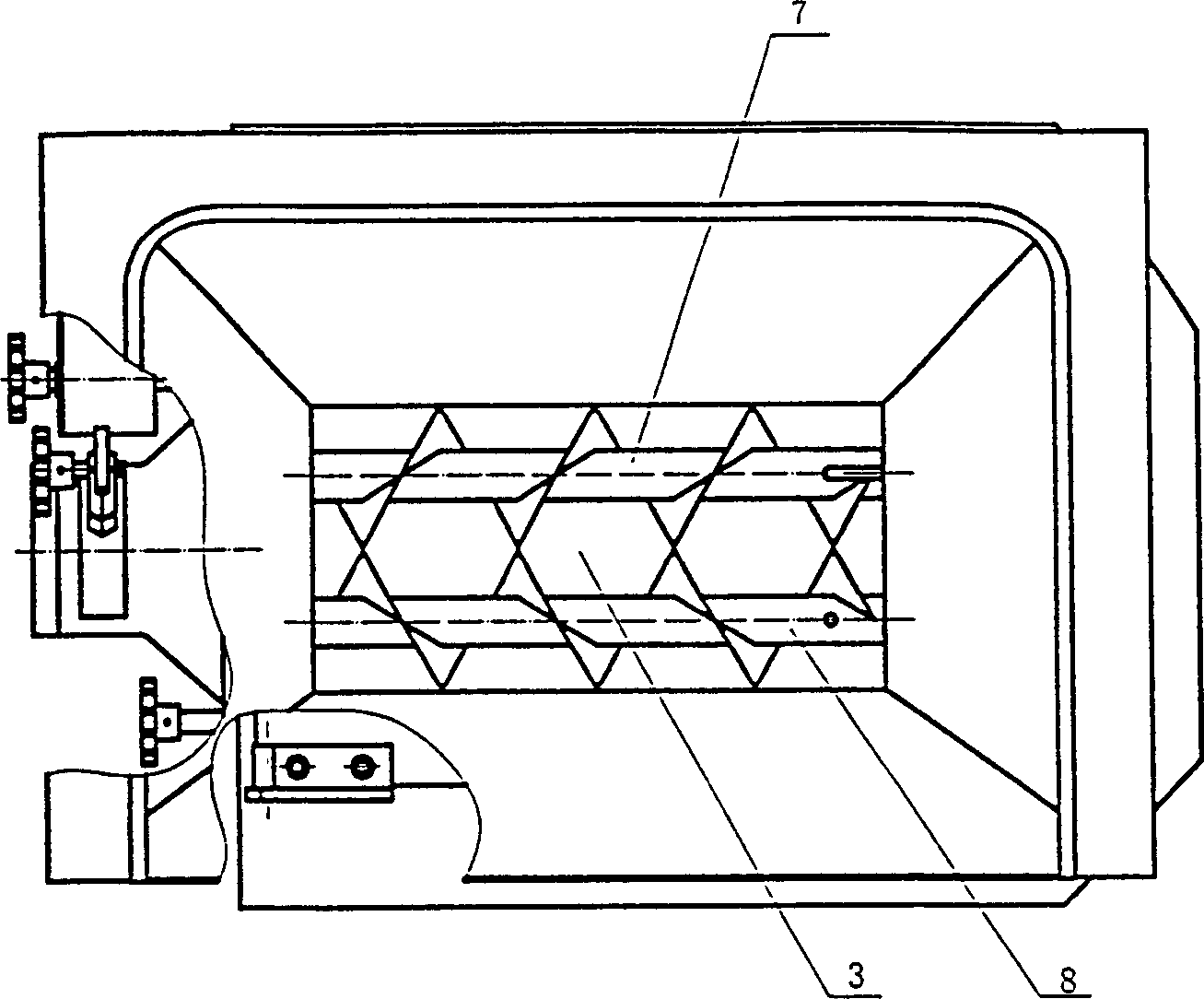

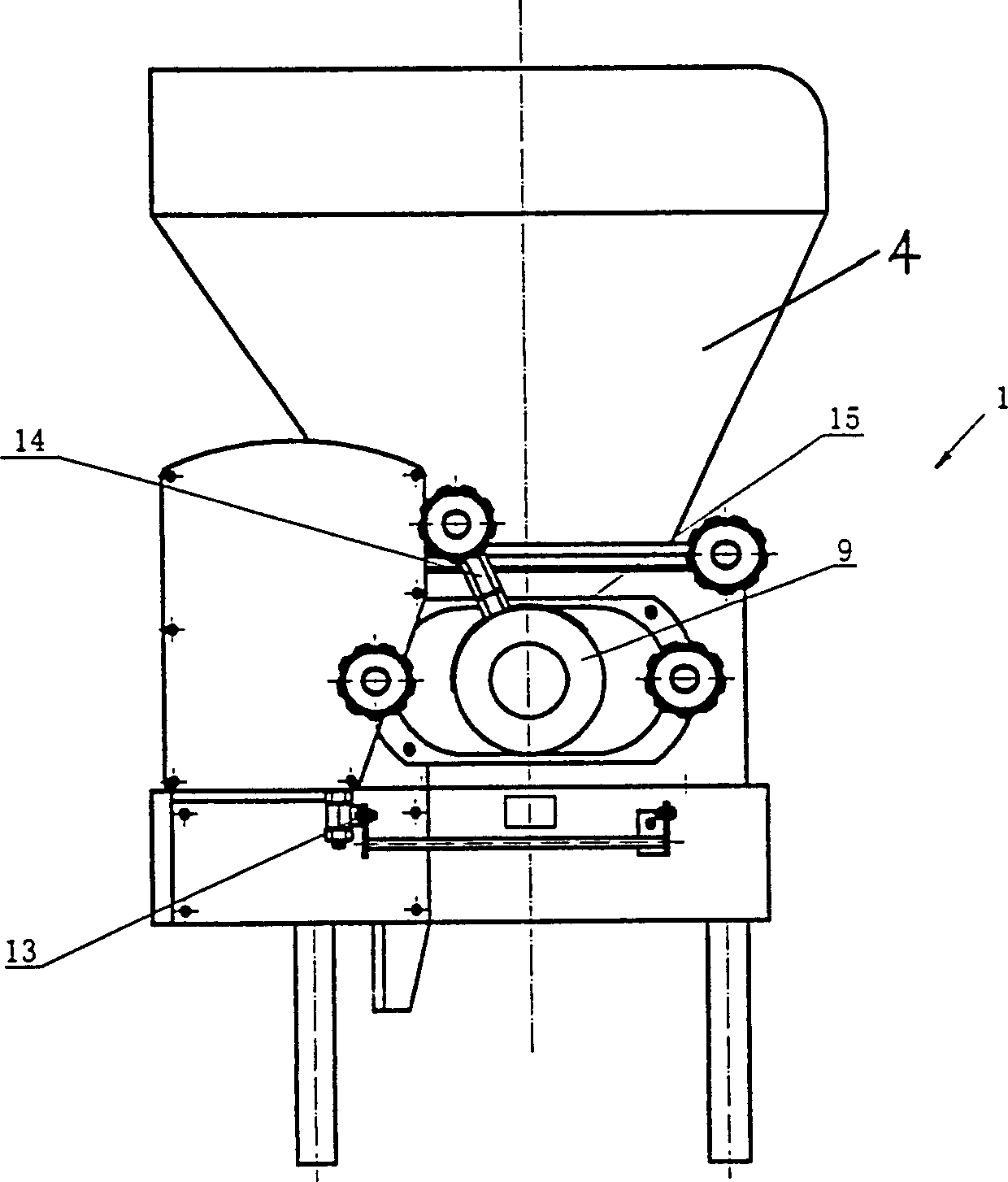

[0019] Such as Figure 1~3 As shown in Figure 7, the cutting machine 1 includes an auger chamber 3, a detachable hopper 4 connected to the entrance of the auger chamber 3, a motor 5 arranged on the frame, a reducer 6 connected to the motor 5, and a motor 5 connected to the auger chamber. The equidistant double augers 7,8 connected to the speed reducer 6 in the 3 are installed in the auger bin 3 outlets, and the cutting sleeves are composed of inner and outer cylinders 9,10. A window 11, 12 is arranged correspondingly at the bottom of the circumference of the inner and outer cylinders 9, 10, and a photoe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com