Special extrusion screw for polyethylene of raised temperature resistance and extrusion method of special extrusion screw

A heat-resistant polyethylene and extrusion screw technology, used in plastic extrusion screw, heat-resistant polyethylene special extrusion screw and its extrusion field, can solve the problem of narrow molecular weight distribution of heat-resistant polyethylene raw materials, reducing screw feeding capacity, The problem of poor plasticizing effect of materials can achieve the effect of improving the effect of melting and plasticizing, improving the blocking phenomenon and enhancing the effect of melting and plasticizing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

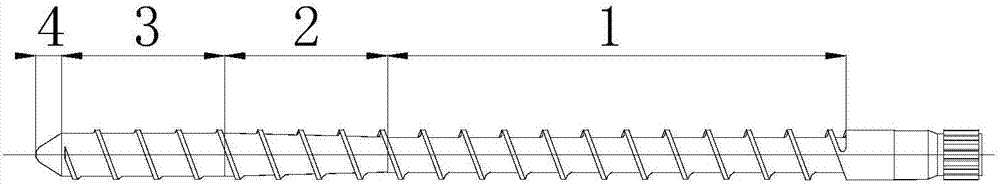

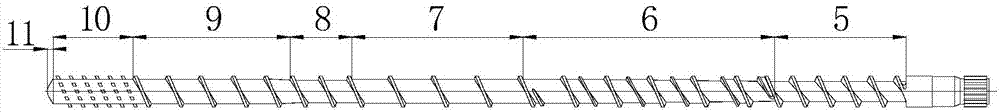

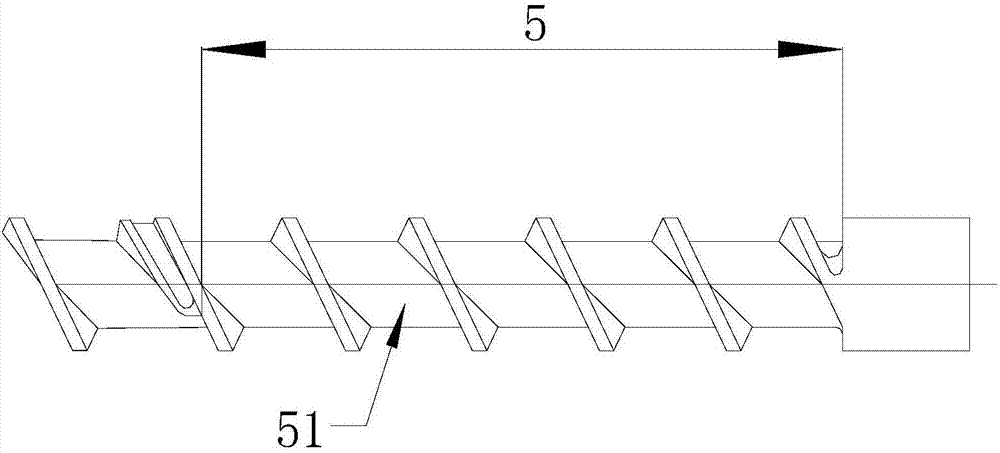

[0044] Such as Figure 2 to Figure 7 As shown, the special extrusion screw for heat-resistant polyethylene in this embodiment includes a feeding section 5, a compression section 6, a first metering section 7, a decompression section 8, a second metering section 9, a mixing section 10 and a screw head 11. The feeding section 5, the compression section 6, the first metering section 7, the decompression section 8, the second metering section 9, the mixing section 10 and the screw head 11 are connected successively, the outer diameter of the screw is 70mm, and the effective length of the screw is the outer diameter of the screw. 38 times of that, the larger length-to-diameter ratio (ratio of screw length to screw outer diameter) can ensure the residence time of the material in the barrel under the condition of high screw speed, so that it can be fully plasticized.

[0045] The feeding section 5 adopts a single thread structure, and the single thread structure forms a feeding groov...

Embodiment 2

[0060] The main feature of this embodiment is that the outer diameter of the additional thread 64 on the compression section 6 is 2.5 mm smaller than the outer diameter of the main thread 63 . All the other are with embodiment 1.

Embodiment 3

[0062] The main feature of this embodiment is that the outer diameter of the additional thread 64 on the compression section 6 is 5 mm smaller than the outer diameter of the main thread 63 . All the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com