Fruit ice cream machine

An ice cream machine and fruit technology, which is applied in the directions of frozen desserts, food science, and applications, can solve the problems of large size and low work efficiency of fruit ice cream machines, and achieve high food utilization, high work efficiency, and simple and reasonable structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

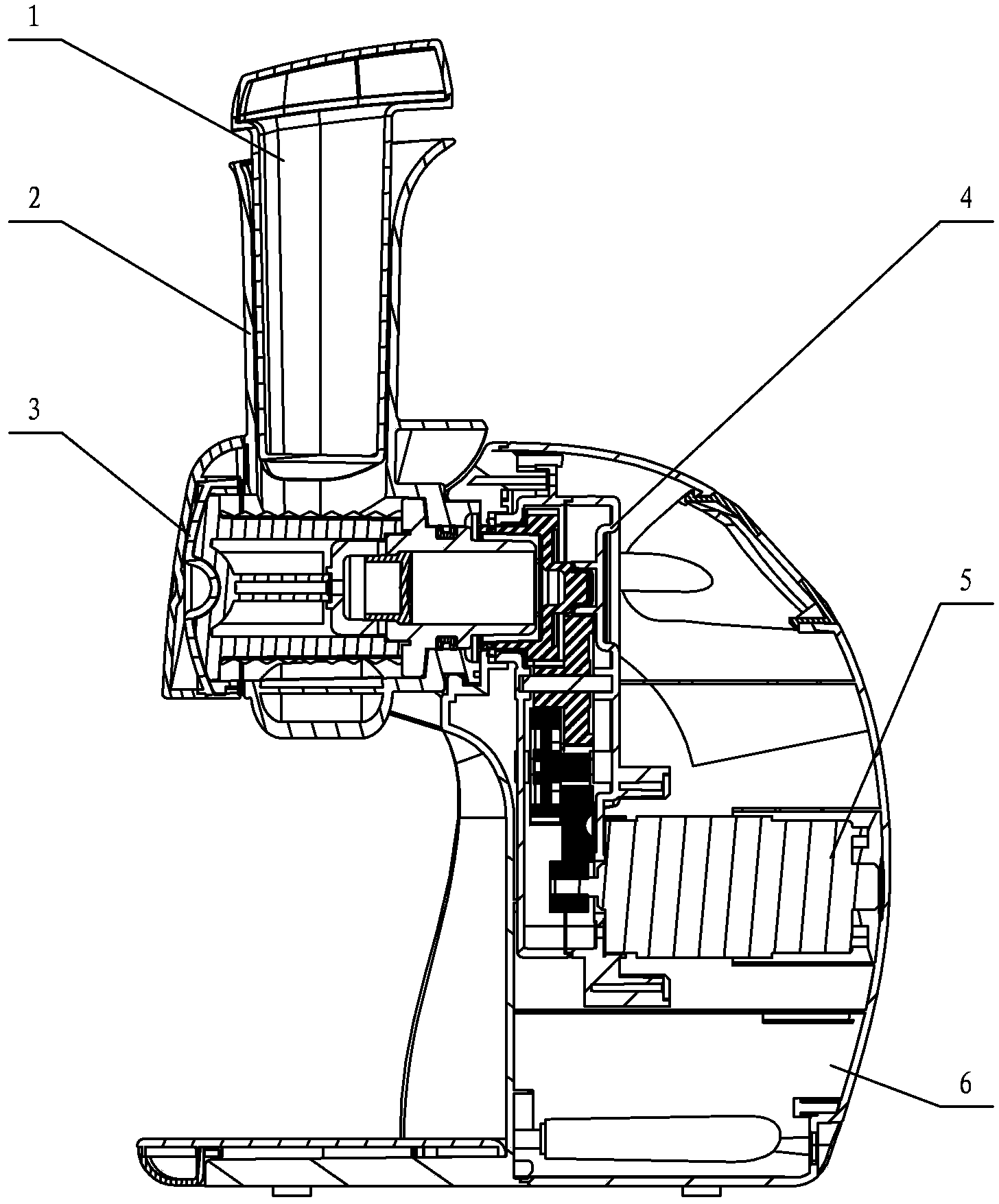

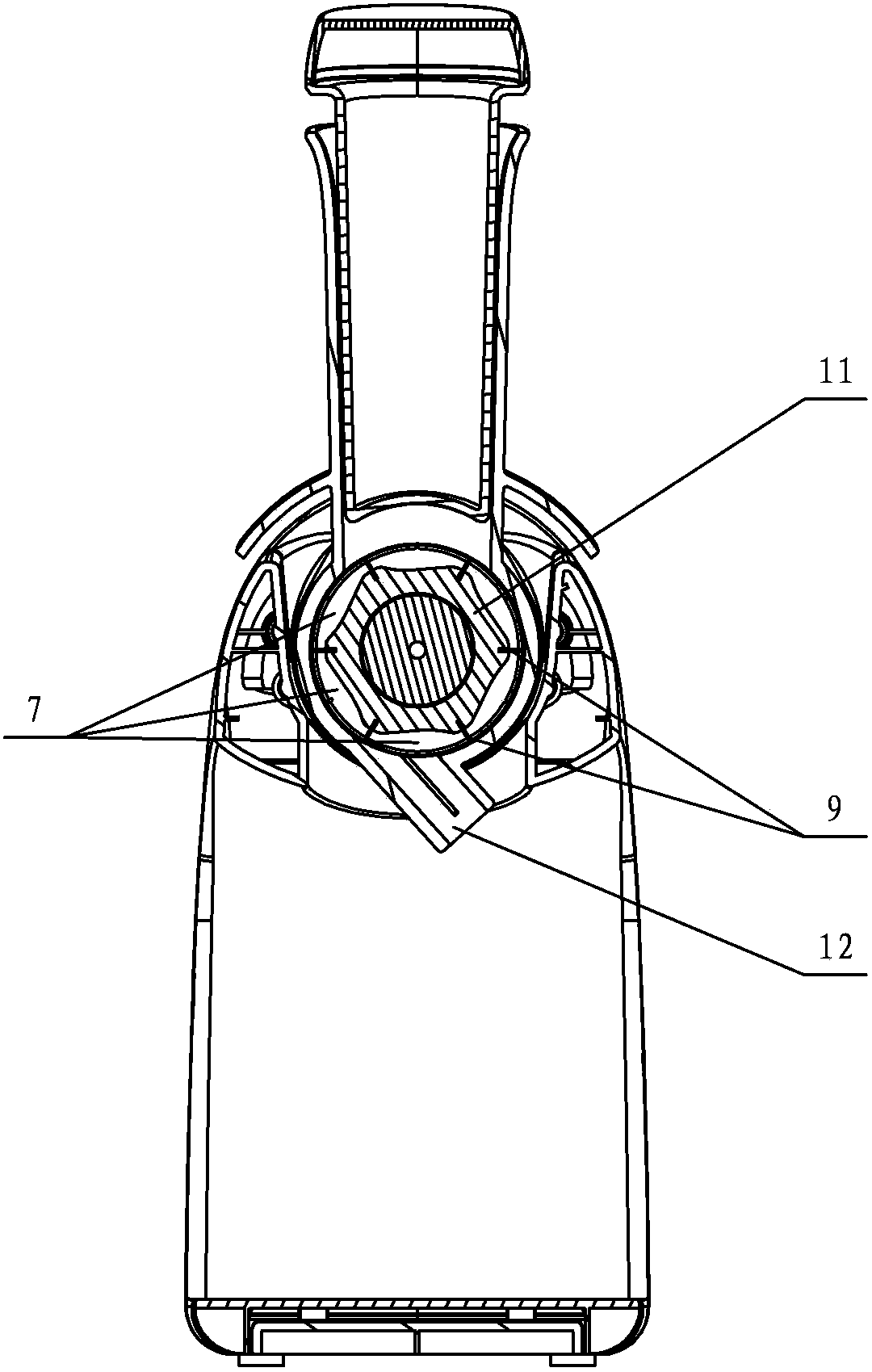

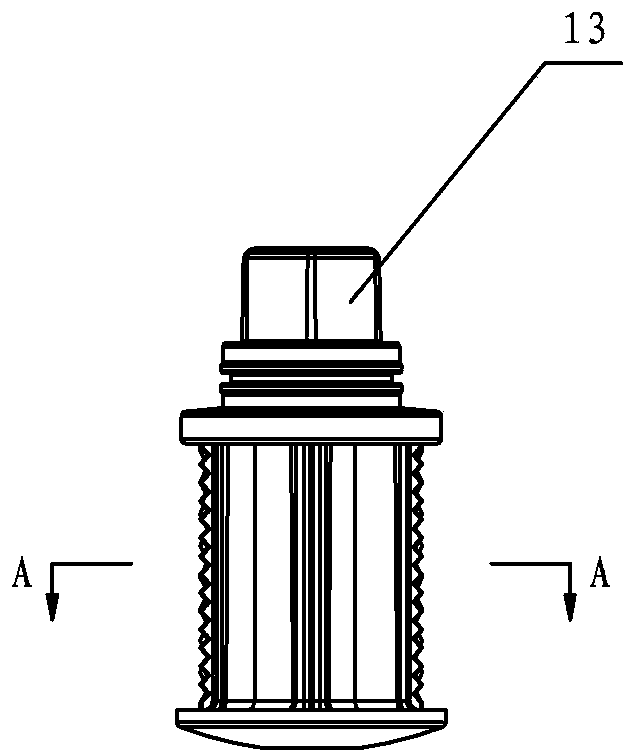

[0024] see Figure 1-Figure 5 , the fruit ice cream machine, including the feeding bin arranged on the base 6, the feeding bin 2 communicates with the feeding bin, the stirring knife is arranged in the feeding bin, the motor 5 arranged in the base 6 passes through the speed reduction mechanism 4 Connected with the connecting head 13 of the stirring knife, the stirring knife includes a prism-shaped knife seat 11 , and the stirring blade 9 is embedded on the corners of the knife seat 11 .

[0025] In this embodiment, the knife seat 11 and the stirring blade 9 divide the feeding bin into more than two stirring chambers 7 . When this product is working, it has the self-priming performance similar to that of a gear pump.

[0026] The cross section of the knife seat 11 is triangular, quadrangular, pentagonal, hexagonal or polygonal.

[0027] A pressing rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com