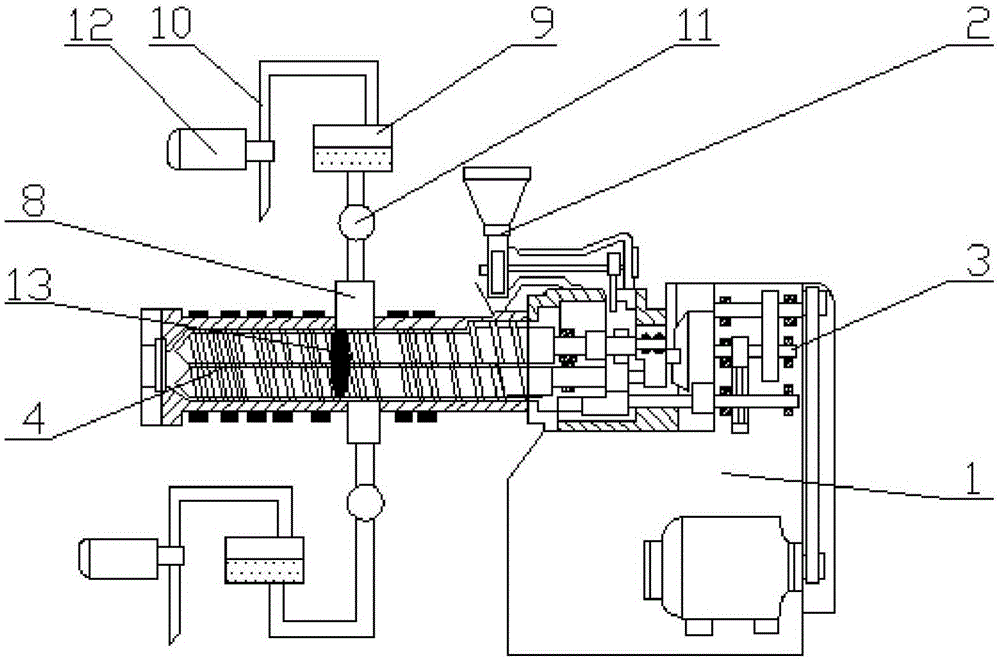

Co-rotating twin-screw compound extruder for producing light diffusion plates and production process thereof

A technology of compound extrusion and light diffusion plate, which is applied in the field of co-rotating twin-screw compound extruder and its production process, can solve the problem of intermittent discharge, black spots, and defective products at the extrusion end of the extruder. Problems such as plasticizing and melting effects of the extruder, to achieve the effect of improving the yield and continuously stabilizing the extrusion process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

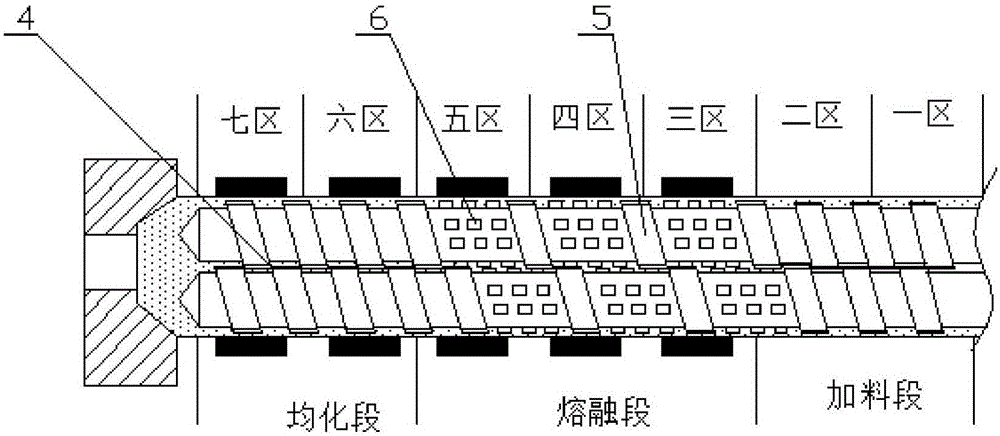

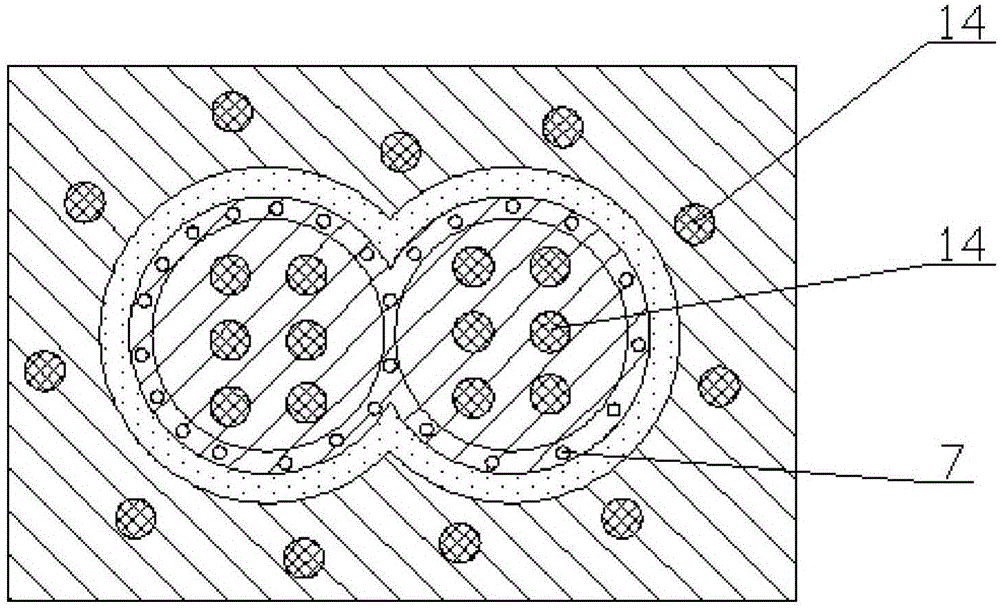

[0035] a. The main machine mixes the PS raw material, diffusing agent and auxiliary agent in the mixer for 3 minutes at high speed; b. The auxiliary machine mixes according to the main machine formula or adds anti-UV material from the raw material and then puts it into the mixer for high-speed stirring 3 minutes; c. The main machine mixing material is directly delivered to the twin-screw barrel by the screw feeding device; the temperature of each zone of the twin-screw is set to 175°C in the first zone; 203°C in the second zone; 210°C in the third zone; 208°C in the fourth zone 220°C in the fifth zone; 220°C in the sixth zone; 215°C in the seventh zone; Zone 195°C; Zone 3 215°C; Zone 4 220°C; Zone 5 220°C; Extract out the water and impurities, remove impurities, improve the purity of the melt, and then extrude the sheet through three-roll embossing and setting; f. Anti-UV and anti-static layer.

Embodiment 2

[0037] a. Main machine mixing PS raw material, diffusing agent and auxiliary agent are stirred in the mixer at high speed for 4 minutes; b. Auxiliary machine mixing is according to the main machine formula or raw materials are added with anti-UV material and then put into the mixer for high-speed stirring 4 minutes; c. The main machine mixing material is directly delivered to the twin-screw barrel by the screw feeding device; the temperature of each zone of the twin-screw is set to 180°C in the first zone; 205°C in the second zone; 215°C in the third zone; 220°C in the fourth zone 225 °C in the fifth area; 225 °C in the sixth area; 220 °C in the seventh area; zone 200°C; zone 3 220°C; zone 4 225°C; zone 5 225°C; Extract out the water and impurities, remove impurities, improve the purity of the melt, and then extrude the sheet through three-roll embossing and setting; f. Anti-UV and anti-static layer.

[0038] Implementation three:

[0039] a. Main machine mixing PS raw mate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com