Preparation process of fried peanuts

A technology for fried peanuts and preparation technology, applied in the direction of food science, etc., can solve the problems of difficulty in removing the outer coat, poor taste of peanuts, etc., and achieve the effect of prolonging the shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

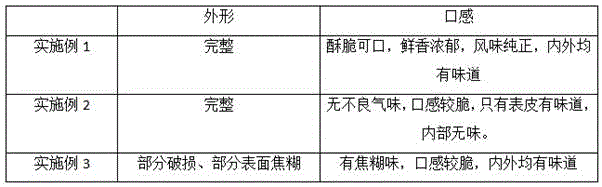

Examples

Embodiment 1

[0023] Production of brine: (1) Divide 25g star anise, 15g cinnamon, 20g cumin, 10g licorice, 10g three Nye, 4g Gan Si, 20g Zanthoxylum bungeanum, 10g amomum, 5g grass cardamom, 15g grass fruit, 8g cloves, etc. into two parts, Put them into two loose gauze bags and tie the mouth of the bag tightly with a string to make a spice bag; then wash and smash 100g of ginger; wash and tie 150g of scallions with their roots; Roast the rock sugar on the fire first, then put it on the cutting board and smash it lightly, then put it into the pot together with 50g of refined oil, stir-fry over low heat until it turns dark red, add 500g of boiling water and stir well, and it will become the color of sugar (3) Put the pot on the fire, add 5000g of pork rib soup, add ginger and onion, add 400g of refined salt and 14g of monosodium glutamate, then put in the spice bag, after boiling, switch to low heat and simmer slowly until the aroma is overflowing , Serve as fresh brine.

[0024] Selection ...

Embodiment 2

[0033] Adopt prior art to make fried peanuts, concrete steps are as follows:

[0034] 1) Select whole grains of peanuts, soak them in salt water with a temperature of 60-80°C and a concentration of 15% for 1-2 hours, filter them out, and set aside;

[0035] 2) Put the peanuts filtered out in 1) into the seasoning liquid, soak for 30-90 minutes and drain;

[0036] 3) Fry the flavored peanuts in 2), the frying temperature is 150-160°C, and the frying time is 6-8 minutes;

[0037] 4) Add the monosodium glutamate to the fried peanuts in step 3) and stir evenly;

[0038] 5) Measure, pack and store the peanuts prepared in step 4) after cooling.

Embodiment 3

[0040] The difference between embodiment 3 and embodiment 2 is that before the peanuts are soaked in salt water, their coat is removed with a peeling machine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com