Device and method for atomizing turbulent agglomerated granules

A technology for agglomerating particles and particulate matter, which is applied in the field of industrial smoke dust particulate matter emission control, can solve the problems of complicated device and difficult promotion, and achieves the effects of convenient operation, low price and good agglomeration effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039]The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

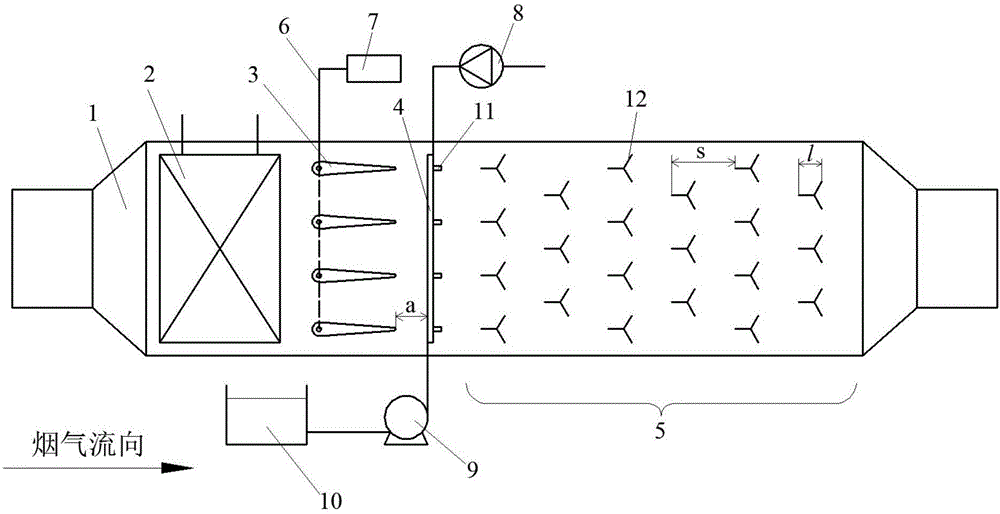

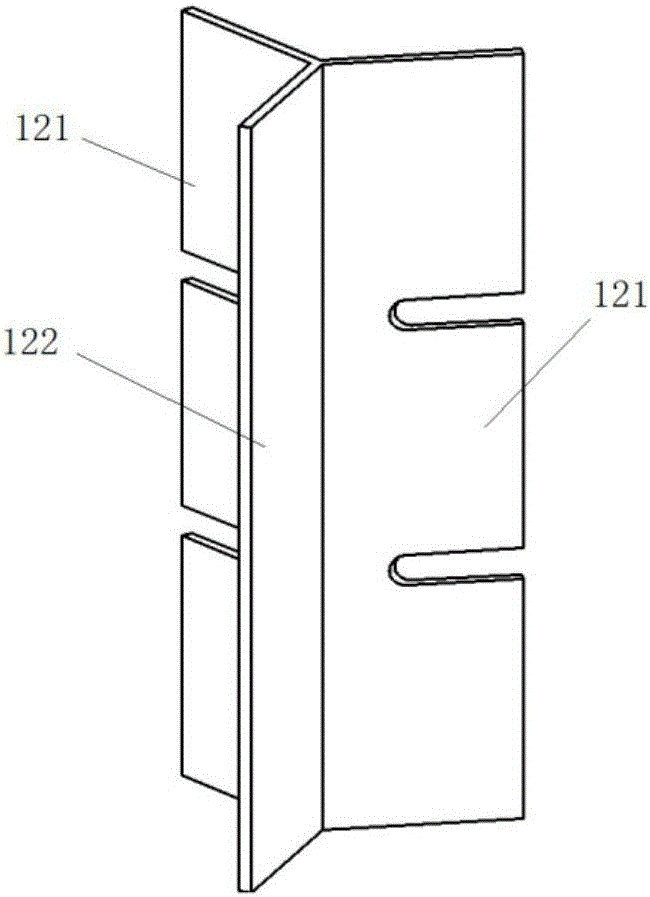

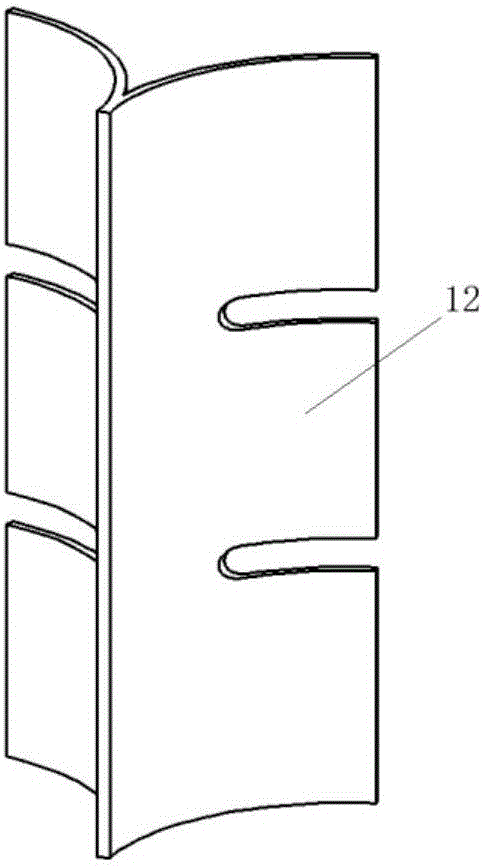

[0040] like figure 1 As shown, the main structure of the device of the present invention includes a housing 1 preferably with a rectangular cross-section, a flue gas heat exchanger 2 , guide vanes 3 , a two-fluid atomizing injection section 4 and a turbulent agglomeration section 5 . The flue gas heat exchanger 2 is a partitioned wall heat exchanger, and the pipes of the heat exchanger can be smooth round tubes or spiral finned tubes. The guide vanes 3 are multiple guide curved surfaces with a streamlined outer contour, and the guide curved surfaces can be rotated and adjusted, preferably fine-tuned, by the linkage control shaft 6 and the control motor 7 connected to the side of the flue of the housing 1 . The two-fluid atomizing injection section 4 includes an air supply pipeline for air sup...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com