Ice cream mixing drum

A technology of ice cream and mixing drum, which is applied in the field of food processing machinery, can solve the problems of small effective contact area, difficult to achieve high-temperature pasteurization, prolong the cooling speed of ice cream, etc., and achieve the effect of high heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

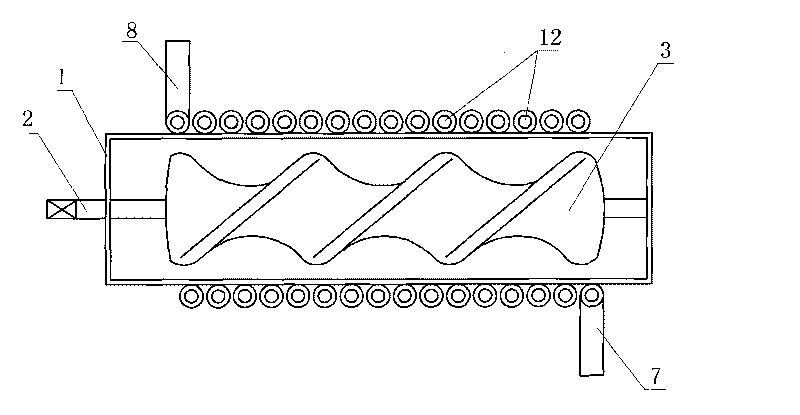

[0015] see figure 1 A traditional ice cream mixer with a coil heat exchanger has a cylinder body 1, a drive shaft 2, and a propeller 3. A coil pipe 12 made of copper pipe is wound outside the cylinder body 1. The working medium inlet 7 of the coil pipe 12 and the working medium The mass outlet 8 is connected to the refrigeration system. Freon vaporizes and absorbs heat in the coil 12 to cool the coil 12 and the cylinder 1. Since the contact between the coil 12 and the cylinder 1 is only point contact, the heat exchange effect is very low.

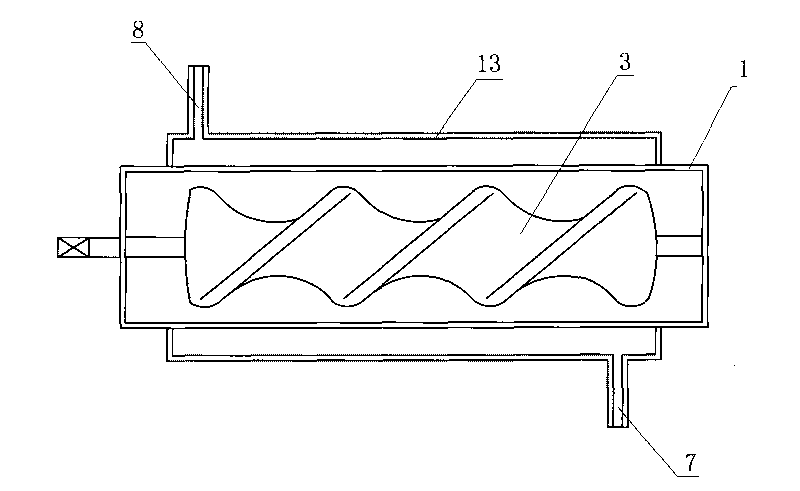

[0016] see figure 2 , the traditional ice cream stirrer equipped with a heat-absorbing sleeve has a cylinder body 1, a drive shaft 2, and a propeller 3, and the cylinder body 1 is surrounded by a heat-absorbing sleeve 13, and the working medium inlet 7 of the heat-absorbing sleeve 13 is connected to the working medium outlet 8 In the refrigeration system, Freon vaporizes and absorbs heat in the heat-absorbing jacket 13 to cool the cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com