Patents

Literature

202 results about "Annual production" patented technology

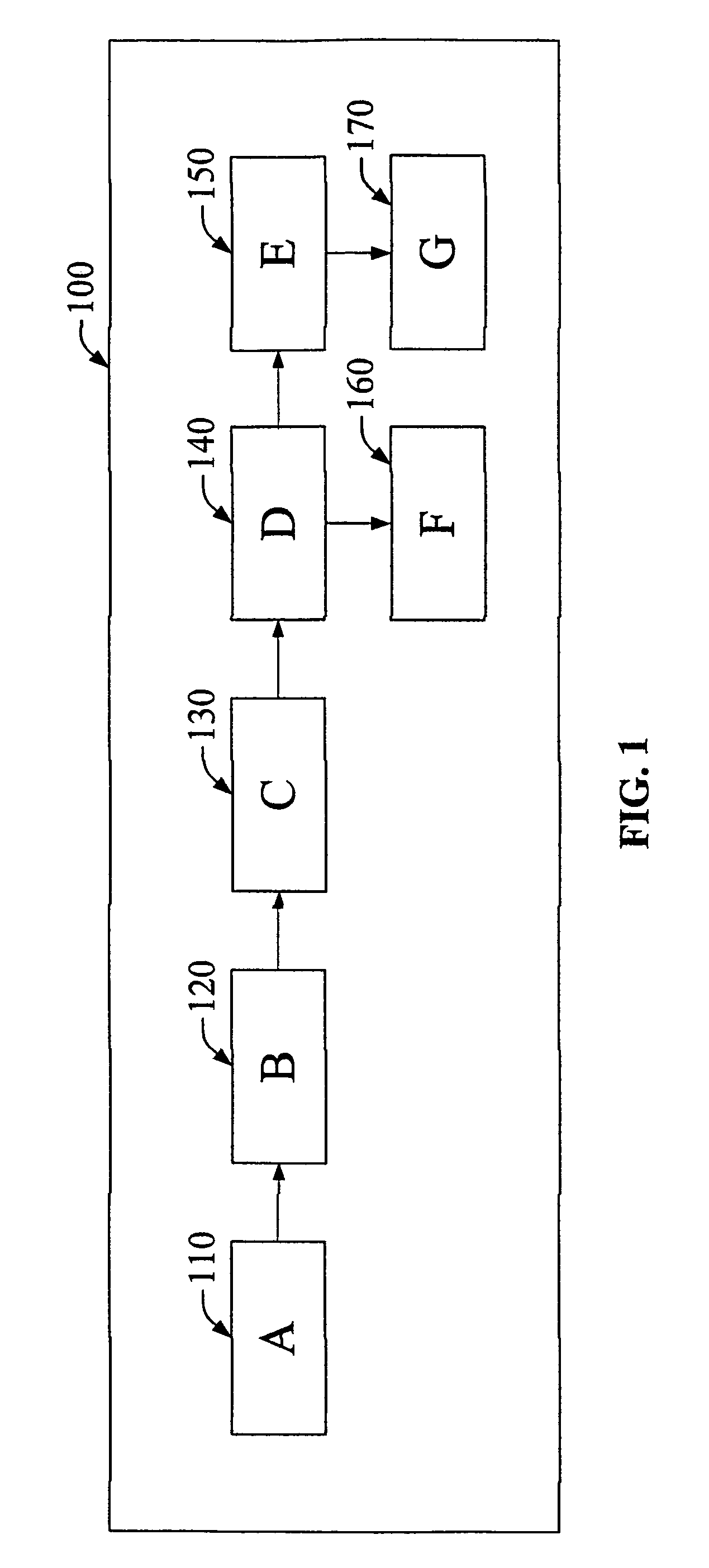

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

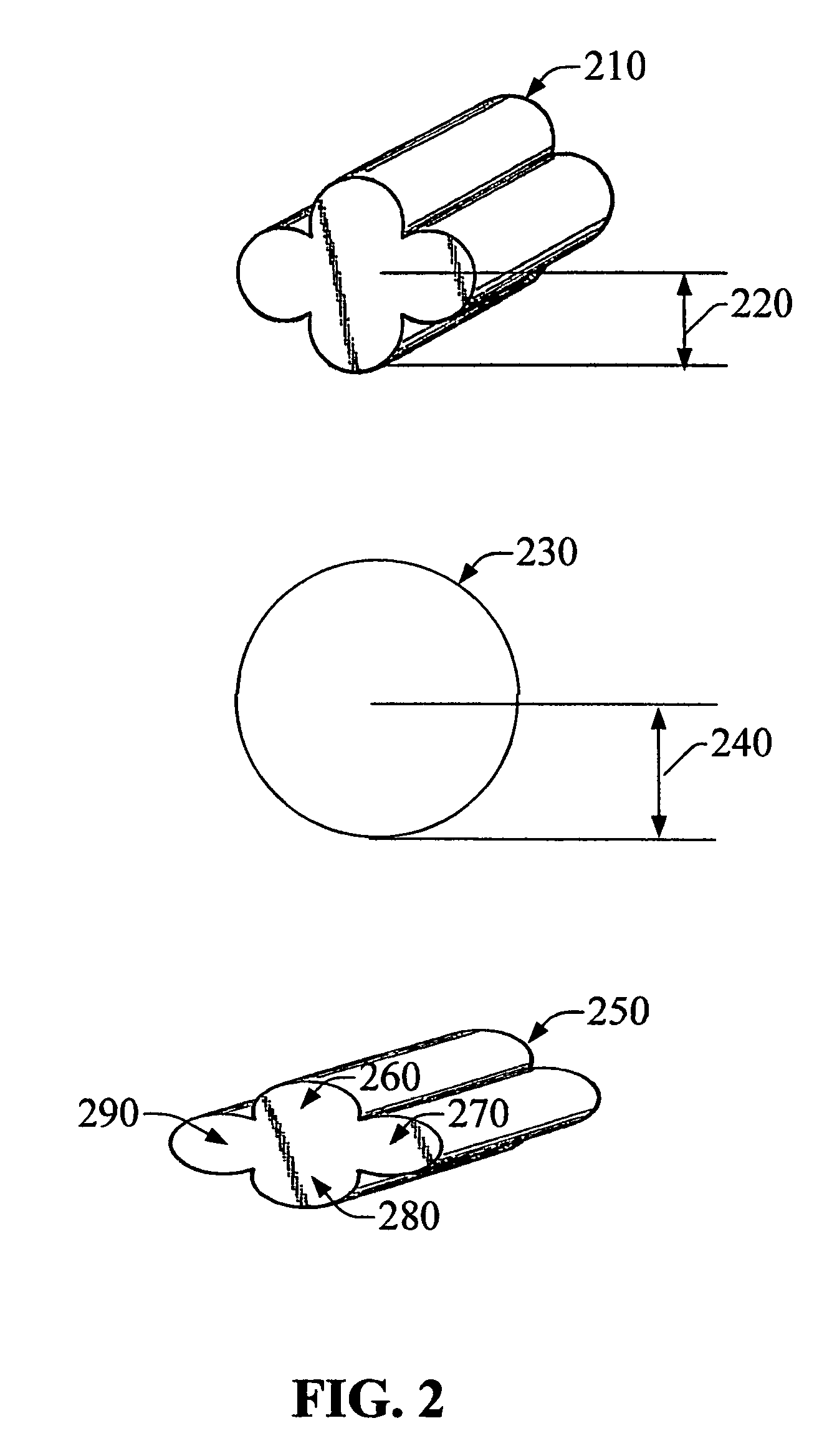

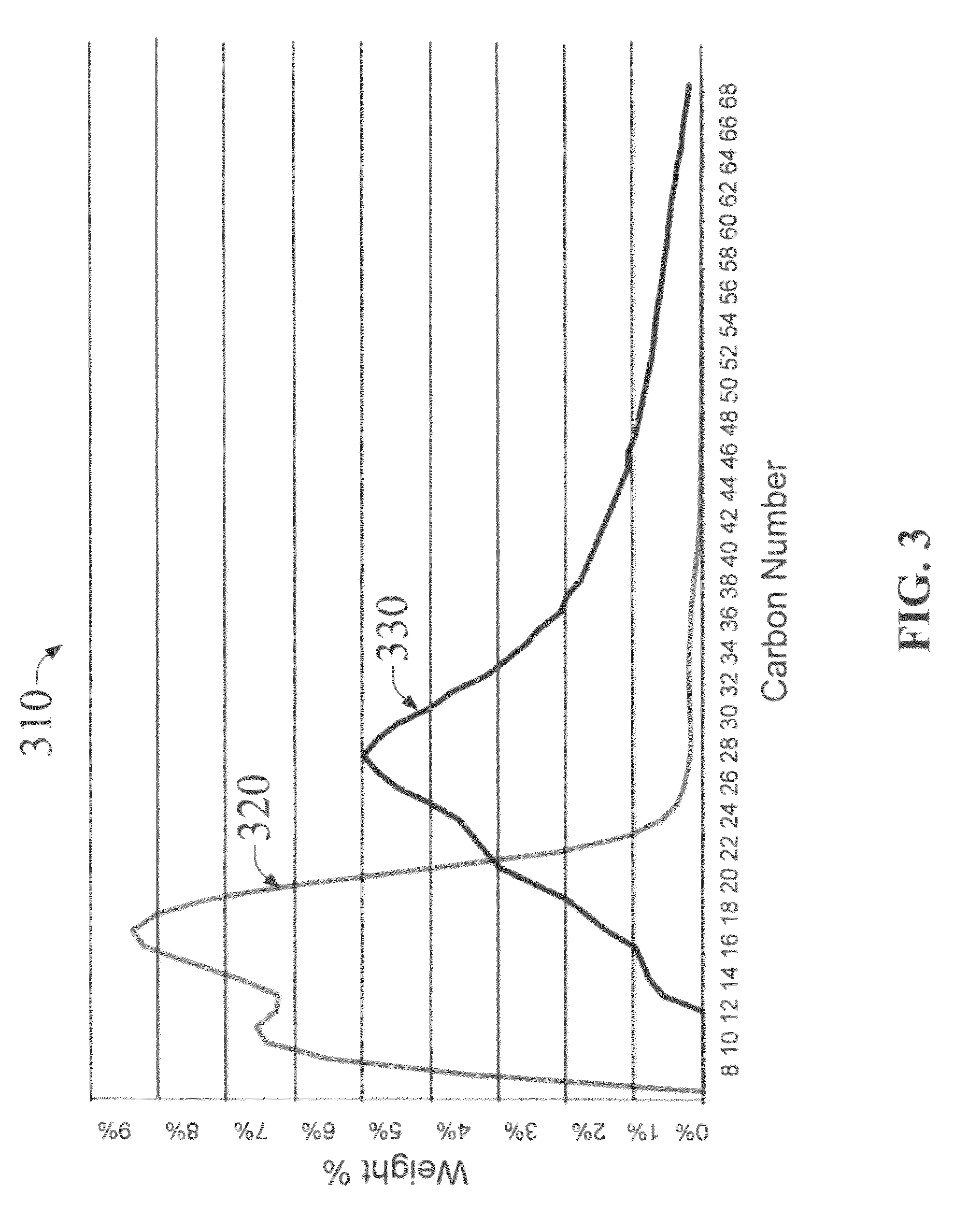

Catalytic process for the direct production of hydrocarbon fuels from syngas

ActiveUS8394862B1High selectivityImprove its cetane contentOrganic compound preparationOxygen compounds preparation by reductionSyngasProcess engineering

A unique process and catalyst is described that operates efficiently at low pressures for the direct production of a high cetane diesel type fuel or diesel type blending stock from stoichiometric mixtures of hydrogen and carbon monoxide. This invention allows for, but is not limited to, the economical and efficient production high quality diesel type fuels from small or distributed fuel production plants that have an annual production capacity of less than 100 million gallons per year by eliminating traditional hydrocracking and other costly upgrading processes. This catalytic process is ideal for distributed diesel fuel production plants such as biomass to fuel production plants and stranded natural gas to diesel fuel production plants, and other applications that require optimized economics based on supporting distributed feedstock resources.

Owner:GREYROCK TECH LLC

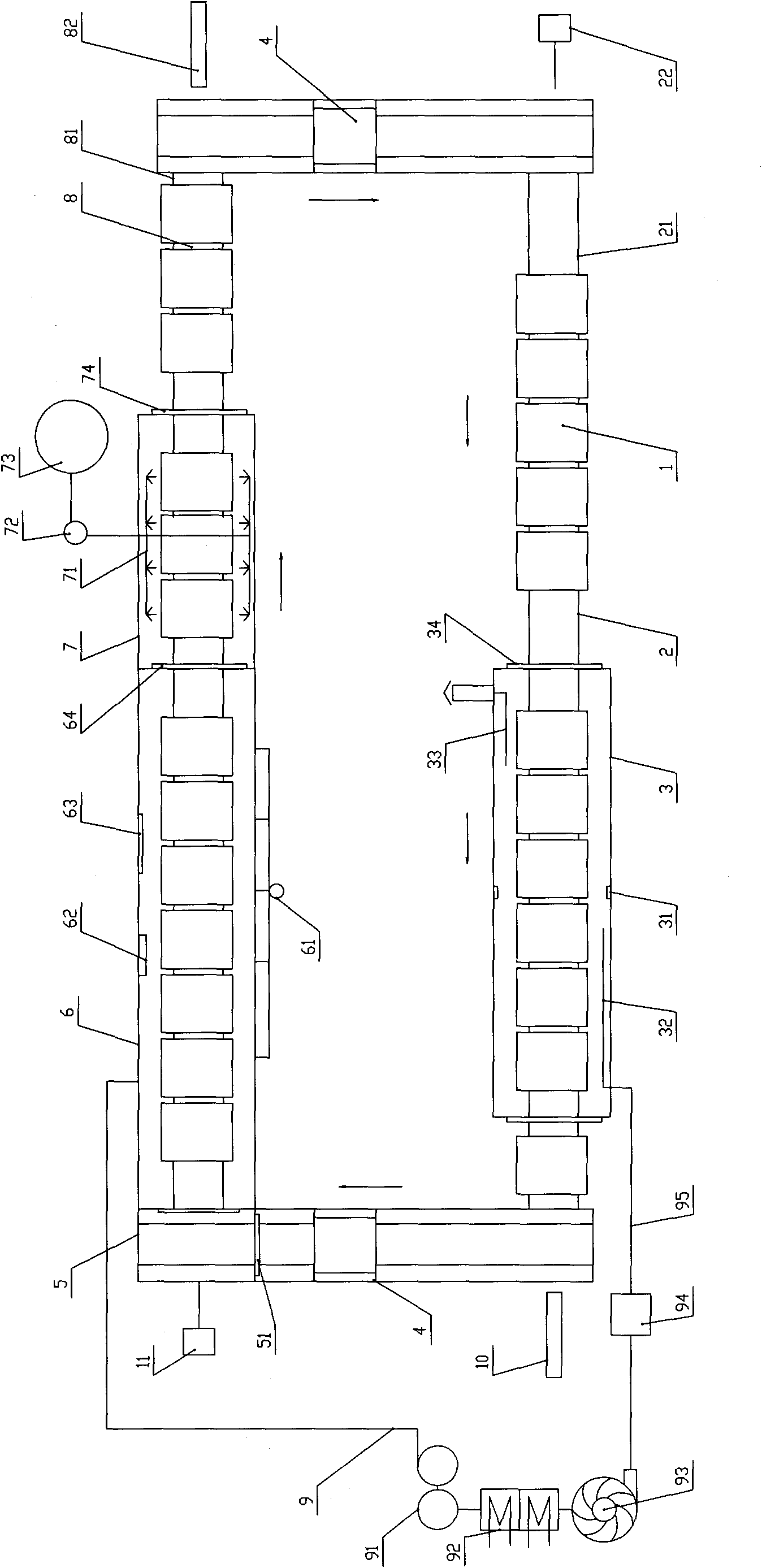

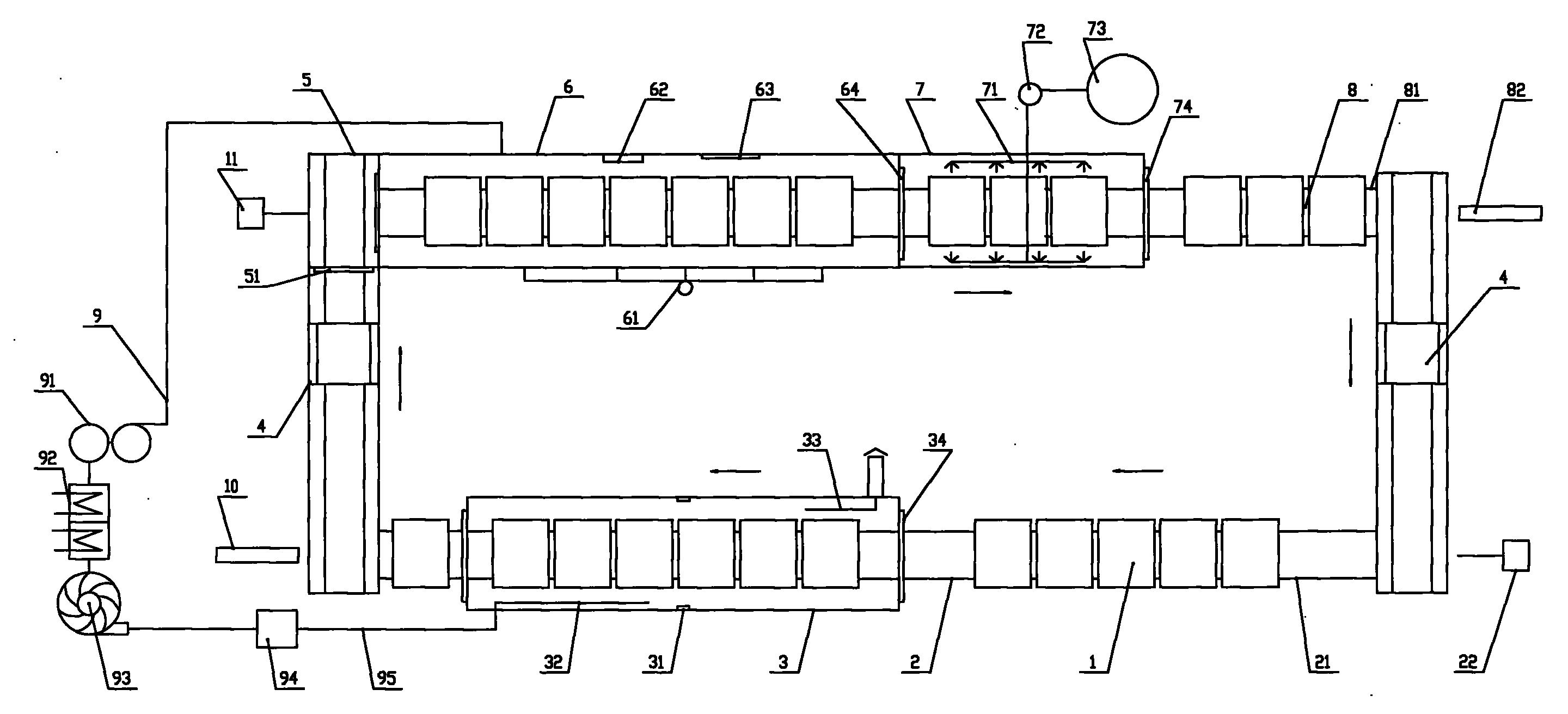

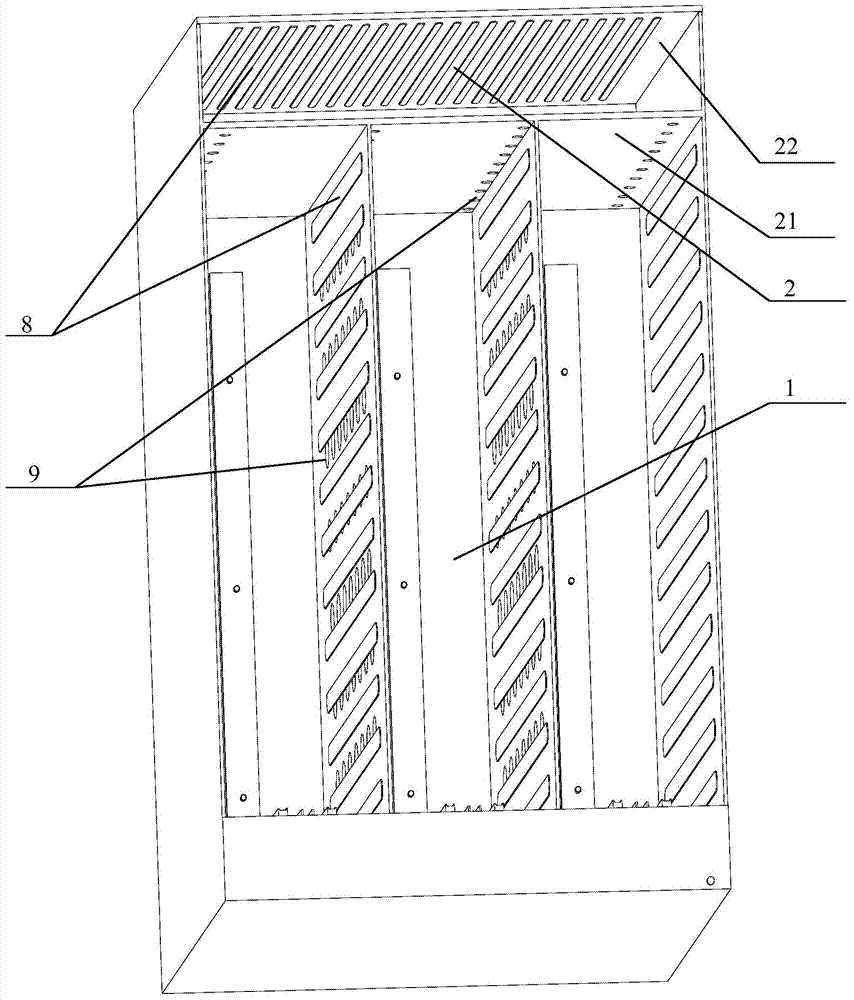

Automatic production line for making charcoal from wood and production process

InactiveCN101805626AQuality improvementSimple structureBiofuelsSpecial form destructive distillationCarbonizationPollution

The invention relates to wood carbonization production equipment and a production process, in particular to an automatic production line for making charcoal from wood and a production process. The automatic production line comprises a plurality of wood trucks, a wood truck conveyor, a drying kiln, a tractor, a trailer, a transfer chamber, a truck pusher, a carbonization kiln, a cooling kiln, a charcoal discharge conveyor and a flue gas dust removal reclaiming device. Flue gas produced in the carbonization kiln is subjected to dust removal, separation and re-combustion through the flue gas dust removal reclaiming device; the produced hot gas is delivered to the drying kiln to dry the wood; and the wood is treated by five stages comprising drying, pre-carbonization, carbonization, burning and cooling to generate high-quality charcoal. The whole production line realizes mechanical operation, has high automation degree, good operating environment and high production efficiency, and greatly reduces the labor intensity of workers; the annual production of one production line is 1,000 to 10,000 tons; and the materials are loaded and unloaded at room temperature, no pollution is emitted, an external heat source is not needed during production, the energy is saved and the environment is produced, the wood is carbonized uniformly, and the quality of the manufactured charcoal is high.

Owner:洛阳圣扬电力科技有限公司

Method for isolated culture of Haworthia succulent plants

InactiveCN102499090ABreed fastLess materialCultivating equipmentsPlant tissue cultureMaterial consumptionBud

The invention provides a method for isolated culture of Haworthia succulent plants, which is characterized by comprising the followings steps of: (1) selecting and disinfecting explants; (2) building a sterile system; (3) cluster bud mulitiplication of the sterile system; (4) culturing rooting; and (5) exercising seedling of test-tube plantlet. The method utilizes tissue culture technology to carry out factorization rapid propagation on the tissue culture so as to have the advantages of less material consumption, rapid propagation, purification, rejuvenation, virus free and the like, the seedling propagation speed can be fasted, and annual production of high-quality seedlings is realized. The method has a positive meaning for development of flowers with the name.

Owner:上海旭东园艺有限公司

Industrial cultivation method of pleurotus eryngii

ActiveCN103999692AFast growthShorten the growth cycleHorticultureFertilizer mixturesBiotechnologyNitrogen dioxide

The invention discloses an industrial cultivation method of pleurotus eryngii. The cultivation method comprises the steps of charging, sterilizing, cooling, inoculating, cultivating, fruiting, harvesting and packing. The cultivation method is characterized in that the modern engineering technology and advanced equipment are utilized, the temperature, humidity, illumination, concentration of nitrogen dioxide and other environments for cultivating and fruiting of pleurotus eryngii are manually set and automatically controlled, so as to realize process-oriented production process, standard production technology, balanced product quality, and annual production of pleurotus eryngii. According to the industrial cultivation method of pleurotus eryngii, the process is simple, the labor productivity, quality rate of pleurotus eryngii and biological conversion are greatly raised, the pollution is reduced, the cost is reduced, and the economic benefits from the cultivation of pleurotus eryngii is increased.

Owner:江苏久禾生物科技发展有限公司

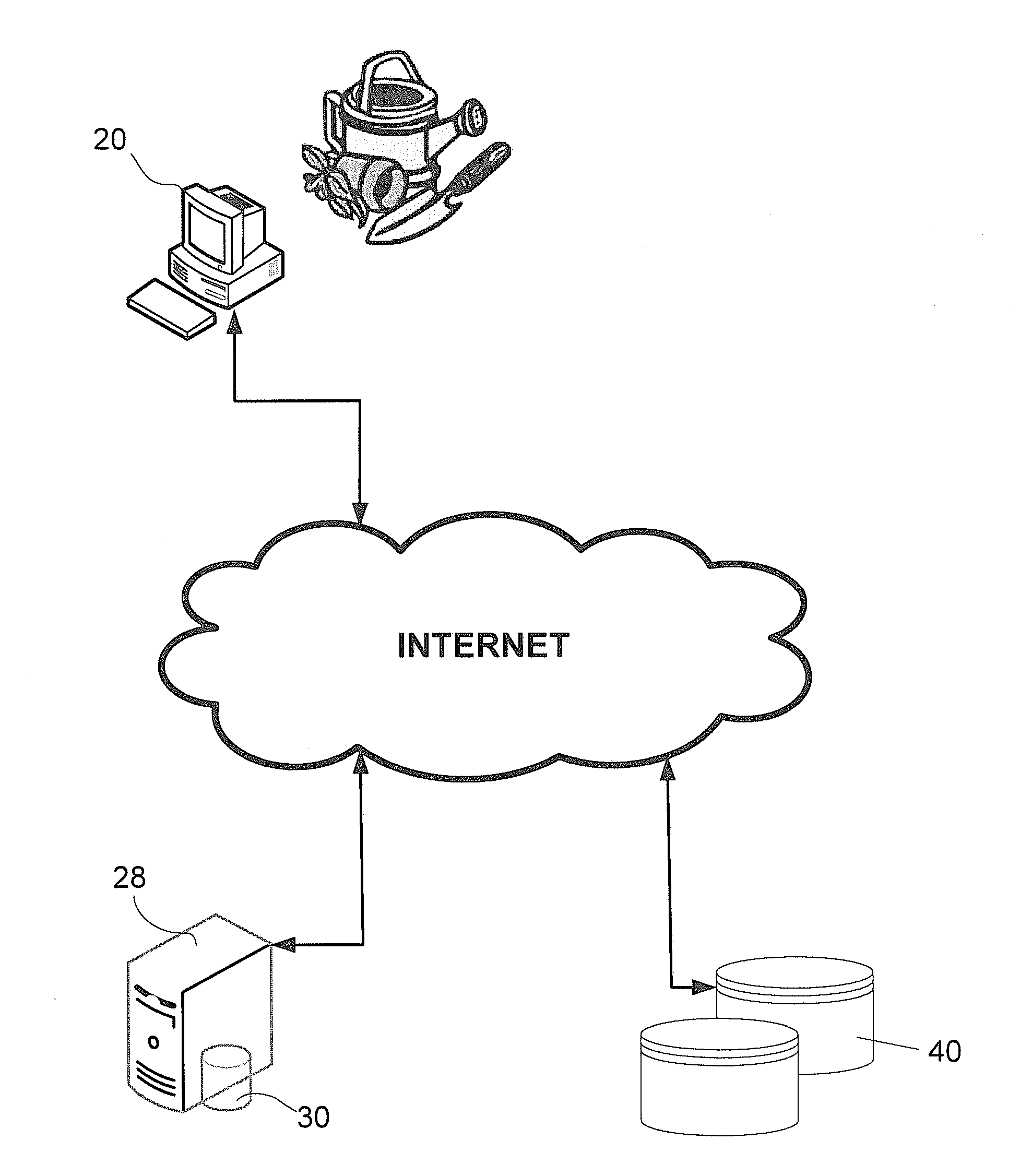

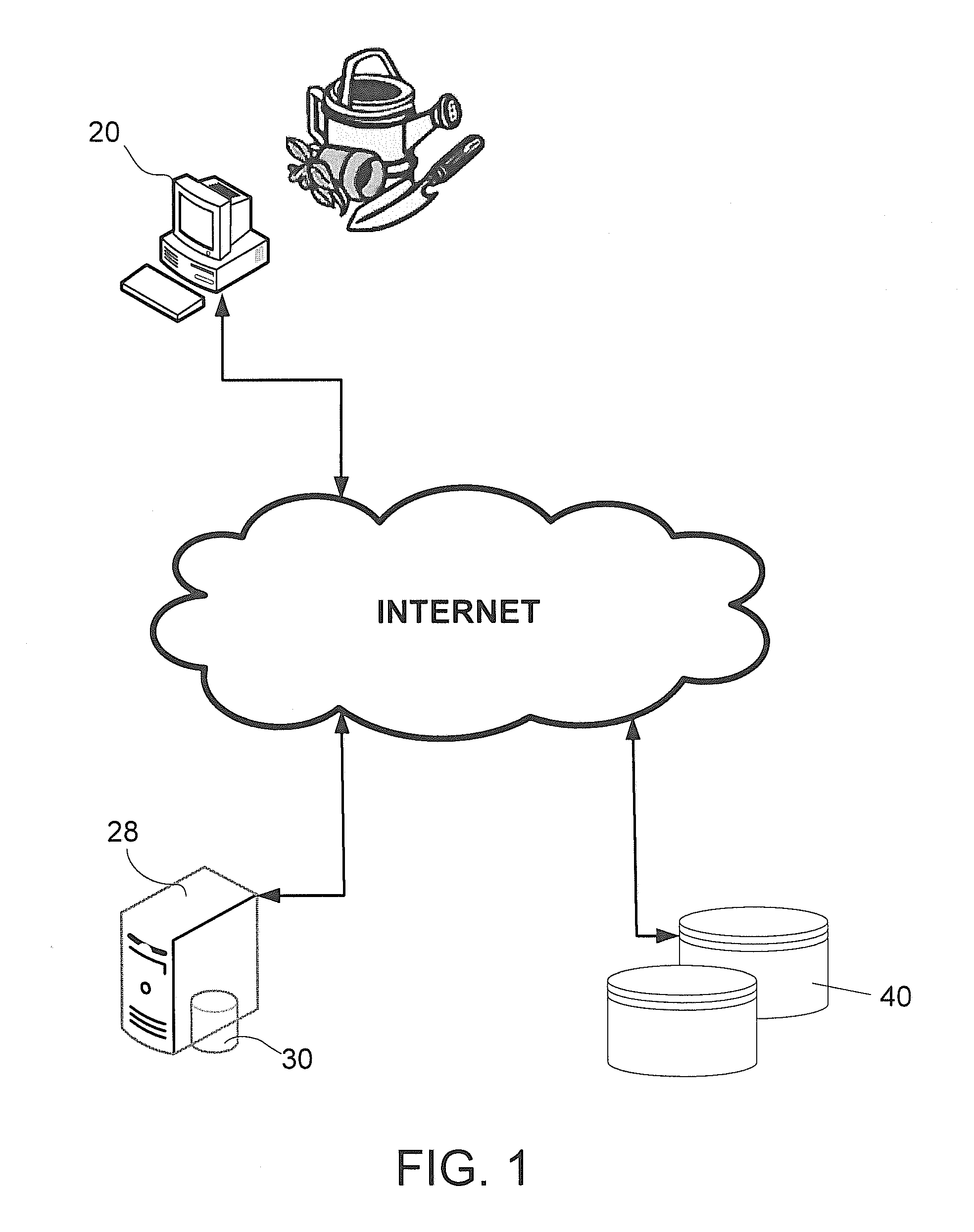

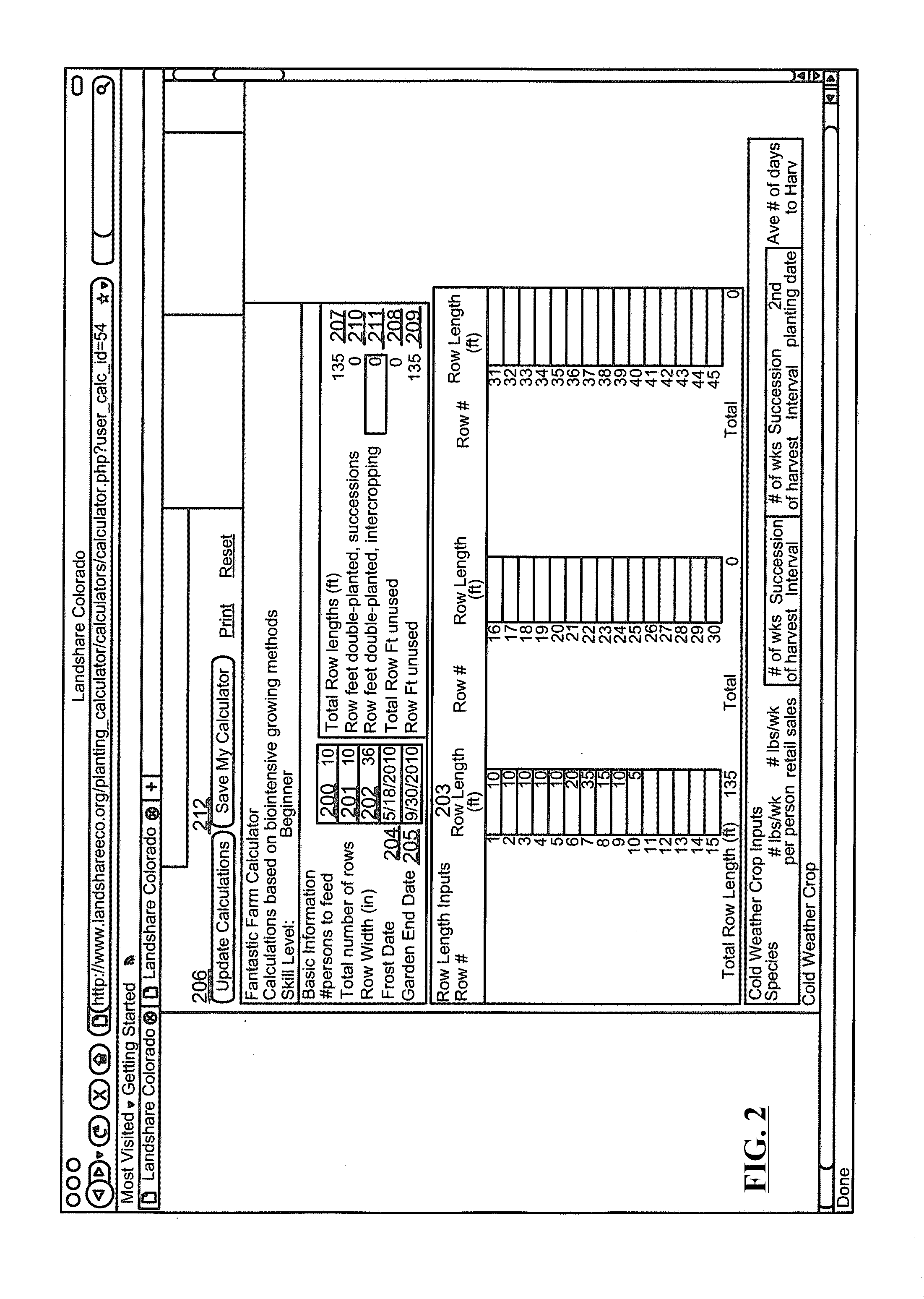

Method and apparatus for managing production complexity of high yield, multiple crop gardening and sustainable farming operations

InactiveUS20110276336A1Solve the lack of spaceData processing applicationsUtility industryComputer science

The presented inventions provide systems and methods (i.e. utilities) in which cultivators of varying skill-levels use a web-based application or software, to manage the complexity involved in planning and implementation of annual production of high-yields of multiple crops over time for a specific number of consumers and / or to fulfill specific retail and / or wholesale sales projections.

Owner:SWEELY TRACY

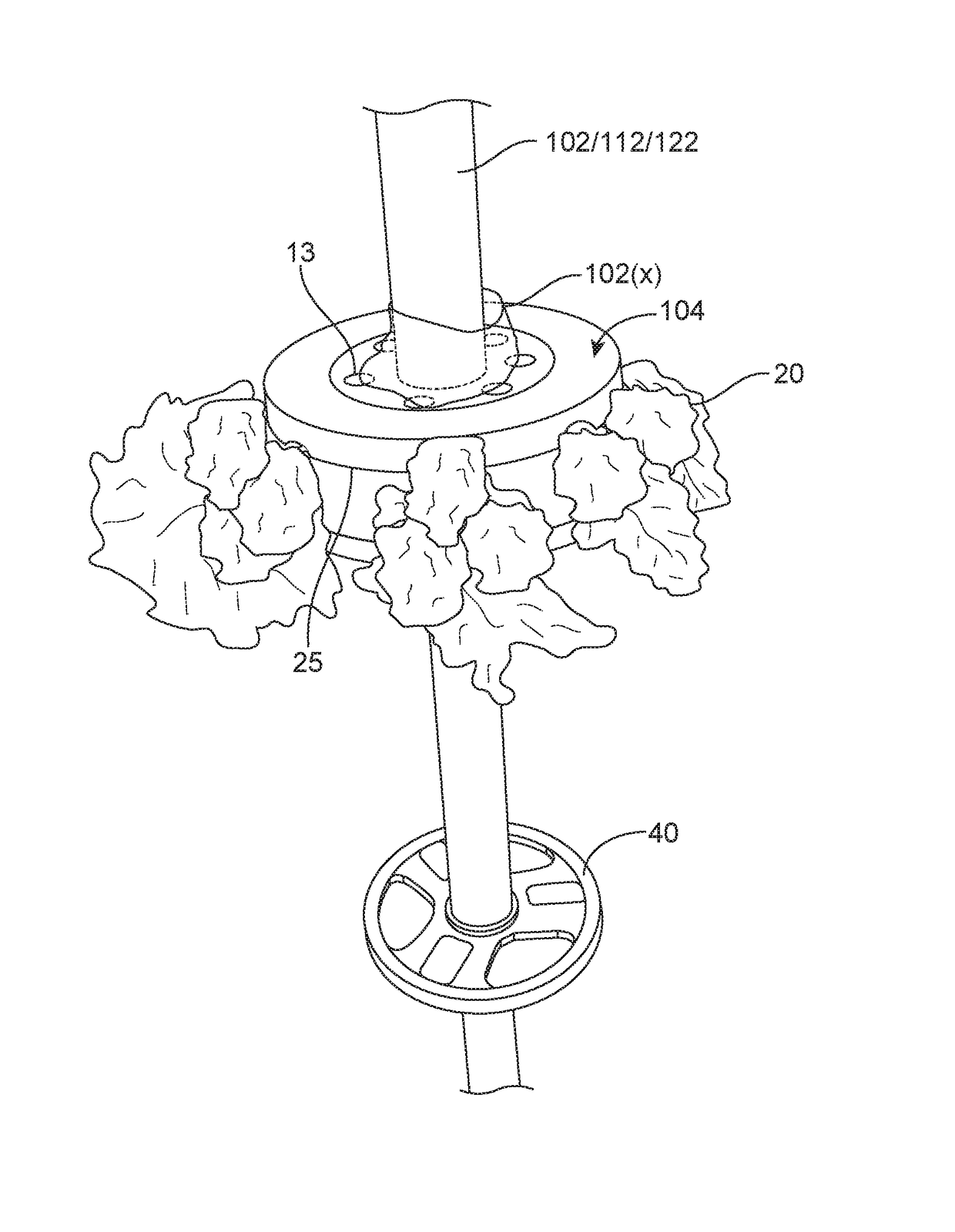

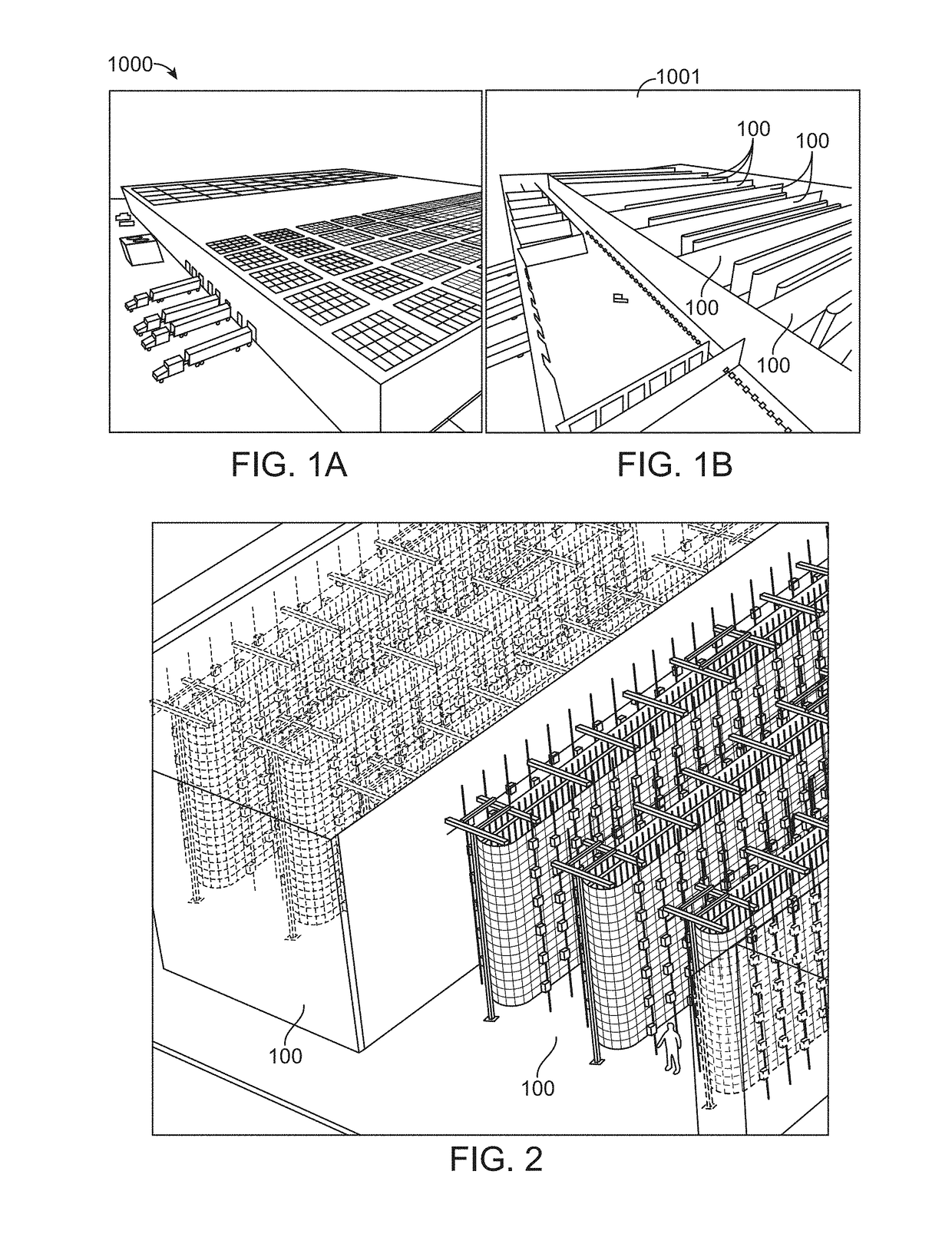

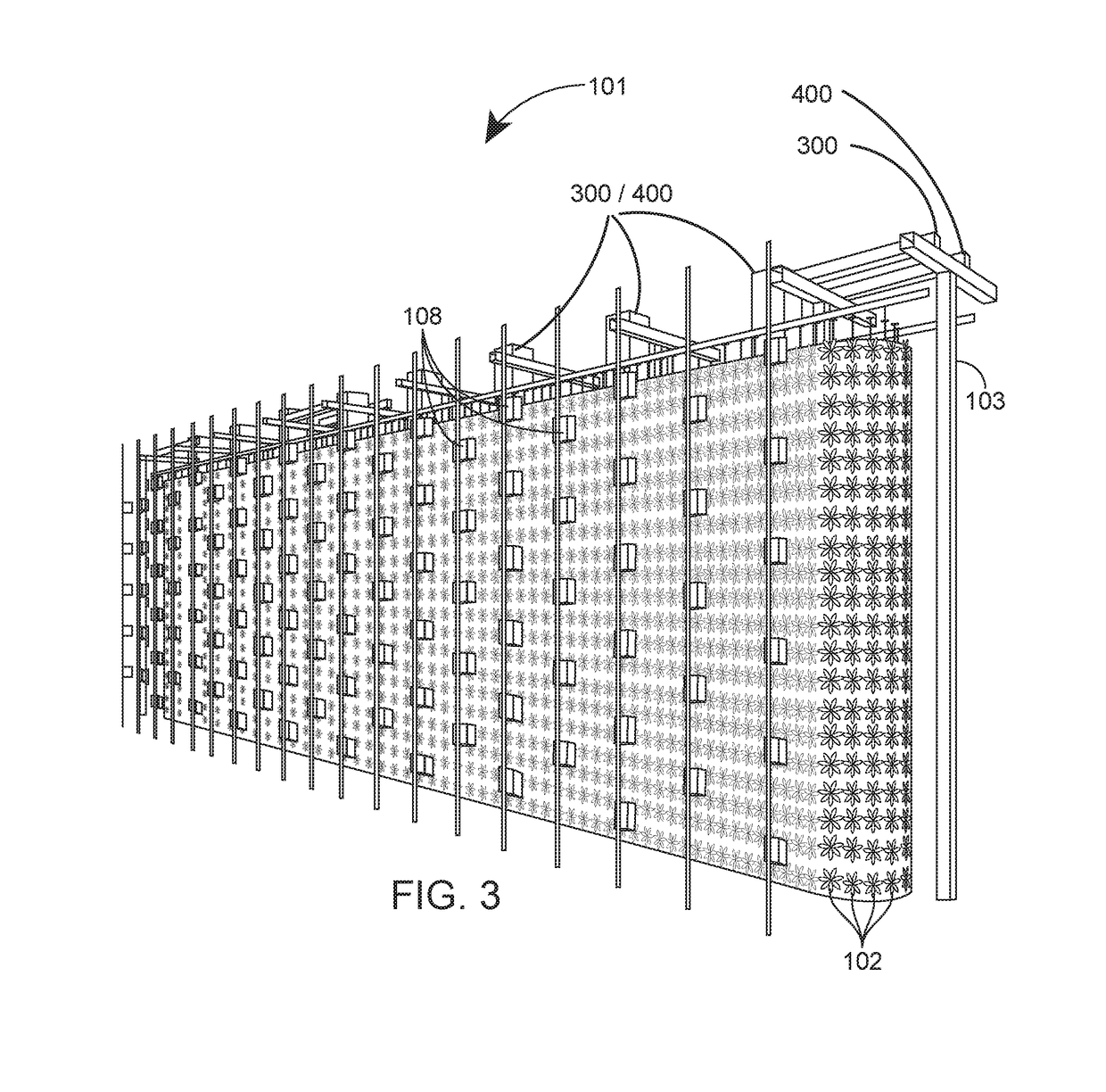

Vertical growth tower and module for an environmentally controlled vertical farming system

InactiveUS20180014471A1High yieldCost per square footSelf-acting watering devicesLayeringHigh densityControl system

A multi-stage, plant growing system is configured for high density growth and crop yields and includes among other things, towers or vertical growth columns, an enclosed controlled environmental growth chamber, interchangeable growth modules, and control systems capable of machine learning wherein the crops are optimally spaced and continually staged in their planting cycles utilizing special growth modules to provide an accelerated and continuous annual production yield. A vertical growth tower for vertical farming comprising a plurality of growth modules, each growth module comprising an enclosure configured to securely hold at least one plant; a drain aperture in the enclosure; and at least one lateral growth opening in the enclosure configured to permit and to encourage lateral growth of the at least one plant away from the enclosure; wherein one or more of the growth modules is configured to stackably support one or more of the other growth modules above and / or below itself within the vertical growth tower.

Owner:MJNN LLC

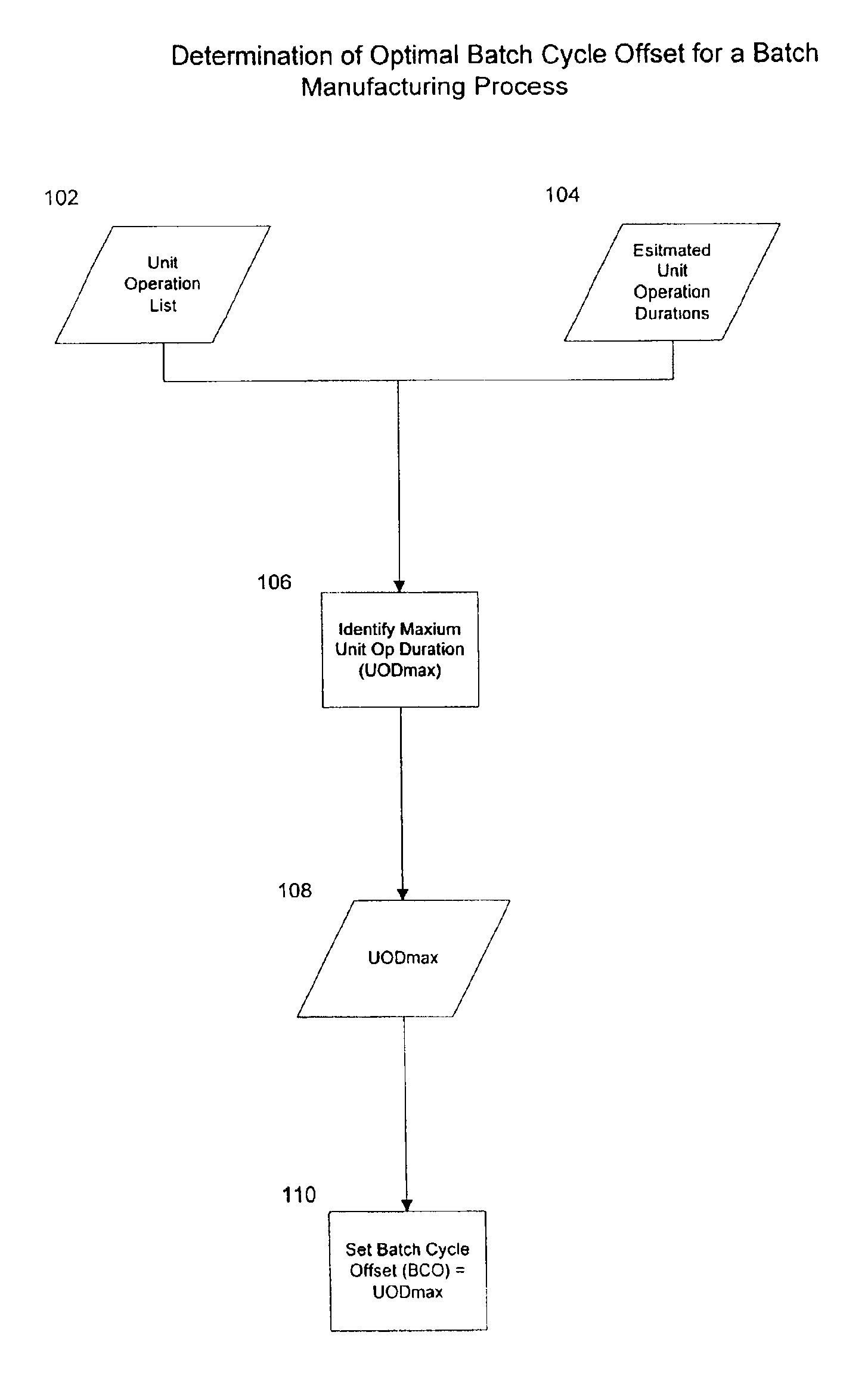

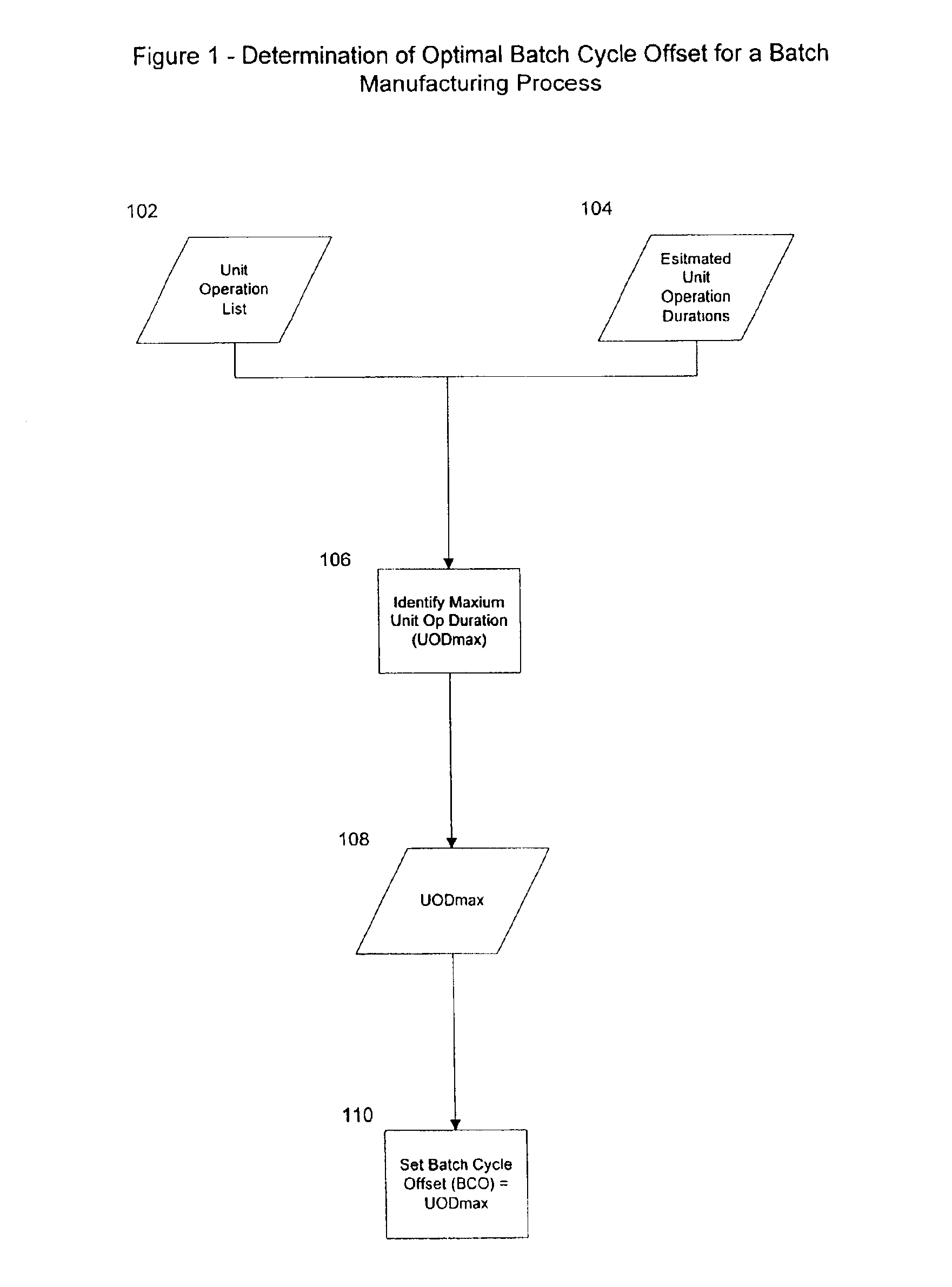

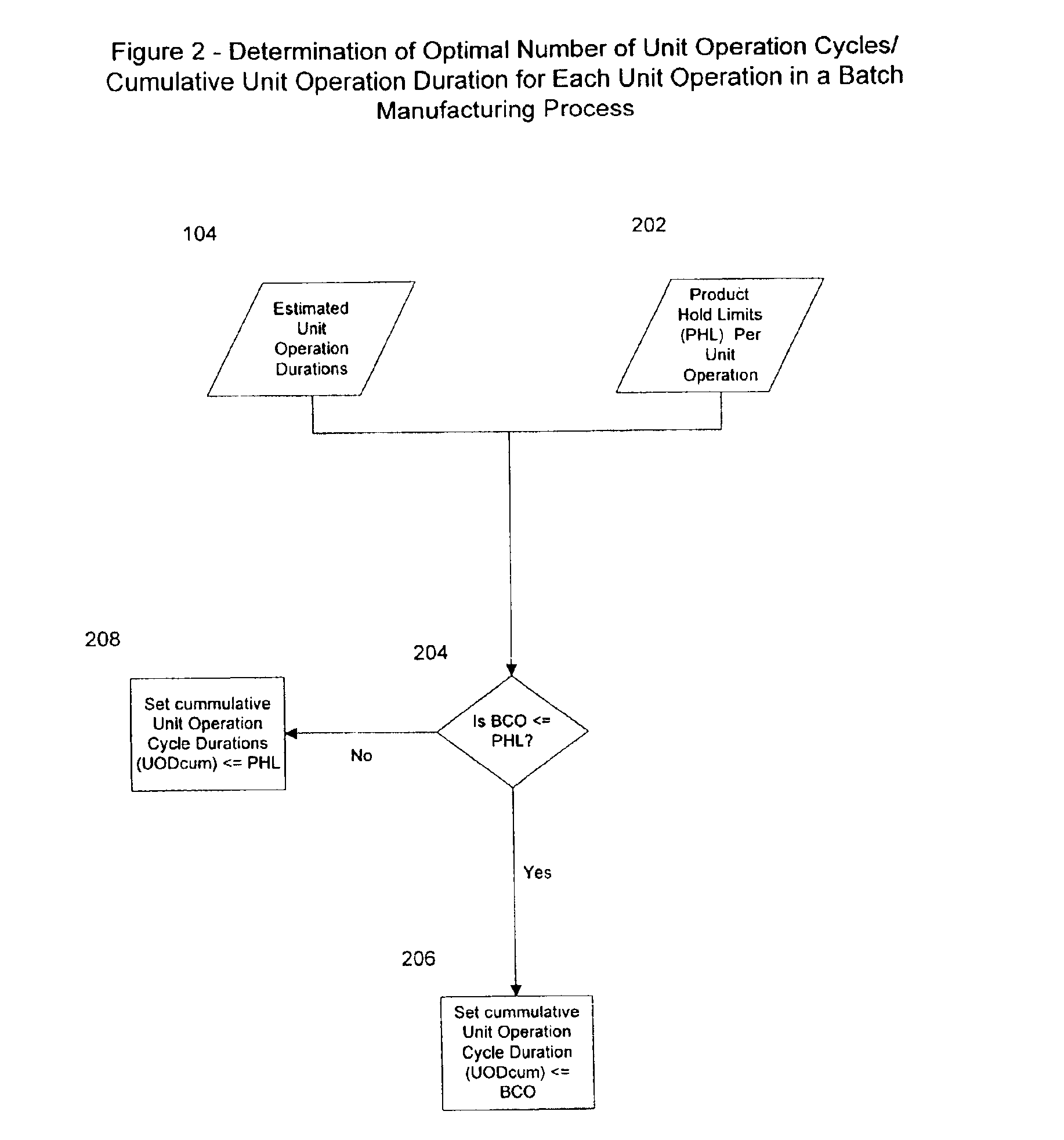

Optimization of manufacturing equipment capacities in a batch manufacturing process

InactiveUS6865432B2Minimizes equipmentReduce physical spaceForecastingTotal factory controlPhysical spaceCost of goods

In an effort to achieve the lowest cost of goods (COG) possible, a key objective in batch manufacturing is to maximize equipment utilization so that the capacity and size of equipment per batch cycle is the smallest possible for a given batch production capacity. This optimization of equipment utilization minimizes equipment and direct utility costs per batch, as well as reduces the physical space and the associated utilities required to support manufacturing operations. The present invention provides a process of: (1) determining the optimal number of batch cycles per year for a required annual production capacity; and (2) determining the optimal number of equipment cycle iterations per batch cycle in a manner that: (a) creates the smallest batch sizes possible; and (b) achieves higher equipment utilization per batch cycle, thereby reducing the capacity and size of equipment required to produce a given batch quantity of product.

Owner:BROWN OWEN (I) (US)

Method for processing tea

ActiveCN101233880ASolve temperature problemsFix stability issuesPre-extraction tea treatmentTea flavoringPolyphenolChlorophyll

The invention pertains to a method for processing tea, in particular to a method for processing gyokurocha tea. The invention aims at providing a processing technique for producing a tea with excellent look, smell and taste to overcome the shortages of complex operation, high labor intensity, low production efficiency, small-scale production, low annual output and failing to meet the market demand in the traditional processing technique. The technical proposal of the invention is the method for processing the tea, which is characterized in that: the processing method comprises the following steps: (a) fresh tea spreading, (b) steaming the tea into green color and dewatering, (c) kneading, (d) drying for the second time, (e) stripping, (f) form regulation, (g) glazing, (h) adding fragrance, (i) selection. The tea processing method of the invention has the advantages of even and regular shape compared with the traditional technique, fragrance, tea water color, taste, color of the leaf bottom and higher content of chlorophyll, tea polyphenols, catechuic acid and theine better than the product produced by the traditional technique.

Owner:恩施市润邦国际富硒茶业有限公司

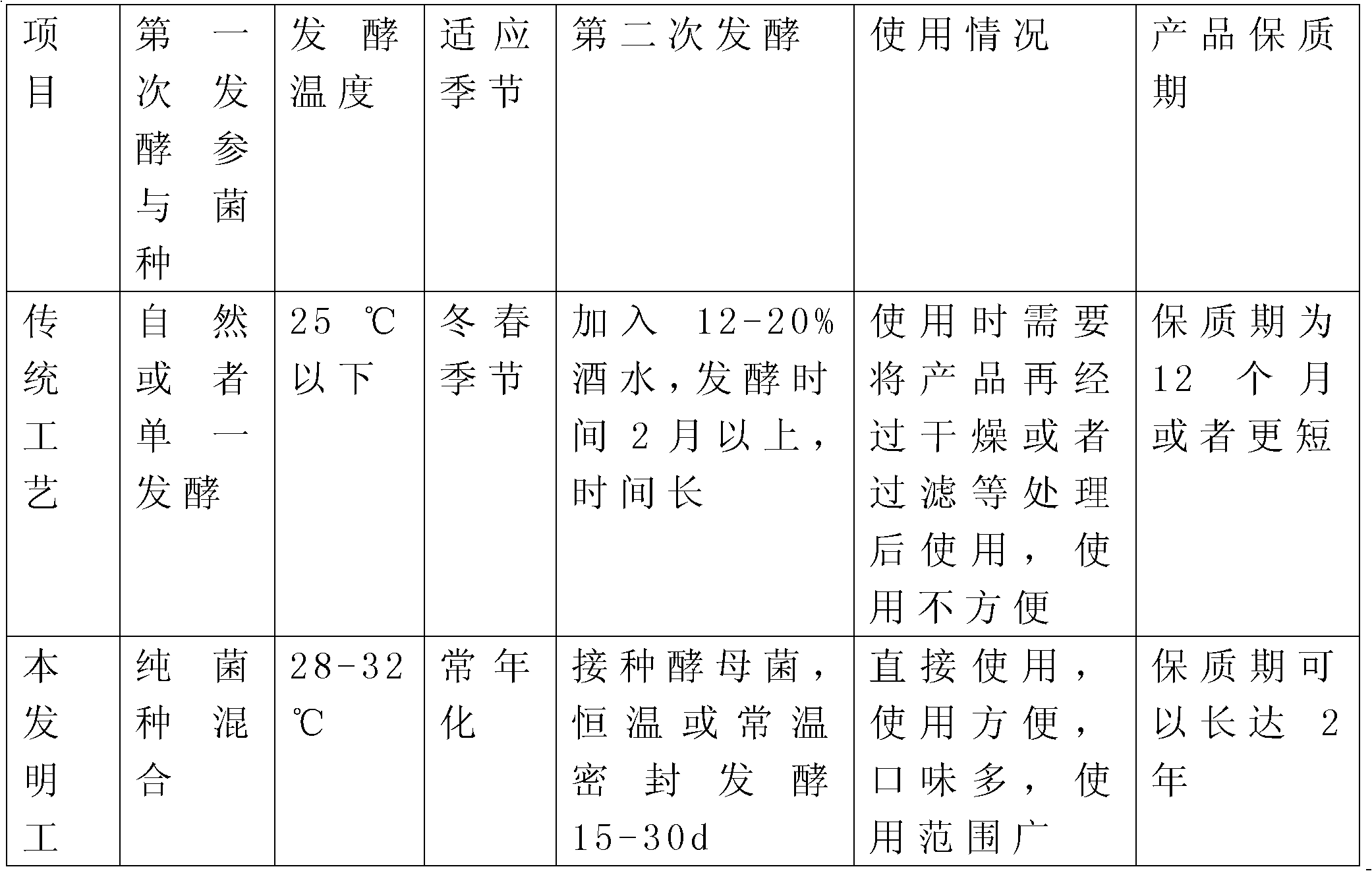

Method for preparing composite Sichuan fermented bean curd

InactiveCN102018181AIncrease the degree of emulsificationImprove nutritional indicatorsFood preparationRhizopusBroad beans

The invention discloses a method for preparing composite Sichuan fermented bean curd, which has the outstanding characteristic that: broad bean paste koji is added in the mixed fermentation process. The method comprises the following steps of: adding mucor and rhizopus chinentis for primary fermentation, adding aspergillus oryzae to prepare the broad bean paste koji, and adding auxiliary materials, yeast powder and lactobacillus powder for secondary fermentation. Compared with the conventional fermented bean curd product, the composite Sichuan fermented bean curd prepared by the method has the advantages that: the emulsifying degree of the fermented bean curd is greatly improved, and the product is red or red brown, has bright color and fine mouthfeel, and is delicious, faint scent and nopeculiar smell; meanwhile, sanitation indexes such as coliforms, aflatoxin B1 and the like are effectively controlled, nutrition indexes such as water-soluble protein, amino acid nitrogen and the like are obviously improved, the fermentation period of the product is obviously shortened, the fermented bean curd can be produced in high-temperature summer, and seasonal production is changed into annual production.

Owner:XIHUA UNIV

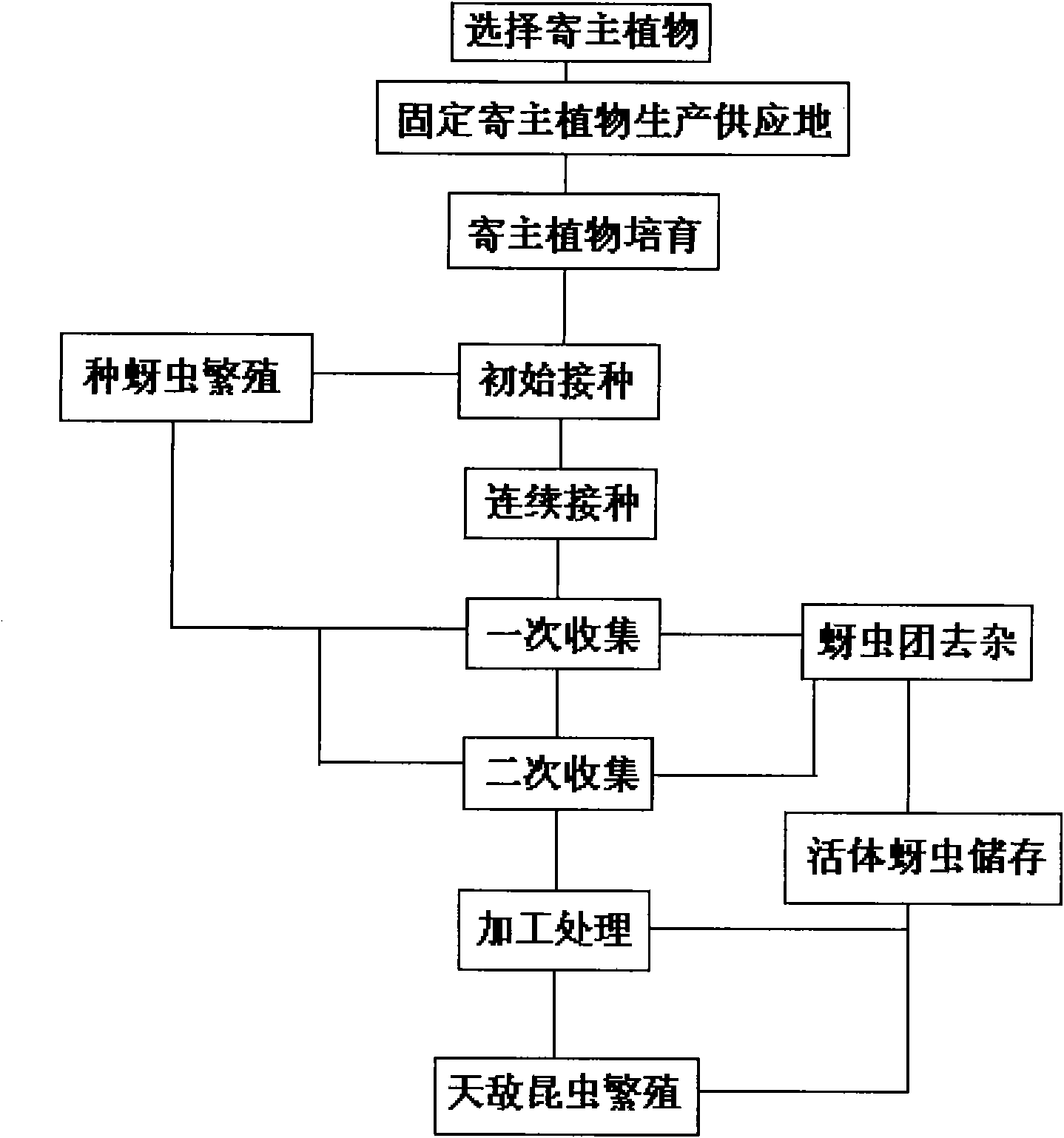

Artificial aphid propagation method

The invention discloses an artificial aphid propagation method. Peas are utilized as a host plant to culture aphids and collect, select and store the propagated aphids. The artificial aphid propagation method realizes the large-scale, low-cost and standardized production of the aphids, makes the annual production of the aphids be possible and provides sufficient fodder or adding ingredients of artificial fodder for the growth and the propagation of natural enemy insects.

Owner:INST OF PLANT PROTECTION CHINESE ACAD OF AGRI SCI

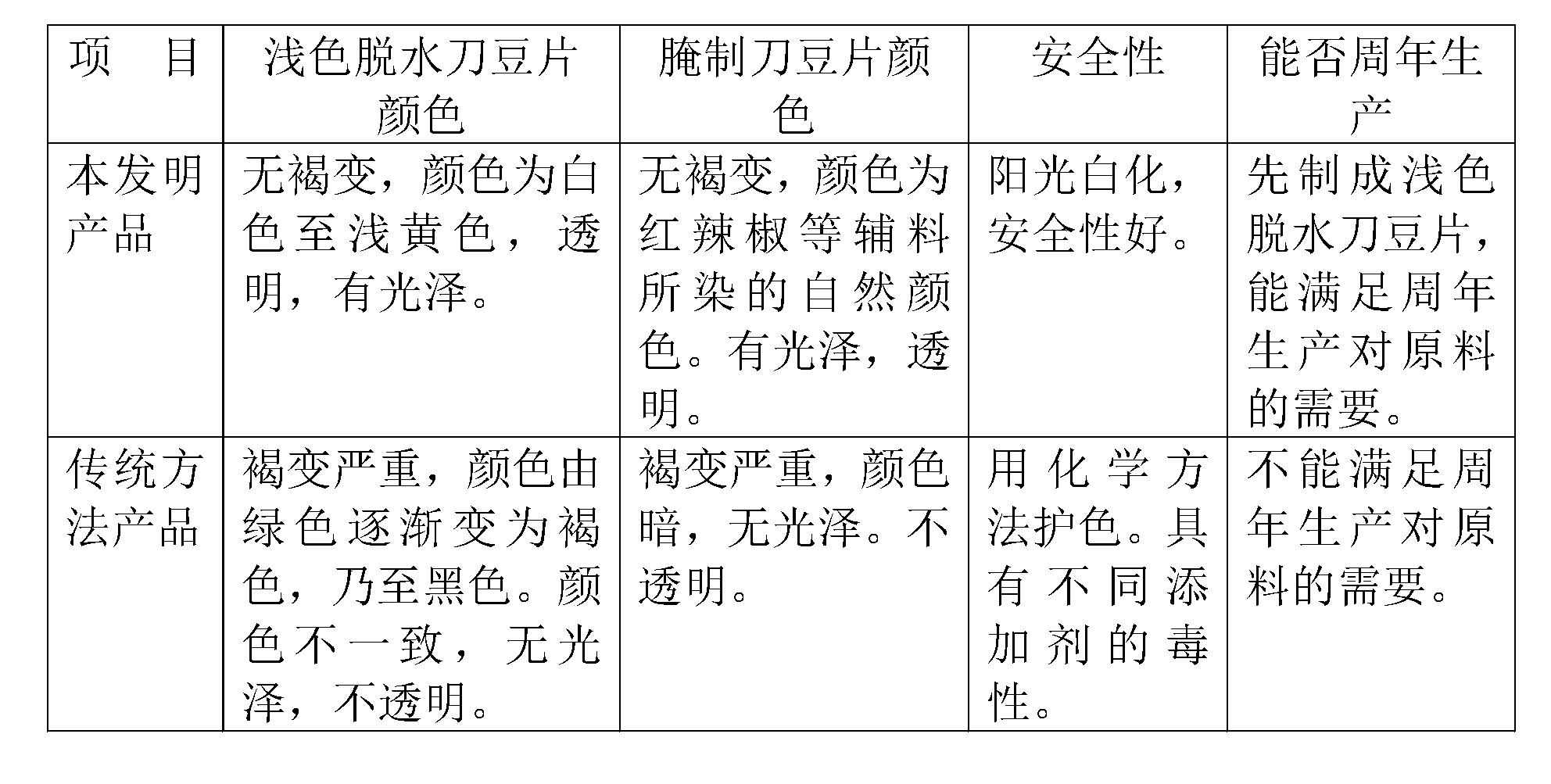

Processing method of light-color air-dried green string bean slices and salted products thereof

ActiveCN102793121AReduce energy consumptionDry fastClimate change adaptationFood preparationAnnual productionString bean

The invention discloses a processing method of light-color air-dried green string bean slices and salted products thereof. The light-color air-dried green string bean slices are prepared through the steps of: selecting fresh green string beans which grow sufficiently but of which the seeds do not expand yet and cutting into slices; blanching in hot water; rinsing; whitening under natural sunshine; and drying. The salted green string bean slices are prepared by uniformly mixing and hermetically fermenting the prepared light-color air-dried green string bean slices and auxiliary materials such as chopped fresh chili. The air-dried green string bean slices and the salted green string bean slices produced by the processing method do not become brown, are transparent and glossy and can keep good natural color; and since no chemical additives are added during processing, the safety of the foods is guaranteed, and the requirements of annual production on the raw materials can be met.

Owner:HUNAN AGRICULTURAL UNIV

Muskmelon organic cultivation annual production method

InactiveCN104823674AHigh Fertilizer Water RequirementsImprove qualityGraftingPlant cultivationFertilizerAnnual production

The invention discloses a muskmelon organic cultivation annual production method and relates to the technical field of muskmelon cultivation. The muskmelon organic cultivation annual production method includes the following steps that 1, a proper place is selected to establish an organic muskmelon production base; 2, a proper muskmelon variety and a stock variety are selected and used for grafting and seedling; 3, a paddy-upland rotation cultivation pattern adopts the sub-steps of spring crop muskmelon, late rice, astragalus sinicus green fertilizer (a first year), early rice, autumn crop muskmelon and vegetable pea (a second year); 4, the spring crop muskmelon is firstly cultivated on half of the base area, the late rice is cultivated after the muskmelon is harvested, the autumn crop muskmelon is firstly cultivated on the other half bas earea, the vegetable pea is cultivated after the muskmelon is harvested, and then cultivation is performed according to the rotation cultivation pattern. According to the cultivation pattern, not only can the production of the organic muskmelon be achieved, but also the production of the spring crop muskmelon and the autumn crop muskmelon every year is achieved, 1-2 batches of muskmelon can be harvested for every crop muskmelon, and therefore the annual production and supply of the organic muskmelon are achieved.

Owner:HUNAN AGRI INFORMATION & ENG RES INST +1

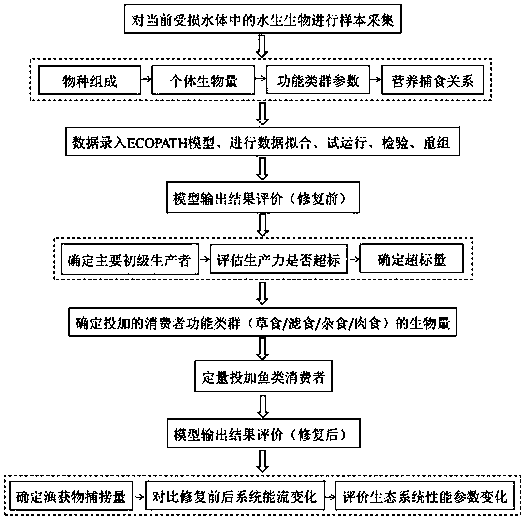

Ecosystem model and biomanipulation technology based eutrophic water body remediation method

InactiveCN108793410AEasy to operateIncrease the number of cyclesBiological water/sewage treatmentEnergeticsCommunity structure

The invention discloses an ecosystem model and biomanipulation technology based eutrophic water body remediation method. Firstly, an ECOPATH model is used to fit the energy flowing mode of the currentecosystem, when the annual production of phytoplankton or aquatic macrophyte in a water body is too high, the minimum primary production requiring for maintaining the operation of the system is takenas the baseline according to the output result of the model, the consumption of the extra primary production in the system is increased through the predation action of fish by using a method of quantitatively adding a fish consumer, and meanwhile, the top-down effect is produced to control the biomass and the community structure of a primary producer. After finishing remediation, the ECOPATH model is used to access the fish catch, the commercial fish species added in the same year are harvested according to the assessment result, so that the balance of energy of the ecosystem is maintained, the fishing catch directly takes away a large quantity of nutritive salts in the water body, and certain economic value is produced. The novel thinking for reference and the technical support are provided for the remediation method taking the scientific experiment as the method from the perspectives of ecology, quantity and energetics, and the method has a very important application value for the ecological remediation of the damaged water body.

Owner:JINAN UNIVERSITY

Production process of advanced grey board paper composite special core paper

ActiveCN110080031AImprove flatnessGood adhesionWaste product additionMechanical/thermomechanical pulpCardboardSludge

The invention relates to the technical field of pulping and papermaking, in particular to a production process of advanced grey board paper composite special core paper. The production process does not use ONP pulp, both surface pulp and bottom pulp adopt 100 percent of OCC pulp, formed paper is good in flatness and is not layered, and the adhesive absorption property and the bonding property of the paper are improved, and the use requirements of the advanced composite grey board paper special core paper are met. Moreover, as core pulp with a larger pulp blending proportion adopts OCC pulp, recovery slag pulp, wood chip pulp and reuse sludge mixed pulp, the quantification, the compactness, the interlayer bonding force, the thickness and the ash content are guaranteed; an ONP pulping line and a paper machine lining section are stopped, so that the pulping power and the installed power of a paper machine are reduced, and the purposes of energy conservation, consumption reduction and product paper improvement are achieved. The produced advanced multi-layer composite special core paper in stead of single grey board paper, has a gram weight range of 280-700 g / m<2> and is used for a corelayer and an inner layer, Through measurement and calculation, the production cost per ton of paper is about 70 yuan; calculated by the annual output of 150,000 tons, the annual production cost can be saved by 10,500,000 yuan.

Owner:LIANSHENG PAPER IND LONGHAI

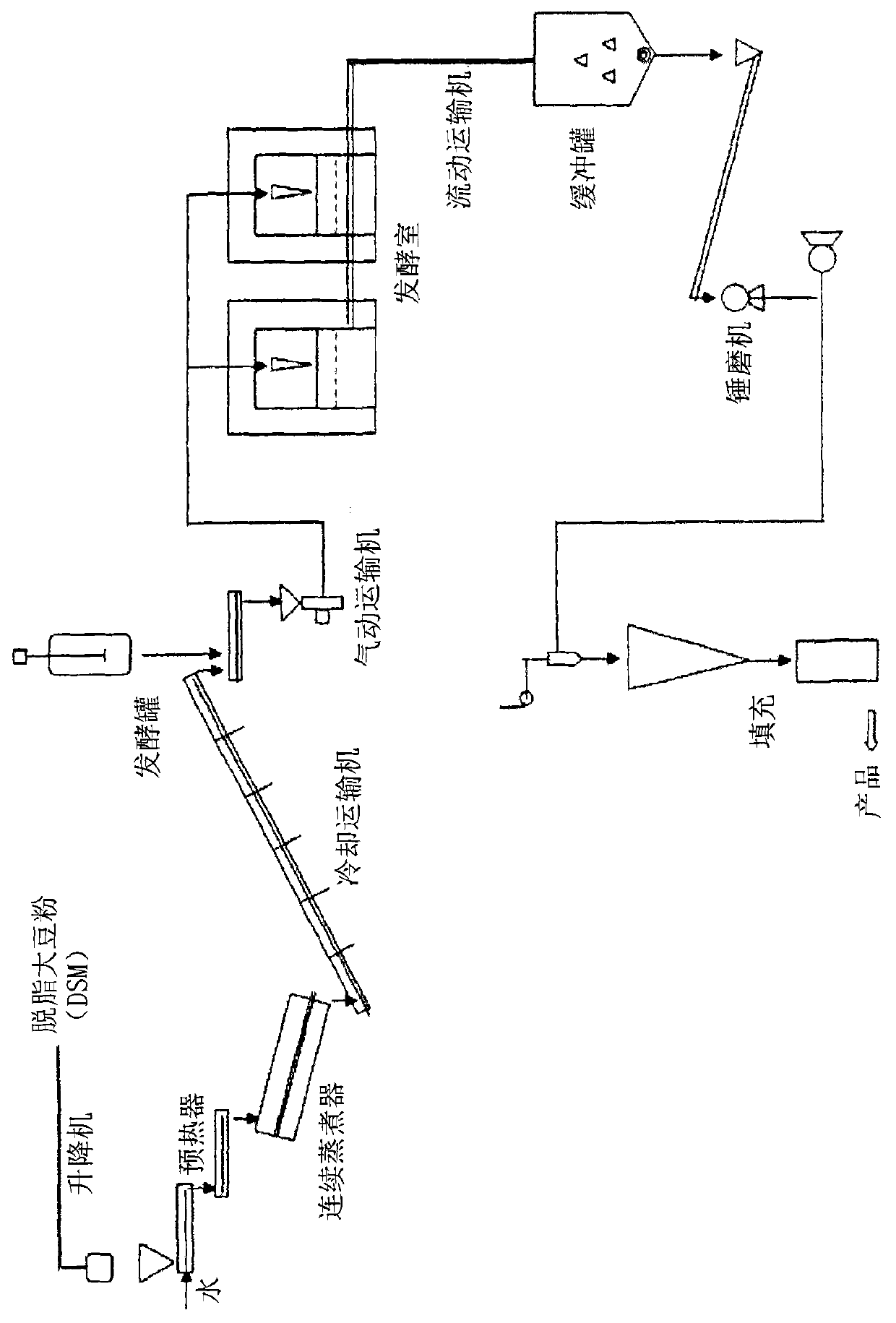

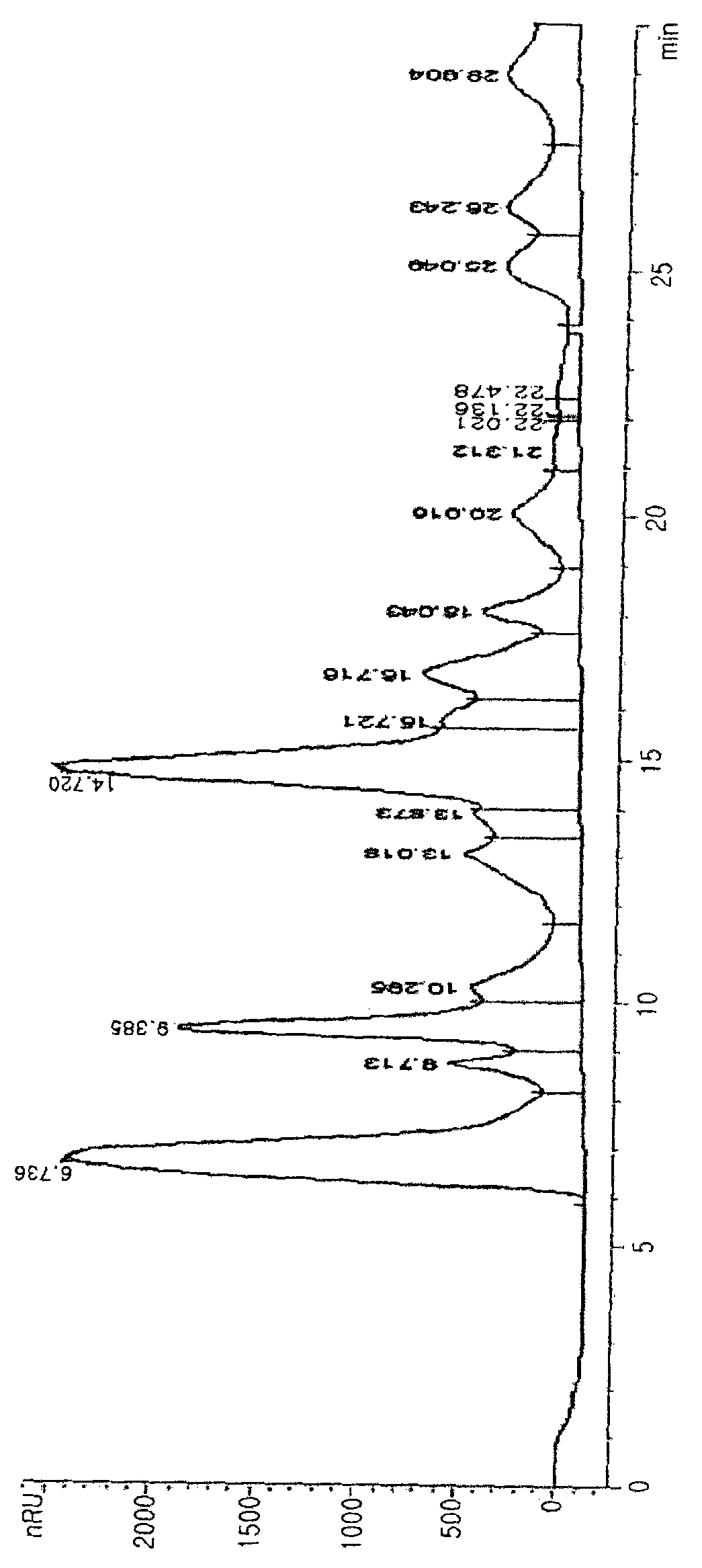

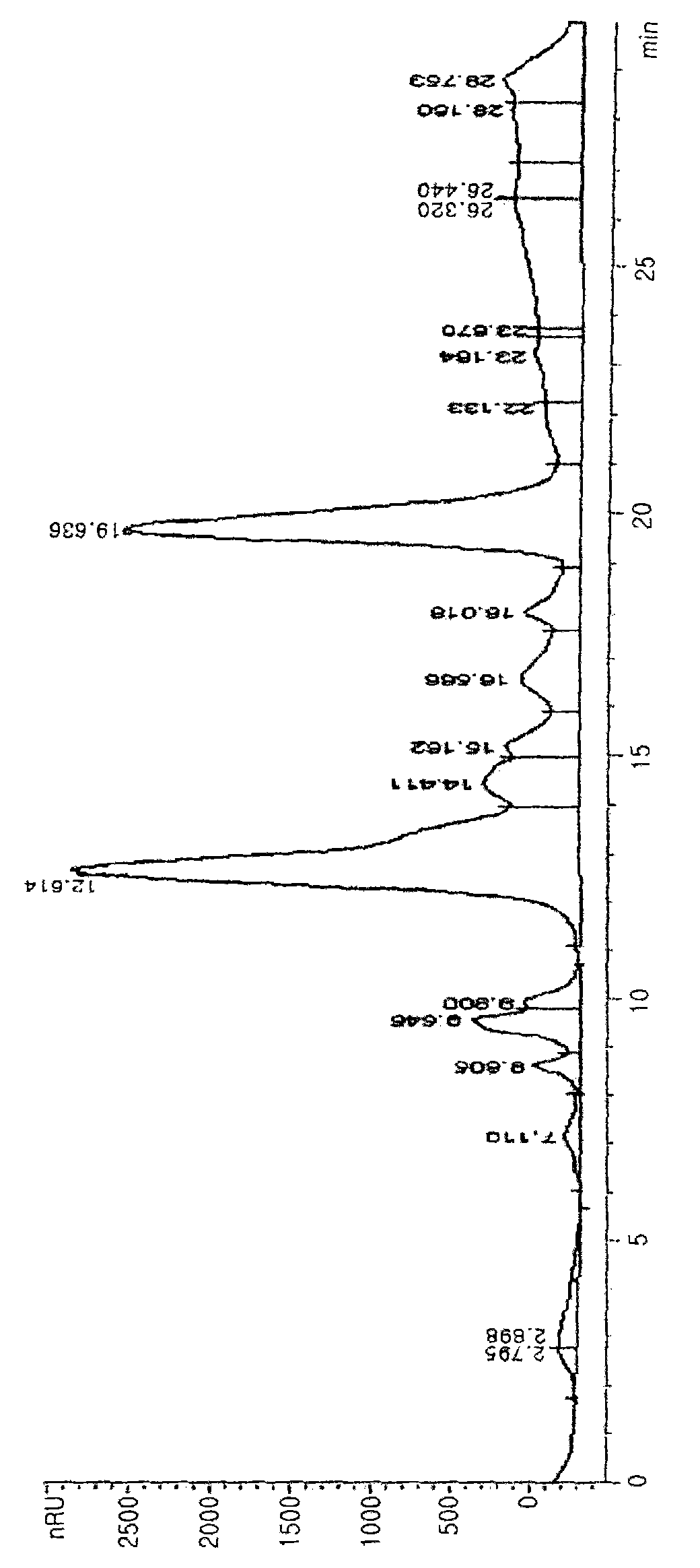

Method for preparing a fermented soybean meal using bacillus strains

ActiveCN102018096AEfficient removalImprove or improve featuresAnimal feeding stuffFood preparationTrypsin inhibitorDigestion

The present invention relates to a method for producing a fermented soybean meal, comprising the steps of: (a) adding water to a soybean meal to perform heat-treatment; (b) cooling the heat-treated soybean meal, and then inoculating a Bacillus strain thereinto; and (c) acquiring a fermented soybean meal by solid fermentation of the Bacillus-inoculated soybean meal, and to a fermented soybean meal produced by the method. The method of the present invention uses a Bacillus strain having excellent properties required for the production of fermented soybean meal, in particular, Bacillus subtilis TP6 strain as a fermentation strain. Therefore, the fermented soybean meal produced by the present invention is a high-quality plant protein source in that various anti-nutritional factors including trypsin inhibitors, soybean oligosaccharides and polysaccharides are almost all removed, its protein content is high, and digestion and absorption rates are also improved by low-molecularization of the proteins. In particular, the TP6 strain capable of removing anti-nutritional factors is used to improve the product quality equivalent to or better than those produced by the known fermented soybean meals while reducing the fermentation time, thereby remarkably increasing the annual production.

Owner:CJ CHEILJEDANG CORP

Process for preparing fermented bean curd powder

InactiveCN102058068AReduce inhibitionRaise the fermentation temperatureFood preparationFreeze-dryingAdditive ingredient

The invention relates to a process for preparing fermented bean curd powder. The process comprises the following steps of: vaccinating equivalent 0.1-0.3 percent pure racemomucor M.H.C-7CCTCCM 201026 subjected to enlargement culture and rhizopus oligosporus CGMCC 3.4392 and fermenting to form a mould billet; adding salt and Chinese rice wine, uniformly mixing and then vaccinating 0.2 percent activated Angel high-temperature-resistant active dry yeast; sealing for fermenting; pulverizing to form a viscous fluid and precooling; drying into freeze-drying powder in vacuum; and bottling and sealing to obtain the fermented bean curd powder. Ingredients can be added to the freeze-drying powder to be prepared into various seasoners which have the fermented bean curd flavor and different applications, and the freeze-drying powder can be widely applied to seasoners of potato chips, flour products, rice products, roasted meat products, and the like and can be also used as an ingredient of instant noodle seasoning bags. The fermented bean curd powder has the advantages of scientific process design and short process period, is particularly suitable for annual production and is obviously different from fermented bean curd products of other forms. The process can be used for realizing industrial continuous production and has the advantages of controllable process, stable quality and wide application and provides a feasible method for developing novel seasoners.

Owner:CHANGSHA TANTANXIANG FLAVORING FOOD +1

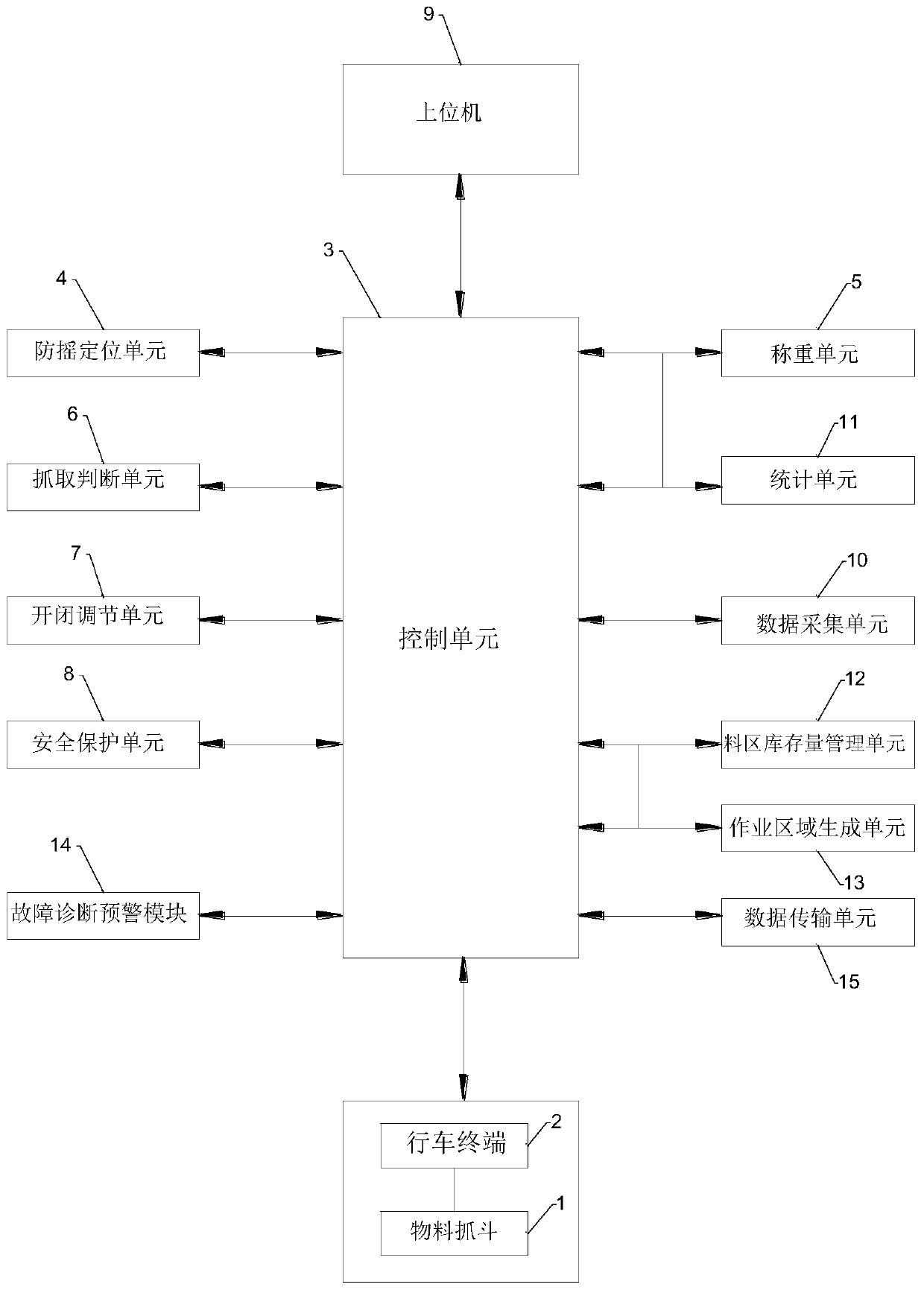

Intelligent control system for material grab bucket

InactiveCN110510524AEfficient and orderly transfer and transportationAccurate and efficient pre-homogenizationSafety gearSequential logicWeight range

Owner:北京坚构创新科技有限公司

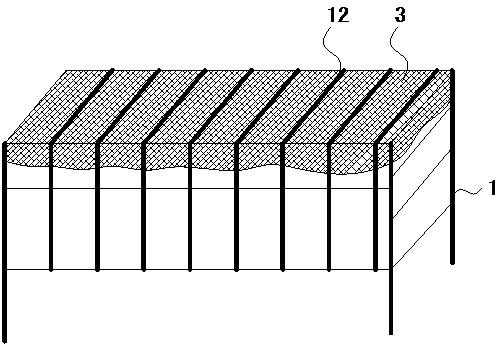

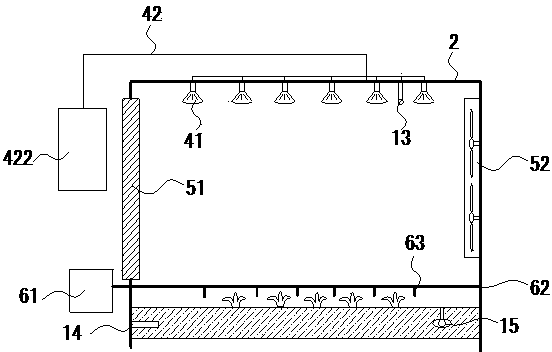

Process of realizing cultivating annual black fungus through punching bags by using intelligent sunlight greenhouse

InactiveCN104885784AHigh technology contentSave landCultivating equipmentsMushroom cultivationPunchingGreenhouse

The invention relates to a process of realizing cultivating annual black fungus through punching bags by using an intelligent sunlight greenhouse. Fungus bags suspended in the sunlight greenhouse, according to the temperature and humidity in the sunlight greenhouse (1), can be automatically or manually sprayed and humidified, automatically or manually ventilated, and automatically or manually heated, so as to realize cultivating annual black fungus through punching bags by using the intelligent sunlight greenhouse in such ways of saving the land and being unaffected by the weather. The black funguses can be cultivated by the process so that the land saving can be realized and the black funguses are not unaffected by the weather, the growing trend can be controlled, the four-season cultivation can be realized, and the yield and benefit can be improved; furthermore, the small-scale distributed black fungus plantation can be changed into an intensive, specialized, standardized, mechanical and standard factory type production way, so that the high quality, high efficiency and high yield of the black funguses can be realized, the technological content of the black fungus cultivation can be improved, the production cost can be reduced, and the targets of increasing yield, synergia, increase income and stable earnings of the annual production can be realized.

Owner:黑龙江佰盛食用菌有限公司

Catalyst and process for the production of diesel fuel from natural gas, natural gas liquids, or other gaseous feedstocks

ActiveUS9090831B2High yieldEasy to processHydrocarbon distillationOxygen compounds preparation by reductionHydrogenGas to liquids

A unique process and catalyst is described that operates efficiently for the direct production of a high cetane diesel type fuel or diesel type blending stock from stoichiometric mixtures of hydrogen and carbon monoxide. This invention allows for, but is not limited to, the economical and efficient production high quality diesel type fuels from small or distributed fuel production plants that have an annual production capacity of less than 10,000 barrels of product per day, by eliminating traditional wax upgrading processes. This catalytic process is ideal for distributed diesel fuel production plants such as gas to liquids production and other applications that require optimized economics based on supporting distributed feedstock resources.

Owner:GREYROCK TECH LLC

Leaf cutting propagating method of primulina hance plant

InactiveCN103081681AAchieve annual productionReduce commercial production costsHorticultureSeedlingAnnual production

The invention discloses a leaf cutting propagating method of a primulina hance plant. The leaf cutting propagating method of the primulina hance plant includes the following steps of (1) selecting cutting time, (2) preparing cutting slips, (3) preparing cutting bed, (4) cutting, (5) managing after cutting, (6) transplanting the primulina hance plant into pots. By means of the leaf cutting propagating method of the primulina hance plant, rapid propagation of the primulina hance plant is achieved, seedlings are rounding and normal in plant type, little difference between the seedlings and stock plants exists, and the quality of seedlings is good and identical. In addition, by means of the leaf cutting propagating method of the primulina hance plant, annual production of the primulina hance plant can be achieved, possibility is provided for commercial production of the primulina hance plant and the cost of the commercial production of the primulina hance plant is reduced.

Owner:云南西双版纳澜沧江园林有限责任公司

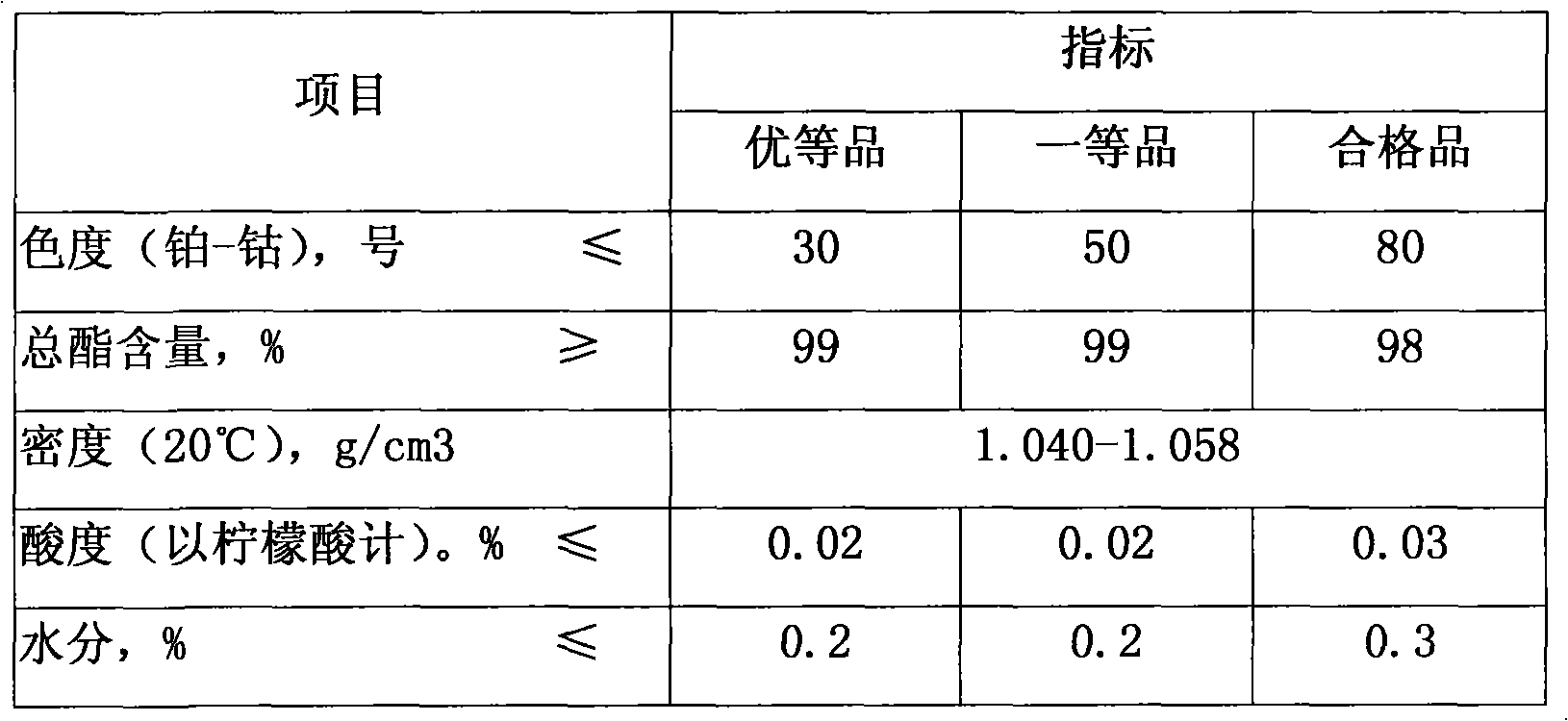

Semi-continuous production process for acetyl tributyl citrate

InactiveCN101591244AAdd alkaline washing processAdditional processing stepsOrganic compound preparationCarboxylic acid esters preparationFiltrationTributyl citrate

The invention discloses a semi-continuous production process for acetyl tributyl citrate (ATBC) serving as an environment-friendly plasticizer, which has a process route that comprises the steps of esterification, dealcoholization, acetylation, deacidification, neutralization and washing, steam stripping, waste water treatment and filtration. For overcoming the drawbacks of the conventional process, the process has a redesigned process flow, realizes continuous operation in the dealcoholization step and the deacidification step of a production device, achieves high production efficiency and stable product quality, changes the flow of a vacuum system in the deacidification step and increases a tail gas alkaline cleaning process. The process adopts the waste water treatment process to perform the dealcoholization and desalination of neutralized waste water to solve an environment protection problem. A whole set of device is a set of semi-continuous production device. Each production line is designed with an annual production capacity of 10,000 tons.

Owner:ZIBO BLUE SAIL CHEM

Cultivation method of chicken leg mushroom all year round

InactiveCN101322460AGuaranteed normal growthAchieve annual productionGaseous substancesGreenhouse cultivationBiotechnologyDisease

An annual cultivation method for coprinus comatus sequentially comprises the following production methods: the technological processes of culture production, fermentation treatment of culture medium, sterilizing inoculation, hairy fungus culture, soil sealing, mushroom production, and the like, are carried out; the culture is produced by a liquid seed production method; reed residues and needle mushroom leftovers are used as culture medium for fermentation treatment; cultural bags adopts open type inoculation, and a two-stage type cultural method is used; the inoculation and the hairy fungus culture are carried out in ordinary steel tube greenhouse; the soil sealing and mushroom production are carried out in the environment of civil air-defense construction. The invention utilizes idle civil air-defense facilities, does not need refrigeration plants without energy consumption and can always keep the environmental temperature of mushroom production at 18-22 DEG C, thereby being capable of not only ensuring coprinus comatus to grow normally but also controlling the generation of important disease palmatum bacteria of coprinus comatus so as to efficiently realize annual production of coprinus comatus; in addition, the mushroom production time can be freely controlled by controlling the soil sealing time so that the biological conversion rate is more than 80% and the yield can be improved more than 25% compared with ordinary cultivation.

Owner:江苏江南生物科技有限公司

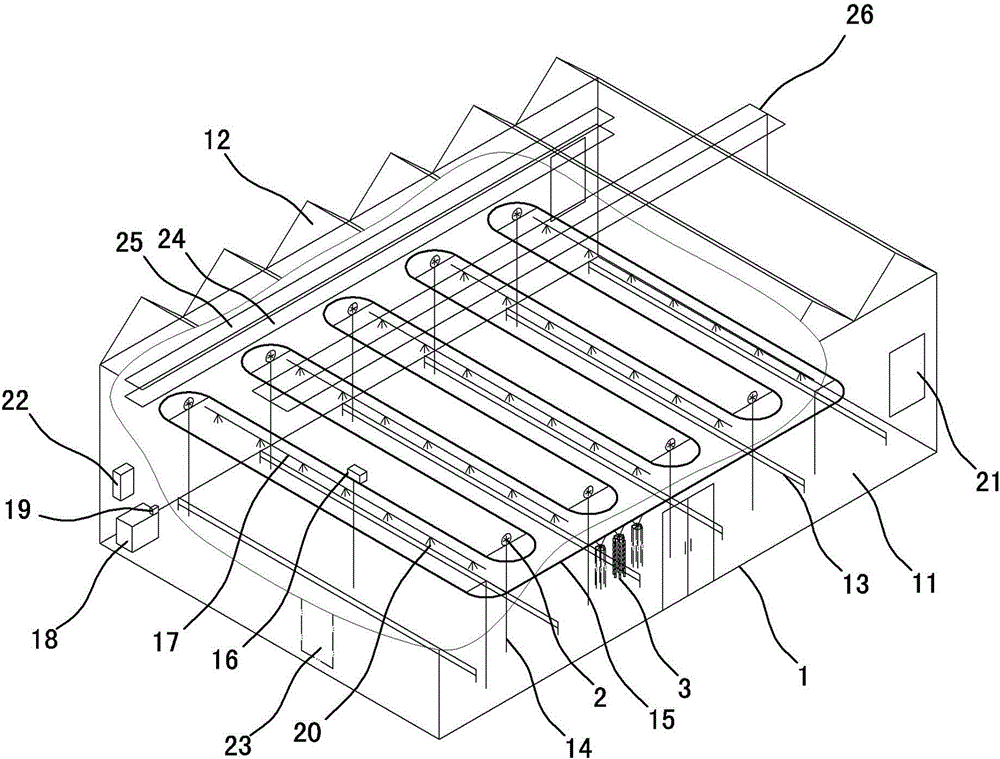

Simple multifunctional intelligent vegetable greenhouse

InactiveCN103461030AImprove planting efficiencyReduce the labor intensity of plantingClimate change adaptationGreenhouse cultivationGreenhouseAgricultural engineering

The invention relates to a simple multifunctional intelligent vegetable greenhouse comprising a greenhouse frame formed by building vertical supports and beam frames and a thin film cover covering on the greenhouse frame. A shielding net is arranged above the greenhouse, spray cooling devices are distributed on the beam frames, a water curtain cooling device is arranged in the greenhouse frame, and a water and fertilizer integrating device is arranged in a planting area of the bottom of the greenhouse frame. Humidity and temperature in the vegetable greenhouse can be controlled effectively and rapidly through the arrangement, environment adaptable to growth of greenhouse vegetables is created, and annual production of vegetables in the greenhouse in a south can be implemented. The water and fertilizer integrating device is arranged at the bottom of the greenhouse frame, uniformity of watering and fertilizing can be improved, the water and the fertilizer can be saved, and quality and quantity of vegetable products can be improved. The simple multifunctional intelligent vegetable greenhouse has important significance for increasing greenhouse vegetable planting benefit and reducing planting labor intensity.

Owner:INST OF AGRI ENG TECH FUJIAN ACAD OF AGRI SCI +1

Method for annually producing drumstick by utilizing air raid shelter

InactiveCN101743856AAchieve annual productionSolve different environmental conditionsHorticultureRAIDBiology

The invention belongs to the edible fungi production technical field and discloses a method for annually producing drumstick by utilizing air raid shelter. The method is characterized in that: the mode of 'spawn running outside and fruiting in shelter' is adopted, massive drumstick bags are produced in high tunnel and vacant room under good aeration condition outside the shelter in season with appropriate temperature; earthing and fruiting are carried out by utilizing the specific natural environment warm in winter and cool in summer in the air raid shelter in winter and summer when fruiting is difficult to implement outside the shelter, and annual production of drumstick is realized without cooling and heating equipment. The invention greatly saves energy source, effectively reduces production cost and also can freely control earthing time according to market demand in different seasons, fruiting period can be artificially regulated, concentration to appear on the market can be avoided, bioconversion is above 85%, and yield can be improved by 30-20% compared with the conventional cultivation.

Owner:镇江市食用菌研究所

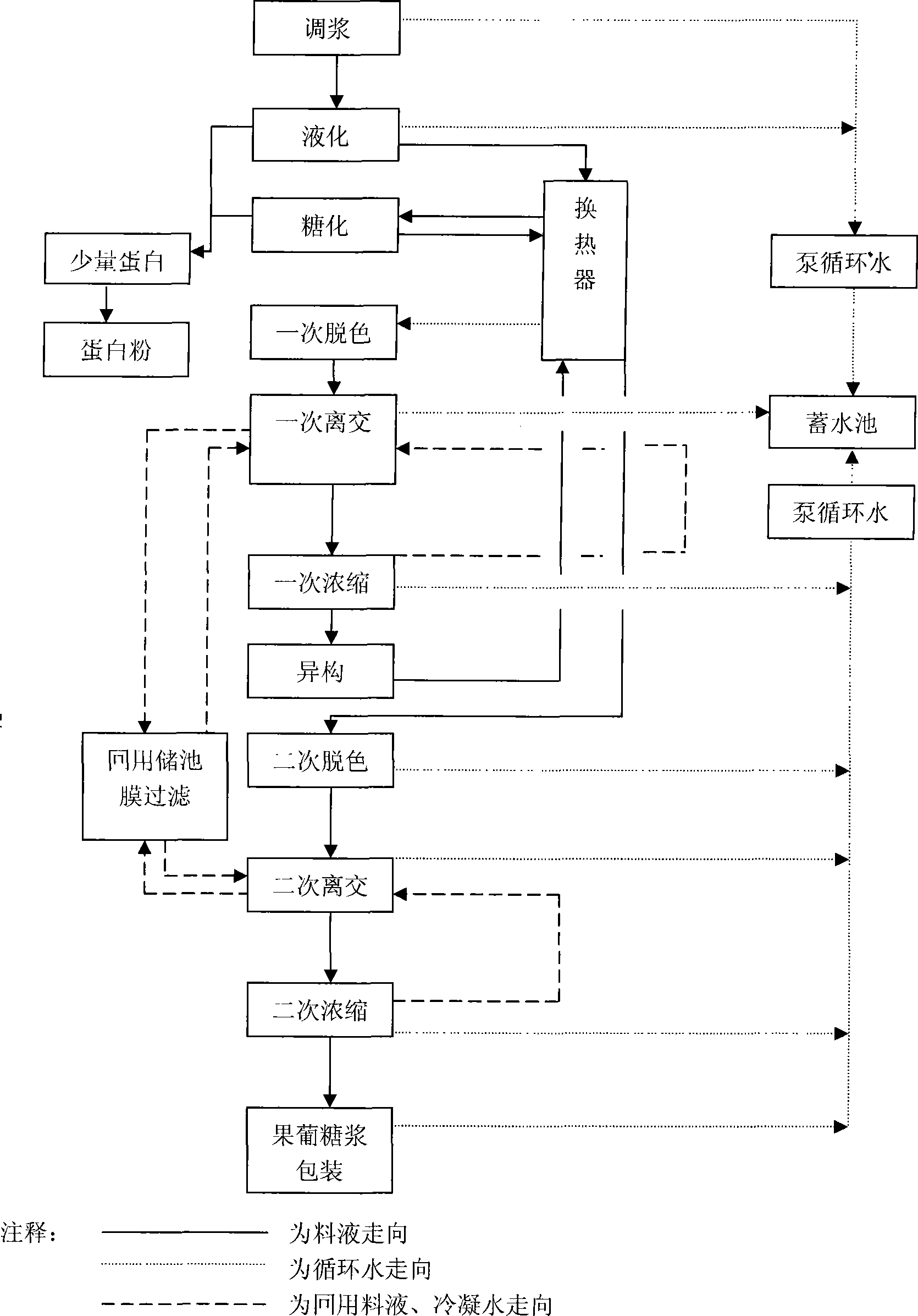

Cleaning production technique for starch sugar

The invention relates to a starch sugar cleaning production technique. In the production system of the starch sugar products that takes starch as the raw material, material, heat energy and water all realize closed cycles without discharging waste material, waste water and waste heat to the environment, wherein, optimized production technique realizes no waste water discharge; waste solid is processed into protein feed; hear exchange is carried out between cold and hot materials to realize heat balance and recycling use of the interior; condensate water, cooling water and circulating water are returned to middle process after being respectively reclaimed and treated. The implement manner is that: production technique is optimized; the utilization rate of the material is improved; no waste fluid is generated in the whole process; the cleaning solution of ion exchanged enzyme and / or isomerase is reclaimed to be used for conditioning; the ion exchanged and regenerated solution is recycled after being reclaimed and treated; small amount of waste solid generated by condensation, saccharification and ion exchange is processed into protein feed. For example, in annual production of 300,000 tons of high fructose corn syrup, 90,000 tons of steam and 1.10 million tons of water can be saved yearly.

Owner:BAOLINGBAO BIOLOGY

Leaf cutting propagating method of river pool primulina tabacum hance

ActiveCN103081680AAchieve annual productionReduce commercial production costsHorticultureSeedlingAnnual production

The invention discloses a leaf cutting propagating method of river pool primulina tabacum hance. The leaf cutting propagating method of the river pool primulina tabacum hance includes the following steps of (1) selecting cutting time, (2) preparing cutting slips, (3) preparing cutting bed, (4) cutting, (5) managing after cutting, (6) transplanting the river pool primulina tabacum hance into pots. By means of the leaf cutting propagating method of the river pool primulina tabacum hance, rapid propagation of the river pool primulina tabacum hance is achieved, seedlings are rounding and normal in plant type, little difference between the seedlings and stock plants exists, and the quality of seedlings is good and identical. In addition, by means of the leaf cutting propagating method of the river pool primulina tabacum hance, annual production of the river pool primulina tabacum hance can be achieved, possibility is provided for commercial production of the river pool primulina tabacum hance and the cost of the commercial production of the river pool primulina tabacum hance is reduced.

Owner:BEIJING FORESTRY UNIVERSITY

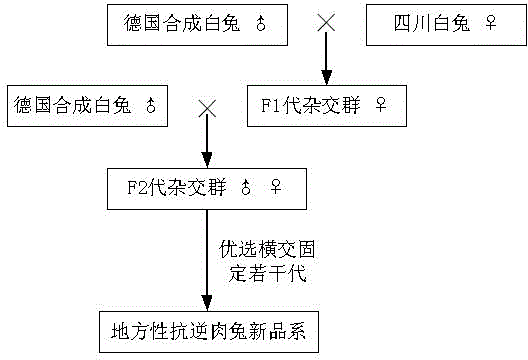

Method for breeding new local stress-resistant meat rabbit species

The invention belongs to the technical field of culture and particularly relates to a method for breeding a new local stress-resistant meat rabbit species. According to the method, Sichuan white rabbits and German synthetic white rabbits are taken as breeding materials, and the new local stress-resistant meat rabbit species is bred through a grading hybridization method. The new meat rabbit species bred through the method has the advantages of the Sichuan white rabbits and the advantages of the German synthetic white rabbits and is strong in stress resistance, and the fattening survival rate reaches over 98%; bucks are strong in sexual desire and high in semen quality; does are obvious in estrus and easy in mating, the blood-nest mating pregnancy ratio reaches up to 82%, the number of annual production births is over 7-8 under the condition of artificially-assisted mating, the continuous production performance is good, and the new meat rabbit species has very strong adaptability to the climate environment and culture characteristics of the southwest of China.

Owner:SICHUAN ANIMAL SCI ACAD

Household vegetable and flower cultivation device capable of using aerosol cultivation

InactiveCN104770284AImprove space utilizationEasy plantingAgriculture gas emission reductionCultivating equipmentsNutrient solutionSeedling

The invention discloses a household vegetable and flower cultivation device capable of using aerosol cultivation. The device comprises a nutrient solution circulating interval, a seedling culture interval, box doors, a controller loading box, a raw material box, plant bearing trolleys, spraying frames and the like, wherein the raw material box and the controller loading box are mounted on side faces of the nutrient solution circulating interval, the seedling culture interval is arranged just above the nutrient solution circulating interval, and the box doors are arranged at the front side of the nutrient solution circulating interval and the front side of the seedling culture interval, so as to form a closed planting cultivation system; the upper part of the nutrient solution circulating interval is a household vegetable and flower cultivation space, the bottom of the nutrient solution circulating interval is a nutrient solution tank for containing a nutrient solution, an upper planting space is partitioned into a plurality of plant planting subspaces through parallel hanging lamp partition plates, and the seedling culture interval is a seedling culture planting space and can be used for loading seedling culture trays. According to the simple aerosol type household vegetable and flower cultivation device disclosed by the invention, a planting frame is of a vertical wall type movable architecture, so that the problems of the existing household vegetable and flower cultivation devices that the space utilization ratio is low, the plant replacement is difficult, nutrient cycling is difficult, annual production cannot be achieved, and the like are solved.

Owner:ZHEJIANG UNIV

Lactic acid bacterium fermented chopped chili processing method

InactiveCN105410783AReduce transportationEasy to transportFood ingredient functionsLactic acid bacteriumFlavor

The present invention discloses a lactic acid bacterium fermented chopped chili processing method, including the following specific steps: selecting and grinding, high temperature soaking and sterilizing, pool loading, lactic acid bacterium fermenting agent adding, fermenting and pickling, and salt adding and storing. The dried chilies are used as raw materials and fermented by artificially inoculating lactic acid fermentation liquid, and the obtained product has a special flavor, aroma and health-care function of fermented chili products. The processing method can improve product quality stability and chili product nutritional value, at the same time solve the raw material problem in annual production of pickles, and save the fermentation time compared to the traditional fermentation. However, the method uses dried red chilies as raw materials and the materials are readily available and suitable for industrial production of the raw material preservation requirements, and the raw material quality can be well controlled. In the processing of the chopped chilies, only about 10%-11% of edible salt is added, which saves energy and lower production costs.

Owner:HUNAN XIANGCHUQING FOOD CO LTD

Method for rapid wet ball milling of electrical porcelain raw materials

InactiveCN102489366AOptimizing Process ParametersShorten milling timeGrain treatmentsEconomic benefitsSpherical shaped

The invention relates to a method for rapid wet ball milling of electrical porcelain raw materials, and belongs to the field of high-strength silicate material manufacture. The method provided by the invention is characterized in that a ball mill medium comprises 45 to 95% of Al2O3 and 80 to 98% of SiO2; the Moh's hardness is in a range of 8 to 9.5; the ball size fai is in a range of 15 to 50 millimeters; balls are spherical and elliptic; a ball mill inner liner comprises tiles having Al2O3 content of 50 to 95%; a ratio of raw materials to water to the balls is 1: (0.55 to 0.95): (1.8 to 2.5); and a ball-mill rotating speed is 25 to 28r / min. The optimized method provided by the invention has the advantages that economic benefits are high; ball-milling time is reduced; an annual production amount is improved by 27180 tons; annually consumed electric power is 926000 kilowatt-hours, wherein electric power consumed in ball milling of a ton of the raw materials is reduced to 33.3 kilowatt-hours from 107.42 kilowatt-hours so that an electric power consumption amount of the method provided by the invention is one third of that of the prior art; and because of change of raw materials of the ball mill inner liner and the balls, equipment overhaul time and a risk caused by raw material component change are reduced and product quality is further improved.

Owner:殷杨合

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com