Patents

Literature

37results about How to "Strong fresh fragrance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Quick-frozen prepared and oil-fried curry flavored sturgeon slice processing method

The present invention discloses a quick-frozen prepared and oil-fried curry flavored sturgeon slice processing method which comprises the following steps: washing, cold water dormancy, slaughtering, decaptitating and peeling, slice anatomizing, slice cutting, rinsing, cryoprotectant treatment, seasoning and marinating, oil-frying, quick-freezing, seasoning, and re-frying. The production process is simple, and the produced products are fresh in fragrance and mellow in taste, attractive in color and luster, rich in flexibility, have broad market prospects, and are convenient in consumption.

Owner:王坤

Pure aquatic animal meat ham sausage or western type ham containing fish meat and preparation method

A ham-style sausage or Western ham is prepared from the meat of aquatic animal and fish through proportionally mixing, adding flavourings and conventional other steps. Its advantages are rich nutrients, special and delicious taste, and good enjoyment to eat it.

Owner:徐伟

Method for producing condiment by organic acid hydrolysis

The condiment producing process including hydrolysis with organic acid or mixed acid comprises the following steps: material pre-treatment; hydrolysis and neutralization; and concoction and filtering to obtain condiment. The said process is mainly used in producing various sea food condiments, including sea food juice, sea food sauce, sea food paste, sea food essence, etc. with sea food leftover as material, and may be also used in producing condiment with animal leftover or grain leftover. The present invention changes wastes into high value products and is suitable for production in different scales.

Owner:陈贵卿

Ham sausage made from formed aquatic mollush and preparing method thereof

InactiveCN1471858ASolve the problem of processing junctionFull of nutritionFood preparationFowlBiotechnology

Owner:青岛波尼亚食品有限公司

Braised chicken sauce and preparing method thereof

The invention discloses a braised chicken sauce and preparing method thereof. By quality percentage, the braised chicken sauce is prepared from 1% green onion, 1% ginger, 1% garlic, 1% green Chinese onion, 1% onion, 3% soybean oil, 3% chicken oil, 2.5% soybean paste, 2.5% thick broad-bean sauce, 1% peanut, 1% sesame, 45.15% water, 8% chicken skeleton, 3% yeast extract, 2% originally brewed rice wine, 5% white granulated sugar, 2% aginomoto, 0.1% I+G, 0.05% VC, 0.05% VE, 0.05% glycine, 0.05% L-alanine, 0.05% ethyl maltol, 0.1% disodium succinate, 1% hydrolyzed vegetable protein, 1% maltodextrin, 0.02% rosemary extract, 0.03% potassium sorbate, 9% salt, 0.05% black pepper particle, 0.05% anise, 0.05% cassia bark, 0.05% dahurian angelica root, 0.05% netmeg, 0.1% natural carotene, and 1% starch; the prepared braised chicken sauce in the invention is full of fresh fragrance, delicious, and widely applied in ordinary home and catering for making braised chicken and other poultry and animal dishes; it is economic and practical, and accessible to standardized production at the highest value of market promotion.

Owner:魏志华

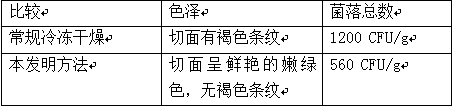

Processing method of fresh and crispy freeze-dried jujubes and jujube slices

The invention discloses a processing method of fresh and crispy freeze-dried jujubes and jujube slices. By adopting acidic electrolyzed water and sterilization and enzyme deactivation treatment and freeze-drying technologies, the dried jujube products have the advantages of intact shape, bright color, high nutrient content, aromatic flavor and good taste. The total number of bacterial colonies ofthe prepared finished products are less than 1000 CFU / g, the number of coliform bacteria of the finished products is less than 30 MPN / 100g, the cross sections of the finished products show vivid verdant color, and the finished products have no band-shaped brown stripes which are usually shown in common freeze-dried products; by adjusting a freeze-drying curve, the moisture content of the productsis controlled to be 4%-10%, the products have rich fresh and aromatic flavor, and the taste of the products is similar to the taste of fresh jujubes; the finished products have crispy taste similar tothe taste of vacuum puffed products and low-temperature fried products and have no greasy feeling; and nutrients are better kept, and the retention rate of vitamin C is higher than 90%.

Owner:早康枸杞股份有限公司

Black wolfberry vinegar and preparation method thereof

The invention discloses black wolfberry vinegar which is characterized that the method comprises the following steps: fermenting normal wolfberry juice to obtain fermented black wolfberry juice, concentrating the fermented black wolfberry juice into black wolfberry concentrated juice, and blending the black wolfberry concentrated juice with current vinegar, wherein the blending proportion of the black wolfberry concentrated juice and the vinegar is 1:10; a blending process comprises the following steps: immersing 1 kilo of clean dry fruits of wolfberries in hot water of 50 DEG C of which the volume is 5 times as much as that of the dry fruits, mixing into slurry, adding 15 kilos of water in the slurry to boil, keeping the slurry for 30 min under 95 to 100 DEG C, filtering the slurry to obtain the normal wolfberry juice, putting the normal juice in a fermenter, sealing the fermenter, keeping temperature between 90 and 95 DEG C, preserving heat and laying the fermenter naturally for fermentation for 6 to 8 hours, regulating the temperature between 70 and 80 DEG C, laying the fermenter continuously and naturally for fermentation for 60 hours, pouring fermented juice, ultrafiltering the fermented juice to obtain the black wolfberry juice, concentrating the black wolfberry juice into 5 kilos of black wolfberry concentrated juice under 45 to 55 DEG C, and blending 1 kilo of black wolfberry concentrated juice into 10 kilos of current vinegar to obtain the black wolfberry vinegar. The black wolfberry vinegar has fresh flavor and dense taste and rich nutrition, which is health-care vinegar beneficial to health.

Owner:徐州绿之野生物食品有限公司

Preparation method of pumpkin and meat bone soup paste or powder

InactiveCN104041872ARich varietyStrong fresh fragranceFood ingredient functionsFood preparationNutrientAnimal science

The invention discloses a preparation method of pumpkin and meat bone soup paste or powder. The method is characterized by comprising the following steps: adding composite pumpkin juice into meat-bone soup to obtain a mixture I, adding chicken oil and seasonings into the mixture I to obtain a mixture II, performing homogenizing, performing vacuum concentrating on the mixture II at a low temperature, and then performing vacuum freeze drying. By adopting the composite animal bone raw material, the contents of nutrients such as collagen protein, amino acid, and nucleotide in the raw material can be increased, so that the nutrients are relatively complete, the fragrance is thick, and the flavor is rich; by adding the composite pumpkin juice, not only can the flavor taste of the paste be enhanced, but also the nutritional value and the medicinal value of the pumpkin and meat bone soup paste or powder can be integrally improved.

Owner:HUBEI UNIV OF TECH

Chicken powder and automatic production technology thereof

ActiveCN104351726AStrong fresh fragranceGreat tasteFood ingredient as antioxidantSugar food ingredientsNutritive valuesCalcium in biology

The invention discloses chicken powder and an automatic production technology thereof. The chicken powder is prepared from the following raw materials by mass percent: 90-92% of chicken raw material, 0.03-0.05% of an antioxidant, 0.02-0.03% of sodium citrate, 1-2% of table salt, 0.5-0.7% of guanylic acid, 3-4% of edible glucose, 0.5-1% of disodium 5'-ribonucleotide, 1-2% of small-molecule amino acid and 1-2% of lecithin. According to the chicken powder prepared by the invention, the content of the chicken raw material reaches about 90%, and the chicken raw material is matched with the auxiliary materials such as guanylic acid, disodium 5'-ribonucleotide, small-molecule amino acid, lecithin, calcium and the like, so that the nutritive value of the product is greatly improved; the prepared chicken powder is rich in fresh fragrance, thus being very good in mouth feel; the prepared chicken powder is very high in contents of protein and calcium, thus having very high marketing values; furthermore, the automatic production technology of the chicken powder is improved, and especially, accurate calculation and yield control are carried out in all production processes, so that the safety of the production line is effectively improved; after the automatic production technology is used, the chicken powder can be continuously produced, the production is uninterrupted, the utilization rate of production equipment can be improved, and intelligence and automation of the production line can be realized; the production cost of products can be lowered, and the market competitiveness of the products can be improved.

Owner:广州市华琪生物科技有限公司

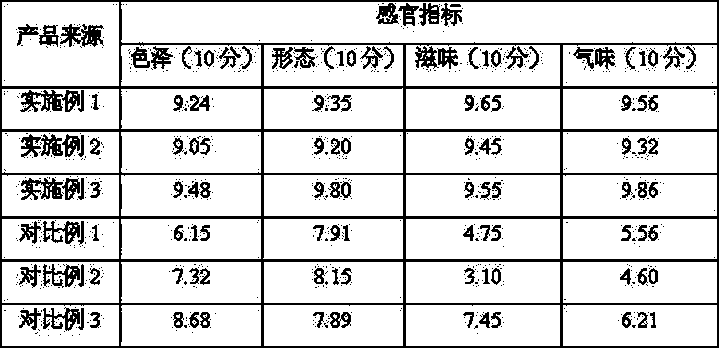

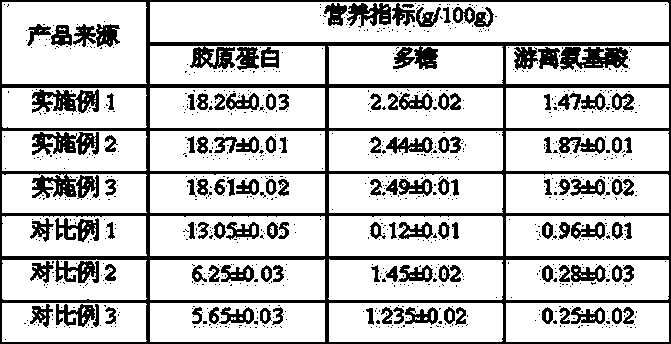

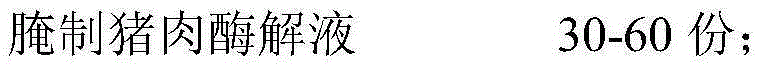

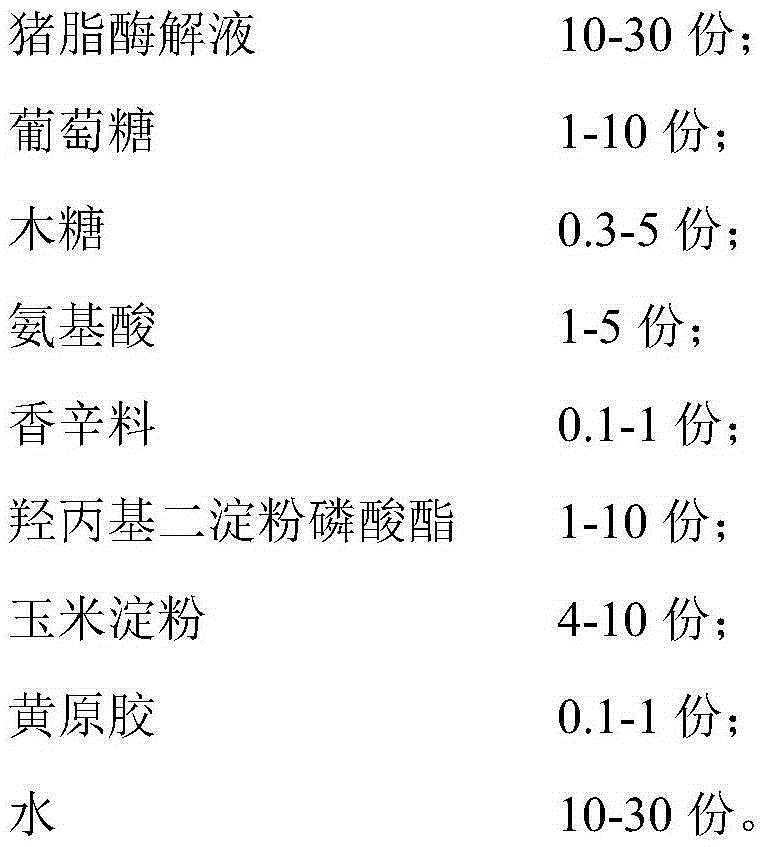

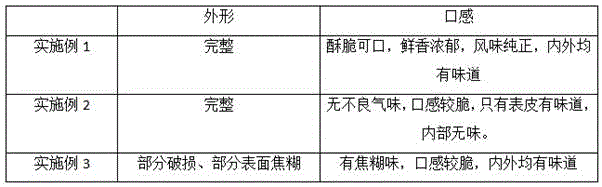

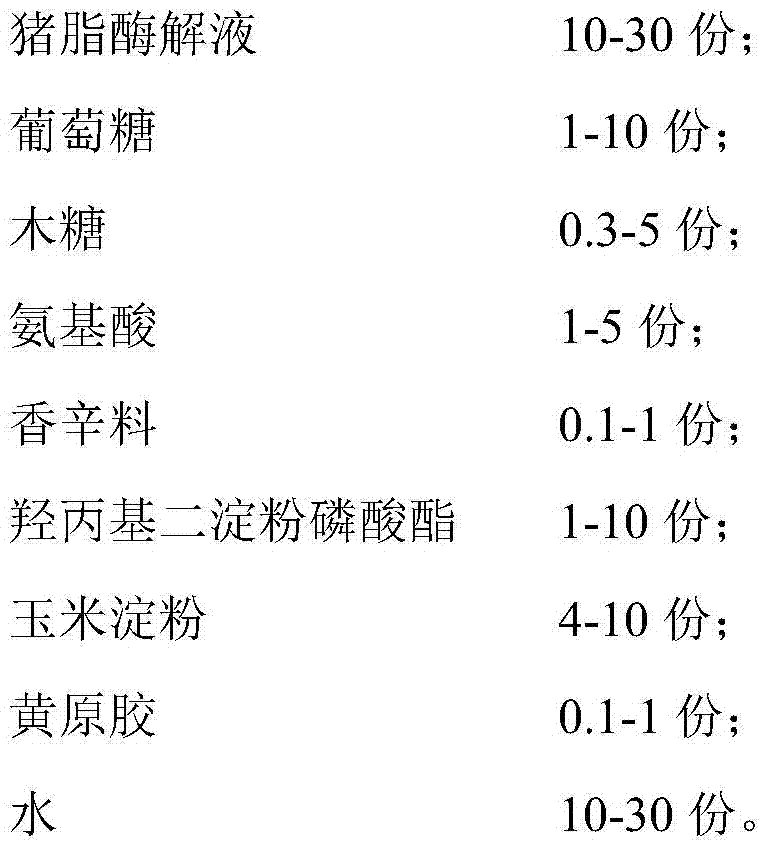

Luncheon meat flavor paste and preparation method thereof

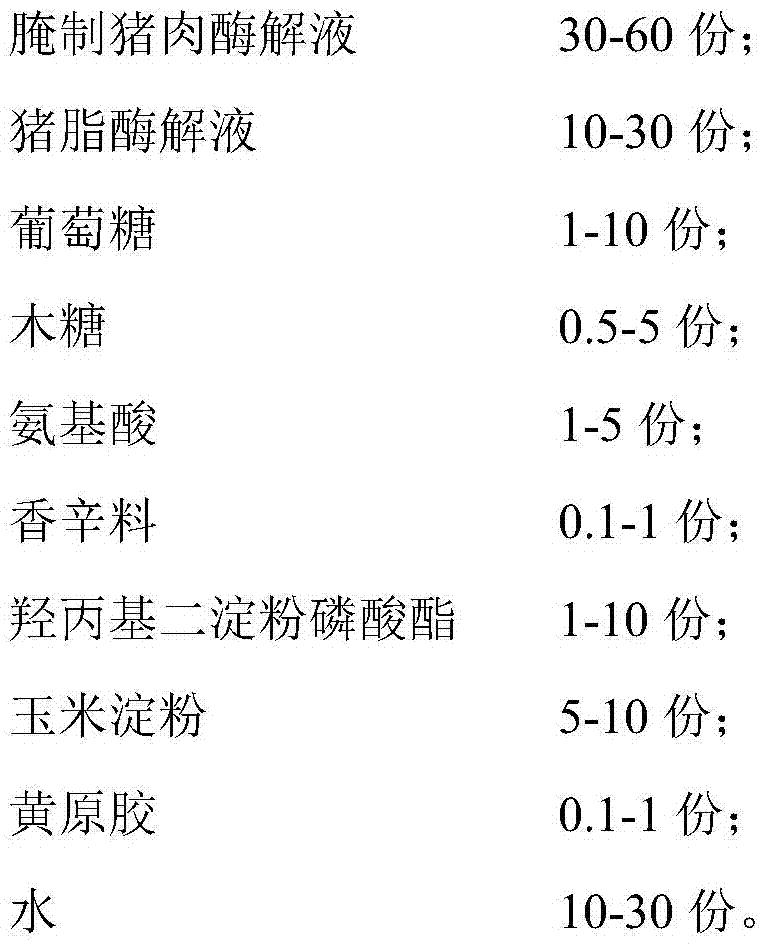

The invention relates to a luncheon meat flavor paste comprising: by weight, 30-60 parts of marinated pork enzymatic hydrolysate, 10-30 parts of lard enzymatic hydrolysate, 1-10 parts of glucose, 0.3-5 parts of xylose, 1-5 parts of amino acid, 0.1-1 parts of spice, 1-10 parts of hydroxypropyl distarch phosphate, 4-10 parts of corn starch, 0.1-1 part of xanthan gum and 10-30 parts of water. The luncheon meat flavor paste adds compositions with different weight part, and has full-bodied fragrance. The luncheon meat used the luncheon meat flavor paste can reduce the fat content and maintain the original flavor and mouthfeel, is healthy, can meet the edible requirement of people, and can be eaten safely.

Owner:SHANDONG TIANBO FOOD INGREDIENTS

Preparation method of seasoning for steamed pork with rice flour

InactiveCN106036744AImprove fresh tasteHigh nutritional valueFood ingredient as mouthfeel improving agentBiotechnologyNutritive values

The invention discloses a preparation method of seasoning for steamed pork with rice flour, belonging to the technical field of food. The method comprises the steps of A. preparing powdered seasoning: respectively frying rice, millet, sticky rice and spices for 3-8min by using small fire, putting the fried rice, millet and sticky rice, starch, green prickleyash, dried chillis, the spices and black pepper into a crusher for crushing, screening the product by using a 40-60-mesh sieve, adding white granulated sugar and table salt into the screened product, evenly mixing and packaging; B. preparing a sauce package, specifically, grinding dried mushroom and dried bamboo fungus into 60-80 meshes, then adding bean sauce, vegetable oil, soy sauce, chicken essence, rice vinegar, ginger powder and potassium sorbate, evenly stirring, and packaging. The steamed pork with rice flour made by using the seasoning prepared by the method is rich in fresh and delicious taste and high in nutritive value; the seasoning has the advantage of enabling the steamed pork with rice flour to be well tasty.

Owner:CHENGDU JINHUI TECH

Pure aquatic animal meat sausage containing shellfish meat and its preparation method

A sausage is prepared from the meat of aquatic aniaml and the meat of shellfish through proportionally mixing, adding flavourings, and conventional other steps. Its advantages are rich nutrients, special and delicious taste, and good enjoyment to eat it.

Owner:青岛波尼亚食品有限公司

Ham sausage made from formed aquatic shellfish and preparing method thereof

A seafood-ham sausage is prepared from the shaped aquatic shellfish through taking its edible part, preserving, proportionally mixing it with the meat blocks or minced meat of domestic animals and fowls, and conventional steps. Its advantages are strong fragrance, unique taste and good enjoyment to eat it.

Owner:徐伟

Flavor broth seasoning and preparation method thereof

ActiveCN104664305BStrong fresh fragranceSuppress fishy smellFood scienceMaillard reactionDL-methionine

Owner:HUBEI HAISHUNDA FOOD SCI & TECH CO LTD

Preparation process of fried peanuts

The invention discloses a preparation process of fried peanuts. The preparation process comprises the following specific steps of: 1, selecting whole-grain peanuts, soaking the peanuts in warm water for 5-10 min, transferring the peanuts into cold water to soak for 1-2 min, and taking out the peanuts for after use; 2, putting the peanuts in a huller to remove the coats; 3, putting the hulled peanuts into brine to soak for 7-8 h, and fishing out the peanuts to drain off; 4, frying the peanuts for 10-11 min at a temperature of 160-170 DEG C; 5, putting the peanuts into seasonings to mix thoroughly, and frying the peanuts again for 1-2 min at a temperature of 150-160 DEG C; and 6, after the frying is finished, fishing out the peanuts to drain off, cooling the peanuts to 10-20 DEG C, and packaging the peanuts. By adoption of the preparation process disclosed by the invention, the prepared fried peanuts are crispy, tasty, fresh in smell and pure in flavor; and the taste can be fully blended into the peanuts, so that the taste is more uniform.

Owner:GUIZHOU XUYANG FOOD GROUP

Pure aquatic animal meat ham sausage or western type ham containing shellfish meat and its preparation method

A ham-style sausage or Western ham is prepared from the meat of aquatic animal and the meat of shellfish through proportionally mixing, adding flavourings, and conventional other steps. Its advantages are rich nutrients, special and delicious taste, and good enjoyment to eat it.

Owner:青岛波尼亚食品有限公司

Ham sausage made from formed aquatic shellfish and preparing method thereof

A seafood-ham sausage is prepared from the shaped aquatic shellfish through taking its edible part, preserving, proportionally mixing it with the meat blocks or minced meat of domestic animals and fowls, and conventional steps. Its advantages are strong fragrance, unique taste and good enjoyment to eat it.

Owner:徐伟

Seafood sauce

The invention discloses a sauce, and particularly discloses a seafood sauce. The formula of the seafood sauce comprises tuna concentrate, soybean flour, wheat flour, peanut pulp, white granulated sugar, water, edible salt, dehydrated garlic, brewed vinegar, chilli powder and xanthan gum. The making method comprises the following steps: performing vacuum concentration on cooking liquor, performingweighing according to the formula, performing uniform stirring to obtain mixed sauce, performing cooking for 40-60min, performing cooling, then adding aspergillus for fermentation, then performing loading into bottles and cans for sterilization, and performing sealed storage so as to obtain the delicious seafood sauce with rich seafood flavor. The beneficial effects of the invention are that, 1, the product is convenient to eat, attractive in smell and fine and unique in taste; and 2, the protein variety and the unsaturated fatty acid content of the seafood sauce are improved by utilizing theconcentrated cooking liquor.

Owner:XINGYE ZHOUSHAN +1

Ham sausage made from formed aquatic mollush and preparing method thereof

InactiveCN1214736CSolve the problem of processing junctionFull of nutritionFood preparationFowlBiotechnology

Owner:青岛波尼亚食品有限公司

Preparation method of pure aquatic animal meat ham sausage or western type ham

A pure aquatic animal meat ham sausage or Western-style ham made of 100% aquatic animal meat, using chopped cephalopod aquatic animal meat as a binder to mix with the main ingredient, and then prepared by conventional methods with seasoning accessories Pure aquatic animal meat ham sausage or Western-style ham, wherein cephalopod aquatic animal meat accounts for 8-95% of the total weight of the ham sausage or Western-style ham. Make full use of the strong adhesiveness of cephalopod aquatic animal meat, replace the livestock and poultry meat in the original ham sausage or Western-style ham with cephalopod aquatic animal meat in the production process, and use 100% aquatic animals to make ham sausage or Western-style ham Become reality. It opens up a new way for aquatic product processing. It maintains the nutrition and original flavor of various aquatic animals to the greatest extent. Compared with the existing aquatic animal meat ham sausage or Western-style ham made of livestock and poultry meat in the market, it has stronger fresh flavor and better taste. More nutritious.

Owner:青岛波尼亚食品有限公司

Black wolfberry vinegar and preparation method thereof

ActiveCN103695280BStrong fresh fragranceVinegar process is simpleVinegar preparationSlurryFood flavor

The invention discloses black wolfberry vinegar which is characterized that the method comprises the following steps: fermenting normal wolfberry juice to obtain fermented black wolfberry juice, concentrating the fermented black wolfberry juice into black wolfberry concentrated juice, and blending the black wolfberry concentrated juice with current vinegar, wherein the blending proportion of the black wolfberry concentrated juice and the vinegar is 1:10; a blending process comprises the following steps: immersing 1 kilo of clean dry fruits of wolfberries in hot water of 50 DEG C of which the volume is 5 times as much as that of the dry fruits, mixing into slurry, adding 15 kilos of water in the slurry to boil, keeping the slurry for 30 min under 95 to 100 DEG C, filtering the slurry to obtain the normal wolfberry juice, putting the normal juice in a fermenter, sealing the fermenter, keeping temperature between 90 and 95 DEG C, preserving heat and laying the fermenter naturally for fermentation for 6 to 8 hours, regulating the temperature between 70 and 80 DEG C, laying the fermenter continuously and naturally for fermentation for 60 hours, pouring fermented juice, ultrafiltering the fermented juice to obtain the black wolfberry juice, concentrating the black wolfberry juice into 5 kilos of black wolfberry concentrated juice under 45 to 55 DEG C, and blending 1 kilo of black wolfberry concentrated juice into 10 kilos of current vinegar to obtain the black wolfberry vinegar. The black wolfberry vinegar has fresh flavor and dense taste and rich nutrition, which is health-care vinegar beneficial to health.

Owner:徐州绿之野生物食品有限公司

A kind of chicken powder and its automatic production process

ActiveCN104351726BStrong fresh fragranceGreat tasteFood ingredient as antioxidantSugar food ingredientsCalcium in biologyNutritive values

Owner:广州市华琪生物科技有限公司

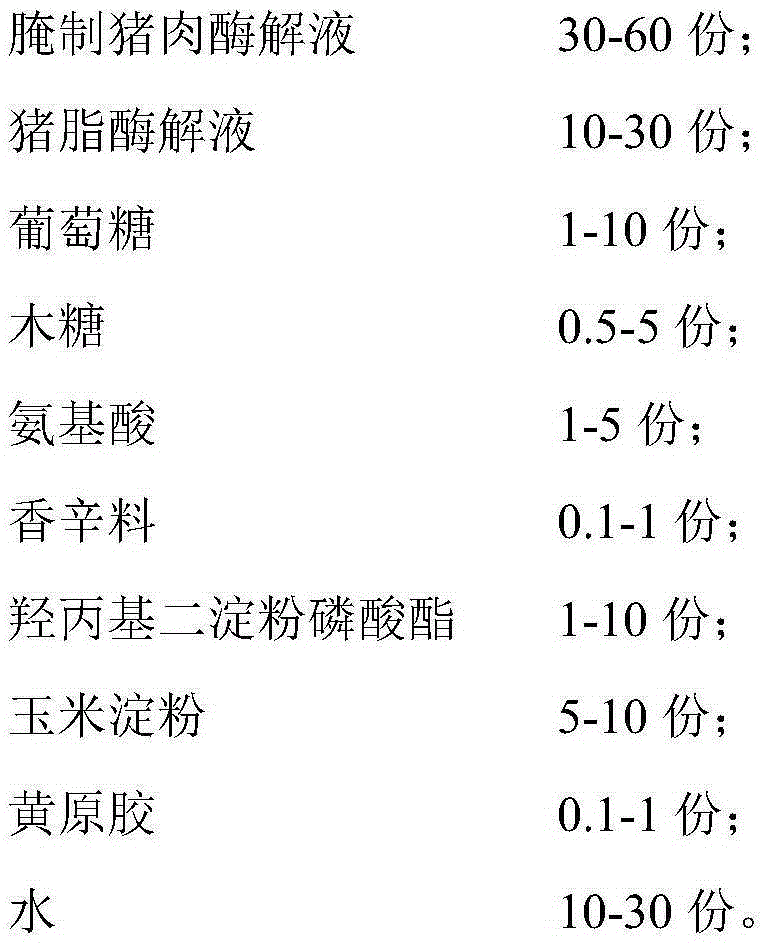

A kind of luncheon meat flavor paste and its preparation method

The invention relates to a luncheon meat flavor paste comprising: by weight, 30-60 parts of marinated pork enzymatic hydrolysate, 10-30 parts of lard enzymatic hydrolysate, 1-10 parts of glucose, 0.3-5 parts of xylose, 1-5 parts of amino acid, 0.1-1 parts of spice, 1-10 parts of hydroxypropyl distarch phosphate, 4-10 parts of corn starch, 0.1-1 part of xanthan gum and 10-30 parts of water. The luncheon meat flavor paste adds compositions with different weight part, and has full-bodied fragrance. The luncheon meat used the luncheon meat flavor paste can reduce the fat content and maintain the original flavor and mouthfeel, is healthy, can meet the edible requirement of people, and can be eaten safely.

Owner:SHANDONG TIANBO FOOD INGREDIENTS

Preparation method of delicious soup

The invention discloses a preparation method of delicious soup. The preparation method comprises the following steps: pretreatment of raw materials, blanching, blanching, burdening, boiling, cooling,packaging and quick-freezing. When the soup is prepared, the old chicken and the chicken are used as main raw materials, and other seasonings are used as auxiliary materials, so that the soup is lessin additive and healthy to eat; during preparation, the fishy smell of the raw materials can be removed through blanching treatment, then the raw materials are boiled for 8-10 hours to be completely fused with other seasonings, and the fresh and fragrant taste is stronger; after preparation, the product is frozen and stored, so that the storage time is longer.

Owner:上海衙宴餐饮管理有限公司

Preparation method of pure aquatic animal meat sausage

A pure aquatic animal meat sausage made of 100% aquatic animal meat, using chopped cephalopod aquatic animal meat as a binder to mix with the main ingredient, and then mixed with seasoning auxiliary materials to make pure aquatic animal meat by conventional methods Meat sausage, wherein the cephalopod aquatic animal meat accounts for 30-95% of the total weight of the aquatic animal meat in the sausage. By making full use of the strong adhesiveness of the cephalopod aquatic animal meat, it becomes a reality to use the cephalopod aquatic animal meat to replace the livestock and poultry meat in the minced aquatic animal meat sausage in the production process. It opens up a new way for aquatic product processing. The nutrition and original flavor of various aquatic animals are kept to the greatest extent. Compared with the existing aquatic animal meat sausage made of livestock and poultry meat as a binder in the market, it has stronger fresh flavor, better taste and richer nutrition.

Owner:青岛波尼亚食品有限公司

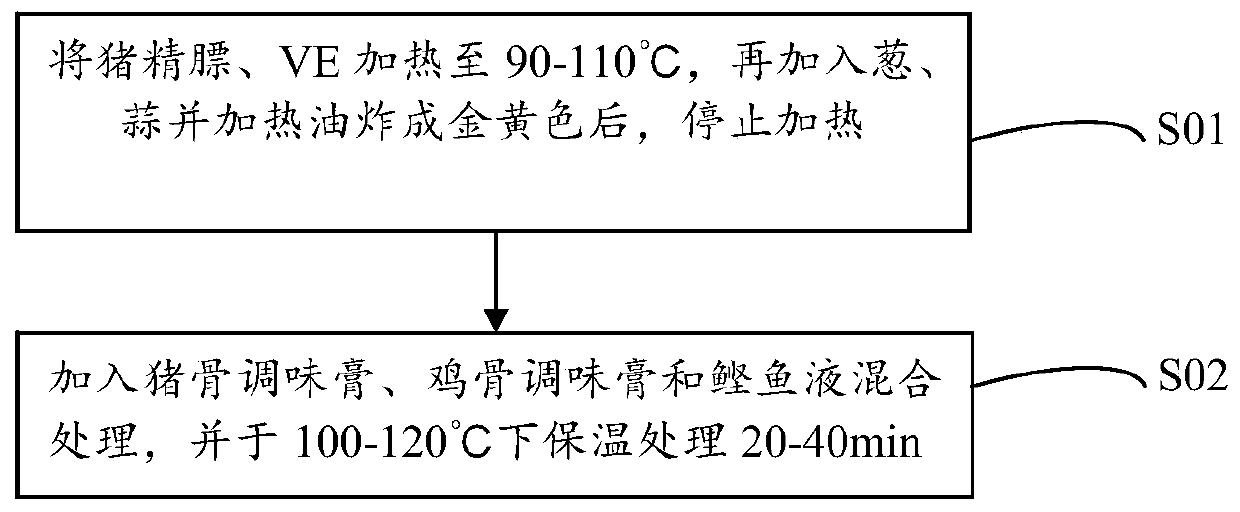

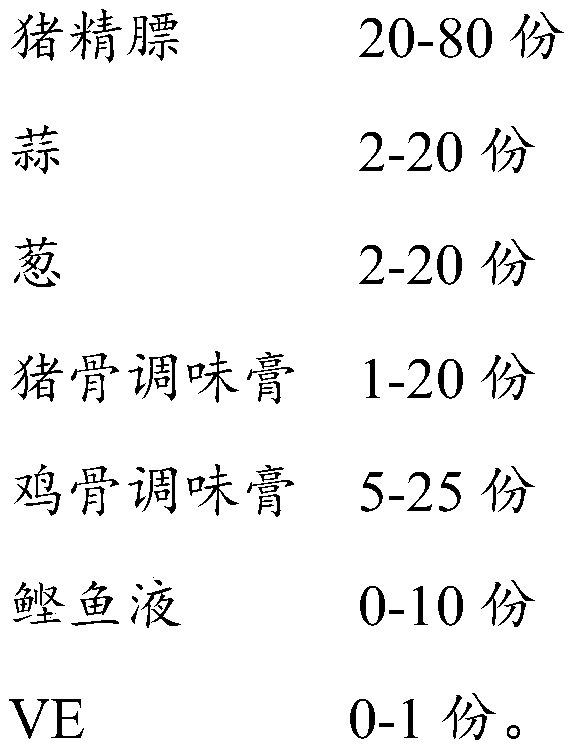

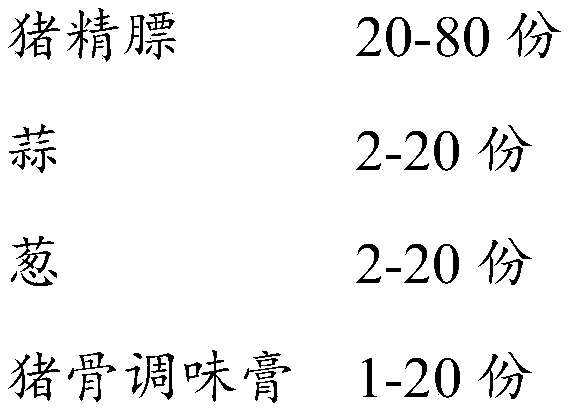

Edible sauce composition, seasoning and application thereof

The invention discloses an edible sauce composition and a decocting method thereof, a seasoning and application thereof. The edible sauce composition is prepared by decocting the following componentsin parts by weight: 20-80 parts of refined pig fat, 2-20 parts of garlic, 2-20 parts of scallion, 1-20 parts of pig bone seasoning paste, 5-25 parts of chicken bone seasoning paste, 0-10 parts of skipjack liquid and 0-1 part of VE. The seasoning comprises the edible sauce composition, and further comprises a powder composition, a vegetable composition and a seasoning oil composition. According tothe invention, the edible sauce composition is prepared by decocting the above components, so the edible sauce composition is in a semi-liquid state, is relatively rich in nutrients, retains the original taste and the original flavor of a bone soup, has natural aroma, and presents taste similar to the taste of dishes stir-fried in a kitchen. The seasoning can be perfectly fused with seasoned instant food to allow the taste of the instant food to be more similar to taste of dishes freshly made in a kitchen; and the seasoning is rich and balanced in nutrition and effectively guarantees the health of seasoned materials.

Owner:JIN MAILANG MIANPIN CO LTD

Sausage made from formed aquatic crustacean and preparing method thereof

InactiveCN1181764CSolve the problem of processing junctionFull of nutritionFood preparationFlavorBiotechnology

The invention relates to a seafood sausage made from shaped aquatic crustacean meat. The crustaceans are first roughly processed, the inedible parts are removed, the edible parts are marinated, and then pre-cooked, and the ratio of 10-90 parts by weight of formed crustacean meat and 1-49 parts by weight of livestock and poultry meat is selected as the main ingredients. Sausages are produced according to conventional techniques. The product of the invention maintains the original flavor and nutrition of the crustacean meat to the greatest extent in the sausage, and has richer fresh flavor and better taste than existing seafood sausages made of crustacean meat mince in the market. The crustacean meat sausage is a real crustacean meat sausage that is delicious and can see the crustacean meat.

Owner:青岛波尼亚食品有限公司

Process for preparing shrimp seed cooked water bamboo

InactiveCN101427754AStrong fresh fragranceNutritional balanceFood preparationNutrientZizania latifolia

The invention discloses a production method of wild rice stem fried with shrimp roe. The method comprises peeling fresh wild rice stem, and cutting into blocks; shredding shallot and ginger; soaking shrimp roe for softening; blanching wild rice stem, cooling, and draining; heating a frying pan with strong fire, adding lard, adding pricklyash peel, stirring with a hand spoon, taking out pricklyash peel when turning black, and heating the frying pan with mild fire; and adding pricklyash peel into another frying pan, adding shredded shallot and ginger, adding fresh soup, adding wild rice stem, adding refined salt and monosodium glutamate, adding softened shrimp roe, boiling, concentrating with mild fire, heating with strong fire, thickening with wet starch, pouring hot pricklyash peel oil, tossing to coat juice and adhere shrimp roe outside wild rice stem, dishing, and covering pease. The product is yellow color and rich flavor, and is crisp and refreshing. The product has balanced nutrients, and has the effects of clearing away heat and toxic materials and relieving restlessness.

Owner:杨国栋

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com