Patents

Literature

791 results about "Particle separation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Particle separation processes such as sedimentation, flotation and filtration are significantly influenced by particle size, and the process chosen can depend greatly on the size of the particles to be removed (see Figure 1.1).

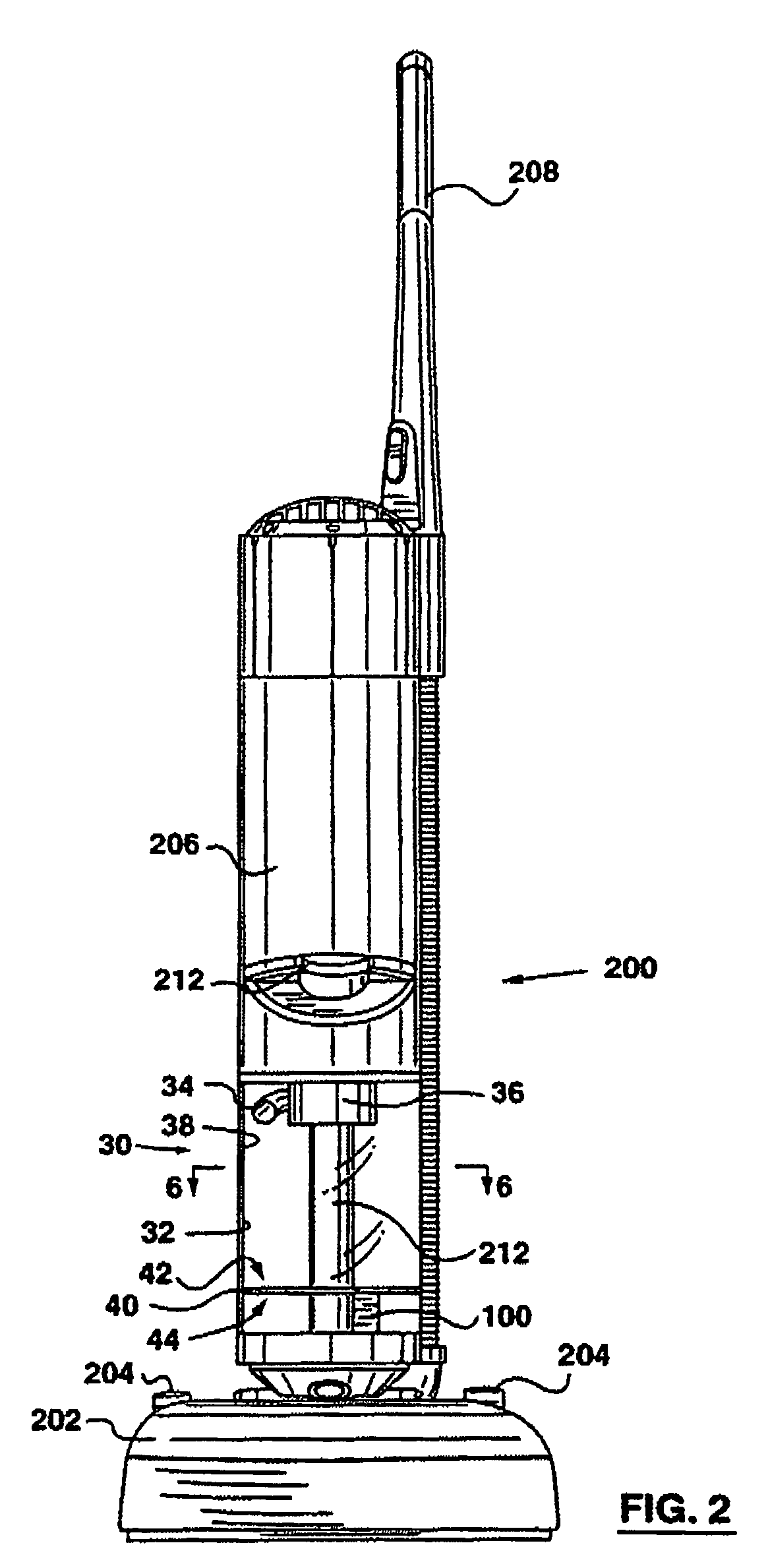

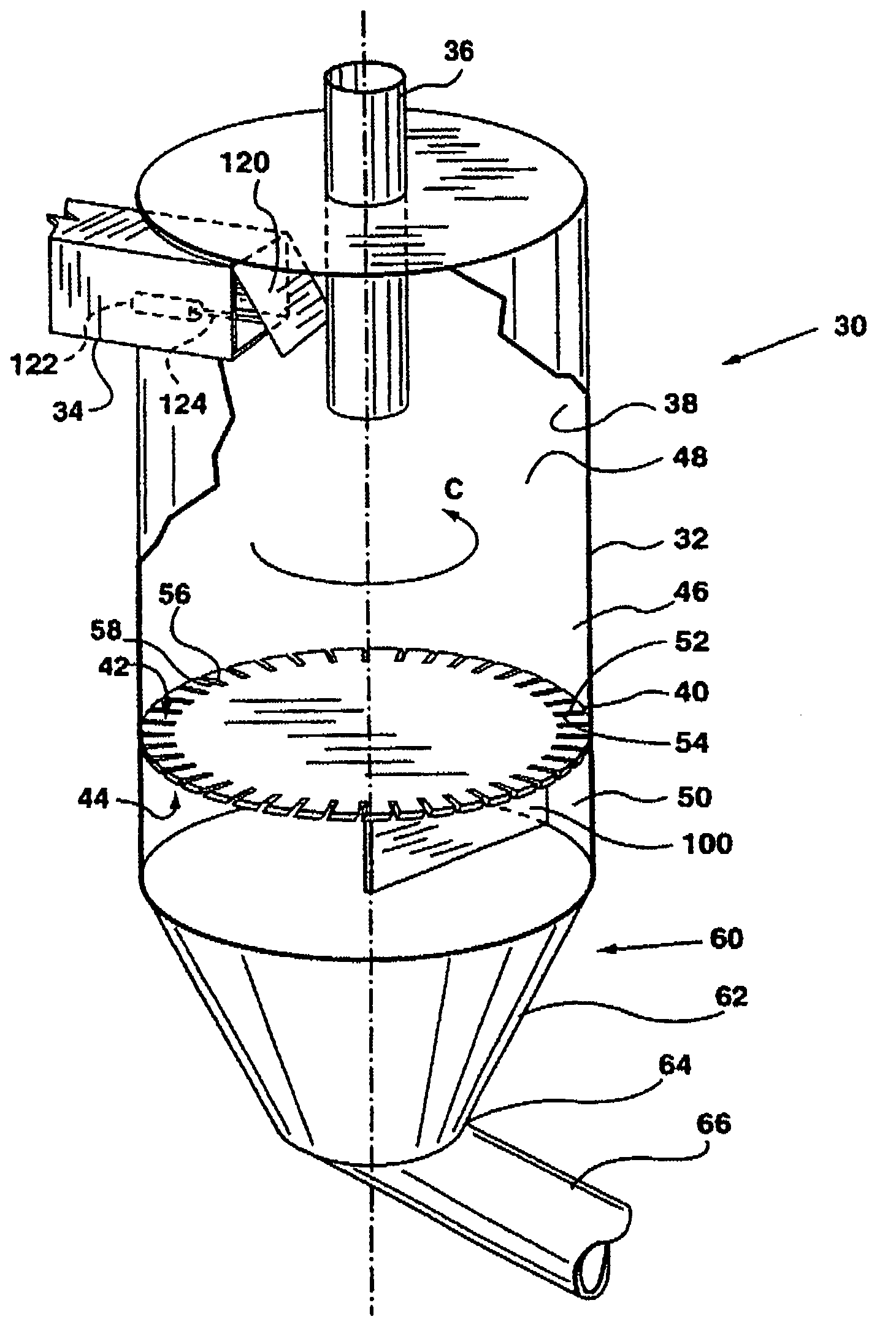

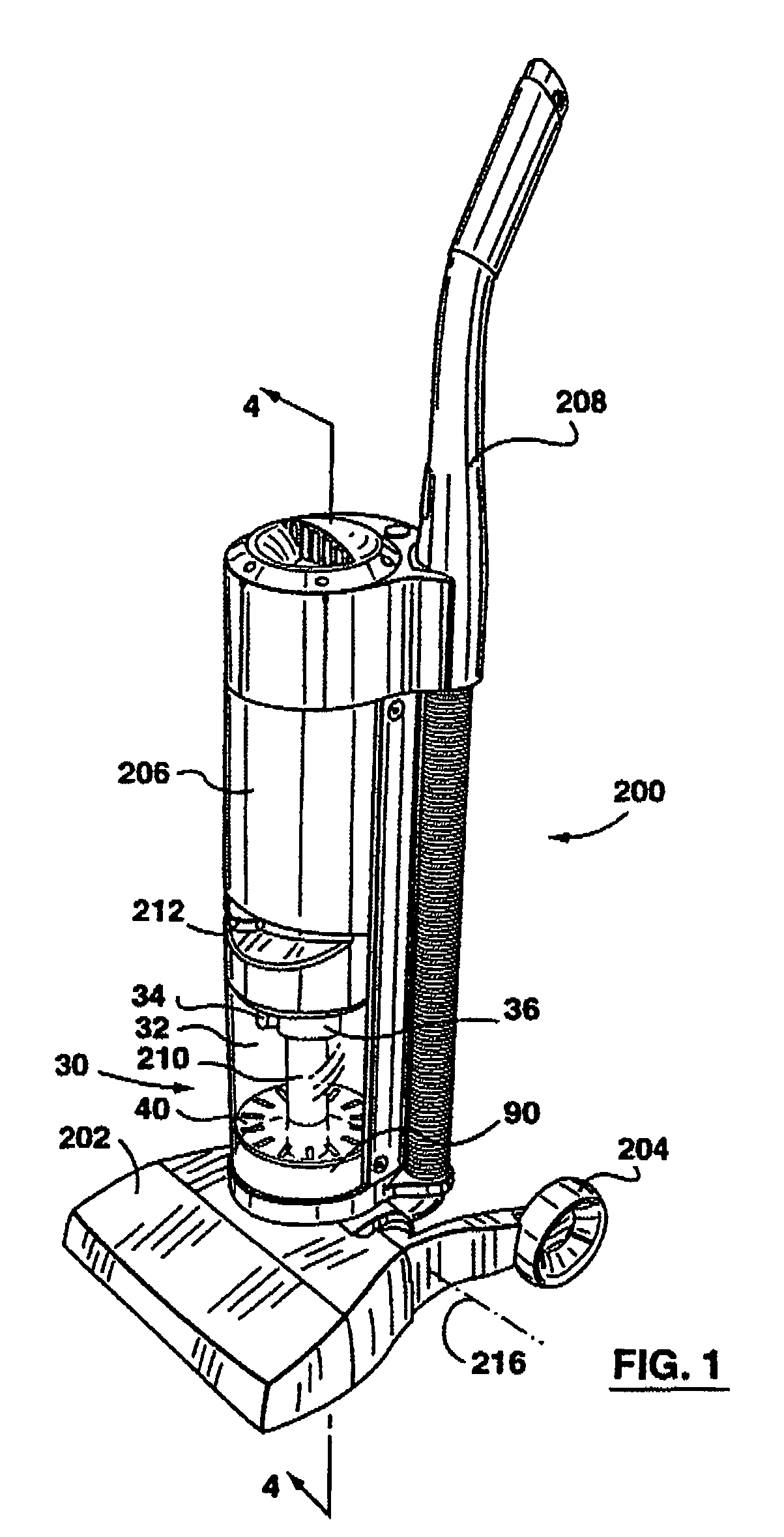

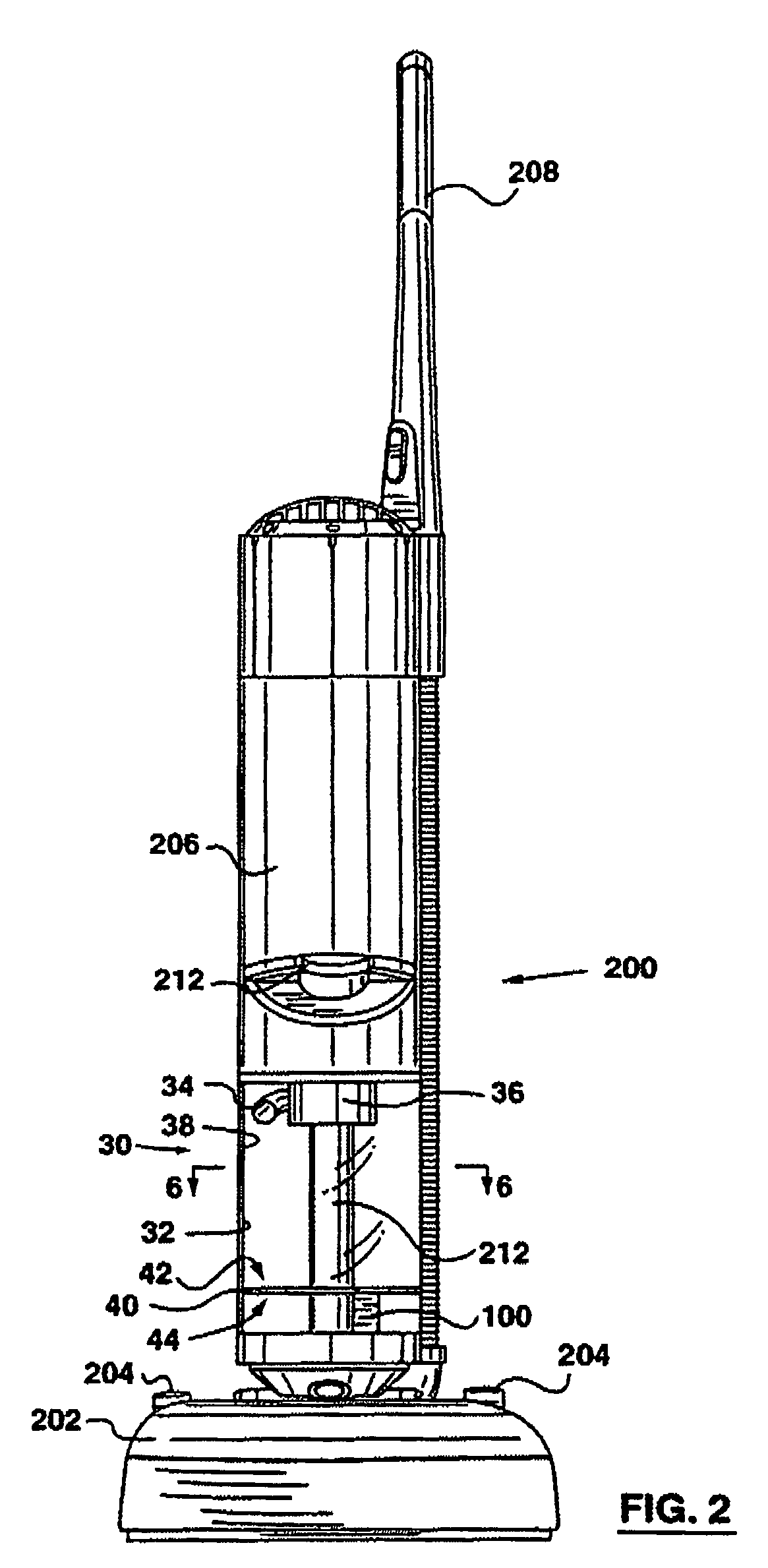

Apparatus and method for separating particles from a cyclonic fluid flow

InactiveUS6874197B1Improve efficiencyPrevent reentrainmentCleaning filter meansSuction filtersEngineeringParticle separation

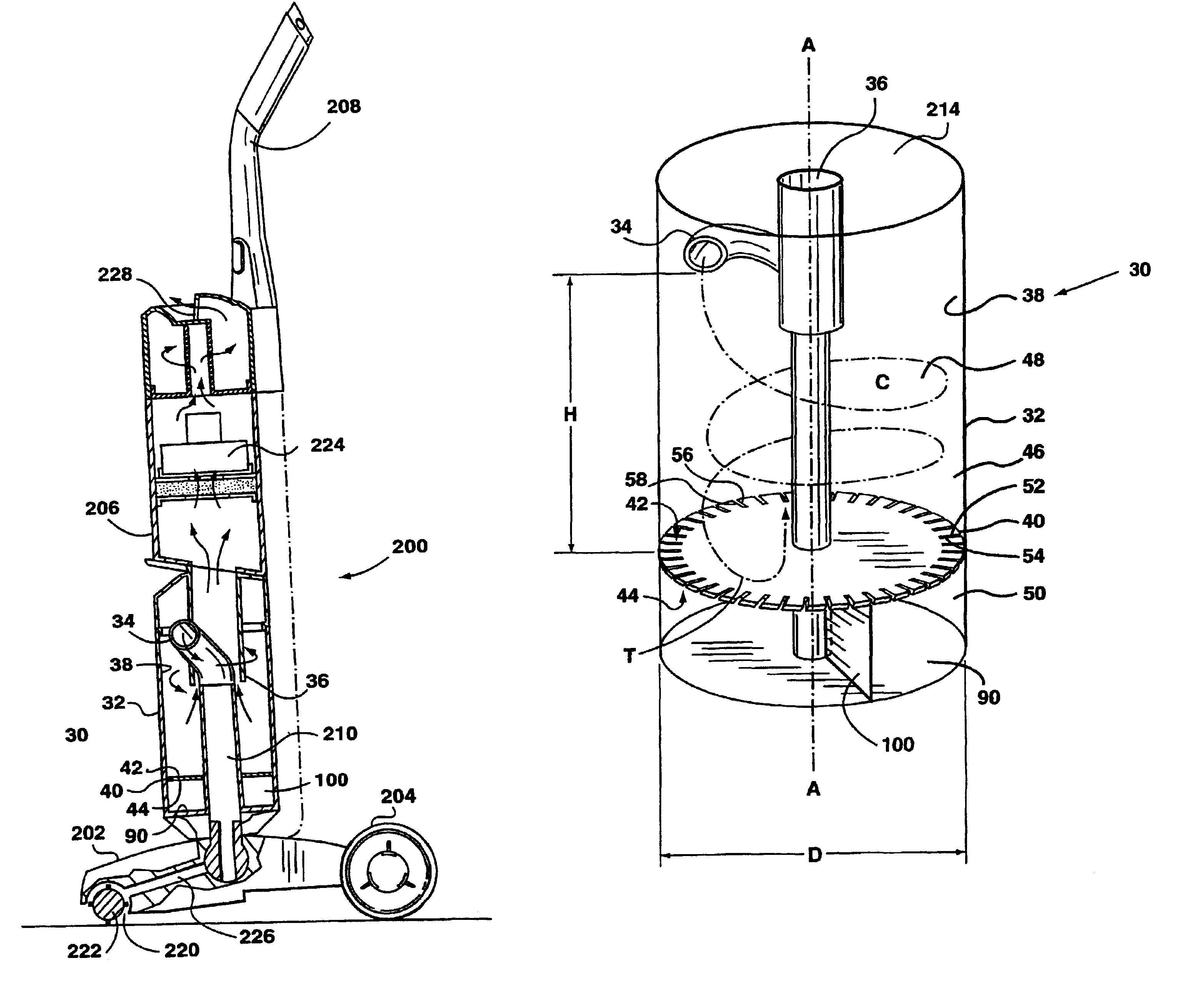

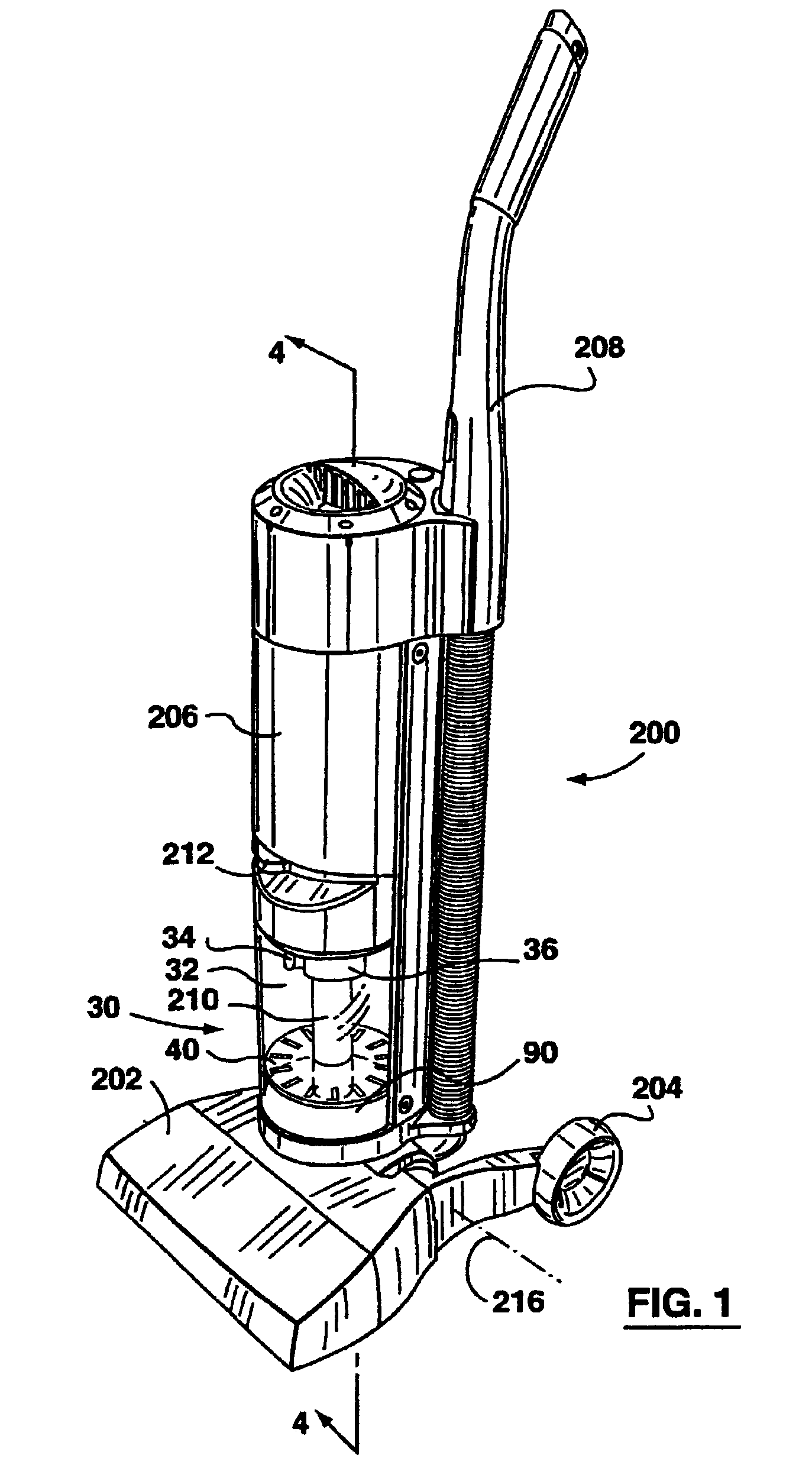

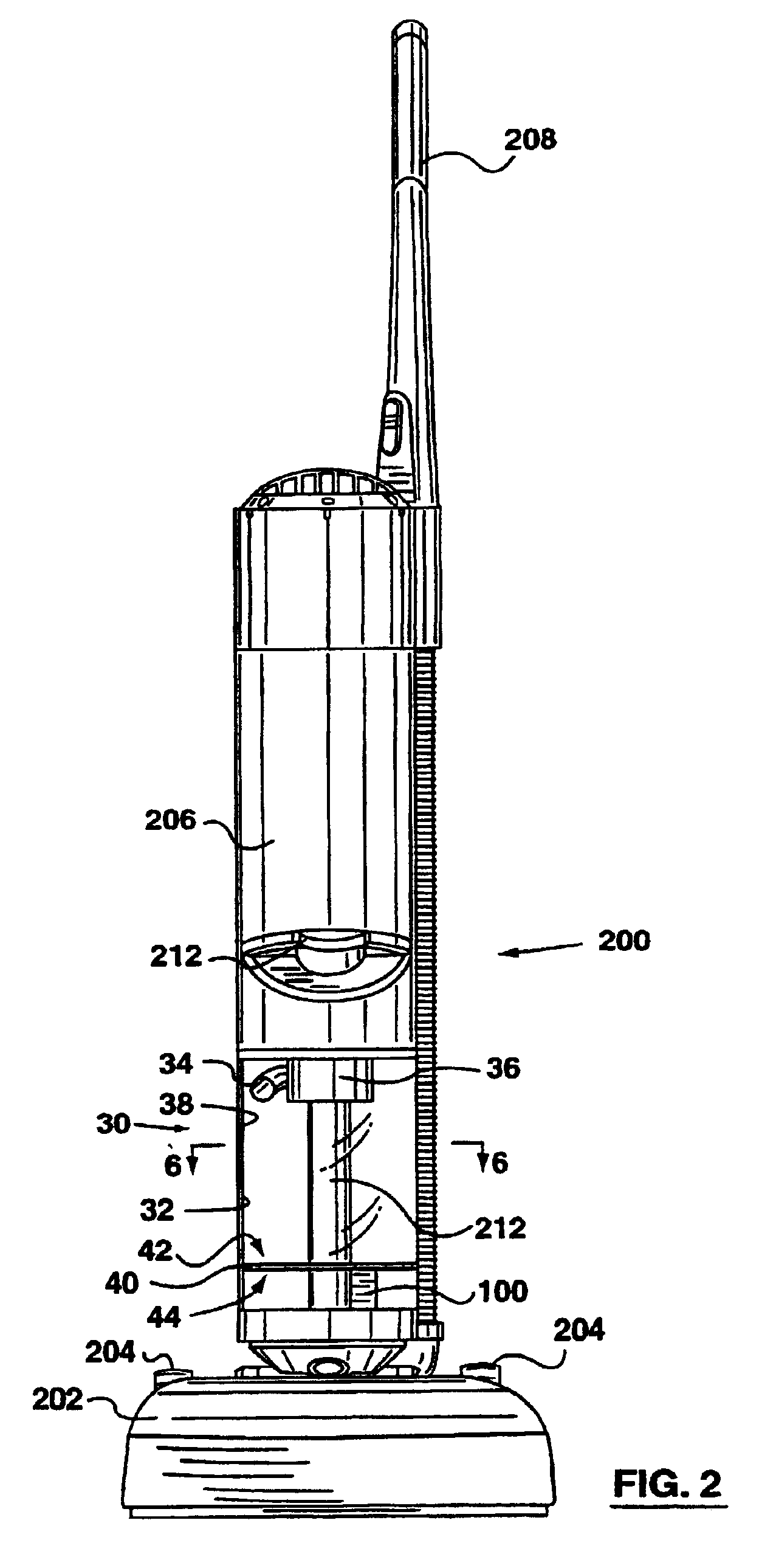

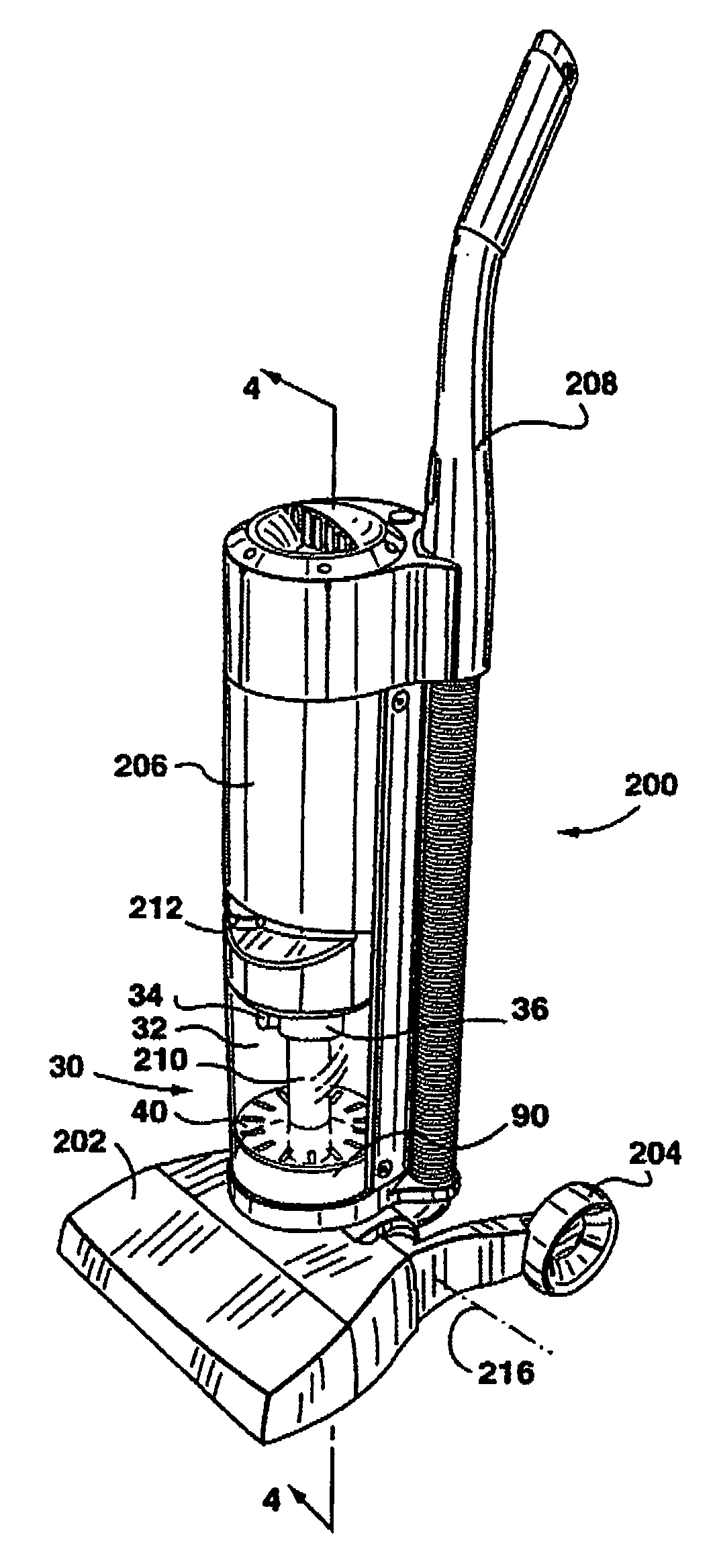

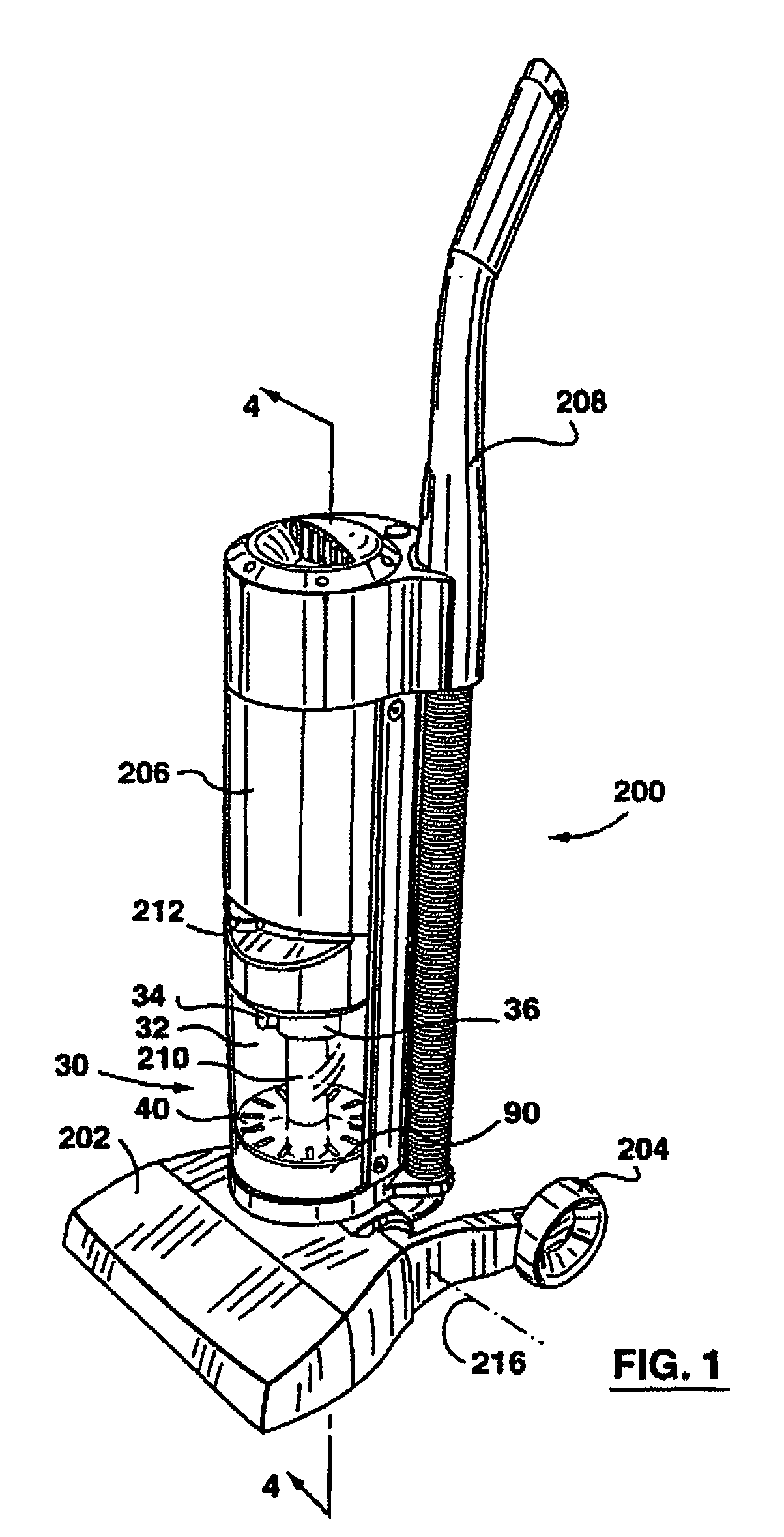

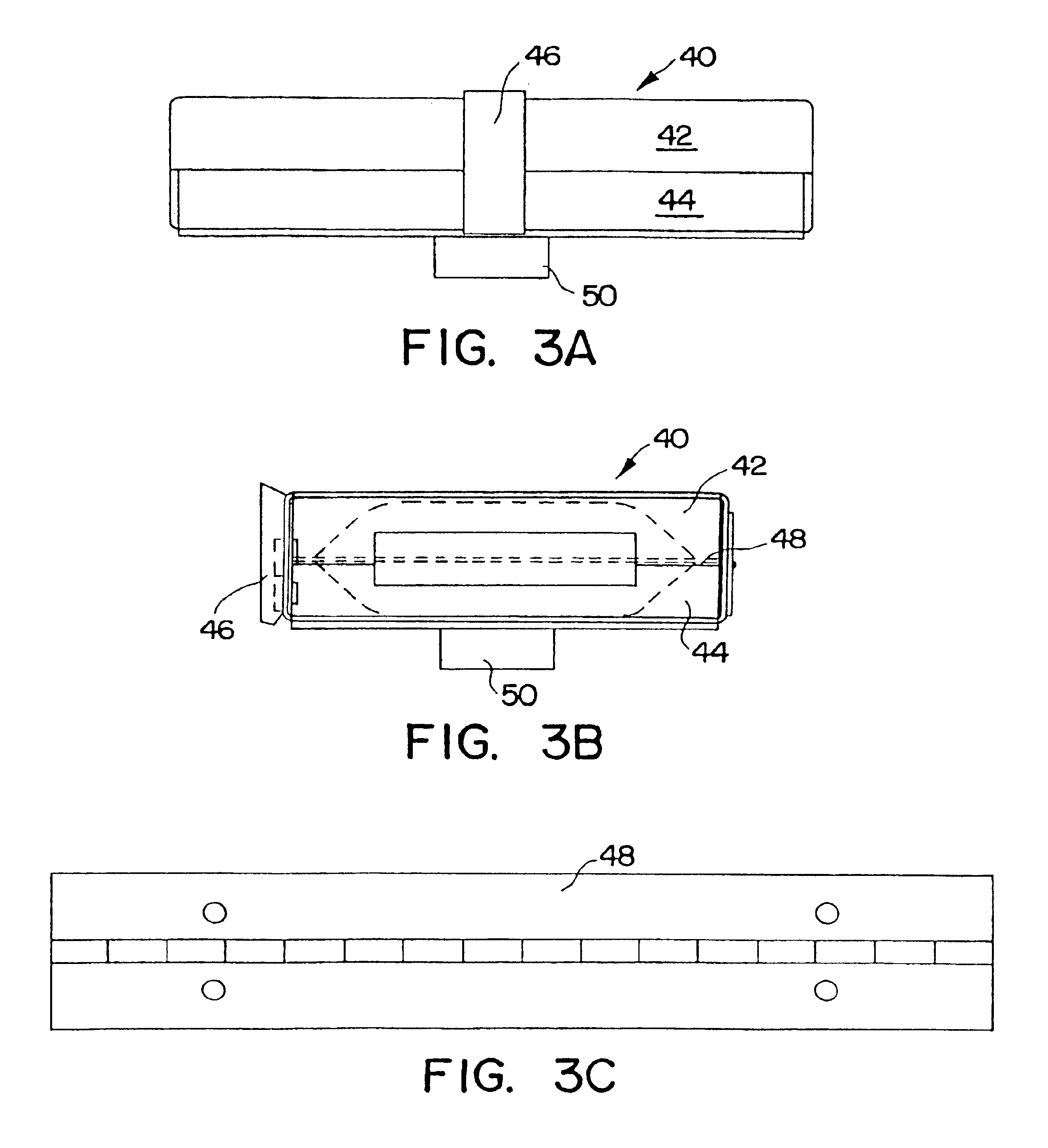

A particle separation member (40) is provided for use with a cyclone separator (30). The particle separation member (40) divides the separator (30) into a cyclone chamber (46) and a particle receiving chamber (50). The cyclone chamber (46) and the particle receiving chamber (50) communicating via a plurality of apertures (52) in the particle separation member (40).

Owner:OMACHRON INTPROP

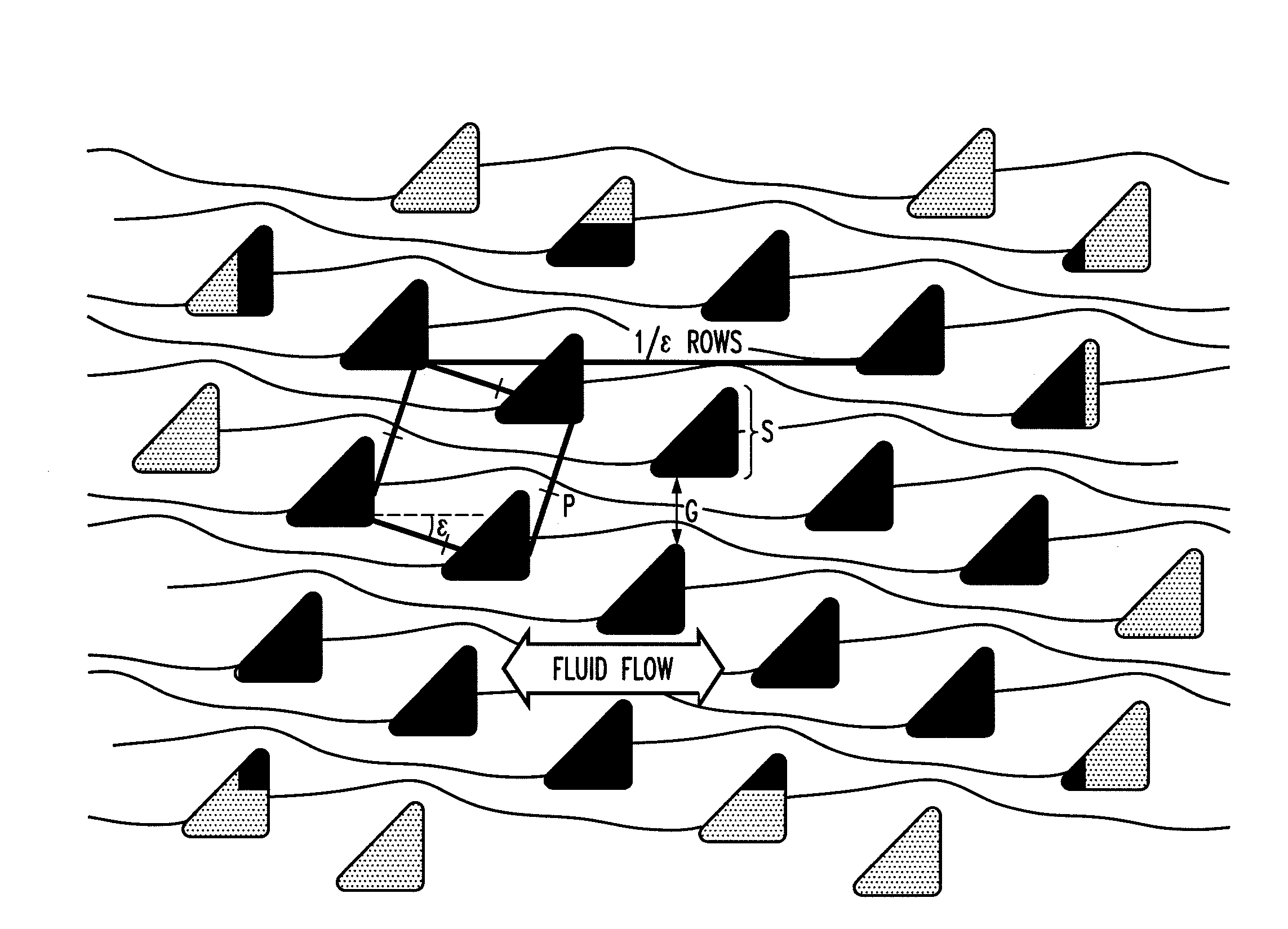

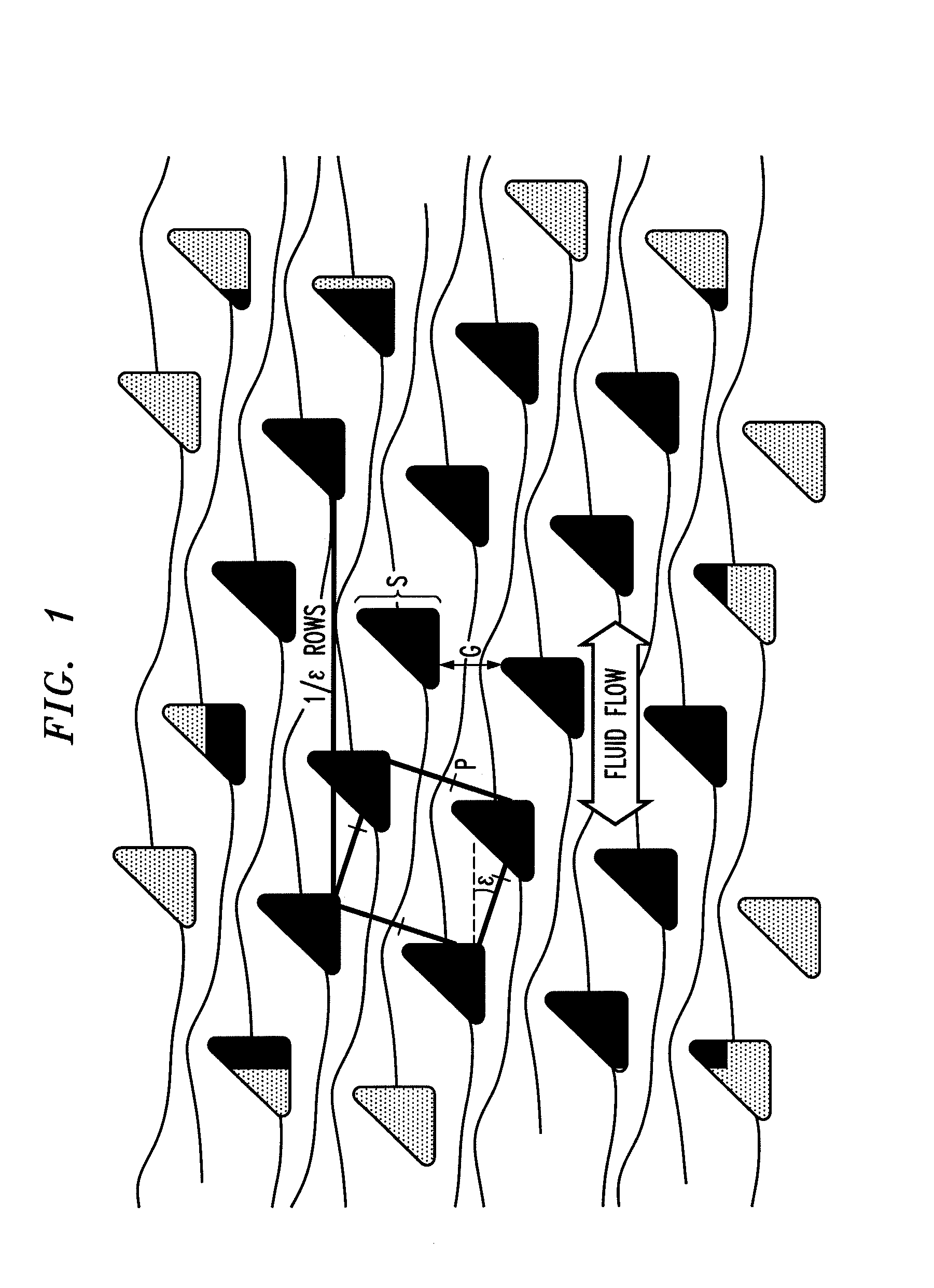

Method for continuous particle separation using obstacle arrays asymmetrically aligned to fields

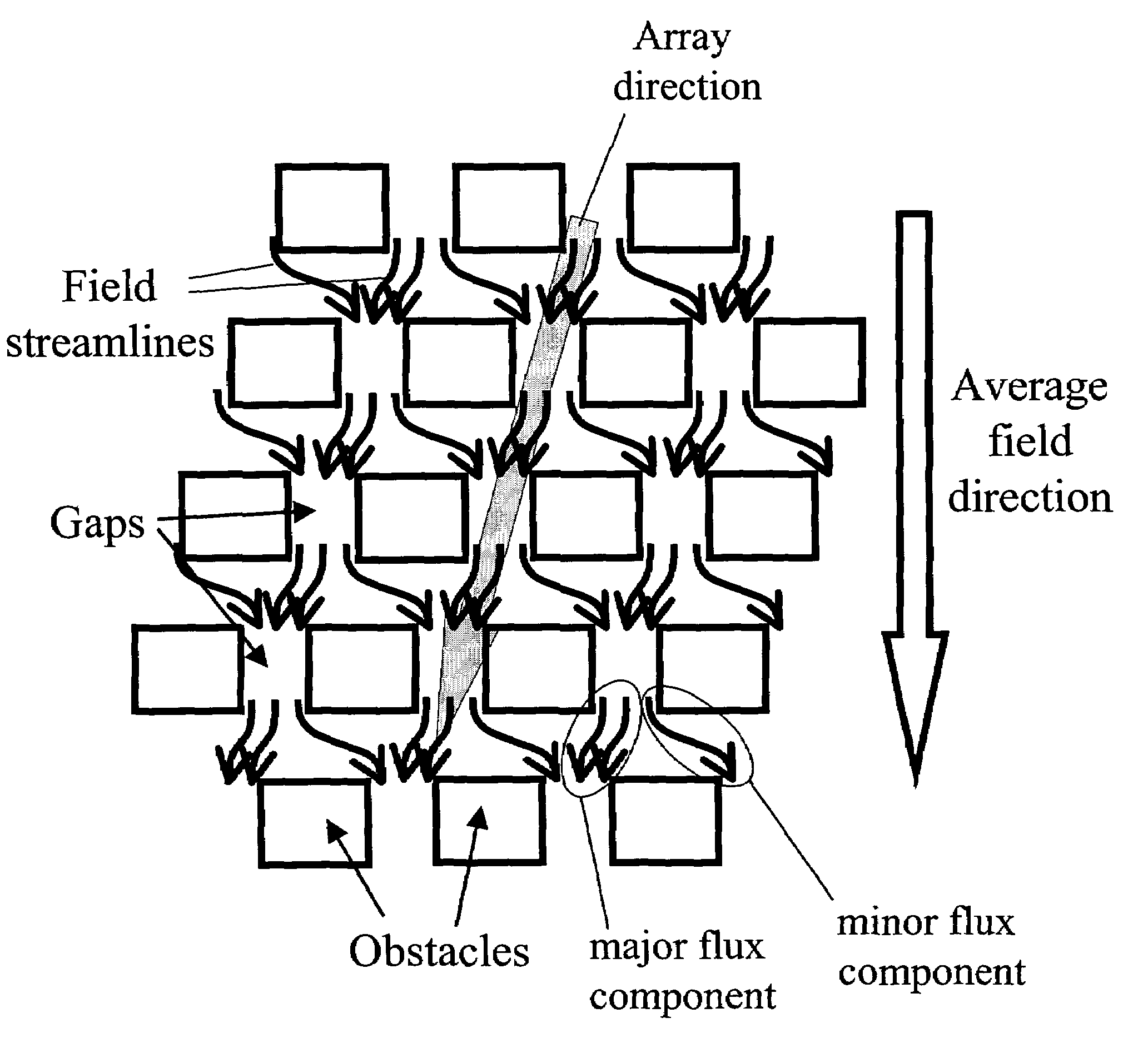

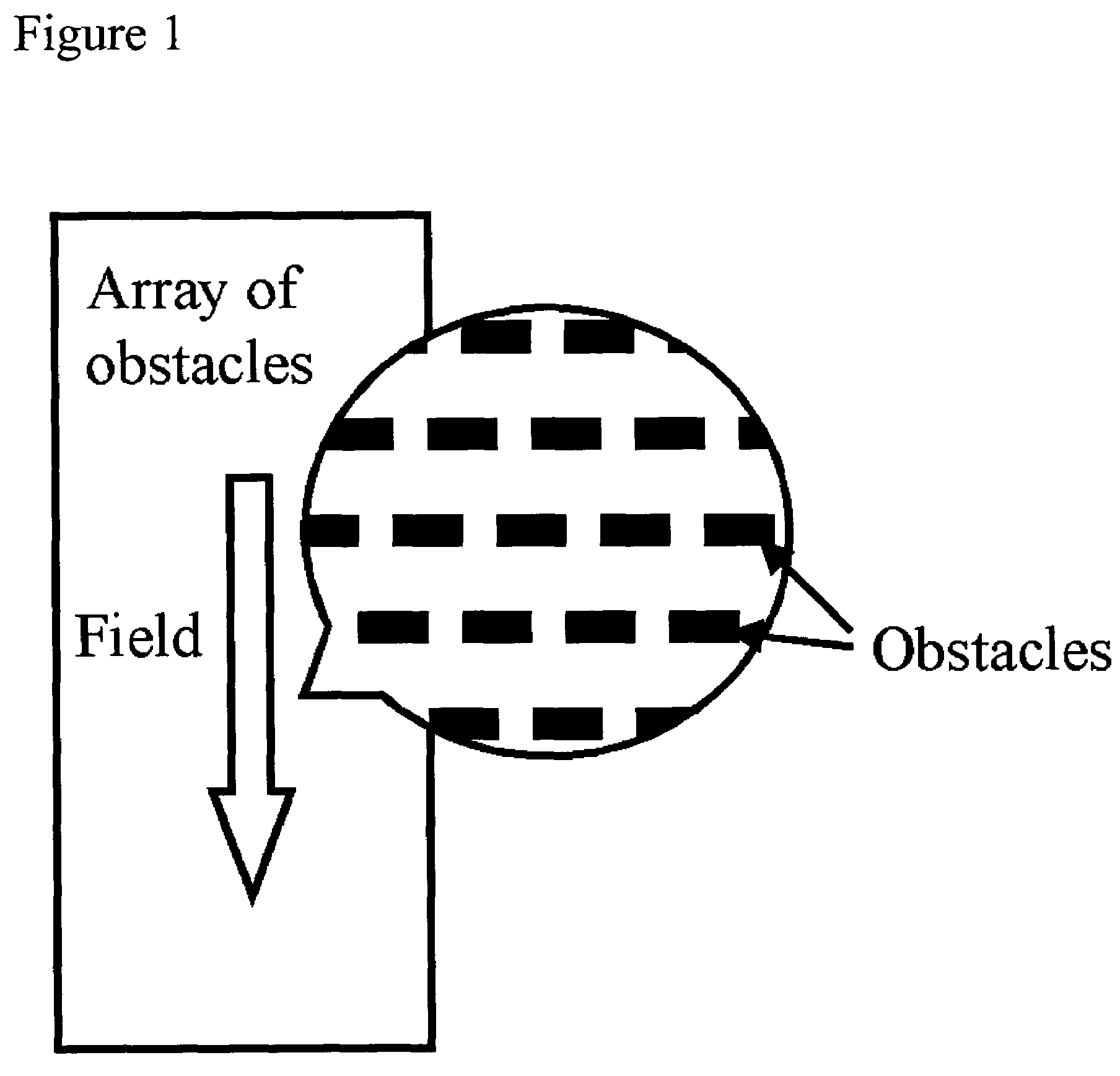

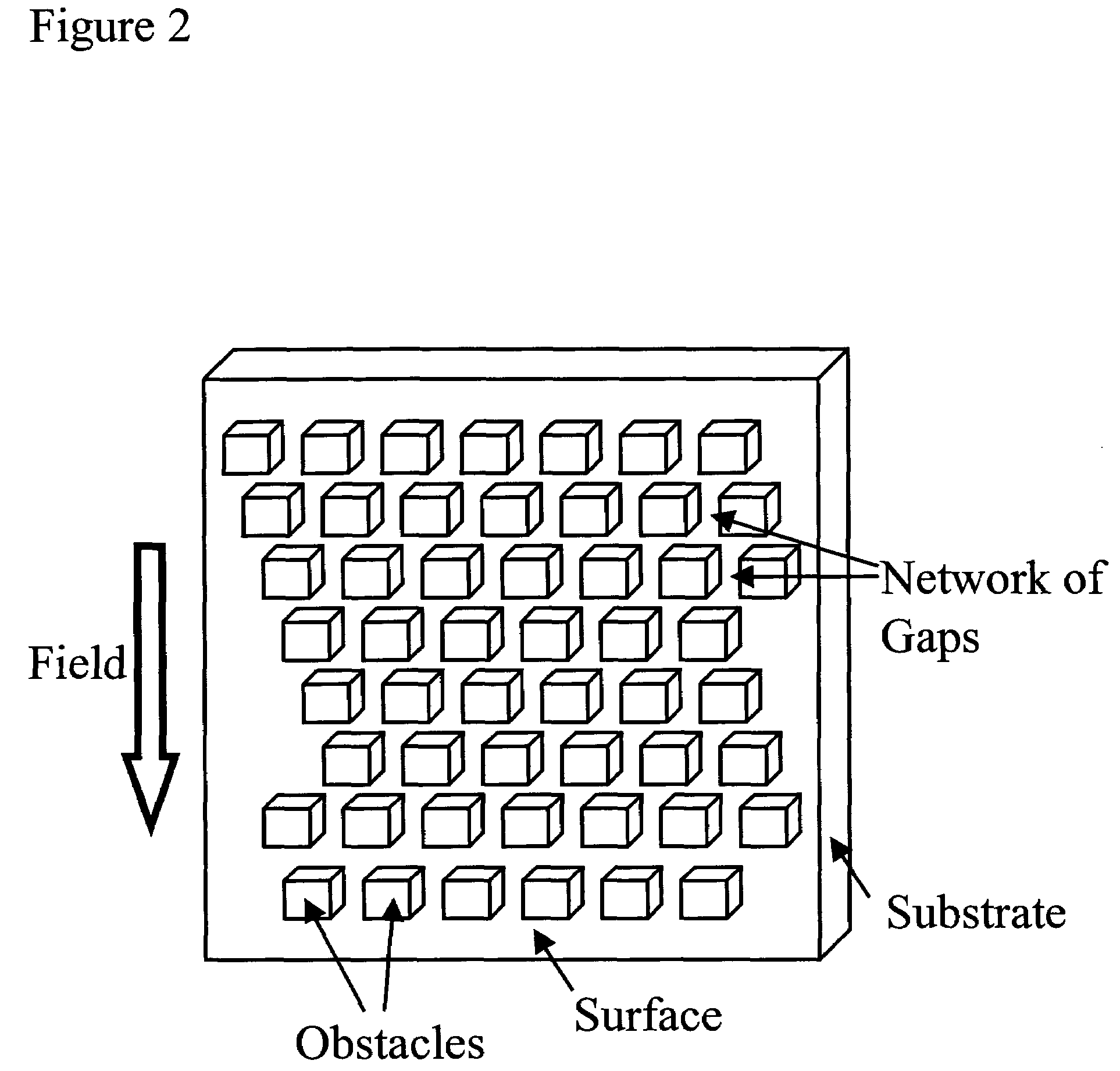

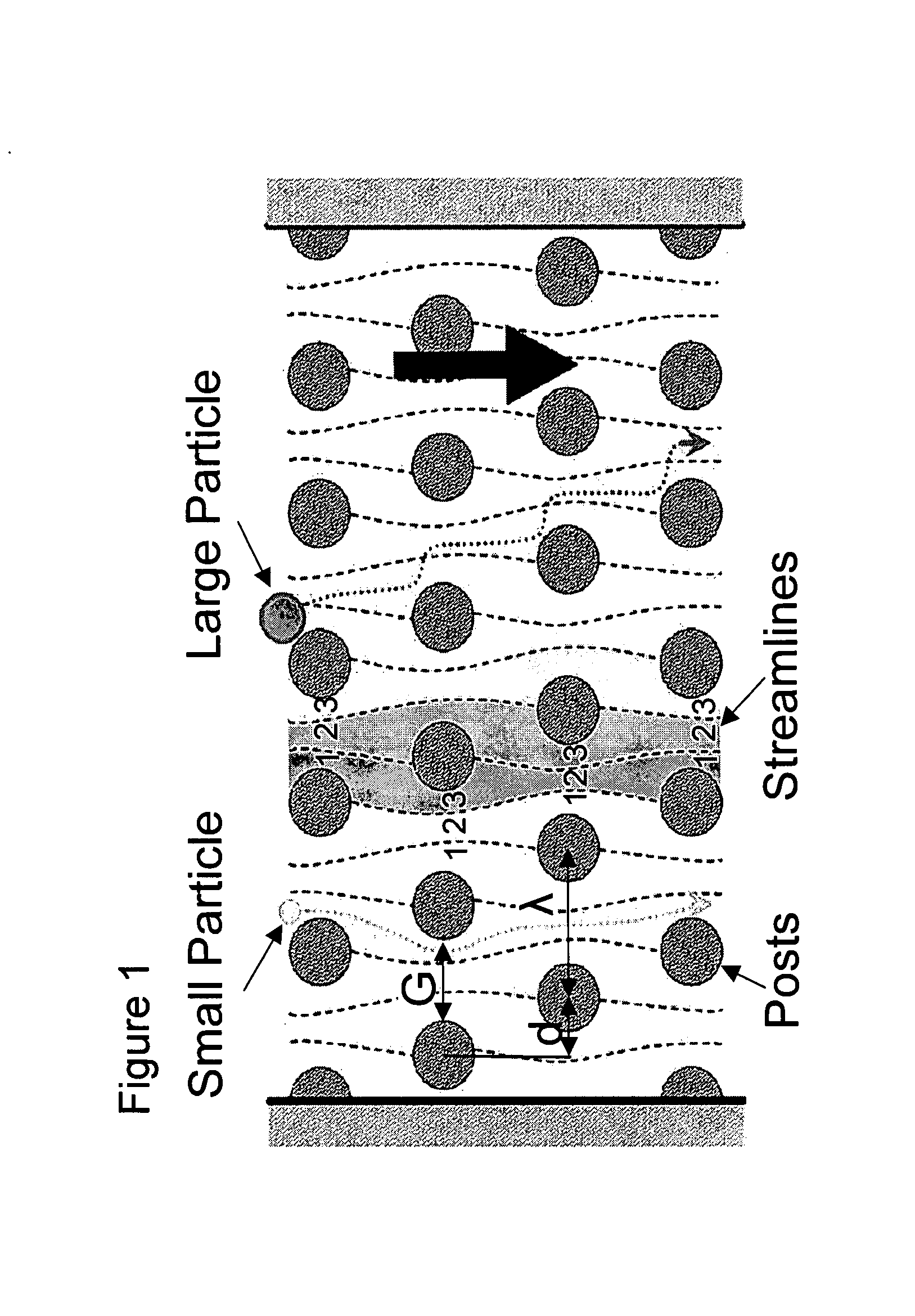

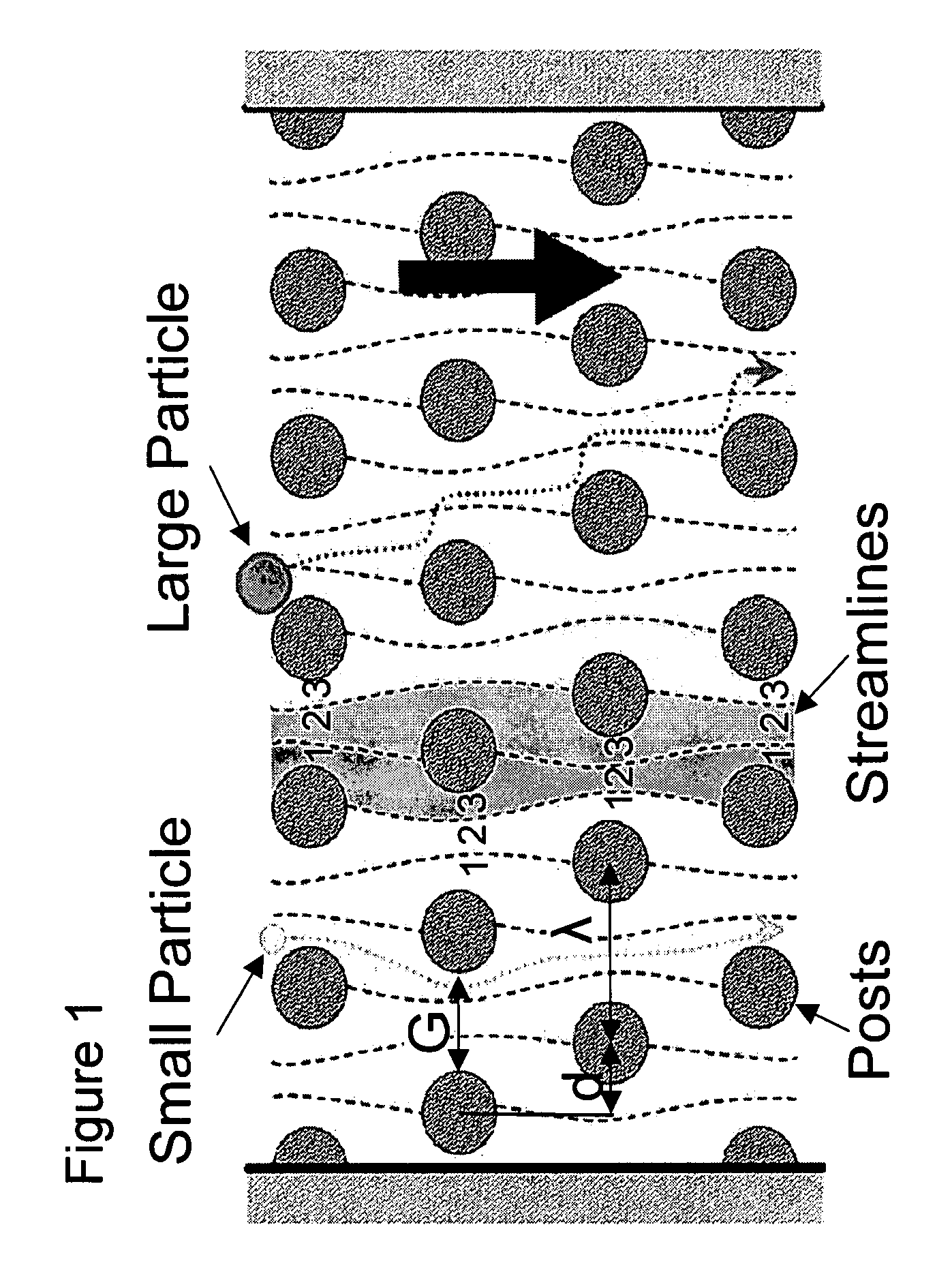

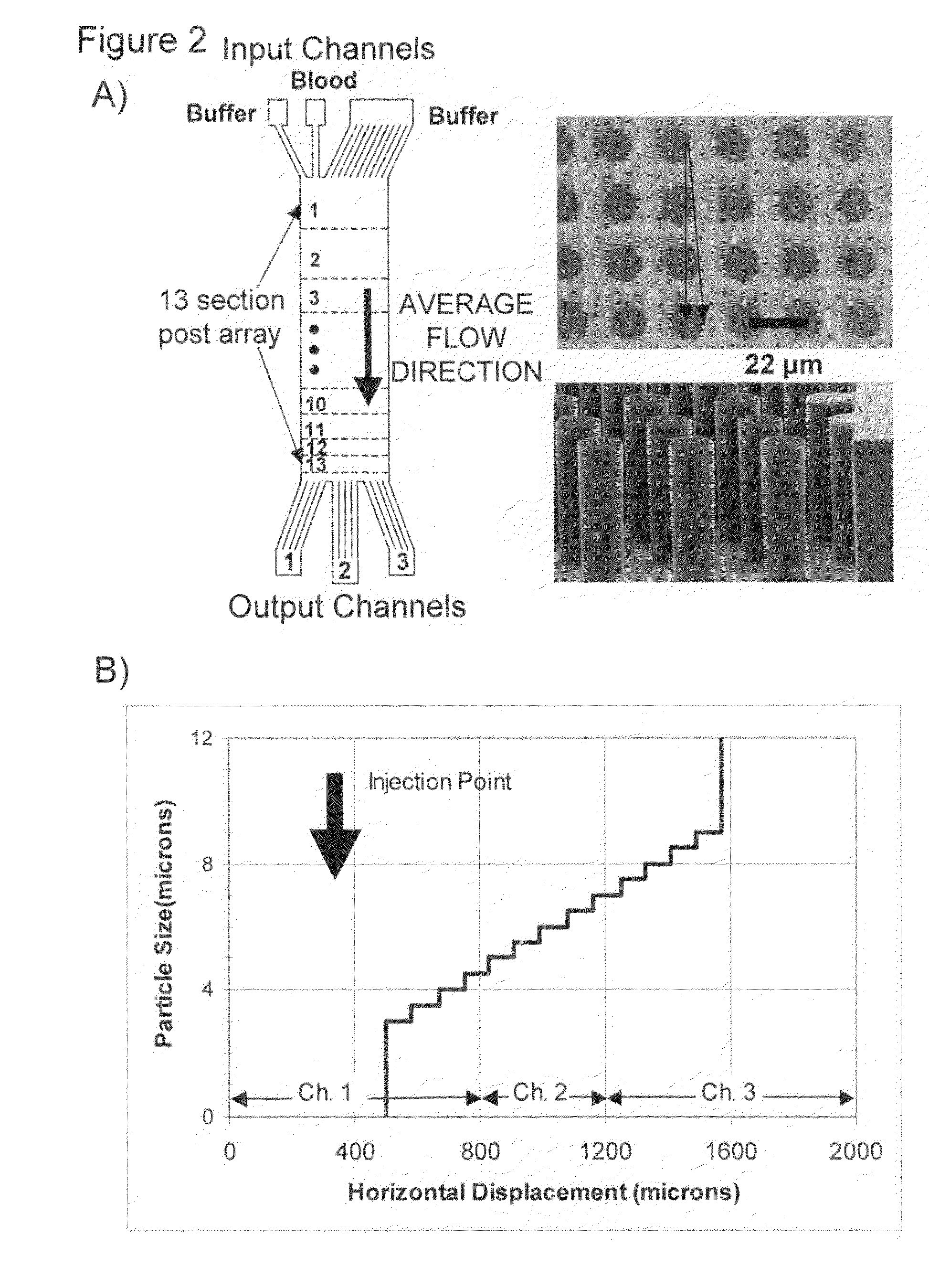

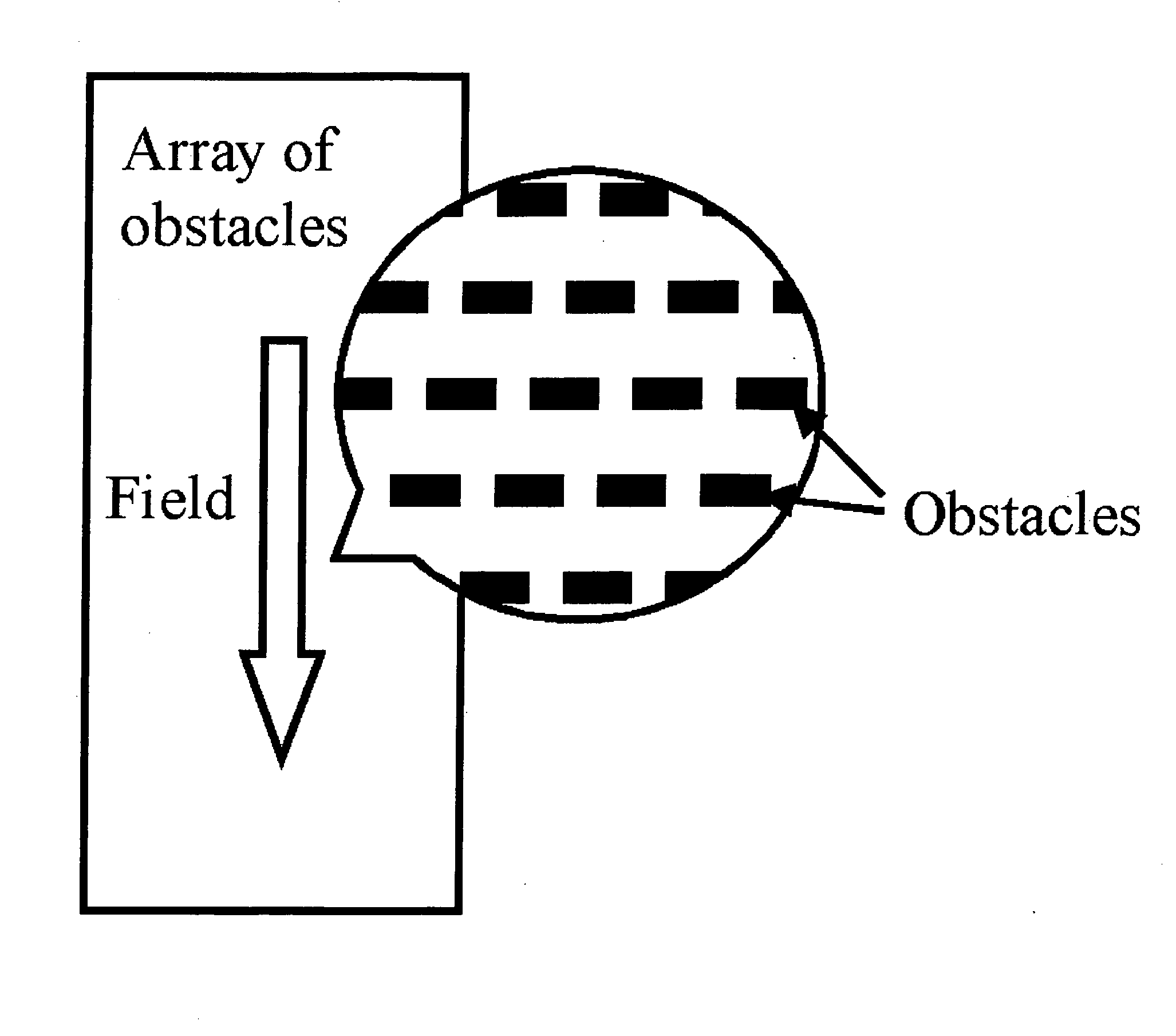

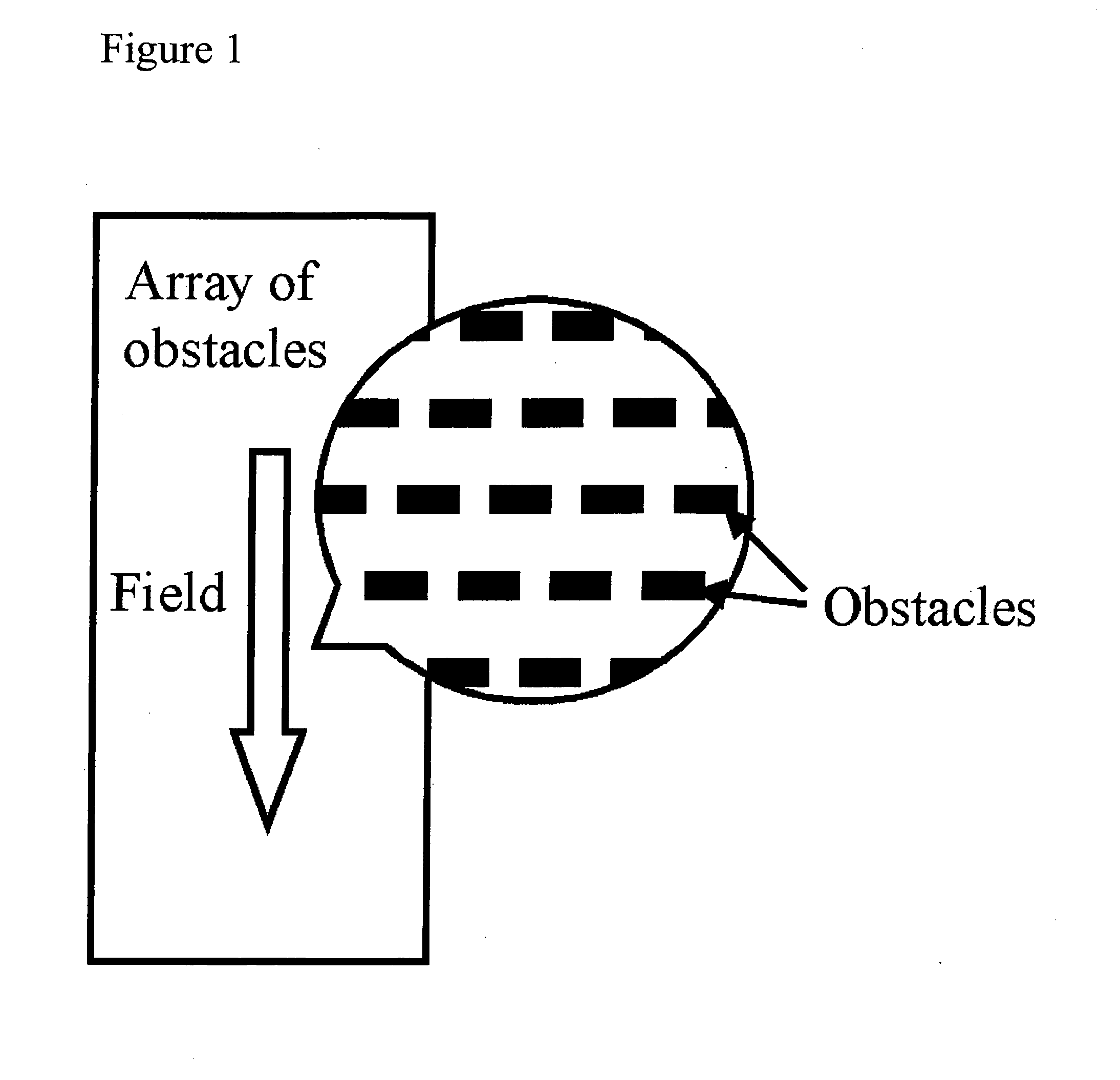

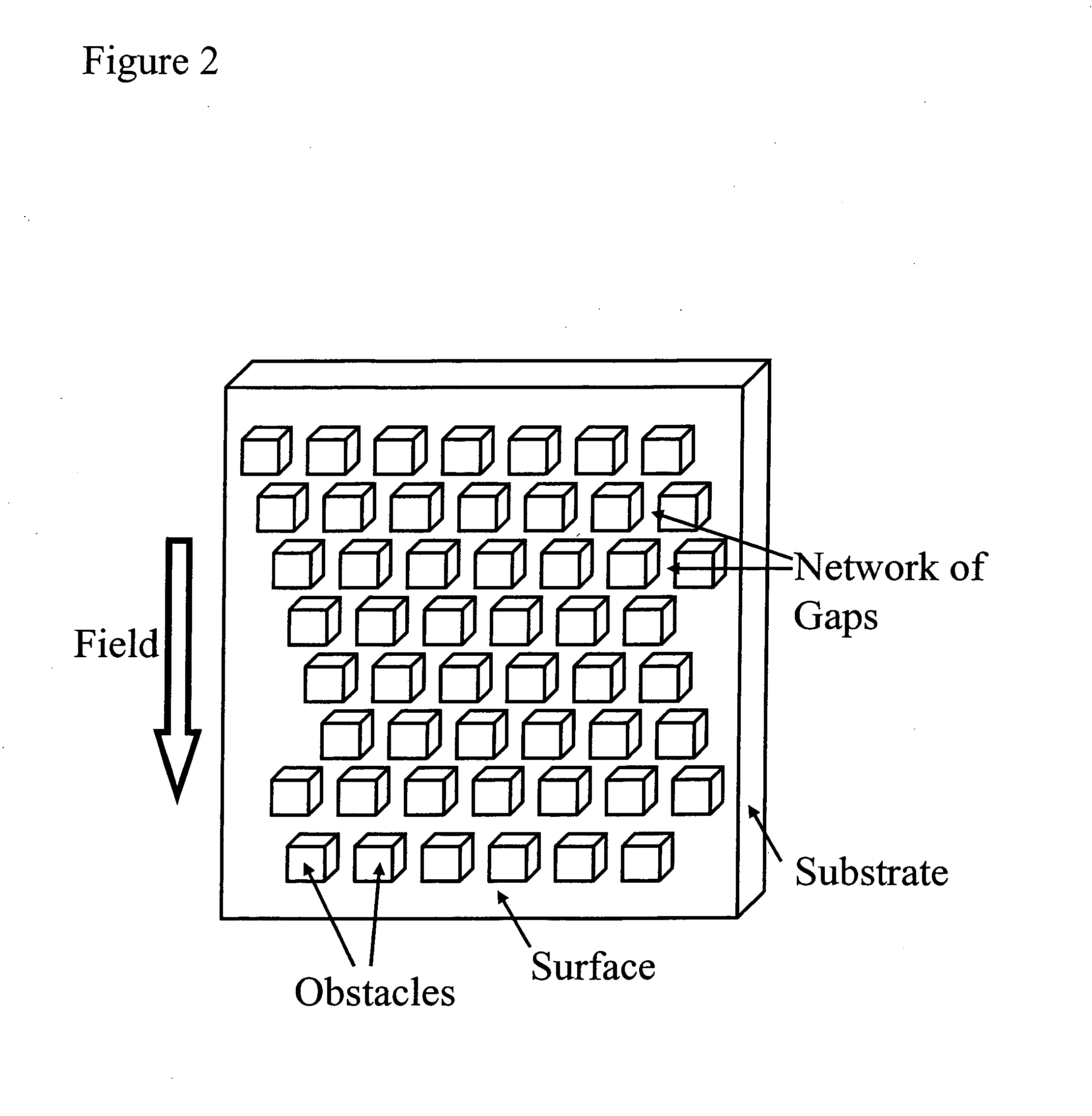

The present invention relates to methods and devices for separating particles according to size. More specifically, the present invention relates to a microfluidic method and device for the separation of particles according to size using an array comprising a network of gaps, wherein the field flux from each gap divides unequally into subsequent gaps. In one embodiment, the array comprises an ordered array of obstacles in a microfluidic channel, in which the obstacle array is asymmetric with respect to the direction of an applied field.

Owner:THE TRUSTEES FOR PRINCETON UNIV

Apparatus and method for separating particles from a cyclonic fluid flow

InactiveUS20060137314A1Prevent reentrainmentEfficient separationCleaning filter meansCombination devicesParticle separationPhysics

A particle separation member is provided for use with a cyclone separator. The particle separation member divides the separator into a cyclone chamber and a particle receiving chamber. The cyclone chamber and the particle receiving chamber communicating via a plurality of apertures in the particle separation member.

Owner:OMACHRON INTPROP

Apparatus and method for separating particles from a cyclonic fluid flow

InactiveUS7449040B2Prevent reentrainmentEfficient separationCleaning filter meansCombination devicesParticle separationPhysics

A particle separation member is provided for use with a cyclone separator. The particle separation member divides the separator into a cyclone chamber and a particle receiving chamber. The cyclone chamber and the particle receiving chamber communicating via a plurality of apertures in the particle separation member.

Owner:OMACHRON INTPROP

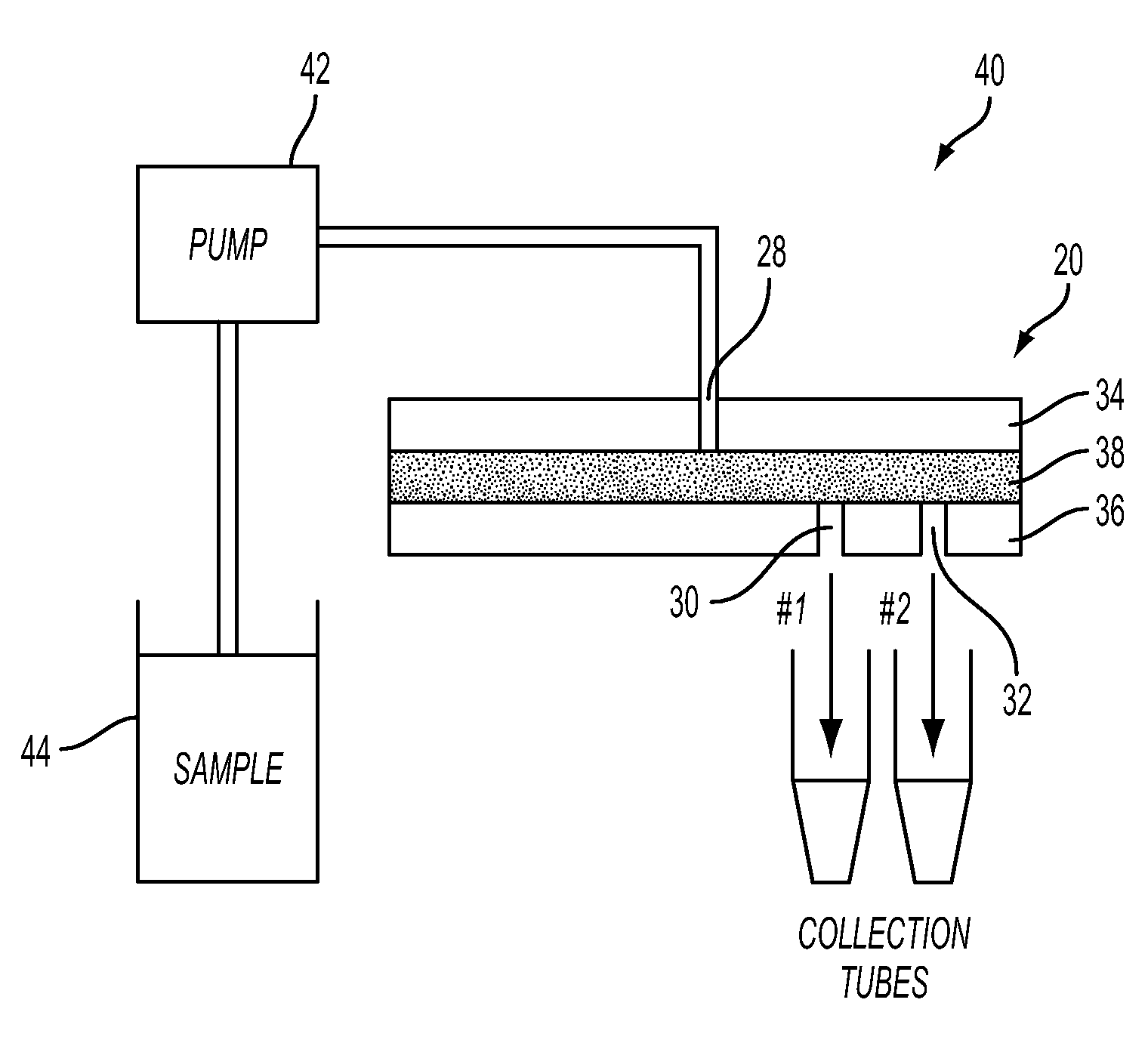

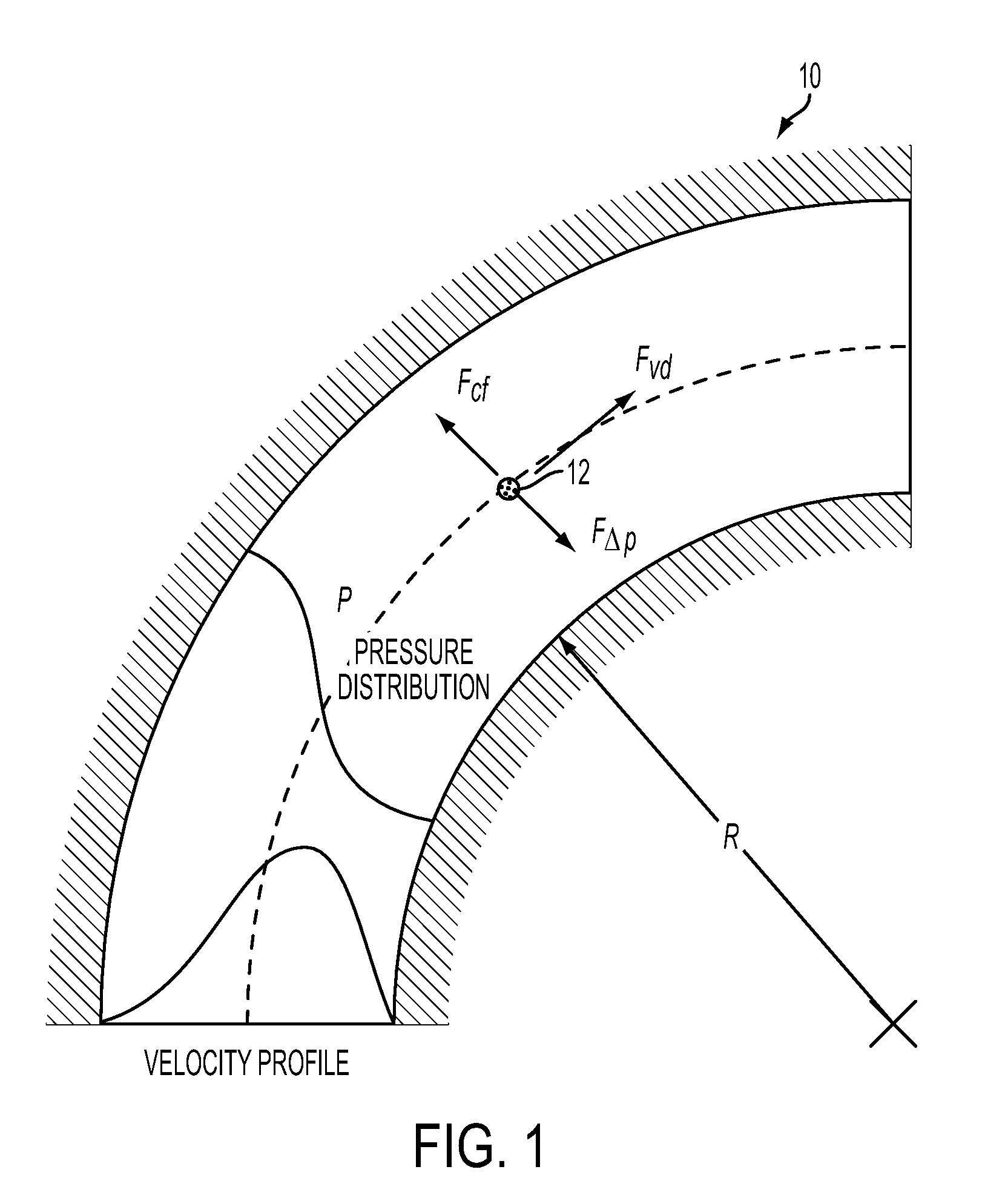

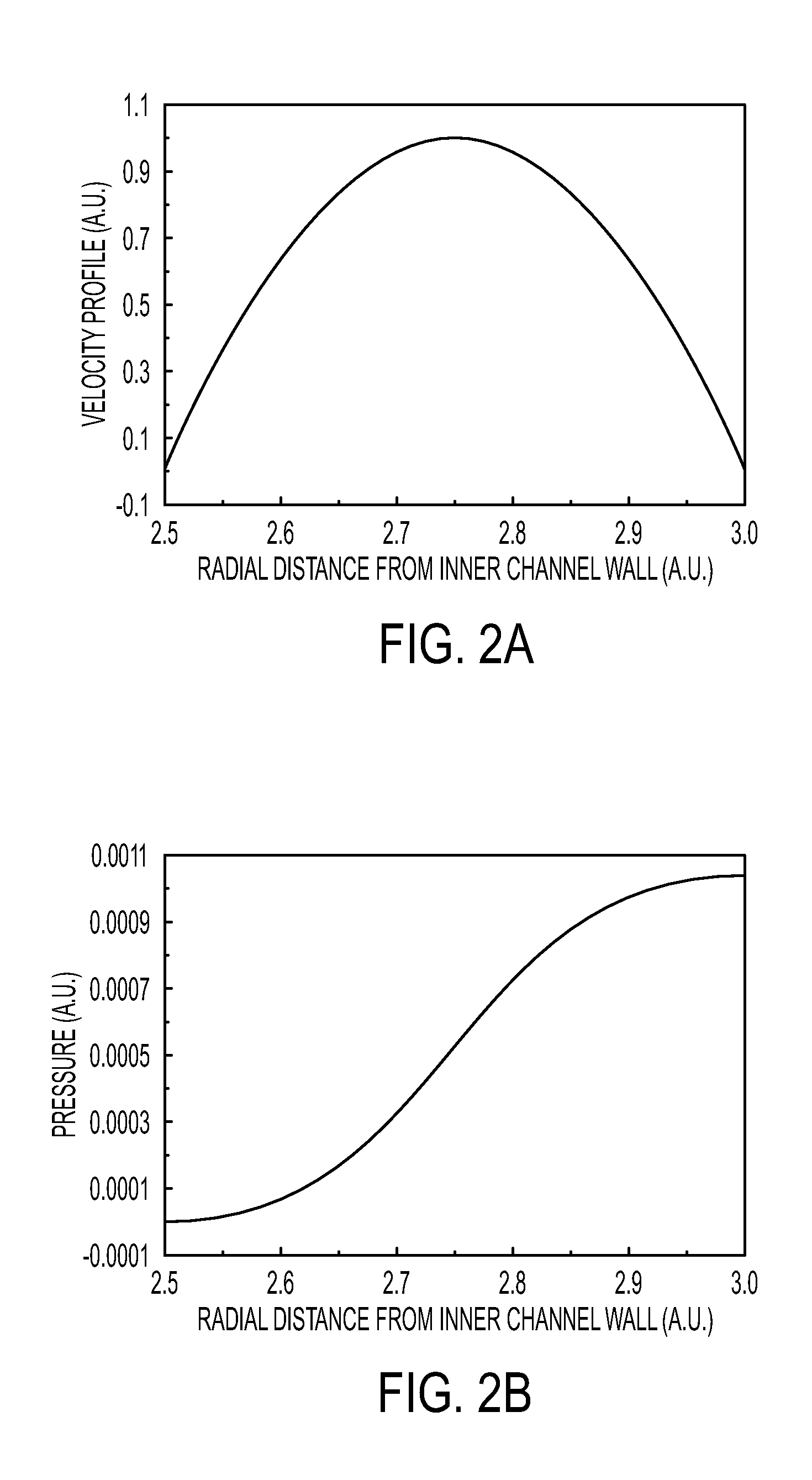

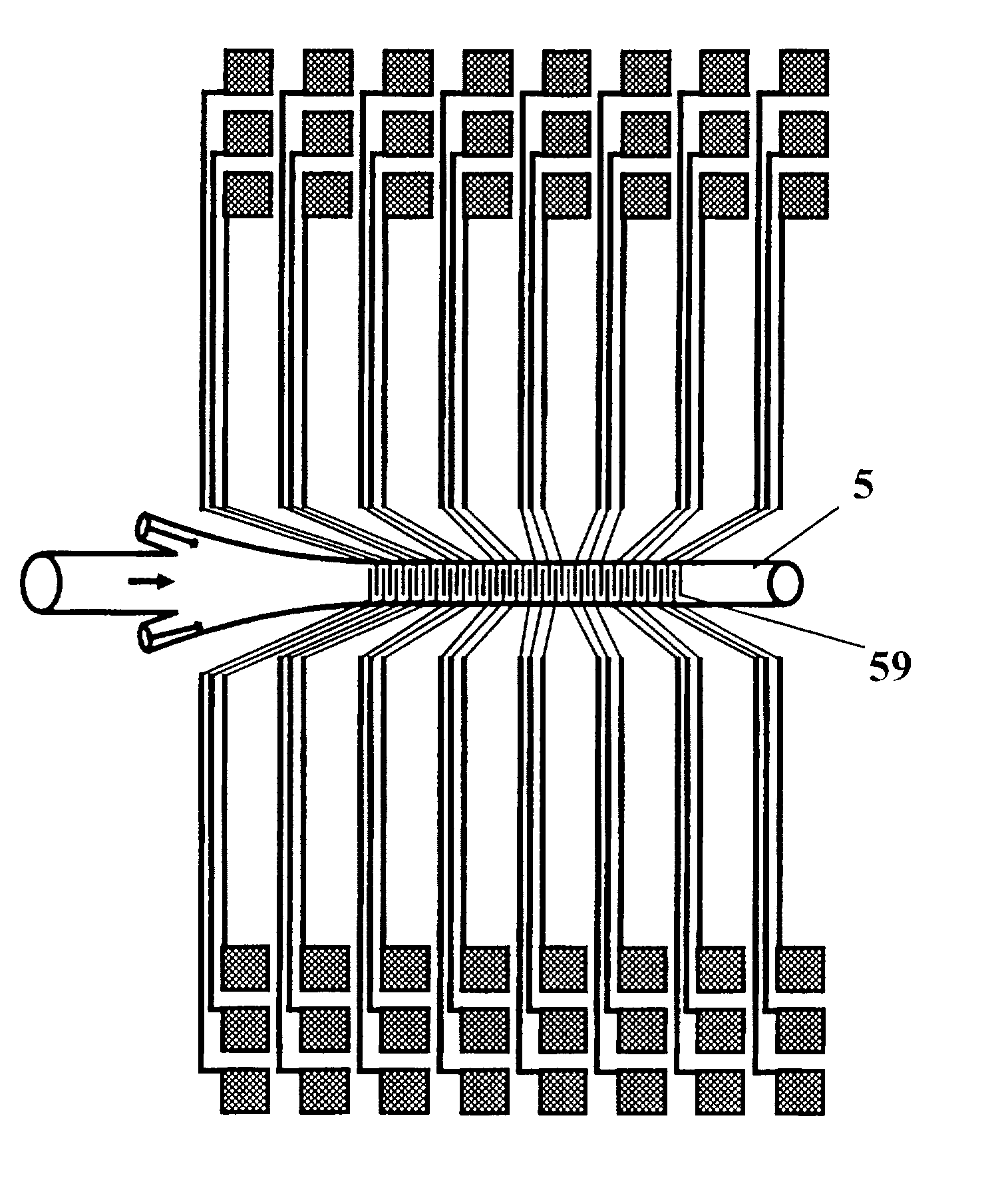

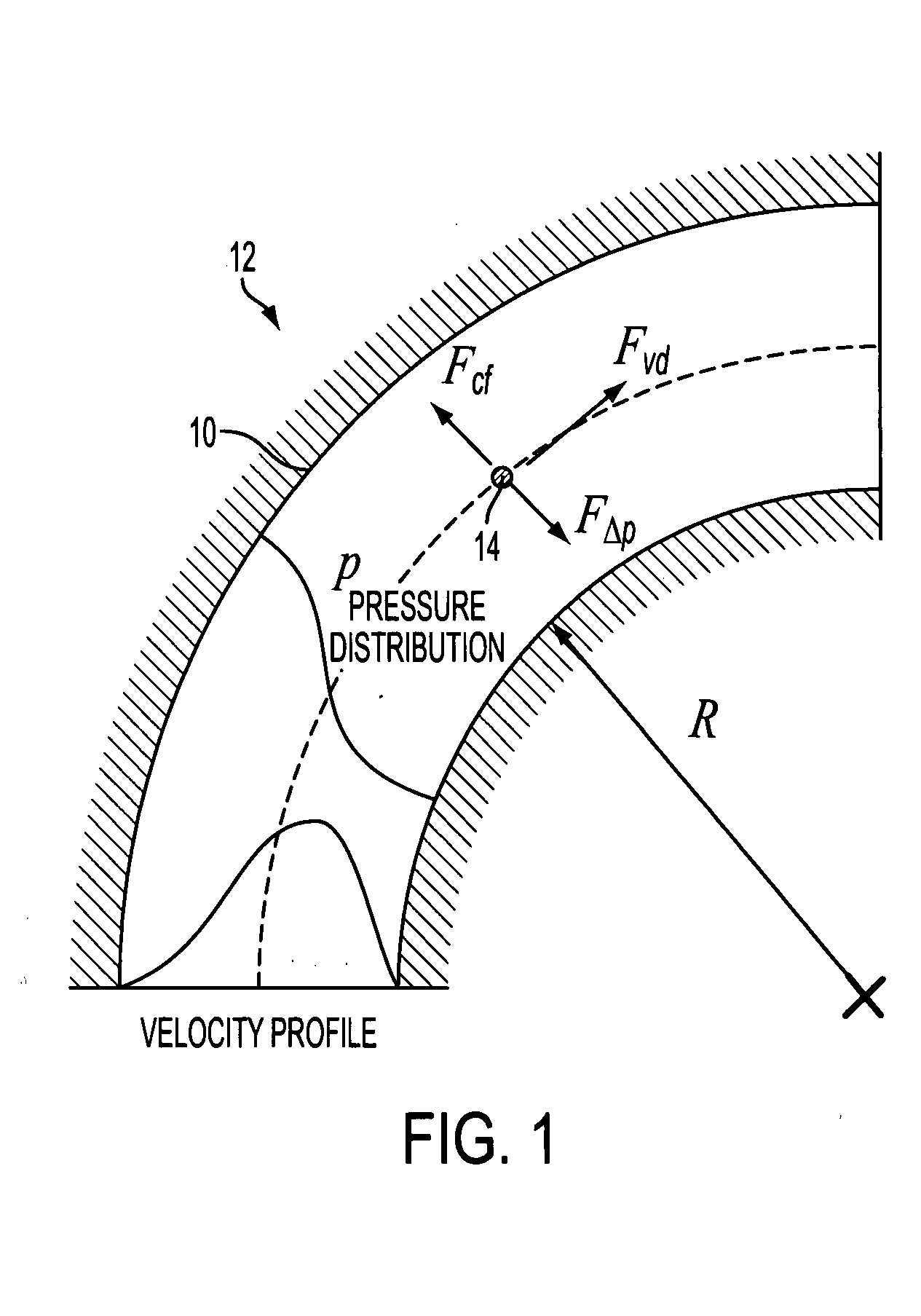

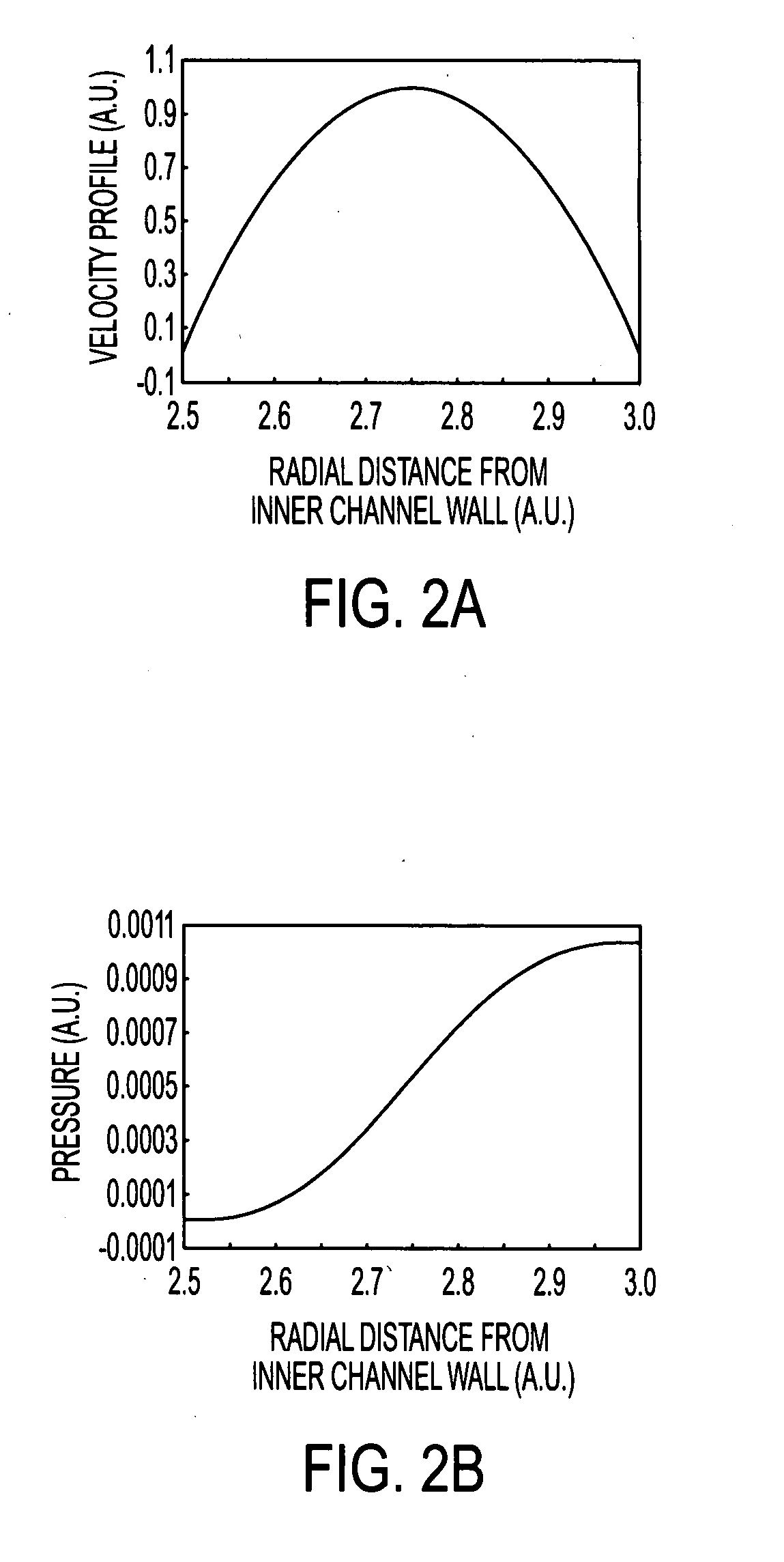

Particle separation and concentration system

This invention is based on size and mass separation of suspended particles, including biological matter, which are made to flow in a spiral channel. On the spiral sections, the inward directed transverse pressure field from fluid shear competes with the outward directed centrifugal force to allow for separation of particles. At high velocity, centrifugal force dominates and particles move outward. At low velocities, transverse pressure dominates and the particles move inward. The magnitudes of the two opposing forces depend on flow velocity, particle size, radius of curvature of the spiral section, channel dimensions, and viscosity of the fluid. At the end of the spiral channel, a parallel array of outlets collects separated particles. For any particle size, the required channel dimension is determined by estimating the transit time to reach the side-wall. This time is a function of flow velocity, channel width, viscosity, and radius of curvature. Larger particles may reach the channel wall earlier than the smaller particles which need more time to reach the side wall. Thus a spiral channel may be envisioned by placing multiple outlets along the channel. This technique is inherently scalable over a large size range from sub-millimeter down to 1 μm.

Owner:XEROX CORP

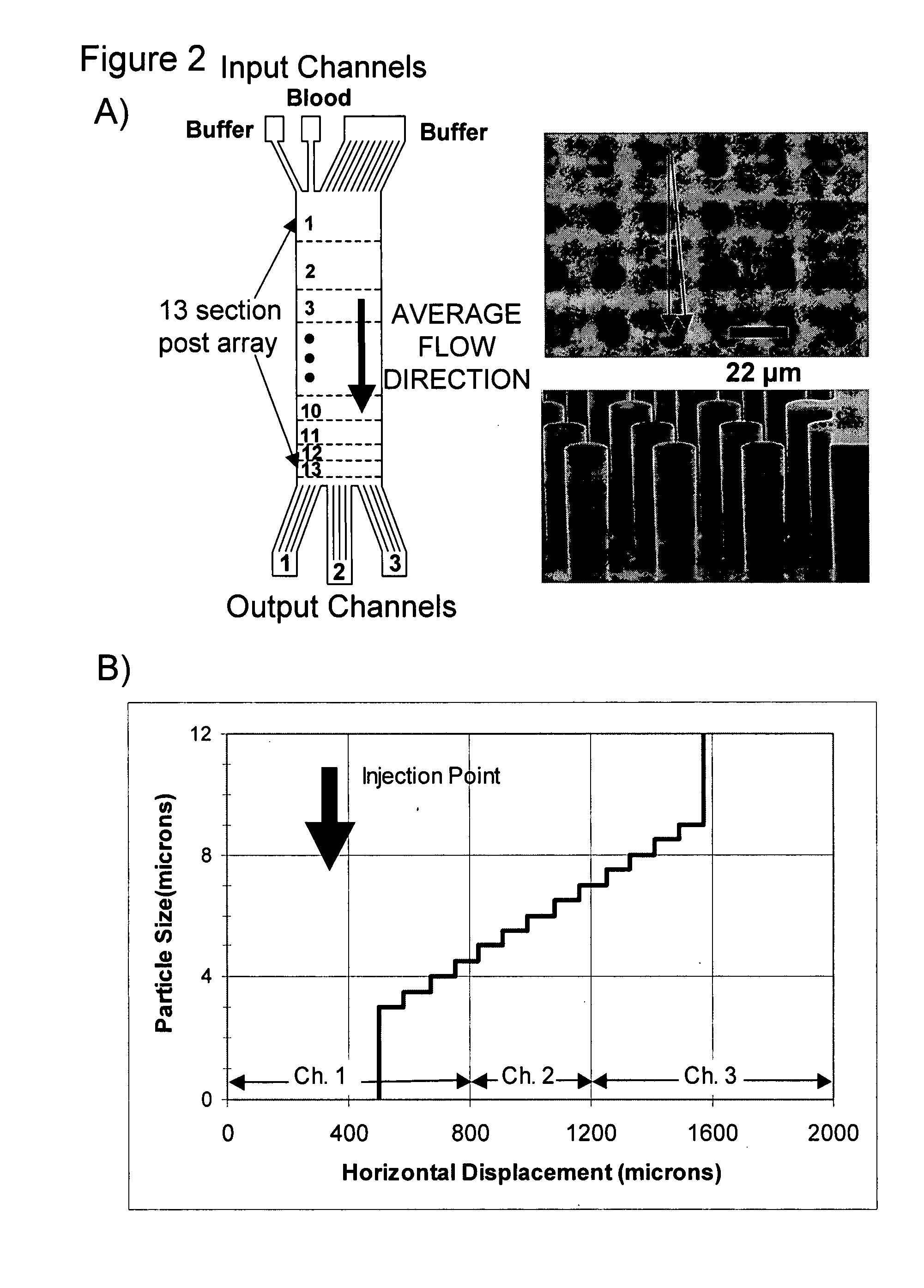

Apparatus and method for continuous particle separation

The invention is directed to an apparatus and a method of separating particles, such as cells, from a heterogeneous fluid, such as blood, where the particles have a large range of sizes.

Owner:THE TRUSTEES FOR PRINCETON UNIV

Apparatus and method for continuous particle separation

Owner:THE TRUSTEES FOR PRINCETON UNIV

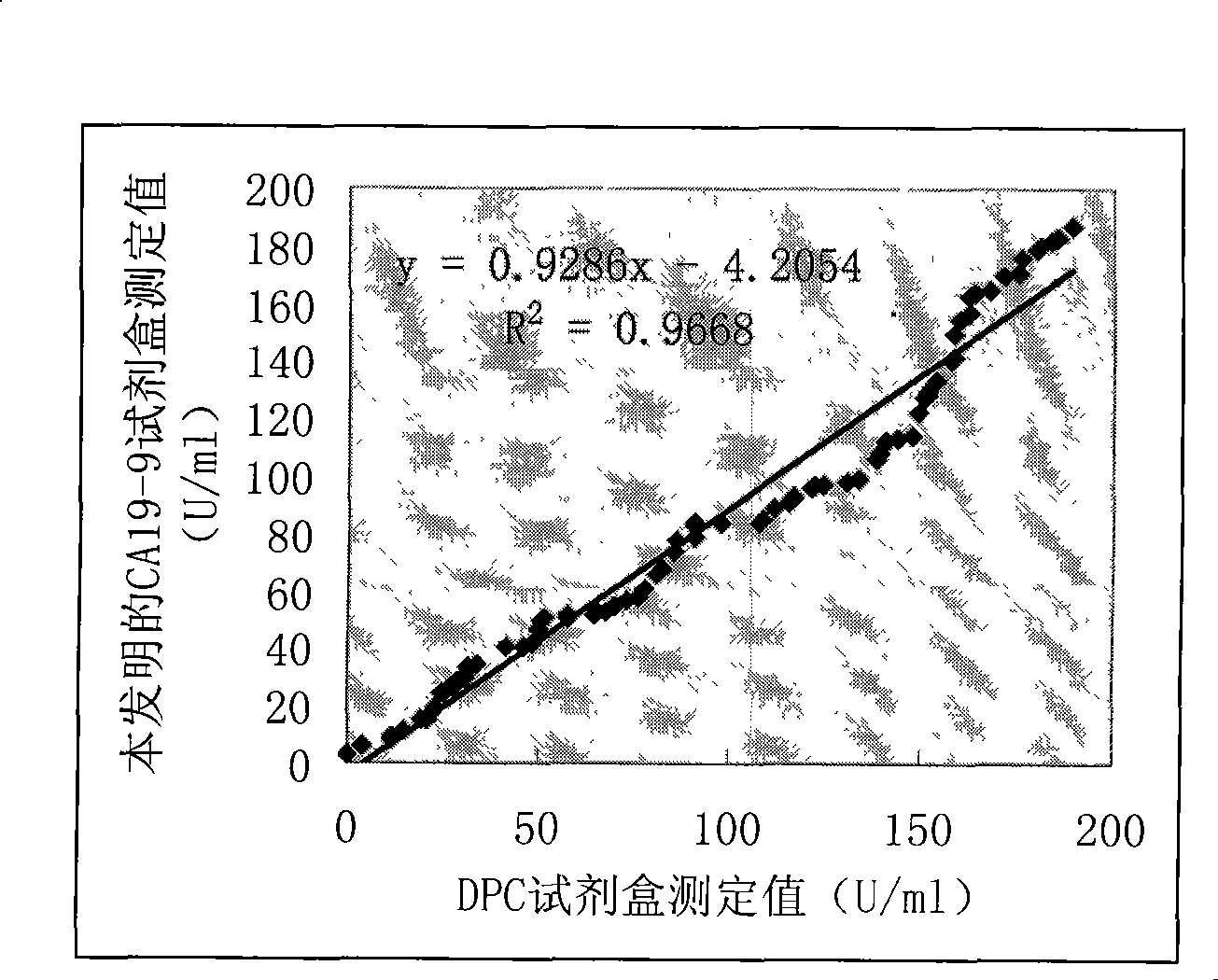

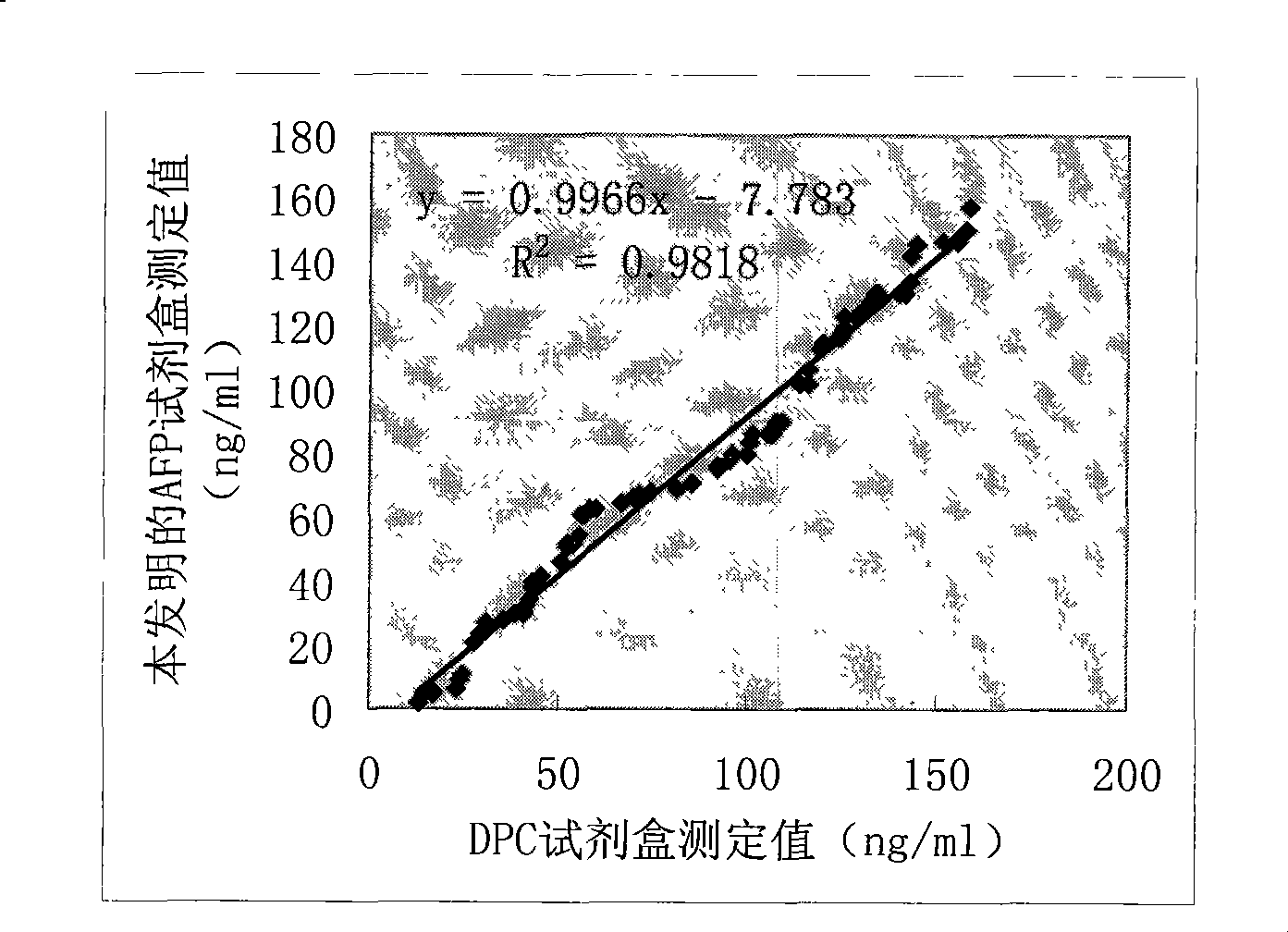

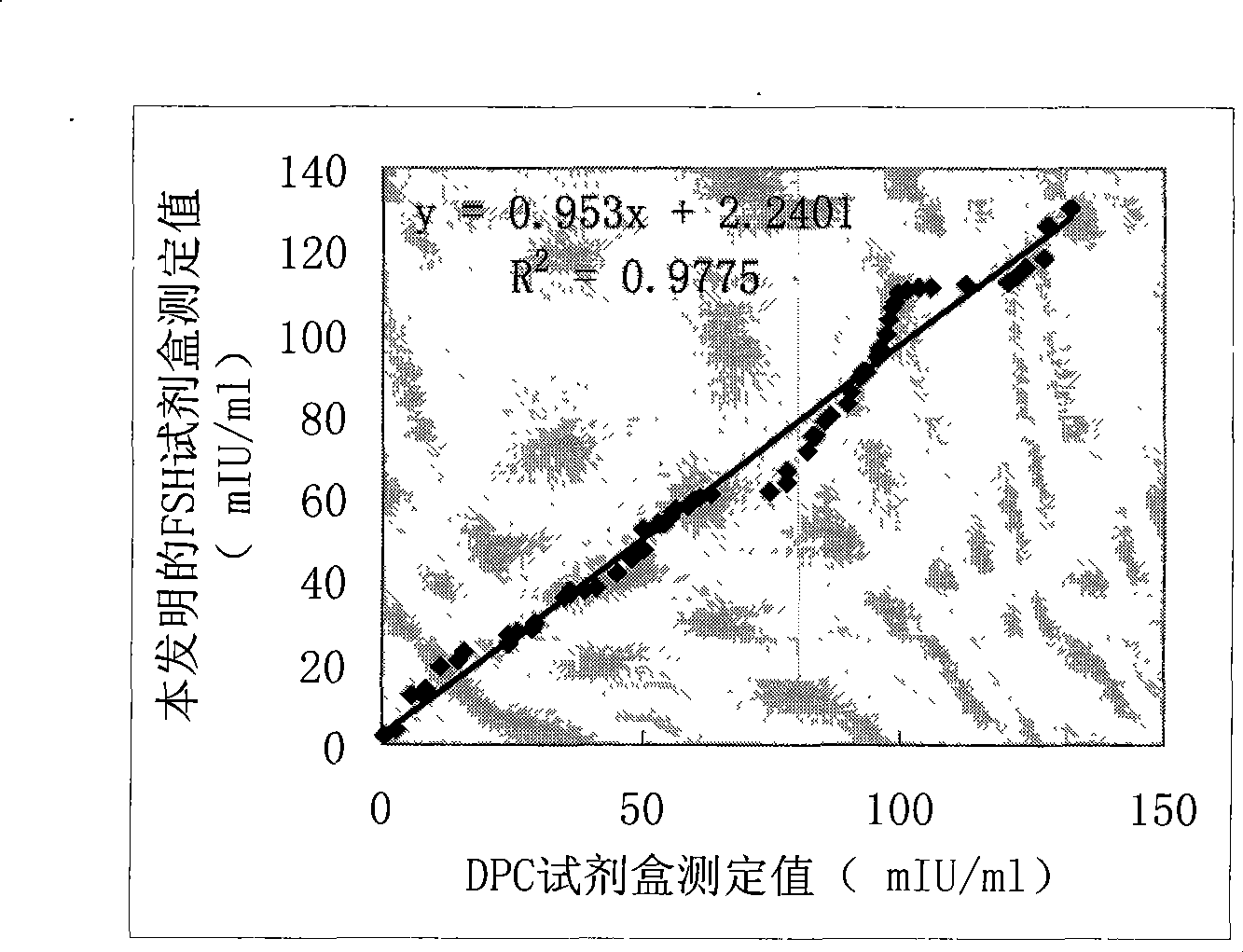

Magnetic microparticle separating chemiluminescence immune analysis determination reagent kit for detecting related sign object and preparing method thereof

ActiveCN101377490AEnsure sensitivityEnsure effectivenessChemiluminescene/bioluminescenceBiological testingDiseaseMicroparticle

The invention relates to the immunoassay medical field, particularly provides a magnetic particle separation chemiluminescence immunoassay assay kit and a preparation method thereof used for detecting disease related markers. The kit of the invention comprises: 1) a calibrator; 2) magnetic particles which are coated with streptavidin; 3) disease related marker antibodies of enzyme markers and biotin markers; and 4) a chemiluminescence substrate. Further, the method for preparing the kit according to the invention includes the following steps: 1) pure raw materials are used to prepare the calibrator; 2) the streptavidin is used to coat the magnetic particles; 3) the mixed liquid of the enzyme and the biotin markers are prepared; 4) the calibrator, the chemiluminescence substrate as well as the mixed liquid of the enzyme and the biotin markers are packaged in a separated way; and 5) a finished product is packaged. The kit has the advantages of convenience, rapidness, sensitivity, stability, and the like.

Owner:CHEMCLIN DIAGNOSTICS CO LTD

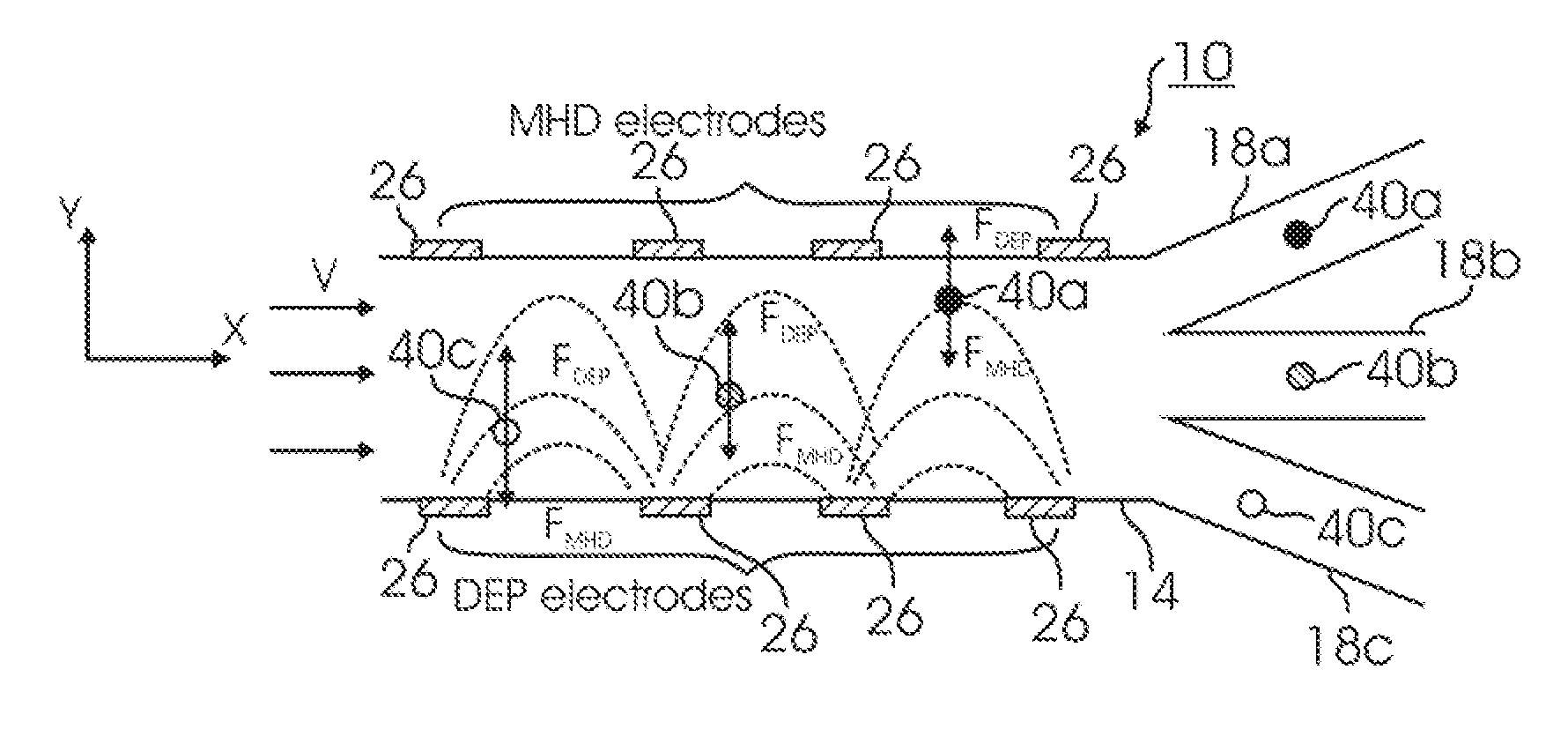

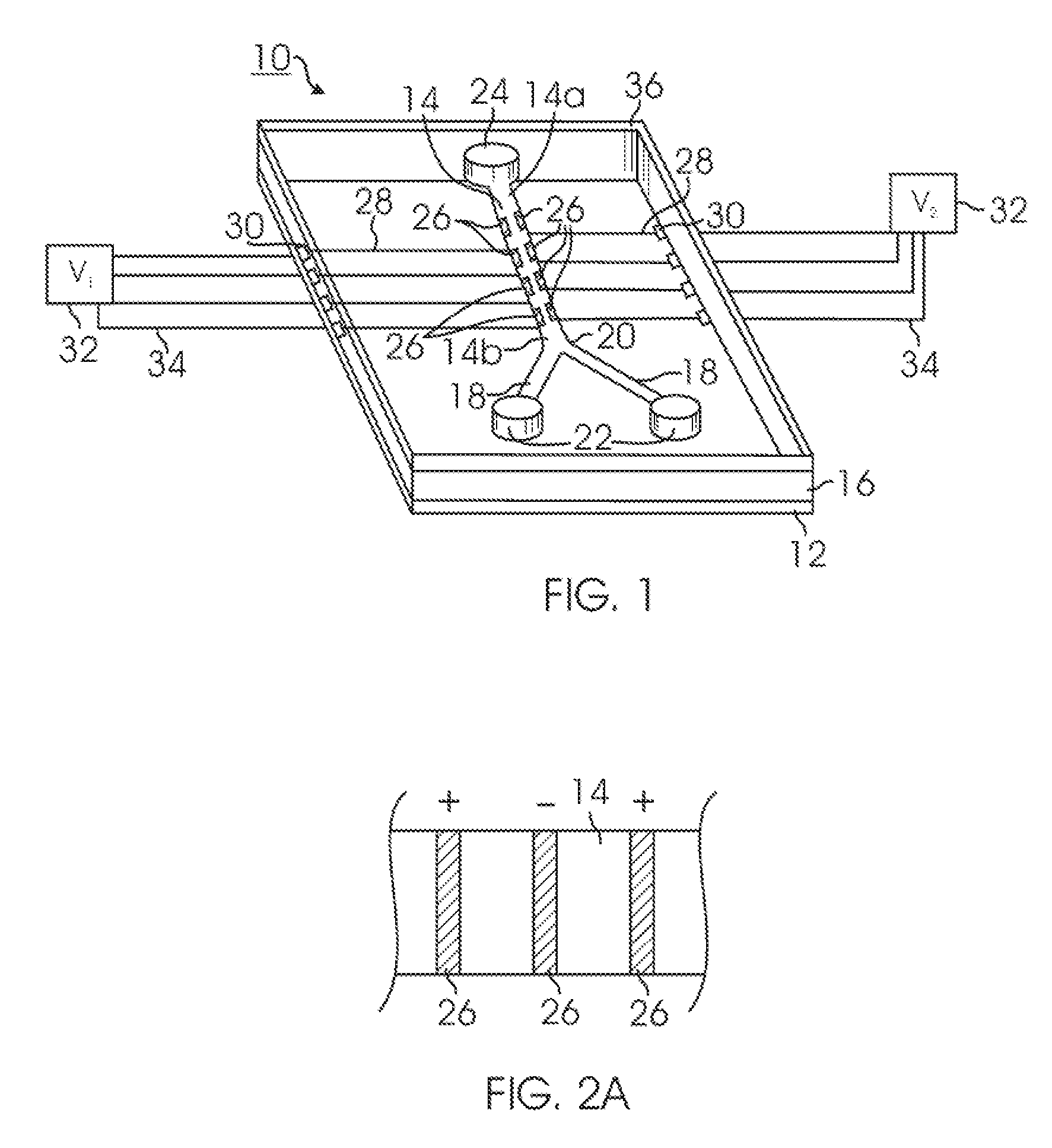

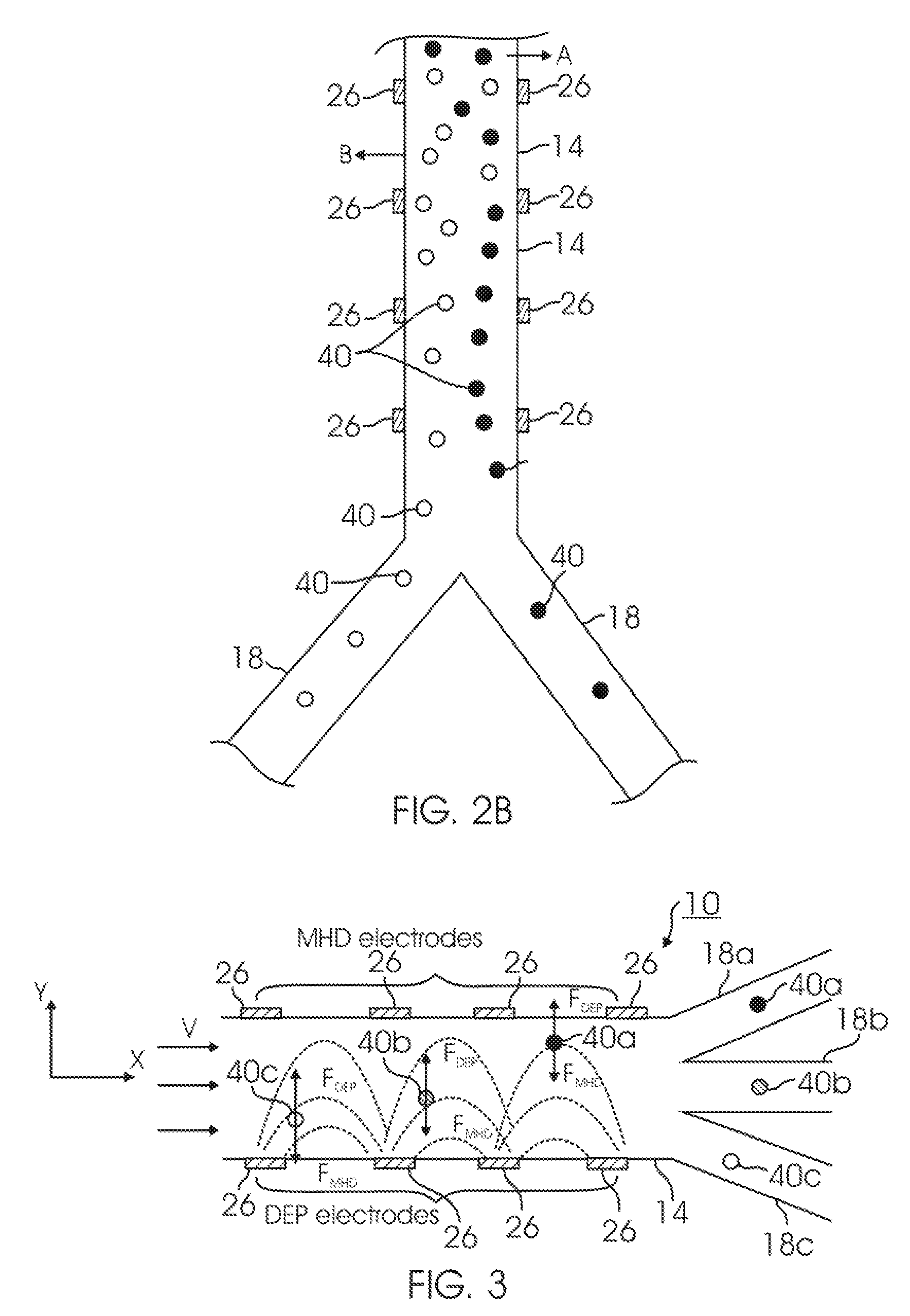

Microfluidic device for cell and particle separation

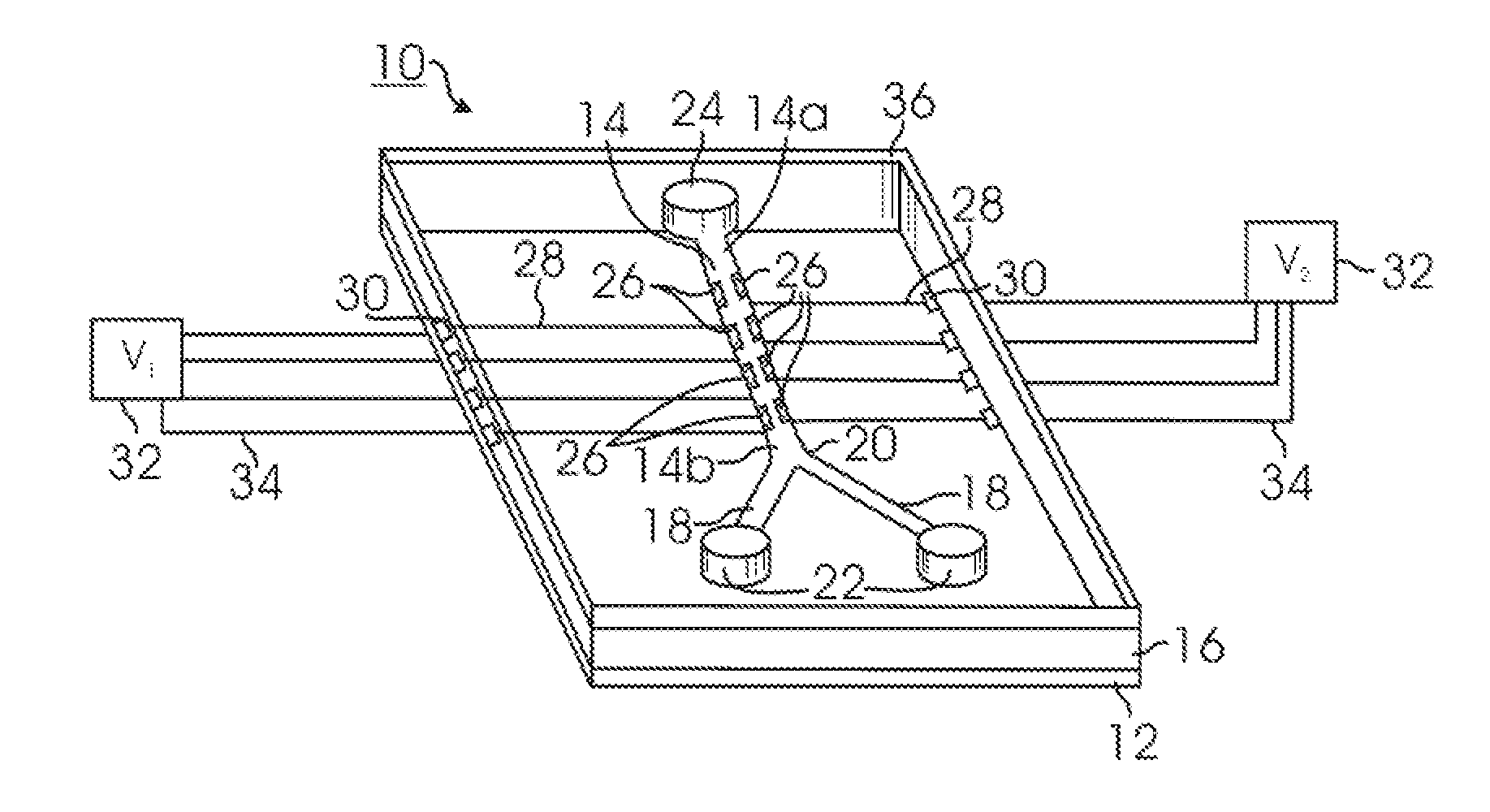

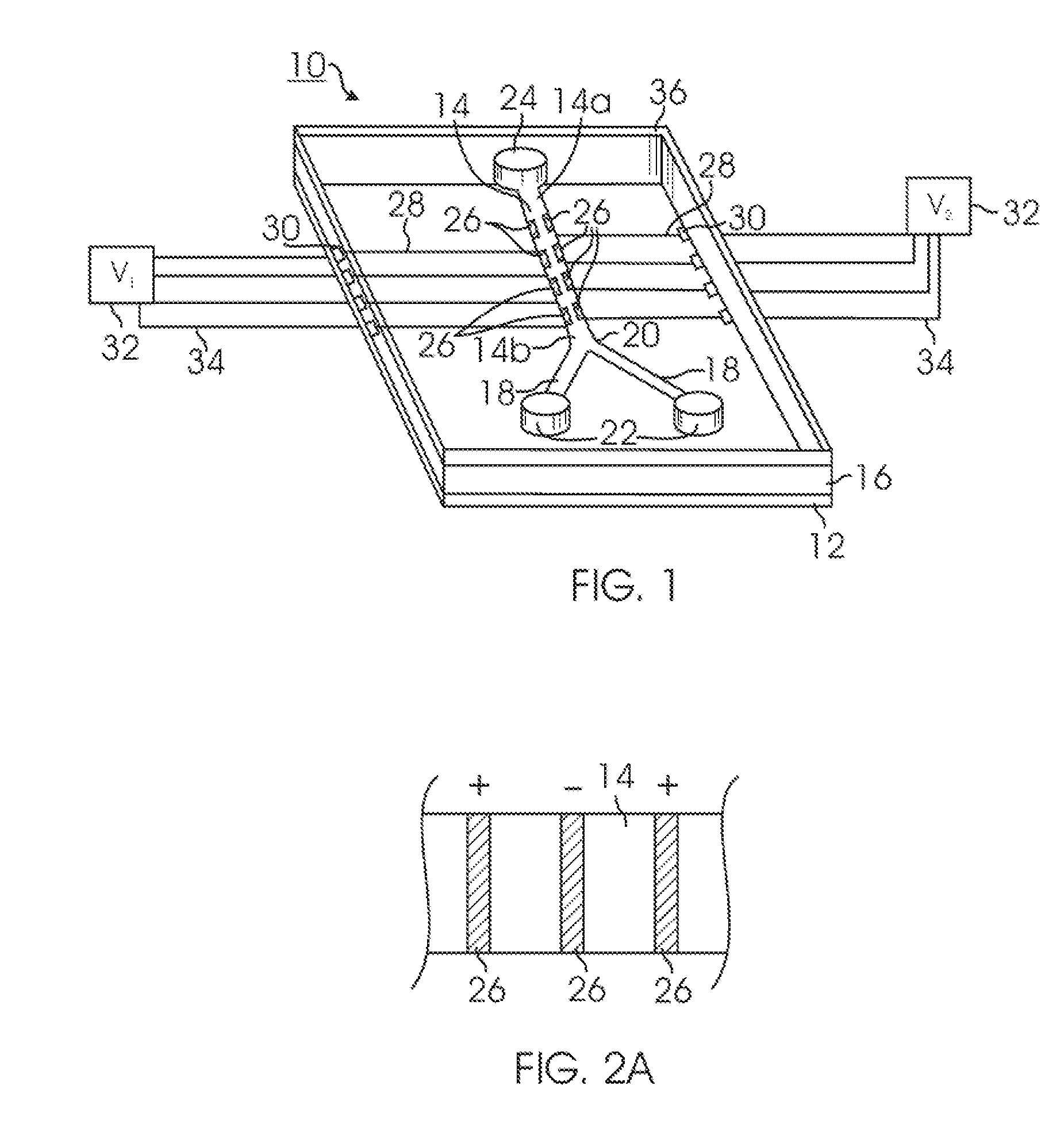

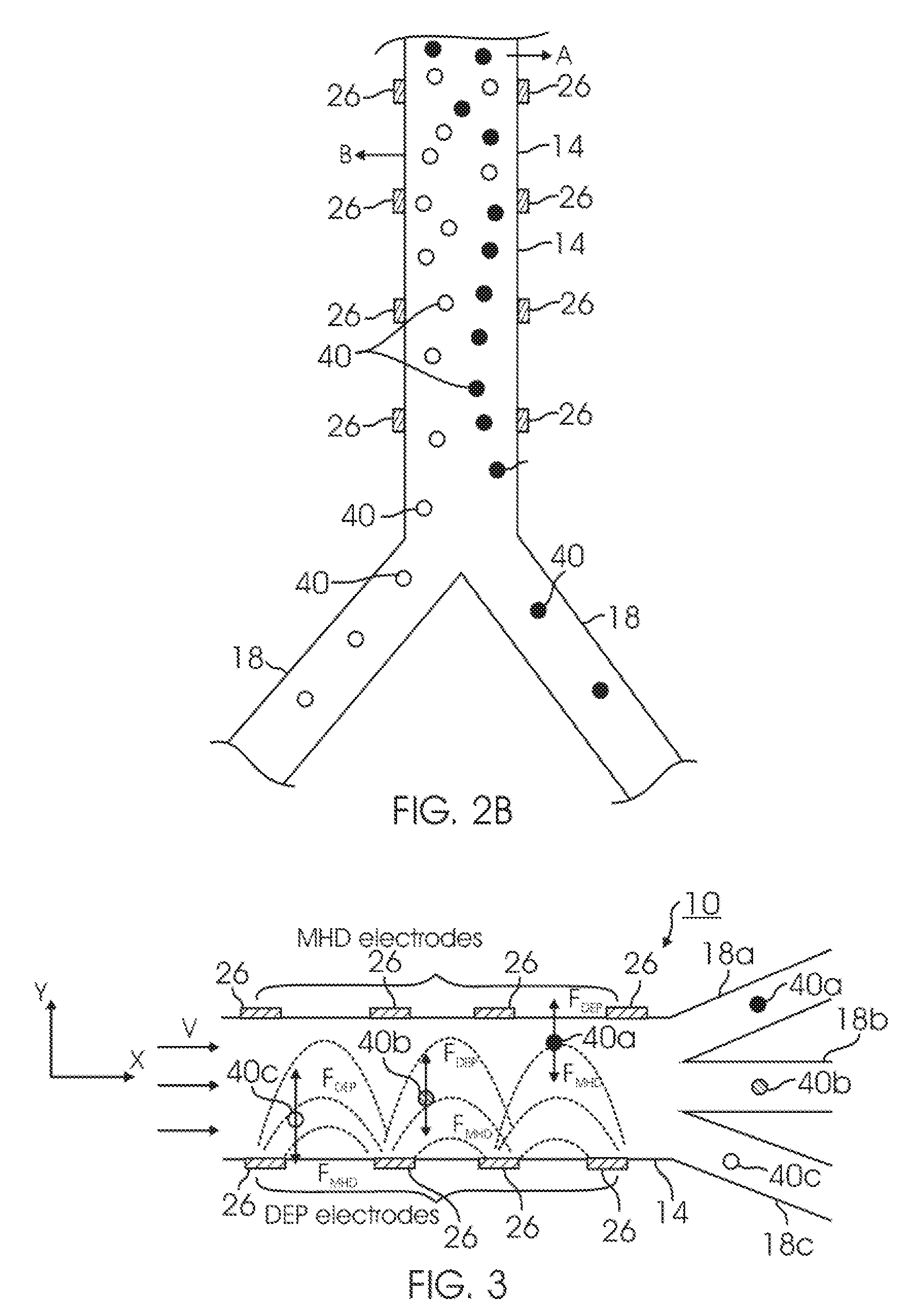

A microfluidic separation device includes a microchannel formed in a substrate and being defined at least by a bottom surface, a first side wall, and second side wall. Fluid containing particles or cells is flowed through the microchannel from an upstream end to a downstream end. The downstream end terminates in a plurality of branch channels. A plurality of vertically-oriented electrodes are disposed on the first wall and on the second wall opposite to the first wall. A voltage source is connected to the plurality of opposing electrodes to drive the electrodes. The opposing, vertically-oriented electrodes may be used to focus a heterogeneous population of particles or cells for subsequent downstream separation via additional electrodes placed on one of the side walls. Alternatively, the opposing, vertically-oriented electrodes may be used to spatially separate a heterogeneous population of particles or cells for later collection in one or more of the branch channels.

Owner:RGT UNIV OF CALIFORNIA

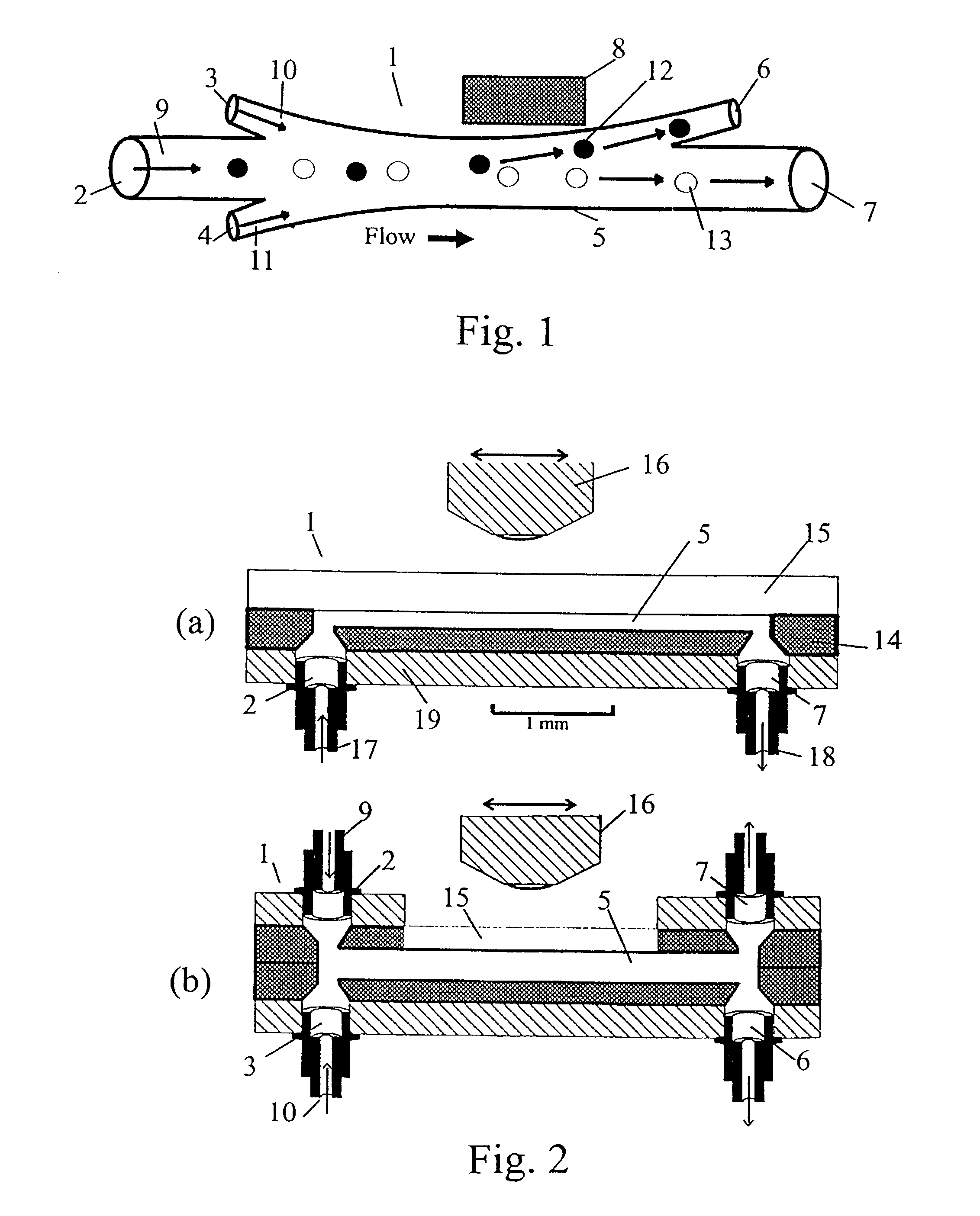

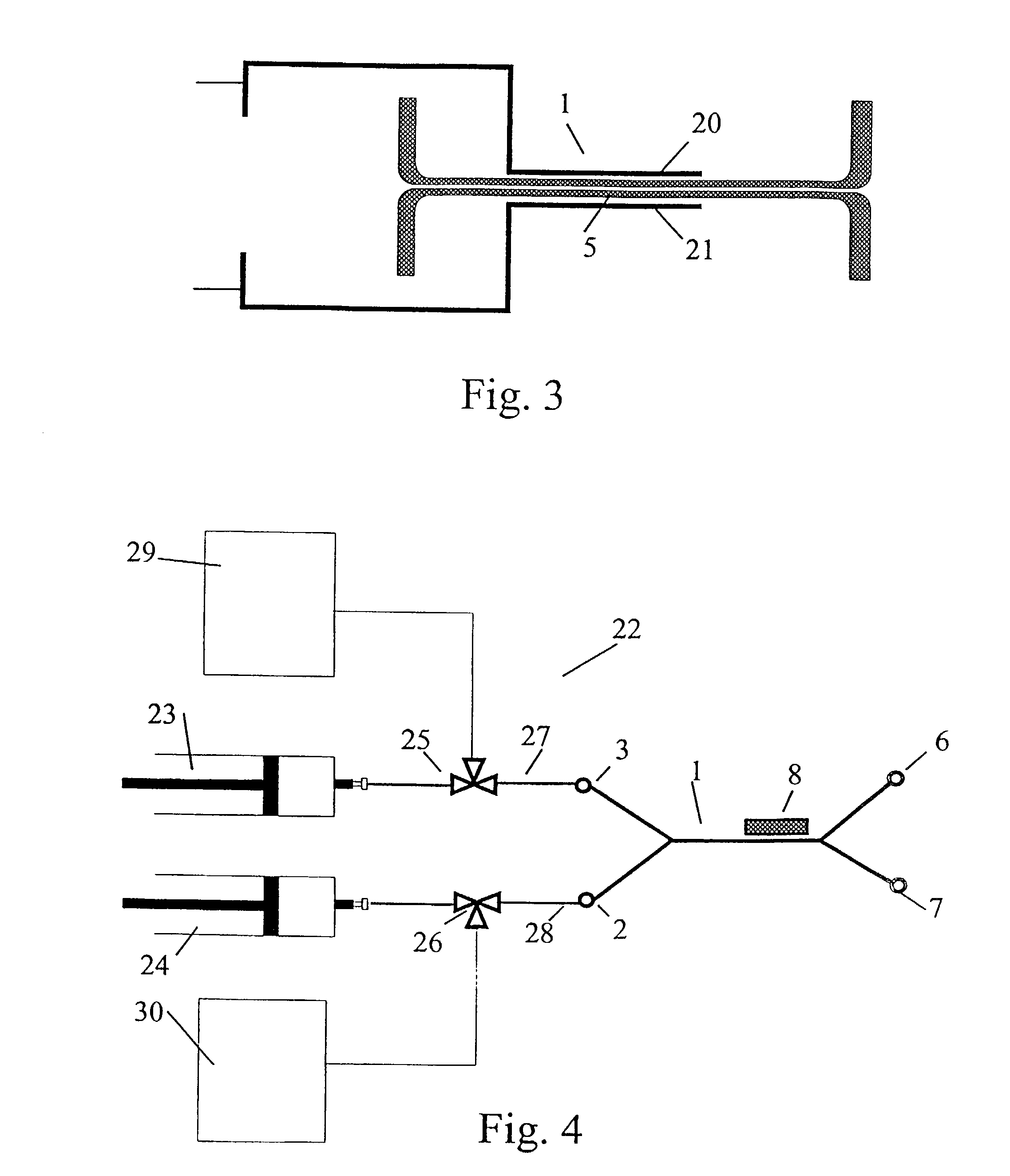

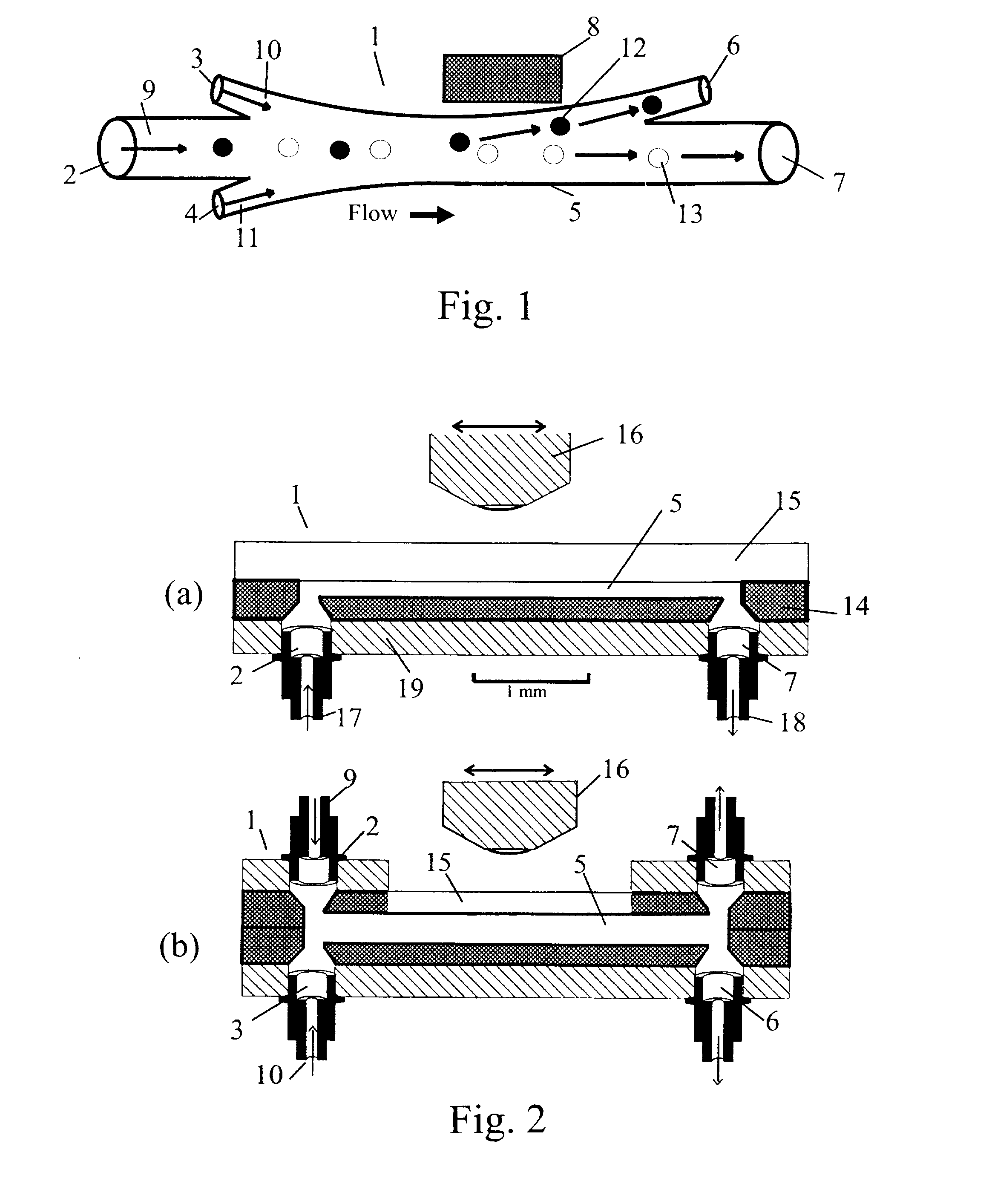

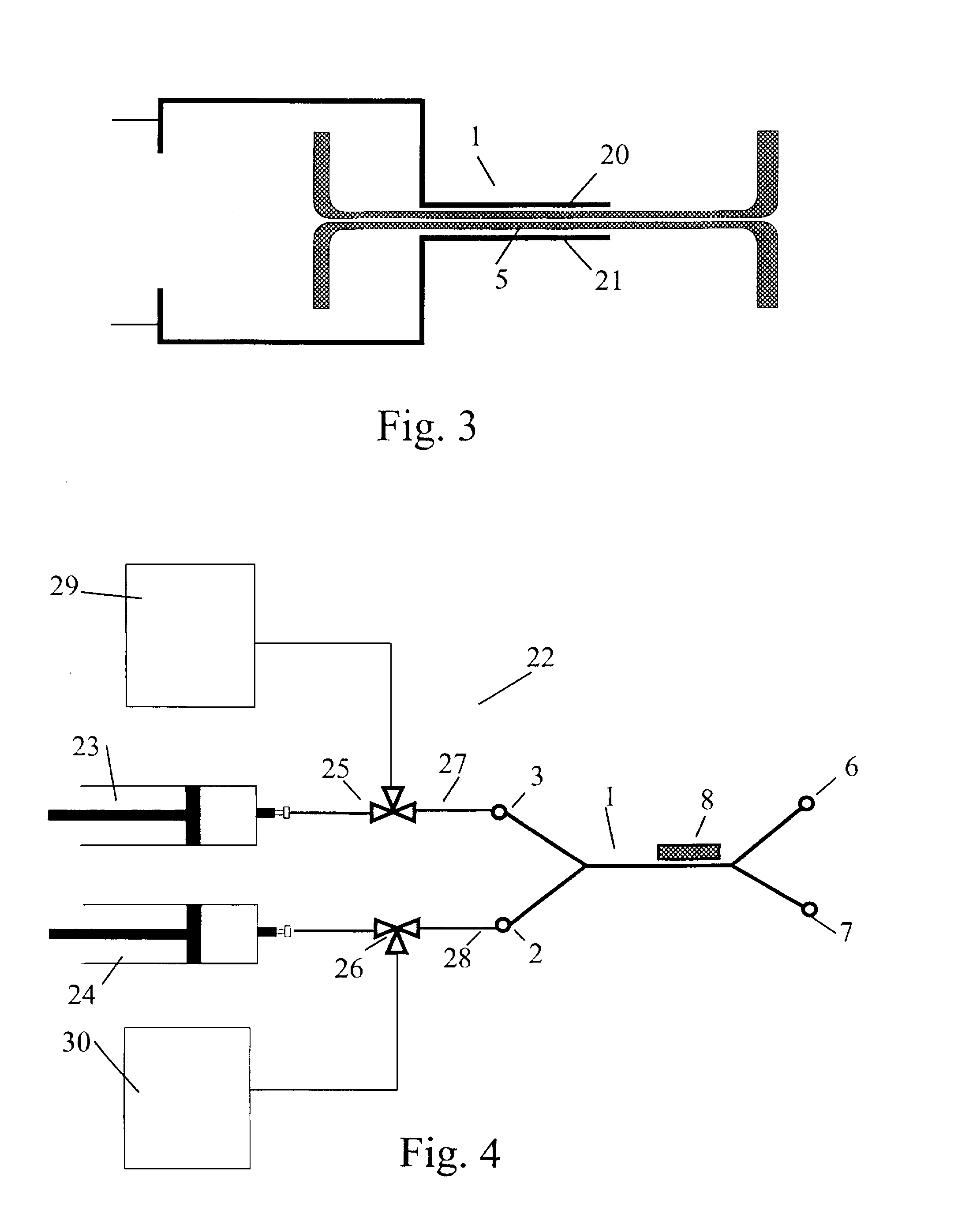

Microflow system for particle separation and analysis

InactiveUS7138269B2High resolutionBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringParticle separation

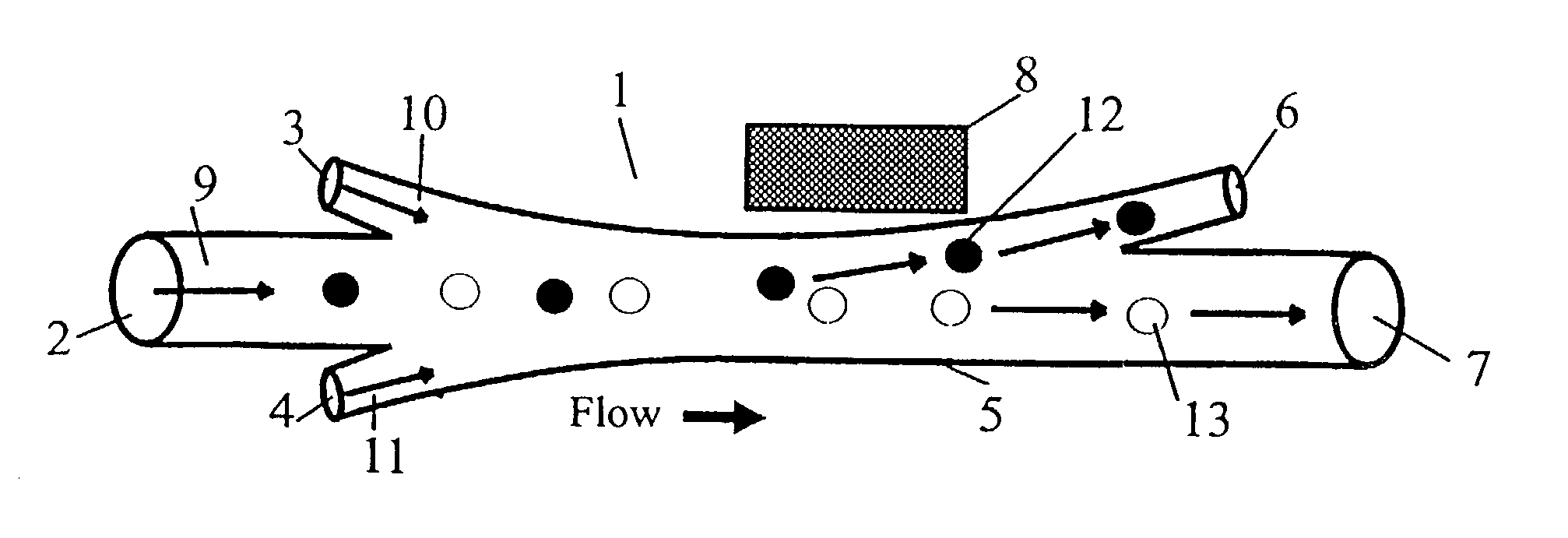

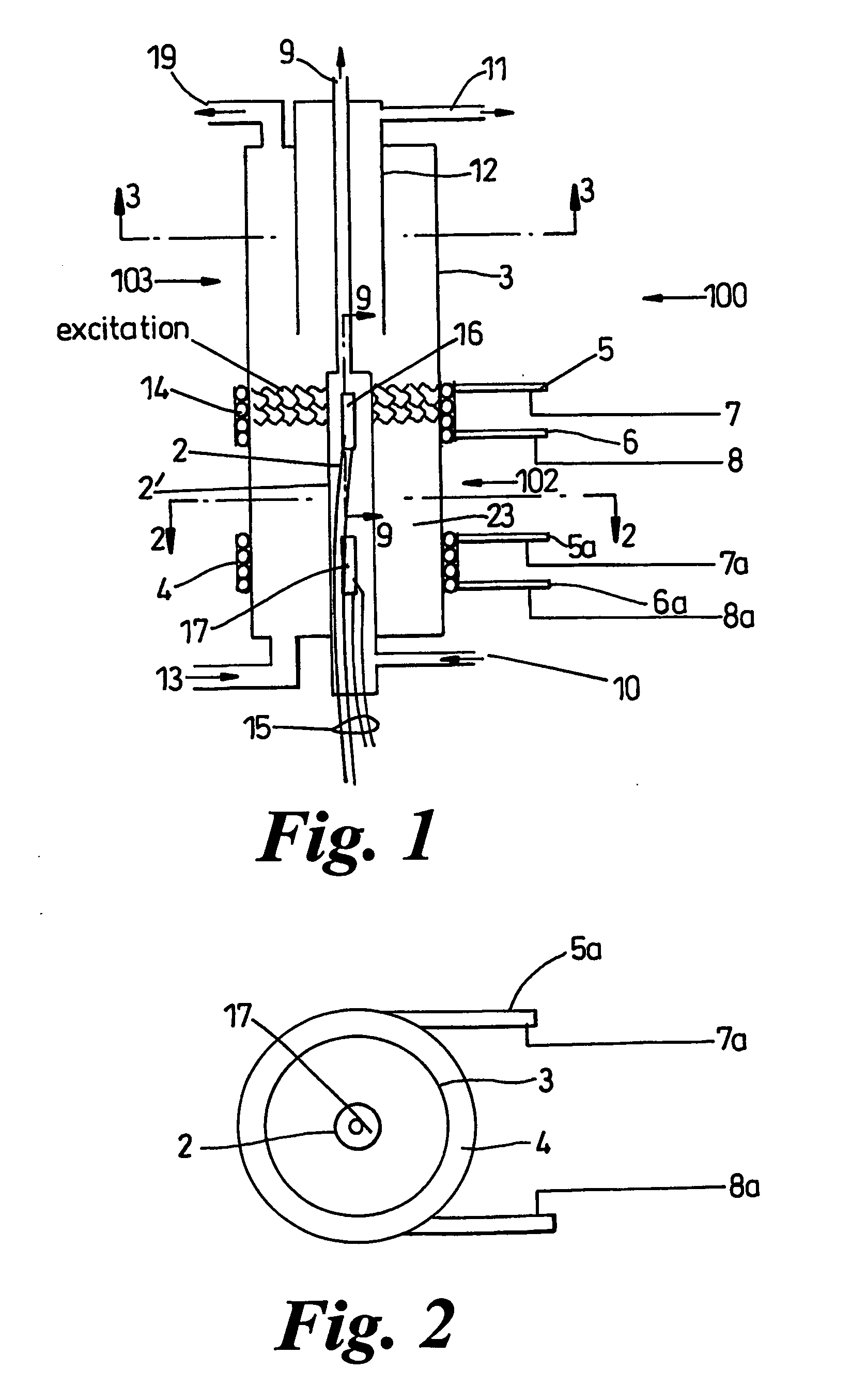

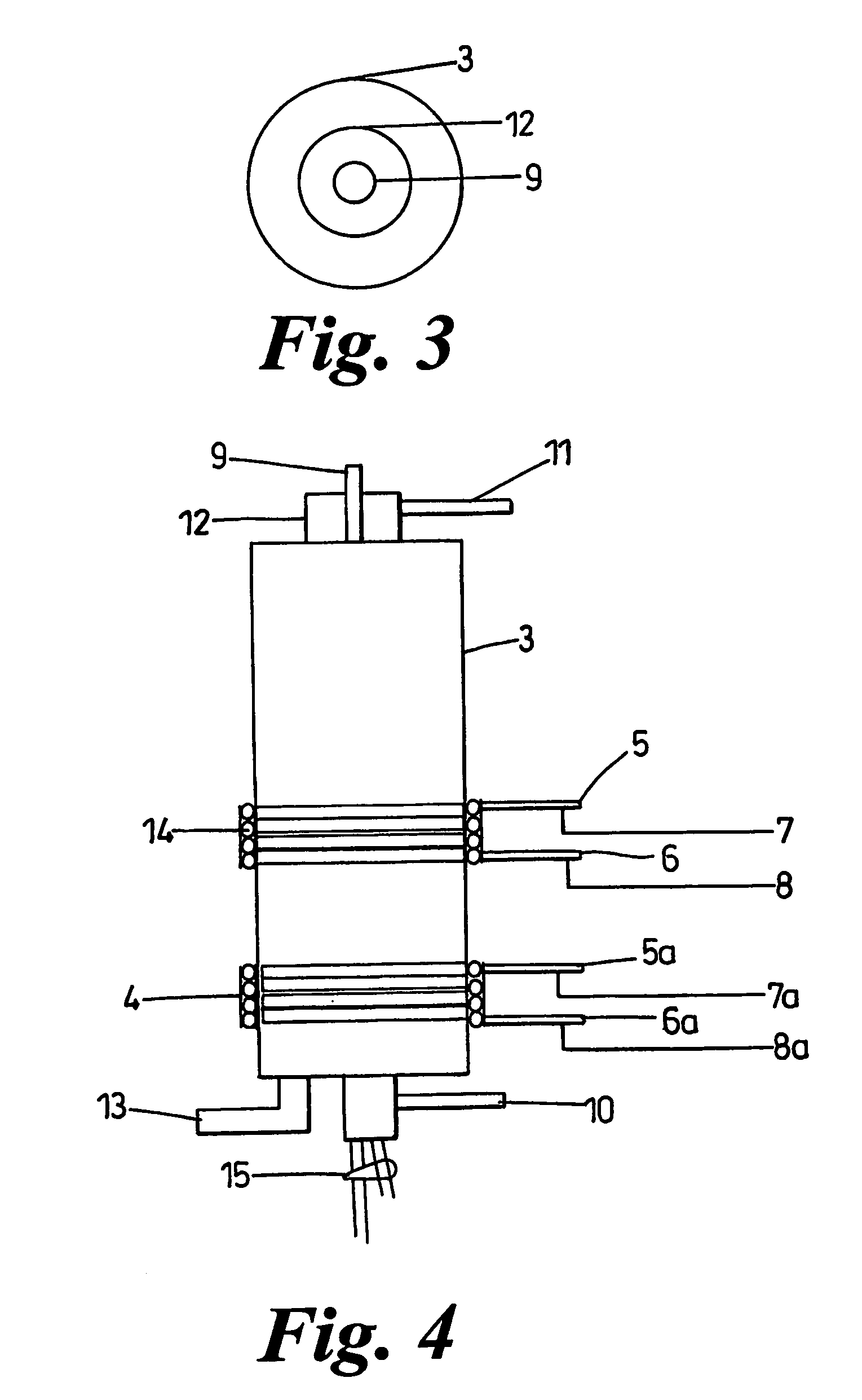

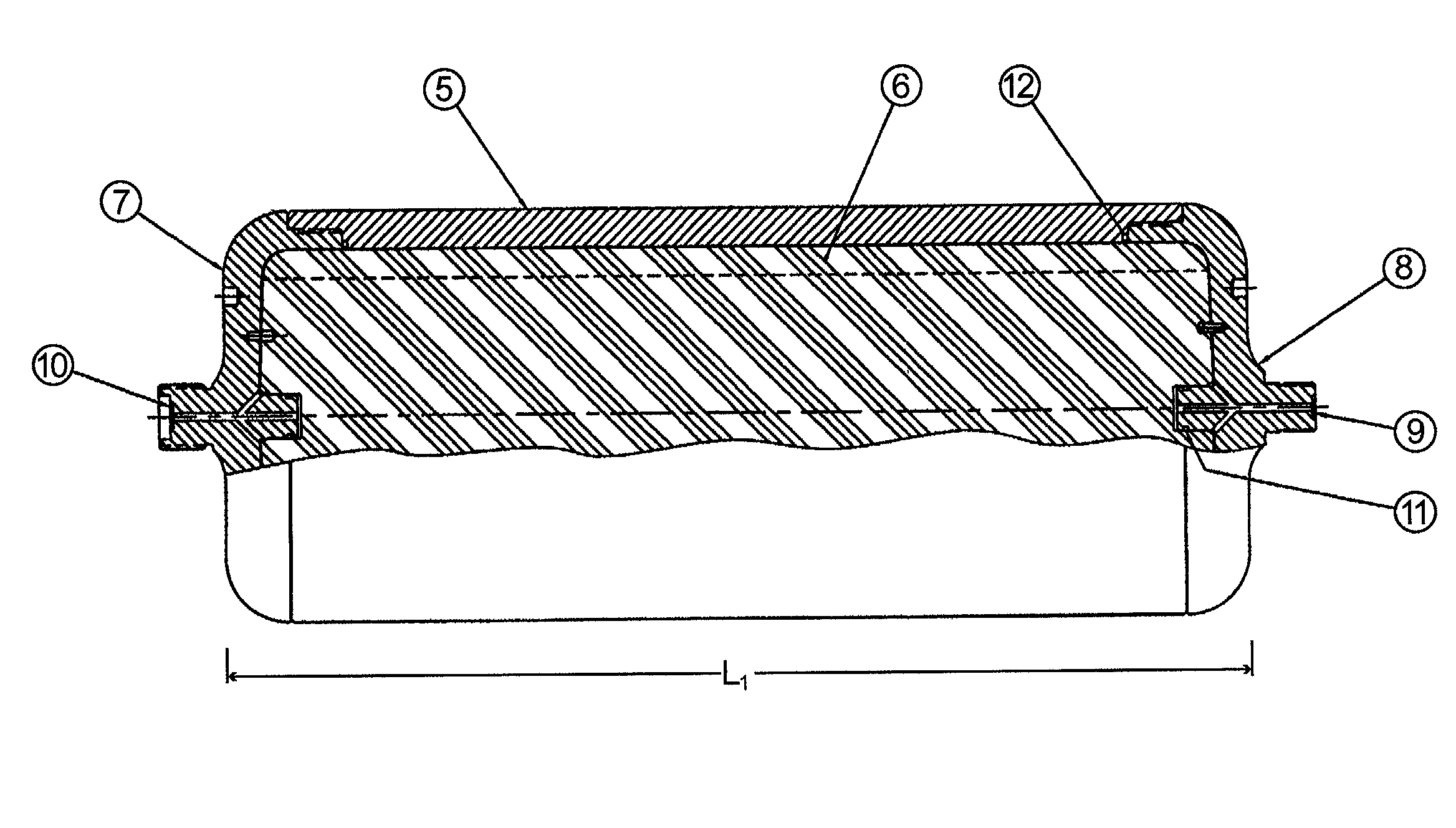

A micro flow system is provided for separating particles, comprising a microfabricated member having a flow channel (5) defined therein for guiding a flow of a fluid containing the particles through the flow channel, first inlet means (2) positioned at one end of the flow channel for entering the fluid into the flow channel, first outlet means (7) positioned at the other end of the flow channel for discharging the fluid from the flow channel, the flow of the fluid containing the particles being controlled in such a way that one particle at the time passes a cross section of the flow channel, the member being positioned in a field that is substantially perpendicular to a longitudinal axis of the flow channel so that particles residing in the flow channel and being susceptible to the field across the flow channel are deflected in the direction of the field. Further, a micro flow system is provided for analyzing components of a fluid comprising a microfabricated member having a flow channel defined therein for guiding a flow of a fluid through the flow channel, first inlet means for entering particles into the flow channel, first outlet means for discharging of fluid from the flow channel and a plurality of assay sites located in the flow channel and comprising immobilized reagents whereby the fluid may be analyzed for a plurality of components while residing in the flow channel.

Owner:INVERNESS MEDICAL SWITZERLAND GMBH

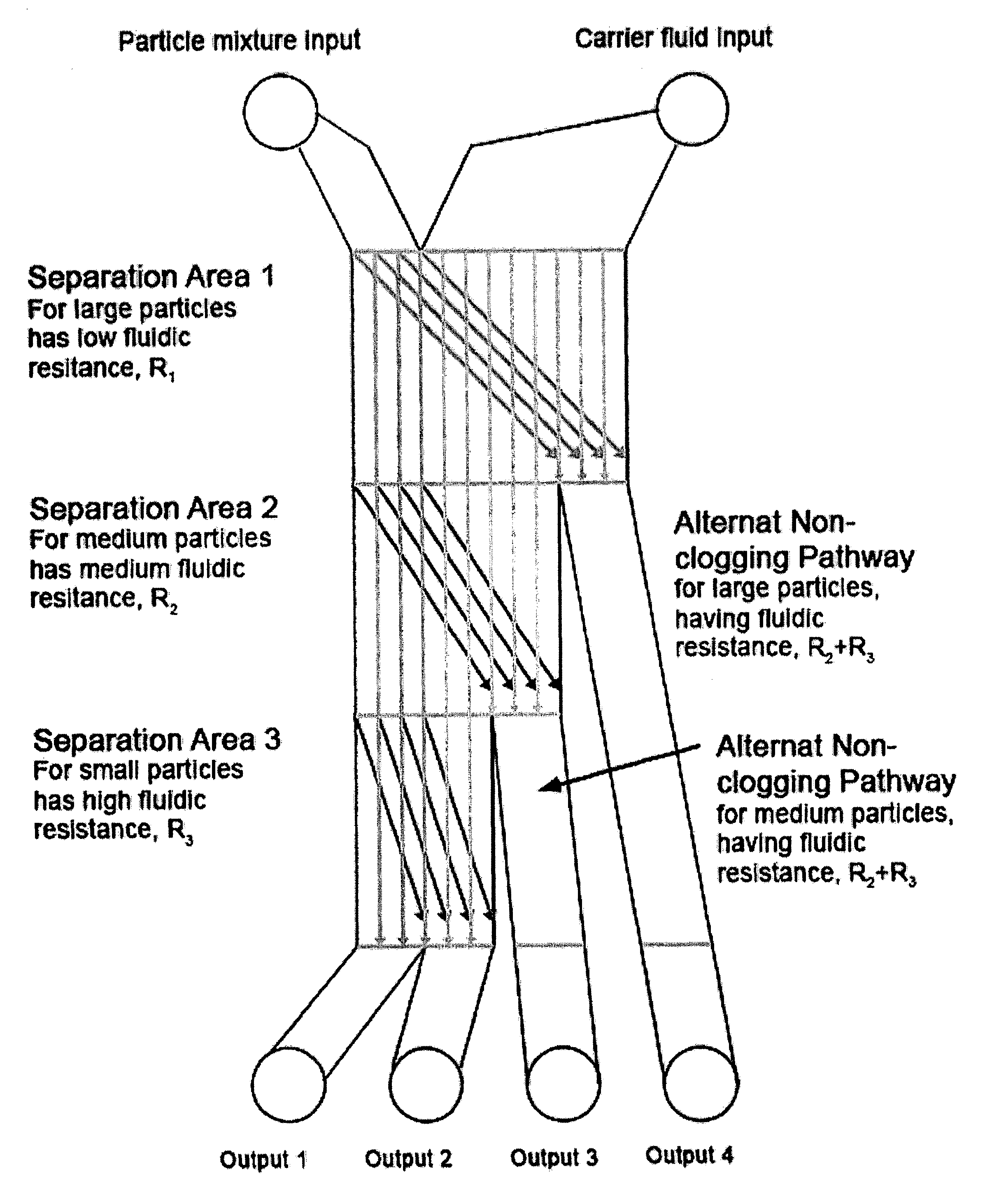

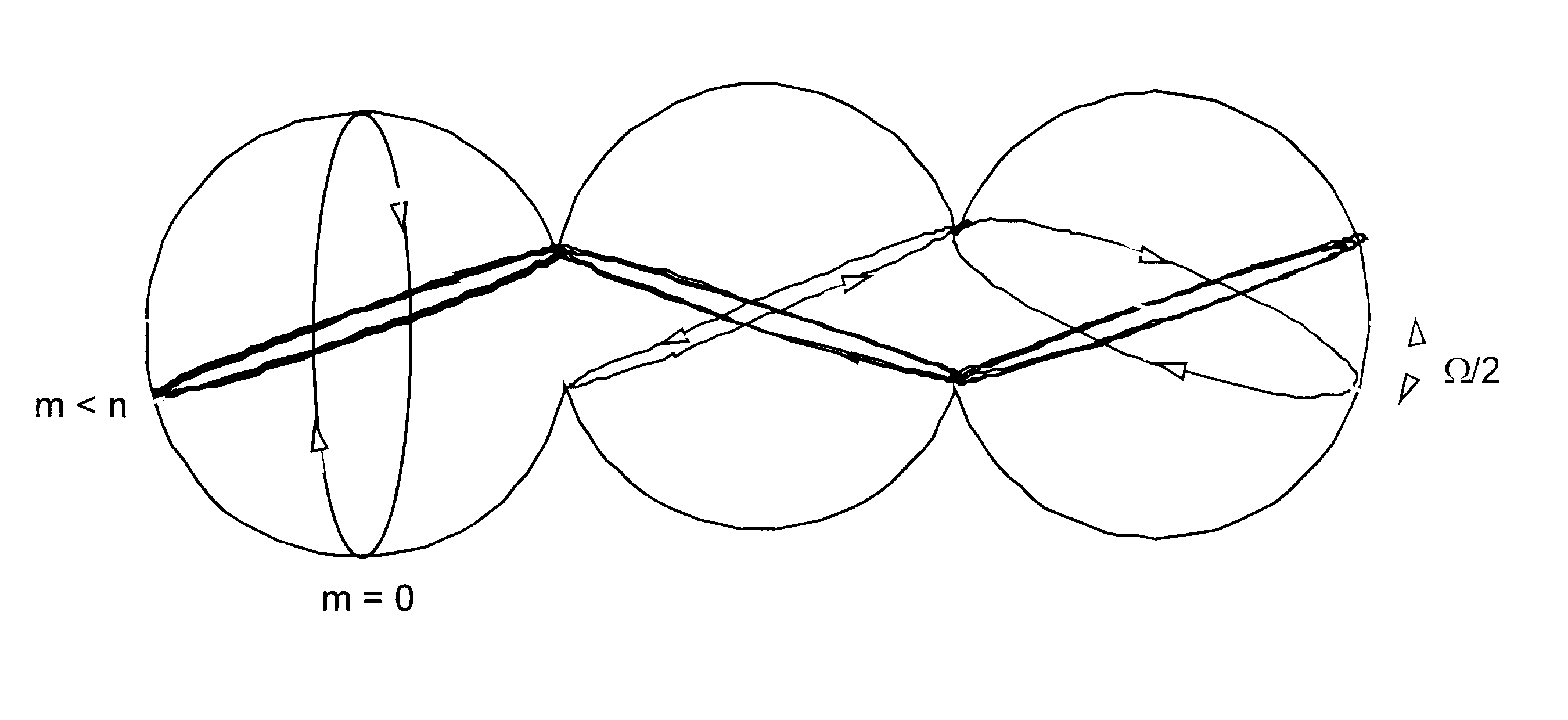

Bump array device having asymmetric gaps for segregation of particles

ActiveUS20100059414A1Easy to operateReduce gapGas current separationComponent separationEngineeringMechanical engineering

The disclosure relates to obstacle array devices (also known as bump array devices) for separating populations of particles by size. Improvements over previous obstacle array devices are realized by causing the fluid velocity profile across gaps between obstacles to be asymmetrical with respect to the plane that bisects the gap and is parallel to the direction of bulk fluid flow. Such asymmetry can be achieved by selecting the shape(s) of the obstacles bounding the gap such that the portions of the obstacles upstream from, downstream from, or bridging the narrowest portion of the gap are asymmetrical with respect to that plane. Improvements are also realized by using obstacles that have sharp edges bounding the gaps. Other improvements are realized by selecting obstacle shapes such that the critical particle dimensions defined by the gaps in two different fluid flow directions differ.

Owner:THE TRUSTEES FOR PRINCETON UNIV

Process for preparing control samples of particles such as microorganisms and cells

Processes for preparing controlled samples of particles, including microorganisms and cells are described. A sample of particles is provided and separated into a predetermined number of desired particles by particle separation means. The predetermined number of particles is dispensed into a receptacle or onto a surface in accordance with a sorting instruction, with the receptacle or surface being positioned by collecting means so as to receive the dispensed particles. A sorting instruction from the particle dispensing means activates the collecting means such that when a sorting instruction has been actuated, so as to deliver a predetermined number of particles into a receptacle or onto a surface which is positioned accurately for sufficient time to collect all sorted particles, the collecting means advances and positions a subsequent surface or receptacle for receipt of particles, the collector means thereafter signaling the particle separation means to commence the next sorting instruction.

Owner:BTF

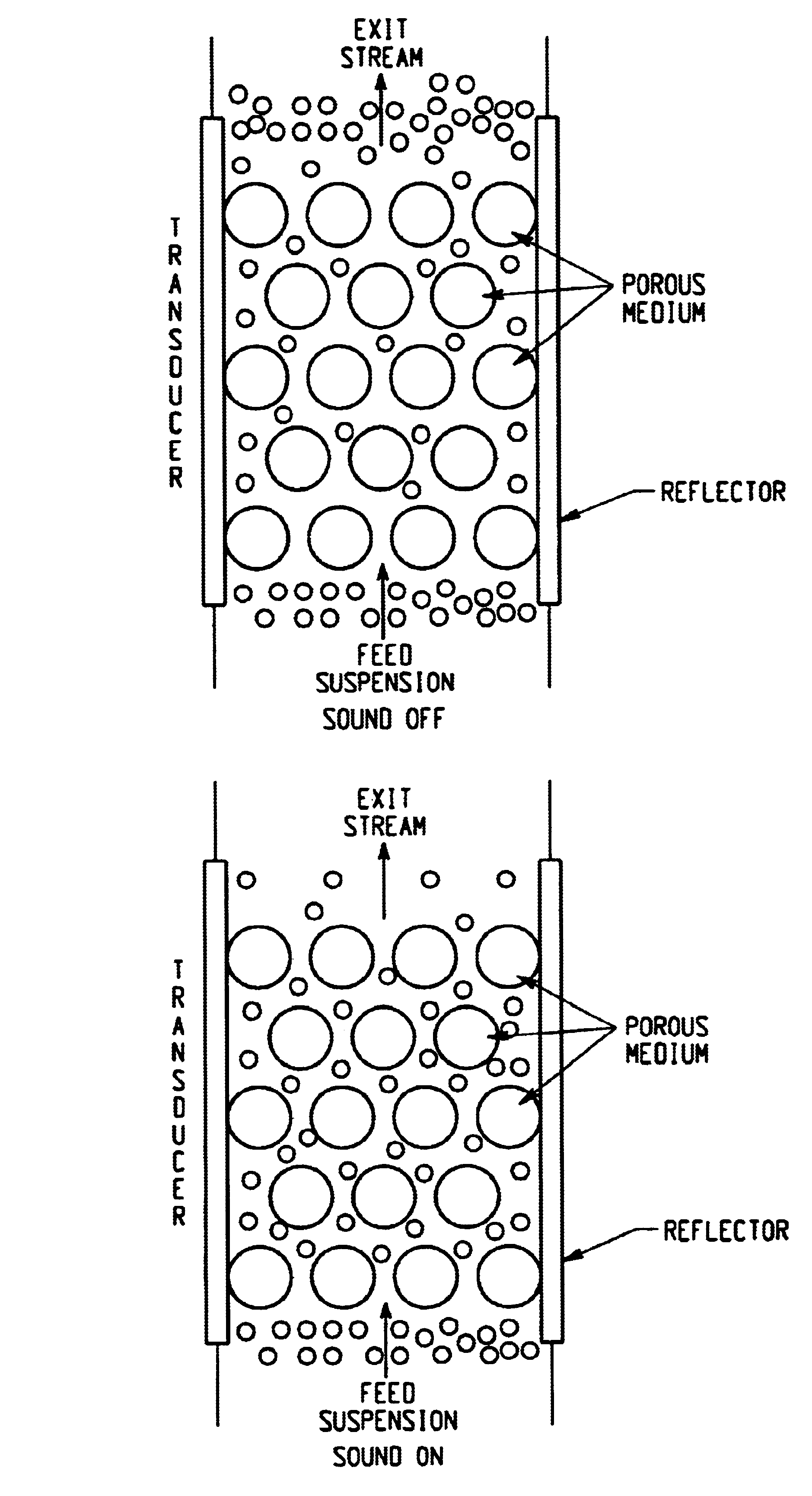

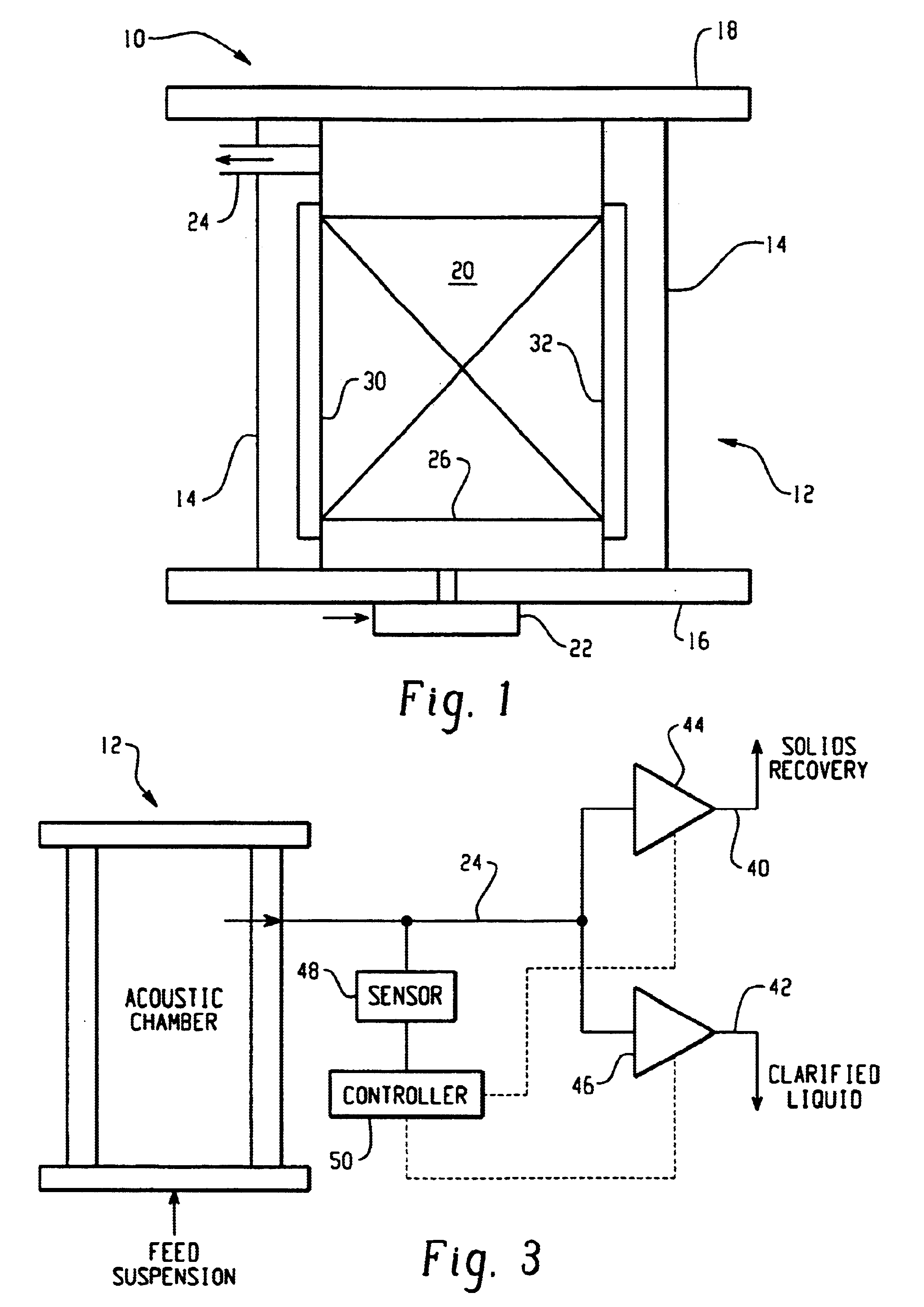

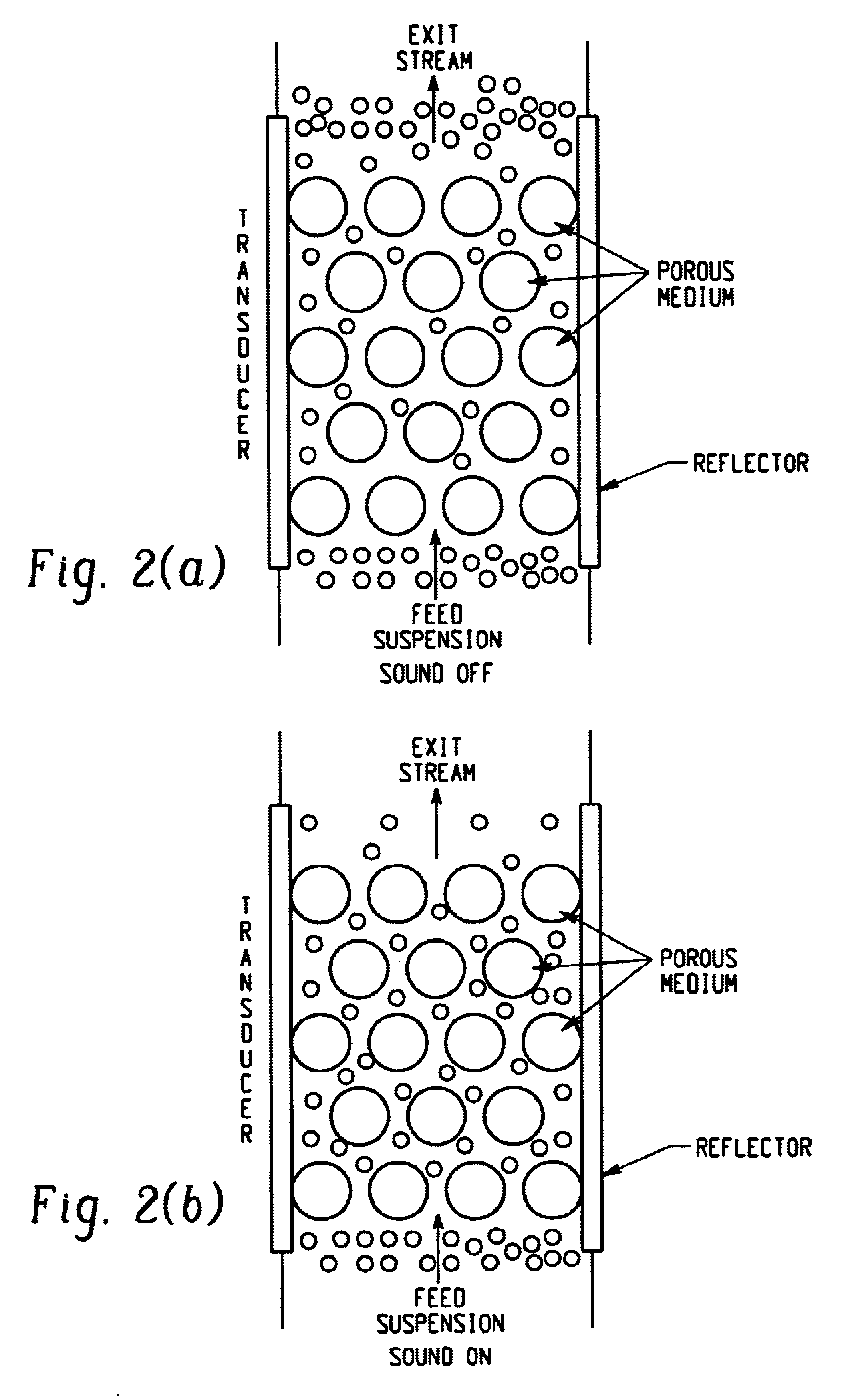

Method and apparatus for acoustically driven media filtration

InactiveUS6797158B2Pressure dropEasy to collectAuxillary pretreatmentWater/sewage treatment with mechanical oscillationsPolyesterPorous medium

A method and apparatus for acoustically enhanced particle separation uses a chamber through which flows a fluid containing particles to be separated. A porous medium is disposed within the chamber. A transducer mounted on one wall of the chamber is powered to impose on the porous medium an acoustic field that is resonant to the chamber when filled with the fluid. Under the influence of the resonant acoustic field, the porous medium is able to trap particles substantially smaller than the average pore size of the medium. When the acoustic field is deactivated, the flowing fluid flushes the trapped particles from the porous medium and regenerates the medium. A collection circuit for harvesting the particles flushed from the porous medium is disclosed. Aluminum mesh, polyester foam, and unconsolidated glass beads are disclosed as porous media.

Owner:CASE WESTERN RESERVE UNIV

Apparatus for separating floating and non-floating particulate from a fluid stream

ActiveUS20050056587A1Reduce the likelihood of cloggingMaximize particulate removal capabilityLiquid displacementLiquid separationParticulatesStream flow

A fluid separation system includes a tank with a storage chamber for retaining floating and non-floating particulates. The tank includes a baffle for retaining floating particulates within the storage chamber and for directing flow out of the storage chamber. The tank also includes a bypass with an inlet flow control zone and an outlet flow control zone. The flow control zones are separated by a weir sized and positioned to regulate the fluid flow through a baffle port into the storage chamber. The weir also provides control of the flow rate at which incoming fluid is diverted directly through the bypass to the tank outlet rather than into the storage chamber. The baffle and / or the weir may be curved, and the baffle may include a complex curve, to aid in the smoothing of the fluid flow within the storage chamber to improve particulate separation.

Owner:CONTECH ENGINEERED SOLUTIONS

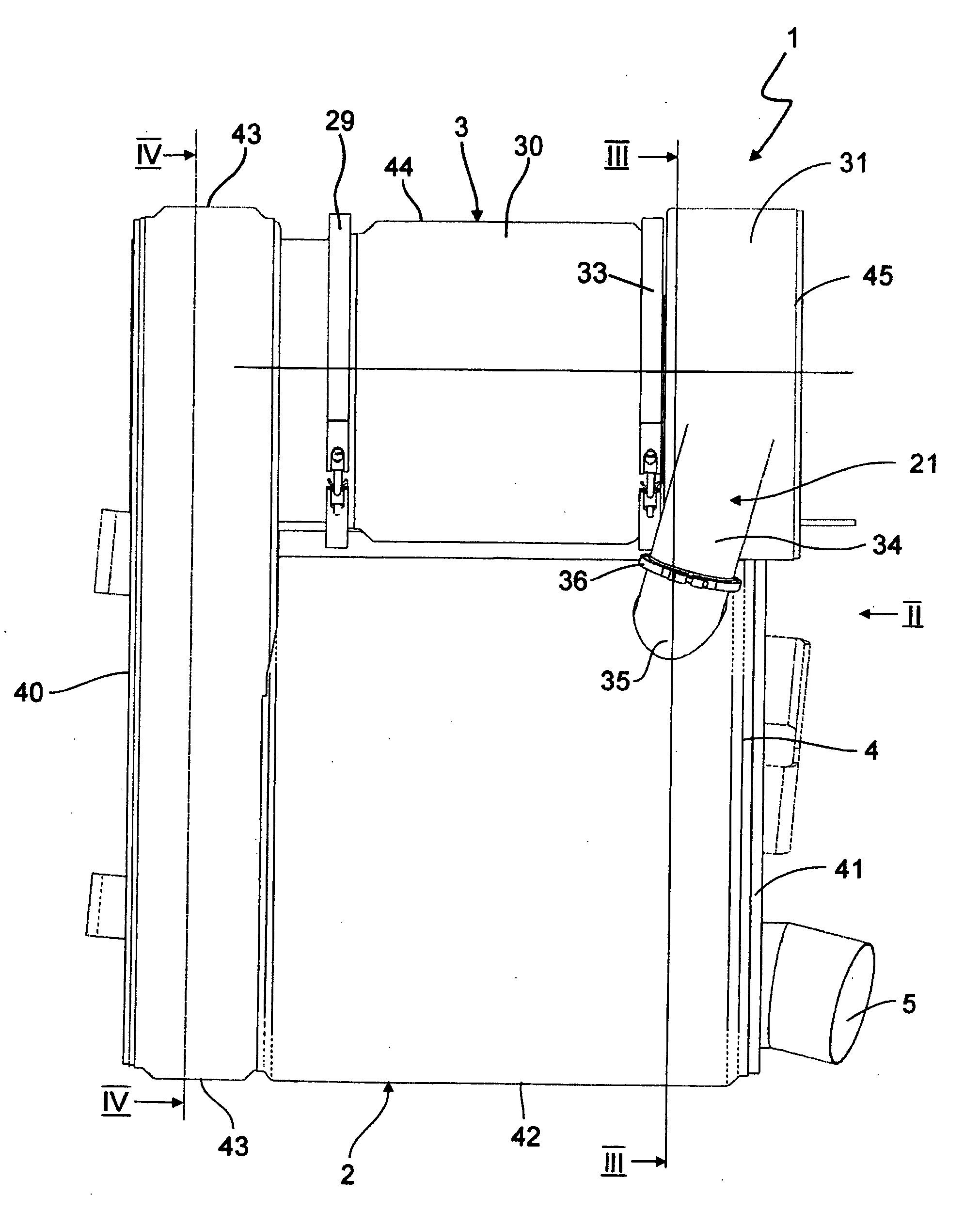

Exhaust gas treatment system

ActiveUS20060156712A1Easy maintenanceCompact designCombination devicesInternal combustion piston enginesExhaust fumesEngineering

The present invention relates to an exhaust gas treatment system for an exhaust system of an internal combustion engine, and comprises a basic housing and an add-on housing mounted thereon so it is at least partially detachable. The basic housing contains at least one inlet pipe which can be connected to the exhaust system and leads into the basic housing, at least one outlet pipe which can be connected to the exhaust system and leads out of the basic housing, at least one SCR catalyst and at least one oxidizing catalytic converter. The add-on housing contains at least one particle separation device and at least one reducing agent feed mechanism.

Owner:PUREM GMBH

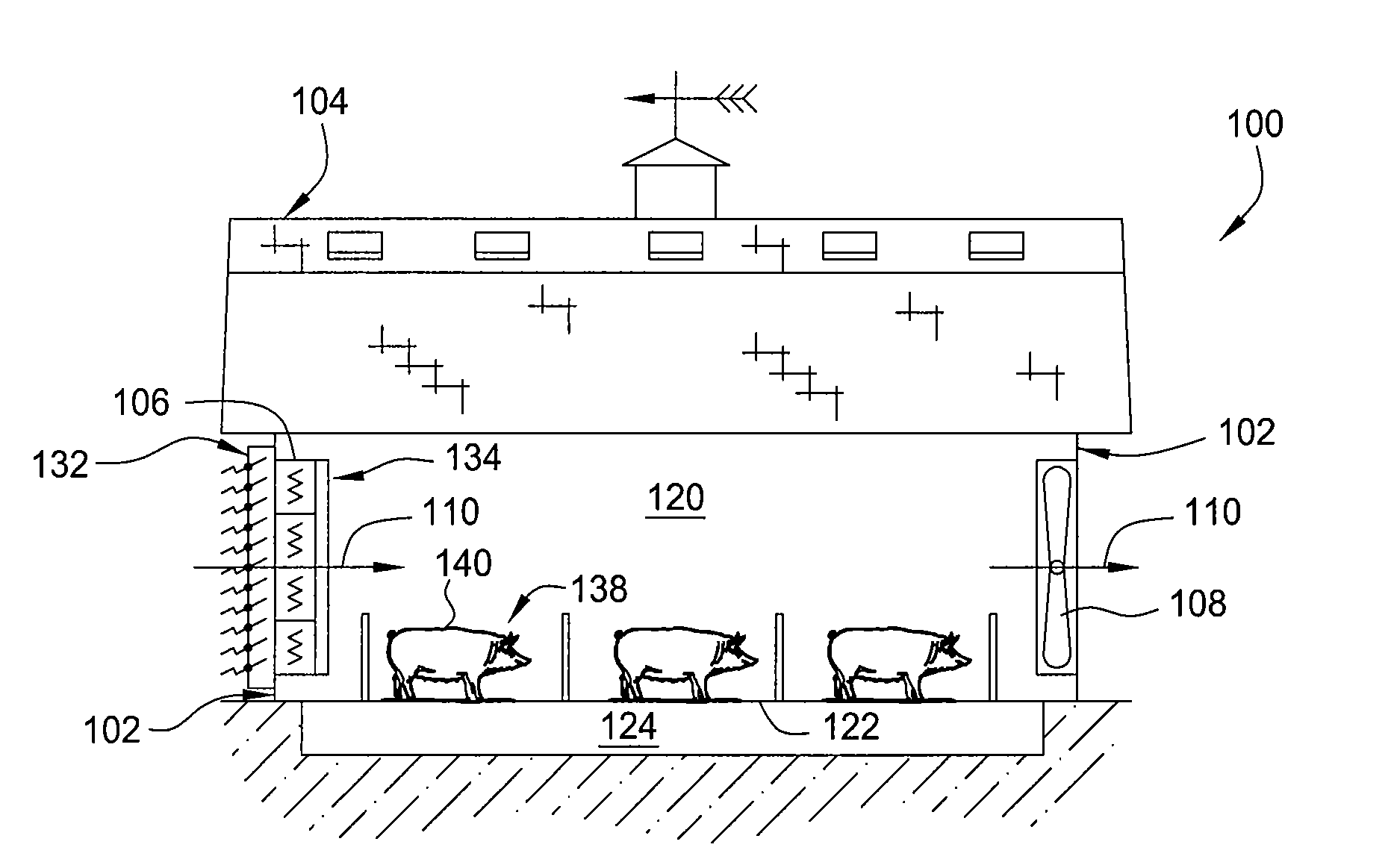

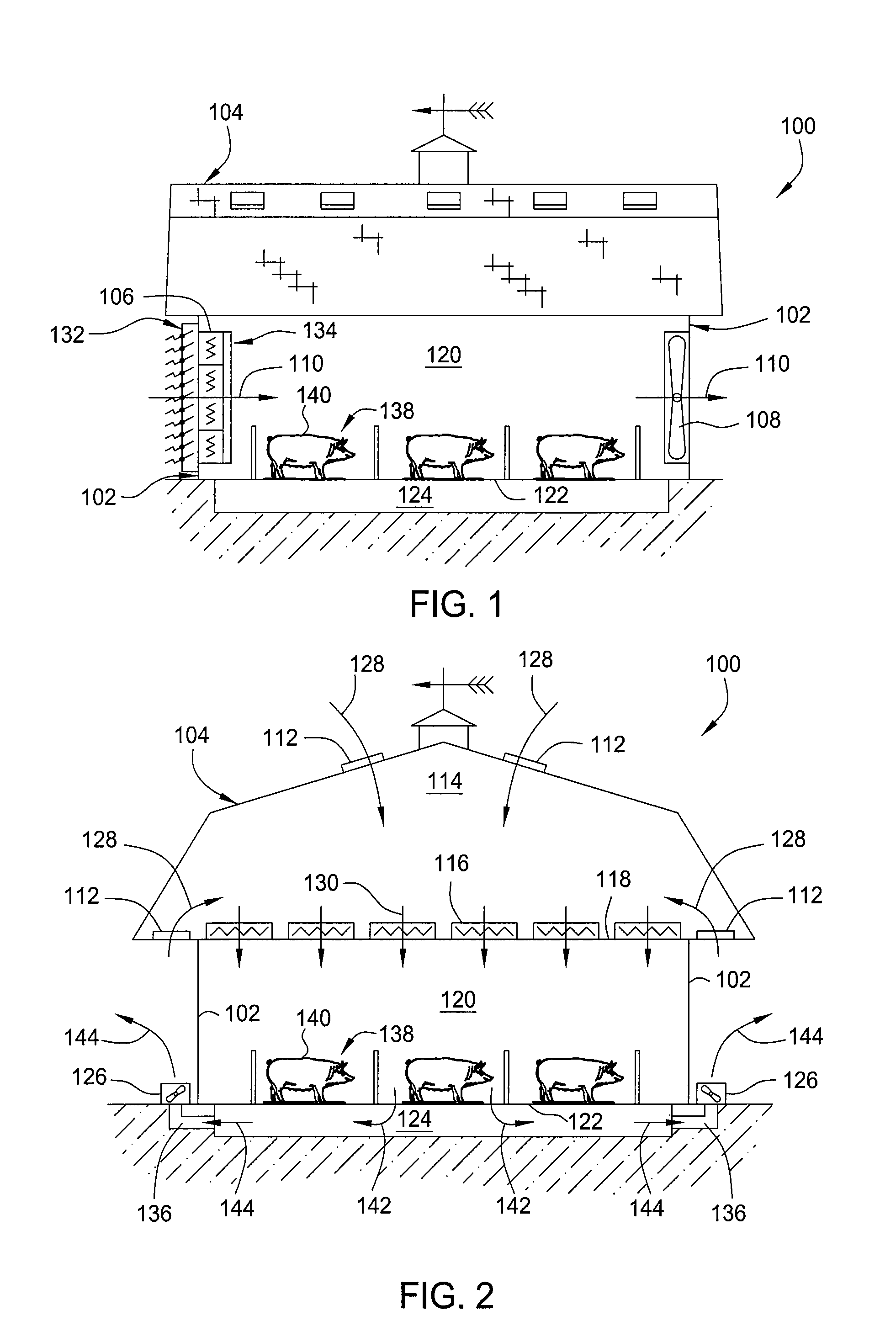

Method and apparatus for providing clean air to animal enclosures

The present invention provides a method and apparatus for economically filtering air into swine farms and other animal enclosures. Advantageously, the invention substantially reduces the risk to airborne transfer of disease into animal enclosures. In one embodiment, a method for providing clean air to an animal enclosure includes providing an animal enclosure having an animal containing volume for containing a plurality of animals, removing air from the internal volume via at least one exhaust fan, and filtering air being pulled into the enclosure by the at least one exhaust fan using a fully sealed filter, the fully sealed filter having a particle separation sufficiently efficient to prevent detection of live (PRRS-) virus downstream the of filter, using polymerase chain reaction (PCR) analysis of samples collected with a cyclonic aerosol collector.

Owner:CAMFIL USA

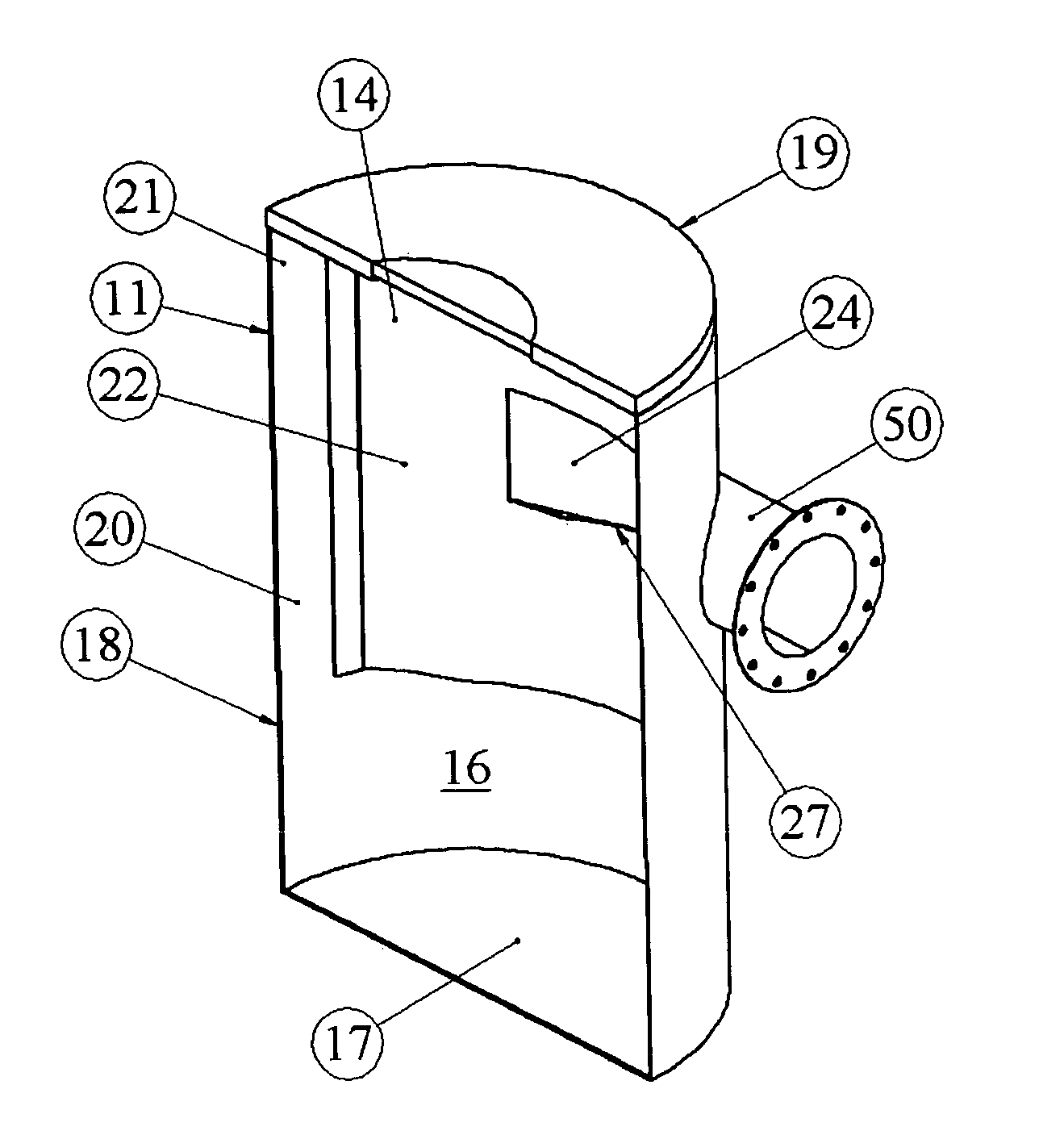

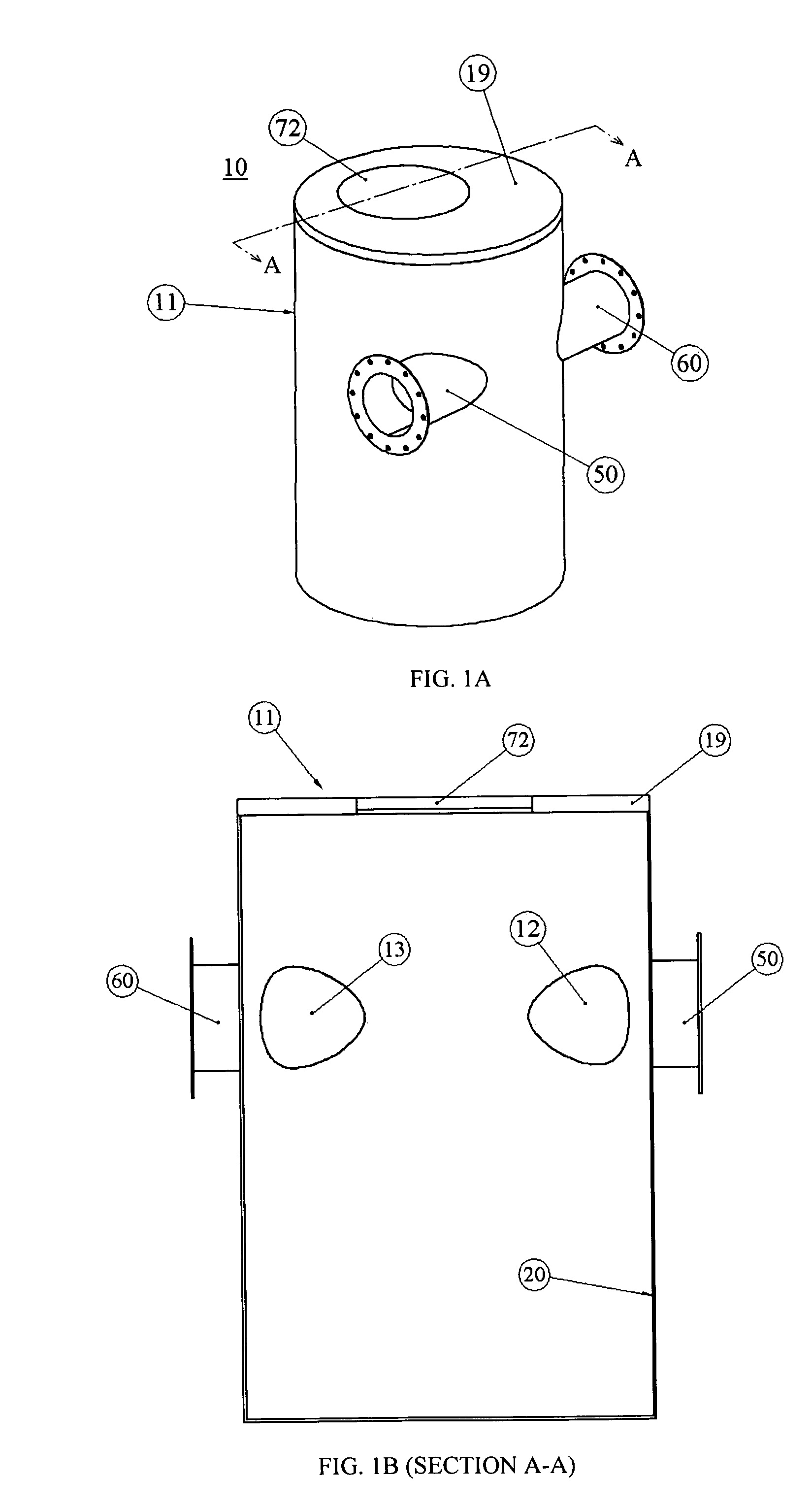

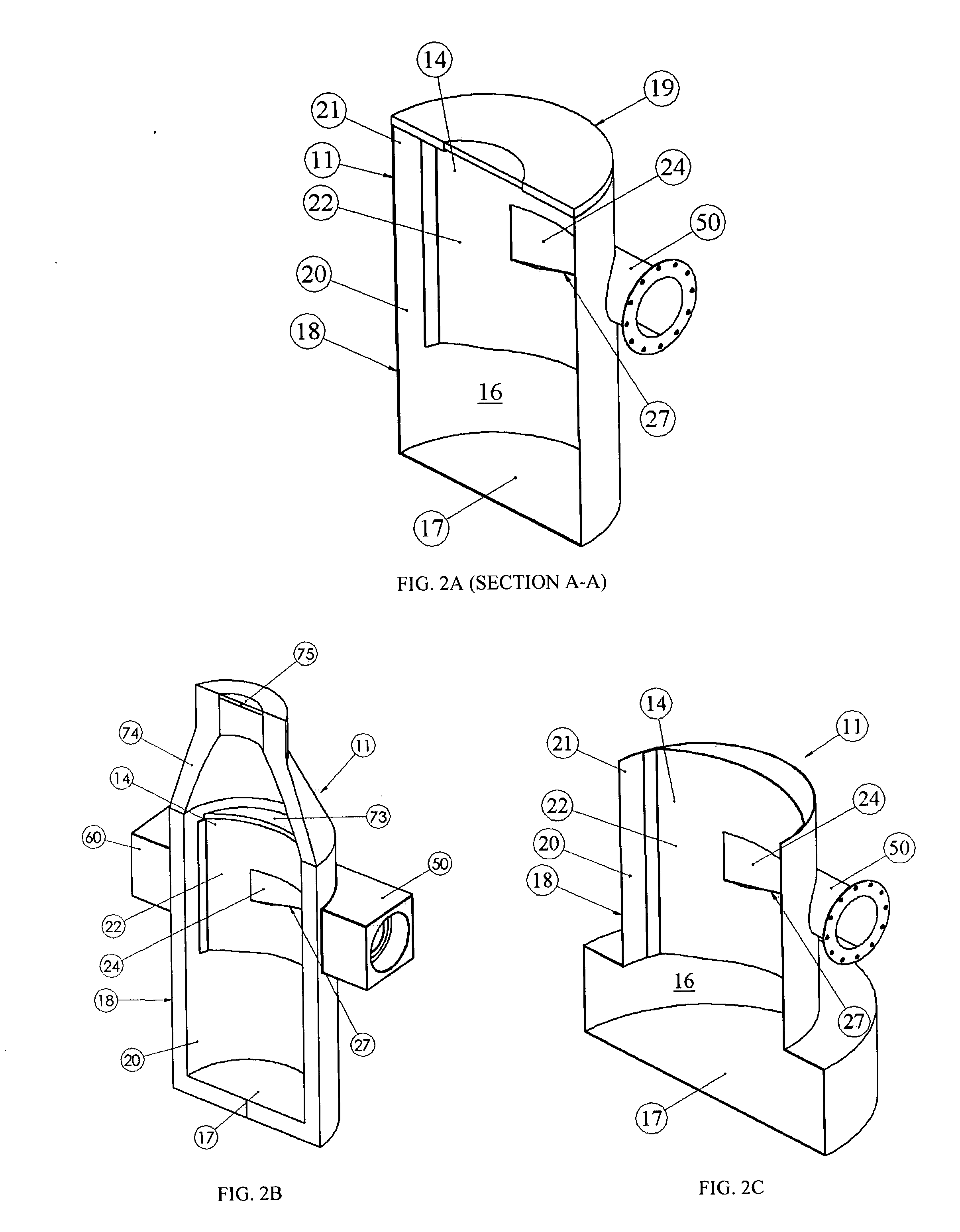

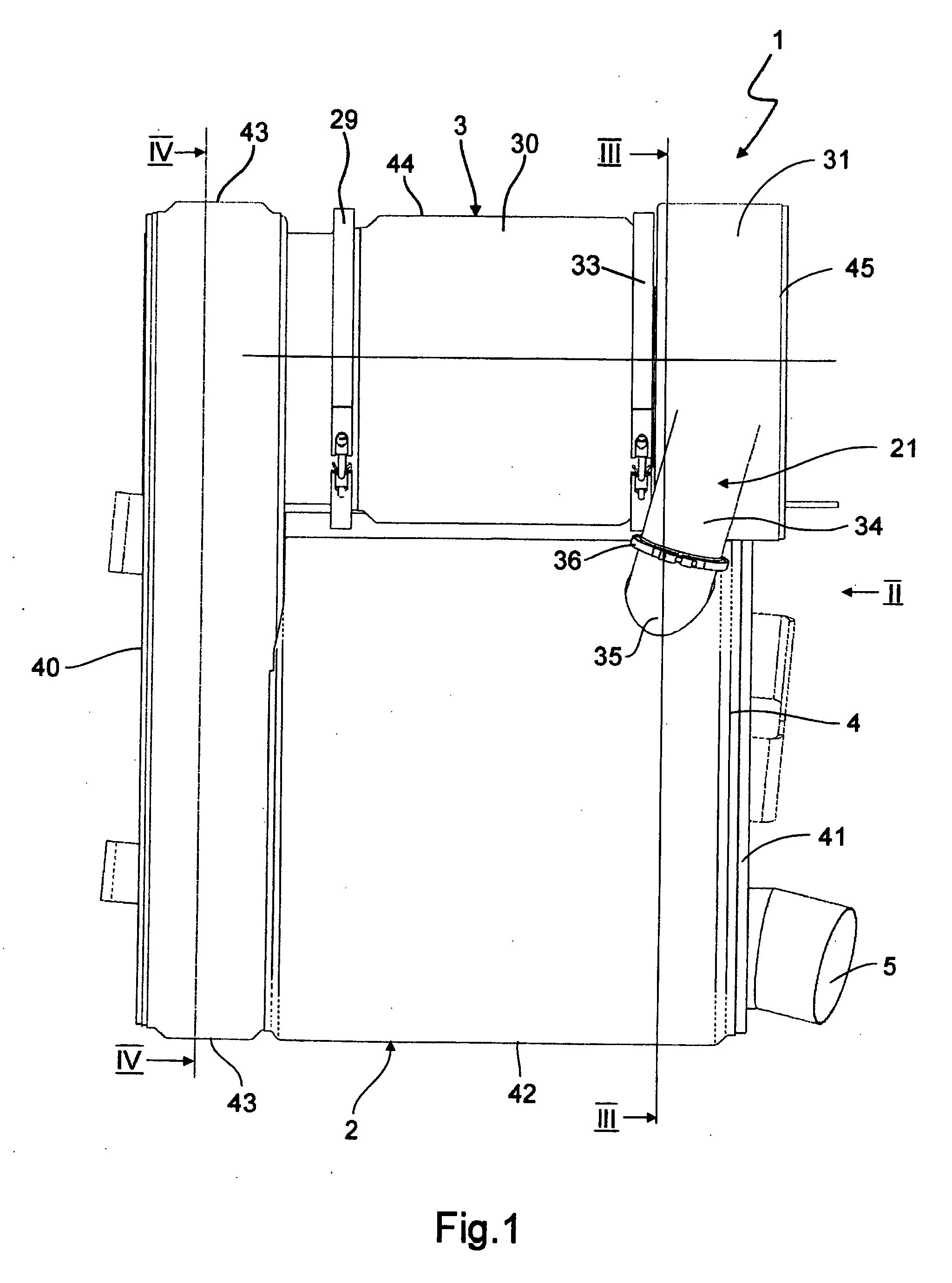

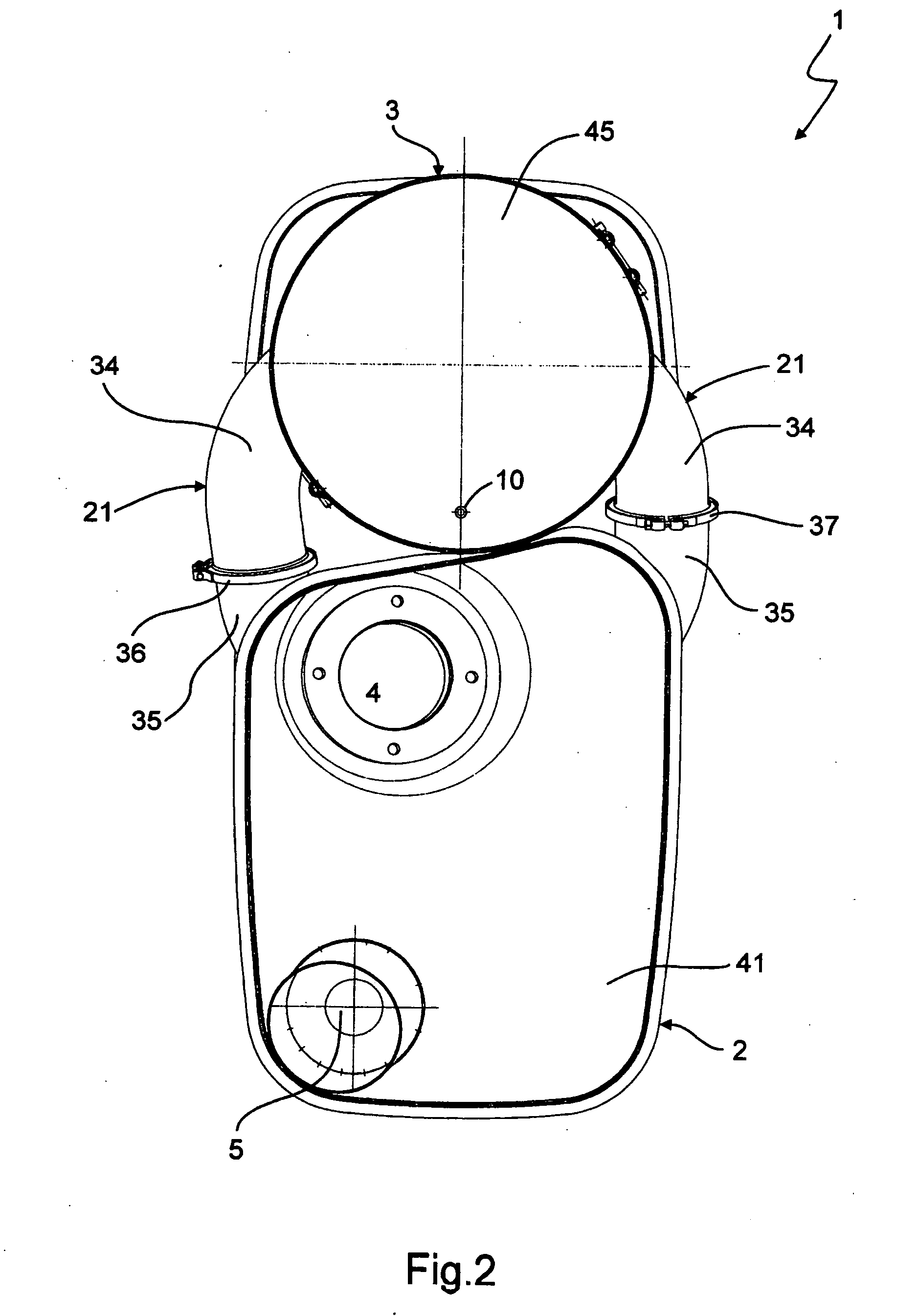

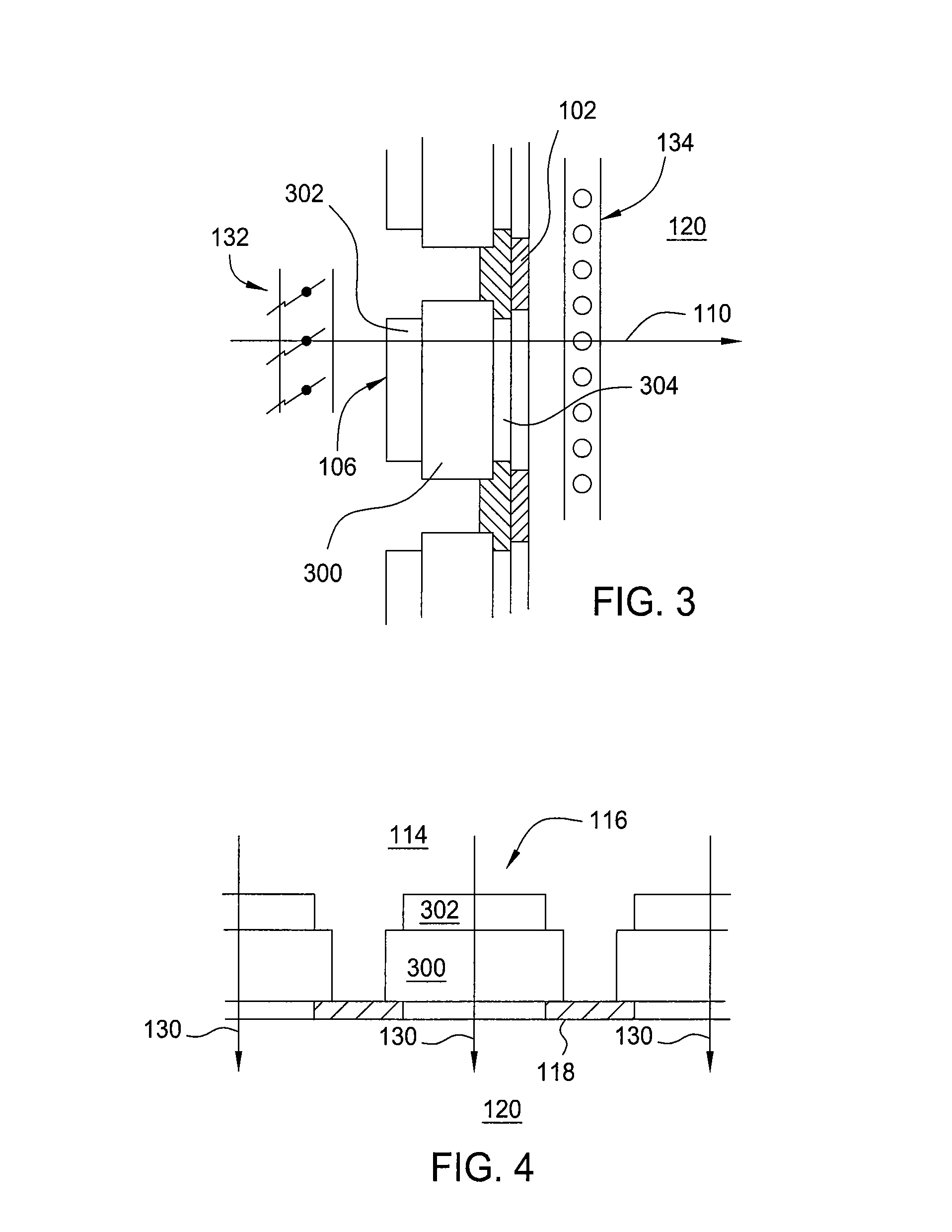

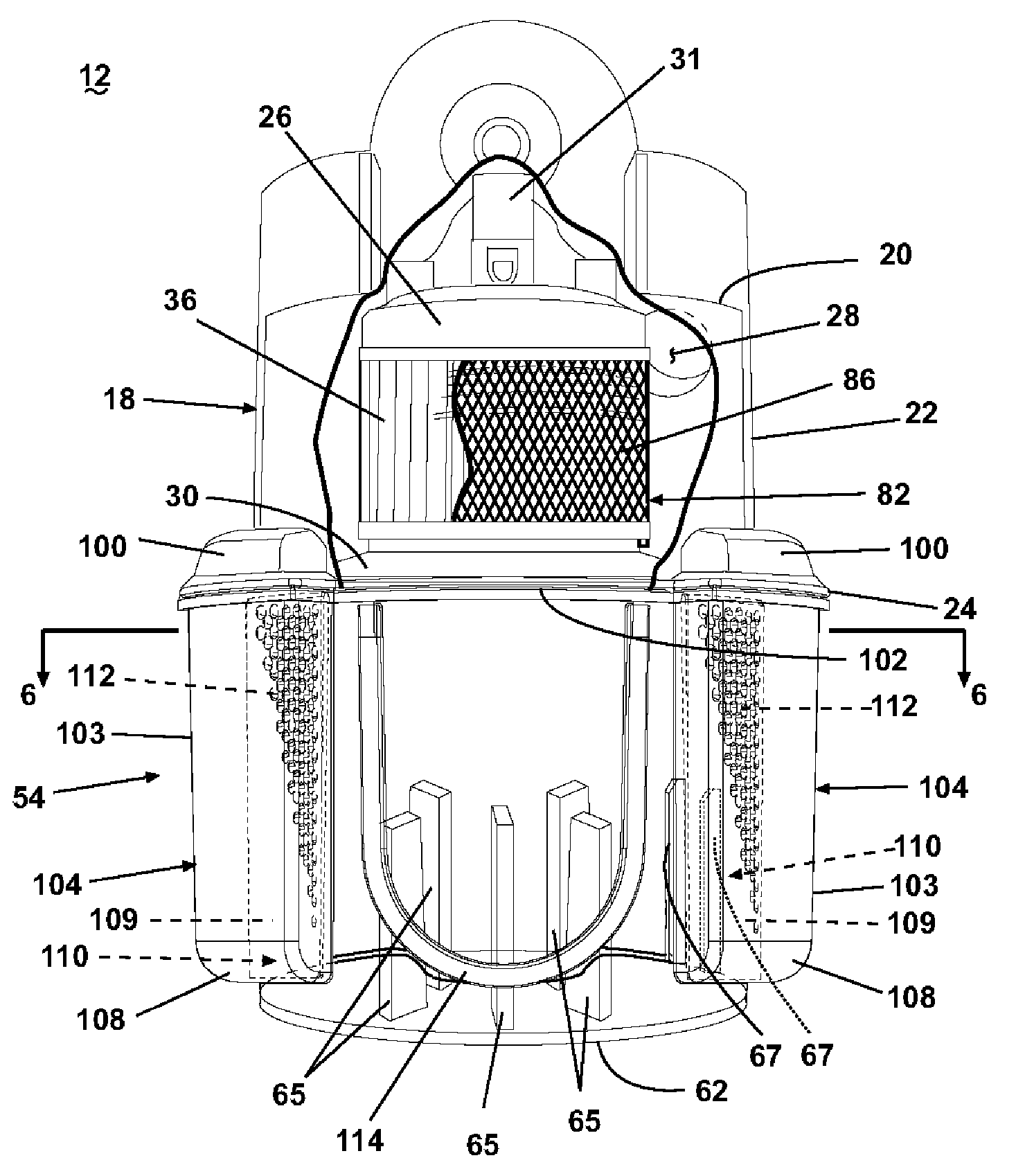

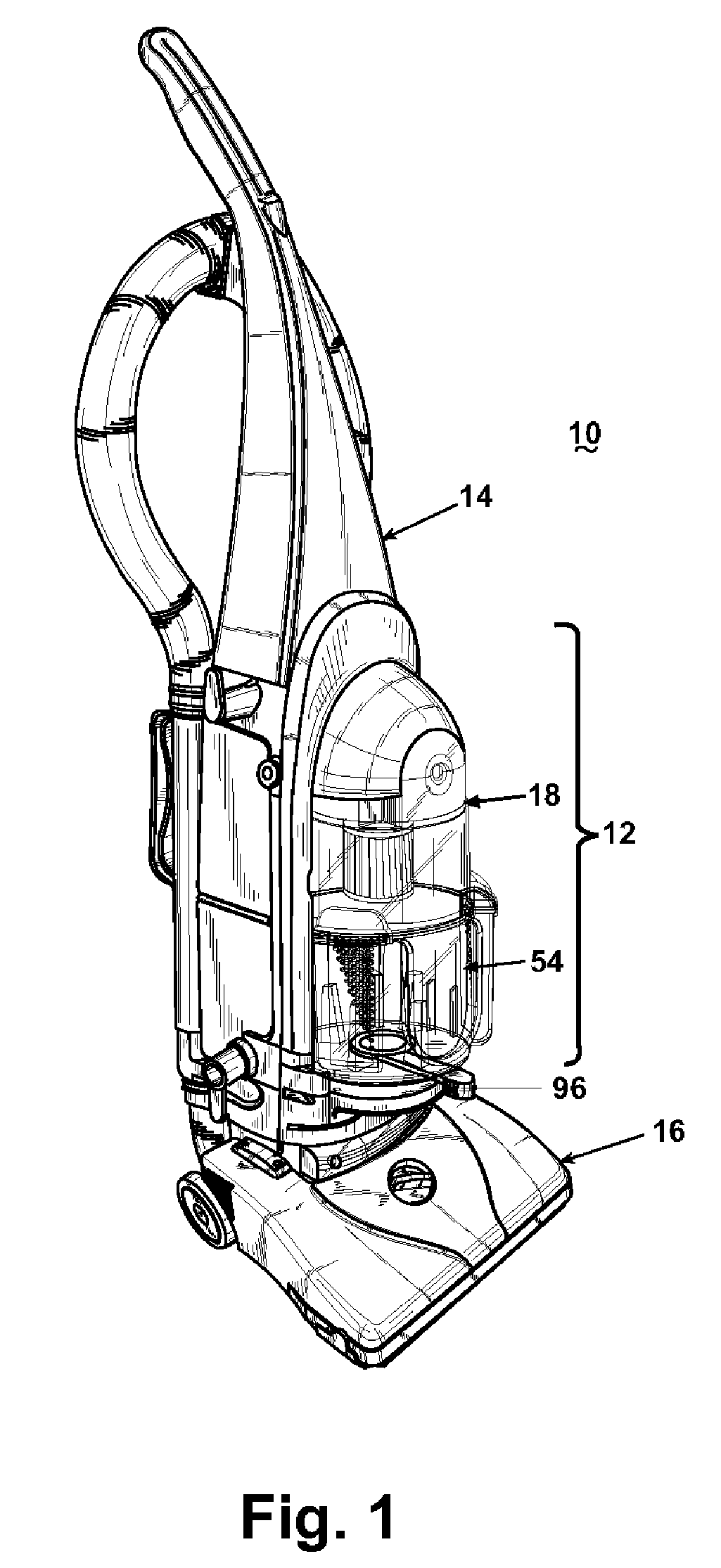

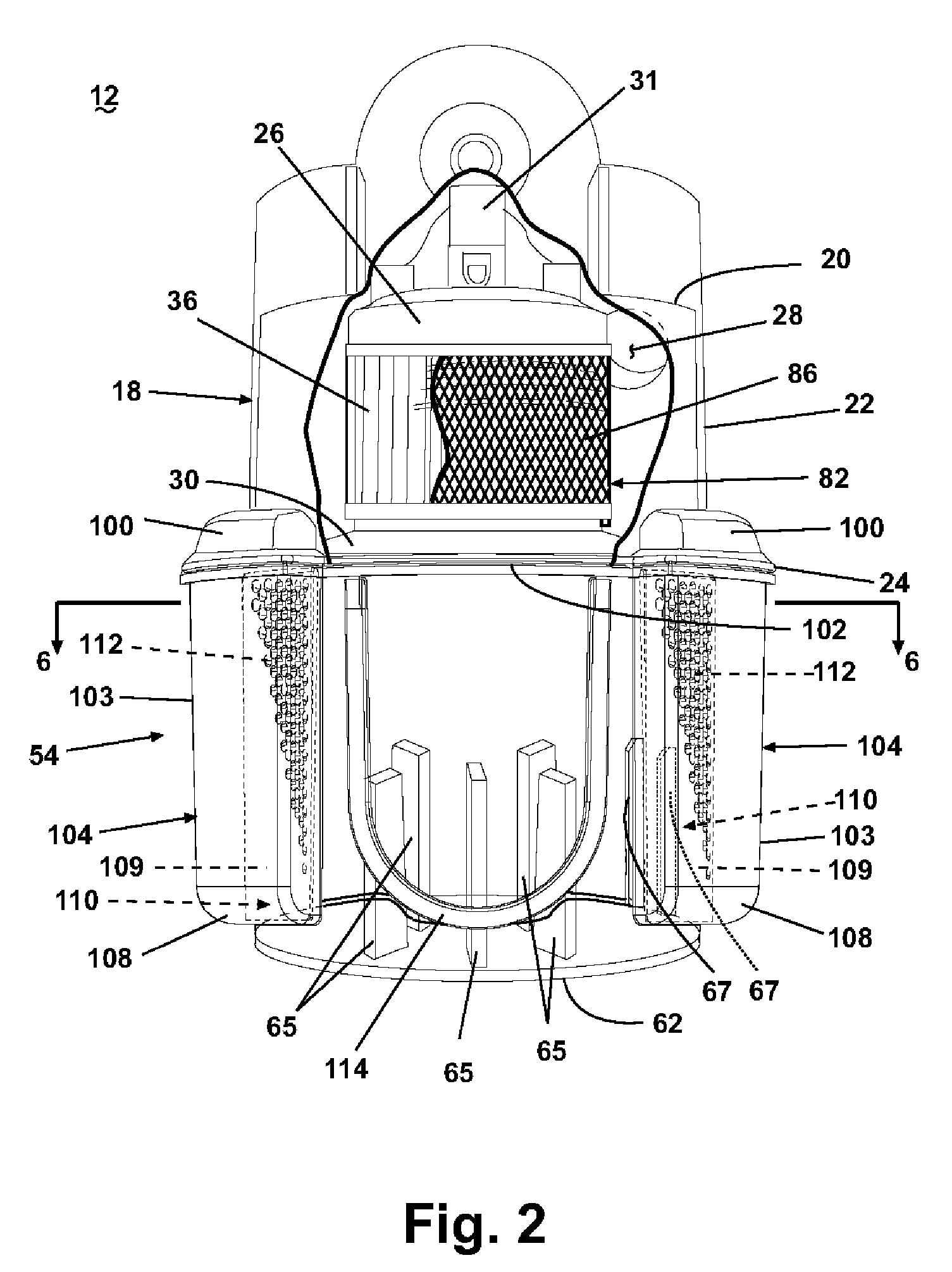

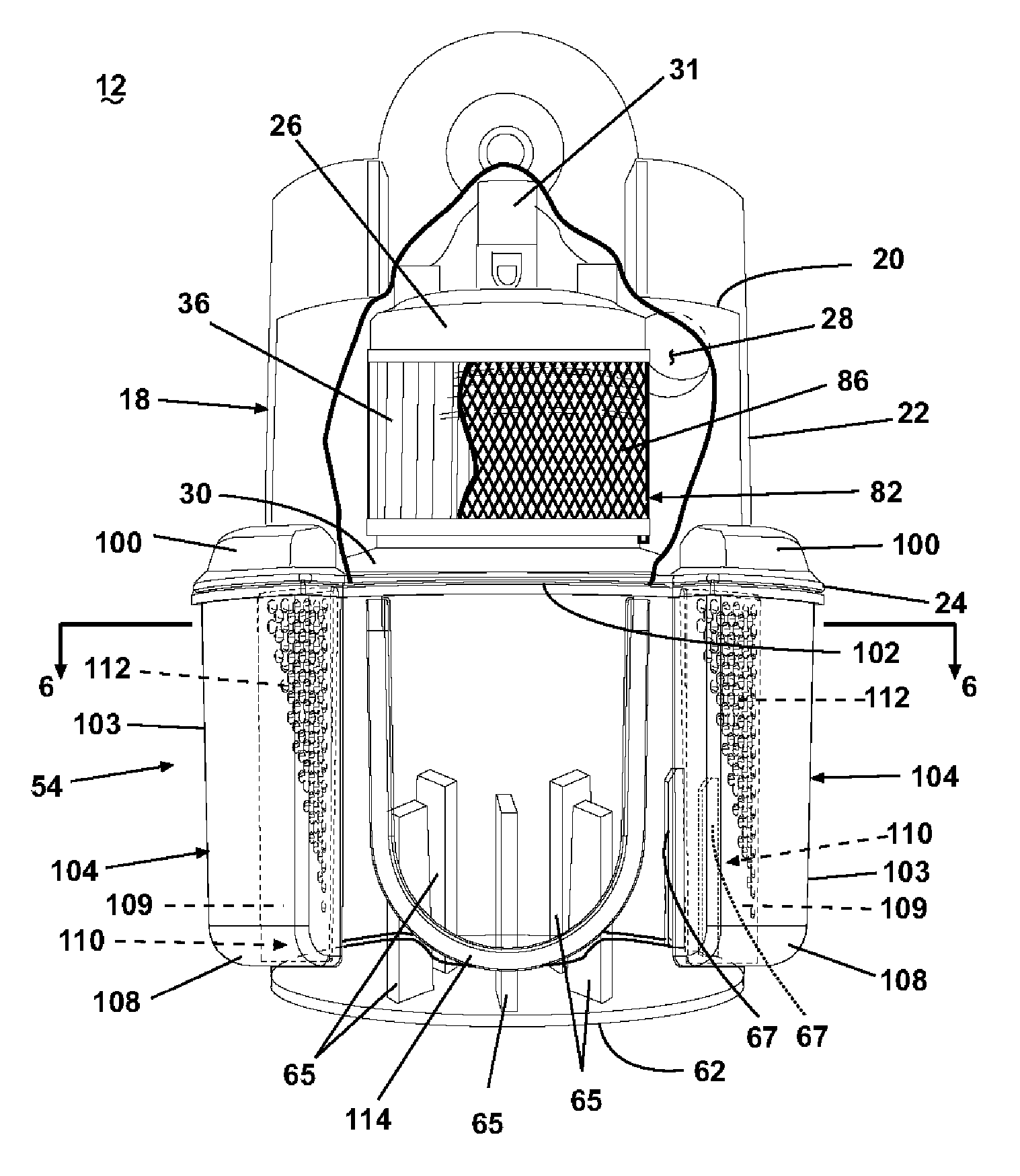

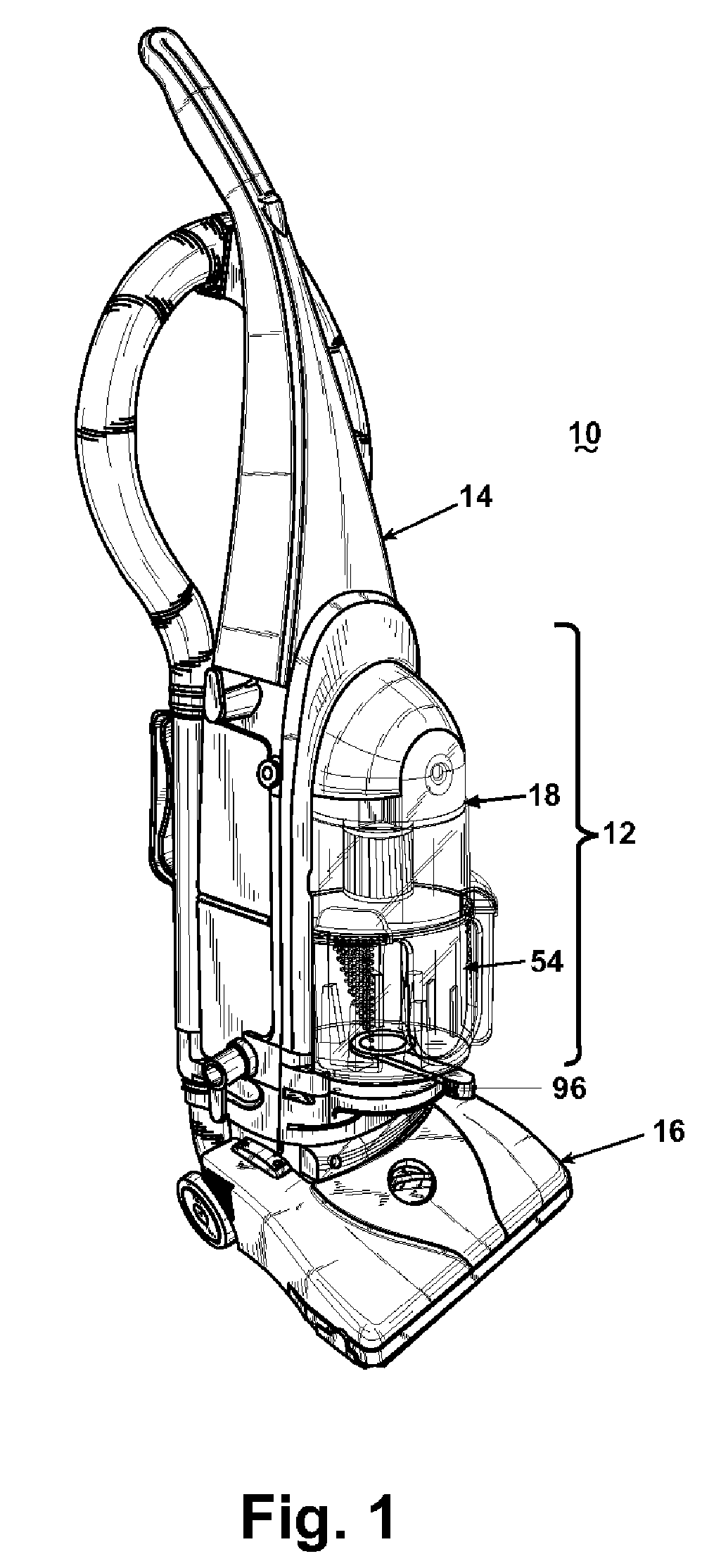

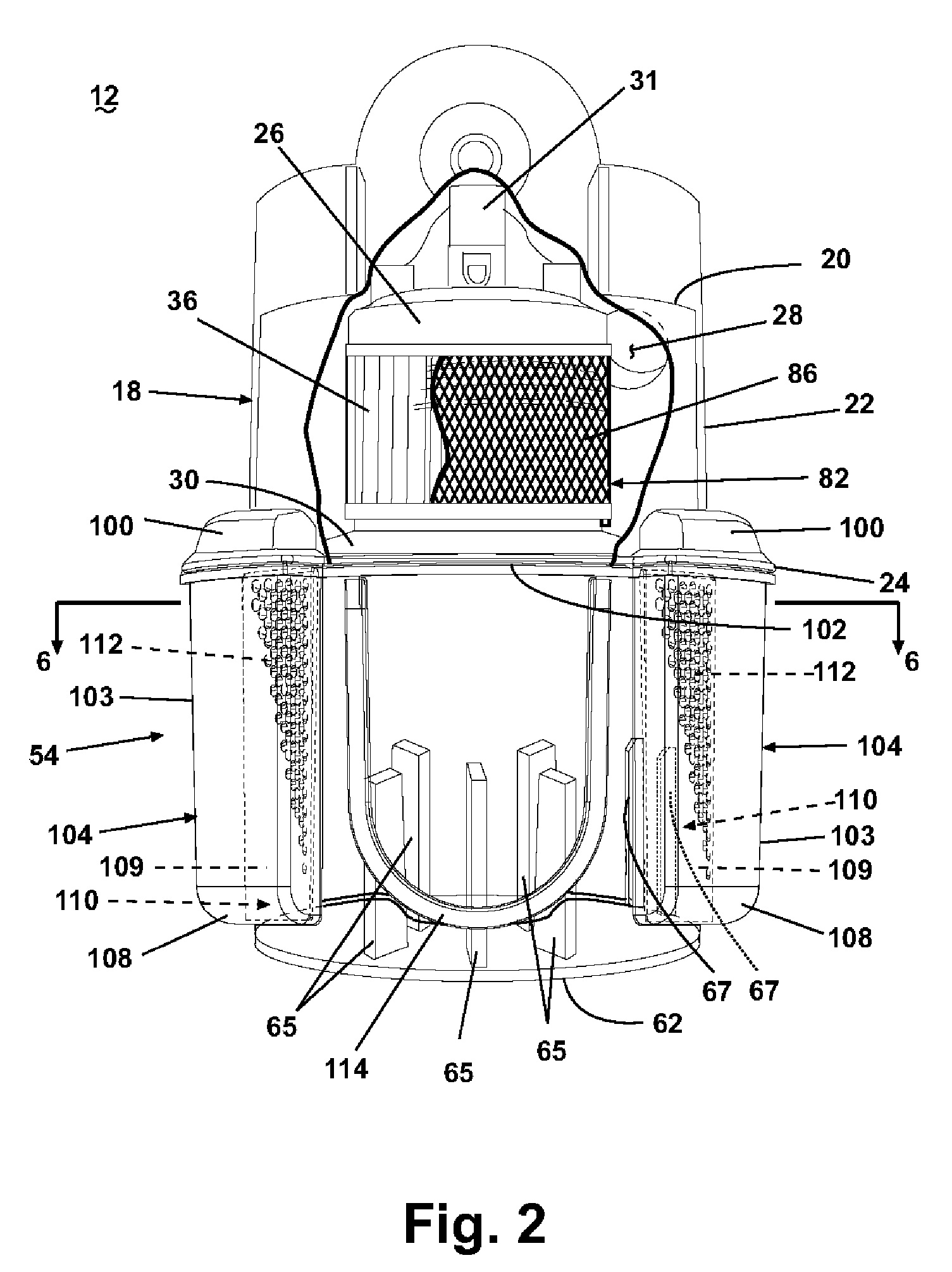

Cyclone separator with fine particle separation member

A cyclone separator assembly comprises a cyclone separator that removes large particles of dirt from a working airstream as it flows through the cyclone separator, and the separated large particles of dirt are deposited into a dirt cup. The cyclone separator assembly further includes a fine particle separation member comprising a plurality of apertures for separating fine particles of dirt from air in the cyclone separator or the dirt cup.

Owner:BISSELL INC

Microflow System for Particle Separation and Analysis

InactiveUS20070207548A1High resolutionElectrostatic separatorsSamplingEngineeringParticle separation

A micro flow system is provided for separating particles, comprising a microfabricated member having a flow channel (5) defined therein for guiding a flow of a fluid containing the particles through the flow channel, first inlet means (2) positioned at one end of the flow channel for entering the fluid into the flow channel, first outlet means (7) positioned at the other end of the flow channel for discharging the fluid from the flow channel, the flow of the fluid containing the particles being controlled in such a way that one particle at the time passes a cross section of the flow channel, the member being positioned in a field that is substantially perpendicular to a longitudinal axis of the flow channel so that particles residing in the flow channel and being susceptible to the field across the flow channel are deflected in the direction of the field. Further, a micro flow system is provided for analyzing components of a fluid comprising a microfabricated member having a flow channel defined therein for guiding a flow of a fluid through the flow channel, first inlet means for entering particles into the flow channel, first outlet means for discharging of fluid from the flow channel and a plurality of assay sites located in the flow channel and comprising immobilized reagents whereby the fluid may be analyzed for a plurality of components while residing in the flow channel.

Owner:INVERNESS MEDICAL SWITZERLAND GMBH

Photonic polymer-blend structures and method for making

InactiveUS6756117B1Tunable optical and mechanical propertyHighly robustLiquid surface applicatorsSynthetic resin layered productsEngineeringMicroparticle

The present invention comprises the formation of photonic polymer-blend structures having tunable optical and mechanical properties. The photonic polymer-blend structures comprise monomer units of spherical microparticles of a polymer-blend material wherein the spherical microparticles have surfaces partially merged with one another in a robust inter-particle bond having a tunable inter-particle separation or bond length sequentially attached in a desired and programmable architecture. The photonic polymer-blend structures of the present invention can be linked by several hundred individual particles sequentially linked to form complex three-dimensional structures or highly ordered two-dimensional arrays of 3D columns with 2D spacing.

Owner:UT BATTELLE LLC

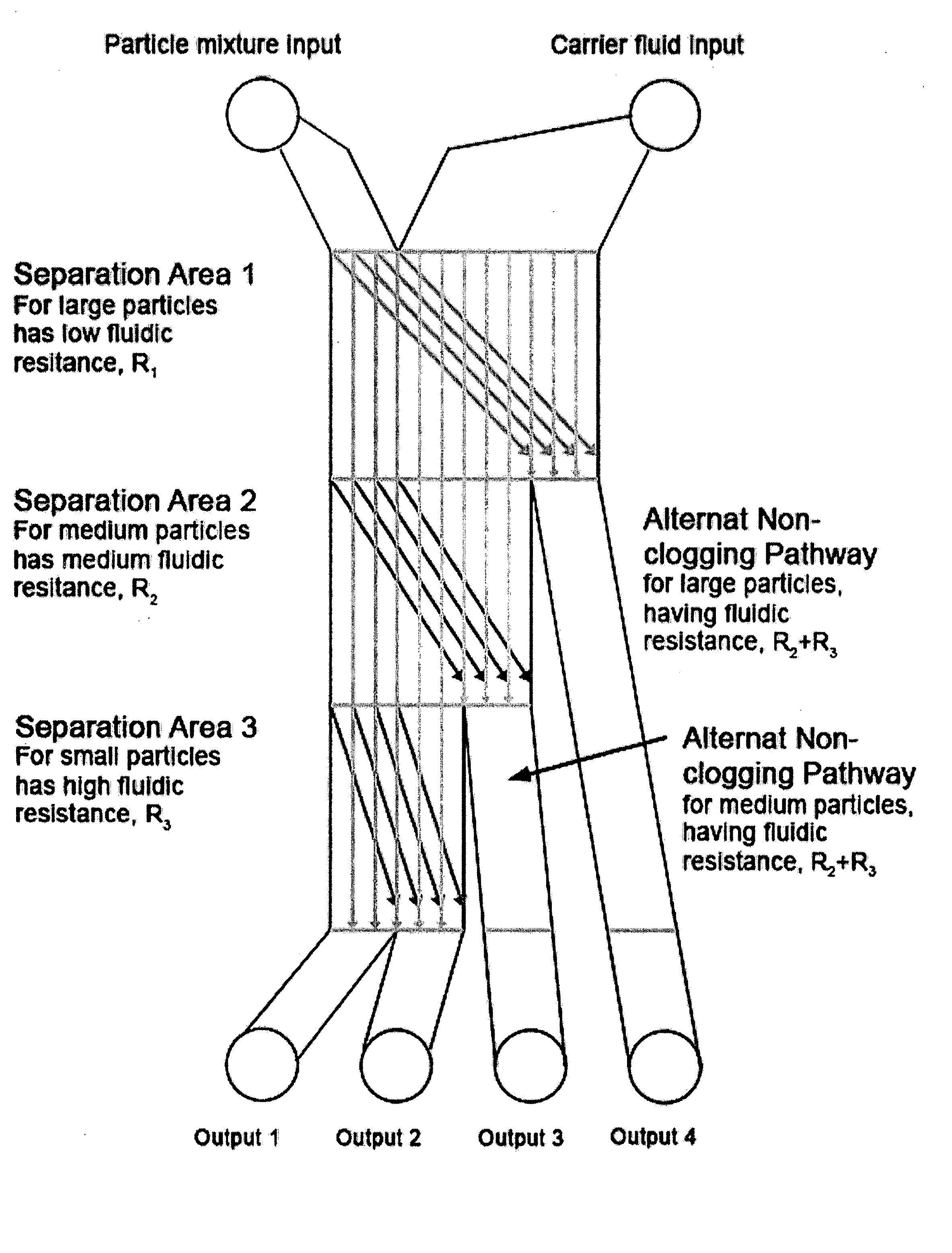

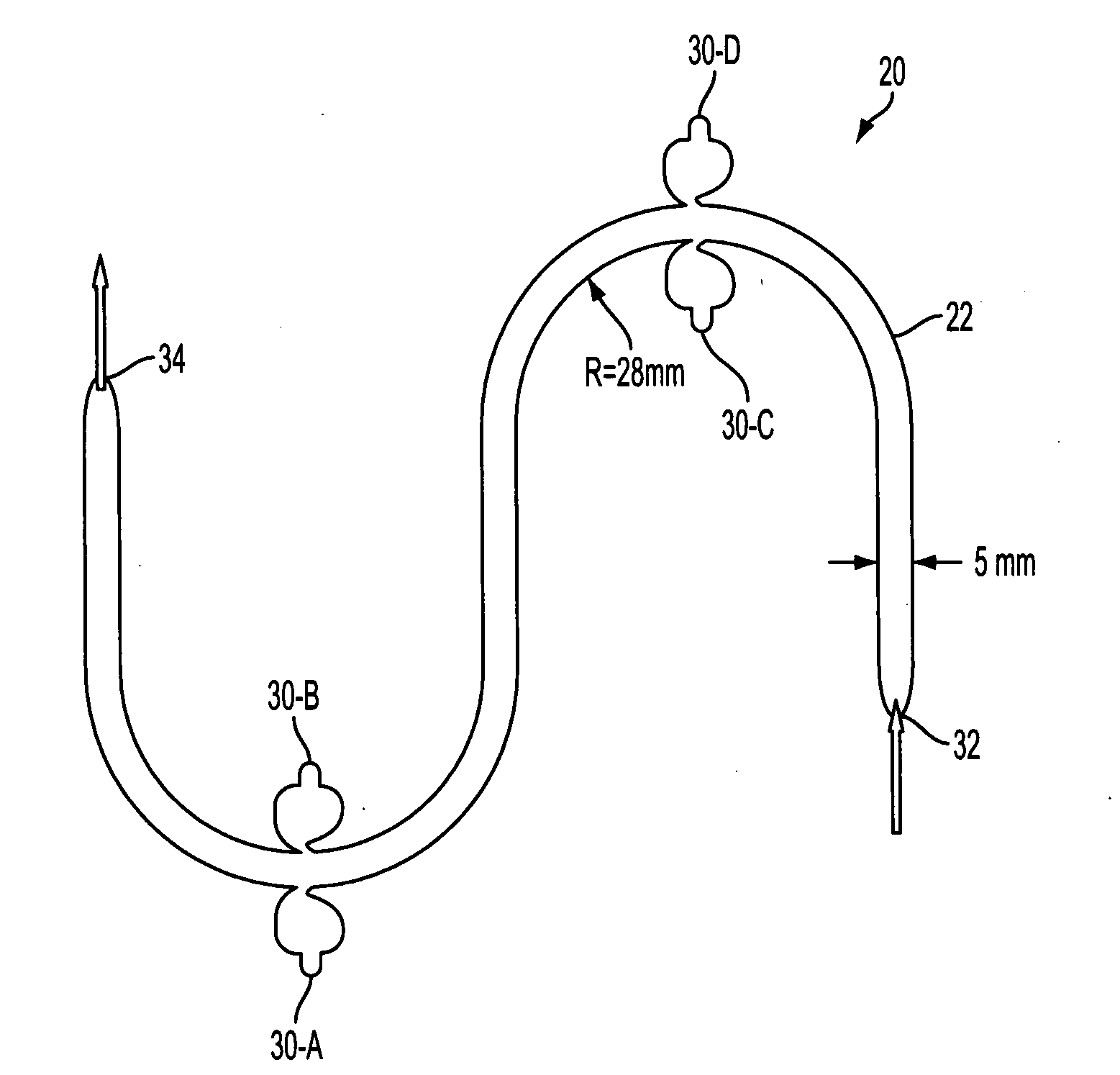

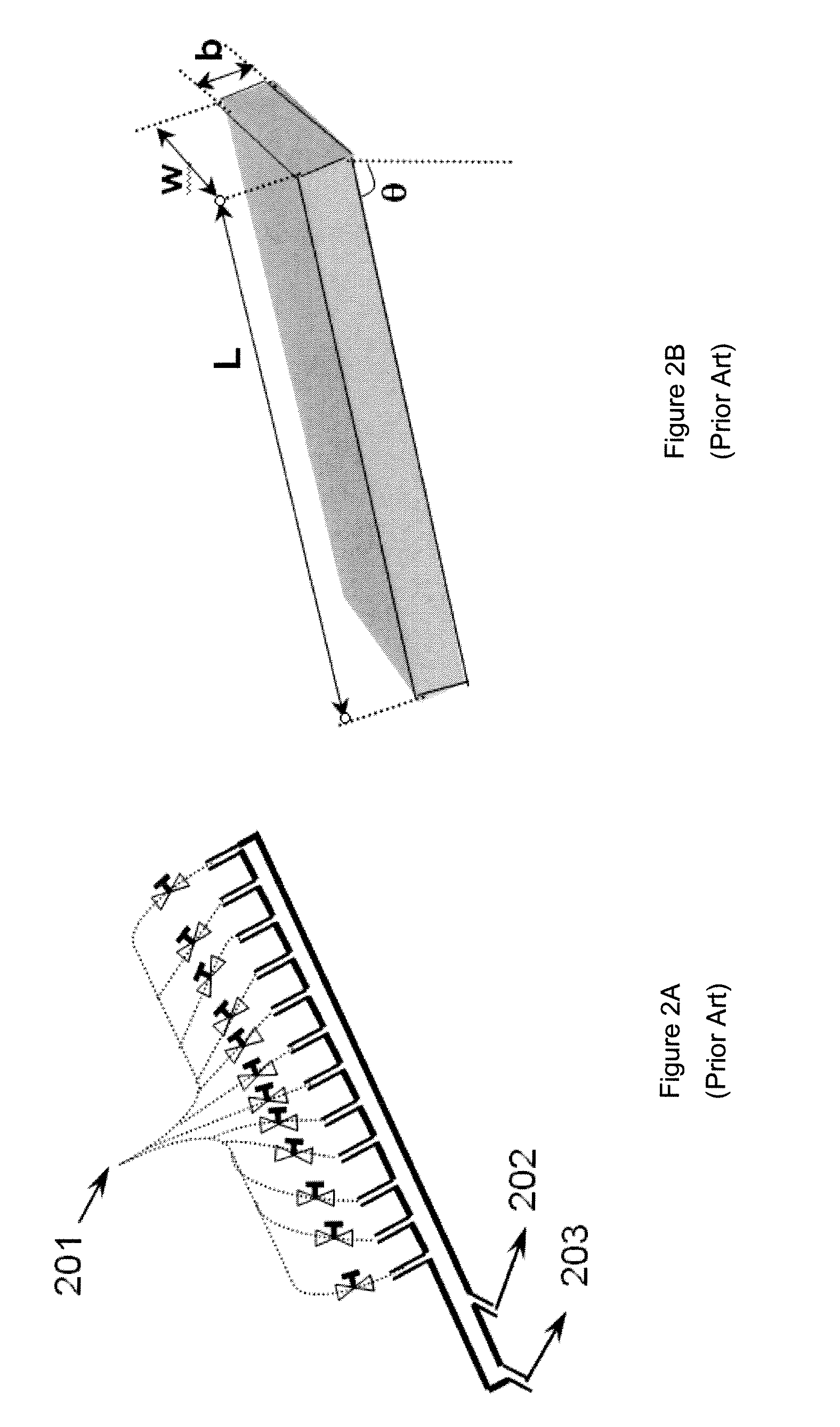

Serpentine structures for continuous flow particle separations

InactiveUS20090050538A1Easy to operateReduce the average velocityLaboratory glasswaresSeparation devicesExternal applicationEngineering

An improved technique for particle separation is provided. A serpentine structure is utilized in a continuous fluid flow environment to allow for suitable separation of particles to occur in a manner that does not require external application of forces to initiate the separation. The geometry of the serpentine structure and associated forces generated in connection with fluid flow therein suffice.

Owner:PALO ALTO RES CENT INC

Cyclone separator with fine particle separation member

A cyclone separator assembly comprises a cyclone separator that removes large particles of dirt from a working airstream as it flows through the cyclone separator, and the separated large particles of dirt are deposited into a dirt cup. The cyclone separator assembly further includes a fine particle separation member comprising a plurality of apertures for separating fine particles of dirt from air in the cyclone separator or the dirt cup.

Owner:BISSELL INC

Method for continuous particle separation using obstacle arrays asymmetrically aligned to fields

The present invention relates to methods and devices for separating particles according to size. More specifically, the present invention relates to a microfluidic method and device for the separation of particles according to size using an array comprising a network of gaps, wherein the field flux from each gap divides unequally into subsequent gaps. In one embodiment, the array comprises an ordered array of obstacles in a microfluidic channel, in which the obstacle array is asymmetric with respect to the direction of an applied field.

Owner:THE TRUSTEES FOR PRINCETON UNIV

Particle separation

InactiveUS20060016728A1Considerably cost-effectiveSave energyWaste water treatment from quariesLiquid separation by electricityHigh pressureParticle separation

A laminar or cyclonic particle separator for gas, liquid-liquid and fluidizable solids separation comprised of a section with a non-metallic housing having an annulus and a chamber, an optional anode cooled with a first coolant in and a first coolant out disposed in the chamber, a DC or pulsating DC power source connected to the anode, at least one magnetic coil disposed adjacent the chamber and cooled with a second coolant, a high voltage pulsating DC power source connected to the magnetic coil, and a fluid (gas, liquid or fluidizable solids) inlet port connected to the housing, and also a section with a non-metallic separator tube connected to the housing and disposed within the housing, a first fluid outlet connected to the annulus through the housing. This device can then separate a stream rich in a targeted element (first fluid) and a stream lean in a targeted element (second fluid) from the device and thus discharge a stream almost free of the targeted element or almost 100% the targeted element.

Owner:SHORTS GRAEME STEWART

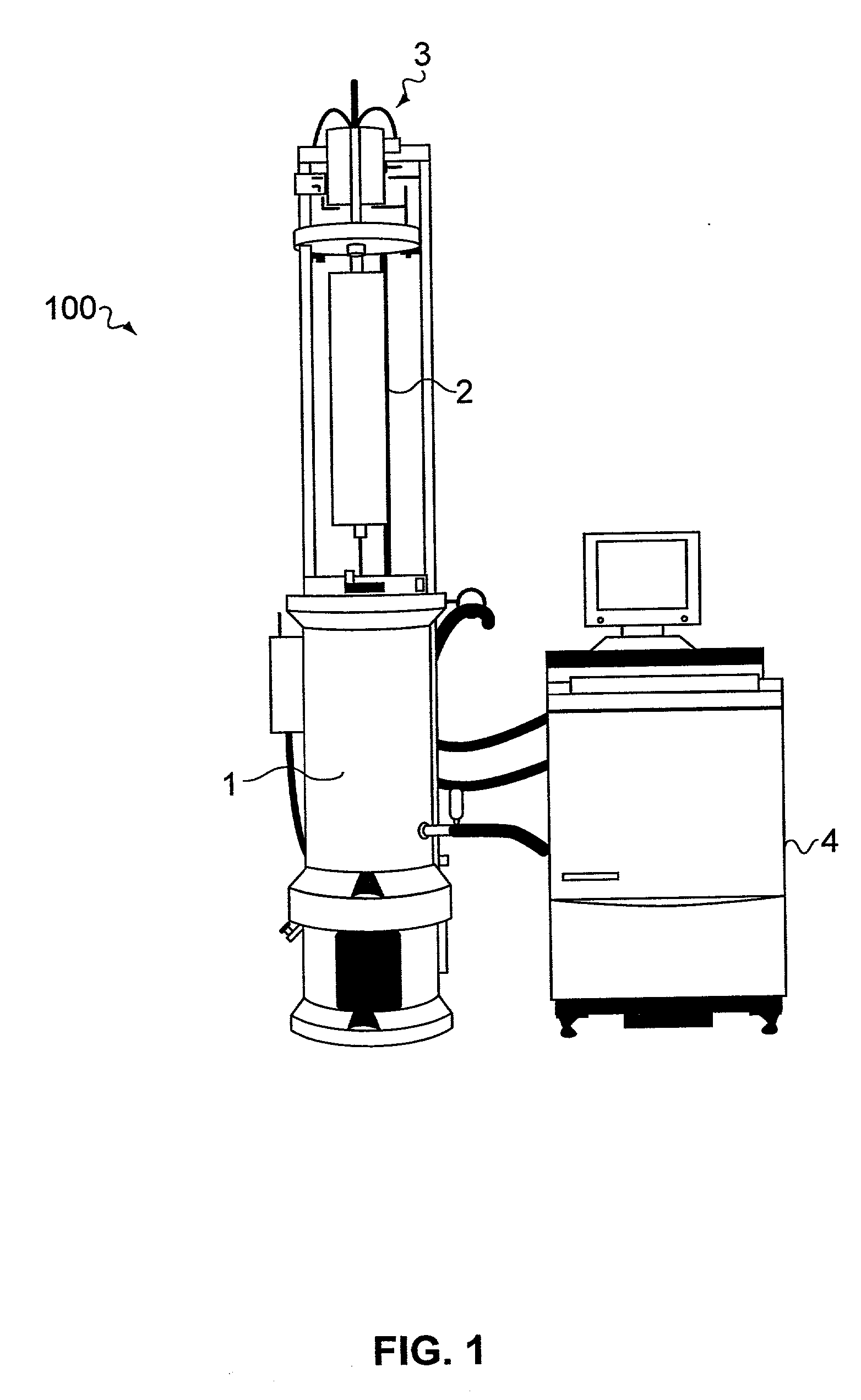

Centrifuge with removable core for scalable centrifugation

InactiveUS20030114289A1Avoid mixingDispersed particle separationRotary centrifugesCentrifugationEngineering

The present invention relates to a centrifuge apparatus. The centrifuge apparatus is operable at certain predetermined parameters depending upon a product to be separated and is useable with a plurality of rotor assemblies. For example, a first rotor assembly of said plurality of rotor assemblies includes a first core having a first core configuration which is contained within a rotor housing of the first rotor assembly to define a first volume capacity such that the product passing through the first rotor assembly having the first volume capacity during rotation of the first rotor assembly in the centrifuge apparatus achieves a first particle separation of the product. A second rotor assembly of said plurality of rotor assemblies includes a second core having a second core configuration which is contained with a rotor housing of the second rotor assembly to define a second volume capacity such that product passing through the second rotor assembly having the second volume capacity during rotation of the second rotor assembly in the centrifuge apparatus achieves a second particle separation of the product. It is observed that the second particle separation is a linear change with respect to the first particle separation.

Owner:ALFA WASSERMANN INC

Microfluidic device for cell and particle separation

A microfluidic separation device includes a microchannel formed in a substrate and being defined at least by a bottom surface, a first side wall, and second side wall. Fluid containing particles or cells is flowed through the microchannel from an upstream end to a downstream end. The downstream end terminates in a plurality of branch channels. A plurality of vertically-oriented electrodes are disposed on the first wall and on the second wall opposite to the first wall. A voltage source is connected to the plurality of opposing electrodes to drive the electrodes. The opposing, vertically-oriented electrodes may be used to focus a heterogeneous population of particles or cells for subsequent downstream separation via additional electrodes placed on one of the side walls. Alternatively, the opposing, vertically-oriented electrodes may be used to spatially separate a heterogeneous population of particles or cells for later collection in one or more of the branch channels.

Owner:RGT UNIV OF CALIFORNIA

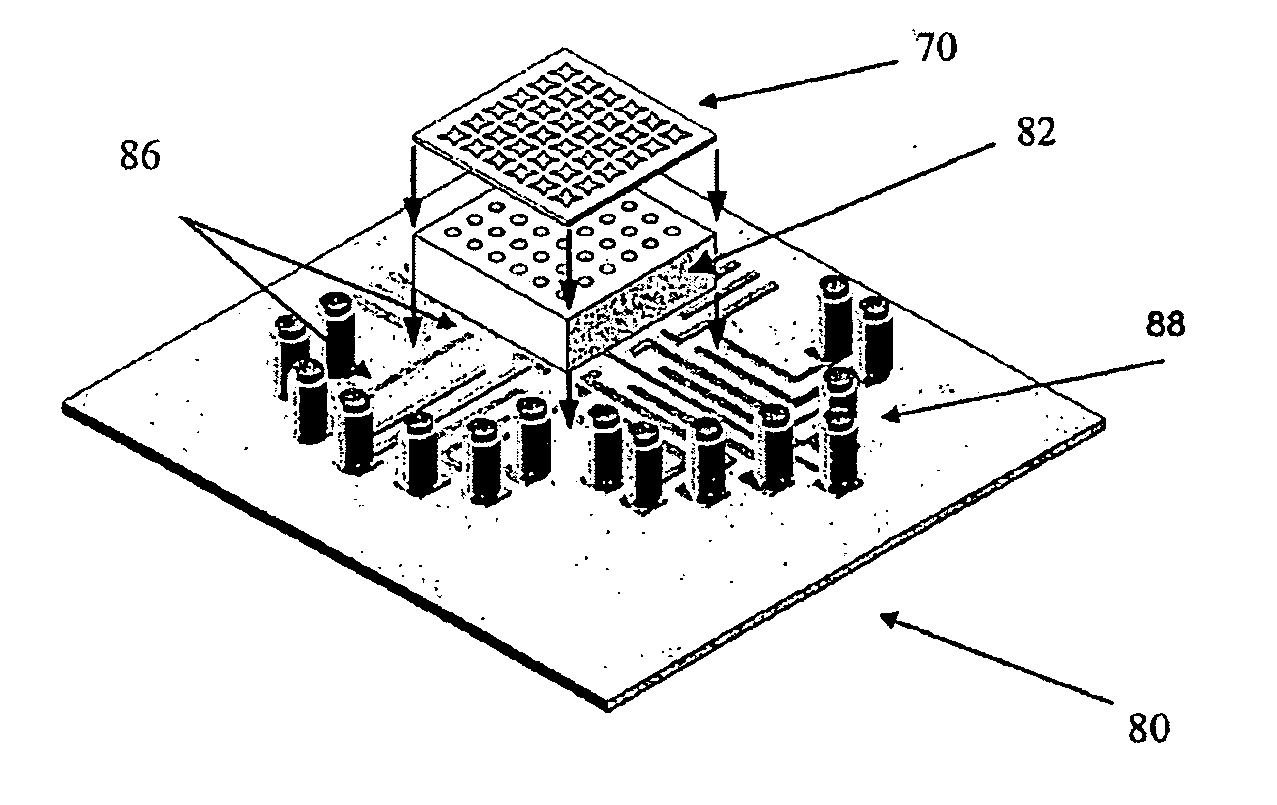

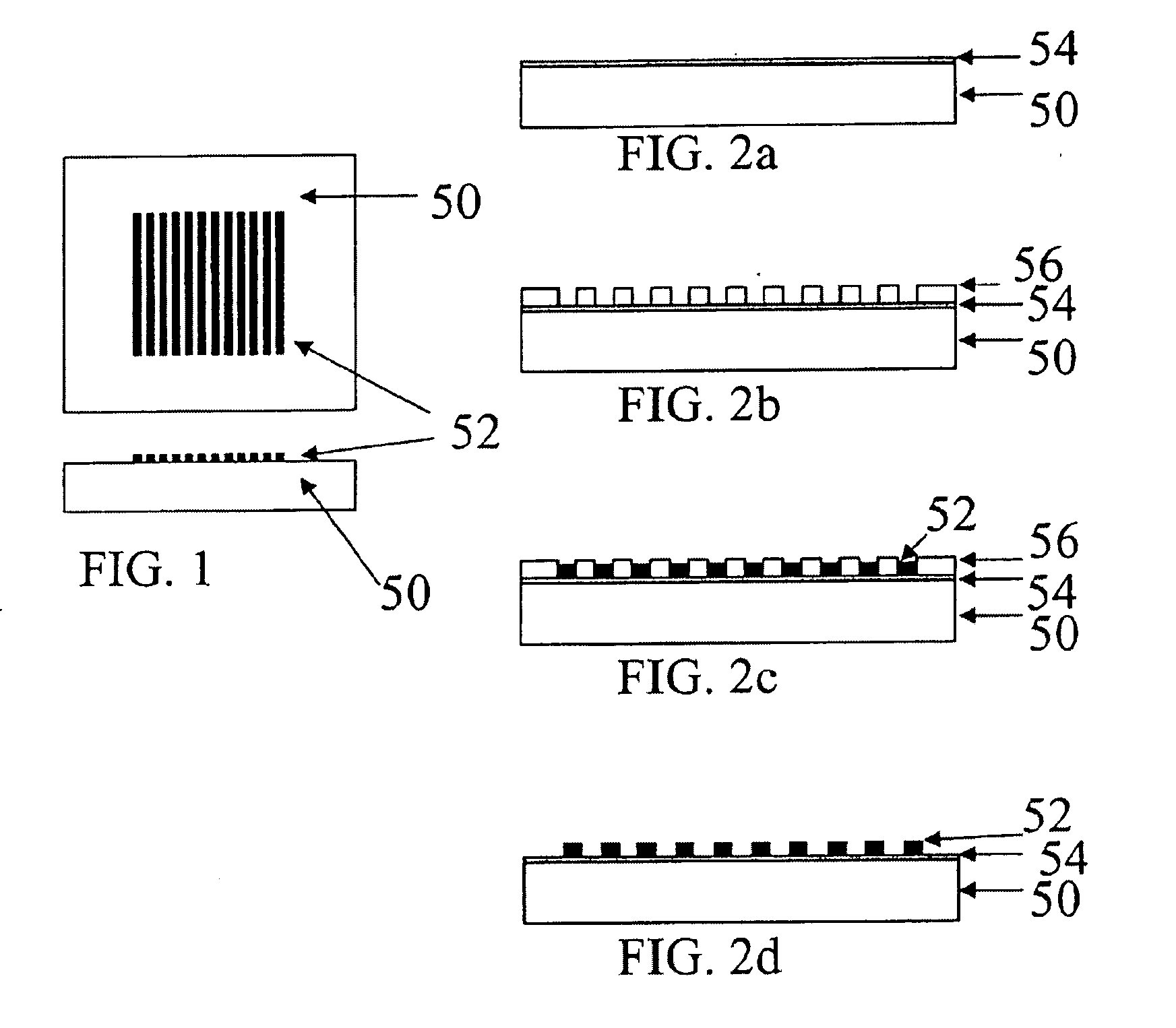

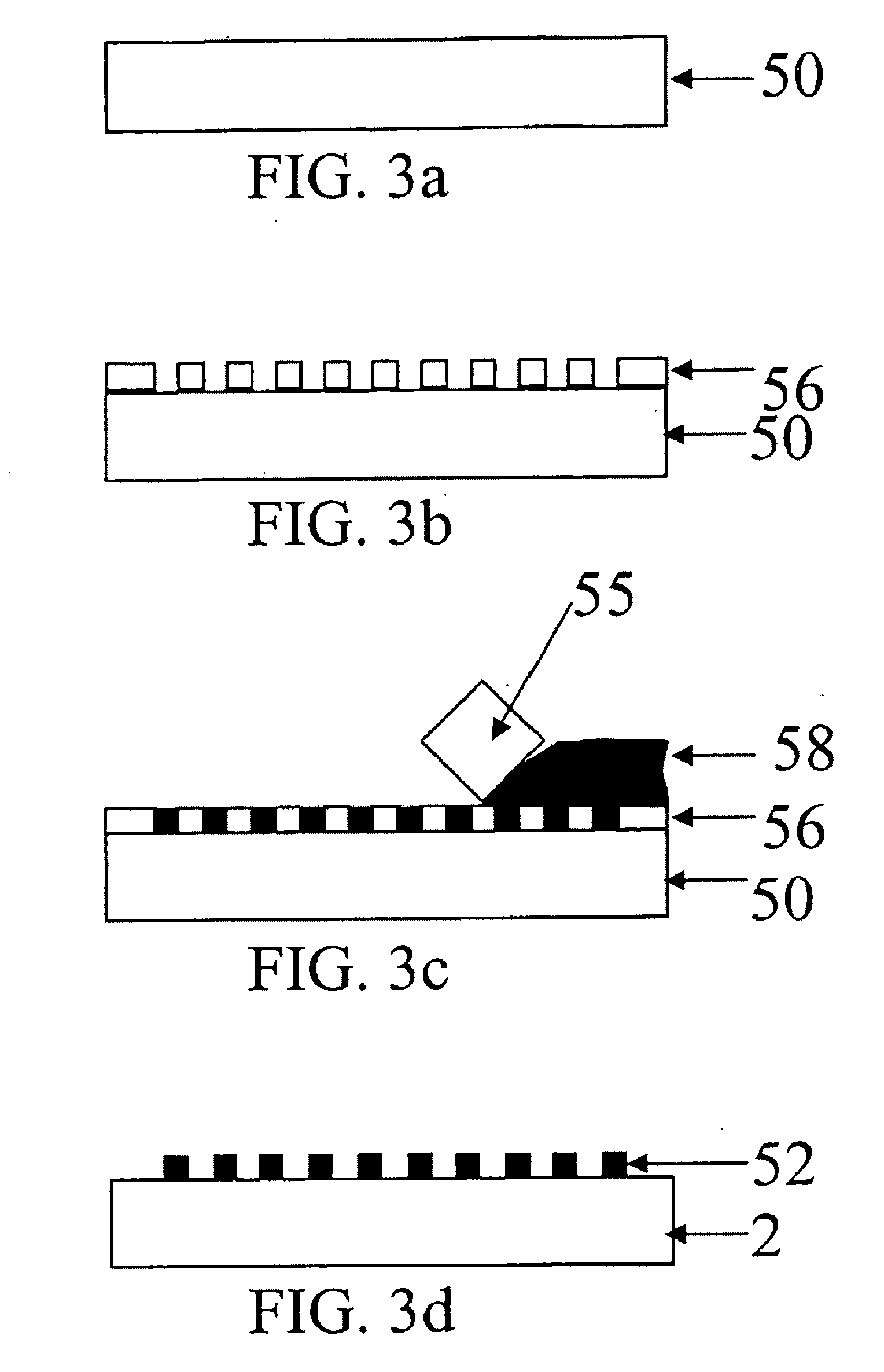

Magnetic bead-based arrays

InactiveUS20080187472A1Easy to separateEasy to replaceSequential/parallel process reactionsFlow mixersFluorescenceMagnetic bead

The present invention relates to magnetic particle separators using micromachined magnetic arrays and more particularly, to magnetic particle separators or manipulators using controlled magnetization on micromachined magnetic arrays for the separation of cells and other biological materials. The present invention also pertains to using such devices for the separation and analysis of biological materials for immunoassays, DNA sequencing, protein analysis, and biochemical detection applications. The present invention can also be viewed as a novel method for fabricating fully integrated permanent magnet components within any microelectromechanical system (“MEMS”) structures. The present invention also provides a magnetic particle separation and manipulation system for rapid separation and accurate manipulation of magnetic particles in two-dimensional electromagnetic arrays, which utilize high throughput biological analyses. A disposable cartridge can be produced in low cost using a low cost substrate such as plastic or other polymer, glass, or metal. Magnetic flux is generated by conventional or micromachined electromagnets a platform system consisting of magnetic flux sources, magnetic flux guidance, and a microprocessor control interface. By controlling direction of electric currents into inductors on the platform system, arbitrary magnetic poles can be generated on Permalloy structures of the cartridge to separate and manipulate magnetic particles. The magnetic particle separator and manipulator in the present invention can be easily combined with automated detection systems such as a fluorescent monitoring system.

Owner:AHN CHONG H +2

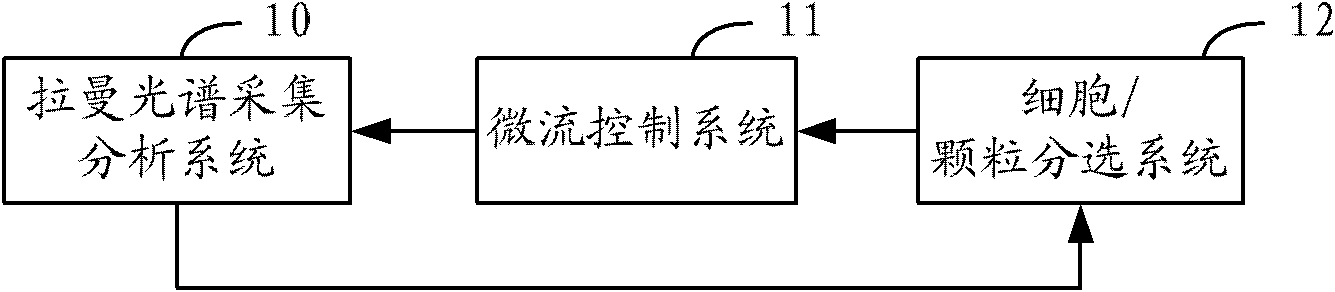

Sorter and sorting method for separating cells and particles

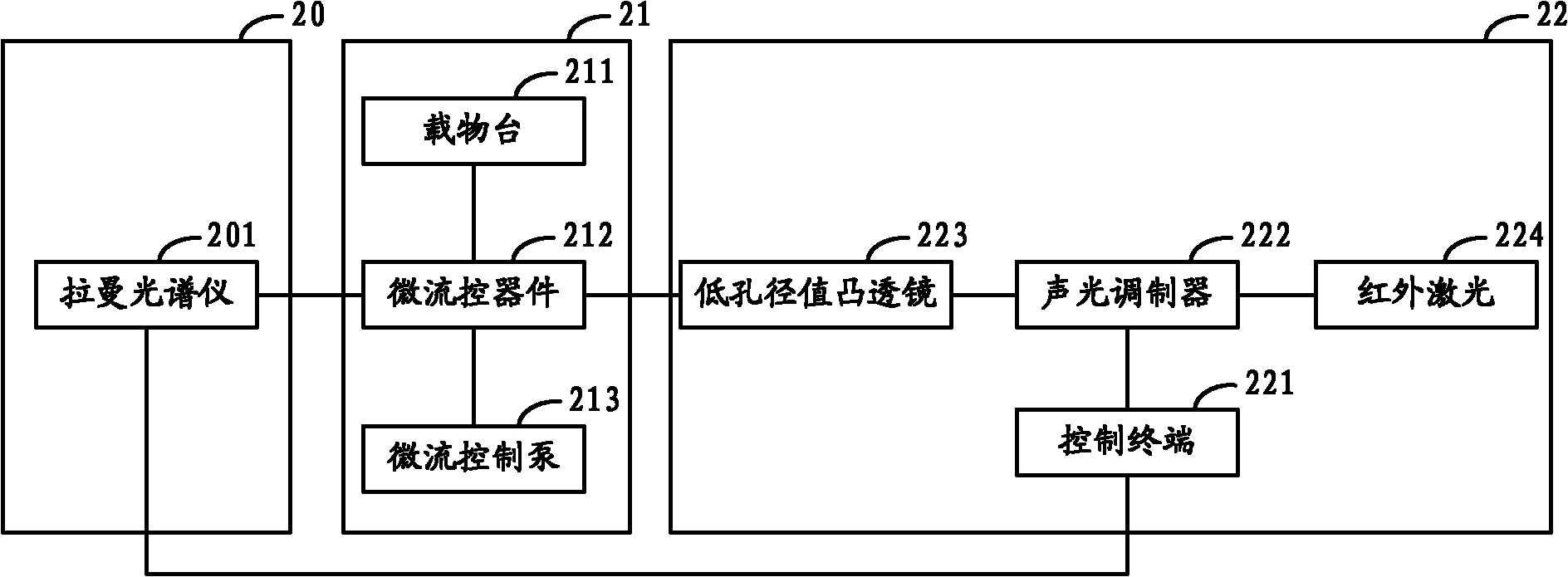

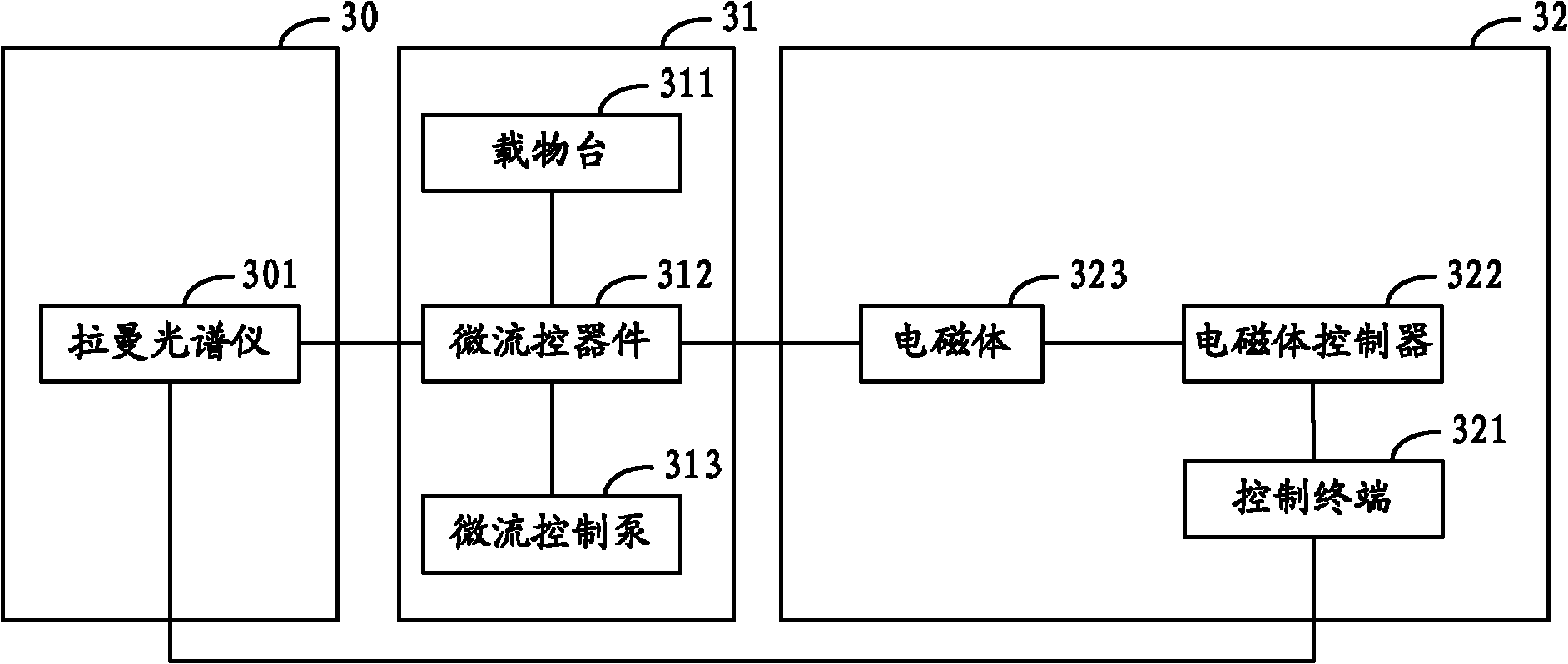

ActiveCN102019277ARich feature informationNon-invasiveNanoparticle analysisPreparing sample for investigationParticle sortingFluorescence

The invention relates to a sorter and a sorting method for separating cells and particles. The sorter comprises a Raman spectrum acquisition analysis system, a micro-flow control system and a cell / particle sorting system, wherein the micro-flow control system is connected with the Raman spectrum acquisition analysis system; the Raman spectrum acquisition analysis system is connected with the cell / particle sorting system; and the cell / particle sorting system is connected with the micro-flow control system. The invention also provides a sorting method for separating the cells and the particles.The sorter can effectively identify and sort nanometer-micron sized cells, nano materials, particles and cell contents, and because the Raman spectrum has the characteristics of high speed, non-invasive property, high information content and the like, the sorting method provides richer characteristic information of the cells or the particles in the same time period compared with methods of fluorescence or radio isotope labeling and the like.

Owner:长春长光辰英生物科学仪器有限公司

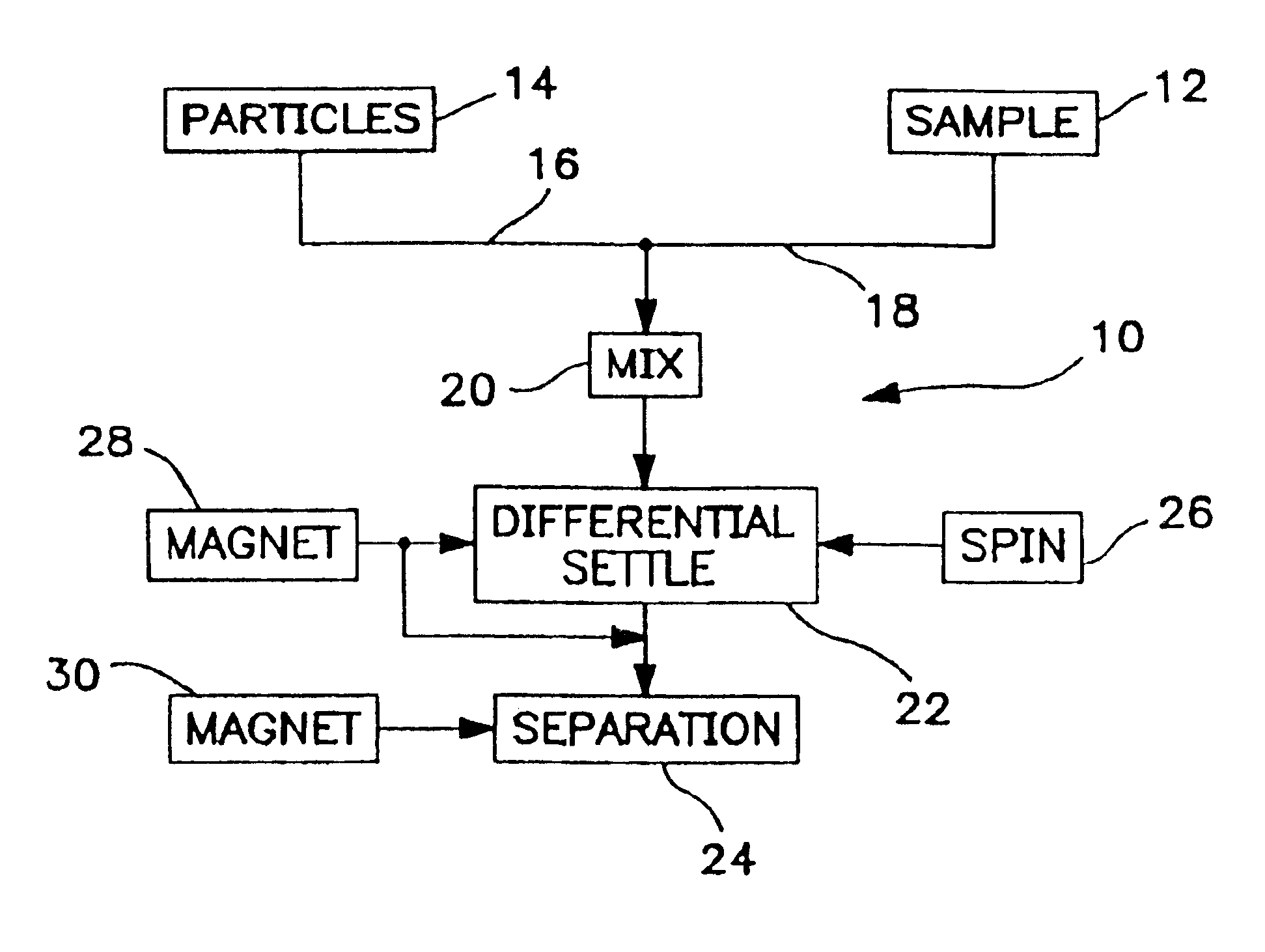

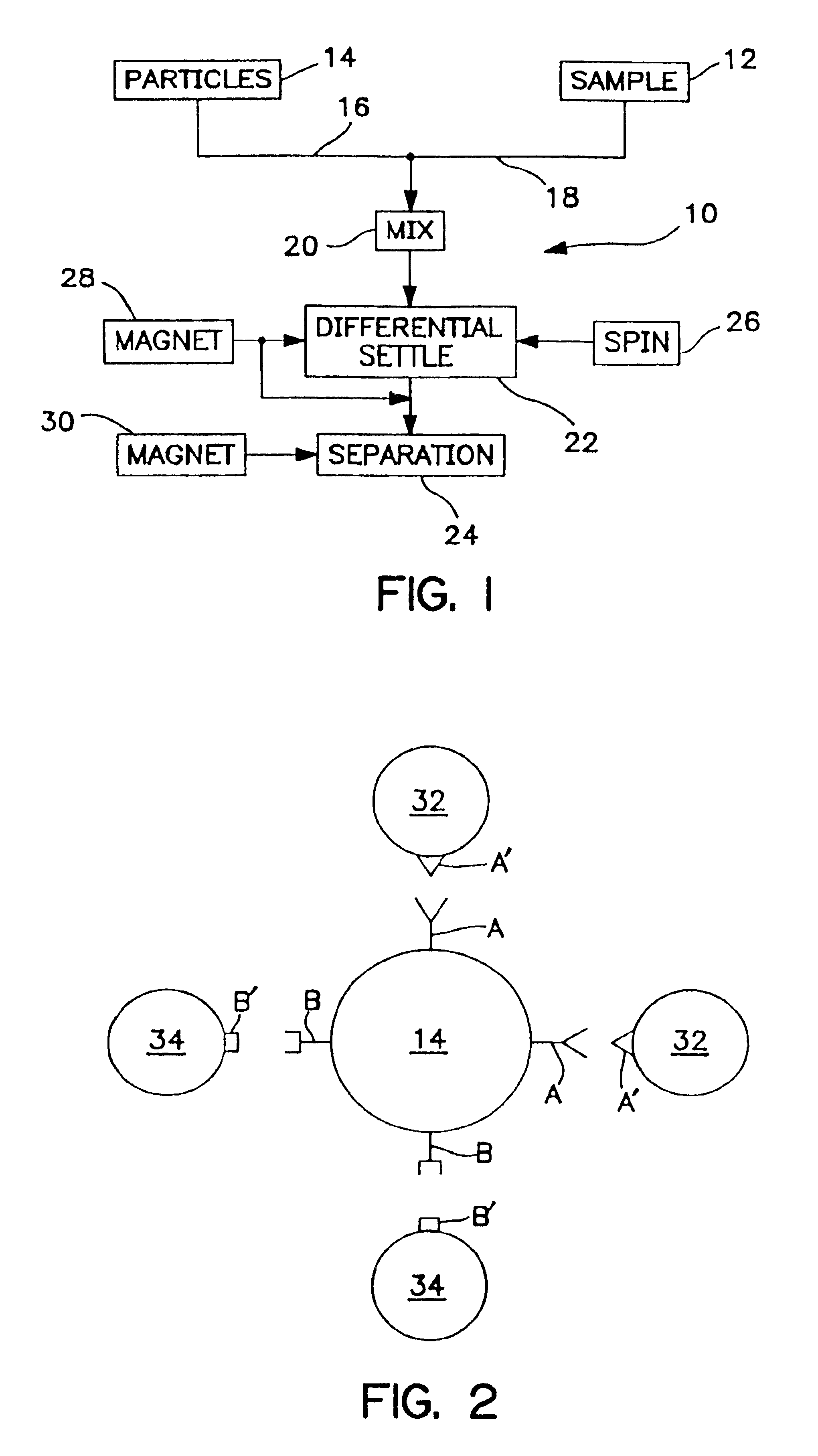

Method of selection of a population or subpopulation of a sample utilizing particles and gravity sedimentation

InactiveUS6900029B1Increase the number ofHigh yieldDead animal preservationSedimentation separationOrganismBiology

A separation procedure for separating a selected desired or undesired population from a biological sample utilizing relatively heavy, dense particles and gravity sedimentation. The particles have one or more reactants bound thereto which are specific to and will bind with the selected population. The particles preferably are mixed with the sample by repeatedly causing the particles to settle through a substantial portion of the sample to bind to the selected population. The particles with the bound selected population then are allowed to preferentially settle in the sample and the supernatant including an enriched population is separated from the particles with the selected population bound thereto. The enriched populations in the biological sample supernatant can be further enriched by multiple removal steps.

Owner:COULTER INTERNATIONAL CORPORATION

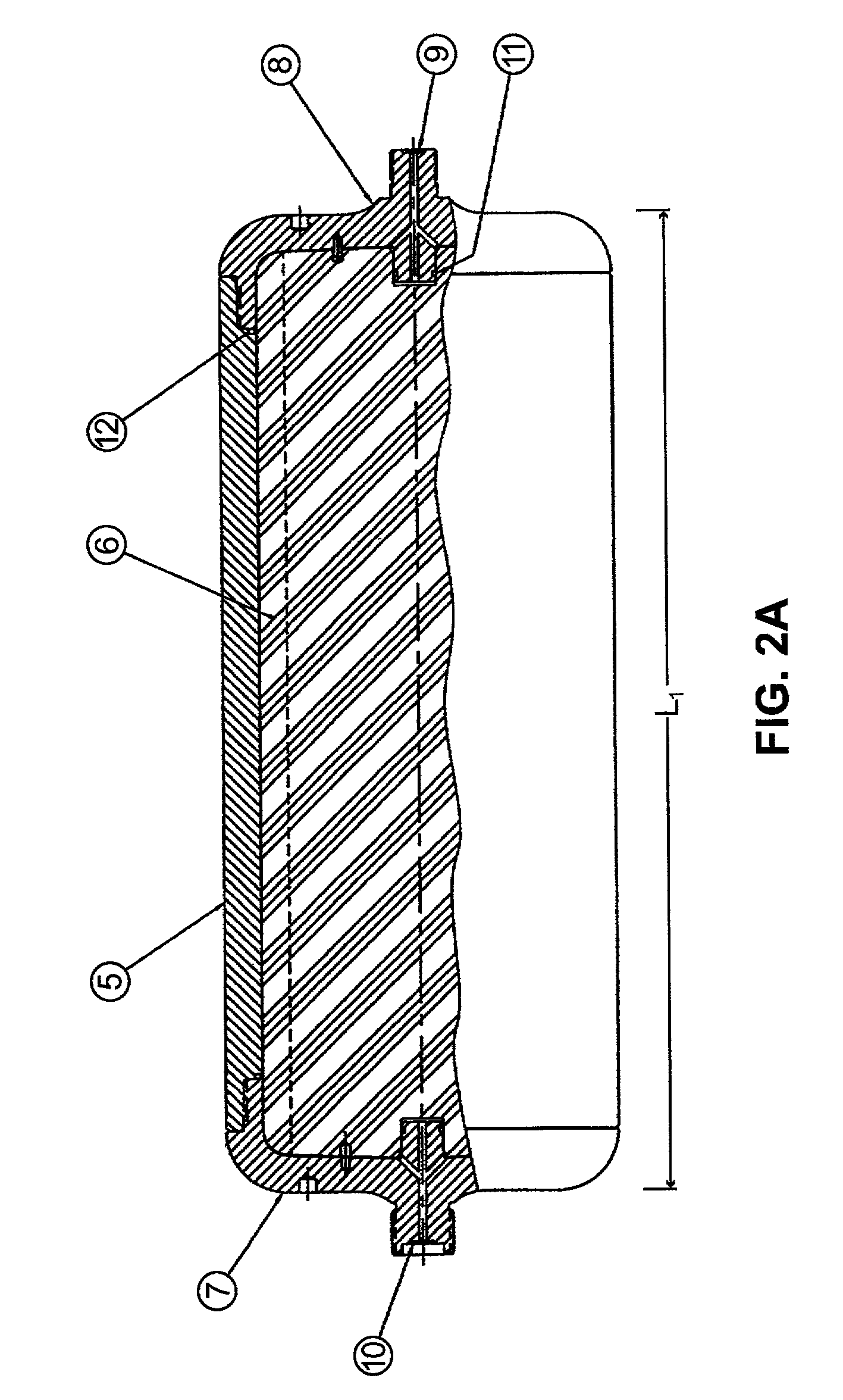

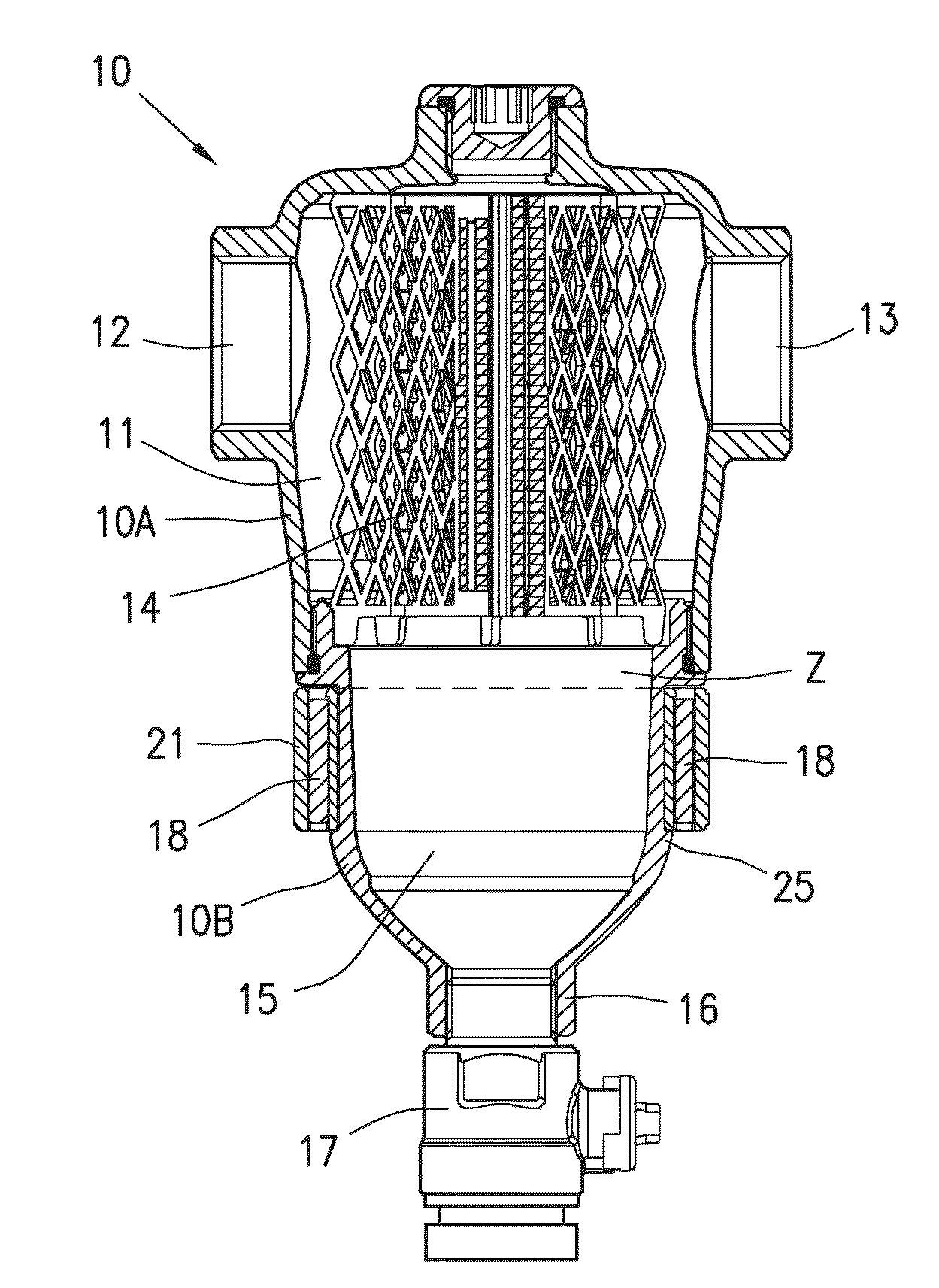

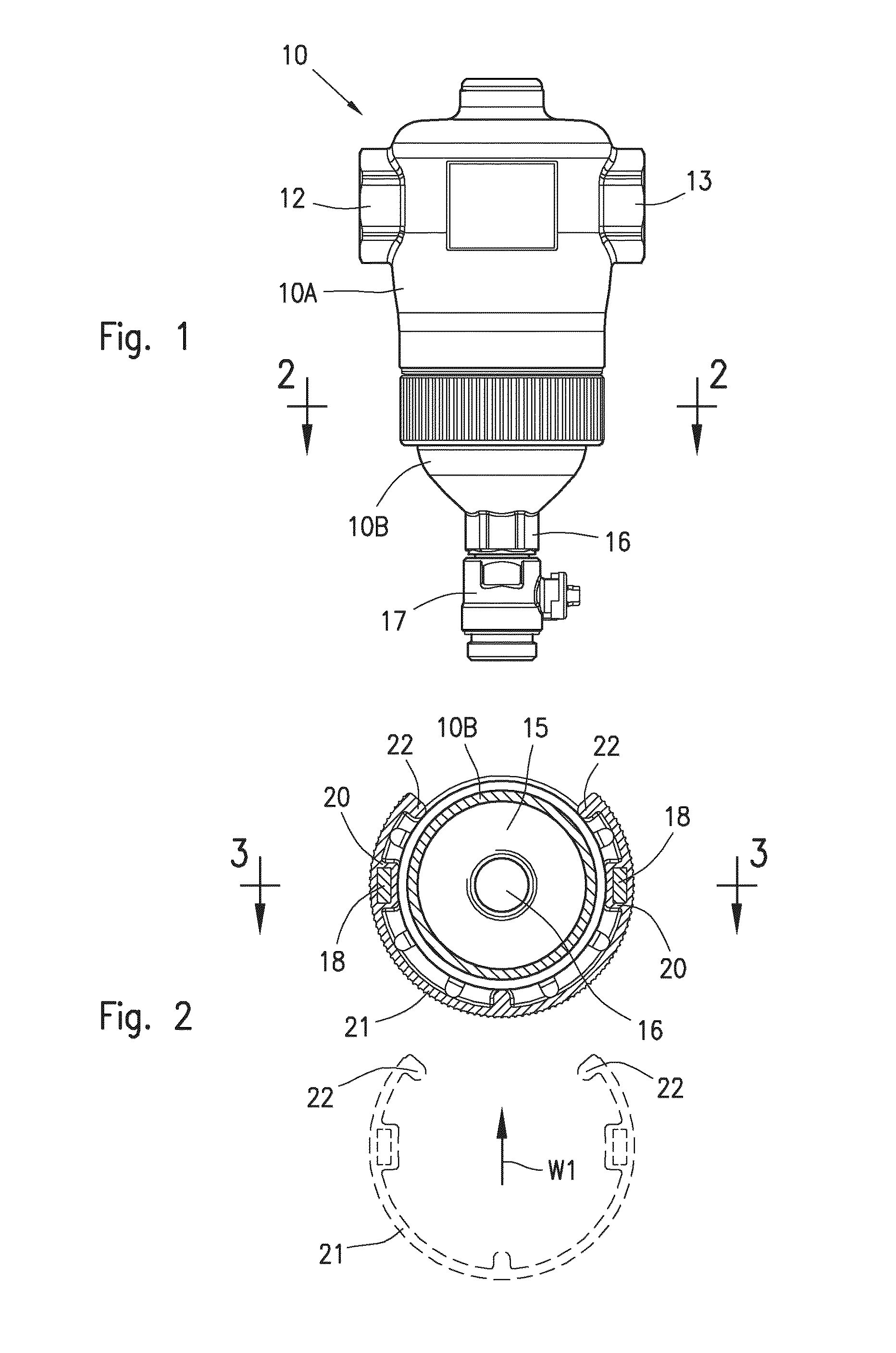

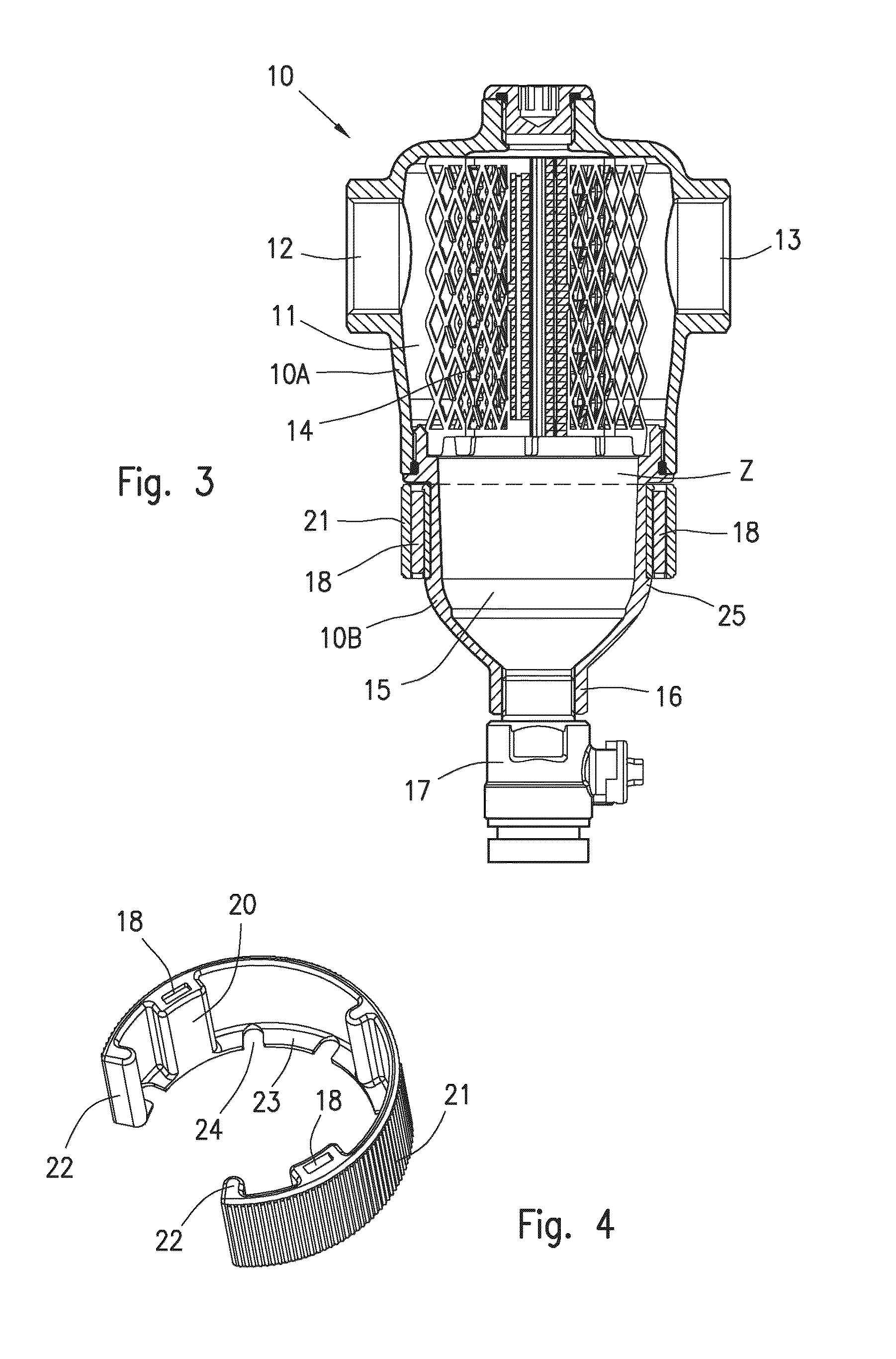

Magnetic particle separator for thermal systems

ActiveUS20140367340A1Facilitates fall downPromote accumulationLighting and heating apparatusElectrostatic separationChemical physicsNon magnetic

A magnetic particle separator (10) suitable for separating magnetic and non-magnetic particles from a thermal fluid flowing in a heating system. The magnetic particle separator (10) comprises a hollow body (10A, 10B) configured with an upper particle separation chamber (11) and for circulation of the thermal fluid between an inlet and an outlet port (12, 13), and a quieting chamber (15) beneath the particle separation chamber (11) for accumulation of the particles separated from the fluid: an annular support element (21) for permanent magnets (18) being removably fastened outside the quieting chamber (15) of the separator (10).

Owner:CALEFFI

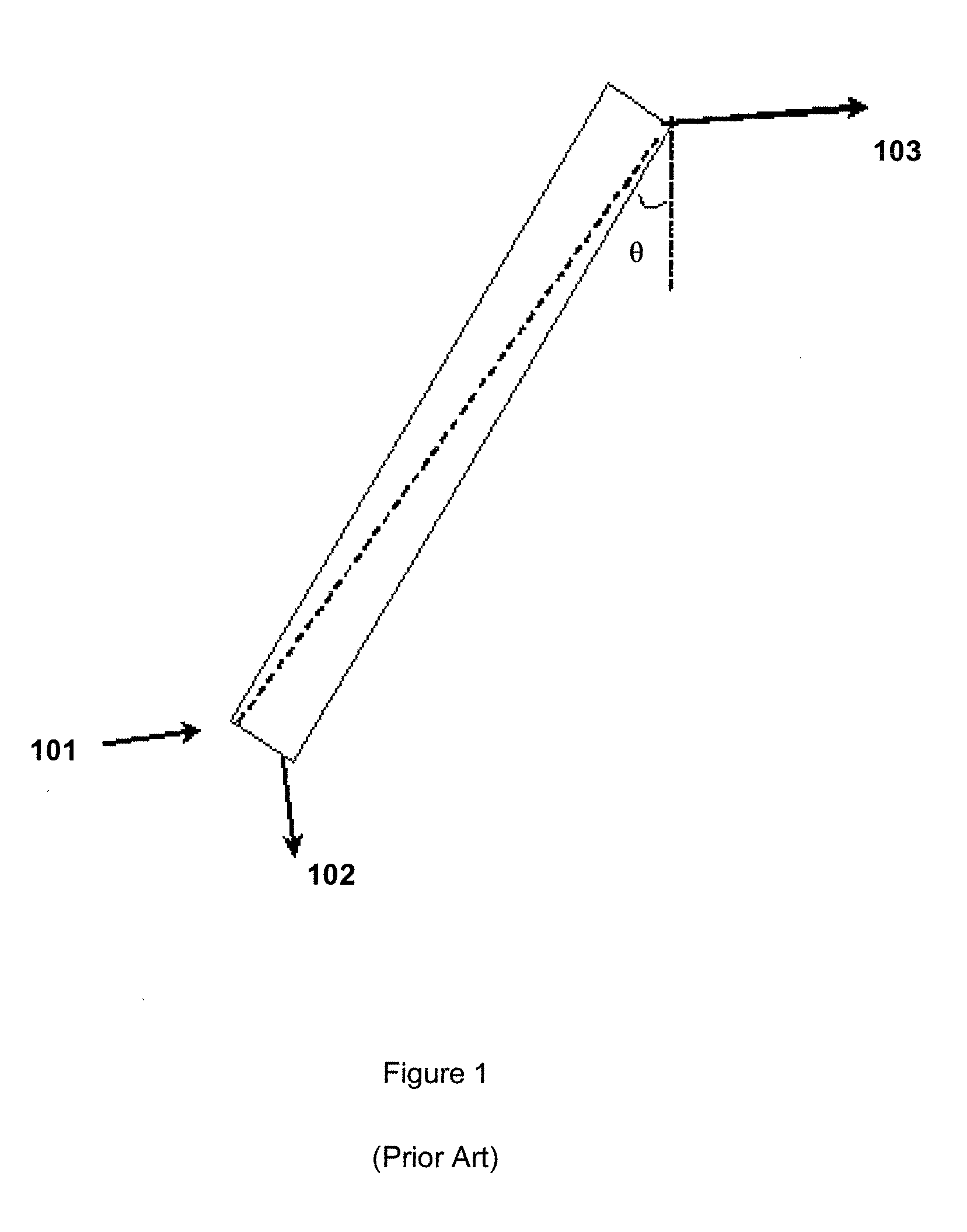

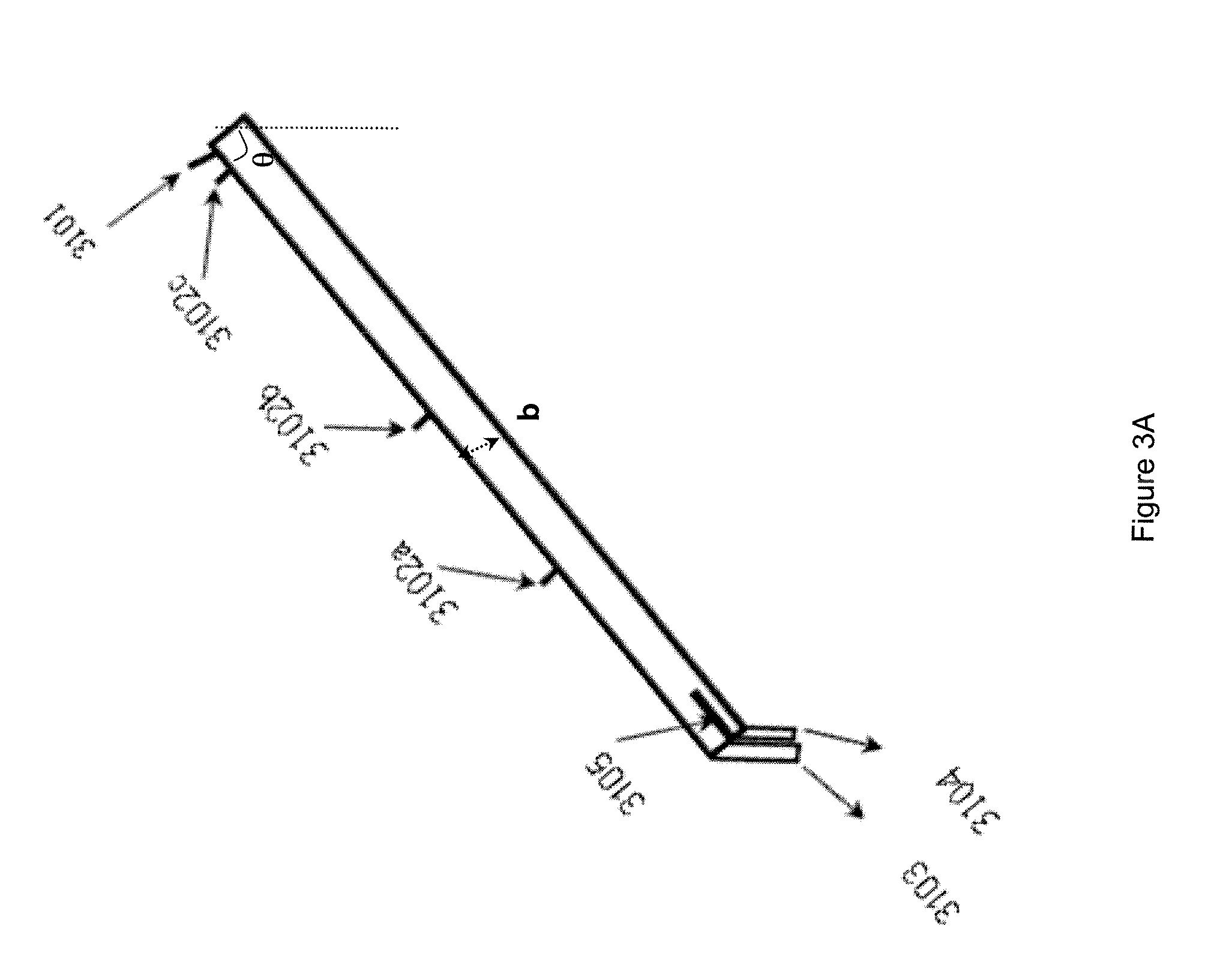

Separating device, an algae culture photobioreactor, and methods of using them

InactiveUS20100093078A1Bioreactor/fermenter combinationsBiological substance pretreatmentsMetaboliteBiofuel

The invention provides a device for separating a first entity and a second entity by flowing them downwardly in an inclined settling chamber. Each entity has its own outlet located at approximately the lowest end of the inclined settling chamber. The device may be used in industrial fields such as pharmaceutics, biologics, and biofuels, for the purposes of large-scale growth and separation of algae biomass, bacteria and yeast cultures; algae metabolite production; and cell separation, among others. The invention exhibits technical merits such as effective particle separation or concentration capacity, robust structure, easy operation, cost-effective manufacturability, disposability, and high productivity in e.g. perfusion photobioreactor systems.

Owner:CLEVELAND STATE UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com