Patents

Literature

87results about How to "Fully plasticized" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hydrofluoropropene blowing agents for thermoplastics

InactiveUS20100112328A1Fully plasticizedLow densityOrganic chemistryOther chemical processesThermoplasticLow density

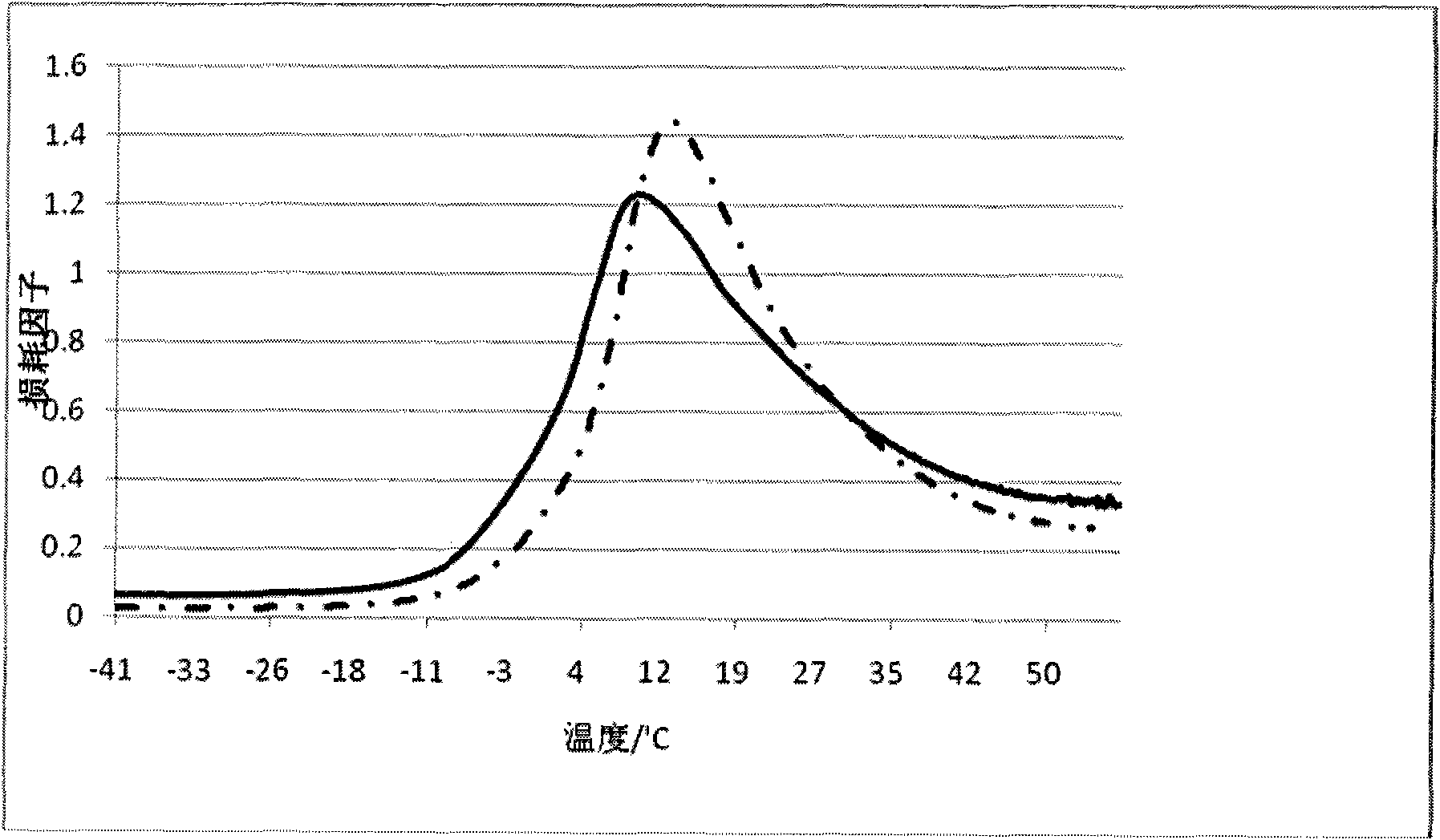

The present invention relates to blowing agent compositions comprising the unsaturated halogenated hydroolefin 3,3,3-trifluoropropene (HFO 1243zf) and combinations including primarily 3,3,3-trifluoropropene (HFO 1243zf). The blowing agent compositions are useful in that they provide sufficient plasticization to permit the production of low density insulating thermoplastic foams with improved k-factor.

Owner:ARKEMA INC

Production method of filled masterbatch formed through plasticization

The invention relates to a production method of a filled masterbatch formed through plasticization. The filled masterbatch is composed of the following components in parts by weight: 5 to 16 parts of carrier resin, 3 to 8 parts of dispersant, 75 to 90 parts of inorganic filler, and 0.5 to 2 parts of surface-active agent. The production method comprises the following steps: stirring and mixing carrier resin and dispersants at a high speed, extruding and granulating the mixture of the carrier resin and dispersants by a co-rotating twin screw extrusion machine, and considering the mixture of the carrier resin and the dispersants as a standby material; stirring and mixing inorganic fillers, the surface-active agent and the standby material at a high speed, discharging and breaking the mixture of the inorganic fillers, the surface-active agent and the standby material, extruding and granulating the mixture of the inorganic fillers, the surface-active agent and the standby material by a co-rotating twin screw extrusion machine with the slenderness ratio: 32 to 48, cooling, and screening, finally obtaining the filled masterbatch. The packed masterbatch made through the production method is good in plasticization, the dispersion effect of the inorganic fillers is good, the whiteness is high, the requirement to the equipment is low, the energy consumption is low, and the yield is high.

Owner:HECHANG GUANGXI CHEM

Hydrofluoropropene blowing agents for thermoplastics

ActiveUS8648123B2Fully plasticizedLow densityLayered productsHalogenated hydrocarbon preparationThermoplasticLow density

The present invention relates to blowing agent compositions comprising the unsaturated halogenated hydroolefin 3,3,3-trifluoropropene (HFO 1243zf) and combinations including primarily 3,3,3-trifluoropropene (HFO 1243zf). The blowing agent compositions are useful in that they provide sufficient plasticization to permit the production of low density insulating thermoplastic foams with improved k-factor.

Owner:ARKEMA INC

Organotin leadless sectional materials

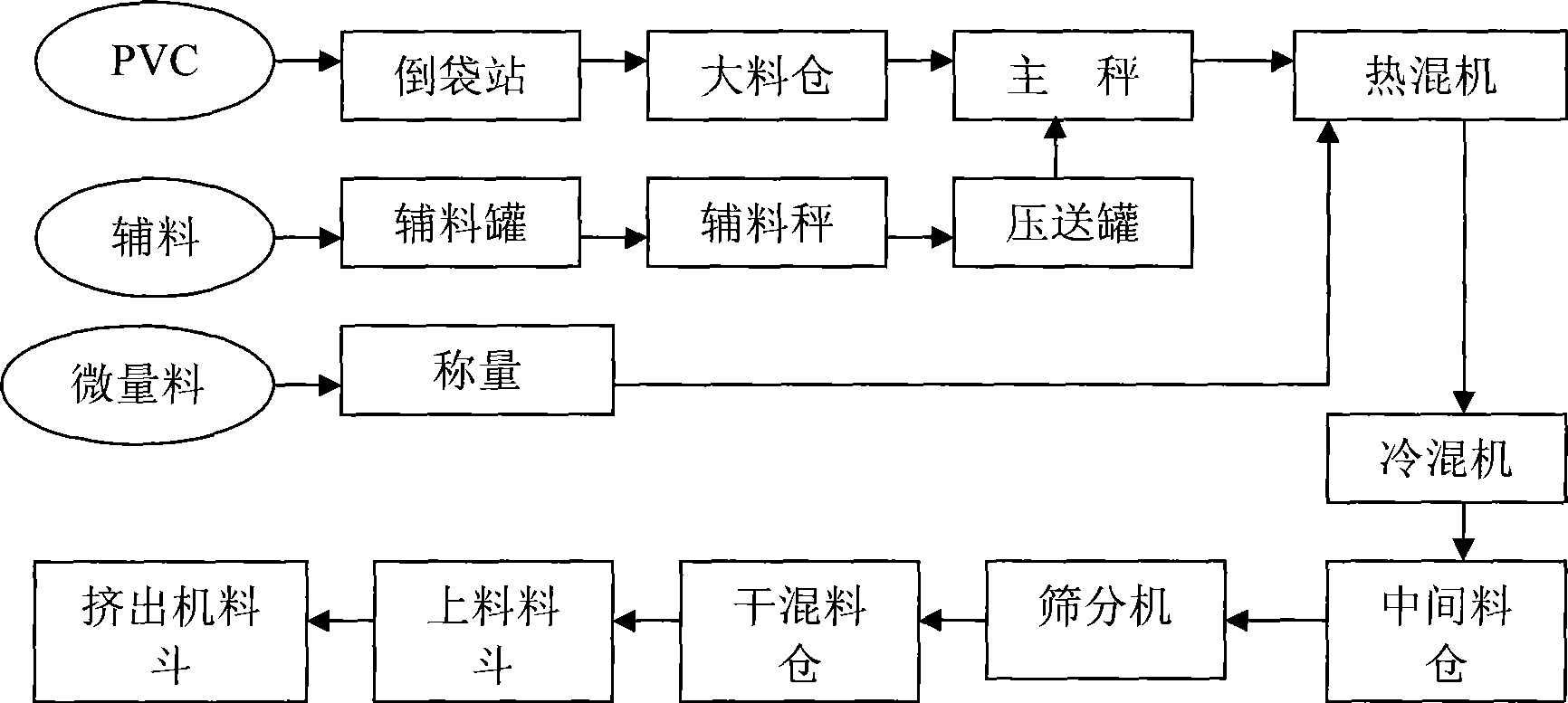

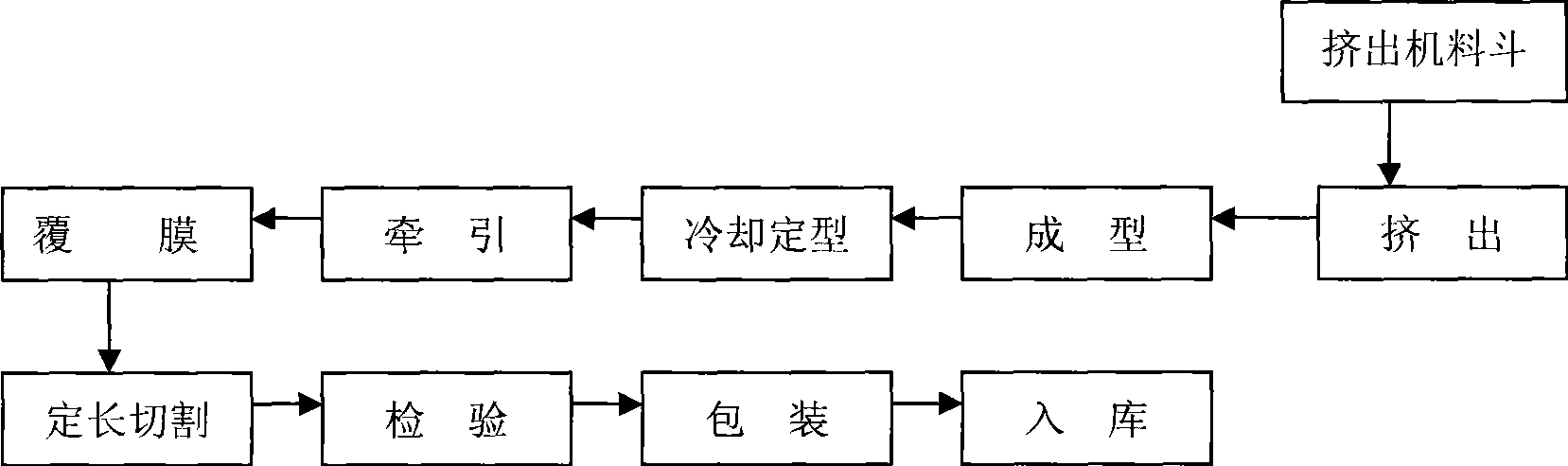

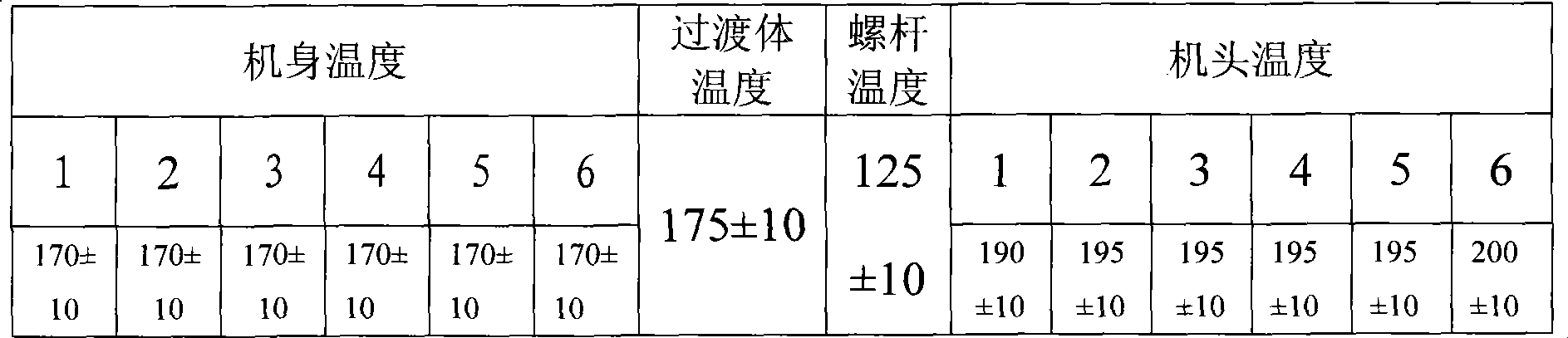

The invention relates to an organotin lead-free proximate matter which consists of the following matters (counted in weight portions): 100 portions of polyvinyl chloride, 1.3 to 1.5 portions of organotin stabilizing agents; 8 to 10 portions of titanium pigment, 8 to 10 portions of Haloflex, 1.3 to 1.5 portions of ACR processing modifiers; 2.0 to 29 portions of compound wax-hard calcium lubricating systems. After being counted according to a prescription, the matters are firstly processed into a mixture, and then the mixture is extruded to be the proximate matters by a double screw extruder. The proximate matter has the advantages of uniform and mild color, good impacting performance and high fillet intensity after a door and a window are assembled; besides, the output rate is high and completely accords with or exceeds the standard demands of GB / T8814-2004. The organotin stabilizing agent which is corresponding to the drinking water quality policy paper of the world health organization in particular completely abandons a lead salt stabilizing agent and thoroughly realizes free of lead.

Owner:XIAN GAOKE BUILDING MATERIALS TECH

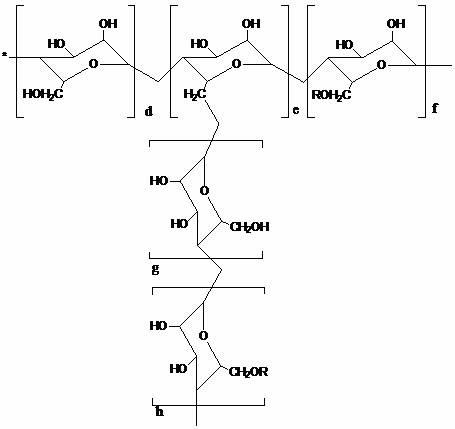

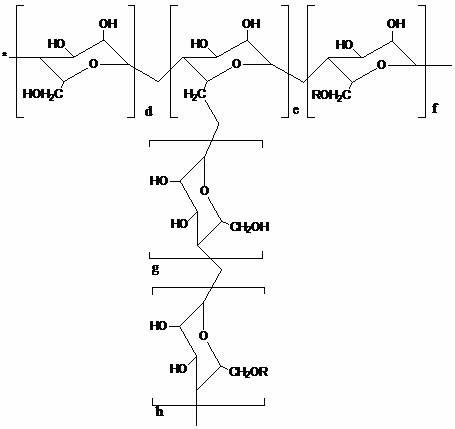

Dry-type fused water-soluble biodegradable film and preparation method thereof

The invention relates to a dry-type fused water-soluble biodegradable film and a preparation method thereof. The main formula components in the film comprise poval and starch. In the preparation method, the poval is subjected to pre-plasticization processing so as to reduce the melting point of the poval, so that the poval is not subjected to decomposition in a temperature interval in the process of co-extrusion, materials maintain required flowability and shearing force, the expected mixing speed and evenly mixing degree are achieved, and finally, a molecule-grade interpenetrating network formed between the starch and the poval is obtained; and on the other hand, the entire plasticization of the starch and the poval is finally obtained through changing the production process and equipment, thereby achieving poval dry fused granulation on a two-screw extruder and processing of a single-layer or multi-layer film product on special film-blowing equipment and completing industrial production. The film has a wide application range, can be used in pesticides, fertilizers, pigments, garden nursing chemical reagents and the like, and also can be used as vegetable seed and plant bags and clothes or food packaging bags.

Owner:ZHUHAI BIOGER BIOTECH

Hydrofluoropropene blowing agents for thermoplastics

ActiveUS20120108688A1Fully plasticizedLow densityOrganic chemistryOther chemical processesThermoplasticLow density

The present invention relates to blowing agent compositions comprising the unsaturated halogenated hydroolefin 3,3,3-trifluoropropene (HFO 1243zf) and combinations including primarily 3,3,3-trifluoropropene (HFO 1243zf). The blowing agent compositions are useful in that they provide sufficient plasticization to permit the production of low density insulating thermoplastic foams with improved k-factor.

Owner:ARKEMA INC

Nano high-air-tightness compressive film and preparation method thereof

The invention discloses a nanometer high-air-tightness compressive film, which consists of the following components: PVC (Polyvinyl Chloride) resin, DOP (Dioctyl Phthalate), DBP (Dibutyl Phthalate), DCHP (Dicyclohexyl Phthalate), a stabilizer, modified nanometer kaolin, calcium carbonate and other aids. The nanometer high-air-tightness compressive film is prepared by performing a calendaring process, an attaching process, a cooling step and a coiling step on each component. The nanometer high-air-tightness compressive film has the advantages that: a DOP-DBP-DCHP compound plasticizer is adopted, so that PVC resin is fully plasticized; the DCHP plays a role in plasticizing, and contributes to making a PVC film structure denser and enhancing the air tightness of the compressive film; the air tightness of the compressive is further improved by adopting the modified nanometer kaolin, and superior physical and mechanical performance of the compressive film is achieved simultaneously; and high-strength industrial polyester screen cloth is taken as an intermediate reinforcing material, so that compressive film provided by the invention has extremely high compressive strength.

Owner:FUJIAN SIJIA ENVIRONMENTAL PROTECTION MATERIAL TECH

Modified PVC (Polyvinyl Chloride) cable material of high-temperature high-moisture resistant sensor and preparation method of modified PVC cable material

InactiveCN107739485ASufficient sourceLow pricePlastic/resin/waxes insulatorsAcrylic resinAntimony trioxide

The invention discloses a modified PVC (Polyvinyl Chloride) cable material of a high-temperature high-moisture resistant sensor and a preparation method of the modified PVC cable material. The PVC cable material is mainly prepared from the following raw materials in parts by weight: 80-120 parts of a PVC resin, 30-60 parts of a thermal-resistant plasticizer, 3-8 parts of a calcium-zinc stabilizer,5-10 parts of coarse whiting, 3-9 parts of calcined kaolin, 3-6 parts of a composite flame retardant, 0.5-2 parts of an acrylic resin and 0.2-1 part of a comprehensive internal and external lubricant, wherein the PVC resin is polyvinyl chloride of which the polymerization degree is within 1800-2000; the thermal-resistant plasticizer is a trioctyl trimellitate plasticizer; and the composite flameretardant is prepared from antimonous oxide and magnesium hydrate through compounding. The modified PVC cable material is capable of meeting national standards of China and customer use requirements,also has the advantages of low cost, high production efficiency and good stability, can be processed into components normally, and is applicable to wide popularization and application.

Owner:王秀云

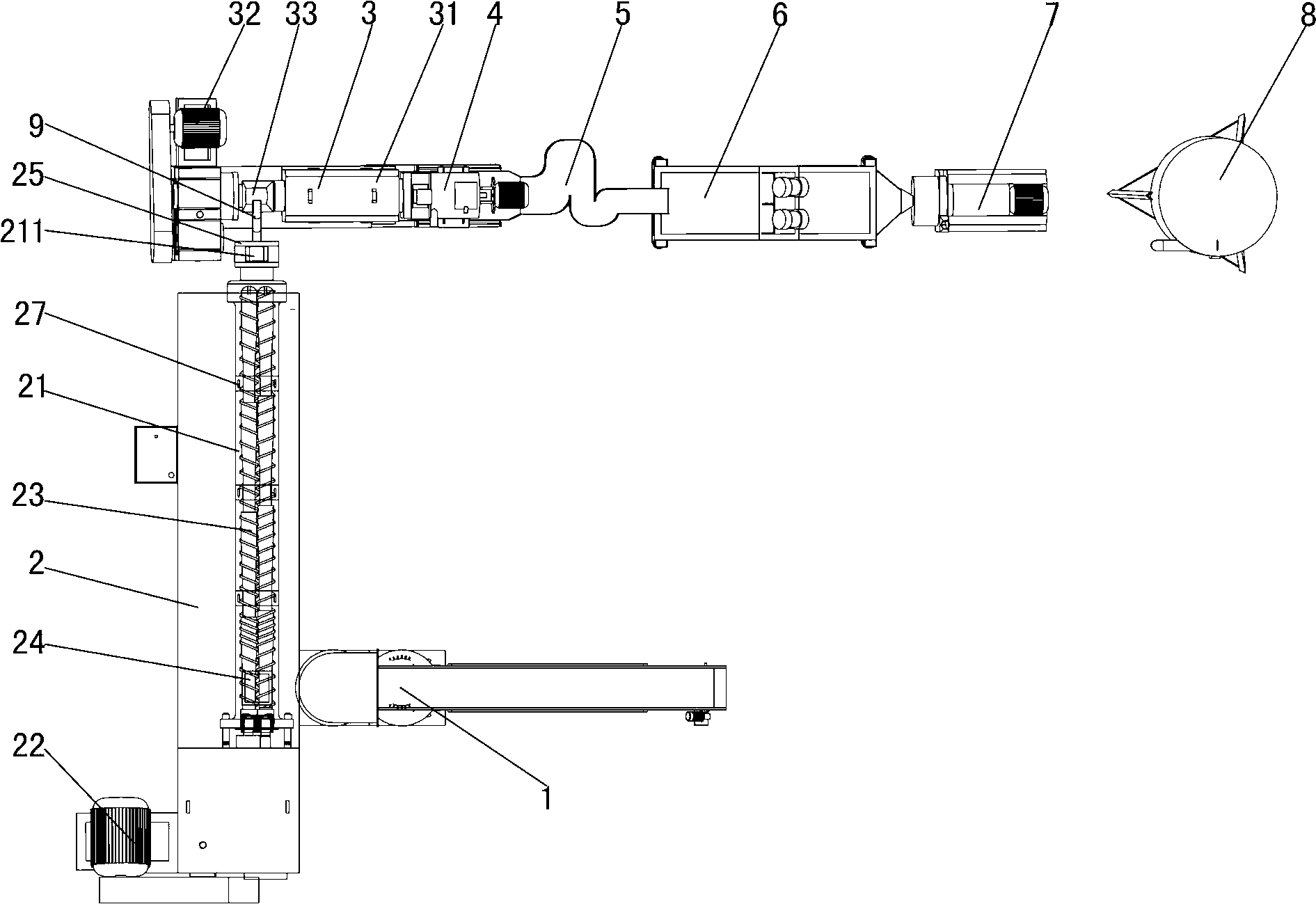

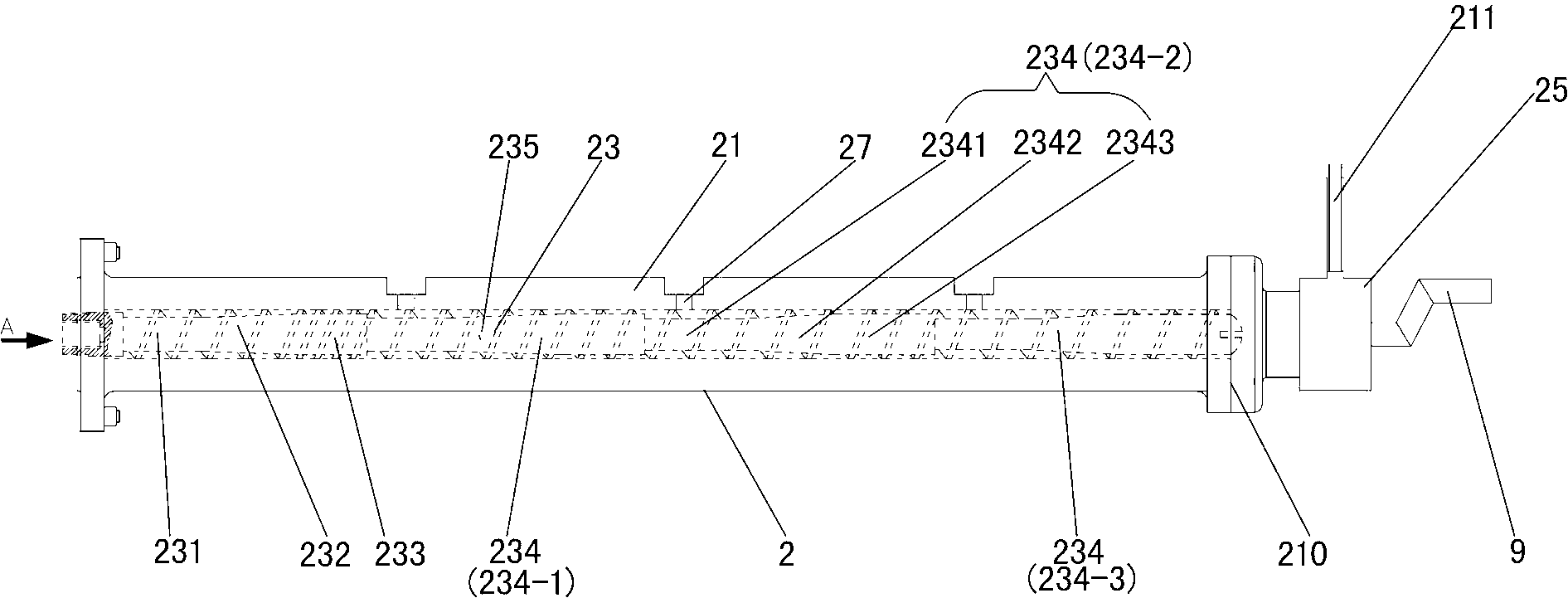

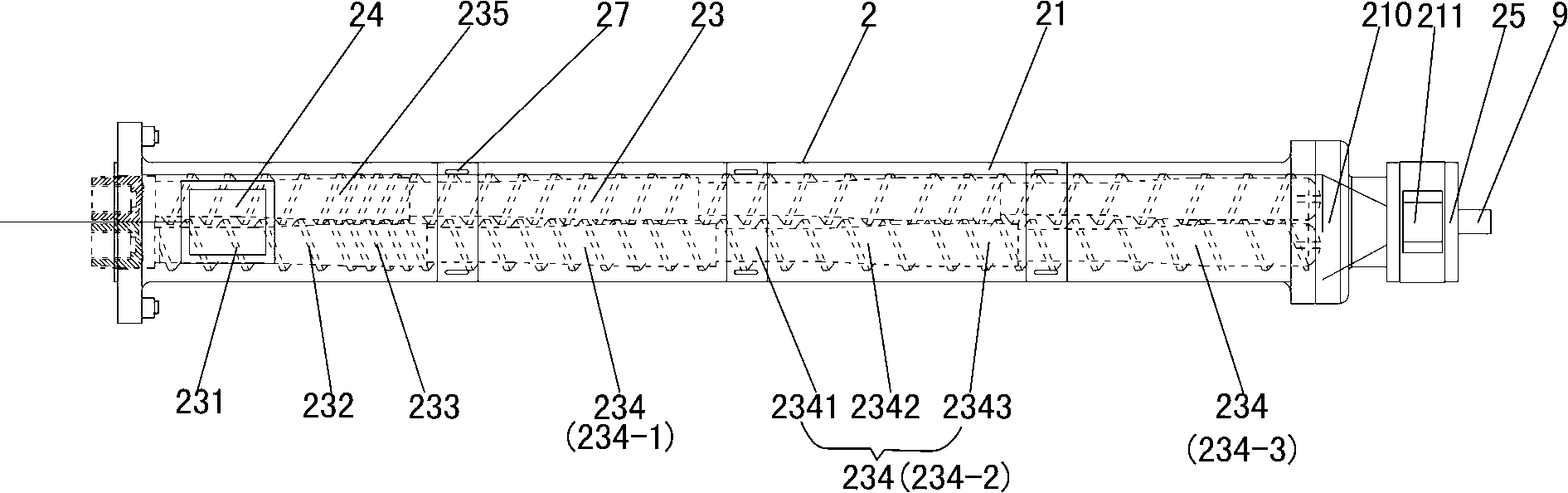

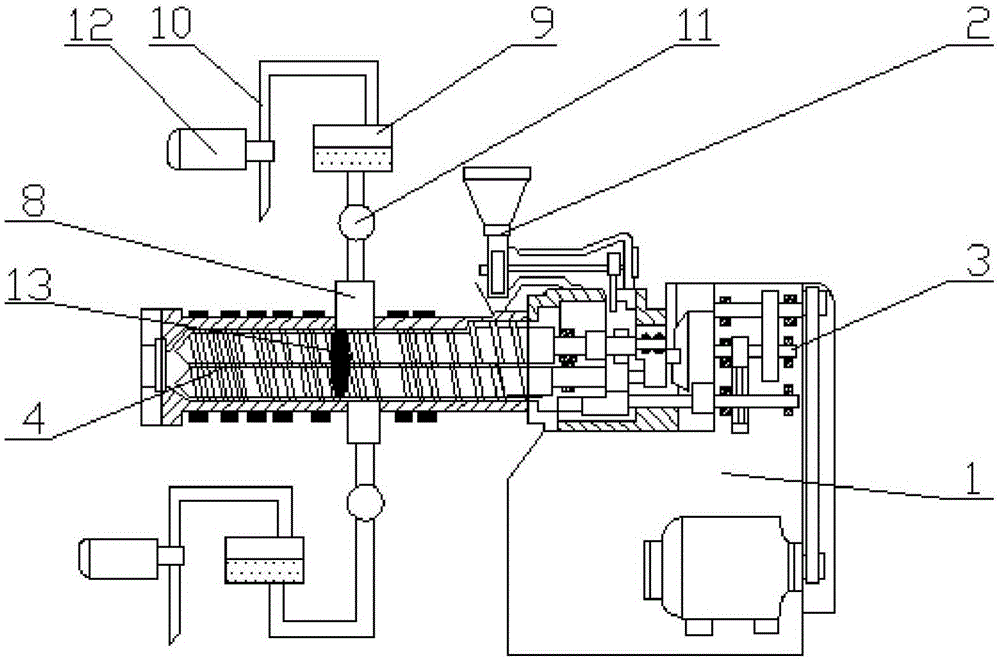

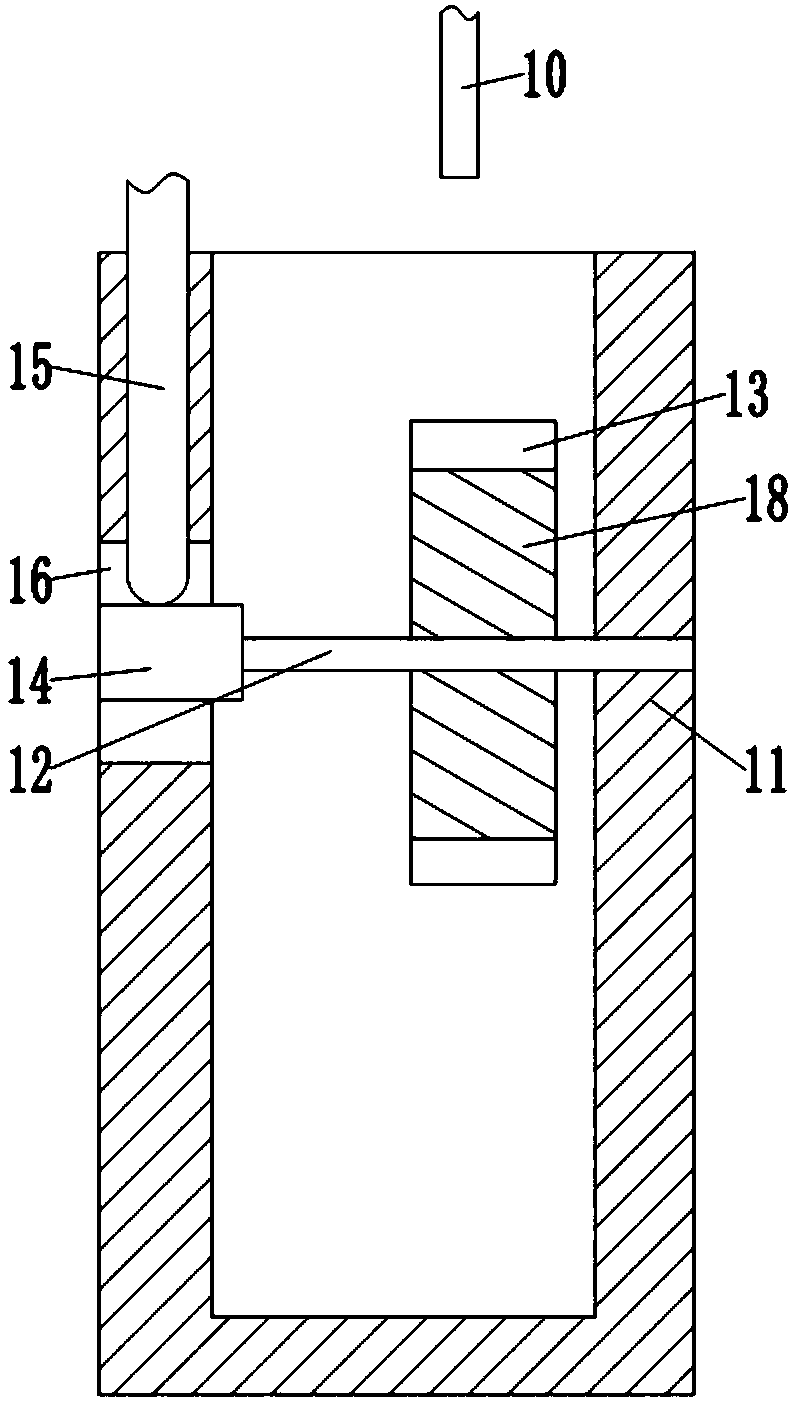

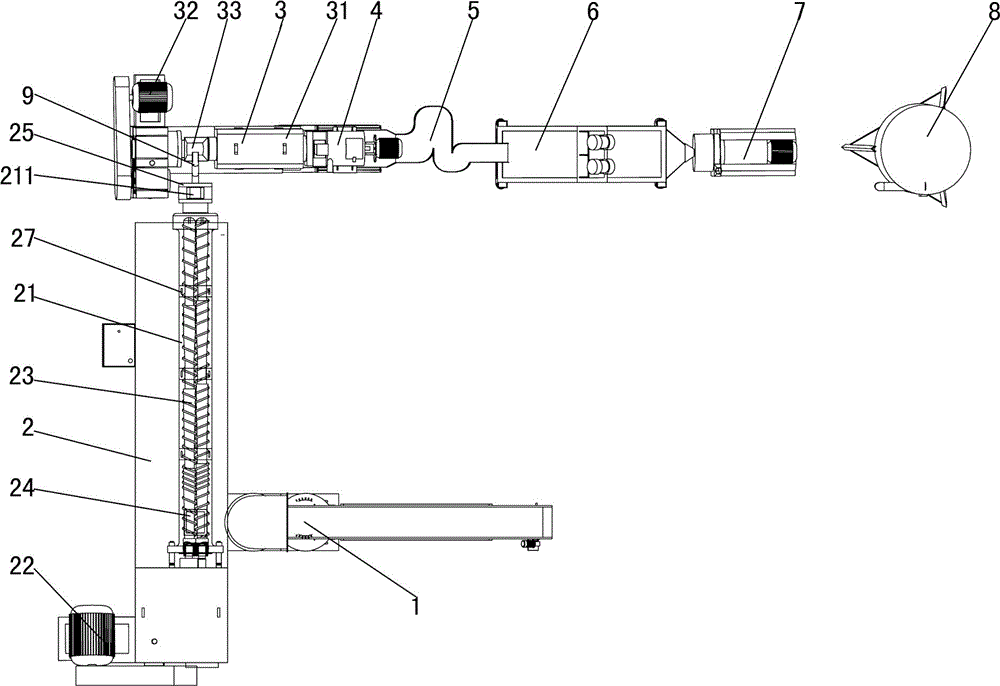

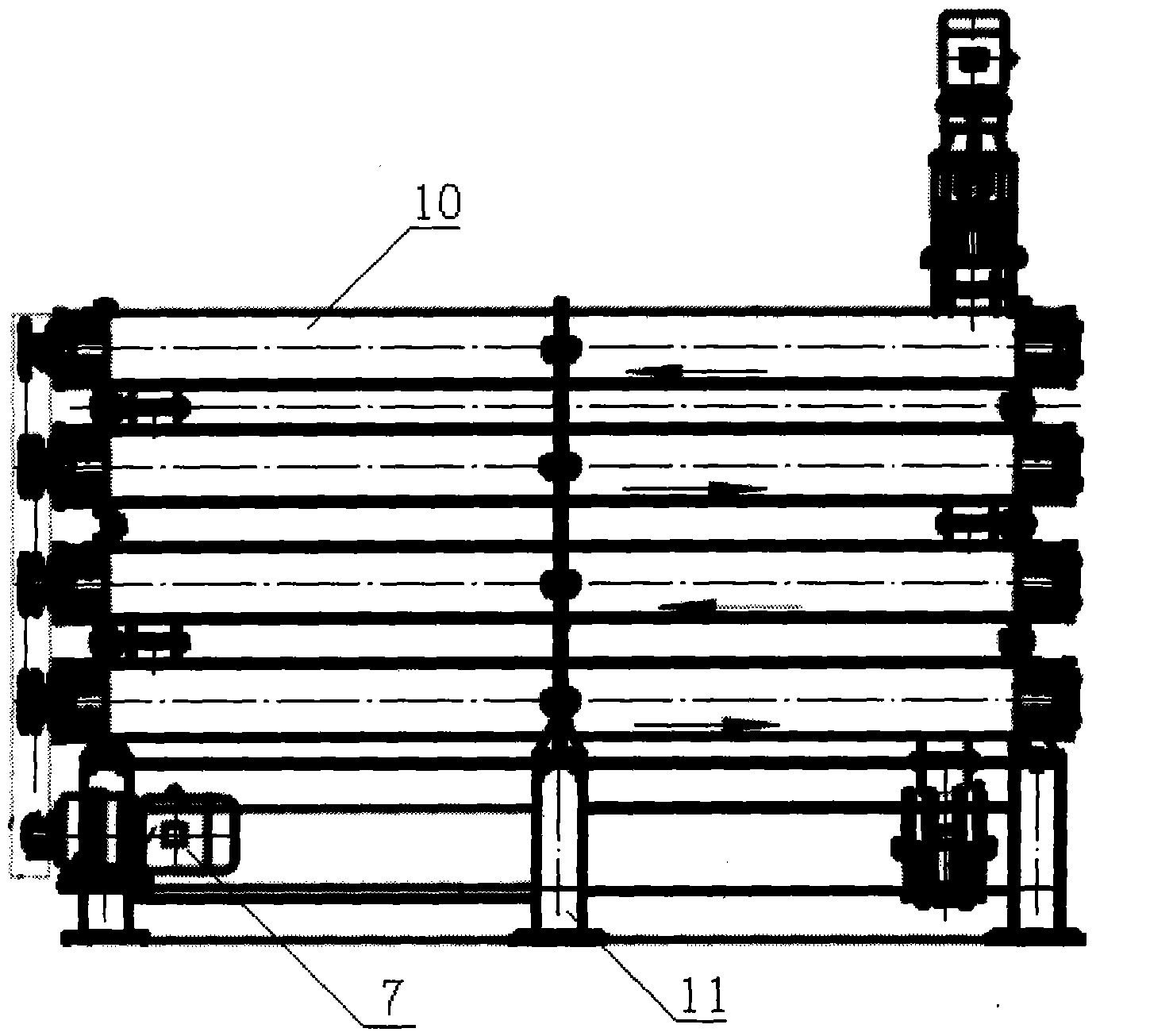

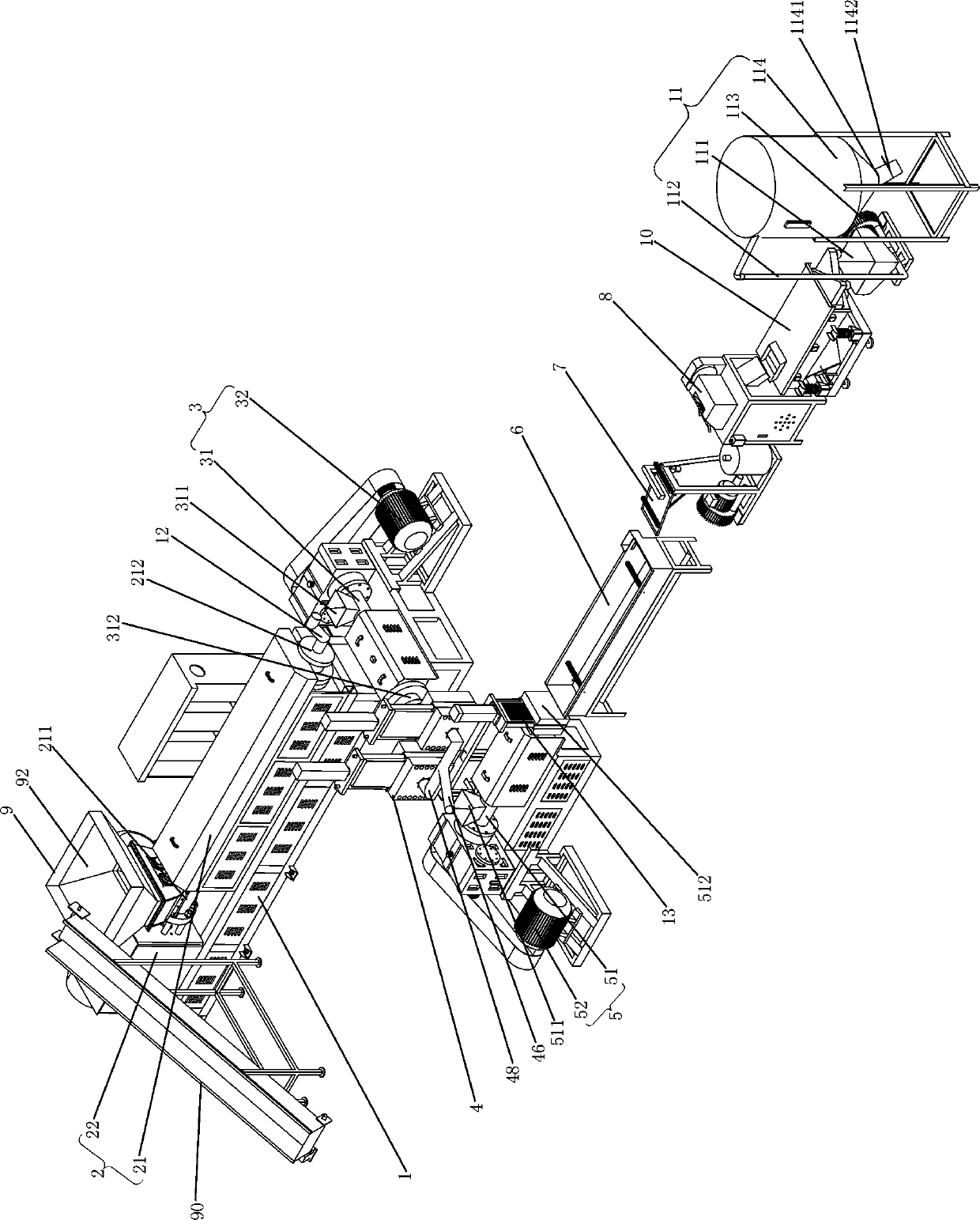

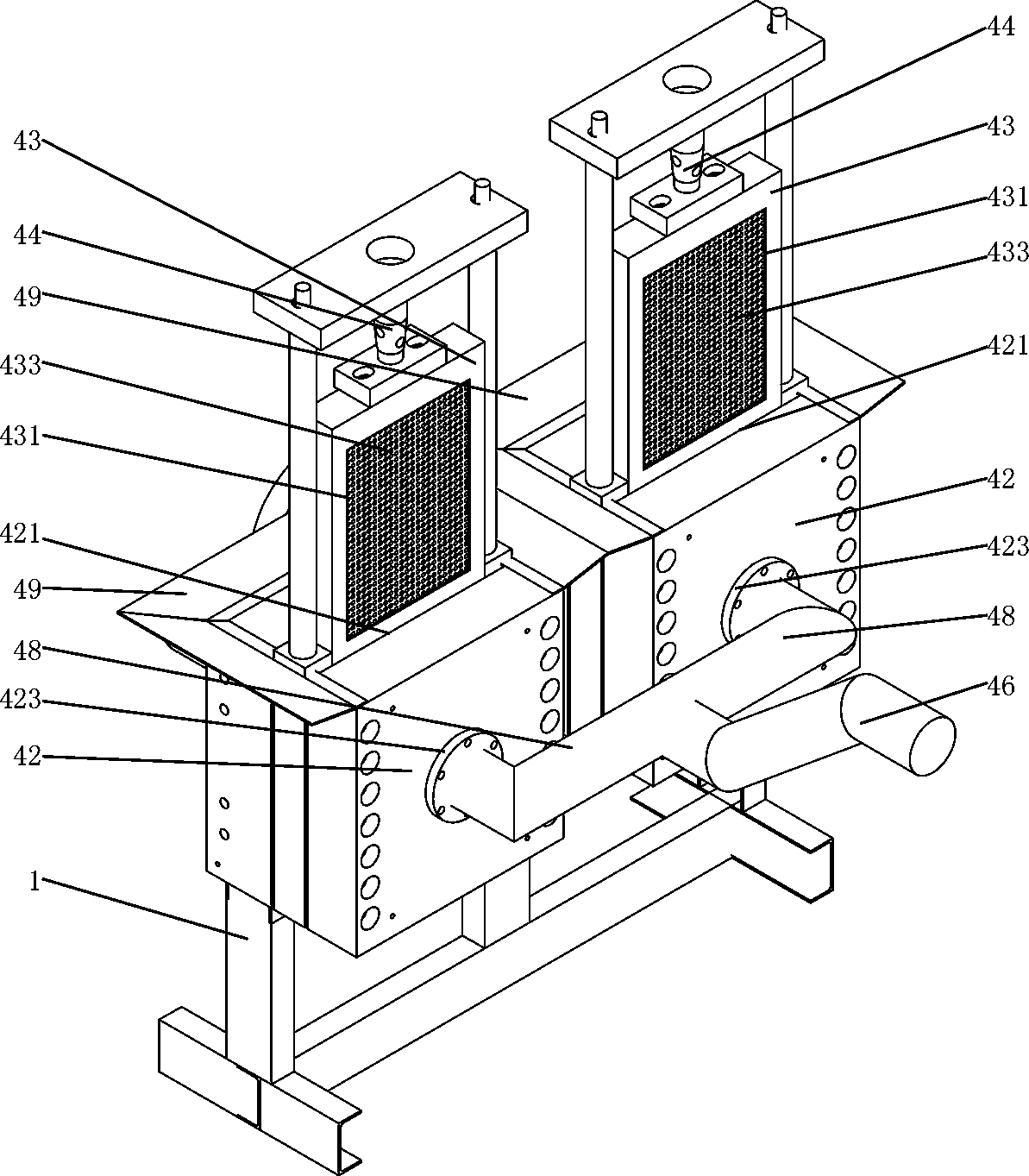

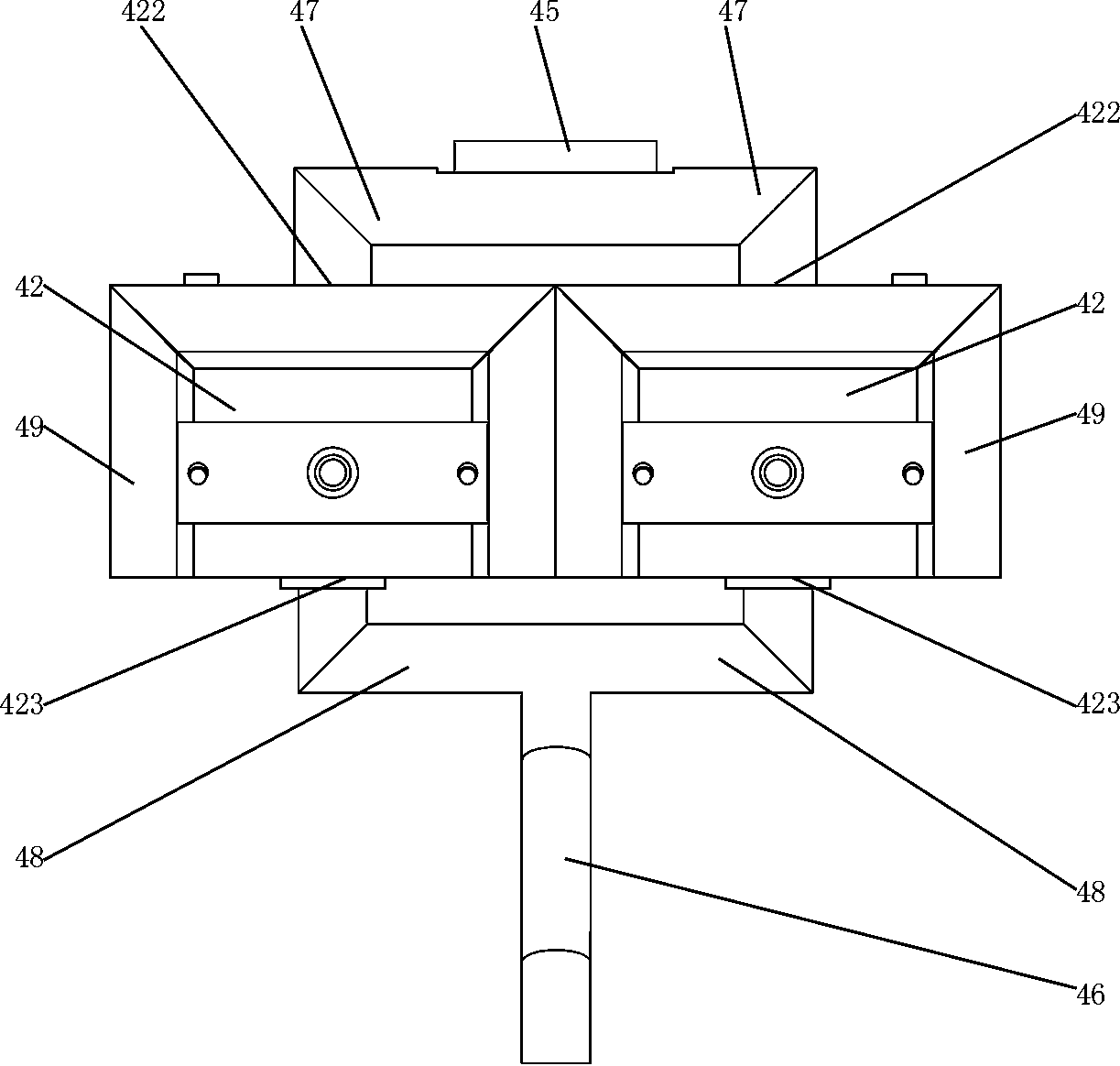

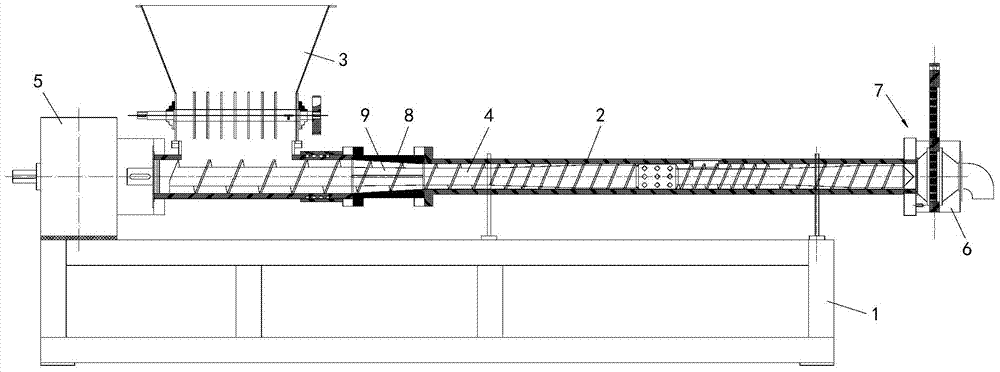

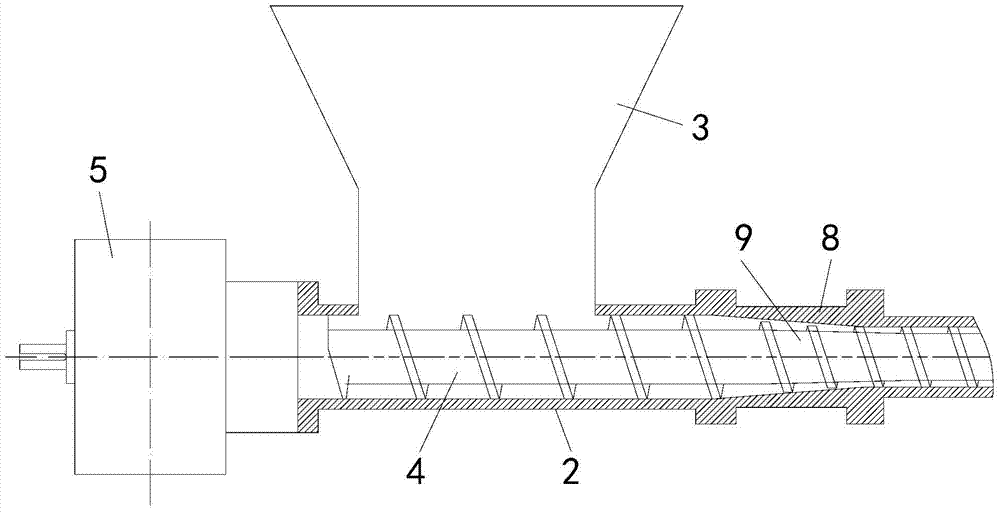

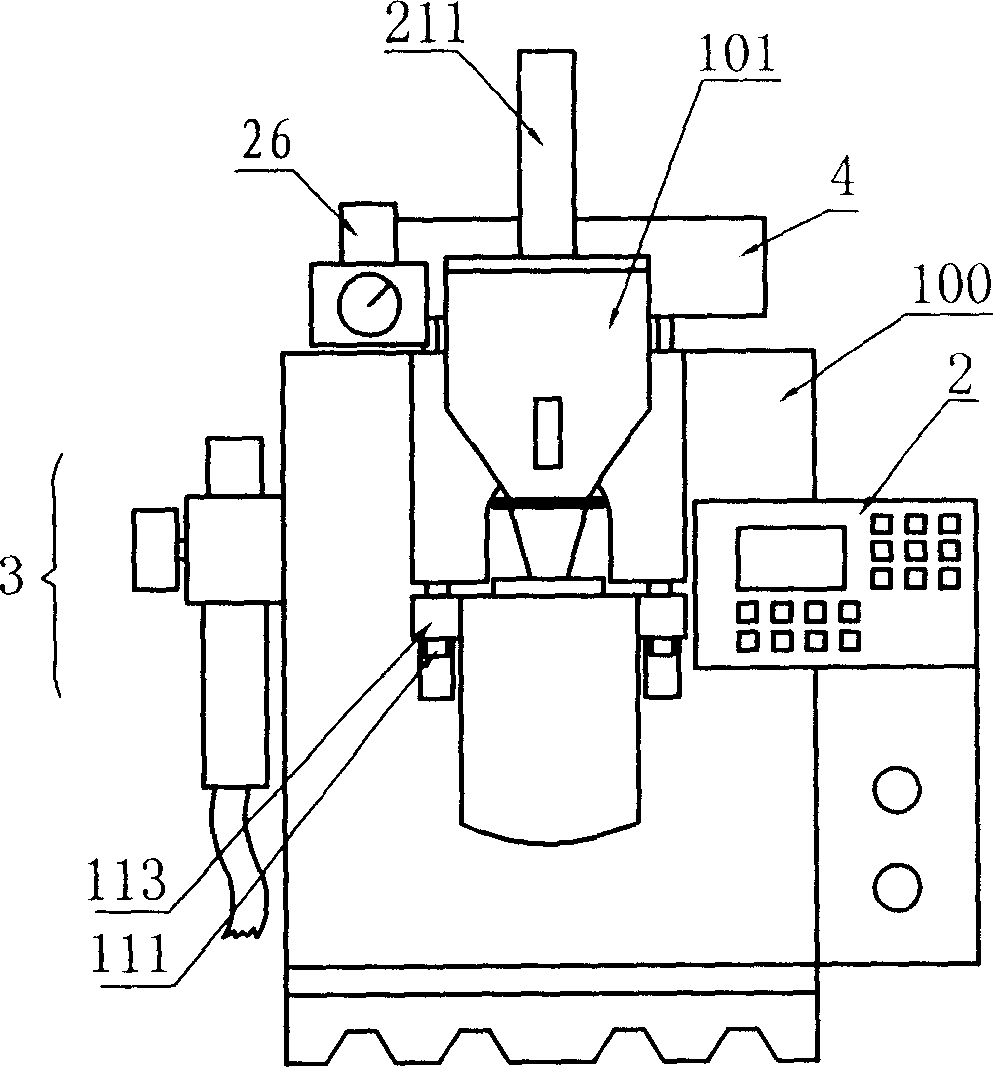

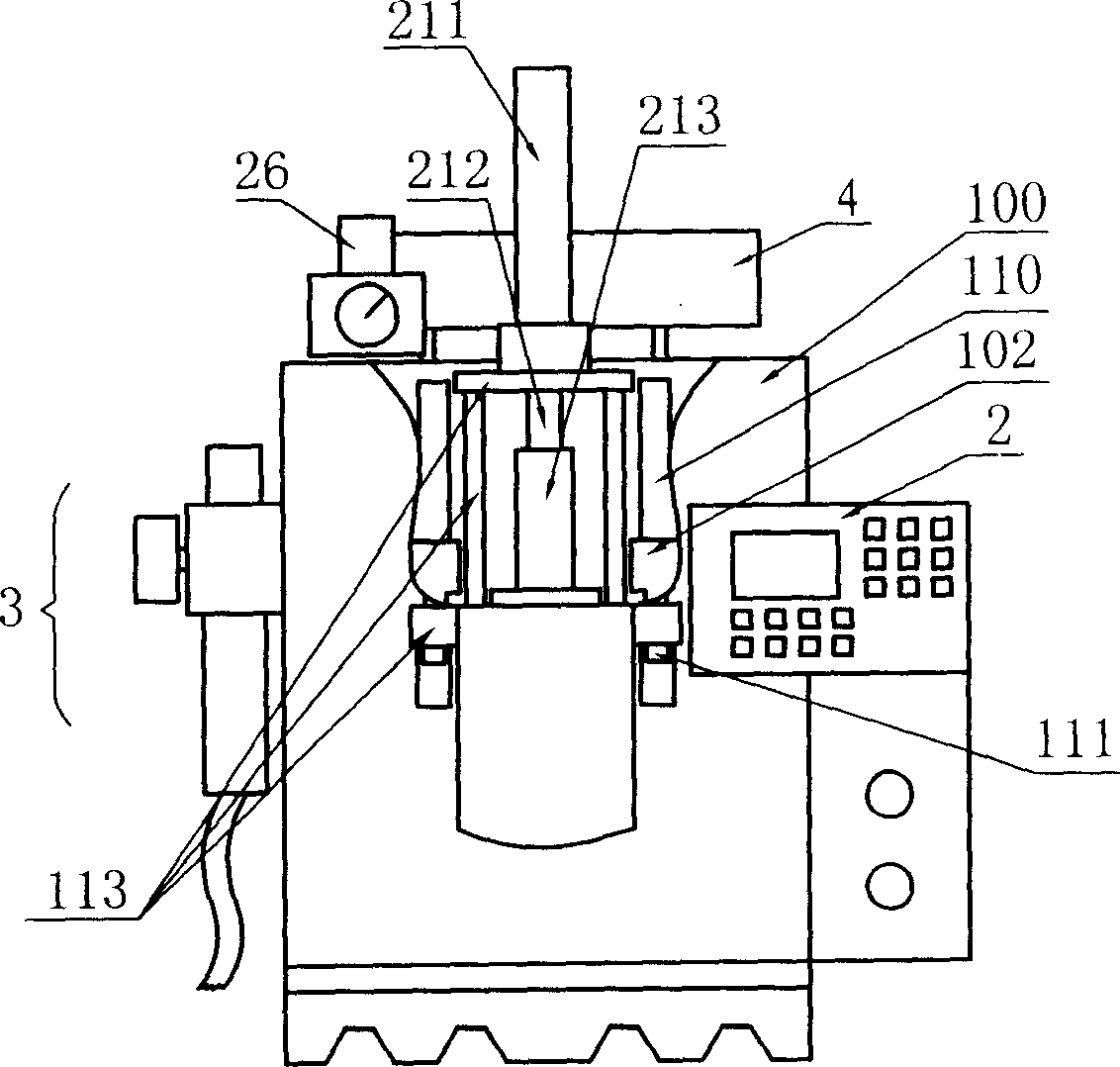

Plastic extrusion granulating unit

ActiveCN103286878ASmooth feedingExcellent performancePelletizingElectrical and Electronics engineering

The invention discloses a plastic extrusion granulating unit which is characterized by comprising a main extruder, a second extruder and a granulating device, wherein the main extruder comprises a main charging barrel and a main driving device; two main screw rods which rotate in different directions are arranged in the main charging barrel, and have opposite thread directions and are meshed with each other; the two main screw rods are in transmission connection with the main driving device; a main feeding hole is formed in the front end of the main charging barrel; a main die head is connected to the rear end of the main charging barrel; the second extruder comprises a second charging barrel and a second driving device; a second screw rod is arranged in the second charging barrel and is in transmission connection with the second driving device; a second feeding hole capable of receiving materials extruded by the main die head is formed in the front end of the second charging barrel; the rear end of the second charging barrel is connected with a second die head; the granulating device corresponds to the position of the second die head. The plastic extrusion granulating unit is smooth in feeding, the recovered plastics can be fully plastified, and plastic granules with good performance are prepared.

Owner:汕头市富达塑料机械有限公司

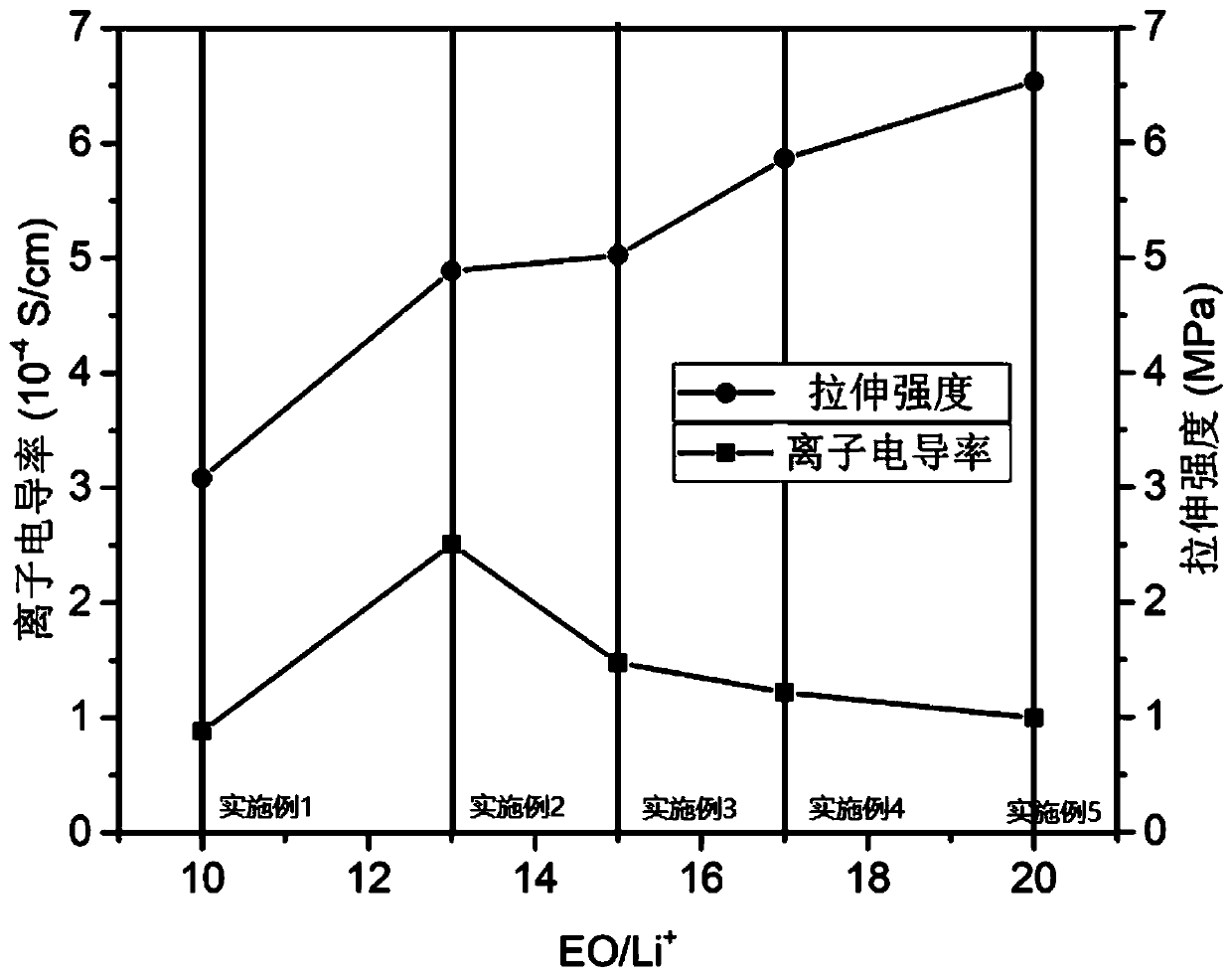

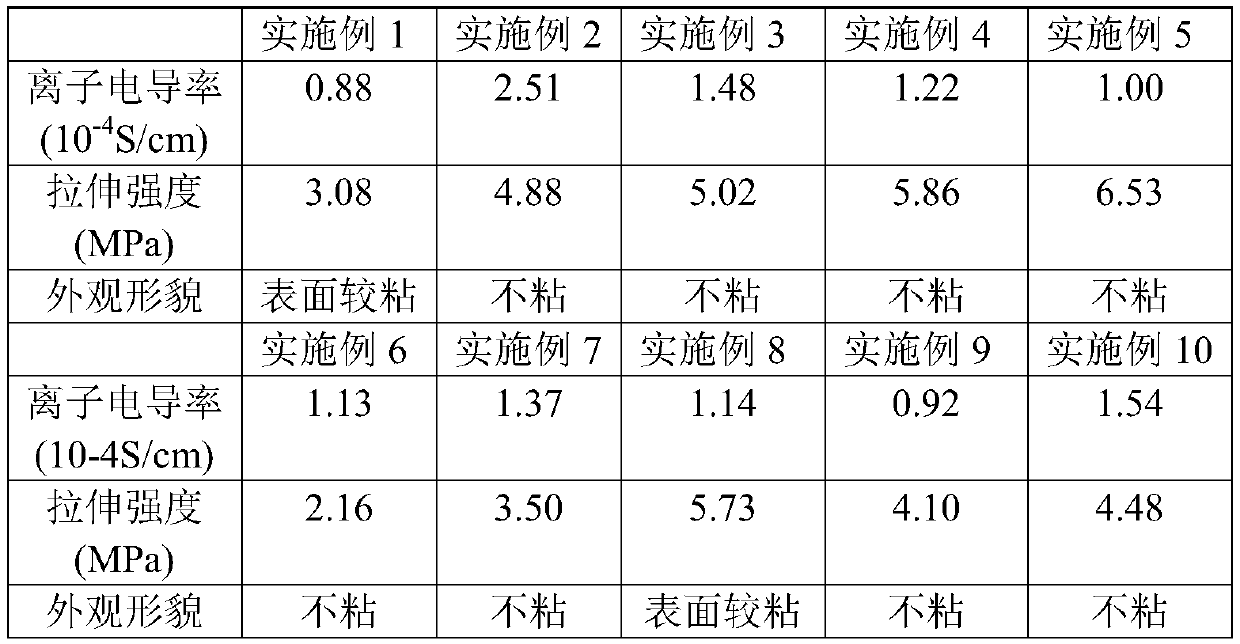

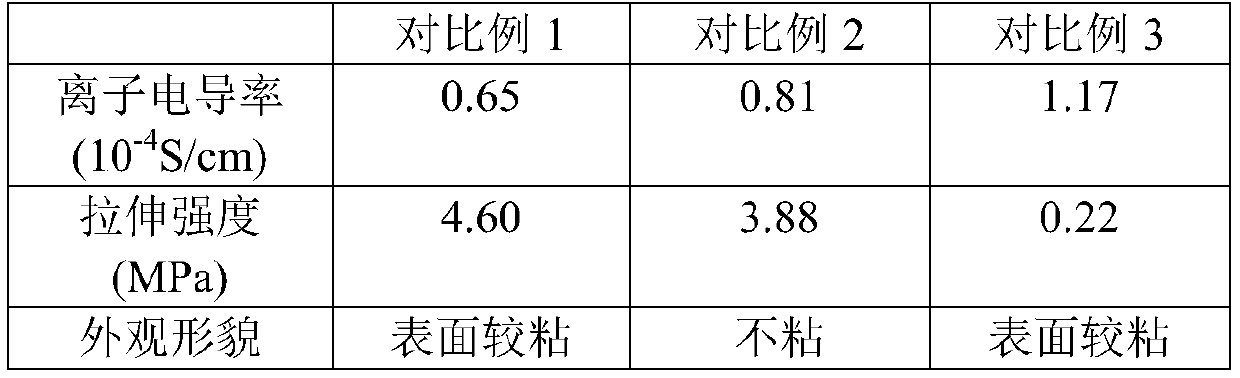

Solid electrolyte film material, preparation method thereof, and battery

ActiveCN110148778AMake up for mechanical propertiesGuaranteed mechanical propertiesSolid electrolytesSecondary cellsSolid state electrolytePolymer science

The invention relates to a solid electrolyte film material, a preparation method thereof, and a battery. The preparation method comprises the following steps: mixing polyoxyethylene, a composite lithium salt, a structure-supporting polymer, a silane coupling agent, an antioxidant, a heat stabilizer and a dispersing agent, and then performing extruding and calendering to form a film through a tensile rheology extrusion process, so as to obtain the solid electrolyte film material, wherein the structure-supporting polymer is one of polyethylene, a vinylidene fluoride-hexafluoropropylene; polyvinyl chloride and an ethylene-(methyl) acrylate polymer or more. According to the solid electrolyte film material disclosed by the invention, the ionic conductivity of a system is improved, and meanwhile, the mechanical property of the system is improved, so that the polymer solid electrolyte film material with good mechanical property and electrochemical property is obtained.

Owner:GUANGZHOU HUAXINKE ENTERPRISE +1

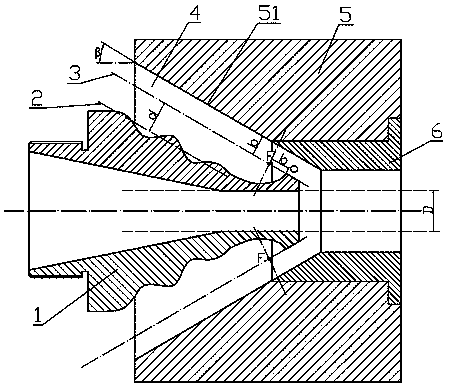

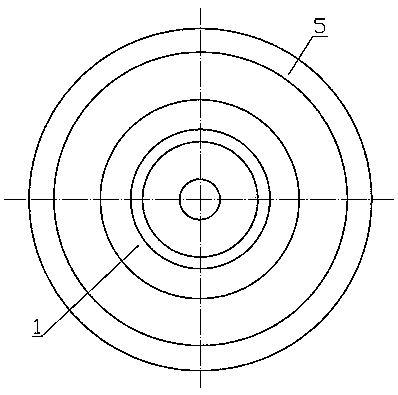

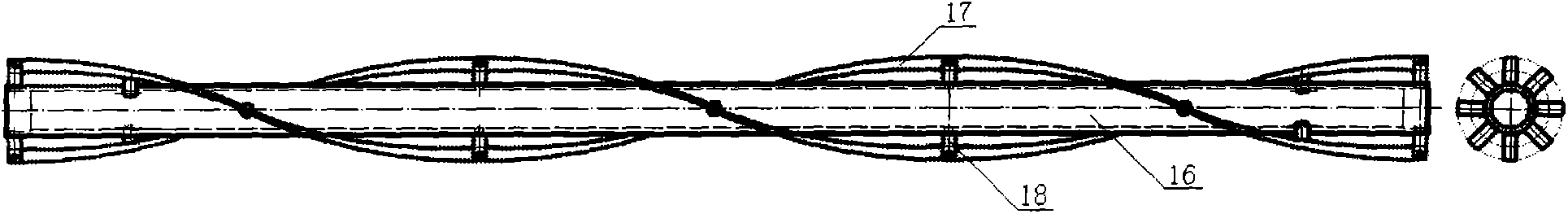

Cable mold capable of realizing highly compact and uniform extrusion molding

PendingCN107696450AConsistent thicknessImprove appearance qualityDomestic articlesCoatingsConical surfaceMaterials science

The invention discloses a cable mold capable of realizing highly compact and uniform extrusion molding. The cable mold comprises a mold sleeve, a mold core and an extrusion molding runner, wherein a work part of the mold core comprises an extrusion corrugation section, an extrusion compaction section and a mold core front cone section, a mold sleeve guide cone hole and a nesting hole which are communicated with each other are formed in the mold sleeve, the work part of the mold core is located in the mold sleeve guide cone hole at intervals, and the axis of the mold core and the center line ofthe mold sleeve guide cone hole are located in the same straight line; a setting nest is nested in the nesting hole of the mold sleeve, a cone hole surface for nesting the guide cone hole on the setting nest and the cone hole surface of the mold sleeve guide cone hole are located in the same cone surface. The extrusion corrugation section adopts a conical structure, and the conical surface of theextrusion corrugation section is a sine curve rotation surface. The extrusion compaction section is a semi-parabola rotation surface extending from the extrusion corrugation section to the mold corefront cone section. An extrusion molding layer of the cable extrusion molding mold has the characteristics of being fully plasticized, uniform, compact, consistent in thickness and good in appearancequality.

Owner:JIANGSU DONGQIANG

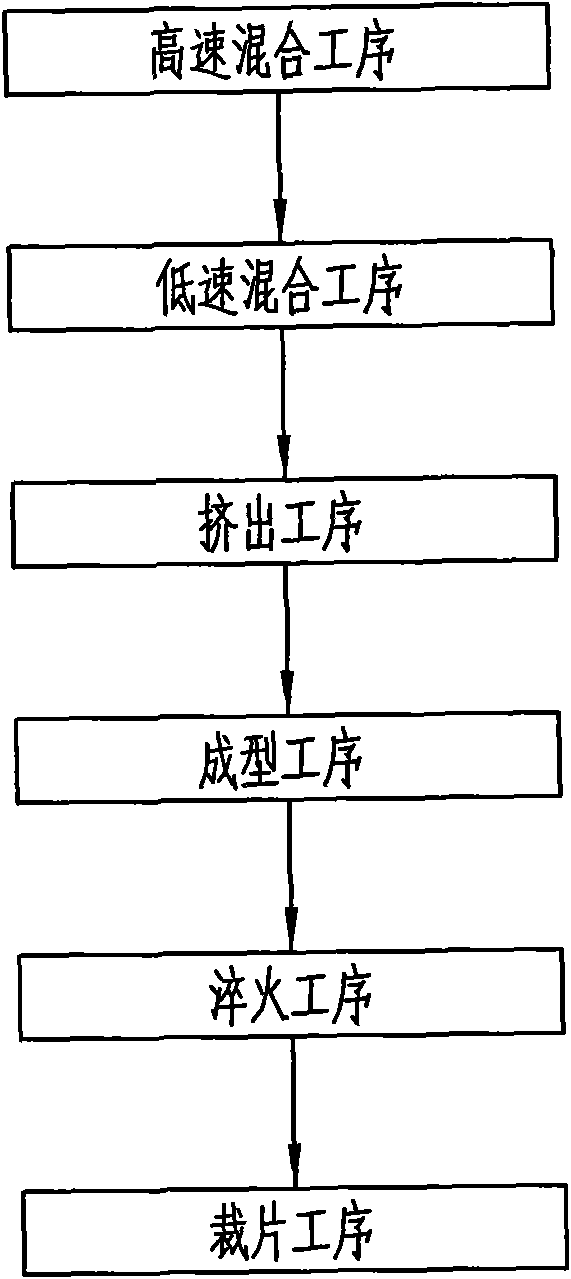

Preparation method of photovoltaic cable sheath layer material

The invention provides a preparation method of a photovoltaic cable sheath layer material. The method comprises the steps that raw materials are put into an internal mixer to be subjected to internal mixing, fusion and blending, plasticized raw materials are obtained, the internal mixing temperature is 160-175 DEG C, and the internal mixing time is 15-25 min; the plasticized raw materials are added into a double-shaft feeder and are pelletized through a single screw extruder, and a sizing material is obtained; and the sizing material is extruded through a wire extruder and then irradiated through an electron accelerator, and the photovoltaic cable sheath layer material is obtained. Internal mixing is conducted in the internal mixer, so that the raw materials are evenly stirred and more sufficiently plasticized; but, in the prior art, the plasticizing is conducted in double screws and is not thorough. The electron accelerator irradiation is used for modification, so that the photovoltaic cable sheath layer material is more resistant to heat, aging and oil, and a thermoset polymer alloy is formed and does not contain any halogen or phosphorus and nitrogen element. The preparation method of the photovoltaic cable sheath layer material is completely environmentally friendly, reduces the cost and improves the working efficiency.

Owner:JIANGSU DASHENG POLYMER

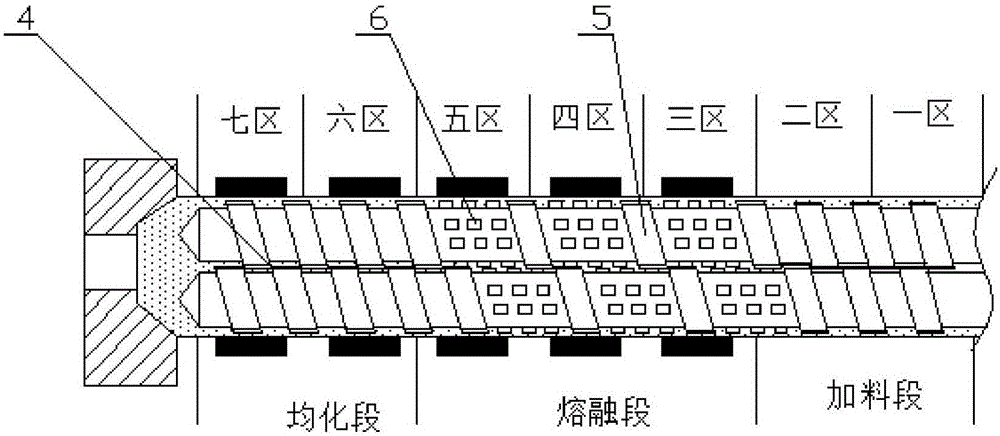

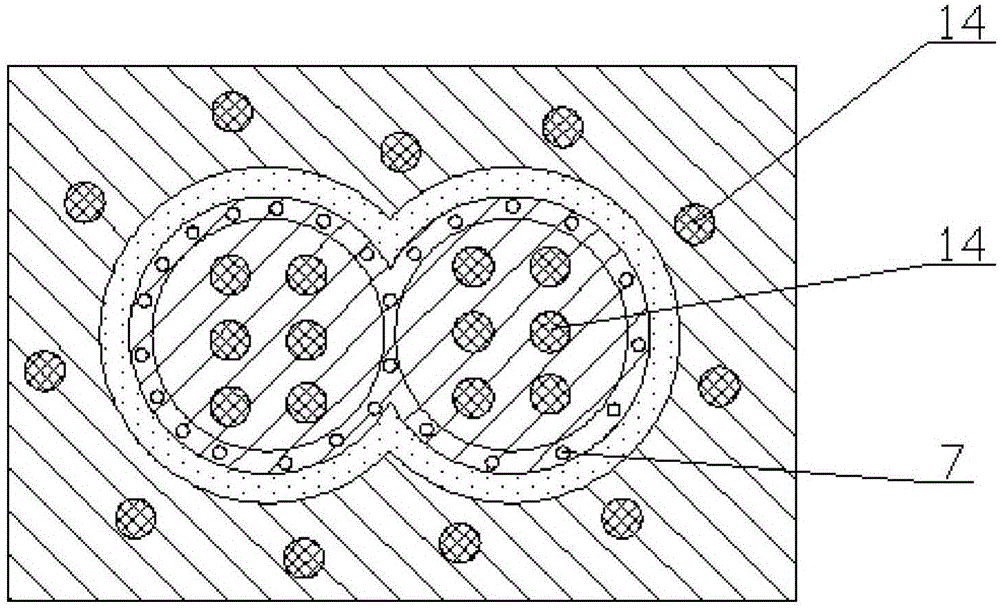

Co-rotating twin-screw compound extruder for producing light diffusion plates and production process thereof

The invention relates to the technical field of equipment for producing light diffusion plates, in particular to a co-rotating twin-screw compound extruder for producing light diffusion plates and a production process thereof. The co-rotating twin-screw compound extruder mainly consists of a frame, a feeing device, a transmission device and an extruding device, wherein the extruding device mainly consists of a feeding section, a melting section and a homogenizing section; the melting section mainly consists of interrupted screw edges and annularly arranged pins; vacuumizing exhaust devices are respectively arranged at the upper and lower ends of the melting section; and multiple discharge holes are formed on screw edges of twin screws in the extruding device in the axial direction of the screws. After the structure is adopted, the melting section consisting of the interrupted screw edges and the annularly arranged pins can be used for fully plasticizing materials; the holes formed in the axial direction of the screw edges are used for making up the defect of extruding out broken materials in the movement engagement process of the twin screws in the extruding process so as to realize continuous and stable material extruding process; and the upper and lower vacuumizing exhaust devices are used for discharging impurities and waste gas to guarantee the quality of the light diffusion plates.

Owner:雄县钰泰橡塑制品有限公司

Low-smell low-VOC modified thermoplastic elastomer material, and preparation method thereof

The invention discloses a low-smell low-VOC modified thermoplastic elastomer material. The low-smell low-VOC modified thermoplastic elastomer material is composed of 5 to 35 parts of polyethylene resin, 10 to 40 parts of SEBS, 10 to 50 parts of food-grade paraffin oil, 0.1 to 1.0 part of an anti-oxidant, 5 to 35 parts of calcium carbonate, 0.1 to 0.5 part of a lubricant, 0.01 to 1.0 part of an acid absorption agent, and 0.1 to 1.0 part of an anti-aging agent. According to a preparation method, low smell and low VOC content raw materials are adopted, small amounts of auxiliary agents such as the anti-oxidant, the lubricant, the acid absorption agent, and the anti-aging agent are adopted for chemical reaction with small molecules generated in preparation process, so that material smell and VOC content are reduced thoroughly. In material preparation process, different temperature zones are adopted to ensure full plasticizing of rubber materials in a screw, so that generation of small molecular substances in material preparation process is reduced greatly, and in addition, modified calcium carbonate is adopted, the internal mutually nested channels are adopted in absorption of small molecular substances and prevention of escape of the small molecular substances. After using as long as one year, the smell grade of the low-smell low-VOC modified thermoplastic elastomer material is equal to or lower than 3 grade, and VOC content reaches index required in GB / T27630-2011.

Owner:联泓(江苏)新材料研究院有限公司

Biodegradation composition, and preparation method and application thereof

ActiveCN102070795AThermoplasticMolecular weight controllableConjugated synthetic polymer artificial filamentsBlow moldingPolymer science

The invention discloses a biodegradation composition, and a preparation method and application thereof. The biodegradation composition consists of a biodegradation resin, dextrin and a plasticizer, wherein the mass ratio of the biodegradation resin to the dextrin is 1:9 to 9:1; the content of the plasticizer is 1 to 30 percent based on the total weight of the biodegradation composition; and the dextrin is prepared from the mixture of dried natural starch and acid solution in melting and mixing equipment. The biodegradation composition is prepared from the mixture of the components in the smelting and mixing equipment. The biodegradation composition provided by the invention has relatively higher physical properties and processability, relatively higher water resistance and medium biodegradation speed, well satisfies the needs of practical application, and can be prepared into various products by universal processing methods such as blowing molding, extrusion molding, injection molding, spinning molding and the like.

Owner:KINGFA SCI & TECH CO LTD +2

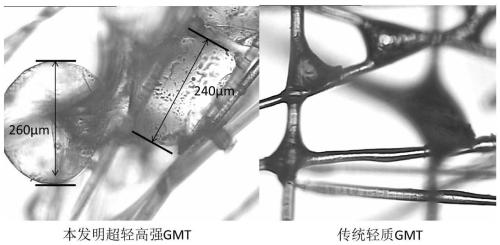

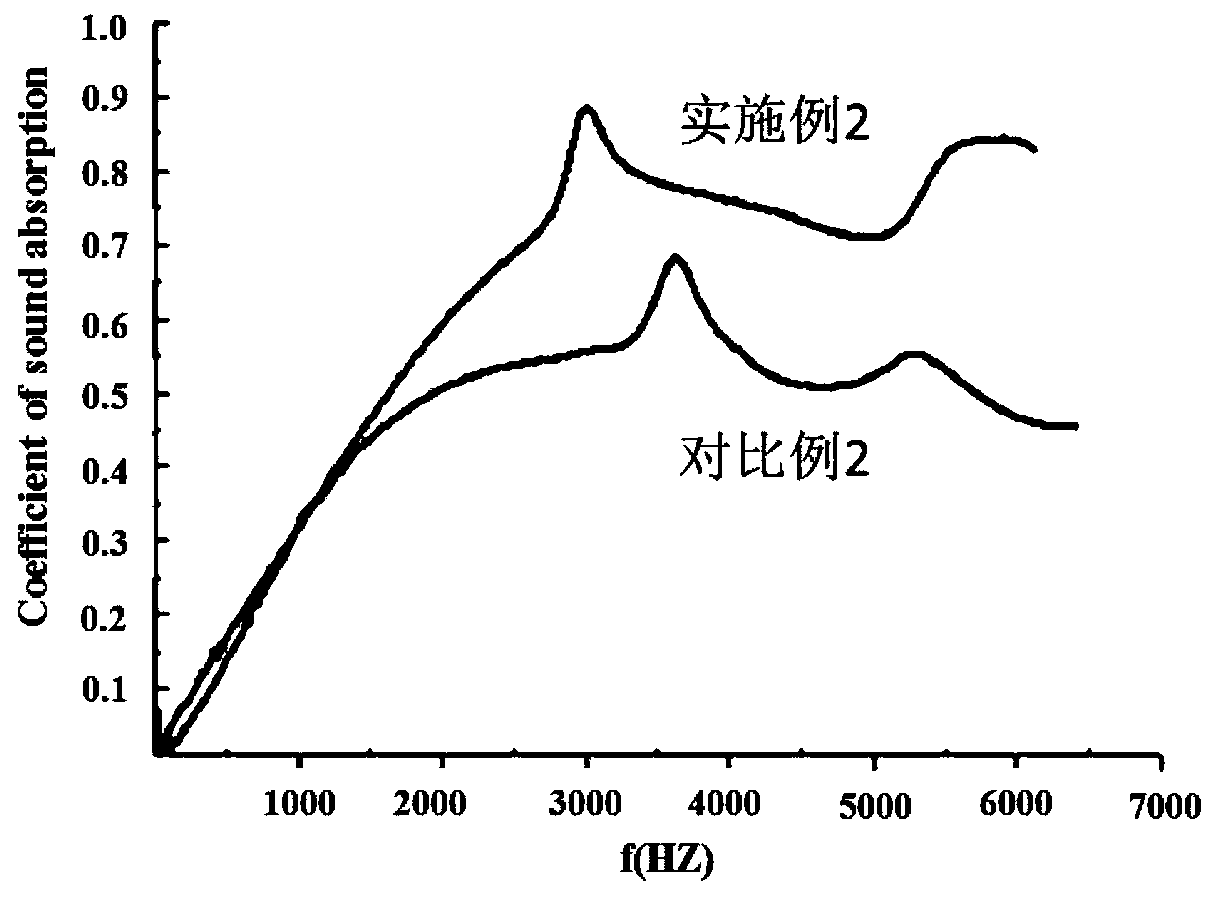

Ultra-light high-strength high-sound-absorption fiber-reinforced thermoplastic foamed composite board and preparation method thereof

InactiveCN111038042ALow manufacturing costSolve uneven thicknessSynthetic resin layered productsLaminationThermoplasticSynthetic fiber

The invention discloses an ultra-light high-strength high-sound-absorption fiber-reinforced thermoplastic foamed composite board and a preparation method thereof, wherein the ultra-light high-strengthhigh-sound-absorption fiber-reinforced thermoplastic foamed composite board is prepared by using a binder uniformly containing a forming agent and a fiber reinforcement body through a non-woven and continuous board-making composite process. According to the invention, plastic synthetic fibers uniformly containing a microsphere foaming agent are prepared by blending the microsphere foaming agent and thermoplastic resin powder as raw materials through a melt spinning procedure; the advantages of a non-woven process can be fully utilized to stably, continuously and efficiently produce the ultra-light high-strength GMT composite board; and the microsphere foaming agent does not fall off in a felt making link, so that the high-quality composite felt containing the microsphere foaming agent canbe prepared safely in batches without increasing additional investment such as newly increased equipment, personnel training and the like, and the manufacturing cost of the section is remarkably reduced.

Owner:浙江华江科技股份有限公司

PE wood plastic particle processing device

The invention relates to the technical field of industry manufacturing, in particular to a PE wood plastic particle processing device. The PE wood plastic particle processing device comprises a material barrel and a screw rotationally arranged in the material barrel. The material barrel comprises a first material barrel body, a second material barrel body and a connecting part used for connectingthe first material barrel body with the second material barrel body. The screw correspondingly includes a first screw body and a second screw body, wherein the first screw body is provided with a highspiral blade, and the second screw body is provided with a low spiral blade. The first material barrel body is provided with a feeding hopper and an exhaust hole, the exhaust hole communicates with an exhaust pipe, and the exhaust pipe is arranged on the feeding hopper. The exterior of the second material barrel body is provided with a cooling water pipe, a water collecting box is further arranged below the cooling water pipe, a rotation shaft is rotationally connected in the water collecting box, the rotation shaft is provided with a wood board in a radial manner, and the rotation shaft is coaxially and fixedly connected with a rectangular prism. The water collecting box is further in sliding connection with a sliding rod. One end of the sliding rod is in sliding connection with the circumferential face of the rectangular prism. By adoption of the scheme, PE wood plastic particle extruded products are uniform in organization component, and the product inner stress is small.

Owner:贵州荣兴新型建材科技有限公司

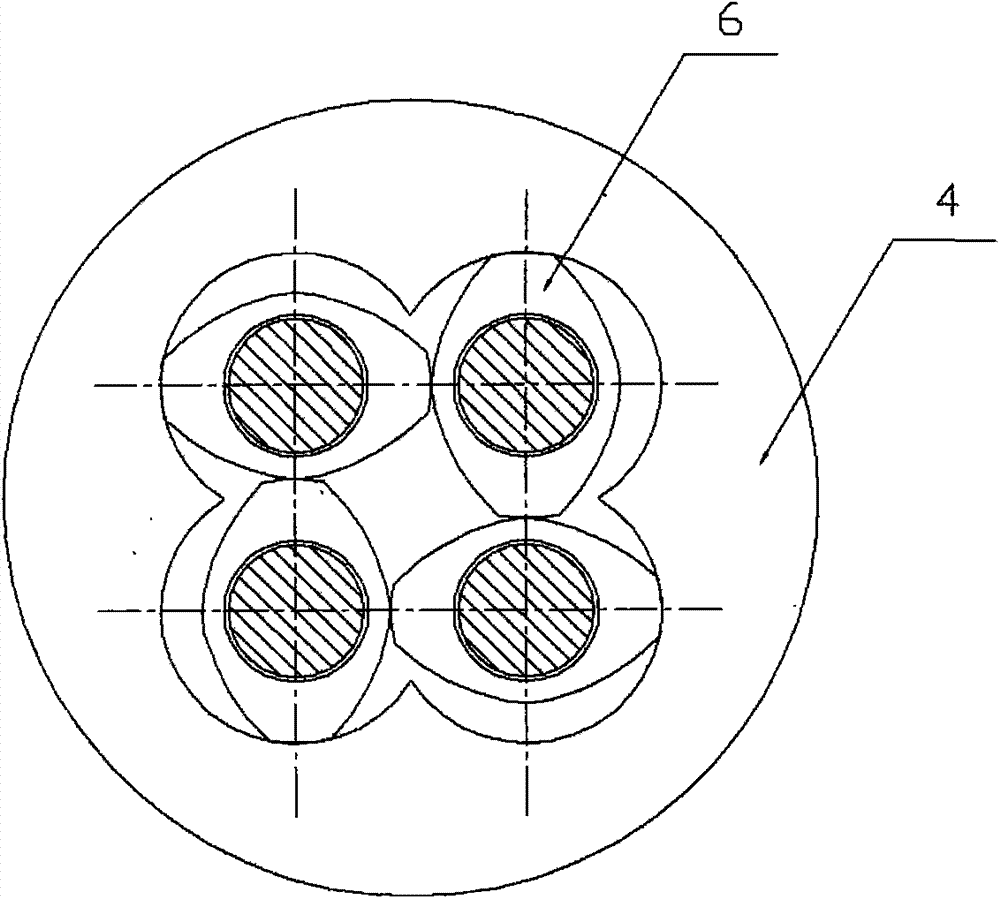

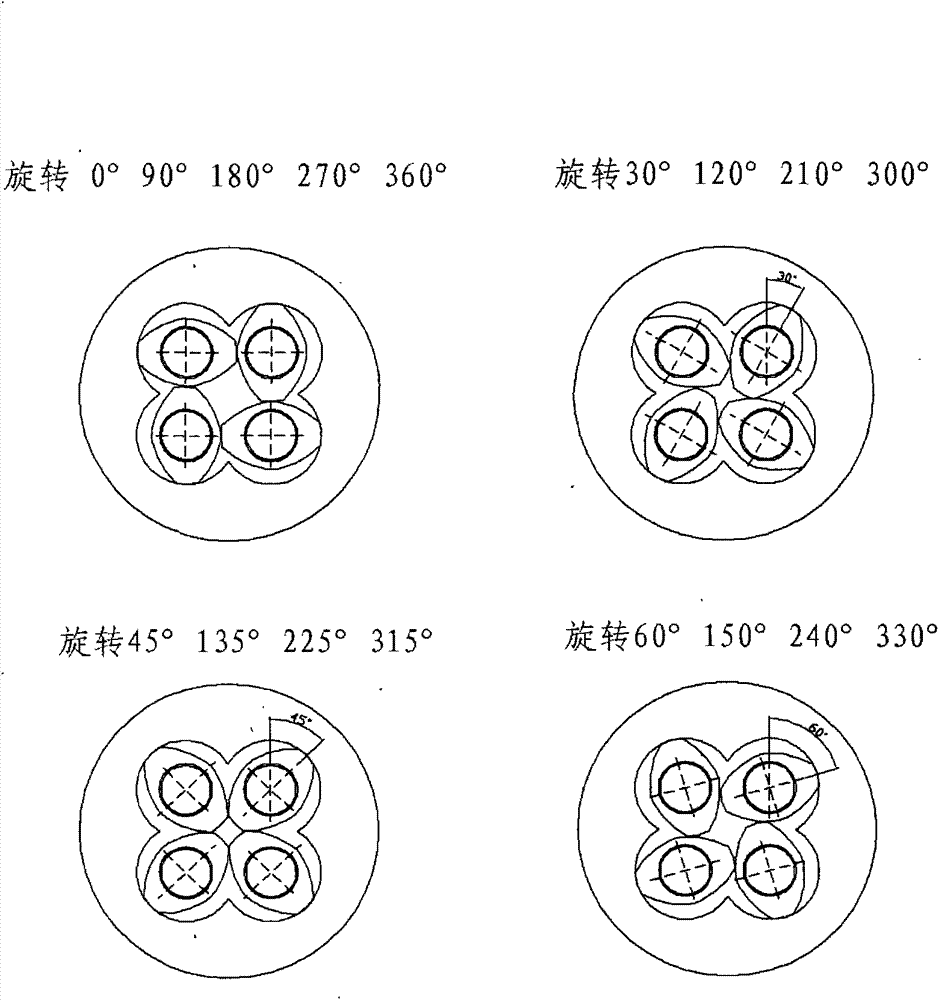

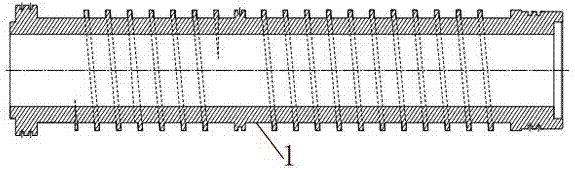

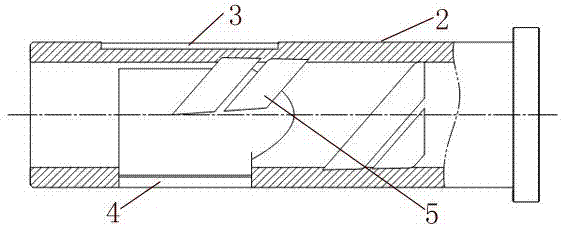

Four-screw mixing extruder

The invention relates to a novel plastic processing machine, in particular relates to a four-screw mixing extruder which is characterized in that a mixing device and an extruding device as well as a mixing working procedure and an extruding working procedure which are needed in the plastic processing process are respectively integrated. The four-screw mixing extruder consists of four screws, wherein the axes of the four screws are parallel to one another, the center distances of the four screws are equal, and a square shape is formed by connecting lines of four central points of the four screws in a vertical cross section. The four screws are respectively in a block combination type; all screw elements are meshed with one another, and a closed central area which is a mixing area can be formed. The four screws can rotate along the same direction, the area of the central area is changed for four times when the four screws turn a circle, and a period is defined by 90 degrees. The material is kneaded and extruded powerfully for tens of thousands of times every minute in the central area and is fully plastified, and all the components are evenly dispersed. The productivity of the four-screw mixing extruder is twice that of a common twin-screw extruder, and the energy consumption of the four-screw mixing extruder is reduced by 50%.

Owner:许汉辰 +2

Feed guide type rubber extruding machine swivel nut

InactiveCN103587101AImprove extrusion qualityIncrease glue outputRubber materialMechanical engineering

The invention discloses a feed guide type rubber extruding machine swivel nut which comprises a front swivel nut and a rear swivel nut, wherein the front swivel nut and the rear swivel nut are movably connected with each other; a feeding opening and a feeding section are arranged on the rear swivel nut; a conical inner thread large-lead spiral groove is formed in an inner hole between the feeding opening and the feeding section. Through the adoption of the conical inner thread large-lead spiral groove, the radial friction to a rubber material when being rotated in the feeding opening and the feeding section along with a screw rod is increased, so that the rubber material can be rapidly changed into linear forwarding from rotation at the feeding section, the feeding opening is enabled to hold the material sufficiently and stably, the rubber material is sufficiently plasticized, particularly the rubber material is prevented from sliding at the feeding opening when the rotation speed of the screw rod is increased, the situation that the rubber material is not sufficiently held at the feeding opening before improvement is completed, the extrusion quality and the rubber yield of the screw rod are greatly improved, and the production capacity is greatly improved; moreover the feed guide type rubber extruding machine swivel nut has the characteristics that the structure is reasonable, the rubber guide speed is fast, the rubber raw material application range is large, and the extrusion efficiency is high.

Owner:JIANGSU MEIDIAN ELECTRICAL MACHINERY TECH

Plastic extrusion granulation unit

The invention discloses a plastic extrusion granulating unit which is characterized by comprising a main extruder, a second extruder and a granulating device, wherein the main extruder comprises a main charging barrel and a main driving device; two main screw rods which rotate in different directions are arranged in the main charging barrel, and have opposite thread directions and are meshed with each other; the two main screw rods are in transmission connection with the main driving device; a main feeding hole is formed in the front end of the main charging barrel; a main die head is connected to the rear end of the main charging barrel; the second extruder comprises a second charging barrel and a second driving device; a second screw rod is arranged in the second charging barrel and is in transmission connection with the second driving device; a second feeding hole capable of receiving materials extruded by the main die head is formed in the front end of the second charging barrel; the rear end of the second charging barrel is connected with a second die head; the granulating device corresponds to the position of the second die head. The plastic extrusion granulating unit is smooth in feeding, the recovered plastics can be fully plastified, and plastic granules with good performance are prepared.

Owner:汕头市富达塑料机械有限公司

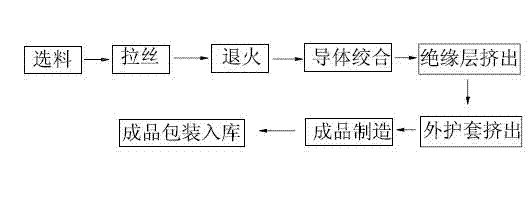

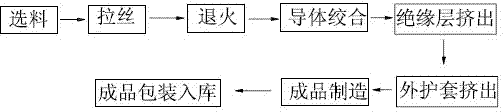

Method for manufacturing cable for high-temperature gas cooled reactor

ActiveCN102347110ARound appearanceCompact appearanceInsulating conductors/cablesTemperature controlCopper

The invention discloses a method for manufacturing a cable for a high-temperature gas cooled reactor, and the method the following process flows: material selection-wire drawing-conductor twisting-finished product manufacturing-finished product packaging storage. The method is characterized by comprising annealing-extrusion of an insulating layer-extrusion of an outer sheath, wherein the annealing step means that an annealing silver plating machine is used for plating silver with the thickness of 6-20mu m on a copper monofilament surface; and the extrusion of the insulating layer and the extrusion of the outer sheath mean that screws with a high compression ratio of 3.5:(1-5.0):1 are used, extrusion equipment is provided with a good cooling device, the extrusion processing temperature of the extrusion equipment is controlled between 360 DEG C and 420 DEG C, a pipe-extrusion mould with the high extension ratio is selected as an extrusion mould, and the selected mating extension ratio is 30-50. The cable manufactured by the method provided by the invention has the characteristics of strong ambient temperature adaptability, high conductivity and strong electromagnetic compatibility.

Owner:SICHUAN MINGXING CABLE

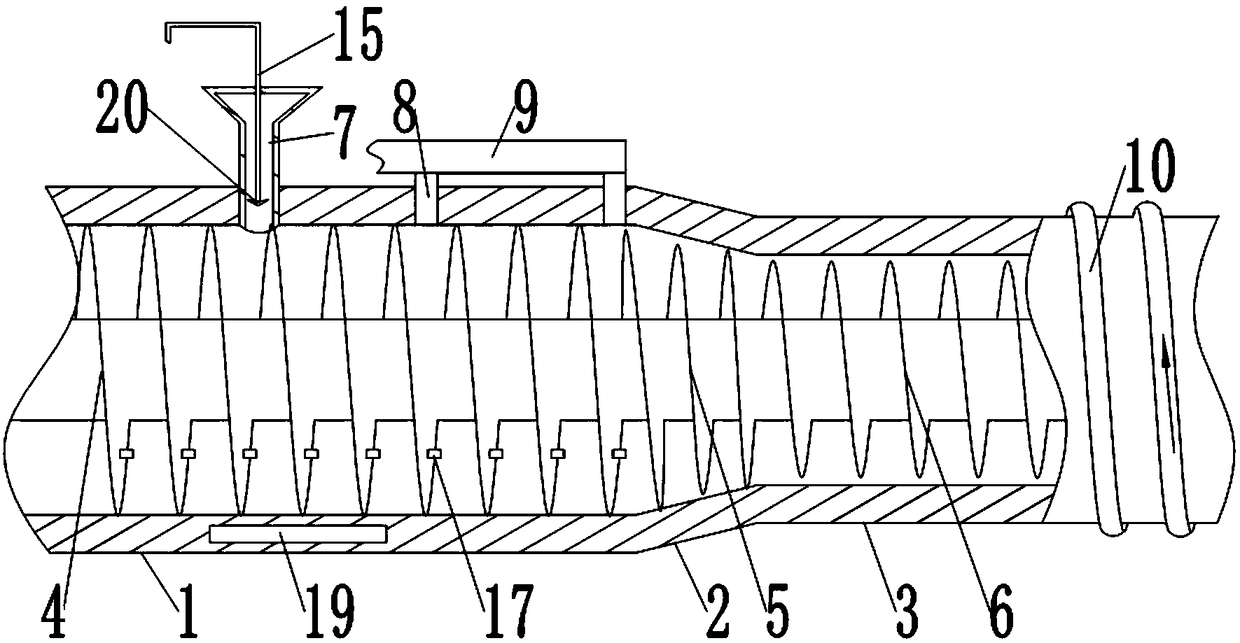

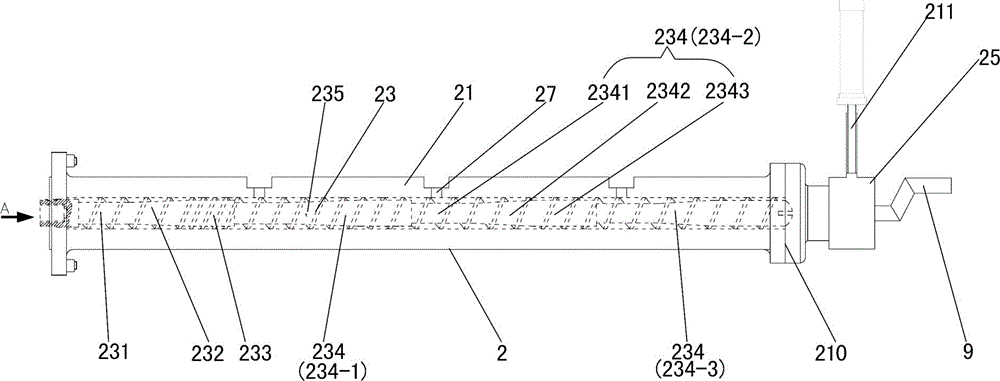

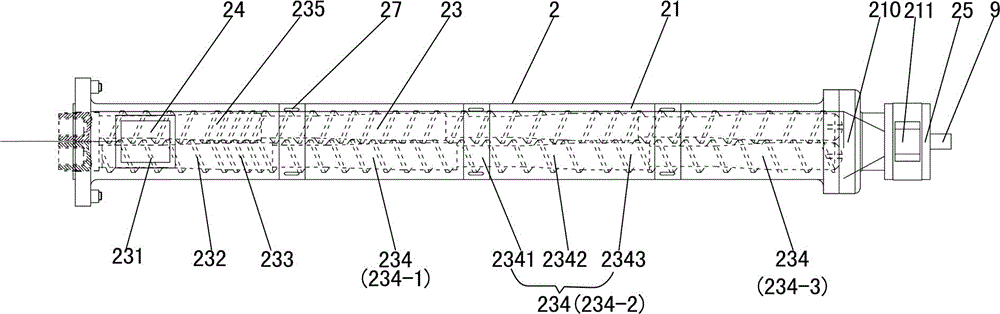

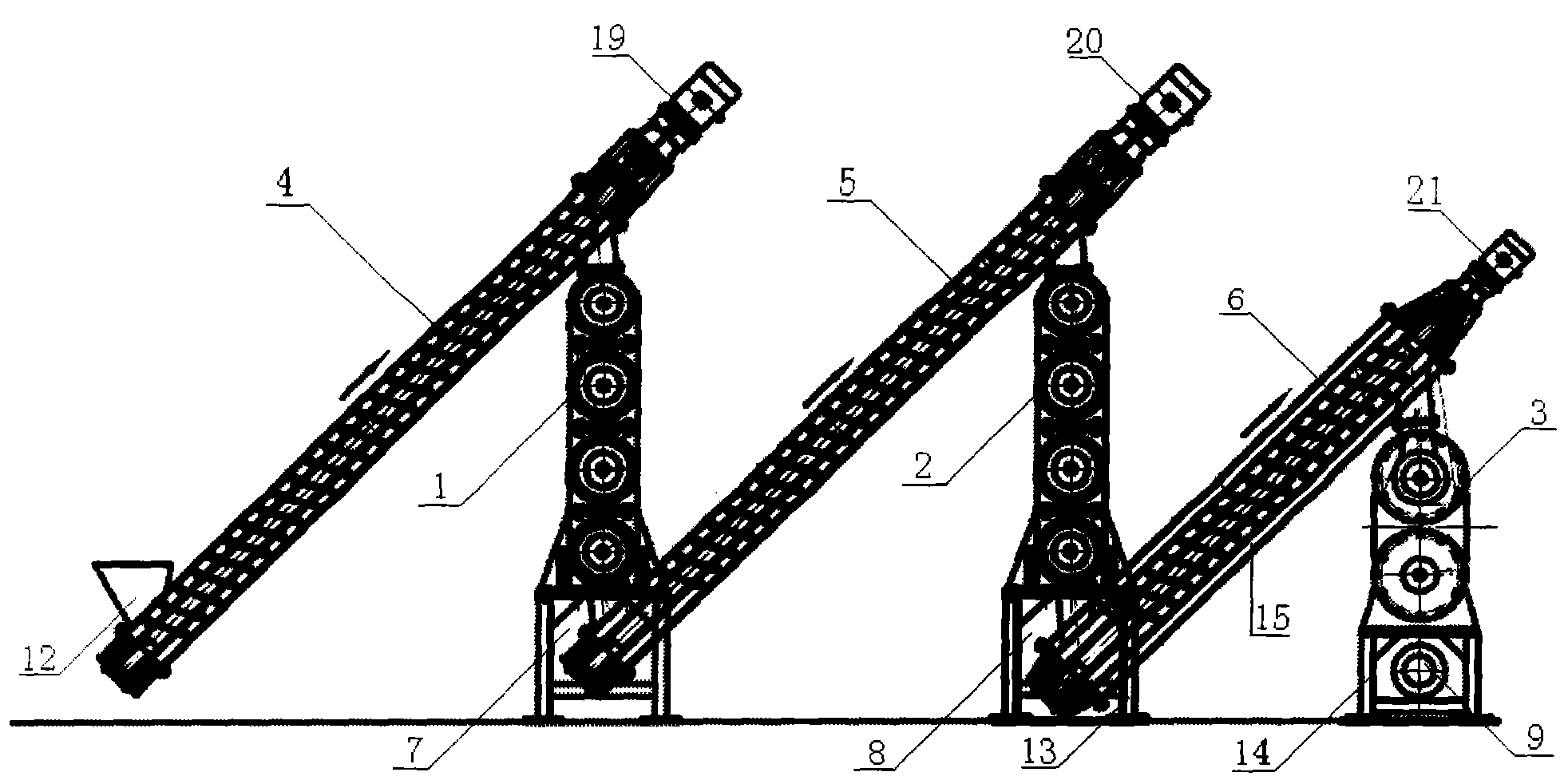

Continuous plasticizing production device and method

The invention relates to a continuous plasticizing production device. The continuous plasticizing production device is characterized in that a heat preserving and maintenance stranding cage set is arranged between a heating plasticizing stranding cage set and a cooling stranding cage set and communicated with the two sets; rubber powder conveying parts arranged in the heating plasticizing stranding cage set, the heat preserving and maintenance stranding cage set and the cooling stranding cage set are composed of rotating shafts and screw blades, wherein the screw blades are connected to the rotating shafts; and the screw blades and the rotating shafts are arranged at a certain spacing. According to the method, the plasticizing of the rubber powder is carried out in three process steps of heating, heat preserving and maintenance, and cooling. The method is characterized in that the rubber powder is uniformly heated, and the heated rubber powder is subjected to heat preserving and maintenance, thus the performance of reclaimed rubber can be recovered, and the plasticizing effect is greatly improved; the designed screw blades of the stranding cage enables sufficient agitating and conveying of the rubber powder in the heating, heat preserving, cooling and other working areas; and particularly the rubber powder is difficulty adhered to the rubber conveying parts.

Owner:张兴和

3D printing environment-friendly material and preparation method thereof

InactiveCN106700458AWith fragranceImprove interface compatibilityAdditive manufacturing apparatusEnvironmental resistanceMasterbatch

The invention provides a 3D printing environment-friendly material and a preparation method thereof. The 3D printing environment-friendly material is characterized by comprising the following components in parts by mass: 50-100 parts of PLA (polylactic acid), 8-15 parts of UHMWPE (ultra high molecular weight polyethylene), 10-12 parts of wood flour, 2-5 parts of a compatilizer, 2-4 parts of a coupling agent, 2-4 parts of a lubricant, 2-3 parts of glass beads and 1-2 parts of white masterbatch. The 3D printing environment-friendly material is low-carbon and environment-friendly, can be completely circulated, recycled and reused, has the natural friendliness of wood, has natural wooden fragrance when being used, is good in size stability, is free of hole blocking or warping and is low in processing condition requirement; in addition, a product made of the material is relatively good in physical mechanical property, acid-base resistance, worm damage prevention and weather resistance such as good ultraviolet ray resistance.

Owner:HEILONGJIANG XINDA ENTERPRISE GRP

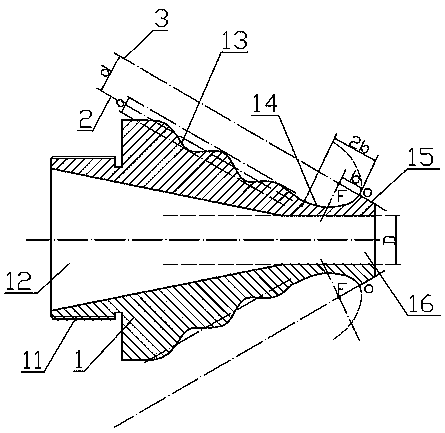

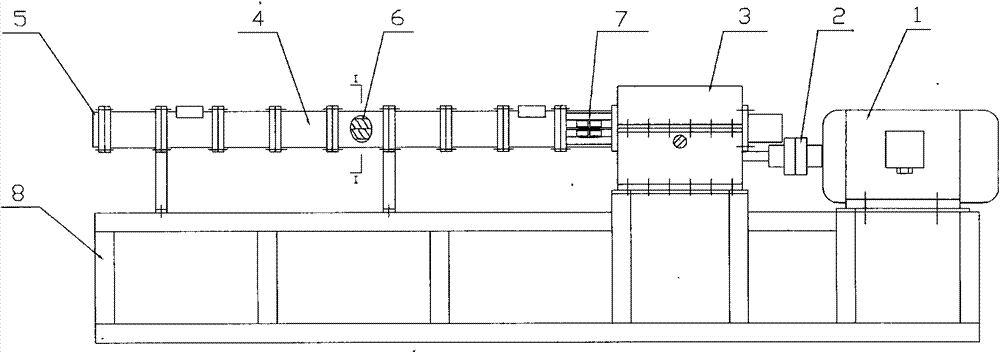

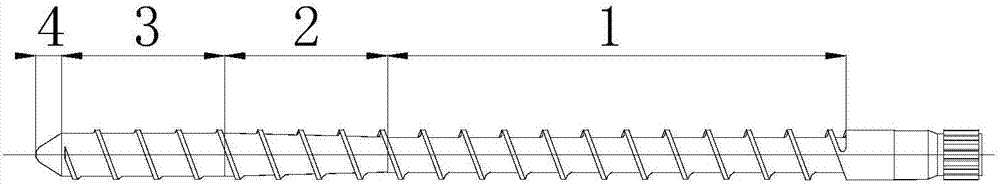

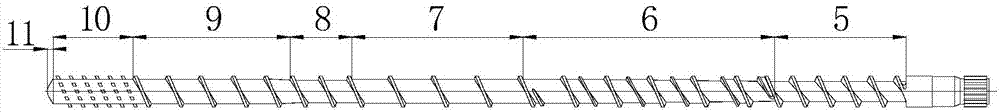

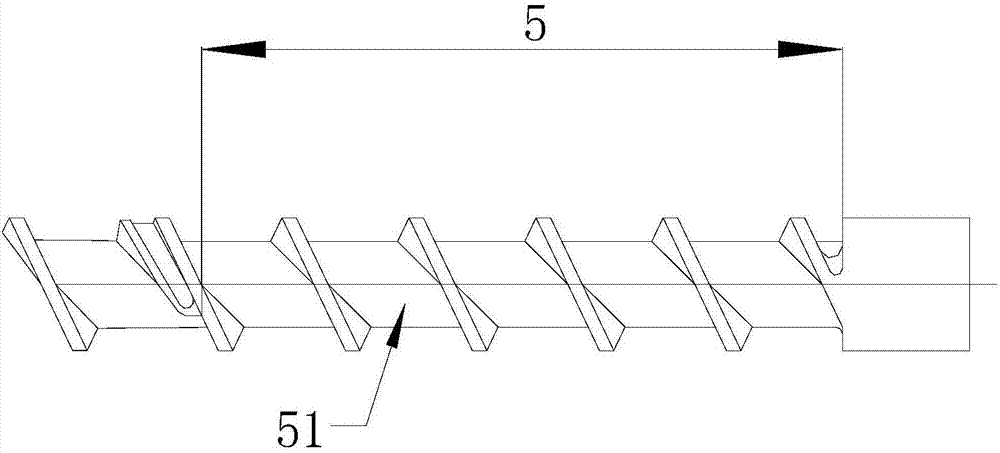

Special extrusion screw for polyethylene of raised temperature resistance and extrusion method of special extrusion screw

The invention discloses a special extrusion screw for polyethylene of raised temperature resistance (PE-RT) and an extrusion method of the special extrusion screw. The special extrusion screw comprises a feeding segment, a compression segment, a first metering segment, a pressure reducing segment, a second metering segment, a mixing segment and a screw head which are connected in sequence, wherein the feeding segment, the pressure reducing segment, the first metering segment and the second metering segment all adopt single-start thread structures; the compression segment adopts a double-start thread structure consisting of a main thread and an auxiliary thread; the auxiliary thread and the main thread intersect at one side of the feeding segment and do not intersect at one side of the first metering segment; and the mixing segment adopts a trapezoidal structure. The special extrusion screw for PE-RT is simple in structure, convenient to use, high in fusing efficiency, uniform in plasticization, high in conveying capability and high and stable in yield at a high rotational speed.

Owner:SOUTH CHINA UNIV OF TECH

Plastic extruding and pelleting unit

The invention discloses a plastic extruding and pelleting unit. The unit comprises a rack, a main extruder, a second extruder, a pelleting device, a third extruder and a first screen changing device,wherein the main extruder comprises a main material barrel and a main driving device, two main screws are arranged in the main material barrel, a main feeding port is formed in the front end of the main material barrel, and a main die head is connected to the rear end of the main material barrel; the second extruder comprises a second material barrel and a second driving device, a second screw isarranged in the second material barrel, a second feeding port is formed in the front end of the second material barrel, and a second die head is connected to the rear end of the second material barrel; and the third extruder comprises a third material barrel and a third driving device, a third screw is arranged in the third material barrel, a third feeding port is formed in the front end of the third material barrel, a third die head is connected to the rear end of the third material barrel, the third feeding port corresponds to the main die head in position, a feeding port of the first screenchanging device communicates with an outlet of the third die head, and a discharging port of the first screen changing device is positioned above the second feeding port. According to the unit, the plasticization of recycled plastic is more sufficient, and impurities in the plastic melt can be filtered out in the plasticization process.

Owner:汕头市富达塑料机械有限公司

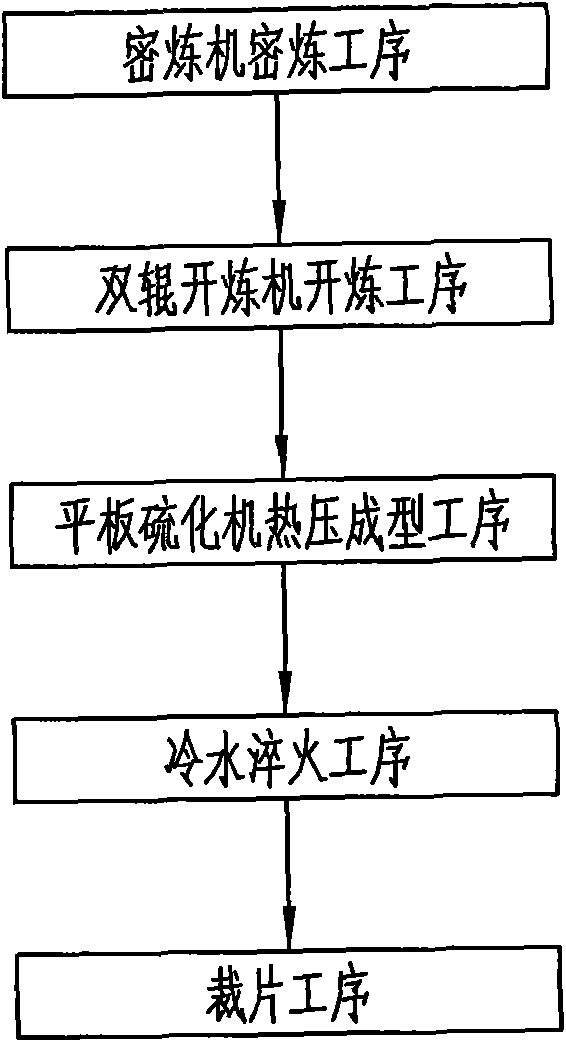

Method for preparing organic small molecule hybrid damping material

The invention relates to a method for preparing organic small molecule hybrid damping material. the current methods for preparing organic small molecule hybrid damping material have high production cost, and obtain the damping material with poor damping performance and mechanical properties. The raw material in the invention comprises: inorganic filling material, filling material surface treatment agent, organic small molecule auxiliary agent and polymer with polarity side group. The invention is characterized in comprising the following processes: high speed mixing by mixing machine; low speed mixing by mixing machine; extruding by conical double screws extruder; and forming by clothes hanger type dies with width of 1.2 meters; and quenching by three-rollers calendar. The invention has a low production cost and simple preparation process, and can be used in large-scale high efficient continuous production; and the prepared damping material has high vibration absorption efficiency and excellent mechanical properties.

Owner:浙江安基阻尼新材料有限公司

Plastic extruder

The invention discloses a plastic extruder. A charging barrel is provided with an internal diameter transition part, and the internal diameter of the internal diameter transition part is gradually reduced from one end part to the other end part of the charging barrel. A screw rod is provided with a rod diameter transition part corresponding to the internal diameter transition part, and the diameter of the rod diameter transition part is gradually reduced from one end part to the other end part of the charging barrel. The rod diameter of the screw rod is changed from large to small, and the internal diameter of the charging barrel is also changed from large to small, so that a material can be extruded gradually tightly when being charged, pressure is increased during extrusion, and furthermore, the molten material is conveniently extruded; the extrusion pressure becomes high, so that the material conveniently enters a hopper to be molten when being charged; moreover, the material does not need to be artificially pressed downwards, so that manpower is greatly reduced.

Owner:SUZHOU ZHONGSU REPROCESSING MACHINERY

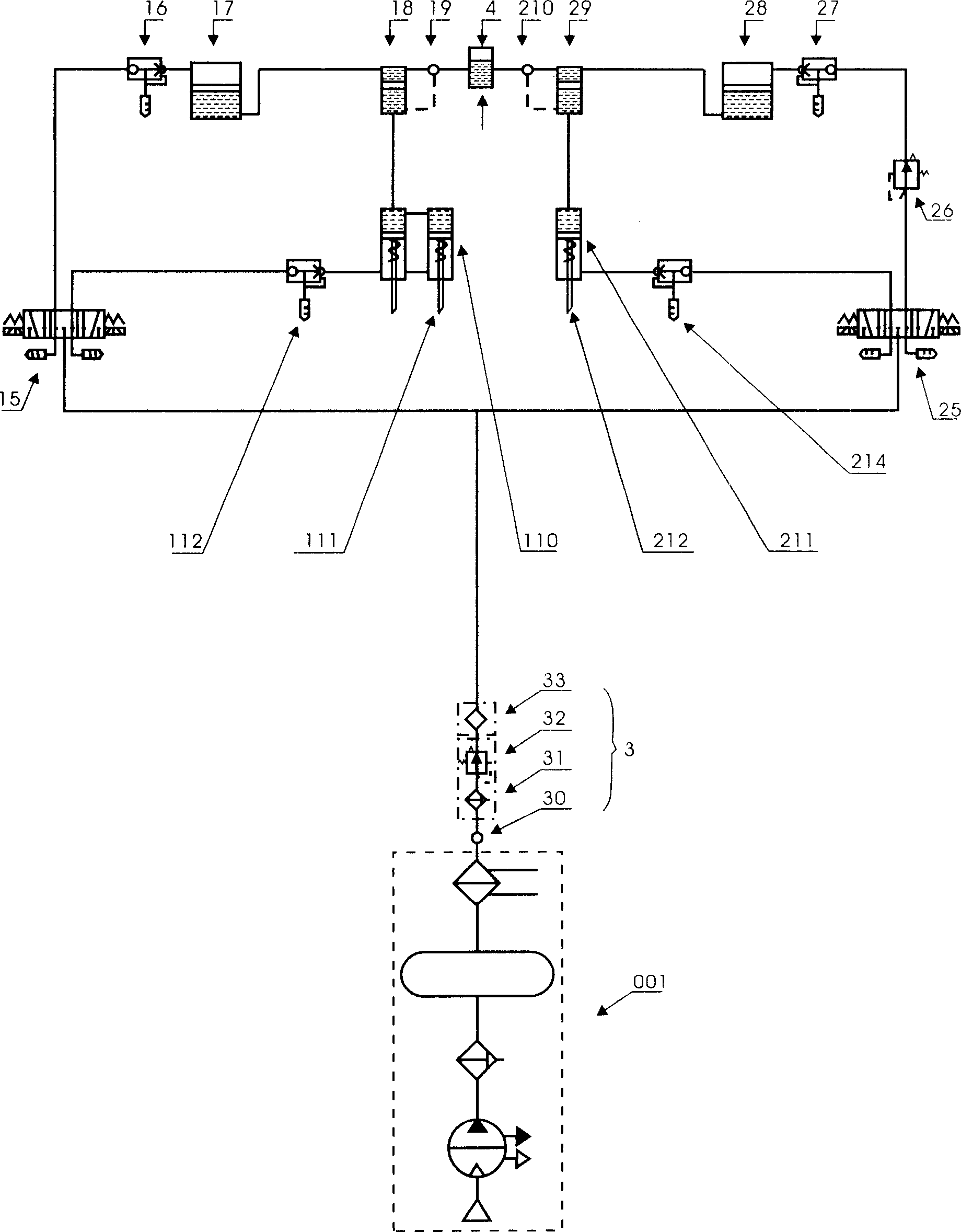

Air-actuated plastic injection machine

The invention relates to an air-powered injection machine, which uses compressed air as power source, via the conversation between air pressure and oil pressure and the boost of oil pressure, to use the hydraulic cylinder to complete the injection; said invention has low energy consumption, small volume and light weight; and it has high efficiency and simple operation; several devices can be parallel connected to use the central air source, to mould the small injection product lower than 15g.

Owner:姚国卿

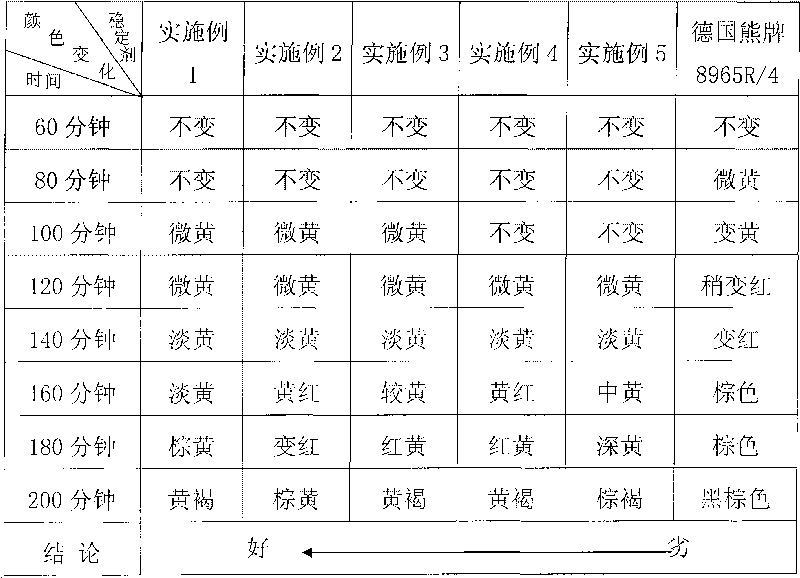

Stabilizing agent used for producing PVC plastic products and preparation technique thereof

InactiveCN101691428AReduces rednessMitigates the rate at which thermal stability degradesDiketoneOrganic acid

The invention belongs to the technical field of the processing of chlorine-containing polymer products, which discloses a stabilizing agent used for producing PVC plastic products and a preparation method thereof. The preparation method is mainly and technically characterized by comprising the following steps: putting organic acid into a reaction kettle sequentially, heating to dissolve the organic acid, putting a catalyst and dissolving the catalyst; then, putting each metal compound sequentially, preparing an intermediate after dewatering, heating, discharging and cooling, then putting the intermediate, other lamellar compounds, an antioxidant, a light stabilizing agent, pentaerythritol ester, diketone, amino crotonate and a lubricant into a compounding kettle and producing the stabilizing agent used for producing the PVC plastic products after compounding and stirring. The stabilizing agent has the characteristics of no toxicity, high stability, superior consistency performance with resin and good weatherability.

Owner:张保发

Flame retardant polyvinyl chloride (PVC) bonding glue and preparation method thereof

InactiveCN103881619AImprove plasticityImprove heat resistanceNon-macromolecular adhesive additivesPolymer sciencePlasticizer

The invention discloses flame retardant polyvinyl chloride (PVC) bonding glue and a preparation method thereof. The bonding glue comprises the following components in percentage by mass: 30-50% of PVC, 10-20% of calcium carbonate, 5-15% of flame retardant, 15-25% of cold-resistant plasticizer DSP, 1-2% of trisalt, 1-2% of basalt, 1-3% of lead stearate and 10-20% of chlorinated paraffin. The bonding glue is convenient to construct, is excellent in aging resistance and has both plasticity and high elasticity, and meanwhile the flame retardant PVC bonding glue disclosed by the invention can achieve rapid bonding, and is good in flame retardant function and aging resistance, good in quakeproof and insulating properties, very high in elasticity and waterproof and air-locked.

Owner:王勇

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com