Patents

Literature

38results about How to "Improve surface stickiness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

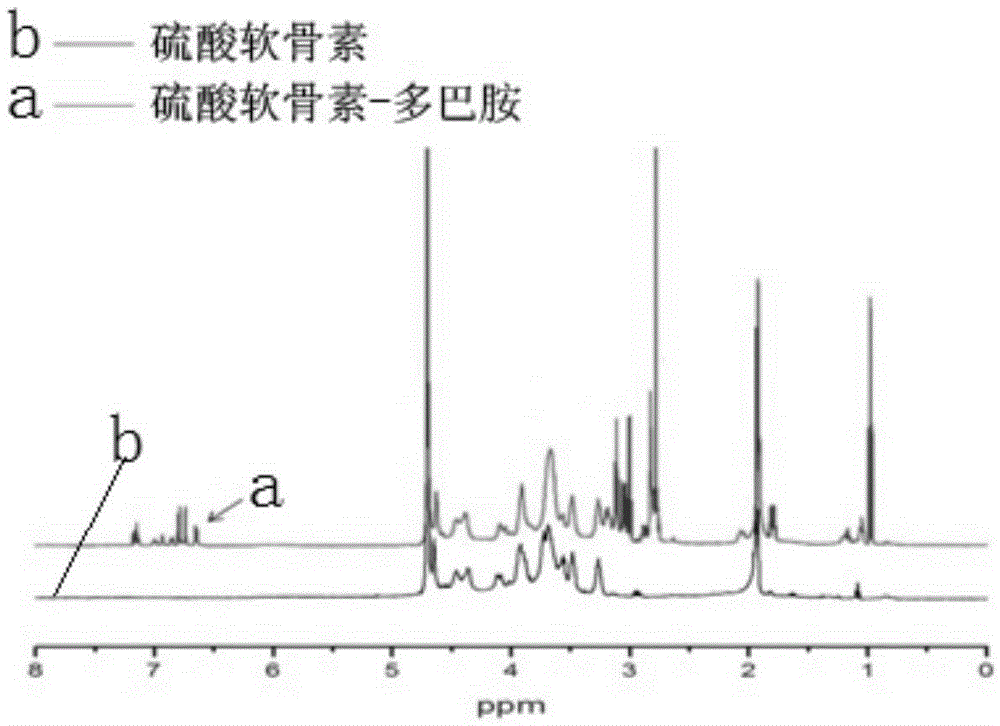

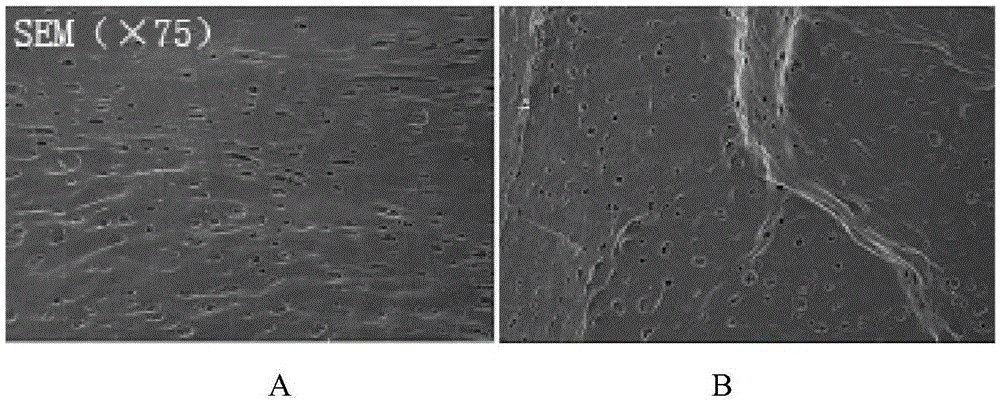

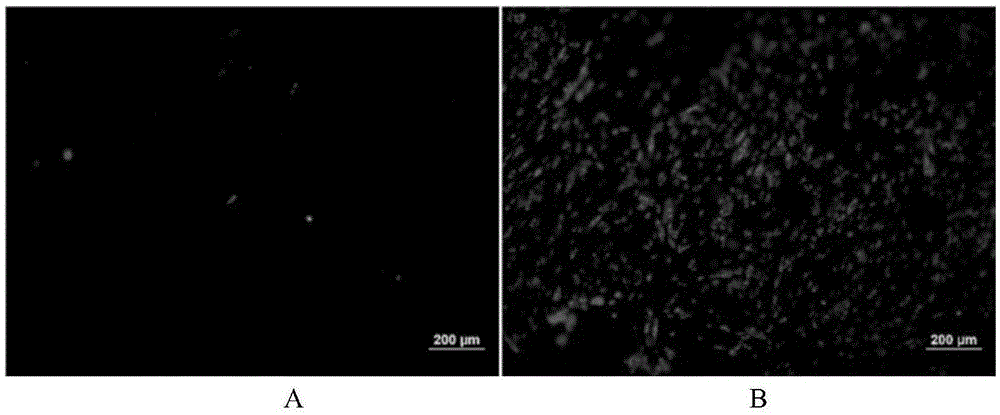

Polysaccharide-dopamine composite biogel and application thereof

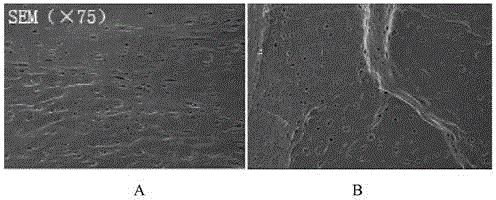

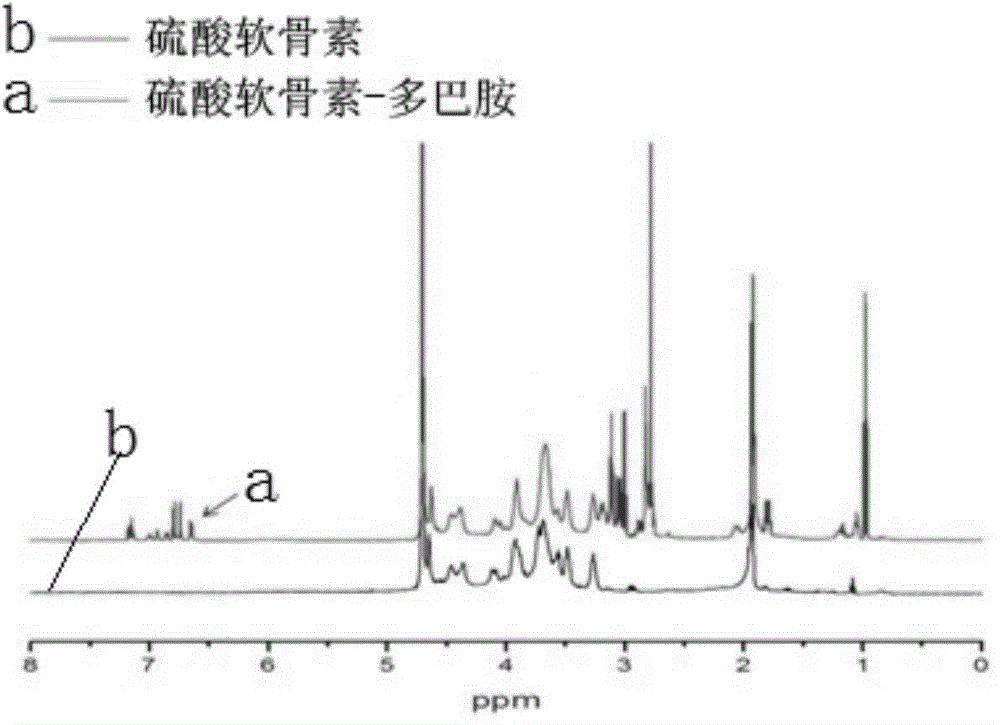

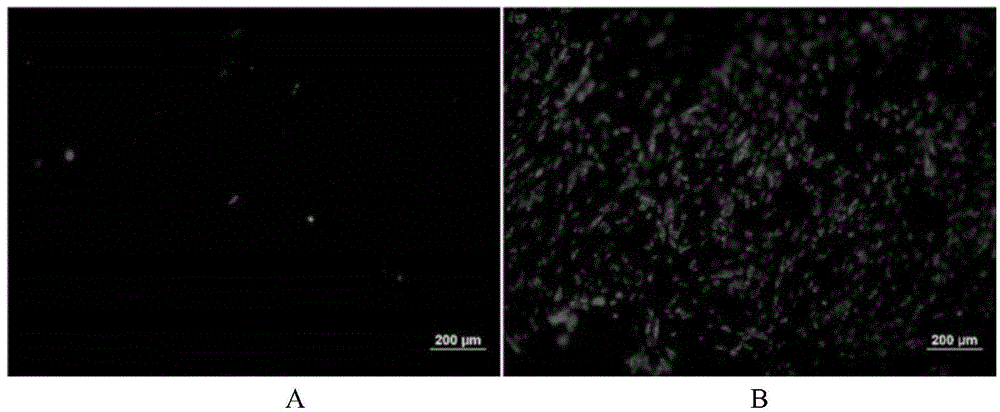

The invention discloses a polysaccharide-dopamine composite biogel and application of the biogel. A preparation method of the biogel comprises the following steps: dissolving 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride and N-hydroxy succinimide sodium in an MES (Methyl Ester Sulfonate) buffer solution with a pH value being 5-6 in an inert gas atmosphere so as to prepare an EDC (ethylcarbodiimide) mixed solution, subsequently adding the EDC mixed solution into a polysaccharide solution for reacting at 20-30 DEG C for 0.5-1 hour, then adding a dopamine solution for further reacting at 20-30 DEG C for 1-4 hours, dialyzing a reactant by taking distilled water as a dialyzate, taking trapped fluid for freezing and drying to obtain the polysaccharide-dopamine composite biogel. The polysaccharide-dopamine composite biogel is simple and effective in modification method and capable of increasing the surface viscidity of the cartilage tissue, reducing loss of therapeutic drugs or implanted cells and facilitating the repairing of the cartilage injury.

Owner:ZHEJIANG UNIV

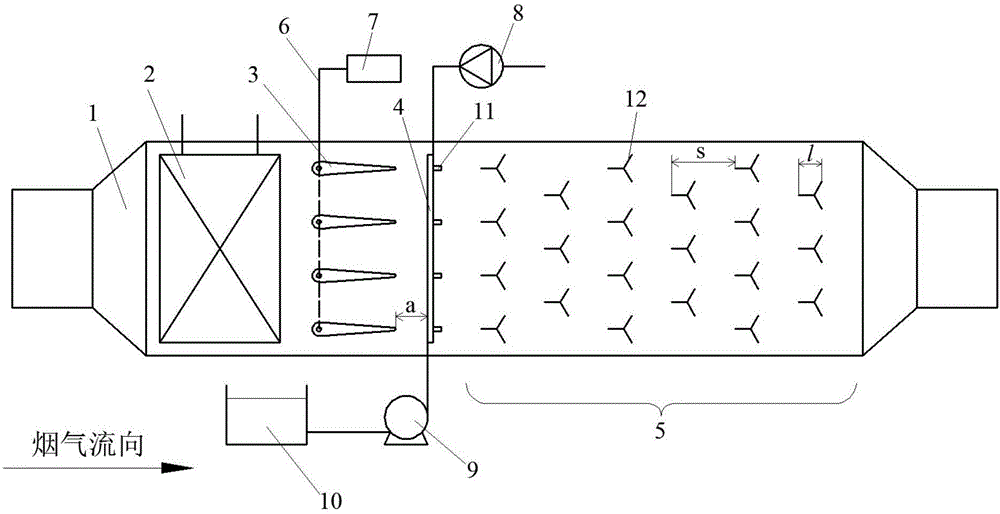

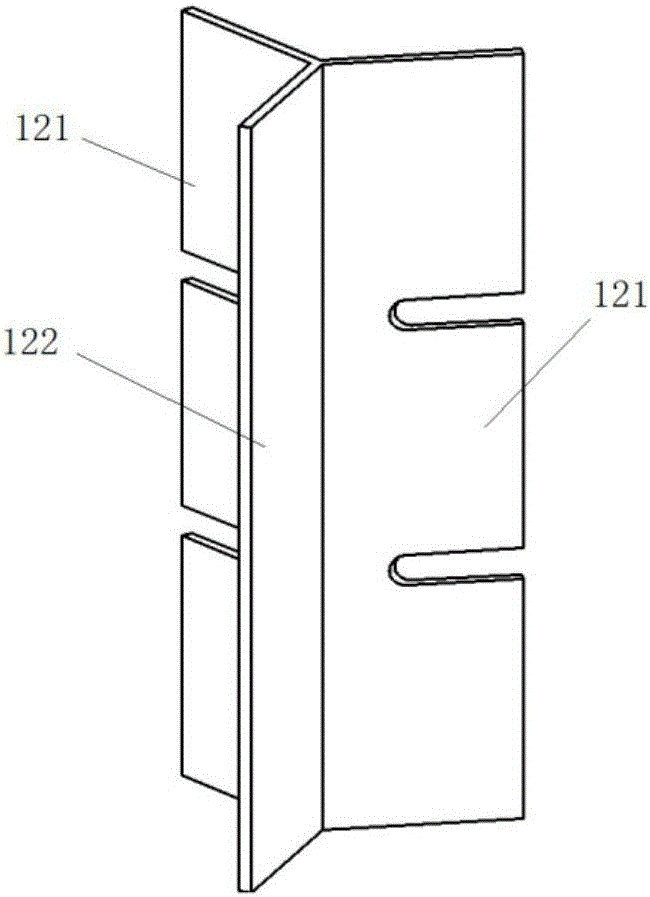

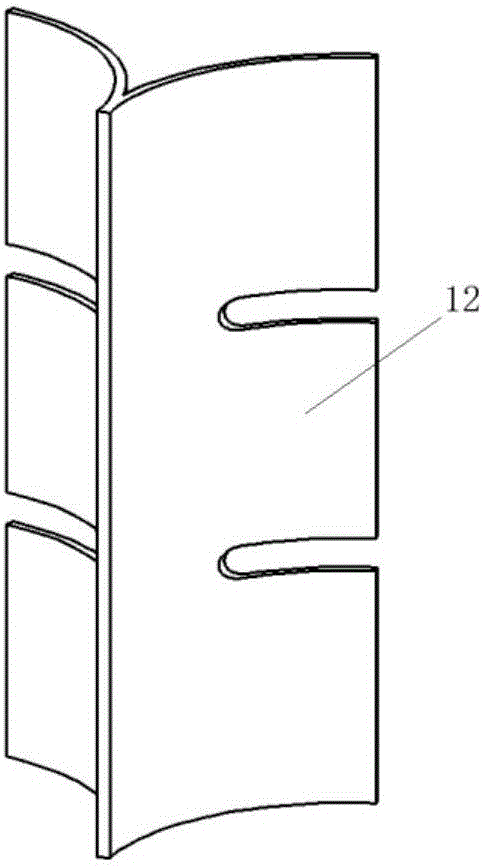

Device and method for atomizing turbulent agglomerated granules

InactiveCN106492581AEfficient collisionImprove controllabilityGas treatmentAuxillary pretreatmentParticulatesAxis of symmetry

The invention discloses a device and method for atomizing turbulent agglomerated granules. The device is simple in structure, good in agglomeration effect and good in universality. The device comprises a shell, wherein a fume channel is formed inside the shell; a fume heat exchanger, guide blades, a double-fluid ejection atomization section and a turbulent agglomeration section are sequentially arranged inside the shell in a fume flowing direction; the fume heat exchanger is used for reducing the temperature of dust-containing fume to T, wherein T is not higher than condensation temperature of steam in the dust-containing fume; the guide blades are used for adjusting the flowing direction so that the flowing direction of granules in the dust-containing fume trends to be accordant with that of the fume; the double-fluid ejection atomization section comprises a gas supply pipeline, a water supply pipeline and double-fluid nozzles; the ejection directions of the double-fluid nozzles for connecting the gas supply pipeline and the water supply pipeline are parallel to the flowing direction of the fume; the turbulent agglomeration section comprises a plurality of turbulent elements which are arranged in sequence or in a staggered manner, and two ends of each turbulent element are fixed on the inner wall of the shell; and the turbulent elements comprise boundary plates which are symmetrically arranged by taking the fume direction as an axis of symmetry, and the front ends of the boundary plates are fixedly connected.

Owner:XI AN JIAOTONG UNIV

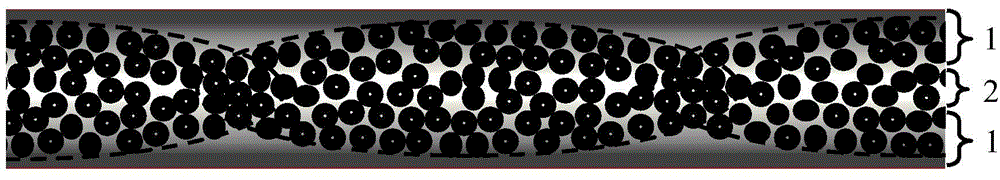

Preparation method of gradient prepreg with air guiding passage in layer

The invention belongs to the technical field of the low-cost preparation of high-performance composite materials and relates to a gradient prepreg having an air guiding function in layer and good process operability and a preparation method of the gradient prepreg. The compound technology parameters in a prepreg preparation process are regulated and controlled, the dipping degree of resin to dry fibers is controlled, the resin is symmetrically distributed in a gradient manner in the middle layer in the thickness direction of the prepreg, the fiber is infiltrated, meanwhile, an air exhaust channel is pre-formed in a prepreg layer, and the gradient prepreg with an air guiding passage in layer can be prepared; the gradient prepreg can be formed and solidified by an out-of-autoclave process, and the forming process cost of the composite material parts can be greatly reduced.

Owner:AVIC BASIC TECH RES INST

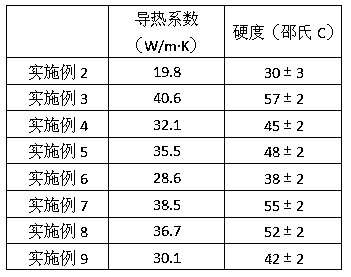

Preparation method of silicone rubber pad

The invention discloses a preparation method of a silicone rubber pad. The preparation method includes the following steps that 1, a nanocarbon material is added to silicone rubber, and after uniform kneading is conducted, a nanocarbon-silicone rubber mixture is obtained; 2, inorganic thermal conductivity power, a catalyst and a mixture composed of simethicone and hydrogen containing silicone oil are added to the nanocarbon-silicone rubber mixture, and rubber compound is obtained after open milling is conducted; 3, physical orientation is adopted for the rubber compound, and a sample pad with the nanocarbon material arranged in the silicone rubber in an oriented mode is obtained; 4, the sample pad is vulcanized, and the finished silicone rubber pad is obtained. By means of the preparation method, nanocarbon can be arranged in the silicone rubber in an oriented mode, a regular nanocarbon oriented thermal conductivity network structure is formed, and thus a product with an ultrahigh thermal conductivity coefficient is obtained.

Owner:DEYANG CARBONENE TECH

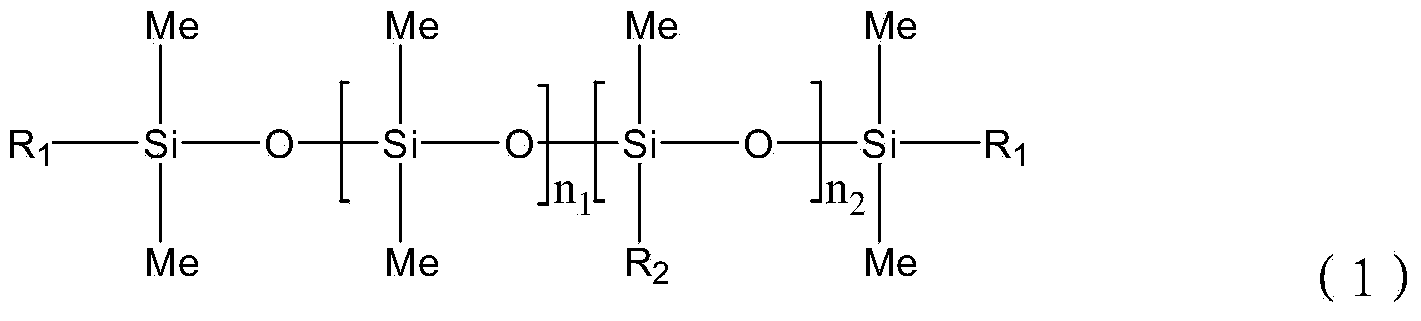

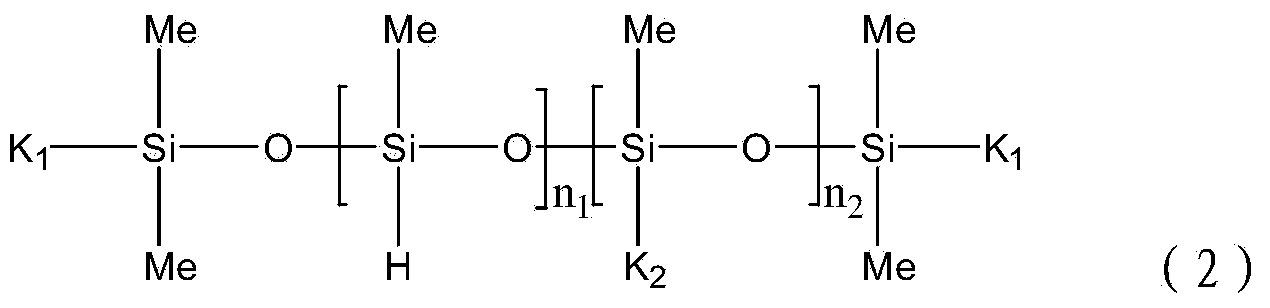

Antistatic organosilicon gel used for heat-conducting gasket and preparation method of the organosilicon gel

The invention relates to antistatic organosilicon gel used for a heat-conducting gasket and a preparation method of the organosilicon gel. The organosilicon gel comprises an A component and a B component in a weight ratio of 1:1. The A component comprises following raw materials by weight: 95-99.84 parts of a basic material, 0.1-1 part of a catalyst, 0.05-2 parts of an adhesive and 0.01-2 parts of an antistatic agent. The B component comprises following raw materials by weight: 84-94.9 parts of the basic material, 5-15 parts of a cross-linking agent and 0.1-1 part of an inhibitor. The organosilicon gel prepared by the invention has good fluidity. After sulfuration, the organosilicon gel has excellent adhesive property, holding power and antistatic property.

Owner:YANTAI DARBOND TECH

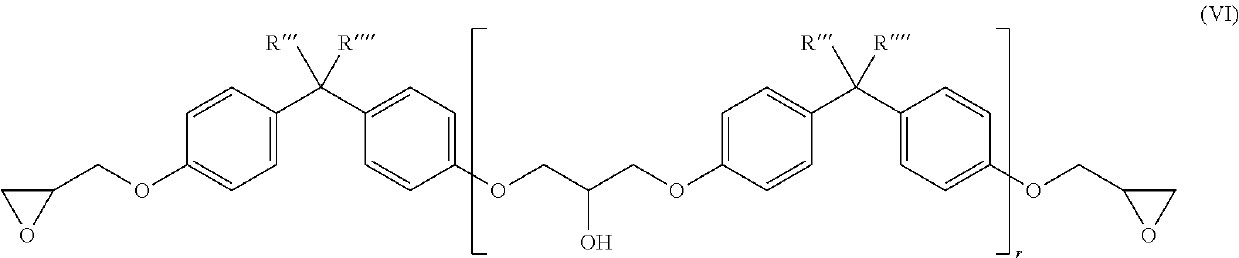

Article of thermosetting epoxy resin composition and carbon fibre fabric, and reinforced structural component made therewith

ActiveUS20180171087A1Easily mountImprove propertiesPolyureas/polyurethane adhesivesSynthetic resin layered productsHigh surfaceStructural component

The present invention relates to a self-adhesive article comprising a non-random fabric of bundles of carbon fibres and a thermosetting epoxy resin composition. The self-adhesive article exhibits high surface adhesion and excellent dimensional stability at room temperature. The self-adhesive article is ideally suited to reinforce structural components, particularly vehicles or ancillary vehicle components. The structural components reinforced by the self-adhesive article exhibit improved impact and torsional strength.

Owner:SIKA TECH AG

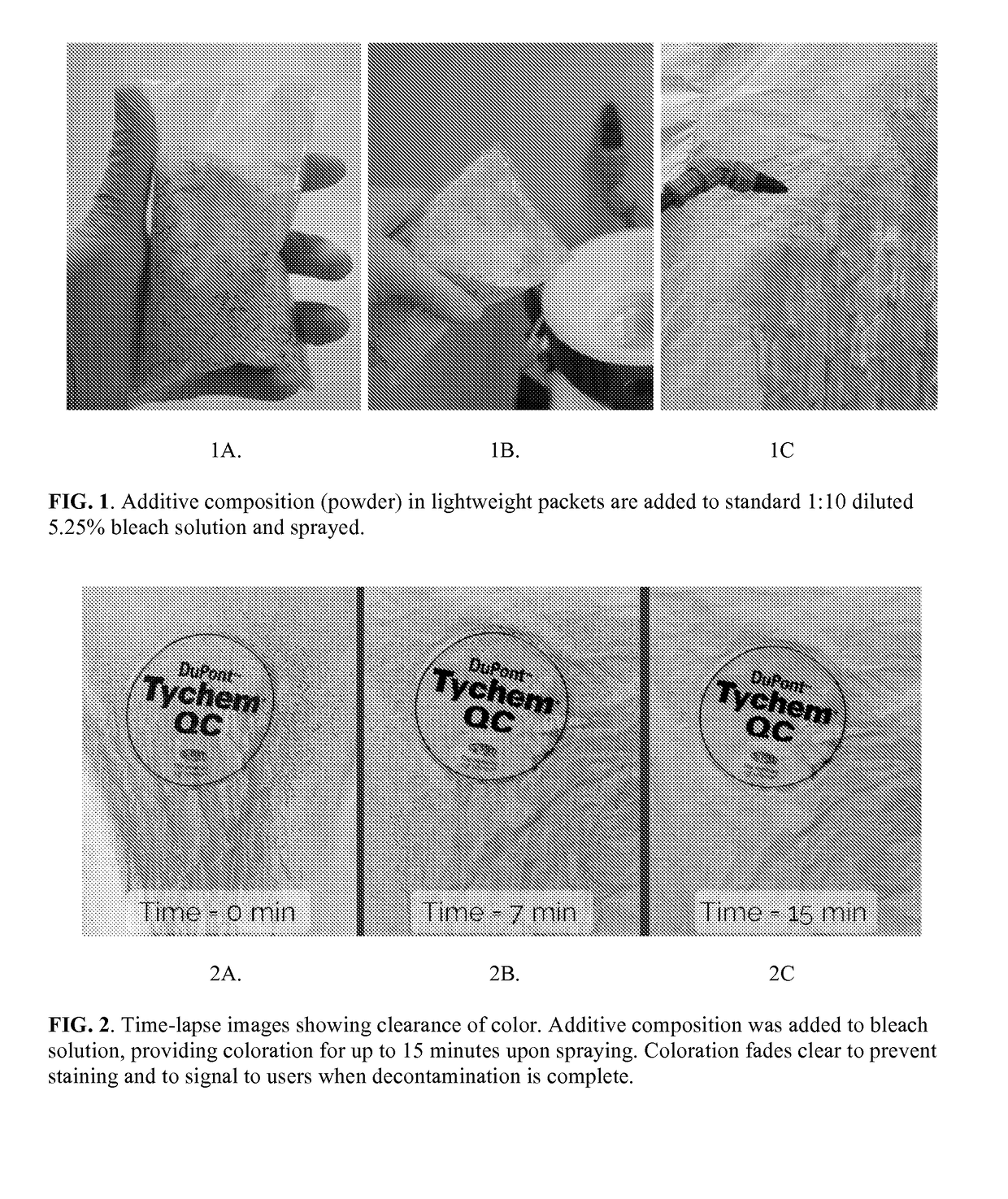

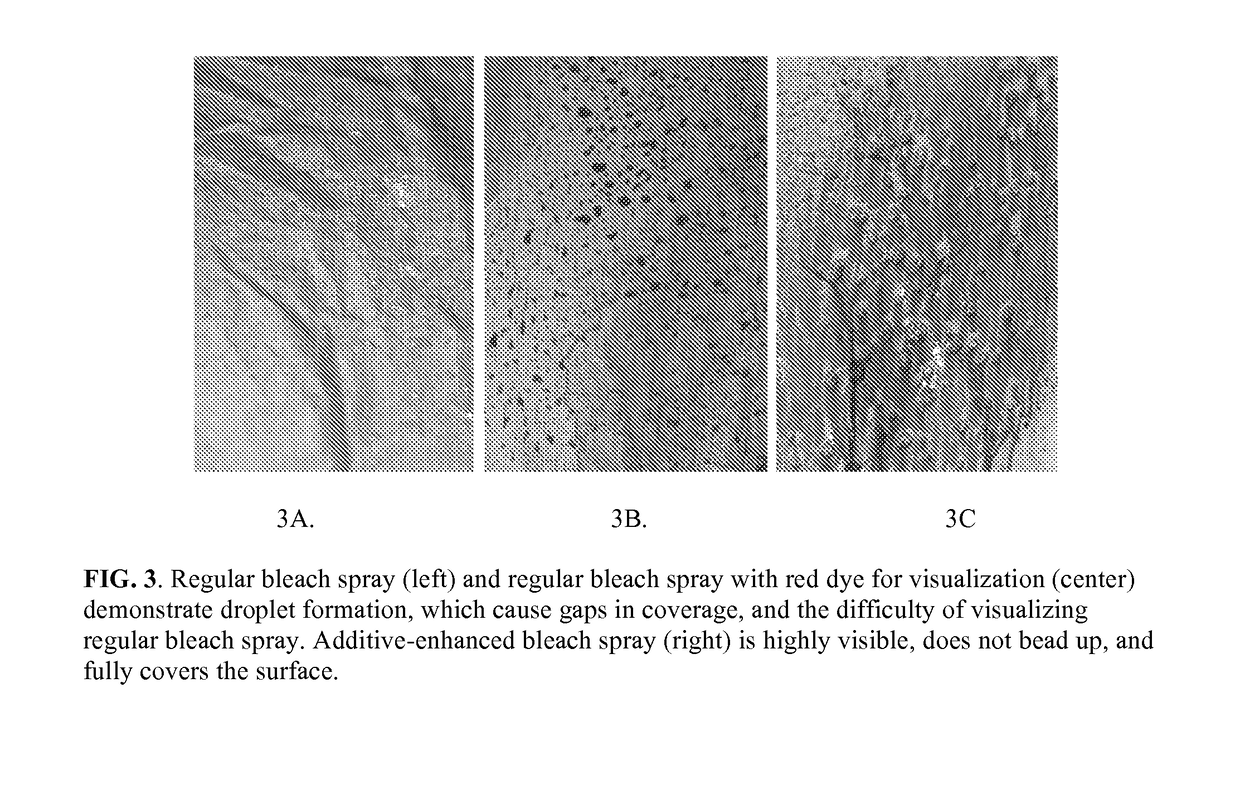

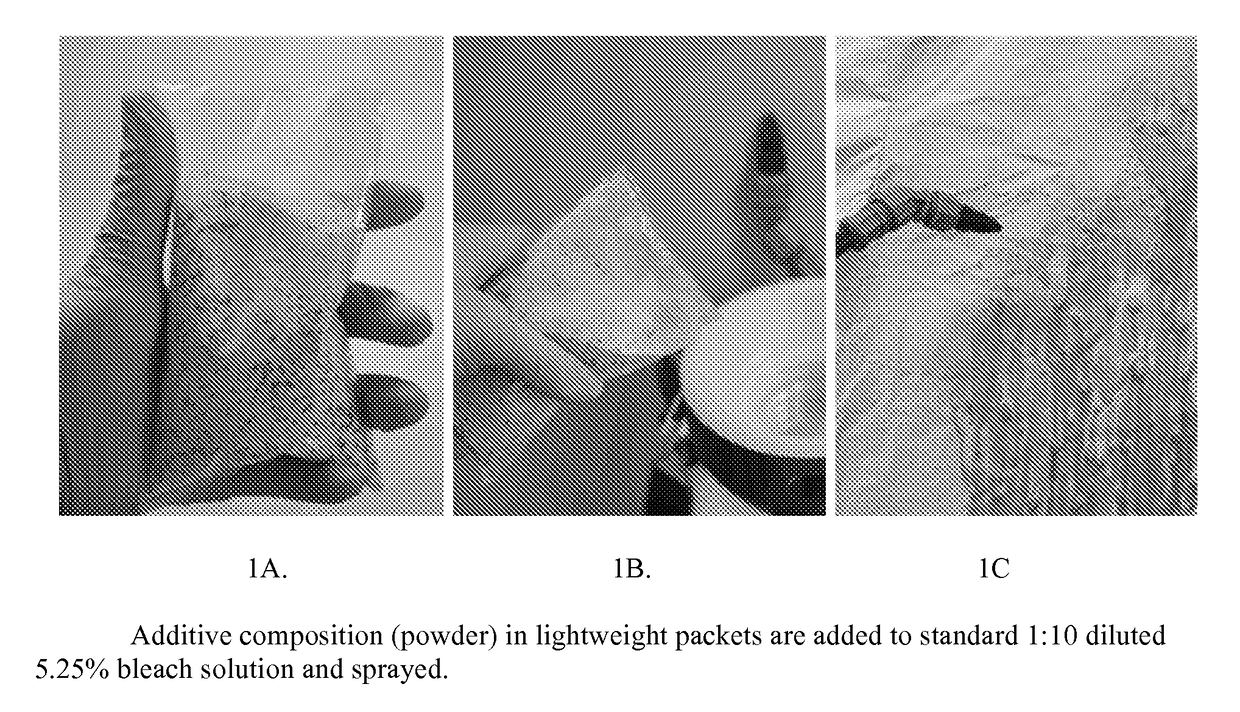

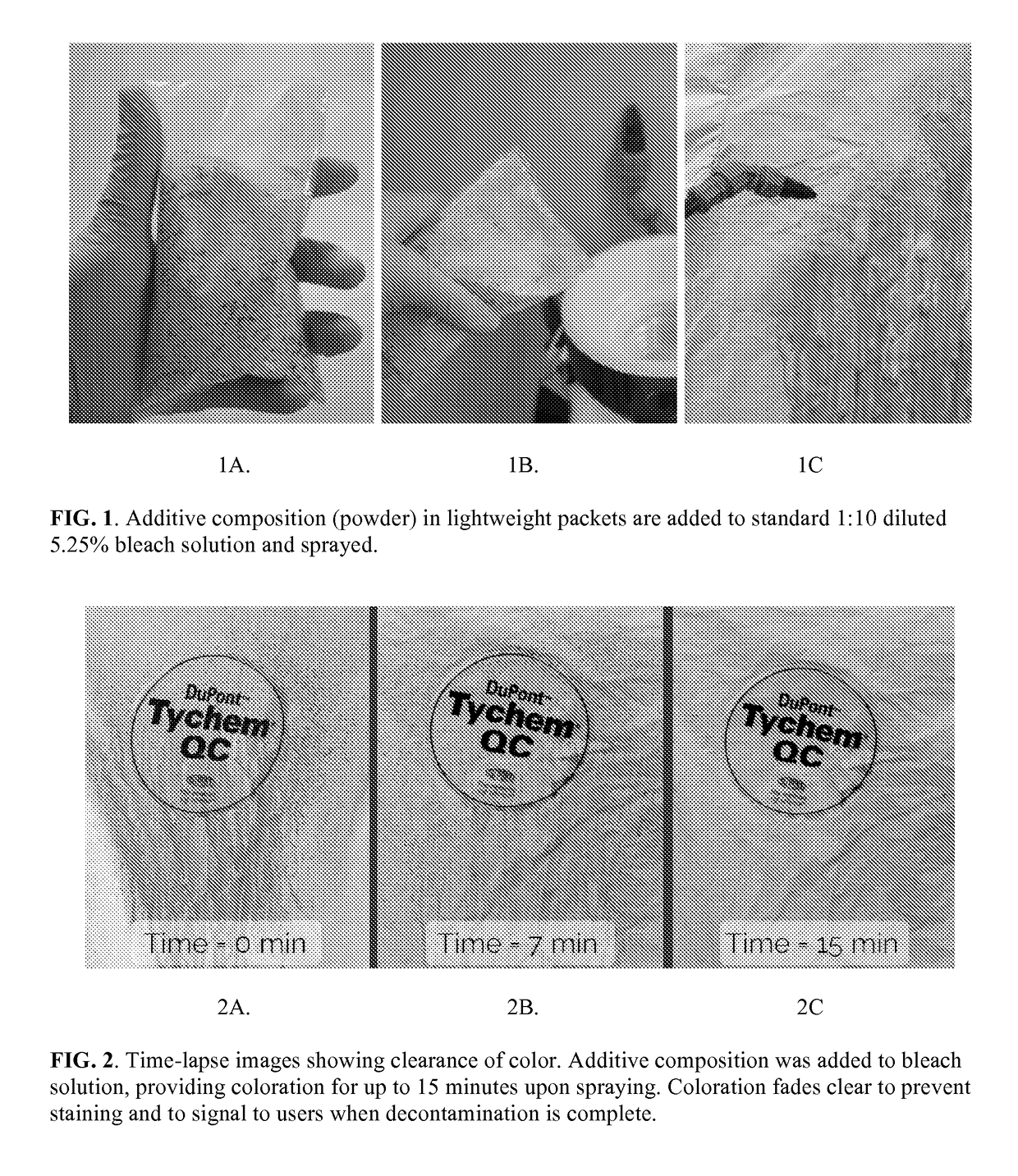

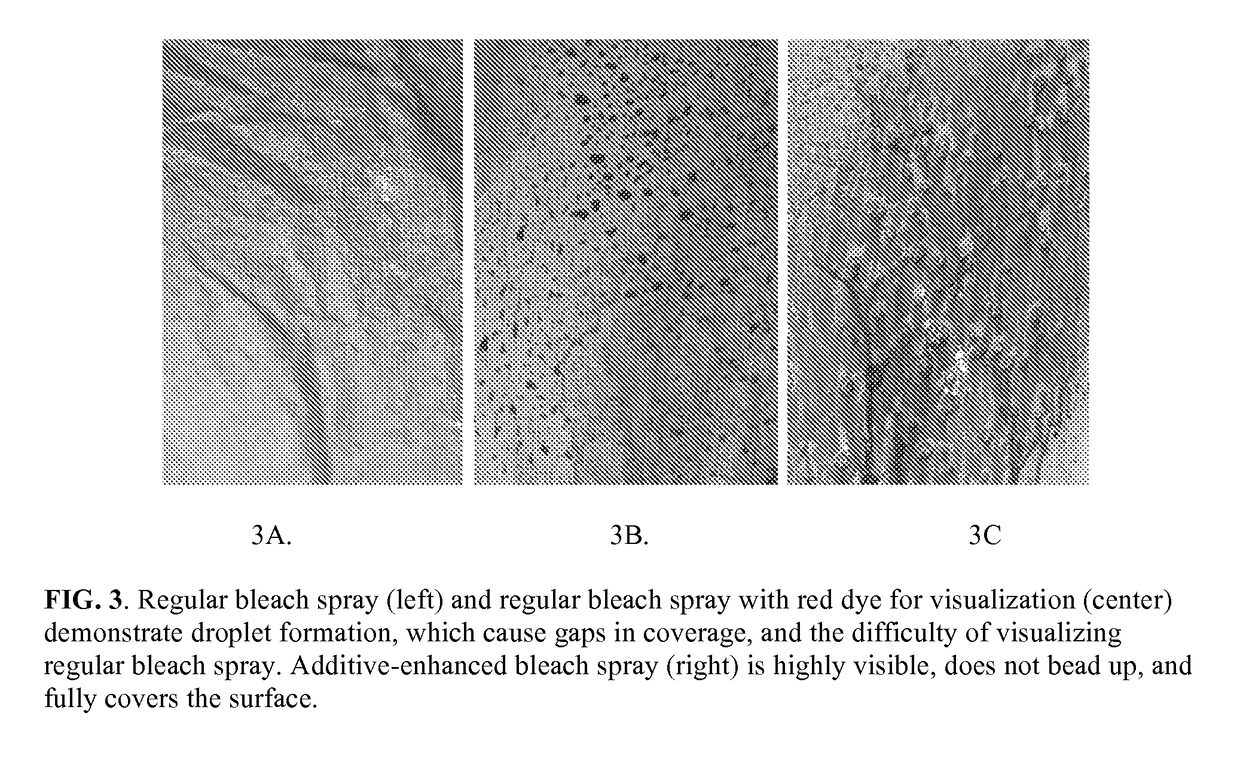

Additive compositions for pigmented disinfection and methods thereof

ActiveUS20170333586A1Improve visualizationImprove surface stickinessBiocideCationic surface-active compoundsVisibilityBleach

The invention provides a powdered composition of additives and a method of use thereof for increasing the visibility, potency and coverage of disinfectant solutions, such as bleach.

Owner:KINNOS INC

Additive compositions for pigmented disinfection and methods thereof

ActiveUS10052398B2Easily visualizedEasy to useBiocideCationic surface-active compoundsBleachEngineering

The invention provides a powdered composition of additives and a method of use thereof for increasing the visibility, potency and coverage of disinfectant solutions, such as bleach.

Owner:KINNOS INC

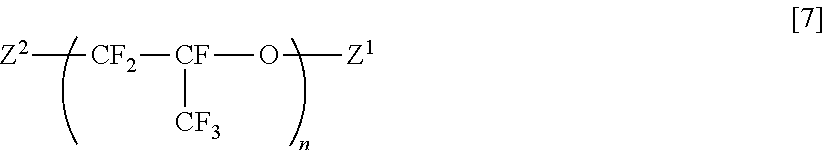

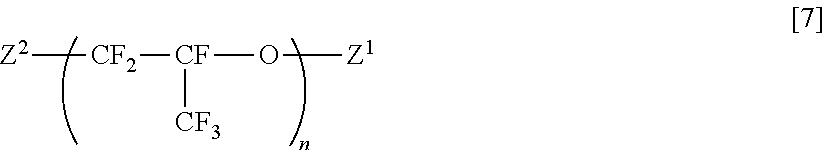

Thermally conductive resin composition and thermally conductive sheet including the same

ActiveUS8912278B2Solve high hardnessLower surfaceSolid-state devicesSpecial tyresPolymer chemistryFluorine

Owner:VALQUA LTD

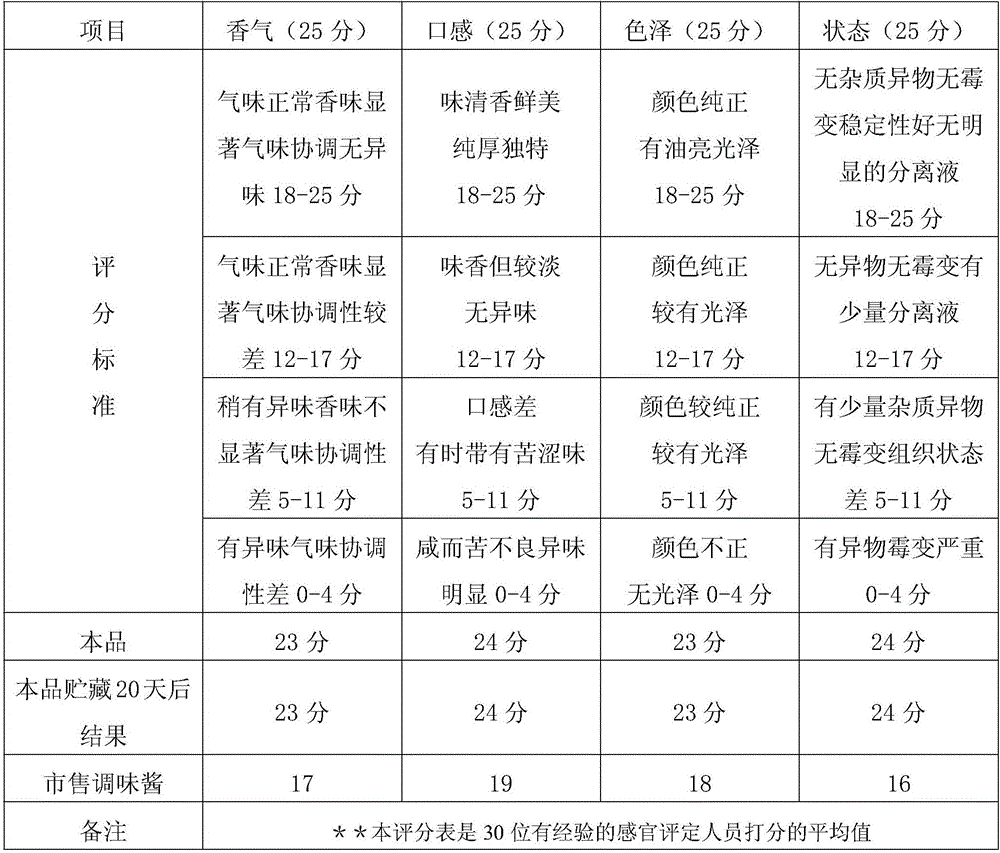

Instant cuttlefish juice seasoning sauce and manufacturing method thereof

InactiveCN106072437AEasy to produceProduction time savingFood ingredient functionsCuttlefishEconomic benefits

The present invention relates to instant cuttlefish juice seasoning sauce and a manufacturing method thereof. The cuttlefish juice seasoning sauce comprises: cuttlefish juice, olive oil, butter, onions, garlics, fresh gingers, green chilies, carrots, brandy, crushed black pepper, oyster sauce, wet sweet potato powder and water. The cuttlefish juice seasoning sauce is obtained by the technologies of blending, canning, sterilizing, etc. The cuttlefish juice seasoning sauce is delicate, smooth, and moist in mouthfeel, and easy to accept by people, contains various human body needed nutrients, and more importantly contains the special components having a certain health-care efficacy. The cuttlefish juice sauce is simple and convenient, time-saving, safe and reliable, and can be eaten safely. More importantly, the manufacturing method turns the cuttlefish juice from wastes to treasures, provides a feasible way for the development and utilization of the cuttlefish juice, meets consumers' sensory requirements, achieves health-care desires, improves the added values of the cuttlefish, and creates new social and economic benefits.

Owner:DALIAN NATIONALITIES UNIVERSITY

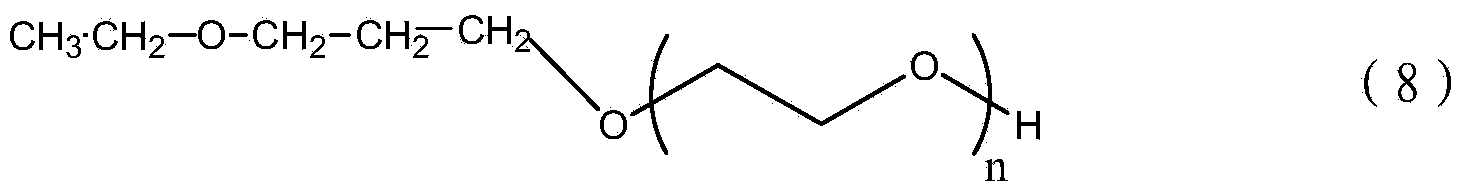

Method of Encapsulating Poly(Alkylene Carbonate) and Mixture Particles Thereof, and Use Thereof

ActiveUS20150132578A1Minimize impactImprove surface stickinessSynthetic resin layered productsCellulosic plastic layered productsVitrificationGlass transition

The present invention relates to a poly(alkylene carbonate) capsule in which a heterogeneous resin is applied on a surface of poly(alkylene carbonate), and a method of manufacturing the same, and provides a poly(alkylene carbonate) capsule preventing blocking where particles agglomerate each other when a resin having surface stickiness at a glass transition temperature or higher is processed in a pellet or chip state and circulated, and a method of manufacturing the same.

Owner:SK GEO CENTRIC CO LTD +1

Biological organic fertilizer and preparation method thereof

InactiveCN108516912APromote thrivingSimple structureBio-organic fraction processingAlkali orthophosphate fertiliserPotassium nitrateTrace element

The invention discloses biological organic fertilizer. Raw materials of the fertilizer includes modified biological carbon, sugarcane leaves, crop straw, corncobs, excrement of livestock and poultry,a fermentation bacterial inoculant, a functional microbial strain, ammonium chloride, potassium nitrate, calcium magnesium phosphate, monopotassium phosphate and compound trace elements. The inventionalso discloses a preparation method of the biological organic fertilizer. Under interaction of each added raw material, nutrients are supplied to meet the growth demands of crops; meanwhile, the utilization rate of fertilizer nutrients can also be increased, the soil structure can be improved, and healthy growth of crops is facilitated.

Owner:ANHUI SIERTE FERTILIZER IND

Thermally conductive resin composition and thermally conductive sheet including the same

ActiveUS20130240778A1Improve heat resistanceGood low hardnessSolid-state devicesHeat-exchange elementsPolymer chemistryFluorine

A thermally conductive resin composition containing (A1) a fluorine-based compound having one to two terminal SiH group(s), in which a content of molecules having two such groups is 60 to 100 mole %, (B1) a fluorine-based compound having one to two terminal alkenyl group(s), in which a content of molecules having two such groups is 60 to 100 mole %, (A2) a fluorine-based compound in which a content of molecules having two terminal SiH groups is 0 to 40 mole %, (B2) a fluorine-based compound in which a content of molecules having two terminal alkenyl groups is 0 to 40 mole %, and (C) a thermally conductive filler, and satisfying, in connection with the content of the fluorine-based compounds, relation of [(A1)+(B1)] / [(A2)+(B2)]=20 / 80 to 80 / 20 and (A1) / (B1) and (A2) / (B2)=20 / 80 to 80 / 20, as well as a thermally conductive sheet including the same are provided.

Owner:VALQUA LTD

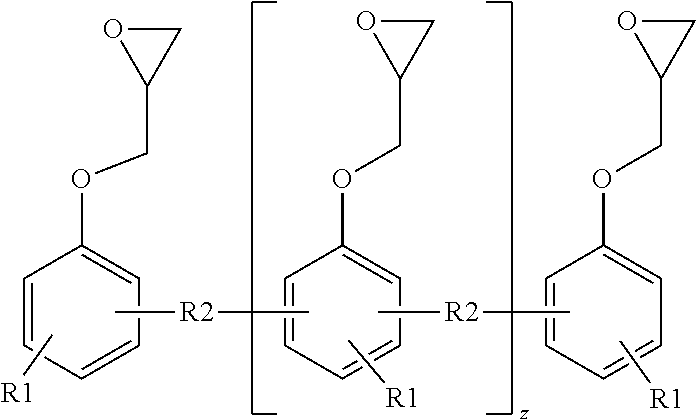

Thermosetting epoxy resin compositions useful as structural reinforcement or structural foam

ActiveUS20190270879A1Little can be alteredImprove surface stickinessEpoxy resin adhesivesEpoxy resin coatingsEpoxyRoom temperature

Thermosetting epoxy resin compositions on the one hand at room temperature in the incompletely cured state exhibit extremely slight alteration in shape and on the other hand develop a high surface tack, and, moreover, in the fully cured state are of high impact strength and at the same time exhibits high adhesion, particularly to metallic substrates. These compositions are ideally suited to the production of self-adhesive reinforcing elements.

Owner:SIKA TECH AG

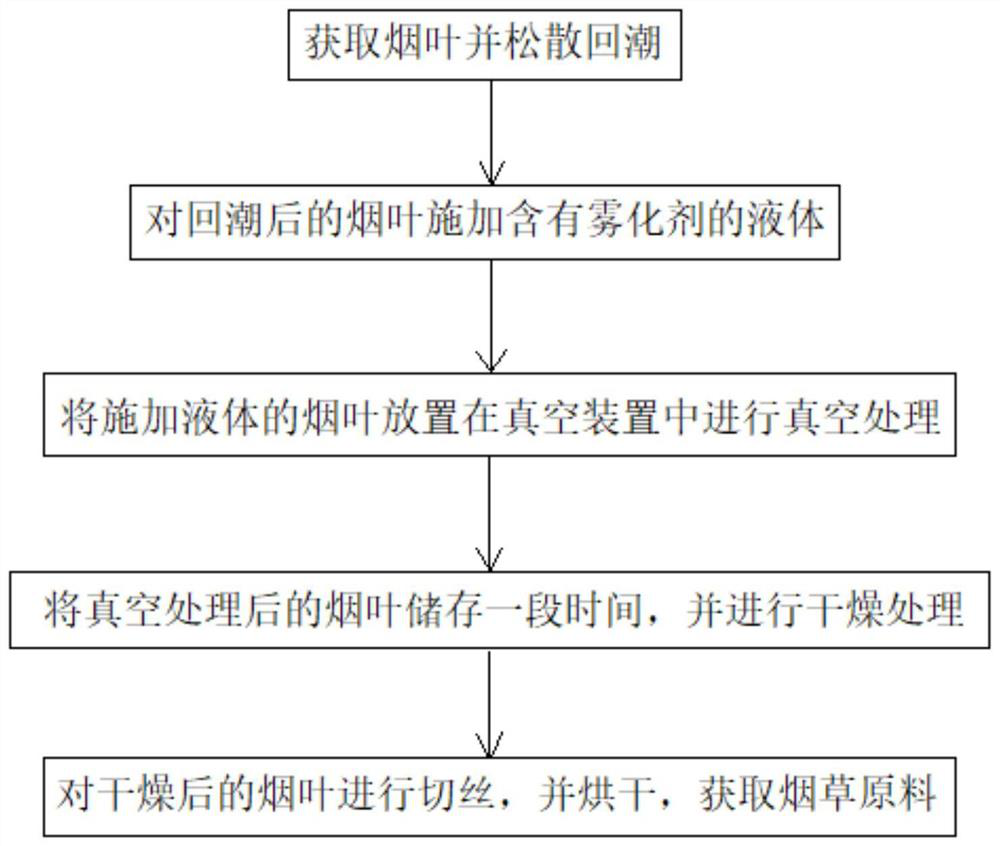

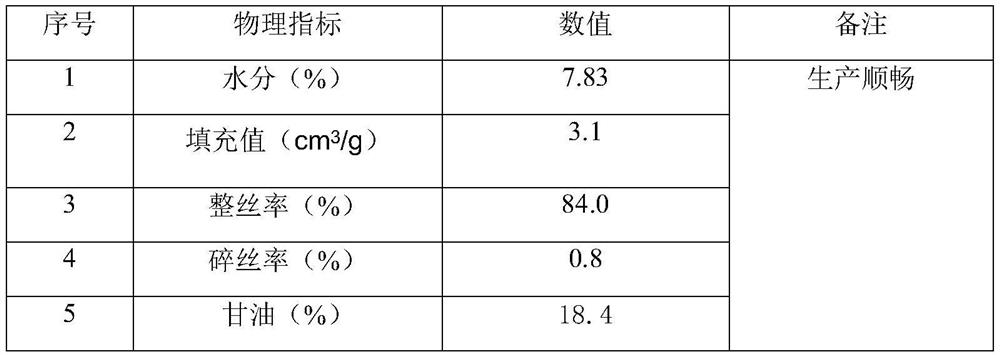

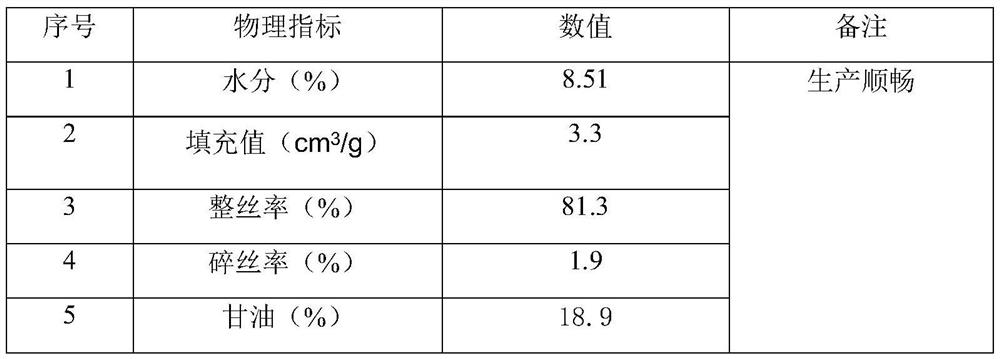

Preparation method of tobacco raw material and heat-not-burn cigarette with tobacco raw material

InactiveCN112369644AIncrease load capacityImprove adsorption capacityTobacco preparationTobacco treatmentBurn cigaretteProcess engineering

The invention discloses a preparation method of a tobacco raw material and a heat-not-burn cigarette with the tobacco raw material. The preparation method of the tobacco raw material comprises the steps of obtaining tobacco leaves and carrying out loosening and moisture regaining; applying liquid containing an atomizing agent to the tobacco leaves subjected to moisture regaining; putting the tobacco leaves to which the liquid is applied into a vacuum device for vacuum treatment; storing the tobacco leaves subjected to vacuum treatment for a period of time, and performing drying treatment; shredding and drying the dried tobacco leaves, and obtaining tobacco raw materials. The heat-not-burn cigarette comprises a filter tip and an atomized tobacco substrate section connected with the filter tip, and tobacco raw materials are arranged in the atomized tobacco substrate section. The loading capacity of the added atomizing agent can be improved, the adsorption effect of the atomizing agent isgood, meanwhile, the atomizing agent can be prevented from adhering to the surface of tobacco shreds to influence cigarette making and tipping production and process quality, and therefore the application range of tobacco raw materials can be widened, and the quality of the tobacco raw materials is improved.

Owner:HUBEI CHINA TOBACCO IND

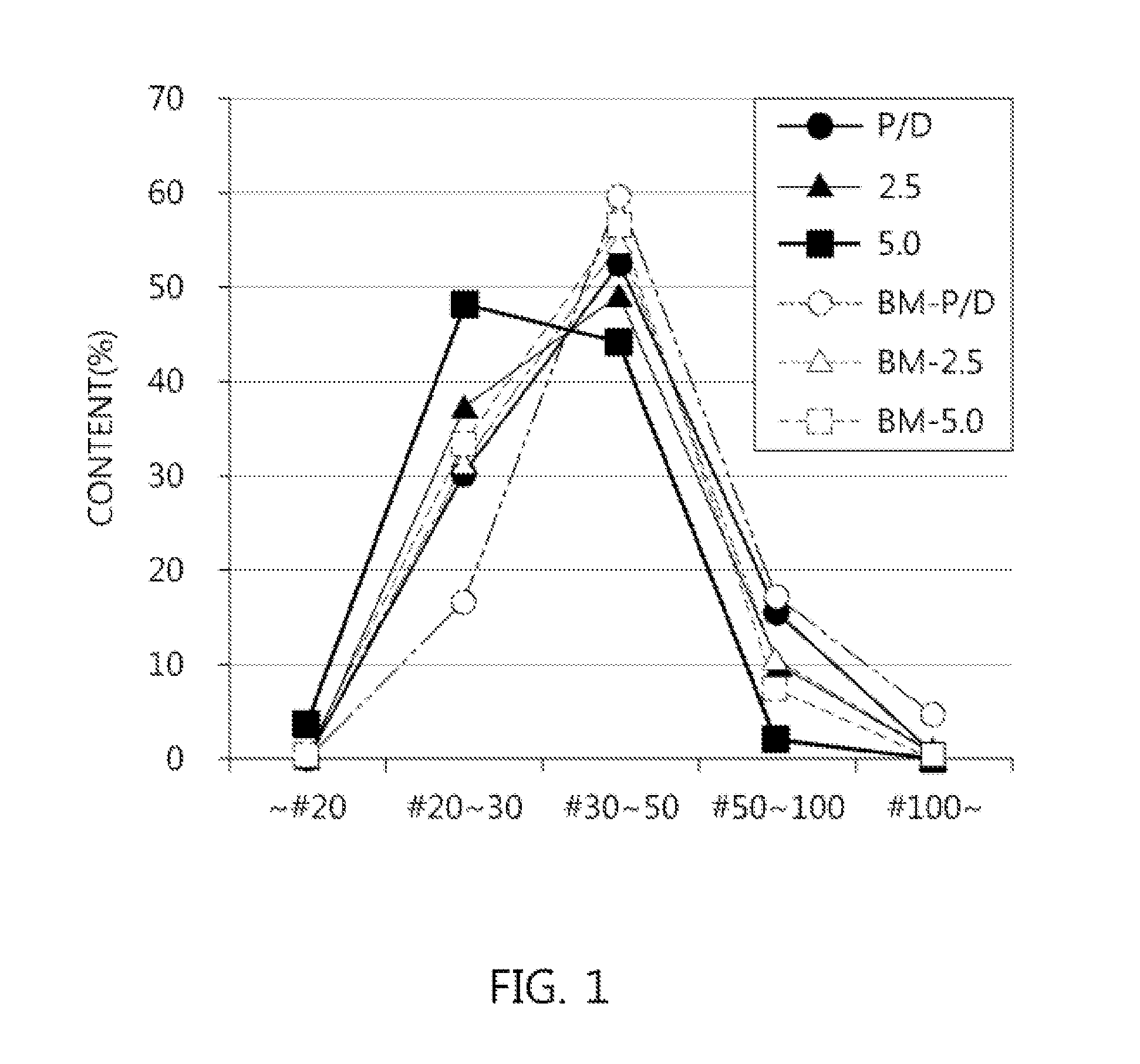

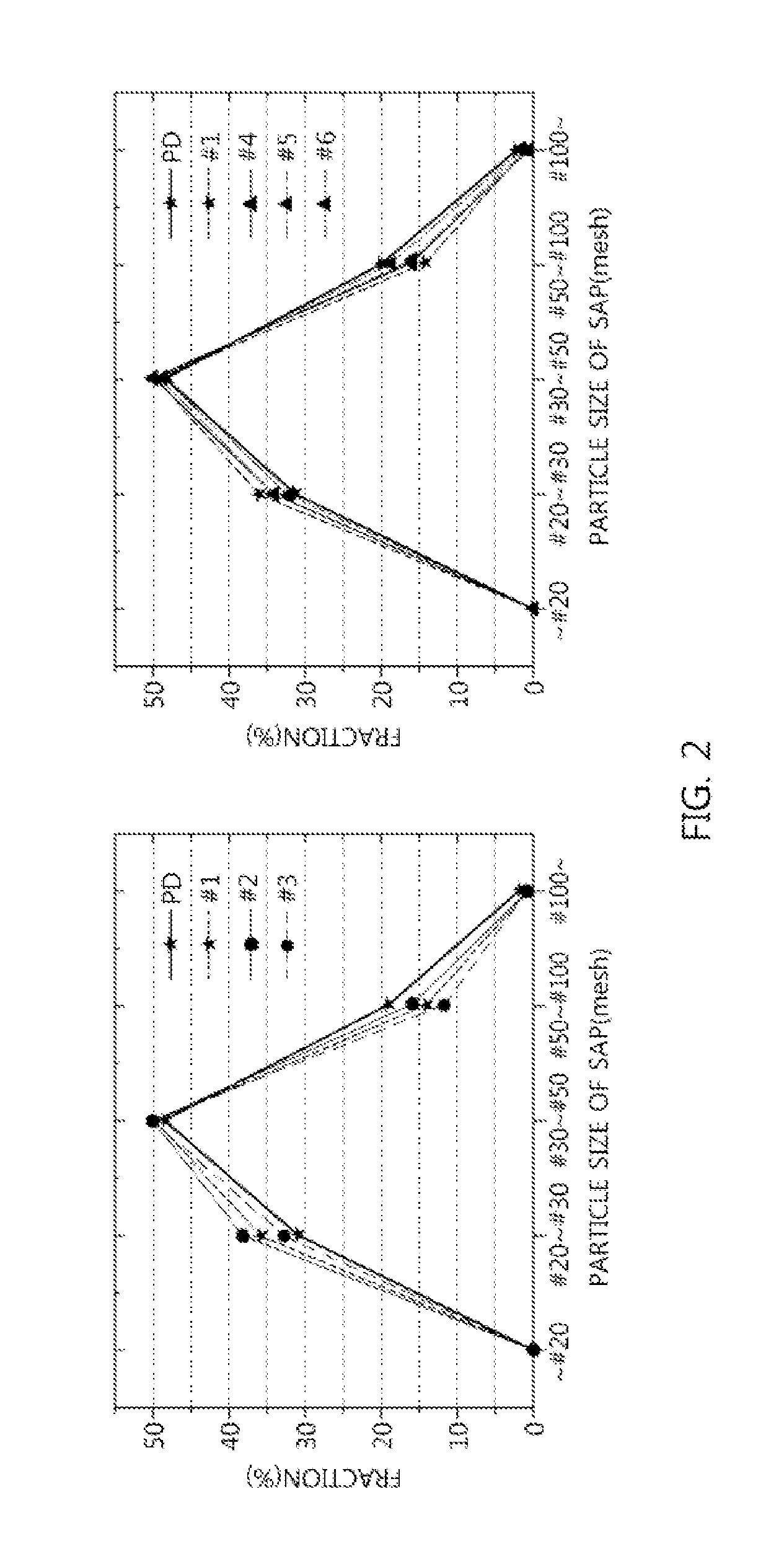

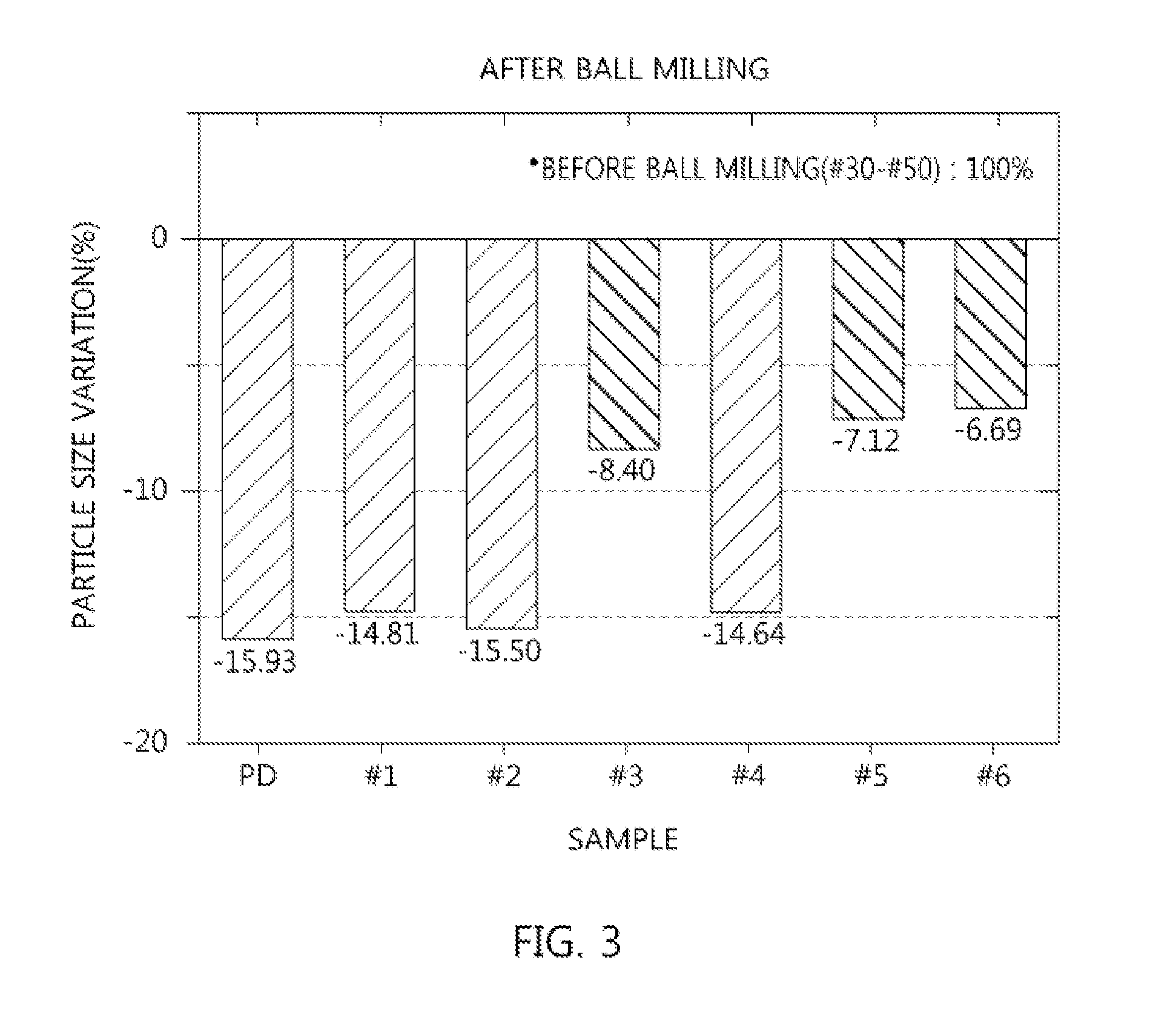

Attrition-resistant superabsorbent polymer and method for producing same

ActiveUS20170050171A1Desired product performanceReduce surface tackOther chemical processesAlkali metal oxides/hydroxidesMicroparticleSuperabsorbent polymer

Disclosed is an attrition-resistant superabsorbent polymer, including a superabsorbent polymer, porous superhydrophobic microparticles, and water, thus increasing moisture content of the superabsorbent polymer and a method of manufacturing the attrition-resistant superabsorbent polymer is also provided.

Owner:LG CHEM LTD

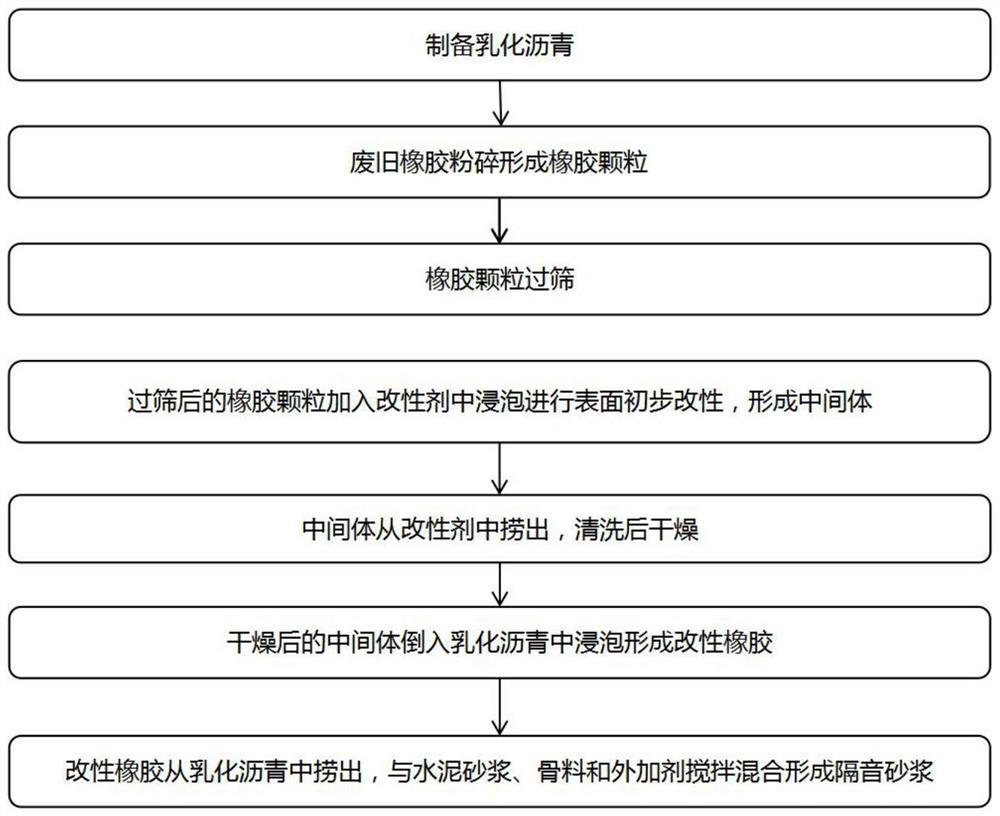

Building rubber particle modified sound insulation mortar and preparation method thereof

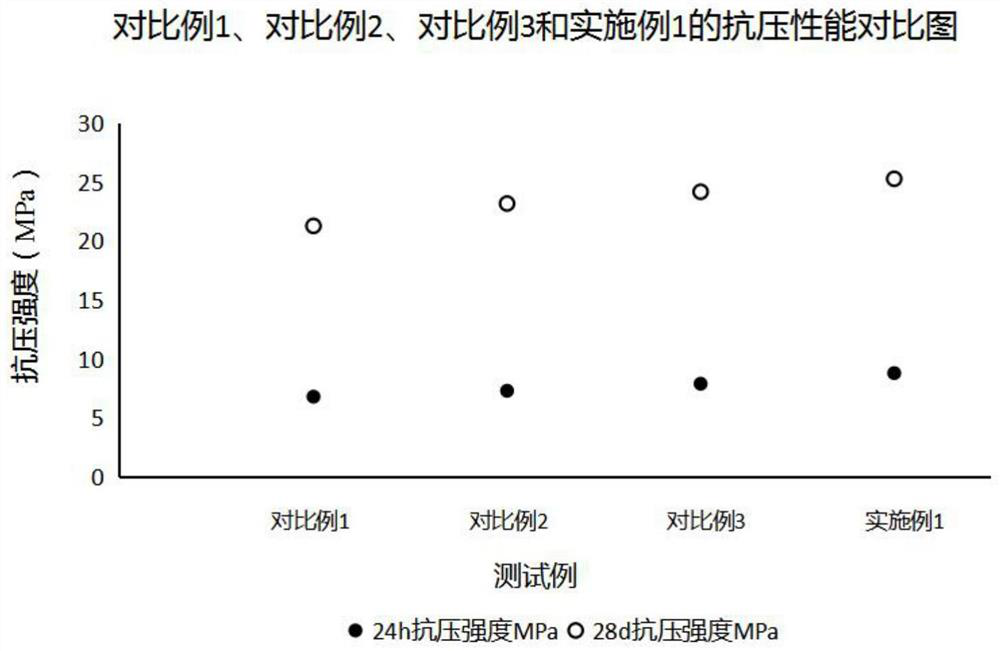

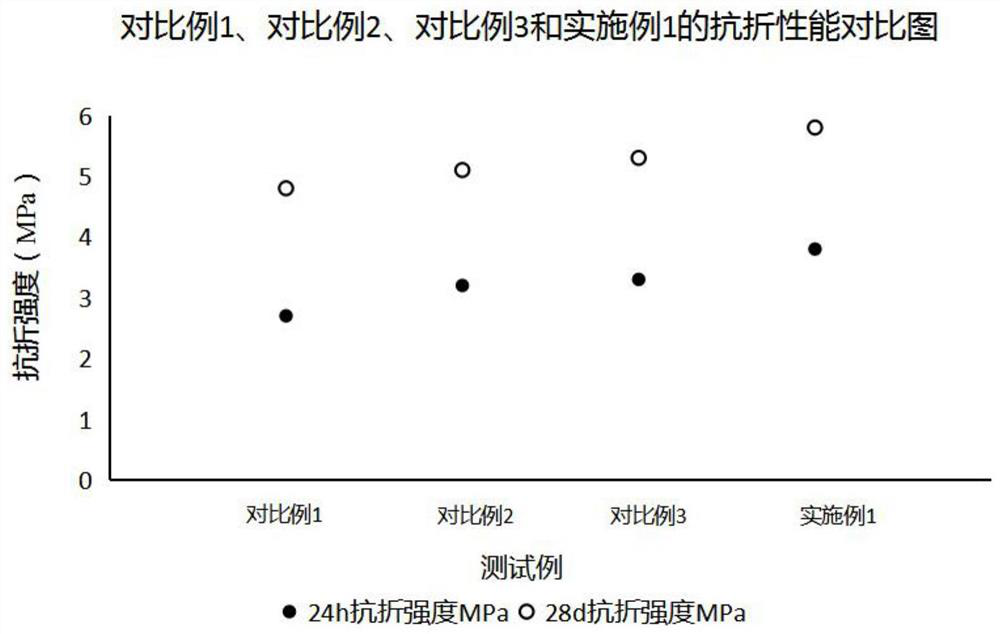

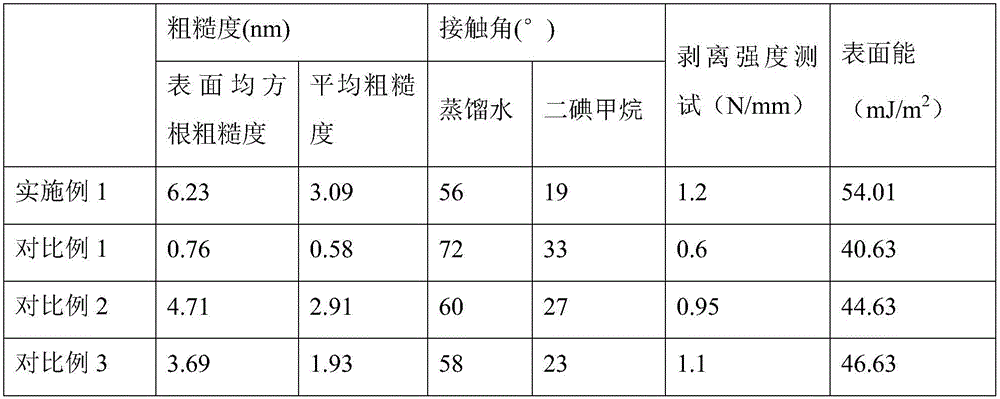

ActiveCN114349457AReduce layeringReduce air contentSolid waste managementPolymer scienceWaste rubber

The invention relates to the technical field of building materials, and discloses rubber particle modified sound insulation mortar for buildings and a preparation method thereof.The rubber particle modified sound insulation mortar for the buildings is prepared from, by mass, 8-15 parts of modified rubber, 29.4-44.8 parts of cement mortar, 40-50 parts of aggregate and 8.5-15.9 parts of admixtures, waste rubber is smashed to form rubber particles, then the rubber particles are sieved, and the sieved rubber particles are dried to obtain the sound insulation mortar for the buildings. Rubber particles are soaked in a modifier to form an intermediate with a rough surface, then the intermediate is fished out, cleaned and dried, then the intermediate is soaked in emulsified asphalt for modification to prepare modified rubber, the modified rubber is fished out of the emulsified asphalt, and the modified rubber is stirred and mixed with cement mortar, aggregate and an additive to form the rubber particle modified sound insulation mortar. According to the sound insulation mortar and the preparation method thereof, the waste rubber is reused to prepare the sound insulation mortar, layering between the rubber and the mortar is avoided, the strength of the sound insulation mortar is guaranteed, and the safety of the sound insulation mortar is improved.

Owner:浙江鼎峰科技股份有限公司

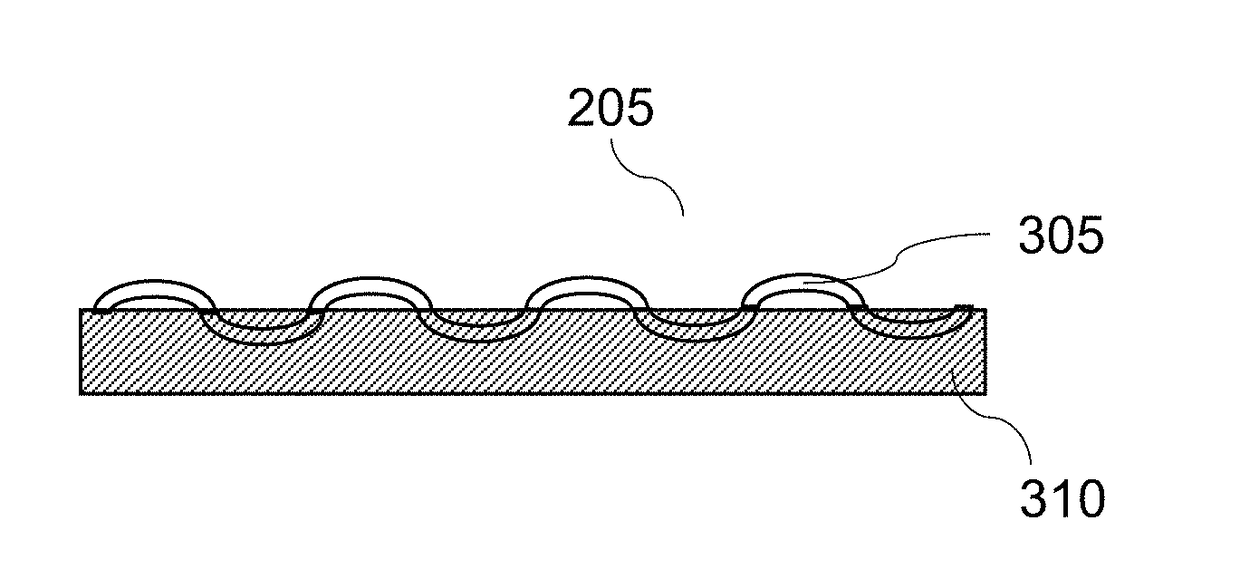

High-viscidity modified PI film

ActiveCN106279746AImprove surface stickinessHigh grafting rateCompression moldingChemical modification

The invention discloses a high-viscidity modified PI film. The surface of the high-viscidity modified PI film is sequentially subjected to physical modification and chemical modification; for the physical modification, at least one layer of the PI film is provided with a convex-concave structure; the depth of the concave structure in the convex-concave structure is smaller than the thickness of the PI film; the convex-concave structure of the PI film is made by using a photoetching mold, or is compressed and formed by a molding pressing mold; for the chemical modification, plasma treatment and surface grafting modification are combined. The prepared high-viscidity modified PI film has the beneficial effects that the viscidity is high; the hydrophilia is high; the adhesion with bonding agents can be favorably improved.

Owner:SUZHOU KECHUANG ELECTRONICS MATERIAL CO LTD

Explosion-proof tire

InactiveCN106317838AImprove explosion-proof performanceReduce forceSpecial tyresCoatingsTire beadVulcanization

The invention discloses an explosion-proof tire which comprises a tire body composed of a tread, a tire body, a buffer layer and a tire bead, wherein the tread is a rubber composition prepared by taking rubber as a matrix and adding with auxiliary materials such as a reinforcing filler, an accelerant, a vulcanizing agent, a vulcanization accelerator and an adhesion promoter; an explosion-proof layer made from high polymer explosion-proof materials is sprayed on the surface of the tread; a plurality of capsule cavities are formed in the tread and filled with leak-repairing glue. With the adoption of a manner of combining the explosion-proof layer, the capsule space and the tread rubber, the explosion-proof layer is sprayed on the surface of the tread, so that the elasticity of the tread surface is increased, and the acting force of a sharp object on the tread rubber is relieved; and moreover, the capsule cavities are formed in the tread rubber, when the sharp object pierces the capsule cavities to reach the tire body, the leak-repairing glue in the capsule cavities reacts with air so as to perform curing, and the condition that running safety is threatened by leakage of high-pressure gas in the inner liner is avoided.

Owner:SICHUAN YUANXING RUBBER

A kind of polysaccharide-dopamine composite biological glue and its application

ActiveCN104056300BEasily damagedPromotes damage repairSurgical adhesivesEster sulfonateBiological glue

The invention discloses a polysaccharide-dopamine composite biogel and application of the biogel. A preparation method of the biogel comprises the following steps: dissolving 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride and N-hydroxy succinimide sodium in an MES (Methyl Ester Sulfonate) buffer solution with a pH value being 5-6 in an inert gas atmosphere so as to prepare an EDC (ethylcarbodiimide) mixed solution, subsequently adding the EDC mixed solution into a polysaccharide solution for reacting at 20-30 DEG C for 0.5-1 hour, then adding a dopamine solution for further reacting at 20-30 DEG C for 1-4 hours, dialyzing a reactant by taking distilled water as a dialyzate, taking trapped fluid for freezing and drying to obtain the polysaccharide-dopamine composite biogel. The polysaccharide-dopamine composite biogel is simple and effective in modification method and capable of increasing the surface viscidity of the cartilage tissue, reducing loss of therapeutic drugs or implanted cells and facilitating the repairing of the cartilage injury.

Owner:ZHEJIANG UNIV

Method of encapsulating poly(alkylene carbonate) and mixture particles thereof, and use thereof

ActiveUS9598535B2Minimize impactImprove surface stickinessMicroballoon preparationThin material handlingVitrificationGlass transition

Owner:SK GEO CENTRIC CO LTD +1

Bead wire coating compound for aircraft radial-ply tire

The invention discloses a bead wire coating compound for an aircraft radial-ply tire, which is prepared by mixing the following raw materials in part by weight: 50 to 100 parts of butadiene styrene rubber, 0 to 50 parts of natural rubber, 30 to 70 parts of powerful powder, 35 to 65 parts of general purpose furnace black N660, 3 to 10 parts of zinc oxide, 0 to 4 parts of stearic acid, 1 to 4 partsof p-Phenylenediamine antioxidant 4020 or 4010NA, 1 to 4 parts of acetone-amine condensation product antioxidant BLE or RD, 1 to 8 parts of insoluble sulfur IS-60 or IS-90, 1 to 3 parts of sulfenamide accelerator NOBS or DZ, 0.5 to 3.0 parts of adhesive AIR-101, 0.5 to 3.0 parts of cobalt boroacylate or cobalt decanoate and 0 to 2.0 parts of tackifying resin DHJH-B through a banbury. The compoundhas good elongation, elasticity and adhesiveness and particularly good bonding strength after thermal ageing, and can meet the requirement of a hexagonal steel ring production process.

Owner:中国化工集团曙光橡胶工业研究设计院有限公司

Low-cost low-temperature plastic dipping PVC glove forming process method

InactiveCN111592725ALow costHigh hardnessDomestic articlesCoatingsPolymer scienceIn situ polymerization

The invention belongs to the field of high polymer materials, and especially relates to a low-cost low-temperature plastic dipping PVC glove forming process method. The low-temperature plastic dippingPVC glove forming process method uses chloro-ether resin and allyl resin monomers, low-temperature plastic dipping of PVC gloves is realized through in-situ polymerization and synchronous crosslinking, the preparation cost is low, a hand mold does not need to be preheated, high temperature production environment is not needed, energy consumption is low, the production working environment and conditions are improved, the prepared PVC gloves are more durable, good in sealing performance, free of peculiar smell, large in elasticity, resistant to acids and alkalis, convenient and comfortable to wear, integrally formed, non-sticky, convenient and safe, free of natural latex allergic protein and free of anaphylactic reaction, and the strength, the corrosion resistance and the hygienic propertyare improved.

Owner:安徽攀望科技有限公司

Diagonal tire for sedan car

The invention discloses a diagonal tire for a sedan car. The diagonal tire comprises a diagonal tire body composed of a tire tread, a tire body, a buffering layer and a tire bead, wherein rubber is used as a base body and supplemented with reinforcing filler, accelerant, vulcanizer, vulcanization accelerator and adhesion promoter to prepare a rubber composition serving as the tire tread, and rubber includes fluoroether rubber, butadiene-acrylonitrile rubber and natural rubber. The diagonal tire tread manufactured from the rubber base body composed of fluoroether rubber, butadiene-acrylonitrile rubber and natural rubber is adopted, compared with a tire tread mainl manufactured from solution polymerized styrene-butadiene rubber, high temperature resistance and deformation resistance of fluoroether rubber are reserved, the diagonal tire is suitable for the sedan car and capable of meeting requirement for different driving environments of people, and the service life of the tire can be prolonged.

Owner:SICHUAN YUANXING RUBBER

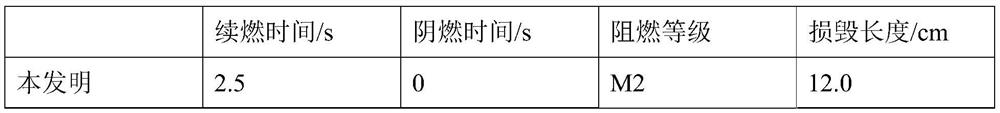

Dedicated membrane material for tent and preparation method thereof

ActiveCN109322167AFully plasticizedProtection against radiation agingTextiles and paperCoated surfaceZinc borate

The invention discloses a dedicated membrane material for a tent. The dedicated membrane material for the tent comprises base cloth, wherein the front and back of the base cloth are spread with firstcoatings, a back second coating is spread on the surface of the first coating on the back of the base cloth, a front second coating is spread on the surface of the first coating on the front of the base cloth, the front second coating comprises the following components in parts by weight: 100 parts of polyvinyl chloride resin, 50-60 parts of a plasticizer, 8-12 parts of tricresyl phosphate, 10-15parts of antimonous oxide, 5-10 parts of zinc borate, 0.7-0.8 part of an ultraviolet absorbent, 0.3-0.4 part of a mould inhibitor, and 2-4 parts of a stabilizer; surface layers with self-cleaning performance are spread on surfaces of the back second coating and the front second coating. The membrane material is compact in structure and has high self-cleaning performance. The invention further discloses a preparation method of the dedicated membrane material for the tent.

Owner:NINGBO TIANDUN WATERPROOF MATERIAL CO LTD

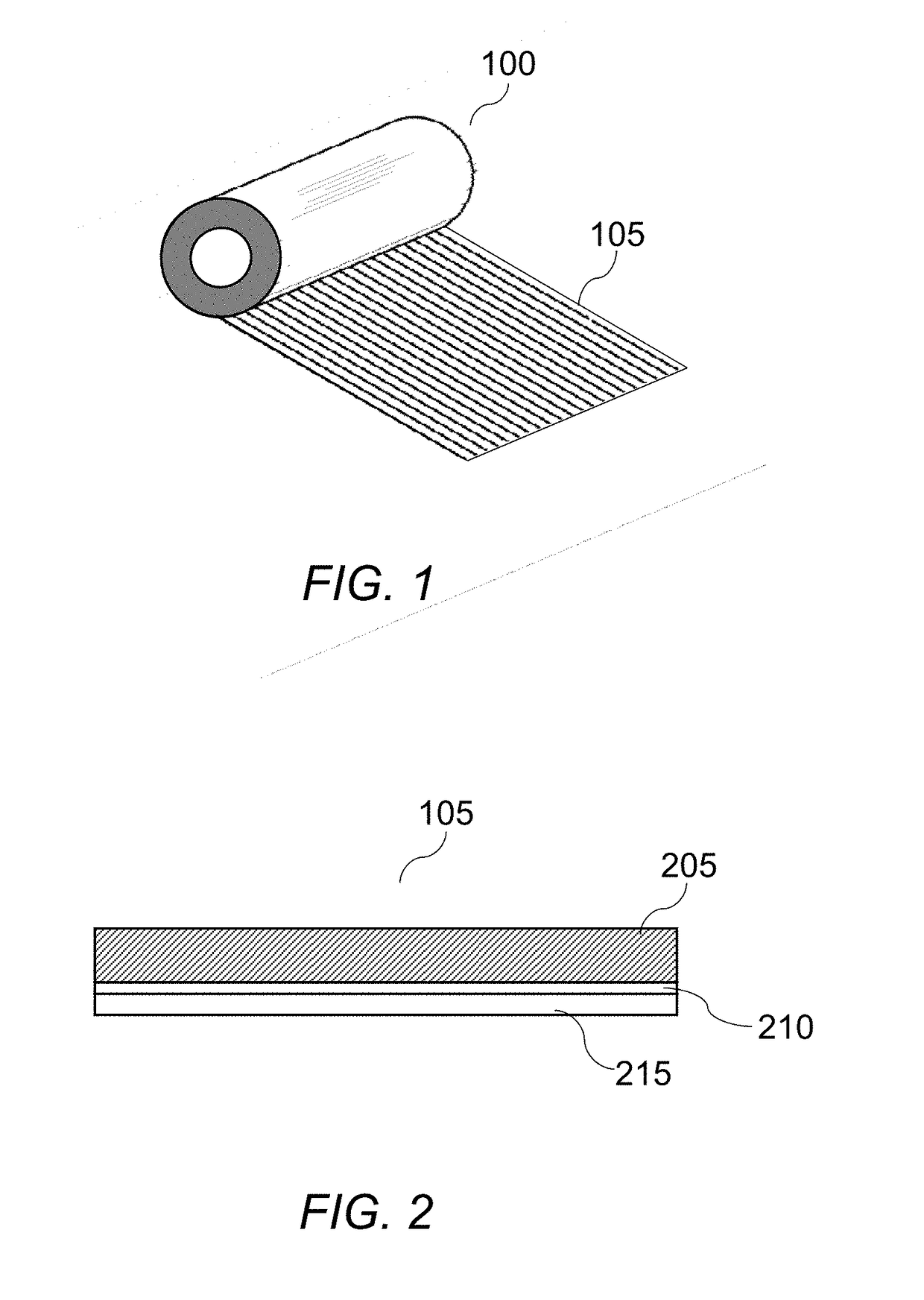

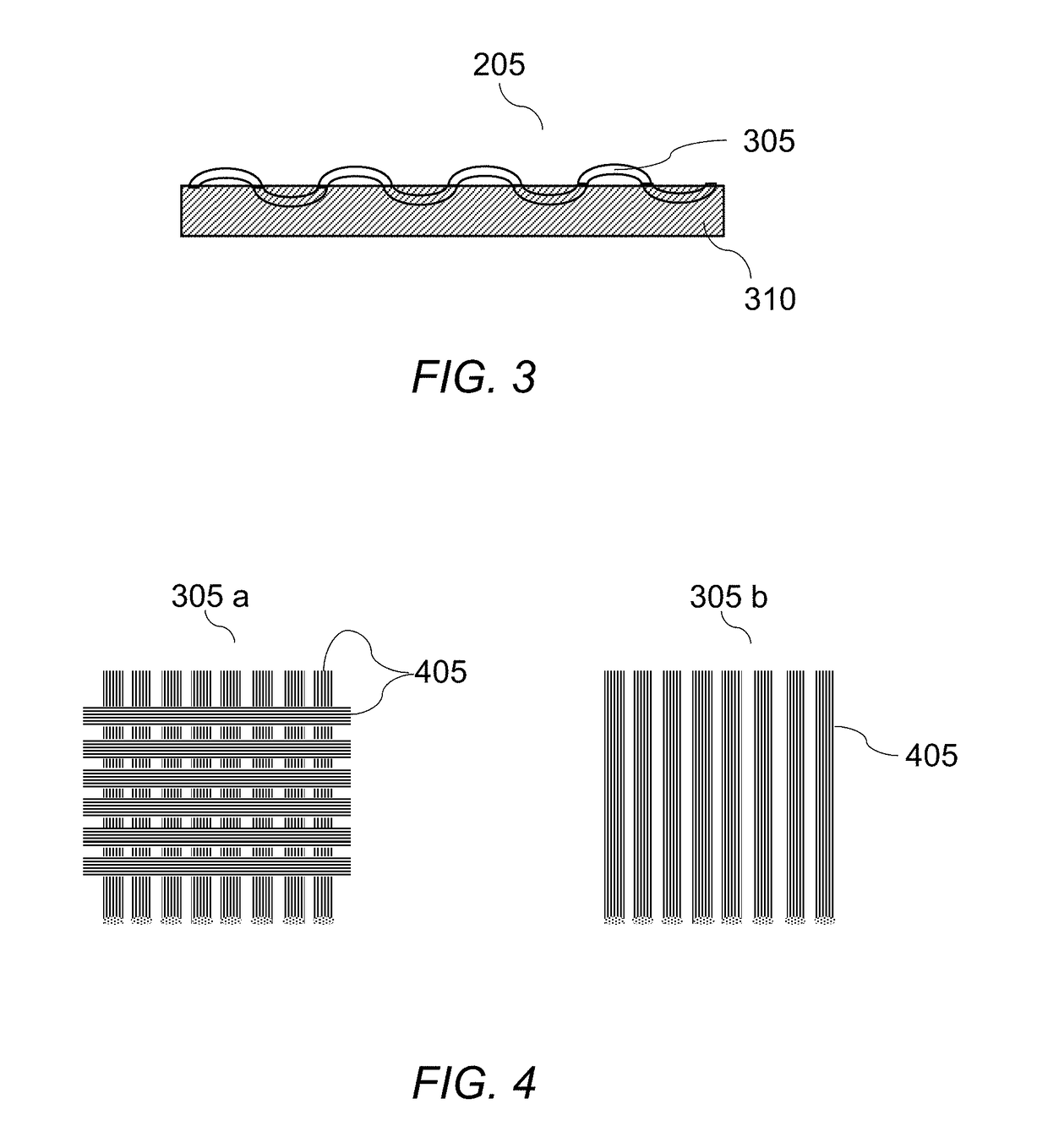

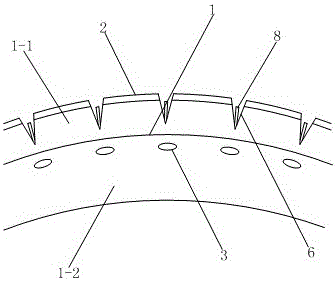

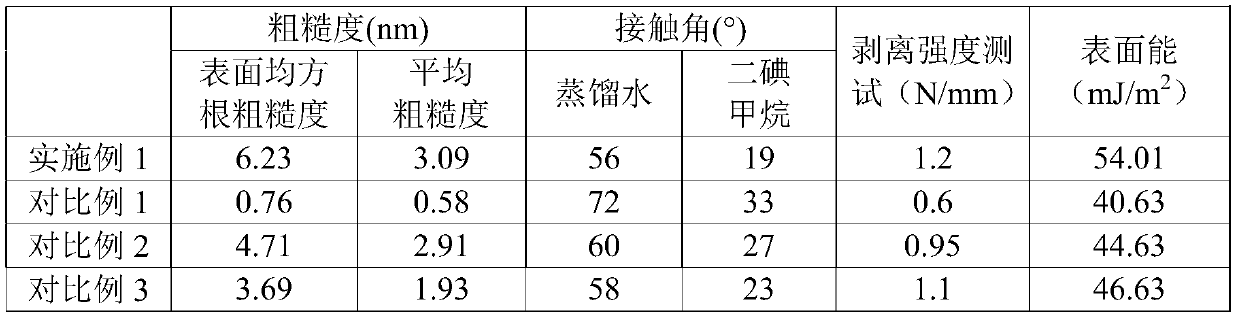

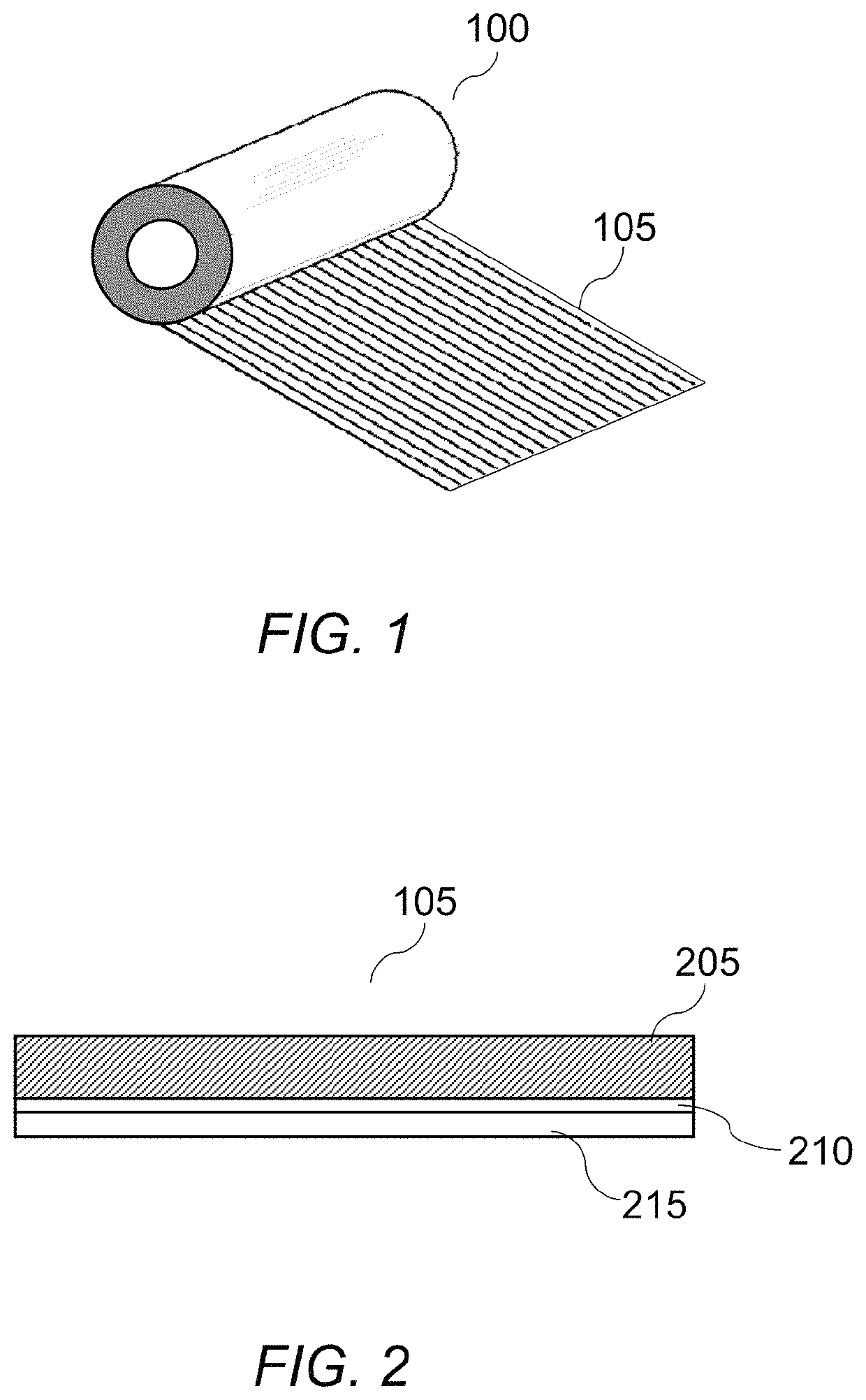

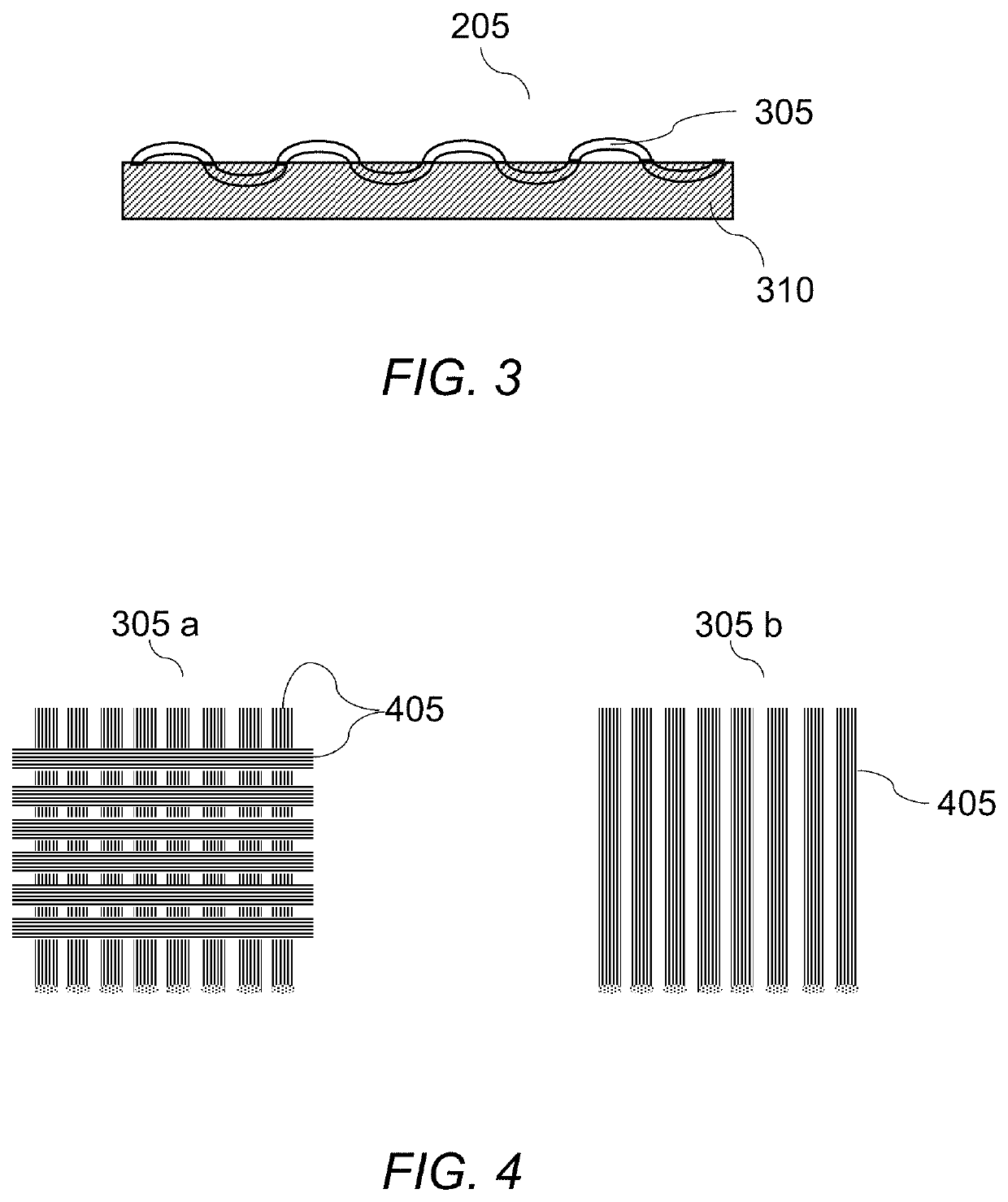

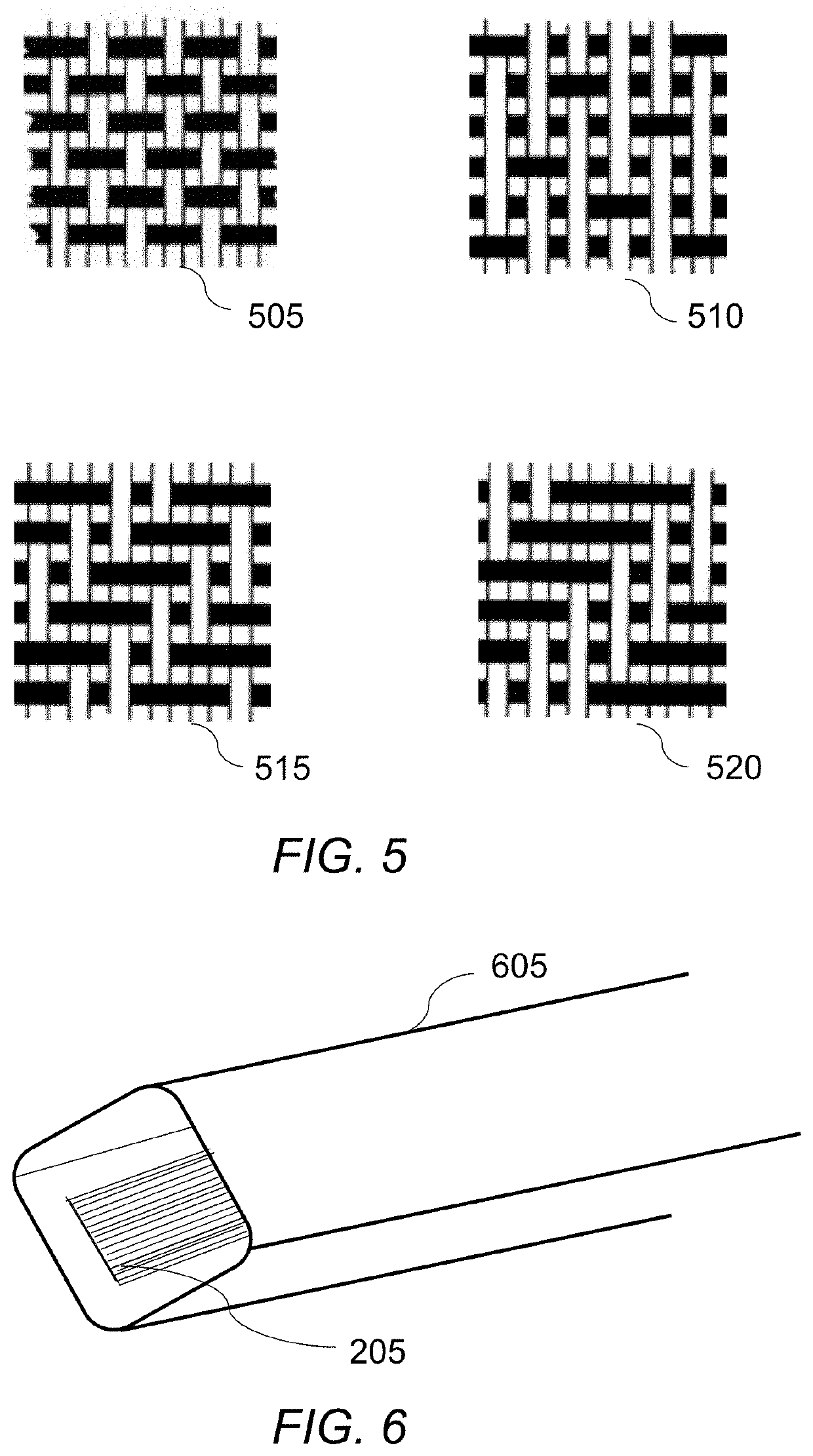

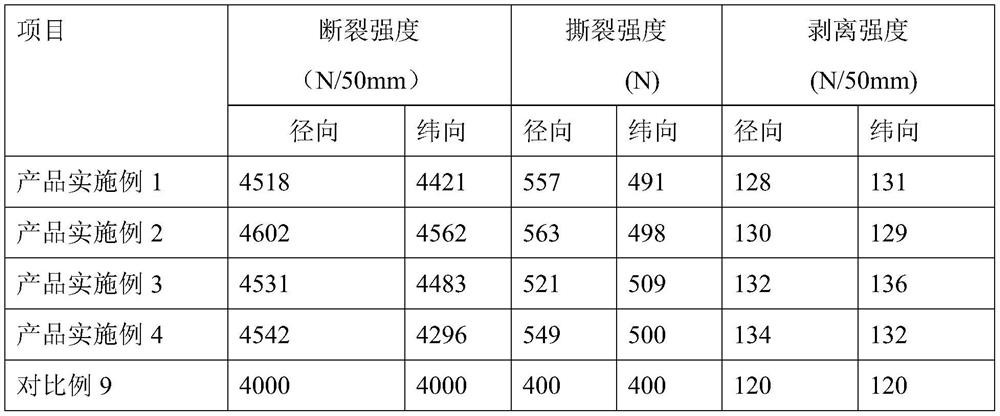

Preparation method of asymmetrically infiltrated high-collimation high-surface-viscosity fabric prepreg

The invention relates to the technical field of additive manufacturing, in particular to a preparation method of asymmetrically infiltrated high-collimation high-surface-viscosity fabric prepreg. In the preparation method, firstly, a continuous resin adhesive film is prepared, after a fabric is led into a prepreg compression roller gap, the fabric unwinding tension is adjusted and optimized by utilizing deviation angle feedback of an infrared tracing line and a fabric weft tracing line, so that the collimation of the fabric prepreg is ensured; the method comprises the following steps: firstly, preparing a fabric prepreg, further ensuring the quality of the fabric prepreg and enhancing the strength of the fabric prepreg, then introducing a resin adhesive film to the upper surface of the fabric, and simultaneously introducing release paper to the lower surface of the fabric, so that a combination of the resin adhesive film, the fabric and the release paper sequentially passes through a heating plate and a hot pressing roller to finish heating and hot pressing, thereby realizing preparation of the fabric prepreg by coating the adhesive film on a single surface. The non-infiltration area on the lower surface of the fabric prepreg is used for vacuum air guide, the requirement of a prepreg / vacuum bag forming process for the high air guide performance of the prepreg is met, and low-cost manufacturing of a high-performance composite material is achieved.

Owner:AVIC COMPOSITES

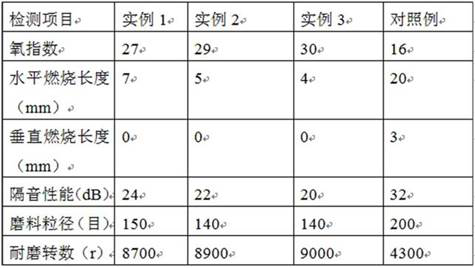

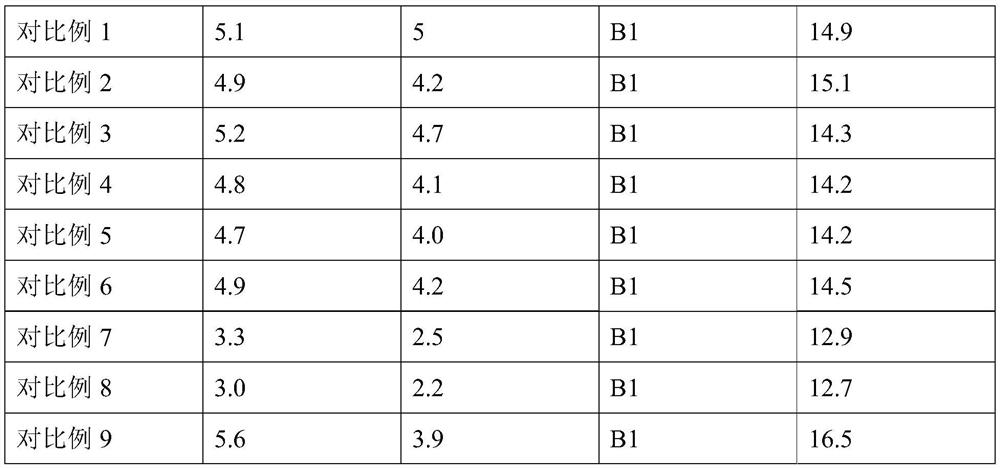

Sound absorbing, flame-retardant and flame-retardant wall cloth and preparation method thereof

PendingCN111648037AImprove wear resistanceImprove flame retardant performanceCovering/liningsFlame-proof filament manufactureMaterials preparationPolymer science

The invention relates to sound absorbing, flame-retardant and flame-retardant wall cloth and a preparation method thereof and belongs to the technical field of decorative material preparation. The preparation method comprises the following steps of preparing a flame-retardant wear-resistant self-made functional material by a high-temperature cooking and thermal oxidation method first; and then compounding the self-made functional material and modified polypropylene meltwater and carrying out spinning, traction and heat bonding to obtain a multifunctional environmental-friendly flame-retardantwall shell fabric. Magnesium oxide and zinc oxide formed by thermal oxidization have a flame retardant property to endow the wall cloth with a flame-retardant function, and friction is reduced by means of high mechanical strength of spherical nano silicon dioxide and rolling slippage thereamong and the inner frictional loss heat is reduced, so that the wear resistance of the wall cloth is furtherimproved. In addition, the heat bonded wall shell fabric after traction and spinning is loose and porous in structure and can resonate to consume energy so as to achieve a purpose of absorbing and emitting sounds in multiple layers. Compared with common wall cloth, the wall cloth not only is flame-retardant and wear-resistant, but also has a sound isolating and absorbing effect and is wide in application prospect.

Owner:泉州市鼎鑫丰泰建筑材料科技有限公司

High viscosity modified pi film

Owner:SUZHOU KECHUANG ELECTRONICS MATERIAL CO LTD

Article of thermosetting epoxy resin composition and carbon fibre fabric, and reinforced structural component made therewith

ActiveUS11161950B2Improve propertiesImprove surface adhesionPolyureas/polyurethane adhesivesSynthetic resin layered productsEpoxyPolymer science

The present invention relates to a self-adhesive article comprising a non-random fabric of bundles of carbon fibres and a thermosetting epoxy resin composition. The self-adhesive article exhibits high surface adhesion and excellent dimensional stability at room temperature. The self-adhesive article is ideally suited to reinforce structural components, particularly vehicles or ancillary vehicle components. The structural components reinforced by the self-adhesive article exhibit improved impact and torsional strength.

Owner:SIKA TECH AG

Tent special membrane

ActiveCN109322167BFully plasticizedProtection against radiation agingTextiles and paperCoated surfacePolymer science

The application of the present invention discloses a special film material for tents, which includes a base cloth, the front and back of the base cloth are coated with a first coating, the surface of the first coating on the back of the base cloth is coated with a second coating on the back, and the base cloth The surface of the first coating on the front is coated with the second coating on the front, and the second coating on the front is composed of the following components in parts by weight: 100 parts of polyvinyl chloride resin, 50-60 parts of plasticizer, tricresyl phosphate 8 to 12 parts, 10 to 15 parts of antimony trioxide, 5 to 10 parts of zinc borate, 0.7 to 0.8 parts of ultraviolet absorber, 0.3 to 0.4 parts of antifungal agent, 2 to 4 parts of stabilizer; the second coating on the back and The surface of the second coating on the front side is coated with a surface layer with self-cleaning performance. The above-mentioned membrane material has a dense structure and strong self-cleaning performance. The application of the present invention also discloses a preparation method of the above-mentioned tent special film material.

Owner:NINGBO TIANDUN WATERPROOF MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com