Patents

Literature

270 results about "Separation procedure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Automated process for isolating and amplifying a target nucleic acid sequence

InactiveUS20050130198A1Efficient and high through-put operationEfficient comprehensive utilizationRotating receptacle mixersBioreactor/fermenter combinationsIsolation proceduresTemperature control

Owner:GEN PROBE INC

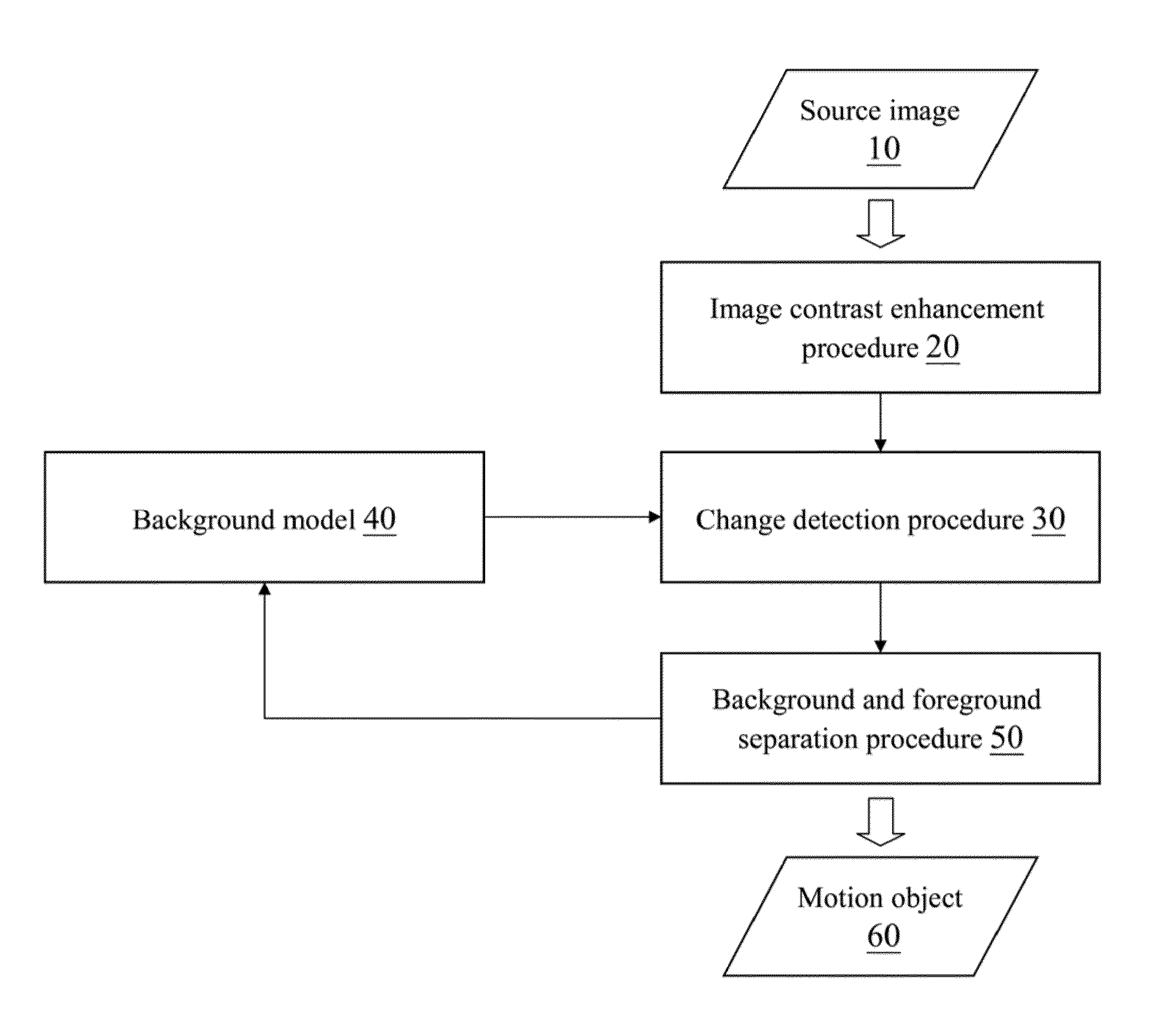

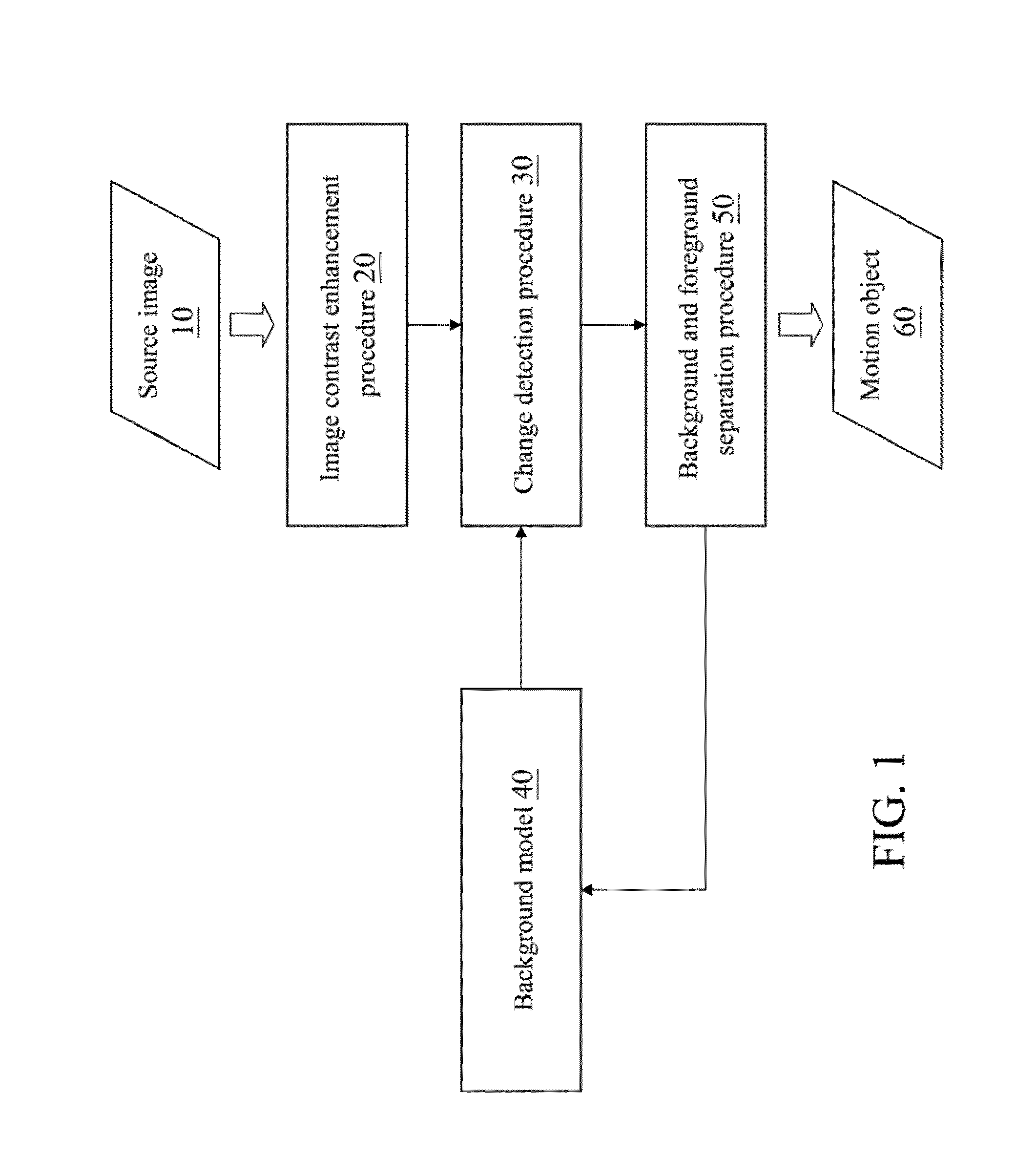

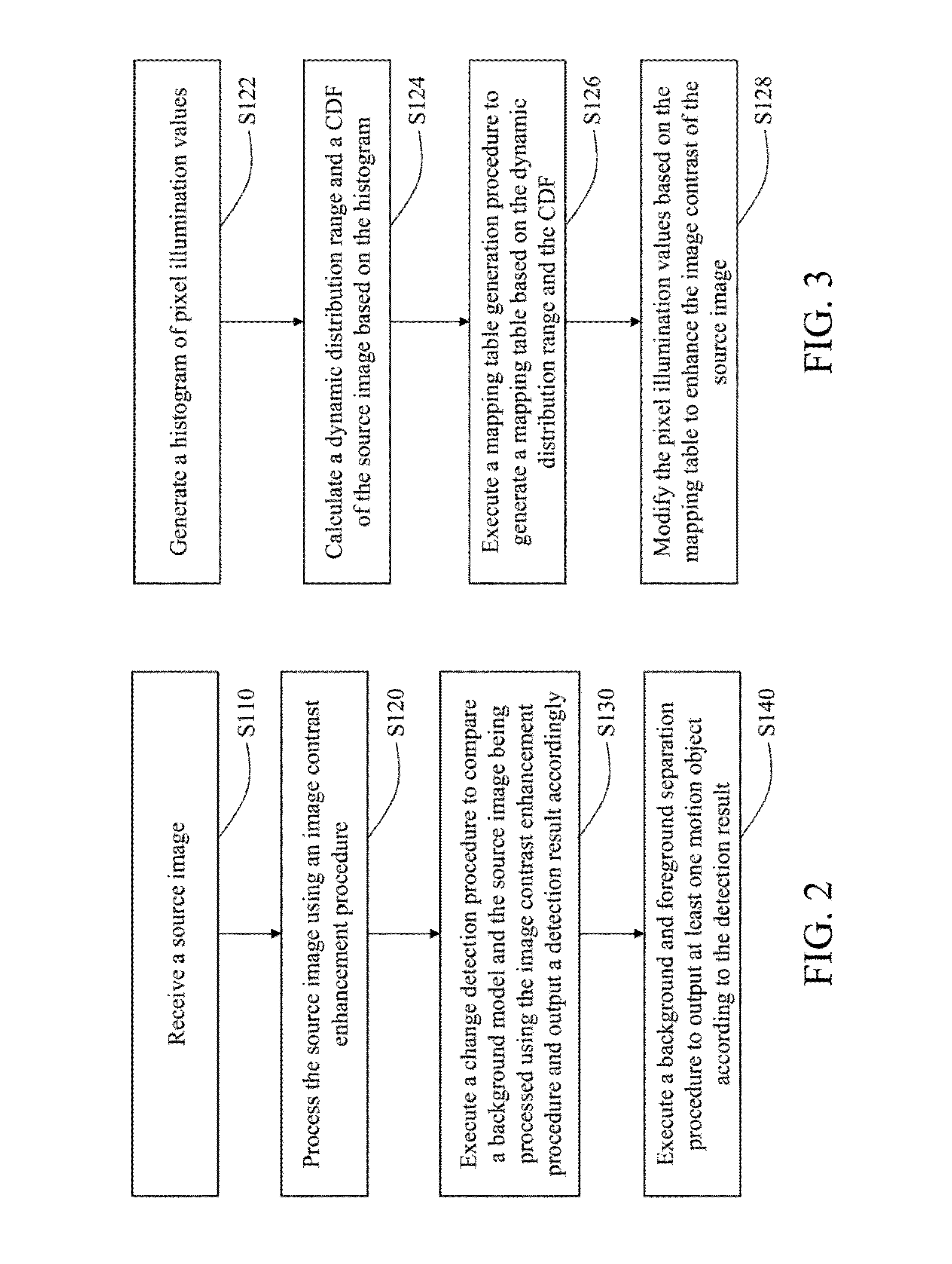

Moving object detection method using image contrast enhancement

InactiveUS20130044951A1Save computing resourcesImprove processing efficiencyImage enhancementImage analysisIlluminanceImage contrast

A moving object detection method using image contrast enhancement includes receiving a source image, in which each pixel has a pixel illumination value; processing the source image using an image contrast enhancement procedure; executing a change detection procedure to compare a background model and the source image being processed using the image contrast enhancement procedure, and outputting a detection result accordingly; and executing a background and foreground separation procedure to output a moving object according to the detection result. The image contrast enhancement procedure may include generating a histogram of pixel illumination values; calculating a dynamic distribution range and a cumulative distribution function (CDF) of the source image based on the histogram; executing a mapping table generation procedure to generate a mapping table based on the dynamic distribution range and the CDF; and modifying pixel illumination values based on the mapping table to enhance image contrast of the source image.

Owner:VATICS

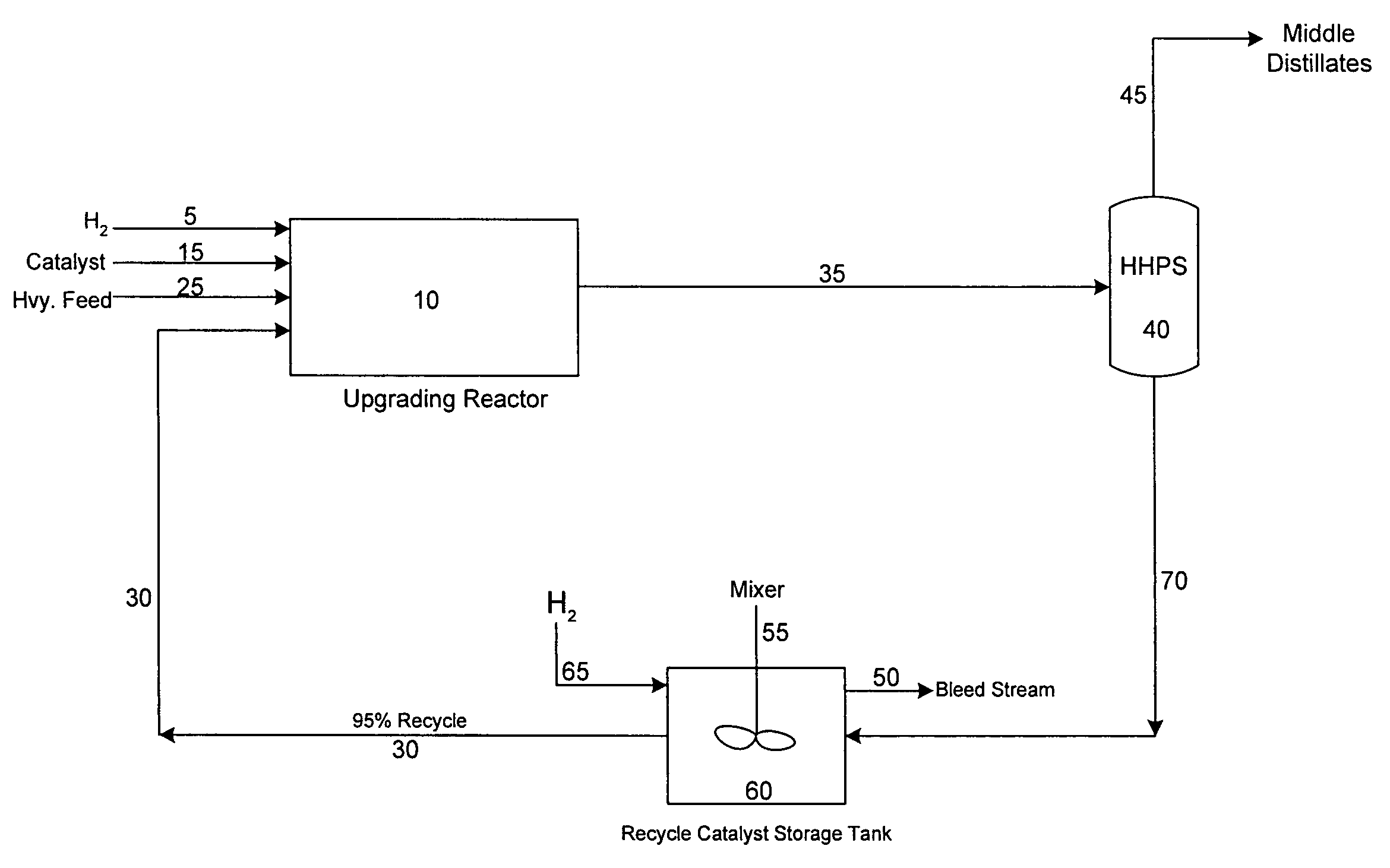

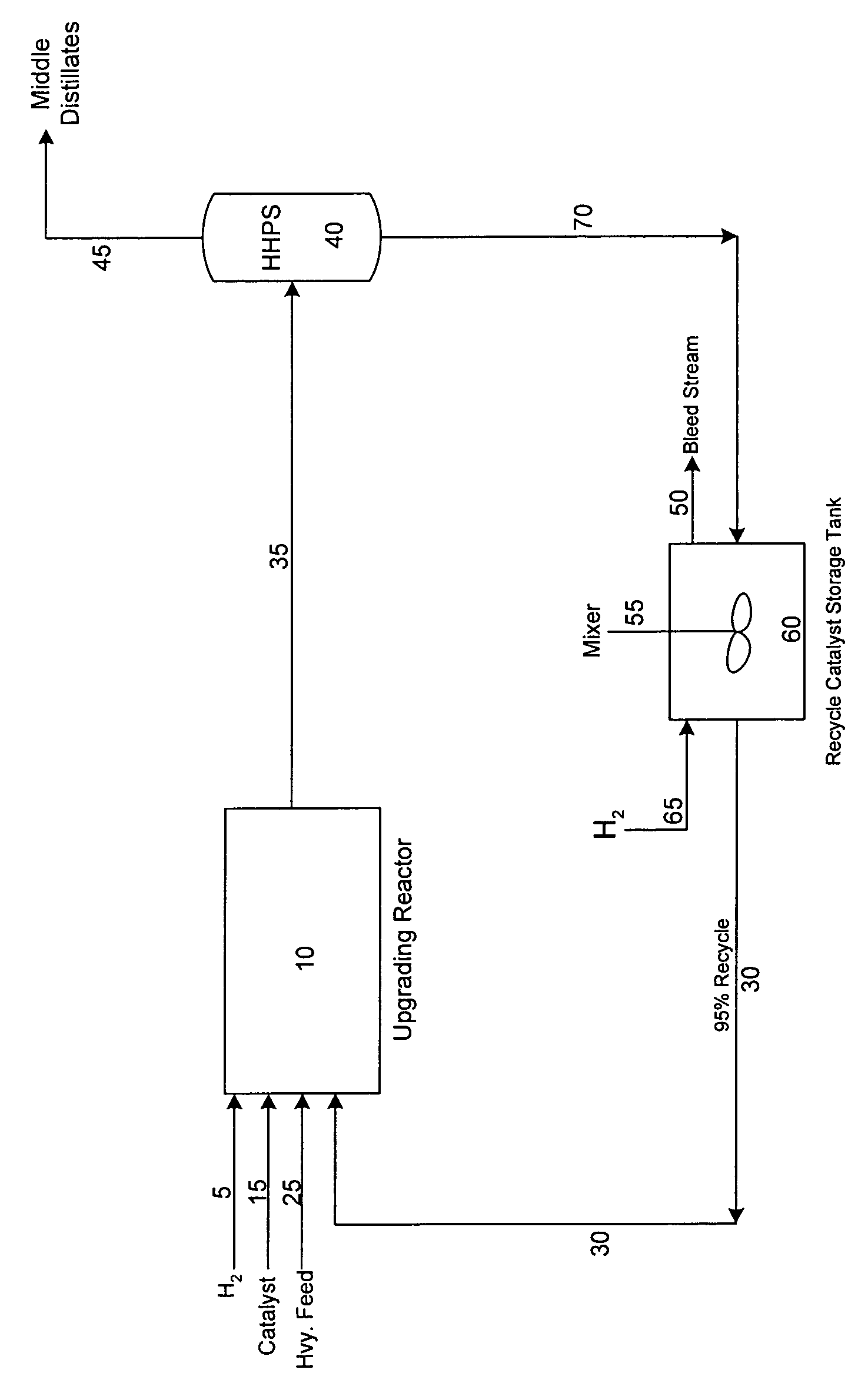

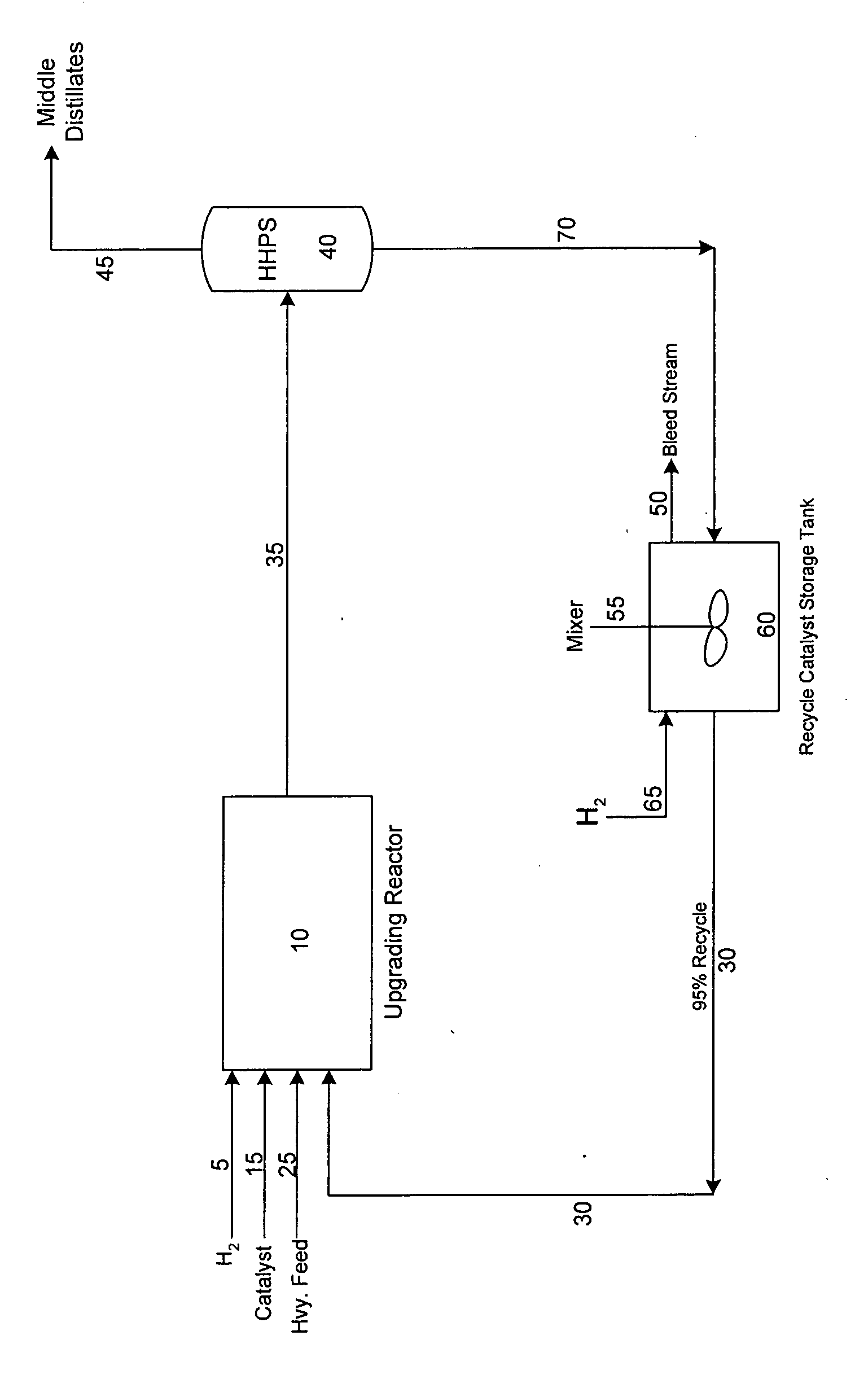

Process for recycling an active slurry catalyst composition in heavy oil upgrading

The instant invention is directed to a process employing slurry catalyst compositions in the upgrading of heavy oils. The slurry catalyst composition is not permitted to settle, which would result in possible deactivation. The slurry is recycled to an upgrading reactor for repeated use and products require no further separation procedures for catalyst removal.

Owner:CHEVROU USA INC

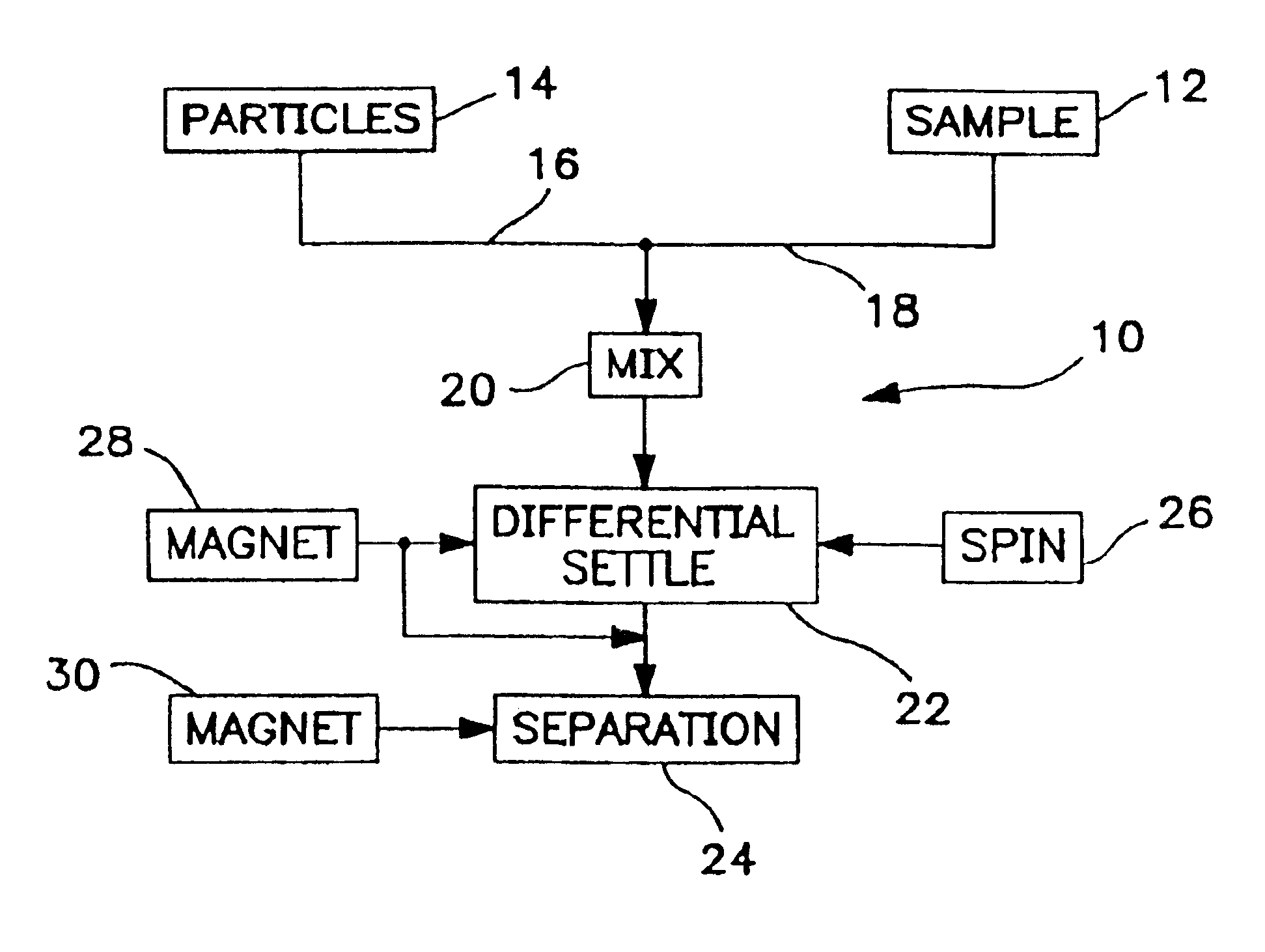

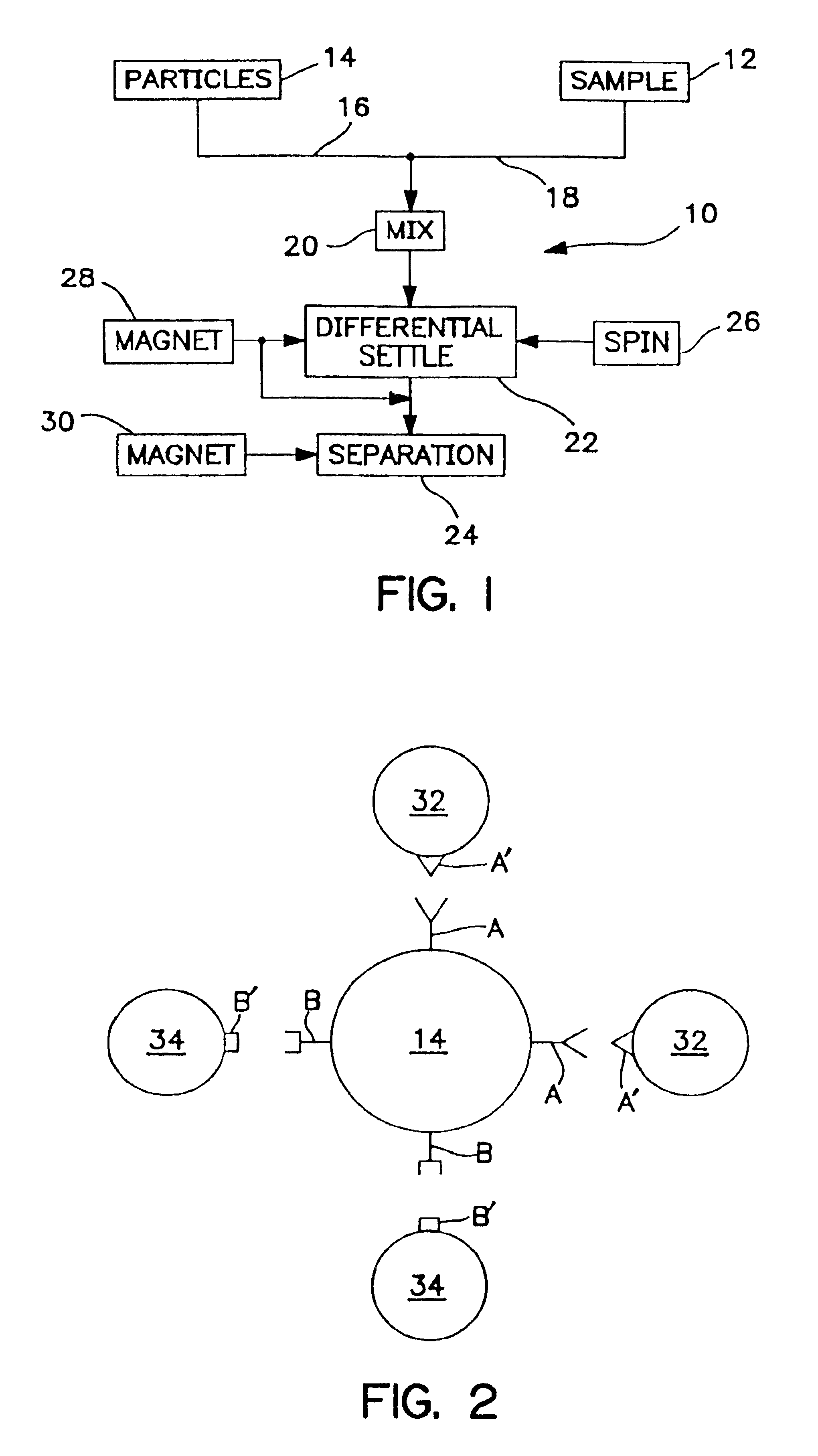

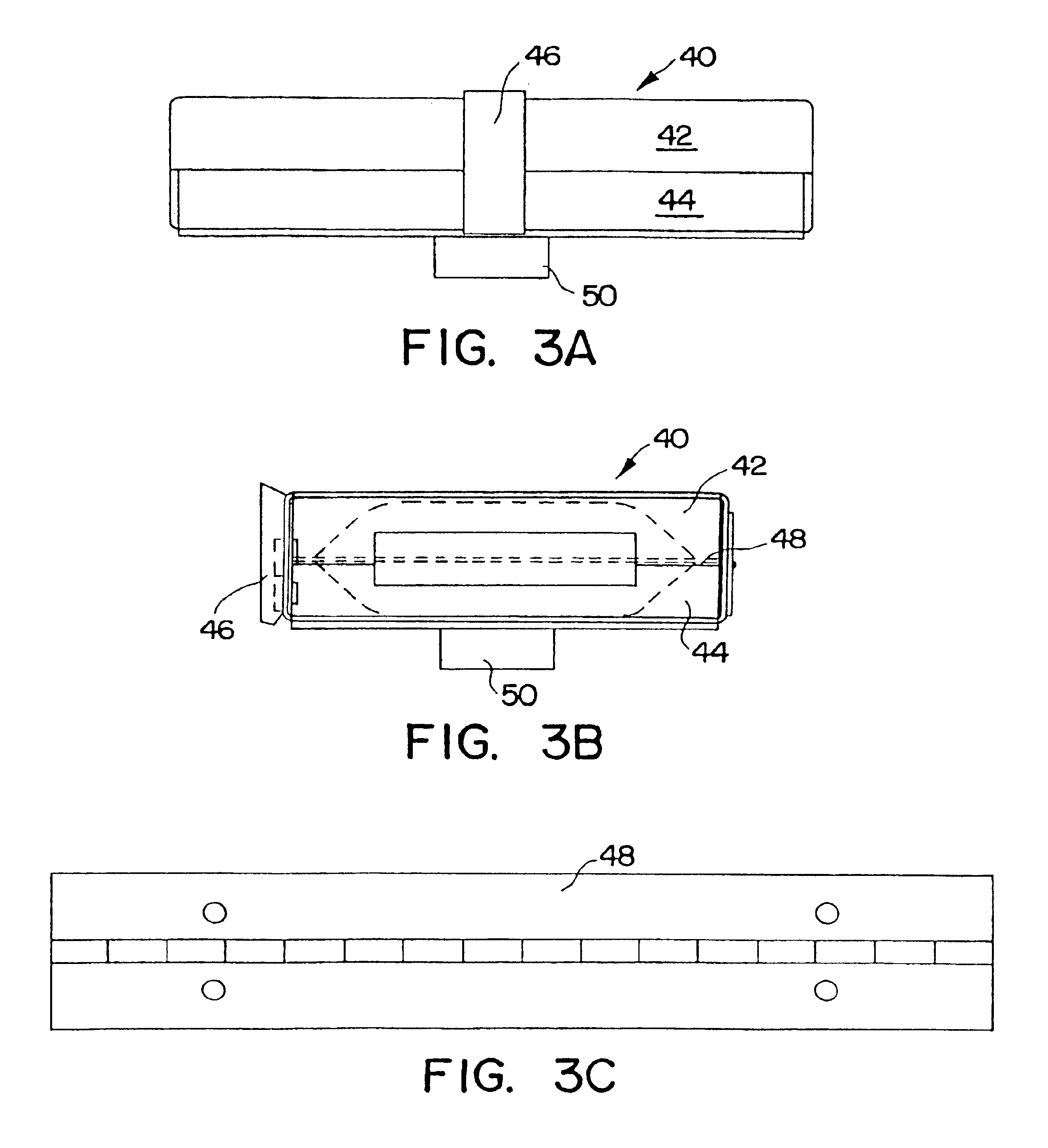

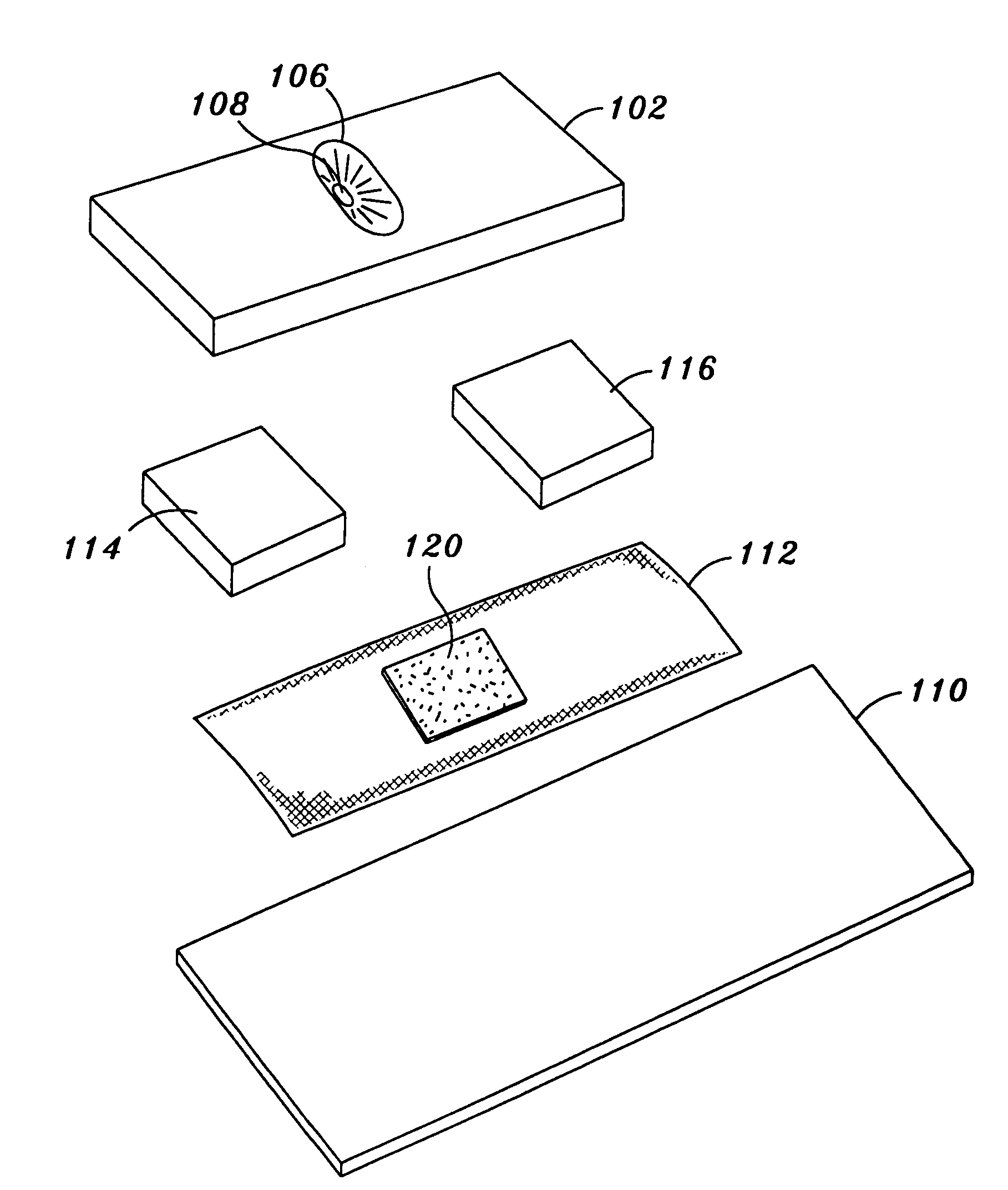

Method of selection of a population or subpopulation of a sample utilizing particles and gravity sedimentation

InactiveUS6900029B1Increase the number ofHigh yieldDead animal preservationSedimentation separationOrganismBiology

A separation procedure for separating a selected desired or undesired population from a biological sample utilizing relatively heavy, dense particles and gravity sedimentation. The particles have one or more reactants bound thereto which are specific to and will bind with the selected population. The particles preferably are mixed with the sample by repeatedly causing the particles to settle through a substantial portion of the sample to bind to the selected population. The particles with the bound selected population then are allowed to preferentially settle in the sample and the supernatant including an enriched population is separated from the particles with the selected population bound thereto. The enriched populations in the biological sample supernatant can be further enriched by multiple removal steps.

Owner:COULTER INTERNATIONAL CORPORATION

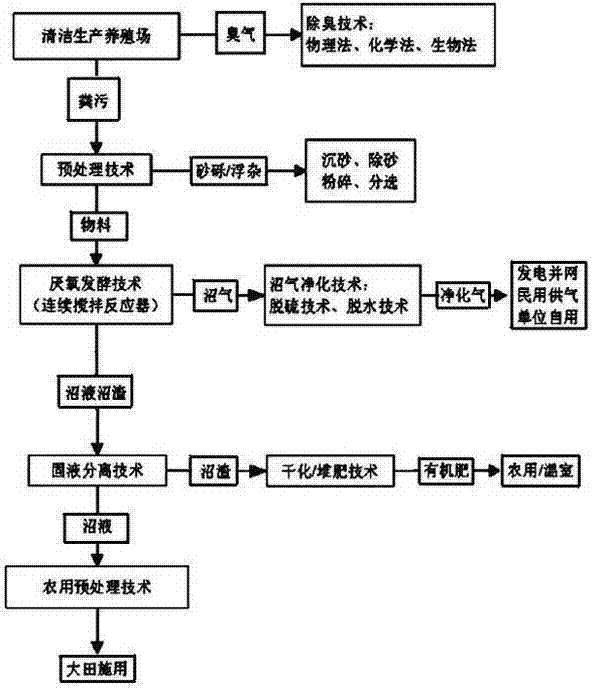

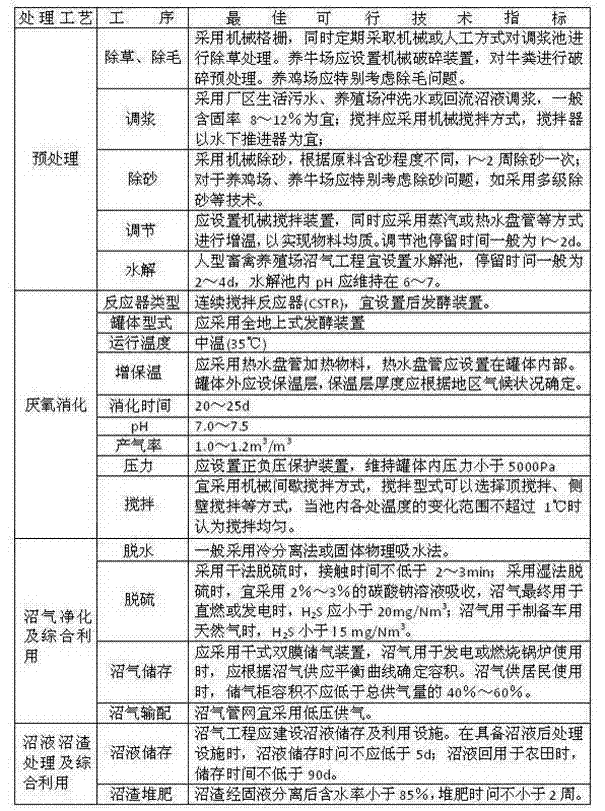

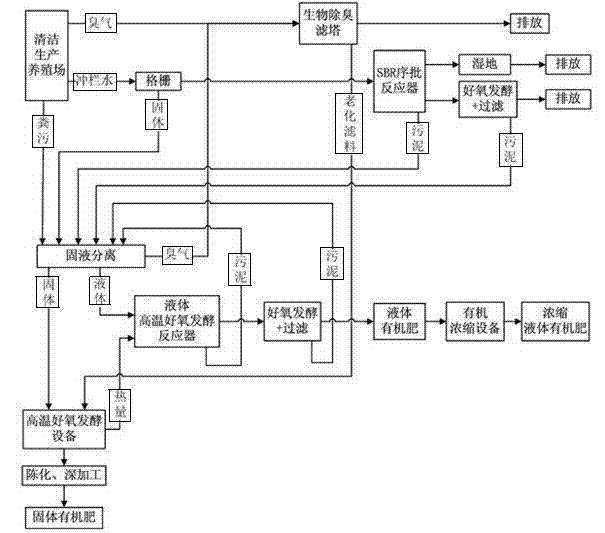

Pollution abatement method for livestock and poultry farm

ActiveCN102964149ALow costLow miniaturizationBio-organic fraction processingClimate change adaptationSequencing batch reactorActivated sludge

The invention discloses a pollution abatement method for a livestock and poultry farm. The method comprises the following steps of: separating feces from fence washing water and rain water at the source; carrying out solid-liquid separation on the feces and the sludge generated in each treatment procedure; conveying the separated liquid part to a plug flow anaerobic fermentation reactor or a liquid high-temperature aerobic fermentation reactor for liquid biological treatment, carrying out aerobic fermentation and filtration to get a liquid organic fertilizer; and conveying the separated solid part to a high temperature aerobic fermentation device, after fermentation, aging and deeply processing the solid part to get a solid organic fertilizer. Bad smell is exhausted after being processed in a biological deodorization filtering tower, and the filter material replaced from the biological deodorization filtering tower is considered as carbon source and conveyed to the solid aerobic fermentation device so as to be treated. Firstly, the fence washing water is treated by a grid impurity removal facility, after being treated by an SBR (Sequencing Batch Reactor Activated Sludge Process) biological reactor and medicated for flocculation and sedimentation, the fence washing water is drained after being purified by a wet land, or drained after being treated by aerobic fermentation reaction and filtering, and the sedimentary sludge and the solid substances under the grid fence are conveyed into a solid-liquid separation procedure so as to be treated. The method can be used for managing or beneficially using all the pollutants, and contributing the effort for establishing the resource-saving and environmentally-friendly society.

Owner:HUNAN SAKAL ENVIRONMENTAL SCI & TECH CO LTD +1

Process for recycling an active slurry catalyst composition in heavy oil upgrading

The instant invention is directed to a process employing slurry catalyst compositions in the upgrading of heavy oils. The slurry catalyst composition is not permitted to settle, which would result in possible deactivation. The slurry is recycled to an upgrading reactor for repeated use and products require no further separation procedures for catalyst removal.

Owner:CHEVROU USA INC

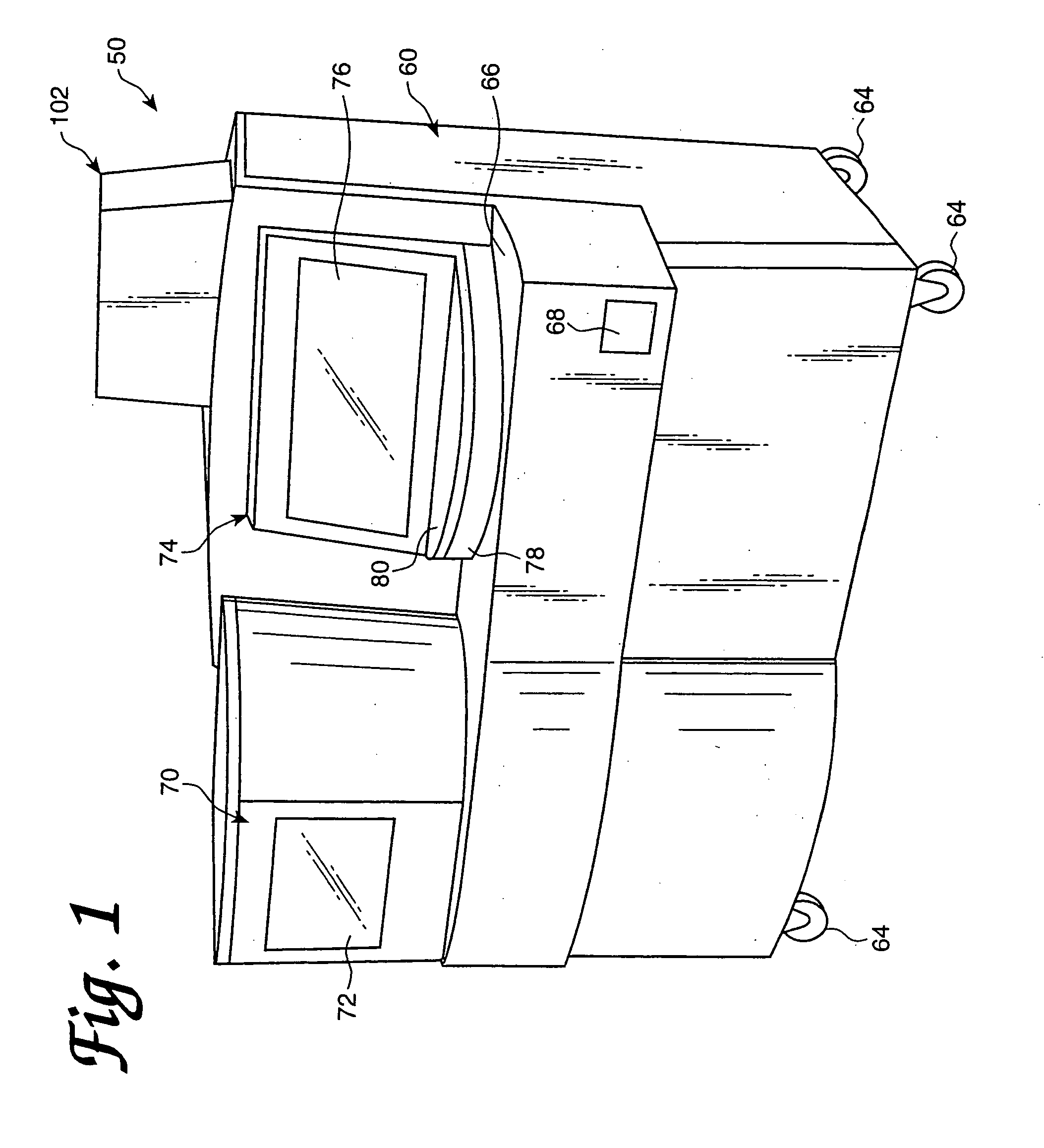

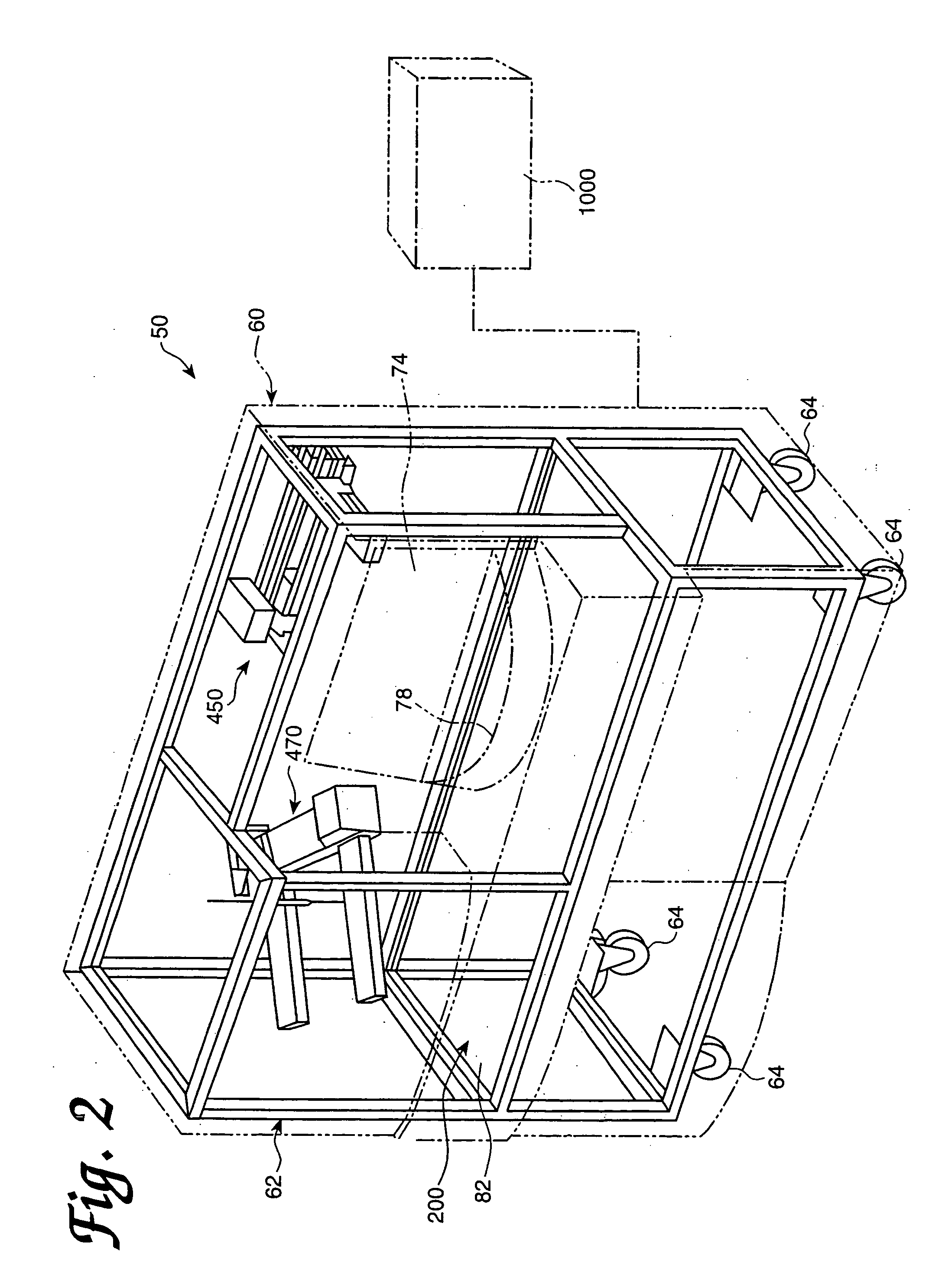

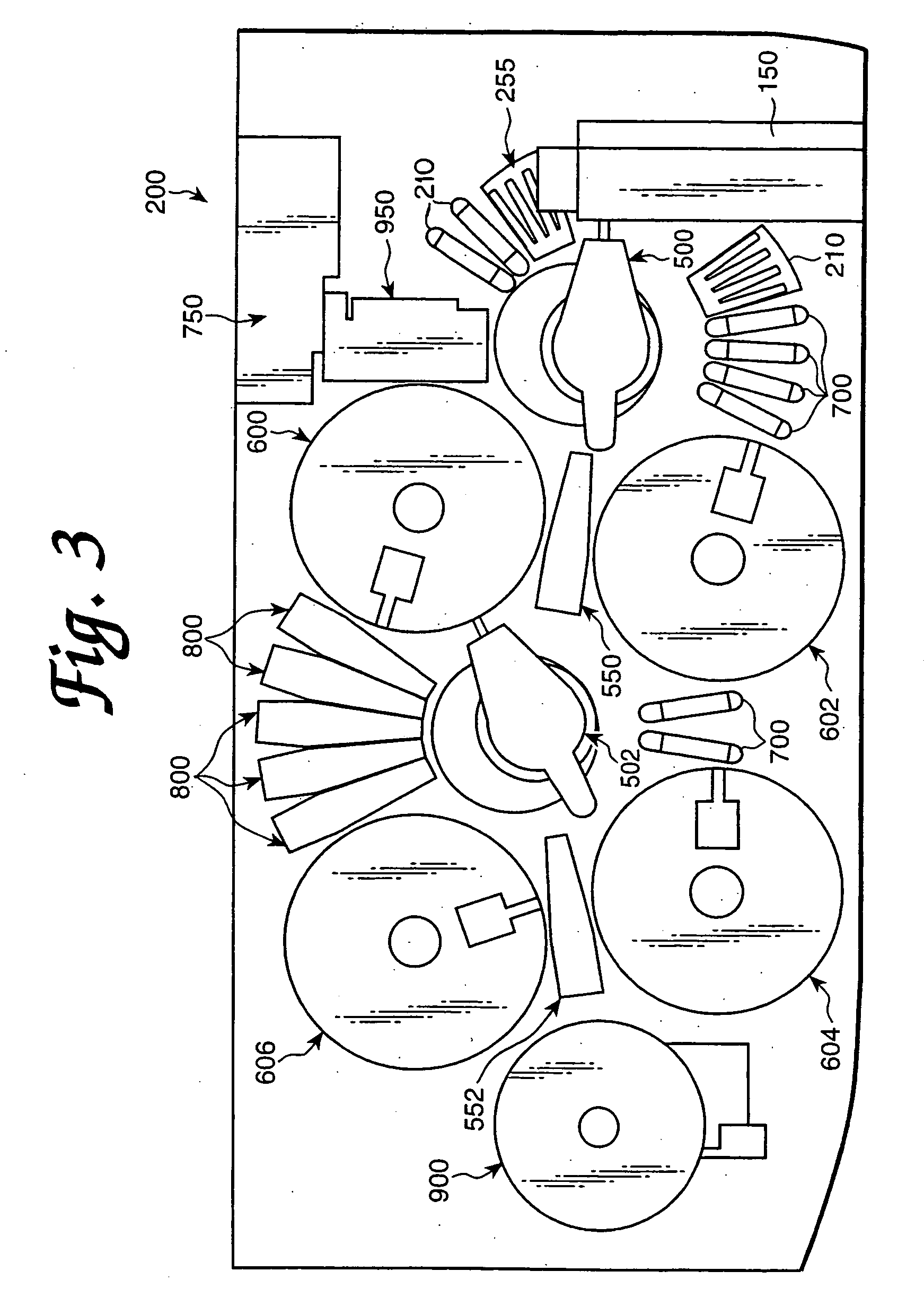

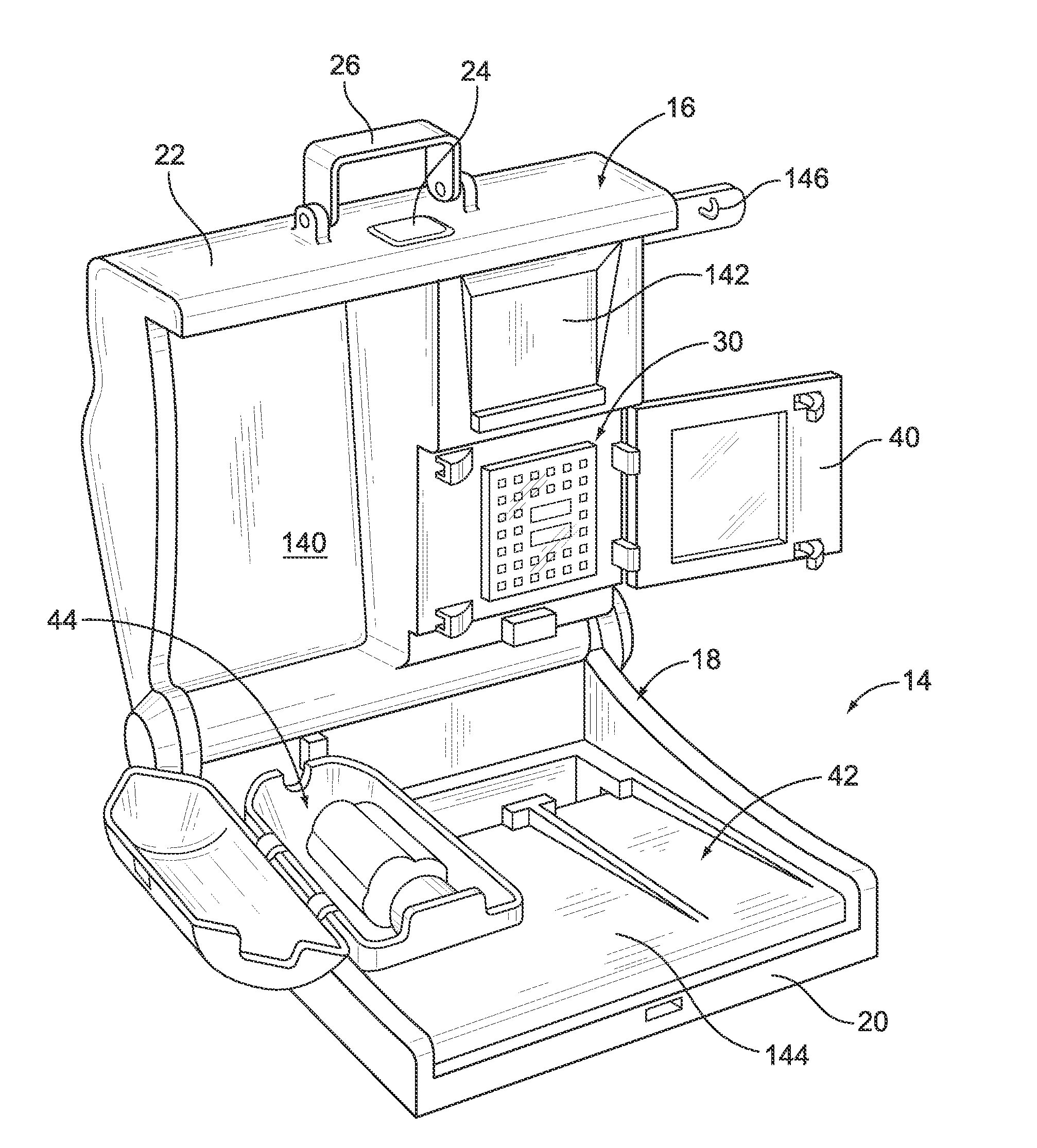

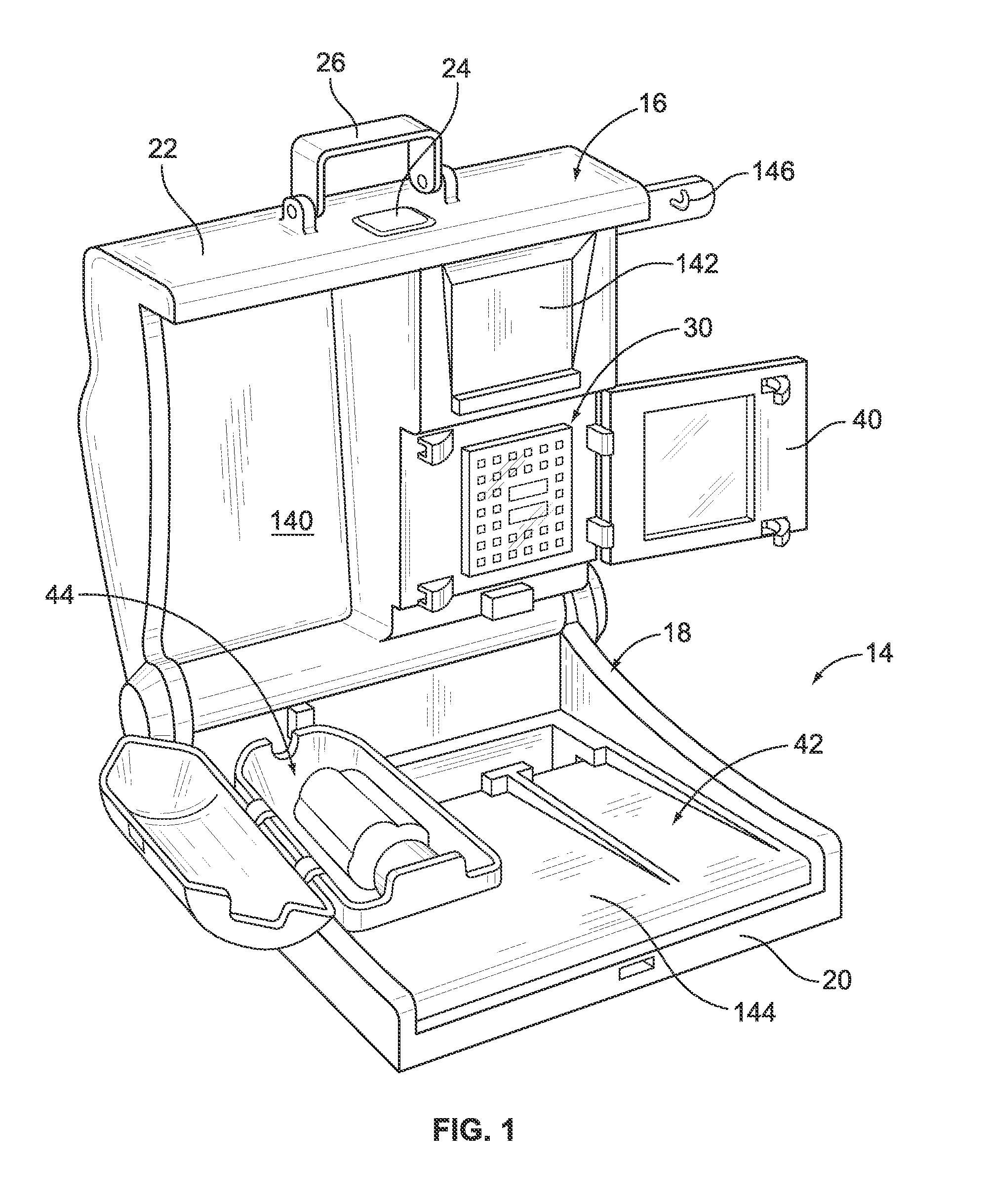

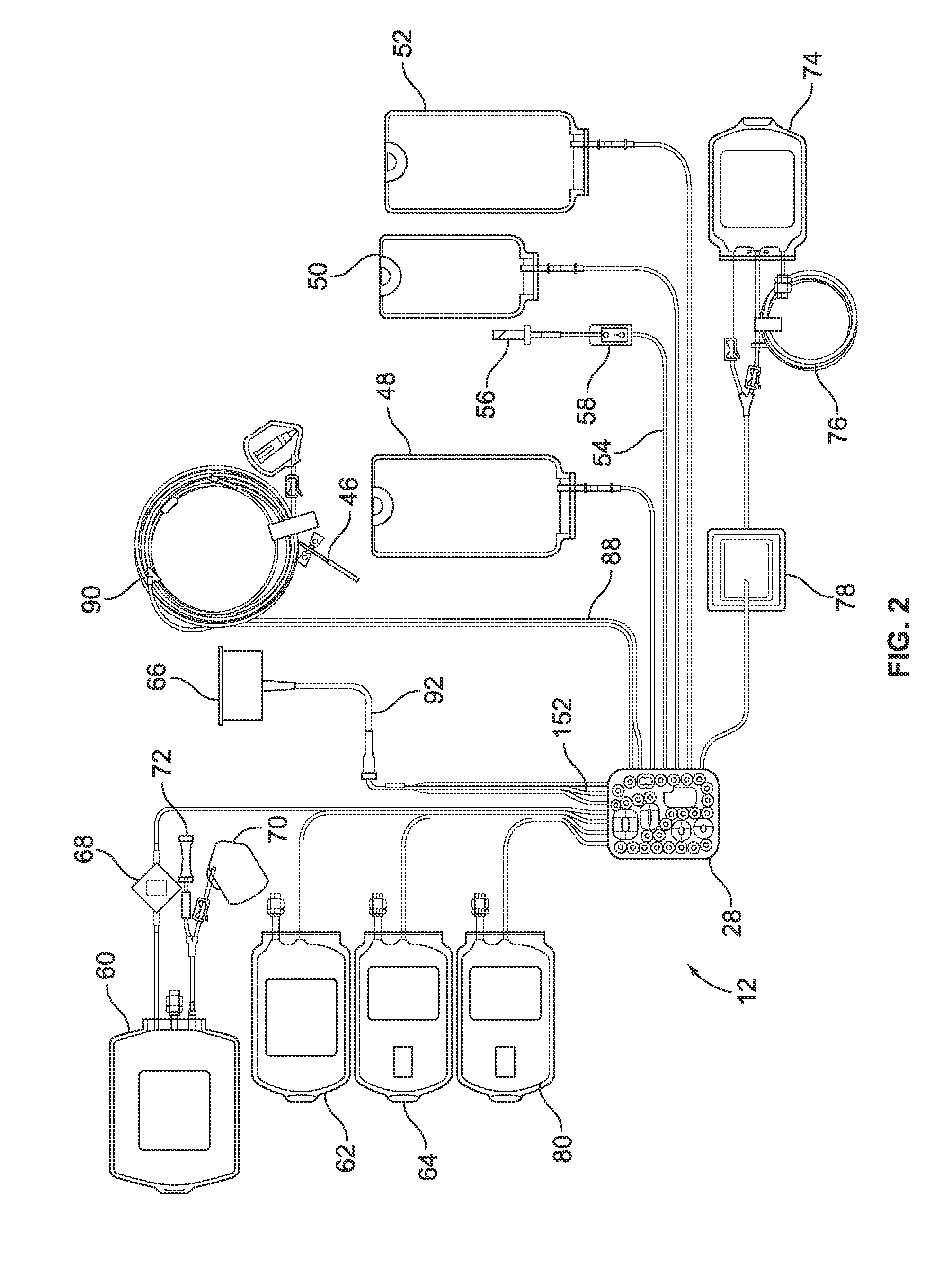

System and method for adjustment of blood separation procedure parameters

ActiveUS20120175313A1Liquid separation auxillary apparatusSemi-permeable membranesBlood separation deviceAnticoagulant

Systems and methods are provided for automatically adjusting the operational parameters of a blood separation procedure. A blood separation device has an inlet for passing fluid thereinto and an outlet for removing fluid therefrom. A pump system is provided for moving fluid into and out of the device. In use, blood is conveyed into the device, where platelets are separated from at least a portion of the blood. A controller determines the amount of platelets in the device. Based at least in part on the amount of platelets in the device, corrective action is taken to avoid platelet aggregation in the device. The corrective action may be conveying an elevated amount of anticoagulant into the blood and / or the device and may be initiated when the determined amount of platelets approaches, meets, or exceeds a threshold predicted likelihood of platelet aggregation.

Owner:FENWAL

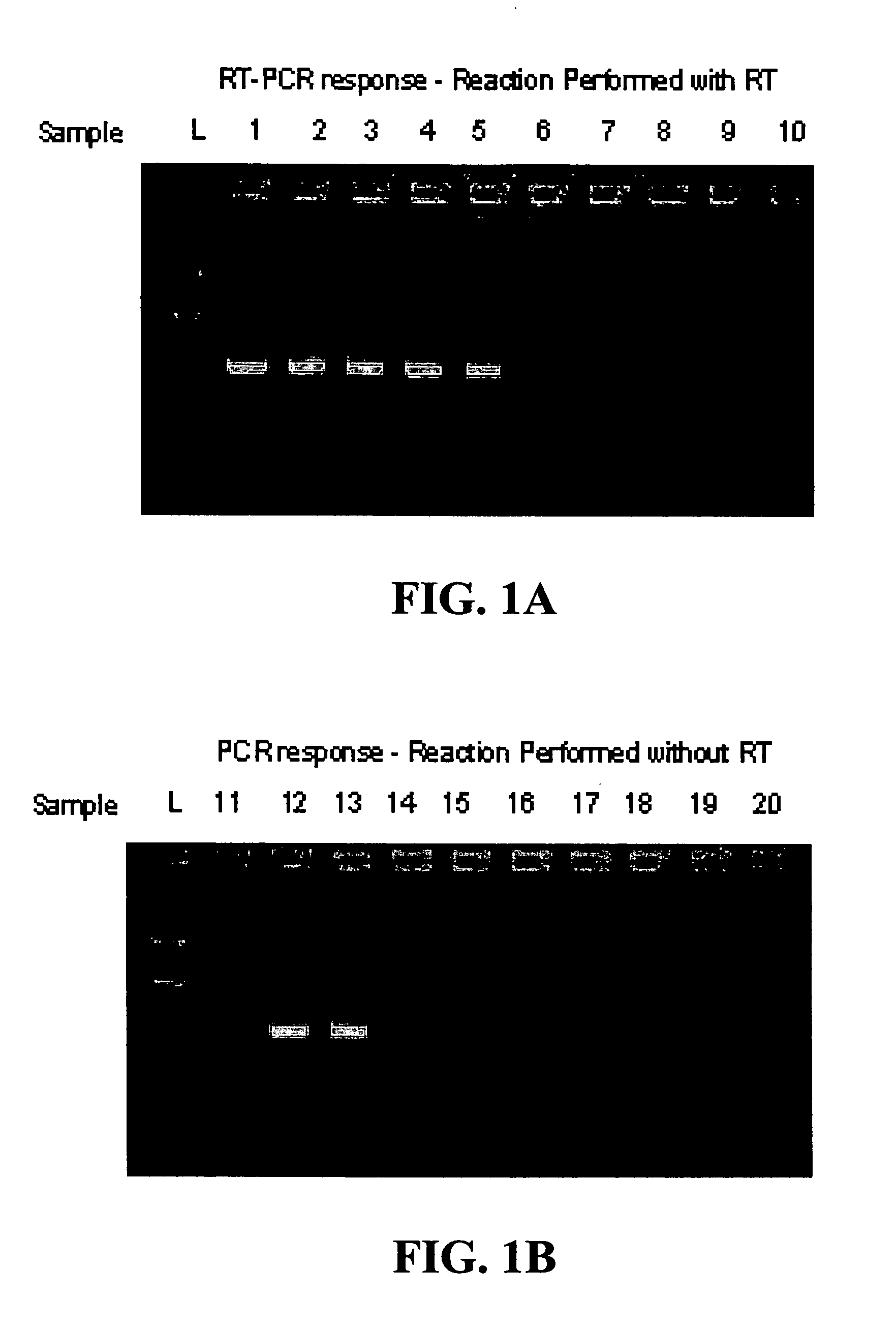

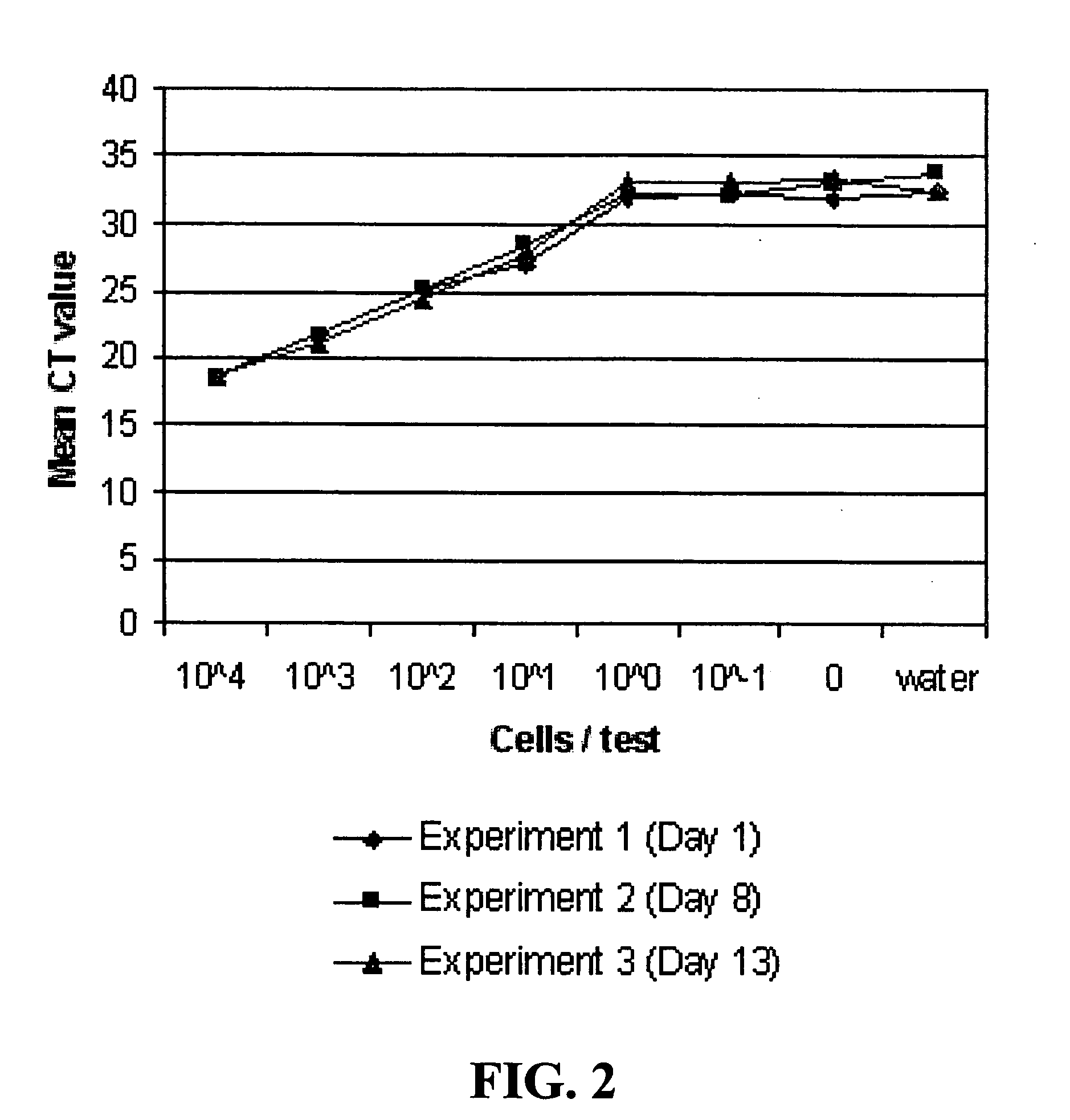

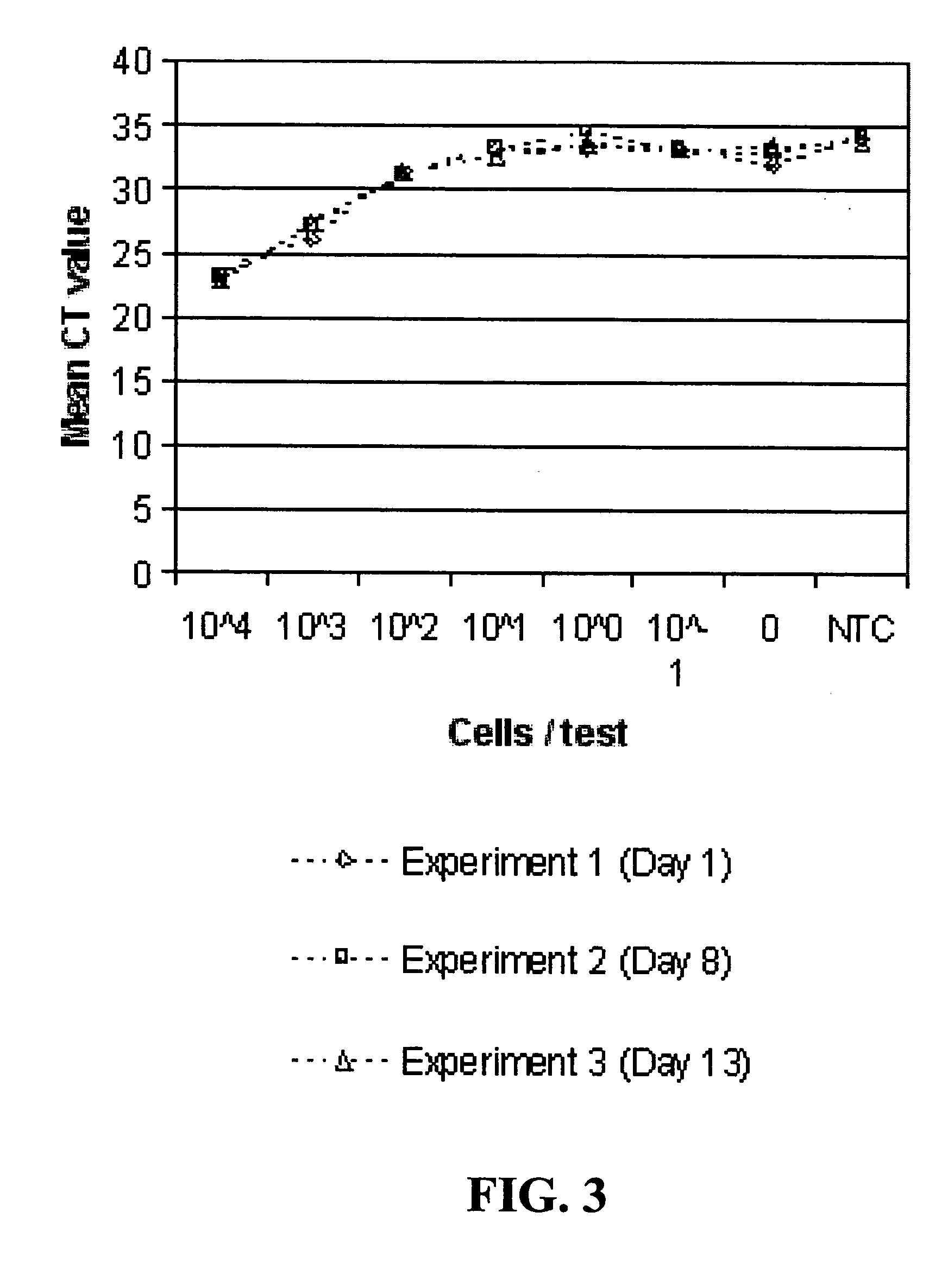

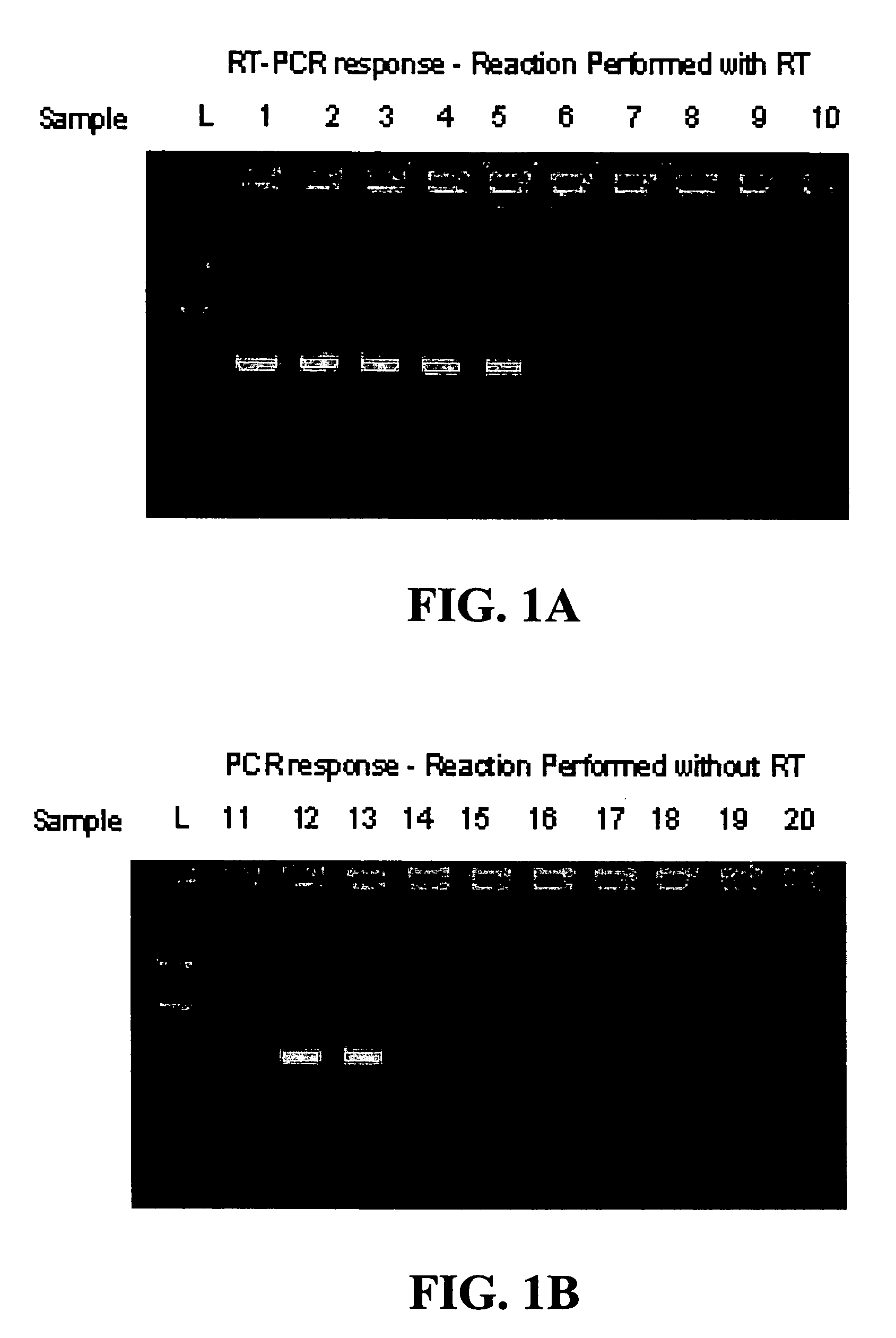

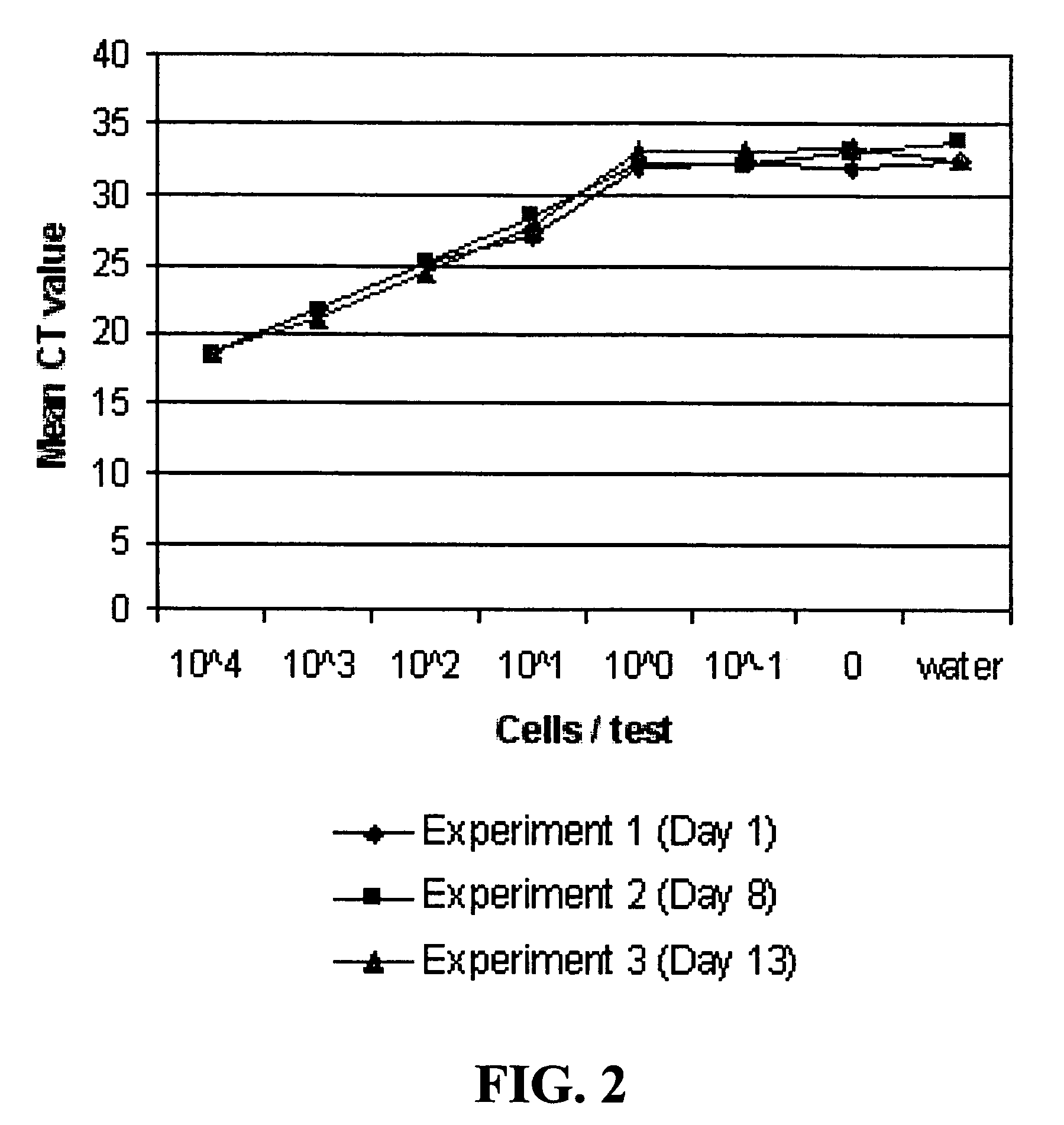

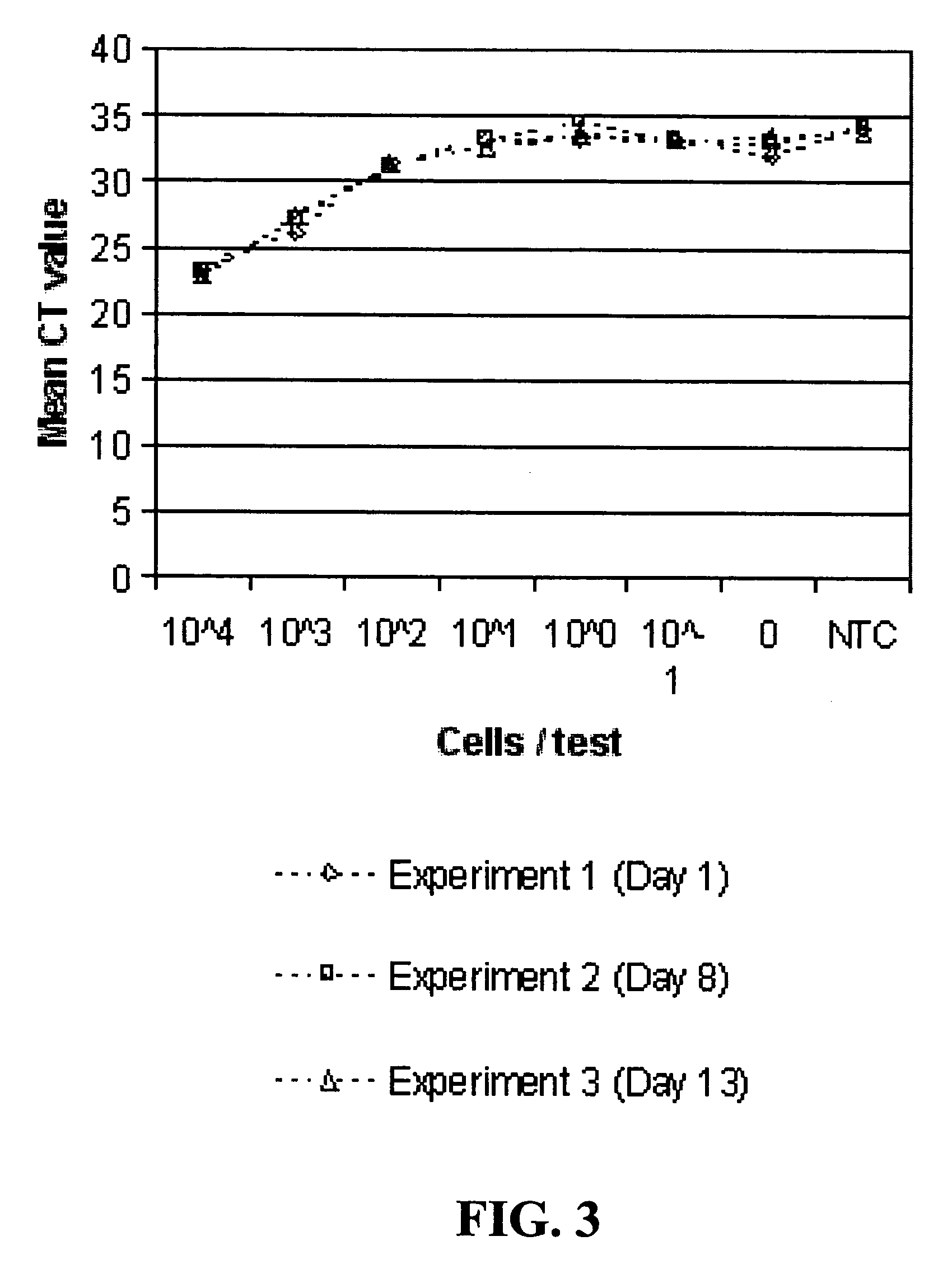

Method for the direct detection of diagnostic RNA

InactiveUS20050266468A1Improve usabilityMicrobiological testing/measurementFermentationIsolation proceduresBiology

Methods for the direct detection of diagnostic target RNA have been developed, which obviate the need for time consuming RNA purification and isolation procedures.

Owner:QUALICON DIAGNOSTICS LLC

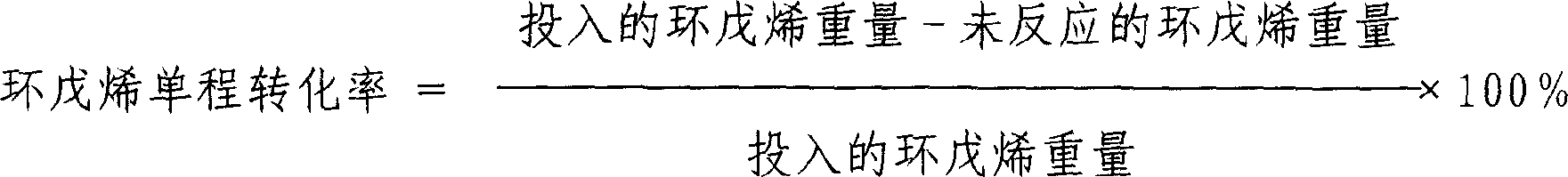

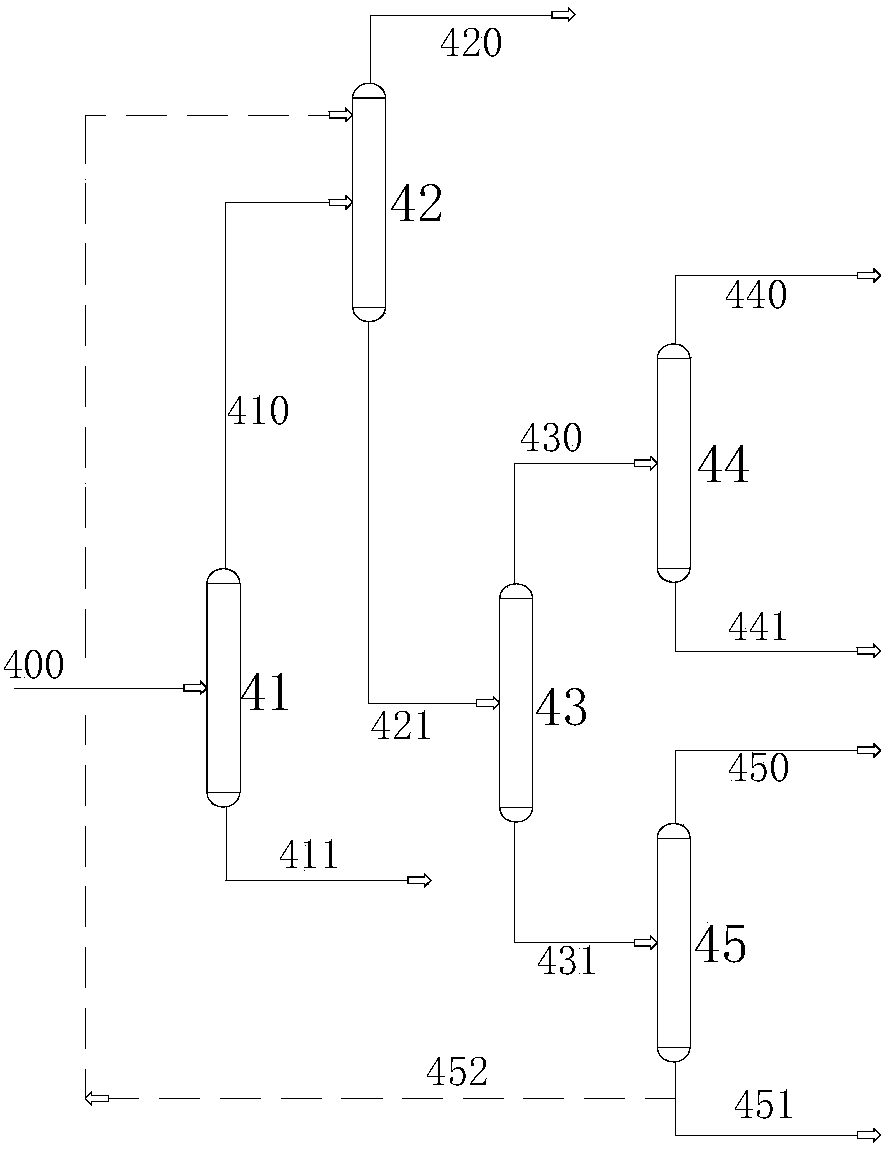

Cyclopentanol preparing and refining method

ActiveCN1676504AEasy to refineHigh selectivityOrganic compound preparationPreparation by hydroxy group additionHydration reactionCyclopentene

This invention is a making and refining method of cyclopentanol, which includes: 1) the materials comprises cyclopentene, phenylic acid solvent, water activator continuously pass through catalyst fixed bed to carry out hydration reaction, and the volume space velocity is 2-15hr to the power -1, the mole ratio of cyclopentene and water is 0.8-5.0, the weight ratio of phenylic acid and cycloamylene is 0.5-1.0. the intensity of activator is 0.01-0.2wt%, the reaction temperature is 130-180deg.C, the reaction pressure is 1.0-3.0MPa, the catalyst is strong acid cation exchange resin with sulfo group anchored on the surface, and the activating solvent is trialkylamine; 2)the reacted materials cool to house temperature and demix into oil phase and aqueous phase, the oil phase materials through continuous distilling separation procedure get non-reacting cycloamylene, refined cyclopentanol and phenylic acid full of solvent. The strong points of this invention are that the conversion of cyclopentene and selectivity of cyclopentanol are high, and the refining of cyclopentanol is simple and low energy consumption.

Owner:SINOPEC SHANGHAI PETROCHEMICAL CO LTD

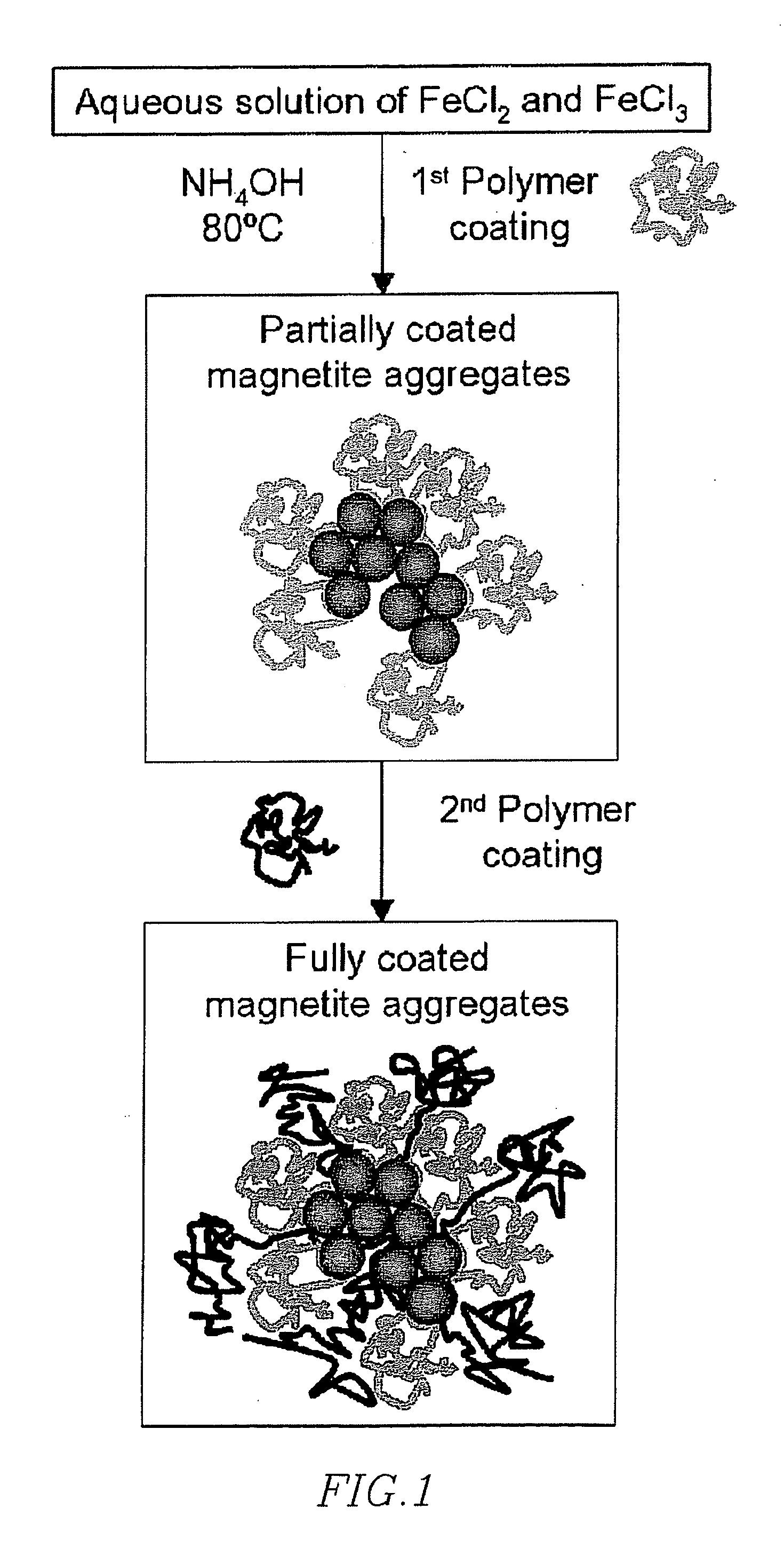

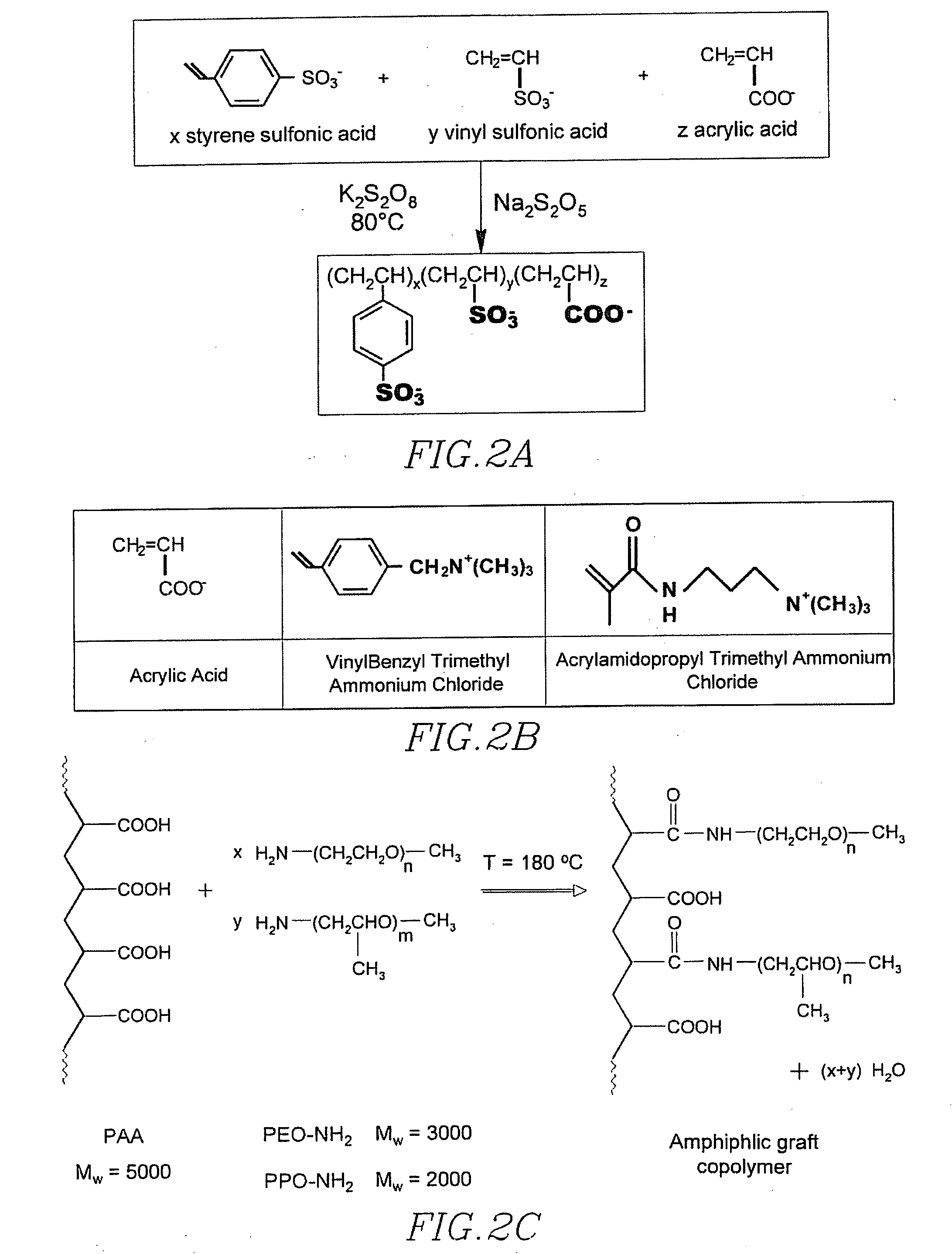

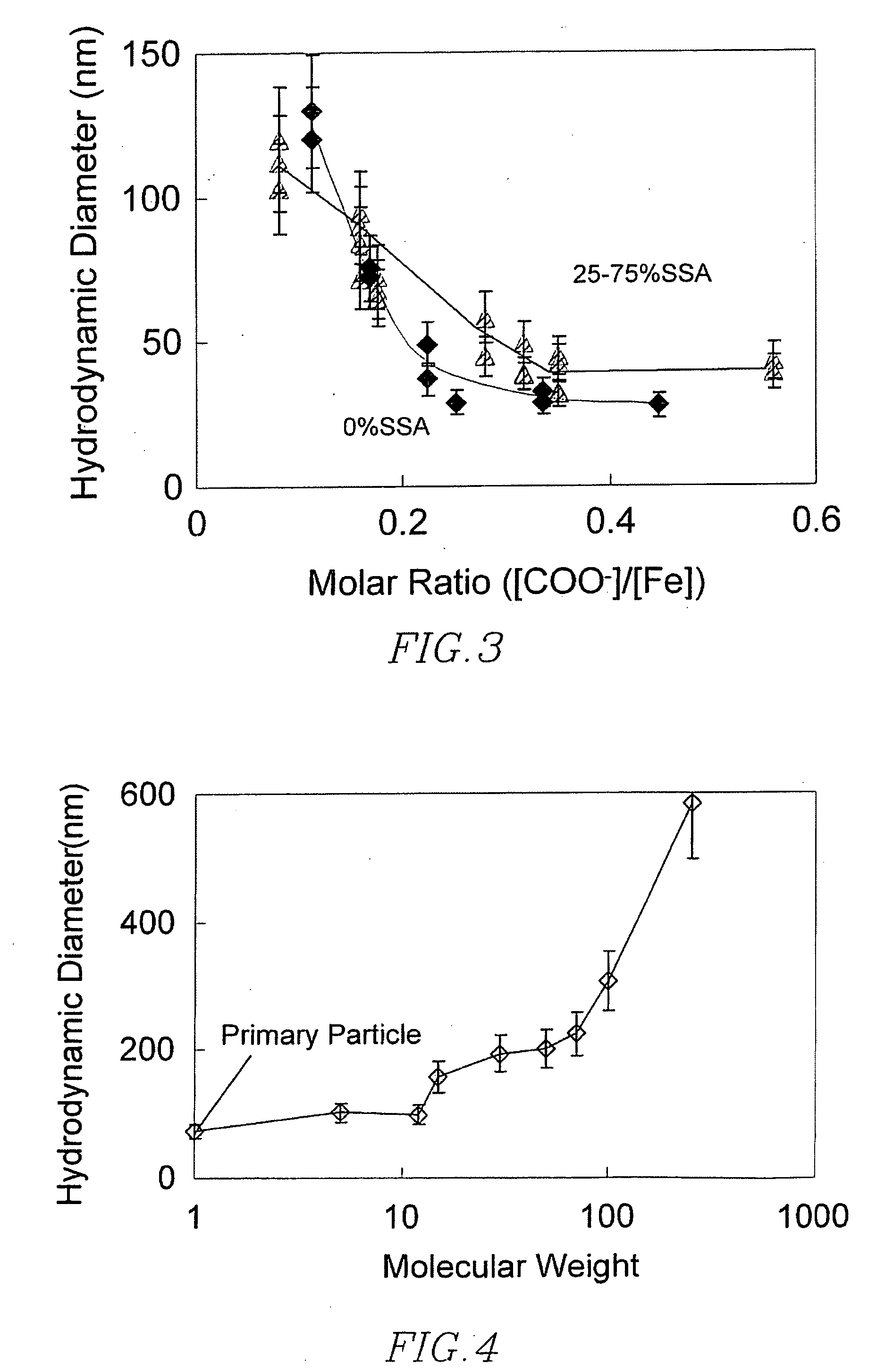

Multi-polymer-coated magnetic nanoclusters

InactiveUS20050215687A1Increase ionic strengthMixingPeptide preparation methodsMagnetite NanoparticlesColloid

The present invention relates to multi-polymer-coated magnetic nanoclusters, aqueous magnetic fluids comprising same, and methods of their use in separation procedures. The multi-polymer-coated magnetic nanoclusters comprise a super paramagnetic core, with a first polymer attached thereto, which does not render the first polymer-super paramagnetic particle complex colloidally stable, and a second polymer attached thereto, which stabilizes the complex of multi-polymer-coated magnetic nanoparticles. Methods of use comprise methods of separation, including separation of expressed protein from cells and viruses expressing the same.

Owner:MASSACHUSETTS INST OF TECH

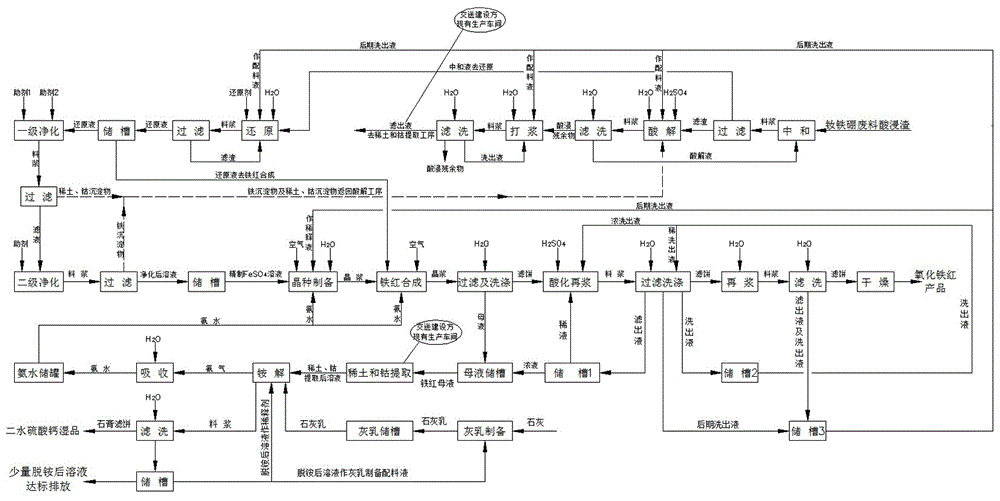

Comprehensive utilization method of neodymium iron boron waste acid leaching slag

The invention discloses a comprehensive utilization method of neodymium iron boron waste acid leaching slag. The neodymium iron boron waste acid leaching slag is mixed with neodymium iron boron waste acid leaching slag acid leaching liquid, prepared by acid leaching and separation procedures, in a neutralization reactor; neutralized slurry is filtered to recover neutralized liquid and neutralized residues; the neutralized liquid serves as a raw material for preparing iron oxide red; the neutralized residues and acid leaching residue eluating liquid, obtained in the acid leaching procedure, are mixed and added in sulfuric acid for acid leaching reaction and filtration to obtain acid leaching liquid and acid leaching residues; the acid leaching liquid is used for neutralizing ingredients; the acid leaching residues and latter eluating liquid, prepared in the oxide iron red preparation procedure, are mixed to prepare pulp; rare earth sulfate in the acid leaching residues is dissolved out by filtering and washing; and filter eluating liquid, prepared after preparation, is sent to a rare earth extracting procedure for preparing a rare earth product. The comprehensive utilization method realizes comprehensive utilization of iron, micro rare earth and cobalt resources in the neodymium iron boron waste acid leaching slag, and realizes effective separation and enrichment of the rare earth and the cobalt elements.

Owner:NANYANG ORIENTAL APPL CHEM RES INST

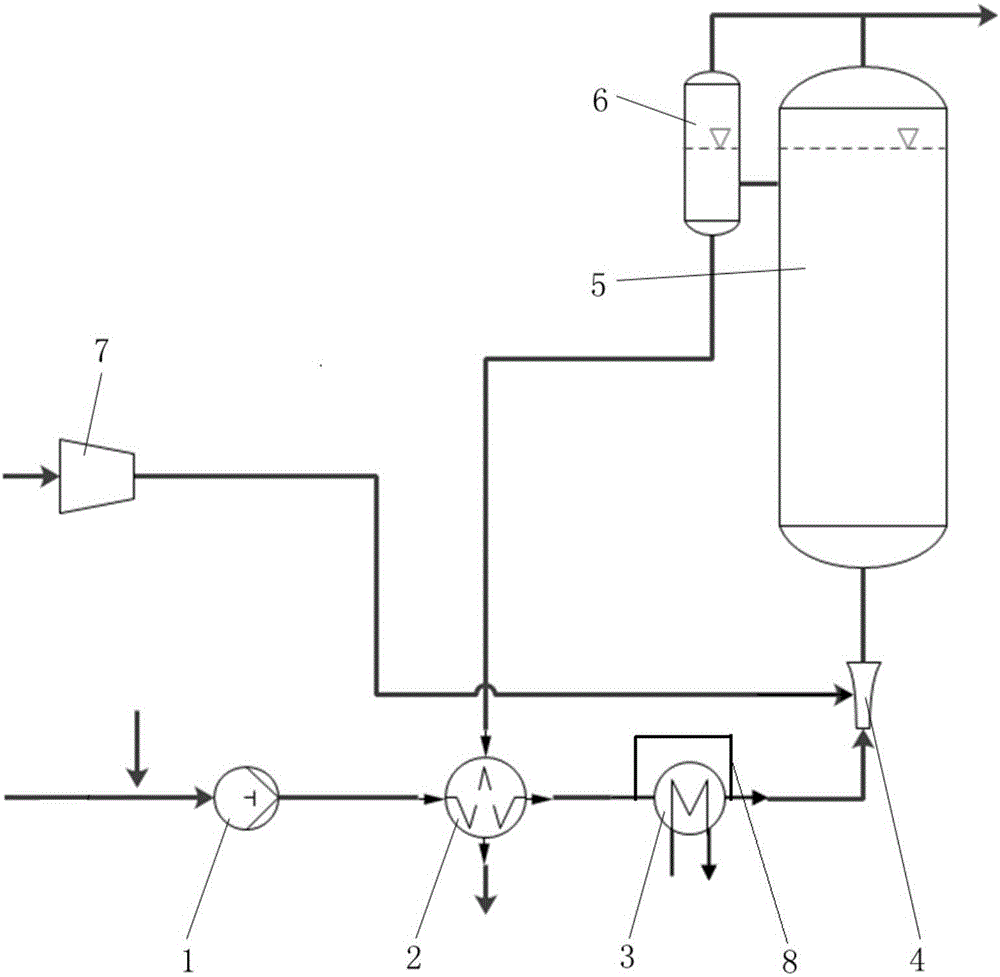

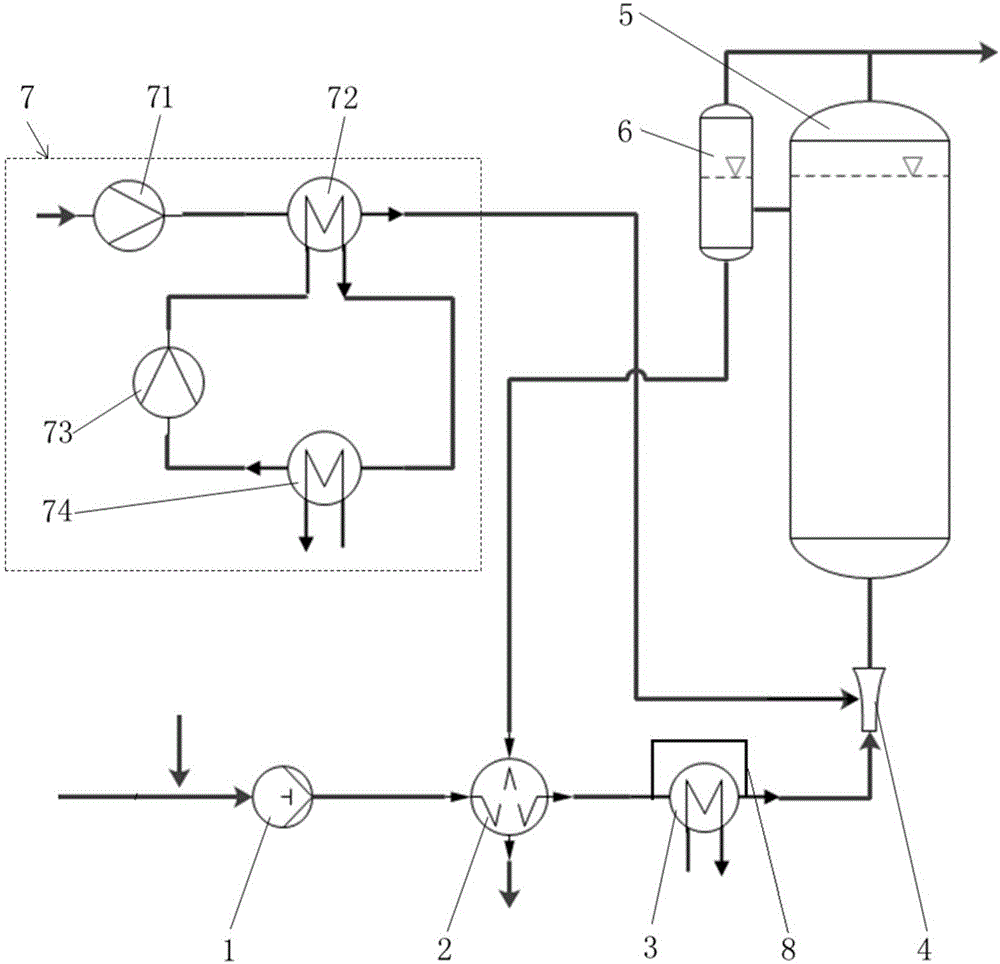

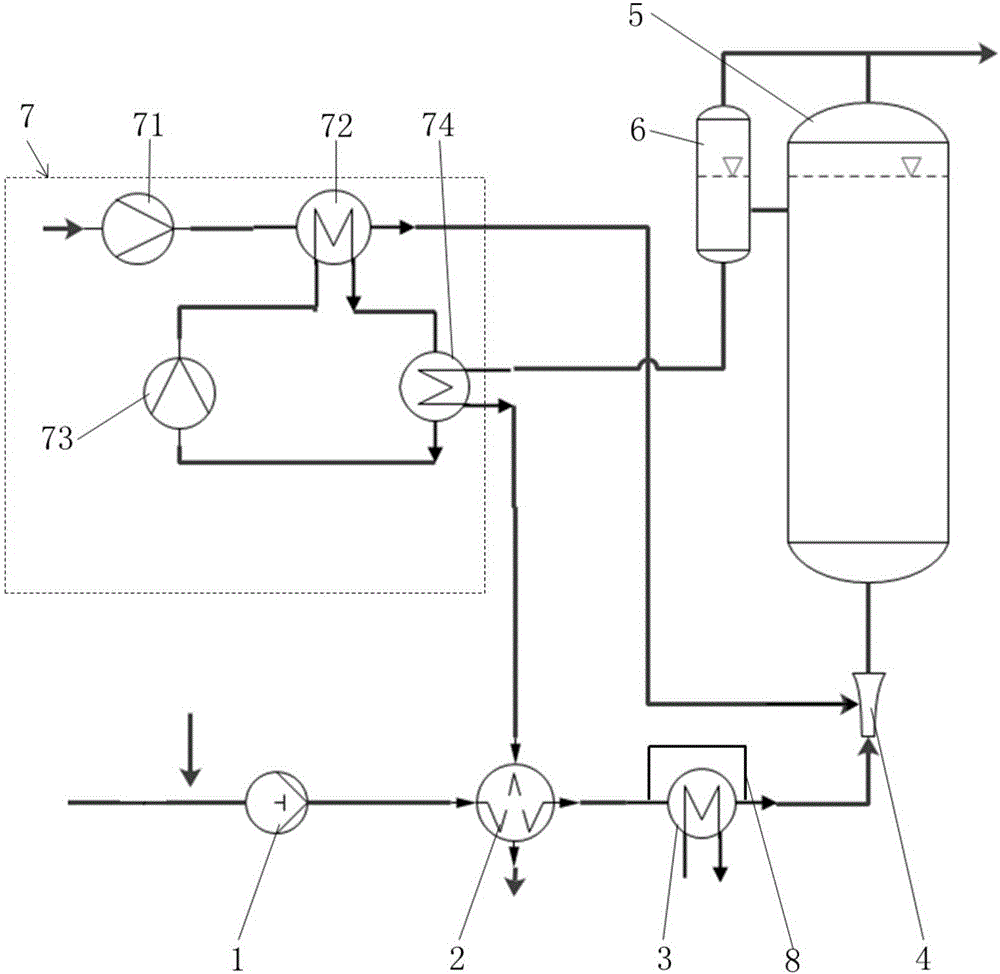

Continuous wet oxidation process for degrading high concentration organic waste water and equipment thereof

PendingCN106348421AEasy to handleSave spaceSpecific water treatment objectivesWater contaminantsHigh concentrationEnergy consumption

The invention discloses a continuous wet oxidation process for degrading high concentration organic waste water, belonging to the field of water treatment. The continuous wet oxidation process for degrading high concentration organic waste water comprises the procedures: a waste water pressurizing procedure: pressurizing waste water to be treated; a waste water heat exchange procedure: carrying out direct and / or indirect heat exchange on the pressurized waste water and treated waste water so the temperature of the pressurized waste water rises; an oxidizer pressurizing procedure: pressurizing an oxidizer; a mixing procedure: thoroughly mixing the pressurized and heated waste water with the pressurized oxidizer; a reaction procedure: causing the mixed waste water and the oxidizer to generate oxidation reaction, obtaining the treated waste water and generating gas; and a separation procedure: continuously separating the treated waste water from gas. The continuous wet oxidation process for degrading high concentration organic waste water has the advantages of high efficiency, less energy consumption, stability of operation and the like.

Owner:羿太环保科技(上海)有限公司

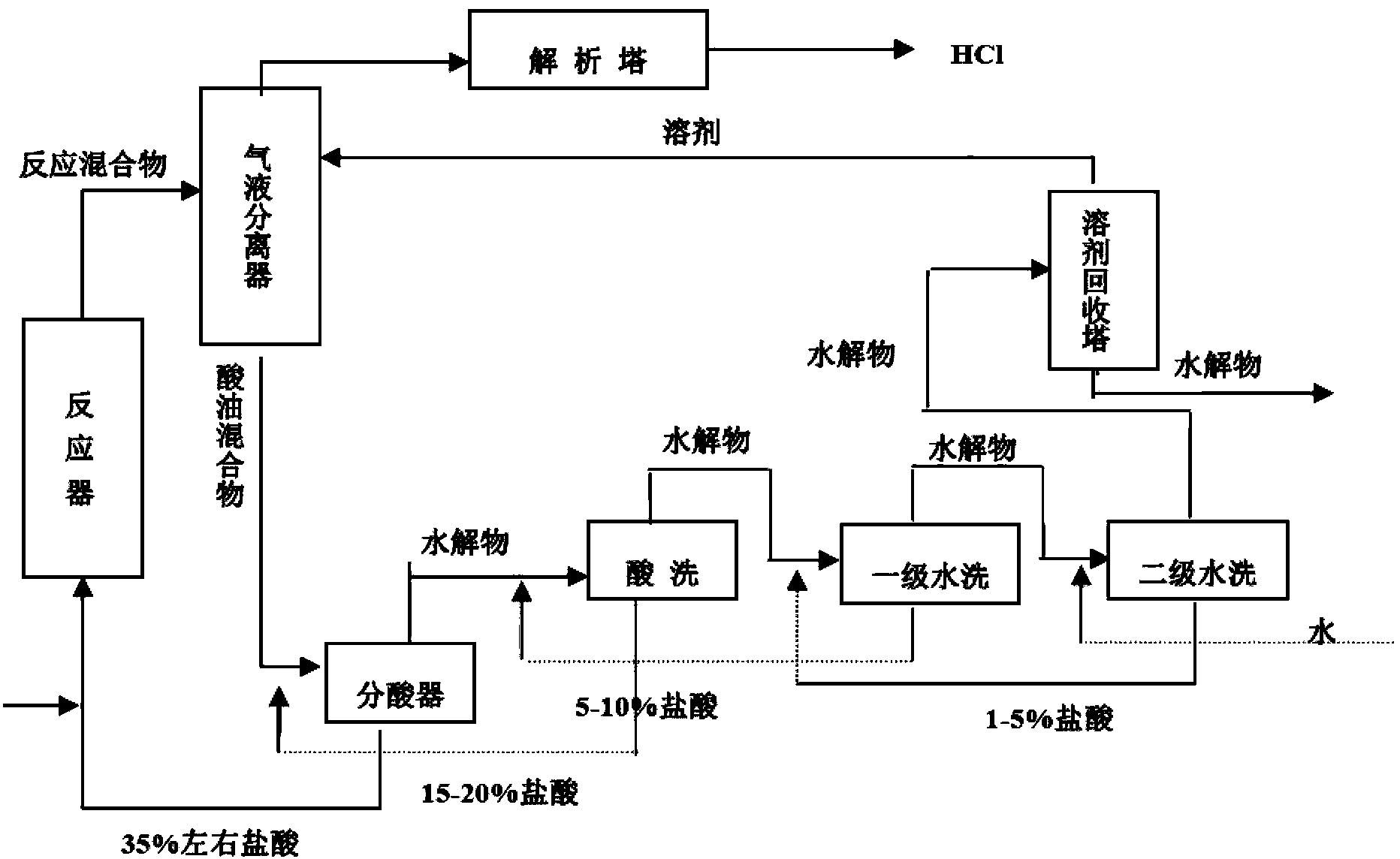

Method for preparing dimethyl silicone polymer by hydrolyzing dimethyl dichlorosilane with concentrated acid

The invention discloses a method for hydrolyzing dimethyl dichlorosilane with concentrated acid. The method comprises the following steps: mixing the dimethyl dichlorosilane with hydrochloric acid to carry out hydrolytic reaction; mixing the obtained reaction liquid with a solvent; finally, performing separating operation on the obtained mixed solution to obtain hydrolysis product and hydrogen chloride gas. Through the adoption of the method, the content of cyclic polysiloxane in hydrolysate obtained from the dimethyl dichlorosilane through the concentrated acid hydrolyzing method is effectively increased; the design is reasonable, hydrolysate with low chlorine ion content can be obtained in no need of multi-stage phase separation procedures, and the hydrochloric acid and solvent obtained after separation can be recycled, so that the resource use ratio is improved, and the production cost is saved.

Owner:HOSHINE SILICON IND CO LTD

Method for recovering silicon powder from cut mortar waste

The invention discloses a method for recovering silicon powder from cut mortar waste. According to the adopted technical scheme, the method comprises the following steps of: carrying out solid-liquid separation on the cut mortar waste to obtain a solid mixture, and adding an ethanol solution of carbon bisulfide to wash away suspended impurities to obtain mixed sand powder; carrying out magnetic separation on the obtained mixed sand powder to remove iron, iron oxides and metal impurities; carrying out acid cleaning; carrying out solution floatation and gravity separation to recover suspended matters, then washing the suspended matters by using ethanol, and drying to obtain high-purity silicon powder. The method disclosed by the invention effectively integrates the silicon powder recovery process through the steps of a solid-liquid separation procedure, a magnetic separation procedure, an acid cleaning procedure, a solution floatation procedure and the like, thus achieving the advantages of simple process, operation controllability, excellent economical performance and no secondary pollution. According to the method for recovering the silicon powder from the cut mortar waste, the recovery rate of silicon powder is higher than 80%, the content of silicon powder monomers is higher than 99%, and the silicon powder can be used as a raw material of a solar silicon wafer and is suitable for industrial popularization and application.

Owner:佳明新材料科技有限公司

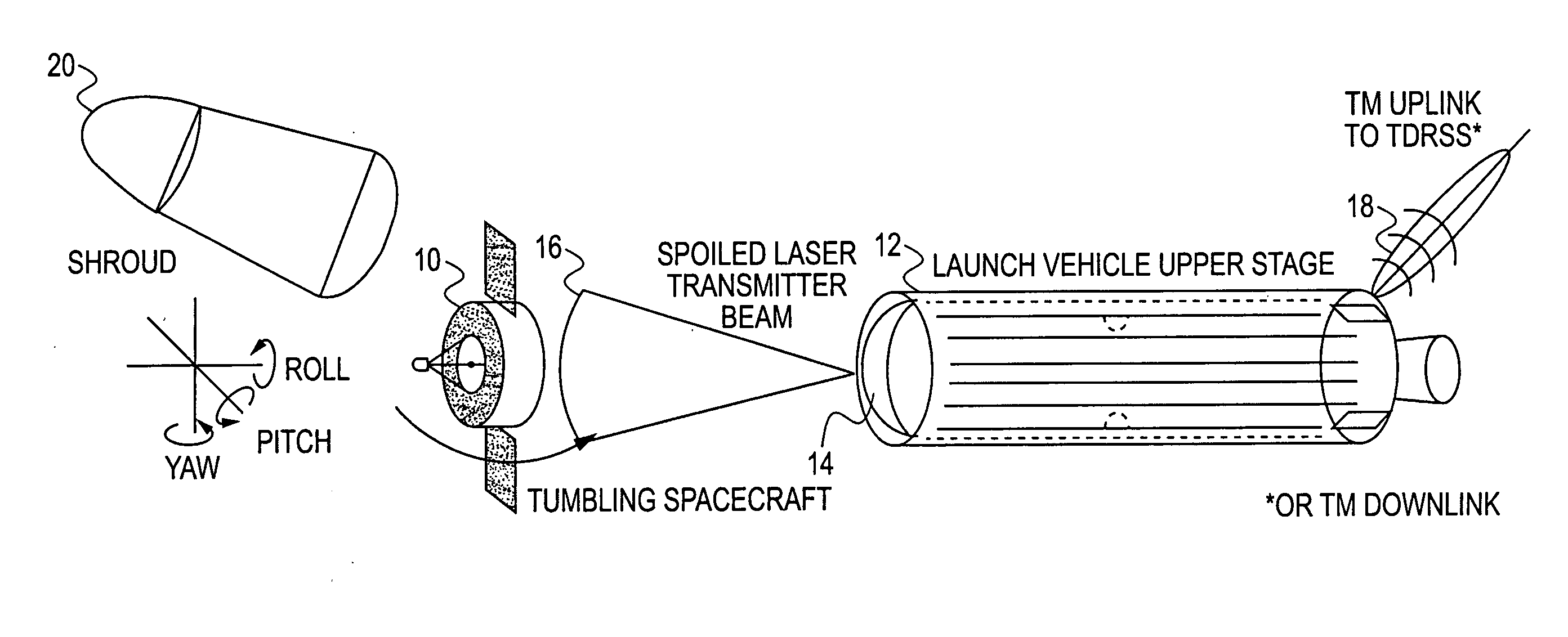

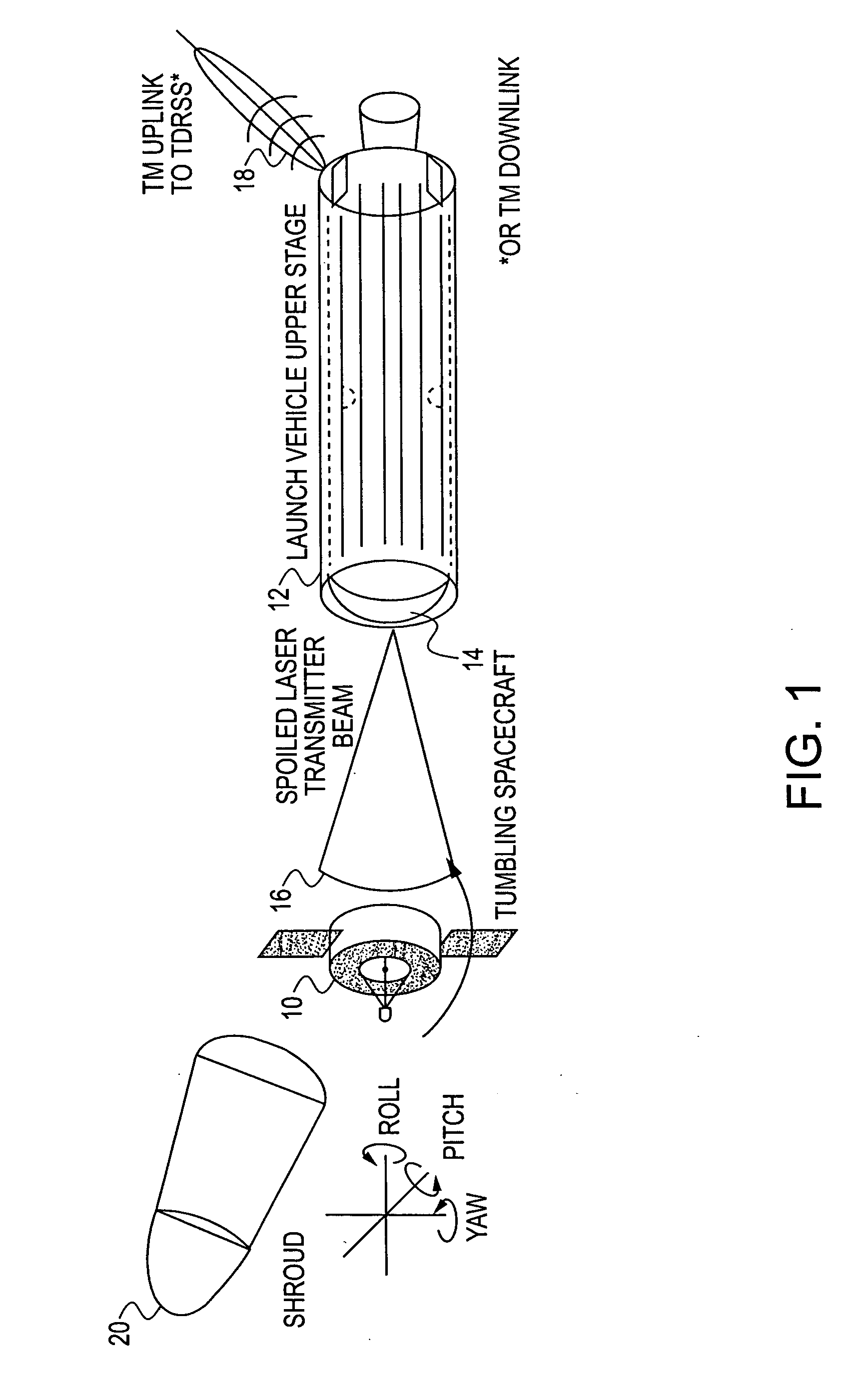

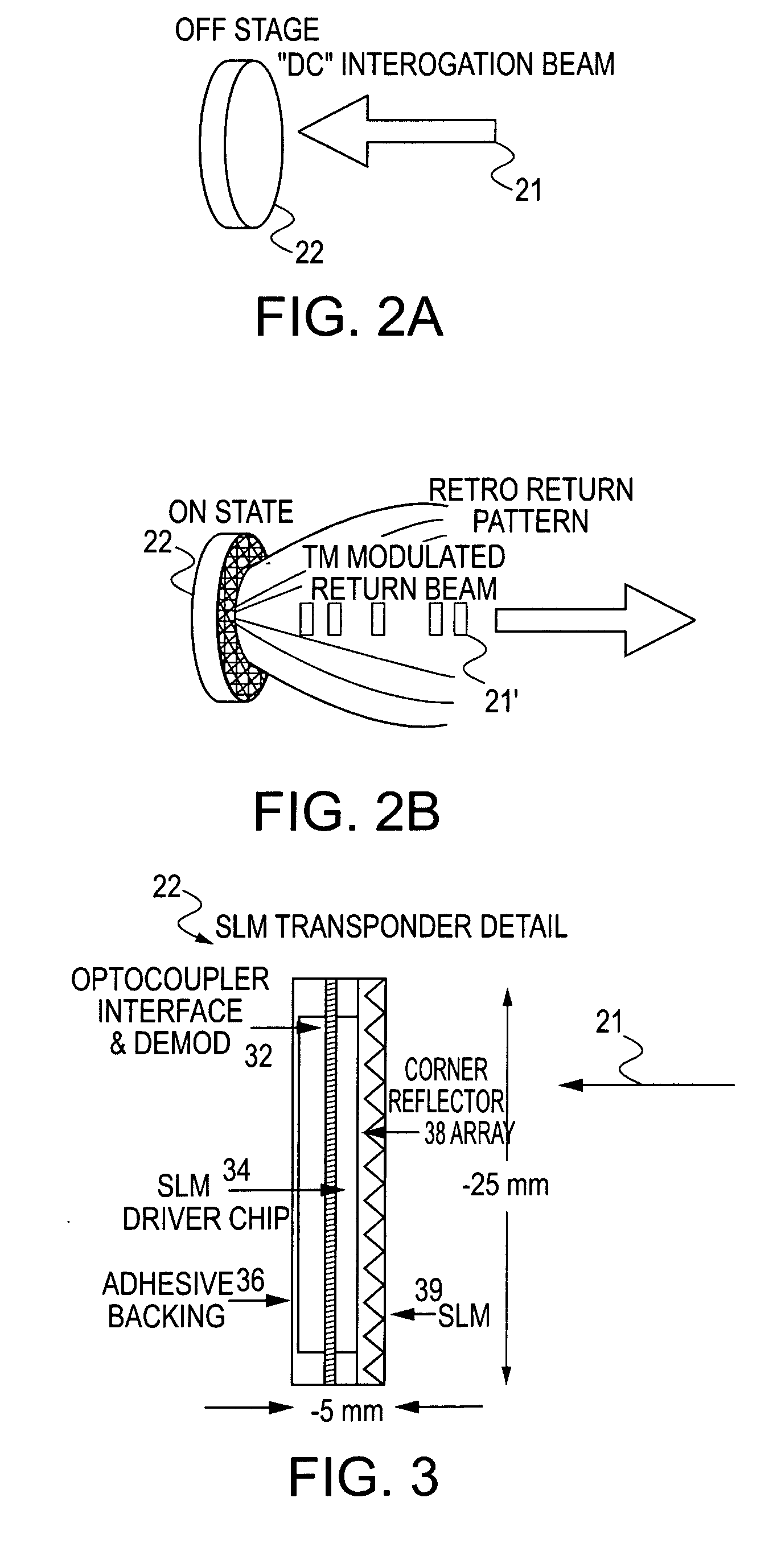

Low-power photonic telemetry system and method for spacecraft monitoring

InactiveUS20050240341A1Little powerAircraft componentsRoad vehicles traffic controlTelecommunications linkPhotonics

An optical telemetry system and method for monitoring the location and status of a spacecraft (e.g., a satellite, a missile, a manned vehicle, etc.) using an optical communication link in an extraterrestrial environment. The system is optimally suited for monitoring the status and location of the spacecraft during a separation procedure of a spacecraft from its launch vehicle and uses a low-power optical communication link between a support craft and a spacecraft to obtain data. The data is then processed by the support craft and relayed to sources external to the support craft using the launch vehicle's telemetry system. Moreover, the system and method can also be used to monitor the status and location of an array (e.g., a three-dimensional array) of space vehicles traveling in space (e.g., an array of satellites).

Owner:FIELHAUER KARL B +1

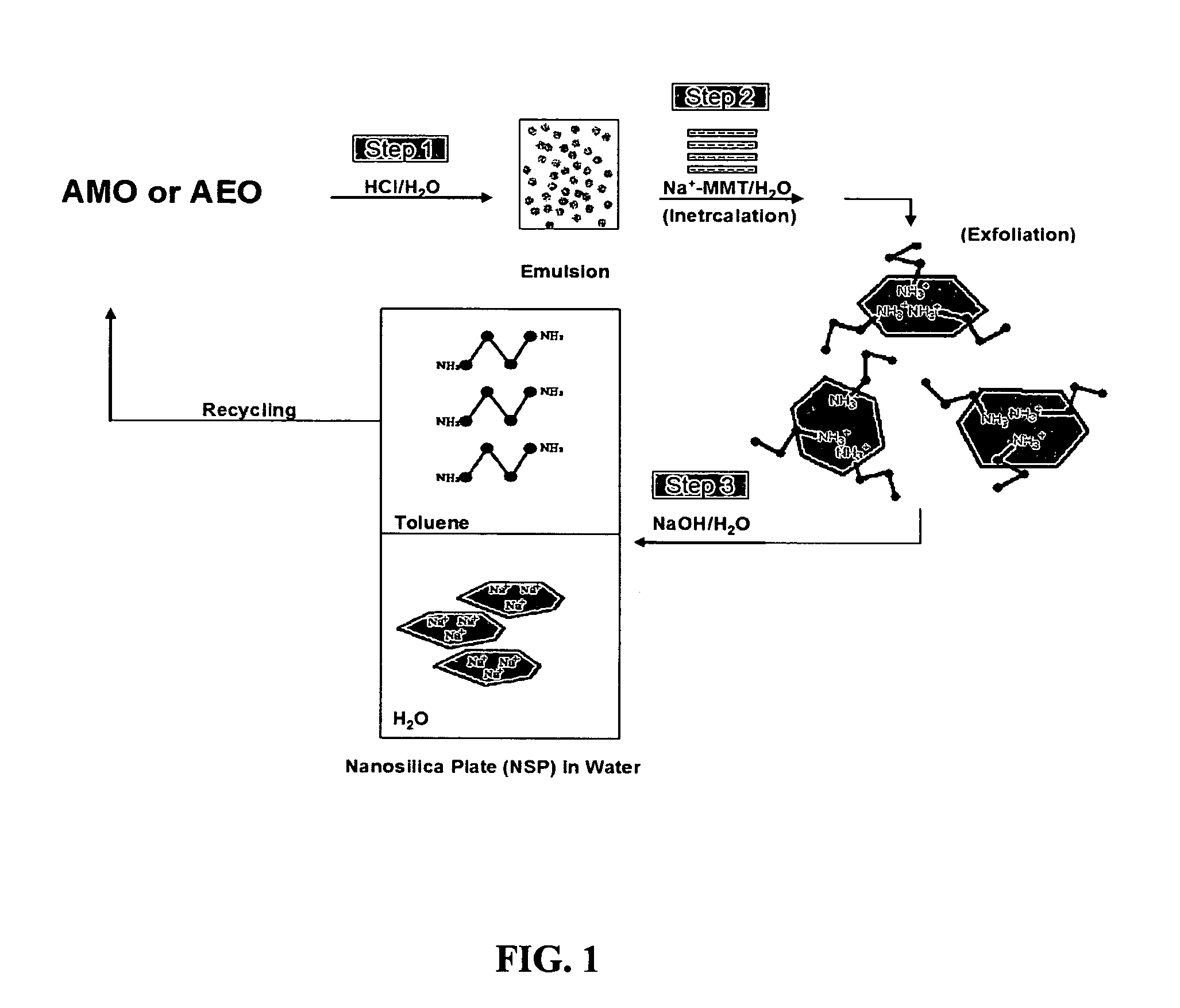

Method for producing nanosilica plates

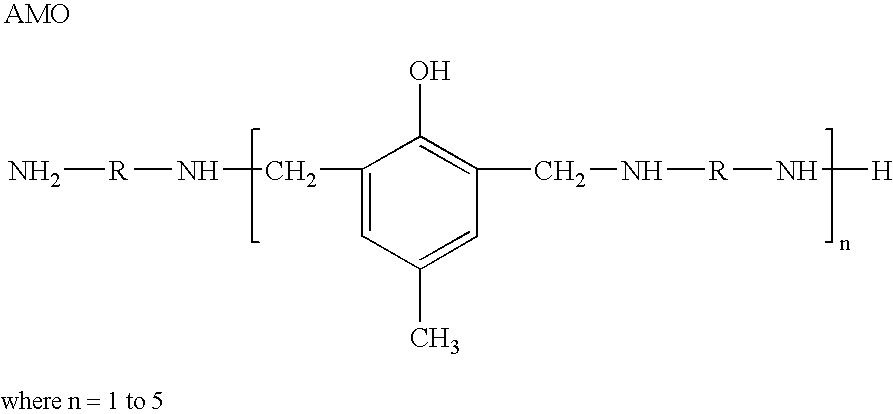

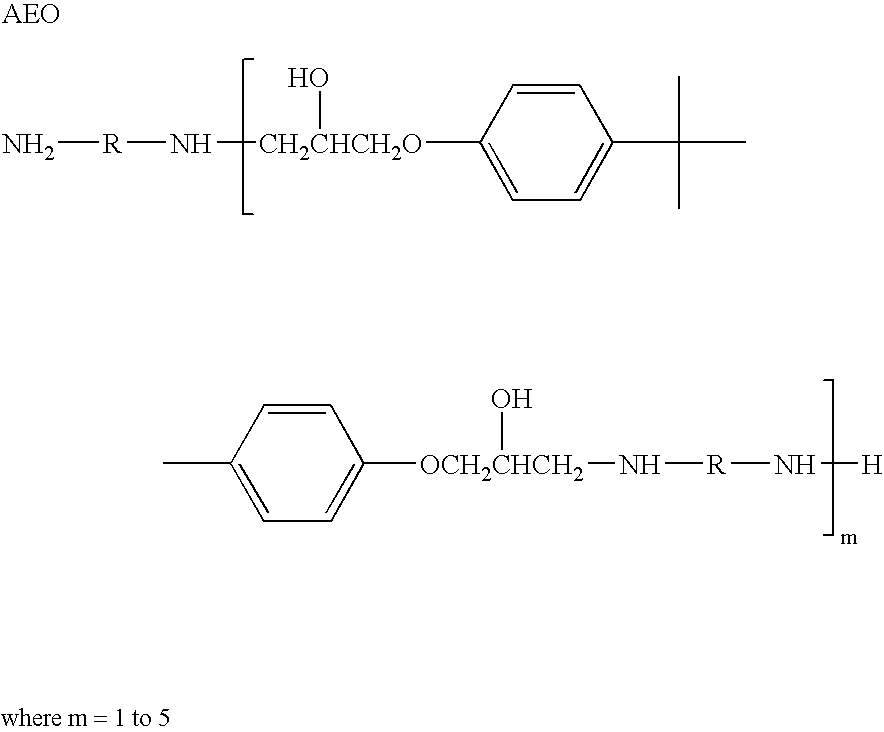

The present invention relates to an exfoliating agent and to a process for producing random form of nanoscale silicate plates. Two types of exfoliating agents are applied in the present invention, which respectively have the formula:wherein R is a polyoxybutylene group, polyoxypropylene group, poly(oxyethylene / oxypropylene) group, or polyoxyethylene group. In this invention, layered silicate clays are exfoliated into random silicate plates by acidifying AMO or AEO with inorganic acid, adding the acidified AMO or AEO to layered silicate clay with agitation, and adding sodium hydroxide or chloride of alkali metal or alkaline-earth metal, in ethanol, water and a hydrophobic organic solvent to the intermediate product and repeating phase separation procedures to isolate random silicate plates from water phase.

Owner:NATIONAL CHUNG HSING UNIVERSITY

Method for recycling hydrofluoric acid from wastewater containing fluorosilicic acid

InactiveCN106185817ARealize resource utilizationHigh recovery rateSilicaHydrogen fluorideSilicon dioxideFluorosilicic acid

The invention provides a method for recycling hydrofluoric acid from wastewater containing fluorosilicic acid. Ammonia or ammonium is added into the wastewater containing the fluorosilicic acid and the fluorosilicic acid is decomposed into sediments of ammonium fluoride and silicon dioxide; magnesium sulfate is added into a solution containing the ammonium fluoride and fluorine in the solution is precipitated and separated out in a magnesium fluoride form; the solution is filtered to obtain magnesium fluoride and a fluoride precipitation post-solution; then the magnesium fluoride is thermally decomposed by sulfuric acid; thermally decomposed steam is condensed and absorbed to obtain the hydrofluoric acid; residues of thermal decomposition are returned back to a fluoride precipitation and separation procedure and are circularly utilized. Lime is added into the fluoride precipitation post-solution, stirring and a mixed solution is evaporated to recycle the ammonia; the recycled ammonia is returned back to a fluorosilicic acid ammonolysis procedure for circular utilization; the method has the advantages of simple process, simplicity and convenience for operation, high fluorine recovery rate, low recovery cost, good working environment and the like.

Owner:CENT SOUTH UNIV

Multi-functional and configurable assay

InactiveUS20050239216A1Efficiently conserveEffective isolationComponent separationImmunoassaysSolution flowSeparation procedure

Novel magnetic assay methods and systems. According to a preferred embodiment, a chromatographic medium is provided that is designed to be contacted with a test solution having activated magnetic particles such that the solution flows bilaterally thereacross. A magnetic field, generated by a magnet or electromagnet, is selectively applied to the medium which causes the charged particles to become substantially bound at a site on the medium specified by the position of the magnet, to thus form a captured line or zone. In one preferred embodiment, the magnetic field is applied at the site on the medium at which the test solution is contacted. The assay is multi-configurable and can be modified to suit a particular immuno-separation procedure or application.

Owner:WAVESENSE INC

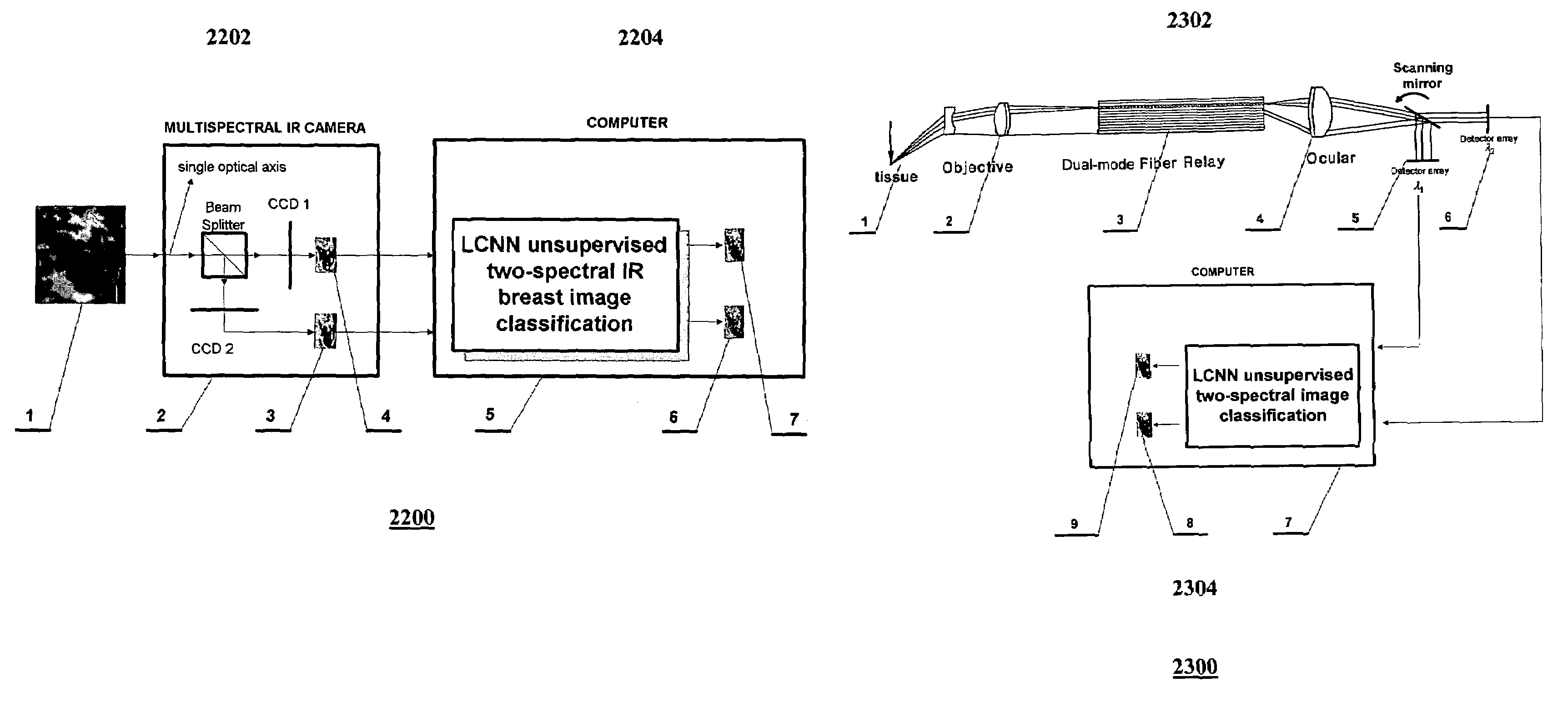

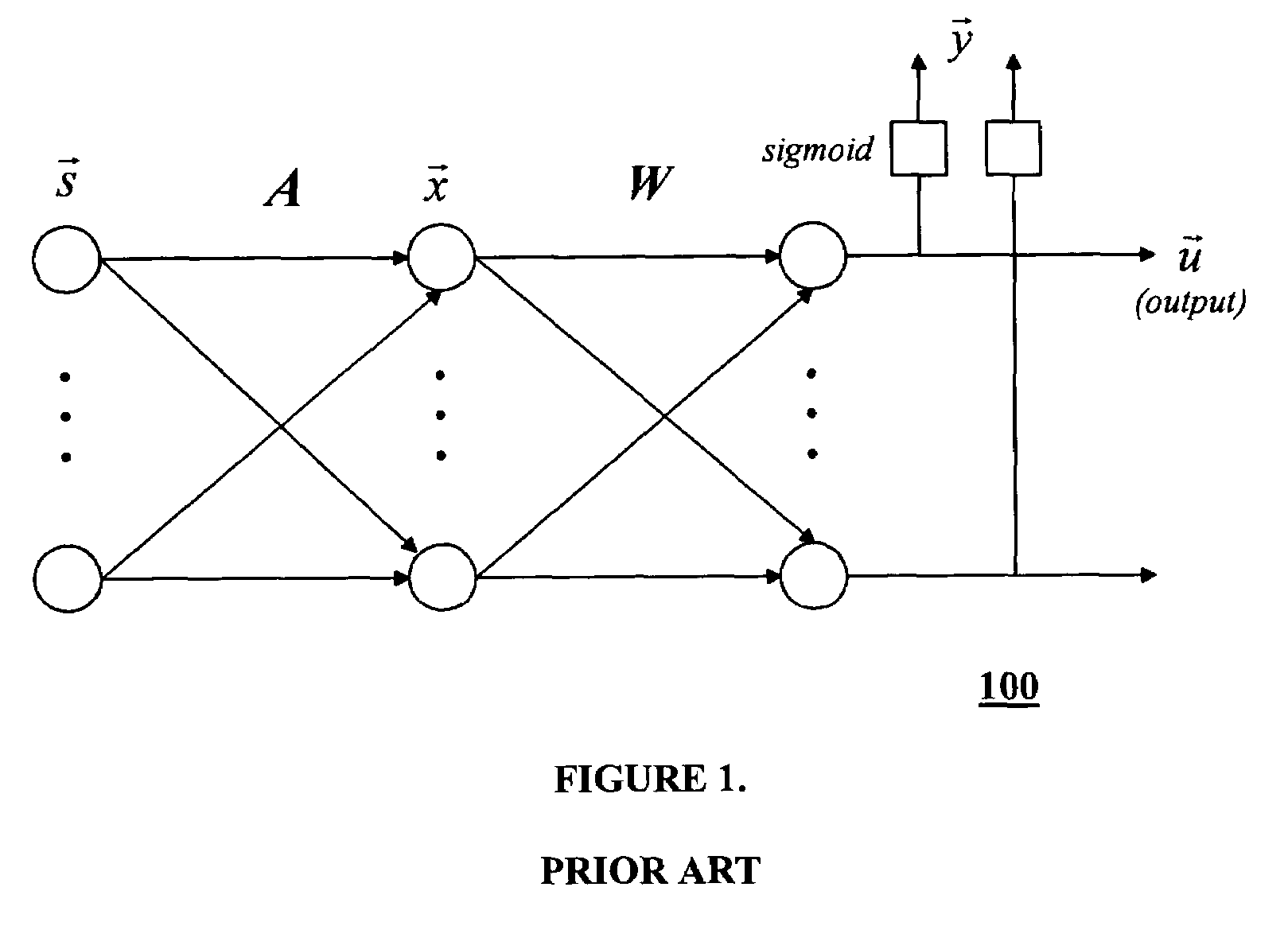

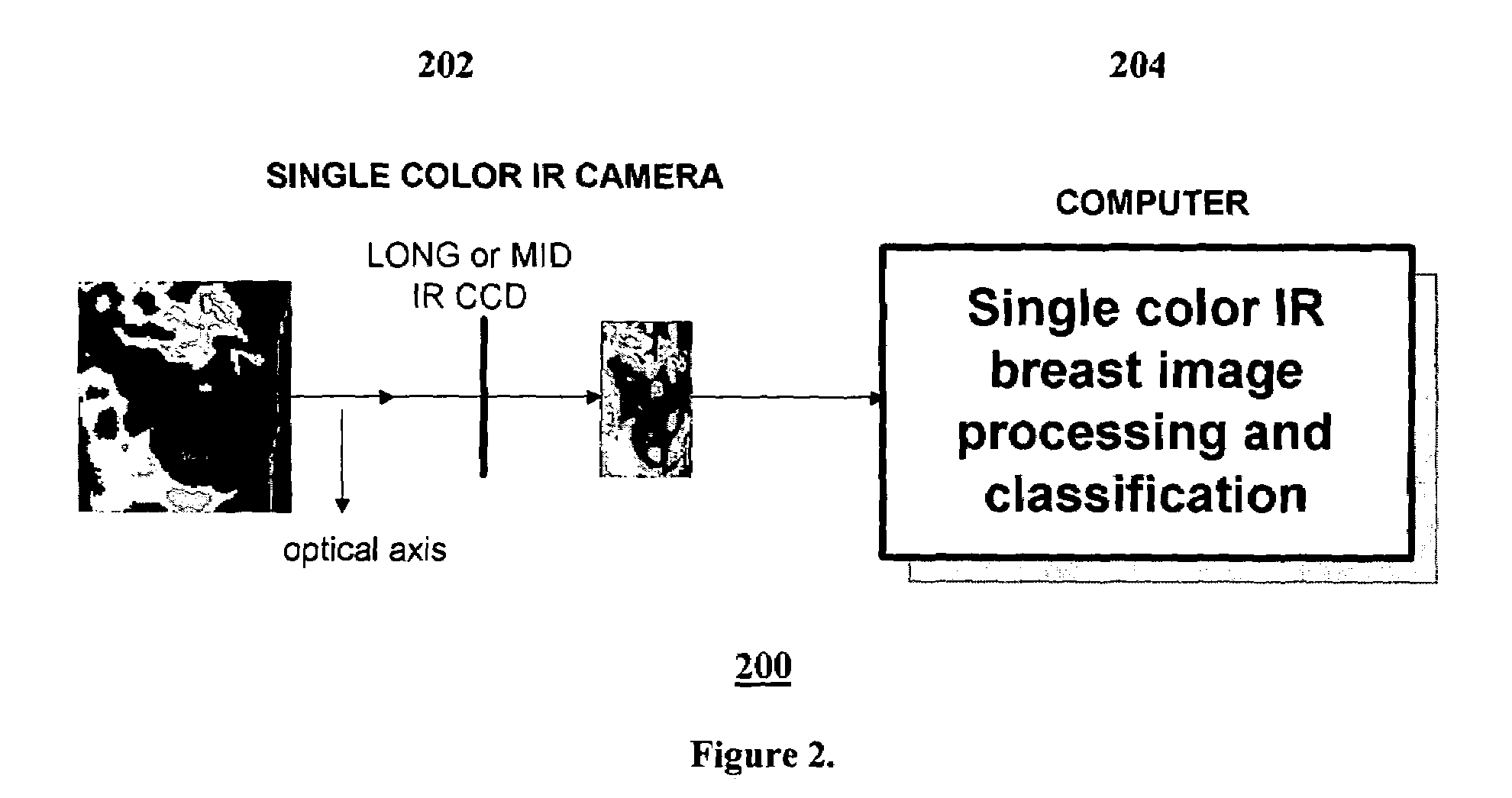

Nonlinear blind demixing of single pixel underlying radiation sources and digital spectrum local thermometer

InactiveUS7366564B2Sensitive and accurateIncrease variabilityMedical data miningImage analysisFrequency spectrumSignal classification

Changes, increase or decrease, in the body fluid flow are passively detected by using a single pixel, non-linear blind de-mixing procedure, which can be extended to general biomedical measurement and diagnoses instruments. More specifically the single pixel, non-linear blind de-mixing procedure is applied on the hot spots of rheumatic arthritis or breast cancer detection problem using passive two-color infrared imaging as well as to passively detect blockages in the body fluid circulatory system that might be of importance for coronary artery bypass surgery, diabetes and deep vein thrombosis. Other applications of the mentioned algorithm include a pair of cameras for video, a pair of antennas for cell phones, and in situ data gathering or imaging using multiple mode fiberoptical sensing as well as selective amplification hearing aids through two-ear binaural processing for de-noise echo cancellation and signal classification.

Owner:THE GOVERNMENT OF THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SEC OF THE NAVY NAVAL RES LAB WASHINGTON

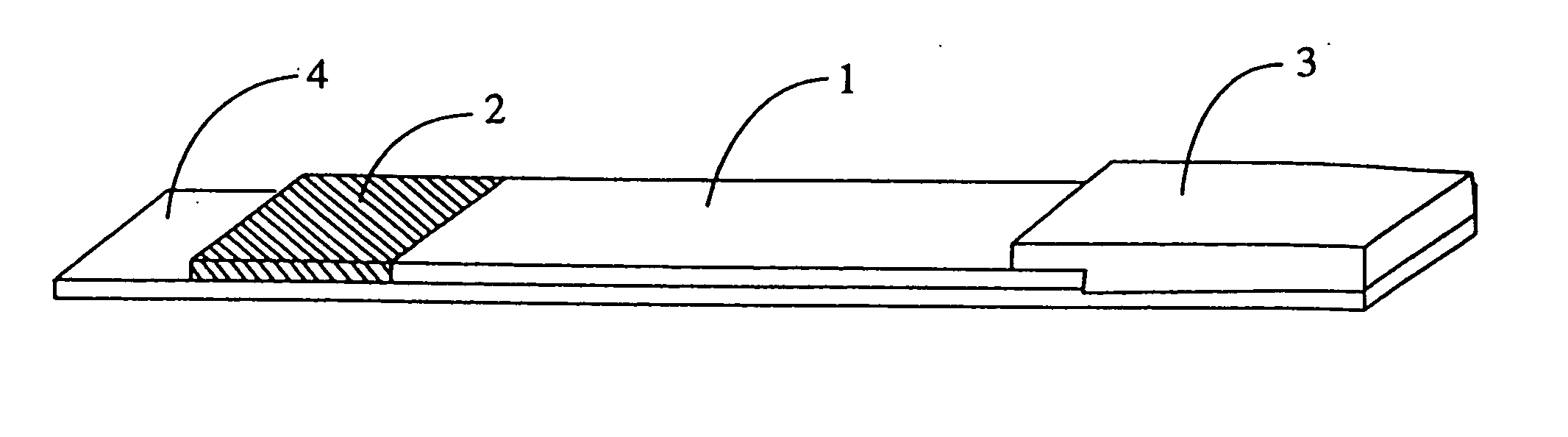

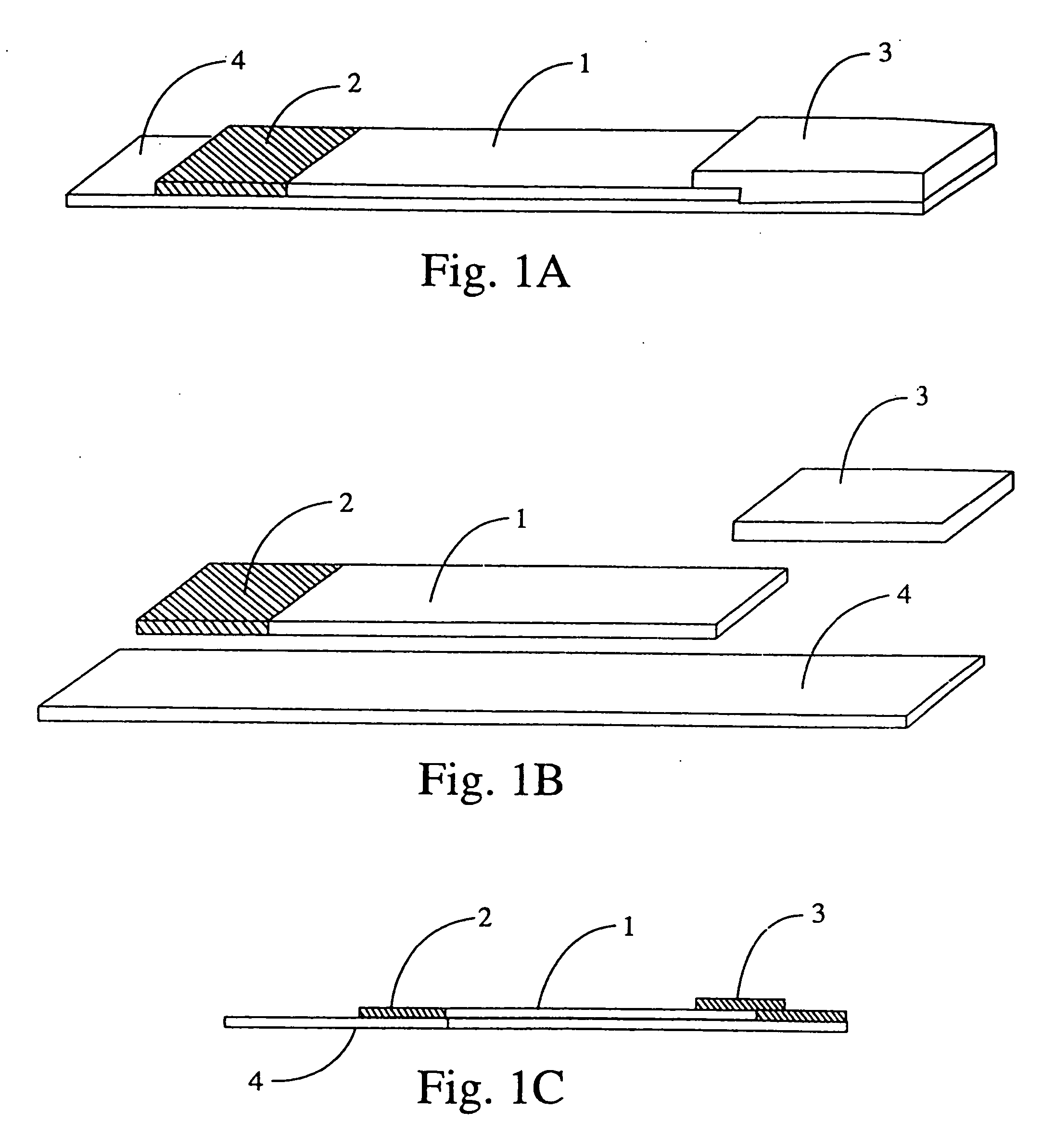

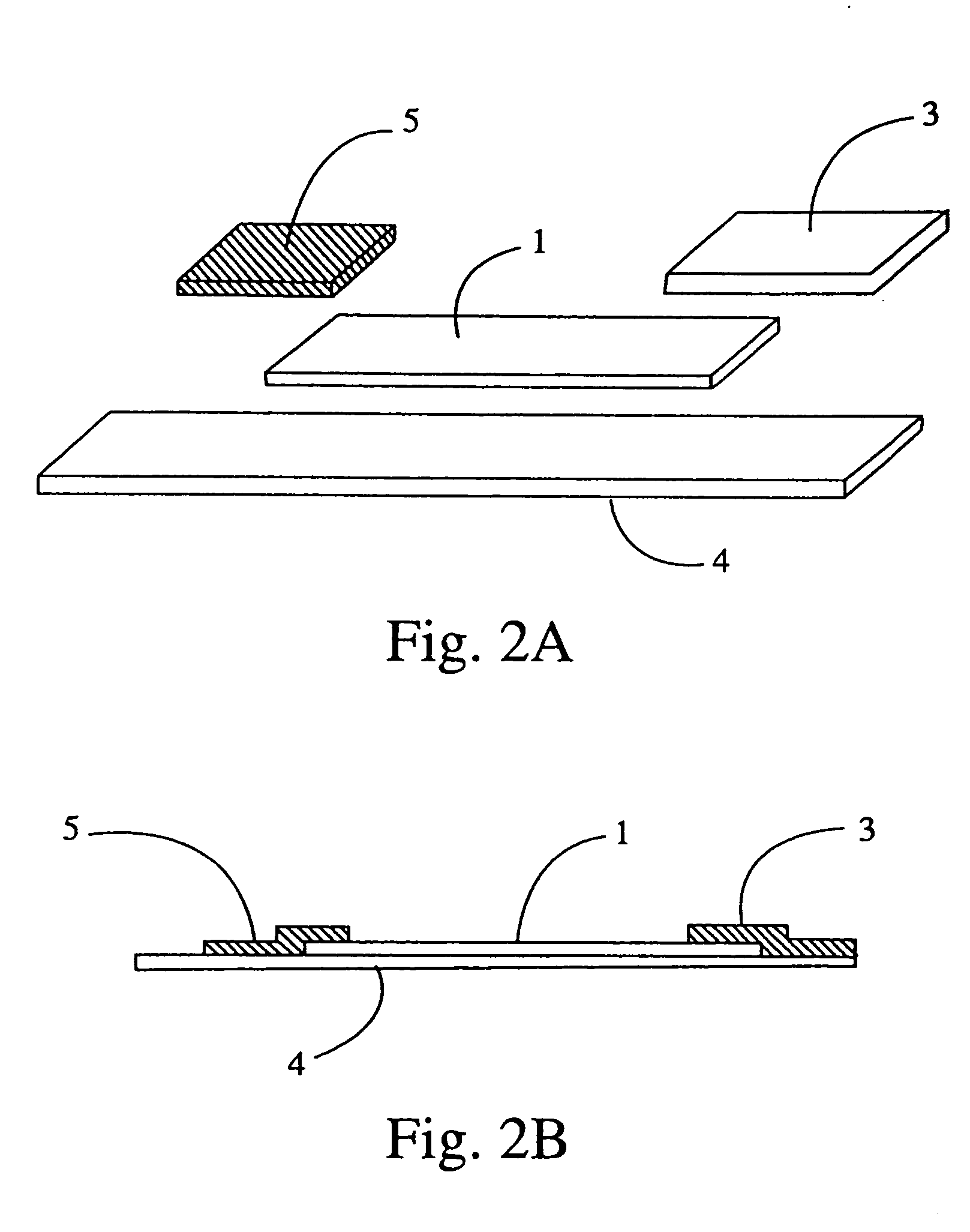

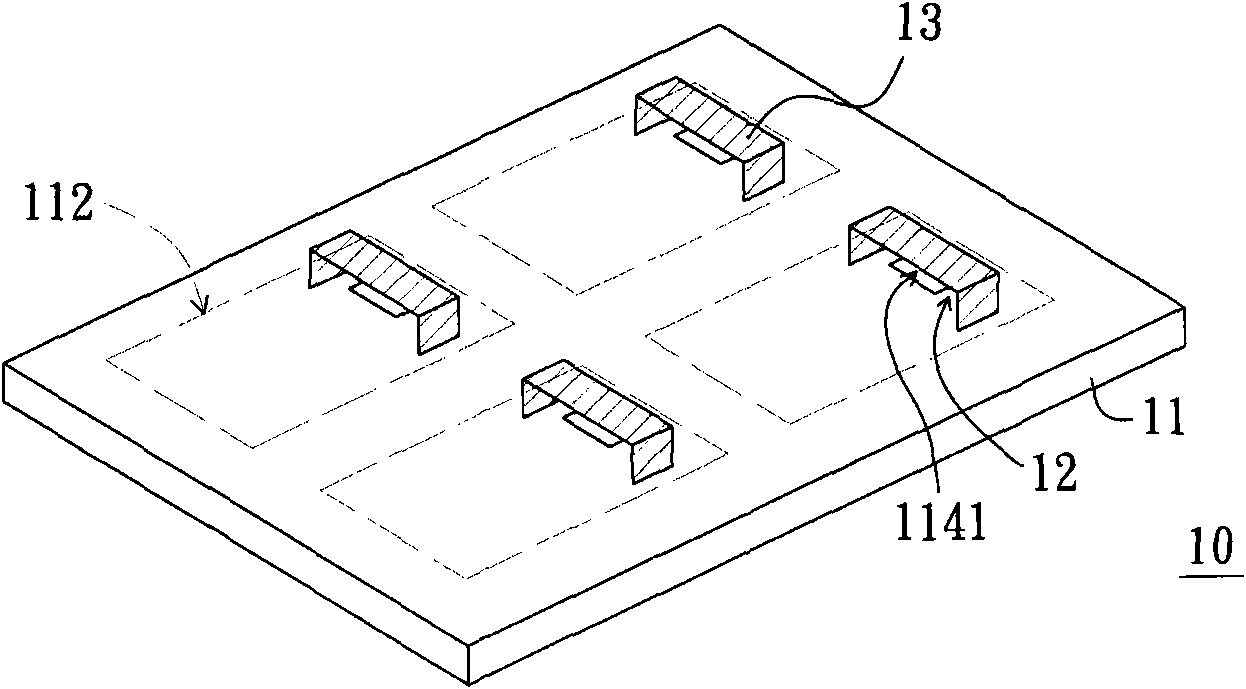

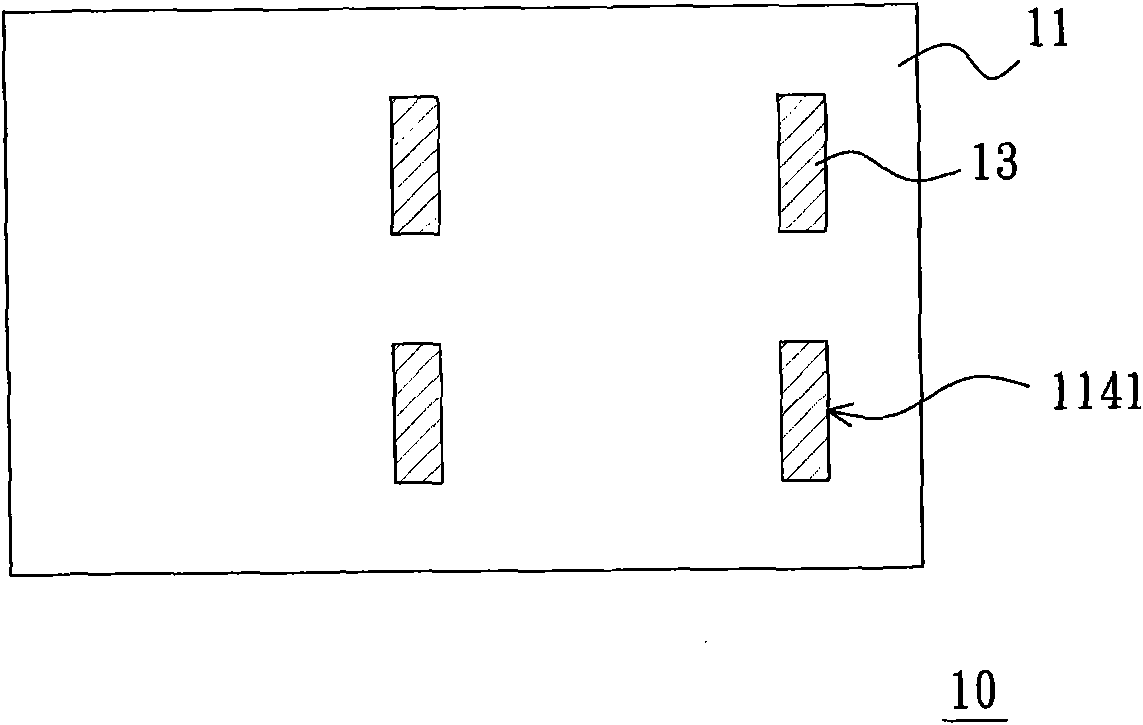

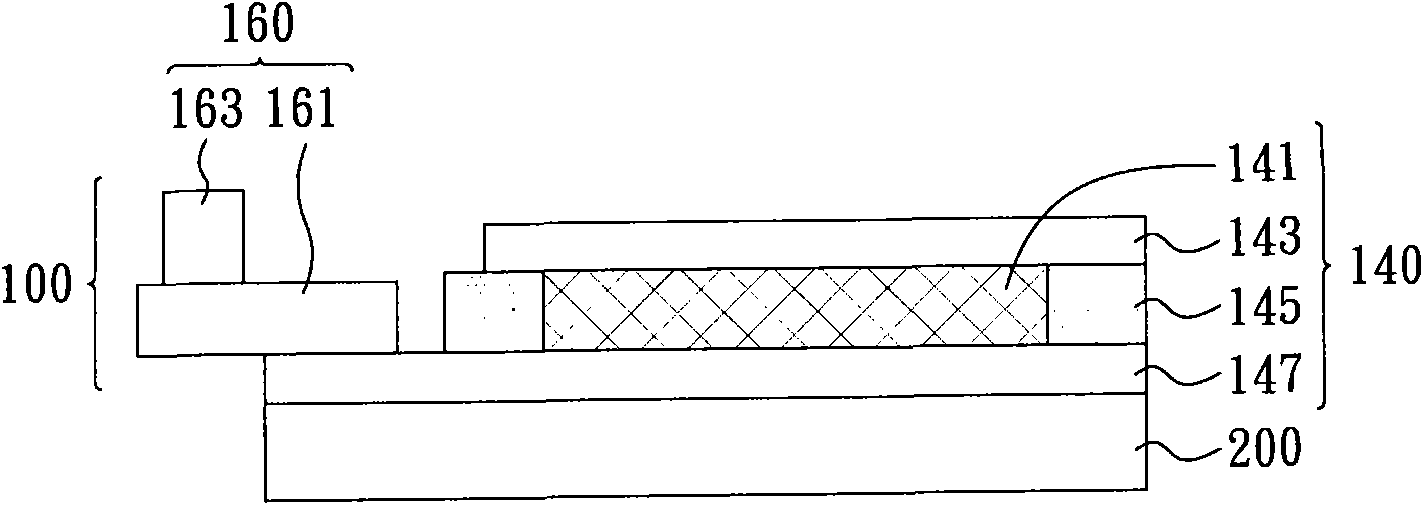

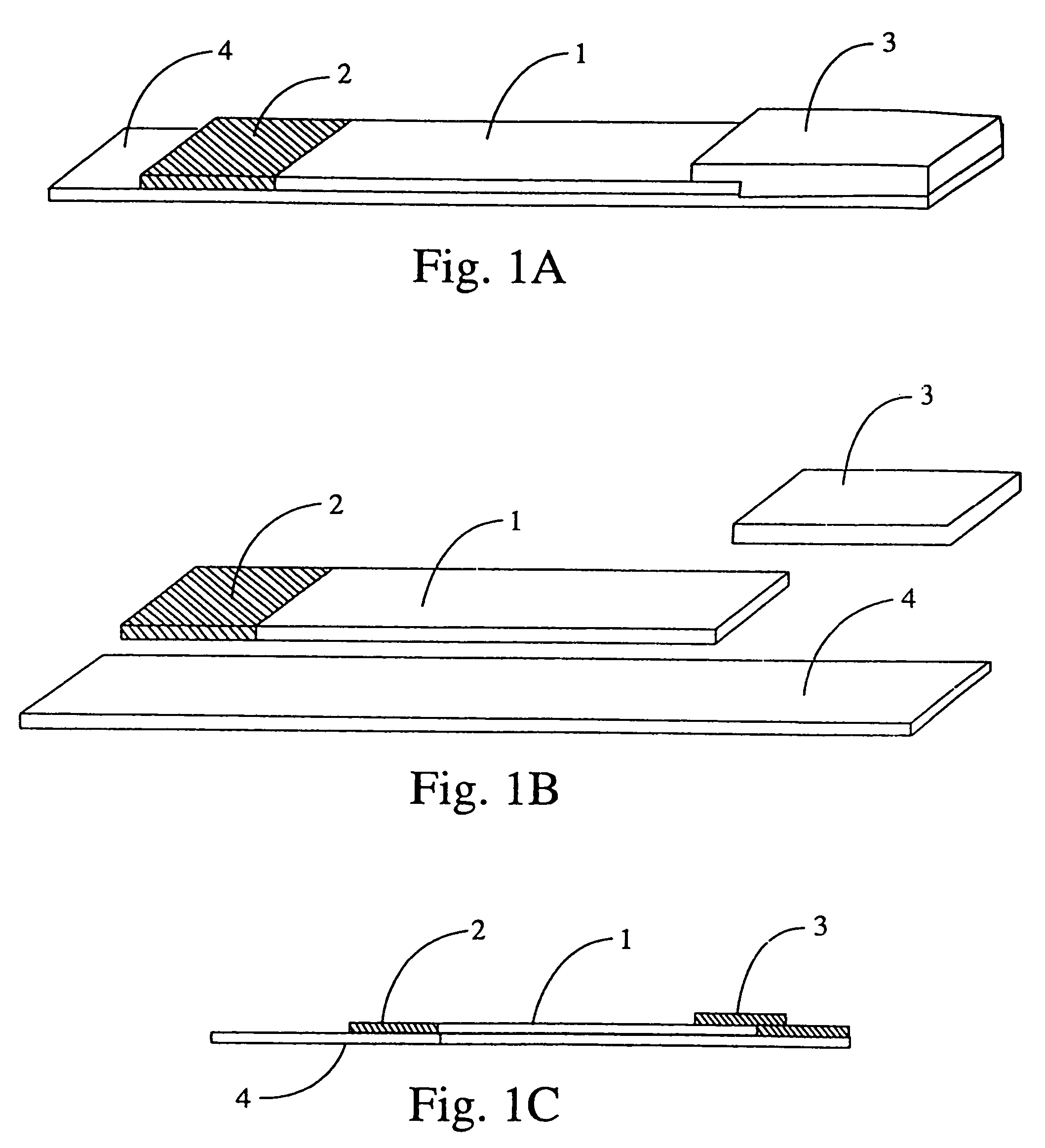

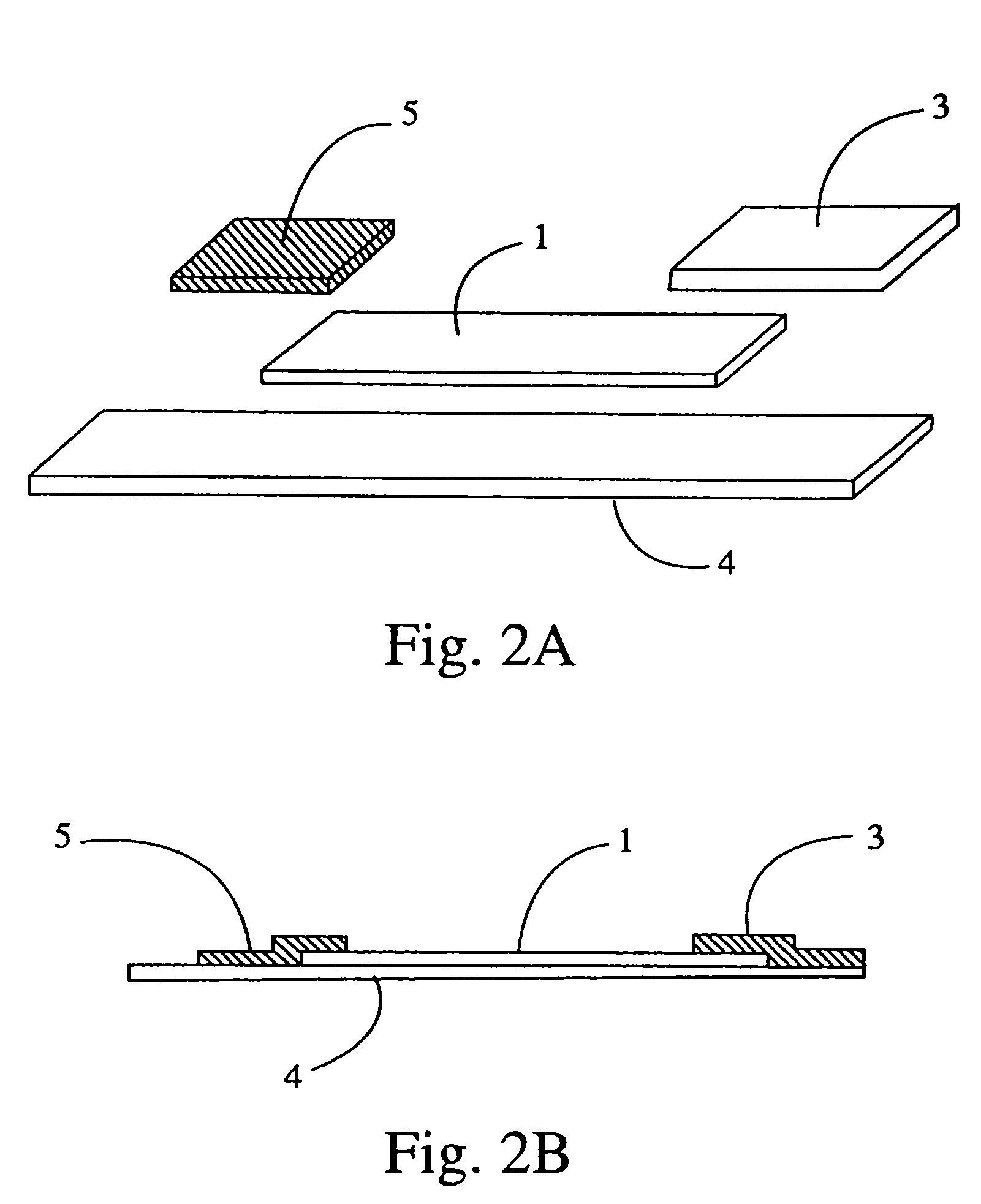

Bearing device and manufacture method of flexible display panel

ActiveCN101574759AImprove production rateAvoid damageWelding/cutting auxillary devicesAuxillary welding devicesEngineeringFlexible display

The invention relates to a bearing device and a manufacture method of a flexible display panel. The bearing device is suitable for a laser separation procedure and bears at least one flexible display panel. The flexible display panel is formed on a transparent substrate and comprises a display body and a drive circuit die set. The bearing device comprises a bearing plate and at least one protection cover, wherein the bearing plate is provided with at least one bearing area for bearing the flexible display panel, and the protection cover is arranged on the bearing plate and positioned at the edge of the bearing area. A containing space is formed between the protection cover and the bearing plate for containing the drive circuit die set. The protection cover covers the drive circuit die set to prevent laser from irradiating on the drive circuit die set. The manufacture method of the flexible display panel comprises the following steps: the flexible display panel is manufactured on the transparent substrate and comprises the display body and the drive circuit die set connected with the edge of the display body; the drive circuit die set of the flexible display panel is covered; and the laser separation procedure is carried out to separate the transparent substrate and the flexible display panel. The invention can prevent the laser from damaging the drive circuit die set and enhance the qualified rate of the flexible display panel.

Owner:E INK HLDG INC

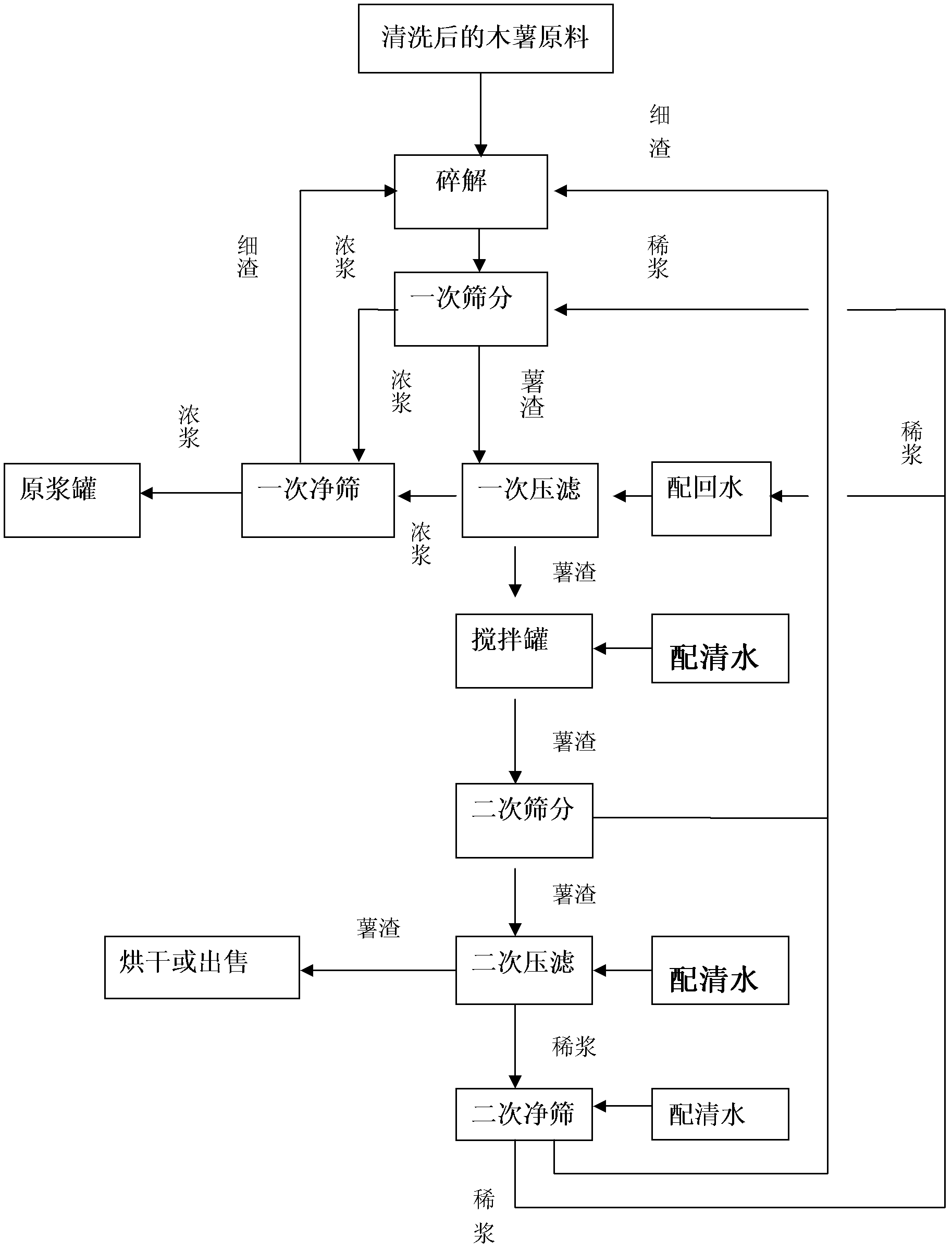

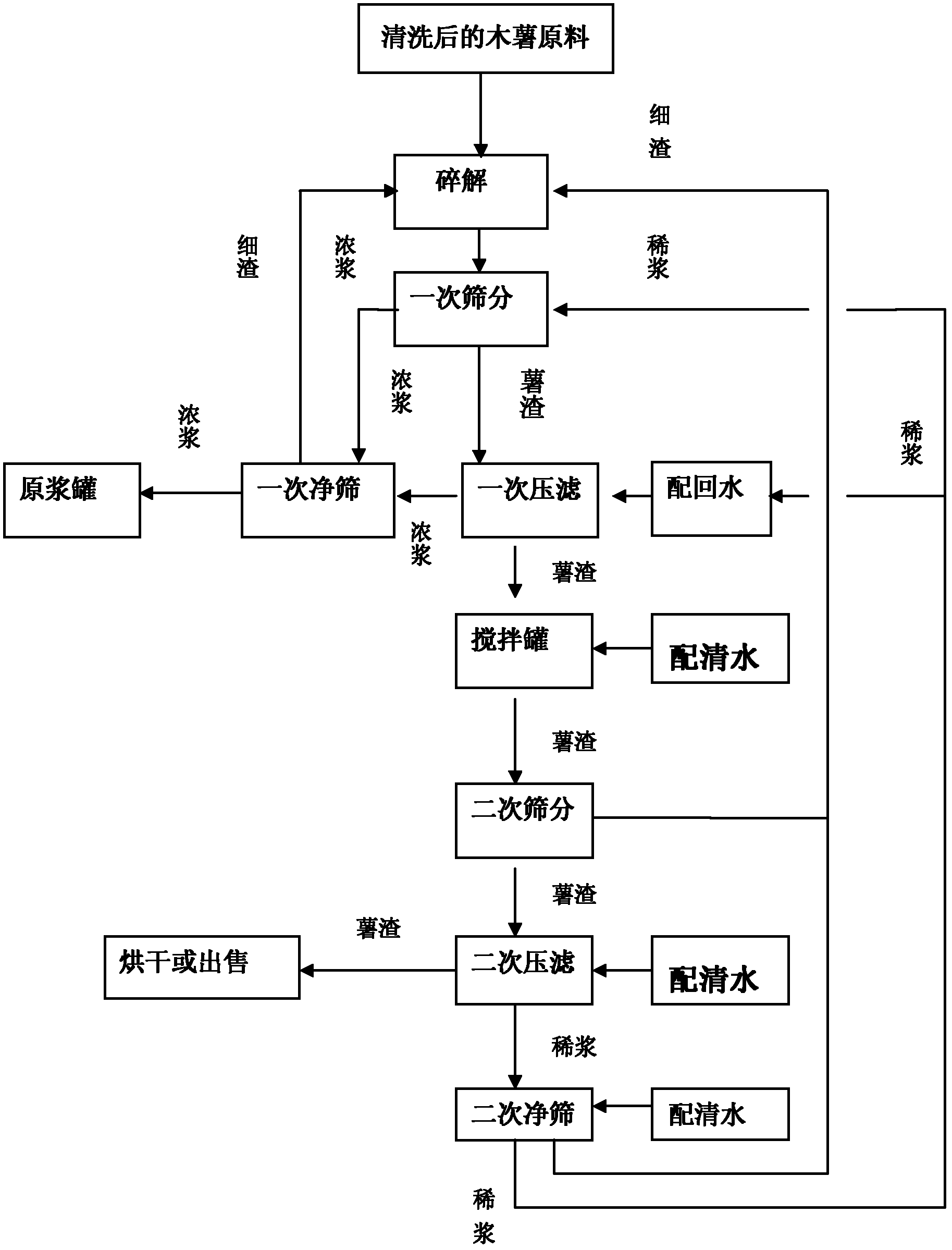

Tuberous starch slurry-residue separation technique by screening and pressure filtration

The invention provides a tuberous starch slurry-residue separation technique by screening and pressure filtration, which modifies slurry-residue separation procedures in tuberous starch production, and combines a vertical screen, a filter press and screen cleansing into a complete stereoscopic elevation difference technological process, wherein the vertical screen is used for separating residues from slurry by means of centrifugal force, the filter press is used for separating the residues from the slurry by means of extrusion force, and the vertical screen and the filter press in matched use can avoid the problem of poor cleanliness when tuberous residues are treated by vertical screen equipment, so that slurry-residue separation effect can be more effectively improved, feeding once is achieved, and multiple procedures including matched use of the emulsion slurry, the residues and process water, pressure drying of the tuberous residues can be completed by means of multiple screening and pressure filtration. Besides, power, automation, the amount of equipment, process water consumption and labor forces can be greatly reduced, the technique has the advantage of saving of operation cost and energy, emulsion slurry concentration is improved, starch extraction ratio is increased, and good technical effect is achieved.

Owner:南宁红枫王淀粉设备有限公司 +1

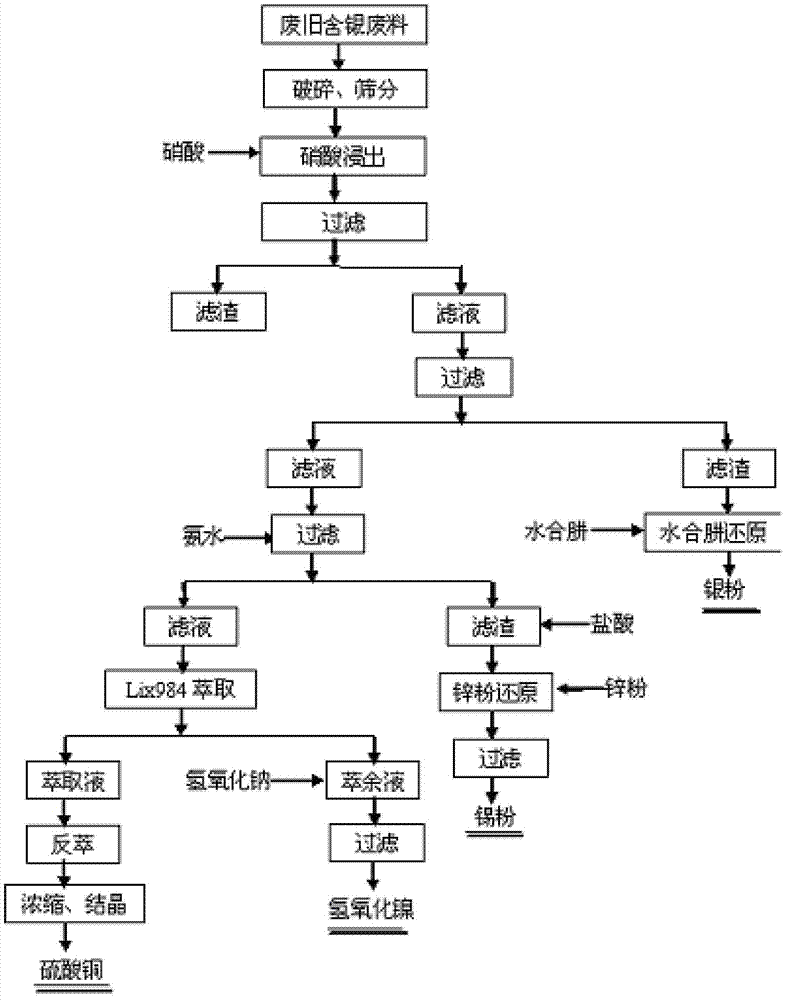

Method for recovering silver or other metals from silver-containing wastes

The invention discloses a method for recovering silver or other metals from silver-containing wastes. The method comprises a physical-process treatment procedure, a nitric acid dissolution procedure, a silver separation and recovery procedure, a tin separation and recovery procedure, a copper separation procedure, and a nickel recovery procedure. By entirely adopting a wet-process recovery technique, all metals can be recovered while the high energy consumption and high pollution defects of the traditional recovery technique can be avoided, and the low-cost and high-efficiency recovery can be realized.

Owner:GUANGDONG BRUNP RECYCLING TECH +1

Preparation method of chili seed antibacterial peptide

InactiveCN105132506AFast preparationReduce manufacturing costPeptide preparation methodsFermentationProteinase activityProtease

The invention discloses a preparation method of chili seed antibacterial peptide. The method comprises the following steps: extracting chili seed crude proteins; carrying out the enzymolysis on the chili seed crude protein by utilizing a food enzymatic agent; separating antibacterial peptide in enzymatic liquid by utilizing the interaction of the antibacterial peptide and bacteria and combining gel chromatography, to obtain the chili seed antibacterial peptide. The antibacterial peptide obtained by utilizing the protease to hydrolyze the chili seeds has characteristics of high safety and high antibacterial performance and has potential application value in the industries such as food, feed, cosmetics and the like. By utilizing the characteristic that the antibacterial peptide is combined with the bacteria, the target separation is realized, the weaknesses of the conventional antibacterial peptide that the separation procedures are complicated and a great amount of chemical reagents are used during the process can be overcome. A chili processed byproduct is used as a raw material, so that the usability of the chili seed resource can be improved.

Owner:KUNMING UNIV OF SCI & TECH

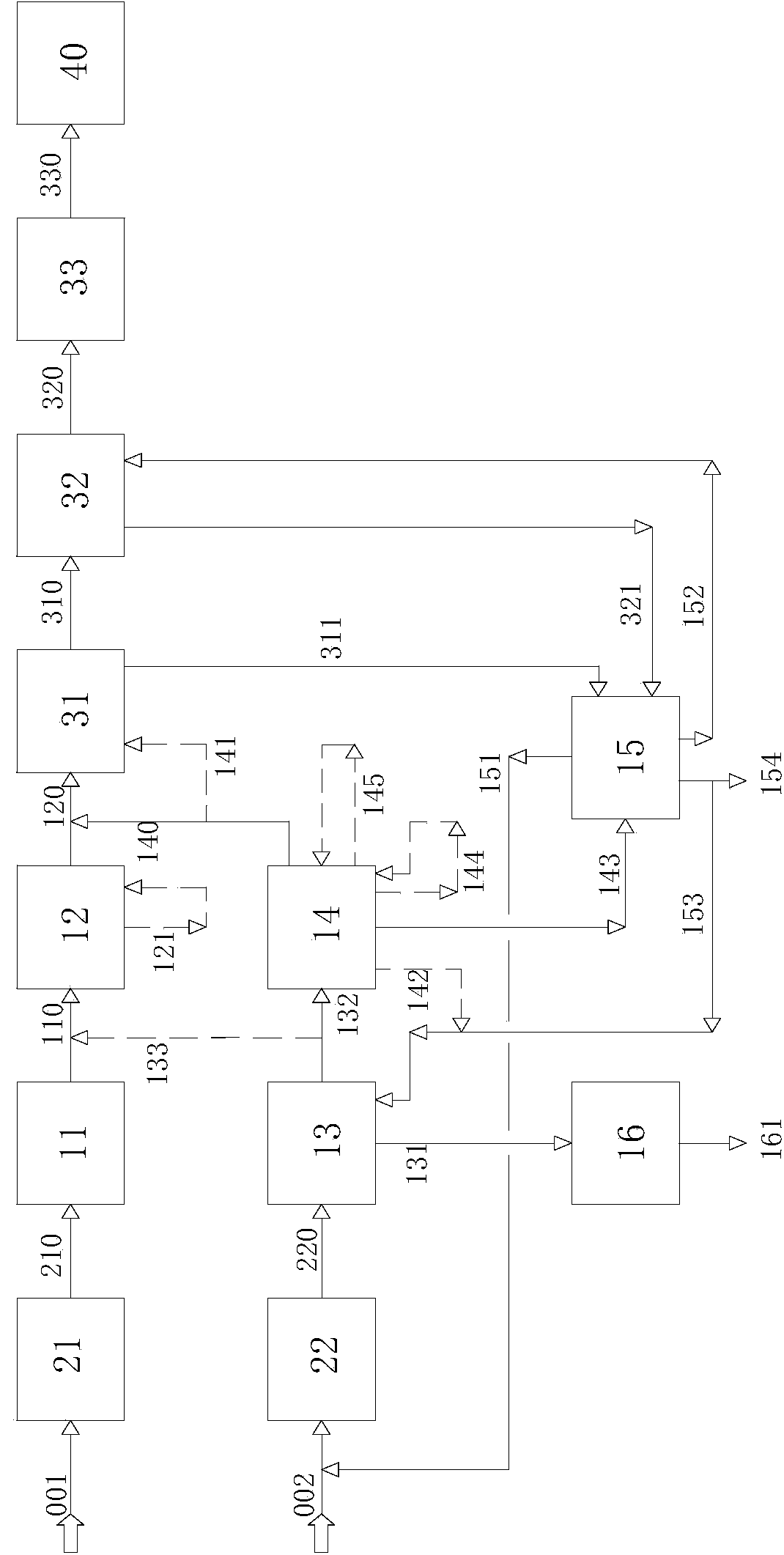

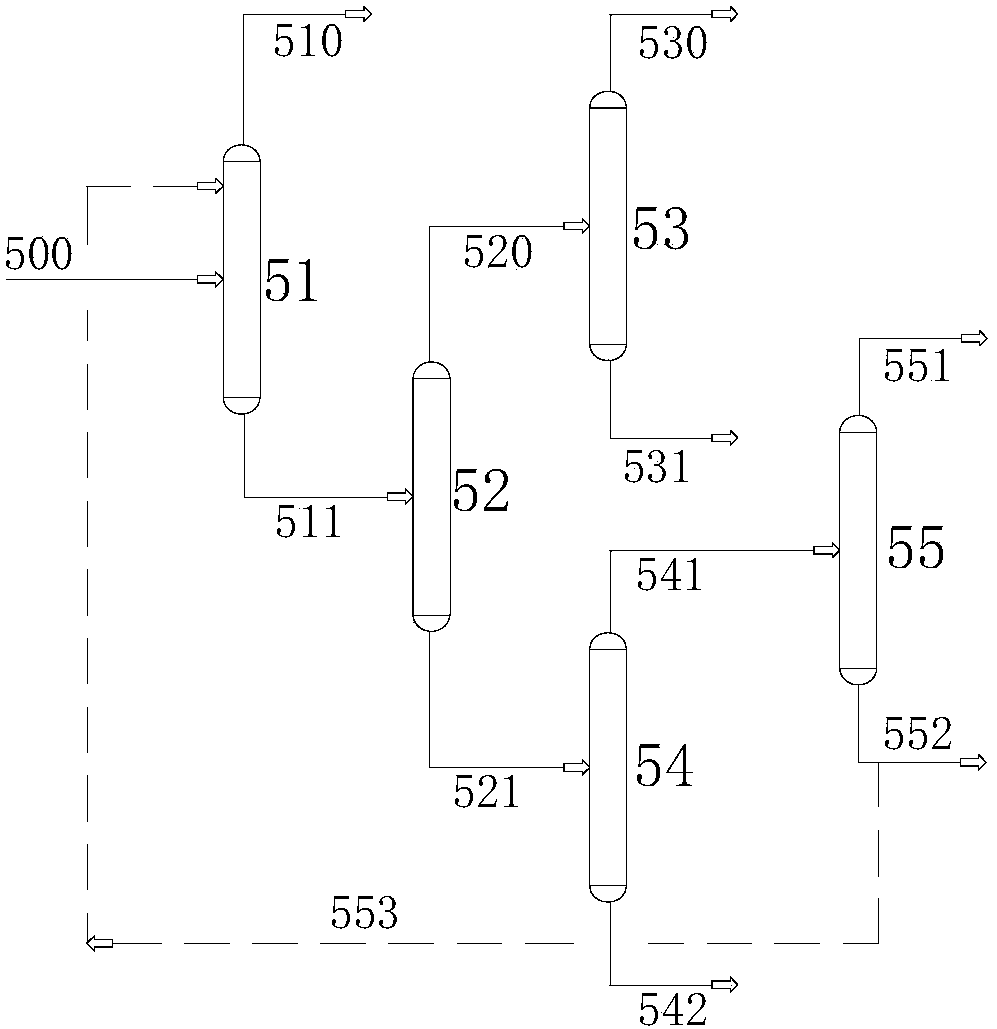

MTO (methanol toolefin) and steam crackingto olefin mixed separation technology

InactiveCN103964990ADistillation purification/separationHydrocarbon from oxygen organic compoundsSeparation technologyAlkene

The invention relates to an MTO (methanol toolefin) and steam crackingto olefin mixed separation technology. Thetechnology comprises an MTOtechnology and a steam cracking toolefin technology. Thetechnology is characterized in that reaction gases produced by an MTO reaction are subjected to cooling and oxide recovery, then are mixed with reaction gases produced by a steam cracking reaction and enter a same separation system forhydrocarbon separation. Compared with the prior art, the technology has the advantages that products of both the MTO reaction and the steam crackingto olefin reaction are mixed at a proper mixing point and then enter same separation procedures, the problem of recovery of oxides in the MTO reaction gases is solved, and different separation procedures are selected according to composition of the reaction gases after mixing. The MTO substitutes for partial or all capacity of thermal crackingto olefin, meanwhile, equipment of an original steam cracking device is used to the maximum extent, and the technology is a feasible method for broadening sources of raw materials of existing steam-crackingethylene devices and reducing high production costs of the existing ethylene devices.

Owner:WISON ENG

Method for the direct detection of diagnostic RNA

Methods for the direct detection of diagnostic target RNA have been developed, which obviate the need for time consuming RNA purification and isolation procedures.

Owner:QUALICON DIAGNOSTICS LLC

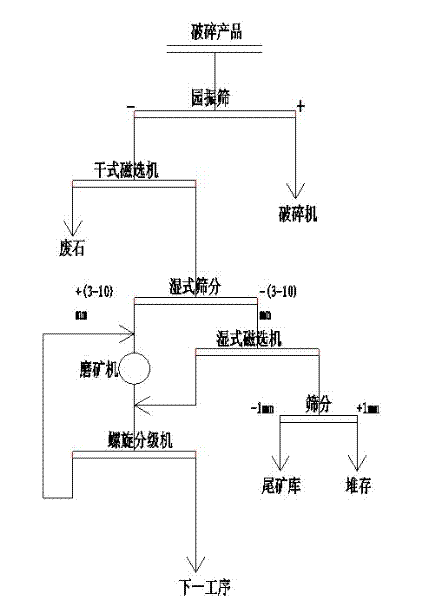

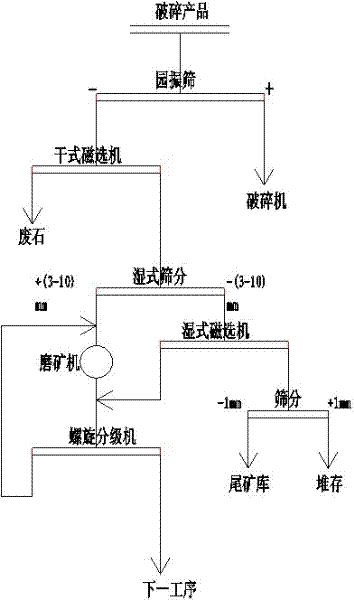

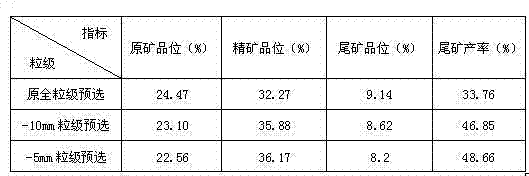

Preliminary separation process for ferromagnetic ore separation

The invention discloses a preliminary separation process for ferromagnetic ore selection, which comprises the following steps of: (1) screening crushed raw ore, returning the oversize product to a crushing machine and crushing, directly performing dry magnetic separation on the undersize product to magnetically separate dry magnetic separation concentrates and dry magnetic separation tailings, and taking the dry magnetic separation tailings as waste ore; (2) performing wet screening on the dry magnetic separation concentrates by using a 3-10 mm screen, performing wet magnetic separation on the undersize product to magnetically separate wet magnetic separation concentrates and wet magnetic separation tailings, grinding the oversize product in a grinding machine, and grading the grinding products; (3) directly grading the wet magnetic separation concentrates, and taking the wet magnetic separation tailings as final tailings; and (4) returning coarse products obtained through grading to the grinding machine and grinding again, forming the closed grinding-grading cycle, and leading overflow products obtained by grading to the next procedure of the ore separation process. The preliminary separation process provided by the invention has the advantages of reasonability of allocation, smoothness of flow, stability of operation, capability of realizing full and reasonable tailing casting and increased productivity and metal recovery rate of the preliminary separation procedure.

Owner:HEBEI IRON & STEEL GRP MINING +1

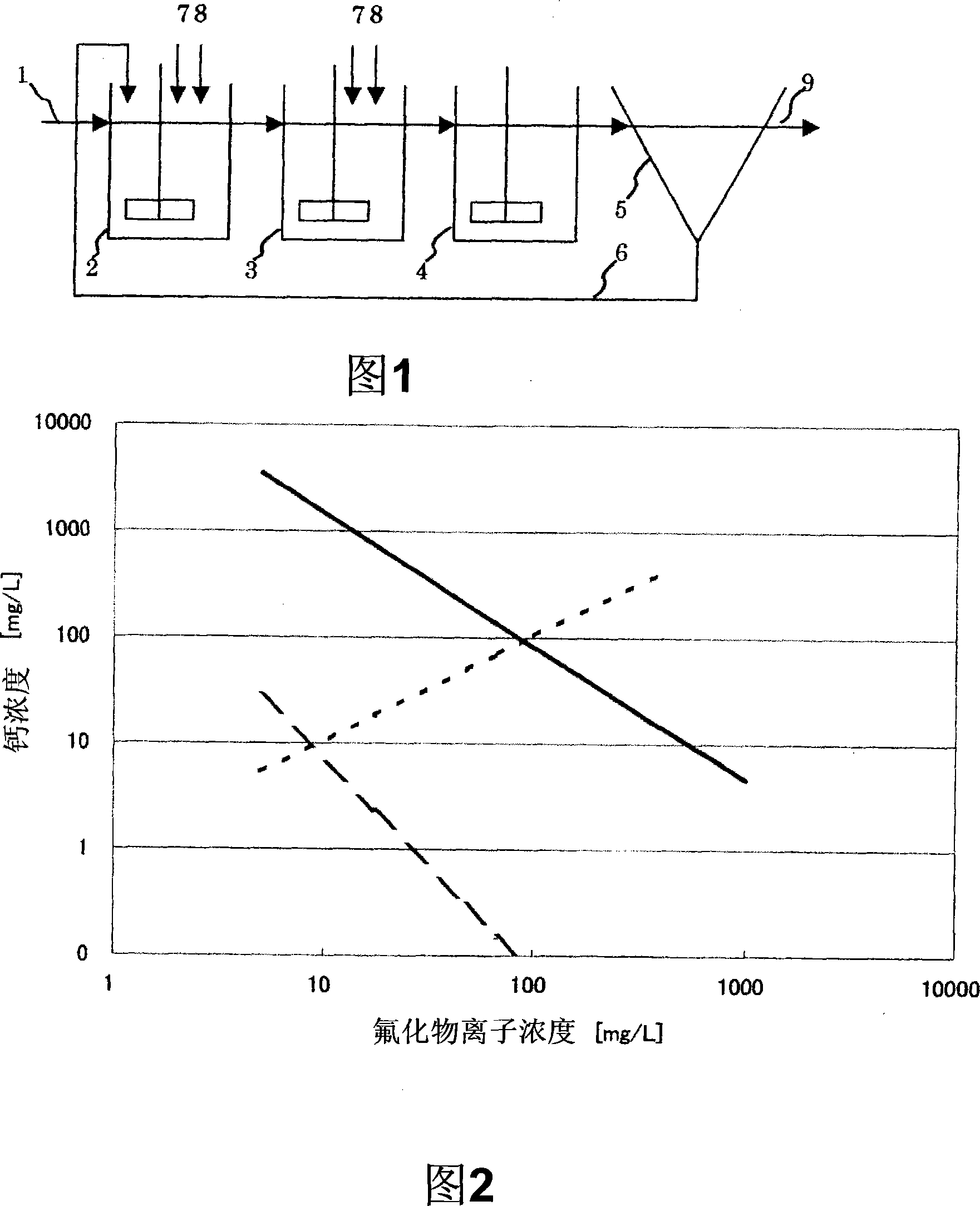

Method for treating fluoric containing drainage

InactiveCN101157507AAdd lessSuppress generationWater treatment parameter controlWater contaminantsSludgeWater quality

The invention provides a treatment method for fluoride-containing wasterwater, which can inhibit precipitation of fine calcium fluoride to get stable treated water and produce sludge with low miosture content in less procedures. The treatment method includes: a reaction procedure of adding calcium compound into the fluoride-containing wasterwater to produce insoluble with calcium fluoride, a separation procedure of performing solid-liquid separation between the sludge with calcium fluoride insoluble and separation water, a sludge return procedure of returning the separated sludge used as returning sludge to the reaction procedure. In the reaction procedure, calcium compound, the equivalent of which is less than the equivalent of the fluoride compound ions, is added to the reaction groove of the first section by using two series connected reaction grooves, to ensure that the density of the calcium ions residues is more than 1 milligram per litre and less than 5 milligram per litre, and the density of the fluoride compound ions residues is less than 80 milligram per litre; calcuim compound, the equivalent of which is more than the equivalent of the fluoride compound residues in the reaction groove of the first section, is added to the reaction groove of the second section, to ensure that the density of the fluoride ions is less than 15 milligram per litre.

Owner:KURITA WATER INDUSTRIES LTD

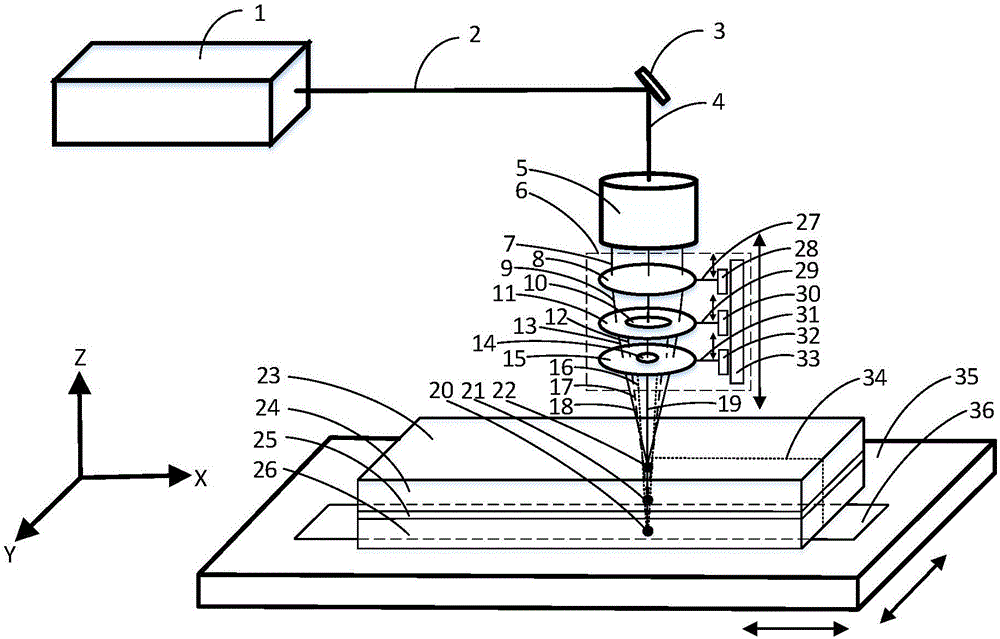

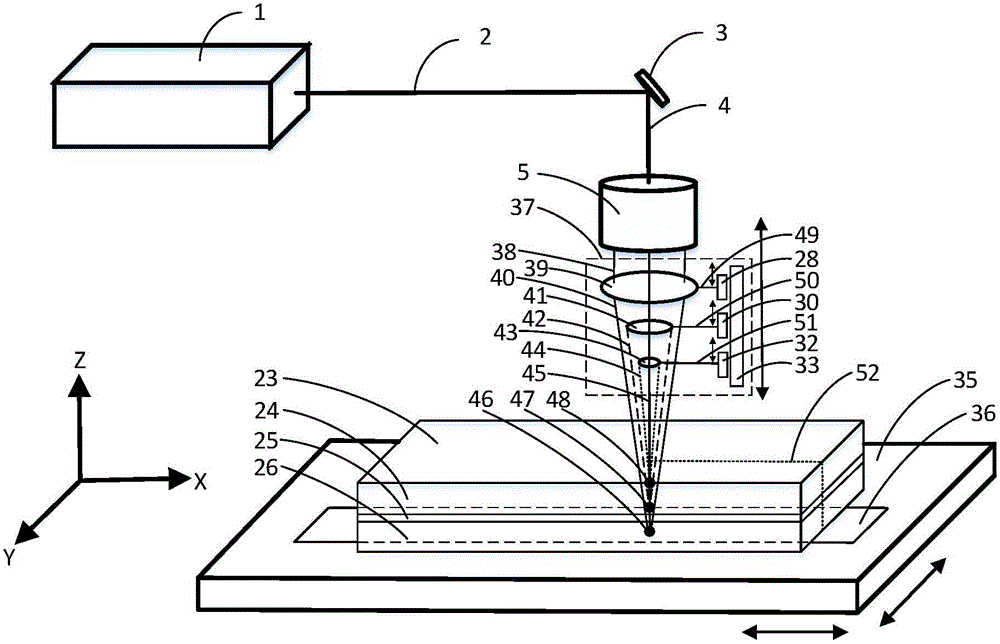

Multi-focus laser laminated glass separating method and device

ActiveCN106271111ASimple processIncrease productivityWelding/soldering/cutting articlesLaser beam welding apparatusOptoelectronicsBeam collimation

The invention discloses a multi-focus laser laminated glass separating method and device. According to the method, a laser beam with transmissivity on laminated glass is adopted; by means of a multi-focus lens set, the laser beamproduces a plurality of focuses to enter the laminated glass, and each layer of glass and each glueing material layer of the laminated glass are provided with at least one laser focus; under the action of the laser focuses, the glass layers and the glueing material layers are separated, the glass layers and the glueing material layers of the laminated glass are cut and separated at the same time through multiple laser focuses moving along the separating direction, and the whole laminated glass is cut and separated at the same time. The device comprises a two-dimensional working platform, a laser, a reflector, an expanded beam collimation lens and the multi-focus lens set, wherein the laser, the reflector, the expanded beam collimation lens and the multi-focus lens set are sequentially located on the same light path. By means of the multi-focus laser laminated glass separating method and device, follow-up manual piece breaking is not needed, and the cutting speed is greatly improved; the multi-focus laser laminated glass separating method and device have the advantages of being simple in separation procedures, high in separation speed, good in separation quality, capable of achieving special-shaped separating and mechanization and the like and are especially suitable for cutting and separating the laminated glass for buildings and automobiles.

Owner:HUAZHONG UNIV OF SCI & TECH

Polymerization inhibitor for preventing self-polymerization or co-polymerization of C5 diolefins

InactiveCN1699311AGood inhibition effectHydrocarbon purification/separationHydrocarbonsButylphthalideComposition B

The invention relates to a polymerization inhibitor for preventing self-polymerization or co-polymerization of C5 diolefins, which comprises composition A: diethylhydroxylamine, composition B: tert-butyl pyrocatechol, and solvent, wherein the solvent is selected from benzene, toluene, dimethylbenzene or ethylbenzene, the weight ratio of the composition A and the composition B being (0.5-6):1, the total content of the composition A and the composition B in the polymerization inhibitor being 25-45wt%. Compared with the prior art, the invention can realize better polymerization inhibiting effect, and no extra separation process is needed in the current C5 distillate separation procedure.

Owner:SINOPEC SHANGHAI PETROCHEMICAL CO LTD

Multi-functional and configurable assay

InactiveUS7390675B2Efficiently conserve and isolatesQuick analysisBioreactor/fermenter combinationsBiological substance pretreatmentsSeparation procedureSolution flow

Novel magnetic assay methods and systems. According to a preferred embodiment, a chromatographic medium is provided that is designed to be contacted with a test solution having activated magnetic particles such that the solution flows bilaterally thereacross. A magnetic field, generated by a magnet or electromagnet, is selectively applied to the medium which causes the charged particles to become substantially bound at a site on the medium specified by the position of the magnet, to thus form a captured line or zone. In one preferred embodiment, the magnetic field is applied at the site on the medium at which the test solution is contacted. The assay is multi-configurable and can be modified to suit a particular immuno-separation procedure or application.

Owner:WAVESENSE INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com