Patents

Literature

311 results about "Ice-cream maker" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A domestic ice cream maker is a machine used to make small quantities of ice cream for personal consumption. Ice cream makers may prepare the mixture by employing the hand-cranking method or by employing an electric motor. The resulting preparation is often chilled through either pre-cooling the machine or by employing a machine that freezes the mixture.

Ice Cream Maker

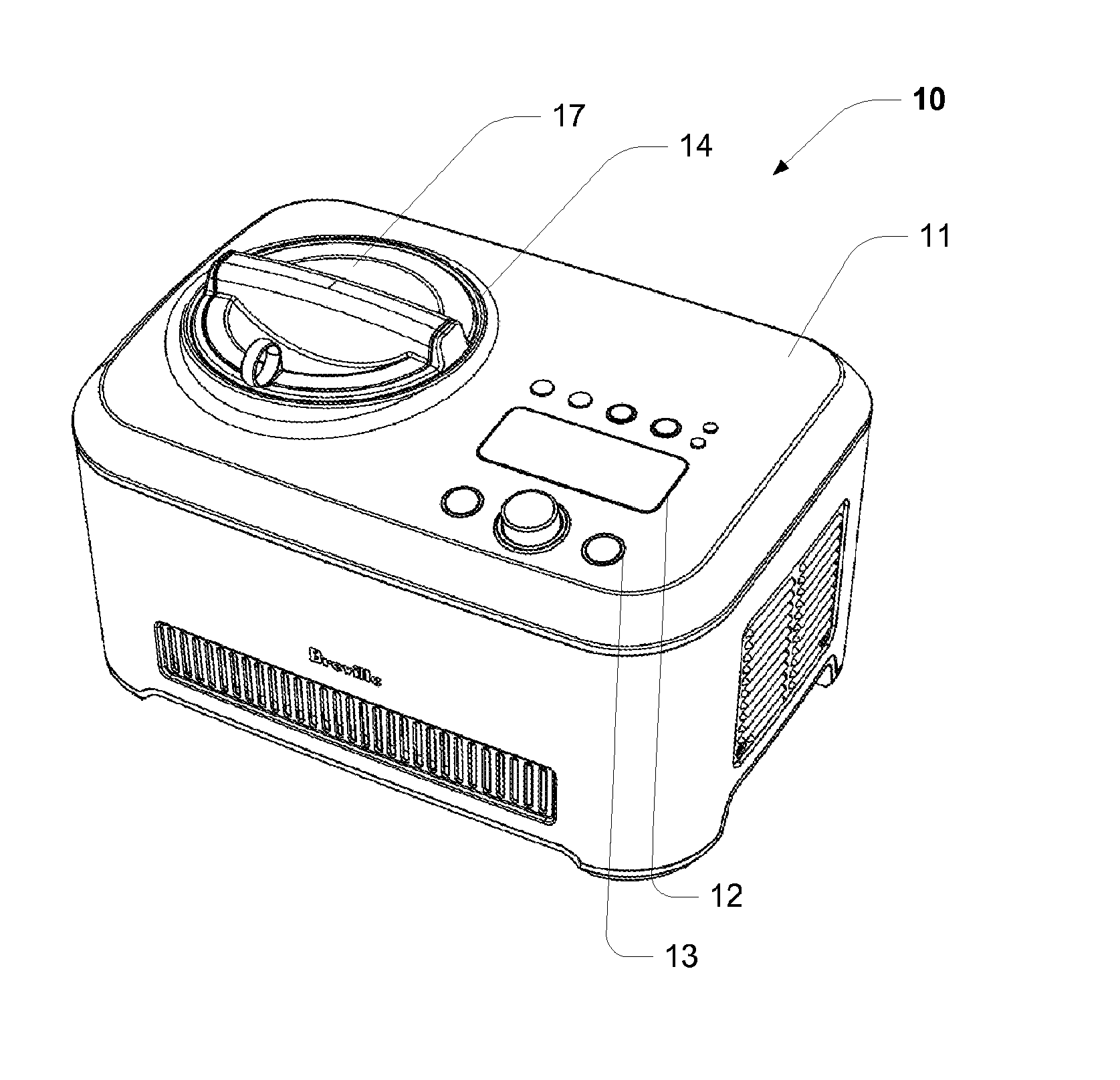

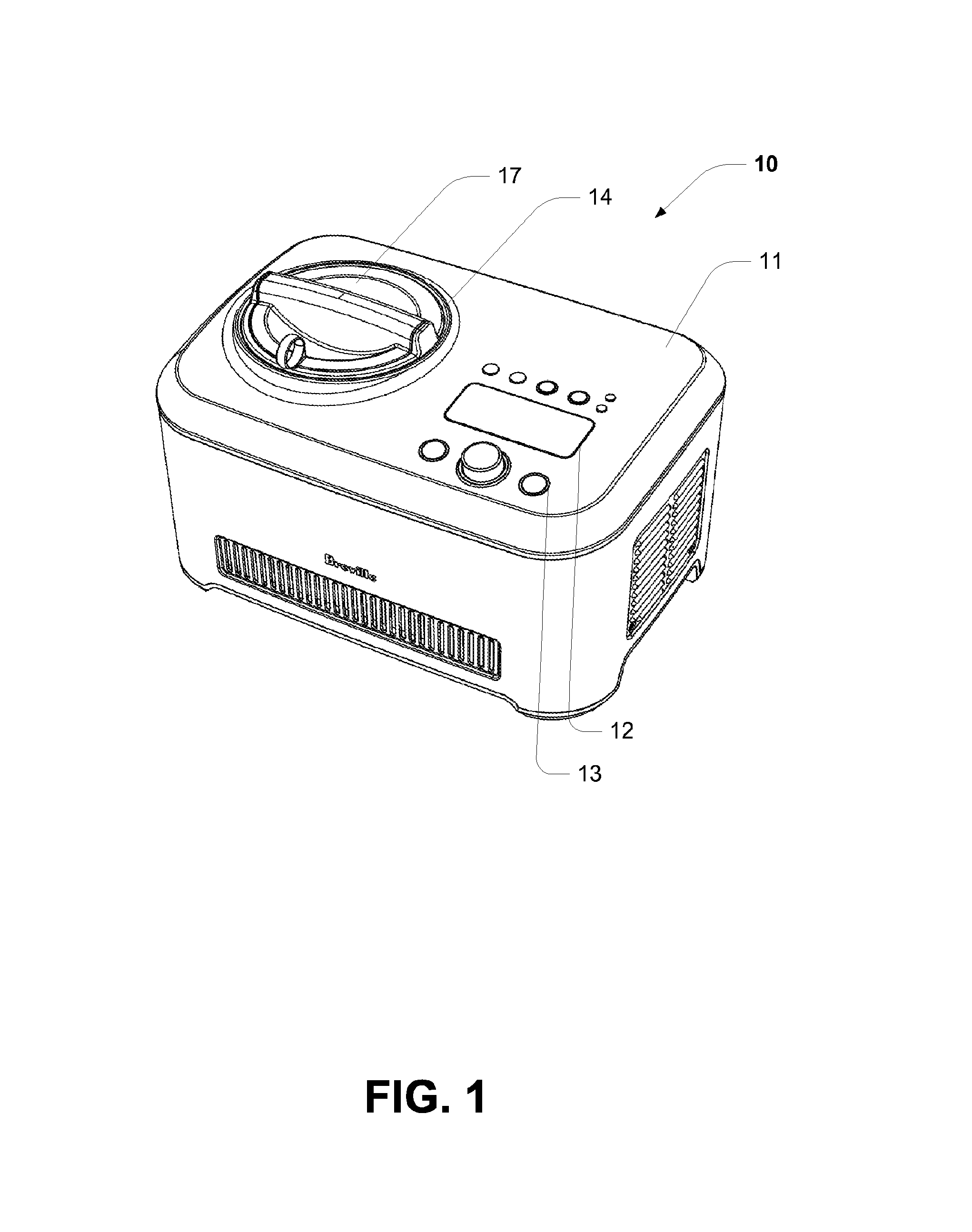

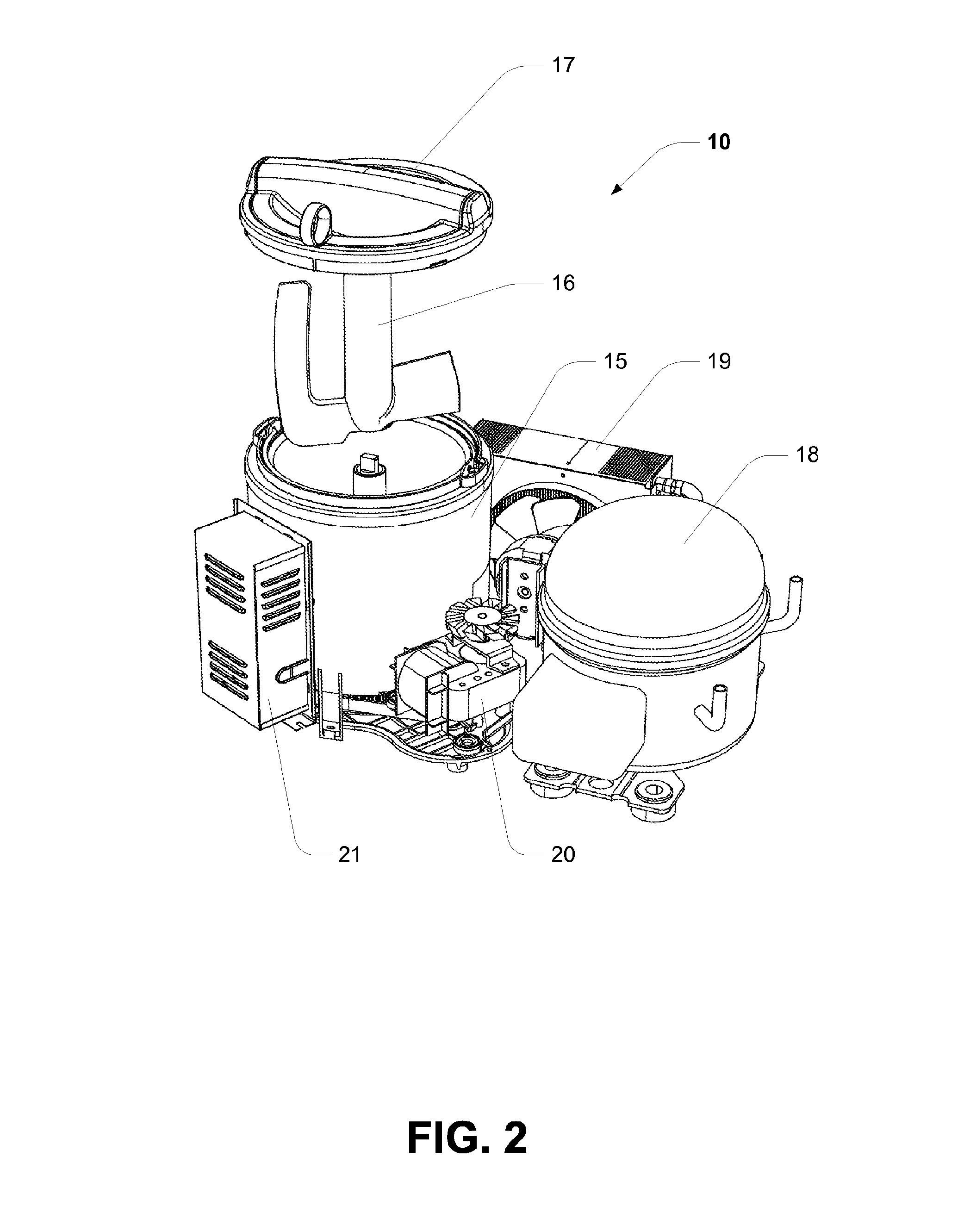

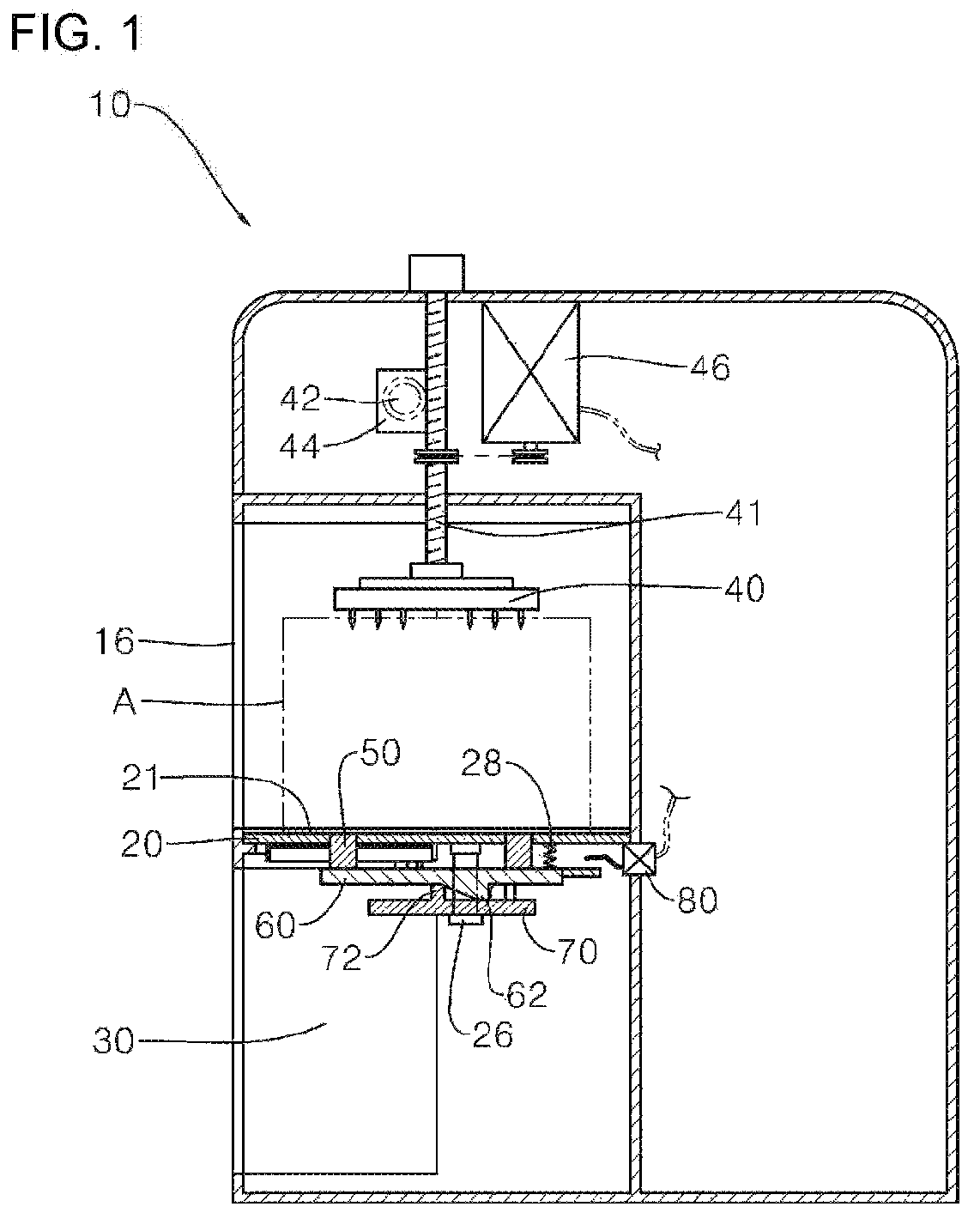

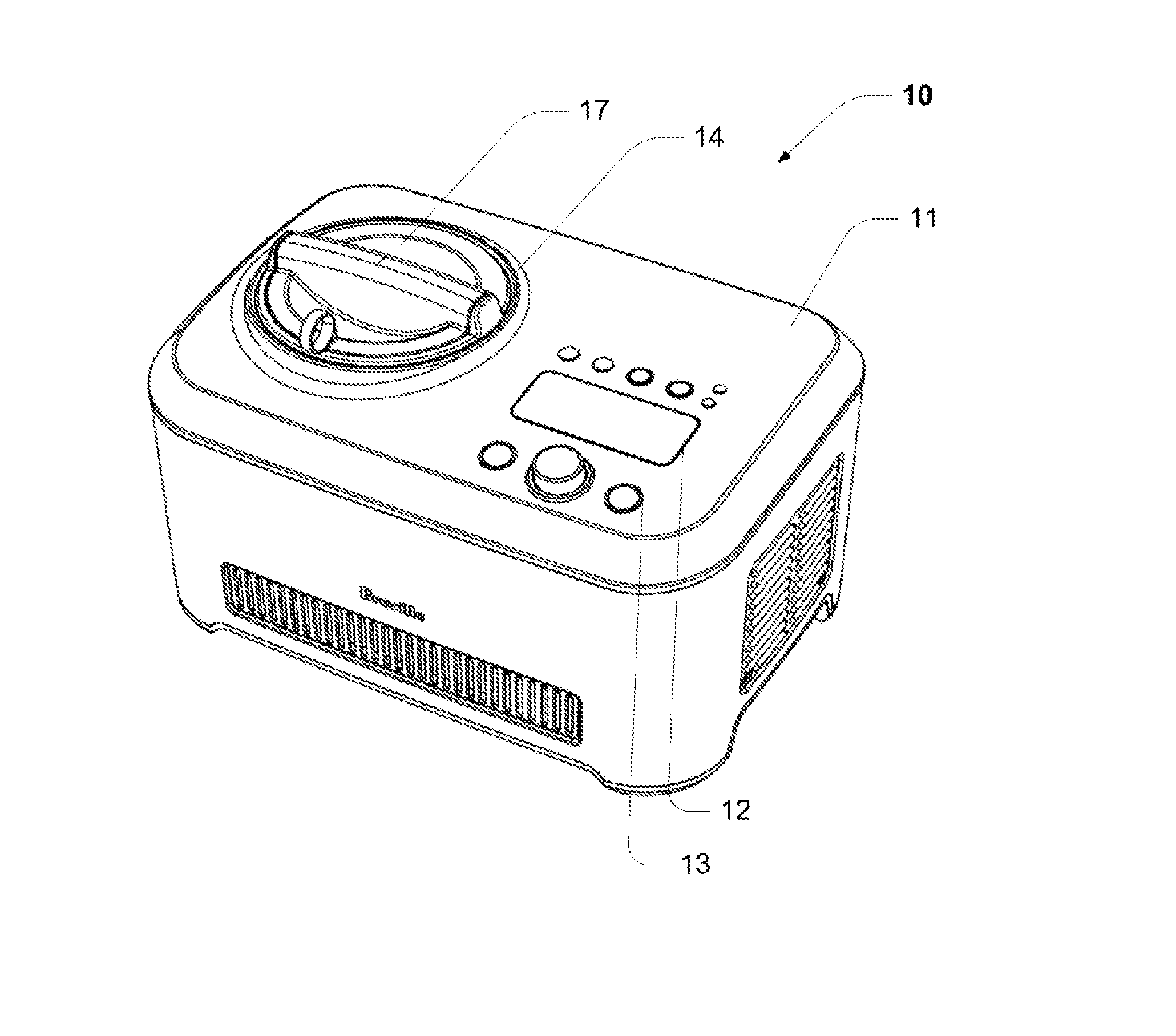

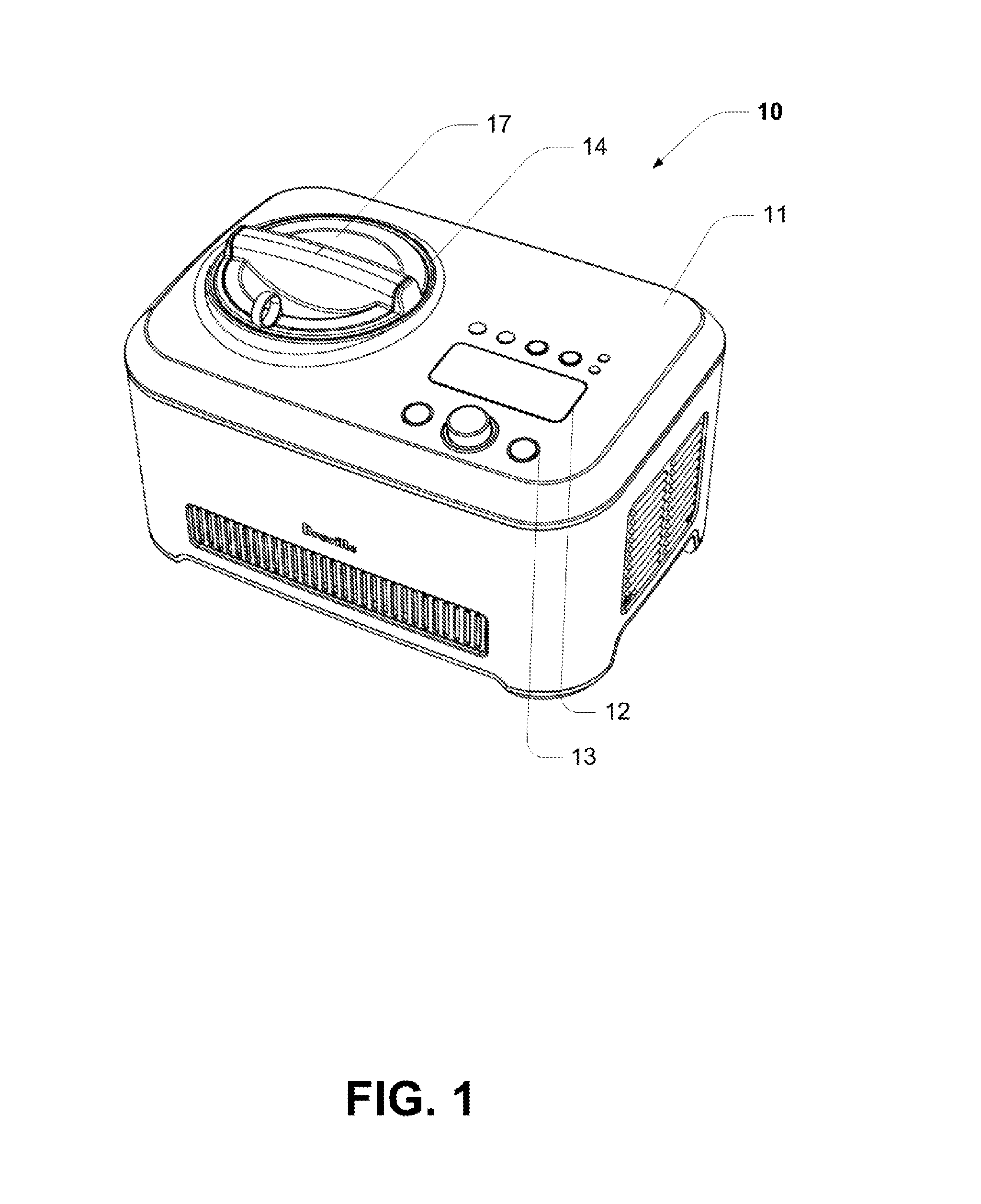

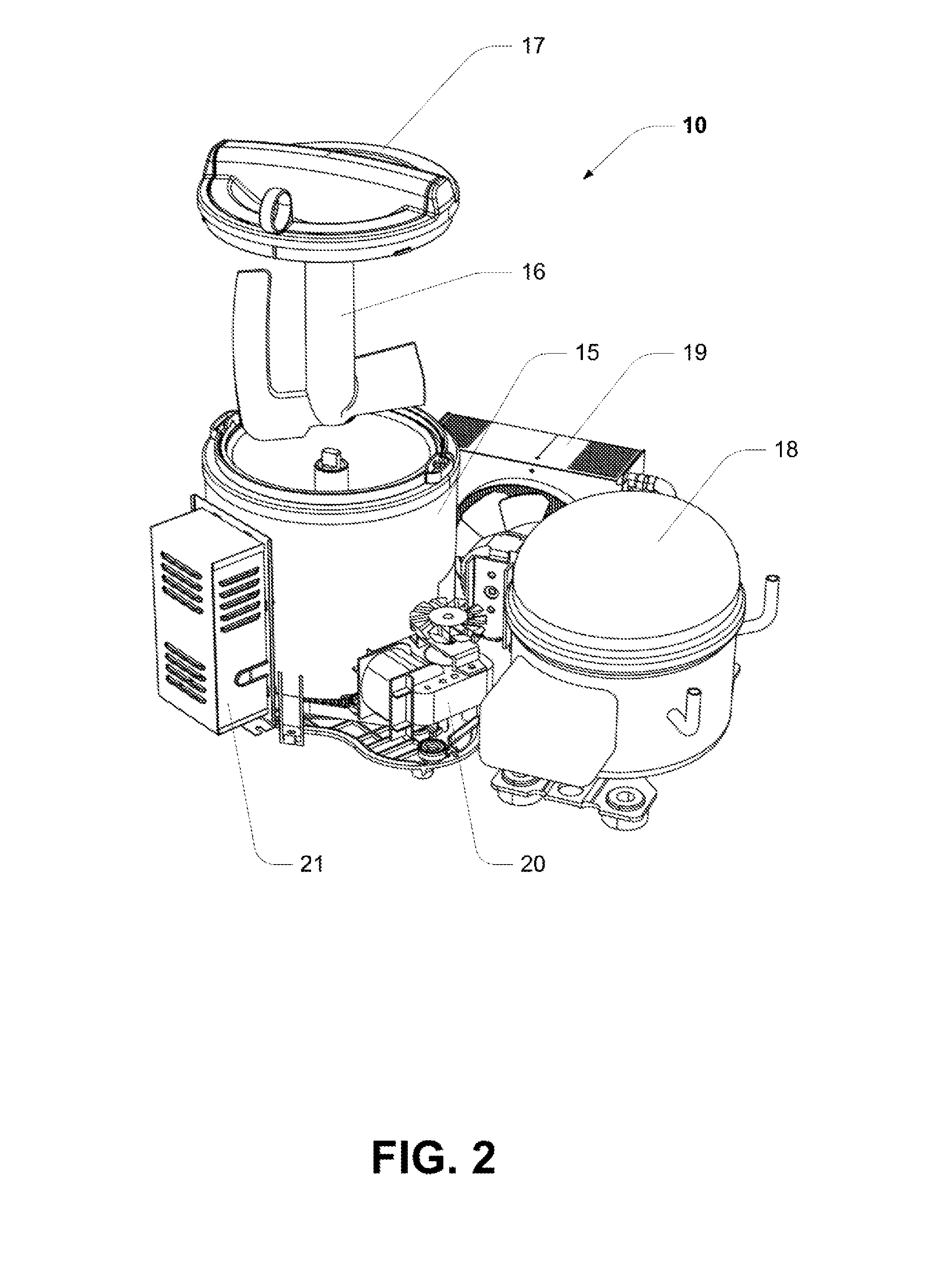

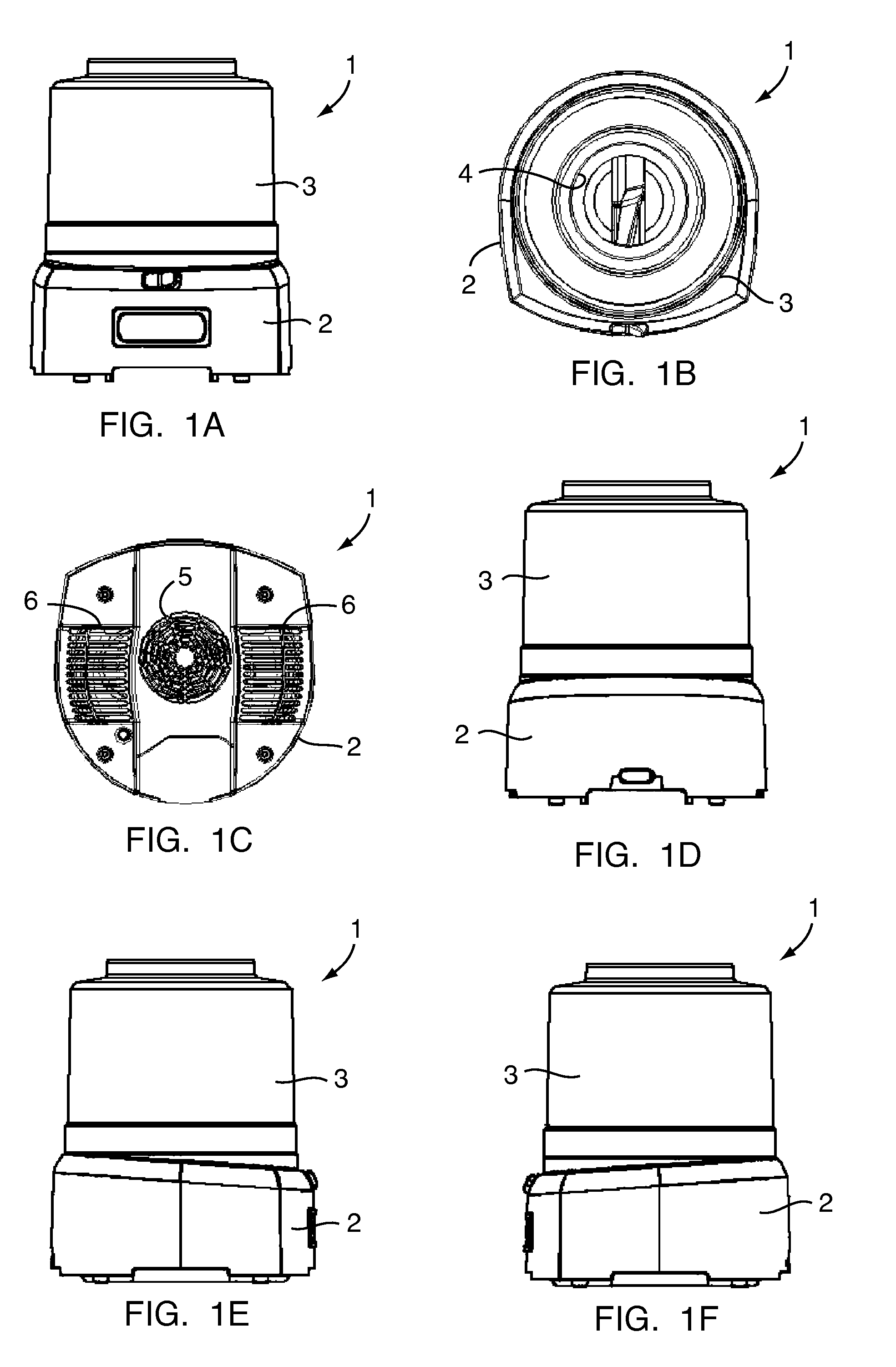

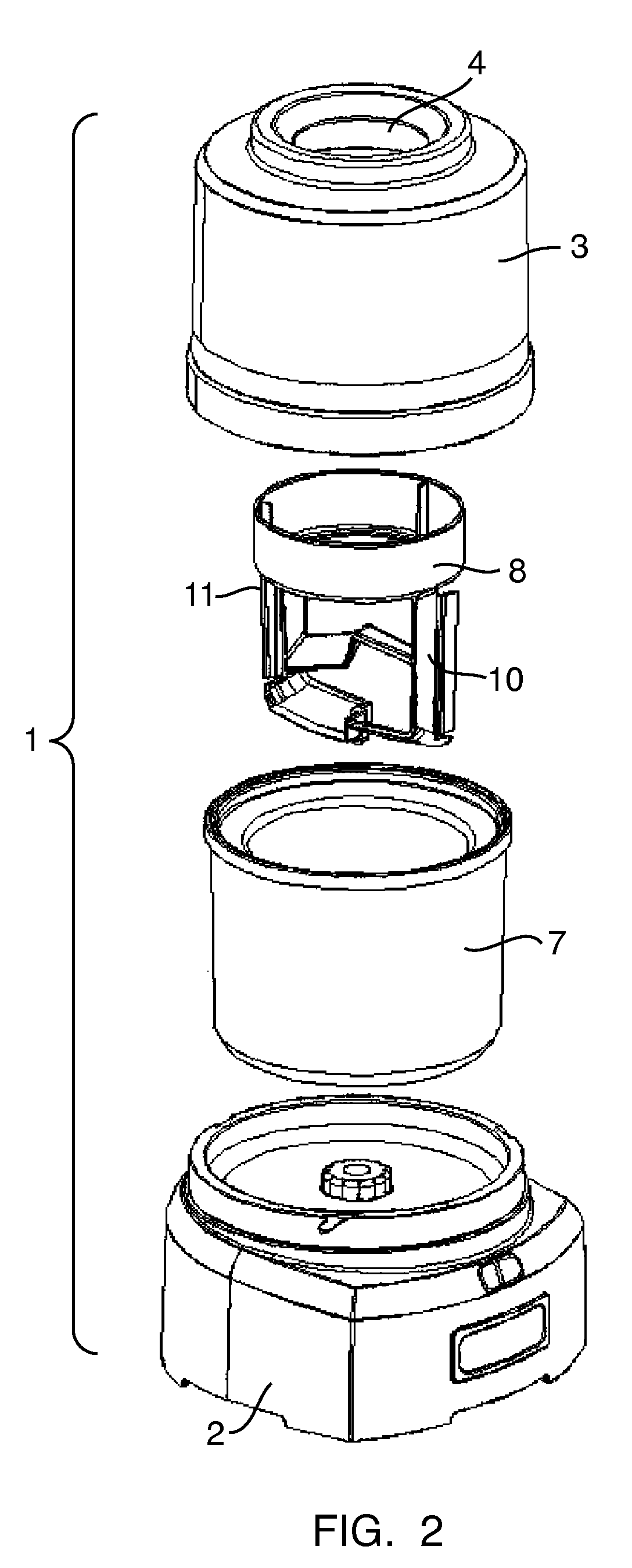

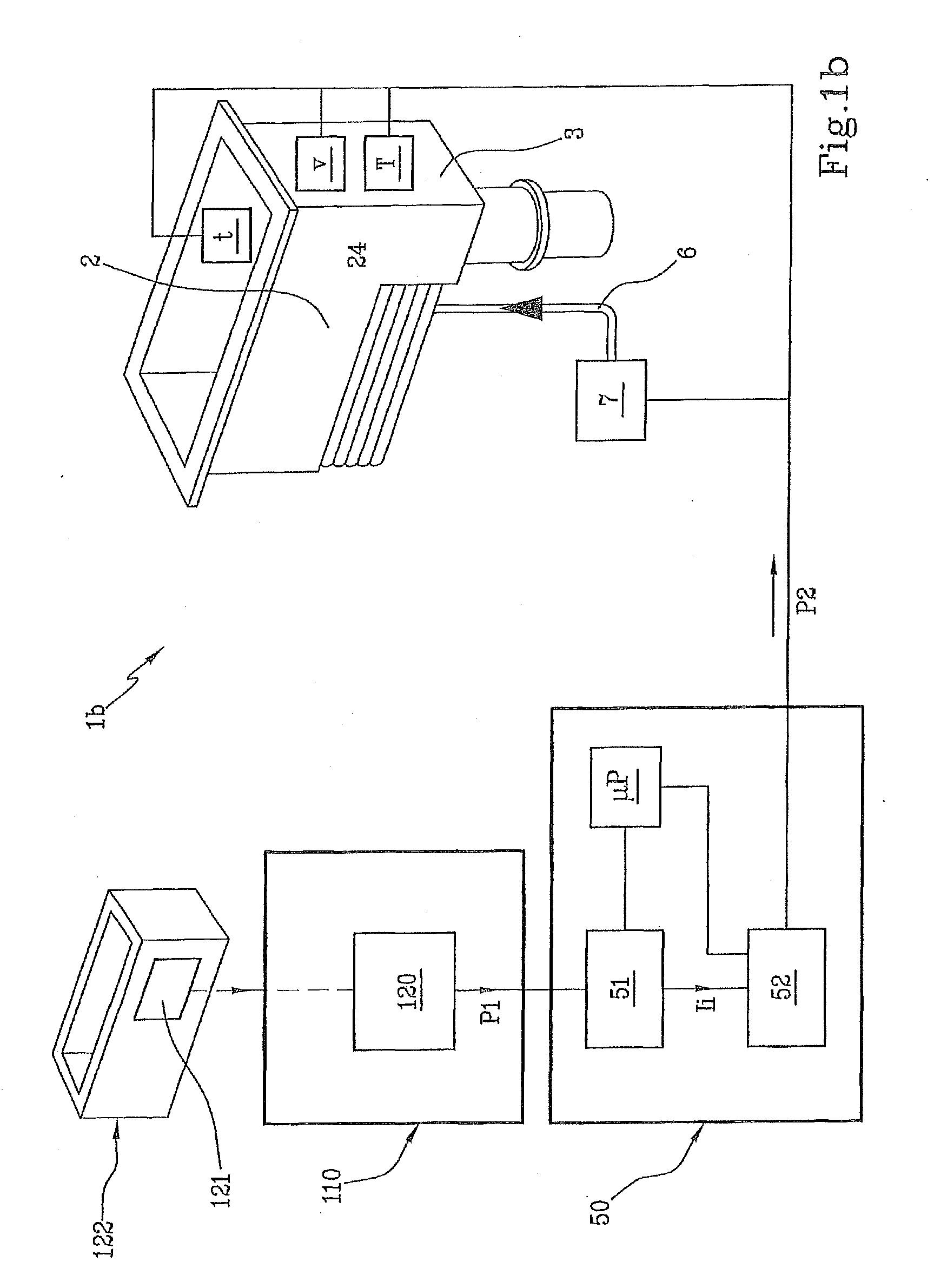

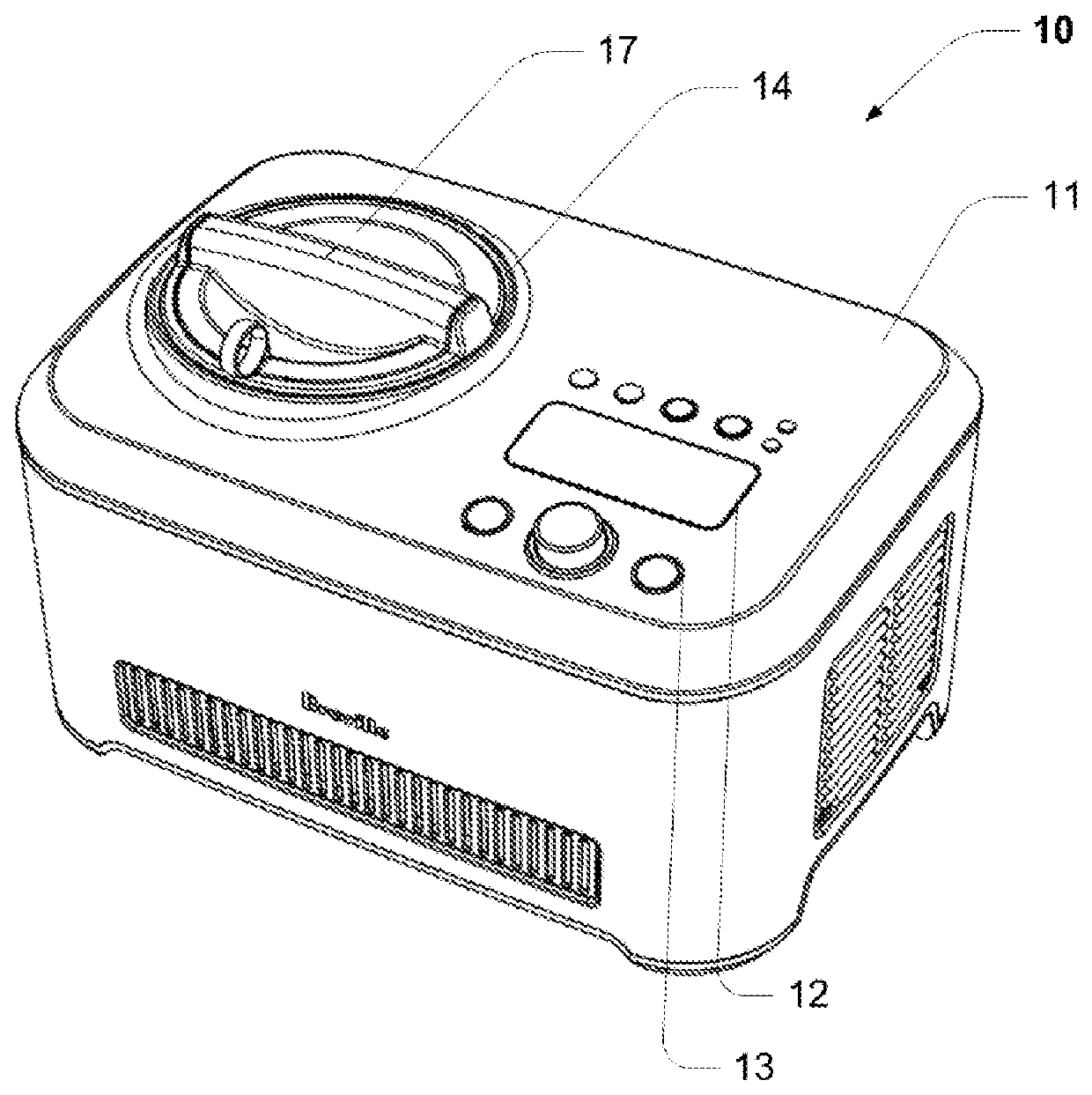

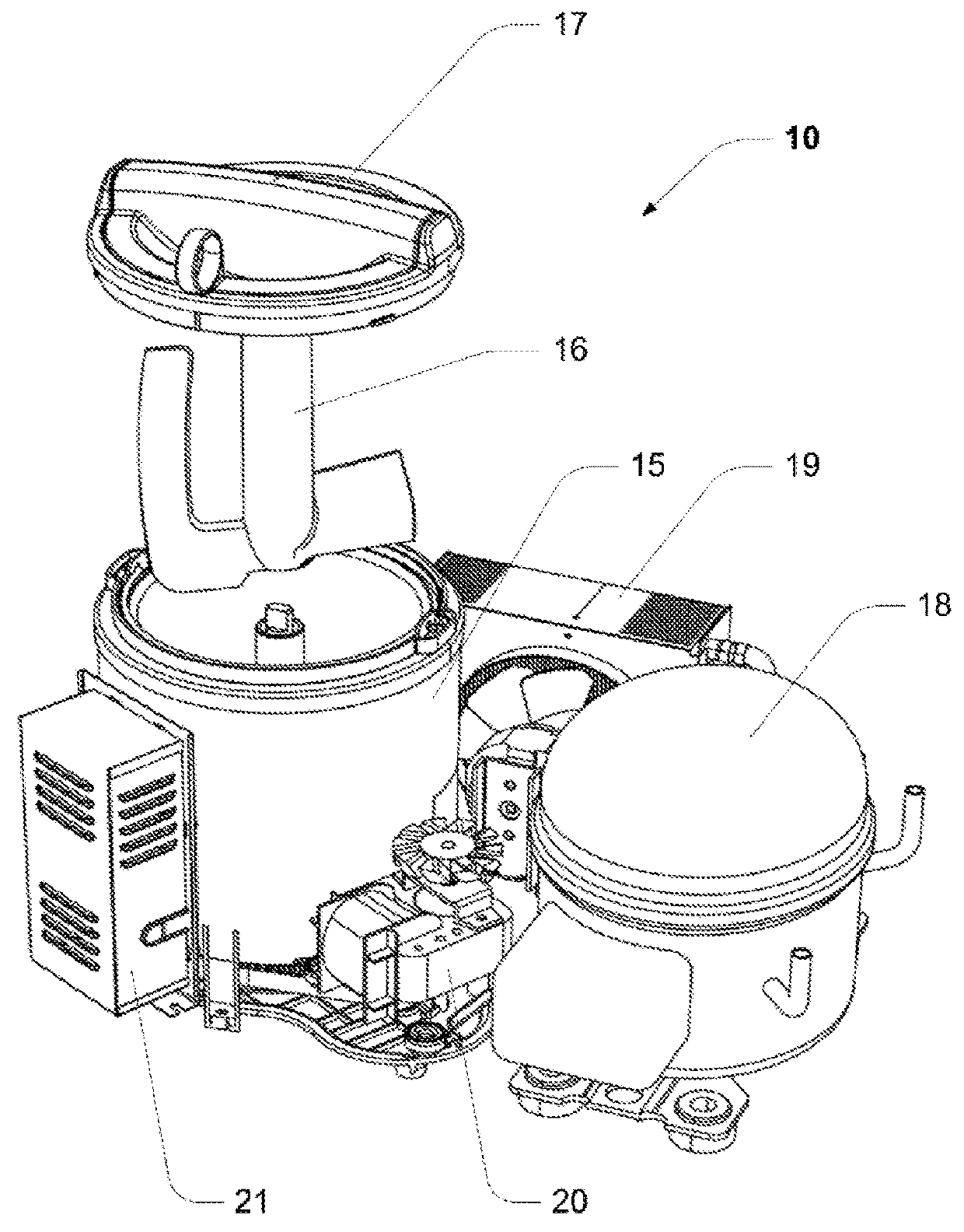

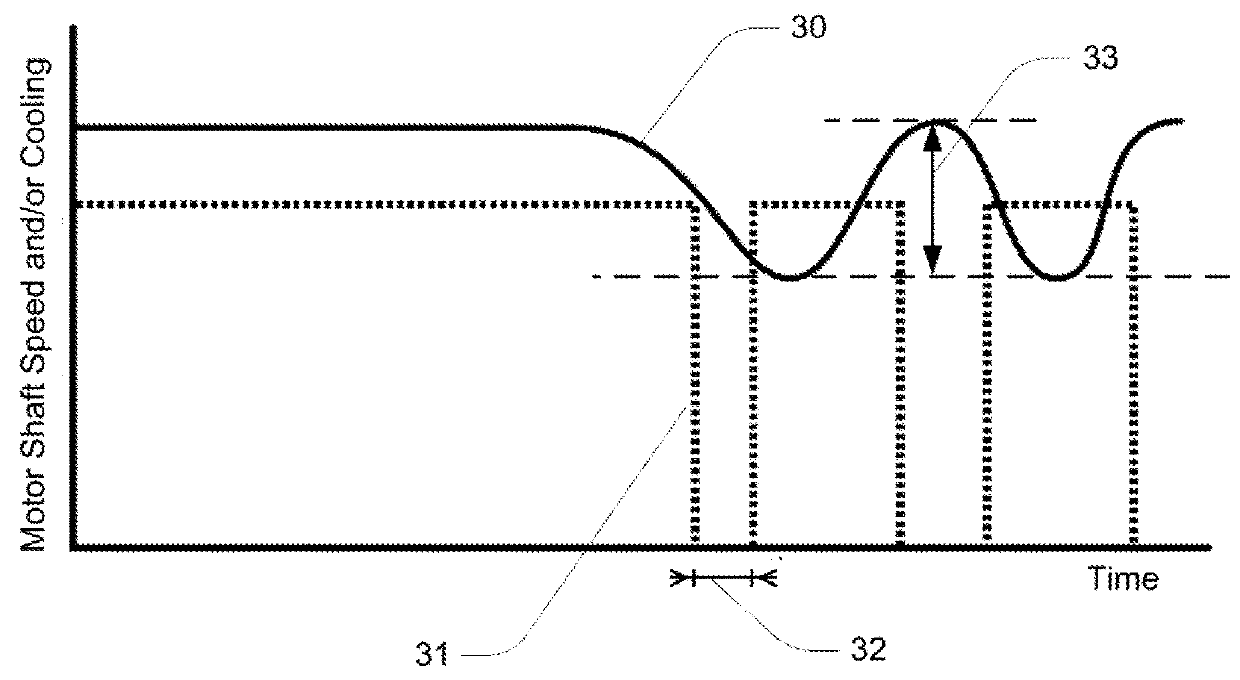

An ice-cream maker comprising: a body having a rotatable paddle; a cooling chamber supported by the body for receiving an ice-cream mixture, the paddle being adapted to move through the ice-cream mixture; a sensor module for detecting a hardness measure of the ice-cream mixture; a processor module coupled to the sensor module for receiving a signal indicative of the hardness measure, the processor module being adapted to control the operation of the paddle. After the ice-cream mixture has reached a selected hardness, the processor module periodically operates paddle to churn the mixture to substantially maintain the mixture at the selected hardness. Before introduction of the mixture, the processor module can operate a cooling element to pre-cool the cooling chamber.

Owner:BREVILLE HLDG PTY LTD

Ice cream machine with specialized motor

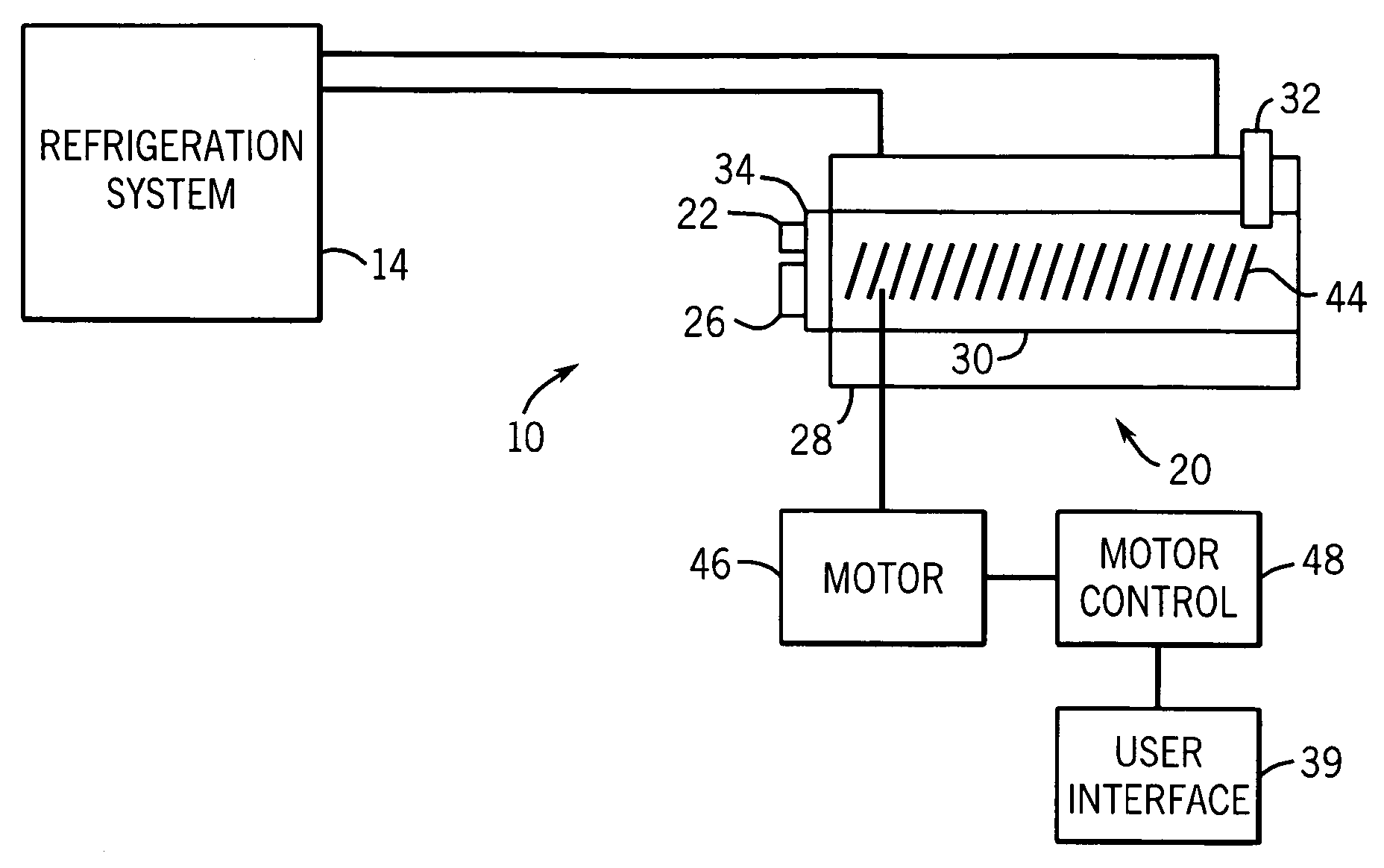

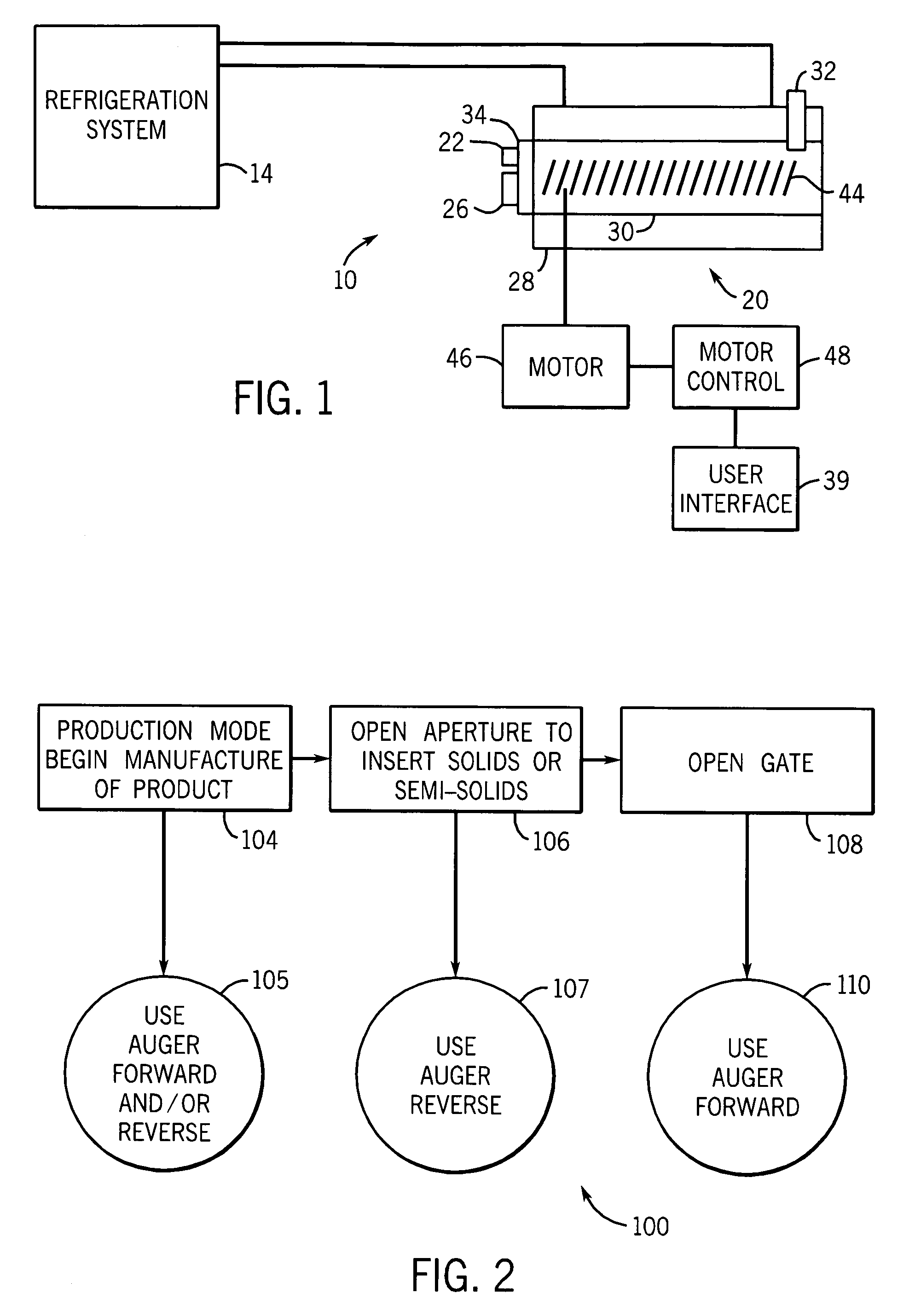

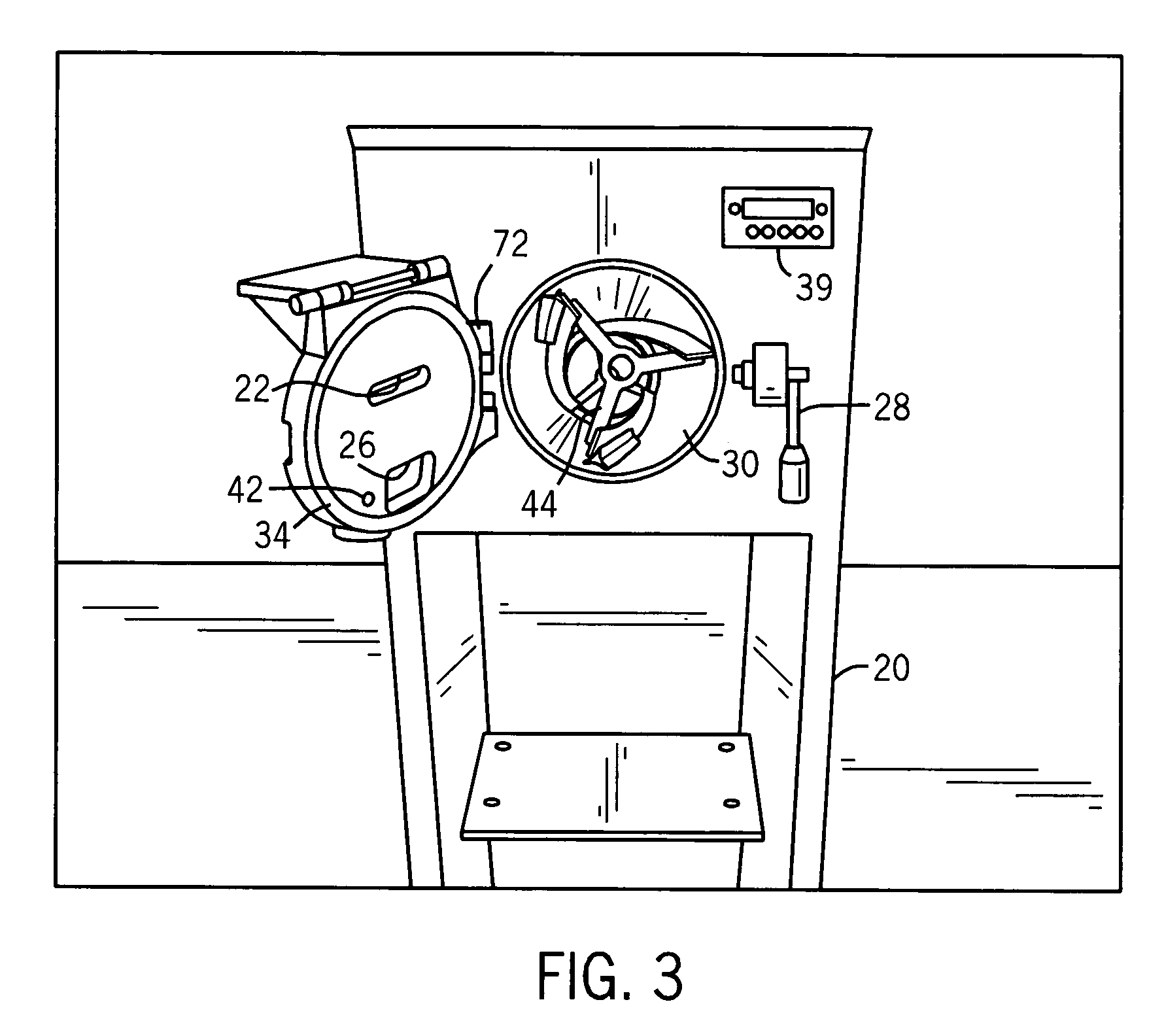

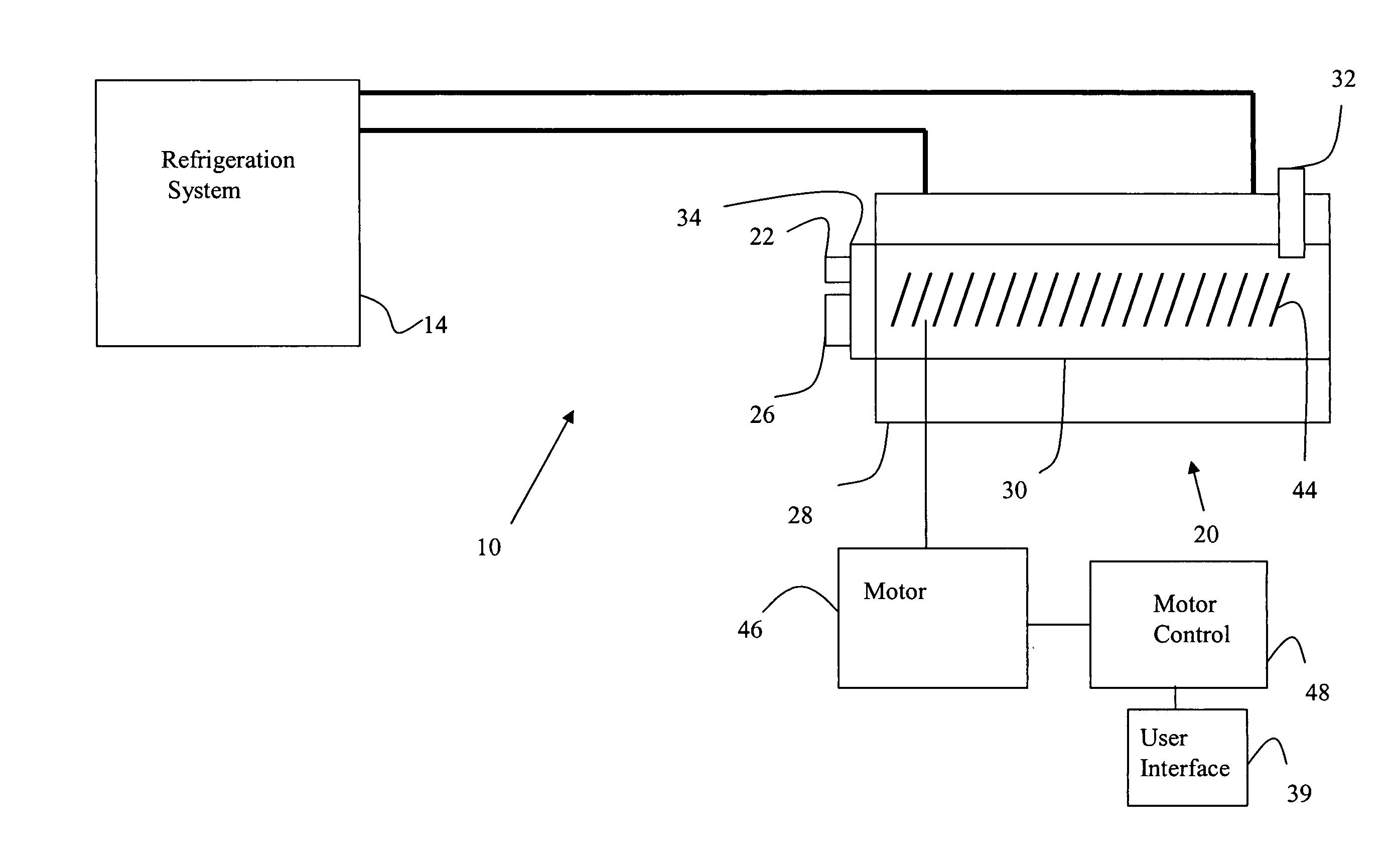

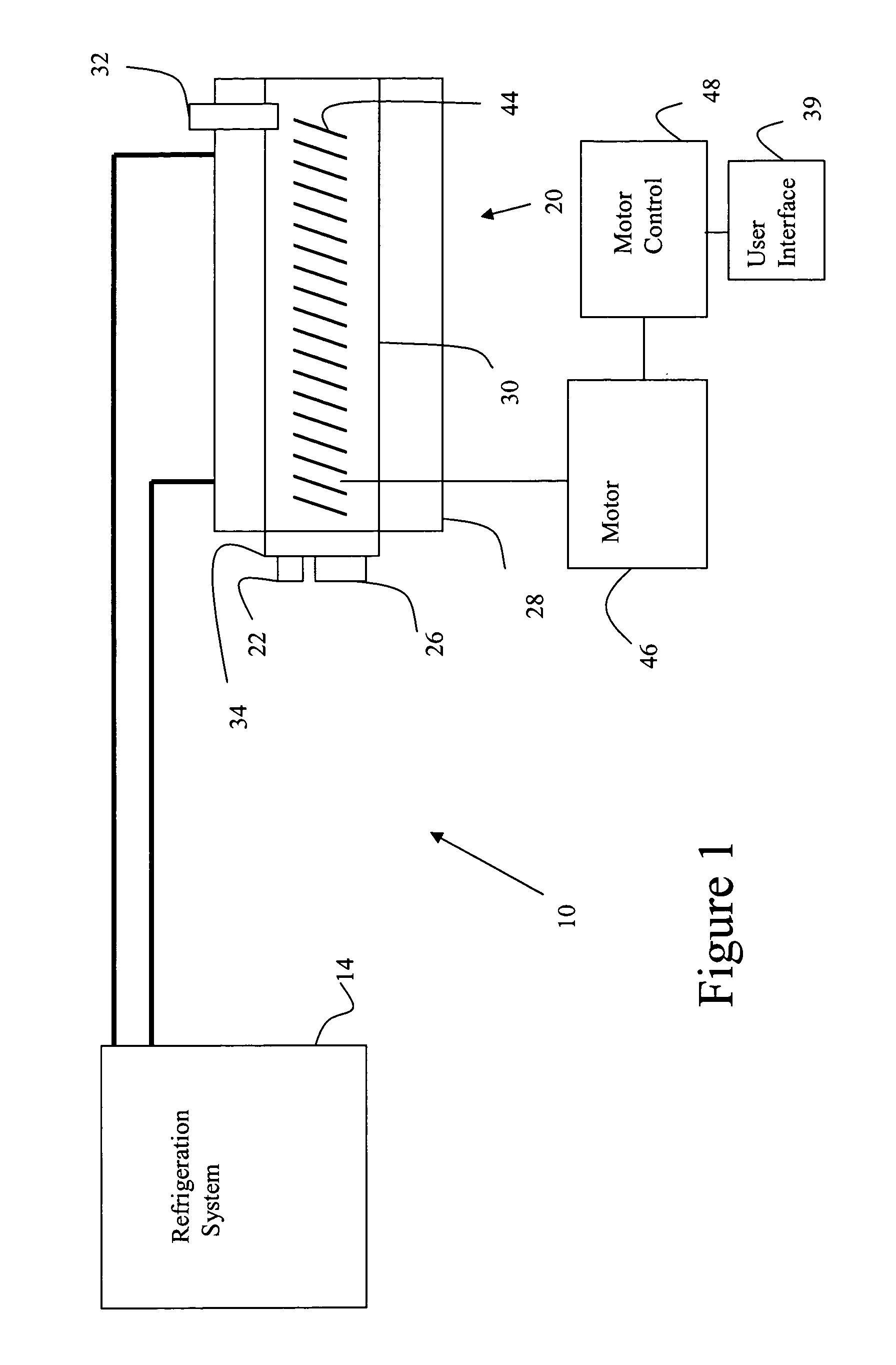

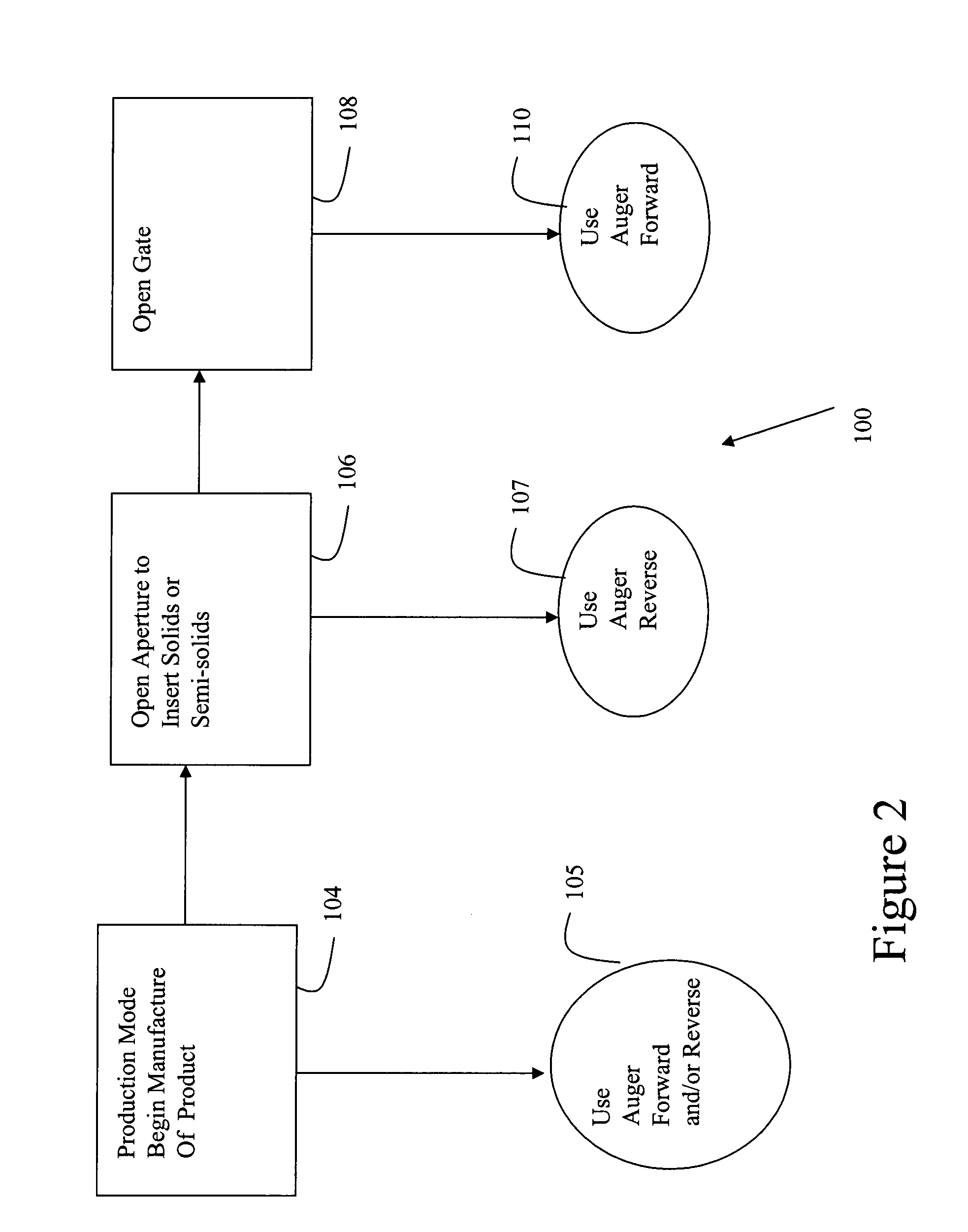

A motor system can be provided for a tank for mixing and chilling ice cream. The motor system includes a variable speed motor having a speed control. The speed control can be utilized to operate the motor in a forward or reversed speed or across a spectrum of more than two forward speeds. The motor can drive an auger. The auger can be operated in reverse to add semi-solid or solid inclusions to ice cream mix. The inclusions can be added through an aperture at the output of the tank. Appropriate time for discharge can be determined by time, temperature, or amperage.

Owner:VOLLRATH

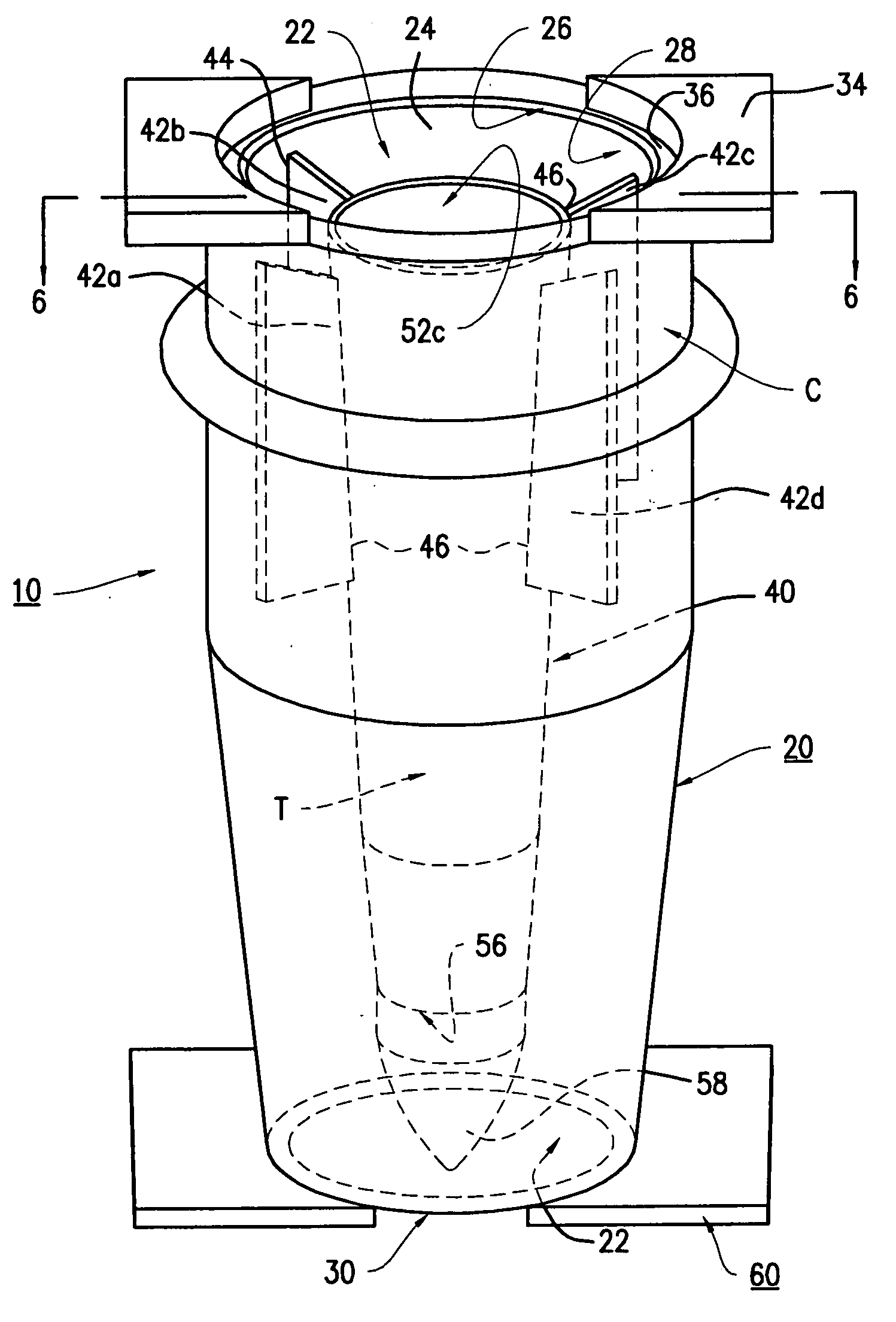

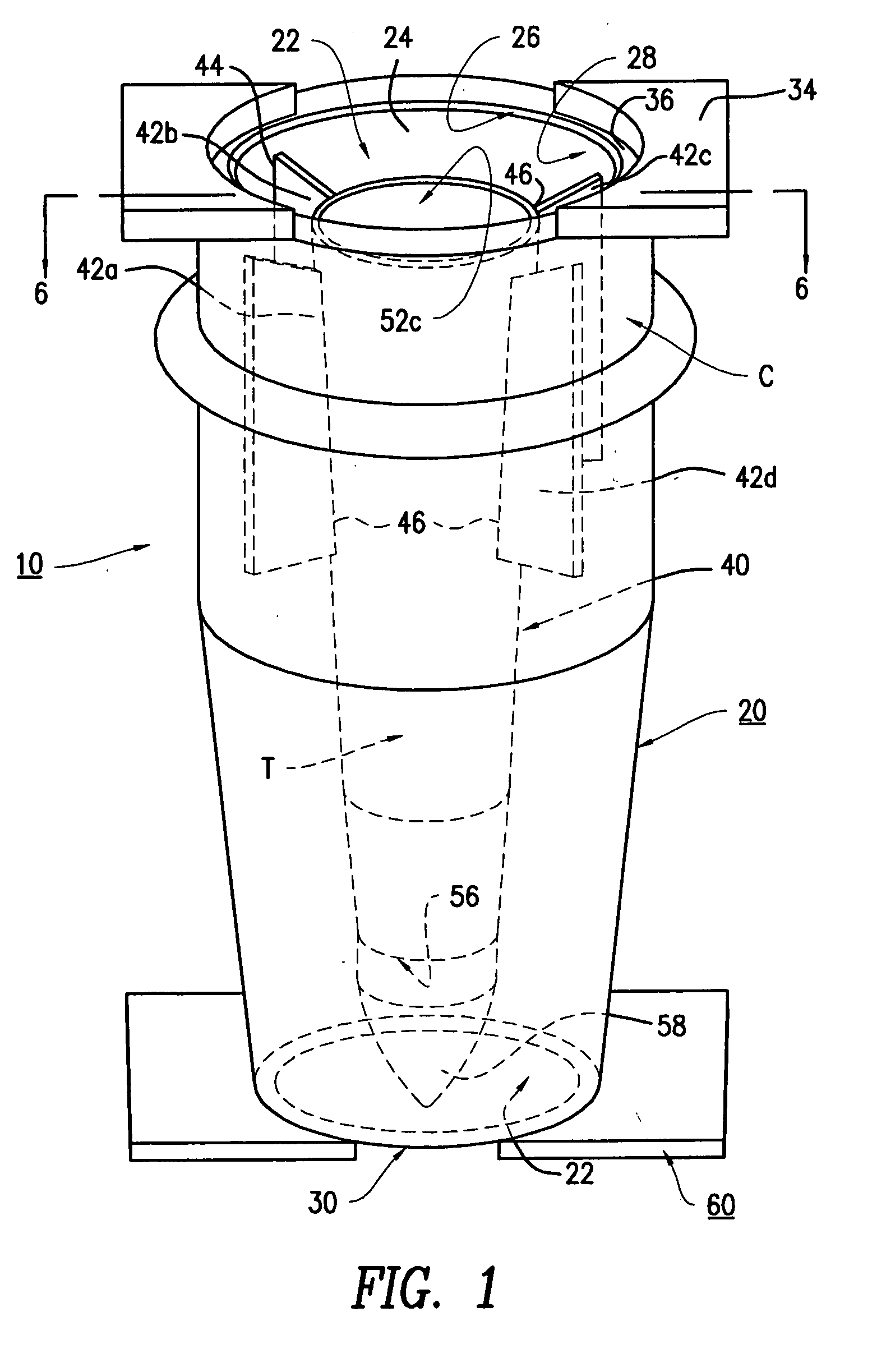

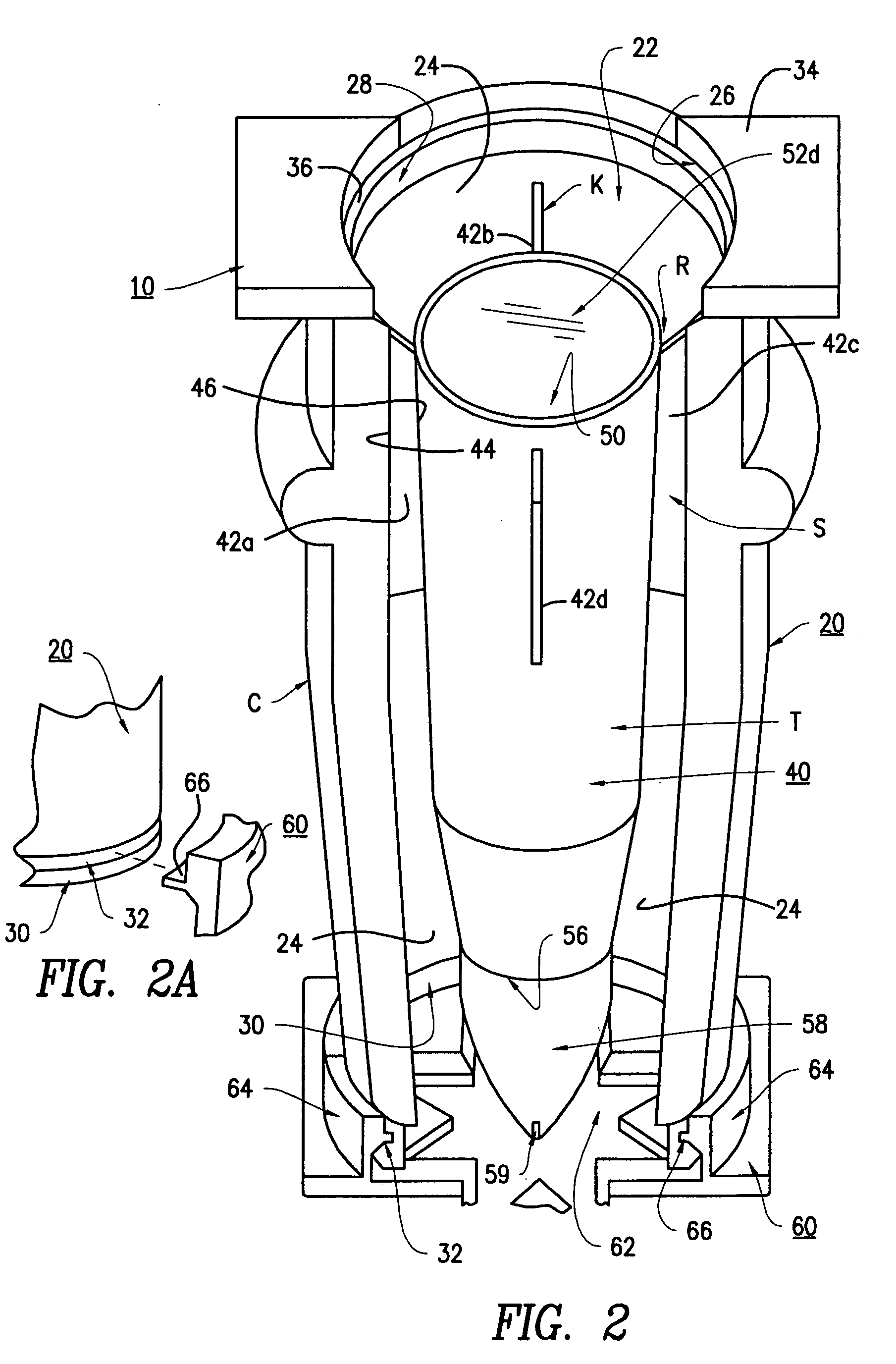

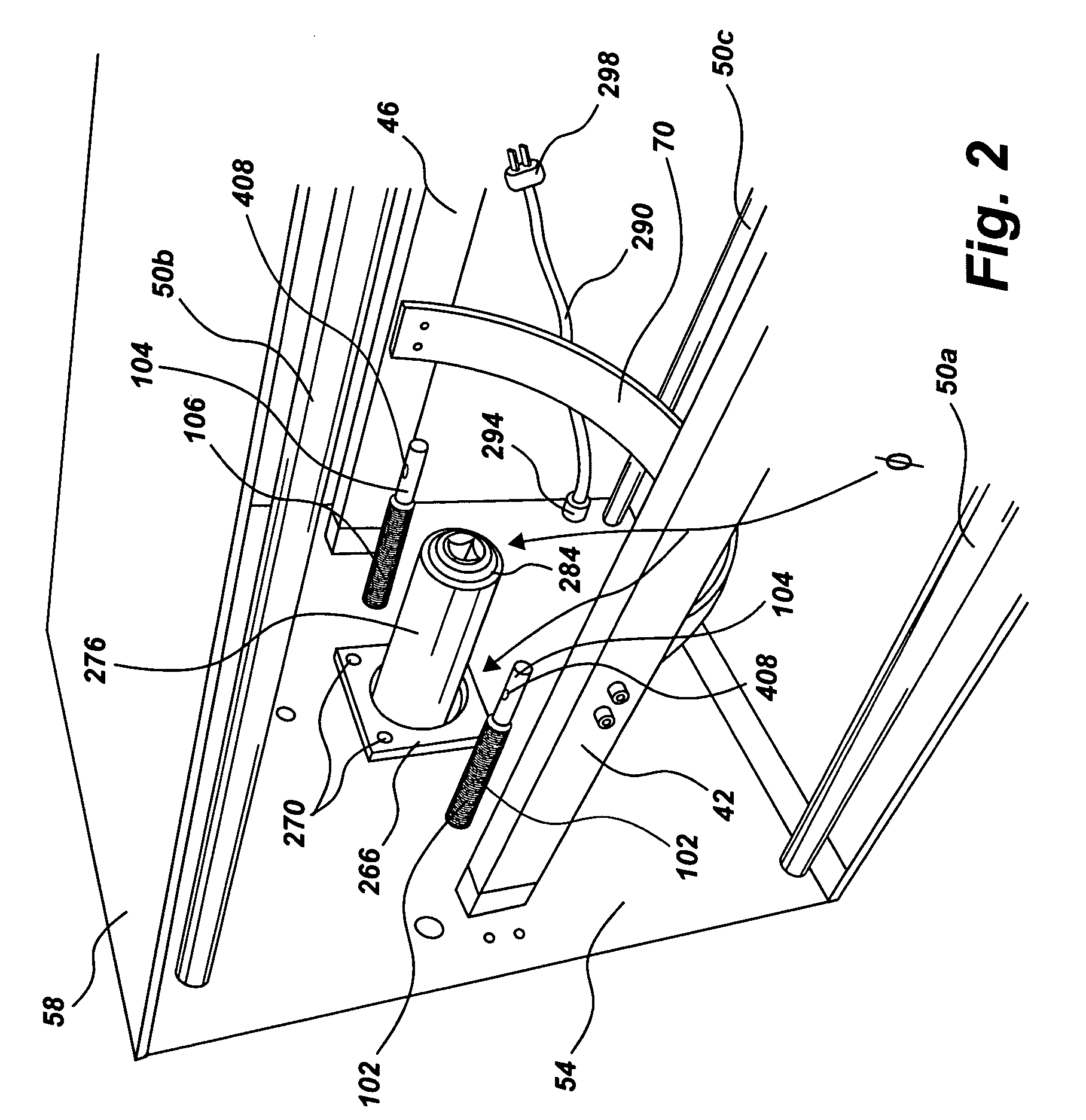

Ice cream machine with specialized motor

A motor system can be provided for a tank for mixing and chilling ice cream. The motor system includes a variable speed motor having a speed control. The speed control can be utilized to operate the motor in a forward or reversed speed or across a spectrum of more than two forward speeds. The motor can drive an auger. The auger can be operated in reverse to add semi-solid or solid inclusions to ice cream mix. The inclusions can be added through an aperture at the output of the tank. Appropriate time for discharge can be determined by time, temperature, or amperage.

Owner:VOLLRATH

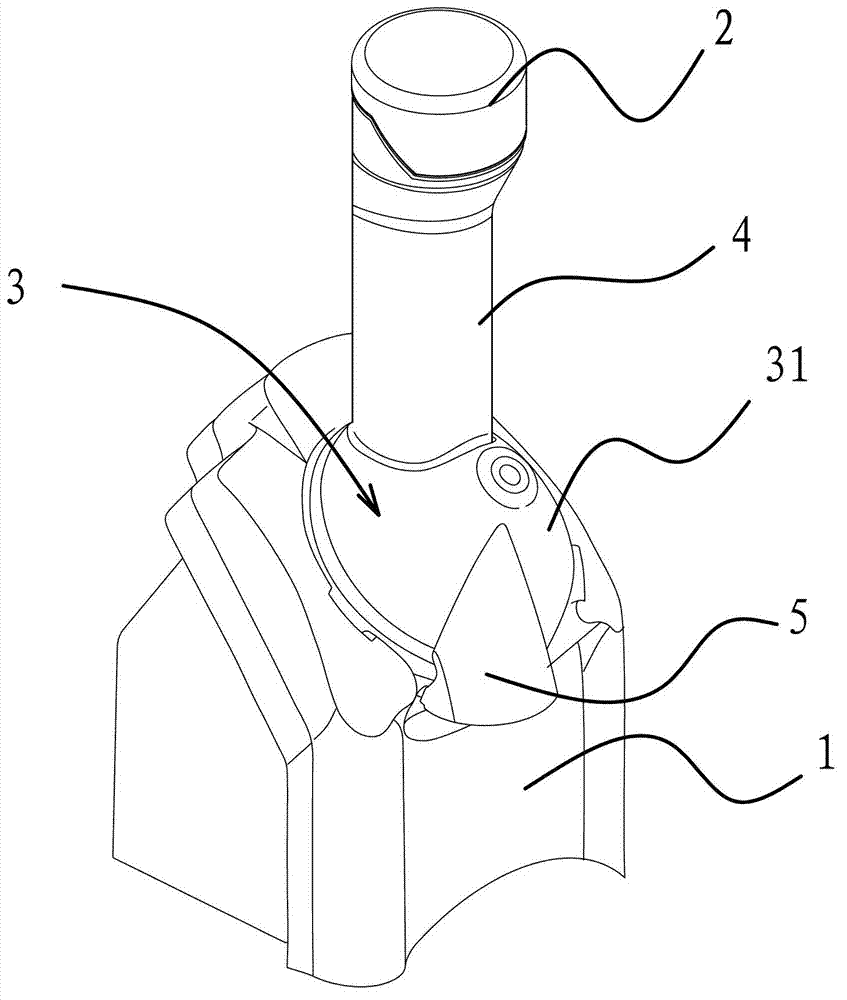

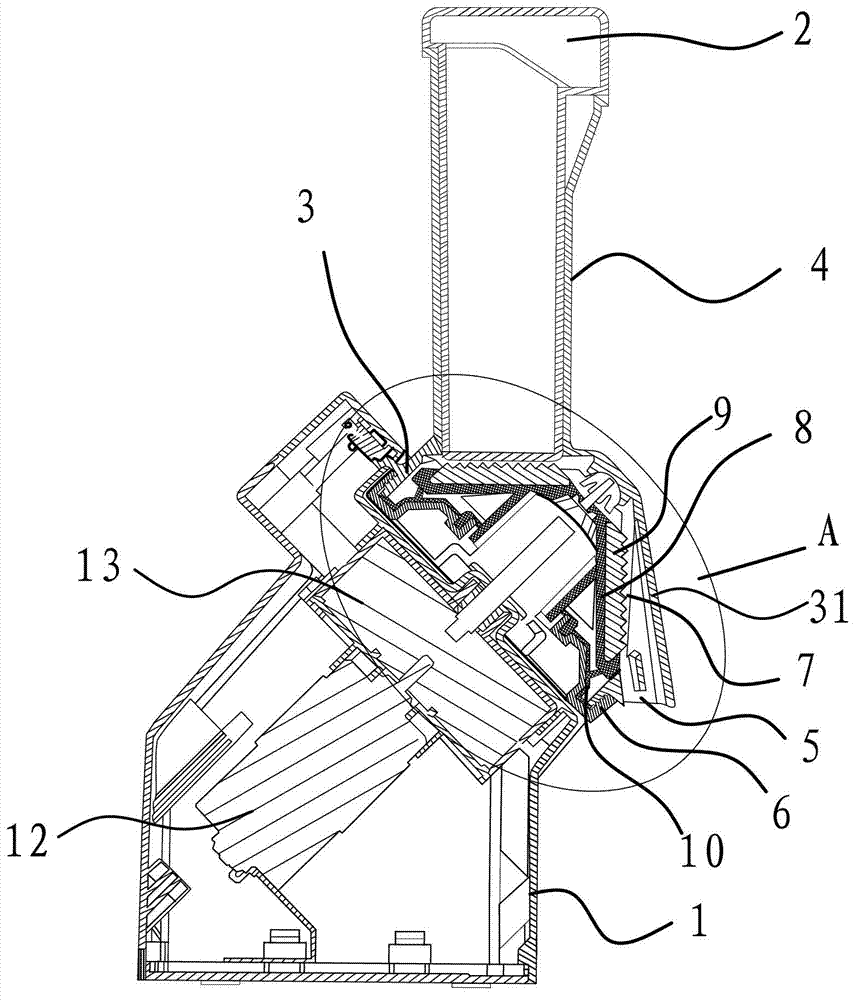

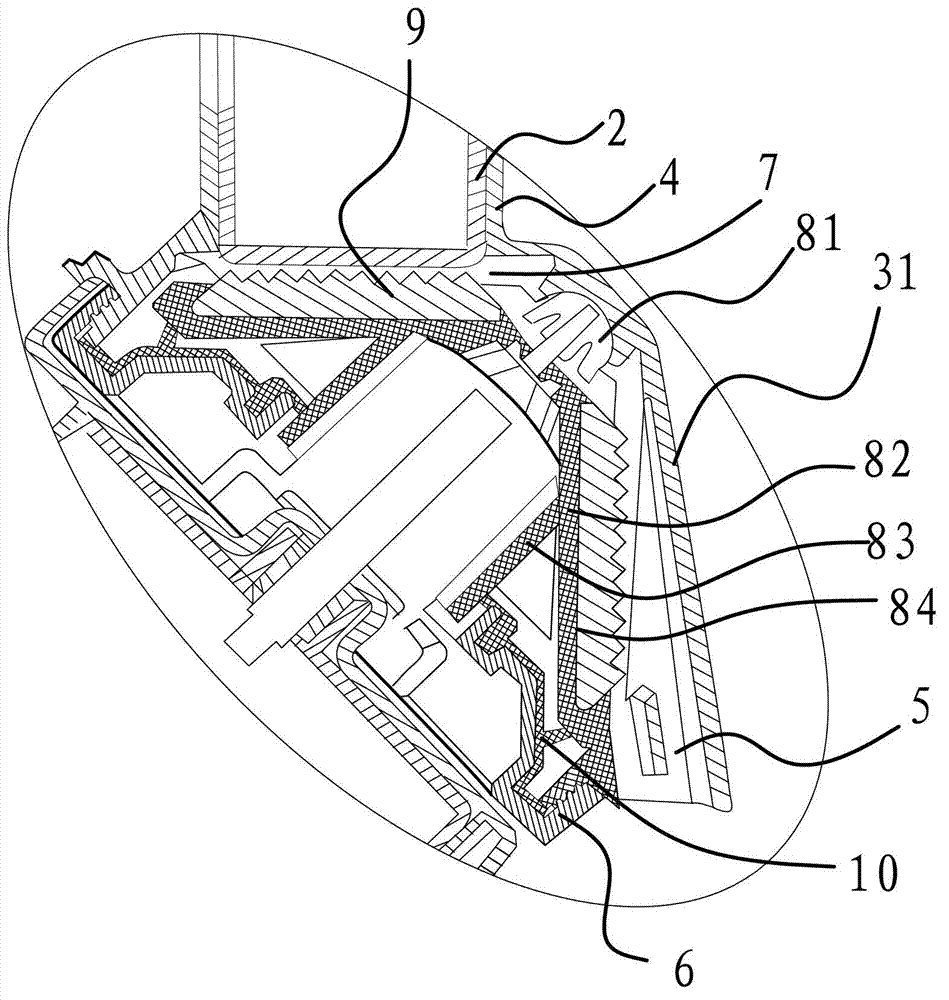

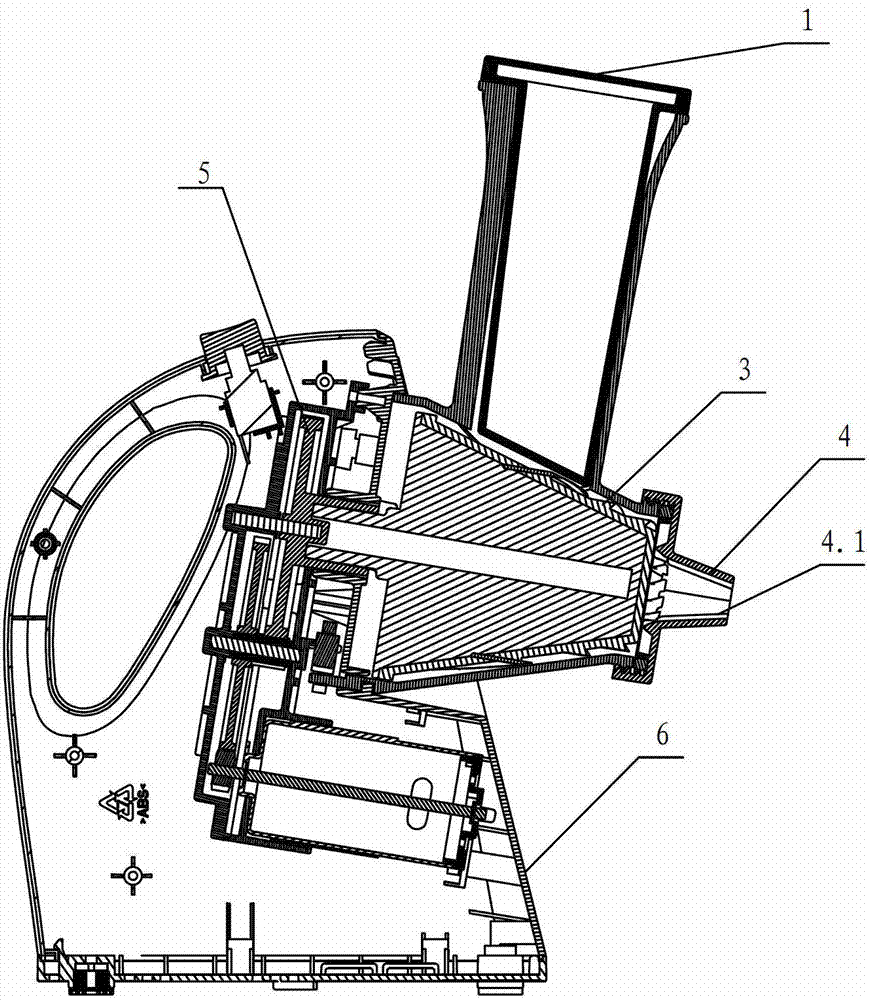

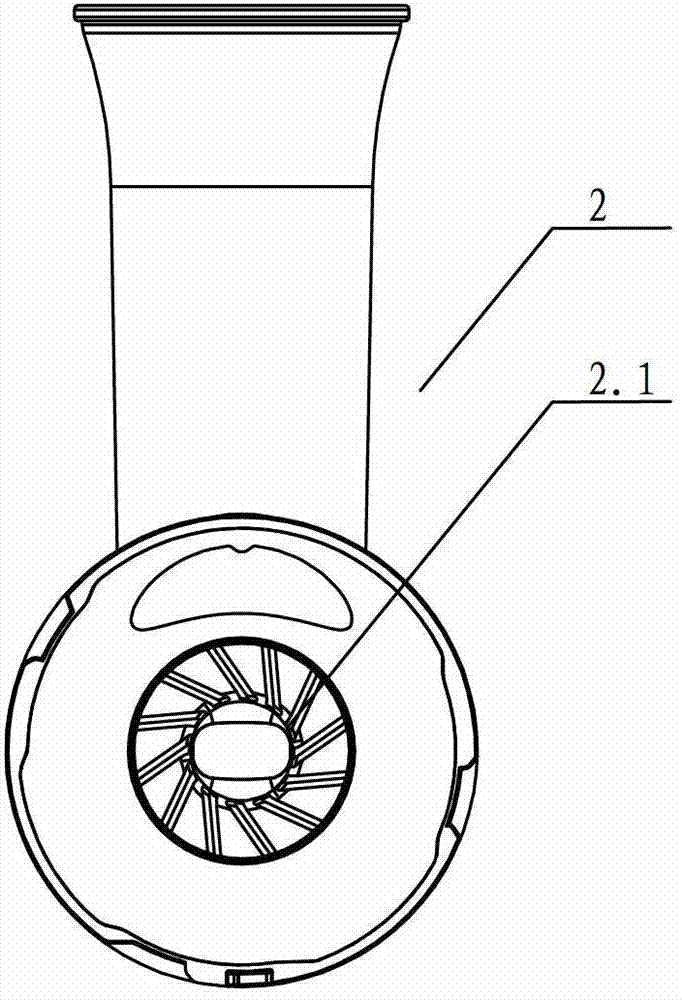

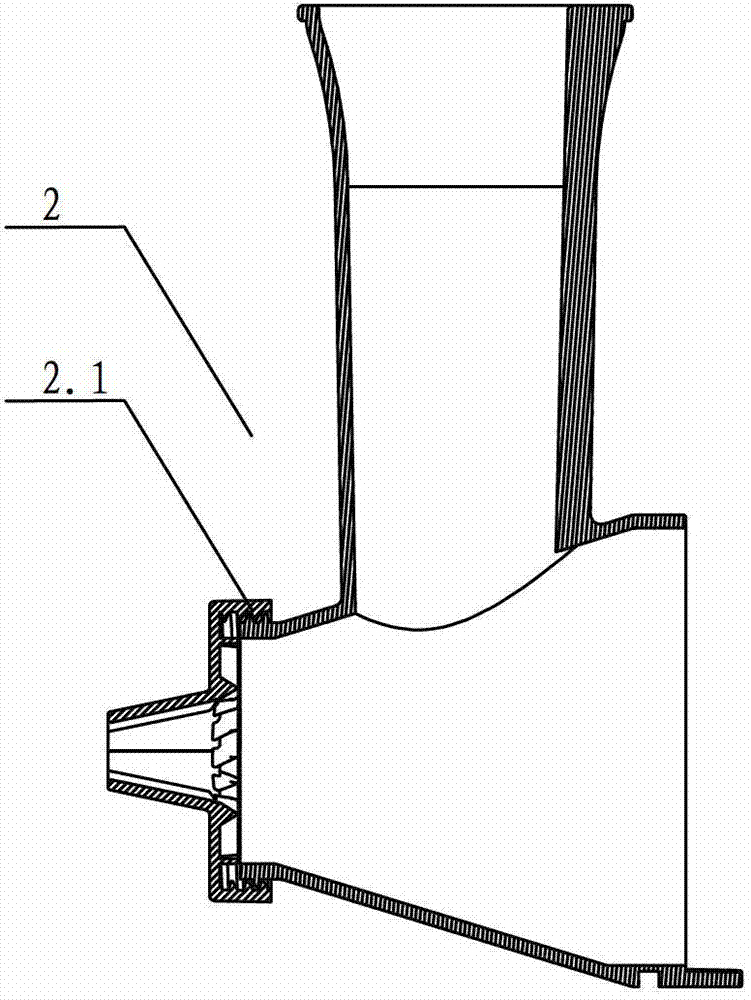

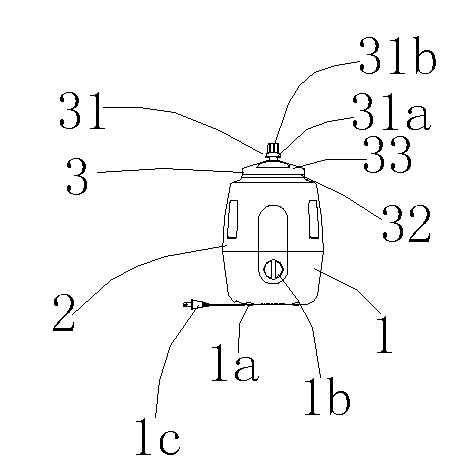

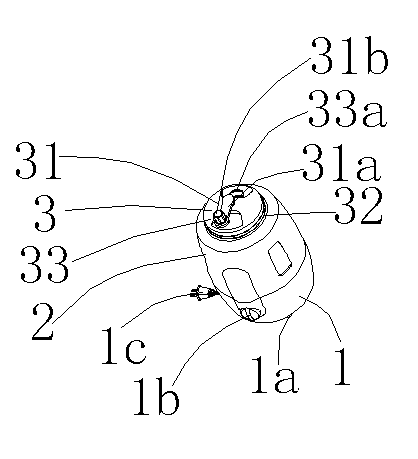

Fruit ice cream machine

InactiveCN103168908AChange the setting directionIncrease the output speedFrozen sweetsReduction driveElectric machinery

The invention provides a fruit ice cream machine, belongs to the technical field of food equipment, and solves the problems of the existing fruit ice cream machine that the discharging speed is low and residual food remains in a stirring cavity. The fruit ice cream machine comprises a machine base, an abrasive disc and an electric motor arranged inside the machine base, wherein the electric motor is connected with the abrasive disc through a speed reducer; the abrasive disc can be driven to rotate through the electric motor; a material containing bin is further arranged above the machine base; the material containing bin consists of a cylindrical feeding barrel and a conical gland; a discharging port is formed in the gland; a plurality of strip-shaped serrated blades are uniformly fixed on the outer circular conical surface of the abrasive disc; each blade is arranged along the rotation direction of the same abrasive disc relative to the straight edge line of the outer circular conical surface of the abrasive disc according to the same inclined angle; and a concave material storage groove is formed in the outer circular conical surface of the abrasive disc between two adjacent blades. According to the fruit ice cream machine, the discharging speed can be increased, and residual ice-cream-shaped food inside the stirring cavity is reduced.

Owner:马剑峰

Machine for shaving and pressing ice cream

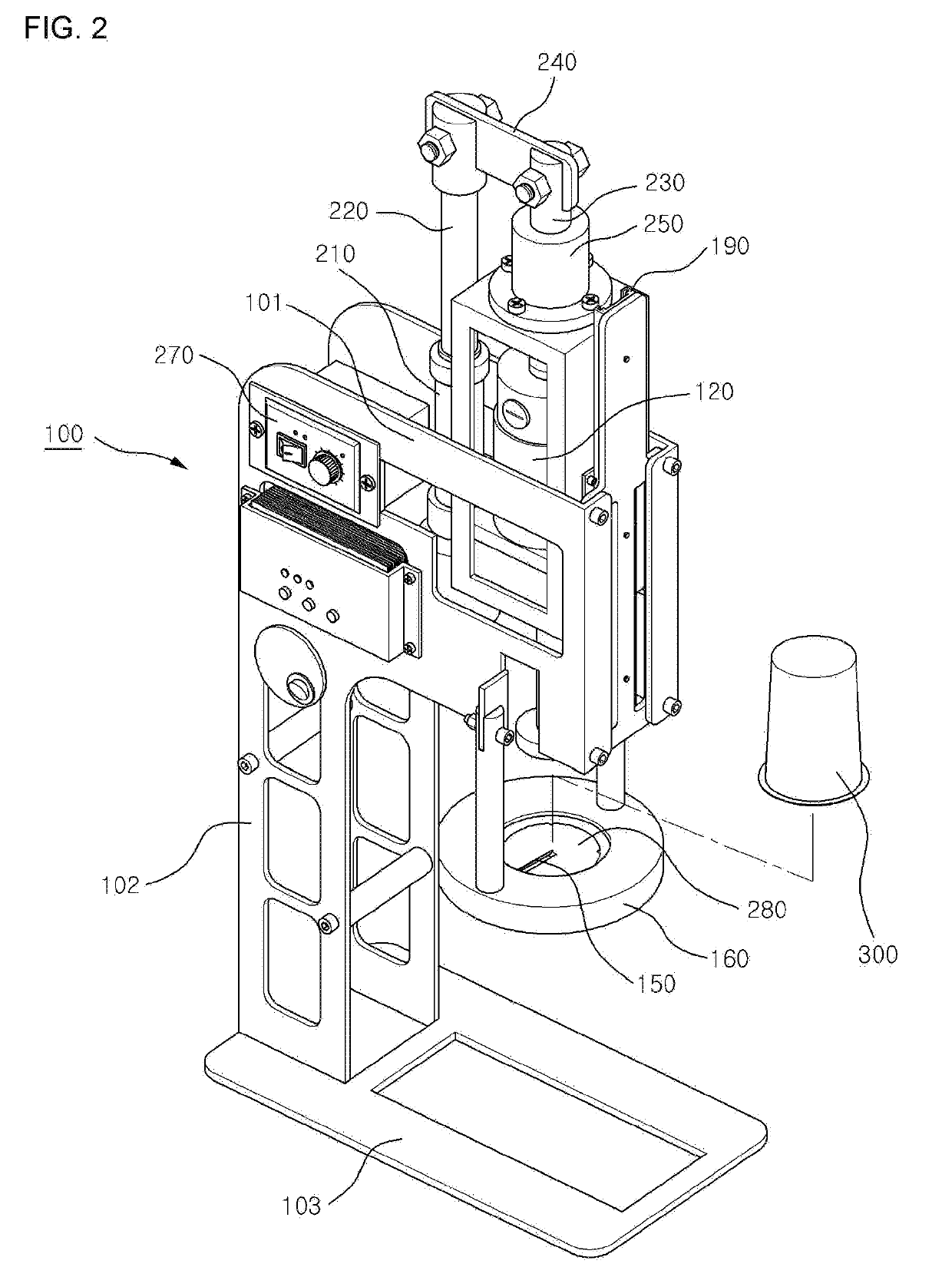

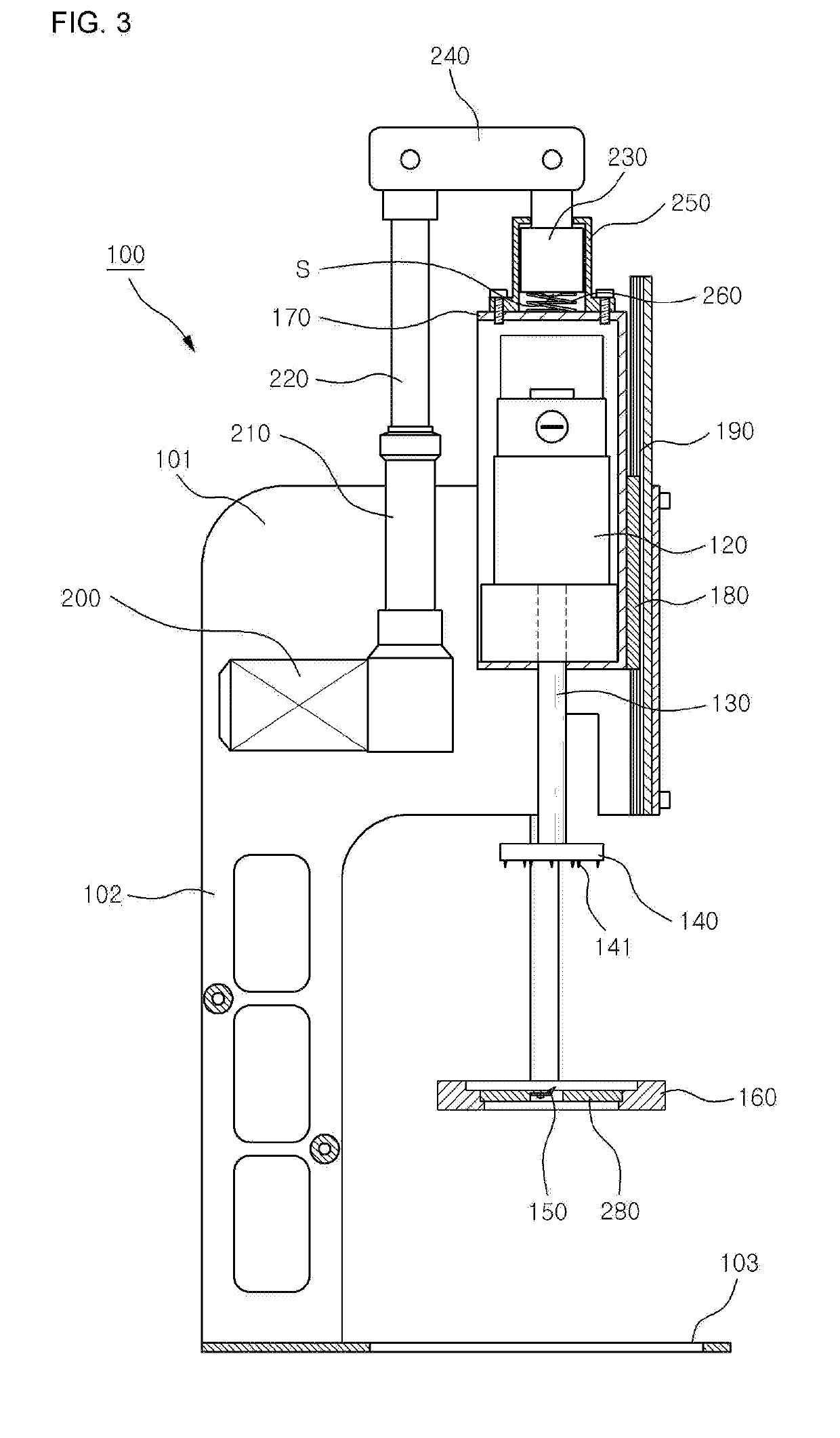

InactiveUS10443917B2Easily dispense soft ice creamLighting and heating apparatusFrozen sweetsWave shapeStationary case

A machine for shaving and pressing ice cream, the machine being capable of: obtaining shaved ice cream having a uniform wave shape and roughness or softness desired by an ice cream eater, since a pressing plate is rotated and moved downwards by a rotary motor embedded in a motor fixing case of a shaving and pressing machine body part and the ascending and descending drive of a driving actuator, thereby easily shaving the ice cream contained in a container in multiple stages; and easily extracting soft ice cream by stopping the driving of the rotary motor and pressing semisolid ice cream, contained in the container, by means of the descending of the pressing plate.

Owner:ESCARLAP AGRI CO LTD

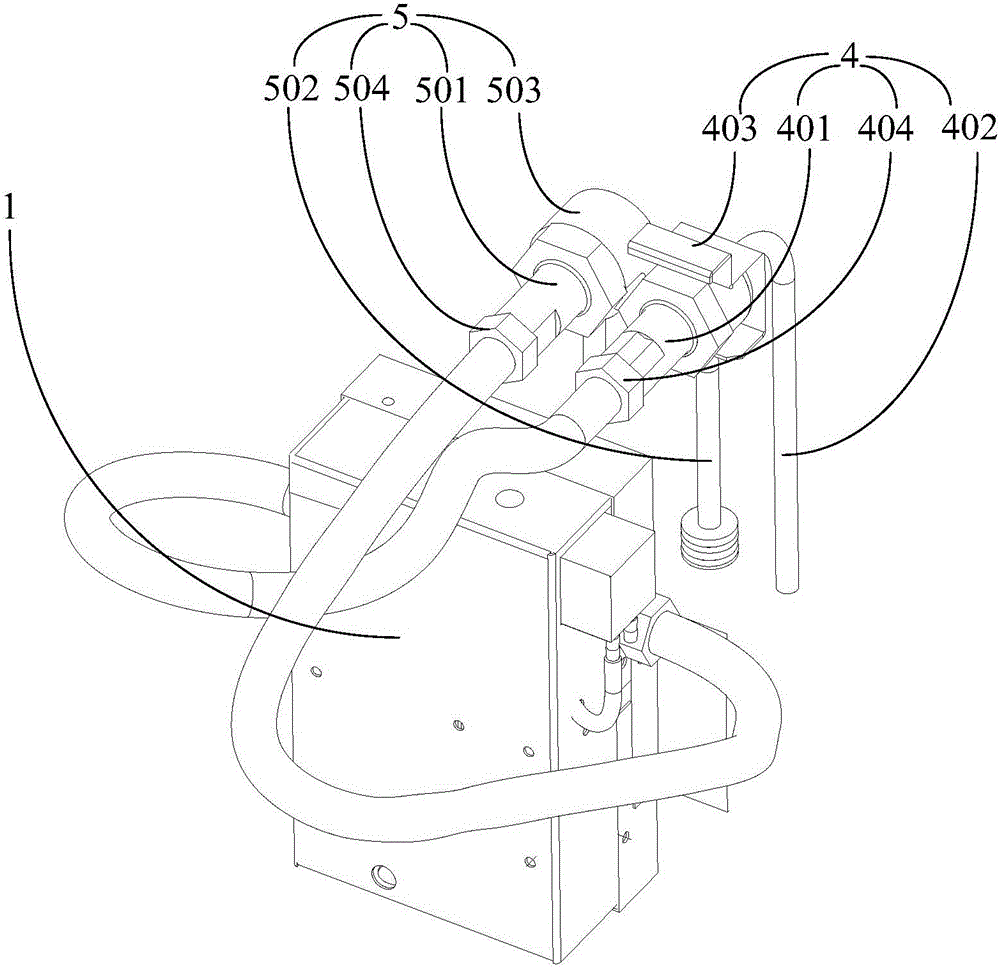

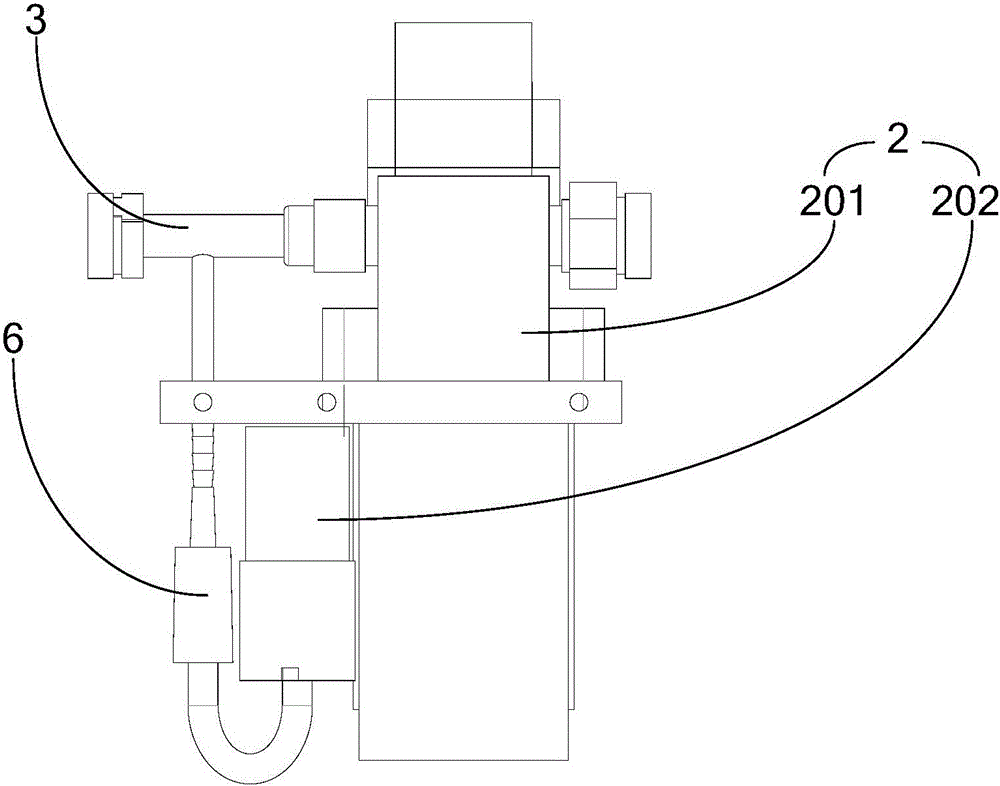

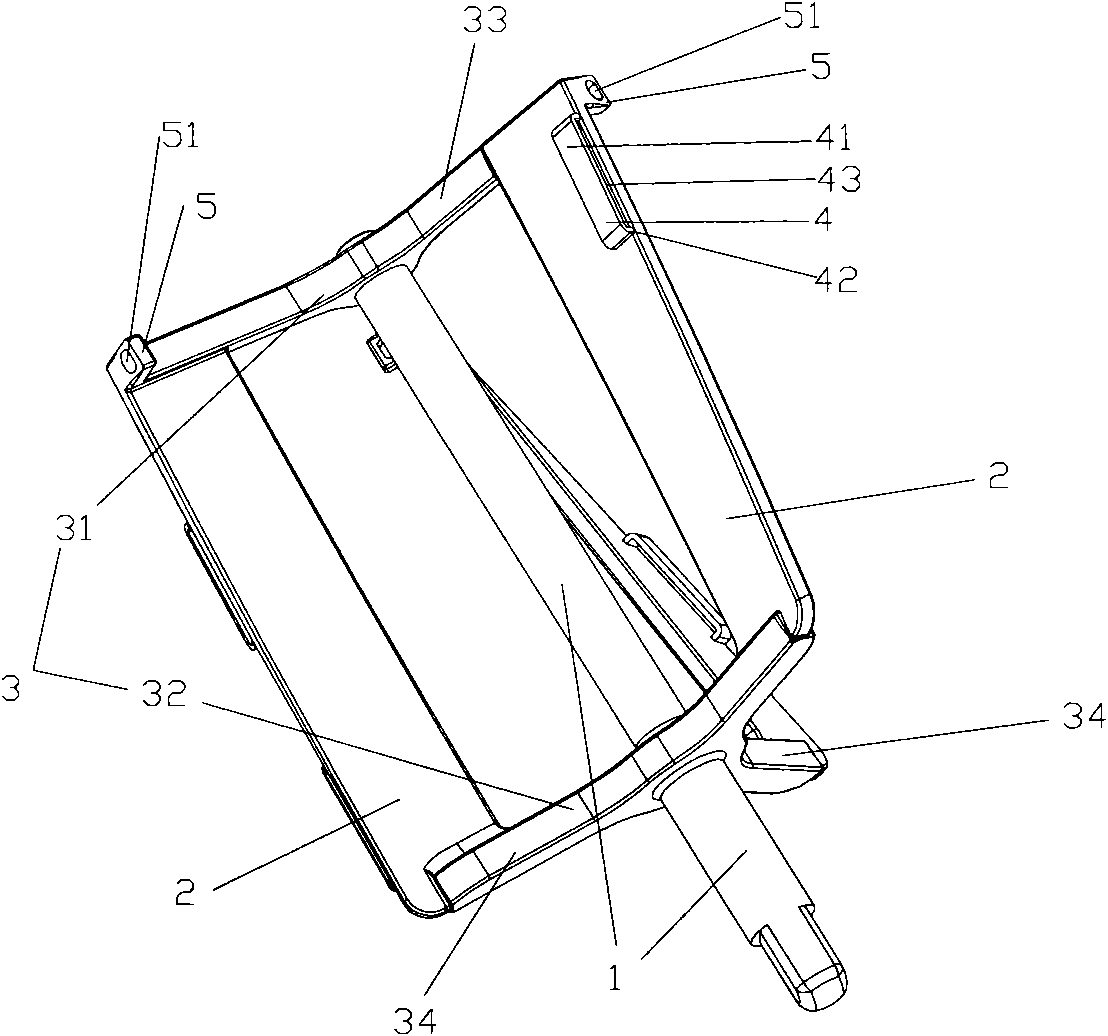

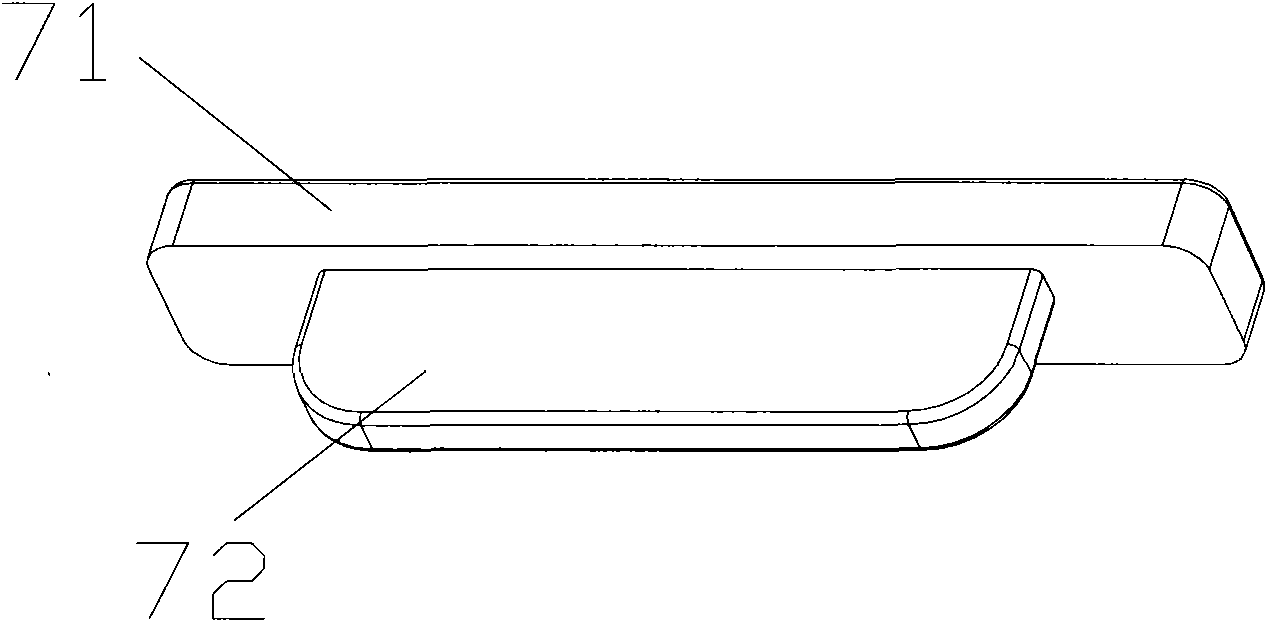

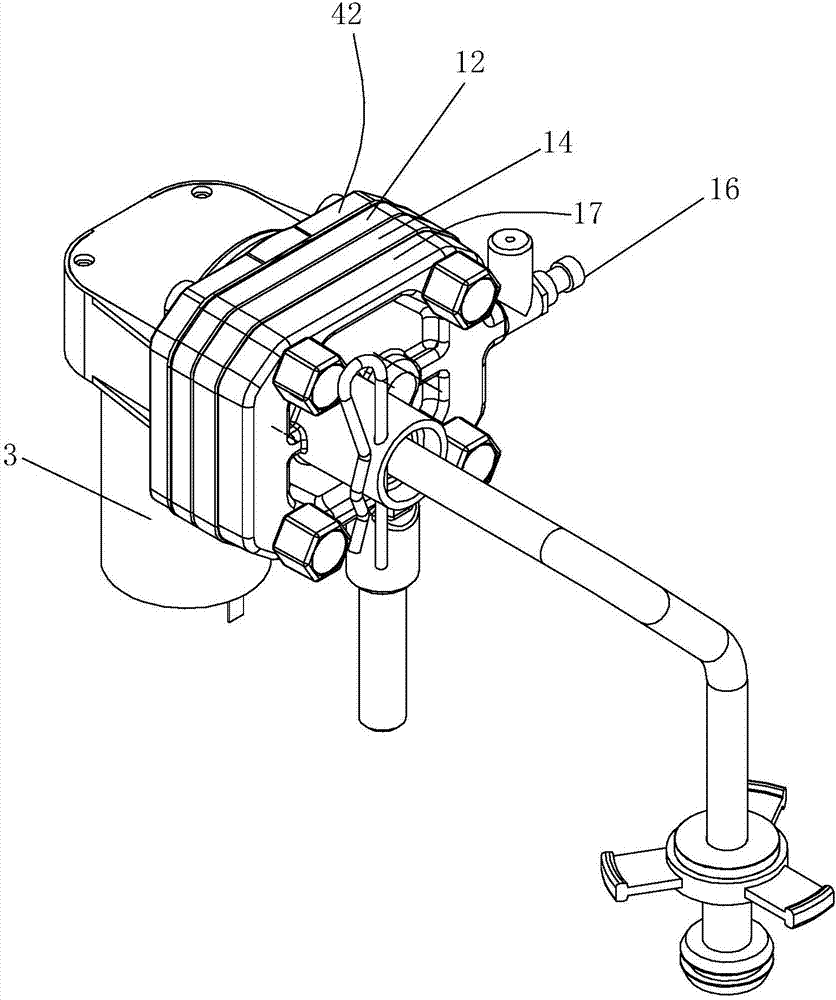

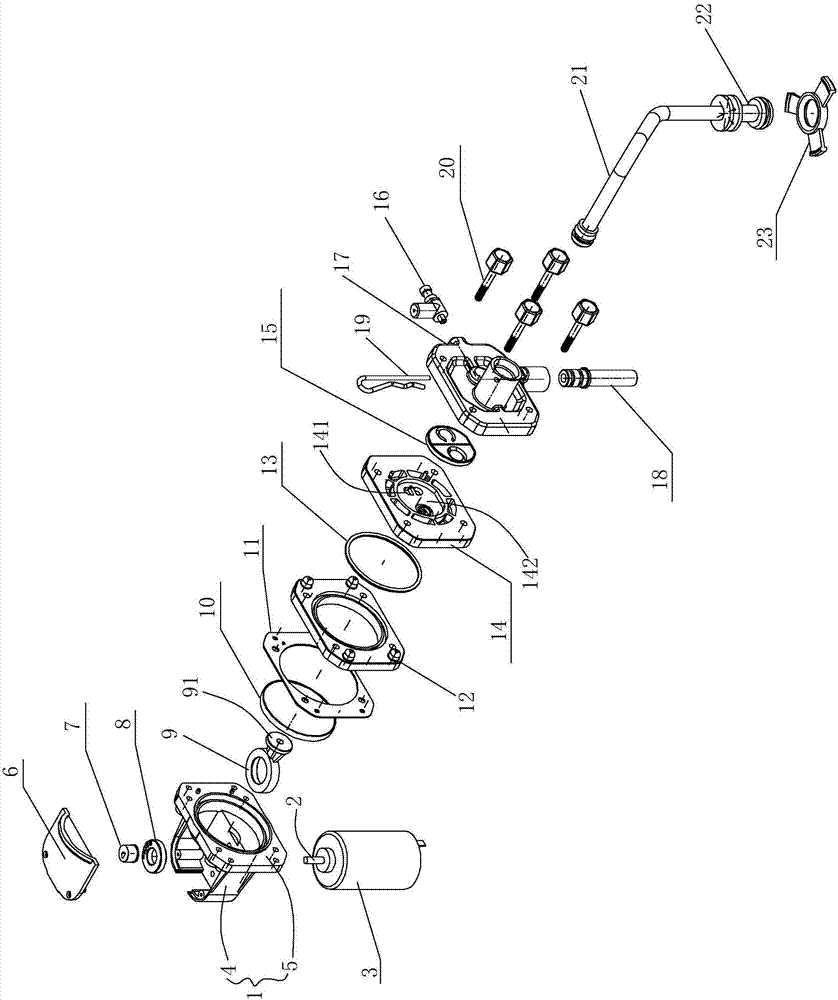

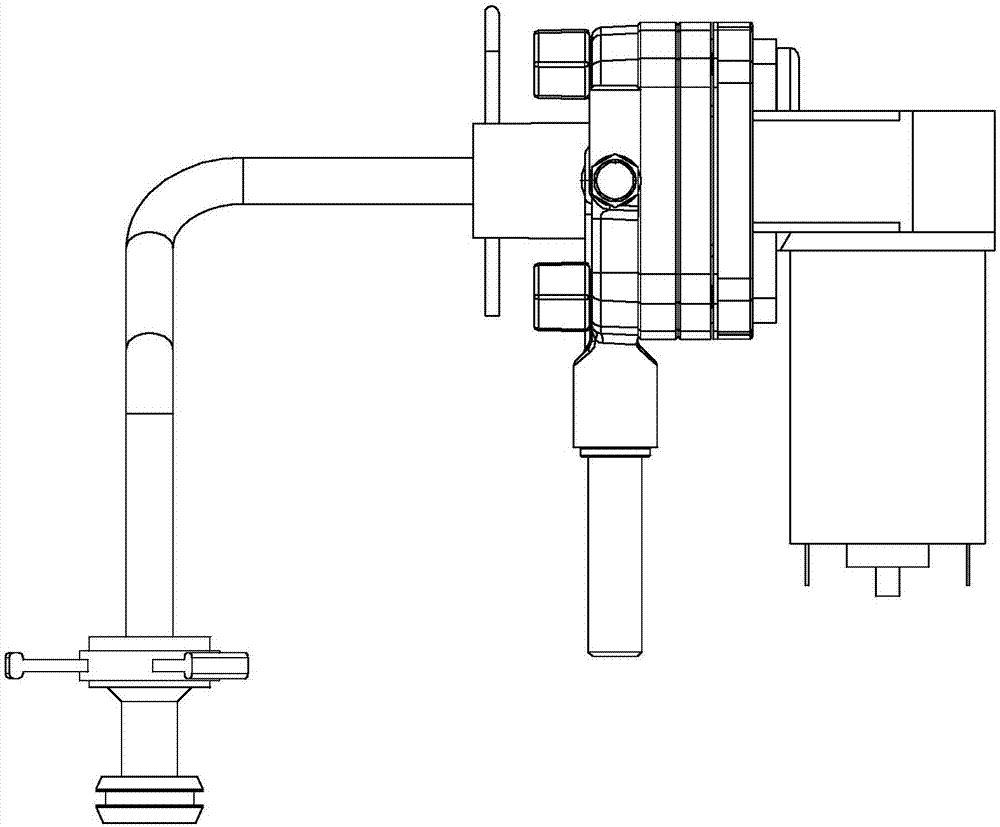

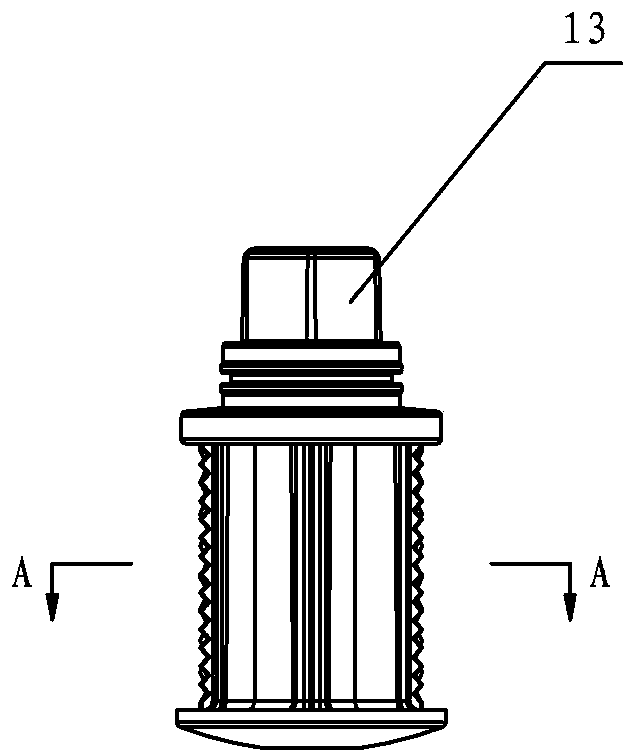

Puffing combination pump apparatus used for ice cream makers, and ice cream maker

InactiveCN105851451AHigh expansion rateLow expansion rateFrozen sweetsIce-cream makerWaste management

The invention discloses a puffing combination pump apparatus used for ice cream makers. The apparatus comprises fixed boxes, combination pumps arranged in the fixed boxes, tee pipe joints, and feeding assemblies and discharging assemblies which are respectively connected with the combination pump; and every combination pump comprises a liquid pump and an air pump which are integrated into one, the feeding openings of liquid pumps are connected with the feeding assemblies, the discharging openings of liquid pumps are in threaded connection with the tee pipe joints, and the air outlets of the air pumps are connected with the discharging assemblies through the tee pipe joints. The puffing combination pump apparatus can effectively improves the puffed rate of ice cream to 55-65%, has a very substantial and stable puffing effect, makes ice cream made by using the apparatus have fine, soft and smooth mouthfeel, and has the characteristics of simple structure, low cost, convenient cleaning and detaching, good reliability, greenness and environmental protection. The invention also discloses an ice cream maker.

Owner:HEYUAN OCEAN POWER TECH +2

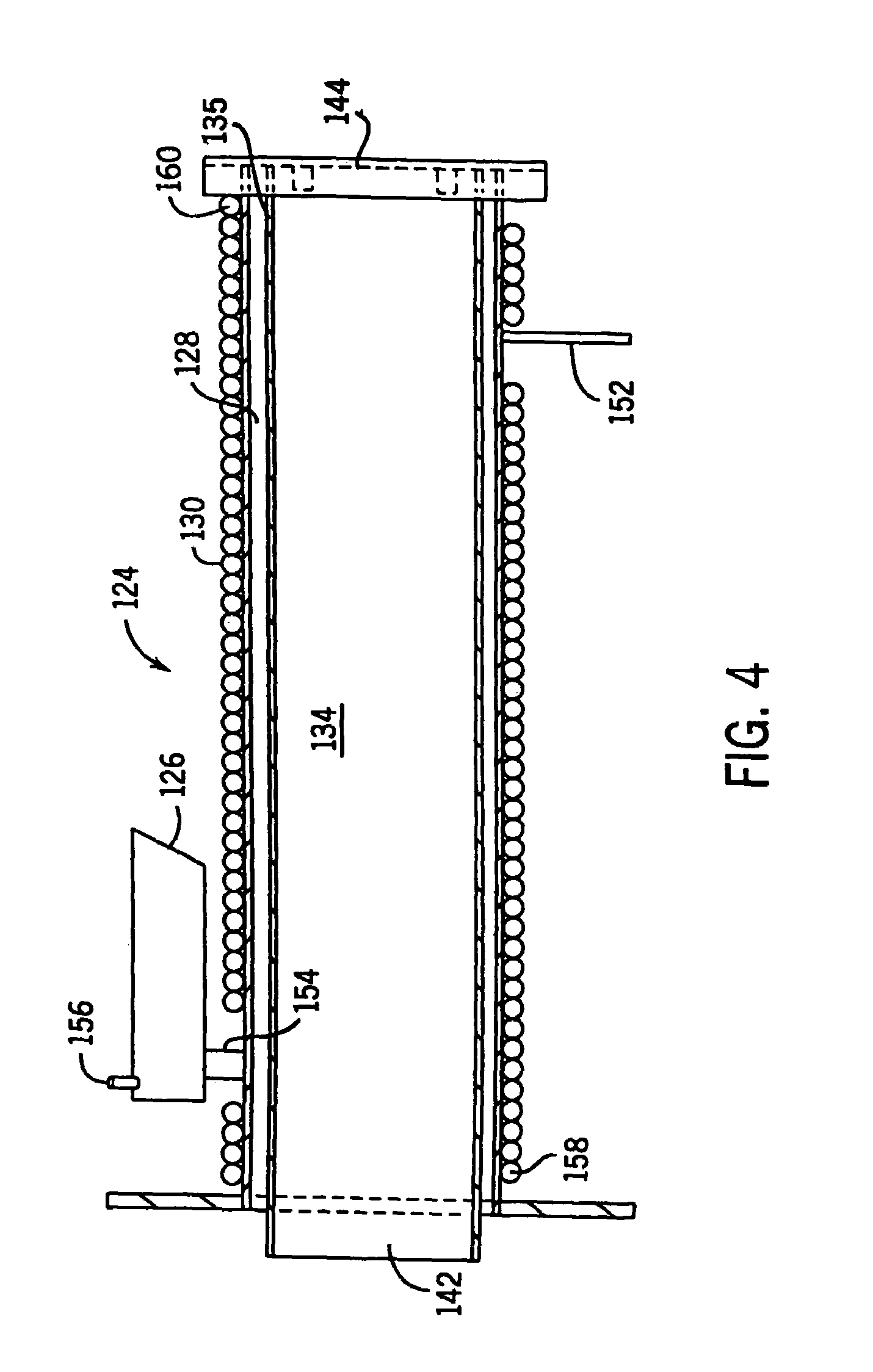

Ice cream machine including a controlled input to the freezing chamber

An ice cream machine for cooling liquid ice cream into frozen ice cream includes an evaporator system with a secondary evaporator. The evaporator system includes a cooling chamber having an ice cream input and an ice cream output. A valve can be placed at the ice cream input to achieve dry freeze operation. The valve can prevent the cooling chamber from being completely filled.

Owner:VOLLRATH

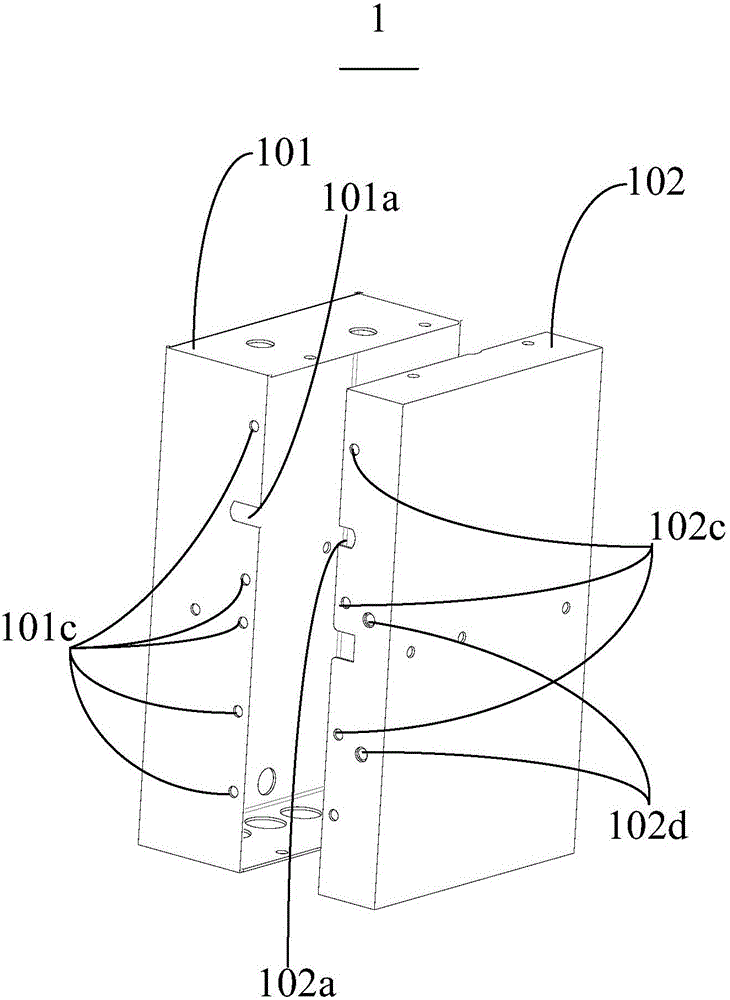

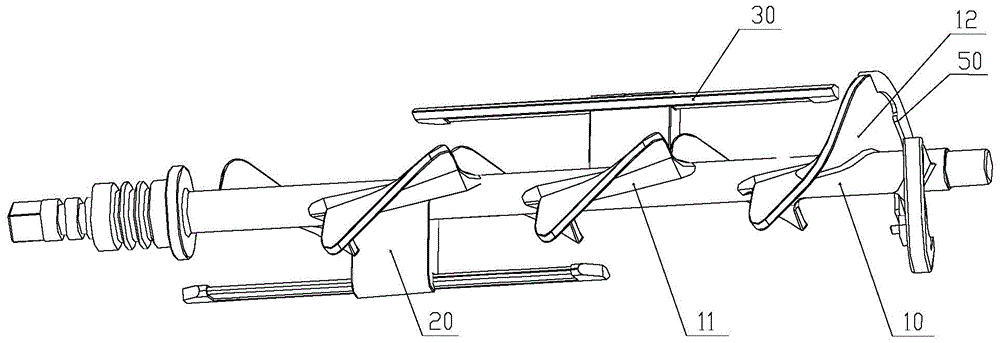

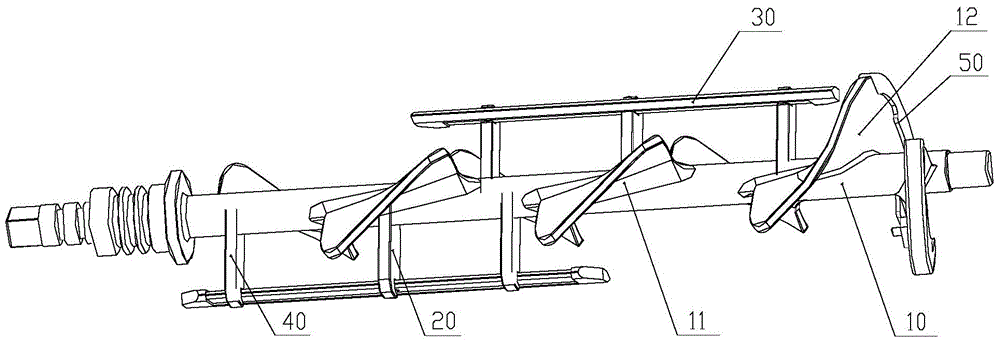

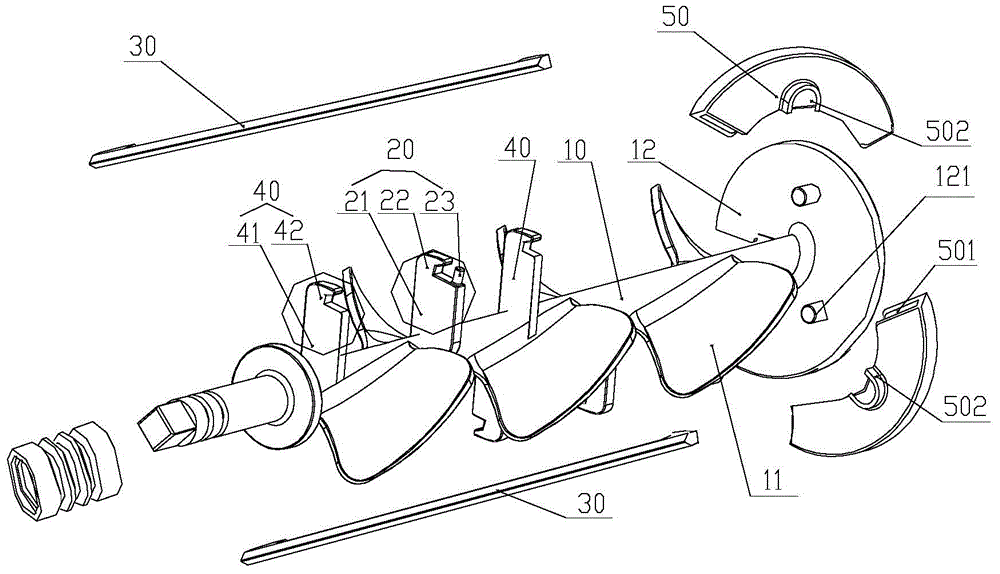

Stirring device of ice cream machine

PendingCN105010708AMeet the requirements of high work efficiencyImprove cooling efficiencyFrozen sweetsPulp and paper industrySlurry

The invention relates to a stirring device of an ice cream machine. The stirring device comprises a stirring shaft and a stirring blade fixed on the outer surface of the stirring shaft, wherein the stirring blade comprises two groups of flaky blades arranged along the axial direction of the stirring shaft and a stripe blade arranged at the tail end of the stirring shaft. The stirring device further comprises a scraper assembly arranged between the two groups of flaky blades, wherein the scraper assembly comprises a first mounting seat and a scraper arranged on the first mounting seat, and the scraper is in pinned connection with the first mounting seat; in the limited range of the first mounting seat, the scraper slides in a way of contacting the first mounting seat and rotates by taking the back of the scraper as a shaft. By using the stirring device of the ice cream machine, delivery and scraping of slurry can be completed independently, the position of the scraper can be adjusted according to the clearance between the stirring device and the wall of a stirring cylinder so that the scraper can be clung to the inner wall of the cylinder and scrape all slurry, and therefore, a series of problems caused by the clearance between the stirring device and the inner wall of the cylinder are overcome, and the stirring device has the effects of being good in scraping effect, strong in thrust and convenient for changing the scraper.

Owner:OCEANPOWER FOOD TECH +2

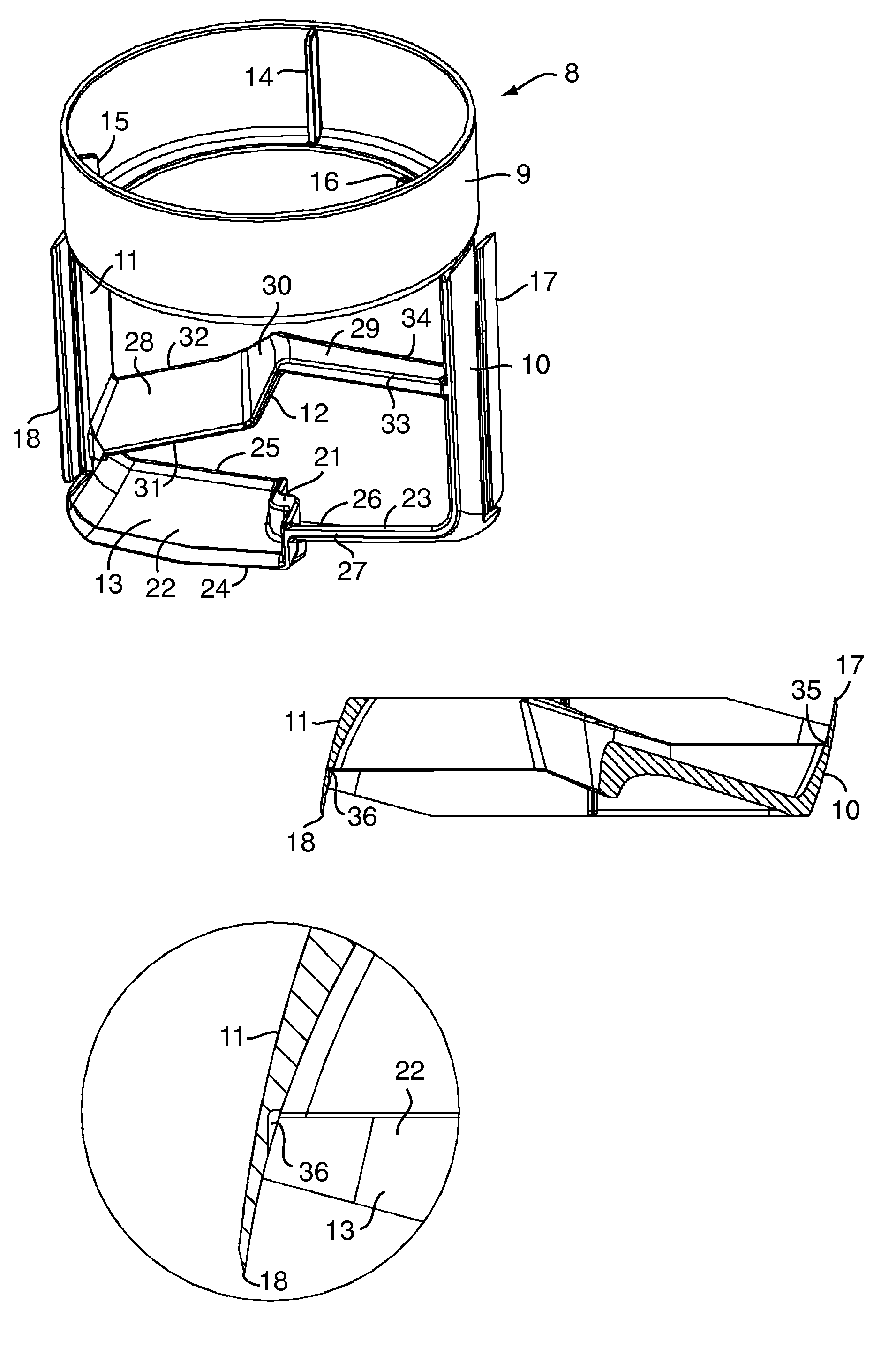

Ice Cream Maker

An apparatus for making a frozen dessert. The apparatus including a reservoir located within a chassis for receiving a liquid dessert mixture and a rotatable paddle located within the reservoir. The paddle can have a body coupled to at least one respective scraper element by a living hinge, such that the scraper element has a scraping edge that is radially-outward biased by the living hinge for abuttingly engaging a wall of the reservoir. The reservoir and the axis of rotation can be substantially horizontally directed, with a substantially vertically-orientated lid closing an opening of the reservoir, the lid defining an aperture for receiving the mixture or enabling egress of the frozen dessert.

Owner:BREVILLE HLDG PTY LTD

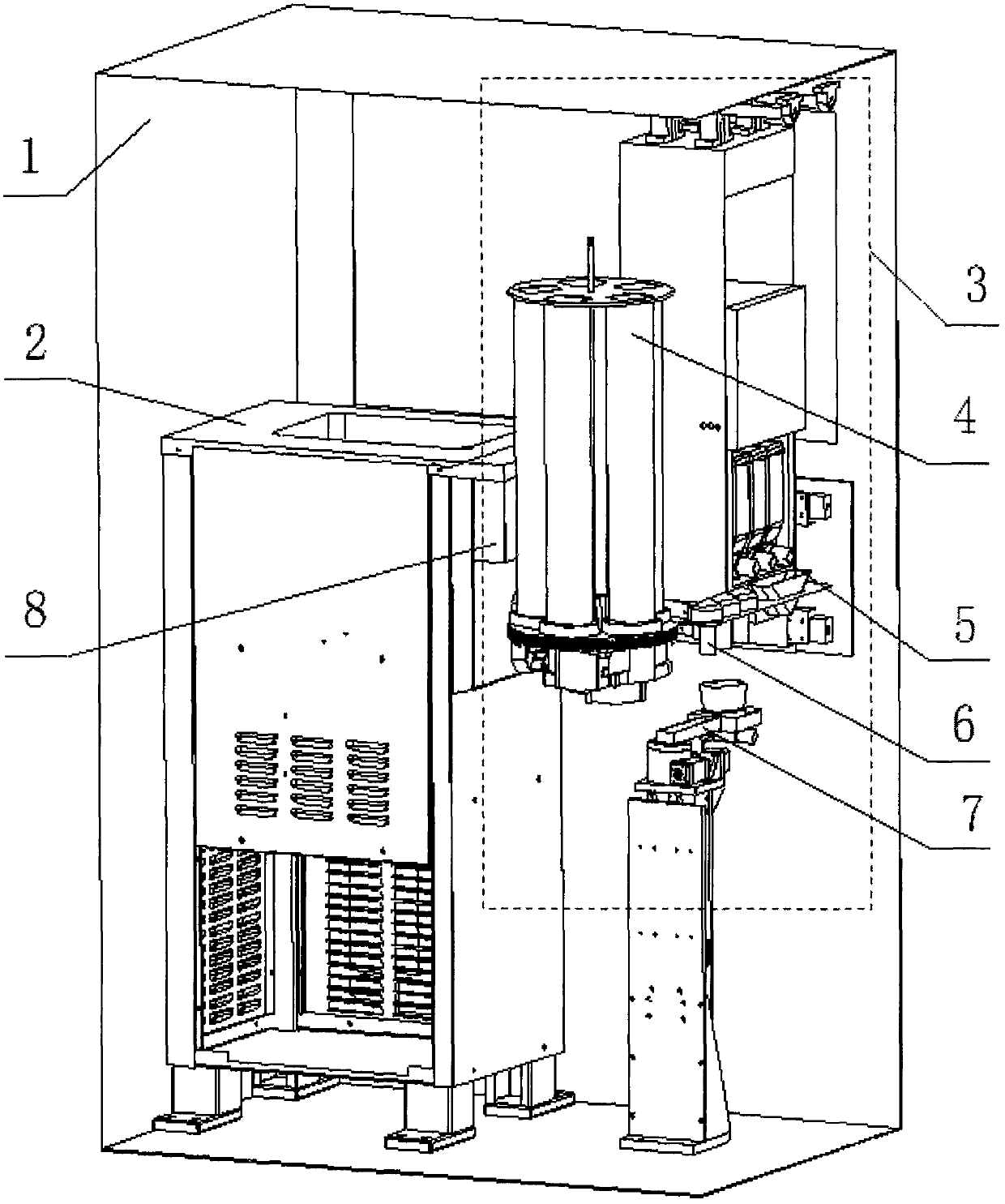

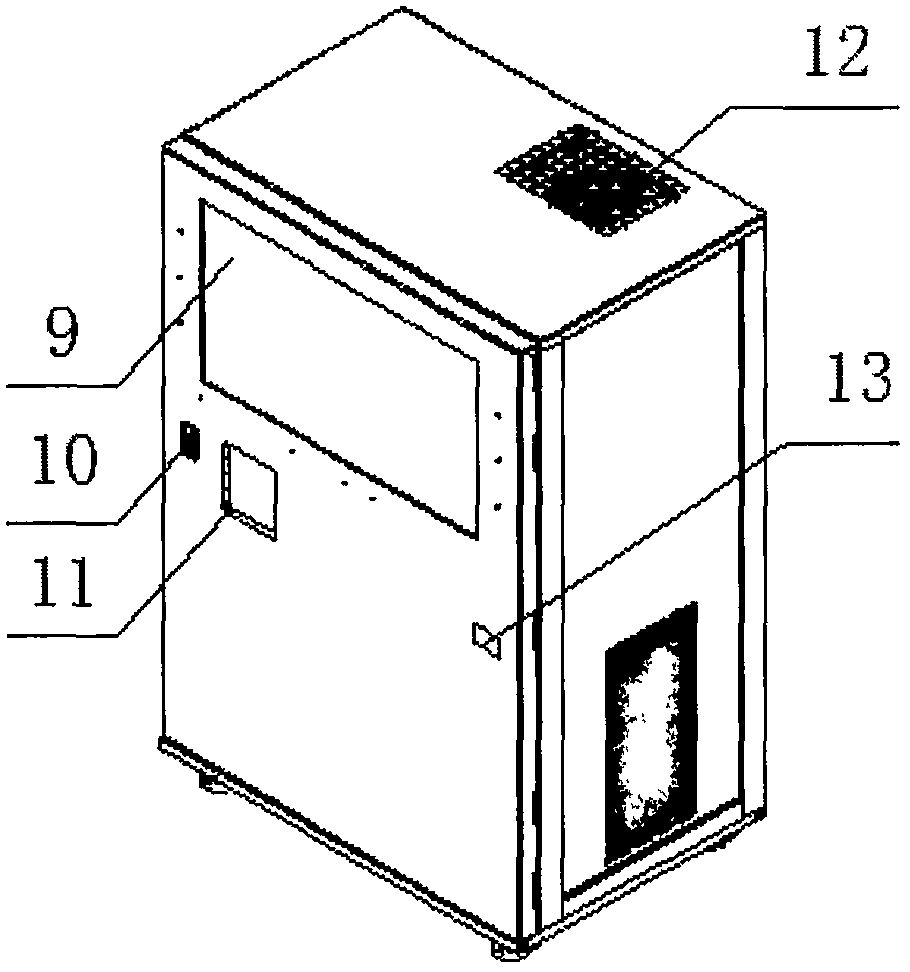

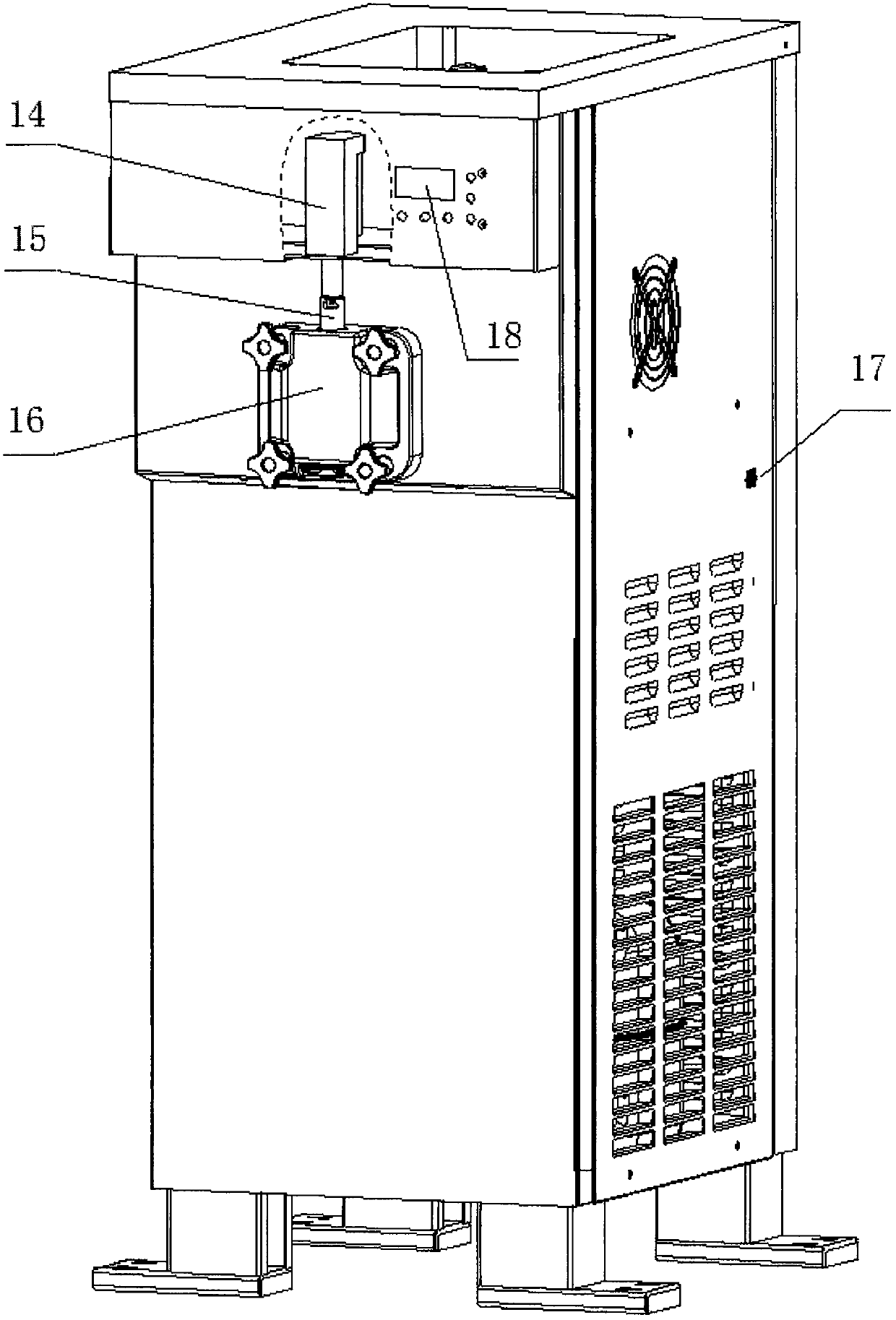

Internet-based novel intelligent ice cream machine

The invention relates to an Internet-based novel intelligent ice cream machine. The machine includes a casing module, an ice cream machine module for holding ice cream and extruding the ice cream, anautomatic selling module, a host computer interaction interface module with a purchase window, a control module and a payment module, and an interconnection and interworking module. The ice cream machine module comprises an ice cream automatic discharging mechanism; the automatic selling module comprises an automatic cup dropping mechanism, a nut adding mechanism and / or a jam adding mechanism, anda conveying mechanism; the casing module comprises a box body, and the box body is provided with a cup taking port; and the conveying mechanism sends an ice cream cup containing the ice cream to thecup taking port. A person only needs to select and pay through the host computer interaction interface module, and the ice cream machine can be automatically controlled to make the ice cream, and therefore, usage is very convenient, specifications are improved, Internet technology is applied to the industry, development can be greatly accelerated, and a prospect is better.

Owner:HUBEI POLYTECHNIC UNIV

Extrusion head and ice cream machine employing same

The invention provides an extrusion head and an ice cream machine employing the extrusion head. The extrusion head comprises a conical body with cutting knives and extrusion threads, wherein continuous cuts respectively formed by merging more than two cutting knives and extrusion screw heads are formed on the surface of the extrusion head; a plane is arranged at the top of the extrusion head; the extrusion screw heads positioned at the upper part of the extrusion head have small inclination; the cutting knives positioned at the lower part of the extrusion head have large inclination; the whole inclination transits gradually; a rotary shaft is arranged at the base part of the extrusion head; the cutting knives are manufactured by adopting plastic or metal; and more than two flow guide grooves evenly distributed in the radial direction are formed in the plane at the top of the extrusion head. The ice cream machine with the extrusion head comprises a material feed cylinder arranged on a machine stand, wherein the extrusion head is inserted into the material feed cylinder transversely or obliquely; and a grinding cover with a material discharge opening is formed in one side surface of the material feed cylinder. The ice cream machine has the characteristics of simple and reasonable structure, low vibration, low noise and wide application range.

Owner:NINGBO BORINE ELECTRIC APPLIANCE

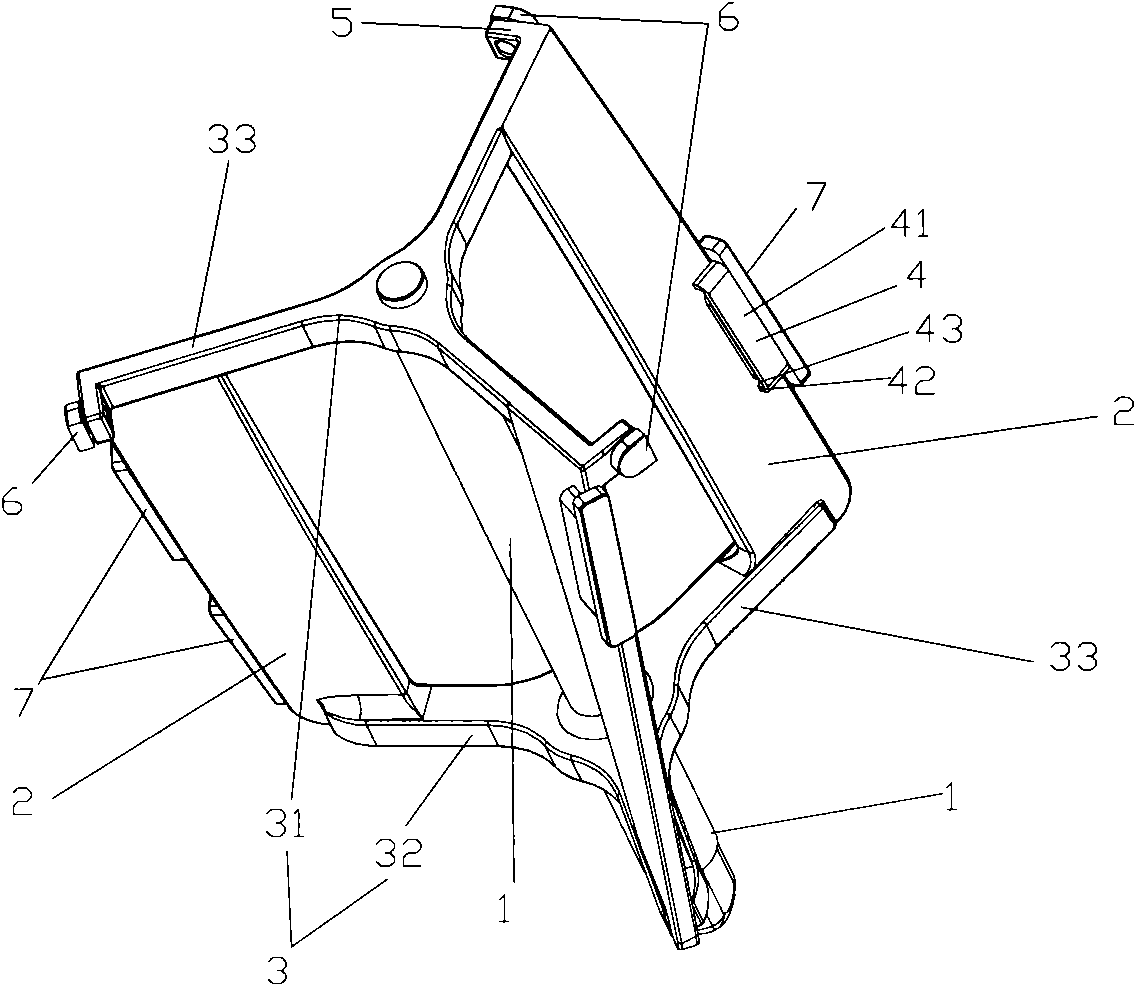

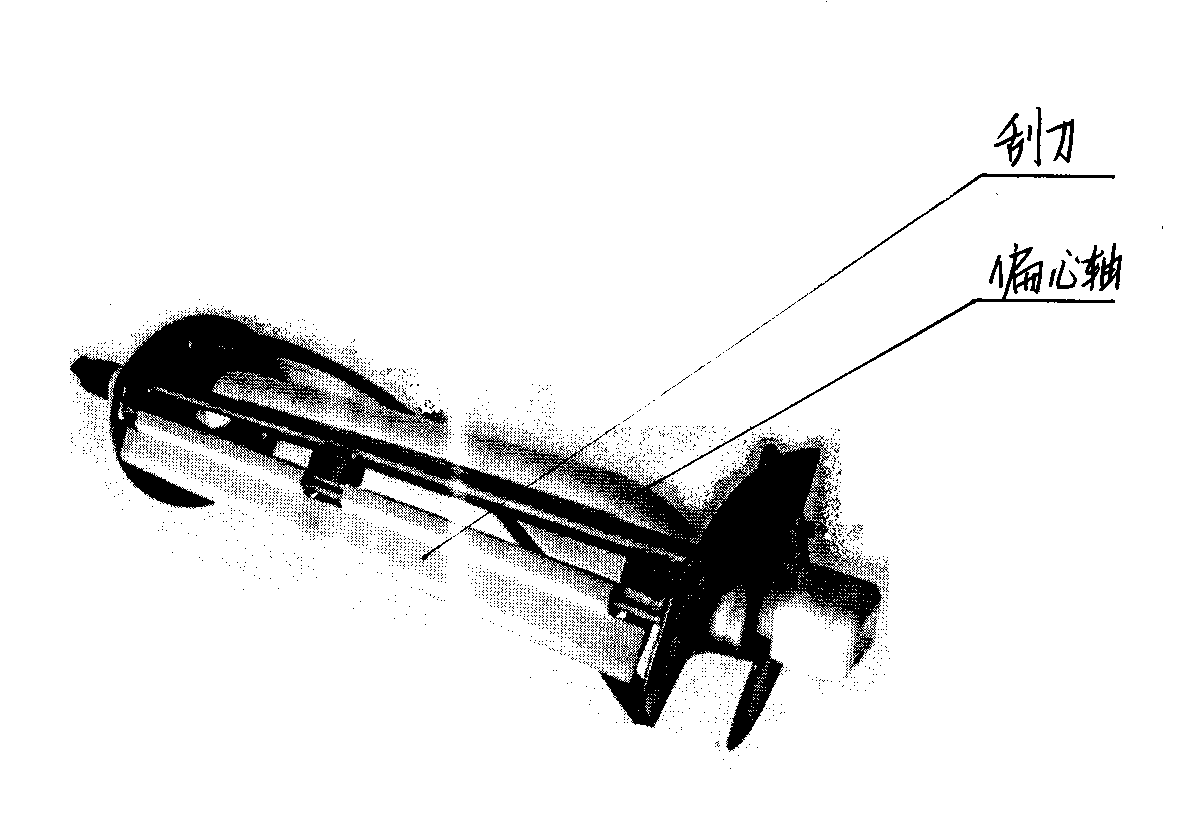

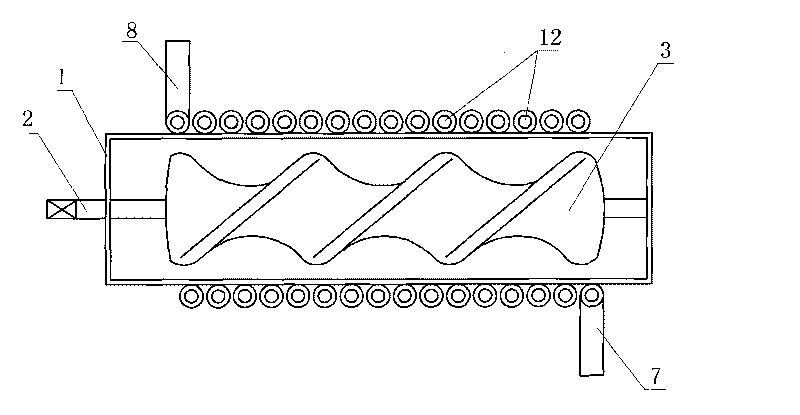

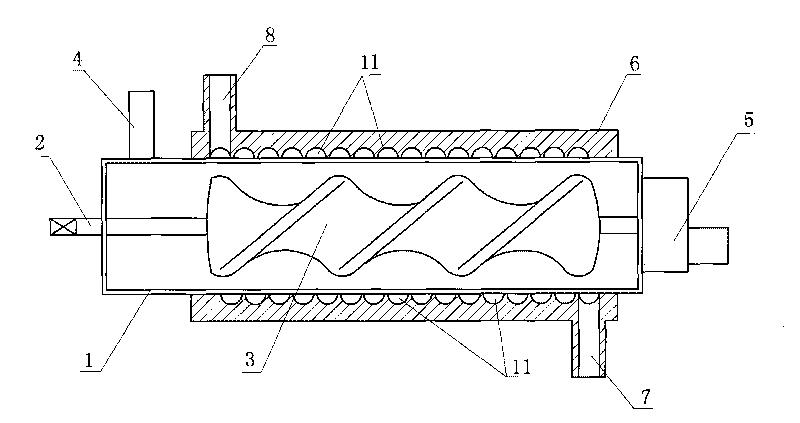

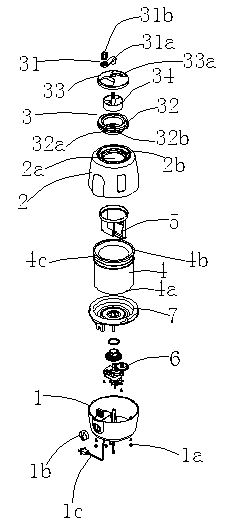

Mixer shaft of hard ice cream machine

InactiveCN101889623AImprove cooling speedImprove uniformityFrozen sweetsEngineeringCentrifugal force

The invention discloses a mixer shaft of a hard ice cream machine. The mixer shaft comprises a central rotating shaft (1), a rotator (3) and a mixing blade (2), wherein the rotator (3) is arranged on the central rotating shaft (1); the mixing blade (2) is arranged on the rotator (3); an outer edge of the mixing blade (2) is provided with doctor knives (7); and the doctor knives (7) are arranged at different heights of the mixing blade (2) and can slide along the mixing blade (2) in the radial direction of the mixer shaft. By adopting the mixer shaft of the hard ice cream machine, the doctor knives can be clung to the inner wall of a freezing cylinder of the hard ice cream machine under the action of centrifugal force during agitation to scrap the inner wall of the freezing cylinder more cleanly so as to increase the refrigeration speed and the refrigeration uniformity of the hard ice cream machine, and ensure that an ice cream cake body cannot have a deteriorated taste due to the interfusion of ice scraps.

Owner:SHENZHEN OCEAN POWER INDUSTRIAL CO LTD +3

Ice cream and topping mixing attachment

Owner:MIMRAN EMILE

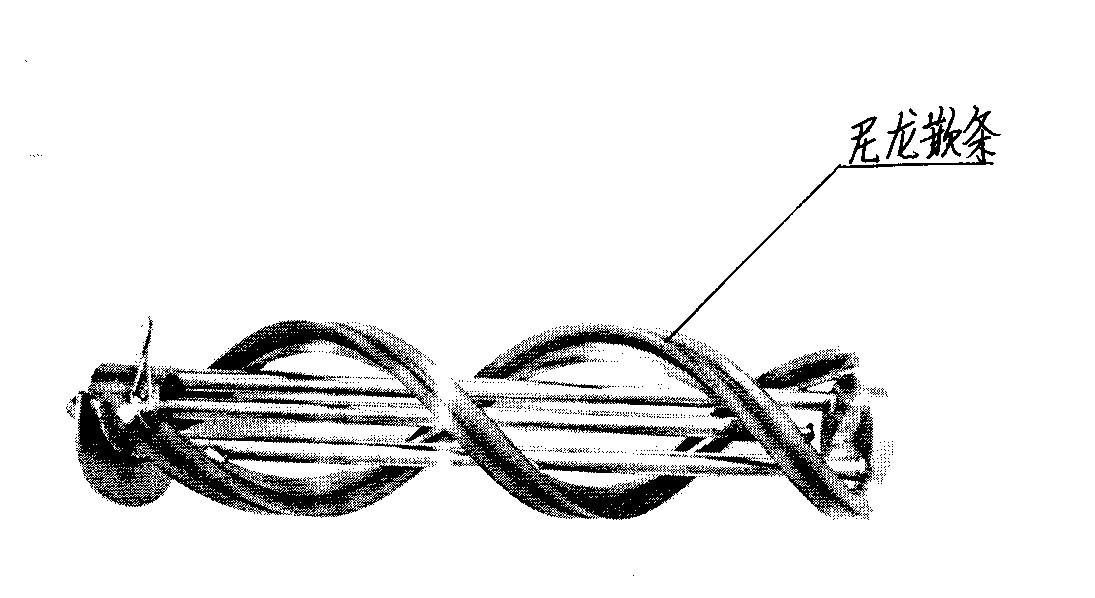

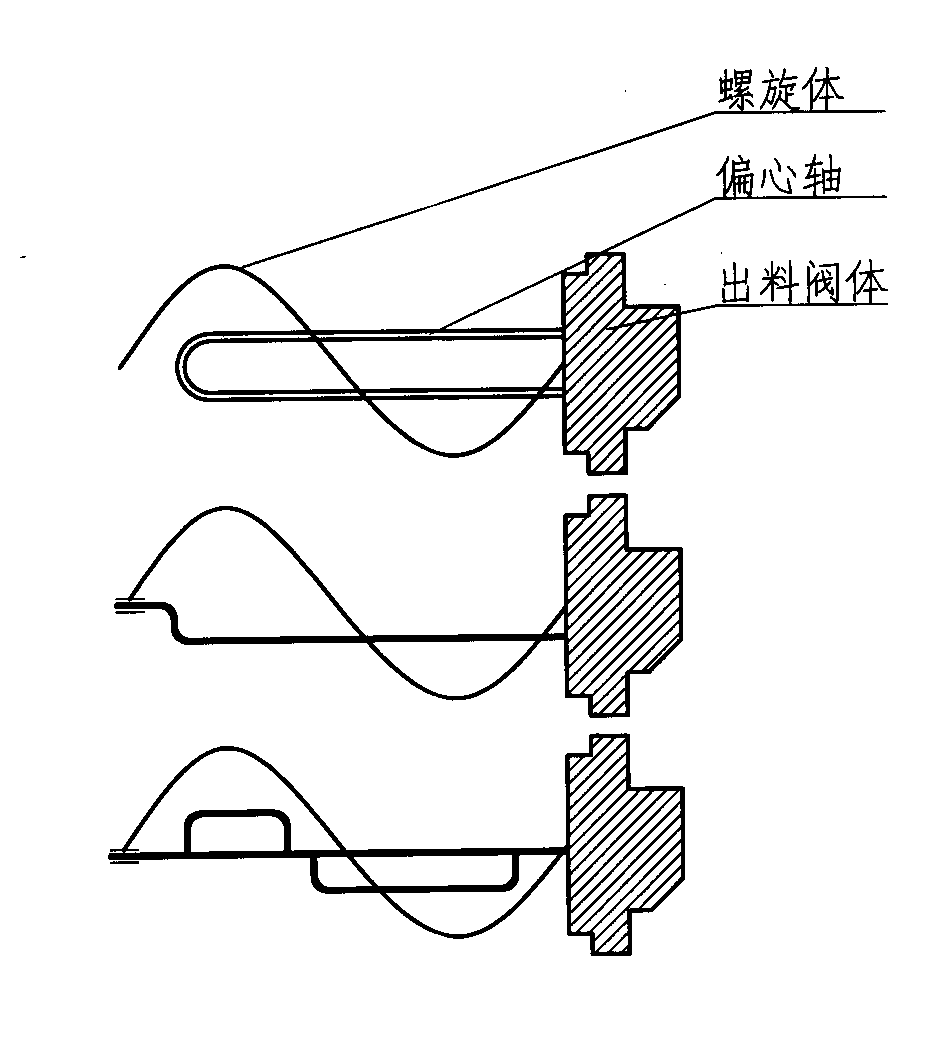

Design for agitating shaft of soft ice cream machine

The invention discloses design for an agitating shaft of a soft ice cream machine. According to the design, the complete agitating shaft is characterized by comprising an excircle-changing spiral body (shown as a figure 6) consisting of two excircle-changing spiral strips, two scrapers (shown as a figure 5) with intermittent edges, and an eccentric shaft (shown as a figure 7) with a spiral blade, wherein the two scrapers are staggered with one edge in the 180-degree direction on the spiral periphery of the spiral body of the agitating shaft, so that the intermittent edges are staggered; and the spiral direction of the spiral blade is opposite to that of the spiral body. The design can meet the design requirements of the agitating shaft of the soft ice cream machine (especially a small soft ice cream machine) on efficient heat exchange, full agitation, stable running and powerful material pushing and feeding.

Owner:杨剑勇

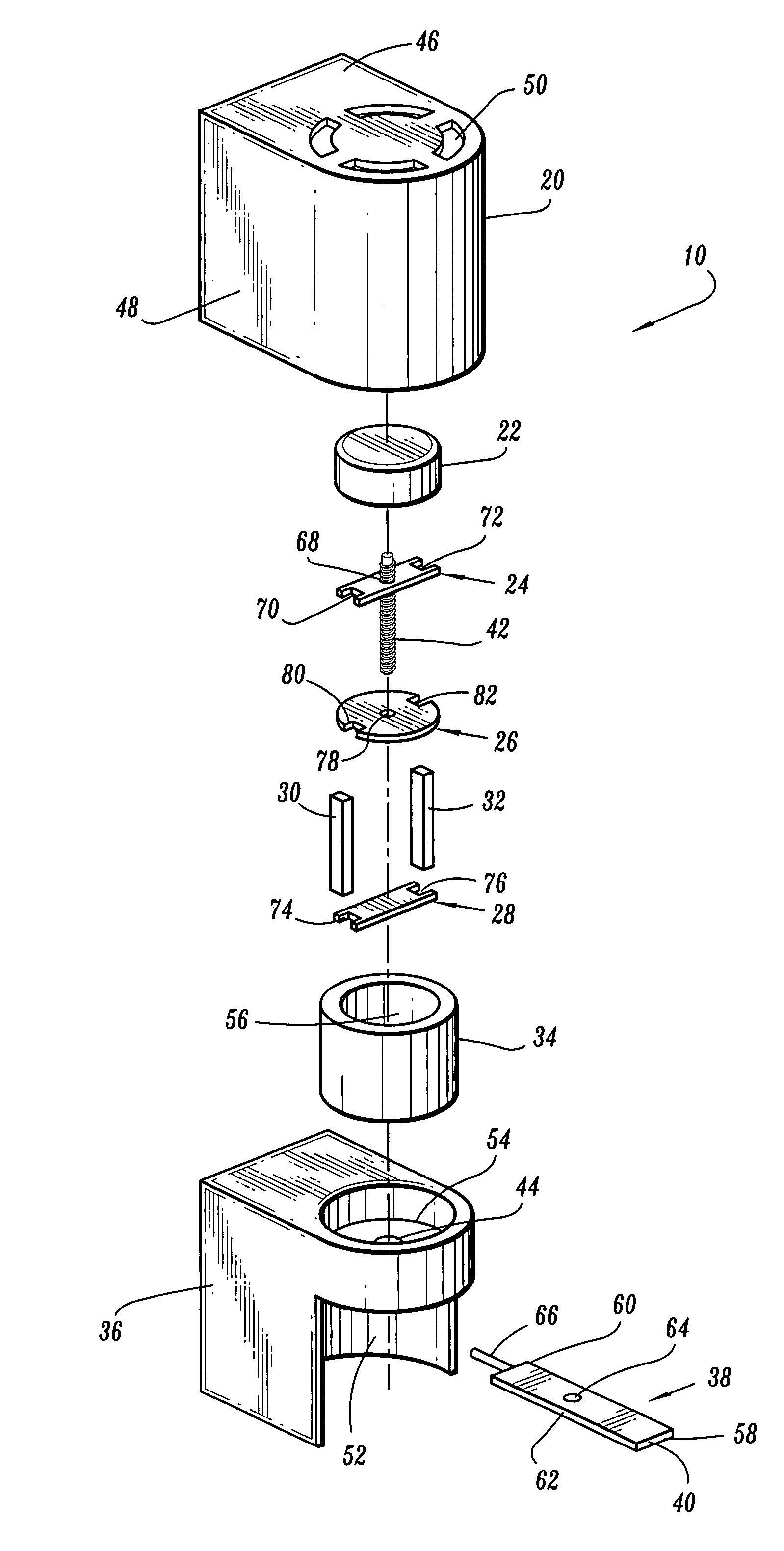

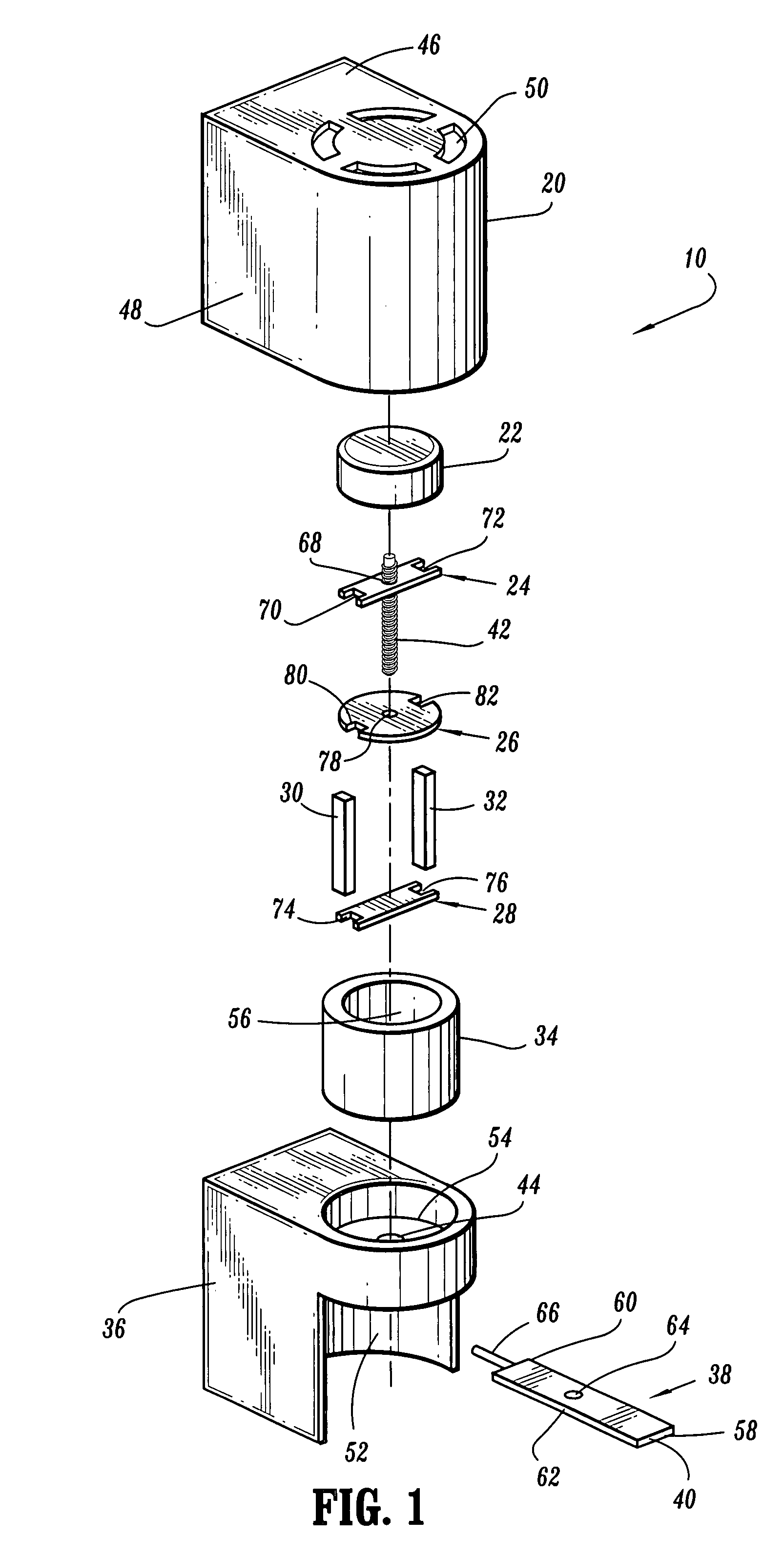

Apparatus for making ice cream having an improved dispenser

An ice cream maker for making ice cream having a vessel, a motor being connected to a dasher in the vessel and a housing for housing the vessel and the motor. The housing has an inlet, an outlet and a valve at the outlet. When said valve is actuated, the ice cream is released from the vessel out of the outlet.

Owner:CONAIR CORP

Mixing paddle for ice cream machine

ActiveUS20120092953A1Effective and efficient movementRotating receptacle mixersRotary stirring mixersEngineeringIce-cream maker

A mixing paddle for use in a conventional ice cream maker includes two vertical arms that have outer contact edges that exceed the inner diameter of the freezer bowl in which they are positioned during use. This enables the contact edges to effectively scrape ice cream ingredients from the inner wall of the bowl during use and direct the ingredients toward the center of the bowl. The mixing paddle also comprises two cross-members that have pin-wheel style shapes that move ice cream ingredients vertically during use. The combined effect of the vertical arms and the cross-members optimally and uniformly mixes the ice cream ingredients during use and ensures efficient cooling.

Owner:CONAIR CORP

Refrigeration control method of ice cream machine

PendingCN111011572AAppropriate cooling capacityQuality assuranceMechanical apparatusFrozen sweetsControl systemIce Creams

The invention discloses a refrigeration control method of an ice cream machine. The ice cream machine comprises a freezing cylinder with a stirrer, a main refrigerating system and a control system. The main refrigerating system comprises a refrigerating loop formed by connecting a compressor, a condenser, a throttling device and an evaporator through a refrigerating pipeline. The control system controls the main refrigerating system to refrigerate ice cream in the freezing cylinder and controls the stirrer to perform stirring. The throttling device is an electronic expansion valve. The controlsystem is further used for acquiring a real-time forming degree value of ice cream materials in the freezing cylinder and controlling the valve opening degree of the electronic expansion valve through forming degree value feedback. The forming degree value is a forming value divided according to the forming degree in the hardness / or viscosity ice cream forming process of ice cream material liquidstate-solid mixed state-solid state-system setting; and the control system controls the valve opening degree of the electronic expansion valve to change along with the change of the forming degree value. The refrigerating capacity in the ice cream material forming process can be accurately controlled.

Owner:HUBEI GUANGSHEN ELECTRIC PROD CO LTD

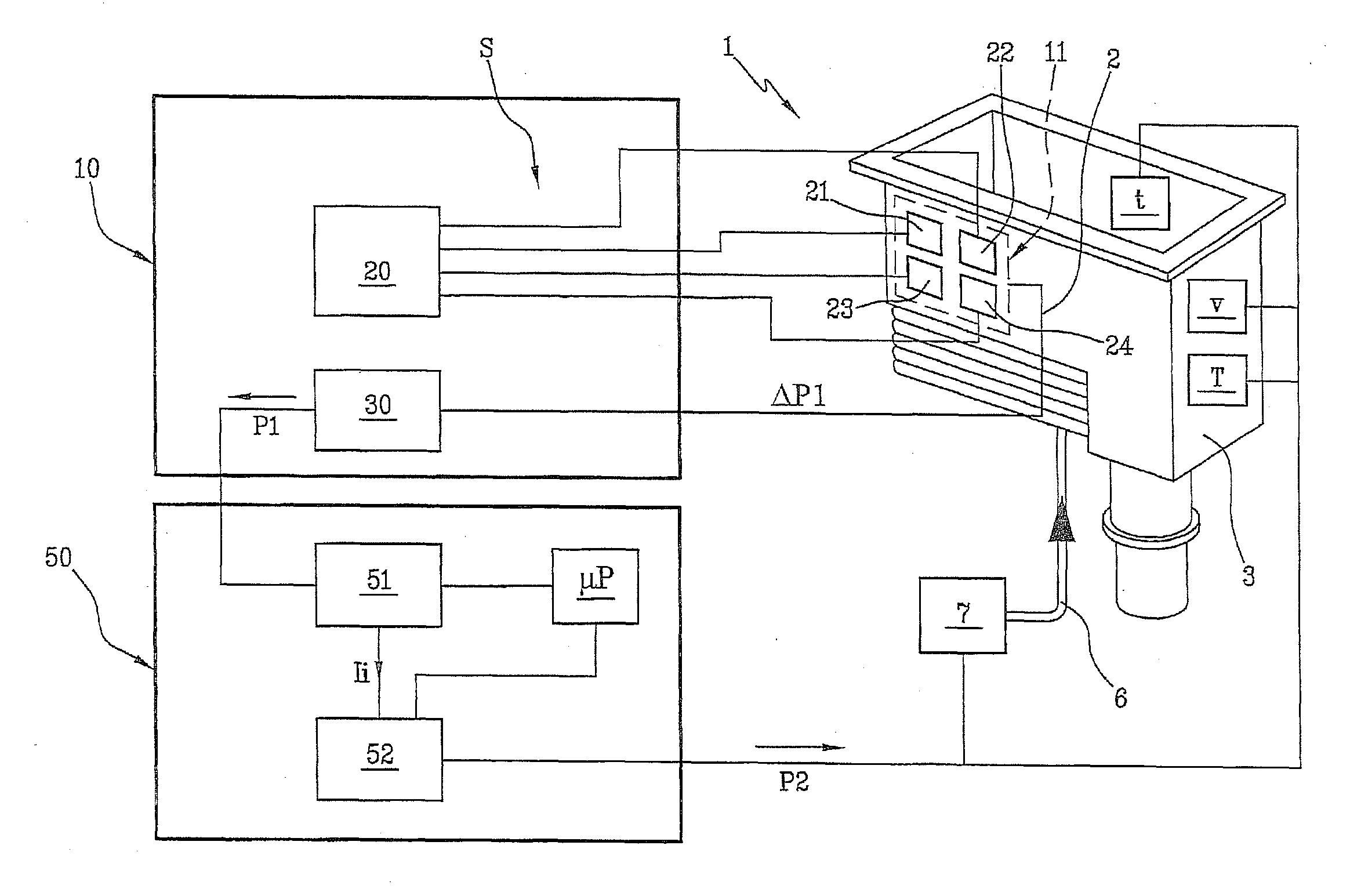

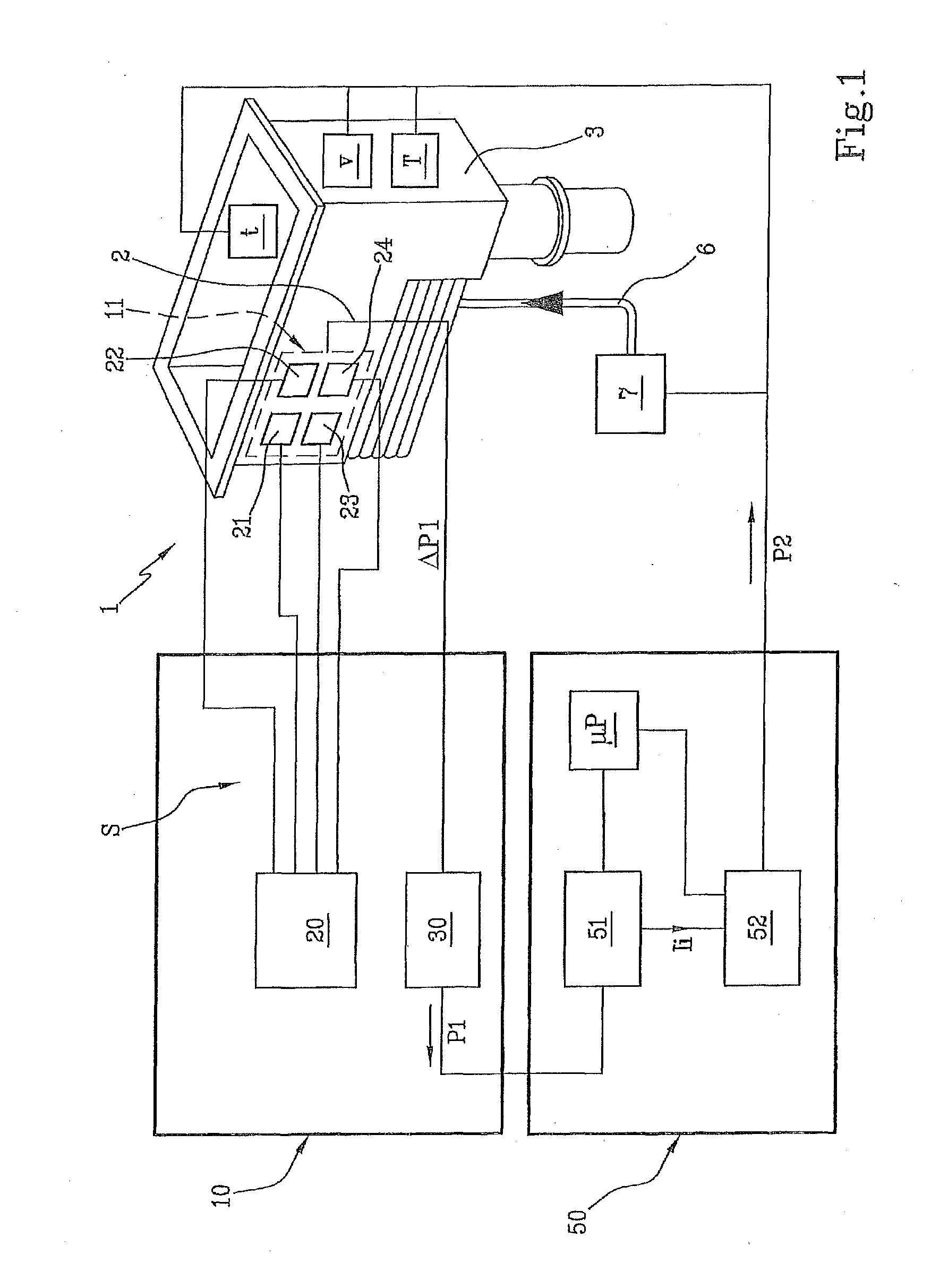

Ice cream machine

The invention describes a machine for making ice-cream which comprises a holding tank and a cooling and / or heating circuit for a liquid or semi-liquid foodstuff to be treated, a detection apparatus capable of detecting a characteristic parameter of this product, and a control unit capable of recognizing the product starting from this parameter, and for setting operating parameters for the machine on the basis of the product recognized.

Owner:ALI - CARPIGIANI GROUP

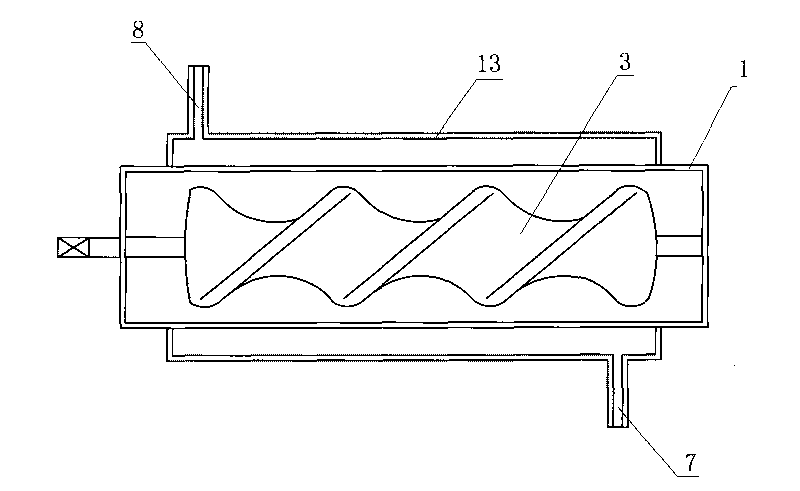

Ice cream mixing drum

The invention relates to an ice cream mixing drum belonging to food processing machinery. The ice cream mixing drum comprises a cylinder body, a drive shaft, a propeller and a heat exchange sleeve, wherein a raw material inlet is arranged at one side of the cylinder body, an ice cream output valve is arranged at the other side of the cylinder body, the propeller is installed in the cylinder body, the drive shaft is connected with the propeller, the heat exchange sleeve encircles the cylinder body and is provided with a working medium inlet and a working medium outlet, and a continuous inside spiral groove is arranged between the working medium inlet and the working medium outlet on the inner wall of the heat exchange sleeve and forms a continuous spiral channel with the outer wall of the cylinder body. In the invention, a working medium channel in a continuous spiral shape combined by the inside spiral groove of the heat exchange sleeve and the outer wall of the cylinder body forces working medium to flow along the spiral channel; the working medium exchanges heat with the cylinder body with longer time and larger contact area when flowing, thereby having the advantage of high heat exchange efficiency; and pasteurization is carried out on ice cream in a stirring cylinder body when heated to 60-80 DEG C. The invention is suitable for use on various ice cream freezers and slush machines.

Owner:黎永雄

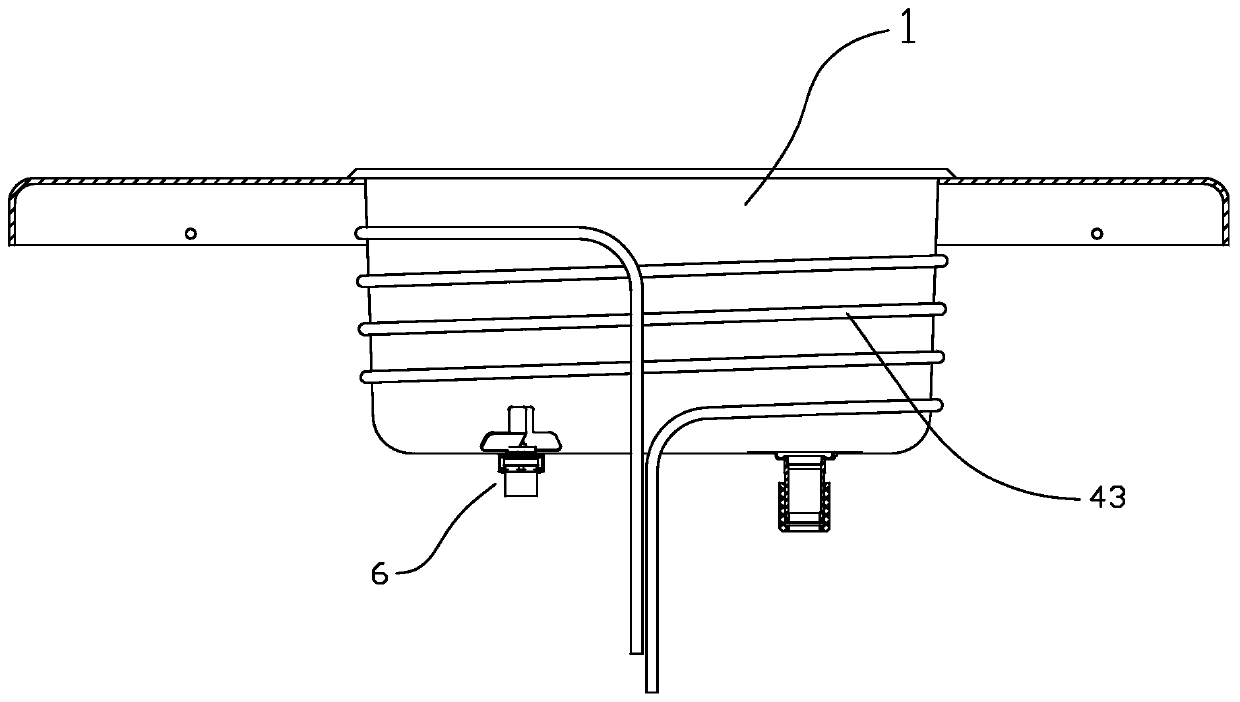

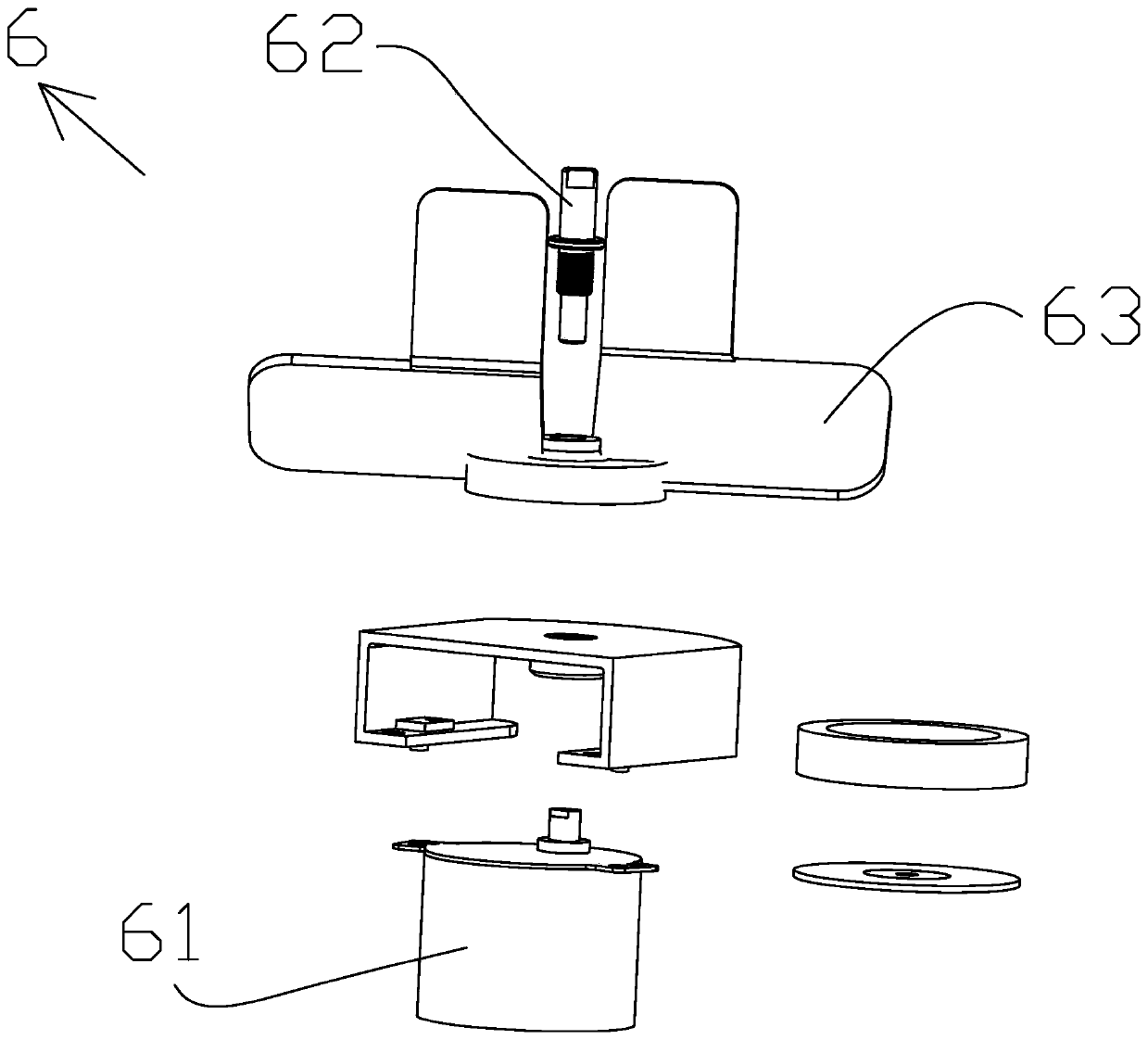

Replaceable freezer cylinder of yogurt or ice cream machine

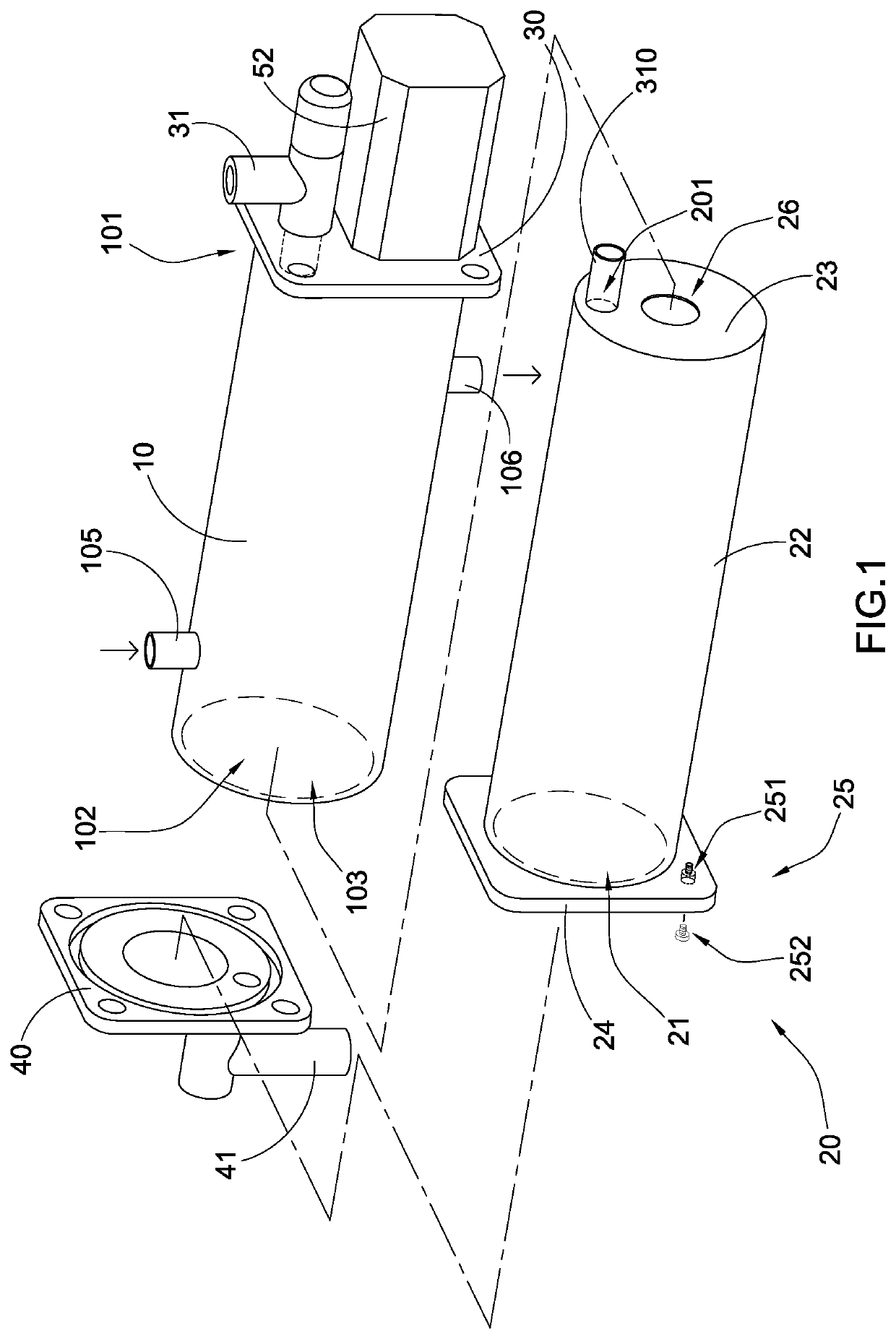

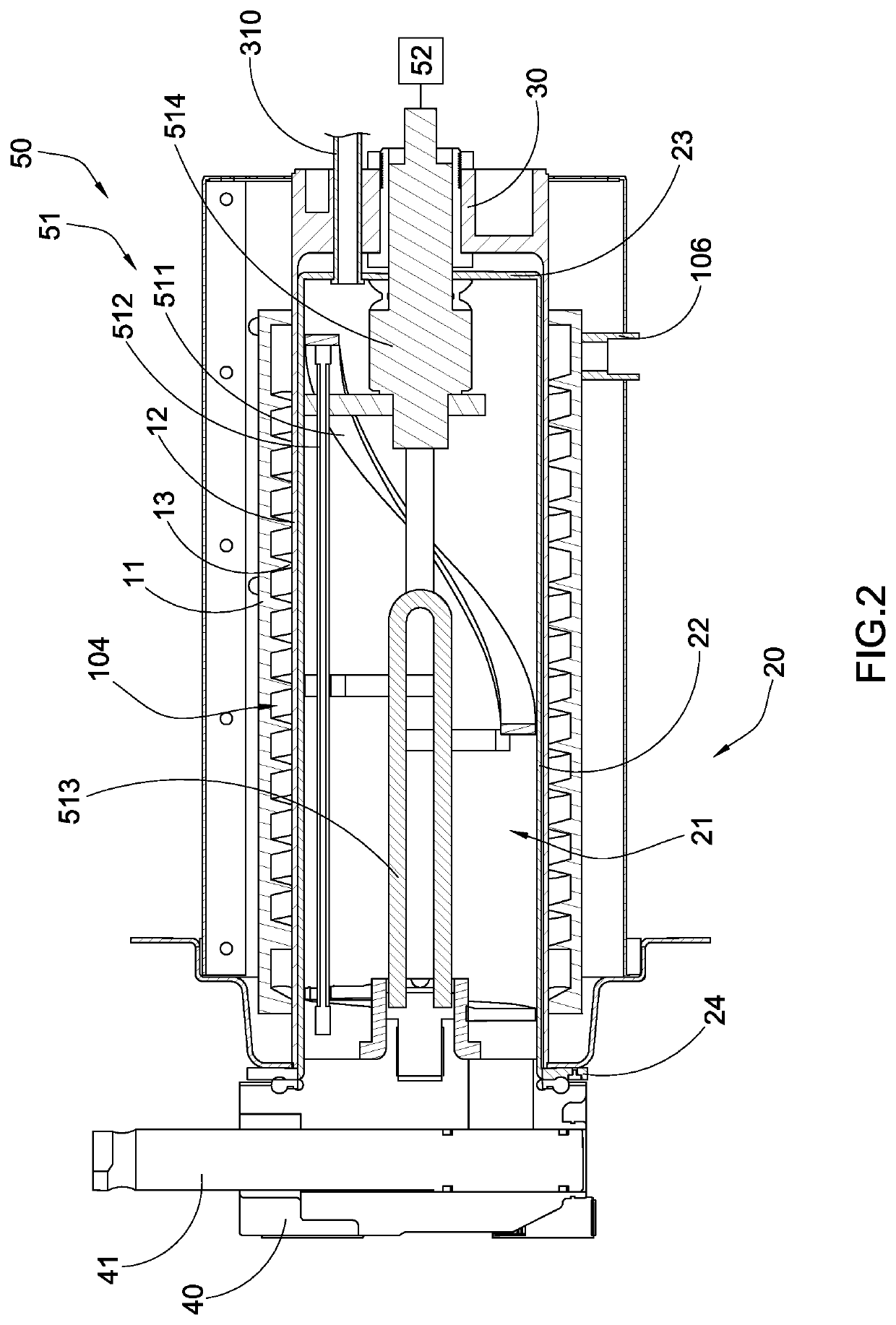

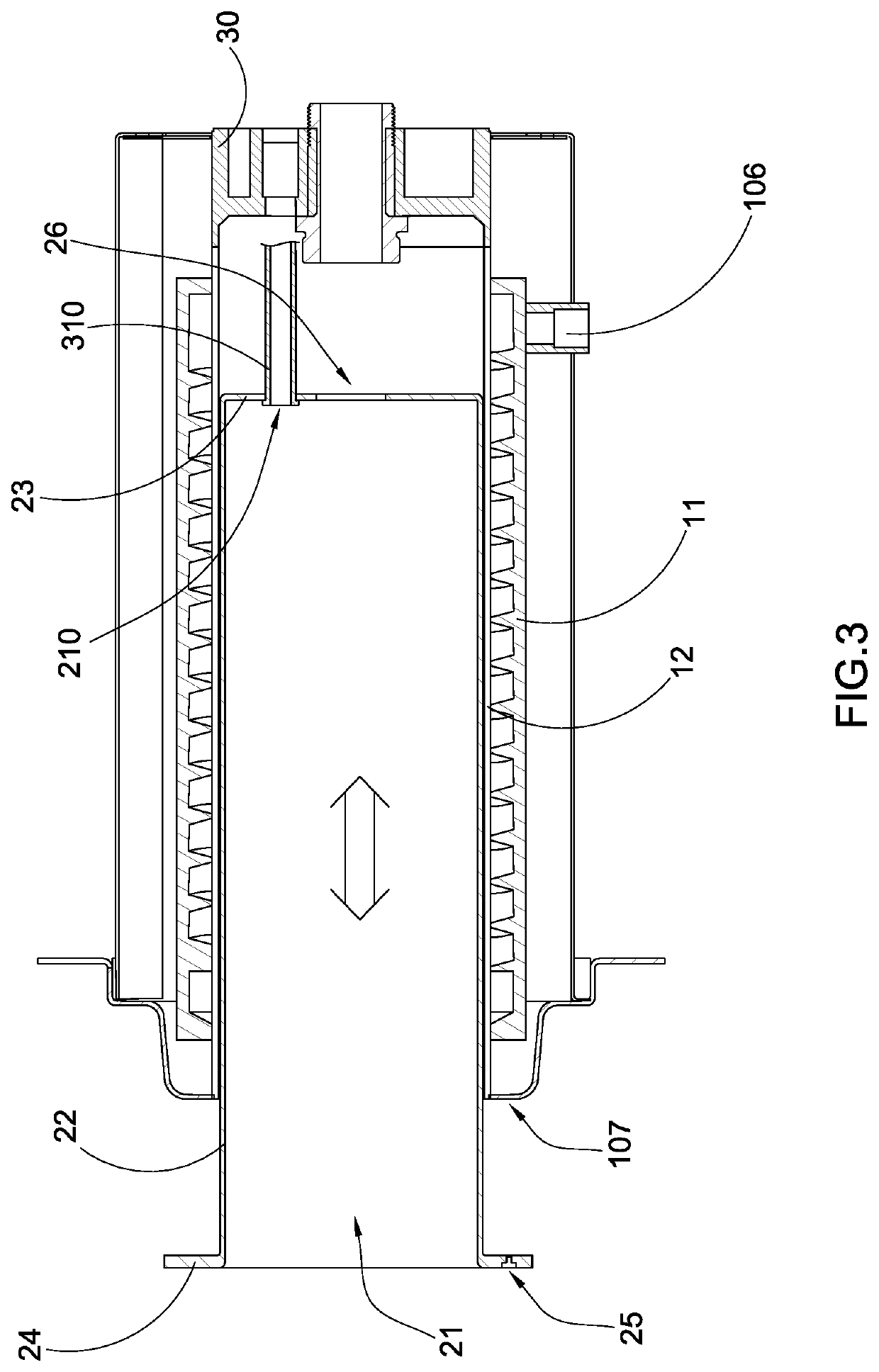

ActiveUS11019832B2Easy to cleanSimple structureMilk preparationDomestic cooling apparatusEngineeringMechanical engineering

An expansion evaporator includes a heat exchanger and a replaceable freezer cylinder detachably received within a receiving channel of the heat exchanger, wherein the replaceable freezer cylinder has a feeding channel for raw material feeding therethrough to thermally communicate with the heat exchanger so as to form a frozen product within the feeding channel. The replaceable freezer cylinder is detached from the heat exchanger for cleaning purpose as the raw material is not contacted with the heat exchanger.

Owner:DONG LINGYU

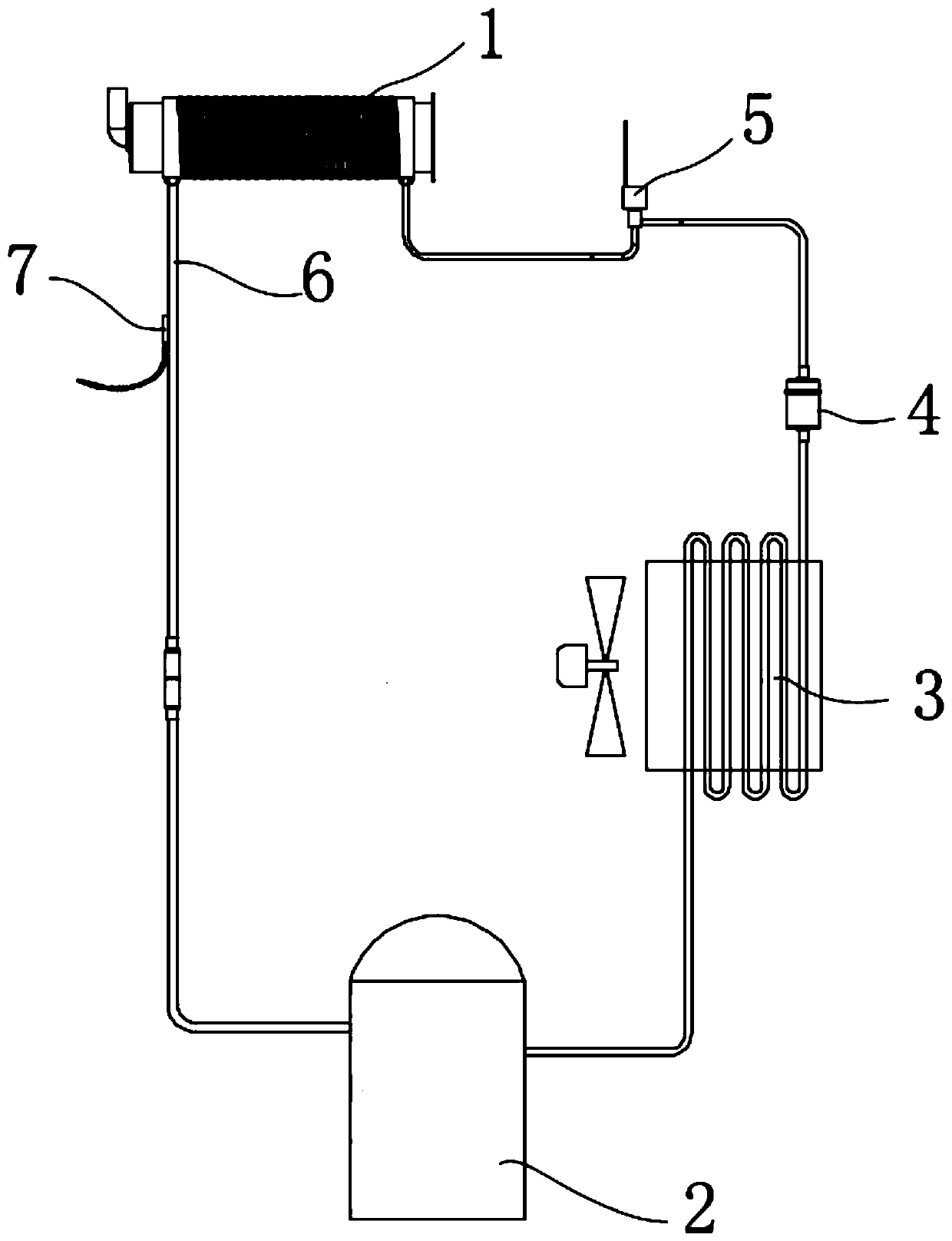

Novel ice cream maker

The invention discloses a novel ice cream maker. The novel ice cream maker comprises a raw material vat, an air intake pipe, a magnetic driving pump and a freezing vat, wherein a raw material outlet is formed in the bottom of the raw material vat; the air intake pipe is arranged in the raw material vat, the upper end of the air intake pipe extends to an opening in the upper end of the raw material vat and communicate with outside air, and the lower end of the air intake pipe is connected with the raw material outlet and a feed opening of the magnetic driving pump; and the raw material outlet is connected with the feed opening of the magnetic driving pump, and a discharge opening of the magnetic driving pump is connected with a feed opening of the freezing vat through a connecting pipe. Compared with the prior art, the ice cream maker disclosed by the invention is simple and compact in structure, few in parts and components and small in size; when the ice cream maker is cleaned, the magnetic driving pump works to inhale water, then the ice cream maker can be thoroughly cleaned, and the parts and the components do not need to be disassembled, so that the working strength is reduced; and besides, ice cream produced by the ice cream maker has the advantages of being high in puffing rate, fine and smooth in mouth feel and smooth.

Owner:上海侨赛制冷设备有限公司

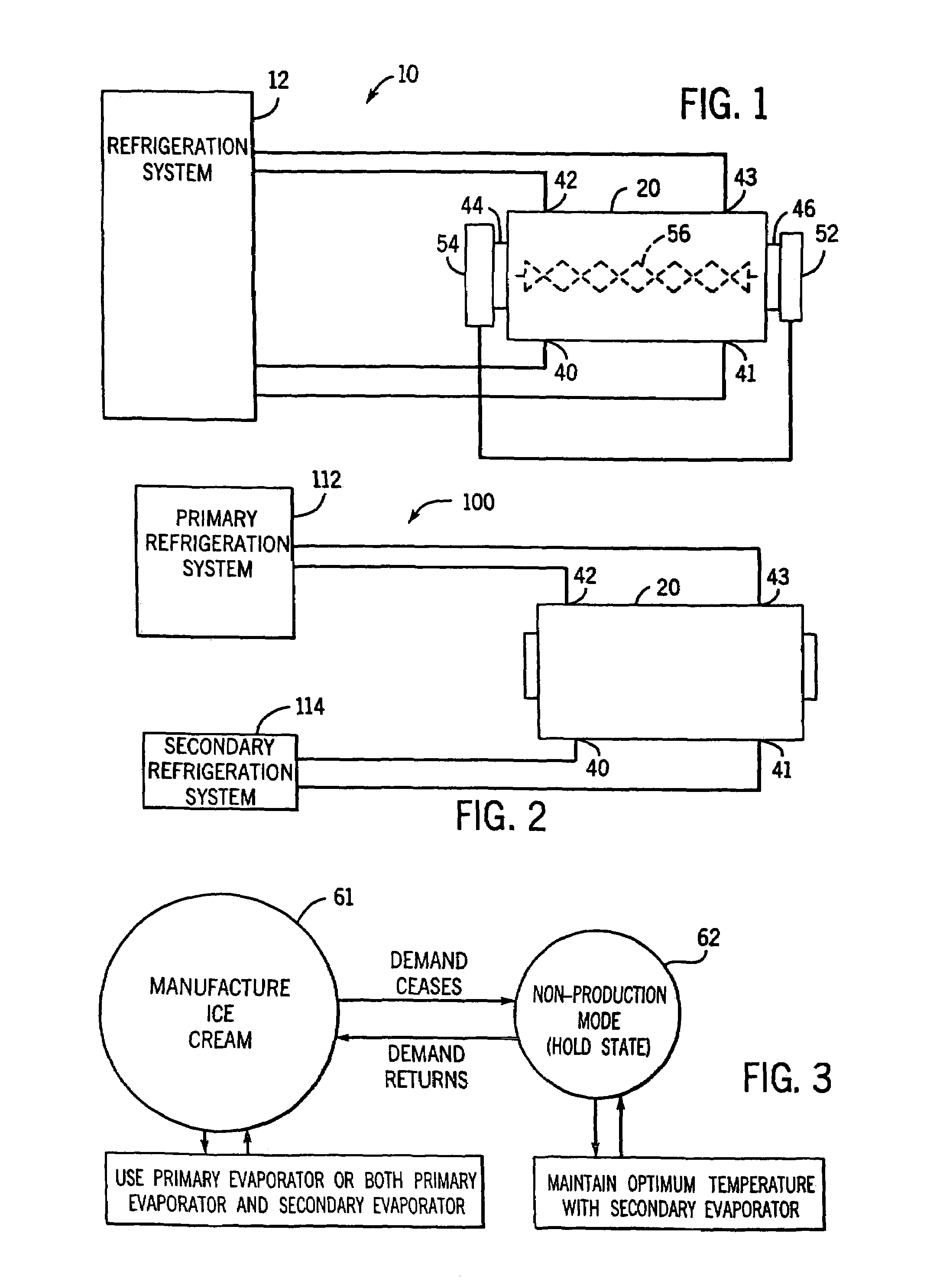

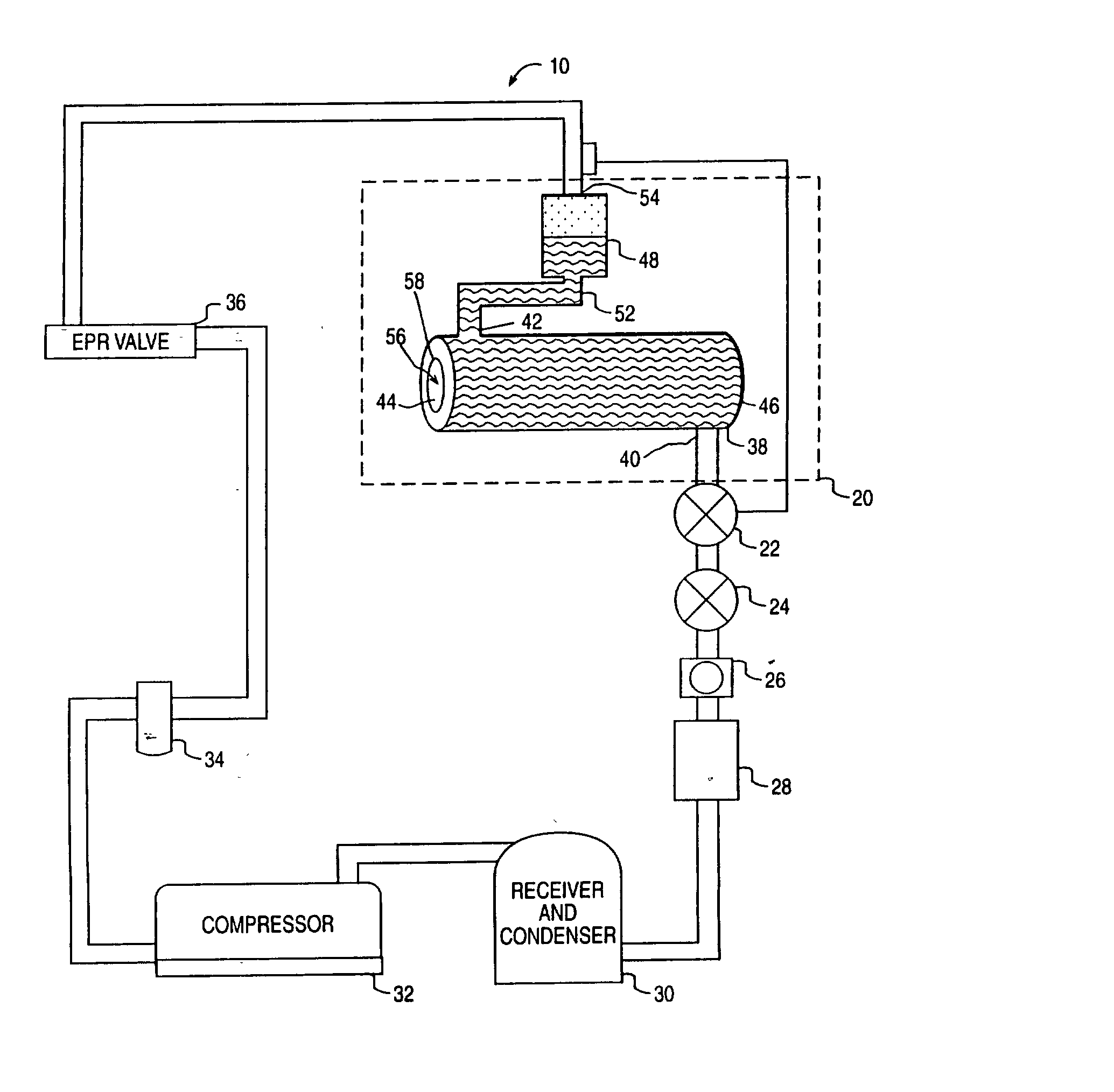

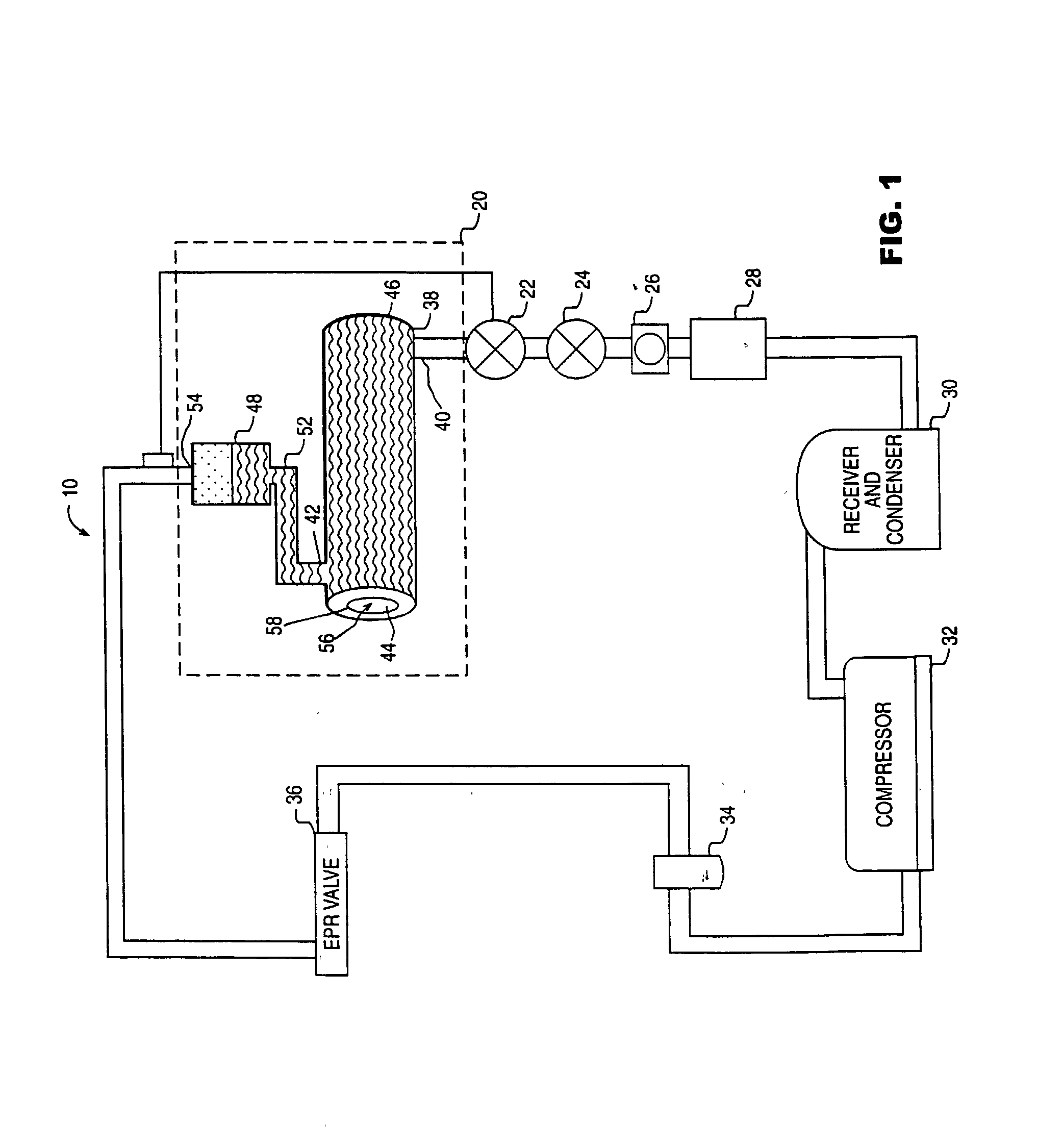

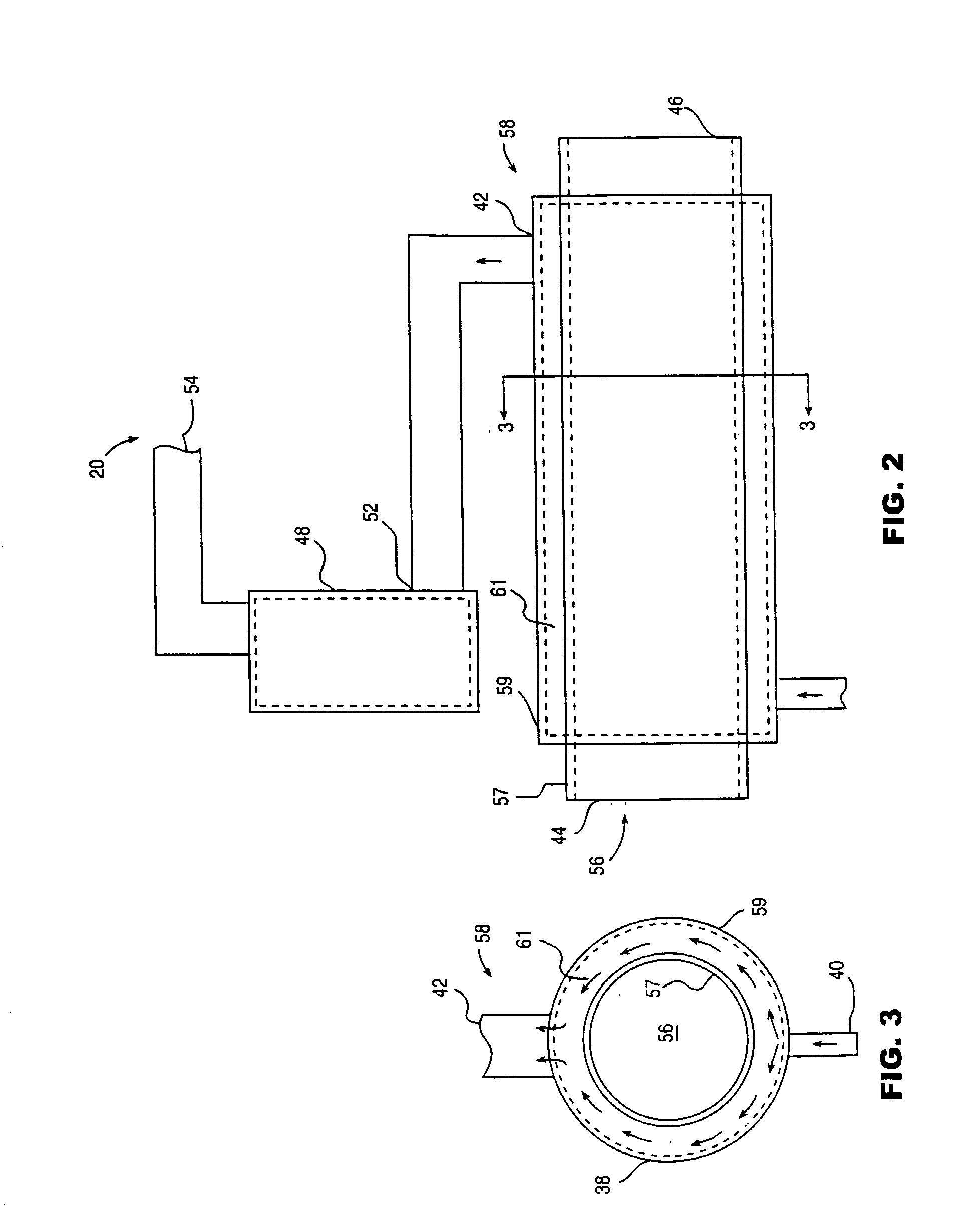

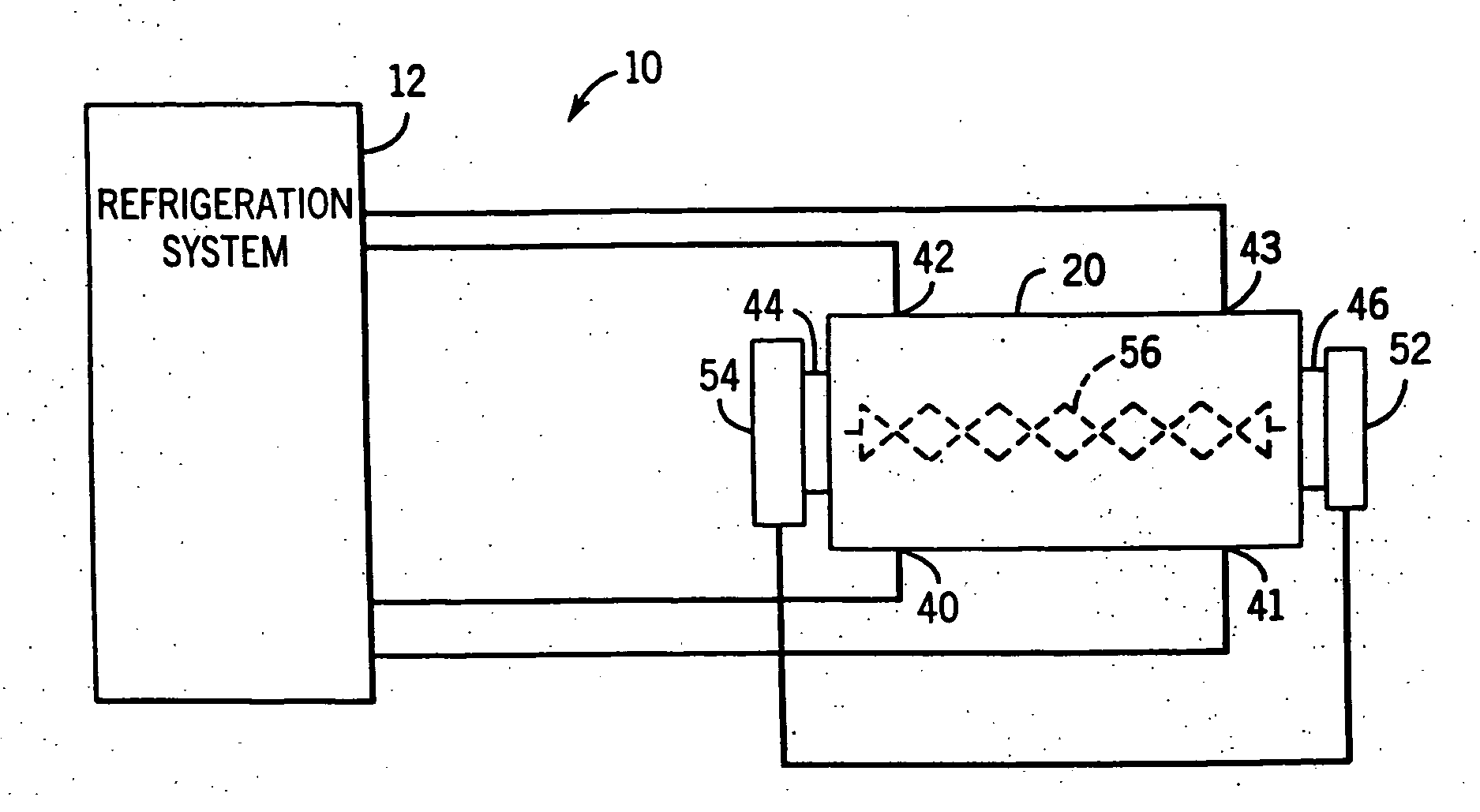

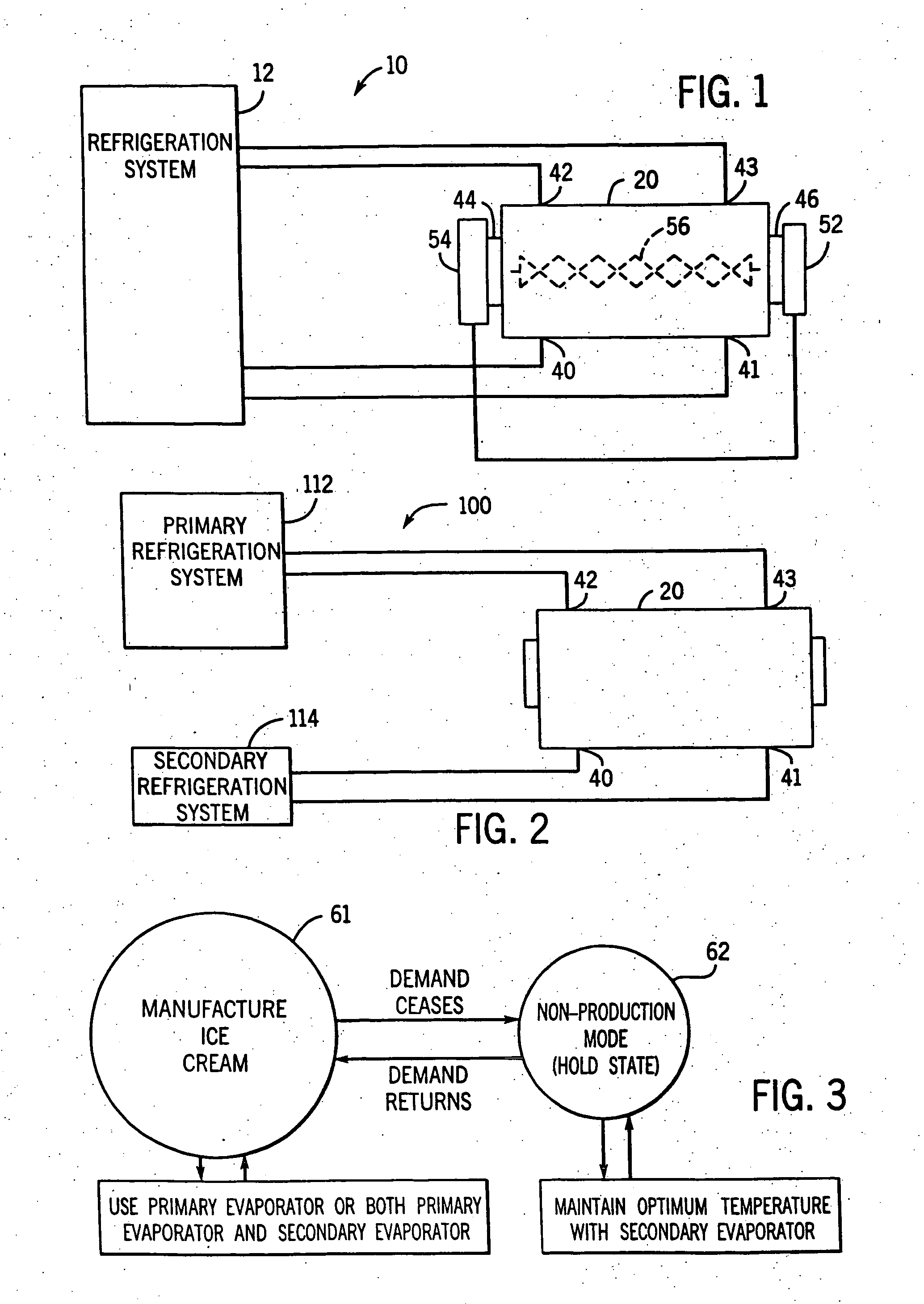

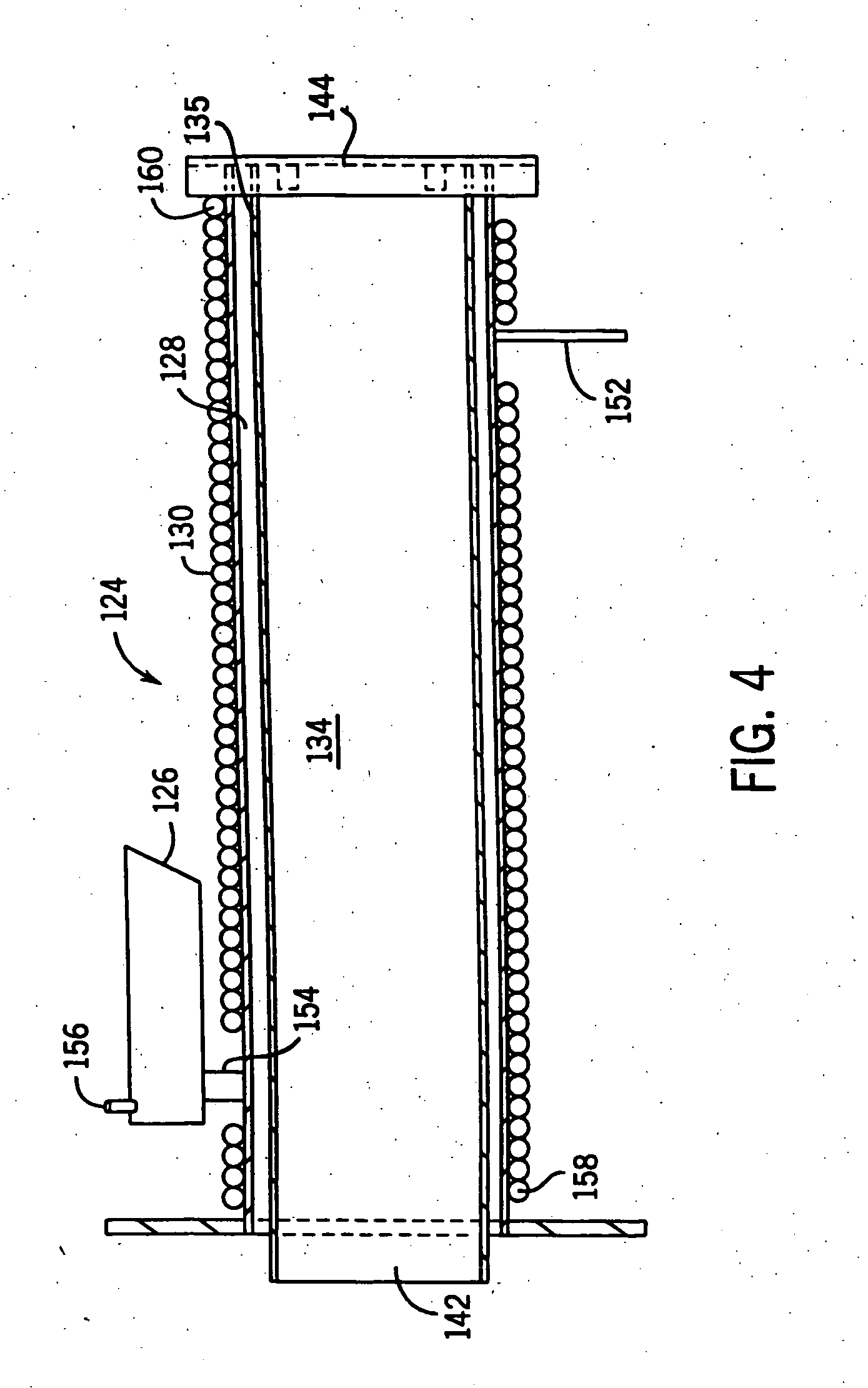

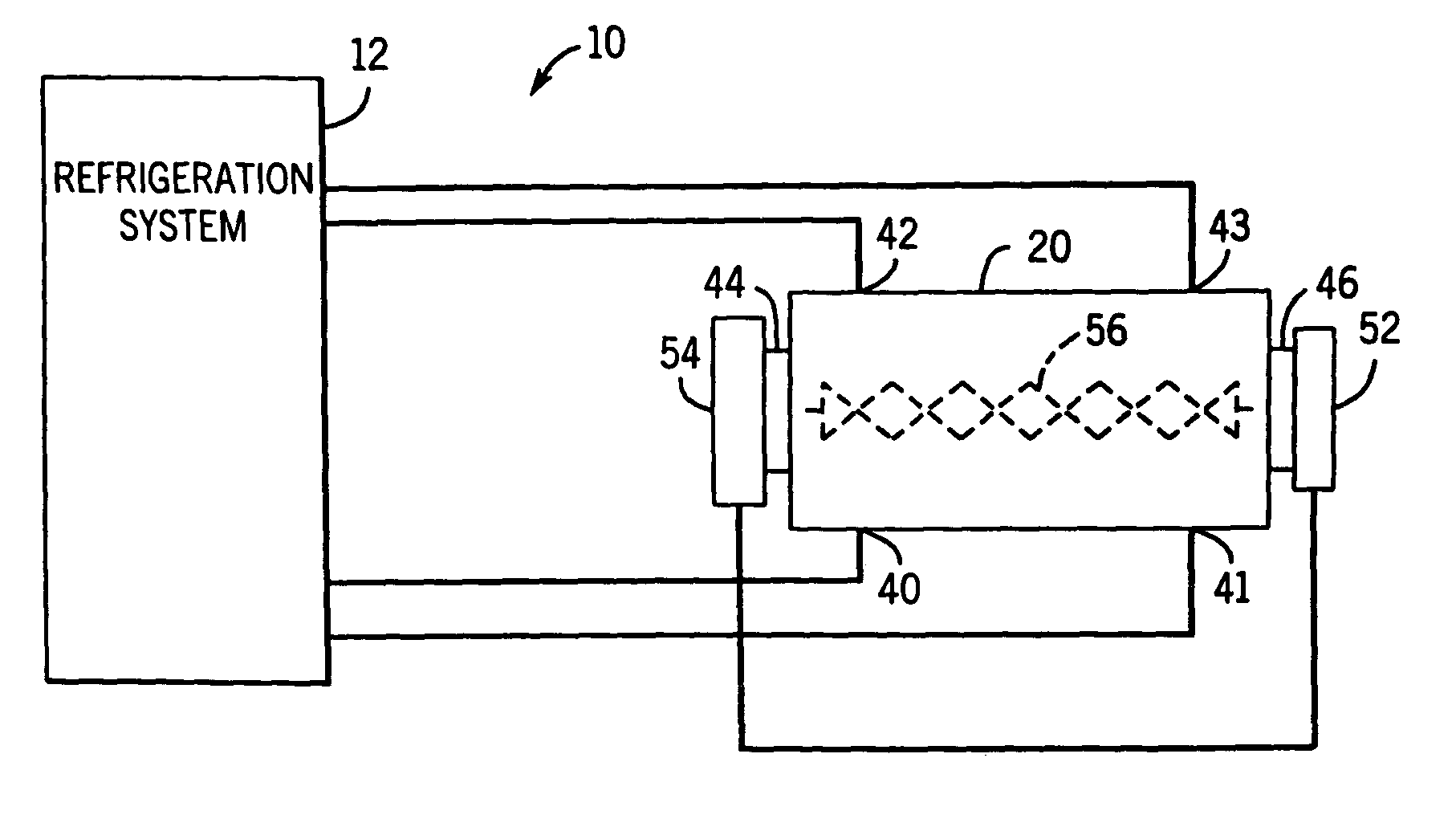

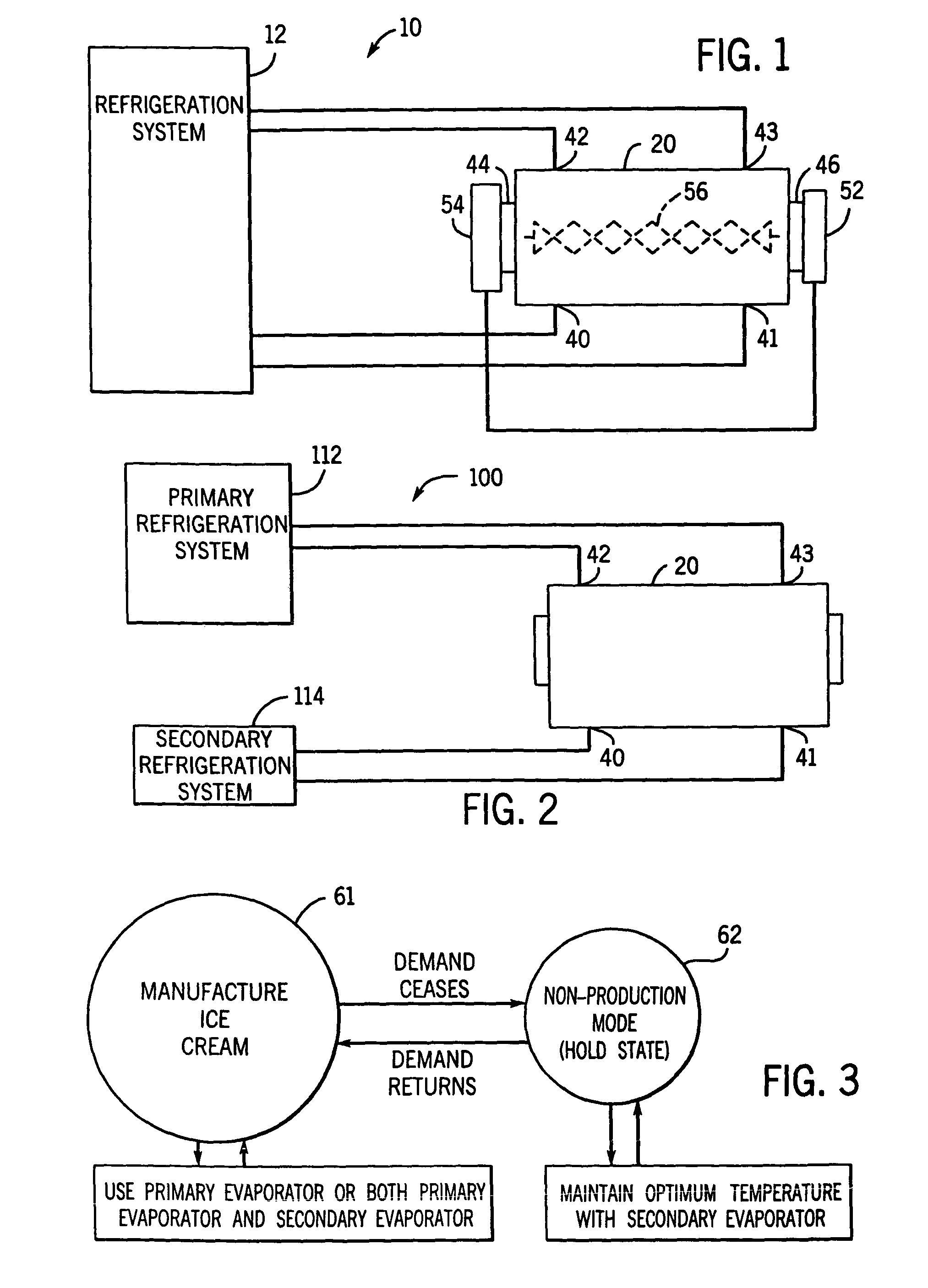

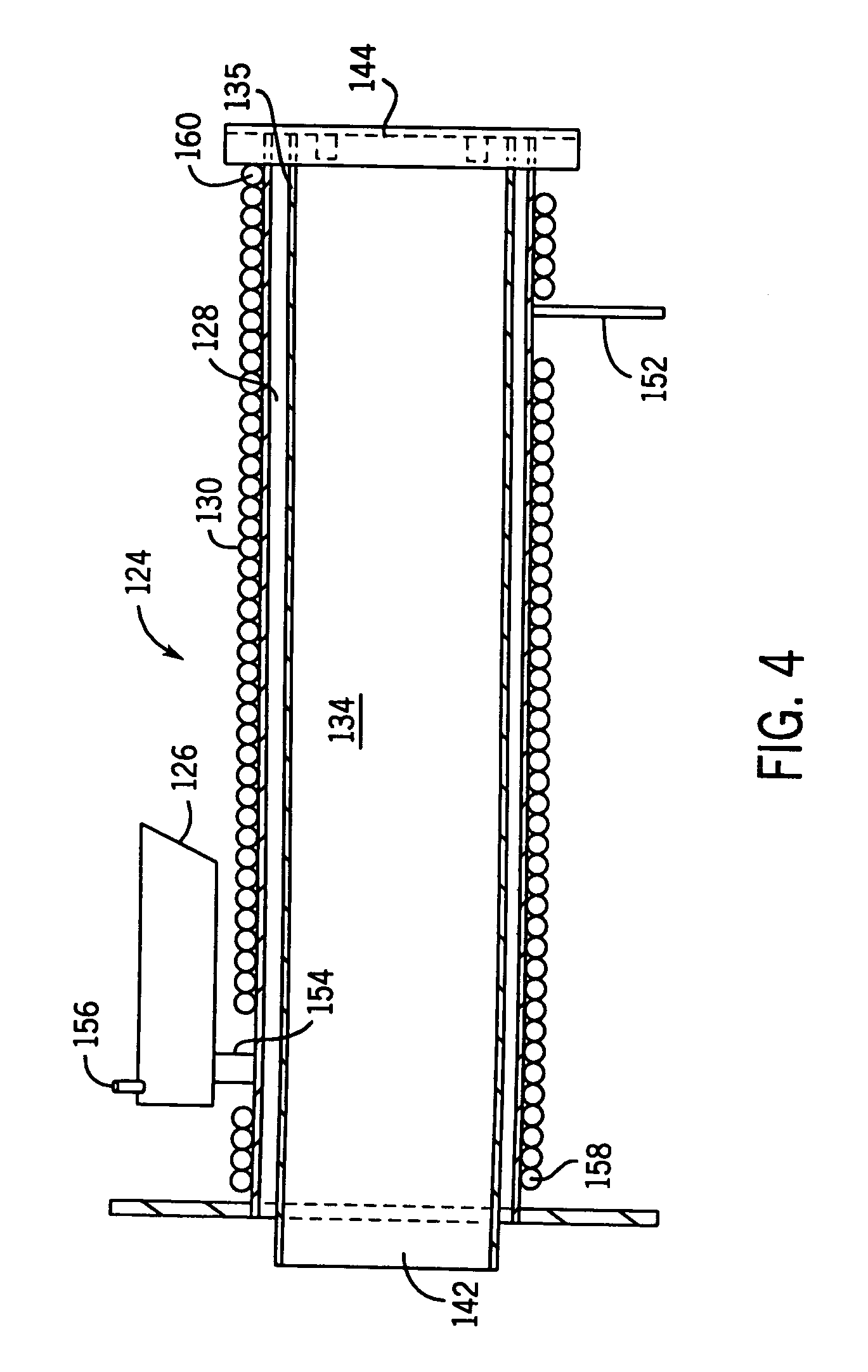

Ice cream machine having an auxiliary evaporator tank

An ice cream machine for cooling liquid ice cream into frozen ice cream includes an evaporator having a cylindrical cooling tank and an auxiliary tank. The auxiliary tank ensures that the cylindrical cooling tank is flooded with liquid refrigerant during normal operation. The flooding of the cylindrical cooling tank provides more efficient and even cooling in an interior cooling chamber. The more efficient cooling allows the ice cream machine to utilize a smaller compressor, thereby reducing the cost and energy consumption of the ice cream machine. The auxiliary tank can be a coil of tubing or a cylindrical container positioned above the cylindrical cooling tank.

Owner:STOELTING

Integrated ice cream puffing pump with inlet air regulation and ice cream maker

The invention discloses an integrated ice cream puffing pump with an inlet air regulation and an ice cream maker. The puffing pump comprises a material pump, wherein the material pump is provided with a material inlet pipe, a pump cavity and a material outlet pipe; the material inlet pipe and the material outlet pipe are both communicated with the pump cavity; the puffing pump also comprises a pump base; the material pump is mounted on the pump base; the side surface of the material pump is provided with an inlet air regulating valve communicated with the pump cavity of the material pump; an ice cream raw material is sucked in by the material pump and is mixed with air, which is sucked in through the inlet air regulating valve, in the pump cavity; a mixed material is discharged through the material outlet pipe. An integrated structural design is adopted by the puffing pump; the side-surface air inflow is carried out; the structure is simple, light and handy. The invention discloses an ice cream maker including the puffing pump at the same time.

Owner:ZHONGSHEN TECH (GUANGDONG) CO LTD

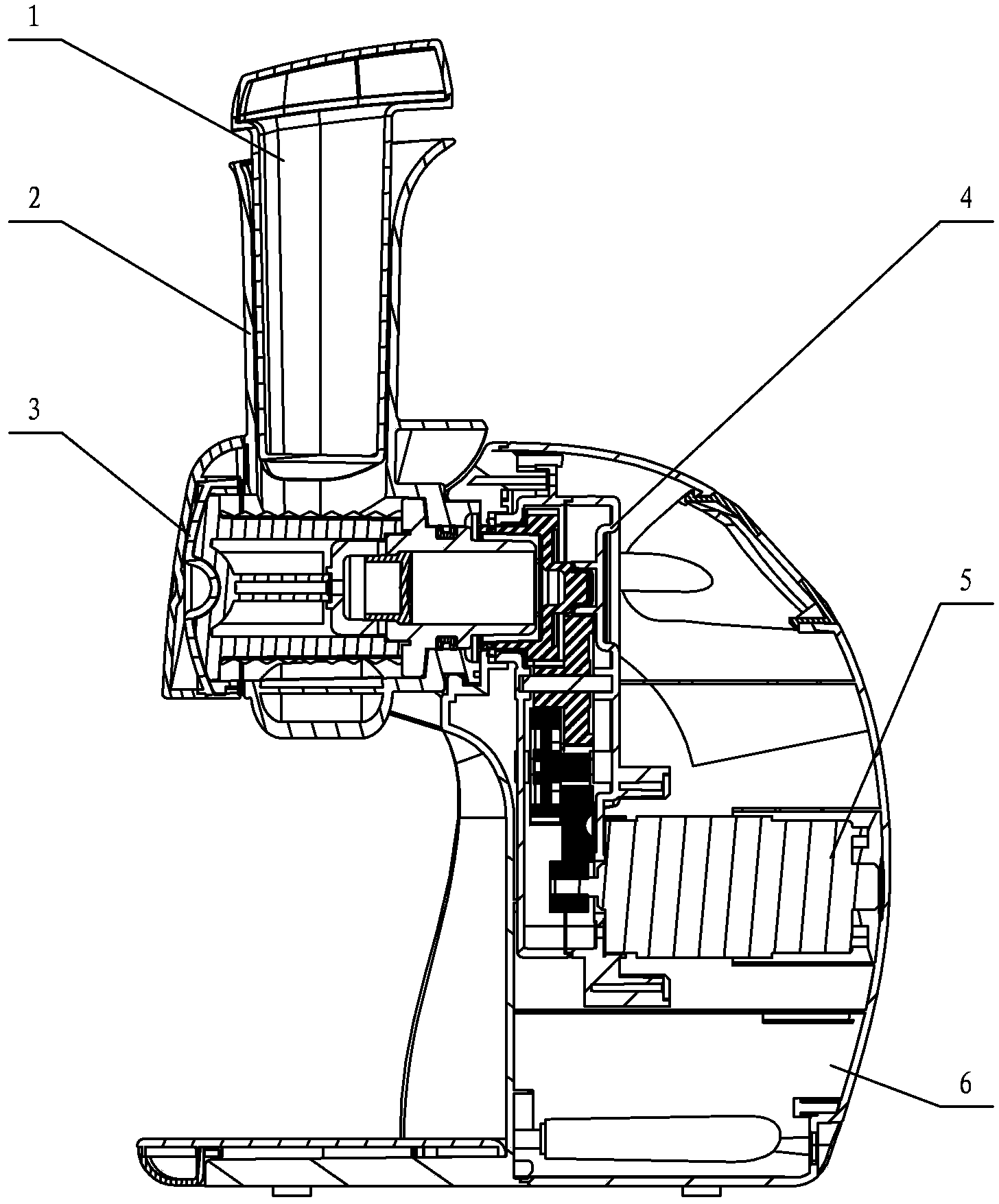

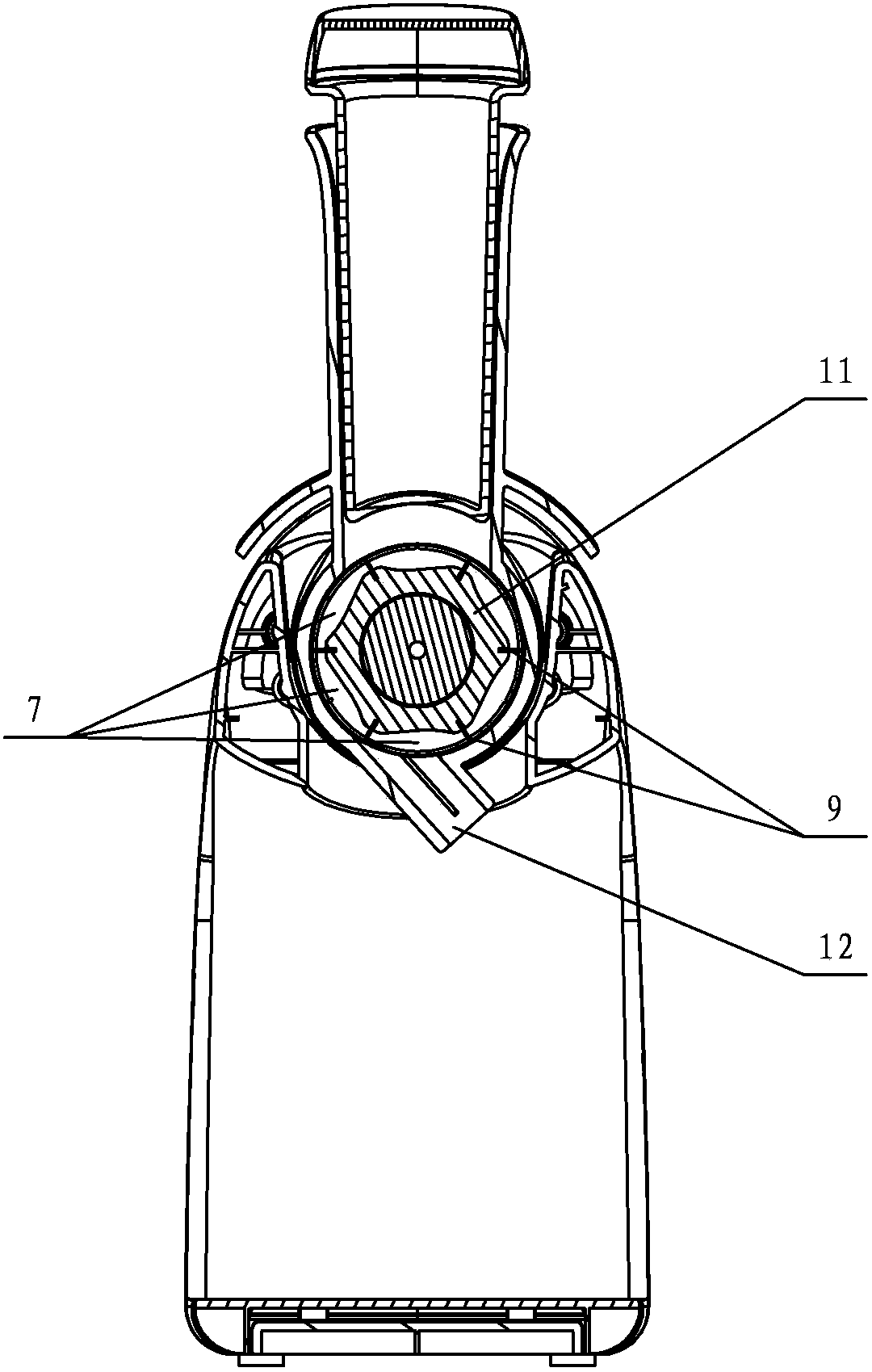

Fruit ice cream machine

A fruit ice cream machine comprises a feeding bin arranged on a machine base, wherein a feeding barrel is communicated with the feeding bin, a stirring cutter is arranged in the feeding bin, a motor arranged in the machine base is connected with a connector of the stirring cutter through a speed reducing mechanism, the stirring cutter comprises a prism-shaped cutter rest, and a stirring blade is embedded into a corner angle of the cutter rest. The cutter rest and the stirring blade divide the feeding bin into more than two stirring cavities. A cross section of the cutter rest is triangular, quadrilateral, pentagonal, hexagonal or polygonal. A press rod is arranged on the feeding barrel. A barrel cover is arranged on the feeding bin. A positioning protrusion is arranged on the barrel cover, a positioning groove is arranged on the cutter seat, the positioning protrusion is inserted into the positioning groove. A discharging port is arranged at the bottom of the feeding bin. The direction of an outlet of the discharging port is opposite to the rotation direction of the stirring cutter. The fruit ice cream machine has the advantages of being simple and reasonable in structure, small in overall size, low in manufacture cost, flexible in operation and high in work efficiency.

Owner:FOSHAN SIXVECTOR DESIGN & CONSULTANT CO LTD

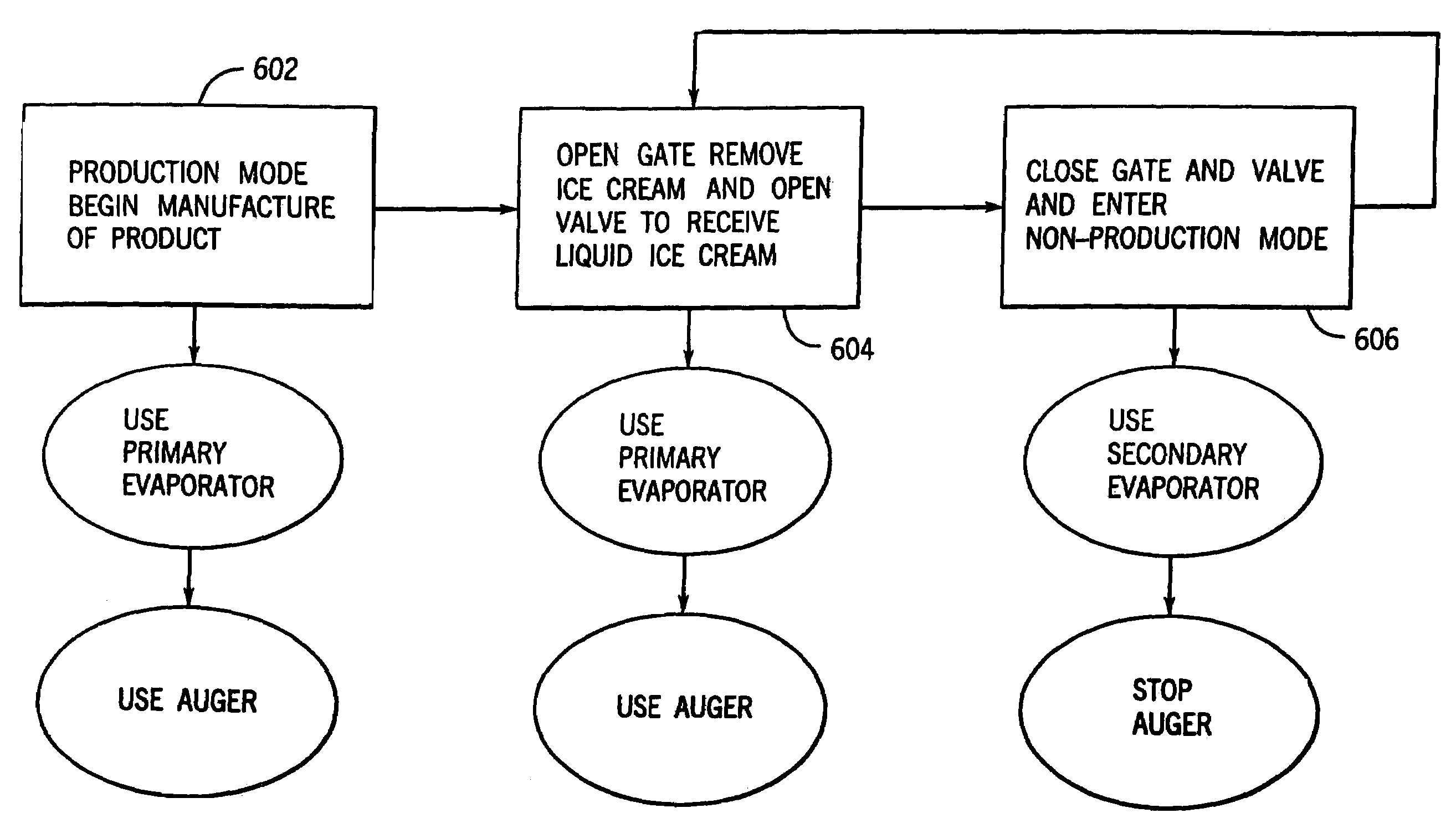

Ice cream machine including a controlled input to the freezing chamber

An ice cream machine for cooling liquid ice cream into frozen ice cream includes an evaporator system with a secondary evaporator. The evaporator system includes a cooling chamber having an ice cream input and an ice cream output. A valve can be placed at the ice cream input to achieve dry freeze operation. The valve can prevent the cooling chamber from being completely filled.

Owner:VOLLRATH

Ice cream machine including a controlled input to the freezing chamber

An ice cream machine for cooling liquid ice cream into frozen ice cream includes an evaporator system with a secondary evaporator. The evaporator system includes a cooling chamber having an ice cream input and an ice cream output. A valve can be placed at the ice cream input to achieve dry freeze operation. The valve can prevent the cooling chamber from being completely filled.

Owner:VOLLRATH

Ice cream machine

The invention discloses an ice cream machine which comprises a shell and an upper cover, wherein the shell is arranged below the upper cover; the shell and the upper cover are matched in an adhering way; the upper cover has an upper cover through hole; manual stirring devices are arranged in the upper cover and the shell in a matching way; each manual stirring device is provided with a hand rocking rod, a hand rocking seat, a hand rocking seat cover and a hand rocking stirring paddle; the hand rocking seat is inserted into the upper cover through hole to be matched with the upper cover in a connecting way; the hand rocking rod is arranged at the upper side of the hand rocking seat cover; the hand rocking stirring paddle is arranged at the lower side of the hand rocking seat cover, and the hand rocking stirring paddle penetrates through the hand rocking seat cover to be matched with the hand rocking rod in a detachable connecting way; the hand rocking seat is adhered to the hand rocking seat cover; the side wall of the hand rocking seat is matched with the shell in the detachable connecting way; the lower side of the hand rocking seat has a hand rocking seat through hole; an ice bucket with a side wall and a bottom filled with refrigerants is arranged below the hand rocking seat, and the ice bucket is internally provided with an ice bucket stirring paddle; the ice bucket stirring paddle is adhered to the hand rocking seat; a driver is arranged below the ice bucket, and the driver is matched with the ice bucket in a linking way; and the lower side of the driver is fixedly connected with the shell.

Owner:NINGBO WUJI ELECTRIC APPLIANCE

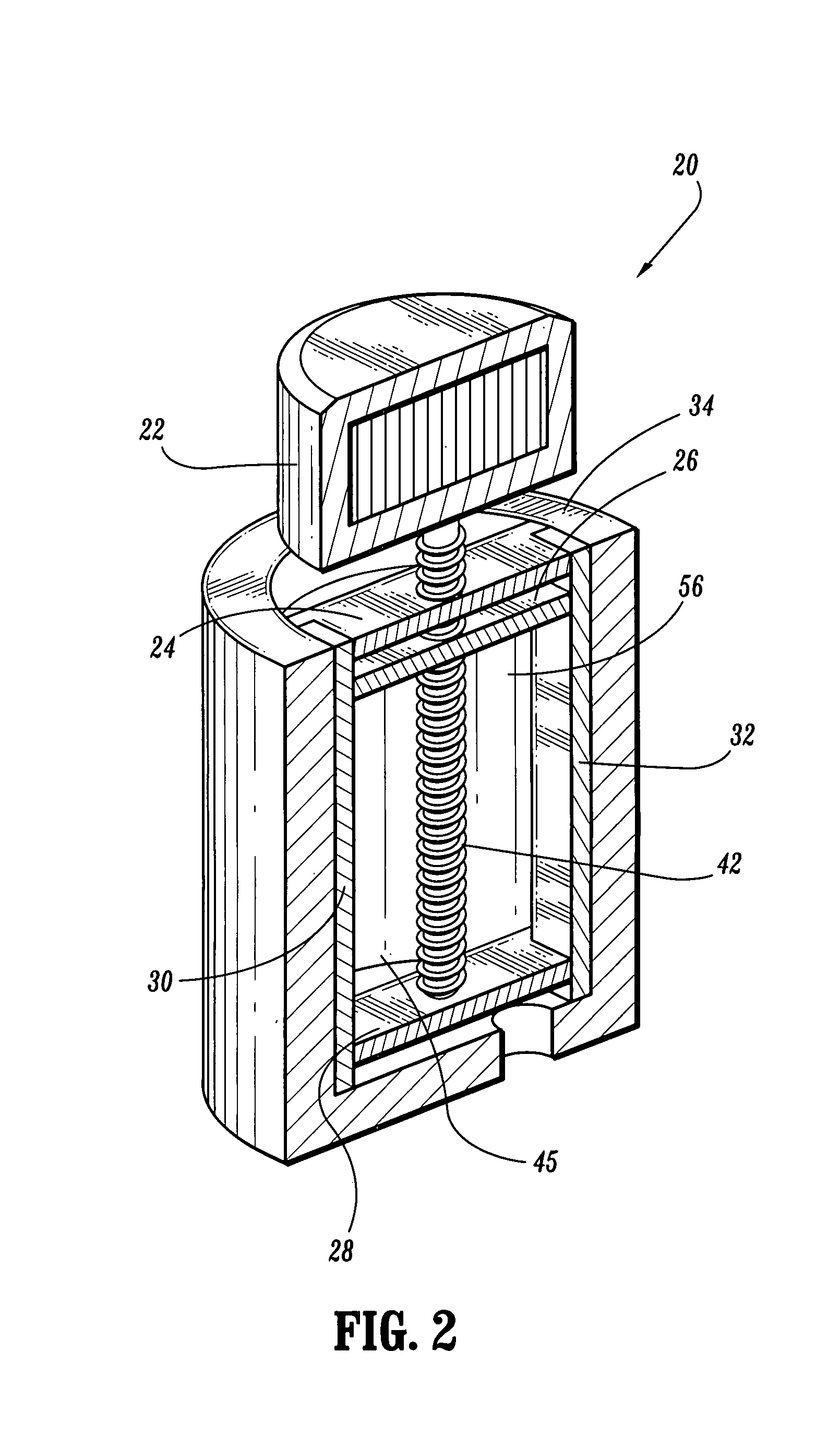

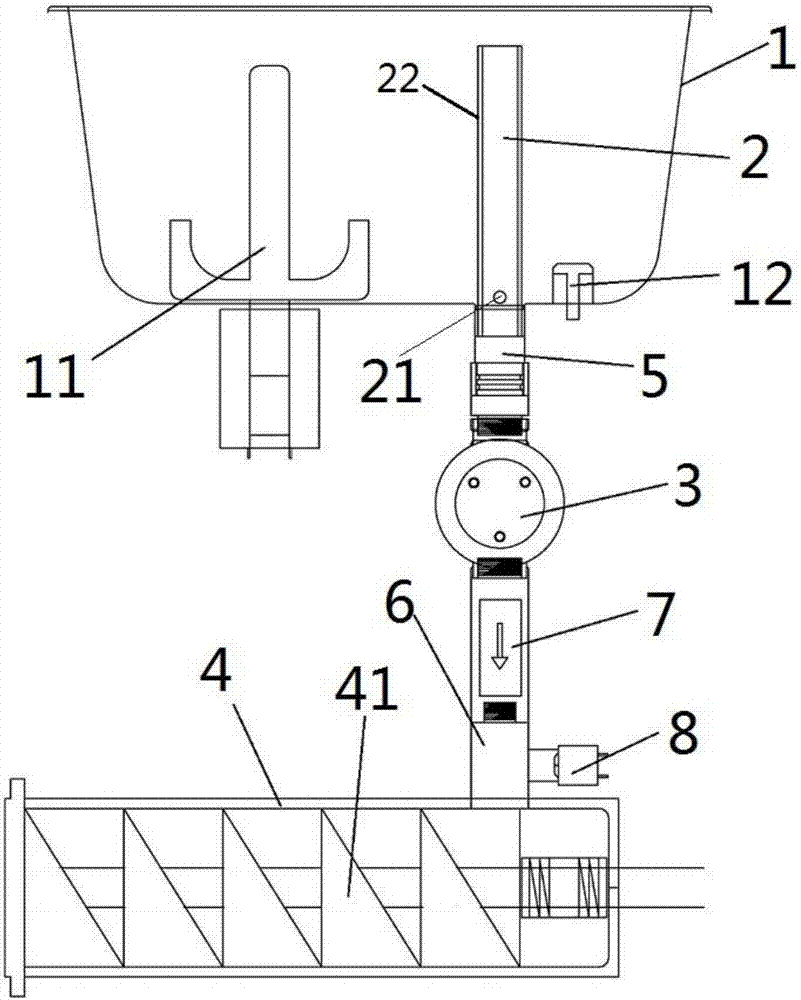

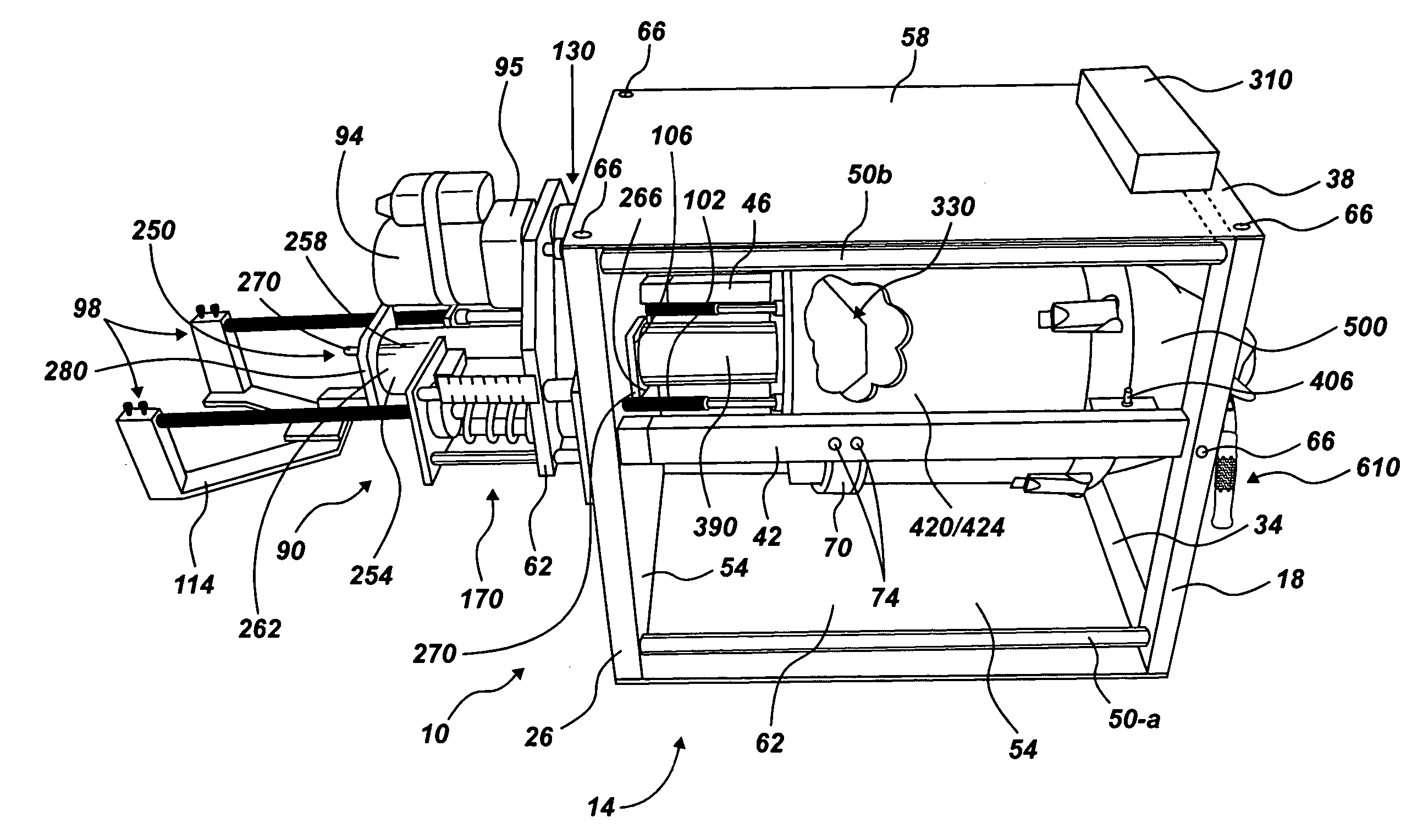

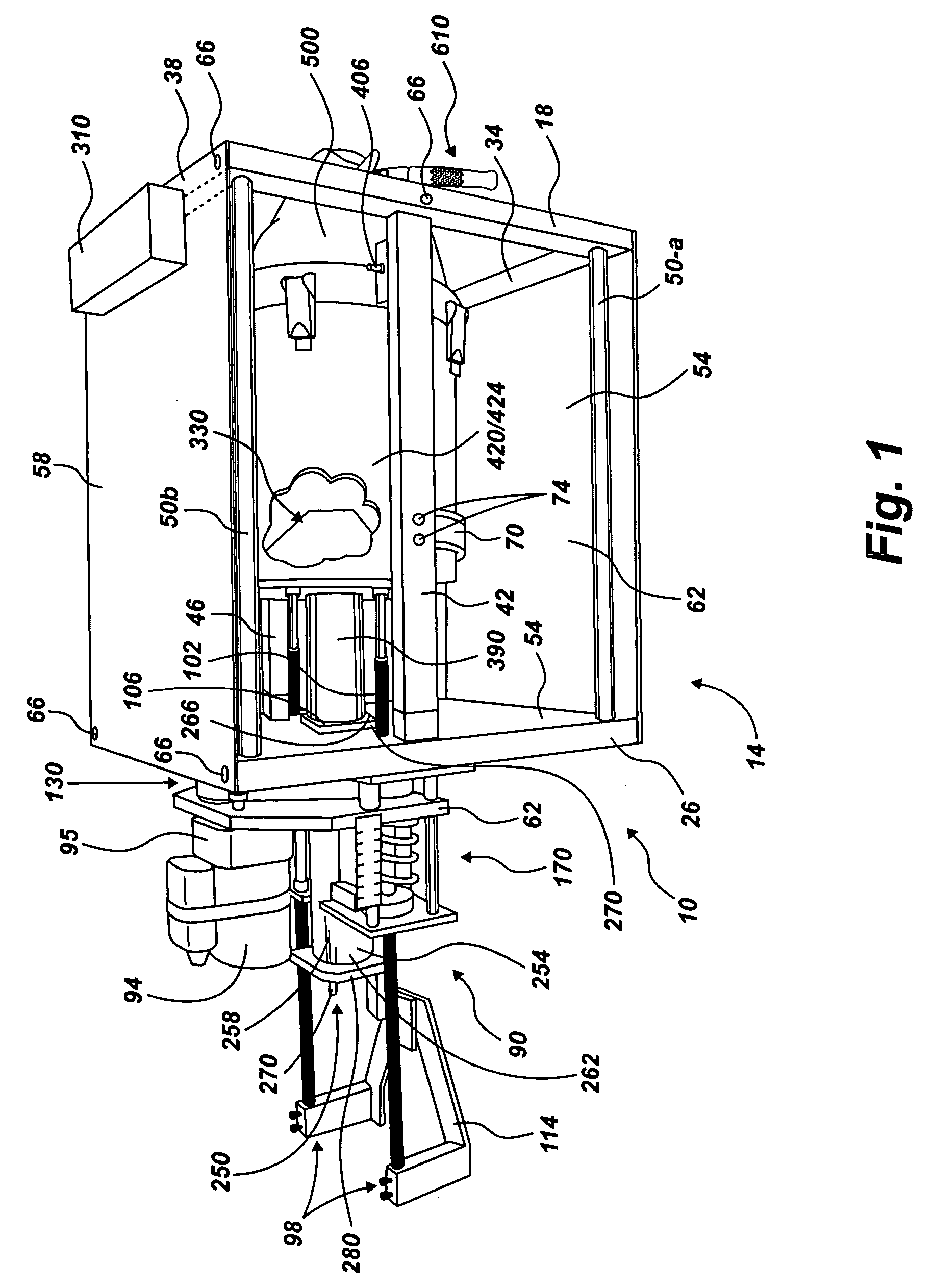

Hard ice cream dispenser

ActiveUS7163128B2Efficient and simple mannerOpening closed containersBottle/container closureEngineeringIce-cream maker

A hard ice cream dispenser configured to dispense hard ice cream. The hard ice cream dispenser comprises a housing support structure; a drive assembly coupled to and supported by the housing, and having a plunger drive means configured to displace a plunger; a sleeve supportable within the housing and configured to receive an inverted container of hard ice cream therein, wherein the sleeve provides lateral and longitudinal support to the ice cream container as the plunger travels through the container; and a nozzle removably coupled to an end of the support sleeve so as to be in fluid communication with the container of ice cream, wherein the nozzle comprises a spout for controlling the volume and cross-sectional size of dispensed ice cream. The plunger is configured to be supported within the housing and removably coupled to the plunger drive means, wherein the plunger functions to displace the ice cream from the container, into and through the nozzle, and out the spout.

Owner:SAVAGE DON H

Ice cream maker

Owner:BREVILLE HLDG PTY LTD

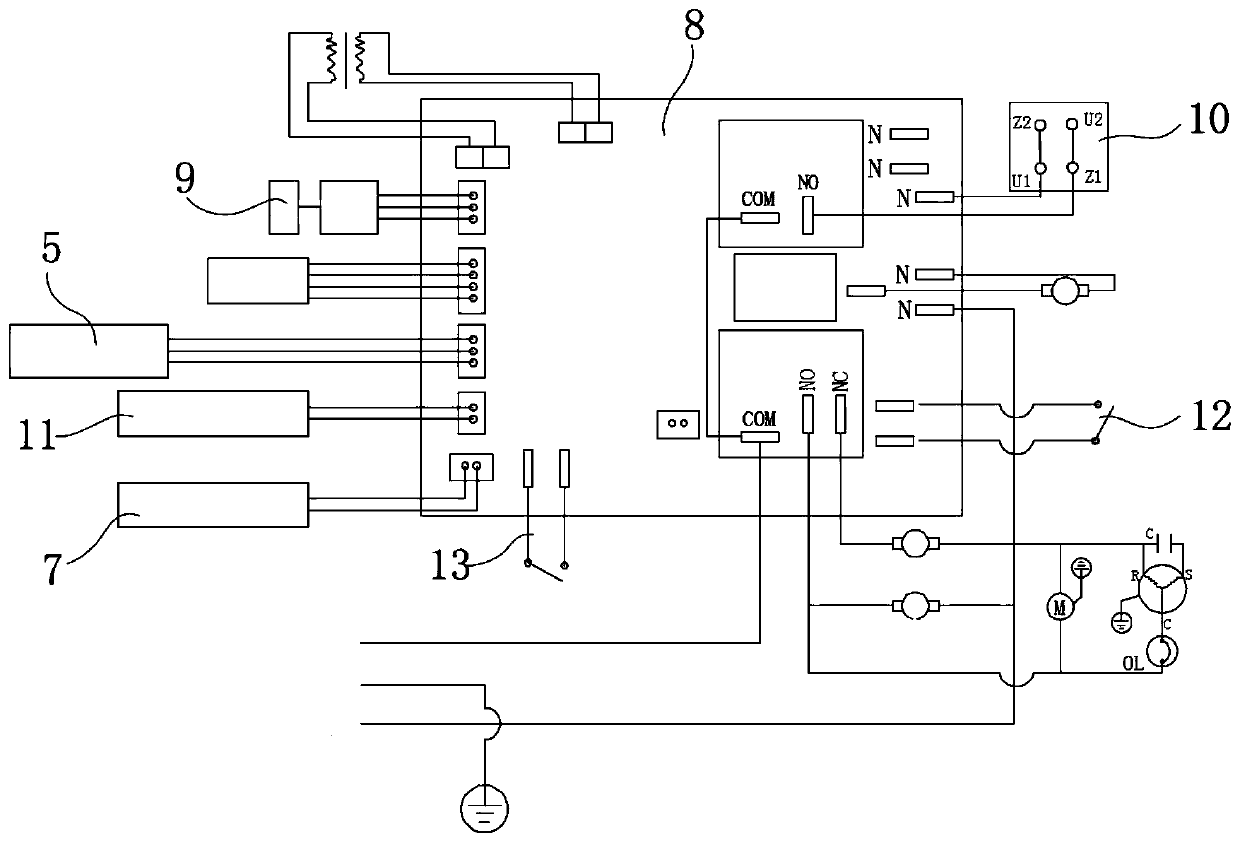

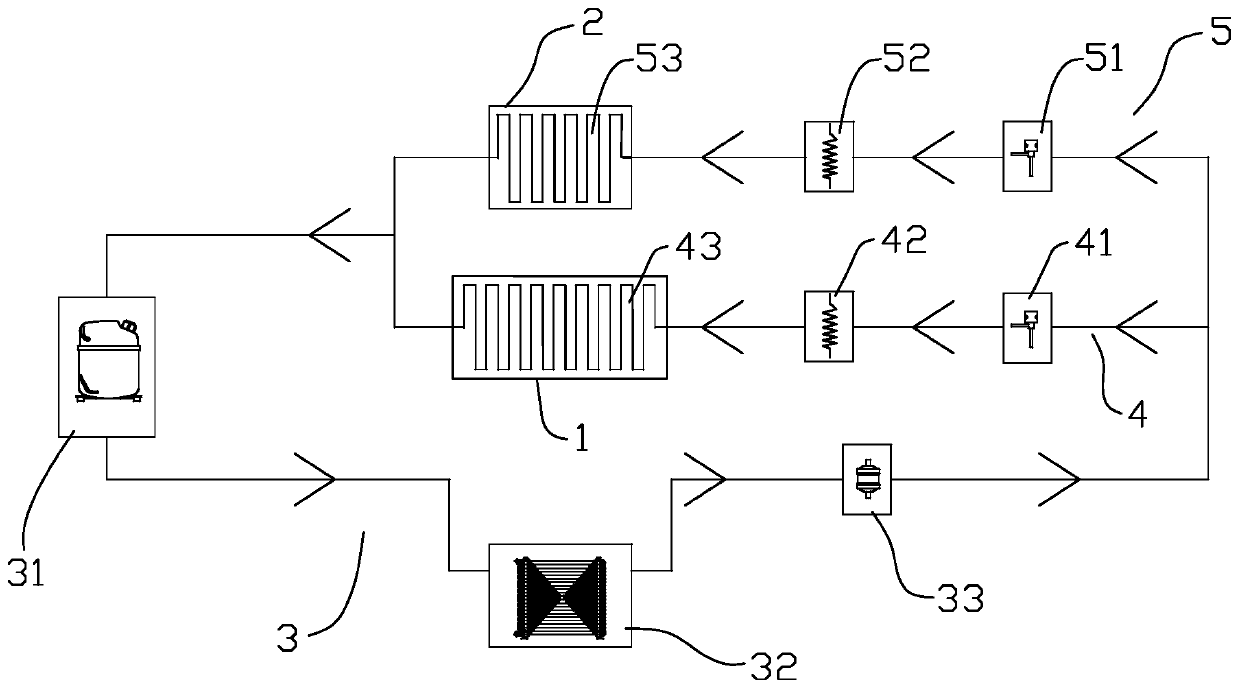

Cold control system of ice cream machine, cold control method and ice cream machine

The invention discloses a cold control system of an ice cream machine, a cold control method and the ice cream machine. The cold control system of the ice cream machine comprises a material tank, a freezing cylinder, a main pipeline, a material tank precooling branch and a freezing cylinder cooling branch. The cold control method comprises a material tank precooling control method, wherein the material tank precooling control method specifically comprises the following steps: detecting the temperature Tc of the material tank, and comparing the temperature Tc with a preset precooling temperature T1; detecting whether the ice cream machine is in an ice cream making process or not; and detecting whether the temperature Tc of the material tank is higher than a second preset temperature T3 or not. The cold control system has the beneficial effects that as one material tank precooling branch is arranged on the freezing cylinder cooling branch in parallel, an independent cooling system is notadditionally arranged, and the production cost of the equipment can be lowered; meanwhile, when ice cream is made by using a main cooling system, material tank precooling operation is not implemented, so that the quality of the ice cream can be stabile; and in addition, precooling is implemented intermediately when the material tank temperature is low, and together with a stirring device, the problem that material pulp is frozen when the material tank is precooled can be avoided.

Owner:HUANGSHI DONPER REFRIGERATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com