Method for recovering silver or other metals from silver-containing wastes

A waste and metal technology, applied in the field of metal resource recycling and regeneration, can solve serious problems, high energy consumption, environmental pollution and other problems, and achieve the effect of low recycling, low pollution and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

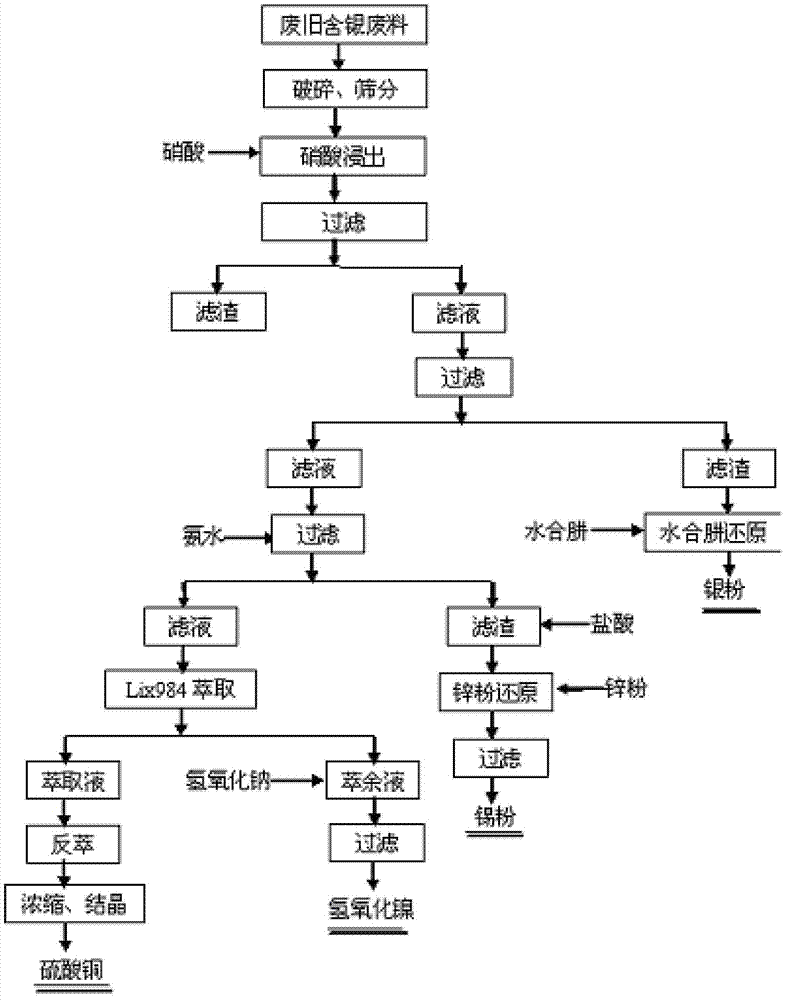

Image

Examples

Embodiment 1

[0039] The first step: take 20Kg of silver-containing waste materials and pulverize them, and sieve them with a 60-mesh standard sieve to obtain silver-containing alloy powders. After testing, the alloy powders contain 54.4% silver, 23.1% copper, 11.7% tin, and 10.8% nickel.

[0040] Step 2: Add 10Kg of silver-containing alloy powder into a 100-liter tetrafluoroethylene-lined reactor, add 40 liters of water, set the reaction temperature to 60°C, and stir at 110 rpm, then continuously add 1:1 nitric acid, carry out nitric acid leaching, the reaction time is controlled at 2 hours, the end point pH is controlled at 2, the leachate is filtered, and the leachate is fixed to 50L. After testing, the leachate contains 107.71g / L of silver and 45.64g / L of copper. Tin 23.07g / L, nickel 21.23g / L.

[0041] Step 3: Add the leaching solution to a 100-liter tetrafluoroethylene-lined reactor, set the reaction temperature to 60°C, and the stirring speed to 100 rpm. The amount of hydrochloric aci...

Embodiment 2

[0046] The first step: get 20Kg of silver-containing waste materials and pulverize them, and then sieve them with a 70-mesh standard sieve to obtain silver-containing alloy powders. After testing, the alloy powders contain 50.6% silver, 23.5% copper, 11.6% tin, and 11.8% nickel. and other substances.

[0047] Step 2: Add 10Kg of silver-containing alloy powder into a 100-liter tetrafluoroethylene-lined reactor, add 40 liters of water, set the reaction temperature to 80°C, and stir at 110 rpm, then continuously add 2.5:1 nitric acid, carry out nitric acid leaching, the reaction time is controlled at 1.5 hours, the terminal pH is controlled at 1.5, the leachate is filtered, and the leachate is constant to 50L.

[0048] Step 3: Add the leaching solution into a 100-liter tetrafluoroethylene-lined reactor, set the reaction temperature to 80°C, stir at 100 rpm, add 1.2 times the theoretical amount of hydrochloric acid, and the reaction time is 3 hours, then filter and wash to obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com