Method for preparing organic small molecule hybrid damping material

A technology of damping materials and small molecules, which is applied in the field of preparation of organic small molecule hybrid damping materials, which can solve problems such as difficulty in achieving large-scale and efficient continuous production, poor damping performance and mechanical properties of damping materials, and large fixed investment in equipment. , to achieve the effect of low equipment price, excellent performance and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

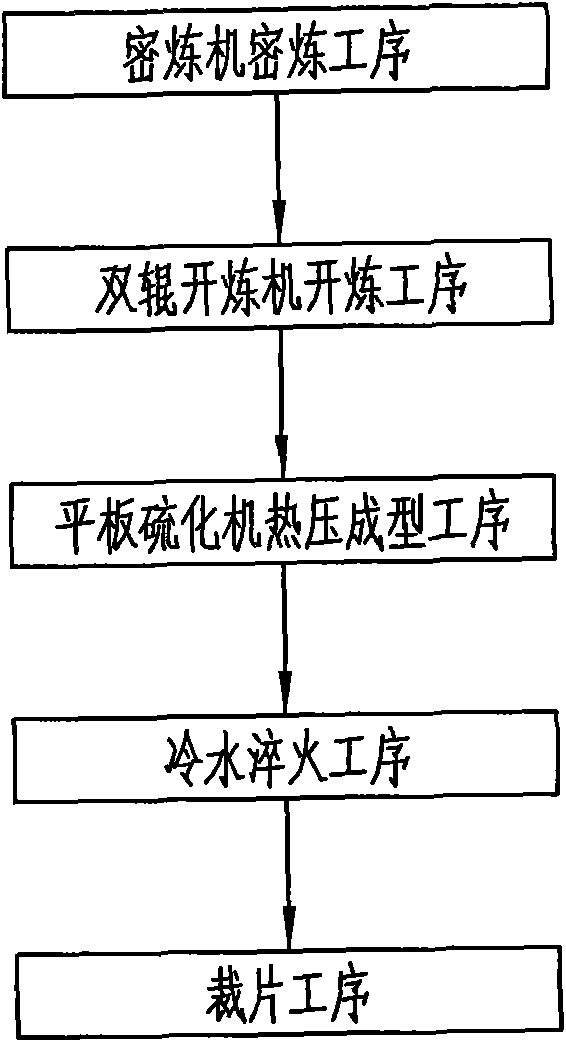

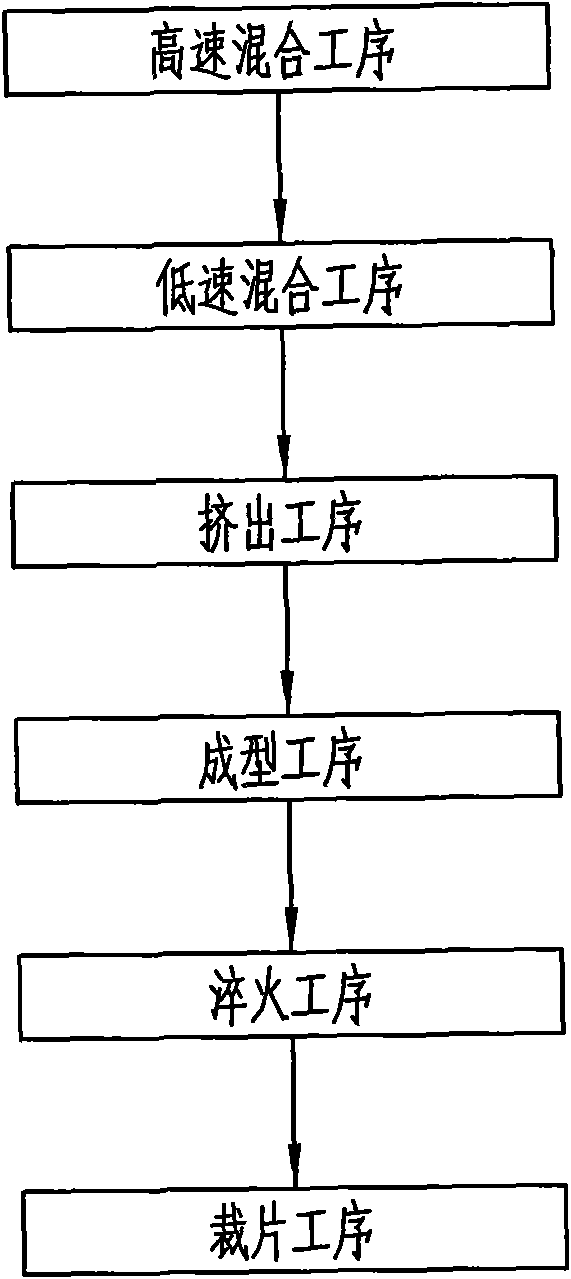

[0025] see Figure 1-Figure 4 , The preparation method of the organic small molecule hybrid damping material in this embodiment sequentially includes a high-speed mixing process, a low-speed mixing process, an extrusion process, a molding process, a quenching process and a cutting process. Wherein the high-speed mixing process and the low-speed mixing process in the present embodiment use SHR-200A high-speed mixer to mix; use screw feeder and SJZ80 / 156 conical twin-screw extruder to extrude in the extrusion process; A 1.2-meter-wide coat hanger mold is used for molding; a three-roll calender is used for quenching in the quenching process. The structure of the SHR-200A high-speed mixer used in this embodiment, the screw feeder, the SJZ80 / 156 conical twin-screw extruder, the 1.2-meter-wide coat hanger mold and the three-roll calender are all the same as those of the prior art or are similar, so they will not be described in detail here. Other types of high-speed mixers and con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com