Patents

Literature

3197results about How to "Delicate taste" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Intelligence-reinforcing health-care dried bean curd and preparation method thereof

InactiveCN103202343AHas the function of intelligence and health careStrong fragranceCheese manufactureFood scienceBiotechnologyVitis vinifera

The invention provides intelligence-reinforcing health-care dried bean curd. The intelligence-reinforcing health-care dried bean curd is processed from raw materials of, by weight, 100 parts of black soybeans, 4-6 parts of Chinese hawthorn seeds, 1-3 parts of black sesame, 1-3 parts of walnut, 3-5 parts of loofah, 3-5 parts of kiwi fruit, 4-6 parts of longan pulp, 5-7 parts of grapes, 3-5 parts of ginseng, 4-6 parts of poria, 2-3 parts of dens draconis, 1-2 parts of polygala root, 1-2 parts of acanthopanax and 1-2 parts of sunflower discs. The intelligence-reinforcing health-care dried bean curd is prepared by boiling the intelligence-reinforcing raw materials to soup, soaking the raw beans, using mixed liquor of the nourishing soup and water as soybean milk grinding water for soybean milk grinding, filtering, boiling soybean milk, adding intelligence-reinforcing flavoring materials, pointing halide, pressing, marinating, packaging and sterilizing. The dried bean curd has nutrient of conventional dried bean curd, as well as has functions of intelligence reinforcing and health care, and is aromatic in taste.

Owner:JINCAIDI FOOD CO LTD

Vaccinium bracteatum thunb.fruit flavor red ginseng fruit jam

InactiveCN105815717AFull of nutritionDelicate tasteSenses disorderFungi medical ingredientsFruit FlavorVaccinium bracteatum

The invention discloses vaccinium bracteatum thunb.fruit flavor red ginseng fruit jam.Vaccinium bracteatum thunb.fruits and red ginseng fruits serve as raw materials, paper mulberry fruits and russula virescens are added, and the vaccinium bracteatum thunb.fruit flavor red ginseng fruit jam is made.The nutritive value of the vaccinium bracteatum thunb.fruits and the red ginseng fruits is fully utilized, the vaccinium bracteatum thunb.fruits and the red ginseng fruits are competitive with traditional Chinese medicine, conduct synergistic interaction and have the effects of removing heat from the liver, achieving detoxication, improving eyesight and dispelling melancholy.The finished product is abundant in nutrition, fine and smooth in taste, mellow, moderate in sour and sweet taste, outstanding in healthcare function, easy to keep and capable of obviously improving the discomfort of people whose eyes are dry and rough and people who see things fuzzily due to long-term excessive eye use when being eaten for a long time.The making technology is simple and easy to achieve, the demands for health of people are met, and scale production can be conducted.

Owner:ANHUI BAOHENG AGRI

Fruity ice cream and its production process

The present invention relates to fruity ice cream and its production process. The fruity ice cream has fruit shell in 0.5-2.5 thickness, top cover and inside soft ice cream comprising fruit juice and ice cream in the same weight ratio. It is produced through the following steps: making the shell with fruit, making the top cover, making fruit juice, making ice cream, storing and transporting, and making fruity ice cream. The present invention makes it possible to ingest the nutrients of fruit while eating ice cream, and the fruity ice cream has different components, unique flavors and excellent functions of quenching thirst and eliminating summer heat.

Owner:陈鹏

Tea jelly sweet

The invention discloses a tea jelly sweet which is prepared from raw material in the formula in parts by weight: 4-10 parts of functional composition, 30-60 parts of maltitol, 30-40 parts of starch syrup, 3.5-7 parts of plural gel, 0.1-10 parts of lecithin, 0.1-3 parts of hydrogenated vegetable oil, 1-3 parts of peppermint oil and 20-40 parts of water, wherein the functional composition comprises one or several of ultra-micropowder or extractions or original materials of pu-erh tea, black tea, green tea, Oolong tea, white tea, yellow tea and dark tea and other functional factors; and the plural gel comprises modified starch, gelatine, agar and carrageenan. The invention has the characteristics of defined functions, attractive appearance, natural aroma, good taste and the like, has no artificially-synthesized pigment and essence and sweetner causing decayed tooth and is suitable for groups to eat for a long term so as to improve the sub-health state.

Owner:云南龙润茶业集团有限公司

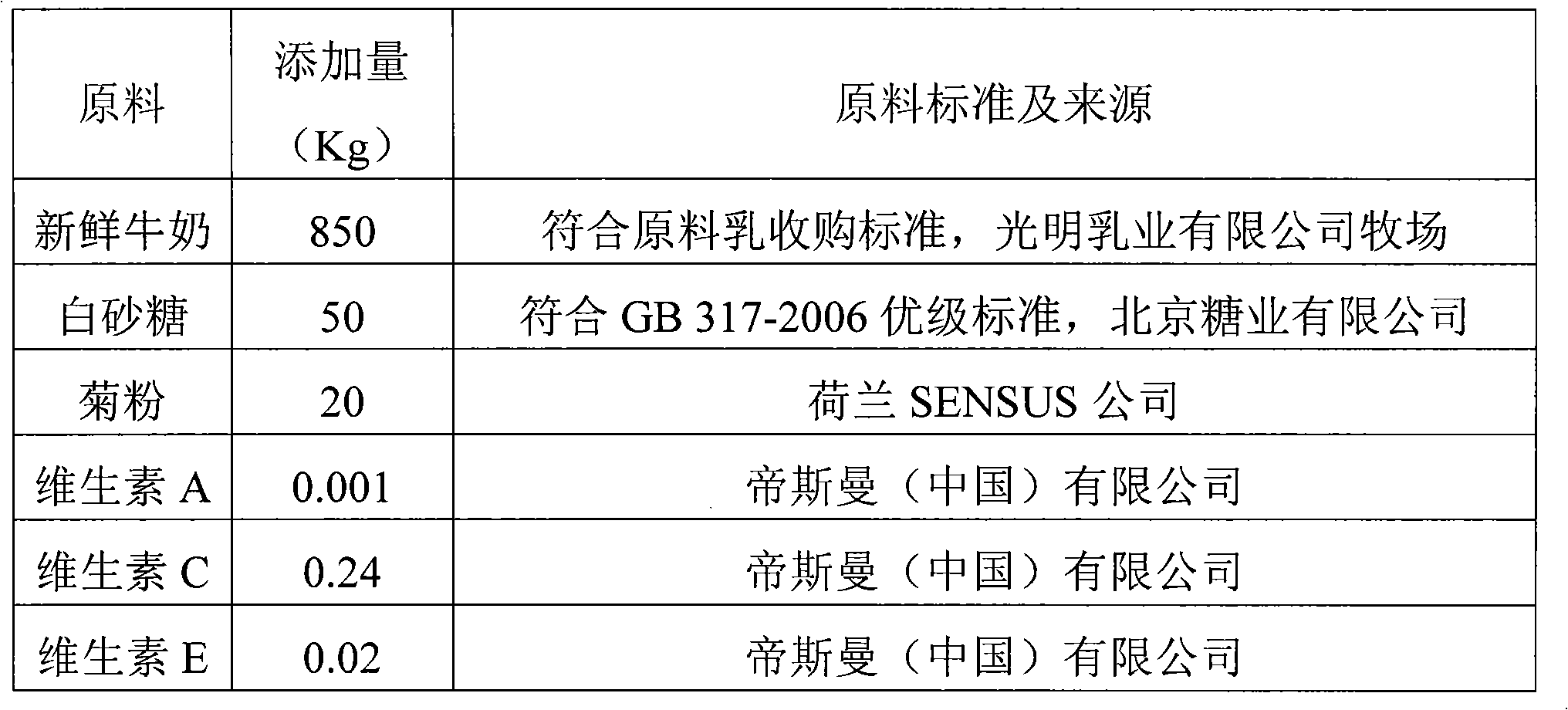

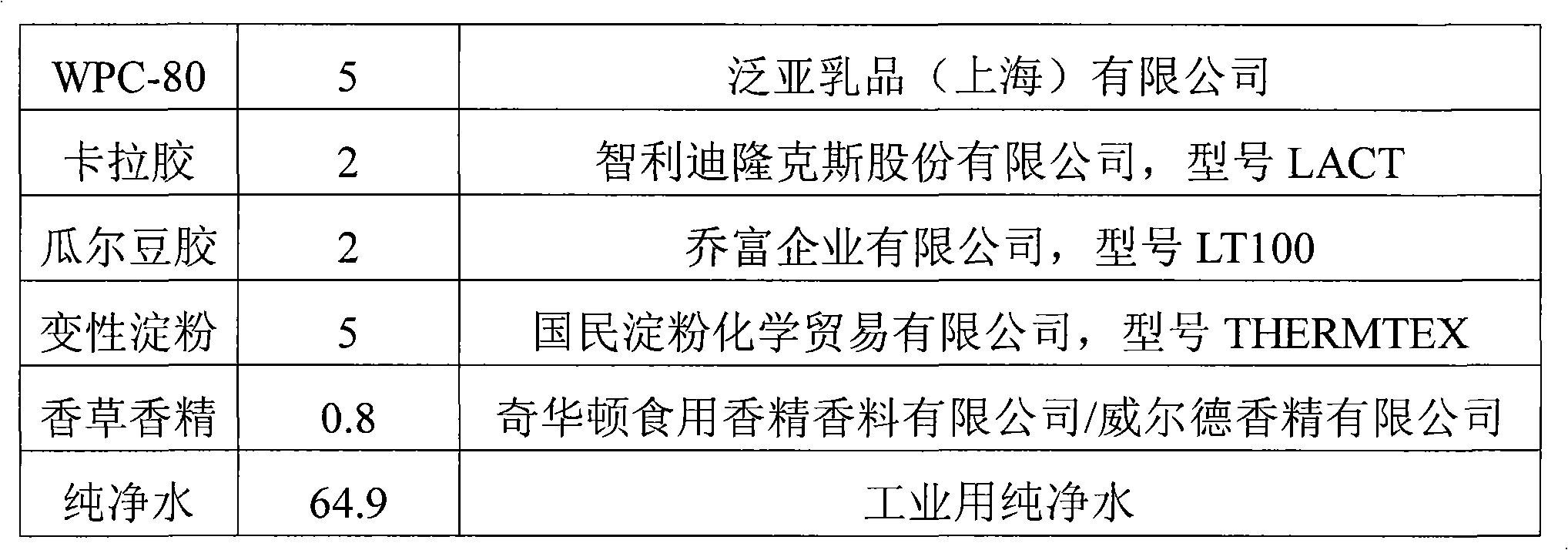

Milk pudding and preparation method thereof

The invention discloses a milk pudding. Based on 1,000 parts of final product, the milk pudding comprises the following components in part by mass: 300 to 850 parts of milk, 0.3 to 150 parts of sweetener, 15 to 30 parts of inulin, 4 to 15 parts of food gelatine, 5 to 20 parts of modified starch, 5 to 30 parts of concentrated whey protein, 0.1 to 1 part of edible essence and 48 to 380 parts of water. The milk pudding has high nutrition, can bi-directionally regulate intestinal flora by adding the inulin, and has special health-care effect on the human body; the milk pudding is semisolid and creamy, has soft, exquisite and fresh mouthfeel, has spoon eating property, is novel milk food, and enriches the category of milk products; the milk pudding is children's food, is also leisure dessert suitable for white-collared workers and the middle and old-aged people, and has a huge consumer market; and the better storage temperature is 4 to 8 DEG C, and the quality guarantee period is 20 to 25 days.

Owner:BRIGHT DAIRY & FOOD

Technology for producing beverage made of both refined and coarse grains

InactiveCN1559304APromote absorptionPromote reproductionFood scienceAdditive ingredientHigh pressure

A beverage with easily absorbed rich nutrients is prepared from one or more of sorghum, millet, corn, soybean, glutinous rice, mung bean, oats, buckwheat and black rice, and onr or more of peanut, almond, hazelnut kernel, walnut kernel, chestnut, melon seed and sesame through grinding or pulverizing, proportional mixing, adding sugar, stabilizer and water, boiling, high-speed shearing, high-pressure puffing and sterilizing.

Owner:SHENBAO INDAL CORP SHENZHEN

High-dietary fiber five-cereal puffing powder and preparation process thereof

The invention relates to high-dietary fiber five-cereal puffing powder and a preparation method, and belongs to the field of food processing. The five-cereal puffing powder comprises the following raw materials: coarse rice powder, wheat meal, oatmeal, millet meal, glutinous corn meal, soybean meal, wheat bran meal, calcium lactate, ferrous gluconate, zinc gluconate, vitamin B1, vitamin B2 and vitamin B6. A method for processing the five-cereal puffing powder comprises the following steps of: screening coarse cereals, grinding, milling, sieving with an 80-mesh sieve, mixing uniformly in a ratio, adjusting the moisture of materials, balancing the moisture, extruding and puffing by using double screws, drying, crushing, and sieving with a 100-mesh sieve, enhancing mineral elements and the vitamins. The high-dietary fiber five-cereal puffing powder has the characteristics that the puffing powder is prepared from natural grain coarse cereals, emulsifying agents and sweeteners are not added, the mineral elements and the vitamins are enhanced, the content of dietary fibers reaches the specified standard of national high-dietary fiber foods, and the puffing powder can be eaten only by being infused by boiling water, so that the high-dietary fiber five-cereal puffing powder is an ideal nutritional and convenient food which is suitable to be eaten by middle and old-aged people.

Owner:HEFEI UNIV OF TECH

Fruit and vegetable colorful health care soybean curd and preparation thereof

A multi-colored health care tofu containing fruit and vegetable comprises the following raw materials with the weight portions of 8 to 10 portions of soybean, 4 to 10 portions of fruits, 8 to 10 portions of vegetables and 0.3 to 1 portions of ecological coagulant, wherein, the fruit and the vegetable are the fruits and the vegetables with the pH of less than 7. The ecological coagulant is the mixture of glucose and plaster which is in the ratio of 1 to 3:22 to 28. The production process comprises screening and sorting soybean, soaking and removing peels, grinding for separation, mixing and coloring by adding the extracted natural vegetable juice and fruit juice, cooking and coagulating, squeezing and forming and packing the finished products. In the invention, algin, mannite, plant fiber, protein, a plurality of amino acids, a plurality of vitamins, a plurality of trace elements including calcium, iron and selenium which are the essential matter inside the body are added, which can effectively prevent a plurality of diseases including high blood pressure, obesity, cardiovascular genomic, biliary calculus and other diseases.

Owner:晏亚清

Preserved meat processing method

InactiveCN103584135AReduce salt contentReduce the content of benzopyreneFood preservationFood preparationPreservativeProduct processing

The invention relates to the field of meat product processing, and particularly relates to a preserved meat processing method. The preserved meat processing method can lower the content of benzopyrene in a preserved meat product by selecting and controlling the smoking temperature, humidity and smoking materials in the smoking step. The processing method provided by the invention can improve the preserved meat pickling temperature properly by using nisin and biological preservatives to shorten the pickling time from 40 days of the conventional art to 15 days, thereby preventing meat deterioration in the pickling process, improving preservation effect of preserved meat, and improving work efficiency.

Owner:HUNAN AGRICULTURAL UNIV +1

Production process of sauce fen-flavor type white spirit

InactiveCN101638618AImprove qualityPure bodiedAlcoholic beverage preparationMicroorganism based processesFood flavorPurified water

The invention relates to a production process of sauce fen-flavor type white spirit, which comprises the following steps: respectively loading smaller lumped koji fen-flavor type base wine and sauce fen-flavor type base wine into a ceramic wine jar and then sealing the base wines for fully storing the smaller lumped koji fen-flavor type base wine for three years and the sauce fen-flavor type basewine for five years; blending the base wines in a proportion of 55 percent of the sauce fen-flavor type base wine and 45 percent of the smaller lumped koji fen-flavor type base wine; then adding purified water to regulate the mixed base wine to required alcoholic strength; and storing the obtained mixed base wine for half a year to obtain a finished product. The blended product has characteristicof clear and sweet taste of the fragrance of smaller lumped koji fen-flavor type while spirit and also has the characteristics of ausgereift, smell fragrance, elegance, exquisite feel and empty left fragrance of the sauce fen-flavor type white spirit. The sauce fen-flavor type white spirit of the invention is hopeful to become a twelfth flavor wine in the national white spirit flavor type classification.

Owner:YUNNAN LANCANGJIANG BEER ENTERPRISE GRP CO LTD

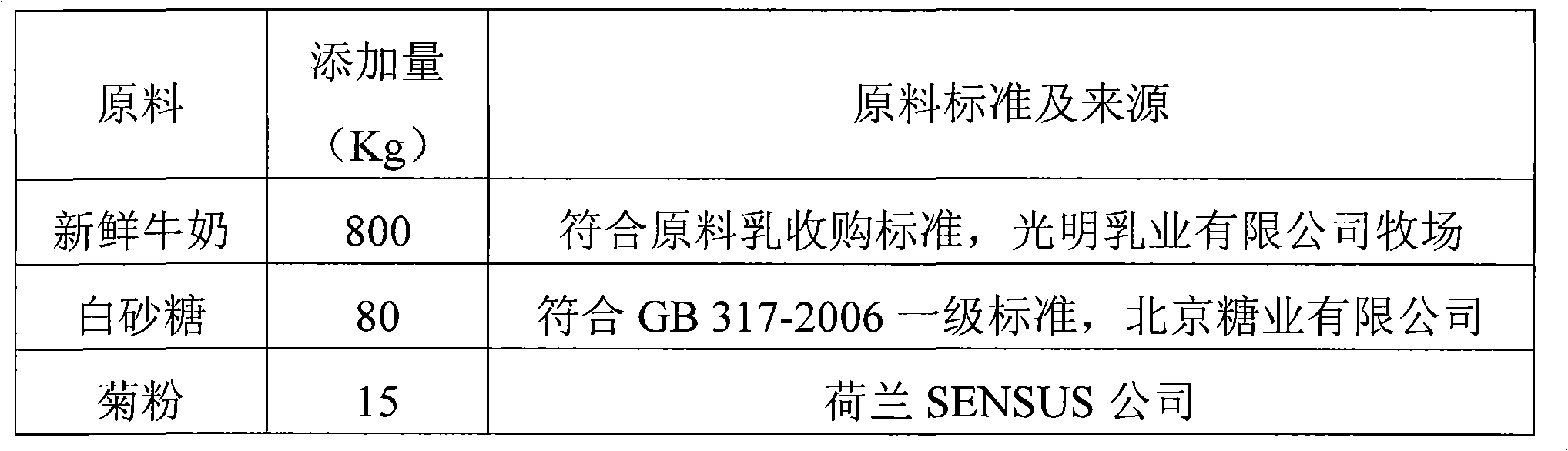

Coffee yoghurt and preparation method thereof

The invention discloses a coffee yogurt, which comprises the following raw materials by mass: 687.9-975.099 parts of cow milk, 50-100 parts of a coffee extract solution or 0.5-30 parts of coffee powder, 0.3-100 parts of a sweetening agent, 3-20 parts of a stabilizer, 1-10 parts of an emulsifier and 0.001-0.1 part of a fermentation strain. The invention also discloses a preparation method of the coffee yoghurt. The method includes the steps of: 1) mixing the coffee extract solution or coffee powder, the sweetening agent, the stabilizer, the emulsifier with the preheated cow milk until the raw materials are dispersed and dissolved; 2) conducting index detection, homogenizing and sterilizing; 3) cooling the mixed material, adding the fermentation strain, and carrying out constant temperature culture; and 4) performing cooling when reaching a fermentation terminal point. The coffee yogurt retains the nutritional value of both yoghurt and coffee, has a stable texture state and a good flavor acceptable to consumers.

Owner:BRIGHT DAIRY & FOOD

Method for preparing fresh grosvener siraitia freeze-dried superfine powder

InactiveCN101720894AIncrease profitPreserve active ingredientsFood shapingFood preparationFreeze-dryingPre treatment

The invention discloses a method for preparing fresh grosvener siraitia freeze-dried superfine powder, relates to processing technology for fruits and vegetables, and provides a method for preparing fresh grosvener siraitia freeze-dried superfine powder, which combines vacuum freeze drying technology with superfine grinding technology to protect effective components of the grosvener siraitia and realize full utilization of the grosvener siraitia. The method comprises the following steps: carrying out pretreatments such as selecting, cleaning, sterilization and the like on the fresh grosvener siraitia; putting the grosvener siraitia on a tray for prefreezing after crushing; putting the prefreezed grosvener siraitia in a vacuum environment for heating and drying at the temperature of between 40 and 120 DEG C; controlling the moisture content of the freeze-dried product to less than 6 percent; and finally, grinding the dried grosvener siraitia until the particle size of the powder reaches 10 to 40 meshes, and then carrying out superfine grinding on the powder by a superfine grinding machine until the particle size of the powder reaches less than 40 microns. Because the product is superfine powder, thus, the fresh grosvener siraitia freeze-dried superfine powder has the advantages of small powder particle, big surface area, delicate taste, quicker absorption and wider application, the superfine powder can be eaten directly, and can also be used as the raw materials of other foods, health-care products, medicaments and cosmetics.

Owner:DAMIN FOODSTUFF ZHANGZHOU CO LTD

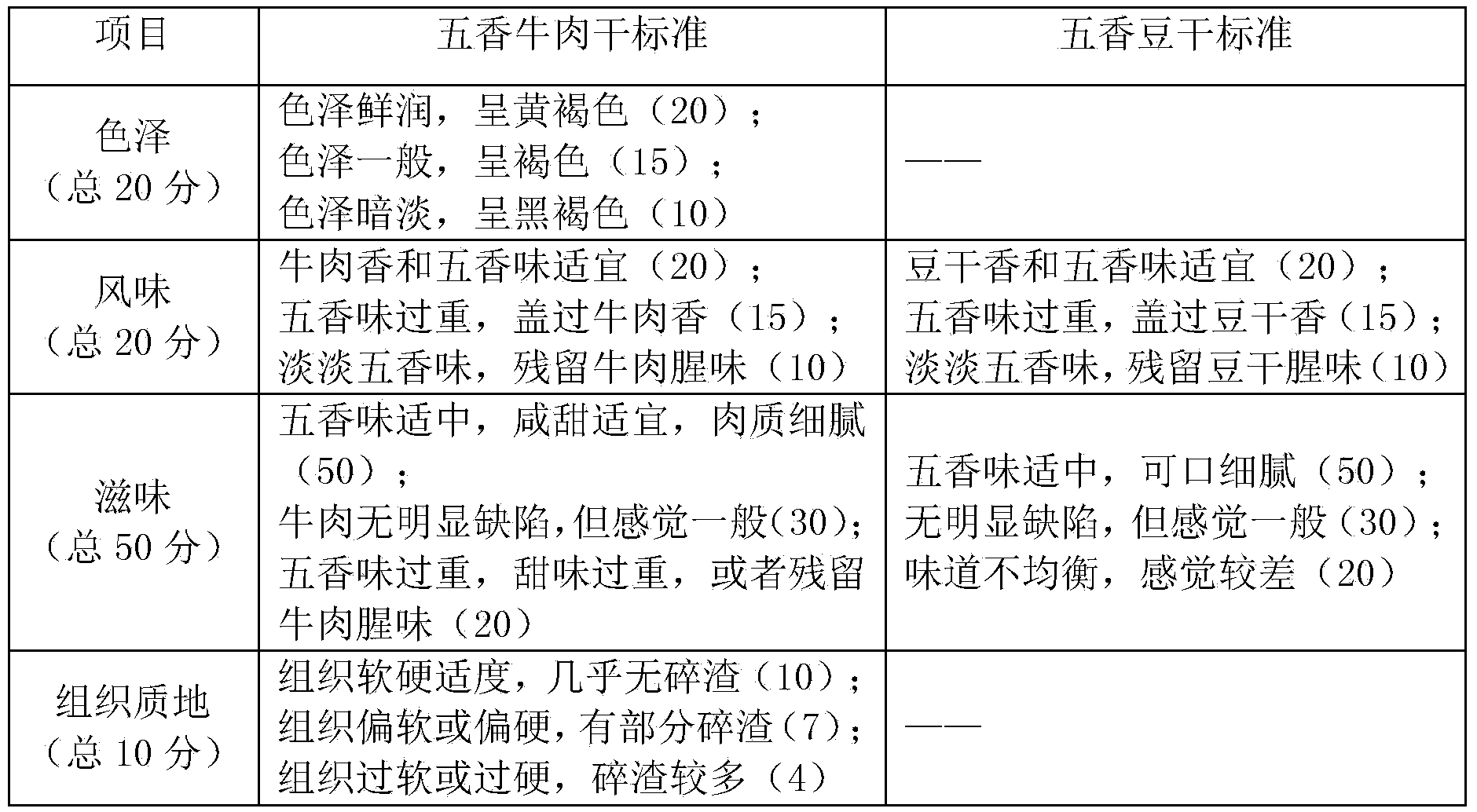

Manufacturing method of spiced beef jerky

ActiveCN103504321ABright colorDelicate tasteFood ingredient functionsFood preparationFlavorAmomum tsao-ko

The invention relates to a manufacturing method of spiced beef jerky. The method comprises the following steps: splitting fresh beef, pickling the cut beef with salt for 8-15 hours, boiling the pickled beef, removing blood-contained water, then slicing the boiled beef; mixing the sliced beef, water, white sugar and spice uniformly according to the proportion of 40-60 parts of beef, 3-5 parts of water, 4-6 parts of white sugar and 1-2 parts of spice; frying the mixed beef at 100-150 DEG C till dry; drying the fried beef at 50-90 DEG C until the moisture in the beef is 15-30%. The spice comprises 5-8 parts of radix angelicae, star aniseed, Chinese prickly ash and amomum tsao-ko each, 2-3 parts of cinnamon, cloves, round cardamom, amomum villosum and rhizoma kaempferiae each, 1 part of old ginger and liquorice each, and 1 part of equally mixed fennel, bay leaf, nutmeg, radix aucklandiae, galanga, mangnolia officinalis, fructus aurantii, tangerine peel and mint. The method has simple steps. The manufactured beef jerky is yellowish brown, bright in color, fine and smooth to be tasted, suitably salty and sweet, and proper in hardness. The spice has the functions of eliminating smell, retaining freshness, tonifying spleen and appetizing, and can be widely applied to seasoning of other food.

Owner:胡海山

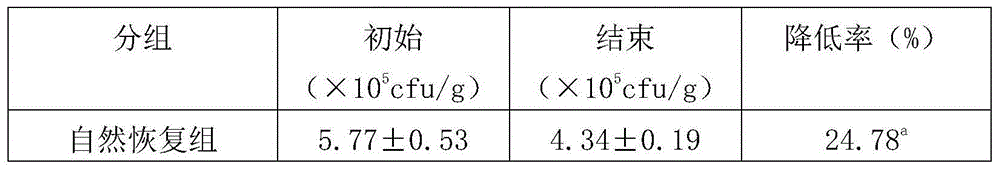

Technological process for preparing fermentation dehydrated beef using composite leaven

InactiveCN101248884AImprove organizational structureEnhance sensory effectFood preparationLactobacillusOrganoleptic

The invention provides a method for producing fermented beef jerky with compound leaven. The bacteria strain used in fermentation is lactobacillus casei and staphylococcus xylosus with volume ratio of 1:3 and volume of addition of 1-1.5%, the fermentation temperature is 20 DEG C, and the fermentation time is 5 days. The addition of lactobacillus casei reduces pH value of the product, improves safety, improves the texture of the product, and shortens fermentation period. At the same time, the addition of staphylococcus xylosus generates a large amount of flavoring substances during fermentation process, improves sensing effect of the product, and the final product has thick fragrance, good taste, and infinitive aftertaste. The inventive method is especially suitable for producing fermented beef jerky, as well as air dried sausage and sausage.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

Fresh and cool enzymolysis grain beverage and preparation method thereof

The invention provides a fresh and cool enzymolysis grain beverage and a preparation method thereof, relating to a non-alcoholic beverage. The invention aims to provide a fresh and cool enzymolysis grain beverage which retains original nutrition and functional components of grains and is fine, fresh and cool in taste, stable in product composition and low in viscosity, and a preparation method thereof. The beverage is prepared from the following raw materials: 8-12% of grains, 0.01-0.2% of sodium citrate, 0.01-0.4% of emulsifier, 0.05-0.5% of stabilizer, 1.0-2.3% of processing auxiliary agent and the balance of water. The preparation method comprises the steps of: pre-cooking or baking the grains, carrying out colloid milling and homogenizing, adding the processing auxiliary agent, carrying out enzymolysis, then inactivating the enzyme, separating, and filtering to obtain coarse fiber and a material liquid C; adding the material liquid C, sodium citrate, emulsifier and stabilizer to hot water, diluting to certain volume with blending water to obtain a blended liquid, cooling, then conveying to an ultrahigh-temperature instantaneous sterilizing system, preheating, degassing, homogenizing, and then carrying out ultrahigh-temperature instantaneous sterilizing; and filling the blended liquid after ultrahigh-temperature instantaneous sterilizing, and then packaging.

Owner:XIAMEN HUIERKANG FOOD

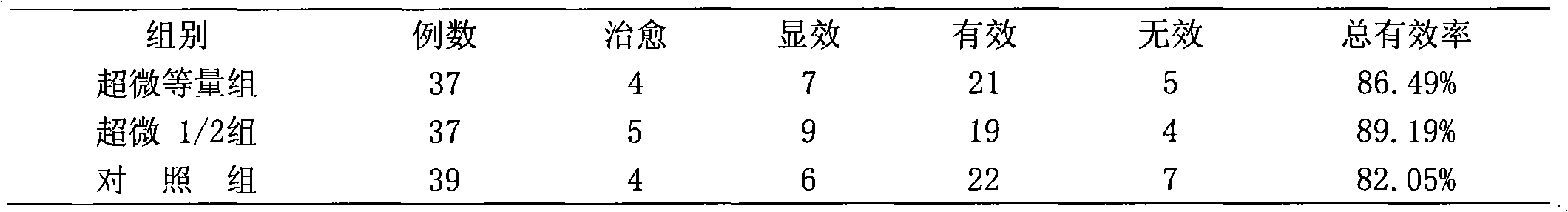

Preparation method of traditional Chinese medicine ultrafine formula particles

InactiveCN101822697AReduce dosageKeep it authenticPteridophyta/filicophyta medical ingredientsGranular deliveryDiseaseAdditive ingredient

The invention discloses a preparation method of traditional Chinese medicine ultrafine formula particles. The preparation method comprises the following steps that: single Chinese medicinal material or traditional Chinese medicine decoction pieces are partially ultrafine-crushed into ultrafine powder, the other parts are coarse-crushed, extracted, concentrated, dried and crushed to obtain dry extract powder, the ultrafine powder and auxiliary materials are added to obtain mixture, and the obtained mixture is mixed uniformly, palletized, granulated and subpackaged. The traditional Chinese medicine ultrafine formula particles is characterized in that the characteristics of the traditional Chinese medicine ultrafine decoction pieces of saving medicine materials and being controllable in quality and convenient in administration. Compared with the traditional Chinese medicine formula particles, the preparation method better preserves the medicinal properties of the traditional Chinese medicines, has the advantages of little used amount of auxiliary materials, convenient identification, benefit to measuring the content of index ingredients, preserves the advantages that the traditional Chinese medicine decoction piece can be added and reduced according to the disease and the traditional decoction has unique curative effect, also overcomes the defects of troublesome decoction and inconvenient administration, and has advanced technique and controllable quality. The invention also discloses a processing method of the Chinese medicinal material, which extracts the raw medicinal materials partially, carries out ultrafining treatment partially and then carries out mixing. The method can obvious improve the utilization ratio and leachability of the Chinese medicinal materials.

Owner:湖南省中医药研究院

Additive-free yogurt and preparation method thereof

Owner:BRIGHT DAIRY & FOOD

Probiotics troche and preparation method thereof

The invention discloses a probiotics troche and a preparation method thereof. Functional leavening agents and germinated brown rice, Chinese herb medicine extract with anti-cold and hot irritability and a stabilizer capable of effectively enhancing the stability are added into a yoghourt fermenting process; poikilothermal yogurt fermentation enables proliferation of lactic acid bacteria to the maximum extent, so that the anti-cold and hot irritability of lactic acid bacteria is improved. yogurt and fruit and vegetable slurry are pre-treated by using a non-hot-working technology so as to prevent infectious microbe infection in the process, improve the juice yield of the fruit and vegetable slurry, increase the content of soluble cellulose of the fruit and vegetable slurry and prevent the fruit and vegetable slurry from brown stain. Moreover, when the fruit and vegetable slurry and the yogurt are mixed, a scientifically compounded freezing protecting agent which is relatively good in anti-freezing effect is added. Finally, the probiotics troche which is smooth in taste, uniform in texture, stable in state, natural in quality, high in viable count, strong in functionality and long in expiration data is prepared. The viable count is (1.75-2.55)x10<11> CFU / g. At normal temperature, the expiration data is 30-36 months.

Owner:TIANJIN ZHONGTIAN JINGKE SCI & TECH

Peanut vegetarian meat ham and production method thereof

Owner:QINGDAO CHANGSHOU FOOD

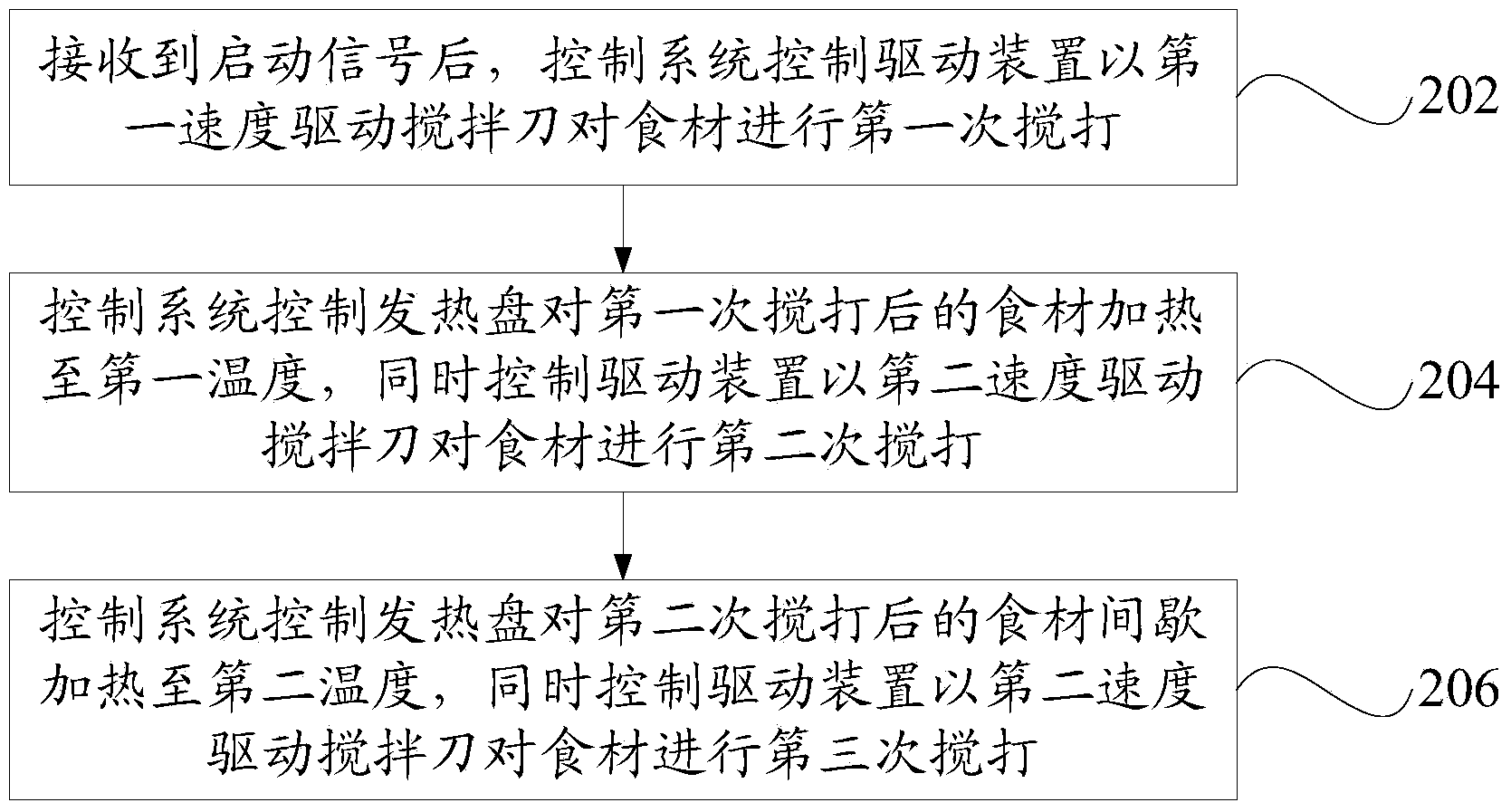

Milk making method of soybean milk maker

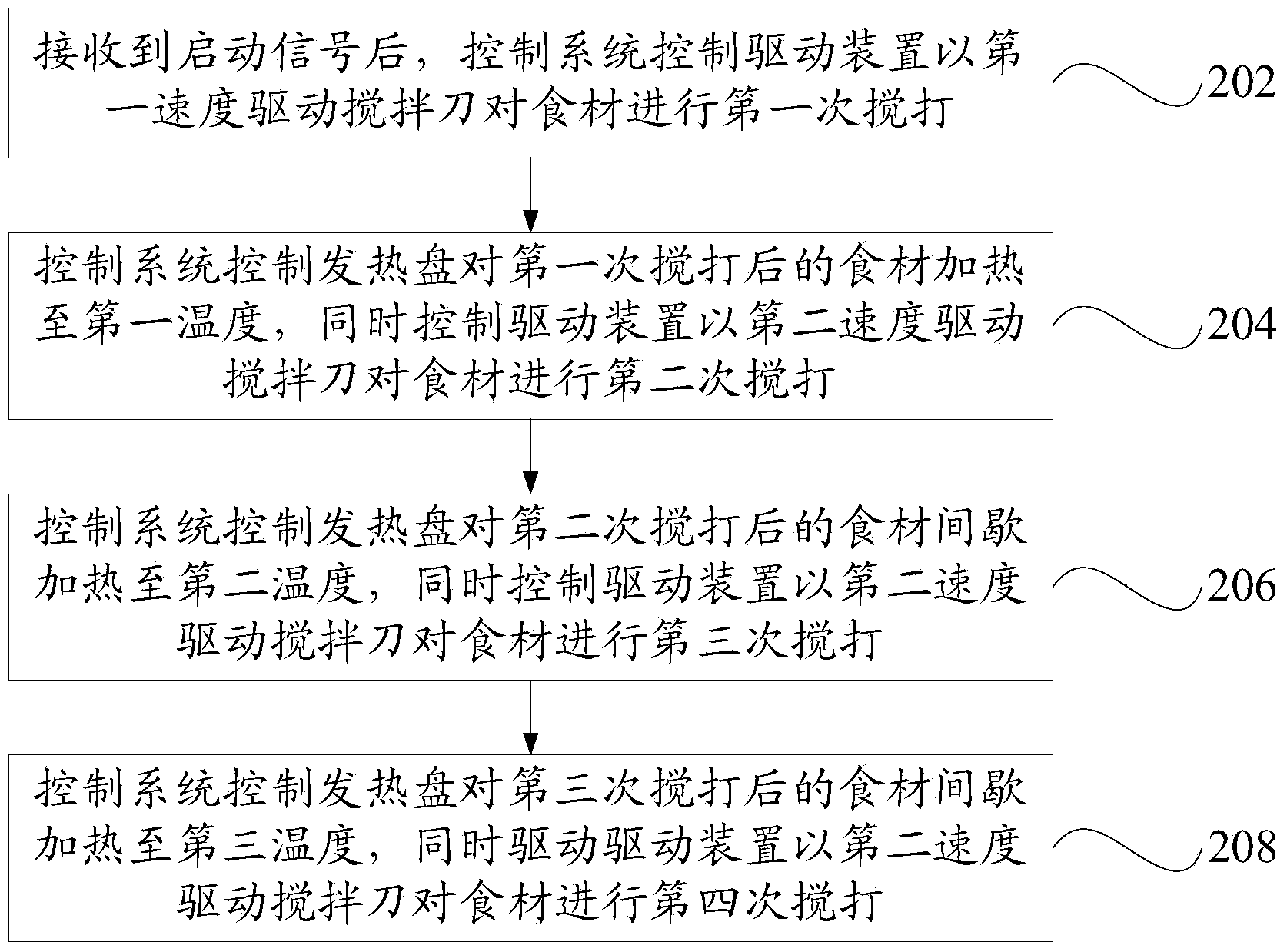

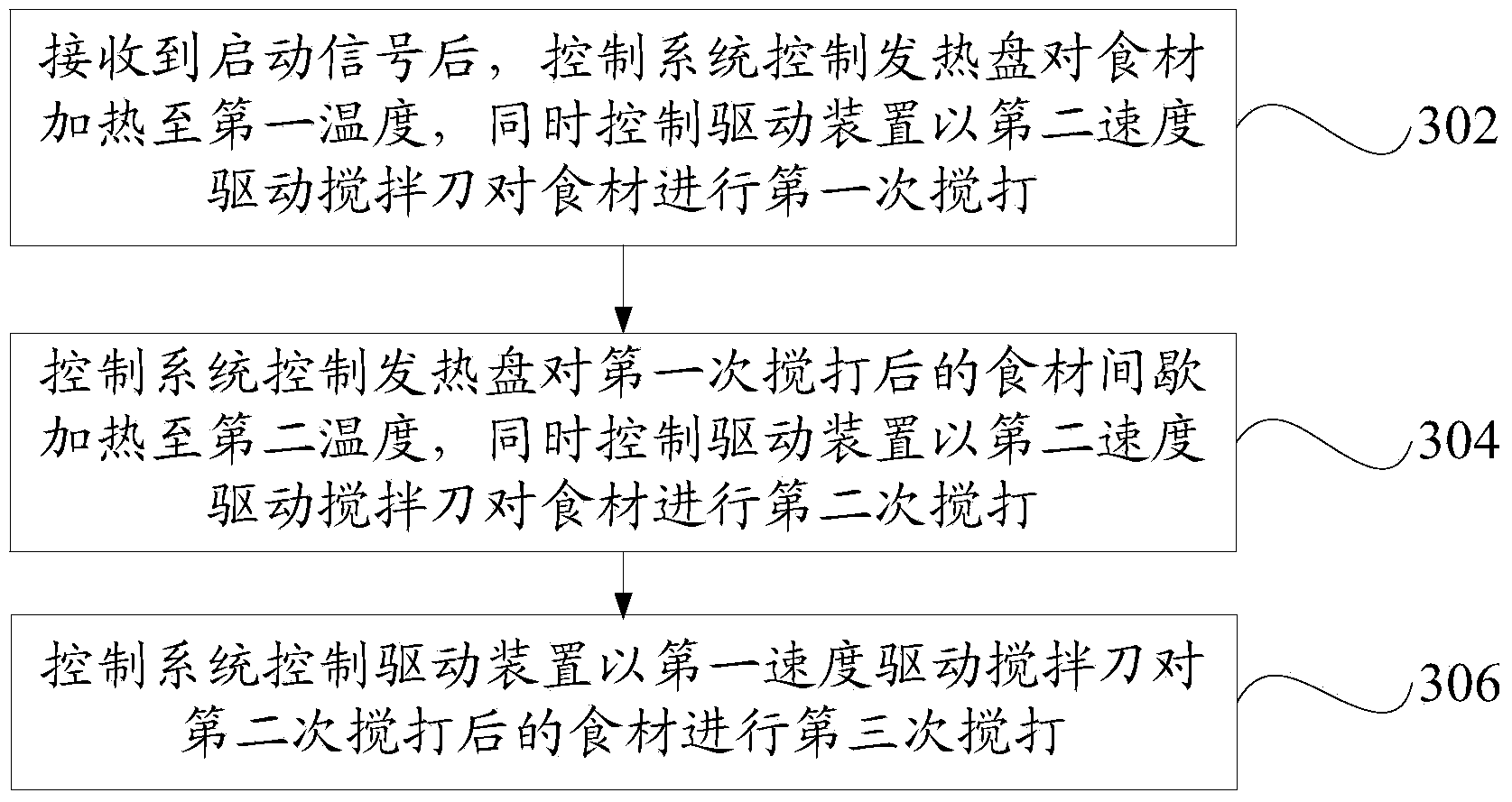

The invention provides a milk making method of a soybean milk maker. The milk making method includes the steps of smashing, heating and boiling. In the smashing step, a control system controls a driving device to drive a stirring cutter at a first speed to stir food materials for the first time after receiving a starting signal; in the heating step, the control system controls a heating plate to heat the food materials subjected to first stirring to a first temperature, and simultaneously controls the driving device to drive the stirring cutter at a second speed to stir the food materials for the second time; in the boiling step, the control system controls the heating plate to intermittently heat the food materials subjected to second stirring to a second temperature, and simultaneously controls the driving device to drive the stirring cutter at a second speed to stir the food materials for the third time. According to the milk making method, the stirring cutter continuously stirs the food materials in the steps of smashing, heating and boiling, so that the problems of smashing failure, layering and sticking during milk making in the prior art are effectively solved, milk made by the soybean milk maker tastes delicate, the soybean milk maker is simple and convenient to wash, and product quality is further improved.

Owner:GUANGDONG MIDEA CONSUMER ELECTRICS MFG CO LTD +1

Caramel-flavor jam and preparation method thereof

The present invention relates to a caramel-flavor jam and a preparation method thereof. The caramel flavor jam is prepared from the following raw materials, by weight: 1 to 2 parts of salvia miltiorrhiza, 2 to 2.5 parts of corn stigma, 1.5 to 3 parts of taraxacum mongolicum, 2 to 4 parts of gynostemma pentaphyllum, 1 to 2 parts of lotus leaf, 1 to 1.5 parts of habenaria ciliolaris, 2 to 2.5 parts of orthosiphon sinensis, 100 to 120 parts of apple, 150 to 160 parts of dragon fruit, 30 to 35 parts of milk, 7 to 8 parts of sesame, 20 to 24 parts of lotus seed, 15 to 17 parts of mung bean, 10 to 12 parts of raisin, 16 to 17 parts of nata de coco, 30 to 35 parts of white sugar, 10 to 12 parts of peanut oil, 0.5 to 0.7 part of lactic acid bacteria and 8 to 10 parts of nutritional additives. According to the present invention, the caramel-flavor jam has the advantages of sweet and delicious taste, delicate mouthfeel, unique flavor and rich nutrients. Multiple fruits are added to supply the human body with vitamins, and the lotus seeds and mung beans contain abundant proteins, dietary fibers and minerals, so that the nutritional value of the jam is significantly increased. Furthermore, the caramel-flavor jam contains multiple Chinese medical herbs, thereby being capable of providing the efficacy of blood nourishing, nerve calming, liver fire clearing, bile draining, qi benefiting and spleen strengthening if taken regularly.

Owner:何群

Non-fermented dipped seasoned preserved vegetable production method

ActiveCN104207068ADelicate tasteShorten the production cycleFood electrical treatmentFood preparationSalty tasteParallel plate

The invention provides a non-fermented dipped seasoned preserved vegetable production method and belongs to the technical field of food processing. The non-fermented dipped seasoned preserved vegetable production method comprises the steps of selecting and slicing specific leaf mustards, then performing pickling and desalination, meanwhile preparing seasoning liquid to enable relative dielectric constant, dielectric loss factor and conductivity of the seasoning liquid at the1Hz frequency to be within a certain range, charging the sliced leaf mustards into a glass jar, dipping the sliced leaf mustards in the seasoning liquid, arranging the whole glass jar in two square parallel plates, connecting the parallel plates to two poles of a power function signal generator, performing processing at room temperature, then taking out and draining the leaf mustards, instantly performing vacuum package with bags, adding sesame oil into the bags, and finally processing products in an ultraviolet radiation sterilization device to obtain finished seasoned preserved vegetable products. The non-fermented dipped seasoned preserved vegetable production method is suitable for production of high-quality non-fermented instant seasoned preserved vegetable and is short in period and standard compared with a traditional process, and due to the fact that materials are carefully selected, the finished products produced by means of the production method are fine and smooth in taste and completely integrate flavored, peppery and salty taste.

Owner:JIANGNAN UNIV

Corn stalk nano-dietary fiber and method of preparing the same

The invention provides corn straw nano dietary fiber and a preparation method thereof. The method adopts cellulase-producing bacteria for pure culture or mixed bacteria cofermentation to ferment corn straws, and carries out the ultra-high pressure homogenization treatment on the fermented corn straws to obtain the nano dietary fiber through spray drying or freeze drying. The corn straws are washed by water to remove impurities, dried, crushed and sieved, mixed evenly with skim milk powder or other substances and the water, sterilized and cooled; and a single-bacterium or multi-bacteria seed liquid of the cellulase-producing bacteria is inoculated into a culture medium for fermentation, a product after the fermentation is rinsed until the pH value is neutral, and the corn straw nano dietary fiber is prepared after homogenization treatment and spray drying or freeze drying. The method has simple preparation technology, mild conditions and no pollution to the environment, and is easy for industrialized production; and the dietary fiber has exquisite taste, increases the solubility, greatly improves water retention ability, water absorptivity and expansive power, and improves the content of soluble dietary fiber by more than 50 percent.

Owner:孟繁宇

Dried jasmine flower and preparing method thereof

InactiveCN103719296AFull of nutritionDelicate tasteCheese manufactureFood scienceLower blood pressureSophora japonica

The invention discloses dried jasmine flower and a preparing method thereof. The dried jasmine flower comprises the following raw materials by weight: 80-90 parts of soybean, 13-15 parts of jasmine flower, 3-5 parts of lily, 2-4 parts of common coltsfoot flower, 2-4 parts of gourd flower, 10-15 parts of maize, 3-4 parts of walnut, 4-6 parts of mulberry, 3-5 parts of thistle, 1-2 parts of sophora japonica twig, 2-4 parts of elm white bark, 4-6 parts of pollen typhae, 3-5 parts of dandelion, 2-4 parts of cucumber root, 1-2 parts of sweet tea root and 5-7 parts of sweet potato vine. The dried jasmine flower is rich in nutrients, delicate in taste and appropriate in saltiness and sweetness. Due to the addition of the jasmine flower to the raw materials, the dried jasmine flower has the functions of clearing liver fire, improving eyesight, promoting the secretion of saliva, slaking thirst, lowering blood pressure, strengthening the heart and resisting ageing, and assists a person in prolonging life, having longevity and keeping the body and the heart healthy. The preparing method is unique. Through the enzymolysis of the raw materials, the nutritional ingredients of the raw materials are more easily released and are more conveniently absorbed by a human body.

Owner:WUHU ZHONGLU IND

Method for extracting rice protein powder by utilizing enzyme-alkali method

The invention provides a method for extracting rice protein powder by utilizing enzyme-alkali method. The method in the invention takes rice residue as raw materials and comprises the following steps: washing with water, eliminating sugar, carrying out milling refining on the colloid, eliminating residue starch by utilizing starch enzyme, pre-extracting alkali protease, adding alkali for extraction, centrifuging and taking the supernate to mix to neutrality, inactivating enzymes and sterilizing, and spraying and drying to obtain the rice protein powder. The rice protein powder produced by utilizing the process has faint yellow color, delicate taste and good solubility, and can be maintained well from physicochemical function. The invention has simple process, few investment device, high yield and purity of products, good solubility, and easily-controlled product quality, is suitable for practice popularization and provides a new route for the extraction of rice protein.

Owner:长沙湘博医药科技有限公司

Minced fillet product producing method

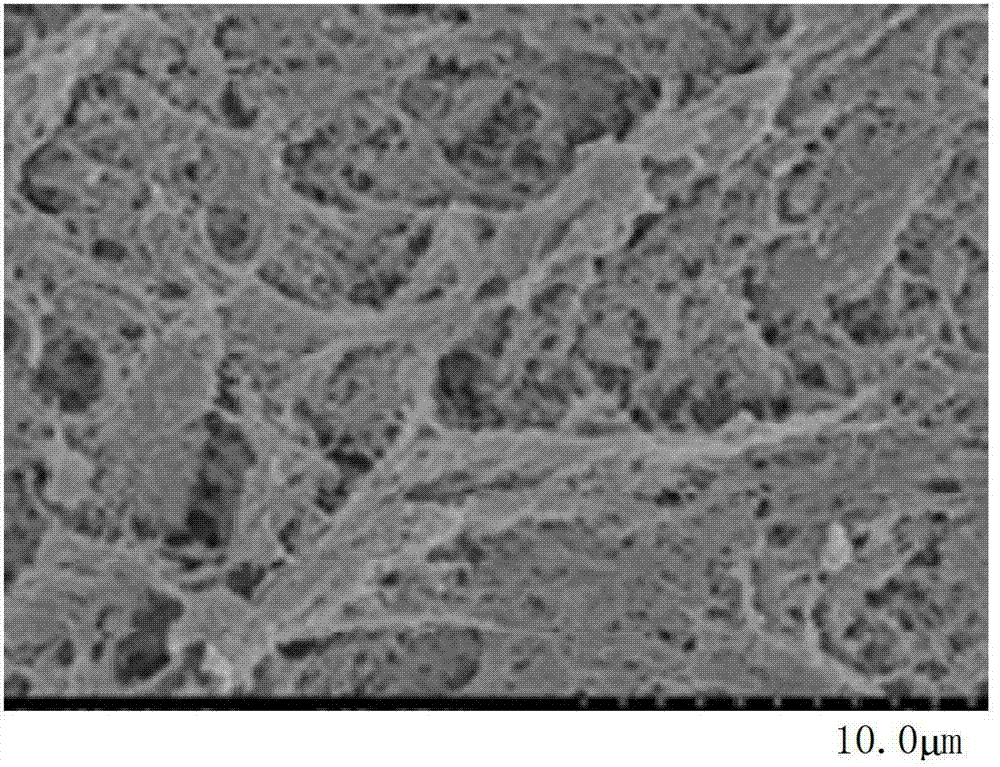

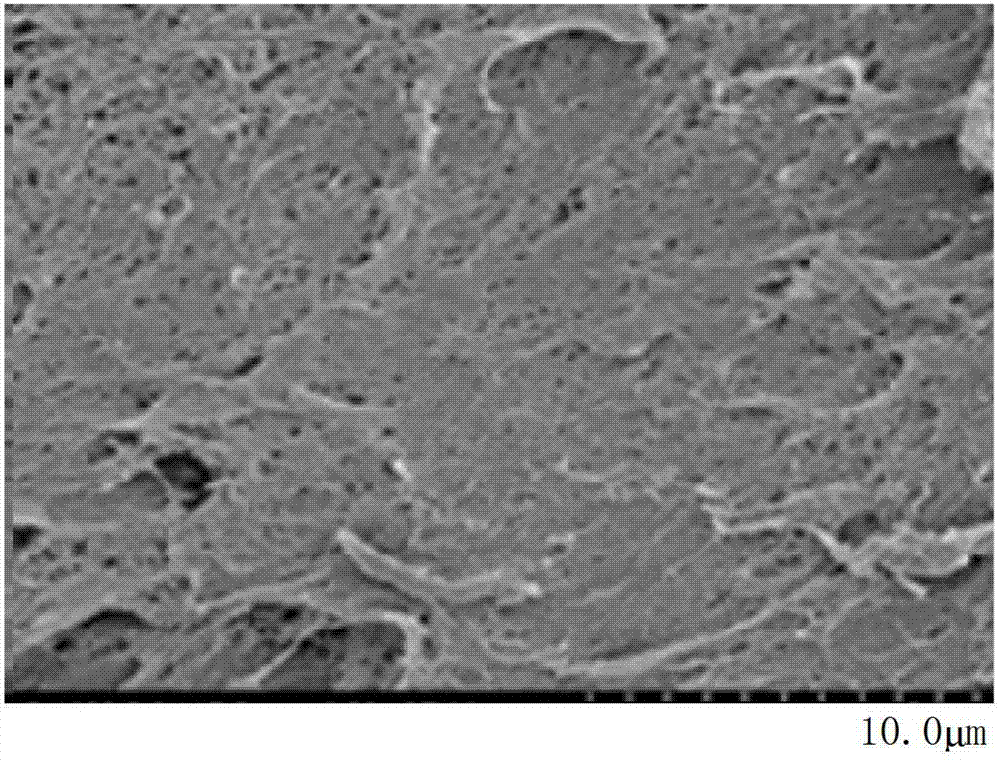

ActiveCN103027317AReduce consumptionReduce manufacturing costFood preparationAquatic productFresh fish

A minced fillet product producing method relates to aquatic product processing and comprises the following steps: grinding without any addictive: adding a protease inhibitor and an acid seasoning aqueous solution into semi-thawed minced fillet, and chopping, blending, grinding and mixing uniformly at 4-10 DEG C; grinding with salt: adding salt and glucolactone into the ground minced fillet, grinding at 4-10 DEG C; gelating: shaping and heating the ground minced fillet, and gelating the minced fillet; and refrigerating: packaging in a sealing way, and refrigerating at 4-10 DEG C to obtain a minced fillet product. Only medium-temperature heating is required, so that the energy consumption is reduced and the production cost is reduced; the minced fillet product producing method is simple in process, low in requirement on equipment, short in production period and high in production efficiency; and the produced minced fillet product is faintly acid, low in fishy taste, strong in fresh fish meat taste, more compact in internal structure and macroscopically dedicate in mouth feel, and is superior in gel strength to he conventional minced fillet product heated at a high temperature.

Owner:SHISHI ZHENGYUAN AQUATIC TECH DEV

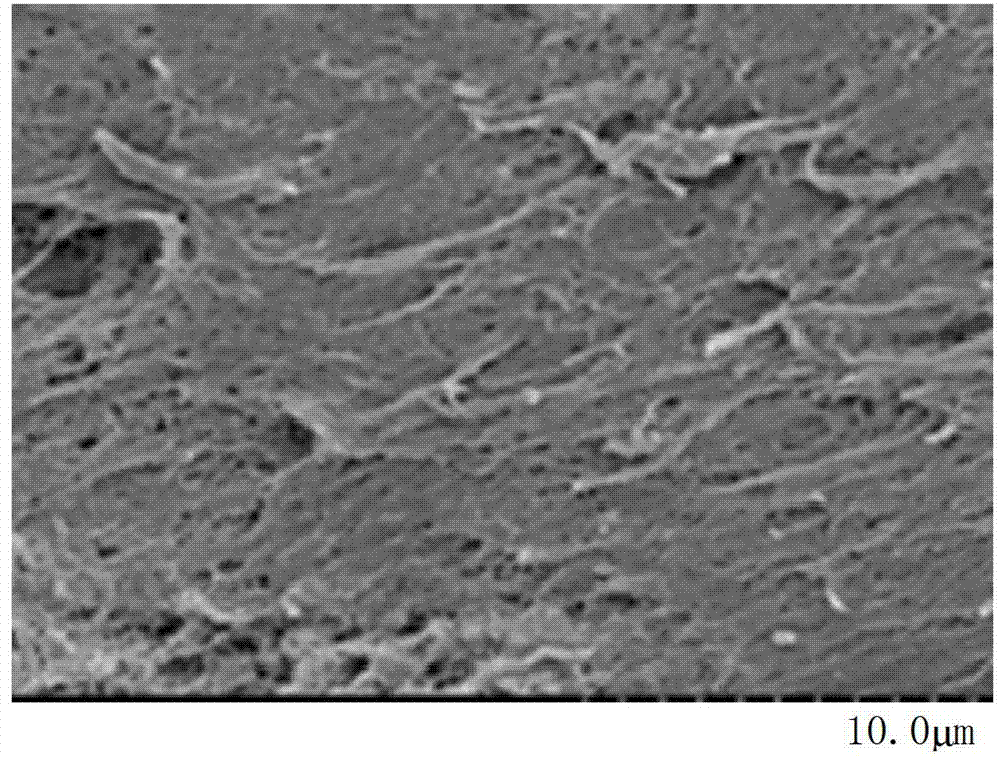

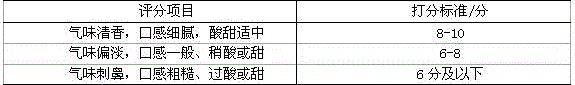

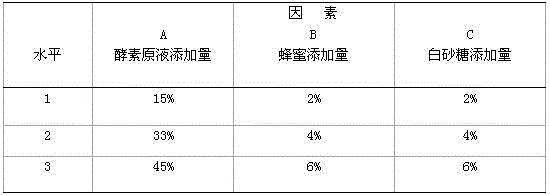

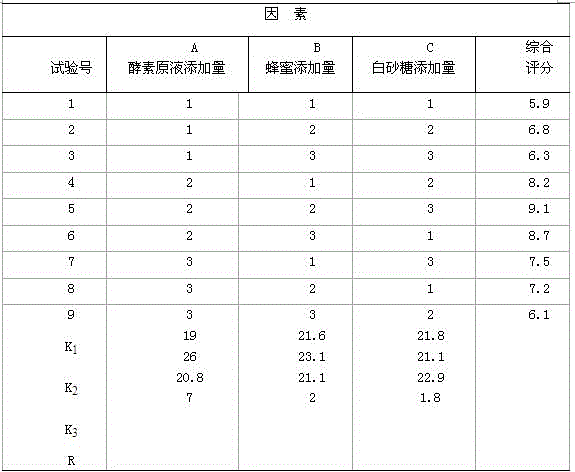

Preparation method of pineapple and orange composite ferment beverage

The invention discloses a preparation method of a pineapple and orange composite ferment beverage. The preparation method comprises the following steps of step I, separately taking raw materials of fresh pineapples and oranges, performing peeling, performing separate dicing and performing uniform mixing so as to obtain fruit raw materials; step II, taking fungus powder, and adding pure water for diluting so as to obtain fermentation fungus water; step III, adding the fungus water to the fruit raw materials until the level of the fungus water exceeds the surfaces of the fruit raw materials, then performing sealing, loading the fruit raw materials and the fungus water, which are sealed, in an incubator for fermentation, after fermentation, taking out the fermented fruit raw materials and the fermented fungus water, performing filtering so as to obtain a ferment stock solution, and placing the ferment stock solution in a refrigerator for after-ripening so as to obtain ferment liquid; step IV, adding honey, pure water and white granulated sugar to the obtained ferment liquid obtained in step III, performing uniform mixing, then adding vitamin C and beta-carotene, and performing homogenizing so as to obtain the pineapple and orange composite ferment beverage. The prepared composite ferment beverage is delicately fragrant in smell, fine and smooth in mouth feel, and moderate in sour and sweet degrees, and the activity of superoxide dismutase (SOD) contained in the composite ferment beverage achieves 100-150U / g.

Owner:LUOYANG INST OF SCI & TECH

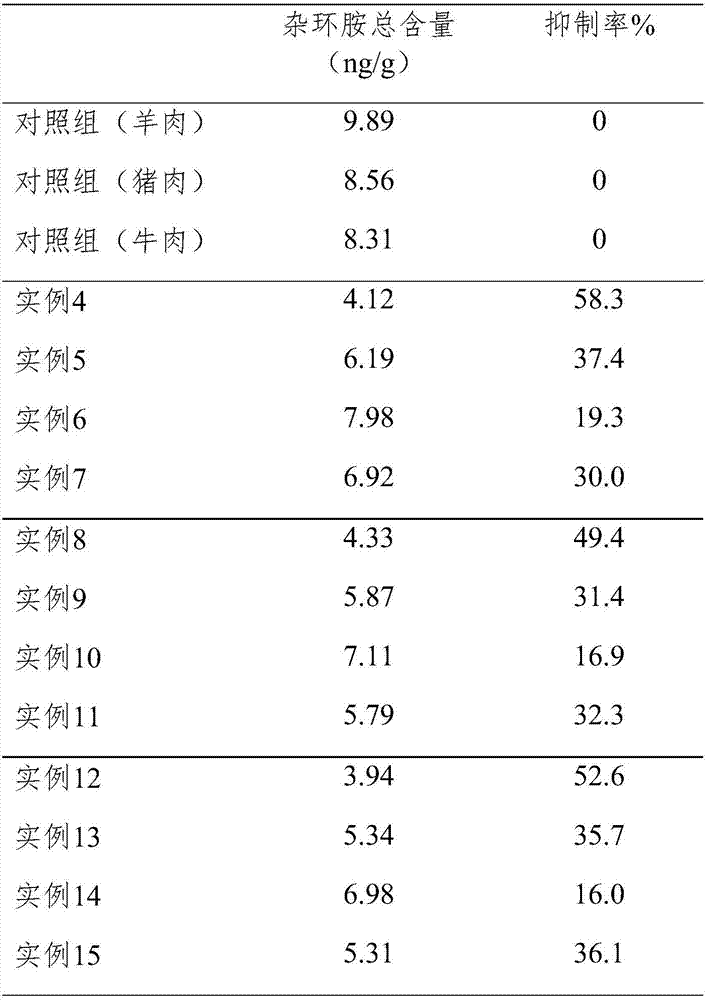

Method for reducing content of heterocyclic aromatic amines in barbecued meat

The invention relates to the technical field of food processing, in particular to a method for reducing the content of heterocyclic aromatic amines in barbecued meat. The method comprises the following steps: (1) cutting raw meat into small pieces for later use; (2) weighing 3.5 to 4.5 percent of table salt, 0.35 to 0.8 percent of natural extracts, 0.75 to 1.3 percent of white granulated sugar, 2.2 to 3.6 percent of spice and 0.8 to 1.35 percent of cooking wine according to the weight of the raw meat, mixing with the meat pieces, and then pickling for 2.5 to 7 hours; (3) stringing the pickledmeat pieces with bamboo sticks, and uniformly barbecuing with carbon fire. The natural extracts added in the method can effectively lower the content of the heterocyclic aromatic amines in the barbecued meat, a proper amount of table salt, white granulated sugar, spice and cooking wine are added in a barbecuing process, and the auxiliary materials have a synergistic effect, so that the inhibitioneffect on the heterocyclic aromatic amines is enhanced, and the barbecued meat tastes better.

Owner:YUNNAN AGRICULTURAL UNIVERSITY

Composite barley green solid beverage and production process thereof

InactiveCN102511894ASolve the reconciliationSolving Dispersion ProblemsFood preparationFreeze-dryingBARLEY GRASS

The invention relates to composite barley green solid beverage and a production process thereof and belongs to the technical field of deep processing of agricultural products. The invention is characterized in that: the composite barley green solid beverage is prepared by using fresh barley grass juice and barley green powder as main raw materials and adding barley grass dreg powder, spiral seaweed powder, xanthan gum, sorbitol, sodium alginate, maltodextrin and sodium carboxymethylcellulose through procedures of sterilizing and packaging, wherein the fresh barley grass juice is used for performing biological green protection by using flammulina velutipes extracting solution; and the barley green powder is prepared through vacuum freeze drying. The composite barley green solid beverage have the characteristics of simple production process, high utilization rate of the raw materials and the like, can be produced industrially, has high nutritional value and high drinking performance and is ideal natural health-care beverage.

Owner:NANJING AGRICULTURAL UNIVERSITY

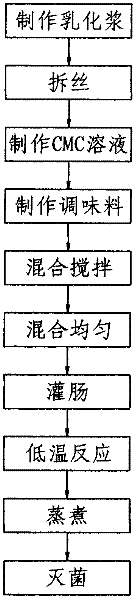

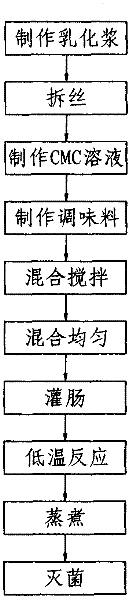

Fermented sausage of dietary fiber and goose

InactiveCN102669711AGrowth inhibitionImprove securityClimate change adaptationFood preparationDietary fiberEconomic benefits

The invention relates to the technical field of deep processing of agricultural products, in particular to a fermented sausage of dietary fiber and goose. The fermented sausage of dietary fiber and goose is made by steps of pickling raw goose, chopping and mixing to obtain goose paste, inoculating mixed leavening agent, stuffing, smoking, curing and packaging. The fermented sausage of dietary fiber and goose is delicate in taste, easy to digest and totally free of goose smell. The fermented sausage of dietary fiber and goose further has the advantages of high nutritional value, high safety, convenience to eat, easiness to preserve, probiotic effectiveness, health caring and the like. The fermented sausage of dietary fiber and goose, developed for society, is novel and instantly serviceable. Product cost is lowered. Economic benefit is improved. Industrial development of the goose industry in China is promoted.

Owner:HENAN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com