Patents

Literature

250results about "Mechanical/thermomechanical pulp" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

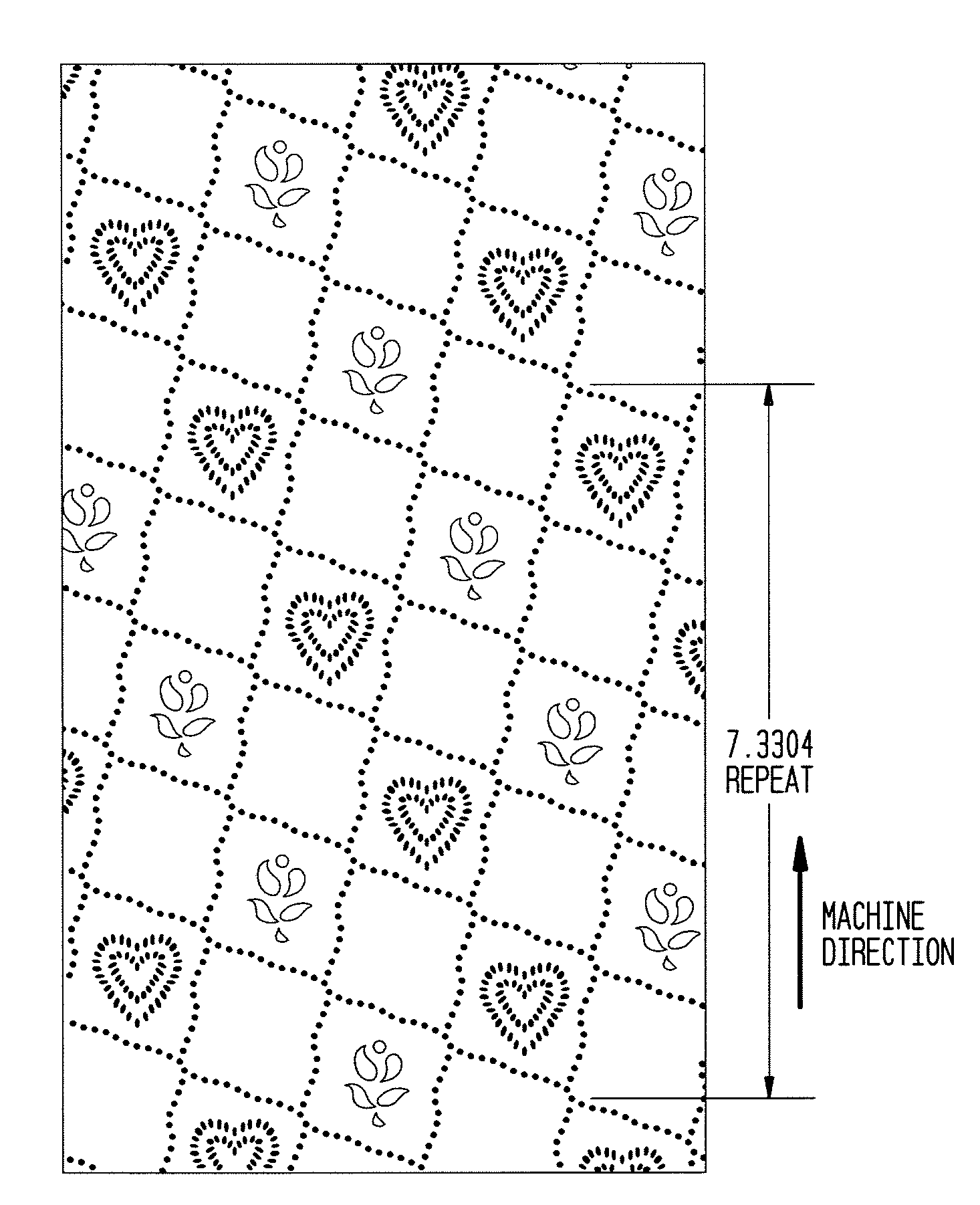

High Softness, High Durability Bath Tissue Incorporating High Lignin Eucalyptus Fiber

ActiveUS20130029106A1Less-wet lintOffsetting costsCellulosic pulp after-treatmentNon-fibrous pulp additionCellulose fiberMaterials science

A cellulosic tissue includes cellulosic fibers selected from the group consisting of chemically pulped fibers and mechanically pulped fibers, the cellulosic fibers have from about 10% to about 50% by weight eucalyptus fibers having a lignin content of at least about 20% by weight, and from about 3% to about 10% by weight regenerated cellulosic microfibers.

Owner:GPCP IP HLDG LLC

Process of manufacturing authenticatable paper products

InactiveUS6054021AConvenient verificationEasy to manufactureSpecial paperPaper after-treatmentFiberWhitening Agents

An authenticatable paper product is prepared by adding to a papermaking furnish fibers treated with from about 50-200 lb / ton of a fluorescent whitening agent (FWA). The paper made from the papermaking furnish will include fluorescent cellulosic fibers in an amount ranging from between 0.1-4.0 lb / ton to achieve FWA concentrations within the range of 1-20 ppm.

Owner:PIXELLE SPECIALTY SOLUTIONS LLC

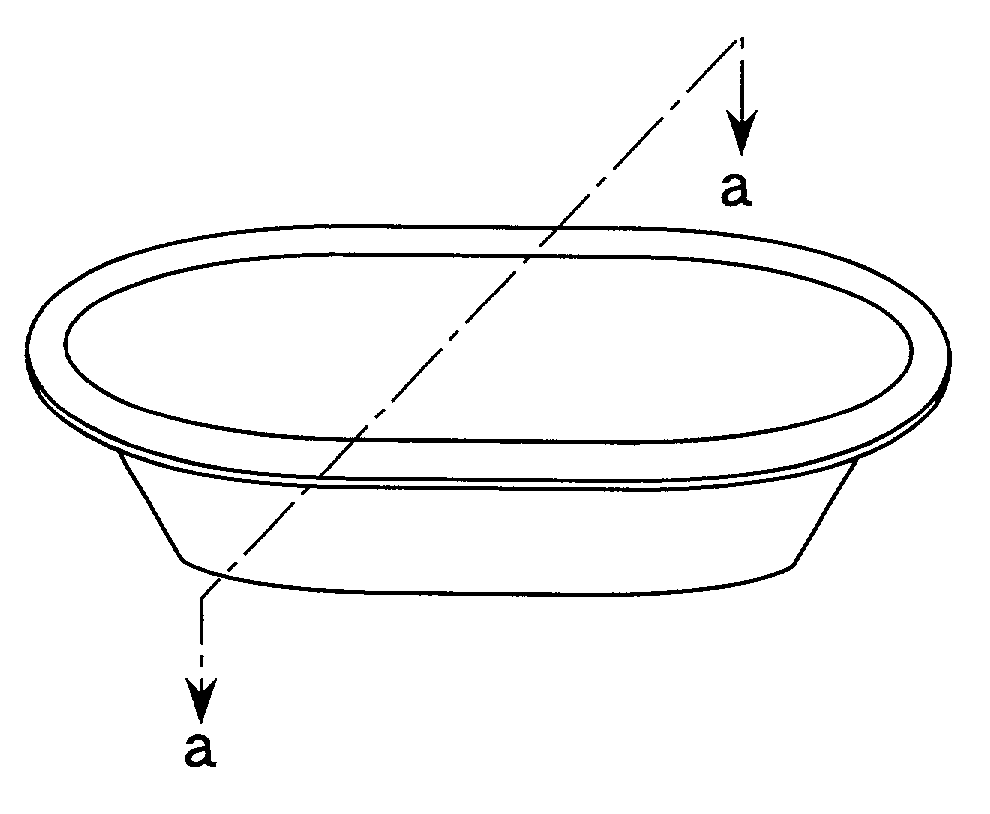

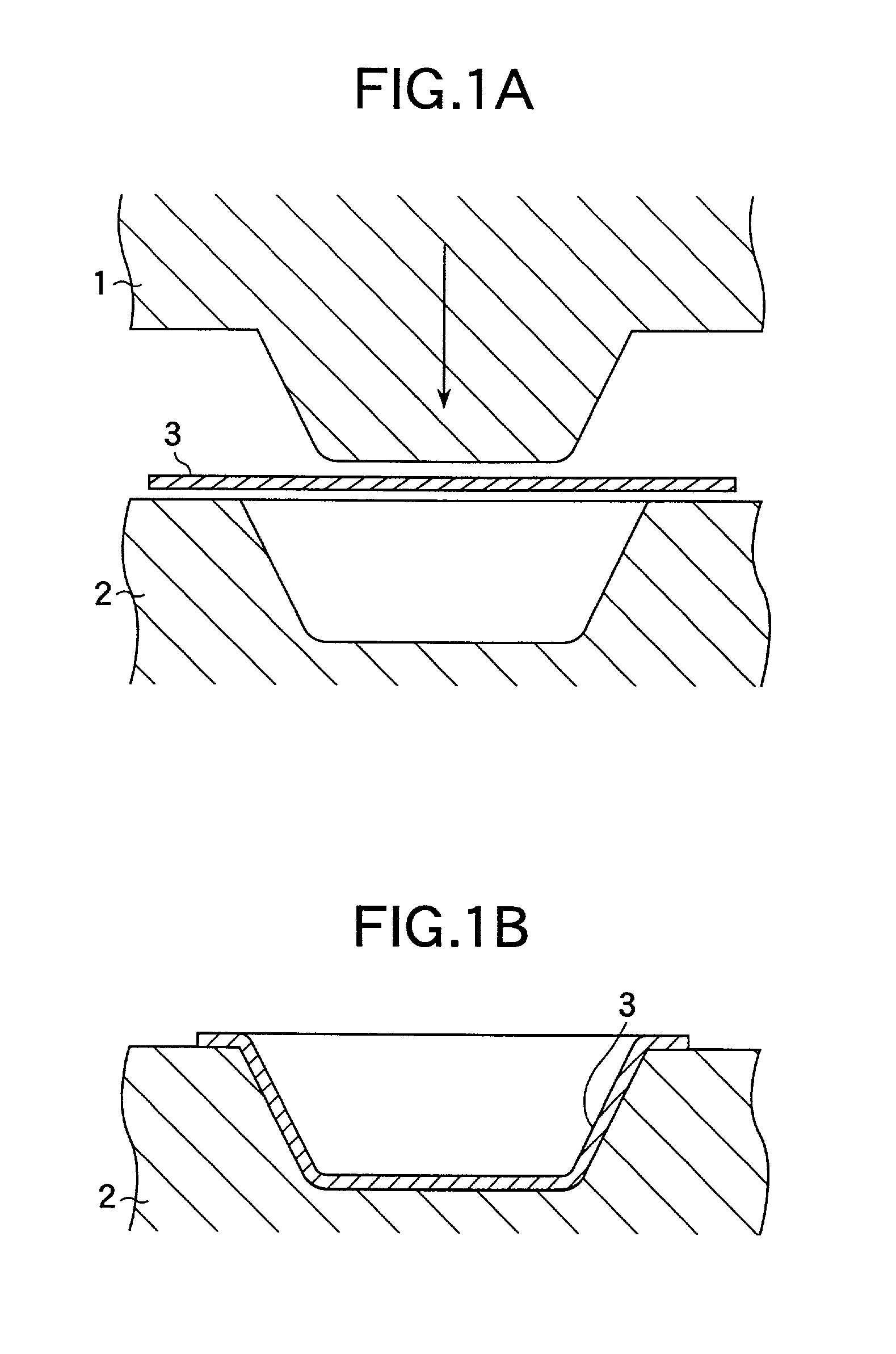

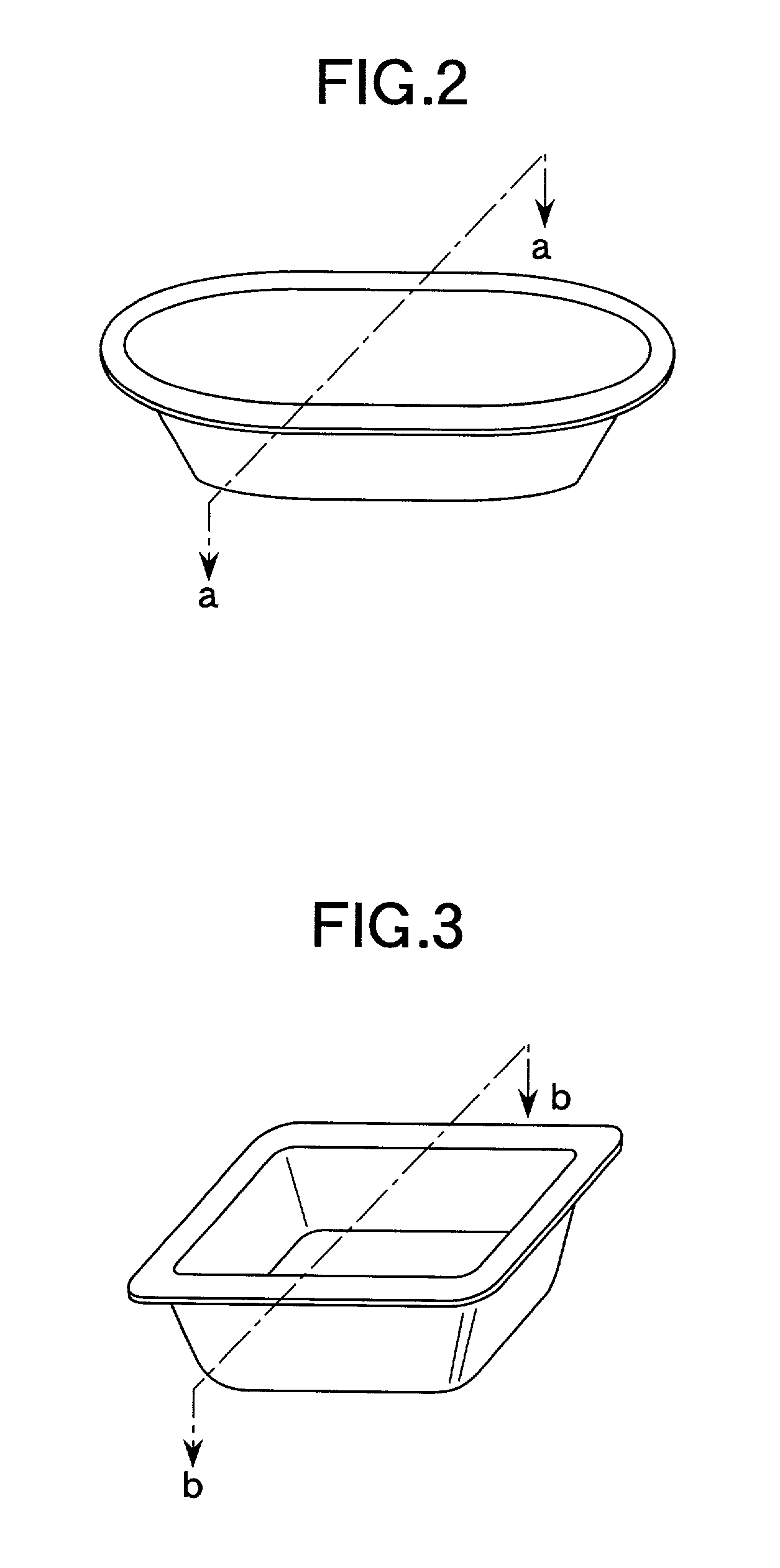

Molding base paper and molded paper vessel produced from it

InactiveUS20020012759A1Mechanical working/deformationSpecial paperCompressive strengthUltimate tensile strength

A molding base paper used for forming paper vessels such as a cup or tray for foods and various industrial products is disclosed which satisfies the following conditions (1) to (4): (1) a tensile strength (JIS-P 8113) of at least 2.0 kN / m, (2) an elongation at break (JIS-P 8113) of at least 1.5%, (3) a critical compression stress, defined by the following formula, in the range of 1 to 10 MPa: <paragraph lvl="0"><in-line-formula>critical compression stress=A / B < / in-line-formula>wherein A represents the compression strength determined by JIS-P 8126, and B represents the area of loaded part of the test piece in the determination of the compression strength, and (4) an amount of the compression deformation, caused by applying compression stress of 20 kgf / cm2in thickness direction, of at least 10 %. The paper vessels are prepared by controlling the water content of the molding base paper at 10 to 20% and then drawing the molding base paper at 100 to 150° C.

Owner:OJI PAPER CO LTD

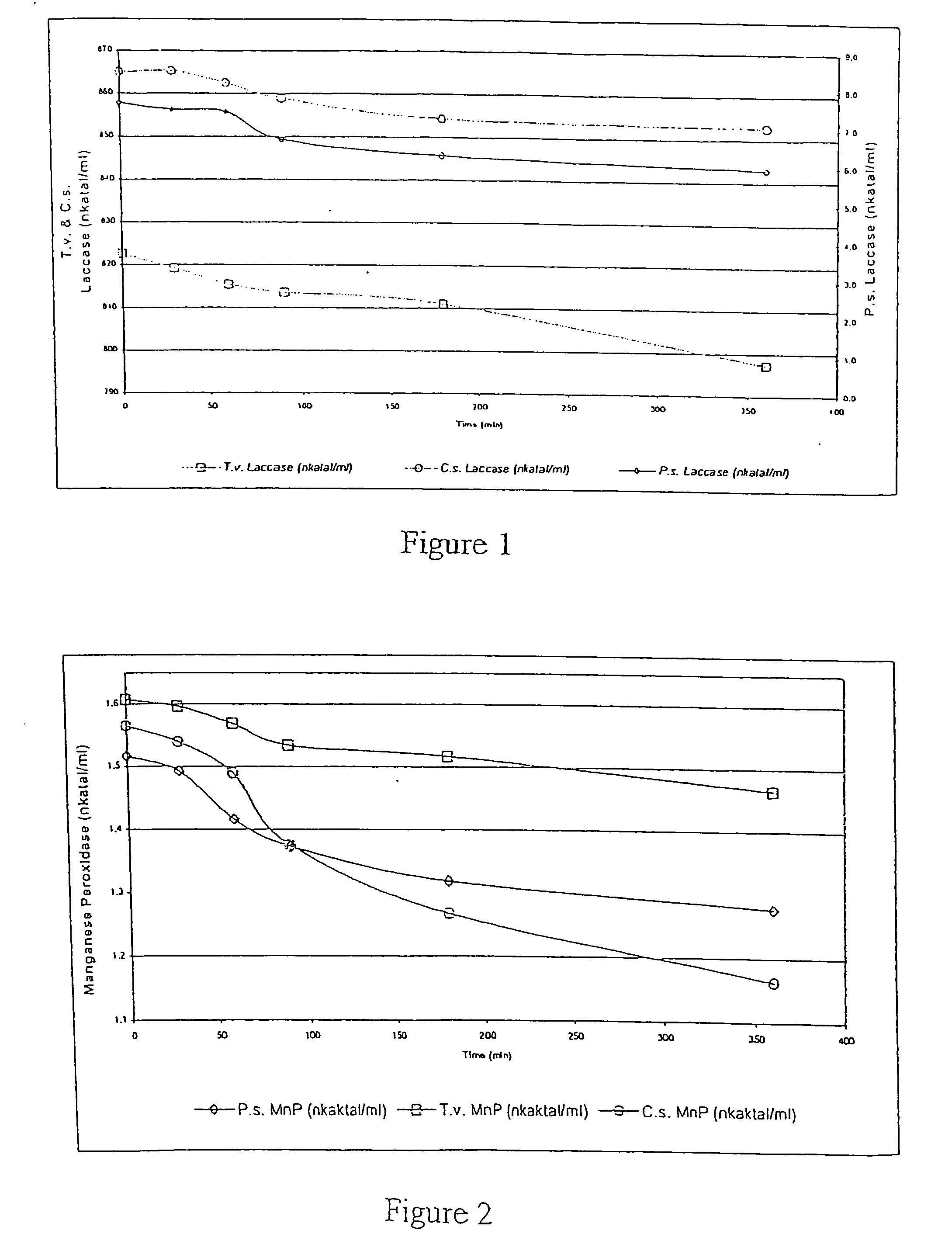

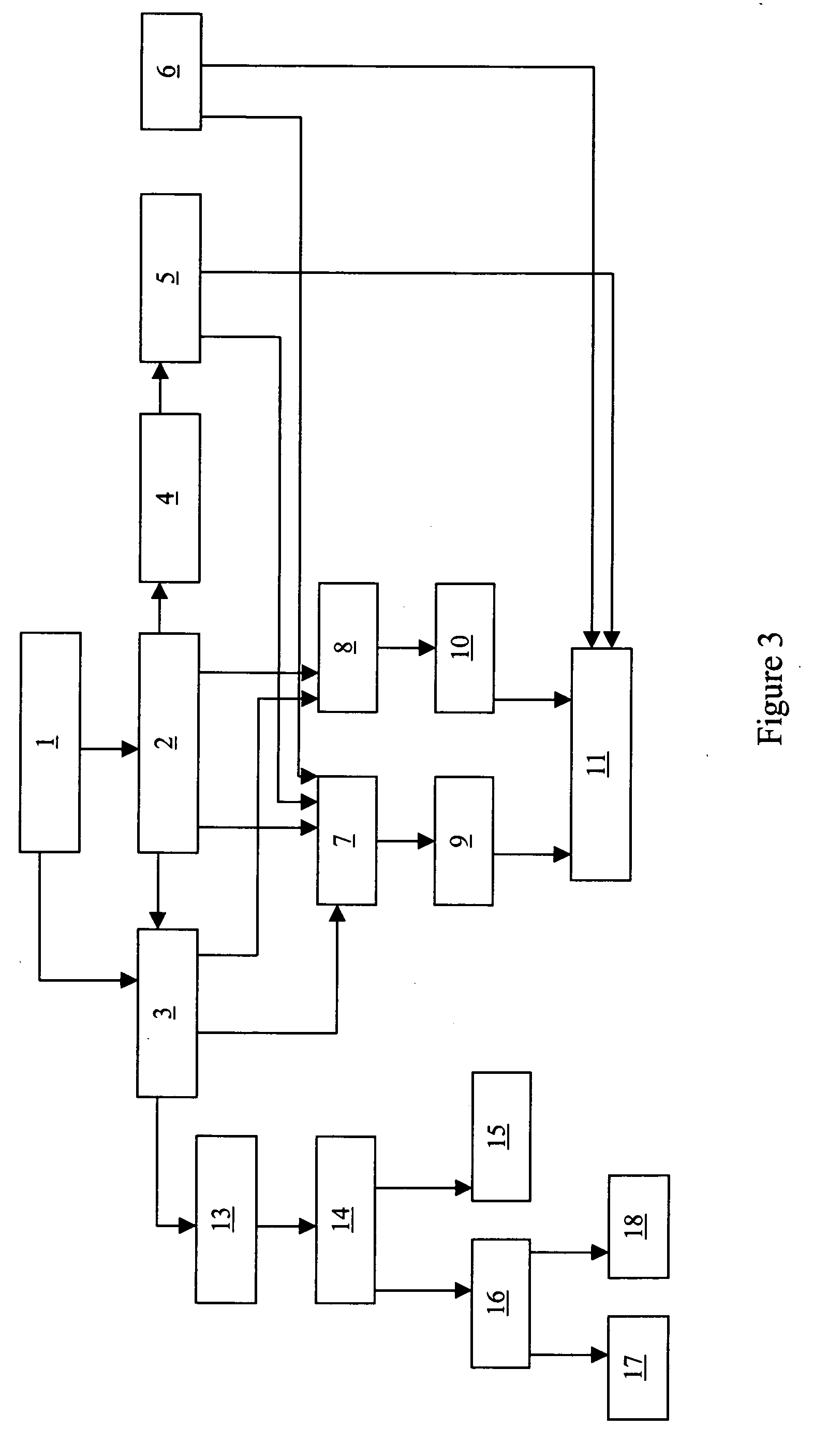

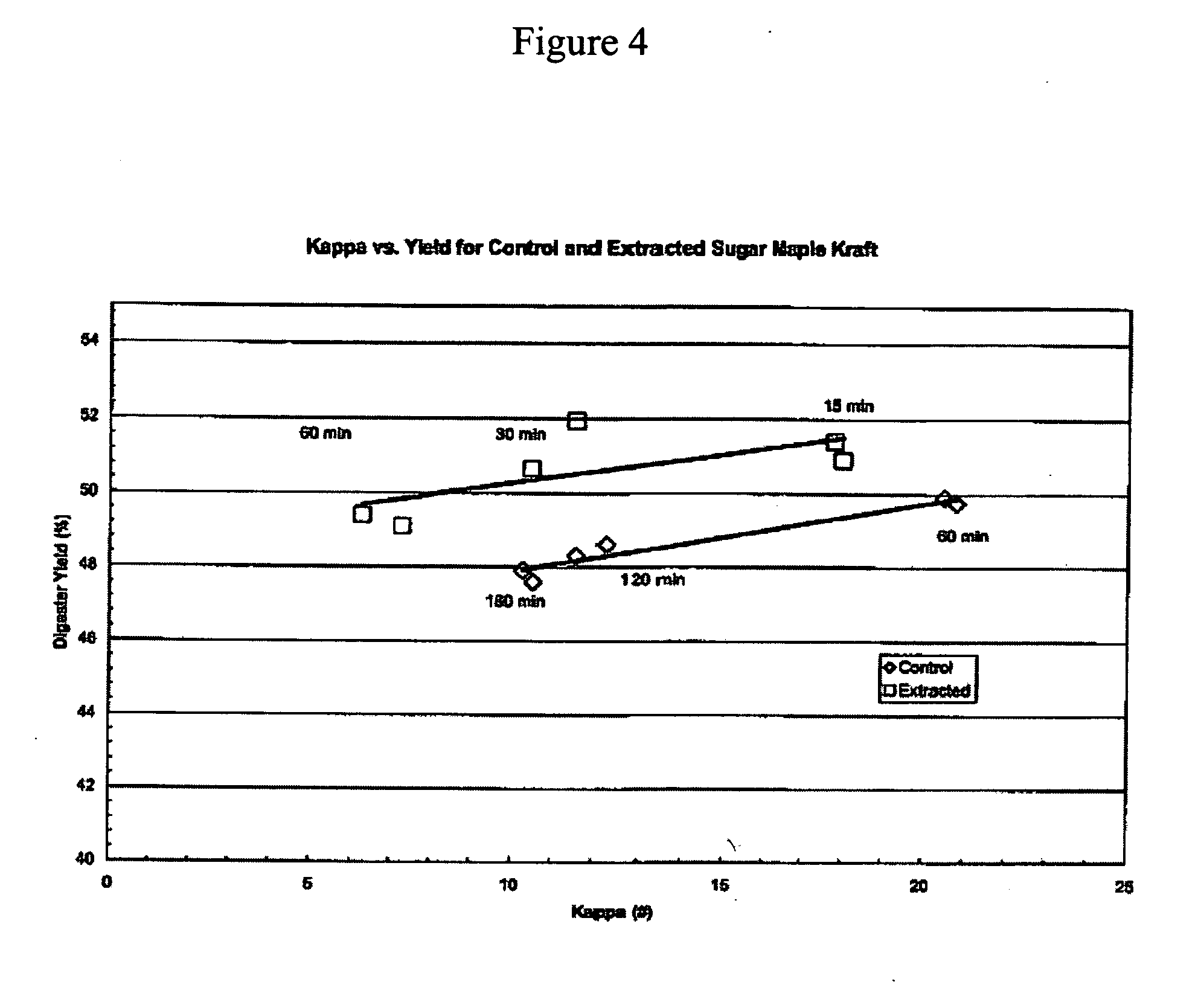

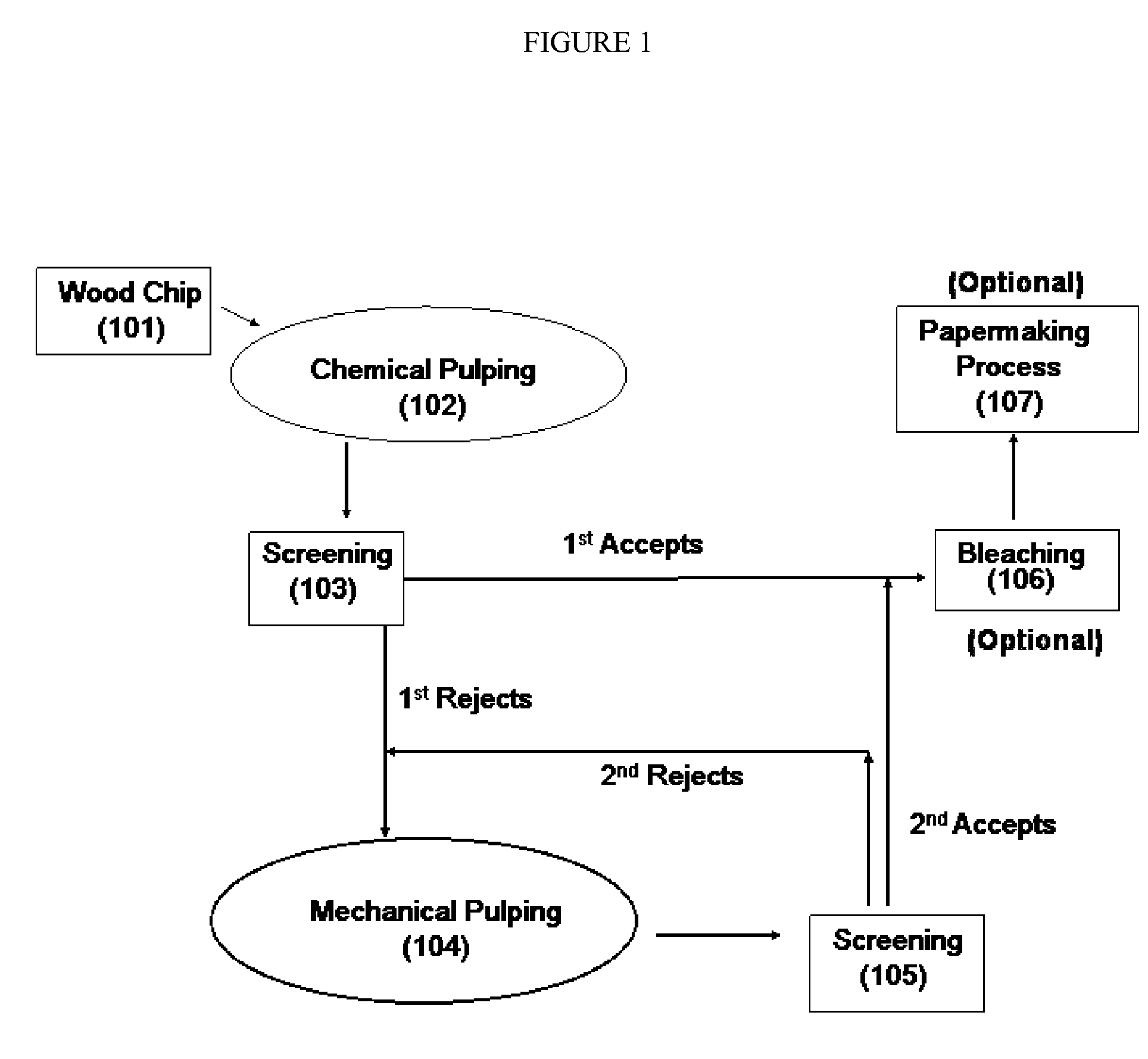

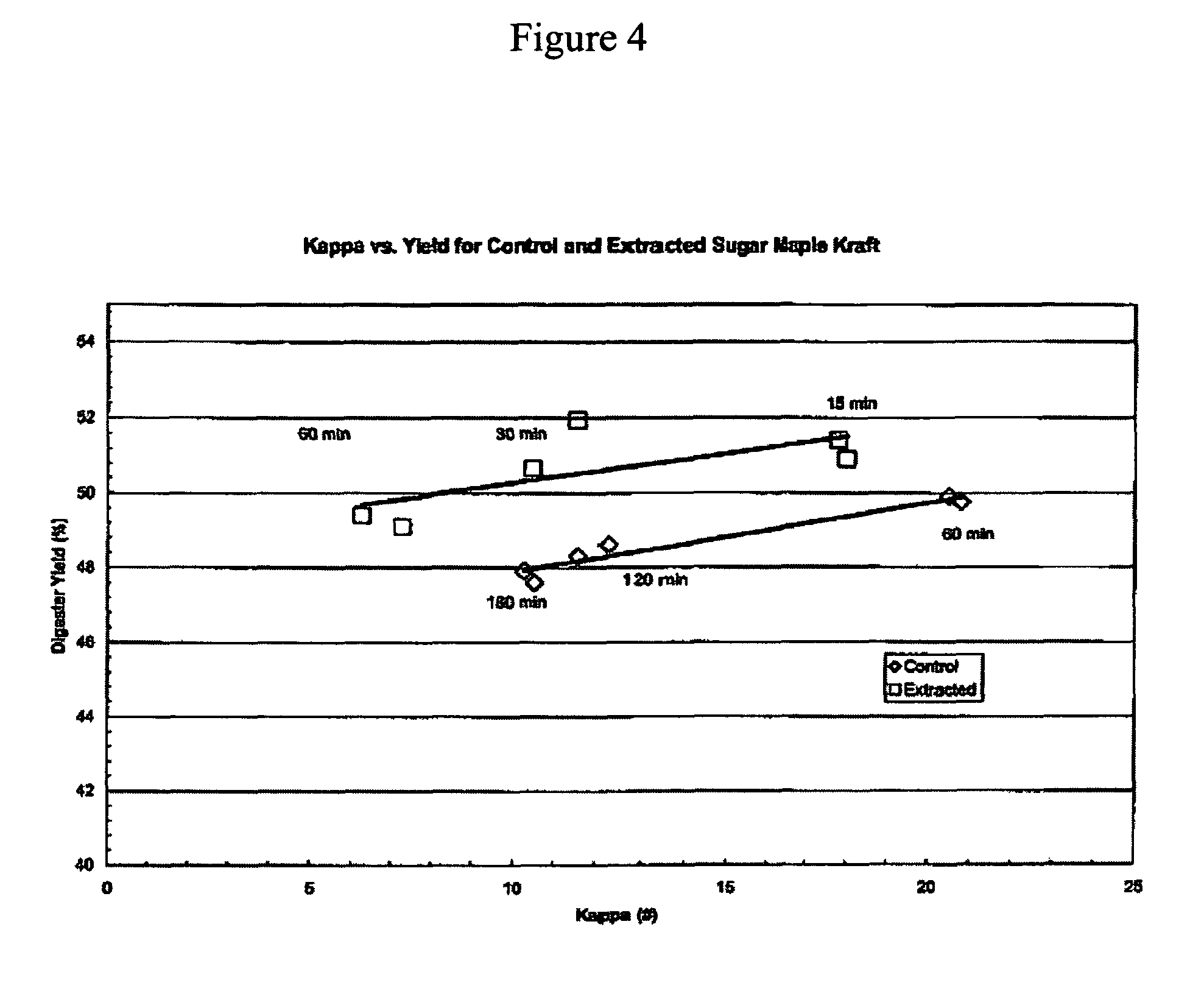

Product and processes from an integrated forest biorefinery

ActiveUS20070079944A1Easy to optimizePretreatment with water/steamPulping with acid salts/anhydridesPulp and paper industrySugar

An omnibus process of pulping and bleaching lignocellulosic materials in which a charge of a lignocellulosic material is biopulped and / or water extracted prior to pulping and bleaching. The lignocellulosic material may be mechanically pulped and bleached in the presence of an enzyme that breaks lignin-carbohydrate complexes. The aqueous extract in embodiments including a water extract step is separated into acetic acid and hemicellulose sugar aqueous solutions.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

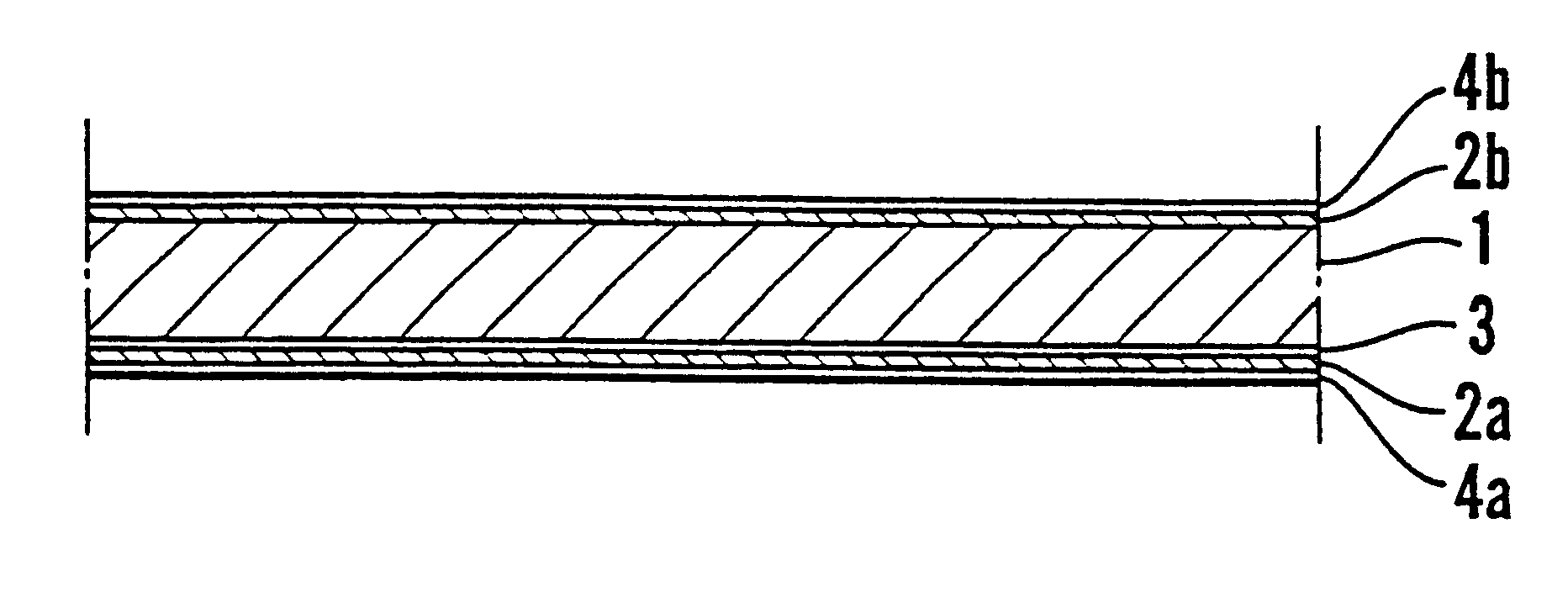

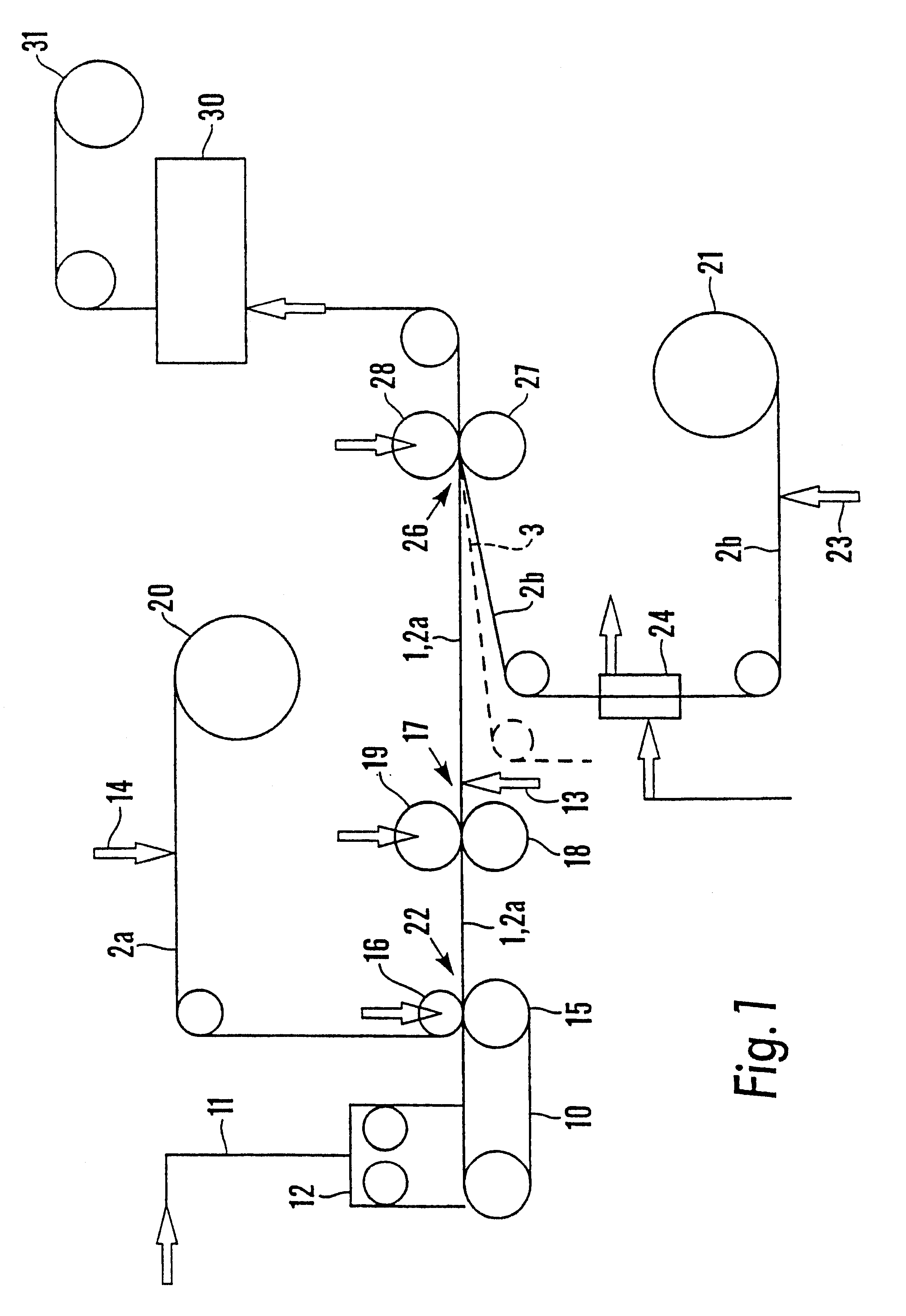

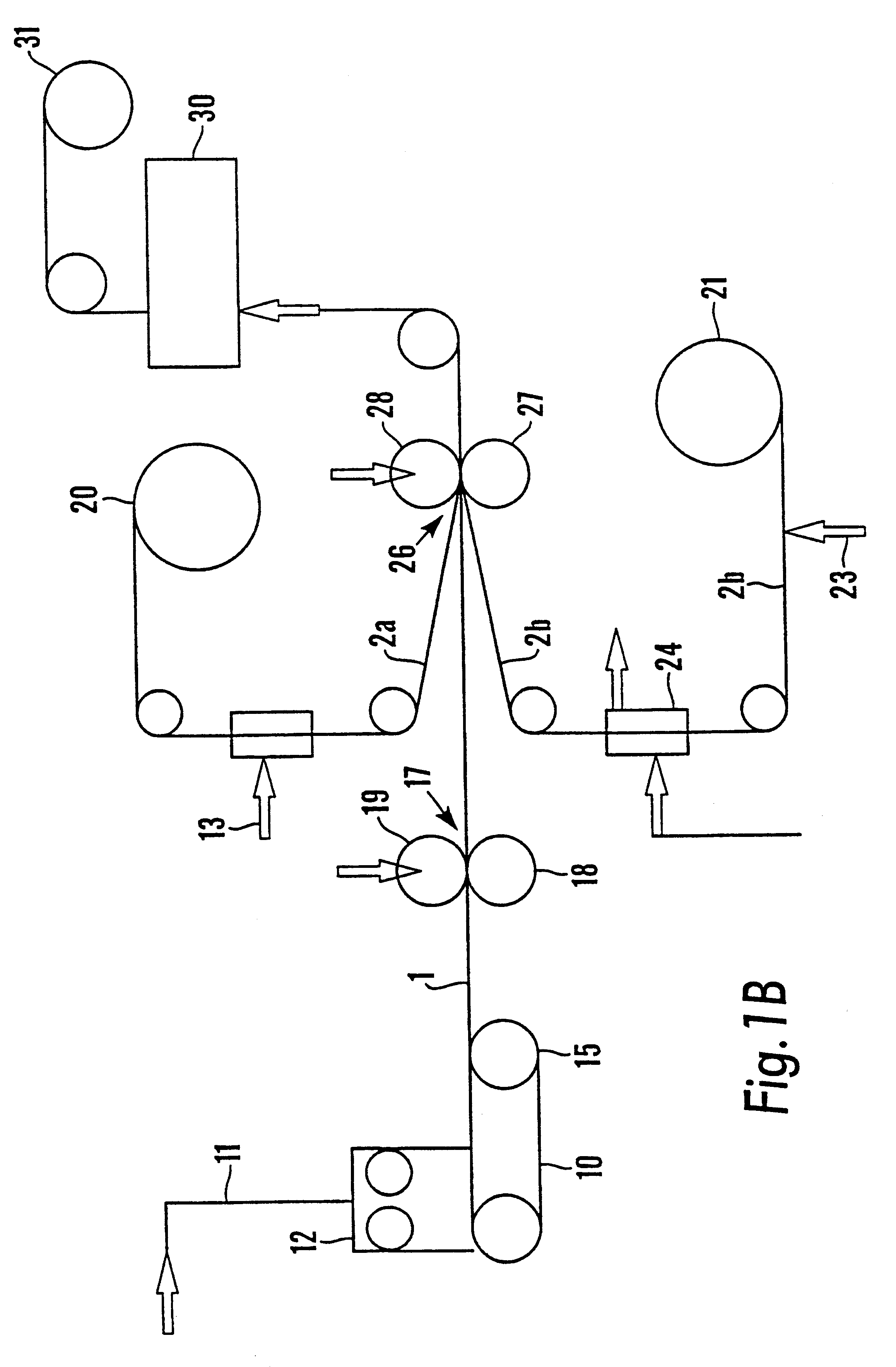

Paper or paperboard laminate and method to produce such a laminate

InactiveUS6537680B1Increase stiffnessFacilitate folding and subsequent creasingNon-fibrous pulp additionWrappersPaperboardCellulose fiber

Paper or paperboard laminate composed of at least one bulk-promoting layer, here termed the bulk layer, and on at least one side at the bulk layer at least one secondary layer, secondary layer and bulk layer being joined to one another directly or indirectly over basically the whole of their surfaces facing one another, 40-95% of the bulk layer consists of cellulose fibers with a freeness of 550-950 ml CSF, the secondary layer / layers has / have a greater density than the bulk layer, and the laminate has a bending stiffness index higher than 2.5 Nm7 / kg3, but less than 14 Nm7 / kg3, calculated as a geometric mean value for machine and transverse direction.

Owner:STORA ENSO AB

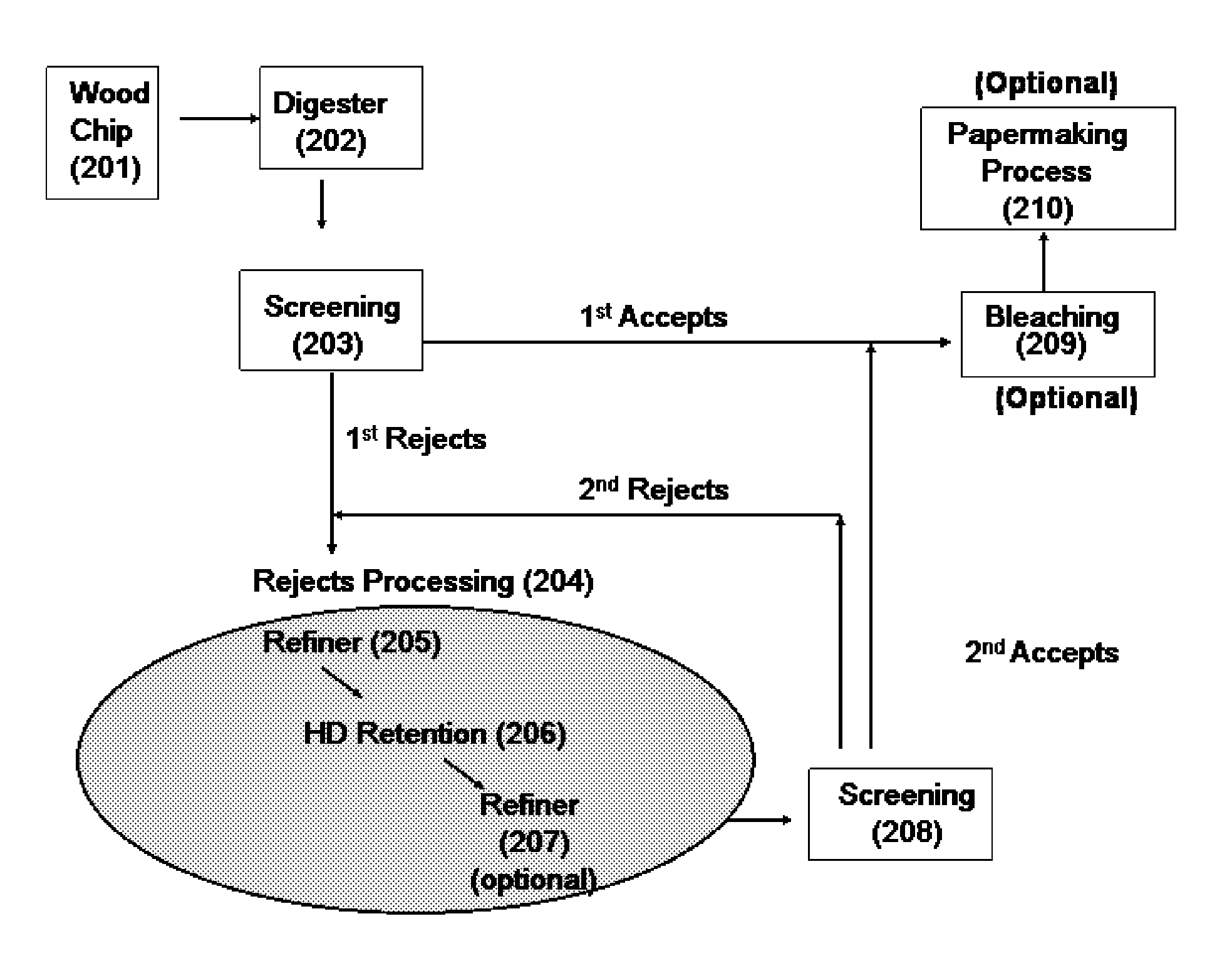

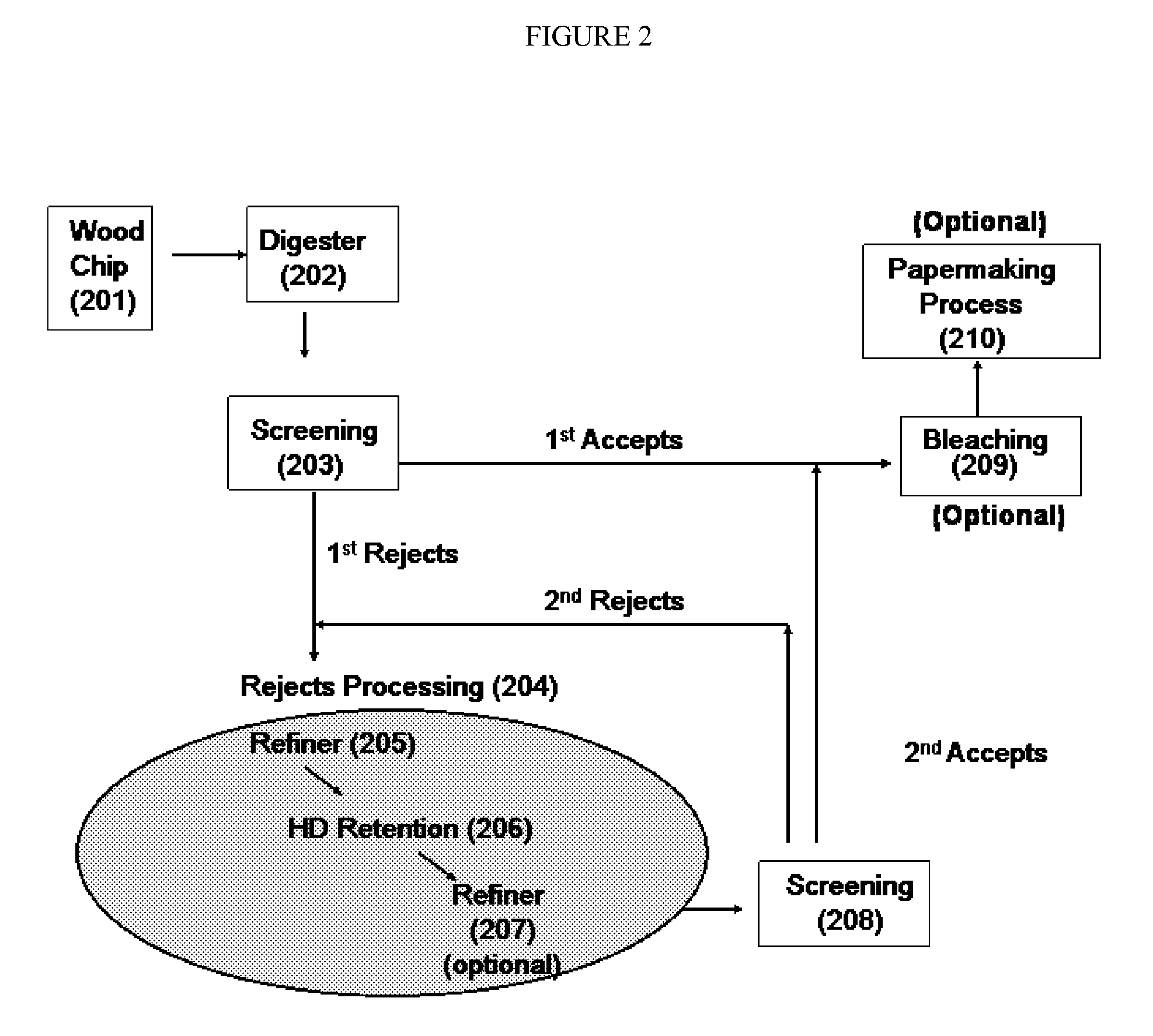

Fiber blend having high yield and enhanced pulp performance and method for making same

InactiveUS20080308239A1Increase stiffnessHigh strengthFibreboardPulp properties modificationFiberKappa number

The present disclosure relates to producing paper or paperboard having improved stiffness and strength, compared to the conventional paperboard at the same basis weight. It also discloses a method of wood pulping having a significantly increased yield and providing fiber pulps with enhanced properties such as strength and stiffness. Wood chips are chemically pulped to a high kappa number, providing a rejects component and an accepts component. The rejects component is subjected to a substantially mechanical pulping process, optionally in a presence of bleaching agent, prior to blending back into the accepts component. The resulting fiber blend is washed, optionally bleached, and subjected to a papermaking process to provide paper or paperboard with enhanced strength and stiffness at low basis weight.

Owner:MEADWESTVACO CORP

Printing paper

InactiveUS6923889B2Increase coverageGood printabilityNon-fibrous pulp additionSpecial paperFiberSurface roughness

The invention relates to coated printing paper which contains mechanical pulp and whose opacity is at least 89%, brightness at least 65% and surface roughness not more than 4.5 μm. The printing paper contains mechanical pulp at least 90 weight-% of the total fiber content of the paper.

Owner:UPM-KYMMENE OYJ

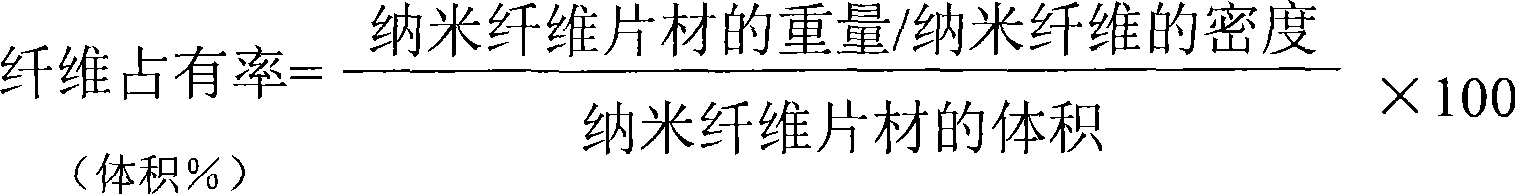

Nanofiber sheet, process for producing the same, and fiber-reinforced composite material

ActiveUS20090264036A1High cellulose fiber crystallinityReduction factorFats/resins/pitch/waxes removal in pulpPrinted circuit aspectsPolymer scienceYoung's modulus

Provided is a nanofiber sheet that sufficiently refined by fibrillation and has high crystallinity of cellulose fiber and can realize a fiber-reinforced composite material exhibiting high transparency, a high elastic modulus, a low coefficient of linear thermal expansion, and high heat resistance and being high in flatness and smoothness. This nanofiber sheet includes crystalline cellulose as the main component and a lignin in an amount of from 10 ppm to 10 wt %. When a fiber / resin composite material obtained by impregnating the nanofiber sheet with tricyclodecane dimethacrylate, subjecting the impregnated product to UV-curing at 20 J / cm2, and heating the cured product in vacuum at 160° C. for two hours includes 60 wt % of the cured tricyclodecane dimethacrylate and 40 wt % of nanofiber, the following physical characteristics (i) to (iii) are satisfied: (i) the parallel light transmittance of light of a wavelength of 600 nm at a sheet thickness of 100 μm is 70% or more; (ii) the Young's modulus is 5.0 GPa or more; and (iii) the coefficient of linear thermal expansion is 20 ppm / K or less.

Owner:ROHM CO LTD +1

Nanofiber sheet and method for manufacturing the same

ActiveUS20110117319A1Transparent highImprove flatnessCellulosic pulp after-treatmentMaterial nanotechnologyCelluloseOptical transmittance

A nanofiber sheet that has a high degree of transparency, a high modulus of elasticity, a low coefficient of linear thermal expansion as well as high degrees of flatness and smoothness, in particular, a nanofiber sheet produced as a uniform and flat sheet having a high optical transmittance with cellulose as the only component. This sheet has the following characteristics: Calculated for a thickness of 60 μm, the transmittance for parallel rays of light having a wavelength of 600 nm is equal to or higher than 70%; The Young's modulus measured in accordance with the JIS K7161 method is equal to or greater than 10 GPa; The coefficient of linear thermal expansion measured in accordance with the ASTM D606 method is equal to or smaller than 10 ppm / K.

Owner:ROHM CO LTD

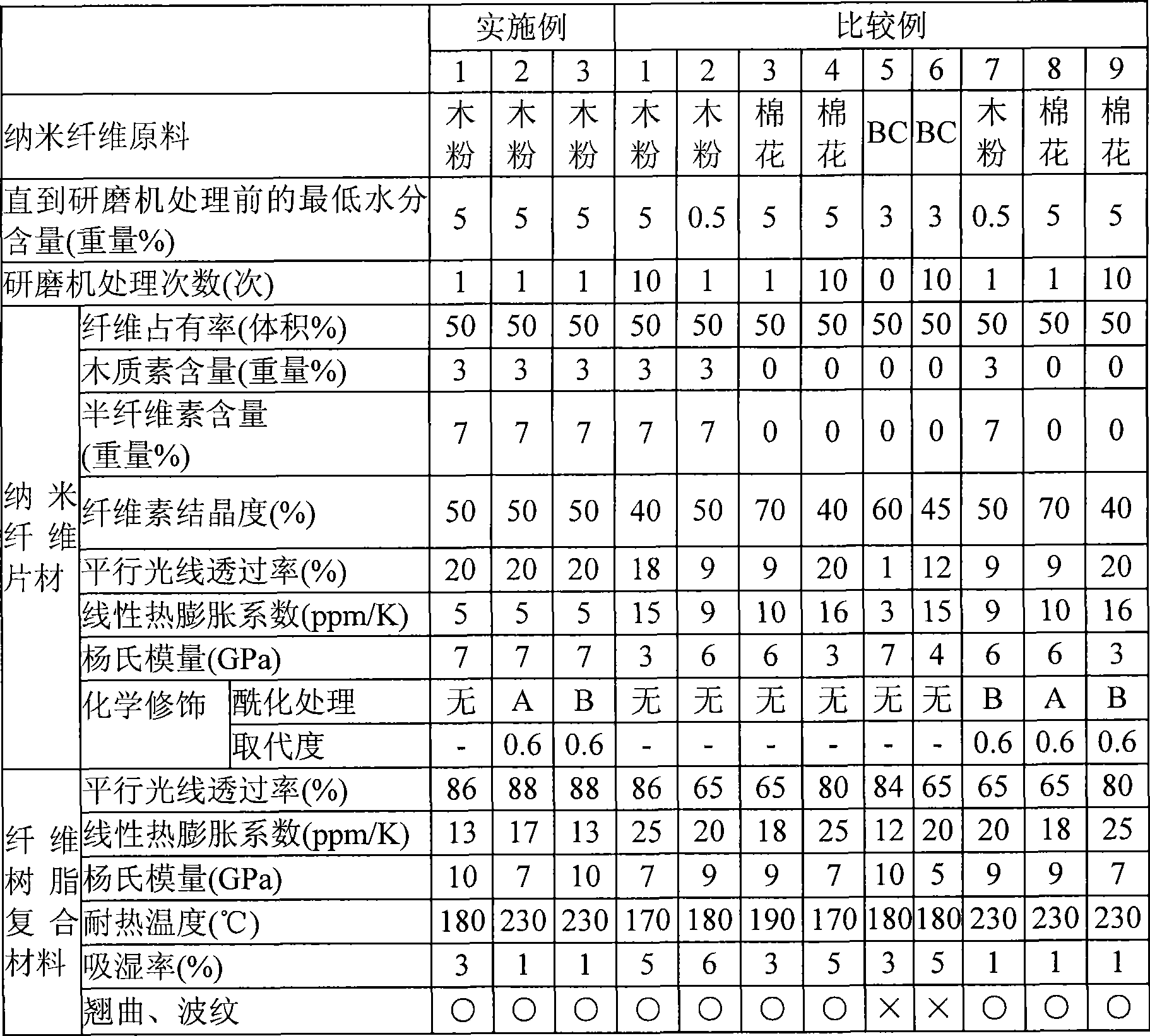

Highly absorbent articles

ActiveUS20200063372A1Excellent characteristicsImprove propertiesReinforcing agents additionPaper/cardboardBursting strengthPolymer science

Absorbent wet laid products are made containing cellulose fibers and cellulose ester staple fibers that are co-refined to obtain products and articles that have improved water absorbency and tensile strength or burst strength or both. The absorbent wet laid products can now be made with a synthetic fiber in the wet laid operation since cellulose ester can be subjected to a refining operation.

Owner:EASTMAN CHEM CO

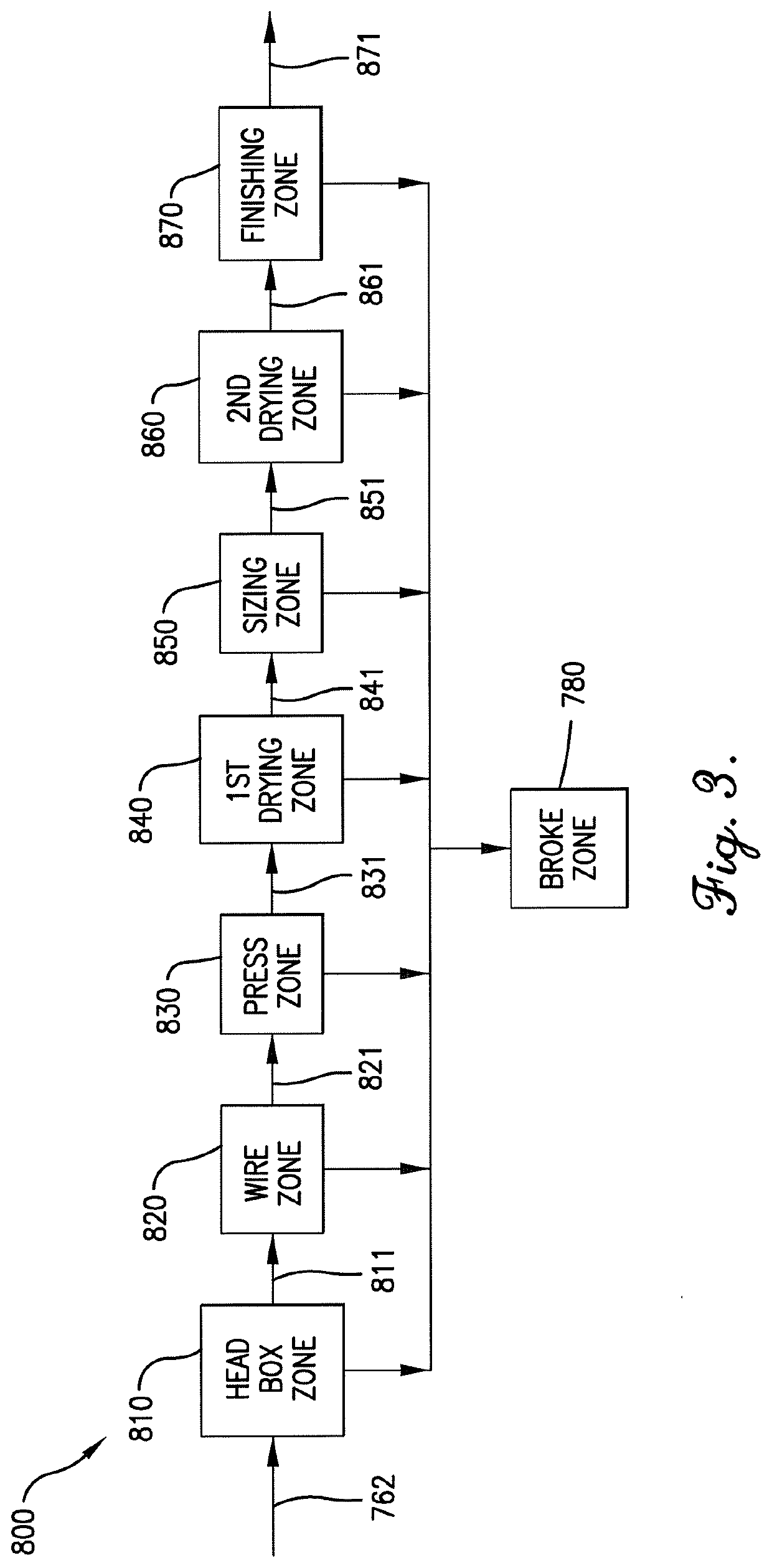

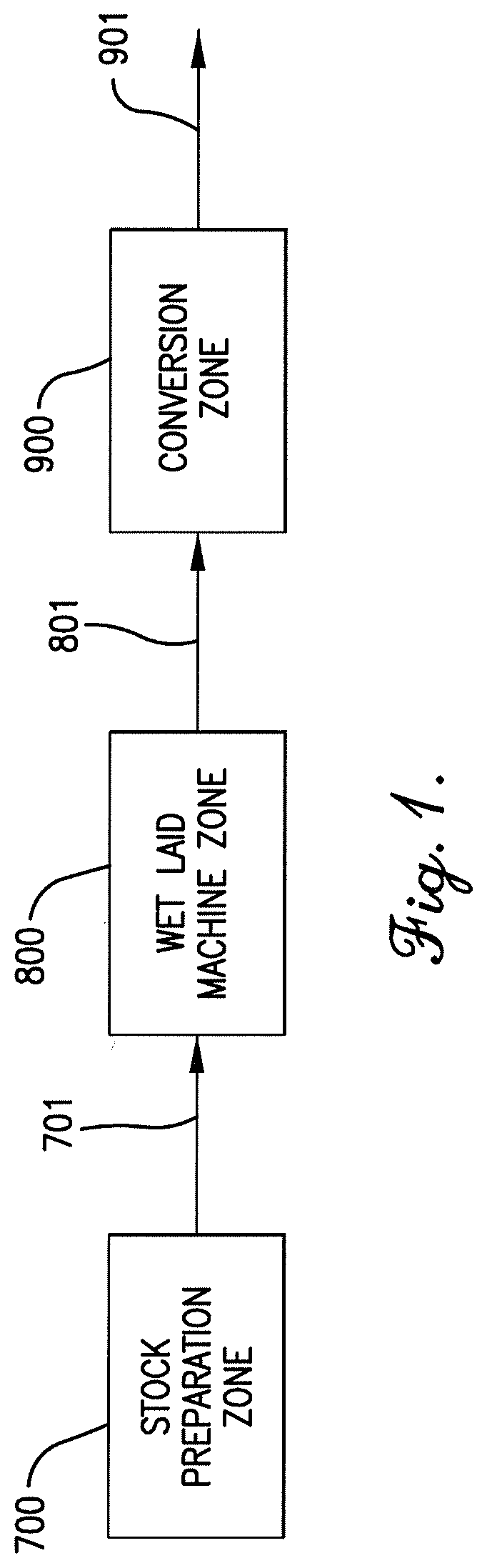

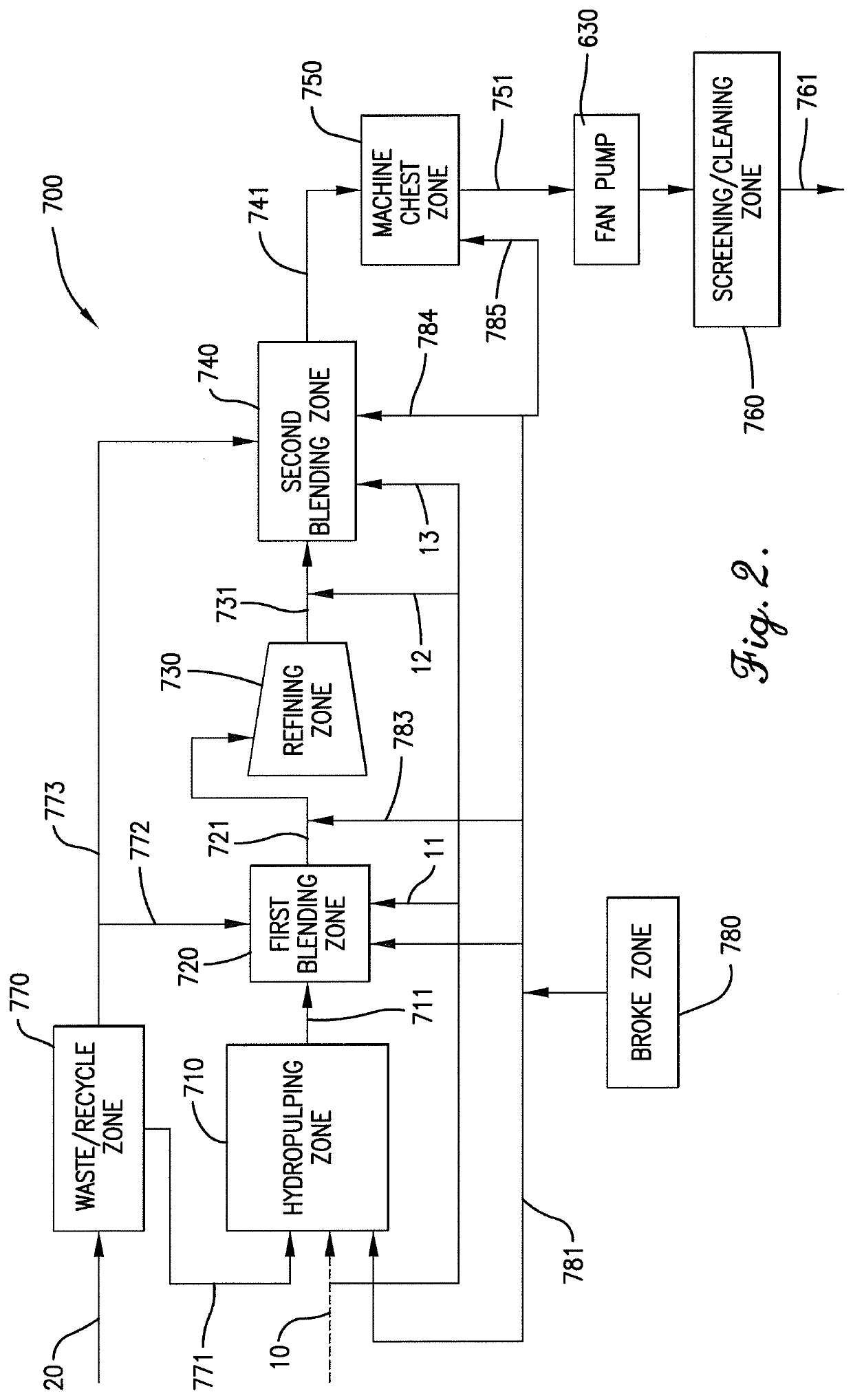

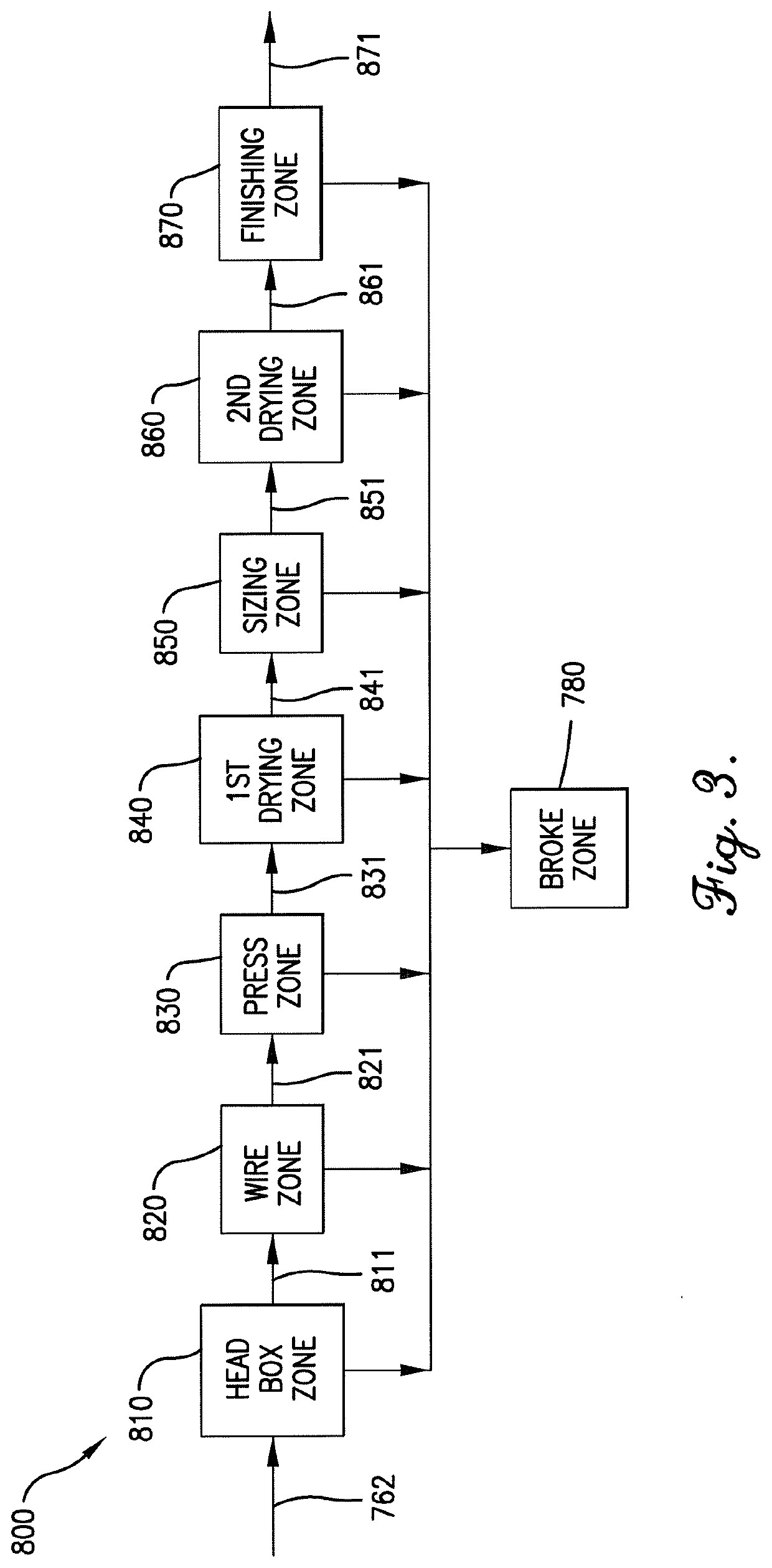

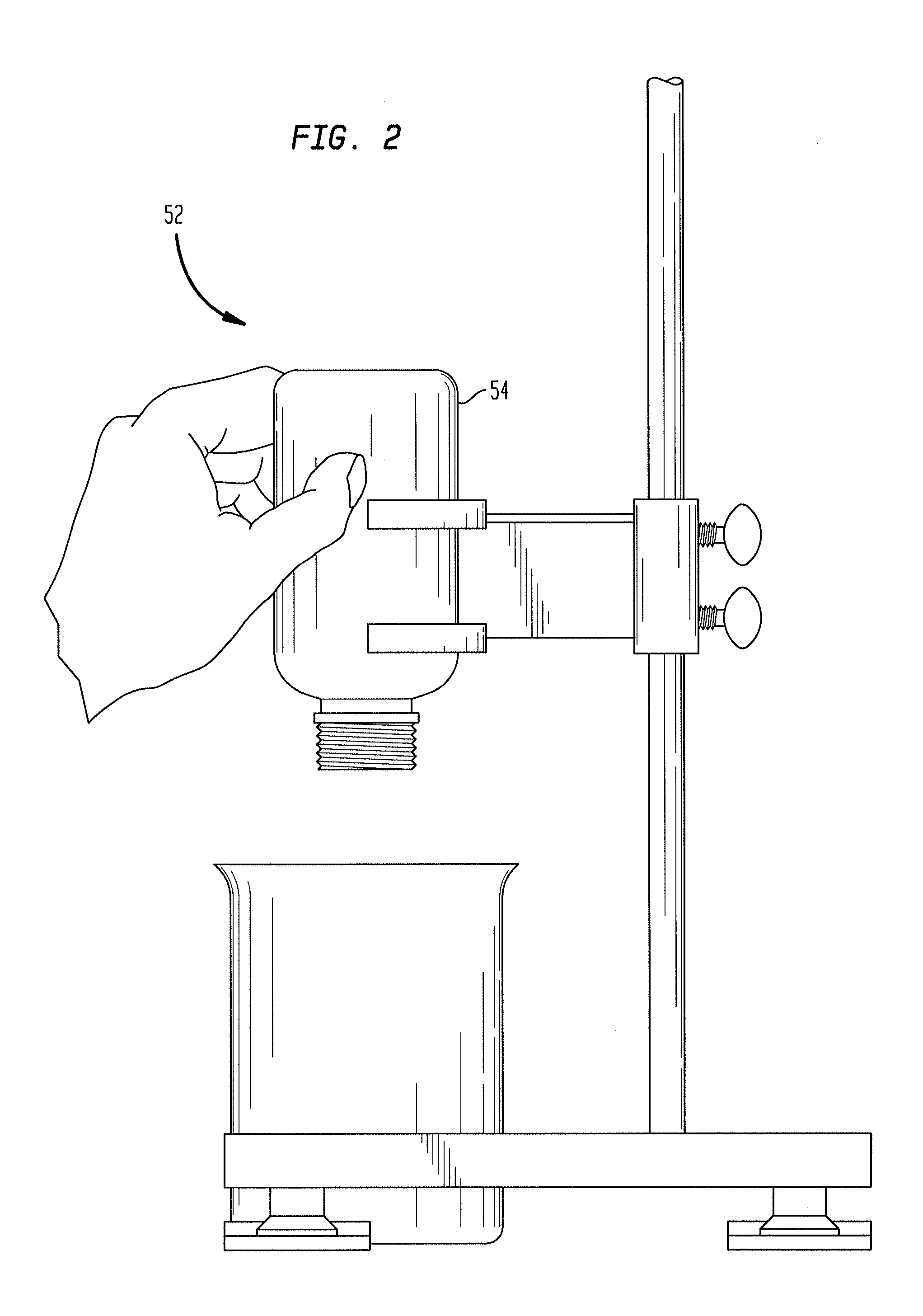

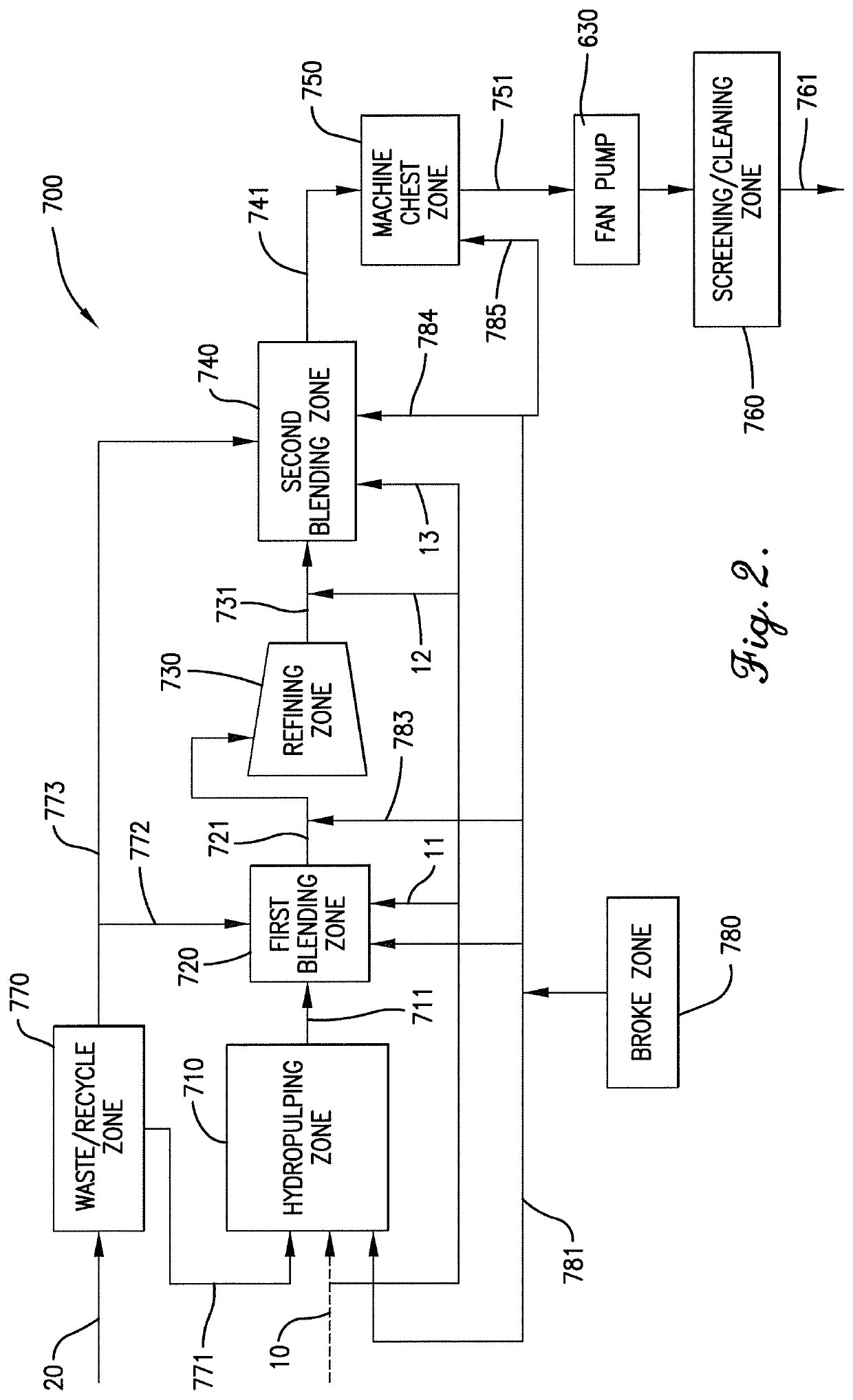

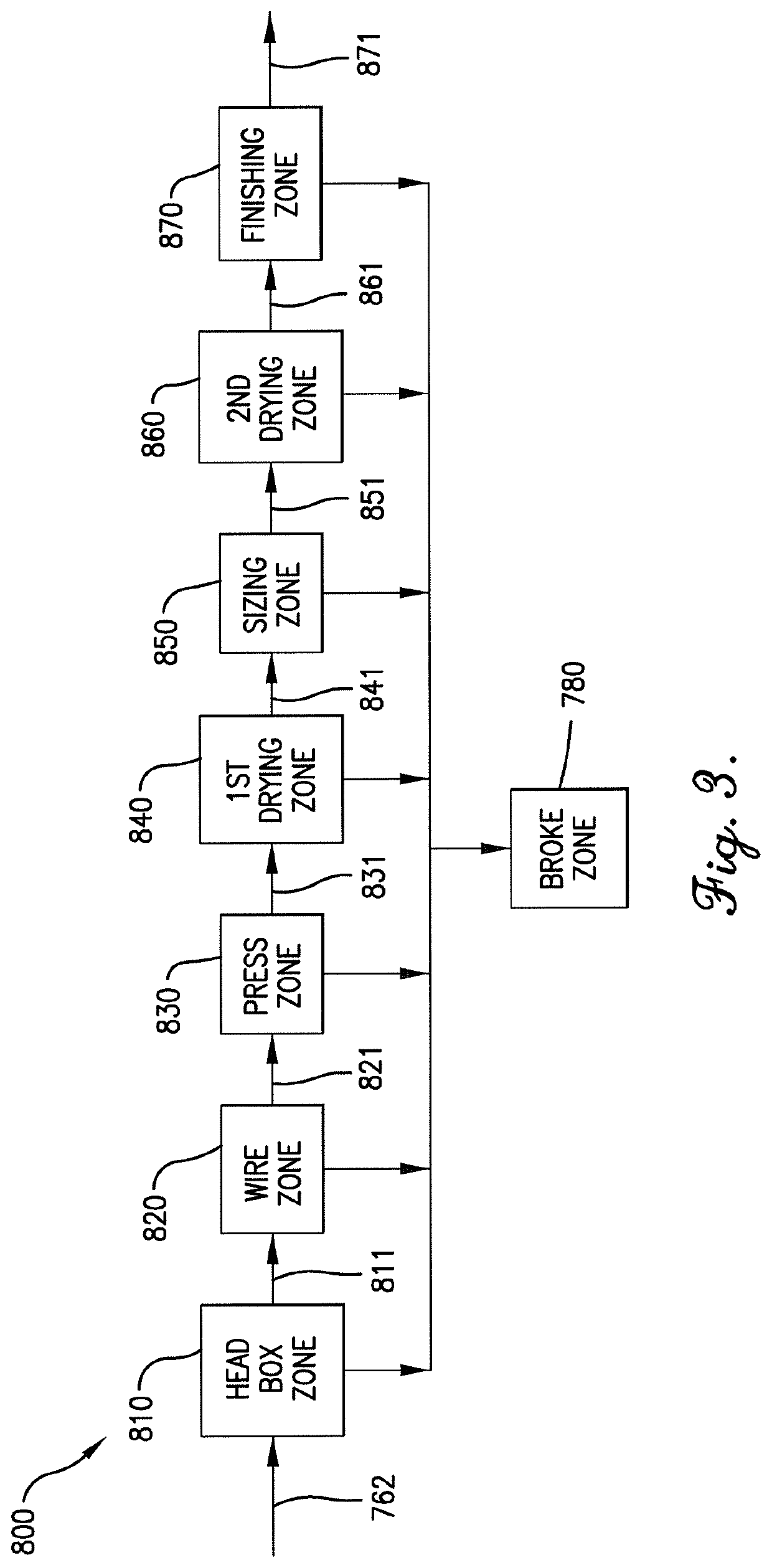

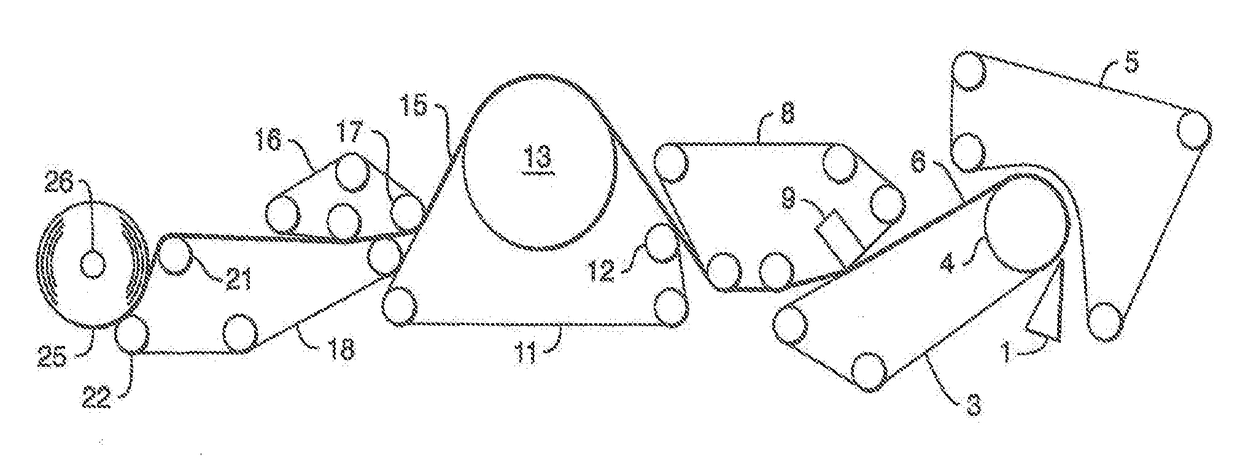

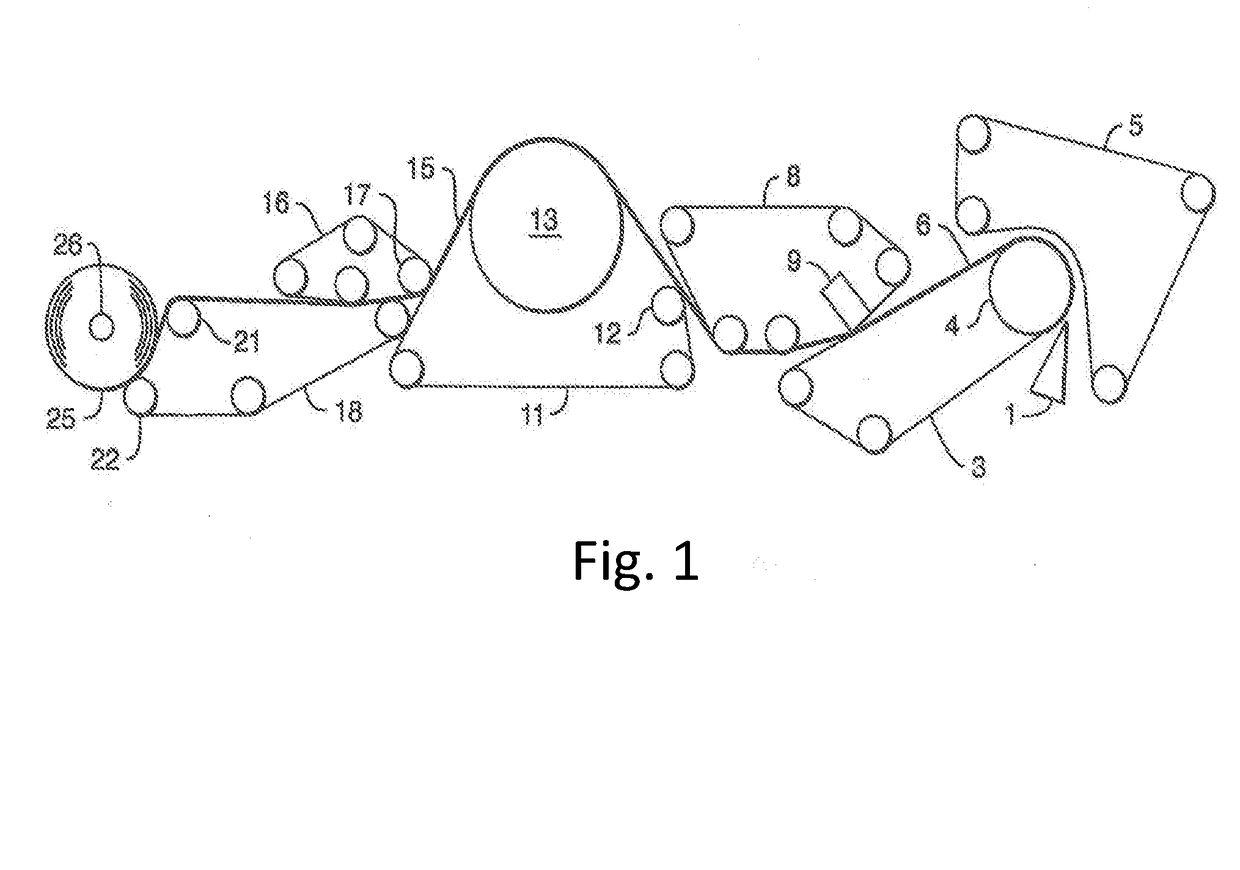

Composition of matter effluent from refiner of a wet laid process

ActiveUS20200063339A1Reduce consistencyLow variabilityFats/resins/pitch/waxes removal in pulpChemical/chemomechanical pulpPolymer scienceCellulose fiber

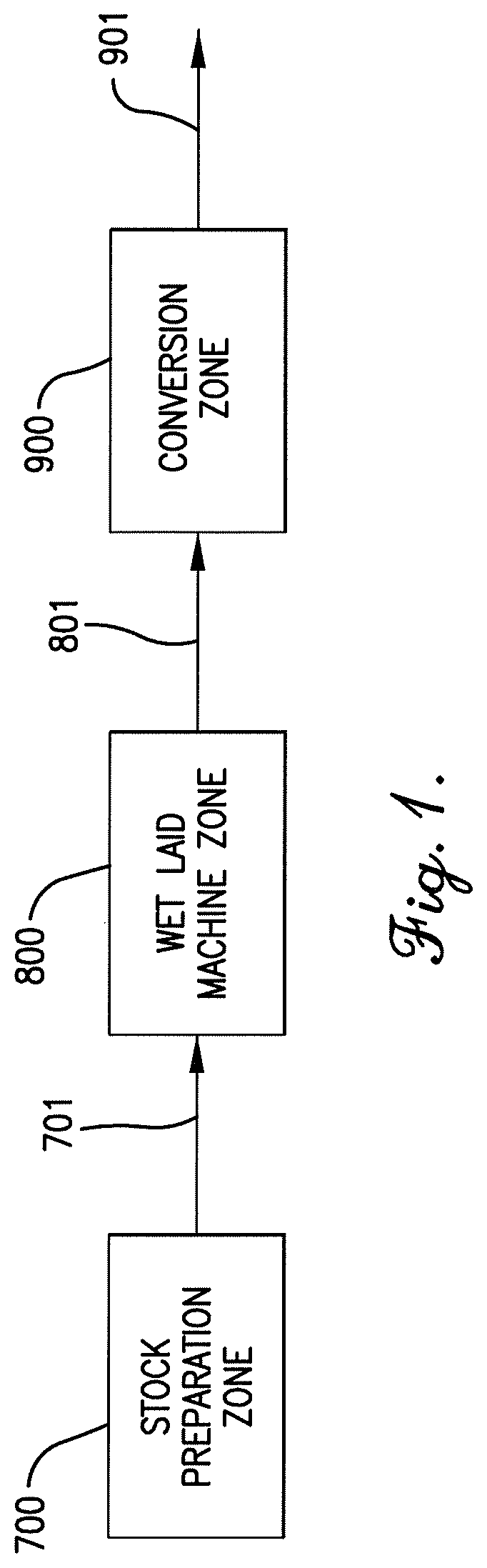

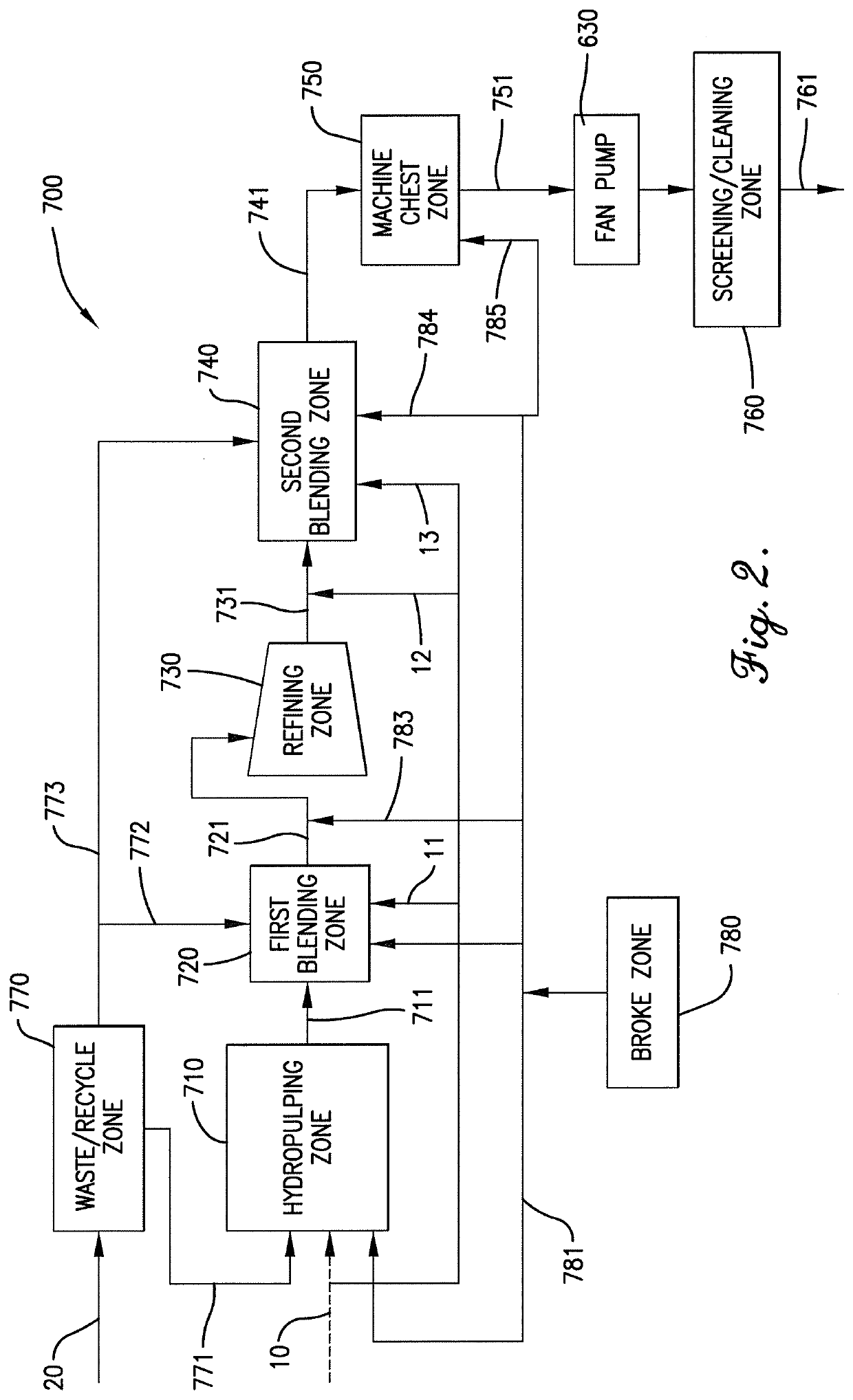

A composition and process for making the composition by co-refining: fibrillated virgin cellulose fibers, waste / recycle cellulose fibers, or both; co-refined cellulose ester (CE) staple fibers having a denier per filament (DPF) of less than 3 and the weight percent of CE staple fibers is less than 30 wt. %, based on the weight of CE staple fibers and said cellulose fibers; and water. The composition can be co-refined to obtain lower Canadian standard freeness yet improved drainage and wet laid products having good tensile strength, air permeability, stiffness, burst strength, and bulk.

Owner:EASTMAN CHEM CO

Oil-proof coating white cardboard and process for producing the same

ActiveCN102926278AAvoid problemsEliminate potential safety hazardsNon-fibrous pulp additionCoatings with pigmentsCardboardCarboxymethyl cellulose

The invention provides an oil-proof coating white cardboard, which comprises a raw paper and a coating layer, wherein the raw paper comprises a surface layer, a core layer and a bottom layer, the coating layer comprises a pre-coating layer, a core coating layer, a surface coating layer and a back coating oil-proof layer, coating compositions of the back coating oil-proof layer comprise 100 parts of pigment, from 50 to 100 parts of latex, from 0 to 50 parts of oil-proof starch, from 0.1-0.6 part of carboxymethyl cellulose, from 0.05 to 0.12 part of dispersing agent, from 0.3 to 1.0 part of water-resistant agent, from 0.3 to 1.2 parts of lubricating agent, 0.0.35 part of antifoaming agent, from 0.05 to 0.2 part of caustic soda and from 0.05 to 0.3 part of bactericide. Oil-proof coating which is used by papers does not use fluorocarbon, thereby avoiding existence of pollution sources such as PFOA and PFOS and the like, and eliminating potential safety hazard that packing papers pollute food. Simultaneously, the oil-proof coating white cardboard is high in oil-proof grade and simple in process, reduces production cost of papers compared with the traditional technology which uses the fluorocarbon, and has excellent economic benefit.

Owner:ZHUHAI S E Z HONGTA RENHENG PAPER

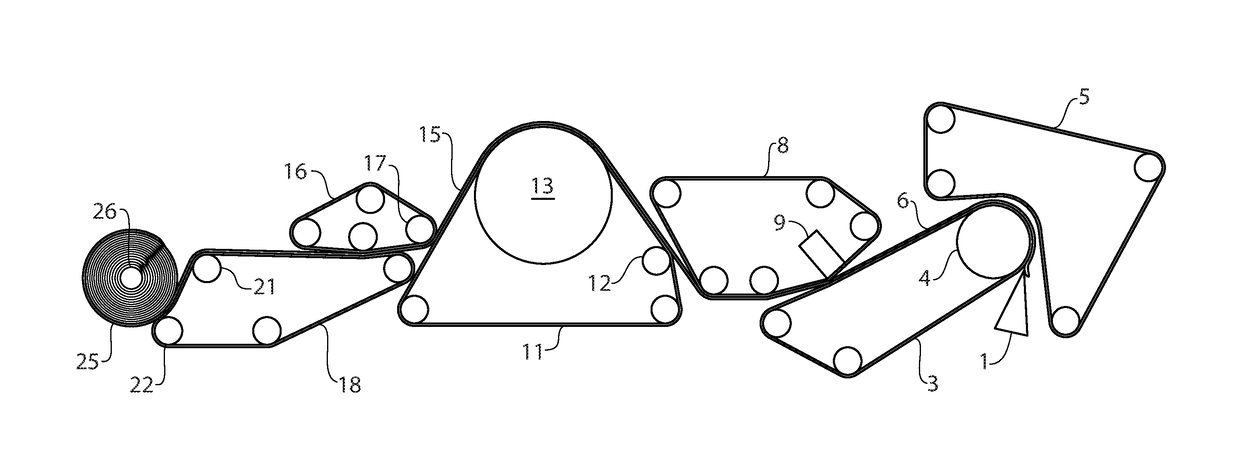

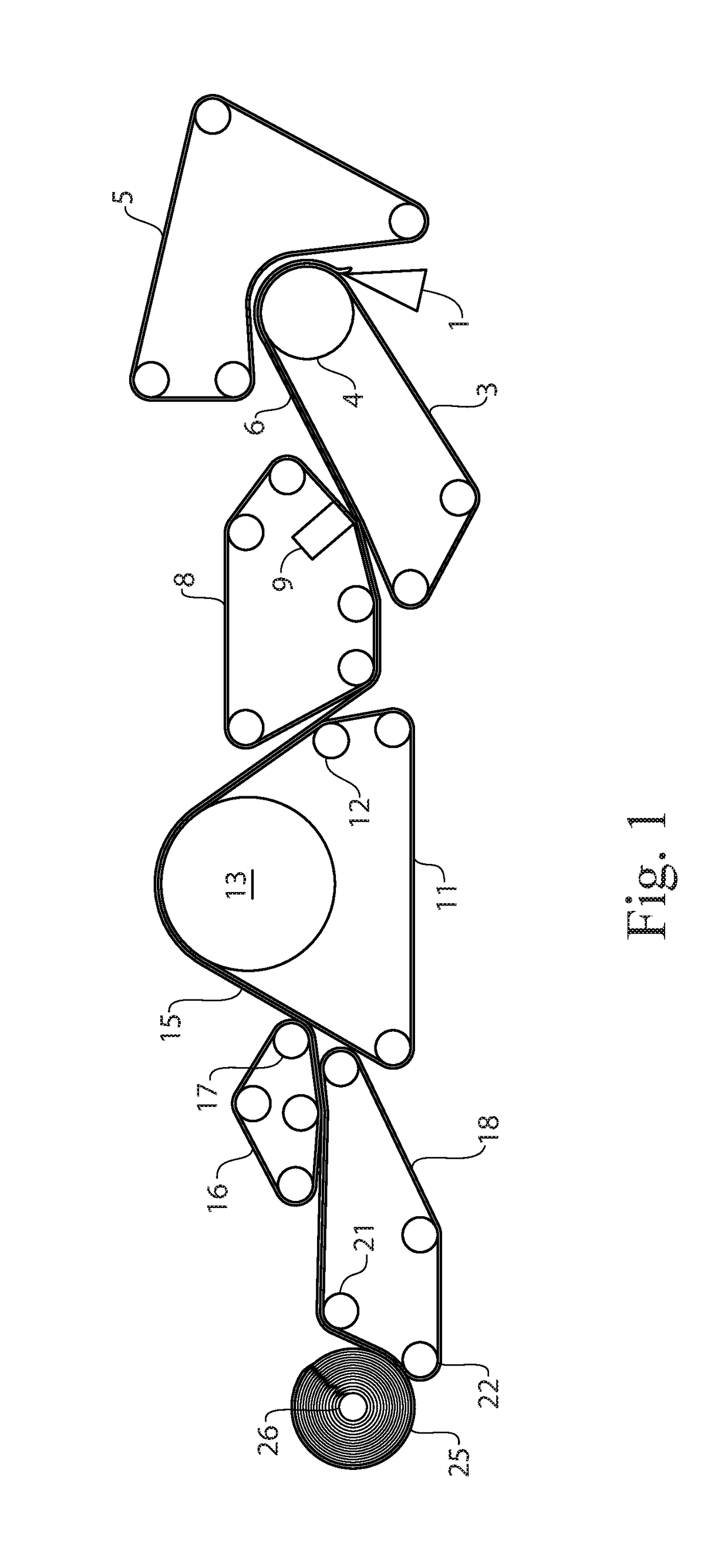

High softness, high durability bath tissue incorporating high lignin eucalyptus fiber

ActiveUS9267240B2Offsetting costsMore durableCellulosic pulp after-treatmentNon-fibrous pulp additionCellulose fiberMaterials science

A cellulosic tissue includes cellulosic fibers selected from the group consisting of chemically pulped fibers and mechanically pulped fibers, the cellulosic fibers have from about 10% to about 50% by weight eucalyptus fibers having a lignin content of at least about 20% by weight, and from about 3% to about 10% by weight regenerated cellulosic microfibers.

Owner:GPCP IP HLDG LLC

Nanofiber sheet, process for producing the same, and fiber-reinforced composite material

ActiveCN101535567AFull transparencyHigh elastic modulusPrinted circuit aspectsWood working apparatusPolymer scienceYoung's modulus

Provided is a nanofiber sheet that sufficiently refined by fibrillation and has high crystallinity of cellulose fiber and can realize a fiber-reinforced composite material exhibiting high transparency, a high elastic modulus, a low coefficient of linear thermal expansion, and high heat resistance and being high in flatness and smoothness. This nanofiber sheet includes crystalline cellulose as the main component and a lignin in an amount of from 10 ppm to 10 wt%. When a fiber / resin composite material obtained by impregnating the nanofiber sheet with tricyclodecane dimethacrylate, subjecting the impregnated product to UV-curing at 20 J / cm 2 , and heating the cured product in vacuum at 160 DEG C for two hours includes 60 wt% of the cured tricyclodecane dimethacrylate and 40 wt% of nanofiber, the following physical characteristics (i) to (iii) are satisfied: (i) the parallel light transmittance of light of a wavelength of 600 nm at a sheet thickness of 100 [mu]m is 70% or more; (ii) the Young's modulus is 5.0 GPa or more; and (iii) the coefficient of linear thermal expansion is 20 ppm / K or less.

Owner:MITSUBISHI RAYON CO LTD +1

High-bulk, wood containing printing paper

InactiveUS20050103458A1Good printabilityIncrease brightnessSpecial paperPaper after-treatmentSingle fiberPulp and paper industry

Coat a starch-based surface-paper-strengthening agent on a base paper made from a paper material that contains at least chemically processed hardwood mechanical pulp and bulk-increasing agent; where it is desirable that the hardwood mechanical pulp with a single fiber density index of 0.20 or more be blended by 10 to 60 weight-% of the total weight of pulp, with the adding amount of bulk-increasing agent adjusted to 0.1 to 1.2 weight-% and the coating amount of starch-based surface-paper-strengthening agent, to 0.3 to 3.0 g / m2.

Owner:NIPPON PAPER IND CO LTD

Composition of matter effluent from refiner of a wet laid process

ActiveUS11306433B2Reduce consistencyLow variabilityFats/resins/pitch/waxes removal in pulpChemical/chemomechanical pulpPolymer scienceCellulose fiber

A composition and process for making the composition by co-refining: fibrillated virgin cellulose fibers, waste / recycle cellulose fibers, or both; co-refined cellulose ester (CE) staple fibers having a denier per filament (DPF) of less than 3 and the weight percent of CE staple fibers is less than 30 wt. %, based on the weight of CE staple fibers and said cellulose fibers; and water. The composition can be co-refined to obtain lower Canadian standard freeness yet improved drainage and wet laid products having good tensile strength, air permeability, stiffness, burst strength, and bulk.

Owner:EASTMAN CHEM CO

Soft tissue comprising non-wood fibers

ActiveUS10145069B2Satisfactory softness and strength and bulkOvercome the small stiffnessPaper/cardboardChemical/chemomechanical pulpFiberMedicine

The present invention provides soft, durable and bulky tissue products comprising non-wood fibers and more particularly hesperaloe fiber. The inventors have discovered that high yield hesperaloe pulp fiber, when incorporated in amounts of at least about 5 percent by weight of the tissue product, produces products having a GMT less than about 1000 g / 3″ and a GM Slope less than about 7.0 kg. At the foregoing tensile strengths and modulus the tissue products of the present invention are also generally soft, such as having a Stiffness Index less than about 10.0, and more preferably less than about 9.0, such as from about 7.0 to about 9.0.

Owner:KIMBERLY-CLARK WORLDWIDE INC

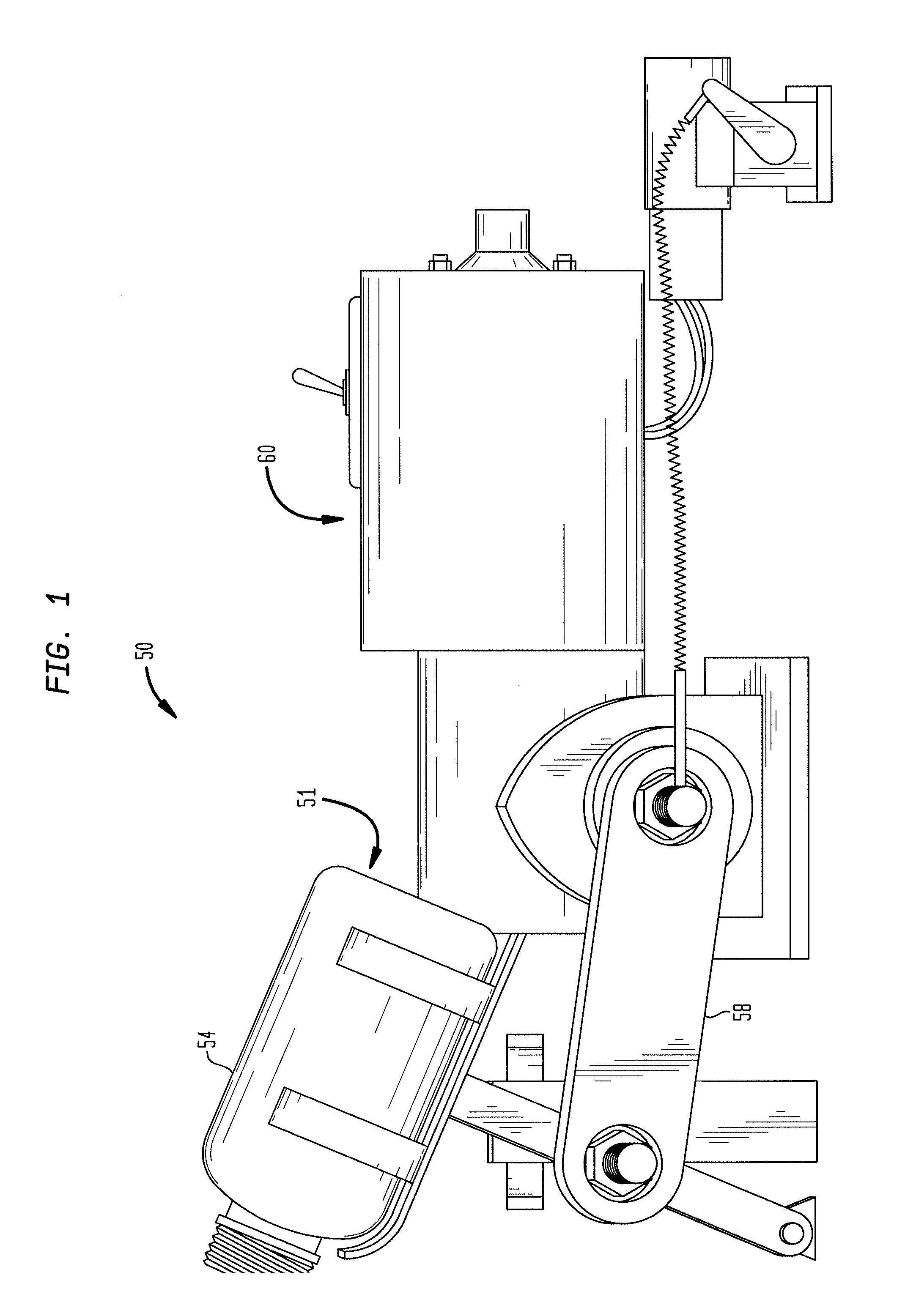

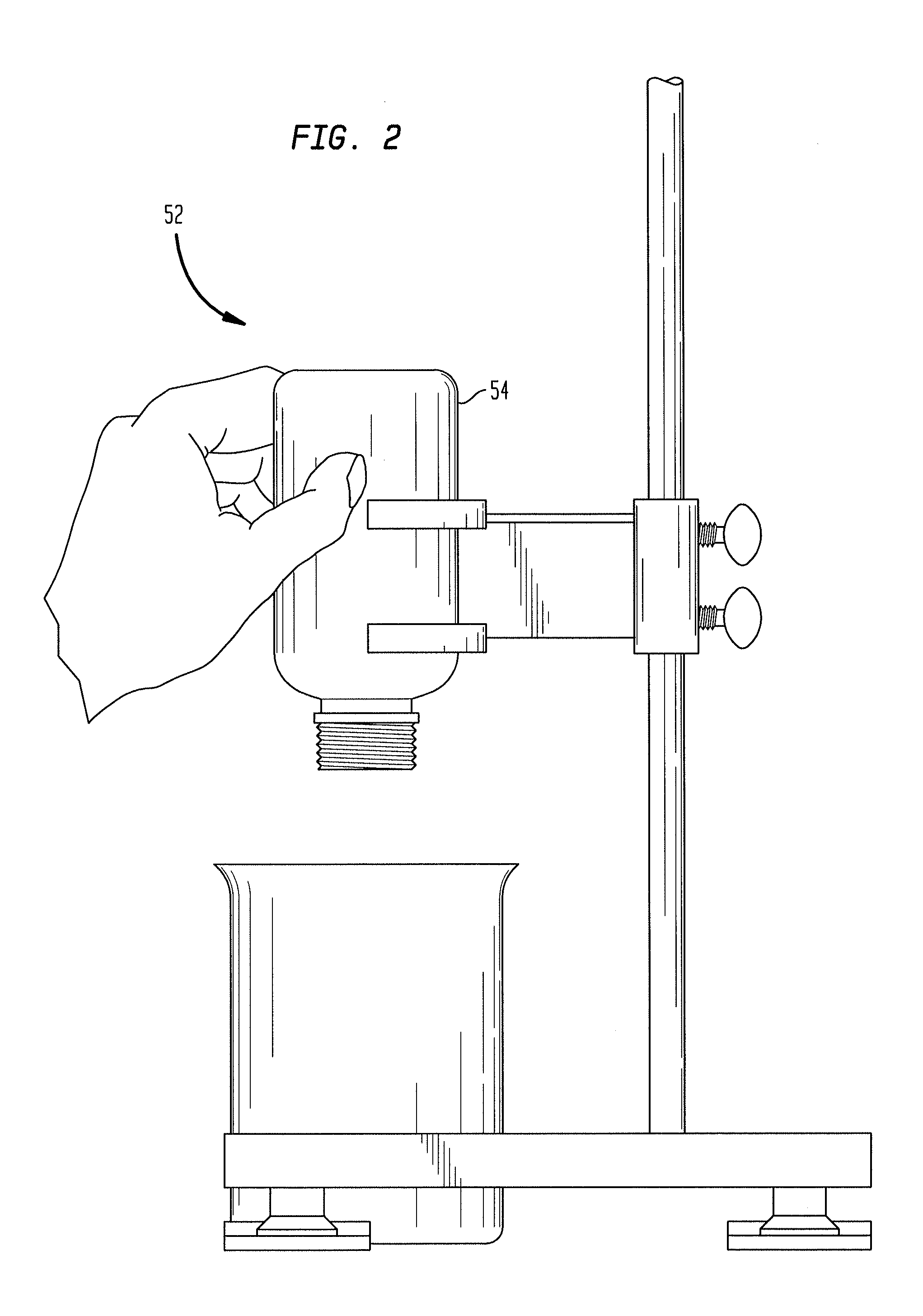

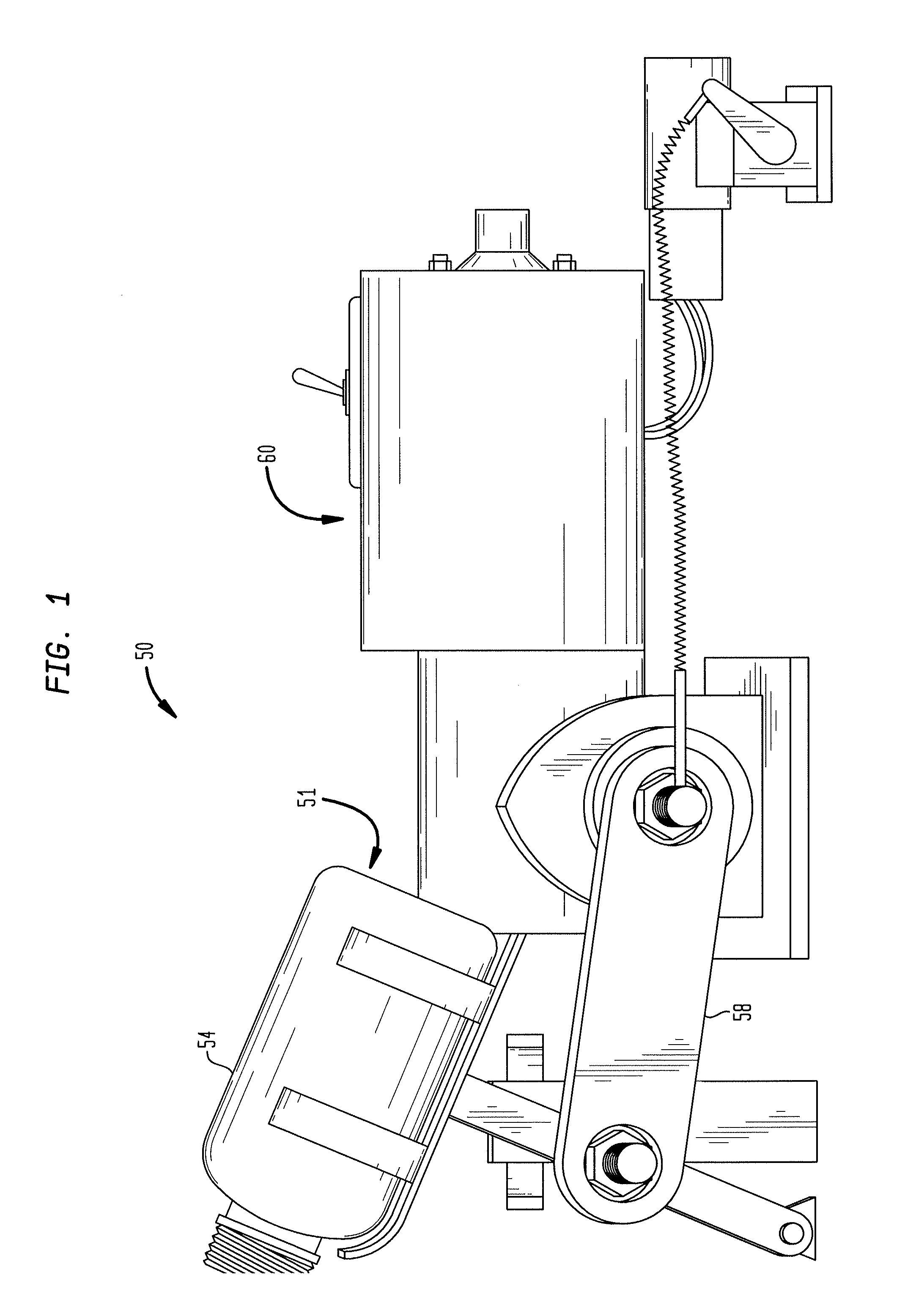

Absorbent paper products having unique physical strength properties

An absorbent towel paper web having a machine direction and a cross-machine direction orthogonal to the machine direction, the web comprising from about 20% to about 90% by weight of the dry fiber basis of the paper web of a refined soft wood pulp fiber mixture comprising from about 18.5% to about 88.5% by weight of the dry fiber basis of the tissue paper web of soft wood pulp fiber, wherein the soft wood pulp fiber is optionally refined before being added to the mixture; from about 0.25% to about 5.0% by weight of the dry fiber basis of the tissue paper web of cationic strengthening polymer, from about 10% to about 60% by weight of the dry fiber basis of the tissue paper web of a hard wood pulp fiber mixture; and not more than about 8% by weight moisture; wherein the paper web has a Mean Square Tensile Strength ranging from about 6 N·m / g to about 12 N·m / g; and wherein the paper web has a Cross-directional Wet Tensile Strength to Cross-directional Dry Tensile Strength Ratio value ranging from about 0.295 to about 0.35.

Owner:MERCER INT

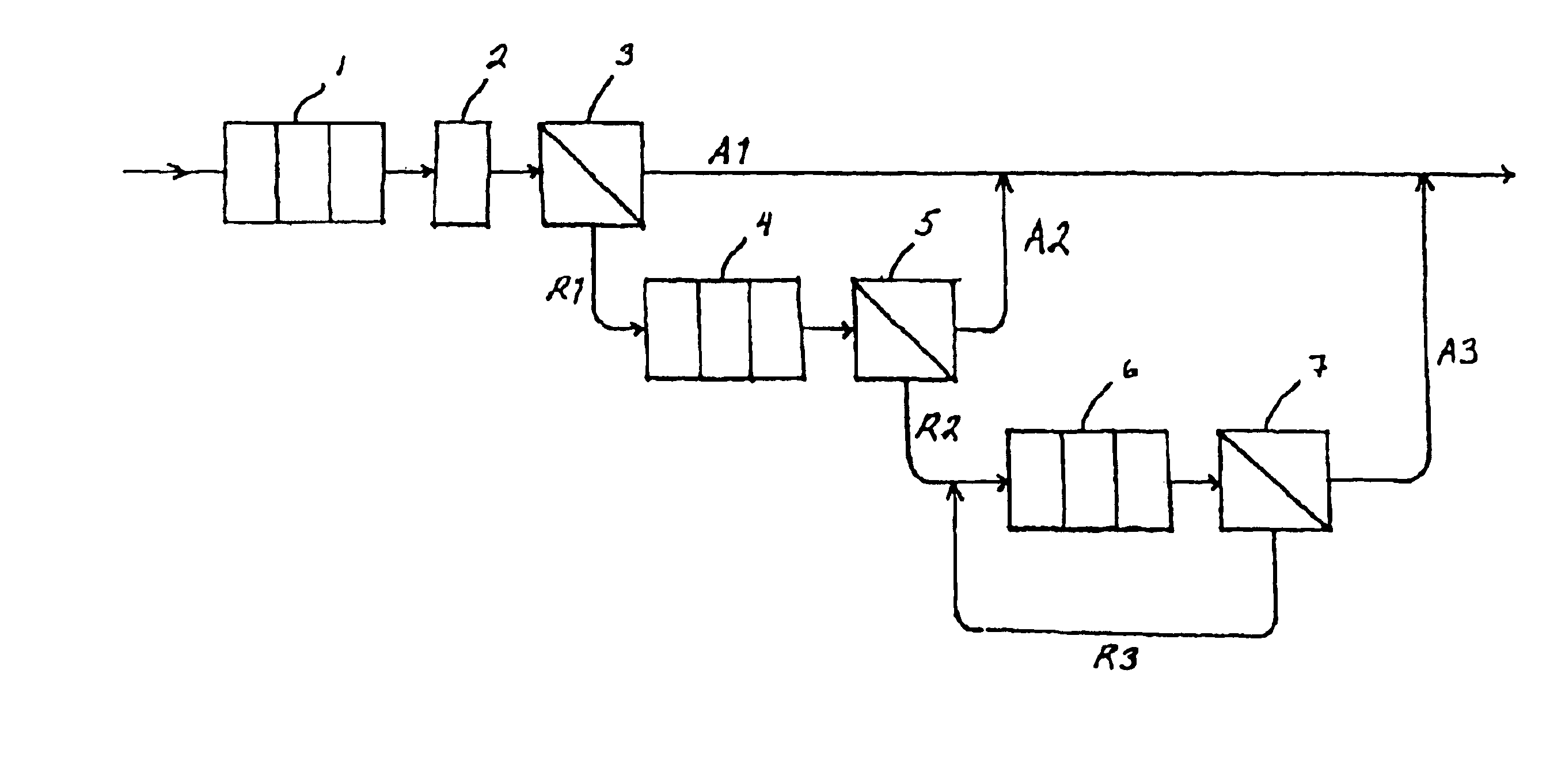

A method and a system for producing nanocellulose, and nanocellulose

InactiveCN103492637AChemical/physical/physico-chemical processesMechanical/thermomechanical pulpNanocellulose

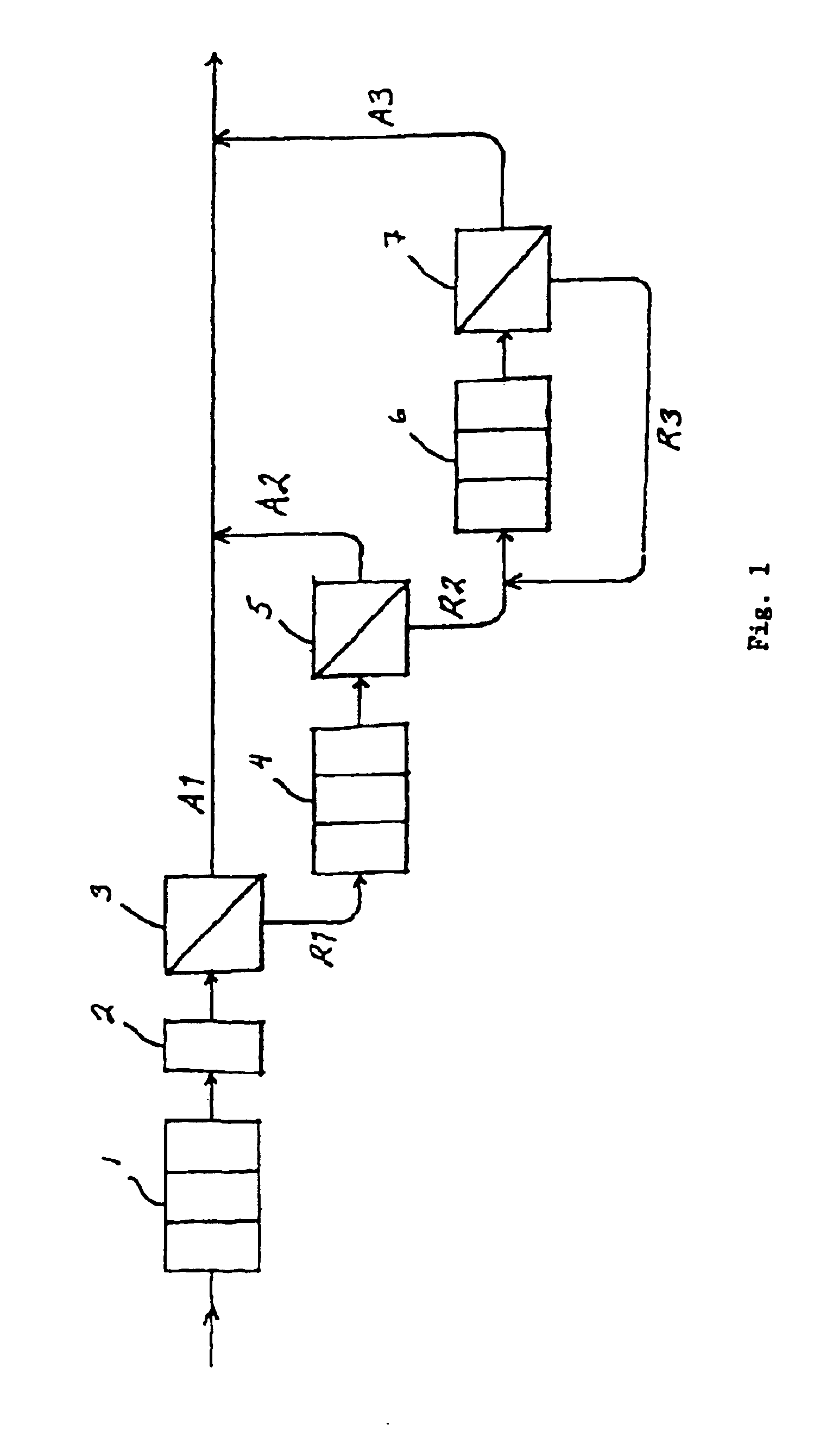

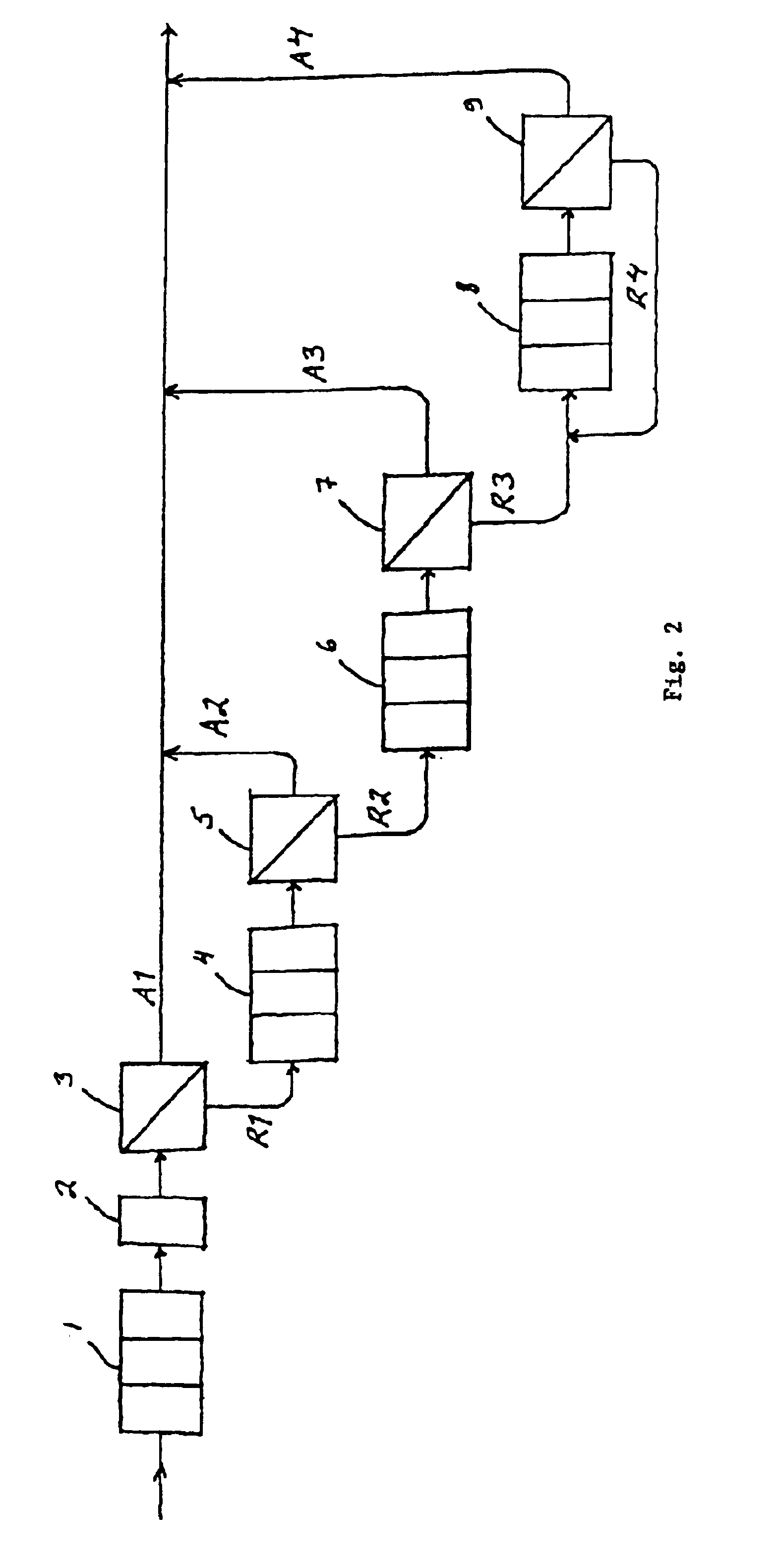

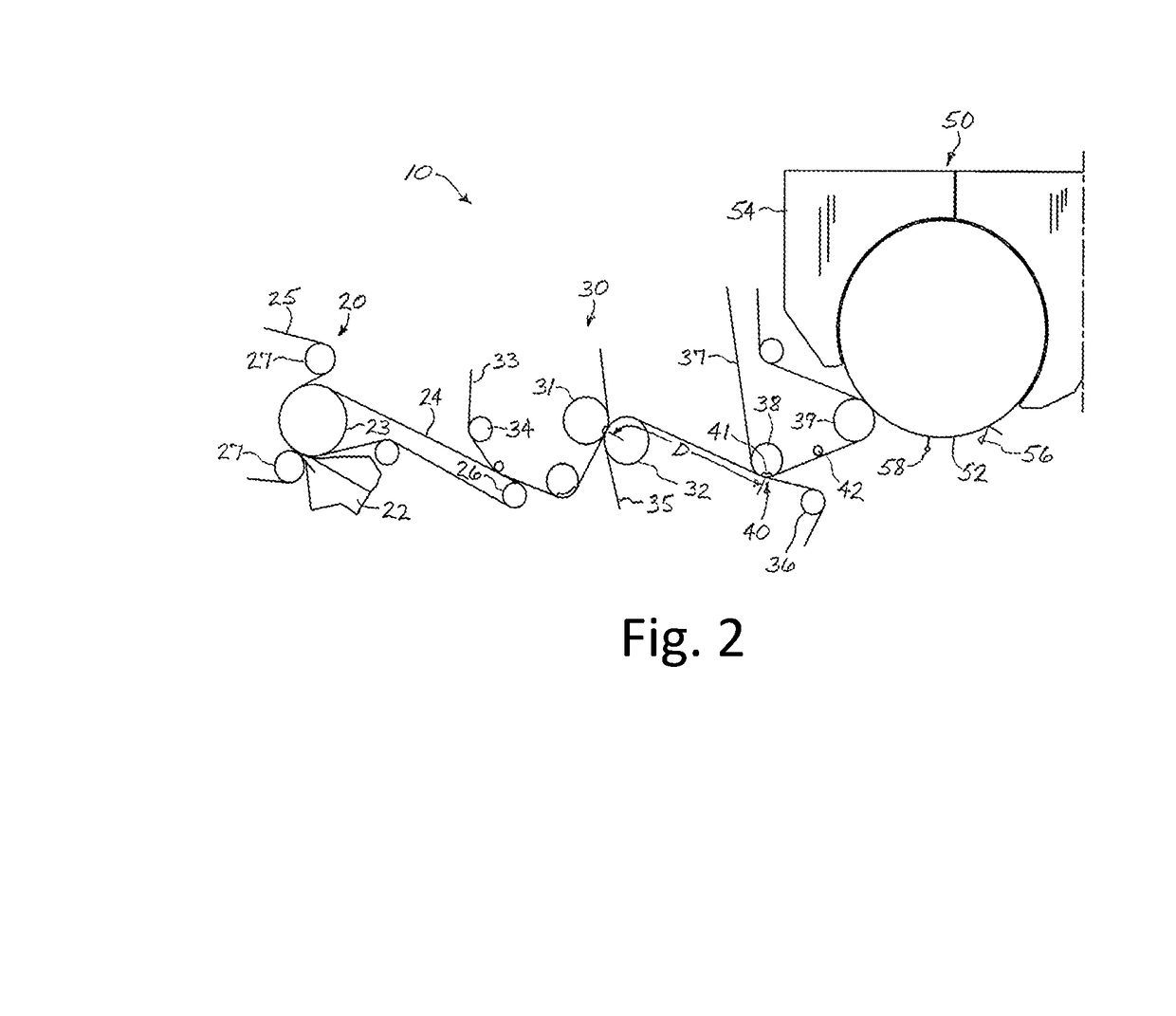

A method and system for producing nanocellulose are provided. Cellulose is refined by a first refiner, the refined cellulose is separated by a first separator in such a manner that at least part of it belongs to an accepted fraction, water is removed from the accepted fraction by a precipitator and the accepted fraction is refined by a second refiner to produce nanocellulose.

Owner:UPM-KYMMENE OYJ

Papermaking process method utilizing paper mulberry bark as raw material

ActiveCN105544282AFlexibleFine paperMechanical/thermomechanical pulpRaw material divisionPapermakingPrimary screening

The invention provides a papermaking process method utilizing paper mulberry bark as a raw material. The method comprises the following steps of firstly, performing primary screening and soaking on the paper mulberry bark, stewing the paper mulberry bark into a paper steamer, then grinding, adding quick lime, soaking for a period of time, then stewing the obtained paper mulberry bark into the paper steamer at a high temperature, washing off the lime and impurities from the obtained paper mulberry bark, kneading for peeling, cutting the peeled raw material into slices by use of a steel knife, putting the slices into a stone cistern, and mashing to obtain a paper pulp; and finally, pouring the mashed paper pulp into a paper channel full of water, fully stirring so as to ensure that the paper pulp forms uniform suspension flocculent in water, then performing papermaking and paper squeezing, and sweeping, stoving and tearing off wet paper with moisture, wherein the produced paper is not added with chemicals, does not cause damage to health of users, is fine and smooth in quality, flexible and tough, smooth in hand feeling, abrasion-resistant, free of wrinkles, long in preservation life and wide in application range, and has the characteristics of safety, no pollution, economical efficiency and environmental friendliness.

Owner:SHAANXI UNIV OF SCI & TECH

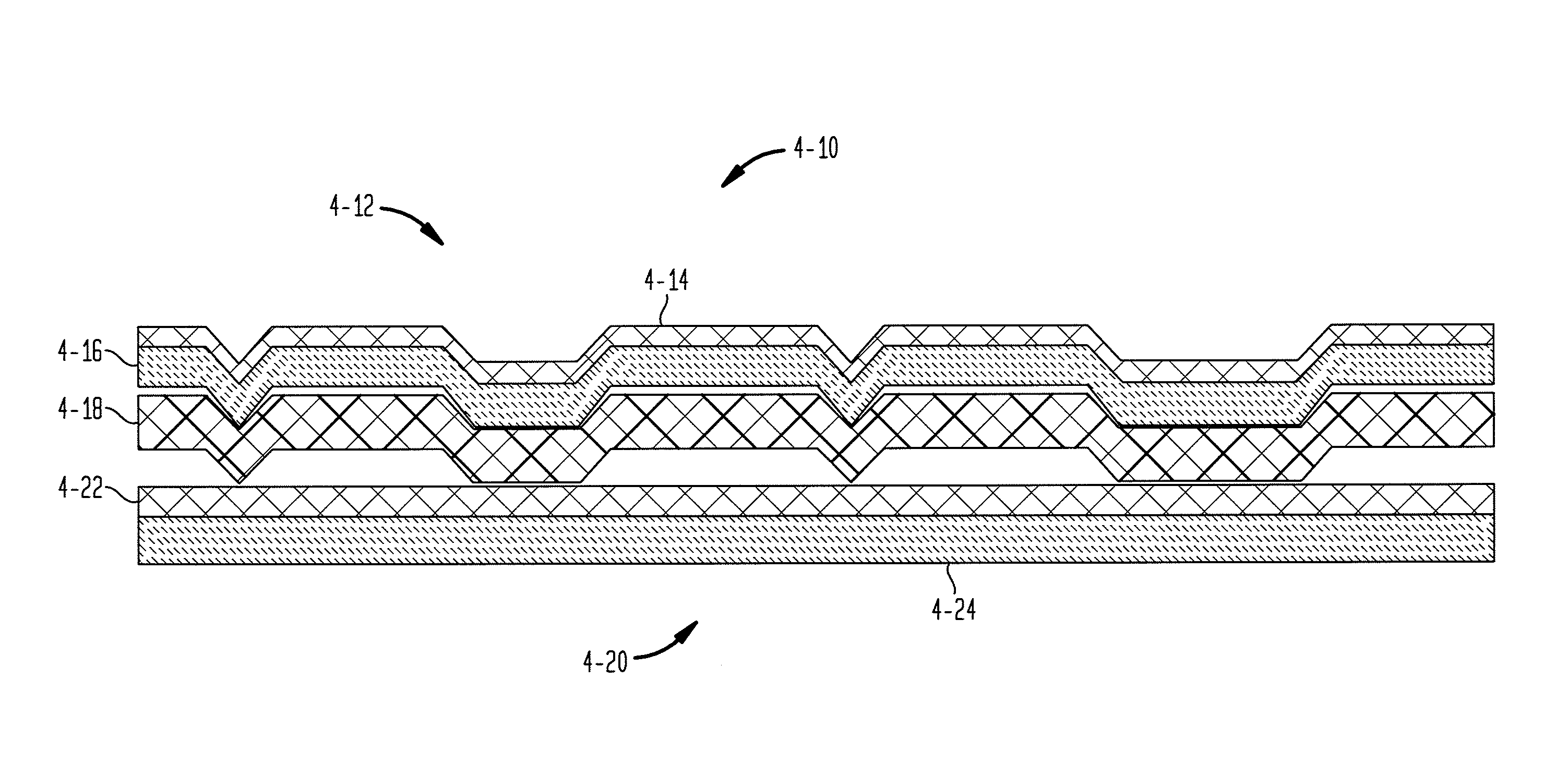

High Quality Paperboard and Products Made Thereof

ActiveUS20080314536A1Increased bending stiffnessHigh strengthNon-fibrous pulp additionPaper after-treatmentCardboardEngineering

The invention relates to a high quality paperboard comprising at least two plies, a first ply having good surface properties and strength, and a second ply for providing the paperboard with bulk wherein the second ply comprises hardwood CTMP. This paperboard has an internal strength and a bending resistance that is comparable with conventional high quality paperboard based on softwood CTMP. The invention also relates to products manufactured of the paperboard.

Owner:STORA ENSO AB

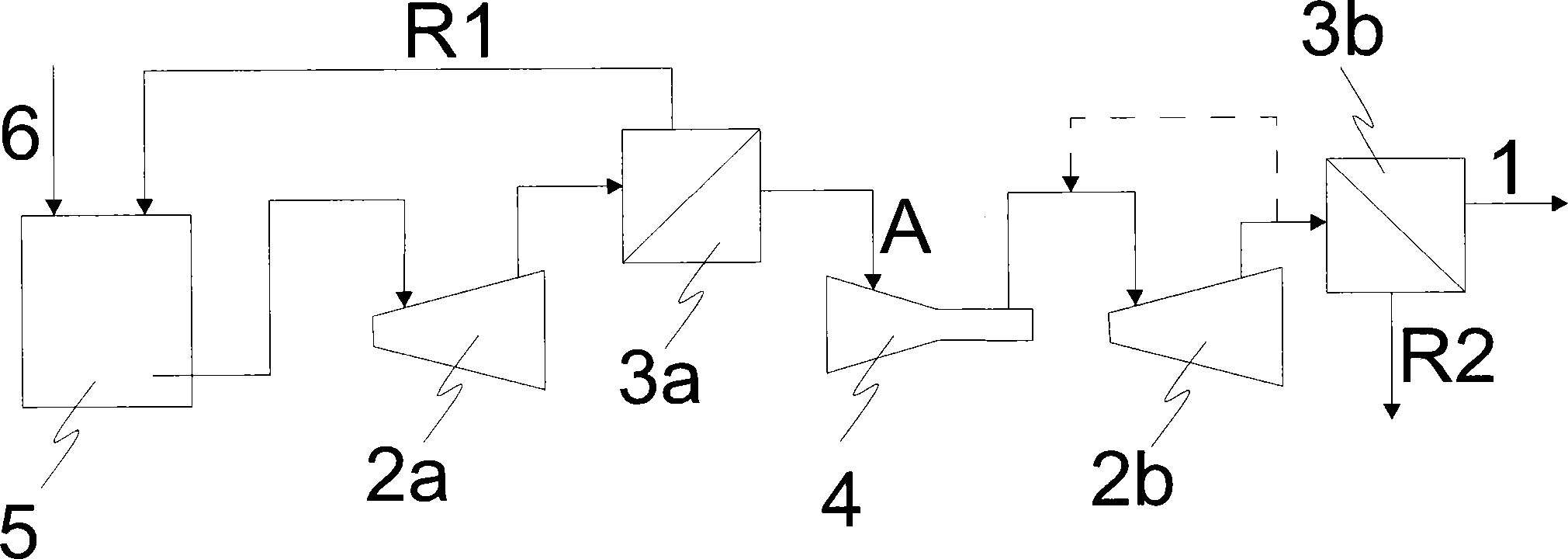

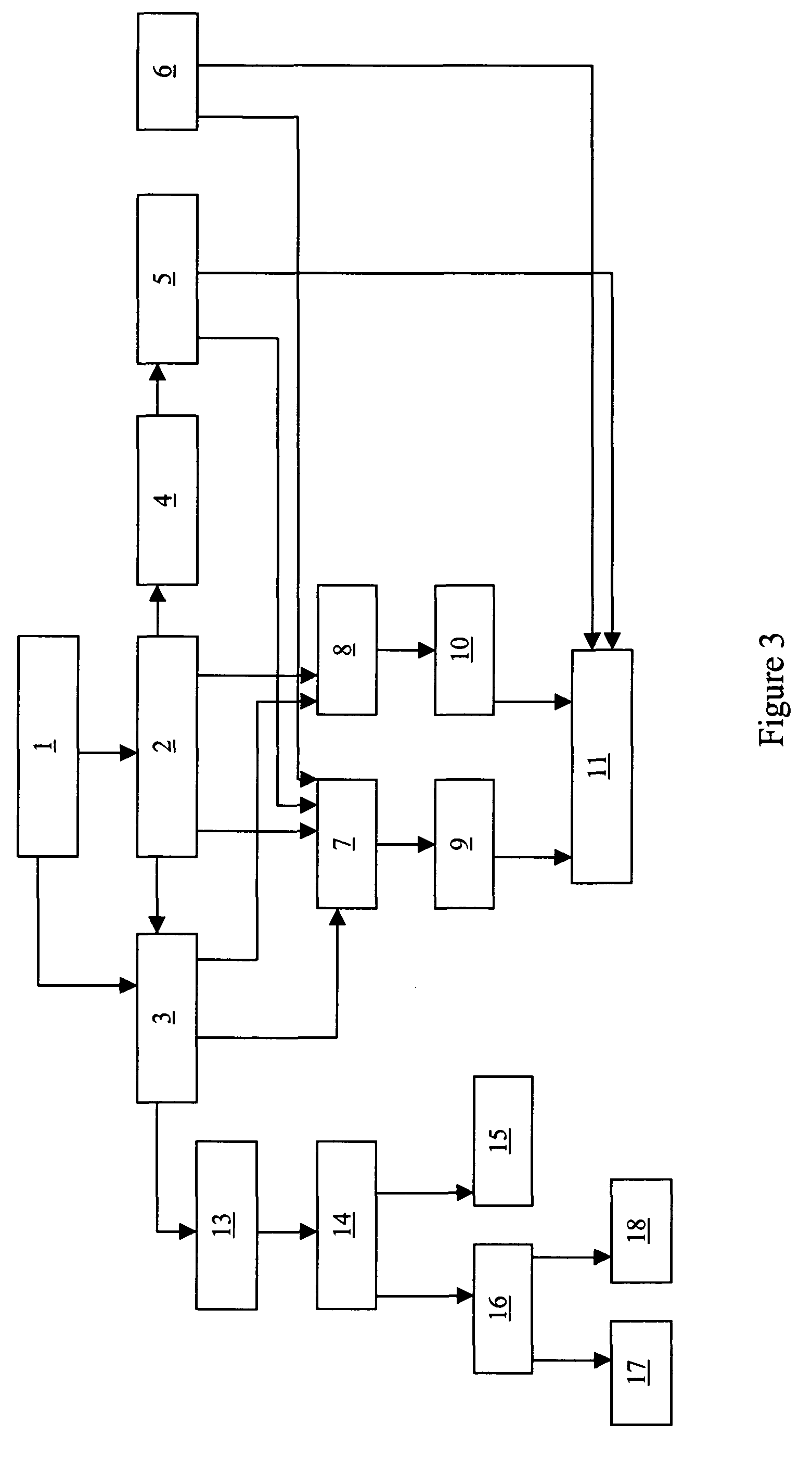

Product and processes from an integrated forest biorefinery

An omnibus process of pulping and bleaching lignocellulosic materials in which a charge of a lignocellulosic material is biopulped and / or water extracted prior to pulping and bleaching. The lignocellulosic material may be mechanically pulped and bleached in the presence of an enzyme that breaks lignin-carbohydrate complexes. The aqueous extract in embodiments including a water extract step is separated into acetic acid and hemicellulose sugar aqueous solutions.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

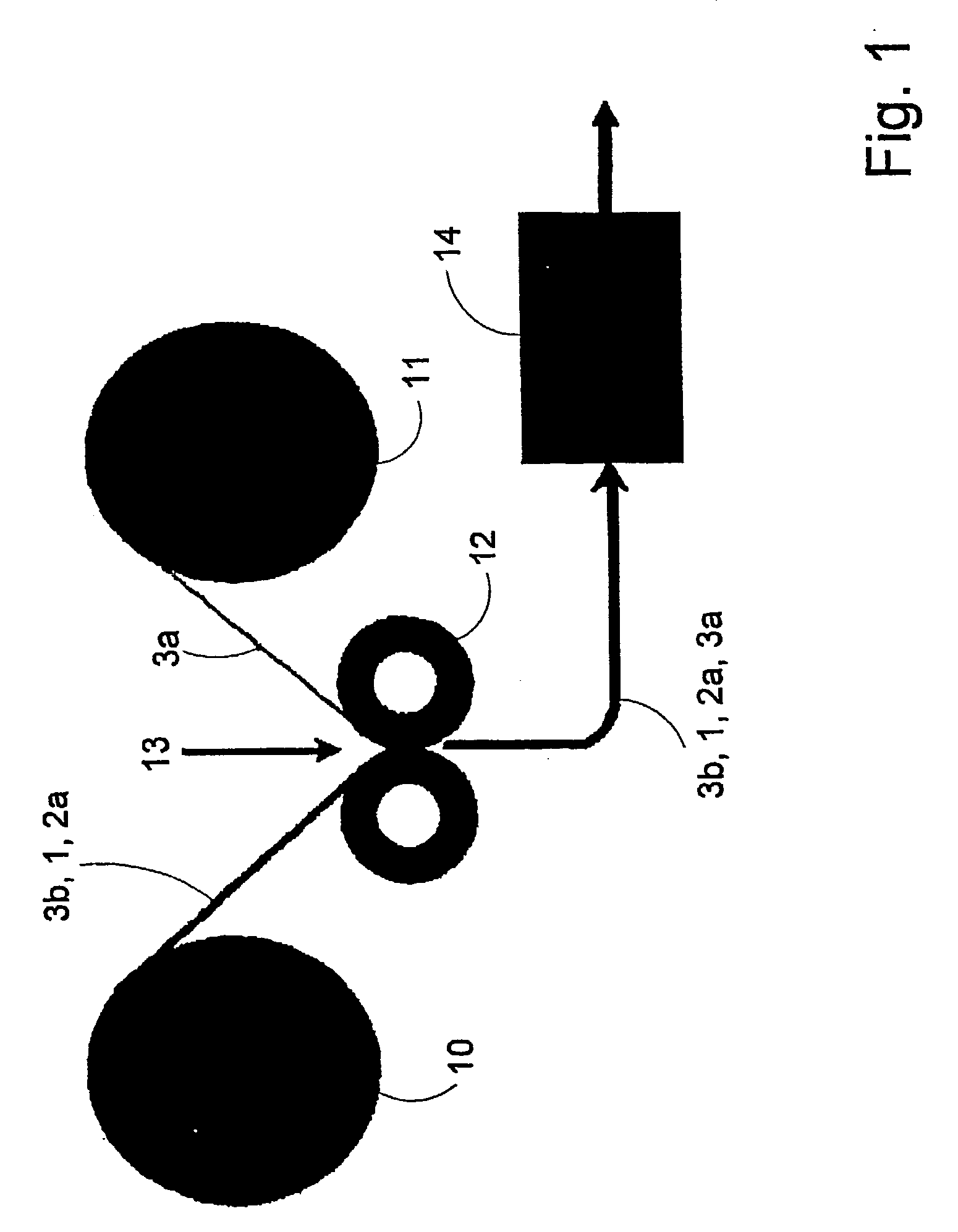

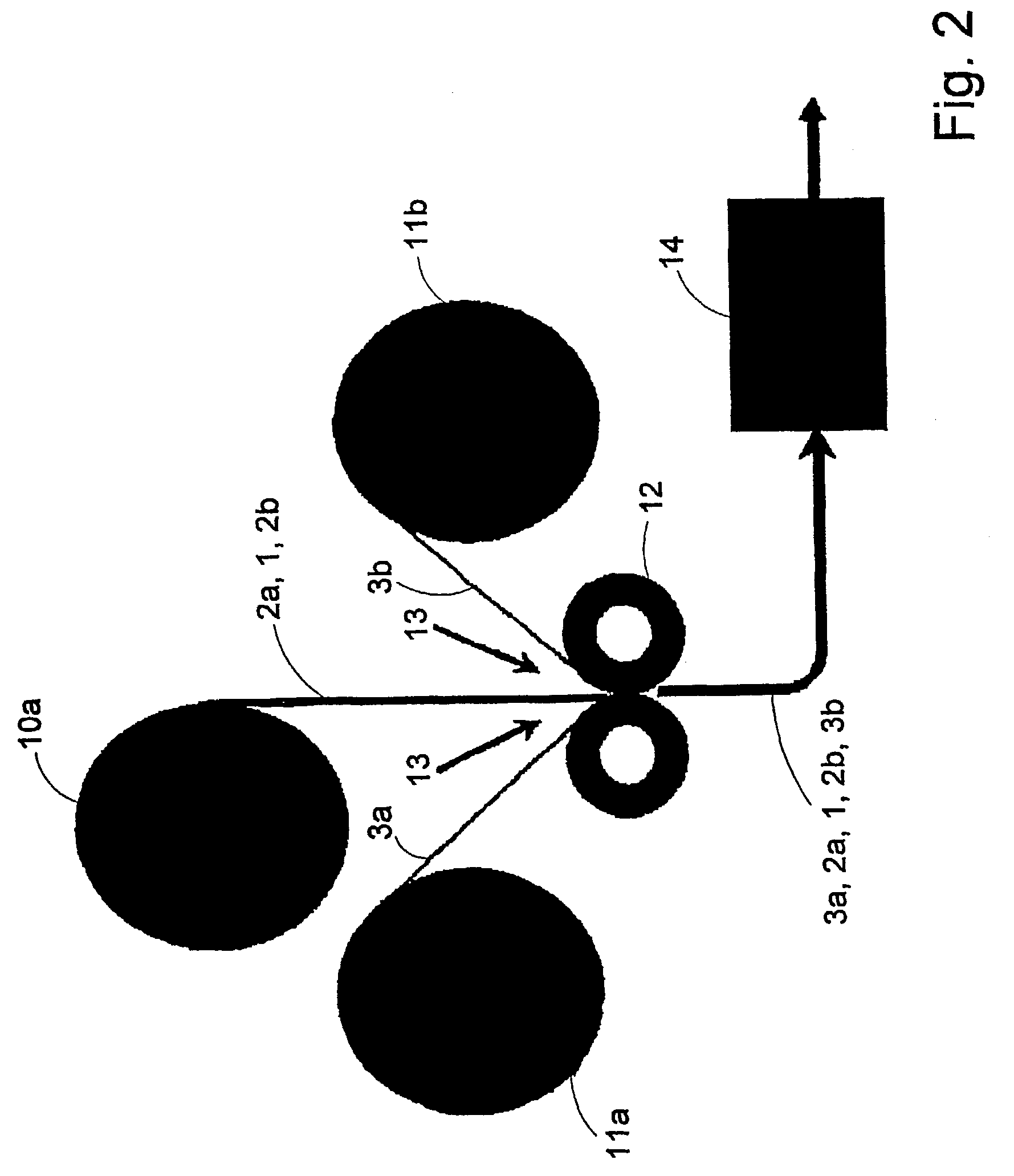

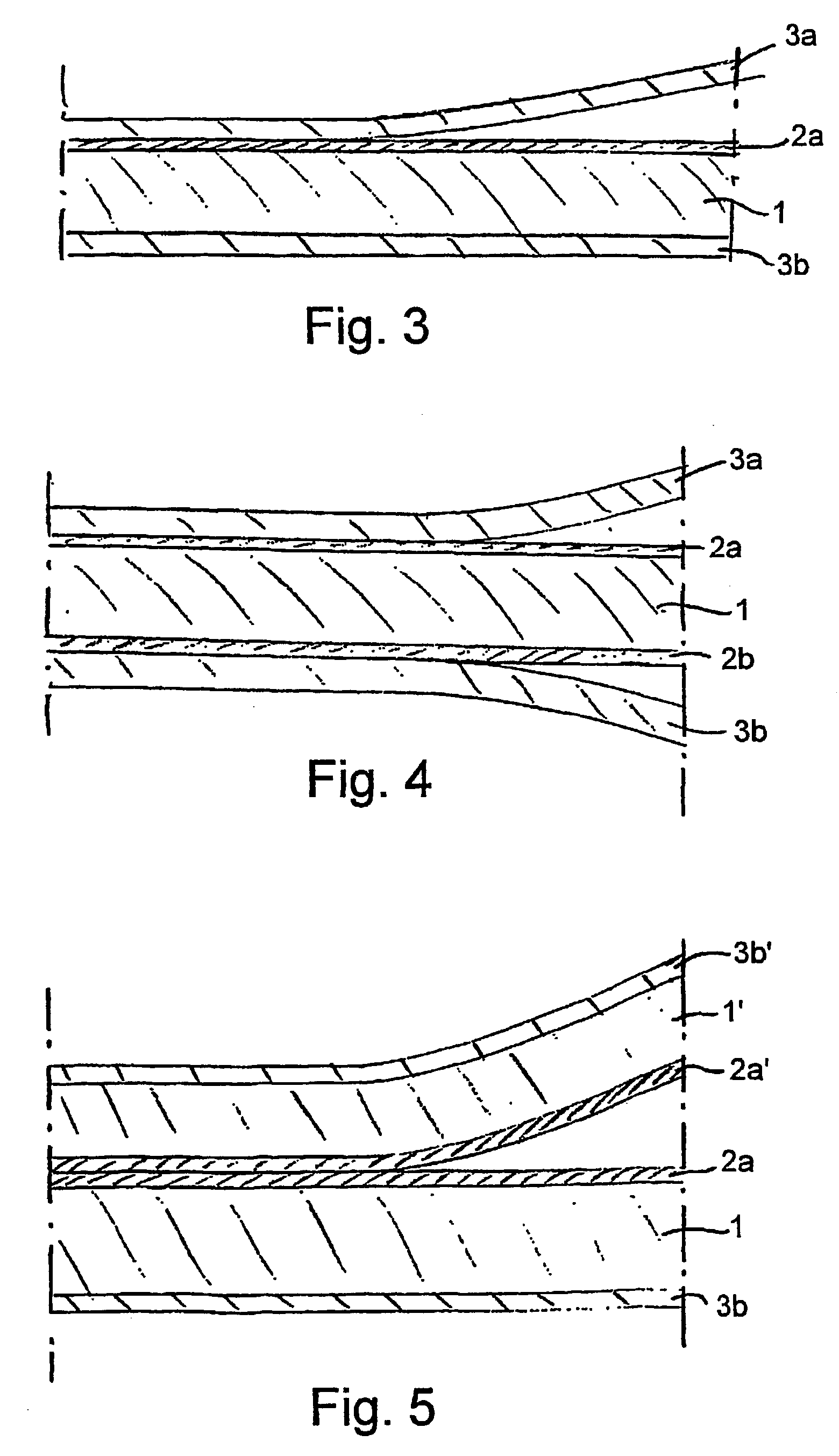

Paper or paperboard laminate and method of producing such a laminate

InactiveUS20030155088A1Reduce in quantityGreat z-strengthNon-fibrous pulp additionWrappersPaperboardCellulose fiber

Paper or paperboard laminate composed of at least one bulk-promoting layer, here termed bulk layer (1), 40-98% of which is composed of cellulose fibres with a freeness value of 550-950 ml CSF, and on at least one side of the bulk layer at least one secondary layer (3a, 3b'), which has a greater density than the bulk layer, the secondary layer and bulk layer being joined indirectly to one another over basically the whole of their opposing surfaces and the laminate having a bending stiffness index greater than 2.5 Nm7 / kg3, but less than 14 Nm7 / kg3, calculated as a geometric mean value for machine direction and cross direction the invention a thin intermediate layer (2a), which has a higher drainage resistance than the bulk layer and has been formed together with the bulk layer, is arranged between the said bulk layer (1) and secondary layer (3a, 3b').

Owner:STORA ENSO AB

Absorbent paper products having unique physical strength properties

An absorbent towel paper product having a machine direction and a cross-machine direction orthogonal to the machine direction, wherein the absorbent towel paper product comprises two plies of absorbent towel paper webs, wherein each paper web comprises from about 20% to about 90% by weight of the dry fiber basis of the towel paper web of a refined long fiber soft wood pulp fiber mixture comprising from about 18.5% to about 88.5% by weight of the dry fiber basis of the towel paper web of long fiber soft wood pulp fiber, wherein the long fiber soft wood pulp fiber is optionally refined before being added to the mixture; from about 0.25% to about 5.0% by weight of the dry fiber basis of the tissue paper web of cationic strengthening polymer, from about 10% to about 55% by weight of the dry fiber basis of the tissue paper web of a hard wood pulp fiber mixture; and not more than about 10% by weight moisture; wherein the two-ply paper product has a Mean Square Tensile Index value ranging from about 10 N·m / g to about 18 N·m / g; and wherein the two-ply paper product has a Cross-directional Wet Tensile Strength to Cross-directional Dry Tensile Strength Ratio value ranging from about 0.295 to about 0.33.

Owner:MERCER INT

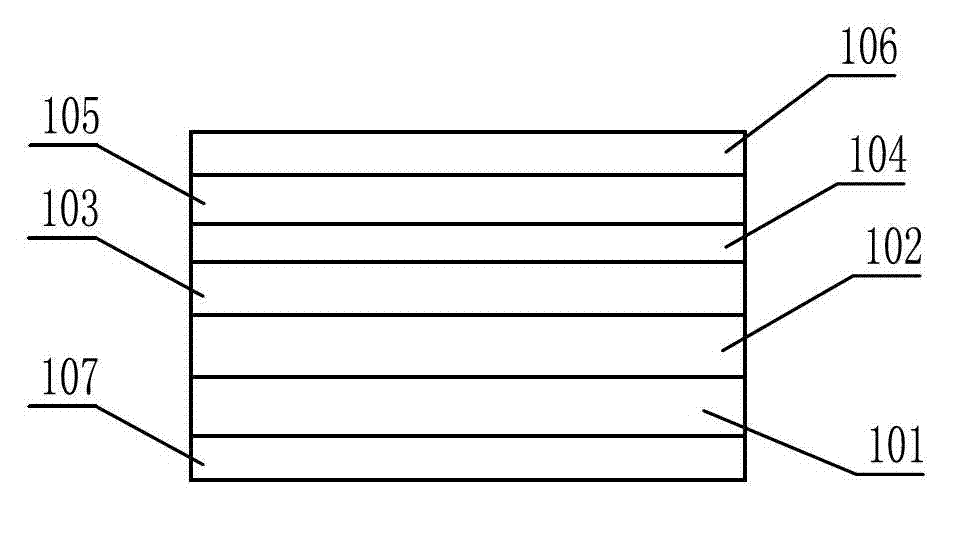

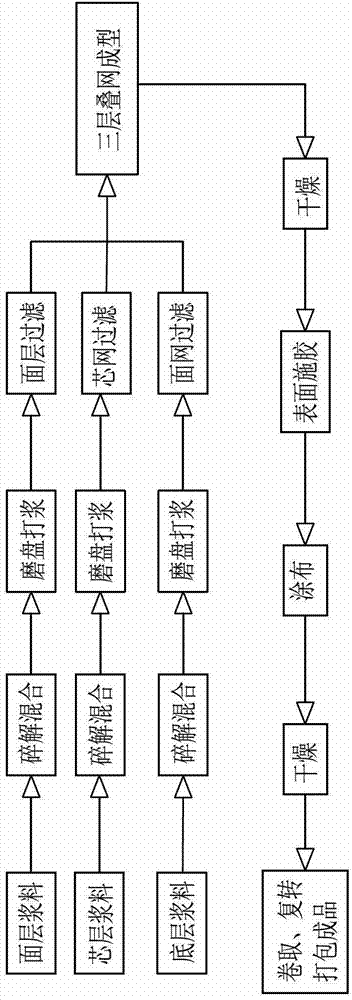

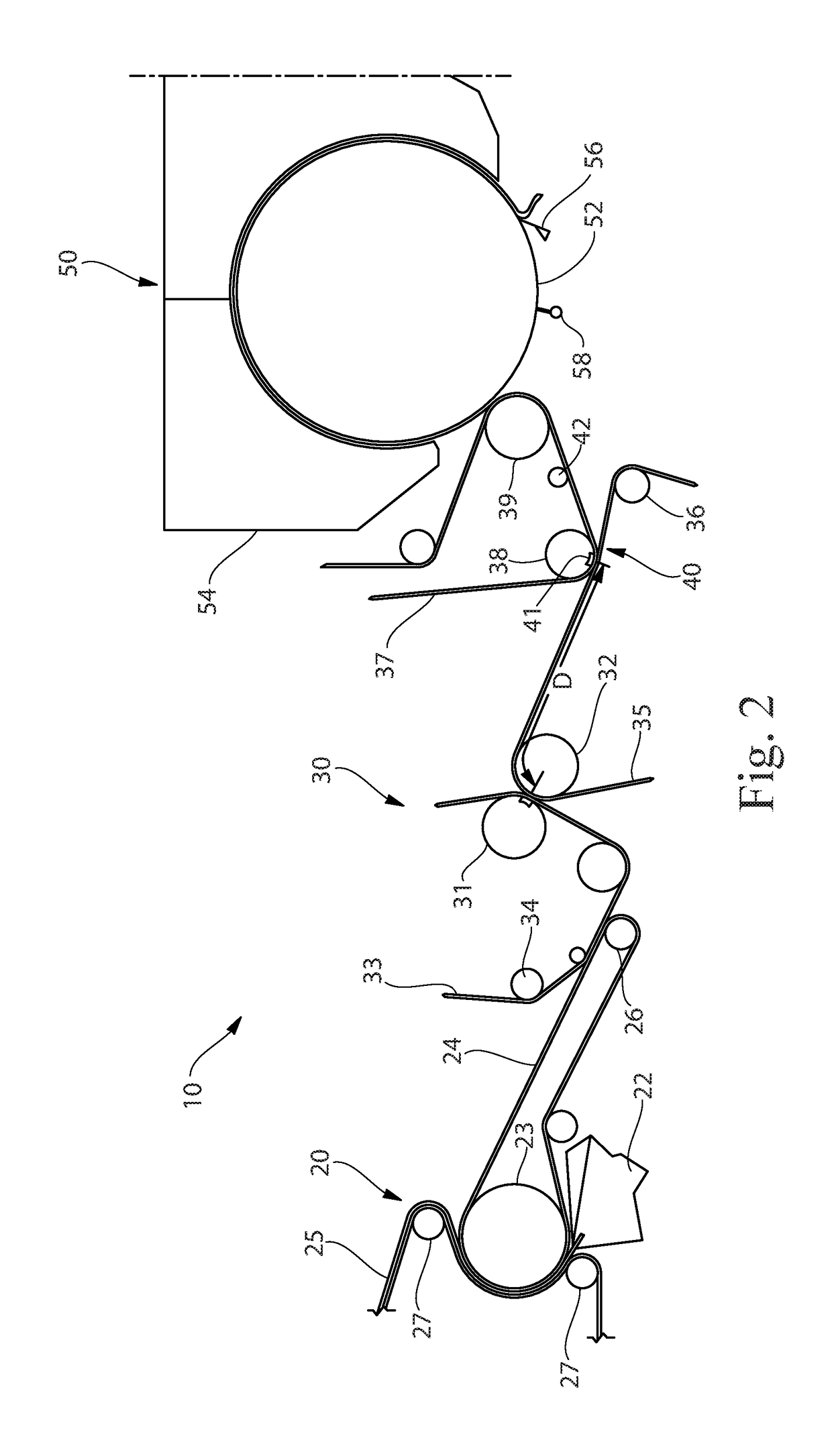

Production process of advanced grey board paper composite special core paper

ActiveCN110080031AImprove flatnessGood adhesionWaste product additionMechanical/thermomechanical pulpCardboardSludge

The invention relates to the technical field of pulping and papermaking, in particular to a production process of advanced grey board paper composite special core paper. The production process does not use ONP pulp, both surface pulp and bottom pulp adopt 100 percent of OCC pulp, formed paper is good in flatness and is not layered, and the adhesive absorption property and the bonding property of the paper are improved, and the use requirements of the advanced composite grey board paper special core paper are met. Moreover, as core pulp with a larger pulp blending proportion adopts OCC pulp, recovery slag pulp, wood chip pulp and reuse sludge mixed pulp, the quantification, the compactness, the interlayer bonding force, the thickness and the ash content are guaranteed; an ONP pulping line and a paper machine lining section are stopped, so that the pulping power and the installed power of a paper machine are reduced, and the purposes of energy conservation, consumption reduction and product paper improvement are achieved. The produced advanced multi-layer composite special core paper in stead of single grey board paper, has a gram weight range of 280-700 g / m<2> and is used for a corelayer and an inner layer, Through measurement and calculation, the production cost per ton of paper is about 70 yuan; calculated by the annual output of 150,000 tons, the annual production cost can be saved by 10,500,000 yuan.

Owner:LIANSHENG PAPER IND LONGHAI

Cup mat body paper and production method thereof

ActiveCN104018388AIncrease bulkImprove water absorptionSpecial paperPaper/cardboardSulfateFood packaging

The invention belongs to the paper making technology and relates to cup mat body paper and a production method thereof. The cup mat body paper is formed by a face layer, a core layer and a bottom layer. Two of needle-point leaf wood pulp, hardwood pulp and mechanical pulp are used as raw material pulp of all the layers. A starch layer is formed between every two layers in a spraying mode so as to improve the bonding strength between every two layers. The needle-point leaf wood pulp is bleached sulfate process needle-point leaf wood pulp, the hardwood pulp is bleached sulfate process hardwood pulp, and the mechanical pulp is chemically bleached hot-ground mechanical pulp. A common triple-lap long-net multi-cylinder paper machine can be used for producing the cup mat body paper which is high in water-absorbing property and large in bulk, meets the requirement of the hygienic standard of the body paper for food packaging and is used for placing food and being packaged in bottle covers.

Owner:ZHENJIANG DADONG PULP & PAPER

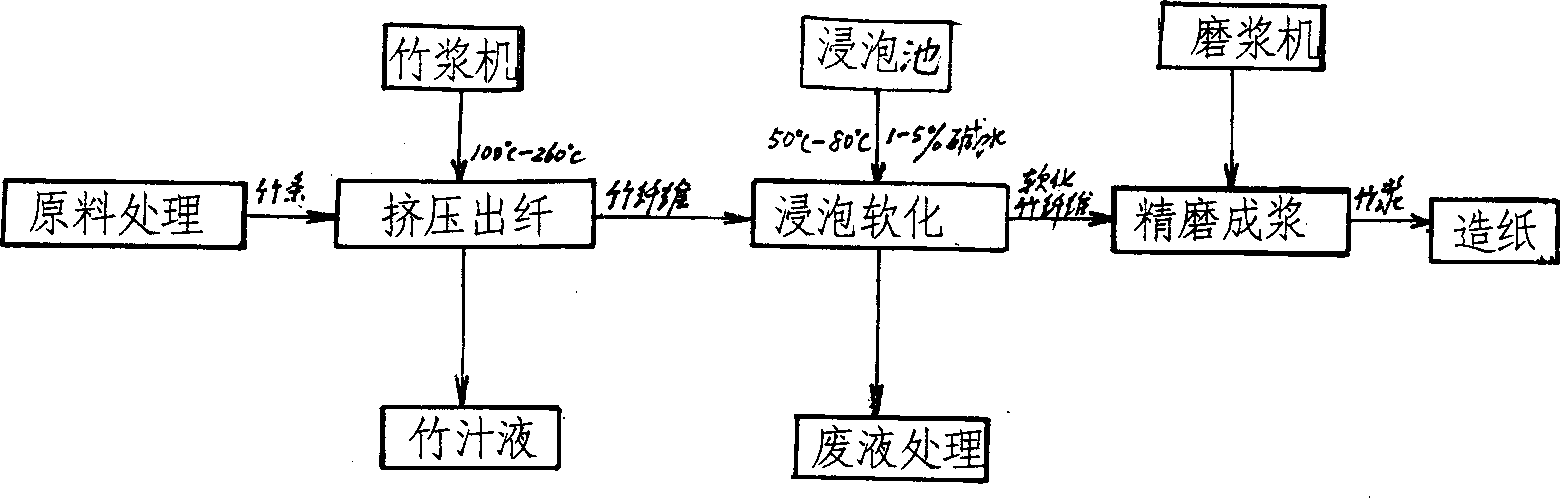

Technological process of mechanically making bamboo pulp

InactiveCN1354303ATime-saving extraction processEnergy saving during extractionMechanical/thermomechanical pulpFiberHigh pressure

The present invention relates to a mechanical pulping method of bamboo pulp, including the procedures of raw material treatment, extrusion to extract fibre, soaking-softening and grinding to make pulp. It is characterized by that the procedure of extrusion to extract fibre uses bamboo pulp-making machine to extrude bamboo material, and separates the bamboo fibre from bamboo juice liquid uner the action of high temp. and high pressure to extract bamboo fibre. The soaking-softening procedure includes the steps: soaking bamboo fibre in hot alkali water whose alkali content is 1%-5% for 1-2 hr. and softening and dissolving lignin and hemicellulose; and the grinding and pulping procedure is to place the soaked bamboo fibre in pulp grinder and grind it to obtain monomer fibre pulp stock.

Owner:李斌

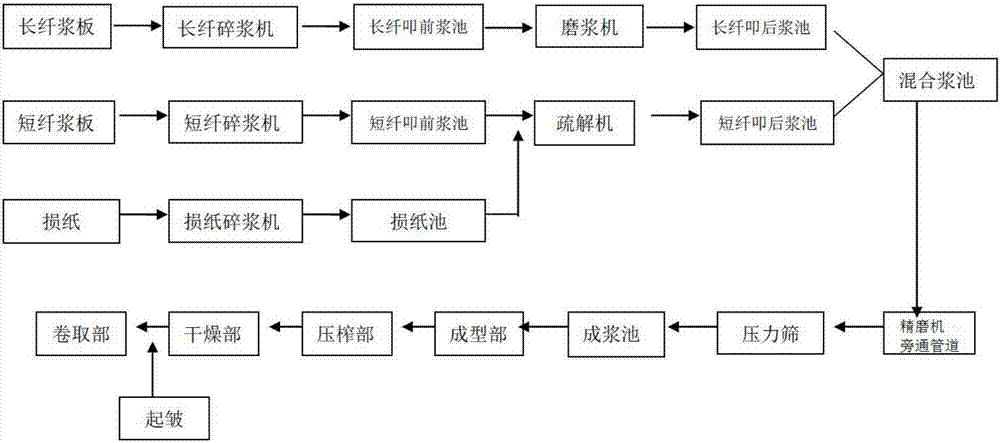

Production method of facial tissue capable of being wetted with water

InactiveCN107313283AHigh bonding strengthIncrease contact areaReinforcing agents additionMechanical/thermomechanical pulpFiberWet strength

The invention relates to a production method of a facial tissue capable of being wetted with water. The production method comprises: respectively adding water to needlebush pulp and hardwood pulp, adjusting the needlebush pulp concentration and the hardwood pulp concentration to 5.0-7.0 wt%, and crushing for 8-15 min; adjusting the needlebush pulp concentration to 4.0-5.0 wt%, and carrying out fiber cutting and fibrillation in a grinder; adding water to adjust the hardwood pulp concentration to 4.0-5.0 wt%, and carrying out fiber defibrating in a defibrating machine; mixing 50-60% of the needlebush pulp and 50-40% of the hardwood pulp, adjusting the concentration to 3.0-4.0 wt%, and carrying out further cutting and fibrillation through the grinder; adding a wet strength agent and a softener to the mixed pulp, and adjusting the concentration to 2.9-3.1 wt%; and diluting the obtained mixed pulp to 0.2-0.25 wt% by using a pulp beating pump, feeding into a papermaking machine, molding, squeezing, and drying to finally prepare the product. According to the present invention, when the prepared facial tissue used for water wiping and sweat wiping, the facial tissue is not broken, and no residue paper exists; the prepared facial tissue can be used as the wet wipe and the face washing towel after the prepared facial tissue is wetted with the water; and the hand feeling and the smoothness of the facial tissue are improved, such that the use is comfortable.

Owner:上海东冠纸业有限公司

Preparation method of high air permeability and water absorption inning paper for sanitary products

InactiveCN107313299AReduce the degree of refiningImprove breathabilityPure paperMechanical/thermomechanical pulpFiberSlag

The invention relates to a method for preparing a high-air-permeability water-absorbing backing paper for sanitary products. Coniferous wood pulp is used as long-fiber raw material, hardwood pulp is used as short-fiber raw material, and they are beaten separately. Processing, mixing according to the long-fiber raw material accounting for 85wt%, the mixed pulp is not processed by a refiner, and after entering the pressure screen to remove slag, it enters the pulp tank, and then after being formed, pressed and dried by a paper machine, it is wrinkled. Get high air permeability absorbent backing paper for hygiene products. Compared with the prior art, the preparation process of the present invention does not add wet strength agent and carboxymethyl cellulose, and the prepared product has good air permeability, high strength, safety, sanitation and environmental protection.

Owner:上海东冠纸业有限公司

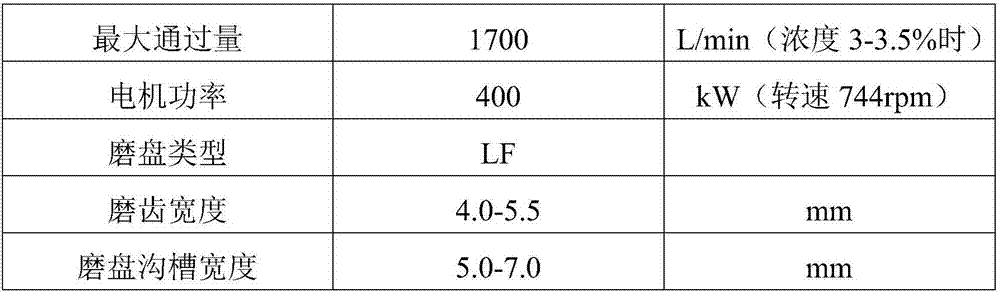

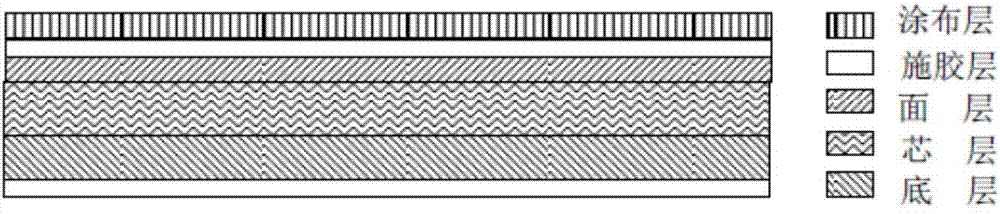

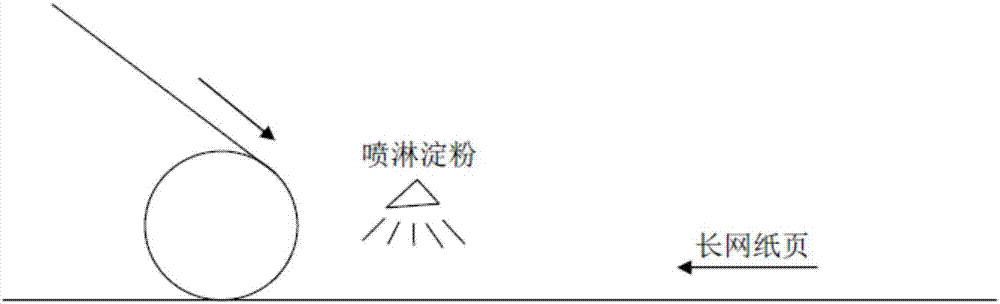

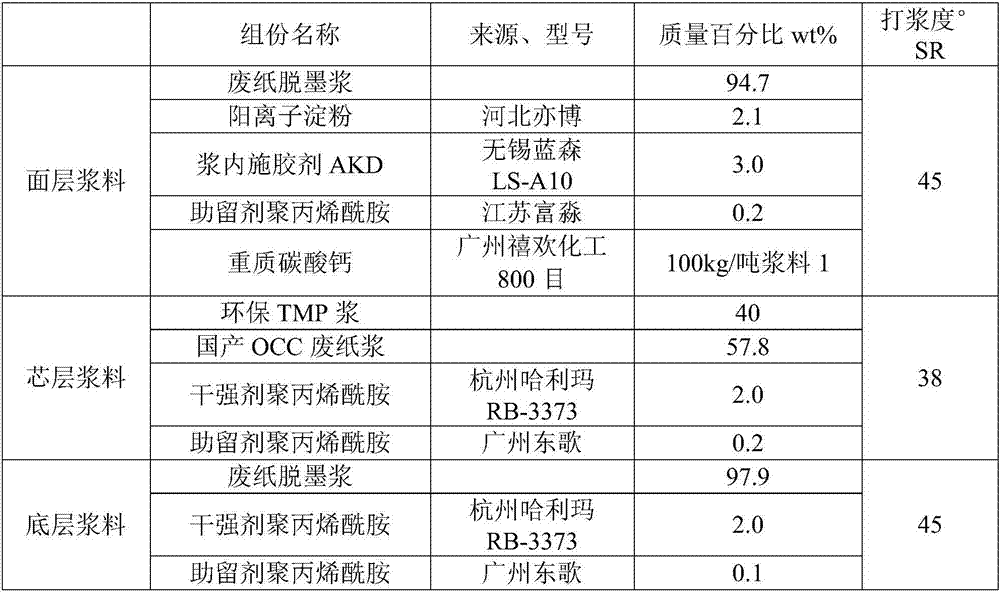

Environment-friendly low-basis-weight coated duplex board with grey back and preparation method thereof

The invention belongs to the technical field of papermaking and particularly relates to an environment-friendly low-basis-weight coated duplex board with grey back and a preparation method thereof. The environment-friendly low-basis-weight coated duplex board with grey back includes a coating layer, a front glue applied layer, a surface layer, a core layer, a bottom layer, and a back glue applied layer, all the layers being laminated by spraying a starch solution. In the invention, a mechanical thermal pulp TMP for producing medium-density polymeric plates is employed, wherein the mechanical thermal pulp is environment-friendly and low-cost, and has wide sources. In addition, the invention mainly provides a production technology of the low-basis-weight coated duplex board with grey back by applying the novel environment-friendly TMP pulp. The technology mainly includes three-layer mesh lamination shaping, spraying starch solution as interlayer adhesive and the like processes, so that the coated duplex board with grey back has excellent performance, is environment-friendly and energy-saving, and is low in cost.

Owner:SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com