Patents

Literature

54 results about "Boiled beef" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Boiled beef is a traditional English dish which used to be eaten by working-class people in London; however, its popularity has decreased in recent years. Traditionally, cheaper cuts of meat were used, because boiling makes the meat more tender than roasting. It was usually cooked with onions and served with carrots and boiled potatoes. It was not uncommon for the beef to be salted in a brine for a few days, then soaked overnight to remove excess salt before it was boiled. In other parts of England cabbage replaced carrots.

Spicy beef sauce and method of processing the same

InactiveCN101411508AHigh nutritional valueBrain-boostingFood preparationNutritive valuesMonosodium glutamate

The invention provides spicy beef paste and a method for preparing the same. Raw materials comprise 50 portions of water boiled beef, 15 portions of refined benne oil, 10 portions of walnut kernel, 8 portions of pignut, 1 portion of white sesameseed, 15 portions of bean paste, 10 portions of sweet flour paste, 8 portions of maltodextrin, 1 portion of sesame oil, 8 portions of hot pepper powder, 4 portions of cooking salt, 4 portions of monosodium glutamate, 4 portions of white sugar, and 4 portions of chicken essence. The raw materials are used to process the spicy beef paste through the processes of salting, boiling, stir-frying and the like. The spicy beef paste is not added with any flavoring essences and substitutes thereof and is prepared from 'green and pollution-free' beef and natural auxiliary materials, through a scientific formulation and according to nutritive values of the beef, the walnut kernel, the pignut, and the white sesameseed. The spicy beef paste has long storage time and is convenient food with high nutritive value.

Owner:GANSU ZHONGHUI AGRI DEV

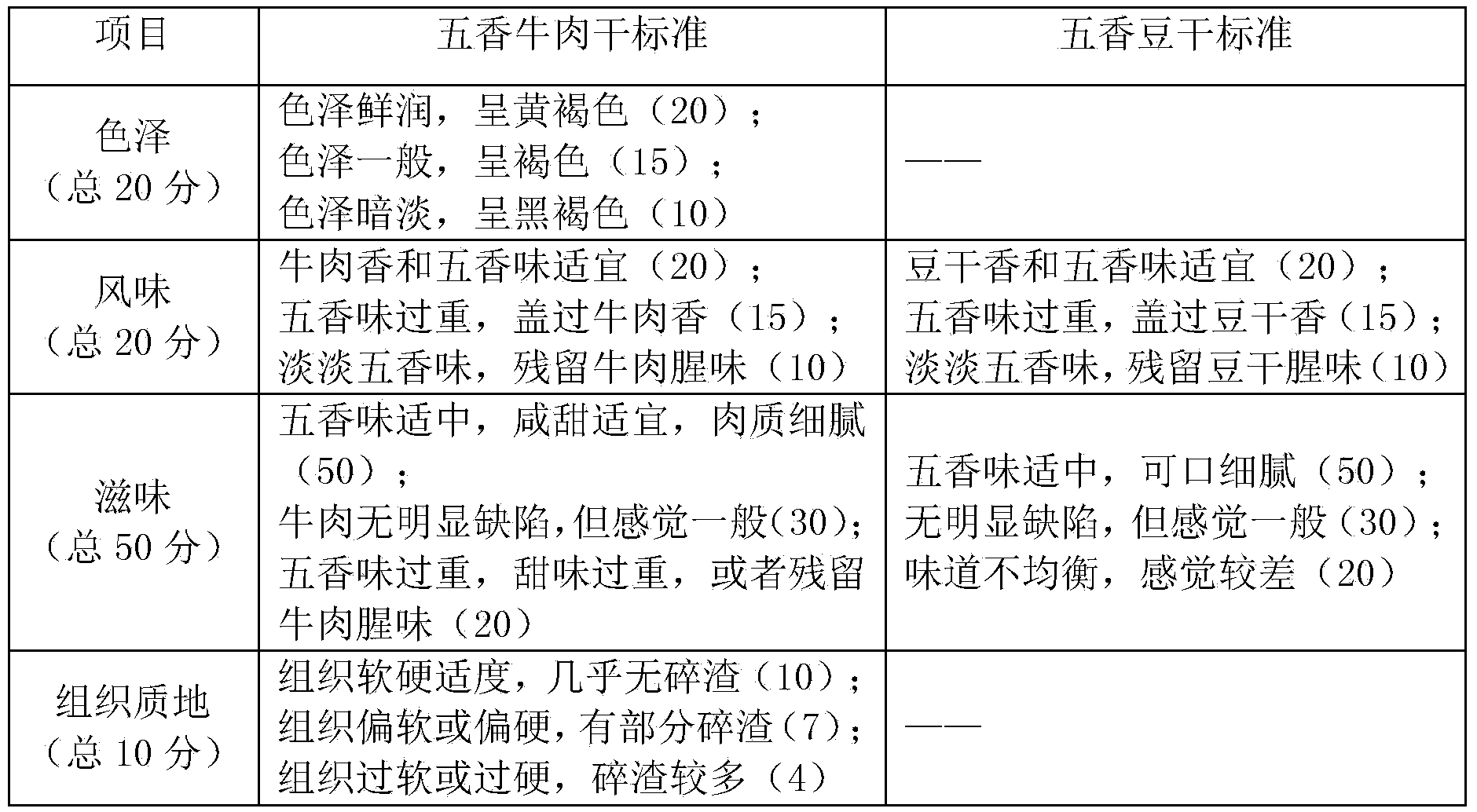

Manufacturing method of spiced beef jerky

ActiveCN103504321ABright colorDelicate tasteFood ingredient functionsFood preparationFlavorAmomum tsao-ko

The invention relates to a manufacturing method of spiced beef jerky. The method comprises the following steps: splitting fresh beef, pickling the cut beef with salt for 8-15 hours, boiling the pickled beef, removing blood-contained water, then slicing the boiled beef; mixing the sliced beef, water, white sugar and spice uniformly according to the proportion of 40-60 parts of beef, 3-5 parts of water, 4-6 parts of white sugar and 1-2 parts of spice; frying the mixed beef at 100-150 DEG C till dry; drying the fried beef at 50-90 DEG C until the moisture in the beef is 15-30%. The spice comprises 5-8 parts of radix angelicae, star aniseed, Chinese prickly ash and amomum tsao-ko each, 2-3 parts of cinnamon, cloves, round cardamom, amomum villosum and rhizoma kaempferiae each, 1 part of old ginger and liquorice each, and 1 part of equally mixed fennel, bay leaf, nutmeg, radix aucklandiae, galanga, mangnolia officinalis, fructus aurantii, tangerine peel and mint. The method has simple steps. The manufactured beef jerky is yellowish brown, bright in color, fine and smooth to be tasted, suitably salty and sweet, and proper in hardness. The spice has the functions of eliminating smell, retaining freshness, tonifying spleen and appetizing, and can be widely applied to seasoning of other food.

Owner:胡海山

Processing technology of composite dried beef having beef liver and tendon

InactiveCN102188007AUnique flavorFlavor loose and flexibleFood preparationMixed materialsSingle lump

The invention discloses a processing technology of composite dried beef having beef liver and tendon; and beef, beef liver, beef tendon, and casein are employed as original accessories. The processing technology comprises the following steps: boiling beef and cutting the boiled beef into small pieces; boiling beef liver and chopping the boiled beef liver into minced one, and then mixing the small pieces of beef and minced beef liver to obtain a material having beef and liver; adding food-grade casein, white sugar, black powdered pepper and water into the material having beef and liver, and performing mixing to obtain a mixed material having beef and liver; stewing, moulding and slicing beef tendon; putting a piece of translucent tendon slice between two layers of the mixed material having beef and liver to form a three-layer overlapping complex; and carrying out hot-air drying, microwave drying, and sterilizing, and then performing packing by a vacuum film or packing in a monoblock candy manner to obtain a finished product. According to the invention, dried beef produced by the processing technology is rich in nutrition, and has a layered shape, distinctive flavor, as well as loose and flexible taste; besides, the product the dried beef is novel. Moreover, the composite dried beef having beef liver and tendon is easy to produce and demands of various consumers can be met. Cattle byproducts resources are utilized fully, which enables the benefit of the beef cattle industry to be promoted.

Owner:GANSU AGRI UNIV +1

Manufacturing method of spicy beef jerky

ActiveCN103504323ABright colorDelicate tasteFood ingredient functionsFood preparationFlavorAmomum tsao-ko

The invention relates to a manufacturing method of spicy beef jerky. The method comprises the following steps: splitting fresh beef, pickling the cut beef with salt for 8-15 hours, boiling the pickled beef, removing blood-contained water, then slicing the boiled beef; mixing the sliced beef with water, white sugar and spice uniformly according to the proportion of 40-60 parts of beef, 3-5 parts of water, 4-6 parts of hot pepper-containing water and 0.5-1 parts of spice; frying the mixed beef at 100-150 DEG C till dry; drying the fried beef at 50-90 DEG C until the moisture in the beef is 15-30%. The spice comprises 5-8 parts of radix angelicae, star aniseed, Chinese prickly ash, and amomum tsao-ko each, 2-3 parts of cinnamon, cloves, round cardamom, amomum villosum and rhizoma kaempferiae each, 1 part of old ginger and liquorice each, and 1 part of equally mixed fennel, bay leaf, nutmeg, radix aucklandiae, galanga, mangnolia officinalis, fructus aurantii, tangerine peel and mint. The method has simple steps. The manufactured beef jerky is yellowish brown, bright in color, fine and smooth to be tasted, suitably salty and sweet, and proper in hardness. The spice has the functions of eliminating smell, retaining freshness, tonifying spleen and appetizing.

Owner:胡海山

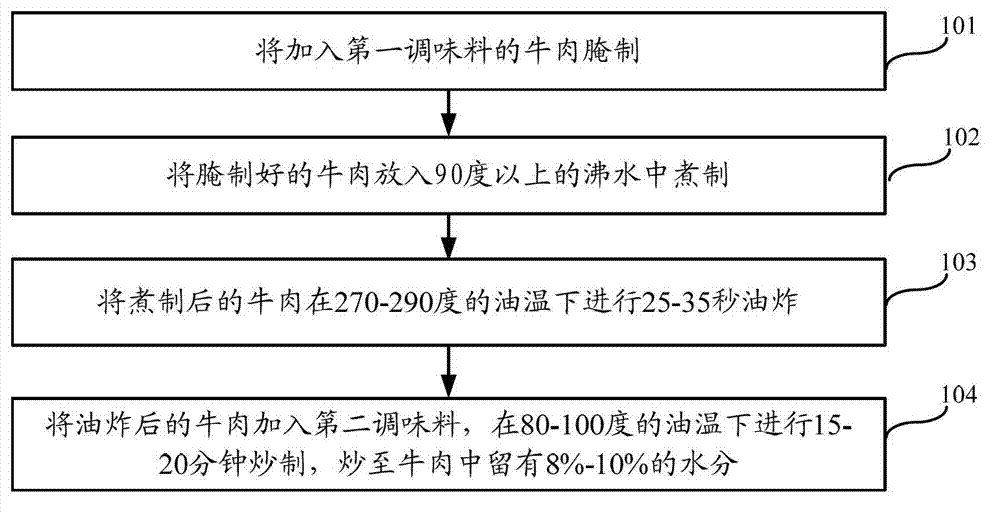

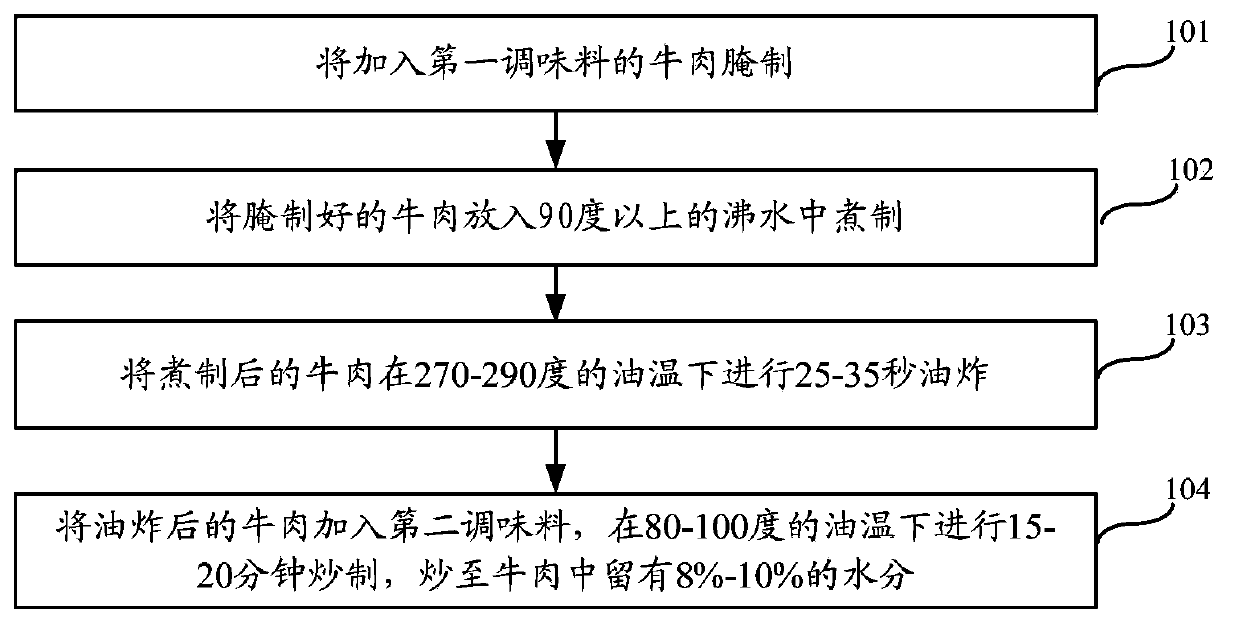

Process for manufacturing sliced dried beef

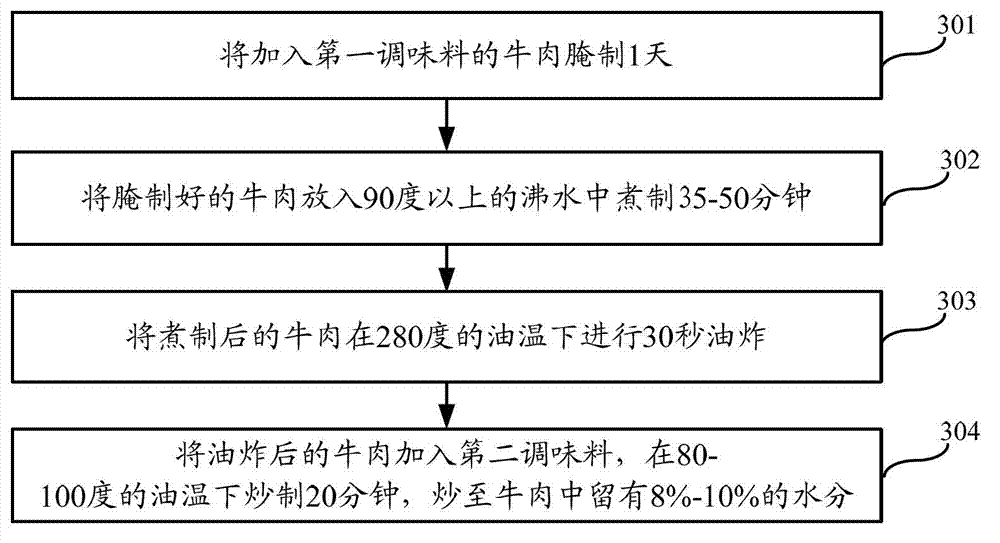

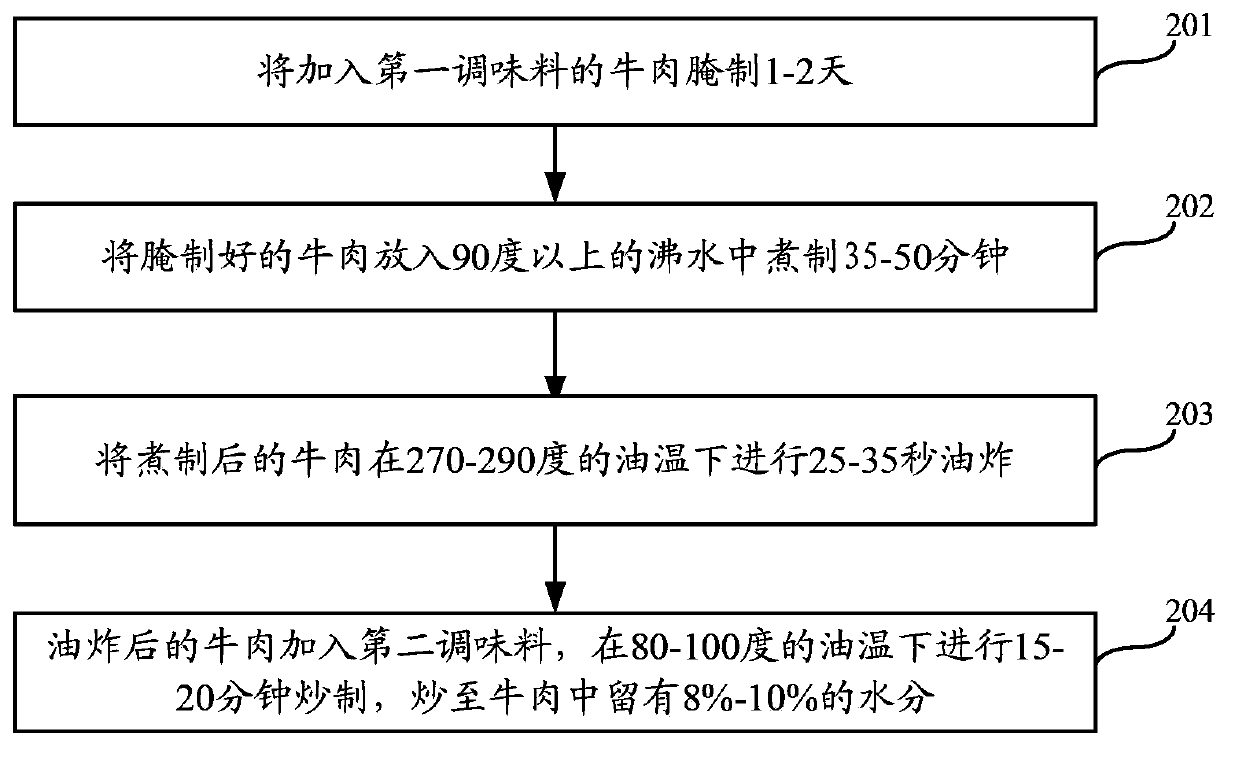

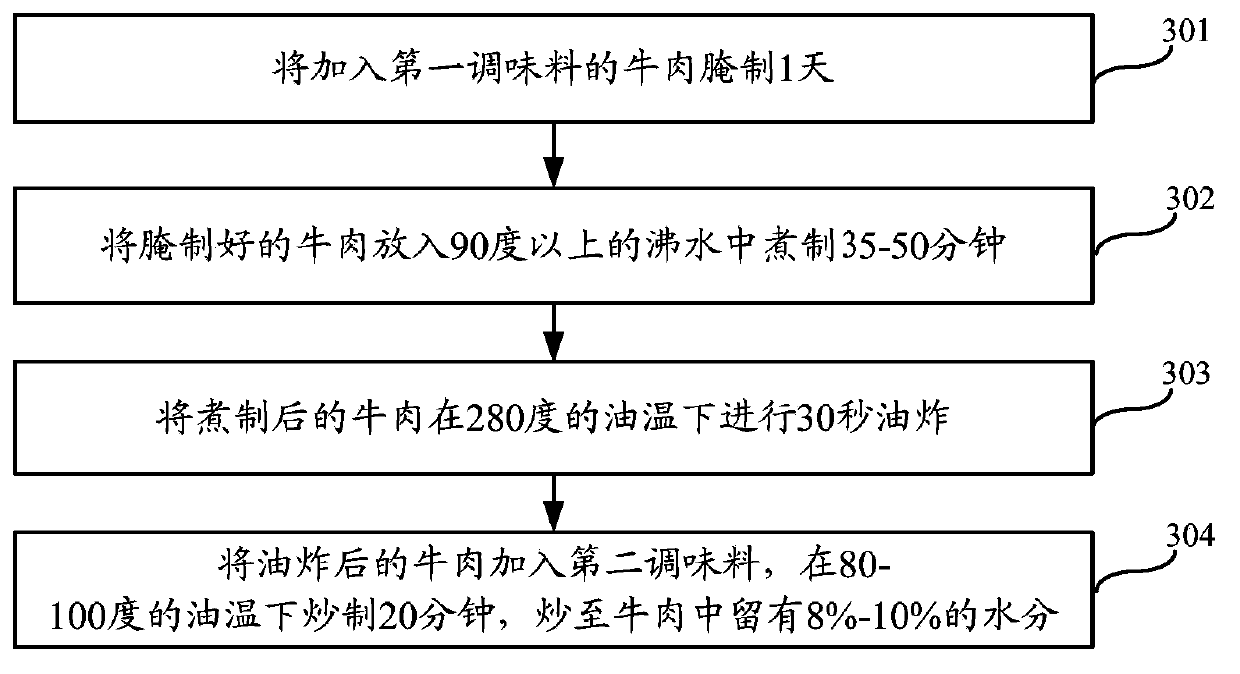

The invention relates to the field of food processing, and in particular relates to a process for manufacturing sliced dried beef. The process comprises the following steps of: pickling beef with first seasoning; putting the pickled beef into boiled water with the temperature higher than 90 degrees, and boiling; frying the boiled beef into oil with the temperature of 270 to 290 DEG C for 25 to 35 seconds; adding second seasoning into the fried beef; and sauting the beef in the oil with the temperature of 80 to 100 DEG C for 15 to 20 minutes until the moisture content in the beef is up to be 8 to 10 percent. By the process for manufacturing the sliced dried beef, the moisture content in the sliced dried beef can be increased, and the sliced dried beef is easy to chew.

Owner:余贤均

Making method of spiced beef

InactiveCN106107560AImprove cleanlinessEnsure hygieneClimate change adaptationFood ingredientsFlavorCarrageenan

The invention discloses a making method of spiced beef. In the making process of the spiced beef, spices are put in a pot after being wrapped by gauze, the flavors of the spices can smoothly pass through holes of the gauze to enter soup, in addition, the spices are isolated from beef, cleanliness and sanitation of the beef are guaranteed, and convenience is brought for people to eat the beef; after being scooped, a thin layer of carrageenan is scattered on the surface of the boiled beef, and therefore the situation that the beef shrinks in the boiling process, so that the beef gets tough can be avoided.

Owner:ANHUI XIANZHIYUAN FOOD

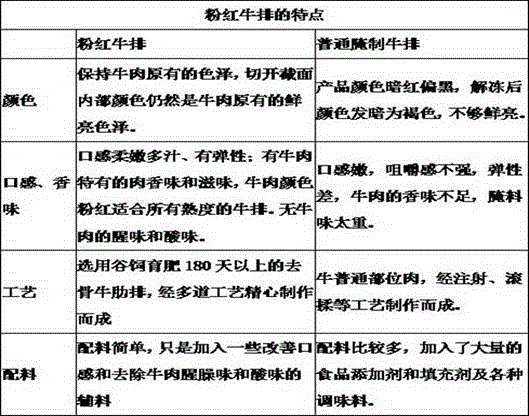

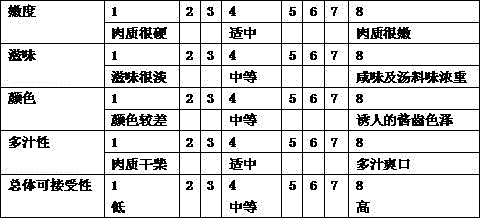

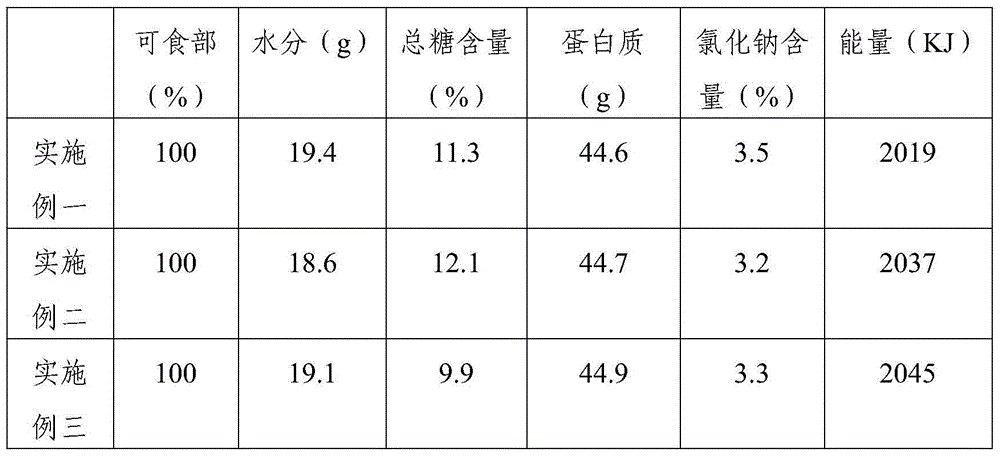

Preparation method of pink western-style beef steak

The invention provides a preparation method of pink western-style beef steak. A frozen beef steak piece with a certain fat content is selected and used as a raw material; the raw material steak piece is unfrozen at 0-4 DEG C under the relative humidity being 80-90%; then a marinade is injected into the raw material steak piece for compression, and rolling and rubbing last for 15-25 minutes; a high temperature resisting steaming and boiling bag is adopted for vacuum package; afterwards, boiling lasts for 20-30 hours in constant circulating water; boiled beef is put into ice water at 0-5 DEG C until the center temperature of the beef is reduced to be 5 DEG C or lower; the bag is opened and dirt on the surface of beef is washed away; the processed beef is put into quick-freezing equipment below subzero 35 DEG C to be quickly frozen for 20-30 hours; afterwards, slitting quantification, vacuum package, and boxed warehousing are carried out. The pink western-style beef steak exceeds the beef steak in the prior art in aspects of taste, fragrance, mouthfeel, and particularly color. The preparation method is simple and convenient in technological preparation, and is suitable for industrial production.

Owner:上海瑞轩食品有限公司

Fragrant spiced beef preparation method

The invention discloses a fragrant spiced beef preparation method which comprises the following operation steps: 1, cutting beef into meat loaves, injecting pickling fluid into each meat loaf and then soaking the meat loaves in the pickling fluid; 2, rolling and rubbing the soaked beef for 80min and adding mixed powder of sodium carbonate and carrageenan into the beef, wherein the mass ratio of the sodium carbonate to the carrageenan is 1 to 1; 3, decocting seasoning water through a seasoning bag, adding 100 to 120mg of monascus red pigment into each kilogram of the seasoning water and putting the rolled and rubbed beef into the seasoning water to be pickled and boiled; 4, vacuum packing the pickled and boiled beef loaves and sterilizing to obtain finished products. The manufactured spiced beef is bright red in color, glossy, fresh and tender in meat quality, palatable in hardness, better in taste, unique in flavor, rich in nutrition, high in yield and suitable for large-scale production.

Owner:安徽省家乡食品有限公司

Production method of blood sugar lowering dried beef

InactiveCN105433135ABright orange colorIncrease appetiteFood preparationMonosodium glutamateBoiling process

The invention discloses a production method of blood sugar lowering dried beef. The method comprises the following steps: 1, cleaning Rosa roxburghii Tratt fruits, removing cores, slicing the Rosa roxburghii Tratt fruits, and uniformly mixing the sliced Rosa roxburghii Tratt fruits with glutinous rice wine, white sugar and Radix Puerariae according to a certain ratio to prepare a Rosa roxburghii Tratt wine; 2, removing bones, fascia and fats from beef, cutting the beef to form long strips, and cleaning the long strips; 3, boiling the long beef strips in water in a jacket kettle for a period of time, and cutting the boiled beef to form thin slices; 4, boiling the thin beef slices, and certain amounts of Chinese prickly ash powder, tea polyphenol, Fructus Tsaoko, soy, paprika, anise, Fructus Foeniculi, monosodium glutamate, ginger, edible salt and the Rosa roxburghii Tratt wine; 5, baking the boiled thin beef slices in a baking chamber; and 6, packaging the baked thin beef slices under a vacuum condition, and disinfecting the packaged thin beef slices. The dried beef produced in the invention has an orange-yellow and bright color, reserves the original taste of beef, and has loose and soft mouthfeel. The Rosa roxburghii Tratt wine and the tea polyphenol are added in the re-boiling process, so the dried beef has the blood sugar lowering efficacy.

Owner:GUIZHOU MOUNT FANJING ECOLOGICAL AGRI INC

Production method of fermented dried beef

The invention discloses a production method of fermented dried beef, and belongs to the technical field of food processing. The method comprises the following steps: preparing a culture solution, preprocessing beef, cleaning the beef, pre-boiling the cleaned beef, re-boiling the pre-boiled beef, fermenting the re-boiled beef, stir-frying the fermented beef, disinfecting the stir-fried beef, and packaging the disinfected beef. No smoking is adopted in the invention, so the dried beef produced in the invention contains no cancerogenic substances easily generated in the smoking process; and the dried beef has an orange-yellow and bright color, so people's appetite is improved. The production method is simple, and the shelf life of the dried beef is long and reaches 1 year or above.

Owner:GUIZHOU MOUNT FANJING ECOLOGICAL AGRI INC

Nutritional beef and lentinula edodes soybean-wheat sauce and processing technology thereof

The invention discloses a technology for preparing nutritional beef and lentinula edodes soybean-wheat sauce. The technology is characterized in that a soybean-wheat sauce base material is prepared first, and then beef, lentinula edodes, ginger, chili, carrot and the like are added into the soybean-wheat sauce base material. The technology comprises the following steps of preheating vegetable oil, adding lentinula edodes, adding soybean sauce, stir-frying till sauce fragrance is given out, then adding the boiled beef and spices, stir-frying fragrance is given out, adding ginger, chili, carrot, salt and the like, stirring uniformly, then immediately turning off the fire, canning, and sterilizing to obtain the finished product. The technology has the following characteristics that the required equipment and operation are simple, the production cost is low, the production environment is easy to control, and the prepared nutritional beef and lentinula edodes soybean-wheat sauce has unique flavor, rich nutrition and delicious taste and has the effects of promoting appetite and helping digestion.

Owner:NANCHANG UNIV

Preparation method of dried beef facilitating digestion

The invention discloses a preparation method of dried beef facilitating digestion. The method comprises the following steps that 1, bones, anadesma and fat are removed for beef, and the beef is cut into long strips and cleaned; 2, the long-strip-shaped beef is put in a layered pot to be boiled and then cut into slices; 3, the beef slices are boiled with a certain amount of pepper powder, tea polyphenol, amomum tsao-ko, soy sauce, chilli powder, star anise, fennel, roots of single roxburgh roses, hawthorns, radix isatidis, radix puerariae, aginomoto, fresh ginger, salt and rice wine; 4, the boiled beef slices are put in a frying pan for stir-frying; 5, sterilization and package are conducted, the stir-fried beef slices are put into vacuum and packaged, sterilization is conducted, and the dried beef is obtained. The prepared dried beef is orange yellow and bright in color and lustre, medicines such as the tea polyphenol, the hawthorns, the radix puerariae, the roots of single roxburgh roses and the radix isatidis are added for boiling in the boiling process, and the prepared dried beef has the effects of invigorating the stomach and promoting digestion.

Owner:GUIZHOU MOUNT FANJING ECOLOGICAL AGRI INC

Sauce flavored beef extract essence with low salt and preparation method of sauce flavored beef extract essence

ActiveCN105011090APreserve the flavorRetention of polypeptide substancesFood preparationMaillard reactionDL-methionine

The invention provides sauce flavored beef extract essence with low salt and a preparation method of the sauce flavored beef extract essence. The preparation method of the sauce flavored beef extract essence with low salt specifically comprises the following steps: (1) boiling out crushed beef in water, and hydrolyzing the boiled beef; (2) adding white sugar, gourmet powder, soy sauce, hydrolyzed plant protein, butter, five spice powder, a yeast extract, onion powder and a Maillard reaction augmentor for performing a reaction to obtain a reactant; (3) adding water, table salt, modified starch, maltodextrin, glyceryl monoaliphatic esters, lecithin, CMC and beef flavoring to the reactant to obtain a mixture, emulsifying the mixture, and filtering the emulsified mixture, wherein the Maillard reaction augmentor comprises L-cysteine hydrochloride, ribose, L- proline, DL-methionine, dextrose monohydrate, xylose, vitamin B1 and L-glycine. According to the sauce flavored beef extract essence with low salt, prepared by the method disclosed by the invention, the content of the salt is under 10%, the effective ingredients and the active ingredients of fragrance are effectively embedded, the beef extract essence is not liable to go bad, and the fragrance is richer.

Owner:GUANGZHOU TIANHUI FOOD

Method for preparing high-nutrition pickled dried beef

InactiveCN101731637AHigh utility valueGood for healthFood preparationAdditive ingredientBright red color

The invention relates to a food processing method, in particular to a method for preparing high-nutrition pickled dried beef, which comprises five steps of pickling roughly, cooking thoroughly, adding plant soot, sealing by a clay jar and drying and packaging, wherein the step of coating the black plant soot on the boiled beef is to set the meat quality off to a bright red color, without blotting a mouth and harming a human body; the step of pickling is to remove meat smell; and the step of sealing by the clay jar is to make the beef completely absorb nutrient components. The dried beef is dry instead of tough, smooth instead of soft, ruddy and bright, delicious in taste, moderate in appetite, lingering in aftertaste, full in color, fragrance and taste and rich in nutrition. The dried beef is black on the surface and red in the center, which makes a person free the imagination to associate the dried beef with Zhang Fei, who is a valiant general in Shu Han during the three kingdoms period, so that eating the beef contains a historical flavor. Compared with the conventional production technology of the air-dried beef, the air-dried beef is produced by pickling by dry-powder ferment so as to shorten the fermentation time and have a good application prospect.

Owner:CHENGDU FANXINJIA TECH

Processing method for improving quality of dried beef

InactiveCN105433136ABright orange colorIncrease appetiteFood preparationMonosodium glutamateWarm water

The invention discloses a processing method for improving the quality of dried beef, and belongs to the technical field of food processing. The method comprises the following steps: preparing a culture solution from peptones, beef extract, sodium chloride, agar and water according to a certain ratio; selecting beef passing health detection, trimming and finishing the selected beef, washing the beef with warm water, boiling the washed beef in water, and slicing the boiled beef to obtain thin beef slices; fermenting the thin beef slices in the culture solution for a period of time; stir-frying the fermented thin beef slices in an oil pot provided with rapeseed oil, and adding certain amounts of Chinese prickly ash, Fructus Tsaoko, soy, Chinese liquor, capsicum, monosodium glutamate and ginger; and packaging and disinfecting the stir-fried thin beef slices in vacuum. Smoking is not adopted in the invention, so the produced dried beef has orange-yellow and bright color, can improve people's appetite, reserves the original taste of beef, also has the fragrance of a preserved product, has the soy fragrance after being chewed, has loose and soft mouthfeel and long aftertaste, and also has long shelf life.

Owner:GUIZHOU MOUNT FANJING ECOLOGICAL AGRI INC

Preparation method of beef with flavor of Yi people

The invention discloses a preparation method of beef with flavor of Yi people. The preparation method comprises the following steps of: S1, removing fasciae, grease and impurities from beef, and chopping the beef into strips; S2, weighing pickling ingredients; S3, uniformly mixing the pickling ingredients with the beef; S4, pickling the beef at 0-10 DEG C for 2-3 days; S5, weighing precooking materials; S6, precooking the pickled beef; S7, boiling the precooked beef; S8, cooling the boiled beef; S9, cooling for determining the nature of the beef; S10, cutting the cooled beef into blocks; S11, roasting the beef blocks; S12, cooling the roasted beef blocks; S13, metering and packaging the cooled beef; S14, sterilizing the packaged beef; and S15, cooling the sterilized beef. the ingredients, such as natural spice Litsea pungens, produced in Yi region and a modern processing technology are adopted, the unique flavor of traditional beef jerky of Yi people is preserved, the processing period is shortened, the yield is improved, the production cost is lowered, the nutrition loss in processing is lowered, the guarantee period of the beef is prolonged, and the beef has the characteristics of environmental friendliness, health, rich nutrition, pure flavor of Yi People and the like.

Owner:XICHANG SIQIXIANG FOOD CO LTD

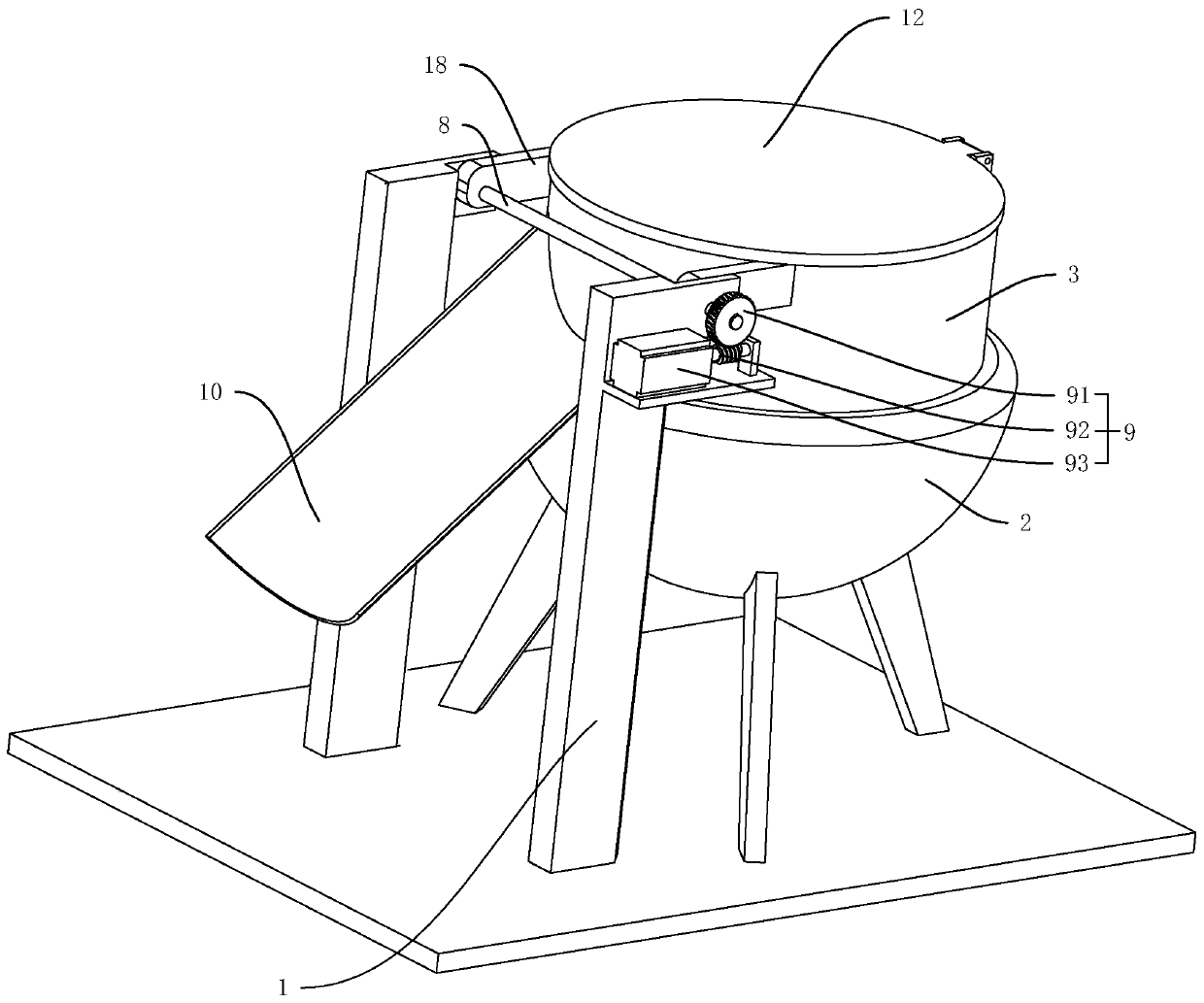

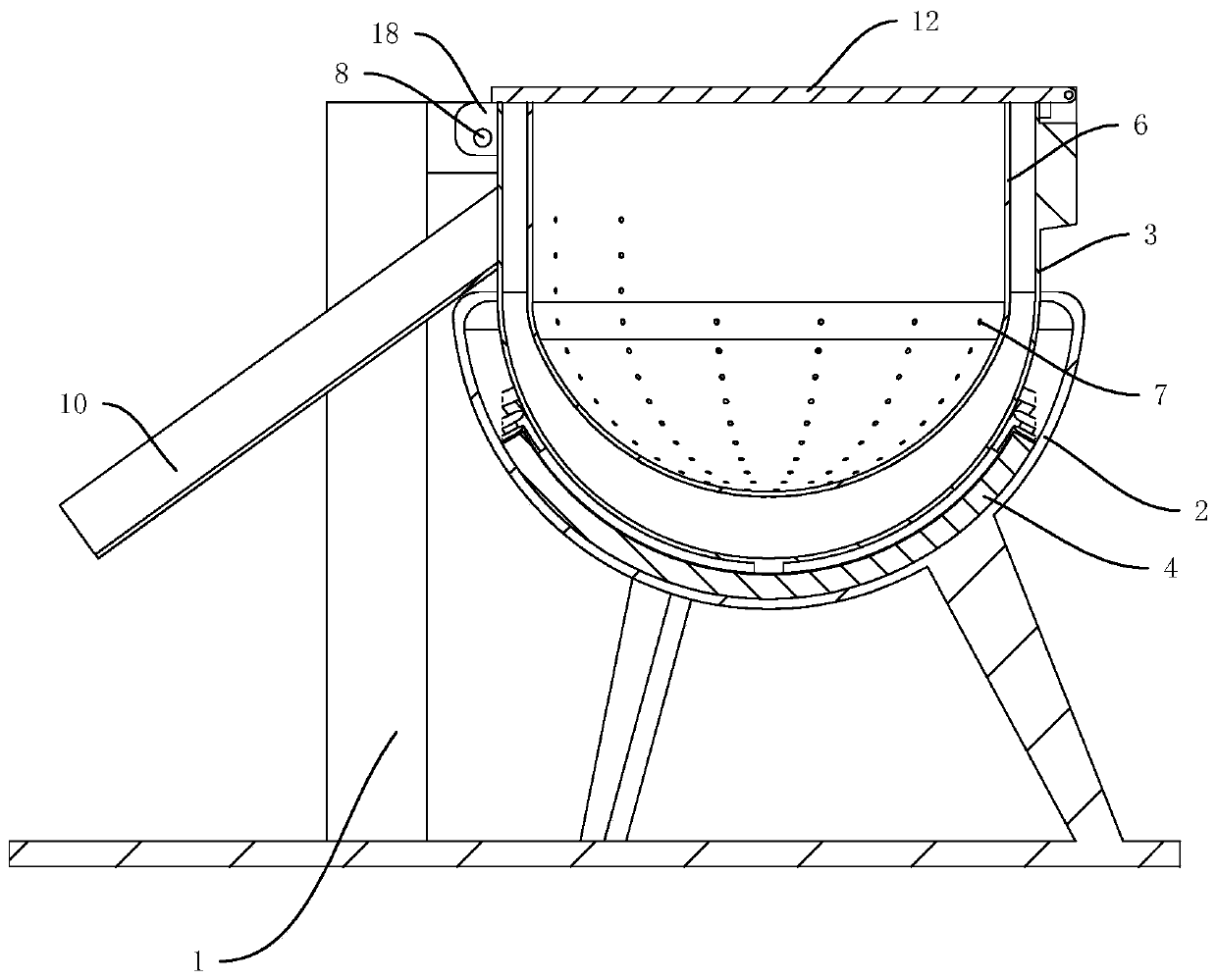

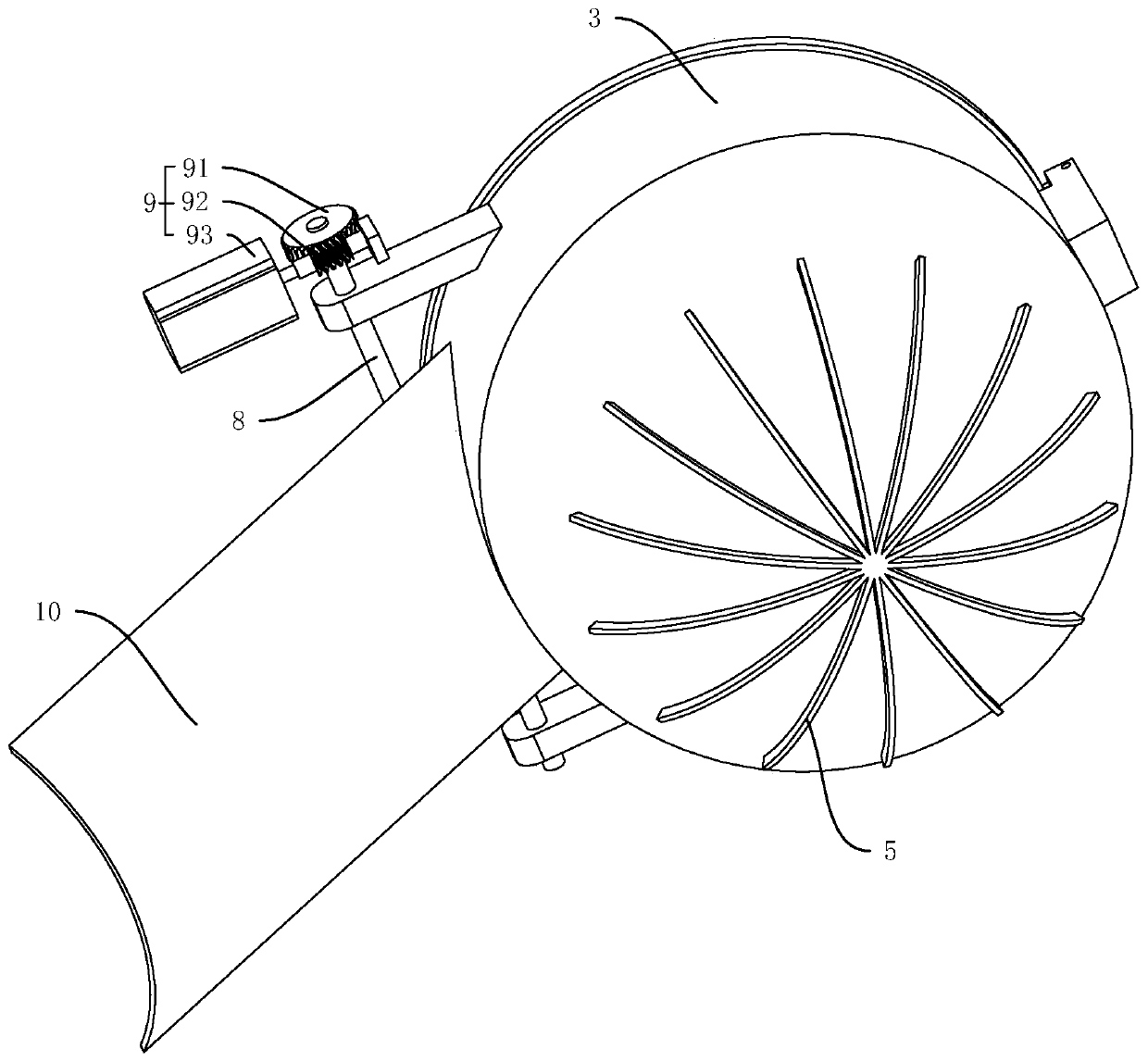

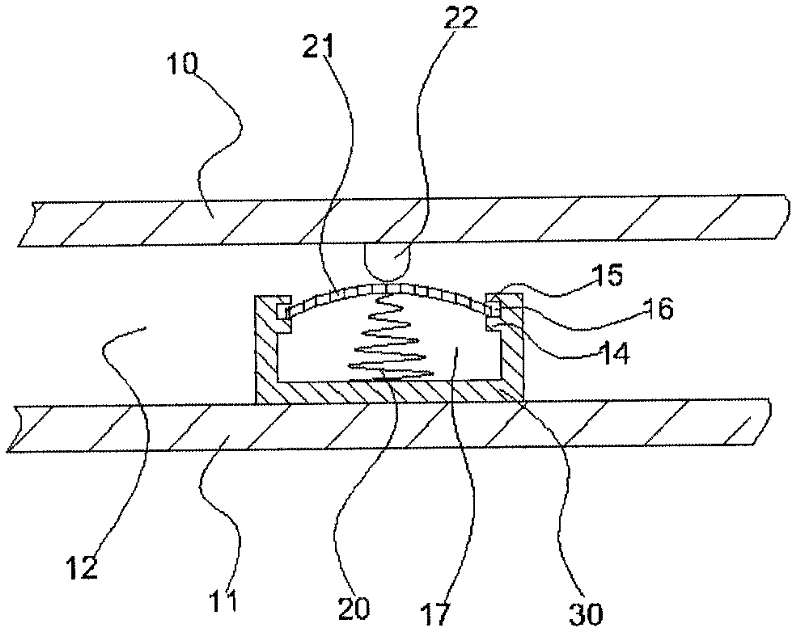

Marinating and boiling equipment for beef processing and using method thereof

PendingCN111296770AReduce pouringEase of mass productionClimate change adaptationFood scienceProcess engineeringFood processing

The invention discloses marinating and boiling equipment for beef processing, and relates to the field of beef food processing. The equipment comprises a supporting frame, a marinating and boiling tank arranged on the supporting frame, a marinating and boiling pot arranged on the marinating and boiling tank and a heating device arranged in the marinating and boiling tank and used for heating the marinating and boiling pot, a marinating and boiling inner container is arranged in the marinating and boiling pot in a hinge mode, the marinating and boiling inner container is a cylinder with an opening in the upper end, and a plurality of through holes are formed in the marinating and boiling inner container; and a driving device is further arranged on the supporting frame, and the driving device drives the marinating and boiling inner container to be turned out of the marinating and boiling pot so as to pour out marinated and boiled beef in the marinating and boiling inner container. By arranging the marinating and boiling inner container and the driving device, the pouring of marinade is reduced when the marinated and boiled beef is poured out, so that the batch production is more convenient.

Owner:浙江麦尚食品有限公司

Frozen ox transverse diaphragm string and frozen ox tendon string processing method

The preparation process of frozen boiled beef skirt cubes on a stick and beef tendon cubes on a stick includes the following steps: taking out raw material beef skirt and beef tendon from cold storage, defrosting by using running water, removing blood water, boiling in water with 100deg.C for 50-70 min, standing still for 20-40 min, taking out, cooling, slicing beef skirt and beef tendon, sticking, checking quality, secondary water-boiling to make sterilization, taking out and draining, quick-freezing, detecting, packaging and boxing so as to obtain the invented product.

Owner:王英贤

Processing method of low-temperature smoked and boiled beef sausage

InactiveCN108041479ABest slicing performanceGreat tasteSugar food ingredientsTemperature controlIce water

The invention discloses a processing method of a low-temperature smoked and boiled beef sausage. The smoked and boiled beef sausage is prepared from the following raw materials in parts by weight: 30-80 parts of beef, 0-30 parts of chicken, 0-10 parts of duck meat, 5-20 parts of ice water, 1-2 parts of edible salt, 0.1-0.4 part of sodium hexametaphosphate and 0.1-0.3 part of sodium tripolyphosphate. The method comprises the following steps: (1) putting the beef, the chicken and the duck meat in parts by weight into a mincer, and conducting mincing; (2) conducting chopping with a chopping temperature controlled at 8-10 DEG C; (3) conducting vacuum sausage filling; (4) conducting drying; (5) conducting cooking; (6) conducting smoking: hanging the cooked sausage body in a smoking furnace at atemperature of 120 to 150 DEG C for 5 to 8min; (7) putting the smoked sausage body into an oven, and conducting baking until the moisture is 50 percent or below; and (8) after cooling, conducting vacuum packaging and sterilization to obtain the finished product. According to the processing method provided by the invention, the obtained smoked beef sausage product is good in slicing performance, good in taste, good in flavor, and easy to digest and absorb, and has strong competitiveness in market.

Owner:河南伊赛牛肉股份有限公司

Production technology of solid peptide-containing beef bone paste

InactiveCN106942626AEfficient SupplementAvoid churnFood ingredient functionsProtein food ingredientsBoiling processNutrients substances

The invention discloses a production technology of solid peptide-containing beef bone paste. The technology comprises the following steps: selecting beef bones and solid peptides as raw materials, adding processed beef bones into a pressure cooker, boiling the beef bones at 1300-1500 DEG C, placing the boiled beef bones in a boiling device, boiling the beef bones in boiling water at 1000-1300 DEG C, transferring the boiled beef bones to sunlight after the surfaces of the beef bones are crisp and soft and have a sponge-shaped reticulation, airing the beef bones, transferring the processed beef bones into a crushing device, transferring the beef bones into a container with the temperature of 180-200 DEG C, continuously stirring the beef bones in the boiling process, grinding the obtained concentrate at 50-60 DEG C for 25-40 min after the obtained soup is sticky, adding the ground concentrate into a cooling pot, and cooling the ground concentrate to obtain the solid peptide-containing beef bone paste. The solid peptide-containing beef bone paste can effectively supplement peptides and other various nutrient substances to human bodies, and prevents the loss of nutrition in the beef bones, and the making technology is simple.

Owner:甘肃犇旺旺生物科技有限公司

Method for producing curry flavored beef tendon

InactiveCN105029464ANo loss of nutrition and deliciousnessKeep the scentFood preservationFood preparationPreservativeAluminum foil

The invention discloses a method for producing curry flavored beef tendon. The method comprises the following steps: (1) preparing raw materials according to parts by weight; (2) boiling beef tendon for 40-60 min, and cutting the boiled beef tendon into sections; (3) sterilizing high-temperature boiling aluminum foil bags, packaging and sealing a mixture of beef tendon and curry marinade, and sterilizing the packaging bags so as to obtain the curry flavored beef tendon. According to the method, the conventional marinating process is taken as the basis, the conventional marinating technology and the food engineering technology are organically combined for industrialized production, no preservative is needed, and multi-stage mild conditioning sterilization is adopted, so that not only are the nutrition and taste of the curry flavored beef tendon not lost, but also the curry flavored beef tendon can be eaten instantly, and is convenient and sanitary. The curry flavored beef tendon can further be eaten after being heated.

Owner:河南省淇县永达食业有限公司

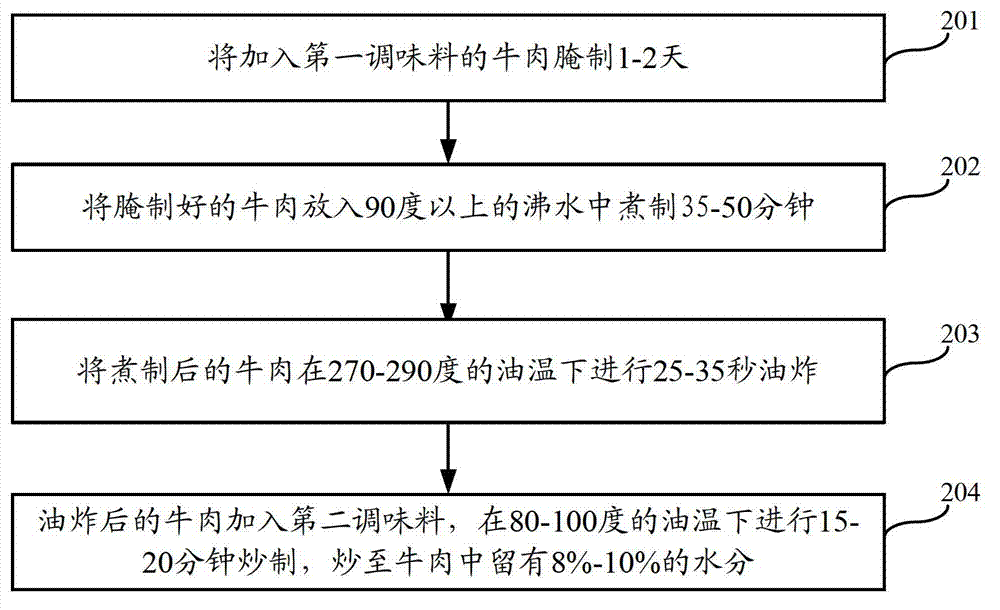

Process for manufacturing sliced dried beef

The invention relates to the field of food processing, and in particular relates to a process for manufacturing sliced dried beef. The process comprises the following steps of: pickling beef with first seasoning; putting the pickled beef into boiled water with the temperature higher than 90 degrees, and boiling; frying the boiled beef into oil with the temperature of 270 to 290 DEG C for 25 to 35 seconds; adding second seasoning into the fried beef; and sauting the beef in the oil with the temperature of 80 to 100 DEG C for 15 to 20 minutes until the moisture content in the beef is up to be 8 to 10 percent. By the process for manufacturing the sliced dried beef, the moisture content in the sliced dried beef can be increased, and the sliced dried beef is easy to chew.

Owner:余贤均

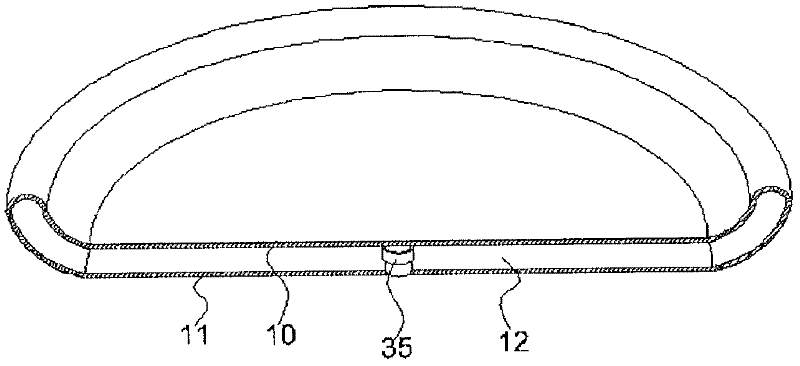

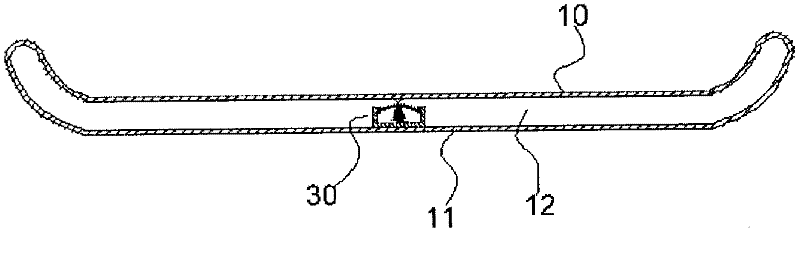

Self-heating container

InactiveCN102448351AWith automatic heating functionEasy to operateDwelling equipmentContainers for heating foodEngineeringFood products

The present invention relates to a heating container. There are types of food which should be eaten after being warmed up at home or in a restaurant. Hot soups or hot stews can be eaten after being heated on a portable gas range. However, it is impossible or very inconvenient to heat panfried foods, boiled beef, fried foods, rice cakes and the like on a gas range. The heating container of the present invention has a self-heating function and is very useful because the heating container allows food to be kept warm until the end of the meal when various foods are placed on the heated heating container, thereby enabling the distinct tastes of the foods to not be lost until the end of the meal.

Owner:金龙辰 +1

Process for producing food combined with beef and tendon

The invention relates to a production process of a food, specifically to a process for producing a food combined with beef and tendon. The food comprises raw materials of beef and tendon. The process includes three steps: a step one including (1) soaking beef tendon with clear water, (2) boiling the soaked beef tendon with clear boiling water, taking the obtained beef tendon out, and preserving the obtained beef tendon with plant spices and sodium nitrite, (3) boiling the preserved beef tendon with clear boiling water, taking the obtained beef tendon out, and adding salt, seafood sauce, light soy sauce, and white sugar for secondary boiling, and (4) putting the well-boiled beef tendon and edible vegetable oil in a kneading machine for uniform mixing; a step two including (1) soaking raw beef, (2) boiling the raw beef with clear boiling water, and (3) removing dirt, dirty blood, fat and fascia, and slicing the obtained beef; and a step three including (1) attaching the tendon and beef according to a ratio, wherein the tendon alternates with the beef, (2) performing vacuum-pumping, bagging and sealing, (3) carrying out high-temperature high-pressure sterilization, and (4) performing arrangement, moulding, bagging and cooling. The process has the advantage that beef and tendon are made into a delicious food combined with beef and tendon. The food is convenient to store, fills the blank of food of such kind, and is suitable for people of all ages.

Owner:重庆钟无极食品有限公司

Spring water boiled beef balls and preparation method thereof

The invention discloses beef balls. The beef balls are prepared from the following raw materials in parts by weight: 300-550 parts of silverside, 2-4 parts of fried garlic and 4-6 parts of fish sauce.A preparation method of the spring water boiled beef balls comprises the following steps of selecting the fresh yellow cattle silverside as the raw material, removing and cutting bones, and removingbeef membranes, beef tendons and impurities; and hammering the silverside, and repeatedly hammering beef until the beef is hammered to generate adhesive colloids. Yellow cattle is adopted as a cattlebreed because yellow cattle meat is fatter than buffalo meat, the yellow cattle meat is fresh, tender and delicate, and the beef taste is rich; and the superior yellow cattle silverside is carefully selected, and is tender in meat quality and good in elasticity, so that the taste and elasticity of the beef balls are greatly improved.

Owner:谢海雄

Preparation method of mouthfeel keeping spiced product

InactiveCN106923208AGreat tasteSolve the problem that it is delicious but cannot be stored at room temperatureMeat/fish preservationClimate change adaptationFlavorRoom temperature

The present invention discloses a preparation method of a mouthfeel keeping spiced product. The preparation method comprises the following steps: frozen beef shanks are taken out, the taken out beef shanks are thawed for 3-4 hours using water at room temperature, then the thawed beef shanks are washed, and impurities and hairs are removed; and the treated beef shanks are cut into similar sizes, and the cut beef shanks are drained for a standby application. Seasoning materials and the beef shanks are weighed according to ratios, the weighed materials are stirred evenly, the stirred materials are put into a pickling room at 0-10 DEG C for at least 12 hours, and then the pickled beef shanks are drained for the standby application. The pickled beef shanks are placed into a steam sandwich pot and the beef shanks are heated with boiling water for 30-50 minutes; the boiled beef shanks are drained for the standby application; then the beef shanks are put into brine to be boiled out for 5-10 minutes, fire is turned off, and the beef shanks are simmered for 25-50 minutes; and the simmered beef shanks are taken out to be cooled for the standby application. The heat-treated beef shanks are placed into packaging bags to be sealed. The packaged beef shanks are placed under a pressure of 300-600 MPa continuously for 3-10 minutes, and the treated beef shanks are taken out for the standby application. The treated beef shanks are sterilized at 95-110 DEG C for 30-60 minutes; and if necessary, then the sterilized beef shanks are sterilized at 110-118 DEG C for 10-20 minutes. The prepared spiced beef has a shelf life up to 60 days or more at room temperature and the taste and flavor not much different from those of the beef after the spicing.

Owner:上海新成食品有限公司

Instant curry beef and preparation method thereof

InactiveCN106360378APure Sichuan flavorSmooth tasteFood ingredient as mouthfeel improving agentReady to eatBran

The invention belongs to the field of food processing, and particularly relates to instant curry beef and a preparation method thereof so as to solve the problem that a preparation method of instant curry beef which is convenient, safe and nutritive does not exist in the prior art. The preparation method of the instant curry beef comprises the following steps of preparing raw materials, decocting a soup base, performing filling, performing sterilization and the like. The preparation method comprises the specific steps of firstly cutting beef into beef dices, and boiling the beef dices; then decocting the soup base according to a certain formula; and after the soup base is decocted, mixing the decocted soup base with the boiled beef dices, performing filling, and performing sterilization so as to obtain the instant curry beef which is ready to eat after being unpacked. According to the method disclosed by the invention, various parameters are set in the processing course of the instant curry beef, and a formula of a secret soup base is adopted, so that the curry beef in industrialized production maintains pure Sichuan taste, and is smooth in mouth feel and rich and fragrant in taste, and a bran-new method is provided for the industrialized production of a Sichuan food.

Owner:CHENGDU XIWANG FOOD

Beef soup, preparation method thereof and method for making Chinese hamburger from beef soup

InactiveCN108783355ARemove fishy smellDelicious meatFood ingredient as taste affecting agentFood ingredient as flavour affecting agentMeat burgerZingiberaceae

The invention discloses beef soup, a preparation method thereof and a method for making a Chinese hamburger from the beef soup, and relates to the technical field of foods. The beef soup is prepared from ox bones, beef, beef offal, beef tallow, water, salt and a spice package, wherein the spice package comprises fennel, star anises, fructus tsaoko, radix angelicae dahuricae, nutmeg, fructus amomirotundus, semen alpiniae katsumadai, cassia bark, rhizoma kaempferiae, dried ginger, clove, radix et rhizoma nardostachyos and zingiberaceae seeds. The preparation method of the beef soup comprises the steps of putting the ox bones, the beef and the beef offal into a pan, adding water, performing boiling over with high heat, performing skimming, adding the spice package, performing boiling with low heat, and then adding the beef tallow and the salt, so as to obtain the beef soup. On the basis of traditional soup taste, the nutmeg, the rhizoma kaempferiae, the beef tallow, etc. are added, so that the boiled beef soup is small in peculiar smell, long in fragrance, and has good health-care and health-preserving functions, and the Chinese hamburger made from the beef soup and unique in flavorand balanced in nutrition can be taken with oneself and Leshan Qiaojiao beef is easy to taste.

Owner:喻建康

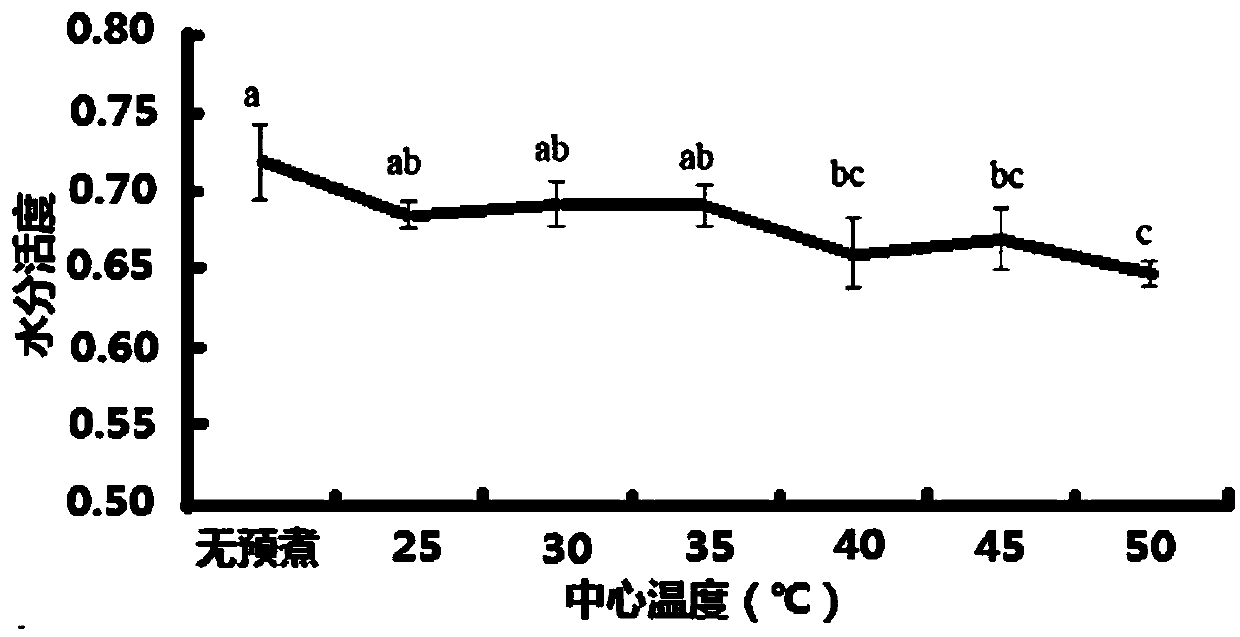

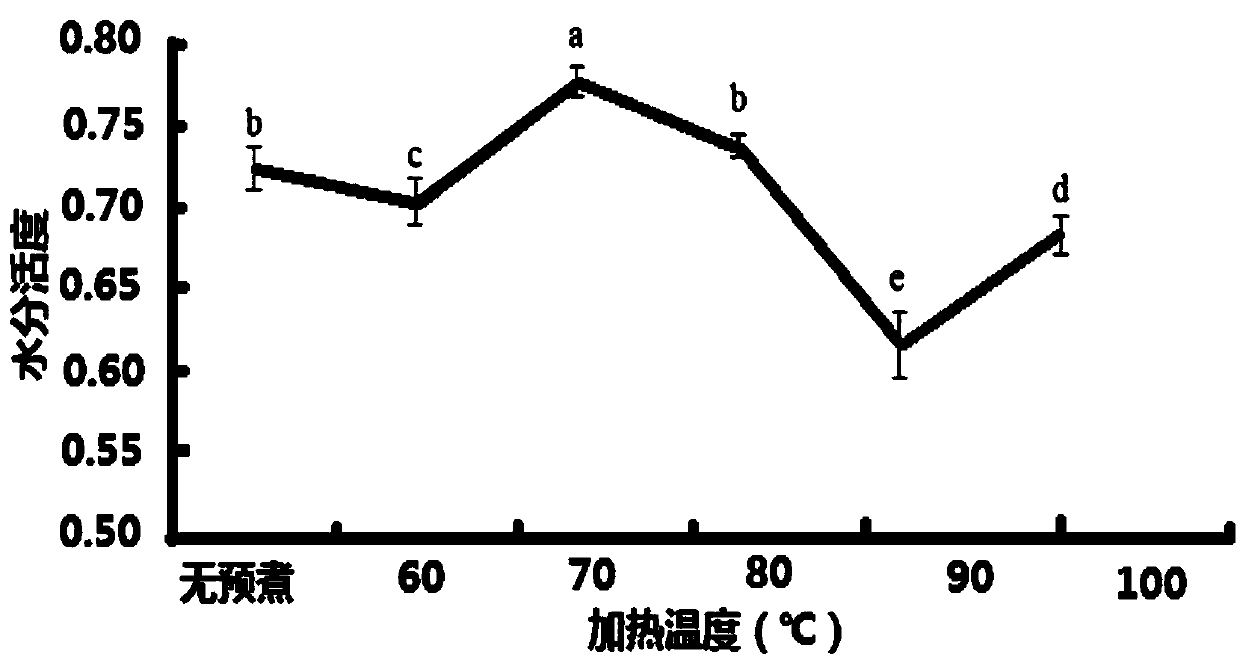

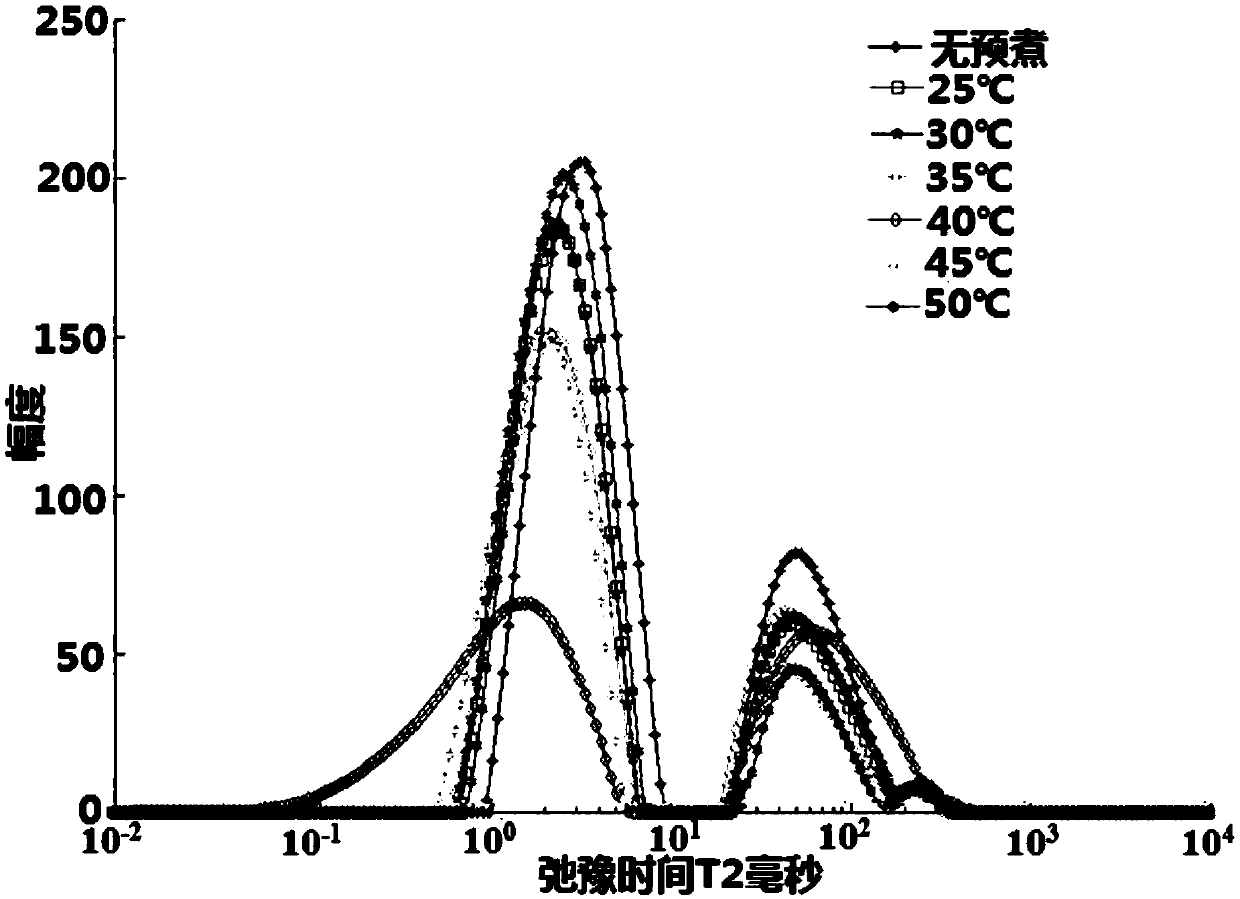

Technology for producing beef jerky product through secondary processing on conditioned precooked beef

ActiveCN109673959ARaise the possibilityReduce riskFood dryingMeat/fish preservation by dryingChemistrySizing

The invention discloses a technology for producing a beef jerky product through secondary processing on conditioned precooked beef. The technology comprises the following steps: carrying out a water bath on fresh beef at a temperature of 4-25 DEG C; taking out the fresh beef when a center temperature is 10 DEG C; absorbing moisture on a surface by absorbent paper; then, carrying out high-temperature and low-temperature boiling in water at the temperature of 90-100 DEG C; strictly controlling a boiling temperature; when the center temperature reaches 40-50 DEG C, taking out the beef; putting the beef in a vacuum packaging bag, and finally, quickly cooling the packaged beef in ice water to obtain the pre-cooked beef; then, through secondary pre-cooking (sizing), slicing, re-cooking and baking to obtain a finished product. The pre-cooking technology is adopted to process raw beef by different program temperatures to obtain the conditioned pre-cooked beef product, the technical barrier ofraw beef pre-cooing is broken down, in addition, the possibility of international trade exchange is increased, and a raw beef importing risk is lowered. The shelf life of the pre-cooked beef jerky isprolonged, the hardness of the beef jerky is medium on an aspect of taste, and therefore, the beef jerky is suitable for more consumers.

Owner:HENAN AGRICULTURAL UNIVERSITY

Production method of rice with beef and konjac on top

A production method of rice with beef and konjac on the top is characterized by comprising steps as follows: (1), taking 100-150 parts of a whole piece of beef, and absorbing moisture on the surface; (2), cutting the beef with the moisture absorbed in Step (1) into slices; (3), cutting 100-120 parts of konjac into pieces, and placing the pieces into a pot for boiling for 30-40 min; (4), placing 10-20 parts of granulated sugar, 10-20 parts of salt, 10-20 parts of cooking wine and 20-30 parts of soy sauce into the boiled konjac in Step (3); (5), placing the beef slices in Step (2) into the boiled konjac in the Step (4), and boiling the beef slices and the konjac for 5-10 min; (6), sprinkling steamed rice with the boiled beef and konjac in Step (5) to obtain the rice with beef and konjac on the top. The production method of the rice with beef and konjac on the top provides more choices for people and is simple, low in cost and easy to popularize.

Owner:林贤文

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com