Patents

Literature

5309 results about "Soya sauce" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Soy sauce (also called soya sauce in British English) is a liquid condiment of Chinese origin, made from a fermented paste of soybeans, roasted grain, brine, and Aspergillus oryzae or Aspergillus sojae molds. Soy sauce in its current form was created about 2,200 years ago during the Western Han dynasty of ancient China, and spread throughout East and Southeast Asia where it is used in cooking and as a condiment.

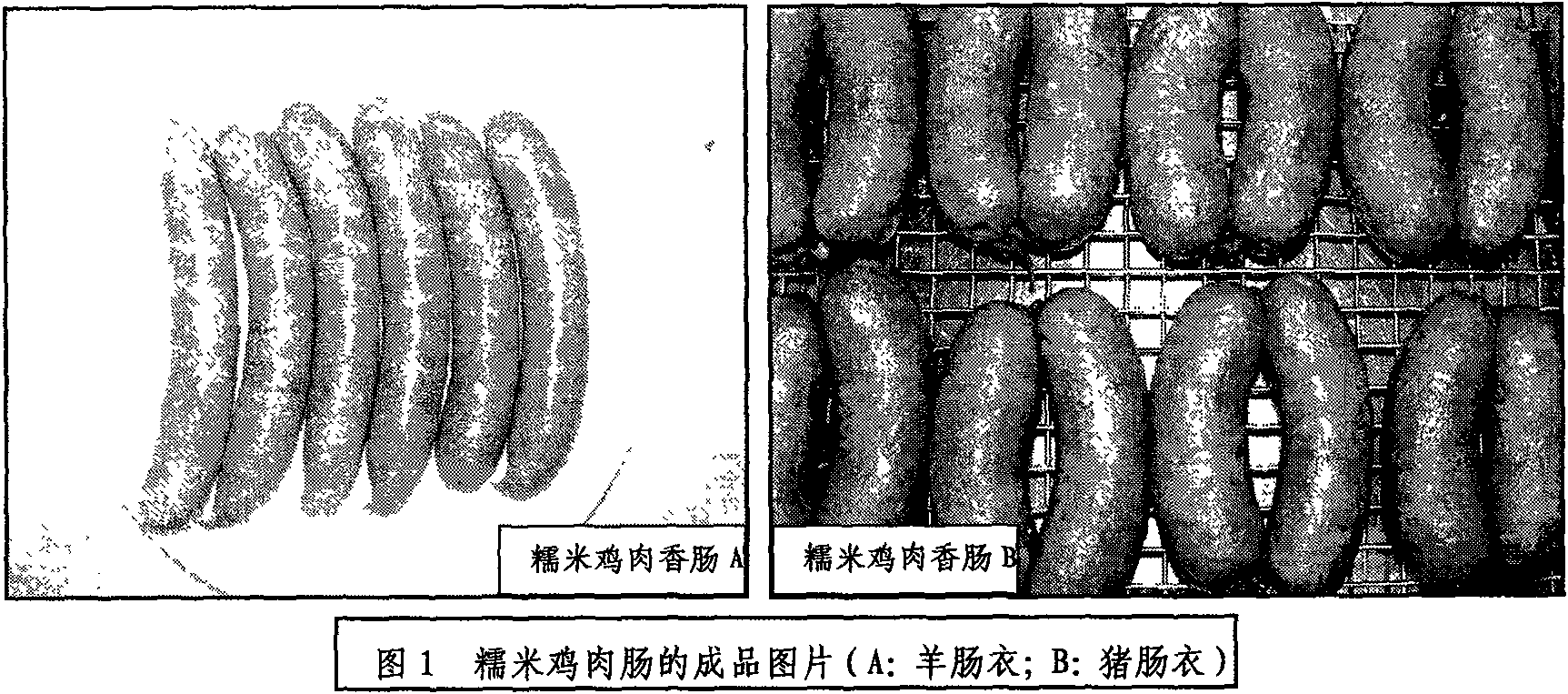

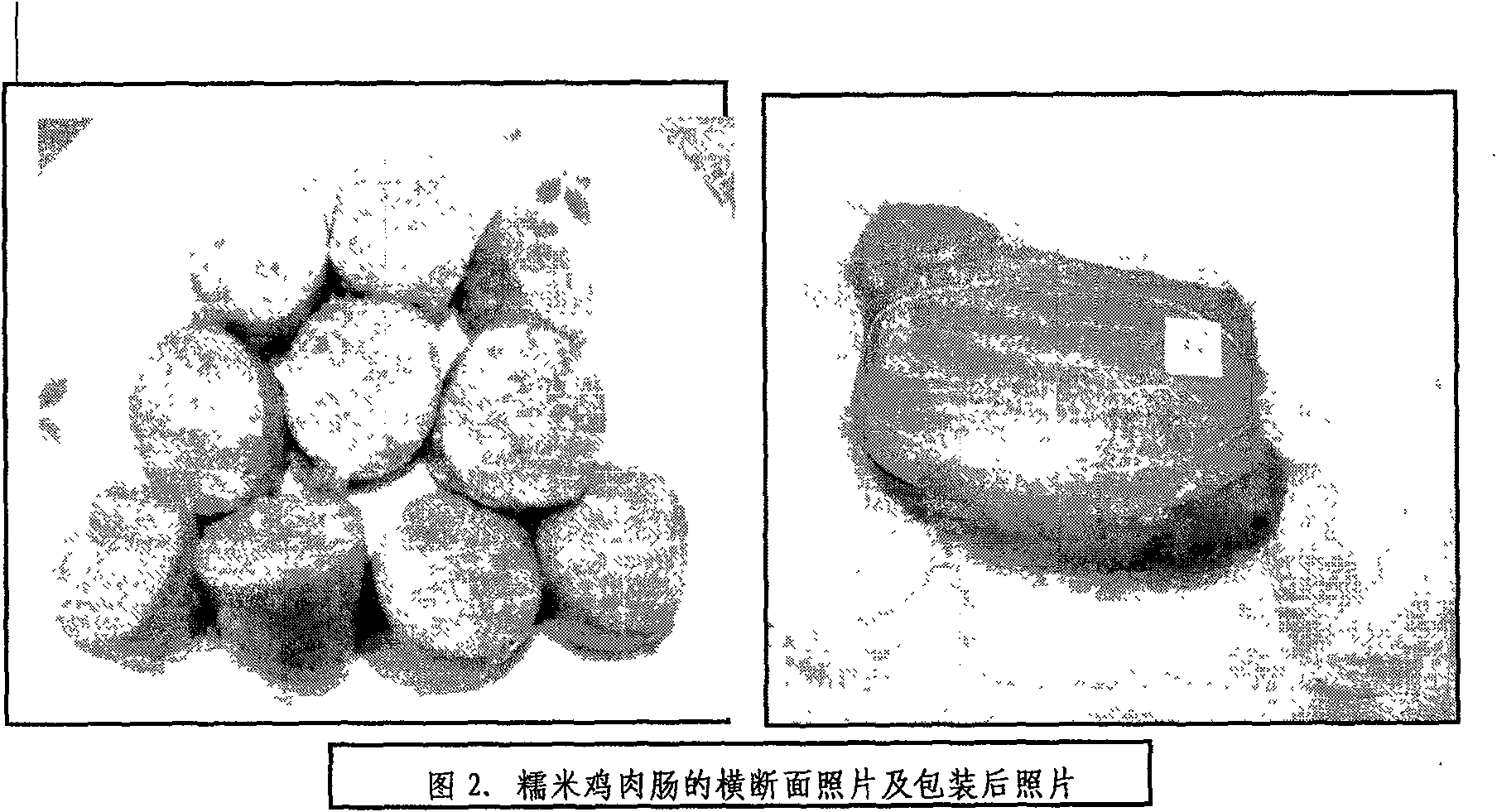

Cereal sausages and production method thereof

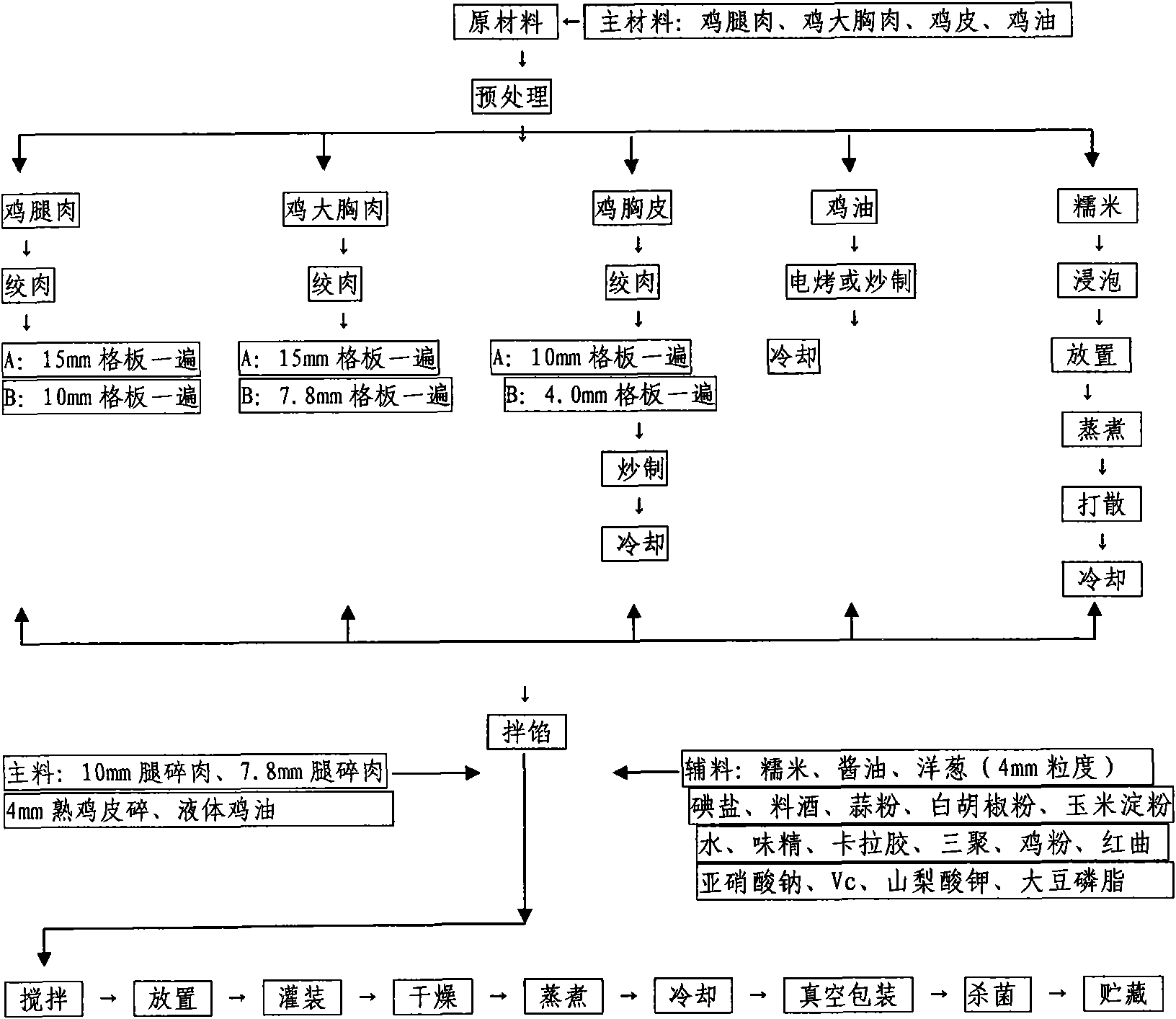

The invention provides sausages added with cereal (the cereal comprises sticky rice, rice, unpolished rice, black rice, purple rice, oat, buckwheat, barley, wholemeal, brown rice and millet; the sausages are pork sausage, beef sausage, mutton sausage, chicken sausage, duck sausage and fish sausage) and a production method thereof. 1. the product comprises the following materials by weight: 40-80% of animal meat, 5-20% of cereal and the products thereof, 10-20% of ice water mixture, 2-10% of animal (plant) fat, 0.1-0.3% of phosphate, 0.002-0.015% of sodium nitrite, 0.4-1.2% of salt, 0.5-5% of sugar, 0.1-0.5% of aginomoto, 0.5- 5% of soy sauce, 1- 8% of spice, 1-10% of starch, 0.1-0.5% of food gum, 0.5-2% of emulsifier, 0.2-2.0% of wine, 0.005-0.025% of edible pigment, 0.02-0.2% of sodium erythorbate, 0.01-0.8% of flavors and fragrances of meat (meat concentrate powder), 0.05-0.15% of preservative, and 0.001-0.005% of antioxidant; in a specific formulation, the sum of the weight percent of each component is 100%. 2. the processing method of the cereal sausages is as follows: choosing materials, preprocessing, mixing stuffing, placing, filling, drying, boiling, cooling, packaging, sterilizing, labeling, metal detecting, X-ray unit detecting, packing, and storing.

Owner:陈静 +2

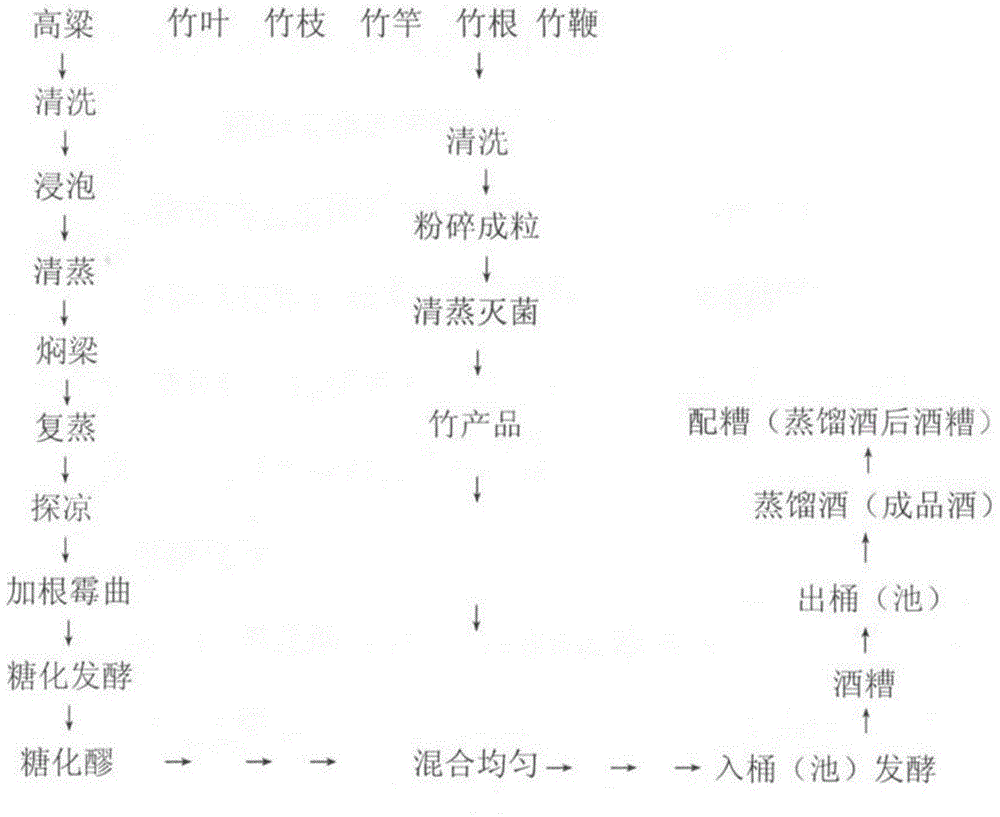

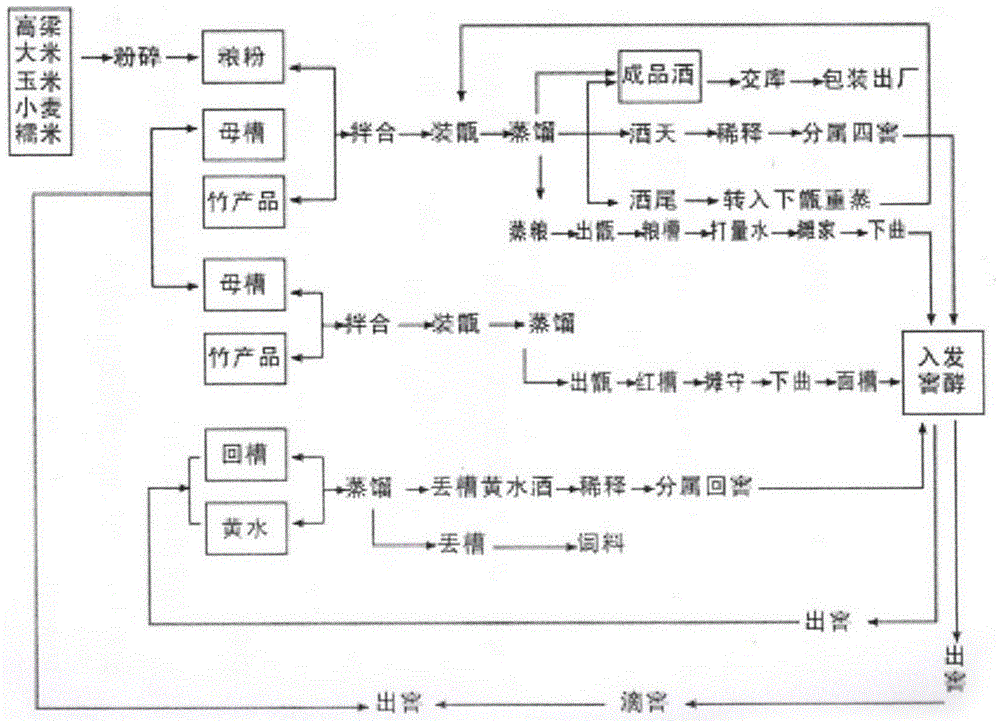

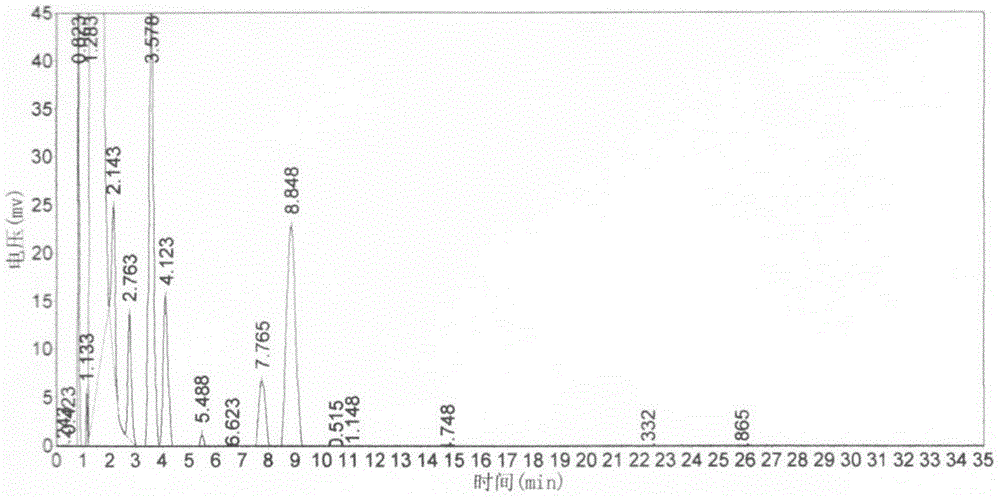

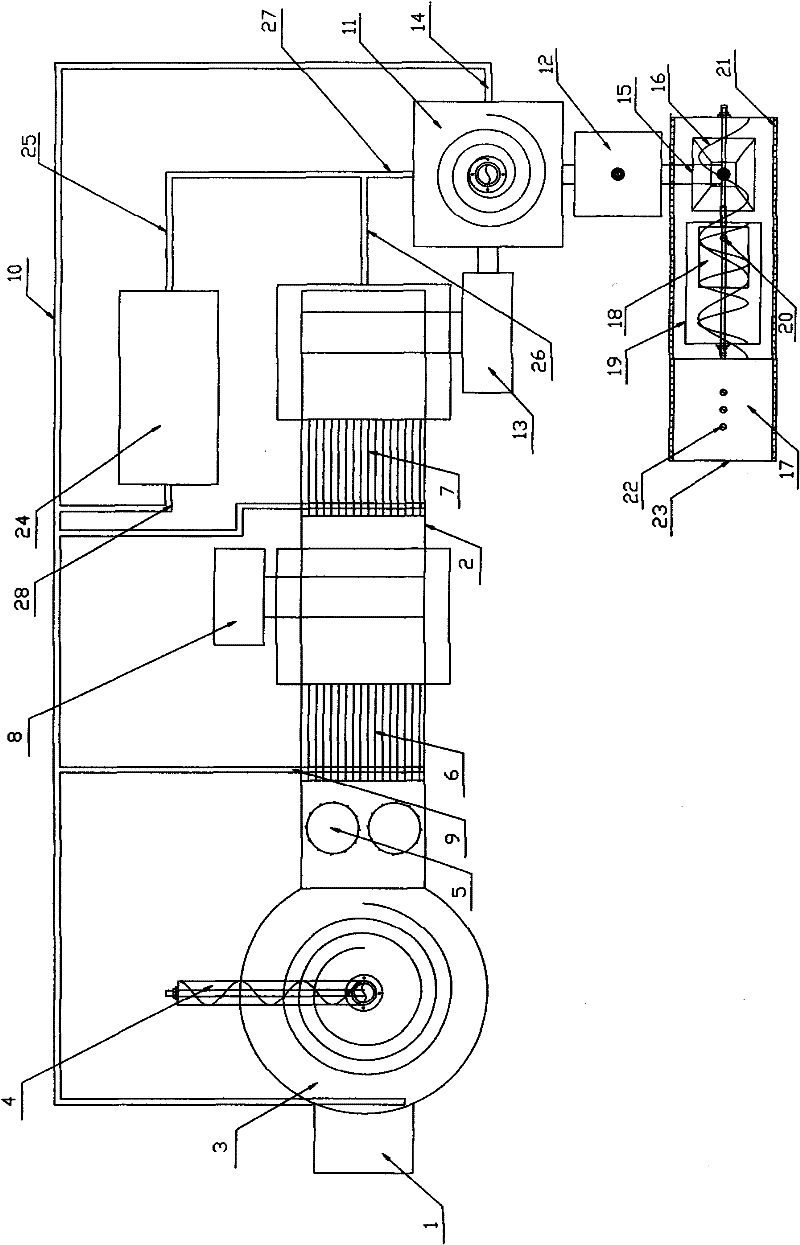

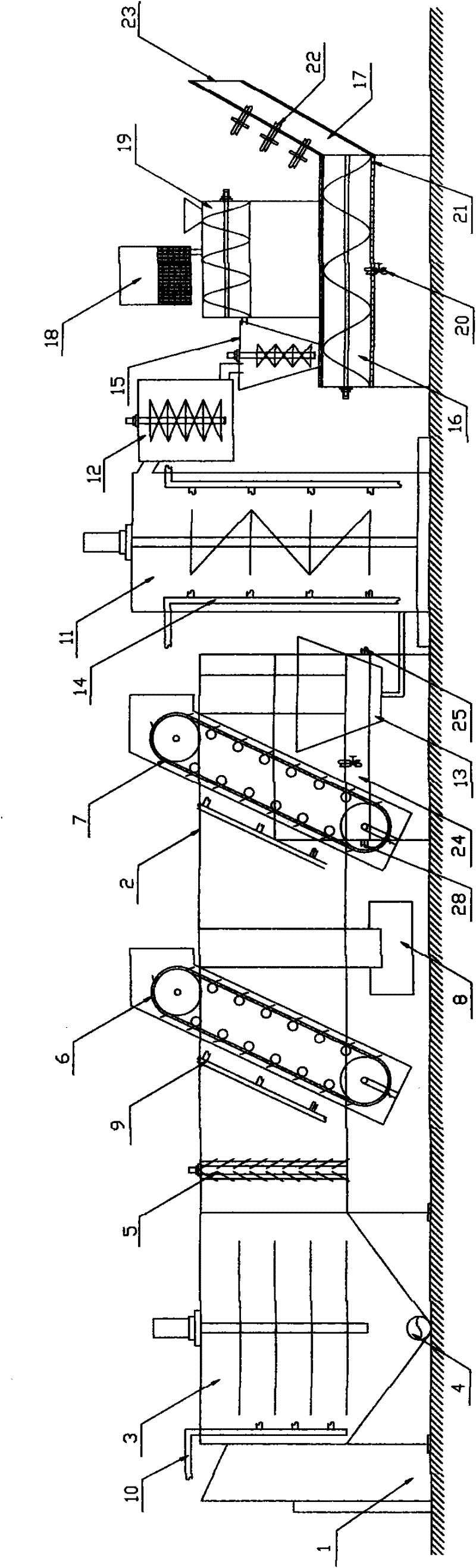

Method of making liquor by virtue of solid fermentation with bamboos as fluff

ActiveCN104651199APromote fermentationEasy to distillAlcoholic beverage preparationDistillationFood flavor

The invention discloses a method of making liquor by virtue of solid fermentation with bamboos as fluff. The method comprises the following steps: crushing clean bamboo products into particles with the particle size of 3-10mm, then steaming the particles of the bamboo products for 10-30 minutes, cooling, mixing the particles serving as the fluff, grains and vinasse, and carrying out solid fermentation to brew Fen-flavor bamboo wines, strong-flavor bamboo wines or soy sauce flavor bamboo wines, wherein the bamboo products are one or more of bamboo stems, bamboo leaves, bamboo branches and bamboo rhizome; and after crushing, the particle sizes of the bamboo rhizome and the bamboo stem are 8-10mm, the particle size of the bamboo branch is 5-8mm, and the particle size of the bamboo leaf is 3-5mm. According to the method disclosed by the invention, the bamboo products and the grains are used for brewing according to a certain ratio, so that the grains can be saved by 10-15 percent under the condition of the same yield of liquor; as different parts of the bamboos in different particle sizes are mixed as the fluff for brewing, the traditional hulls can be completely replaced; meanwhile, as the bamboos and the grains form a particle size gradient, fermentation and distillation of the grains are facilitated.

Owner:四川活之酿酿酒公社有限公司

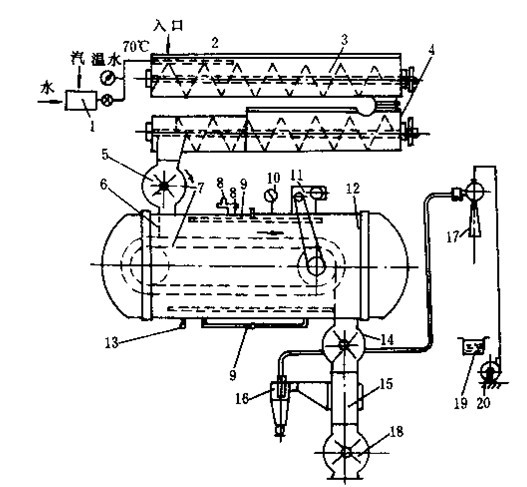

Low-salt liquid state fermented soy sauce production process

The invention discloses a low-salt liquid state fermented soy sauce production process, comprising the following main processes: preparing koji in a koji-maker machine; mixing the wheat which is fried and smashed with koji, inoculating the mixture in soybean meal and bran which are cooked; preparing finished koji in a koji making disc machine; mixing the finished koji with brine, sending the mixture in a fermenting vat for fermentation; preparing the finished soy sauce through soaking, pouring oil, filtrating, mixing, sterilizing and filling to obtain the finished soy sauce. The soy sauce is characterized in that materials containing zygosaccharomyces Rouxii 2.180 accounting for 1.5-2.5% of the total weight of materials and torulopsis candida 2.202 accounting for 1.5-2.5% of the total weight of materials are added during the medium term of the fermentation process and the raw materials--soybean meal and bran are cooked by high temperature short-time continuous cooking process. Compared with the prior art, the raw material digestion rate can reach 88-90%, the protein utilization rate can reach 83%, the activity of neutral protease of the finished koji can reach 2000mu / g, the enzymesystem is complete, the defects such as long period of high-salt liquid state fermentation (180 days), burnt flavour and heavy bitter taste of low-salt solid state fermentation and the like are overcame and the produced soy sauce is characterized by strong soysauce-like aroma, alcohol-like aroma and ester-like aroma and the like.

Owner:QIANHE CONDIMENT & FOOD CO LTD

Highland barley, Litsea coreana and sweet potato beef jerky and preparation method thereof

InactiveCN103222644ANutritional diversityFull of nutritionFood preparationMonosodium glutamateFood flavor

The invention discloses highland barley, Litsea coreana and sweet potato beef jerky and a preparation method of the highland barley, Litsea coreana and sweet potato beef jerky. The highland barley, Litsea coreana and sweet potato beef jerky comprises the following raw materials, by weight ratio, 50-60 parts of beef jerky, 1-1.5 parts of salt, 2-3 parts of soybean sauce, 1-2 parts of monosodium glutamate, 5-10 parts of white sugar, 1.5-2 parts of yellow rice wine, 0.2-0.3 part of tsaoko amomum fruits, 0.5-0.8 part of Chinese red pepper, 0.3-0.4 part of cinnamon, 0.4-0.6 part of dried orange peel, 0.2-0.3 part of radix angelicae, 0.4-0.6 part of fresh ginger, 0.1-0.2 part of grape leaves, 5-8 parts of highland barley, 10-15 parts of Litsea coreana, 3-5 parts of dogbane leaves, 2-4 parts of mint, 1-2 parts of sunflower discs, 2-3 parts of wild chrysanthemum flowers and 8-12 parts of sweet potato powder. The highland barley, Litsea coreana and sweet potato beef jerky has the advantages of being rich in nutrition, red and bright in color and luster, tasty and special in flavor, having high elasticity and chewiness, Litsea coreana fragrance and sweet highland barley and sweet potato fragrance, and being novel, and is leisure food which is green, healthy, non-additive, suitable for people of all ages and both sexes, and capable of satisfying requirements of different crowds.

Owner:BENGBU FENGMU BEEF & MUTTON PRODS

Biological organic composite fertilizer containing humic acid chelate

The invention discloses a production method for a biological organic composite fertilizer containing humic acid chelate and belongs to the field of biological organic fertilizers. The biological organic composite fertilizer containing the humic acid chelate is produced by taking a mixture of chicken manure, pig manure and cow manure, corn straws, rape straws, melon vine, pine shells, chaff powder, rice bran and hulls, fungus dregs, beer grains, acid-sludge, starch dregs, soy sauce residure, aginomoto residues, oil residues, oil cakes, mildewed feeds, organic fertilizer fermentation agents, humic acid chelate ferrum, humic acid chelate copper, humic acid chelate magnesium, humic acid chelate zinc, humic acid chelate calcium and humic acid chelate manganese as raw materials through bacterium adding, full rotting, doping and granulation. The biological organic composite fertilizer containing the humic acid chelate has the advantages of low production cost, complete fermentation, thorough sterilization, high bioactivity, high humic acid chelate trace element content, zero odor, zero bacterium, convenience in use and the like.

Owner:江苏恒旺现代农业科技发展有限公司

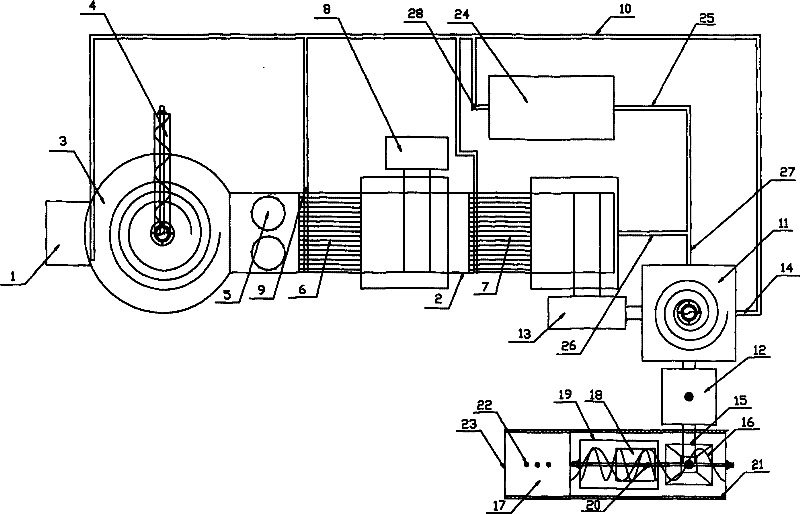

Processing method and processing system for kitchen garbage resourcilization

InactiveCN102690134AReduce moisture contentWater content automatic controlBio-organic fraction processingSolid waste disposalOil and greaseWater use

The invention relates to a processing method and a processing system for kitchen garbage resourcilization. The processing method comprises waterpower decomposition, fragmentation, sorting, dehydration, crushing, anaerobic fermentation and oil-water separation; the processing system comprises a feeding device, a waterpower conveying decomposition tank, a fragmentation preselection apparatus, a dehydration crushing apparatus, an anaerobic fermentation mixing apparatus and an oil-water separation apparatus. The method and system provided in the invention adopt sorting by using water. Advanced treatments of sorting to remove impurity, fragmentation, dehydration, desalination, oil removing and the like are automatically carried out to substances of different properties in the kitchen garbage by using water as a carrier combining with mechanization equipment, according to dissolvability and different proportion of the substances; organic substances separated from the kitchen garbage are fermented and prepared into organic fertilizers; and grease in separated oil-contained sewage is recycled by oil-water separating. The method and the system in the invention thoroughly remove substances of oil, salinity, soy sauce, vinegar and the like in the kit garbage that against fermentation composting. The method and the system have the characteristics of high removal rate of salinity and grease, high dehydration efficiency, good automatic sorting effect, realization of resource regeneration and no secondary pollution.

Owner:焦社杰 +2

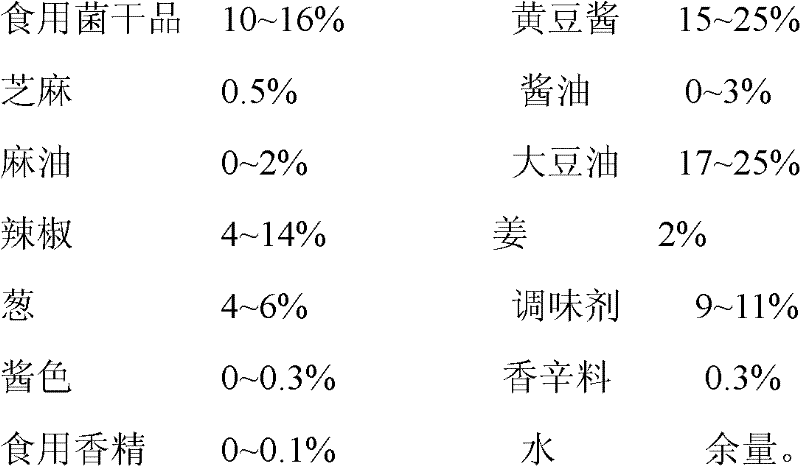

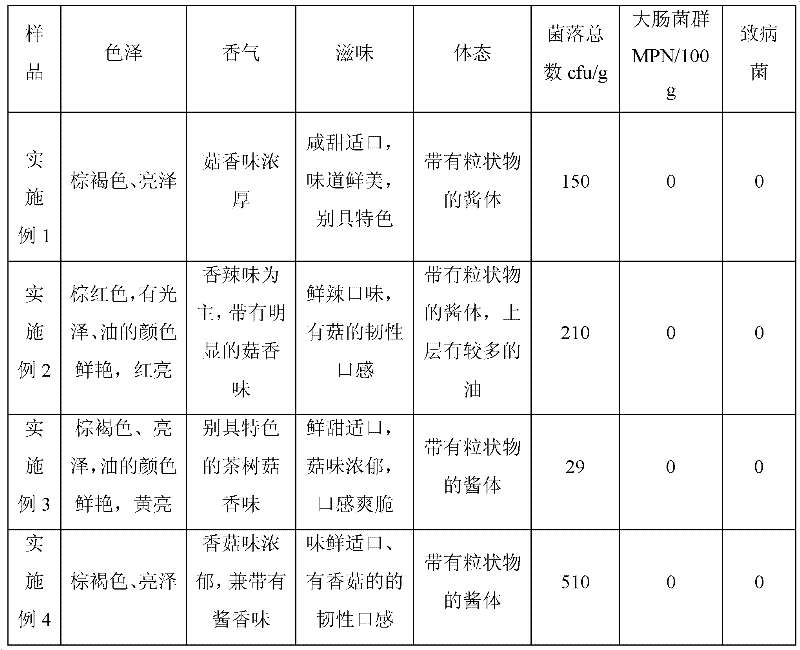

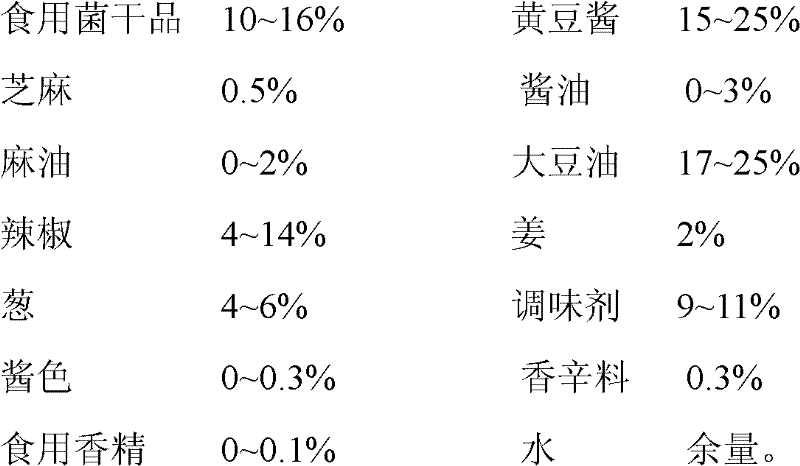

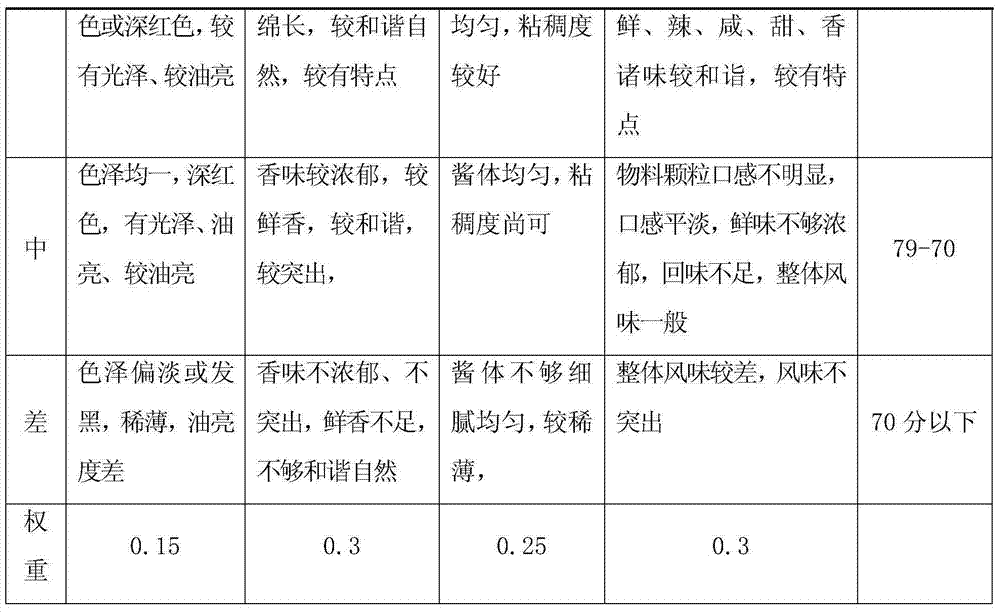

Assorted mushroom sauce and preparation method thereof

The invention provides assorted mushroom sauce which is prepared by the following components by weight: 10-16% of edible mushroom dry materials, 15-25% of soybean sauce, 0.5% of sesame, 0-3% of soy sauce, 0-2% of sesame oil, 17-25% of soybean oil, 4-14% of capsicum, 2% of ginger, 4-6% of scallion, 9-11% of flavoring agents, 0-0.3% of caramel, 0.3% of spice, 0-0.1% of edible essence, and the balance of water. The assorted mushroom sauce provided by the invention maintains original flavor and nutrition of mushrooms; various raw materials and ingredients are added; the prepared seasoning sauce not only can be eaten together with rice or bread, is nutritive and convenient, but also can be used for cooking and seasoning, can enhance the fragrance and delicious taste of dishes, and improve the attraction of dishes.

Owner:LEE KUM KEE XIN HUI FOOD

Muslim mushroom beef sauce and preparation method thereof

ActiveCN104172127AImprove tendernessHigh in nutrientsLactobacillusFood preparationVegetable oilFood flavorings

The invention discloses Muslim mushroom beef sauce and a preparation method thereof, belonging to the technical field of food seasonings. The Muslim mushroom beef sauce comprises the following raw materials in parts by weight: 30-300 parts of vegetable oil, 10-100 parts of diced beef, 2-20 parts of dry red peppers, 2-10 parts of chilli sauce, 20-60 parts of mushrooms, 2-50 parts of garlic, 1-10 parts of shallot, 1-20 parts of fresh ginger, 2-15 parts of table salt, 0.3-3 parts of mixed soybean sauce, 1-5 parts of white granulated sugar, 0.8-2 parts of pepper and 0.1-5 parts of spice. Beef is specially pickled, is quickly frozen and is added with oil to be fried, so that mutton smell is removed, flavor is enhanced, and the beef is rich in nutrition and crisp in taste. The Muslim mushroom beef sauce has the beneficial effects that the raw materials are finely selected, a formula is precise and scientific, various requirements on nutrition, flavor and color are met, the process is scientific and reasonable, the flavors of the beef, the mushroom, the chilli sauce and the spice are harmonious, and the Muslim mushroom beef sauce is crisp in taste and is chewable.

Owner:宁夏红山河食品股份有限公司

Compositions for improving the organoleptic qualities of cooked foodstuffs

Compositions for generating a cooked flavor in a foodstuff, comprising specified flavor precursors that react on heating to generate the flavor and maintain a reactive association after inclusion in the foodstuff. The compositions may include combination of a sulphur source, e.g. hydrogen sulphide, methane thiol, a sulfur-containing amino acid, thiamine, cystine, sodium sulphide, ammonium sulphide, ammonium polysulphide, onions, garlic, shallots, eggs, methionine, and mixtures thereof, and at least one reductone, e.g. a furanone, a ketone, a pyrone, an aldehyde, a carbonyl compound, isomaltol, maltol, pyruvaldehyde, hydroxyacetone, 3-deoxyglucosone, 5-hydroxy-5,6-dihydromaltol, 2,3-butanedione, 3-hydroxy-2-butanone, a process flavor, cooked vegetable concentrates, soy sauce, and mixtures thereof.

Owner:KERRY INGREDIENTS UK

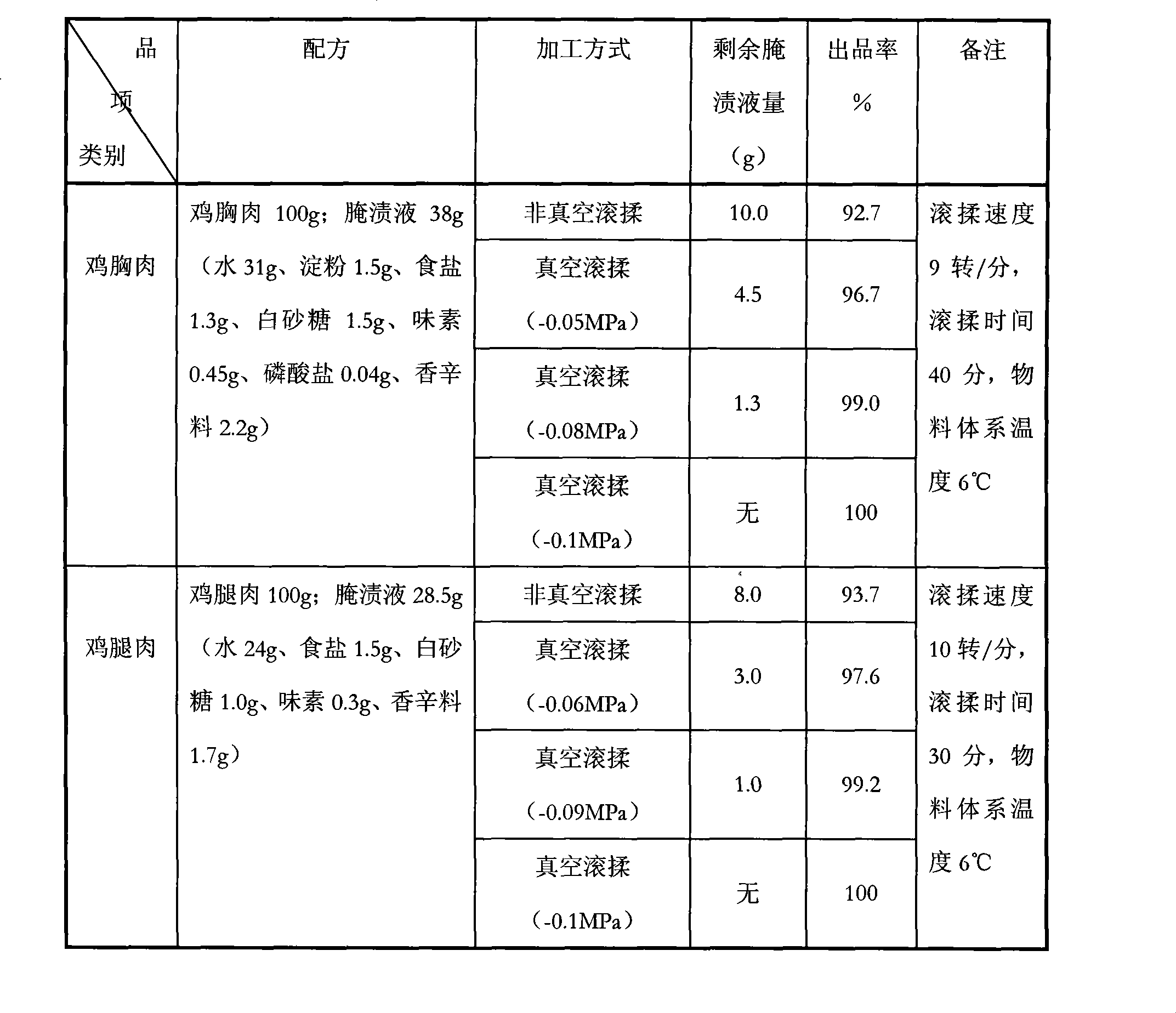

Vacuum curing rolling method of meat products

InactiveCN101396128AFully and evenly combinedHigh yieldMeat/fish preservationFood preparationPhosphateSquid

The invention relates to a meat vacuum pickling, rolling and rubbing method which comprises the following steps: pickling liquid is prepared, the meat and the pickling liquid are mixed and the obtained mixture is rolled and rubbed in a rolling and rubbing machine, the rolling and rubbing process is carried out in vacuum environment with the vacuum degree of minus 0.05 to minus 0.1MPa. The meat can be fresh meat or unfrozen meat comprising one of chicken meat, duck meat, goose meat, pork, beef, mutton, squid, cuttle fish and cod fish or the combination of two or a plurality of thereof. The pickling liquid comprises drinking water and one of or combination of a plurality of common salt, white granulated sugar, gourmet powder, mirin, soy sauce, starch, flour, isolated protein, phosphate, saleratus, cooking wine, spices, essence, pigments and food modifiers.

Owner:DACHAN GREAT WALL FOOD SHANGHAI

Brewing technology for soybean sauce

InactiveCN105053962AIncrease contentImprove protein utilizationFood thermal treatmentFood preparationWheat BransProtein

The invention discloses a brewing technology for soybean sauce. The brewing technology comprises the following steps: (1) soybean soaking: adding soybeans into water for soaking; (2) stewing: stewing the soybeans to obtain cooked soybeans; (3) mixing: mixing flour and roasted wheat bran to obtain a flour mixture, and mixing the cooked soybeans and the flour mixture to obtain a mixture; (4) inoculation: cooling the temperature of the mixture to be below 30 DEG C, and inoculating aspergillus oryzae; (5) distiller's yeast making: conveying the mixture into a leavening room for cultivation, wherein in the earlier stage of cultivation, the distiller's yeast temperature is 28-35 DEG C, and in the later stage of cultivation, the distiller's yeast temperature is 20-25 DEG C until the distiller's yeast is formed; and (6) fermentation: mixing the finished distiller's yeast and salty water, performing fermentation under normal temperature for more than 4 months. According to the brewing technology, the contents of reducing sugar and amino acid nitrogen in the soybean sauce can be effectively increased, the non-enzymatic browning effect in a soybean sauce brewing process is enhanced, and the flavor and the color of the soybean sauce are enhanced; and furthermore, the distiller's yeast contains rich protease, and the utilization rate of proteins in the soybean sauce brewing process is increased.

Owner:GUANGDONG MEIWEIXIAN FLAVORING & FOOD

Sweet spicy meat jam and its making process

The present invention relates to a kind of sweet spicy meat jam and its making process. The materials include: deep fried chili food 10-14 weight portions, farm animal meat 3-4 weight portions, dry salted and fermented soya paste 3-5 weight portions, soybean 1.5-2.5 weight portions, sauce 0.3-0.5 weight portions, sugar 0.4-0.6 weight portions, cooking wine 0.4-0.6 weight portions, malt syrup 0.1-0.3 weight portions, crushed pricklyash 0.1-0.3 weight portions, chicken essence 0.1-0.3 weight portions, soybean oil 13-18 weight portions, salt 0.4-0.8 weight portions, potassium sorbate 0.01-0.02 weight portions, scallion 0.8-1.2 weight portions, and ginger 0.4-0.6 weight portions. The farm animal meat may be pork, beef or chicken. The sweet spicy meat jam is one kind of snack food with good taste and rich nutrients.

Owner:JILIN GOLD TOWER IND GRP

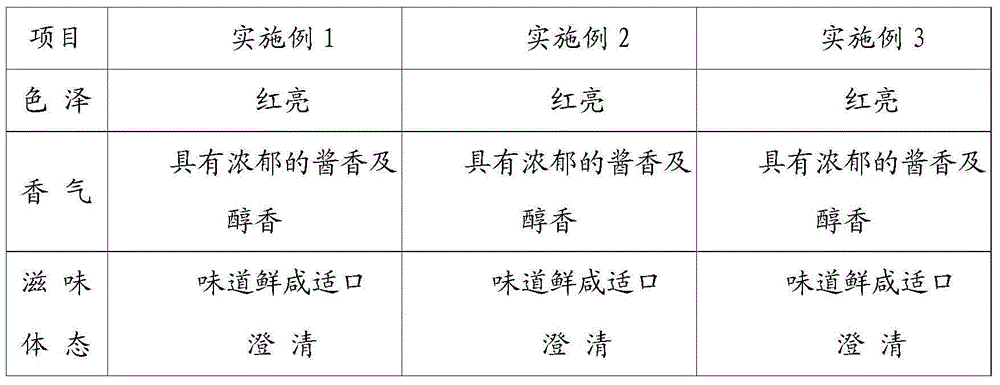

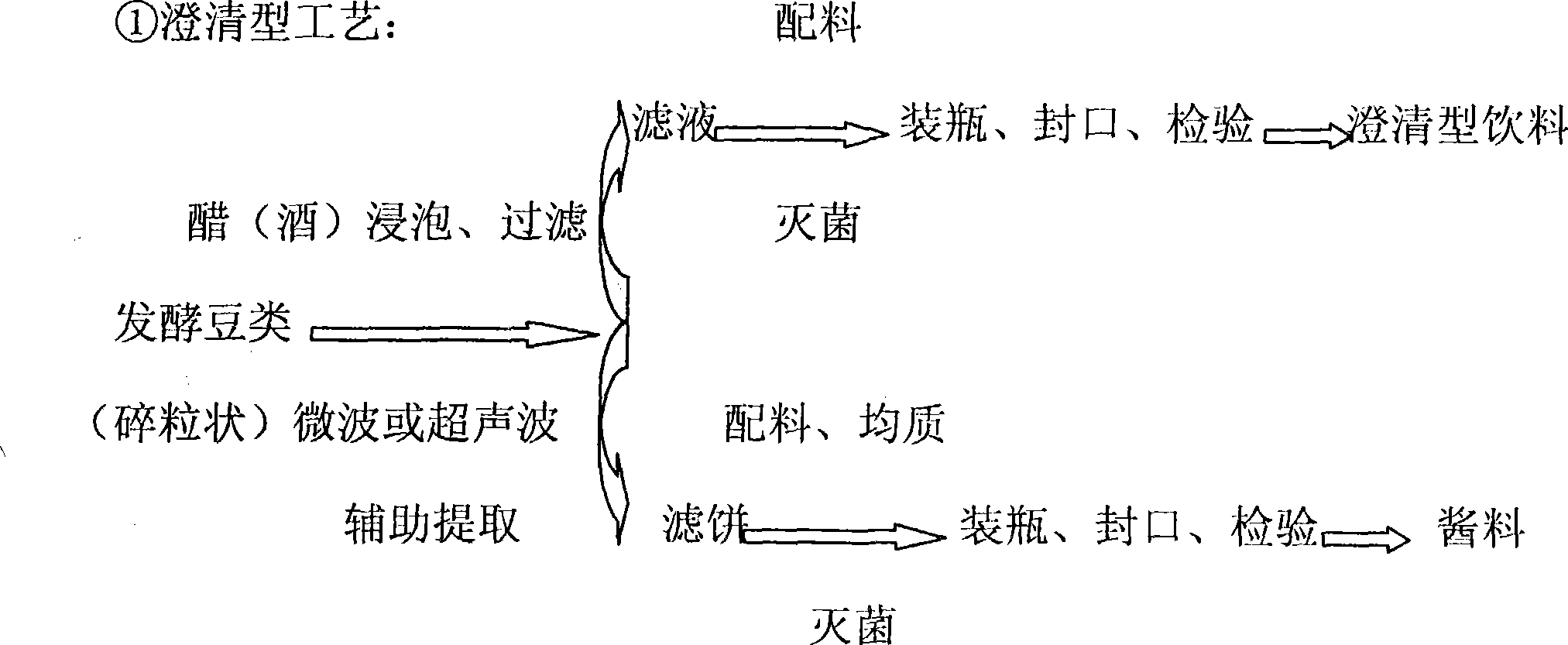

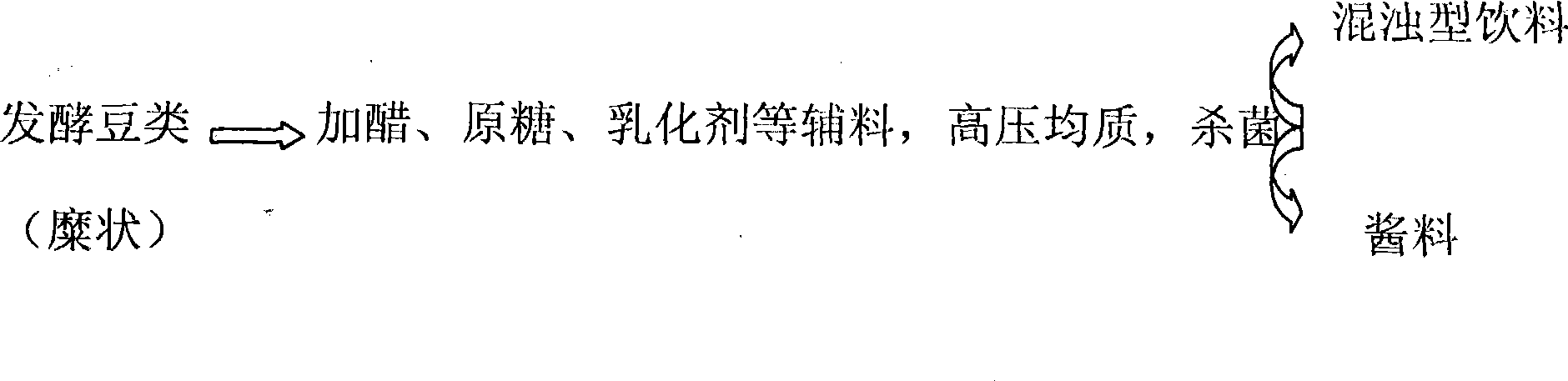

Drink and sauce produced by using fermenting soybean food

InactiveCN101518315APromote digestion and absorptionAchieving perfect integrationPre-extraction tea treatmentAlcoholic beverage preparationFruit juiceCholesterol

The invention provides a drink and a sauce having rich nutrients and multiple health-care functions, which are prepared by leaching fermented soybeans with added vinegar (wine, fruit juice, water or tear), deep processing and adding raw sugar and other auxiliaries containing rich nutrients and bioactivators. Soybeans undergo germination, fermentation and other extremely complex biochemical processes to form hundreds of nutrients and activators with the nutrients of the soybeans. A large number of Chinese and foreign documents prove that the substances have health care functions such as human body free radical clearing, arteries hardening prevention, immunity improvement, cancer resistance, blood fat and cholesterol reduction, blood pressure reduction, blood sugar reduction, bowel loosening for relieving constipation, intestinal microecology improvement, beneficial bacteria propagation and bacterium resistance and suppression. The invention aims to solve a technical problem that the nutrients were not fully used by Chinese people in the past 2,000 due to high salinity (such as that of lobster sauce, soybean paste, preserved bean curd and soy sauce) and disagreeable flavor (such as that of natto and tempe). The invention provides a novel drink and a novel sauce which contain nutrients and bioactivators of fermenting soybeans, are edible and contribute to absorption. Till now, no records of the uses of the soybean food have been found in Chinese and foreign documents. The drink and the sauce fill the gap of health care products in China, are expected to contribute to the promotion of the health care cause in China.

Owner:袁维理 +2

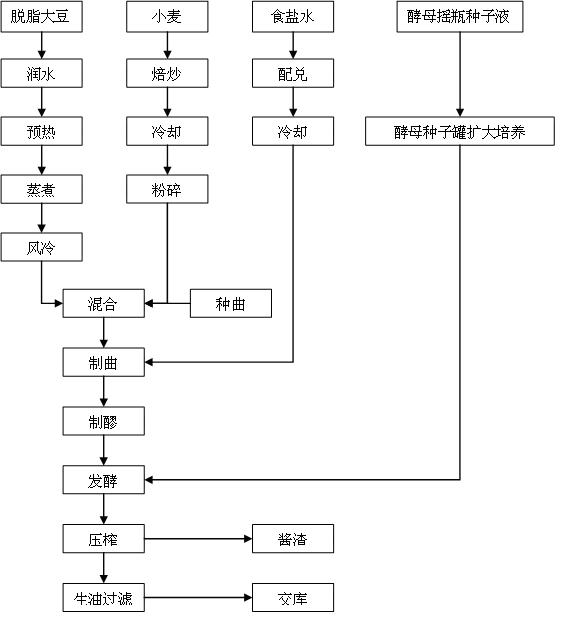

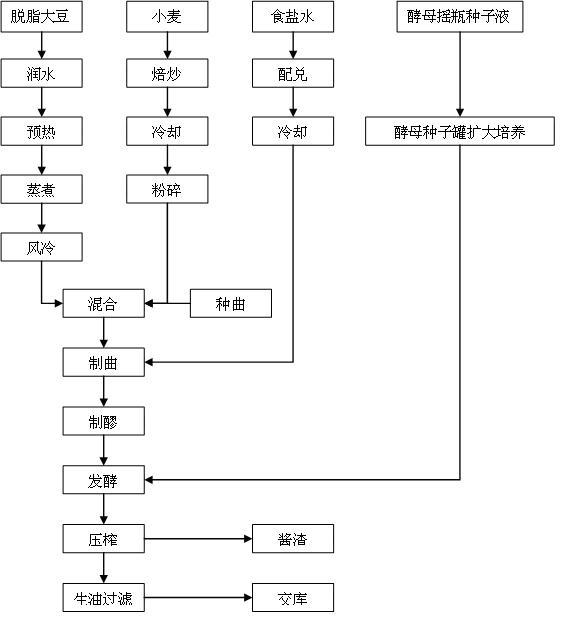

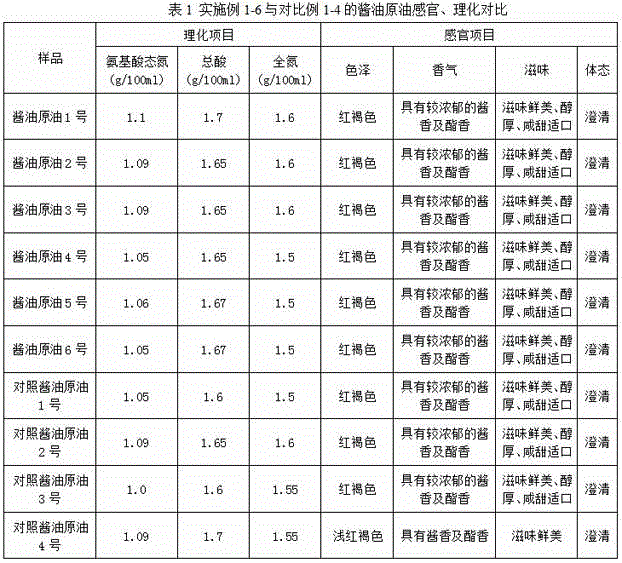

Soy sauce production method capable of ensuring high protein conversion rate and utilization rate

The invention discloses a soy sauce production method capable of ensuring high protein conversion rate and utilization rate, which belongs to the technical field of soy sauce seasoning production. In the method, bean pulp and wheat are taken as raw materials; a soy sauce finished product is obtained by a continuous cooking process, a process of mixing and fermenting a plurality of strains, subsequent treatment and filling; and the special raw materials treated by the continuous cooking process are mixed with screened and domesticated aspergillus oryzae strains with high proteinase activity, fermentation and starter propagation are performed on the mixture, and aroma-increasing high-salt yeast strain fermentation liquor with specific aroma-increasing flavor is added in a subsequent sauce mash fermentation stage for the soy sauce seasoning production. The soy sauce production method has the advantages of advanced equipment and treatment process, high raw material conversion rate and utilization rate, low cost, high product quality and the like.

Owner:JIAJIA FOOD GRP

Flavor soup-stock seasoning and preparation method thereof

ActiveCN104664305AStrong fresh fragranceSuppress fishy smellFood preparationMaillard reactionDL-methionine

The invention provides flavor soup-stock seasoning which comprises the following raw materials: pork, pig bone clear soup, lard, chicken, chicken bone clear soup, chicken oil, water, L-cysteine hydrochloride monohydrate, DL-methionine, VC, glucose, a yeast extract, table salt, aginomoto, soybean peptides, gingers, onions, modified starch, edible essence, compound protease, flavourzyme, light soy sauce, hydrolyzed vegetable protein powder, CMC, white sugar, I+G and potassium sorbate. The meat raw materials and the soup are subjected to Maillard reaction step by step to obtain the flavor soup-stock seasoning. According to the soup-stock seasoning, the optimum formula of the flavor soup-stock seasoning is determined; the soup-stock flavor is enhanced through pork enzymolysis, chicken enzymolysis and Maillard thermal reaction; through combination of the soybean peptides, the pig bone clear soup and the chicken bone clear soup and with the aid of spice and the edible essence, the prepared seasoning looks like milk-white thick paste, has a strong bone soup flavor and tastes delicious and mellow; a dish can be delicious with a little seasoning; and the seasoning is convenient to use.

Owner:HUBEI HAISHUNDA FOOD SCI & TECH CO LTD

Manufacturing method for spiced beef

The invention discloses a manufacturing method for spiced beef. The manufacturing method is characterized by comprising the following steps of: cleaning and slicing, sliced beef is frozen in a freezer at a temperature of 15 DEG C below zero-18 DEG C below zero for 20-24 hours, pickling, light-stewing, primarily stewing in soy sauce, secondarily stewing in soy sauce, deep frying, slicing, mixing with stuff, packing, vacuum sealing and sterilizing. The beef mixed with stuff oil is packed and sealed on a vacuum sealing machine, after being placed in a sterilizing device for sterilization at a temperature of 121 DEG C for 20 minutes, the spiced beef is cooled into a normal temperature and then is encased.

Owner:NANCHONG GUOJIANGLONG FOOD

Brewing process of soy sauce

The invention discloses a brewing process of a soy sauce, which comprises the following steps: (1) preparation of soy sauce koji, namely, mixing cooked soybeans with wheat or flour, adding strains for preparing the soy sauce koji; and (2) fermentation, namely, mixing the soy sauce koji with a saline solution so as to obtain a soy sauce mash, and carrying out high-salt liquid-state fermentation, wherein the salinity of the soy sauce mash in the early stage of the fermentation is controlled at 14.0-15.5g / 100 ml, after the fermentation is performed for 45-75 days, the salinity of the soy sauce mash is adjusted to 18.0-19.0g / 100 ml, and fermentation goes on, so that soy sauce liquor is obtained. In the process, low-salt fermentation is performed before high-salt fermentation, so that the utilization rate of raw materials is improved, the fermentation cycle is short, and the productivity is greatly improved; and the obtained soy sauce has an outstanding fragrance and a delicious taste, and has no difference with a soy sauce prepared by using a traditional high-salt liquid-state fermentation method.

Owner:GUANGDONG CHUBANG FOOD

Carvier and its preparing method

The invention discloses caviar and preparing method, which comprises the following parts: 55-65% main ingredient with caviar predisposed by salt, 7-10% spice liquid with purple perilla, ginger, hot pepper, cinnamon, clove, toasted garlic, cardamom, octagonal, tsaoko and peppertree, flavoring with sesame paste, aromatic oil, salad oil, chickens' extract, table salt, soy sauce, vinegar, honey, cooking wine and white pepper powder. The making method of caviar comprises the following steps: weighing raw material according to formula; extracting flavoring liquid; placing manufactured caviar; packing; sterilizing; storing into warehouse; removing pepper from caviar; fitting for Chinese taste; fitting for spreading widely.

Owner:胡仲君

Preserved meat fillet, and its preparing method

A preserved meat (beef or pork) is prepared from edible meat, soy, ginger juice, yellow wine, flavouring wine or liquor, gourmet powder, edible salt, sugar, VC, spices powder, sodium nitrite, potassium sorbate, milk powder, bone powder and cane sugar through slicing meat, mixing it with others, spreading on screen, baking, roasting and packing.

Owner:SHANDONG NORMAL UNIV

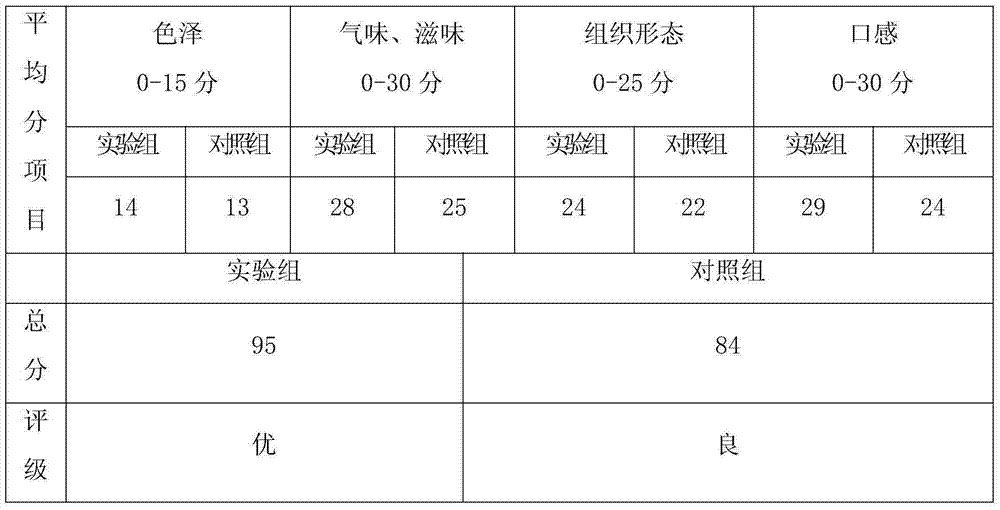

A hot and spicy sauce and a preparation method thereof

InactiveCN104489614AKeep the tasteSwelling and looseningFood ingredient as taste affecting agentFood ingredient as flavour affecting agentFood flavoringsBroad beans

The present invention discloses a hot and spicy sauce and a preparation method thereof, and belongs to the field of food seasoning technology. The preparation method comprises the following main steps: preparing each raw material according to characteristics of the raw materials, heating siritch to 180-200 DEG C, adding ginger and garlic into the siritch, sauting the ginger and garlic until fragrant, adding thick broad-bean sauce into the mixture, maintaining product temperature at about 95 DEG C and stir-frying the mixture for 3-6 minutes, frying the mixture with pepper, shii-take and chilli paste, edible fungus and diced tofu for about 10 minutes, adding inspissated juice of Chinese wolfberry, red date and apple, spice material and soy sauce into the mixture, frying the mixture for additional 5 minutes at a product temperature of about 95 DEG C, adding salt, edible fungus powder, crushed peanut and sesame, continuing frying the mixture for 5 minutes, adding zanthorylum oil, stopping the fire, and maintaining product temperature at above 65 DEG C for hot filling. The hot and spicy sauce prepared in accordance with the above-mentioned preparation method is rich in nutrition, beautiful, ruddy and shiny in color, rich in gloss, salty and spicy and natural in taste, harmonious in fragrance, and crispy and chewy in taste.

Owner:湖南辣啦食品科技有限公司

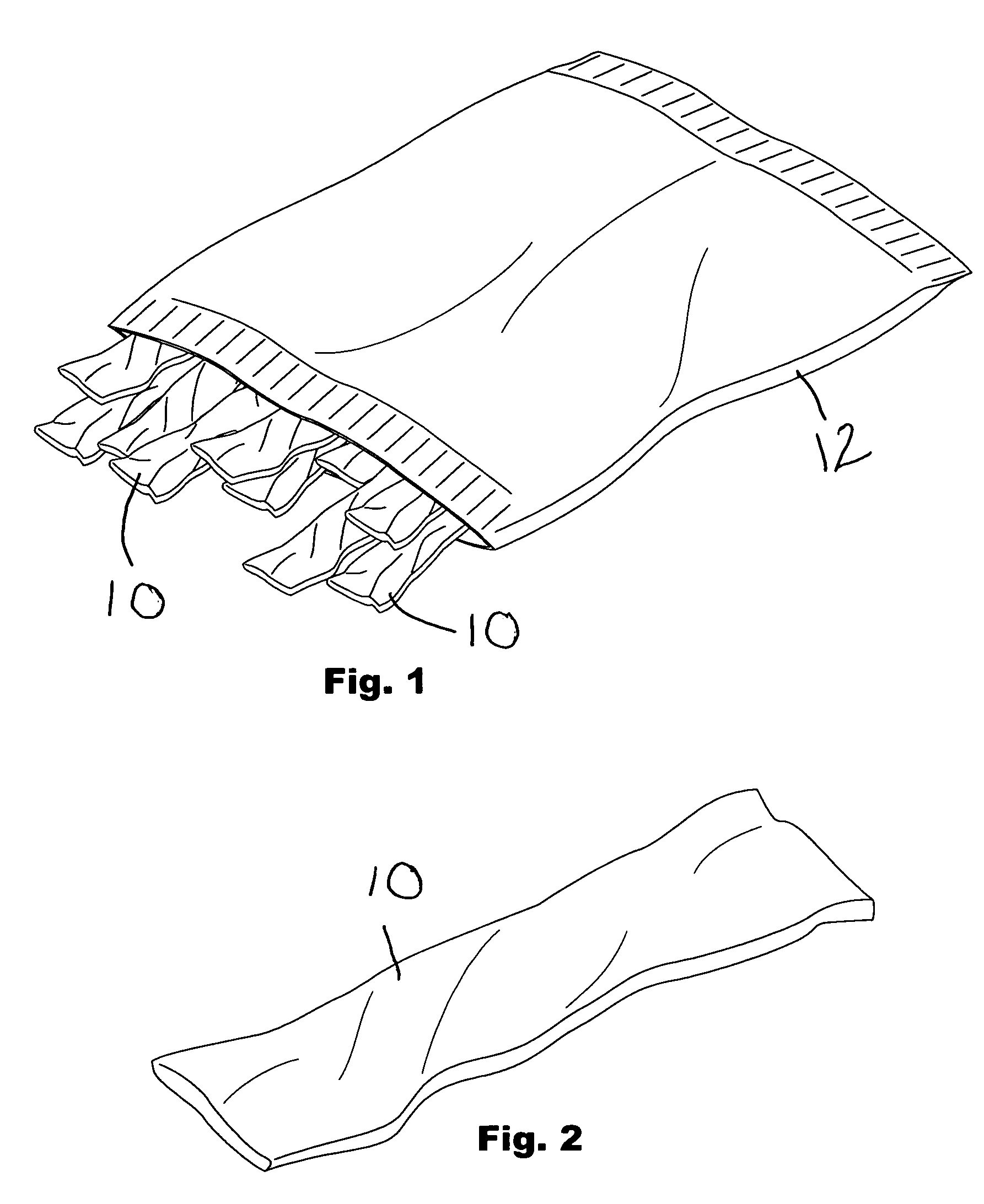

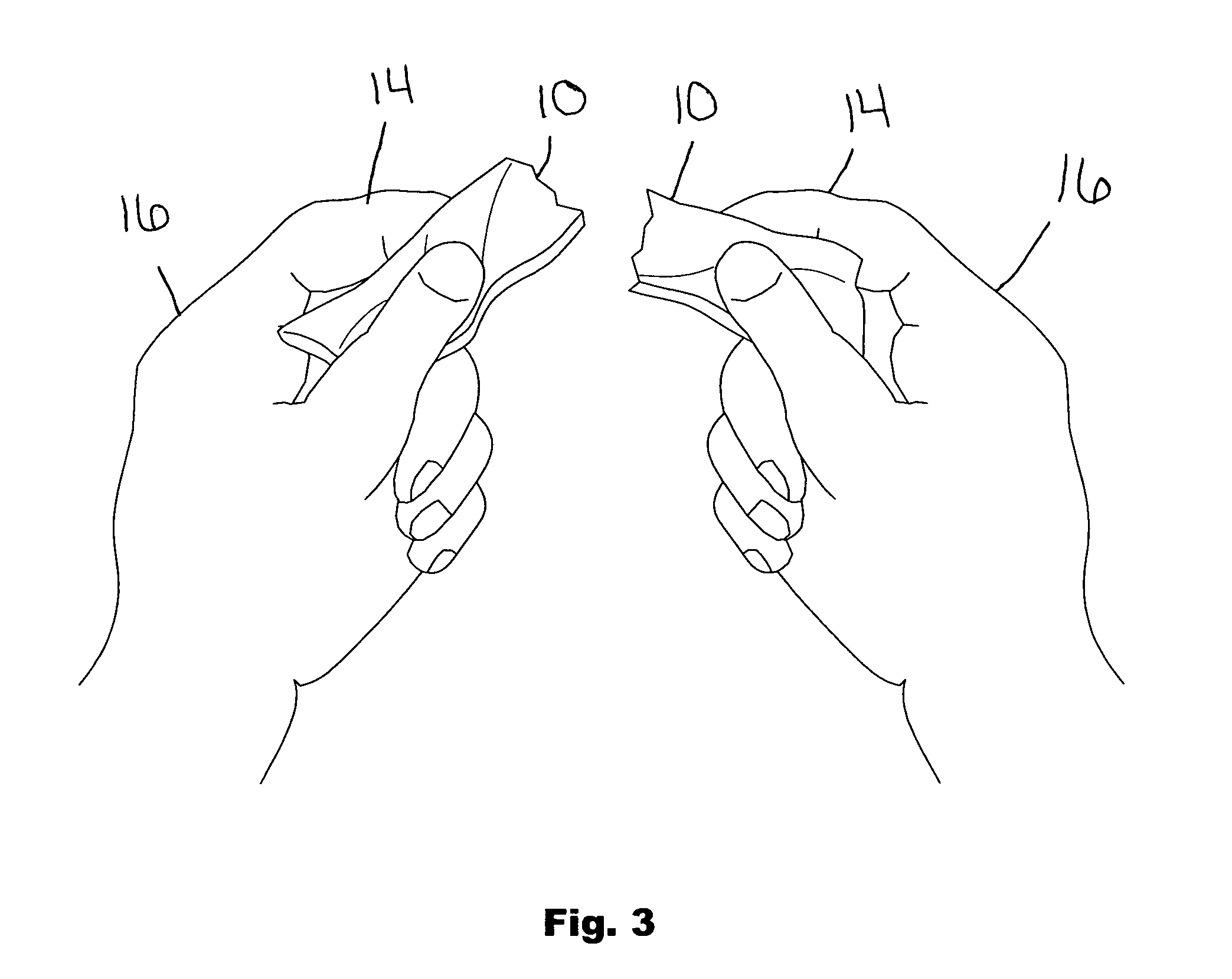

Method for making beef jerky

InactiveUS20050163912A1Thinly slicedEasily brokenFood preparationMeat/fish preservation by dryingAdditive ingredientLiquid smoke

A method and process for producing a new type of beef jerky having a unique and distinctive aroma and flavor includes marinating the thinly sliced jerky strips with ingredients that include soy sauce, teriyaki sauce, Worcestershire sauce, mesquite liquid smoke and salt for up to two hours thereby producing aromatic beef jerky strips that can be easily broken into bite size portions by one's hands and fingers.

Owner:WHITE RANDALL

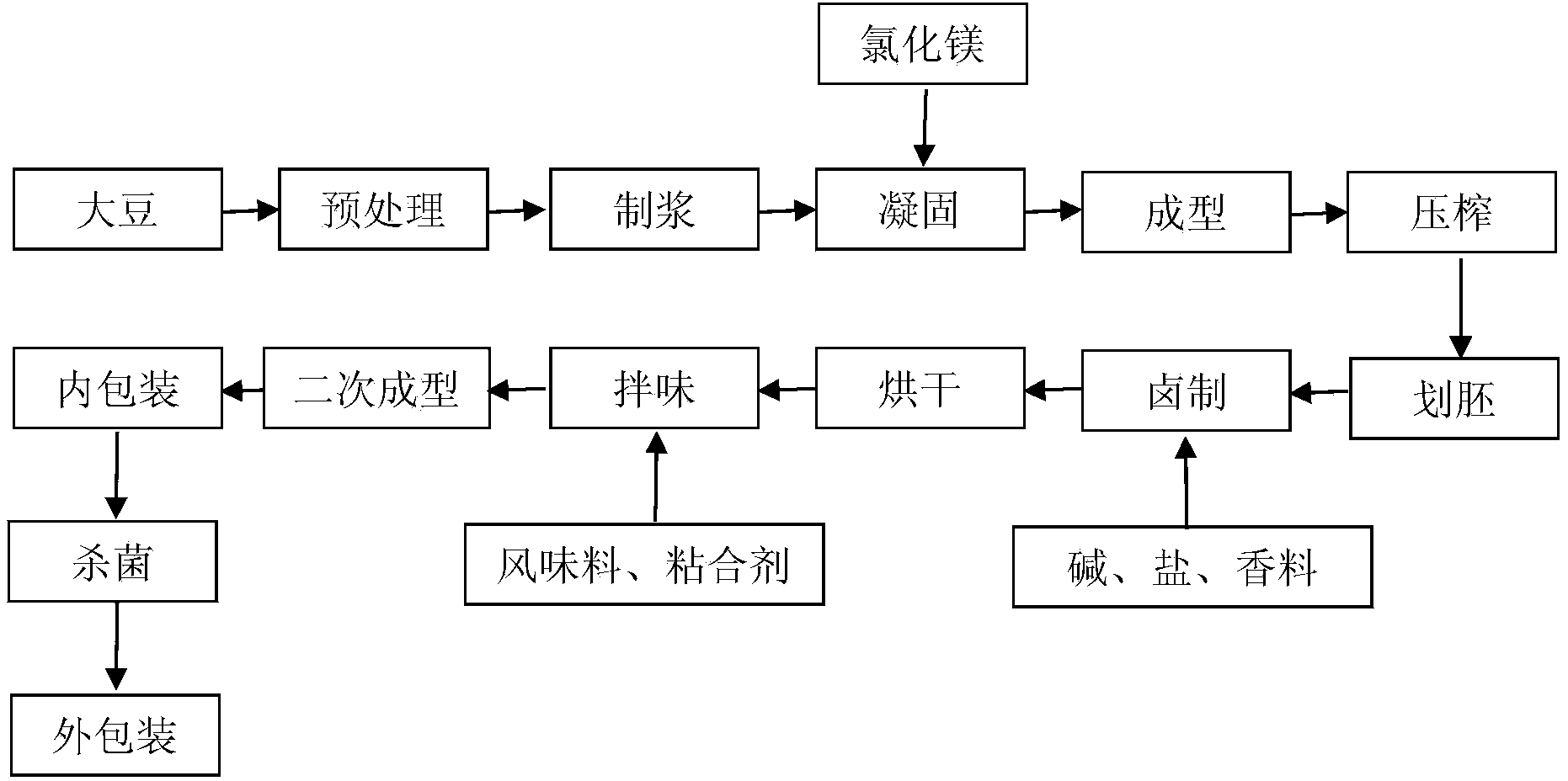

Preparation method of marinated dried bean curd

The invention provides a preparation method of marinated dried bean curd, and relates to the technical field of food processing. The method comprises the following steps: (1) cleaning soybeans, and soaking; (2) grinding into thick liquid; (3) cooking the thick liquid, and filtering; (4) putting a coagulator into soybean milk while stirring to obtain bean curd jelly; (5) squeezing the obtained bean curd jelly to obtain a dried bean curd blank; (6) cutting the dried bean curd blank into white blanks with small specifications; (7) stewing in soy sauce; (8) drying; (9) feeding flavor seasonings and an adhesive, and molding for a second time; and (10) sterilizing and packaging. According to the marinated dried bean curd prepared by the method, the flavor seasonings are closely combined with the dried bean curd; the marinated dried bean curd is novel in shape and unique in mouth feel and flavor.

Owner:SICHUAN NANXI DALIANGXIN FOOD

Preparation method of black garlic juice and black garlic powder

The invention discloses a preparation method of black garlic juice and black garlic powder, and belongs to the technical field of deep processing of food products. The preparation method is characterized in that whole black garlic with peel is utilized as a raw material; water is utilized as an extraction solvent; and a water-soluble component of black garlic is extracted through the processes ofcrushing and extraction, squeeze and solid-liquid separation. The extracted liquid component can be prepared into black garlic juice or concentrated black garlic juice for liquid food ingredients such as black garlic beverages, black garlic vinegar, black garlic soy and the like, and residual garlic residues and garlic peel are prepared into ultra-micro garlic powder rich in amino acids and dietary fiber through the processes of drying and ultra-micro crushing. The ultra-micro garlic powder can be utilized as an ingredient of instant seasoning powder, local-flavor cakes and the like.

Owner:JINAN INST OF FRUIT PRODS CHINA GENERAL SUPPLY & MARKETING COOP

Soybean sauce employing multi-strain starter propagation and production technology thereof

ActiveCN103907897AMeet production requirementsLow decarboxylase activityFood preparationBiotechnologyLactic acid bacterium

The invention discloses a soybean sauce employing multi-strain starter propagation and a production technology thereof. By adopting the method, the starter propagation process of a plurality of strains for naturally brewed soybean sauce is simulated, and yeast, lactic acid bacteria and composite aspergillus oryzae are adopted for starter propagation in common. The multi-strain starter propagation comprises the following steps: inoculating 0.1-0.5% of aspergillus oryzae and a koji material containing 10<3>-10<5> yeasts per gram at the initial starter propagation stage according to the weight of the raw material; and inoculating a koji material containing 10<3>-10<5> yeasts per gram after loosening koji for the first time. The yeast quantity in finished koji is 10<5>-10<7>cfu / g, the lactobacilli count is 10<5>-10<7>cfu / g, and the ratio of the lactic acid bacteria to the yeasts is (20:1) to (1:1) by collaborative symbiotic roles of three brewing microorganisms in the starter propagation process, flavor microorganisms (lactic acid bacteria and yeasts) with a proper proportion are provided for the fermentation stage of the soybean sauce, and the flavor of the soybean sauce product is finally enhanced.

Owner:应城市恒茂食品有限公司

Fermented black garlic residue powder and preparation method thereof

ActiveCN102302165AEasy to eatEdible widelyAnimal feeding stuffCocoaAdditive ingredientAllium sativum

The invention discloses fermented black garlic residue powder and a preparation method thereof. The fermented black garlic residue powder is characterized in that the preparation method disclosed by the invention comprises the steps of: carrying out fermentation treatment by adding yeast into garlic residues of which garlicin (garlic oil) is extracted; preparing black garlic residues by fermenting and ripening under the conditions of constant temperature and humidity through temperature regulation and humidity; refrigerating and drying; grinding into superfine powder with the water content below 3 percent through a 150-200 mesh sieve; and vacuum packing. The black garlic residue powder provided by the invention obtained through the fermentation process has the advantages that the wholesome nutrition is improved, the utility value of the garlic residues is greatly improved, the garlic residues with healthcare function can be widely edible, and the fermented black garlic residue powder can be applied to beverage, fruit jam, bread, snack, fruit jelly, chocolate, soy sauce, vinegar and other foods or as seasoning ingredients, and can also be used as livestock and poultry feed additives.

Owner:江苏鑫瑞源食品有限公司

Method for manufacturing five-bean dried tofu

InactiveCN102239928ASolve a single problemSolve modeling difficultiesCheese manufactureFood scienceDry beanColloid

The invention discloses a method for manufacturing five-bean dried tofu, and the method comprises the following steps: 1. taking good-quality dry beans, dipping for 12-15 hours after cleaning, decontaminating, jordaning and filtering; 2. taking dry mixed beans, dipping, preliminarily grinding, jordaning again in a vertical colloid mill and filtering; and 3. mixing filtrates obtained in the step 1 and the step 2, carrying out once marinating, twice stewing in soy sauce, twice pressing and the like. According to the method, the problem of single raw material can be solved, and various types of beans are collocated to form a product trophic structure system with relative balanced nutrition by use of health promotion principle. The secondary shaping technology of the dried tofu is improved, so that the product has the advantages of better texture toughness and firmer pattern structure, and the problem that the bean product is difficult to shape can be solved. The five-bean dried tofu is packaged into a strip shape by use of a full-automatic stretch film packaging machine to achieve the purposes of improving the appearance shape and improving the efficiency by 10 times.

Owner:XIHUA UNIV +1

Method for preparing soy sauce

The invention relates to a method for preparing soy sauce, and the method comprises the following steps of: cooking soybean cakes or soybeans and mixing the soybean cakes or the soybeans with flour; cooling and inoculating Aspergillus oryzae yeast essence to prepare yeast; mixing the yeast with salt water with the weight which is 1-3 times as much as the yeast; heating at 45-55 DEG C for 1-2 hours and cooling to 20-30 DEG C; and after fermenting for 60-90 minutes by utilizing a high-salt diluted soy sauce brewing method, squeezing and filtering to obtain a soy sauce raw liquid. Compared with the common soy sauce, the soy sauce prepared by the invention has the advantage that the peptide content is improved by more than 50%.

Owner:SOUTH CHINA UNIV OF TECH

Process for quick production of low salt fish sauce

A method for quickly brewing the low-salt squid soy sauce features that the by-product generated by processing squid is used as one of its raw materials, the endogenous proteinase is used for its hydrolyzing at 35-55 deg.C for 48-72 hr, and their soy leaven is used for its fermenting at 40-55 deg.C for 21-28 days and then at 30-38 deg.C for 7-12 days.

Owner:OCEAN UNIV OF CHINA

Retort pouch of rabbit flesh and the manufacture method thereof

The invention discloses a retort pouch of rabbit flesh and the manufacture method thereof. The main ingredient is a whole rabbit or rabbit parts like rabbit legs. Spices and flavouring include: Star anise, pepper, hemp pepper, cinnamon, white Kou, clove, cumin, chili, sugar, aromatic flavour, fresh interest phosphorus, sugar, salt, MSG, soy sauce, and cooking wine, etc.The process of manufacture: boil the spices with water into spice solution, inject the solution into the rabbit flesh and treat the flesh with technologies like pickling and vacuum massage, etc. Then, the rabbit flesh is sauced and baked and packed vacuum, and sterilized at high-temperature before becoming the product.The product and the manufacture method thereof unites the modern meat processing techniques with reasonably designed recipe, the character of the rabbit flesh is thus strengthened and given full play to. The invention also provides a routinized and standard method suitable for mass production.The product is convenient to serve, tastes fresh and boasts a unique flavour. The promotion of this product is easy and proper.

Owner:青岛康大食品有限公司

Method for producing microbial fermentation bait for sea cucumbers

InactiveCN101611767AReduce the numberSimple production processClimate change adaptationAnimal feeding stuffEcological environmentSludge

The invention relates to microbial fermentation bait, in particular to a method for producing microbial fermentation bait for sea cucumbers. Soya bean meal, bran, rice bran, soy sauce residue, mussels, algae and sea floating sludge taken as fermentation raw materials, and Saccharomyces cerevisiae, Candida, Bacillus subtillis, lactobacillus and photosynthetic bacteria taken as beneficial microflora are subjected to inoculation at a temperature of between 25 and 30 DEG C for solid fermentation to produce the microbial fermentation bait for sea cucumbers. The method has the characteristics of simple production process, easy operation, wide sources of production raw materials, low cost, easy promotion, short production period, more fermentation products, good product quality, easy application and the like. When applied in sea cucumber culture, the microbial fermentation bait can improve the survival rate and immunity of the sea cucumbers, quicken the growth and development of the sea cucumbers, improve the ecological environment of culture pond water and purify water quality, and is ideal good-quality microbial fermentation bait for the sea cucumbers.

Owner:SHENYANG INST OF APPLIED ECOLOGY - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com