Floatation method and device for coarse-particle floatation column

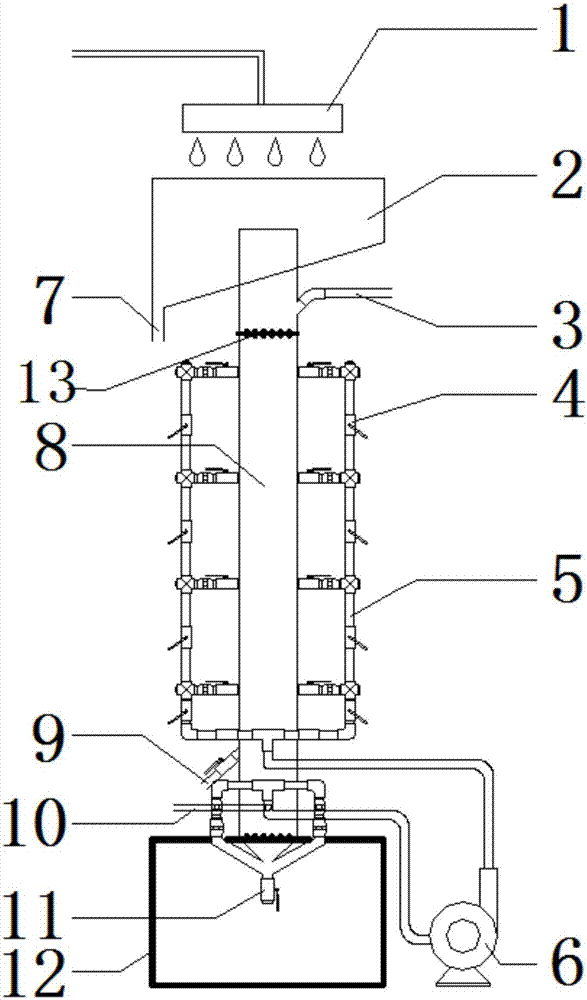

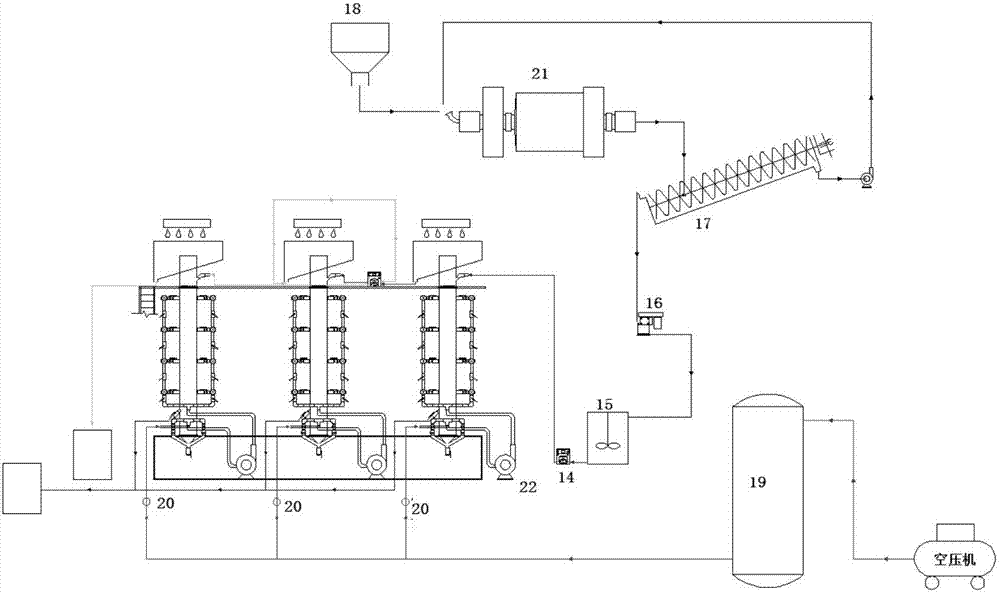

A flotation column and coarse particle technology, used in flotation, solid separation, etc., can solve the problems of chemical properties that have a great influence on the flotation effect, small contact probability between bubbles and particles, and fine-grained gangue staying in it. Expand the upper limit of flotation particle size, advanced equipment, and improve the effect of pipeline blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0050] The test material is a certain bauxite. Multi-element chemical analysis of raw ore, in which Al 2 o 3 The mass fraction accounts for 62.3%, SiO 2 The quality score accounts for 11.54%. The aluminum-silicon ratio of raw ore is 5.40, which belongs to the typical low-aluminum-silicon ratio bauxite. Crush the raw ore to -3mm and mix well. Grinding until the grinding particle size is -0.074mm accounts for 75%. The analysis results of the grinding particle size are shown in Table 3.

[0051] Table 1 Polychemical analysis results of ore samples (mass fraction) / %

[0052]

[0053] Table 2 Mineral composition of test ore samples / %

[0054]

[0055] Table 3 Grinding particle size composition

[0056]

[0057]

[0058] It can be seen from Table 2 that when the grinding particle size reaches -200 mesh, the particle size accounts for 75%, and the -0.038mm particle size accounts for 27.48%. In terms of bauxite selection, the grinding fineness can be appropriately ...

Embodiment 2

[0066] In the test, 2kg of grinding products were weighed in the mixing tank, and the concentration of the pulp was adjusted to 24%. Sulfuric acid was added to the pulp with the adjusted concentration as a pH regulator and inhibitor, and the collector GJBW was added after stirring for 2 minutes. The pulp is fed into the flotation column by the pulp pump, and the flotation time is 10 minutes, and the foam is scraped every 5 minutes.

[0067] Table 5 Test results of the new flotation column

[0068]

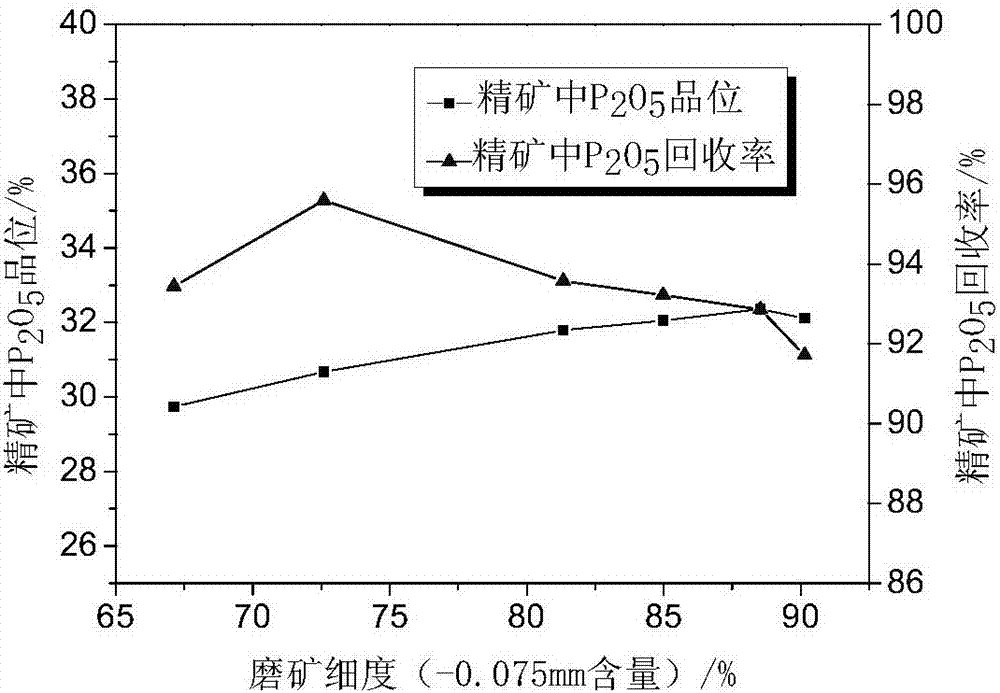

[0069] It can be seen from the grade curve in the figure that with the increase of the grinding fineness, the P in the concentrate 2 o 5 The grade of the ore showed a slow growth trend. When the grinding fineness exceeded 88.53%, the concentrate grade decreased. It can be seen from the recovery curve that with the increase of the grinding fineness, the P in the concentrate 2 o 5The recovery rate showed a trend of first increasing and then decreasing. This is because when th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com