Brewing process of soy sauce

A soy sauce and process technology, applied in the field of soy sauce brewing technology, can solve the problems of low utilization rate of raw materials, long fermentation period, inhibition of protease, etc., and achieve the effects of shortening fermentation period, improving umami and sauce flavor, and promoting formation and transformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

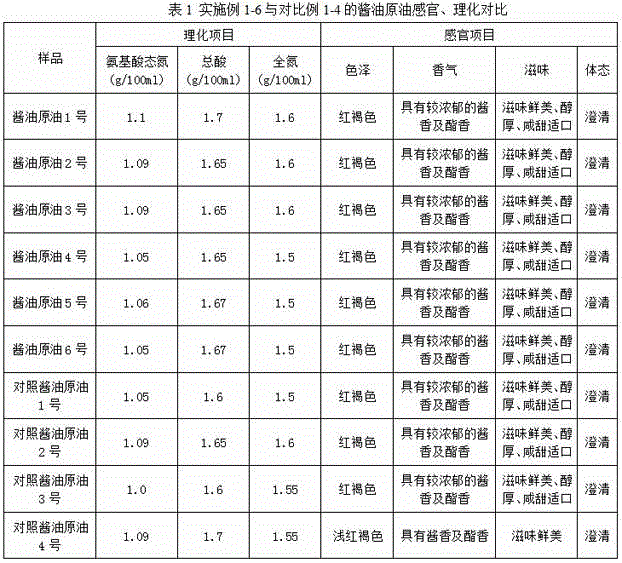

Examples

Embodiment 1

[0031] (1) Soybeans are steamed under 0.16Mpa steam pressure for 5 minutes, mixed with flour at a mass ratio of 1:0.6, cooled and inoculated with Aspergillus oryzae koji essence with 0.04% (w / w) of soybean mass, at 28-36°C and humidity 95% Under the conditions of culturing for 44 hours, soy sauce Daqu was obtained;

[0032] (2) Mix soy sauce Daqu and 21.0g / 100ml of brine according to the mass ratio of 1:2.3 to make moromi. The salt content is 15.0 g / 100ml. Fermentation is carried out using the high-salt dilute soy sauce brewing method recorded in GB18186-2000, and the fermentation is 45 Days later, refined salt was added to the soy mash and re-oiled to dissolve, so that the salt was divided into 18.0g / 100ml, and then continued to ferment until 120 days later, the oil was released to obtain crude oil, which was filtered to obtain No. 1 soy sauce crude oil.

Embodiment 2

[0034] (1) Soybeans are steamed under 0.16Mpa steam pressure for 5 minutes, mixed with flour at a mass ratio of 1:0.4, cooled and inoculated with Aspergillus oryzae koji essence of 0.04% (w / w) soybean mass, at 28-36°C and humidity 95% Under the conditions of culturing for 44 hours, soy sauce Daqu was obtained;

[0035] (2) Mix soy sauce Daqu and 21.0g / 100ml of brine to form a soy mash with a mass ratio of 1:2.3. The salt content is 15.0 g / 100ml. Fermentation is carried out using the high-salt dilute soy sauce brewing method recorded in GB18186-2000, and the fermentation is 60 Days later, refined salt was added to the soy mash and re-oiled to dissolve, so that the salt was divided into 18.0g / 100ml, and then the oil was released after 120 days of continuous fermentation to obtain crude oil, which was filtered to obtain No. 6 soy sauce crude oil.

Embodiment 3

[0037](1) Soybeans are steamed under 0.1Mpa steam pressure for 20 minutes, mixed with flour at a mass ratio of 1:0.4, cooled and inoculated with Aspergillus oryzae koji essence of 0.05% (w / w) soybean mass, at 28-36°C and humidity 95% Under the conditions of culturing for 44 hours, soy sauce Daqu was obtained;

[0038] (2) Mix soy sauce Daqu with 21.0g / 100ml of brine to form moromi at a mass ratio of 1:2.35, with a salt content of 15.0 g / 100ml, and use the high-salt dilute soy sauce brewing method recorded in GB18186-2000 to ferment for 75 Days later, refined salt was added to the soy mash and re-oiled to dissolve, so that the salt was divided into 18.0g / 100ml, and then continued to ferment until 120 days later, the oil was released to obtain crude oil, which was filtered to obtain No. 2 soy sauce crude oil.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com