Preparation method of tobacco raw material and heat-not-burn cigarette with tobacco raw material

A raw material and tobacco technology, which is applied in the field of tobacco raw material preparation, can solve the problems of unstable flue gas, large fluctuation of suction resistance, sensory quality and influence on smoking experience, so as to improve smoking experience, improve filling value, and improve smoke Effects of branch structure and sensory quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

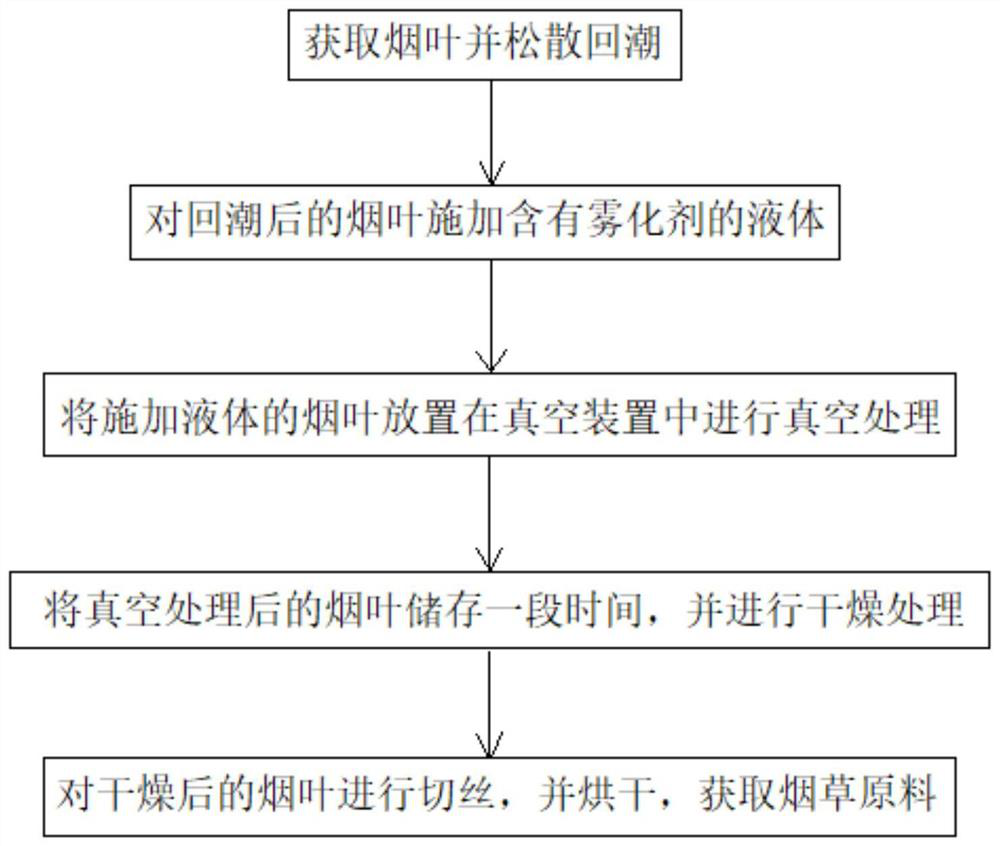

[0042] Such as figure 1 Shown, the preparation method of tobacco raw material of the present invention, comprises the following steps:

[0043] (1) Obtaining tobacco leaves and loosening and re-moisturizing can increase the moisture and temperature of tobacco leaves.

[0044] (2) Applying a liquid containing an atomizing agent to the moistened tobacco leaves.

[0045] (3) Place the tobacco leaves applied with the liquid in a vacuum device for vacuum treatment, which can promote the absorption of the atomizing agent.

[0046] (4) Storing the vacuum-treated tobacco leaves for a period of time and performing drying treatment can further promote the absorption of the atomizing agent, and dry the unabsorbed atomizing agent to prevent the surface viscosity of the tobacco leaves from being too high. Wherein, storing the vacuum-treated tobacco leaves for a period of time can make the moisture and temperature of the vacuum-treated tobacco leaves reach an equilibrium state.

[0047] ...

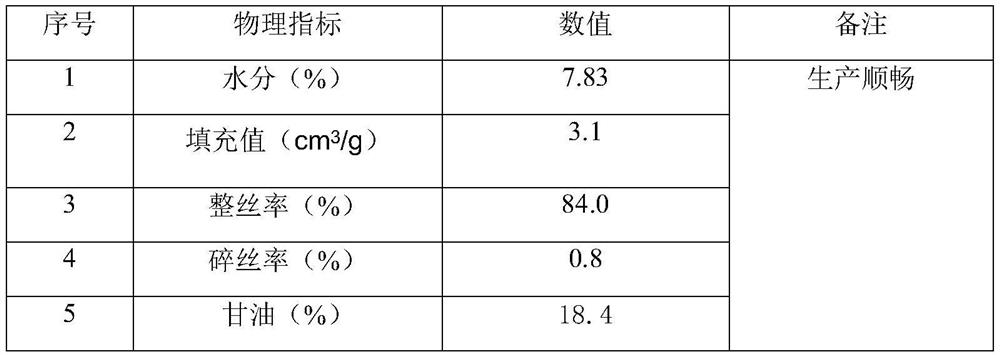

Embodiment 1

[0081] Example 1: Flue-cured tobacco type A

[0082] Sheet tobacco is fed, unpacked, sliced, loosened and dampened. The moisture content of the dampened tobacco leaves is 18% to 22%, and the temperature is 60 to 80 degrees Celsius.

[0083] Store the rehydrated tobacco leaves for 2 hours, and then apply an atomizing agent. Based on the quality of the added rehydrated tobacco leaves, the mass percentage of the applied atomizing agent is 30%, and the temperature of the atomizing agent is 60-65 degrees Celsius.

[0084] Put the tobacco leaves after applying the atomizing agent into food-grade 304 stainless steel, take the cover and send it to a vacuum device for 120 seconds for vacuum treatment, and the vacuum degree is 0.83 MPa.

[0085] The vacuum-treated tobacco leaves are stored for 2 hours and then dried at a hot air temperature of 105 degrees Celsius.

[0086] Shred the dried tobacco leaves with a width of 0.8-1.0 mm, dry the shreds after the shreds, and pack the shredded ...

Embodiment 2

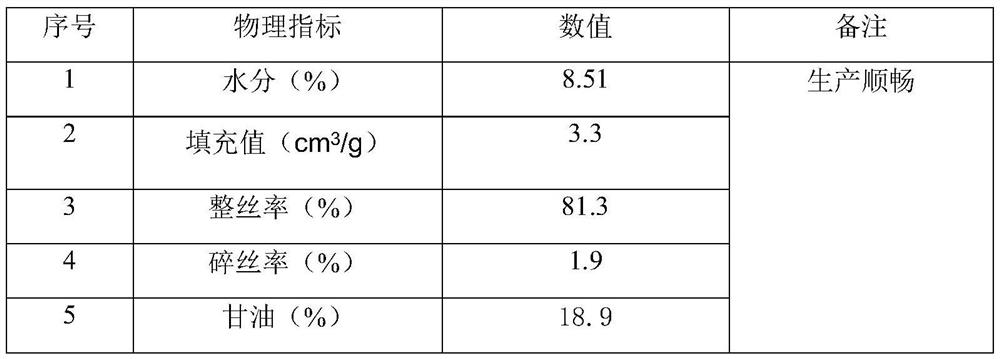

[0094] Example 2: flue-cured tobacco type B

[0095] Sheet tobacco is fed, unpacked, sliced, loosened and dampened. The moisture content of the dampened tobacco leaves is 18% to 22%, and the temperature is 60 to 80 degrees Celsius.

[0096] Store the rehydrated tobacco leaves for 2 hours, and then apply an atomizing agent. Based on the quality of the added rehydrated tobacco leaves, the mass percentage of the applied atomizing agent is 30%, and the temperature of the atomizing agent is 60-65 degrees Celsius.

[0097] Put the tobacco leaves after applying the atomizing agent into food-grade 304 stainless steel, take the cover and send it to a vacuum device for 120 seconds for vacuum treatment, and the vacuum degree is 0.83 MPa.

[0098] The vacuum-treated tobacco leaves are stored for 2 hours and then dried at a hot air temperature of 105 degrees Celsius.

[0099] Shred the dried tobacco leaves with a width of 0.8-1.0 mm, dry the shreds after the shreds, and pack the shredded ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com