Ball-milling wet-process mixing equipment for producing lithium battery negative electrode material precursor

A negative electrode material, wet mixing technology, applied in the direction of mixers, chemical instruments and methods, shaking/oscillating/vibrating mixers, etc., can solve the problems that are difficult to remove, have low impact and grinding effects, and adhere to the inner cylinder Inner surface and other problems, to achieve the effect of enhanced grinding quality, heavy impact and enhanced grinding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

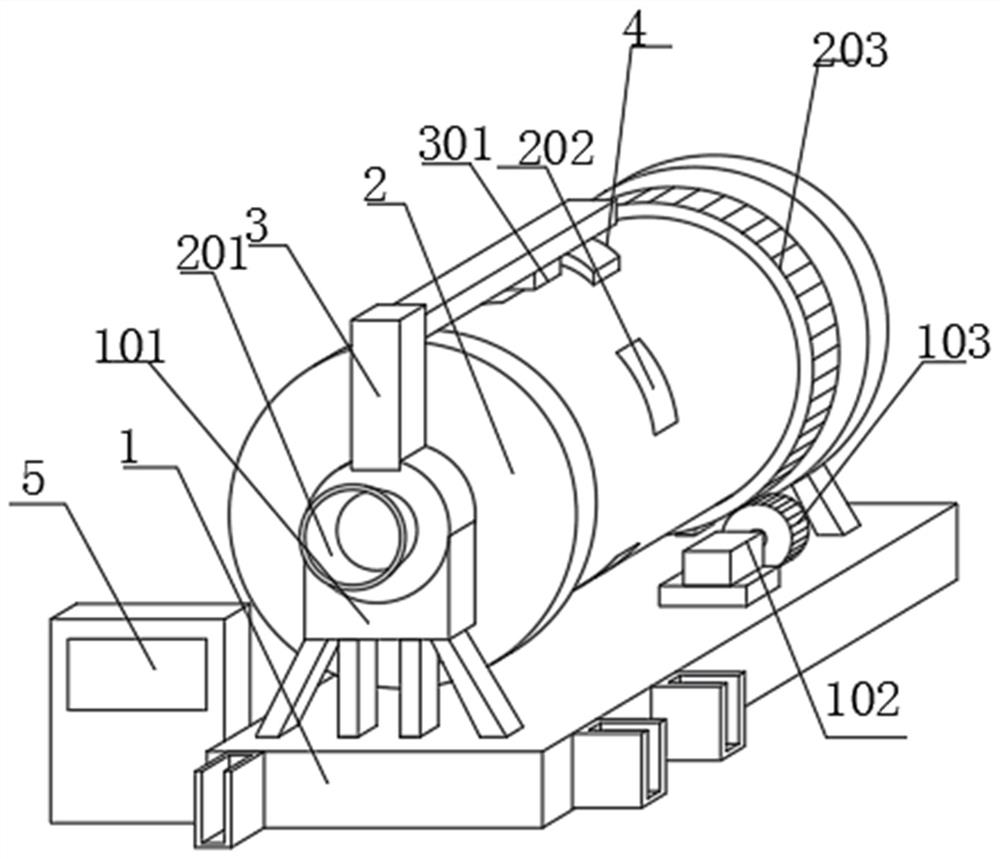

[0034] Such as Figure 1-5 As shown, a ball mill wet mixing equipment for the production of precursors of lithium battery negative electrode materials includes a support base plate (1), and a roller mechanism (2) is arranged above the support base plate (1). The roller mechanism (2) is a double Layer cylinder structure, the two ends of the roller mechanism (2) are rotatably connected with the connecting frame (3), the end of the connecting frame (3) is fixedly installed with the electromagnet (4), and the electromagnet (4) is located on the roller mechanism (2) Directly above the side of the support plate, a controller (5) is fixedly installed, and the controller (5) controls the intermittent power supply of the electromagnet (4).

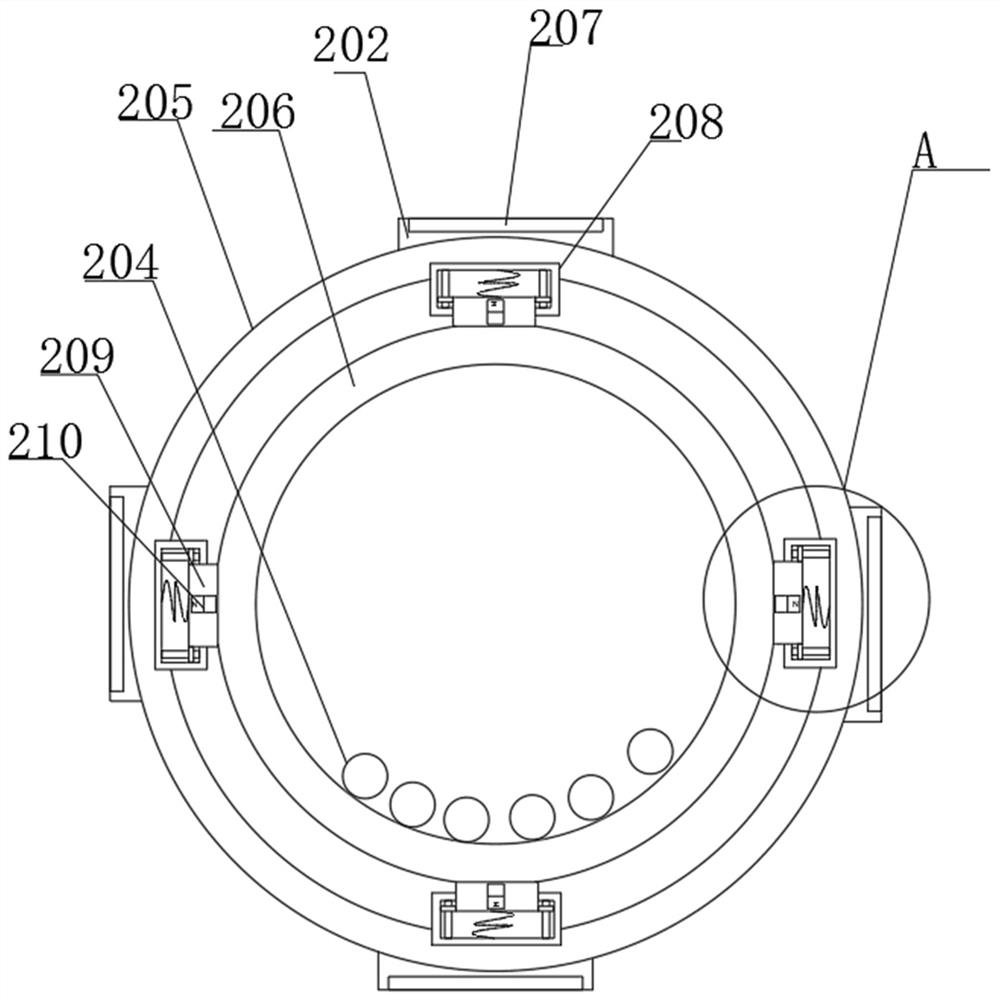

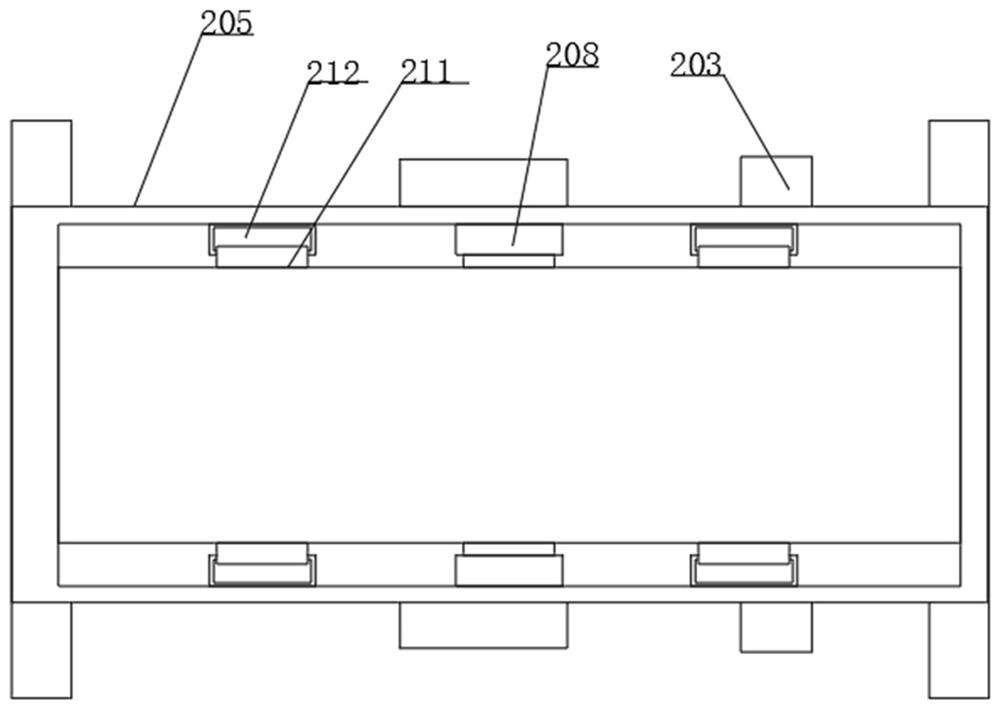

[0035] In this embodiment, the drum mechanism (2) includes an inner cylinder (206) located on the inside and an outer cylinder (205) located on the outside, and the input end of the inner cylinder (206) is provided with a raw material input port (2...

Embodiment 2

[0044] Such as Figure 1-5 As shown, a ball mill wet mixing equipment for the production of precursors of lithium battery negative electrode materials includes a support base plate (1), and a roller mechanism (2) is arranged above the support base plate (1). The roller mechanism (2) is a double Layer cylinder structure, the two ends of the roller mechanism (2) are rotatably connected with the connecting frame (3), the end of the connecting frame (3) is fixedly installed with the electromagnet (4), and the electromagnet (4) is located on the roller mechanism (2) Directly above the side of the support plate, a controller (5) is fixedly installed, and the controller (5) controls the intermittent power supply of the electromagnet (4).

[0045] In this embodiment, the drum mechanism (2) includes an inner cylinder (206) located on the inside and an outer cylinder (205) located on the outside, and the input end of the inner cylinder (206) is provided with a raw material input port (2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com