Patents

Literature

65results about How to "Avoid frying" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

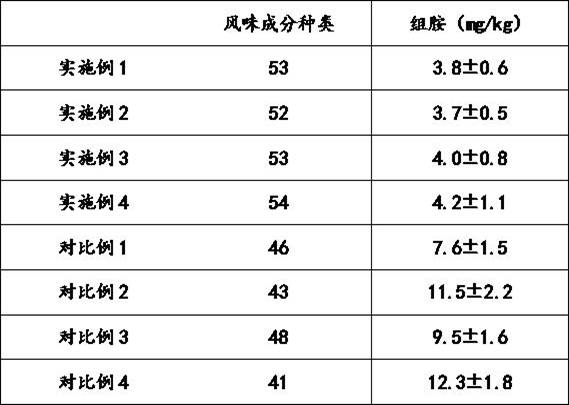

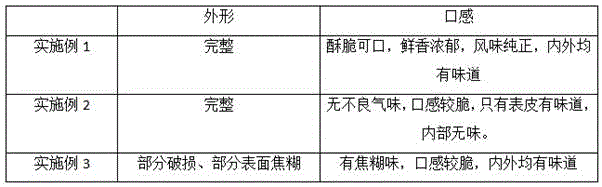

Instant edible mushroom and preparation thereof

InactiveCN101238878AUse with cautionAvoid fryingFood preparationSarcodon aspratusTricholoma matsutake

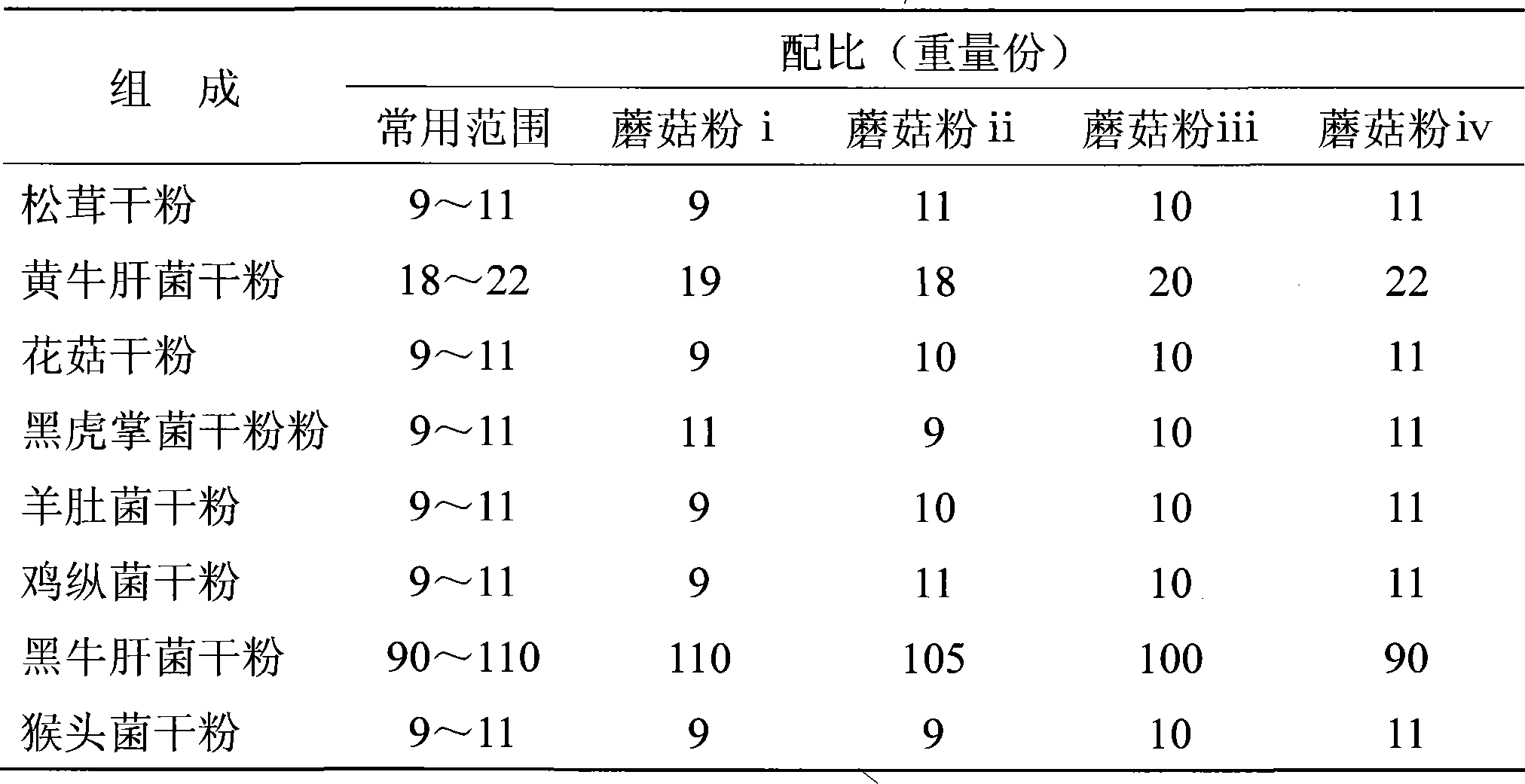

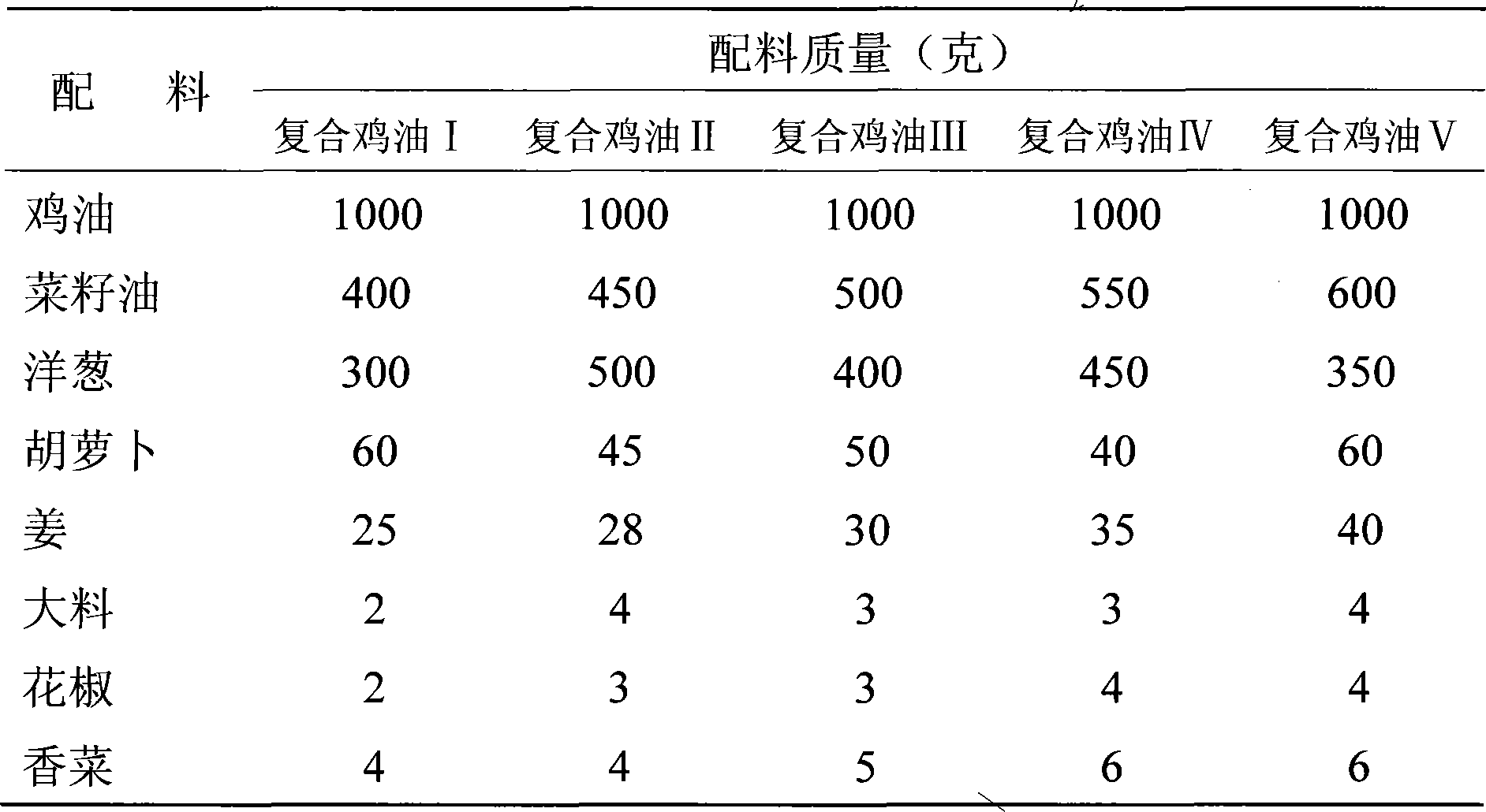

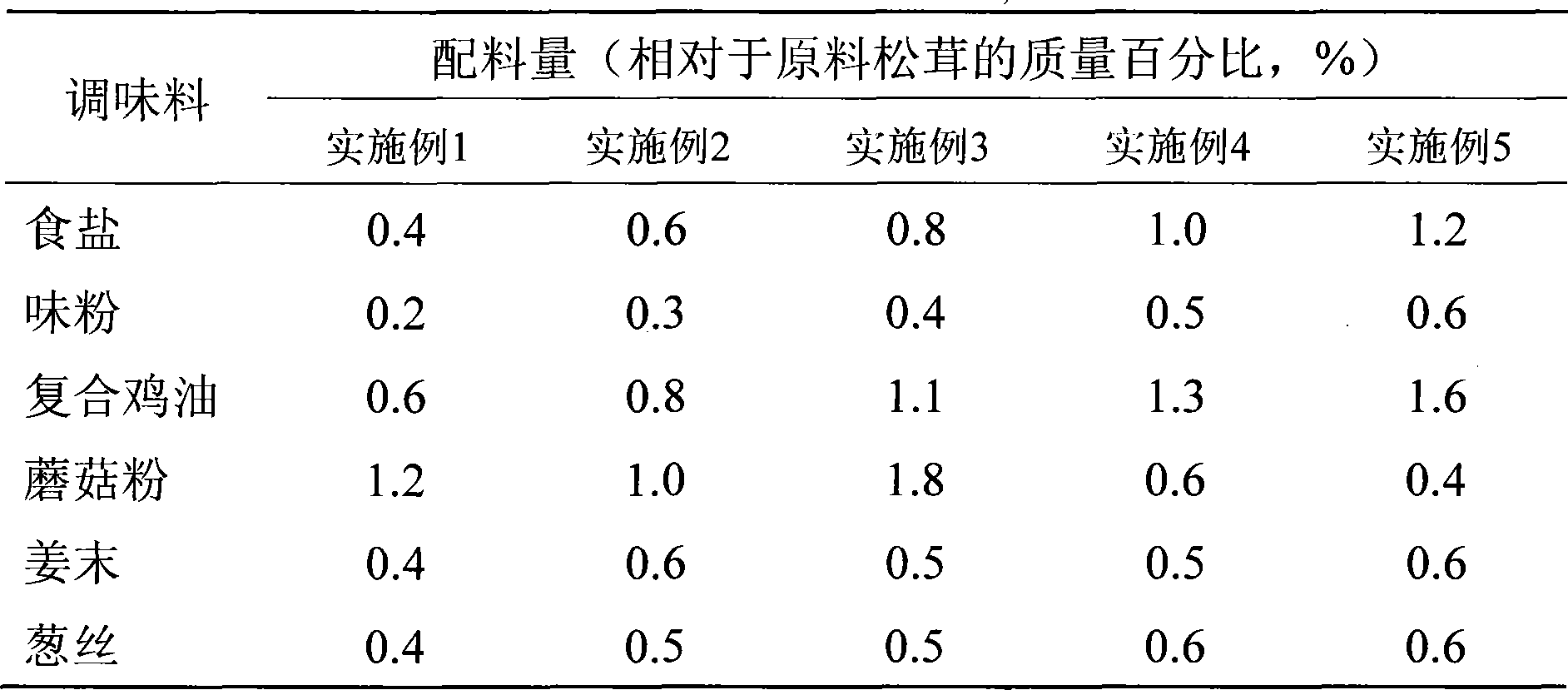

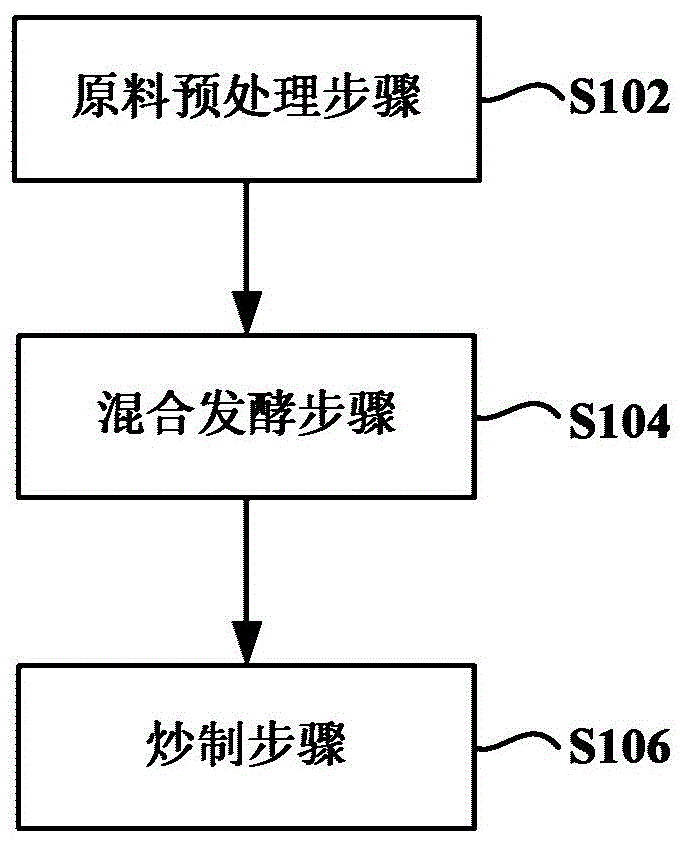

The invention provides a preparation method for instant edible fungi. The seasoner comprises mushroom powder, wherein the composition of mushroom powder is as follows (mass ratio): tricholoma matsutake dry powder 9-11, butter mushroom dry powder 18-22, flower mushroom dry powder 9-11, sarcodon aspratus dry powder 9-11, toadstool dry powder 9-11, termitomyces albuminosus dry powder 9-11, boletus aereus dry powder 90-110, hericium erinaceus dry powder 9-11. The preparation method for instant edible fungi has features of simple technological process, low cost and the made-up instant product has good taste, no sense of oily and with deep natural fragrant of fungus.

Owner:穆佃富

Low-fat and high cellulose soya-bean food, and its processing method

InactiveCN1692810AGreat tasteImprove the body's immunityFood preparationCelluloseNutritive Sweeteners

A low-fat high-fibre soybean food with health-care function is proportionally prepared from soybean dregs, water, wheat flour, salt, non-nutritive sweetening agent, edible soda, garlic powder, honey, onion juice, egg plant oil, butter, shortening agent and flavouring.

Owner:ZHEJIANG UNIV

Production method of fried bean sauce with mushroom and beef

The invention provides a production method of fried bean sauce with mushroom and beef, wherein the main ingredients include beef stuffing or shredded beef, minced mushroom, flour paste and fermented soya paste, the beef stuffing or shredded beef are refrigerated and defreezed under atmospheric temperature, water-loss reducer and anti-oxidizing agent are charged into laminated pan to be boiled, at last soup stock and thickening agent are also charged.

Owner:杨秀敏

Oil red pepper and production method thereof

ActiveCN104814403ABright red colorStrong fragranceFood preparationMonosodium glutamateChilli con carne

The invention provides an oil red pepper and a production method thereof. The oil red pepper includes the following raw materials in parts by weight: 100 parts of fresh red peppers, 50-80 parts of edible oil, 30-60 parts of tomatoes, 10-30 parts of garlic, 10-30 parts of fresh ginger, 0-15 parts of minced meat, 2-8 parts of edible salt, 1-10 parts of white wine, 1-15 parts of crystal sugar, 1-10 parts of wheat sauce, 0-15 parts of mushrooms and 1-7 parts of monosodium glutamate. The oil red pepper has fresh red color and luster, rich fragrance, has a combination of fragrant flavor, and acid and spicy taste, and is fragrant and hot and delicious. Besides, the oil red pepper also has a combination of the oil fragrance of oil prepared red pepper sauce, the delicate fragrance of water prepared red pepper sauce, and the sour taste of fermented red pepper sauce, has a fragrant, spicy and acid taste level sense, and can significantly promote appetite. Research shows that the appearance and mouth feel of the product have relative high market evaluation.

Owner:DAFANG WUJI LAOZIHAO FOOD CO LTD

Ceramic heating body as well as core and atomizer utilizing ceramic heating element

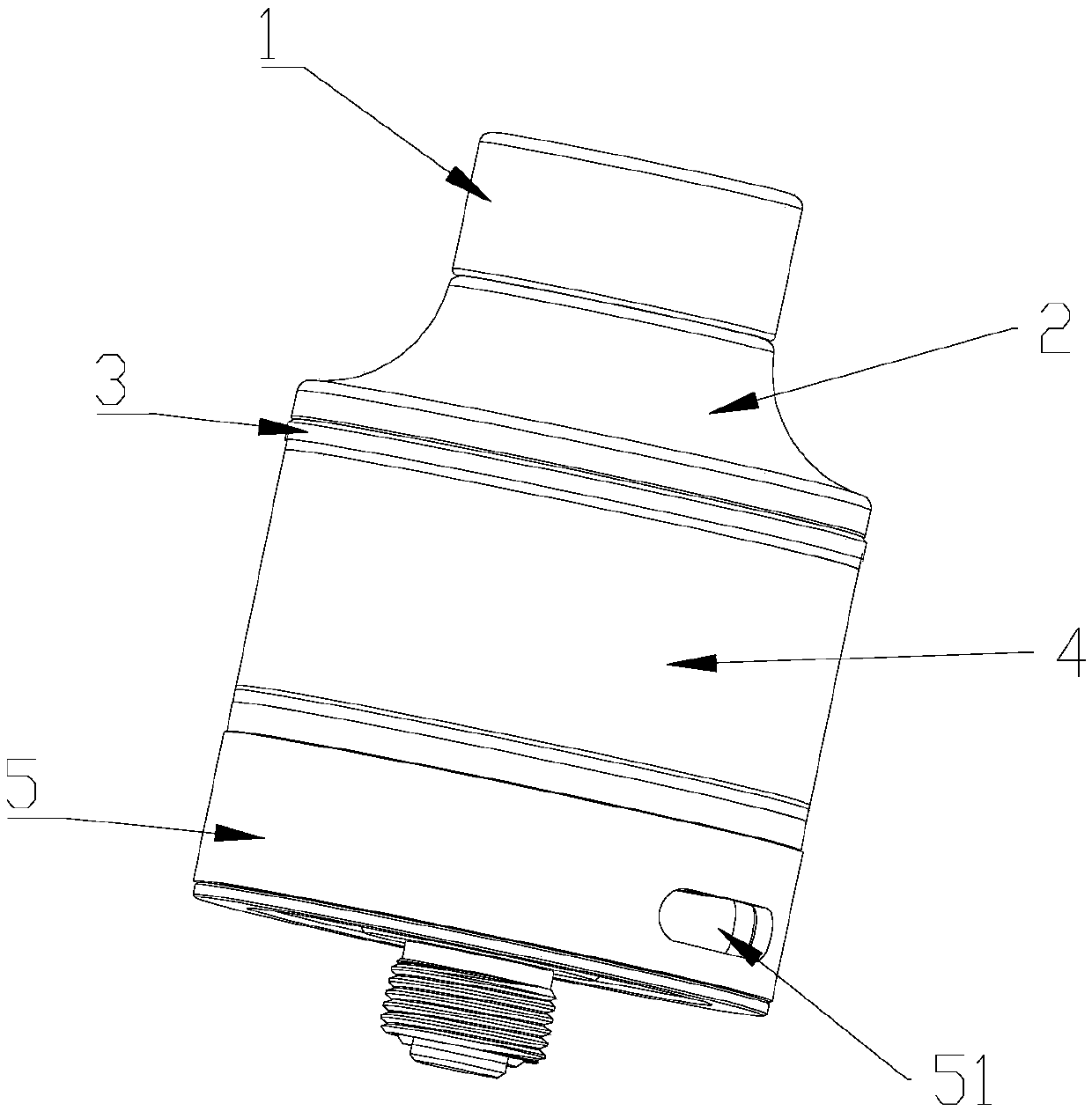

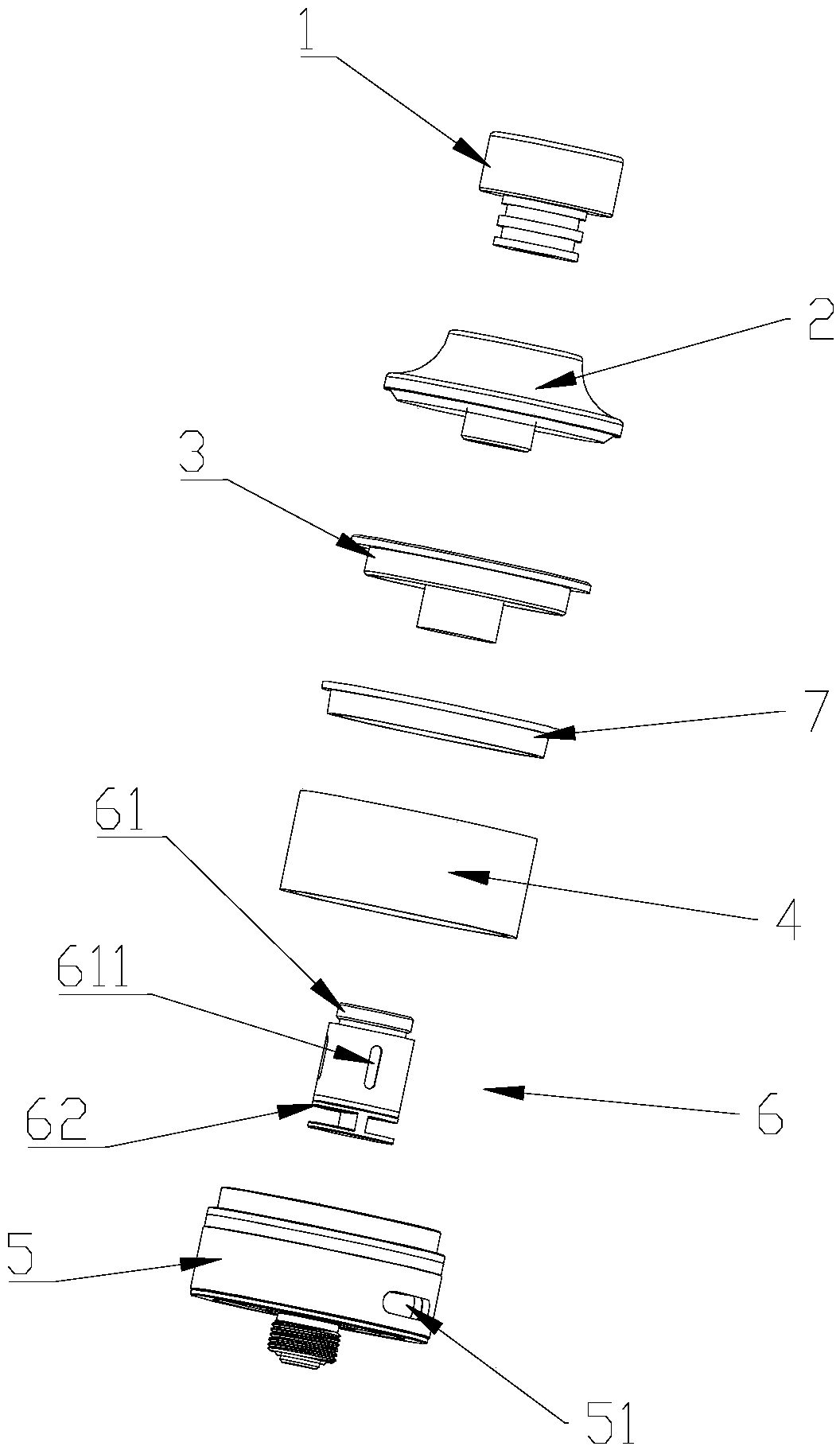

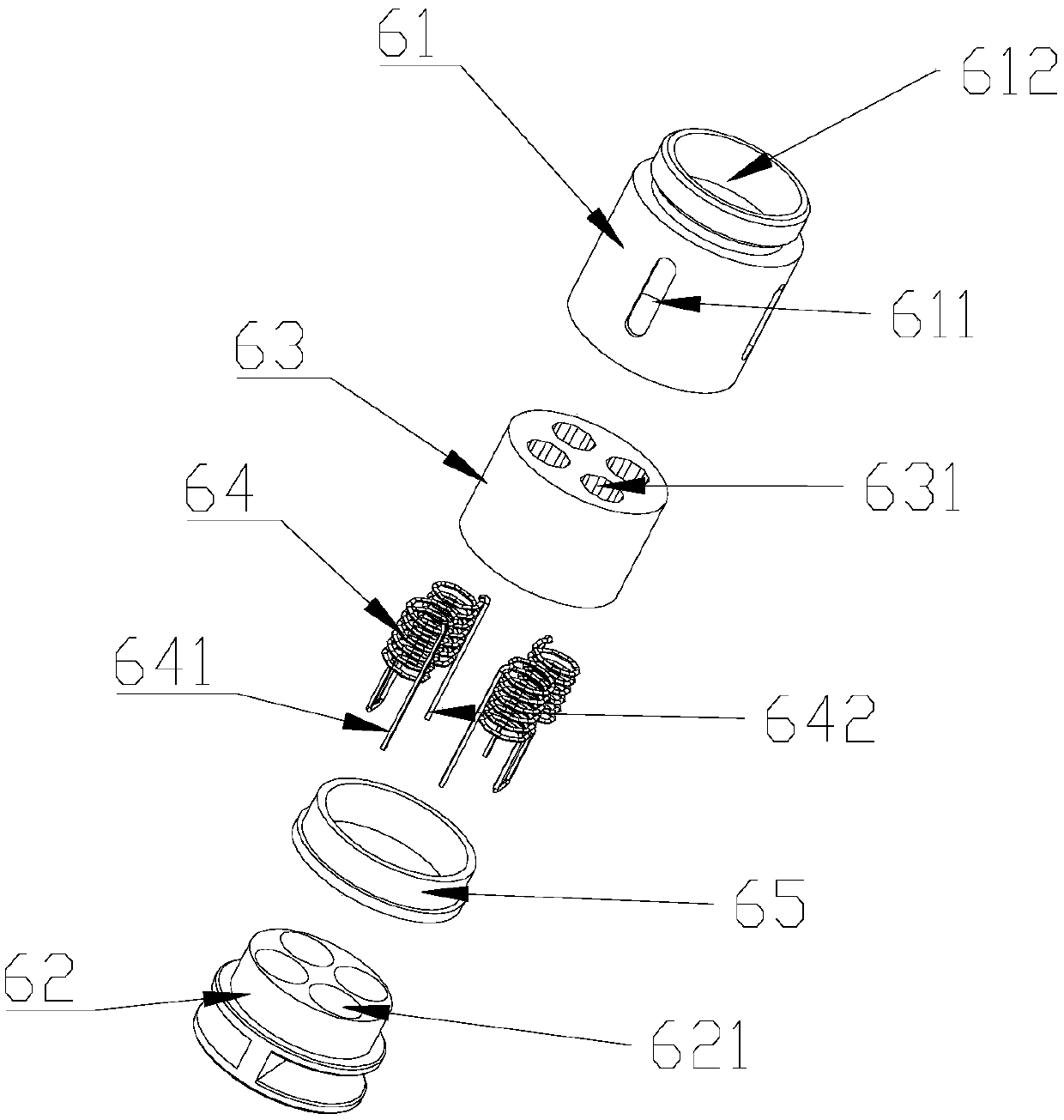

PendingCN109674097AEvenly heatedUniform heating, so that the e-liquid in the oil-conducting cotton can be evenly atomizedTobacco devicesMouthfeelHeating element

The invention relates to a ceramic heating body as well as an atomization core and an atomizer which utilize the ceramic heating body. The ceramic heating body comprises a suction nozzle, an upper cover, an oil injection ring, an oil storage bin and a base, wherein the base and the oil injection ring are respectively arranged at two ends of the oil storage bin, the atomization core is arranged inthe oil storage bin, and the lower end of the atomization core is sealed and fixed in the base; an oil injection hole is formed in the oil injection ring and is communicated with the oil storage bin,the upper cover is arranged at the upper end of the oil injection ring, the suction nozzle is arranged at the upper end of the upper cover and is communicated with an atomization hole in the upper endof an outer cover through the upper cover and the oil injection ring. According to the ceramic heating body, an oil bursting phenomenon can be effectively prevented, and the good taste can be still preserved in a high-power working state, so that the user experience is effectively improved.

Owner:欧俊彪

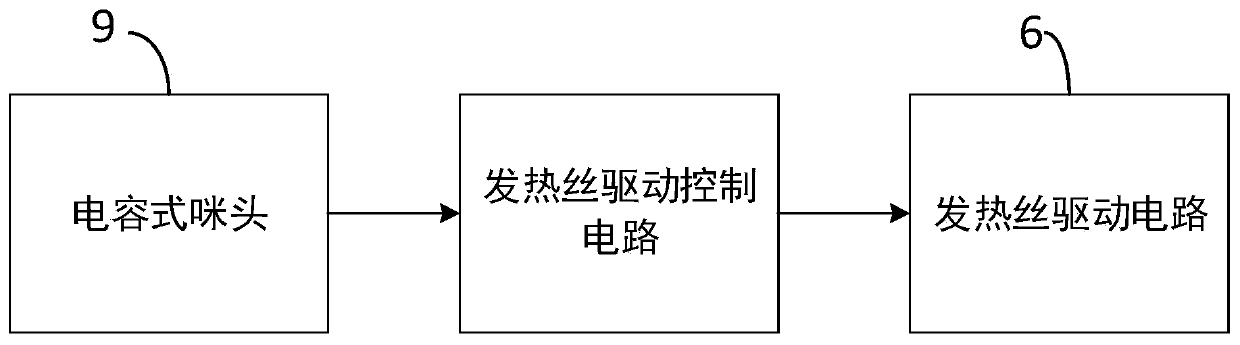

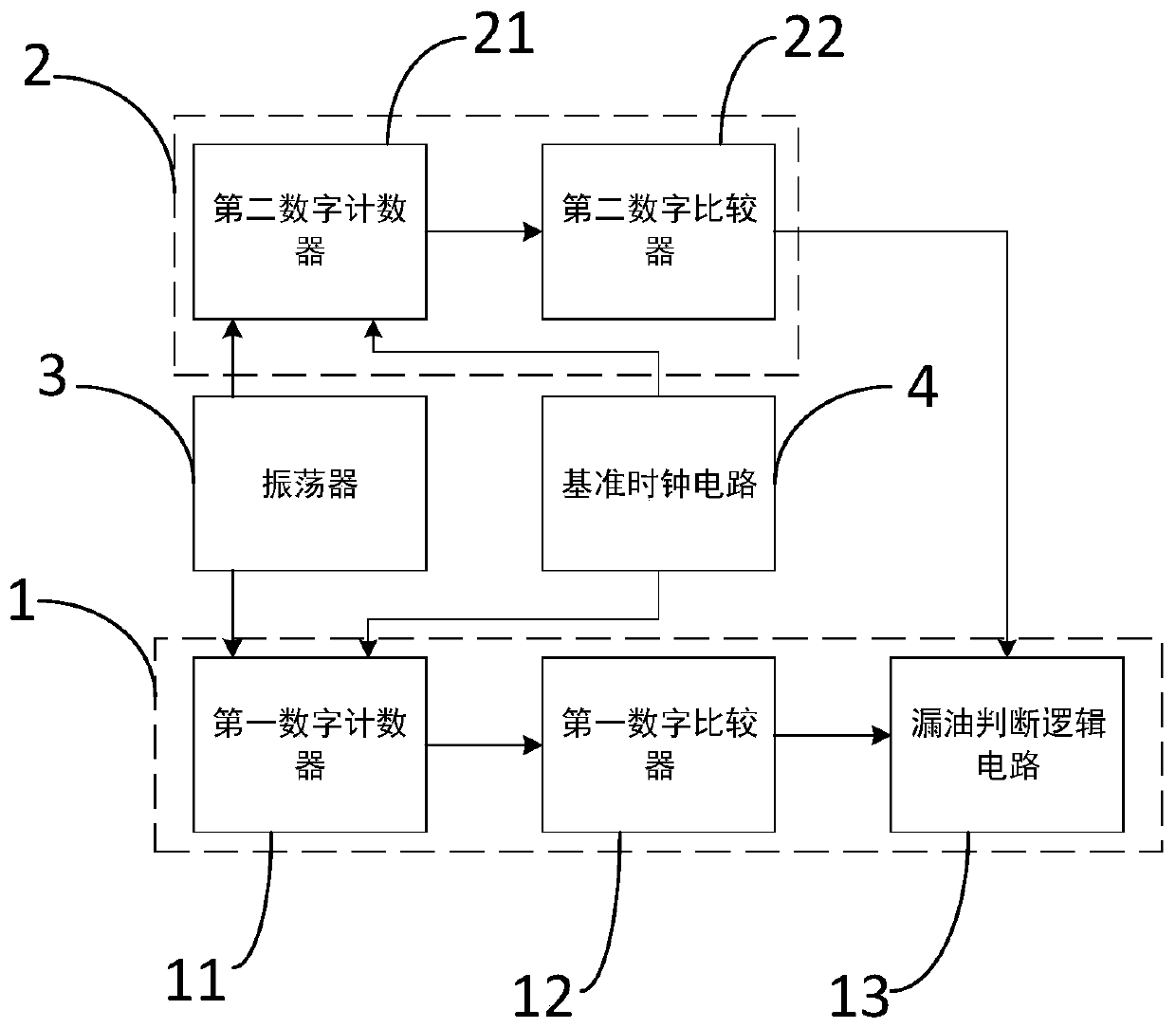

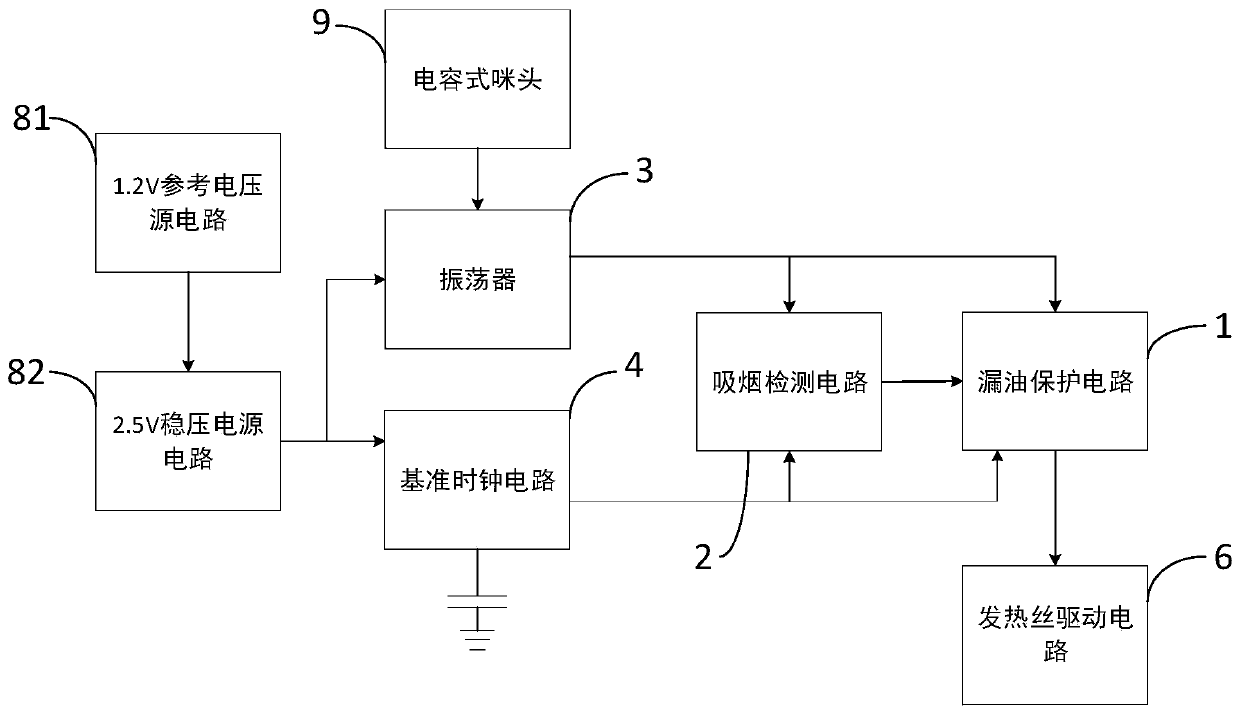

Oil leakage prevention electronic cigarette heating wire driving control circuit and method, chip and electronic cigarette

Owner:SHENZHEN CHITAI ELECTRONICS TECH CO LTD

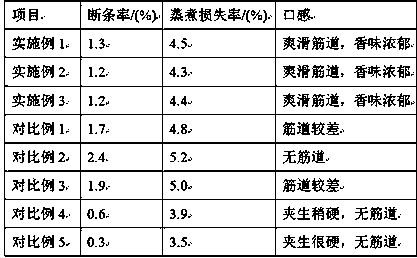

Preparation method of instant tough and chewy coarse cereal nutritious noodles

InactiveCN110292094AFull of nutritionSmooth ripeningVegetable proteins working-upFermentationMouthfeel

The invention mainly relates to the technical field of noodle processing, and discloses a preparation method of instant tough and chewy coarse cereal nutritious noodles. The method comprises the stepsof coarse cereal dough making, first dough kneading, first fermentation, second dough kneading, second fermentation, shaping, curing and drying. The instant tough and chewy coarse cereal nutritious noodles prepared through the preparation method of the instant tough and chewy coarse cereal nutritious noodles are rich in nutrition, tough, chewy, smooth, free of additive, natural and healthy, in the eating aspect, a lot of cooking time is saved; boiling water is added in the coarse cereal powder, stirring is conducted, the coarse cereal powder can be rapidly cured at a high temperature, the aroma and cohesiveness of the coarse cereal powder are increased, the coarse cereal powder can be rapidly bonded with flour, noodle processing and shaping are facilitated, and the tough and chewy taste of the noodles is improved.

Owner:太和县叶顺食品厂

Spicy chili oil and preparation method thereof

The invention discloses spicy chili oil and a preparation method thereof. The chili oil comprises 600 parts of rapeseed oil, 144 parts of chilies, 12.2 parts of sesame, 5.7 parts of pepper powder, 4.8parts of peanut meal, 3 parts of Sichuan pepper meal, 3 parts of roses, 3 parts of scallions, 3 parts of garlic and 0.6 part of spice. The preparation method comprises the following steps of pulverizing the chilies and the spice to obtain chili powder and spice powder; heating 300 parts of the rapeseed oil to 280 DEG C, and naturally cooling the oil to obtain cold oil; heating the rest of the rapeseed oil to 280 DEG C; adding the scallions and the garlic, conducting frying until a spicy smell is generated, and taking out the mixture to obtain hot oil; adding 50 parts of the cold oil into thehot oil; when the oil temperature is lowered to 220 DEG C, adding the sesame and the chili powder into the hot oil; after the color of the chili powder is changed, adding the rest of the cold oil foruniform mixing, and then adding the peanut meal, the Sichuan pepper meal, the pepper powder, the spice powder and the roses to obtain a finished product. The chili oil can solve the problems that existing chili oil is light in spicy smell, poor in spicy smell persistence and too hot and greasy.

Owner:罗远孺

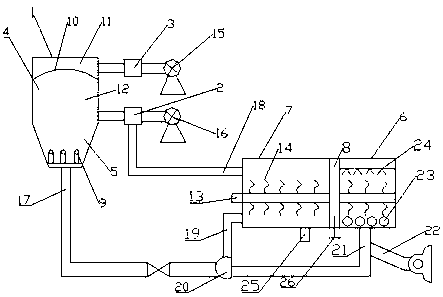

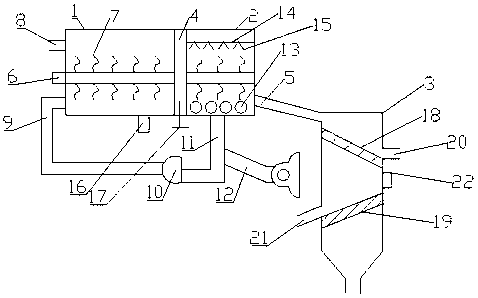

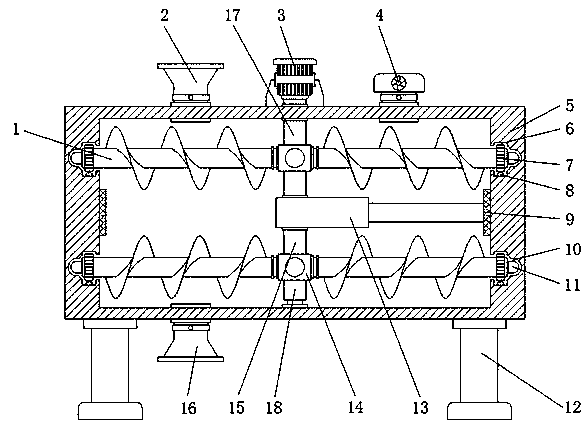

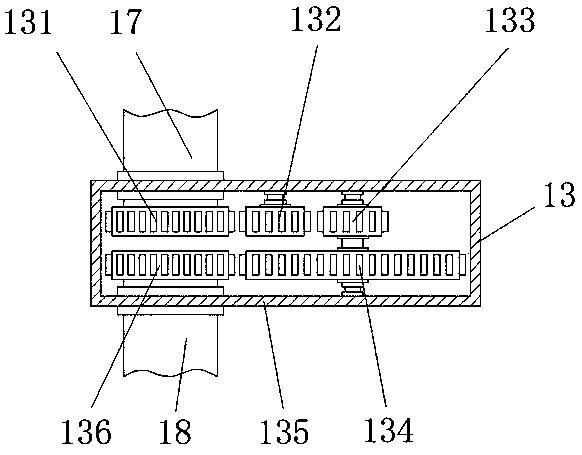

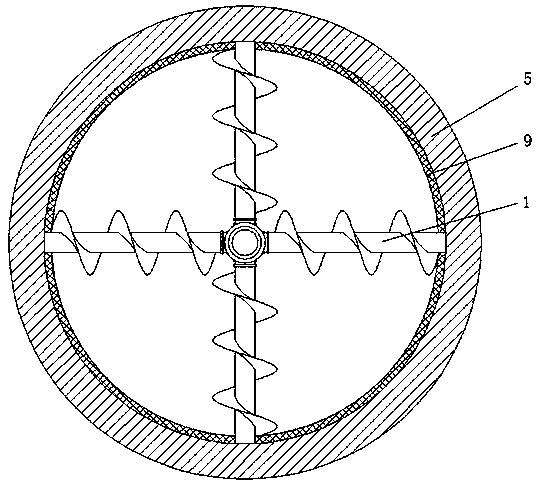

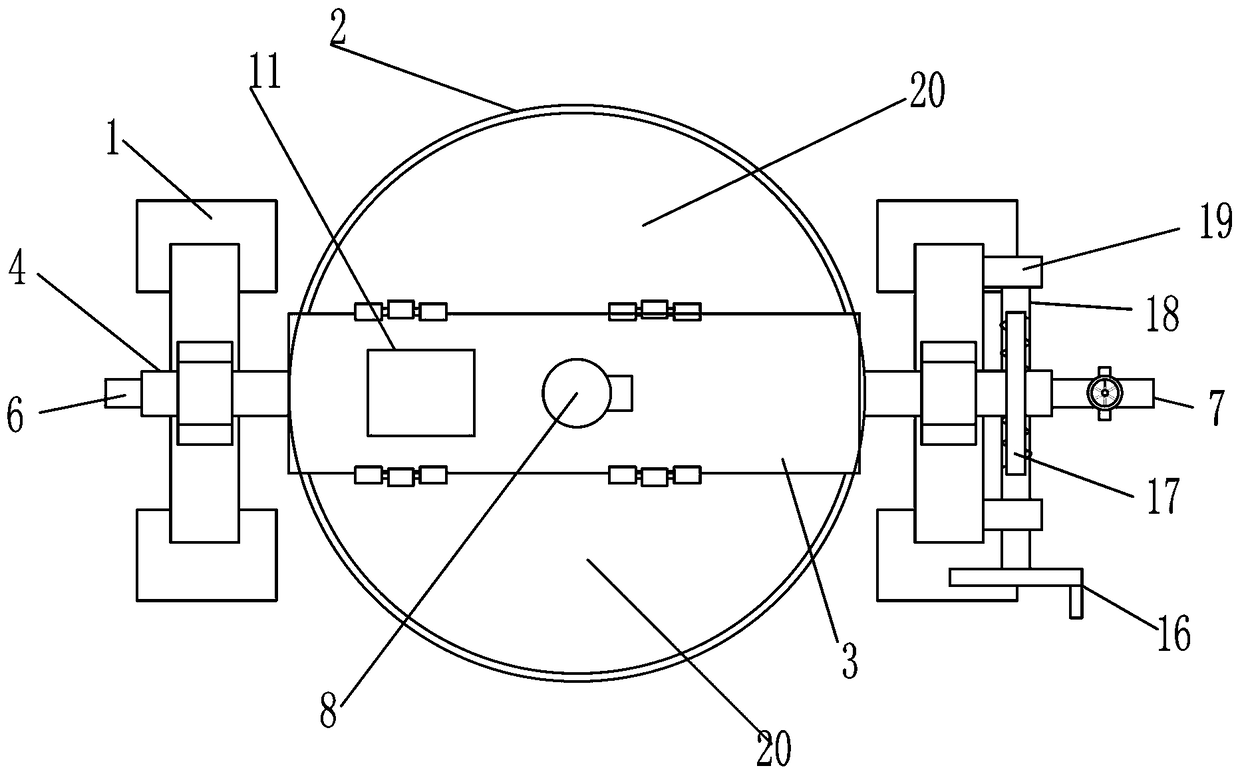

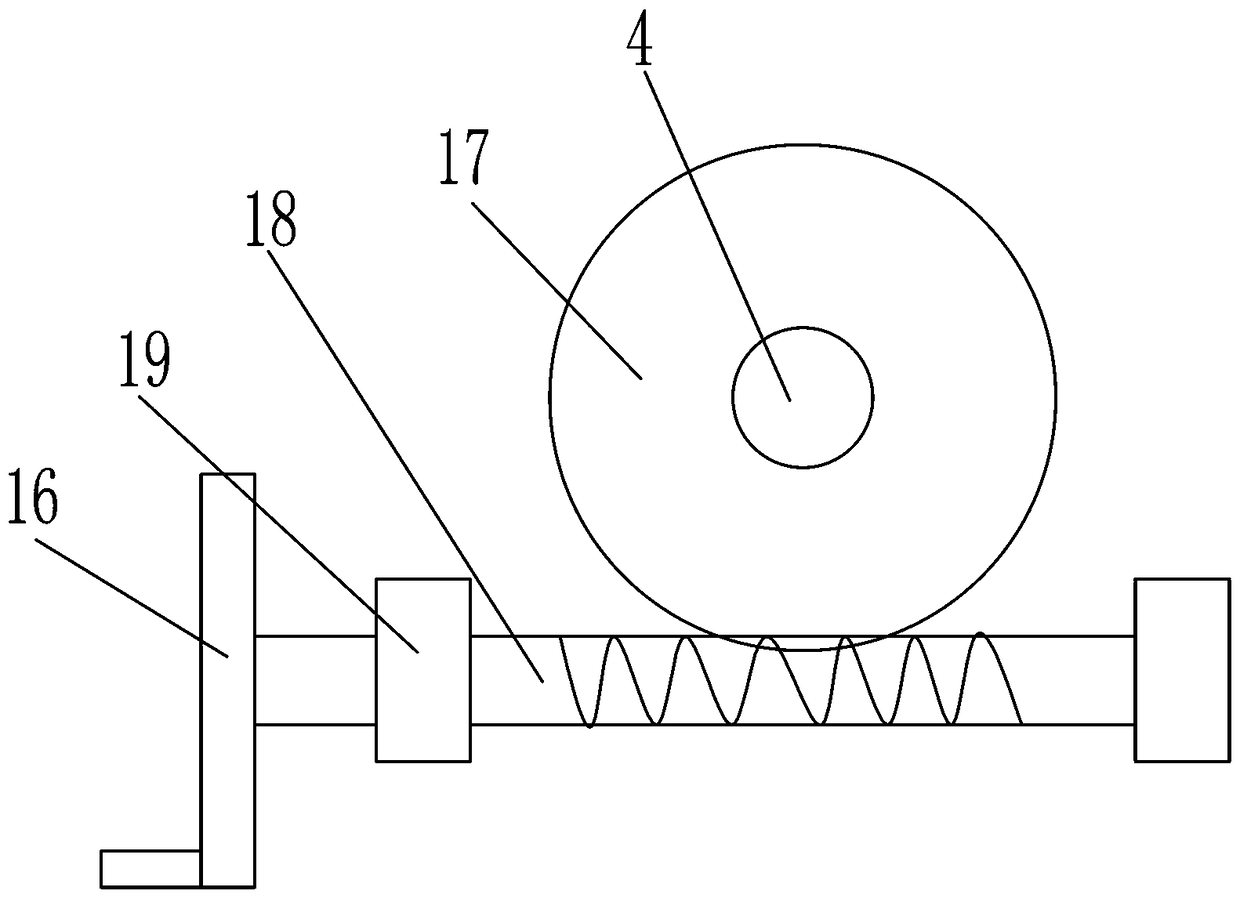

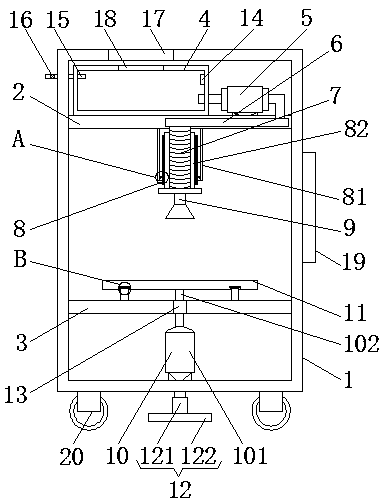

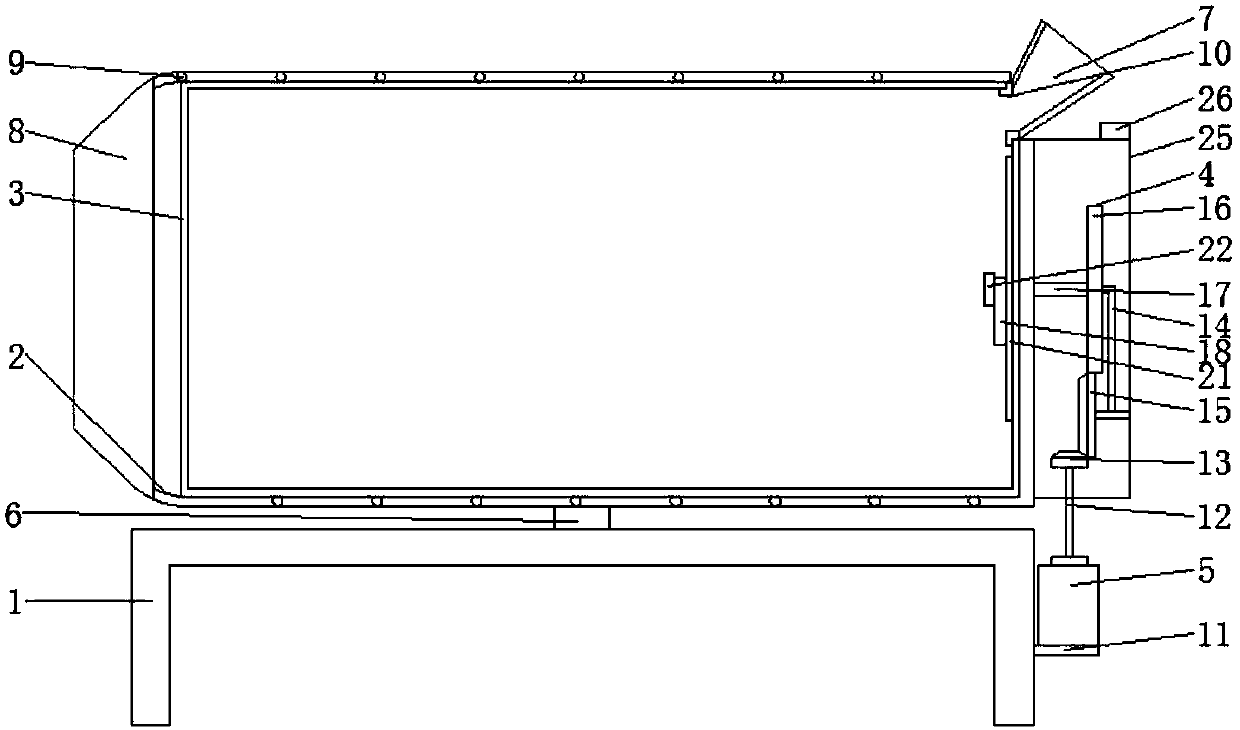

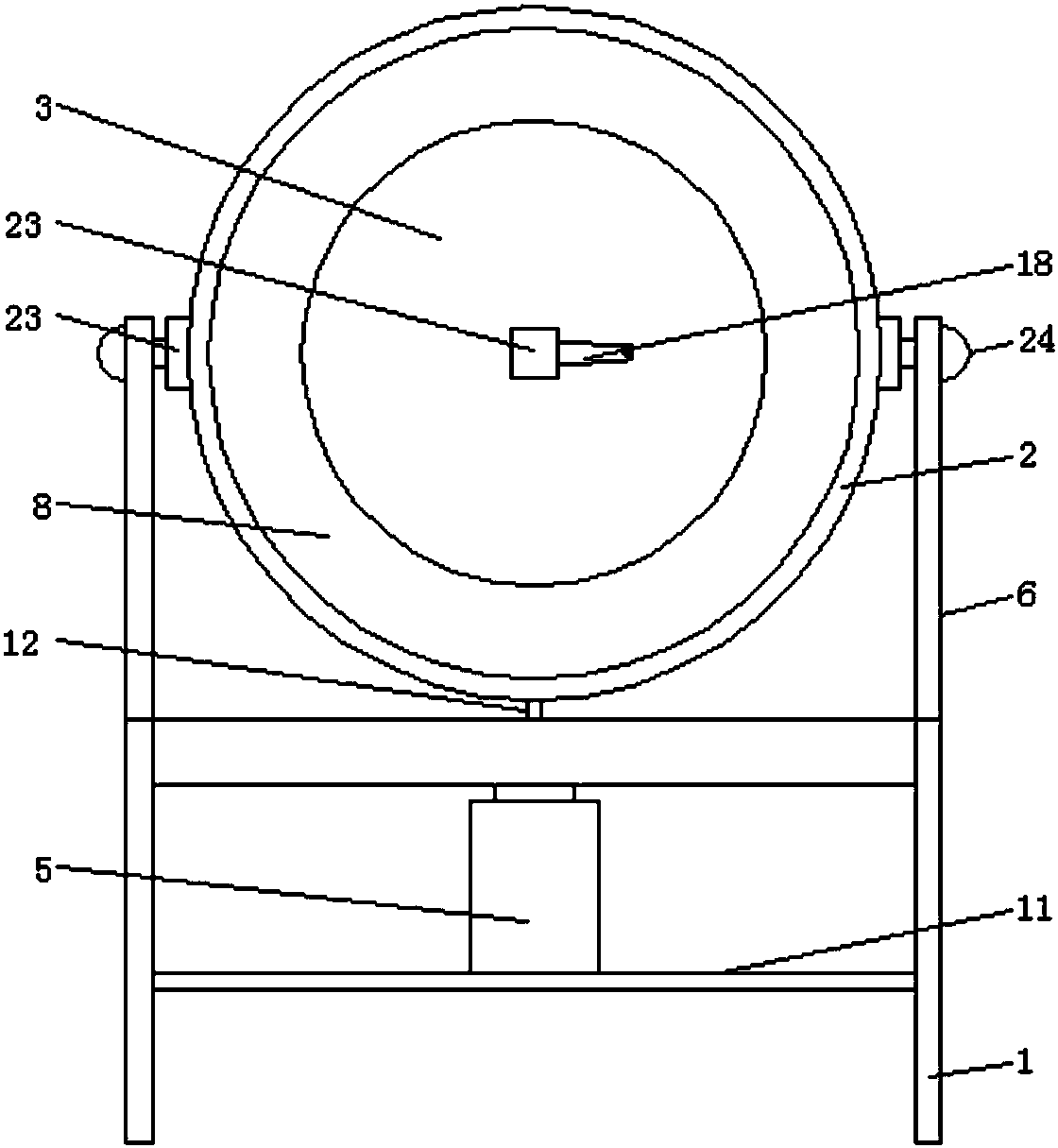

Sesame seed stir-frying device with preheating

The invention discloses a sesame frying device with preheating, which includes a preheating drying device and a roasting device. The preheating drying device includes a drying barrel, a collection chamber and an impurity chamber. The drying barrel includes a fixedly connected drying chamber and a drying chamber. Drying cone, the drying cone is located at the lower part of the drying chamber; the roasting device includes a frying device and a cooling drum, the frying device includes a drum, the cooling drum is arranged at the outlet end of the drum, and the cooling drum passes through the intermediate piece and the drum Connected, the cooling cylinder is provided with a cooling outlet. The sesame frying device with preheating of the present invention has wide applicability, preheating and drying can greatly improve the efficiency of sesame frying, the frying device ensures that the sesame is evenly fried, and the frying situation can be monitored at any time during the frying process, At the same time, the excess high temperature during the frying process can be used to fry the sesame seeds at a low temperature. The fried sesame seeds can be cooled in time, and the entire processing process can also ensure continuity.

Owner:黄林海

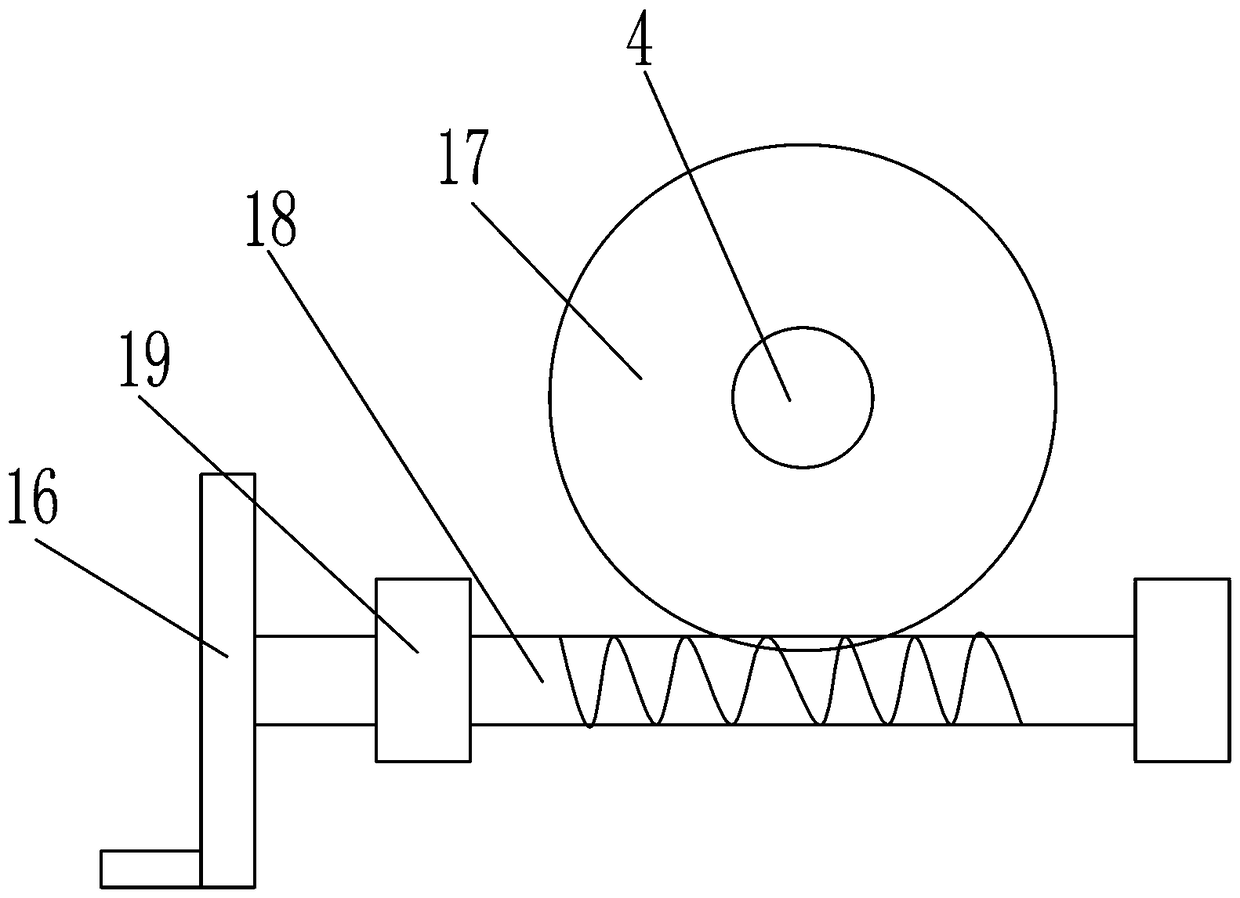

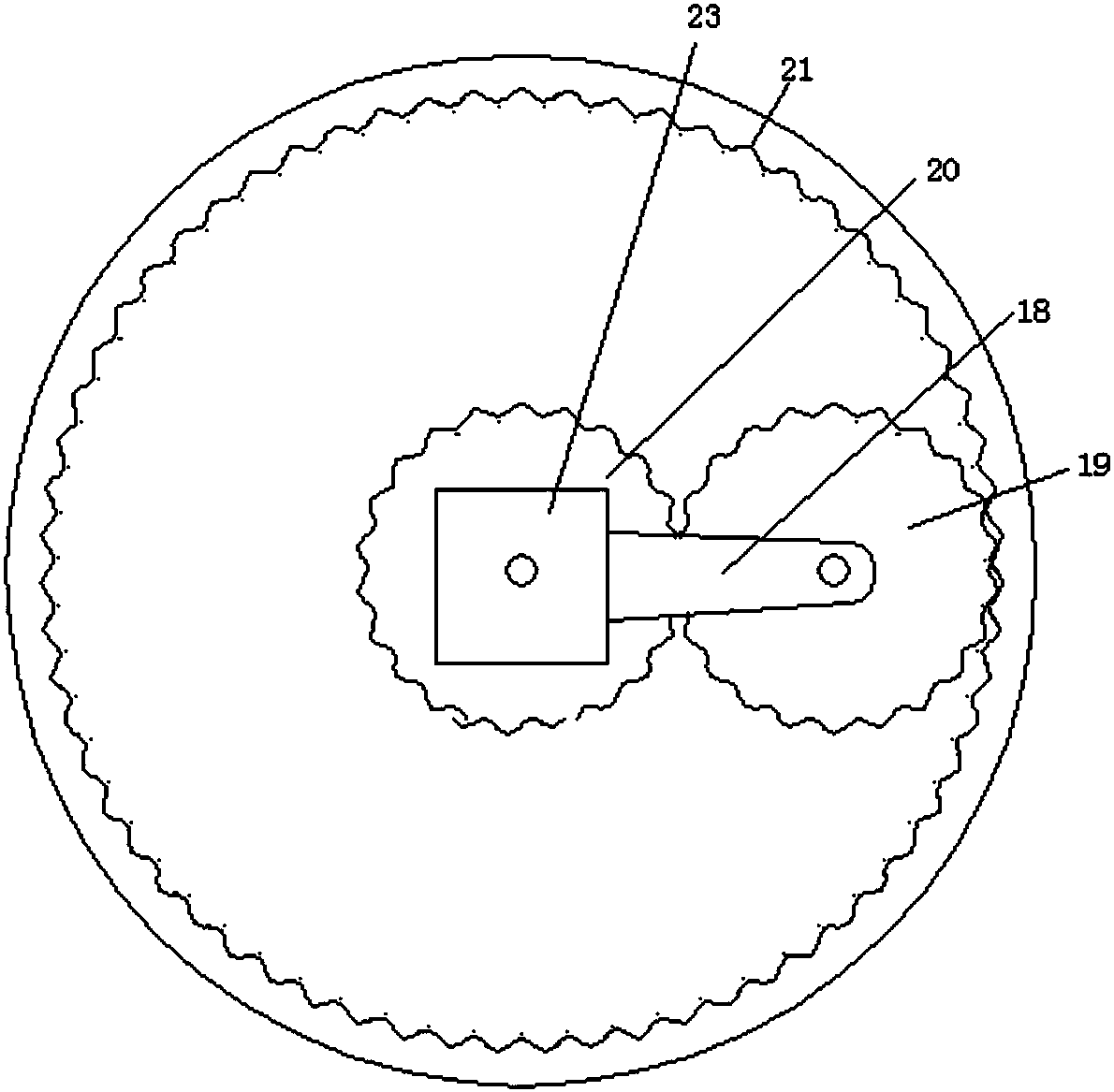

Seasame roasting device for sesame seed candy

InactiveCN107692278AStir fry evenlyAvoid under-cooking or fryingSievingScreeningEngineeringMiddleware

The invention discloses a sesame roasting device for sesame sugar, which comprises a roasting device and a grading device. The roasting device includes a roasting device and a cooling cylinder. The cylinder is connected with the rotating cylinder through an intermediate piece, and the cooling cylinder is provided with a discharge port, which is connected with the classification device. Through the sesame roasting device of the present invention, it is ensured that the sesame is evenly stir-fried, and the roasting situation can be monitored at any time during the roasting process to avoid the occurrence of insufficient roasting or frying, and at the same time, the excess high temperature in the roasting process can be used to affect the temperature of the sesame seeds. Follow-up low-temperature frying, but also timely and effective cooling.

Owner:黄林海

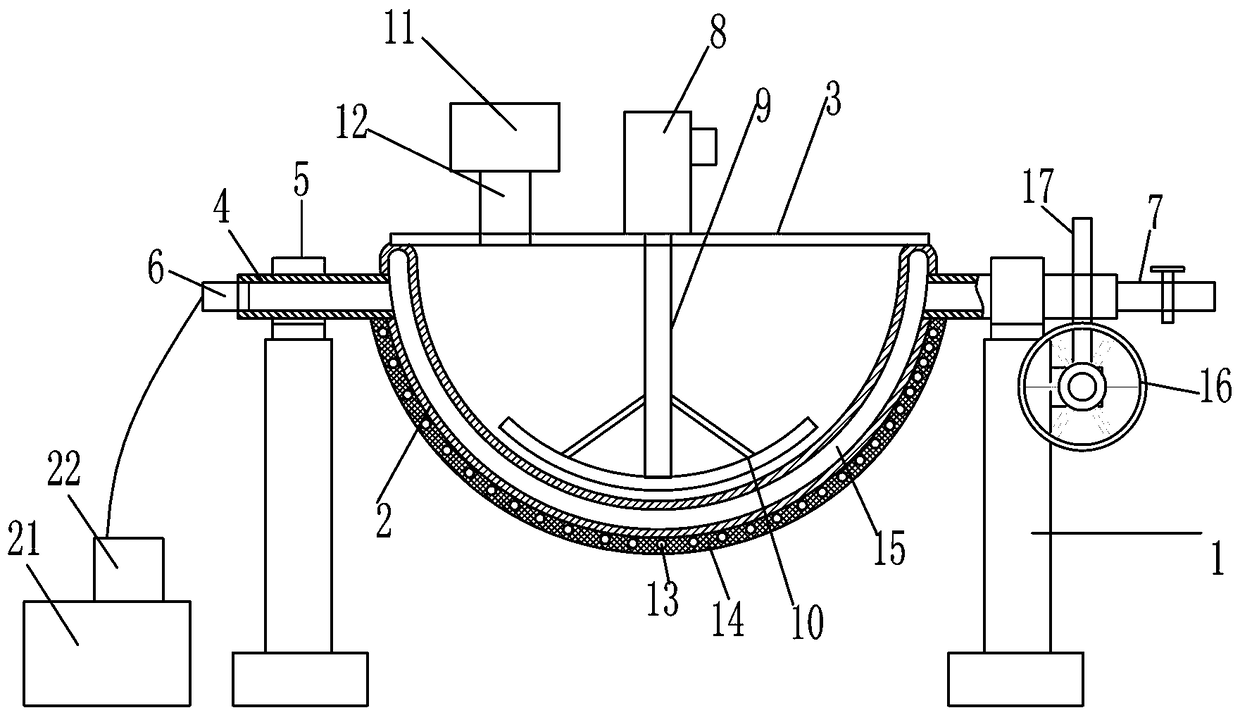

Discharge device of medicine frying pan used for Chinese herbal medicine processing

PendingCN108498338AHeat stableRise steadilyPharmaceutical product form changeDomestic articlesTurbineChinese drug

The invention relates to a discharge device of a medicine frying pan used for Chinese herbal medicine processing, comprising a discharge hand wheel, a discharge worm, a discharge turbine and a shaft sleeve, wherein the shaft sleeve is fixedly connected with a support, the discharge worm is connected into the shaft sleeve by a bearing, the discharge hand wheel is arranged at one end of the discharge worm, the discharge worm is meshed with the discharge turbine, and the discharge turbine is arranged on a rotating shaft. The discharge worm is rotated by rotating the discharge hand wheel, so thatthe discharge turbine rotates; the discharge turbine is arranged on the rotating shaft and is connected with the rotating shaft by a bearing, so that the rotating shaft can be driven to rotate by therotation of the discharge turbine, so that a pan inclines laterally to pour fried Chinese herbal medicine out of the pan, thus realizing the aim of automatically discharging.

Owner:禹州市厚生堂中药有限公司

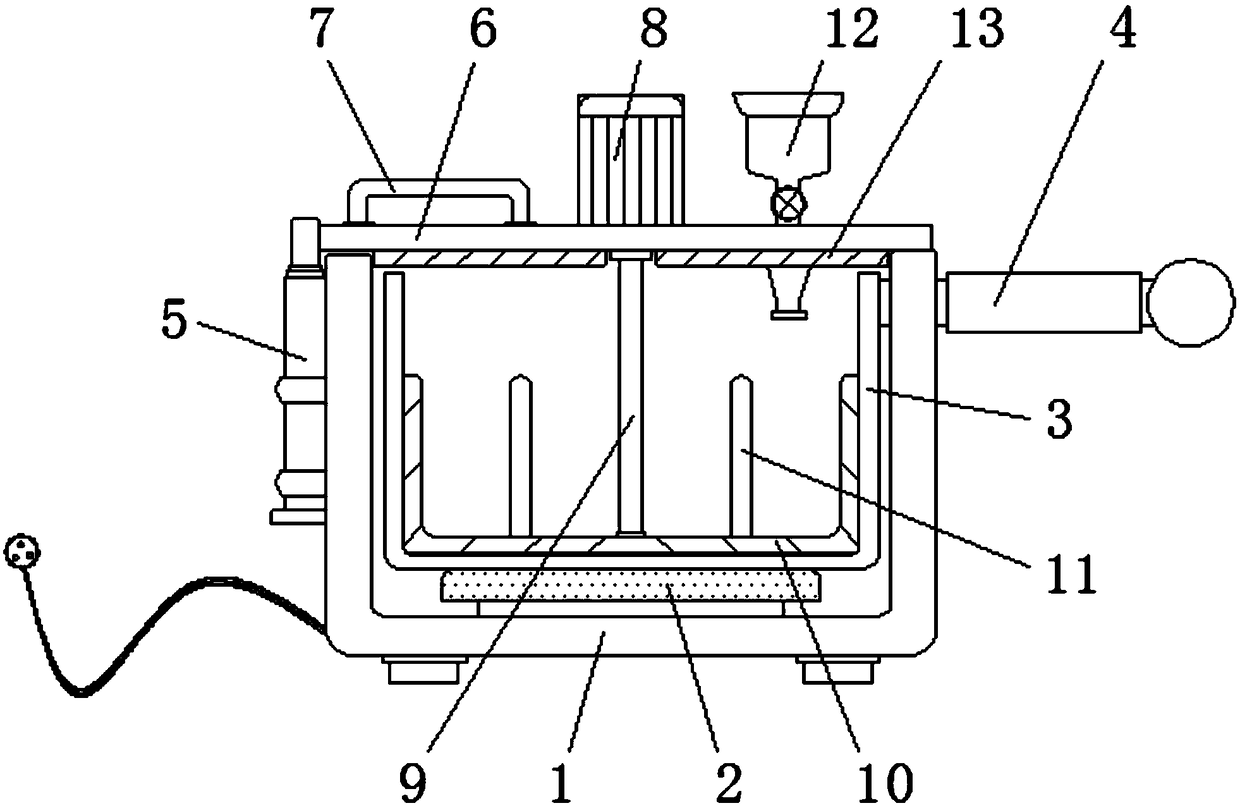

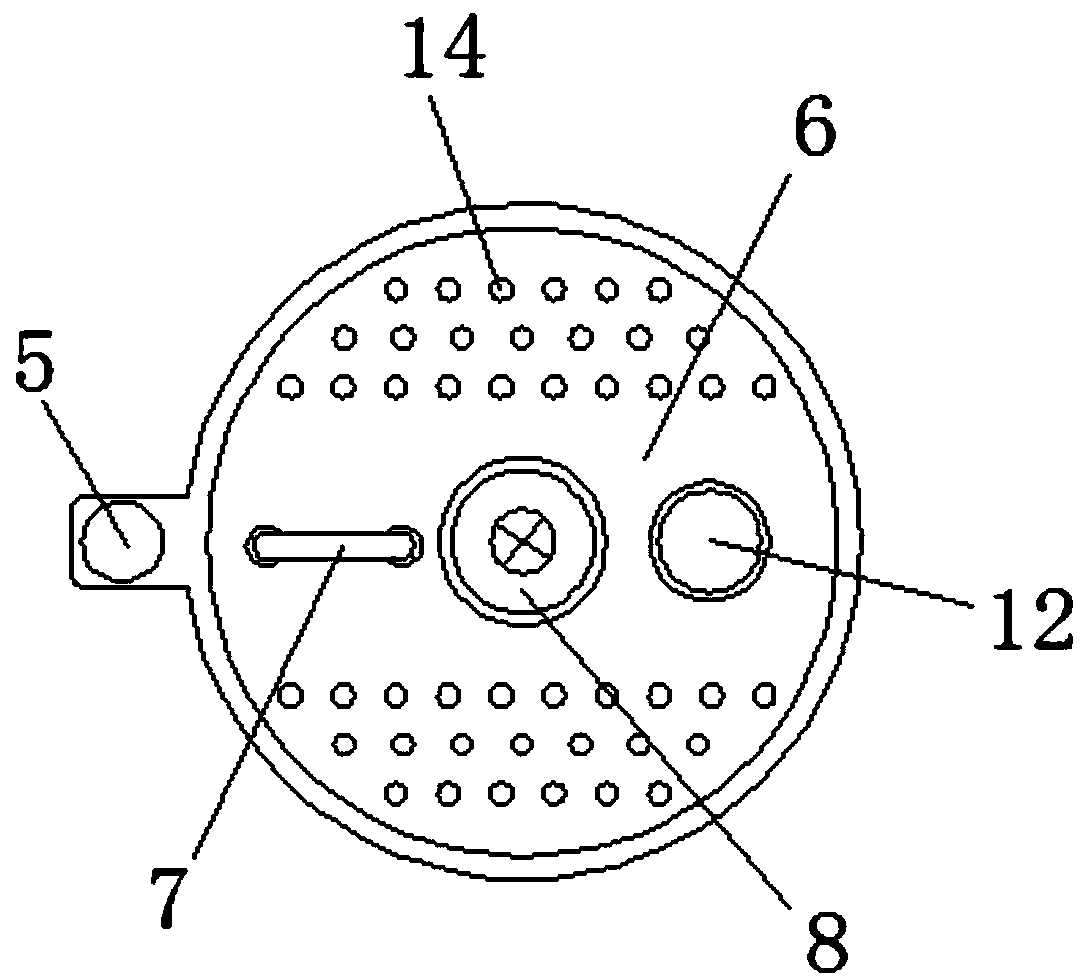

Coffee beans electric frying machine and application method thereof

The invention discloses a coffee beans electric frying machine and an application method thereof. The coffee beans electric frying machine comprises a box body, wherein the center of an inner cavity of the box body is provided with a transmission column, the bottom of the transmission column is rotatably connected with the box body by virtue of a rotating shaft, the top of the transmission columnpenetrates through the box body, an extension end of the transmission column is connected with an output shaft of a driving motor in a transmission manner, the transmission column is of a two-sectionstructure, an inversion mechanism is rotatably arranged between two ends of the transmission column by virtue of a bearing sleeve, two sides of a vertical end of the outer surface wall of the transmission column are respectively symmetrically provided with a limiting sleeve in a welding manner, a vertical end of an outer surface wall of the limiting sleeve is rotatably connected with a spiral rodby virtue of a rotating shaft, one end of the spiral rod is successively provided with a gear sleeve and a limiting block in a welding manner, the inner side bottom of an annular gear groove is connected with an annular rack in a welding manner, and one side of the top of the box body is communicated with a pressurizing air pump. In the coffee beans electric frying machine, by virtue of the rotation of the two groups of spiral rods, coffee beans can be sufficiently stirred and crushed, the pressure in the inner cavity of the box body can be increased by virtue of the pressurizing air pump, andthe heating speed and heating effect of the coffee beans can be improved.

Owner:NATURAL MEDICINE INST OF ZHEJIANG YANGSHENGTANG

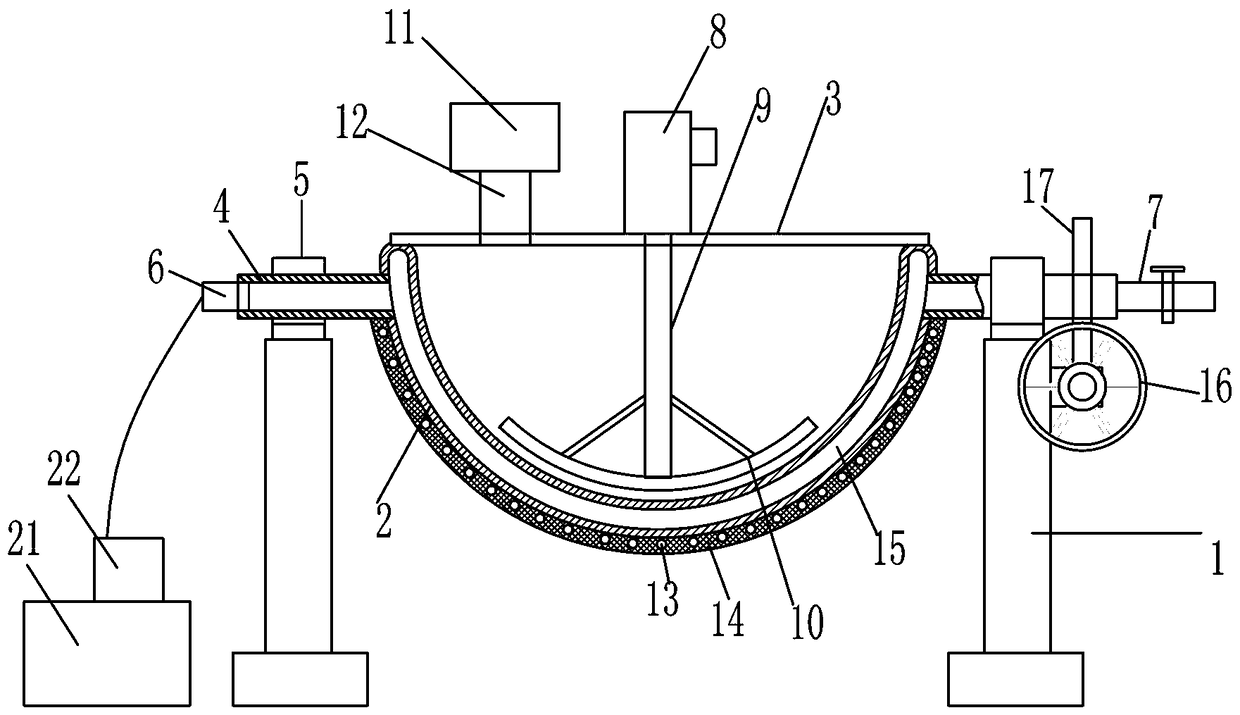

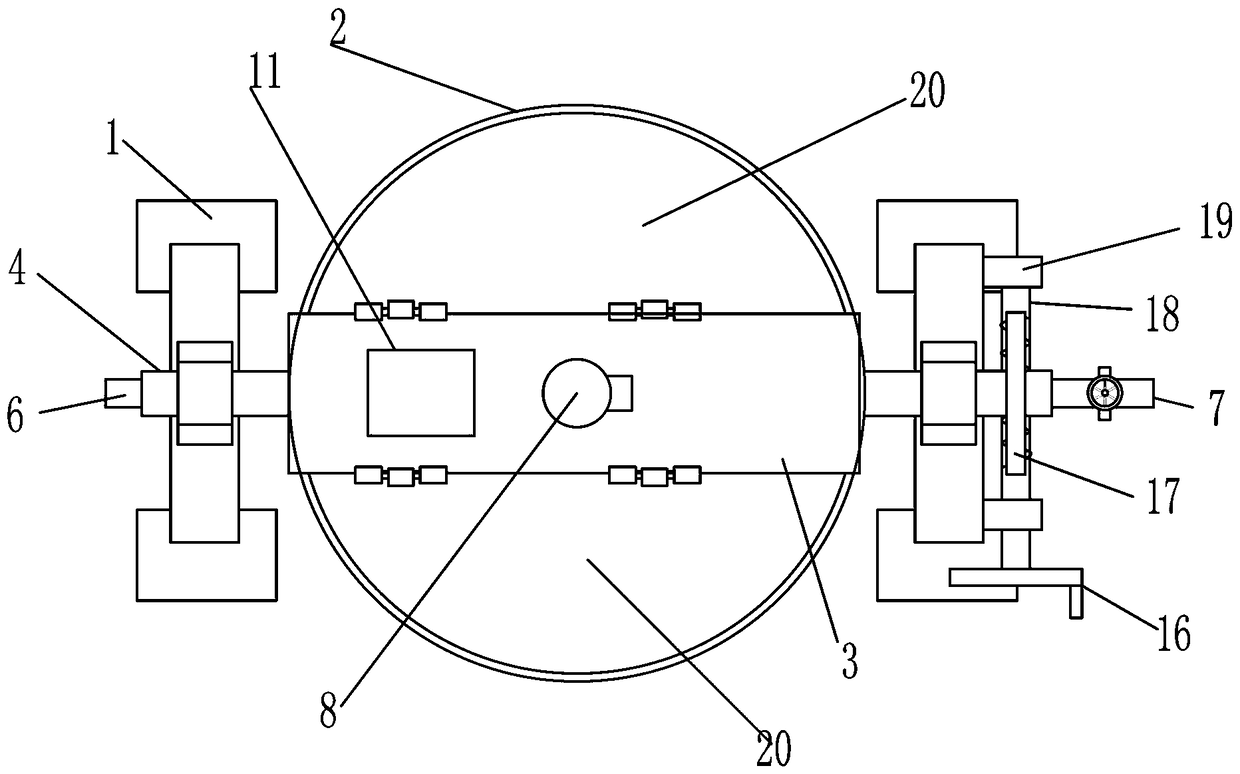

Medicine frying pan used for Chinese herbal medicine processing

InactiveCN108498339AHeat stableRise steadilyPharmaceutical product form changeDomestic articlesHeat conductingEngineering

The invention relates to a medicine frying pan used for Chinese herbal medicine processing. The pan is of a hemispherical structure with an opening at the upper end and is a double-layer pan, an innerchamber is formed between an inner layer and an outer layer, rotating shafts are arranged at two sides of the pan, the rotating shafts are hollow rotating shafts, the hollow rotating shafts are communicated with the inner chamber of the pan and are connected with a support by bearings, the rotating shaft at one side of the pan is connected with an oil inlet pipe, the rotating shaft at the other side of the pan is connected with an oil return pipe, a discharge device is arranged on the support, the discharge device is connected with the rotating shaft at one side of the pan, a support plate isarranged on the pan, two ends of the support plate are in fastened connection with the opening at the upper end of the pan, a stirring device and an exhaust device are arranged on the support plate,a pan cover is arranged at each of two sides of the support plate, the pan covers are hinged with the support plate, and a heating device is arranged outside the pan. The Chinese herbal medicine in the pan is heated by utilizing heat conducting oil, and is stirred constantly in the frying process, so as to prevent the Chinese herbal medicine from being burnt; and the exhaust device is arranged onthe pan cover, and is used for pumping away smoke generated in the important drying process.

Owner:禹州市厚生堂中药有限公司

Instant fat-reducing balls and preparation method thereof

The invention relates to instant fat-reducing balls. The balls comprise the following raw materials: konjak flour, soybean dregs fiber powder, wheat germ powder, tomato powder, apple powder, carrot powder, tartary buckwheat powder, cassia seed powder, lotus leaf powder, barley seedling powder, dioscorea root powder, xylitol, xanthan gum, carrageenan, sodium chloride, potassium chloride, a flavoring agent, a toning agent, a food-grade additive for flavouring, and water; the raw materials and water are mixed, and after stirring, boiling, food texture and structure recombination, the product is produced. The raw material powder is ultrafine powder whose micronization treatment is carried out by an ultrafine pulverizer, taste is adjusted by xylitol, xanthan gum and carrageenan are used for adjusting mouthfeel, and homogenization of the product quality is realized based on autoclaving technology; the instant fat-reducing ball product is rich in dietary fiber with low calories, and can adjust metabolism of stomach and intestine, promote peristalsis of intestinal tract, so that fat-reducing effects are realized.

Owner:FEIDONG SHILIUYUAN FOOD

Tea leaf stir-frying machine

InactiveCN107751428AFried evenlyAvoid fryingPre-extraction tea treatmentAgricultural engineeringMotor shaft

The invention discloses a tea frying machine, which comprises a base, a frying barrel, a frying device, a frying rod and a motor. Support rods are respectively fixedly connected to both sides of the top center of the base, and the two sides of the frying barrel The side is movably connected to the support rod, the upper right end of the frying barrel is provided with a material inlet, and the left end is provided with a discharge port, the inside of the frying barrel is connected with an electric heating tube, and the frying device is set On the right side of the frying barrel. The present invention can solve the problem of extremely low efficiency and high labor intensity in the prior art of manual frying, and solves the problem that tea leaves are easily burnt and wasteful. The present invention is simple in structure and easy to use. Tube heating can prevent overheating, and through the turning of the frying rod, it can effectively prevent the scorching of tea leaves caused by long-term heating at the same place, and the frying device can make the roasted tea leaves more uniform, greatly Improve the frying quality of tea.

Owner:ANHUI SHITAI COUNTY XIHUANGSHAN TEA IND

Frying pan with automatic frying function

InactiveCN108618585AAvoid fryingEasy to cleanCooking insertsVessels with intergral heatingEngineeringFrying-pans

A frying pan with an automatic frying function mainly comprises a pan body and a motor. A heating plate is mounted on the inner lower portion of the pan body, an inner pan is arranged on the heating plate, a handle is fixed onto the right side of the inner pan, a telescopic rod is fixed onto the surface of the pan body, a pan cover is connected onto the telescopic rod, the motor is mounted on thepan cover, a stirring rod is fixed in the middle of a stirring scraper, a water adding head is mounted on the pan cover, a sealing pad is fixed onto the inner side of the pan cover, an air hole is formed in the surface of the pan cover, and a clamp slot is formed in the side edge of the pan body. Dishes are stirred by rotation of the stirring scraper and can be conveniently automatically turned and stir-fried, the stirring scraper is connected with the bottom of the inner pan and can be used for conveniently stirring the bottom of the inner pan and the dishes, and the problem of burning of thedishes is avoided.

Owner:ZHONGSHAN YUANHENG HOUSEHOLD ARTICLES

Production method of fried bean sauce with three delicacies and shredded meat

The invention provides a production method of fried bean sauce with three delicacies and shredded meat characterized in, using chicken stuffing or shredded chicken, minced mushroom, flour paste and salted and fermented soya paste as main ingredients, unfreezing the chicken stuffing or shredded chicken under atmospheric temperature, charging water-loss reducer, anti-oxidizing agent and anti-agglomeration agent, frying in laminated pan, charging soup stock and thickening agent.

Owner:杨秀敏

Cooking system and method using food material cleaning box

The invention discloses a cooking system and method using a food material cleaning box. The cooking system comprises automatic cooking equipment with an automatic cleaning function and a dish-up function and further comprises a user side and the food material cleaning box which are matched with the automatic cooking equipment, and the user side is connected with the automatic cooking equipment through network. According to the scheme, raw materials are put into the food material cleaning box, when the automatic cooking equipment needs to be used, the packaged food material cleaning box needs to be put into the automatic cooking equipment only, after using is completed, the food material cleaning box is taken out and recycled, and the problem of smell mixing of dishes cannot be caused. Varieties of the dishes which can be cooked are multiple, so that the user side is directly used for selecting the variety of the raw materials, quantification for the raw materials can be carried out conveniently by the automatic cooking equipment through the food material cleaning box, a user inputs cooking parameters through the user side conveniently, so that the situation that the dishes are stir-fried not enough or burnt due to the fact that the user has a bad grasp of the cooking time and quantity of the raw materials is avoided, the process of preparing the raw materials by the user is further omitted due to the food material cleaning box, and the equipment is more convenient and fast to use.

Owner:杭州板牙科技有限公司

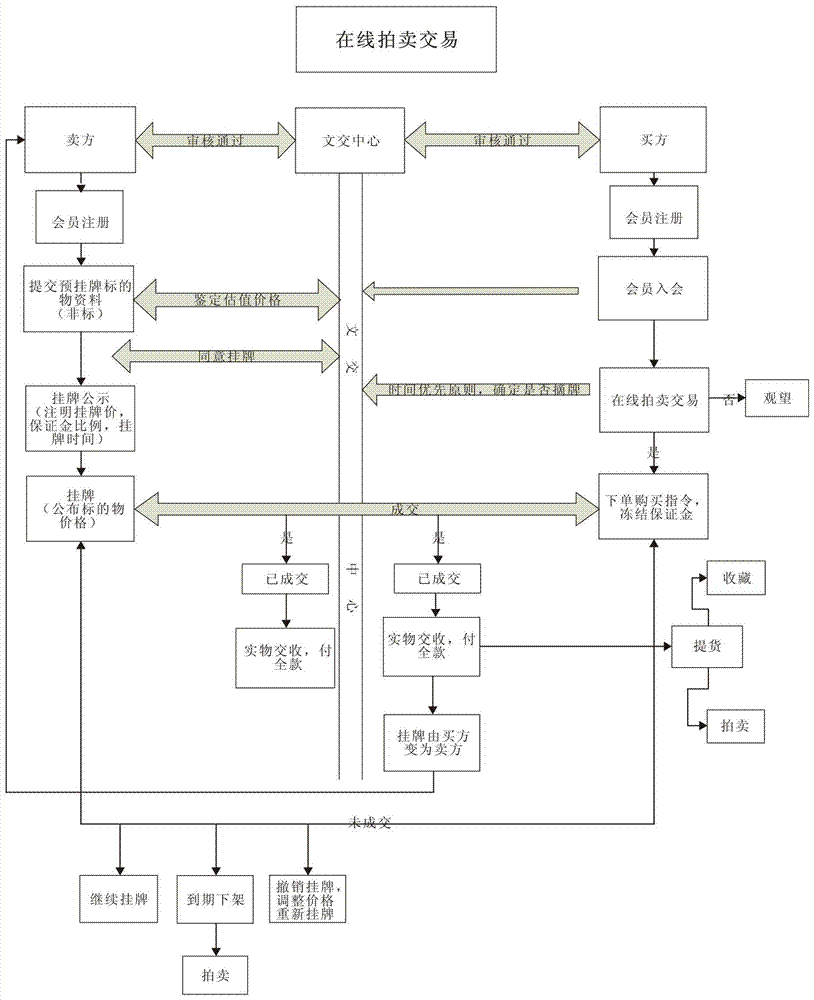

Artwork online transaction method

InactiveCN106920161AAvoid fryingPromote rational and safe operationBuying/selling/leasing transactionsSubject matterComputer science

The present invention discloses an artwork online transaction method. The method comprises a plurality of steps, and the artwork is auctioned by the bidder in a price raising or price reduction manner, so that the traditional continuous bidding transaction is canceled. According to the method disclosed by the present invention, in a mode capable of price raising or price reduction, the price fluctuation is balanced, the subject matter is prevented from being exploded, and without control by the dealer, the physical delivery is guaranteed, so that with fully market participation, financial support to the development of the real economic is realized in a real sense, the rational and secure operation of the online transaction platform is facilitated, and the attraction to the bidders is increased.

Owner:苏州微拍文化产权交易有限公司

Red palm oil hotpot condiment and preparation method thereof

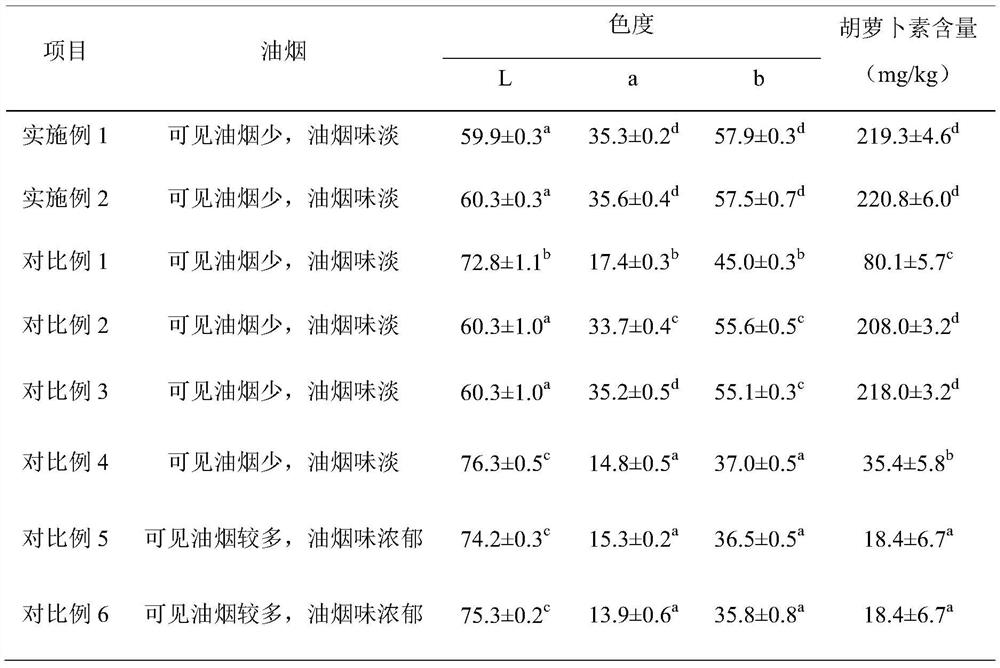

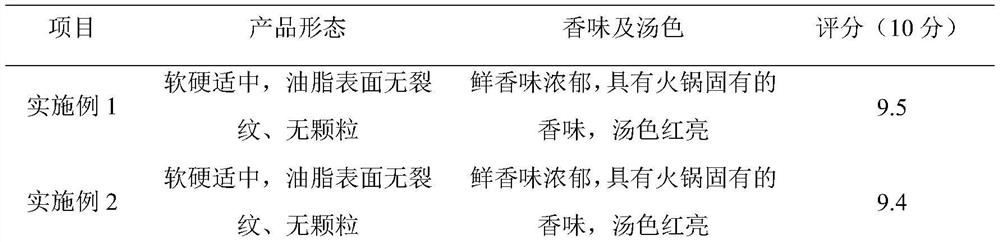

ActiveCN113068814AShorten frying timeSolve decompositionClimate change adaptationLipidic food ingredientsBiotechnologyNutritive values

The invention discloses a red palm oil hotpot condiment and a preparation method thereof, and belongs to the technical field of hotpot condiment preparation. The red palm oil is used for completely replacing beef tallow to serve as the unique grease raw material of the hotpot condiment, by adopting the method of segmented feeding, segmented stir-frying and segmented cooling, the problems that beef tallow is adopted as grease in the existing hotpot condiment to affect human health and severely remain taste, and the hotpot condiment prepared by the traditional processing method can destroy the nutritional ingredients of the red palm oil and change the color of the grease are effectively solved, the nutritional value of the hotpot condiment, especially the content of carotene in the product, is increased, the hotpot condiment is endowed with red and bright color, the use of capsanthin and stir-frying of glutinous rice cake chili are avoided, and the red palm oil hotpot condiment with both color, aroma and taste and nutritional value is prepared.

Owner:四川天味食品集团股份有限公司 +1

Method of preparation of a coated food product

ActiveUS20130259988A1Accurate predictionReduce riskFood coatingFood preparationCooking processFood products

The disclosure relates to a method for preparation of a food product. The method comprises the following steps: applying on the food product a batter composition; applying on the food product a coating composition; applying oil on the food product, wherein said batter composition, said coating composition and said oil form a coating of the food product; subjecting the food product and the coating to a hot air cooking treatment in an impingement oven at such a temperature and for such a period of time that the coating is cooked while the food product remains substantially untreated by the hot air cooking treatment, wherein the temperature of the hot air cooking treatment is in the range of 230° C. to 290° C. and wherein the hot air in the hot air cooking treatment is applied on both the top and the bottom of the food product.

Owner:JOHN BEAN TECH AB

Processing method of residue-free beef tallow hotpot condiment

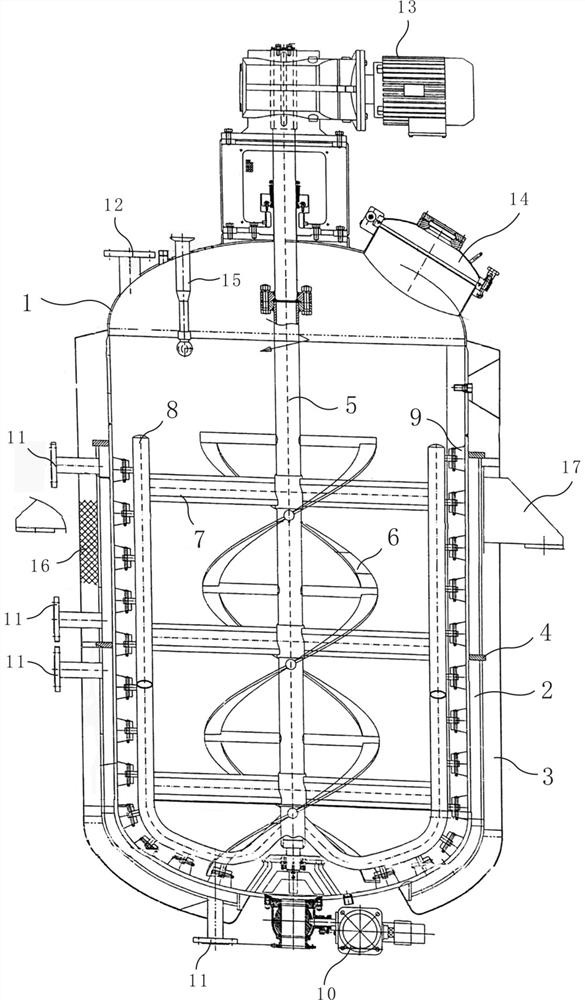

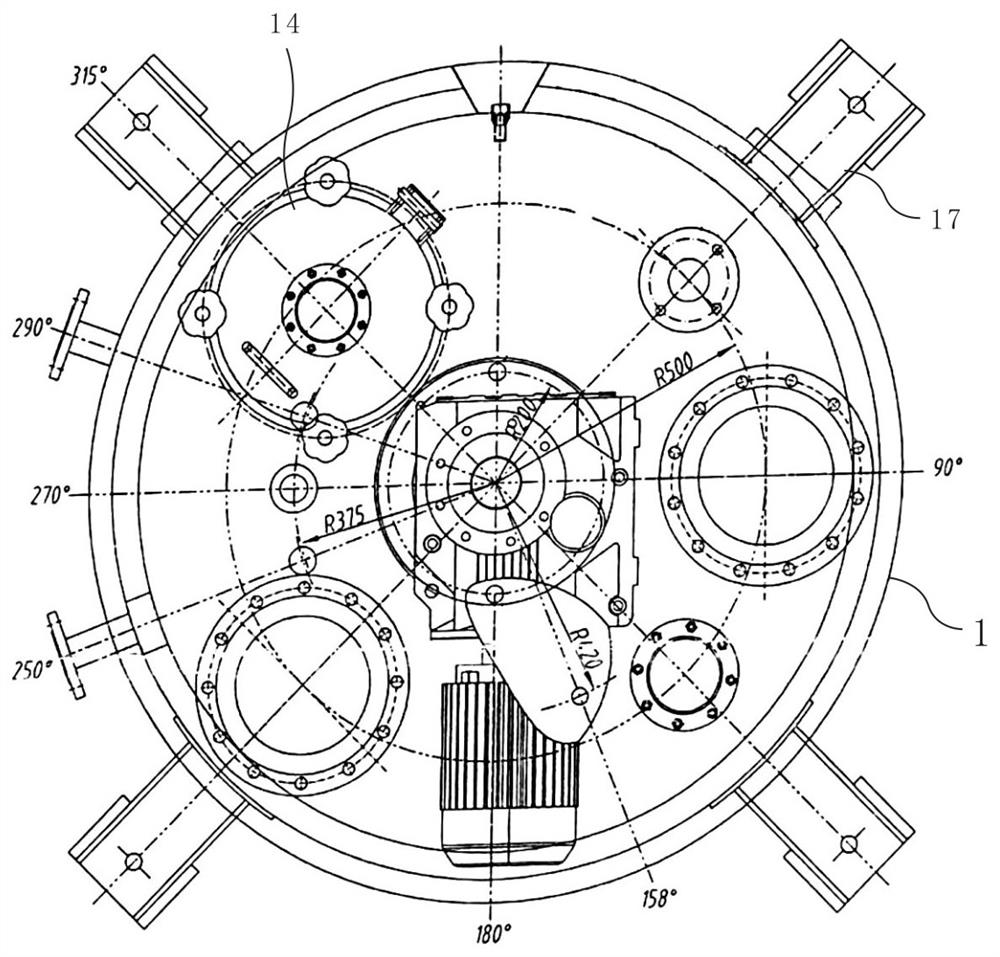

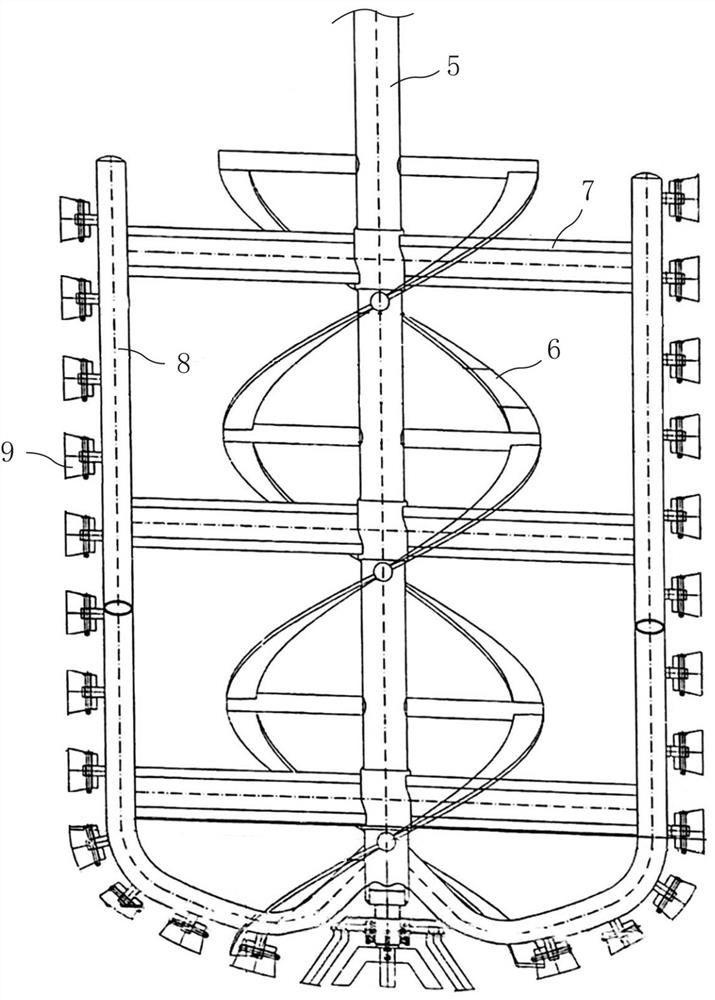

PendingCN113575909AReasonable designIngenious structureFood shapingForeign matterProcess engineering

The invention belongs to the technical field of compound seasoning processing, and particularly discloses a processing method of a residue-free beef tallow hotpot condiment. A reaction kettle is used for stir-frying the hotpot condiment, the reaction kettle is reasonable in design and ingenious in structure, and compared with stir-frying of a traditional stir-frying pan, the closed cylindrical kettle body serves as a hotpot condiment carrier, the proportion of various raw materials is strictly controlled, and the stir-frying temperature and stir-frying time of the various raw materials in the stir-frying process are coordinated. The hotpot condiment is stir-fried under the relatively closed condition, the fragrance components of the hotpot condiment raw materials are reserved to the maximum extent, the quality of the hotpot condiment is better, the risk that foreign matter enters the hotpot condiment is also reduced. Meanwhile, the stir-frying efficiency is also very high, and automatic control is facilitated.

Owner:四川漫味龙厨生物科技有限公司

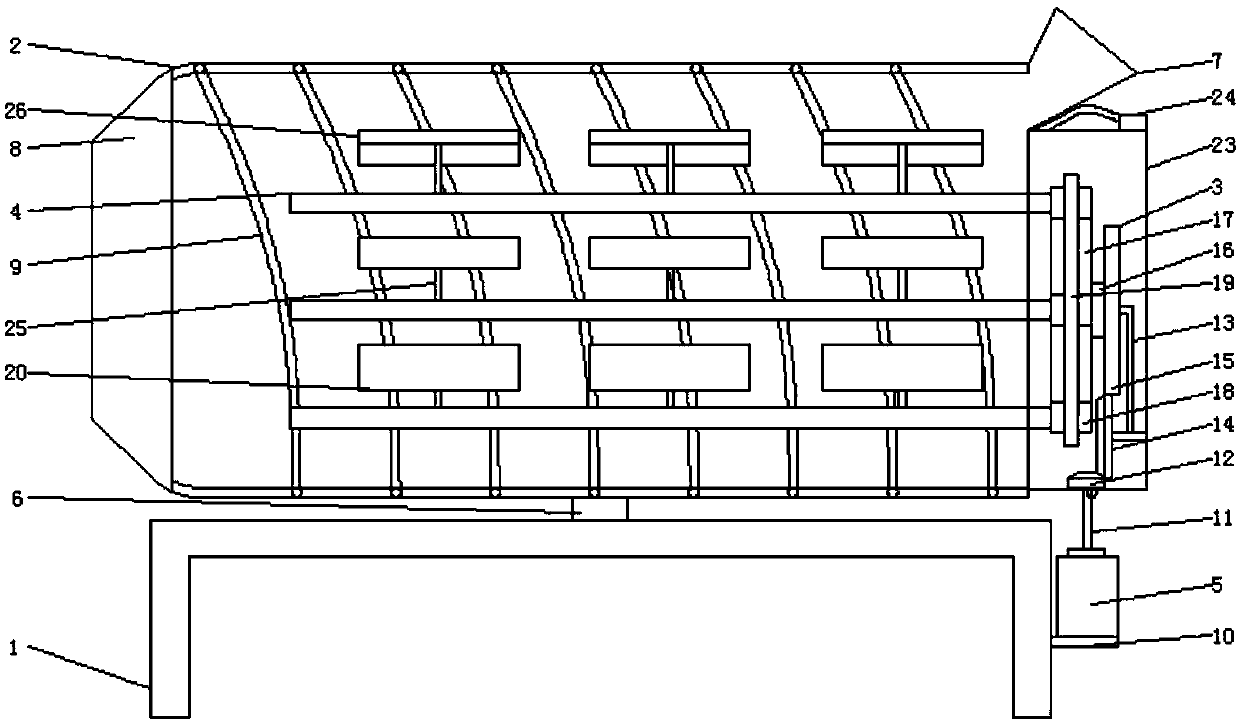

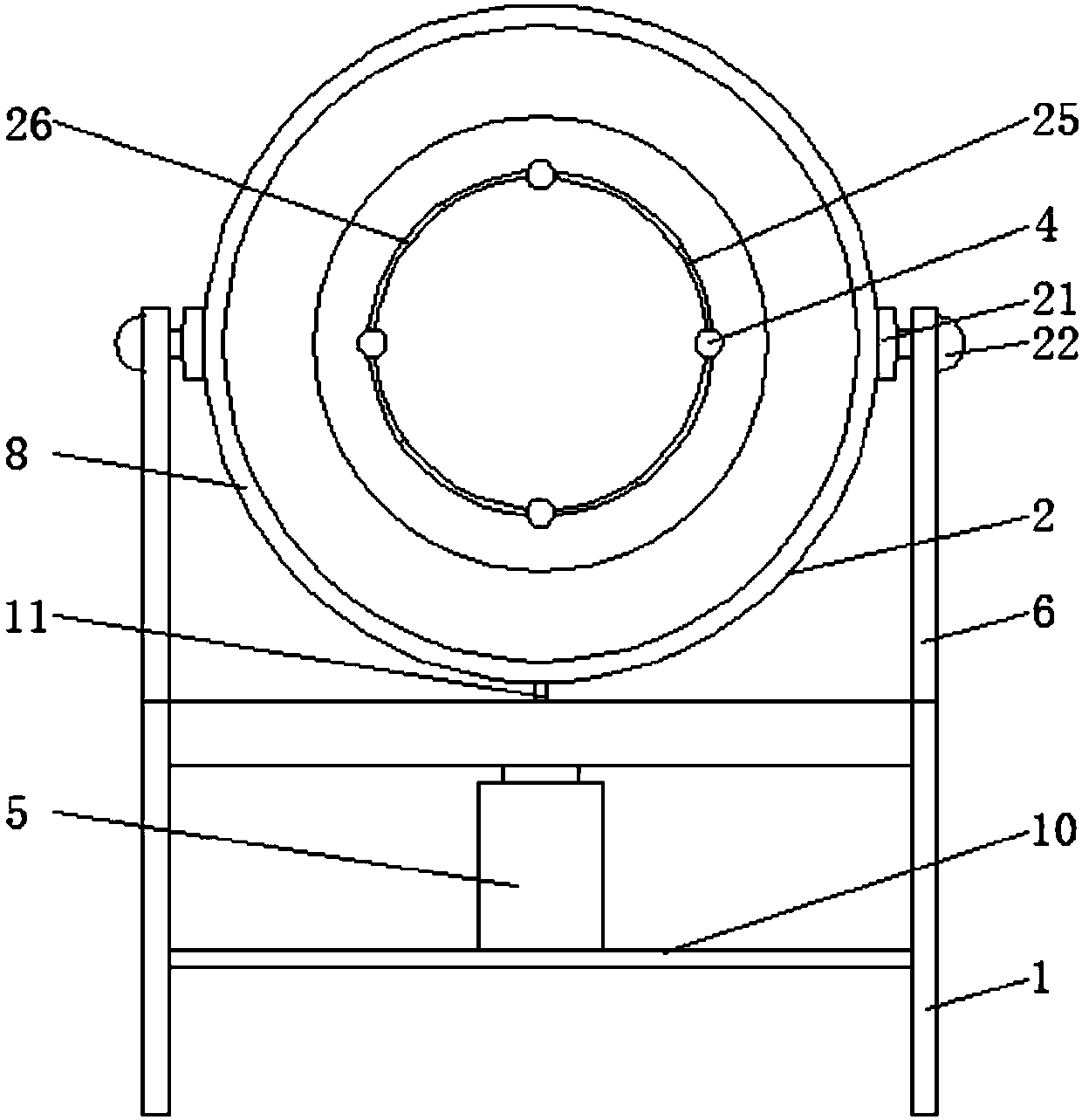

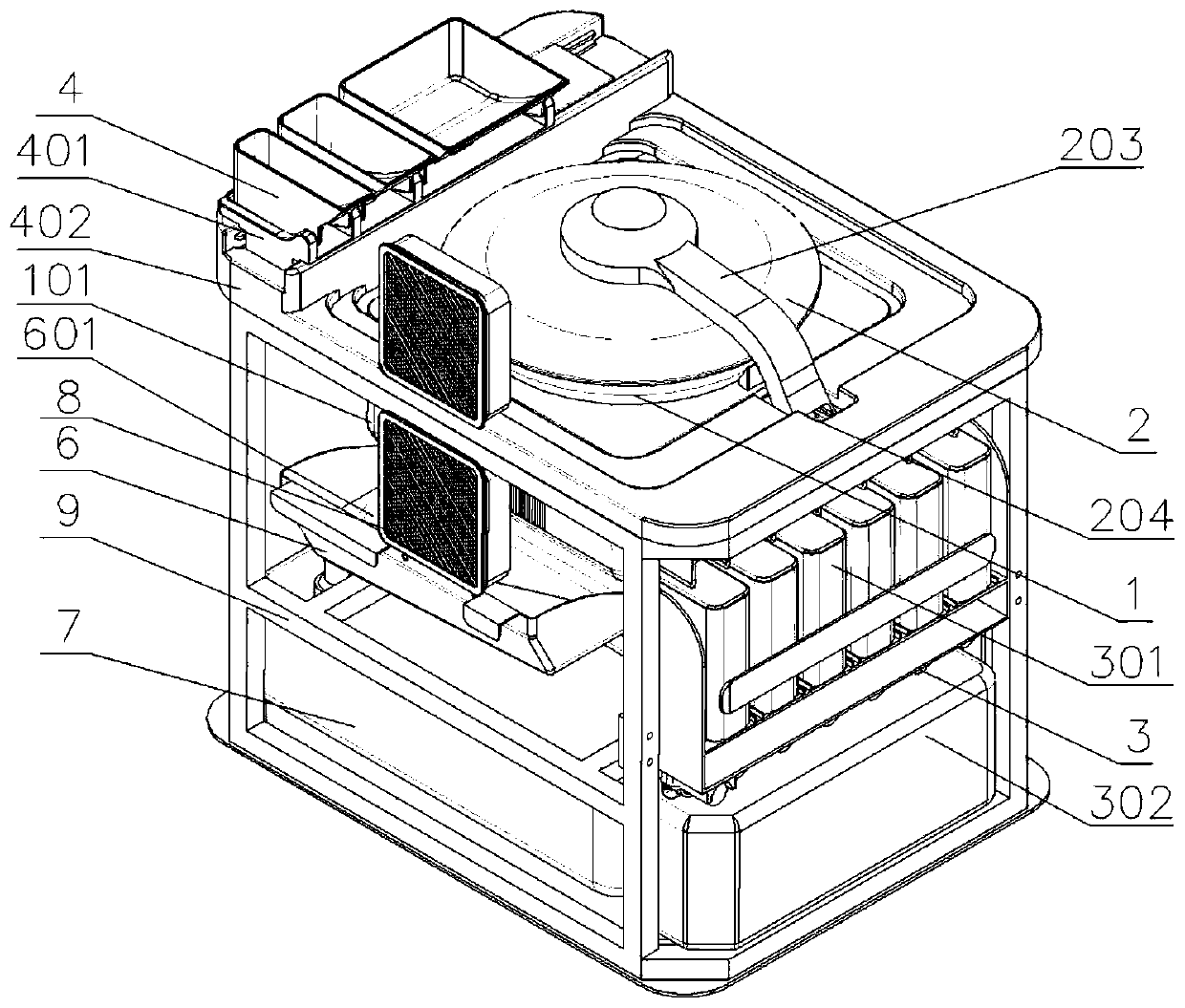

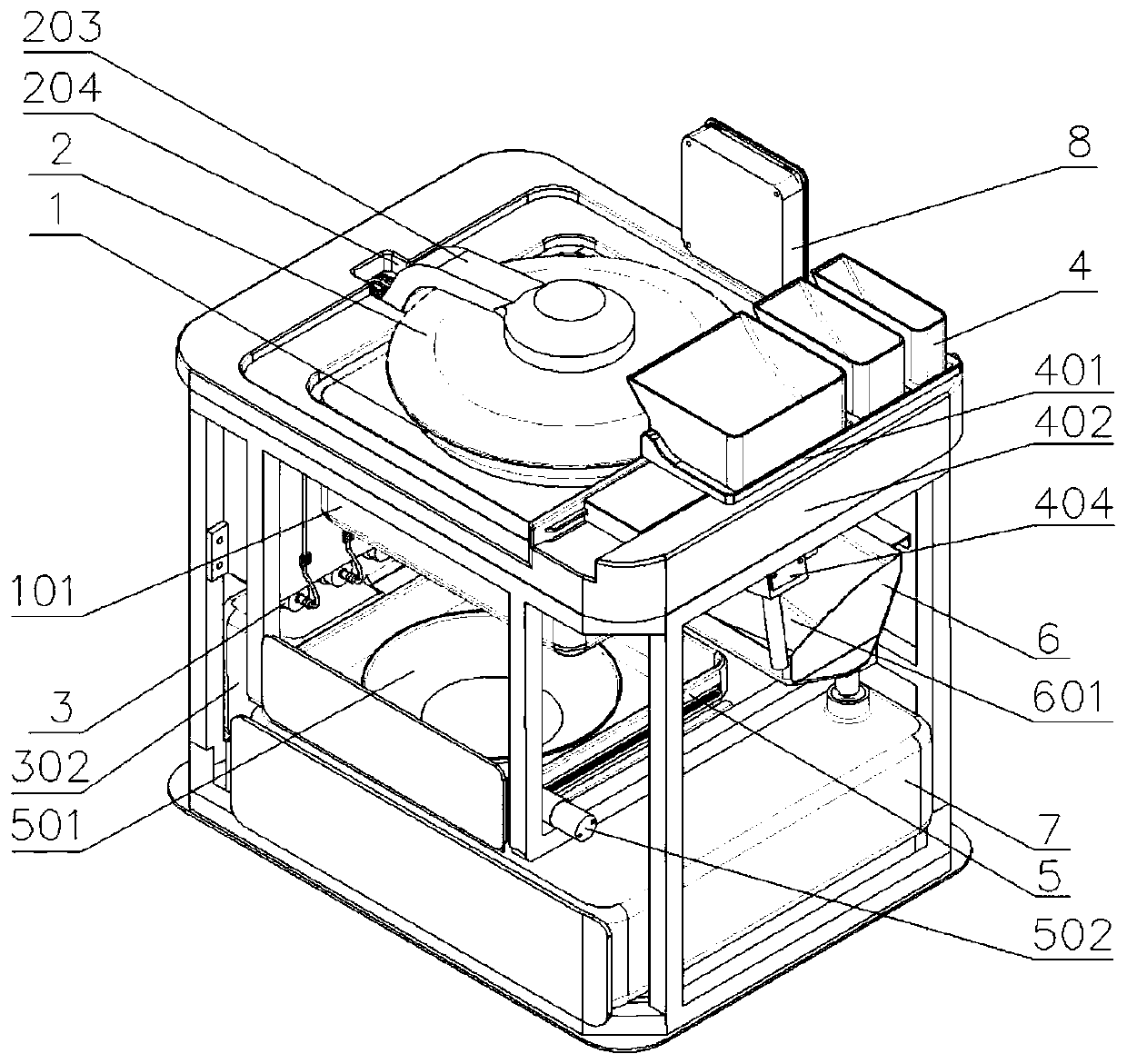

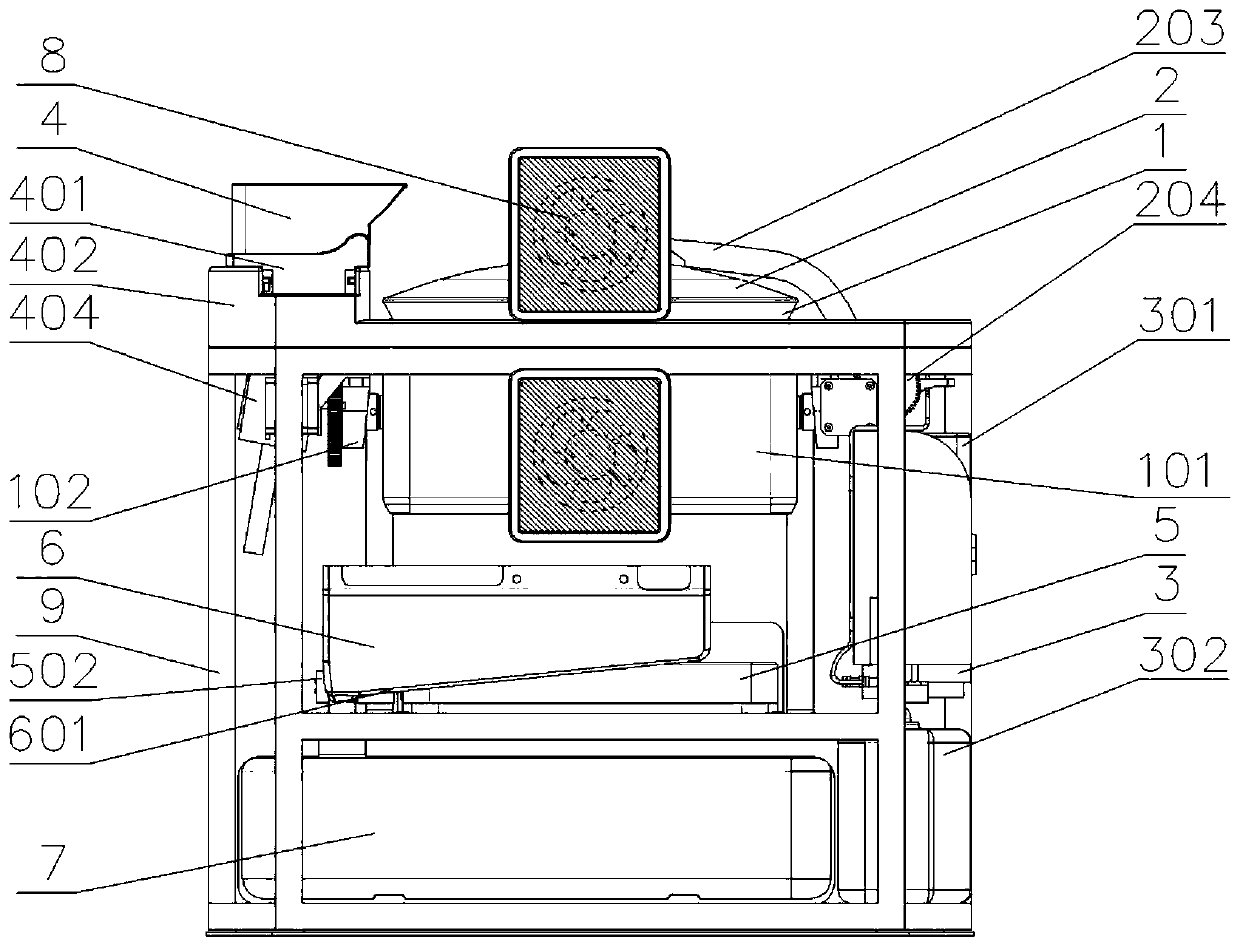

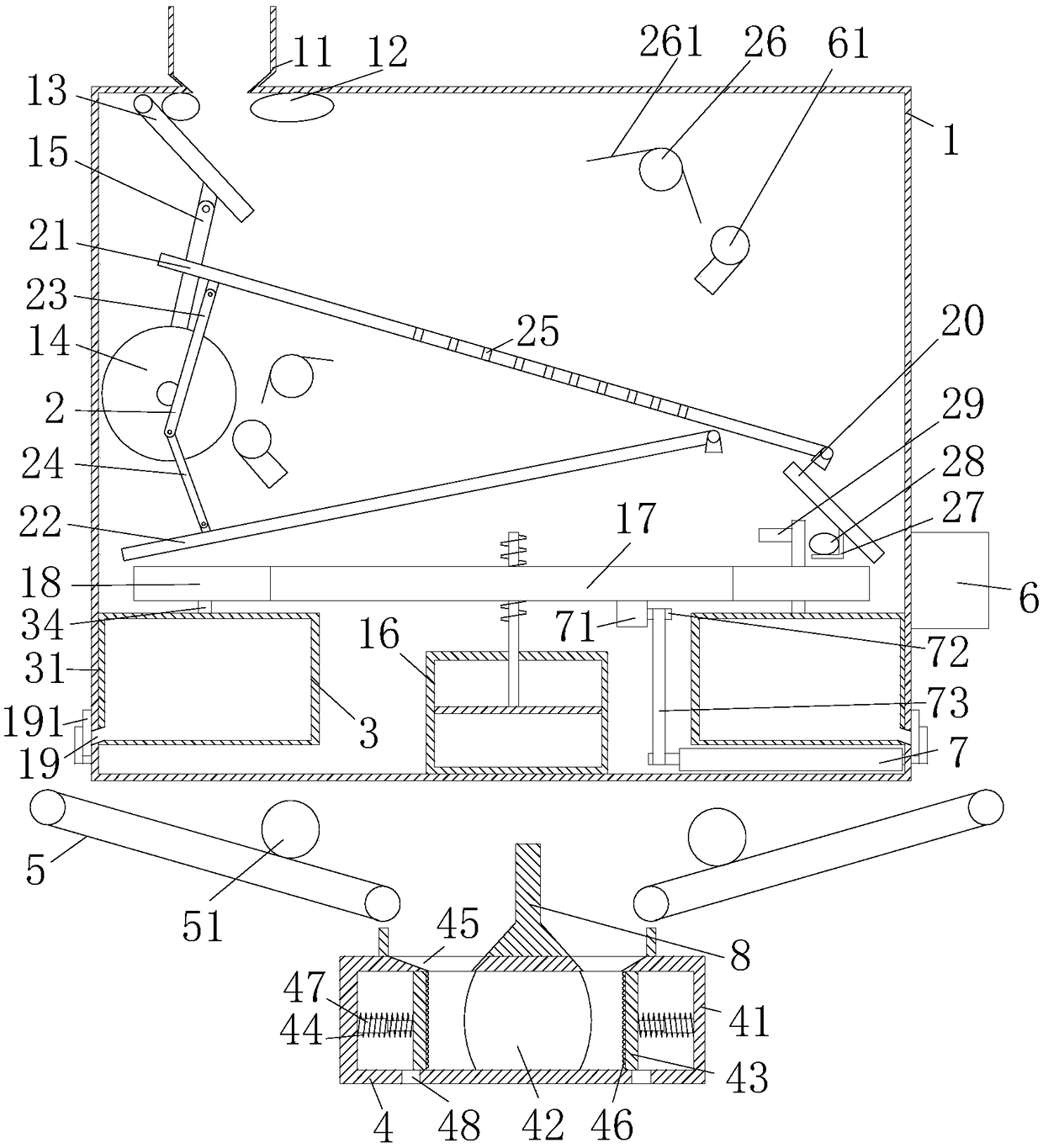

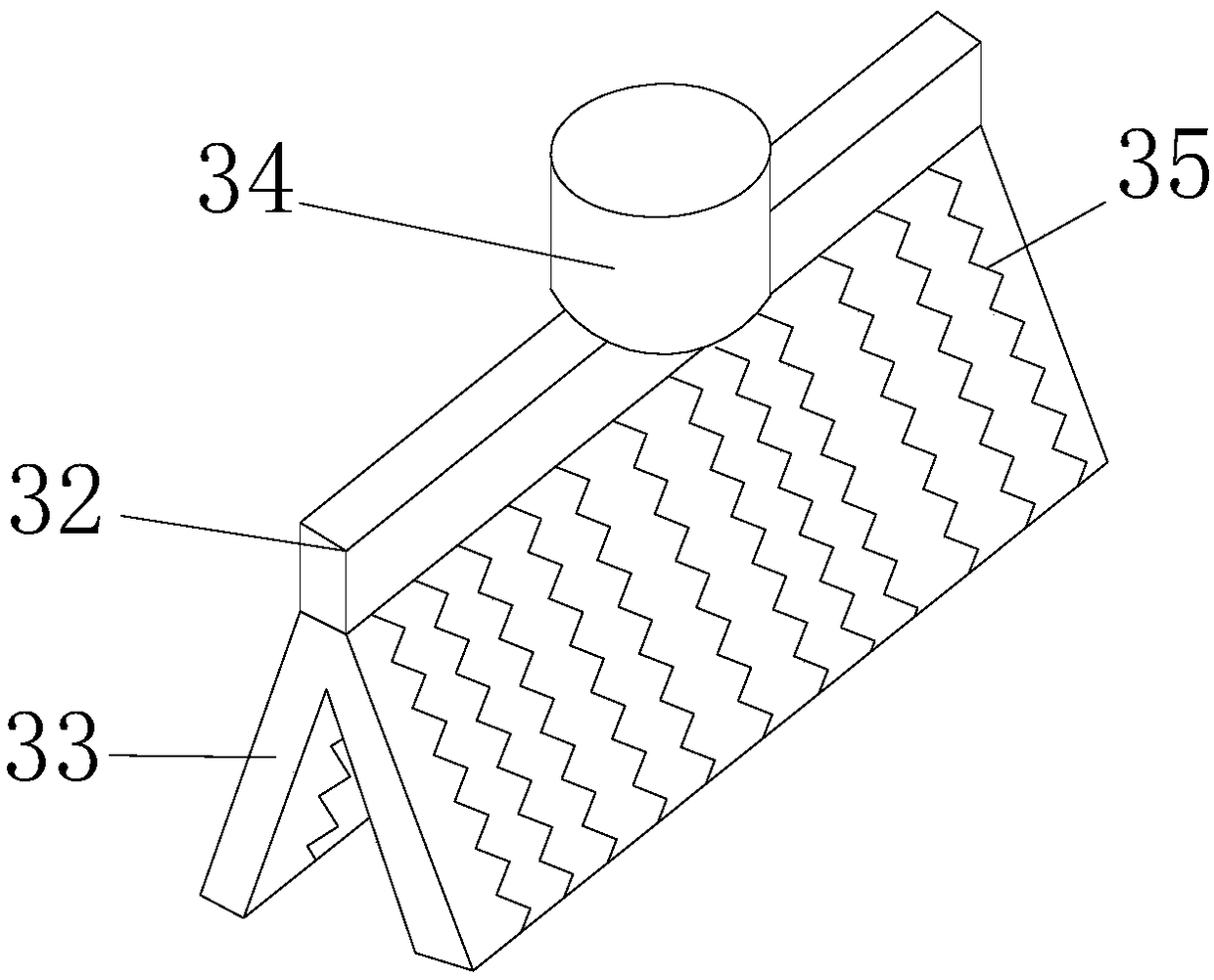

Tea production system

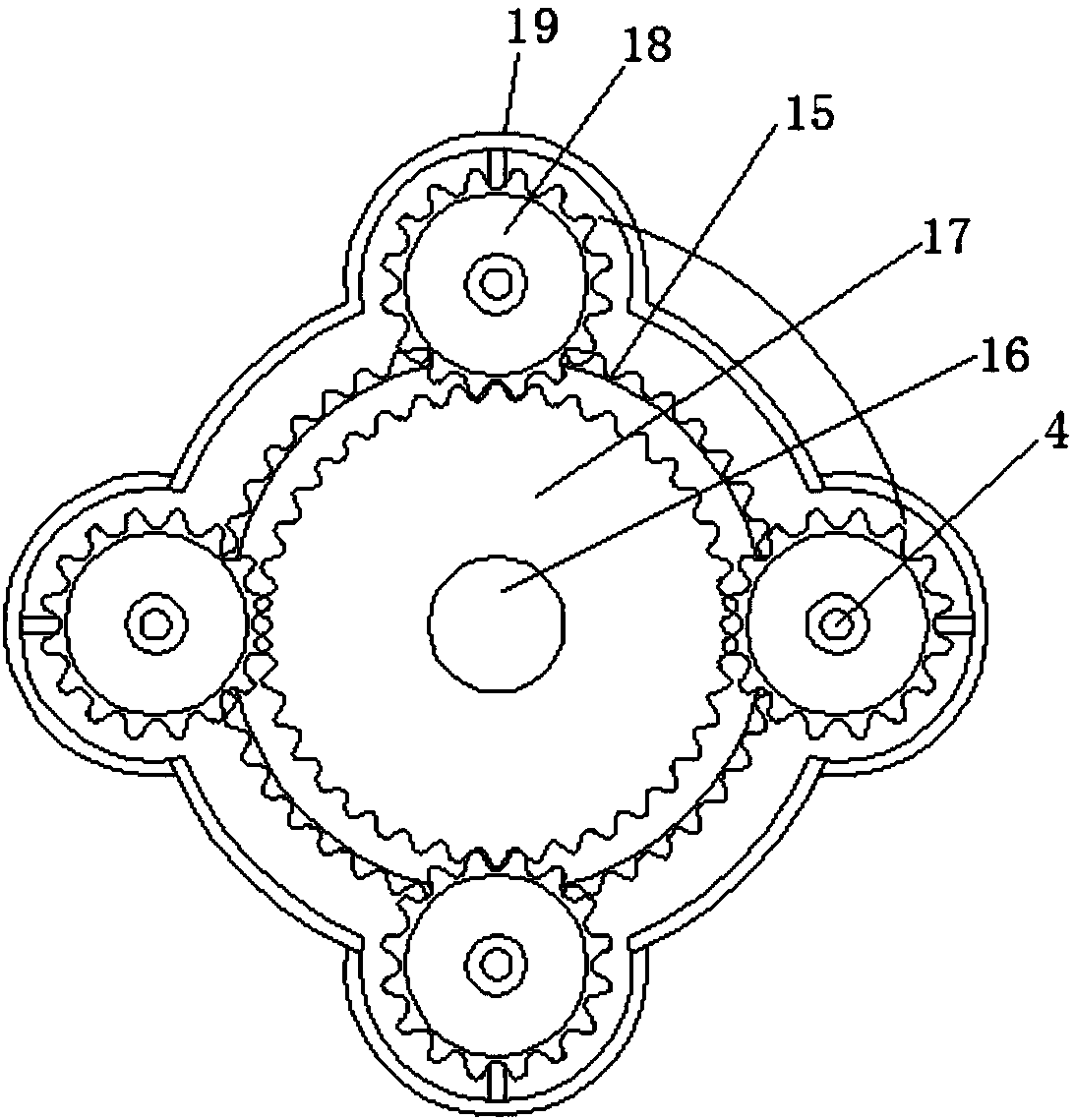

The invention belongs to the technical field of tea production, and specifically discloses a tea production system. The tea production system comprises a frame, a material inlet, a fixation unit, stir-frying units, and a wrapping-rolling unit; each of the stir-frying unit comprises a stir-frying barrel, a fixing rack, stir-frying blades and a rotating shaft; the rotating shafts are fixedly connected with centers of two driven gears; the rotating shafts penetrate through the stir-frying barrels, and is fixed with the fixing racks in the stir-frying barrels; the stir-frying blades are fixedly connected, under the fixing racks, with the interior of the stir-frying barrels; the stir-frying blades are triangular in sectional view; and heating plates are arranged on surface on two sides of the stir-frying blades. A driving gear rotates so as to drive the driven gears to rotate, so that the rotating shafts fixedly connected with the driven gears are driven to rotate; and thus, the stir-fryingblades rotate forwards and backwards inside the stir-frying barrels so as to prevent charring of part of tea leaves due to excessive heating caused by inertial attachment of the tea leaves onto the stir-frying blades during unidirectional rotation, so that more thorough stir-frying on the tea leaves is achieved. Moreover, temperature of the heating plates in the two stir-frying units is different, so that classified stir-frying is realized.

Owner:邹成浩

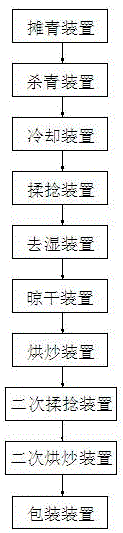

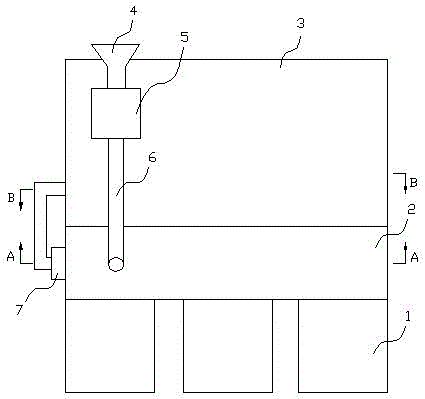

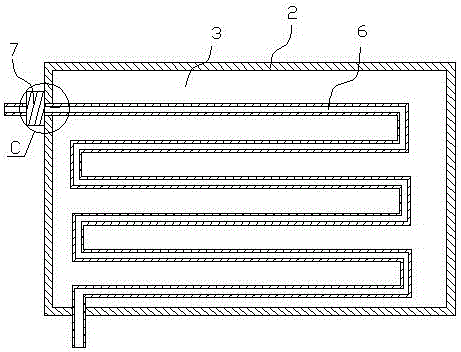

Fine machining technology for green tea and machining system thereof

The invention relates to the filed of tea producing and processing, and especially relates to a fine machining technology for green tea. The fine machining technology for the green tea comprises the following steps: carrying out picking, tedding fresh tea leaves, deactivating enzymes, carrying out cooling, carrying out rolling, removing dampness, carrying out air-drying, carrying out baking and carrying out packaging. The invention further relates to a fine machining system for green tea. The fine machining system for the green tea comprises a tea-leaf tedding device; the tea-leaf tedding device is connected to an enzyme deactivating device; the enzyme deactivating device is connected to a cooling device; the cooling device is connected to a rolling device; the rolling device is connected to a dampness removing device; the dampness removing device is connected to an air-drying device; the air-drying device is connected to a baking device; the baking device is connected to a second-rolling device; the second-rolling device is connected to a second-baking device; and the second-baking device is connected to a packaging device. Purpose of the invention is to provide a fine machining technology and a machining system for the green tea. The green tea is baked by utilizing hot air and artificial stir-frying, so that temperature for stir-frying can be very well controlled so as to prevent the tea leaves from being burnt; at the same time, tea trimming and tipping can be carried out during artificial stir-frying, so that qualities of the green tea are further improved.

Owner:湖南会同宝田茶业有限公司

Safety helmet paint spraying device and method capable of changing paint spraying range and convenient to use

The invention relates to the technical field of safety helmet paint spraying equipment, and discloses a safety helmet paint spraying device and method capable of changing the paint spraying range andconvenient to use. The safety helmet paint spraying device comprises a box internally sequentially provided with a supporting plate and a partition plate from top to bottom. A liquid storage box is fixedly arranged on one side of the upper surface of the supporting plate. The part, on the supporting plate, of one side of the liquid storage box is fixedly provided with a high-pressure pump, an inlet of the high-pressure pump communicates with an outlet of the liquid storage box through a pipeline, an outlet of the high-pressure pump communicates with an inlet of a water collecting pipe, an outlet of the water collecting pipe communicates with an inlet of a corrugation pipe, and an outlet of the corrugation pipe communicates with an inlet of a sprayer. According to the safety helmet paint spraying device capable of changing the paint spraying range and convenient to use, through the arrangement of a moving device and meshing between teeth and a tooth disc, the distance between the sprayer and a workbench can be changed, the spraying range can be adjusted at any time, adjustment can be conducted according to the diameter of safety helmets, waste is prevented, and usage is more flexible.

Owner:CHONGQING COOPER TECH CO LTD

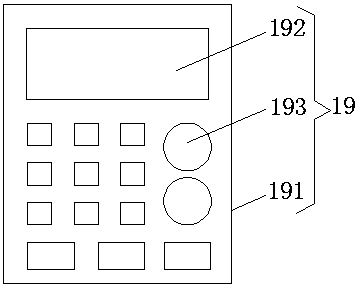

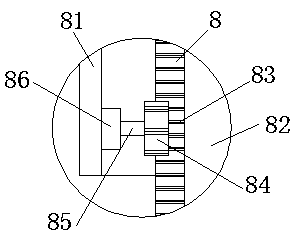

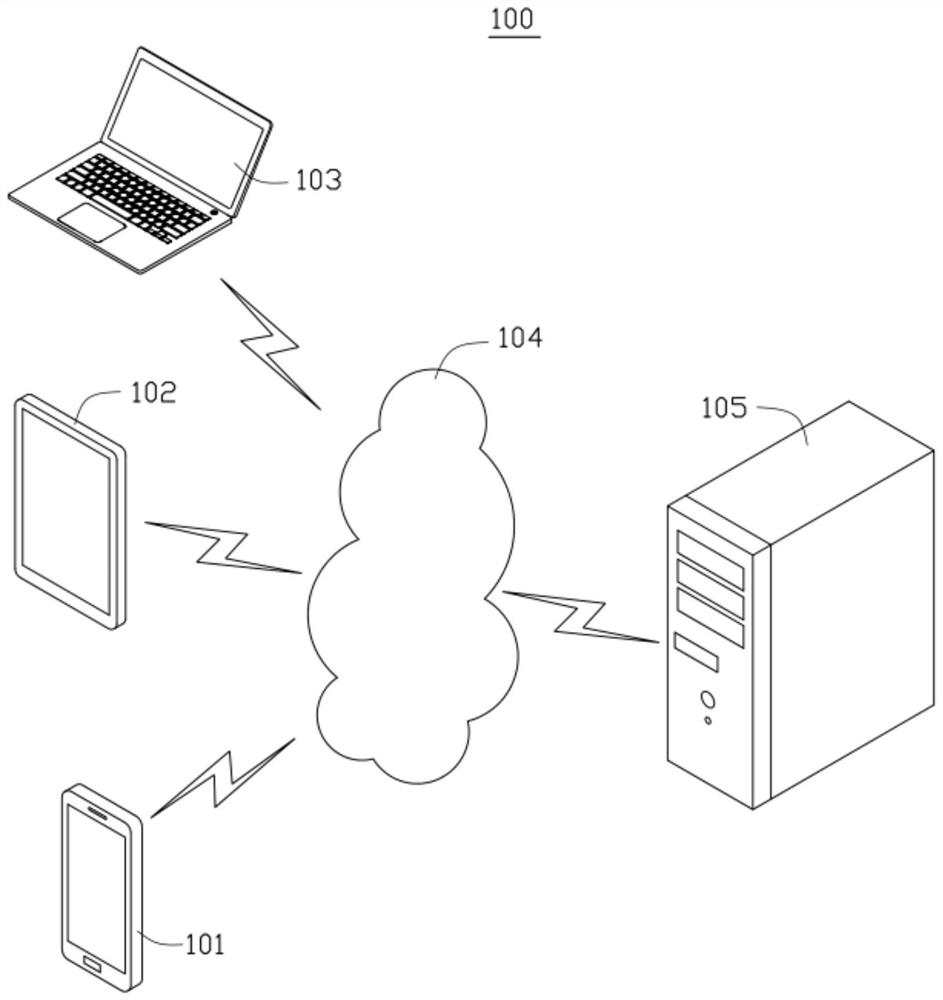

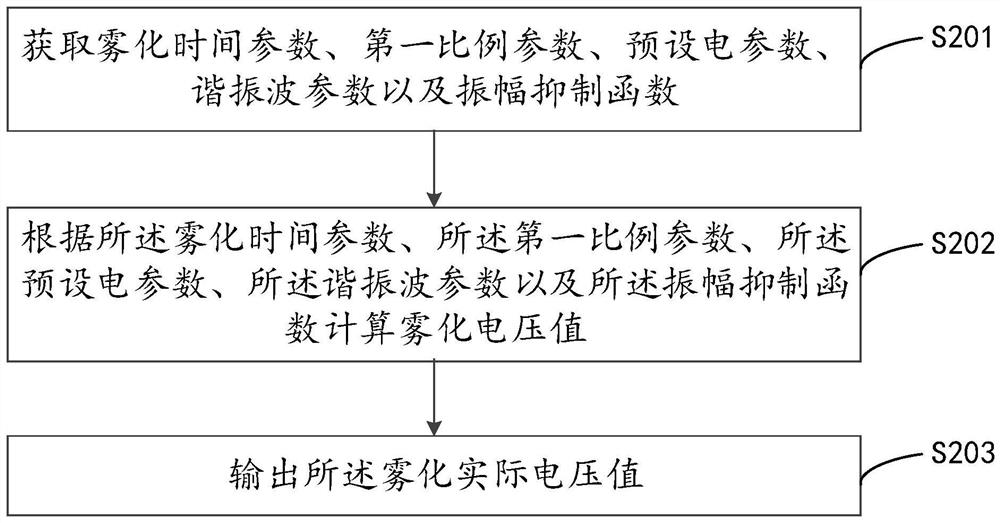

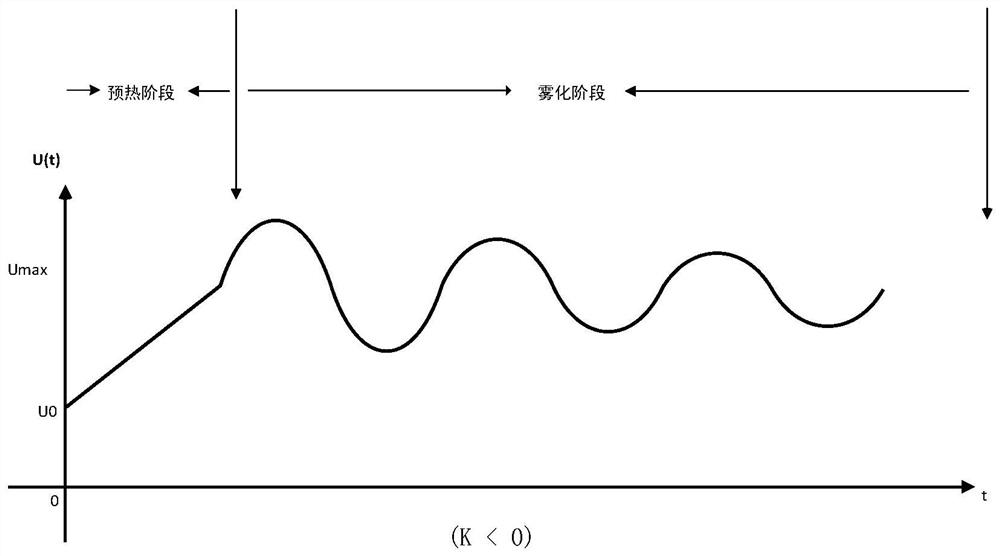

Atomization output method based on resonance wave and related equipment thereof

PendingCN114521684AImprove the suction experiencePrevent fryingTobaccoComputational physicsAerosolize

The embodiment of the invention belongs to the field of aerosol generation devices, and relates to a resonance wave-based atomization output method, which comprises the following steps: acquiring an atomization time parameter, a first proportion parameter, a preset electrical parameter, a resonance wave parameter and an amplitude suppression function; an atomization voltage value is calculated according to the atomization time parameter, the first proportion parameter, the preset electrical parameter, the resonance wave parameter and the amplitude suppression function; and outputting an atomization voltage value. The invention further provides related equipment for atomization output based on the resonance waves. According to the atomization output method in the resonance wave mode, after suppression is conducted through the amplitude suppression function, if the atomization voltage value obtained through continuous calculation is in the progressive increase state, the aerosol generated by the atomization aerosol base material changes in taste and is higher and higher in fullness, and if the atomization voltage value obtained through continuous calculation is in the progressive decrease state, the aerosol generated by the atomization aerosol base material is higher in fullness. The aerosol generated by the atomized aerosol base material is changed in taste, and the fullness becomes weaker and weaker, so that the requirements of different users are met, and the smoking experience of the users is improved.

Owner:SHENZHEN JIER TECH CO LTD

Solid bean paste and preparation method and use method thereof

PendingCN111920012AExtended shelf lifeIncrease cooking rangeFood scienceBiotechnologyMonosodium glutamate

The invention discloses solid bean paste as well as a preparation method and a use method thereof. The solid bean paste comprises the following components in parts by weight: 80-100 parts of broad-bean, 20-30 parts of broad-bean fermentation extracting solution, 4-6 parts of monosodium glutamate, 2-3 parts of spices, 3-4 parts of white granulated sugar and 0.5-0.8 part of anti-caking agent. The invention aims to solve the problems that in the using process of existing broad-bean, the using range is limited, cooking time and cooking temperature are difficult to master and taste of food materials.

Owner:SICHUAN PROVINCE DANDAN CONDIMENT

Drum type tea leaf stir-frying machine

InactiveCN107581293AFried evenlyEasy to fryPre-extraction tea treatmentAgricultural engineeringEngineering

The invention discloses a drum type tea leaf stir-frying machine, which comprises a base, a heating barrel, a stir-frying barrel, a stir-frying device and a motor, wherein support rods are fixedly connected to two sides of a central position of the top part of the base respectively; two sides of the heating barrel are movably connected with the support rods; a feed inlet is formed in the right upper end of the heating barrel; a discharge hole is formed in the left end of the heating barrel; an electrical heating pipe is connected into the heating barrel; the stir-frying device is arranged at the right side of the heating barrel. The drum type tea leaf stir-frying machine provided by the invention can solve the problems that according to manual stir-frying in the prior art, the efficiency is low and the labor intensity is high, solves the problem that tea leaves are easily burnt so as to cause waste, and is simple in structure and convenient to use; the electrical heating pipe is used for heating, so that overheating can be prevented; the stir-frying barrel is used for stirring, so that the phenomenon that the tea leaves are burnt due to being heat for a long time at the same placeis effectively prevented; the stir-fried tea leaves can be more uniform through the stir-frying device, so that the stir-frying quality of the tea leaves is greatly improved.

Owner:ANHUI SHITAI COUNTY XIHUANGSHAN TEA IND

Preparation process of fried peanuts

The invention discloses a preparation process of fried peanuts. The preparation process comprises the following specific steps of: 1, selecting whole-grain peanuts, soaking the peanuts in warm water for 5-10 min, transferring the peanuts into cold water to soak for 1-2 min, and taking out the peanuts for after use; 2, putting the peanuts in a huller to remove the coats; 3, putting the hulled peanuts into brine to soak for 7-8 h, and fishing out the peanuts to drain off; 4, frying the peanuts for 10-11 min at a temperature of 160-170 DEG C; 5, putting the peanuts into seasonings to mix thoroughly, and frying the peanuts again for 1-2 min at a temperature of 150-160 DEG C; and 6, after the frying is finished, fishing out the peanuts to drain off, cooling the peanuts to 10-20 DEG C, and packaging the peanuts. By adoption of the preparation process disclosed by the invention, the prepared fried peanuts are crispy, tasty, fresh in smell and pure in flavor; and the taste can be fully blended into the peanuts, so that the taste is more uniform.

Owner:GUIZHOU XUYANG FOOD GROUP

Dendrobium nobile planting and production extraction process

The invention discloses a dendrobium nobile planting and production extraction process which comprises the following steps: S1, harvesting: selecting firm and full stems and branches of three or moreyears during harvesting, shearing from the bases of old stems by using scissors, and keeping tender plants to continuously grow so as to ensure continuous harvesting; S2, processing the fresh dendrobium nobile, namely cleaning the fresh dendrobium nobile before use, removing roots and leaves, and cutting the fresh dendrobium nobile into sections; storing the fresh dendrobium nobile in a shady, cool and anti-freezing place by using wet sand; and S3, processing the dried dendrobium nobile, namely removing impurities after harvesting, slightly scalding or baking to be soft by using boiled water until sheaths are completely rubbed, drying, and processing the dried dendrobium nobile into dendrobium nobile for sale. The method comprises the following steps: separating picked fresh stems according to thickness and length, respectively stir-frying the fresh stems in a pot with strong fire, taking the fresh stems out of the pot, kneading with hands, removing leaf sheaths, and re-frying for 1-2times until stem branches are soft. The material is twisted into a thread shape one by one and dried at a time with slow fire, so that the dendrobium nobile becomes a first-grade product called dragonhead phoenix tail, the appearance of the dendrobium nobile is guaranteed, the dendrobium nobile is prevented from being burnt, and the medical value of the dendrobium nobile can be better achieved.

Owner:安徽霍山大汉仙草生物科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com