Patents

Literature

90results about How to "Improve the suction experience" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

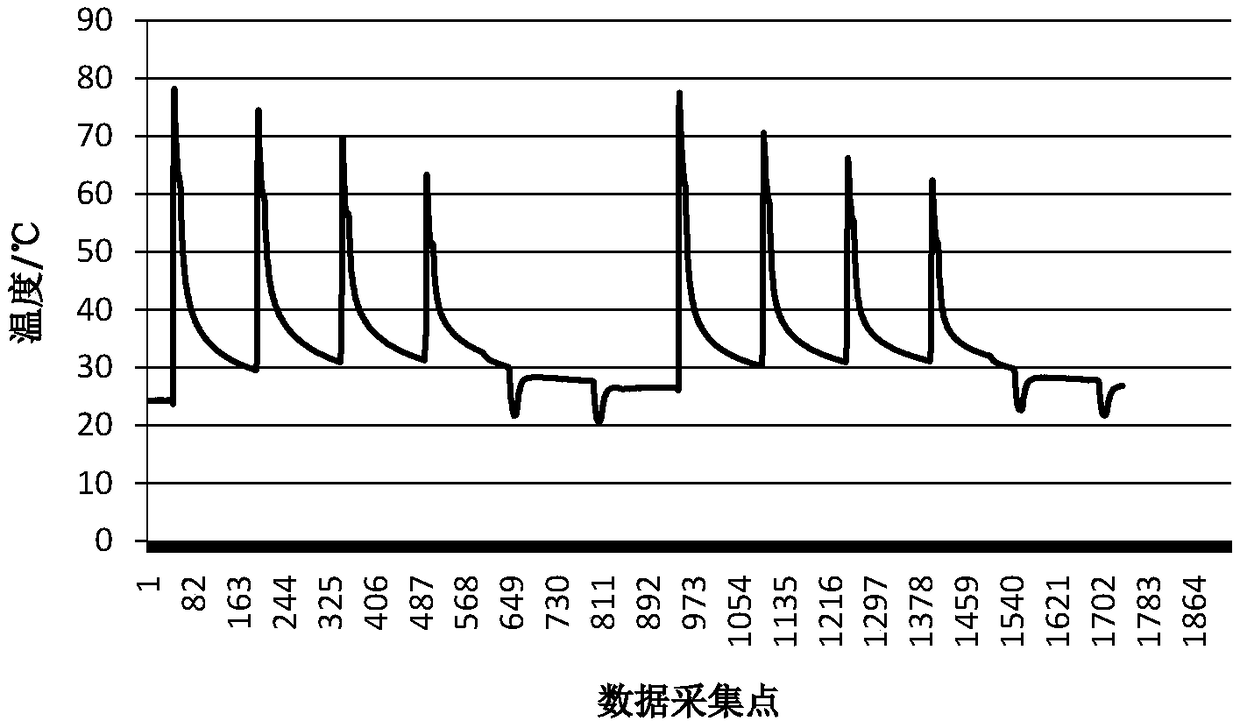

Electronic atomizing device and control method of heating element thereof

PendingCN109730360AImprove heating efficiencyIncrease temperatureTobacco devicesComputer moduleProcess engineering

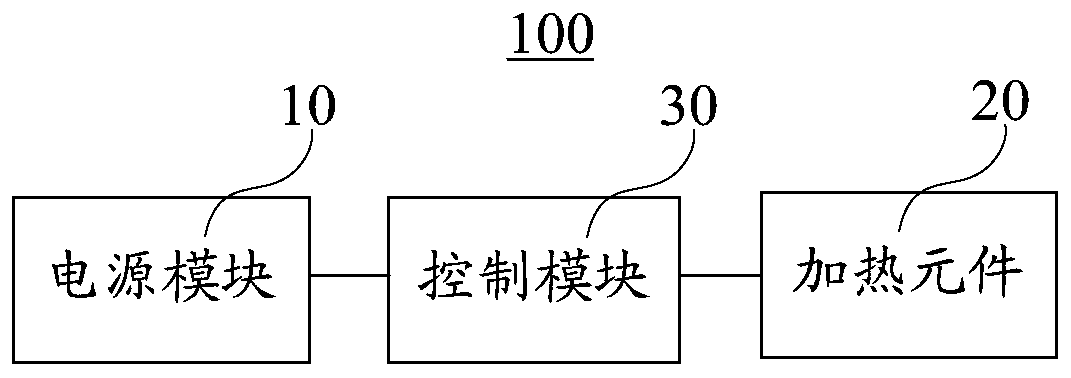

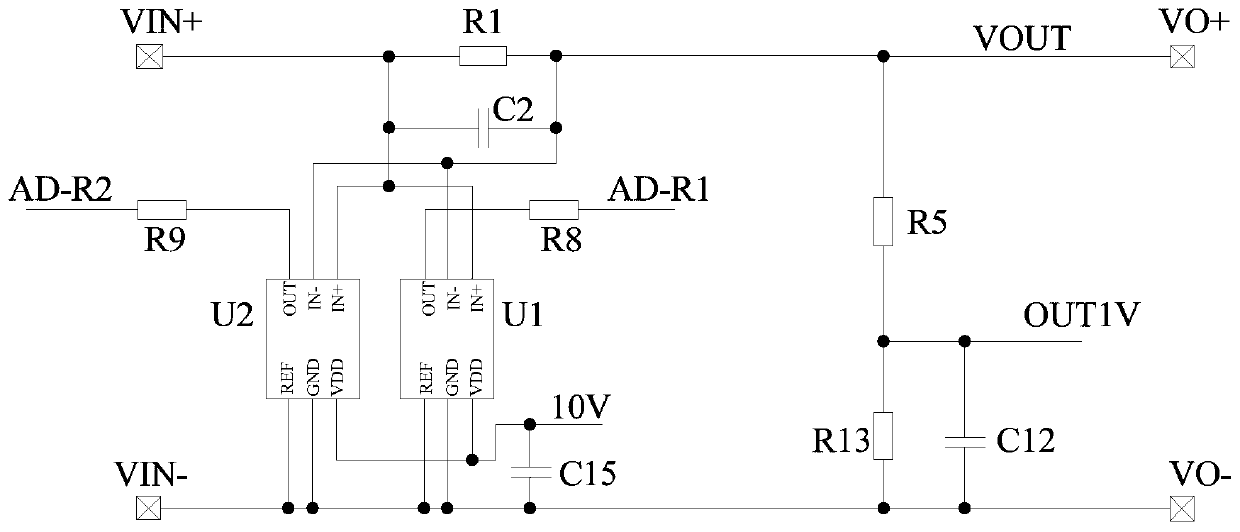

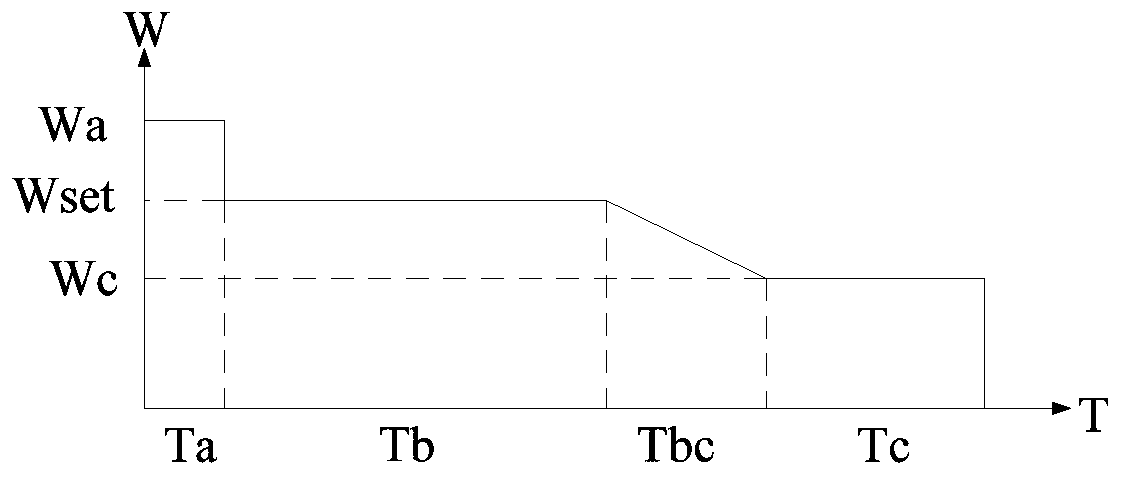

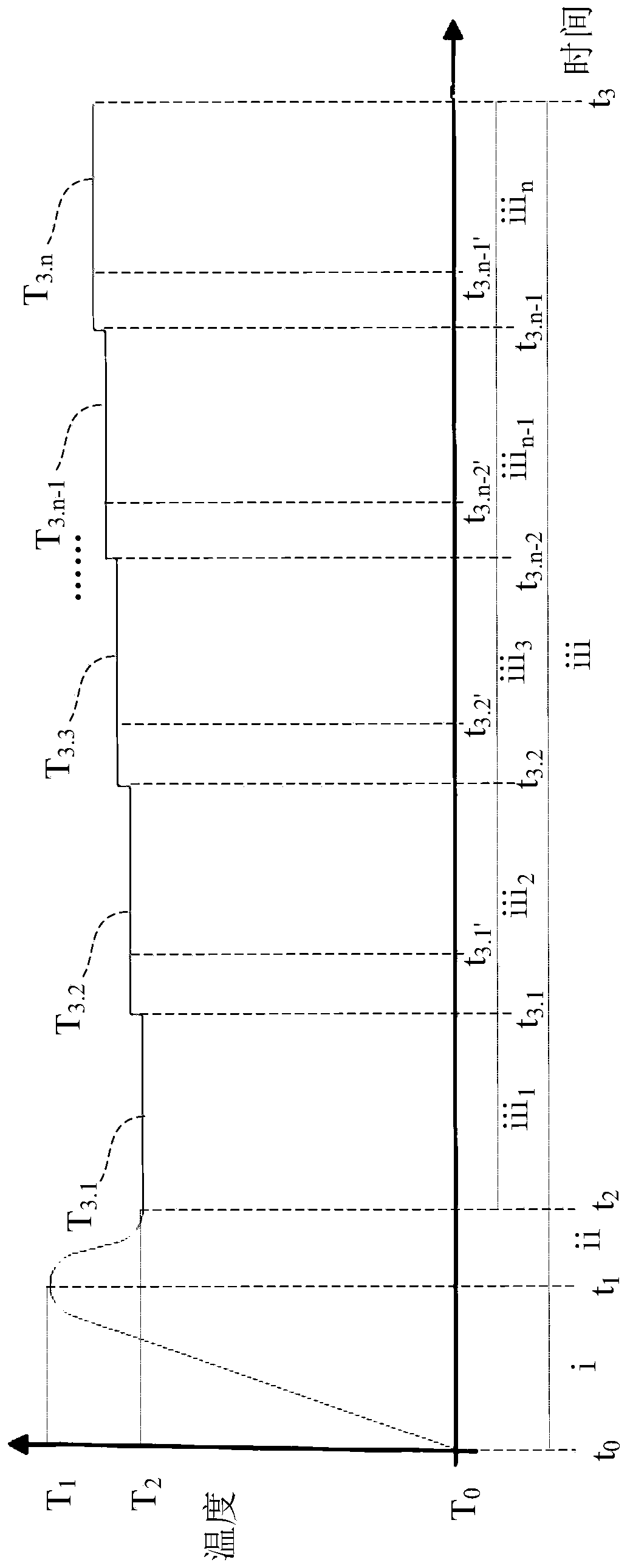

The invention discloses an electronic atomizing device and a control method of a heating element thereof. The electronic atomizing device comprises the heating element, a power supply module and a control module. The heating unit is used for heating an aerosol to generate a matrix, the power supply module is used for providing electric power to the heating element, and the control module is used for controlling the heating element in a first time period to work with a first parameter value; in a second time period, the control module controls the heating element to work with a second parametervalue lower than the first parameter value; in a third time period, the second parameter value of the heating element which works is reduced to a third parameter value and the heating element works in a fourth time period with the third parameter value. In this way, the heating efficiency can be accelerated, so that the heating element is quickly heated, and the condition that temperatures of theheating element in the third and fourth time periods are too high as a result of heat accumulation property of the heating element can be prevented, so that the tastes of the aerosols generated in the heating stages by the electronic atomizing device are uniform, and the smoking experience of a user is improved.

Owner:SHENZHEN SMOORE TECH LTD

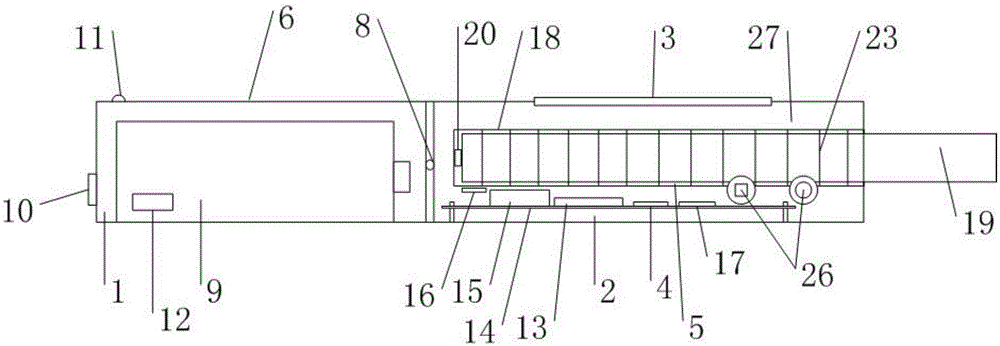

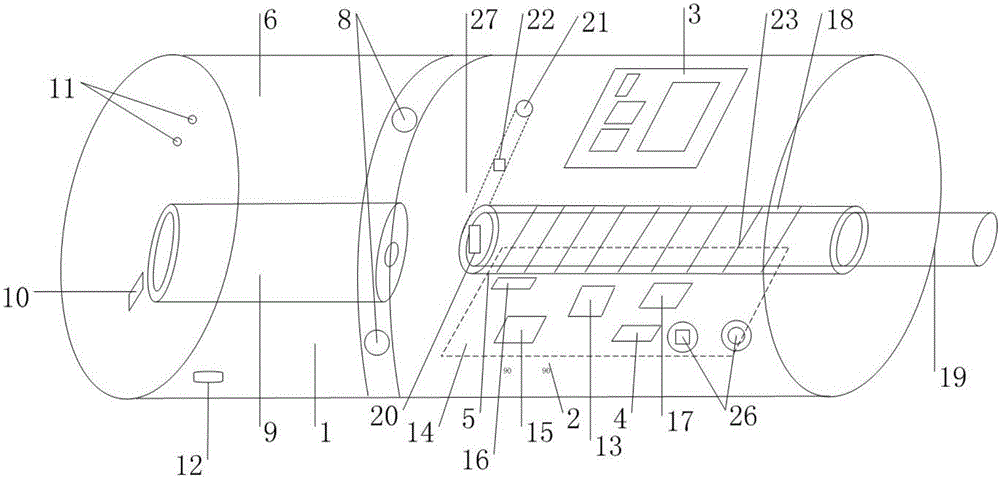

Intelligent electric heating cigarette system

InactiveCN105146756AImprove the suction experienceRegulation stabilityTobacco pipesElectrical batteryEngineering

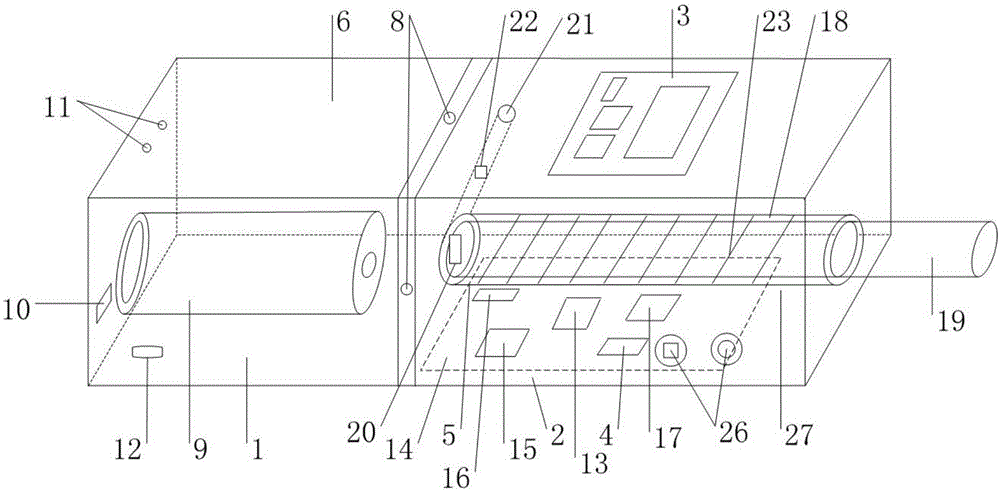

The invention provides an intelligent electric heating cigarette system which comprises a power module, a heating module, a control module, a liquid crystal display module, a wireless communication module, an outer shell and a data terminal. The power module is mainly composed of an efficient rechargeable battery, a cylindrical cavity is formed in the heating module, and a common cigarette can be directly placed in the cylindrical cavity to be heated. An embedded microprocessor serves as a core of the control module. The liquid crystal display module comprises a liquid crystal display, and current heating temperature, the battery remaining capacity, the number of times of smoking and the number of smoked cigarettes can be displayed in real time, and are sent to the data terminal through the wireless communication module. The data terminal can monitor and analyze relevant data, and the smoking habit of a user can be fed back to the user. According to the intelligent electric heating cigarette system, heating temperature can be adjusted at any time, the temperature is intelligently controlled through an intelligent control algorithm, the smoking experience of the user is improved, meanwhile, the limited smoking quantity of the user can be set and controlled, and health management is achieved.

Owner:NANJING UNIV OF SCI & TECH

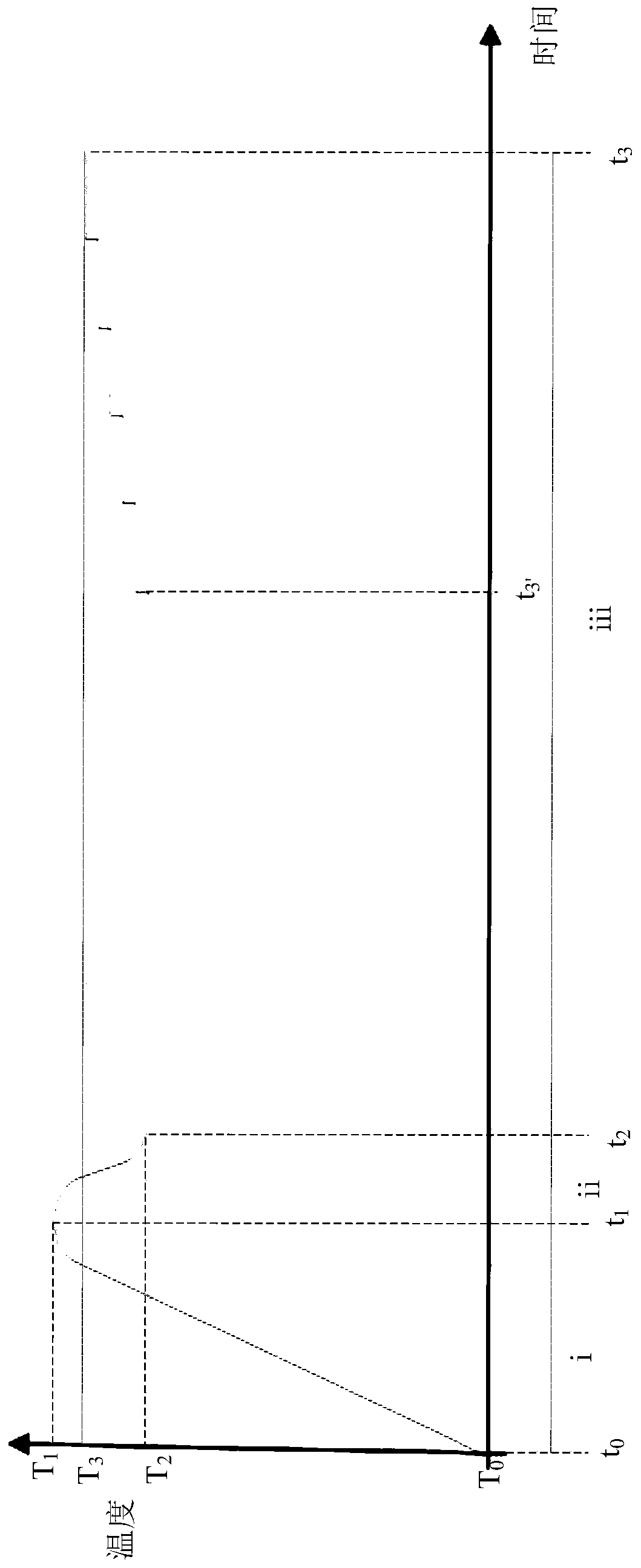

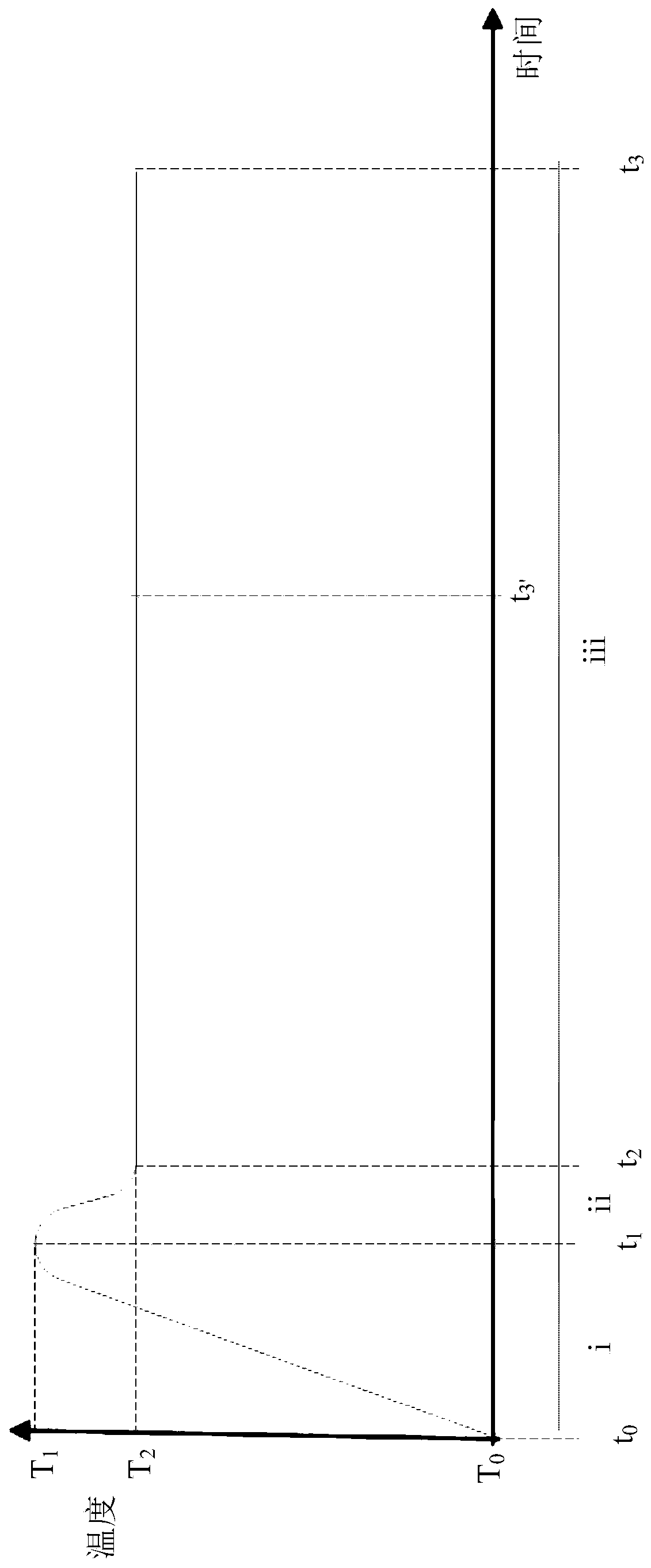

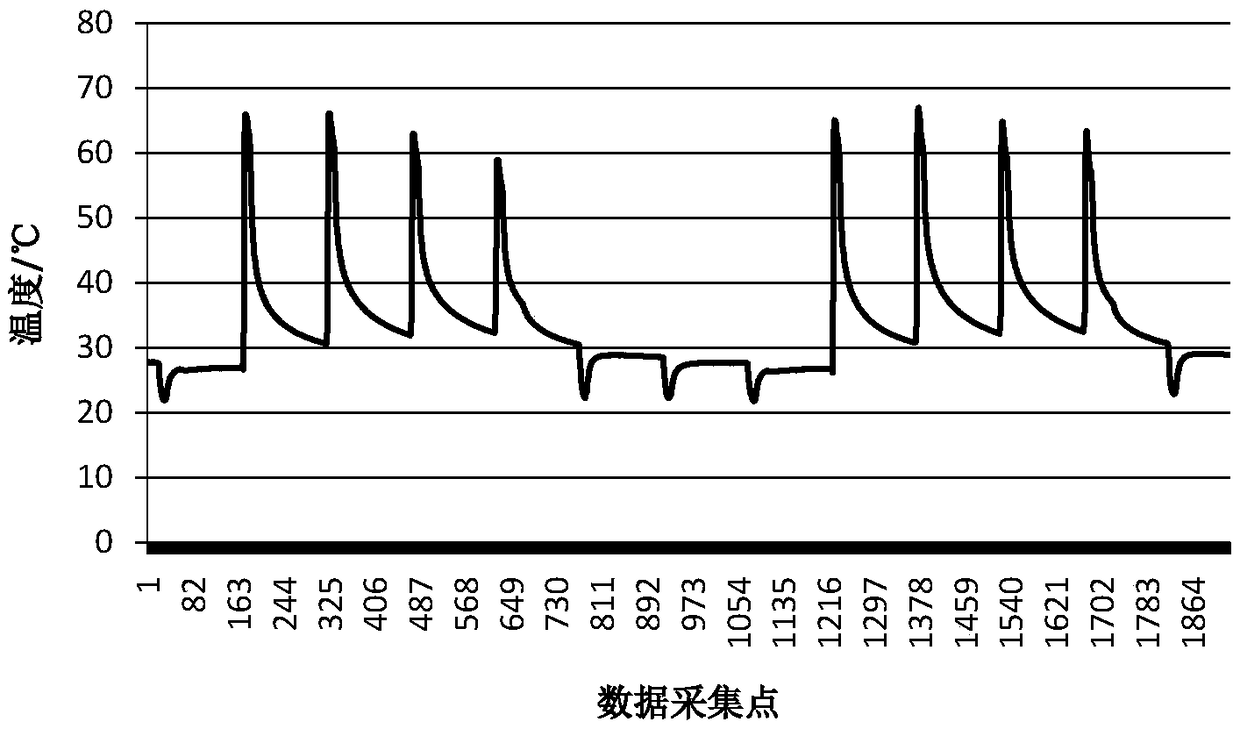

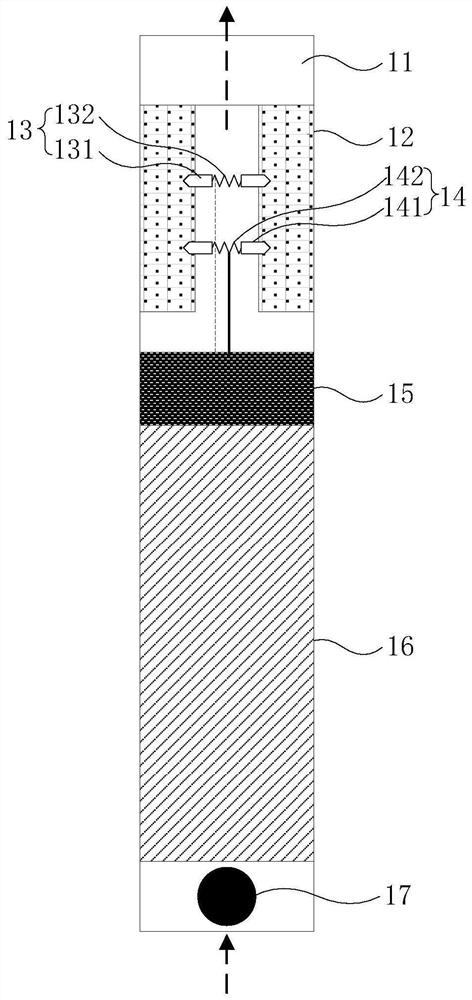

Temperature control method, aerial fog production device and aerial fog production system

ActiveCN110367593AGuaranteed supplyAvoid wastingTobacco devicesTransportation and packagingTemperature controlAerosol Mist

The invention provides a temperature control method applied to an aerial fog production device. The aerial fog production device comprises a detection element and a heating element for heating an aerial fog production base material. The specific temperature control method comprises the steps of in a first stage, controlling the heating element to rise a temperature from an initial temperature to afirst temperature; in a second stage, controlling the heating element to decrease the temperature from the first temperature to a second temperature; and in a third stage, controlling the heating element to carry out constant temperature operation at a second temperature, and controlling the heating element to rise the temperature to a third temperature if the detection element detects suction. The invention also provides the aerial fog production device and an aerial fog production system. Temperature change of the heating element is controlled according to a suction behavior of a consumer;in the third stage, the temperature of the heating element is risen only when the suction is detected; aerial fog supply quantity produced when the consumer sucks is guaranteed to satisfy a requirement all the time; and electric energy and the aerial fog production base material are prevented from being wasted. The temperature control method is relatively intelligent. Suction experience of the consumer is improved.

Owner:SHANGHAI NEW TOBACCO PRODUCTS RESEARCH INSTITUTE CO LTD

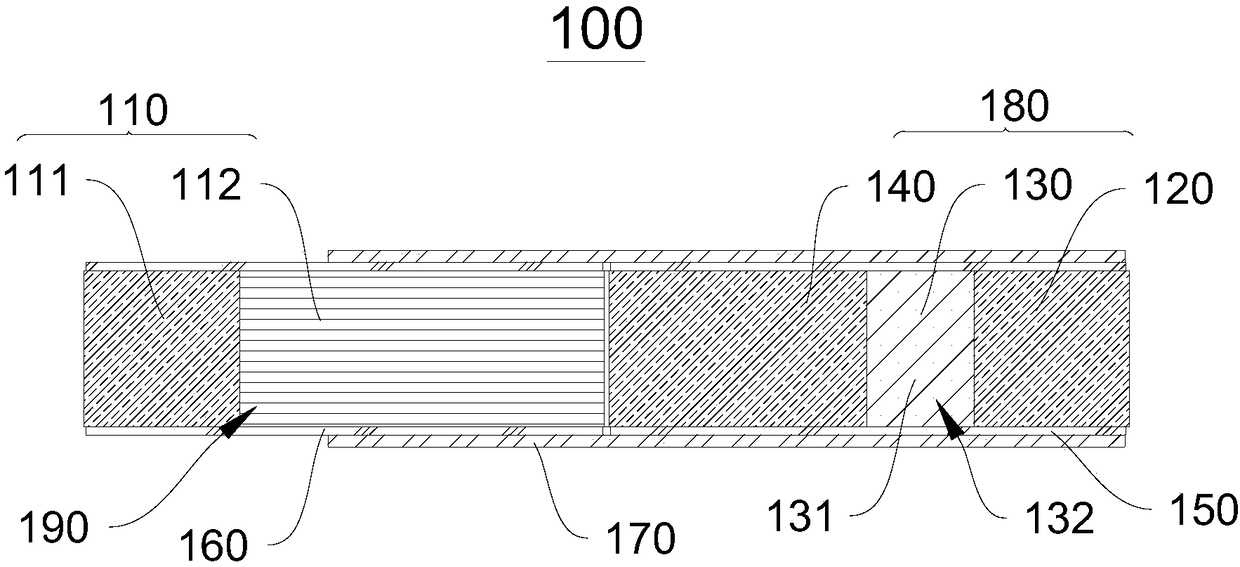

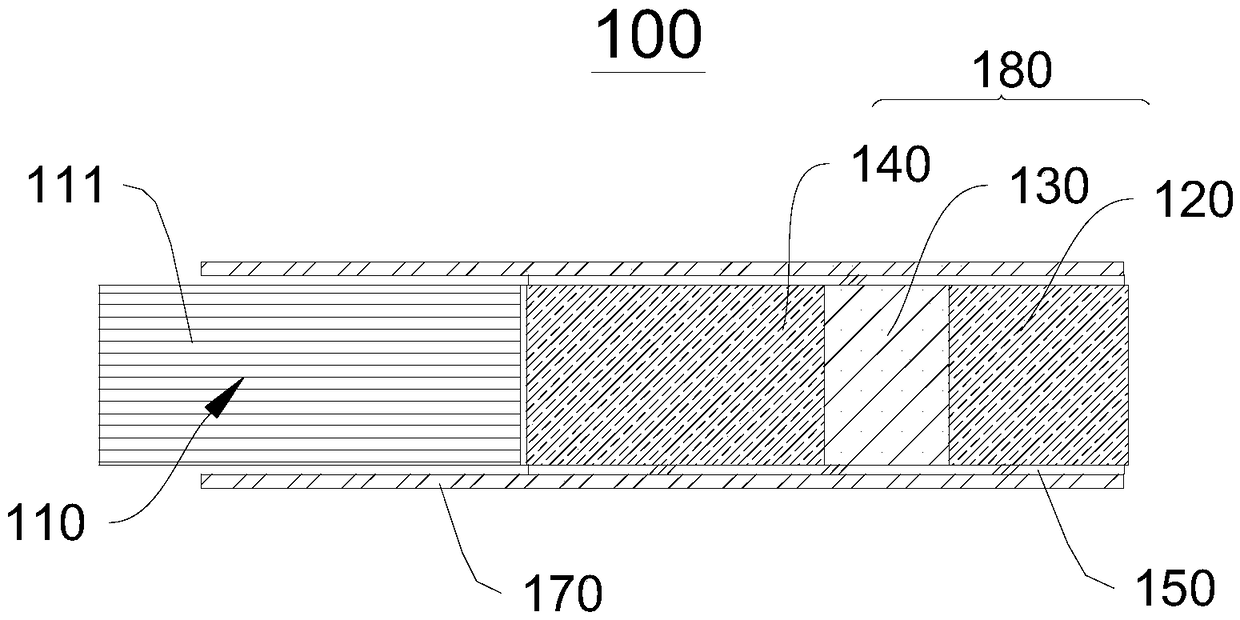

Fragrant cigarette cartridge and fragrance suction device

PendingCN109480339AImprove the suction experienceSolve insufficient atomizationTobacco devicesFlavorAdditive ingredient

The invention relates to the technical field of cigarettes incombustible in heating, in particular to a fragrant cigarette cartridge and a fragrance suction device. The fragrant cigarette cartridge comprises a filter tip section, a second cavity base, a perfume section and a first cavity base, wherein the filter tip section, the second cavity base, the perfume section and the first cavity base aresequentially and coaxially connected, aerial fog produced by atomizing tobacco tar at an atomization portion sequentially passes through the first cavity base, the perfume section, the second cavitybase and a gas flow channel in a filter tip and carries out a fragrant ingredient of fragrant particles in the perfume section, and the first cavity base can effectively filter out incompletely atomized tobacco tar. By adding the fragrant particles in the perfume section formed between the first cavity base and the second cavity base, fragrance choices of smoking are increased, and the smoking experience of users is improved.

Owner:SICHUAN SANLIAN NEW MATERIAL CO LTD +1

High-aroma heat-not-burn tobacco and preparation method thereof

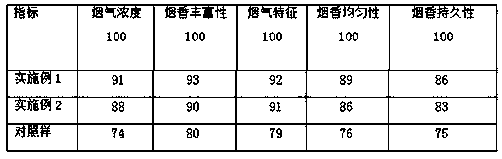

InactiveCN108703398AIncrease smoke concentrationSmoke features are obviousTobacco preparationTobacco treatmentFlavorAlcohol

The invention belongs to the technical field of cigarettes and particularly relates to high-aroma heat-not-burn tobacco and a preparation method thereof. The preparation method is characterized by including the steps of (1) microwave swelling; (2) tobacco leaf crushing; (3) suspension preparing; (4) spraying; (5) drying and balancing, wherein the step (3) of suspension preparing includes: mixing well a mixture of a polyol, purified water, anhydrous ethyl alcohol, tobacco extract, a tobacco flavor, a binder and a dispersing aid, and leaf particles of the step (2) in a certain mass ratio to obtain homogenous suspension. The tobacco particles and the flavor are made into the suspension that is sprayed to microwave-swelled tobacco stems, and the defects are overcome that, for instance, the traditional heat-not-burn tobacco smoke has low concentration, poor aroma richness, obscure smoke characteristics, non-uniform aroma, and poor duration.

Owner:CHINA TOBACCO JIANGXI IND CO LTD

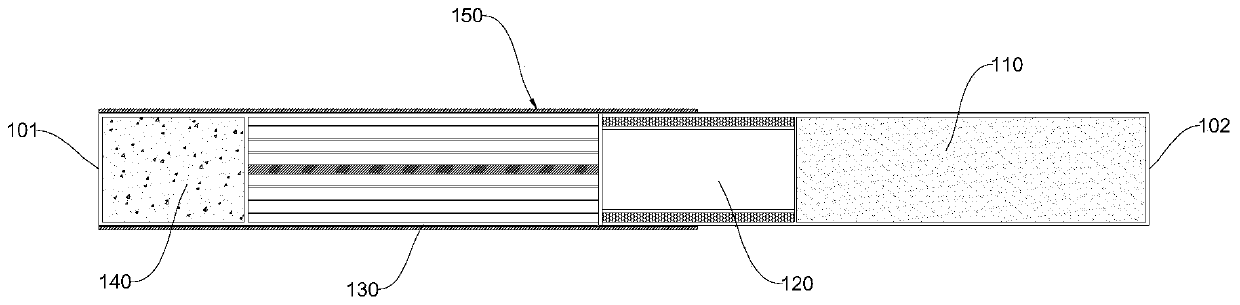

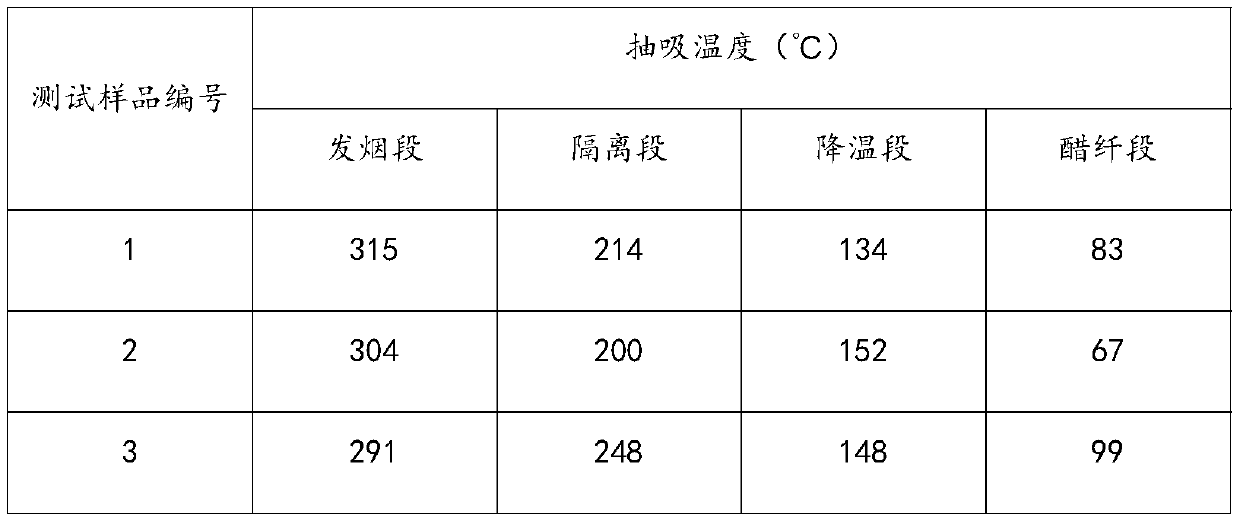

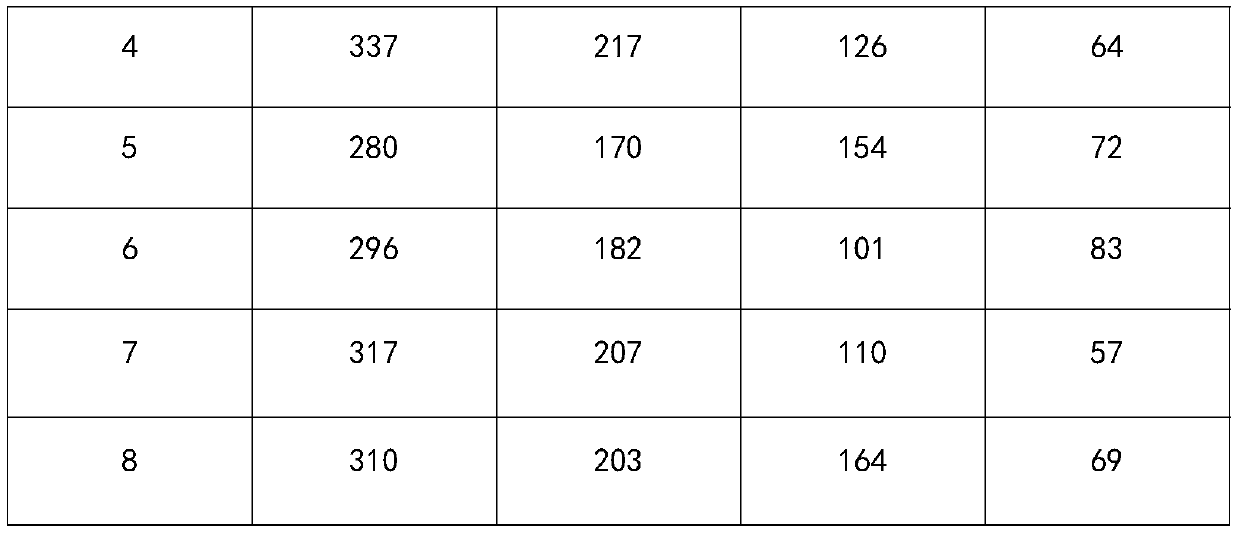

Smoke generating product and electronic cigarette

The invention relates to the technical field of heat-not-burn cigarettes, in particular to a smoke generating product and an electronic cigarette. The smoke generating product comprises a smoke generating section, an isolating section, a flavor blending and cooling section and a cellulose acetate fiber section, wherein the smoke generating section, the isolating section and the flavor blending andcooling section all contain tobacco components; the sum of the tobacco components in the smoke generating section, the isolating section and the flavor blending and cooling section accounts for 30% or above of the total raw material mass of the smoke generating product; the smoke generating section is connected with the isolating section, the isolating section is connected with the flavor blending and cooling section, and the flavor blending and cooling section is connected with the cellulose acetate fiber section; a plurality of gas flowing channels are formed in the flavor blending and cooling section. According to the smoke generating product, the number of smoking can be increased, the user experience is improved, and meanwhile the utilization rate of tobacco raw materials is increased.

Owner:SICHUAN SANLIAN NEW MATERIAL CO LTD +1

Tobacco composition for paper-making method reconstituted tobacco leaves and application thereof to heat-not-burn cigarettes

InactiveCN110150723AIntact void structurePromote absorptionTobacco preparationTobacco treatmentHeat not burnEngineering

The invention discloses a tobacco composition for paper-making method reconstituted tobacco leaves and application thereof to heat-not-burn cigarettes. The tobacco composition is prepared from a stemgroup raw material and a leaf group raw material dividedly, based on a conventional paper-making reconstituted tobacco leaf process, a stem group tobacco powder wet part is added into a film base before film base forming, leaf group tobacco powder is added into coating liquid, and the core material paper-making method reconstituted tobacco leaves applied to the heat-not-burn cigarettes are prepared. By utilizing the tobacco composition, the absorption property of the film base of the paper-making method reconstituted tobacco leaves can be improved, the adding requirement of a high-content smoke agent is met, an aroma framework of the heat-not-burn cigarettes is perfected, the quality pursuit of the heat-not-burn cigarettes is reached in the aspect of sensory quality, the aroma quality is good, the smoke concentration is high, the strength is high, the texture is fine and smooth, mixed gas slightly exists, the remaining taste is clear, and harmoniousness is good.

Owner:ZHONGYAN SHIWEICE (YUNNAN) RECONSTITUTED TOBACCO CO LTD

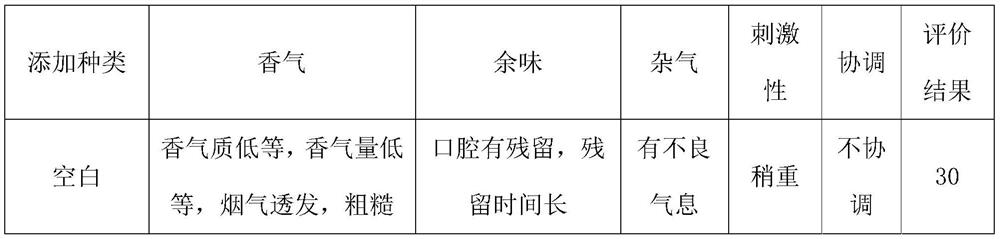

Essence additive for temperature drop section of heating non-burning cigarette, preparation method and application of essence additive and heating non-burning cigarette

InactiveCN110537720AImprove durabilityImprove comfortTobacco preparationTobacco devicesTemperature dropPolymer science

The invention discloses an essence additive for a temperature drop section of a heating non-burning cigarette, a preparation method and application of the essence additive and the heating non-burningcigarette and relates to the technical field of heating non-burning cigarettes. The essence additive for the temperature drop section of the heating non-burning cigarette comprises first essence, wherein the extraction temperature of the first essence is 60-255 DEG C, preferably 60-200 DEG C and more preferably 60-150 DEG C. By adopting the essence extracted under the specific extraction temperature as the additive, the first essence is suitable for the temperature drop section of the heating non-burning cigarette through optimization of the extraction temperature, and generated fragrance hasthe advantages of good durability, high comfort, consistency in previous taste and later taste and the like. When the essence additive is added to the temperature drop section of the heating non-burning cigarette, the smoking experience of the heating non-burning cigarette can be remarkably improved.

Owner:SICHUAN SANLIAN NEW MATERIAL CO LTD +1

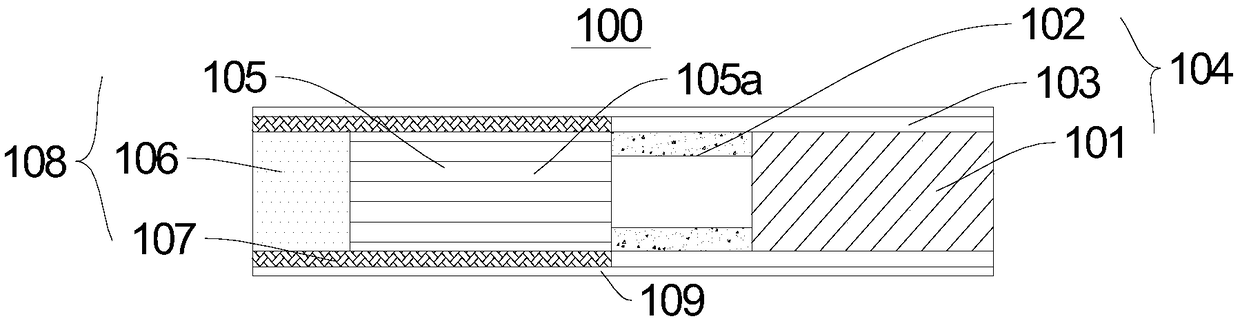

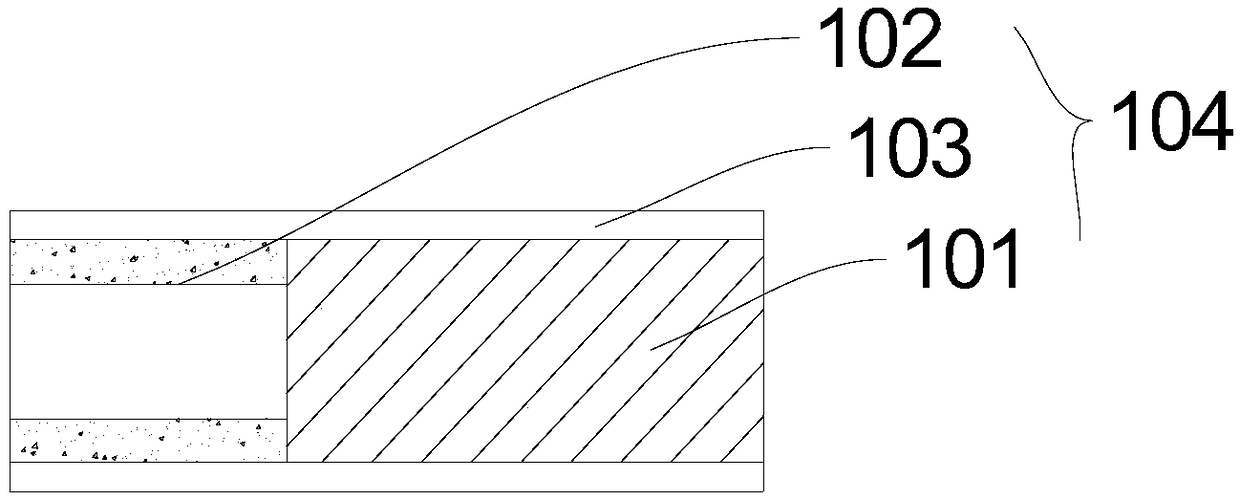

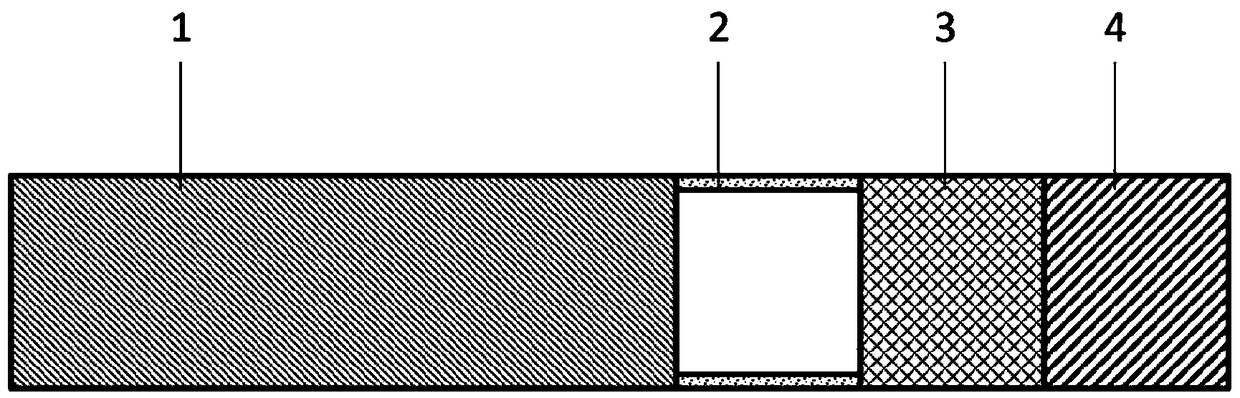

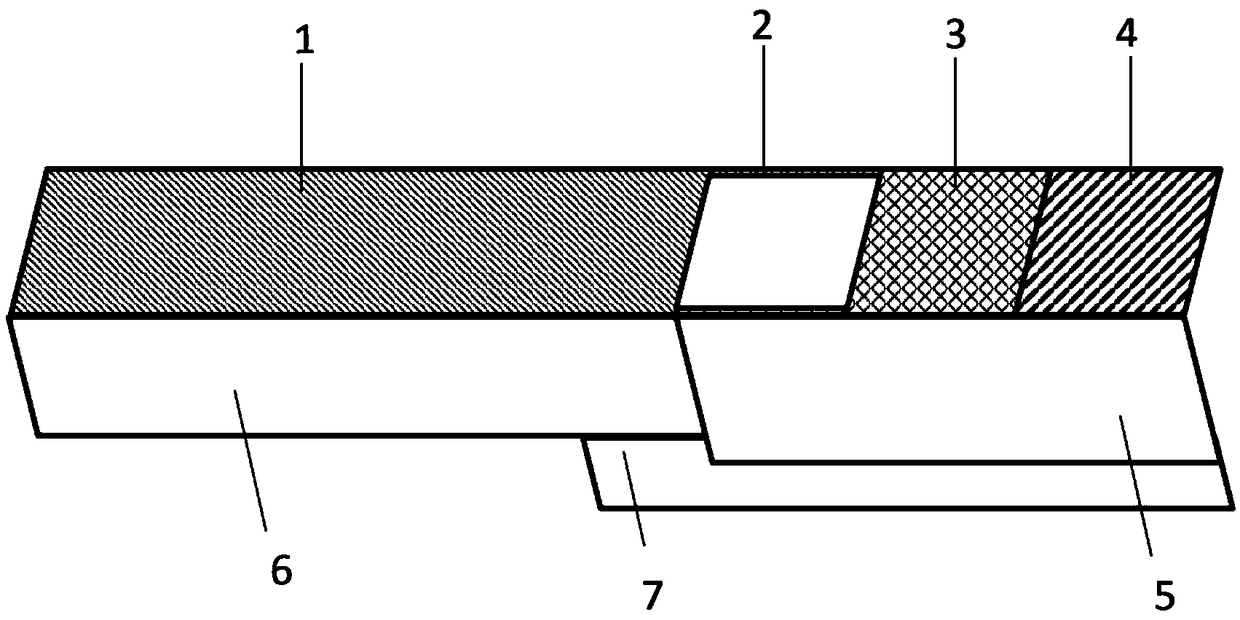

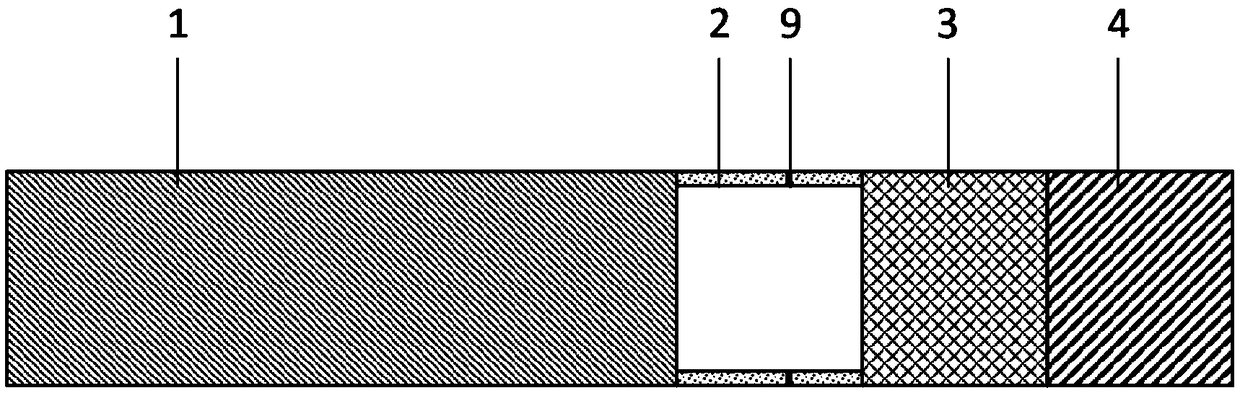

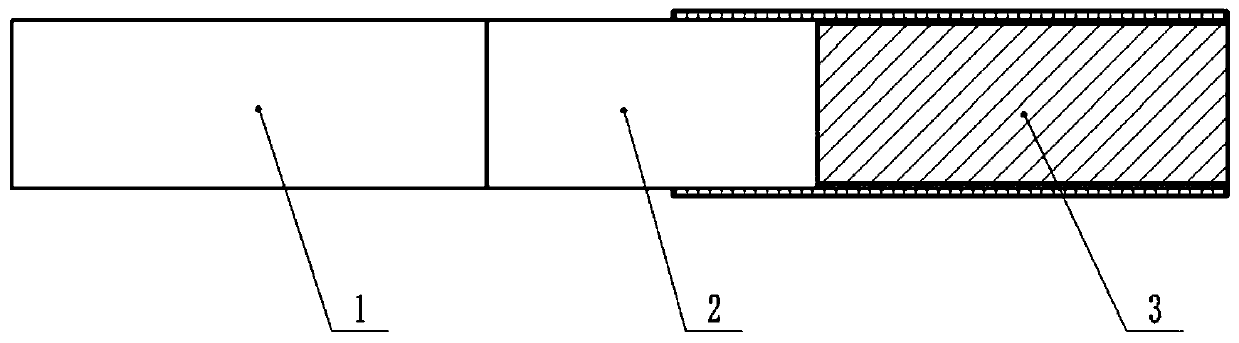

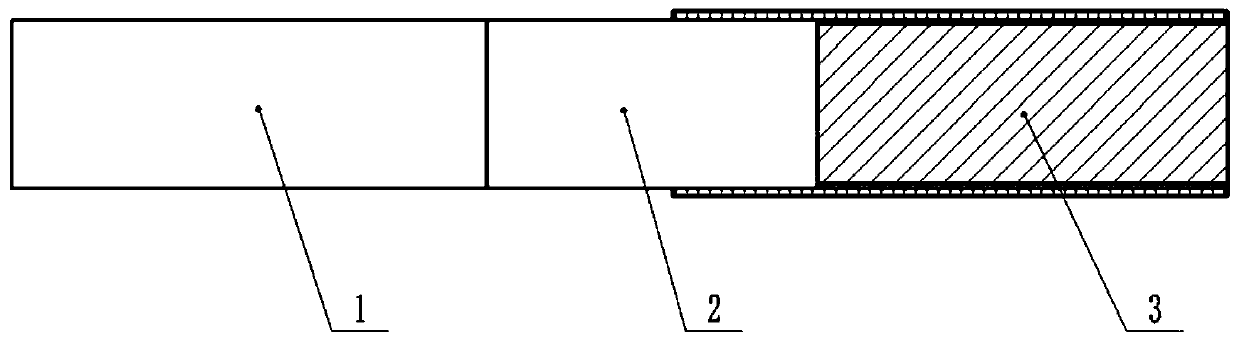

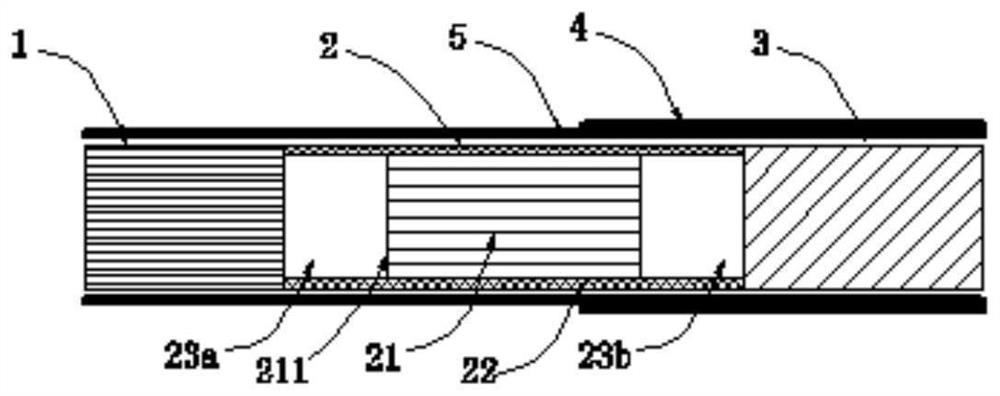

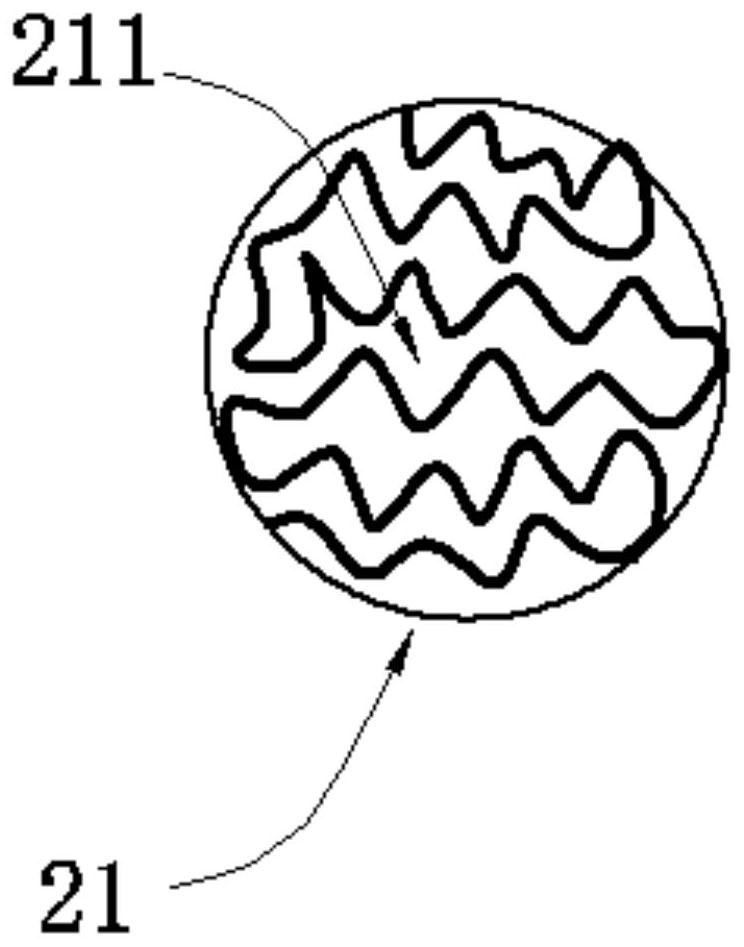

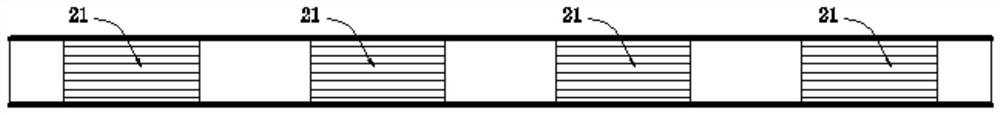

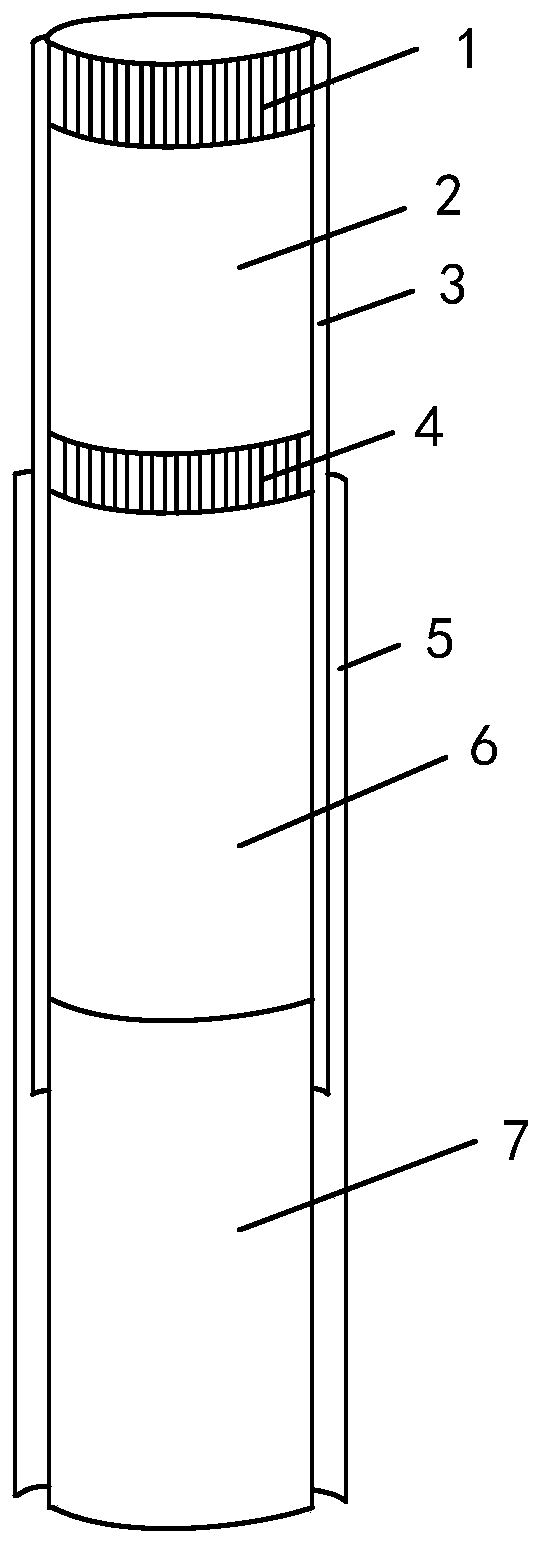

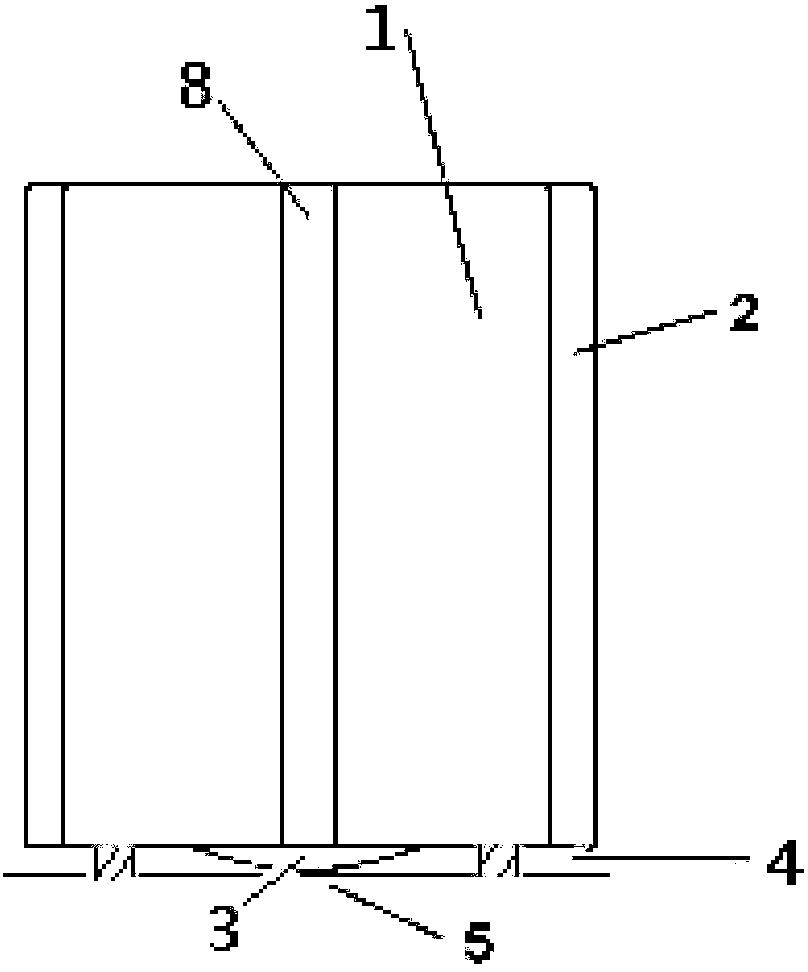

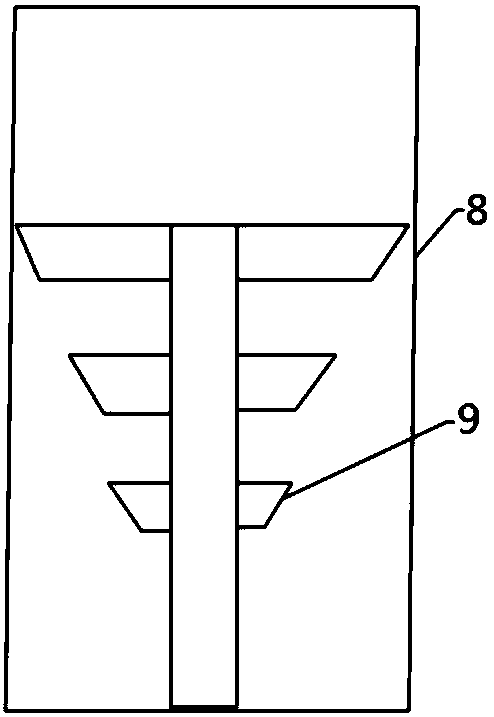

Cigarette body for circumferential heating non-burning cigarette

PendingCN109497618AAvoid problems that affect the tasteMeet design requirementsTobacco devicesFiberCooking & baking

The invention discloses a cigarette body for a circumferential heating non-burning cigarette. The cigarette body is formed by successively connecting a cigarette core substrate (1), a paper tube unit(2), a filter rod unit (3) and a condensing unit (4). The paper tube unit (2), the filter rod unit (3) and the condensing unit (4) are wrapped by composite molding paper (5). The cigarette core substrate (1) is wrapped by cigarette paper (6). The composite molding paper (5) and the cigarette paper (6) are wrapped by tipping paper (7). The condensation unit (4) is processed by a high-molecular polymer material or a high-molecular polymer silk and diacetate fiber silk blend material. The paper tube unit is added between the cigarette core substrate and the filter rod unit to avoid the fact thata high-molecular polymer material of the filter rod unit collapses under direct or indirect baking of circumferential heating and generates plastic smell. The cigarette body structure is more in linewith the design requirements of the circumferential heating non-burning cigarette.

Owner:CHINA TOBACCO YUNNAN IND

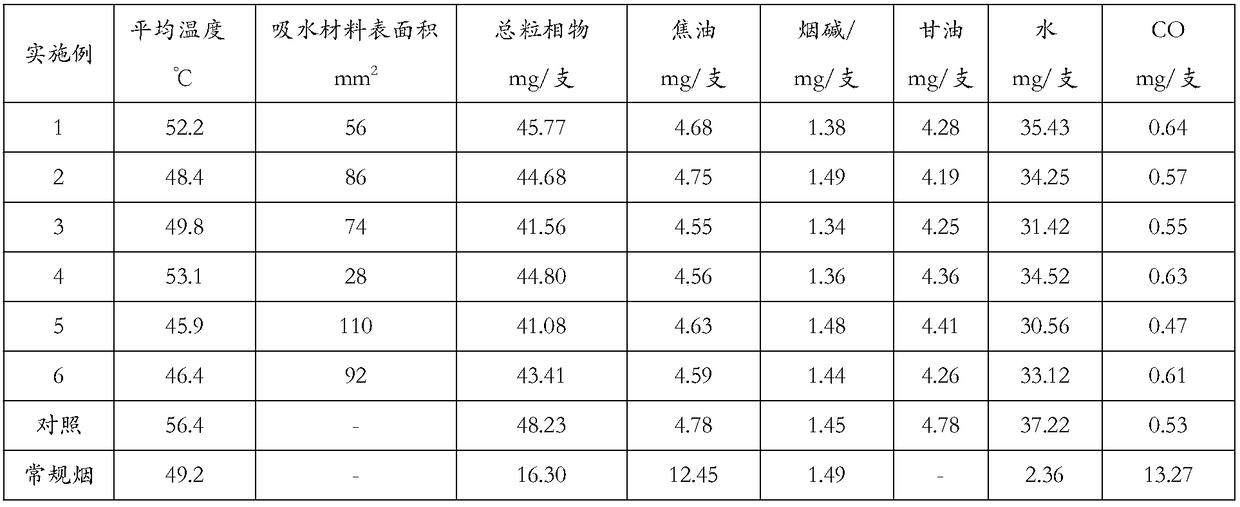

Heated non-combustible cigarette cooling section and preparation method thereof

The invention relates to a heated non-combustible cigarette cooling section which comprises a heat insulation paper tube and water absorbing material particles in the tube. Water absorbing materials are selected from water absorbing agents, water absorption silicone, degreasing cotton, sponge and sodium polyacrylate or drying agents, and heat insulation paper is corrugated paper. According to thecooling section, vapor in smoke is absorbed, the outer layer of the cooling section is made of anti-scald paper, so that the temperature of the smoke can be effectively reduced, the suction experienceof a consumer is improved, tar content and harmful smoke are reduced when original fragrance and smoke amount of cigarettes are retained, harm of the smoke to human bodies is greatly reduced, and psychological and physical requirements of the consumer are met.

Owner:YUNNAN TOBACCO BIOLOGICAL TECH CO LTD +1

Cooling and filtering material and preparation method and application thereof

InactiveCN111155356AEasily brokenImprove the problem of shrinking and collapsing and blocking the flue gas channelTobacco smoke filtersCalendersPlant fibreProcess engineering

The invention discloses a cooling and filtering material as well as a preparation method and application thereof. Plant fiber dispersion liquid and PLA fiber dispersion liquid are evenly mixed, then papermaking is conducted, then calendaring is conducted, and the cooling and filtering material is obtained. Good folding resistance and high-temperature resistance of plant fibers are fully utilized,the plant fibers support the composite material, the fracture problem of a polylactic acid film in the folding and rolling process is solved, and the problems that polylactic acid serves as a coolingmaterial, contracts and collapses as a phase change material after absorbing heat and blocks a smoke channel are solved; the filtering effect, namely the filtering performance, generated by the adsorption and interception effects of the adopted plant fibers is reduced, so that the cooling and filtering material is more suitable for producing non-combustible cigarettes with smaller smoke generationamount, the aroma saturation of smoke is favorably improved, and the smoking experience is improved. The cooling section and the filtering section are combined into one section, so that the cooling section is longer, and the cooling effect is better. Meanwhile, the production cost is reduced, and the production process is simplified.

Owner:SOUTH CHINA UNIV OF TECH

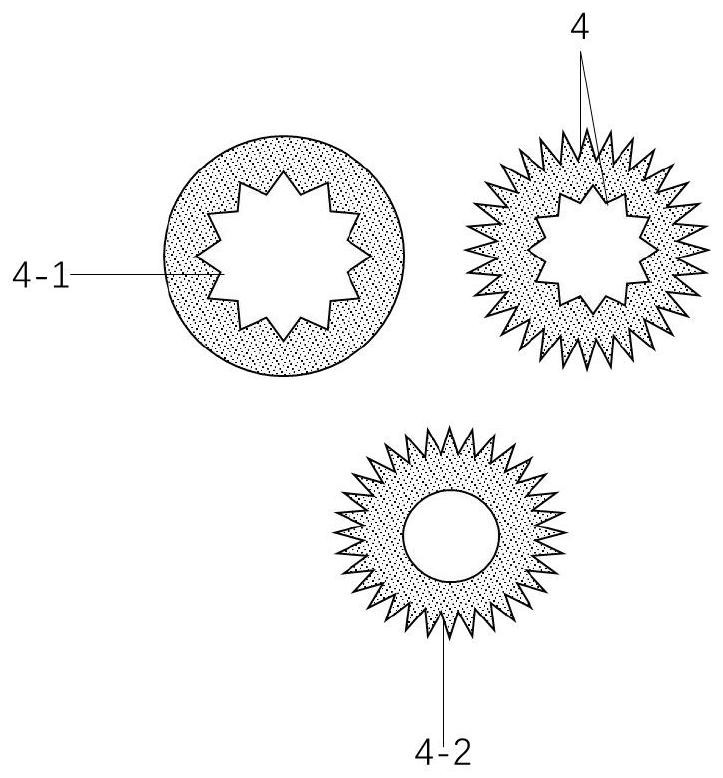

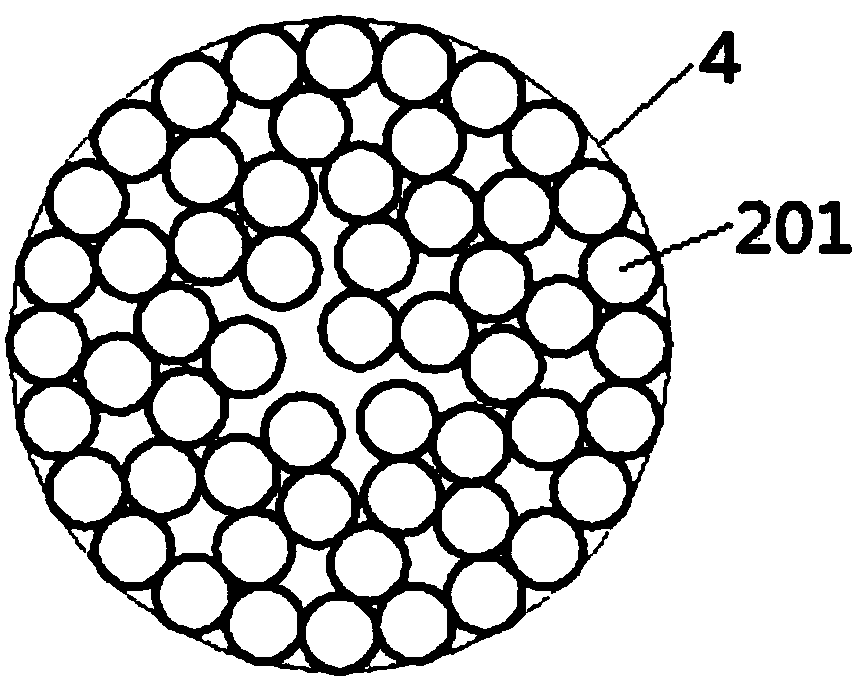

Electronic atomization device and atomizer and atomization assembly thereof

PendingCN111449300AImprove uniformityImprove the suction experienceTobaccoEngineeringMechanical engineering

The invention relates to an electronic atomization device and an atomizer and an atomization assembly thereof. The atomization assembly comprises a porous body and a cylindrical net-shaped heating body. The porous body comprises a central through hole, the heating body is of a hollow structure with two through ends, and the heating body is arranged in the central through hole and is tightly connected to the porous body. According to the atomization assembly, the cylindrical net-shaped heating body is arranged in the central through hole of the porous body and is tightly connected to the porousbody, so that the overall heating uniformity of the heating body can be improved, the scorched smell caused by local high temperature is avoided, and the smoking experience and atomization efficiencyare improved.

Owner:SHENZHEN SMOORE TECH LTD

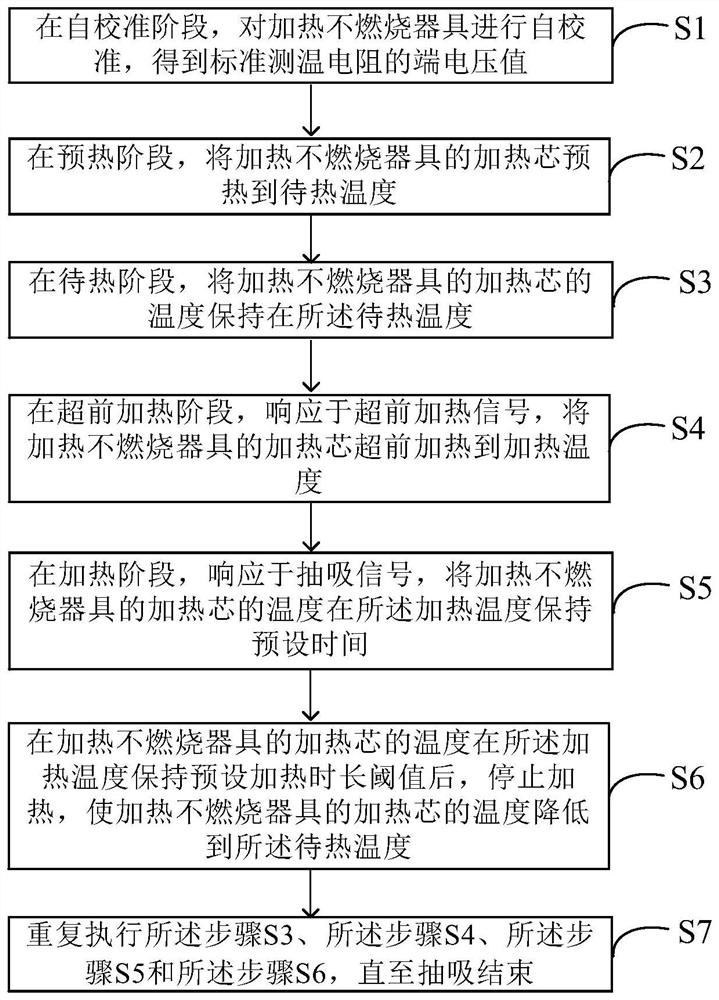

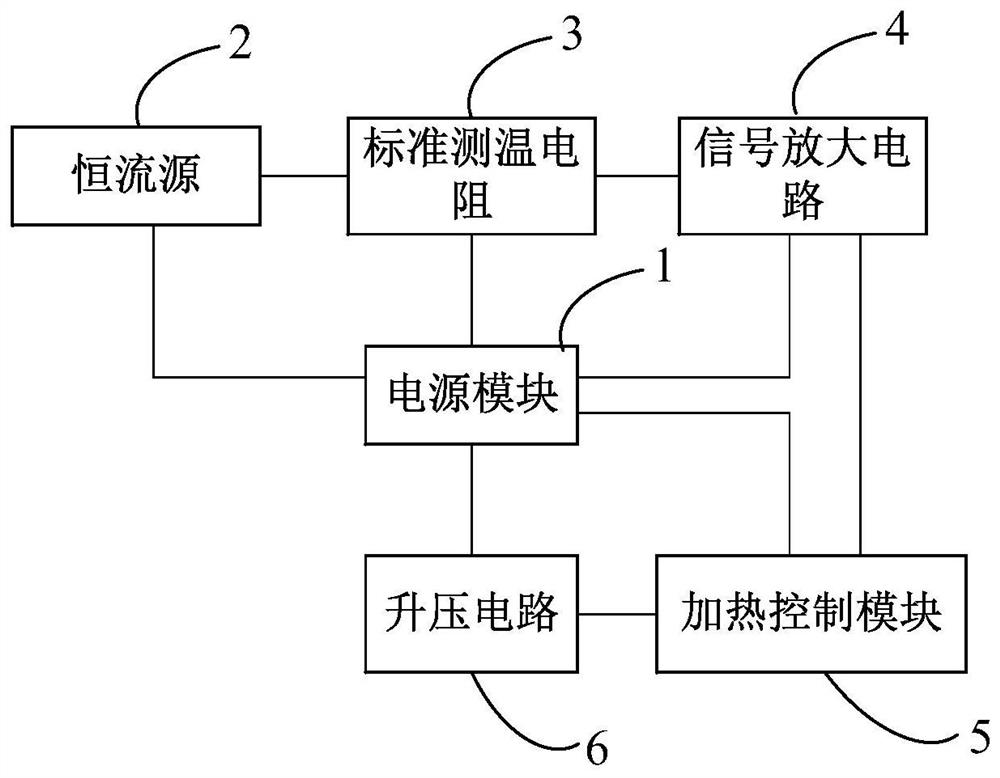

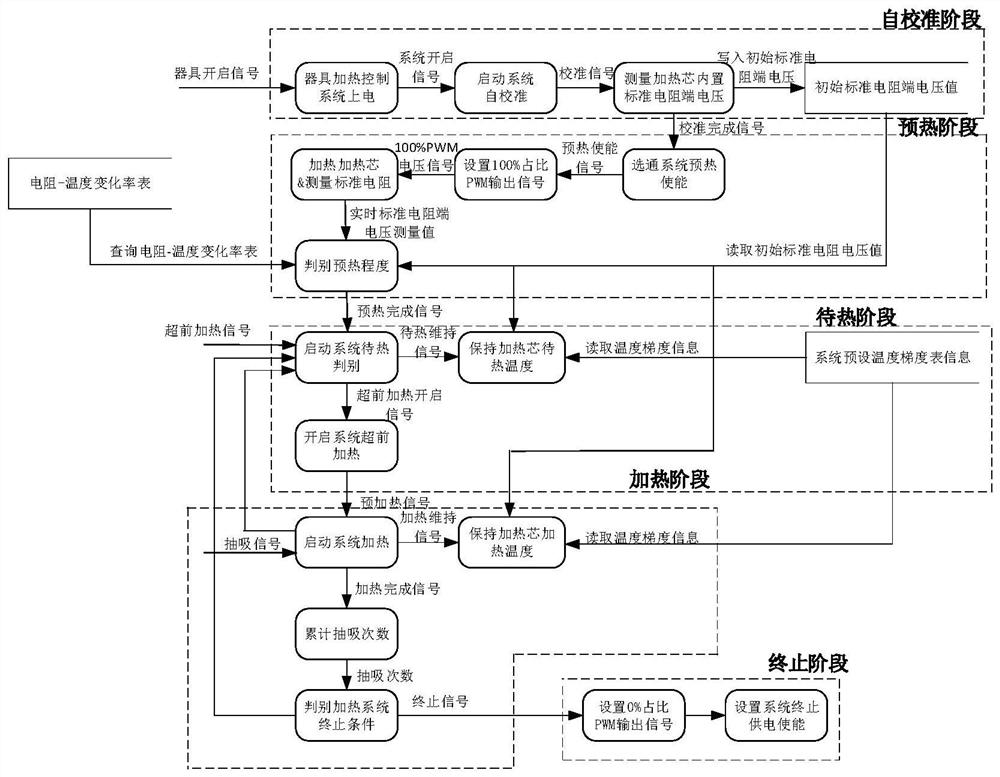

Advanced triggering smoking set heating control method

PendingCN112754084ALower maintenance temperatureImprove the suction experienceTobaccoThermodynamicsEngineering

The invention discloses an advanced triggering smoking set heating control method, which comprises the following steps: carrying out self-calibration on a heating non-combustion appliance to obtain a standard temperature measurement resistor end voltage value; in the preheating stage, preheating a heating core to a to-be-heated temperature; in the to-be-heated stage, keeping the temperature of the heating core at the to-be-heated temperature; in the advanced heating stage, in response to an advanced heating signal, heating the heating core to a heating temperature in advance; in the heating stage, in response to a suction signal, keeping the temperature of the heating core at the heating temperature by a threshold preset heating duration; after the heating temperature of the heating core is kept at the threshold preset heating duration, stopping heating, and cooling the heating core to the to-be-heated temperature; and repeating the processes of waiting for heating, advanced heating, heating and cooling until suction is finished. According to the advanced triggering smoking set heating control method, the heating effect of the heating smoking set is ahead of the actual smoking action of the user, the smoking experience of the user is improved, the maintaining temperature of the non-heating stage of the smoking set is greatly reduced, and the invalid loss of energy of the smoking set is reduced.

Owner:CHINA TOBACCO HENAN IND

Cavity type heating cigarette with reconstituted tobacco

PendingCN112335931ASimple structureSimple processing technologyCigar manufactureEngineeringSmoke Emission

The invention provides a cavity type heating cigarette with reconstituted tobacco, which comprises a tobacco section, a cigarette core filter stick cavity section and a near lip section which are sequentially and coaxially connected, and an external wrapping material for limiting the tobacco section, the cigarette core filter stick cavity section and the near lip section; and the cigarette core filter stick cavity section is composed of a cigarette core filter stick and a paper tube wrapping the cigarette core filter stick, the cigarette core filter stick is composed of reconstituted tobacco,and the two ends of the interior of the paper tube are each provided with a cavity with the specified length. According to the heating cigarette, by arranging the reconstituted tobacco core filter stick cavity section, a certain cooling effect is achieved, the problem that the temperature of smoke is too high is solved, the burning feeling and irritation are reduced, meanwhile, the smoke amount insmoke can be guaranteed, and the smoking experience feeling and satisfaction feeling of consumers are further improved. In addition, the heated cigarette is rich in cigarette aroma, and the front-endaroma and the rear-end aroma are basically consistent.

Owner:NANTONG JIN YUAN NEW MATERIALS CO LTD

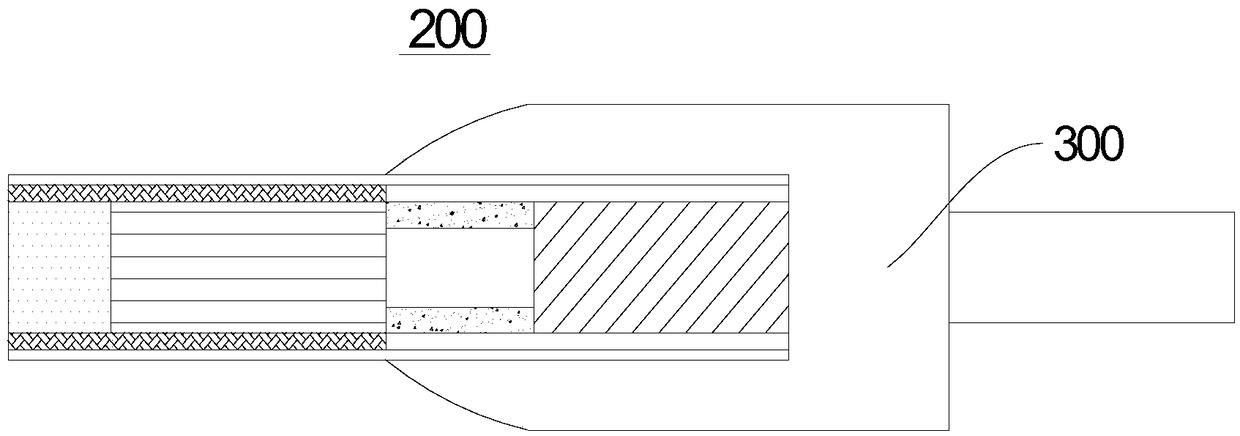

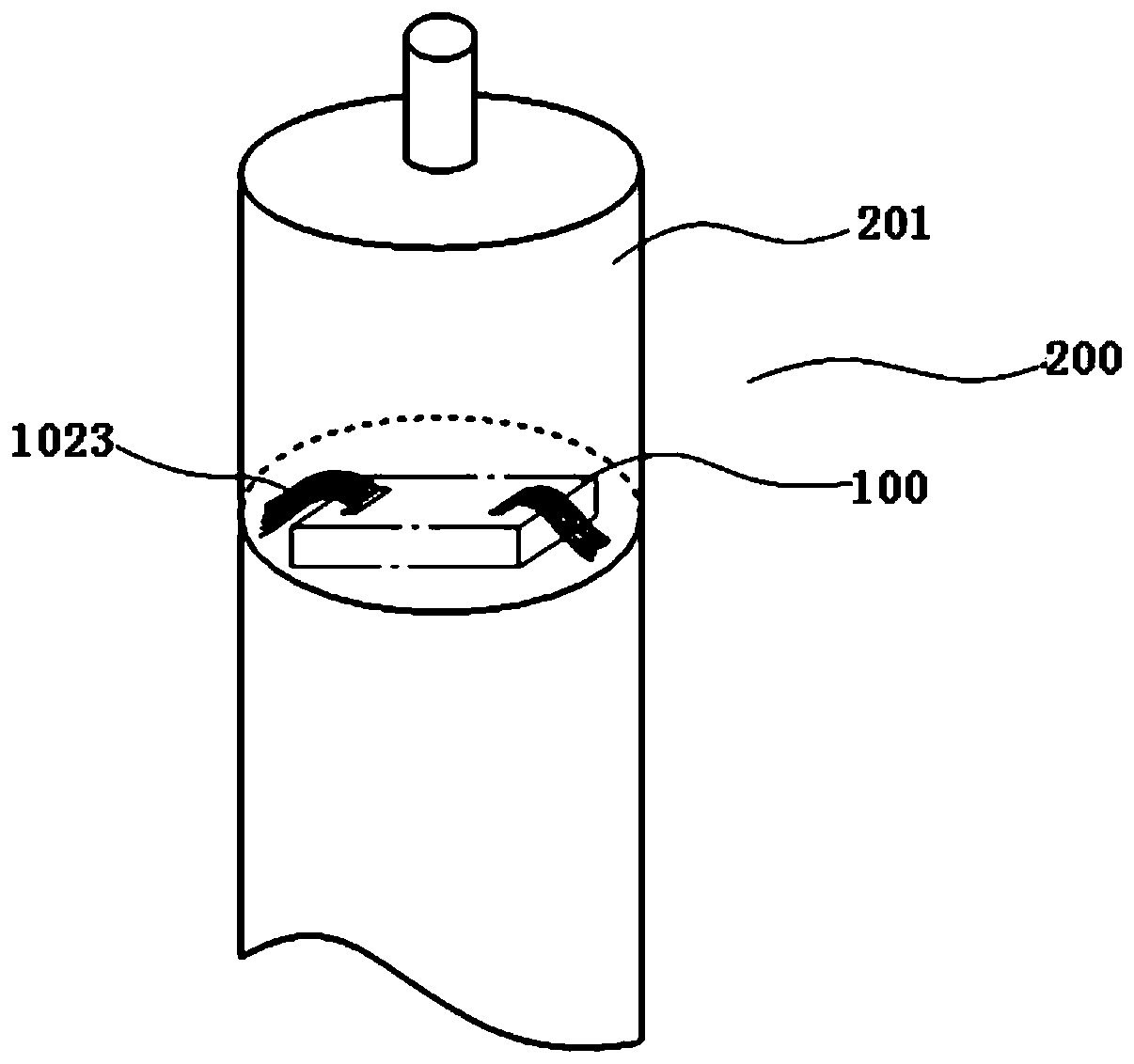

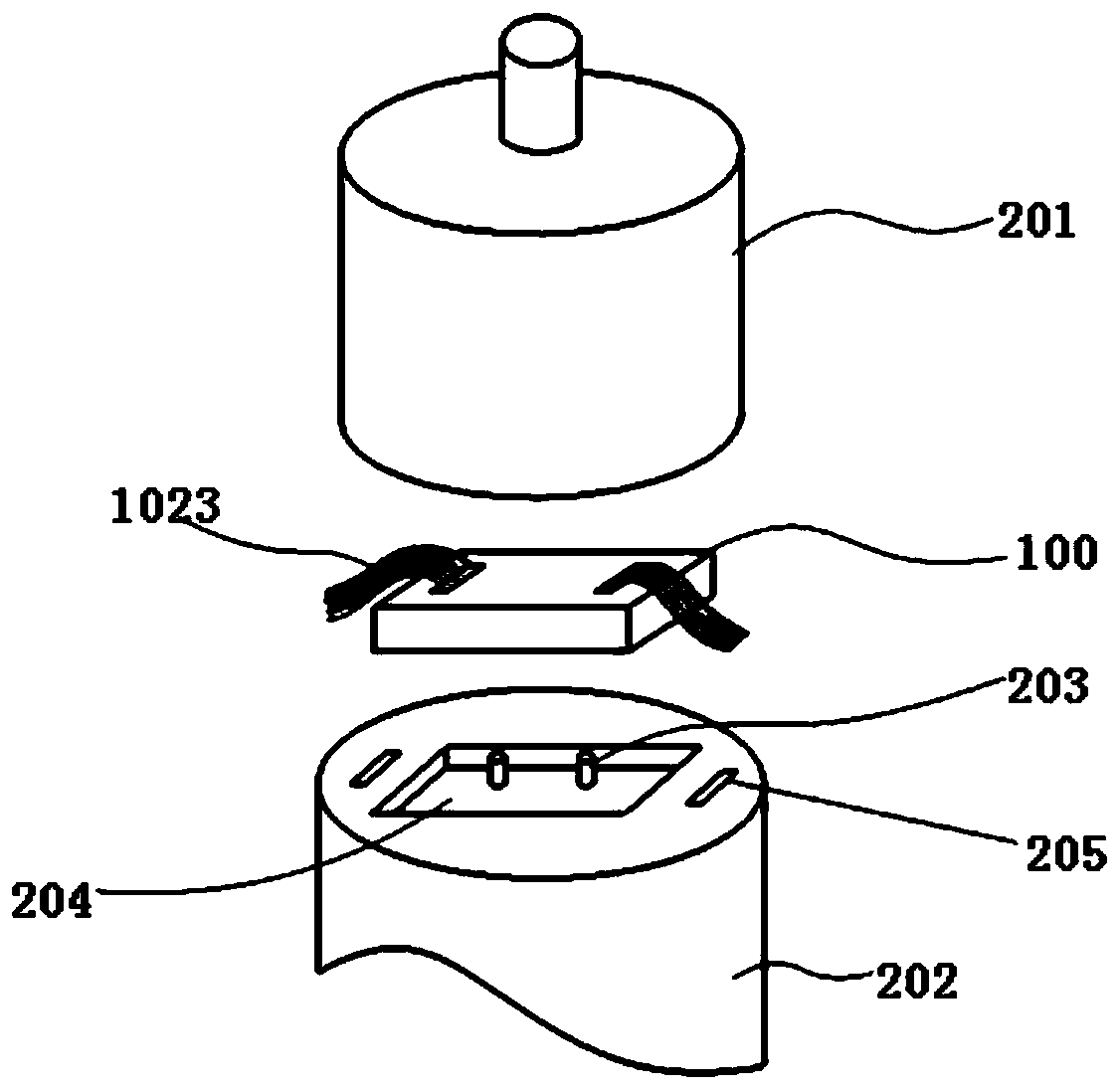

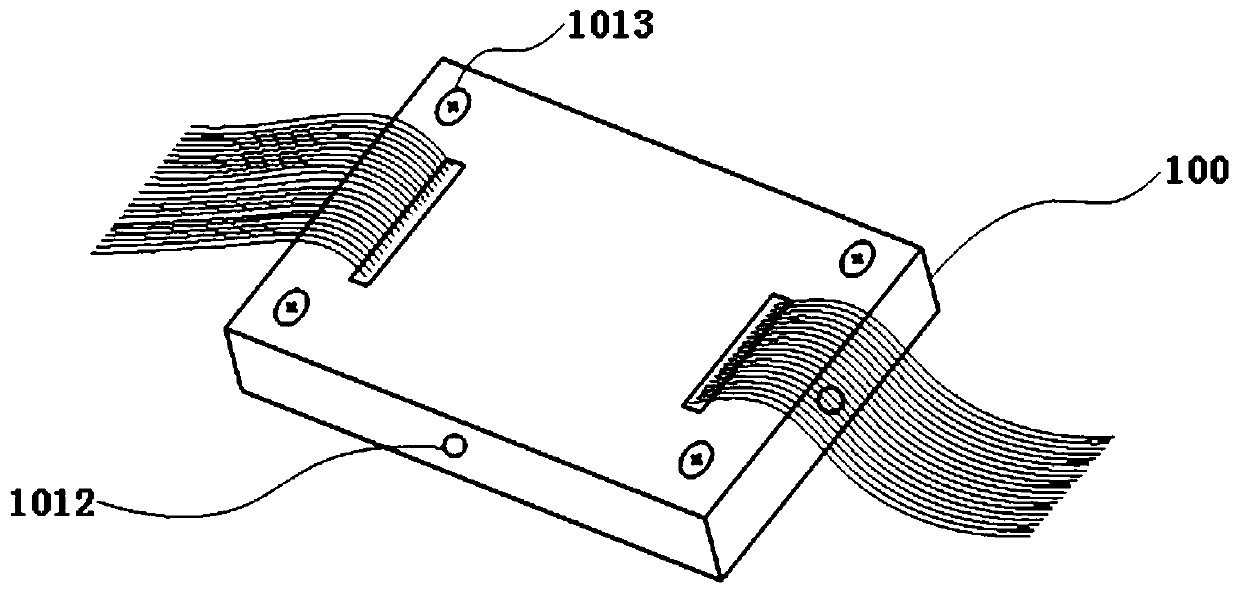

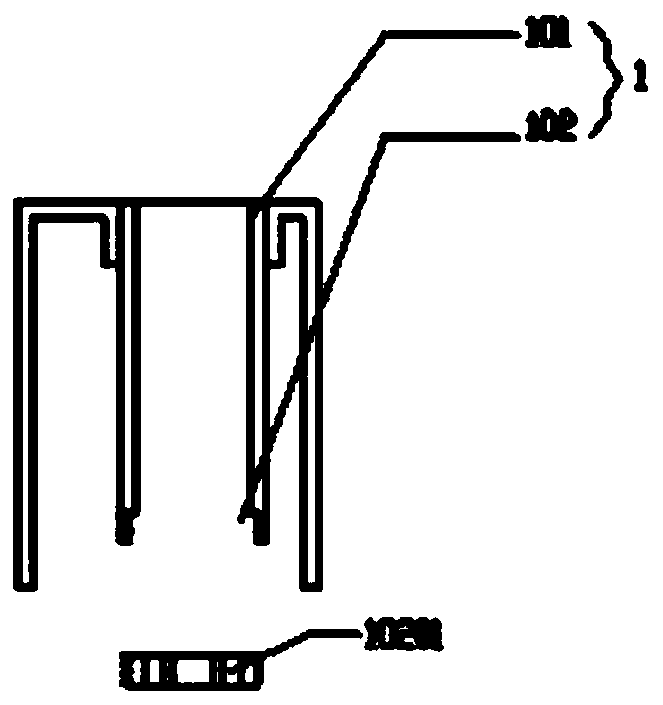

Electronic cigarette with improved atomizing device

PendingCN109770442ARealize fixed-point quantitative releaseHigh selectivityOhmic-resistance electrodesHeater elementsLiquid smokeControl system

The invention discloses an electronic cigarette with an improved atomizing device. The electronic cigarette comprises a suction nozzle (201) and a main unit (202), the main unit (202) is provided withan atomizing core mounting groove (204), an atomizing core (100) is accommodated in the atomizing core mounting groove (204), and the suction nozzle (201) and the main unit (202) are subjected to integrated-type or split-type connection; the atomizing core (100) comprises a shell (101), a liquid storage part (102) and a heating part (103), a wire (1023) penetrates through a first wire hole (1011)to be electrically connected with a power supply and a control system, and a first air guide hole (1012) and a second air guide hole (1037) are in airflow breakover connection. According to the electronic cigarette, a micro-electro mechanical technology is adopted, e-liquid in a liquid storage bin can be partially or all heated and atomized targetedly, a consumer can select the e-liquid with thetaste he / she likes according to the personal preference for heating and atomizing, and personalized smoking experience of the electronic cigarette is truly achieved.

Owner:CHINA TOBACCO YUNNAN IND

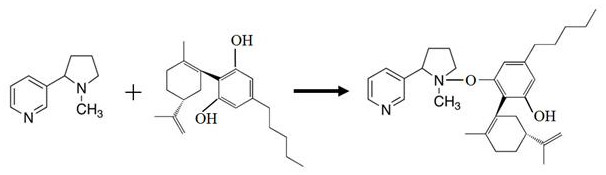

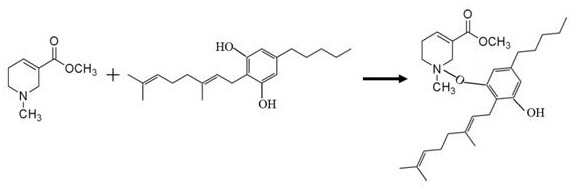

Alkaloid and phenol reaction composition, atomized liquid, atomization bomb and electronic atomizer

PendingCN113100490ADifferent structureImprove the original throat irritationTobacco treatmentChemical reactionAlkaloid

The invention discloses an alkaloid and phenol reaction composition, atomized liquid, an atomization bomb and an electronic atomizer. The alkaloid and phenol reaction composition comprises a composition R-PH-O-N-I obtained by chemical reaction of alkaloid and phenol, the general formula of the chemical reaction is R-PH-OH + N-I = = R-PH-O-N-I. A reactant alkaloid and a reactant phenol are added into a reaction container, heating is performed, and heating and stirring are continuously performed at 40-300 DEG C for 0.1-6000 minutes to obtain the alkaloid and phenol reaction composition. Through the mode, according to the alkaloid and phenol reaction composition, the atomized liquid and the atomized bomb, the problems that in an electronic atomizer, alkaloid originally chokes the throat and has stimulation smell are solved, the alkaloid and phenol reaction composition is beneficial to the mouth and cannot cause acidosis, excessive acid, sour odor and the like, and faster, more pleasant and satisfied smoking experience can be obtained.

Owner:ZHANGJIAGANG ALIEN NEW MATERIAL TECH CO LTD

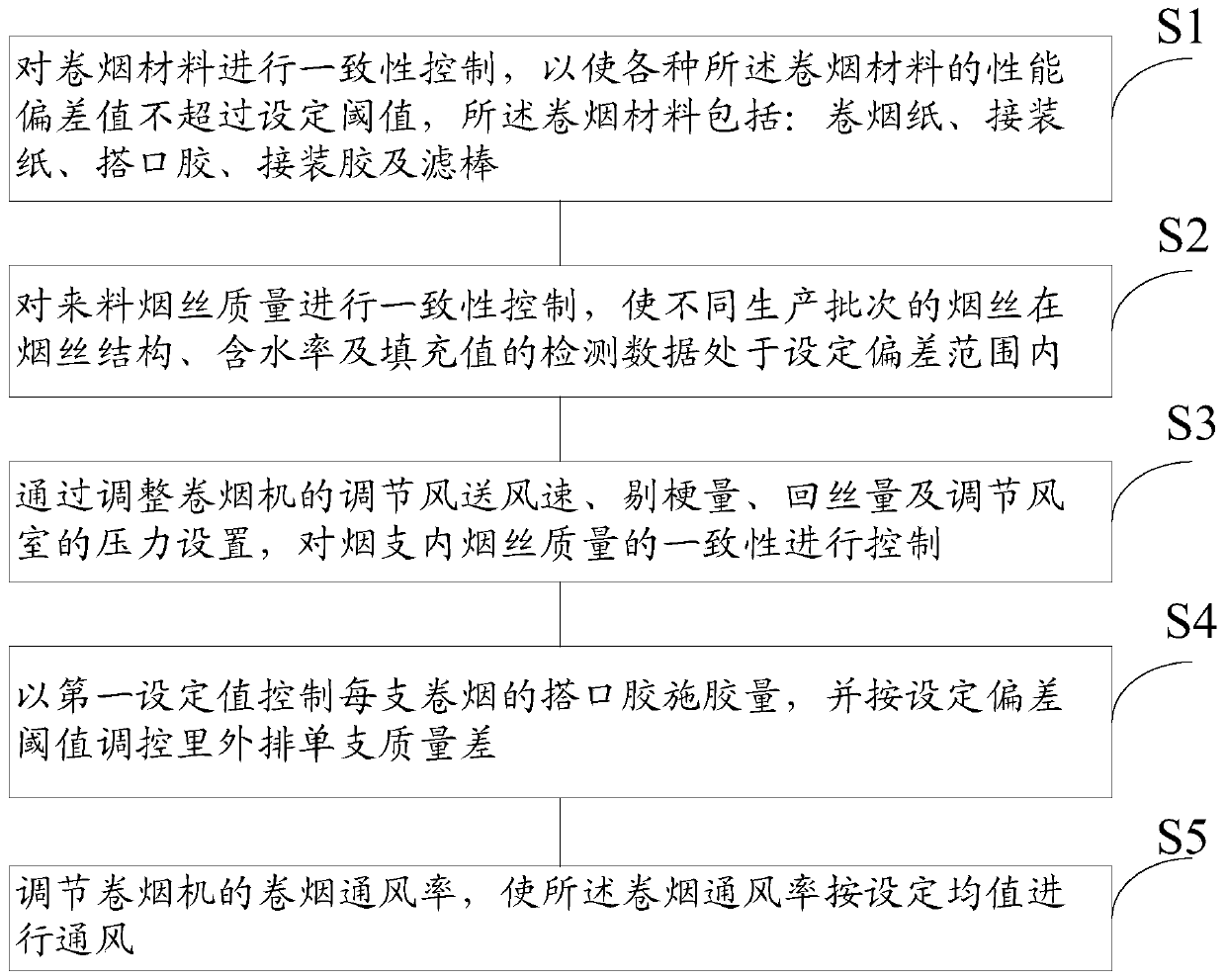

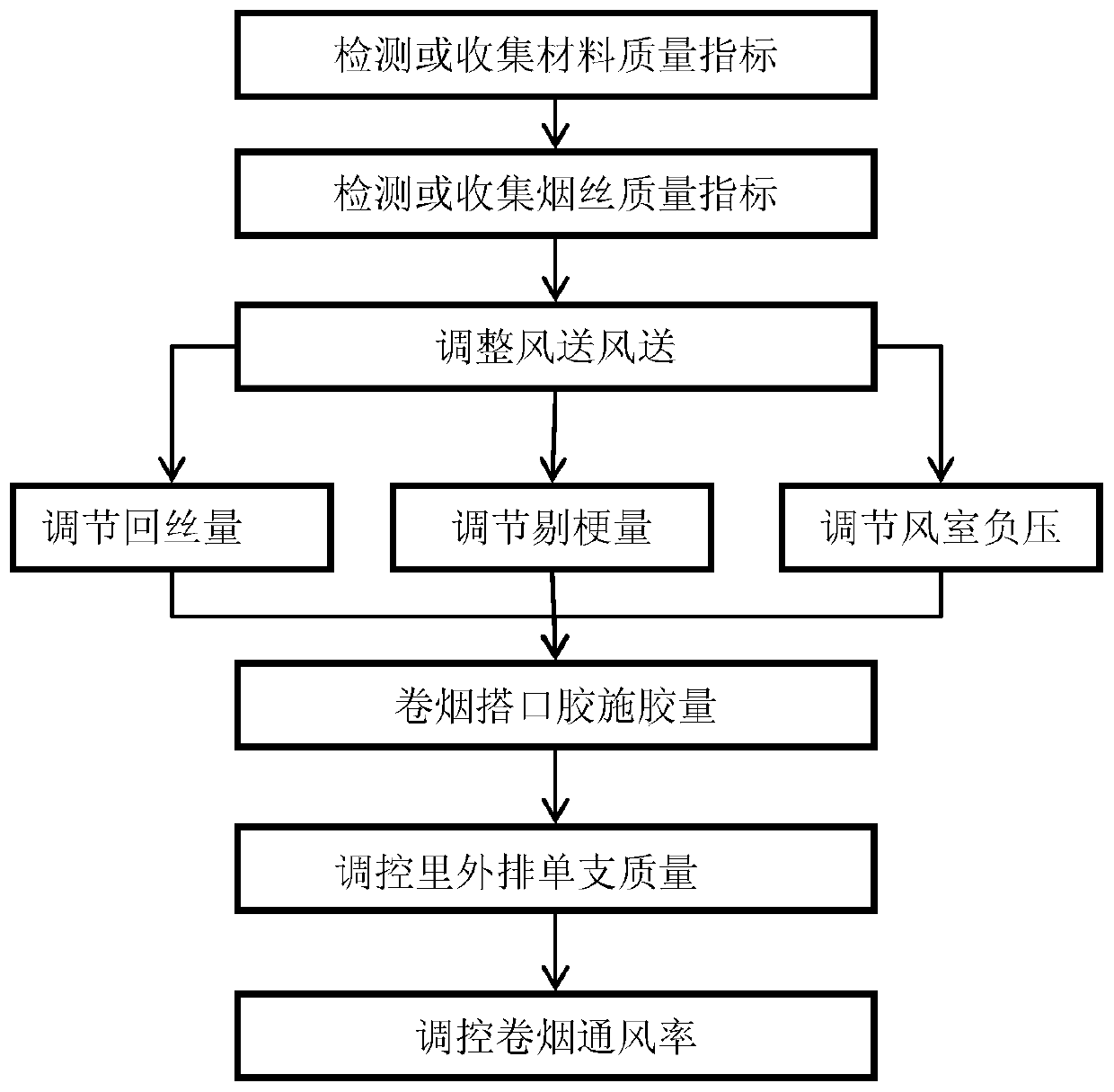

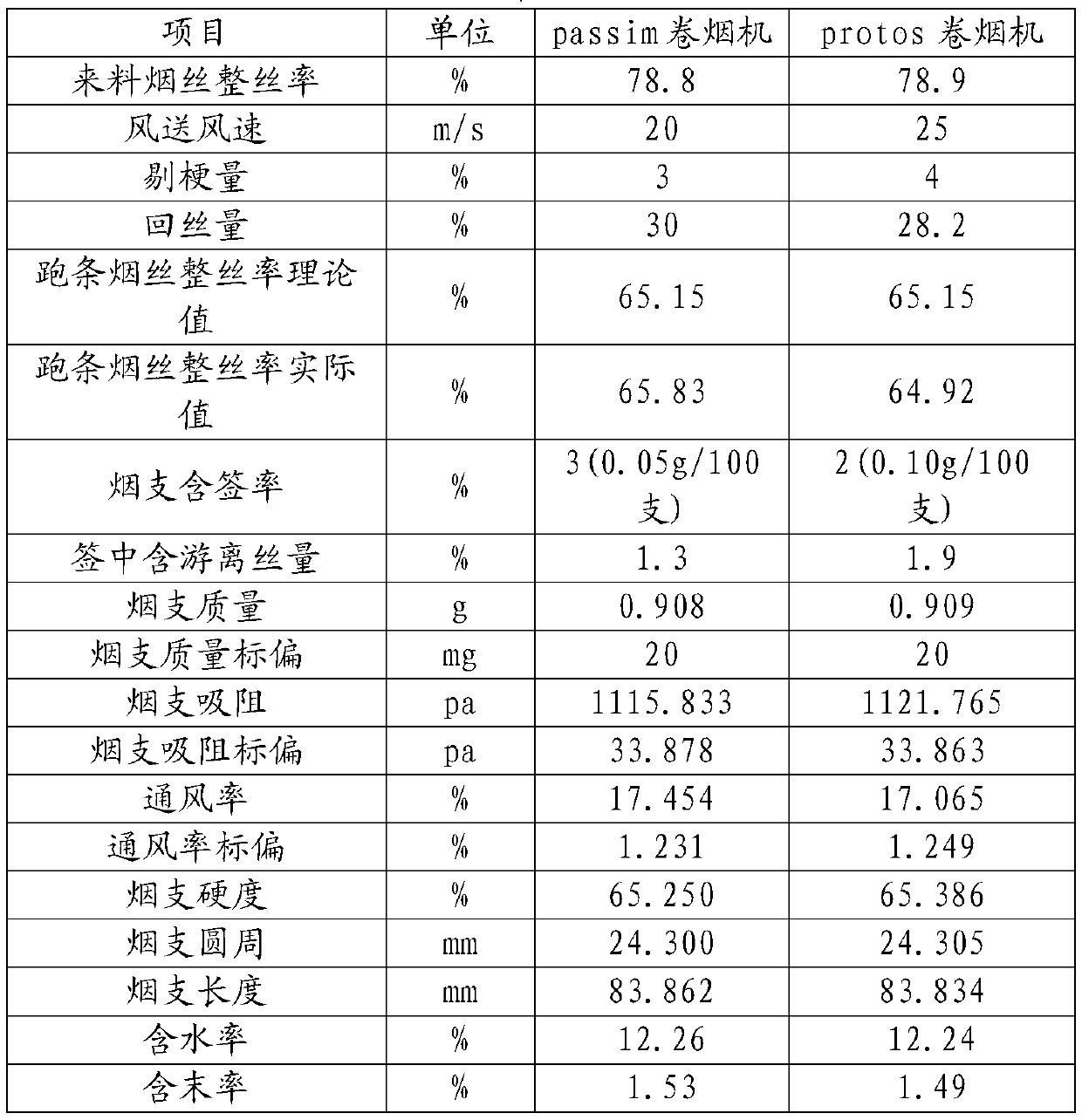

Method for controlling cigarette quality consistency of cigarette making machine

ActiveCN110876484AImproved consistency of cigarette qualitySolve the problem of cigarette quality differentiationCigarette manufactureConsistency controlEngineering

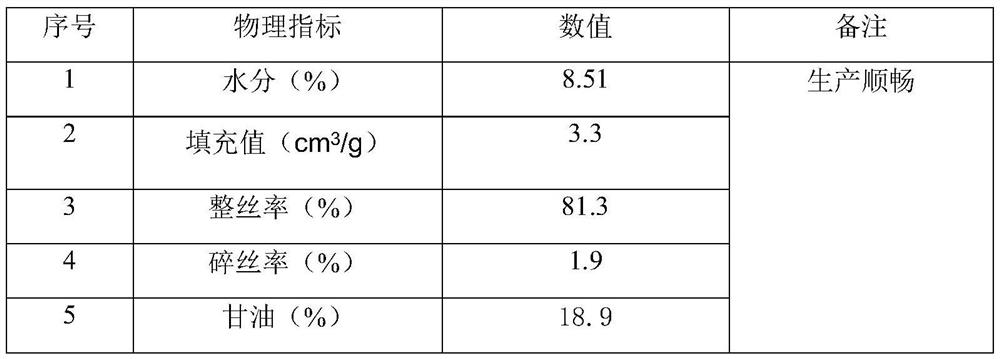

The invention provides a method for controlling cigarette quality consistency of a cigarette making machine, which comprises the following steps of: performing consistency control on cigarette materials to ensure that the performance deviation value of each cigarette material does not exceed a set threshold value, whrein the cigarette materials comprise cigarette paper, tipping paper, lap adhesive, tipping adhesive and filter sticks; carrying out consistency control on the quality of the incoming tobacco shreds, so as to eanble the detection data of the tobacco shreds of different production batches in the tobacco shred structure, the moisture content and the filling value are within a set deviation range; controlling the consistency of the quality of tobacco shreds in cigarettes by adjusting the adjusting air supply speed, the stem removing amount and the tobacco shred returning amount of the cigarette making machine and adjusting the pressure setting of the air chamber. The cigarettequality difference problem of existing cigarette making machines of different types can be solved, the cigarette quality consistency can be improved, raw material consumption is reduced, and the smoking experience is improved.

Owner:CHINA TOBACCO HENAN IND

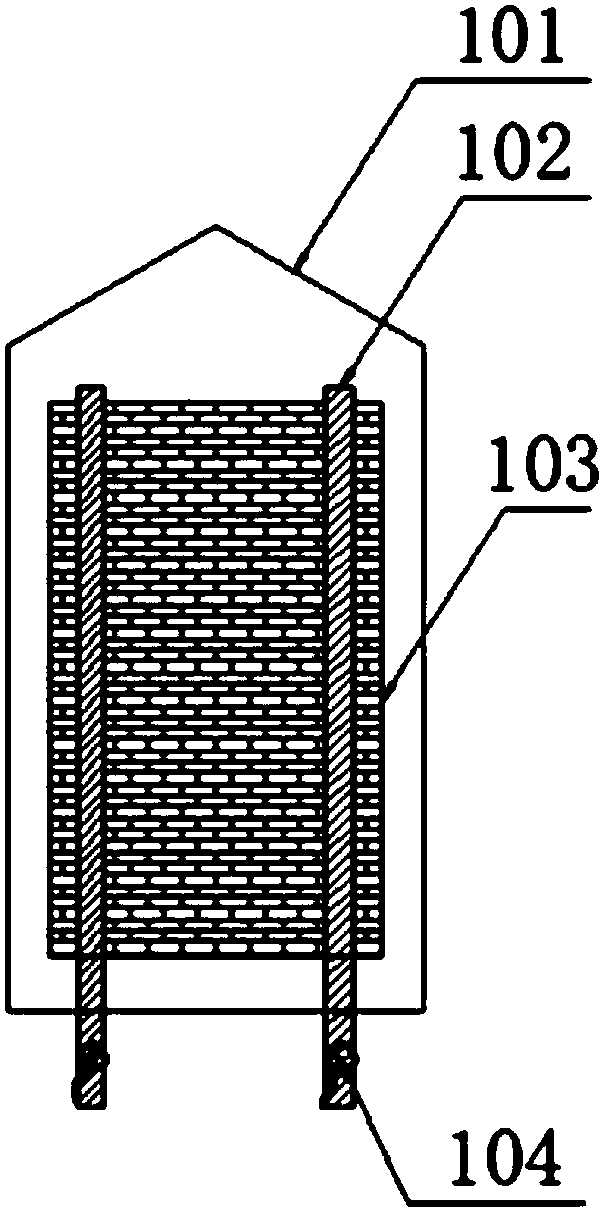

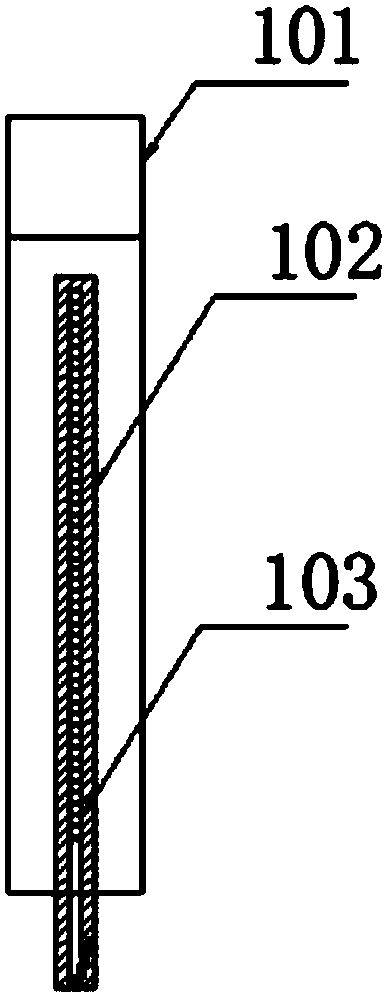

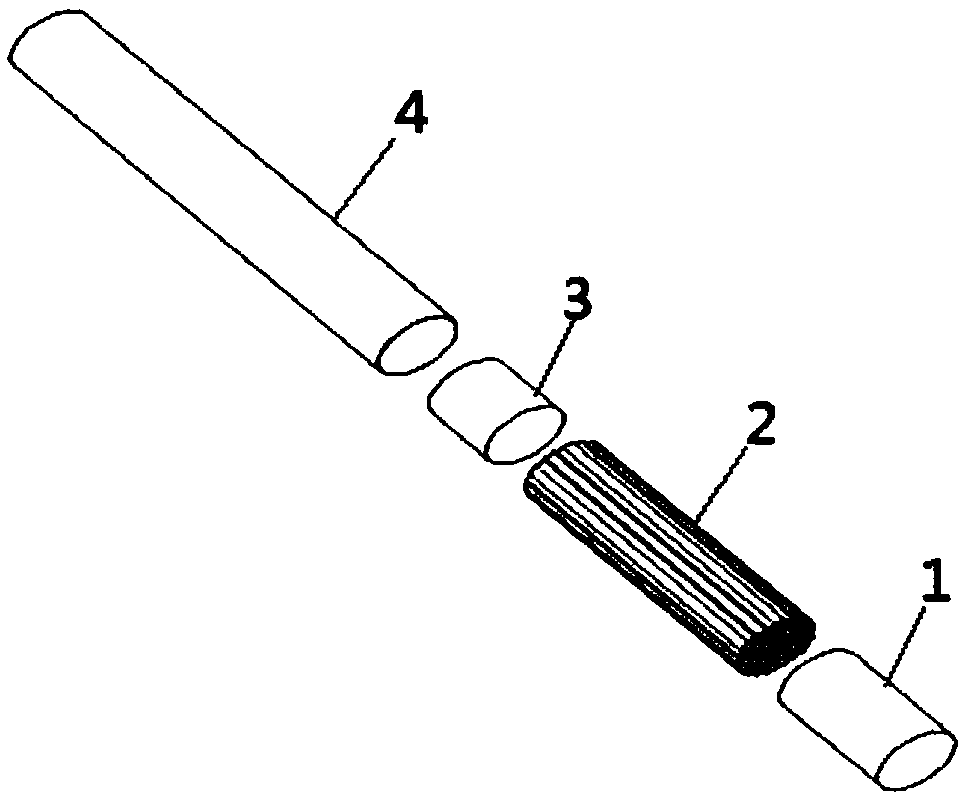

Electric heating type low-temperature cigarette heating element

PendingCN108113052AFast heatingHigh electrothermal conversion efficiencyTobacco devicesElectricityConductive materials

The invention discloses an electric heating type low-temperature cigarette heating element, which comprises a carbon nanomaterial (103) sheet, conductive materials (102) are attached to the two opposite ends, which are far from each other, of the carbon nanomaterial (103) sheet, and the lower ends of the conductive materials (102) are provided with electrodes (104). The whole external surface composed of the carbon nanomaterial (103) sheet and the conductive materials (102) is packaged with a heat transfer material (101). The electric heating type low-temperature cigarette heating element disclosed by the invention has high heating speed and high electro-thermal conversion efficiency, and can greatly increase controllability and smoking experience when used in an electric heating type low-temperature cigarette smoking appliance.

Owner:CHINA TOBACCO YUNNAN IND

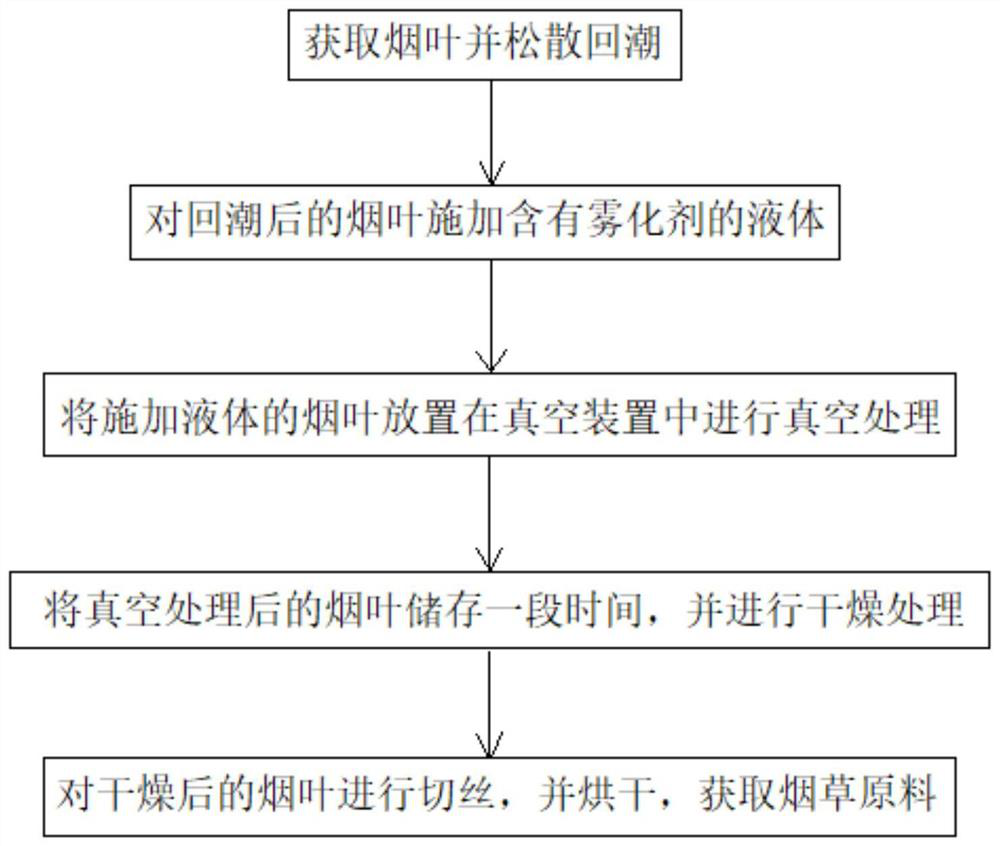

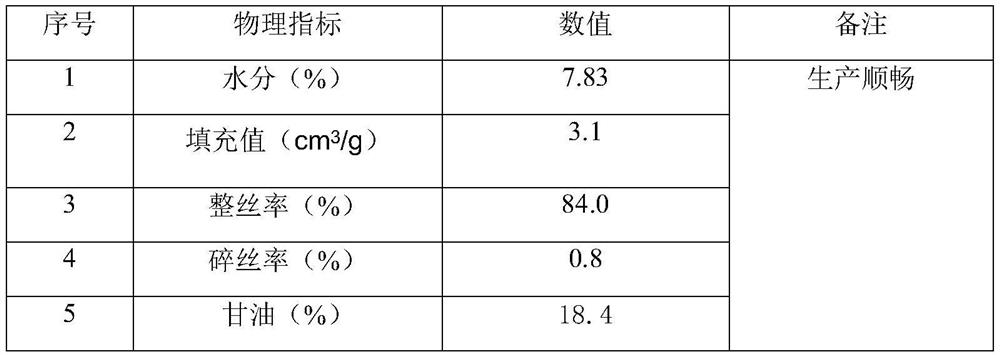

Preparation method of tobacco raw material and heat-not-burn cigarette with tobacco raw material

InactiveCN112369644AIncrease load capacityImprove adsorption capacityTobacco preparationTobacco treatmentBurn cigaretteProcess engineering

The invention discloses a preparation method of a tobacco raw material and a heat-not-burn cigarette with the tobacco raw material. The preparation method of the tobacco raw material comprises the steps of obtaining tobacco leaves and carrying out loosening and moisture regaining; applying liquid containing an atomizing agent to the tobacco leaves subjected to moisture regaining; putting the tobacco leaves to which the liquid is applied into a vacuum device for vacuum treatment; storing the tobacco leaves subjected to vacuum treatment for a period of time, and performing drying treatment; shredding and drying the dried tobacco leaves, and obtaining tobacco raw materials. The heat-not-burn cigarette comprises a filter tip and an atomized tobacco substrate section connected with the filter tip, and tobacco raw materials are arranged in the atomized tobacco substrate section. The loading capacity of the added atomizing agent can be improved, the adsorption effect of the atomizing agent isgood, meanwhile, the atomizing agent can be prevented from adhering to the surface of tobacco shreds to influence cigarette making and tipping production and process quality, and therefore the application range of tobacco raw materials can be widened, and the quality of the tobacco raw materials is improved.

Owner:HUBEI CHINA TOBACCO IND

Heterochromatic blasting bead and application thereof

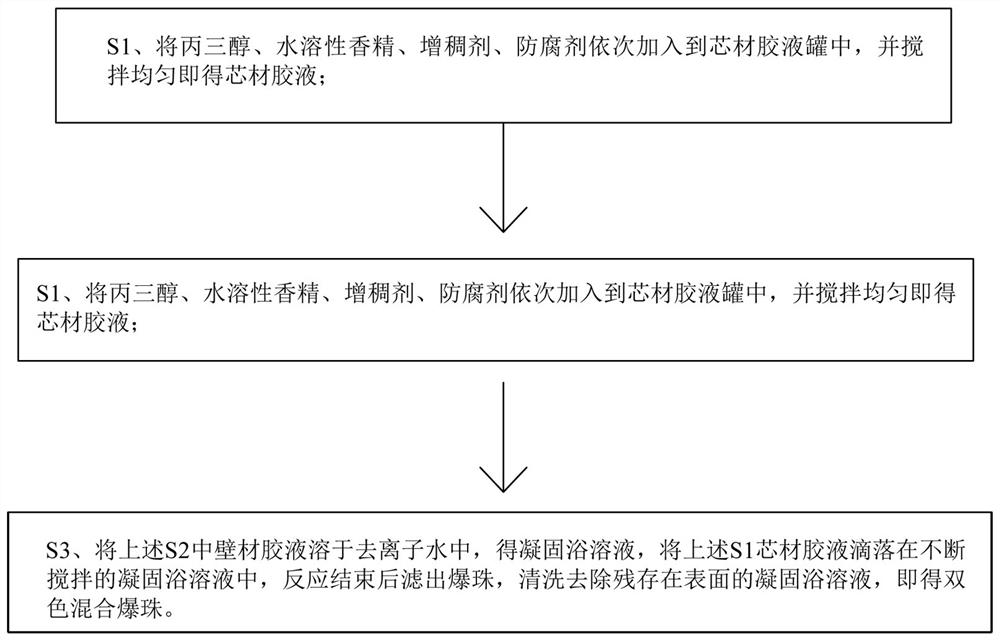

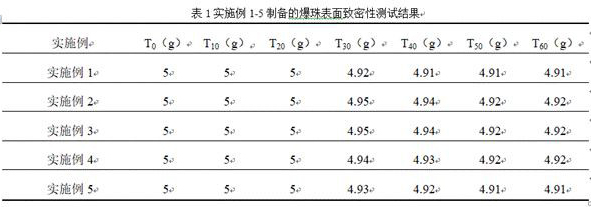

PendingCN113876027AImprove compactnessImprove brittlenessTobacco treatmentTobacco smoke filtersCellulosePreservative

The invention discloses a heterochromatic blasting bead and application thereof. The blasting bead comprises a core material and a wall material, and the core material is prepared from, by weight, 20-30 parts of glycerol, 1-5 parts of water-soluble essence, 1-2 parts of thickening agent and 1-2 parts of preservative, the wall material is prepared from the following raw materials in parts by weight: 100-200 parts of a color developing glue solution, 5-10 parts of hydroxy propyl cellulose, 5-30 parts of sodium alginate, 5-20 parts of chlorate and 1-20 parts of glycerol. According to the blasting bead, a two-color blasting bead is formed in a forming device, the appearance color of the blasting bead can be selected in a colorful mode, the appearance is good, the compactness of the outer side surface of the blasting bead is good, essence cannot permeate out of the interior, the blasting bead with the different colors is used in a transparent cigarette filter tip, and the experience feeling of consumers can be greatly improved.

Owner:HUBEI CHINA TOBACCO IND +1

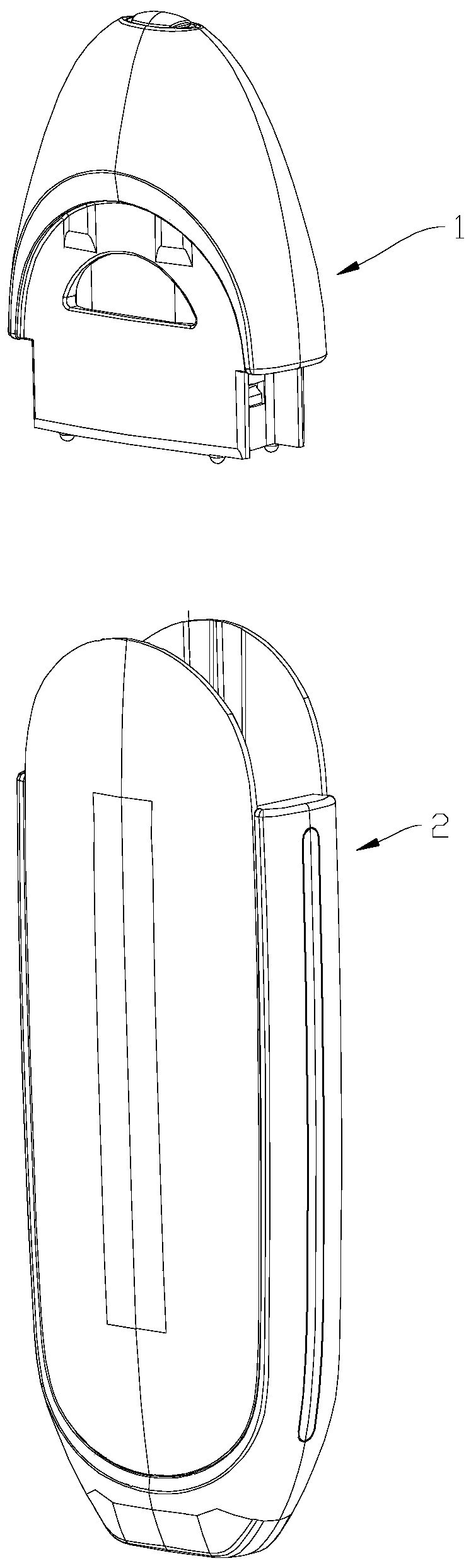

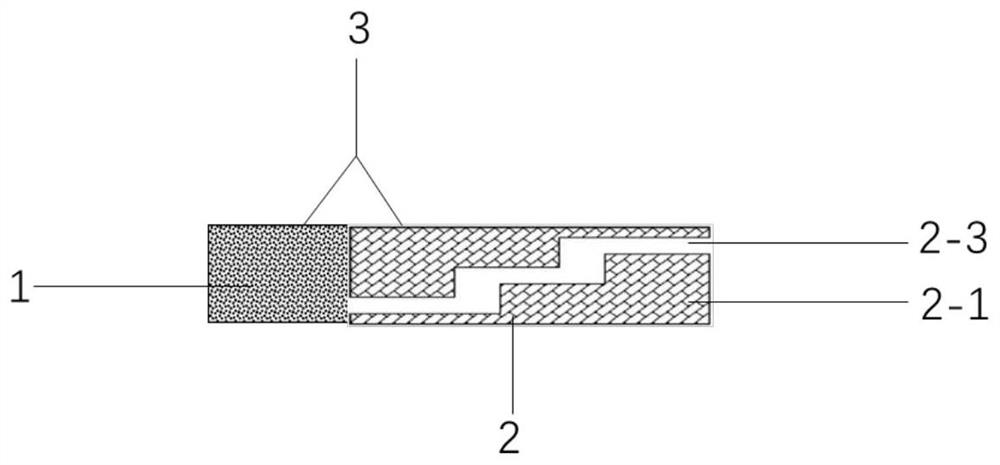

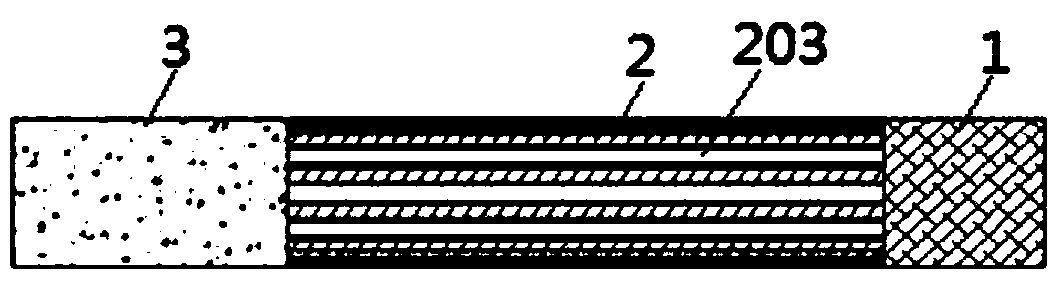

Heat-not-burn smoke cartridge with binary structure

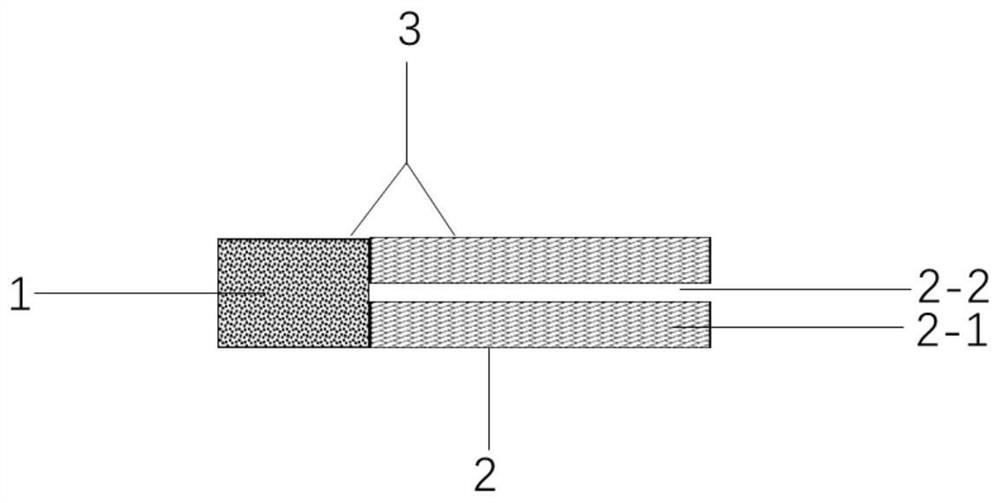

PendingCN112704276ASimple structureImprove the suction experienceCigar manufactureBio-packagingThermodynamicsSmoke Emission

The invention relates to a heat-not-burn smoke cartridge with a binary structure. The heat-not-burn smoke cartridge is formed by sequentially connecting a smoke generation section (1) and a smoke constraint section (2) in a wrapping and twisting mode through outer-layer wrapping paper (3). According to the heat-not-burn smoke cartridge, in the smoking process, the smoke generation section makes contact with a heating element of the heater, smoke is released and flows through the smoke constraint section, the effects of reducing the smoke temperature and guiding smoke are achieved, and cooled high-concentration smoke is transmitted to the oral cavity of a consumer; the heat-not-burn smoke cartridge has the advantages of being high in smoke generating amount and low in smoke temperature and the like; and the heat-not-burn smoke cartridge is simple in structure and easy to industrialize, and has a very good industrial application prospect.

Owner:YUNNAN TOBACCO BIOLOGICAL TECH CO LTD

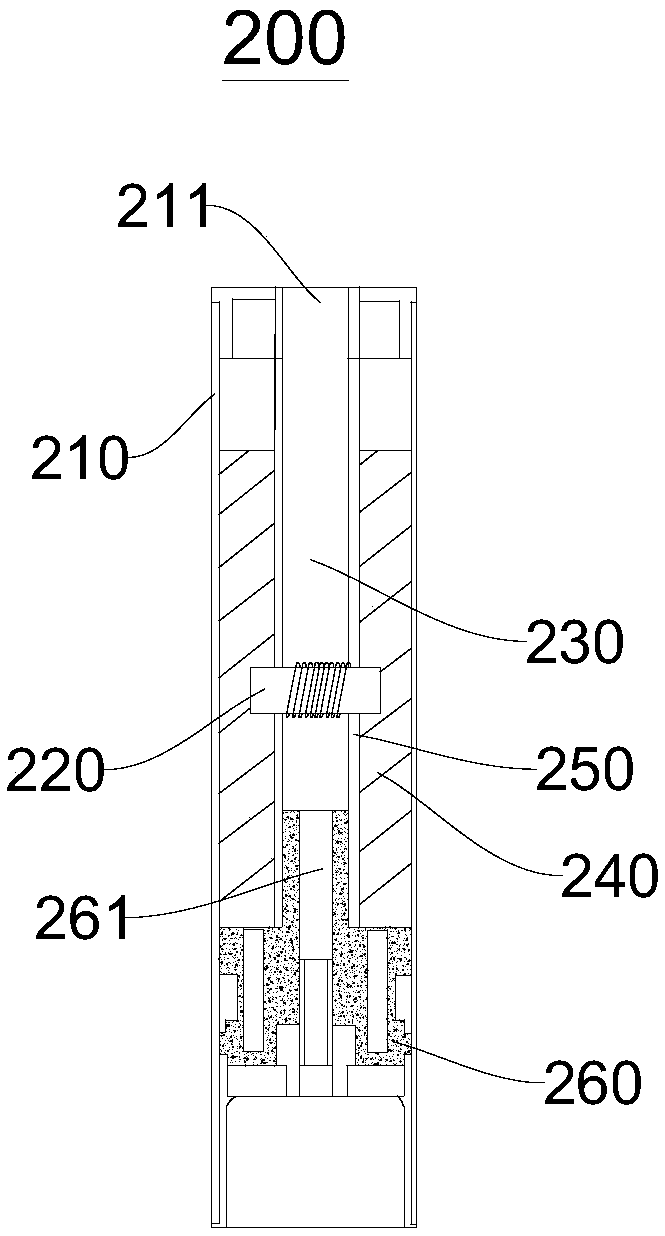

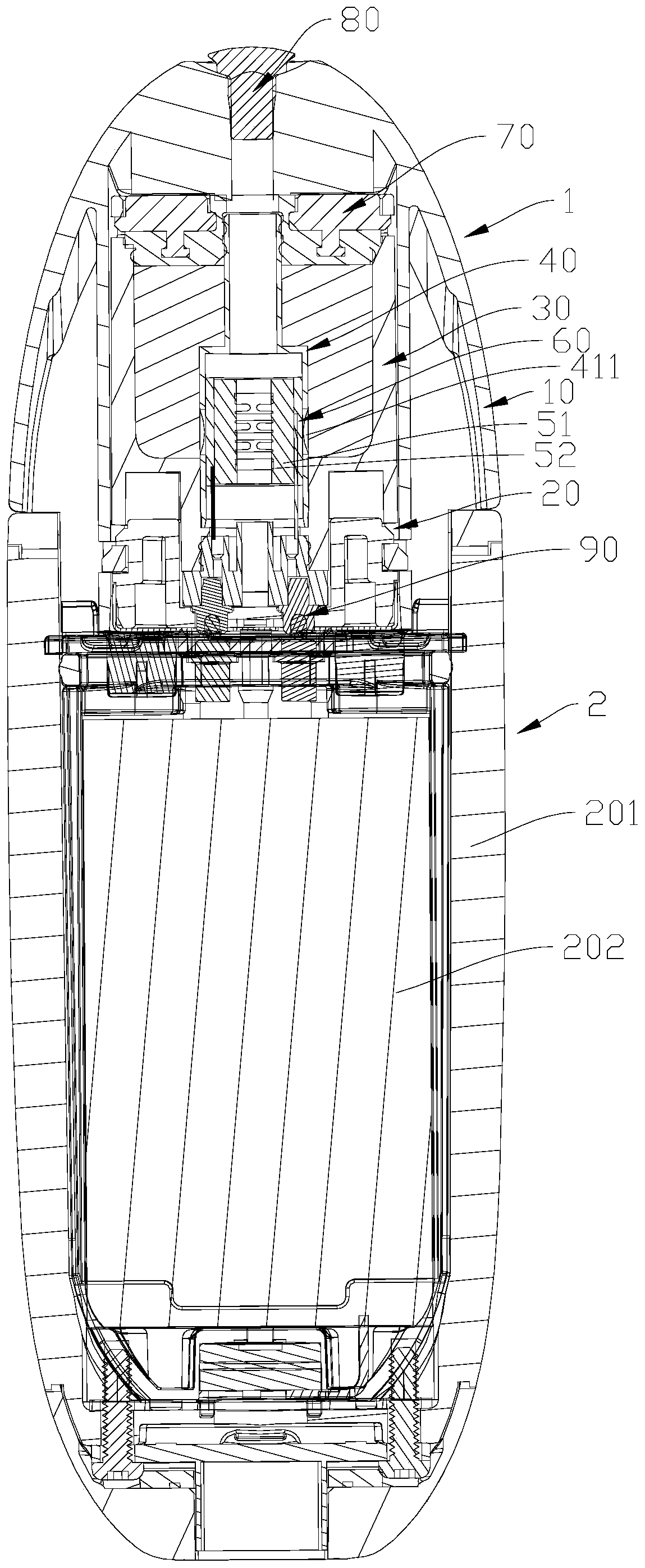

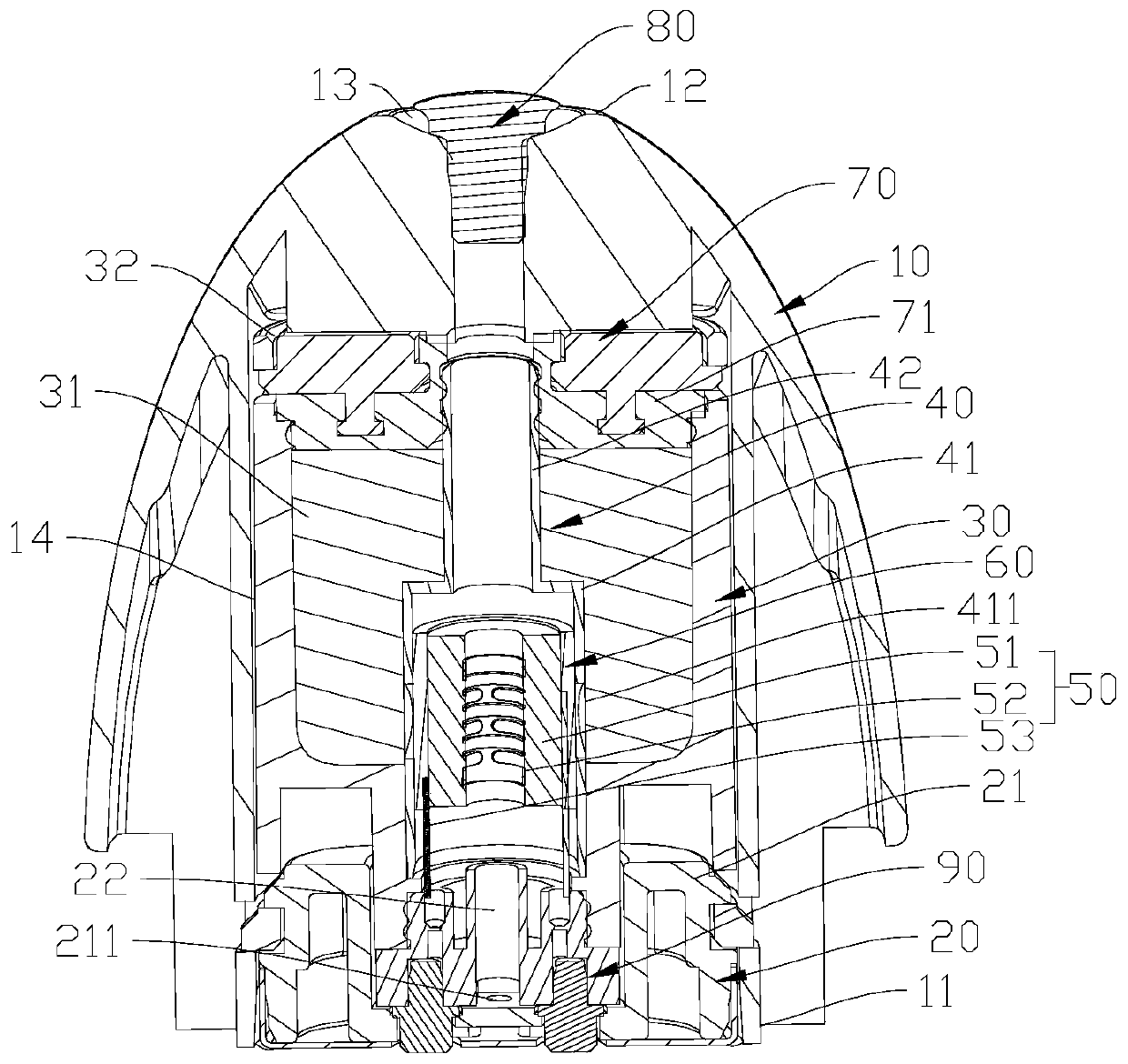

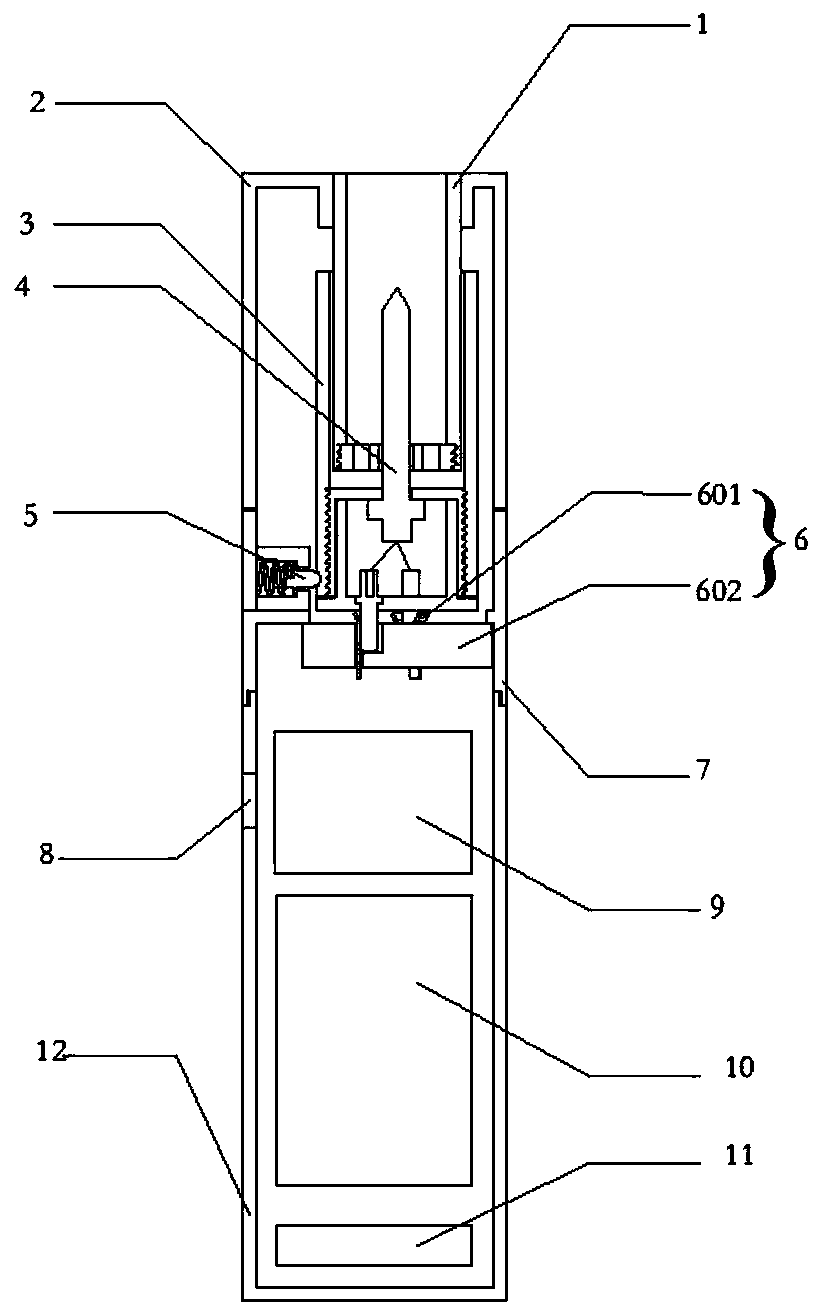

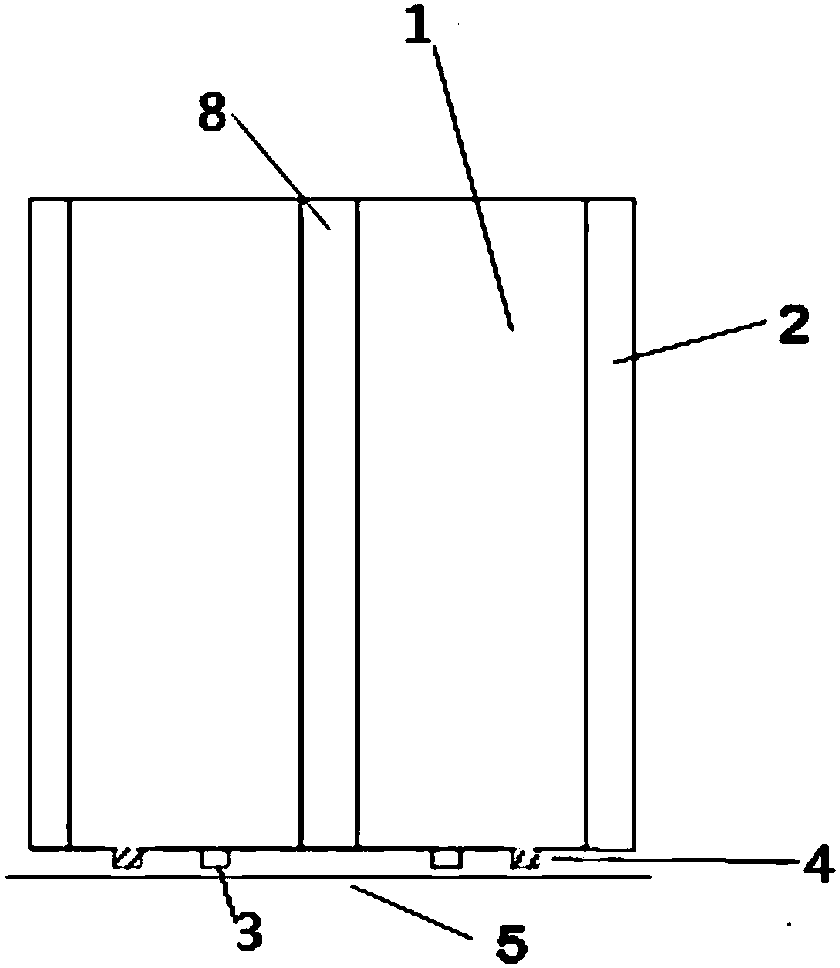

Convenient-to-clean low-temperature cigarette smoking set with replaceable heating assembly

PendingCN110447976AImprove cleanlinessSolve the inconvenience of cleaningTobacco devicesEngineeringElectrode

The invention relates to a convenient-to-clean low-temperature cigarette smoking set with a replaceable heating assembly. The convenient-to-clean low-temperature cigarette smoking set comprises the following components including a cigarette cup assembly (1), a heating assembly (4), a protection cover (3) and a positioning assembly (5), wherein the cigarette cup assembly (1) comprises a cigarette tube (101) used for accommodating smoking products and a bottom supporter (102); the heating assembly (4) comprises a heating element (401) and an electrode (404); the protection cover (3) is arrangedoutside the cigarette cup assembly (1) and the heating assembly (4) in a sleeving way; the heating assembly (4) is detachably connected with the protection cover (3); a concave opening (301) is formedin the protection cover (3); an upper casing (2) is arranged outside the protection cover (3) in a sleeving way; and the positioning assembly (5) also comprises a positioning seat (503) and a positioning post (501). The cigarette cup assembly is designed into a structure consisting of two parts including the cigarette tube and the bottom supporter, and can be taken out from the smoking set to becleaned, so that the cleanness degree of the smoking set is greatly improved.

Owner:深圳市长能汇科科技有限公司

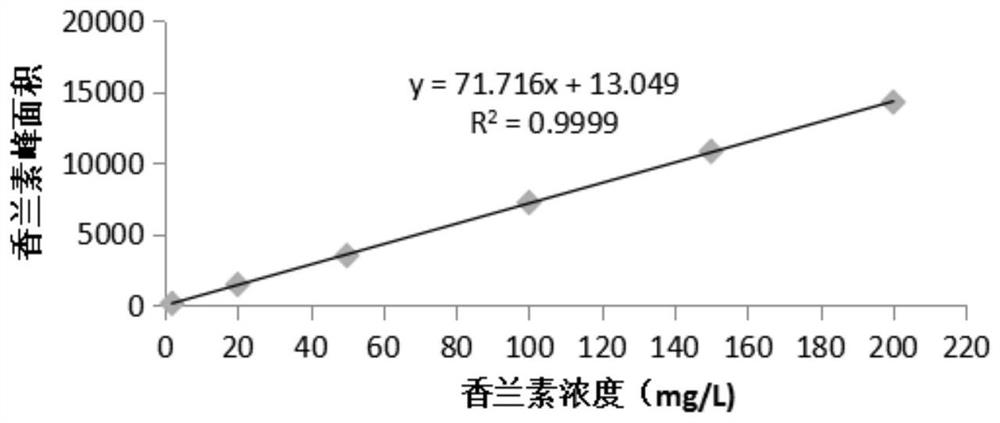

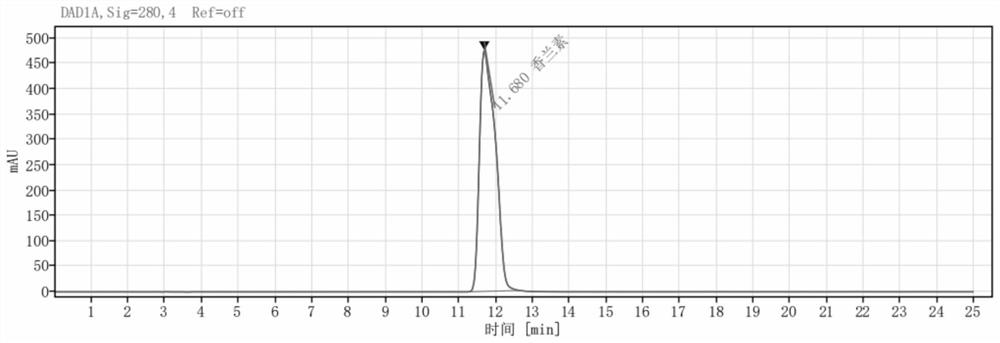

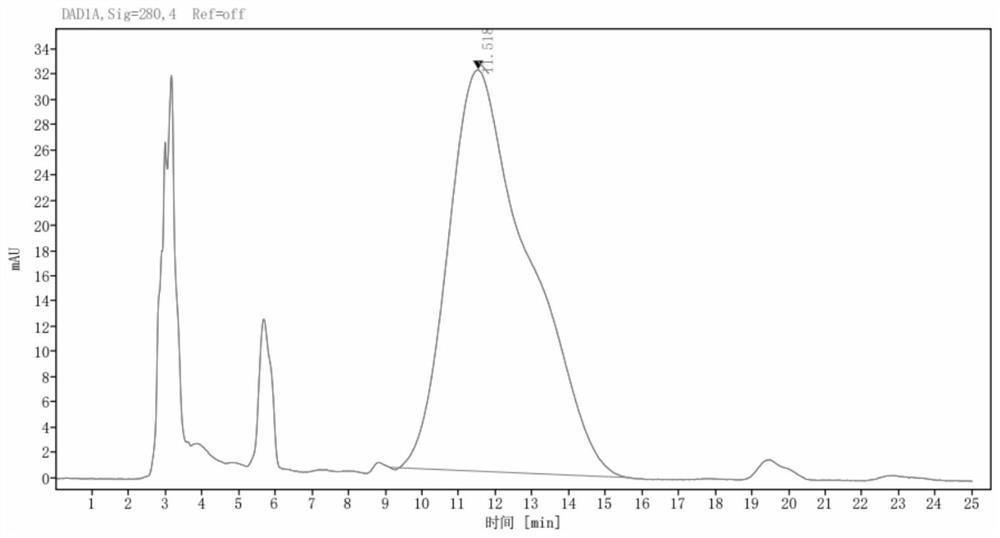

Bacillus subtilis and method for producing vanillin by using bacillus subtilis

PendingCN113957017AKeep naturalImprove the suction experienceTobacco preparationBacteriaBacilliBacillus sp. BI

The invention provides bacillus subtilis. A strain name is bacillus subtilis Imau 2-12, the bacillus subtilis is preserved in the China Center for Type Culture Collection, and the preservation number is CCTCC NO: M2021774. According to the bacillus subtilis (Bacillus subtilis) Imau 2-12, vanillin can be produced by biotransformation of ferulic acid, and new engineering strain is provided for extraction and production of vanillin. The bacillus subtilis can be used for preparing fermentation liquor in a ferulic acid fermentation culture medium, the fermentation liquor can be applied to cigarettes, special fragrance is added, and the smoking experience is improved.

Owner:INNER MONGOLIA KUNMING CIGARETTE CO LTD

Essential oil particles and preparation method thereof, filter tip and electronic cigarette

InactiveCN113057373AControl the volatilization speedSmooth releaseTobacco treatmentTobacco smoke filtersPolyvinyl alcoholElectronic cigarette

The invention discloses essential oil particles and a preparation method thereof, a filter tip and an electronic cigarette. The preparation method of the essential oil particles comprises the following steps: dissolving polyvinyl alcohol in water to obtain a polyvinyl alcohol solution; adding a complexing agent, an emulsifier and essential oil into the polyvinyl alcohol solution, and stirring and mixing to obtain a mixed solution; and adding an alkaline solution into the mixed solution to solidify the mixed solution, filtering out solidified particles, washing and freeze-drying at low temperature to obtain the essential oil particles. According to the technical scheme, the particle capable of releasing fragrance can be provided and applied to the filter tip of the electronic cigarette.

Owner:SHENZHEN ZHIYE TECH CO LTD

Cooling cigarette holder, preparation method and heated non-combustible cigarette

InactiveCN109430937AReduce the temperatureImprove drynessTobacco smoke filtersTobacco devicesSodium phosphatesEngineering

The invention relates to a cooling cigarette holder, a heated non-combustible cigarette and an application. The cooling cigarette holder comprises a cooling section, the cooling section comprises carriers, cooling materials are applied onto the surfaces of the carriers, the carriers are distributed in the cooling section to form a plurality of channels penetrating the cooling section, the coolingmaterials are provided with a crystallization water compound, the crystallization water compound is at least one of ferrous sulfate, aluminum potassium sulfate dodecahydrate, sodium phosphate dibasicdodecahydrate, magnesium sulfate heptahydrate, copper sulfate pentahydrate and sodium sulfate decahydrate, and preferably, the carriers are provided with paper. According to the cooling cigarette holder, the temperature of smoke entering a mouth of a smoker can be effectively reduced by 10 DEG C or more, the crystallization water compound absorbs heat and releases crystallization water, the temperature of smoke of the heated non-combustible cigarette can be effectively reduced in first, second and third times of smoking.

Owner:CHINA TOBACCO HUNAN INDAL CORP

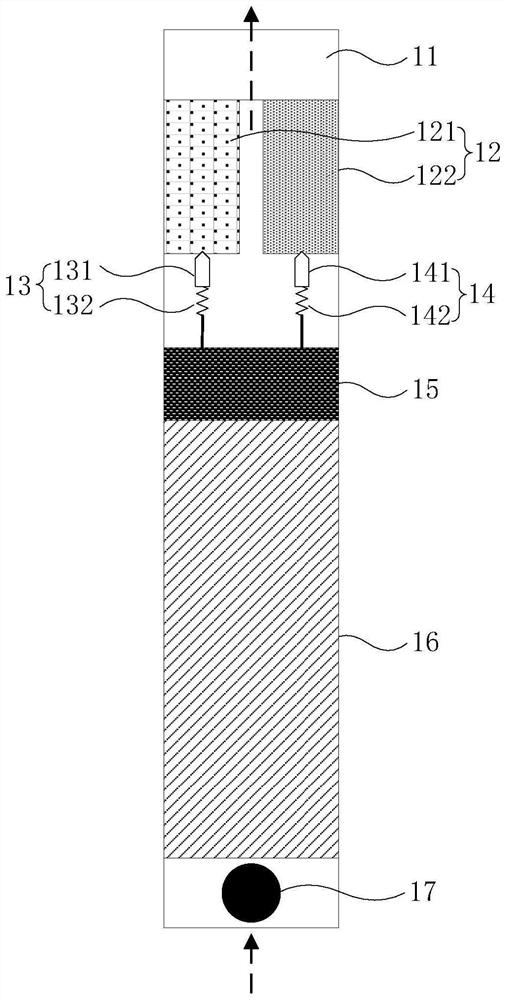

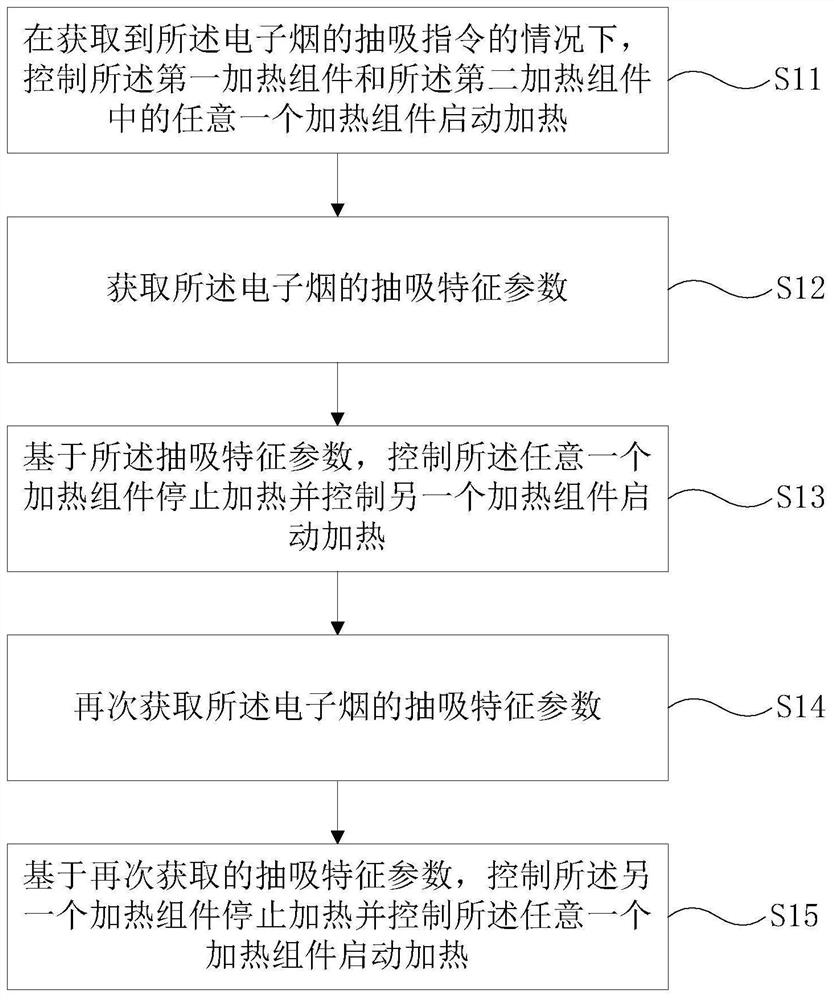

Electronic cigarette and control method thereof

PendingCN114073331AAvoid sticky core phenomenonImprove the suction experienceOhmic-resistance heating circuitsTobaccoThermodynamicsProcess engineering

The invention discloses an electronic cigarette and a control method thereof. The electronic cigarette comprises at least one liquid storage unit used for storing a liquid capable of generating aerosol, a first heating assembly and a second heating assembly which are both configured to receive the liquid from the liquid storage unit and heat the liquid to generate aerosol for a user to suck, and a circuit which is electrically connected with the first heating assembly and the second heating assembly, wherein the circuit is configured to enable the first heating assembly and the second heating assembly to alternately start heating based on smoking characteristic parameters of the electronic cigarette when the electronic cigarette is smoked. By enabling the first heating assembly and the second heating assembly to start heating alternately, the phenomenon of core pasting caused by untimely or insufficient oil supply in the smoking process of a user is avoided, and the smoking experience of the user is improved.

Owner:SHENZHEN FIRST UNION TECH CO LTD

Heating non-combustible cigarette

PendingCN110192668AImprove the suction experienceEnsure safetyCigar manufactureTobacco smoke filtersEngineeringAerosol

The invention discloses a heating non-combustible cigarette. The cigarette comprises a filter stick arranged at one end of the cigarette, a plug arranged at the other end of the cigarette, and a cigarette strip arranged between the filter stick and the plug. The cigarette strip comprises an aerosol matrix filled inside the cigarette strip, and the forming paper which wraps the outer surface of theaerosol matrix and is used for fixing the aerosol matrix. When a user inserts a cigarette into a heating non-combustible smoking set, the plug can plug substances contained in the aerosol matrix intothe cigarette strip. Therefore, tobacco leaves and the like in the cigarette cannot fall into the smoking set. The safety of the user when the user is using the heating non-combustible smoking set isguaranteed. The difficulty of cleaning the smoking set by the user is reduced.

Owner:INNER MONGOLIA KUNMING CIGARETTE CO LTD

Composite cartridge for ultrasonic atomization electronic cigarette and manufacturing method of composite cartridge

PendingCN109805445AReduce self-heatingGuaranteed working lifeTobacco devicesLiquid smokeElectronic cigarette

The invention relates to a composite cartridge for an ultrasonic atomization electronic cigarette. The composite cartridge comprises a liquid storage part for storing tobacco juice and an anti-seepagelayer surrounding a periphery of the liquid storage part, wherein the liquid storage part is mainly made of loose solid materials; a liquid guide piece for leading out the tobacco juice in the liquidstorage part to a liquid guiding piece on an ultrasonic atomizing sheet of an ultrasonic atomizing electronic cigarette appliance is arranged at the bottom of the liquid storage part; and a solid smoking part made of tobacco materials is further arranged at the bottom of the liquid storage part. The cartridge provided by the invention is a composite cartridge which can be used in the ultrasonic atomization electronic cigarette, has the smoke volume and rapid smoke output performance of an ordinary electronic cigarette during smoking, also has low-temperature smoke aroma and other beneficial effects, and has good smoking experience feeling.

Owner:CHINA TOBACCO HUNAN INDAL CORP

Cooling filter rod and cigarette

ActiveCN109588768AAvoid burnsImprove adsorption capacityTobacco smoke filtersTobacco devicesWater vaporPolyethylene glycol

The invention relates to a cooling filter rod and a cigarette. The cooling filter rod comprises a cooling section; a plurality of passages running through both ends of the cooling section are formed in the cooling section; a ratio of a total cross section area of the plurality of passages to a cross section area of the cooling section is 1-9 to 10; the side walls of the passages are coated with acooling material; and the cooling material comprises at least two of low-molecular-weight PEG (polyethylene glycol), a medium-molecular-weight PEG and high-molecular-weight PEG. The cooling filter roddisclosed by the invention has the advantages of ensuring a smoke volume of fume, reducing a temperature of the fume entering an oral cavity and the like; by design of a cooling rod structure and thecooling material composition, not only can the fume be easy to rapidly and smoothly flow out of a fuming section, but also the temperature of the high-temperature fume before the fume enters the oralcavity can be obviously reduced, so that comfort and satisfaction of smoking are promoted; and problems of excessive water vapor, small smoke volume and bad taste, which are generated when an existing HNB (Heat Not Burning) cigarette is smoked by first three mouths, also can be solved.

Owner:CHINA TOBACCO HUNAN INDAL CORP

Atomized smoke generating material for heat-not-burn product and preparation method of atomized smoke generating material

PendingCN113208146AImprove functionalityDelicate smokeTobacco preparationTobacco treatmentCoffeaProcess engineering

The invention discloses an atomized smoke generating material for a heat-not-burn product and a preparation method of the atomized smoke generating material. The atomized smoke generating material is prepared by the following steps: crushing unbaked green coffee beans into a coffee powder, and extracting to obtain a coffee extract and coffee extraction residues; and finally, uniformly mixing and stirring the coffee extract, the coffee extraction residues, a tea substrate, the smoke generating agent and the additive, and preparing into granules or flakes to obtain the atomized smoke generating material. The preparation process is simple and suitable for industrial homogeneous large-scale production, and the atomized smoke generating material provided by the invention is remarkable in safety and functionality and has a good market value and economic value.

Owner:福建东方世宏投资有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com