Patents

Literature

231results about How to "Quick squeeze" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

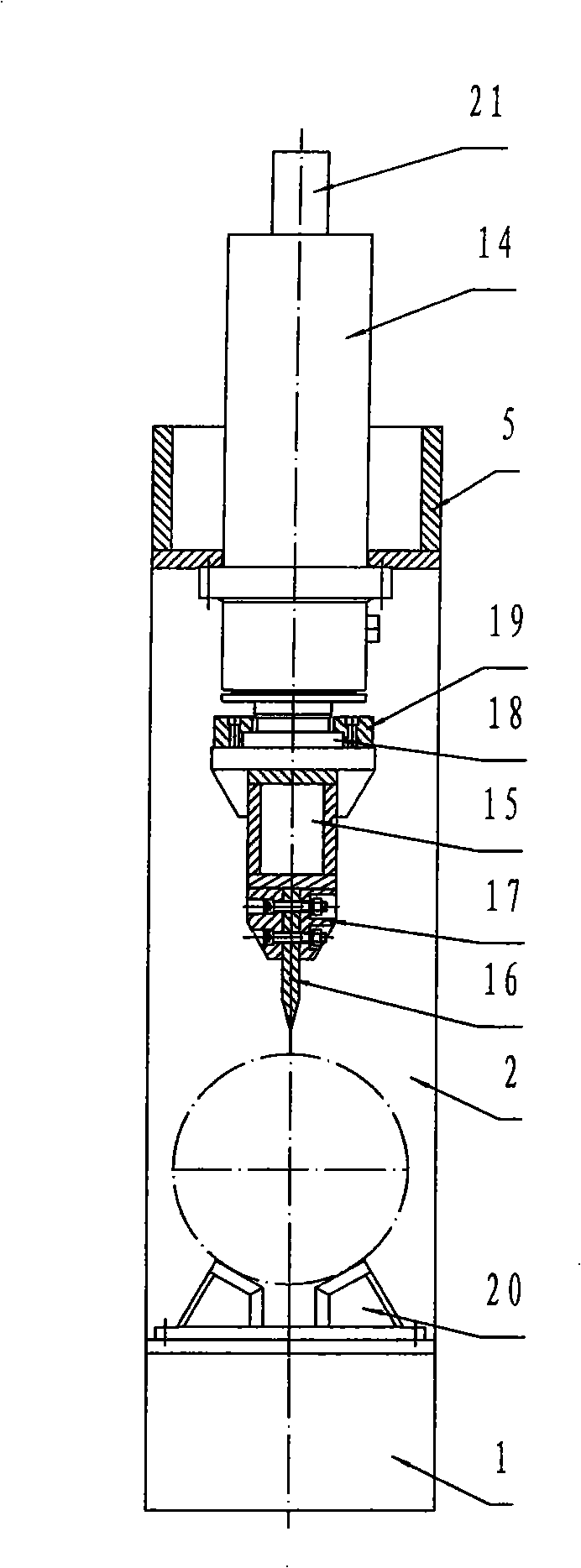

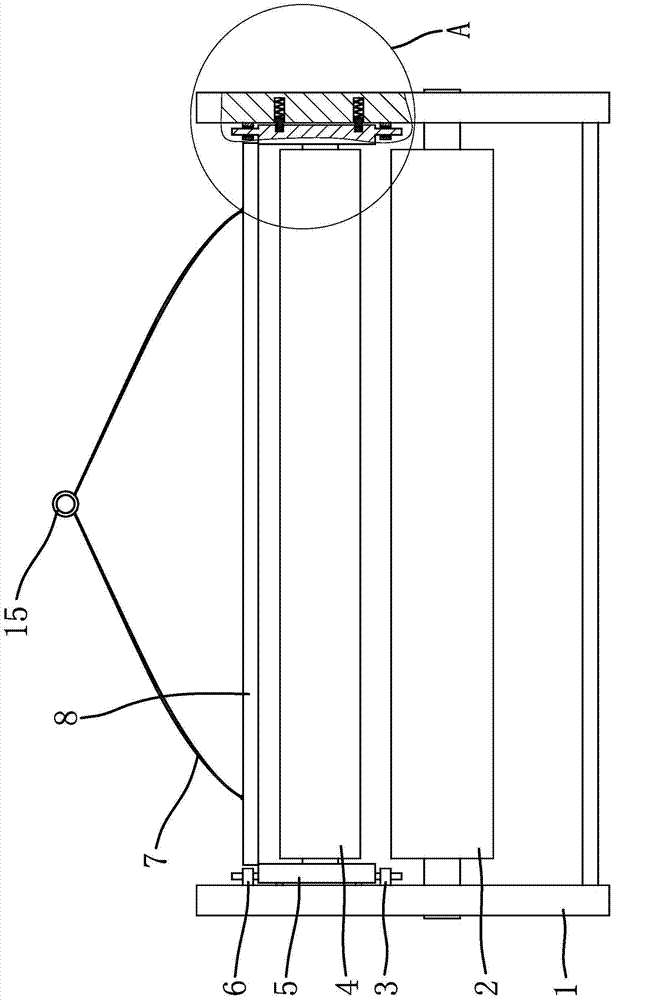

Pop-top can flattening equipment

The invention discloses pop-top can flattening equipment. The pop-top can flattening equipment comprises a fixing seat and is characterized in that an extrusion cylinder penetrating up and down is arranged at the upper end of the fixing seat, a feeding channel for placing a zip-top can is arranged on one side of the upper end of the extrusion cylinder, the front end of the feeding channel is provided with a turnover plate capable of turning the zip-top can into the extrusion cylinder through an inserting shaft, an extrusion device capable of extruding the extrusion cylinder is arranged at theupper end of the extrusion cylinder, a sealing device capable of sealing the lower end of the extrusion cylinder is arranged at the lower end of the extrusion cylinder, the fixing seat is provided with the extrusion device which can drive the turnover plate to rotate to turn the pop-top can into the extrusion cylinder and then drive the extrusion device after the zip-top can in the extrusion cylinder is extruded, and the sealing device is driven to open the driving device enabling a zip-top ring in the extrusion cylinder to fall out. The pop-top can flattening equipment is simple in structureand convenient to use.

Owner:GUANGDONG KNOWLEDGE CITY OPERATION SERVICES CO LTD

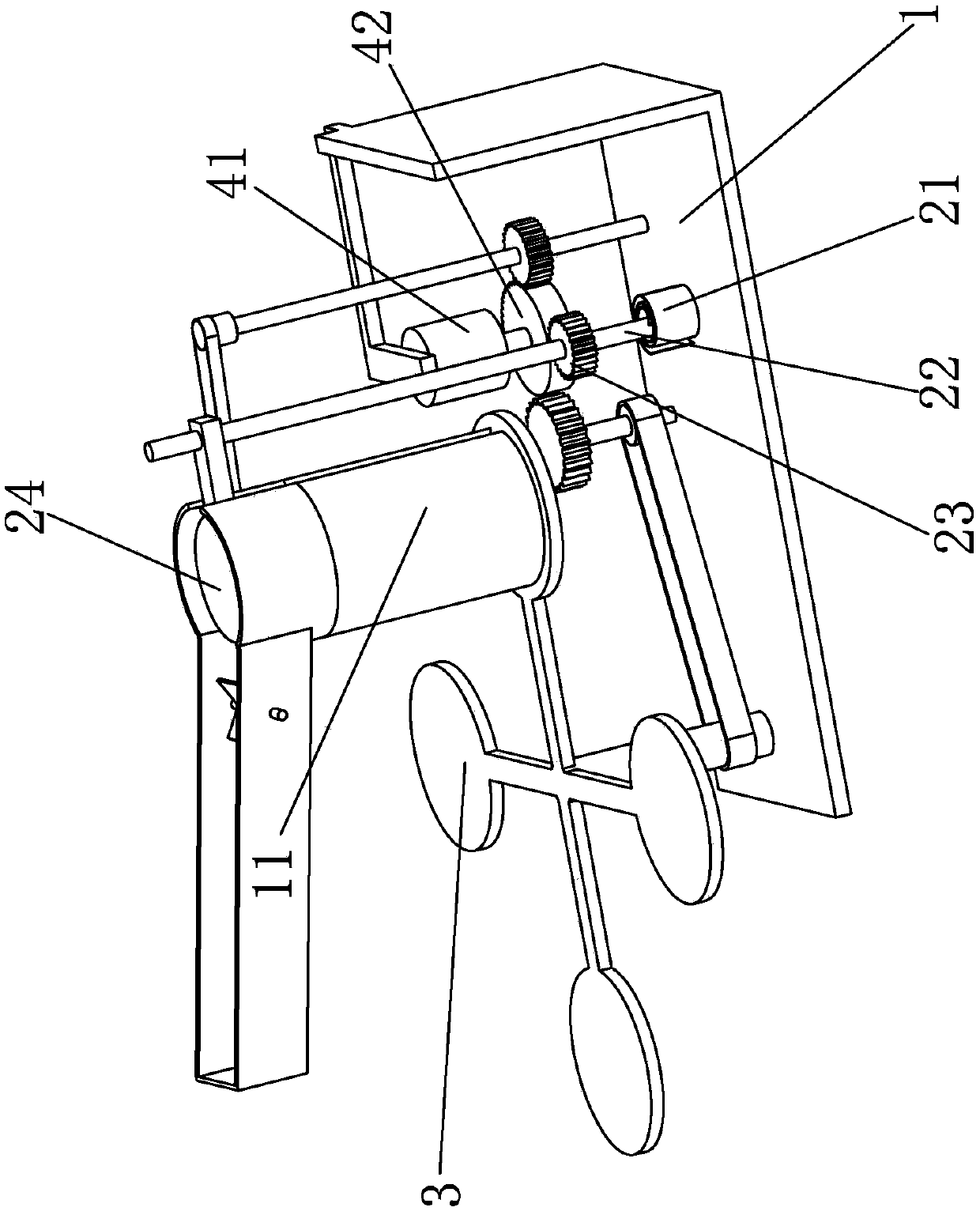

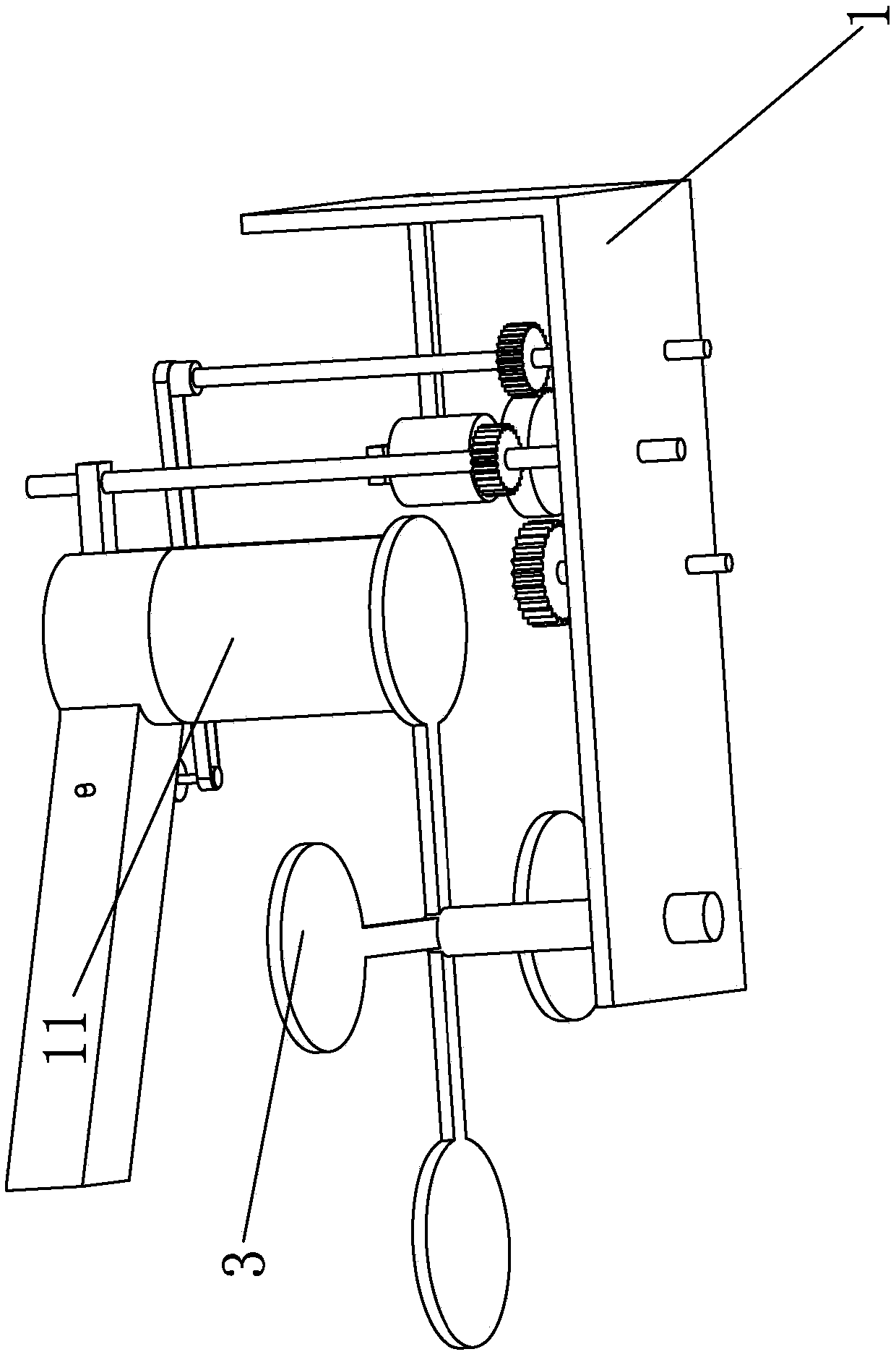

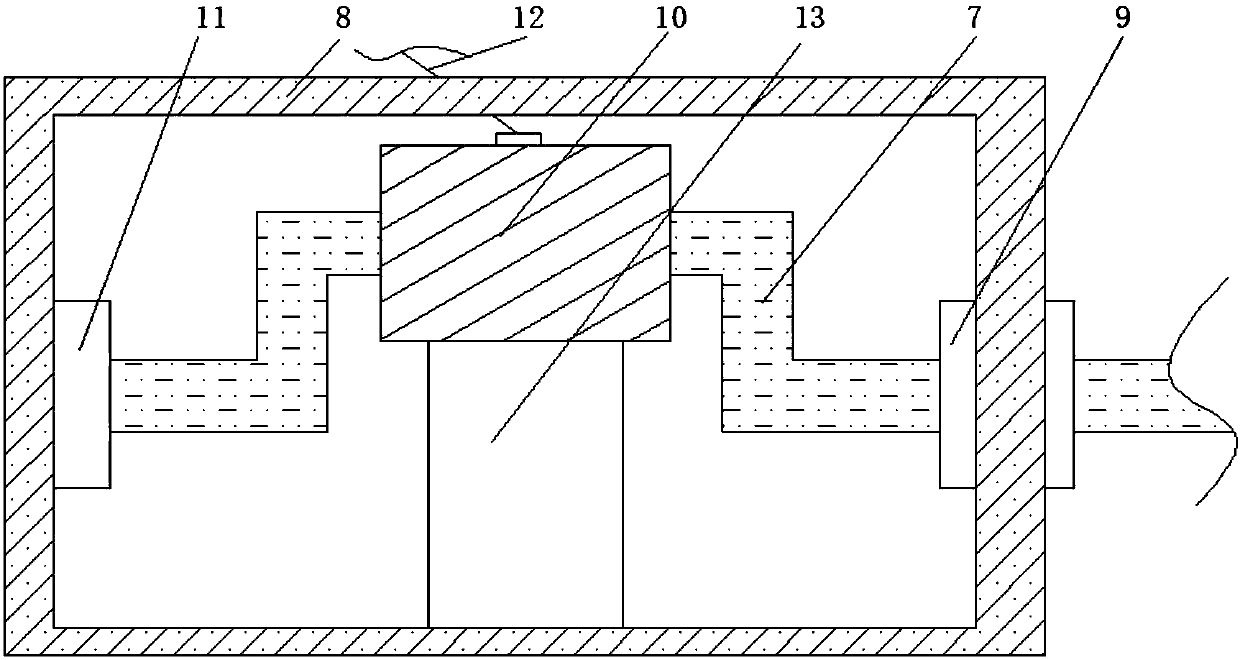

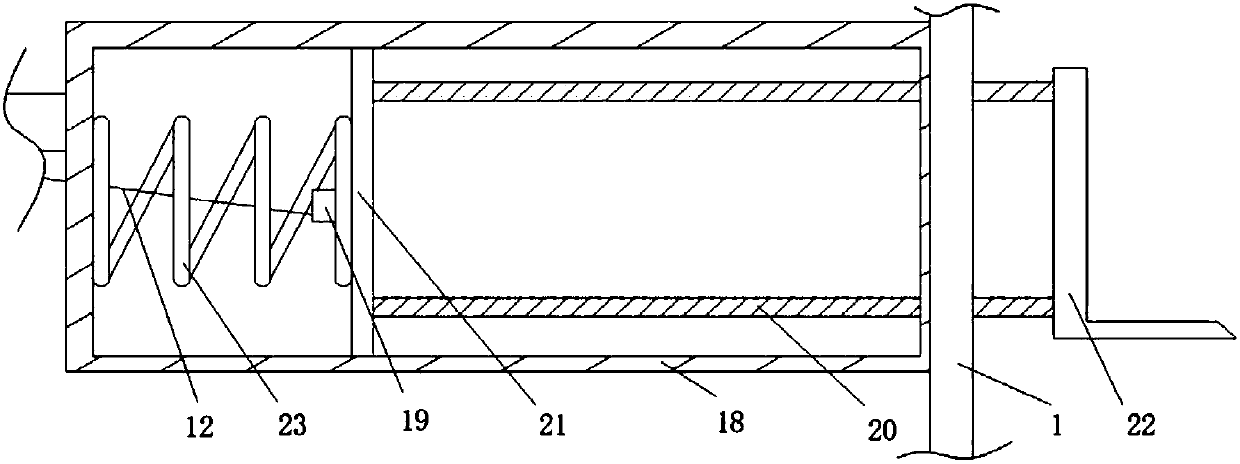

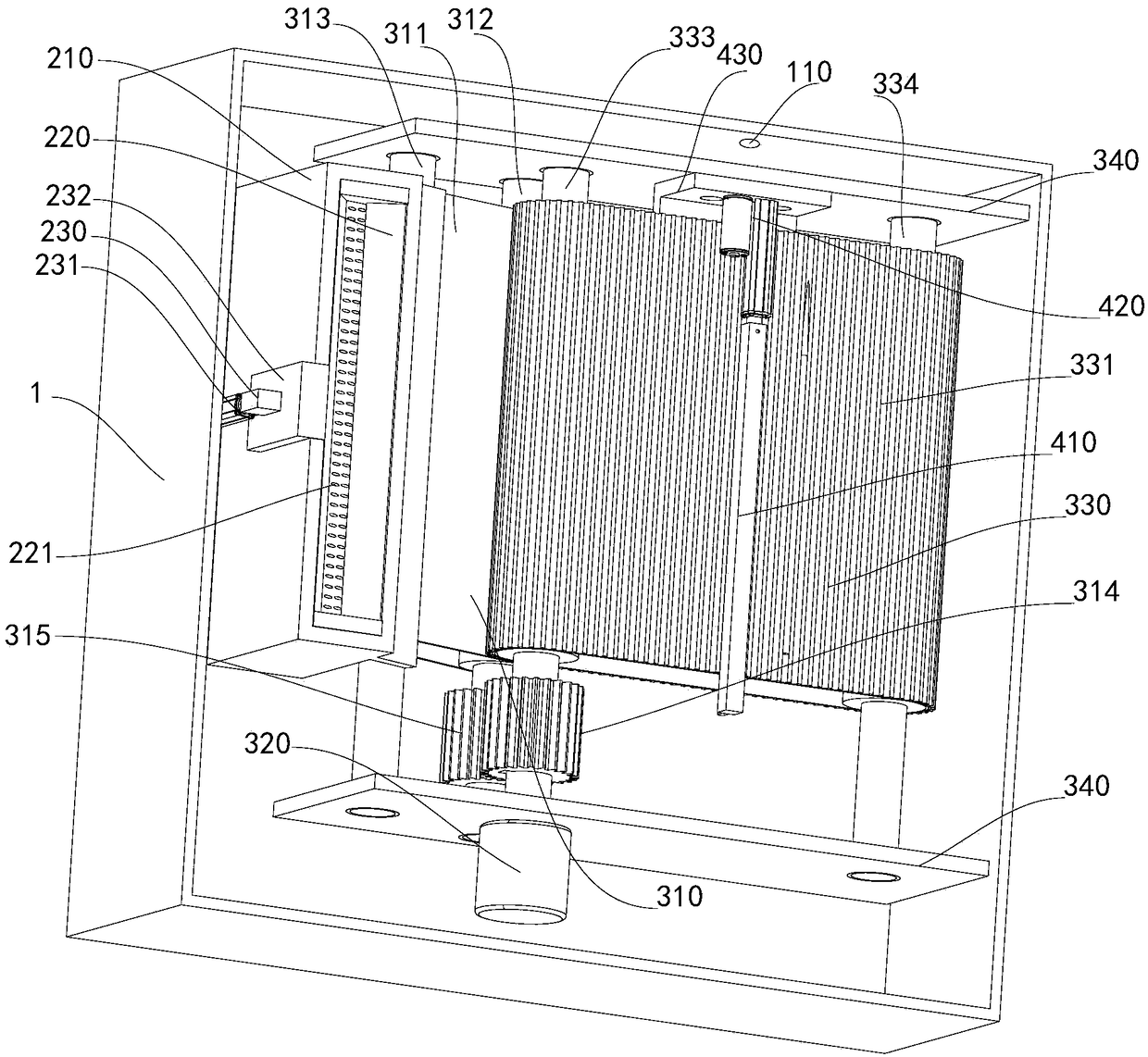

Solid-liquid separating device for garbage treatment

InactiveCN107694173AQuick squeezeEasy dischargeStationary filtering element filtersEngineeringBearing surface

The invention relates to the technical field of garbage treatment equipment, and discloses a solid-liquid separation device for garbage treatment, which includes a body, a motor is fixedly connected to the top of the body, and a first gear is fixedly connected to the output end of the motor. The second gear meshes, and the inner wall of the second gear is fixedly connected with a rotating rod. One end of the rotating rod passes through the first bearing and the rotating sleeve in turn and is fixedly connected with the inner wall of the second bearing. The surface of the second bearing is fixedly connected to one side of the chassis. The inner wall of the casing is fixedly connected to the top of the body, the surface of the rotating sleeve is fixedly connected with one end of the wire rope through a connecting block, and the surface of the rotating sleeve is fixedly connected with a push rod. Through the cooperation of the motor and the rotating sleeve, the mixed garbage can be squeezed quickly, and then the liquid in the garbage can be quickly discharged through the cooperation of the first filter, which can effectively improve the effect of separating mixed garbage. Prevent gravity blocks from drifting.

Owner:赵顺豪

Injection positioning device for endocrine clinic

ActiveCN108325028AAdjust the clamping effectQuick squeezeInfusion syringesIntravenous devicesMechanical engineering

Owner:苏清燕

High-speed extrusion high-strength deforming magnesium alloy and preparation method thereof

The invention discloses a high-speed extrusion high-strength deforming magnesium alloy and a preparation method thereof. The provided magnesium alloy is subjected to high-speed extrusion under the condition of a high extrusion ratio, i.e. the extrusion speed can be more than 25 m / min under the conditions that the extrusion ratio is not less than 30 and the profile size is complicated, thus mainly solving the problem of greatly increased manufacturing cost due to low post-machining deformation rate of the high-strength magnesium alloy. The magnesium alloy finally obtained through extrusion has very high mechanical properties, and is applicable to blanks and the like for 3C (computer, communication, consumer electronics) product shells, leisure product bearing structures and aerospace components. The preparation process of the material is simple and low in cost, and has favorable industrialization prospects.

Owner:TIANJIN DONGYI MAGNESIUM PROD +1

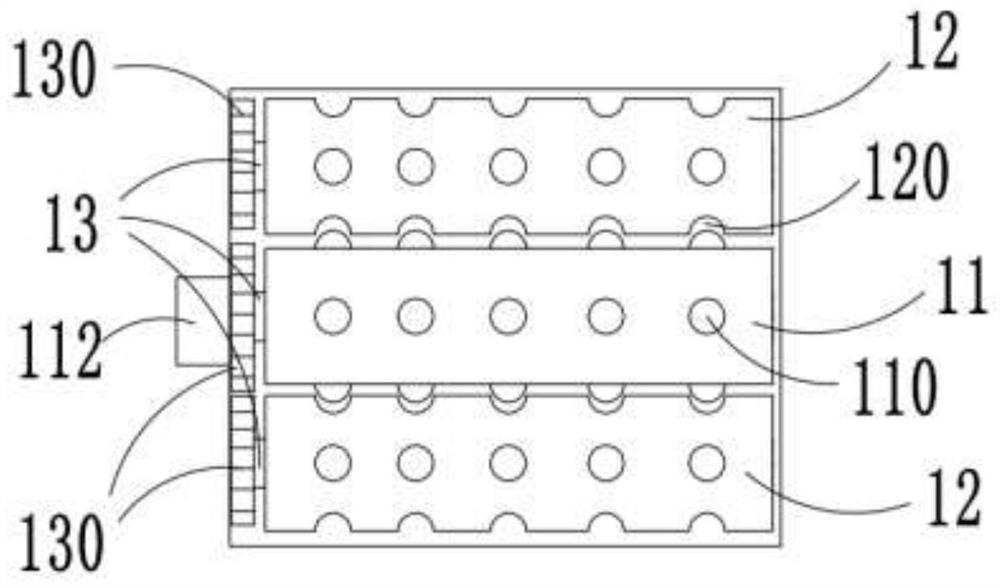

Bread cutting and forming apparatus

InactiveCN1771815AQuick squeezeQuick cutDough shaping and cutting apparatusReduction driveEngineering

The bread cutting and forming apparatus includes one frame, cutting machine, forming machine and control circuit. It features the cutting machine including auger compartment, detachable material bin, motor, reducer, two augers set inside the auger compartment and connected to the reducer and two layer cutting sleeve; and the forming machine including three-layer reciprocating horizontal conveyer belts, driving motor, reducer, reducing kneading channel of semi-circular cross section in the top of the upper layer conveyer belt, reducing vertical kneading channel in the middle layer conveyer belt, pressing channel comprising one pair of rolls to connect the middle layer conveyer belt and the low layer conveyer belt, and spring support damping plate in the top of the lower layer conveyer belt. The bread cutting and forming apparatus can produce unbaked bread in regular shape.

Owner:THE QUARTERMASTER EQUIPMENT RESEARCH INSTITUTE OF THE GENERAL LOGISITIC DEPARTME

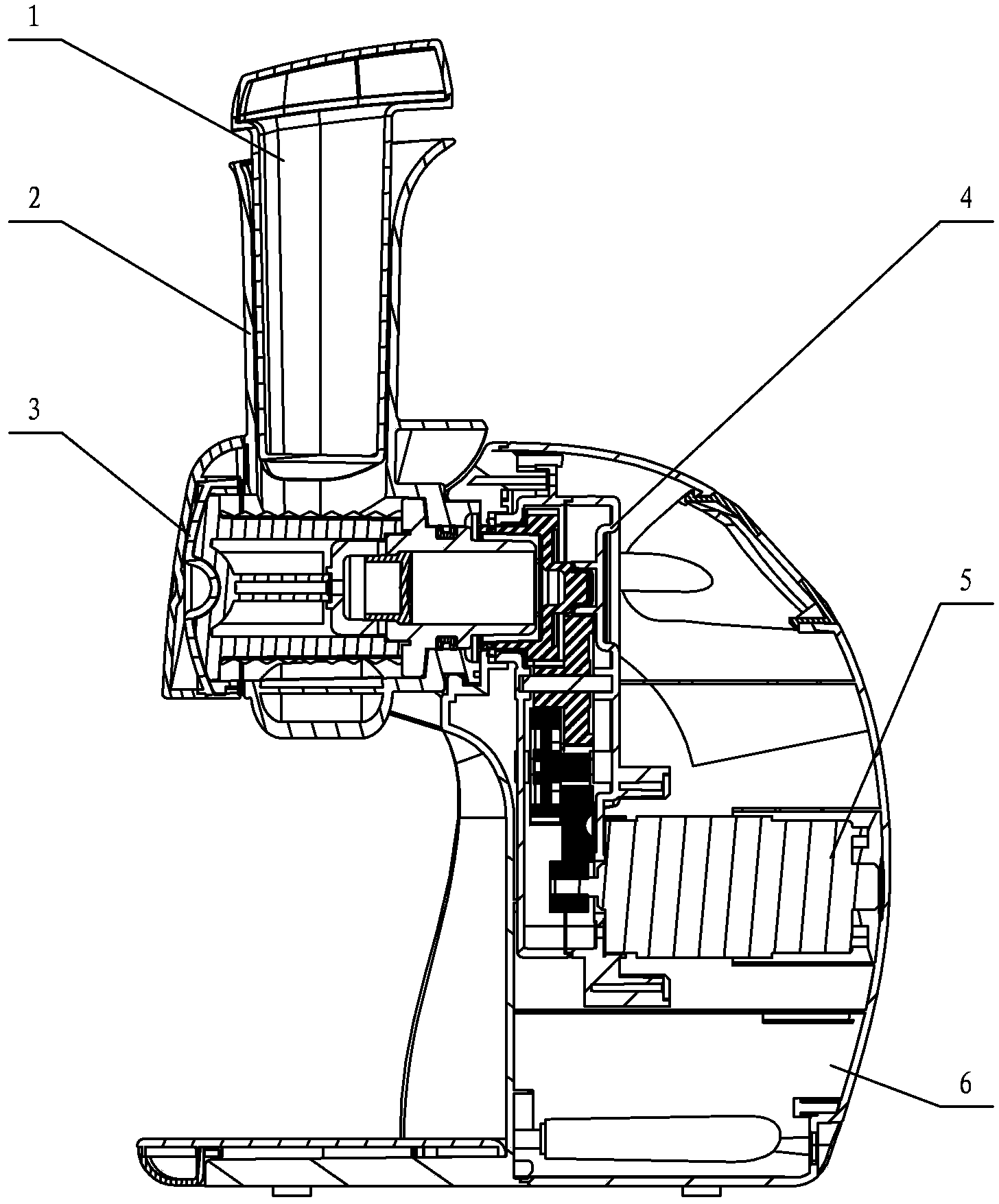

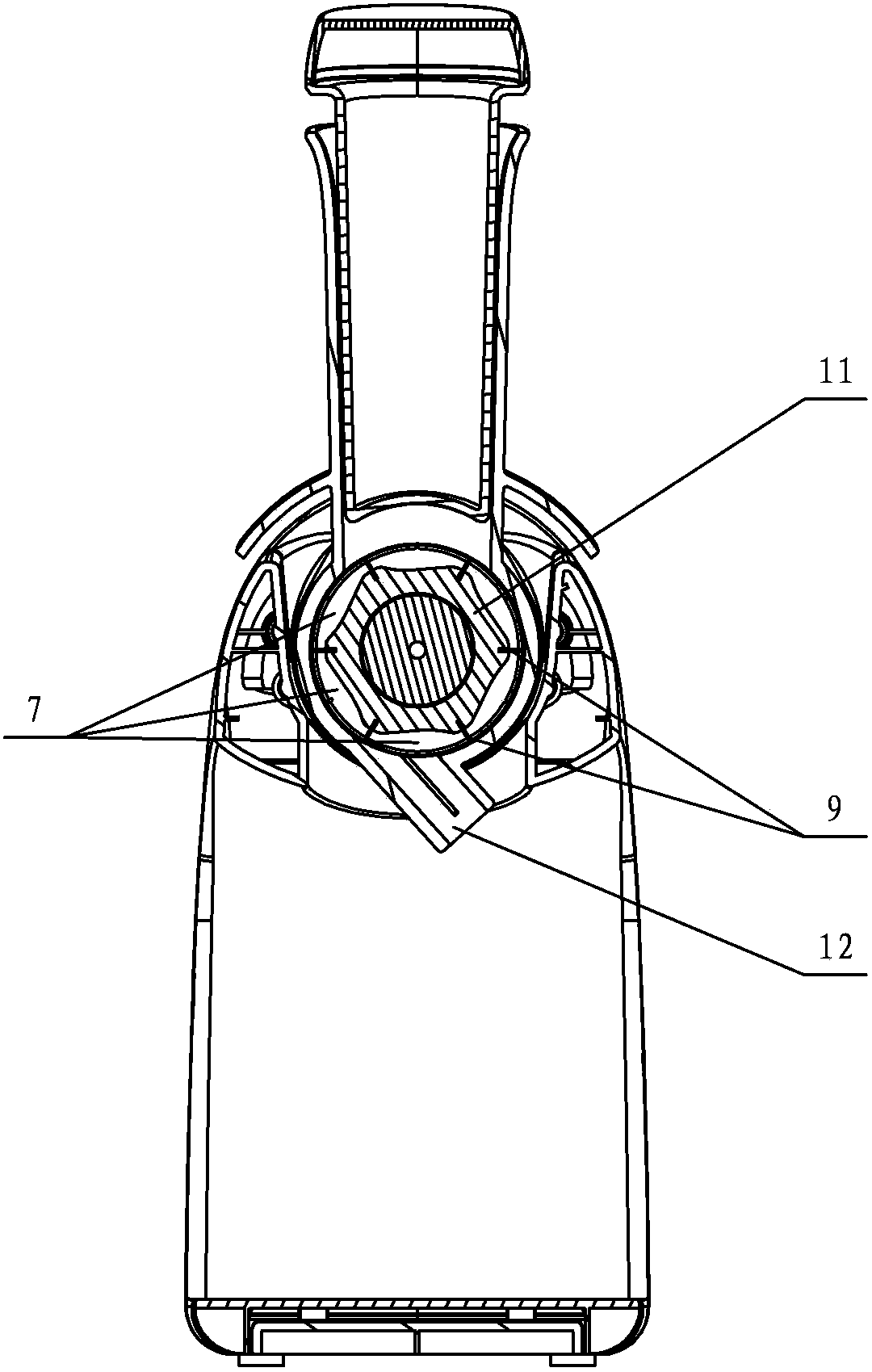

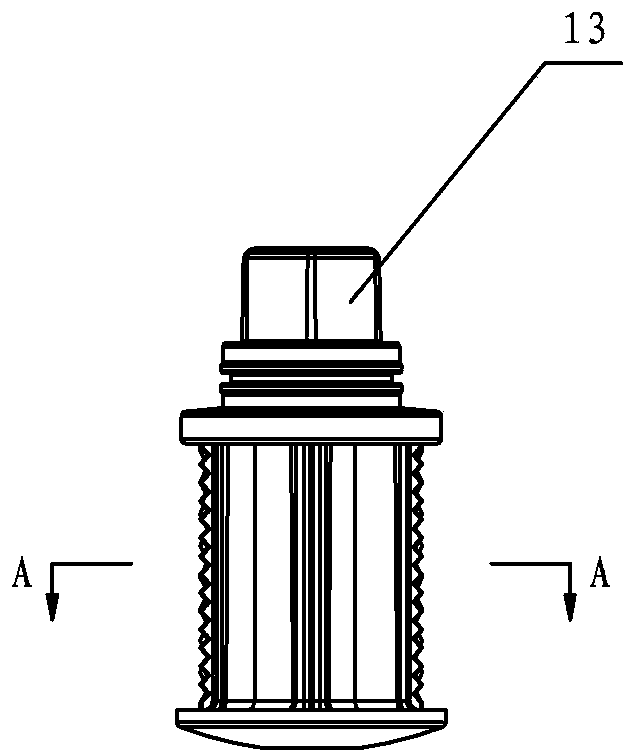

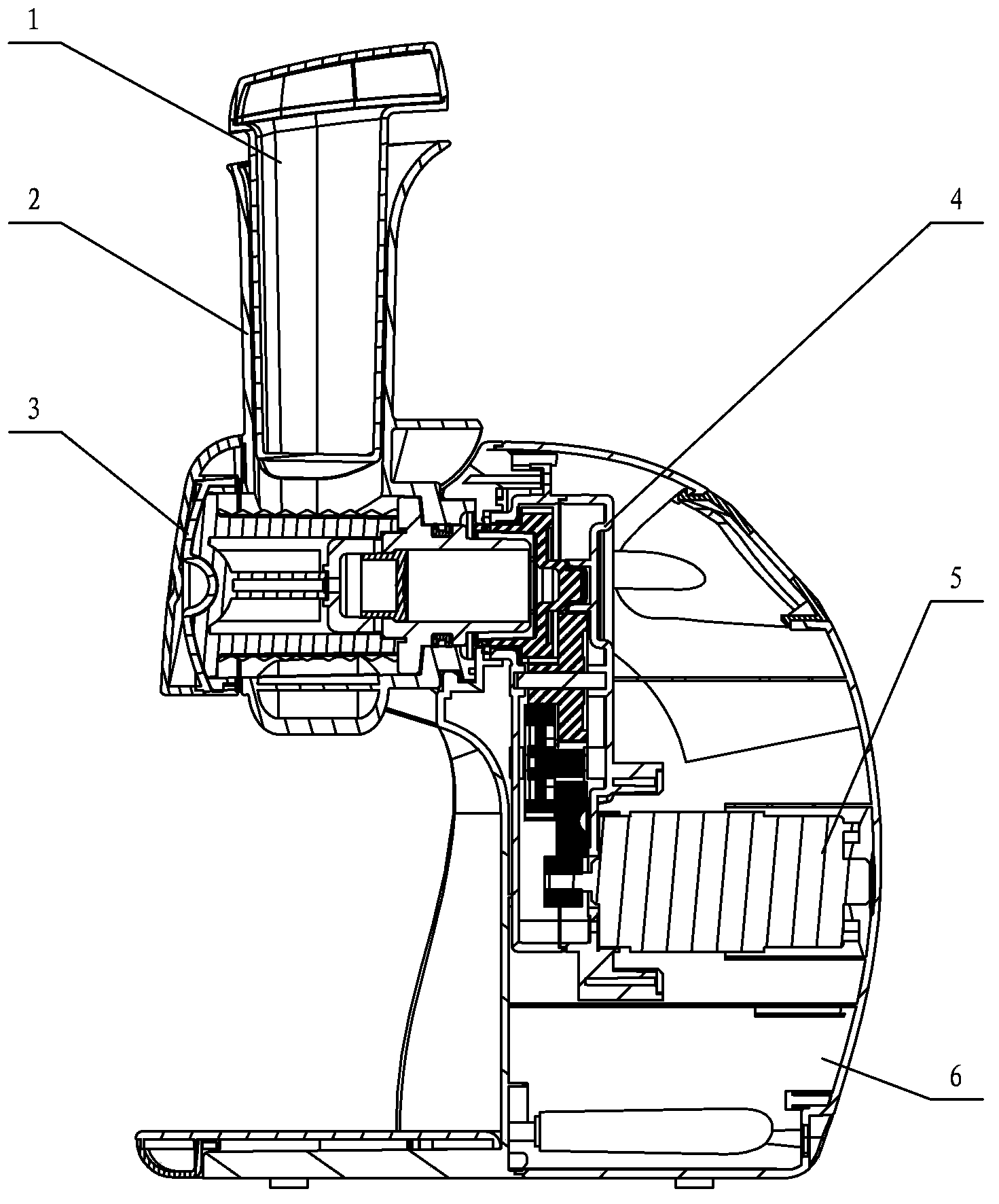

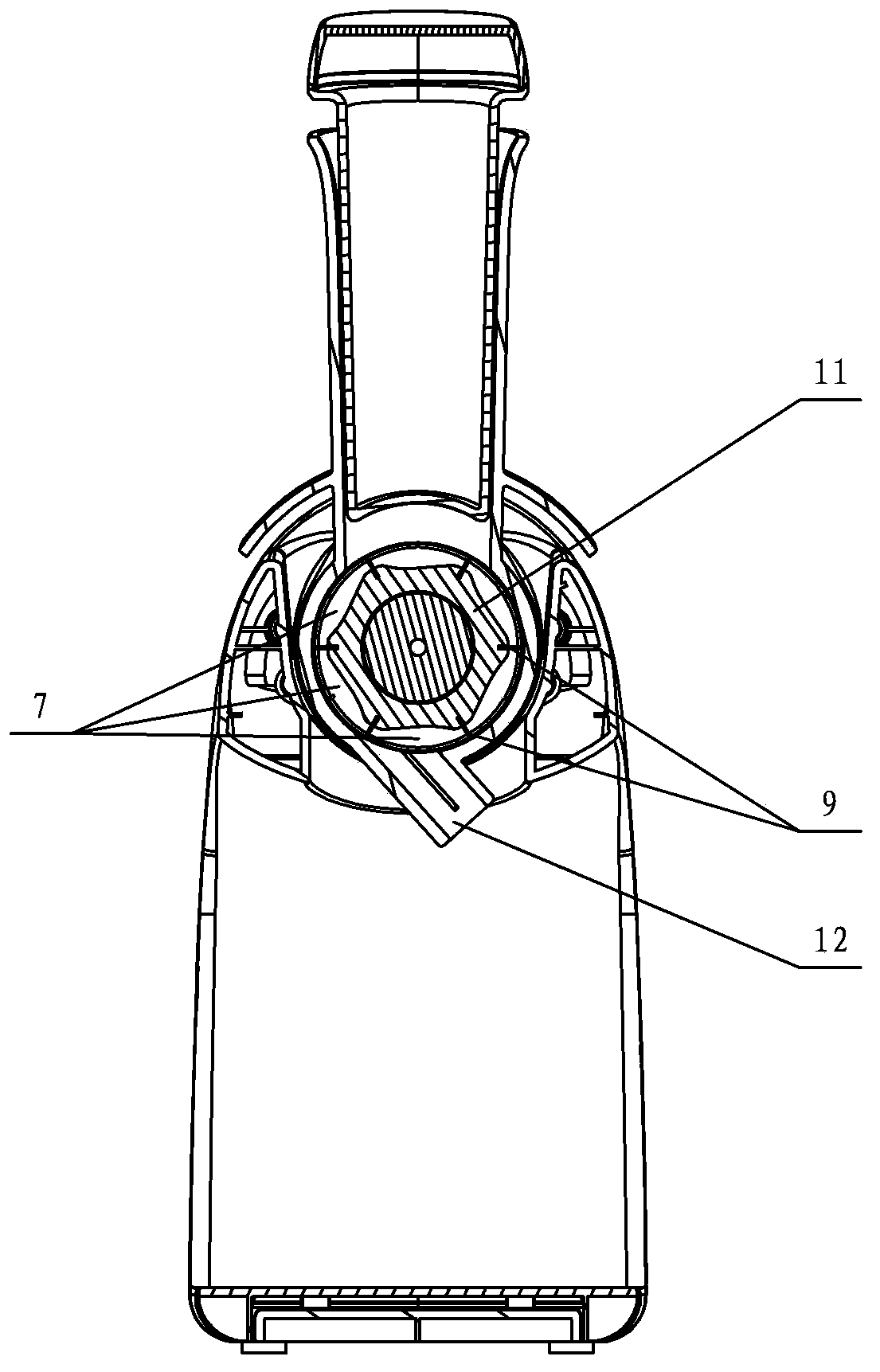

Fruit ice cream machine

A fruit ice cream machine comprises a feeding bin arranged on a machine base, wherein a feeding barrel is communicated with the feeding bin, a stirring cutter is arranged in the feeding bin, a motor arranged in the machine base is connected with a connector of the stirring cutter through a speed reducing mechanism, the stirring cutter comprises a prism-shaped cutter rest, and a stirring blade is embedded into a corner angle of the cutter rest. The cutter rest and the stirring blade divide the feeding bin into more than two stirring cavities. A cross section of the cutter rest is triangular, quadrilateral, pentagonal, hexagonal or polygonal. A press rod is arranged on the feeding barrel. A barrel cover is arranged on the feeding bin. A positioning protrusion is arranged on the barrel cover, a positioning groove is arranged on the cutter seat, the positioning protrusion is inserted into the positioning groove. A discharging port is arranged at the bottom of the feeding bin. The direction of an outlet of the discharging port is opposite to the rotation direction of the stirring cutter. The fruit ice cream machine has the advantages of being simple and reasonable in structure, small in overall size, low in manufacture cost, flexible in operation and high in work efficiency.

Owner:FOSHAN SIXVECTOR DESIGN & CONSULTANT CO LTD

Method of using traditional oil pressing set to produce linseed oil in low temperature

InactiveCN101228905AReduce viscosityIncrease speedEdible oils/fatsLinseed oilComponents of crude oil

The invention discloses a method for producing low temperature pressing linseed oil with the conventional oil press, which comprises the following steps: placing the well selected linseed raw material into a flaker for flaking; placing the linseed embryo into a steam cooker and cooking in a temperature of 40-50 DEG C; and then stir-frying the linseed embryo in a temperature of 58-60 DEG C; putting the well fried embryo material into a common oil press to press for one minute in normal temperature and acquiring low temperature crude oil and oil cake; then repetitively stir-frying and the first pressing to the oil cake to acquire low temperature crude oil and oil cake. The invention is characterized in that adopting the common oil press to press in low temperature can damage less nutrition and produce oil product with high quality and can not destroy other components of linseed.

Owner:SHANDONG LUHUA GROUP

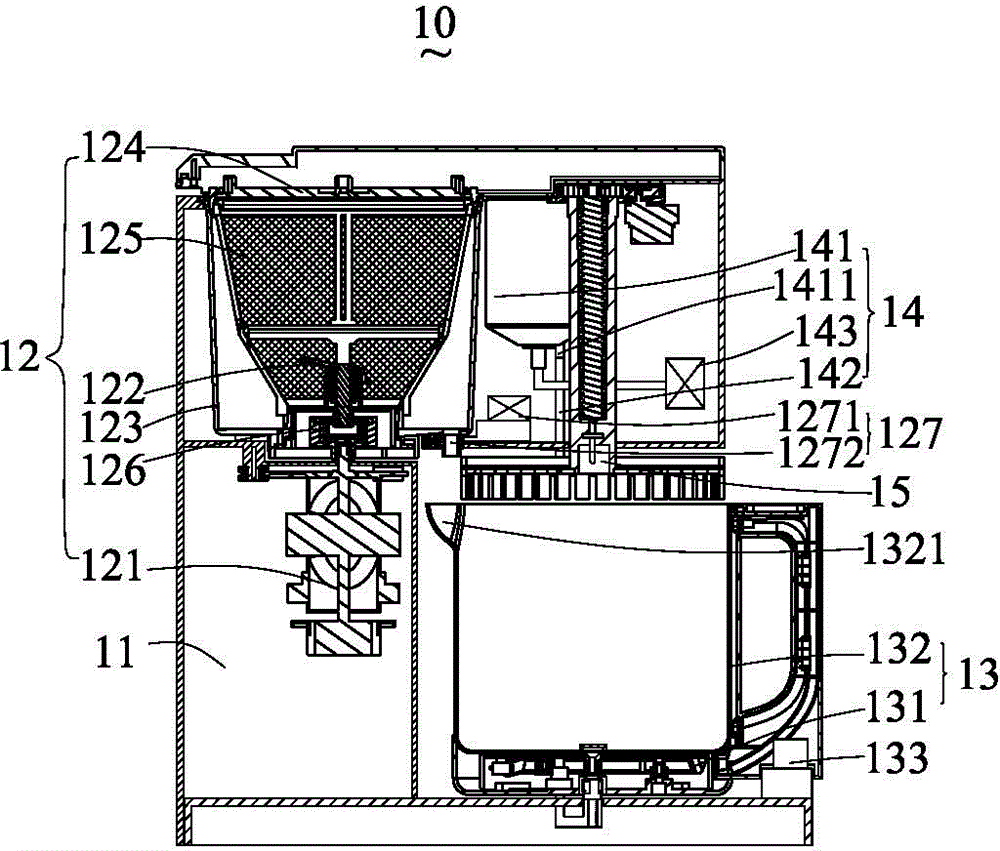

Technology for preparing bean curd/uncongealed bean curd by virtue of household bean curd machine

ActiveCN104642558ALong storage timeSimple structureCheese manufactureFood scienceElectric machinerySlurry

The invention relates to a technology for preparing bean curd / uncongealed bean curd by virtue of a household bean curd machine. The technology comprises the following steps: (a) in a crushing stage, adding water and materials to a crushing cup, wherein the motor drives a crushing tool to rotate and crush the materials into slurry, and the crushed slurry is filtered through a filter and then is discharged into a slurry boiling cup; (2) in a slurry boiling stage, heating the slurry in the slurry boiling cup by virtue of a heating element until the slurry is cooked, and cooling the slurry to a certain temperature; (c) in a marinating and solidifying stage, discharging the a marinating agent in a marinating box into the slurry boiling cup, marinating and then standing for a certain period of time; and (d) in a pressing stage, driving a pressure plate to advance along the inner wall of the slurry boiling cup by a drive mechanism, infiltrating yellow serofluid into the position above the pressure plate through a drainage groove and / hole in the pressure plate, and forming the bean curd below the pressure plate. Therefore, water sealing is achieved above the bean curd to be isolated from air; the bean curd is prevented from being polluted by bacteria; the storage time of the bean curd is relatively long; and meanwhile, the yellow serofluid can also play a role in natural heat preservation.

Owner:JOYOUNG CO LTD

Method for preparing sulfur-free konjac fine flour

The invention discloses a method for preparing sulfur-free konjac fine flour. The method comprises the following steps of: a, selecting a raw material: selecting fresh konjac without rot or foreign matters as the raw material, wherein pesticide residue and heavy metal residue of the fresh konjac are qualified according to the detection; b, peeling and removing apical buds: peeling and removing the apical buds from the selected qualified fresh konjac; c, cleaning: cleaning the fresh konjac; d, quickly squeezing: conveying the cleaned fresh konjac to a squeezer to perform quick squeezing to obtain konjac residue; e, crushing: crushing the konjac residue into granules of 40 to 120 meshes; and f, drying: drying the granules obtained at the step d at the temperature of between 120 and 160 DEG C to obtain the sulfur-free konjac fine flour. The method for preparing the sulfur-free konjac fine flour simplifies the production process and reduces the production cost; the fresh konjac does not produce brown stain during sulfur-free processing; and the obtained sulfur-free konjac fine flour has good luster and high quality.

Owner:HUBEI YIZHI KONJAC BIOTECH

Fruit ice cream machine

A fruit ice cream machine comprises a feeding bin arranged on a machine base, wherein a feeding barrel is communicated with the feeding bin, a stirring cutter is arranged in the feeding bin, a motor arranged in the machine base is connected with a connector of the stirring cutter through a speed reducing mechanism, the stirring cutter comprises a prism-shaped cutter rest, and a stirring blade is embedded into a corner angle of the cutter rest. The cutter rest and the stirring blade divide the feeding bin into more than two stirring cavities. A cross section of the cutter rest is triangular, quadrilateral, pentagonal, hexagonal or polygonal. A press rod is arranged on the feeding barrel. A barrel cover is arranged on the feeding bin. A positioning protrusion is arranged on the barrel cover, a positioning groove is arranged on the cutter seat, the positioning protrusion is inserted into the positioning groove. A discharging port is arranged at the bottom of the feeding bin. The direction of an outlet of the discharging port is opposite to the rotation direction of the stirring cutter. The fruit ice cream machine has the advantages of being simple and reasonable in structure, small in overall size, low in manufacture cost, flexible in operation and high in work efficiency.

Owner:FOSHAN SIXVECTOR DESIGN & CONSULTANT CO LTD

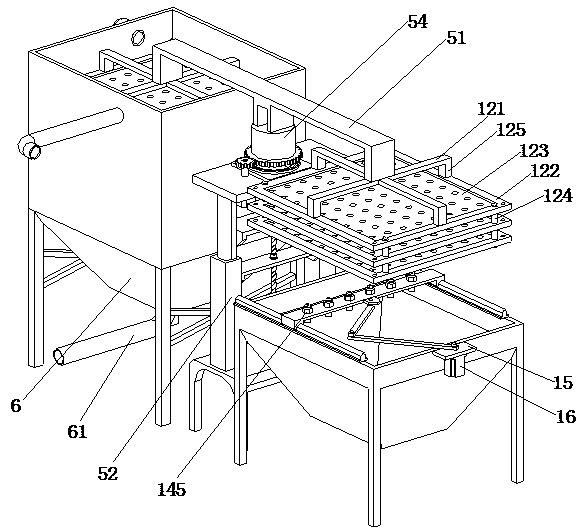

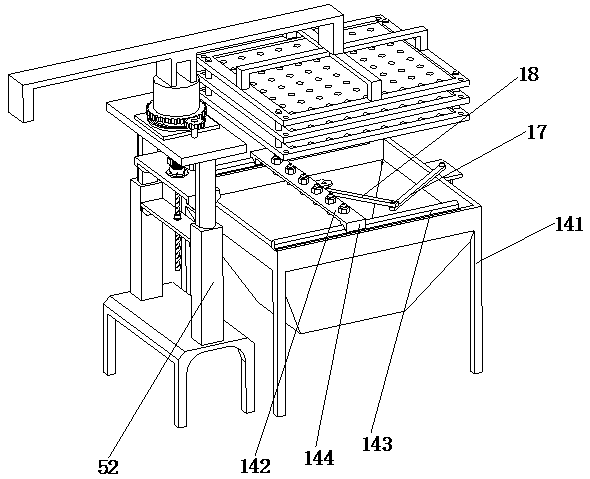

Wastewater treatment equipment for aquaculture seawater

ActiveCN111217500AAchieve bactericidal effectFully absorbedSeawater treatmentWaste water treatment from animal husbandryPolycultureSewage

The invention discloses wastewater treatment equipment for aquaculture seawater. The invention relates to the technical field of wastewater treatment equipment. The equipment comprises an impurity filtering mechanism, a filtering box, a controller, a multi-stage treatment mechanism and a detection backflow mechanism, wherein the multi-stage treatment mechanism comprises an algae polyculture pond,a material mixing assembly, a sterilization assembly and a bacterium treatment cylinder, the impurity filtering mechanism comprises two multi-stage filtering parts, a position conversion assembly anda filter screen mesh dredging assembly, and the position conversion assembly comprises a mounting transverse plate, a height adjusting part and a rotating part. According to the invention, continuousautomatic treatment of aquaculture wastewater can be realized, under the action of the impurity filtering mechanism, a filter screen adhered with impurities can be replaced, meshes of the filter screen adhered with impurities can be dredged, and when the bacterium content and the nitrogen and phosphorus content do not reach the standard, a second water pump can convey sewage which does not reach the standard into the filtering box again, so that secondary purification operation on the sewage is realized.

Owner:SHANDONG BUSINESS INST

Automatic bottom grinding and opening turning device for pot

InactiveCN109676480AQuick squeezeGrinding pressure is uniformGrinding wheel securing apparatusGrinding feed controlEngineeringConveyor belt

The invention discloses an automatic bottom grinding and opening turning device for a pot. The device comprises a working platform and a conveyor belt, wherein a machine chamber is formed in one innerend of the working platform; a single-chip controller and a time controller are mounted at one side of the inner wall of the machine chamber through mounting grooves; a rotating motor is arranged atthe inner upper end of the machine chamber through a fixing part; a heat radiating bottom chamber is mounted at the bottom part of the machine chamber through a screw; a cooling fan is arranged in theheat radiating bottom chamber through a mounting part; a pot body fixing die is arranged at one end of the top part of the working platform, and a mounting support is mounted in the pot body fixing die through a bolt; a box body is arranged on the top part of the mounting support through a bolt; and an electric air charging pump is mounted in the box body through a mounting plate. The device is multifunctional, simple to operate, low in mechanical cost, and convenient to produce, and meets various demands in the pot producing and grinding processes, and can be widely popularized and used.

Owner:宁波华数机器人有限公司

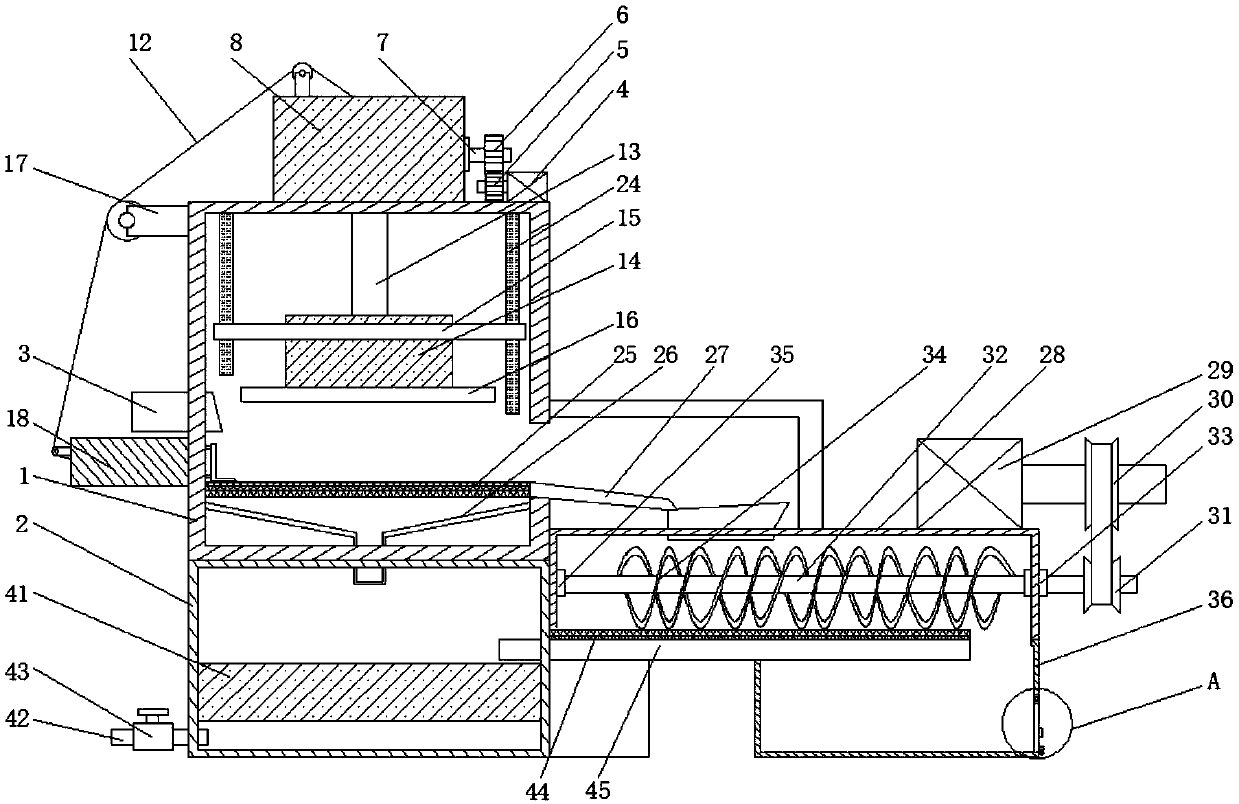

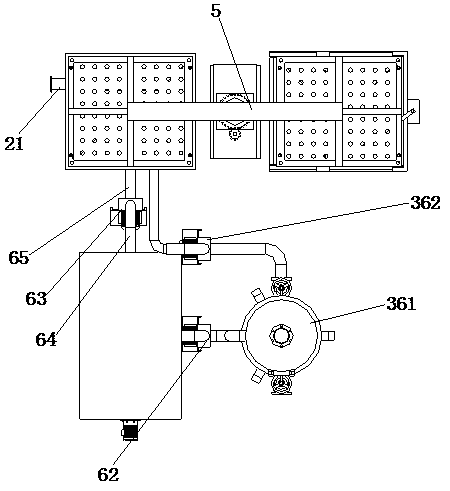

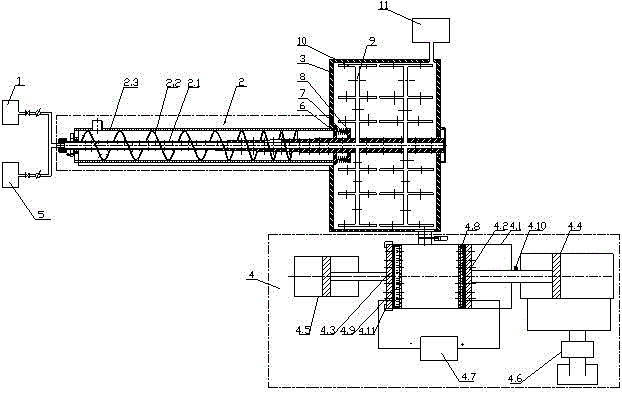

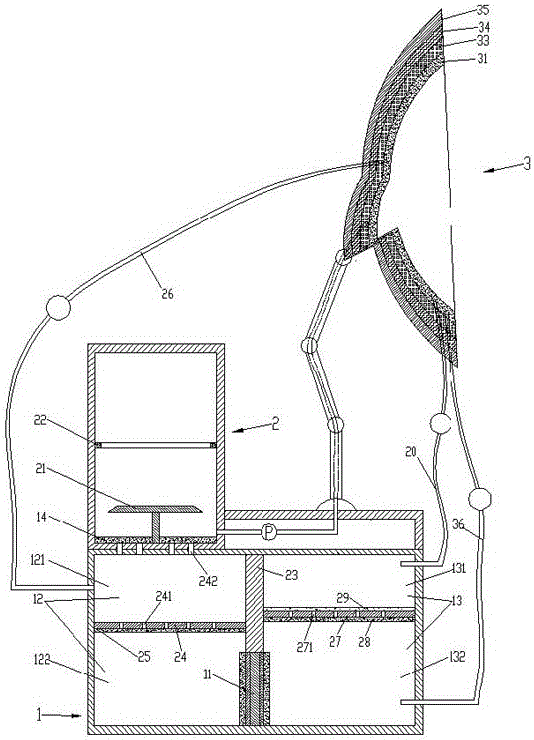

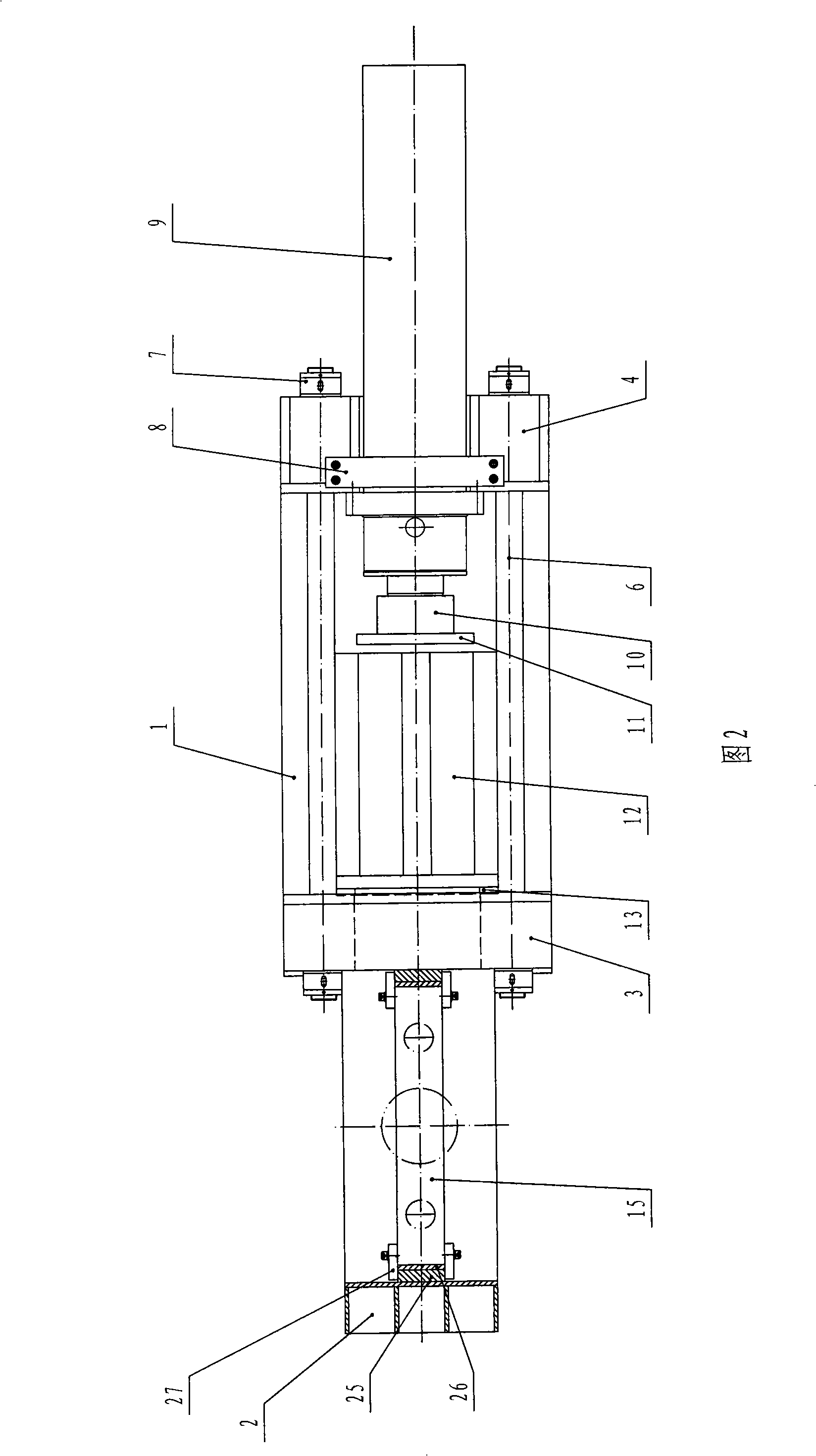

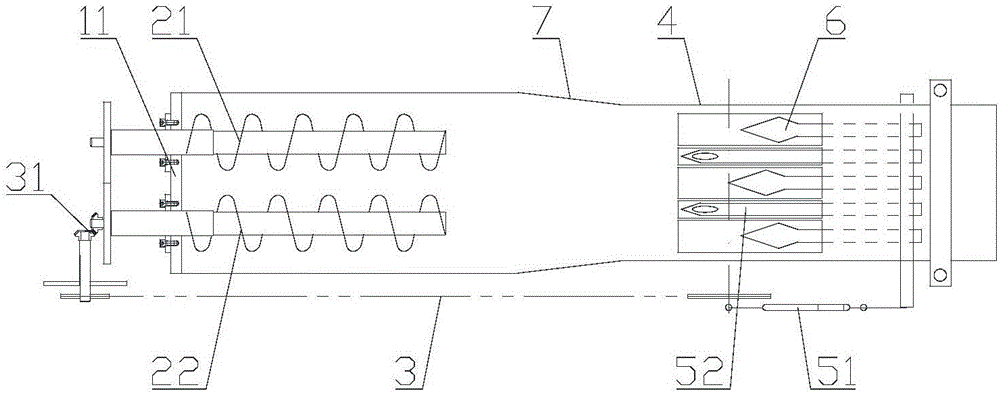

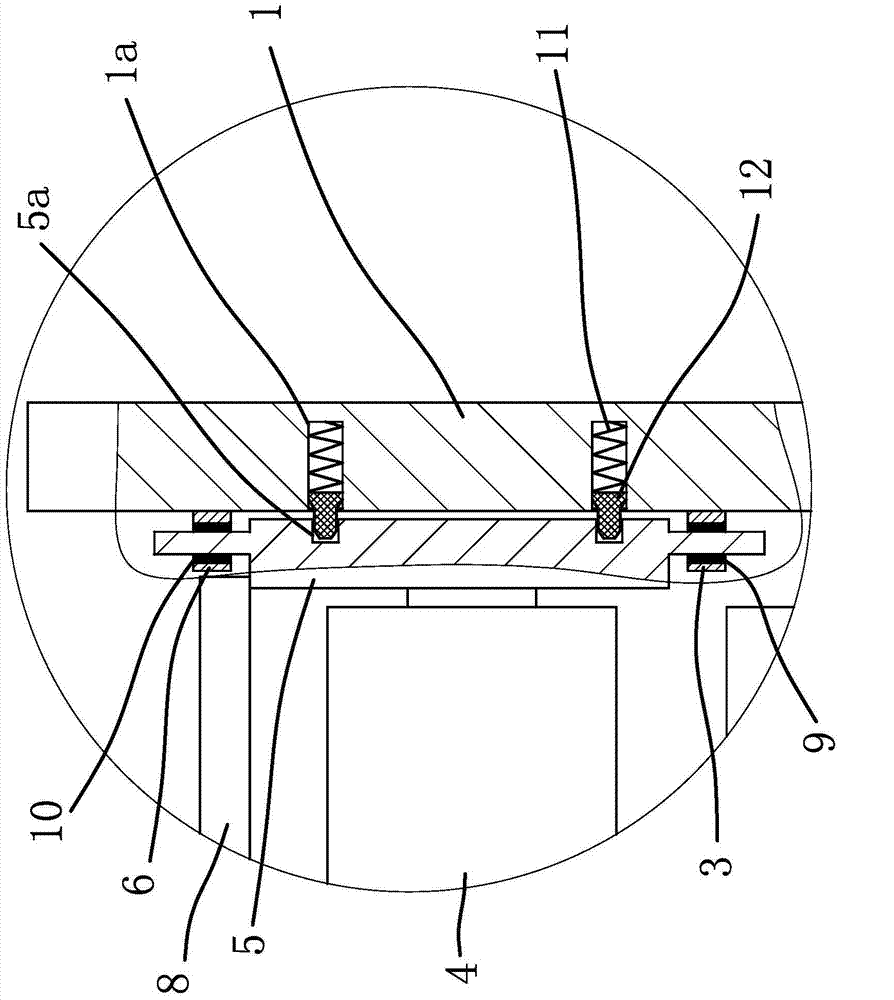

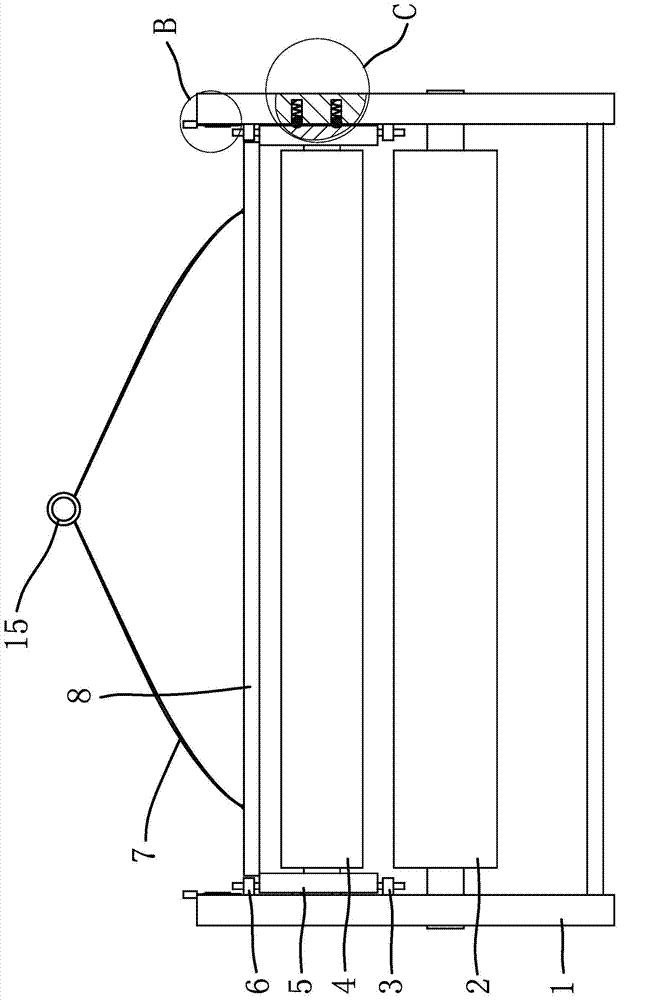

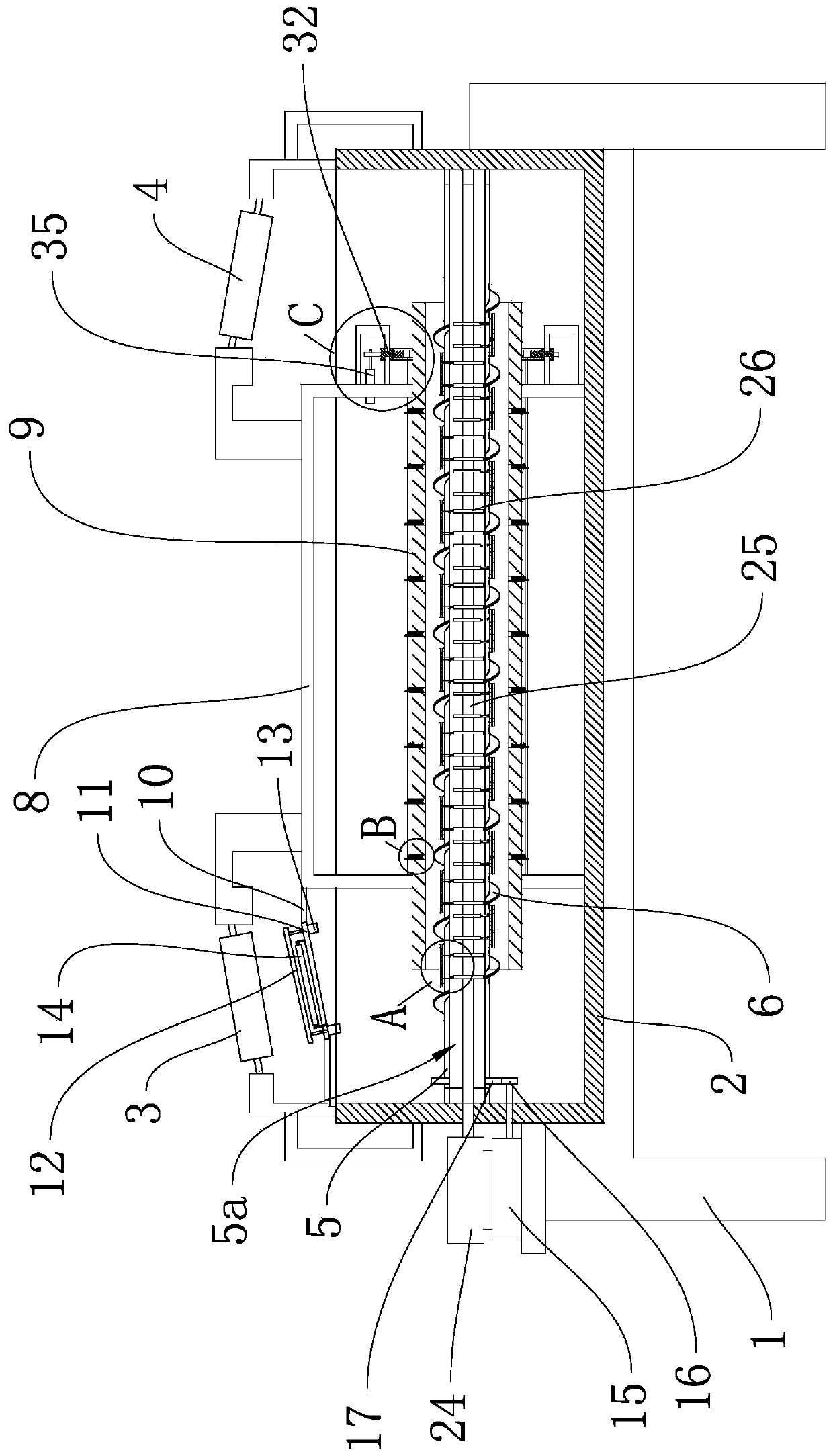

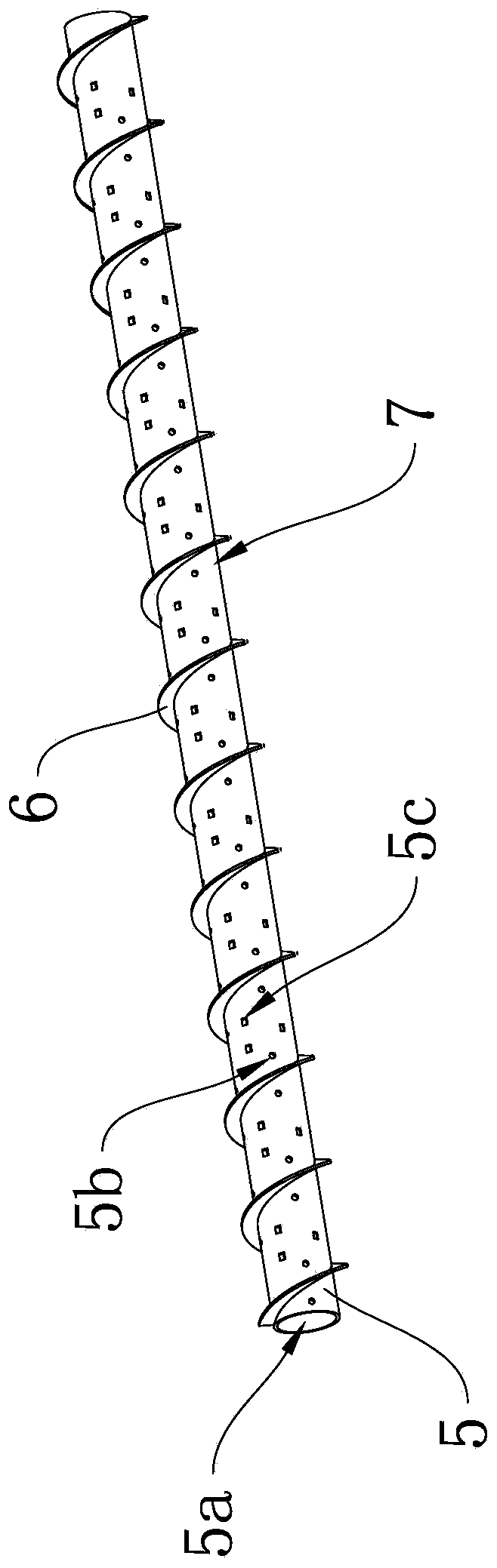

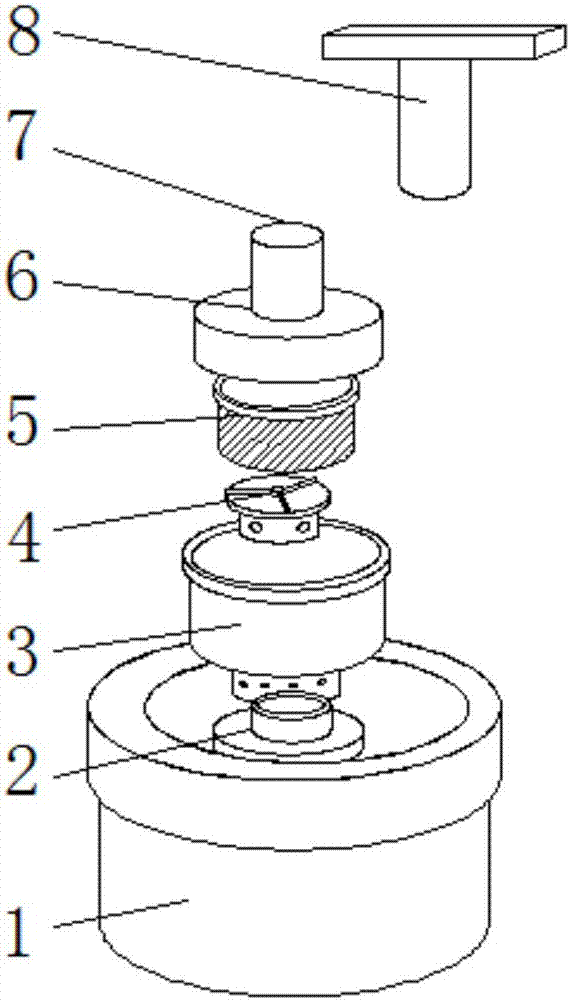

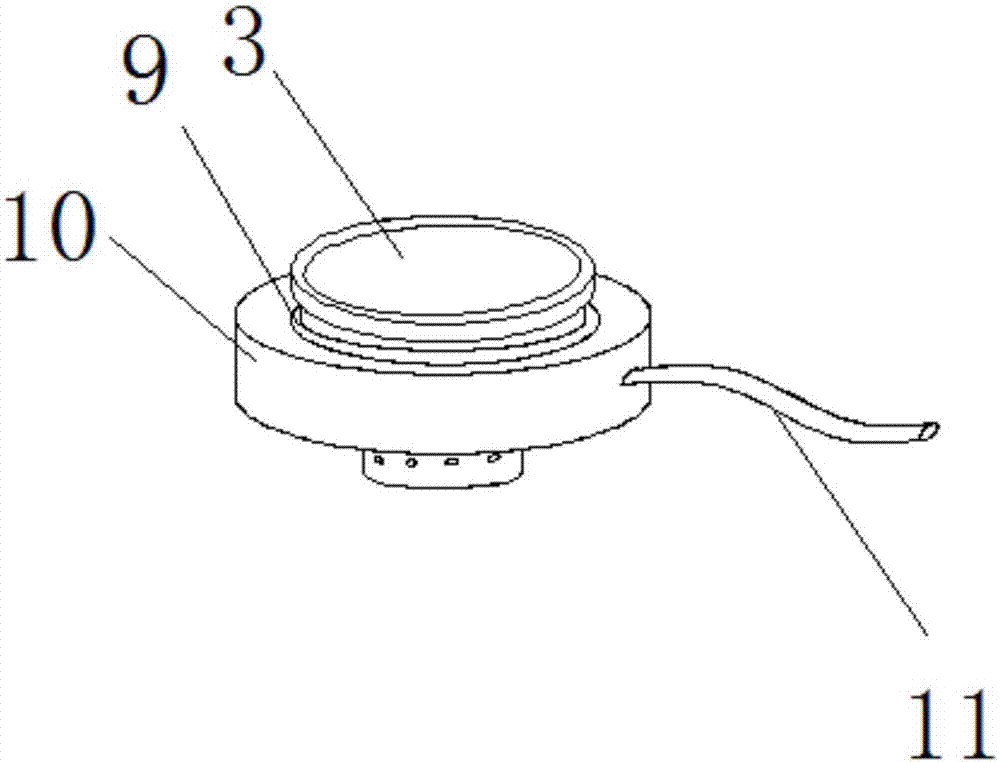

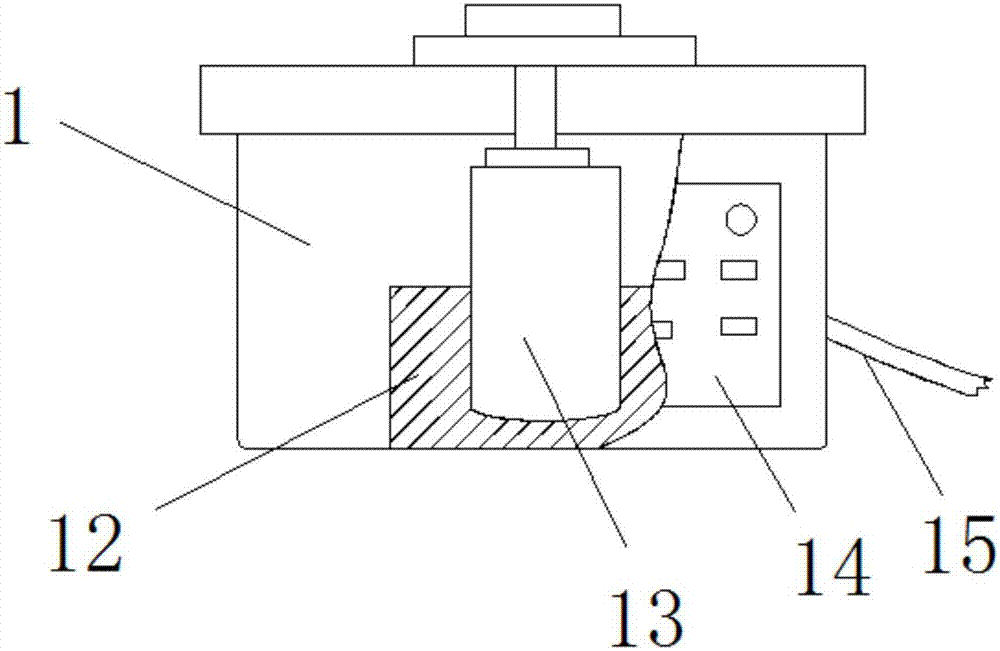

High-dryness sewage sludge treatment apparatus

InactiveCN105819637AAchieve high dryness dehydrationFavorable effect follow-up treatmentSludge treatment by de-watering/drying/thickeningSludge treatment by oxidationElectricitySpiral blade

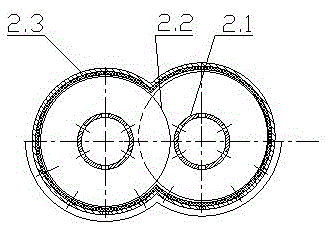

The invention discloses a high-dryness sewage sludge treatment apparatus, comprising an active gas generator (1), a spiral filtering apparatus (2), an oxidation drum (3) and an ultrahigh-voltage electro-osmosis dehydration apparatus (4), wherein the spiral filtering apparatus (2) comprises a spiral shaft (2.1), spiral blades (2.2) and a spiral drum (2.3); the spiral shaft (2.1) is installed in the spiral drum (2.3); the spiral blades (2.2) are arranged on the spiral shaft (2.1) and arrayed between the spiral shaft and the inner wall of the spiral drum; the spiral shaft is hollow; an end inlet of the spiral shaft is communicated with the active gas generator; the wall of the spiral shaft is provided with a vent allowing active gas to enter; the tail end of the spiral drum (2.3) is connected with the oxidation drum (3); the spiral filtering apparatus (2) is of a double-spiral structure; and an outlet of the oxidation drum (3) is communicated with the ultrahigh-voltage electro-osmosis dehydration apparatus (4). The high-dryness sewage sludge treatment apparatus provided by the invention has a wide application scope and low energy consumption, is beneficial for sludge reduction and enables treated sludge to have low water content.

Owner:CHINA JILIANG UNIV

Deseeding and squeezing device for wine processing and production and processing method thereof

ActiveCN112175762AAvoid affecting post-cleaning workAvoid Interfering with Cleaning WorkJuice extractionWine preparationGrape seedProcess engineering

The invention provides a deseeding and squeezing device for wine processing and production and a processing method thereof, and belongs to the technical field of grape processing. The deseeding and squeezing device comprises a pulp squeezing element, a seed filtering element, a control element, a peeling element and a power supply. The deseeding and squeezing device has the advantages that the cleaned grape particles can be peeled, squeezed and deseeded, so as to meet the requirement of wine brewing; when the pulp squeezing element works, because a buffer press sheet is arranged on an auxiliary squeezing roller, the pressure between the auxiliary squeezing roller and a main squeezing roller can be partially buffered, so as to avoid the influence to the mouth feel of the brewed wine due tocrushing of grape seeds and difficulty in separation from grape juice; and when the seed filtering element works, the grape seeds can be quickly separated, and the pulp which is not thoroughly squeezed can be secondarily squeezed, so as to ensure the low content of grape juice in the filtered pulp, avoid the waste of grape juice, and increase the output of wine.

Owner:ZUNYI NORMAL COLLEGE

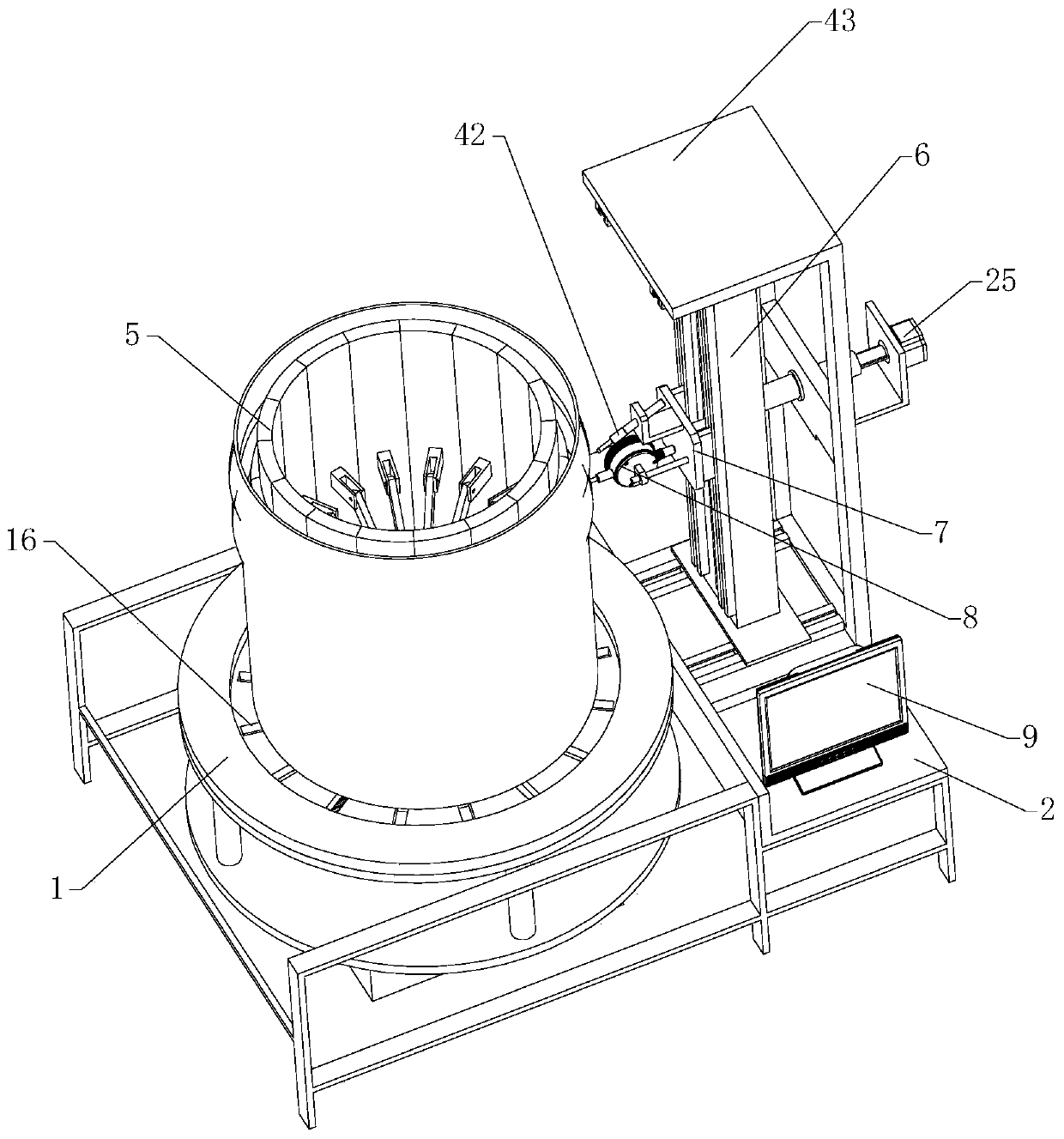

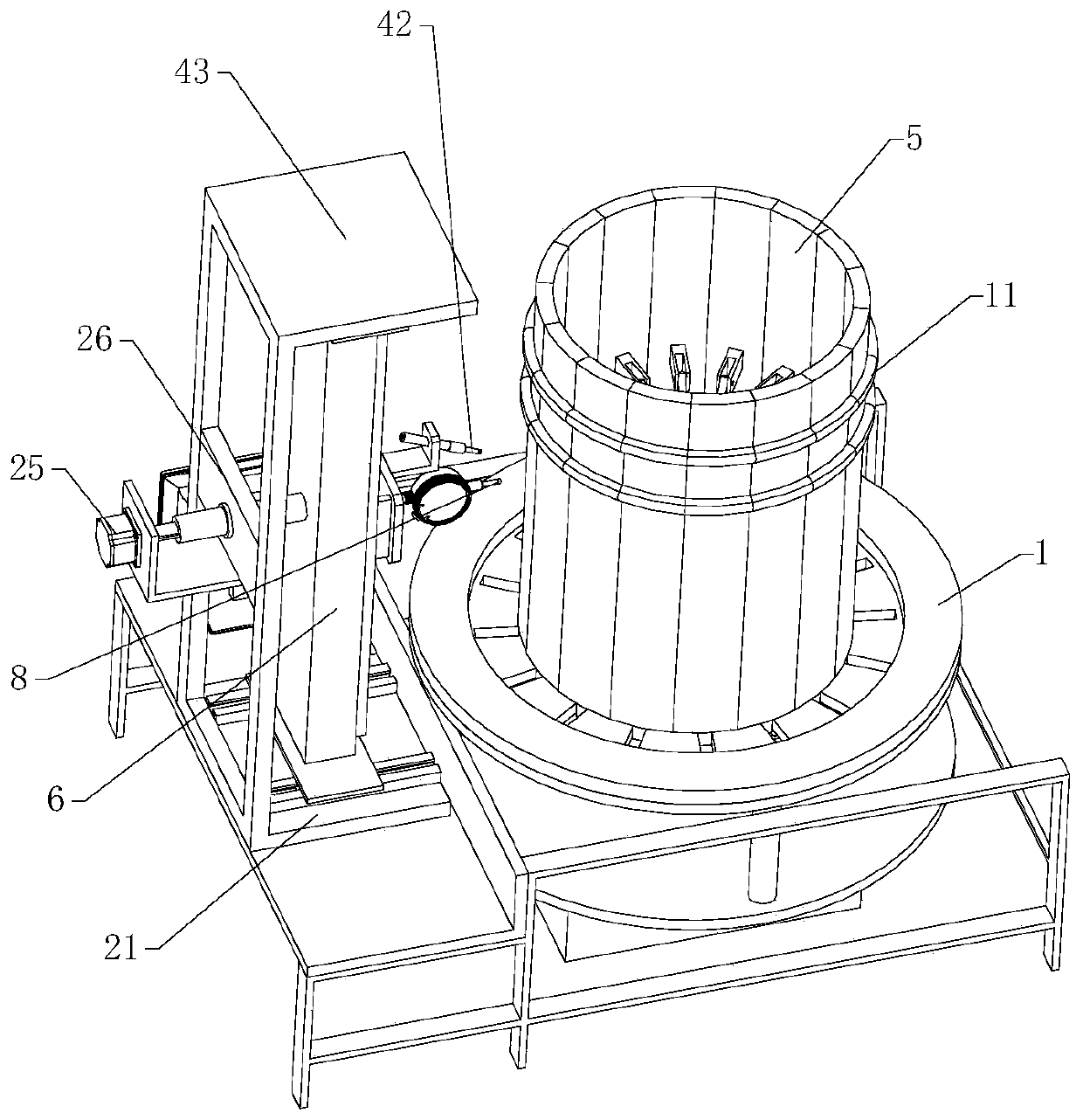

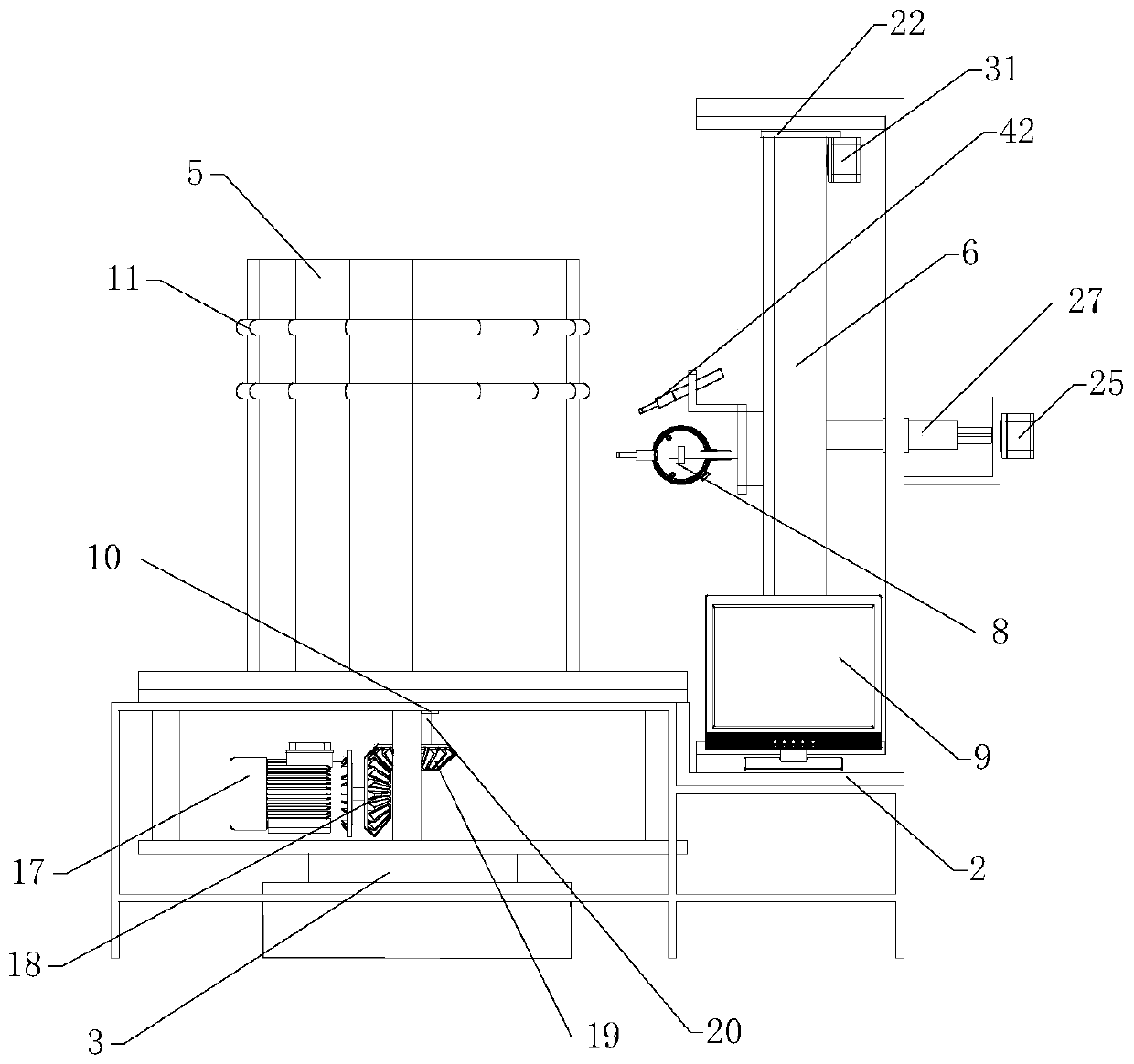

Barrel forming equipment with bounce value detecting and marking function and method thereof

ActiveCN111238334AQuick squeezeAutomatic detectionMechanical measuring arrangementsMicrometerMarking out

The invention relates to the technical field of barrel machining, in particular to barrel forming equipment with a bounce value detecting and marking function. The equipment comprises a rotary table and a detection table located on one side of the rotary table. A turntable is arranged at the bottom of the rotary table. An annular placing groove is formed in the top of the rotary table. A tensioning and extruding mechanism is arranged in the annular placing groove. The tensioning extrusion mechanism comprises a plurality of extrusion blocks. A tensioning driving mechanism is arranged in the turntable. A horizontal moving mechanism is arranged on one side of the tensioning and extruding mechanism. The horizontal moving mechanism comprises a rectangular box. A lifting mechanism is arranged inthe rectangular box. The lifting mechanism comprises a lifting plate capable of moving up and down. A micrometer is arranged on the lifting plate. The output end of the micrometer extends in the direction of the tensioning and extruding mechanism, a controller is arranged on one side of the top of the detection table. The controller is electrically connected with the tensioning driving mechanism,the horizontal moving mechanism, the lifting mechanism and the micrometer, and the equipment can rapidly extrude and form a barrel and can automatically conduct detection and marking.

Owner:JIAOZUO UNIV

Facial mask machine and use method thereof

ActiveCN106389181ARealize self-disinfectionGuaranteed freshnessCosmetic preparationsToilet preparationsElectrolysisPower flow

The invention relates to a facial mask machine and a use method thereof. The facial mask machine comprises an electrolytic cavity, a juice squeezing cavity and a facemask for pasting a facial mask, wherein the electrolytic cavity is divided into a cathode cavity and an anode cavity by a PEM (proton exchange membrane) electrolysis electrode; a control circuits controls the magnitude of current and / or voltage of the PEM electrolysis electrode; a sponge liquid absorbing layer, a vibration sponge liquid absorbing layer, a vibration diffusion layer enabling juice therein to diffuse to a face, a cold-hot temperature adjusting layer for adjusting the temperature of the facemask for pasting the facial mask, and a shell are arranged by laminating in the facemask for pasting the facial mask in sequence from an outer layer to an inner layer; one surface, facing to a human face, of the sponge liquid absorbing layer is provided with a plurality of liquid outlet holes in cooperation with a human face curve; the sponge liquid absorbing layer communicates with the anode cavity by virtue of an ozone tube which can be opened and closed; a first waterproof air-permeable film is arranged between the cathode cavity and the juice squeezing cavity; and the juice squeezing cavity communicates with the sponge liquid absorbing layer.

Owner:FUZHOU PINXING TECH DEV

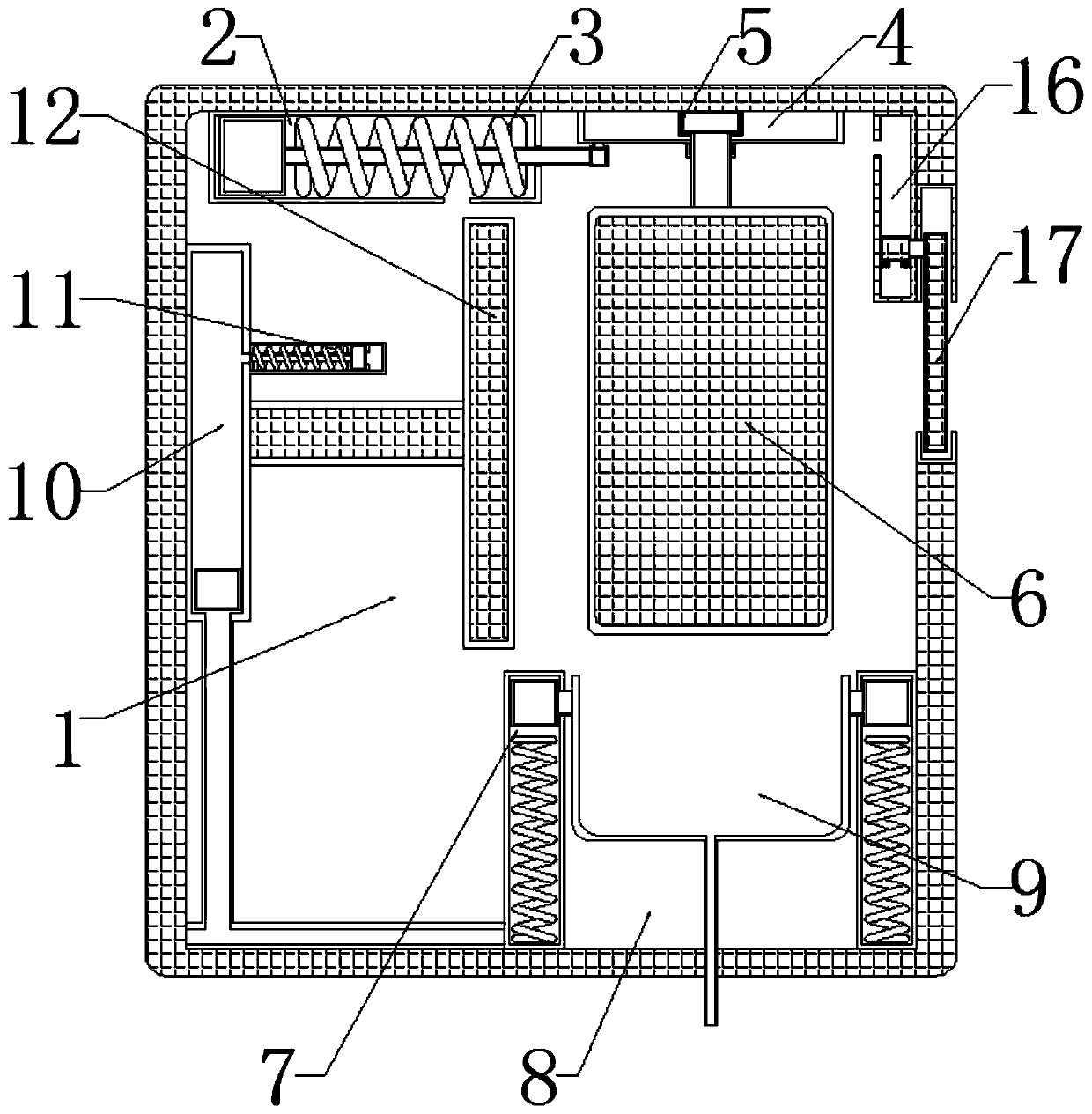

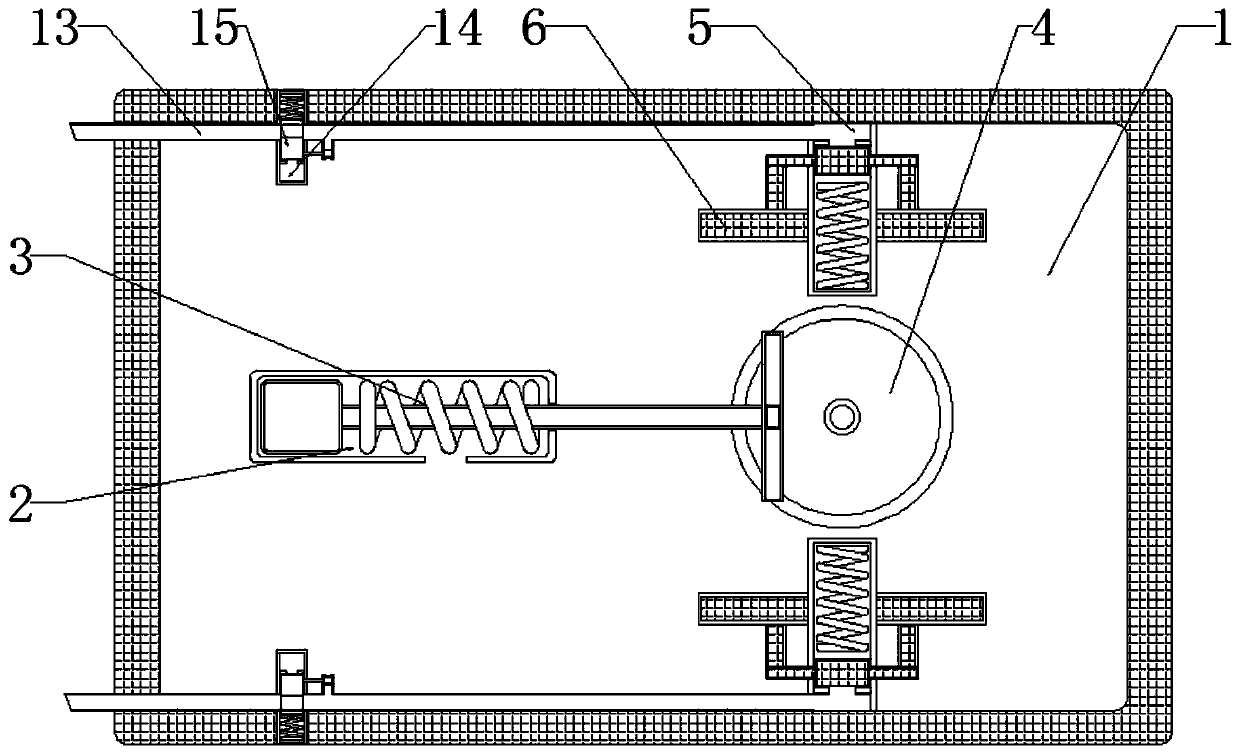

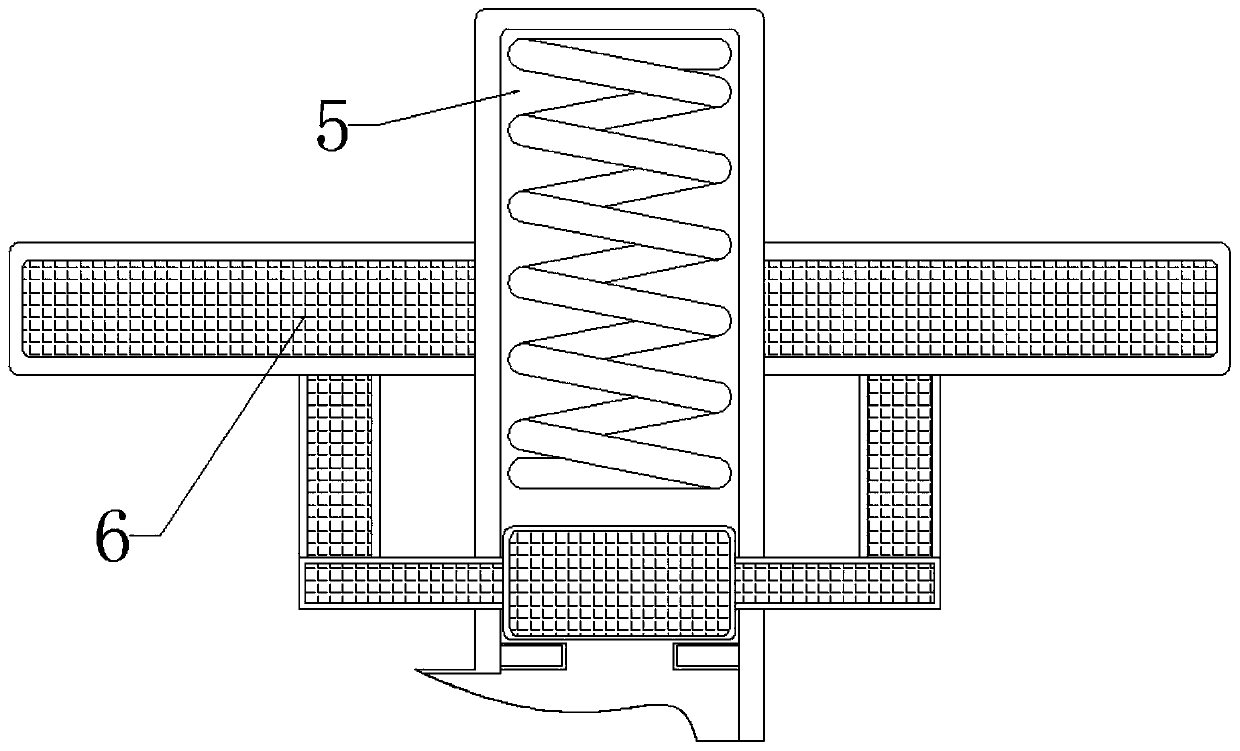

Horizontal pressing type medical waste water separation and treatment device

The invention discloses a horizontal pressing type medical waste water separation and treatment device. The horizontal pressing type medical waste water separation and treatment device comprises a base. A treatment box is fixedly arranged above the base. A water separation chamber and a water storage chamber are arranged inside the treatment box. A fixed seat is fixedly arranged on the portion, below a box body, of the outer portion of the left side of the treatment box. A motor bracket is fixedly arranged in the middle part of the upper portion of the fixed seat. A motor is fixedly mounted atthe upper end of the motor bracket. An incomplete gear is arranged in the portion right in front of the center of the motor in a connected manner. A gear frame is connected to the outer portion of the incomplete gear in an engaged manner. A push rod is fixedly connected to the position, on the right side of the gear frame, of the middle of an outer frame. The middle portion of the push rod is incontact connection with a sliding block. A connecting rod is fixedly connected to the right end of the push rod. A second spring is fixedly connected to the middle part of the left side of the connecting rod. The right side of the push rod penetrates the interior of the second spring. Sliding rods are correspondingly and fixedly connected to the upper part and the lower part of the right side of the connecting rod. By the adoption of the horizontal pressing type medical waste water separation and treatment device, the extrusion effect is more remarkable, and all water in medical waste can be squeezed out quickly, so that a part of water is prevented from flowing into the soil and polluting the soil in the process of collective burning.

Owner:陈鹏

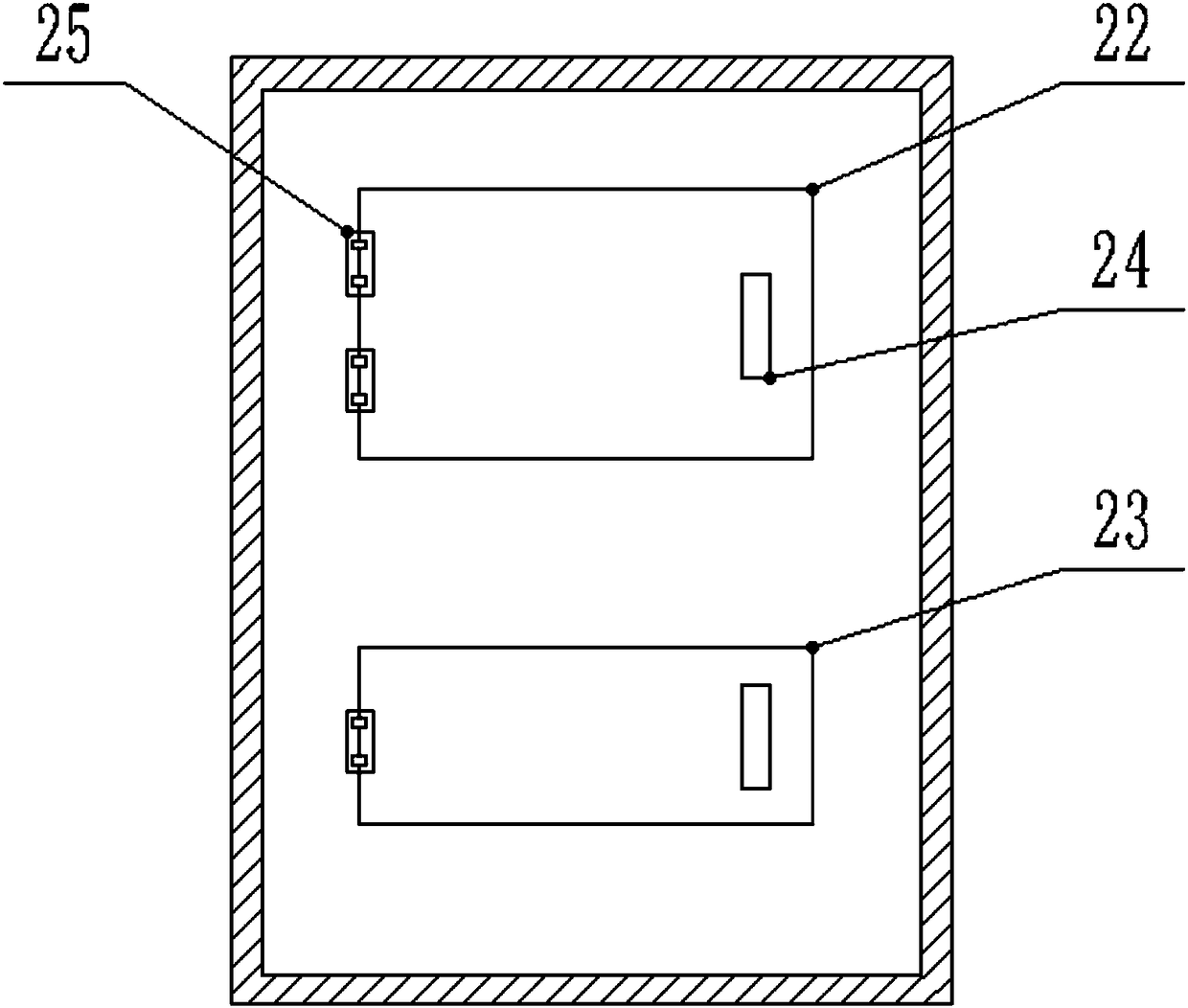

Acupuncture needle box with disinfecting function

InactiveCN109229950AAvoid pollutionAvoid enteringRod article dispensingChemicalsAcupuncture needlesEngineering

The invention relates to an acupuncture needle box with a disinfecting function. The acupuncture needle box comprises a box body, a sterilization assembly, a storage assembly and a needle dischargingassembly, wherein the sterilization assembly and the storage assembly are arranged in the box body; the storage assembly comprises a needle receiving conveyor belt, a driving mechanism and a storage belt. A needle inlet end of the needle receiving conveyor belt is connected to a needle outlet end of the sterilization assembly, a needle inlet end of the storage belt is connected to the needle outlet end of the needle receiving conveyor belt, the storage belt is arranged above the needle receiving conveyor belt, the storage belt includes a first conveyor belt and elastic clamping boards, and thefirst conveyor belt is provided with a plurality of elastic clamping boards that are arranged at equal intervals along a width direction thereof; a clamping slot matched with an acupuncture needle isformed between two adjacent elastic clamping boards; acupuncture needles positioned at the needle out end of the needle receiving conveyor belt are extruded into corresponding clamping slots when thestorage belt is driven to run via the driving mechanism; the needle discharging assembly is arranged on the box body. The beneficial effects of the acupuncture needle box are that fingers of medicalworkers can be prevented from being punctured during needle taking processes, and the acupuncture needles can be sterilized.

Owner:WUHAN BAIQI TECH CO LTD

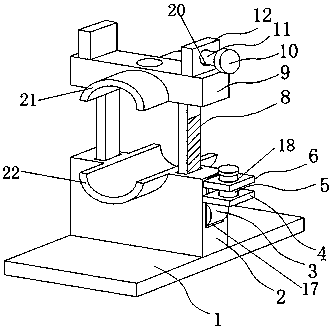

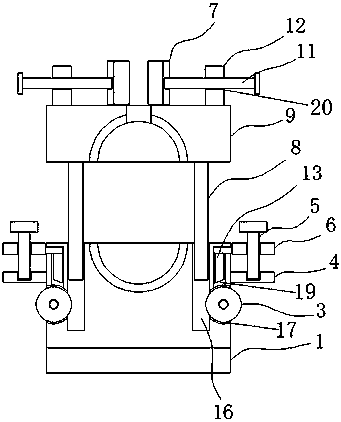

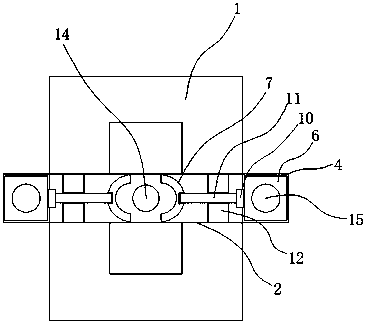

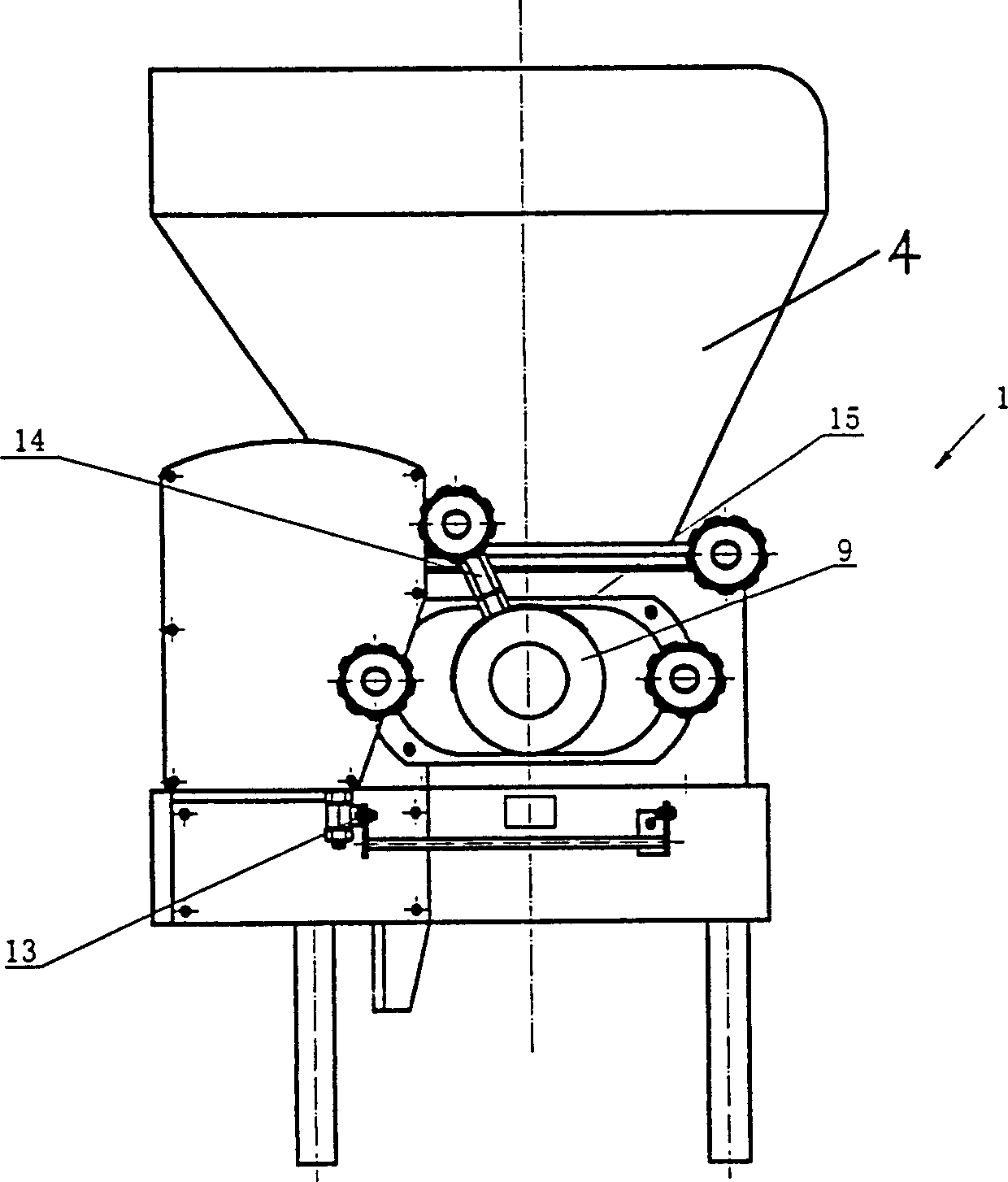

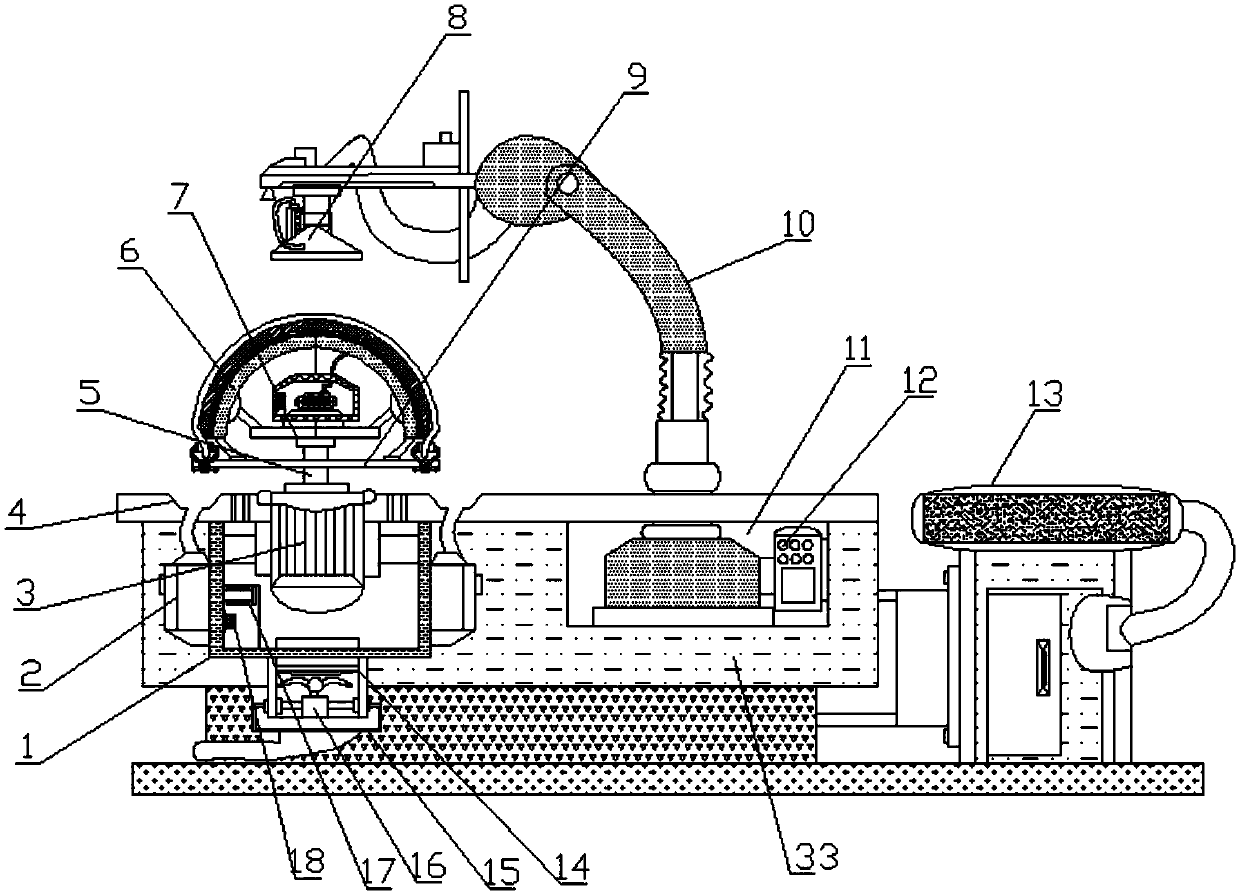

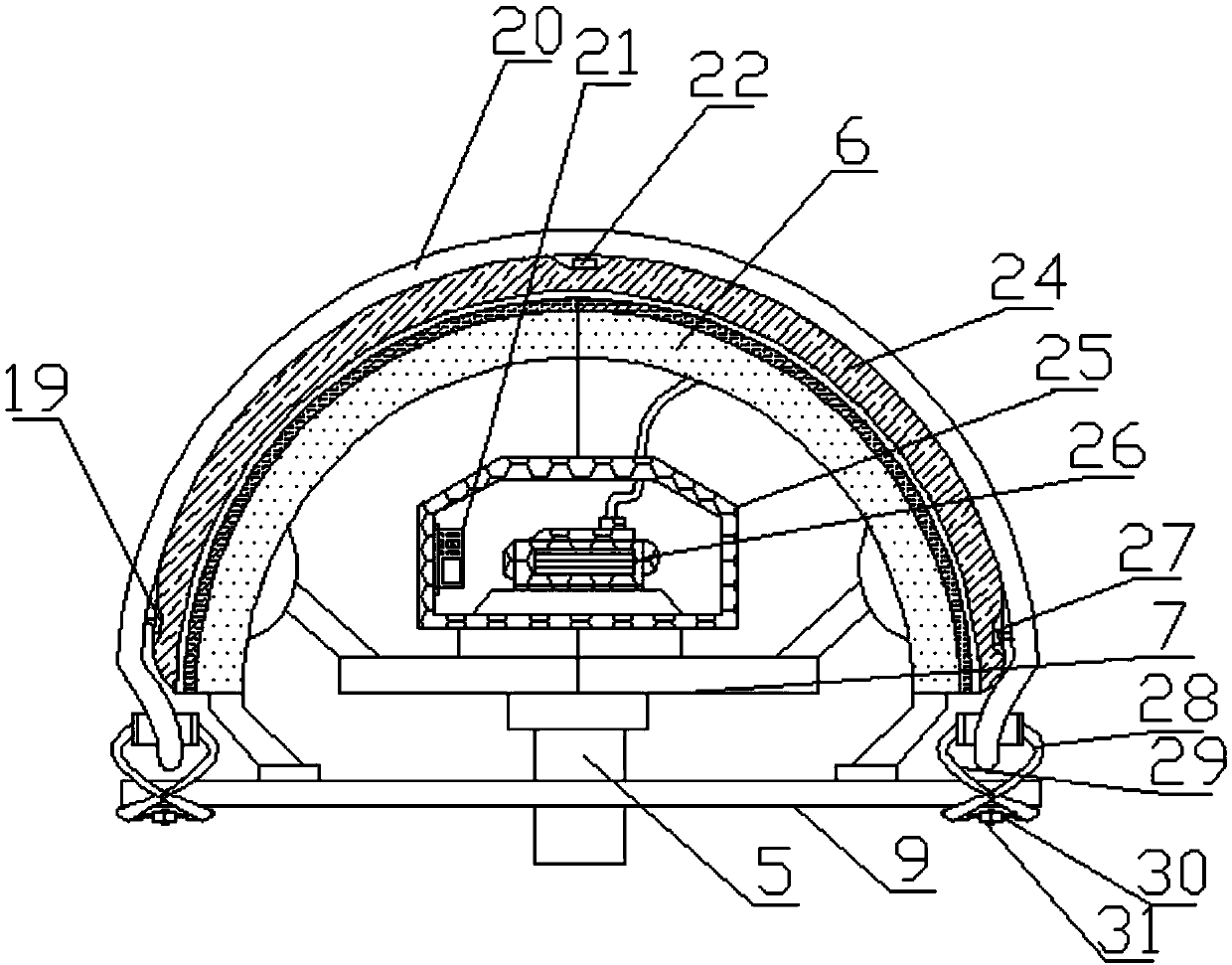

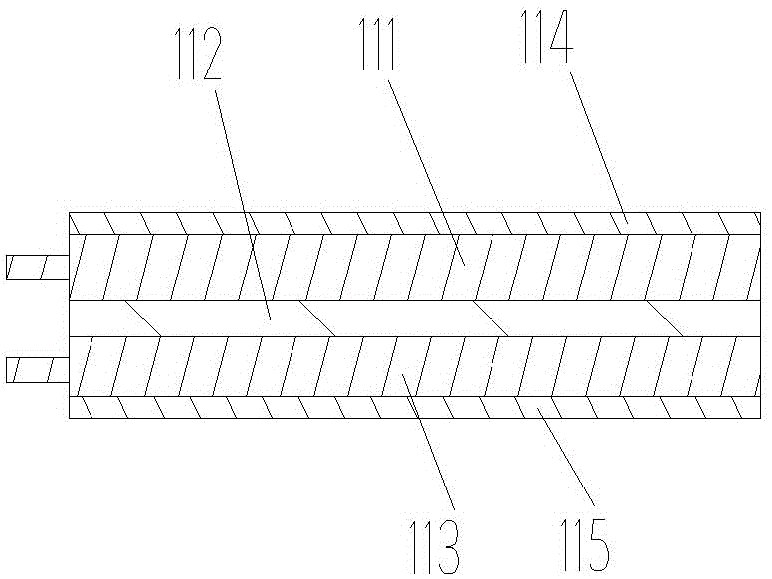

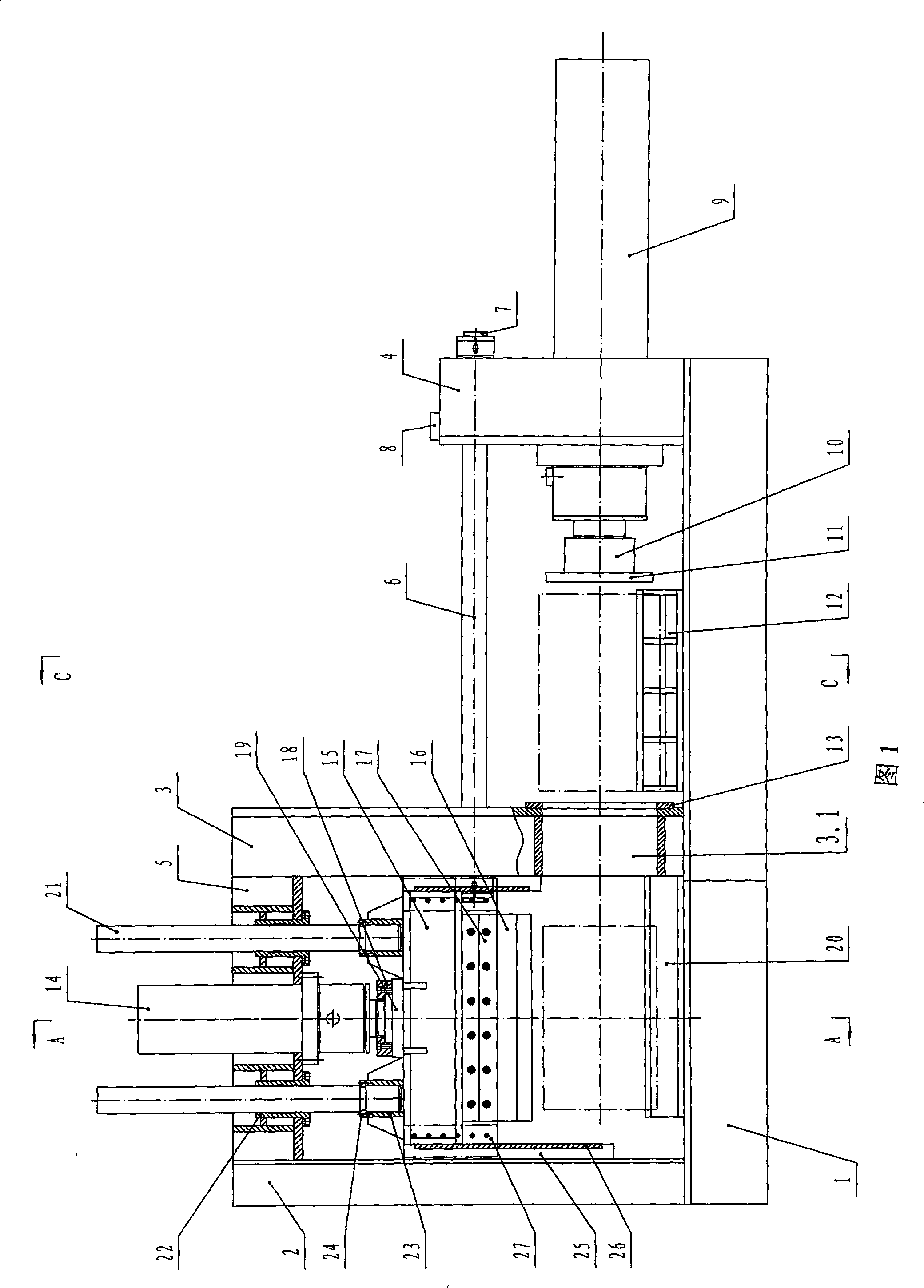

Novel inching horizontal type extrusion clipper

InactiveCN101337325AReduce labor intensityEasy to addShearing machinesOther manufacturing equipments/toolsEngineeringKnife blades

The invention relates to a novel inching horizontal extruding and shearing machine, which is mainly used for extruding and shearing nonferrous metallic strontium. The extruding and shearing machine comprises a machine frame, an extruding device and a shearing device, wherein the machine frame comprises a bottom base (1), a first vertical wallboard (2), a second vertical wallboard (3), a third vertical wallboard (4), an upper beam (5) and a pull rod (6), wherein the first vertical wallboard (2), the second vertical wallboard (3) and the third vertical wallboard (4) are vertically arranged on the bottom base (1); a horizontal channel (3.1) is formed under the second vertical wallboard (3); the extruding device comprises an extrusion oil cylinder (9), an extrusion head (10), an extrusion head front plate (11) and a charging V-shaped block (12), wherein the extrusion oil cylinder (9) is horizontally mounted on the third vertical wallboard (4); the charging V-shaped block (12) is mounted upwards on the bottom base (1); the shearing device comprises a shear oil cylinder (14), a shear knife base (15), a shear knife blade (16) and a discharging V-shaped block (20), wherein the shear oil cylinder (14) is horizontally mounted on the upper beam (5); the discharging V-shaped block is mounted on the bottom base. The extruding and shearing machine integrates the extruding and the shearing functions, and has the advantages of convenient charging, rapid extrusion, easy shear, etc.

Owner:JIANGSU HUAHONG TECH STOCK

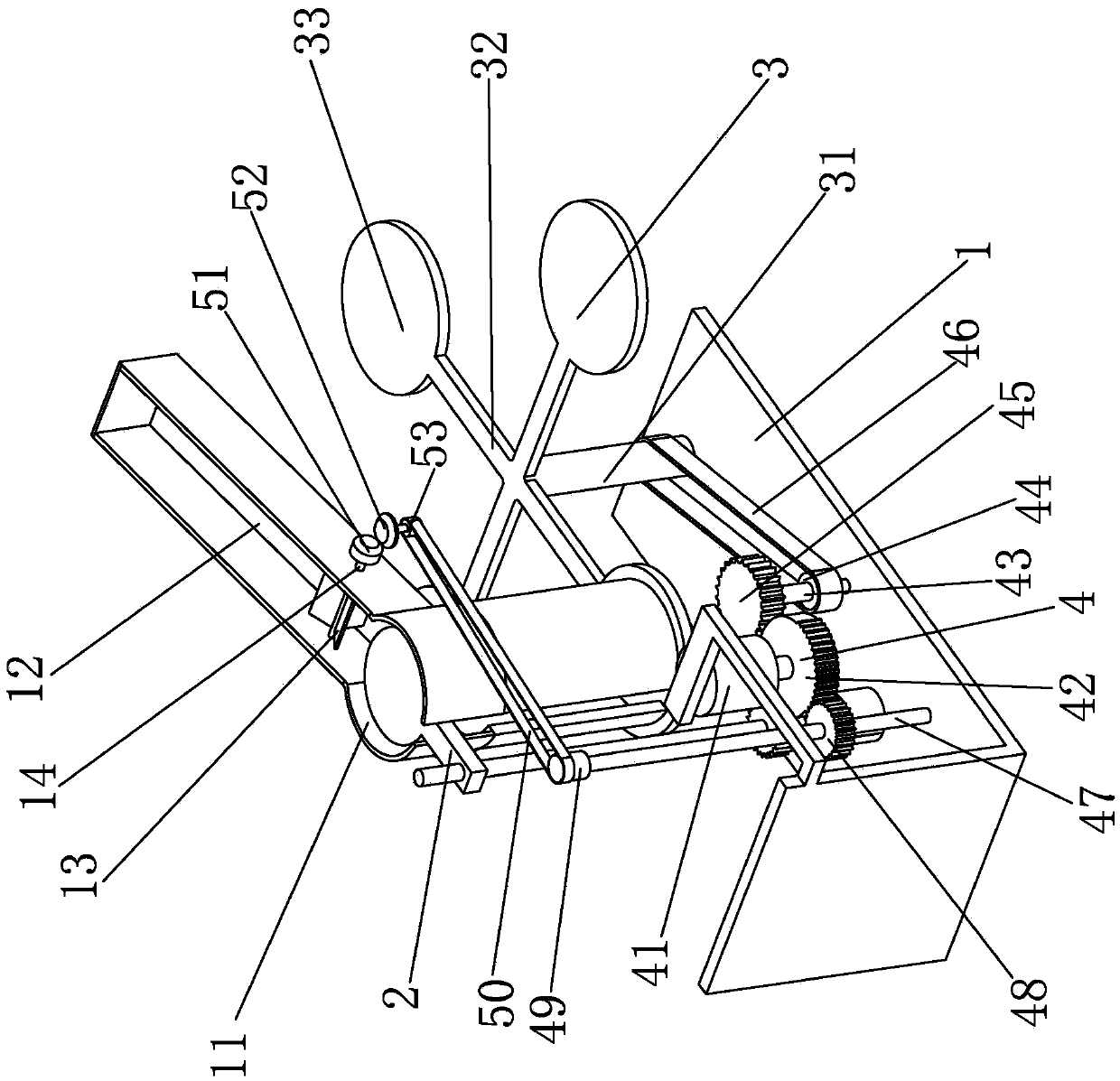

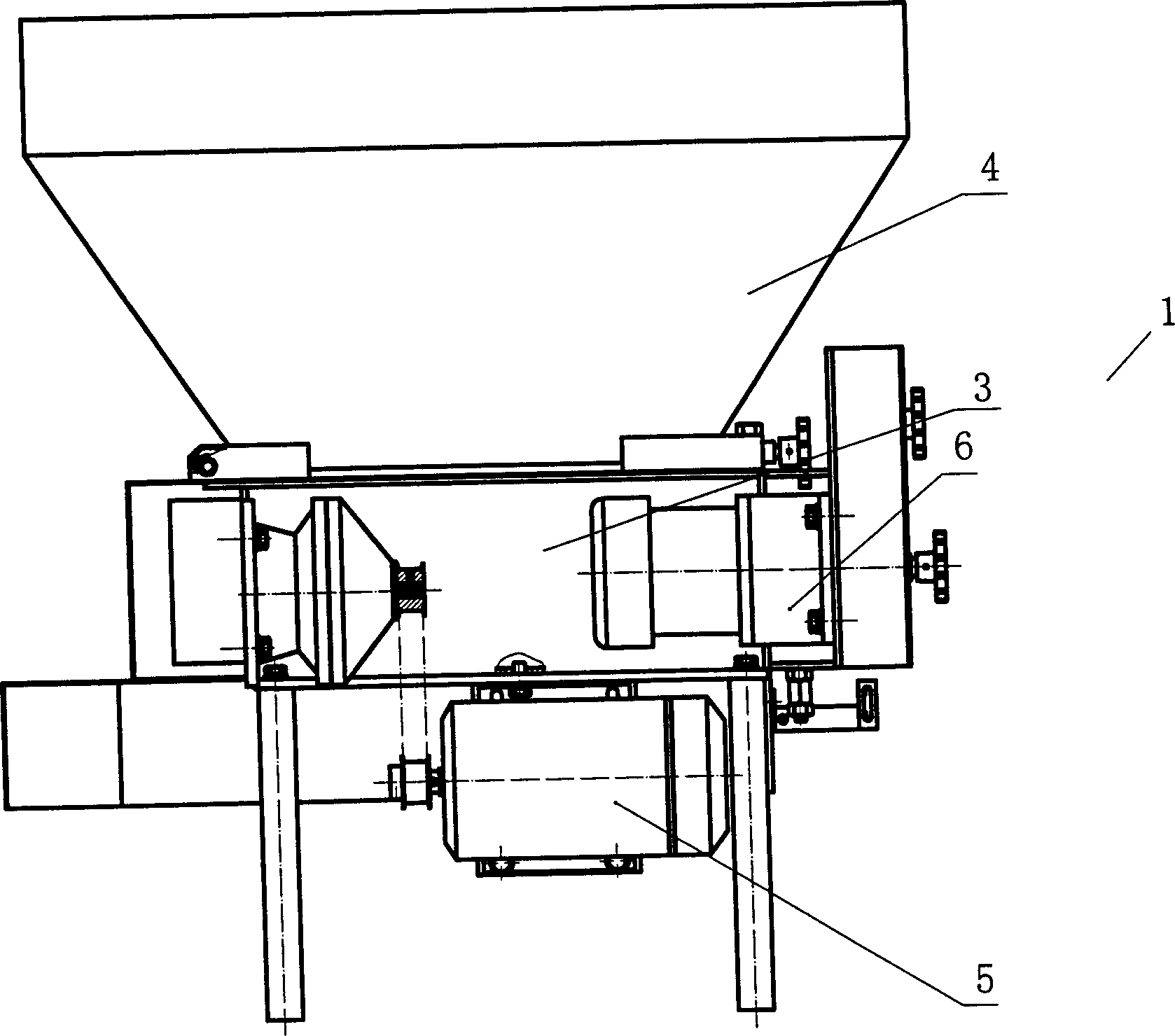

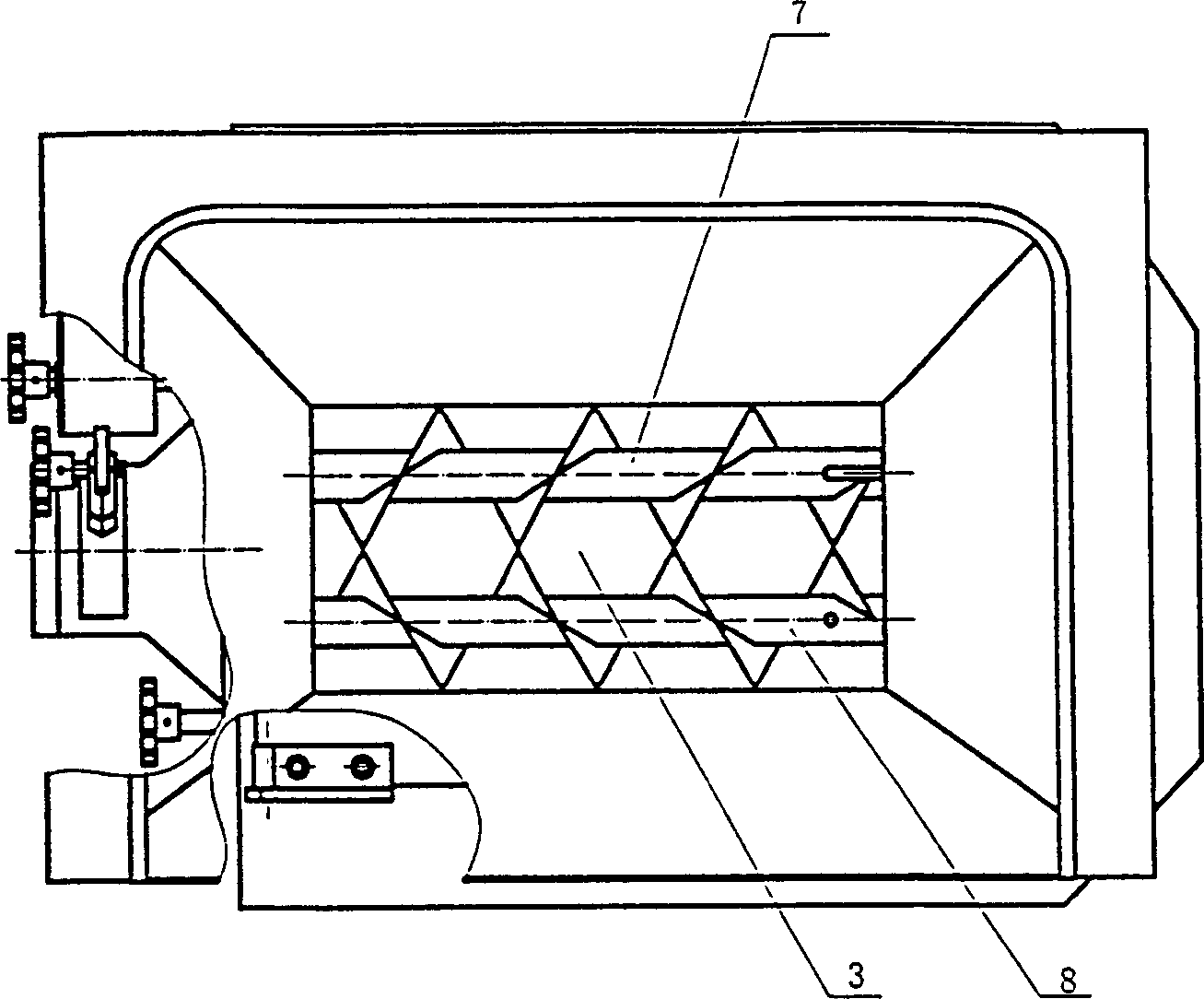

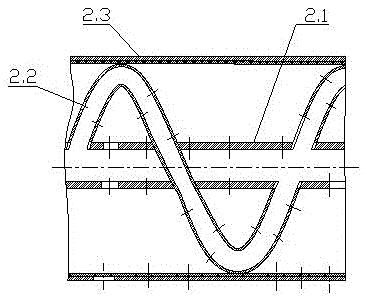

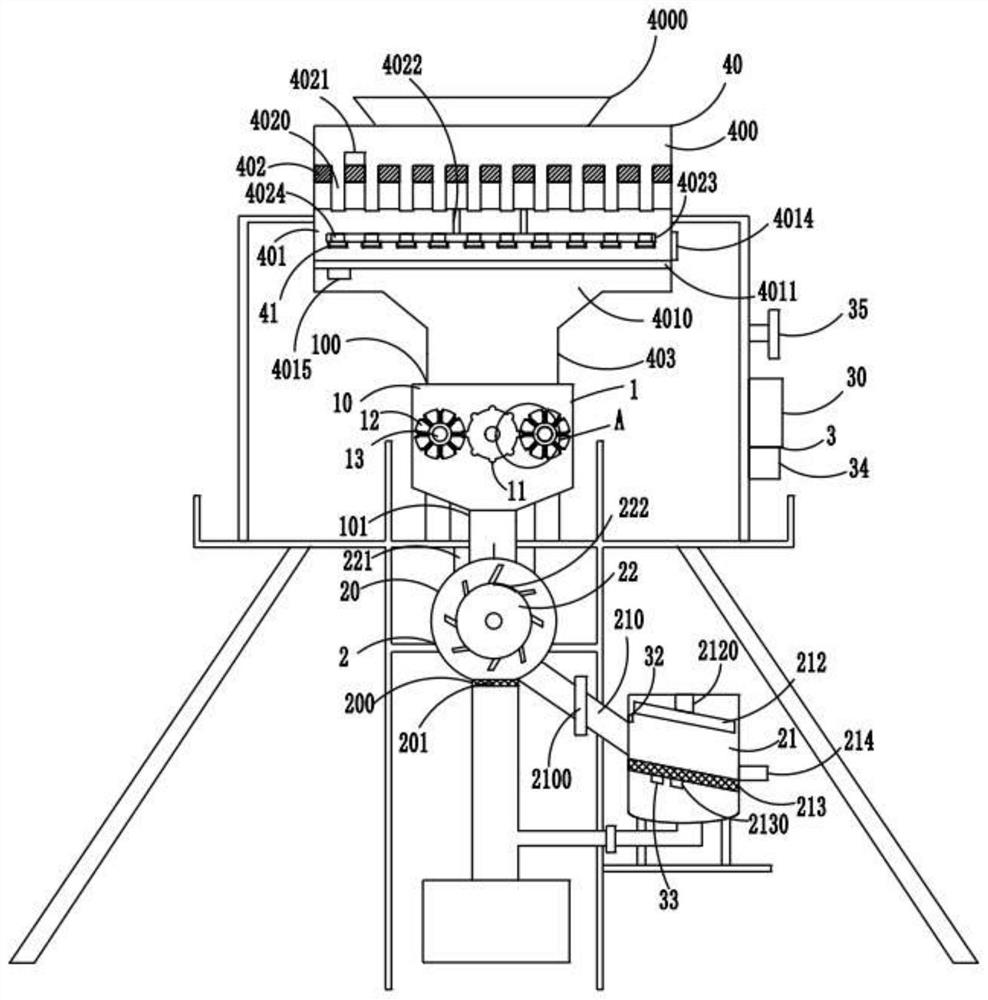

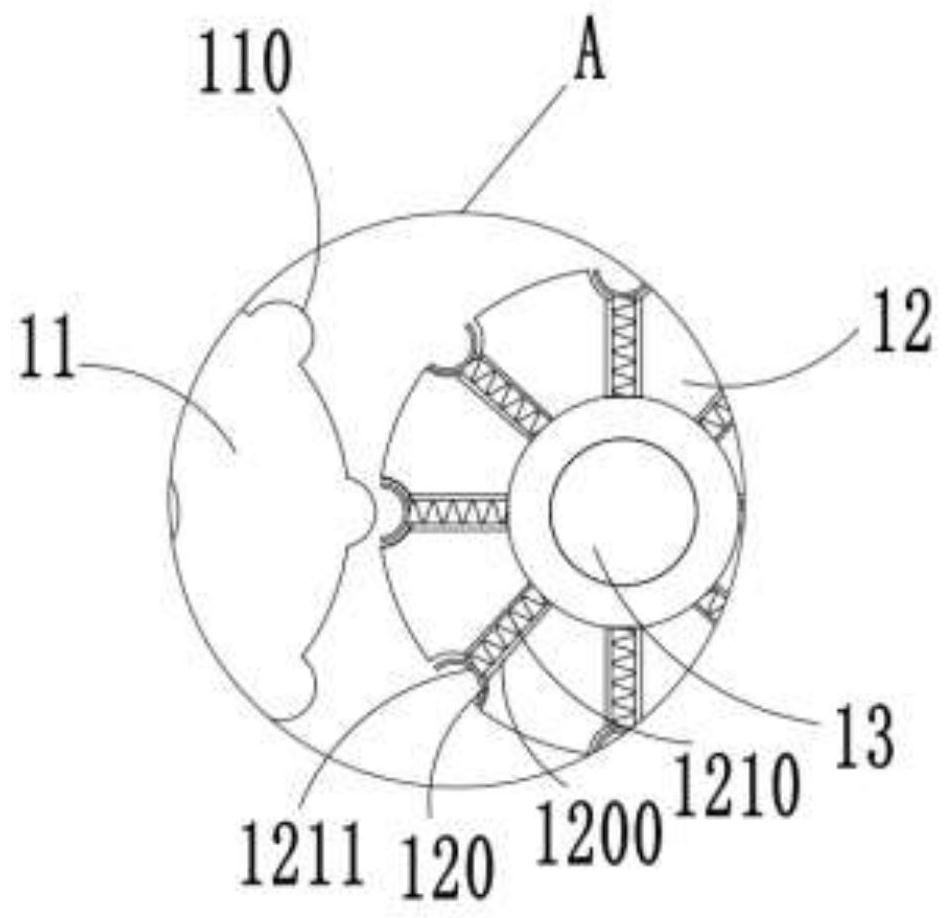

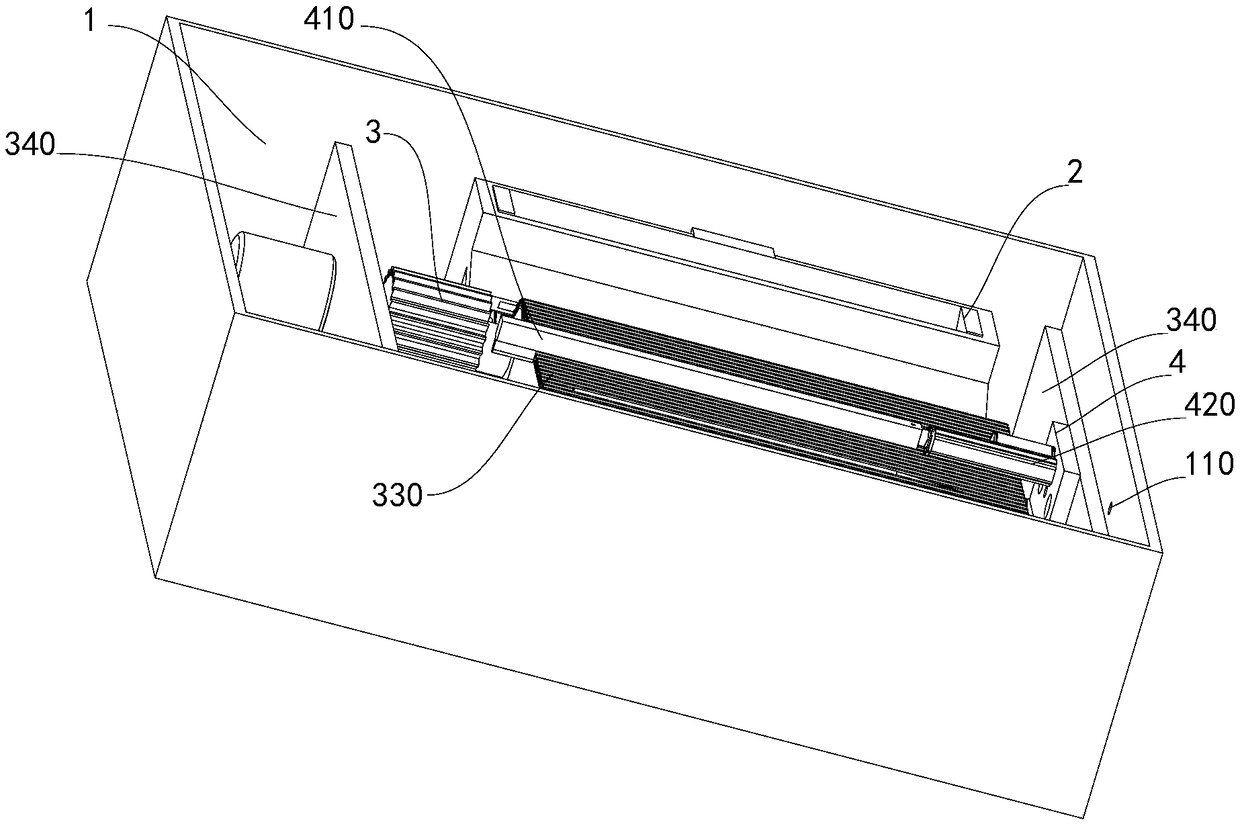

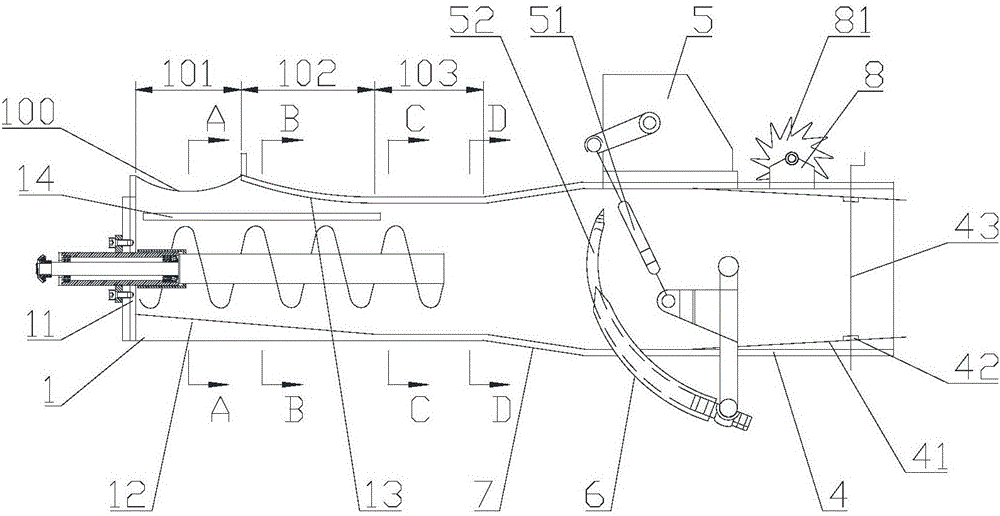

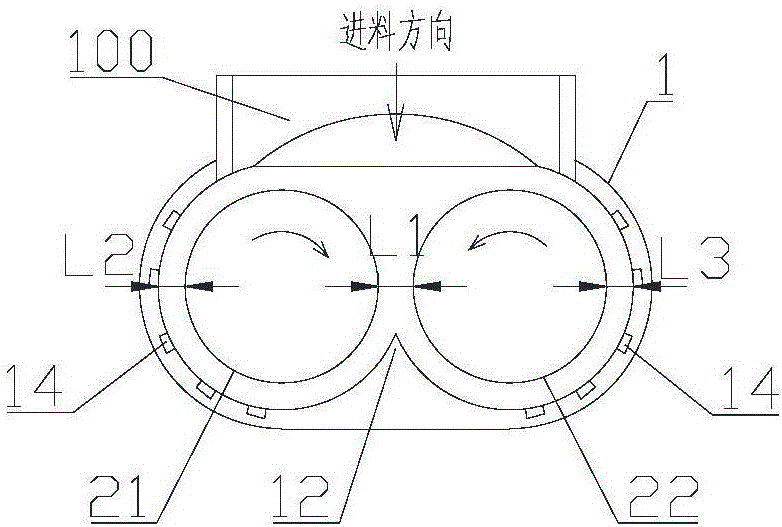

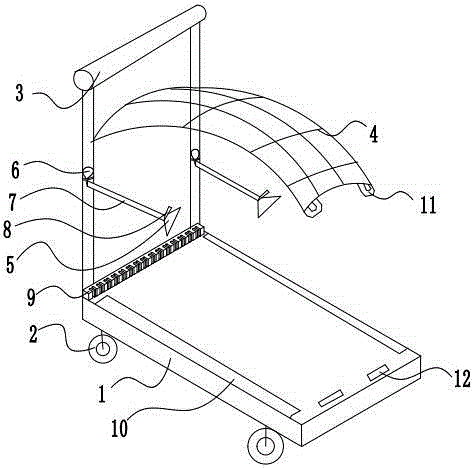

Twin-screw compression straw baler

The invention discloses a twin-screw compression straw baler, and belongs to the field of agricultural machinery. The problems of complex structure and heavy weight of a baler in the prior art are solved. According to the technical scheme, the twin-screw compression straw baler mainly comprises a twin-screw straw compressor, a baling device and a driving device, wherein the twin-screw straw compressor comprises a charging barrel, a first helical blade and a second helical blade; the charging barrel is provided with a feed inlet; the first and second helical blades are arranged abreast in the charging barrel; the charging barrel is communicated with the baling device, and is used for delivering straws to the baling device through the first and second helical blades; the first and second helical blades are driven by the driving device; the helical directions of the first and second helical blades are opposite; the rotating directions of the first and second helical blades are opposite and back to the feed inlet. The twin-screw compression straw baler is mainly used for compressing and baling the straws.

Owner:平阳县凯达包装机械厂

Method for extracting peanut oil comprehensively and efficiently

InactiveCN104560369AImprove qualityImprove oil yieldFatty oils/acids recovery from wasteFatty substance recoveryPeanut mealEconomic benefits

The invention discloses a method for extracting peanut oil comprehensively and efficiently. The method is characterized by comprising the following steps: (1) pre-treating peanut; (2) peeling and crushing the peanut; (3) pressing oil by a spiral oil press; (4) smashing and steaming peanut meal; (5) heating and stir-frying; (6) collecting the peanut oil from peanut cake. According to the peanut oil prepared by the method, nutritional ingredients are not damaged; the peanut meal is utilized fully after the oil press; due to the adoption of the adhesion effect principle of the peanut meal, the oil extraction rate of the peanut oilseeds and the quality of peanut oil are improved; moreover, the remaining ingredients can serve as animal feeds. According to the method, by controlling the temperature and increasing the rotation speed of the oil press, quick press can be implemented, the pressing efficiency is improved, the production process is simple and easy to master, and the production cost is low, so that the method has economic benefit.

Owner:刘夏

Adjusting mechanism for laser interstice of laser machine

InactiveCN104742509AEasy to adjustImprove general performanceRotary pressesLaser patterningEngineering

The invention provides an adjusting mechanism for a laser interstice of a laser machine, belongs to the technical field of machinery and solves the technical problems that in the prior art, the laser interstice of a laser pattern printing device can not be adjusted, the device can not adapt to the laser operation of packaging film with different types of thickness, and the universality is poor. According to the adjusting mechanism for the laser interstice of the laser machine, a laser roller and a press roller are connected to a stand of the laser machine, the laser interstice is located between the laser roller and the press roller, the adjusting mechanism comprises two lock plates, a connecting rod, locking pieces and springs, the two ends of the press roller are connected to the inner sides of the corresponding lock plates respectively, the locking pieces and the springs are connected to the stand, under the elastic effect of the springs, the locking pieces can abut against the outer sides of the lock plates correspondingly, the lock plates are enabled to be located on the stand, the connecting rod is arranged horizontally, and the two ends of the connecting rod are fixedly connected with the upper ends of the corresponding lock plates respectively. The adjusting mechanism for the laser interstice of the laser machine has the advantages of being convenient to adjust and great in universality.

Owner:浙江阳天包装材料有限公司

High-efficiency fabric dyeing device

ActiveCN109881409AImprove dyeing efficiencyConvenient for continuous dyeingTextile treatment machine arrangementsVibration treatmentWrinkleDyeing

The invention provides a high-efficiency fabric dyeing device, belongs to the technical field of machinery, and solves the technical problems that the existing dyeing efficiency is low, and a fabric easily wrinkles. The high-efficiency fabric dyeing device comprises a rack, wherein the rack is fixedly provided with a dyeing box internally provided with a dye, the rack is also provided with an unreeling cylinder and a reeling cylinder, the unreeling cylinder and the reeling cylinder are located at the two sides of the dyeing box, a fixing mechanism for preventing the fabric from falling off from the unreeling cylinder is arranged between the unreeling cylinder and the dyeing box, the dyeing box is internally and rotationally provided with a first rotating shaft, the surface of the first rotating shaft is provided with a spiral barrier strip, the barrier strip and the surface of the first rotating shaft form a channel for the fabric to pass through, the barrier strip is used for preventing the fabric from overlapping, the first rotating shaft is driven by a driving mechanism to rotate, and the first rotating shaft is provided with a hollow channel. The high-efficiency fabric dyeing device has the advantages that the dyeing efficiency is high, and the fabric does not easily wrinkle.

Owner:QUZHOU UNIV

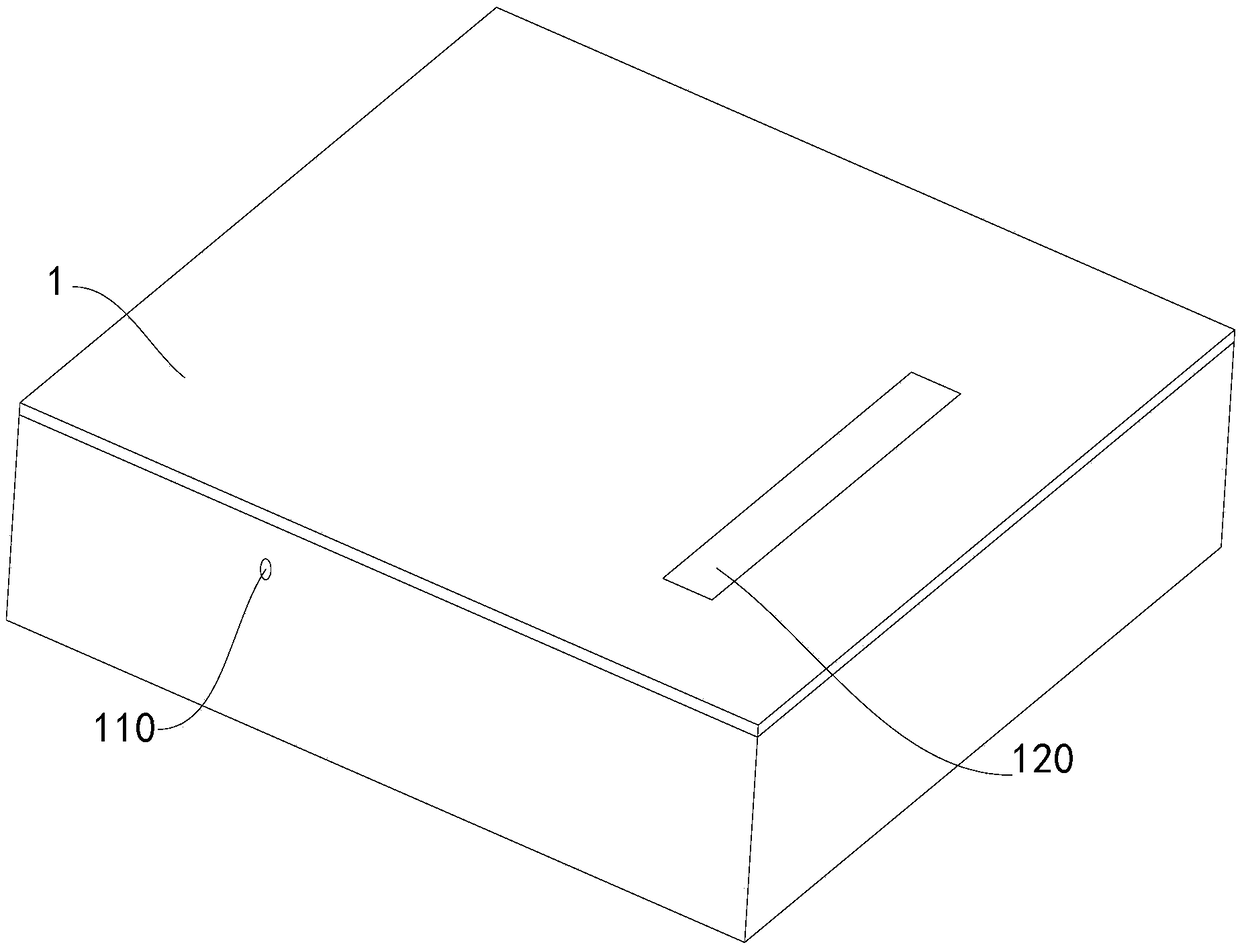

Automatic household down jacket squeezing fast drying device

InactiveCN111411495AFully dryPrevent movementTextiles and paperLaundry driersStructural engineeringMechanical engineering

The invention relates to the technical field of clothes processing, and discloses an automatic household down jacket squeezing fast drying device. The automatic household down jacket squeezing fast drying device comprises a processing machine. A power track is movably connected into the processing machine. A reset spring is movably connected into the power track. A rotating table is movably connected into the processing machine. A squeezing track is movably connected into the processing machine. The lower side of the squeezing track is movably connected with a squeezing plate. The bottom of the inside of the processing machine is movably connected with water outlet tracks, and a pressure bin is movably connected between the two water outlet tracks. Air pressure inside the power track is increased to drive the rotating table to rotate through a T-shaped rod, down jackets can be dried completely, and therefore the cleaned down jackets can be squeezed automatically, and full drying can beachieved after water remaining inside the down jackets is squeezed out; and moreover, the down jackets can be roasted completely under the effect of the rotating table, and the phenomenon of drying unevenness is prevented.

Owner:义乌端服贸易有限公司

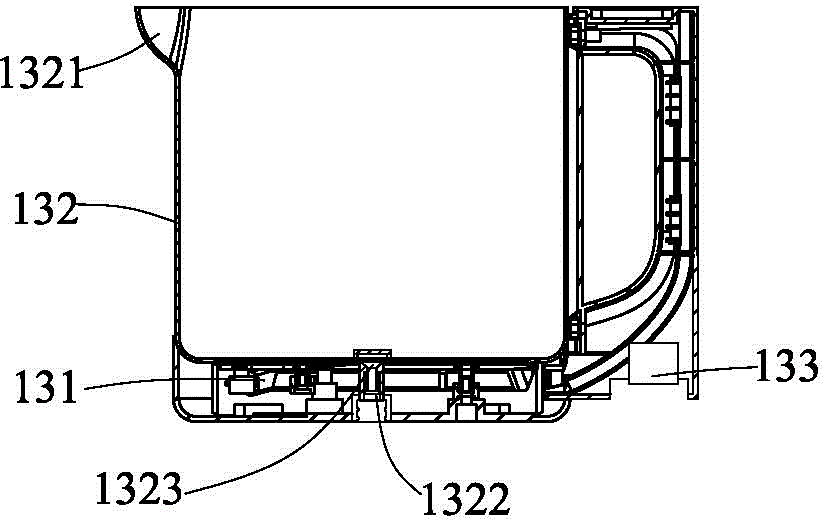

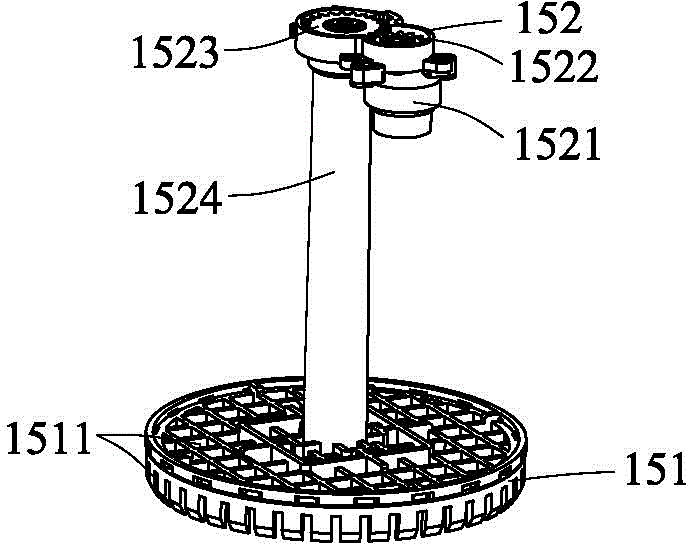

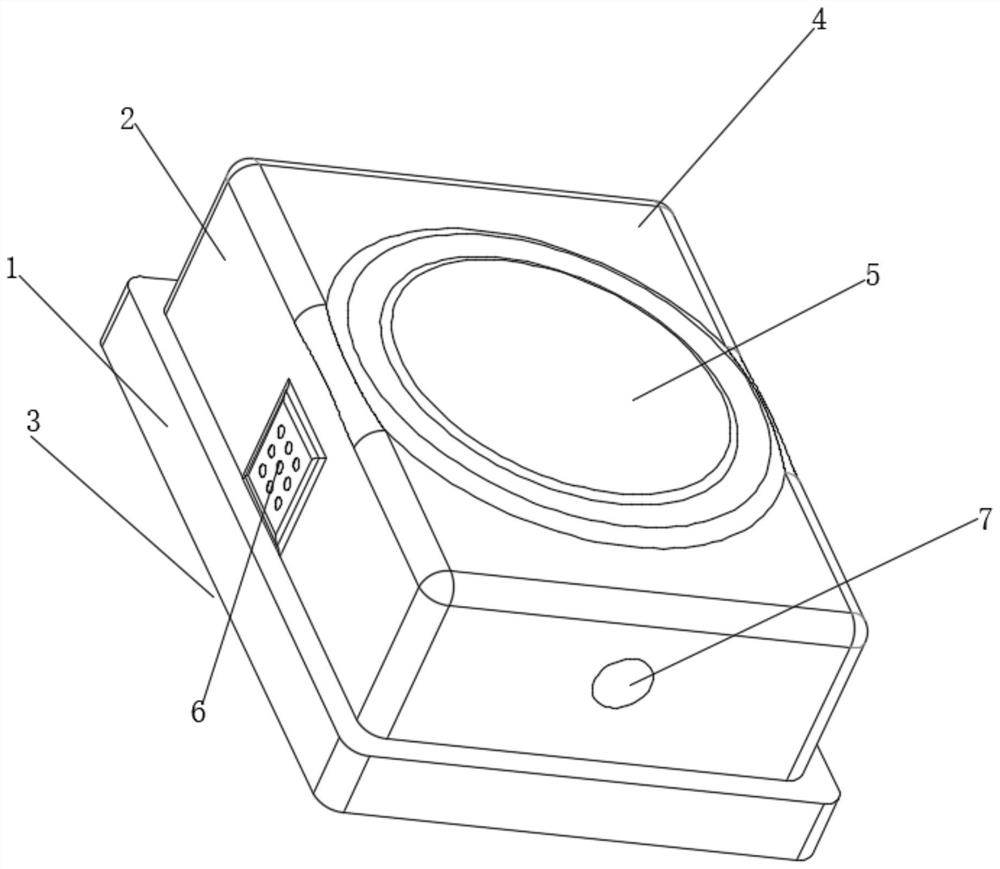

Juice squeezing device

InactiveCN107213962AIncrease collection volumeSpeed up extractionJuice extractionRotary centrifugesSlagFlesh

The invention discloses a fruit juice extracting device, which comprises a extracting device body, a connector assembly is arranged at the center of the bottom of the top groove of the extracting device body, and the connector assembly is rotatably connected to the bottom of an extraction cylinder, and the extraction cylinder is provided with a A slag collecting basket, and a crushing cutterhead is arranged on the inner bottom plate of the slag collecting basket, a sealing cover is arranged at the top opening of the extraction cylinder, and a feeding port is arranged at the center of the upper surface of the sealing cover, and the juice extracting device also includes A push rod used in conjunction with the juice extraction device. In the present invention, the slag collection basket is driven by the motor to rotate, and centrifugal force is used to separate the pulp and juice, the separation is cleaner, and the efficiency of extracting juice and the amount of juice collected are improved. Secondly, a push rod is provided to extract the pulp inside the extraction cylinder. Squeeze onto the crushing cutterhead, which improves the efficiency of the crushing cutterhead to crush the pulp.

Owner:CHENGDU YANXINGGUO TECH CO LTD

Clamping device for production and machining based on circular mechanical parts

InactiveCN113369944APrevent under-cleaningDeformation fastPositioning apparatusMaintainance and safety accessoriesMechanical componentsMachining

The invention relates to the technical field of mechanical production and machining, and discloses a clamping device for production and machining based on circular mechanical parts. The clamping device comprises a base, wherein a clamping box is fixedly installed at the top of the base, a fixing device is fixedly installed on the side, away from the clamping box, of the base, a plurality of clamping plates are arranged inside the clamping box, a photoscope is arranged at the top of the clamping box, a control panel is fixedly installed on the front face of the clamping box, and through holes are formed in the two sides of the clamping box. According to the clamping device, the performance that an air bag can be rapidly deformed and rapidly recovered under the action of stress is utilized, the air bag is arranged in the device, when the air bag is extruded, the device can be rapidly extruded, and therefore the working efficiency is improved, and the situation that the circular mechanical parts are not sufficiently cleaned is prevented.

Owner:许凤英

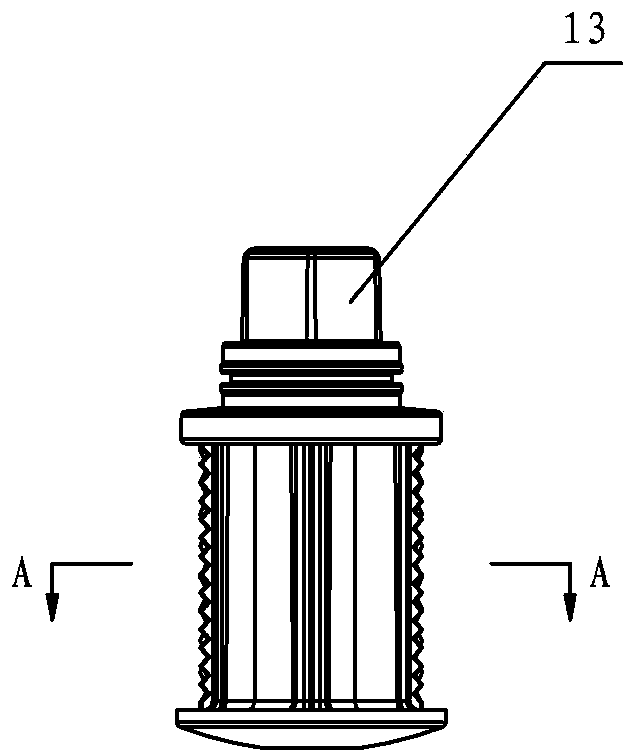

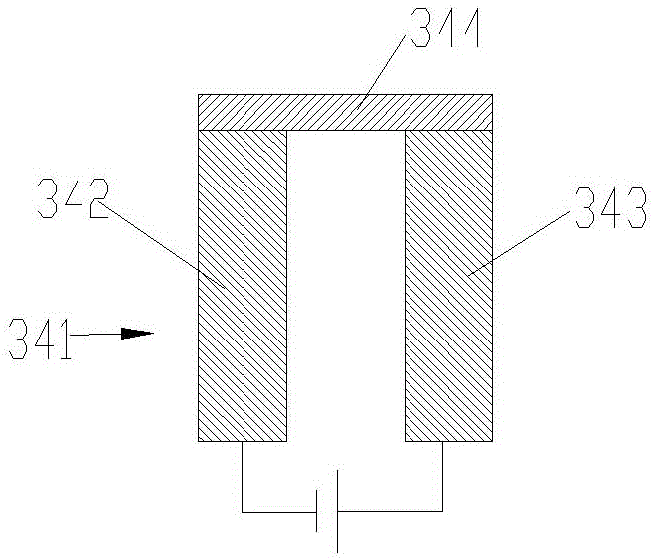

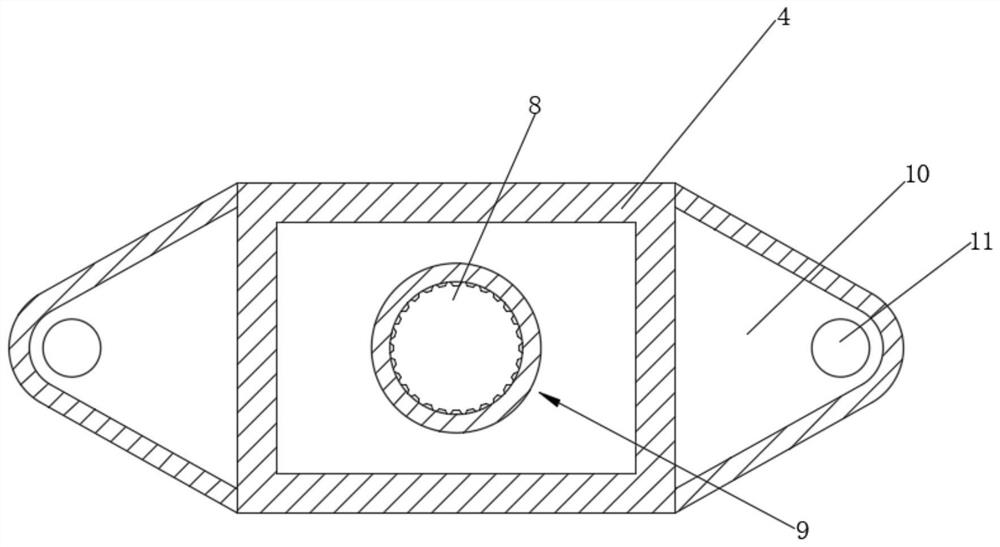

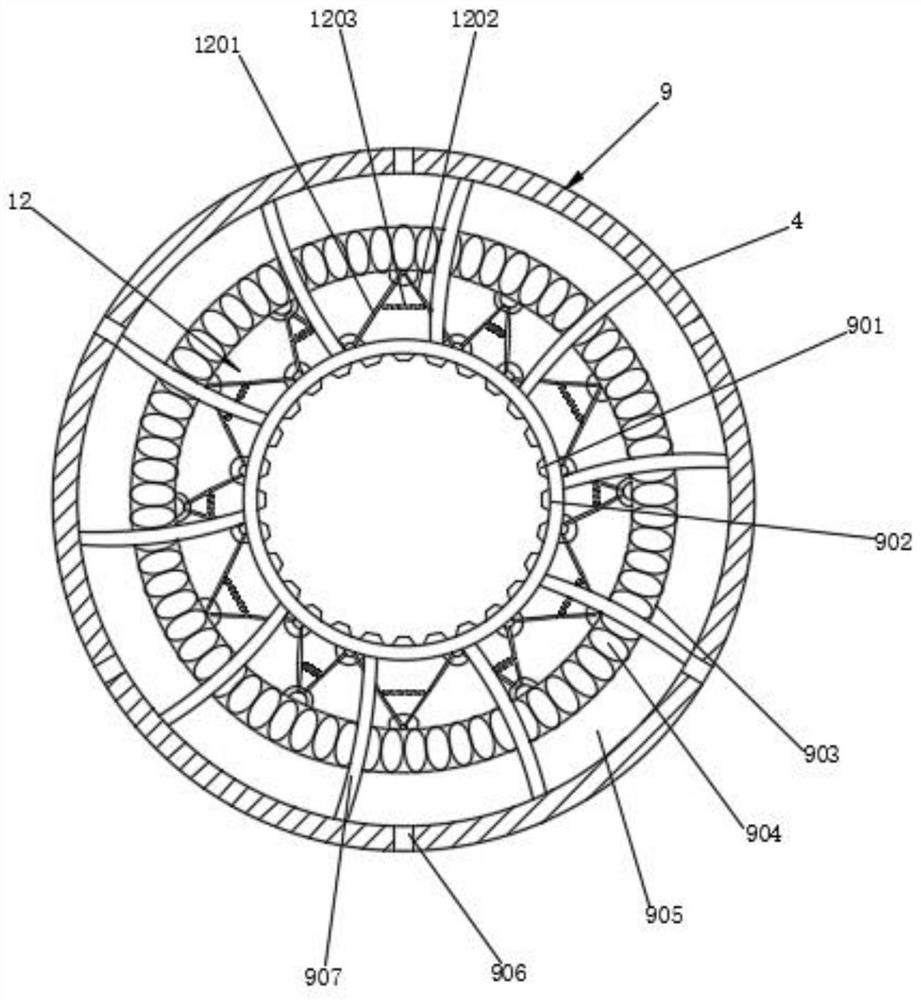

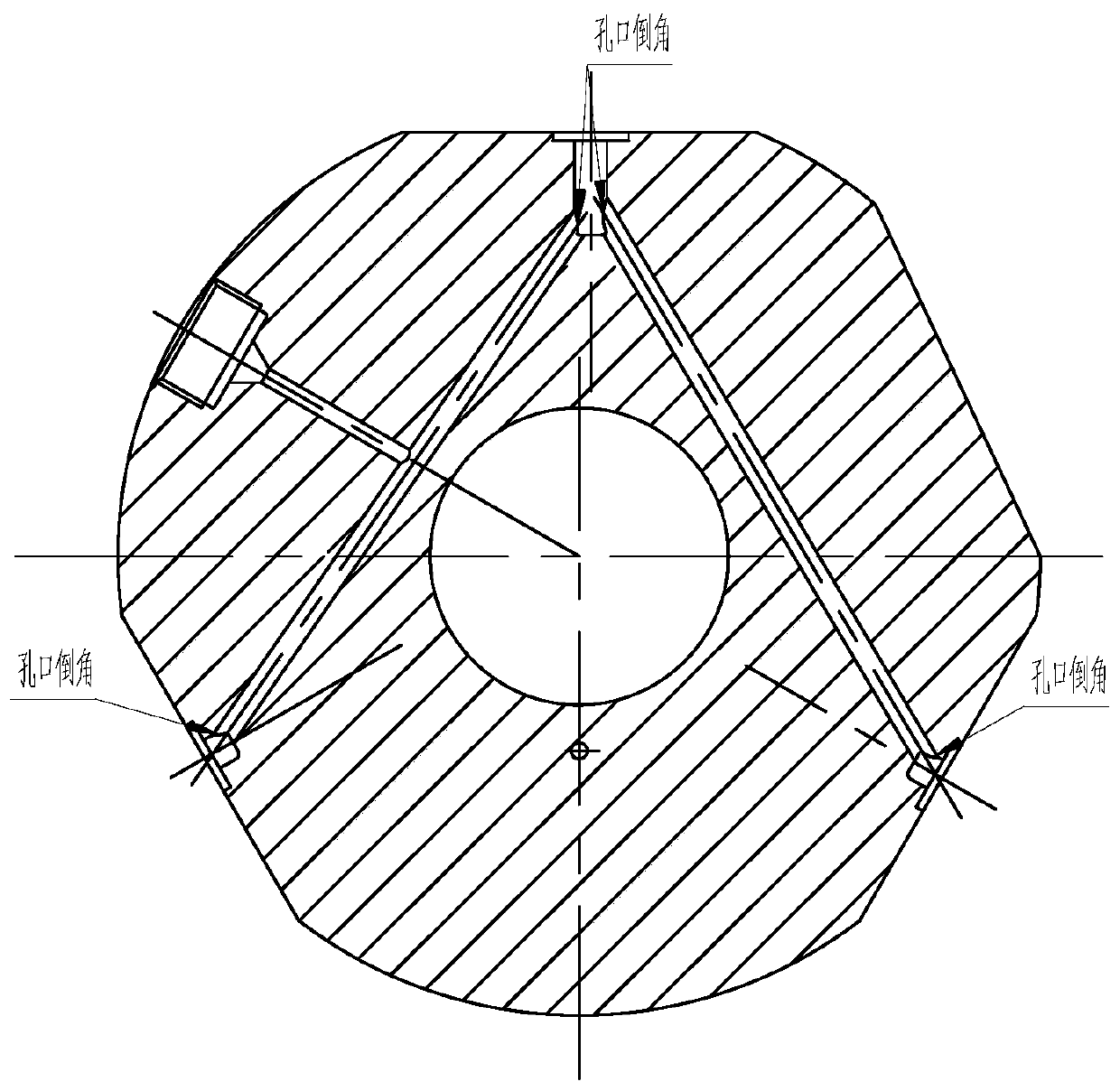

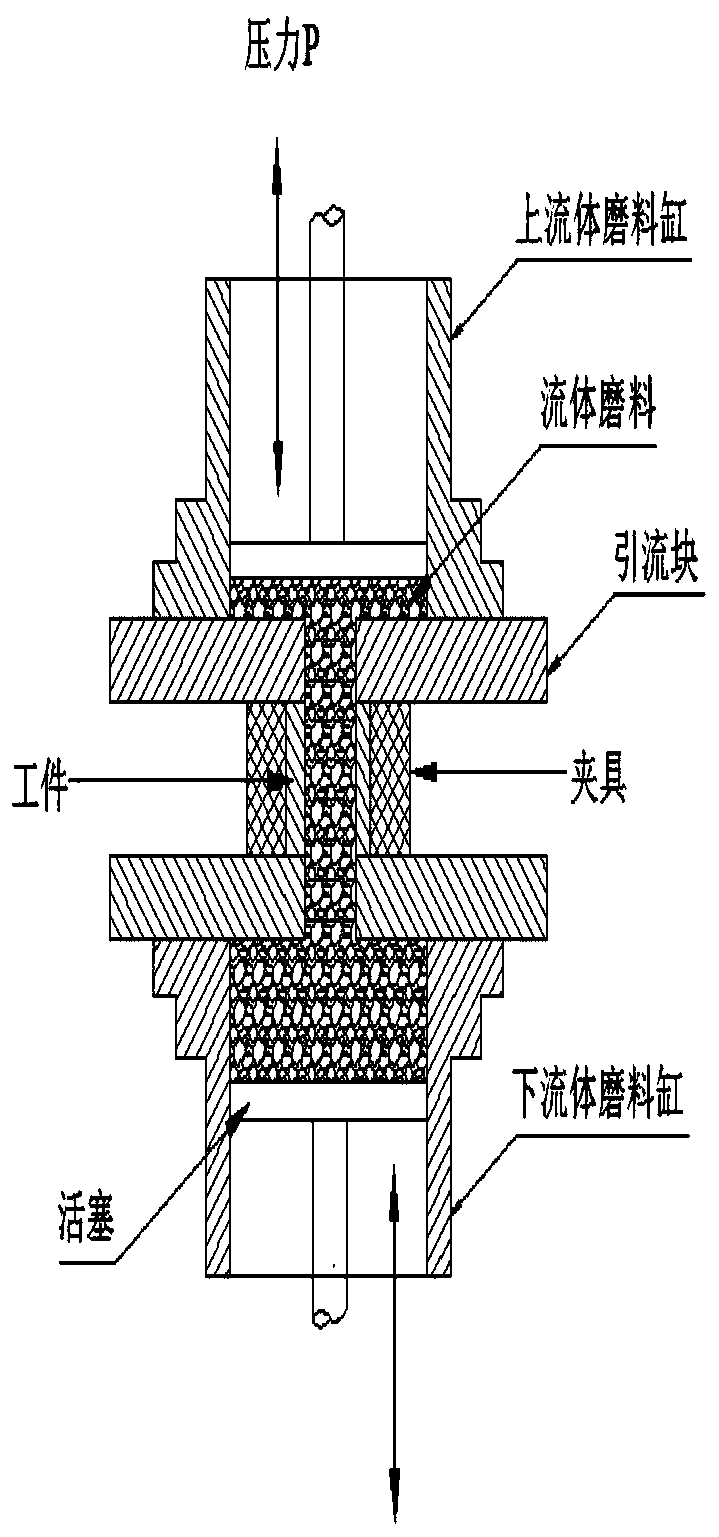

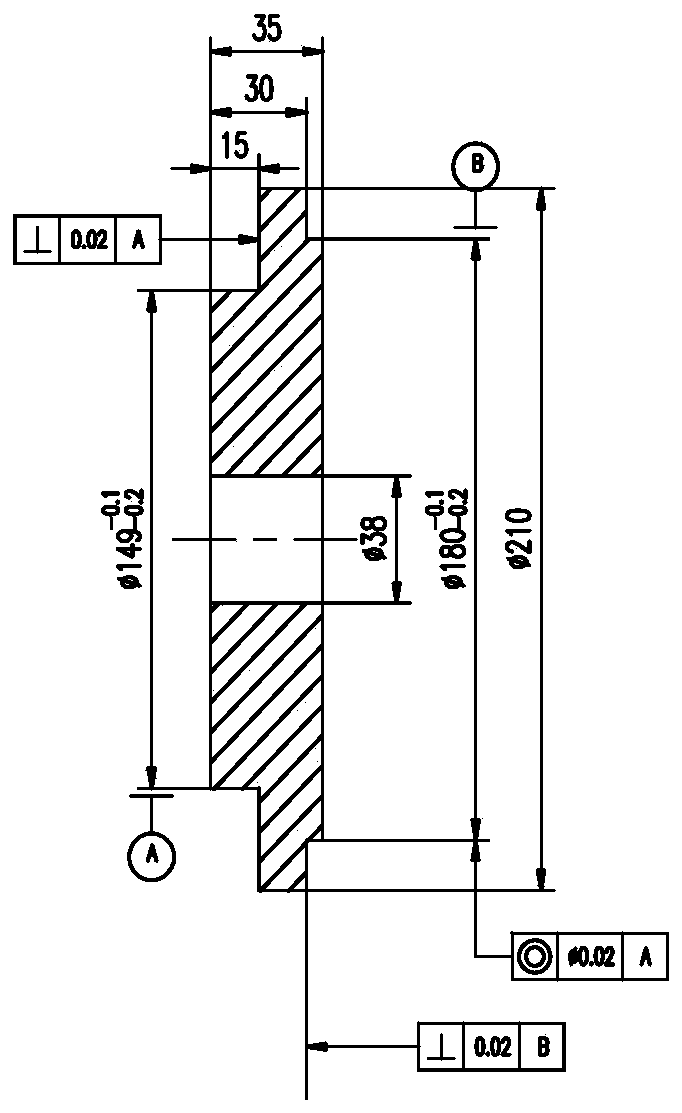

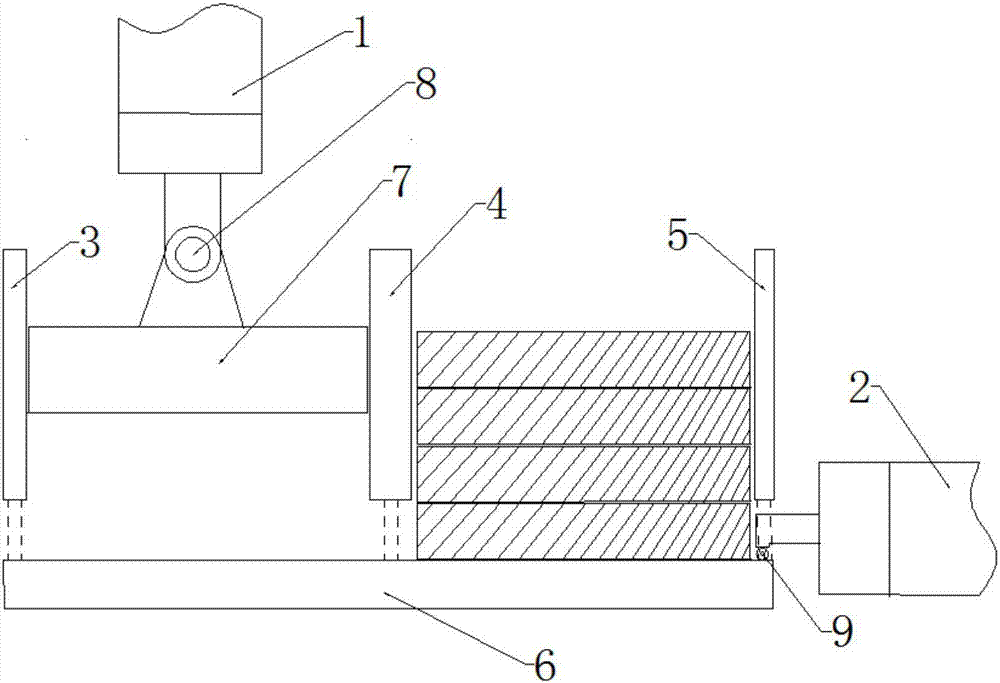

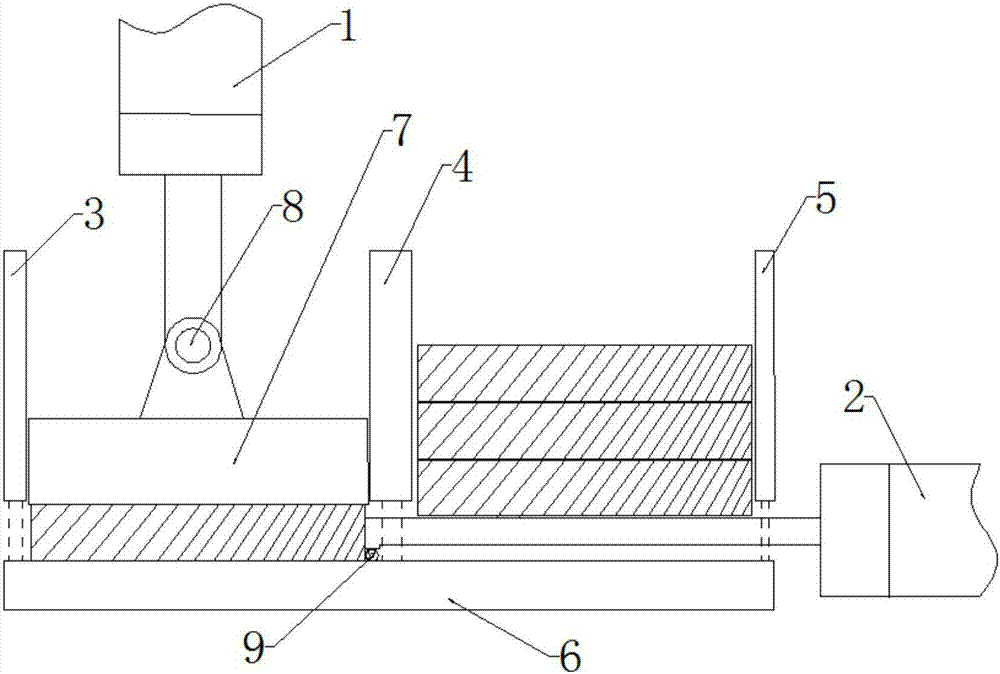

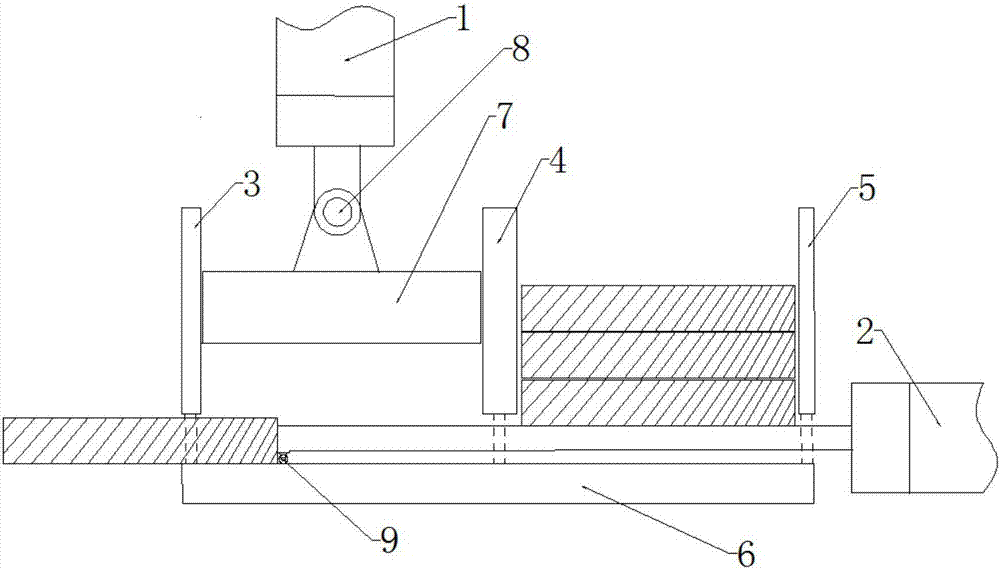

Abrasive flow flexible clamp

PendingCN111113251AQuick squeezeImprove processing qualityEdge grinding machinesPolishing machinesPhysicsAbrasive flow machining

The invention discloses an abrasive flow flexible clamp. The abrasive flow flexible clamp comprises an upper end cover, a cylinder sleeve and a lower end cover; the cylinder sleeve is an annular cylinder, and the upper end cover and the lower end cover are arranged at the upper end and the lower end of the cylinder sleeve correspondingly; a to-be-machined part is located in the cylinder sleeve andarranged on the lower end cover, material passing holes are formed in the upper end cover and the lower end cover, and the material passing hole in the lower end cover is in communication with a to-be-machined hole system in the to-be-machined part; and when abrasive flow machining is conducted on the to-be-machined part, abrasive is fed into the to-be-machined hole system of the part from a lower fluid abrasive cylinder through the material passing hole in the lower end cover, after the abrasive flows out of the to-be-machined hole system and is led out of an upper fluid abrasive cylinder through the material passing hole in the upper end cover, and after the abrasive in the lower fluid abrasive cylinder flows out completely, the abrasive collected in the upper fluid abrasive cylinder isreversely guided so as to machine the to-be-machined hole system, and the process is repeated. According to the abrasive flow flexible clamp, a pump body inclined hole can be rapidly extruded, protruding burrs on the edges of crossed holes are removed, the pump body machining quality is improved, and the pump body cleanliness requirement is met.

Owner:STATE RUN NO 616 FACTORY

Design method for flattening aluminum alloy thin plate

InactiveCN107377679AReduce labor intensityIncrease productivityMetal-working feeding devicesPositioning devicesHydraulic cylinderEngineering

The invention discloses a design method for flattening an aluminum alloy thin plate. Two hydraulic cylinders, a flattening plate, fixing plates, a bottom supporting plate and a roller are included. The design method is characterized in that one of the hydraulic cylinders is connected with the flattening plate; the corresponding fixing plates are arranged around the flattening plate, wherein the fixing plates are fixed to one end of the bottom supporting plate; and the other hydraulic cylinder and the corresponding fixing plate are installed at the other end of the bottom supporting plate, wherein the roller is installed between a pushing rod of the hydraulic cylinder and the bottom supporting plate. By controlling and driving telescopic rods of the two hydraulic cylinders, ingress-egress and flattening of the aluminum alloy thin wall plate are achieved, the labor intensity of workers is reduced, and the production efficiency is improved. The device is reasonable in structure, safe in use and rapid in extrusion.

Owner:HUNAN UNIV OF TECH

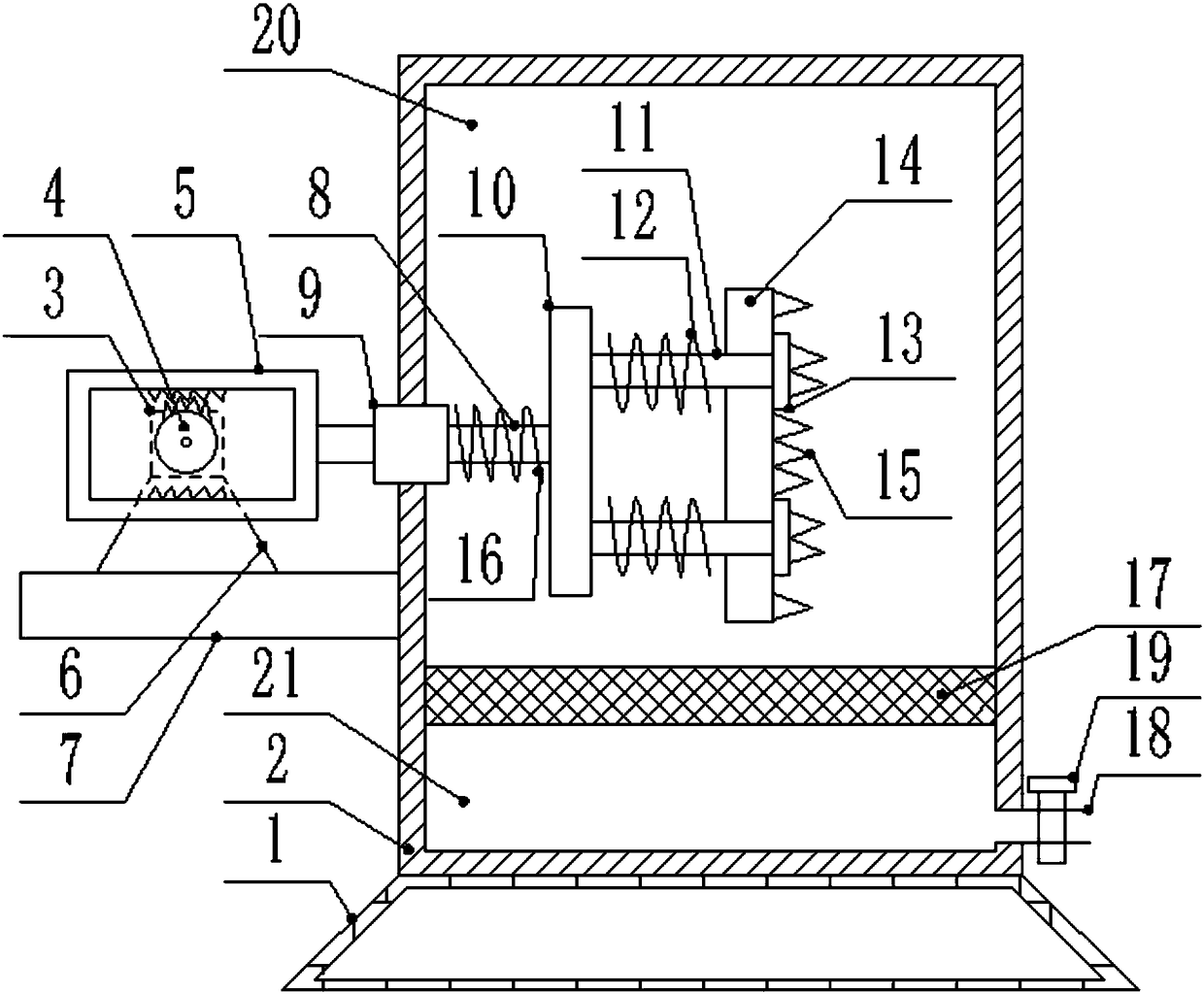

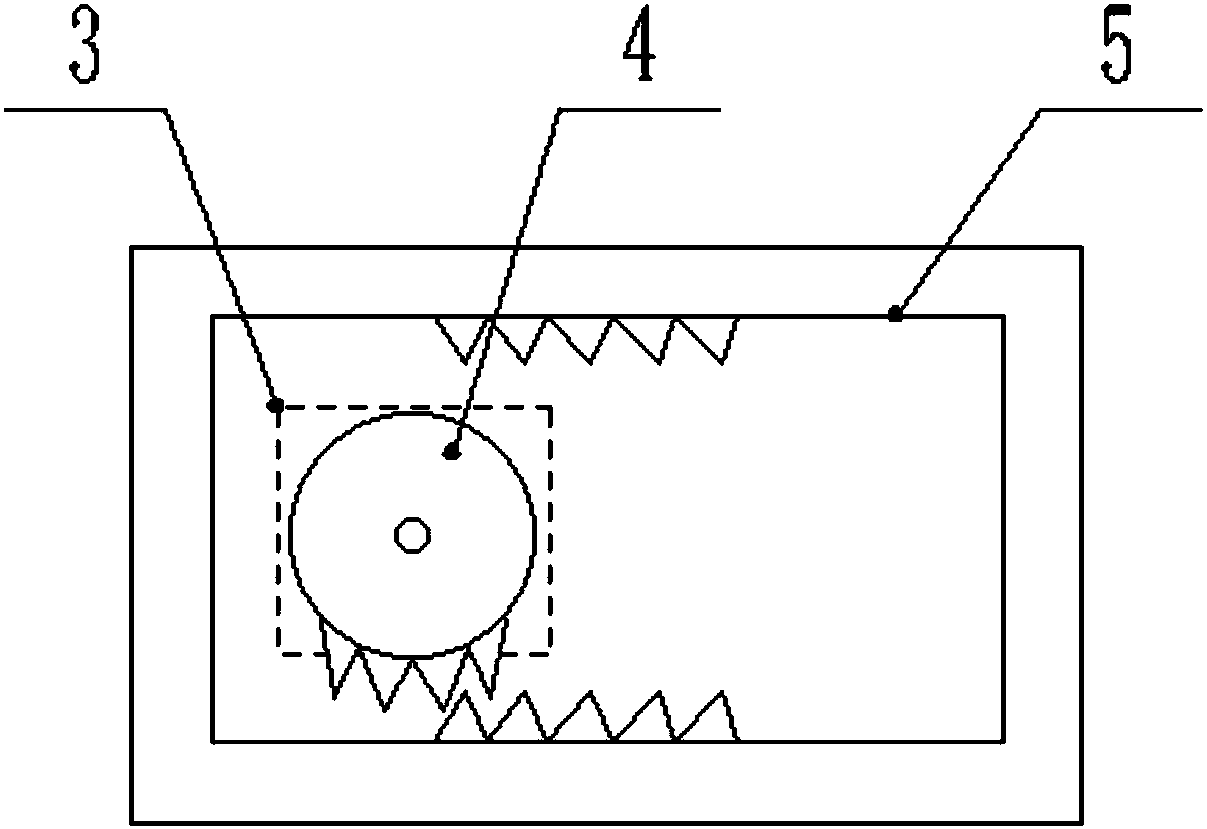

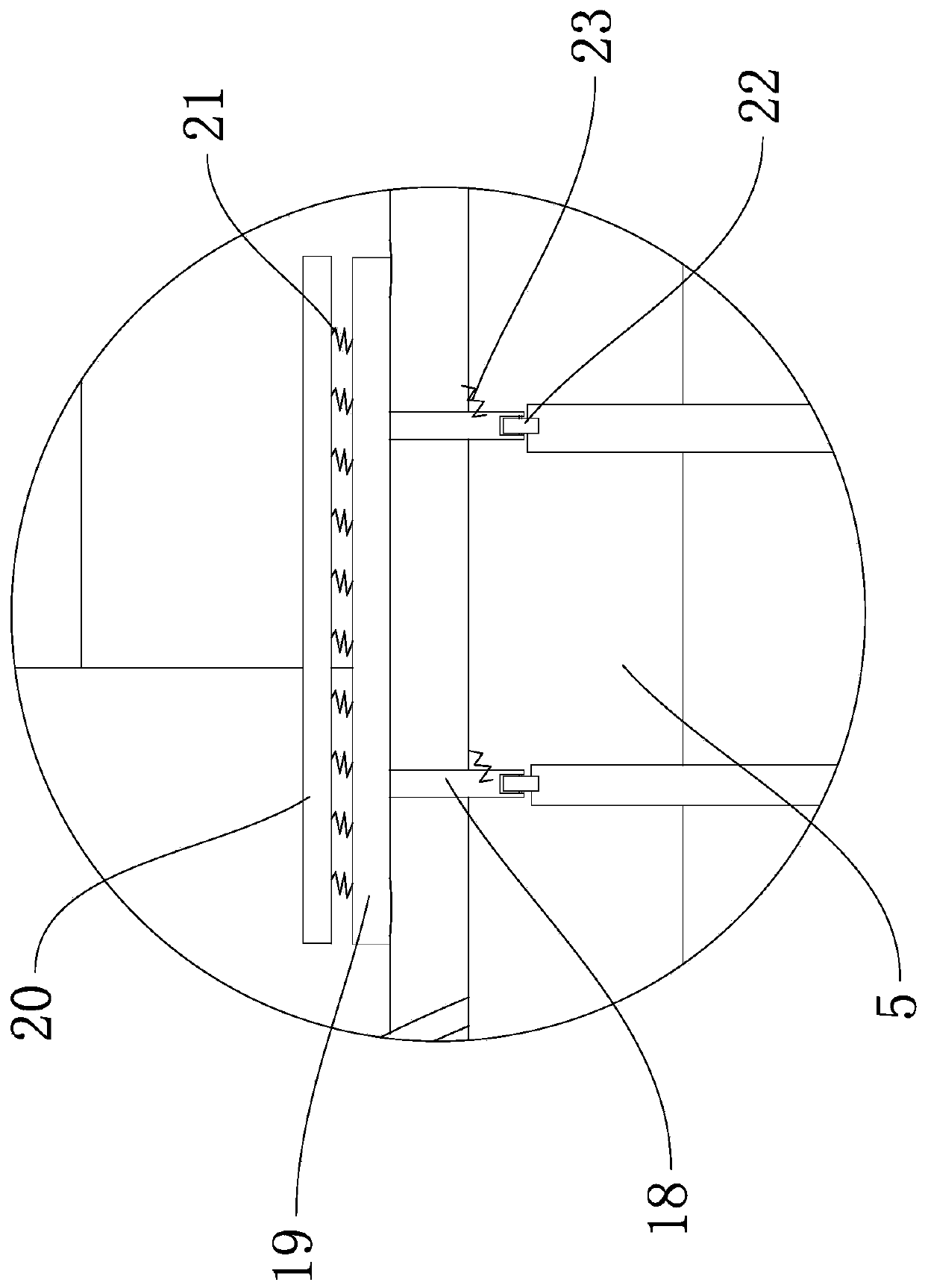

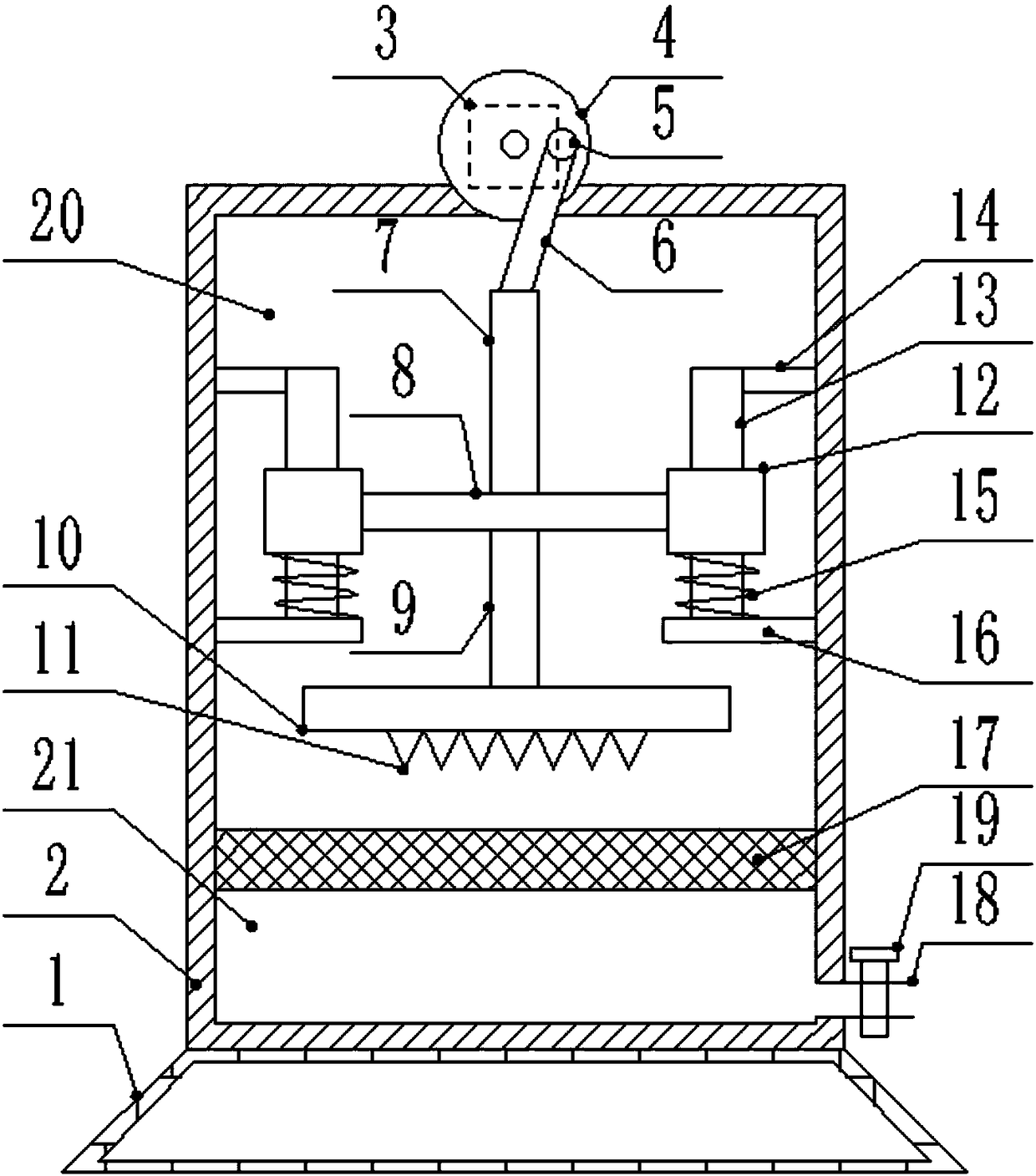

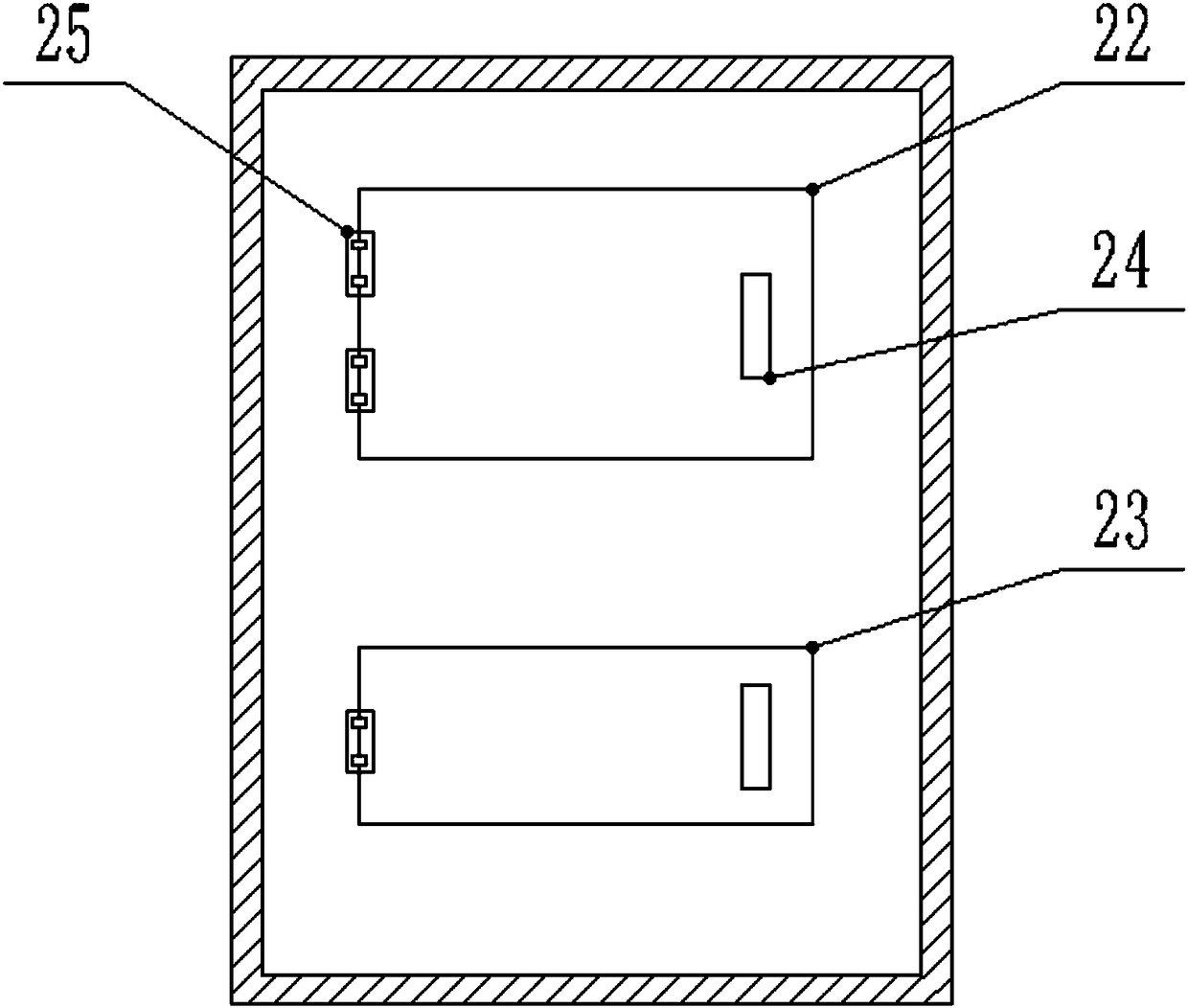

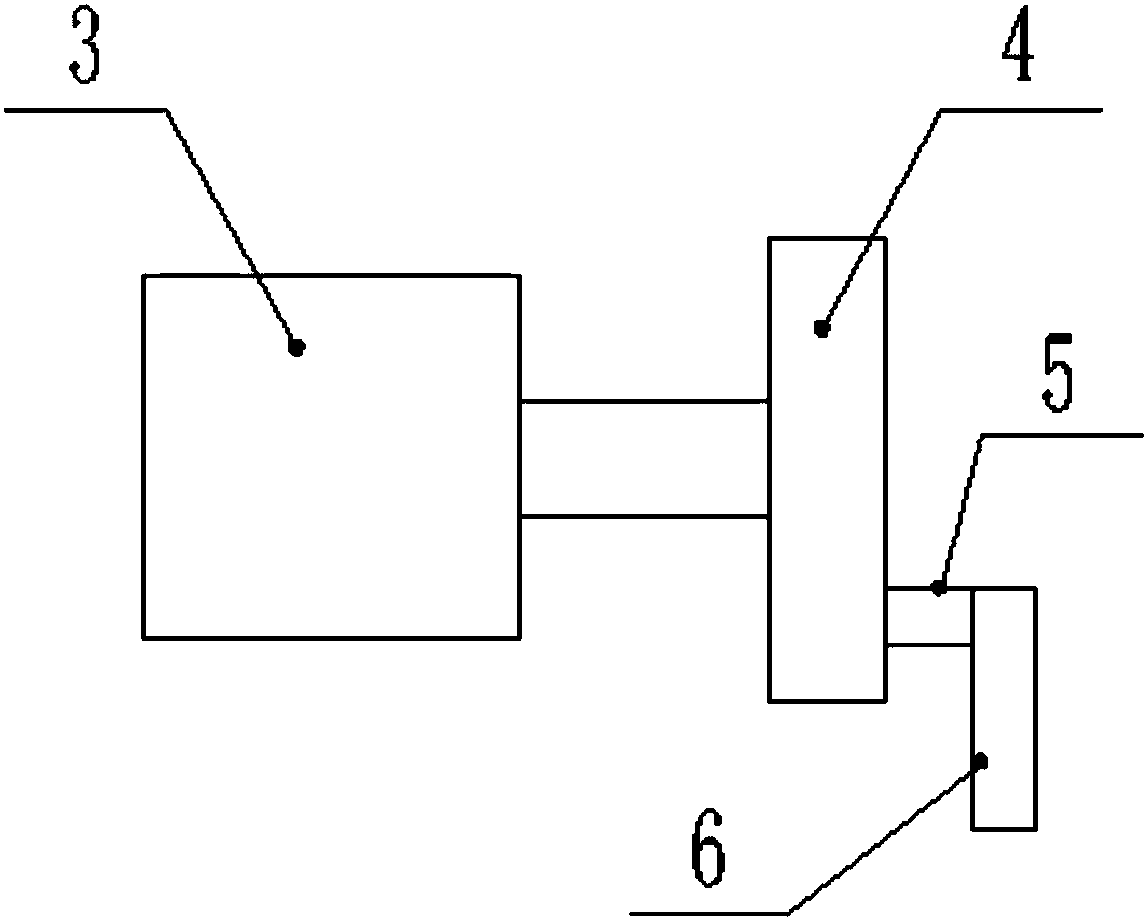

Vertical pressing type medical waste water separation treatment device

The invention discloses a vertical pressing type medical waste water separation treatment device which comprises a base, wherein a treatment box is fixedly mounted above the base; a water separating chamber and a water storage chamber are formed in the treatment box; a motor is fixedly mounted in the middle of the surface of an external box above the treatment box; a position right ahead of the center of the motor is connected with a round wheel; a sliding block is fixedly connected with the right side of the surface in the center of the round wheel; a crank is fixedly connected with a position below the surface of the sliding block; a push rod is fixedly connected with the lower end of the crank; the lower end of the push rod is fixedly connected with a first connecting rod; a fixed rod is fixedly connected with the middle below the first connecting rod; an extruding plate is fixedly connected with the lower end of the fixed rod; sawteeth are fixedly mounted on the lower surface of the extruding plate; slidable sliding blocks are fixedly connected with the left and right ends of the first connecting rod; and a sliding rod is in contact connection with the interior of the middle ofeach of the slidable sliding blocks. The vertical pressing type medical waste water separation treatment device is more obvious in extruding effect, can rapidly extrude water out in medical waste completely to prevent the situation that part of moisture flows into the soil to pollute the soil during the collective burn process.

Owner:陈钦先

Glass conveyor

InactiveCN105173725ASimple structureEasy to manufactureCharge manipulationConveyor partsEngineeringPulley

The invention relates to a glass conveying device, in particular to a glass conveyor. The glass conveyor comprises a bottom board, sliding wheels and a handle, wherein the sliding wheels and the handle are arranged on the bottom board. The handle is located at one end of the bottom board. The handle is provided with an elastic net cover used for binding glass. The net cover is provided with clamping pieces. Buckles in which the clamping pieces are inserted are arranged at the other end, away from the handle, of the bottom board. The handle is further provided with suction cups and air bags capable of being manually squeezed. Air pipes for communication are arranged between the air bags and the suction cups. The suction cups are provided with squeezing blocks used for closing the air pipes and exhausting air. The bottom board is detachably connected with a clamping groove where glass is clamped and located. The glass conveyor can be used for conveying glass of various sizes.

Owner:深圳市光华中空玻璃工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com